Soybean milk powder and making method thereof

A technology for soybean milk powder and whole milk powder, which is applied in the food field, can solve the problems that diabetics cannot eat, the steps of removing fishy smell are complicated, and it is easy to cause anger, etc., and achieves prevention of cardiovascular aging lesions, good emulsifying effect, and difficulty in stratification. effect of precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

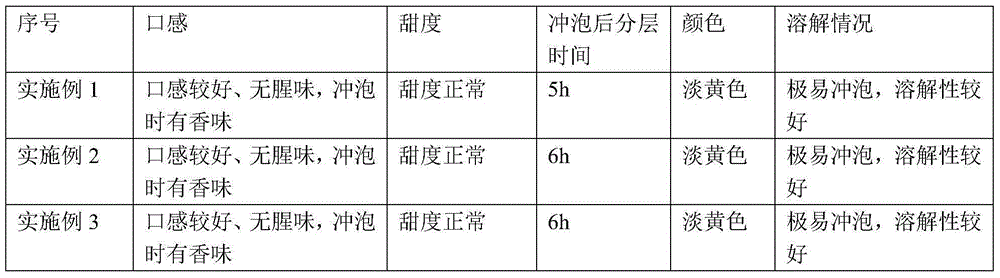

Examples

Embodiment 1

[0049] A soybean milk powder made from the following raw materials in parts by weight: 200 soybeans, 200 black beans, 50 red beans, 20 barley, 8 cranberries, 8 cocoa powder, 4 jujubes, 40 whole milk powder, 7 starch, citric acid 0.5, emulsifier 3, additive 6, phospholipid oil 6, amino acid 3 (phenylalanine).

[0050] Among them, the emulsifier is a 1:1:1:2 mixture of xanthan gum, locust bean gum, acacia gum, and sucrose ester.

[0051] Wherein, the additive is made of the following substances by weight:

[0052] Stevia, licorice, Luo Han Guo, jujube, hawthorn, wolfberry, poria cocos, and purslane are 1:2:3:2:1:1:2:1.

[0053] The preparation method of above-mentioned soybean milk powder, comprises the following steps:

[0054] ① Weigh raw materials according to the above weight parts and weight ratio;

[0055] ② Raw material pretreatment

[0056] Pretreatment of soybeans, black beans, and red beans:

[0057] Clean the soybeans, black beans, and red beans. After cleaning, ...

Embodiment 2

[0067] A soybean milk powder, made from the following raw materials in parts by weight: soybean 150, black bean 220, red bean 80, barley 10, cranberry 10, cocoa powder 5, jujube 6, whole milk powder 60, starch 10, citric acid 0.7, emulsifier 4, additive 8, phospholipid oil 9, amino acid 5 (arginine: phenylalanine: proline = 1:1:1).

[0068] Among them, the emulsifier is a 1:1:1:2 mixture of xanthan gum, locust bean gum, acacia gum, and sucrose ester.

[0069] Wherein, the additive is made of the following substances by weight:

[0070] Stevia, licorice, Luo Han Guo, jujube, hawthorn, wolfberry, poria cocos, and purslane are 1:2:3:2:1:1:2:1.

[0071] The preparation method of above-mentioned soybean milk powder, comprises the following steps:

[0072] ① Weigh raw materials according to the above weight parts and weight ratio;

[0073] ② Raw material pretreatment

[0074] Pretreatment of soybeans, black beans, and red beans:

[0075] Clean the soybeans, black beans, and red...

Embodiment 3

[0085] A soybean milk powder made from the following raw materials in parts by weight: soybeans 250, black beans 150, red beans 30, barley 30, cranberries 2, cocoa powder 5, jujube 2, whole milk powder 50, starch 7, citric acid 0.6, emulsifier 4, additive 8, phospholipid oil 8, amino acid 1 (glycine:phenylalanine=1:1).

[0086] Among them, the emulsifier is a 1:1:1:2 mixture of xanthan gum, locust bean gum, acacia gum, and sucrose ester.

[0087] Wherein, the additive is made of the following substances in weight ratio:

[0088] Stevia, licorice, Luo Han Guo, jujube, hawthorn, wolfberry, poria cocos, and purslane are 1:2:3:2:1:1:2:1.

[0089] The preparation method of above-mentioned soybean milk powder, comprises the following steps:

[0090] ① Weigh raw materials according to the above weight parts and weight ratio;

[0091] ② Raw material pretreatment

[0092] Pretreatment of soybeans, black beans, and red beans:

[0093] Clean the soybeans, black beans, and red beans. A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com