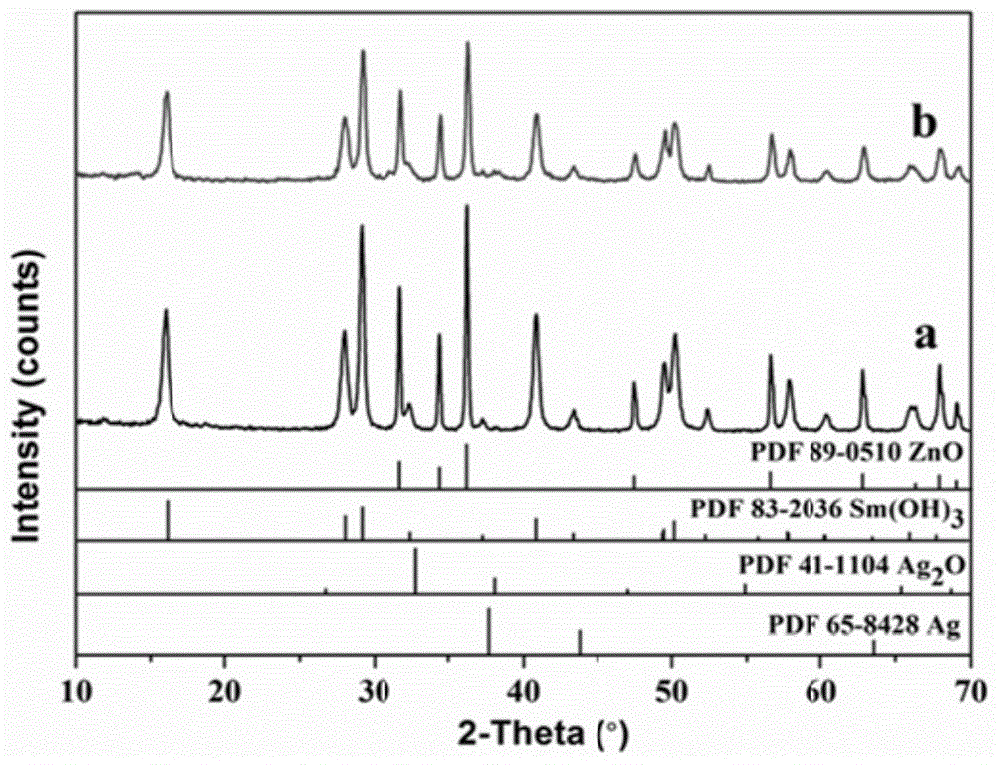

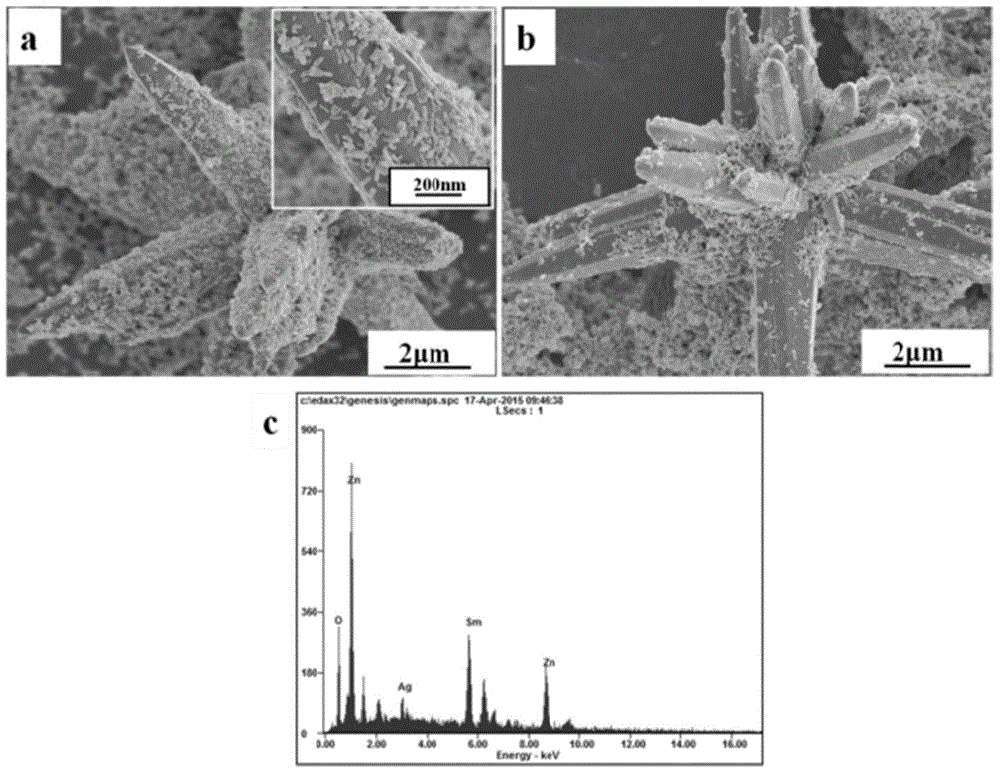

Method for preparing AgO/Sm(OH)3/ZnO nanometer complex by using two-step method

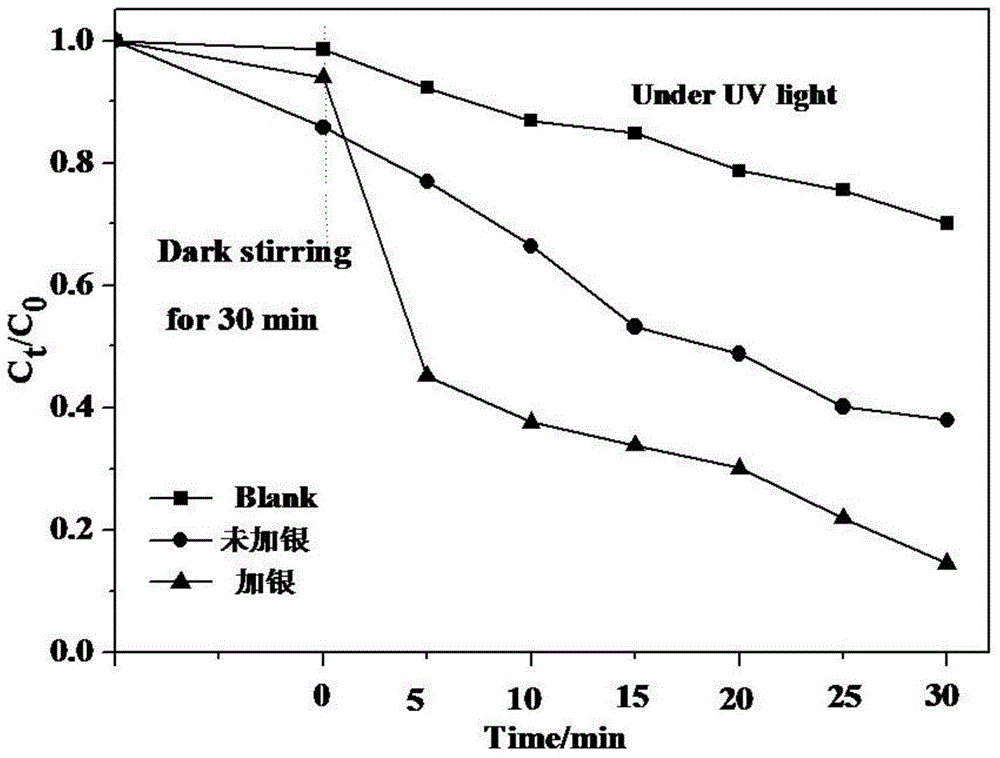

A nanocomposite, step-by-step technology, applied in metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of only 1% solar energy utilization rate and low visible light. , to achieve the effects of controllable morphology, low reaction cost and good industrialization prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in an appropriate amount of deionized water to prepare Sm 3+ Concentration is solution A of 2mol / L; Analytical pure Zn(NO 3 ) 2 ·3H 2 O was dissolved in an appropriate amount of deionized water to prepare Zn 2+ Solution B with a concentration of 0.5mol / L;

[0029] 2) Mix solutions A and B at a volume ratio of 10:1 and adjust the pH to 9 with ammonia solution, and continue stirring to form a reaction precursor evenly;

[0030] 3) Pour the reaction precursor solution into a homogeneous hydrothermal reactor with a filling ratio of 40%; after sealing the reactor, react in a homogeneous reactor at 200°C for 12 hours, and cool to room temperature naturally after the reaction;

[0031] 4) Wash the product by centrifugation for 4 to 6 times with deionized water and absolute ethanol in sequence, collect the product and dry it in vacuum at 70°C for 1 hour to obtain Sm(OH) 3 / ZnO precursor;

[0032] 5) The analyti...

Embodiment 2

[0034] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in an appropriate amount of deionized water to prepare Sm 3+ Concentration is the solution A of 0.5mol / L; Analytical pure Zn(NO 3 ) 2 ·3H 2 O was dissolved in an appropriate amount of deionized water to prepare Zn 2+ Solution B with a concentration of 1mol / L;

[0035] 2) Mix solutions A and B at a volume ratio of 12:1 and adjust the pH to 10 with ammonia solution, and continue stirring to form a reaction precursor;

[0036] 3) Pour the reaction precursor solution into a homogeneous hydrothermal reaction kettle, seal the kettle and put it in a homogeneous reactor, react at 180°C for 48 hours, and cool it down to room temperature naturally after the reaction;

[0037] 4) Wash the product by centrifugation with deionized water and absolute ethanol for 4 to 6 times in sequence, collect the product and dry it in vacuum at 80°C for 0.5h to obtain Sm(OH) 3 / ZnO precursor;

[0038] 5) The analytically pure Sm(O...

Embodiment 3

[0040] 1) The analytically pure Sm(NO 3 ) 3 ·6H 2 O was dissolved in an appropriate amount of deionized water to prepare Sm 3+Concentration is solution A of 2mol / L; Analytical pure Zn(NO 3 ) 2 ·3H 2 O was dissolved in an appropriate amount of deionized water to prepare Zn 2+ Solution B with a concentration of 0.5mol / L;

[0041] 2) Mix solutions A and B at a volume ratio of 20:1 and adjust the pH to 12 with ammonia solution, and continue stirring to form a reaction precursor;

[0042] 3) Pour the reaction precursor solution into a homogeneous hydrothermal reactor with a filling ratio of 50%; after sealing the reactor, react in a homogeneous reactor at 150°C for 20 hours, and cool to room temperature naturally after the reaction;

[0043] 4) Wash the product by centrifugation for 4 to 6 times with deionized water and absolute ethanol in sequence, collect the product and dry it in vacuum at 80°C for 2 hours to obtain Sm(OH) 3 / ZnO precursor;

[0044] 5) The analytically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com