Patents

Literature

262 results about "Filling ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fill rate is the ratio of job orders received to job orders filled. When the fill rate begins to decline, it should be taken as a warning sign, says an expert at Talent Plus Staffing, a company that takes pride in their 85% fill ratio, as compared to the industry average of 46%.

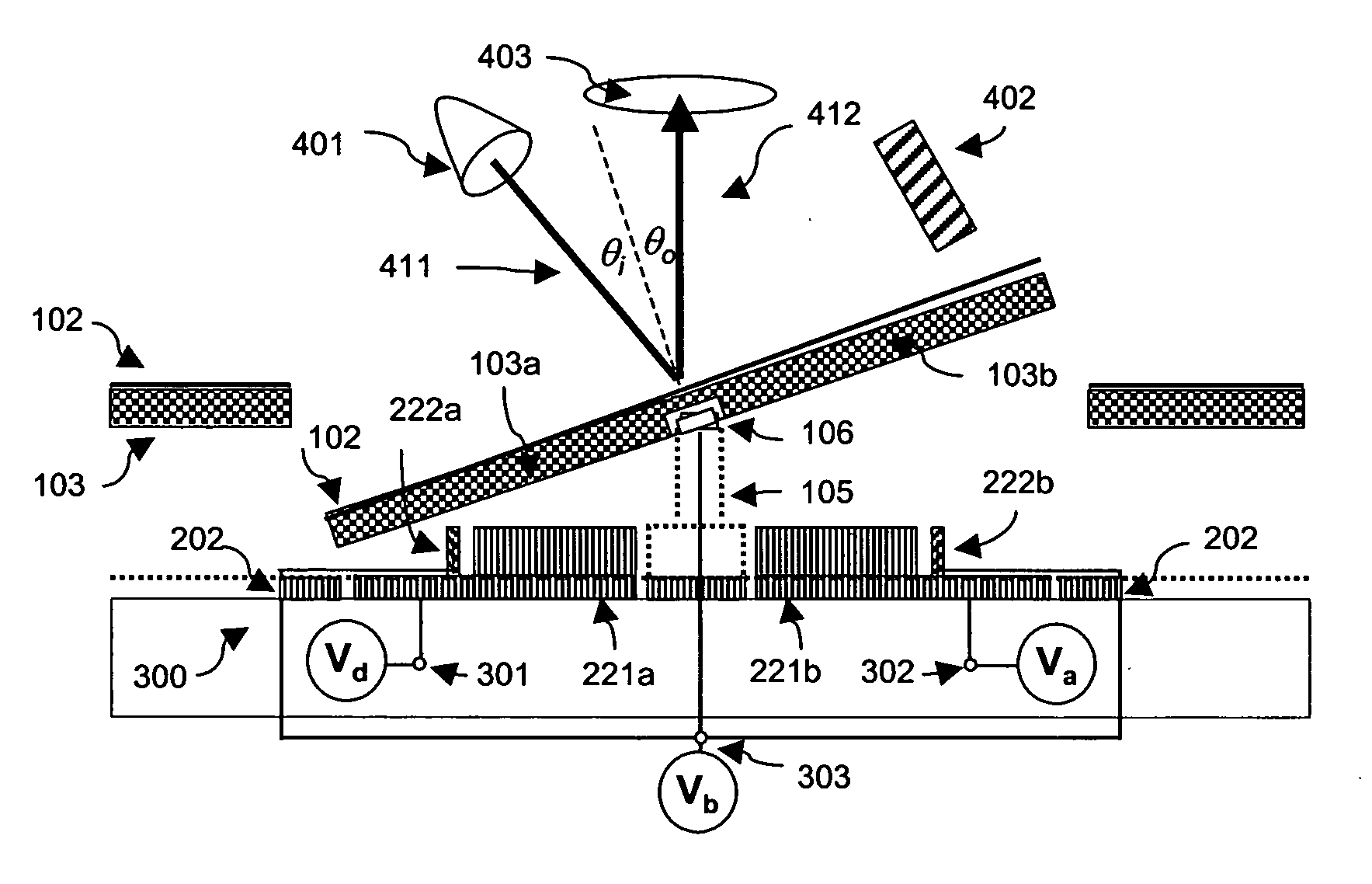

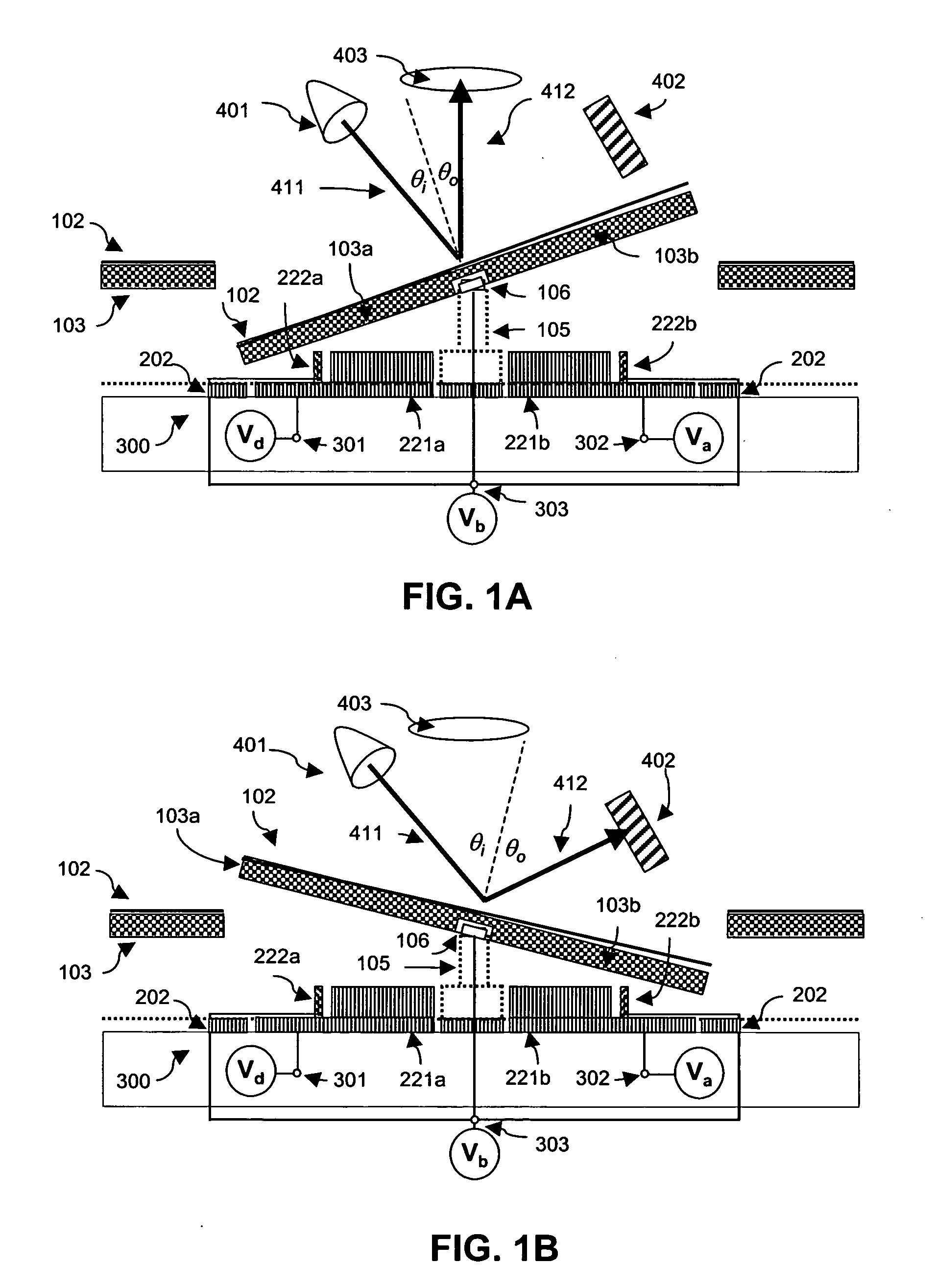

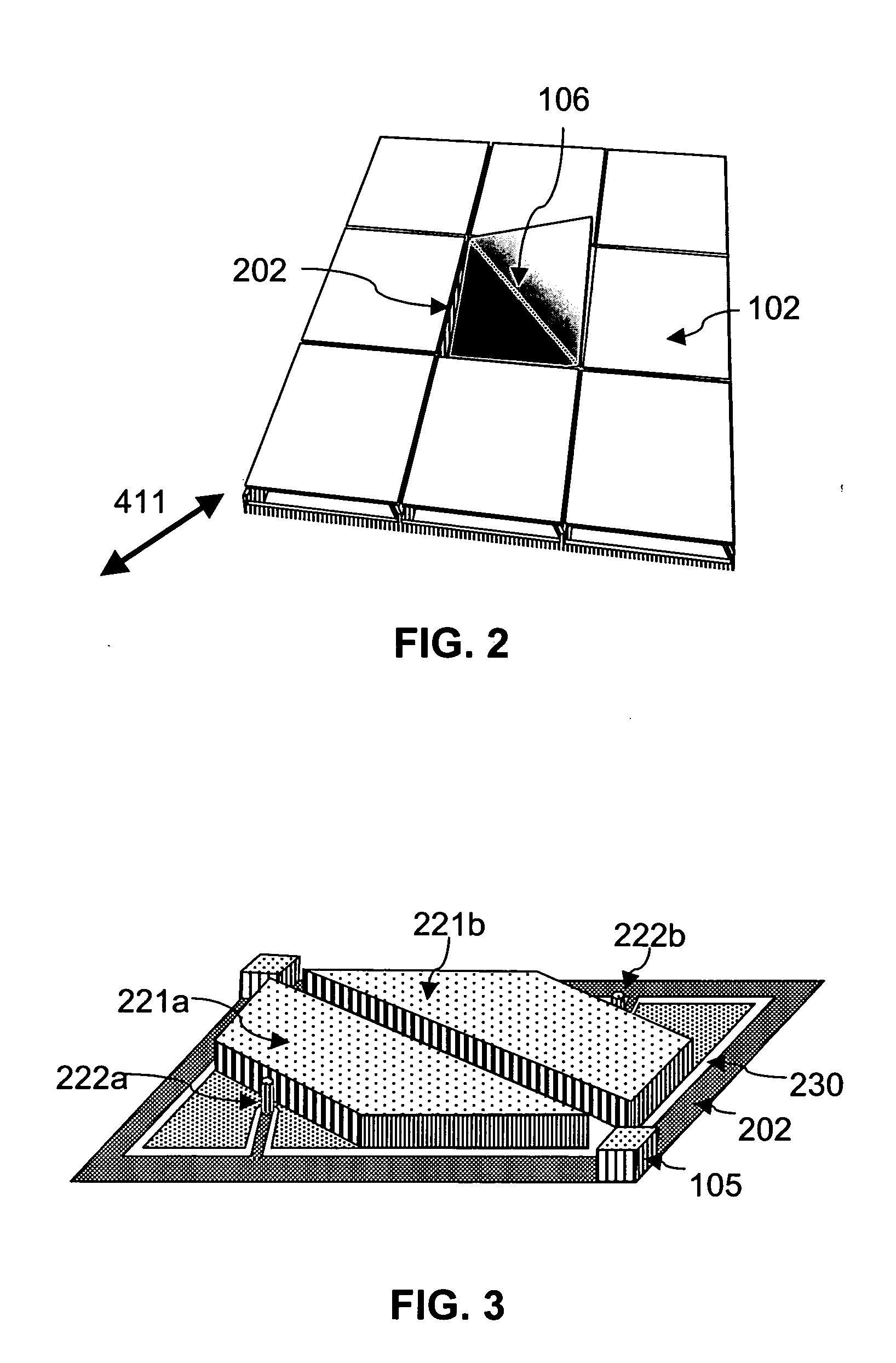

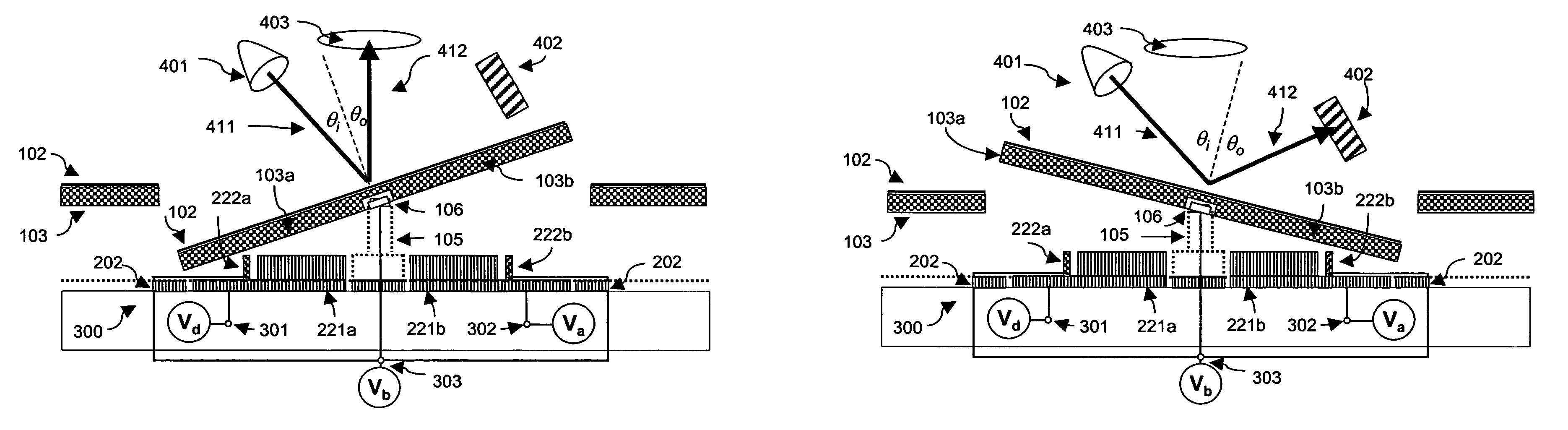

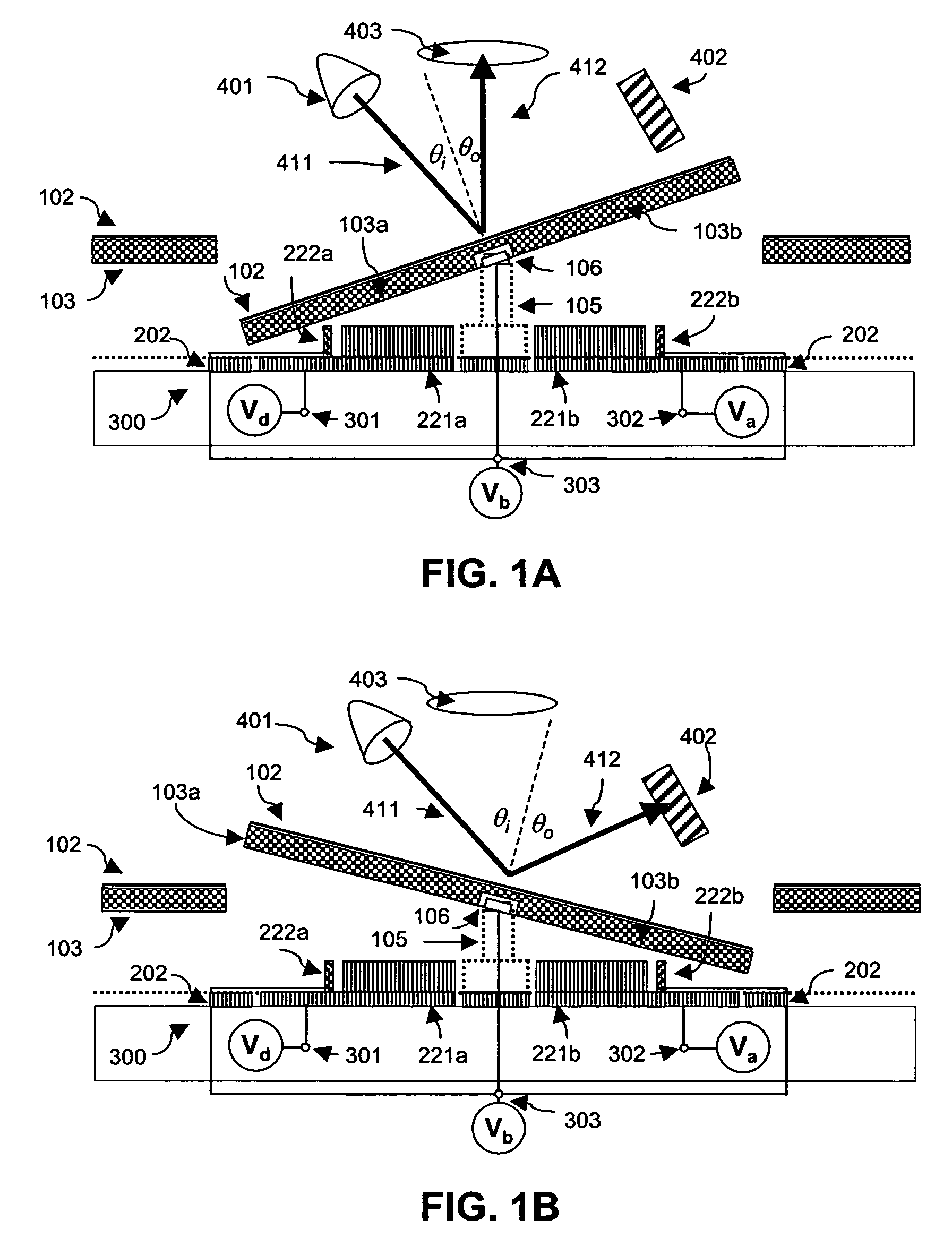

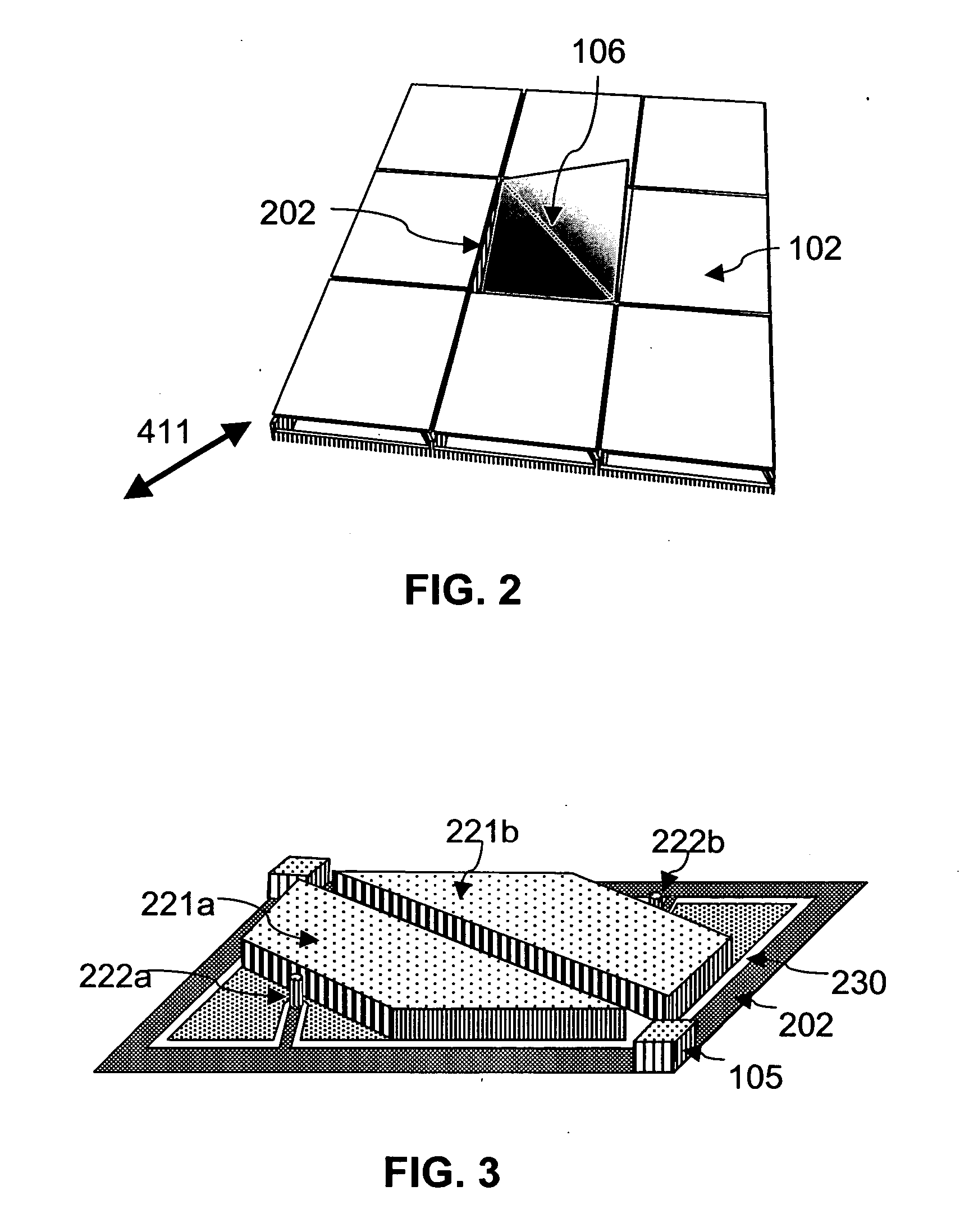

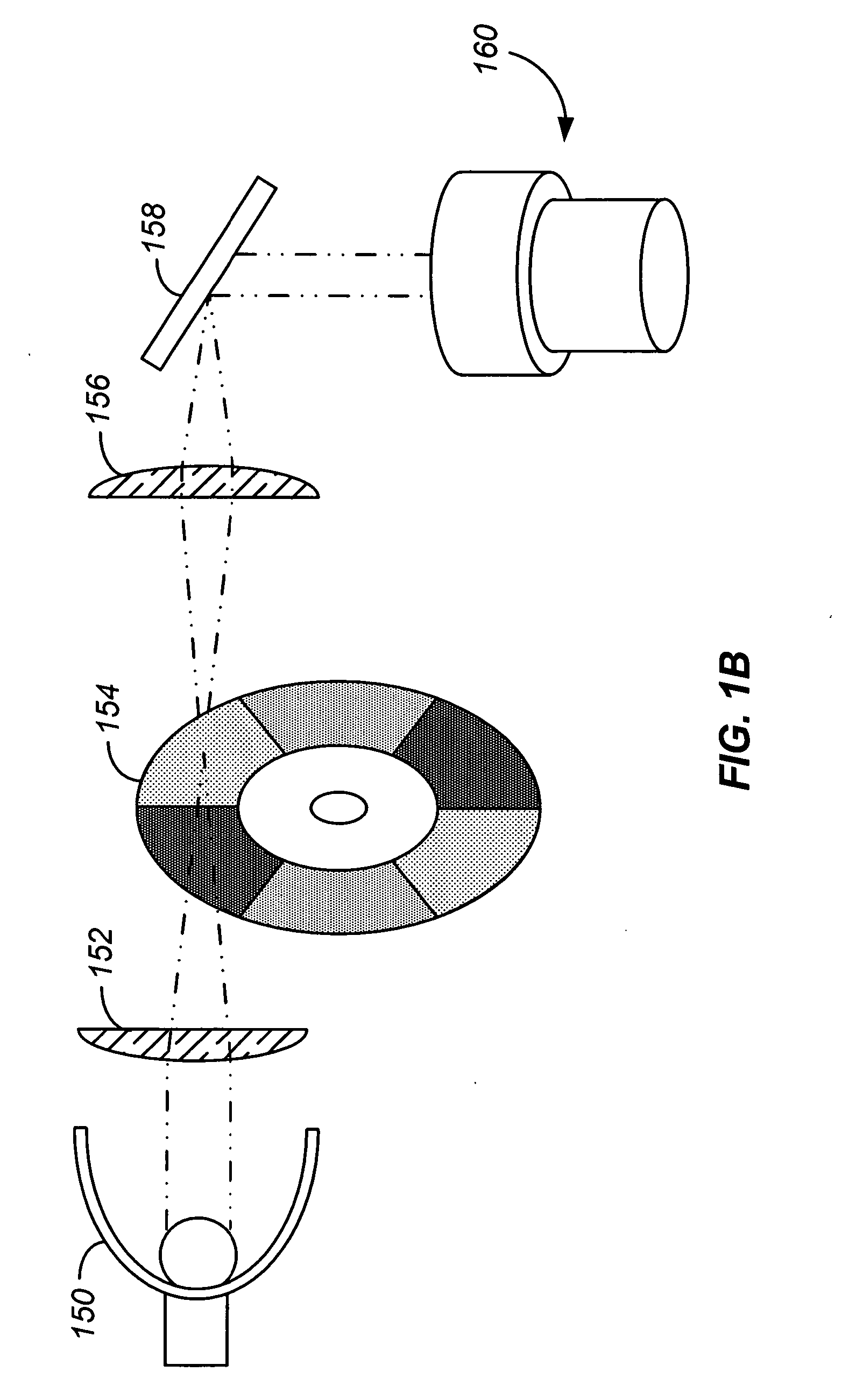

High contrast spatial light modulator and method

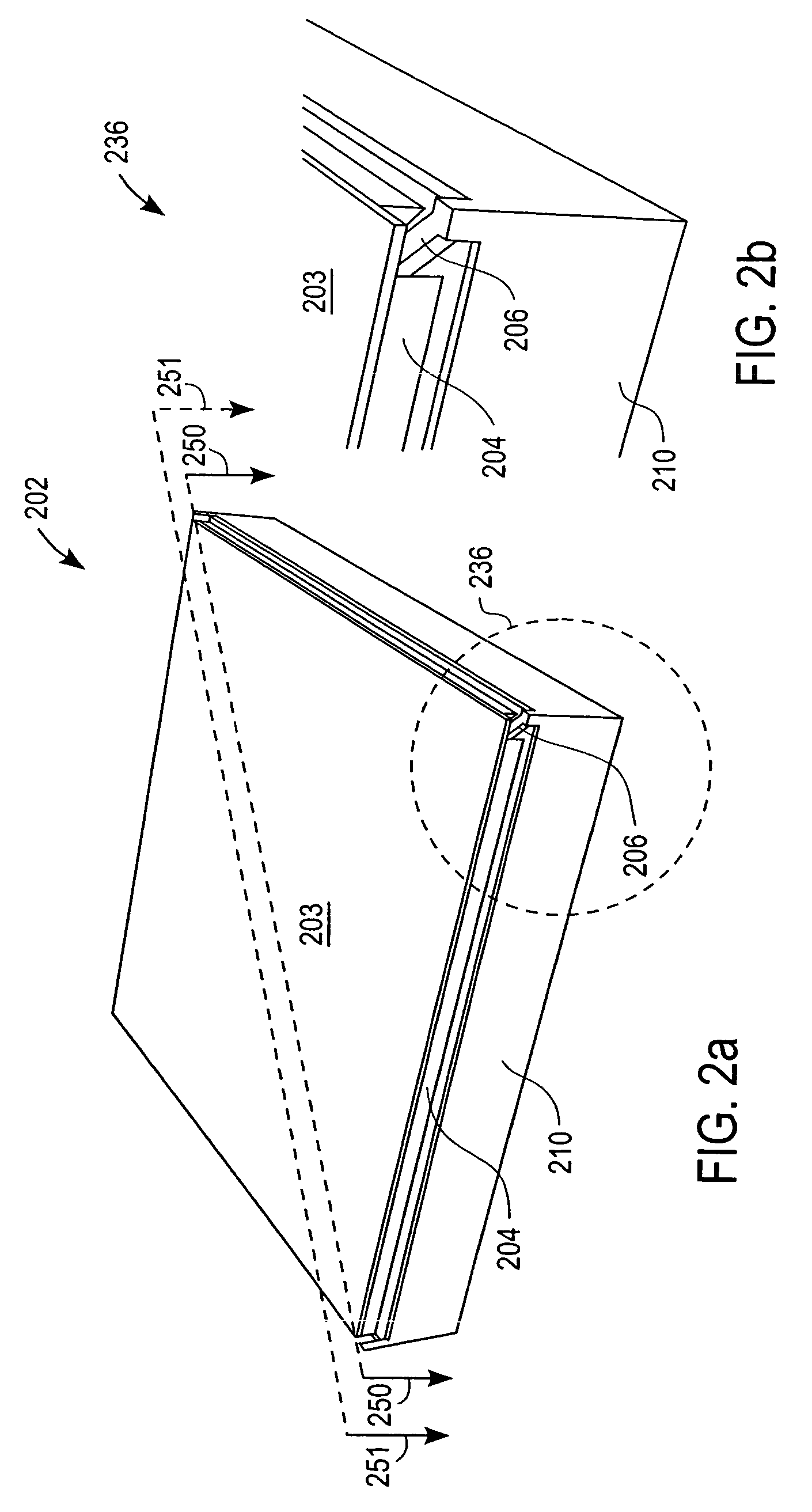

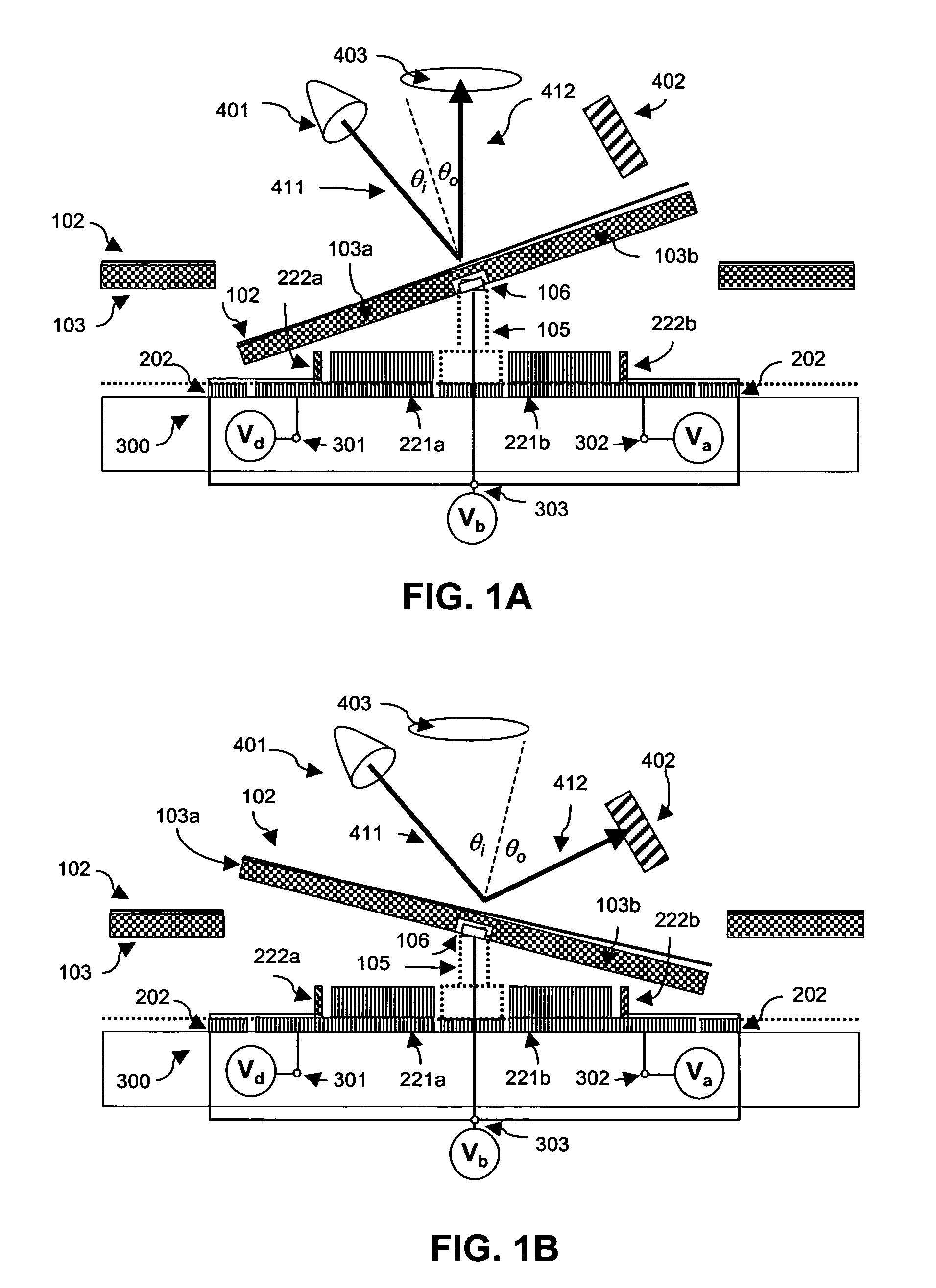

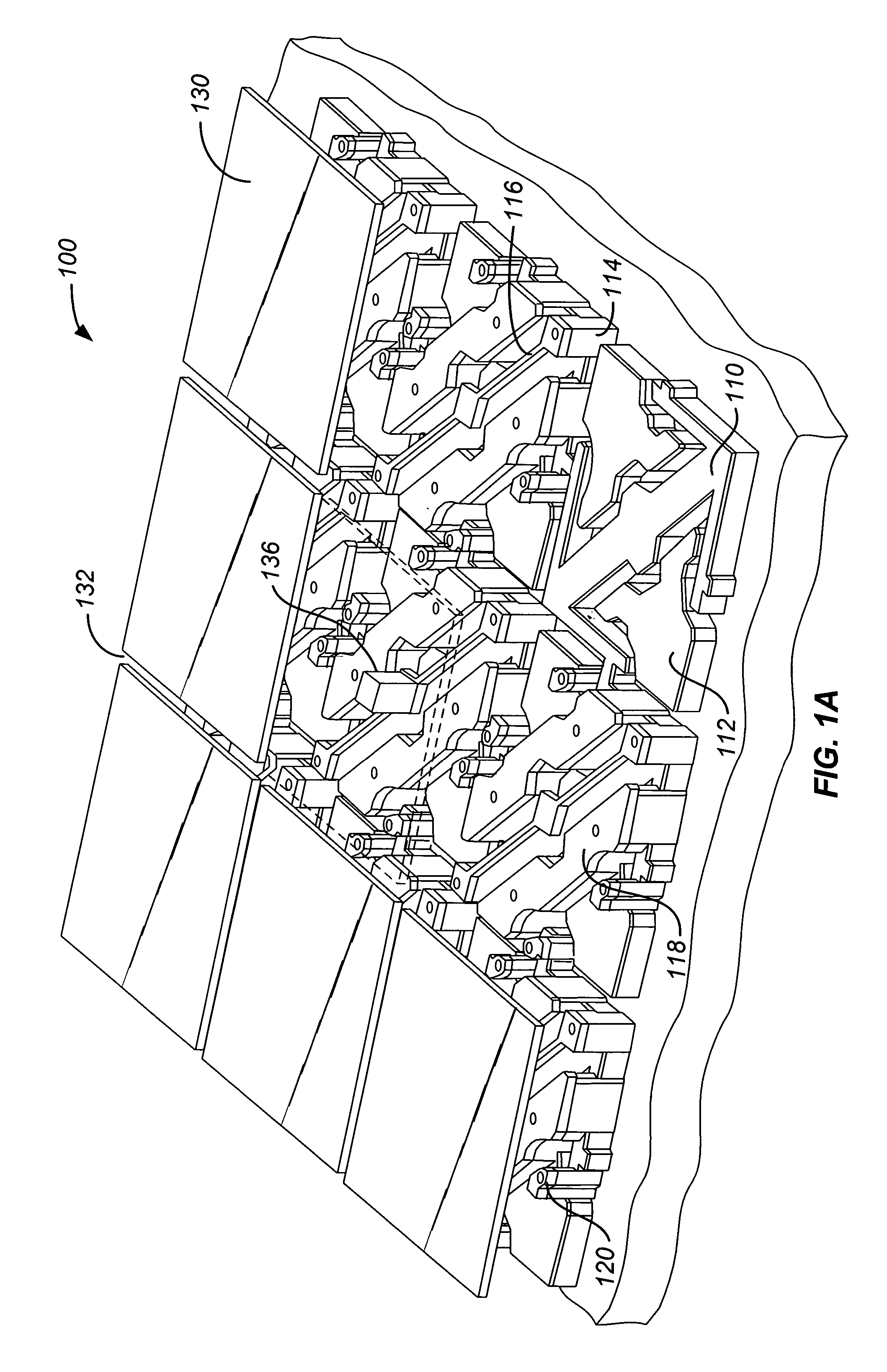

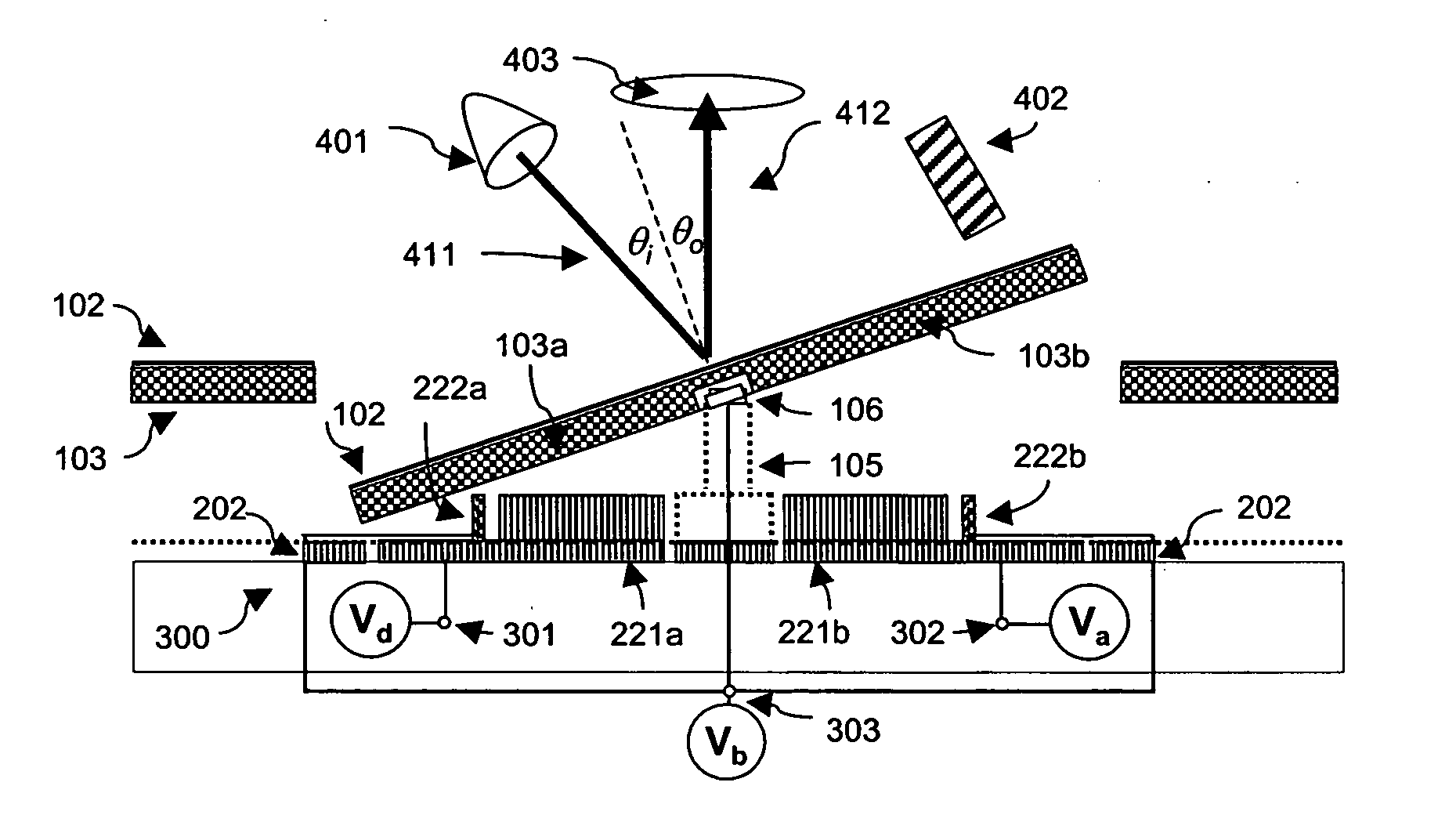

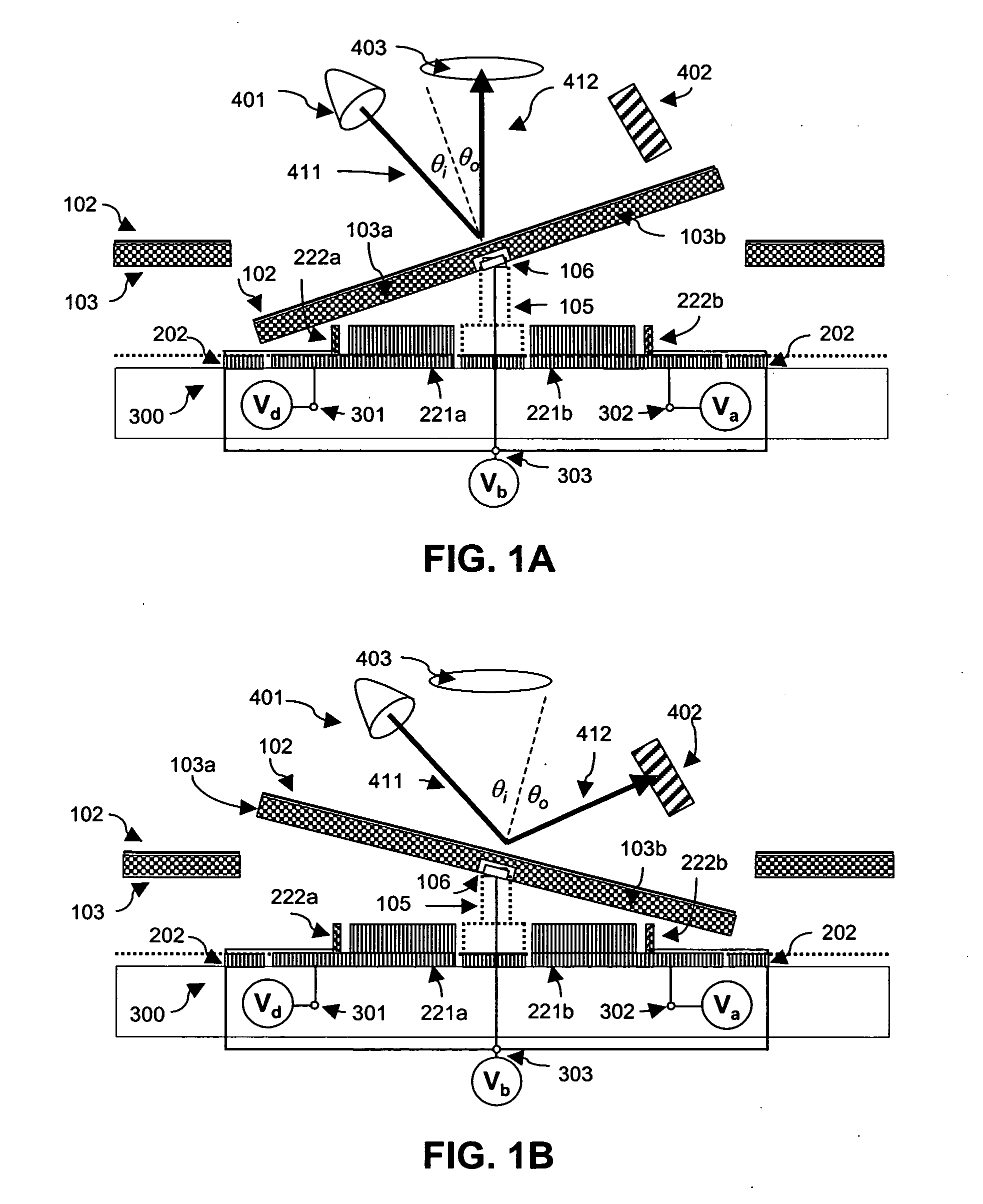

ActiveUS20050128564A1Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro-mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

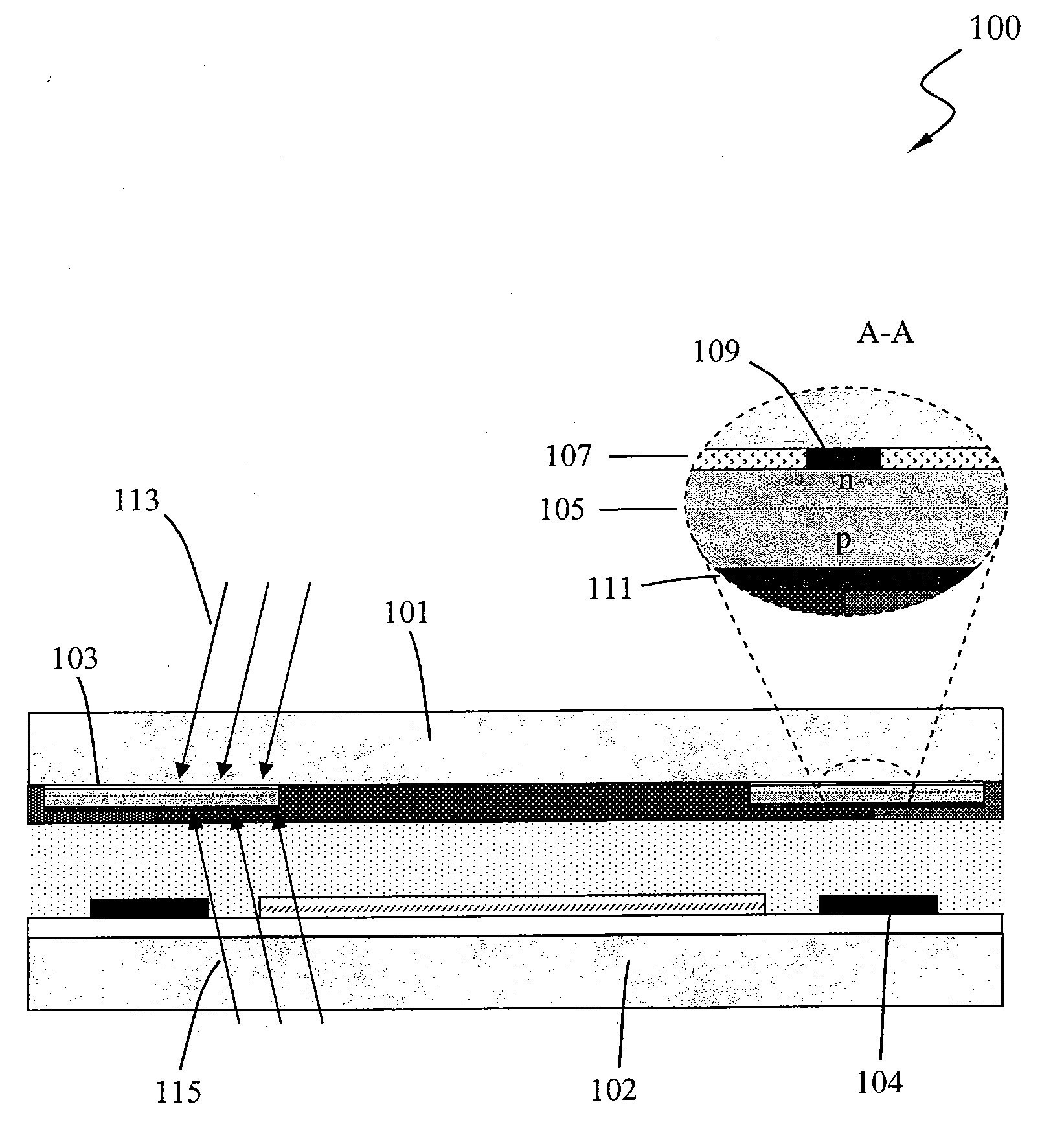

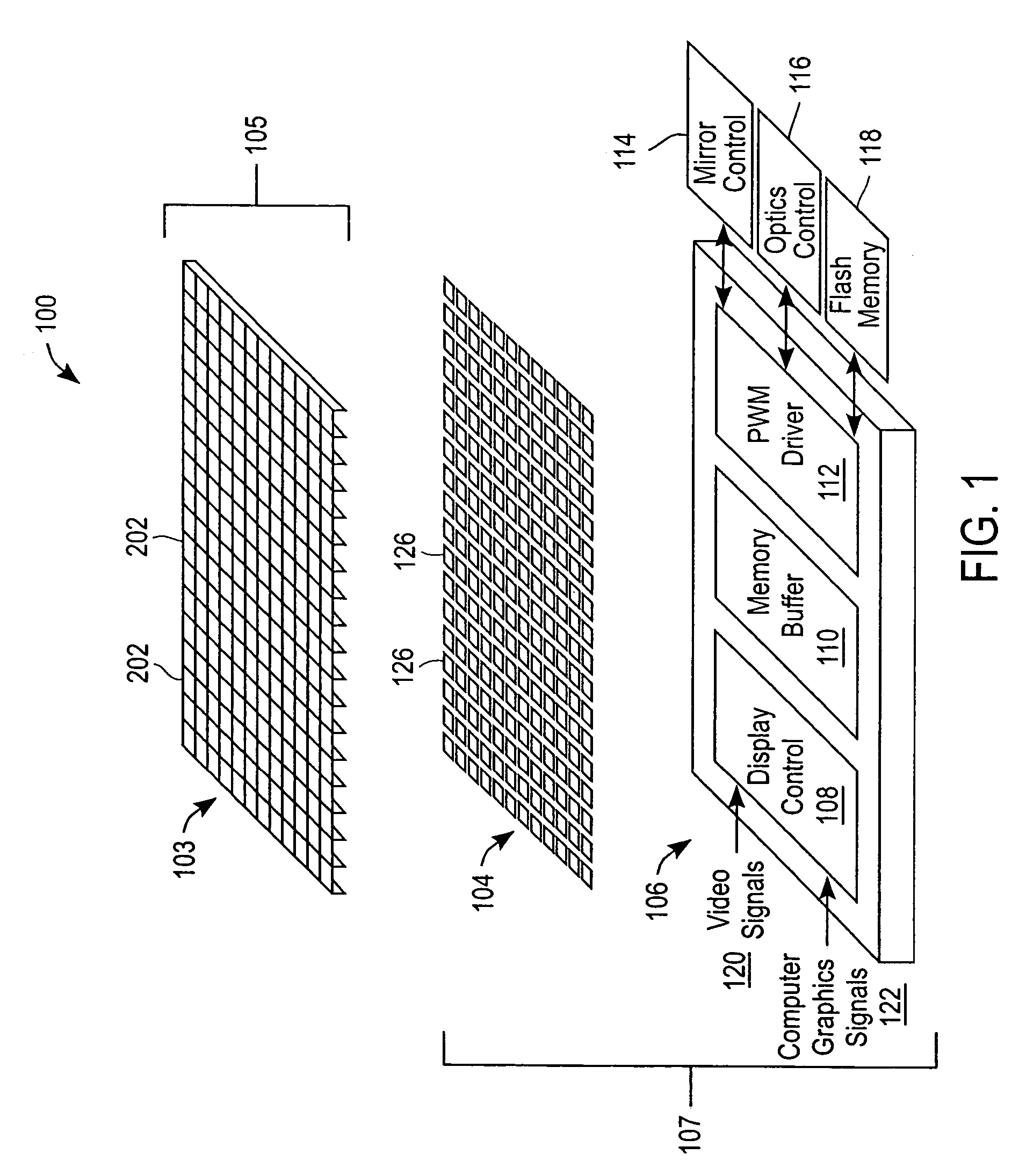

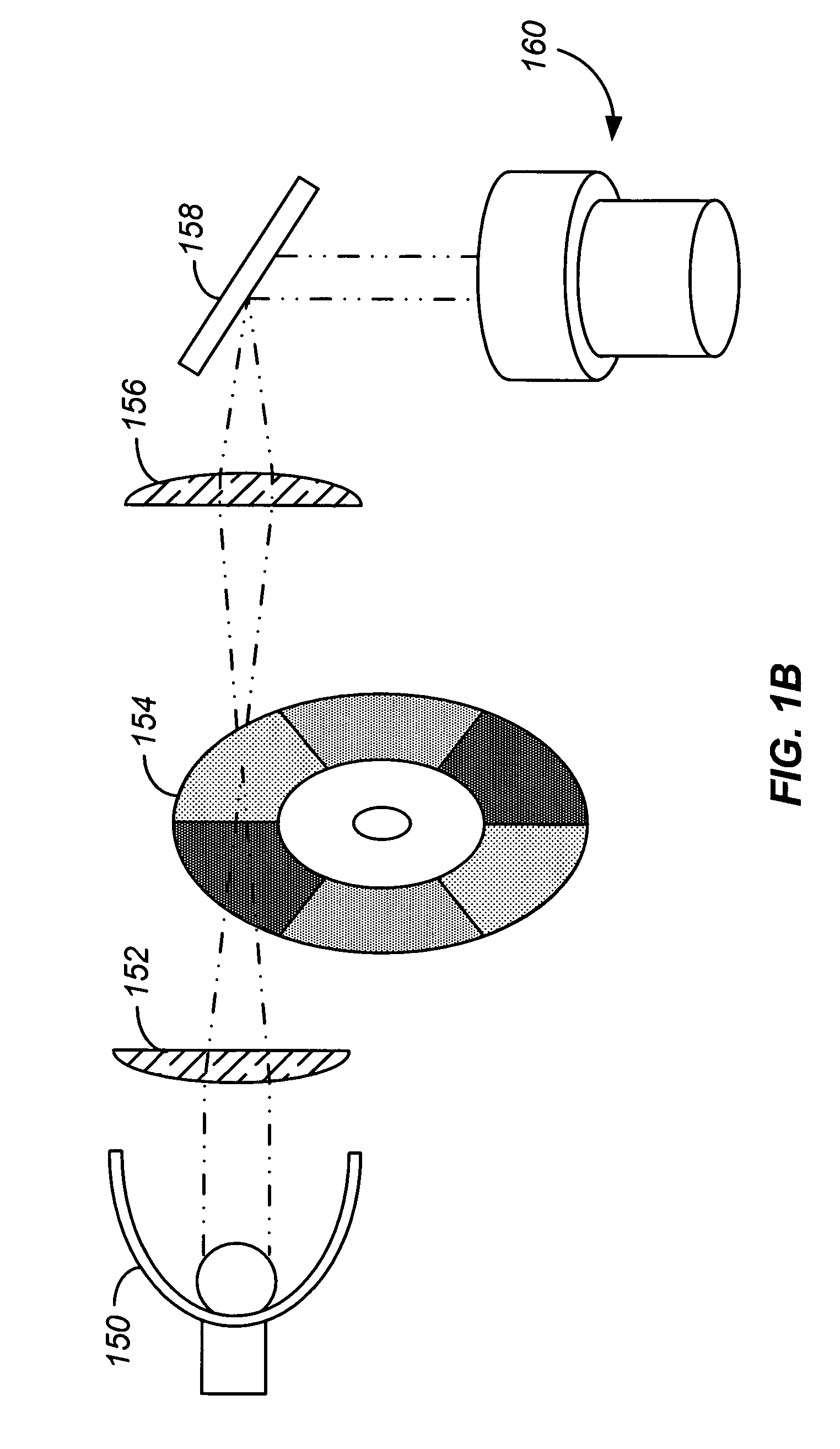

Method and Structure for Integrated Solar Cell LCD Panel

InactiveUS20070102035A1Improve fill rateIncrease cell areaPV power plantsPhotovoltaic energy generationEngineeringSolar cell

The present invention relates to a method and device for integrating solar cell on LCD panels for photovoltaic electricity generation for portable electronic devices. According to one embodiment of the present invention, the black matrix region on the color filter substrate in a LCD panel is replaced by a solar cell region. A lens array substrate is coupled between the light source layer and the TFT to focus the backlight to increase the solar cell layer area while maintaining high fill ratio of the LCD pixels. The solar cell material is selected from at least silicon, a single crystal silicon, poly-crystalline silicon, amorphous silicon, gallium arsenide, cadmium telluride, copper indium diselenide, organic / inorganic, or hybrid cells. The substrate material is selected from glass, metal, plastic or polymer.

Owner:XIAI CHARLES YANG

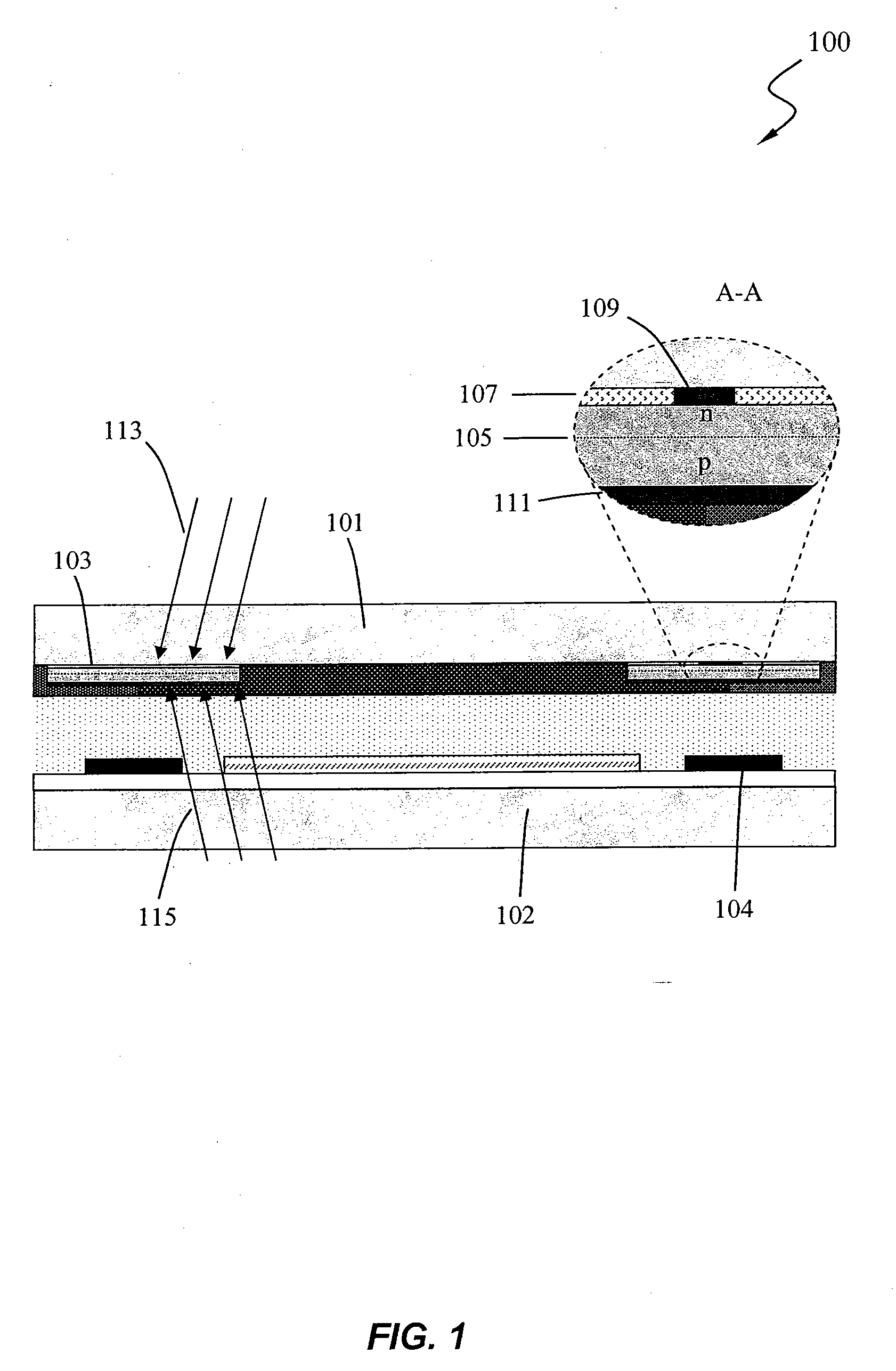

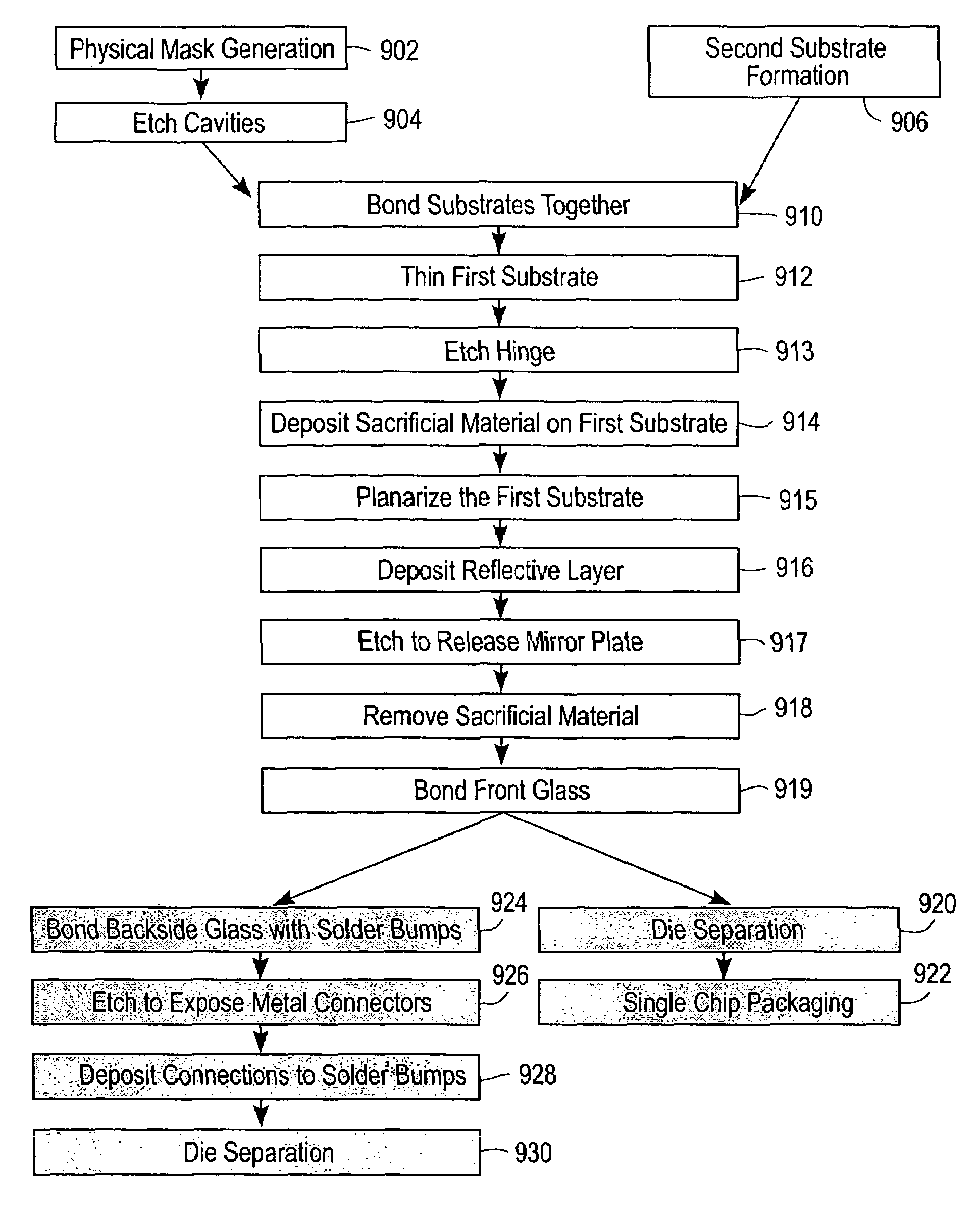

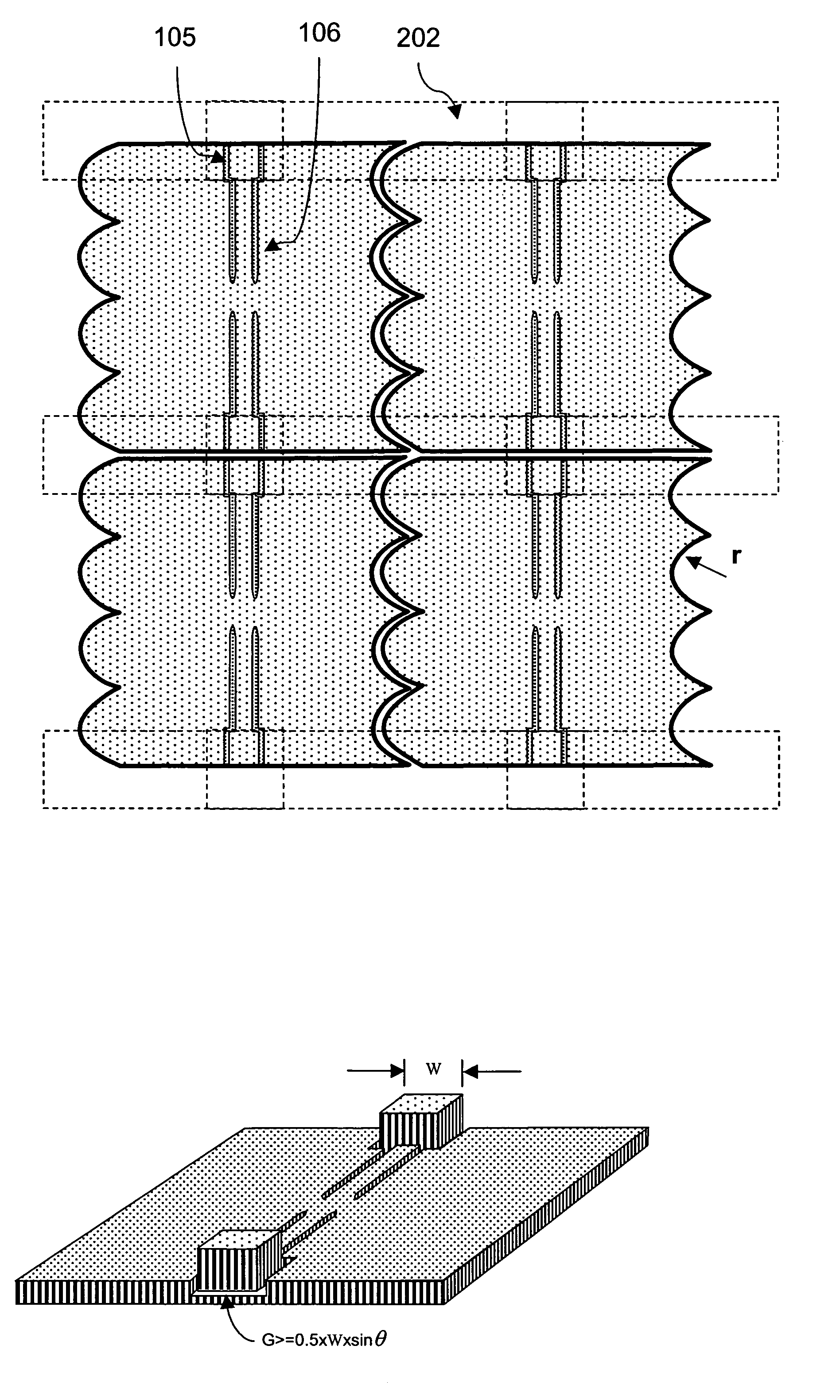

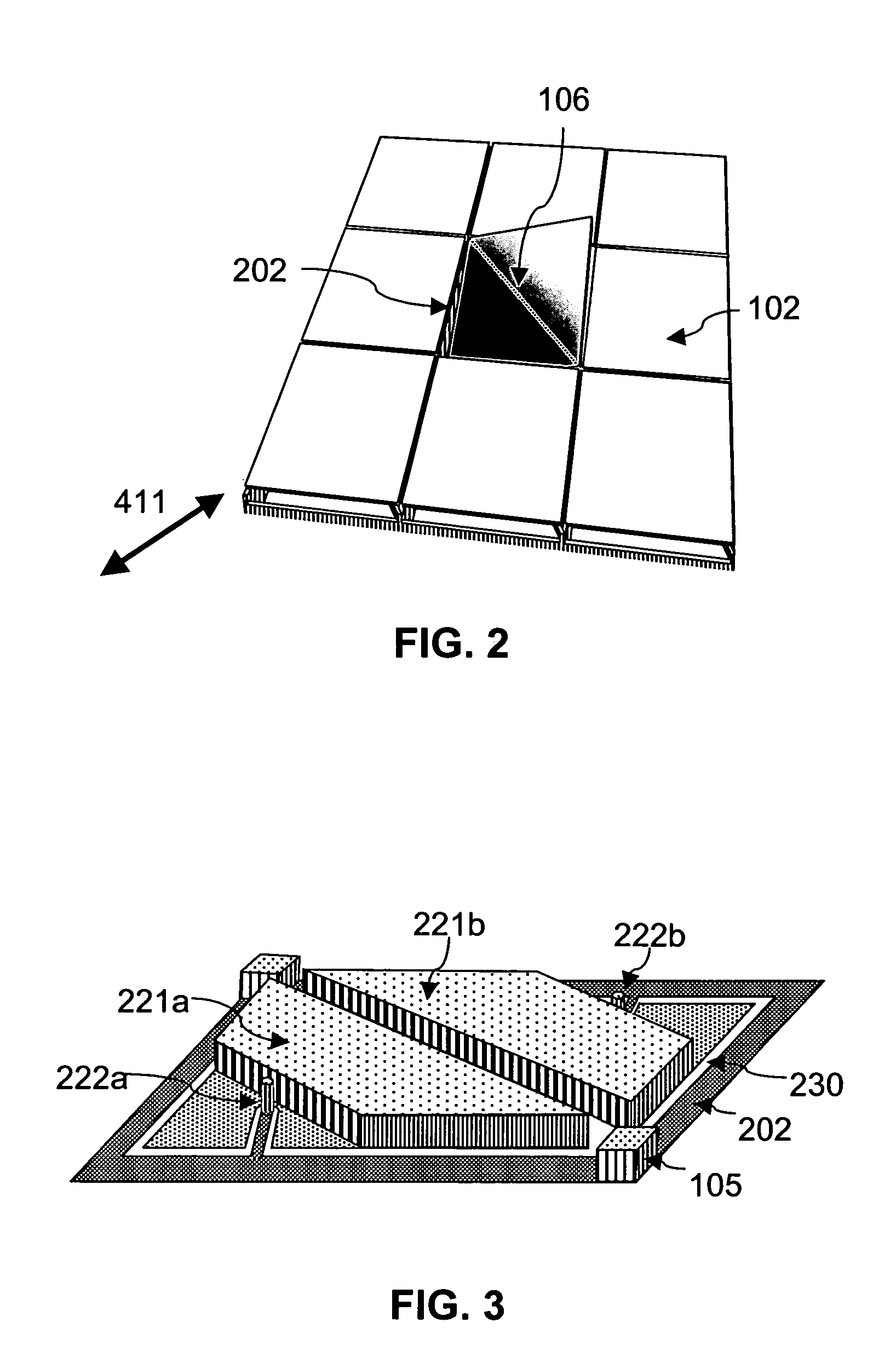

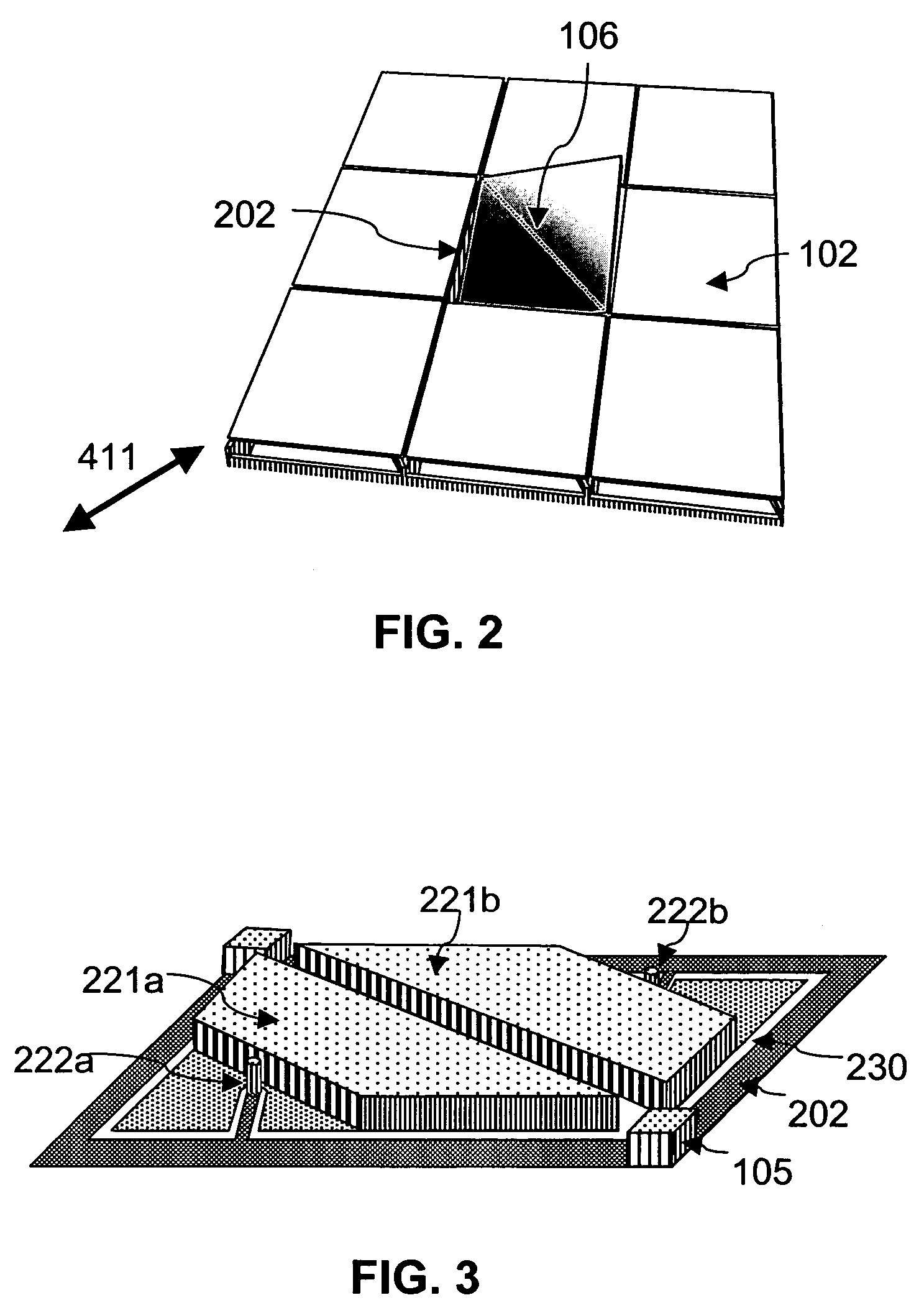

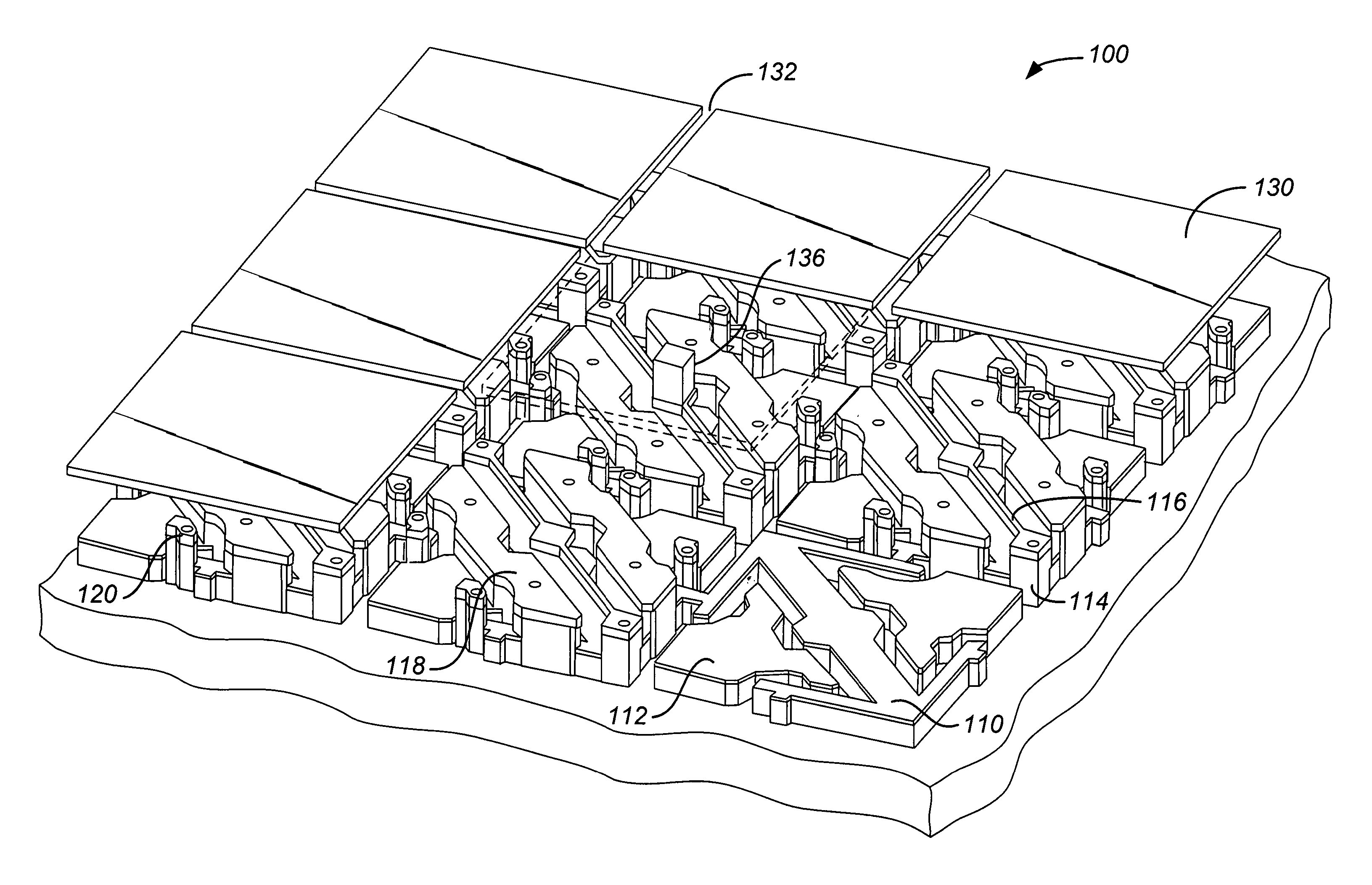

Fabrication of a high fill ratio reflective spatial light modulator with hidden hinge

InactiveUS7034984B2Easy to manufactureImprove optical efficiencySemiconductor/solid-state device manufacturingNon-linear opticsSpatial light modulatorSingle crystal

Fabrication of a micro mirror array having a hidden hinge that is useful, for example, in a reflective spatial light modulator. In one embodiment, the micro mirror array is fabricated from a substrate that is a first substrate of a single crystal material. Cavities are formed in a first side of the first substrate. Separately, electrodes and addressing and control circuitry are fabricated on a first side of a second substrate. The first side of the first substrate is bonded to the first side of the second substrate. The sides are aligned so the electrodes on the second substrate are in proper relation with the mirror plates that will be formed on the first substrate and that the electrodes will control. The first substrate is thinned to a pre-determined, desired thickness, a hinge is etched, a sacrificial material is deposited, the upper surface of the first substrate is planarized, a reflective surface is deposited to cover the hinge, a mirror is released by etching and the sacrificial layer around the hinge is removed to release the hinge so the hinge can rotate about an axis in line with the hinge.

Owner:MIRADIA INC

High contrast spatial light modulator and method

ActiveUS7167298B2Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro-mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

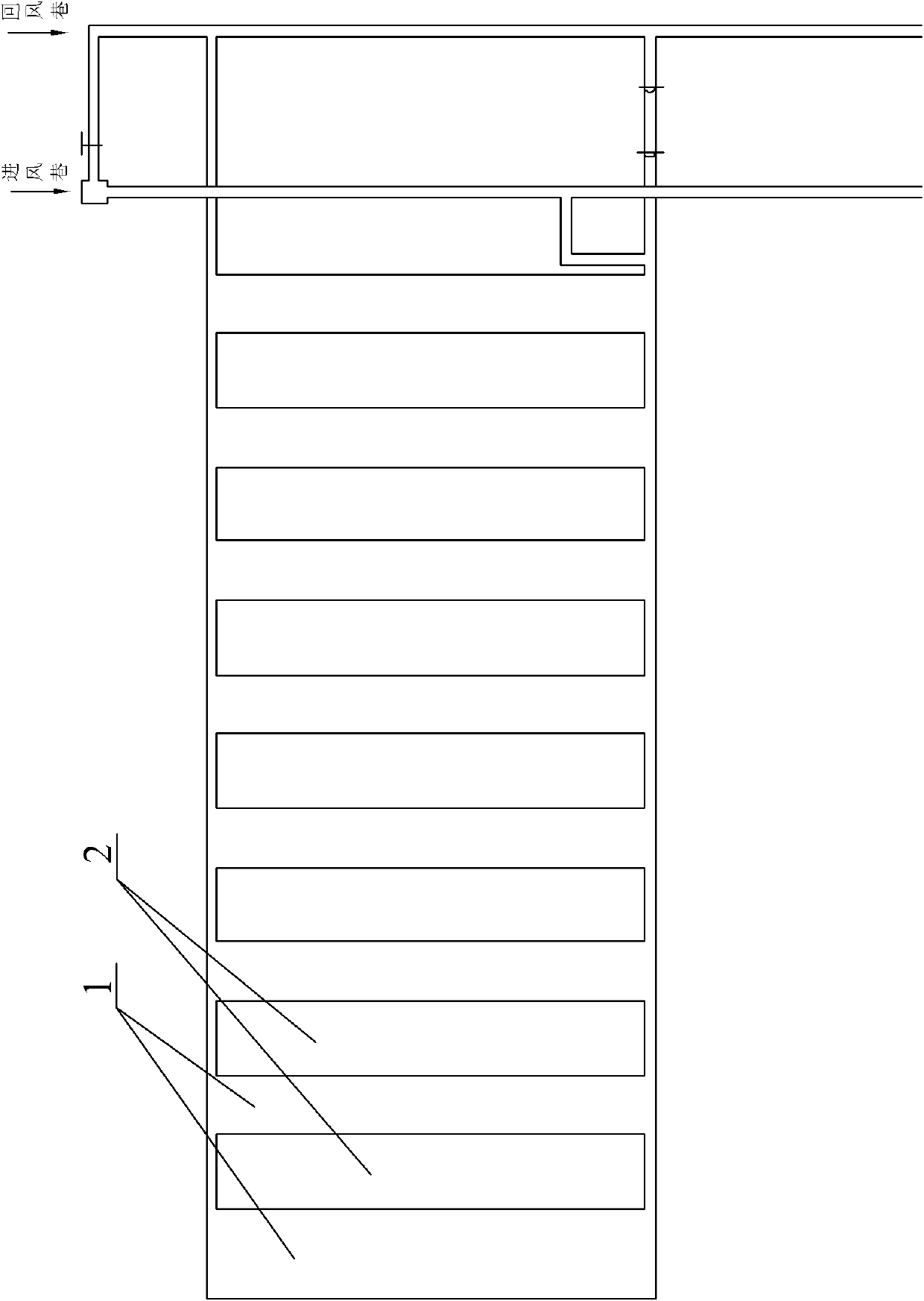

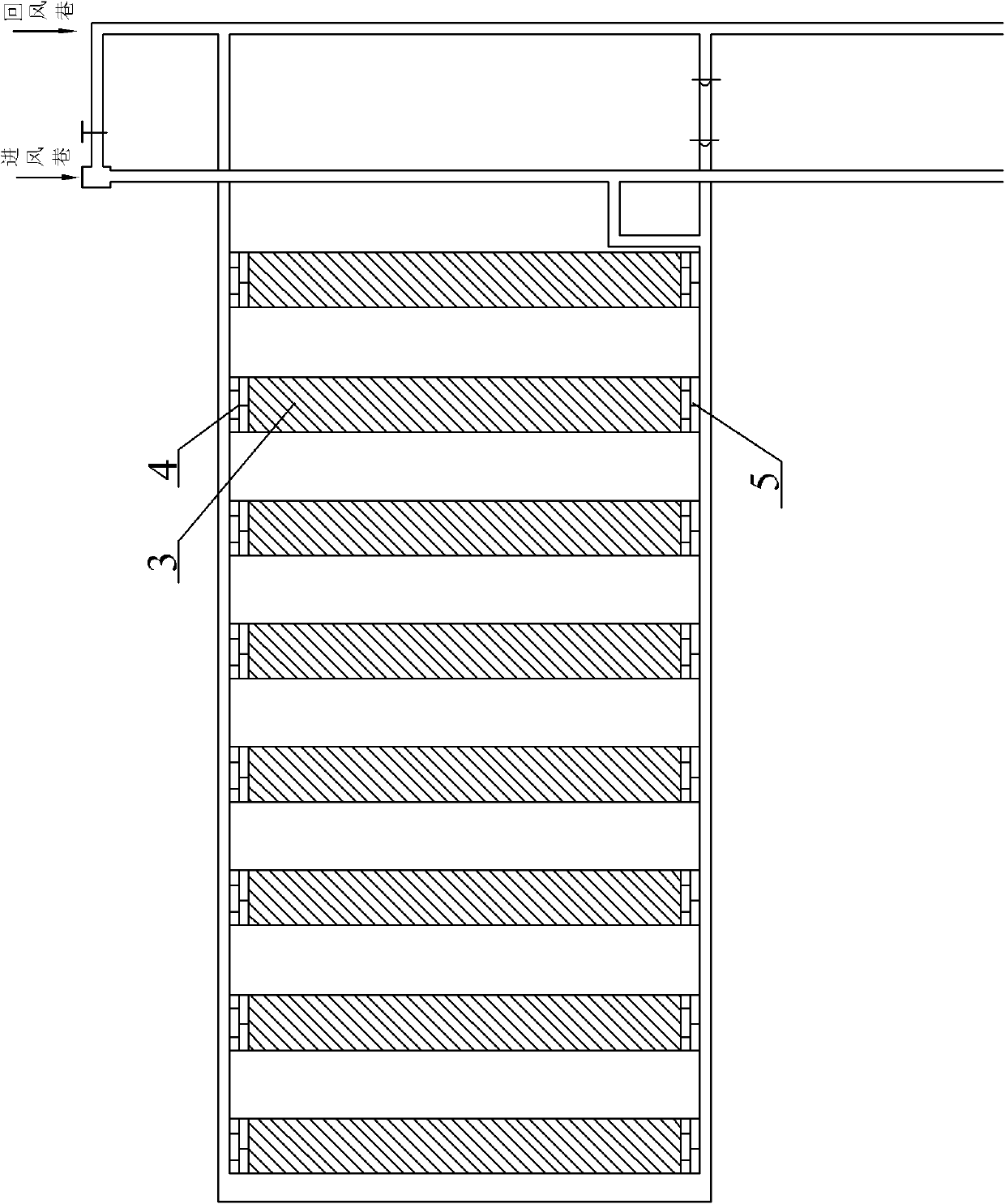

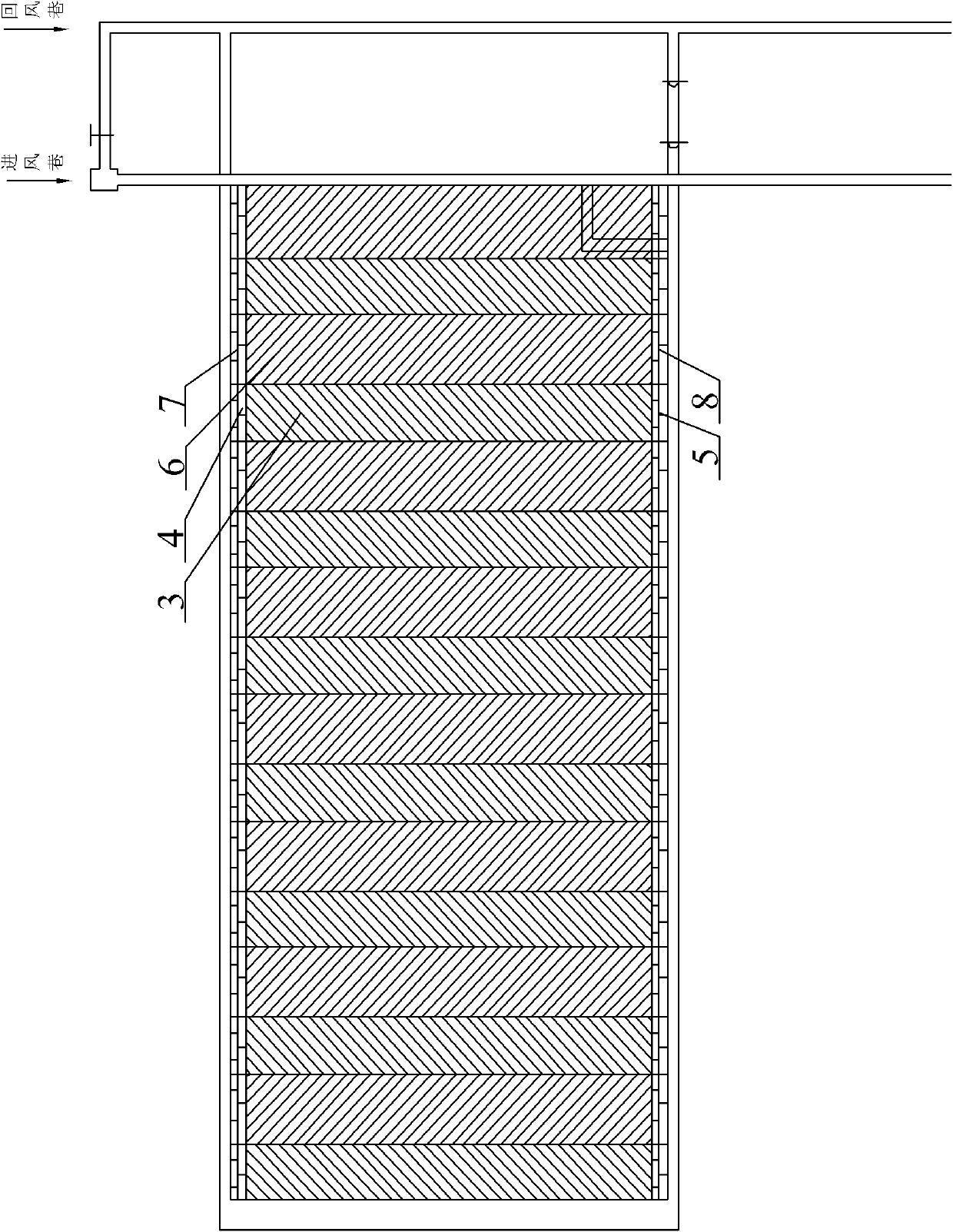

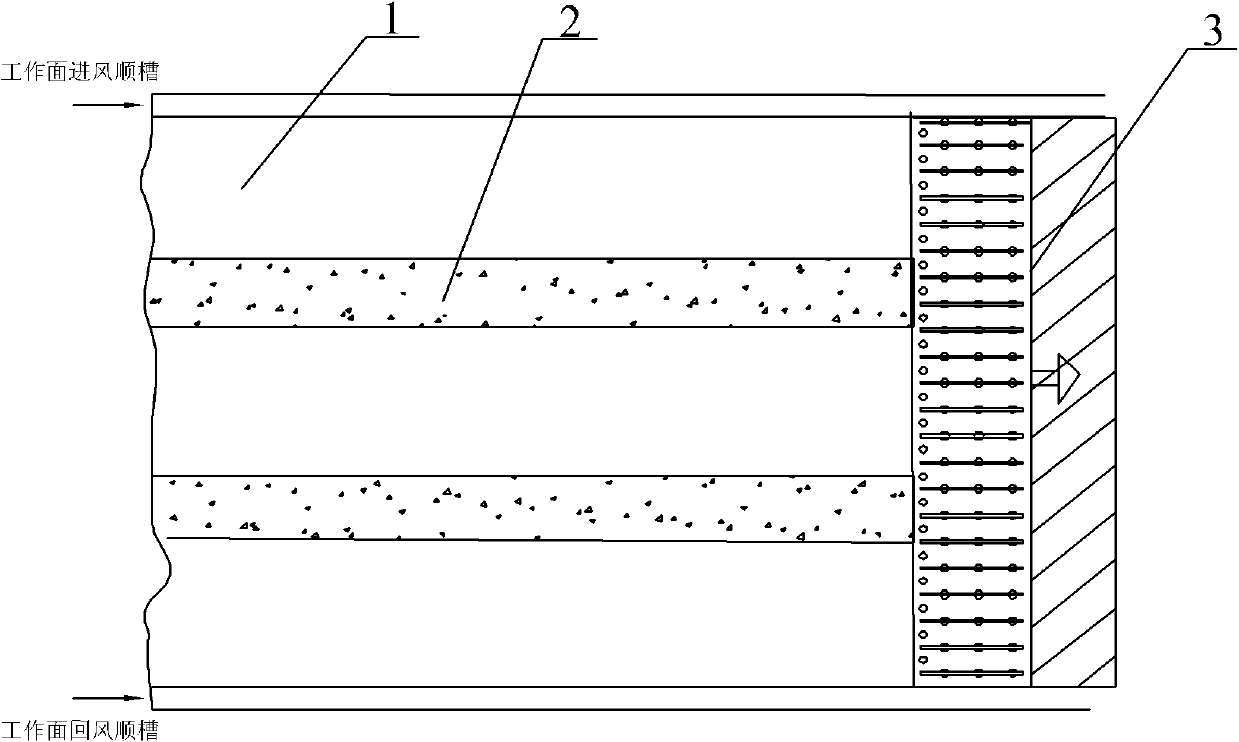

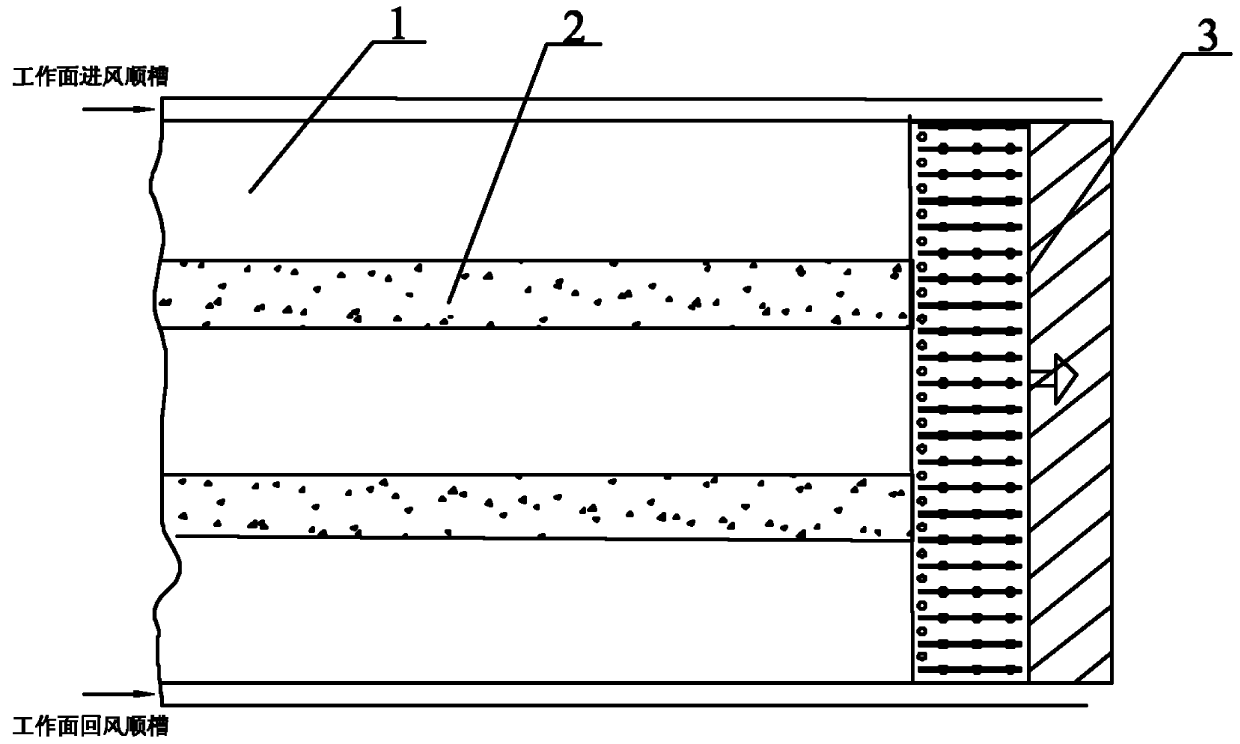

House pillar type cutting and filling method of medium coal seam for controlling movement deformation of overlying rock

InactiveCN102011588AImprove securityIncrease productivityUnderground miningSurface miningEngineeringCoal pillar

The invention belongs to the field of coal cutting and filling, in particular to a house pillar type cutting and filling method of the medium coal seam for controlling the movement deformation of the overlying rock, which is suitable for the coal face with the coal seam thickness more than 2 meters. The method comprises the following steps: determining the initial weighting interval L and the periodic weighting interval M of the main roof according to the main roof initial weighting interval theory; arranging the rooms and the coal pillars at intervals; and using the material with high expansibility in water during the filling according to the method comprising the following steps of mining the rooms, filling the empty rooms, mining the coal pillars and filling the empty zones of the coal pillars. The method provided by the invention can determine the most economical filling ratio through controlling the key layer to maximize the benefits; the method provided by the invention can control the movement deformation of the overlying rock absolutely within the allowed range when realizing the pulling without pillars, and realize the extremely small gentle uniform sinking of the ground; and the method provided by the invention can realize the mining of the coal resource with high recovery rate under any condition by using the material with high expansibility in water, and greatly enhance the security of coal face. When the rooms are mined, a plurality of coal face of rooms can be arranged at intervals to enhance the working efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

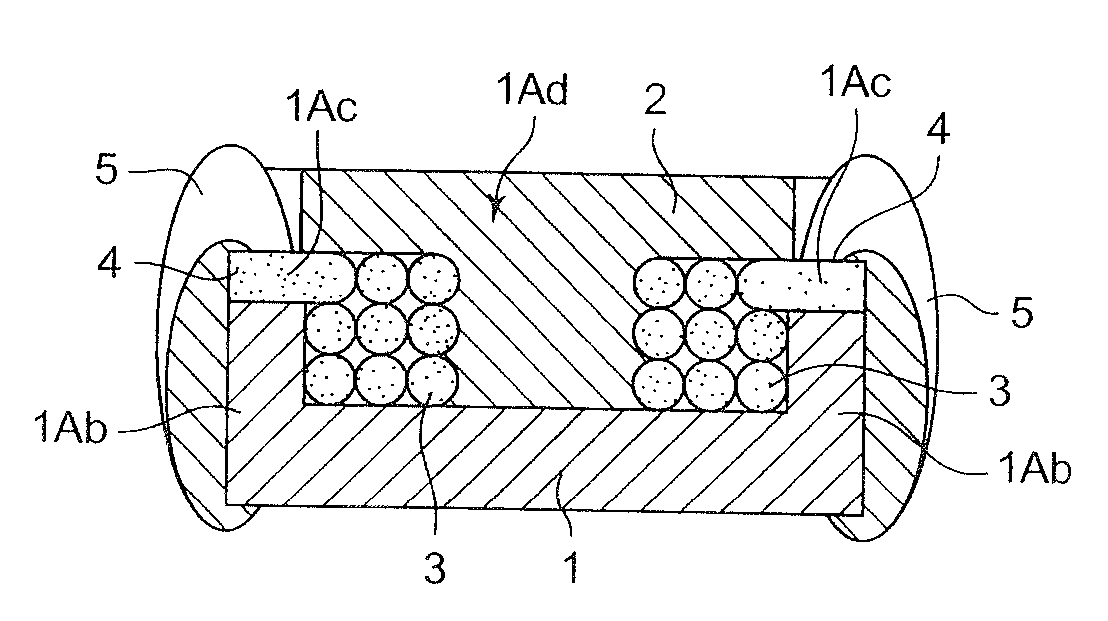

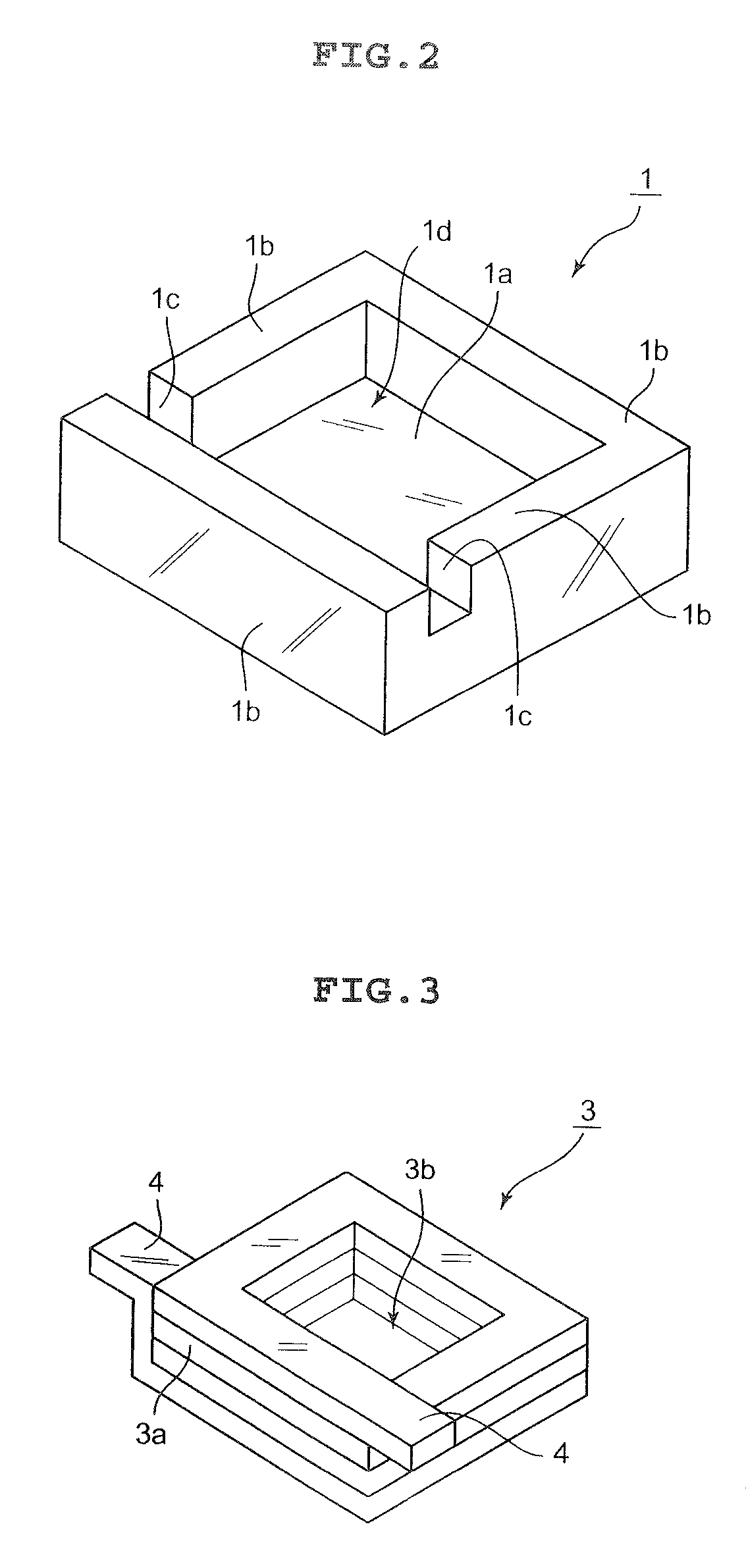

Magnetic element and method of manufacturing magnetic element

ActiveUS20060186978A1Improve permeabilityEasy to manufactureTransformers/inductances casingsTransformers/inductances coils/windings/connectionsElectrical conductorEngineering

Owner:SUMIDA CORP

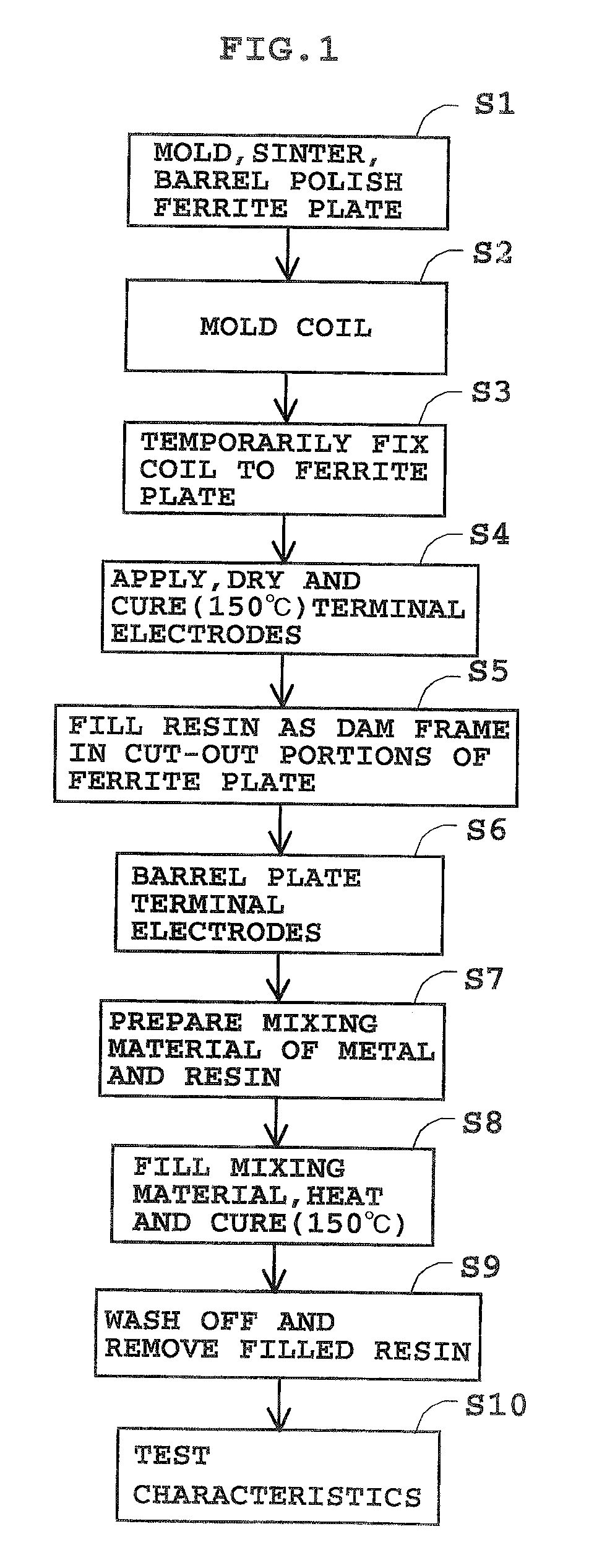

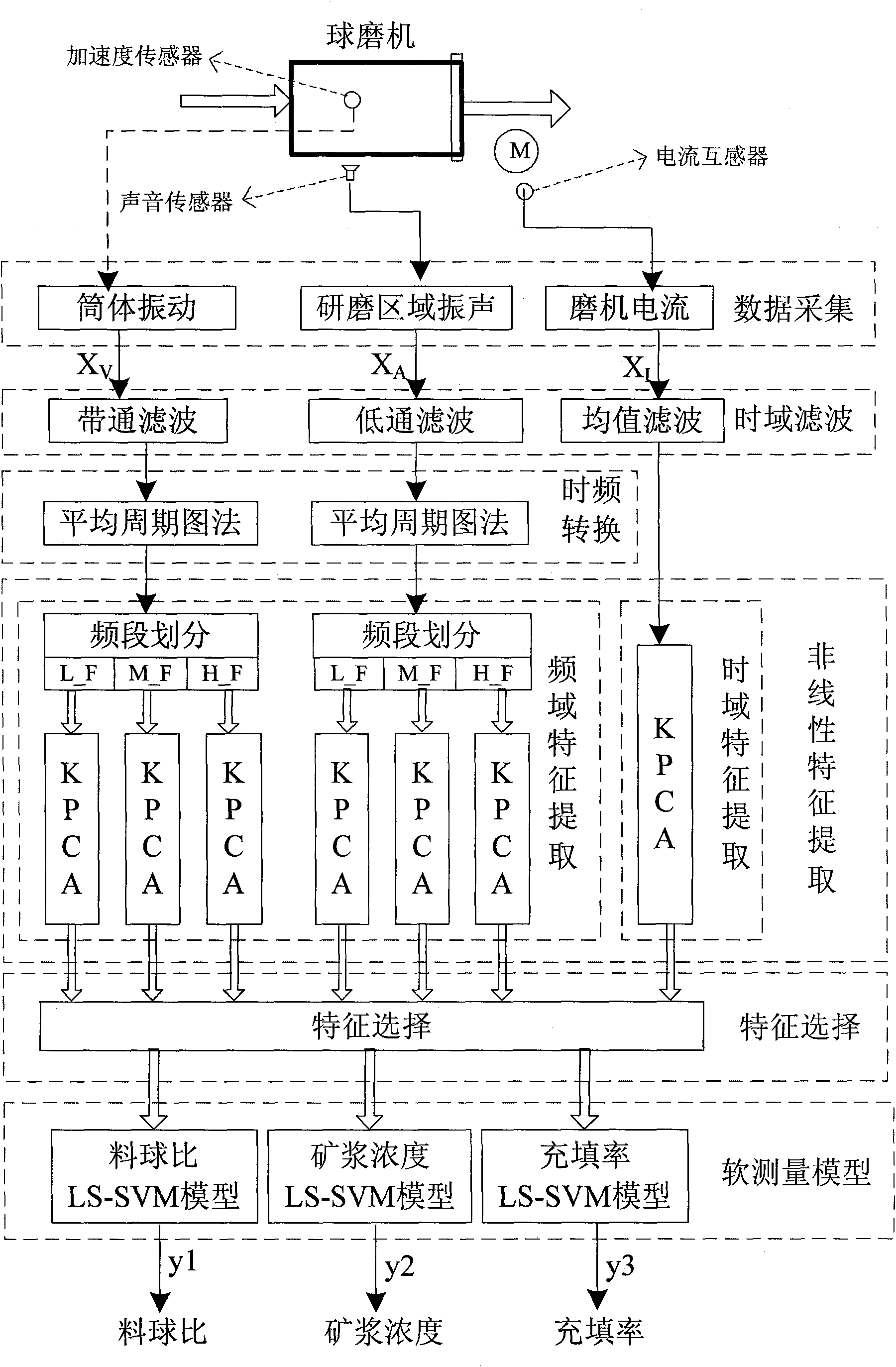

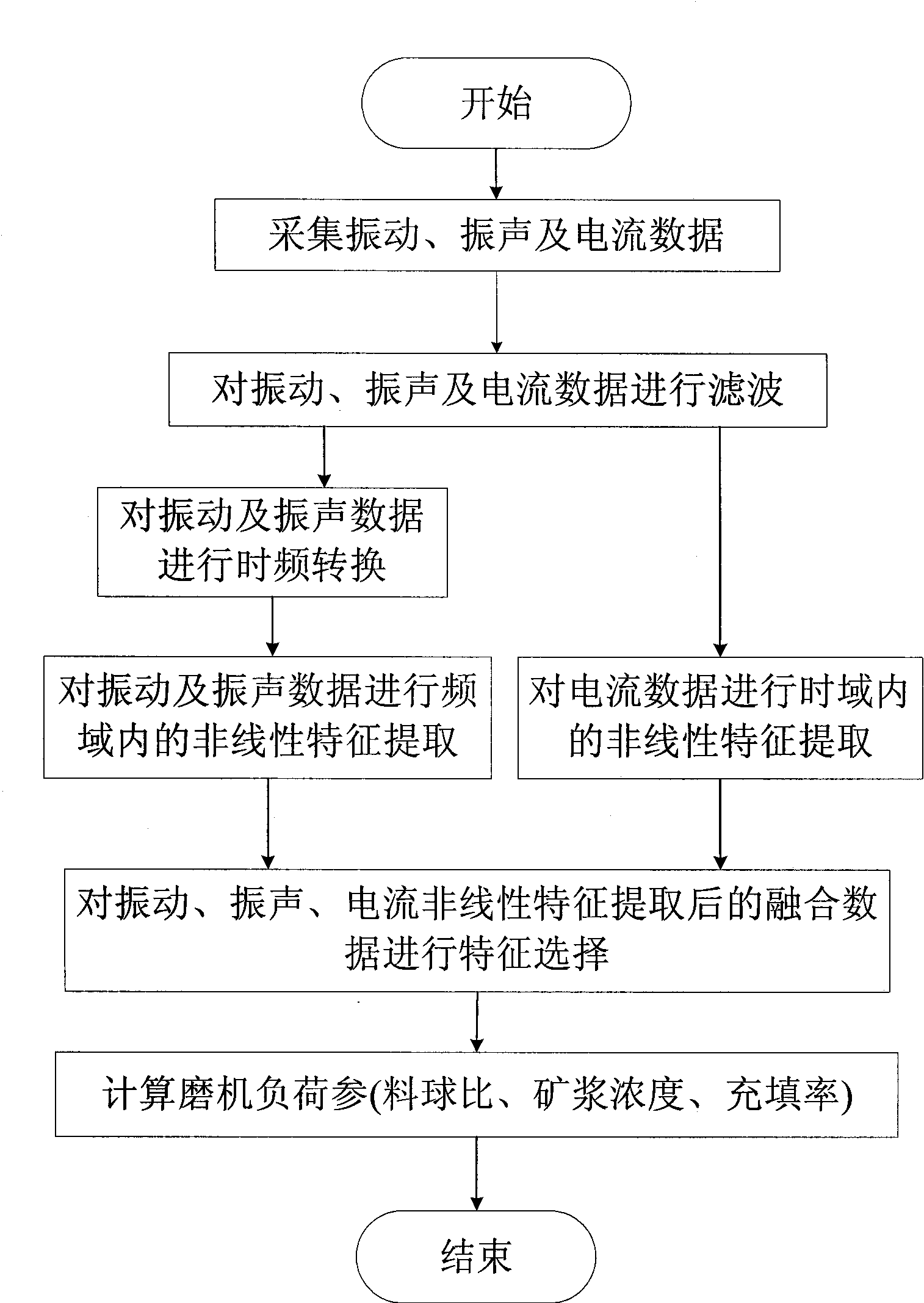

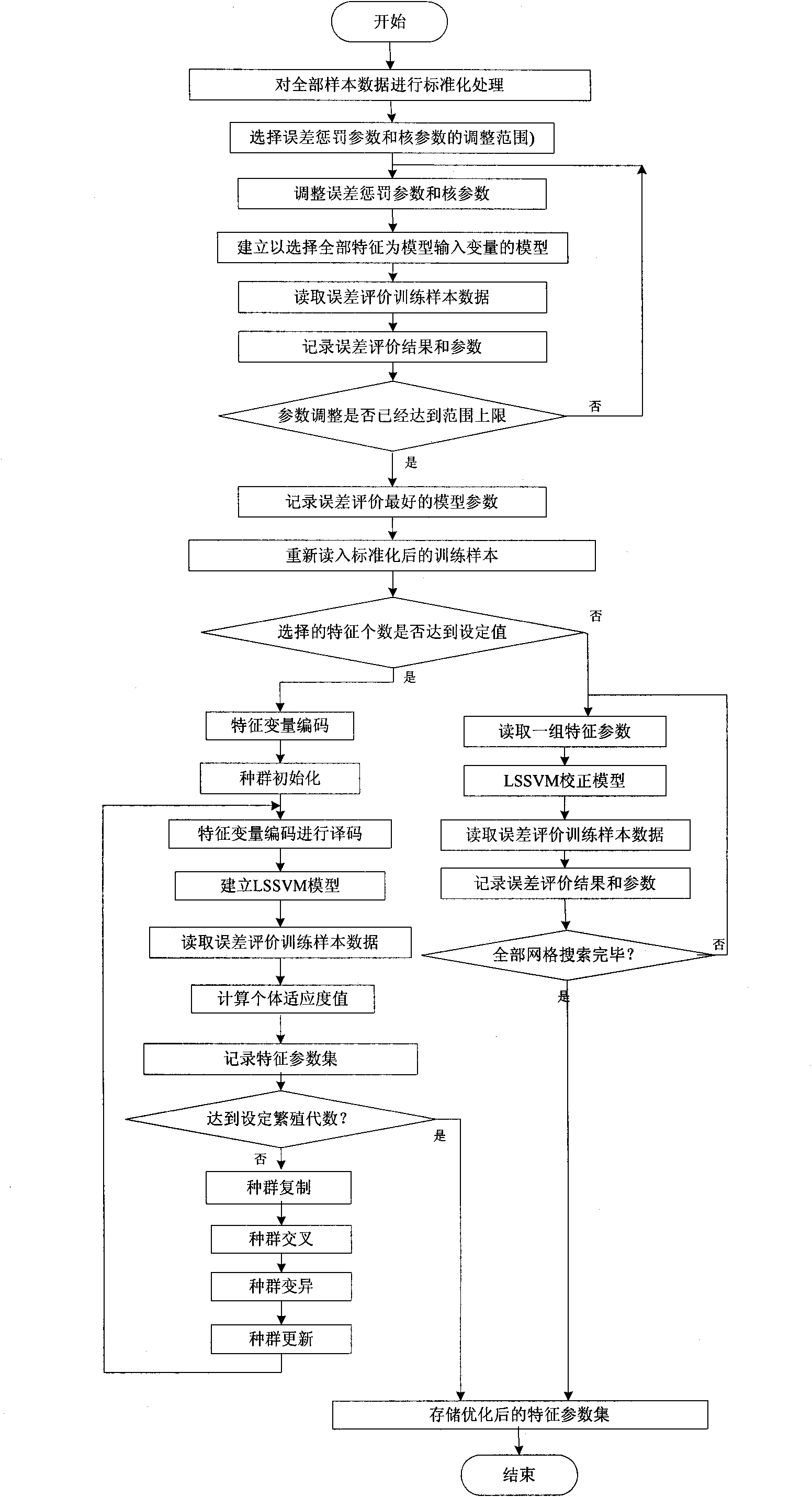

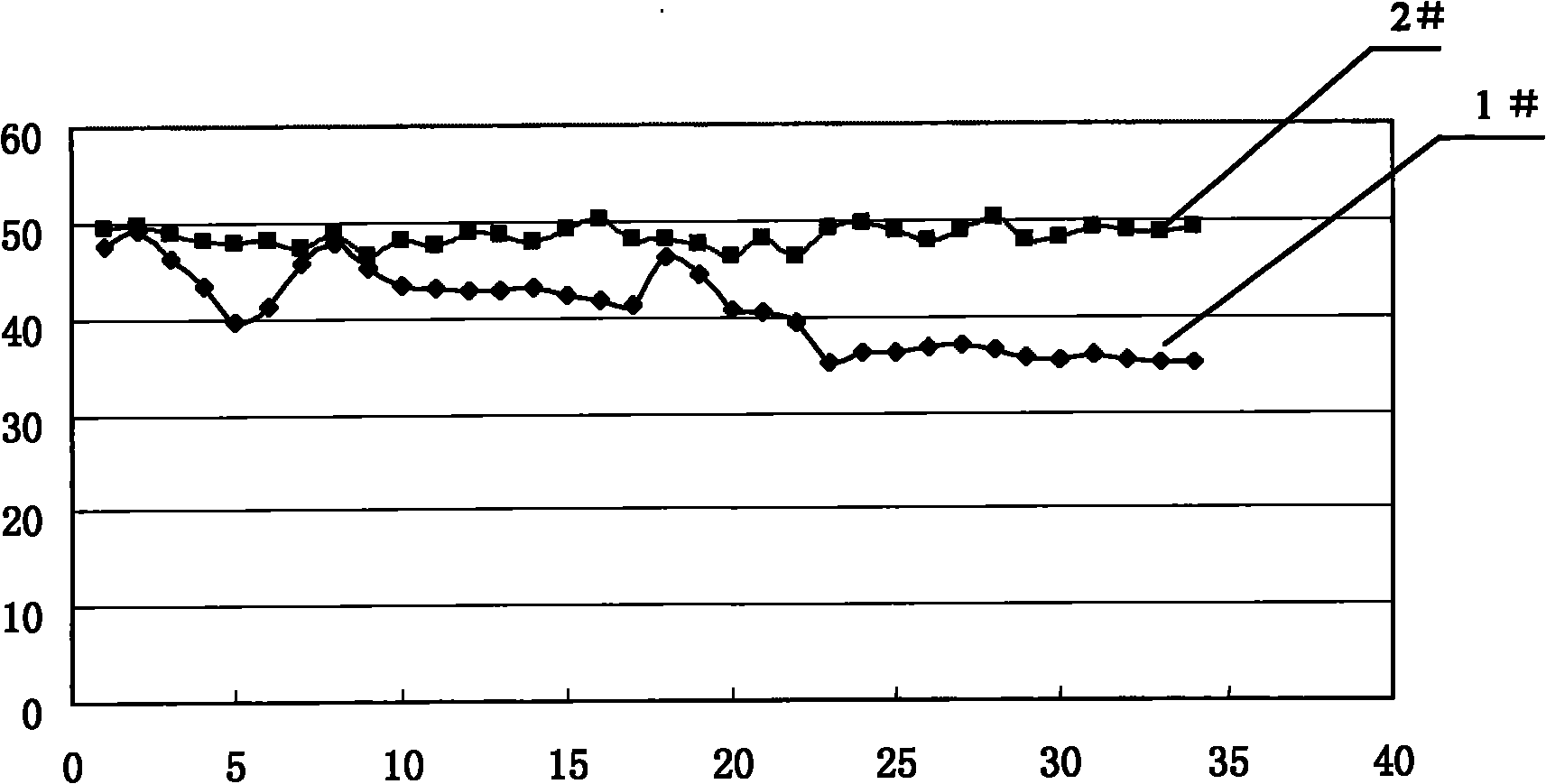

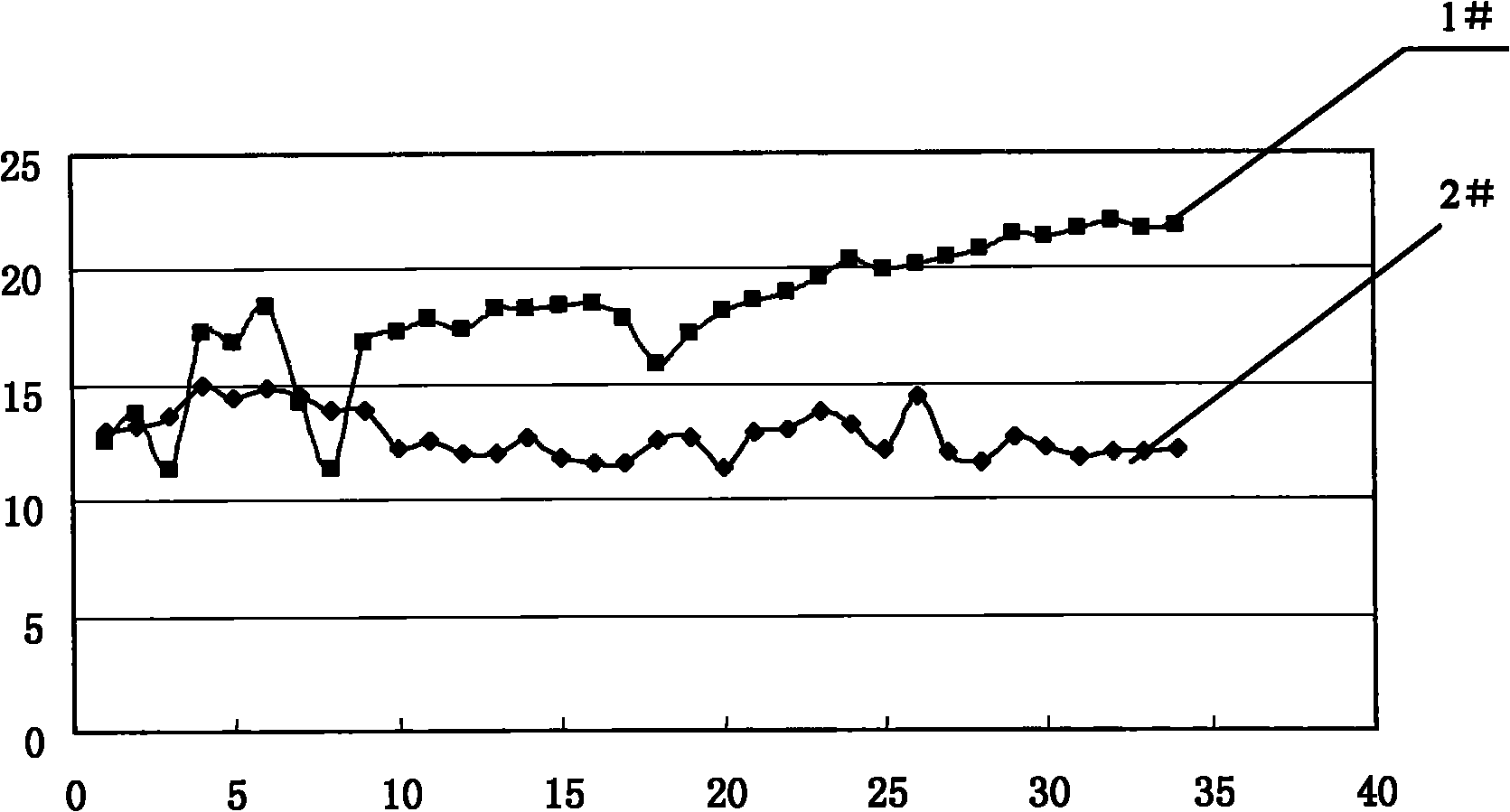

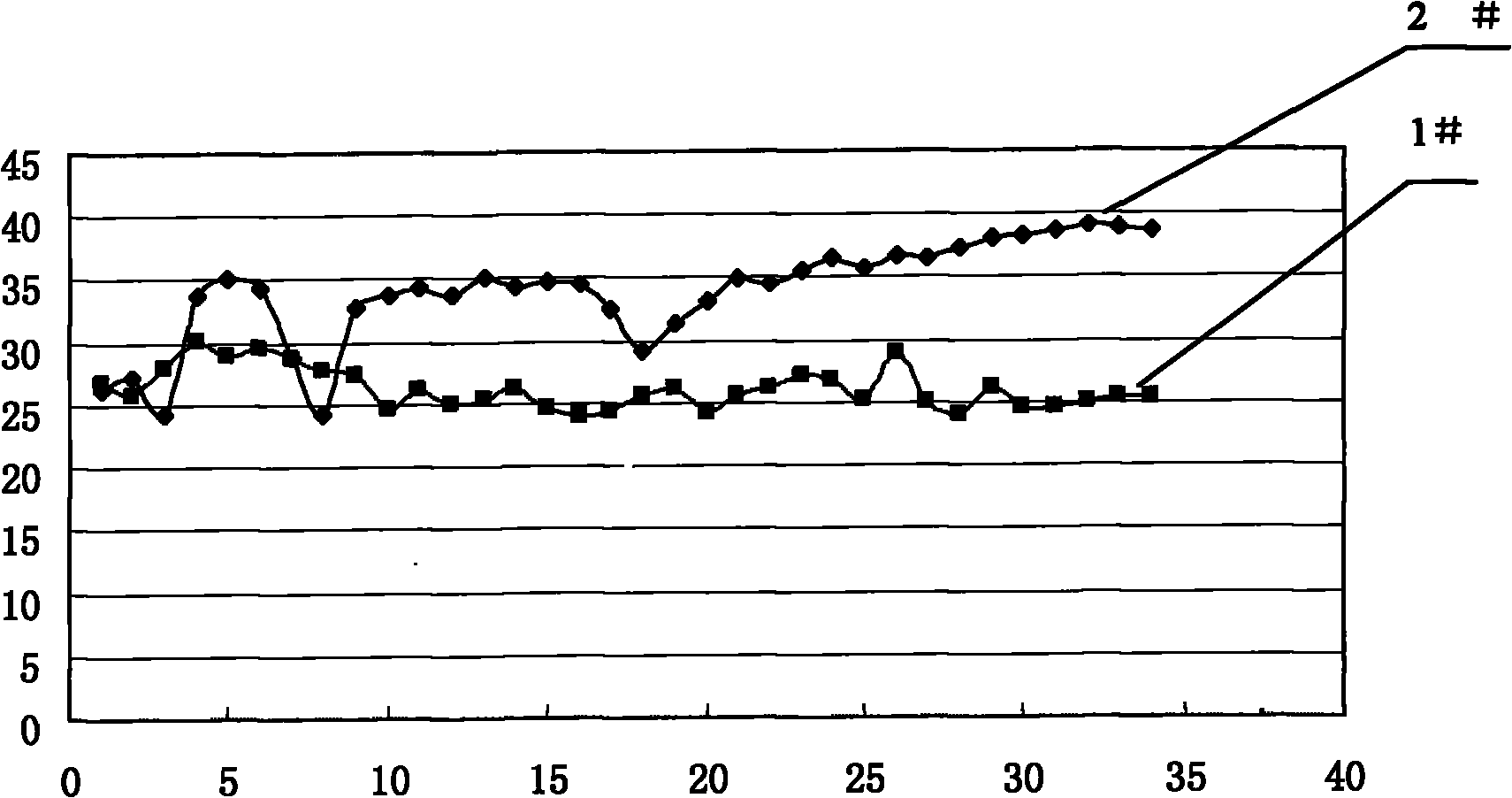

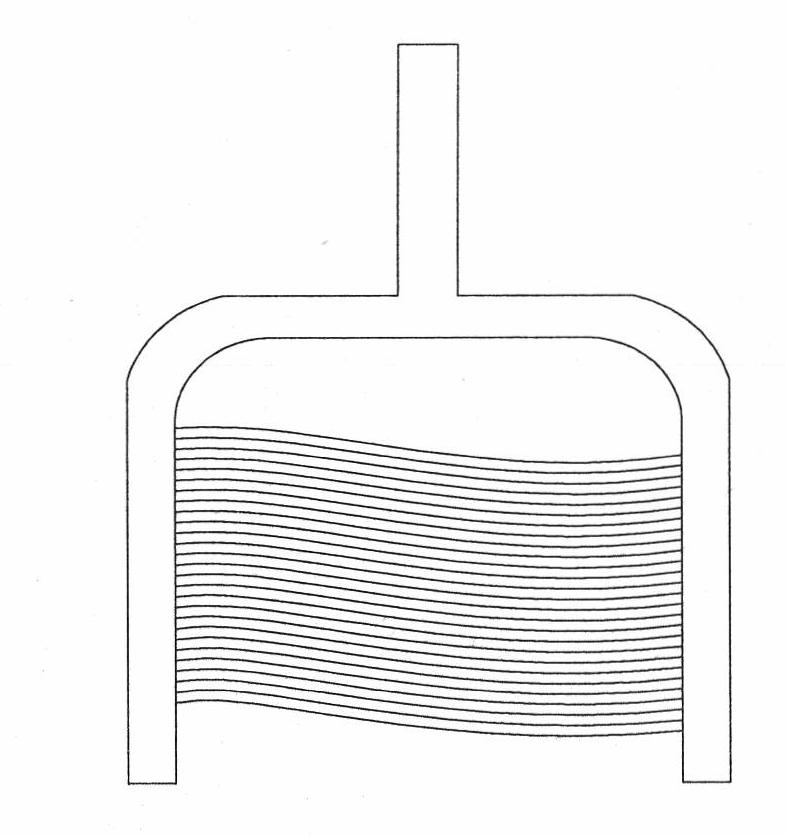

Soft sensing method for load parameter of ball mill

ActiveCN101776531AThe frequency band features are obviousObvious high frequency featuresSubsonic/sonic/ultrasonic wave measurementCurrent/voltage measurementLeast squares support vector machineEngineering

The invention relates to a soft sensing method for load parameters of a ball mill. The method is that a hardware supporting platform is used to obtain vibration signals, vibration sound signals and current signals of a ball mill cylinder to soft sense ball mill internal parameters (ratio of material to ball, pulp density and filling ratio) characterizing ball mill load. The method comprises the following steps that: the vibration, the vibration sound, the current data and the time-domain filtering of the ball mill cylinder are acquired, time frequency conversion is conducted to the vibration and the vibration sound data, kernel principal component analysis based nonlinear features of the sub band of the vibration and the vibration sound data in frequency domain are extracted, nonlinear features of the time domain current data are extracted, feature selection is conducted to the fused nonlinear feature data and a soft sensing model based on a least squares support vector machine is established. The soft sensing method of the invention has the advantages that the sensitivity is high, the sensed results are accurate, the practical value and the popularization prospect are very good, and the realization of the stability control, the optimization control, the energy saving and the consumption reduction of the grinding production process is facilitated.

Owner:NORTHEASTERN UNIV

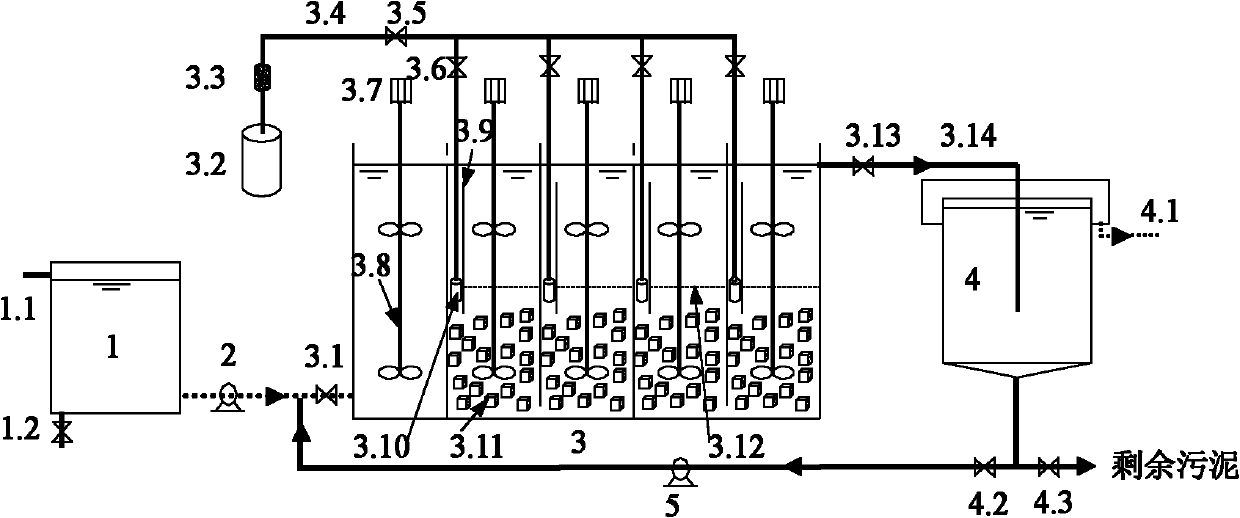

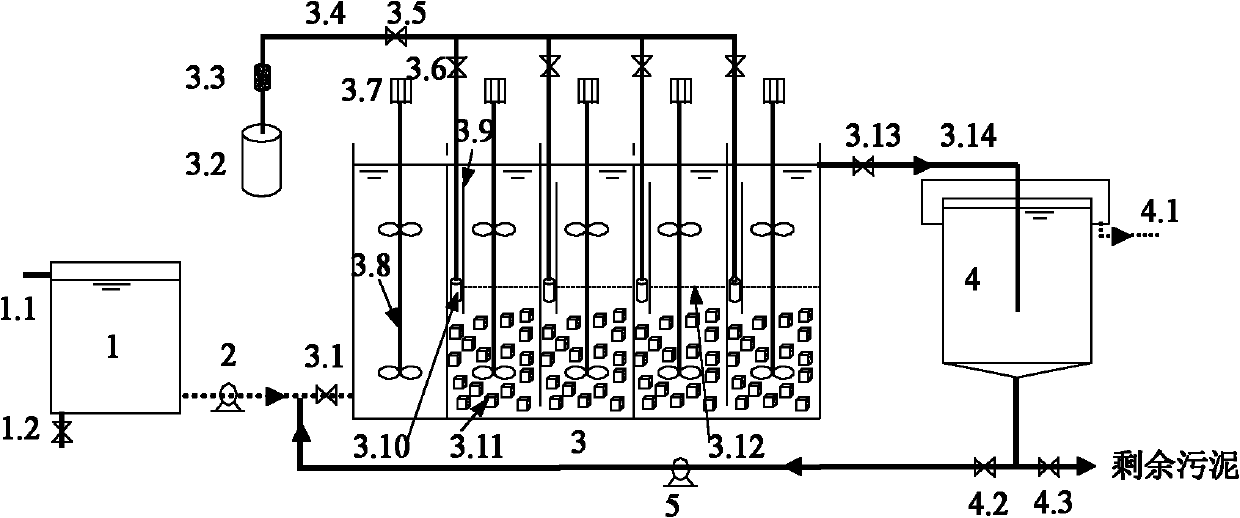

Device and method for denitrification of single stage autotroph in low-cellulose nitrate (CN) high-ammonia nitrogen waste water

ActiveCN102101720AAchieve separationEasy to controlTreatment with aerobic and anaerobic processesCelluloseSludge

The invention discloses a device and a method for denitrification of single stage autotroph in low-cellulose nitrate (CN) high-ammonia nitrogen waste water. The device comprises a raw water tank, a water inlet pump, a reactor, a secondary sedimentation tank and a sludge reflux pump, wherein overcurrent holes are arranged in the water flow direction of the reactor in an up-and-down alternative form and connected with various grid chambers, an anoxic zone grid chamber is arranged at the front end of the reactor, and an aerobic zone grid chamber is arranged at the back end of the reactor; the anoxic zone grid chamber is provided with a stirrer and an agitator blade; the aerobic zone grid chamber is provided with the stirrer, the agitator blade, an aeration riser pipe and an intermediate perforated clapboard; and the aeration riser pipe is internally provided with an aeration head, and sponge filling material is filled below the intermediate perforated clapboard, wherein filling ratio is 30-50%. In the method, shortcut nitrification is achieved above the aerobic zone through low dissolved oxygen (DO is 0.5 <-1>mg / L) and free ammonia (FA) inhibition so that ammonia nitrogen is converted to nitrite nitrogen; and anoxicammoxidation biomembrane acts on the lower part of the aerobic zone, the nitrite nitrogen and ammonia nitrogen are converted to nitrogen, thereby achieving denitrification of autotroph. The method has the advantages of low oxygen consumption, less sludge output and no extra carbon source.

Owner:彭永臻

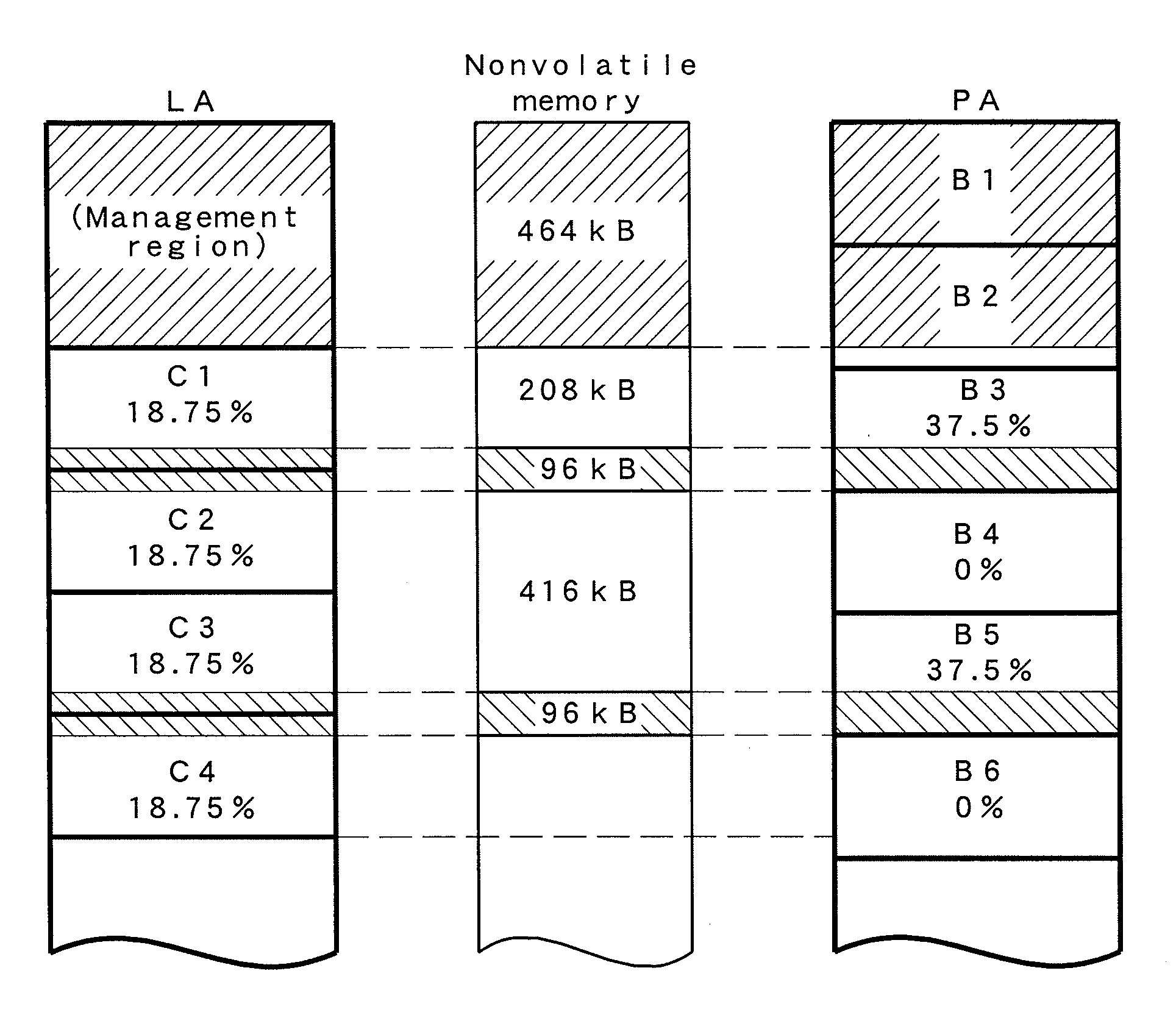

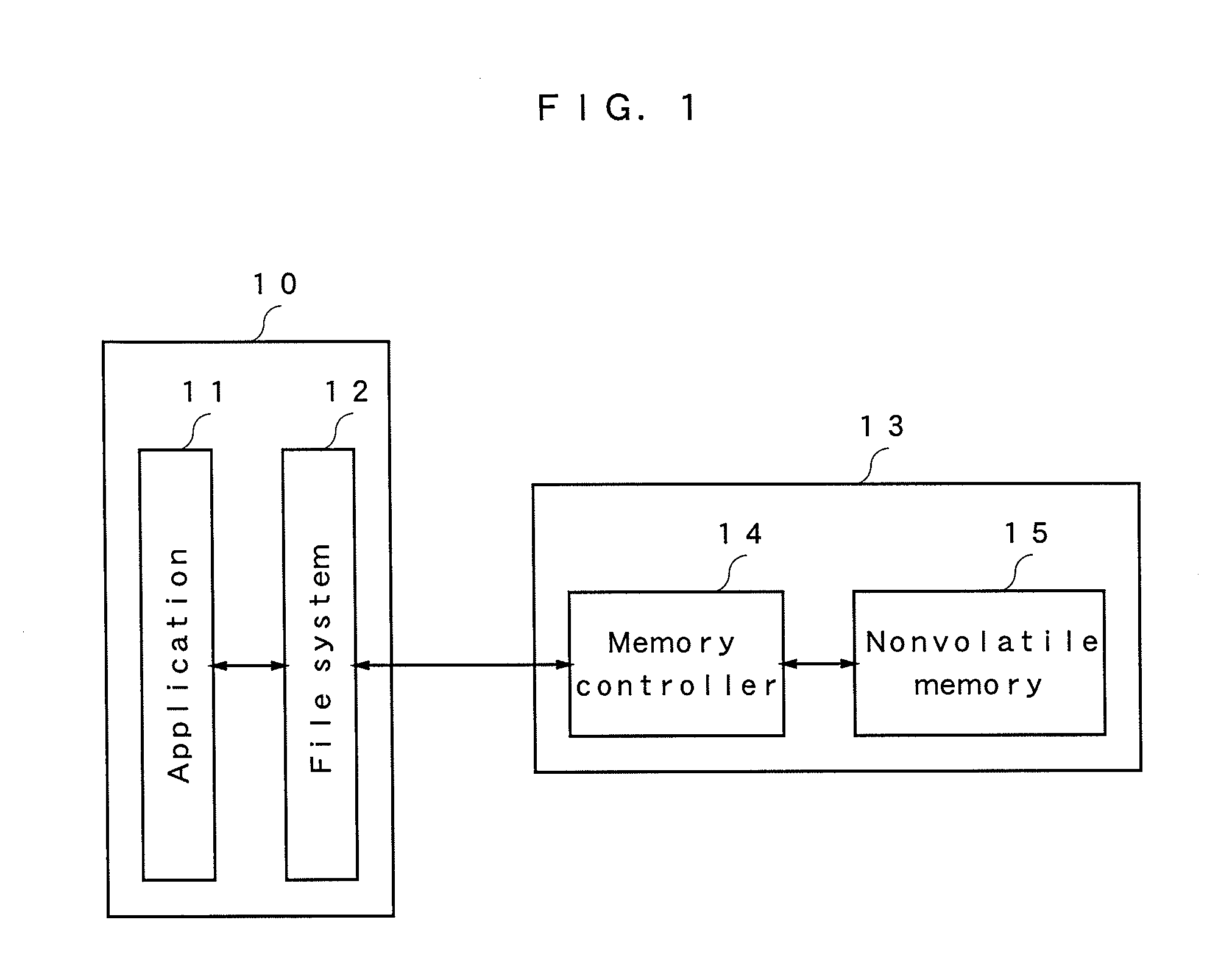

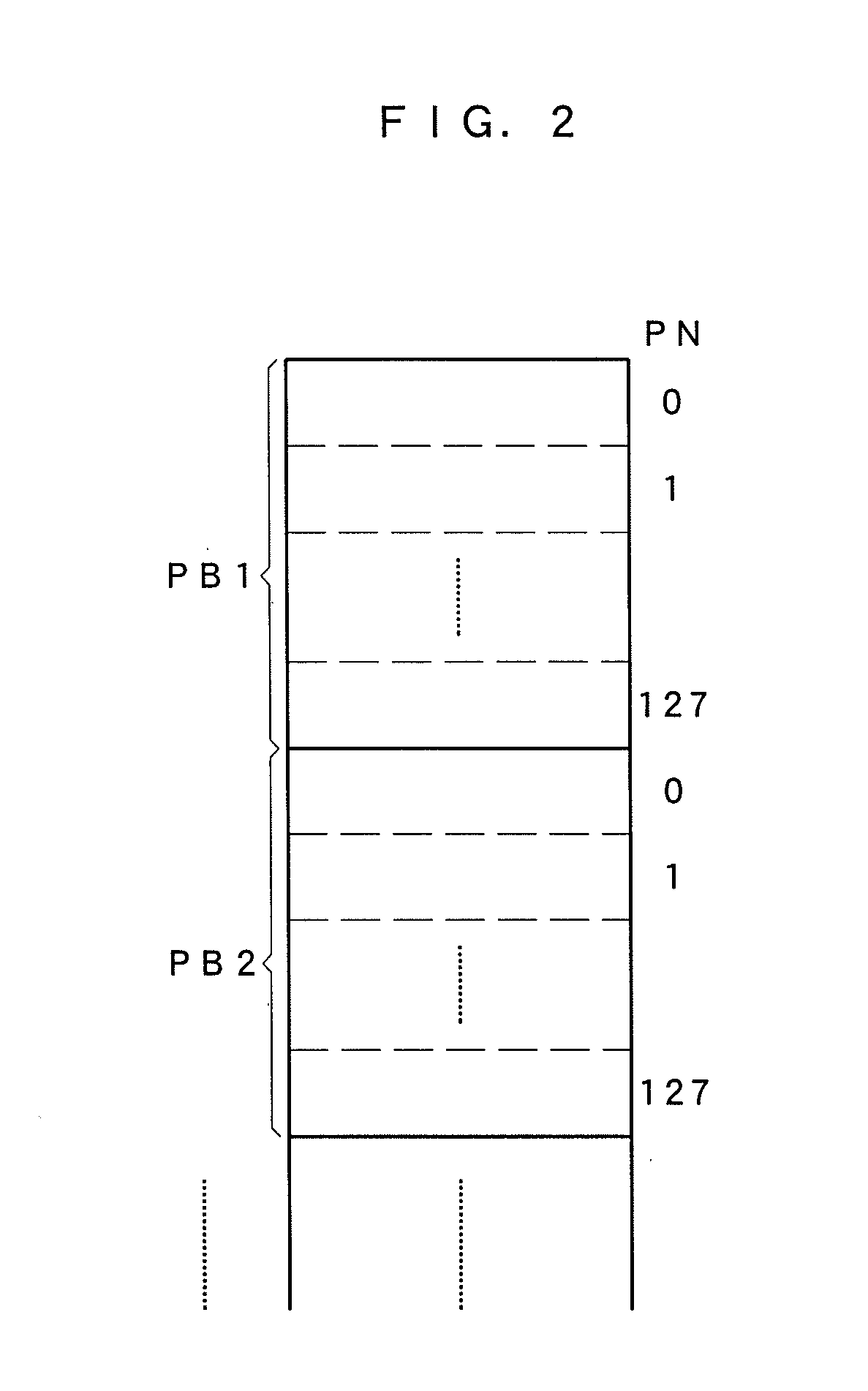

Memory controller, nonvolatile memory device, access device, and nonvolatile memory system

ActiveUS20100115185A1Memory architecture accessing/allocationMemory adressing/allocation/relocationPhysical addressMemory controller

Without corresponding to different address spaces between an access device (100) and a nonvolatile memory device (200), the access device (100) designates a file ID to manage a data storing state only in a physical address space in the nonvolatile memory device (200). The access device (100) sends the nonvolatile memory device (200) a transfer rate through a transfer rate transmitting unit (121). A filling-up rate calculating unit (251) calculates a filling-up rate of a physical block corresponding to an assurance speed required by the access device (100). A remaining amount corresponding to the transfer rate is sought by using the calculated rate and is transmitted to a remaining amount receiving unit (122) of the access device (100).

Owner:PANASONIC CORP

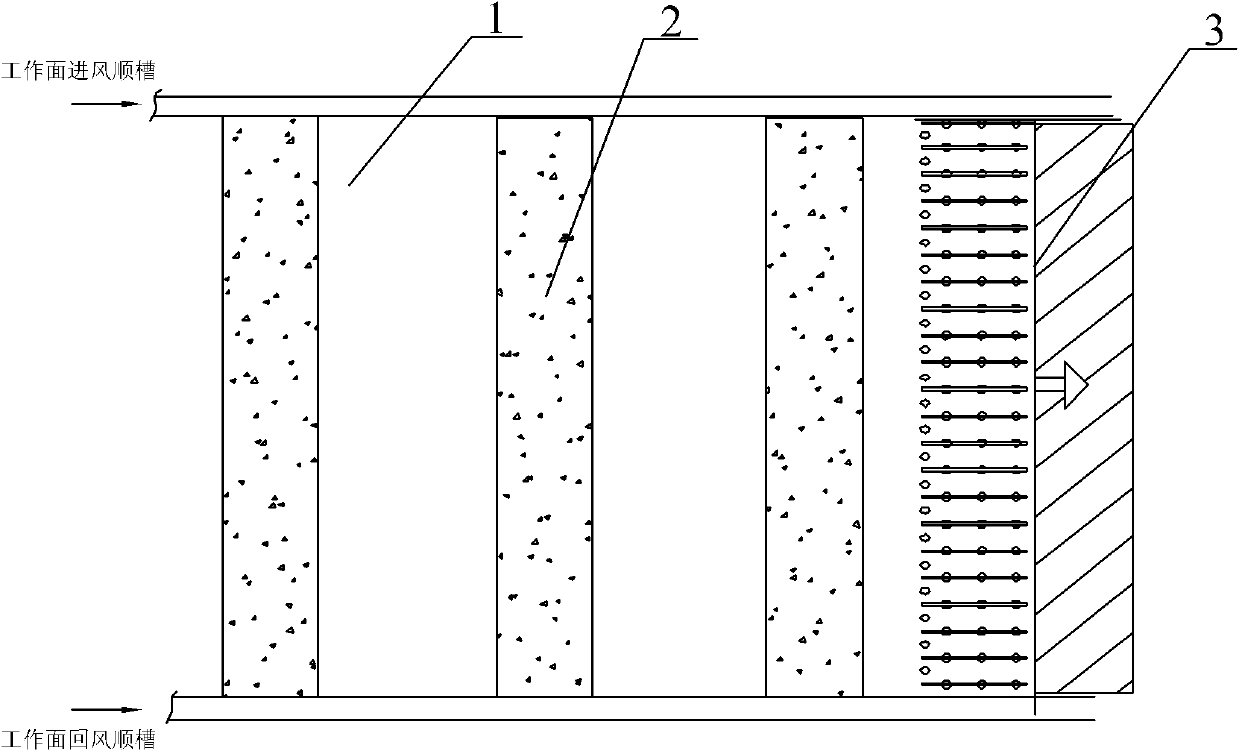

Strip-type filling method of high water-swelling material for controlling movement and deformation of overlying strata

The invention belongs to the fields of coal mining and filling, and particularly relates to a strip-type filling method of a high water-swelling material for controlling movement and deformation of overlying strata. The filling method is applicable to a coal mining face of a coal bed with the thickness of less than 3m. The method comprises the following steps: determining the limit span L and the safety span M of key strata according to a key strata theory for strata control, then determining the width N of a filling strip through calculation according to the support strength of a filling material, and filling the filling strip with the high water-swelling material. In the invention, by controlling the key strata, the most economical filling ratio can be determined and the maximum benefit can be realized; when no-coal pillar extraction is realized, movement and deformation of the overlying strata are fully controlled within the allowable range, thus realizing gentle and uniform surface subsidence in small quantity; by means of the high water-swelling material, high-recovery mining of coal resources under any condition is realized, and the safety degree of the coal mining face is greatly improved; and normal excavation engineering layout is not affected during the filling process, thus reducing influence on production and achieving high production efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

High contrast spatial light modulator

ActiveUS7245415B2Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

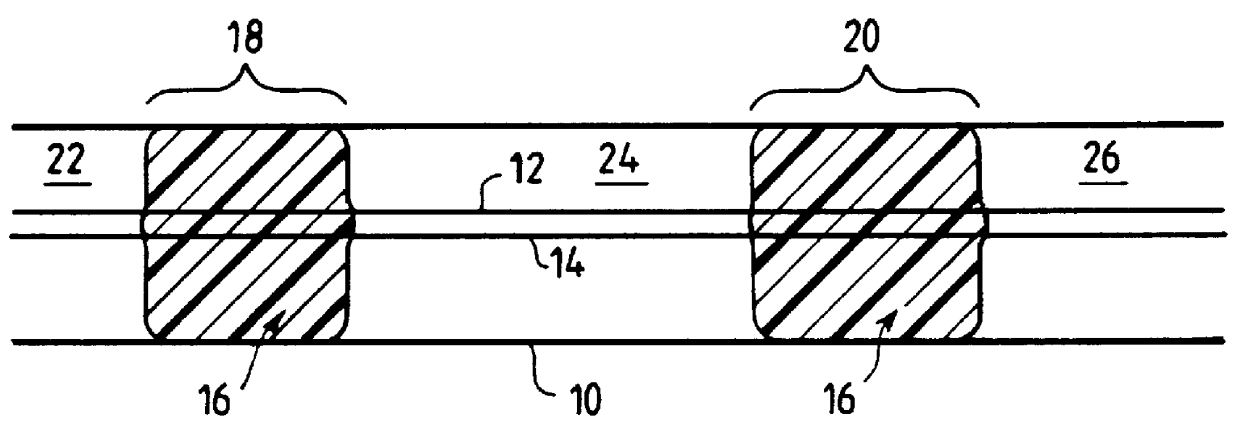

Sealed tube cable containing at least one optical conductor

InactiveUS6151434AControl pressurePrevent movementFibre mechanical structuresUltrasound attenuationFiber

A cable comprises a leakproof tube containing at least one optical fiber together with a filler material which holds the fiber(s) in place inside the tube and which provides the tube with longitudinal sealing. The filling ratio of the fiber-holding material is less than a determined limit so as to provide at least one expansion volume inside the tube so that the partial pressure of hydrogen remains low enough to avoid giving rise to significant attenuation in the transmission properties of the optical fiber.

Owner:ALCATEL LUCENT SAS

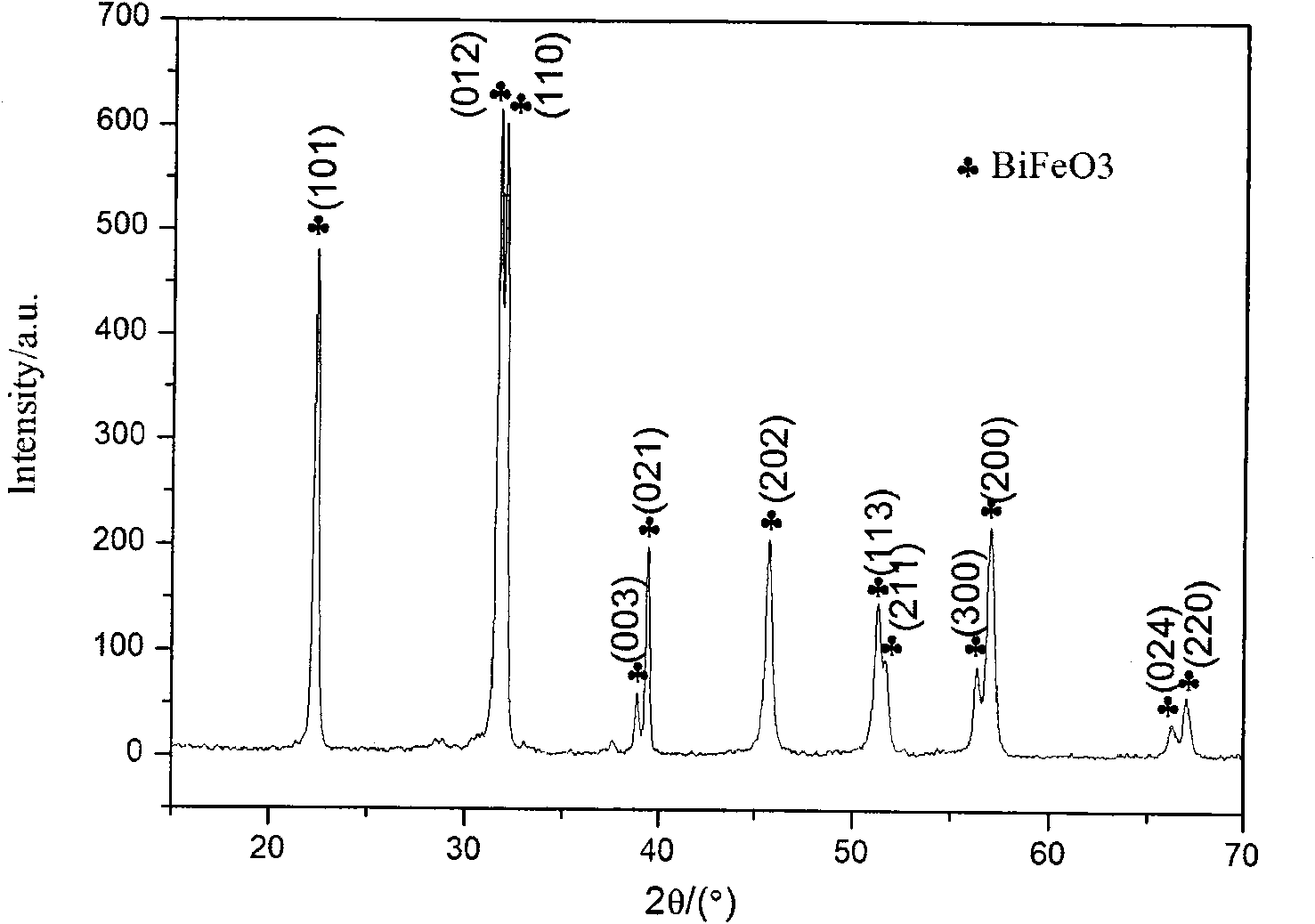

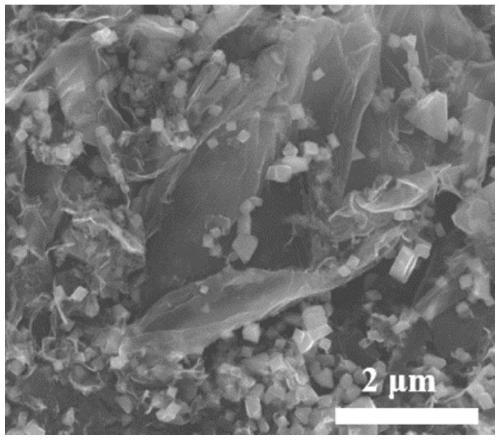

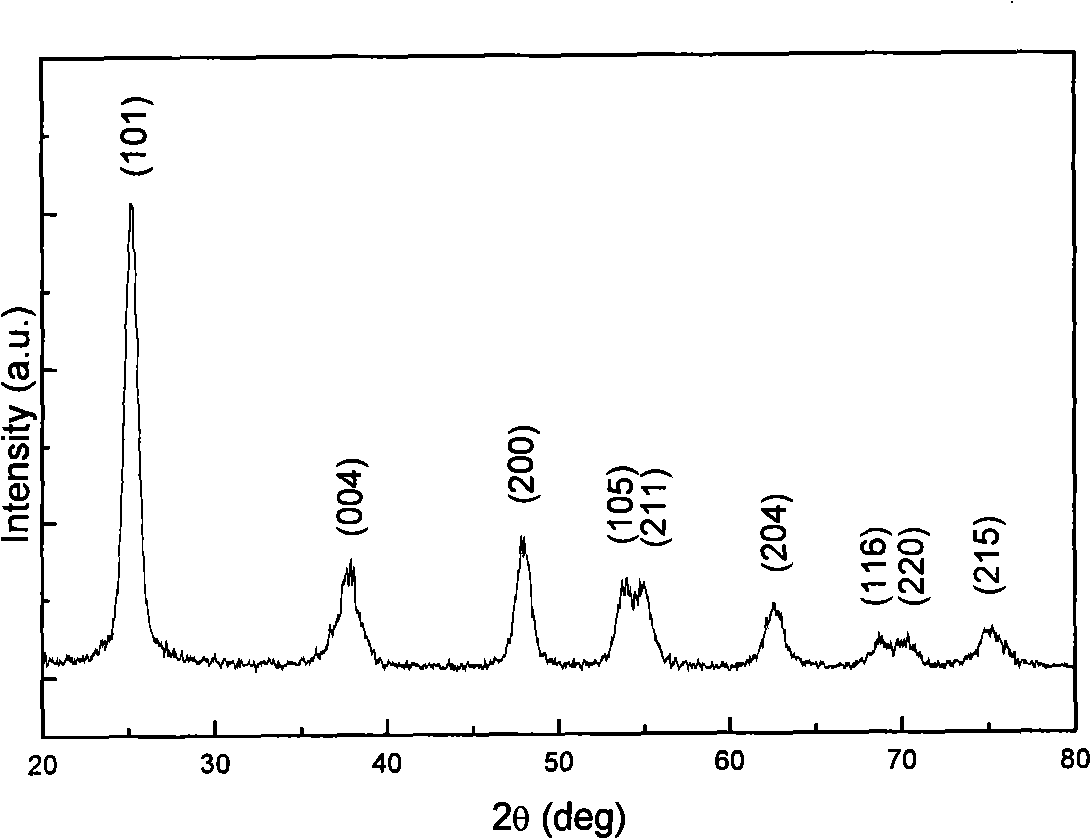

Method for preparing bismuth ferrite powder by microwave hydrothermal method

The invention discloses a method for preparing bismuth ferrite powder by microwave hydrothermal method, comprising: (1) dissolving FeCl3.6H2O and Bi(NO3)3.5H2O in proper amount of glycol to prepare into a parent salt solution; (2) dripping the parent salt solution into an aqueous ammonia solution with the concentration being 0.1-0.5mol / l and dripping speed being less than 2ml / min, and after finishing dripping, continuing to stir for 0.4-1h to obtain a deposit; (3) washing the deposit with de-ionized water repeatedly, ageing, and preparing a hydrothermal reaction precursor; and (4) adding the precursor solution into a microwave hydrothermal reaction kettle with the filling ratio being 60-75%, adding a mineralizer into the reaction kettle, placing the reaction kettle into a microwave assistant hydrothermal synthesizer to react for certain period, taking out a product in the reaction kettle, washing with de-ionized water to obtain a neutral product, washing the neutral product with absolute ethanol, and drying at room temperature to obtain the bismuth ferrite powder. The invention has the advantages of complete crystallization of BiFeO3, uniform grain fineness distribution, simple technical control, short technical cycle and energy saving.

Owner:SHAANXI UNIV OF SCI & TECH

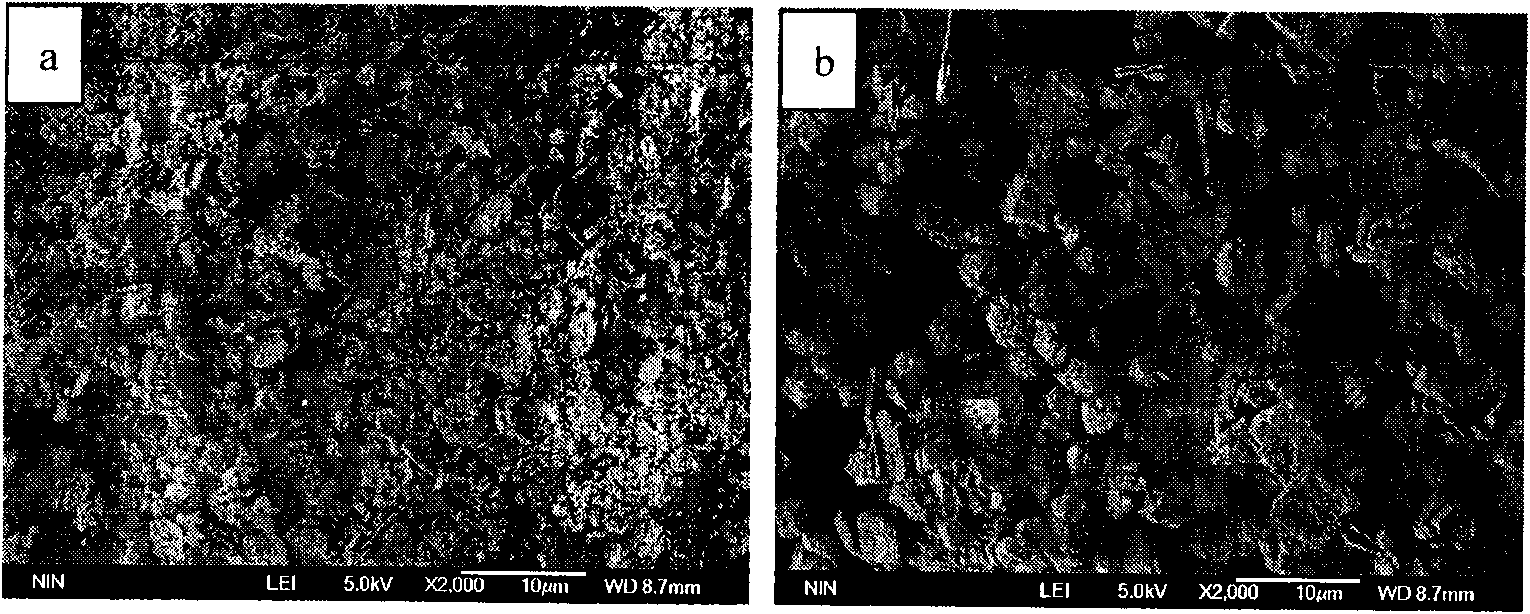

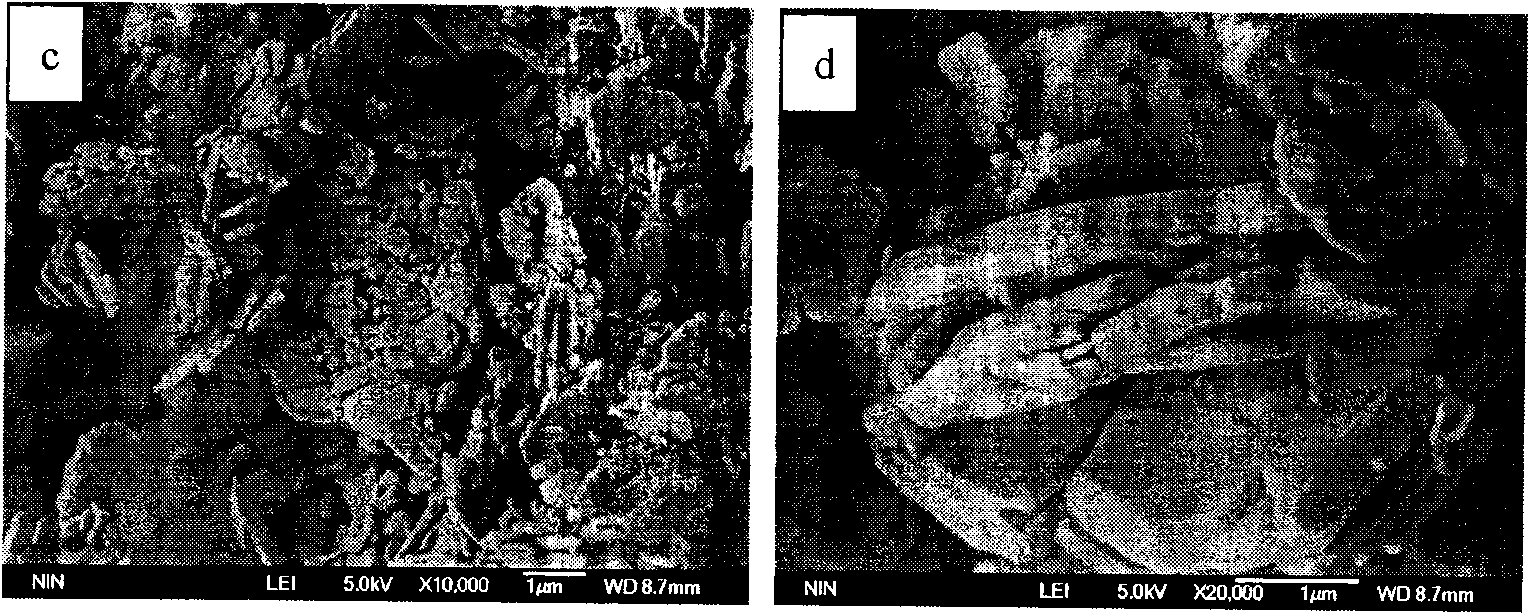

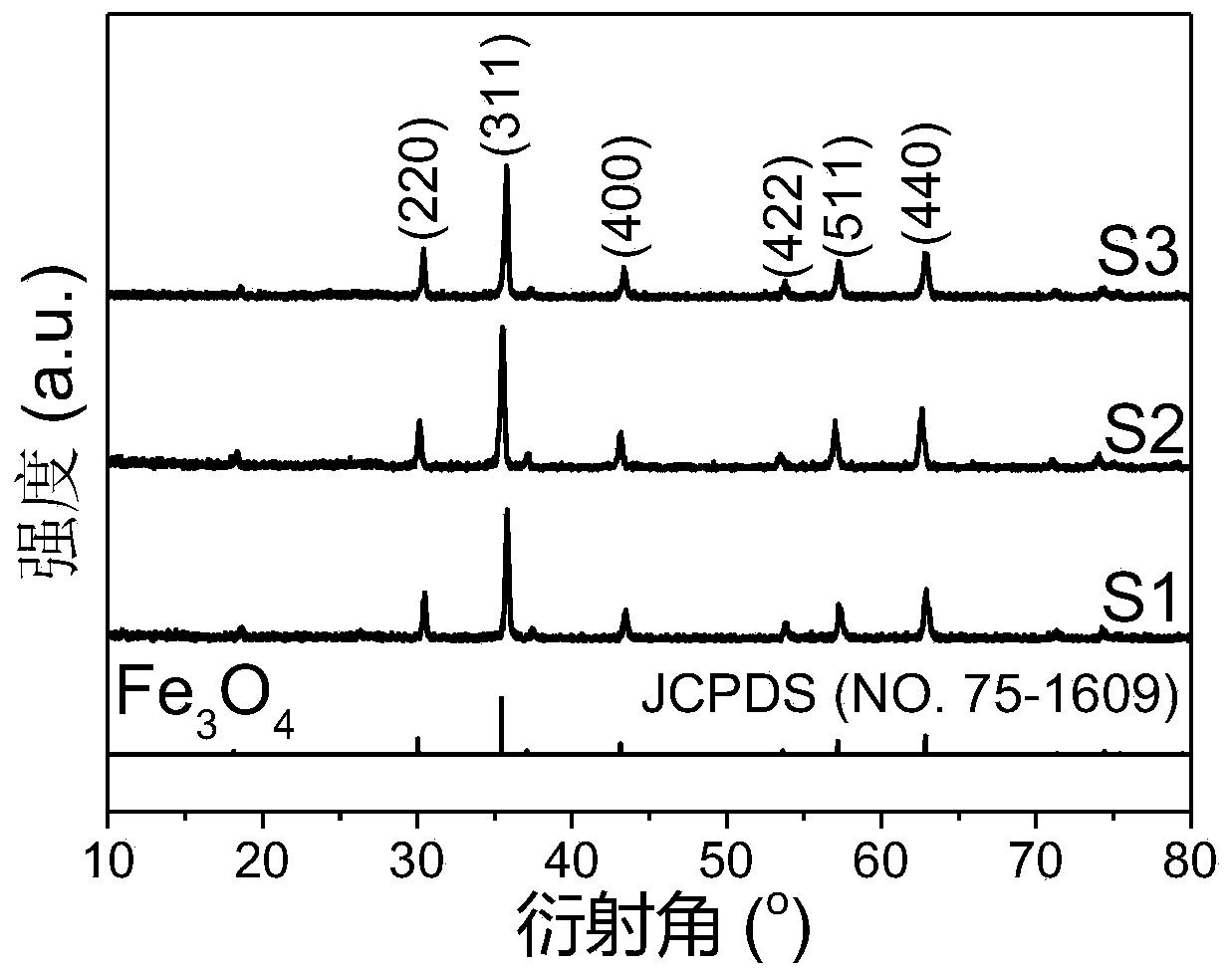

Metal-organic frame-derived ferroferric oxide@carbon/reduced graphene oxide nano composite wave-absorbing material and preparation method thereof

ActiveCN110012656ASimple and fast operationNothing producedOther chemical processesMagnetic/electric field screeningEnvironmental resistanceN dimethylformamide

The invention discloses a ferroferric oxide@carbon / reduced graphene oxide nano composite wave-absorbing material and a preparation method thereof. By using graphene oxide as a template, ferric chloride hexahydrate as a metal salt, terephthalic acid as an organic ligand, and N,N-dimethylformamide as a solvent, the ferroferric oxide@carbon / reduced graphene oxide nano composite material is prepared by a solvothermal-high temperature pyrolysis two-step method. The preparation method is environmentally friendly, generates no toxic by-products, and has a simple preparation process. The prepared nanocomposite material has a good microwave absorption capacity, a wide absorption frequency band, a low thickness, light weight and a low filling ratio, can absorb electromagnetic waves in different wavelength bands by adjusting the addition amount of graphene oxide in a precursor and the thickness of a coating layer, and has an important application value in the field of electromagnetic absorptionand electromagnetic shielding.

Owner:ANHUI UNIV OF SCI & TECH

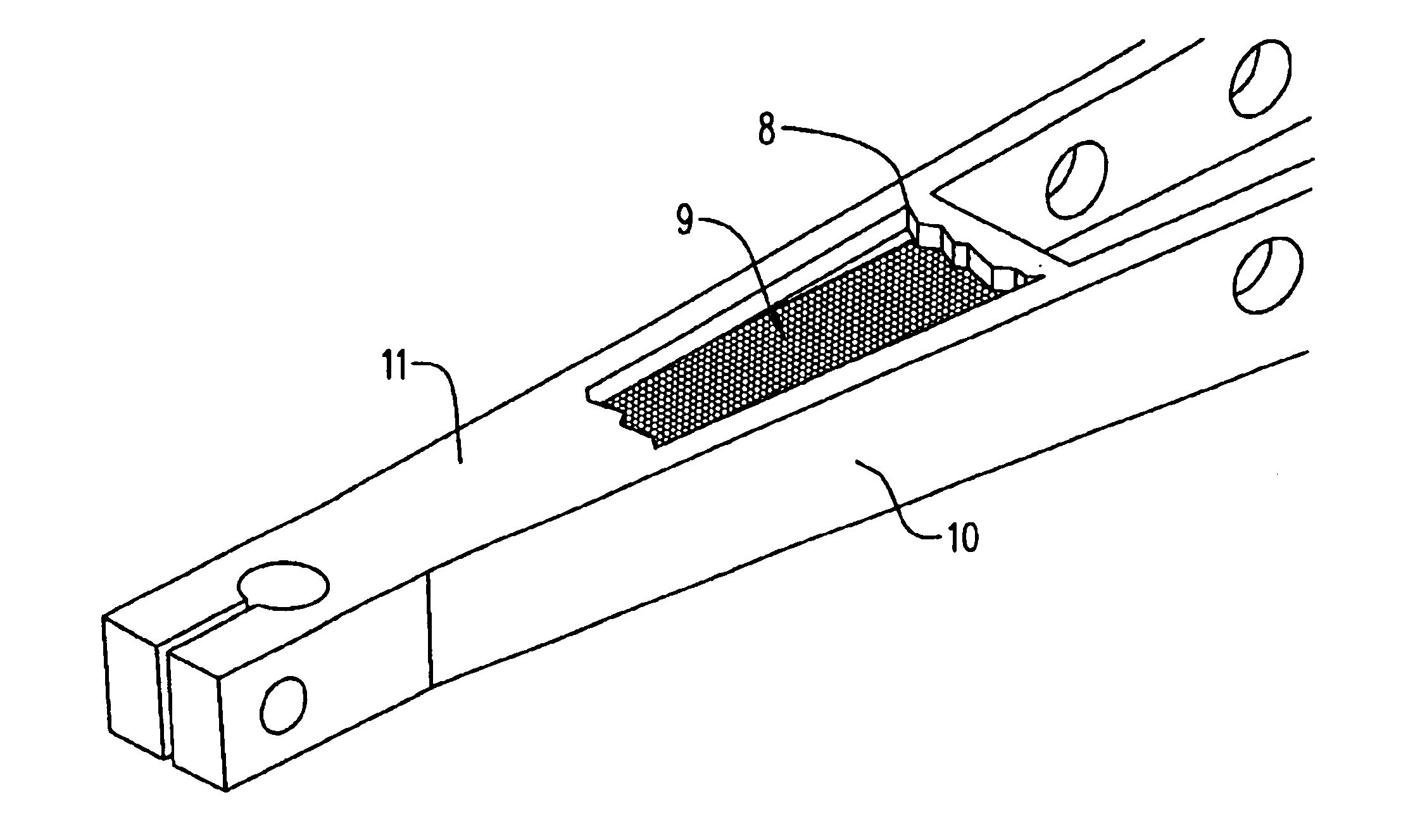

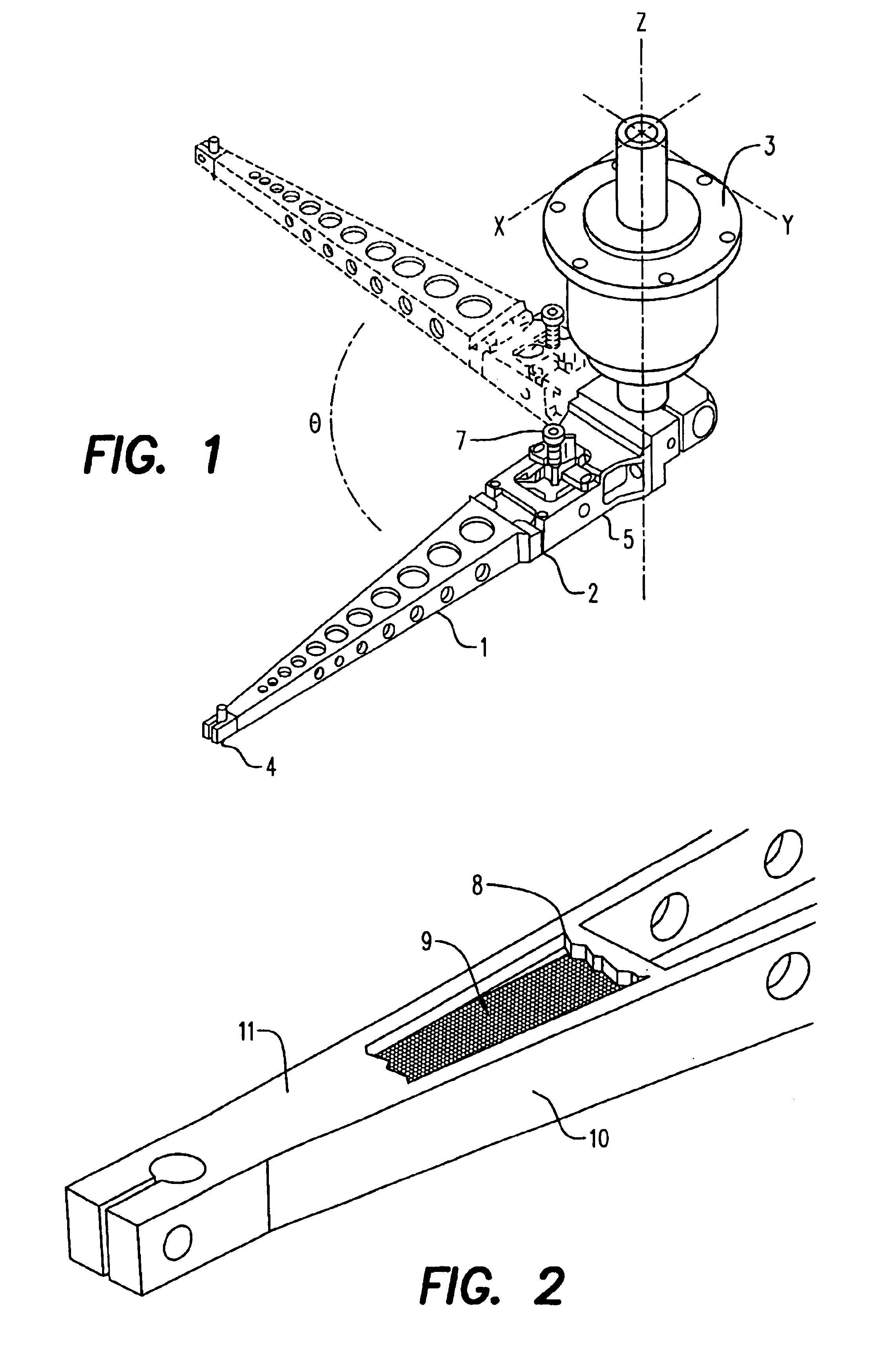

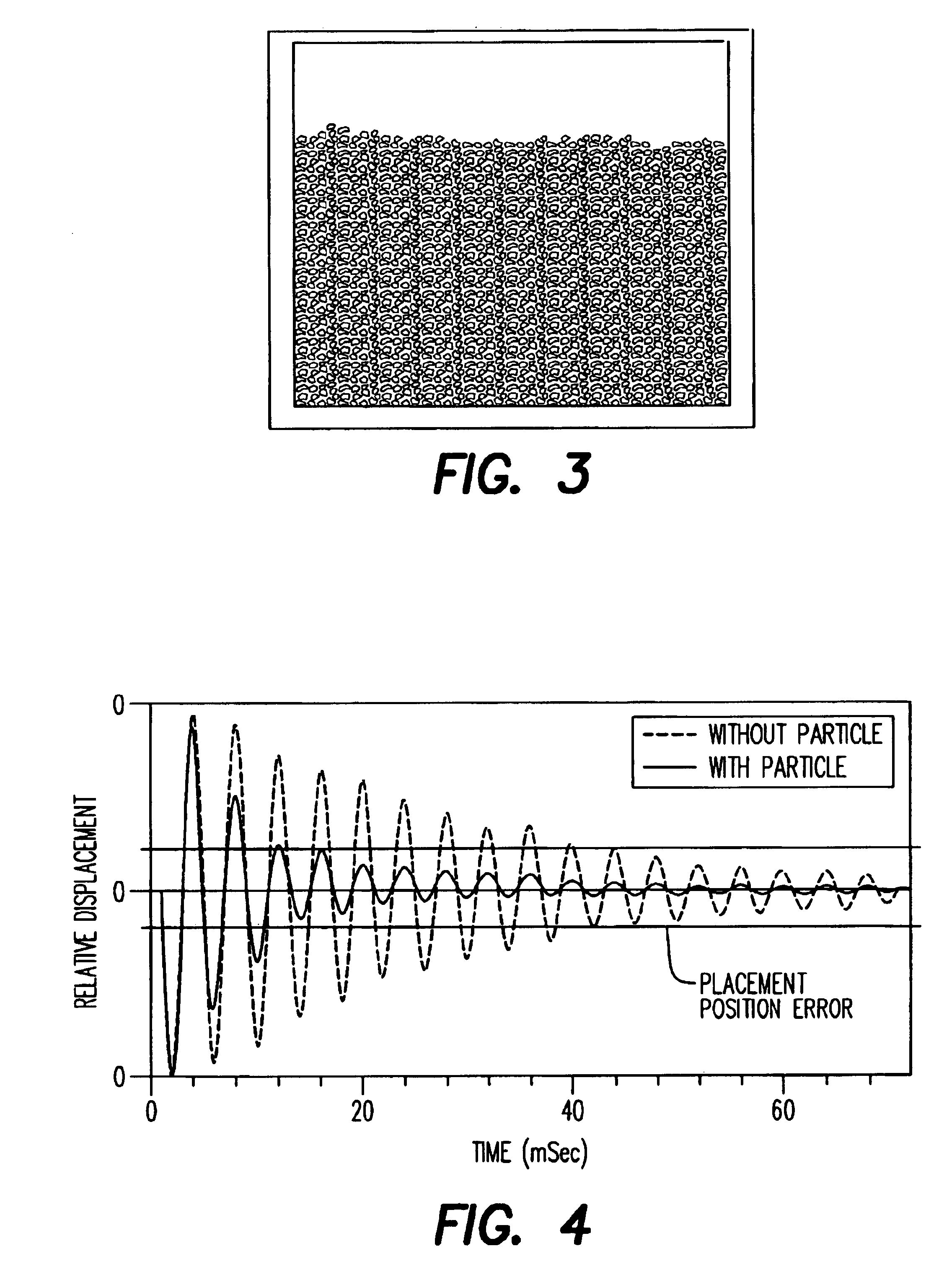

High speed pick and place apparatus

A pick and place apparatus comprises a bond arm adapted for rotation about an axis between a pick location and a place location. The bond arm is formed with a cavity at an end of the arm remote from the axis, within which cavity are located a plurality of damping particles for damping unwanted vibrations of the bond arm. The particles may be irregular tungsten granules with a diameter between 0.3 and 1.2 mm and a filling ratio of about 75%.

Owner:ASM ASSEMBLY AUTOMATION LTD

Novel method for proportioning ore grinding media

The invention relates to the technical field of ore grinding medium addition for large ball mills, in particular to a novel method for proportioning ore grinding media, which comprises the following steps of: (1) making regulations on composition of feed granularities for a ball mill; (2) adding two ore grinding media different in diameter at the same time according to the regulated composition of feed granularities; (3) keeping two ore grinding media different in diameter in proportion by weight of 1: (0.9-1.1); (4) keeping the filling ratio of the ore grinding media for the ball mill at 38-42%; and (5) determining the adding quantity and the adding cycle of the ore grinding media in each time according to the effective volume of the ball mill, wherein the ore grinding media are steel balls, the adding cycle of the ore grinding media respectively is 24h, 12h, 8h, 4h, or 2h, and the steel ball is 127mm, 120mm, 110mm, 100mm or 80mm in diameter. The method for proportioning the ore grinding media has the beneficial effects that the yield of coarse grade products is reduced, the yield of fine grade products is increased, the ore grinding efficiency of the ball mill is improved, and the composition of ore grinding granularities is improved at certain degree to satisfy the requirement of follow-up grading work.

Owner:ANSTEEL GRP MINING CO LTD

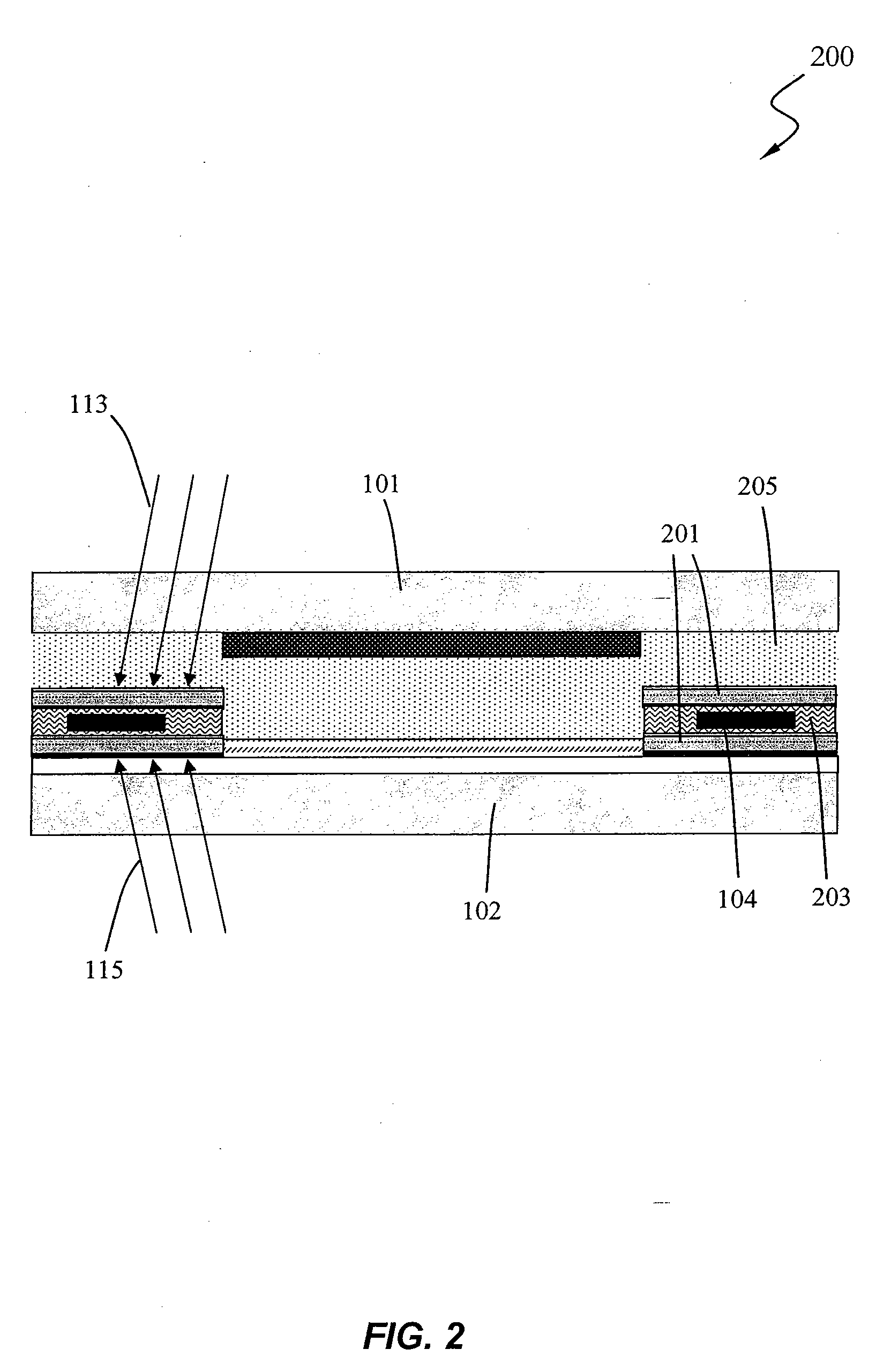

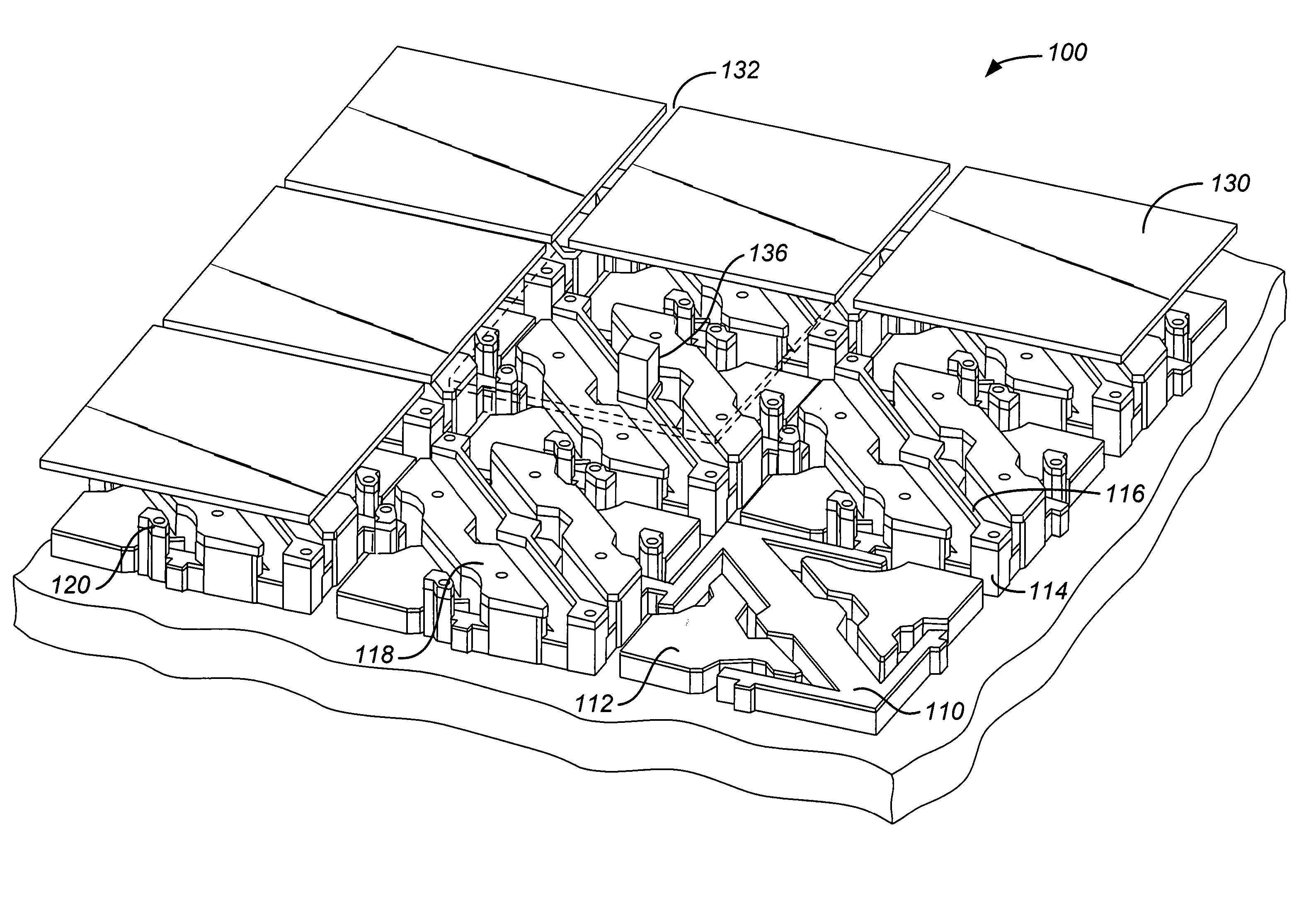

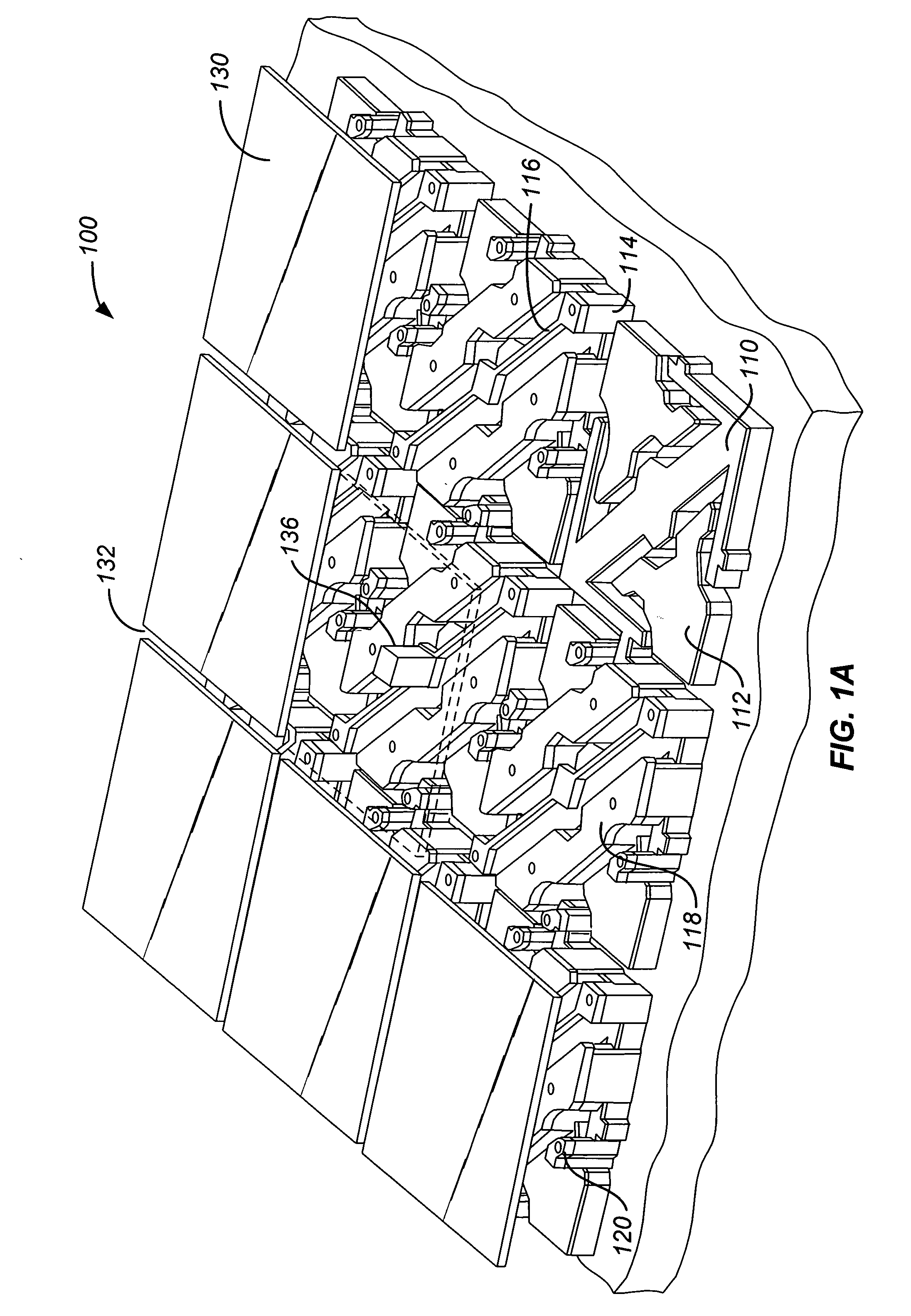

Fabrication of a high fill ratio silicon spatial light modulator

InactiveUS20070097485A1Improve fill rateIncrease bonding areaNon-linear opticsOptical elementsSpatial light modulatorFilling materials

A method for forming an optical deflection device includes providing a semiconductor substrate comprising an upper surface region and a plurality of drive devices within one or more portions of the semiconductor substrate. The upper surface region includes one or more patterned structure regions and at least one open region to expose a portion of the upper surface region to form a resulting surface region. The method also includes forming a planarizing material overlying the resulting surface region to fill the at least one open region and cause formation of an upper planarized layer using the fill material. The method further includes forming a thickness of silicon material at a temperature of less than 300 ° C. to maintain a state of the planarizing material.

Owner:MIRADIA INC

High contrast spatial light modulator

ActiveUS20060245030A1Increase contrastHigh active reflection area fill-ratioOptical elementsSpatial light modulatorFilling ratio

A high contrast spatial light modulator for display and printing is fabricated by coupling a high active reflection area fill-ratio and non-diffractive micro mirror array with a high electrostatic efficiency and low surface adhesion control substrate.

Owner:SPATIAL PHOTONICS

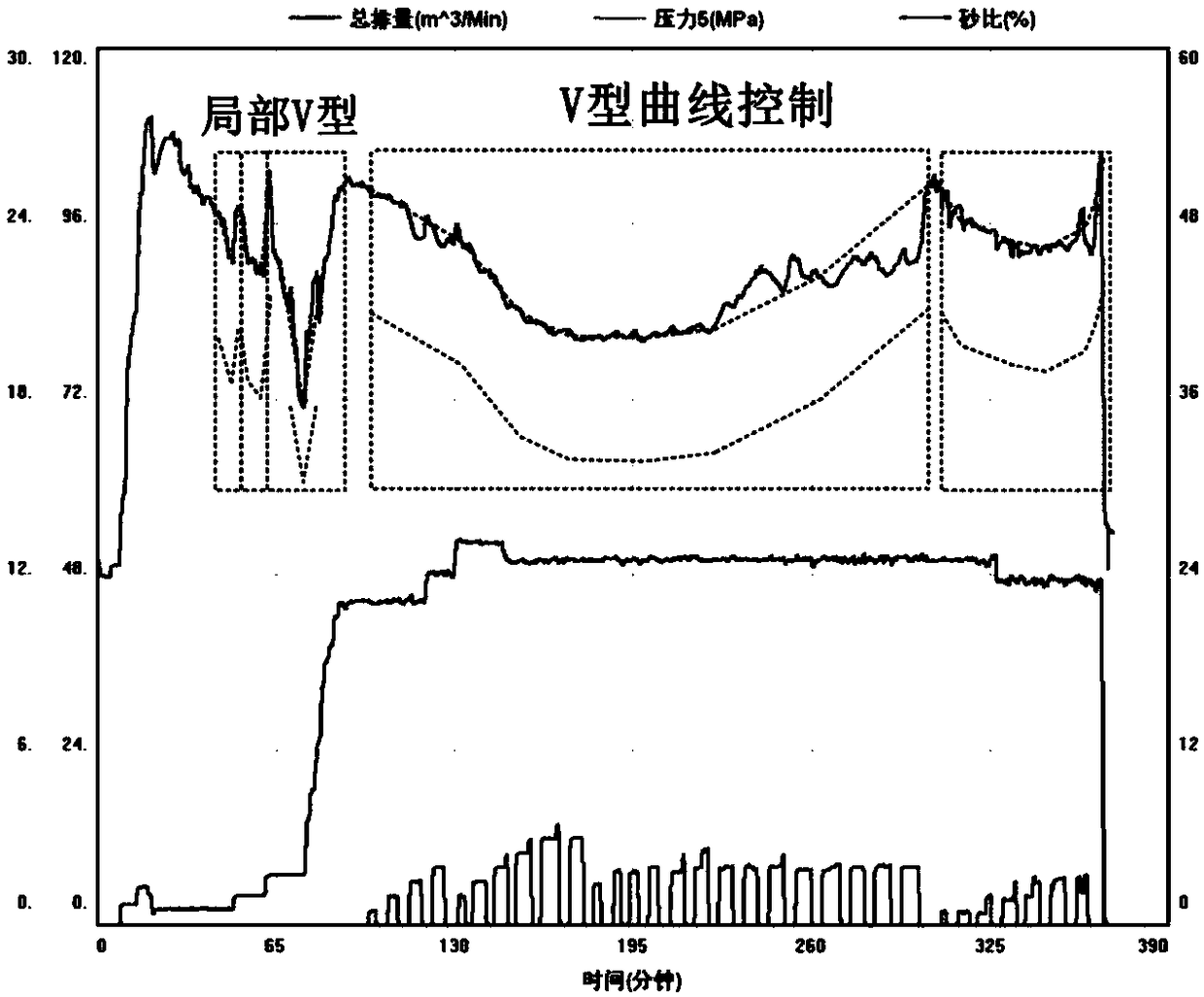

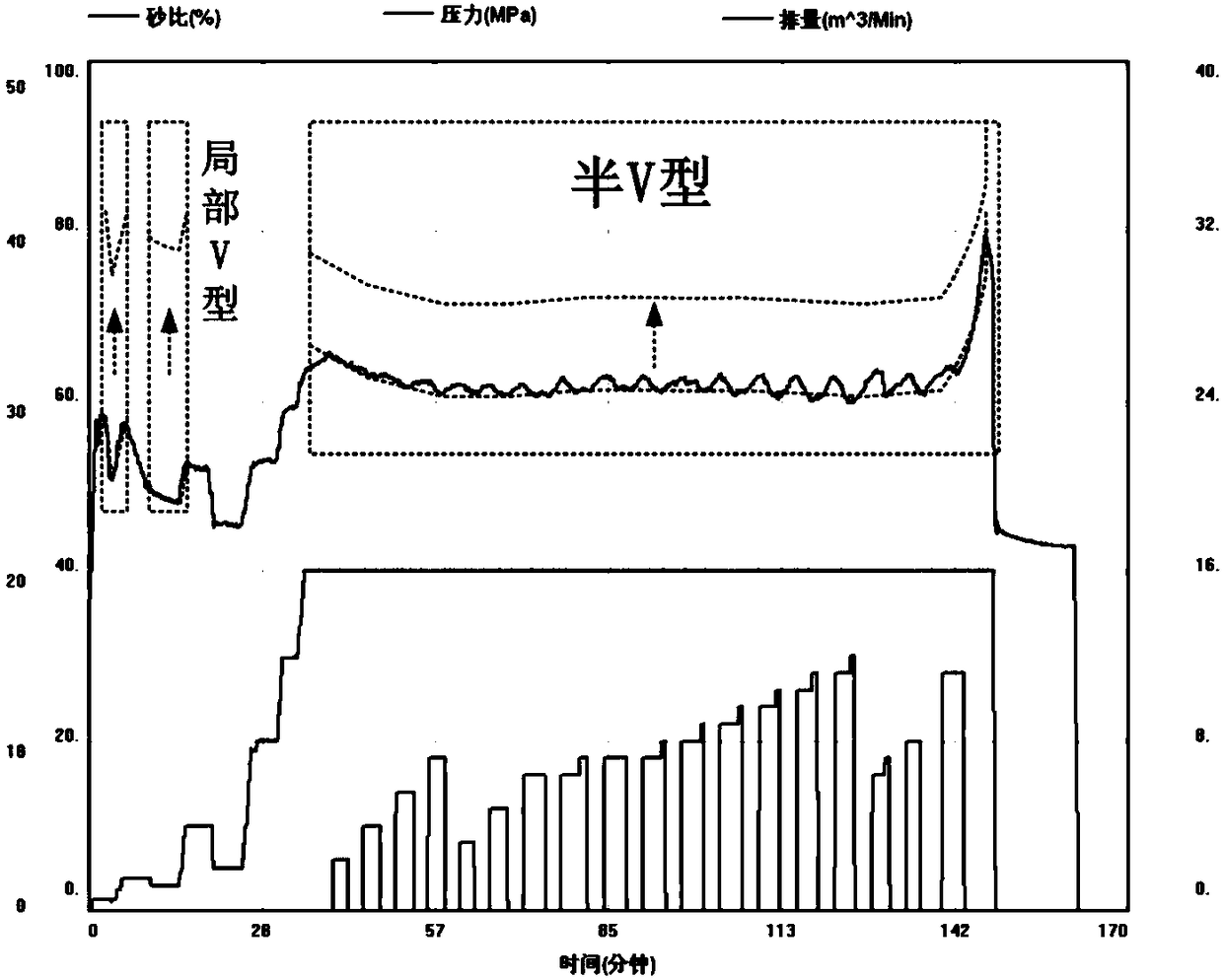

Fracturing method for deep shale gas through V-shaped pressure curve

ActiveCN109113703AIncrease the effective transformation volumeImprove fill rateFluid removalLiquid ratioPressure curve

The invention discloses a fracturing method for deep shale gas through a V-shaped pressure curve. The fracturing method comprises the steps of (1) key reservoir parameter evaluation, (2) optimizationof fracture parameters and fracturing construction parameters, (3) perforation position determination and perforation operation, (4) acid pretreatment, (5) variable-displacement and low-viscosity slick water joint forming construction, (6) powder pottery construction for adding different sand liquid ratios into low-viscosity slick water, (7) medium-particle-size proppant construction for adding different sand liquid ratios into medium-viscosity slick water, (8) high-viscosity gel and large-particle-size carrying proppant construction, and (9) displacing operation. According to the fracturing method, complexity of fracturing fractures of the deep shale gas is improved, the filling ratios of systems with different scales of fractures such as near wells, far wells, main fractures and micro-fractures are increased, the effective stimulation volume of the deep shale gas is increased, and the yield increasing and stabilizing effects after pressure are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

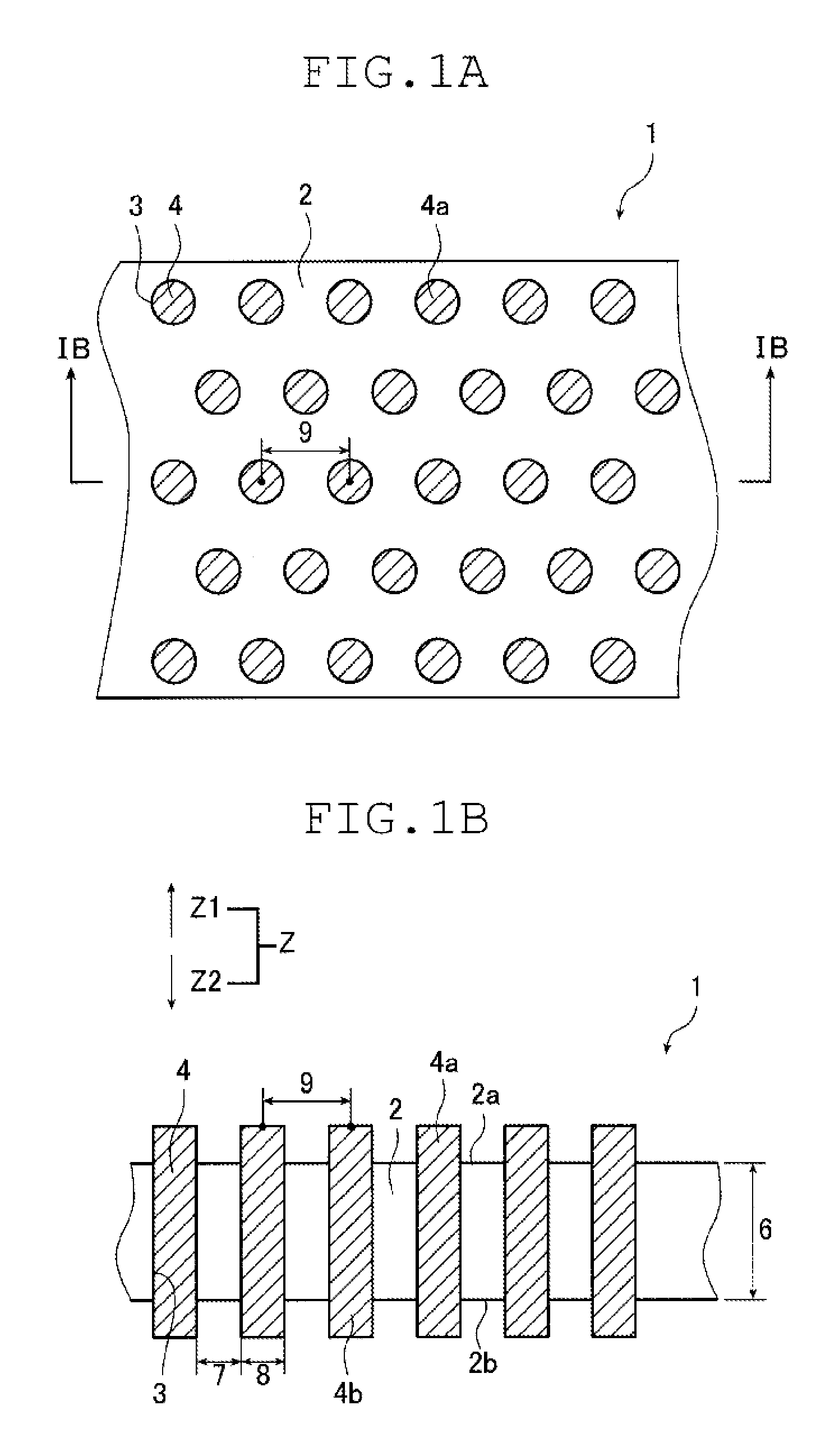

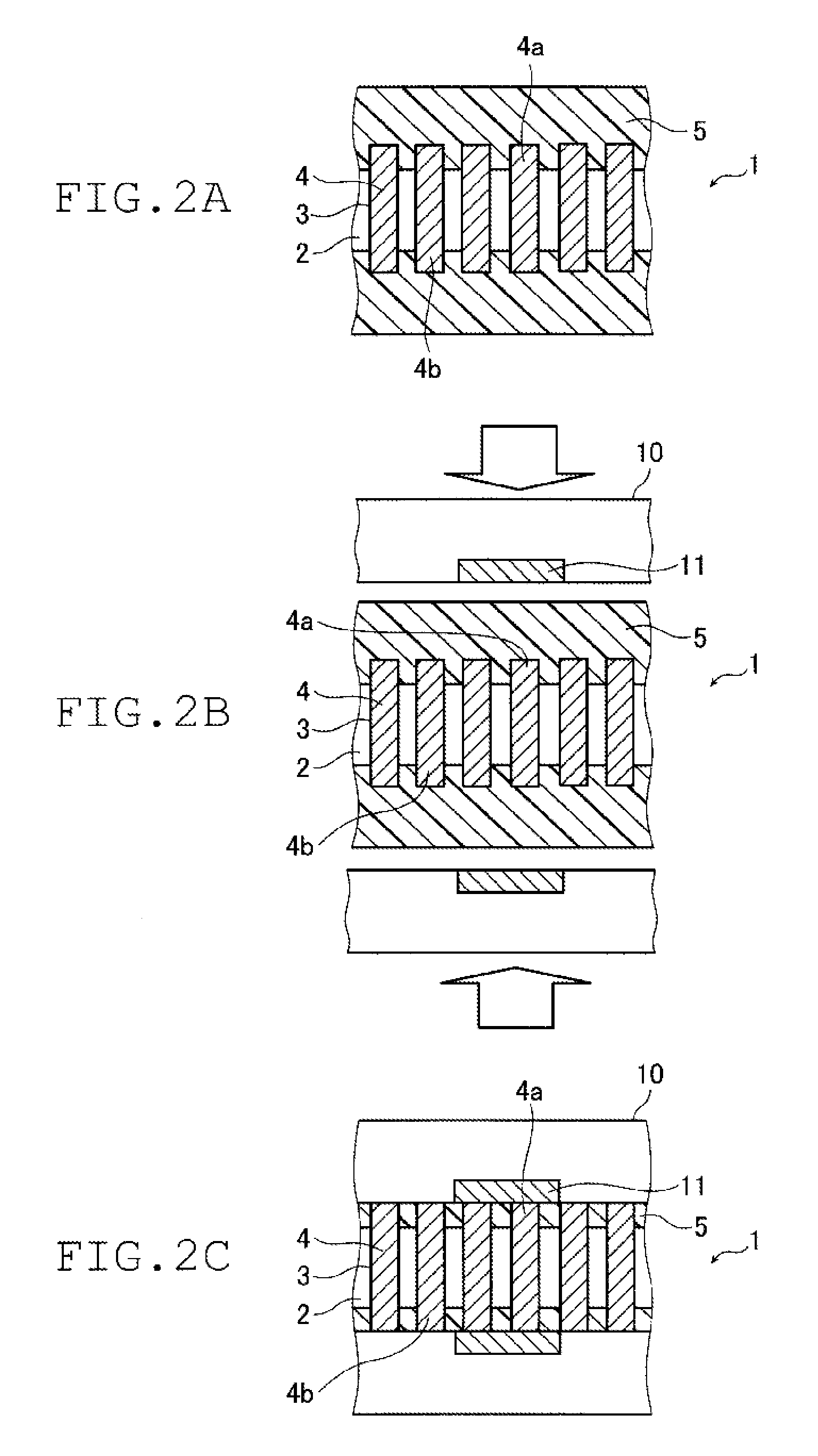

Microstructure, and method for production thereof

InactiveUS20110117357A1Improve long-term stabilityFirmly connectedPorous dielectricsNon-insulated conductorsVolumetric Mass DensityUltimate tensile strength

A microstructure which has excellent long-term stability and is capable of simple joining by thermocompression bonding at a high joint strength is provided. The microstructure includes an insulating base in which through micropores with a pore size of 10 to 500 nm are disposed at a density of 1×106 to 1×1010 micropores / mm2. The through micropores are filled with a metal at a filling ratio of at least 30% and a polymer layer is formed on at least one surface of the insulating base.

Owner:FUJIFILM CORP

High fill ratio silicon spatial light modulator

ActiveUS20070097487A1Improve fill rateIncrease bonding areaOptical elementsSpatial light modulatorFilling ratio

An optical deflection device for a display application. The optical deflection device includes a semiconductor substrate including an upper surface region and one or more electrode devices provided overlying the upper surface region. The optical deflection device also includes a hinge device including a silicon material and coupled to the upper surface region. The optical deflection device further includes a spacing defined between the upper surface region and the hinge device and a mirror structure including a post portion coupled to the hinge device and a mirror plate portion coupled to the post portion and overlying the hinge device.

Owner:MIRADIA INC

Epoxy resin encapsulating material composition

ActiveCN101173159ALow initial viscosityLow coefficient of linear expansionOther chemical processesSemiconductor/solid-state device detailsEpoxyChemical composition

An epoxy resin encapsulation material composition, the composition contains epoxy resin, a curing agent and inorganic filler particles containing a coupling agent, wherein the particle diameter of the inorganic filler particles containing a coupling agent is 0.1-200 microns , wherein the inorganic filler particles containing a coupling agent whose particle diameter is not more than 3 microns account for 5-20% by volume of the total amount of the inorganic filler particles containing a coupling agent. The epoxy resin encapsulating material composition provided by the present invention can greatly increase the filling ratio of the inorganic filler, thus making the epoxy resin encapsulating material composition provided by the present invention have low initial viscosity, excellent fluidity, and linear expansion coefficient Low, the production cost of obtaining epoxy resin encapsulation materials with the same initial viscosity is greatly reduced. In addition, the composition provided by the invention has excellent dielectric properties and is suitable for the packaging of various electronic components sensitive to stress, especially for automatic packaging of electronic components requiring high precision.

Owner:靖江德方科技服务有限公司

Micro-electrolysis flocculation method for treating acid waste water containing heavy metals in mine

InactiveCN101948200AWide variety of sourcesLow priceWaste water treatment from quariesMultistage water/sewage treatmentElectrolysisWater quality

The invention discloses a micro-electrolysis flocculation method for treating acid waste water containing heavy metals in mine. The treatment step is as follows: waste water pretreatment, iron-carbon micro-electrolysis and flocculation and precipitation, wherein the waste water is pretreated and then fed into an iron-carbon bed reactor with an iron-carbon mass filling ratio of 1-5 for reacting and staying for 5 mintues-6 hours, and most of heavy metal pollutants in the waste water are removed and recycled through micro-electrolysis reaction; the pH value is regulated to be 6.5-10 by effluent so as to carry out the flocculation and precipitation for further removing impurity ions, and the purification effect of the waste water can be enhanced by adding a new flocculant according to the water quality conditions; and after solid-liquid separation, the effluent of the waste water can be reused due to reaching the standard or discharged. The invention has the advantages of low treatment cost, small occupied area, high recovery of the heavy metals in the waste water and the like, and has wide application prospect in the field of treating the waste water in mine.

Owner:KUNMING UNIV OF SCI & TECH

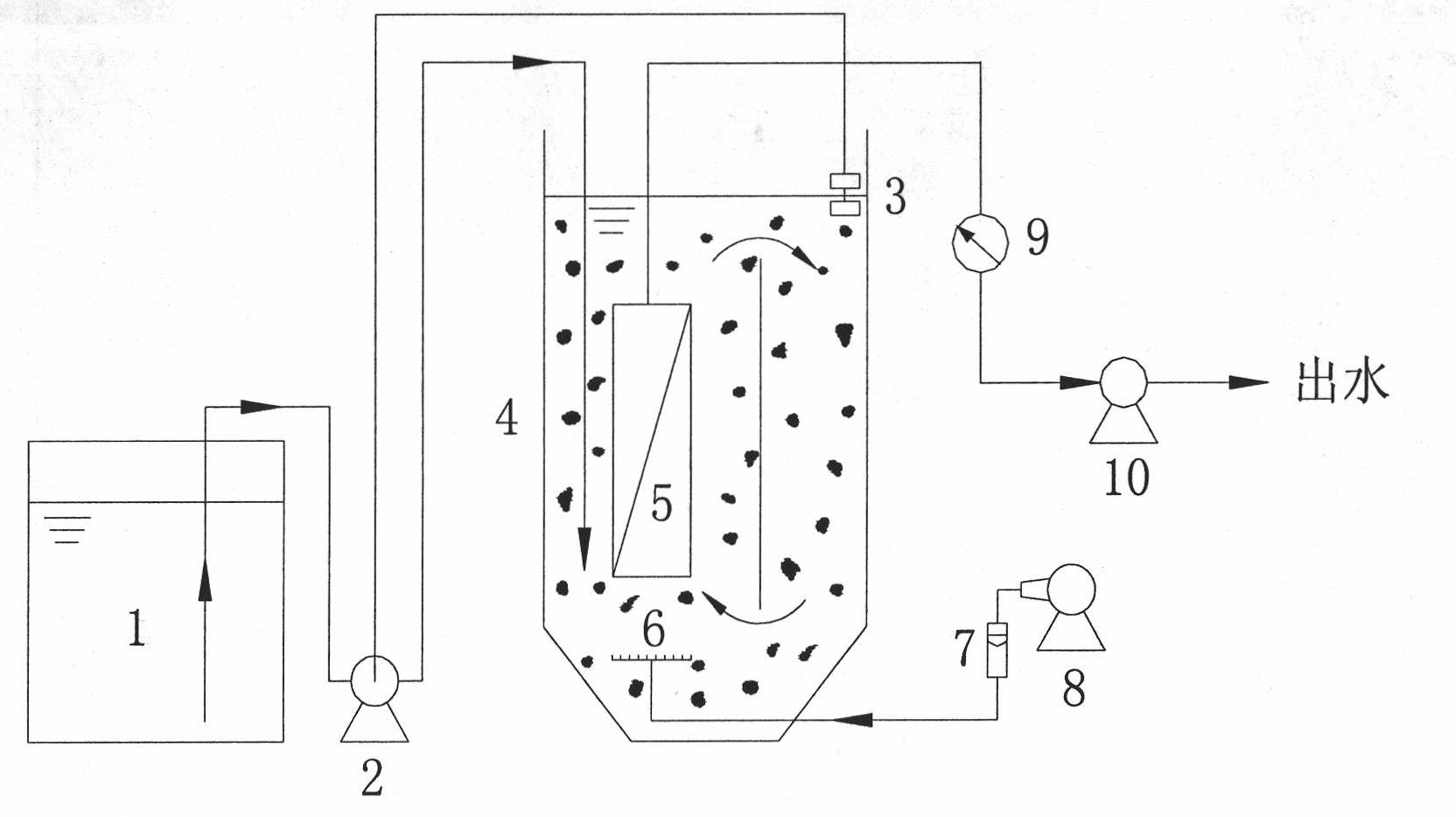

Fluidized bed film bioreactor for sewage treatment

InactiveCN102167469AReduce pollutionExtended service lifeMultistage water/sewage treatmentWaste rubberTotal nitrogen

The invention discloses a fluidized bed film bioreactor for sewage treatment, which belongs to the technical field of water and waste water treatment. The invention utilizes a process combining a biological fluidized bed with a film bioreactor, i.e. the reactor is filled with self-produced carrier granules with a diameter of about 5mm, wherein the carrier granules are made of waste rubber powder, activate carbon and adhesive, and the filling ratio is 10-30% of the effective volume of the reactor. By means of the synergistic effect of the carriers and sludge to finish the film forming process, microorganism is grown on the filler to reduce the concentration of the sludge in the reactor, change the environment running condition of the reactor and slow down the film pollution, thus further prolonging the service life of the film and improving the treatment capacity of the film. By filling the self-produced carrier granules in the film bioreactor and using the filler to change and regulate the interior microenvironment of the fluidized bed film bioreactor, such as dissolved oxygen (DO), the quantity of the filler and the water retention time, a local anoxic zone is formed, thus further realizing the synchronous nitration and denitrification function and improving the removal efficiency of total nitrogen as well as the denitrification efficiency. The fluidized bed film bioreactor for sewage treatment has a simple structure, does not feed the addition of chemical agent, is convenient and efficient to run and operate, can obtain high-quality outlet water, saves energy, can remove various pollutants such as organic matters, total nitrogen and the like, is suitable for treatment of organic waste water such as industrial and domestic waste water and the like, and can be hopefully applied in engineering practice.

Owner:BEIJING FORESTRY UNIVERSITY

Forward coal mining by filling method

InactiveCN101749020ASolve stressSolve problems such as air leakage in gobsUnderground miningSurface miningMining engineeringEarth surface

The invention provides a forward coal mining technique by a filling method, comprising the following characteristics: simultaneously pushing the working surface and the gate road of coal mining, thereby tunneling, mining and filling old empty region. The invention can reduce 20-30% of tunneling rate and 10-15% of workers, the filling ratio of the goaf reaches over 95%. The problems that the maintenance is difficult to carry out because of great pressure of the surrounding rock along retaining, the goaf leaks air, the production is continuously tense, coal resource is wasted and the like are solved, and the non-disturbance of earth surface is effectively controlled.

Owner:ZIBO WANGZHUANG COAL MINE

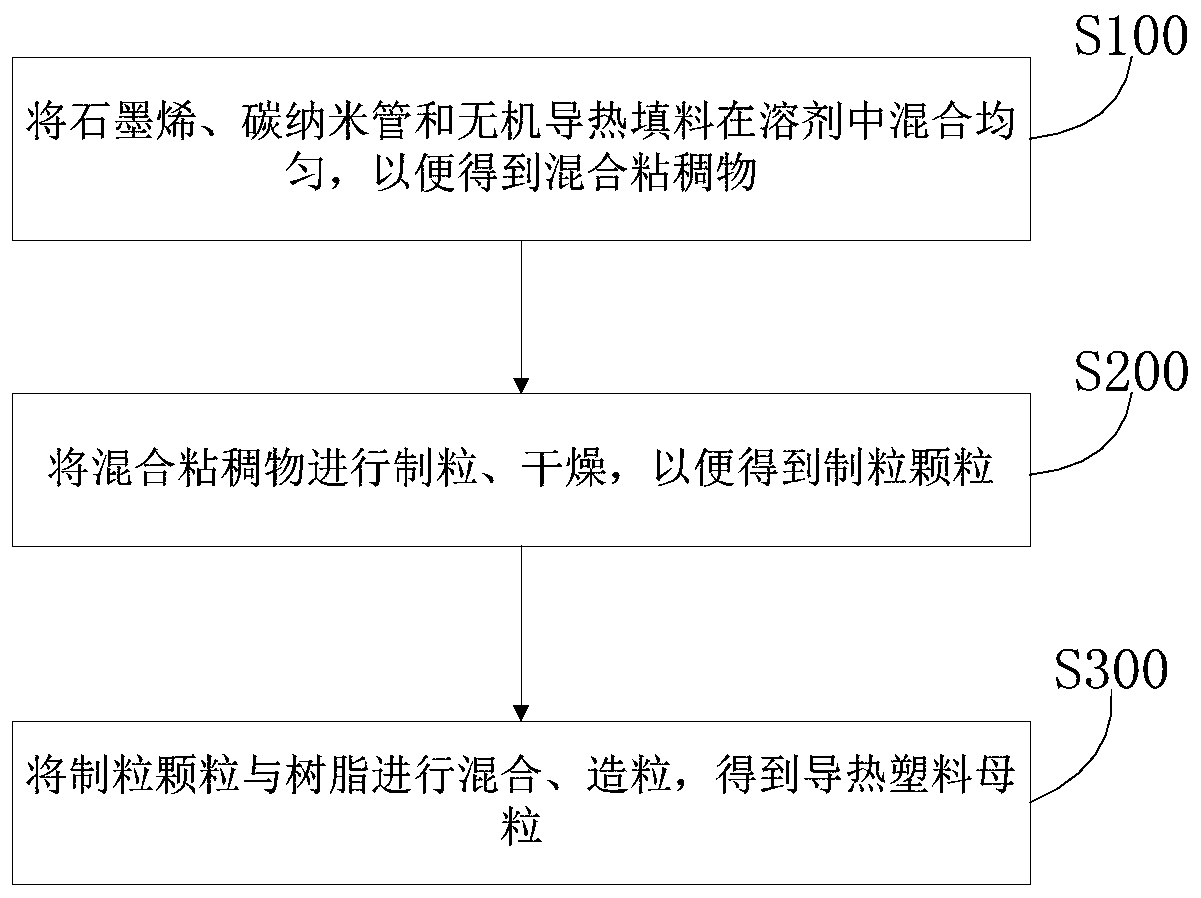

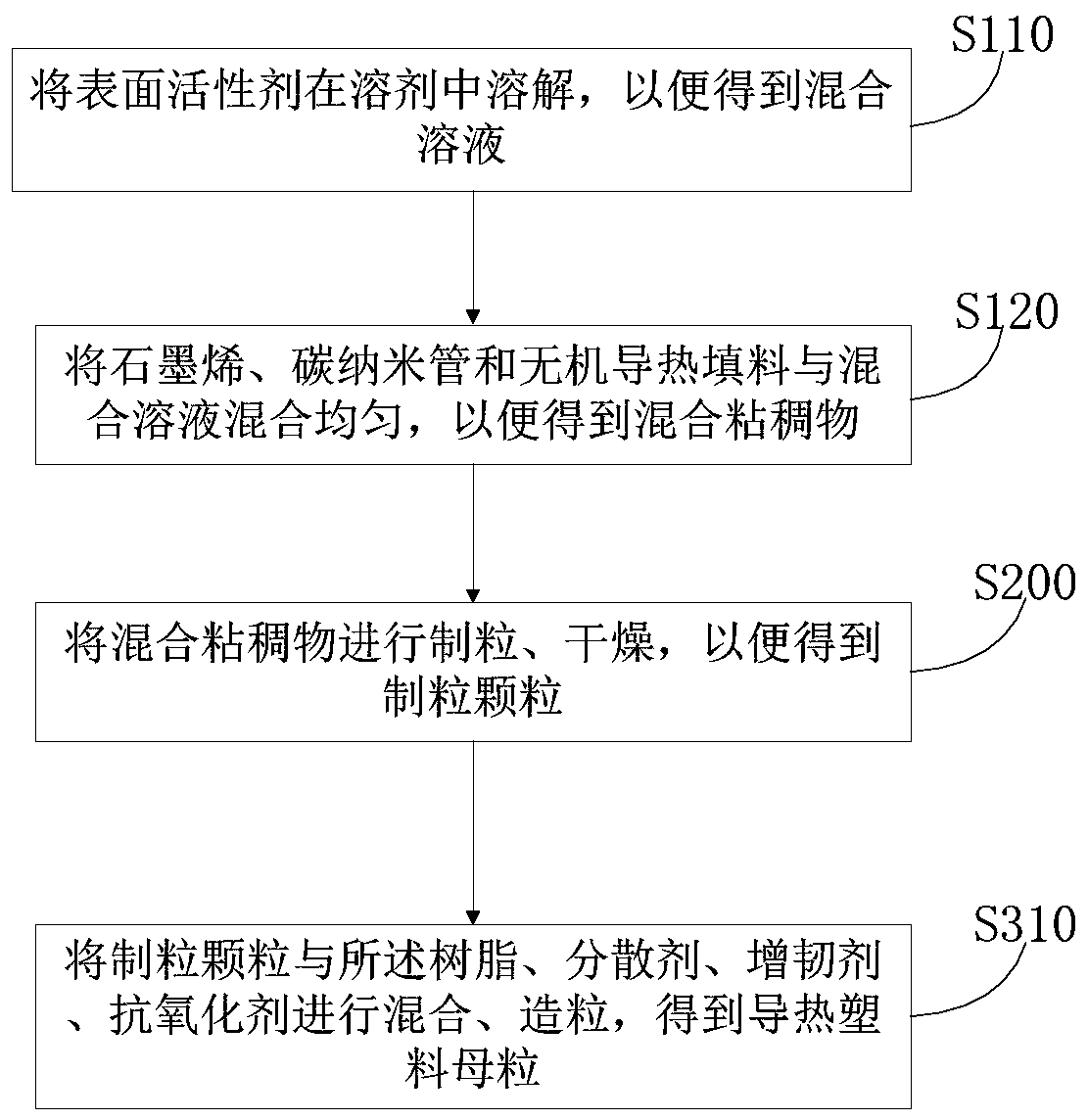

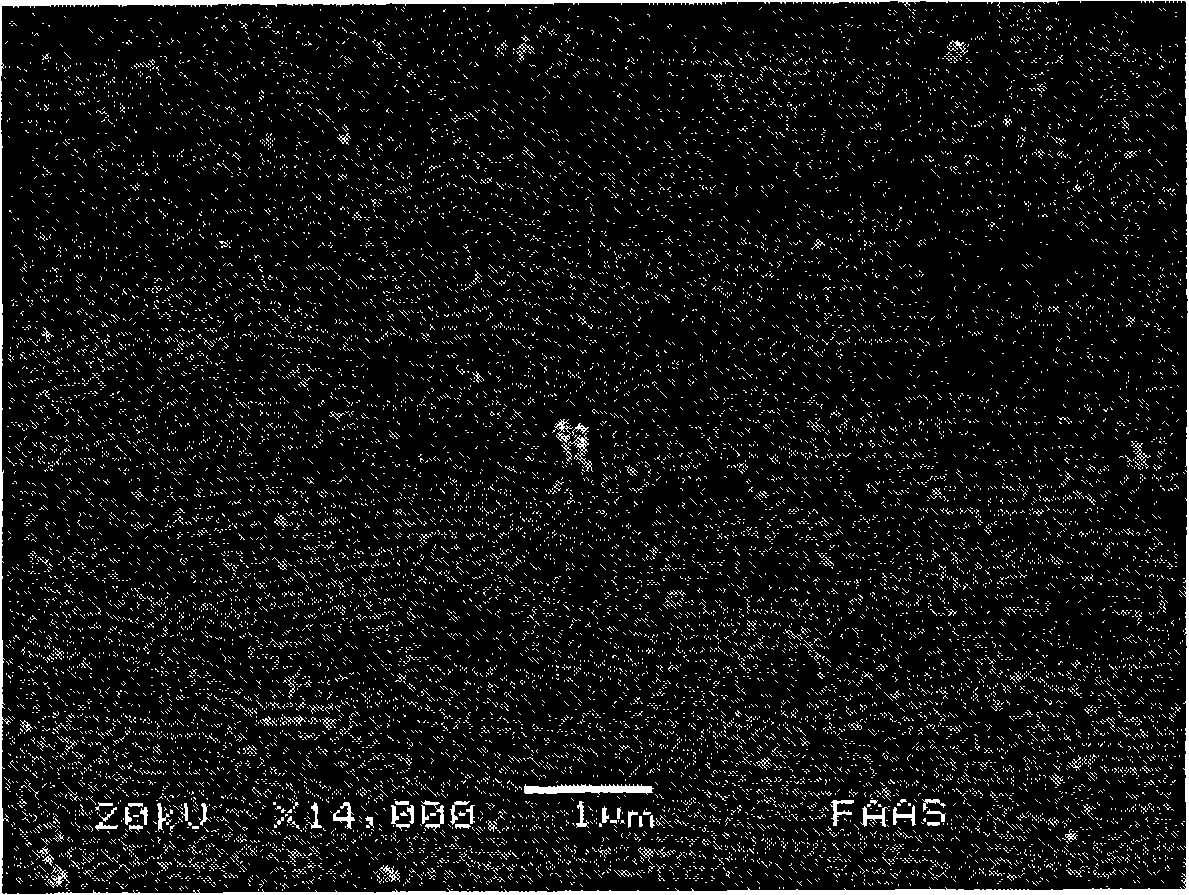

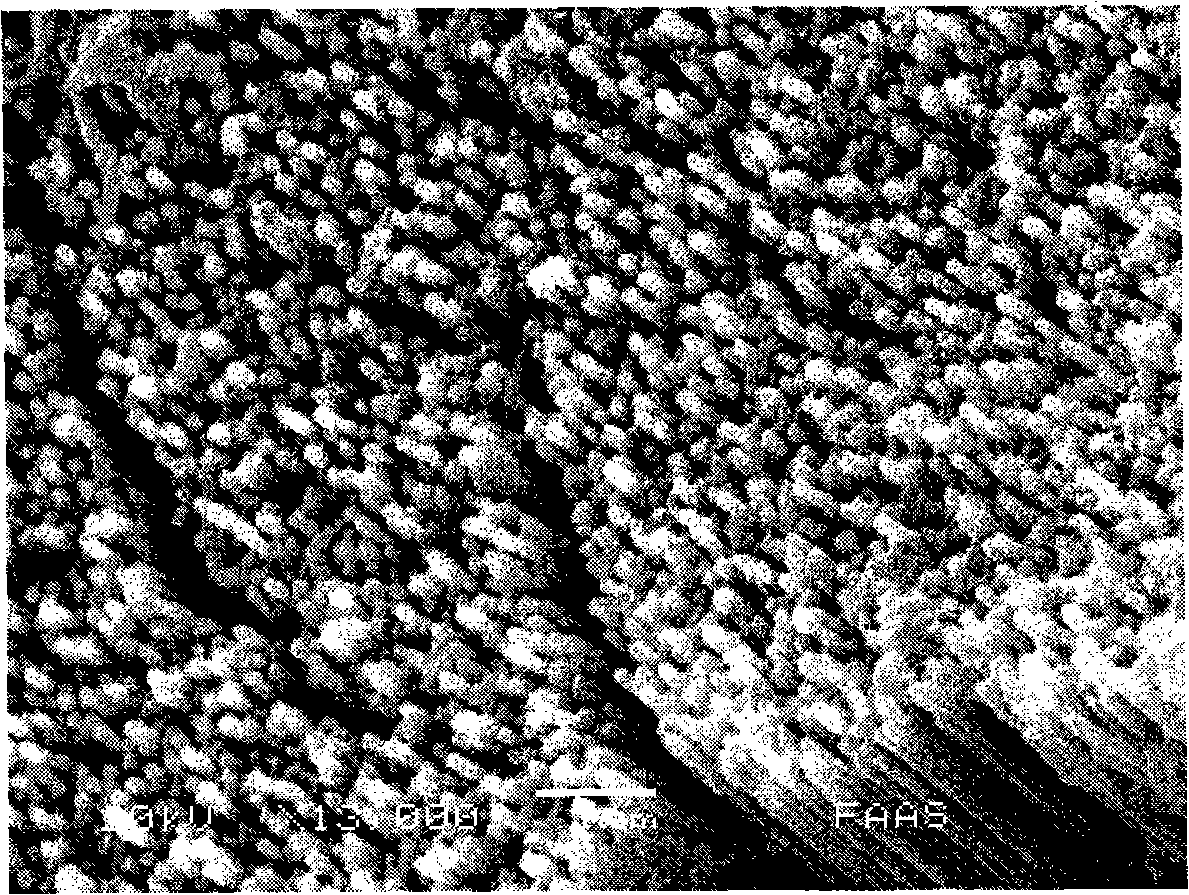

Heat-conducting plastic master batch, preparation method thereof and heat-conducting plastic

InactiveCN110172166AImprove thermal conductivityEvenly dispersedHeat-exchange elementsHeat conductingCarbon nanotube

The invention provides a heat-conducting plastic master batch, a preparation method thereof and heat-conducting plastic. The heat-conducting plastic master batch comprises resin, graphene, carbon nanotubes and a micron-sized inorganic heat-conducting filler. Thus, the nanoscale graphene and carbon nanotubes and the micron-sized inorganic heat-conducting filler complement each other in geometric dimensions and dimensions, the accordingly generated synergistic effect not only can significantly improve the heat-conducting performance of the heat-conducting plastic master batch, but also ensures the uniform dispersion of the graphene, carbon nanotubes and inorganic heat-conducting filler in the resin to obtain the heat-conducting plastic master batch with high filling density and uniformity; the mixing method can increase the filling ratio of the graphene, obtain the concentrated master batch of a network structure (heat-conducting network) formed by the graphene, the carbon nanotubes andthe inorganic heat-conducting filler in the resin, and the good construction of the heat-conducting network structure can significantly improve the heat-conducting performance of the heat-conducting plastic master batch and also improve the mechanical strength and impact toughness of the heat-conducting plastic master batch.

Owner:ENN GRAPHENE TECH CO LTD

Method for preparing titanium oxide nano-wire array

The invention discloses a method for preparing a titanium dioxide nano-wire array, which belongs to the technology field of preparation of nano material. The method is realized by the following proposal: one side of an AAO template is coated with a working electrode; at the room temperature, a liquid A and a liquid B are prepared for reservation; the liquid A consists of the ethanol and the esters while the volume ratio of the ethanol and the esters is 15:4 to 15:3.5; the liquid B consists of the ethanol, an acetic acid and a deionized water while the volume ratio of the ethanol, the acetic acid and the deionized water is 15:4:1.8 to 15:4:2. The liquid A is added to the liquid B slowly while stirring and a nitric acid is added to regulate the PH value, then a sol which is stable at the room temperature is formed. The alumina template which is coated with the electrode is taken as a cathode; Electrophoretic deposition is carried out in the sol; then the titanium dioxide nano-wire array can be obtained when the template after electrophoretic deposition is annealed at a certain temperature. The method adopts the electrophoretic deposition to prepare the titanium dioxide nano-wire array in the alumina template, and the titanium dioxide nano-wire array has high filling ratio and is compact and can be widely used in the field of photocatalysis solar cell and dye-sensitized solar cell.

Owner:HUAQIAO UNIVERSITY

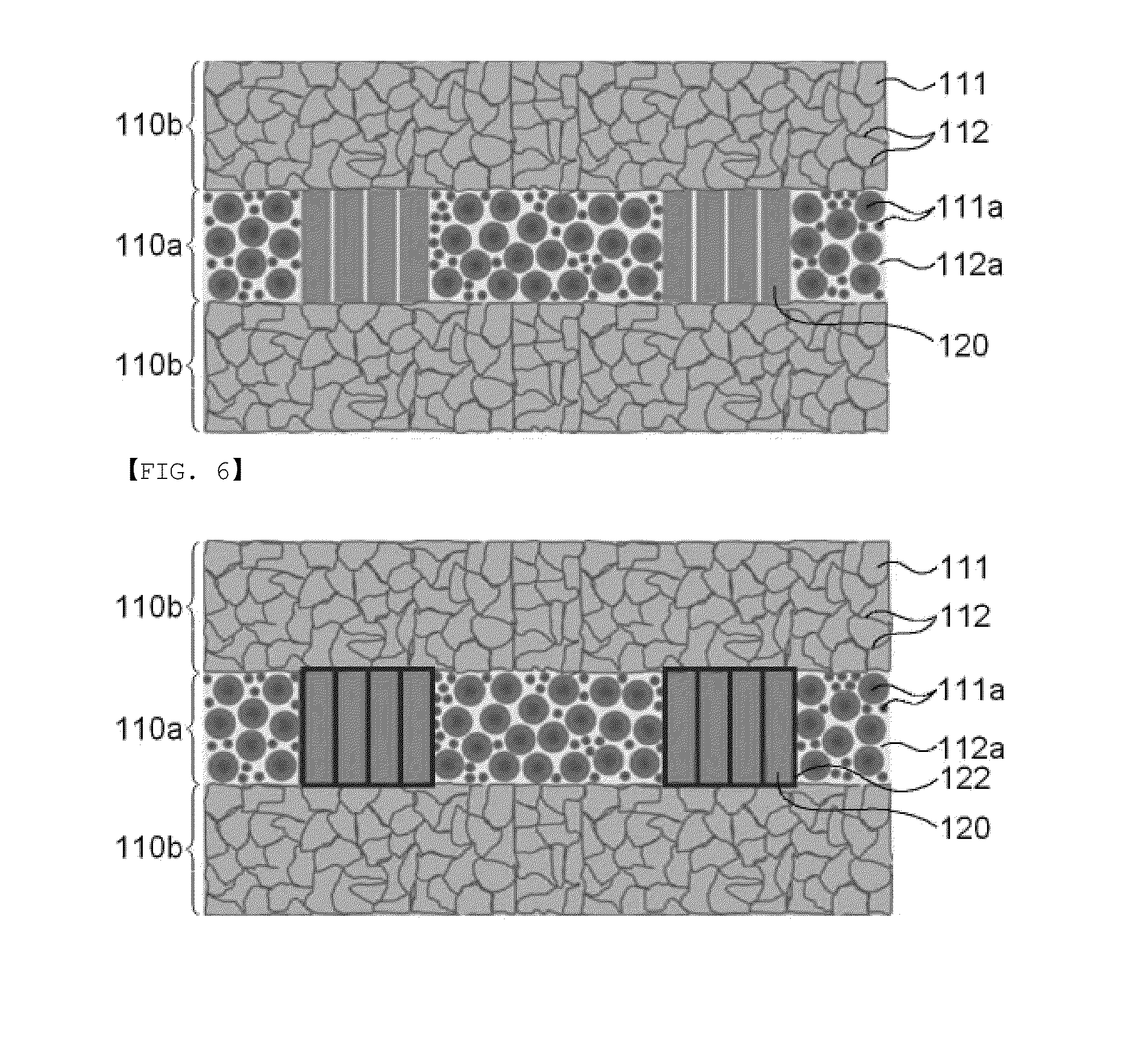

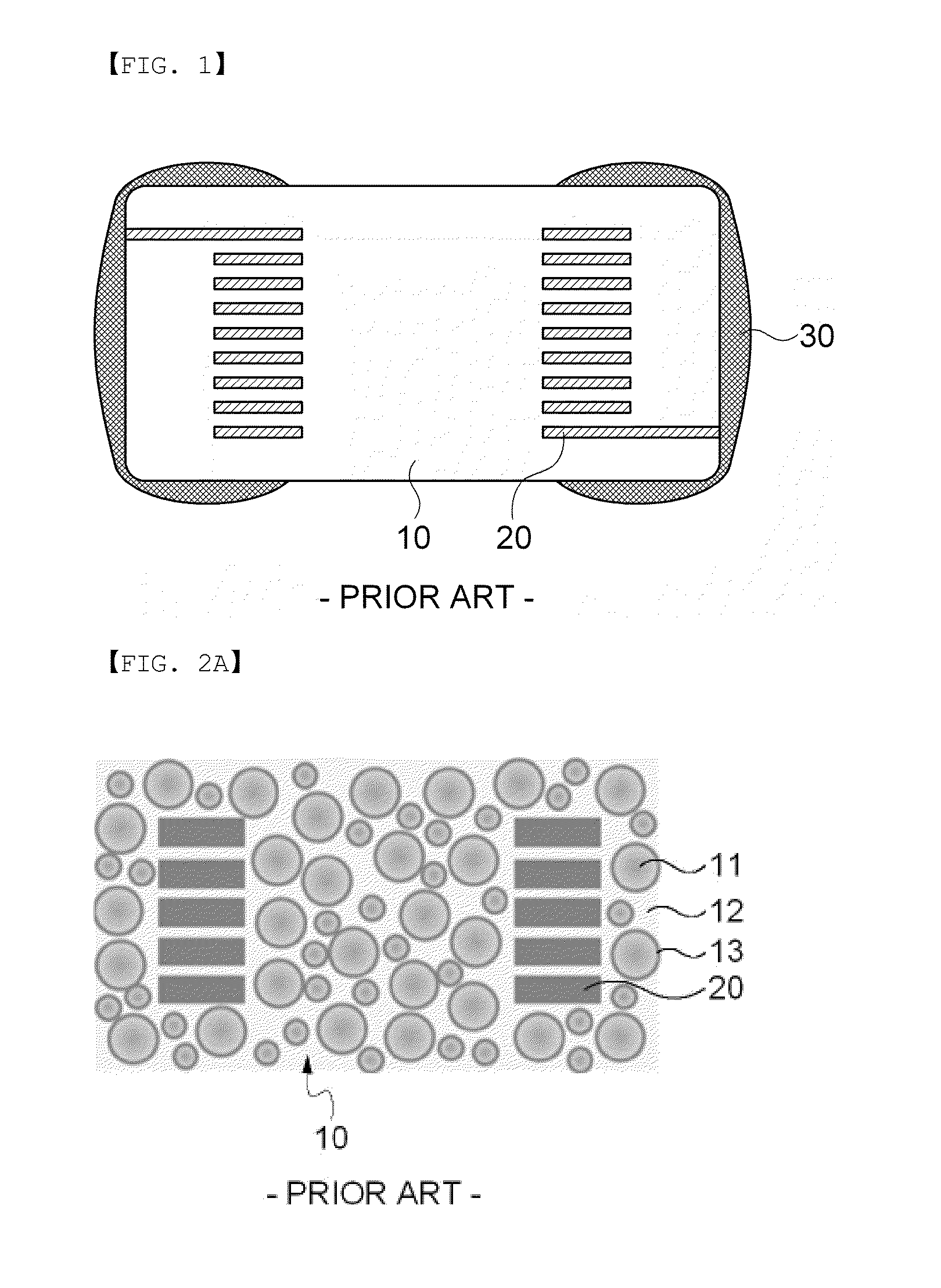

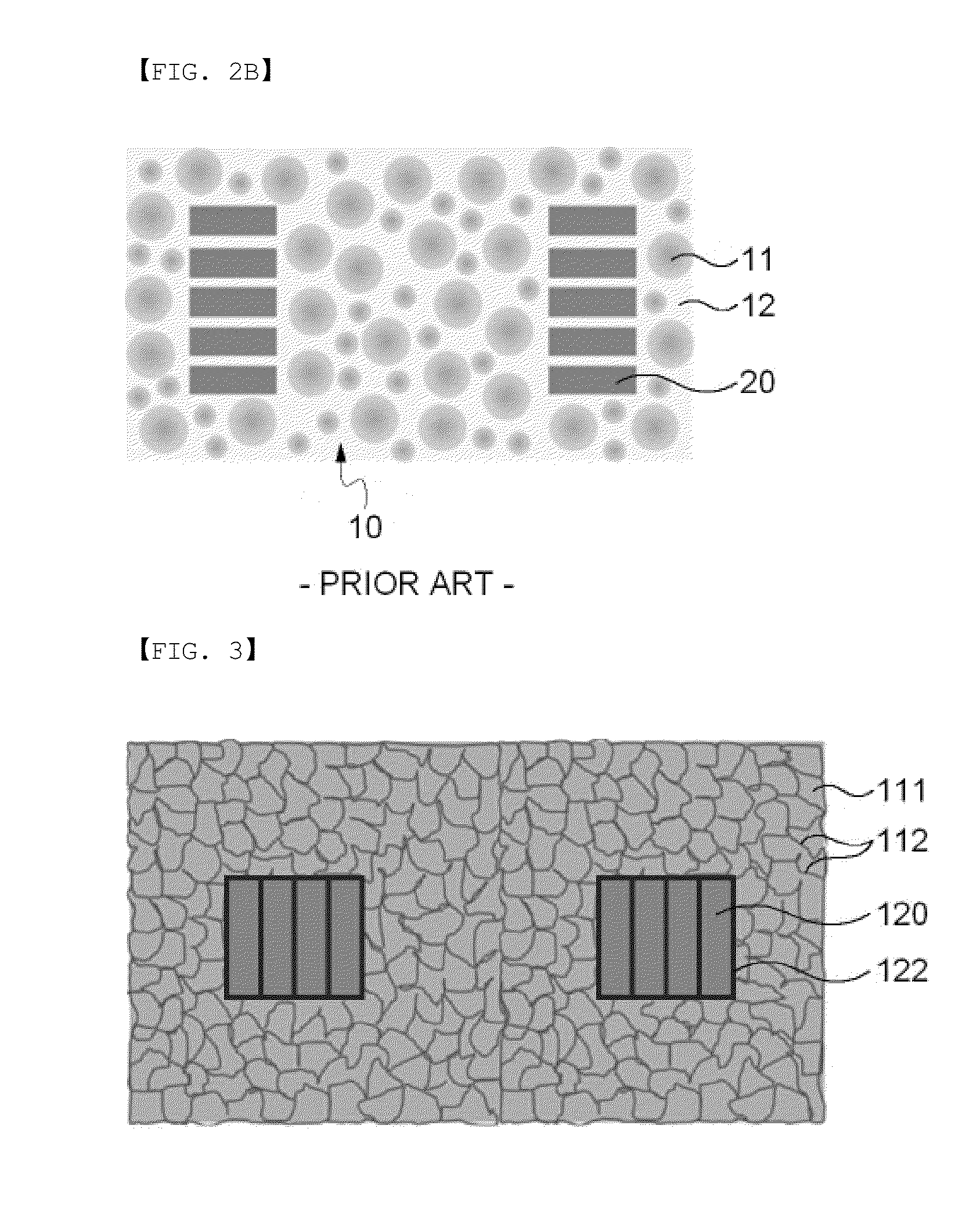

Multilayered power inductor and method for preparing the same

ActiveUS20140132387A1High Capacity FeaturesImprove fill rateTransformers/inductances coils/windings/connectionsInorganic material magnetismInductorMetal powder

Disclosed herein are a multilayered power inductor including an inner electrode coil pattern formed on a ceramic substrate; an outer electrode layer; and a magnetic layer made of a metal powder insulated along a grain interface of the metal powder included in a part or the whole of a chip, and a method for preparing the same. According to the exemplary embodiments of the present invention, the magnetic layer made of the metal powder insulation-coated with the ceramic material along the grain interface of the magnetic metal powder can be used for a part or the whole of the chip, thereby increasing the filling ratio of the magnetic metal powder to 90% within the magnetic layer. Therefore, a high-capacity power inductor can be implemented to effectively improve efficiency characteristics.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

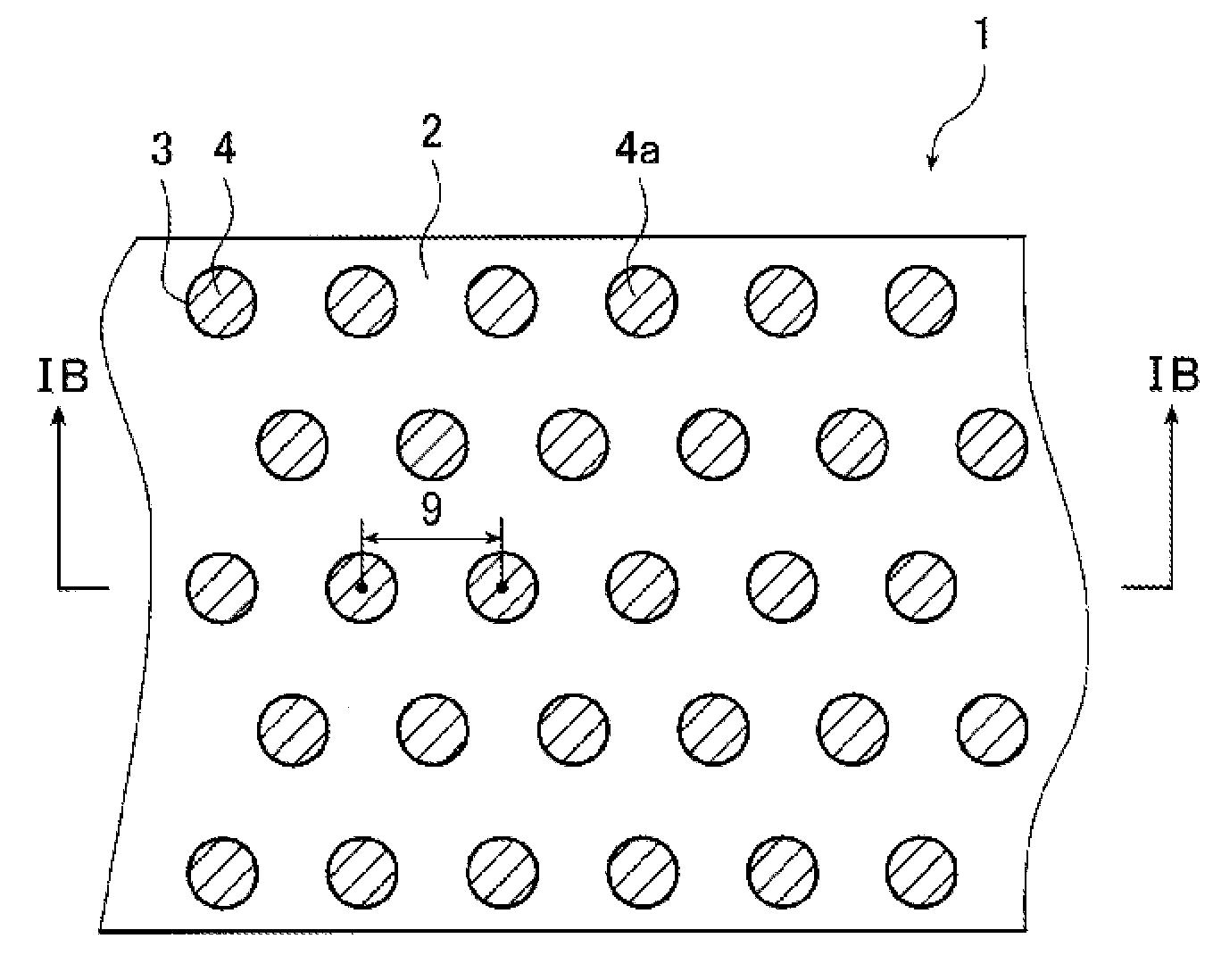

Monolithic ceramic electronic component

InactiveUS6270906B1Fixed capacitor electrodesFixed capacitor dielectricElectronic componentFilling ratio

A monolithic ceramic component has inner electrodes which are thin having a thickness of from about 0.2 mum to 0.7 min, and thereby, delamination is inhibited even though ceramic layers are thin, having a thickness up to about 3 mum. The mean particle size of the ceramic grains of the ceramic layers is up to 0.5 mum, so that the concavities and convexities at the interfaces between the inner electrodes and the ceramic layers can be reduced. Preferably, metal powder in a paste used to form the inner electrodes has a mean particle size of from about 10 to 200 nm, and thereby, the metal filling ratio and the smoothness of the inner electrodes can be enhanced, and the coverage can be improved.

Owner:MURATA MFG CO LTD

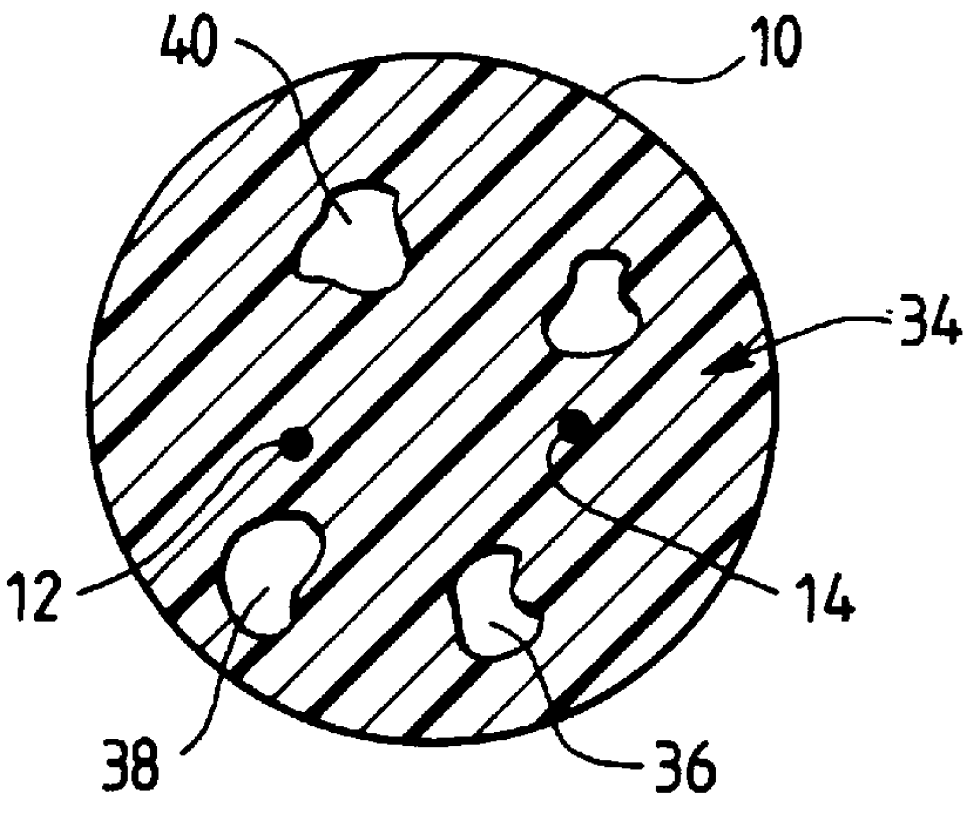

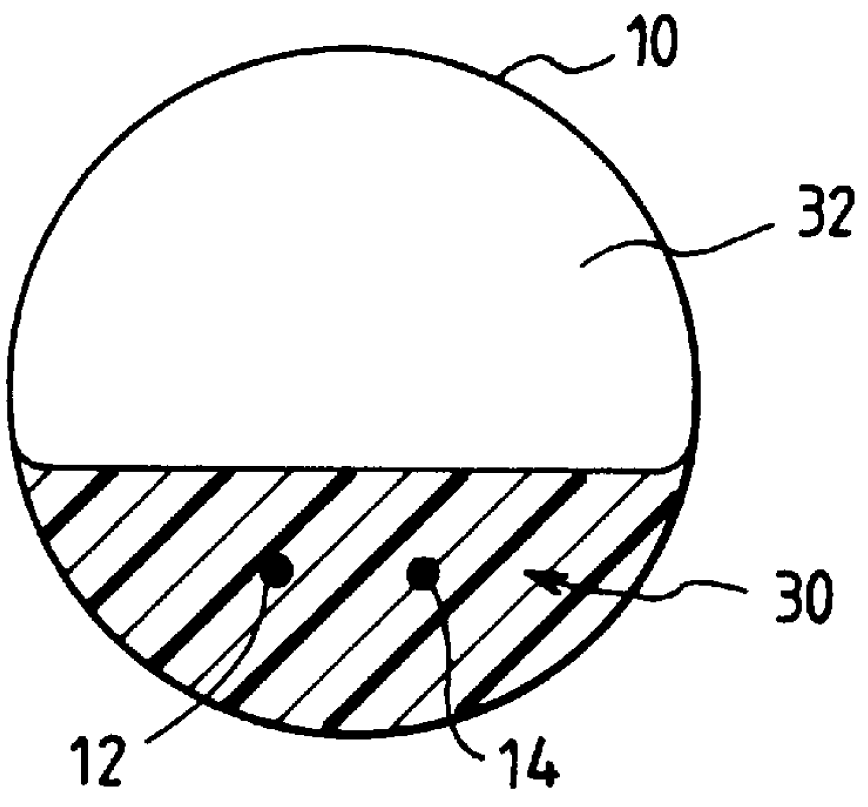

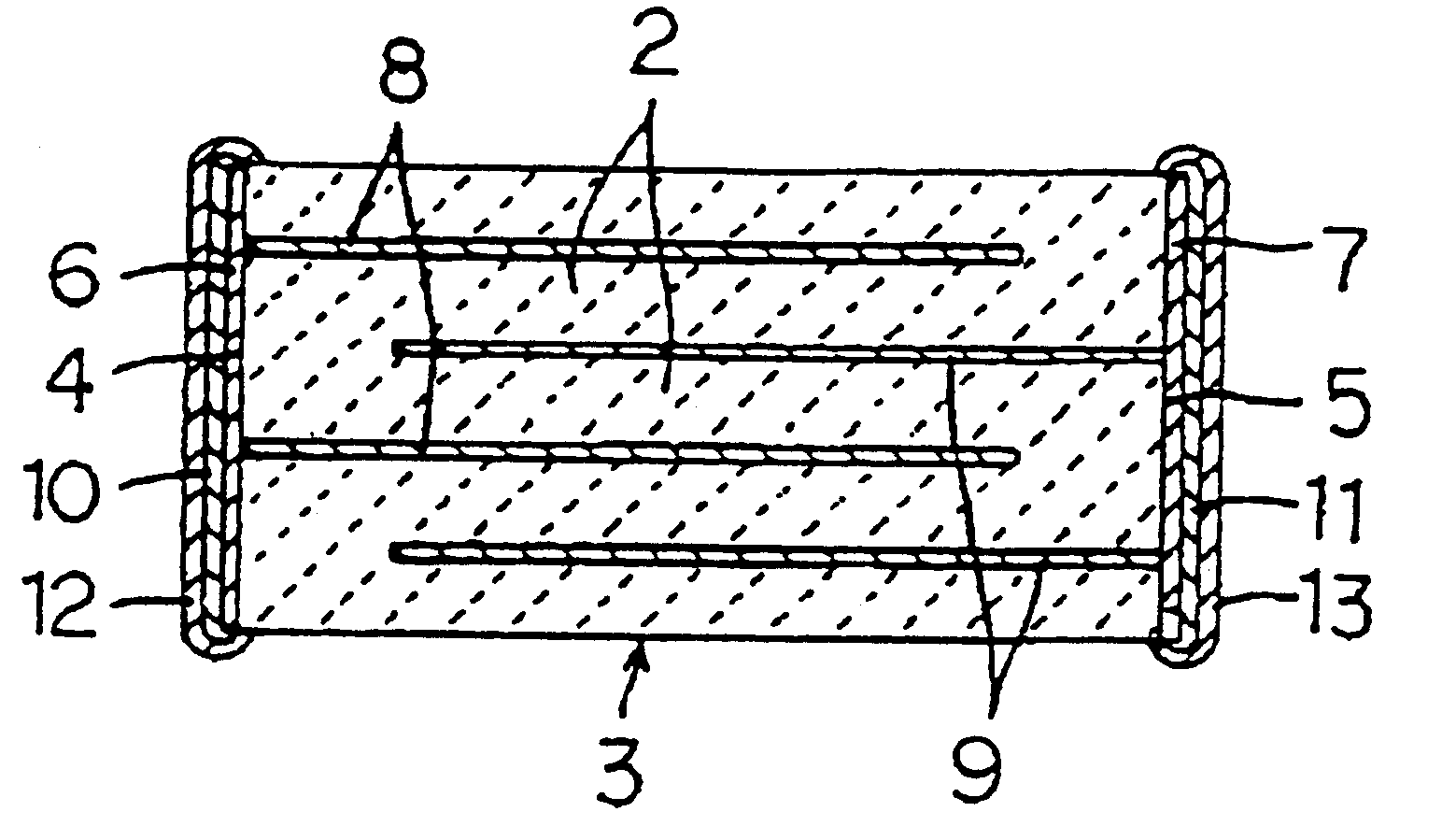

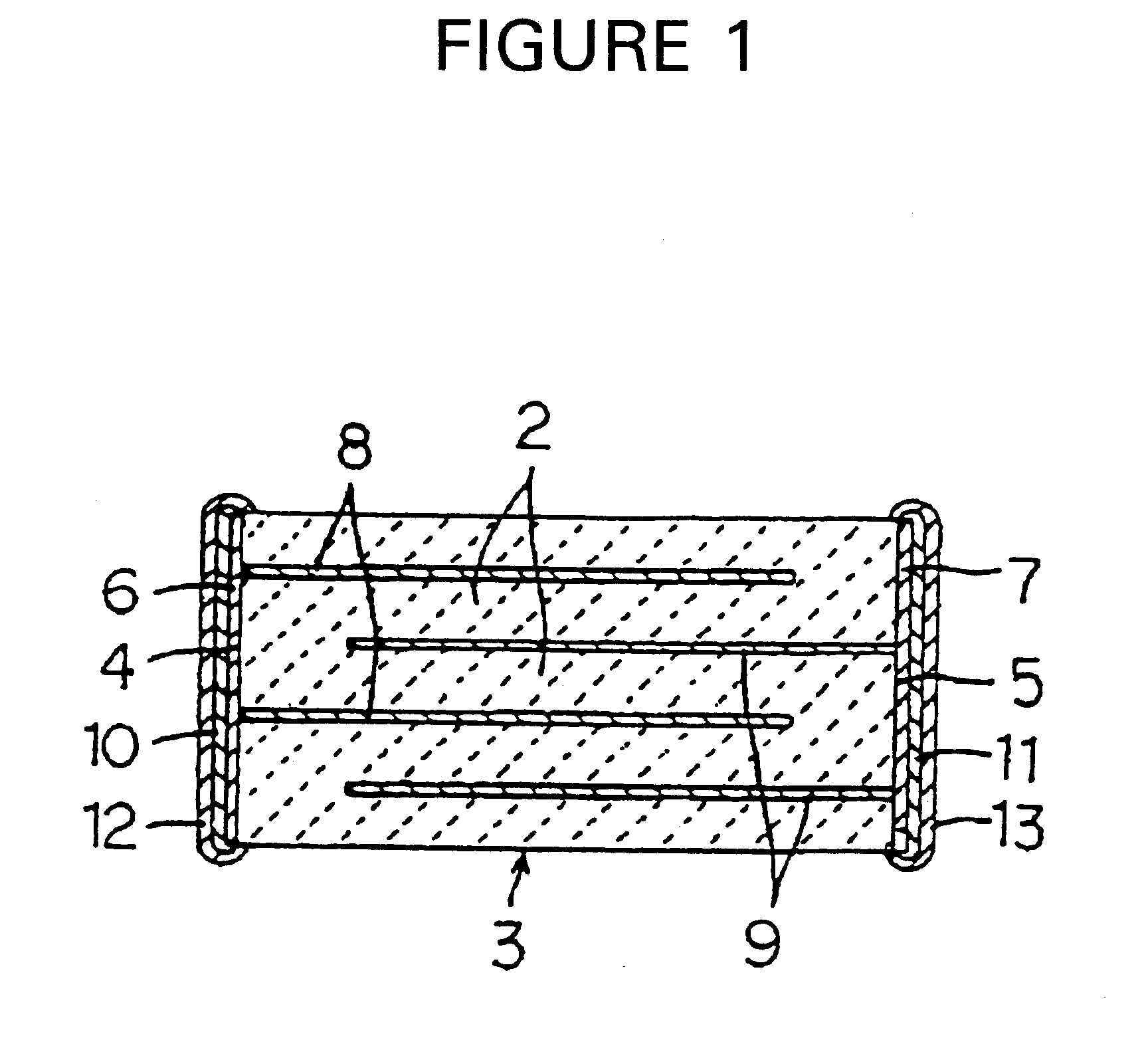

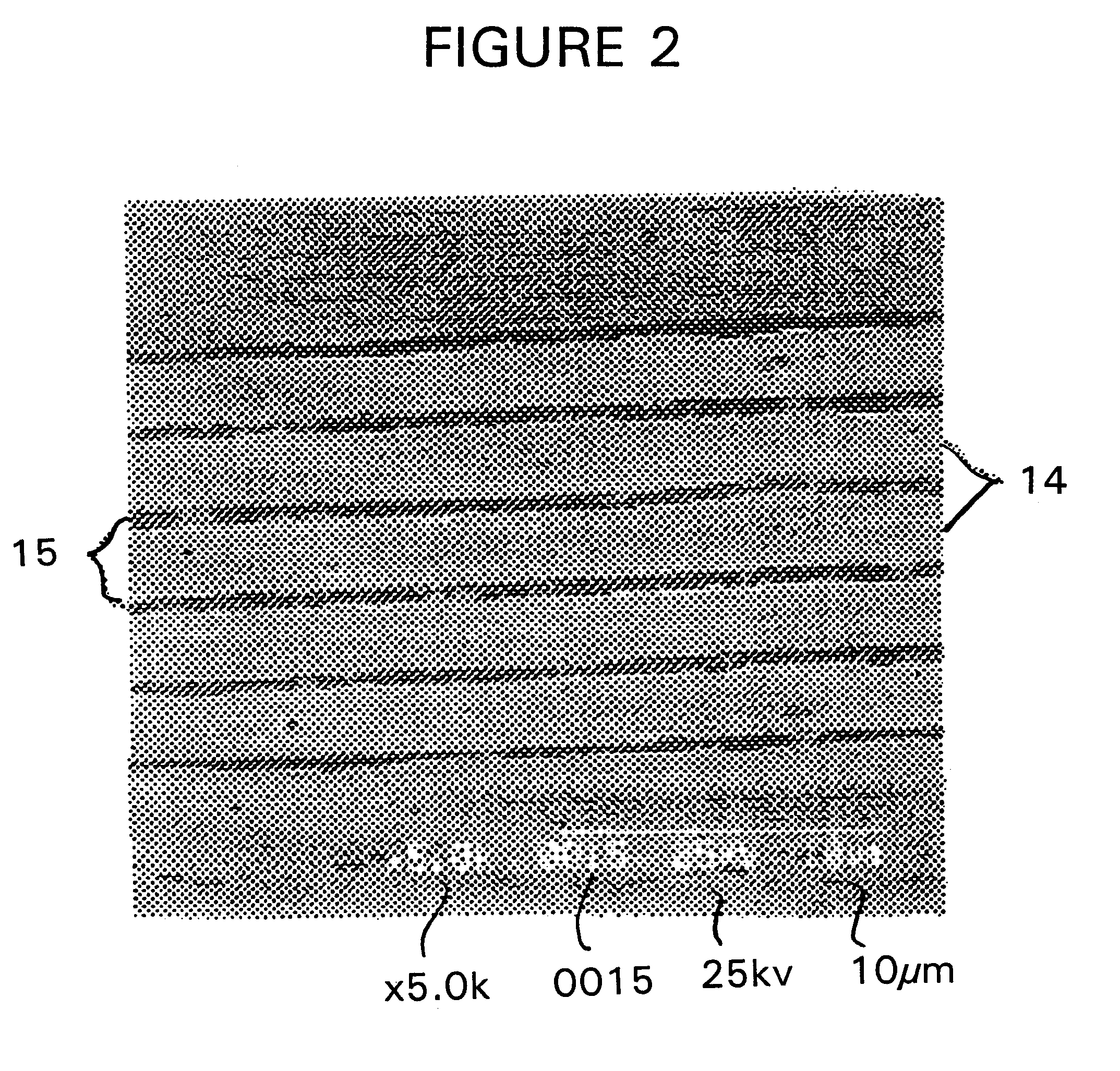

Continuous fiber-reinforced thermoplastic resin pellets and manufacturing method of the same

ActiveUS20100098946A1Good dispersionSatisfactory outward appearanceSynthetic resin layered productsCoatingsFiber bundleVolume filling

To provide continuous fiber-reinforced thermoplastic pellets having a good dispersion property of a reinforcing fiber bundle in injection molded articles and capable of achieving a satisfactory outward appearance of the injection molded articles and satisfying a mechanical strength of the injection molded articles by fully exerting the reinforcing effect, and a manufacturing method of the same.In continuous fiber-reinforced thermoplastic resin pellets manufactured by letting a long reinforcing fiber bundle be impregnated with molten thermoplastic resin and pultruding the resin-impregnated reinforcing fiber bundle with twisting, followed by the cutting of a rod-shaped composition formed of the twisted resin-impregnated reinforcing fiber bundle into pellets, a volume filling ratio Vf, which is a proportion of a cross section area of the reinforcing fiber bundle in a cross section area of a pellet cross section in a direction perpendicular to a pellet longitudinal direction, is in a range of 70% to 20%, and a twisting pitch P given by P=L / d (where L is a traveling length of a twist in a rod-shaped composition longitudinal direction per rotation of the rod-shaped composition, and d is a diameter of a circle comparable to an area of a rod-shaped composition cross section) is in a range of 2.5 to 36 (m / rev·m).

Owner:KOBE STEEL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com