House pillar type cutting and filling method of medium coal seam for controlling movement deformation of overlying rock

A mining method and room-and-pillar technology, applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of low mining recovery rate and low safety level, and achieve improved safety level, high production efficiency, protection and attachment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention are further described below in conjunction with accompanying drawings:

[0040] Concretely combined with 10 with a thickness of 2.6 to 3.2 meters -3 Coal seam room-and-pillar filling mining is described in detail to the present invention:

[0041] (1) Roof lithology analysis and filling size determination:

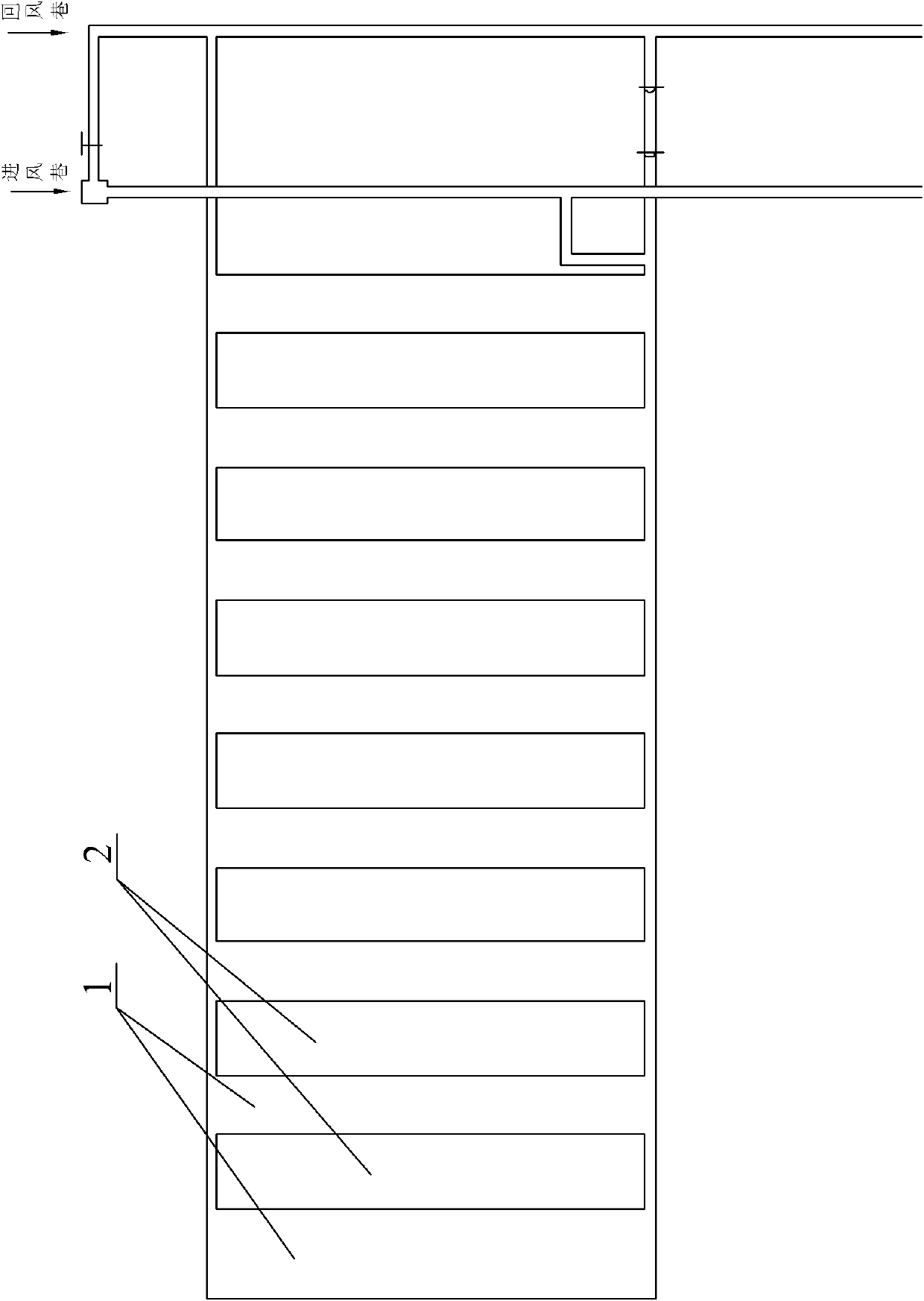

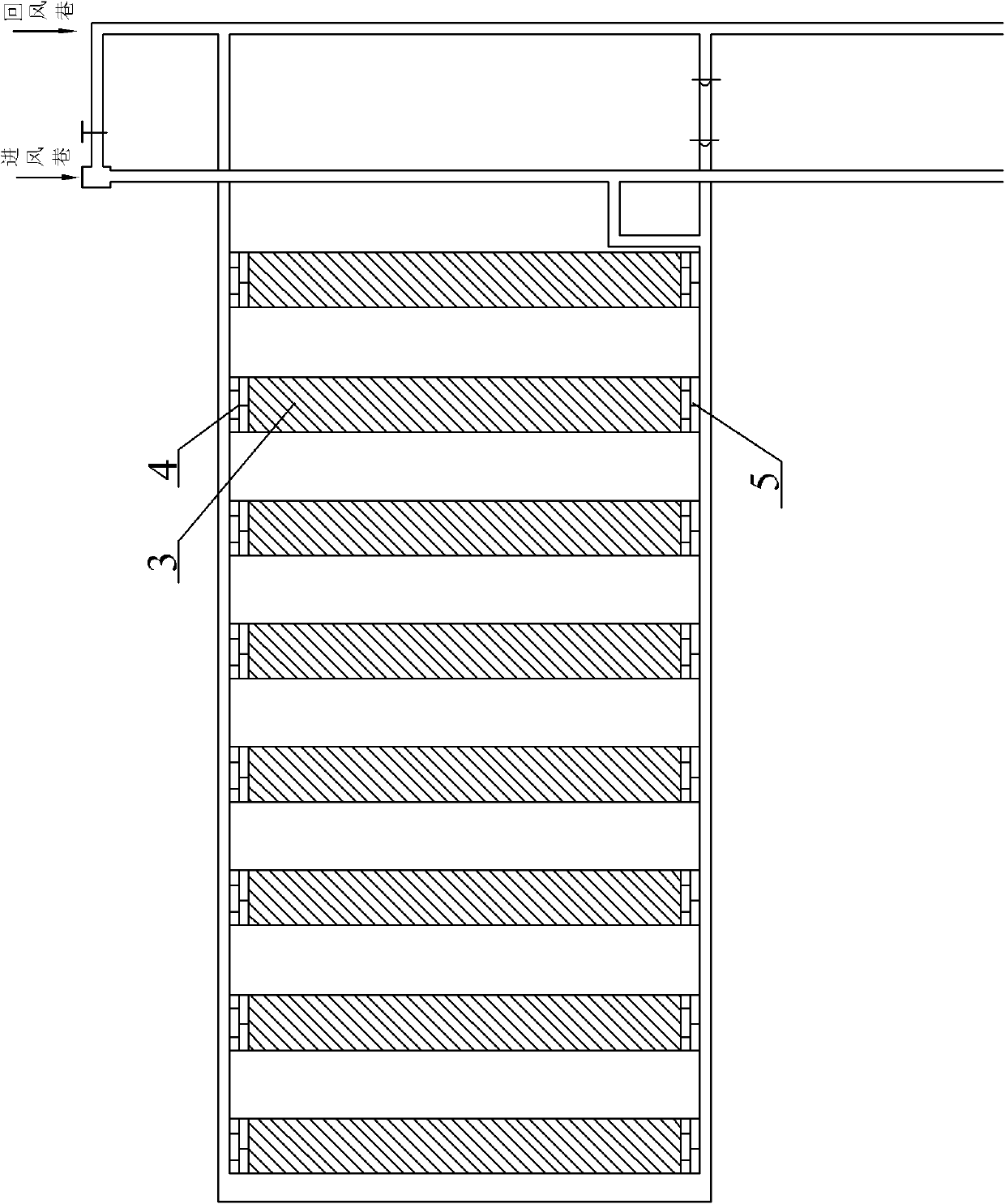

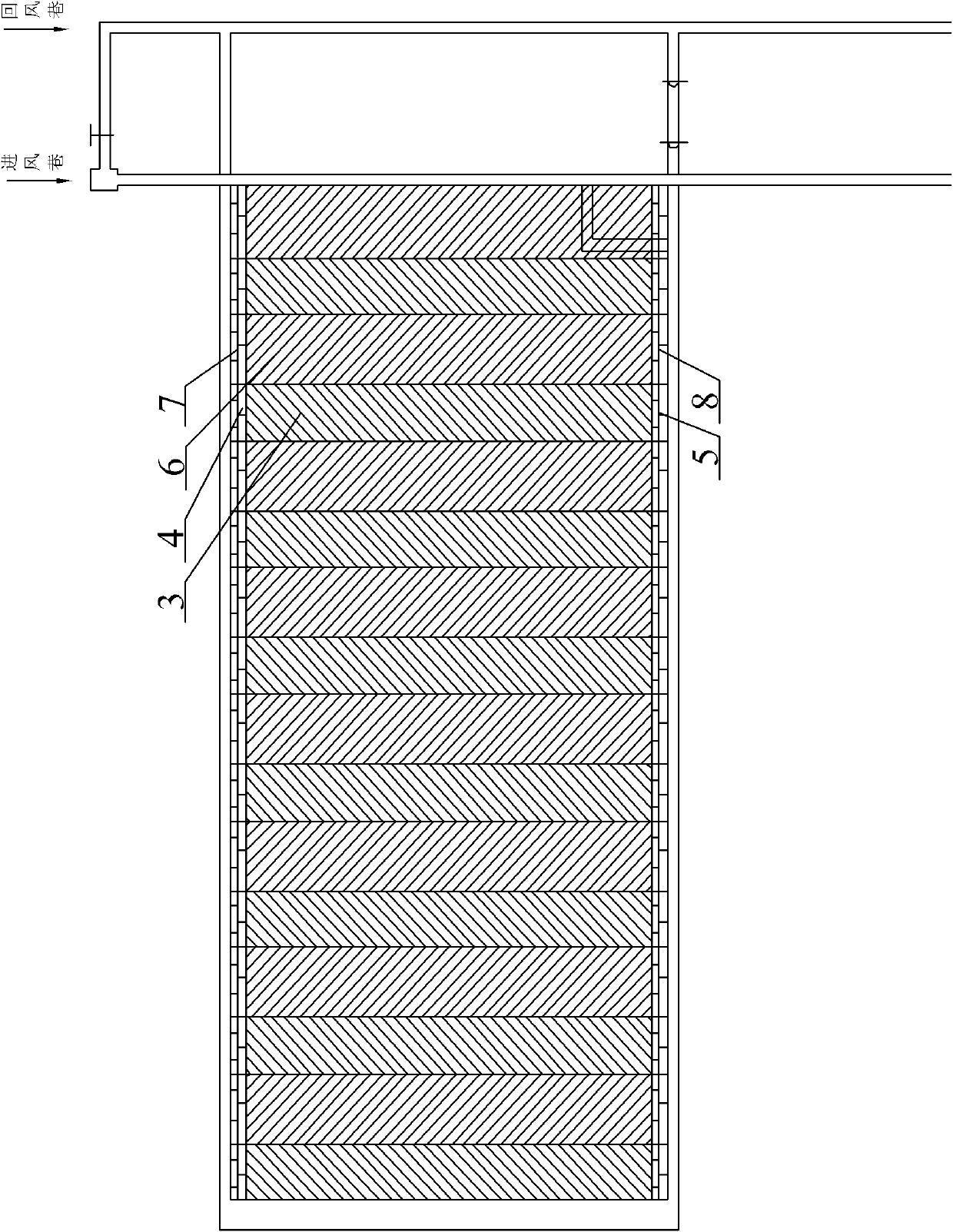

[0042] 10 -3 The thickness of the coal seam is 2.6-3.2 meters, the inclination angle is 5°-8°, lean coal. The floor is carbonaceous mudstone with a thickness of 1.2 meters, and the roof is siltstone with a thickness of 4.5 meters. According to actual mining measurements, the initial pressure step distance L is 25-30 meters, and the periodic pressure step distance M is 17-20 meters. For the sake of safety, the width N of the coal room designed for mining is 12 meters, the width R of the reserved coal pillar is 15 meters, and the coal room 1 and the coal pillar 2 are set at intervals.

[0043] (2) Mining coal room:

[0044] A...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com