Patents

Literature

116results about How to "Even mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Friction material and method of mix-fibrillating fibers

A friction material comprising a fibrous reinforcement, a friction modifier and a binder, characterized by being free from asbestos fiber and containing, as the organic fibrous reinforcement, a mixture of a dry aramid pulp with at least one member selected from the group consisting of a wet aramid pulp, a woodpulp and an acrylic pulp.

Owner:AKEBONO BRAKE IND CO LTD +1

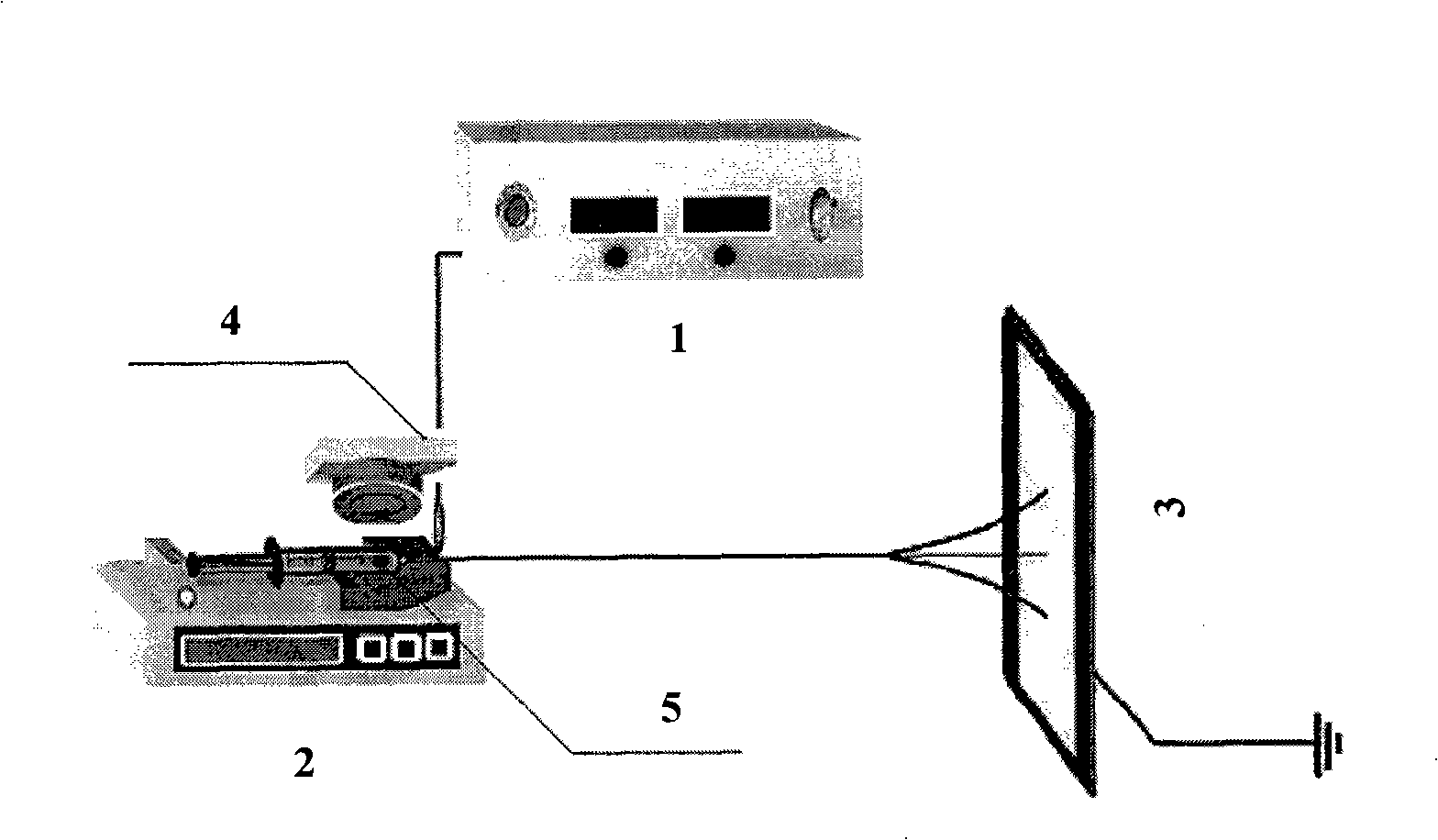

Method for preparing organic and inorganic nanometer assorted fibre

InactiveCN101338459AEven mixing effectUniform dispersionOther chemical processesPharmaceutical delivery mechanismFiberWater baths

The invention relates to a preparation method of an organic / inorganic nano-assorted fiber. The preparation method comprises the procedures that (1) inorganic substance suspends in dimethyl acetamide or formic acid spinning solvent in the water bath with the temperature of 20 to 60 DEG C; macromoleclar polymer is added and stirred at the rotating speed of 200 to 450rpm and swells for 24 hours in the water bath with the temperature 20 to 60 DEG C; and the macromoleclar polymer is cooled to room temperature to acquire dope with even dispersion: and (2) the dope is poured into a liquid reservoir; a bullet-shaped syringe needle is adopted as a capillary for spraying a streamlet; after HYEF spinning, the dope is dried under vacuum and normal temperature; and optional post-treatment is carried out, the functional composite nano fiber is made. The preparation method is simple with mild preparation condition and simplifies compound process. The composite nano fiber has high superficial area and is widely dispersed, so the composite nano fiber is applicable for preparing a drug delivery system, anti-bacterial textile, material separation, the water pollution treatment of metal ions and organic compound, etc.

Owner:DONGHUA UNIV

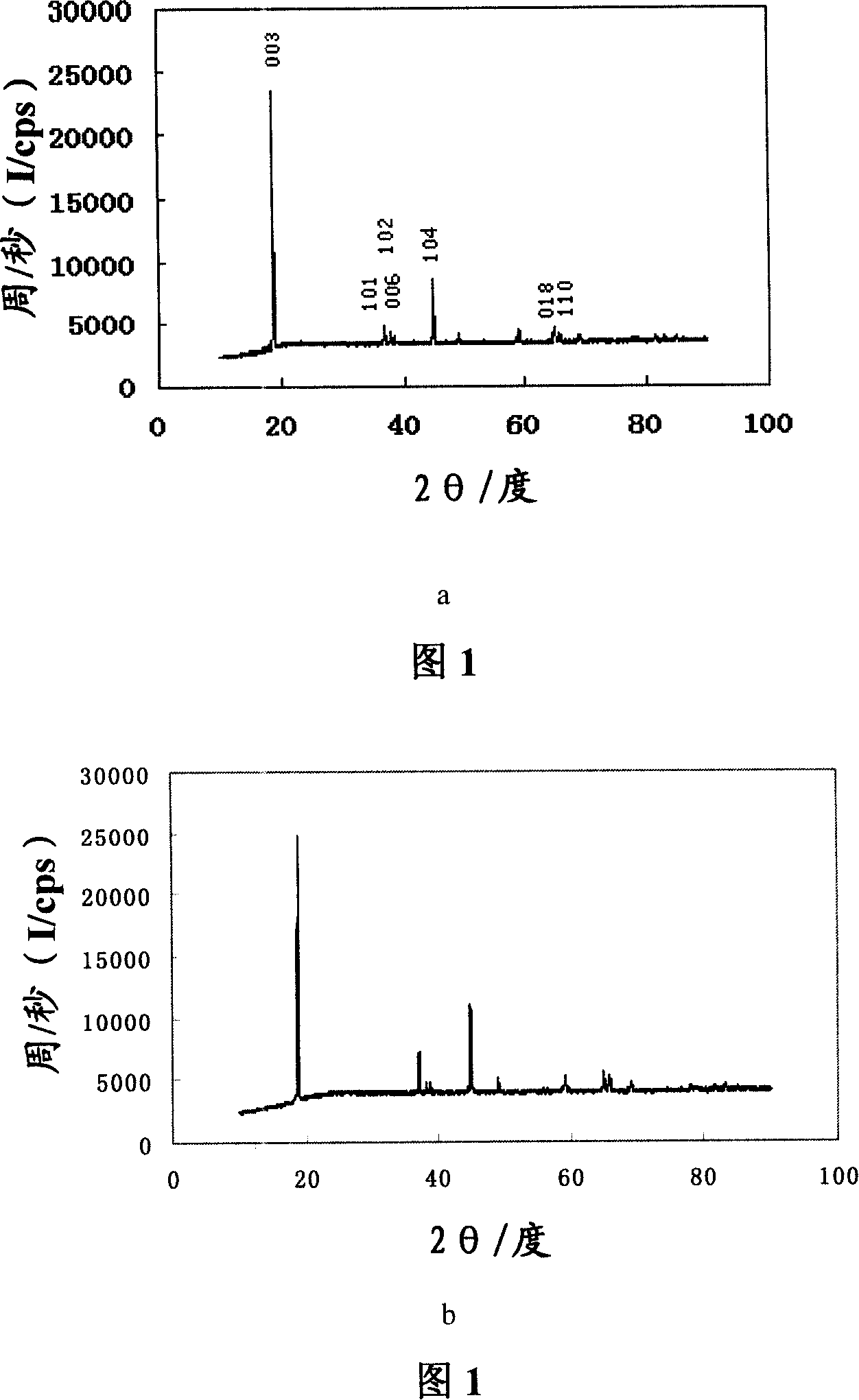

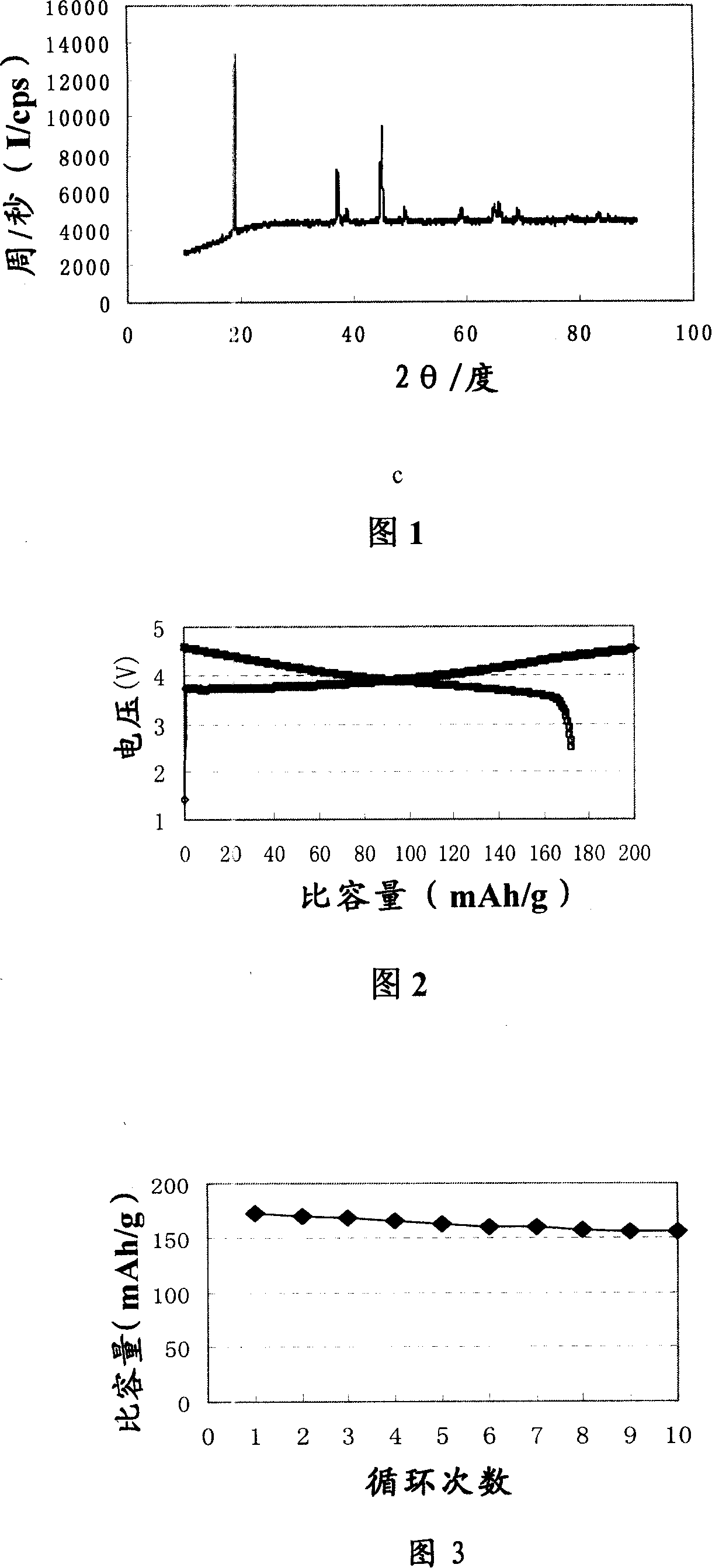

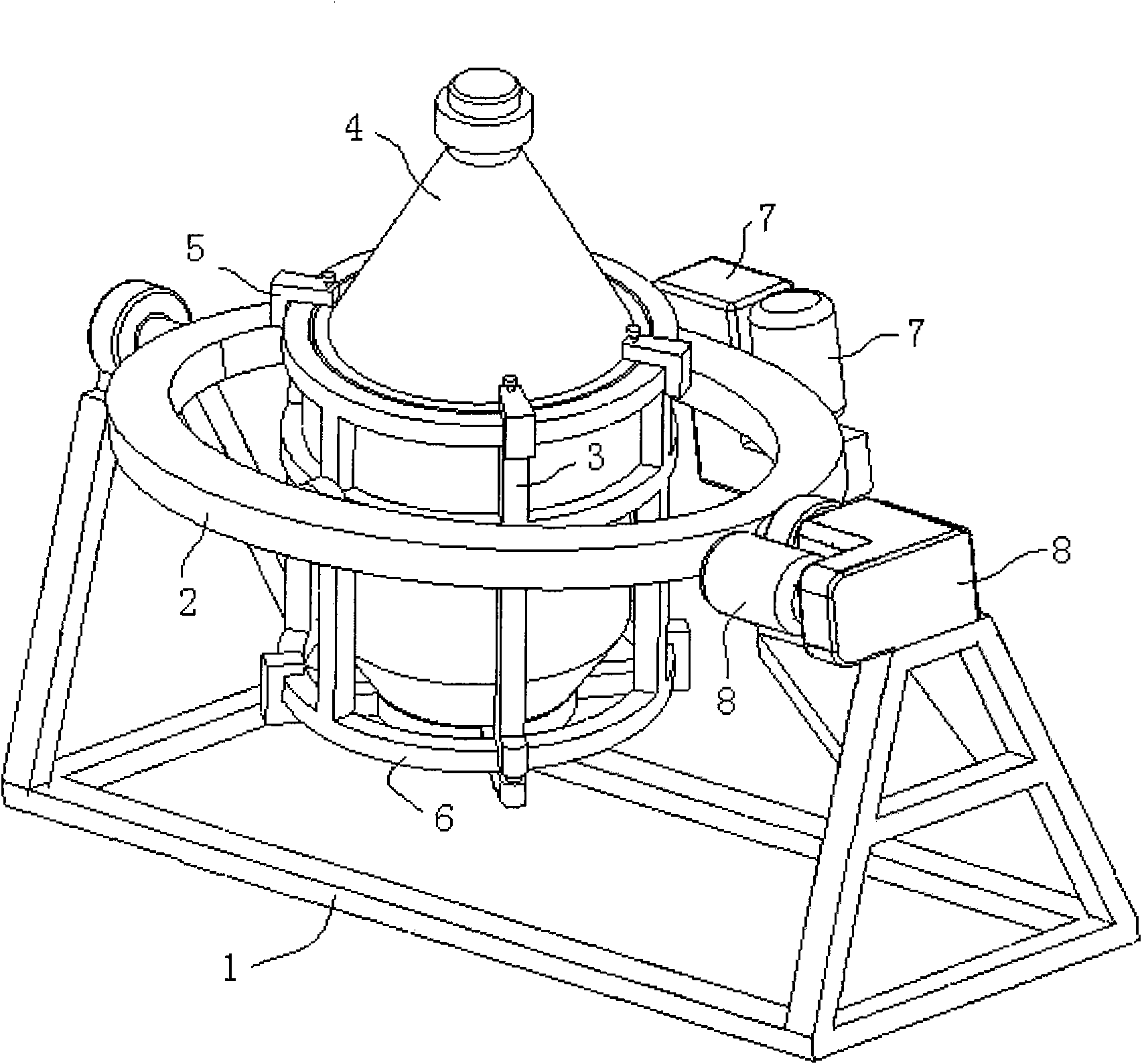

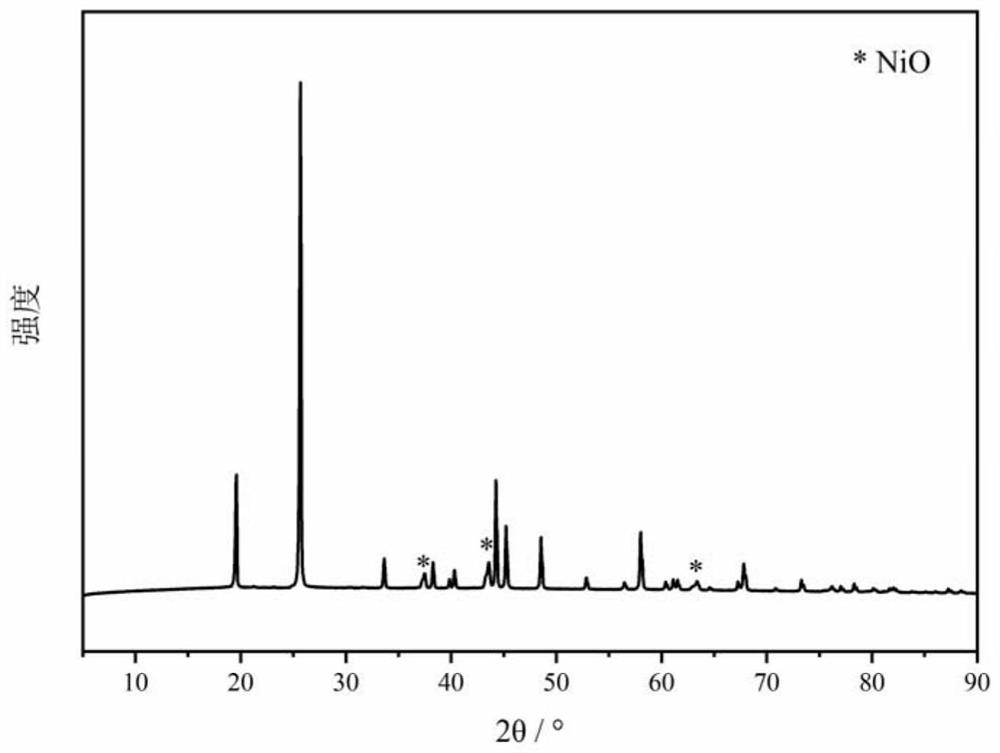

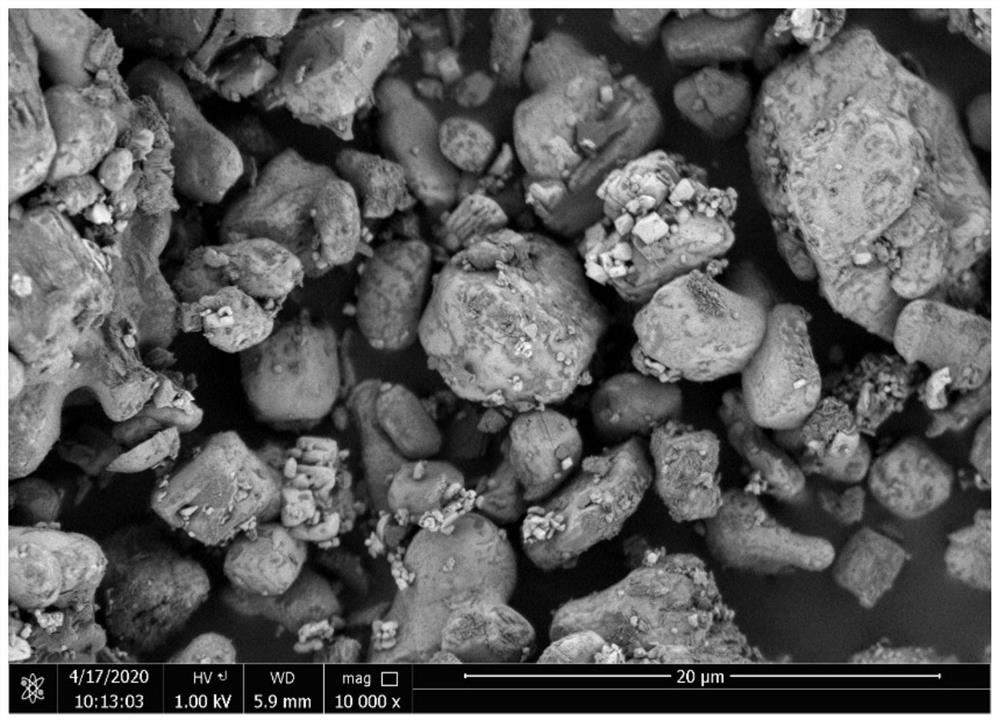

Method for preparing layered lithium, nickel, cobalt and manganese oxide anode material for lithium ion battery

The present invention relates to a method to prepare cathode material of layered lithium-nickel-cobalt-manganese oxide applied to lithium ion battery. The corresponding materials of metal manganese powers, compounds of lithium, metal cobalt or compounds of cobalt and compounds of nickel are weighted according to the molar ratio expressed and required in the chemical formula LiyNixCo1-2xMnxO2. In the formula, x is more than zero but less than 0.5 and y is more than or equal to 0.9 but less than 1.1; a solvent is added in the materials for wetmilling; and to be dried after wetmilling; then the materials is sintered under high temperature and then to be grinded to acquire the cathode material of layered lithium-nickel-cobalt-manganese oxide. The present invention has the advantages that a wetmilling mixing method is adopted which improves the mixing effect of the materials; a solid phase method is adopted to compound which has the advantages of simple technics process and low cost and is suitable for Industrialized mass production and avoids the complex flows of the body of a wet method before preparation; the metal manganese powers are adopted to replace the traditional manganese compound as materials which greatly improves the tap density of products and can realize higher volume capacity.

Owner:CHINA AUTOMOTIVE BATTERY RES INST CO LTD

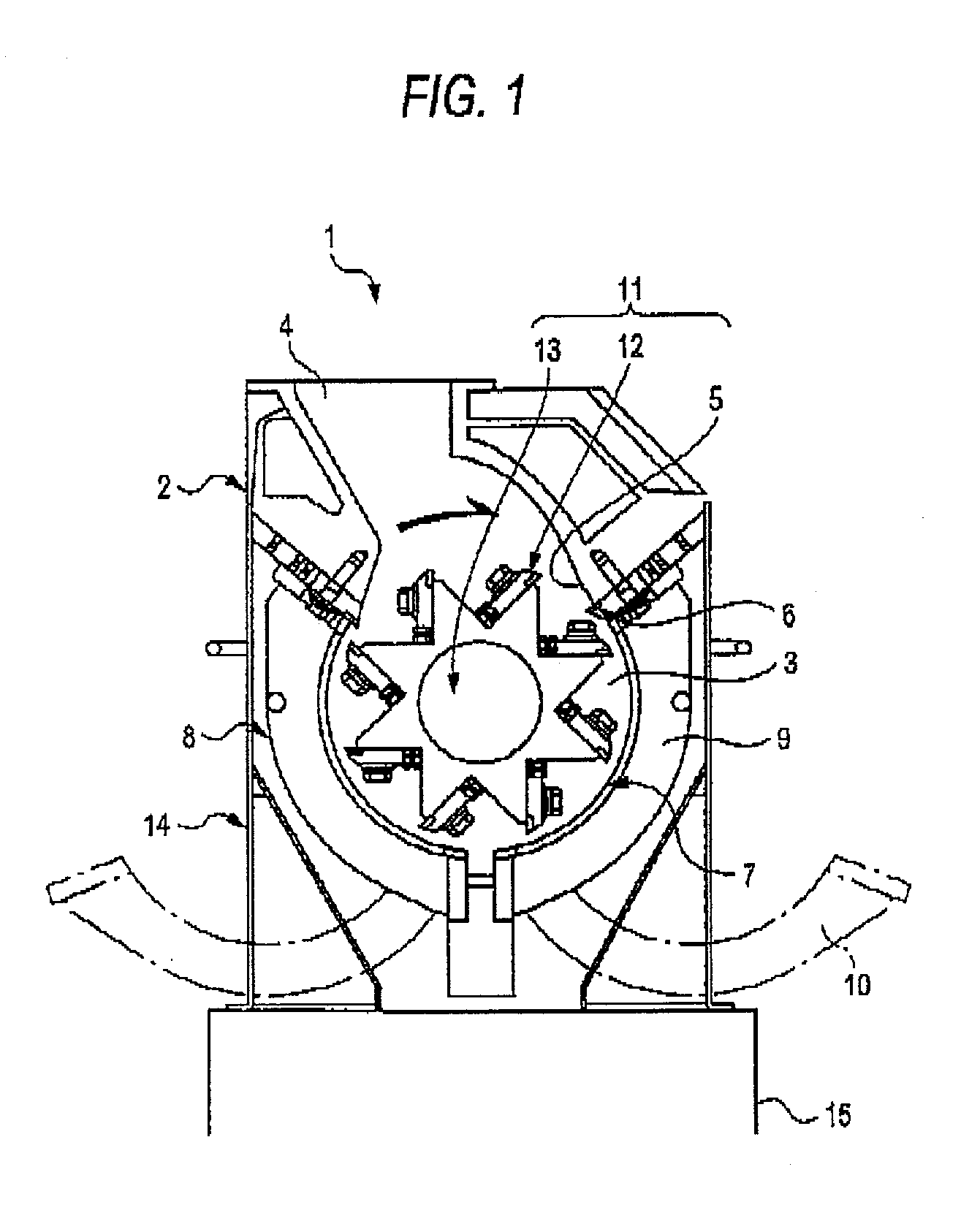

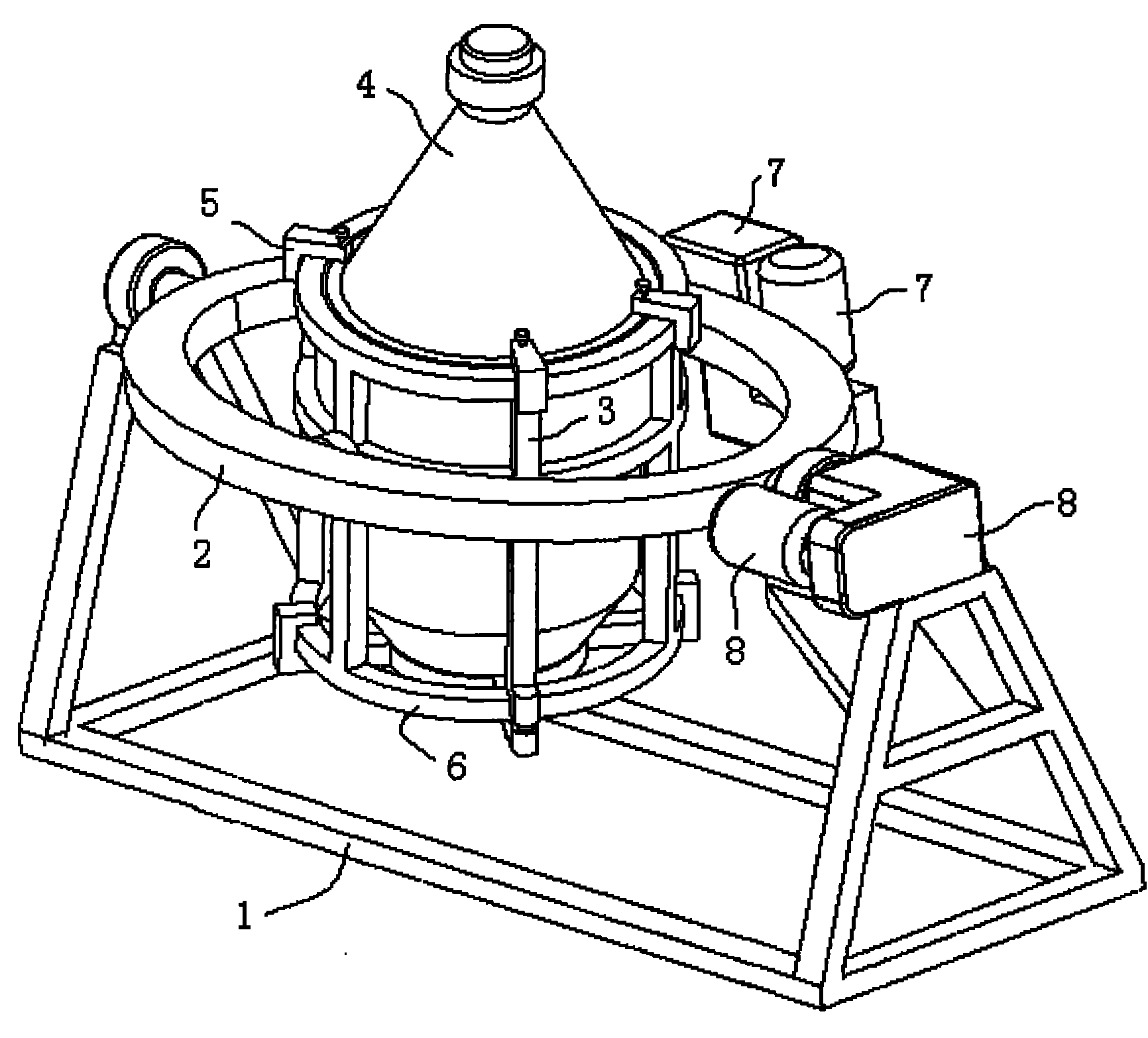

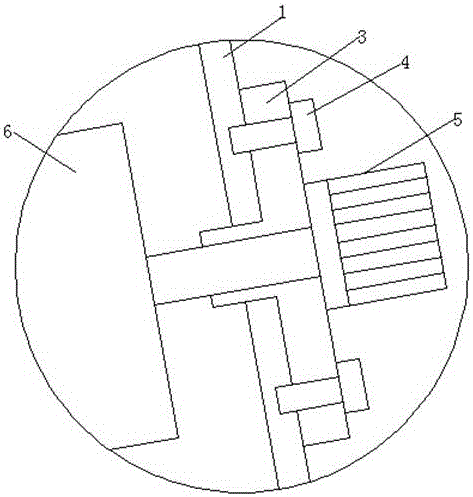

Three-dimensional mixer and three-dimensional mixing method

InactiveCN102091554AEasy to liftEasy to disassembleRotating receptacle mixersEngineeringMixing effect

The invention relates to a three-dimensional mixer, which is characterized by comprising a main body bracket, a main rotating body, an auxiliary rotating body, an upper port clamp and a supporting bottom lamp of a mixing tank, a reduction gearbox and a motor for the auxiliary rotating body, and a reduction gearbox and a motor for the main rotating body, wherein the main body bracket is connected with the main rotating body capable of rotating around a first horizontal shaft by a bearing; the main rotating body is also connected with the auxiliary rotating body capable of rotating around a second horizontal shaft by a bearing; the second horizontal shaft is vertical to the first horizontal shaft; the mixing tank is fixed on a frame by the upper port clamp and the supporting bottom clamp; the upper port clamp and the supporting bottom clamp are fixed on the auxiliary rotating body through pin structures; the reduction gearbox and the motor for the auxiliary rotating body are fixed on the main rotating body and a torque of the reduction gearbox of the auxiliary rotating body is transmitted to the auxiliary rotating body; and the reduction gearbox and the motor for the main rotating body are fixed on the main body bracket. According to the three-dimensional mixer, the mixing efficiency and the mixing effect are greatly improved, and equipment is easier to operate and has longer service life.

Owner:BEIJING ZHONG KE SAN HUAN HI TECH +1

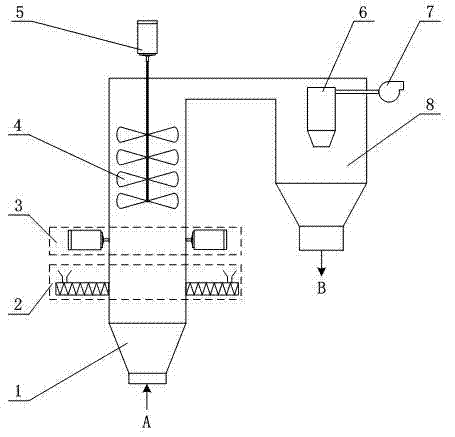

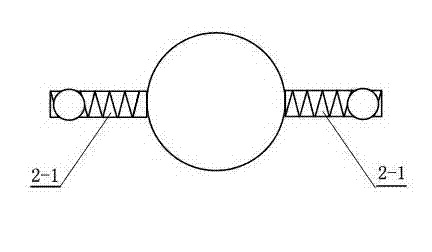

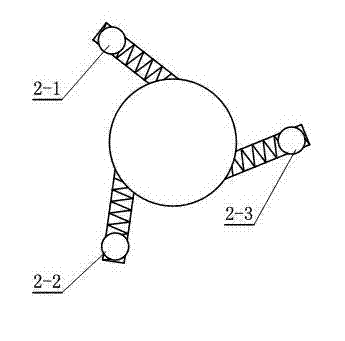

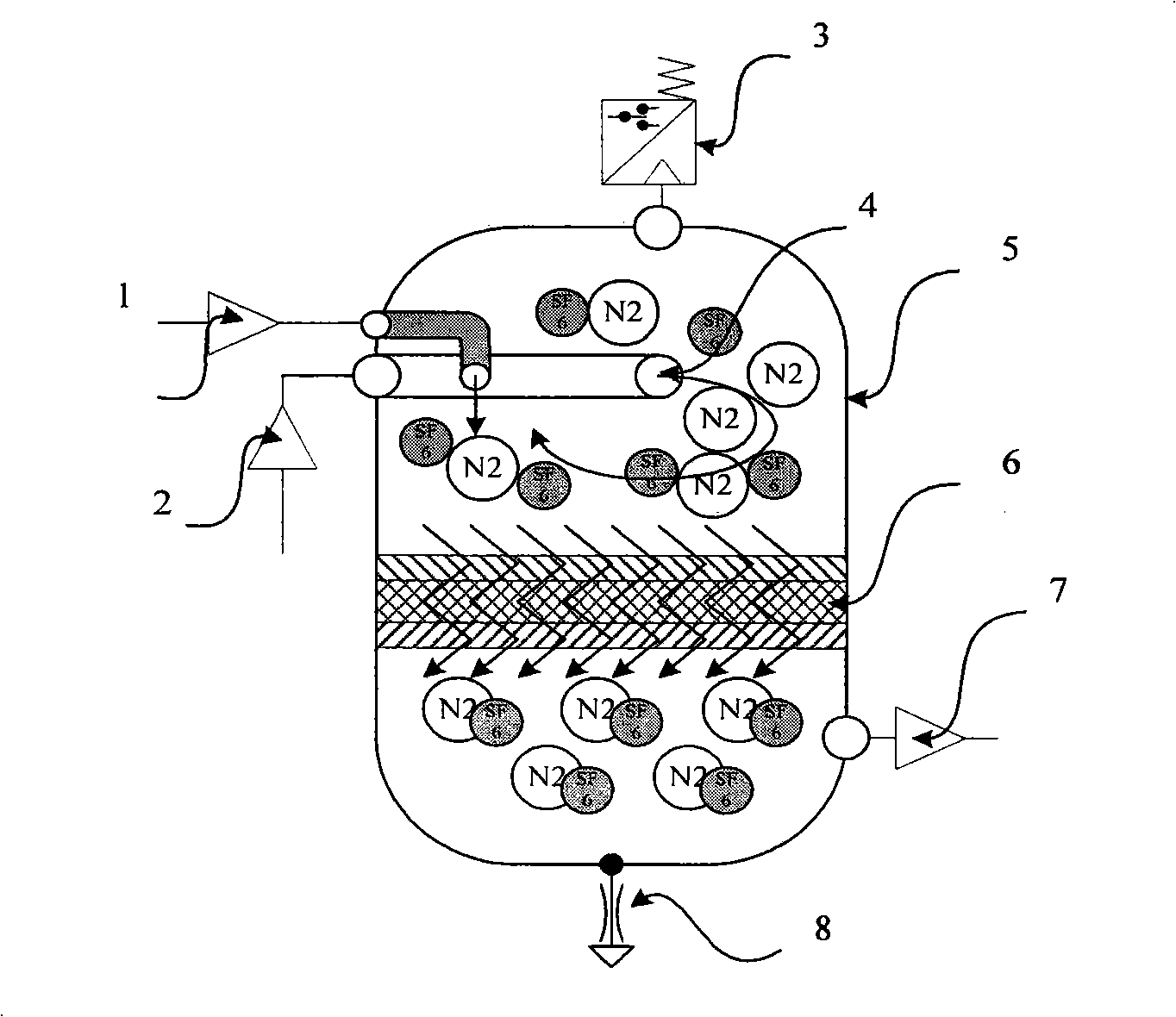

Gas-liquid mixing device for supercritical hydrothermal combustion reactor and application thereof

PendingCN109237508ALower requirementEven mixing effectLiquid fuel feeder/distributionCombustion chamberEngineering

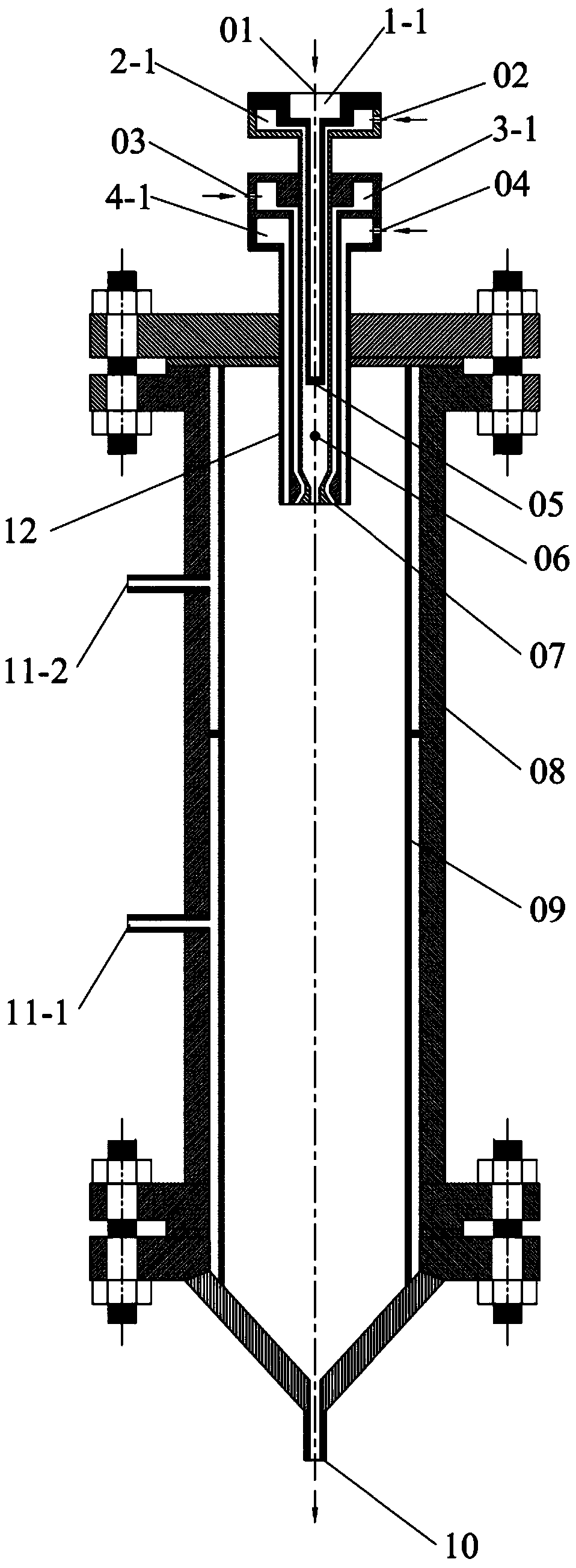

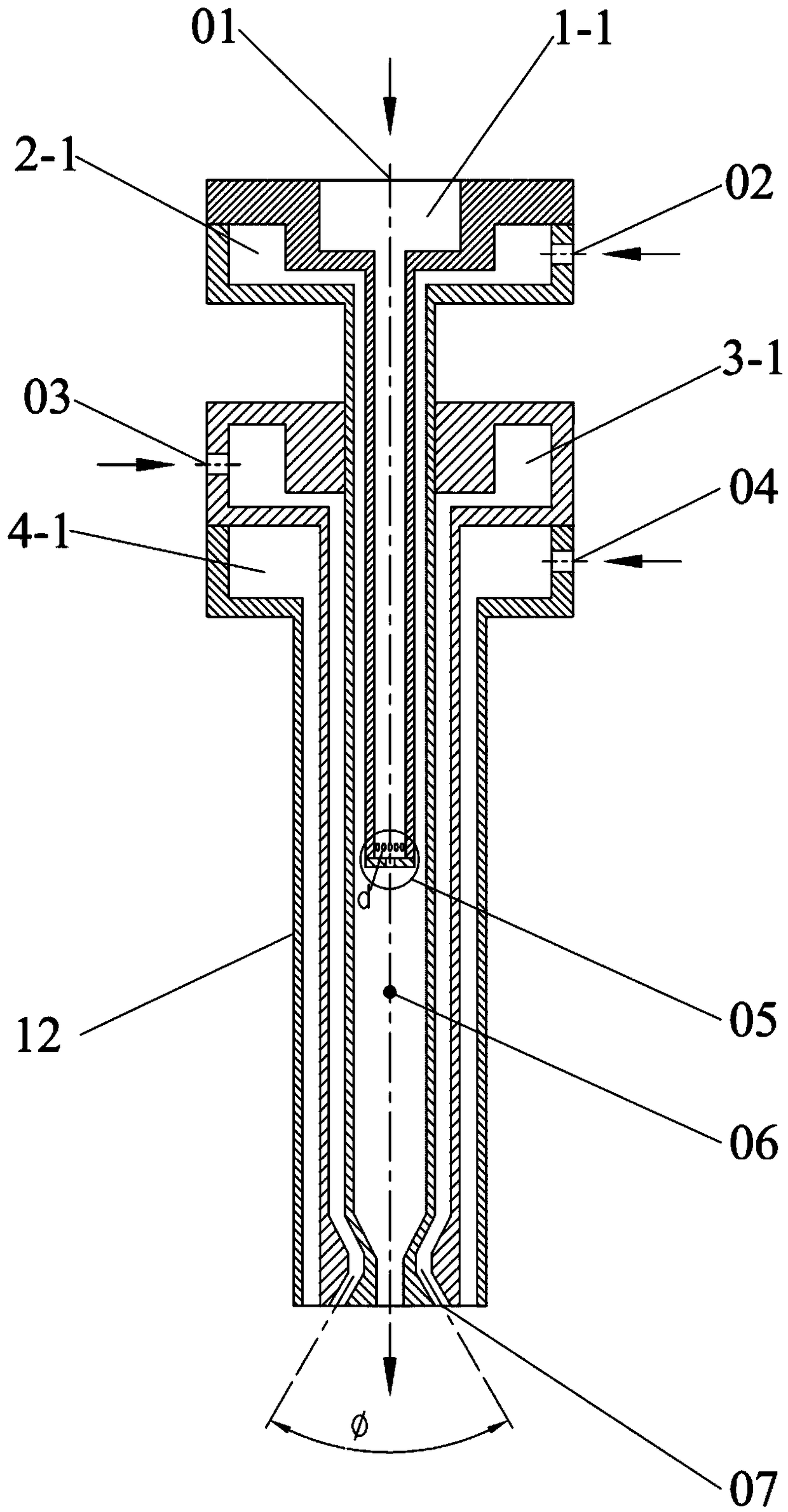

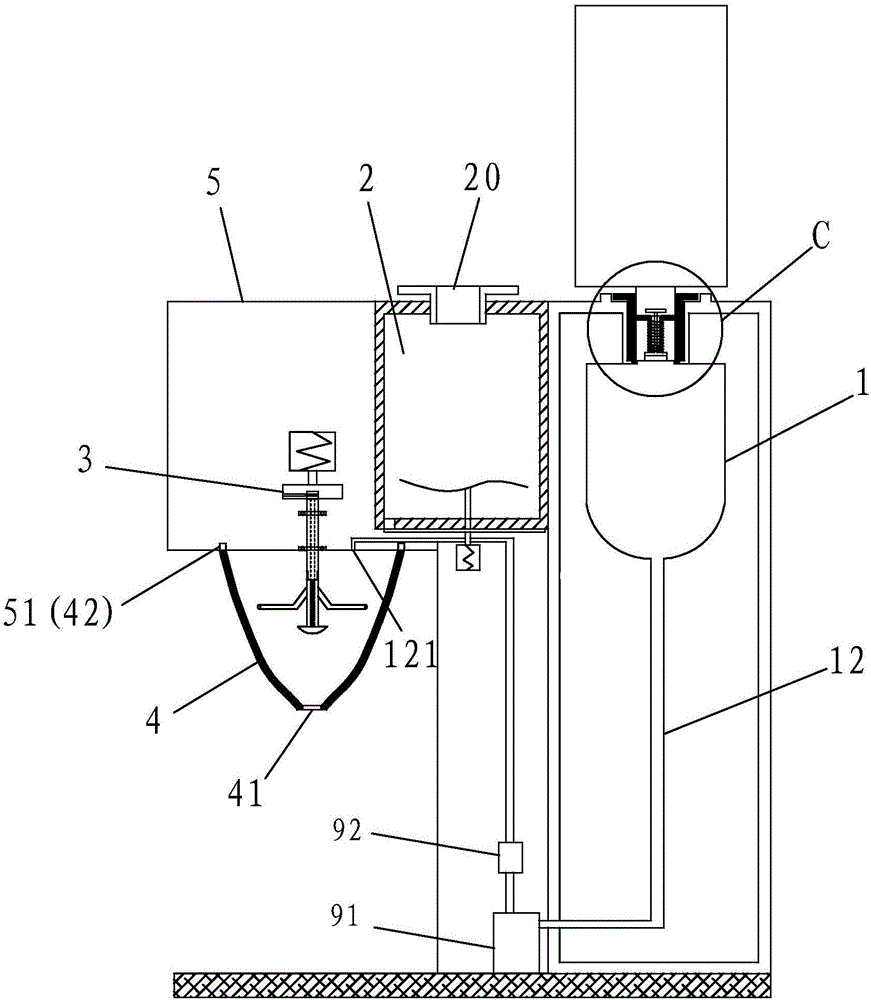

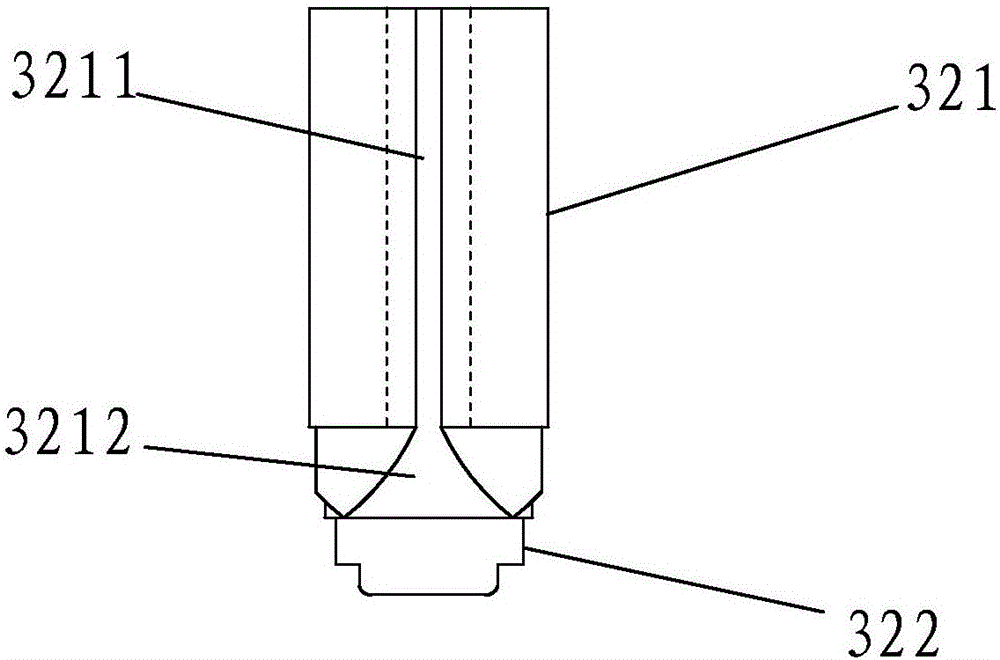

The invention discloses a 'gas-liquid mixing device for a supercritical hydrothermal combustion reactor and application thereof', and belongs to supercritical hydrothermal combustion technologies. Thegas-liquid mixing device comprises a cylindrical pipe (12), and is characterized in that a fuel guiding pipe (1-1), a first oxidizing agent guiding pipe (2-1) and a material guiding pipe (3-1) are arranged in the cylindrical pipe (12), wherein the fuel guiding pipe (1-1), a first oxidizing agent guiding pipe (2-1) and the material guiding pipe (3-1) are mutually independent; a combustion chamber(06) is formed into an inner cavity in the lower portion of the cylindrical pipe (12); the fuel guiding pipe (1-1) is arranged in the center of the cylindrical pipe (12), a fuel atomizing nozzle (05)is arranged at the lower end of the fuel guiding pipe (1-1), and a nozzle outlet faces the combustion chamber (06); the lower end of the first oxidizing agent guiding pipe (2-1) faces the combustion chamber (06), and a material entering the material guiding pipe (3-1) and the combustion chamber (06) can be subjected to heat exchange; a feeding atomizing nozzle (07) is arranged at the bottom end ofthe material guiding pipe (3-1).

Owner:成都九翼环保科技有限公司

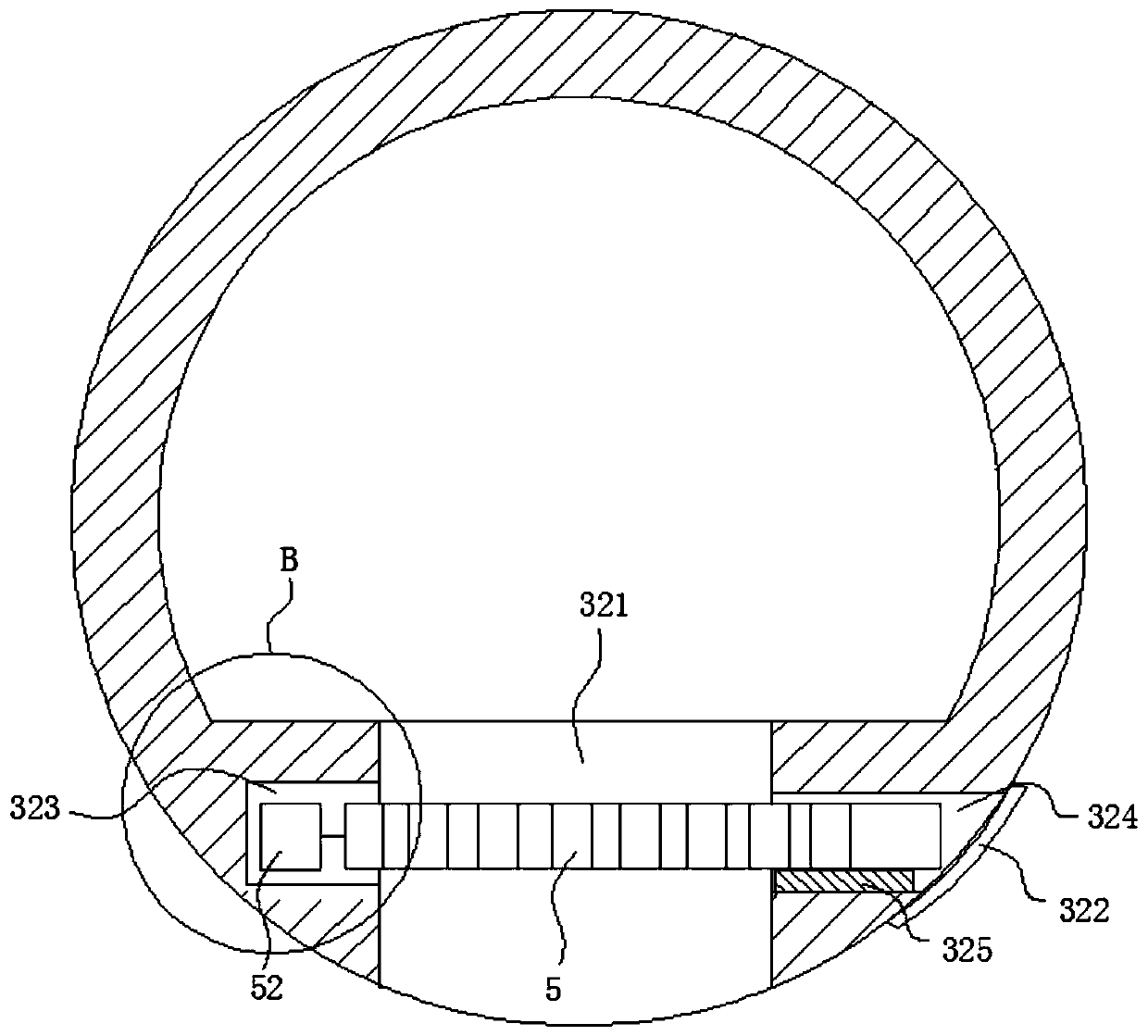

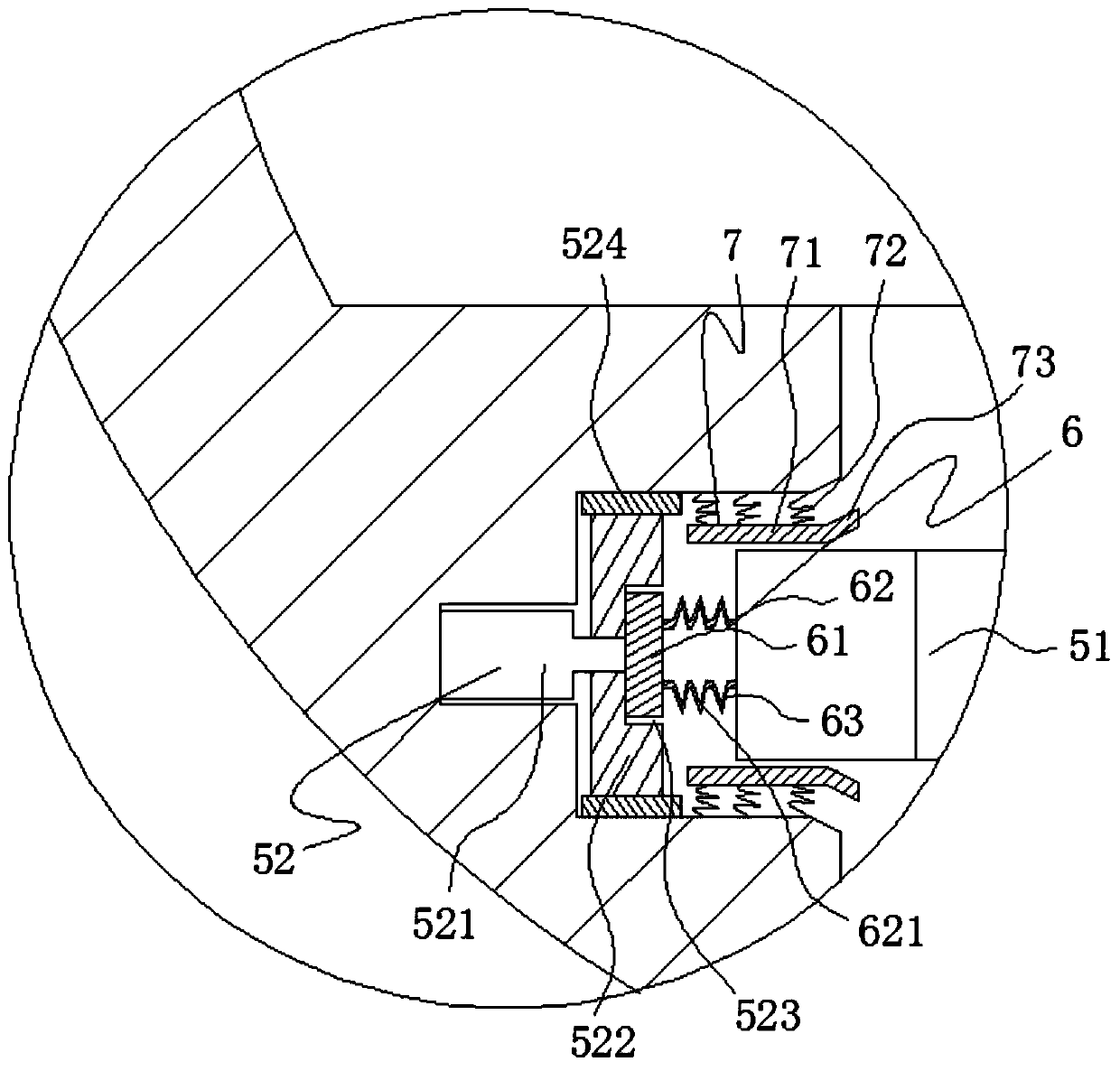

Stirring linkage component and milk preparer

The invention discloses a stirring linkage component and a milk preparer. The milk preparer comprises a milk powder bin, a mixing bin and the stirring linkage component, the milk powder bin is provided with a powder outlet, dry milk powder is supplied for the mixing bin through the powder outlet, the mixing bin is connected with a water outlet, water is supplied for the mixing bin through the water outlet, the mixing bin is provided with a liquid outlet, the stirring linkage component comprises a stirring rod, a plug, a driving motor and a linkage mechanism, the stirring rod and the plug are vertically arranged on the linkage mechanism, the plug and the stirring rod are connected with the driving motor through the linkage mechanism in a transmission manner, the linkage mechanism drives the stirring rod to rotatably stir, and displacement linkage of the plug is simultaneously driven by the linkage mechanism. According to the milk preparer, liquid milk is stirred and simultaneously flows out from the liquid outlet, uniformity of milk powder solution is greatly improved, and the milk preparer has the advantage that milk powder is rapidly prepared.

Owner:牛村科技(深圳)有限公司

Granule-adding method and device for granule-containing liquid drink processing technique

ActiveCN101480266AReduce complexityIncrease the amount of controlMilk preparationPre-extraction tea treatmentLiquid stateEngineering

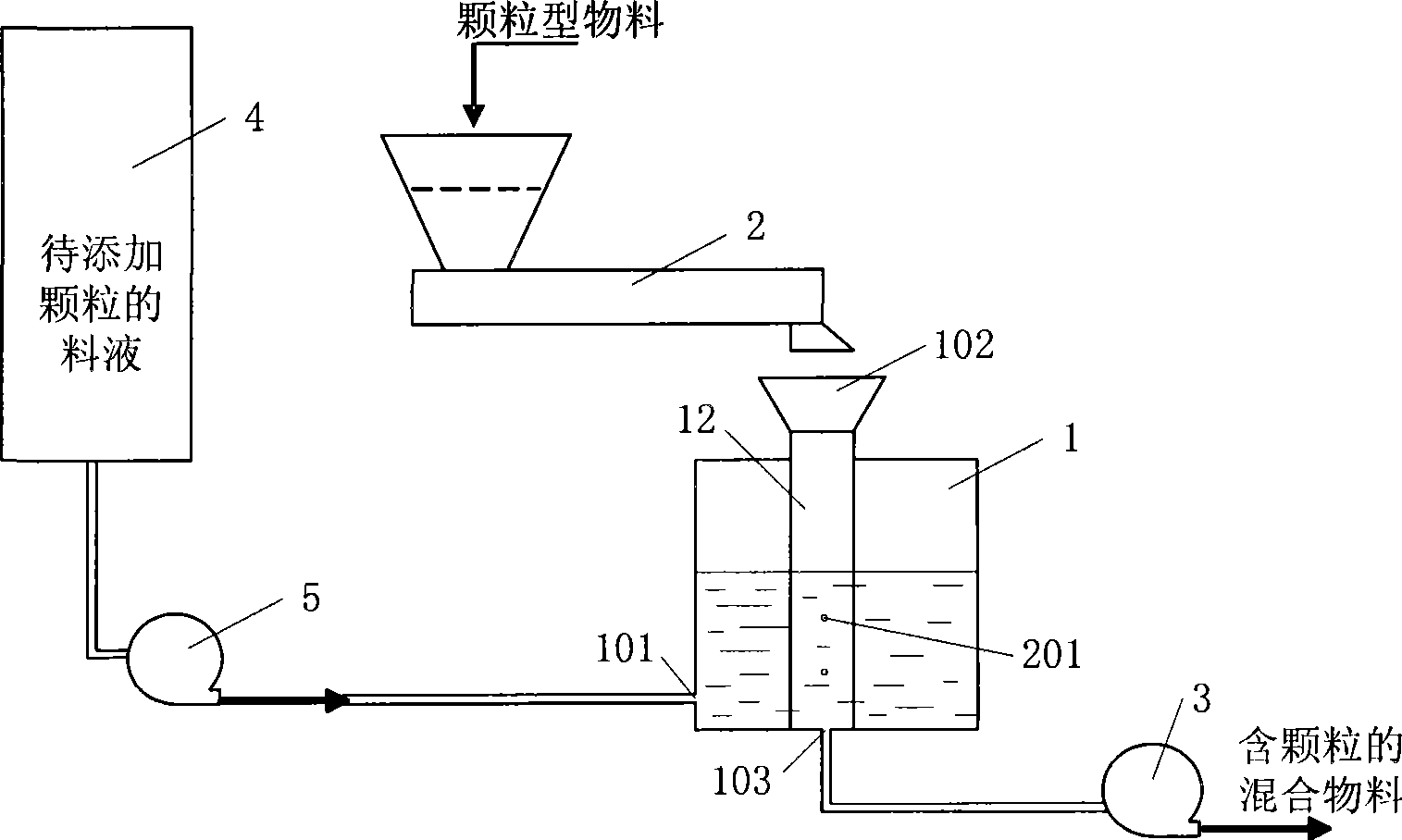

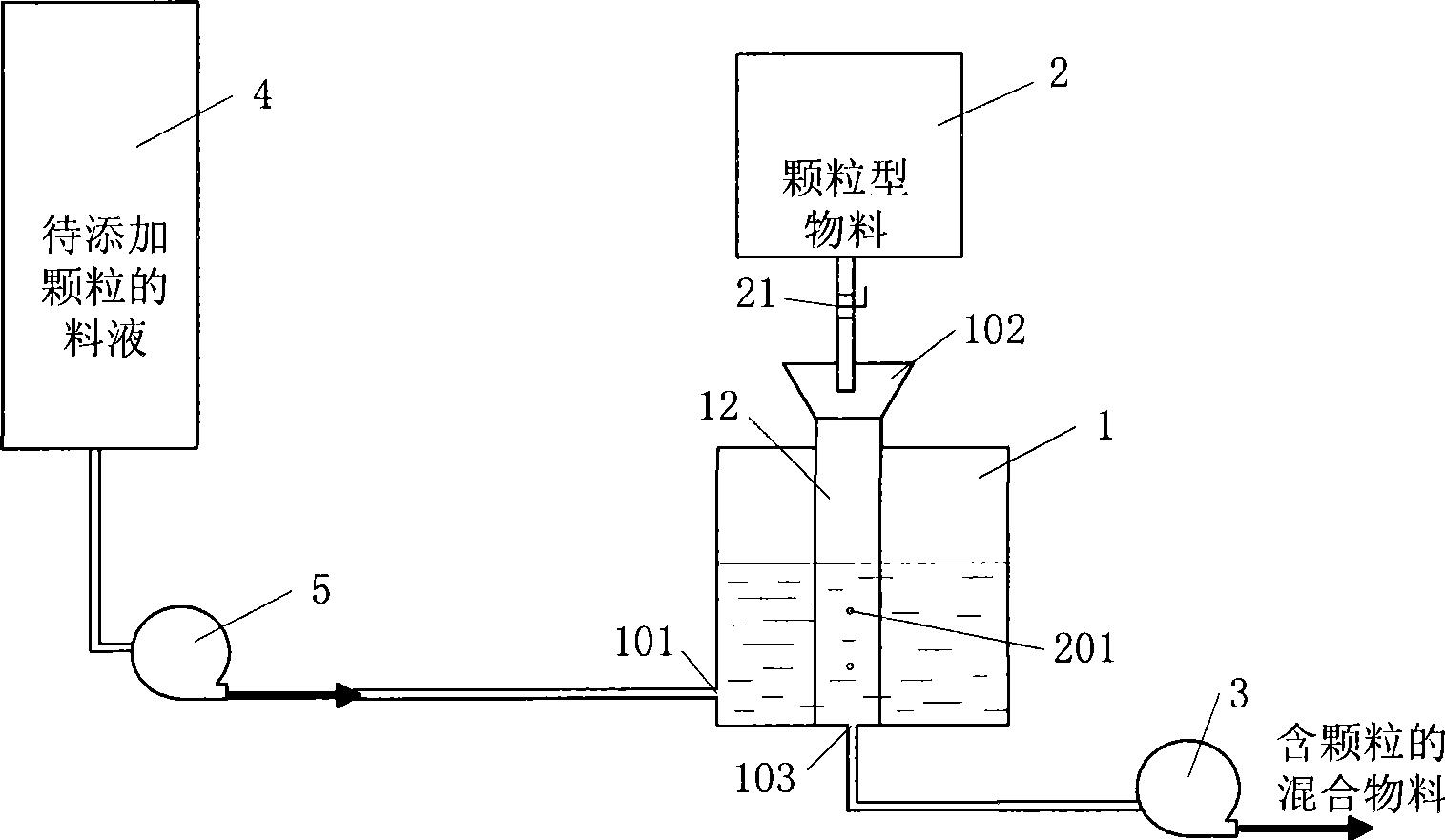

The invention provides a method and a device for adding granules in the process of inclusion granule liquid drink. The technical scheme of the device is mainly achieved as follows: a feeding pipe is arranged in a compensating groove, the wall of the feeding pipe is provided with holes, the bottom end of the feeding pipe contacts with the bottom surface of the compensating groove in a sealing way so as to enable feed liquid to be added with granules to enter into the feeding pipe from the holes on the wall of the feeding pipe after entering into the compensating groove, granular materials enter into the feeding pipe from the upper port of the feeding pipe, the feed liquid to be added with granules are mixed with the granular materials in the feeding pipe to form inclusion granule mixed materials which are led out of a mixed material outlet arranged on the bottom surface of the compensating groove corresponding to the bottom end surface of the feeding pipe from the compensating groove so that the granular materials are uniformly added into the feed liquid on line. The invention also provides a method for producing the inclusion granule liquid drink by the method and the device for adding granules.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

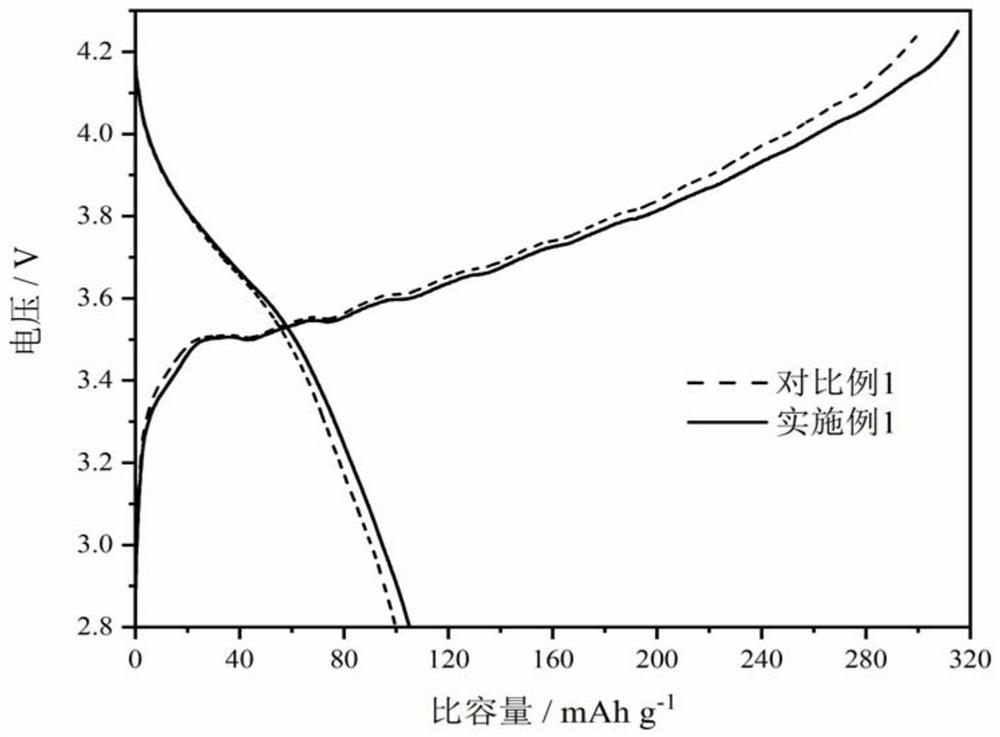

Positive additive and preparation method and application thereof

PendingCN111653770AImprove the first Coulombic efficiencyImprove charging capacitySecondary cellsPositive electrodesLithium-ion batteryBattery cell

The invention discloses a positive additive as well as a preparation method and application thereof. The chemical formula of the positive additive is Li2Ni1-xMxO2, wherein x is equal to 0-0.5, and when x is larger than 0, M is at least one of Co, Mn, Cu, Fe and Cr. The Li2Ni1-xMxO2 prepared by the preparation method disclosed by the invention has the characteristics of high charging capacity and low first effect; when the additive is added into the positive plate of the lithium ion battery, lithium can be removed before the positive electrode material in the battery formation process to replace the positive electrode material to provide lithium required to be consumed for forming an SEI film by a negative electrode, so that the initial coulombic efficiency of the battery is improved, and the cycle performance is improved.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

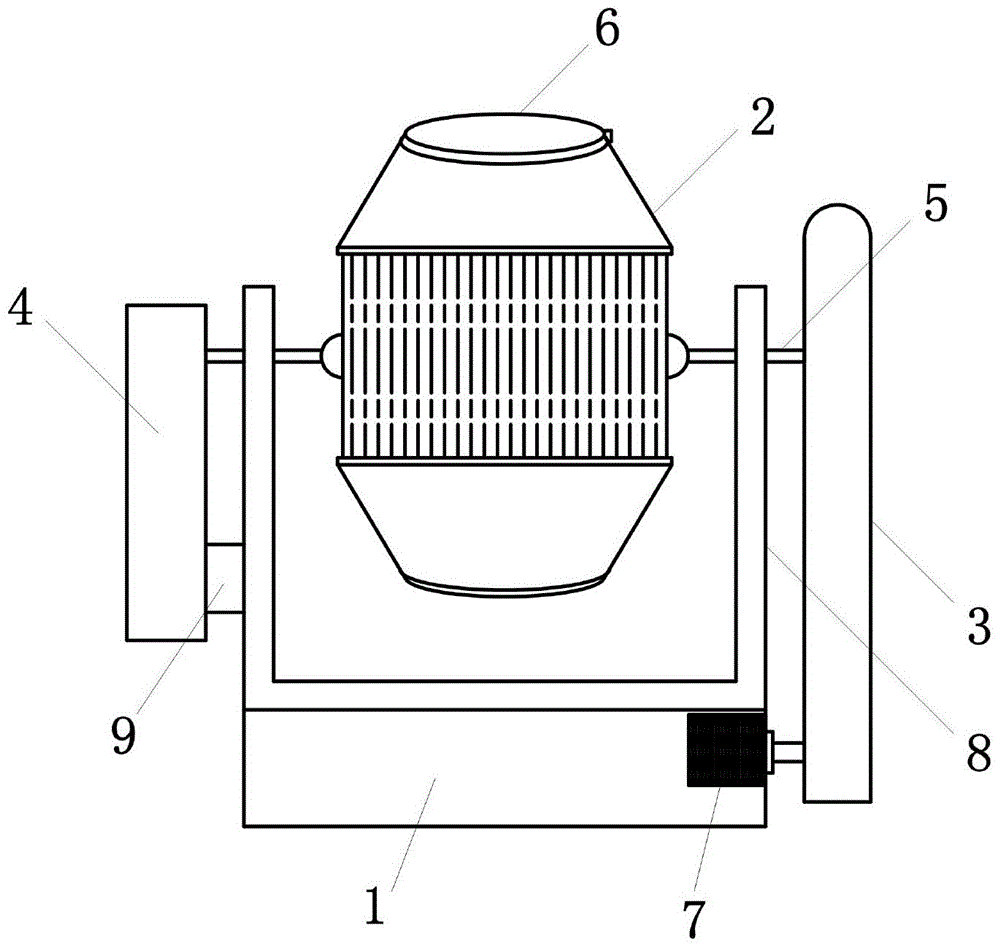

Uniform mixing type mixing machine for line cutting fluid

InactiveCN106422912AWell mixedLarge rotationRotating receptacle mixersTransportation and packagingEngineeringMixing effect

The invention provides a uniform mixing type mixing machine for line cutting fluid, relating to the field of machining. The mixing machine comprises a mixing bucket and a base, wherein the mixing bucket is located on the top of the base, a sealing lug is arranged at a middle shaft of the right side of the mixing bucket and is fixedly connected with the mixing bucket through a fixed screw, and a protruded end of the sealing lug penetrates through the mixing bucket and extends into the mixing bucket; and a first motor is fixedly mounted on one side, far from the mixing bucket, of the sealing lug, a rotating shaft of the first motor penetrates through the sealing lug, extends into the mixing bucket and is fixedly connected with a rotary column, and one end of, far from the rotating shaft of the first motor, of the rotary column is movably connected with the inner wall of the mixing bucket through a first connecting column. The uniform mixing type mixing machine has the beneficial effects that the rotation range of the mixing bucket is extended, materials can be uniformly mixed, the time consumed for mixing is shortened, the use is convenient, a uniform mixing effect is achieved, the time and the labor are saved, and the working efficiency is high.

Owner:WUXI JINWU AUX AGENT FACTORY CO LTD

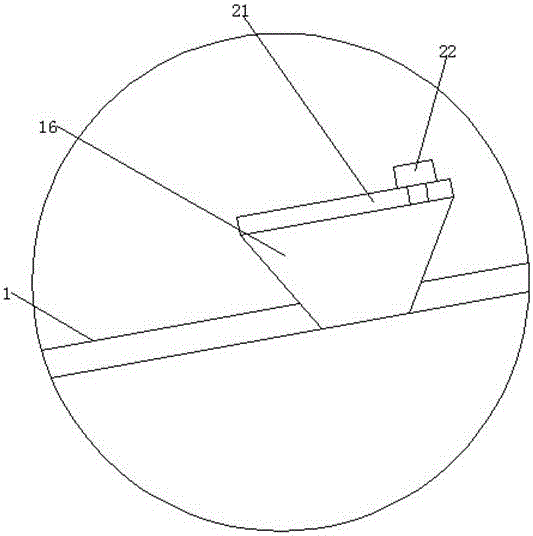

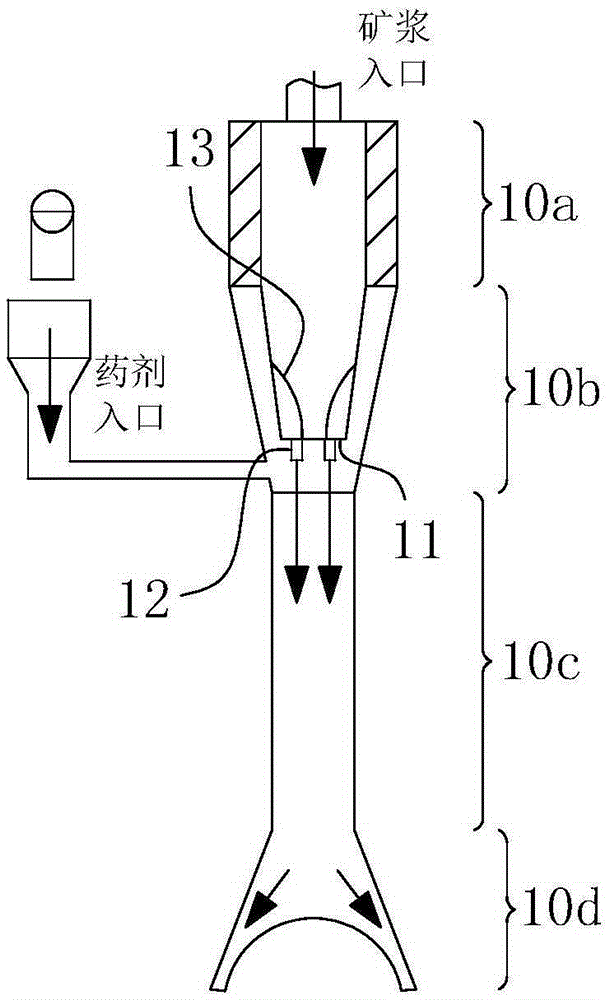

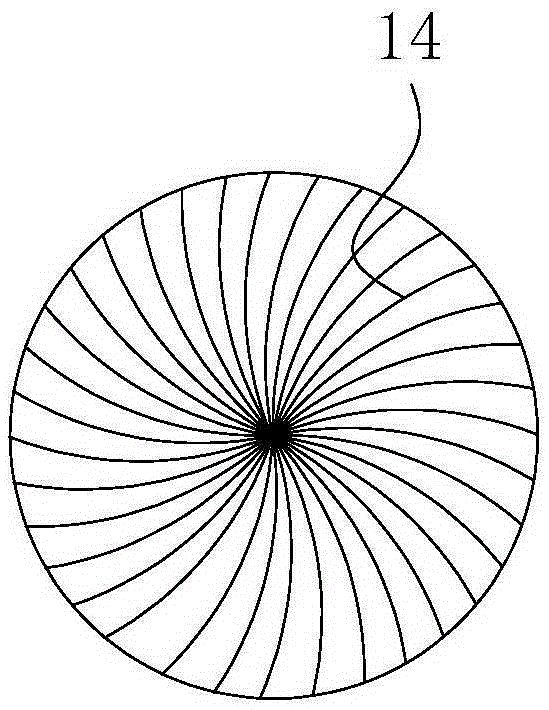

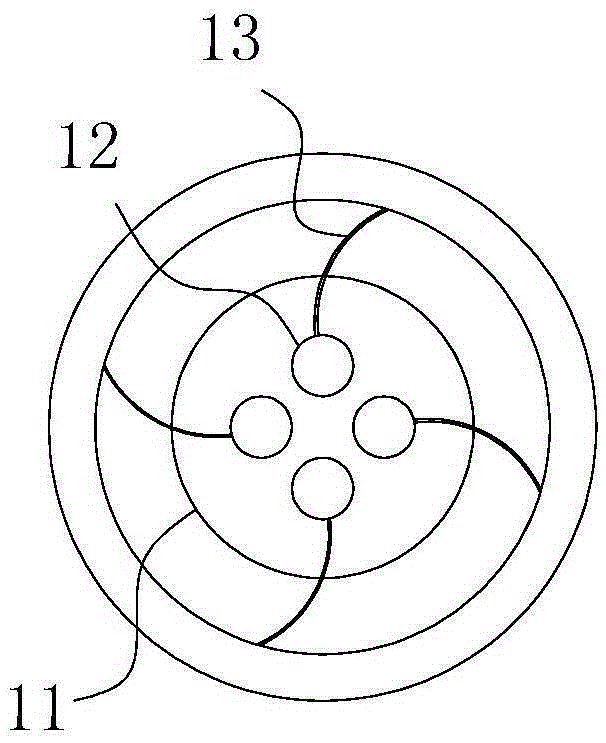

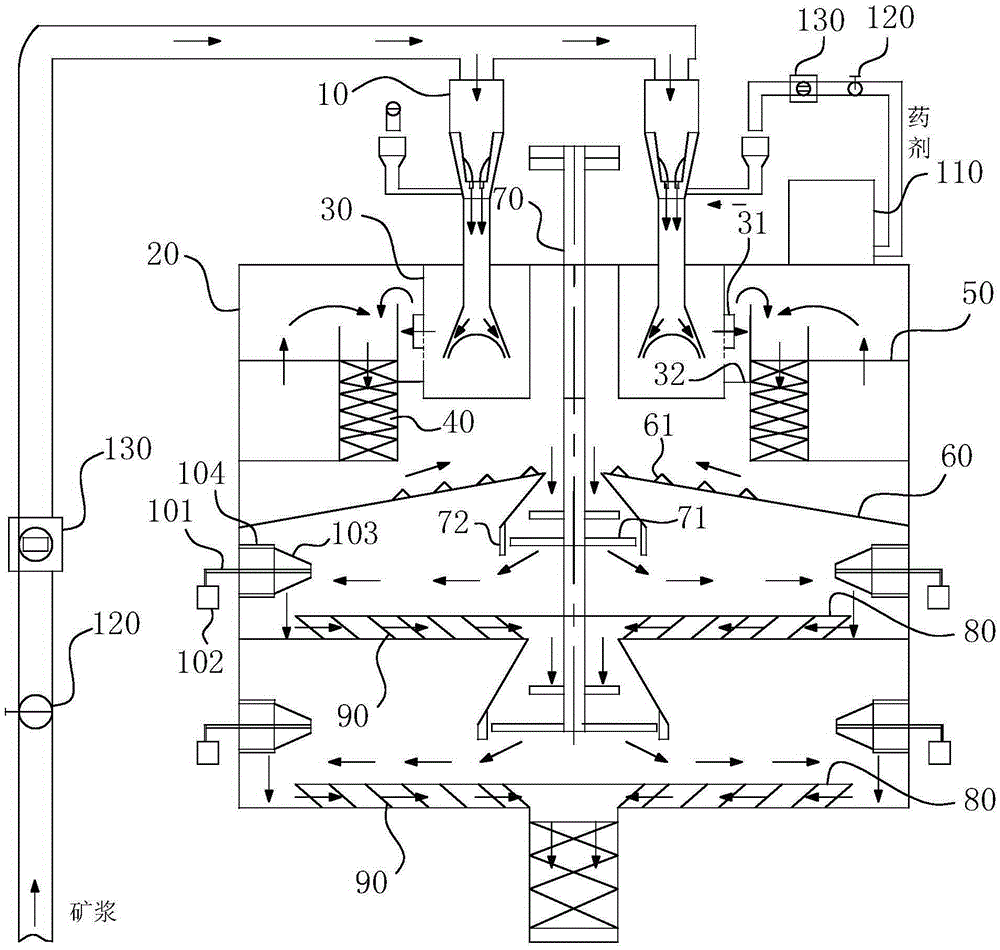

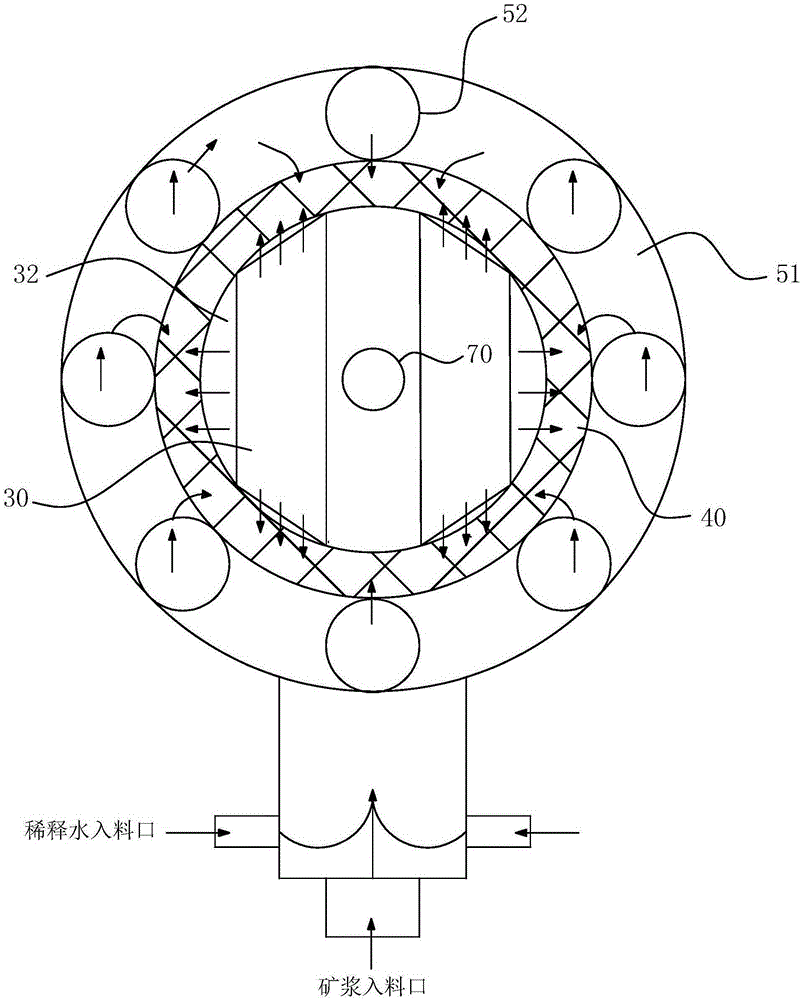

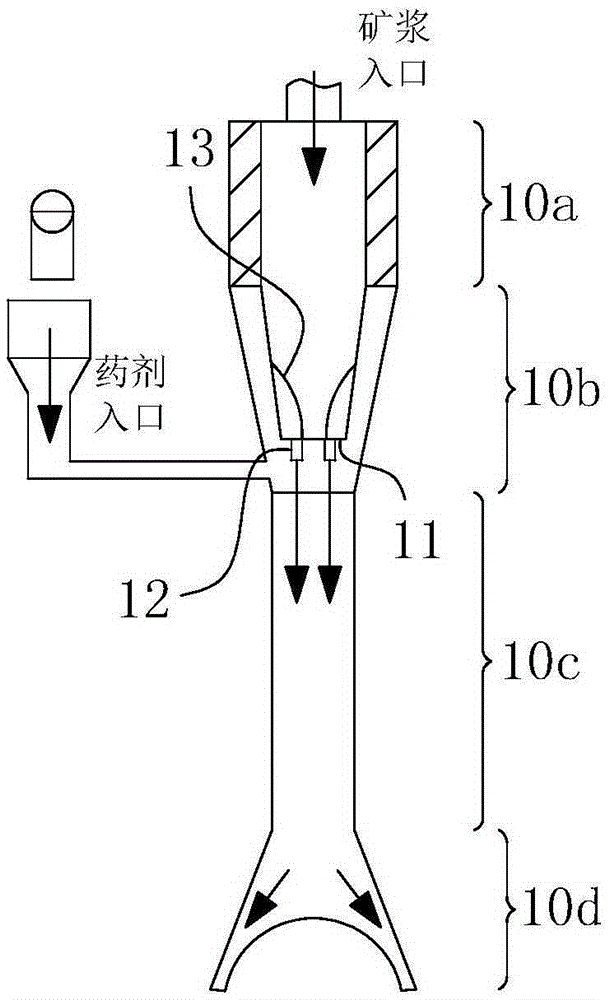

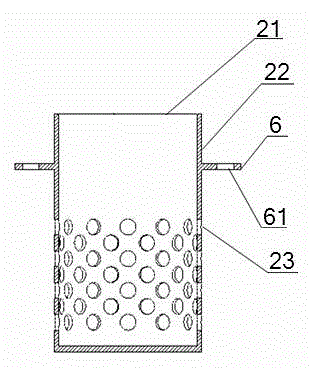

Jet medicament disperse system and fine coal particle pulp mixing modification equipment applying same

ActiveCN105289346AHomogeneous Mix Feed RequirementsPromote rapid formationFlow mixersMixer accessoriesHybrid systemEngineering

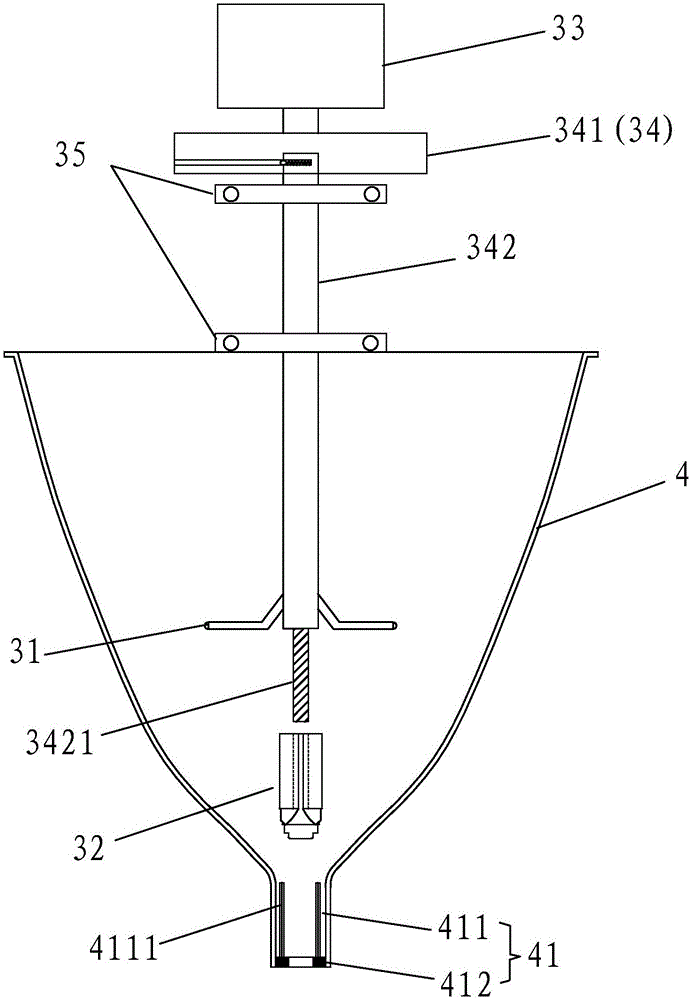

The invention relates to the field of coal slurry pre-treatment, and in particular relates to a jet medicament disperse system and fine coal particle pulp mixing modification equipment applying the same. The jet medicament disperse system comprises a pipe body, wherein the tail end of an inlet section of the hollow pipe chamber of the pipe body is provided with a nozzle baffle plate, and nozzles are arranged on the nozzle baffle plate; guide vanes are arranged at a side board surface of the nozzle baffle plate located at the chamber where the inlet section is located; all the nozzles are arranged at the side positions, close to the axis of the pipe body, of the corresponding guide vanes in one-to-one correspondence; an expansion section is of a forked type pipe body structure distributed along the circumferential direction of the axis of the pipe body. The system can effectively realize the uniform mixing feeding requirements of a medicament, ore pulp, and even clean water in a controllable manner. The fine coal particle pulp mixing modification equipment comprises a mixing box and a graded mixing system arranged in the mixing box, the top of the mixing box is provided with a medicament atomization dispersing system and the bottom is provided with the jet medicament disperse system; the equipment is especially suitable for the pulp mixing modification requirement of fine-particle coal difficult to float, the working efficiency of the equipment is high and the pre-treatment process is quick and convenient.

Owner:ANHUI UNIV OF SCI & TECH

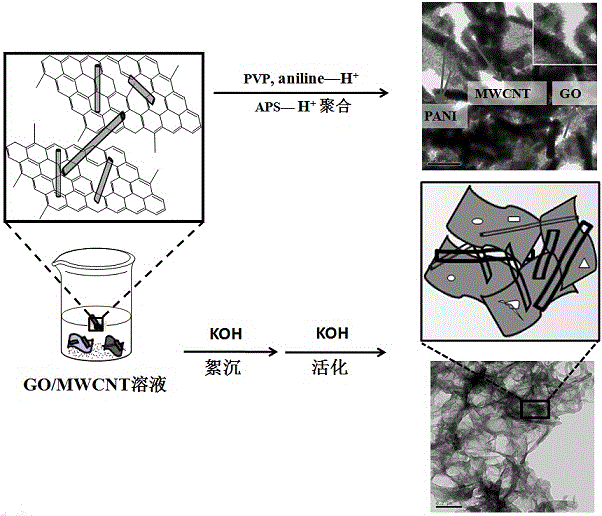

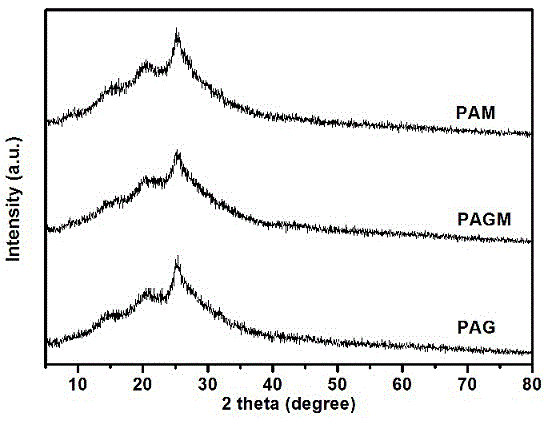

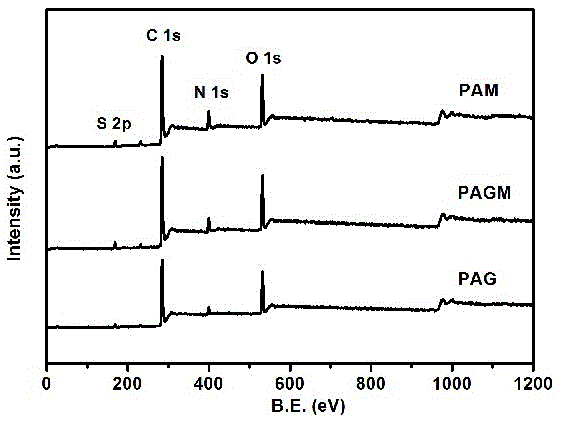

Positive/negative electrode material for high-performance asymmetric capacitor and preparation method for positive/negative electrode material

InactiveCN105609329ALarge specific surface areaImprove adsorption capacityHybrid capacitor electrodesHybrid/EDL manufacturePotassium hydroxideCarbon nanotube

The invention relates to a positive / negative electrode material for a high-performance asymmetric capacitor. The positive electrode material is a high-specific-capacity ternary composite material: polyaniline / graphene oxide / multi-wall carbon nanotube; the negative electrode material is a potassium hydroxide activated GO / MWCNT composite material with a high specific surface area and high conductivity. An electrochemical test for the ternary positive electrode material can prove that the electrochemical performance of the ternary composite material is far better than that of a binary composite material; an electrochemical test for a simple asymmetric capacitor assembled by the negative electrode material also proves that a relatively good electrochemical performance is obtained; the preparation method is simple in process, and the raw materials are free of toxins and hazards; the microcosmic ternary structure of the obtained positive electrode material represents integrated characteristics, wherein GO provides sufficient specific surface areas and are loaded with polyaniline nanorods; the MWCNT coated with polyaniline is bridged between GO pieces; and the negative electrode material shows porous and loosening characteristics, so that the positive / negative electrode material has relatively bright application prospects in the capacitor electrode materials.

Owner:HUBEI UNIV

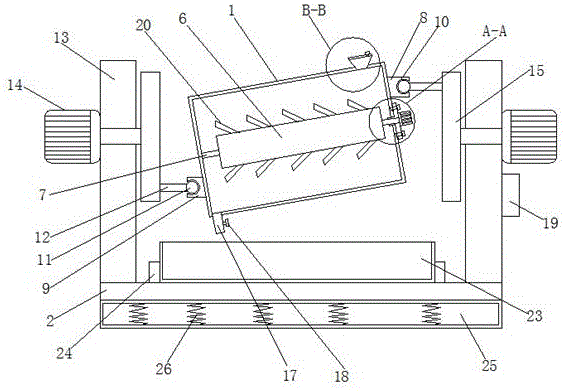

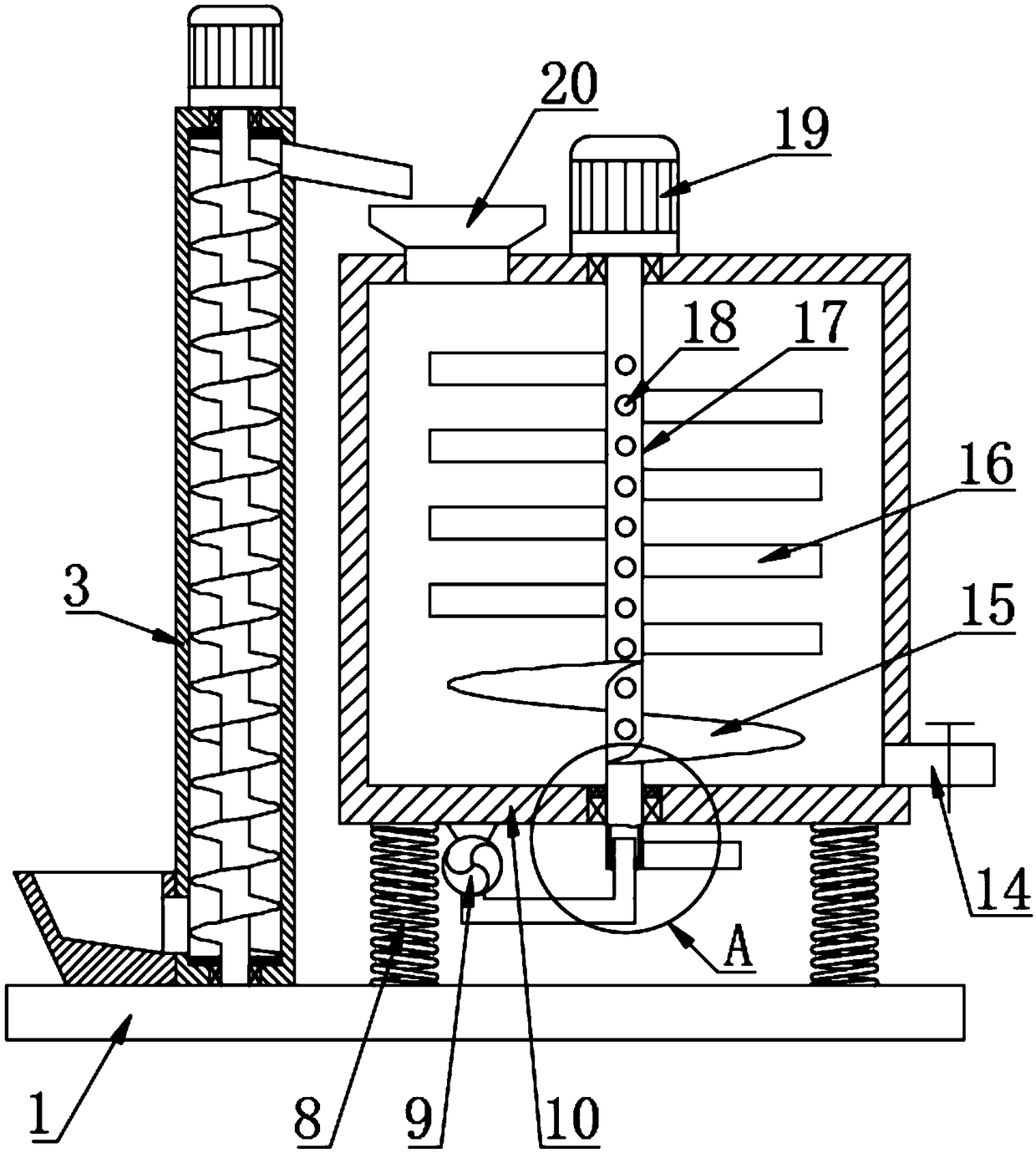

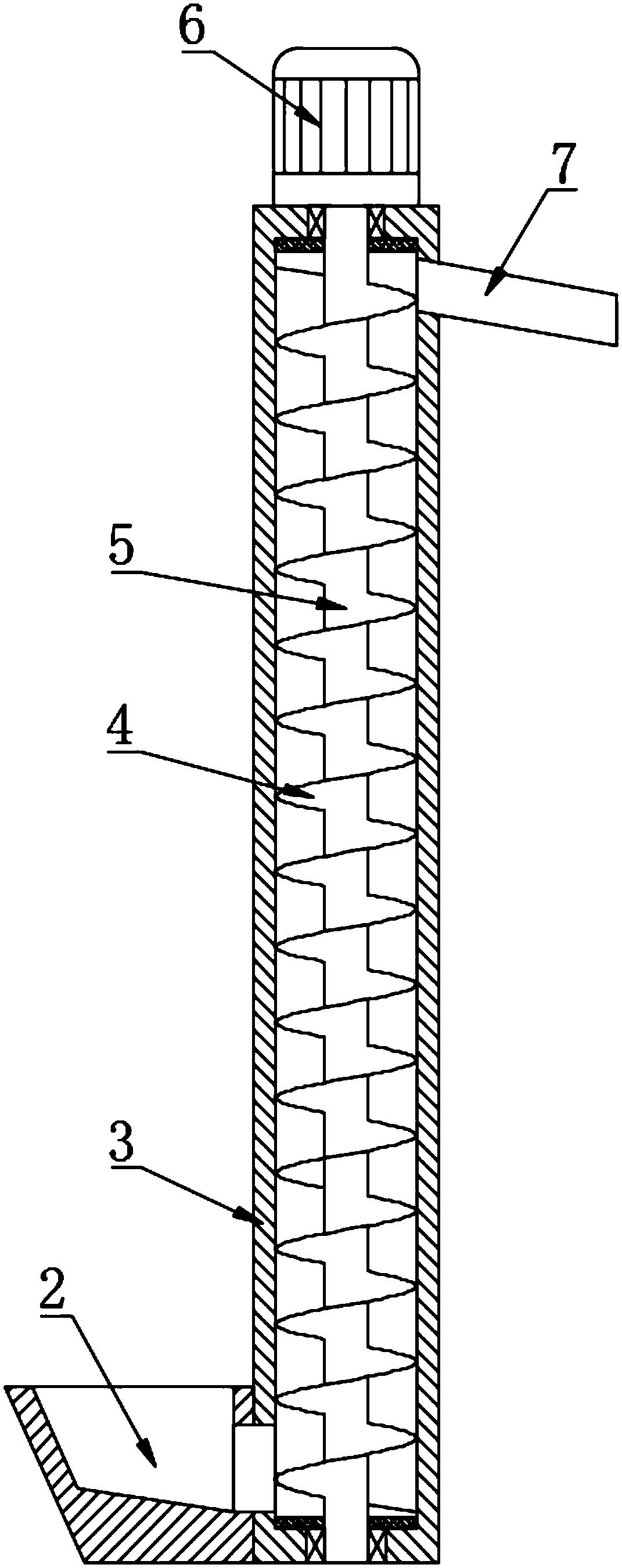

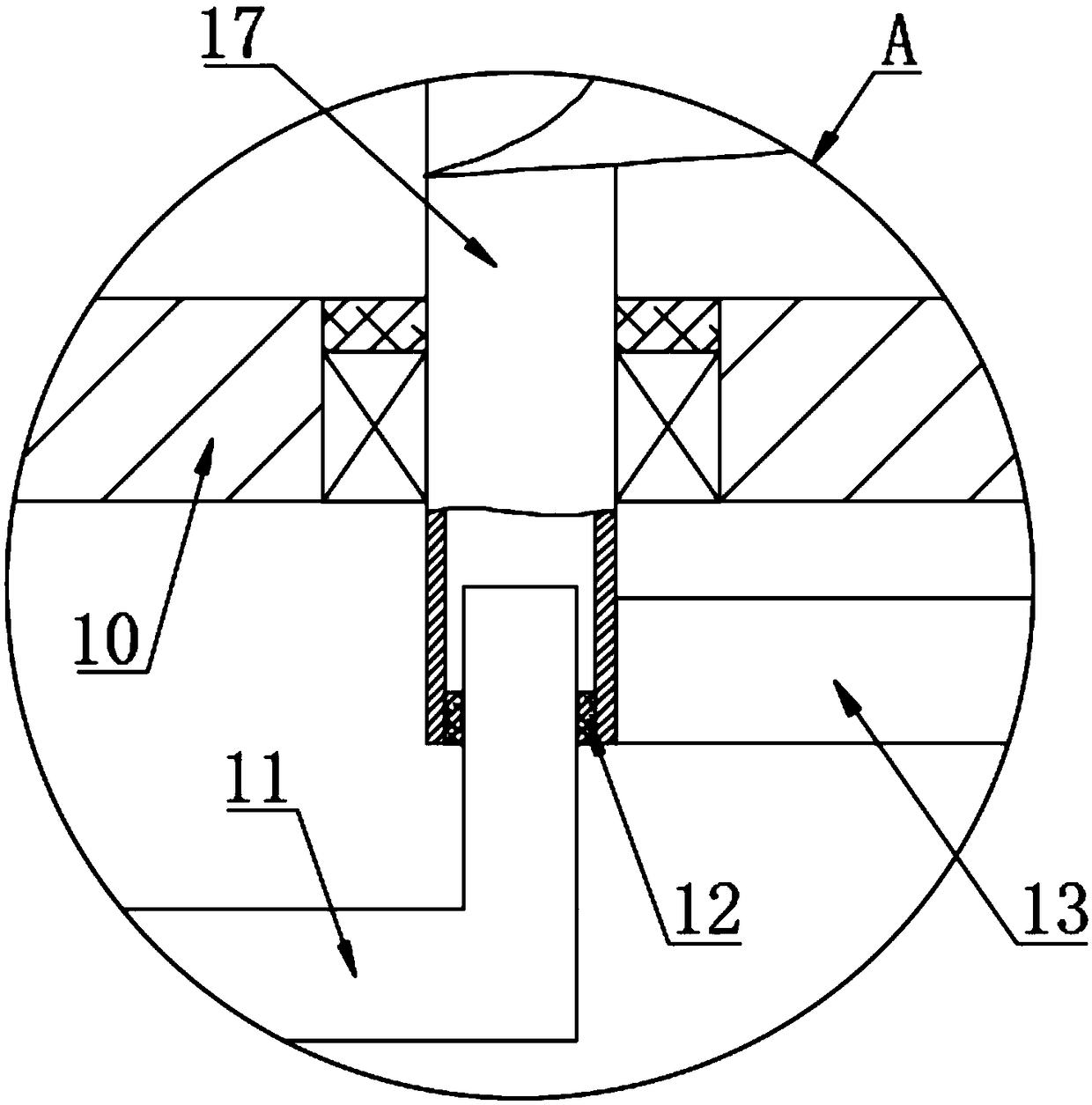

Feed mixing device with drying function

InactiveCN108654482AEven mixing effectEvenly distributedShaking/oscillating/vibrating mixersFeeding-stuffSpiral bladeEngineering

The invention discloses a feed mixing device with a drying function. The feed mixing device comprises a base. A mixing tank is connected with the top of the base by a plurality of support springs; a feeding hopper is arranged on the left side of the top of the mixing tank, a second gear motor is fixedly arranged in the center of the top of the mixing tank, a motor shaft at the bottom of the secondgear motor penetrates the top wall of the mixing tank and is fixedly connected with a hollow rotary shaft, the bottom of the hollow rotary shaft penetrates the bottom wall of the mixing tank, and a balancing weight is fixedly connected with the right lower corner of the hollow rotary shaft; a plurality of stirring blades are fixedly mounted on the hollow rotary shaft, the hollow rotary shaft is further fixedly provided with a second spiral blade which is positioned at the inner bottom of the mixing tank, a discharge pipe is connected with the right lower corner of the mixing tank. The feed mixing device has the advantages that the stirring blades and spiral blade can simultaneously rotate, and accordingly feed can be uniformly mixed; the mixing tank is supported by the support springs, the balancing weight can rotate, accordingly, the mixing tank can swing and move in mixing procedures, and feed mixing effects can be improved.

Owner:朵慧文

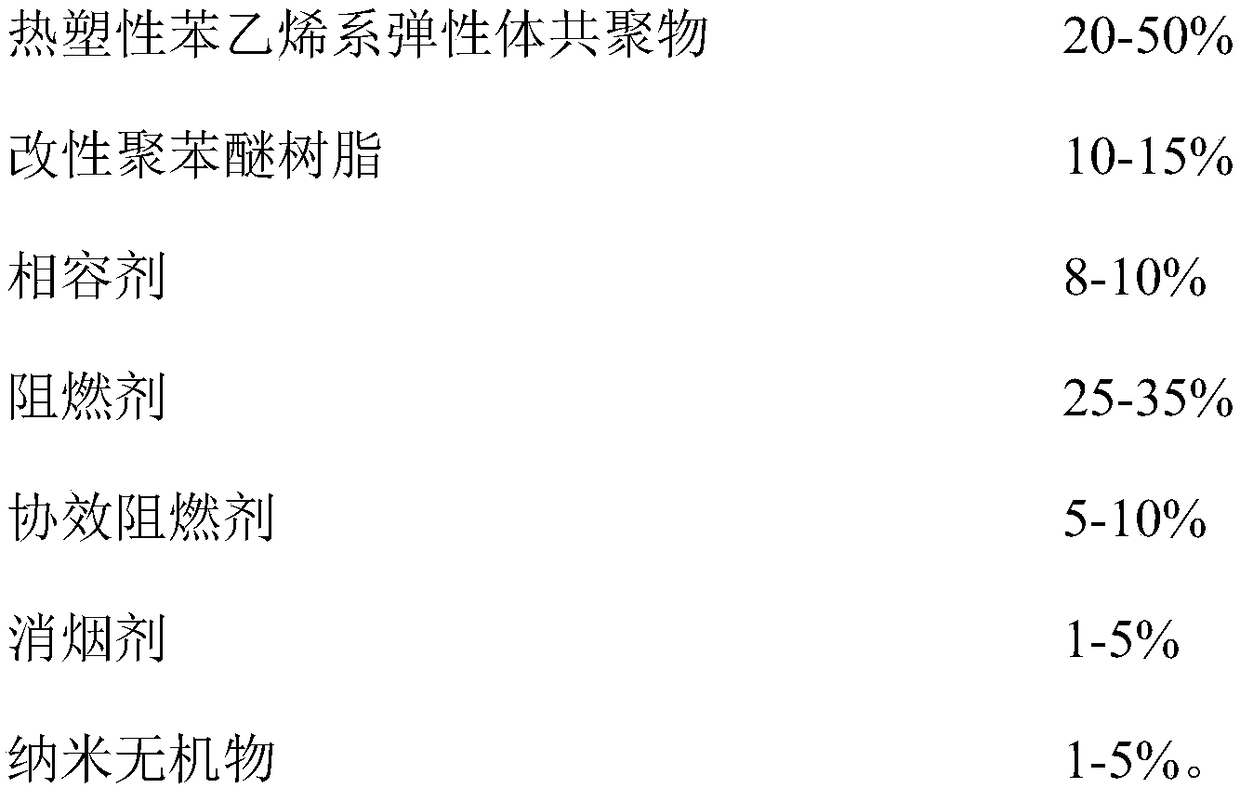

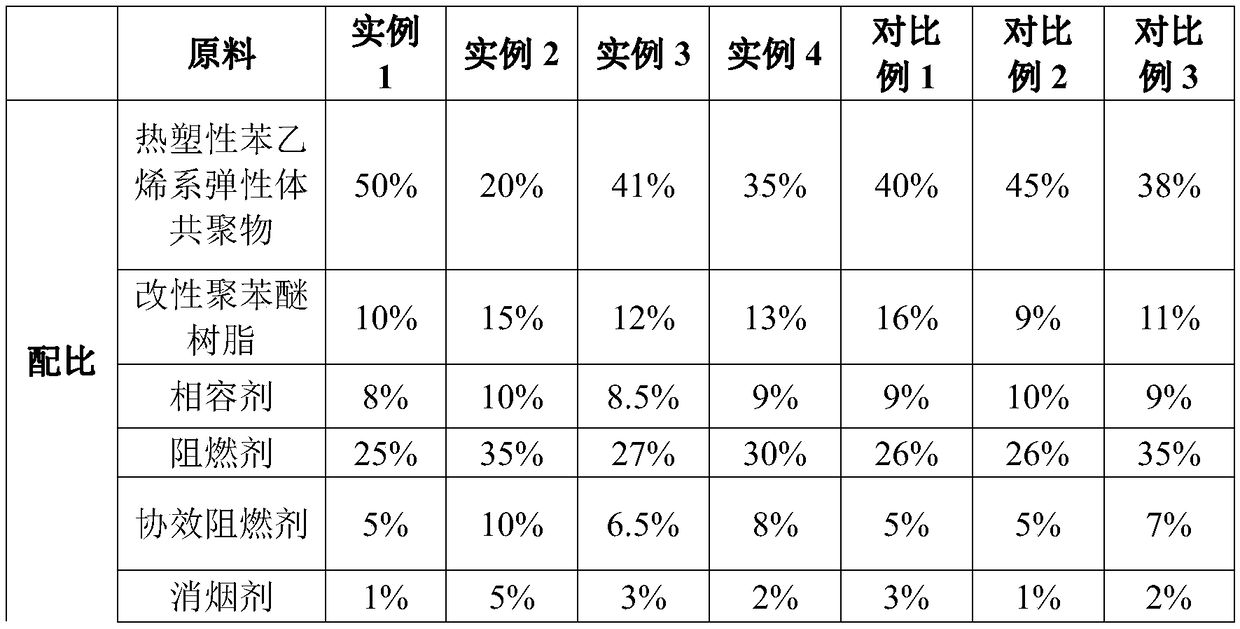

Flame-retardant anti-dripping hot melting adhesive membrane for flexible flat cable (FFC), and preparation method of hot melting adhesive membrane

InactiveCN108774472AStable flame retardant anti-droplet effectEvenly distributedNon-macromolecular adhesive additivesFilm/foil adhesivesElastomerHalogen

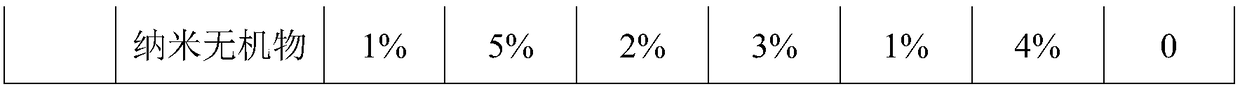

The invention relates to a flame-retardant anti-dripping hot melting adhesive membrane for a flexible flat cable (FFC), and a preparation method of the hot melting adhesive membrane. The hot melting adhesive membrane for the FFC is prepared from the following components by mass percent: 20-50% of thermoplastic styrene elastomer copolymer, 10-15% of modified polyphenylene ether resin, 8-10% of compatibilizer, 25-35% of flame retardant, 5-10% of synergistic flame retardant, 1-5% of smoke suppressant and 1-5% of nano inorganic matter. The flame-retardant anti-dripping hot melting adhesive membrane for the FFC can reduce the adding amount of the halogen flame retardant, and has the characteristics of being low in smoke quantity and good in flame-retardant and anti-dripping effects.

Owner:广东莱尔新材料科技股份有限公司

Sludge dewatering process combining physical and chemical methods

ActiveCN102126823AEven mixing effectImprove efficiencySludge treatment by de-watering/drying/thickeningSludge cakeProcess engineering

The invention relates to a sludge dewatering process combining physical and chemical methods, in particular to a sludge treatment process which combines physical and chemical methods to achieve a higher dewatering rate. The process comprises the following steps: 1) delivering primary sludge into a sludge modifying machine; 2) adding a dewatering assistant into the sludge modifying machine, and stirring for 5-10 minutes; 3) adding a second dewatering assistant into the sludge modifying machine, and continuing to stir for 5-10 minutes; 4) discharging the sludge from the sludge modifying machine to obtain modified sludge; and 5) mechanically dewatering the modified sludge to obtain sludge cakes of which the water content is not higher than 40%. When being used for treating sludge, the invention has the advantages of high efficiency, low investment and low operating cost.

Owner:浙江旺能生态科技有限公司

Improved method for preparing nutrition powder

The invention relates to an improved preparation method of nutritive powder and the steps thereof are as follows: (1) seeds granule of crop and dehydrated fruits and vegetables which are acquired according to adding proportion are together grinded into powder; (2) the powder prepared in the last step is screened to obtain the nutritive powder. Since the seeds granule of crop and dehydrated fruits and vegetables are also evenly blended during seeds granule of crop and dehydrated fruits and vegetables are together put into a pulverizer to be grinded into powder, the preparation method of the invention can achieve good even blending effect and consume no extra energy for the blending process and also ensure no risk of dust explosion; in addition, due to extremely even blending, the nutritive powder of fruits and vegetables prepared by the method of the invention has uniform color and strong flavor and less loss of tendon measurement of the nutritive powder at the same adding proportion.

Owner:王定文

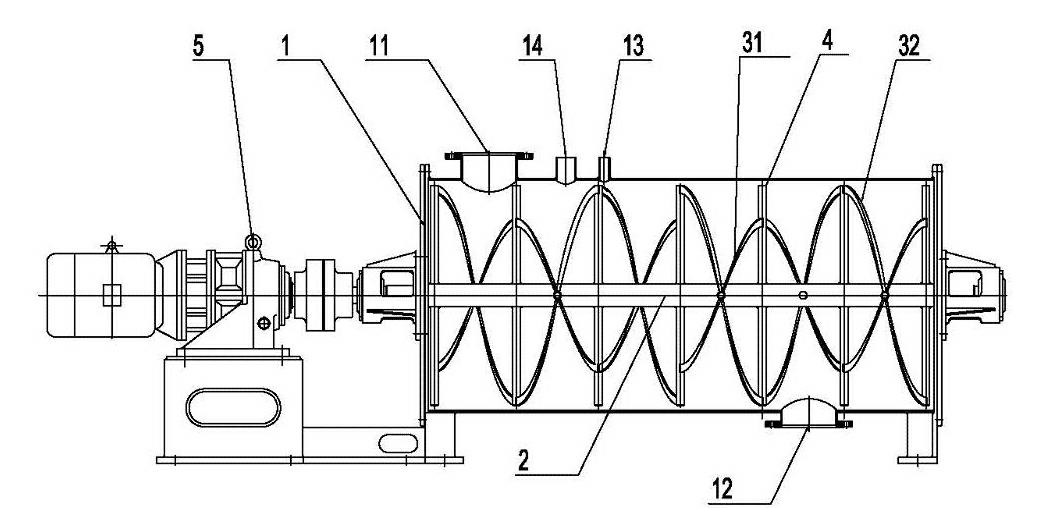

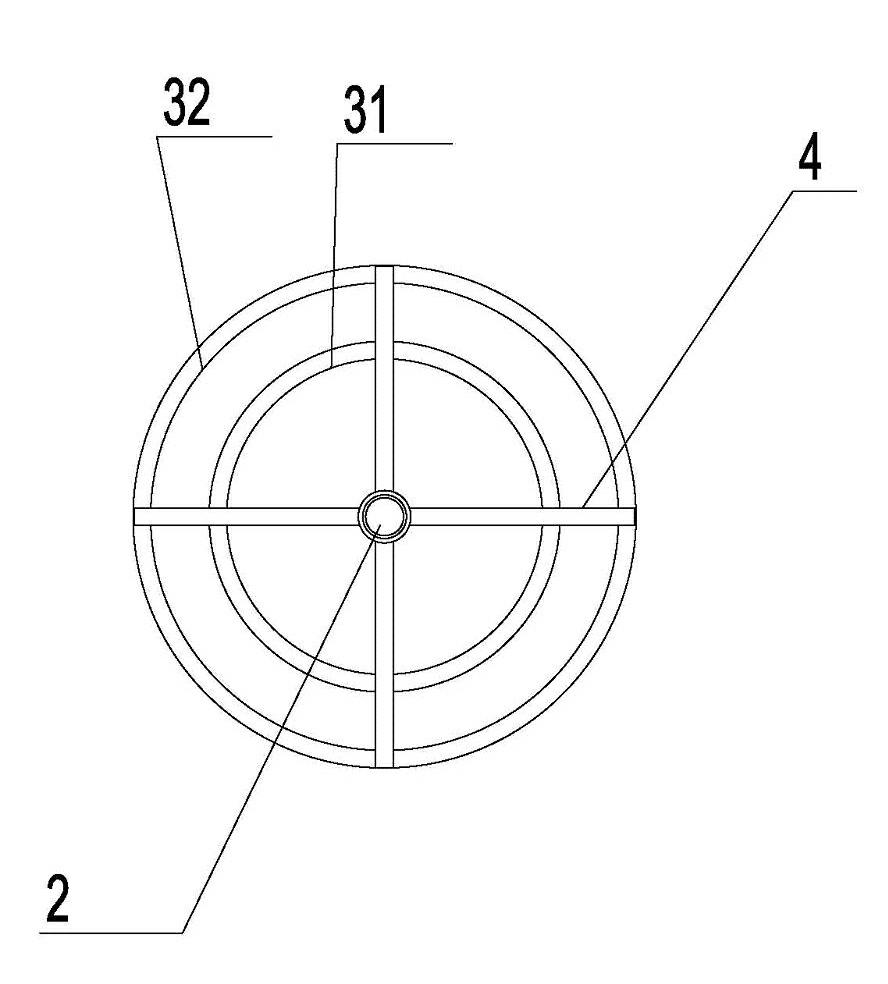

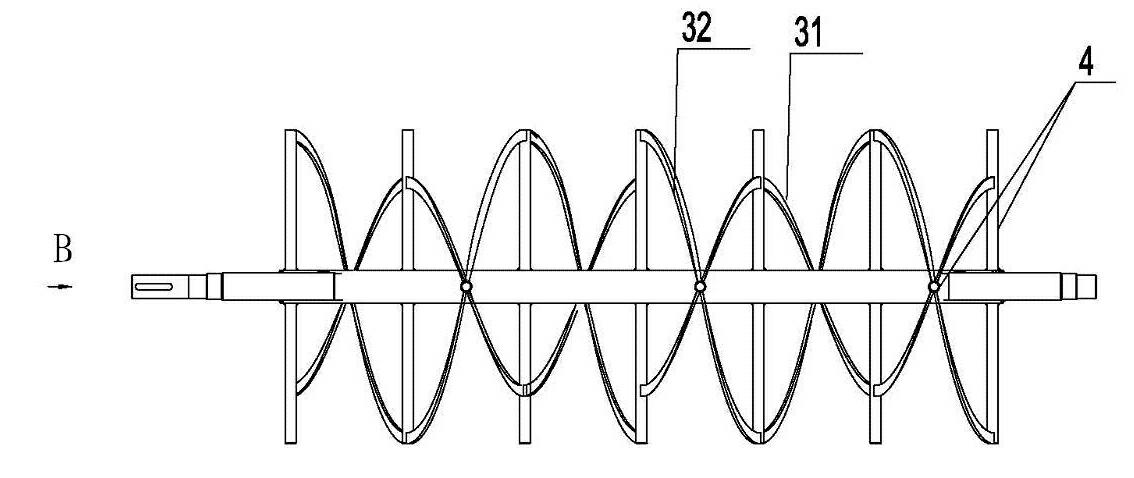

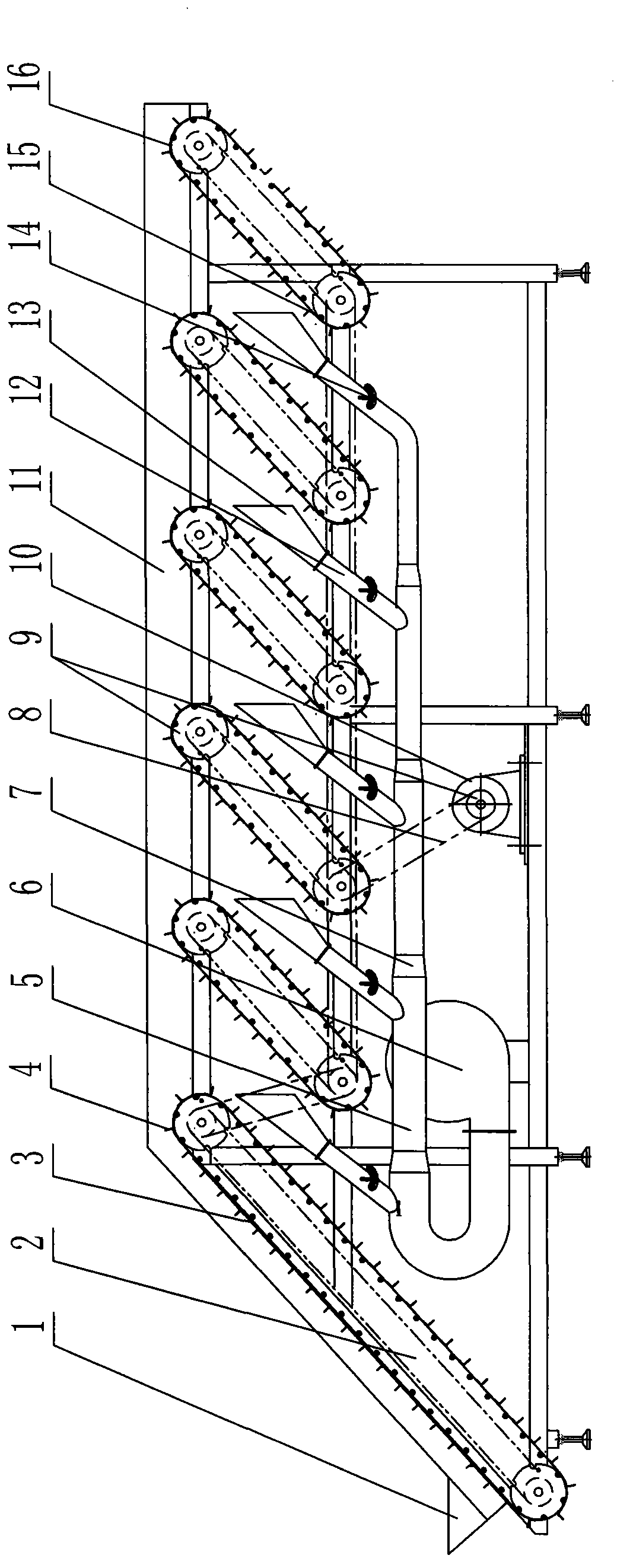

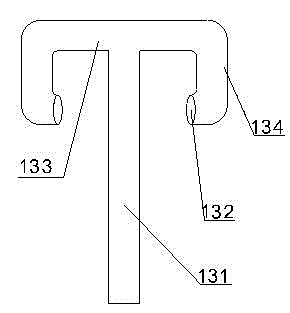

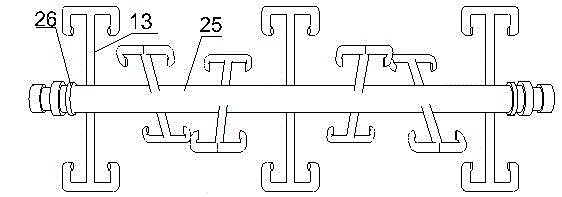

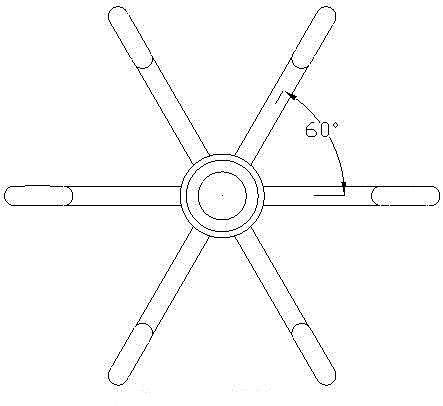

Automatic stillage air-drying machine

InactiveCN103255017AGood total power consumptionSmall total power consumptionAlcoholic beverage preparationSmall footprintSprocket

The invention relates to an automatic stillage air-drying machine, and aims to provide an automatic stillage air-drying machine which is low in energy consumption, high in cooling efficiency, small in occupied area and convenient to use, can promote fermentation and cannot be cleaned. The automatic stillage air-drying machine comprises a stander, inclined conveyers arranged on the stander, an air supply device and a driving motor, wherein the driving motor is connected with the inclined conveyers through chain wheels and chains. The structural key point is that a plurality of inclined conveyers are arranged; and the material feeding end of the back inclined conveyer is arranged below the material discharging end of the front inclined conveyer.

Owner:黄先全

Anaerobic reaction tank for processing intensive cattle farm excreta

InactiveCN104649728AReduce frictional resistanceSave powerBio-organic fraction processingClimate change adaptationDrawing ratioCross over

The invention discloses an anaerobic reaction tank for processing intensive cattle farm excreta. The outer layer of the anaerobic reaction tank is designed with a jacket structure and the inside of the anaerobic reaction tank is provided with a stirring plate, wherein the stirring plate is composed of a stirring plate main rod, a stirring plate port, a stirring plate radius rod and a stirring plate wing rod; the stirring plate main rod is fixed on a rotary shaft; the included angle between the adjacent stirring plate main rods is 30-90 degrees; and two ends of the rotary shaft are provided with sealing rings and are connected with the tank body through a bearing. The anaerobic reaction tank is horizontally designed, and the draw ratio is 1: (1-4). The space between the jacket and the anaerobic reaction tank body is 20-40 mm; and the cross section of the stirring plate port is round or oval. The anaerobic reaction tank is in a jacket design for providing energy to preserve the heat so that the materials are uniformly heated; a plurality of stirring plates are in a cross-over design structure so that the stirring efficiency is effectively improved and the organic matters are completely metabolized.

Owner:XUZHOU INSTITUTE OF TECHNOLOGY

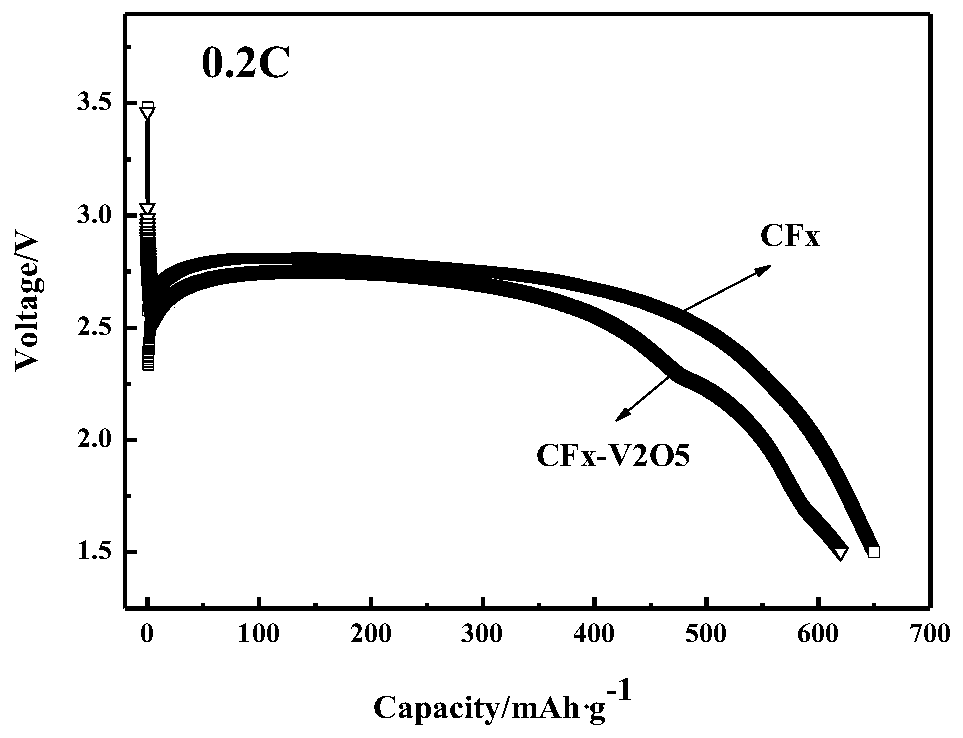

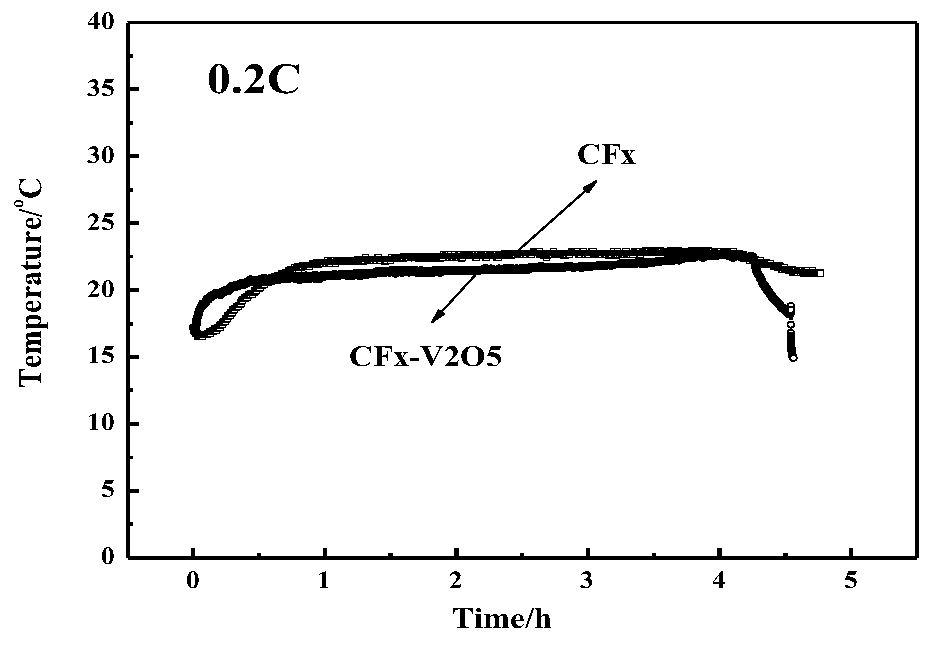

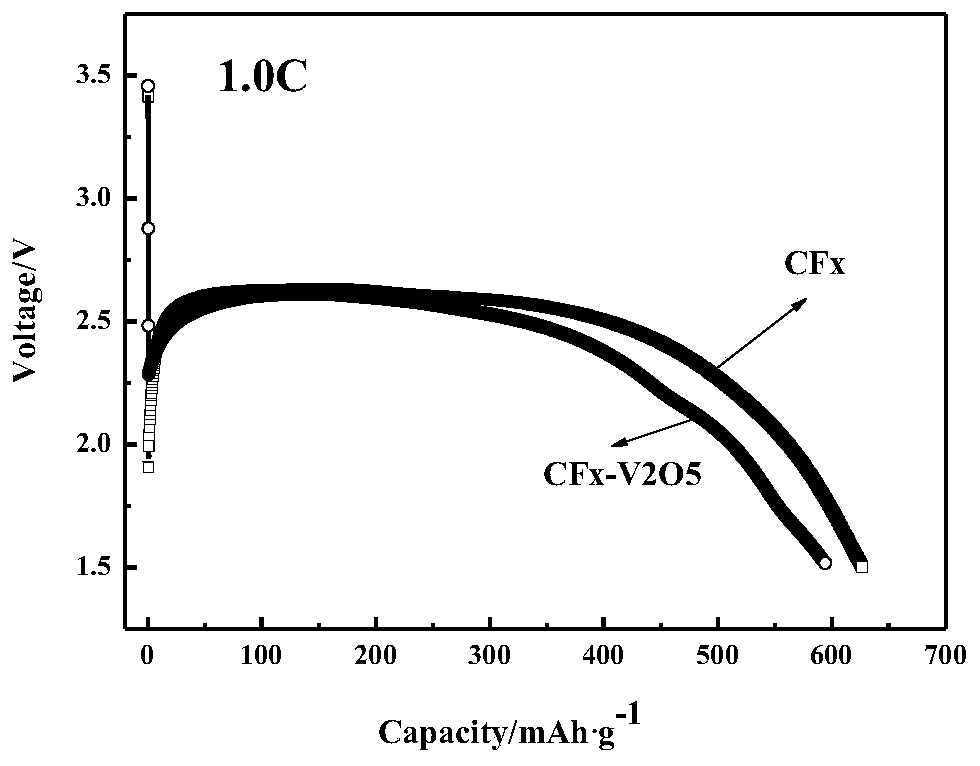

V2O5-carbon fluoride mixed positive electrode material and preparation method thereof

ActiveCN110707313AMake up for the voltage lag problemHigh voltageCell electrodesPhysical chemistryBattery cell

The invention relates to the technical field of lithium battery materials, in particular to a V2O5-carbon fluoride mixed positive electrode material and a preparation method thereof. According to theinvention, a V2O5 material is doped in a carbon fluoride positive electrode material, so that the advantages that the V2O5 material has higher discharge platform voltage, good high-current discharge capacity, very small heat generation during the discharge process and the like are fully utilized, the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material is solved, the large-current discharge capacity of the carbon fluoride positive electrode material is effectively improved, the rate capability of the lithium carbon fluoride battery is greatlyimproved, the temperature rise during the discharge process of the lithium carbon fluoride battery is reduced, and the application range of the lithium carbon fluoride battery is expanded. Under theaction of a dispersing agent, the two materials are mixed in a high-energy ball milling manner, so that the problem of voltage lag at the initial discharge stage of the carbon fluoride positive electrode material and the problem of high heat productivity under a high-current discharge condition are further solved. According to the present invention, the zirconium oxide balls are added during the high-energy ball milling process, so that the uniformity of the mixed materials is further improved.

Owner:GUIZHOU MEILING POWER SUPPLY CO LTD

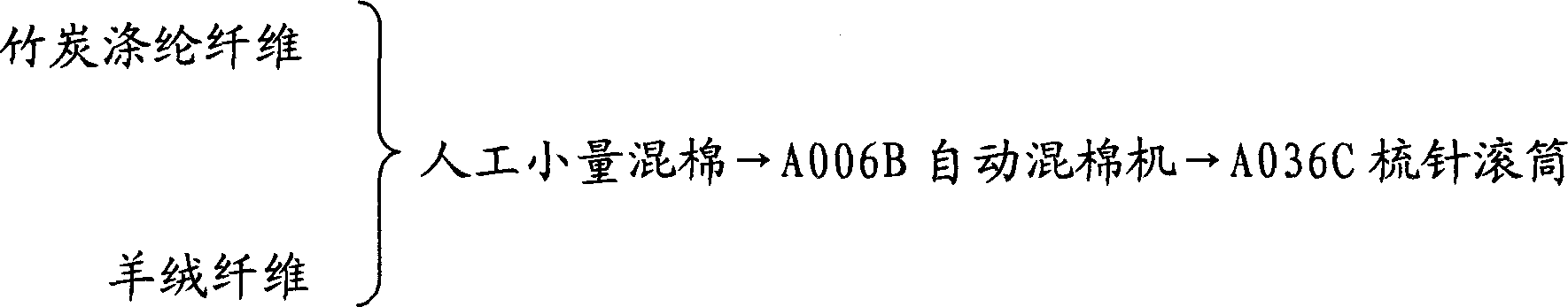

Bamboo carbon dacron fiber, cashmere fiber, Long-staple cotton fiber blended yarn and producing method thereof

The present invention discloses a bamboo carbon polyester fibre, cashmere fibre and long-staple cotton fibre blended yarn and its preparation method. It is made up by using 20-50% of bamboo carbon polyester fibre, 5-20% of cashmere fibre and 30-70% of long-staple cotton fibre through a certain preparation process. The performance indexes of said blendd yarn are as follows: single yarn breaking strength is 9.0-18.0 cN / tex, the coefficient of variation CV value of single yarn breaking strength is 8.0-22.0% and the coefficient of variation CV value of yarn evenness is 12.5-24.0%.

Owner:WUXI PAIHO TEXTILES CO LTD

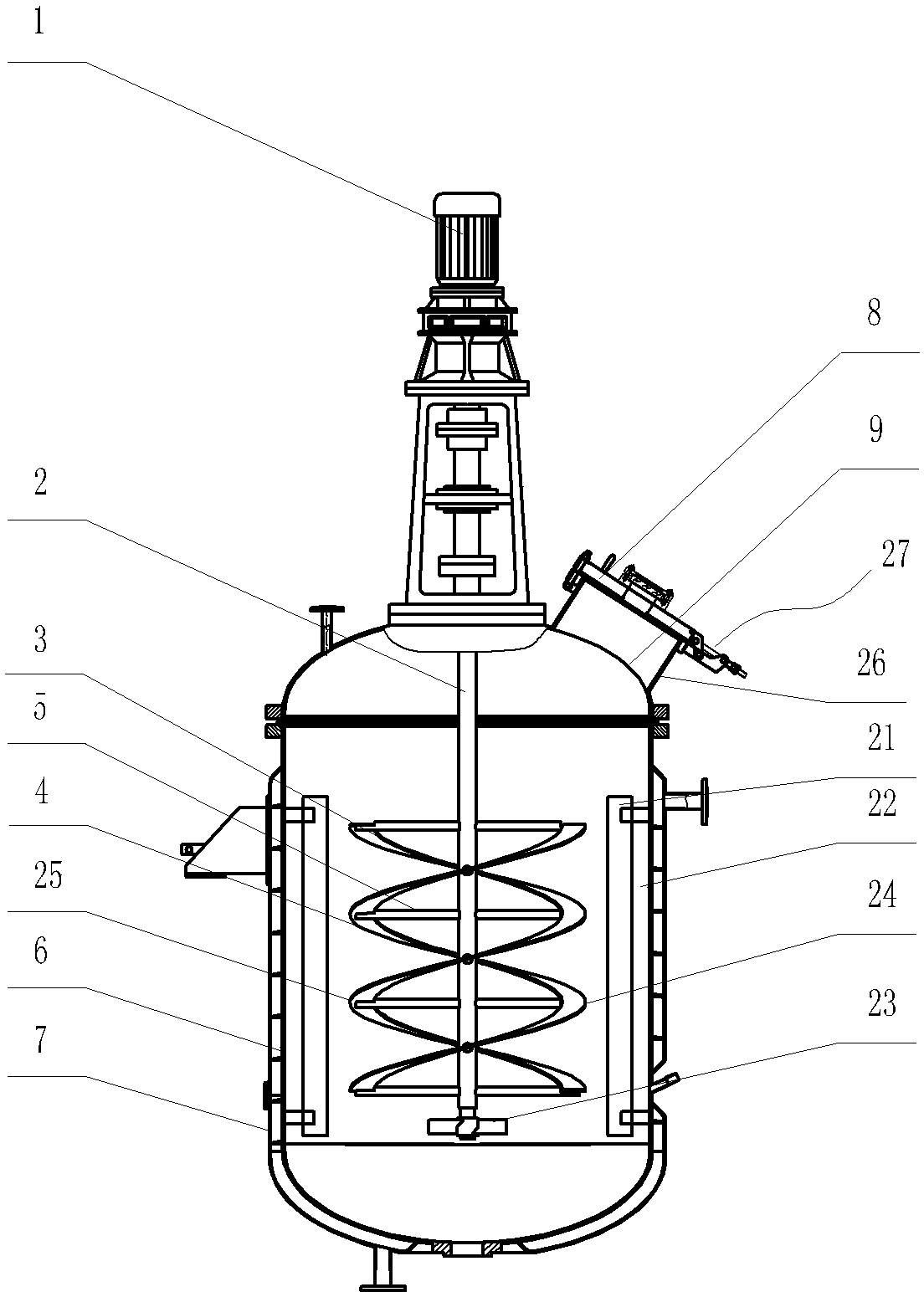

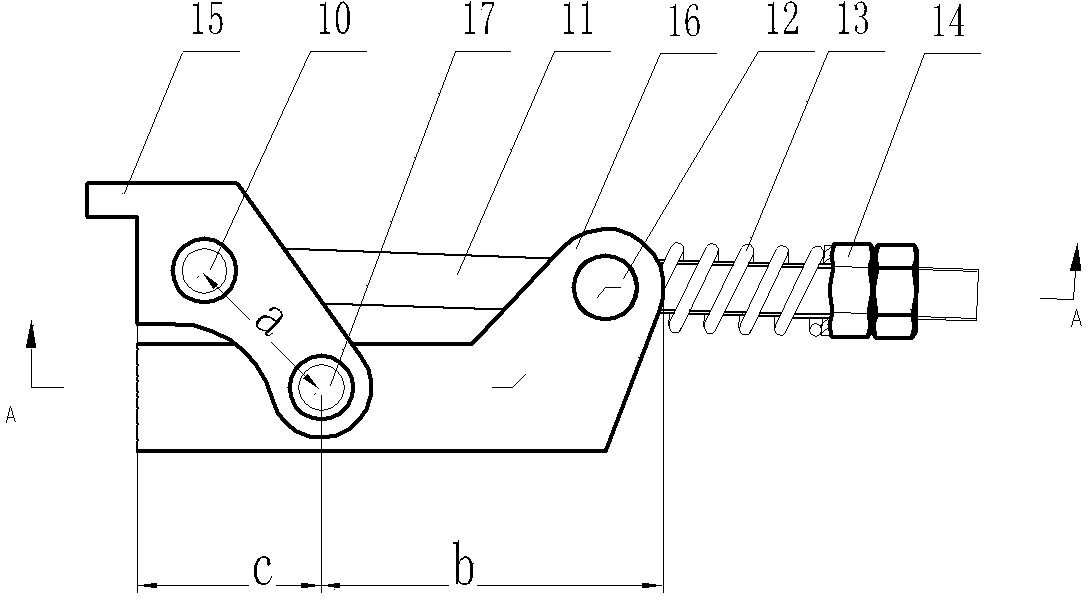

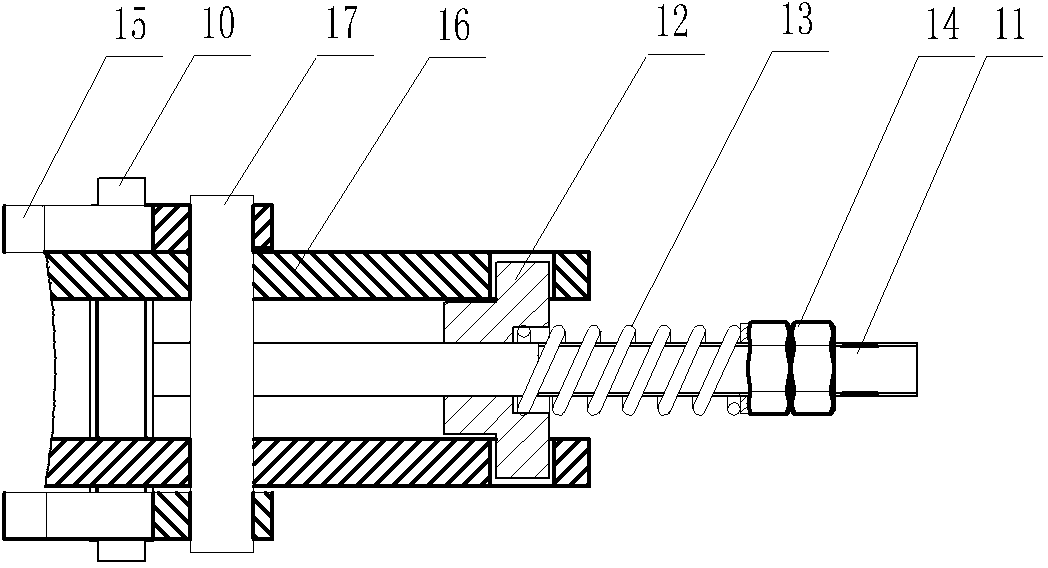

Reaction still

ActiveCN103480319AWell mixedEven mixing effectChemical/physical/physico-chemical stationary reactorsPulp and paper industry

Owner:WUXI MINGYAN EQUIP CO LTD

Equipment of deeply slurry mixing and modifying for coal slime

ActiveCN105289389AIncrease flow rateEfficient and deep pulping and modifying functionRotary stirring mixersMixer accessoriesImpellerEngineering

The invention relates to the field of coal slurry pretreatment, in particular to equipment of deeply slurry mixing and modifying of coal slime for slurry mixing and modifying of high-ash fine coal slime difficult to float. The equipment comprises a mixing box; agentia dispersion tanks are arranged at the top of a chamber of the mixing box, and an annular dispersion unit and an annular ore pulp feed chutes are arranged at the outside of the agentia dispersion tanks in sequence; a fallplate with a dip angle is arranged below a discharge port of the annular dispersion unit; vane wheels are arranged below the fallplate with the dip angle, and stator walls encircle the vane wheels; a liquid outlet of the mixing box is formed in bottom end surface of the mixing box; double row side-by-side nozzles with dispersed jet flows for providing agentia mixed liquor to the agentia dispersion tanks are arranged at the top end surface of the mixing box; two agentia dispersion tanks are arranged in parallel along the tank direction; diffusers of each nozzle with the dispersed jet flow extents into chambers of corresponding agentia dispersion tank. The equipment can play a very good role in modifying of floated coal slime and is particularly suitable for the demand of slurry mixing and modifying of fine coal difficult to float, the work efficiency of the equipment is high and a treatment process is rapid and convenient.

Owner:ANHUI UNIV OF SCI & TECH

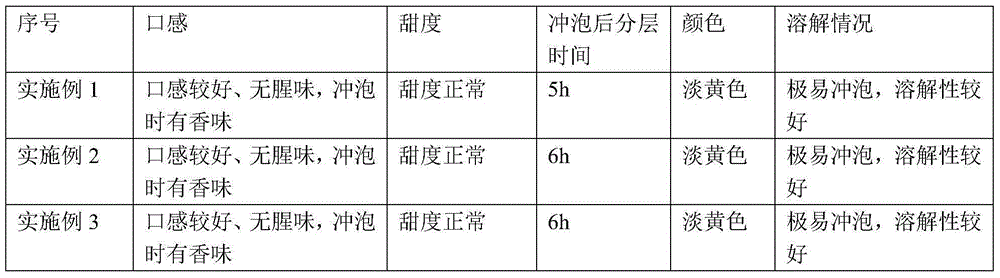

Soybean milk powder and making method thereof

The invention discloses soybean milk powder and a making method thereof, and belongs to the technical field of foods. The soybean milk powder is prepared from, by weight, 150-250 parts of soybeans, 150-250 parts of black beans, 20-80 parts of small red beans, 10-30 parts of pearl barley, 5-10 parts of cranberries, 5-10 parts of cocoa powder, 20-60 parts of whole milk powder, 5-10 parts of starch, 0.2-0.8 part of citric acid, 1-5 parts of emulsifying agents, 2-10 parts of additives and 2-10 parts of phosphatide oil. According to the soybean milk powder, the sugar-free sweet formula is adopted, the mouthfeel is good, delamination is not prone to occurrence, the deodorization process is simple, and the health care function is achieved. The adopted additives are all prepared from the pure natural plant raw materials of sweet stevia, licorice roots, grosvenor momordica fruit, jujubes, haws, Chinese wolfberries, poria cocos and herba portulacae, and on one hand, the raw materials have the health care function; on the other hand, the raw materials are mixed according to proportions, the function of a flavoring agent is achieved, and the mouthfeel of the soybean milk powder is improved; in addition, according to the raw materials, saccharose is not adopted, so that the soybean milk powder can also be taken by diabetics.

Owner:陈尚龙

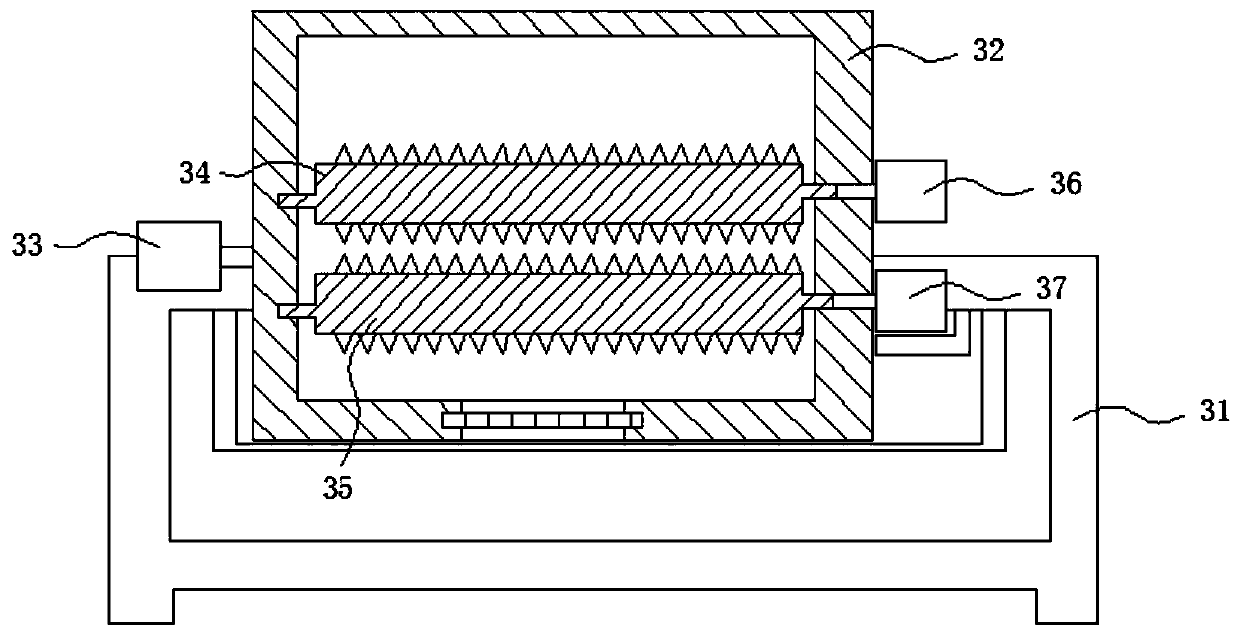

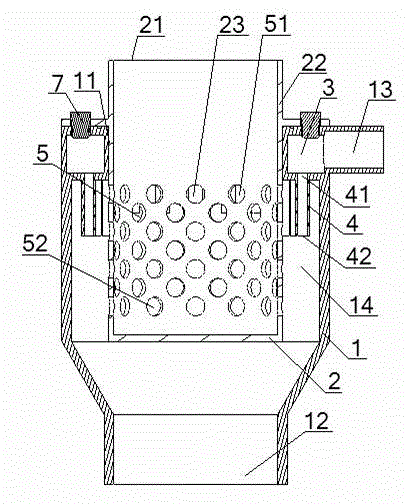

Mixing device for lithium battery positive electrode or negative electrode preparation materials

ActiveCN102513015AAvoid Purity LossOmit stop feedingCombination devicesCell electrodesFluidized bedBaghouse

The invention relates to a mixing device for lithium battery positive electrode or negative electrode preparation materials. The device is mainly composed of a fluidized bed, spiral feeders, vibration motors, spiral agitating blades, a spiral agitating motor and a settling chamber. Specifically, the spiral feeders are arranged at the lower parts of the fluidized bed; the middle part of the fluidized bed is provided with the vibration motors; the upper part inside the fluidized bed is equipped with the spiral agitating blades, the top of which is in connection with the spiral agitating motor; the top of the fluidized bed is connected to the settling chamber, the inside of which is provided with a cyclone separator and bag-type dust collector that is connected to a fan outside the settling chamber; the lower end of the fluidized bed is provided with an air vent, by which fluidized air that does not react with the lithium battery positive electrode or negative electrode preparation materials is introduced, and the lower end of the settling chamber is provided with a material outlet. The device of the invention is characterized by strong mixing ability, fast speed, low energy consumption, high degree of automation, and ability of sealing operation, so that it can better adapt to the requirements of large-scale industrial production.

Owner:济宁市无界科技有限公司

Processing technology for preparing high-strength concrete

InactiveCN110540390ATake advantage ofReduce processing costsSievingScreeningHigh strength concreteFiber

The invention discloses a processing technology for preparing high-strength concrete. The processing technology comprises the following steps: (1) raw material preparation: taking cement, sand, water,a water reducing agent, phenolic fiber and montmorillonite, wherein the sand is obtained by crushing construction waste by a crushing apparatus; (2) dry mixing: putting the cement, the sand, the water reducing agent, the phenolic fiber and the montmorillonite into a material mixing machine for dry material pre-mixing to obtain a mixture A after uniform mixing; and (3) wet mixing: putting the mixture A into a stirrer, adding water and a fine aggregate into the stirrer, and then performing uniform stirring to obtain the slurry-like concrete. According to the processing technology, the dry mixing operation is first performed before the wet mixing, so that a mixing uniformity degree of the dry powder materials is relatively high during mixing, and the processing technology ensures that various materials are all mixed together.

Owner:鄱阳县恒基建材有限公司

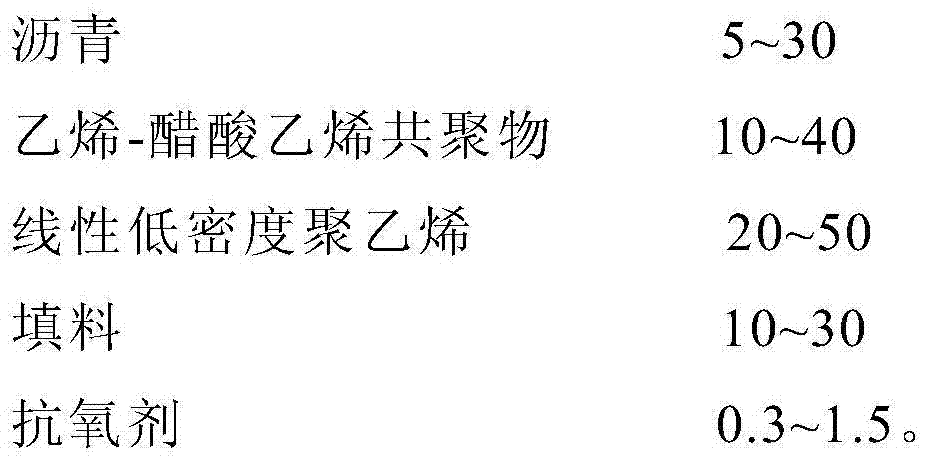

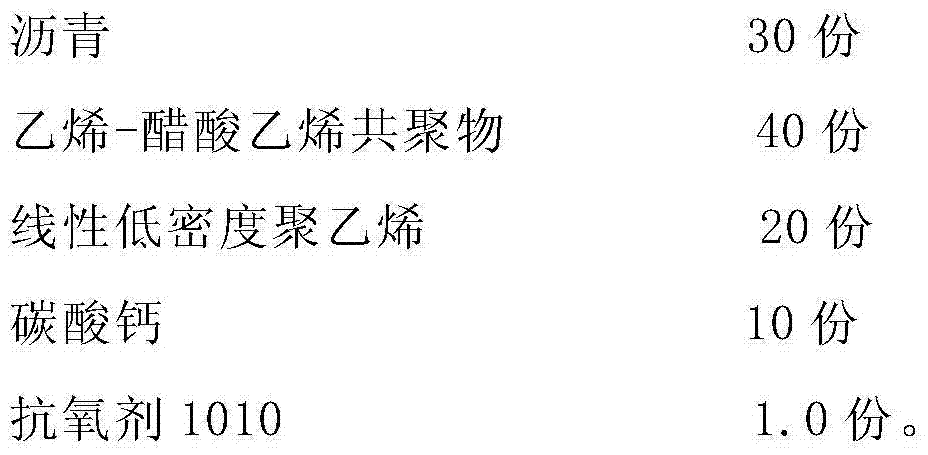

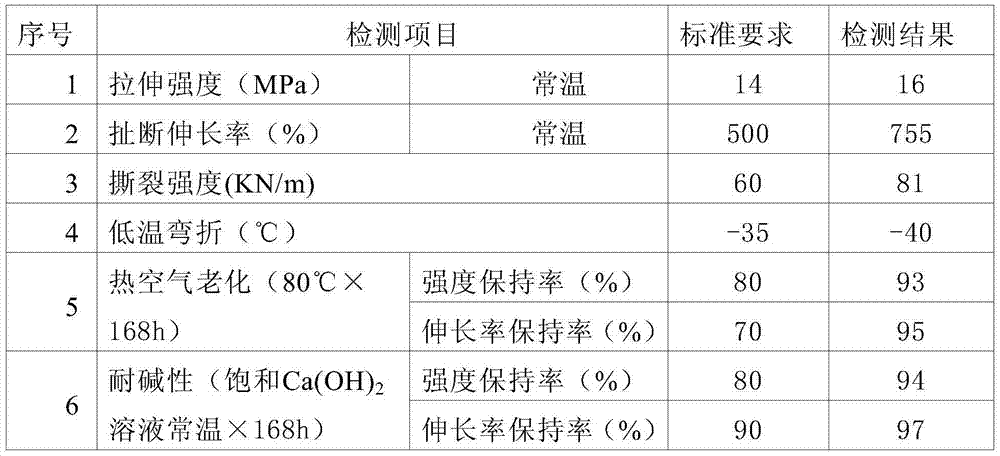

Plastic waterproof plate and preparation method therefor

InactiveCN104844886AImprove mechanical propertiesExcellent hot melt welding performanceBuilding insulationsLow-density polyethyleneLinear low-density polyethylene

The invention discloses a plastic waterproof plate and a preparation method therefor. The plastic waterproof plate is prepared from raw materials comprising an ethylene-vinyl acetate copolymer, linear low density polyethylene, asphalt, filler and an antioxidant. The plastic waterproof plate disclosed by the invention has excellent aging resistance and chemical medium corrosion resistance of the asphalt, excellent flexibility, tensile strength and wear resistance of the linear low density polyethylene and excellent low-temperature flexibility and sweat soldering performance of the ethylene-vinyl acetate copolymer. The composition of the product is environmentally friendly and the product can be widely suitable for waterproofness and seepage resistance of civil engineering such as a plurality of tunnels, underground civil engineering, city subways, water conservancy, artificial lakes, refuse landfills, waste residue treatment fields of petroleum plants, sewage adjusting pools and the like.

Owner:XIANYANG DONGFANG YUHONG BUILDING MATERIAL CO LTD

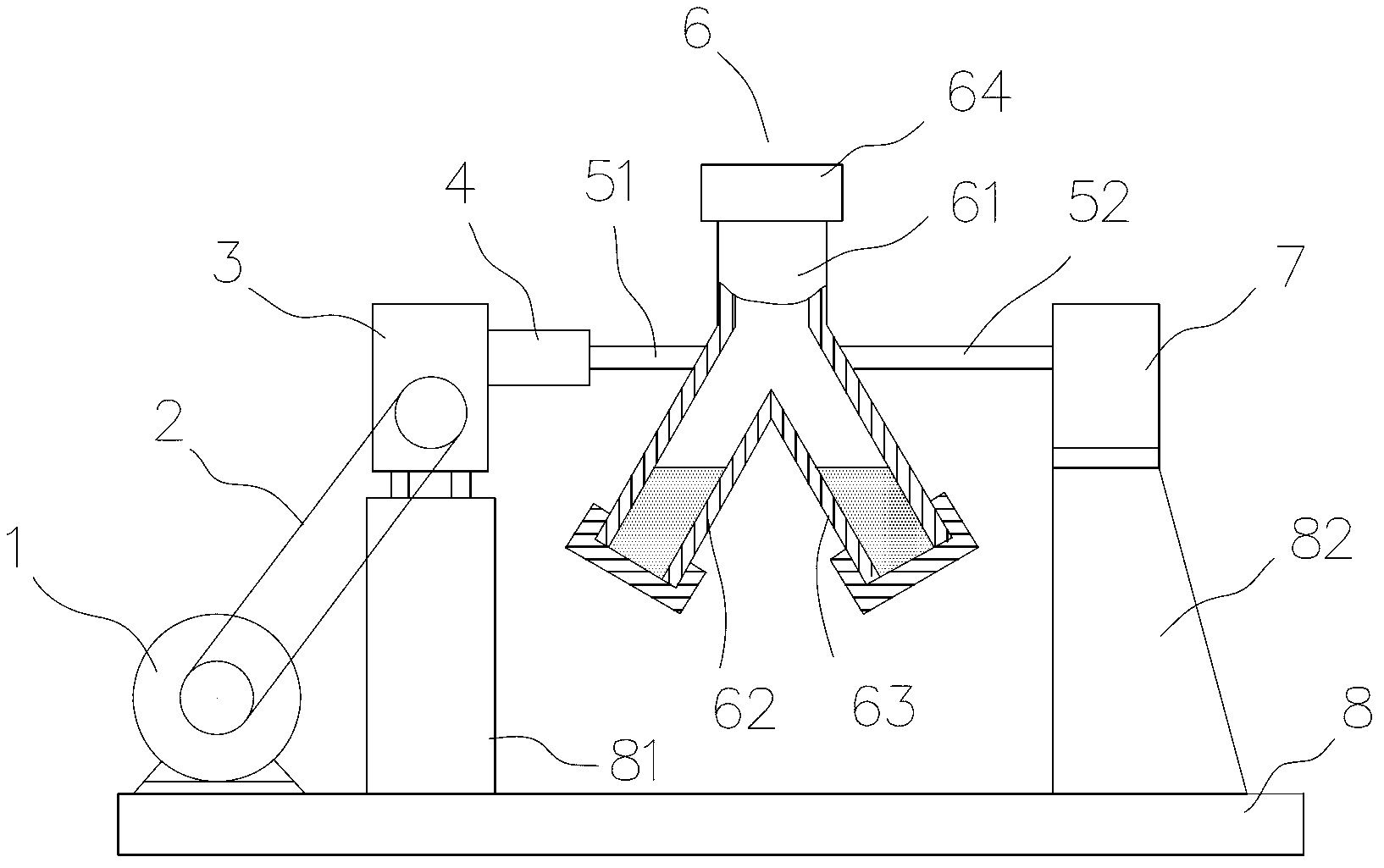

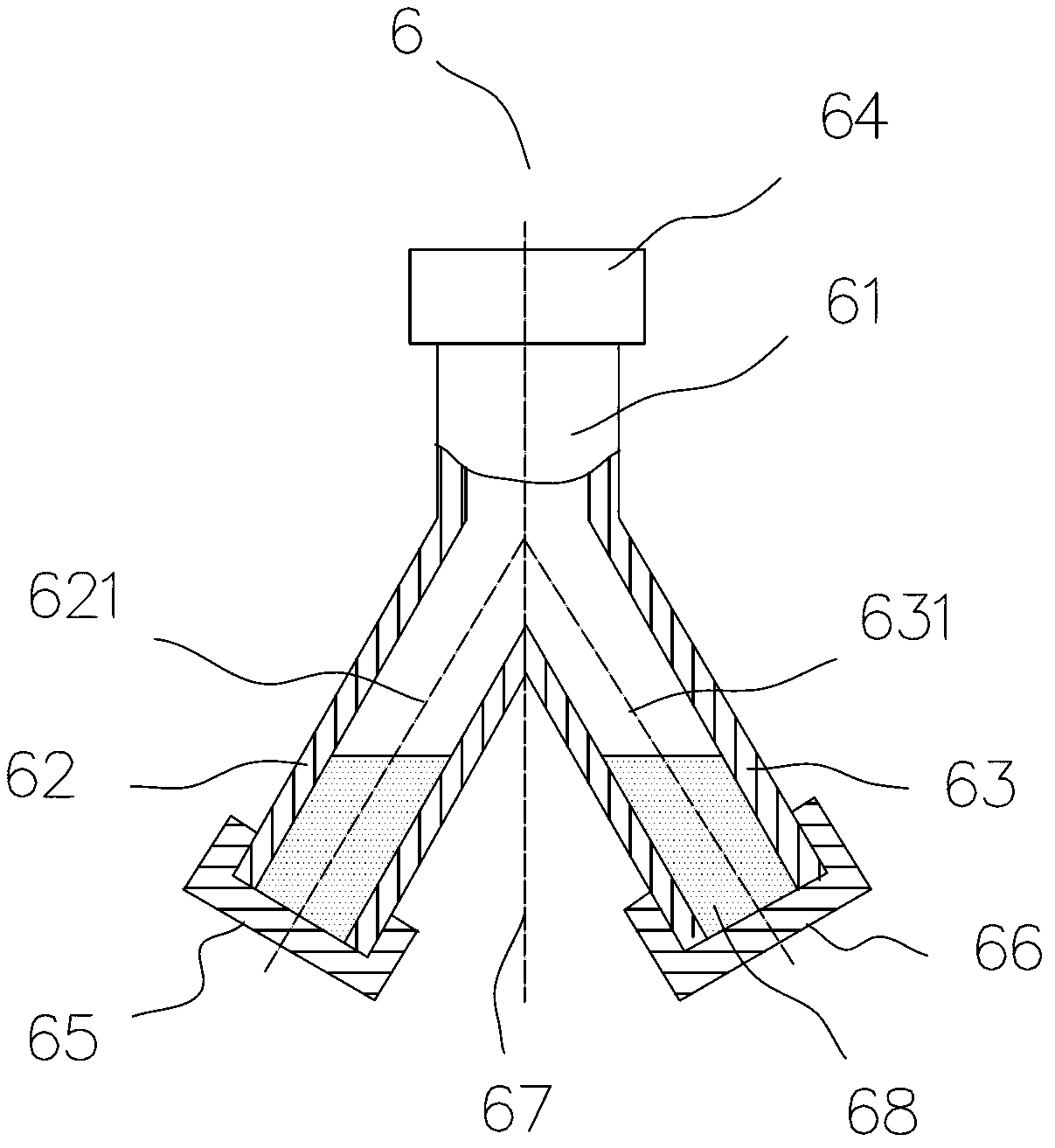

Y-shaped mixer used for sintered powder

InactiveCN103212331AInhibition of segregationQuality improvementRotating receptacle mixersTransportation and packagingEngineeringMechanical engineering

The invention relates to a Y-shaped mixer used for sintered powder. The Y-shaped mixer comprises a mixing container, a bracket and a driving device, wherein the mixing container consists of three cylindrical barrels which are connected to be in a Y-shape, the diameters of inner chambers of the three cylindrical barrels are the same, one cylindrical barrel which is arranged vertical to a rotating shaft is a main barrel, the other two cylindrical barrels are sub-barrels, the two sub-barrels are symmetrically arranged at the inner side end of the main barrel, an included angle between symmetry centers of the two sub-barrels is 30-50 degrees, the rotating shaft is fixed on two sides of the inner side end of the main barrel and arranged vertical to the symmetry centers of the two sub-barrels, and a cover is arranged at the outer side end of the main barrel. The Y-shaped mixer is even in mixing, can effectively prevent the segregation phenomenon, and has the advantages of short mixing time and high efficiency.

Owner:安徽聚芯智造科技股份有限公司

Feed premixing apparatus

InactiveCN106311038ASimple structureLow investment costRotating receptacle mixersFeeding-stuffEngineeringFodder

The invention discloses a feed premixing apparatus. The apparatus comprises a pedestal, the pedestal is provided with a supporting rack, the supporting rack is provided with a hopper, a rotating shaft is arranged at two sides of the hopper, the rotating shaft is arranged on the supporting rack, a transmission device and a fixing device are respectively arranged at two sides of the pedestal, a speed reduction motor is arranged in the pedestal, the speed reduction motor is connected with one end of the rotating shaft through the transmission device, and the other end of the rotating shaft is connected with the fixing device. The feed premixing apparatus has the advantages of simple structure, low investment cost, small occupied area, uniform mixing effect, no mixing dead angles in the hopper, and meeting of market demands.

Owner:JIANGSU KINDFULL FEED TECH

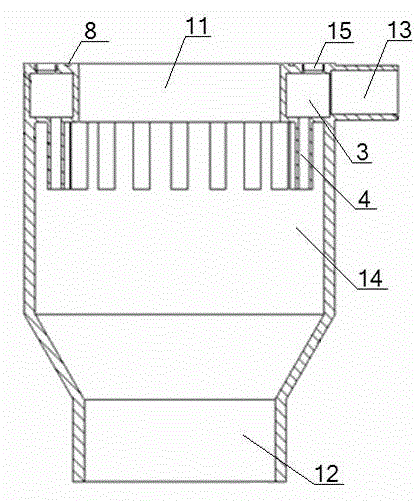

Efficient gas mixing device for magnesium alloys

ActiveCN101332416AImproved combustion safetyQuality improvementMaintainance of heating chambersMixer accessoriesCardingFiltration

The invention relates to a magnesium-alloy high-efficient gas mixing device which comprises a mixing pot, a first gas inlet joint, a second gas inlet joint and a pressure switch are arranged at the upper side end of the pot wall of the mixing pot in a seal and perforation way, a gas outlet joint is arranged at the lower side end of the pot wall of the mixing pot in a seal and perforation way and a discharging valve is arranged at the lower side end of the pot wall of the mixing pot; a ventilation pipe that is connected with the first gas inlet joint is of a right-angle bend pipe with a pipe mouth being arranged downwards; a ventilation pipe that is connected with the second gas inlet joint is of an arc bend pipe and a pipe mouth thereof is arranged horizontally and inwards to form a rotary spraying nozzle; a carding net which can carry out the second carding and filtration to the mixing gases is arranged at the middle-lower part of an inner cavity of the mixing pot. The invention uses two or more than two sorts of gases with different qualities for mixing, the gases are input from the gas inlet joint and injected into a mixing gas pot by the rotary spraying nozzle, so the high-pressure airflow and the fluid-state rotation movement can be formed, and two gases with different qualities are evenly and fully mixed together by the second carding and filtration by the stainless steel wire carding net. The device has the outstanding advantages of full and even mixing and stable output flux.

Owner:NINGBO XUNHUI ELECTRIC APPLIANCE

Foam composite material and forming method thereof

The invention belongs to the field of foam material and specifically relates to a foam composite material and a preparation method thereof. According to the preparation method, foaming master batch isprepared at firstly, scattering of a powdery foaming agent in alloying can be avoided, and a mixing effect is enhanced; mica and hollow glass beads are added to achieve a lubricating effect on flowing of a plastic matrix, so that physical foam holes of foam glass powder in the matrix and foam holes generated by decomposition of the foaming agent are mutually matched; the foam composite material with good foaming performance can be prepared under a synergistic effect of other ingredients.

Owner:CHANGZHOU UNIV

Engine mixer

ActiveCN104314713AShorten the lengthFast control responseInternal combustion piston enginesFuel supply apparatusMomentumEngineering

The invention discloses an engine mixer which comprises a mixer body and a mixer tube core, wherein the mixer body adopts a hollow structure of which two ends are opened and comprises an air inlet end, a mixed gas outlet end and an inner cavity; the inner wall of the air inlet end and the outer wall of the mixer tube core are matched in an inserting manner; a natural gas inlet pipe is connected onto the outer wall of the air inlet end and is communicated with the mixed gas outlet end through the inner cavity; the mixed tube core adopts a hollow structure of which one end is opened; an opening end of the mixed tube core is an air inlet; the air inlet is communicated with the inner cavity through a plurality of through holes formed in the tube wall of the mixer tube core. According to the engine mixer, natural gas flow beams are dispersed by using greater momentum of air flow beams, so that the mixing uniformity of natural gas and air is improved, and the flowing resistance is reduced.

Owner:DONGFENG COMML VEHICLE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com