Preparation method for alcohol ether type environment-friendly lubricant base oil

A lubricating base oil, environmentally friendly technology, applied in lubricating compositions, base materials, petroleum industry, etc., can solve problems such as unimproved low temperature performance, limitations, etc., achieve high viscosity index, low pour point, overcome corrosion and Effects of pollution problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

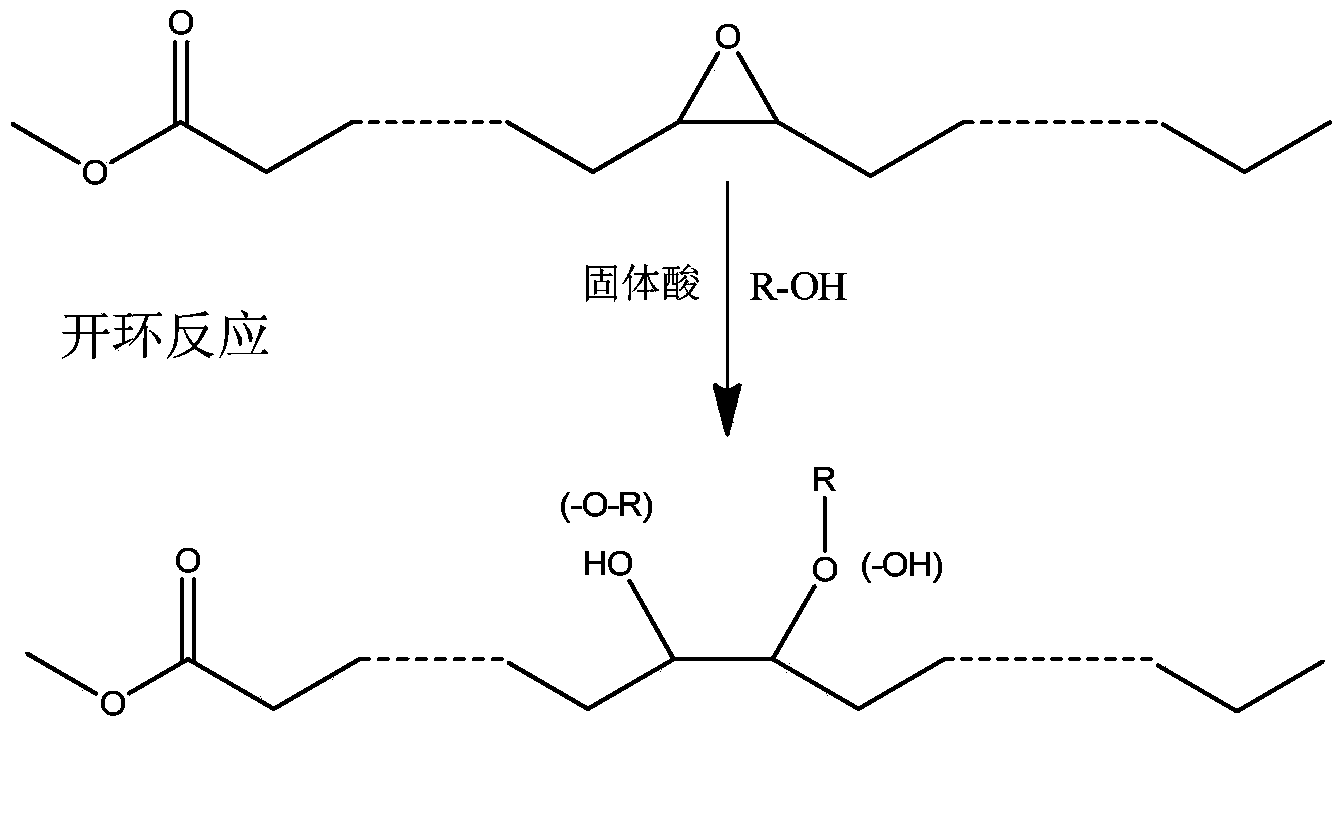

Method used

Image

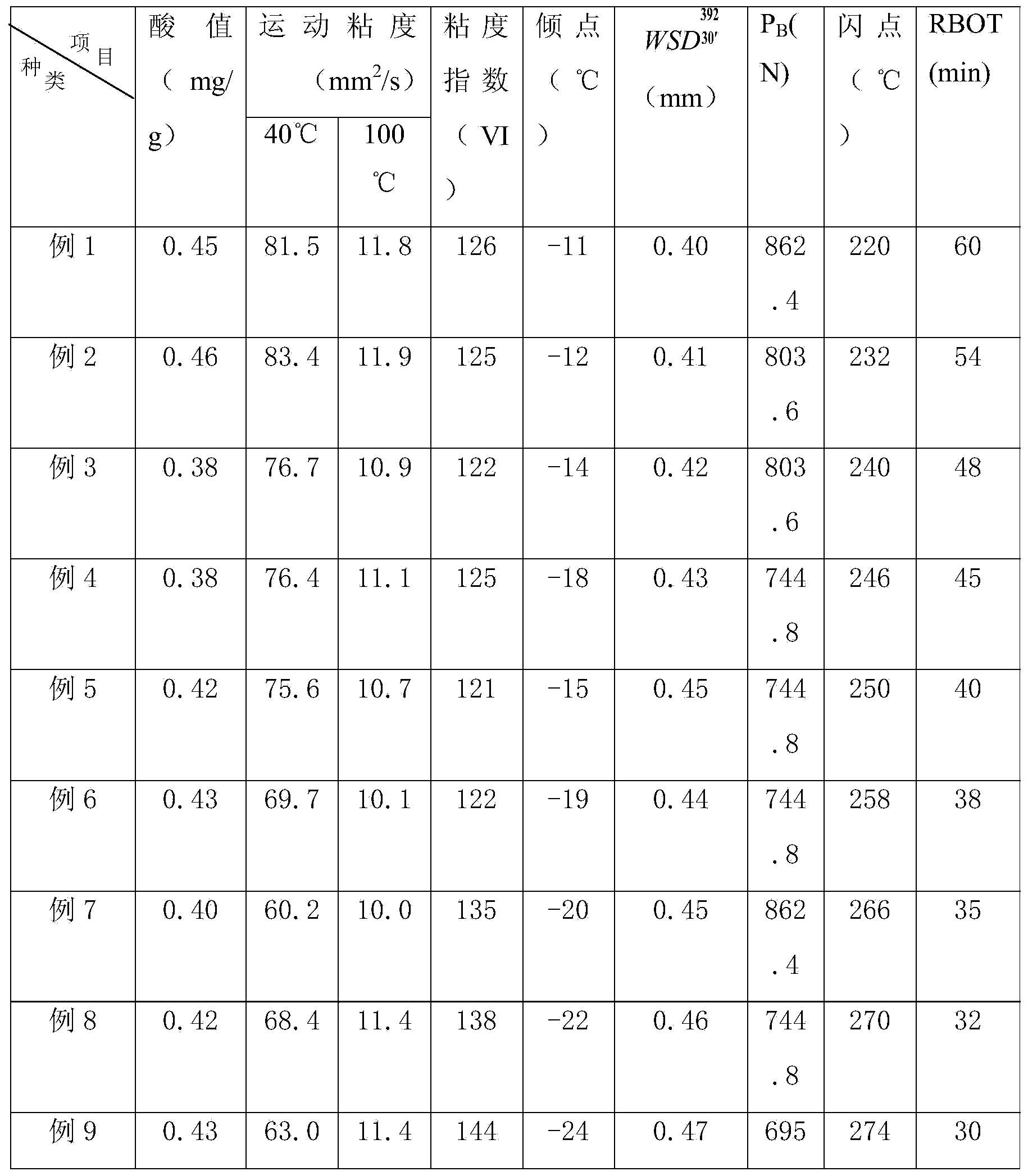

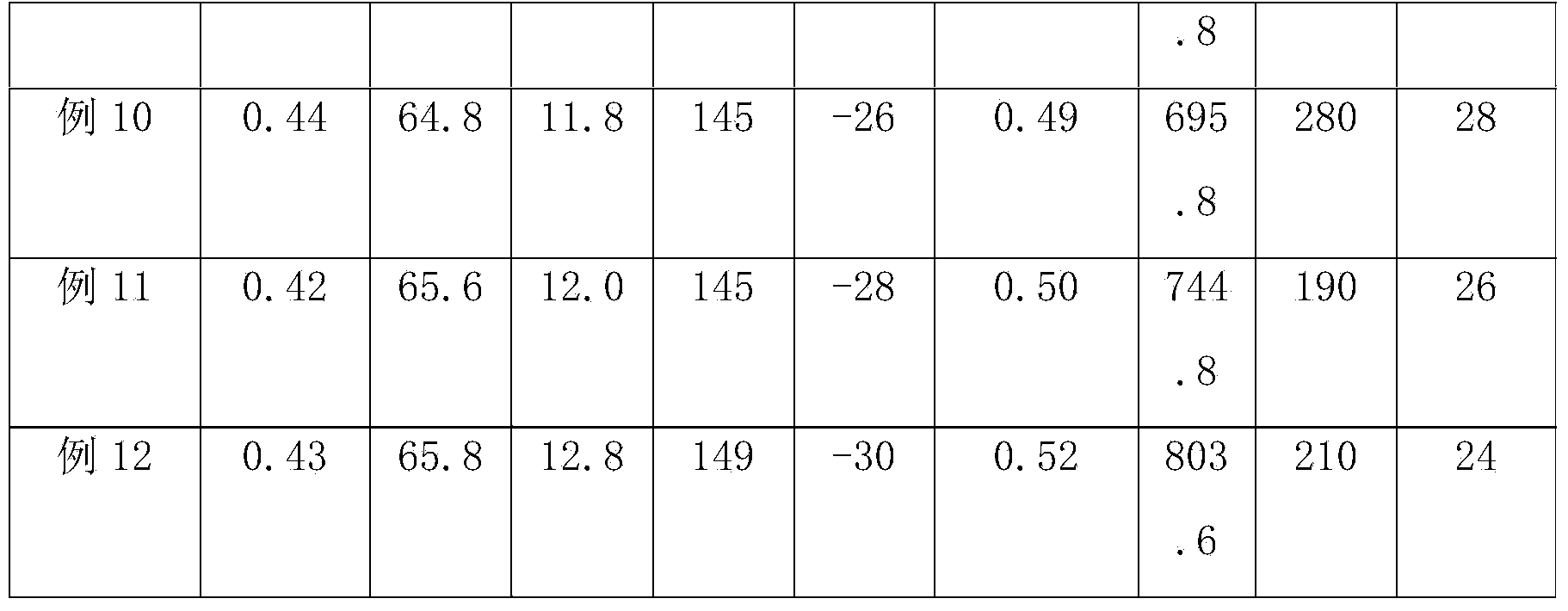

Examples

Embodiment 1

[0025] Weigh 68g ethanol and 6g immobilized heteropolyacid catalyst PW 12 / SiO 2 Put it in a four-necked flask with a condenser tube and a thermometer, heat it to 30°C under stirring, then add 200g of epoxidized soybean oil fatty acid methyl ester, and record the initial epoxy value of the reaction system as 5.46, and at this temperature ring-opening reaction. During the reaction process, samples were taken every 30 minutes, and the epoxy value was measured. When the epoxy value was less than 0.08 (t=4.5h), the reaction was stopped. The above solution is cooled to room temperature, and the immobilized heteropolyacid catalyst PW is recovered by suction filtration. 12 / SiO 2 , the filtrate was placed in a separatory funnel, washed with alkali and water until pH = 7, and then distilled under reduced pressure to finally obtain a clear and transparent isomerized oil alcohol ether.

Embodiment 2

[0027] Weigh 84.4g of isopropanol and 6g of solid-loaded heteropolyacid catalyst TPA / SBA-15 and put them in a four-necked flask with a condenser tube and a thermometer, heat to 30°C under stirring, then add 200g of epoxy rapeseed oil Fatty acid methyl ester, the initial epoxy value of the reaction system was measured to be 5.46, and the ring-opening reaction was carried out at this temperature. During the reaction process, samples were taken every 30 minutes, and the epoxy value was measured. When the epoxy value was less than 0.08 (t=5h), the reaction was stopped. The above solution was cooled to room temperature, and the immobilized heteropolyacid catalyst TPA / SBA-15 was recovered by suction filtration. The filtrate was placed in a separatory funnel, washed with alkali and water until pH = 7, and then distilled under reduced pressure to finally obtain a clear and transparent Isomerized fatty alcohol ether.

Embodiment 3

[0029] Weigh 114.4g n-butanol and 7g immobilized heteropolyacid catalyst SiMo 12 / C is put in the four-necked flask that has condenser tube and thermometer, is heated to 35 ℃ under stirring state, then adds 200g epoxy castor oil fatty acid methyl esters, records the initial epoxy value of reaction system 5.46, and in The ring-opening reaction proceeds at this temperature. During the reaction process, samples were taken every 30 minutes, and the epoxy value was measured. When the epoxy value was less than 0.08 (t=4h), the reaction was stopped. Above-mentioned solution is cooled to room temperature, reclaims solid-loaded heteropolyacid catalyst SiMo through suction filtration. 12 / C, put the filtrate in a separatory funnel, wash with alkali and water until pH = 7, and then distill under reduced pressure to finally obtain a clear and transparent isomerized oil alcohol ether.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| oxidation induction time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com