Patents

Literature

296 results about "Lyonium ion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In chemistry, a lyonium ion is the cation derived by the protonation of a solvent molecule. For example, a hydronium ion is formed by the protonation of water, and CH₃OH⁺₂ is the cation formed by the protonation of methanol.

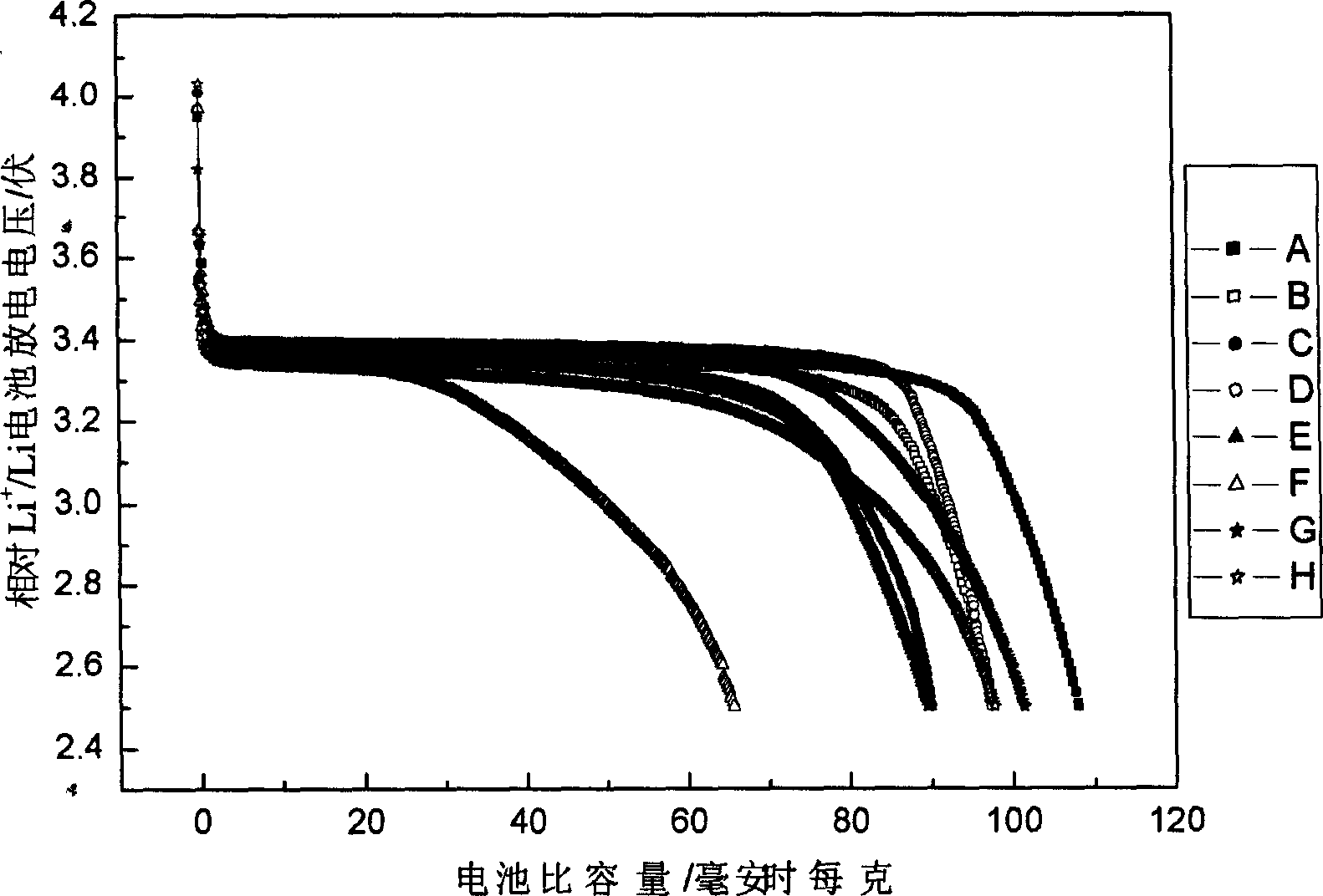

Lithium ion battery anode material manganese lithium phosphate and preparation method thereof

ActiveCN101320809AImprove electronic conductivityEvenly dispersedElectrode manufacturing processesPhosphorus compoundsCapacitanceLithium iron phosphate

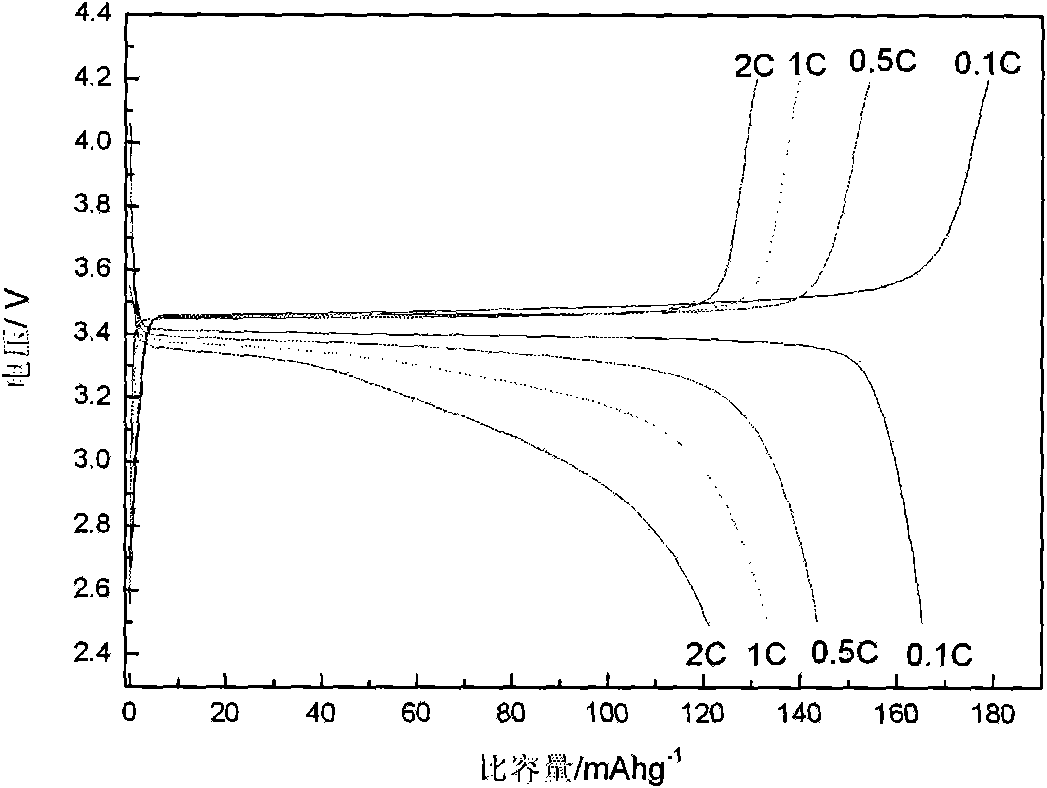

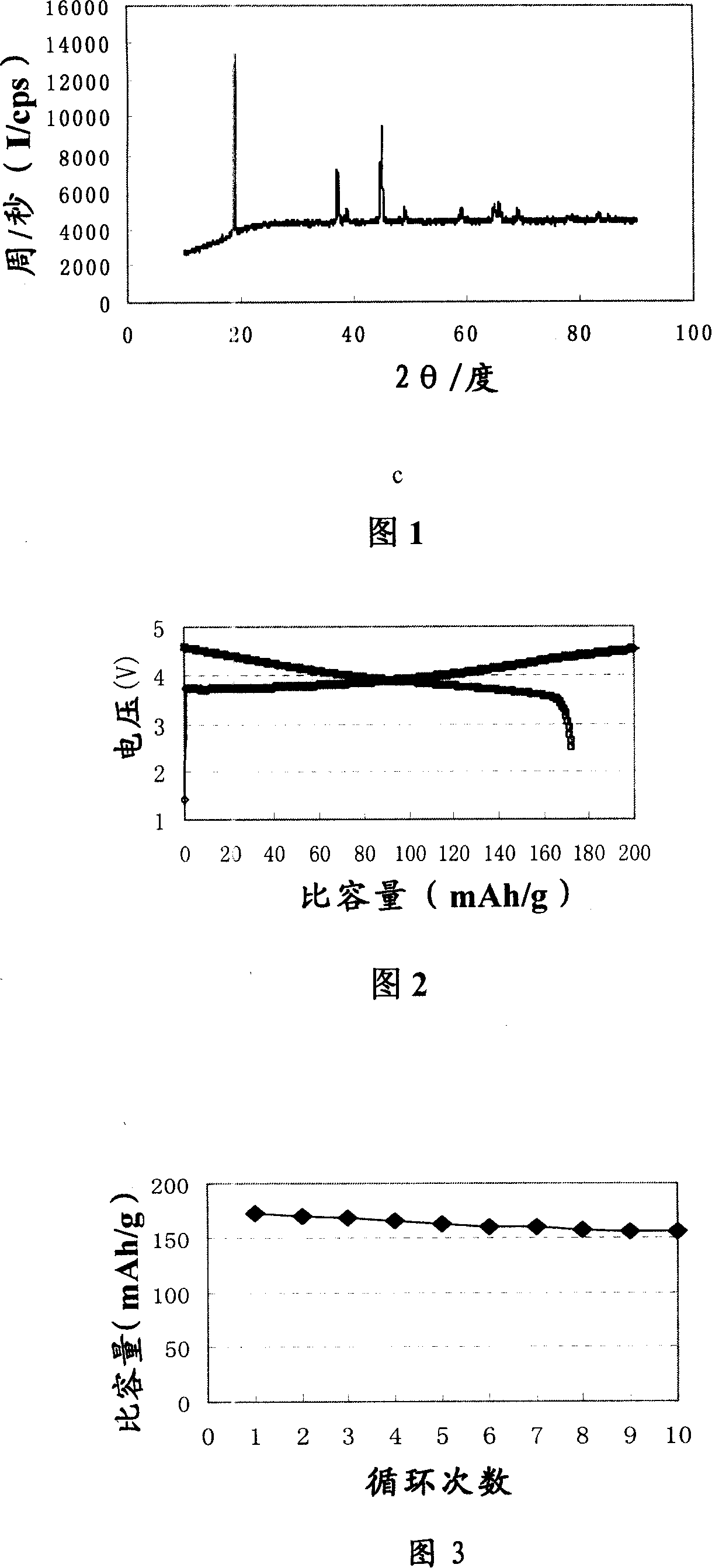

The invention discloses a manganese / lithium phosphate of lithium iron battery positive pole material and a production method thereof, the technical issue to be solved is to improve electrochemical performances of the positive pole material. The material of the invention includes substrates of manganese / lithium phosphate which are covered by a carbon material covering layer, the lithium covering the manganese / lithium phosphate behind the carbon material covering layer is spherical and has microscopic characteristics of being near spherical, rhombic, tapered, tabular, layered or / and block-shaped as well as of having 0.5-30 mum long and short axles. The production method comprises the following steps of: production of nanometer particles, liquid phase mixed reaction, production of precursor, sintering treatment, covering organic substances. Compared with the prior art, the invention improves the electron conductivity of the manganese / lithium phosphate by covering with carbon liquid phase, the carbon sufficiently covers active materials to efficiently prevent particle aggregation, the invention has the characteristics of about 4V of discharge voltage, high discharge and charge capacitance, excellent circulation stability, high safety, simple process, low cost and little influence on the environment.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

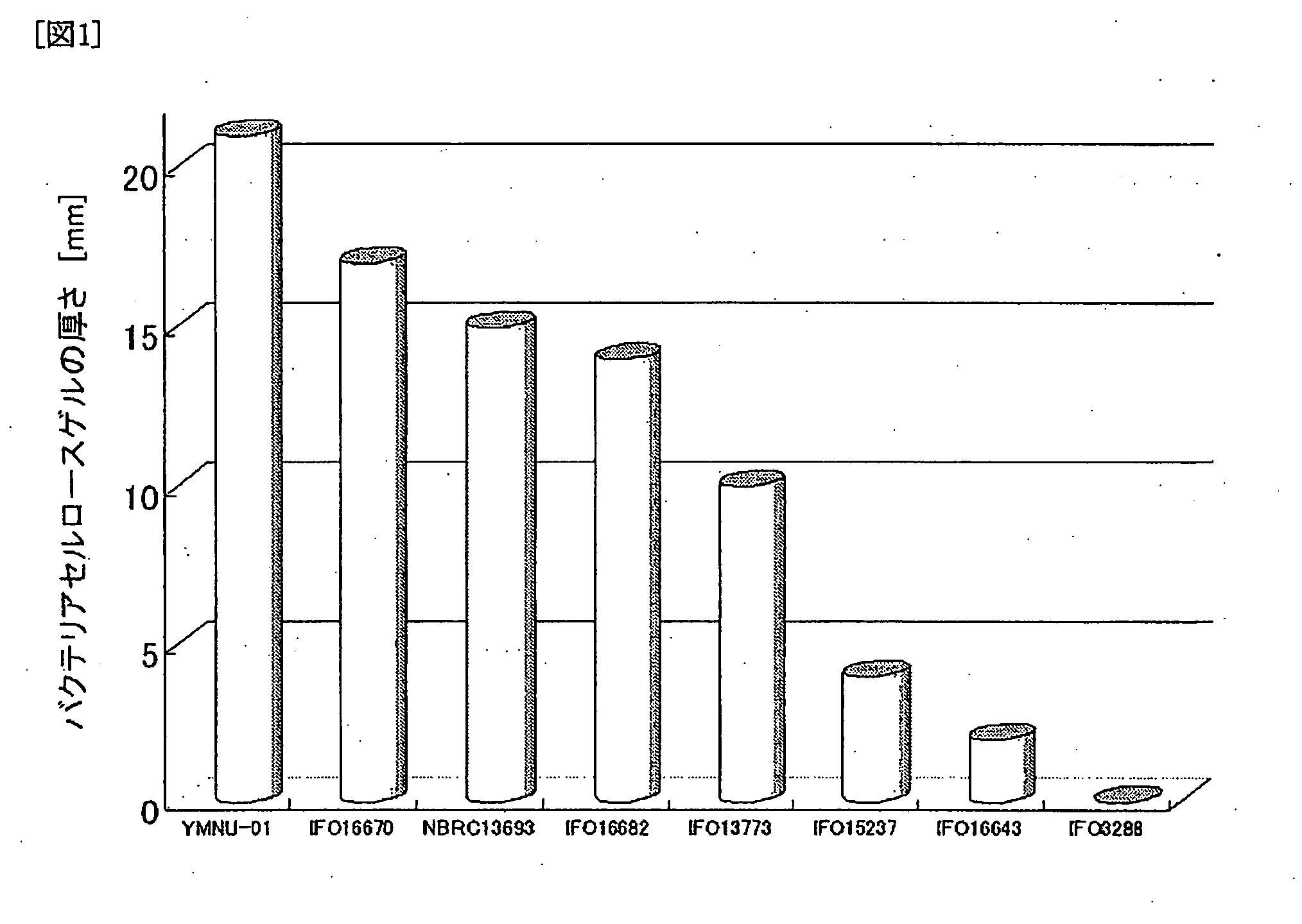

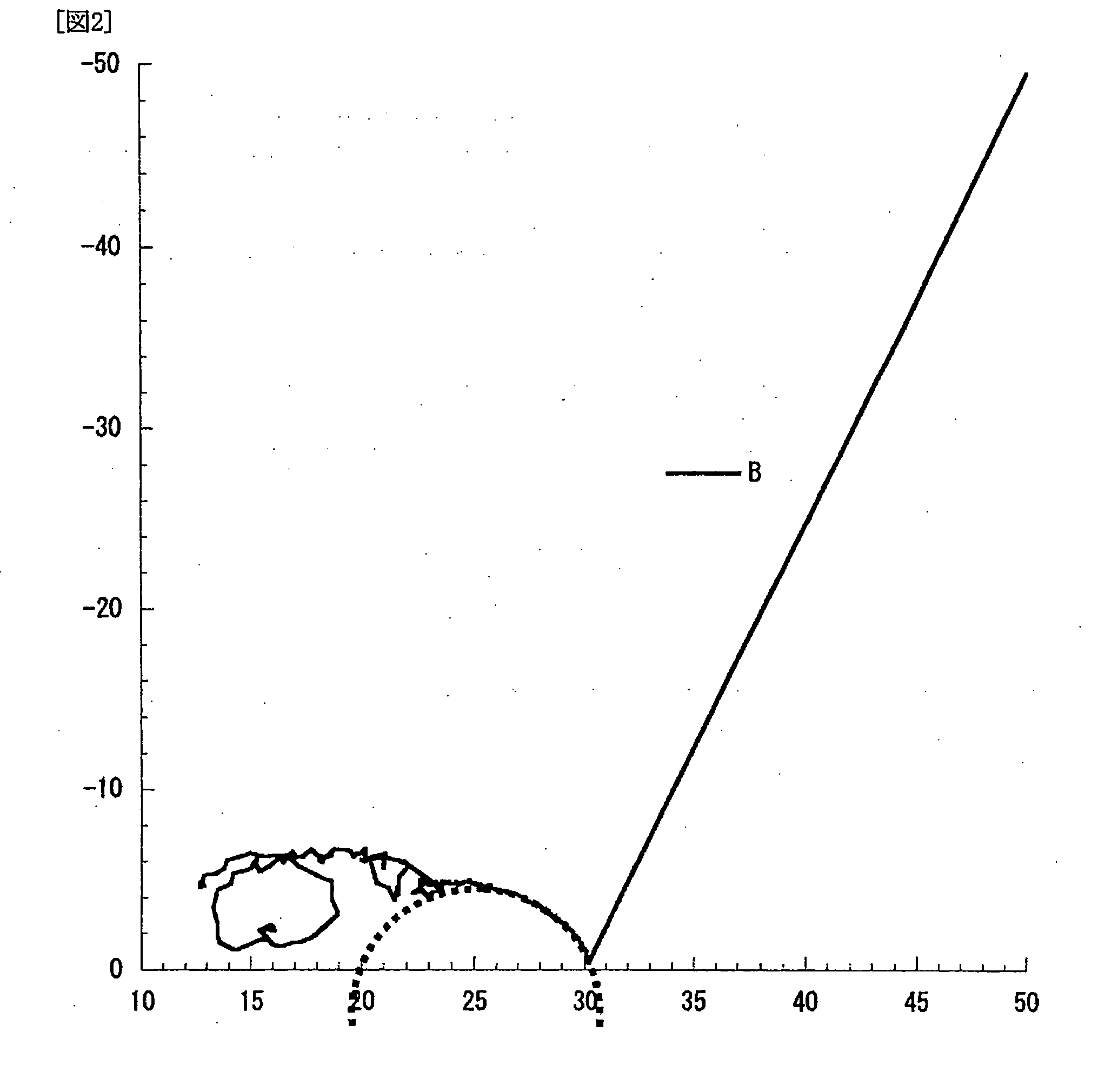

Lithium Ion Conductive Material Utilizing Bacterial Cellulose Organogel, Lithium Ion Battery Utilizing the Same and Bacterial Cellulose Aerogel

InactiveUS20080220333A1High mechanical strengthImprove performanceMaterial nanotechnologyConductive materialConductive materialsSolvent

A lithium ion conductive material that excels in mechanical strength, exhibiting high ion conductivity; a bacterial cellulose composite material having an inorganic material and / or organic material incorporated therein; and a bacterial cellulose aerogel. The water of bacterial cellulose hydrogel is replaced by a nonaqueous solvent containing a lithium compound. Bacterial cellulose producing bacteria are grown in a culture medium having an inorganic material and / or organic material added thereto. The bacterial cellulose hydrogel is dehydrated and dried.

Owner:YANO SHOICHIRO +5

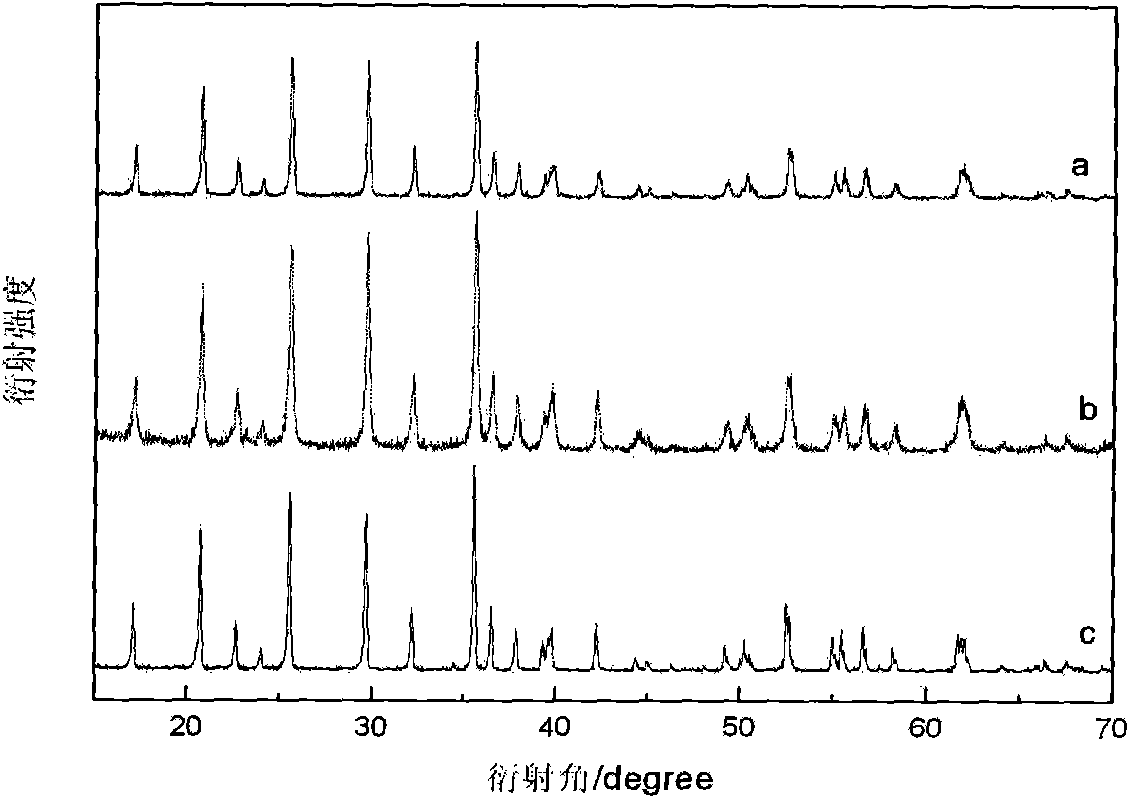

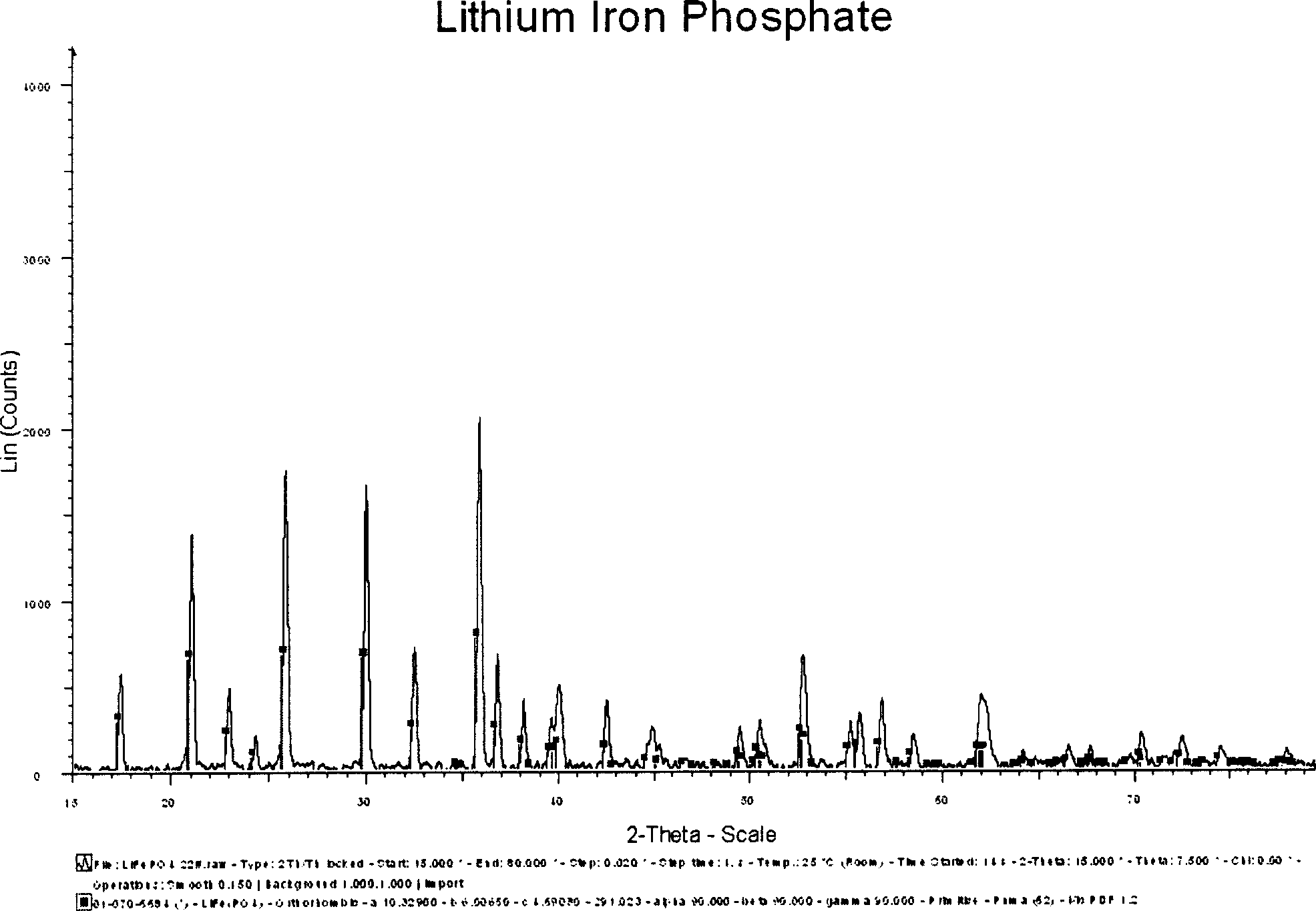

Prepn process of oxygen place doped lithium ferric phosphate powder

InactiveCN1772604AIncrease base capacityImprove cycle electrical performanceCell electrodesPhosphorus compoundsDopantLithium iron phosphate

The present invention belongs to the field of electrochemical power source material preparing technology, and is especially preparation process of oxygen place doped lithium ferric phosphate powder. The oxygen place doped lithium ferric phosphate as positive pole material in lithium ion cell has the molecular expression LiFeP(MxO4-x), and is prepared through mixing the dopant and the mother body material and sintering the mixture, or through solid phase reaction of the dopant and the mother body material. The preparation process has effective doping in the oxygen place of mother body material and the prepared material can raise the capacity and the circular discharge performance of the cell effectively and thus can find its wide application as positive pole material in secondary lithium ion cell and power cell.

Owner:TSINGHUA UNIV

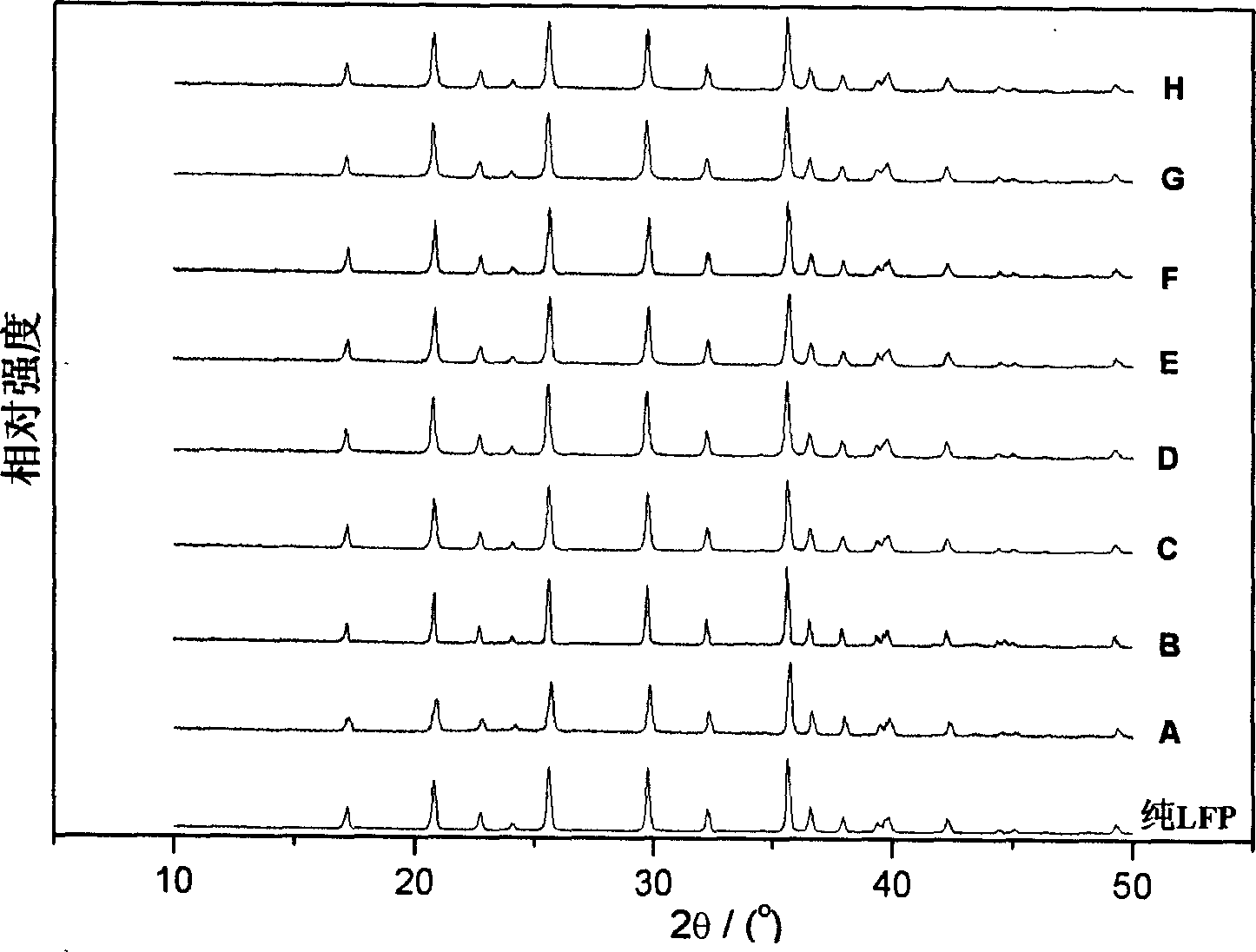

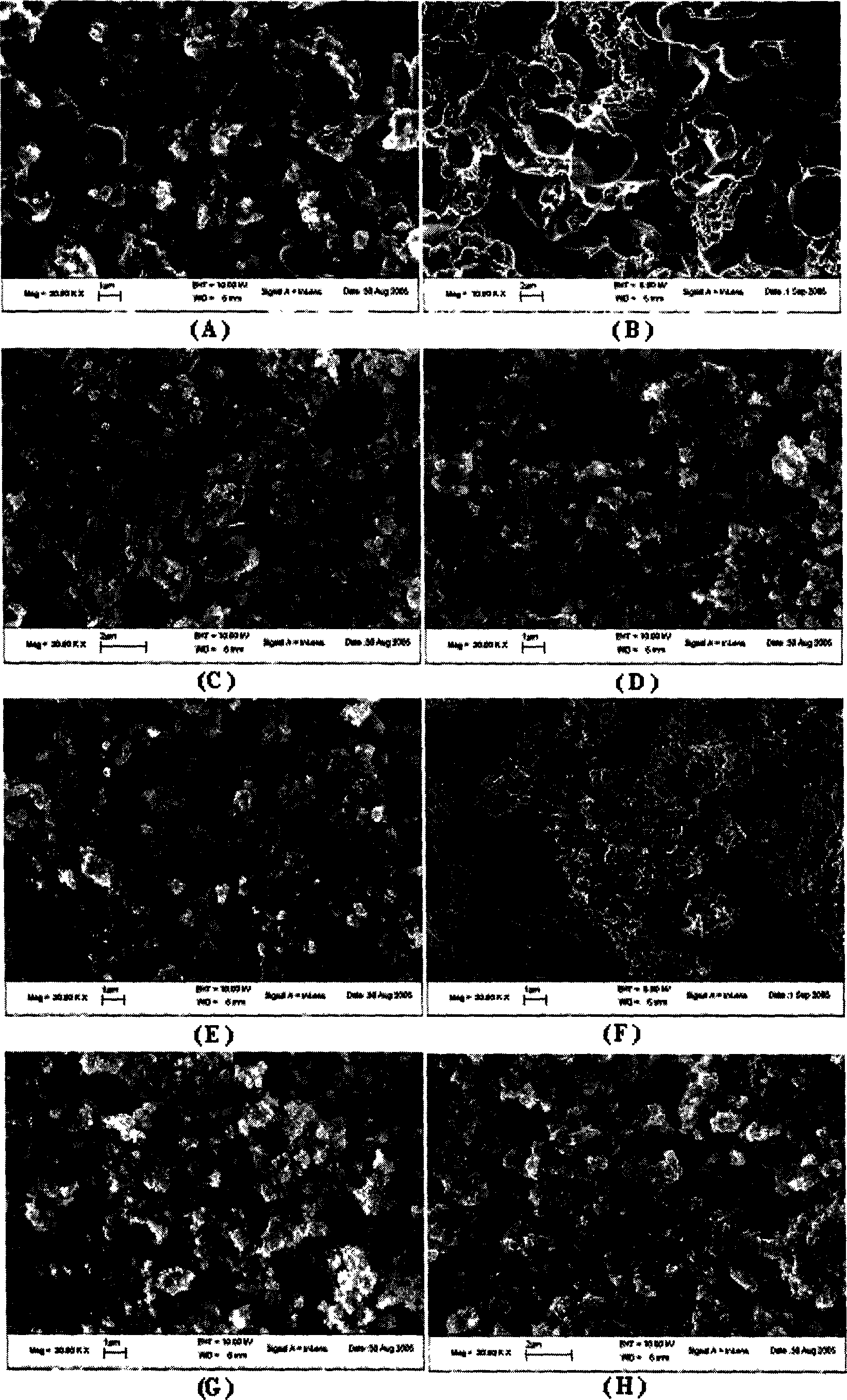

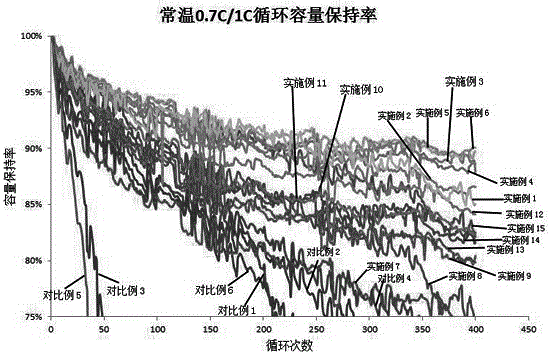

Composite-coated lithium iron phosphate and preparation method therefor, and lithium ion battery

ActiveUS20180097228A1Improve conductivityHigh activityMaterial nanotechnologyElectrode thermal treatmentNanonetworkConductive polymer

A composite-coated lithium iron phosphate in a three-dimensional nanonetwork layered structure and a preparation method therefor, and a lithium ion battery, wherein a composite is prepared by compounding a conducting polymer, graphene and a carbon nano tube. The preparation method for the coated lithium iron phosphate comprises the following steps: doping the composite and anhydrous ferric phosphate in situ in the process of preparing the anhydrous ferric phosphate, serving as a lithium iron phosphate precursor, then mixing the composite in-situ doped anhydrous ferric phosphate, a lithium source, a traditional carbon material and a solvent to obtain slurry, spray drying the slurry, and calcining to obtain the composite-coated lithium iron phosphate in a three-dimensional nanonetwork layered structure. The preparation method is simple and has a wide raw material source, low cost and very broad practical application prospect. Serving as an anode material of the lithium ion battery, the coated lithium iron phosphate has higher electrical conductivity and cycling stability, and more excellent comprehensive electrochemical performance.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

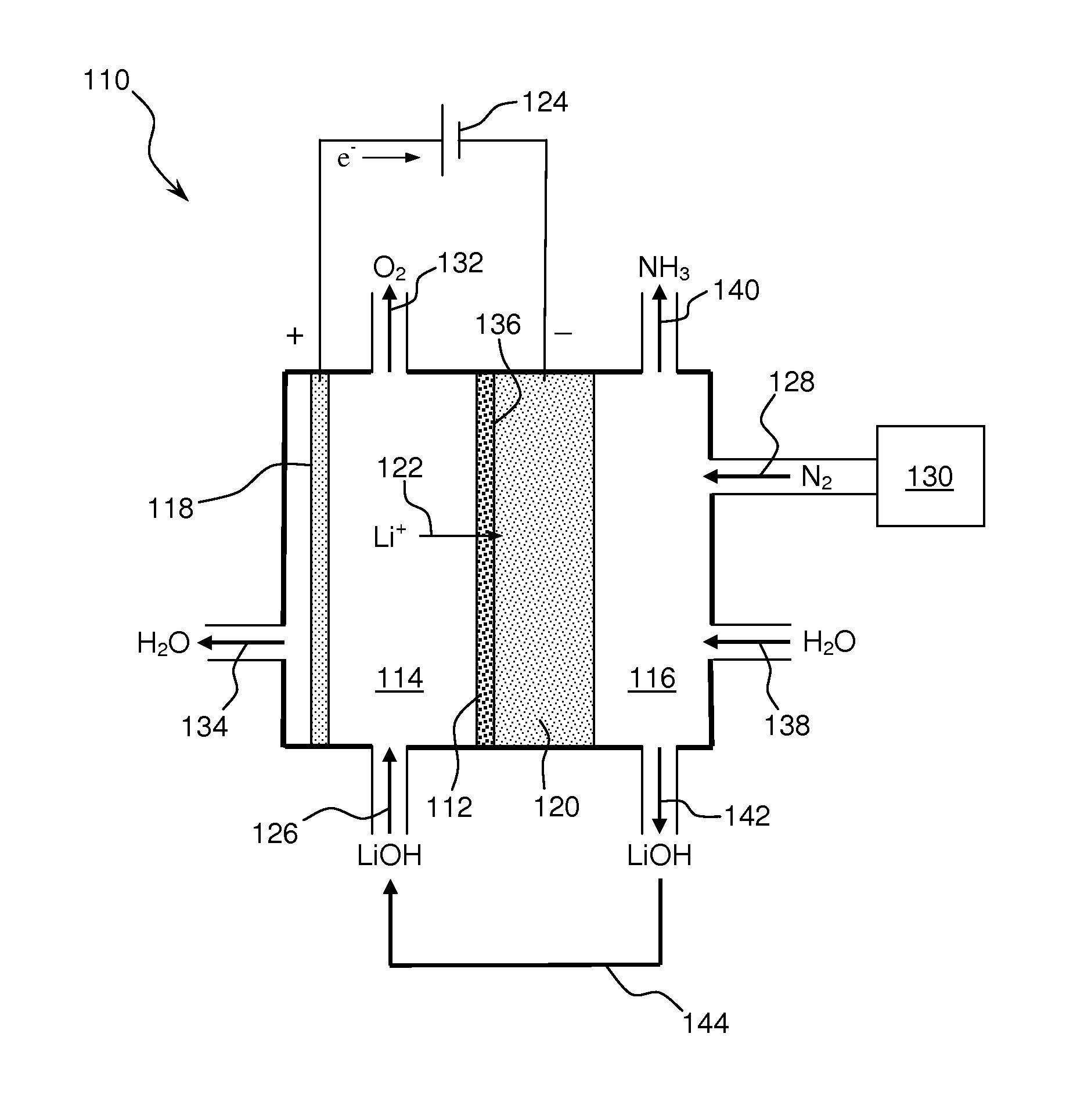

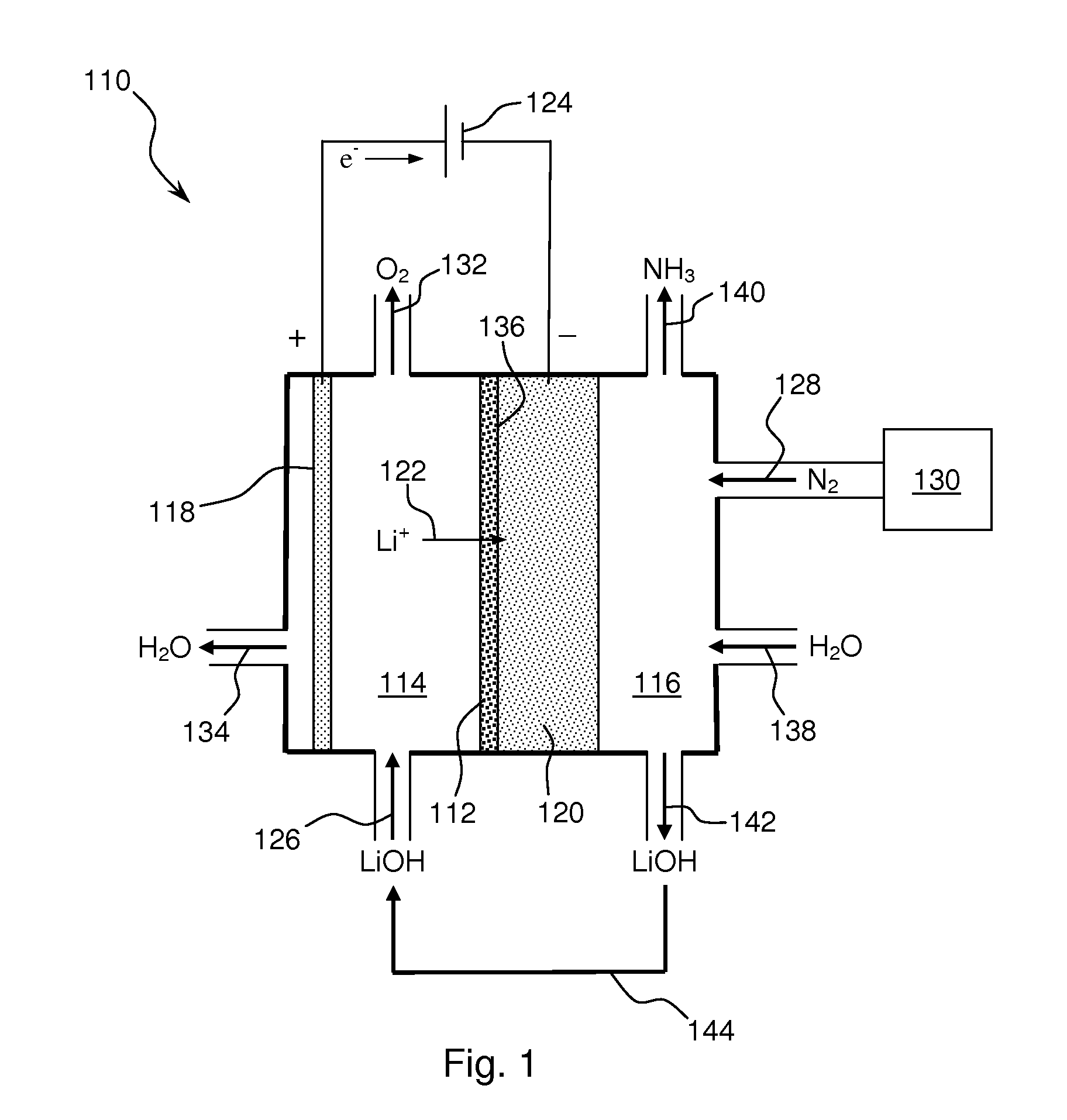

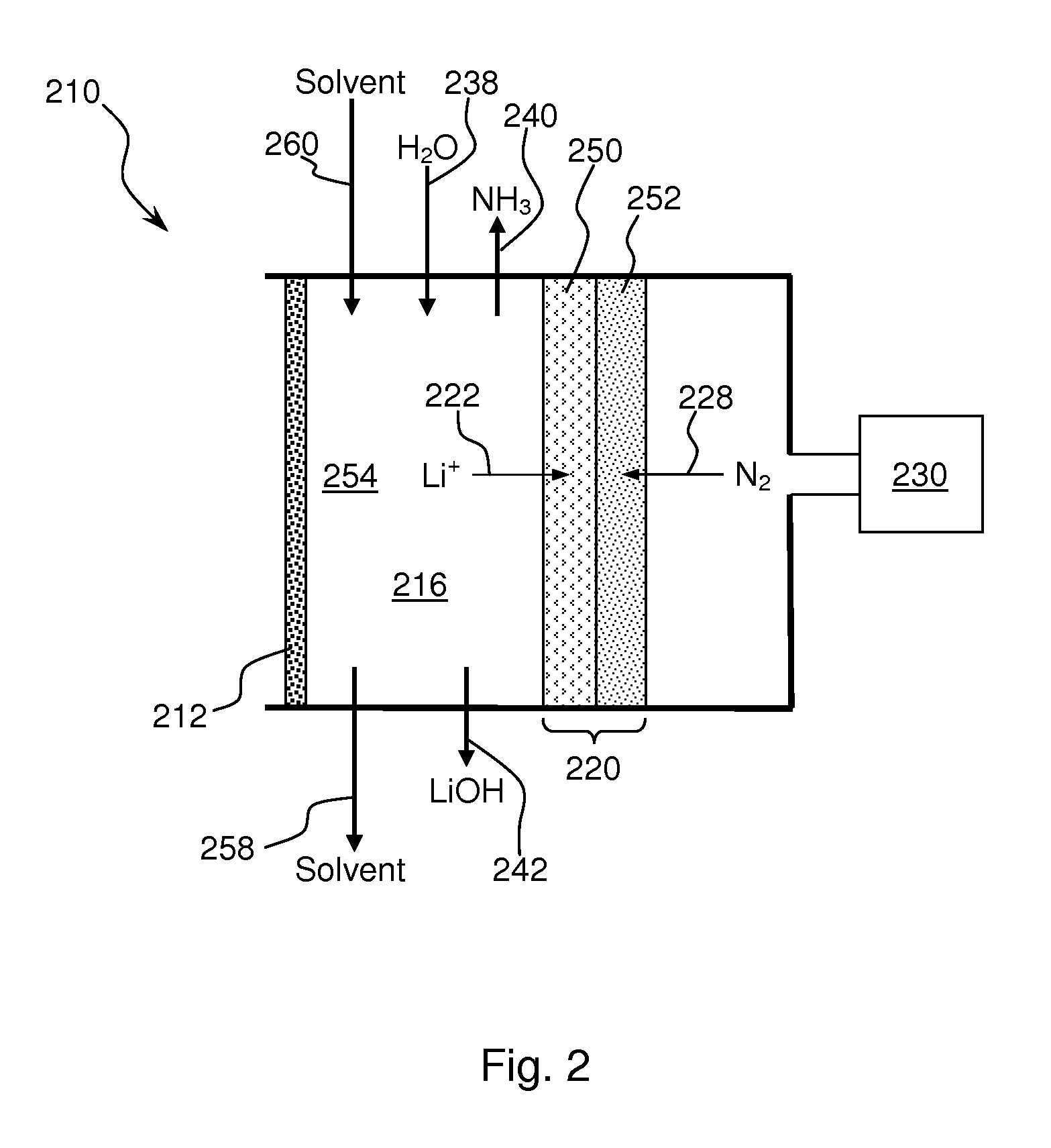

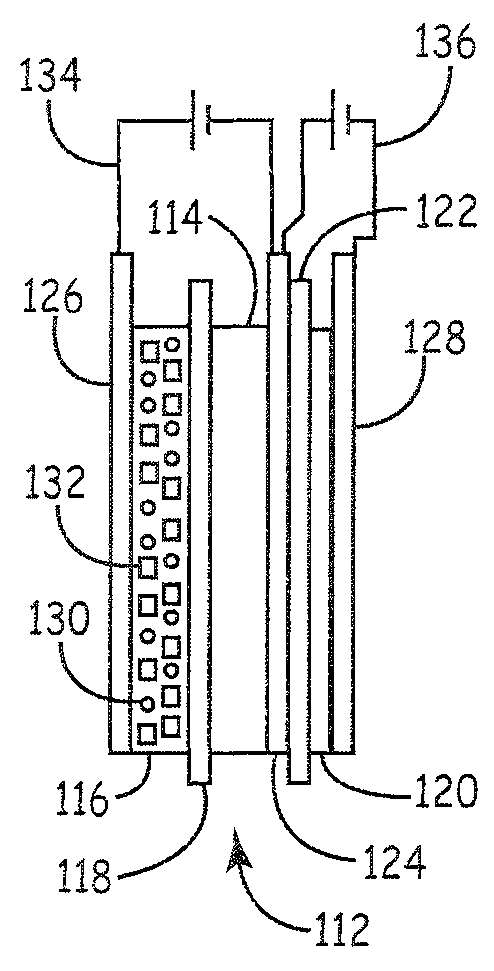

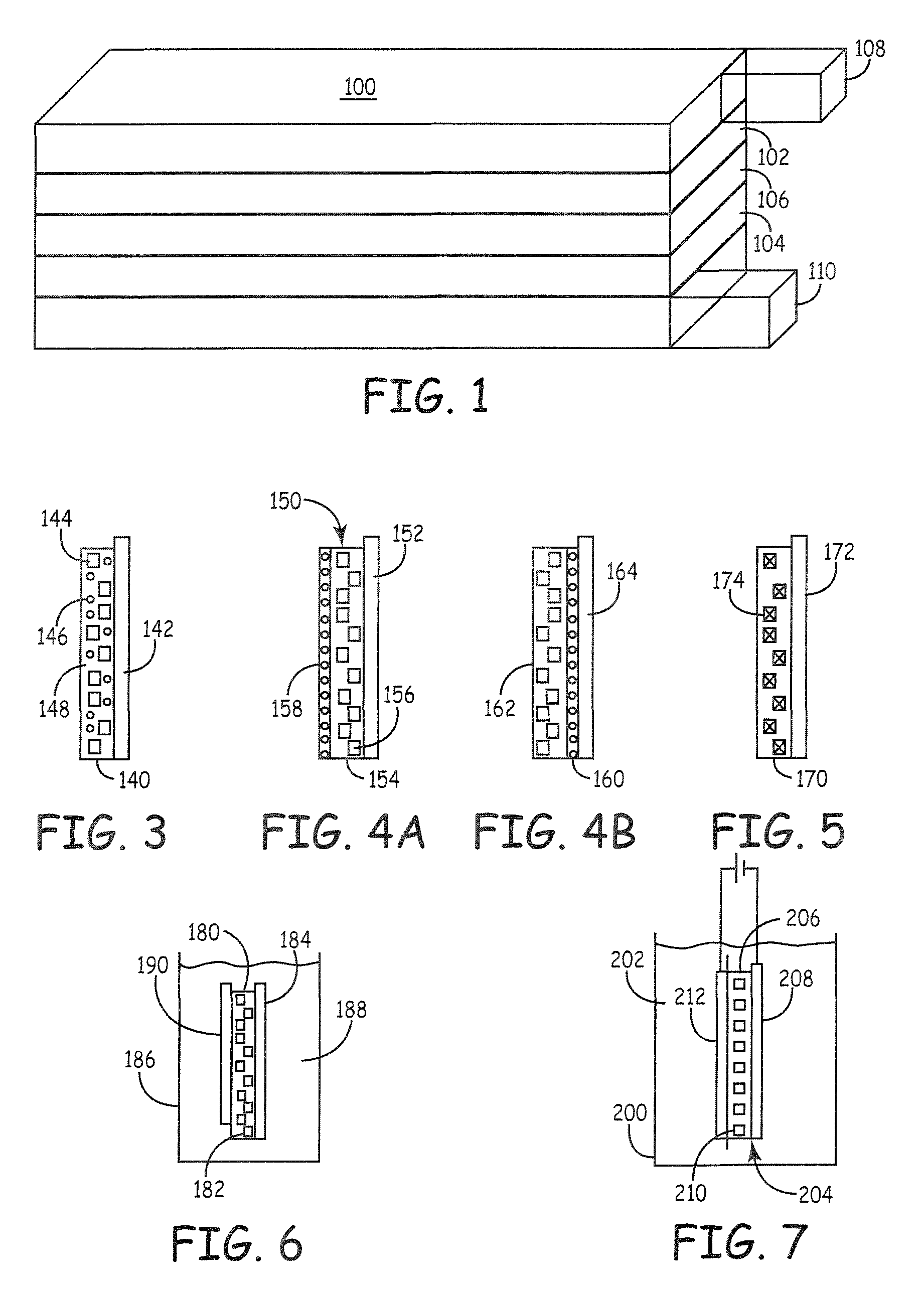

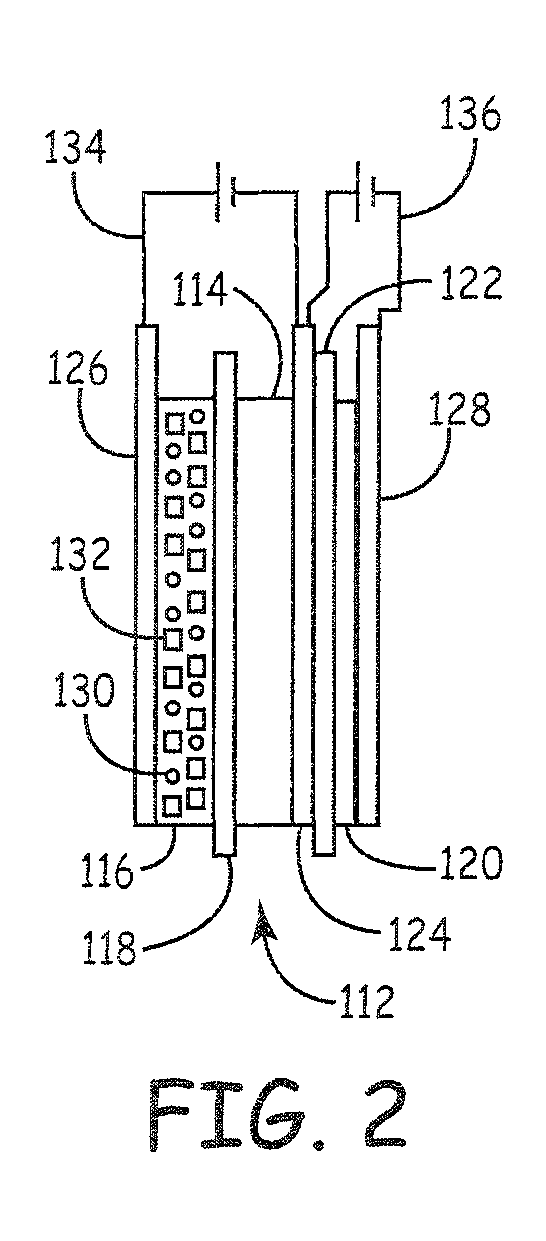

Ammonia synthesis using lithium ion conductive membrane

Ammonia is synthesized using electrochemical and non-electrochemical reactions. The electrochemical reactions occur in an electrolytic cell having a lithium ion conductive membrane that divides the electrochemical cell into an anolyte compartment and a catholyte compartment. The catholyte compartment includes a porous cathode closely associated with the lithium ion conductive membrane. The overall electrochemical reaction is: 6LiOH+N2→Li3N (s)+3H2O+3 / 2O2. The nitrogen may be produced by a nitrogen generator. The non-electrochemical reaction involves reacting lithium nitride with water and / or steam as follows: Li3N (s)+3H2O→3LiOH+NH3 (g). The ammonia is vented and collected. The lithium hydroxide is preferably recycled and introduced into the anolyte compartment. The electrolytic cell is shut down prior to reacting the lithium nitride with water. The cathode is preferably dried prior to start up of the electrolytic cell and electrolyzing Li+ and N2 at the cathode.

Owner:ENLIGHTEN INNOVATIONS INC

Method for recovery of lithium from used lithium ion cell with ion sieve

InactiveCN1451771AControl flow rateWaste accumulators reclaimingBattery recyclingLithiumPhysical chemistry

A process for recovering Li from used Li-ion battery by ion sieve includes dissolving the Li-ion battery in acid, adsorbing the Li ions by lambda-MnO2 ion sieve, and eluting Li ions out by diluted hydrochloric acid solution. Its advantages are high recovery yield and purity, and environmentally friendly.

Owner:WUHAN UNIV OF TECH

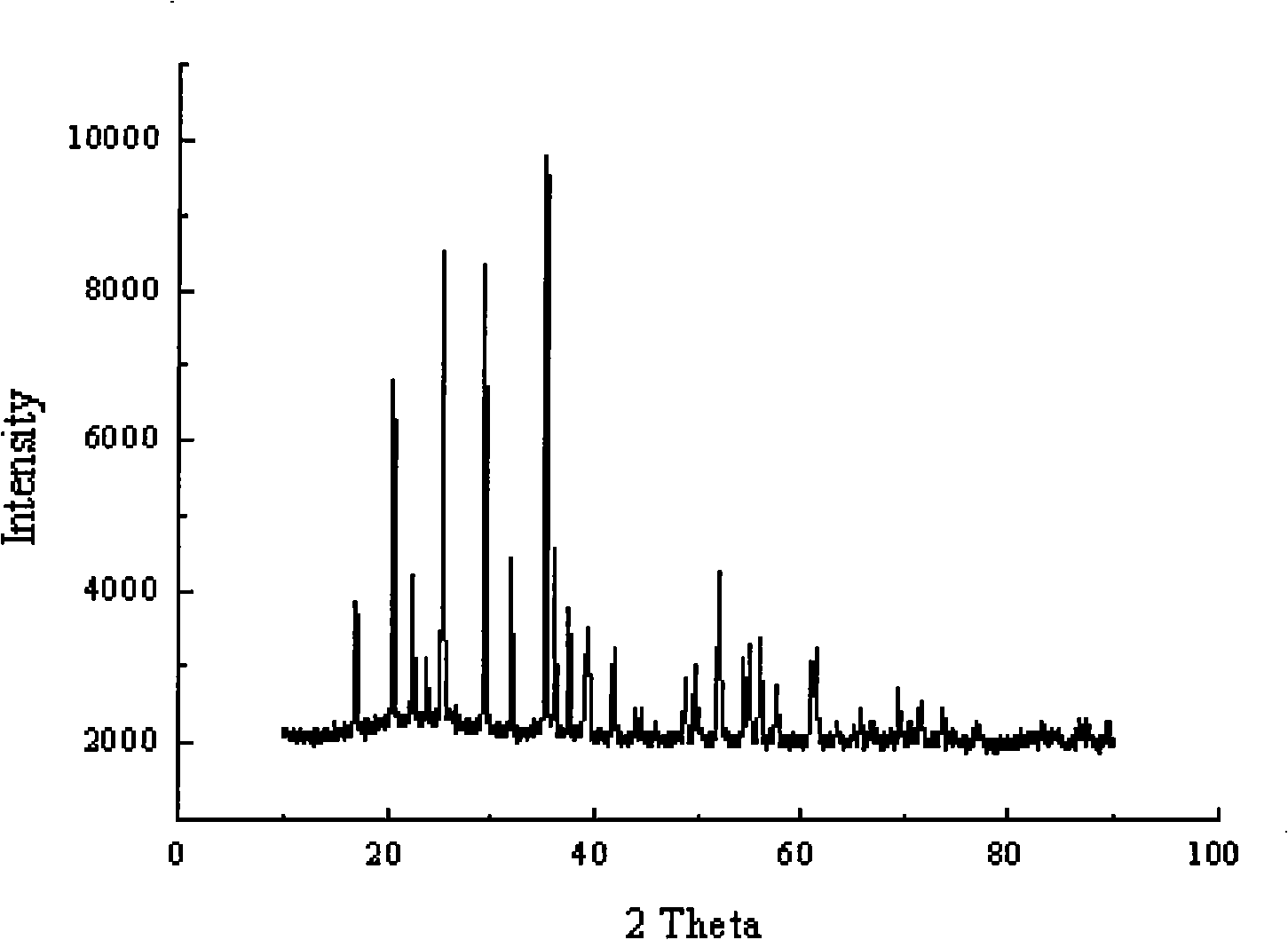

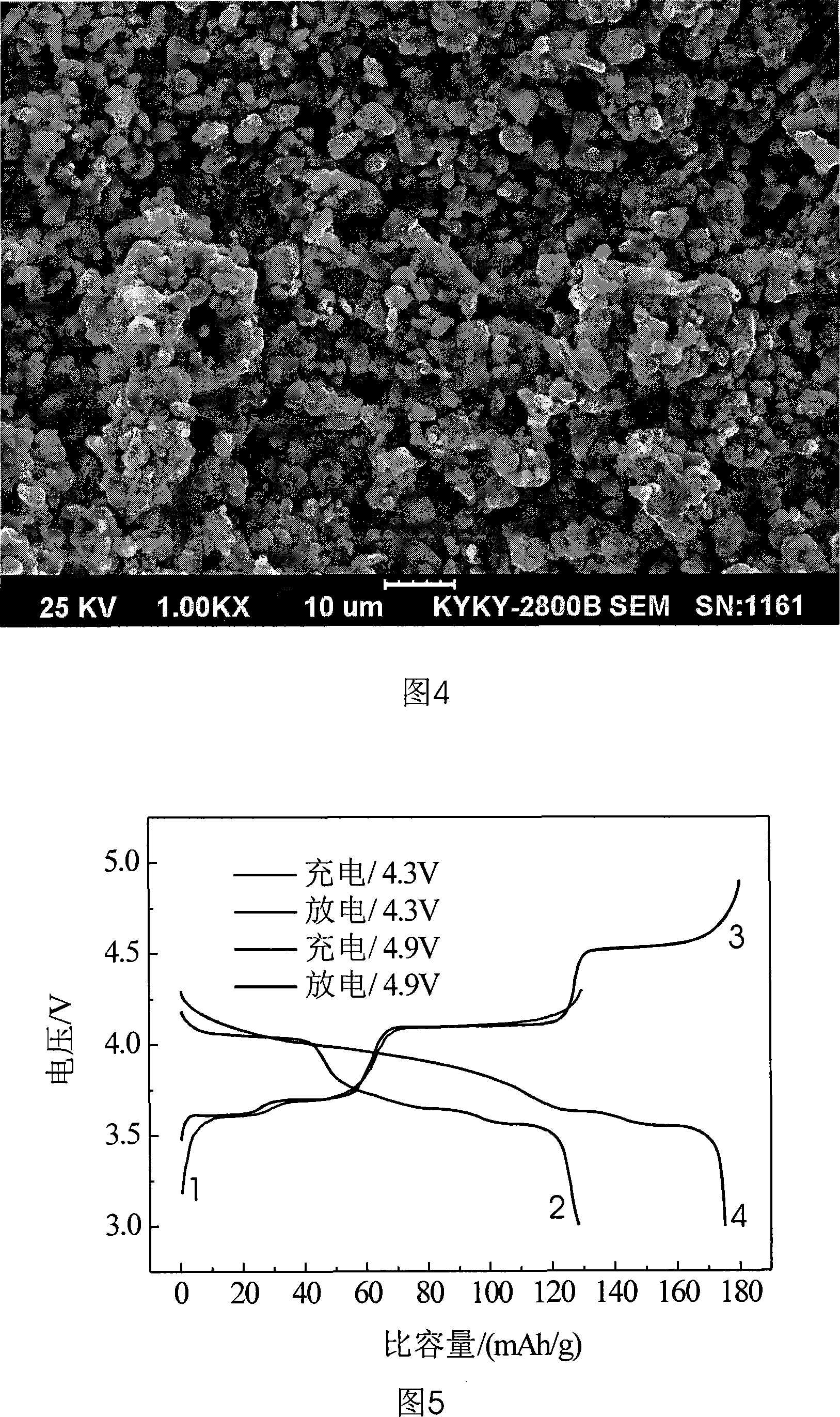

Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

ActiveCN101355159AWell mixedImprove performanceCell electrodesManganates/permanganatesLithium hydroxideManganate

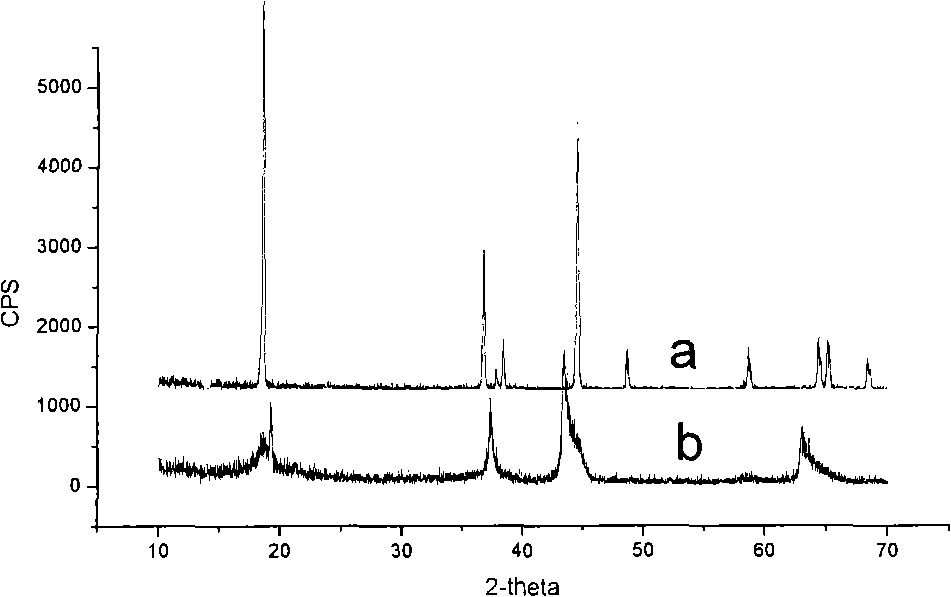

The invention relates to a method for preparing a LiCoxNiyMnzO2 anode material for a lithium ion battery. The method comprises the following steps that soluble salts of nickel, cobalt and manganese undergo coprecipitation to prepare composite carbonate of nickel, manganese and cobalt; then, the carbonate is reacted with lithium hydroxide; moreover, when the carbonate is converted into hydroxide, lithium is deposited on the surface of the prior particles containing nickel, cobalt and manganese in the form of lithium carbonate. In this way, even mixing of lithium and elements such as nickel, cobalt and manganese is realized to obtain a top-quality precursor for preparing the LiCoxNiyMnzO2 material; moreover, the precursor can be made into a LiCoxNiyMnzO2 product with excellent properties after twice sintering. The method has the advantages of simple and easily controlled technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Polymer electrolyte based on vinylene carbonate and polyethylene (methyl) acrylate and preparation method of polymer electrolyte

The invention discloses a polymer electrolyte based on vinylene carbonate and polyethylene (methyl) acrylate and a preparation method of the polymer electrolyte. The electrolyte is characterized in that a lithium salt is dispersed in a solid-state polymer matrix, the content of the lithium salt in the solid-state polymer matrix accounts for 5-50wt%, and the solid-state polymer matrix is a copolymer of the vinylene carbonate and the polyethylene (methyl) acrylate or a copolymer of the vinylene carbonate, the polyethylene (methyl) acrylate and a framework monomer. The solid-state polymer electrolyte is simple to prepare, is high in room-temperature conductivity and can be used as an electrolyte of a lithium ion battery.

Owner:HARBIN INST OF TECH WUXI RES INST OF NEW MATERIALS +1

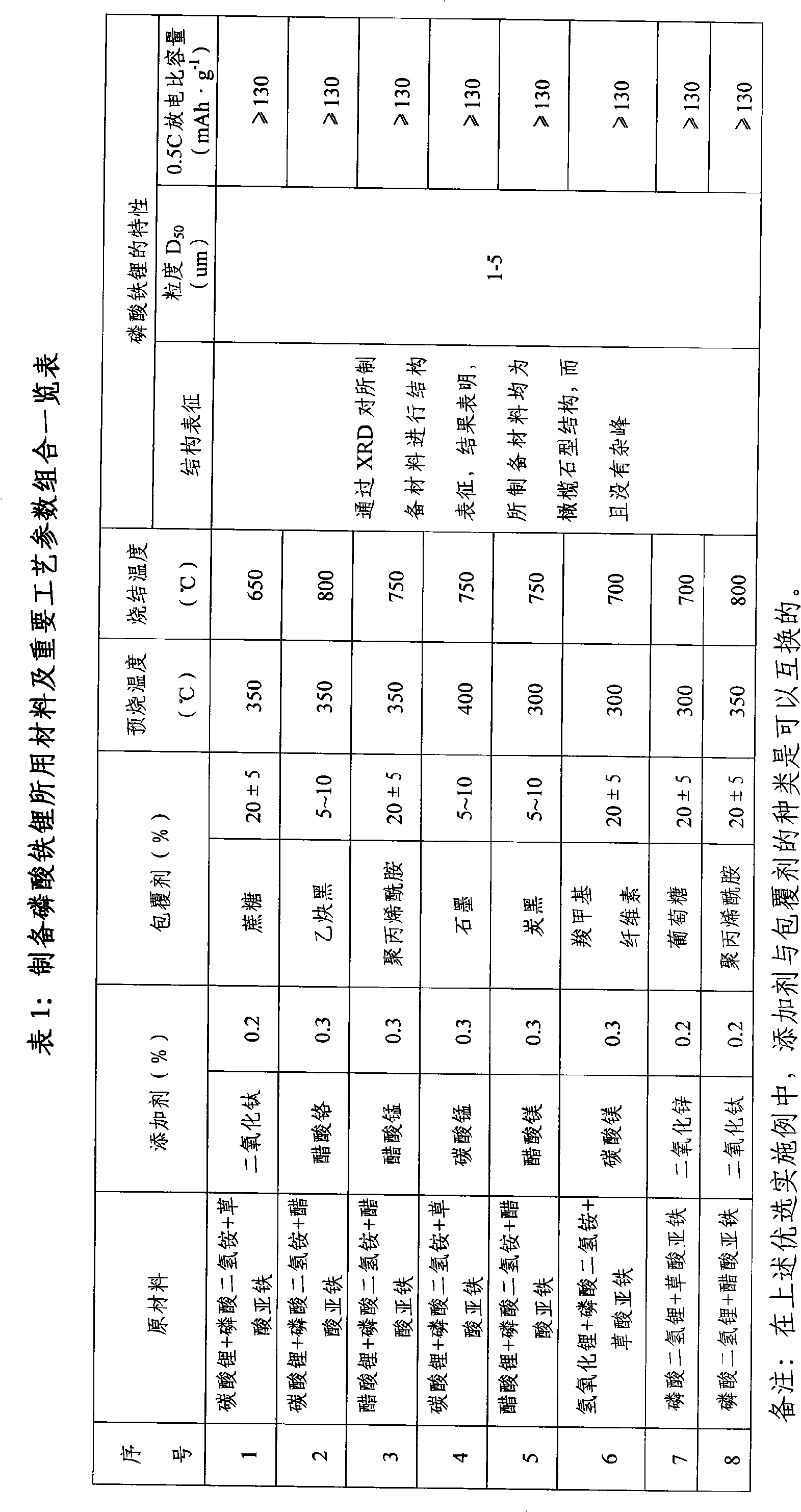

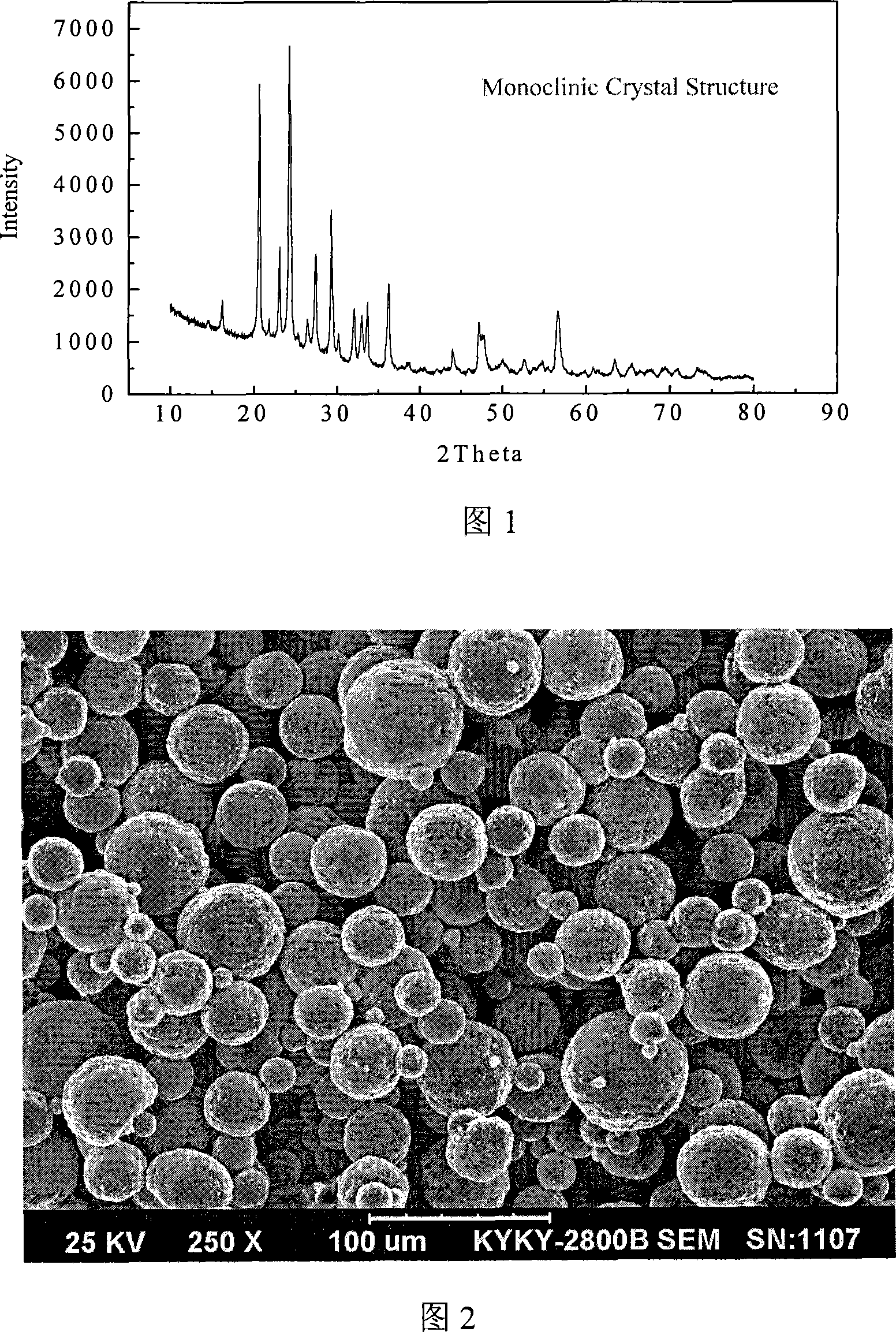

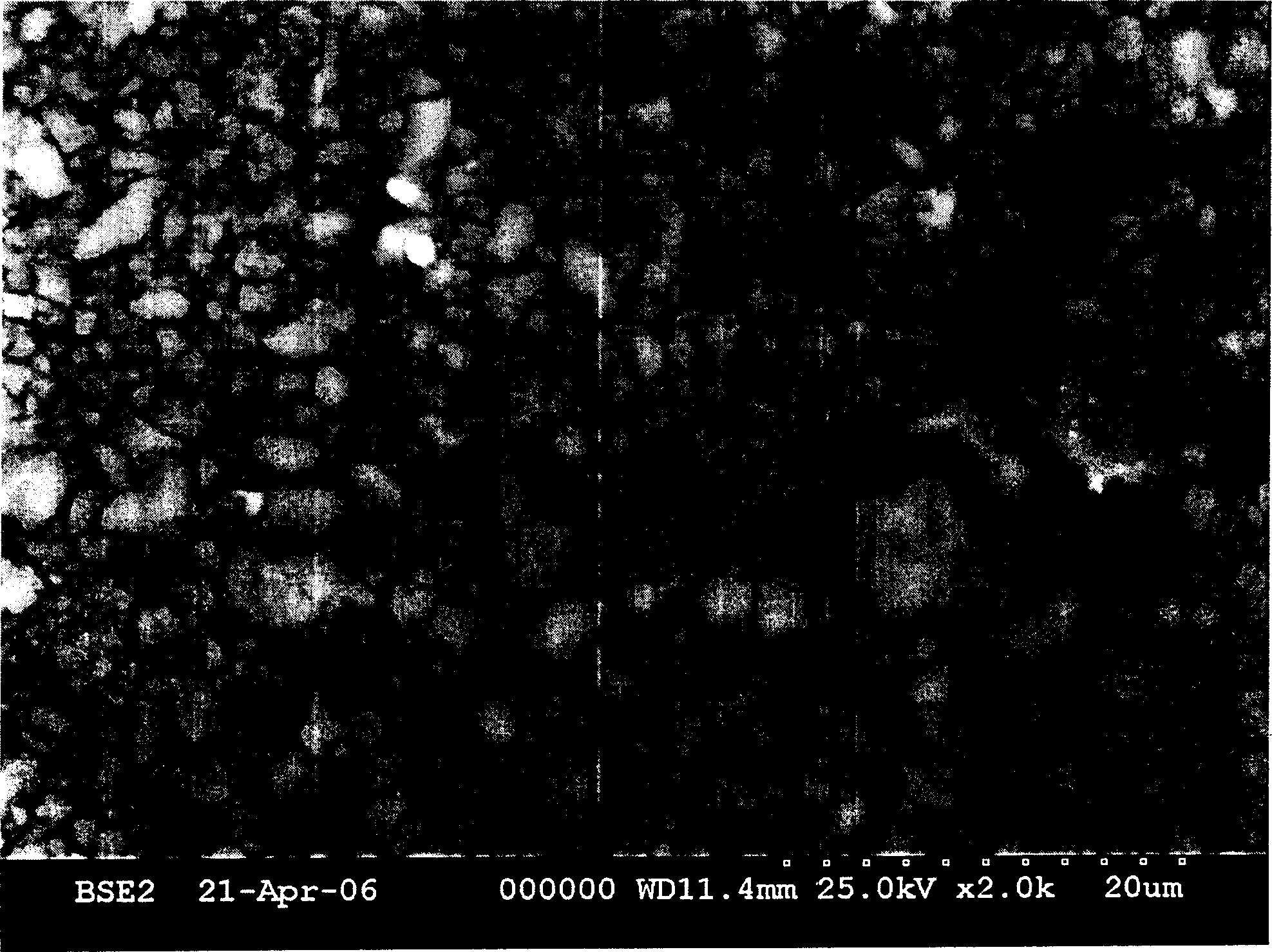

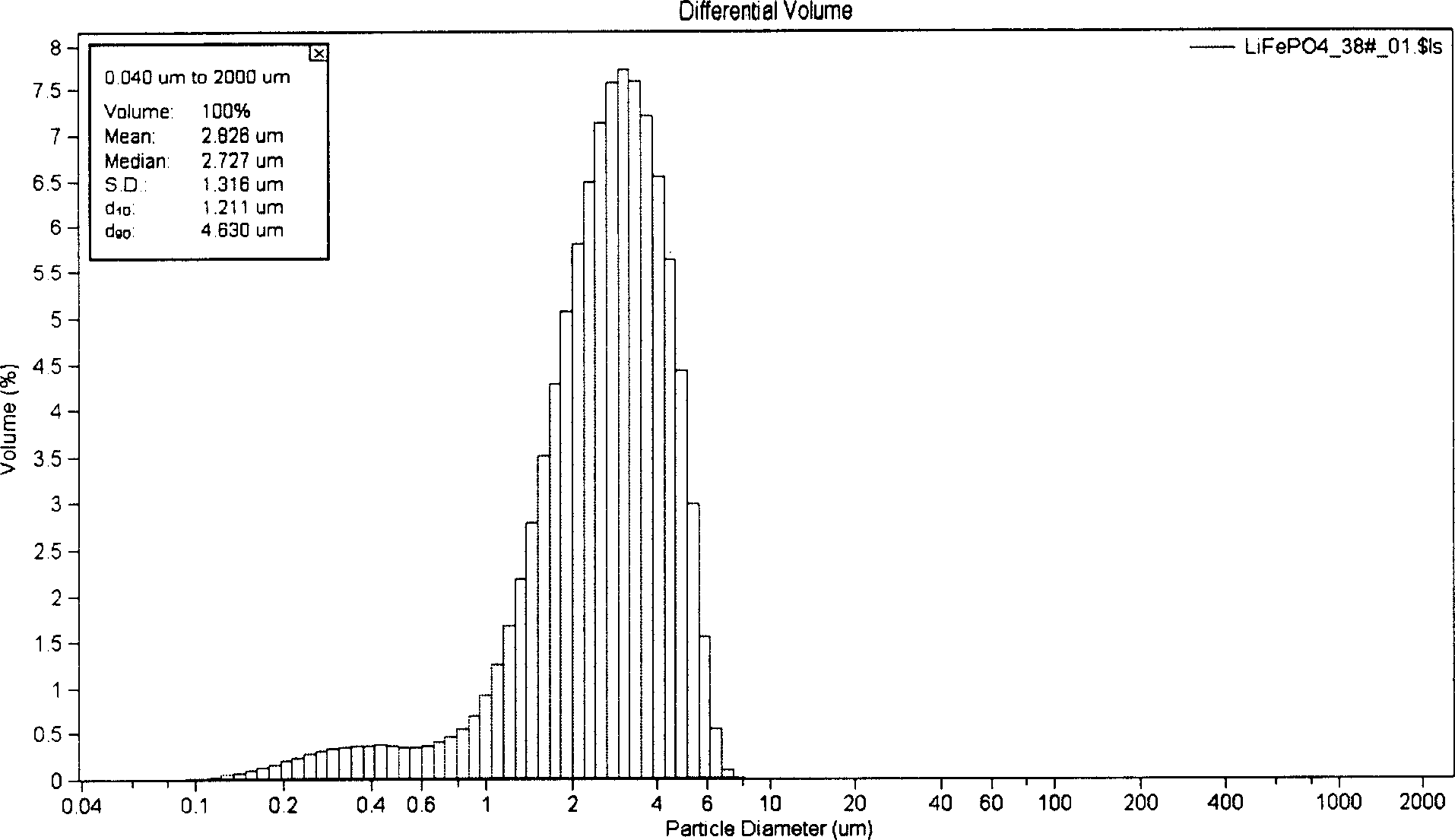

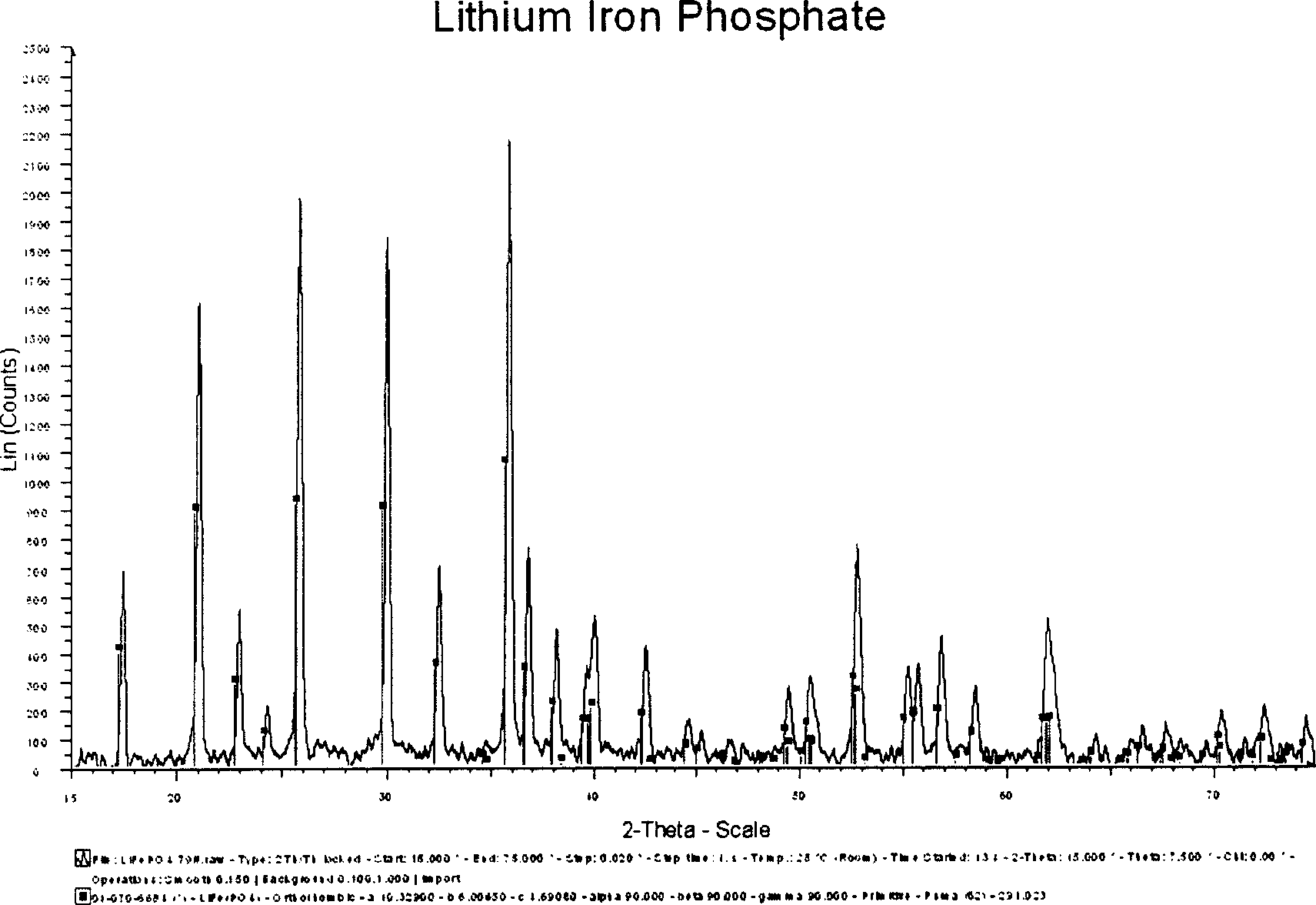

Preparation of lithium iron phosphate positive electrode material for lithium ion power cell

InactiveCN101339995ANo danger of flammabilityImprove securityElectrode manufacturing processesPhosphorus compoundsWater wetPhosphate

The invention discloses a preparation method of a lithium iron phosphate anode material used in a lithium-ion power battery. The preparation method takes ammonium dihydrogen phosphate and lithium carbonate or lithium hydroxide or lithium acetate and ferrous oxalate or ferrous acetate or takes the lithium dihydrogen phosphate and the ferrous oxalate or ferrous acetate as raw materials, the raw materials are prepared according to the ratio of Li, P and Fe of 1:1:1 or the ratio of LiH2PO4 to Fe of 1:1, and is added with micro amount of nano-metallic oxide or metal salt. After the process of mixing by a water wet method, spraying, drying, rolling and prilling, the mixture is pre-sintered for 10 minus or plus 2 hours at the constant temperature of 300-400 DEG C and is clad with carbon for prilling after being cooled; and then after the process of mixing by the water wet method, spraying, drying, rolling and prilling, the mixture is sintered for 10 minus or plus 2 hours at the temperature of 650-800 DEG C and then is cooled to obtain the lithium iron phosphate which is made after being crashed by gas stream and being compacted. The preparation method has the prominent advantages of safe preparation process, simple operation procedure, easy realization of industrialization and stable material performance of the product.

Owner:中国兵器工业第二一三研究所

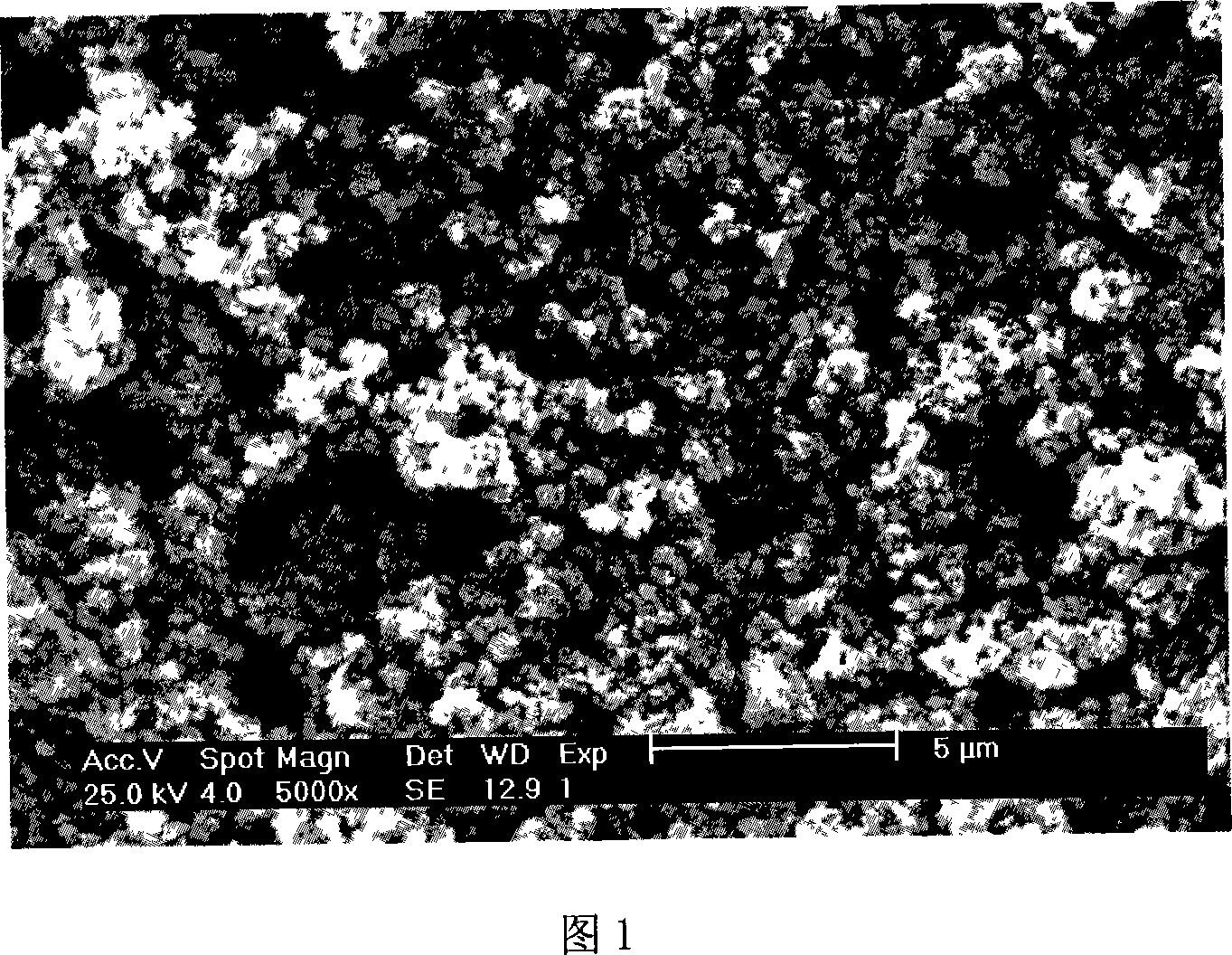

Lithium ion cell anode material lithium vanadium phosphate and preparation method thereof

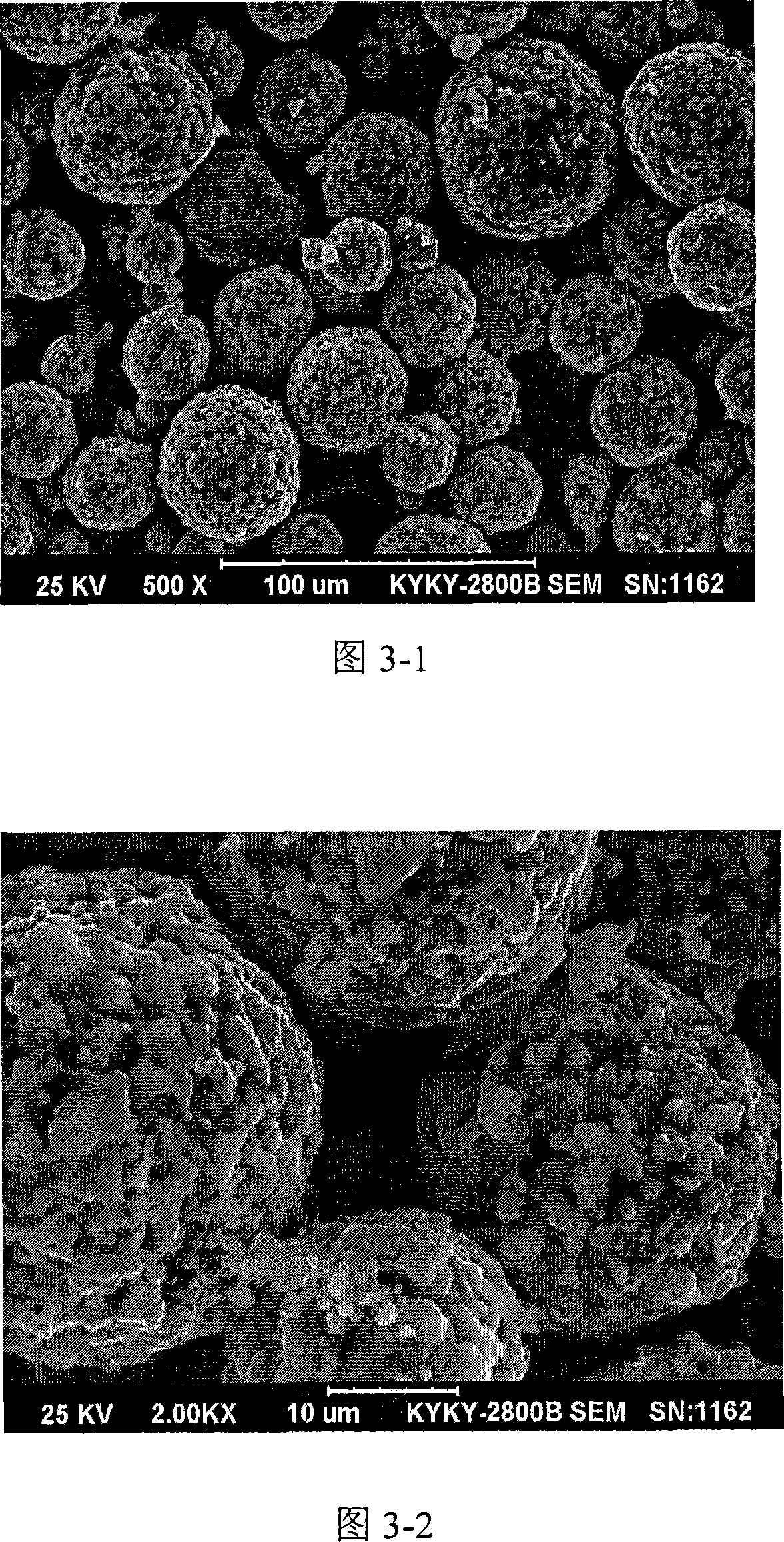

ActiveCN101145611ASmall and evenly dispersedAvoid reunionElectrode manufacturing processesPhosphorus compoundsHigh rateConductive materials

The invention discloses a lithium vanadium phosphate anode material used in a lithium battery and a preparation method thereof, and solves the technical problem that can improve the electrical conductivity and high-rate discharge property of the anode material. The inventive anode material comprises a matrix coated outside with a conductive nano-composite material with a particle size of 5-50 Mu m and a specific surface area of 5-25m<2> / g. The inventive anode material is prepared by the following steps: wet-method superfine ball mill, liquid-phase mixture reaction, spray drying, pretreatment, calcinations treatment, coating with conductive composite material, and fusion. Compared with the prior art, the invention can synthesize lithium vanadium phosphate anode material by the secondary molding liquid phase method of nanoparticles, and the product purity is high, the particle agglomeration is efficiently prevented. The synthetic lithium vanadium phosphate anode material has a discharge voltage about 4V, three discharge voltage platform zones, higher charge / discharge capacity, excellent rate discharge capability and loop stability, and low cost; and is suitable for the industrial production.

Owner:SHENZHEN CITY BATTERY NANOMETER TECH

Preparation method of lithium ionic cell positive pole material ferric phosphate lithium

InactiveCN101140985AWell mixedConducive to speed upElectrode manufacturing processesPhosphorus compoundsLithium iron phosphatePhosphate

Owner:HEBEI UNIV OF TECH

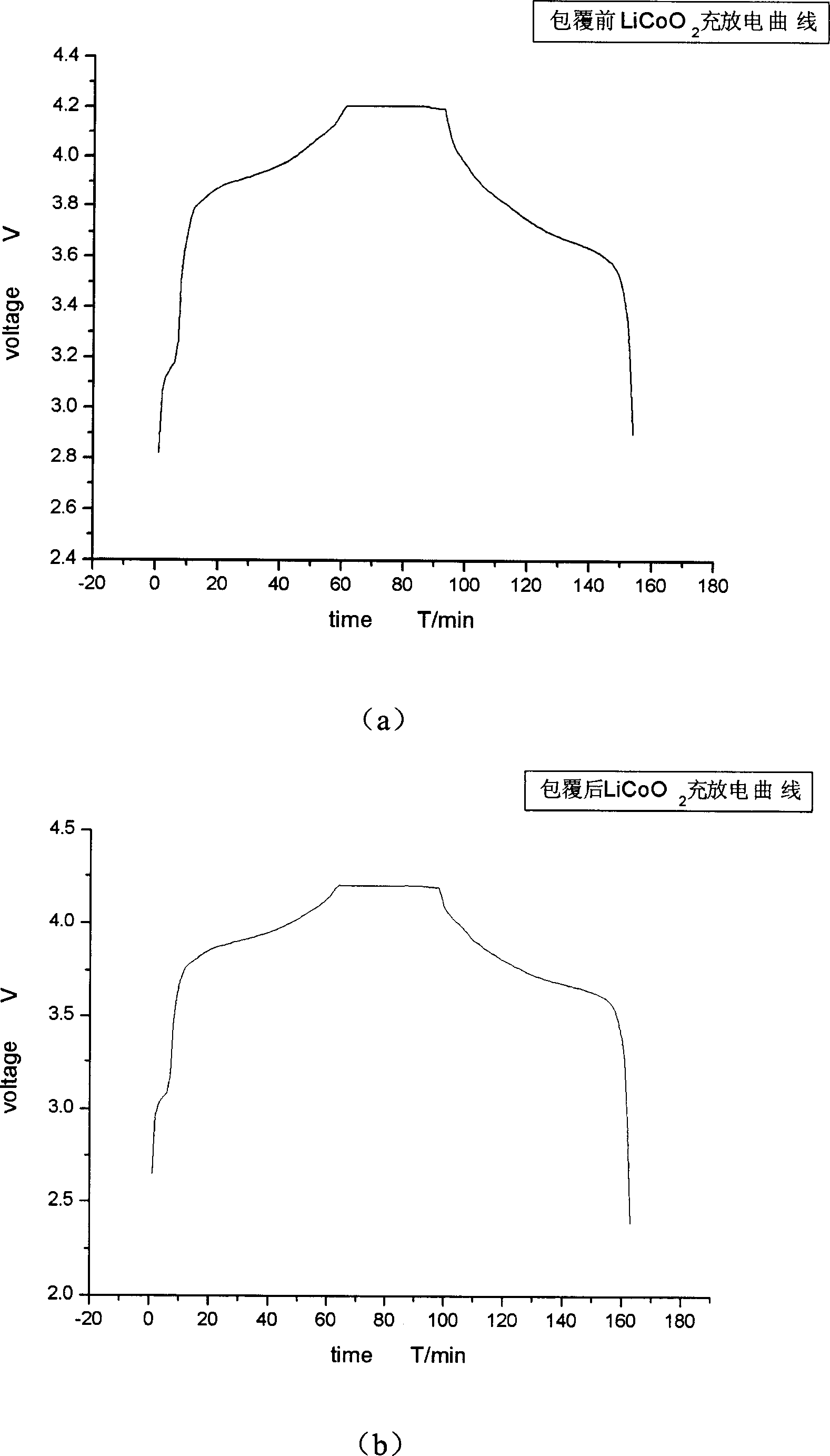

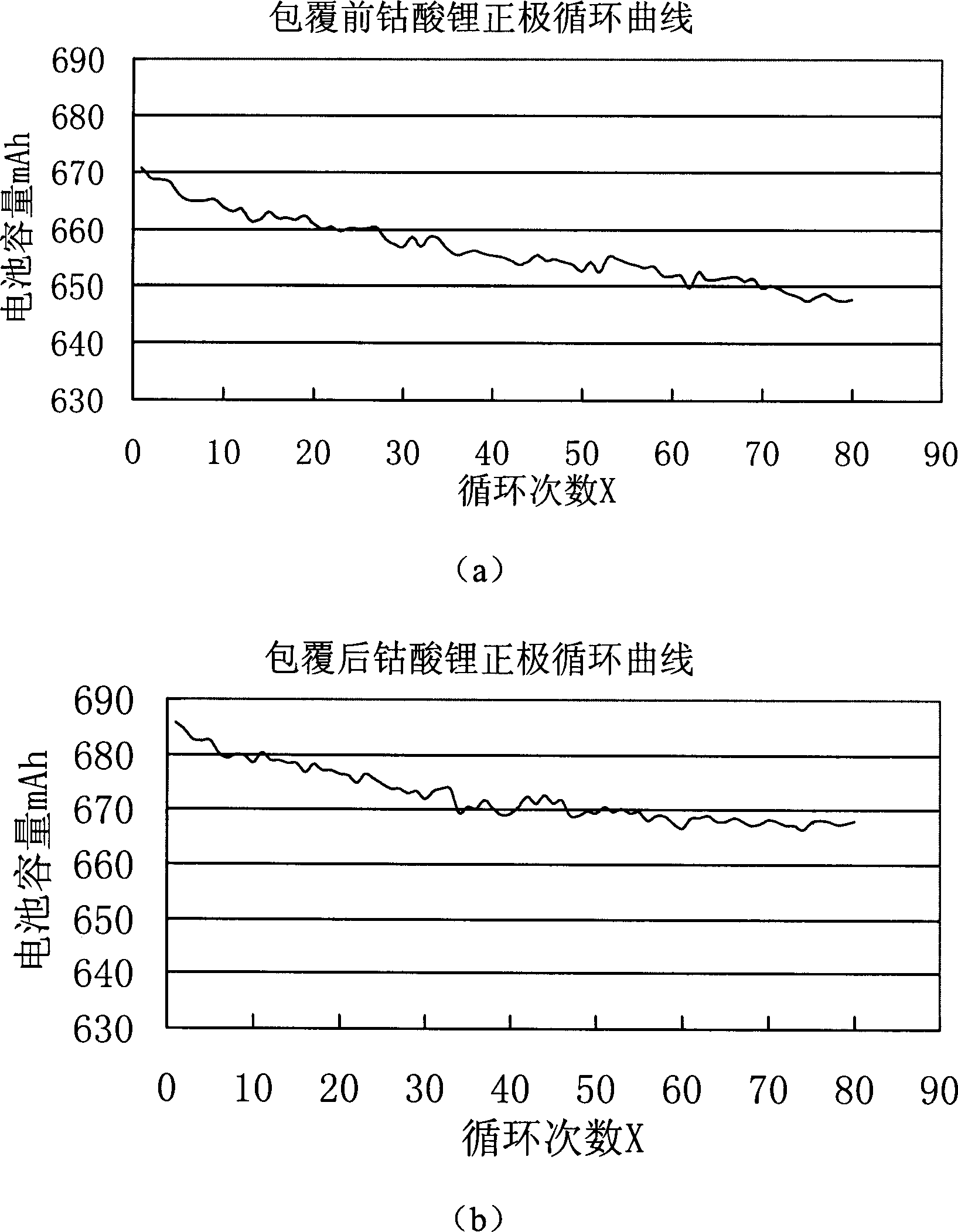

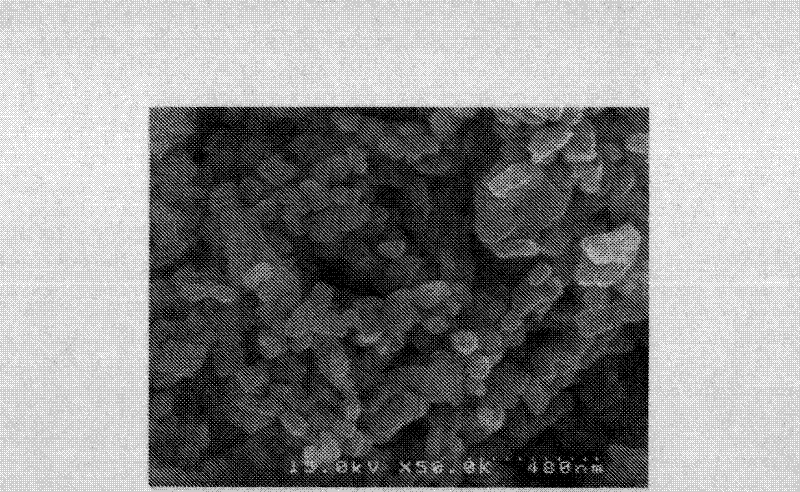

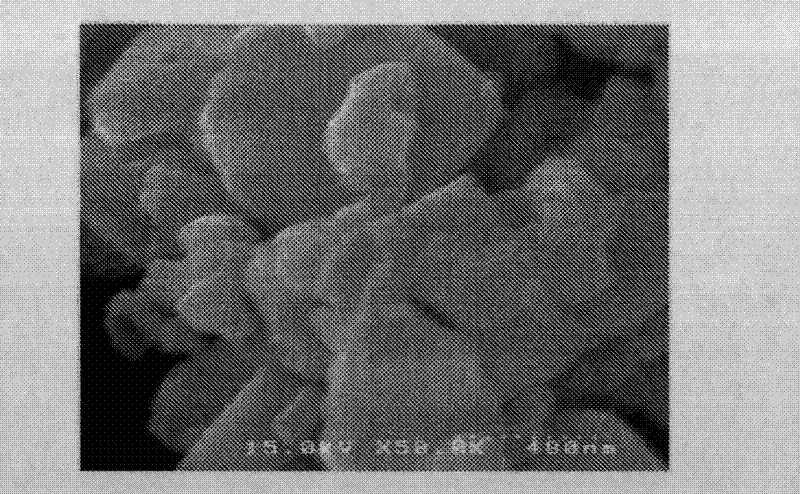

Method for modified cladding composite, anode material LiCoO* of lithium ion battery, and batteries

ActiveCN1797822AAvoid the problem of specific capacity dropAvoid disadvantagesElectrode manufacturing processesLithium compoundsAdhesiveMolecular materials

The composite material is LiCoO2 powdered material with surface being coated by conductive glass layer. The method includes steps: (1) mixing the said powdered material with solution capable of generating oxide or conductive glass layer for coating surface of the powdered material; (2) adding solution of organic high molecular material to admixture in step (1) or after step (1); (3) after procedures of de-watering, firing and calcining the admixture so as to obtain coated LiCoO2. The battery includes positive pole made from the disclosed composite material. The organic high molecular material not only disperses material to be coated, but also plays function of binder so that oxide or conductive glass layer can be dispersed in solution evenly and can coat on surface of LiCoO2 powdered material evenly. The invention raises thermal stability and reserves good process performance.

Owner:TIANJIN GUOAN MGL NEW MATERIALS TECH CO LTD

Lithium ion battery composite anode material LiFePO4-Li3V2(PO4)3/C and method for making same

InactiveCN101114709ARich sourcesLow priceElectrode manufacturing processesPhosphorus compoundsHigh rateChemical compound

The invention discloses a composite anode material LiFePO4-Li3V2(PO4)3 / C for lithium ion batteries and a preparation method for the composite anode material, wherein, the LiFePO4 and the Li3V2(PO4)3 of the complex chemical compound LiFePO4-Li3V2(PO4)3 / C are stoichiometrie compounds; the substance quantity ratio of the LiFePO4 and the Li3V2(PO4)3 is that LiFePO4 / Li3V2(PO4)3 is equal to an 1 / x, and the x is more than zero and less than or equal to 1; the LiOH®qH2O, Li2CO3 or CH3COOLi®q2H2O is mixed uniformly with FePO4, 4H2O,V2O5, NH4H2PO4 and the polyethylene glycol to be blended to be the rheological phase after being added with water, and an obtained rheological phase precursor is roasted in the inert atmosphere for three to twenty hours under the temperature of 600-800 DEG C, which produces the composite anode material LiFePO4-Li3V2 (PO4)3 / C for lithium ion batteries. The prepared composite anode material for lithium ion batteries has the advantages of large capacity, high efficiency of charge-discharge, good cycle efficiency, good high-rate performance, which is suitable for industrial production.

Owner:WUHAN UNIV

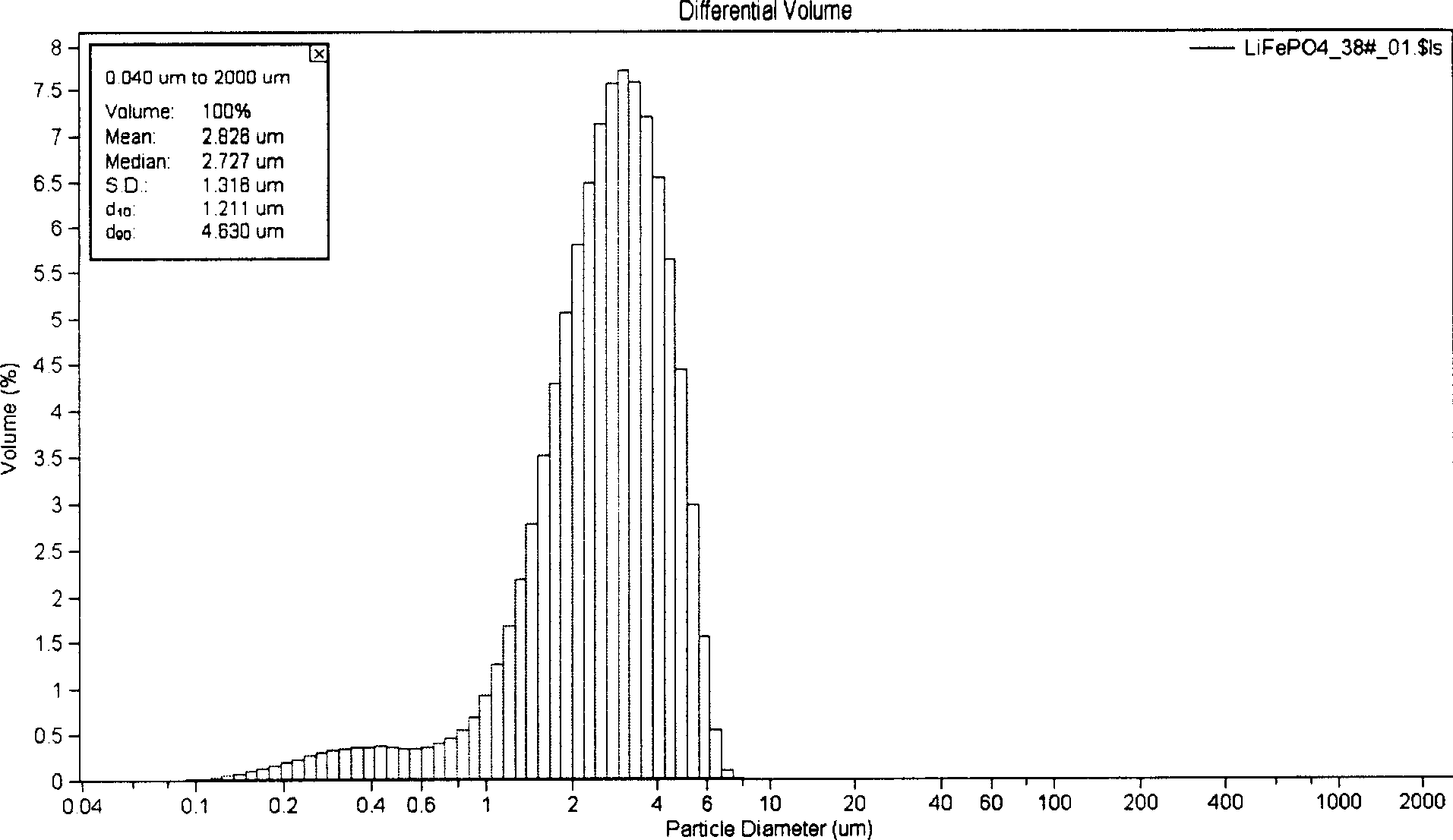

Method for producing positive electrode active material for lithium ion battery, positive electrode active material for lithium ion battery, electrode for lithium ion battery, and lithium ion battery

InactiveCN102356488AGenerate efficientlyNarrow particle size distributionCell electrodesLi-accumulatorsPhosphoric acidSodium-ion battery

Owner:SUMITOMO OSAKA CEMENT CO LTD

Multi-element in-situ co-doped ternary material precursor as well as preparation method and application thereof

The invention discloses a multi-element in-situ co-doped ternary material precursor as well as a preparation method and an application thereof. The chemical formula of the precursor is (NixCoyMnz)(1-a-c)MaNc(OH)(2+k), wherein x is larger than or equal to 1 / 3 and smaller than or equal to 0.9, y is larger than 0 and smaller than or equal to1 / 3, z is larger than 0 and smaller than or equal to 0.4, the sum of x, y and z is 1, a is larger than or equal to 0.0001 and smaller than or equal to 0.01, and c is larger than or equal to 0.0001 and smaller than or equal to 0.01; radius of a doped ion M is close to that of the lithium ion, and M is selected from one or more of Mg<2+>, Zn<2+>, Zr<4+>, Nb<5+>, Ta<4+>, In<3+>, Sc<3+>, Y<3+>, Ce<4+> and Gd<3+>; radius of a doped ion N is close to that of metal ions Mn and Co in the ternary material, and N is selected from one or more of Al<3+>, Ti<4+>, Ge<4+>, W<6+> and V<5+>. In the preparation process of the ternary material precursor, two kinds metalions with different radii are introduced in situ, so that the doped metal ions are uniformly distributed in a precursor phase, and uniform mixing on the atomic grade is realized. The two kinds of metal ions with different radii are doped in different positions, cell parameters have coordinated variation, so that not only can a lithium ion transmission channel be expanded, but also good lattice structure of the ternary material can be kept, and the ternary material with excellent electrochemical performance is obtained.

Owner:圣戈莱(北京)科技有限公司

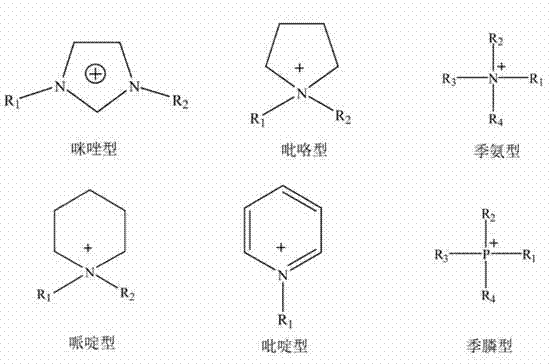

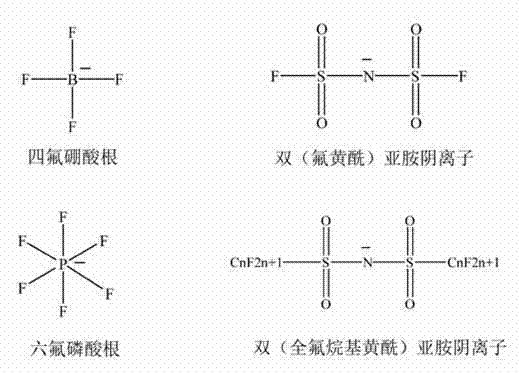

Ionic liquid mixed electrolyte for lithium ion battery

InactiveCN103094610AImprove solubilityImprove thermal stabilitySecondary cellsTetrafluoroborateQuaternary ammonium cation

The invention discloses an ionic liquid mixed electrolyte for a lithium ion battery. The ionic liquid mixed electrolyte comprises lithium salt, ionic liquid and a non-aqueous organic solvent, wherein the lithium salt is one or mixture of two of lithium bis borate and lithium difluoroborate; cations in the ionic liquid are selected from one of imidazole cations, piperidine cations, pyridine cations, pyrrole cations, quaternary ammonium cations and quaternary phosphine cations; anions in the ionic liquid are selected from one of tetrafluoroborate radicals, hexafluorophate radicals, difluorosulfimide anions and diperfluoroalkylsulfimide anions; and the non-aqueous organic solvent is selected from any one or mixture of several of linear carbonate, cyclic carbonate, linear ether and cyclic ether. The ionic liquid mixed electrolyte is high in thermal stability, wide for an electrochemical stability window, high in conductivity, low in viscosity and good in compatibility with an anode material and a cathode material of the lithium ion battery at the same time.

Owner:JIANGXI YOULI NEW MATERIALS

Method for preparing lithium iron phosphate of anode material of lithium ion battery

InactiveCN101645504AWell mixedThe production process is simpleElectrode manufacturing processesPhosphorus compoundsSodium-ion batteryCharge discharge

The invention relates to a method for preparing lithium iron phosphate of an anode material of a lithium ion battery. The method synthesizes a reactive precursor under the liquid-phase condition and calcines the precursor at high temperature to prepare the lithium iron phosphate of the anode material of the lithium ion battery, and comprises the following steps: dissolving a lithium source, a phosphorus source compound and a doped element compound in deionized water; adjusting the pH value of the mixture between 2 and 4; and after carrying out sufficient reaction, adding the conductive organicprecursor and an iron source compound into the reacted mixture and stirring and mixing the obtained mixture evenly to obtain a mixture containing lithium, iron and phosphorus and doped metal elements, and then calcining the mixture to obtain the lithium iron phosphate of the anode material of the lithium ion battery. Compared with the prior art, the method has reasonable process and simple operation, well controls the chemical composition of the material and the shape and size of granules through simple process steps, improves the electrical conductivity and the lithium-ion diffusion rate ofthe material, greatly improves the magnification charge-discharge and cycle performance of the synthesized material, and is suitable for industrialized production.

Owner:赵兵

Electrolytes in Support of 5 V Li ion Chemistry

InactiveUS20120225359A1Negatively performanceNegatively propertyMaterial nanotechnologyHybrid capacitor electrolytesPhosphateHigh energy

This invention described the preparation of a series of compounds selected from the group comprising tris(1,1,1,3,3,3-hexafluoro-iso-propyl)phosphate, tris(perfluoroethyl)phosphate, tris(perfluoro-iso-propyl)phosphate, bis(1,1,1-trifluoroethyl)fluorophosphate, tris(1,1,1-trifluoroethyl)phosphate, hexakis(1,1,1-trifluoroethoxy)phosphazene, tris(1,1,1-trifluoroethoxy)trifluorophosphazene, hexakis(perfluoro-t-butyl)phosphazene and tris(perfluoro-t-butyl)phosphate. These compounds may be used as co-solvents, solutes or additives in non-aqueous electrolytes in various electrochemical devices. The inclusion of these compounds in electrolyte systems can enable rechargeable chemistries at high voltages that are otherwise impossible with state-of-the-art electrolyte technologies. These compounds are chosen because of their beneficial effect on the interphasial chemistries formed at high potentials, such as 5.0 V class cathodes for new Li ion chemistries. These compounds may be used in Li ion battery technology and in any electrochemical device that employs non-aqueous electrolytes for the benefit of high energy density resultant from high operating voltages.

Owner:ARMY US SEC THE

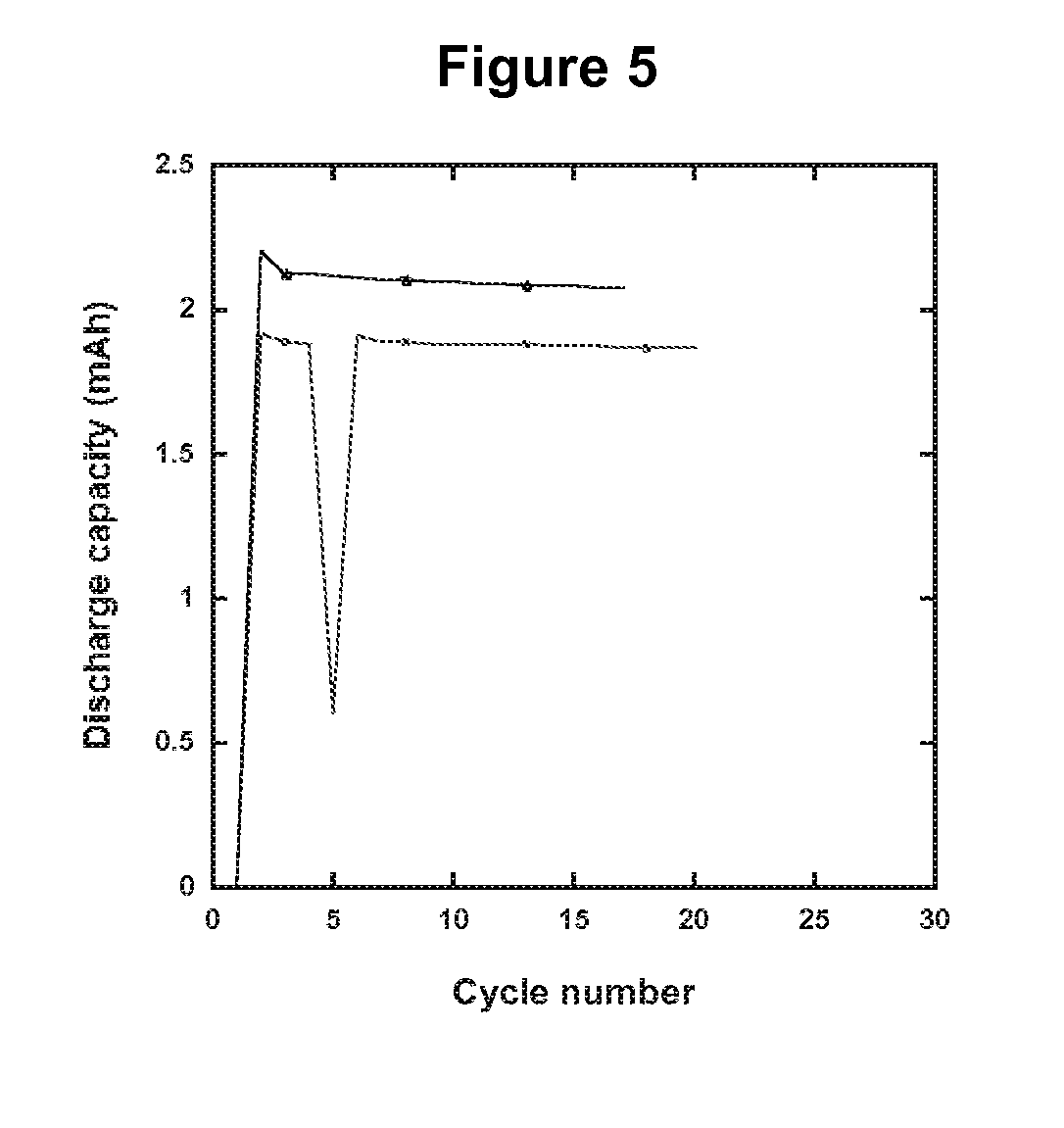

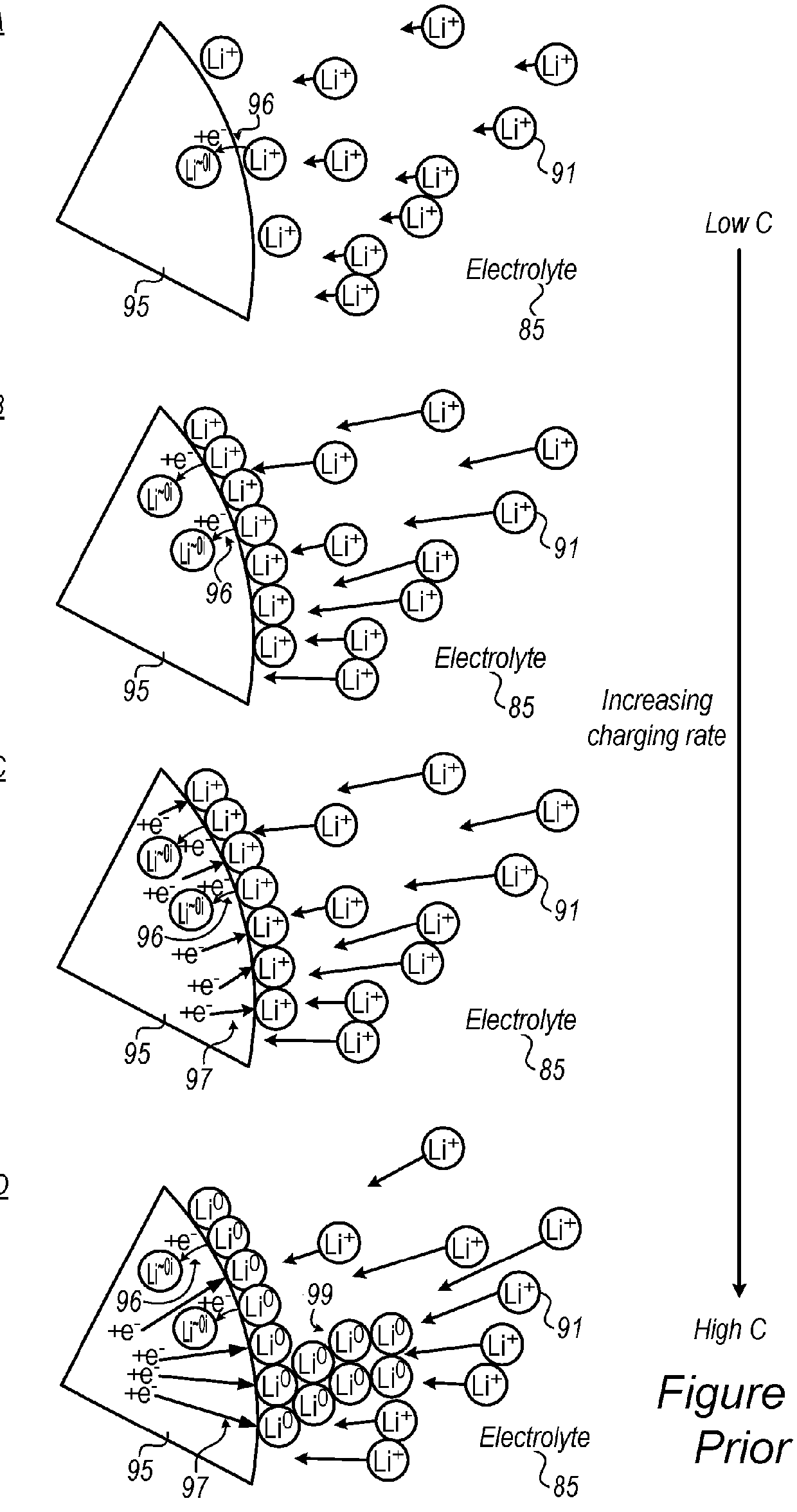

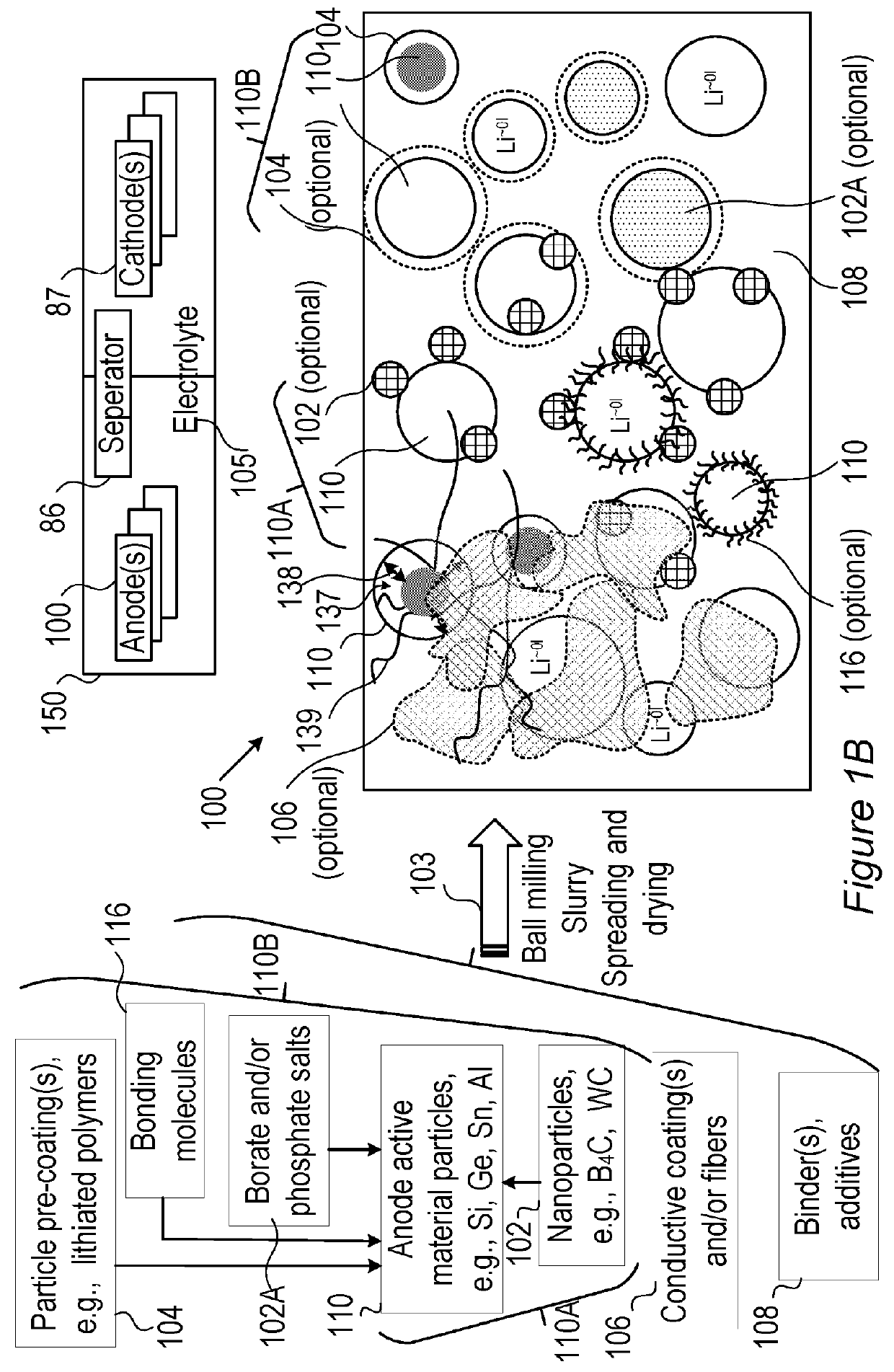

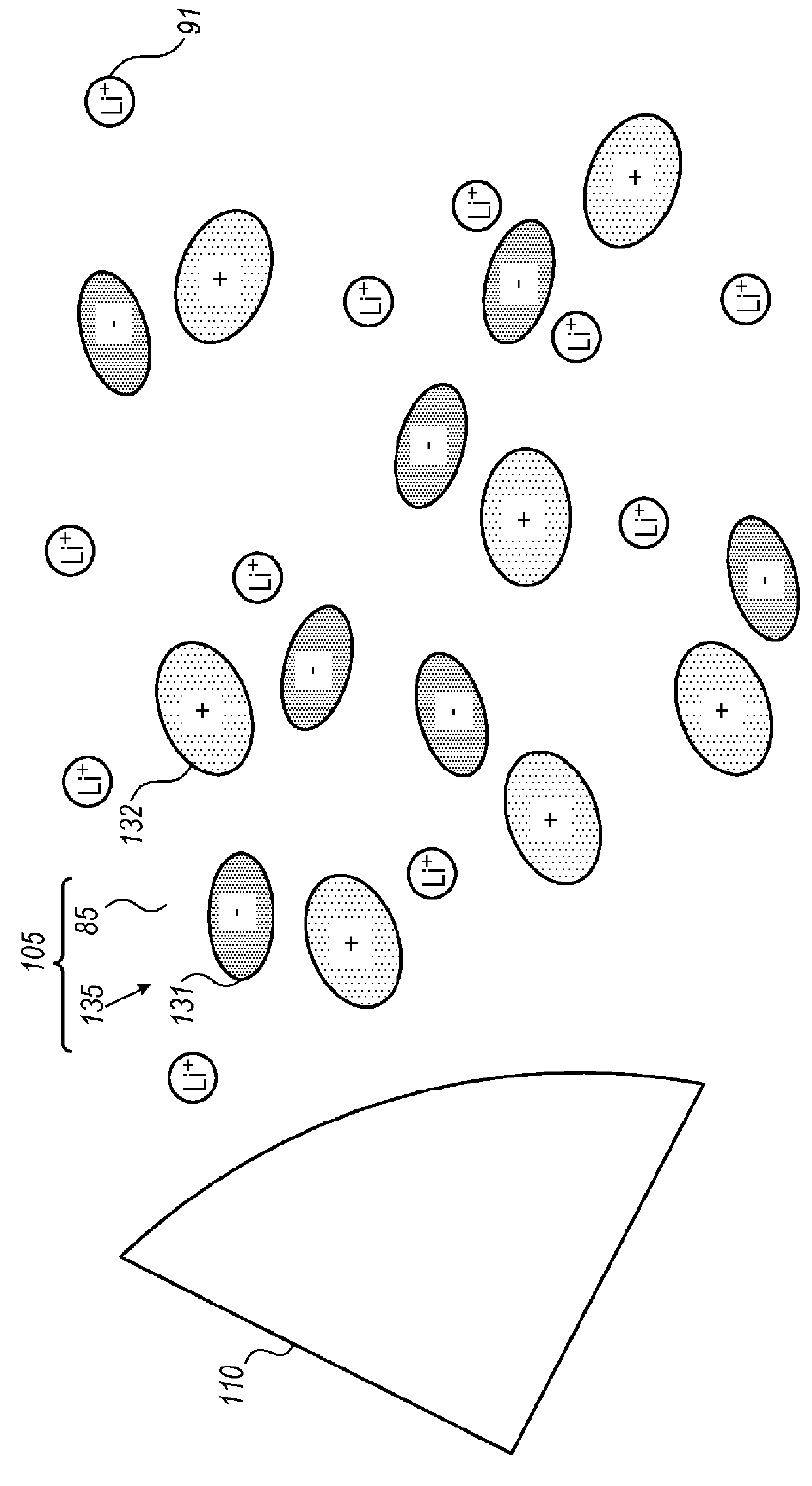

Lithium ion batteries with supplemental lithium

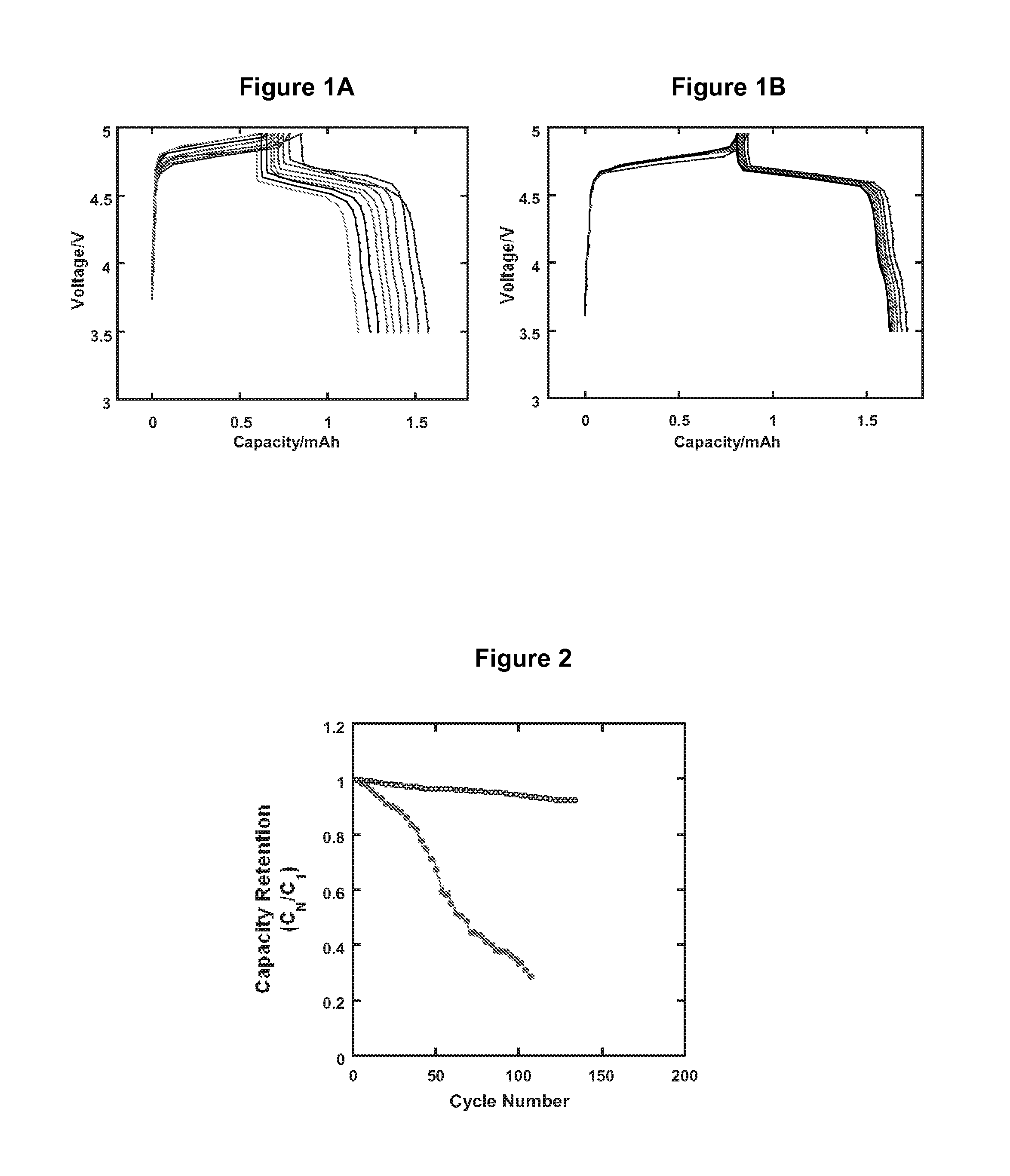

ActiveUS9166222B2Electrode manufacturing processesFinal product manufactureManganeseElectrochemistry

Supplemental lithium can be used to stabilize lithium ion batteries with lithium rich metal oxides as the positive electrode active material. Dramatic improvements in the specific capacity at long cycling have been obtained. The supplemental lithium can be provided with the negative electrode, or alternatively as a sacrificial material that is subsequently driven into the negative electrode active material. The supplemental lithium can be provided to the negative electrode active material prior to assembly of the battery using electrochemical deposition. The positive electrode active materials can comprise a layered-layered structure comprising manganese as well as nickel and / or cobalt.

Owner:IONBLOX INC

Ferrous phosphate doping lithium anode material and preparation process

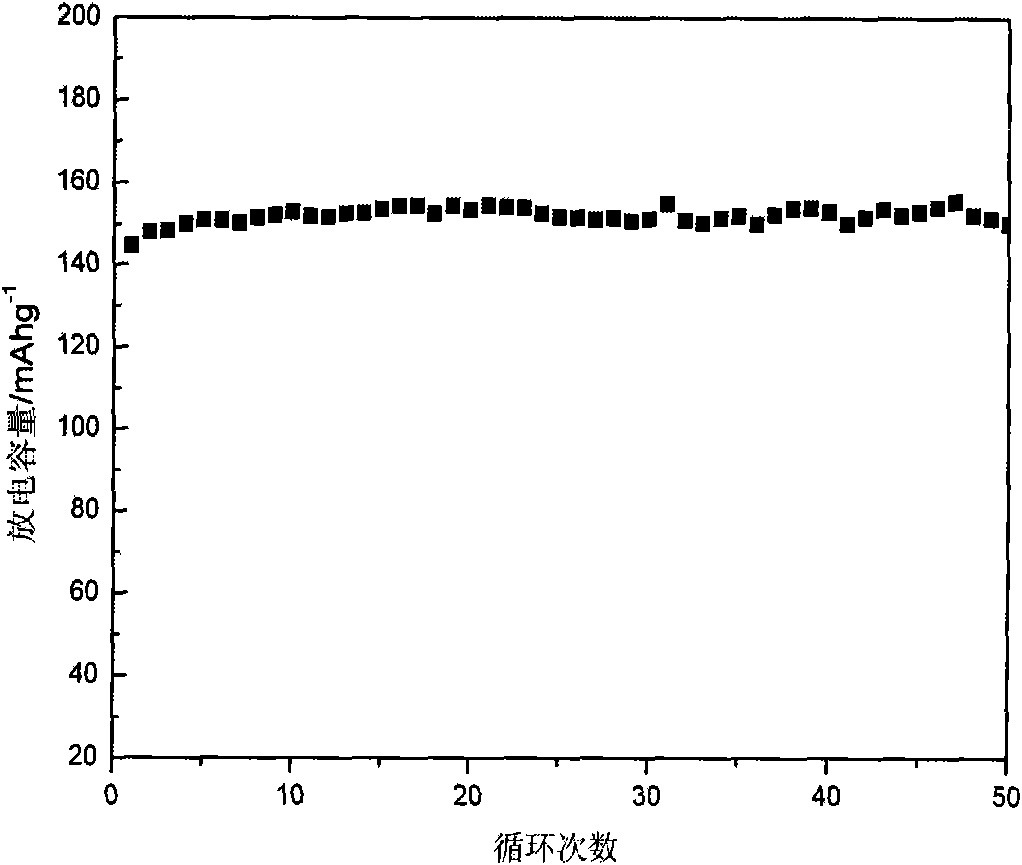

InactiveCN1921187AImprove discharge capacityLow costElectrode manufacturing processesPhosphorus compoundsPhosphateFerrous salts

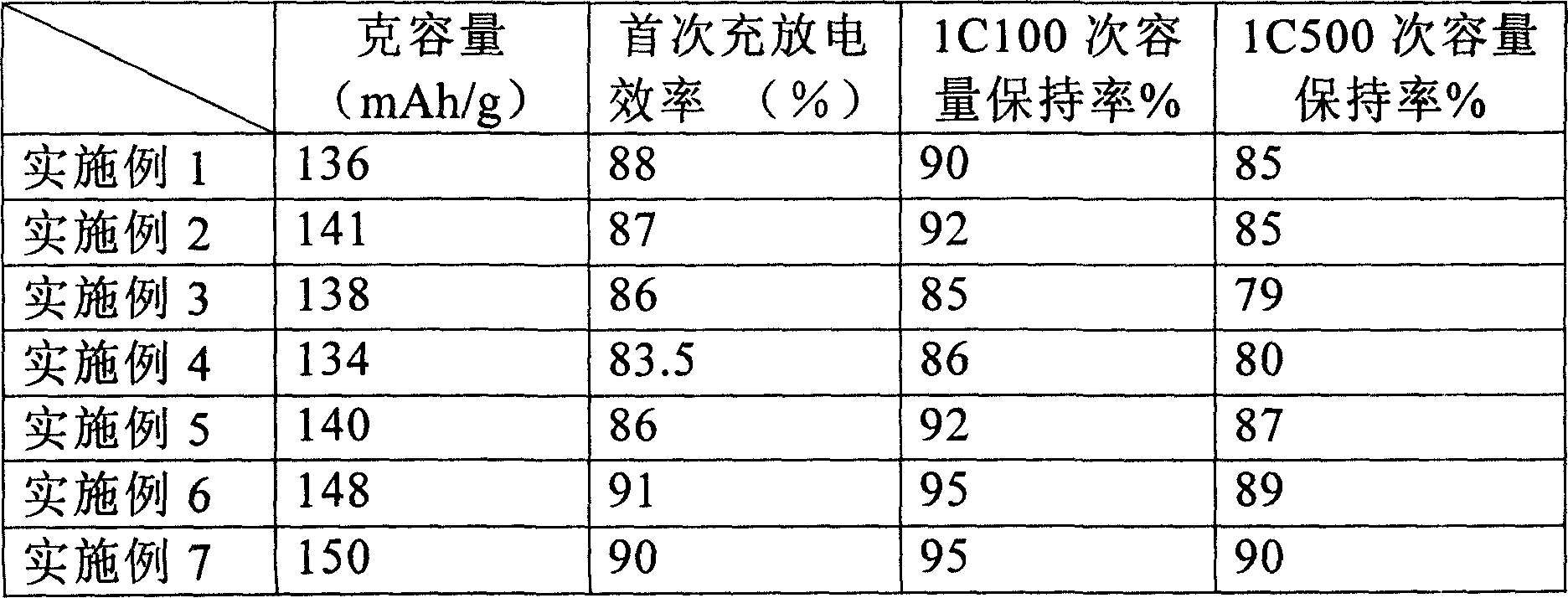

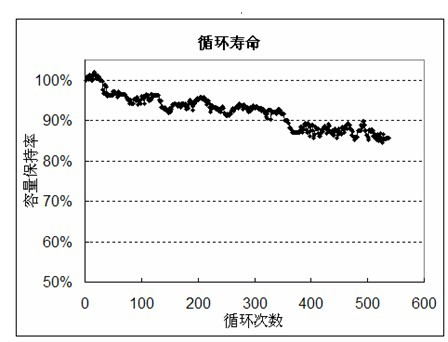

The invention relates to a lithium anode material doped with phosphate ferrous iron, and relative preparation. Wherein, the product has common advantages of lithium battery, while its discharge capacity can reach 150mAh / g, the 500-circled capacity is over 90%, with low cost. The invention is characterized in that: its formula is LiFe0.99M0.01PO4 / C; M is Cr, Zn, and Ca; the preparation comprises that (1) mixing and grinding lithium carbonate, ferrous salt, chromate salt, zinc salt, calcium salt, phosphorus source and glucose; (2), preheating the powder material in step (1) in inertia gas and low temperature; (3), grinding the material in step (2), under inertia gas, to be burnt, cooled and screened at 300-deal screen. The invention can be used in the anode of lithium battery.

Owner:XINXIANG ZHONGKE SCI&TECH

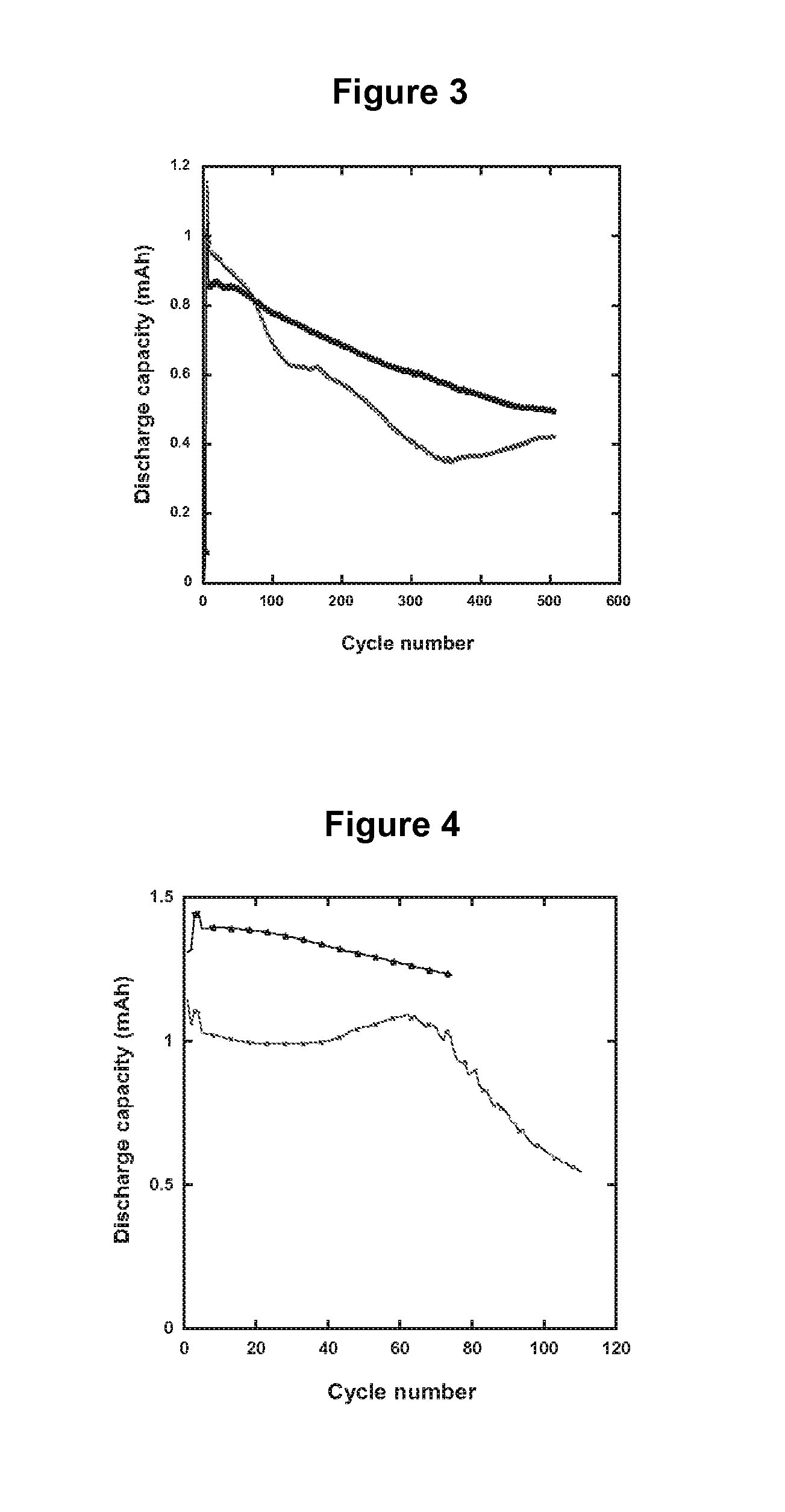

Electrolytes for lithium ion batteries

Electrolytes, lithium ion cells and corresponding methods are provided, for extending the cycle life of fast charging lithium ion batteries. The electrolytes are based on fluoroethylene carbonate (FEC) and / or vinylene carbonate (VC) as the cyclic carbonate component, and possibly on ethyl acetate (EA) and / or ethyl methyl carbonate (EMC) as the linear component. Proposed electrolytes extend the cycle life by factors of two or more, as indicated by several complementary measurements.

Owner:STOREDOT

Semiwet method of preparing lithium ferrous phosphate and its prepared lithium ferrous phosphate

InactiveCN1903707AQuality improvementWell mixedCell electrodesPhosphorus compoundsPhosphateWater insoluble

The present invention provides a method for preparing ferrous lithium phosphate by using semi-wet method. Said method includes the following steps: in the compounds containing Li, Fe and P selecting one water-insoluble compound and others are water-soluble, placing the above-mentioned water-insoluble compound into the above-mentioned water-soluble compound solution to obtain a suspension; in said suspension Li content, Fe content and P content must be met with the following formula: [mLi+n(1-m) / n M]:Fe:qPO4=1:1:1(1), in formula (1) n is chemical valence of alloying element M, m is mole number of Li, (1-m) / n is mole number of alloying element M and P and q respectively are mole numbers of Fe and PO4; adding reduction electro-conductive additive, spraying and pyrolyzing suspension so as to obtain precursor powder, roasting said precursor powder and pulverizing to obtain the invented product.

Owner:新乡市华鑫电源材料有限公司

Electrolyte for lithium-ion battery and lithium-ion battery employing electrolyte

InactiveCN105742709AReduce viscosityImprove wettabilityOrganic chemistrySecondary cellsHigh temperature storageLyonium ion

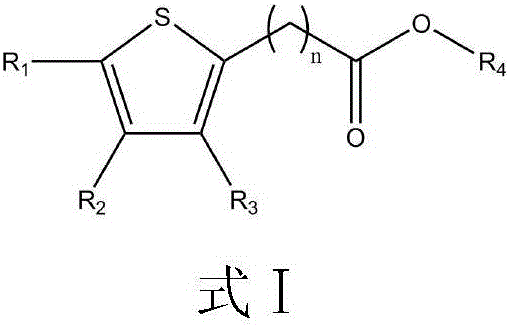

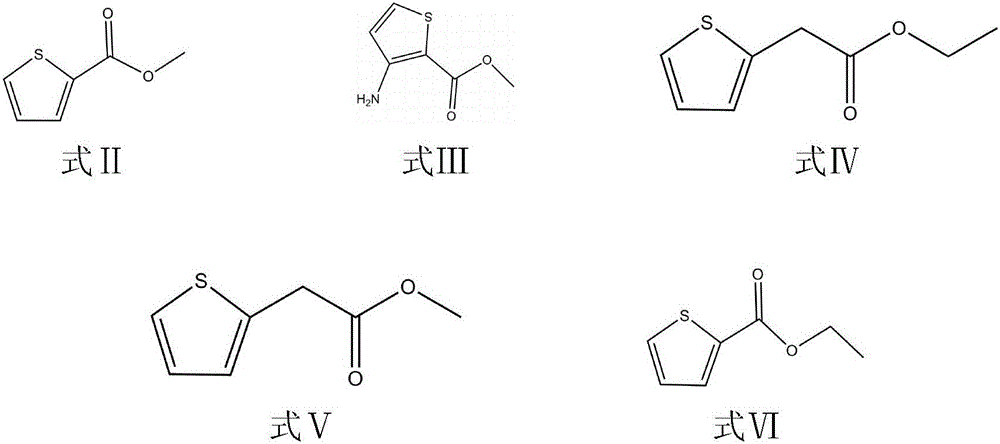

The invention relates to the technical field of lithium-ion batteries, in particular to a high-voltage and high-compaction electrolyte for a lithium-ion battery and the lithium-ion battery employing the electrolyte. The electrolyte comprises a lithium salt, a non-aqueous organic solvent and an additive, wherein the additive comprises fluoroethylene carbonate, a nitrile compound and a compound with a structure shown in the formula I; R1, R2 and R3 in the formula I are independently selected from hydrogen, halogen, hydroxyl, amino, a sulfo group, nitryl, carboxyl, an aldehyde group and alkyl or alkoxy of which the carbon atom number is 1-3 respectively; R4 is selected from hydrogen, amino or alkyl of which the carbon atom number is 1-3; and n is selected from an arbitrary integer between 0 and 2. Compared with the prior art, the battery employing the electrolyte is excellent in infiltration effect and high in development capacity under the conditions of high voltage and high compaction and has excellent cycle performance and high-temperature storage performance through synergistic effects of the fluoroethylene carbonate, the nitrile compound and the compound with the structure shown in the formula I.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

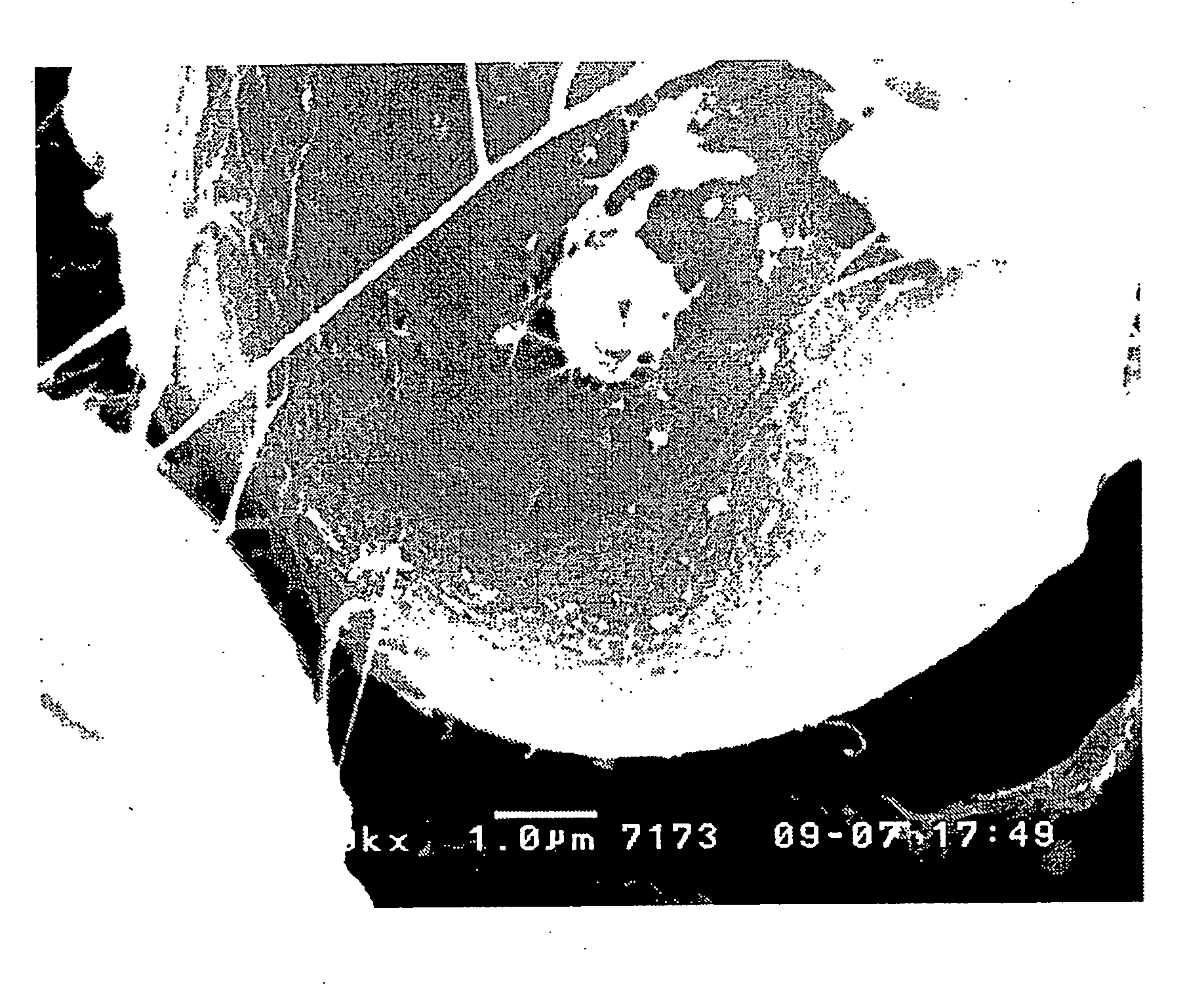

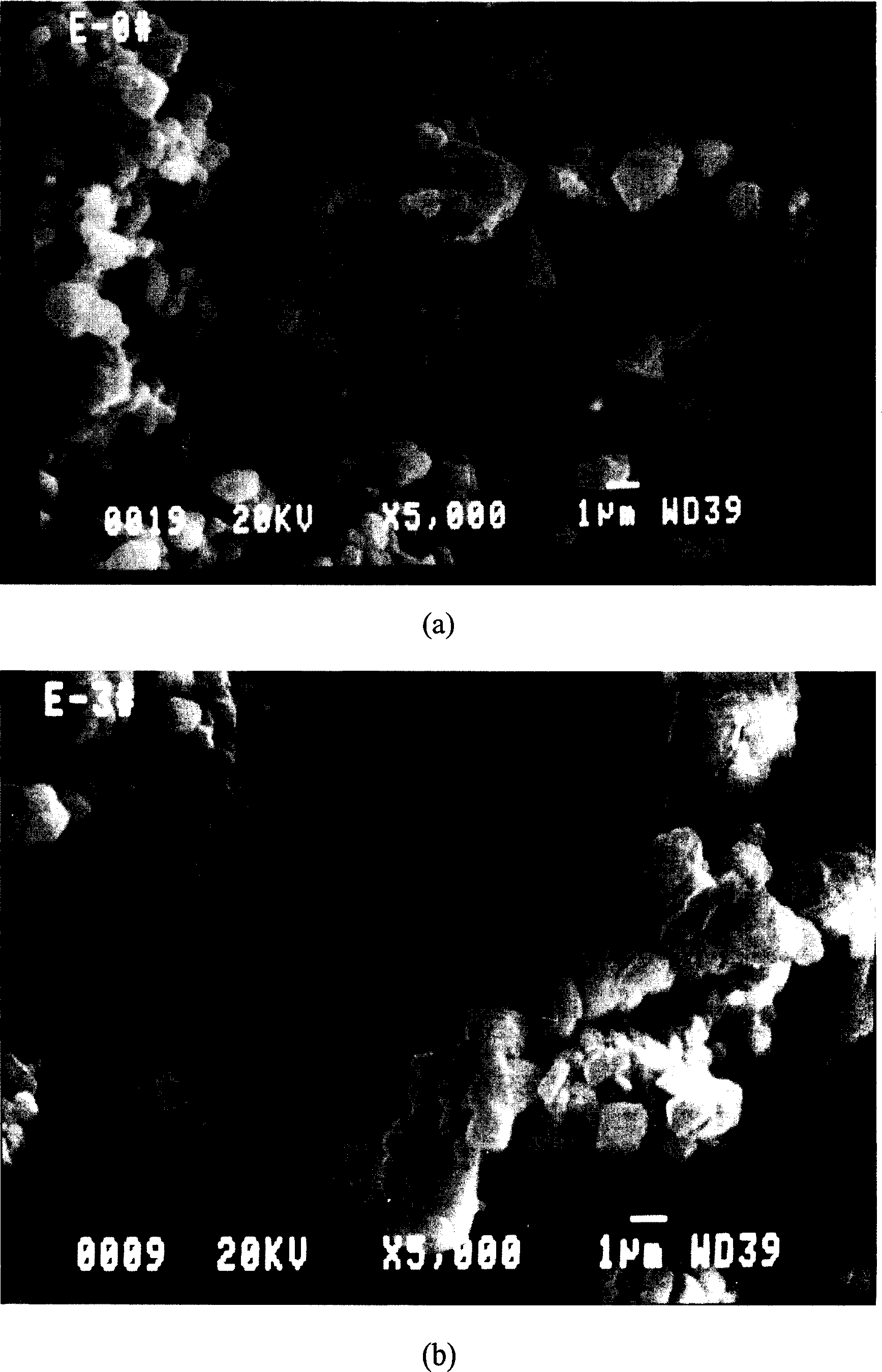

Lithium Ion Battery Cathode Material and Lithium Ion Battery

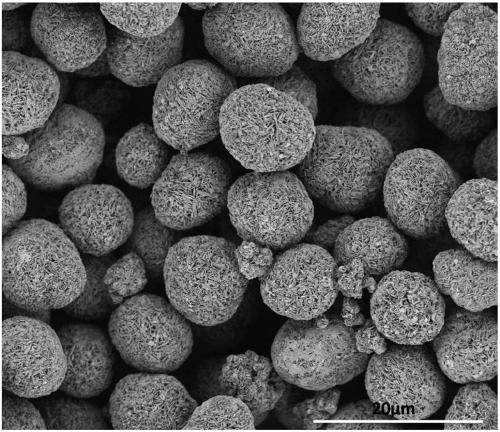

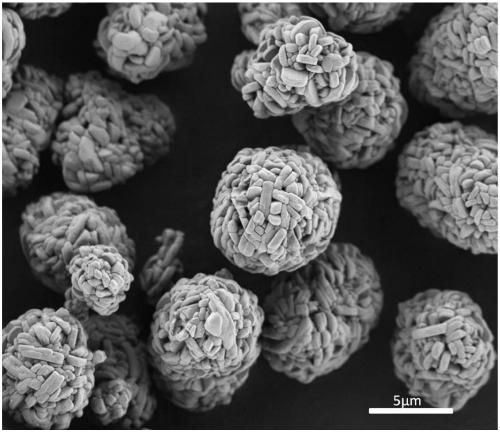

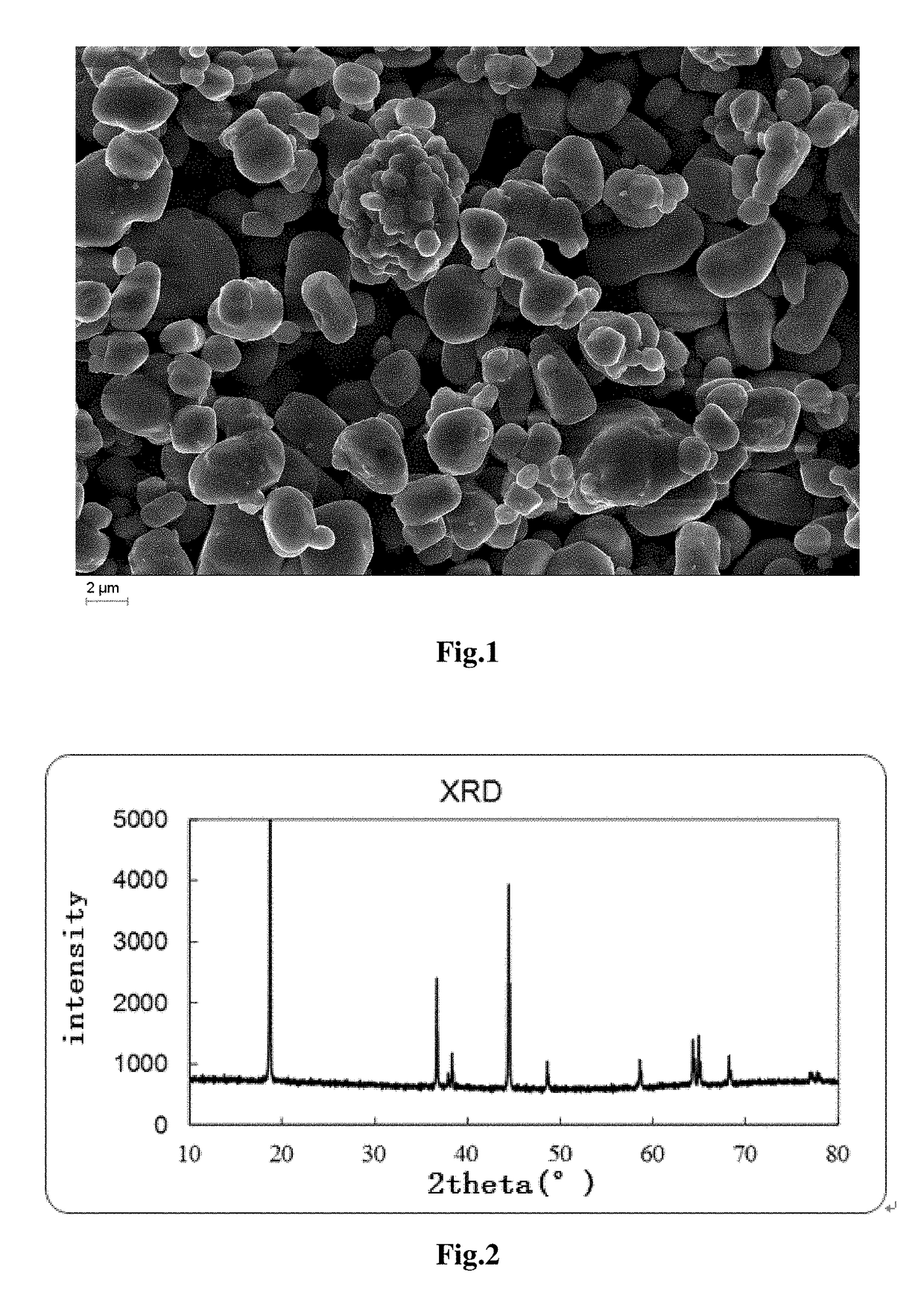

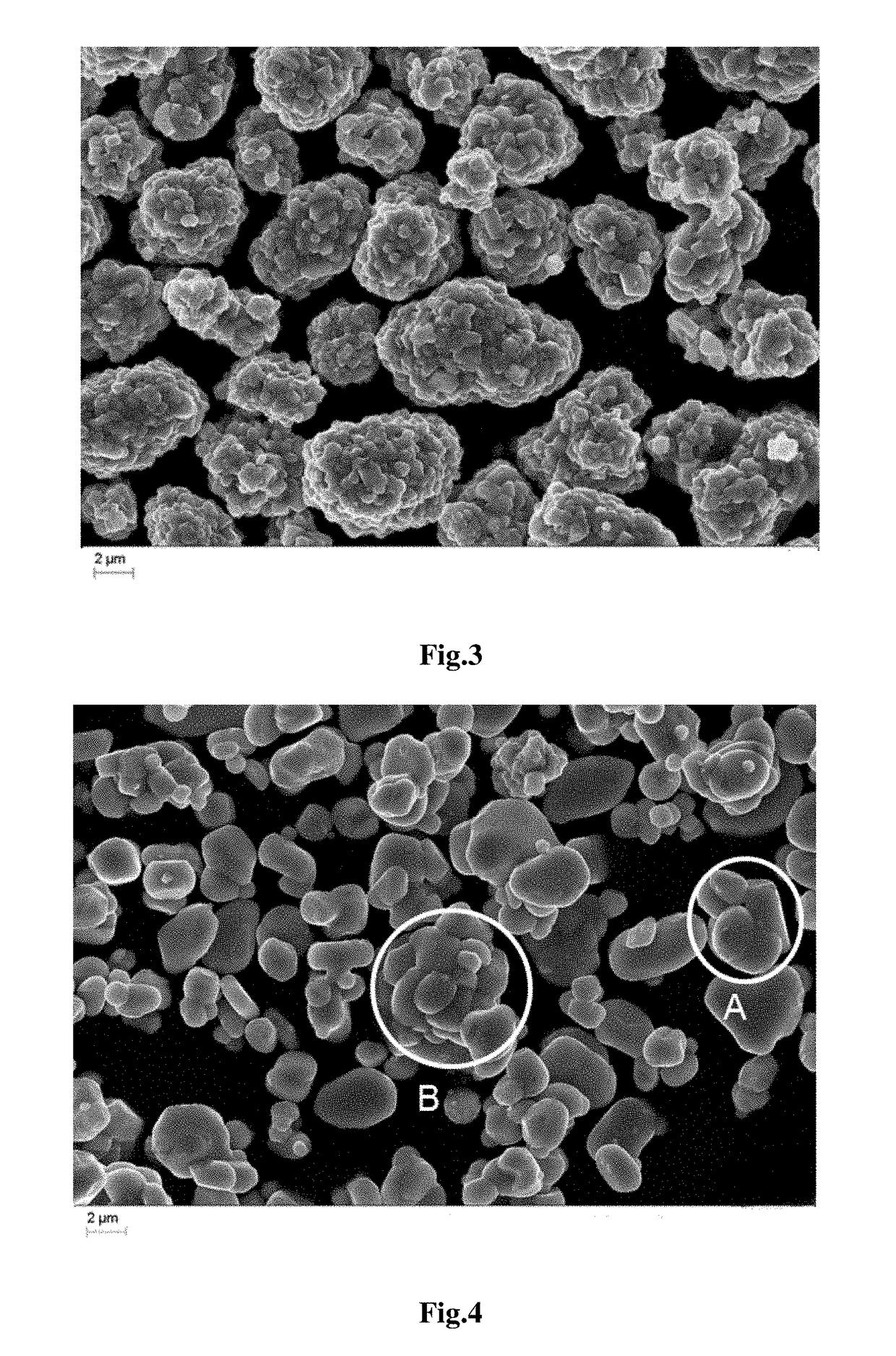

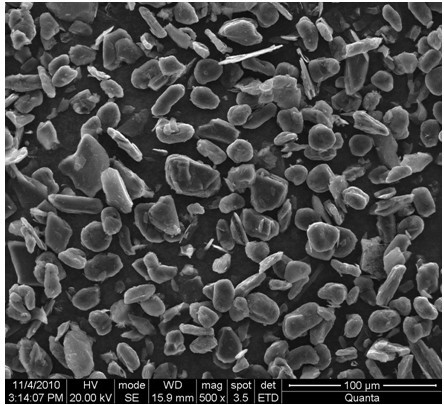

ActiveUS20190020024A1Improve performanceUniform shapeSecondary cellsPositive electrodesRare-earth elementScanning electron microscope

The present invention relates to a lithium ion cathode material and a lithium ion battery. The chemical formula of the cathode material is: LiaNixCoyMnzMbO2, wherein 1.0≤a≤1.2; 0.00≤b≤0.05; 0.30≤x≤0.60; 0.10≤y≤0.40; 0.15≤z≤0.30; x+y+z=1; M is one or two or more selected from the group consisting of Mg, Ti, Al, Zr, Y, W, Mn, Ba and rare earth elements; wherein the scanning electron microscope observation shows that, the cathode material consists of secondary particles agglomerated by 10 or less primary single crystal particles and secondary particles agglomerated by more than 10 primary single crystal particles, and wherein, the area percentage of the secondary particles agglomerated by 10 or less primary single crystal particles is greater than 80%, and the area percentage of the secondary particles agglomerated by more than 10 primary single crystal particles is less than or equal to 20%. The lithium battery prepared by the cathode material of the present invention has good cycling performance, the preparation method thereof is simple, and can be conveniently and massively produced.

Owner:GUIZHOU ZHENHUA E CHEM INC

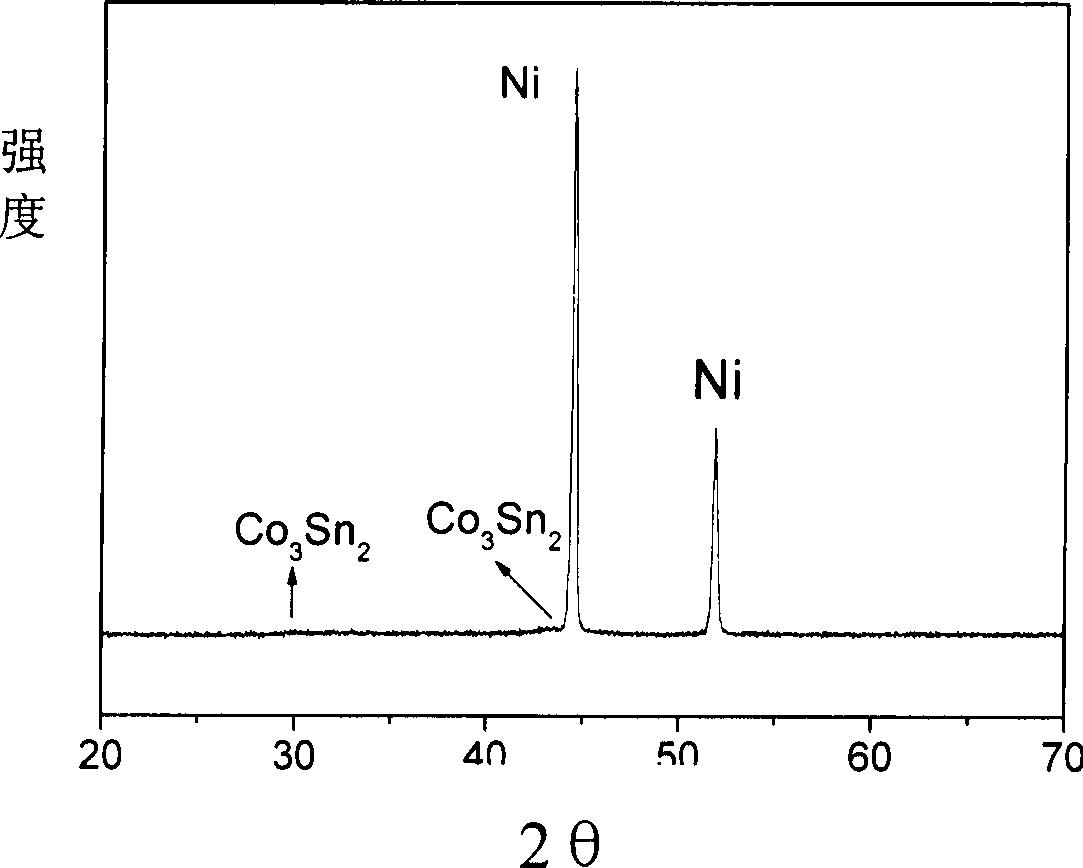

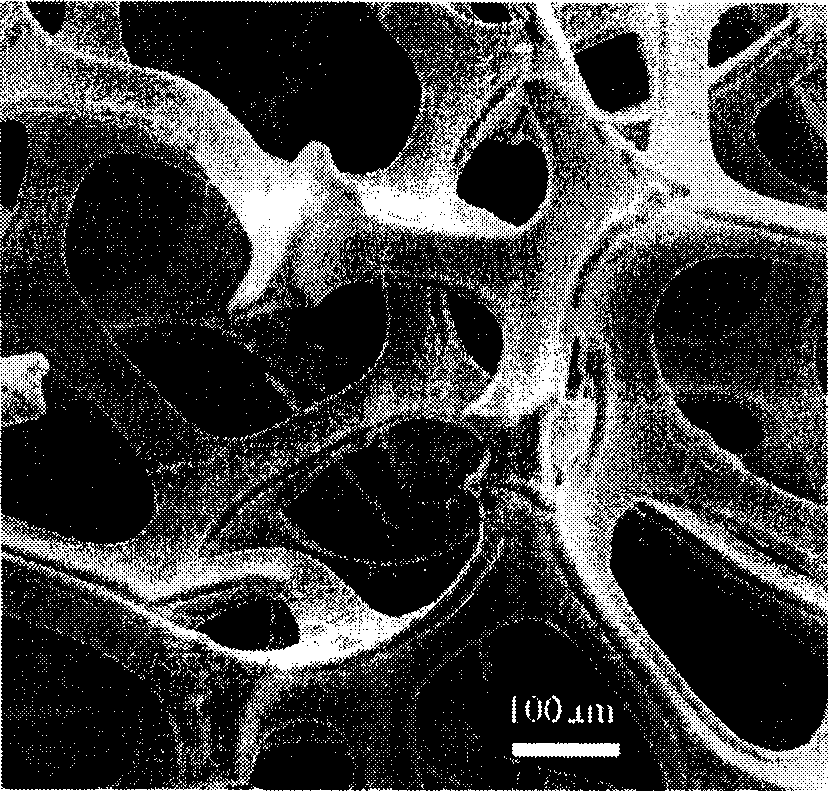

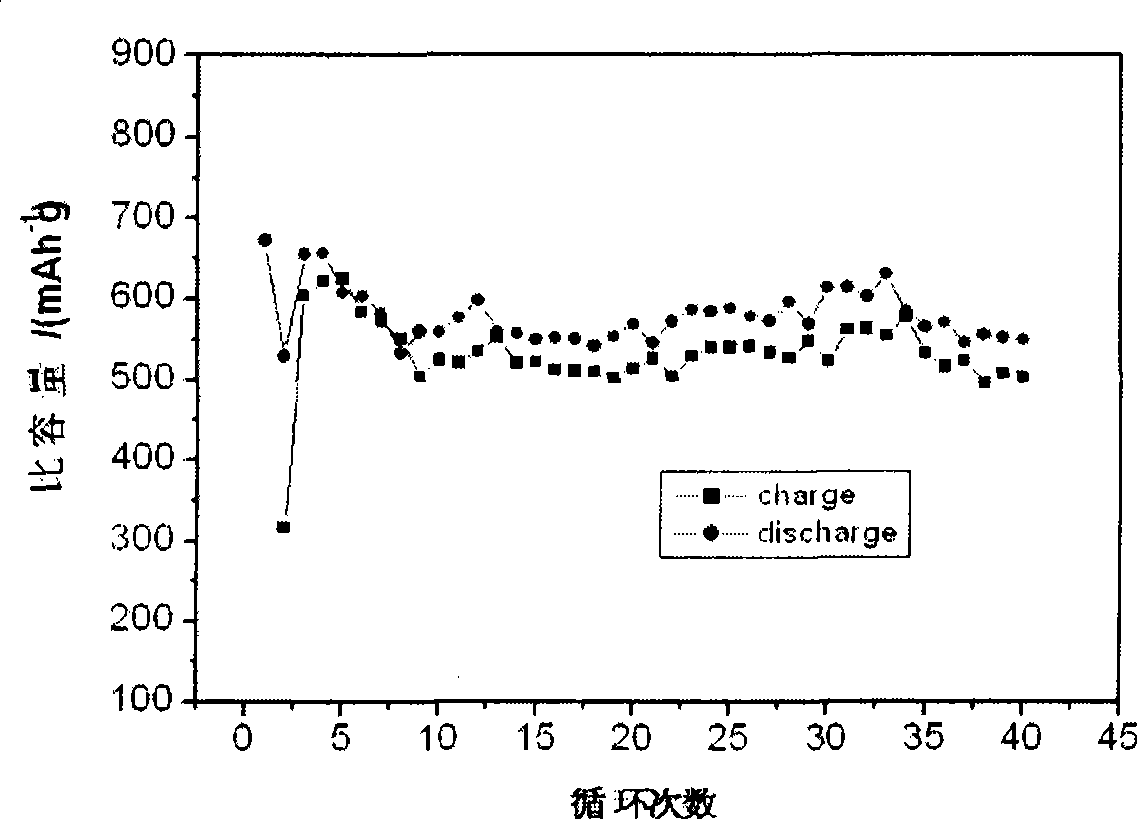

Electrochemical deposition preparation for lithium ionic cell tin-cobalt alloy film electrode

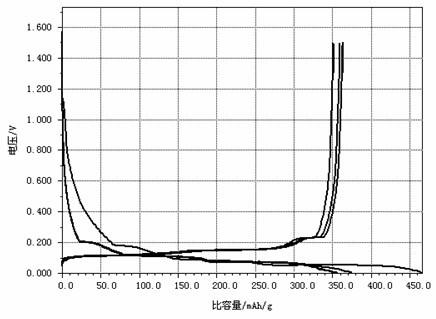

InactiveCN101476139AThe preparation process is easy to controlSimple processAlkaline accumulator electrodesThin film electrodeLyonium ion

The invention provides an electrical chemical depositing method for preparing lithium battery tin-cobalt alloy thin film electrode which has characteristics that foam nickel with a plurality of holes is used as basic body, the tin-cobalt alloy thin film is obtained by electrical chemical depositing on the foam nickel basic body for manufacturing lithium battery tin-cobalt alloy thin film electrode. The method has advantages of simple practical and low cost, and the tin-cobalt alloy thin film electrode is distributed on the foam nickel basic body that can ease electrode expansion in charge / discharge cycle process for improving cycle performance of battery. The method has latent application prospect in the lithium battery electrode material field.

Owner:HEFEI UNIV OF TECH

Preparing method of highly conductive lithium iron phosphate anode material of lithium ionic cell

InactiveCN101335347AOrderly dispersionEvenly dispersedElectrode manufacturing processesPhosphorus compoundsLithium iron phosphateCarbon nanotube

The invention discloses a preparation method of a lithium iron phosphate anode material with high conductivity of a lithium ion battery. A carbon nano-pipe is added into lithium iron phosphate which is mixed with a conductive agent and a polyvinylidene fluoride binder. The carbon nano-pipe goes through at least one of such treatments as ball milling, gas pretreatment, purification treatment, acidification treatment and esterification treatment, which can effectively improve the purity of the carbon nano-pipe and reduce surface energy and twisting degree of the carbon nano-pipe, and lead the carbon nano-pipe to be arranged in order and scattered in the lithium iron phosphate, and form a conductive network with very small volume resistivity to improve the conductivity of the lithium iron phosphate. The adoption of the carbon nano-pipe as the conductive agent causes that the lithium iron phosphate which is used as the anode material of the lithium ion second battery has relatively good charge and discharge capability with large rate.

Owner:HANGZHOU LECHENG ELECTRONICS CO LTD

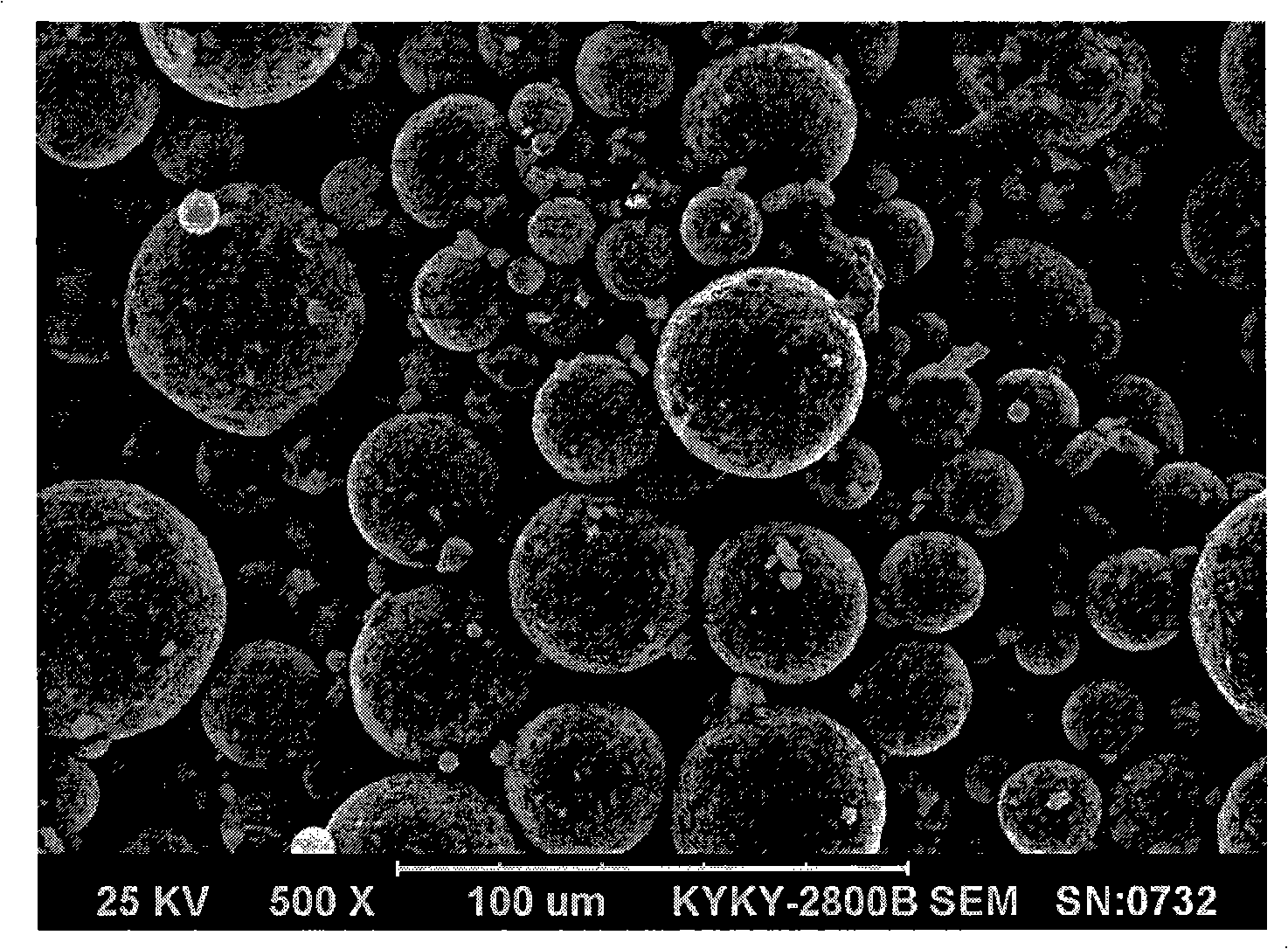

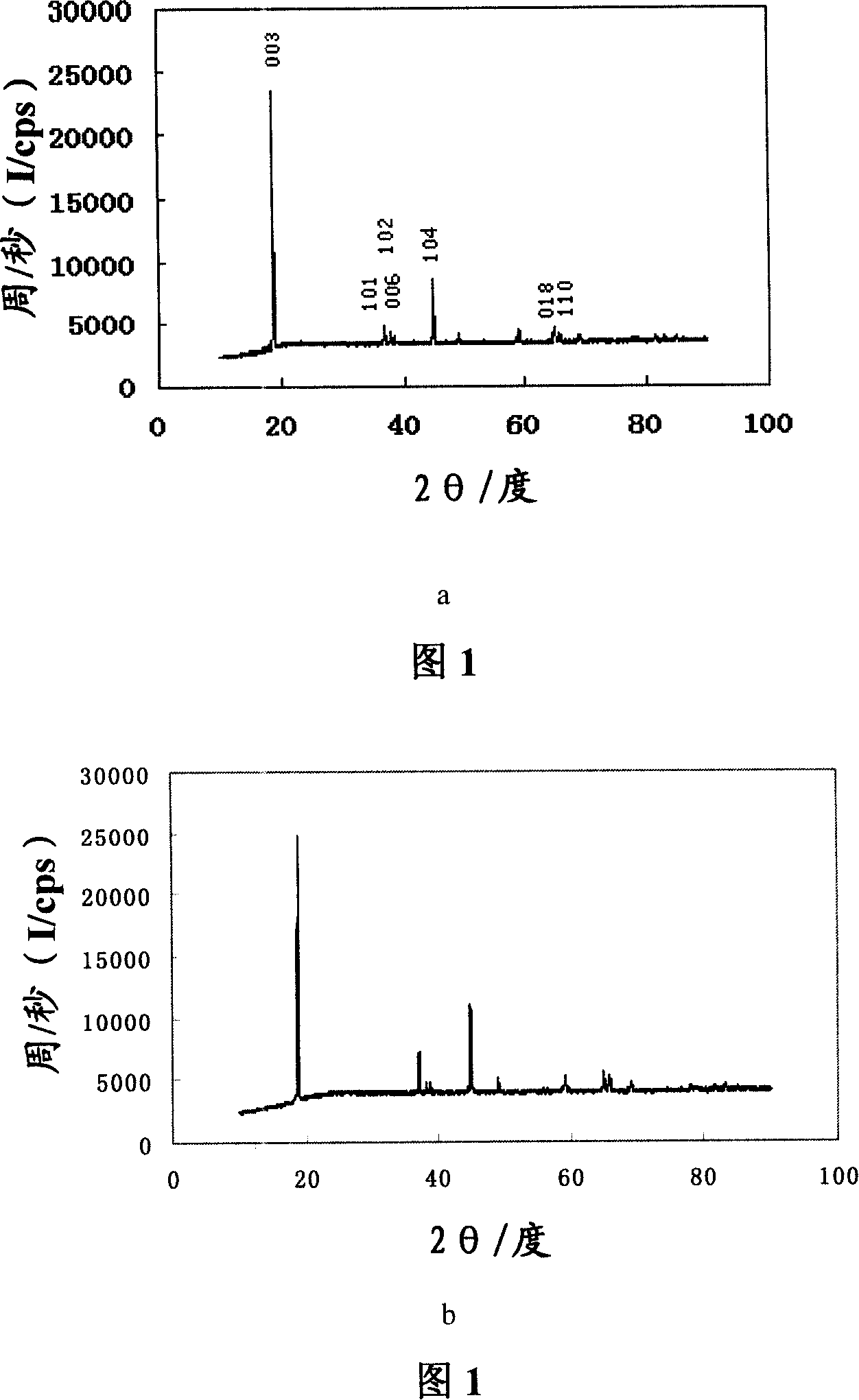

Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

The present invention relates to a method to prepare cathode material of layered lithium-nickel-cobalt-manganese oxide applied to lithium ion battery. The corresponding materials of metal manganese powers, compounds of lithium, metal cobalt or compounds of cobalt and compounds of nickel are weighted according to the molar ratio expressed and required in the chemical formula LiyNixCo1-2xMnxO2. In the formula, x is more than zero but less than 0.5 and y is more than or equal to 0.9 but less than 1.1; a solvent is added in the materials for wetmilling; and to be dried after wetmilling; then the materials is sintered under high temperature and then to be grinded to acquire the cathode material of layered lithium-nickel-cobalt-manganese oxide. The present invention has the advantages that a wetmilling mixing method is adopted which improves the mixing effect of the materials; a solid phase method is adopted to compound which has the advantages of simple technics process and low cost and is suitable for Industrialized mass production and avoids the complex flows of the body of a wet method before preparation; the metal manganese powers are adopted to replace the traditional manganese compound as materials which greatly improves the tap density of products and can realize higher volume capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

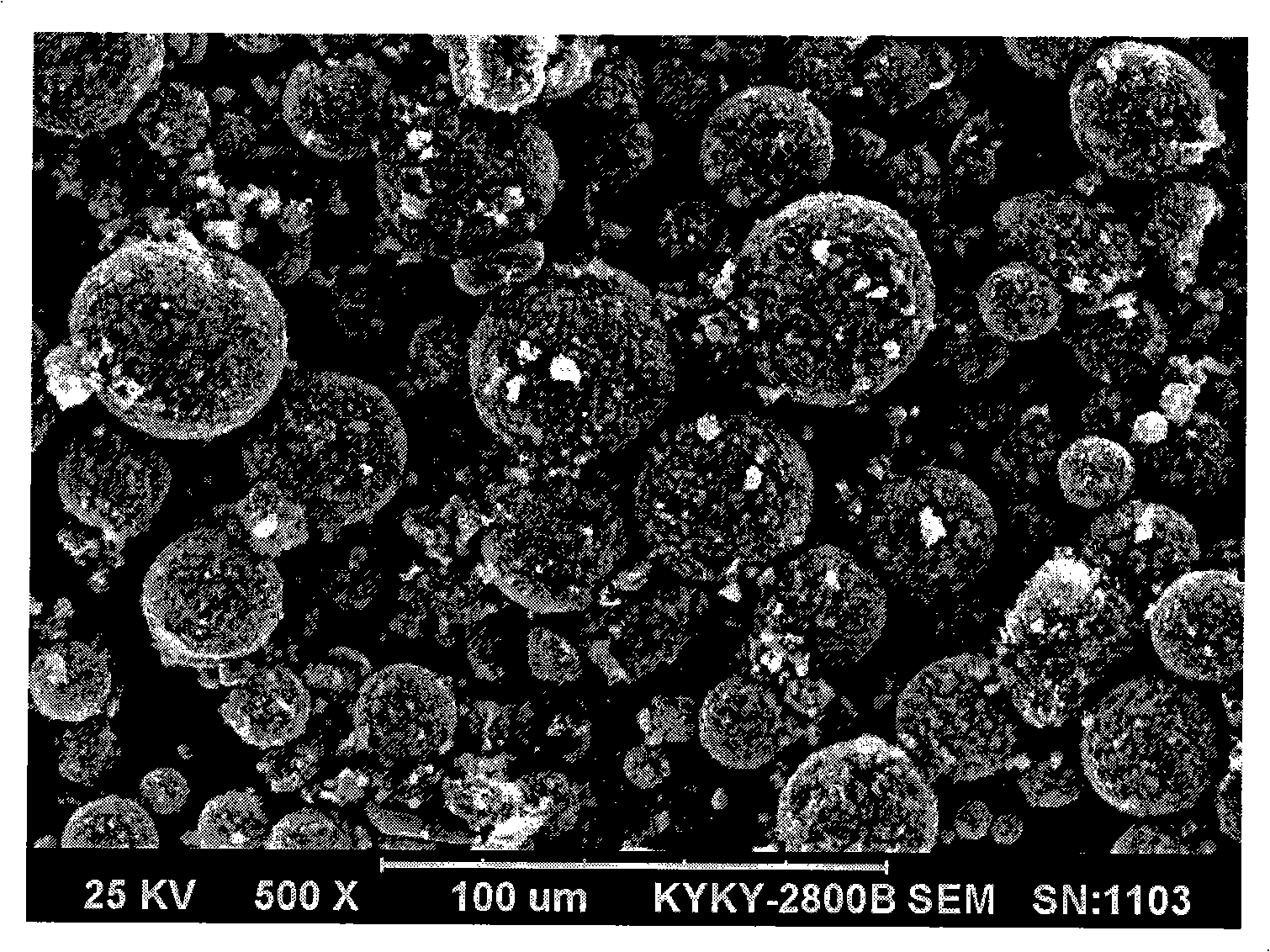

Method for preparing lithium ion battery anode material nickle cobalt lithium manganate

ActiveCN101355161AImprove performanceImprove electrochemical performanceCell electrodesManganates/permanganatesLithium hydroxideManganese

The invention relates to a method for preparing a LiCoxNiyMnzO2 anode material for a lithium ion battery, belonging to the preparation technical filed of the anode material of the lithium ion battery. The method comprises the following steps that manganese compound, nickel compound, LiCoO2 and lithium hydroxide are taken as raw materials; a well precursor combined by lithium, manganese, cobalt and nickel is obtained through hydrothermal reaction; then, a lithium source is added in the precursor to obtain a precursor through grinding; and finally, LiCoxNiyMnzO2 with excellent properties is obtained after the precursor is baked once. The method has the advantages of simple and easily controlled technological process, low production cost of prepared product and stable and controllable product performance, and can be used in industrial production.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

Negative electrode active material and negative electrode for lithium ion secondary battery

ActiveCN102290572AImprove low temperature performanceExcellent rate performanceCell electrodesElectric vehicleLyonium ion

The invention discloses a cathode active substance and cathode used for a lithiumion secondary battery. In the cathode active substance used for the lithiumion secondary battery, a mixture of spherical or torispherical graphite, massive artificial graphite the particle length-width ratio of which is 1.0-3.0 and needle-like artificial graphite the particle length-width ratio of which is 1.0-4.0 is taken as a substrate; non-graphite carbon materials are cladded outside the mixed substrate; the cladding amount is 1-20% of the mass of the mixed substrate; the non-graphite carbon material is asphalt or resin; the gram specific capacity of the cathode active substance is 350-370mAh / g, the particle size is 4.0-45mu m, the specific surface area is 1.0-4.0m<2> / g, the compacted density of the powder body is 1.65-2.10g / cm<3>, and the layer space (d002) is 0.3354-0.3370nm. The cathode active substance provided by the invention has the beneficial effects of improving the conductivity performance of materials, ensuring the excellent multiplying power and circular stability of materials, and satisfying different high-end requirements, especially the requirements of electric automobiles (EV), hybrid electric vehicles (HEV) and batteries in the energy storage field.

Owner:JIANGXI ZHENGTUO NEW ENERGY TECH CO LTD

Wet method of preparing lithium ferrous phosphate and its prepared lithium ferrous phosphate

The present invention provides a method for preparing ferrous lithium phosphate by using wet method. Said method includes the following steps: making required water-soluble compounds containing Li, Fe and P and containing alloying element M respectively be dissolved in water; stirring them and placing them into a reactor to obtain a suspension, in which the Li content, Fe content and P content must be met with the following formula: [mLi+n(1-m) / n M]; pFe:qPO4=1:1:1, in said formula n is chemical valence of alloying element M, m is mole number of Li, (1-m) / n is mole number of alloying element M and the P and q respectively are mole numbers of Fe and PO4; adding reduction electro-conductive additive, spray drying suspension, roasting and pulverizing so as to obtain the invented product.

Owner:北京环宇赛尔新能源科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com