Patents

Literature

121 results about "Solution combustion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Solution combustion synthesis of nanomaterials. Abstract. Solution combustion (SC) is an effective method for synthesis of nano-size materials and it has been used for the production of a variety (currently more than 1000) of fine complex oxide powders for different advanced applications, including catalysts, fuel cells, and biotechnology.

Preparation method of cobalt oxide/graphene composite nano material

InactiveCN103145199ASimple processShort preparation timeMaterial nanotechnologyGrapheneNitrogen gasOrganic fuel

The invention relates to a preparation method of a cobalt oxide / graphene composite nano material, which is characterized by comprising the following steps: (1) preparing a 0.01-1.00 mol / L cobalt nitrate-organic fuel mixed solution, wherein the mol ratio of organic fuel to metal ions is 0.9-2; (2) preparing a 0.1-1.0 mg / ml graphene oxide dispersion solution; (3) calculating the volumes of the mixed solution obtained in the step (1) and the graphene oxide dispersion solution obtained in the step (2) according to the mass ratio of cobalt oxide to graphene in the designed product and the required preparation amounts, and mixing the mixed solution and the graphene oxide dispersion solution by ultrasonic to obtain a dispersion solution for atomization; (4) filling the dispersion solution obtained in the step (3) into an ultrasonic atomization device, carrying the generated atomized liquid drops into a 500-1100 DEG C pipe furnace by argon or nitrogen gas at the flow rate of 0.3-1.2 L / minute, and initiating solution combustion reaction; and (5) collecting the solid reaction product. The invention has the advantages of shorter technical procedure, simple synthesis equipment and continuous preparation process, can directly obtain the final powder product by one step, and can easily implement industrialized preparation.

Owner:NANCHANG UNIV

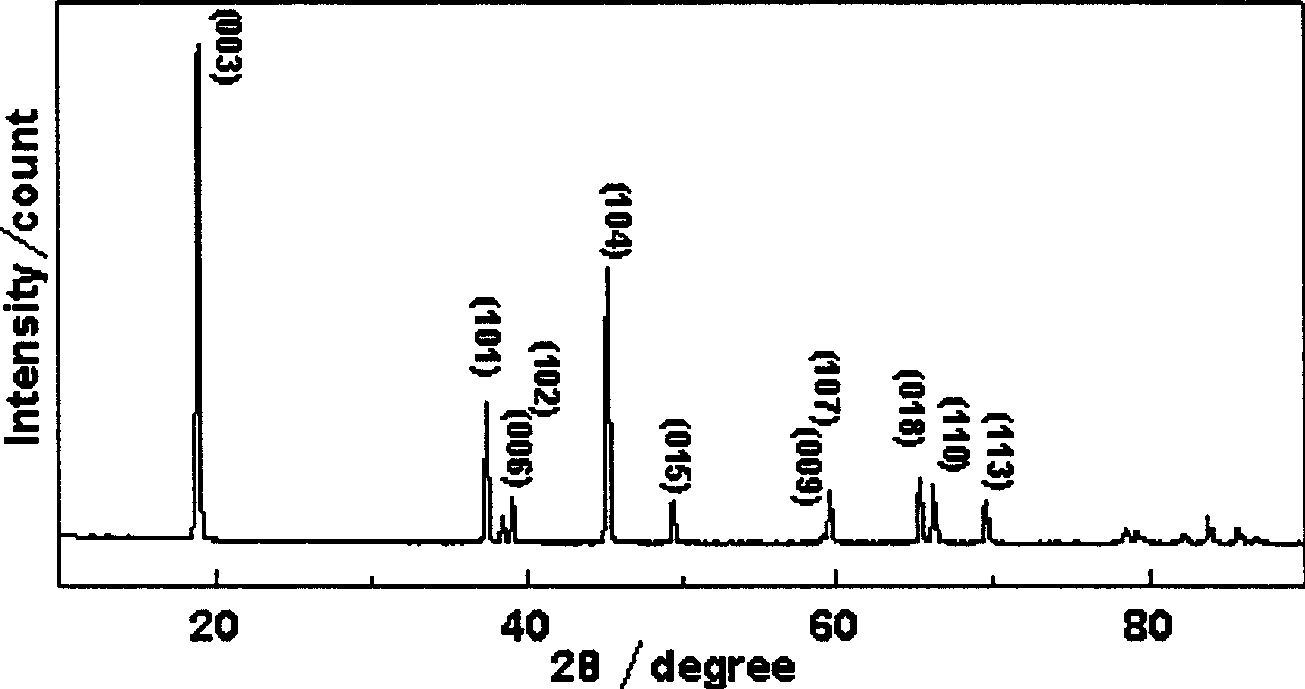

Preparation method for cubic-phase lithium lanthanum zirconium oxide solid-state electrolyte nano material

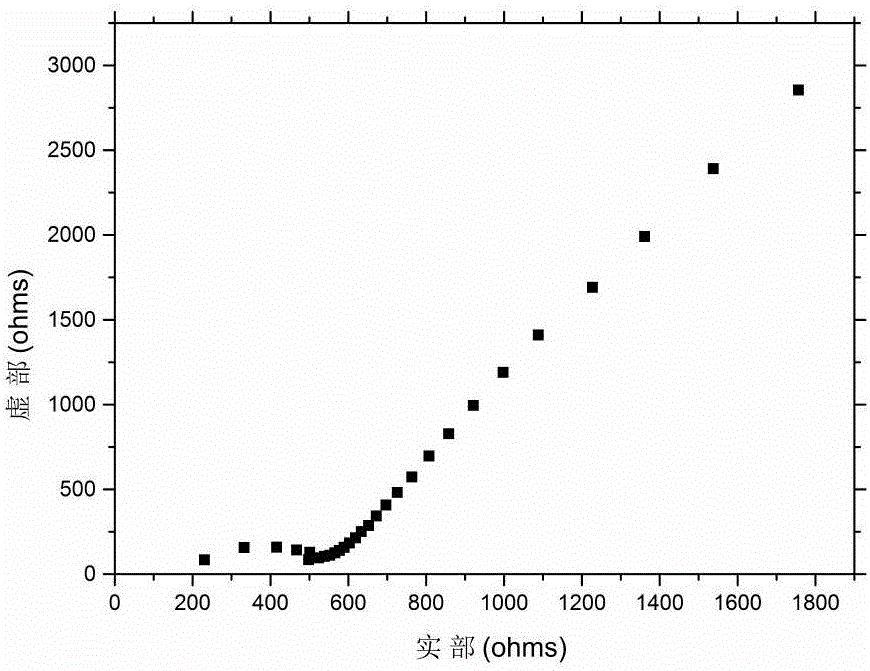

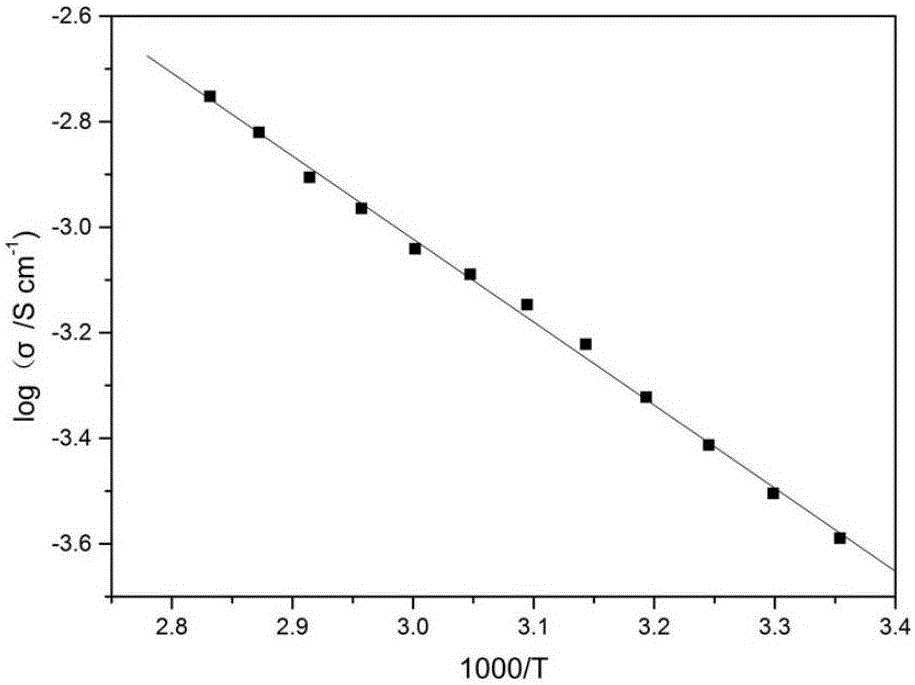

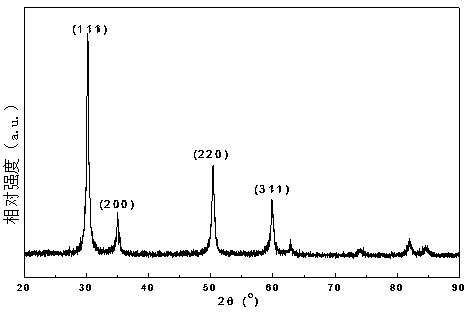

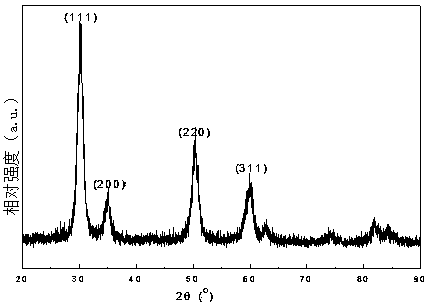

ActiveCN105932327ARich sourcesLow priceSecondary cellsElectrolyte immobilisation/gelificationSolid state electrolyteRoom temperature

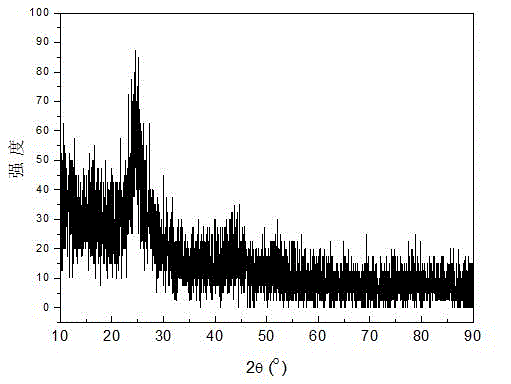

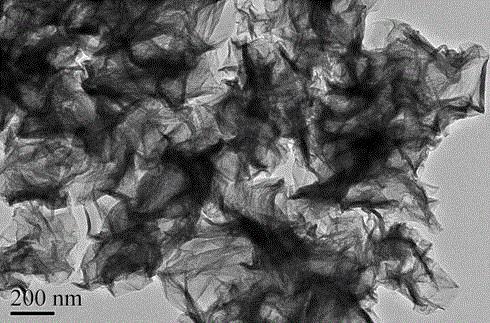

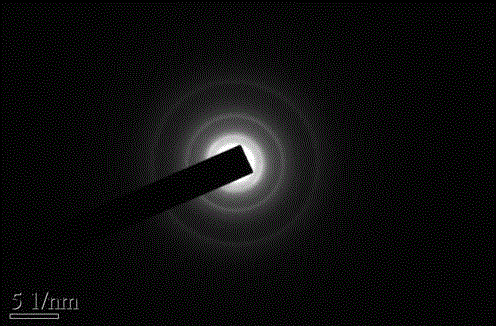

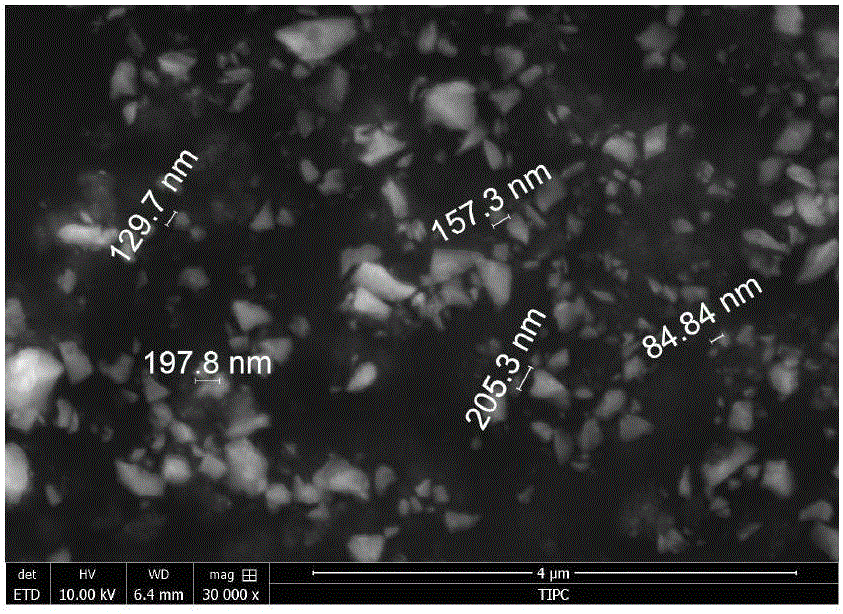

The present invention provides a preparation method for a cubic-phase lithium lanthanum zirconium oxide solid-state electrolyte nano material. A simple solution combustion synthesis technology is adopted, and a solid-state electrolyte material is obtained after heat treatment, and the solid-state electrolyte material has relatively high room temperature ionic conductivity and can be used as a solid-state electrolyte of a full solid-state battery. The preparation method of solution combustion synthesis is simple, and a prepared precursor is synthesized by one step, and element distribution is uniform. The layer thickness of a precursor particle is 100- 200 nano-meters, and the particle has a big specific surface area, so that element diffusion is facilitated at a high temperature, and a reaction is complete. Compared with other methods such as a sol-gel method and a solid phase method, the method has great technical advantages: low costs, high yield, simple operation and feasible industrial production.

Owner:UNIV OF SCI & TECH BEIJING

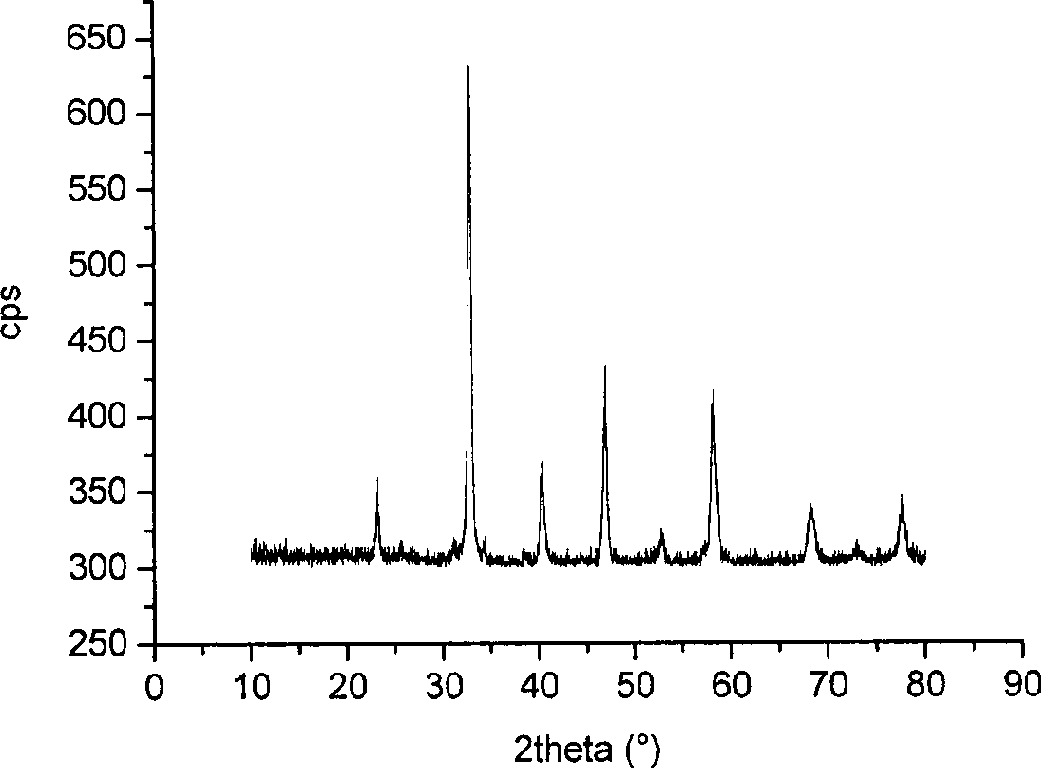

Preparation method of yttria-stabilized zirconia tetragonal nano powder with high specific surface area

ActiveCN103524128ASolve serious sintering and agglomerationSolution areaMaterial nanotechnologyZirconium hydrideSolution combustion

A preparation method of an yttria-stabilized zirconia tetragonal nano powder with high specific surface area. The method is characterized by comprising the following steps: (1) respectively weighing zirconium oxychloride octahydrate?and an yttrium raw material according to a stoichiometric ratio of zirconium and yttrium in (Y2O3)x(ZrO2) 1-2x (0.005<=x<=0.150), according to the amount of a target product, converting the yttrium raw material into an yttrium nitrate solution by dissolving, and then completely dissolving the zirconium oxychloride octahydrate; (2) respectively adding a soluble salt and organic fuel to the solution obtained in the step (1), heating for dissolving, continuing heating and concentrating to a sticky state, igniting in a heating furnace chamber at 400-1000 DEG C, and taking out the powder after complete combustion; and (3) washing, filtering and drying the powder obtained in the step (2). The invention effectively solves the problems of serious particle sintering agglomeration and small specific area in the process of solution combustion for synthesis of zirconium oxide; the powder has specific surface area as high as 378 m<2> / g and particle size about 2.8 nm; and the materials are more accessible and cheaper, so as to facilitate industrialized preparation.

Owner:赣州点金新材料科技有限公司

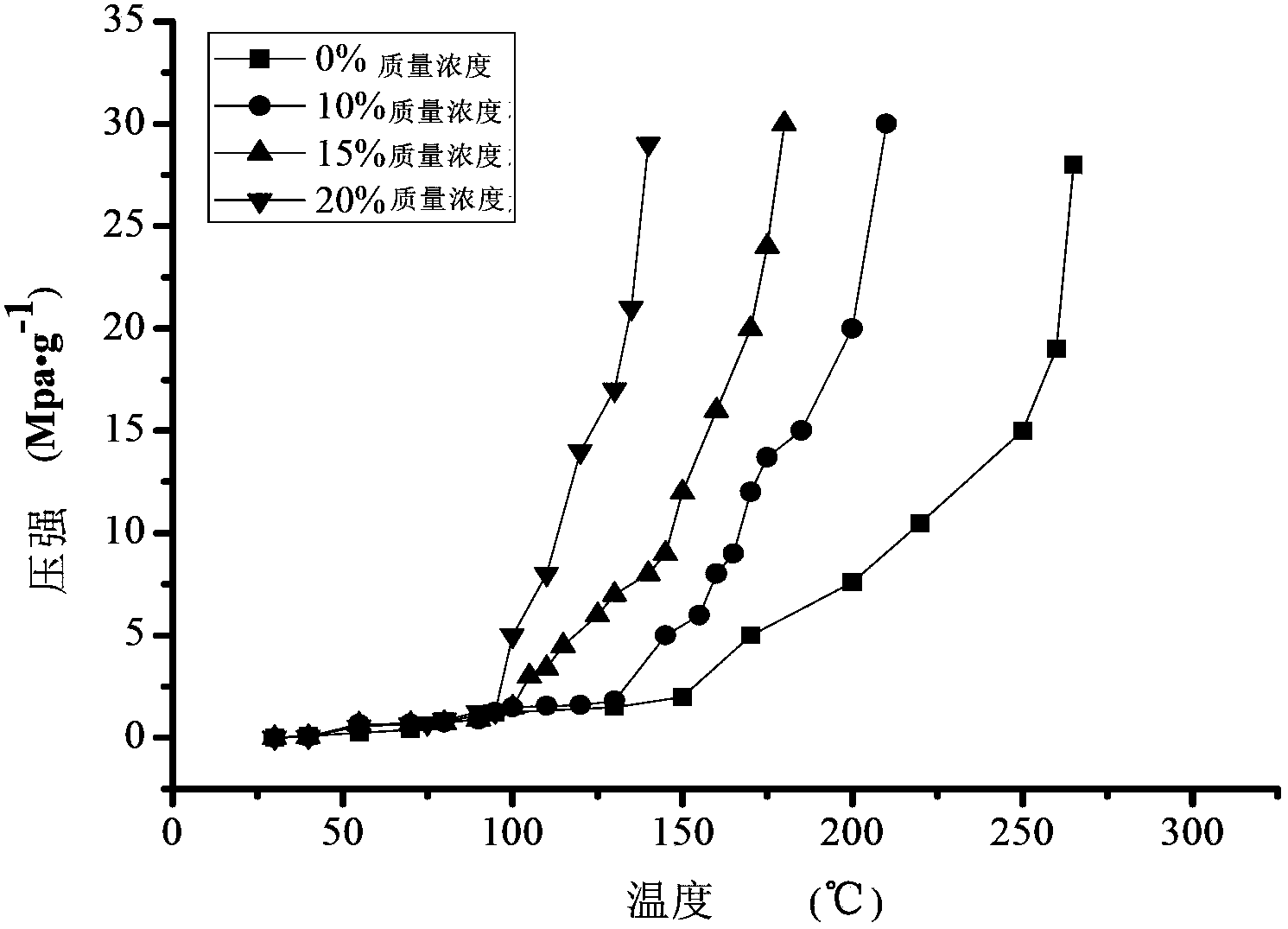

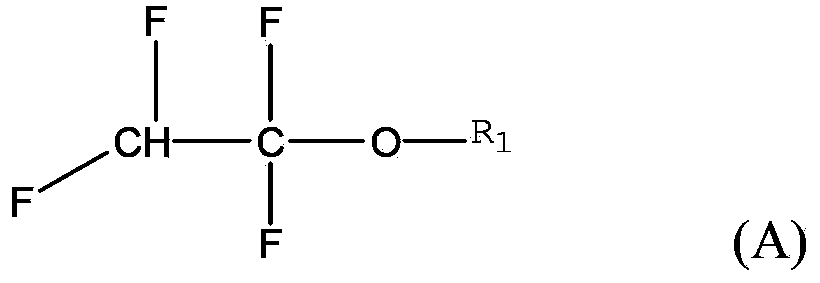

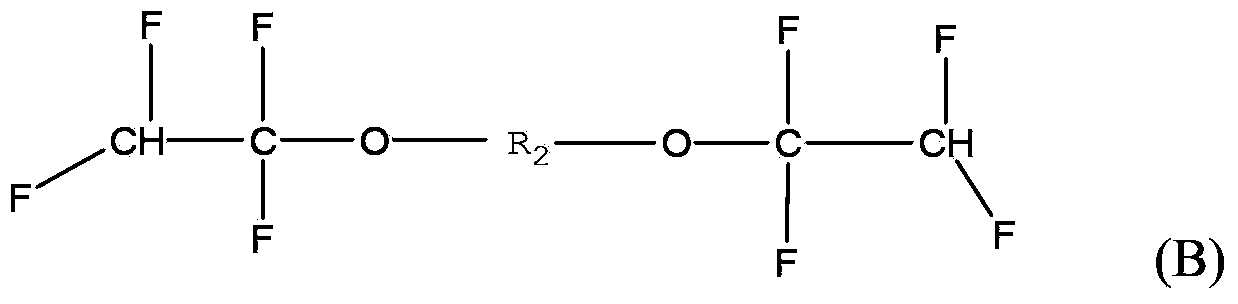

High safety battery electrolyte solution

ActiveCN104124470AImprove securityStop burningSecondary cellsElectrolytesElectrical batteryPhysical chemistry

The invention discloses a high safety battery electrolyte solution, which includes an electrolyte and a solvent. The solvent is a mixed solvent of carbonic ester and a fluoro-ether solvent. The electrolyte solution provided by the invention can significantly improve the safety performance of batteries, and effectively prevent electrolyte solution combustion or even explosion due to overheat of batteries.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

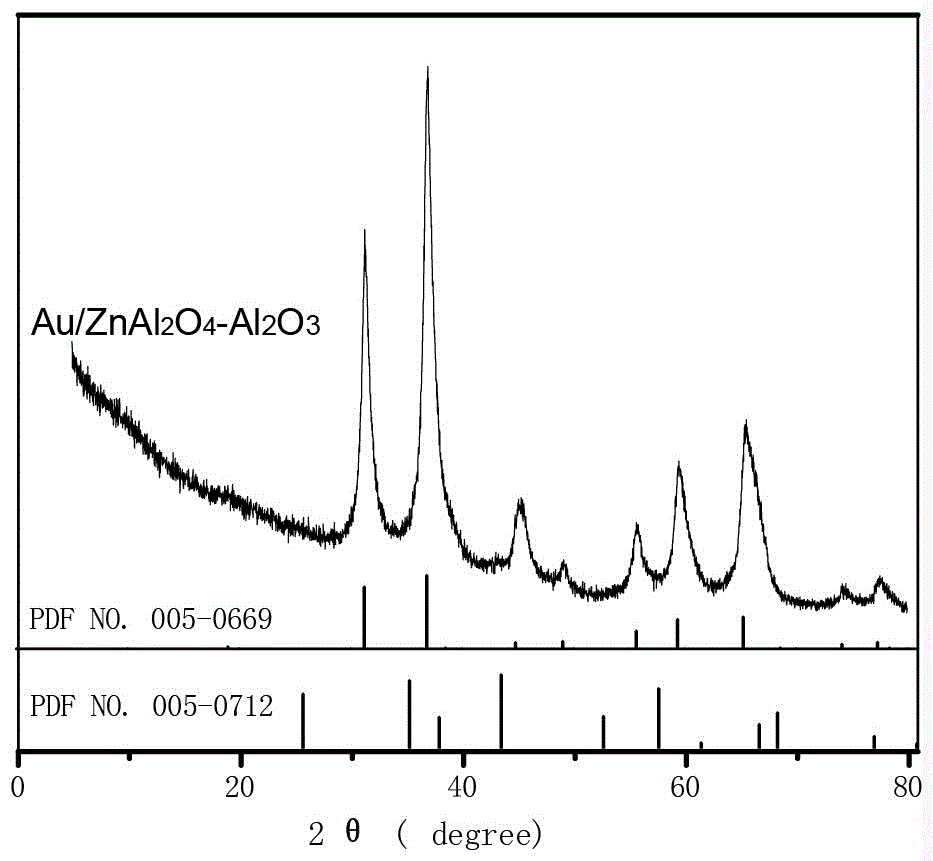

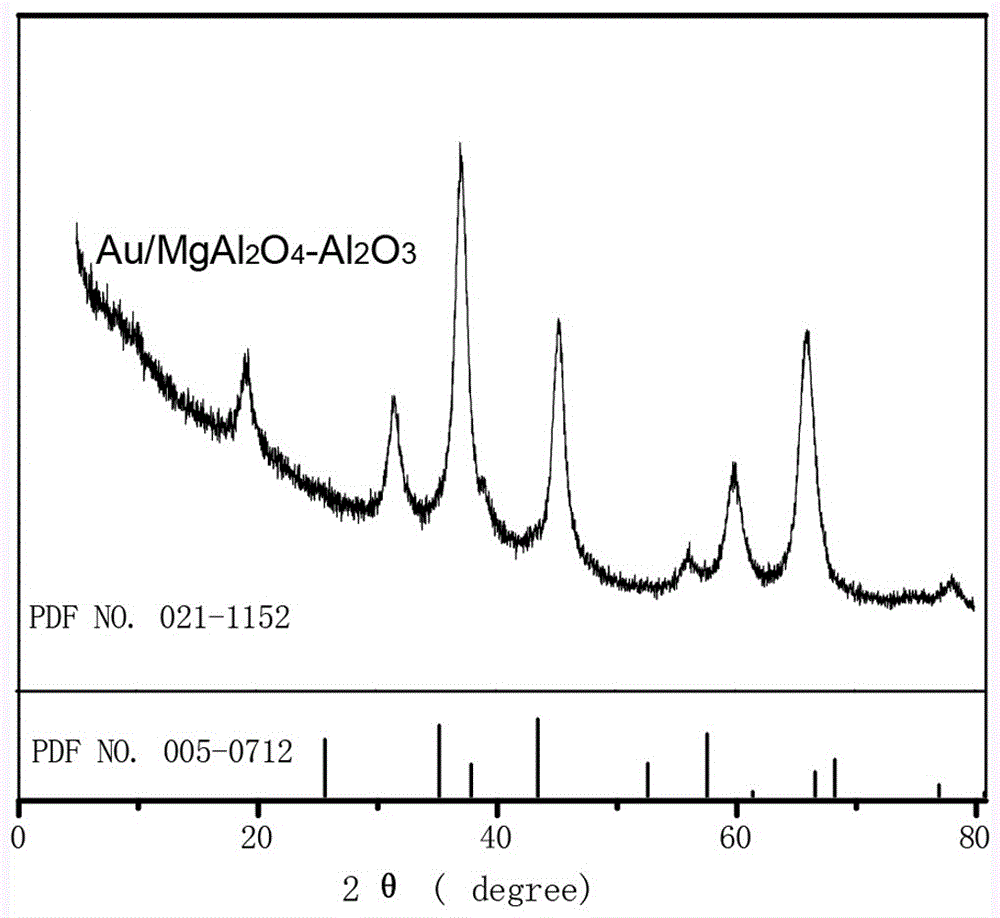

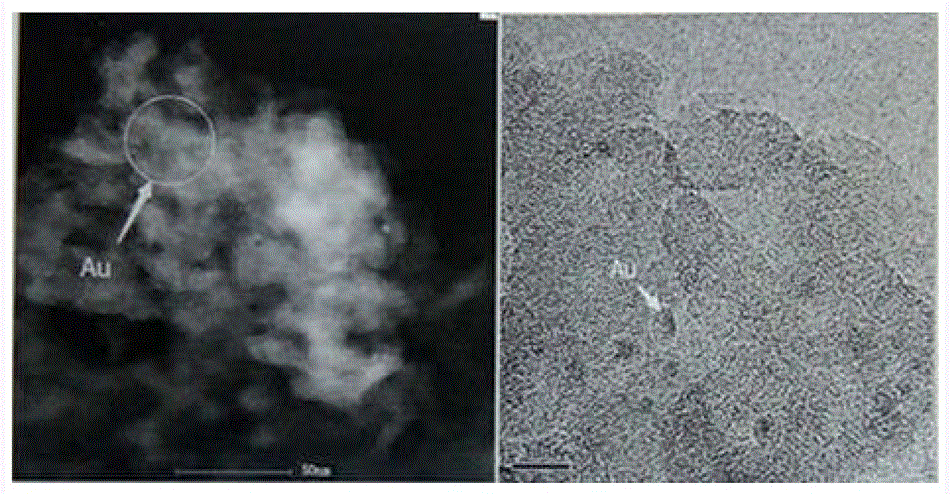

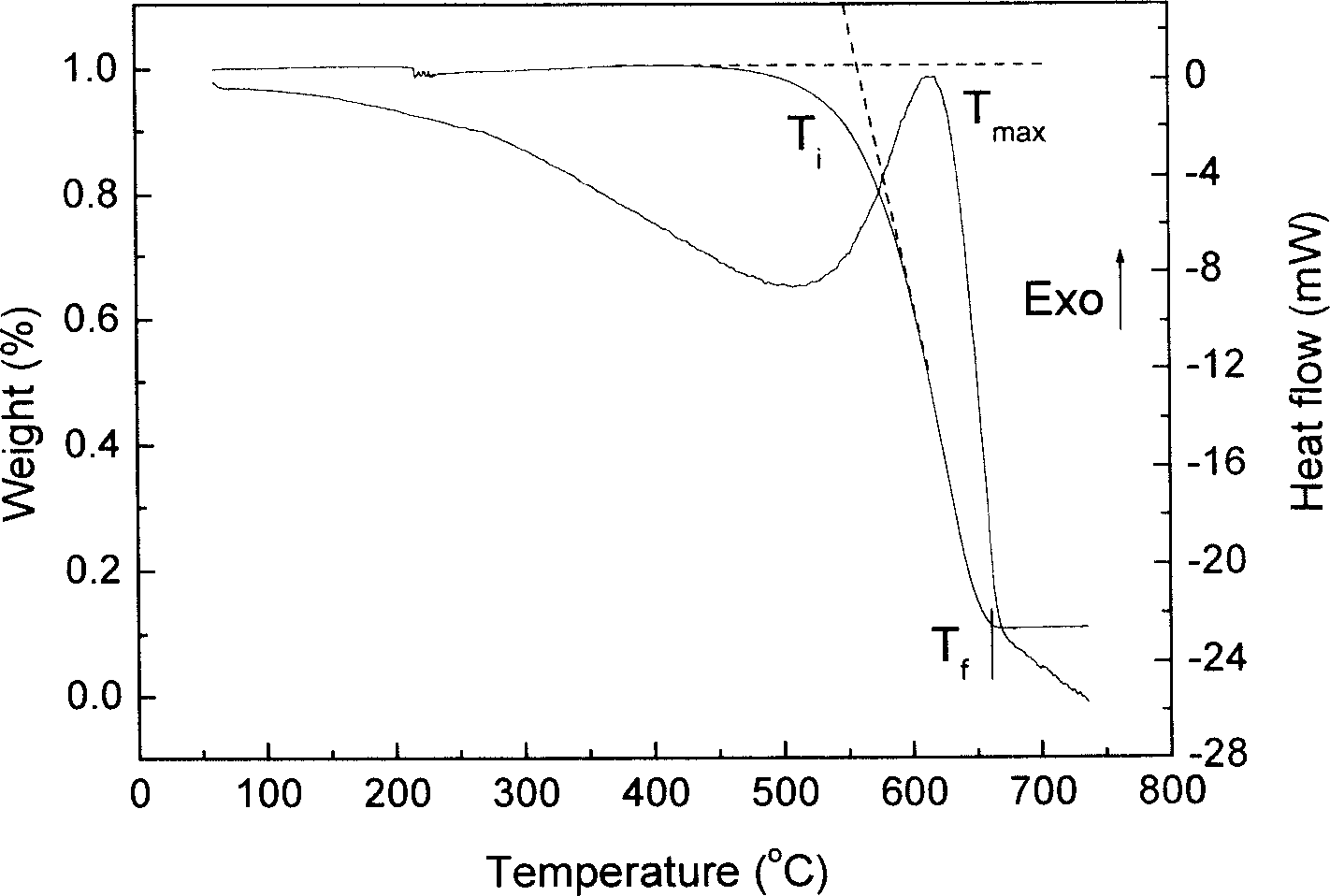

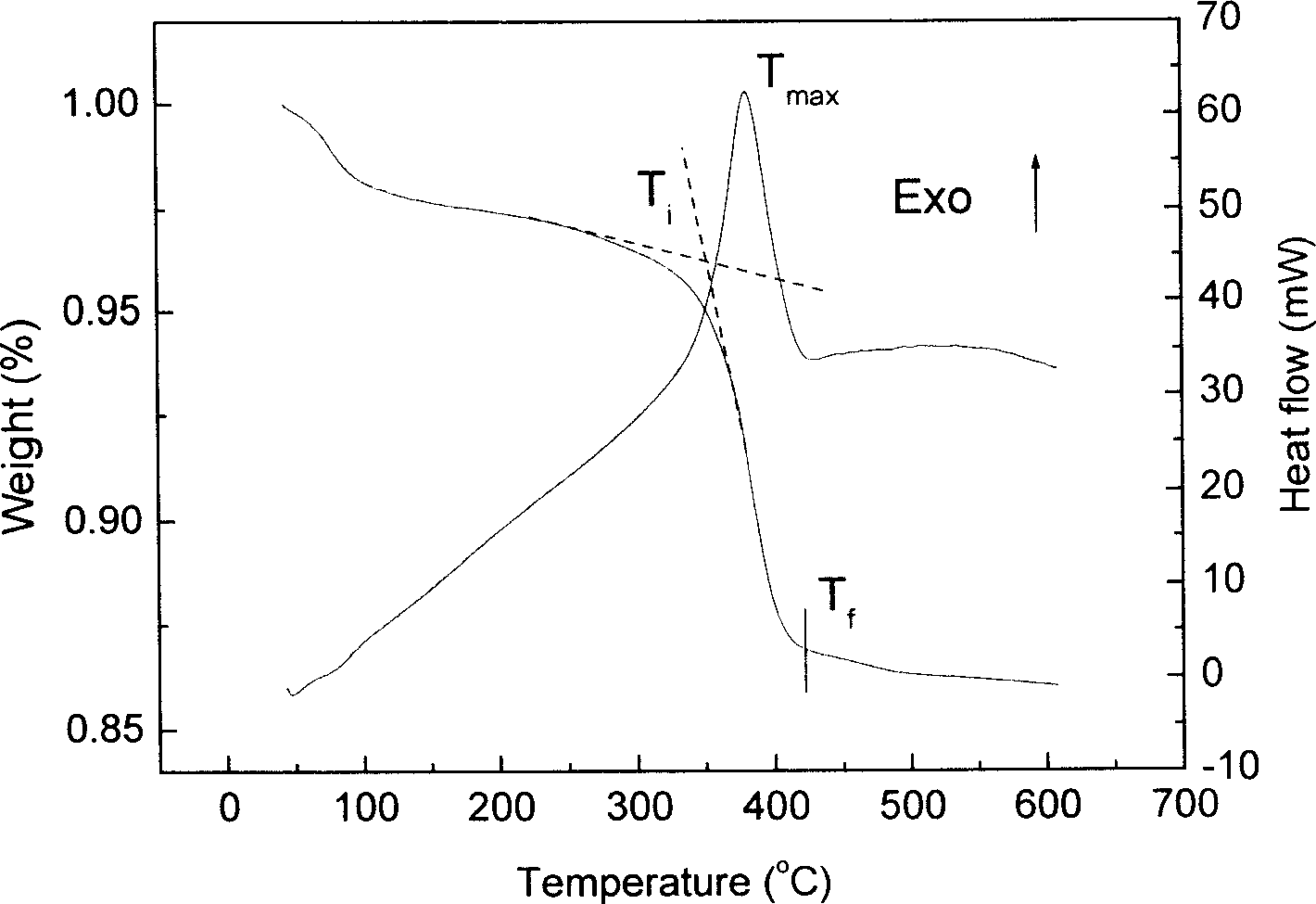

High-activity and high-stability supported nanometer gold catalyst, preparation and application method

InactiveCN106334555AImprove reaction stabilityGood dispersionHeterogenous catalyst chemical elementsDispersed particle separationHigh activityHigh rise

The invention discloses a high-activity and high-stability supported nanometer gold catalyst, preparation and an application method. An active component is Au, and a carrier is M1M2O-MOx composite oxides, wherein M1 is one or two or more of Mg, Cu, Ni and Zn, M2 is one or two or more of Al, Fe and Co, and MOx is one of Al2O3, TiO2 and SiO2. The M1M2O-MOx is prepared by adopting an impregnation method or a solution combustion method, metal M1 and M2 salts are introduced and calcinated under the temperature of 700-1200 DEG C so that M1 and M2 can generate a spinel or perovskite structure on the surface of the MOx oxides, the gold catalyst supported by the M1M2O-MOx has the advantages that the preparation process is simple, large-scale production is easy, the catalytic activity is high, and the reaction stability performance is excellent, 1% CO in air can be completely oxidized under the temperature of minus 40-50 DEG C to produce CO2, and the wide application prospect is achieved in CO2 reduction of a closed CO2 laser and air purification of the environment such as a mine self-rescuer, a safety rescue capsule, a high-rise building, a tunnel, a closed place, a submarine and a space station.

Owner:YANTAI UNIV

Catalyst for lowering combustion temperature of soot in diesel exhaust gas and preparation method thereof

InactiveCN1721066APromote regenerationMeet the low temperature requirements of the exhaust gasDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsPotassiumRare earth

The present invention relates catalyst to reduce burning temperature of carbon smoke particle in exhaust gas from diesel truck. Use LaNiO3 or La2NiO4base perovskite type composite oxide with B position atom of Ni as base, with assistant active constituent of kalium, cobalt, rare earth or palladium. It is prepared with sol-gal process or solution combustion method. It can reduce the burning temperature from 550Deg to 250~400Deg and satisfy low temperature require in the main; the burning speed enhances almost one times and very useful.

Owner:UNIV OF JINAN

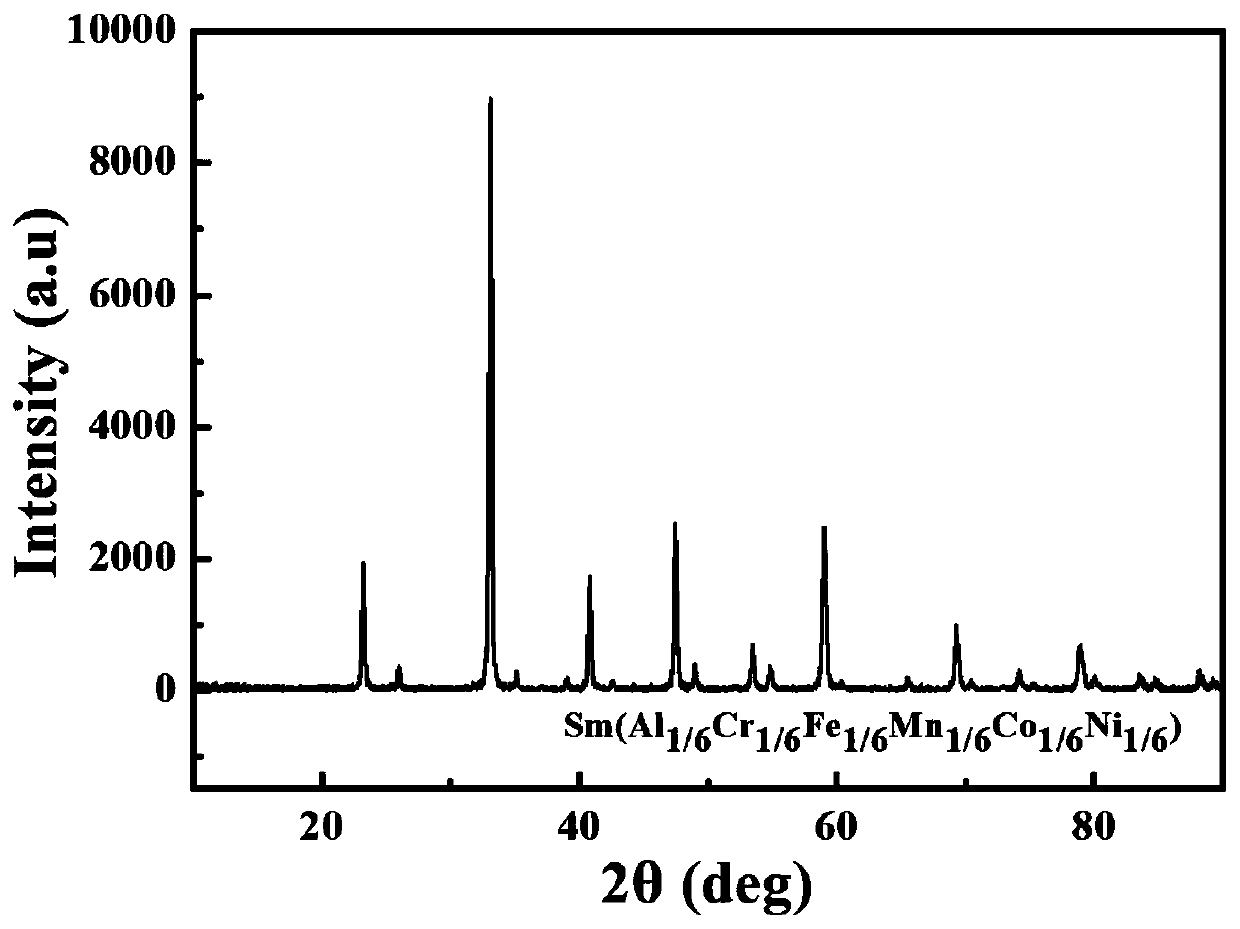

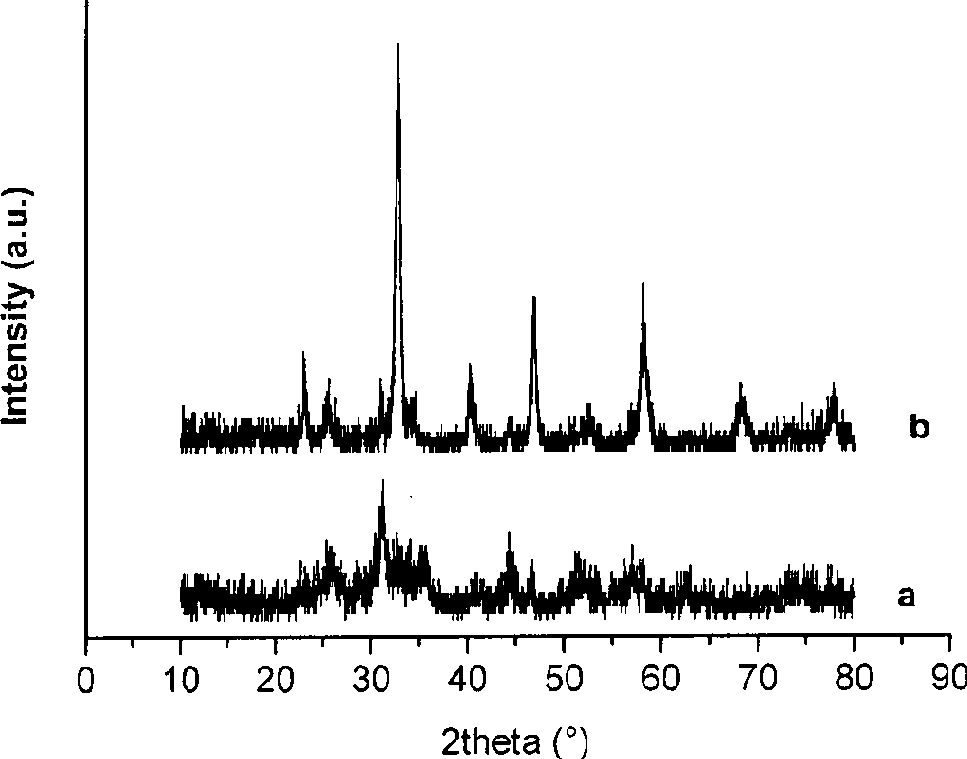

Novel perovskite type high-entropy oxide material with six-membered high-entropy B site, and preparation method thereof

The invention provides a novel perovskite type high-entropy oxide material with a six-membered high-entropy B site, and a preparation method thereof, and relates to the technical field of high-entropyoxide materials. The chemical formula of the material is RE(Al1 / 6Cr1 / 6Fe1 / 6Mn1 / 6M1 / 6N1 / 6)O3, wherein RE is one of rare earth cations such as La<3+>, Pr<3+>, Nd<3+>, Sm<3+>, Gd<3+> and Y<3+>, and M and N are any two of divalent cations such as Co<2+>, Ni<2+>, Mg<2+> and Zn<2+>. The perovskite type high-entropy oxide nanocrystal powder prepared by adopting a solution combustion technology has a theadvantages of high specific surface area, porous structure, uniform chemical composition and microstructure, convenience in regulation of the microstructure, and final realization of regulation of performances as required.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

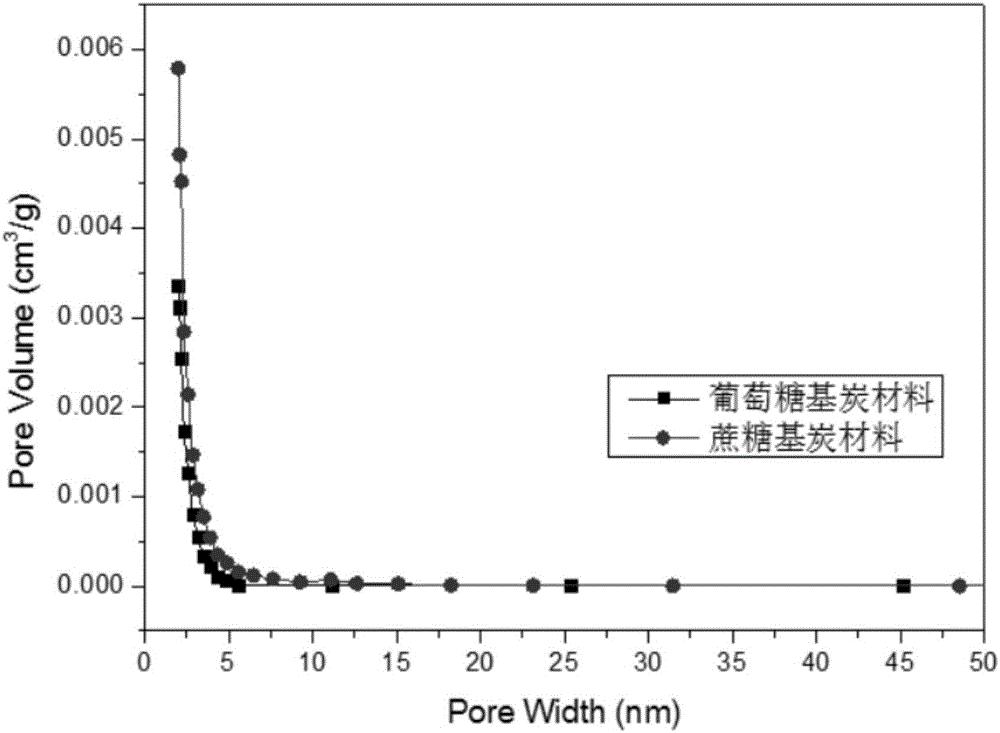

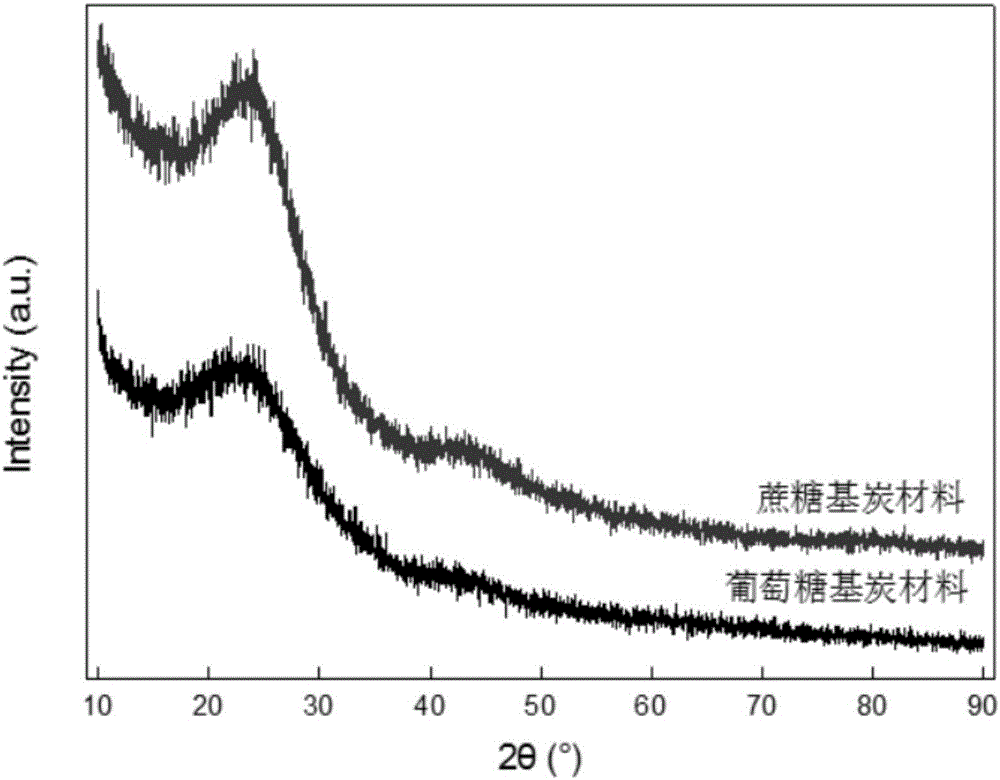

Biomass charcoal material and preparation method thereof

InactiveCN106829923ASimple processShort preparation cycleNano-carbonMaterials preparationFoaming agent

The invention relates to a biomass carbon material and a preparation method thereof, and relates to the technical field of carbon material preparation. The preparation method comprises the following steps: (1) preparing a carbon source mixed liquid: adding a biomass carbon source into deionized water, stirring evenly to obtain a carbon source mixed liquid; (2) preparing a combustion liquid: adding Combustion agent, oxidant and foaming agent are stirred evenly to obtain combustion liquid; (3) calcining combustion liquid to obtain initial carbon material; (4) washing initial carbon material; (5) drying and washing initial carbon material to obtain the described biochar material. A kind of biomass charcoal material and preparation method described in the present invention adopts the solution combustion method, which is very energy-saving, and can be charcoalized in one step; the preparation method is simple, the preparation period is short, and the reproducibility is good; the prepared biomass charcoal material The nano-thin layer structure is uniform, and the microstructure and specific surface area are good.

Owner:SHIHEZI UNIVERSITY

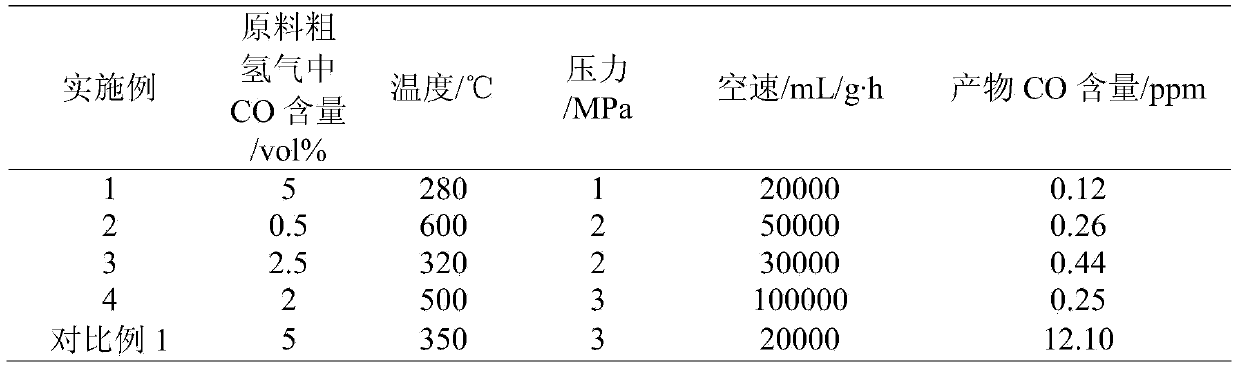

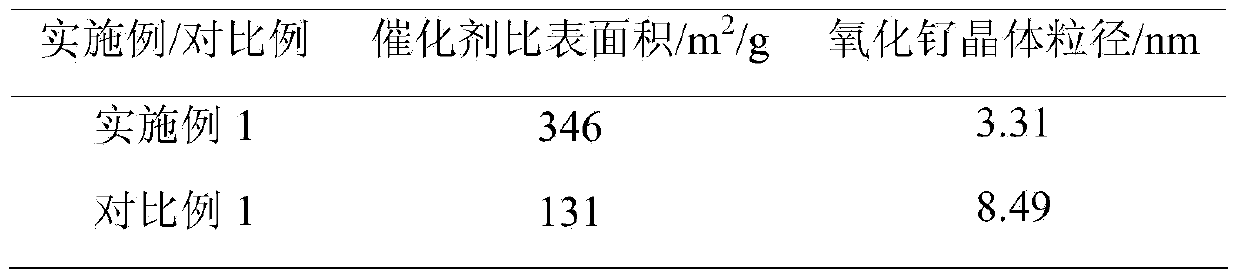

Precious metal methanation catalyst prepared by using solution combustion method and preparation method and applications thereof

InactiveCN103801290AImprove catalytic performanceLarge specific surface areaHydrogen separation using solid contactMetal/metal-oxides/metal-hydroxide catalystsMethanationSolution combustion

The invention discloses a precious metal methanation catalyst prepared by using a solution combustion method, which comprises the following components in percentage by weight: 1-10% of precious metal oxides and 90-99% of a carrier. The precious metal methanation catalyst disclosed by the invention has the advantages that the catalyst is applicable to a trace CO methanation process, and stable in catalytic performance.

Owner:TAIYUAN UNIV OF TECH +1

Method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing

PendingCN110722171AEvenly dispersedSmall particlesAdditive manufacturing apparatusTransportation and packagingSpray GranulationSolution combustion

The invention provides a method for preparing rare earth oxide doped tungsten and molybdenum spherical powder for 3D printing, and belongs to the technical field of powder metallurgy powder preparing.According to the specific preparing method, a low-temperature solution combustion synthesizing method is adopted for preparing rare earth oxide / tungsten oxide (molybdenum oxide) composite powder, then, hydrogen reduction is conducted to obtain rare earth oxide doped nano tungsten (molybdenum) powder, then, atomizing granulation equipment is used for granulating nano powder, and after the nano powder is roasted, ground and screened, the spherical tungsten (molybdenum) powder for 3D printing can be obtained. Raw materials are simple and easy to obtain, the equipment is simple, the technology israpid, a large number of products can be prepared within the short time, and the method is suitable for large-scale production. The rare earth oxide in the prepared tungsten and molybdenum sphericalpowder can be evenly scattered, particles are fine, oxide particle segregation cannot happen, and the rare earth oxide adding amount can be adjusted through the low-temperature solution combustion synthesizing process. The prepared tungsten and molybdenum spherical powder is excellent in sphericity degree and mobility and is extremely suitable for the 3D printing technology.

Owner:UNIV OF SCI & TECH BEIJING

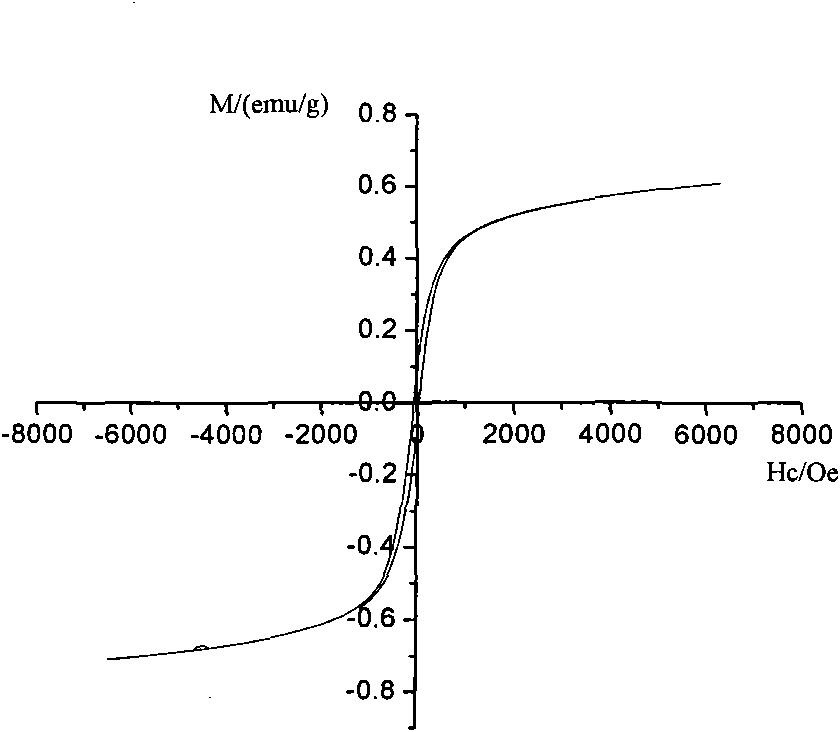

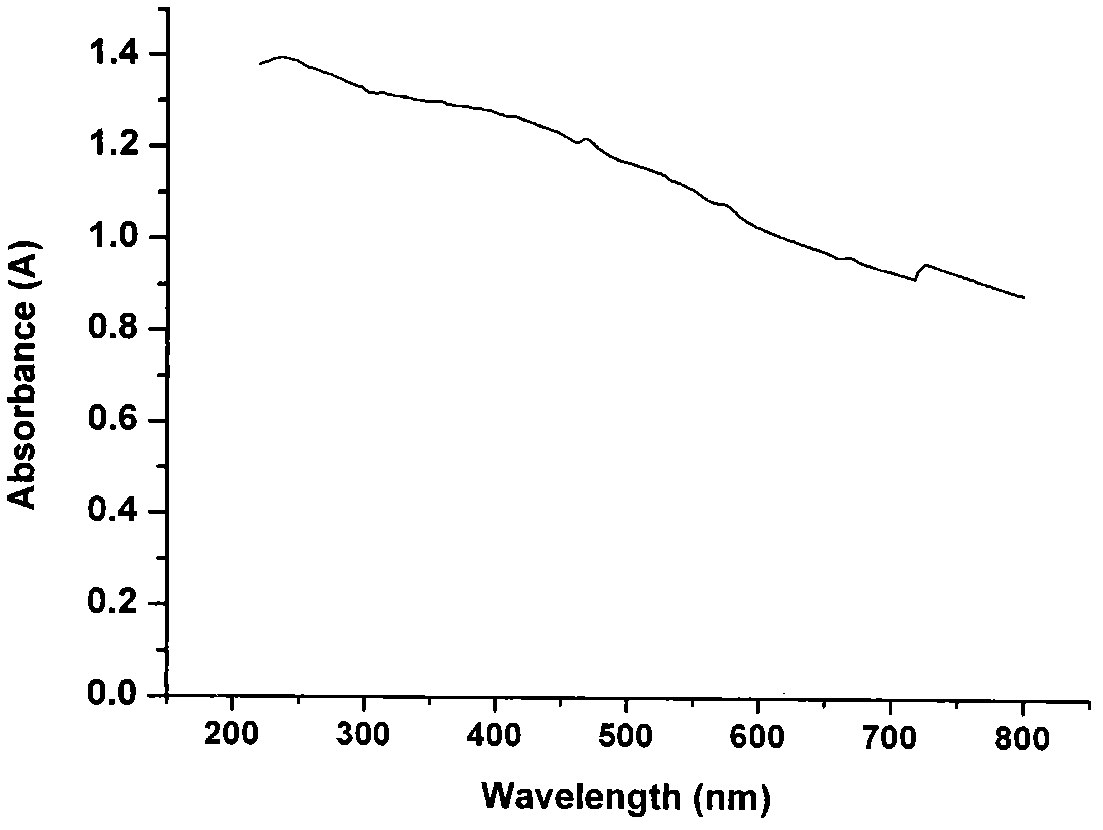

Preparation of magnetic photocatalyst for absorption and photocatalytic degradation of dye waste water

InactiveCN101584987AGood paramagnetismImprove adsorption capacityWater/sewage treatment by irradiationOther chemical processesHelianthineUltraviolet lights

The invention relates to method for preparing superfine perovskite type LaFexMn(1-x)O3 (in which x is equal to 0.2 to 0.9 but not equal to 0.5) and precursor powder thereof by using stearic acid solution combustion method, comprising the following steps: lanthanum nitrate, ferric nitrate, manganese chloride and stearic acid with the mol ratio of 1: x: 1-x: 7 to 1: x: 1-x: 10 (in which x is equal to 0.2 to 0.9 but not equal to 0.5) are weighted, stearic acid is firstly melted, and then other reactants are added, the temperature is controlled between 110 DEG C and 117 DEG C, stearic acid complex solution is formed after reaction in enough time, the solution is disposed in a muffle furnace at the temperature of 300 to 500 DEG C, precursor-mixed oxide is obtained after combustion, and superfine perovskite type LaFexMn(1-x)O3 (in which x is equal to 0.2 to 0.9 but not equal to 0.5) powder is obtained after the precursor is calcined in the muffle furnace at the temperature of 600 to 800 DEG C for 1 to 2 hours. The obtained perovskite type oxide and precursor thereof are used for absorption and photocatalytic degradation of dye waste water such as helianthine, rhodamine B, alizarin red, and the like, both having good effects of absorption and photocatalytic degradation no matter in doors, under ultraviolet light or sunlight; and the catalyst is easy to recycle.

Owner:ZHONGBEI UNIV

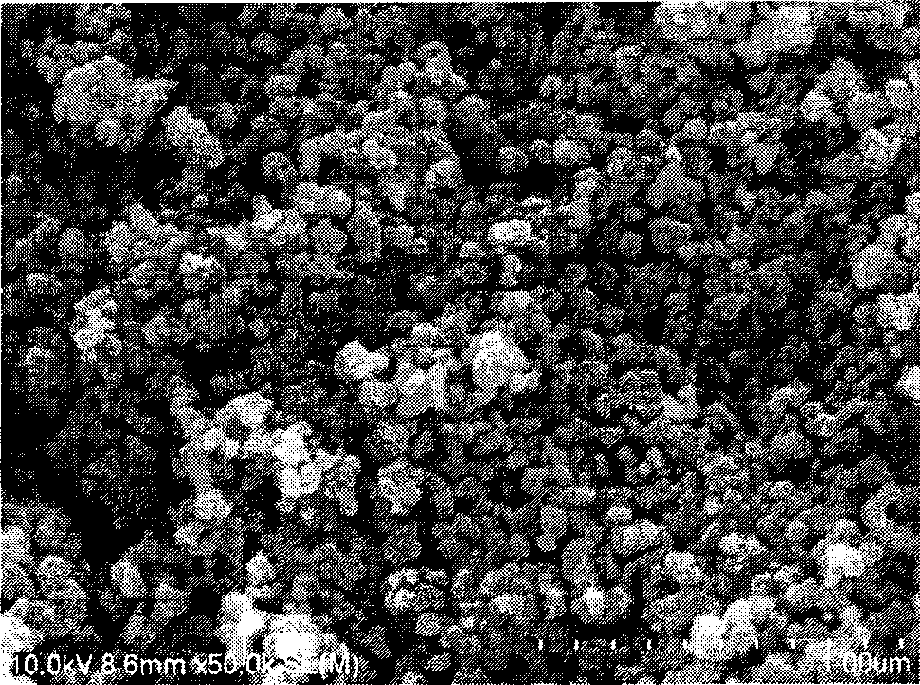

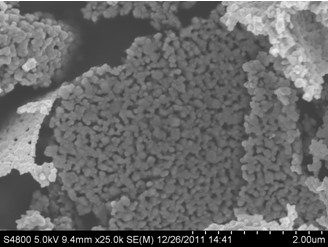

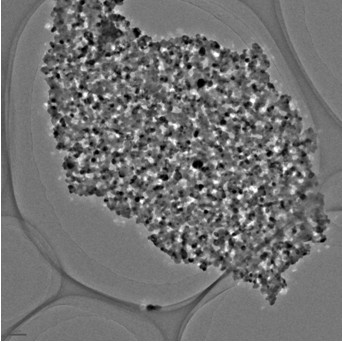

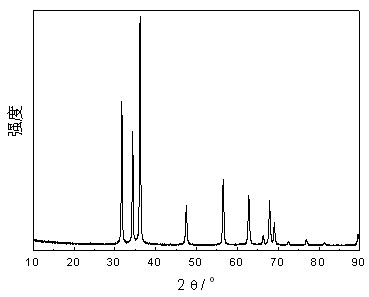

Method for producing nanometer structure cobalt tetroxide sub-micron hollow balls

The invention relates to a method for producing nanometer structure cobalt tetroxide sub-micron hollow balls. The method mainly comprises the steps of (1) weighing an appropriate amount of cobalt materials according to the amount of the produced target product, formulating into a cobalt nitrate solution with the concentration of 0.02-0.10 mol / L; (2) adding an appropriate amount of glycin into the solution obtained in the step (1), ultrasonically dissolving, mixing uniformly; (3) putting the mixed solution obtained in the step (2) into an ultrasonic atomization device for atomization, carrying the produced atomized liquid drops by using air of 0.3-1.0 L / minute into a tube furnace of the temperature of 700-1000 DEG C to cause the combustion reaction of the solution; and (4) collecting solid reaction products by using a collection device to obtain the nanometer cobalt tetroxide sub-micro hollow balls. With the production method of the invention, spinel type cobalt tetroxide sub-micro hollow balls with uniform size and regular shape are obtained without post heat treatment, so that the process flow is greatly shortened, and the synthesis equipment is simple.

Owner:NANCHANG UNIV

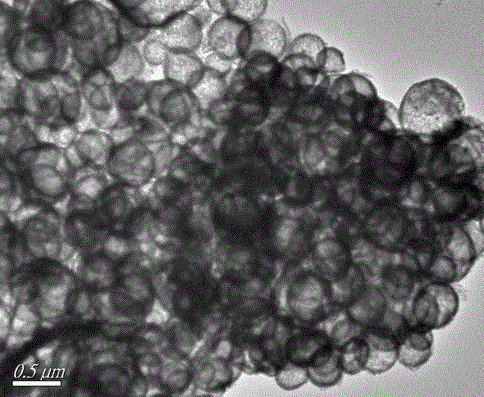

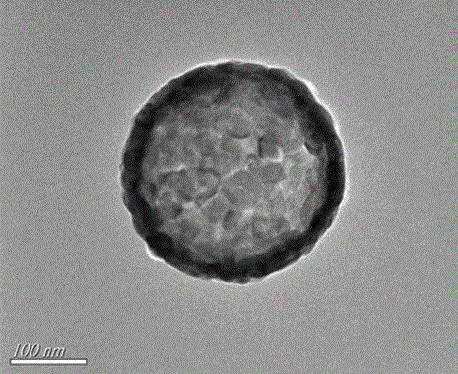

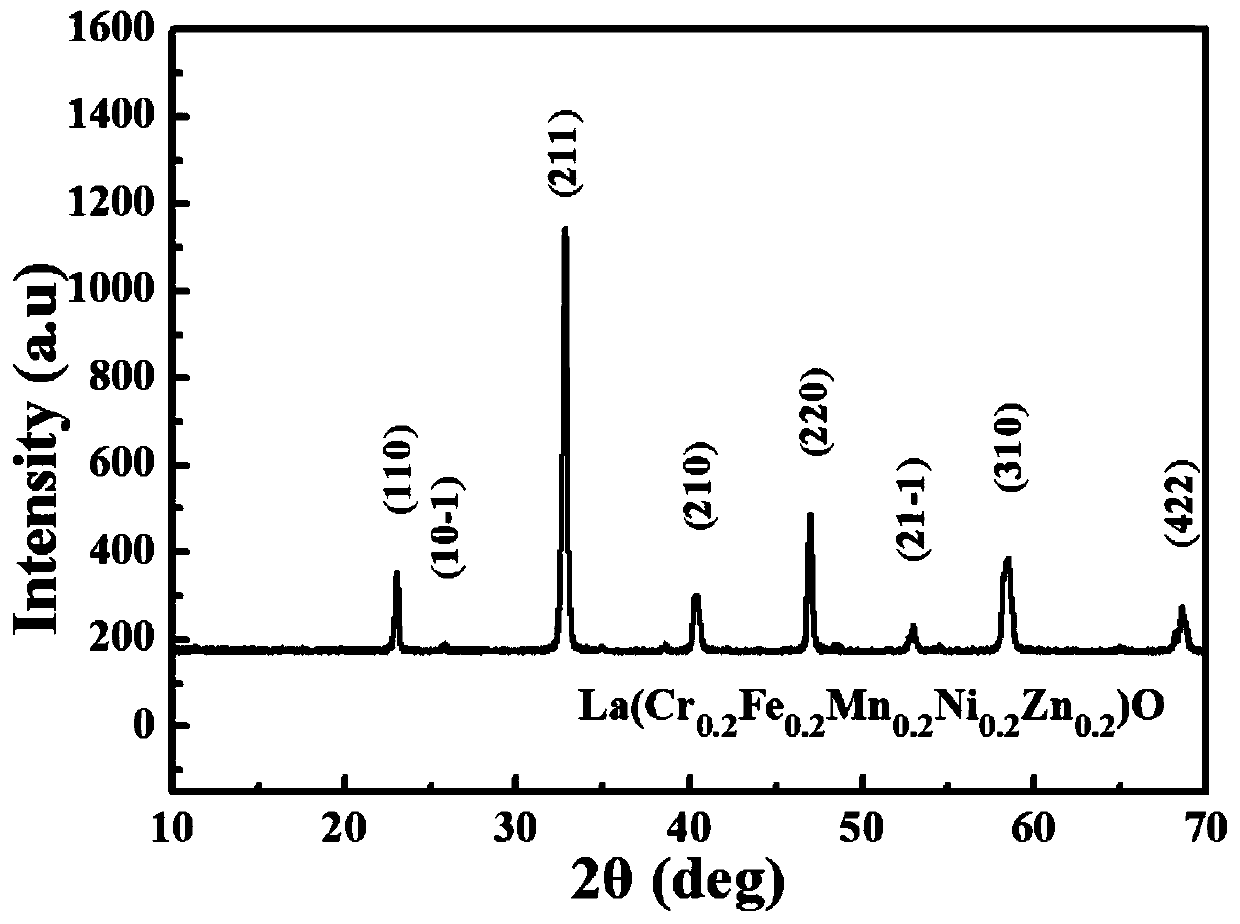

Novel B-site five-membered high-entropy perovskite type oxide material and preparation method thereof

InactiveCN110467227ALarge specific surface areaEasy to controlMaterial nanotechnologyCobalt compoundsChemical compositionSynthesis methods

The invention discloses a novel B-site five-membered high-entropy perovskite type oxide material and a preparation method thereof. The chemical formula of the high-entropy perovskite type oxide material is RE(Cr<0.2>Fe<0.2>Mn<0.2>M<0.2>N<0.2>)O<3>, wherein RE is one selected from the group consisting of La<3+>, Pr<3+>, Nd<3+>, Sm<3+>, Gd<3+> and Y<3+>; and M and N are any two selected from the divalent cations consisting of Co<2+>, Ni<2+>, Mg<2+> and Zn<2+>, but do not contain Co<2+> and Ni<2+> at the same time. According to the invention, the porous perovskite type high-entropy oxide nanocrystalline powder material with a high specific surface area, uniform chemical composition and a microstructure can be controllably prepared by adopting the solution combustion synthesis method; the high-entropy oxide material with a perovskite structure is designed by changing the composition of B-site cations in perovskite, so the physical and chemical properties of the high-entropy oxide materialare customized; and the preparation method is convenient to operate, high in practicability and convenient to promote.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing perovskite type LaFe0.5Mn0.5O3 by geoceric acid solution combustion method

InactiveCN101412542ARaw materials are easy to getSimple processIron oxides/hydroxidesManganese oxides/hydroxidesMixed oxideNitrate

The invention provides a method for preparing superfine perovskite type LaFe0.5Mn0.5O3 by a stearic acid solution combustion method. The method comprises the following proposal: respectively weighing lanthanum nitrate, ferric nitrate, manganese chloride and the stearic acid according to mol ratio of 1 to 0.5 to 0.5 to 7-10; dissolving the lanthanum nitrate, the ferric nitrate and the manganese chloride solids in the melted stearic acid at a temperature of between 110 and 117 DEG C to form stearic acid complex solution with enough reaction time; placing the solution in a muffle at a temperature of between 300 and 500 DEG C, and combusting the solution to obtain mixed oxide; and obtaining nanometer LaFe0.5Mn0.5O3 powder after calcining the mixture in the muffle at 600 DEG C for 1 hour. The crystallization degree of the obtained powder can be higher if the calcination temperature is higher.

Owner:ZHONGBEI UNIV

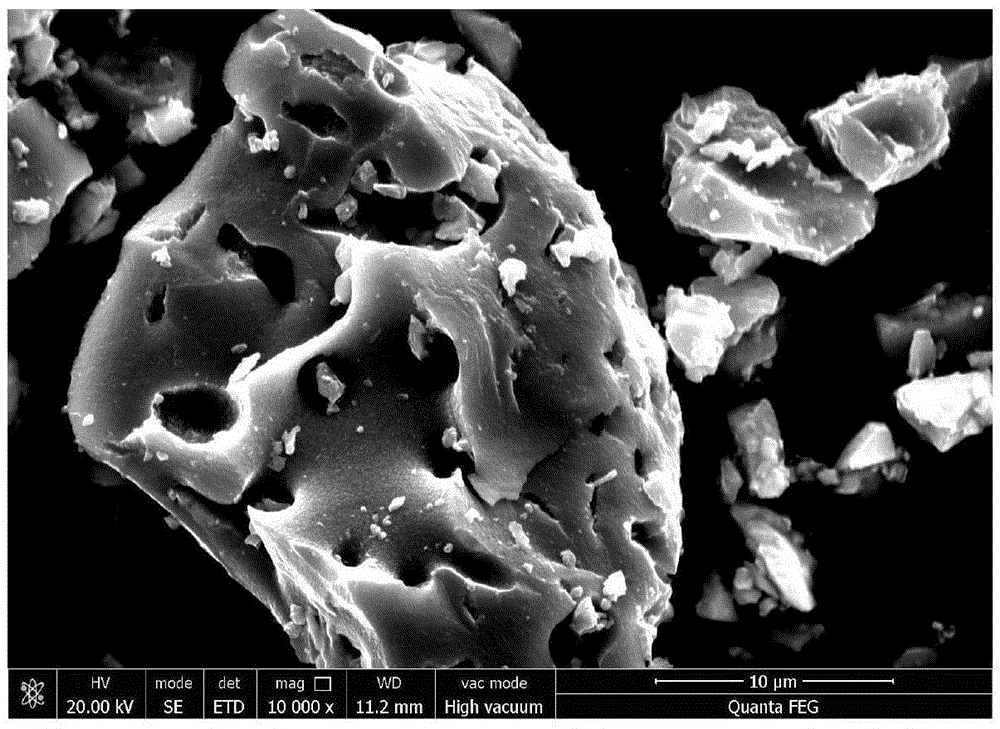

Preparation method of porous carbon loaded tungsten carbide composite material

ActiveCN111545231AWell mixedAvoid reunionMaterial nanotechnologyCatalyst activation/preparationPtru catalystPorous carbon

The invention discloses a preparation method of a porous carbon loaded tungsten carbide composite material, and belongs to the technical field of material science. According to the material, tungstencarbide nanoparticles are uniformly loaded on a carbon skeleton with a large number of network pore channel structures in a high-dispersion manner. The specific preparation method comprises the following steps: taking metal nitrate, a tungsten source, fuel and a soluble organic carbon source as raw materials; carrying out a solution combustion synthesis reaction to obtain a precursor in which tungsten oxide and other metal oxides are uniformly embedded in a carbon matrix, and carrying out subsequent high-temperature carbonization and acid washing to remove the oxides by using a synergistic coupling pore-forming effect, thereby obtaining the porous carbon-loaded tungsten carbide material with the specific surface area of 1,000 m < 2 > / g or above. According to the invention, raw materials are easy to obtain, the process is simple, and the equipment requirement is low; the prepared porous carbon-loaded tungsten carbide powder material is fine in particle, narrow in particle size distribution and good in dispersity, has high specific surface area and pore volume, is uniformly loaded with tungsten carbide particles, is not easy to fall off, can remarkably reduce the cost of an electrocatalyst and improve the hydrogen evolution catalytic performance of the electrocatalyst as a platinum-substituted catalyst, and has a good industrial application prospect.

Owner:UNIV OF SCI & TECH BEIJING

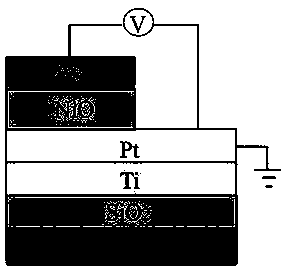

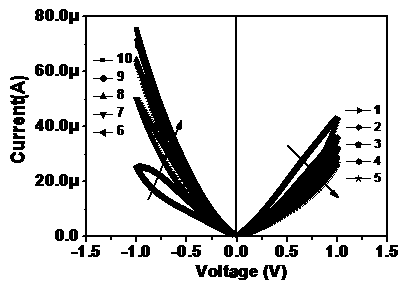

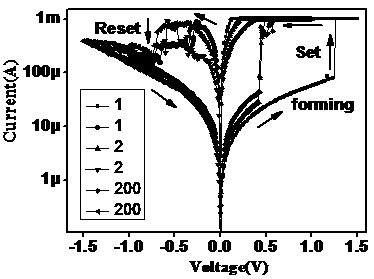

NiO-based memristor device with analog and digital multifunctions and prepared by adopting solution combustion method, and preparation method thereof

InactiveCN108365089AReduce manufacturing complexityReduce non-linear variation characteristicsElectrical apparatusSolution combustionEngineering

The invention relates to the technical field of microelectronics, and more particularly relates to a NiO-based memristor device with analog and digital multifunctions and prepared by adopting a solution combustion method, and a preparation method of the NiO-based memristor device. The NiO-based memristor device with analog and digital multifunctions and prepared by adopting the solution combustionmethod comprises a substrate, a metal bottom electrode, a NiO-based variable-resistance dielectric layer and a metal top electrode from bottom to top. The preparation of the NiO-based memristor device is characterized in that the NiO-based variable-resistance dielectric layer is prepared by adopting the solution combustion method and a coating process. The preparation method has the advantages that a variable-resistance dielectric layer thin film is prepared by adopting the solution combustion method and a printing process, and the film forming temperature is low, the equipment is simple, novacuum is required, the cost is low and the thin film is suitable for large-area preparation when compared with the traditional process of preparing thin films through vacuum deposition.

Owner:SUN YAT SEN UNIV

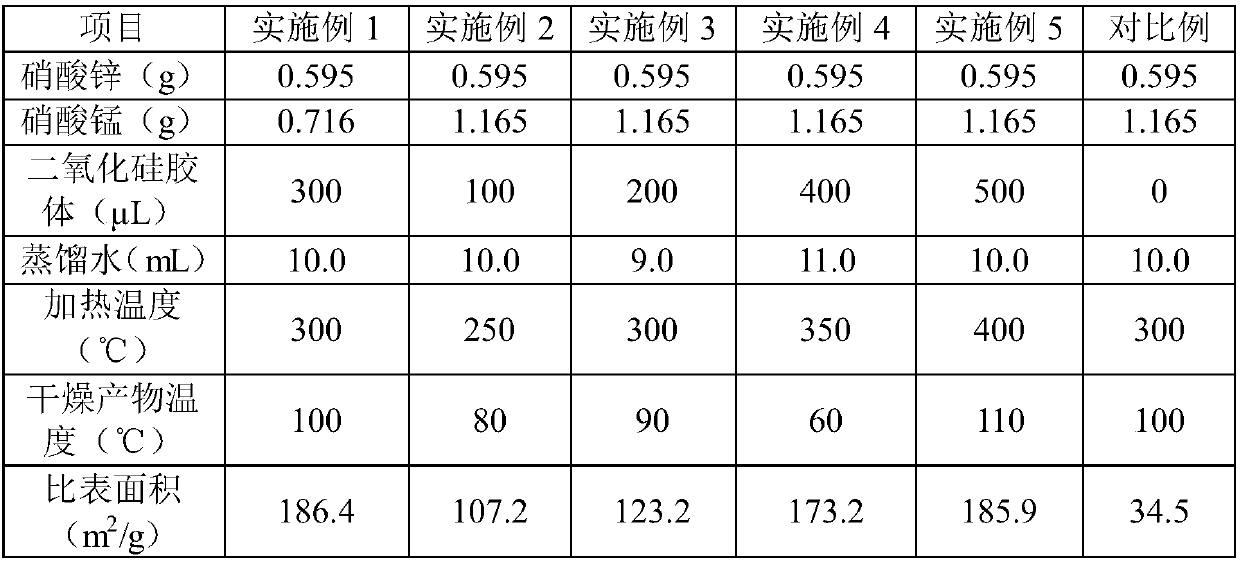

Preparation method of high specific surface area ZnMn2O4

InactiveCN107792887ALow densityLarge specific surface areaMaterial nanotechnologyManganates/permanganatesSurface-active agentsZinc nitrate

The invention discloses a preparation method of high specific surface area ZnMn2O4. The method comprises the following steps: dissolving zinc nitrate and manganese nitrate into water, then adding a right amount of glycine into the solution, stirring for dissolving, and then adding a certain amount of SiO2 colloid into the solution; heating the reaction mixture at the temperature of 250-400DEG C until a combustion reaction occurs; after the reaction is finished, washing the product with distilled water, and then etching the solid product for 24h at the temperature of 80 DEG C by using a sodiumhydroxide solution; after that, drying to obtain the high specific surface area ZnMn2O4. The preparation method provided by the invention adopts a solution combustion method, so that the temperature required to initiate the reaction is lower and is only 250-400 DEG C; a surface active agent does not need to be additionally used, batch production is easy to realize, the method is simple in technology and short in production cycle, and operation is easy to implement; the prepared ZnMn2O4 material has the characteristics of being low in density, large in specific surface area (reaching up to 186.4m<2> / g), good in permeability, and the like, thus having good application prospect in the fields such as environment, catalysis as well as energy storage and conversion.

Owner:JIANGSU UNIV OF TECH

Preparation method for ZnO two-dimensional porous material

InactiveCN102583505APromote crystallizationSimple preparation processZinc oxides/hydroxidesActive agentPhysical chemistry

The invention discloses a preparation method for a ZnO two-dimensional porous material. According to the invention, zinc nitrate is used as an oxidizing agent and a zinc source, glycine is used as a fuel, an organic / inorganic mixture is obtained through solution combustion, then organic matters are removed through heat treatment, inorganic matters are crystallized, and the ZnO two-dimensional porous material with good crystallization is obtained. Compared to conventional technologies for preparing ZnO porous powder, the method provided in the invention has the advantages of a simple process, no need for any template or surfactant and good suitability for large scale production.

Owner:ZHEJIANG UNIV

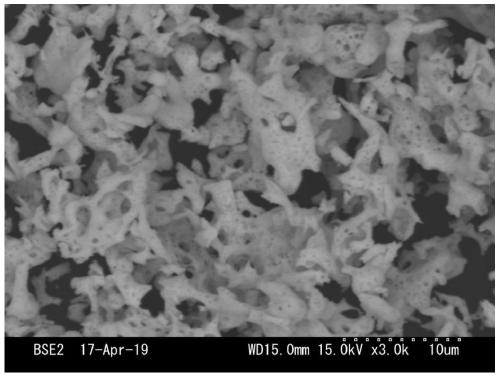

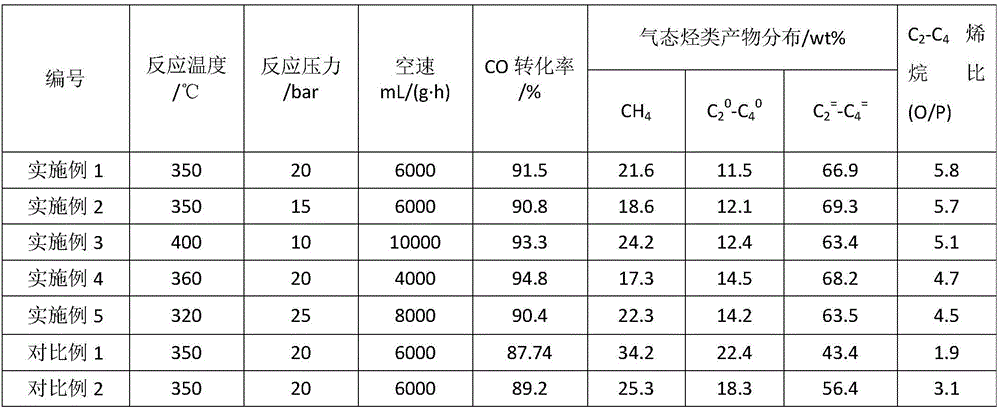

Iron-based catalyst used in preparation of low-carbon olefin from synthetic gas, and preparation method and application thereof

ActiveCN106378135AImprove technical effectGood dispersionHydrocarbon from carbon oxidesCatalystsActive componentFixed bed

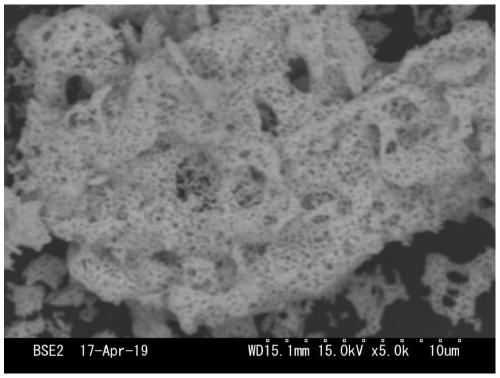

The invention discloses a preparation method for an iron-based catalyst used in preparation of low-carbon olefin from synthetic gas. According to a concrete technical scheme in the invention, the preparation method comprises the following steps: preparing an alpha-Al2O3 carrier by using a solution combustion method; and loading an active component Fe and an auxiliary agent onto the alpha-Al2O3 carrier by using an impregnation combustion method so as to prepare the iron-based catalyst. The alpha-Al2O3 carrier prepared by using the method is in a cellular and fluffy shape and has a large specific surface area, abundant pore structures and high degree of crystallization; and the active component Fe is loaded on the carrier by using the impregnation combustion method, so the preparation flow and time for the catalyst are shortened, dispersion of the active component on the carrier is promoted, and catalytic activity is improved. When the prepared iron-based catalyst is applied to preparation of low-carbon olefin from synthetic gas via a fixed bed, the selectivity of produced low-carbon olefin is high while the selectivity of methane is low, and the olefin / paraffin (O / P) ratio of C2-4 components in the product is substantially increased.

Owner:TAIYUAN UNIV OF TECH

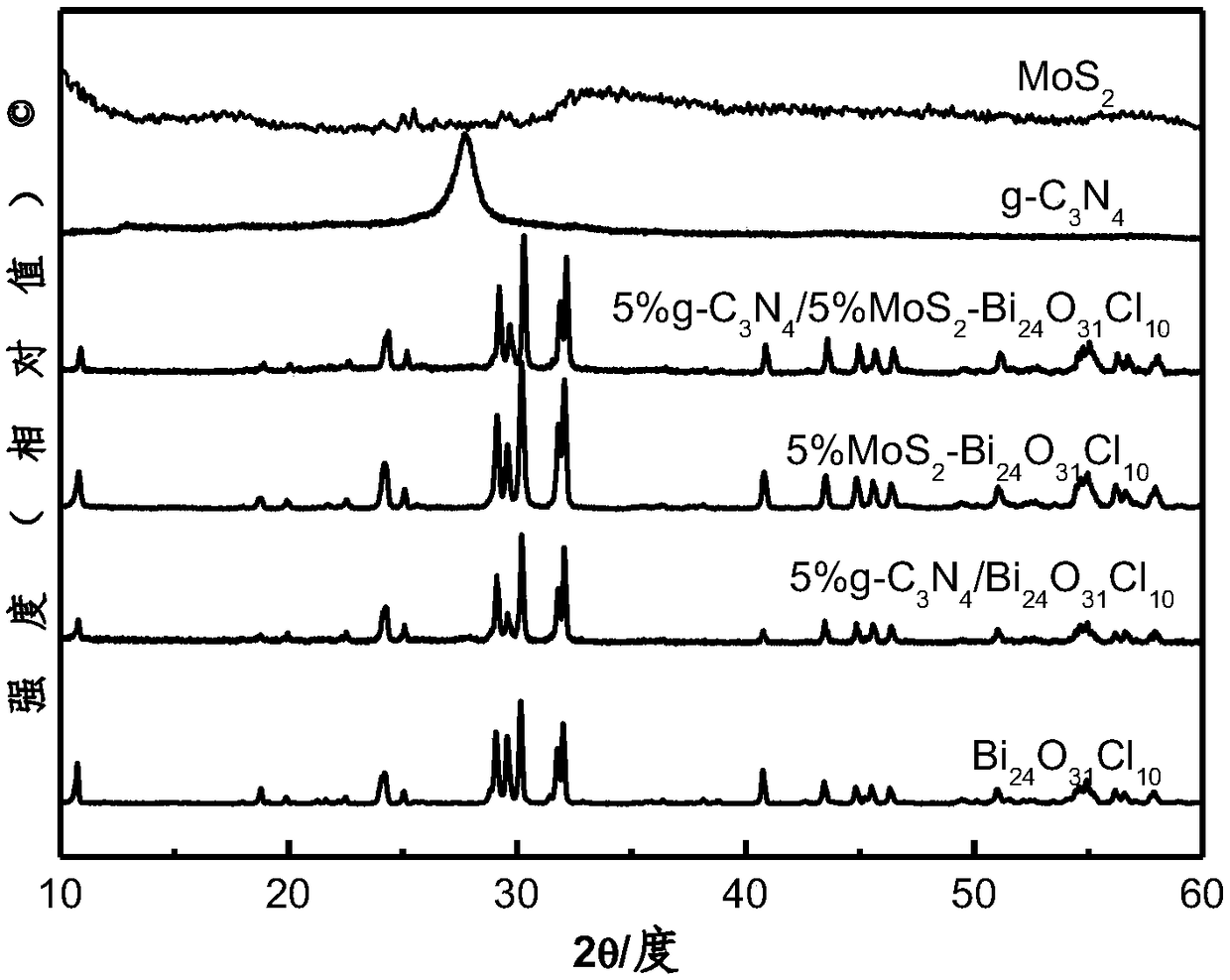

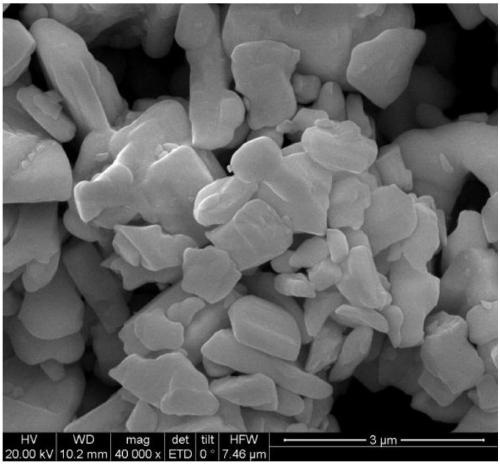

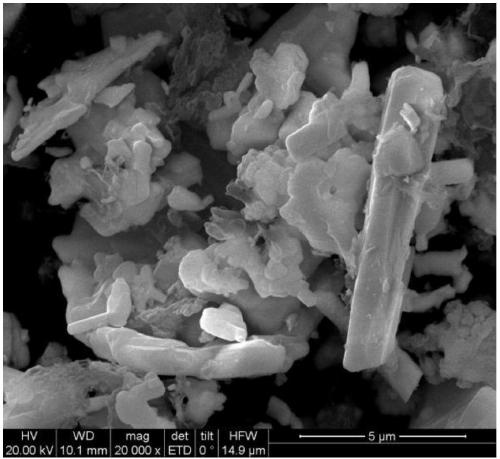

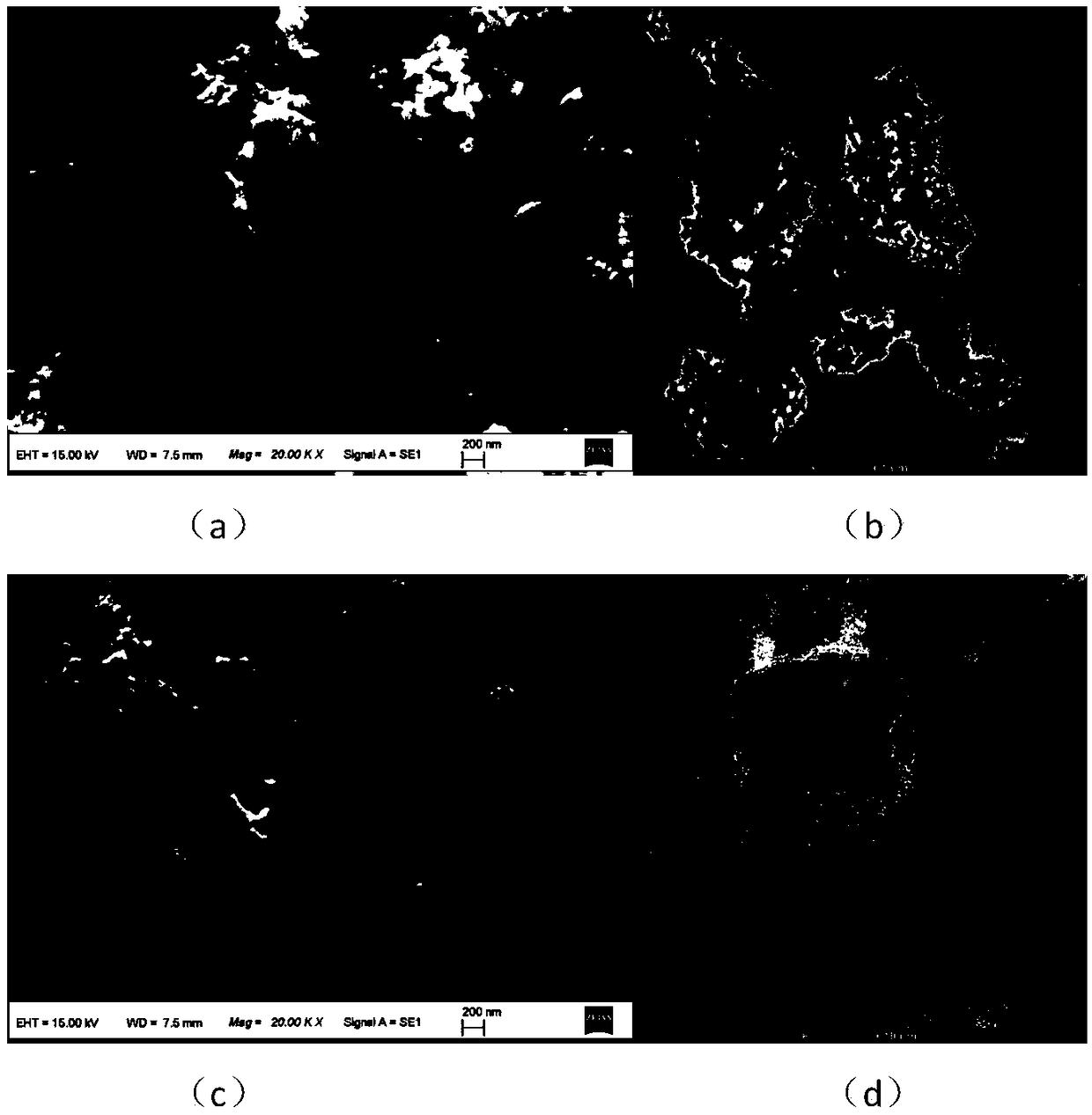

Preparation method of high-activity MoS2/g-C3N4/Bi24O31Cl10 composite photocatalyst

ActiveCN108940332AImprove photocatalytic efficiencySimple methodPhysical/chemical process catalystsWater/sewage treatment by irradiationThioureaNew energy

The invention belongs to the technical fields of new materials, new energy utilization and environmental pollution treatment, and relates to a preparation method of a high-activity MoS2 / g-C3N4 / Bi24O31Cl10 composite photocatalyst. The preparation method comprises the following steps: preparing Bi24O31Cl10 by taking bismuth nitrate, ammonium chloride and citric acid as raw materials through an improved solution combustion method; preparing g-C3N4 by taking melamine and acetic acid as raw materials through a one-step thermal polymerization method; preparing MoS2 by taking ammonium molybdate and thiourea as a raw material and dimethylformamide as a solvent through a hydrothermal method; and carrying out an ultrasonic mixing reaction on the Bi24O31Cl10 subjected to ultrasonic dispersion with the g-C3N4 and the MoS2 in a methanol solution, and then carrying out washing, centrifuging and drying to obtain the composite photocatalyst. The method is simple, is easy to implement, is low in cost and good in repeatability, and has a wide application prospect in the fields of water photodecomposition, photocatalytic oxidation of environment pollutants, and the like.

Owner:NORTHEASTERN UNIV

RGO/Cu composite material and preparation method thereof

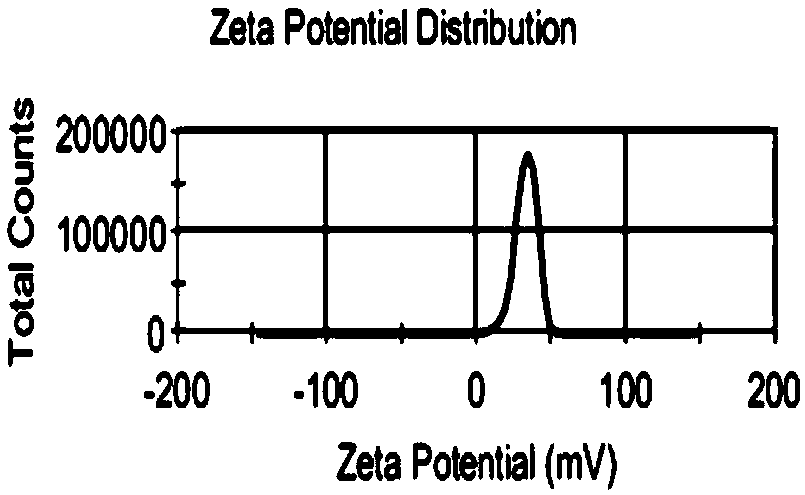

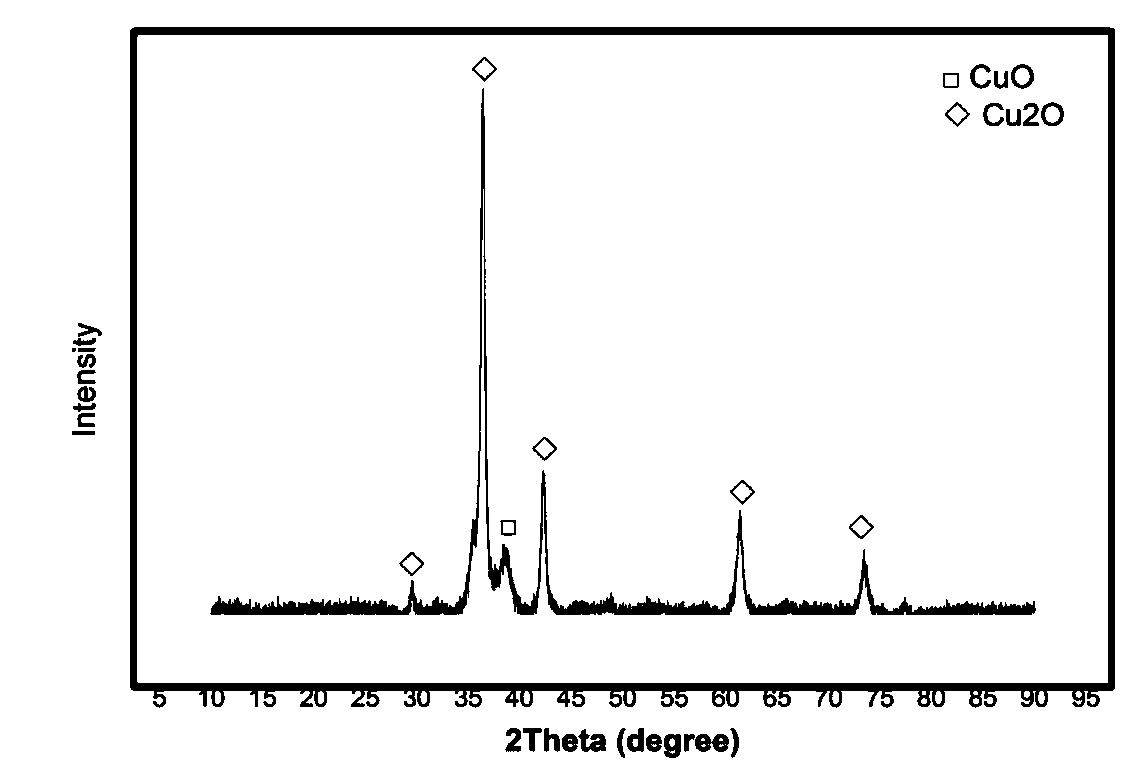

The invention relates to an rGO / Cu composite material and a preparation method thereof. Porous sheet-shaped Cu2O is prepared through a solution combustion method, and the copper-base composite material with a different rGO content is prepared through a transposition strategy. When prepared cuprous oxide suspension liquid and graphene oxide colloids are mixed, positive charge-carried Cu2O colloidsare tightly adsorbed on the surfaces of negative charge-carried GO colloids, and therefore GO is evenly dispersed. RGO restrains the growth of particles during reduction, it is ensured that the rGO / Cucomposite material in a powder shape has high sintering activity, and the relative density of sintering is easily increased. Under a grain refinement and dislocation resistance mechanism, rGO is evenly dispersed in a copper matrix, so that the rGO / Cu composite material is enhanced.

Owner:HUNAN UNIV

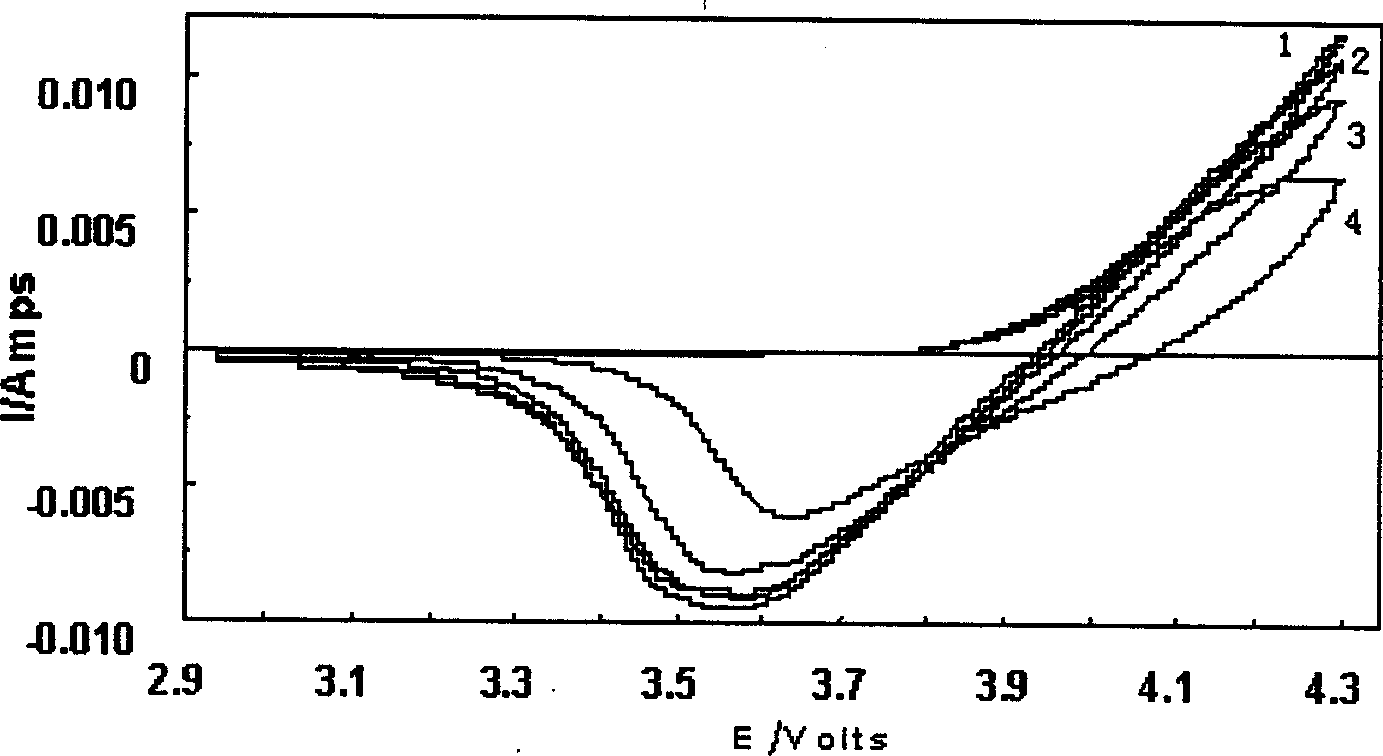

Method of synthetizing lithium ion cell positive electrode material through solution burning

InactiveCN1564345AAchieving stoichiometric ratiosReduce mixElectrode manufacturing processesSecondary cellsCarboxylic acidLyonium ion

In the invention, nitrate is as oxidant; organic carboxylic acid is as fuel. Mixing water solution is prepared by according mol ratio lithium nitrate : nitrate M(NO3)2 : organic carboxylic acid = 1.0-1.2 : 1 : 0.5-2.5. Through burning reaction of solution, the following results are reached: each metallic ion is mixed evenly in atom level; active powder material of anode of lithium ion cell LiMO2(M=Co1-x, Nix, Co1-xMnx) in super fine granularity is obtained; holding temp and holding time can be reduced, and energy is saved.

Owner:UNIV OF SCI & TECH BEIJING

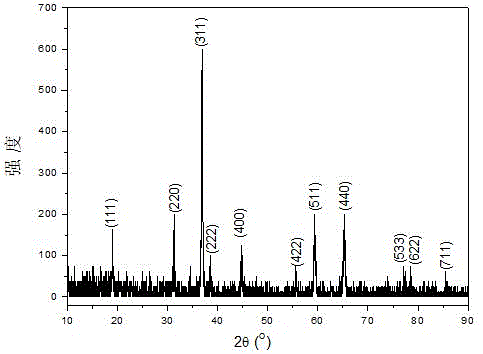

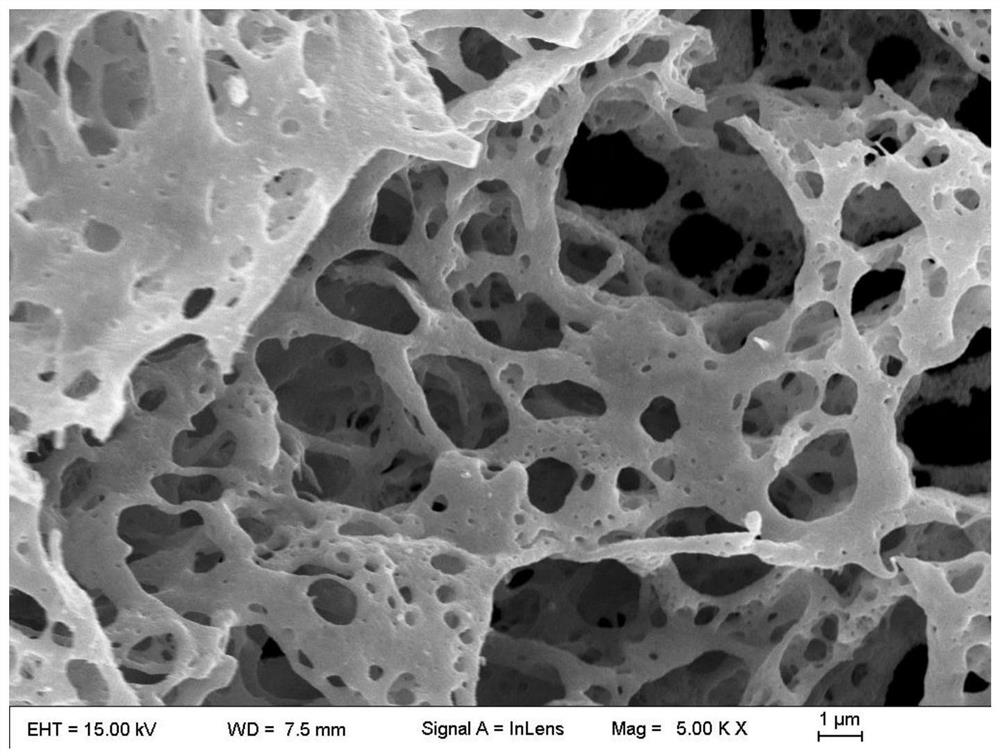

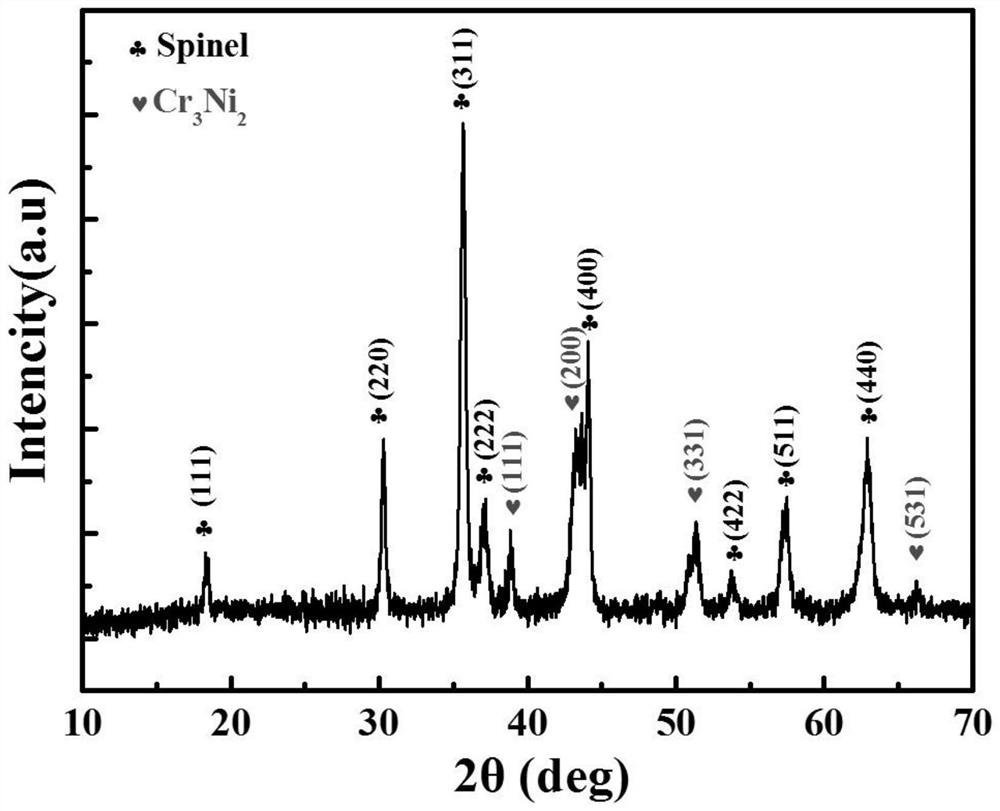

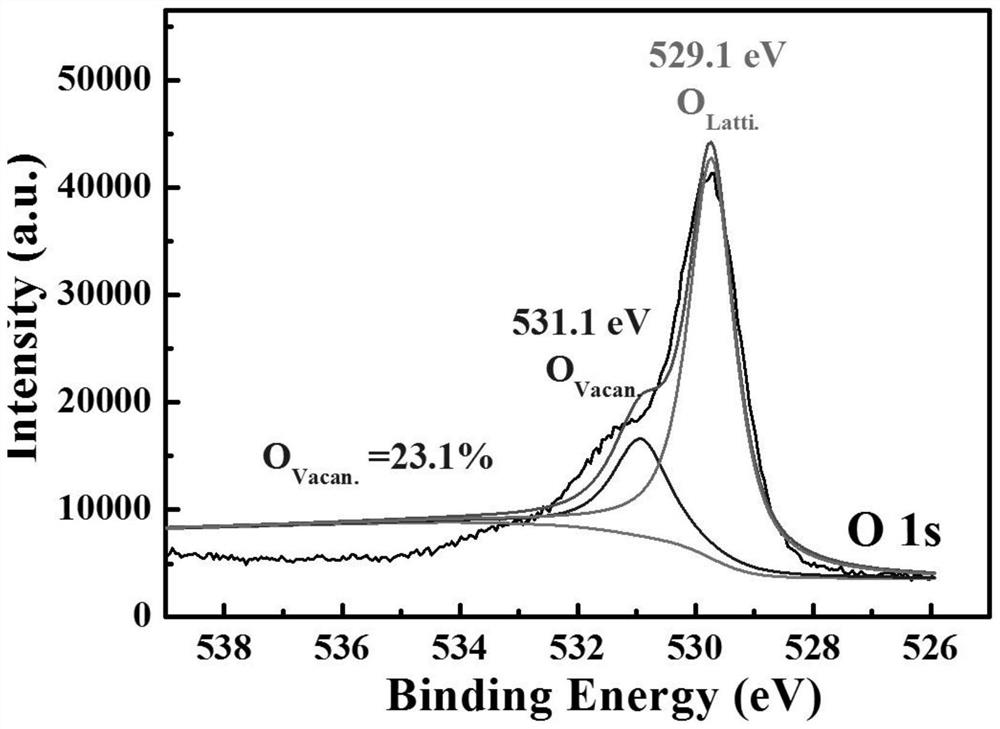

High-entropy oxide lithium ion battery negative electrode material with high conductivity and preparation method thereof

ActiveCN112599749AImprove conductivityIncrease oxygen vacanciesCell electrodesSecondary cellsChemical physicsElectrical battery

The invention discloses a high-entropy oxide lithium ion battery negative electrode material with high conductivity and a preparation method, a chemical formula of the high-entropy oxide lithium ion battery negative electrode material is (CoCrCuFeNi)3 / 5O4-delta, and delta is oxygen vacancy concentration; according to the material, reasonable metal elements Co, Cr, Cu, Fe and Ni are selected, and asmall amount of dispersedly distributed high-conductivity metal particles are introduced into a spinel type high-entropy oxide matrix through a solution combustion reaction one-step method; on the other hand, oxygen vacancy of the spinel type high-entropy oxide is improved by controlling the reaction conditions. By introducing high-conductivity dispersed metal particles and oxygen vacancies, theconductivity of the spinel type (CoCrCuFeNi)3 / 5O4-delta high-entropy oxide lithium ion negative electrode material is improved, so electrochemical performance is improved; by regulating and controlling reaction conditions, lithium ion negative electrode materials with different contents of oxygen vacancies and dispersed conductive metal particles can be prepared, and certain specific use requirements are met.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Preparation method and application of spherical tantalum pentoxide

InactiveCN103274468ASimple methodAchieve energy saving and emission reductionElectrolytic capacitorsTantalum compoundsPhysical chemistrySolution combustion

The invention belongs to the technical field of photocatalytic materials, and particularly relates to a preparation method and application of spherical tantalum pentoxide. The preparation method comprises steps as follows: a solution containing a certain amount of tantalum ethoxide is firstly prepared as a raw material, and then ignited with naked fire; in the solution combustion process, water and CO2 are generated, and tantalum ethoxide and the generated water are subjected to hydrolysis reaction on the interface; and Ta2O5 is continuously generated on the interface as the combustion process proceeds, and finally disappears when all the solution is combusted, thereby forming the Ta2O5 spherical powder material. The experiment indicates that the nano spherical Ta2O5 powder prepared by the method can be used for photocatalytic degradation of organic pollutants or preparation of dye-sensitized solar cell photoanodes. Compared with the prior art, the method provided by the invention has the advantages of simple technique, no need of special equipment, and no generation of any waste liquid, and can implement energy saving and emission reduction in the production process.

Owner:FUDAN UNIV

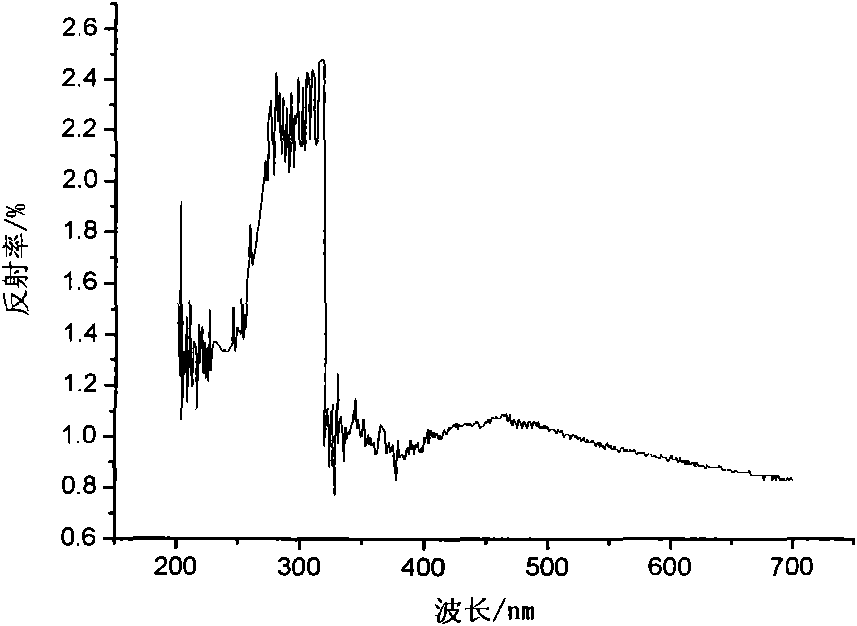

Method for processing explosive wastewater

InactiveCN103214058AHigh saturation magneticLow coercivityWater/sewage treatment by irradiationOther chemical processesCerium nitrateUltraviolet lights

The invention relates to a method for preparing ultrafine perovskite type La1-xCexMn0.1Fe0.9O3-d (x=0.1-0.3) by a stearic acid solution combustion method. The method comprises the following steps: weighting lanthanum nitrate, cerium nitrate, manganese chloride, ferric nitrate and stearic acid according to mole ratio of 1-x: x: 0.1: 0.9: (7-10)(x=0.1-0.3), under the condition of oil bath heating, melting stearic acid, performing magnetic stirring at constant temperature, melting cerium nitrate, manganese chloride and a ferric nitrate solid in molten stearic acid, controlling the temperature of 120-125 DEG C, reacting for more than 6 hours to generate a stearic acid solution, placing in a muffle furnace at the temperature of about 300-500 DEG C, heating for combusting to obtain a precursor mixed oxide, then calcining in the muffle furnace at the temperature of 700-800 DEG C to obtain the perovskite type La1-xCexMn0.1Fe0.9O3-d (x=0.1-0.3) ultrafine powder, adding the obtained perovskite type catalyst La1-xCexMn0.1Fe0.9O3-d (x=0.1-0.3) in 10-150 mg / L of TNT model explosive waste water, adjusting the pH value of waste water to 3-5, stirring at room temperature and adsorbing for 1-30 minutes, and then irradiating for 0-2 hours under ultraviolet light and sunlight.

Owner:ZHONGBEI UNIV

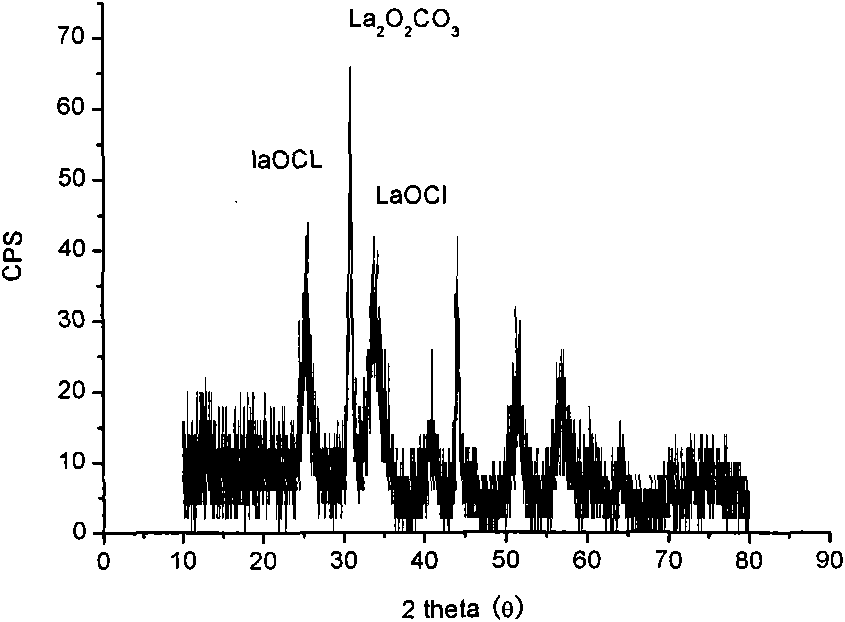

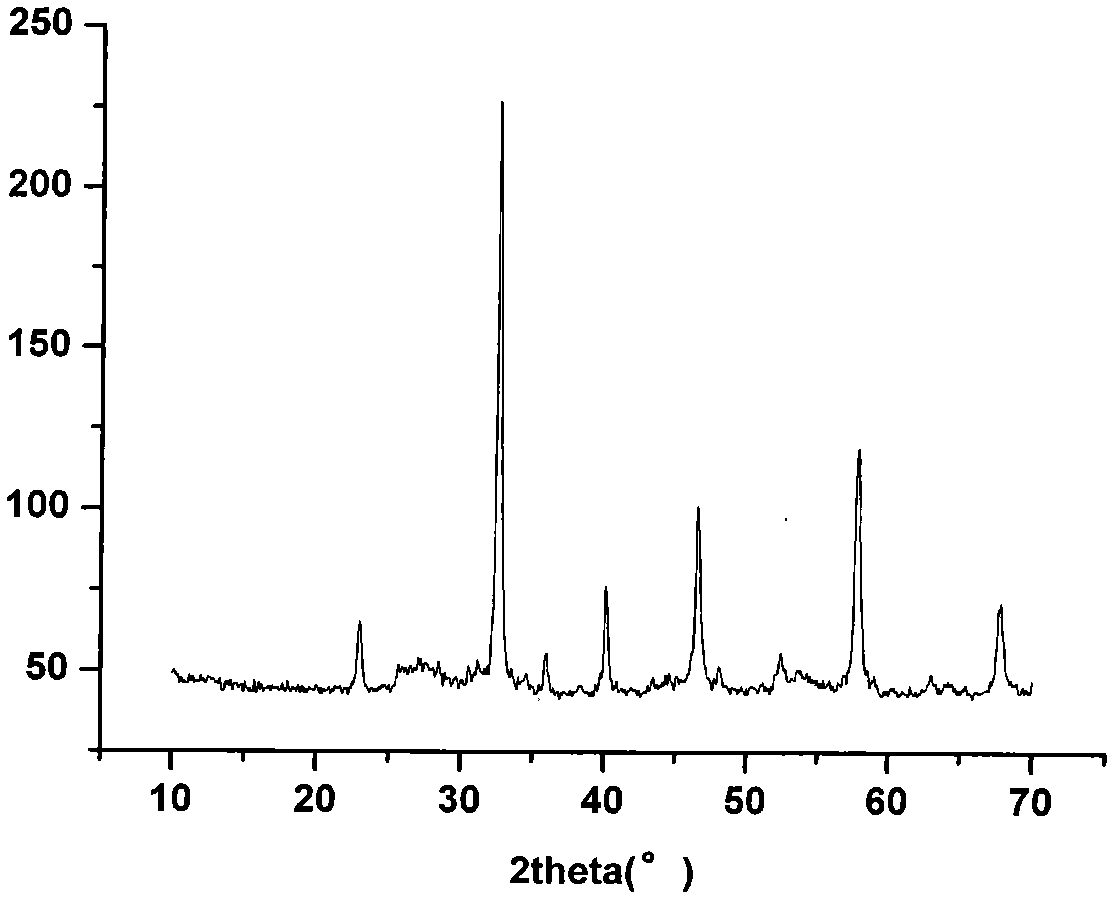

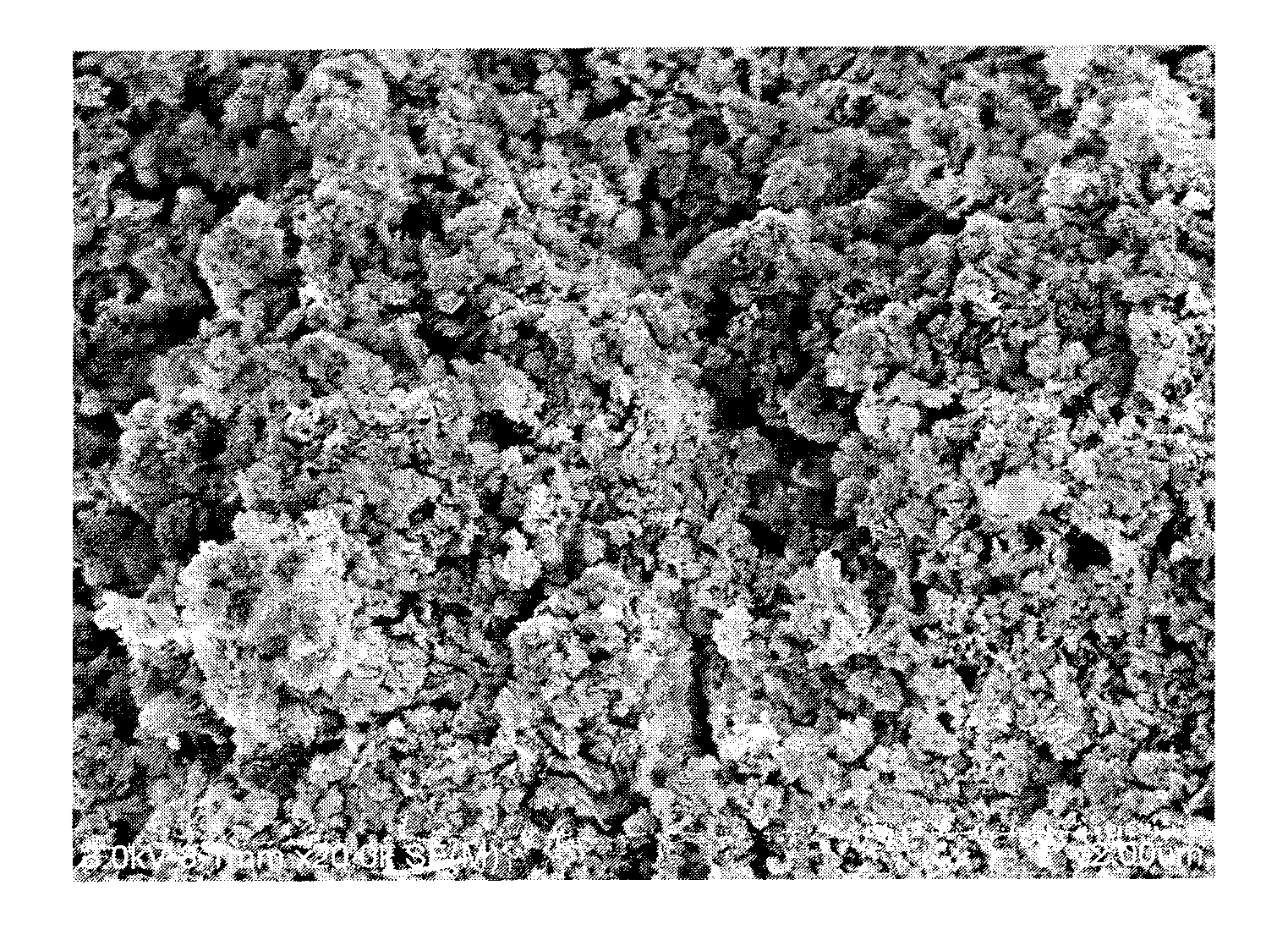

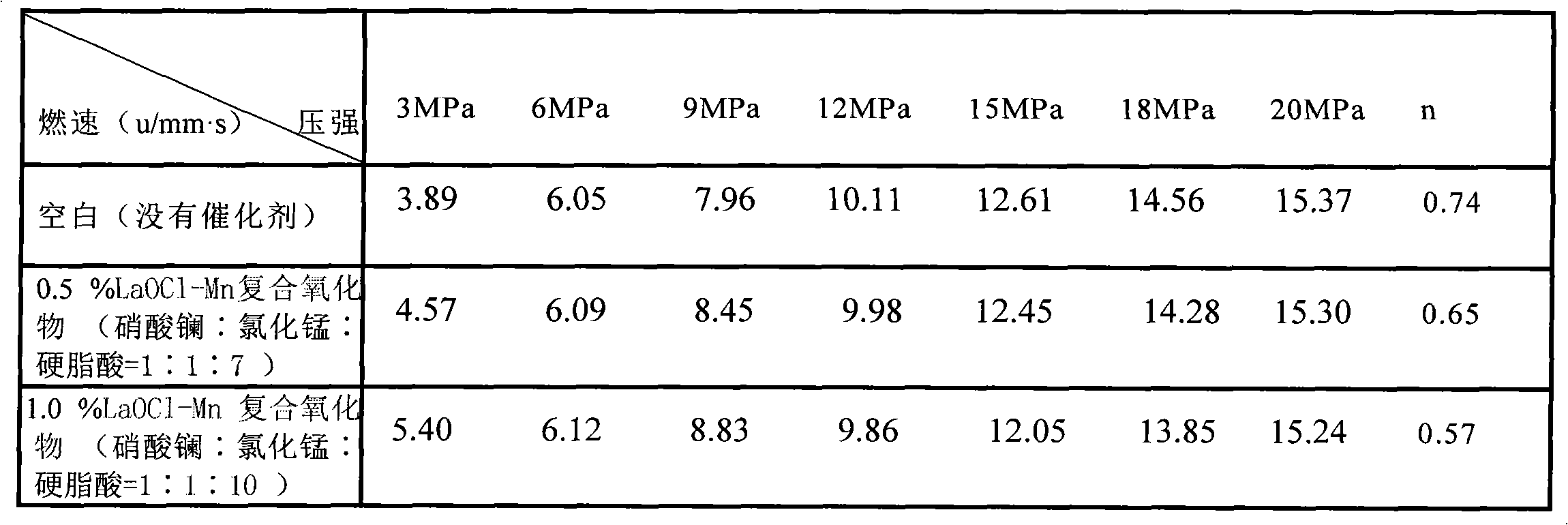

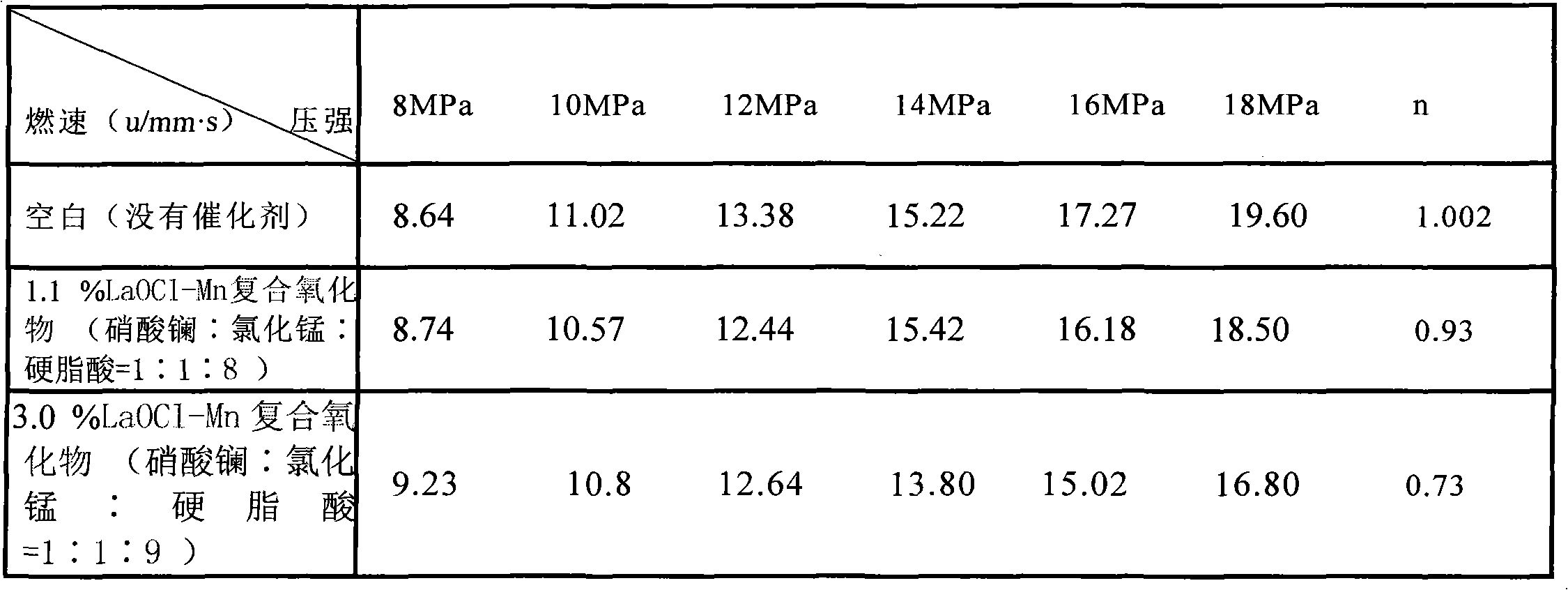

Catalyst for accelerating burning rate used for reducing pressure exponent of nitramine propellant

InactiveCN103212429AGood compatibilitySimple manufacturing processPhysical/chemical process catalystsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsHigh energyChloride

The invention relates to a method for preparing LaOCl-Mn composite oxide by using an eleaostearic acid solution combustion method, which comprises the following steps: 1) weighting lanthanum nitrate, manganese chloride and eleaostearic acid according to mol ratio of 1:1:x(x=7.0-10.0), under the oil bath heating condition, melting eleaostearic acid, performing magnetic stirring at constant temperature, melting lanthanum nitrate and manganese chloride solids in the melted eleaostearic acid, controlling the temperature at 110-118 DEG C to generate an uniform eleaostearic acid complex solution, placing in a muffle furnace at 500-600 DEG C, and then combusting to obtain the LaOCl-Mn composite oxide. The obtained LaOCl-Mn composite oxide can be directly used in the nitramine high energy propellant, thereby the pressure exponent of the propellant is reduced, and the combustion performance of the propellant is increased. The employed preparation technology has the advantages of rapidity, simpleness and convenience, the required raw materials are easily available and nontoxic, the preparation technology can realize industrialization easily.

Owner:ZHONGBEI UNIV

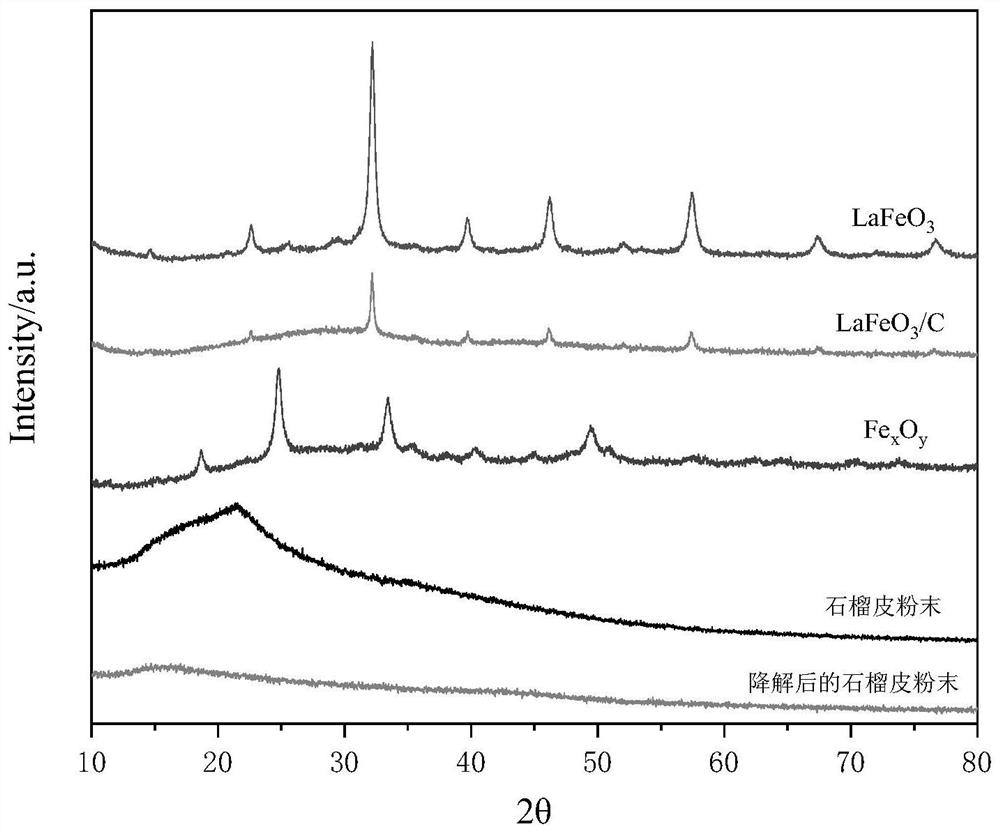

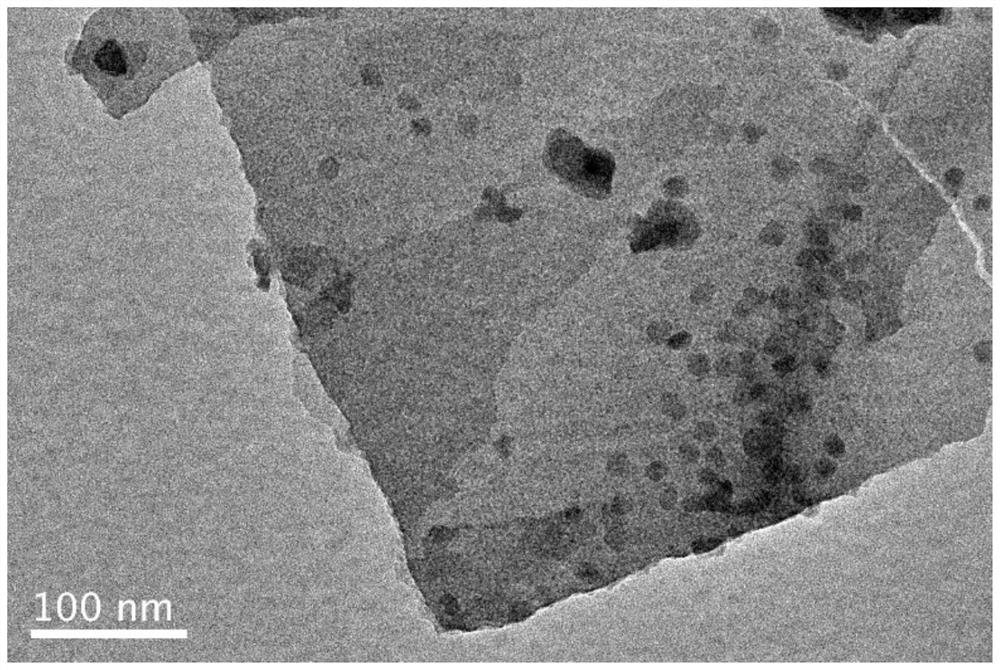

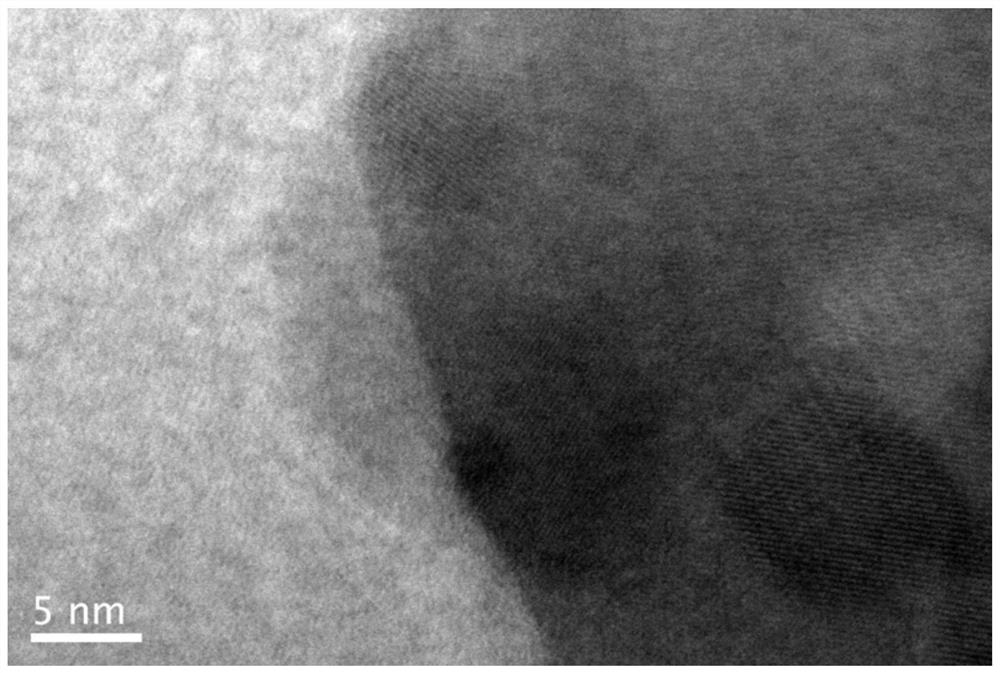

Method for preparing rare earth perovskite/biochar composite material from forestry and agricultural residues and application of rare earth perovskite/biochar composite material

ActiveCN112604690AIncrease temperatureReduce reunionMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionAgricultural residueEnvironmental engineering

The invention belongs to the field of green synthesis of carbon-based composite materials, and particularly relates to a method for preparing a rare earth perovskite / biochar composite material from forestry and agricultural residues and application of the rare earth perovskite / biochar composite material. The method comprises the following steps: cleaning, drying and grinding forestry and agricultural residues, adding the ground forestry and agricultural residues, rare earth nitrate and transition metal nitrate into deionized water in proportion, and conducting heating and stirring in a water bath to obtain turbid liquid; dropwise adding ammonia water to adjust the pH value to be neutral, and conducting drying and grinding to obtain powder; and calcining the obtained powder in a muffle furnace, conducting grinding to obtain the rare earth perovskite / biochar composite material. The rare earth perovskite / biochar composite material is applied to photocatalytic synthesis of ammonia. A two-dimensional biochar nanosheet loaded rare earth perovskite composite material is prepared from rich forestry and agricultural residues in nature as raw materials by a solution combustion method at a low temperature, and has the advantages of good dispersibility, low raw material cost, simple and convenient synthesis method and the like, and the prepared rare earth perovskite / biochar composite material has an excellent photocatalytic synthesis ammonia effect.

Owner:CHANGZHOU UNIV

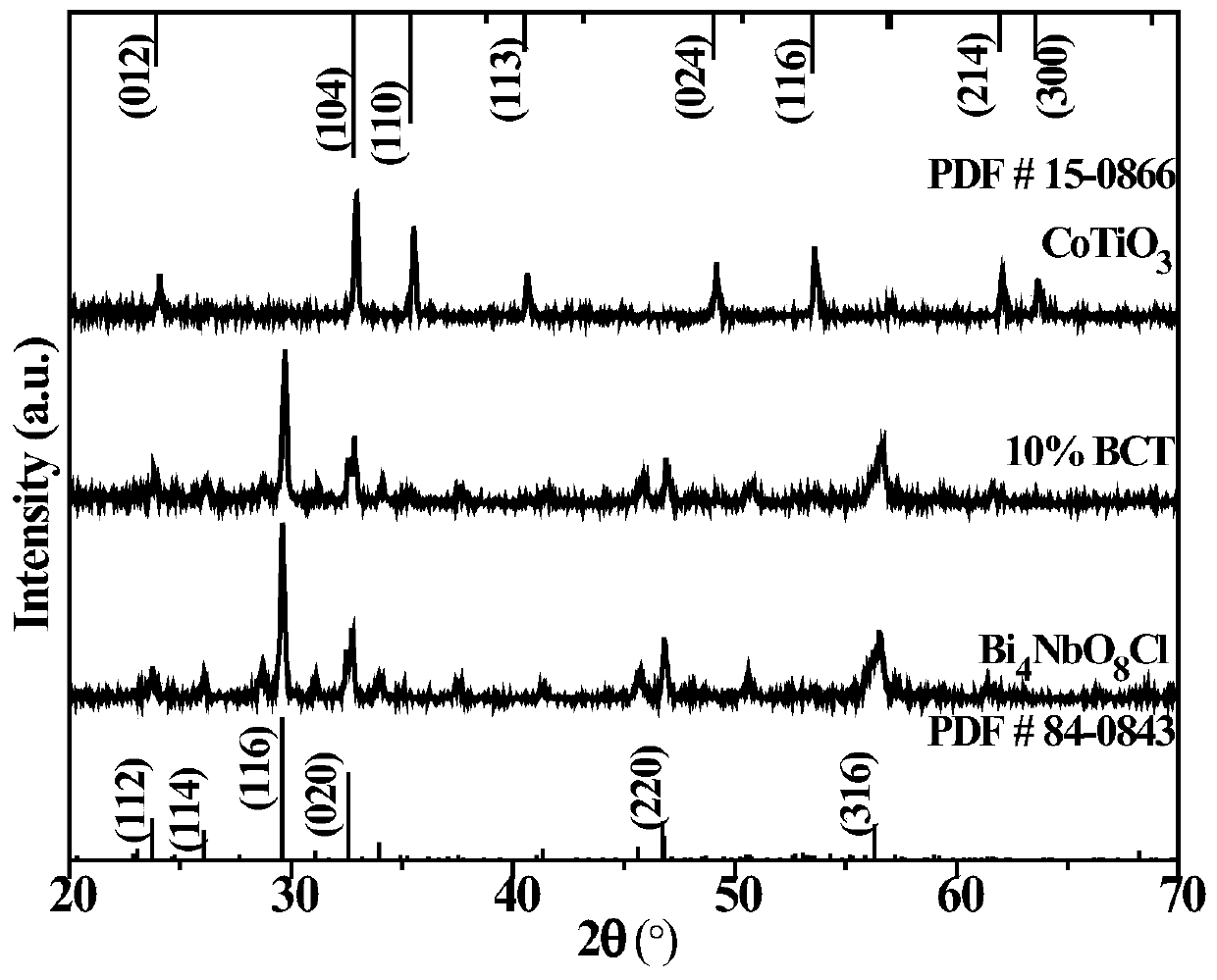

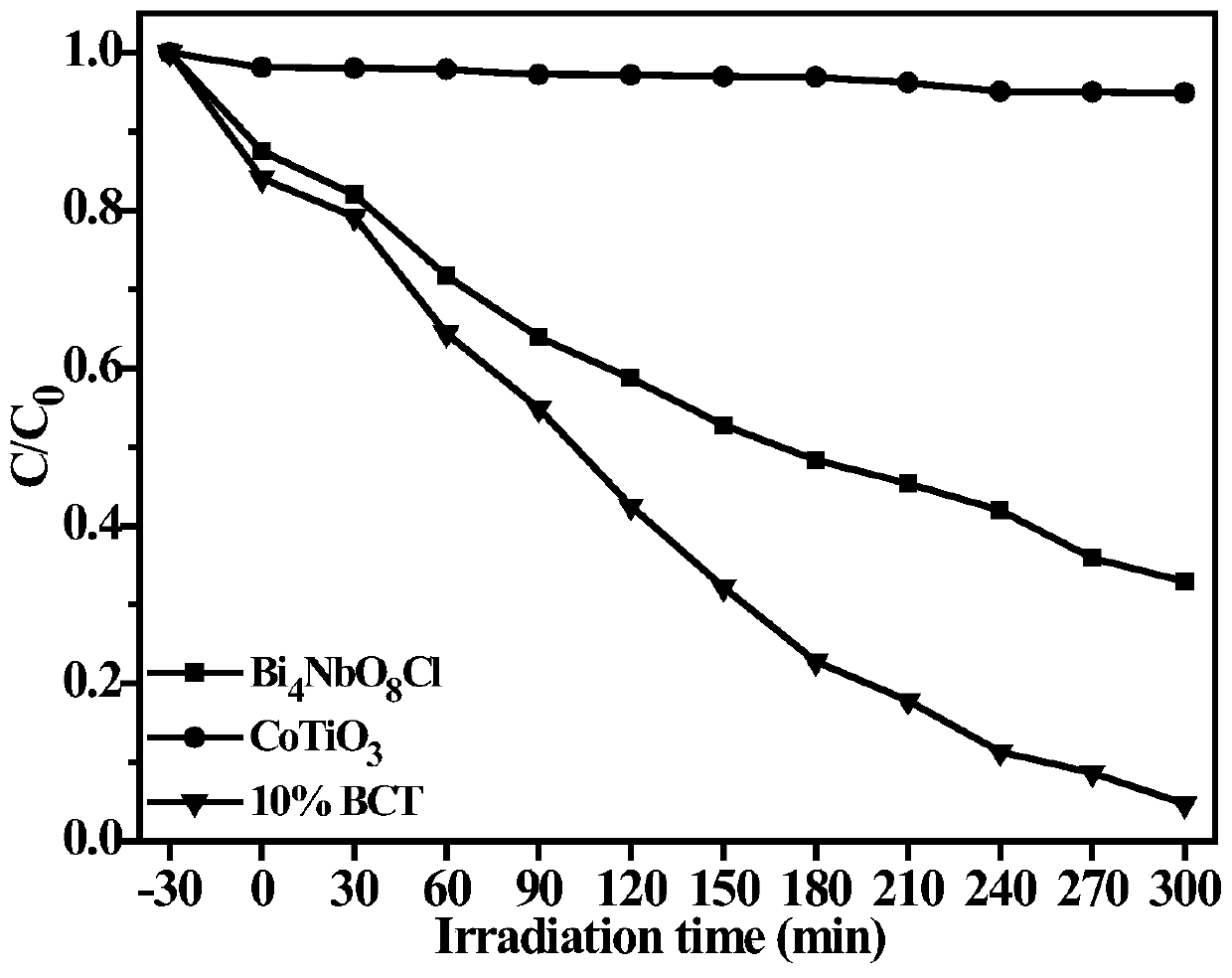

Preparation method of CoTiO3/Bi4NbO8Cl composite photocatalyst material

InactiveCN110605128AEasy to prepareLow costWater/sewage treatment by irradiationWater treatment compoundsHeterojunctionSemiconductor materials

The invention belongs to the field of photocatalysts, and provides a CoTiO3 doped Bi4NbO8Cl composite photocatalyst for degrading organic wastewater and a preparation method of same. Bi4NbO8Cl powderand CoTiO3 powder are prepared through a solution combustion method and a precipitation calcination method respectively, and then the CoTiO3 / Bi4NbO8Cl composite photocatalyst is prepared through mechanical means such as grinding and ultrasonic treatment. The Bi4NbO8Cl is of a single-layer perovskite structure formed by [Bi2O2]<2+>, [NbO4]<3->, [Bi2O2]<2+> and [C1]<->, and the interior of the Bi4NbO8Cl has a strong electric field, so that better electron and hole separation can be caused to enhance the photocatalytic activity. CoTiO3 is used as an excellent narrow-band-gap semiconductor material of ABO3 type perovskite oxide, and has good photoresponsiveness in a visible light region. The CoTiO3 and the layered Bi4NbO8Cl are compounded to form the heterojunction photocatalyst, so that the visible light response range of the Bi4NbO8Cl is widened, the compounding efficiency of photon-generated carriers is reduced, the photocatalytic efficiency of the photocatalyst is improved, and the photocatalytic degradation efficiency of the photocatalyst on organic wastewater is improved.

Owner:青岛耀创高新科技有限公司 +1

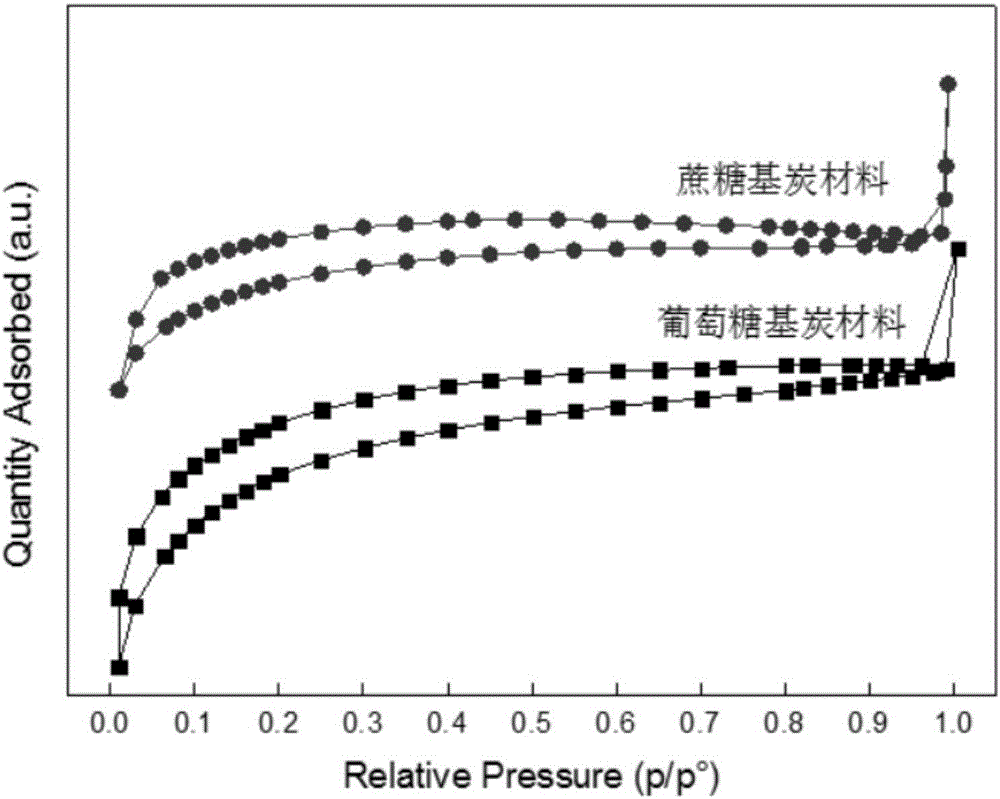

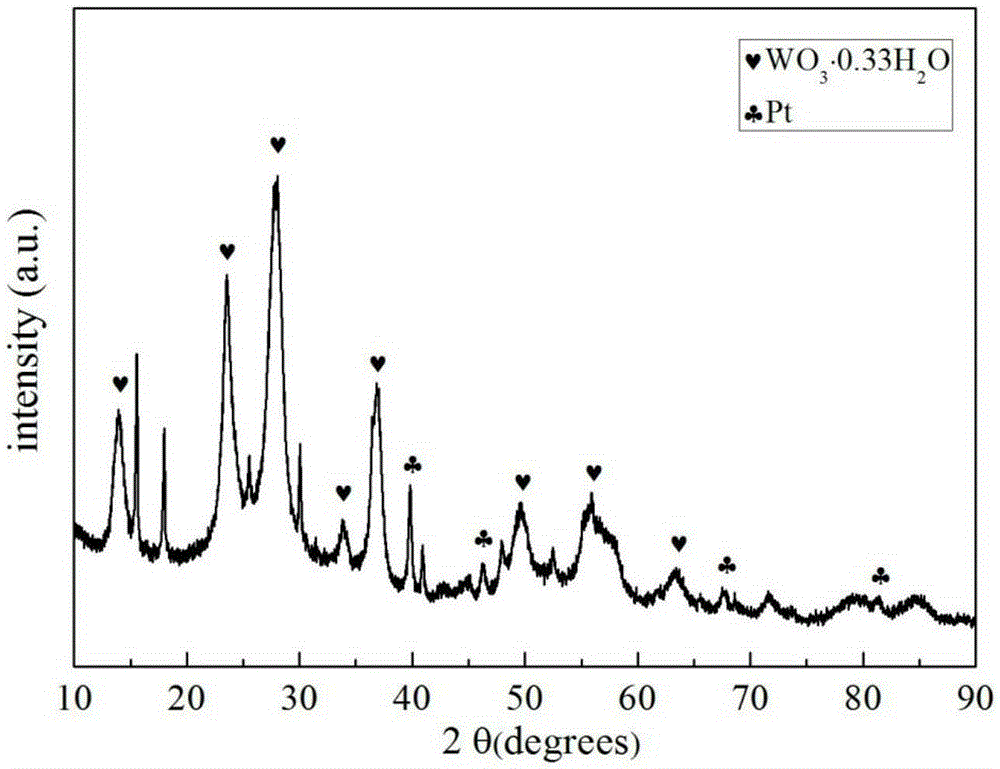

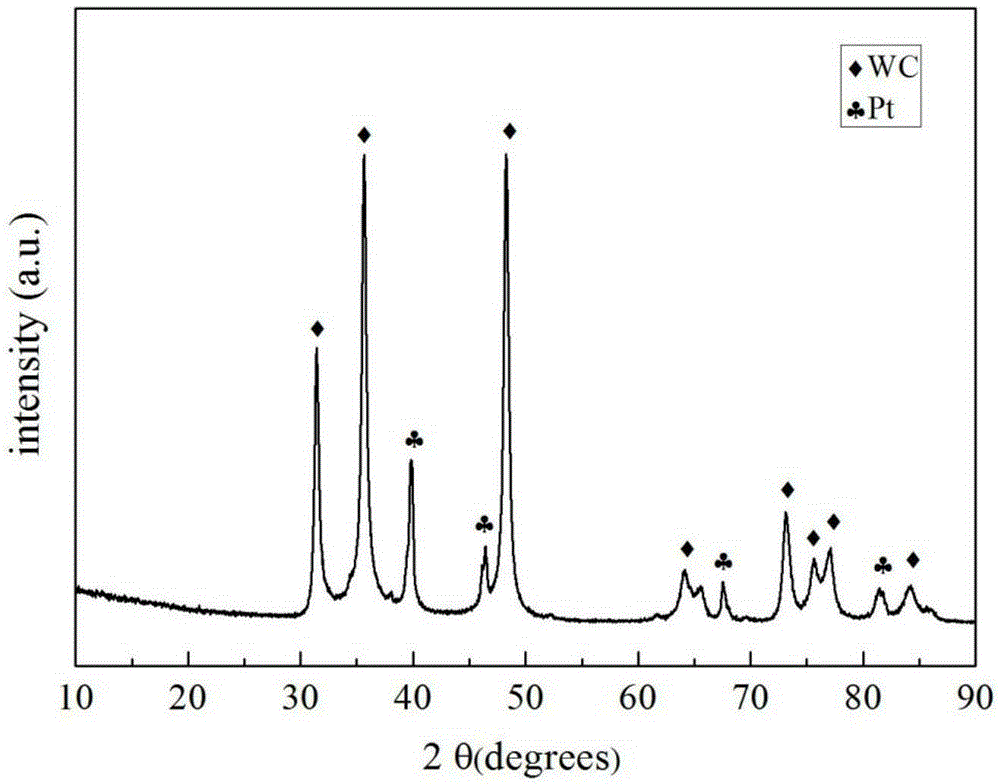

Method for preparing tungsten carbide platinum-loading catalyst in solution combustion synthesis mode

ActiveCN105312070AQuick and easy to manufactureHigh reactivityPhysical/chemical process catalystsNano catalystTungstate

The invention provides a method for preparing a tungsten carbide platinum-loading catalyst in a solution combustion synthesis mode, and belongs to the technical field of nano-catalyst powder preparing. Ammonium tungstate serves as a tungsten source, chloroplatinic acid serves as a platinum source, water-soluble organic substances such as citric acid, glucose and saccharose serve as carbon sources, urea serves as fuel, and nitric acid serves as an oxidizing agent. The technology process includes the steps that 1, the ammonium tungstate, the chloroplatinic acid, the carbon sources, the urea and the nitric acid are dissolved into distilled water in a certain proportion; 2, the mixed solution is heated and stirred on a closed electric furnace, and the solution is volatilized and concentrated to precursor powder; 3, after the precursor powder is ground, a carbonization reaction is carried out in a tube furnace shielded with argon, the reaction temperature is controlled to range from 900 DEG C to 1,100 DEG C, the reaction time is 4 hours to 10 hours, and tungsten carbide platinum-loading catalyst powder is obtained after the reaction is finished. The method is simple in preparing technology and short in production cycle, industrial production is facilitated, and the prepared Pt / WC catalyst has the large-scale application and popularization potential.

Owner:UNIV OF SCI & TECH BEIJING

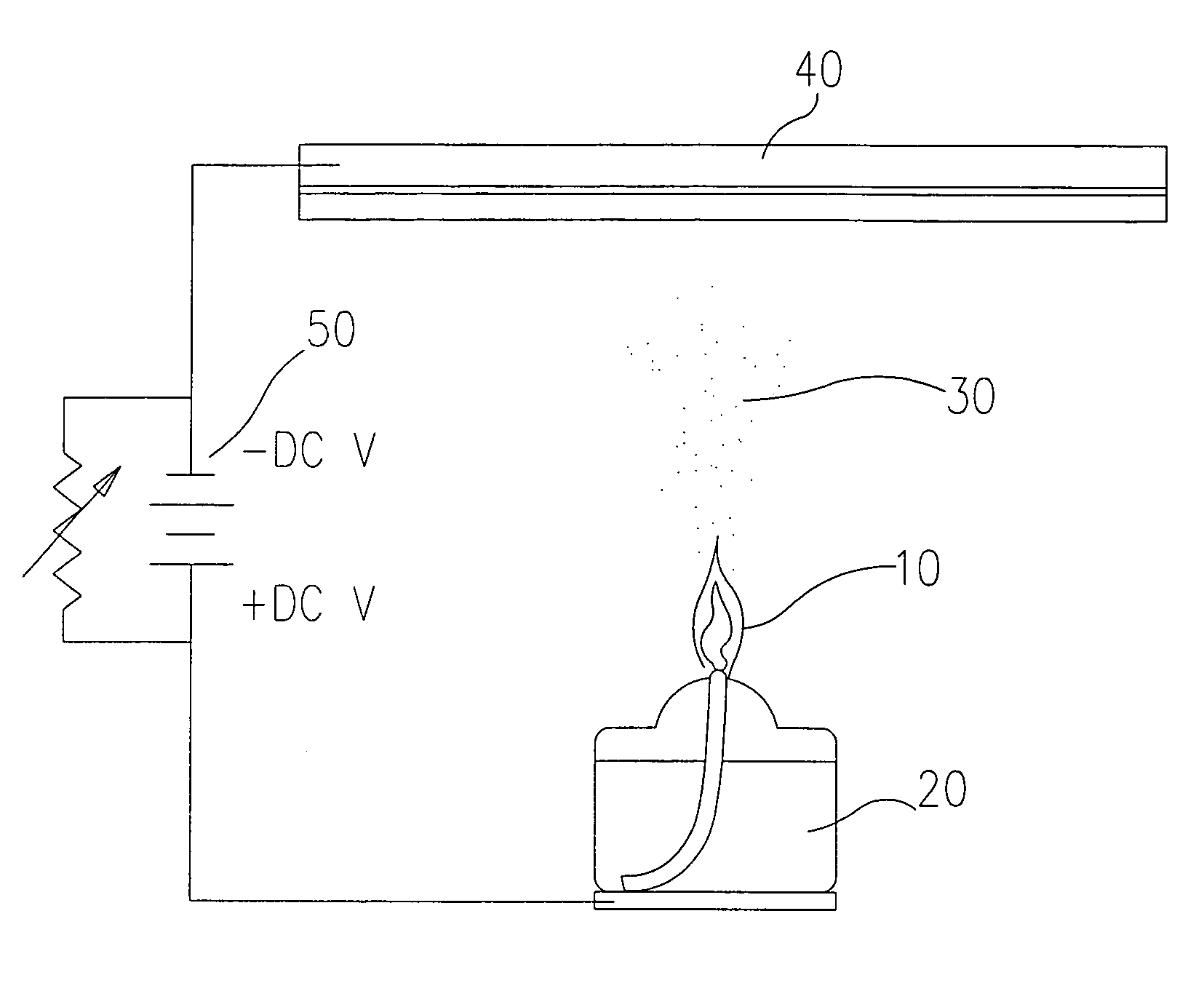

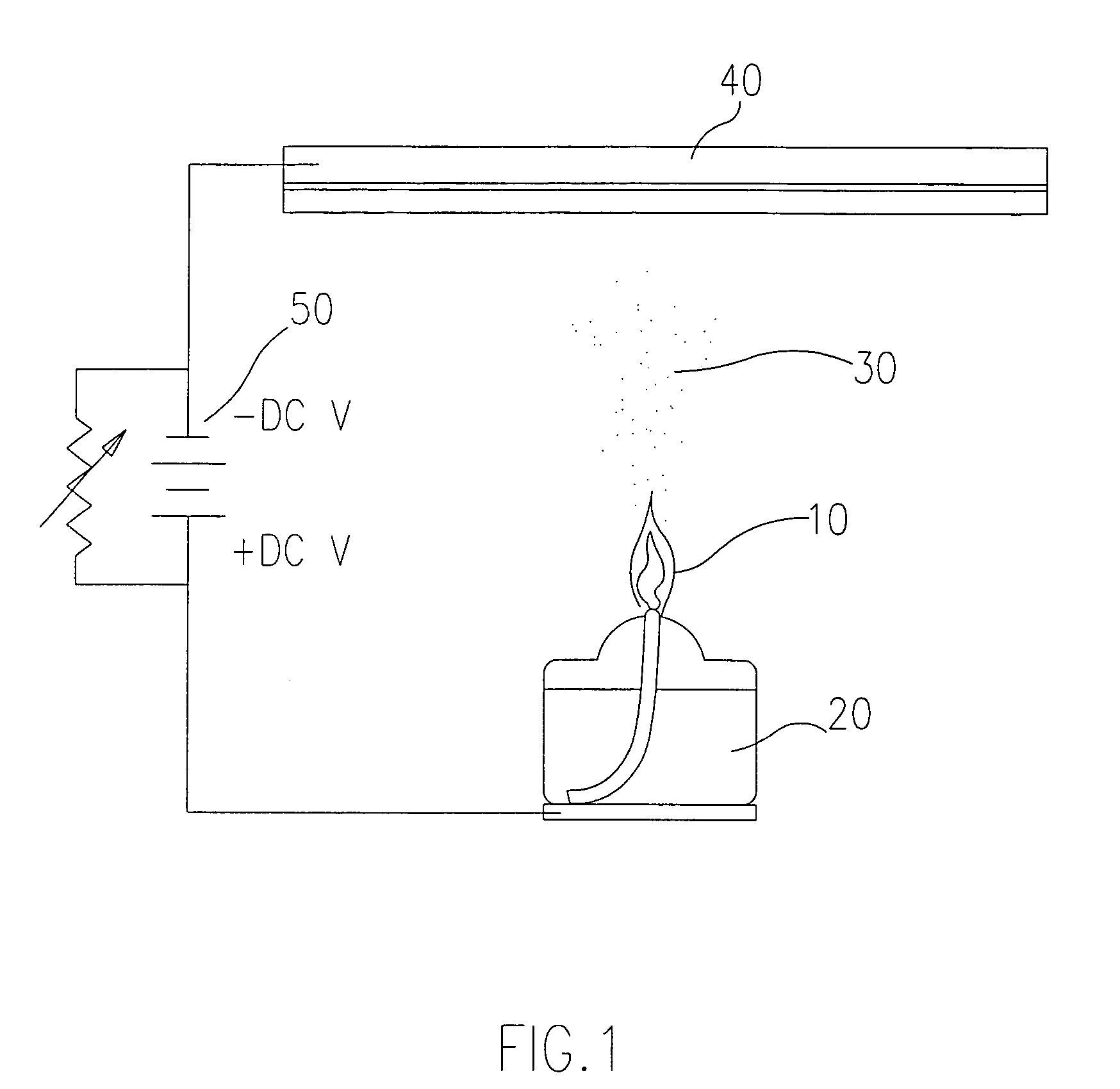

Flame synthesis and non-vacuum physical evaporation

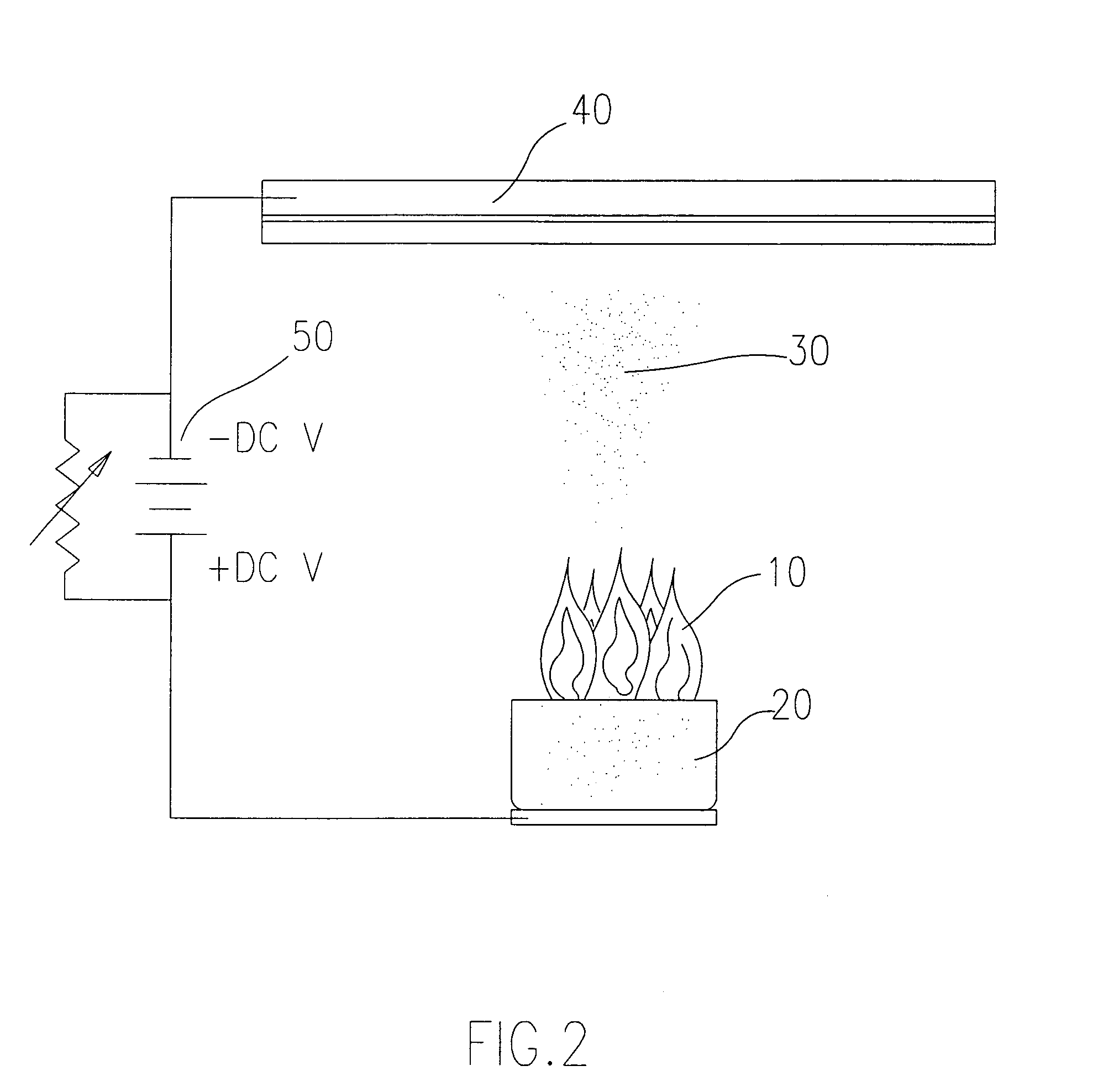

InactiveUS7066977B2Quality improvementHigh surface energyRare earth metal oxides/hydroxidesMaterial nanotechnologyOrganic solventEvaporation

A method for producing fine or ultra fine powder particles comprising mixing a metal alkoxide with a non-metallic hydride in an organic solvent, agitating the mixed solution, and then burning the mixed solution. The burning process comprises igniting the solution directly or burning the solution in situ. A self-sustaining flame will result. When the precursor solution burns, the metallic compound will be co-fired with the organic solvent. As a result, fine or ultra fine particles of mixed metal will burst from the flame, or thrust through the flame and be synthesized.

Owner:HUANG FU KUO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com