Polystyrene foam plate and manufacturing method thereof

A technology of polystyrene foam and production method, which is applied in chemical instruments and methods, manufacturing tools, ceramic molding machines, etc., can solve the problems of inability to meet building fire protection requirements, and the foam board cannot reach non-combustible grade A, and can meet building fire protection requirements. Requirements, easy to operate, and the effect of preventing delayed combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0025] Embodiment 2: a kind of manufacture method of polystyrene foam board, it comprises five steps, wherein step one to step four are with step one to step four in embodiment 1, and step five is to make magnesium oxychloride cement polystyrene After the ethylene foam board is laminated with an inorganic adhesive layer on both surfaces. All the other methods are the same as in Example 1.

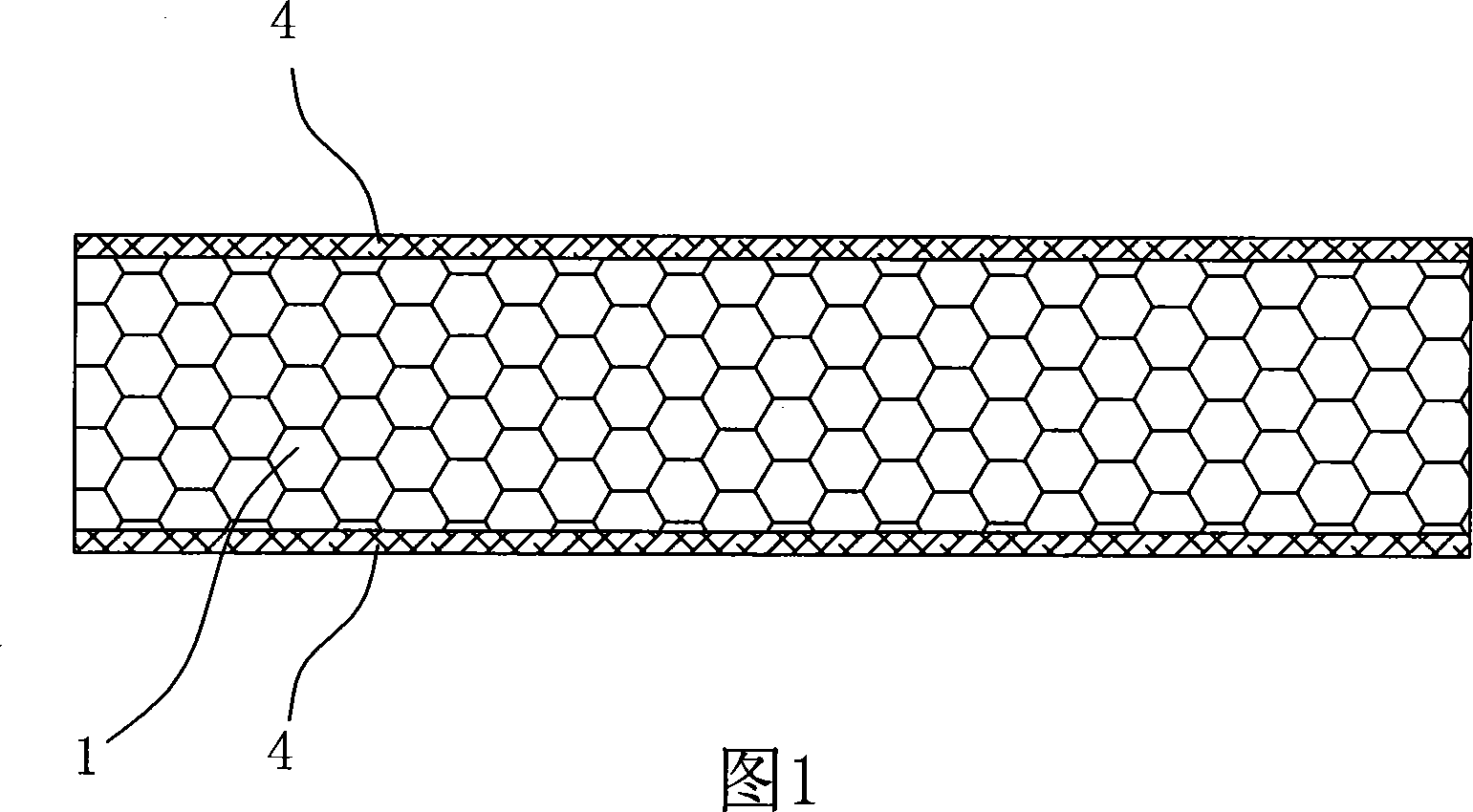

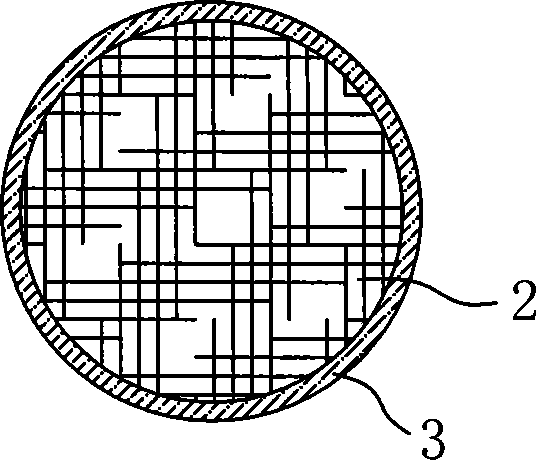

[0026] Adopt the polystyrene foam board that above-mentioned method makes, as shown in Figure 1, it comprises magnesium oxychloride cement polystyrene foam board 1, is compounded at the inorganic glue of magnesium oxychloride cement polystyrene foam board 1 two sides respectively Layer, magnesium oxychloride cement polystyrene foam board 1 is composed of countless foam particles 2 , and the surface of each foam particle 2 is covered with magnesium oxychloride cement layer 3 . The inorganic adhesive layer 4 includes a glass fiber layer, and a magnesium oxychloride cement layer that penetrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com