Patents

Literature

90results about How to "Low process equipment requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

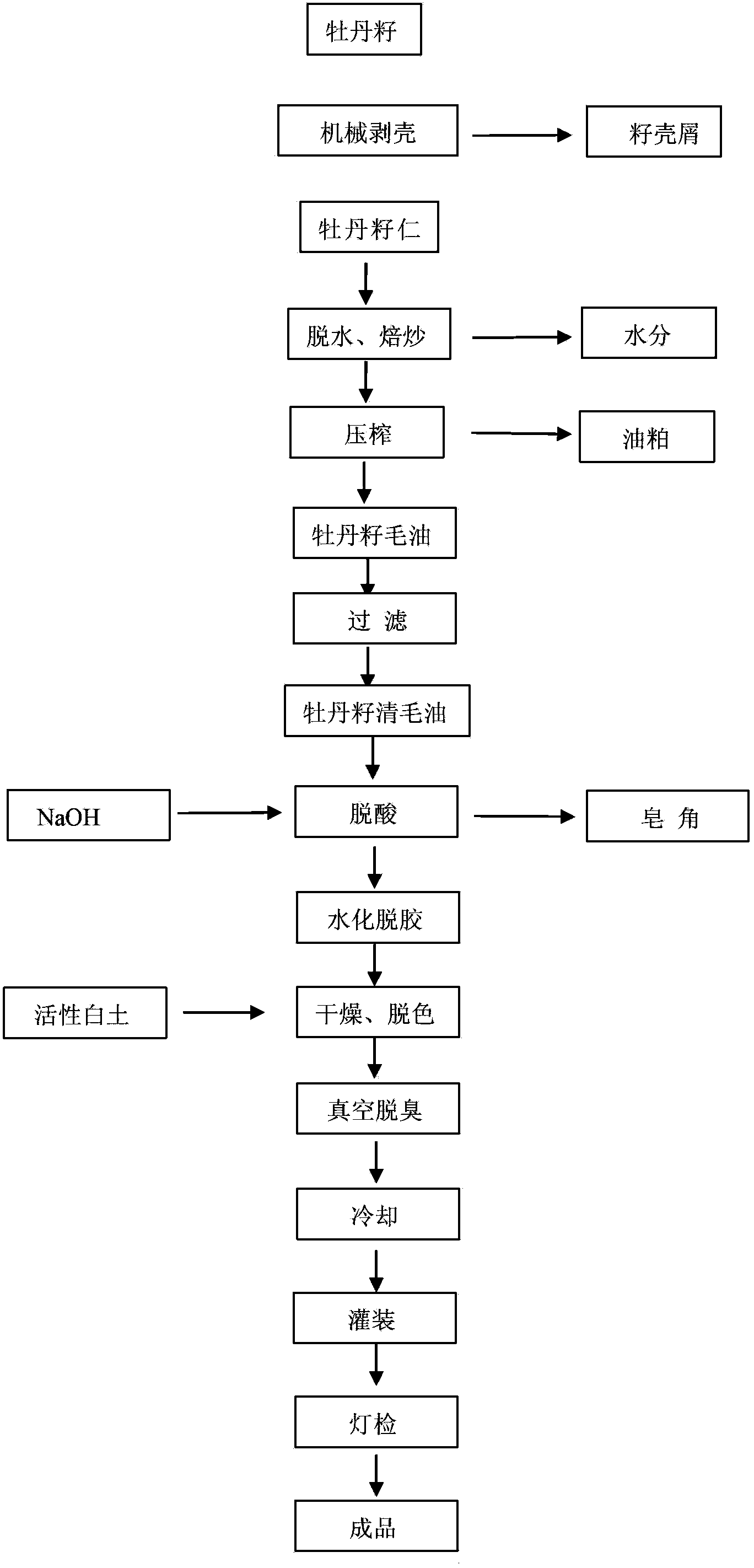

Preparation method of peony seed oil

InactiveCN103416490ALow process equipment requirementsReduce investmentEdible oils/fatsChemistryControllability

A preparation method of peony seed oil comprises the following process flow: 1, preprocessing; 2, squeezing and filtering; 3, precipitating; 4, deacidifying; 5, degumming; 6, drying and decoloring; 7, carrying out vacuum deodorization; 8, carrying out quality inspection, and filling; and 9, carrying out lamp inspection, sealing a case after the products are qualified, and carrying out storage warehousing. The preparation method has the advantages of simplicity, low requirements on a process apparatus, small investment, and easy scale production; and the peony seed oil obtained through the method has a good quality controllability.

Owner:洛阳花瓣舞生物技术有限公司

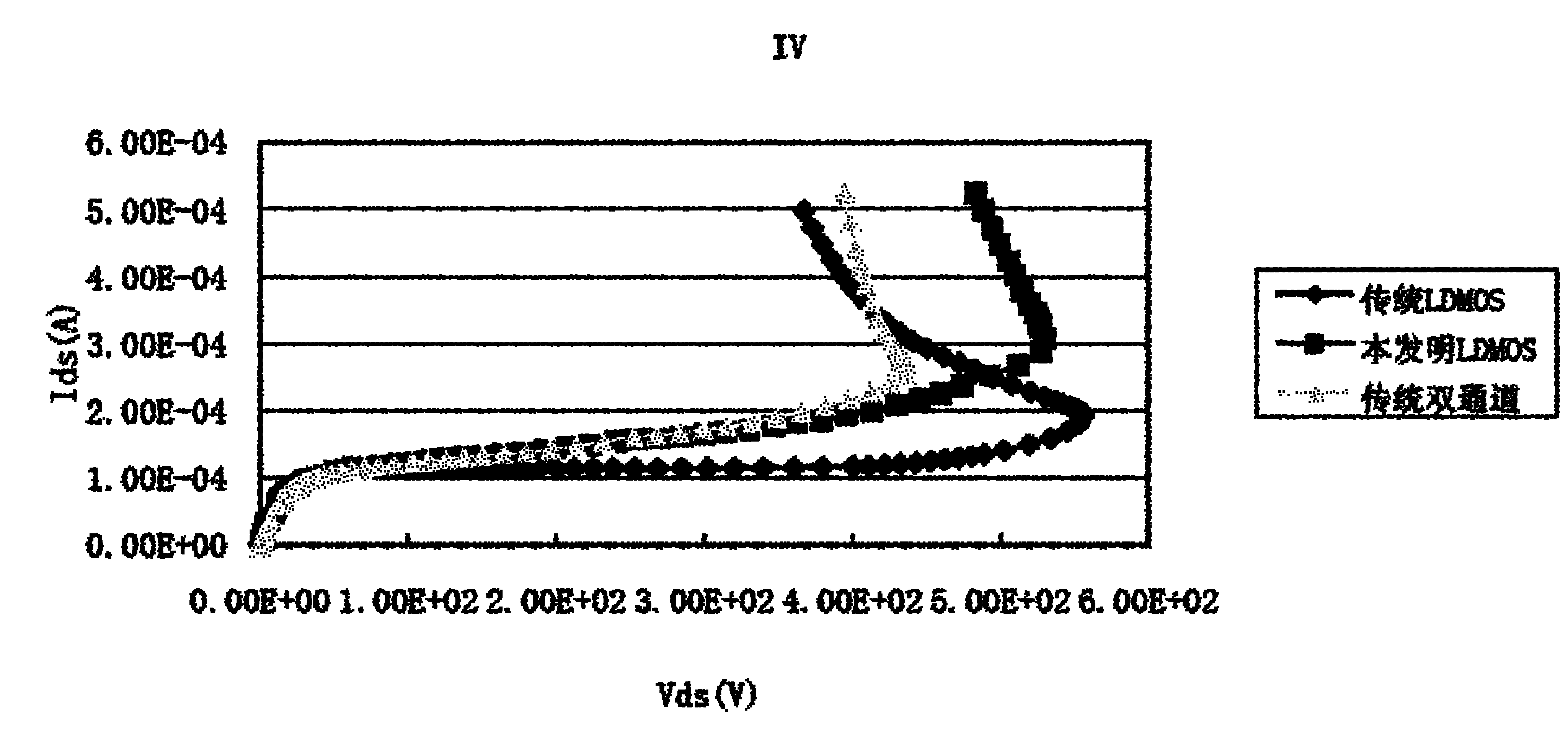

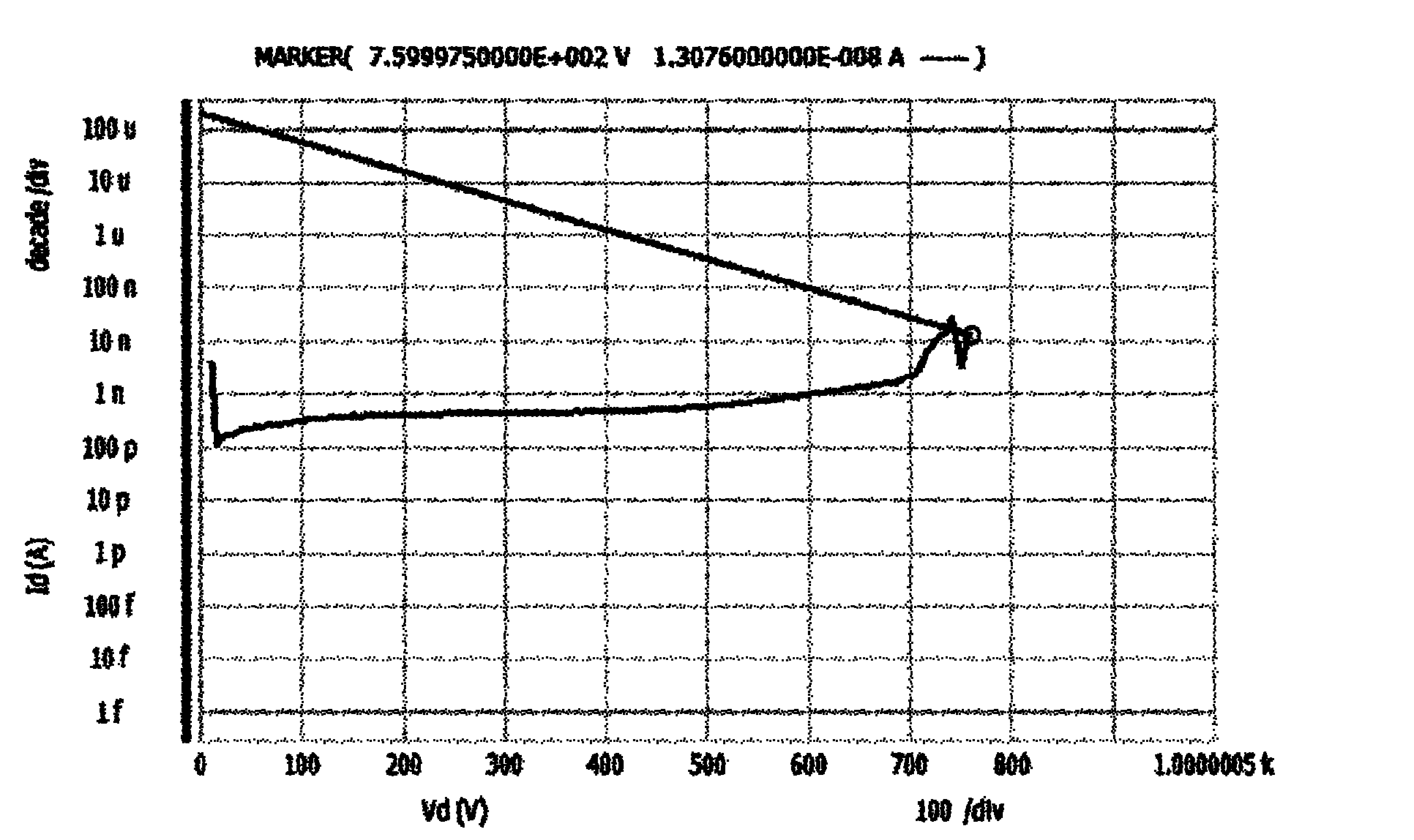

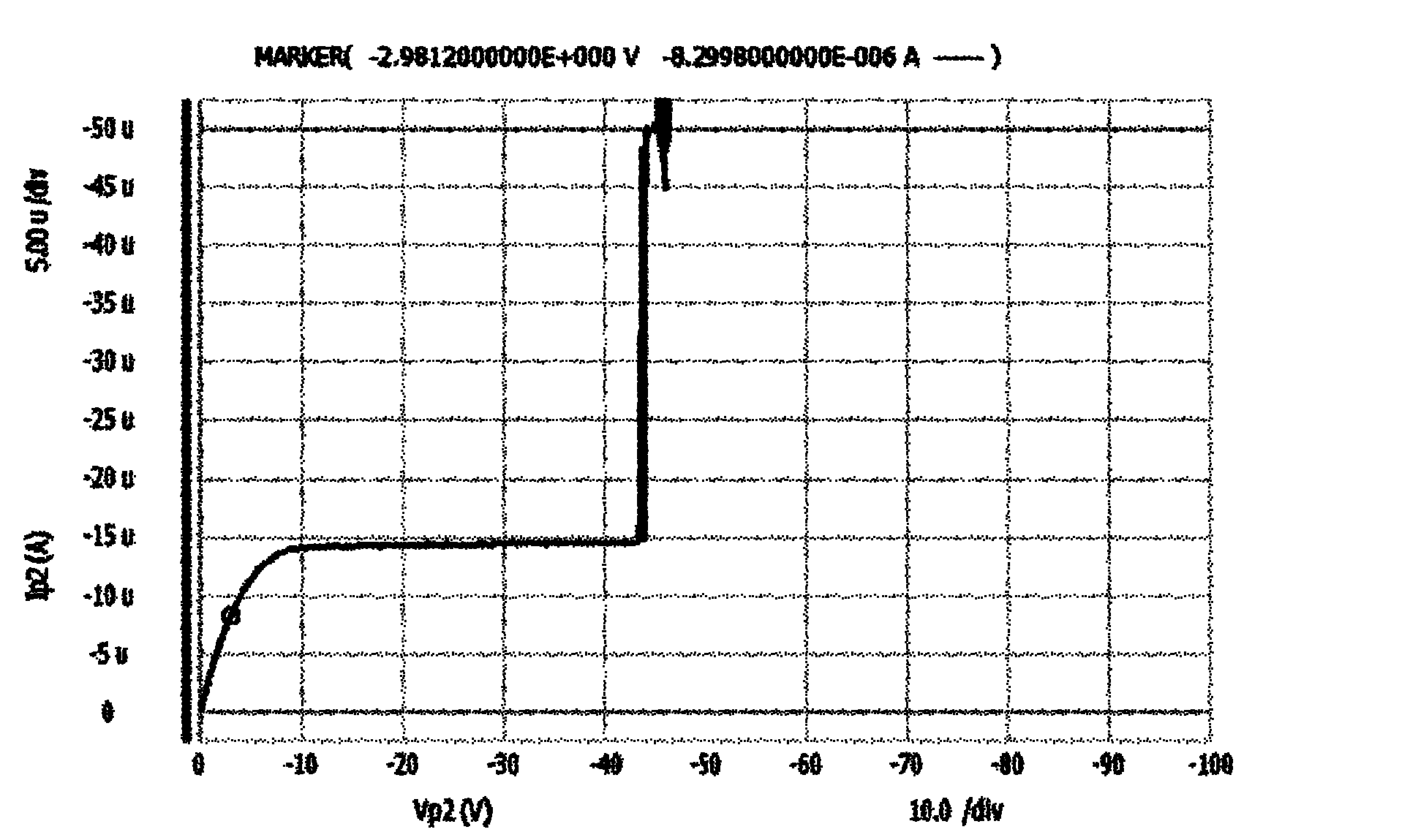

LDMOS (laterally diffused metal oxide semiconductor), semiconductor device integrated with same and manufacturing method thereof

InactiveCN102097389AEasy to integrateThe process steps are simpleSemiconductor/solid-state device manufacturingSemiconductor devicesLDMOSCMOS

The invention discloses an LDMOS (laterally diffused metal oxide semiconductor), a semiconductor device integrated with the LDMOS and a manufacturing method thereof. The semiconductor device comprises an LDMOS 1, a CMOS (complementary metal oxide semiconductor) 2, an NPN 3 and a buried channel resistor 4 which are arranged in a P type substrate 10. The LDMOS 1 comprises an N type drift region 20, a P+ well contact region 40, a P type body region 70, an N+ source region 50, an N+ drain region 60, a gate dielectric layer 100, a source metal 80, a drain metal 90, a field oxidation layer 110 and a metal front medium 120 as well as a P type field reducing layer 30A and at least one P type buried well 30B, wherein no gap is kept between the N type drift region 20 and the P type body region, the P type buried well 30B is arranged below the P type body region 70 and is contacted with the P type body region 70, the P type field reducing layer 30A is arranged below the field oxidation layer 110 and is surrounded by the N type drift region, and a gap is kept between the P type filed reducing layer 30A and the field oxidation layer 110. The LDMOS in the invention has low on resistance and high withstand voltage and is easy to integrate, and the whole manufacturing process of the semiconductor device has simple steps and has low requirement to equipment.

Owner:SHENZHEN CHIP HOPE MICRO ELECTRONICS LTD

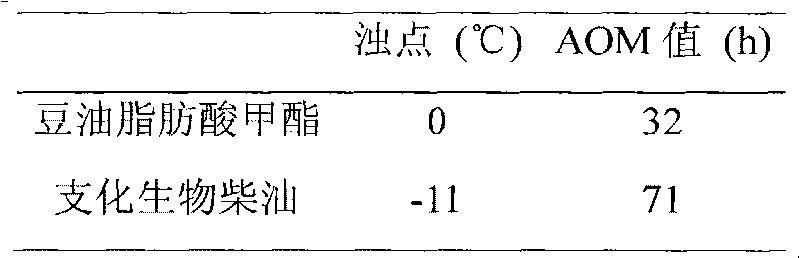

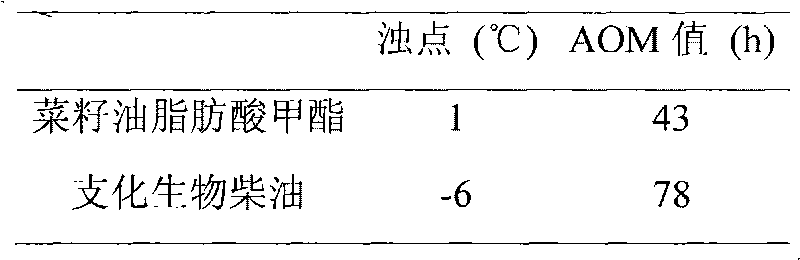

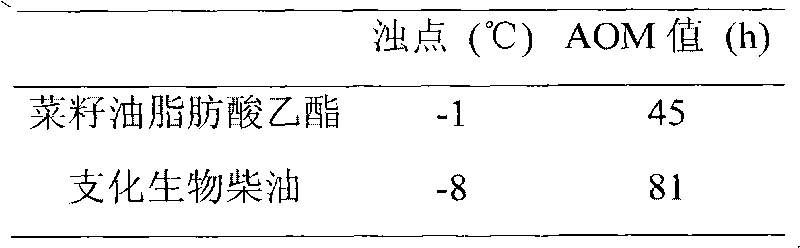

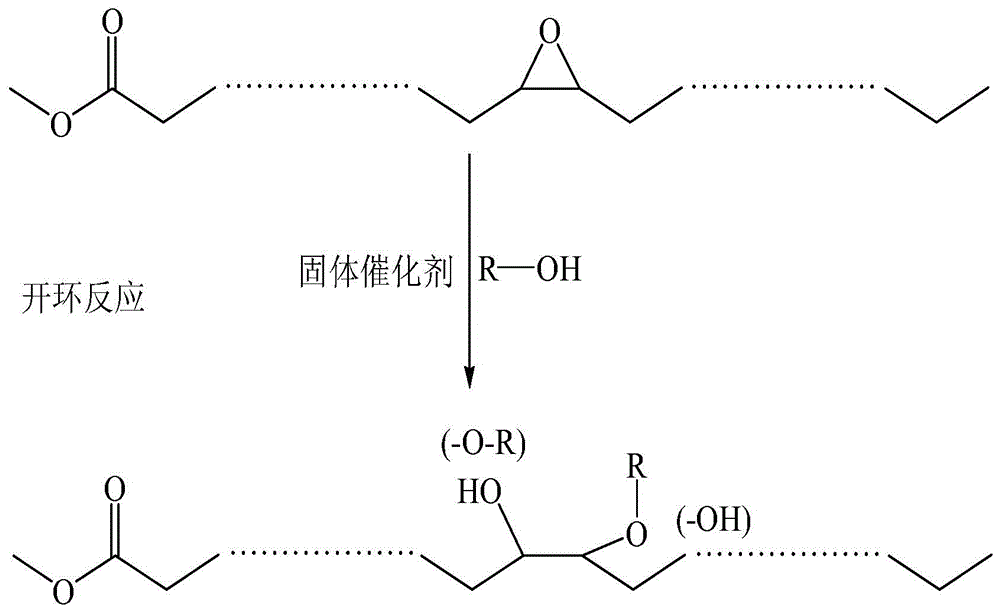

Method for producing branched biodiesel

InactiveCN101760328AImprove oxidation stabilityImprove low temperature fluidityFatty acid isomerisationBiofuelsProcess equipmentBiodiesel

The invention relates to a method for producing branched biodiesel, which belongs to the technical field of new energy production. The method is characterized in that the method adopts two steps of reaction to convert biodiesel into branched biodiesel. In the epoxidation process, biodiesel is mixed with formic acid, stirred and heated, the mixture of catalyst and hydrogen peroxide is dripped, reacted mixture is transferred into a separating funnel after reaction is finished, the upper layer of liquid is taken and washed by water until becoming neutral, and thereby epoxidized biodiesel is obtained; in the ring-opening reaction, the epoxidized biodiesel is mixed with fatty alcohol, added with catalyst and stirred for reaction, 5 percent of Na2CO3 is added, mixture is washed and then poured into the separating funnel, so that an ester layer is separated out, and after low-boiling point components are evaporated, the branched biodiesel is obtained. The invention improves the oxidative stability and low-temperature fluidity of biodiesel at the same time, has the advantages of low requirement on processing equipment, simple operation, mild reaction condition and the like, and is suitable for industrialized mass production.

Owner:DALIAN UNIV OF TECH

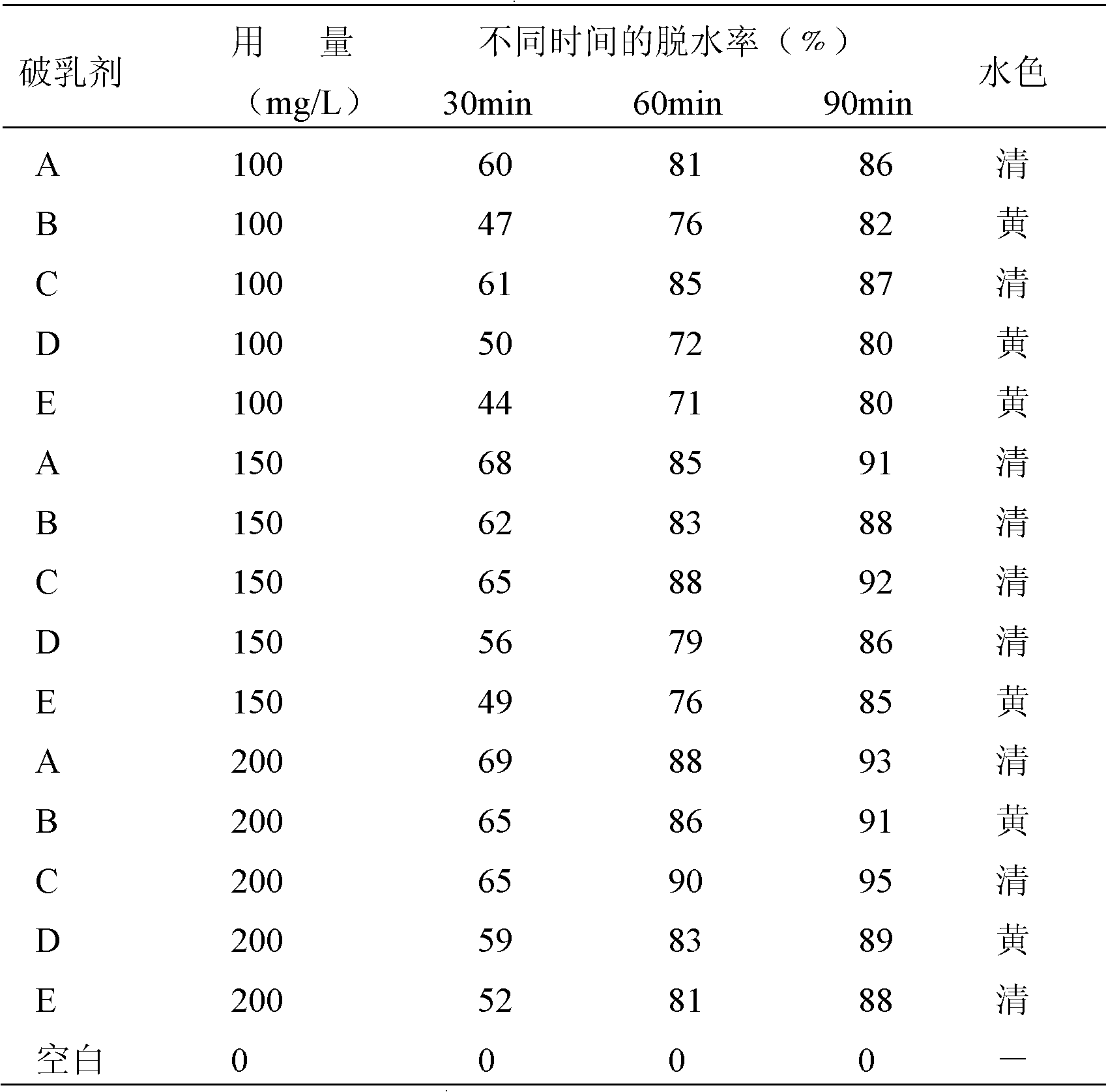

Quick petroleum deemulsifier and preparation method thereof

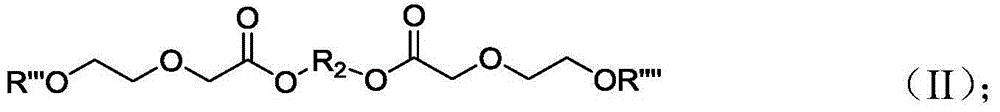

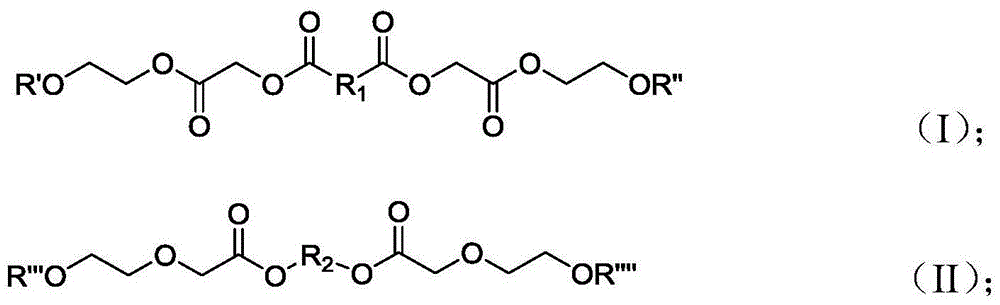

ActiveCN102533314AEasy to operateLow process equipment requirementsDewatering/demulsification with chemical meansPolyethylene polyamineChemistry

The invention discloses a quick petroleum deemulsifier and a preparation method thereof. The method comprises the following steps of: (1) performing esterification reaction on polyethylene polyamine, nonylphenol ethoxylates, and diethanol amine polyether with acryloyl chloride respectively to obtain acrylic acid polyethylene polyamine polyether ester, acrylic acid nonylphenol polyether ester, and acrylic acid diethanol amine polyether ester respectively; and (2) performing free radical polymerization reaction on the acrylic acid polyethylene polyamine polyether ester, acrylic acid nonylphenol polyether ester, acrylic acid diethanol amine polyether ester, methacrylic acid, and butyl acrylate in water in presence of initiator under the anaerobic condition, and performing termination reaction by using a terminator to obtain the quick petroleum deemulsifier. The deemulsifier has high dehydration rate in a very short time period, and is suitable for development of offshore oil fields; and the preparation method has the characteristics of low requirement on processing equipment and is easy to operate.

Owner:CHINA NAT OFFSHORE OIL CORP +1

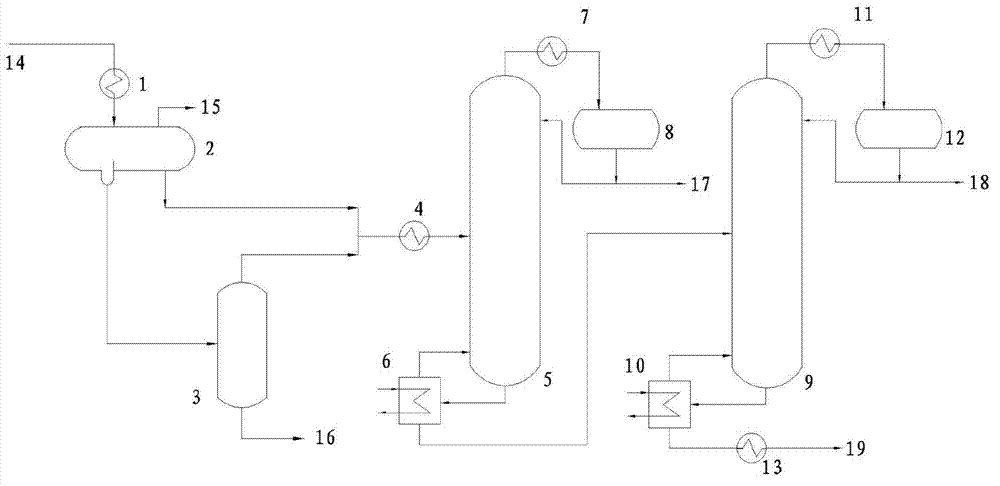

Method for separating benzene/toluene and methanol-alkylated reaction product

InactiveCN102731243AReduce gas loadThe amount of acetic acid decreasedDistillation purification/separationHydrocarbonsBenzeneToluene

The invention discloses a method for separating benzene / toluene and a methanol-alkylated reaction product. The method comprises the steps of: condensing the alkylated reaction product and separating a water phase and an oil phase from the condensed alkylated reaction product by an oil-water separation tank; making the water phase enter an efficient oil-water separator to be subjected to deep separation so as to separate the oil phase and the water phase; making the oil phase separated by the oil-water separator and the efficient oil-water separator enter an equal-diameter benzene / toluene tower to rectify to separate; returning the components on the top of the benzene / toluene tower to a reactor for continuously reacting or discharging out the components as process products from the benzene / toluene tower; making the components on the bottom of the tower continuously enter a dimethylbenzene rectification tower to rectify; and, finally separating the dimethylbenzene product. The process provided by the invention reduces the rectification need of benzene / toluene in the equipment. A separation process of alkylated reaction products that reduces the investment cost of the equipment is provided. The rectification efficiency and the recovery rate of the products are enhanced.

Owner:NINGXIA BAOTA PETROCHEM GROUP

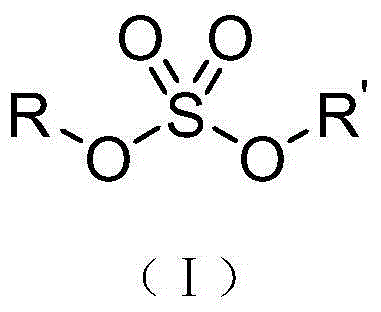

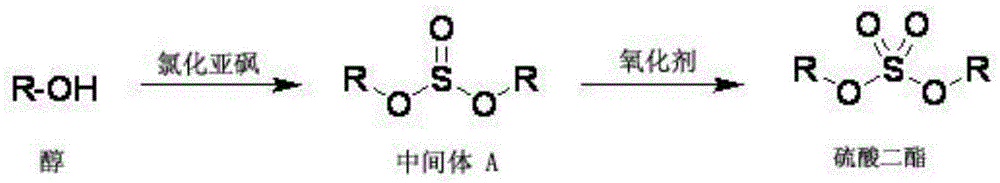

Method for compounding high-purity sulfuric acid esters

InactiveCN104945286ARaw materials are easy to getLow costSulfuric acid esters preparationProcess equipmentAlcohol

The invention discloses a method for compounding high-purity sulfuric acid esters, wherein alcohol and thionyl chloride react to generate a midbody A, the midbody A is reacted in oxidizing agents to generates sulfuric acid esters. The method for compounding the high-purity sulfuric acid esters has the beneficial effects that the method for compounding the high-purity sulfuric acid esters use the alcohol, the thionyl chloride and the oxidizing agents as raw materials, wherein the alcohol, the thionyl chloride and the oxidizing agents are easy to obtain, and are low in cost. The method for compounding the high-purity sulfuric acid esters is high in selectivity, does not have side effect, is high in yield and strong in universality, and is suitable for all complex high grade sulfuric acid esters. The method for compounding the high-purity sulfuric acid esters is simple in production operation, is low in demands on process equipment, does not have corrosivity, does not need strict production conditions such as high pressure high temperature or high pressure low temperature and the like, is easy for industrial scale production and small in pollution to environment, and accords with environmental protection requirements of green production.

Owner:CHENGDU BAISHIXING SCI & TECH IND

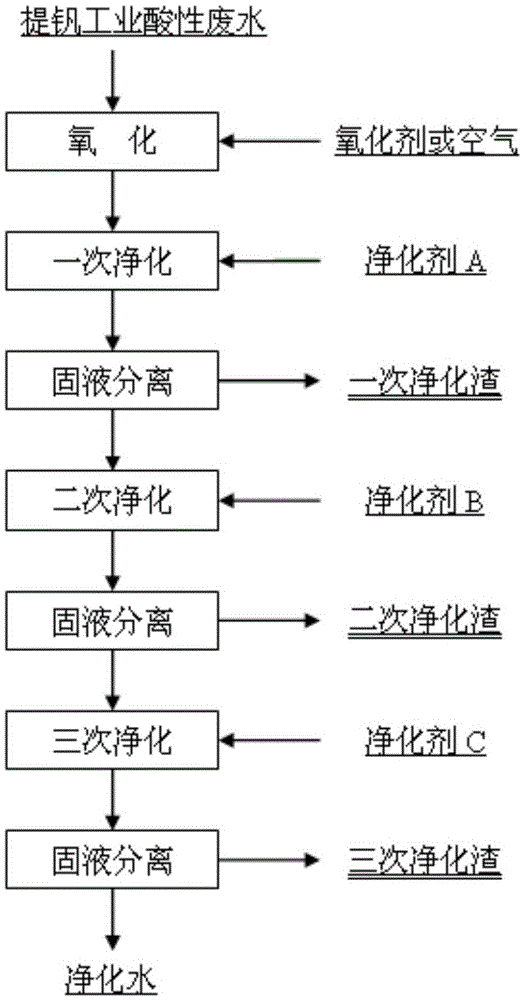

Method for treating vanadium extracting industrial acid wastewater and comprehensively recycling valuable metal

ActiveCN105567976AControl parameters are clearly definedEasy to controlCalcium/strontium/barium sulfatesCement productionWastewaterBarium sulfide

The invention discloses a method for treating vanadium extracting industrial acid wastewater and comprehensively recycling valuable metal. The method comprises the following steps that aeration and oxidation are carried out on the acid wastewater, and then a purifying agent A is added and is at least one of limestone, unslaked lime, slaked lime and lime milk; stirring is carried out for reacting, and the pH of the reaction endpoint is controlled to be equal to 4.5 to 5.0; filtering and washing are carried out, and primary purifying liquid and primary purifying residues are obtained; a purifying agent B is added to the primary purifying liquid, and is at least one of unslaked lime, slaked lime and lime milk; stirring is carried out for reacting, and the pH of the reaction endpoint is controlled to be equal to 6.5 to 7.5; filtering and washing are carried out, and secondary purifying liquid and secondary purifying residues are obtained; and a purifying agent C is added to the secondary purifying liquid and is at least one of sodium dimethyldithiocarbamate (SDD), sodium sulfide and barium sulfide, stirring is carried out for reacting, filtering is carried out, and third purifying liquid and third purifying residues are obtained. The method has the beneficial effects of being simple in process step, low in treatment cost, good in valuable metal comprehensive recovery effect and the like.

Owner:SHENGTONG YIHE TIANJIN ENTERPRISE MANAGEMENT CONSULTING CO LTD

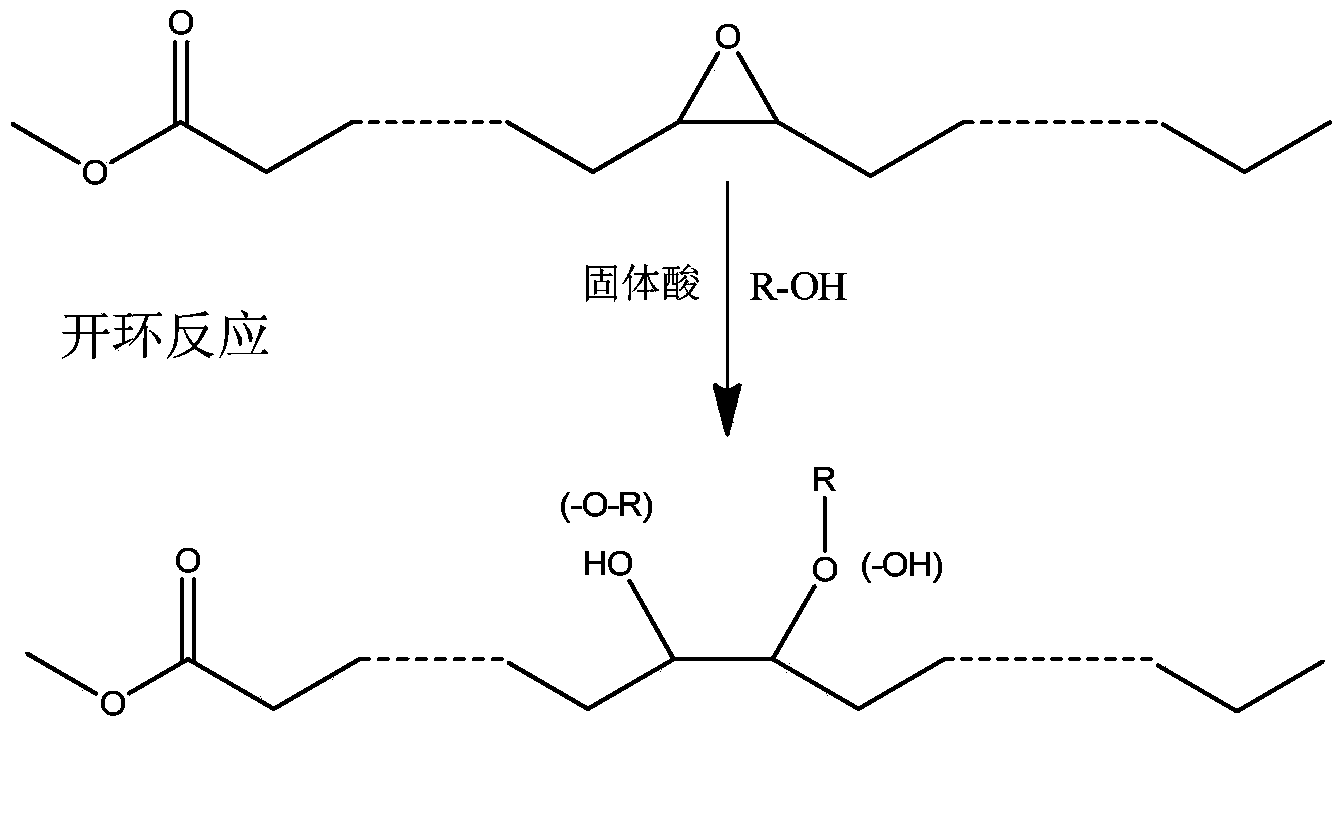

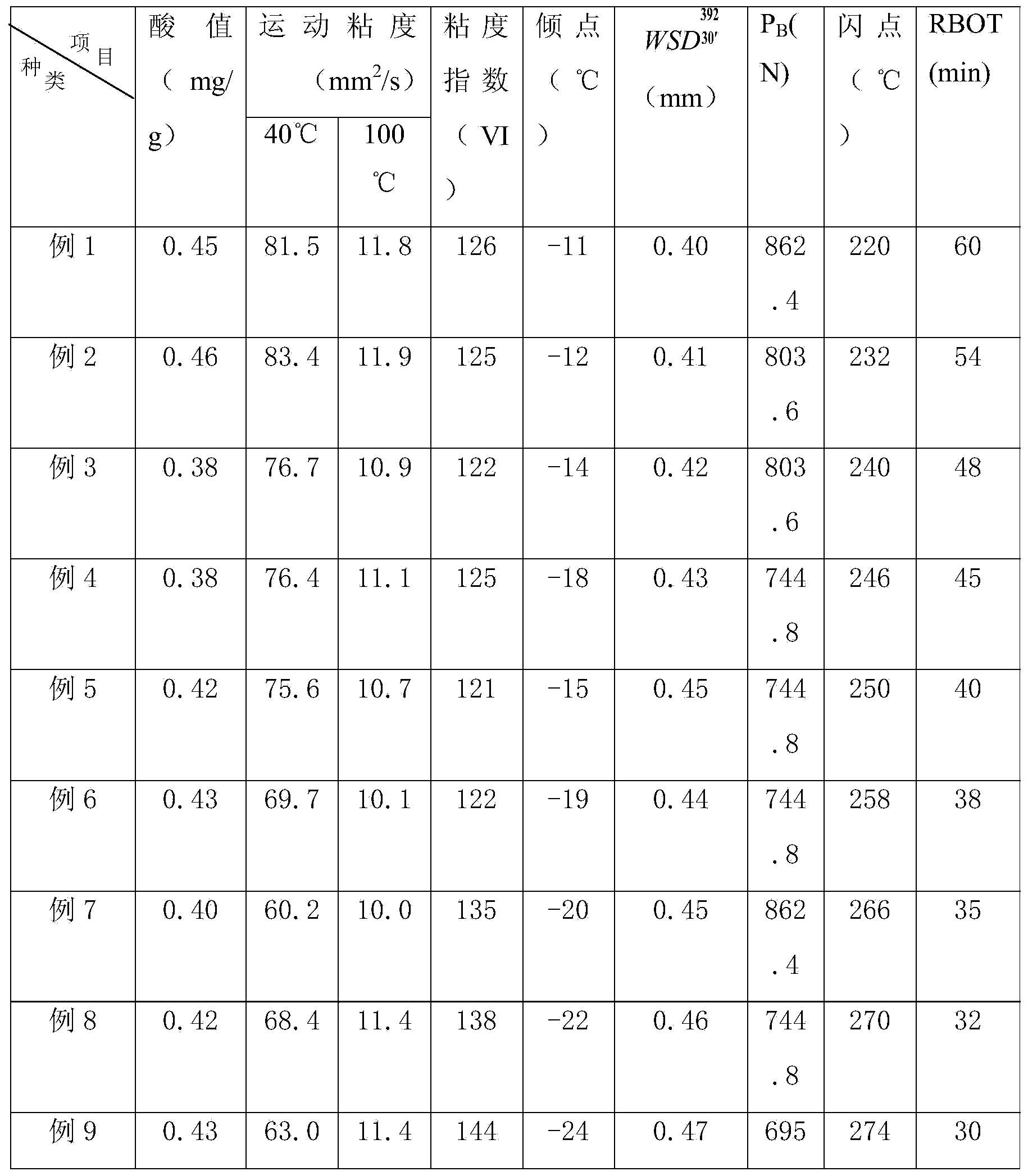

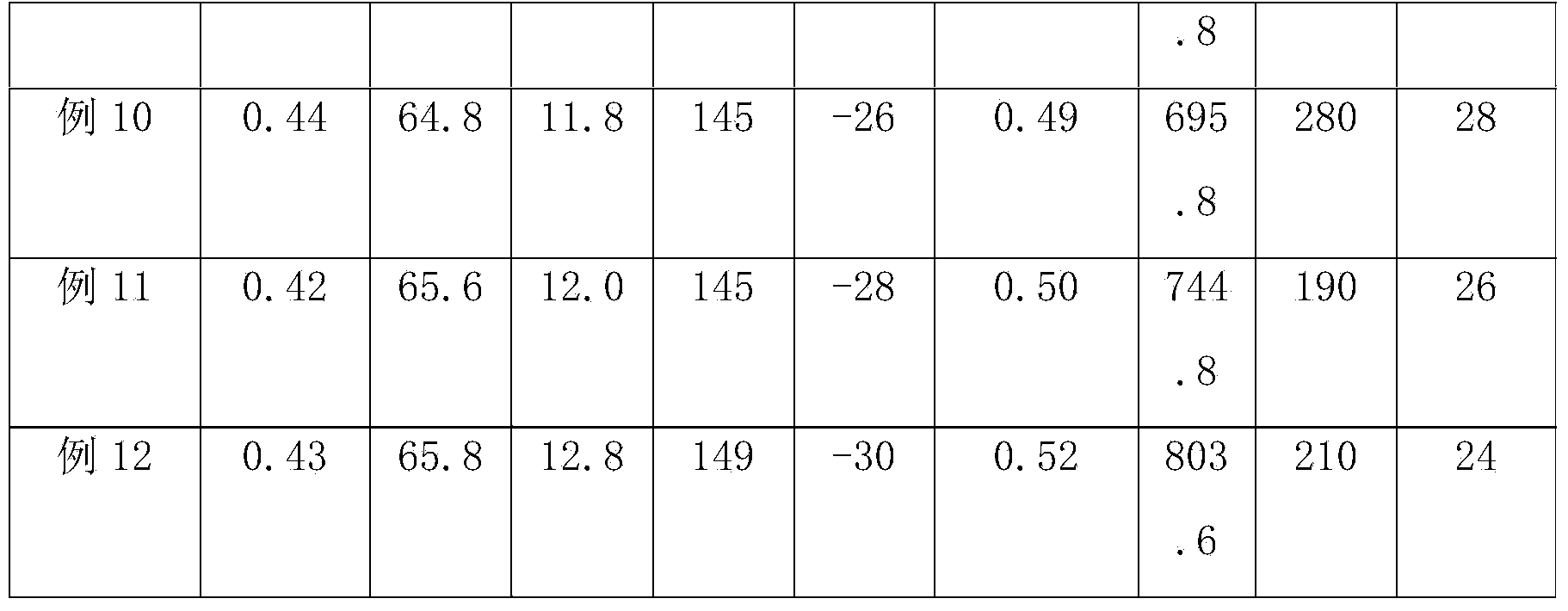

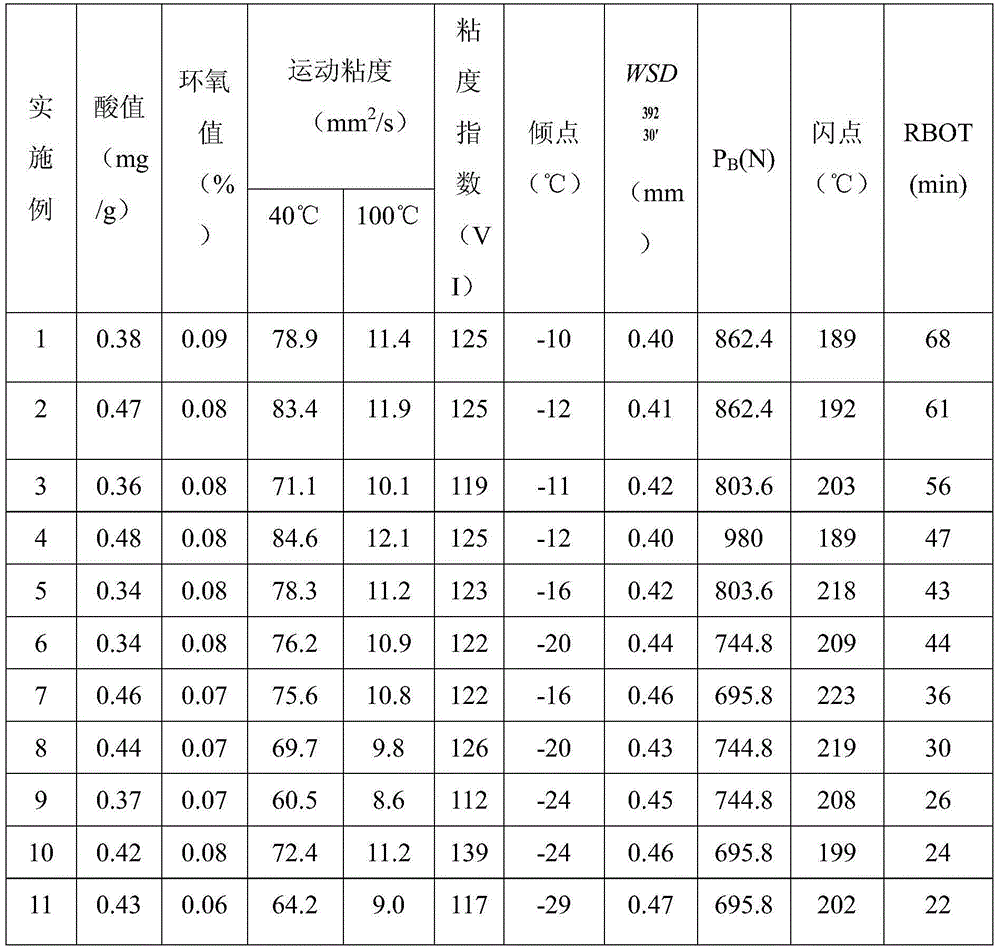

Preparation method for alcohol ether type environment-friendly lubricant base oil

ActiveCN103805308AGood physical and chemical propertiesHigh catalytic activityBase-materialsEpoxyBiodiesel

The invention belongs to the technical field of lubricant modification technique, and particularly relates to a preparation method for alcohol ether type environment-friendly lubricant base oil. The preparation method comprises the steps: putting fatty alcohol and supported heteropoly acid catalyst into a four-neck flask with a condensed pipe and a thermometer, stirring and backflowing under the heating condition, then adding epoxy biodiesel, carrying out ring-opening reaction under the heating condition, determining the epoxy value of a reaction system in the reaction process, stopping reaction when the epoxy value is less than 0.08, cooling the reaction system to room temperature, performing suction filtration to recover the supported heteropoly acid catalyst, putting the filtrate into a separating funnel, washing to be neutral, and then performing decompression distillation, finally to obtain isomerized grease alcohol ether.

Owner:SHANDONG XINGQIANG CHEM IND TECH RES INST CO LTD

Low-alcohol probiotics beverage and processing method thereof

InactiveCN105316158ALow costLow process equipment requirementsAlcoholic beverage preparationFruit juiceSaccharomyces

The invention discloses low-alcohol probiotics beverage and a processing method thereof. The method includes: processing fruit to obtain clear fruit juice, processing with a pulse electric field with the frequency being 10-30Hz and electric field intensity being 30-40 kV / cm for 100-200 microseconds, and processing with ultrasonic waves with the frequency being 30-50kHz for 20-40 seconds to obtain processed juice; mixing lactobacillus bulgaricus, streptococcus thermophilus, lactobacillus casei and lactobacillus plantarum to obtain mixed lactic acid bacteria, and fermenting at 30-50 DEG C for 8-24 hours to obtain lactic acid concentrate, wherein the mass ratio of lactobacillus bulgaricus to streptococcus thermophilus to lactobacillus casei to lactobacillus plantarum is 1-2 to 1-3 to 1-2 to 2-3; processing the lactic acid concentrate with the ultrasonic waves with the frequency being 30-40kHz for 10-20 seconds, adding 200-400mg / L of saccharomyces cerevisiae into the lactic acid concentrate to perform alcoholic fermentation at 10-20 DEG C for 25-40 days, and filtering with a 0.45-micrometer filter membrane after the fermentation to obtain the low-alcohol probiotics beverage. The produced low-alcohol probiotics beverage is rich in various probiotics such as the lactic acid bacteria and saccharomyces cerevisiae and has typical fruit and lactic acid fragrance, and fragrance substances in fermented wine are well kept.

Owner:HUIZHOU UNIV

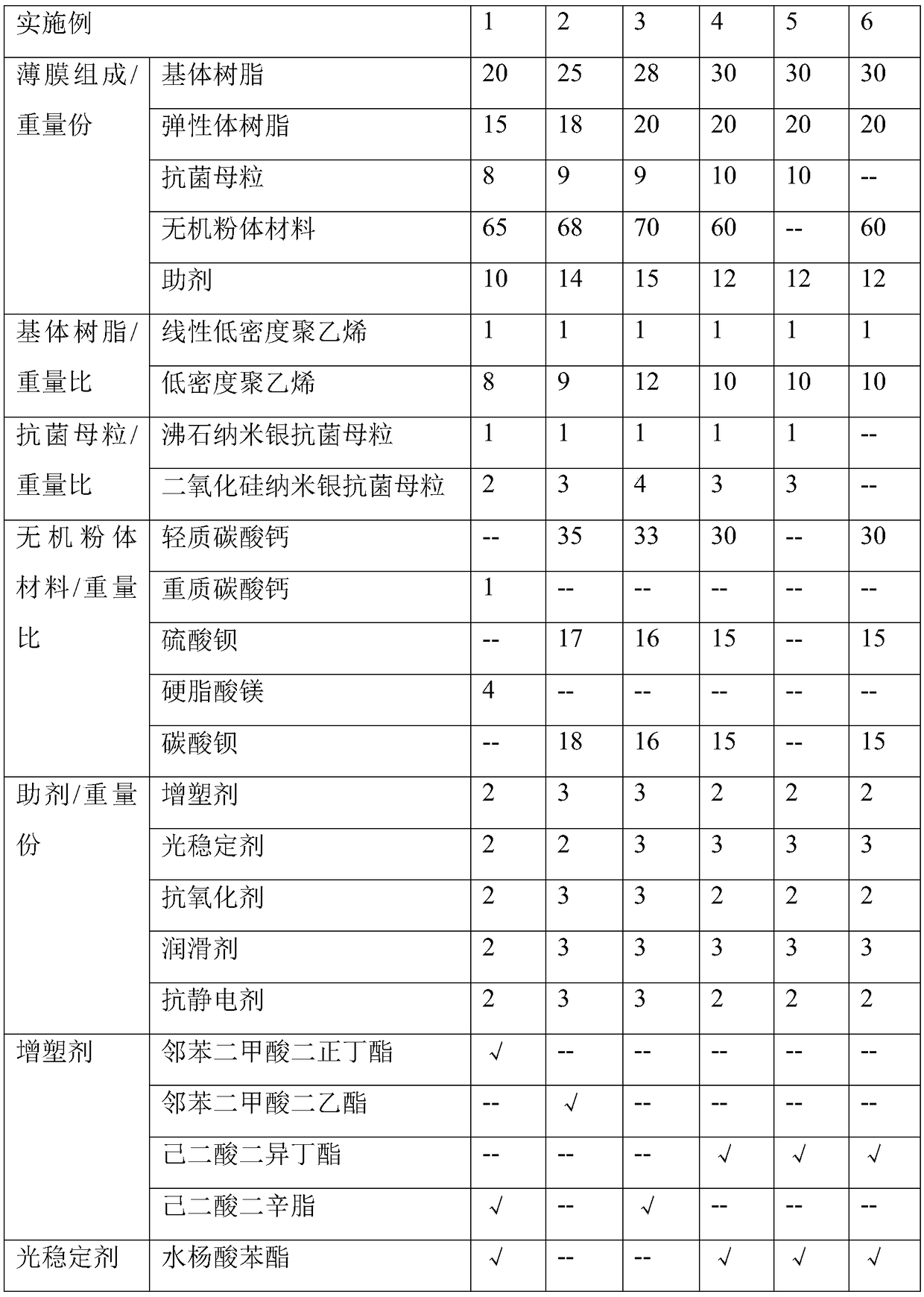

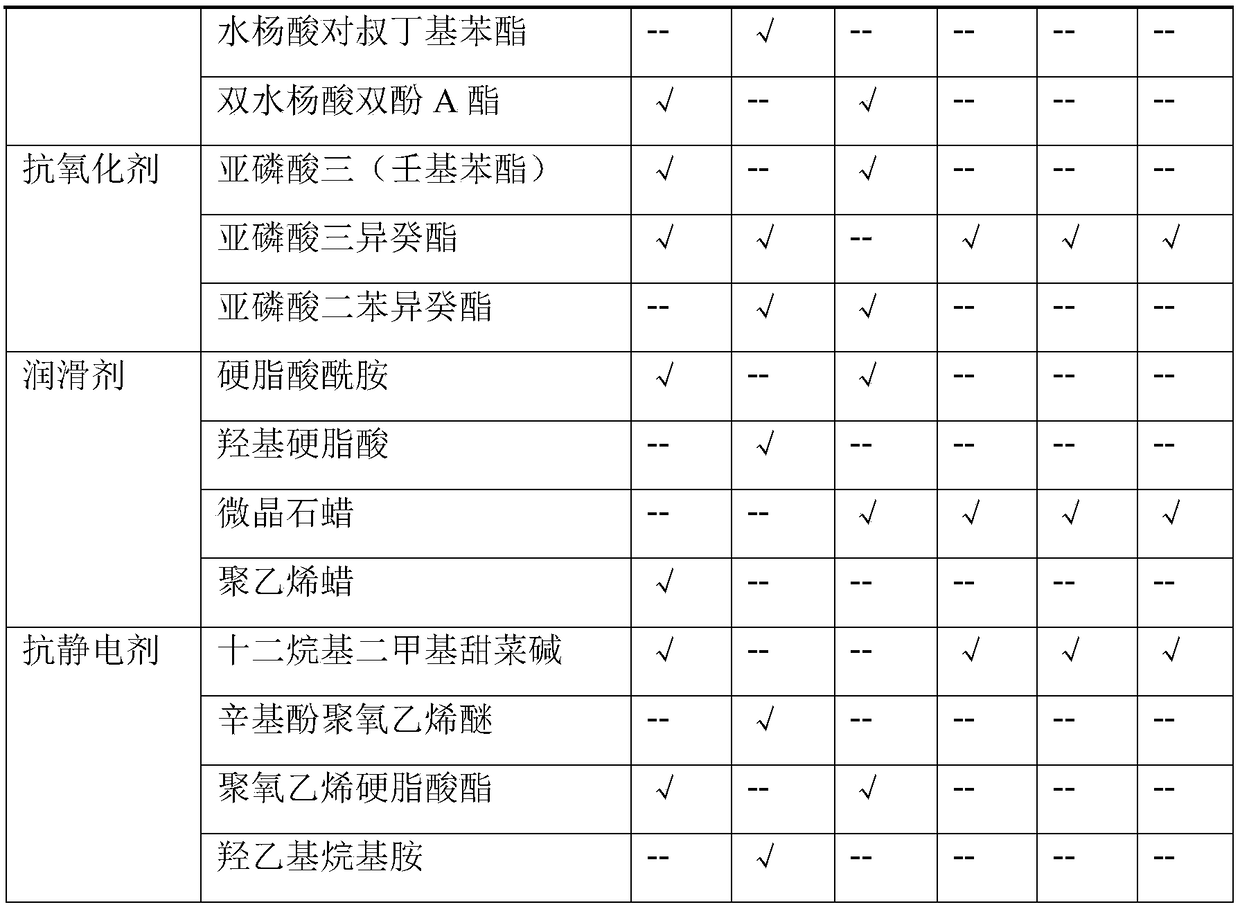

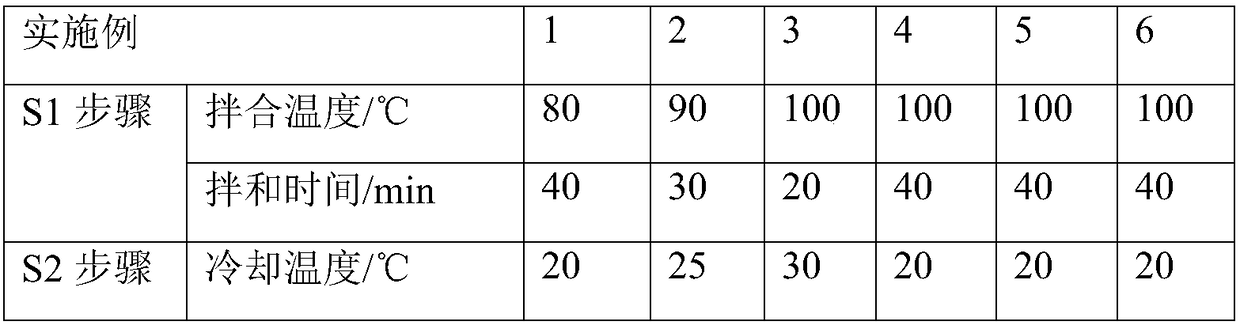

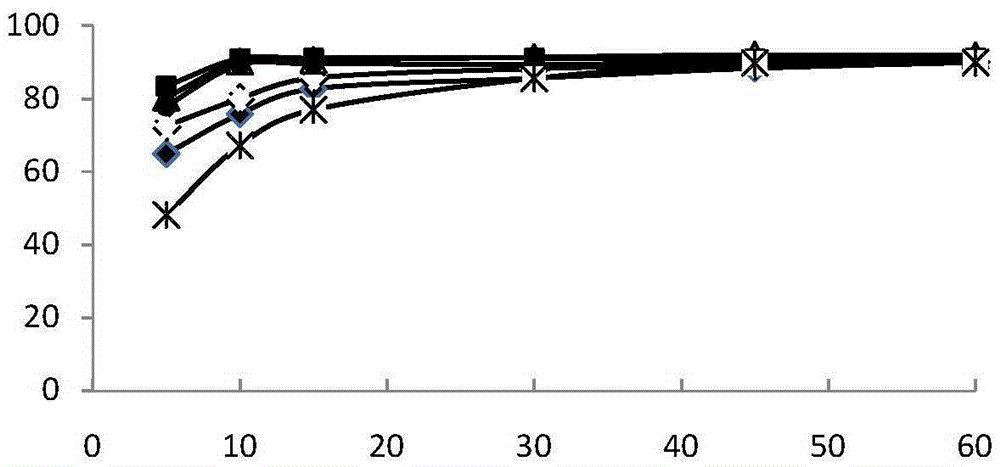

Waterproof and air-permeable elastic film and preparation method thereof

The invention relates to a waterproof and air-permeable elastic film and a preparation method thereof. The elastic film contains the following components: matrix resin, elastomer resin, an antibacterial master batch, an inorganic powder material and an aid. The preparation method comprises the following steps: (S1) crushing the inorganic powder material, adding the matrix resin, the elastomer resin, the antibacterial master batch, and the crushed inorganic powder material into a high-speed kneading machine, stirring, adding the mixture into a double screw granulator, and carrying out granulation, extrusion, grain dicing and cooling, so as to obtain a resin master batch for later use; and (S2) uniformly mixing the resin master batch obtained in the step (S1) with the aid, carrying out internal mixing and plastification so as to obtain a sizing material, filtering, carrying out calendering by virtue of a calendering machine, carrying out cooling shaping by virtue of a cooling wheel set,and carrying out clipping and reeling, so as to obtain the elastic film. The prepared elastic film has the waterproof and air-permeable properties and has the advantages of good waterproof and air-permeable properties and antibacterial effect and simple preparation process.

Owner:宁波爱克创威新材料科技有限公司

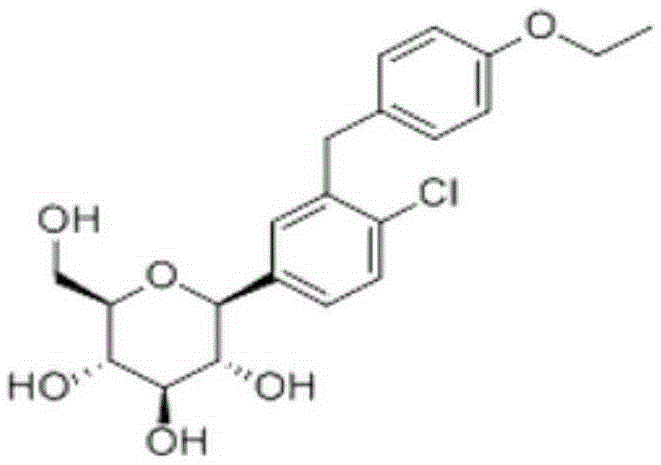

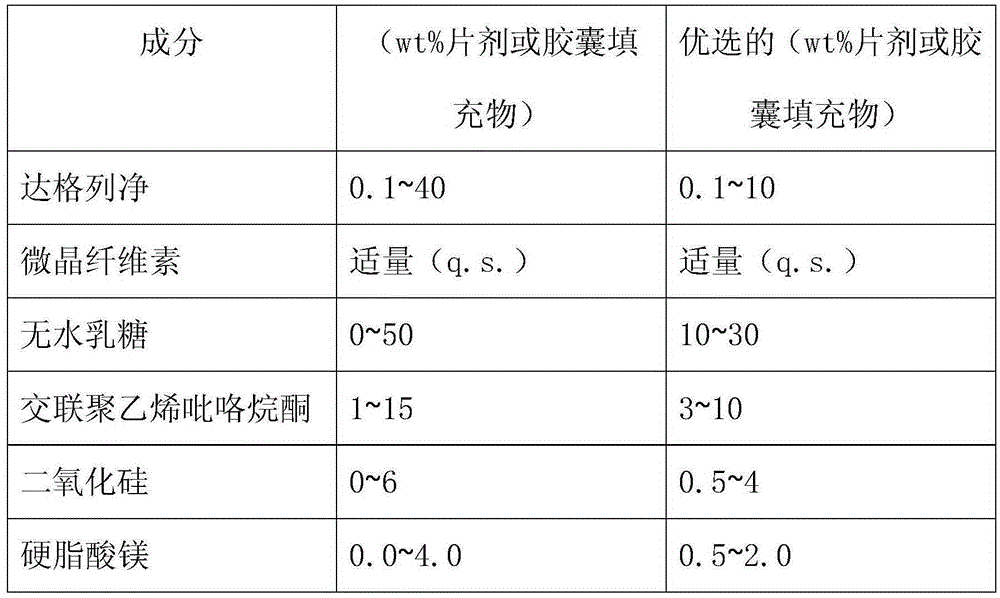

Dapagliflozin medicinal composition and preparation method thereof

InactiveCN106727368ANon-fibrousLiquidityOrganic active ingredientsMetabolism disorderMedicineAdhesive

The invention provides a dapagliflozin medicinal composition. The dapagliflozin medicinal composition is characterized by consisting of the following components in percentage by mass: 1 to 95 percent of a dapagliflozin and microcrystalline cellulose composition, 0 to 95 percent of a filling agent / an adhesive, 0 to 20 percent of a disintegrant, 0.1 to 5 percent of a lubricating agent and 0 to 10 percent of a flow aid. According to the dapagliflozin medicinal composition, microcrystalline cellulose serves as a carrier material; according to a method provided by the invention, the dapagliflozin and microcrystalline cellulose are mixed and heated so that the dapagliflozin is molten; the dapagliflozin covers the surface of the microcrystalline cellulose in a liquid form; after the dapagliflozin is cooled, the dapagliflozin is solidified on the surface of the microcrystalline cellulose to form a dapagliflozin and microcrystalline cellulose compound; the specific surface area of the dapagliflozin is increased, so that the medicine dissolving speed can be improved and the quality is stable; the preparation method provided by the invention is simple and feasible, and is suitable for industrial production.

Owner:SHANGHAI SUNTECH PHARMA

Semi-solid flow variable rheolytic pressure casting forming method for flame-retardant magnesium alloy

InactiveCN108315621AImprove mechanical propertiesImprove flame retardant performanceCombustionPressure casting

The invention provides a semi-solid flow variable rheolytic pressure casting forming method for a flame-retardant magnesium alloy. The alloy comprises the following components of , by mass, 6.5- 9.5 wt% of Al, 0.5-2.5 wt% of Zn, 0.5-2.5 wt% of Y, 0.2-2 wt% of Ca, 0.5-1.5 wt% of Ce and the balance Mg. The method comprises the following steps of preparation of flame-retardant magnesium alloy semi-solid slurry and semi-solid rheological pressure casting. According to the semi-solid flow variable rheolytic pressure casting forming method, three elements of Y, Ca and Ce are simultaneously added into Mg-Al-Zn, oxidation and combustion of the magnesium alloy can be further prevented, so that the strength and the heat treatment strengthening effect of the magnesium alloy are improved; filling andsolidification are carried out under a low-pressure high-speed condition through a pressure casting process, the semi-solid slurry flows in a laminar flow mode during the filling process, so that theoverall structure of the casting is compact, the surface quality is high, and the room temperature mechanical property of the obtained flame-retardant magnesium alloy is excellent.

Owner:SHANGHAI JIAO TONG UNIV

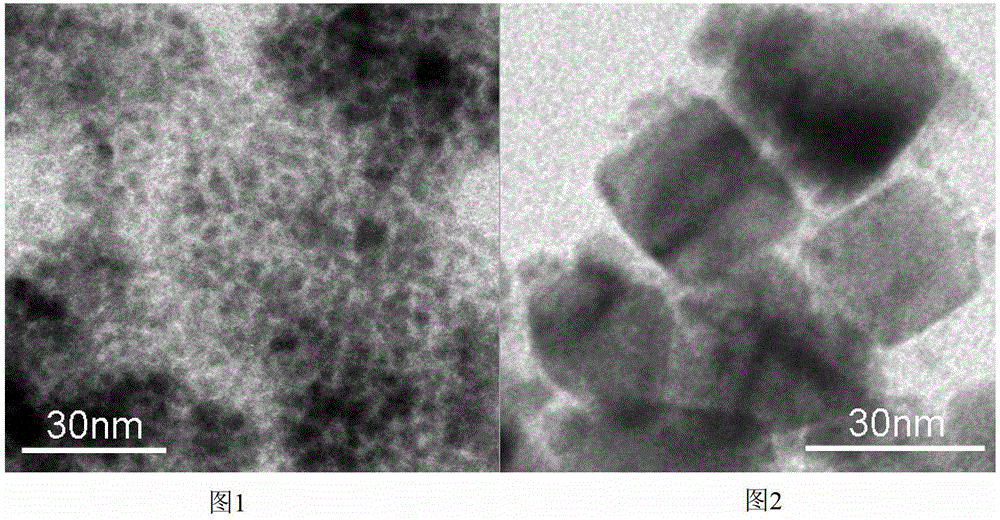

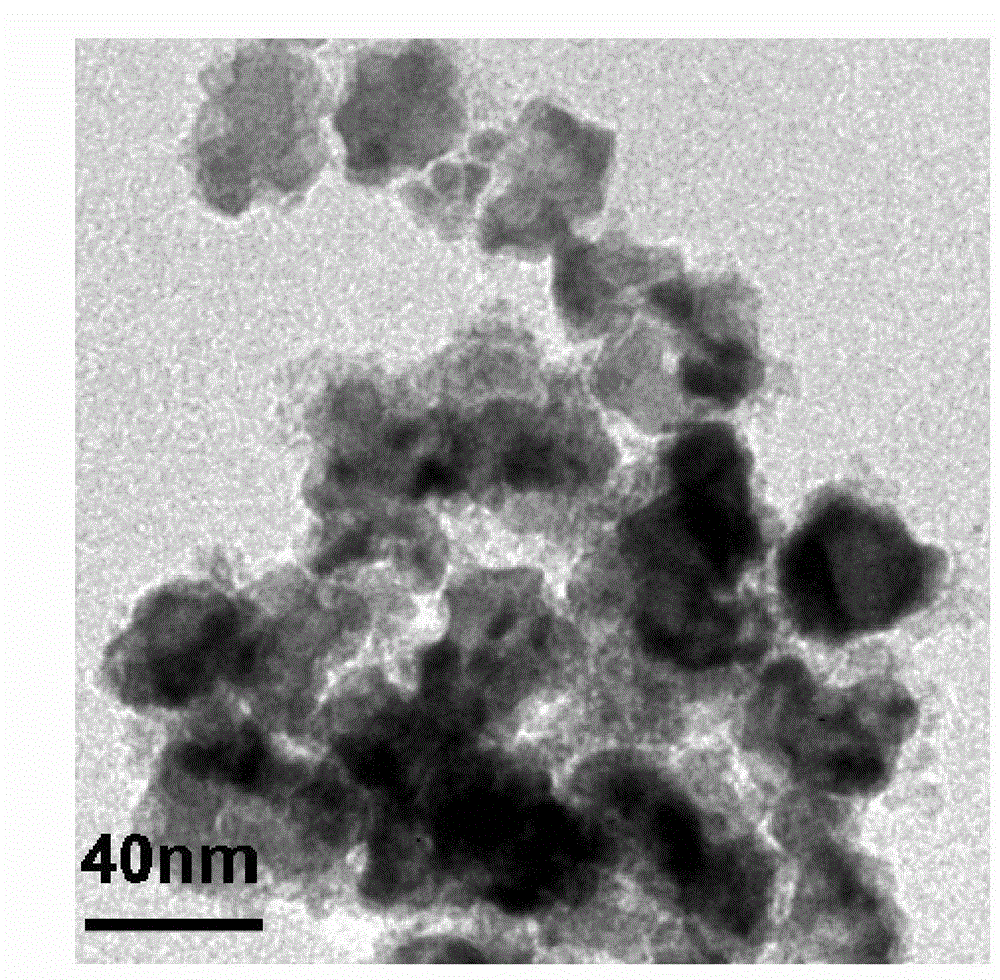

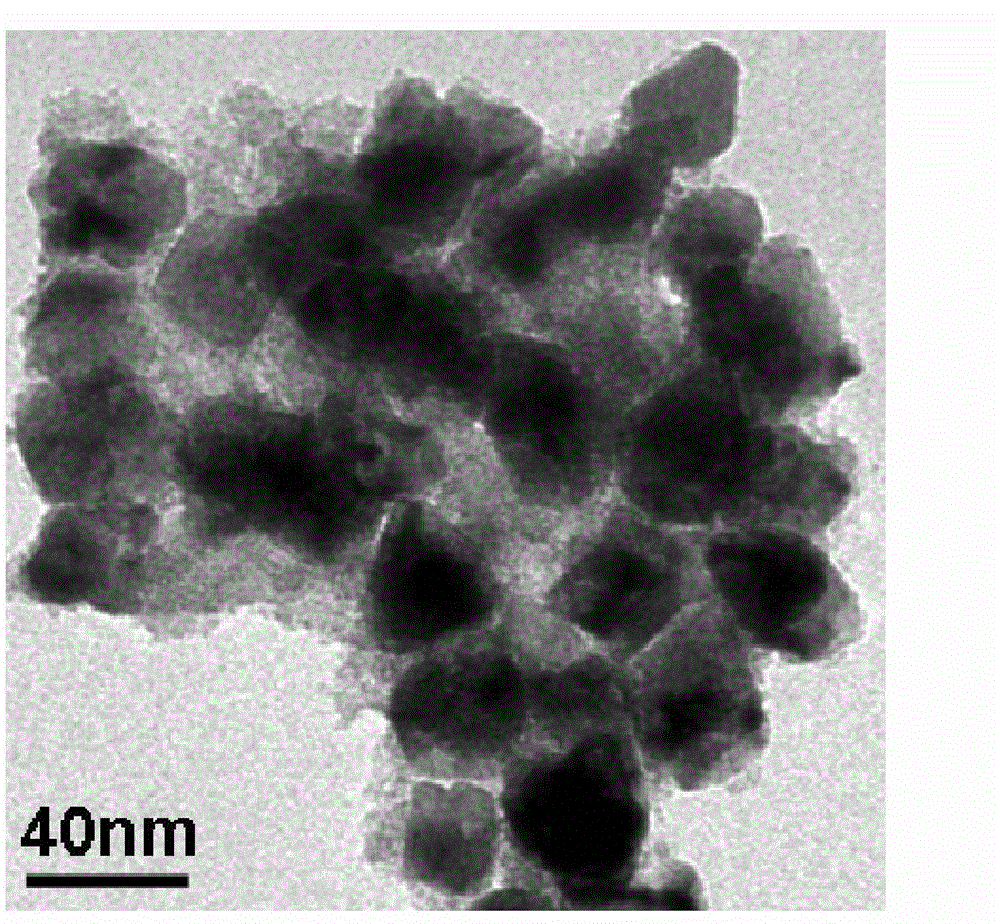

Method for preparing nanometer Pd electrocatalyst

InactiveCN102872860AShape is easy to controlGood size controlCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsNanotechnologyHexagonal phase

The invention discloses a method for preparing a nanometer Pd electrocatalyst. The method comprises a hexagonal phase lyotropic liquid crystal preparation process, a Pd salt precursor reduction process and a unit aftertreatment process; and the shape of the generated nanometer Pd can be regulated and controlled by changing reaction time, illumination intensity and the like. By the method, the shape and the size of the prepared nanometer Pd electrocatalyst can be controlled and regulated; nanometer Pd electrocatalysts with controllable sizes and shapes are obtained according to different reaction time and bulb power; and the method is suitable for preparing electro-catalysis formaldehyde and other organic small molecular electrocatalysts. The preparation method is mild in condition, simple in process, short in production period and uniform in product and makes the nanometer Pd electrocatalyst easily produced on a large scale.

Owner:ANHUI UNIV OF SCI & TECH

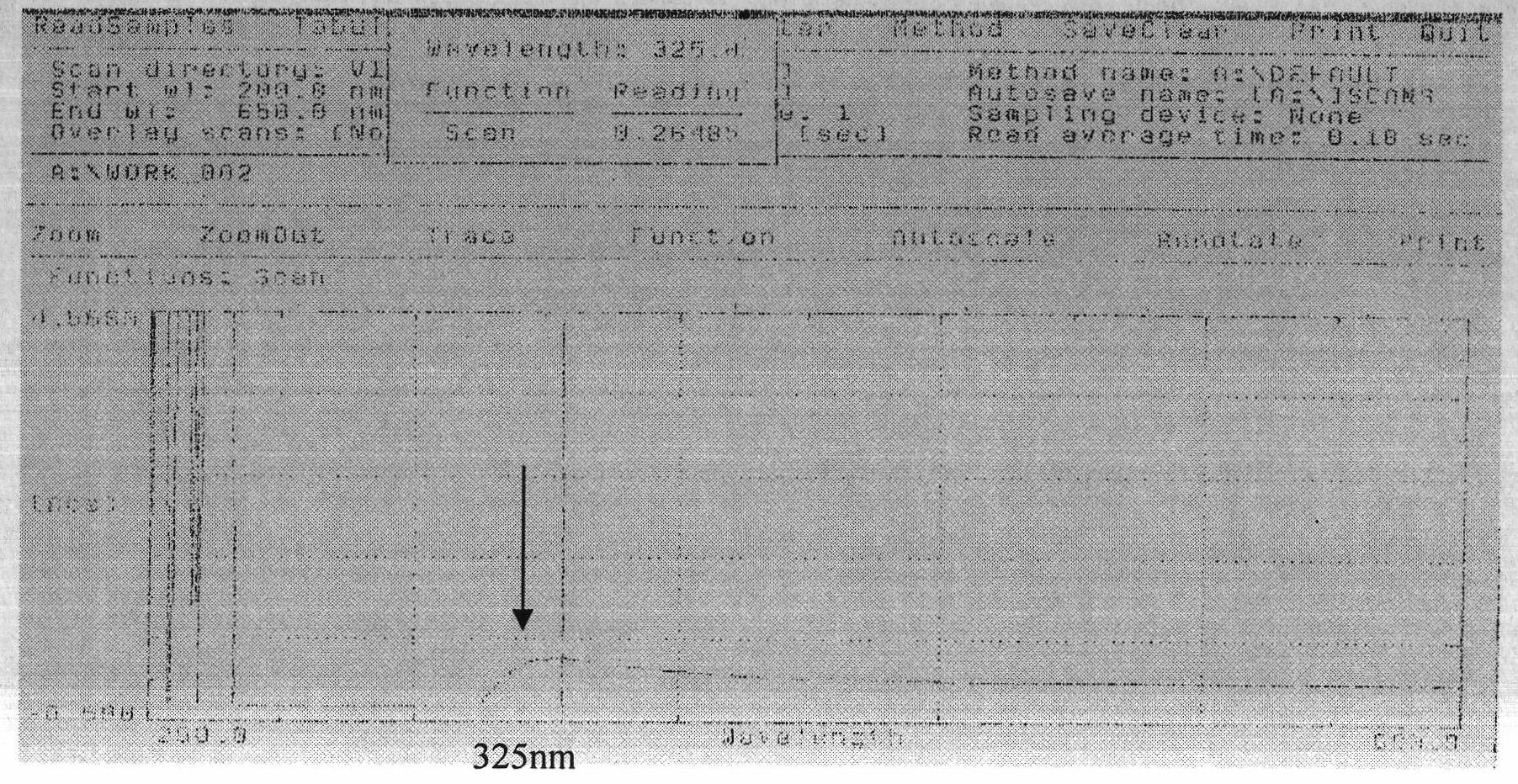

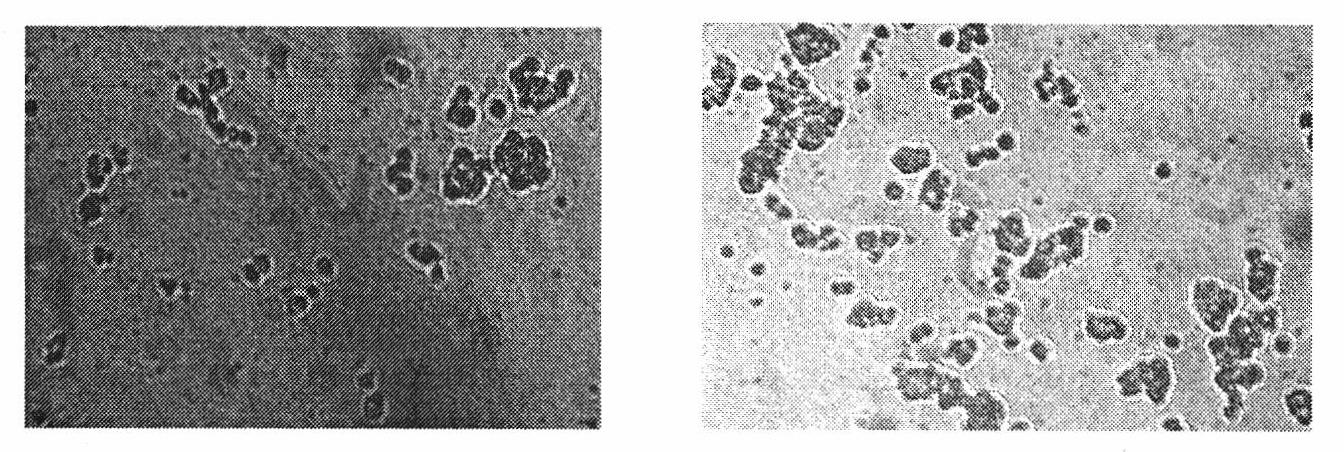

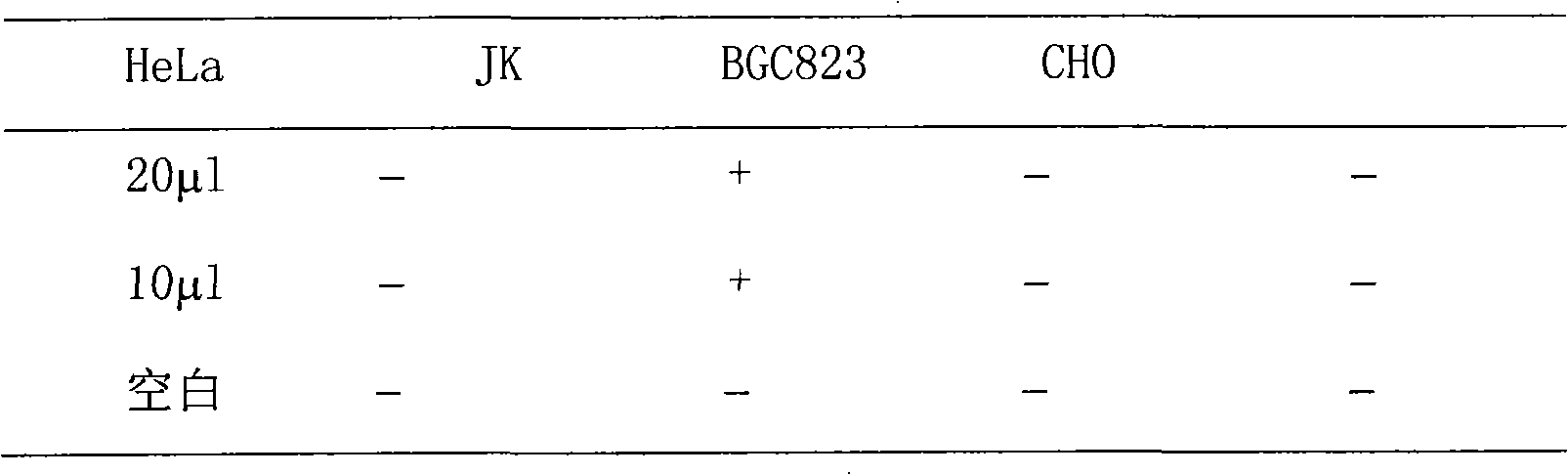

Sansevieria trifasciata saponin, preparation method and application thereof

InactiveCN101804132AEasy to operateLow costAntineoplastic agentsPlant ingredientsProcess equipmentHuman gastric carcinoma

The invention discloses sansevieria trifasciata saponin, a preparation method and application thereof. The method comprises the following steps of: making the sansevieria trifasciata into dry powder, extracting by using water, alcohol or methanol, extracting by using petroleum ether or ether, and extracting by using butyl alcohol or pentanol to obtain the sansevieria trifasciata total saponin extract. The method for preparing the sansevieria trifasciata saponi optimizes the process conditions, has simple operation and low cost, has low requirement on process equipment, can reduce the consumption of solvents and enhance the leaching rate. The sterilized sansevieria trifasciata has obvious inhibition function on the growth of JurKet, has no activity killing effect on human cervical carcinoma cells (HeLa) and human gastric carcinoma cells (BGC823), and has no injury to normal Chinese Hamster Ovary (CHO), and the cell grows normally without any obvious change.

Owner:JILIN AGRICULTURAL UNIV

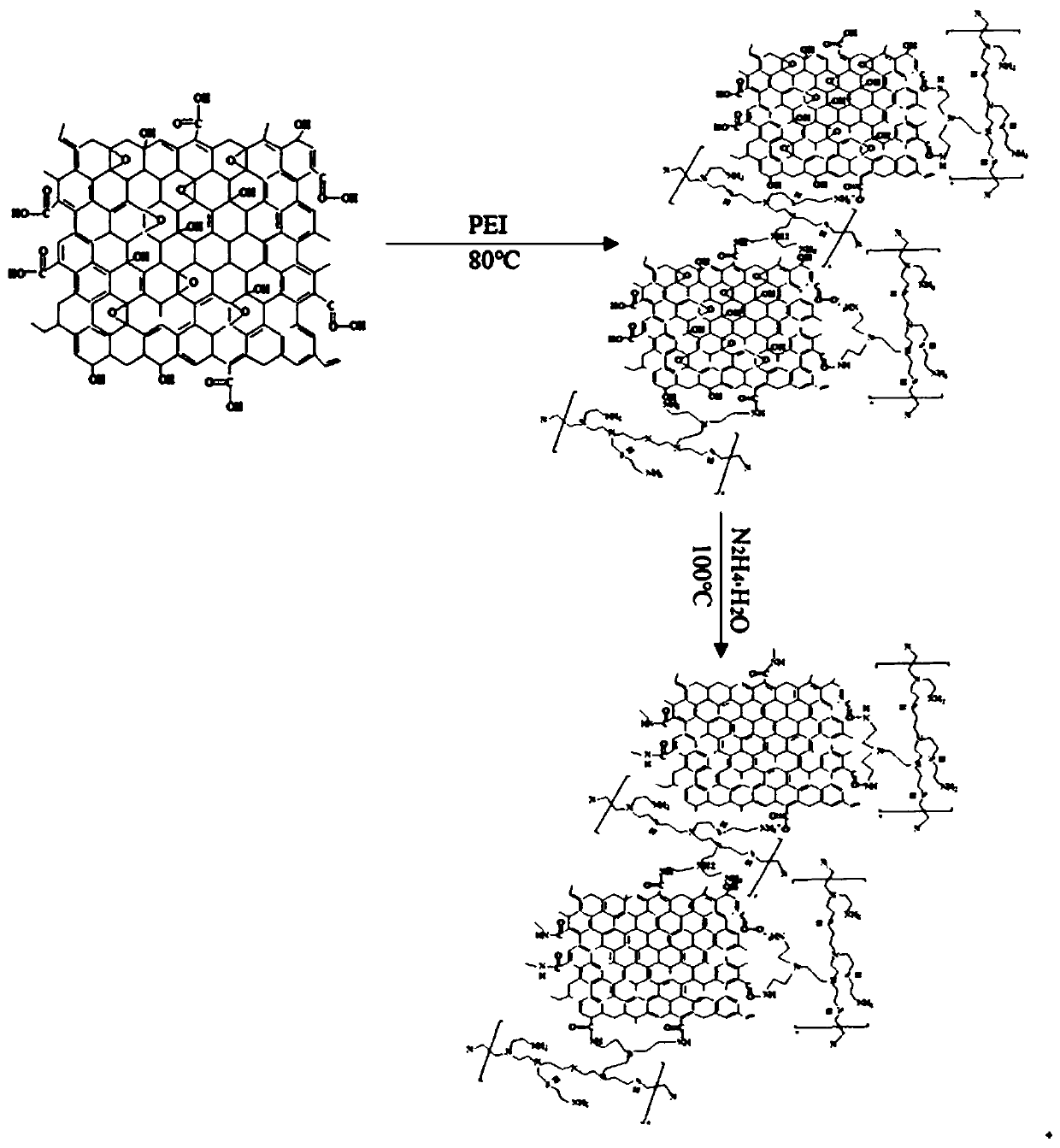

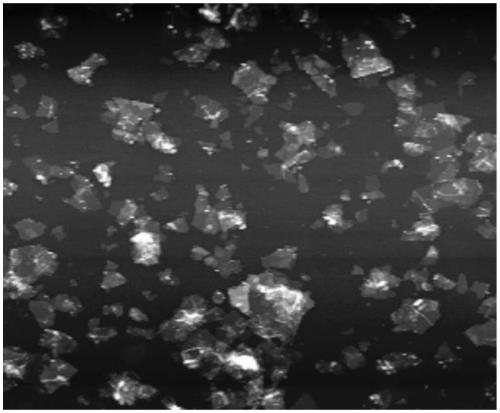

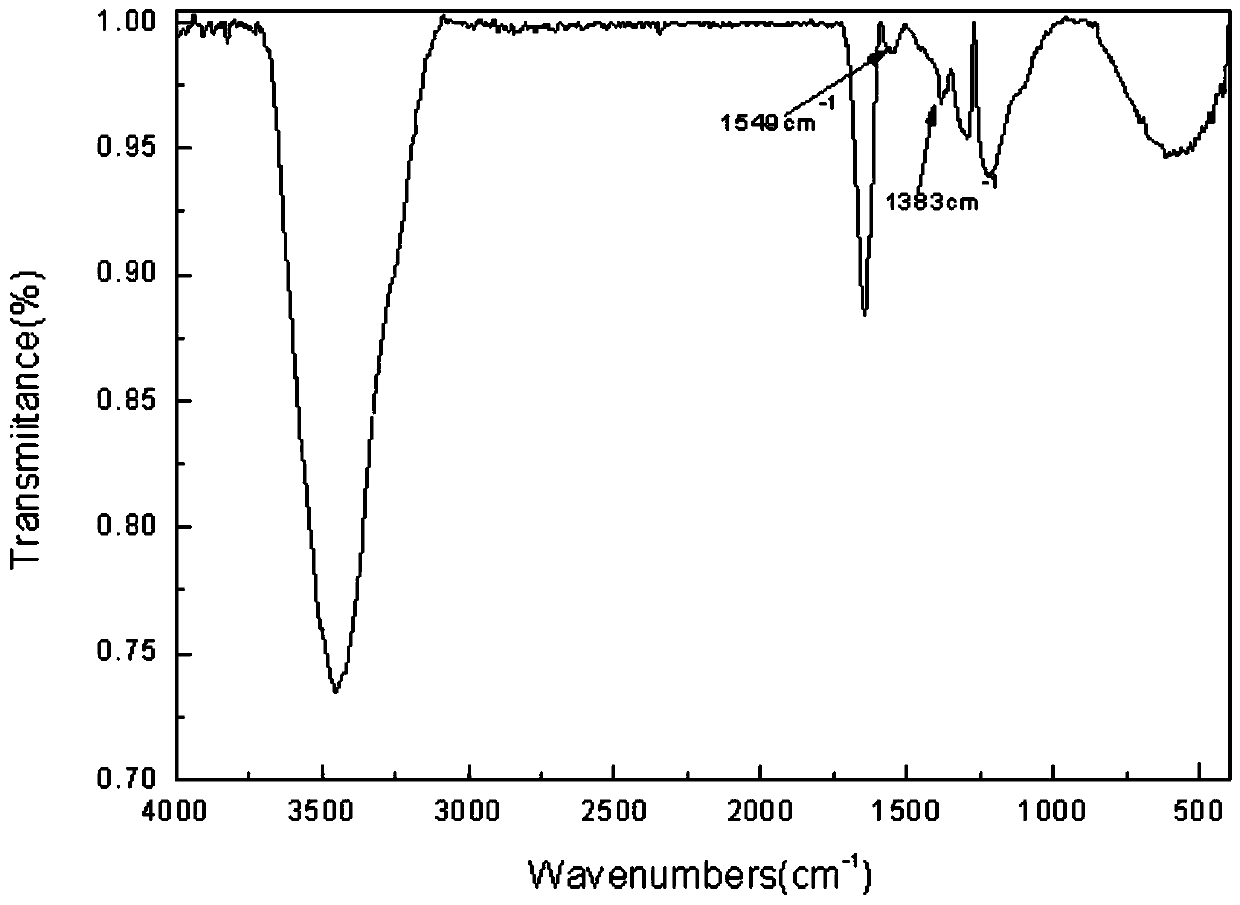

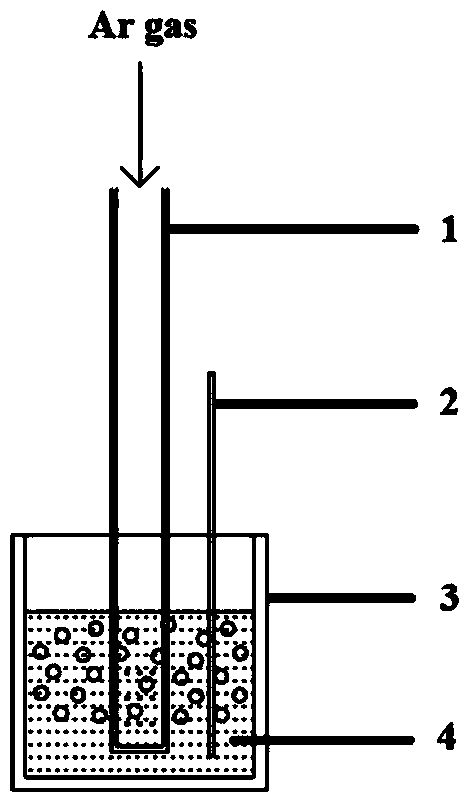

Preparing methods for modified graphene and modified graphene slurry

The invention relates to preparing methods for modified graphene and modified graphene slurry. The preparing method for the modified graphene includes (1) a step of preparing graphene oxide, namely astep of subjecting graphite powder to preoxidation and Hummer's oxidation to obtain the graphene oxide; (2) a step of uniformly dispersing the graphene oxide into water in a concentration of 5 g / L to15 g / L, adjusting the pH until the solution is alkaline, adding a carboxyl activator at 70-90 DEG C, stirring the mixture, adding an aqueous solution of branched polyethyleneimine, and reacting the mixture, with the molecular weight of the branched polyethyleneimine being 1,000-3,000; (3) a step of adding an alkaline reductant into the reaction solution of the step (2), performing filtration afterthe reaction is finished, and cleaning and drying a product to obtain the modified graphene. The modified graphene prepared by the method can be uniformly and stably dispersed into water and ethanolwhich are common organic and inorganic solvents.

Owner:GUANGZHOU SPECIAL PRESSURE EQUIP INSPECTION & RES INST

Semi-solid rheological squeeze casting forming method of flame retardant magnesium alloy

The invention discloses a semi-solid rheological squeeze casting forming method of flame retardant magnesium alloy. The method includes the steps of the early processes of conventional melting, refining and slagging-off and two subsequent technological processes of semi-solid slurry preparation and semi-solid rheological squeeze casting; the semi-solid slurry preparation is achieved through imposing air bubble to flame retardant magnesium alloy melt to be stirred, and then squeeze casting forming is conducted on the obtained semi-solid slurry. Through the method, the semi-solid rheological squeeze casting forming of the flame retardant magnesium alloy is achieved, a primary phase and a secondary phase in the flame retardant magnesium alloy can be refined respectively, the casting overall organization is dense, the casting surface is high in quality, and the mechanical property and the surface quality of a product are greatly improved; the pouring temperature is decreased from 700 DEG C in a traditional process to about 600 DEG C, energy consumption can be lowered, impact to a mould is decreased, oxidation losses of magnesium alloy materials are lowered, and the utilization rate of the materials is improved.

Owner:SHANGHAI JIAO TONG UNIV

High-thermal-conductivity carbon fiber composite material and preparation method thereof

ActiveCN113881228ALower interface thermal resistanceImprove thermal stabilityHeat-exchange elementsFibrous compositesFunctional composite

The invention relates to the field of functional composite materials, in particular to a high-thermal-conductivity carbon fiber composite material and a preparation method thereof. Carbon fibers are used as a main construction unit of a high-orientation heat transport network, and graphene oxide which has a self-assembly characteristic and has a lattice structure similar to that of the carbon fibers is used as a bridging agent. A self-supporting network structure that is three-dimensionally interconnected between carbon fibers and graphene oxide and is highly oriented in a specific direction is constructed by ice template method or hydrothermal reduction assembly, and composite materials with high thermal conductivity are prepared after compounding with a polymer matrix. According to the prepared high-orientation carbon fiber self-supporting structure, the graphene oxide serves as a bridging agent, wrapping of a traditional polymer binder is avoided, the carbon fibers are effectively connected with one another through the graphene oxide, and a synergistic orientation three-dimensional heat conduction enhanced network structure is jointly formed; and the heat-conducting property of the composite material is obviously improved under the condition of low filling amount.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

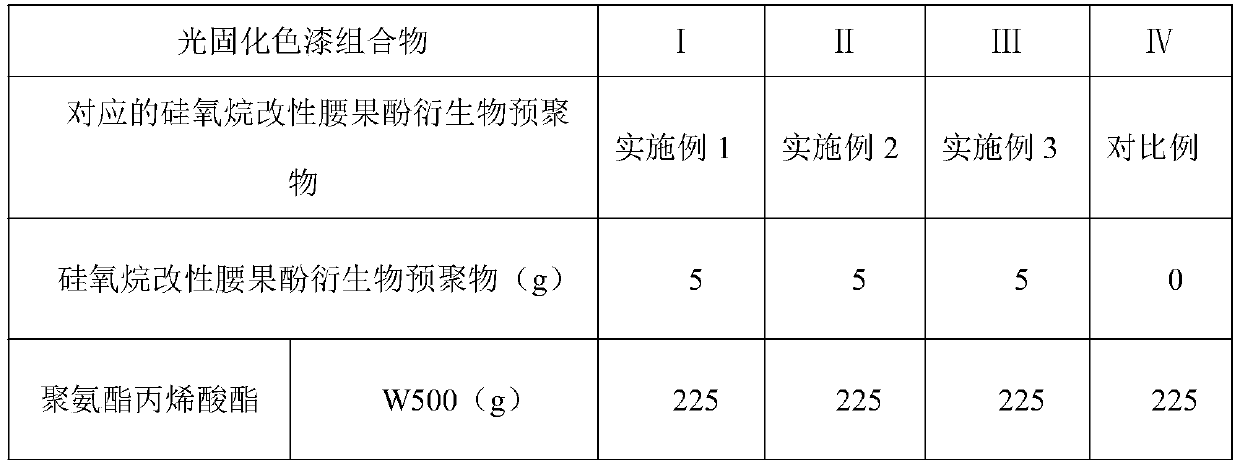

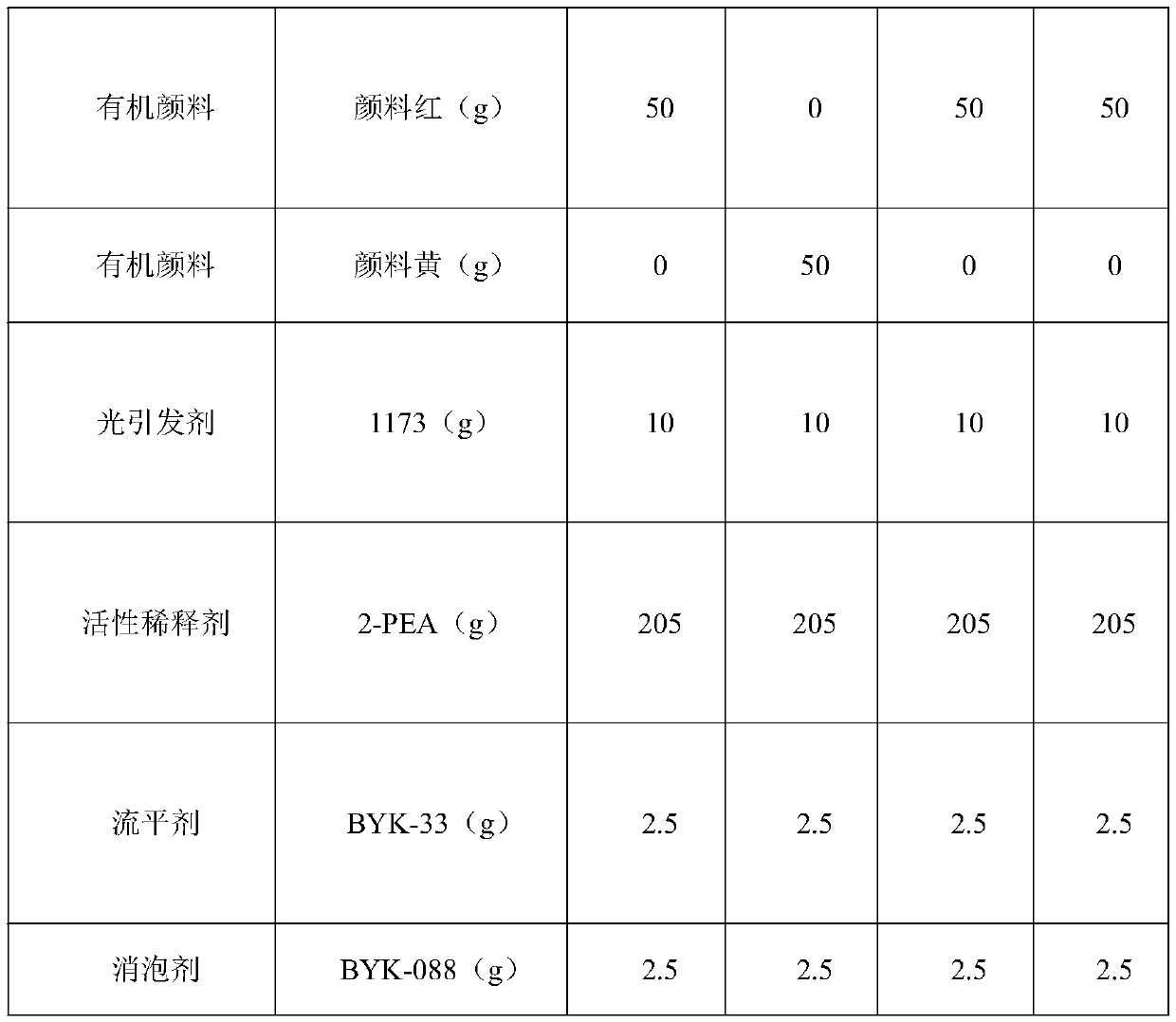

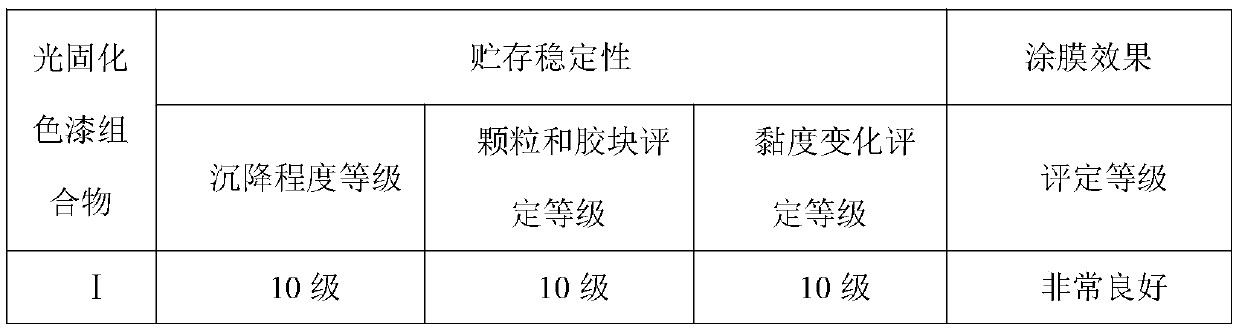

Siloxane modified cardanol derivative prepolymer as well as preparation method and application thereof

ActiveCN111393597AGood storage stabilityImprove wettabilityPolyurea/polyurethane coatingsPtru catalystSilanes

The invention belongs to the technical field of high-molecular polymerization, and discloses a siloxane modified cardanol derivative prepolymer as well as a preparation method and application thereof.The siloxane modified cardanol derivative prepolymer is prepared by putting cashew nut shell oleyl alcohol, isocyanate propyl silane and a catalyst into a reaction kettle in a nitrogen protective atmosphere, reacting at 80-90 DEG C, sampling, monitoring an NCO characteristic peak by adopting a Fourier infrared spectrometer until the NCO characteristic peak completely disappears, cooling, filtering and discharging. The molar ratio of OH of the cashew nut shell oleyl alcohol to NCO of the isocyanate propyl silane is 1: (0.5-1). The cashew nut shell oleyl alcohol can interact with pigment through large pi conjugation or hydrogen bonds, the wettability of the pigment can be improved, and the cashew nut shell oleyl alcohol is used for dispersing the pigment. Meanwhile, the cardanol derivativeprepolymer is grafted to the surface of the pigment, so that the storage stability of the pigment is greatly improved.

Owner:广州五行材料科技有限公司

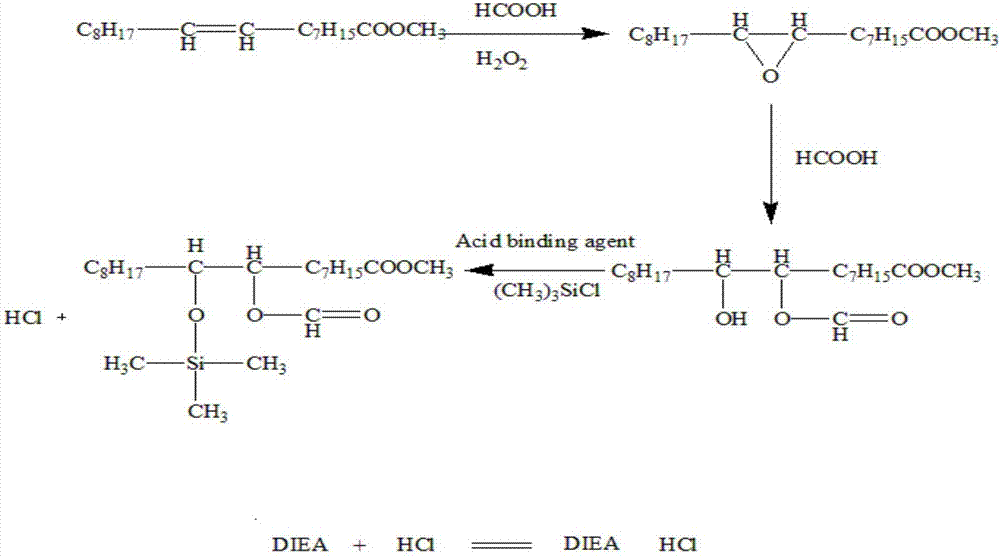

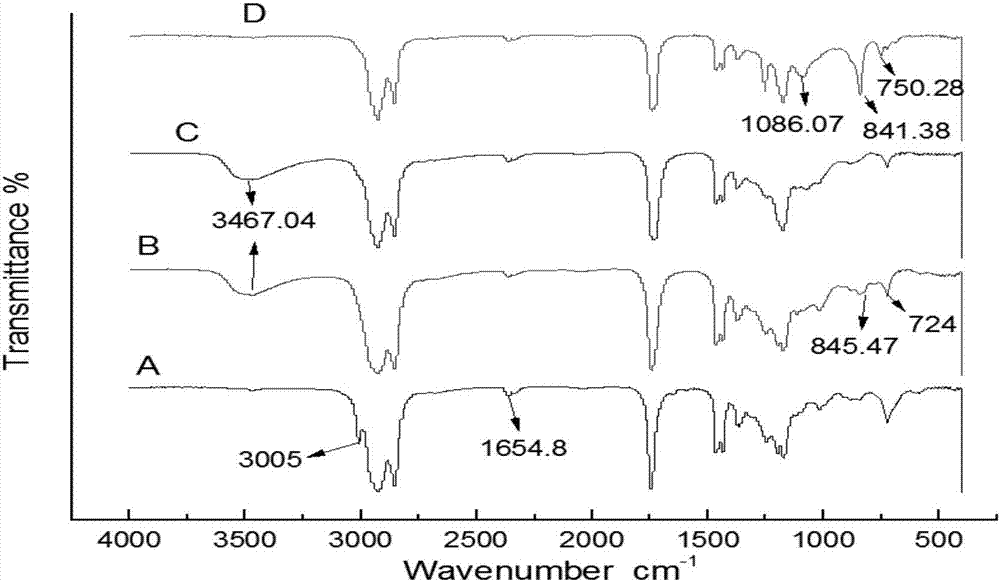

Method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester

The invention provides a method for preparing silicon-based biolubricant base oil from organosilicon modified fatty acid ester. The method comprises the following specific steps: mixing fatty acid ester with organic acid and a catalyst and adding the mixture into an epoxidation reaction kettle, dropwise slowly adding an oxidizing agent, reacting, standing for layering, fetching a supernatant liquid and distilling to obtain epoxidized aliphatic ester; carrying out a ring-opening reaction between epoxidized aliphatic ester and organic acid, washing to neutral level after the reaction and carrying out reduced pressure distillation to obtain a ring-opening product; stirring the ring-opening product and heating to reaction temperature, dropwise adding organosilicon and an acid binding agent according to requirements and carrying out a silylation reaction, directly carrying out reduced pressure distillation after the reaction, and separating a solid to obtain the silicon-based biolubricant base oil. By the above method, the disadvantage that biolubricant base oil produced by existing technologies has poor oxidation stability and poor viscosity-temperature characteristic is overcome. The production process is environment-friendly, and energy consumption is low. The industrial acid binding agent used in the method is low-cost such that cost of the product is reduced.

Owner:NANJING UNIV OF TECH

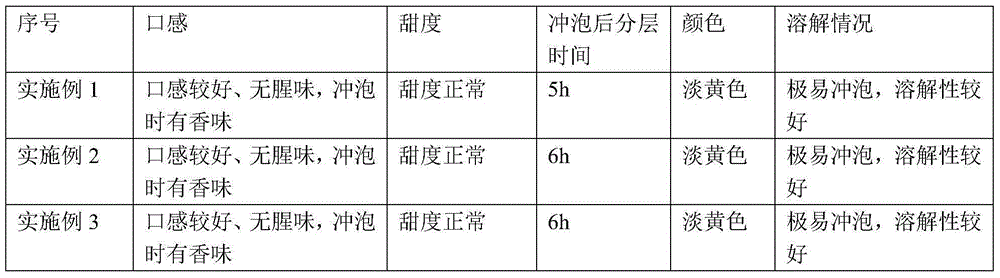

Soybean milk powder and making method thereof

The invention discloses soybean milk powder and a making method thereof, and belongs to the technical field of foods. The soybean milk powder is prepared from, by weight, 150-250 parts of soybeans, 150-250 parts of black beans, 20-80 parts of small red beans, 10-30 parts of pearl barley, 5-10 parts of cranberries, 5-10 parts of cocoa powder, 20-60 parts of whole milk powder, 5-10 parts of starch, 0.2-0.8 part of citric acid, 1-5 parts of emulsifying agents, 2-10 parts of additives and 2-10 parts of phosphatide oil. According to the soybean milk powder, the sugar-free sweet formula is adopted, the mouthfeel is good, delamination is not prone to occurrence, the deodorization process is simple, and the health care function is achieved. The adopted additives are all prepared from the pure natural plant raw materials of sweet stevia, licorice roots, grosvenor momordica fruit, jujubes, haws, Chinese wolfberries, poria cocos and herba portulacae, and on one hand, the raw materials have the health care function; on the other hand, the raw materials are mixed according to proportions, the function of a flavoring agent is achieved, and the mouthfeel of the soybean milk powder is improved; in addition, according to the raw materials, saccharose is not adopted, so that the soybean milk powder can also be taken by diabetics.

Owner:陈尚龙

Method for activating humic acid through physical and chemical combined solid-phase ball milling

InactiveCN106518532ALower requirementNo emissionsOrganic fertilisersFertilizer mixturesPhysical chemistryBall mill

The invention relates to a method for activating humic acid through physical and chemical combined solid-phase ball milling. The method comprises the following steps: firstly, smashing the weathered coal containing inactivated humic acid and filtering through a 60-mesh sieve, thereby acquiring powdered weathered coal A; adding a solid activating agent B and a synergist C into the weathered coal A and uniformly mixing; putting A, B and C into a ball mill; and setting a rotating speed at 60-80rpm and ball-milling for 60min-90min, thereby acquiring an activated product rich in humic acid. Compared with the traditional chemical activating method, the method has the advantages that more than 50% of energy consumption is saved and no dust or harmful gas is discharged; under the effect of the synergist, the humic acid with a micro-molecule structure is easily generated; the stimulation effect on crops and the improving effect on soil are further benefited; and the method is a low-cost, high-efficiency and environment-friendly activating method.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

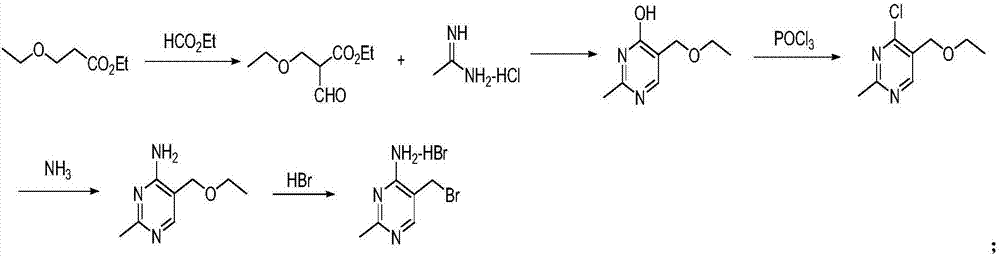

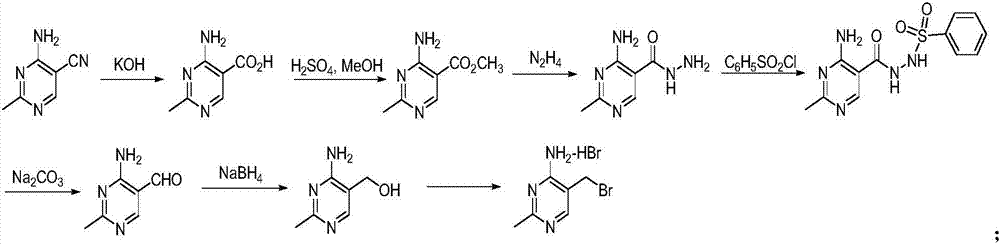

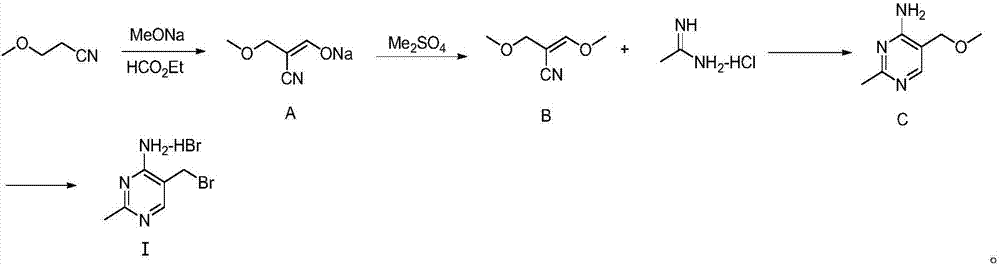

Synthesizing method for 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide

InactiveCN107382877ACheap to prepareRaw materials are easy to getOrganic chemistryHydrobromideSodium methoxide

The invention discloses a synthesizing method for 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide. The method comprises the following steps: acquiring formylated midbody sodium salt A by reacting 3-methoxypropionitrile with ethyl formate under the effect of sodium methylate; reacting the midbody sodium salt A with dimethyl sulfate, thereby acquiring a midbody B; condensing the midbody B with acetamidine hydrochloride, thereby acquiring a midbody C; and reacting the midbody C with hydrobromic acid, thereby acquiring a target product 4-amino-2-methyl-5-(brooethyl) pyrimidine hydrobromide I. According to the invention, the raw material source is wide and the cost is low; the synthesizing method is simple in production operation and has low requirement for processing equipment; the rigorous production conditions, such as, anhydrous condition, anaerobic condition and high-pressure hydrogenation, are not required; the reaction condition is mild; the method is easy for large-scale industrial production; the process is simple; the production period is short; the production efficiency is high; the production method is green and environmentally friendly and is suitable for large-scale industrial production.

Owner:CHENGDU BAISHIXING SCI & TECH IND

Polyurethane polymer capable of being quickly degraded as well as preparation method and application thereof

ActiveCN104788641AImprove mechanical propertiesEasy to processOrganic compound preparationPreparation by ester-hydroxy reactionState of artAcetic acid

The invention relates to the technical field of modified polymer materials, and especially relates to a polyurethane polymer capable of rapidly decomposing, a preparation method and applications thereof. The polyurethane polymer comprises hard sections and soft sections, wherein the hard sections comprise analogous glycolic acid structures. Degradable analogous glycolic acid structures are introduced into the polyurethane hard sections of the polyurethane polymer, and the structures are easy to degrade in natural environment; furthermore the polymer has a good mechanical performance and processing property, and can be applied to fields of food package, ground film, synthesis leather, and shoe materials.

Owner:SHANGHAI HUAFENG MATERIAL TECH RES INST LLP +1

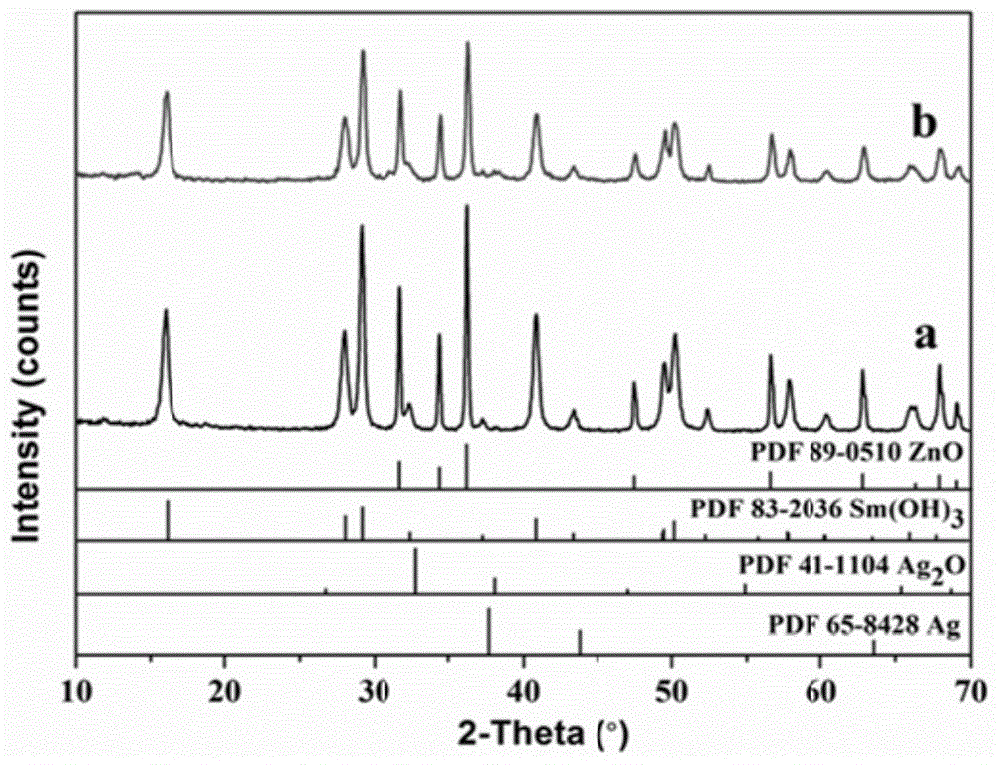

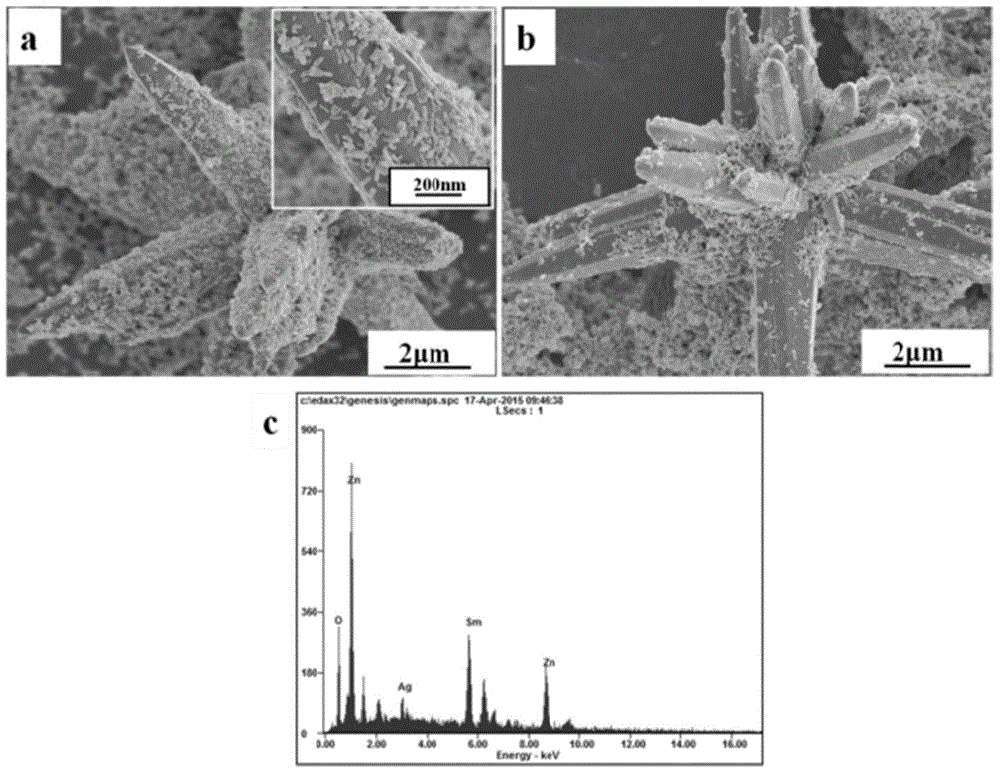

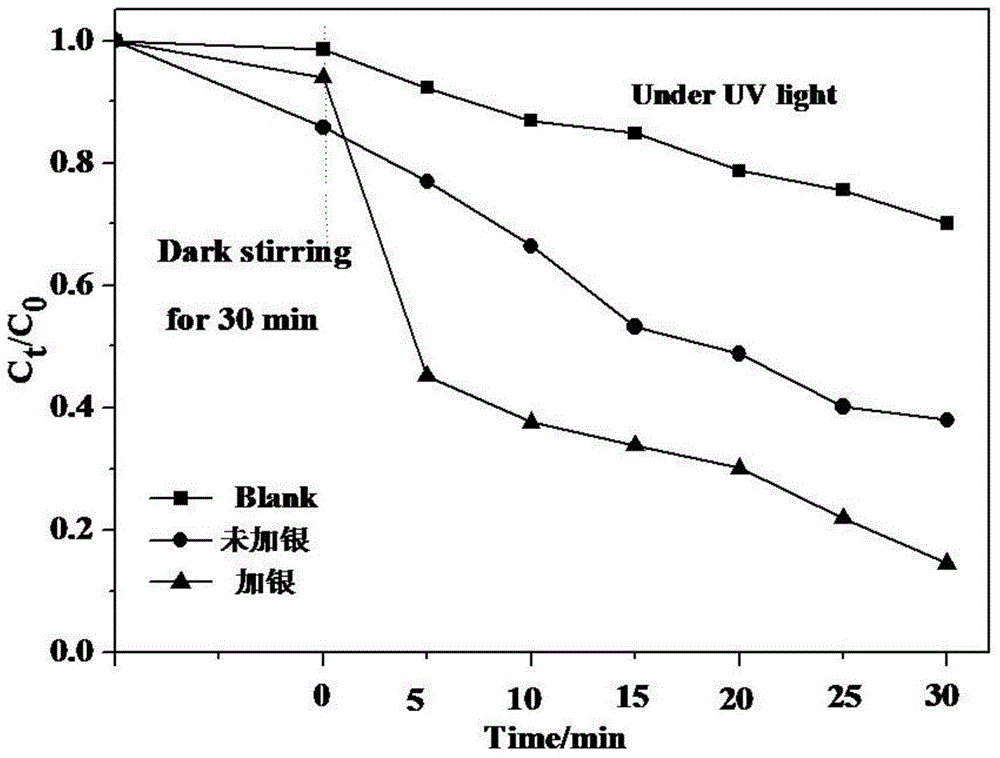

Method for preparing AgO/Sm(OH)3/ZnO nanometer complex by using two-step method

ActiveCN105056947AHigh purityHigh crystallinityMetal/metal-oxides/metal-hydroxide catalystsWater bathsProcess equipment

The present invention discloses a method for preparing a AgO / Sm(OH)3 / ZnO nanometer complex by using a two-step method. The method comprises: preparing a solution A with a Sm<3+> concentration of 0.5-2 mol / L; preparing a solution B with a Zn<2+> concentration of 0.5-2mol / L; mixing the solution A and the solution B, and adjusting the pH value to 9-12 with an ammonia water solution to form a reaction precursor solution; carrying out a homogeneous reaction on the precursor solution, and naturally cooling to a room temperature after completing the reaction; washing, collecting the product, and carrying out vacuum drying for 0.5-2 h at a temperature of 60-80 DEG C so as to obtain a Sm(OH)3 / ZnO precursor; and dispersing the precursor in an ethanol solution of silver nitrate, placing into a water bath kettle, heating for 1-3 h at a temperature of 60-80 DEG C, cooling to a room temperature, and carrying out centrifugation washing drying on the production area so as to obtain the AgO / Sm(OH)3 / ZnO nanometer complex. According to the present invention, the reaction medium is the aqueous solution, the safety is high, the feasibility is strong, the process equipment requirements are low, and the operation is simple.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of povidone iodine powder

The invention relates to a novel method for preparing povidone iodine solid powder. The method particularly comprises the following steps: in the presence of an organic solvent, complexing a polyvinylpyrrolidone solid and iodine, and carrying out liquid-solid separation to obtain the povidone iodine solid powder. Compared with the existing processes, the method has the advantages of low uncomplex iodine content in the product, stable product quality, and low requirements for technological equipment, and is suitable for industrial production.

Owner:CHANGZHOU UNIV

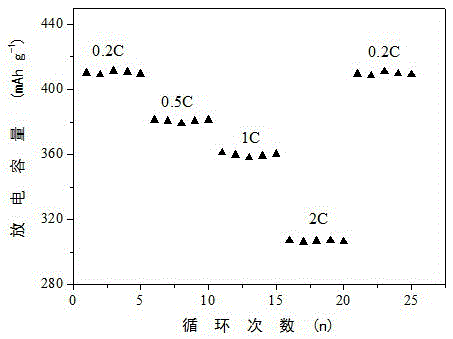

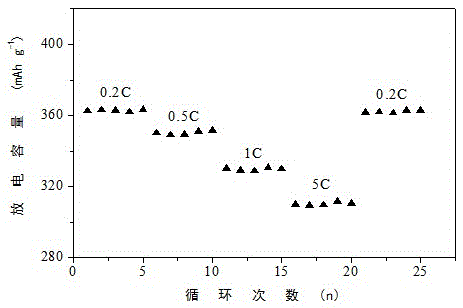

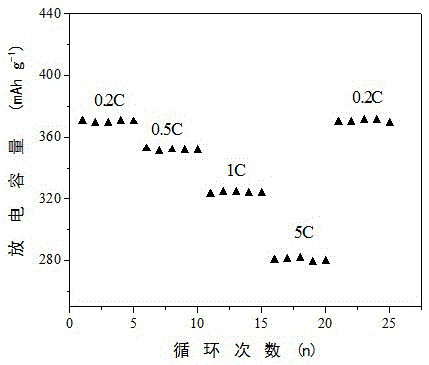

Graphene-based lithium-ion battery cathode and preparation method thereof

InactiveCN105489838AImprove power performanceReduce usageCell electrodesSecondary cellsEnvironmental resistanceDoped graphene

The invention relates to a graphene-based lithium-ion battery cathode and a preparation technology thereof. According to the technology, cathode slurry taking graphite doped graphene as an active substance is prepared and applied to copper foil, and the lithium-ion battery cathode is prepared. A novel polystyrene-polyisoprene-polystyrene block polymer binder is adopted in the technology, has higher binding force for graphene and can provide high elasticity and improve performance of the graphene-based lithium-ion battery cathode, the obtained high-energy density type cathode has 410 mAh / g of energy density during 0.2 C charging and discharging, and the power type cathode has 310 mAh / g of energy density during 5 C charging and discharging. Raw materials are economical and easy to obtain, and the technology is simple and environment-friendly.

Owner:ZHEJIANG EPTONG TECH CO LTD

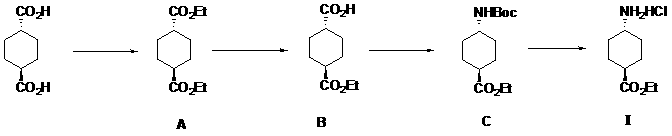

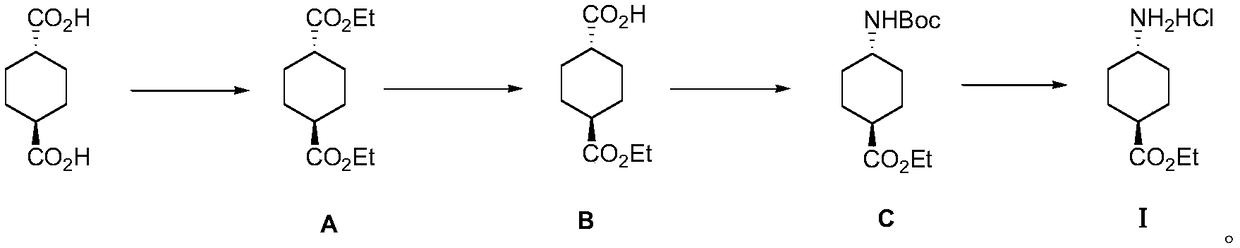

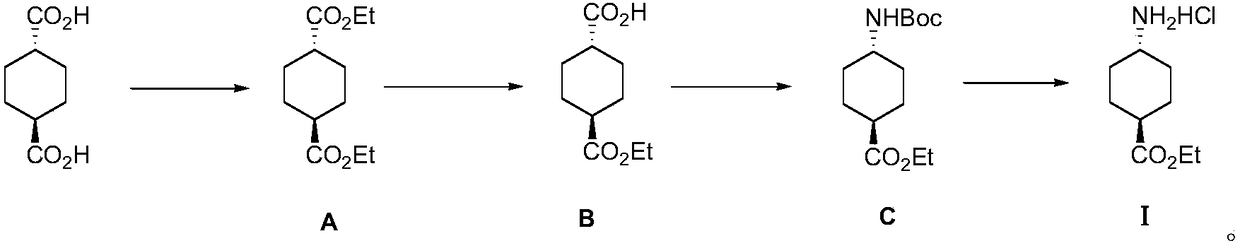

Method for preparing ethyl trans-4-amino-cyclohexanecarboxylate hydrochloride

InactiveCN109280014AImprove efficiencyLow process equipment requirementsCarbamic acid derivatives preparationOrganic compound preparationEthyl acetateReaction step

The invention discloses a method for preparing ethyl trans-4-amino-cyclohexanecarboxylate hydrochloride, and belongs to the field of organic chemistry. Trans-1,4--cyclohexanedicarboxylic acid is usedas an initial material and reacts with anhydrous ethanol to produce intermediate diester A under the condition of a sulfuric acid catalyst, monoester is hydrolyzed by intermediate diester A to obtainintermediate monoacid B, the intermediate monoacid B and DPPA are subjected to Curtius rearrangement to obtain intermediate C, the intermediate C is deprotected by hydrogen chloride ethyl acetate solution to obtain final product ethyl trans-4-amino-cyclohexanecarboxylate hydrochloride I. The process adopted by the invention has the advantages of short reaction steps, cheap raw materials, mild reaction conditions and high yield, and is suitable for industrialized large-scale production.

Owner:CHENGDU BAISHIXING SCI & TECH IND

Lithium source active material, positive pole piece, lithium ion capacitor and preparation method thereof

InactiveCN109346335AHigh specific capacityReduce reversibilityHybrid capacitor electrodesCell electrodesCapacitancePorous carbon

The invention discloses a lithium source active material, a positive pole piece, a lithium ion capacitor and a preparation method thereof, wherein the positive pole piece comprises a current collector, the lithium source active material, a capacitor material, a conductive agent and a binding agent, wherein the lithium source active material is preferably one or more of Li5FeO4, Li6CoO4, Li6MnO4, and Li5FexCo1-xO4; the capacitor material is one or more of graphene, activated carbon, porous carbon and other nano materials; and the weight percentages of the following raw materials as follows: 45-5% of lithium source active material, 85-60% of capacitor material, 8-1.0% of conductive agent and 4-1% of binding agent. The positive pole piece has the advantages of being safe, uniform in lithium intercalation, low in technological equipment requirement, high in operability and the like, and is suitable for batch production.

Owner:桑顿新能源科技(长沙)有限公司

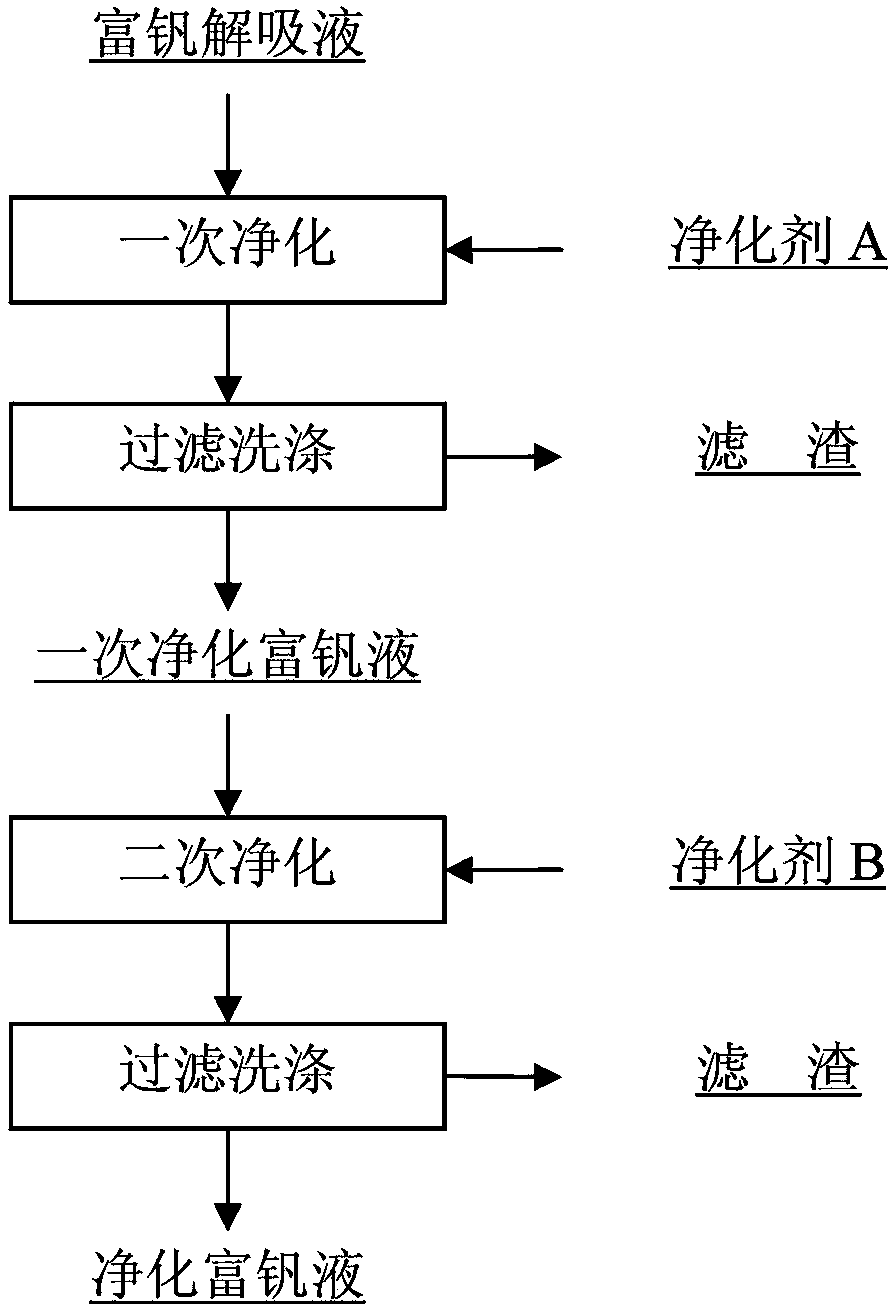

Method for removing silicon and phosphorus impurities from rich-vanadium desorption liquid

The invention discloses a method for removing silicon and phosphorus impurities from rich-vanadium desorption liquid. The method comprises the following steps that the temperature of the rich-vanadium desorption liquid is regulated to 10 DEG C to 100 DEG C; purifying agents A are added, wherein the purifying agents A are at least one kind of materials from quicklime, slaked lime and lime milk, the full reaction is carried out after the stirring, the obtained reaction liquid is filtered and washed, the primary purified rich-vanadium liquid is obtained; the pH value of the primary purified rich-vanadium liquid is regulated to 8 to 10; and purifying agents B are added, wherein the purifying agents B are magnesium chloride and / or magnesium sulfate, the full reaction is carried out after stirring, the obtained reaction liquid is filtered and washed, and the purified rich-vanadium liquid is obtained. The method has the advantages that the process steps are simple, the purification cost is low, the vanadium loss rate is low, the silicon and phosphorus removal effect is good, and the like.

Owner:CHANGSHA RES INST OF MINING & METALLURGY

A kind of method that epoxy biodiesel prepares biological lubricating oil base oil

ActiveCN103497839BHigh catalytic activityImprove catalytic selectivityFatty acid isomerisationBiofuelsEpoxyBiodiesel

The invention aims at solving the defects of long reaction time and high reaction temperature of a heterogeneous etherification ring-opening reaction of epoxy biodiesel of prior arts, and provides a method for preparing biological lubricating oil base oil by using epoxy biodiesel. The method comprises the steps that: (1) under a condition of ultrasonic-assisted heat and mass transfer, the heterogeneous etherification ring-opening reaction is carried out, wherein long-chain fatty alcohol and a metal-ion-load-type cation exchange resin solid catalyst are mixed and heated to a reaction temperature; epoxy biodiesel is added for carrying out the ring-opening reaction; when an epoxy value is smaller than 0.1, the reaction is stopped; the reaction mixture is cooled to room temperature, and is washed by using distilled water; a lower-layer aqueous phase and the solid catalyst are separated, and the solid catalyst is recovered; an upper-layer organic phase is washed to neutral; and vacuum dehydration and light component removing are carried out, such that isomerized fatty alcohol ether is obtained; and (2) the product obtained in the step (1) is subjected to clay discoloration, such that clear and transparent biological lubricating oil base oil is obtained. According to the adopted catalyst, the catalytic active agent has high selectivity.

Owner:如东文园投资开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com