Method of synthetizing lithium ion cell positive electrode material through solution burning

A technology for lithium ion batteries and cathode materials, which is applied in the field of preparation of energy functional materials, can solve the problems of uneven diffusion of transition metal ions in solid-phase reactions, time-consuming and energy-consuming synthesis of active materials, and high synthesis temperature, and achieves reduced energy consumption and heat preservation. The effect of short time and fast self-burning speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

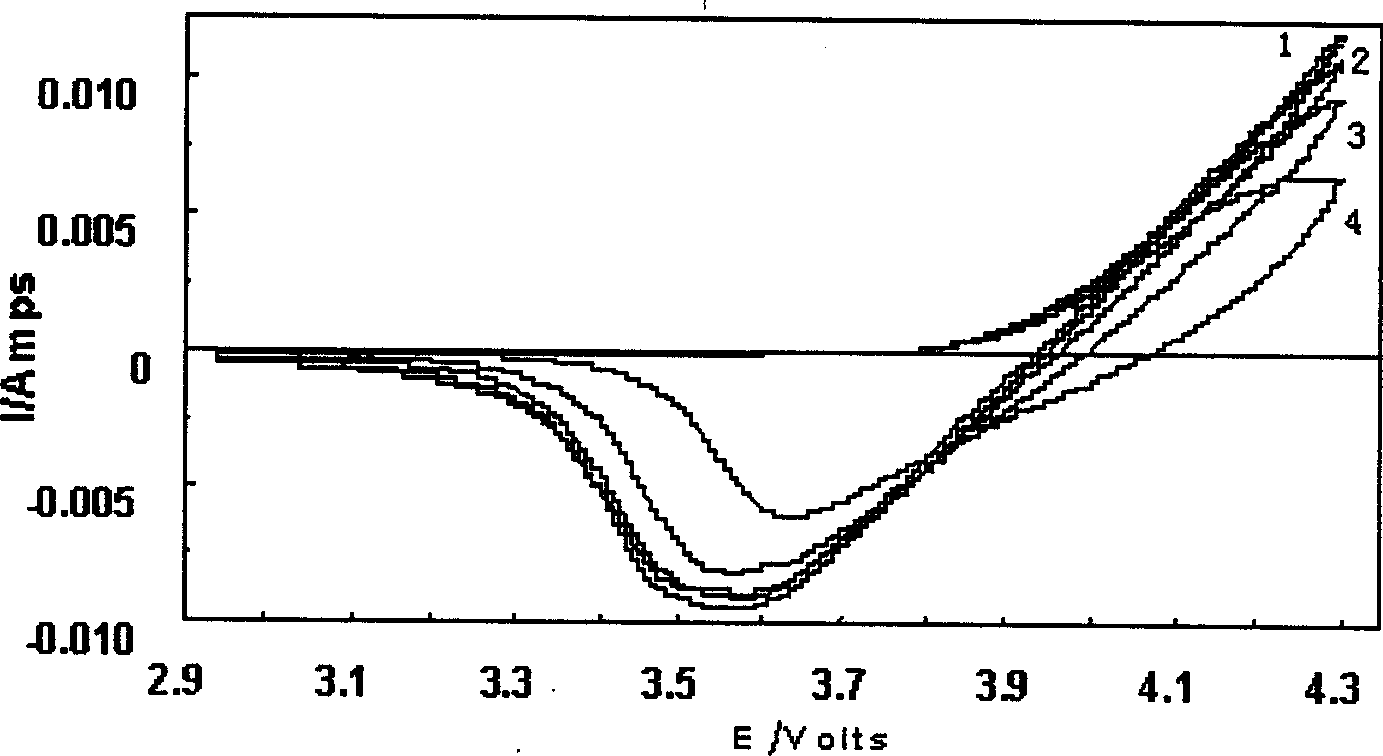

[0017] 1. LiNO 3 (Analytical pure 99%) 2.537 grams, Co (NO 3 ) 2 ·6H 2 O (analytically pure 99%) 5.355 grams, Ni (NO 3 ) 2 ·6H 2 O (analytically pure 99%) 3.566 grams, citric acid (C 6 h 8 o 7 ·H 2 O) (analytical purity 99%) 5.724 g, made into 15 ml of aqueous solution, and electromagnetically stirred at 80° C. for 20 minutes.

[0018] 2. Move the solution from the evaporating dish into a muffle furnace that has been kept at 350°C. The solution absorbs heat and evaporates. After 5 minutes, it boils and burns, releasing yellow-brown gas, and the product is black and fluffy. Naturally cool down with the furnace, take out and lightly grind and granulate, then raise the temperature to 850°C at 100°C / hour and keep it for 6 hours to synthesize the sample LiCo 0.6 Ni 0.4 o 2 .

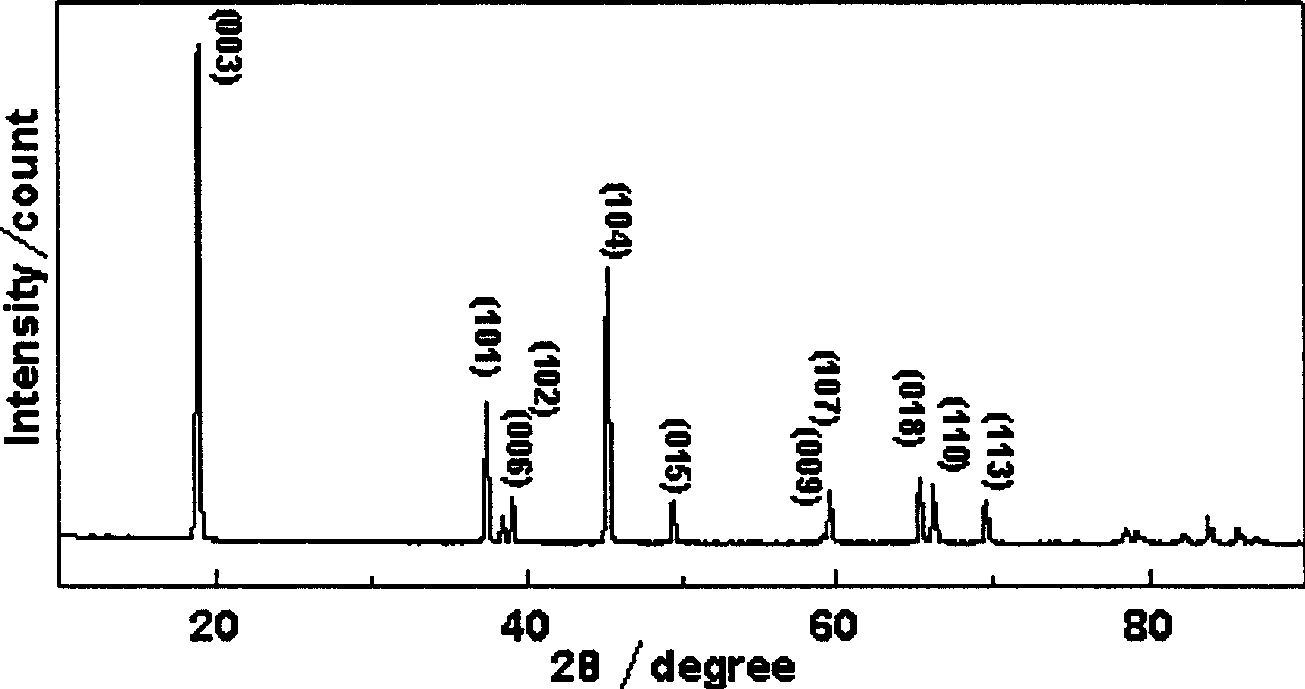

[0019] Synthetic sample LiCo 0.6 Ni 0.4 o 2 The XRD pattern such as figure 1 As shown, the diagram shows that the crystal form is complete, and its diffraction peak is sharp, indicating that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com