Patents

Literature

60results about How to "Reduce sinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Self-compaction filling paste body and preparation process thereof

The invention discloses a self-compaction filling paste body and a preparation process thereof, relates to a filling material with self-compaction performance for coal mine cut and fill mining and a corresponding proportion stirring process, and belongs to the field of construction materials. The self-compaction filling paste body is characterized by being prepared by uniformly mixing coal gangue, coal ash, cements, high-efficiency water reducing agent and water according to proper proportion, wherein the slurry concentration of the paste body is 75-85 percent; and in terms of mass percentage, the proportion of the coal gangue to the coal ash to the cements to the water reducing agent to the water is 45-55 percent to 15-20 percent to 10-15 percent to 3-5 percent to 15-25 percent. The paste body is high in flowability, stability and filling performance, low in bleeding rate and uniform and consistent in quality, and fully fills every corner of a worked-out section; the bleeding and the segregation of the aggregates are avoided; the convenience in transportation and control is achieved; a pipeline is not blocked during transportation; and original mine wastes are adopted for the paste body for realizing the filling so as to protect the environment.

Owner:TAIYUAN UNIV OF TECH

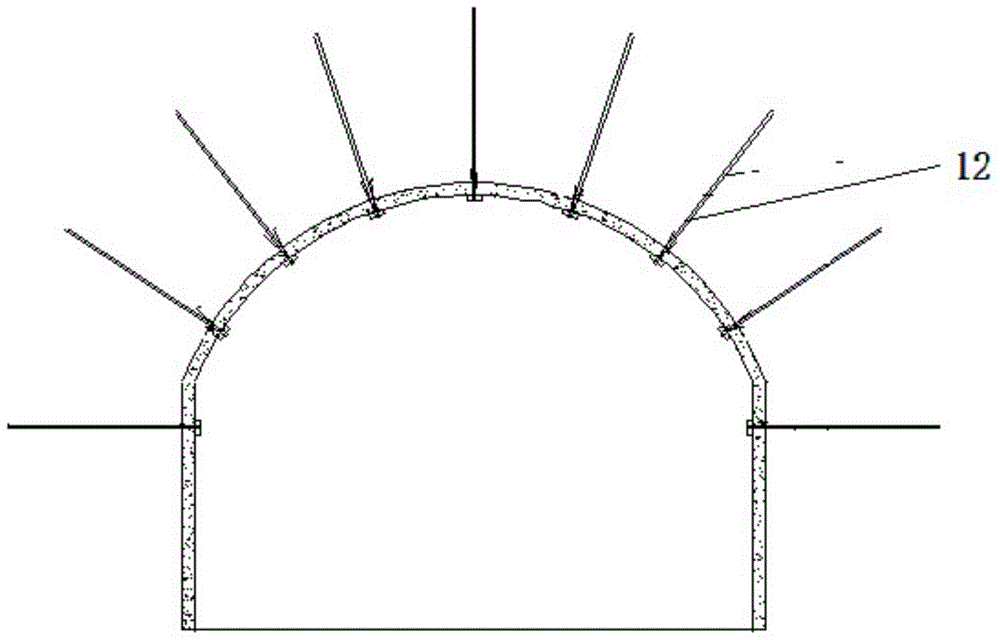

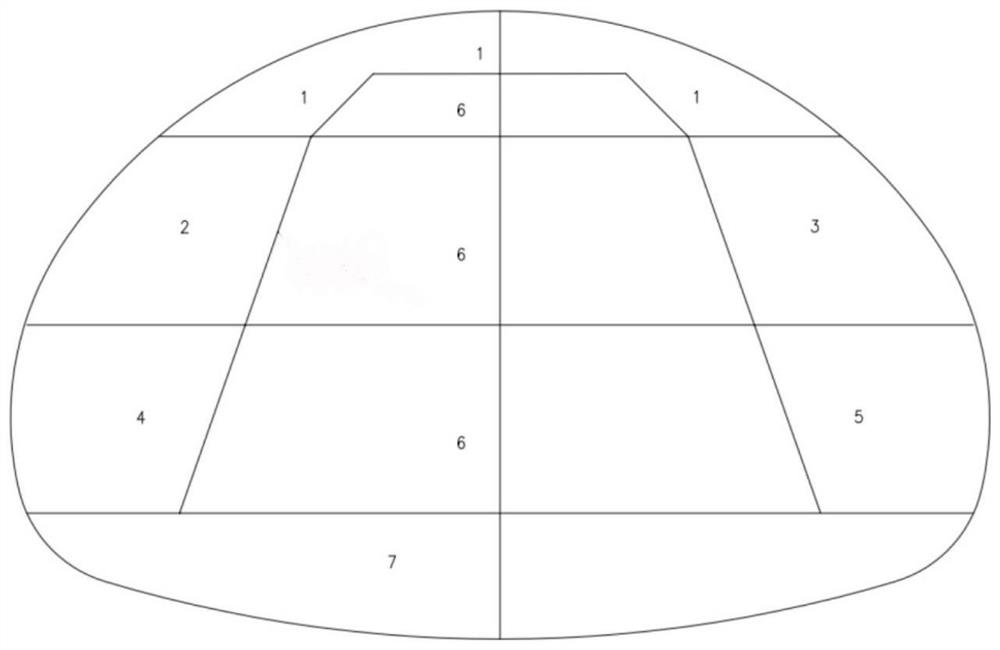

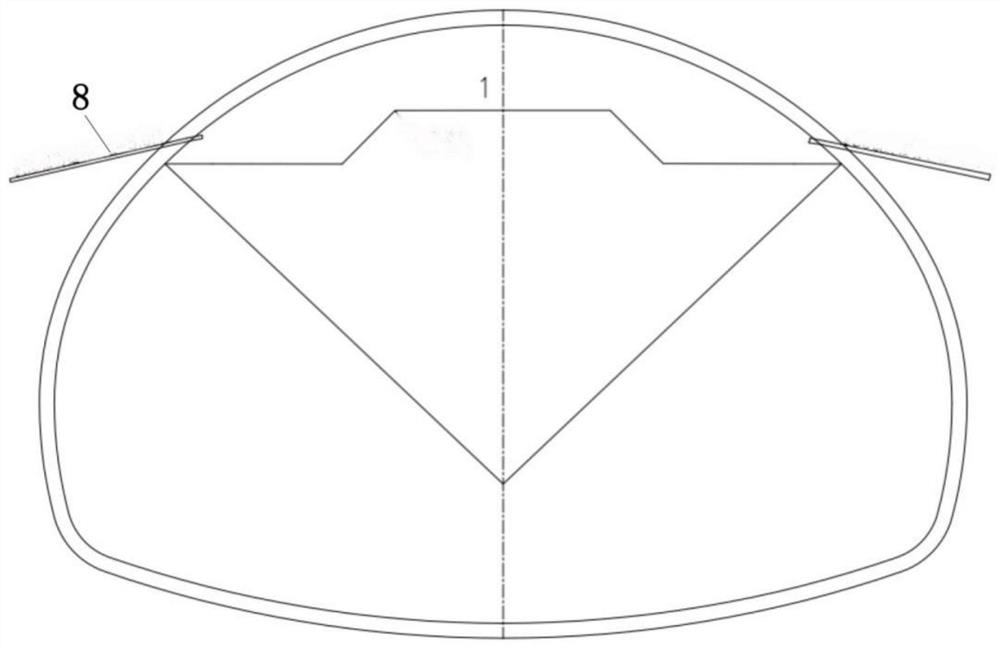

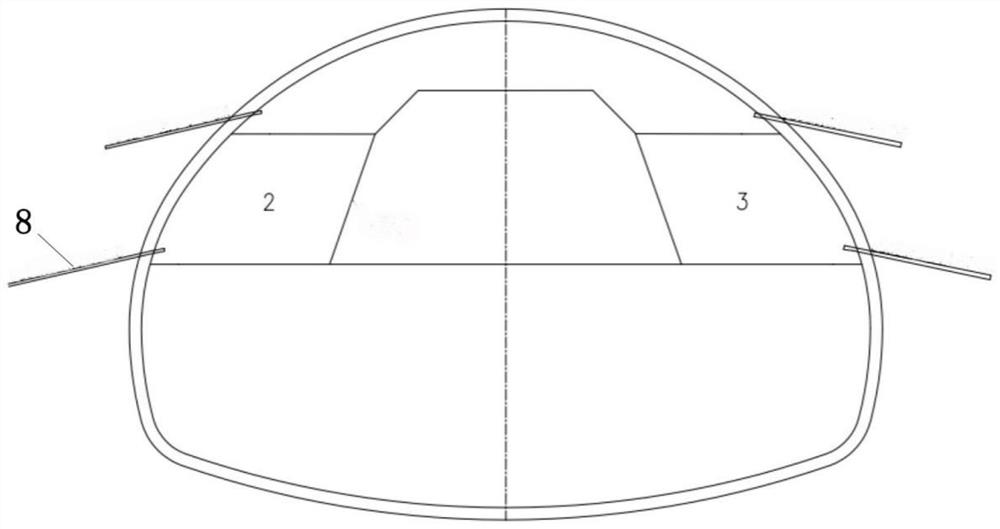

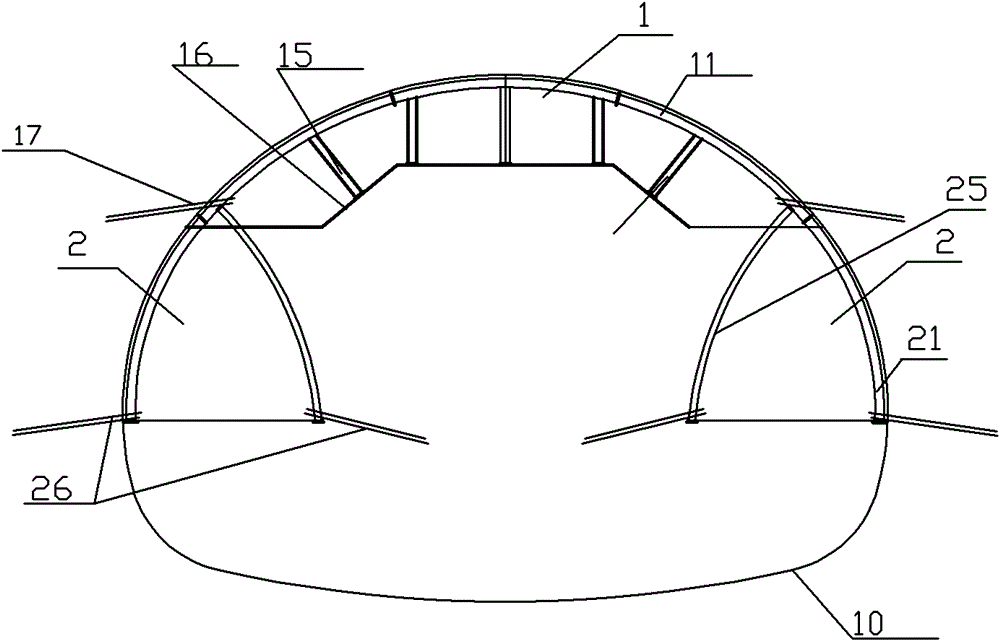

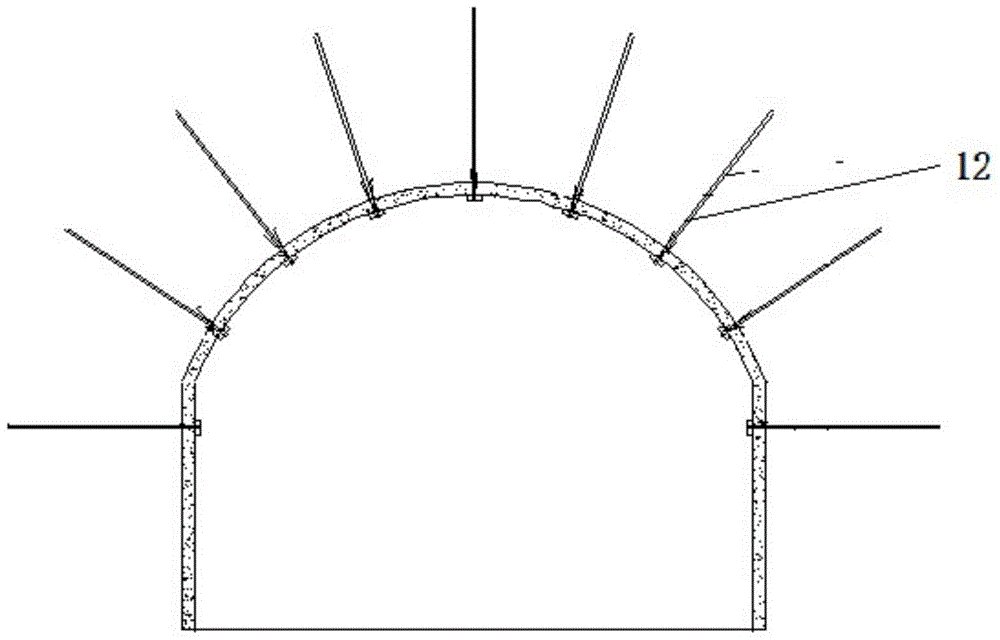

Construction method for soft surrounding rock section of large-span tunnel portal

ActiveCN102071947AAvoid advanced sideAvoid progressUnderground chambersTunnel liningSteel frameLarge core

The invention discloses a construction method for a soft surrounding rock section of a large-span tunnel portal. The construction method comprises the following steps of: excavating an arc-shaped pilot tunnel on the top of a tunnel section; performing initial support in time after the excavation process is finished and performing temporary support at the same time; excavating upper pilot tunnels on the left side wall and the right side wall at the same time; performing initial support in time after the excavation process is finished and performing temporary support on the core soil side wallsat the same time; excavating lower pilot tunnels on the left side wall and the right side wall at the same time, wherein the depth of circulation drilling for each time is 0.5 m; performing initial support in time after the excavation process is finished and performing temporary support on the lower parts of the core soil side walls at the same time; performing large core soil excavation; reserving core soil steps; installing inverted arch steel frames and injecting C25 concrete in time, so that the initial support of the whole tunnel forms a closed ring as soon as possible; and dismantling the temporary support. By the top arc side wall pilot tunnel construction method, vault subsidence can be favorably controlled; and the method is applicable to tunneling excavation construction for strongly differentiating a surrounding rock portal when the tunnel portal is under the protection of a large pipe roof section.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

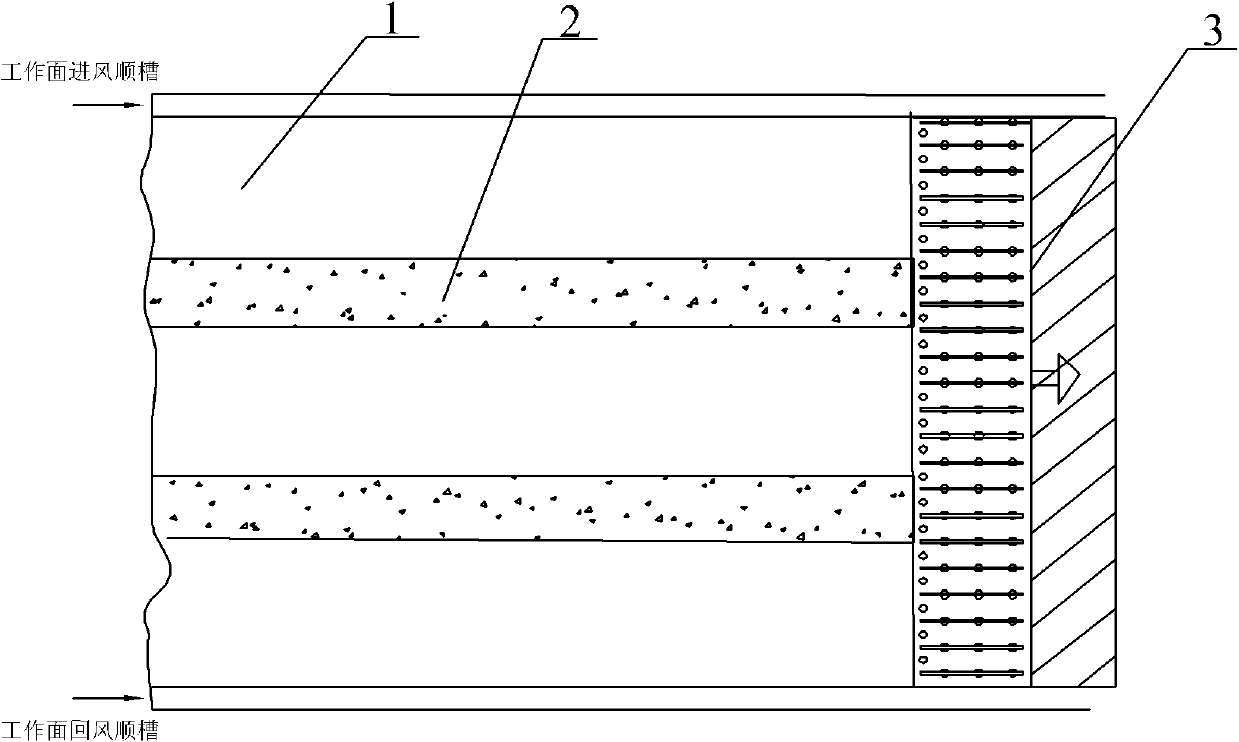

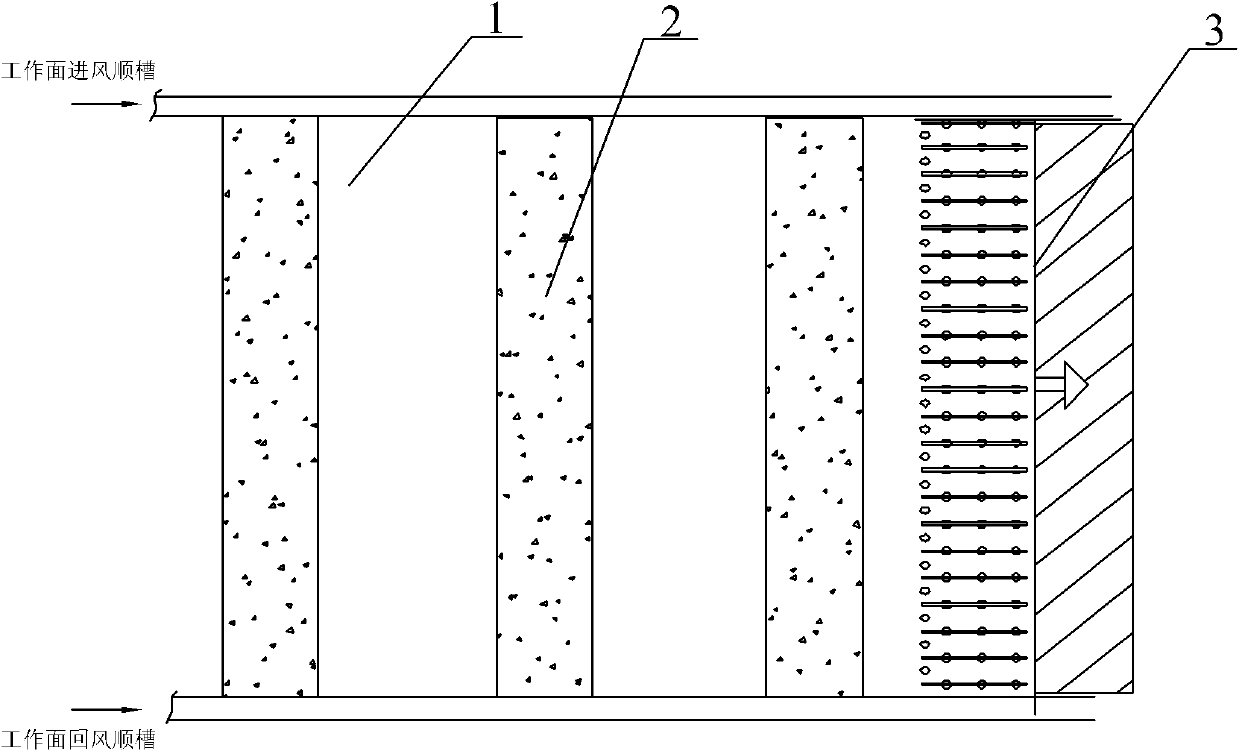

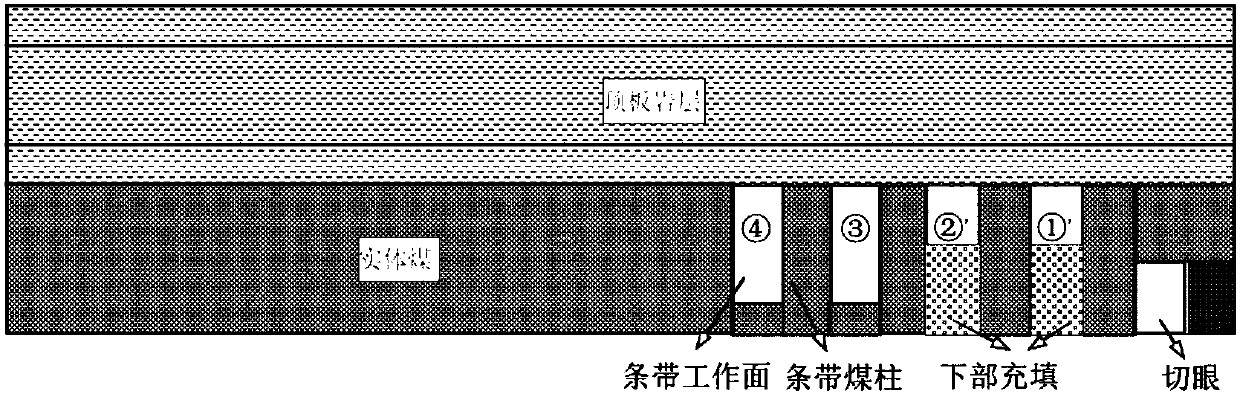

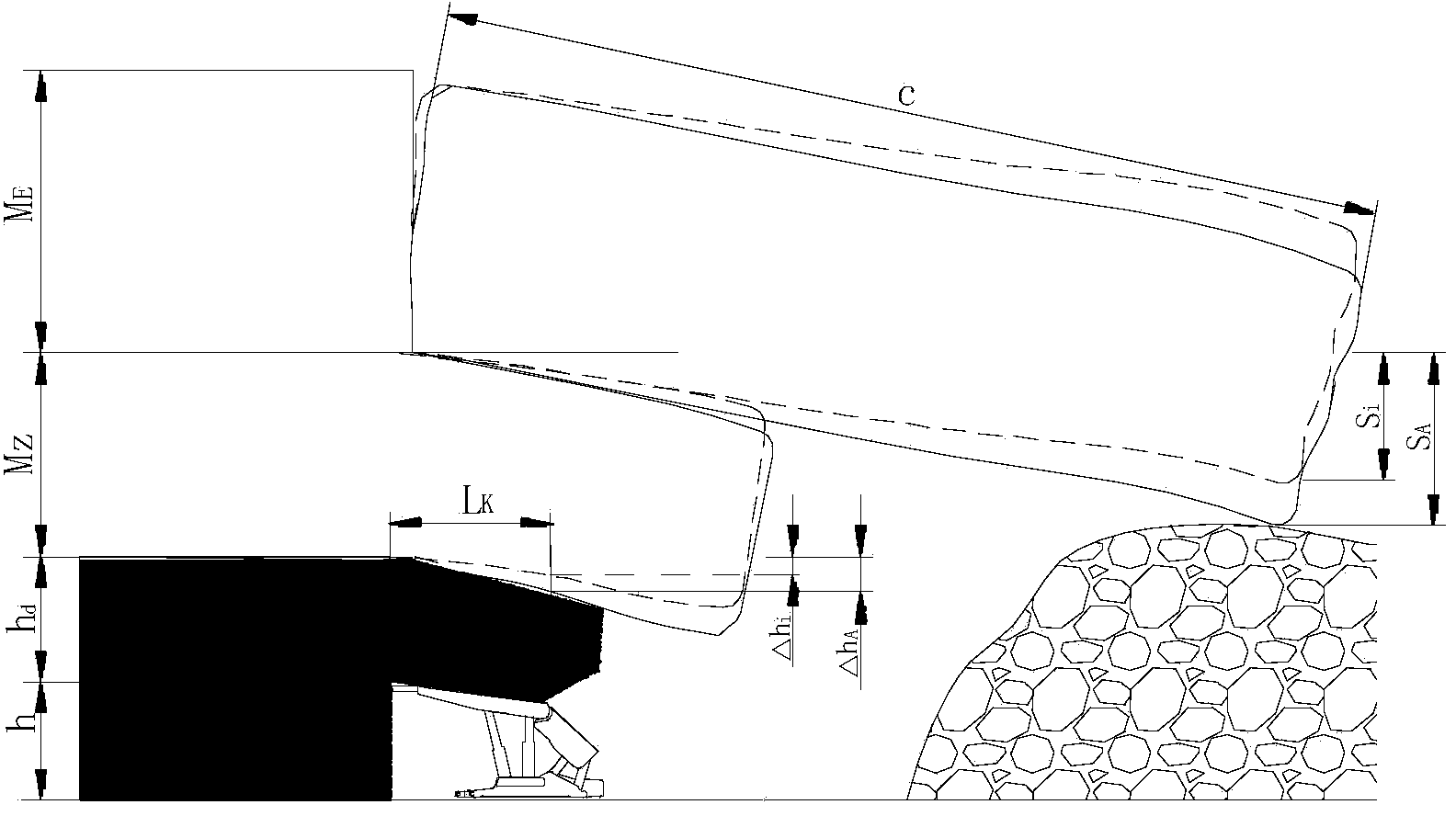

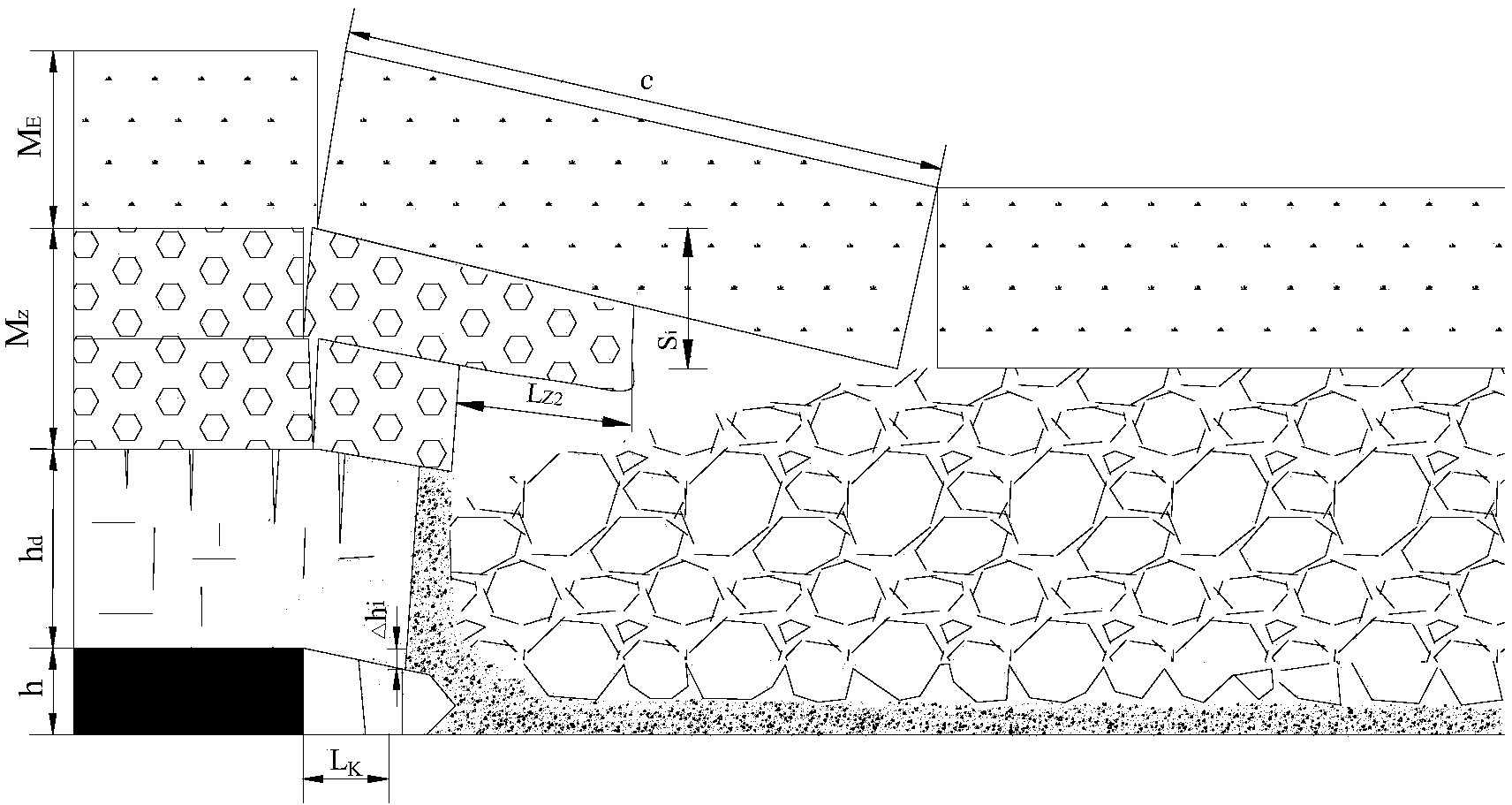

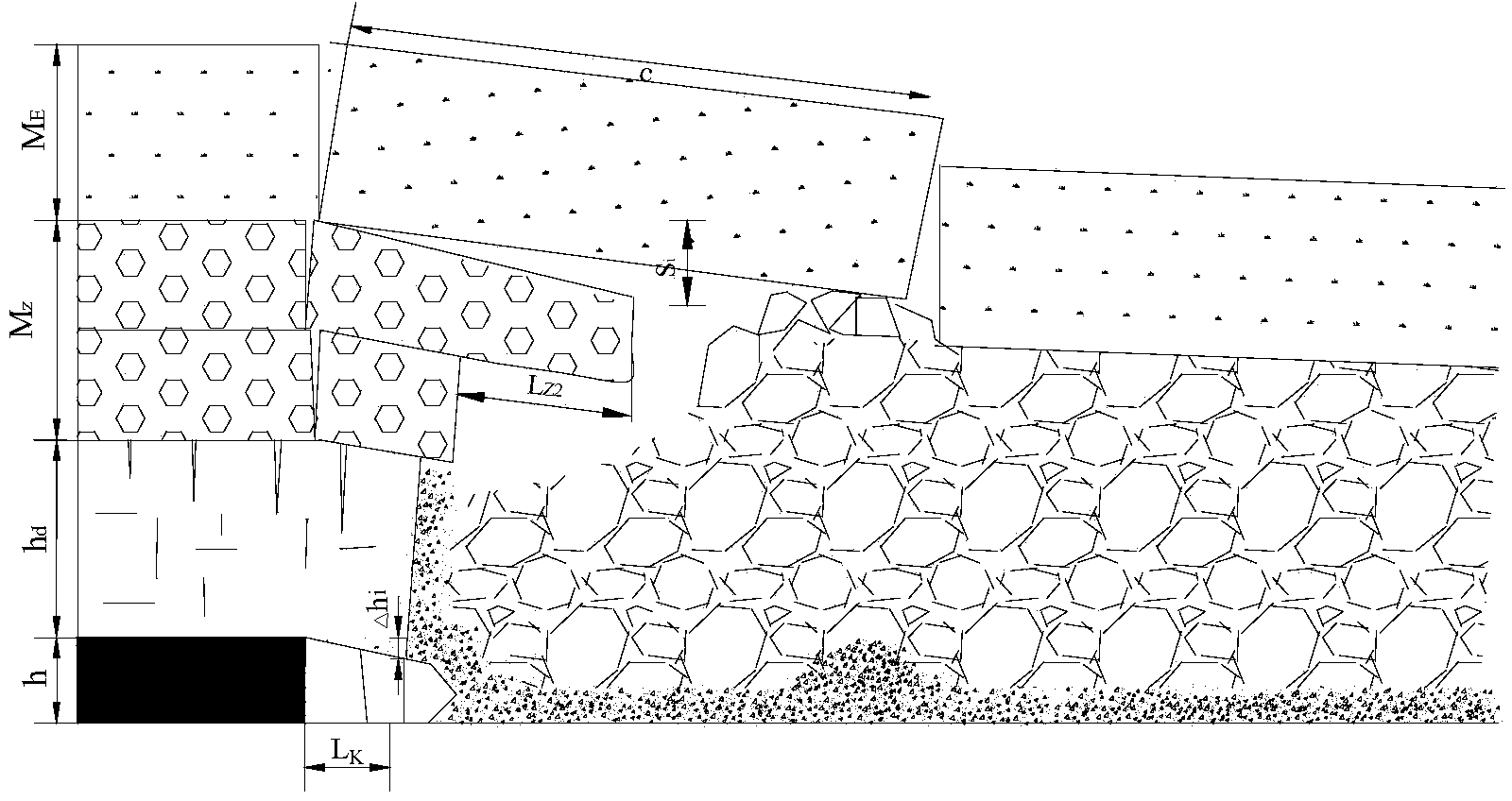

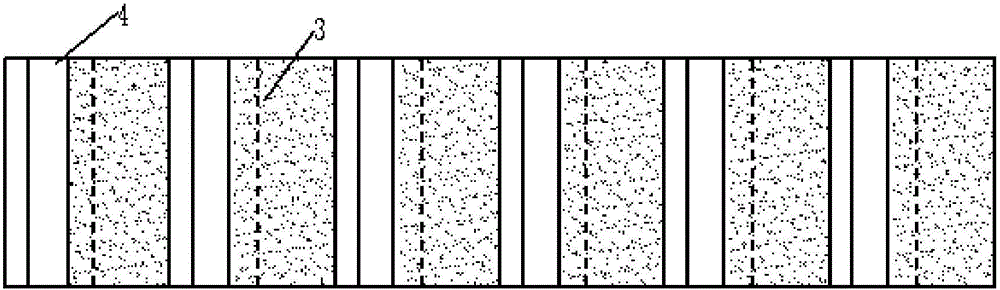

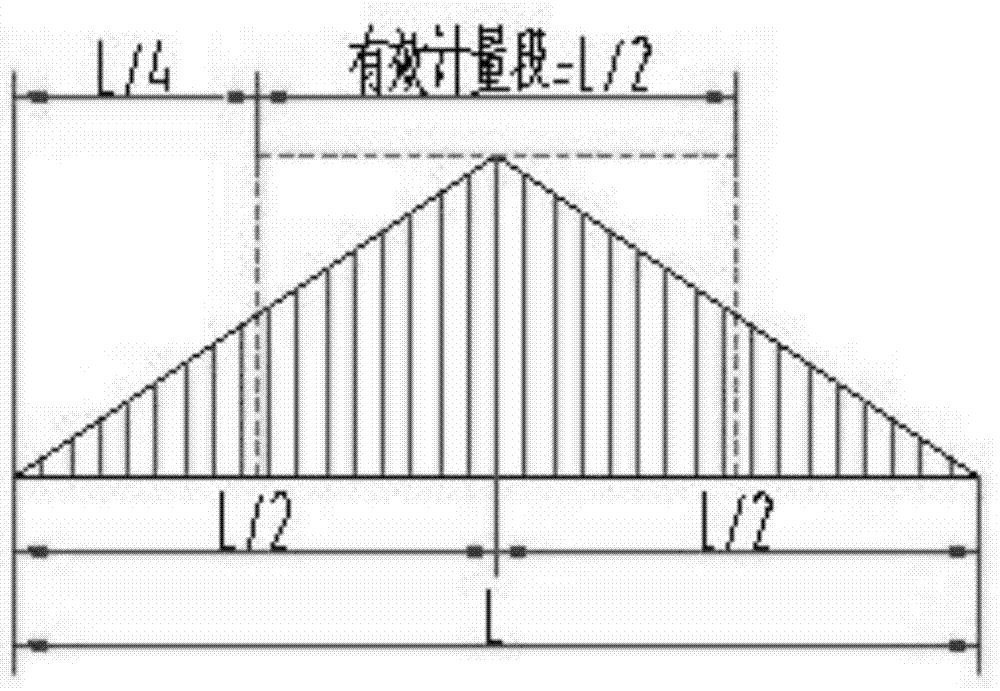

Strip-type filling method of high water-swelling material for controlling movement and deformation of overlying strata

The invention belongs to the fields of coal mining and filling, and particularly relates to a strip-type filling method of a high water-swelling material for controlling movement and deformation of overlying strata. The filling method is applicable to a coal mining face of a coal bed with the thickness of less than 3m. The method comprises the following steps: determining the limit span L and the safety span M of key strata according to a key strata theory for strata control, then determining the width N of a filling strip through calculation according to the support strength of a filling material, and filling the filling strip with the high water-swelling material. In the invention, by controlling the key strata, the most economical filling ratio can be determined and the maximum benefit can be realized; when no-coal pillar extraction is realized, movement and deformation of the overlying strata are fully controlled within the allowable range, thus realizing gentle and uniform surface subsidence in small quantity; by means of the high water-swelling material, high-recovery mining of coal resources under any condition is realized, and the safety degree of the coal mining face is greatly improved; and normal excavation engineering layout is not affected during the filling process, thus reducing influence on production and achieving high production efficiency.

Owner:ZIBO WANGZHUANG COAL MINE

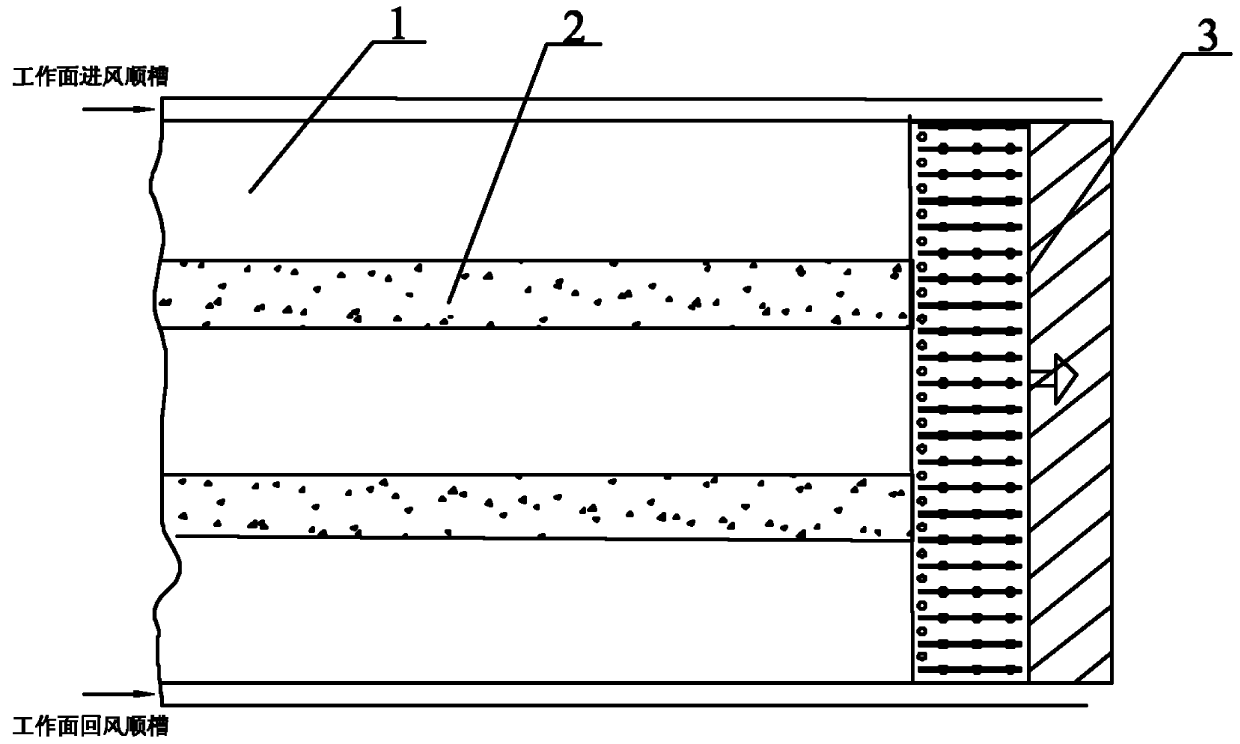

Coal mine strip mining and coal pillar filling and replacement method

InactiveCN107829736APromote recoveryMaintain stabilityUnderground miningSurface miningGround subsidenceEngineering

The invention relates to a coal mine strip mining and coal pillar filling and replacement method, wherein the method includes first-stage mining of mining of a strip working face and filling of a strip goaf area, and second-stage mining of replacement of the strip coal pillar and filling of the strip coal pillar goaf area. With the method of strip mining and coal pillar replacement, the mine recovery rate can be greatly increased to 60%-70%, and the ground subsidence amount of the mining area is greatly reduced, and the stability of an aquifer structure is maintained, so as to achieve the purposes of water conservation and coal mining.

Owner:XIAN UNIV OF SCI & TECH +1

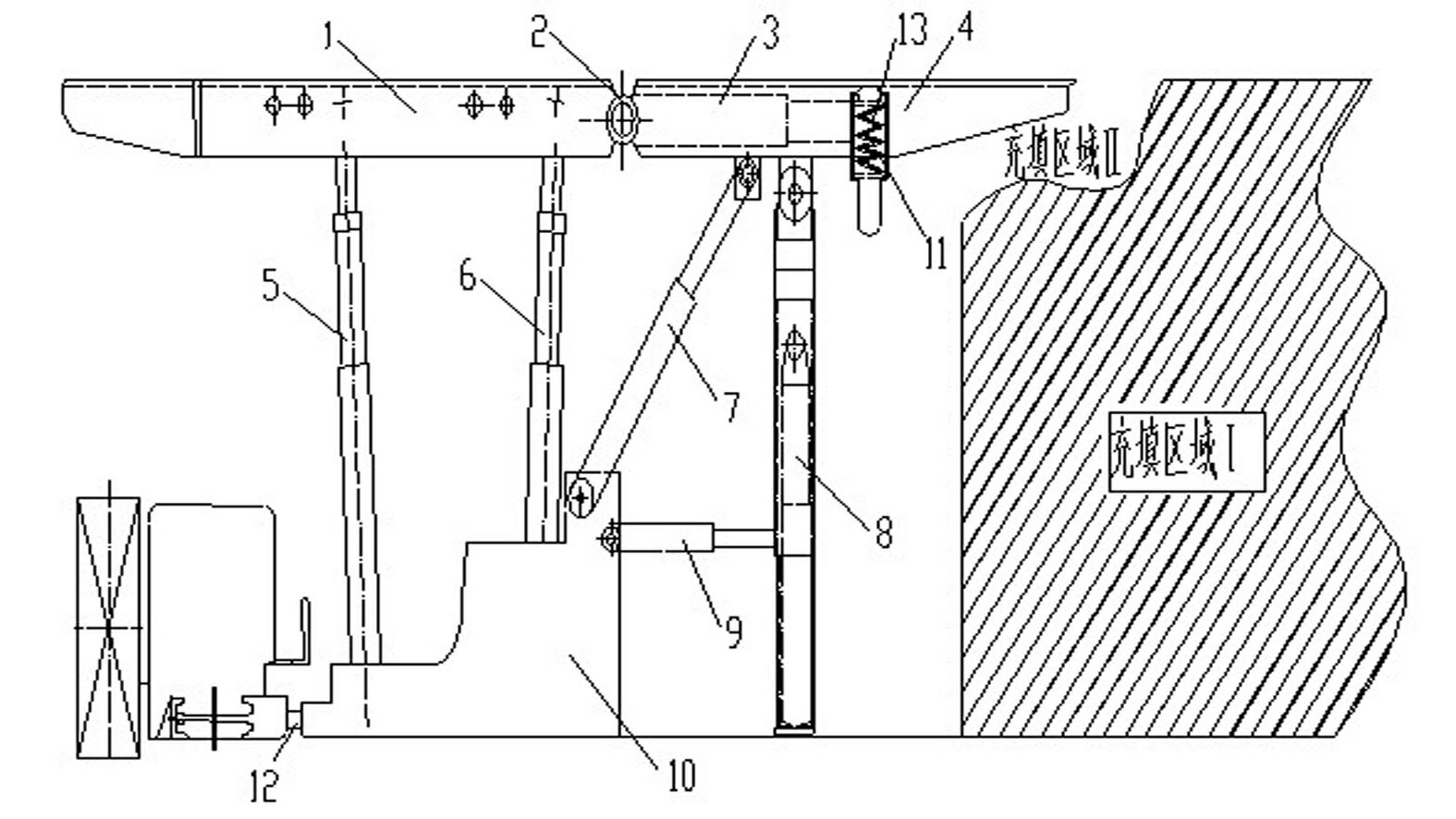

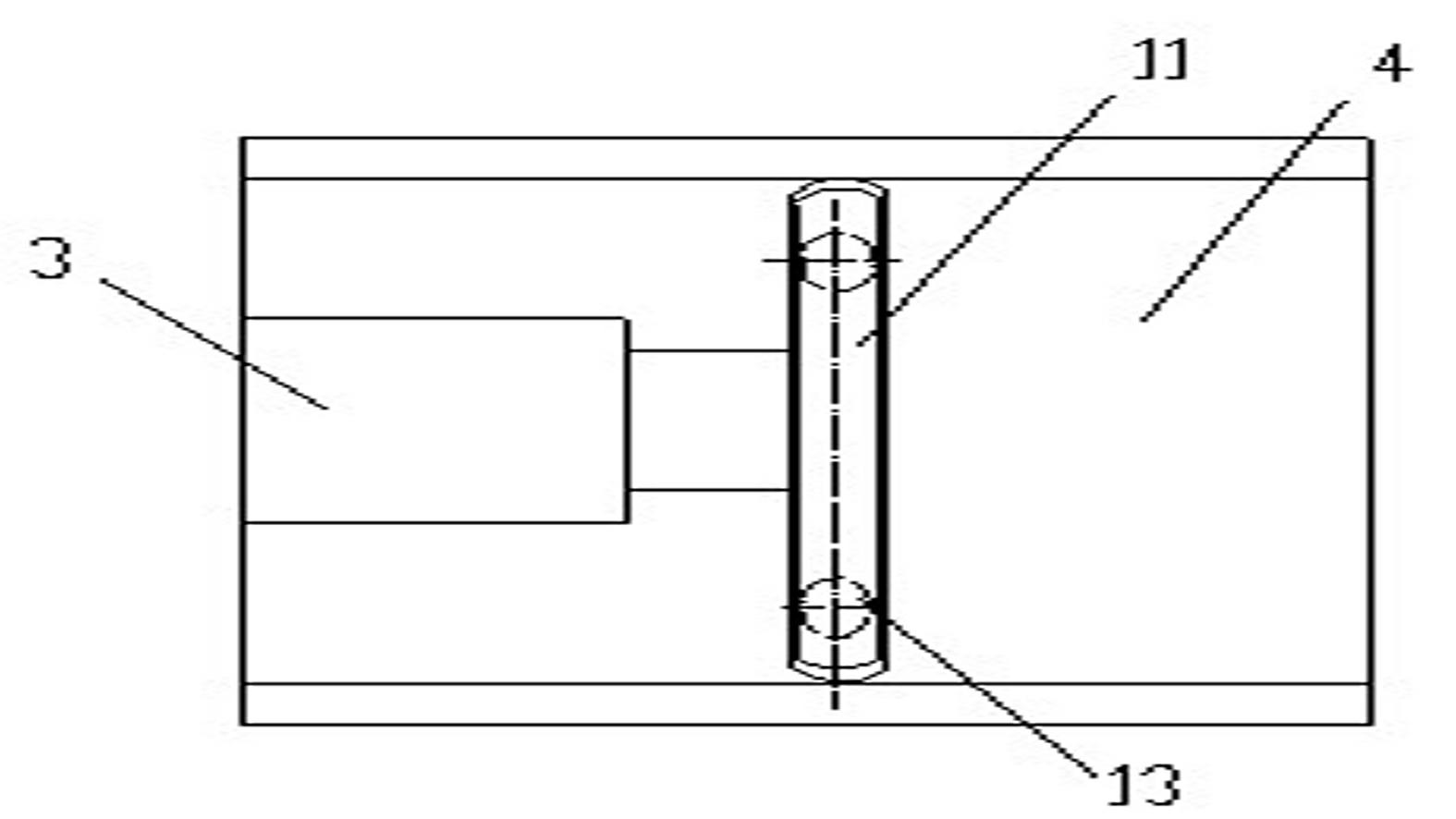

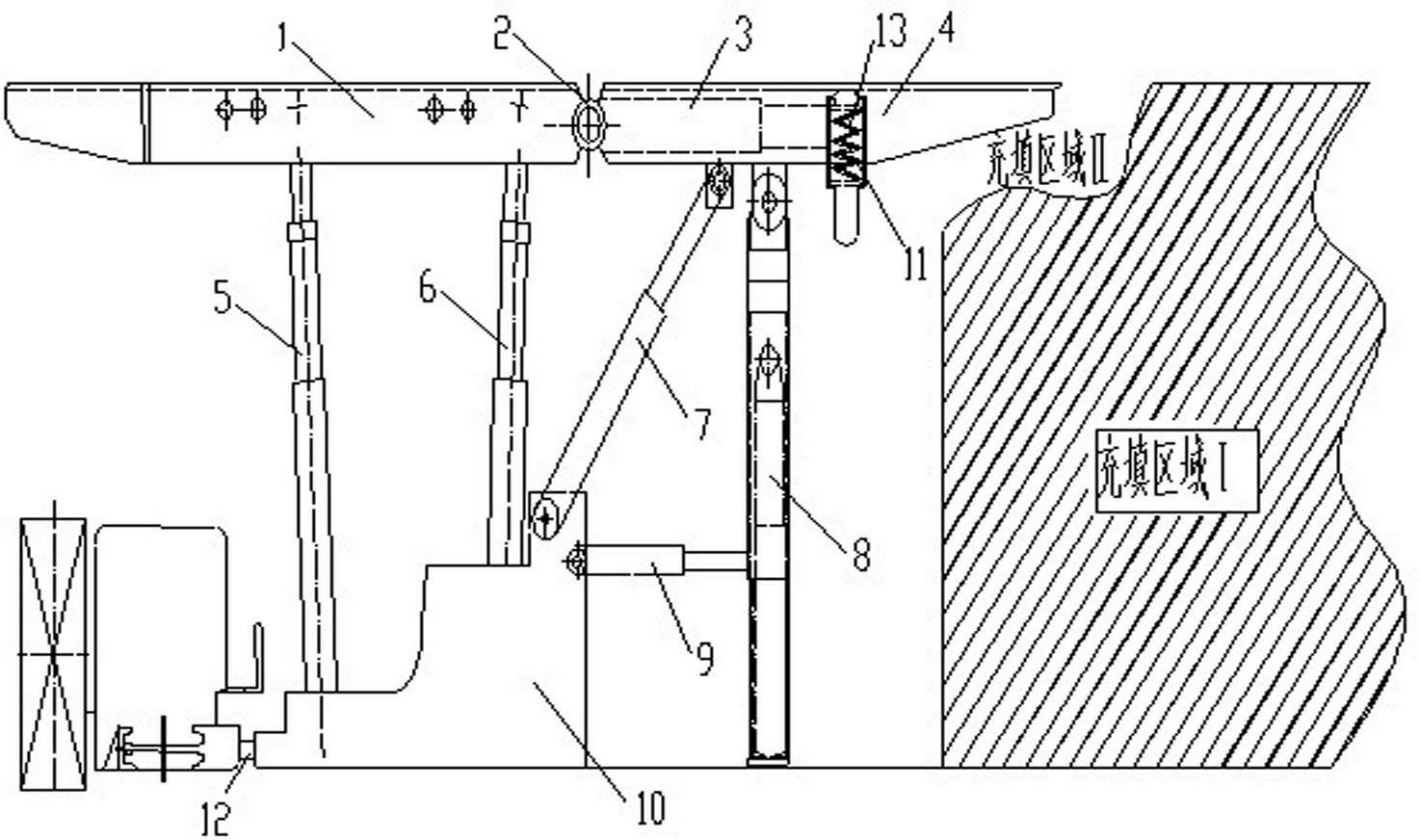

Method for filling gob

ActiveCN102493839AReduce sinkageSimple structureMaterial fill-upMine roof supportsPush and pullJackscrew

The invention provides a method for filling a gob. In the filling process, when filling paste arrives at the position of an elastic baffle, a pushing device which is arranged on a tail beam of a hydraulic support pushes and pulls the elastic baffle back and forth to ensure that the filling paste refills the gob after being pushed to the gob which is not filled fully behind the hydraulic support; the pushing device is hinged with a pushing jack at the left end of the tail beam of the hydraulic support; the right end of the pushing jack is connected with the elastic baffle; and the filling paste is formed by uniformly mixing coal gangue, coal ash, a cementing material and water in the mass percent ratio of 45:20:15:20. According to the method, the pushing device which is arranged on the tail beam of the hydraulic support has a simple structure and is convenient to operate; and according to particle sizes and different ratios of components, the materials of the filling paste are convenient to transport and control, are condensed quickly and have certain expansibility and a good roof-contacting effect to ensure that surface subsidence can be effectively controlled.

Owner:TAIYUAN UNIV OF TECH

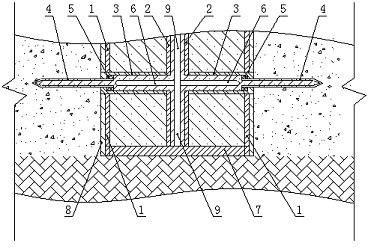

Coal face paste-like filling method and slurry-baffling device

InactiveCN101881180AIncrease each filling heightReduce the empty head distanceMaterial fill-upCoal miningEngineering

The invention discloses a coal face paste-like filling method and a slurry-baffling device. The method mainly comprises the following steps: the slurry-baffling device is arranged on a breaking-off prop of a coal face; the traditional filling method is adopted to fill paste-like until the filling height of the paste-like is as high as the height of a slurry-baffling curtain, thus the mined-out region is completely filled; when filling work is finished and the paste-like is semisolid and does not flow, the next cycle of normal coal mining is performed; when one cycle is finished, the slurry-baffling device is recycled, then the breaking-off prop is drawn back; and when the working face reaches a filling interval, the above steps are performed circularly. By using the method of the invention, each filling height of paste-like is increased, the unsupported roof distance of the mined-out region is reduced, the filling effect of the mined-out region is improved, the roof pressure of the working face and the sinking amount of the overlying roadway are reduced, the surface zero subsidence is thoroughly realized, the problems of the flooding accidents of goal water and floor water and the spontaneous combustions of the mined-out region and the hillock are effectively solved.

Owner:新汶矿业集团有限责任公司孙村煤矿

Mine pressure control method of intense mine pressure appearance fully mechanized top coal caving face

InactiveCN104141506AEasy to operateEasy to implementMine roof supportsSpelunkingQuantitative expression

The invention discloses a mine pressure control method of an intense mine pressure appearance fully mechanized top coal caving face, and belongs to the field of roof control of a fully mechanized top coal caving face. The control method mainly comprises the following steps: firstly defining the mine pressure appearance level of the fully mechanized top coal caving face and application conditions for the mine pressure control method, then establishing a caving face 'support-surrounding rock' relation quantitative expression-a roof position state equation according to actually measured mine pressure parameters, so as to provide theoretical support to a mine pressure control technology, ensuring that the support is positioned in a 'limited deformation' operating state depending on the critical operating resistance of the support, so as to realize a restraining method for roof subsidence, and to achieve a mine pressure control minimum goal of guaranteeing normal production during weighting, and finally adopting a method of decreasing the roof subsidence in a roof supporting scheme of adopting gob strip interval coal pile in a mine pressure appearance key region, so as to guarantee the coal pressure control ideal goal during weighting. The method is applied to wide promotion in the intense mine pressure appearance fully mechanized top coal caving face control.

Owner:青岛本末岩控技术有限公司 +1

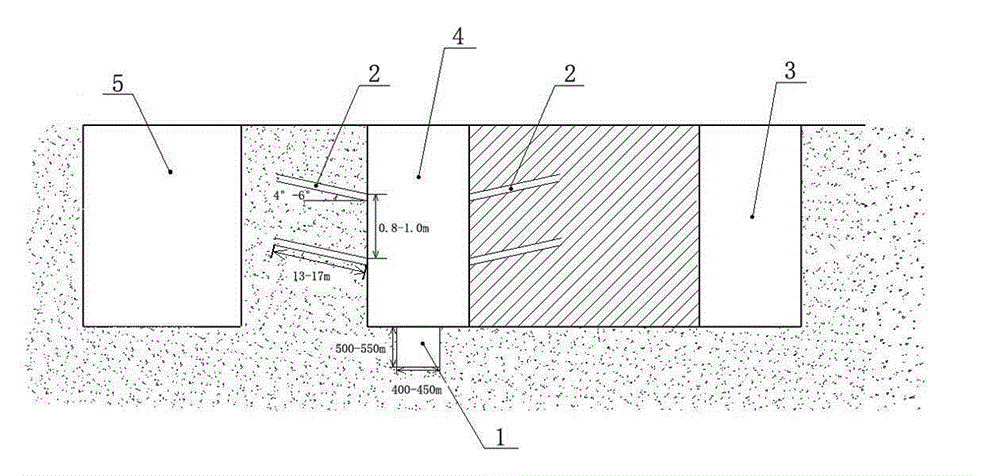

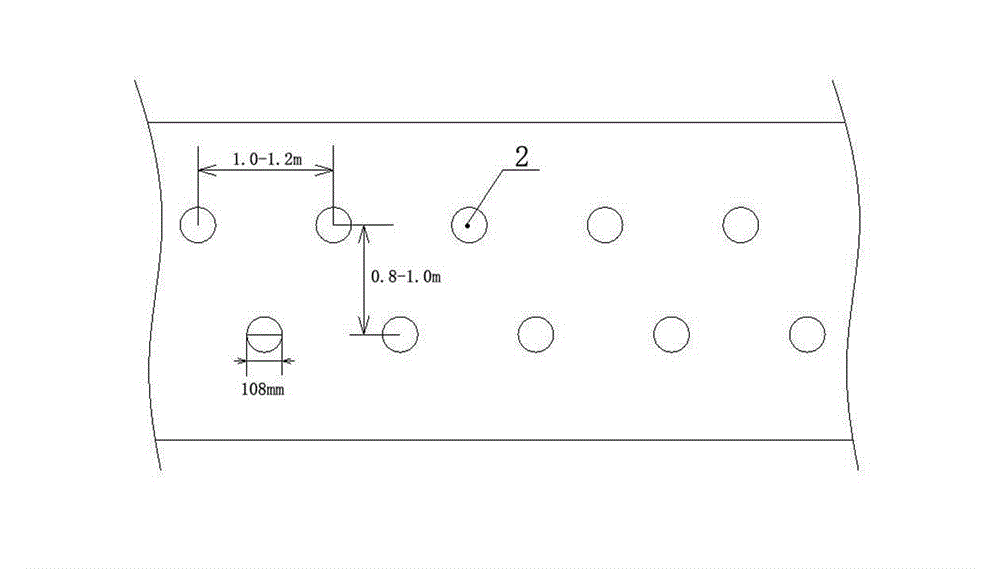

Pressure relief method aimed at strata behaviors of gob side entries of fully mechanized caving faces

InactiveCN103061808AReduce sinkageLow degree of fragmentationMining devicesSpelunkingStress distribution

The invention relates to a pressure relief method aimed at strata behaviors of gob side entries of fully mechanized caving faces and solves the problem of the absence of effective methods for strata behaviors of mines at present. The method comprises building a pressure relief groove which is 500mm to 550mm deep and 400mm to 450mm wide on a center line of a gob side entry bottom plate, and building at least two rows of pressure relief holes which are 13mm to 17mm deep and incline upwards by 4 degrees to 6 degrees from top to bottom on two sides of the gob side entry, wherein the two adjacent rows of the pressure relief holes are arranged in a triangular mode. According to the pressure relief method, the stress distribution of gob side entries is transferred in advance through pressure relief technologies of building of the pressure relief groove and the pressure relief holes and the like, strata behaviors of gob side entries are weakened, the passivity is converted into the initiative, the problem is solved fundamentally from the source, and the mine pressure is controlled.

Owner:DATONG COAL MINE GRP

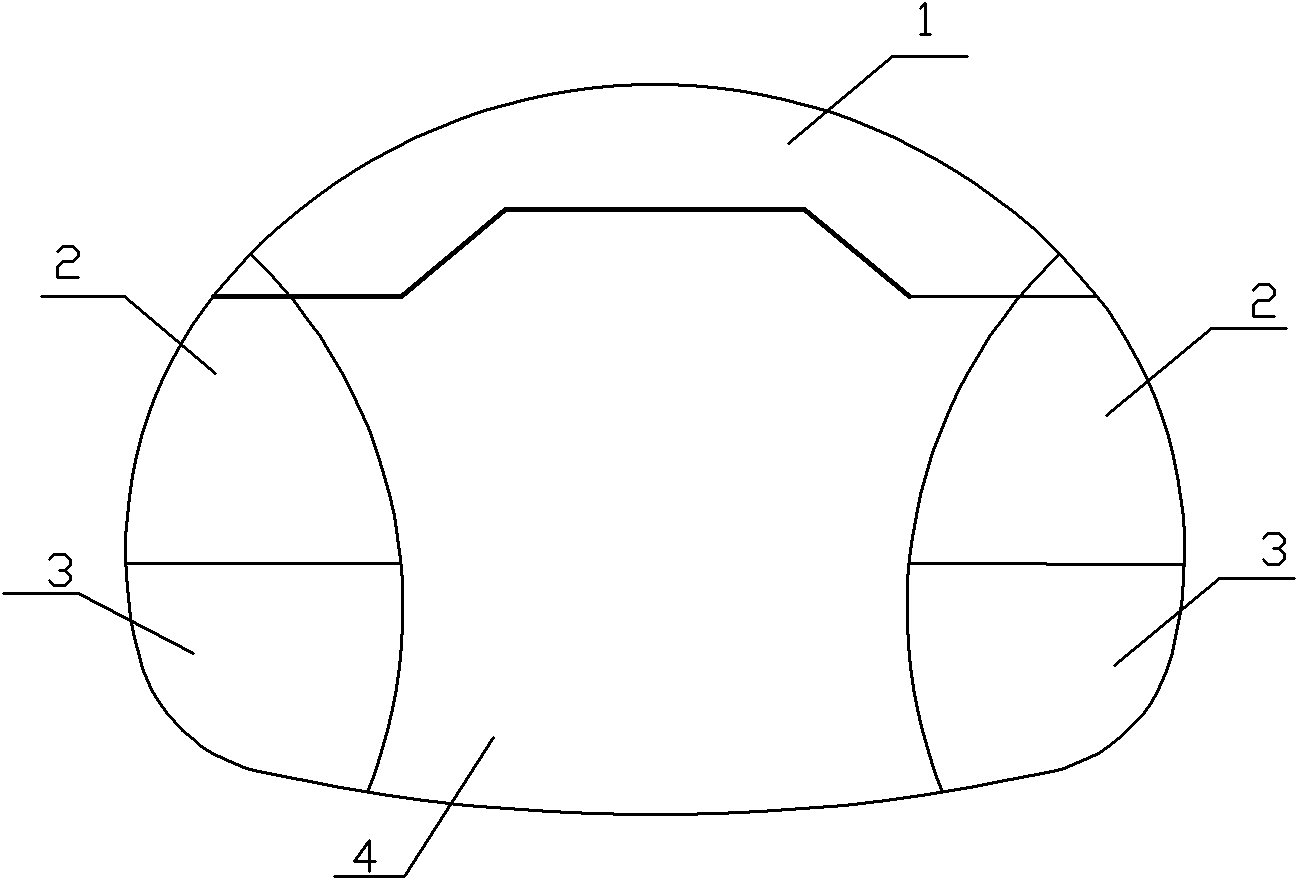

Large-section underground cave reducing-span pier structure and use method thereof

The invention relates to a coal mine support structure of a large-section roadway and an underground cave, in particular to a large-section underground cave reducing-span pier structure and a use method thereof. 1-8 base steel cylinders with diameter of 0.5-1.2m are installed in the middle of a large-section underground cave, a telescopic steel cylinder is sleeved in the upper end of each base steel cylinder in a matched way, a regulating through hole with corresponding height is disposed between the telescopic steel cylinder and the sleeved steel cylinder both of which are fixed by transversely inserting a limit reinforced steel bar, reinforced frames are arranged in the telescopic steel cylinder and the base steel cylinders, and concrete is poured in the telescopic steel cylinder and the base steel cylinders to form a reducing-span pier, and the height of the pier can be regulated by the limit reinforced steel bar according to the height change of the roadway. The invention has wide application range, simple structure and easy operation, can provide higher support strength for the roadway and the underground cave, and can realize the efficient span reduction of the large-section roadway and the underground cave.

Owner:CHINA UNIV OF MINING & TECH

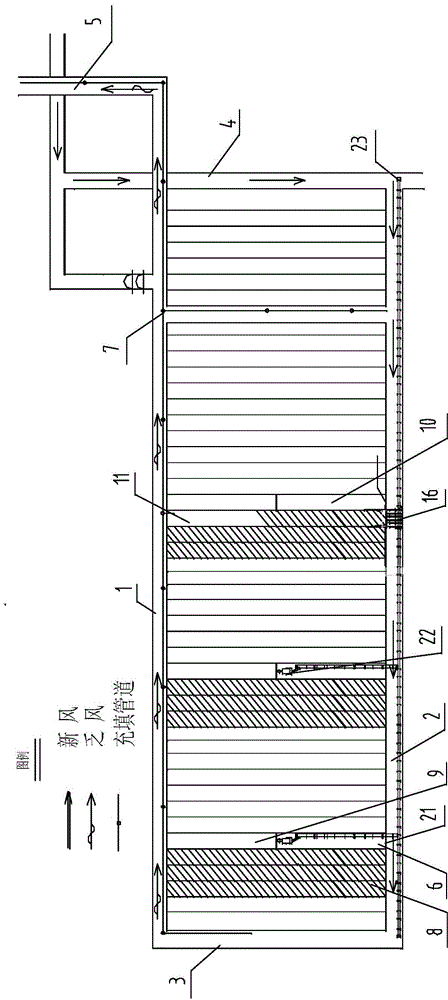

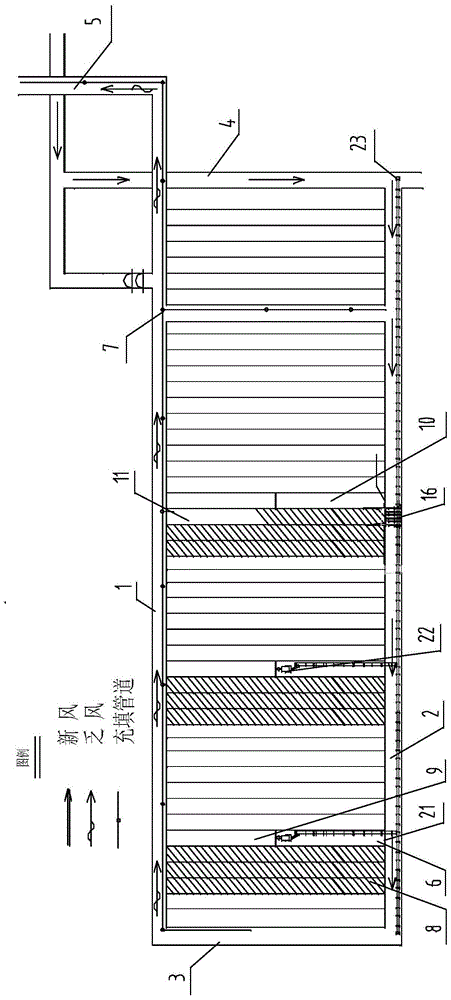

Coal mining and filling integrated method for coal mine

ActiveCN104675399AImprove fill rateFissure zone loweringUnderground miningSurface miningSocial benefitsEcological environment

The invention discloses a coal mining and filling integrated method for a coal mine. The method comprises the following steps: (1) digging out an air returning and filling pipeline lane, a boundary air lane and a transportation and air intaking lane of a mining region on a working surface of the mining region; (2) mining coal with a narrow strip channel in the working surface of the mining region, in which a ventilating system is formed, after coal mining in each narrow strip channel is finished, communicating the transportation and air intaking lane of the mining region with the air returning and filling pipeline lane of the mining region through narrow strip channels; (3) transporting coal mine cementing filling material slurry into a narrow strip channel excavating region formed after the coal mining in the narrow strip channels is finished for filling; and (4) mining the coal in the narrow strip channels while filling the narrow strip channel excavating region. The mechanical cementing, filling and milling method for the coal mining, disclosed by the invention, is beneficial to sufficiently developing underground coal resources, protecting the ecological environment and ground vegetation, releasing a large number of dull coal and prolonging the service life of a mine, and has remarkable economic benefits and social benefits.

Owner:内蒙古晨德建设工程有限公司

Production method for machine tool guide rail casts

ActiveCN102941316AUnique feeding abilityImprove feeding capacityFoundry mouldsFoundry coresMold fillingSlag

The invention relates to a production method for thick large casts with large plane, in particular to a production method for machine tool guide rail casts. The method is characterized by including the following steps: system pouring, mould manufacturing, core manufacturing, core assembly and pouring. The production method is unique, strengthens feeding capability of the casts in the mold filling and solidification processes, reduces shrinkage porosity shortcomings, reduces slag inclusion shortcoming at the large plane position of the casts, saves production cost, improves production efficiency and improves product quality of the casts.

Owner:KOCEL EQUIP

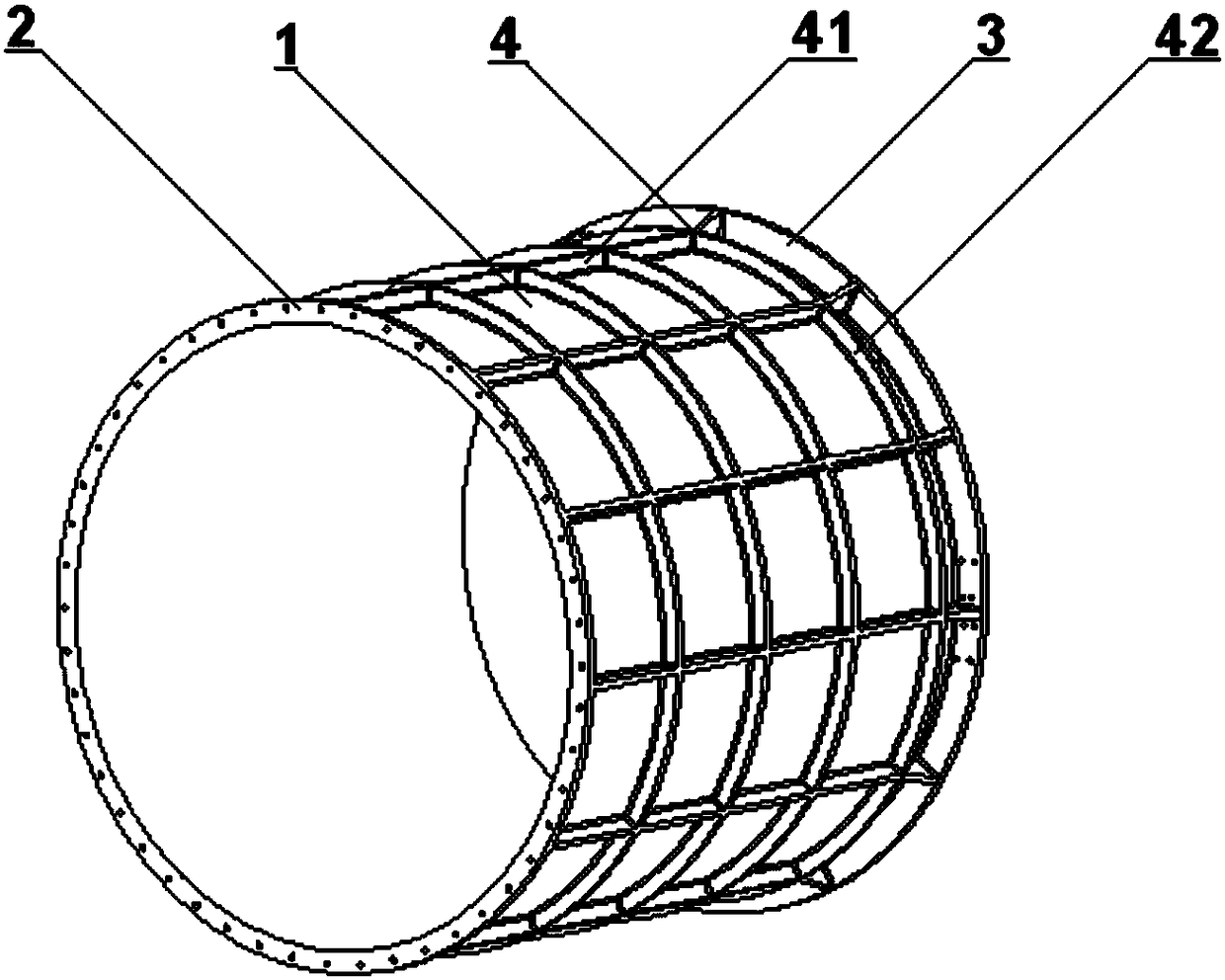

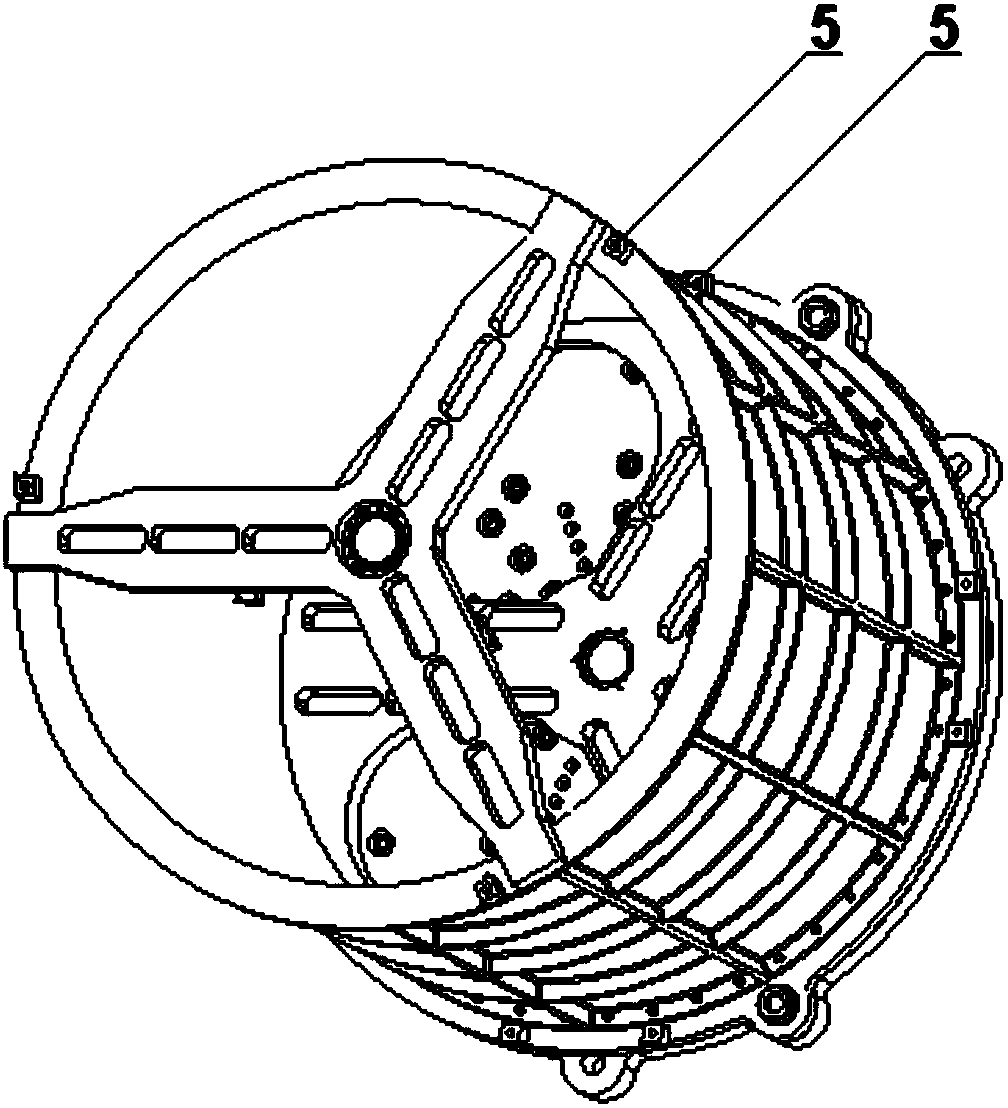

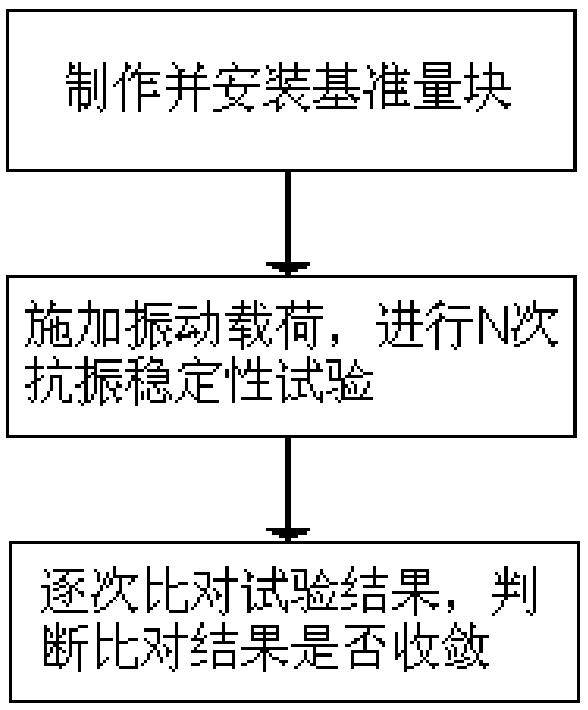

High rigidity and light space camera lens cylinder and test method for vibration resistance stability thereof

ActiveCN109387997AImprove stabilitySmall axial length changeOptical apparatus testingVibration testingCamera lensEntire lens

The invention discloses a high rigidity and light space camera lens cylinder and a test method for vibration resistance stability thereof. The cylinder comprises a cylinder body, a main mirror flange,a secondary mirror flange and a reinforcing rib. The cylinder body is a hollow cylinder. One end of the cylinder body is provided with a main mirror flange for connecting a space camera main mirror,and the other end of the cylinder is provided with the secondary mirror flange for connecting the space camera secondary mirror. The outer side of the cylinder body is provided with a reinforcing ribfor reinforcing the structure. The cylinder body, the main mirror flange, the secondary mirror flange and the rib are integrally formed by three-dimensional braiding silicon carbide. According to theinvention, the overall structure of the lens cylinder is optimized by integrally forming the cylinder body, the flanges and the reinforcing rib through using the three-dimensional braiding of siliconcarbide materials, and the defect that the traditional metal support structure is too heavy and has a large self-expansion coefficient is overcome; by designing the vibration resistance stability testmethod of the lens cylinder structure, the stability of the entire lens cylinder is ensured; and the problem of quite poor stability of the conventional resin-based composite material is solved.

Owner:BEIJING RES INST OF SPATIAL MECHANICAL & ELECTRICAL TECH

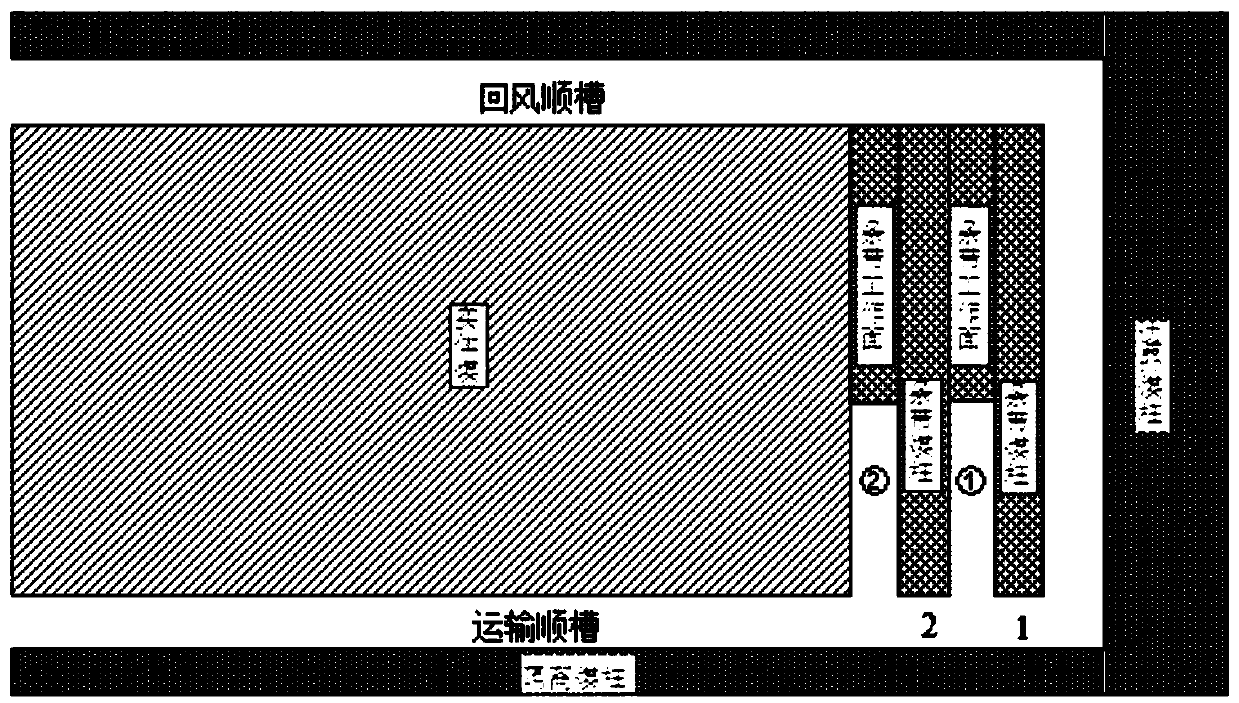

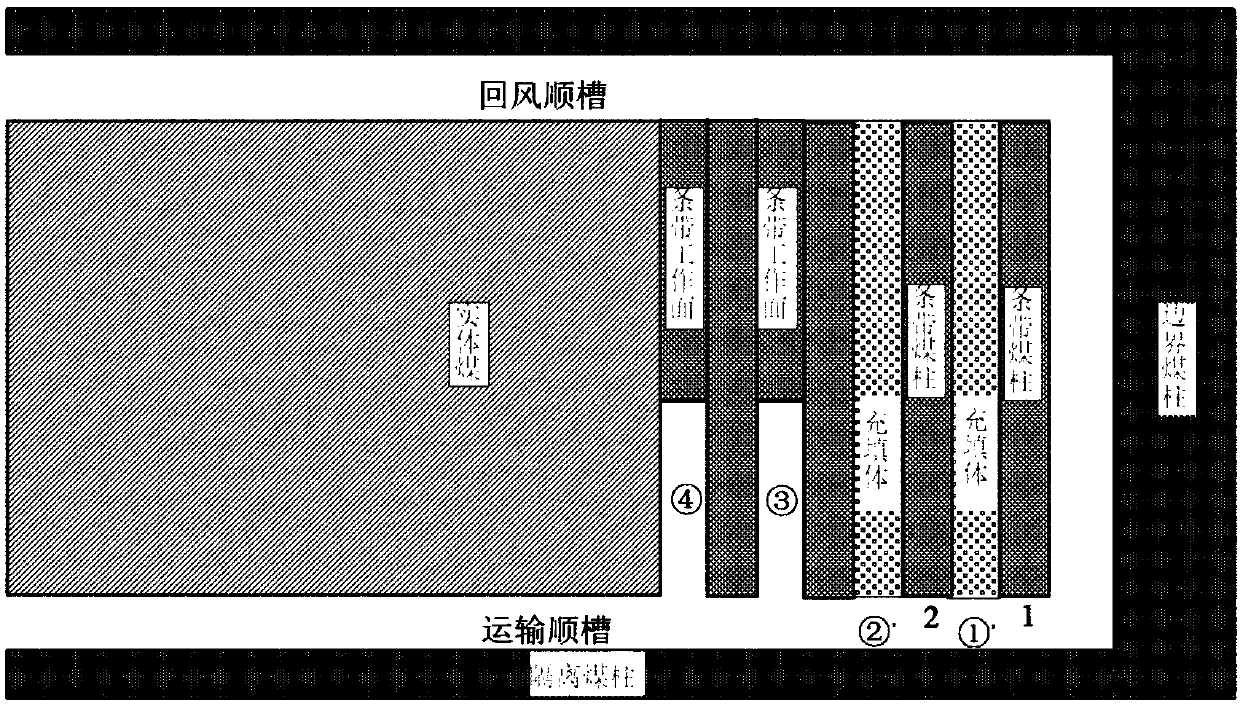

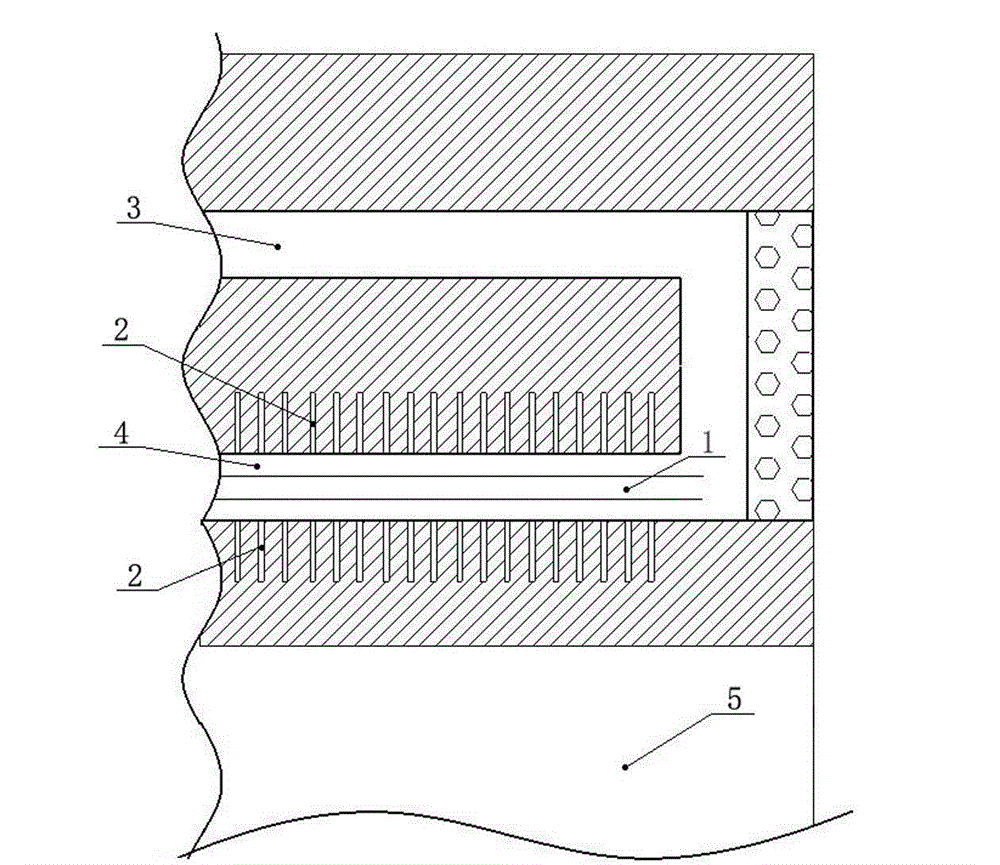

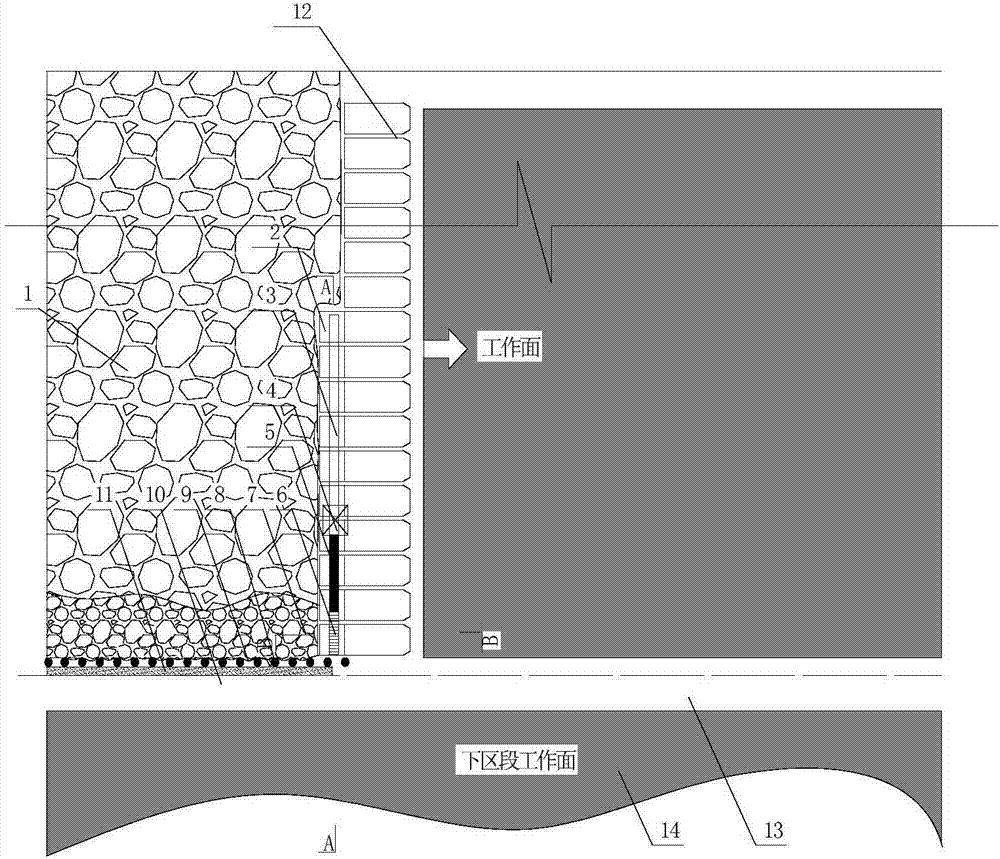

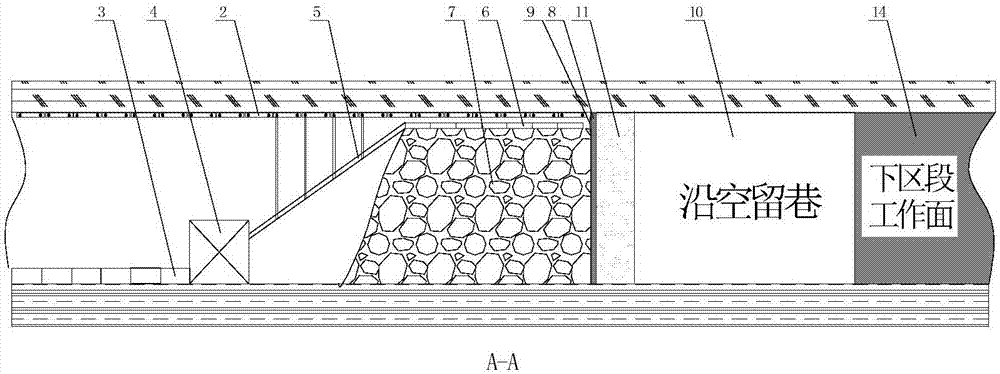

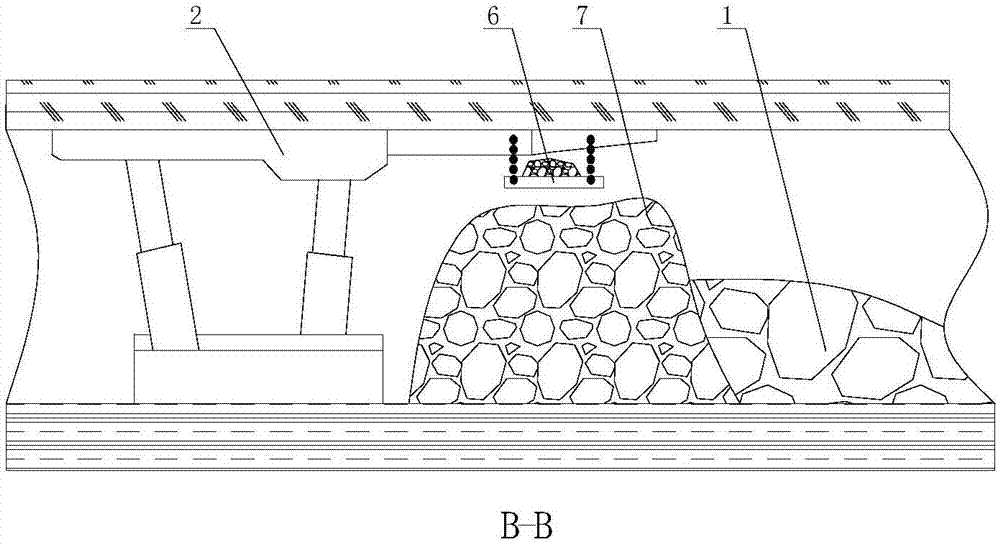

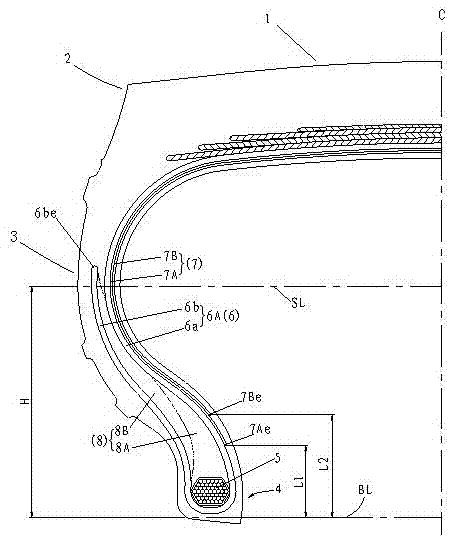

Method for building middle-thickness coal-bed gob-side entry roadside support body supported by gangue

InactiveCN107387083AReduce sinkingReduce breakageUnderground miningSurface miningFilling materialsEngineering

The invention relates to a method for building a middle-thickness coal-bed gob-side entry roadside support body supported by gangue, which belongs to the field of coal mine support. The method mainly comprises the following steps: (1) tunneling a working face roadway which is 0.5 to 1.0 m wider than a complexing roadway; (2) changing a working face support portion to be a top coal caving long tail beam support, arranging a scraper conveyor, a transport crushing machine, a belt conveyor and a downward conveyor behind a working face, and throwing gangue dropped when in backstopping of the working face to a position of an end of the working face; (3) before the gangue is piled, previously adopting a wooden pillar and a reinforcing mesh along the edge of the original roadway to protect the roadway; (4) building a narrow filling body behind the working face; and (5) repeating the steps (1) to (4) to form a continuous roadside support body which is used by a next working face. By adopting the method, the deflection of a roof can be reduced, the supporting force of the gangue at the gob side for the roof can be increased, and the roadway maintaining effect can be improved; and the consumption of the filling materials can be saved, and the roadway cost and the labor intensity of workers can be reduced.

Owner:CHINA UNIV OF MINING & TECH

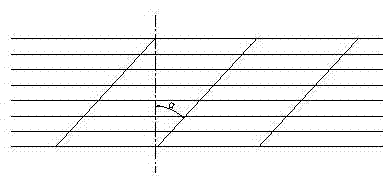

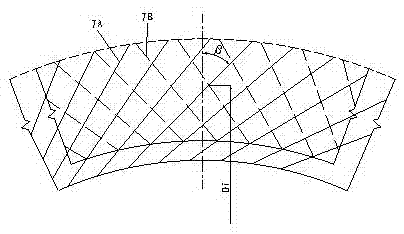

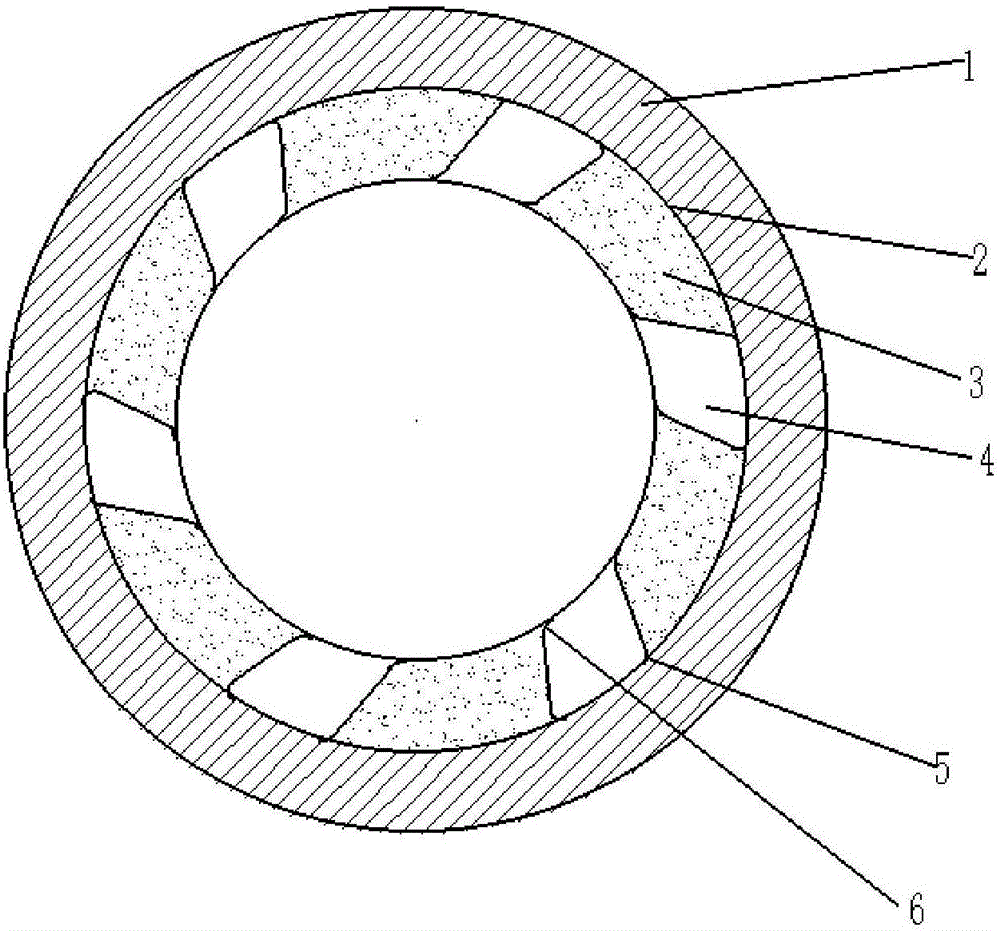

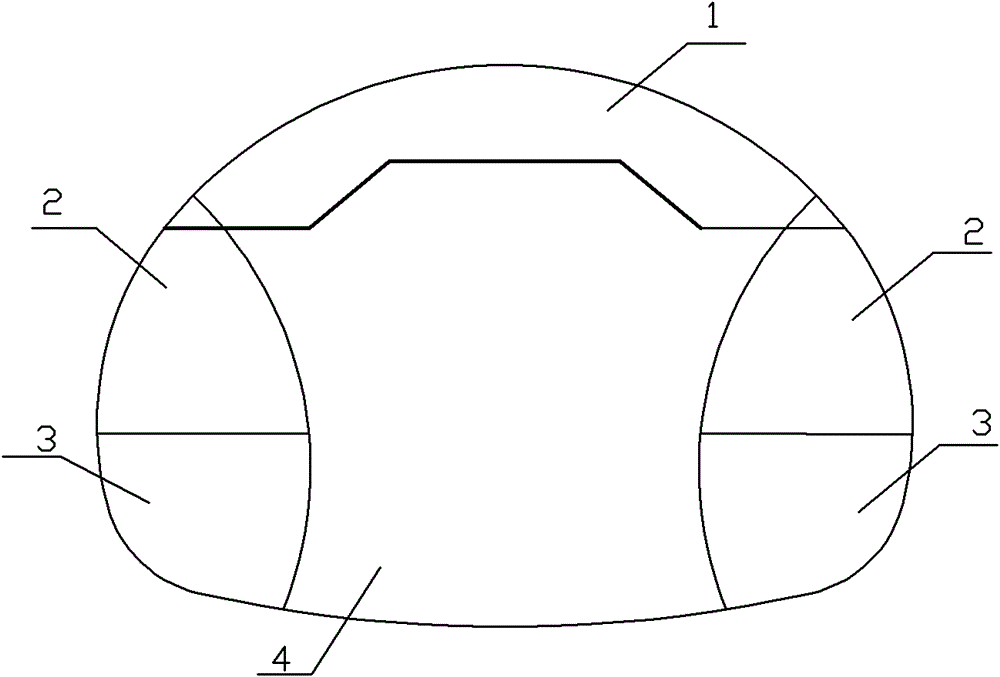

Inflation industrial radial tire

InactiveCN105437870AReduce sinkageImprove lateral rigidityHeavy duty tyresHeavy duty vehicleMechanical engineeringRadial tire

The invention relates to an inflation industrial radial tire and belongs to the field of tires. The inflation industrial radial tire is provided with a tire body and is characterized in that the tire body comprises a layer of tire body curtain cloth; the tire body curtain cloth comprises a main body part extending between a pair of steel wire rings and passing through a tire surface and a tire side and a winding part winding from the peripheral inside to the outside across the steel wire rings; a reinforced curtain cloth layer is arranged on the peripheral inner side of the layer of tire body curtain cloth and comprises two reinforced layers provided with curtain lines intersecting obliquely relative to the radial direction of the tire; the winding part of the tire body curtain cloth extends to the ends of the reinforced layers near a tire horizontal shaft in the radial direction of the tire and is located in the area of a tire ring.

Owner:TRIANGLE TIRE

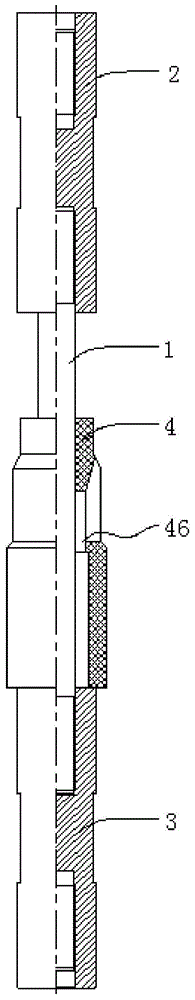

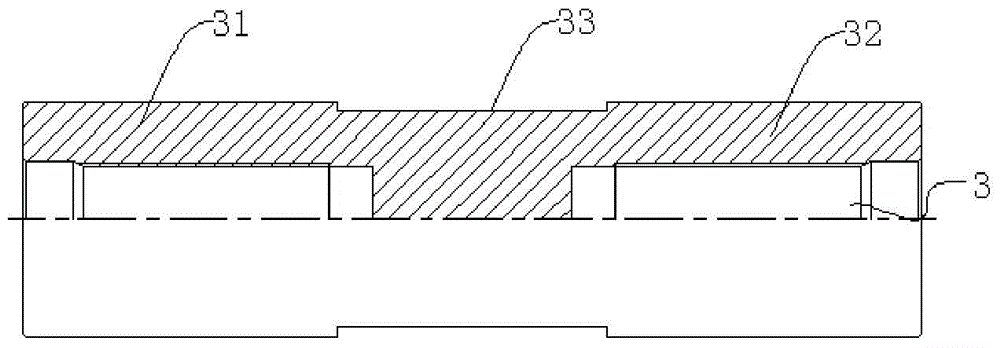

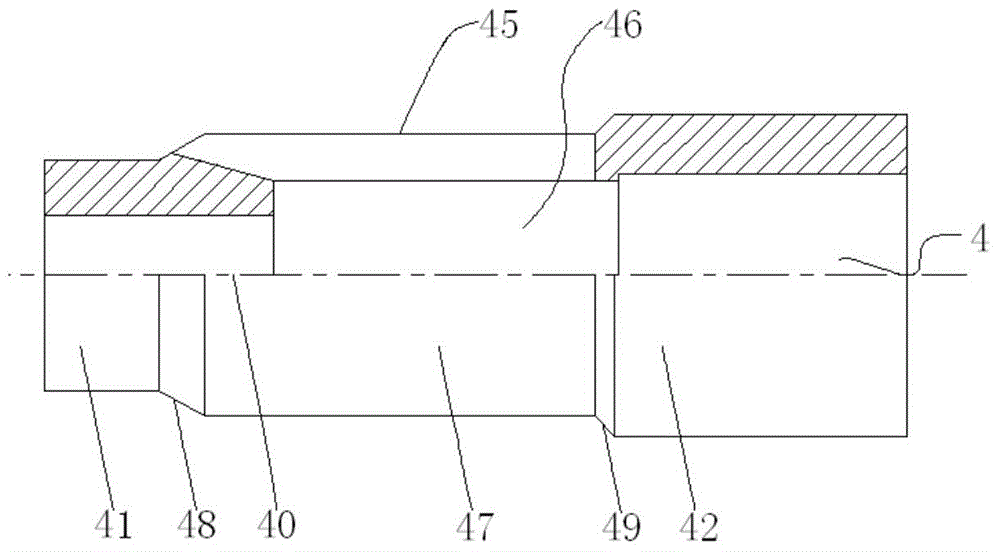

Pumping-aiding device of oil pumping rod and sand blocking oil outlet sliding sleeve thereof

The invention discloses a pumping-aiding device of an oil pumping rod and a sand blocking oil outlet sliding sleeve thereof. The pumping-aiding device of the oil pumping rod comprises a core rod, wherein the upper end of the core rod is connected with an upper connecting hoop; the lower end of the core rod is connected with a lower connecting hoop; the sand blocking oil outlet sliding sleeve can glidingly sleeve the middle part of the core rod and is a hollow step shaft; the hollow part is a step through hole; a first shaft section and a second shaft section are at least formed on the step shaft from top to bottom; the outer diameters of the first shaft section and the second shaft section are sequentially increased; a transition surface is formed between the first shaft section and the second shaft section; a lateral opening is axially and downwards formed in the place which contains the transition surface and is communicated with the step through hole to form an oil passage; the maximum inner diameter of the sand blocking oil outlet sliding sleeve is smaller than the outer diameter of the lower connecting hoop. According to the pumping-aiding device of the oil pumping rod and the sand blocking oil outlet sliding sleeve provided by the invention, pumping-aiding, sand-blocking and righting functions can be simultaneously realized, and the pumping-aiding device and the sand blocking oil outlet sliding sleeve are simple in structure.

Owner:PETROCHINA CO LTD

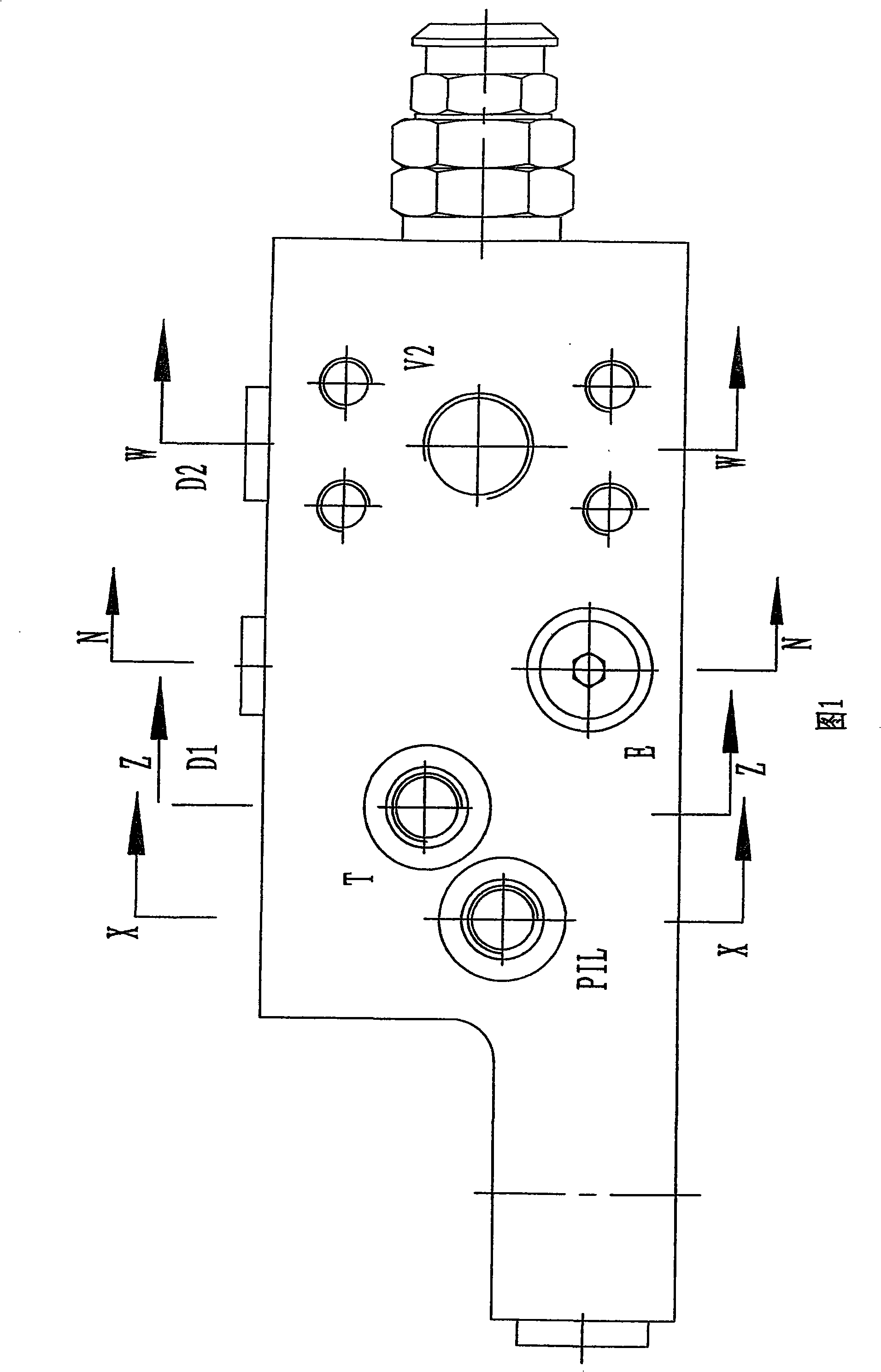

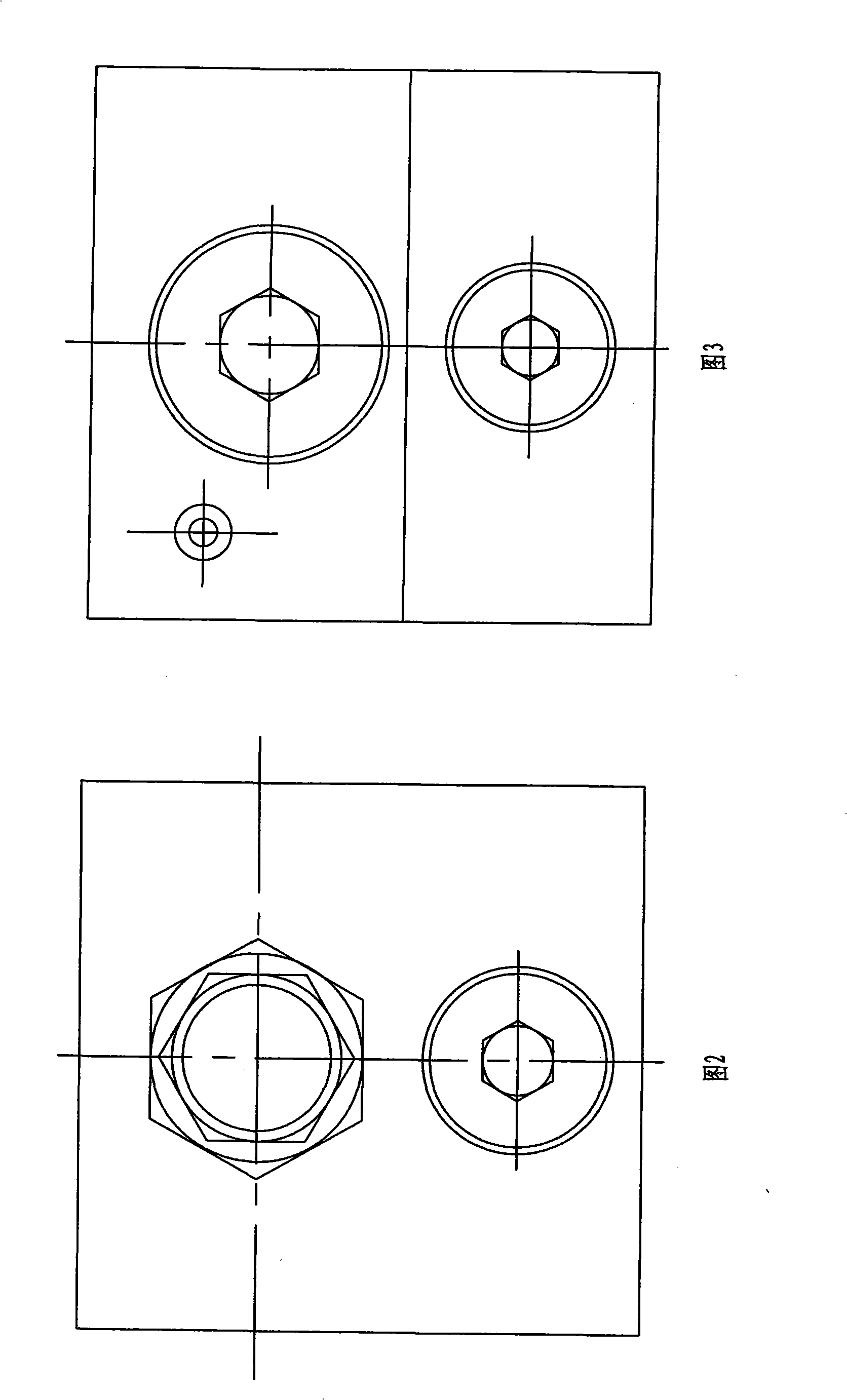

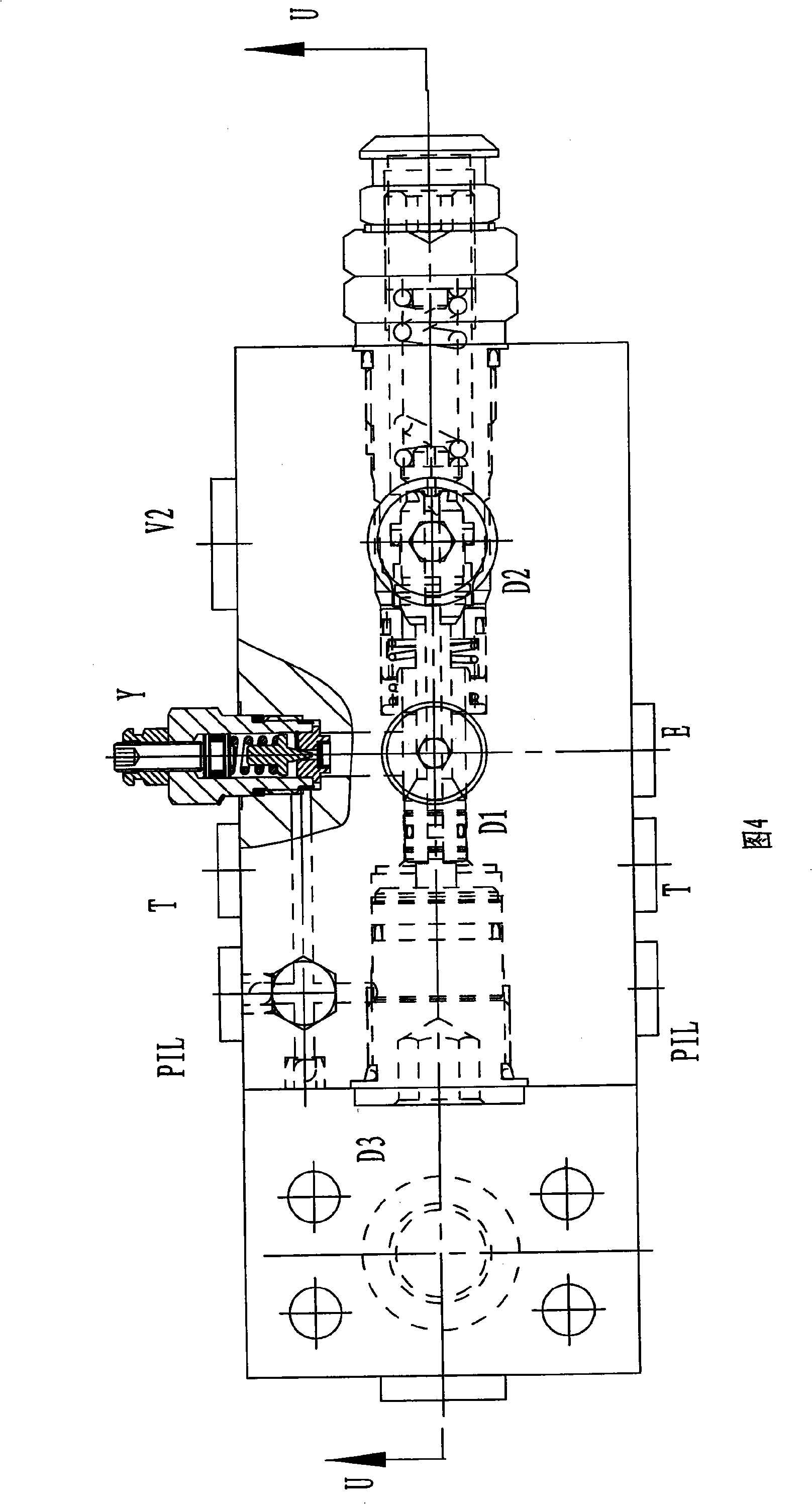

Luffing jib maintaining valve for hydraulic shovel

ActiveCN101294402AReduce boom sinkagePrevent natural declineMechanical machines/dredgersPistonValve stem

The invention relates to a movable arm maintaining valve used for hydraulic excavators, which is installed between the bottom of a movable arm hydraulic cylinder and a movable arm control valve of a hydraulic excavator and mainly used for controlling the lifting, maintaining and descending of a movable arm. The movable arm maintaining valve comprises a valve block (1) opened therein with a first valve opening and a second valve opening and provided thereon with an overflow valve (44), wherein a piston (4), a valve stem (6), a left spring holder I (8), a spring I (9), a right spring holder (11) and a maintaining valve (14) are sequentially arranged inside the first valve opening from the left to the right, a core I (20) of the maintaining valve (14) is connected with the valve stem (6), the valve opening site where the valve stem (6) locates communicates with the overflow valve (44), a left spring holder II (29), a spring III (28), a right spring holder II (26) and a non-return valve (23) are sequentially arranged at the right side from the left to the right, the core II (25) of the non-return valve (23) are matched with the inner hole of the right spring holder II (26), and the left side of the second valve opening communicates with the rodless cavity of the movable arm hydraulic cylinder of the hydraulic excavator. The inventive movable arm maintaining valve can remarkably reduce the sinkage of the movable arm, so as to be safer and more reliable.

Owner:JIANGSU CHANGLING HYDRAULIC CO LTD

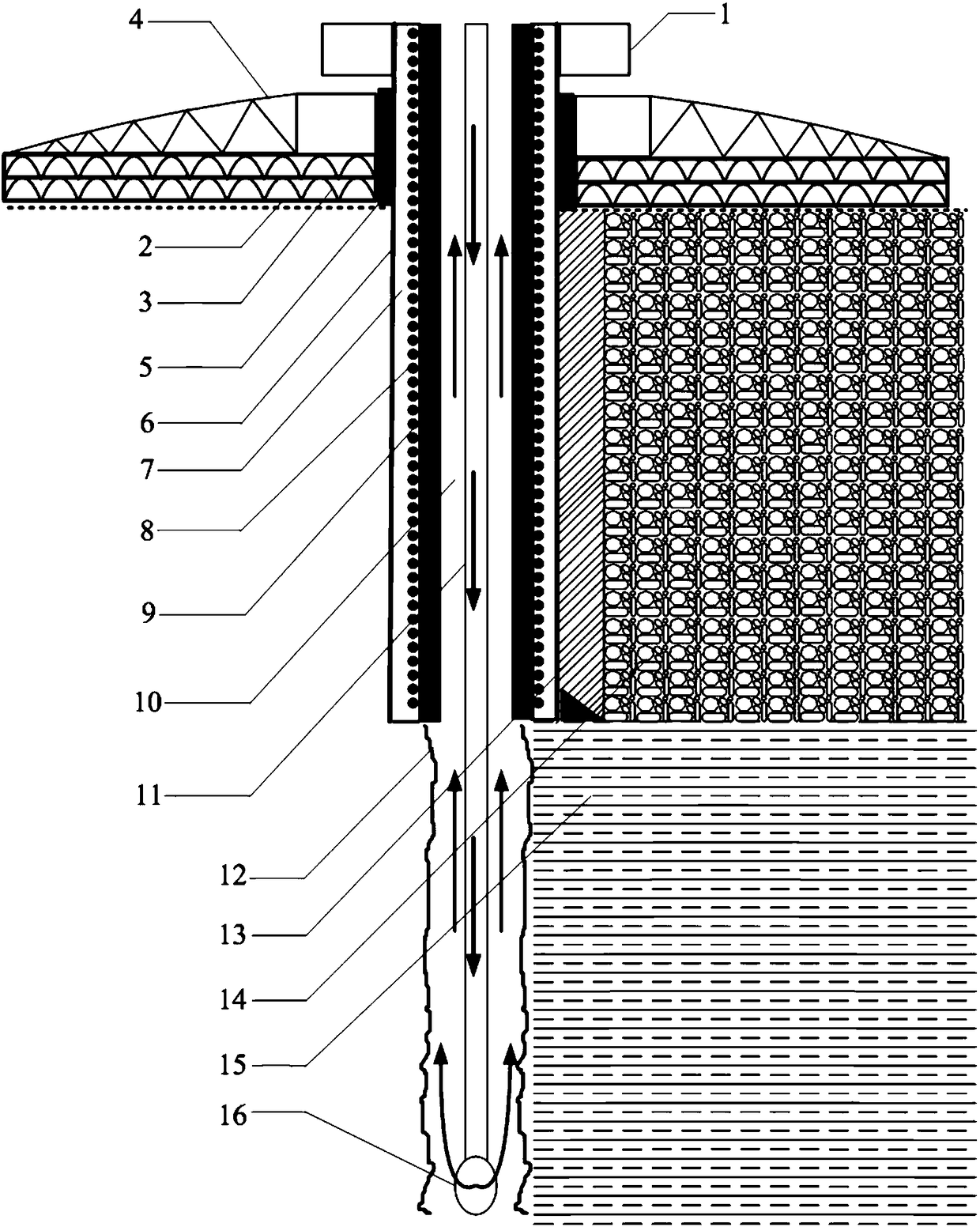

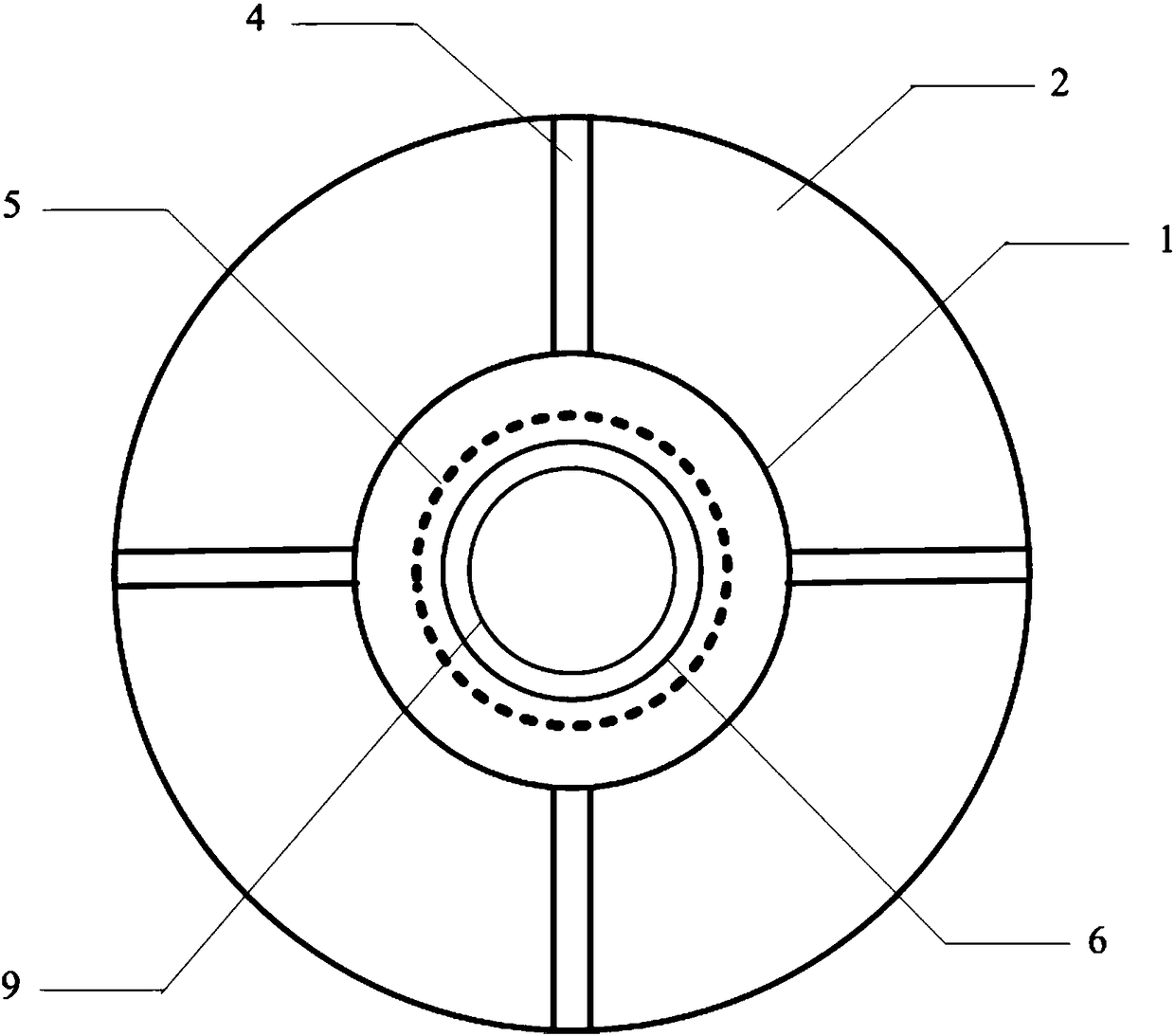

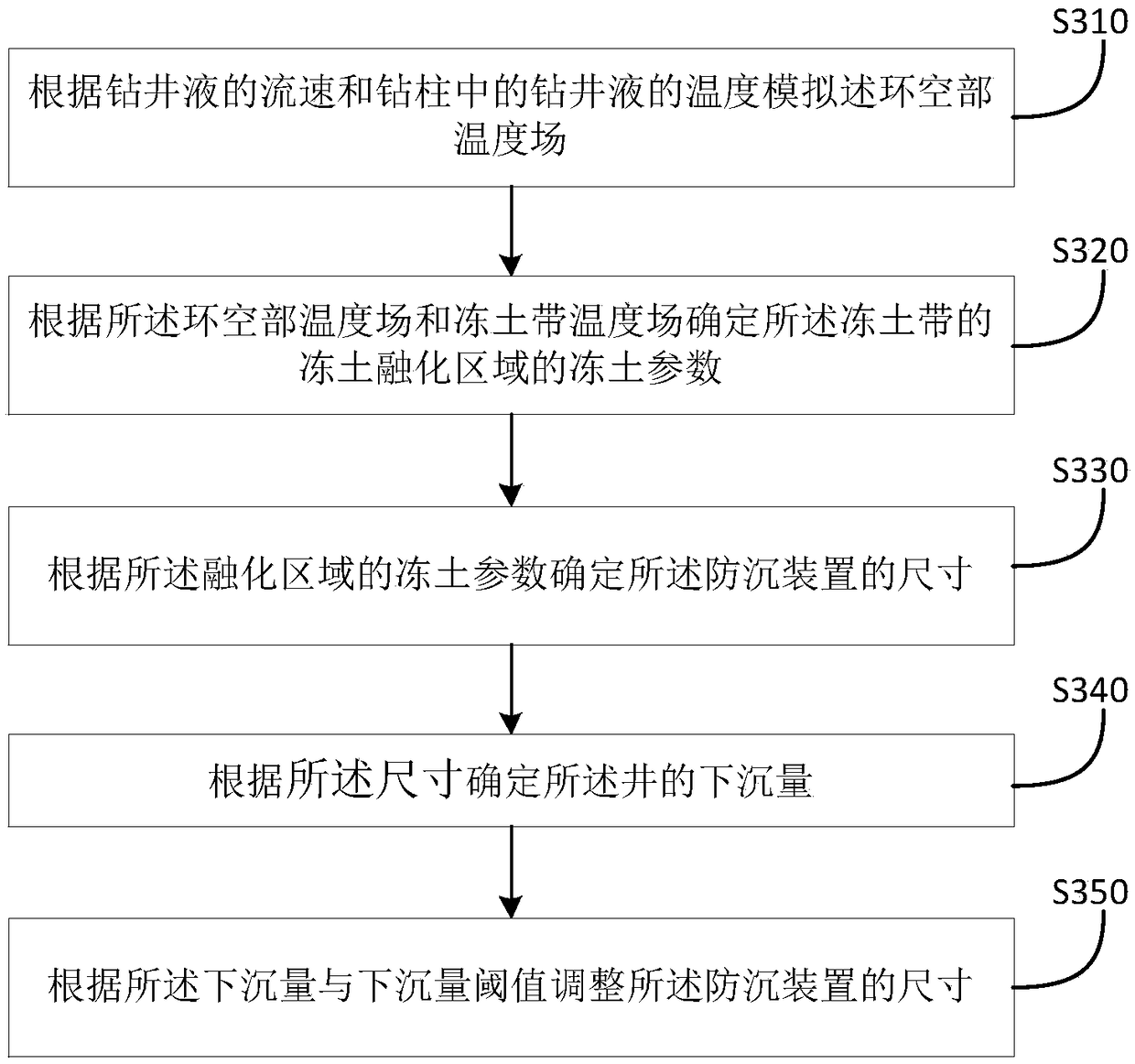

Anti-settling device, verification method and device thereof and device for preventing sedimentation of well

The embodiment of the invention provides an anti-settling device, a verification method and device thereof and a device for preventing sedimentation of a well, and belongs to the field of well drilling. The anti-settling device is arranged in a well opening area of the well during well drilling and used for preventing sedimentation of the well. The anti-settling device includes an anti-settling base and a connection locking device, an opening corresponding to the well opening is formed in the center of the anti-settling base, and the anti-settling base is distributed in the well opening area during well drilling. The connection locking device is arranged on the opening and used for connecting and locking a sleeve arranged in the well with the anti-settling base. The device for preventing sedimentation of the well includes the anti-settling base and the verification method used for the anti-settling base. The anti-settling device, the verification method and device thereof and the device for preventing sedimentation of the well can achieve reduction of pressure intensity of various well drilling devices on the well opening and a tundra under the well opening and further decrease thesedimentation amount of the well to achieve stable well drilling.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

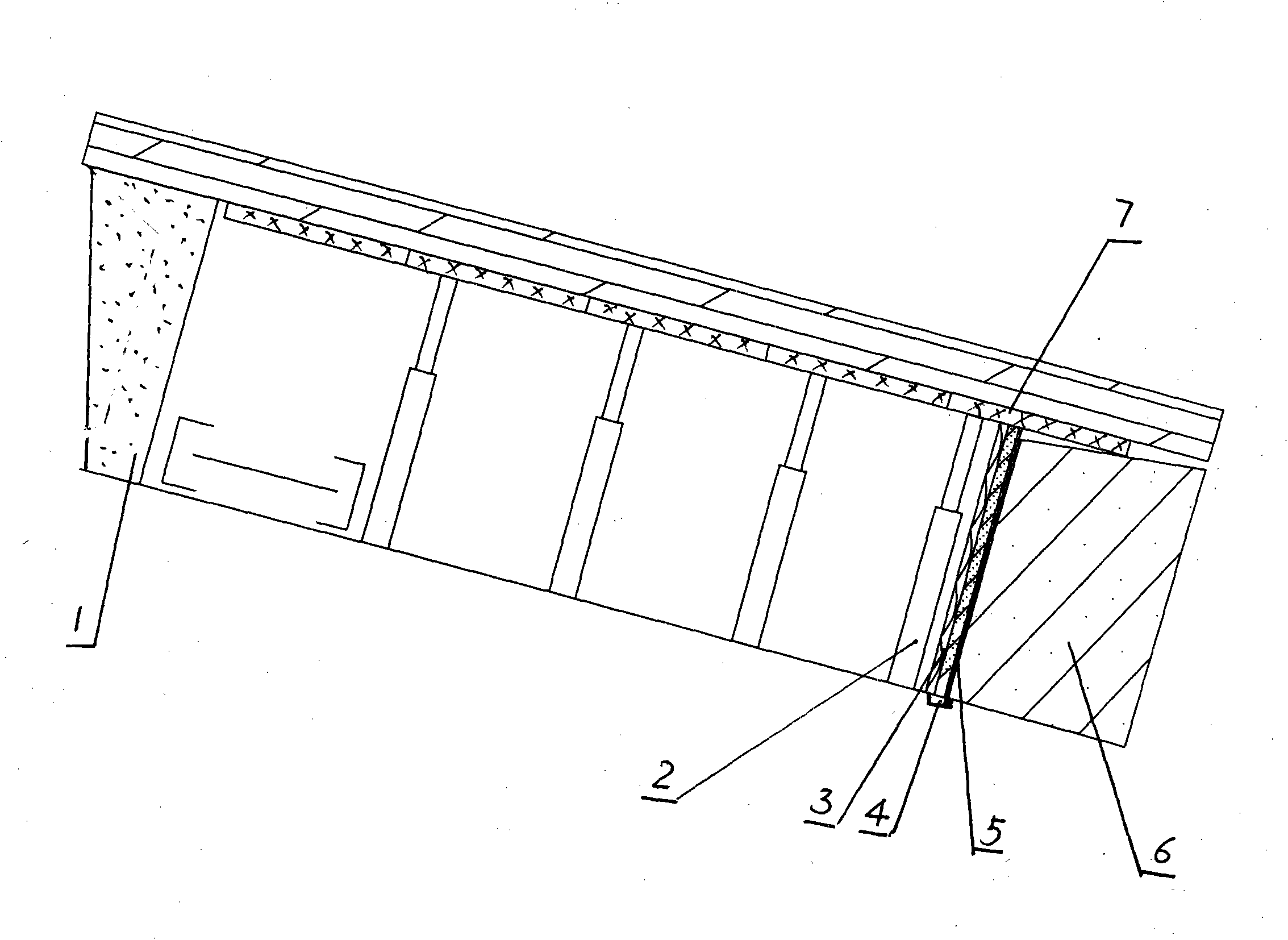

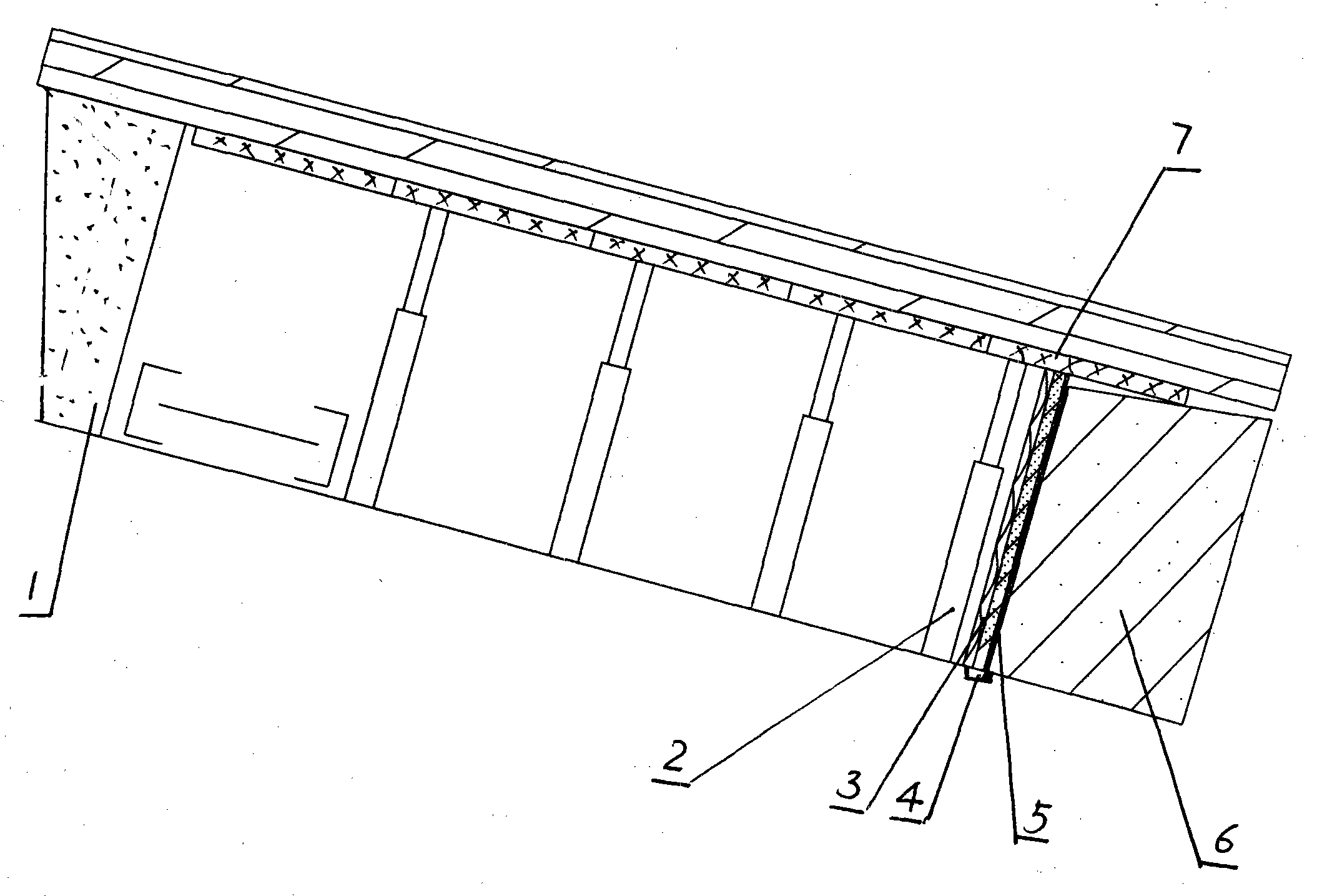

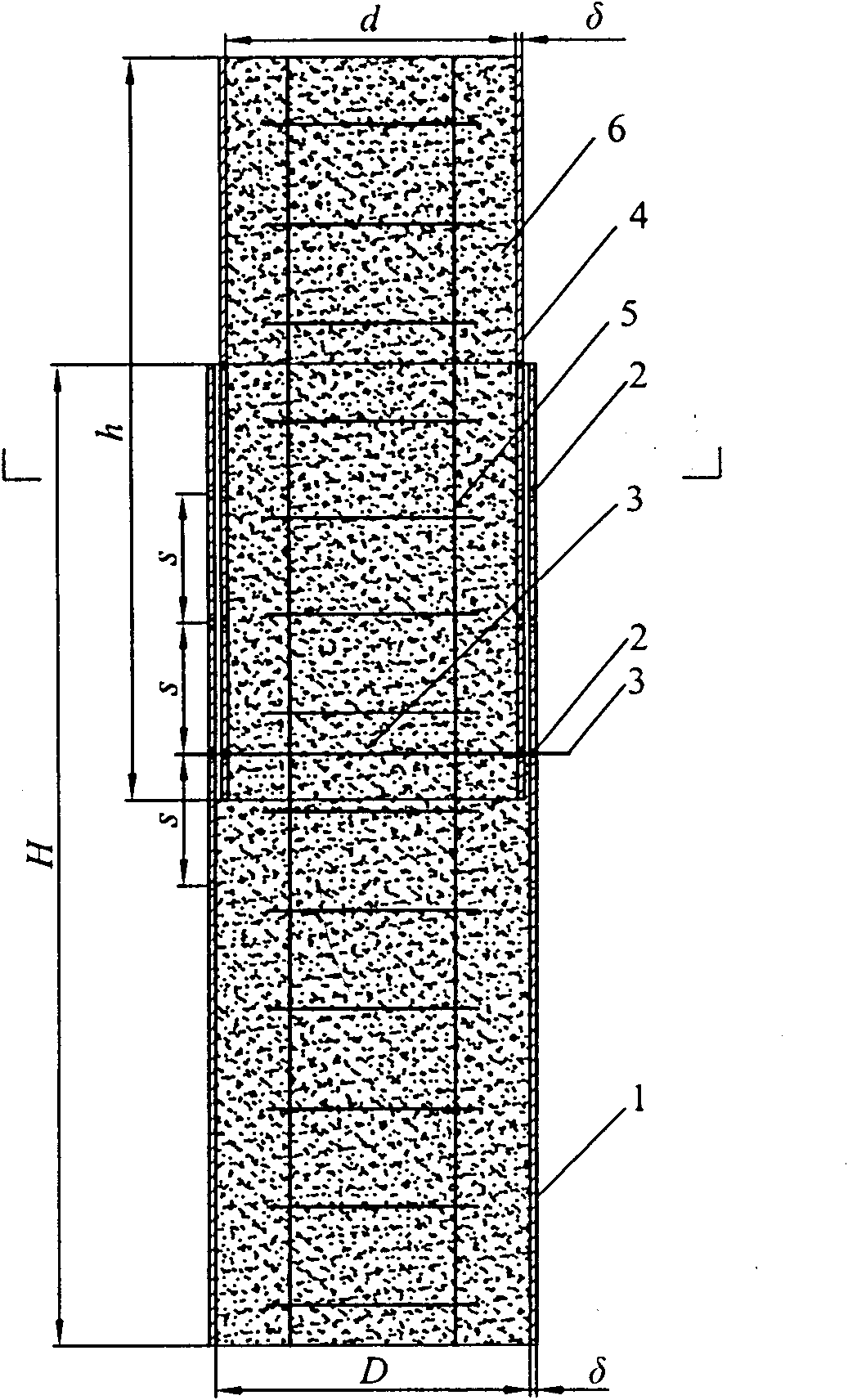

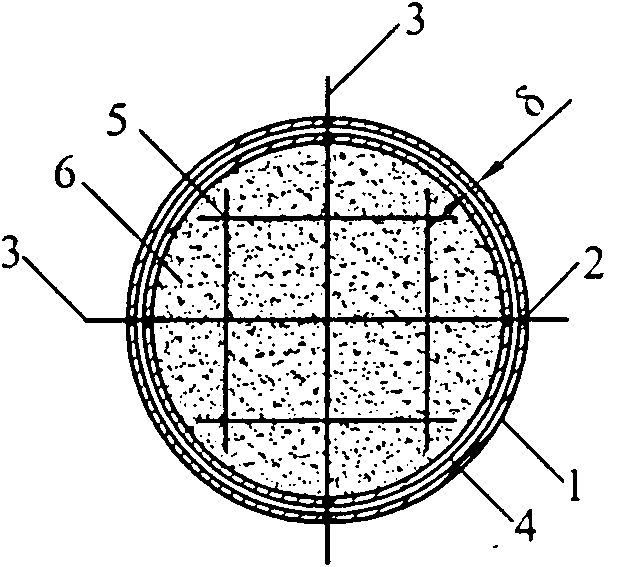

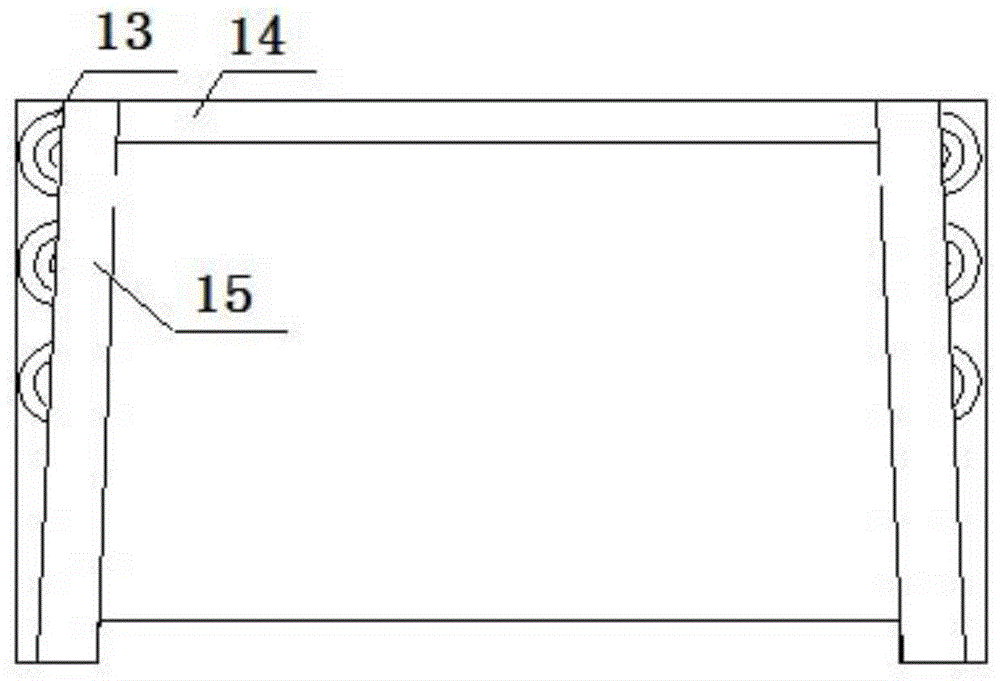

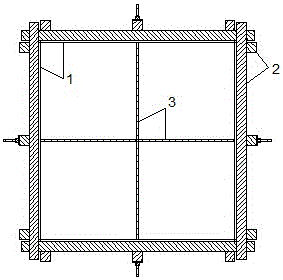

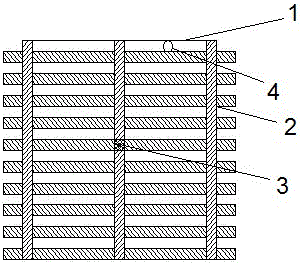

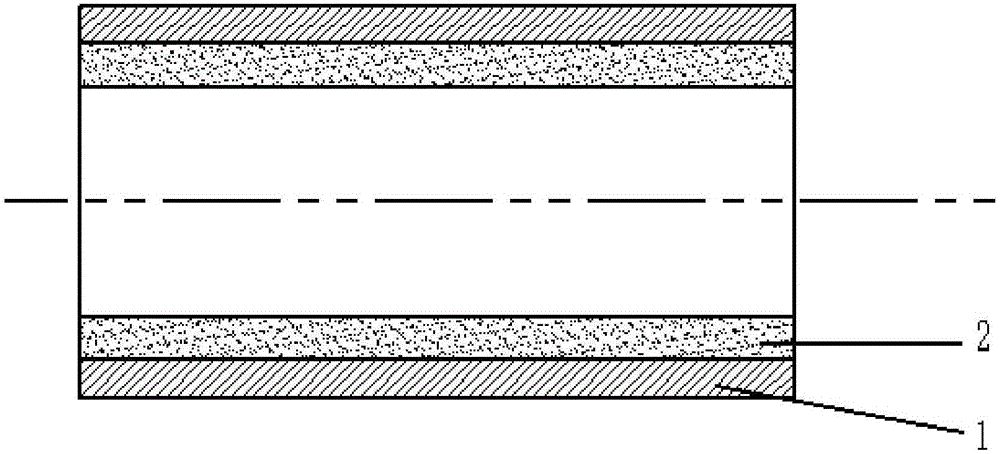

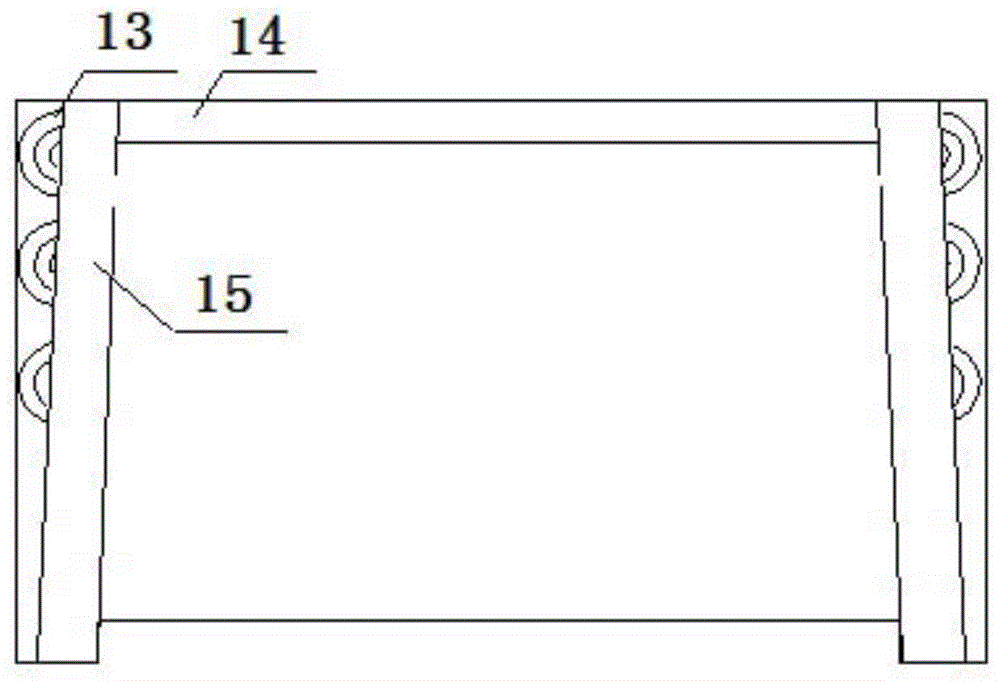

Stack column type filling formwork and using method thereof

The invention discloses a stack column type filling formwork and a using method thereof. The stack column type filling formwork is arranged below a top plate, supporting frames spliced together define a cuboid frame structure on the periphery, single supporting frames or integrated bodies formed by single-side-spliced supporting frames are arranged on the two opposite faces of the formwork respectively, and every two adjacent faces are formed by perpendicularly splicing supporting frames at the edges. Each supporting frame is composed of a baffle, framework sleepers and counter-pulled anchor ropes, wherein the framework sleepers are composed of a plurality of parallel transverse sleepers and three parallel vertical sleepers, the transverse sleepers and the vertical sleepers are arranged in a perpendicularly crossing mode, and the counter-pulled anchor ropes are arranged on the vertical sleepers in the formwork center on each side. The framework sleepers make direct contact with the top plate after being spliced to support the top plate. A filling opening is formed in the upper portion of the part, on one side of the formwork, of the baffle. After filling of the formwork, the overall compressive strength of filling columns is improved, the later compression amount of the filling columns is reduced, and the top sinking amount is reduced.

Owner:TAIYUAN UNIV OF TECH

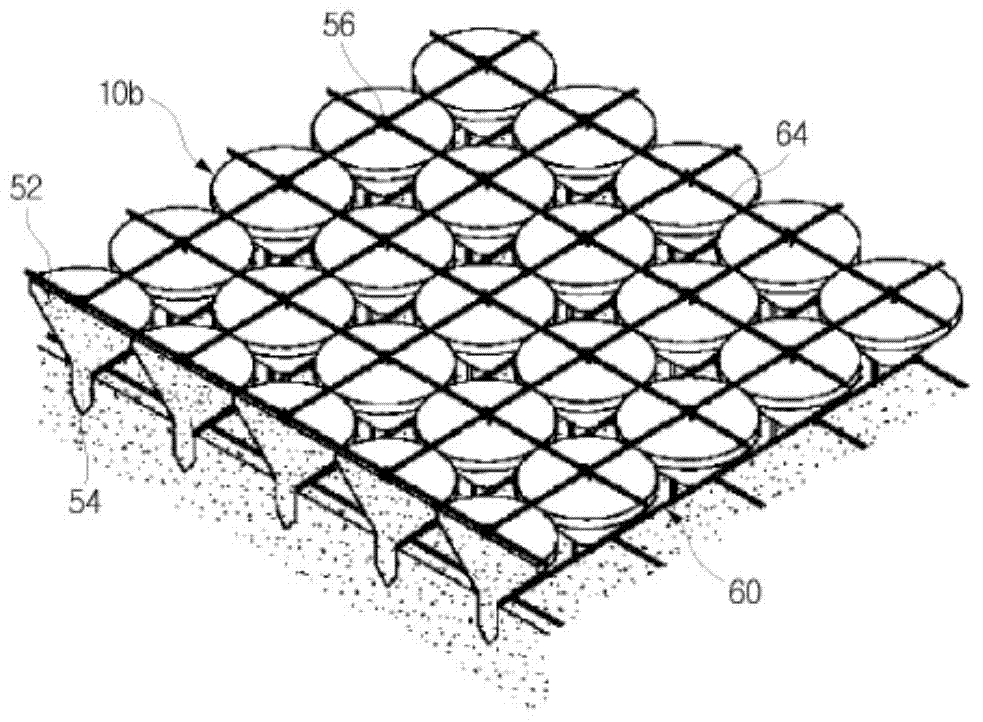

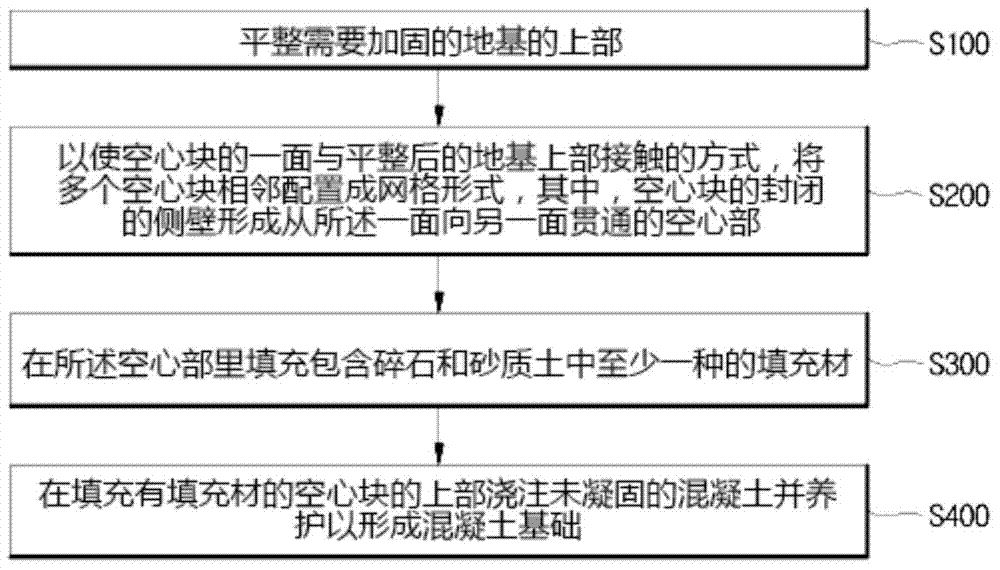

Method for constructing matrix foundation using hollow blocks

Provided is a method for constructing a matrix foundation using hollow blocks comprising the steps of: leveling the ground to be reinforced; arranging a plurality of hollow blocks adjacent to each other, so that one side of the hollow blocks come into contact with the leveled ground, the hollow blocks having closed side walls dividing the central space which penetrates from one side to the other side thereof; and filling the central space with filler material comprising crushed rock and / or sandy soil. The present invention allows the ground with inadequate bearing capacity for supporting above-ground structure to support same by reinforcing the ground without having to construct a deep foundation, such as a stake.

Owner:ACEALL

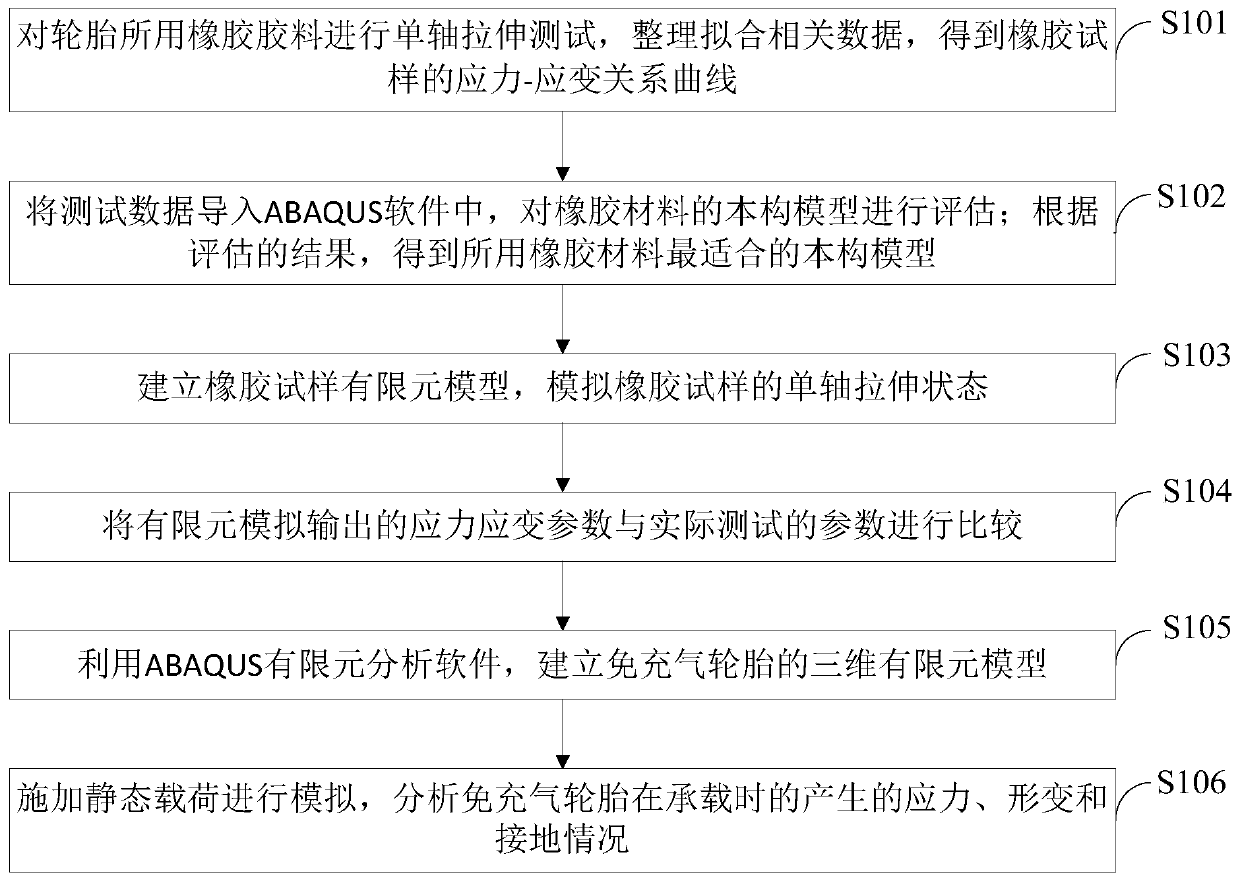

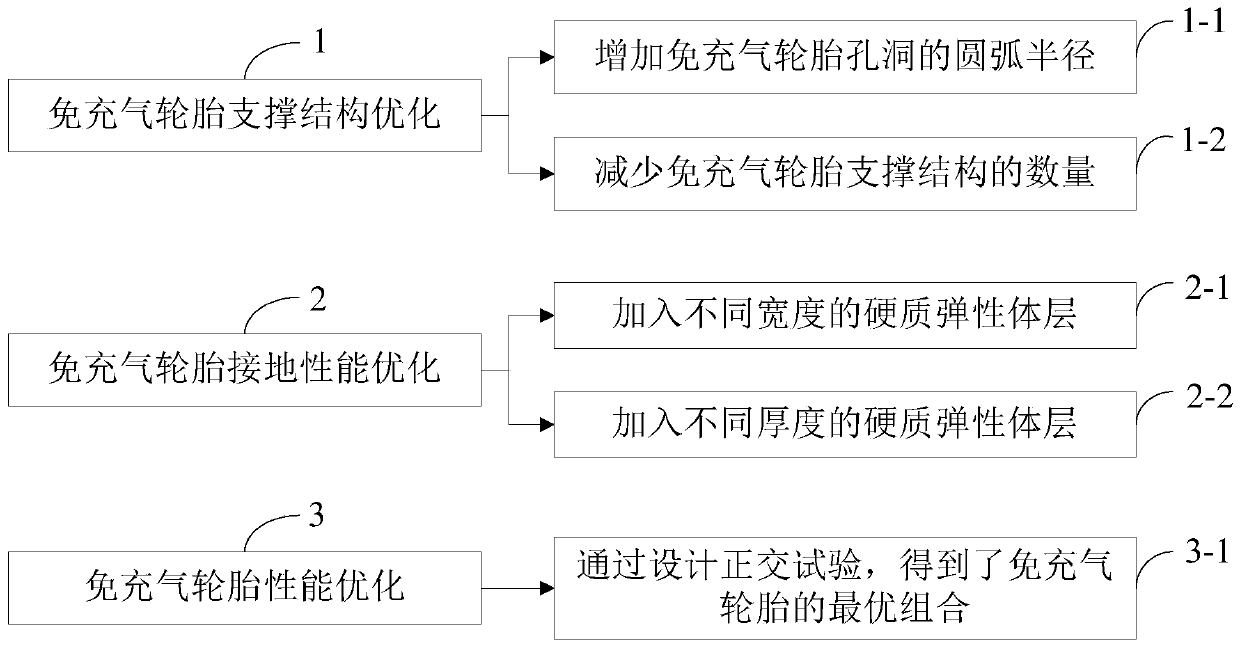

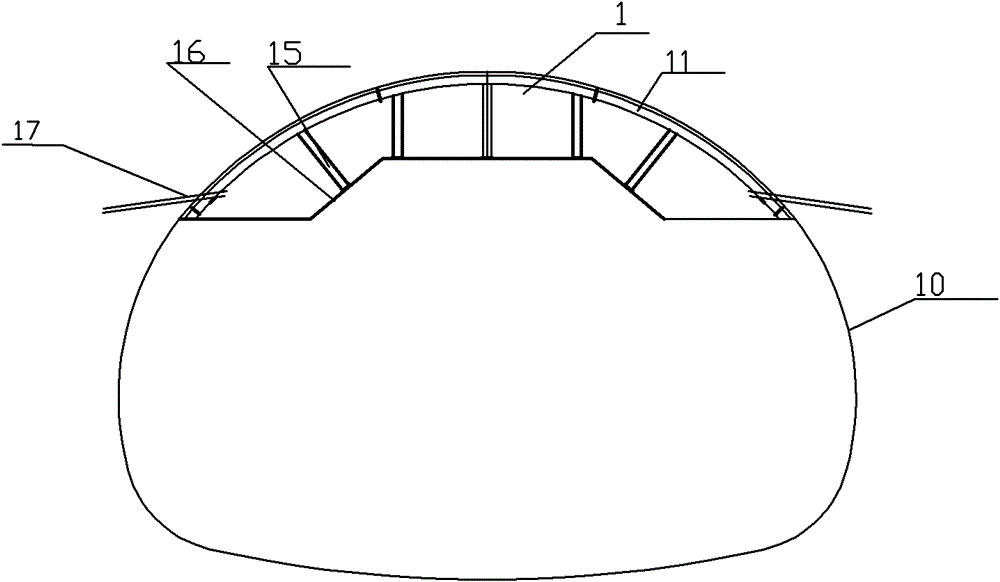

Finite element simulation analysis and performance optimization method for non-pneumatic tire

ActiveCN110688794AReduce stressReduce strainSustainable transportationDesign optimisation/simulationElastomerFatigue damage

The invention belongs to the technical field of tire performance optimization, and discloses an inflation-free tire finite element simulation and performance optimization method which comprises the following steps: fitting tire rubber uniaxial tensile test data based on ABAQUS professional software, establishing a finite element model of an inflation-free tire, and carrying out finite element analysis on a supporting structure and a tread part of the tire. By increasing the arc radius of the non-pneumatic tire hole and reducing the number of the non-pneumatic tire supporting structures, the stress-strain concentration phenomenon can be effectively weakened, the fatigue damage probability of the supporting structures is reduced, and the performance of the non-pneumatic supporting structuresis improved. The hard elastomer layer with certain width and thickness is added between the supporting structure and the tread, so that the performance of the supporting structure of the non-pneumatic tire can be improved, the ground contact stress is uniformly distributed, and the ground contact performance of the non-pneumatic tire is improved. The optimal combination of the non-pneumatic tireis obtained by designing an orthogonal test, and the supporting structure and the grounding performance of the optimal combination non-pneumatic tire are greatly improved.

Owner:QINGDAO UNIV OF SCI & TECH

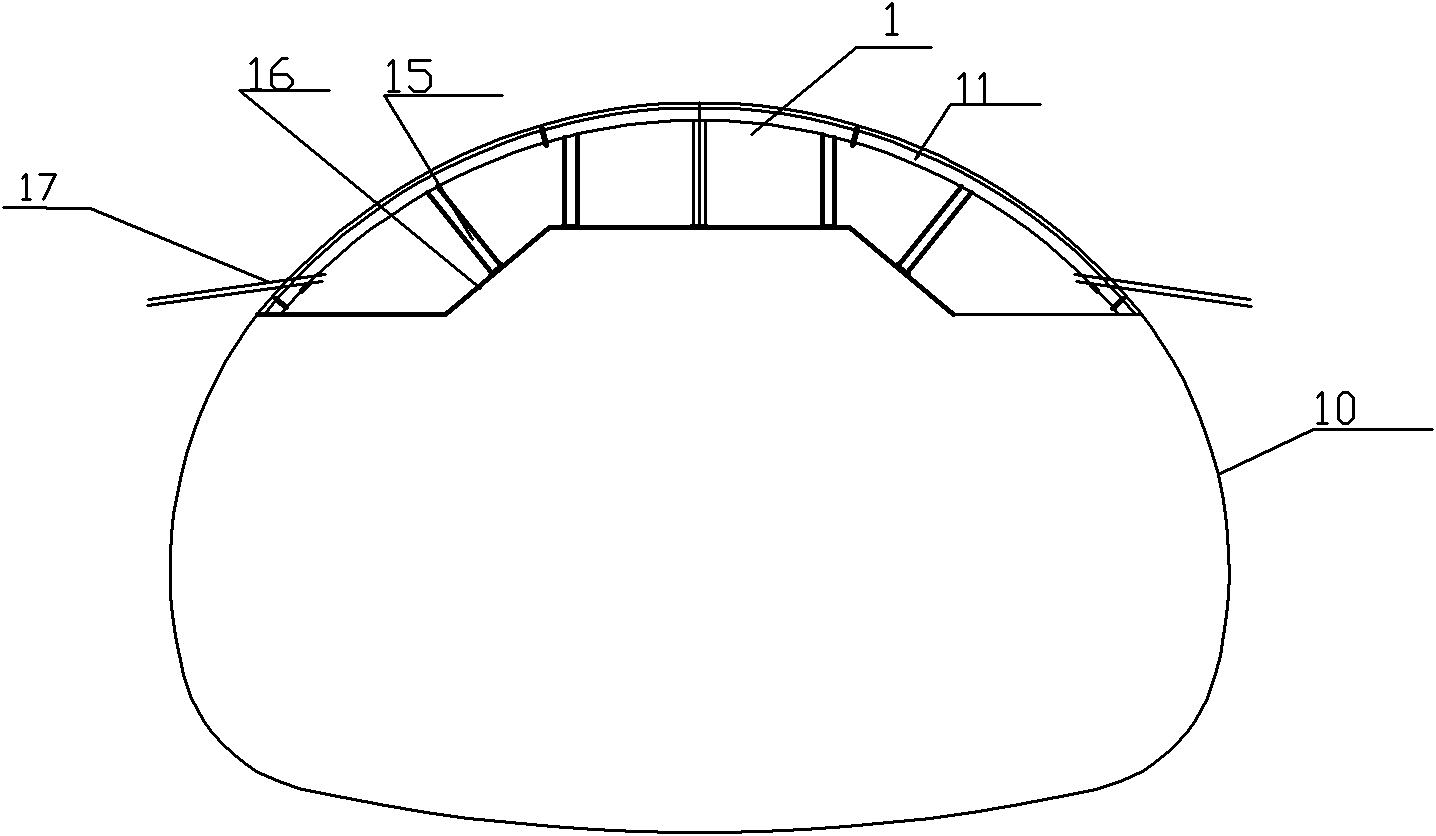

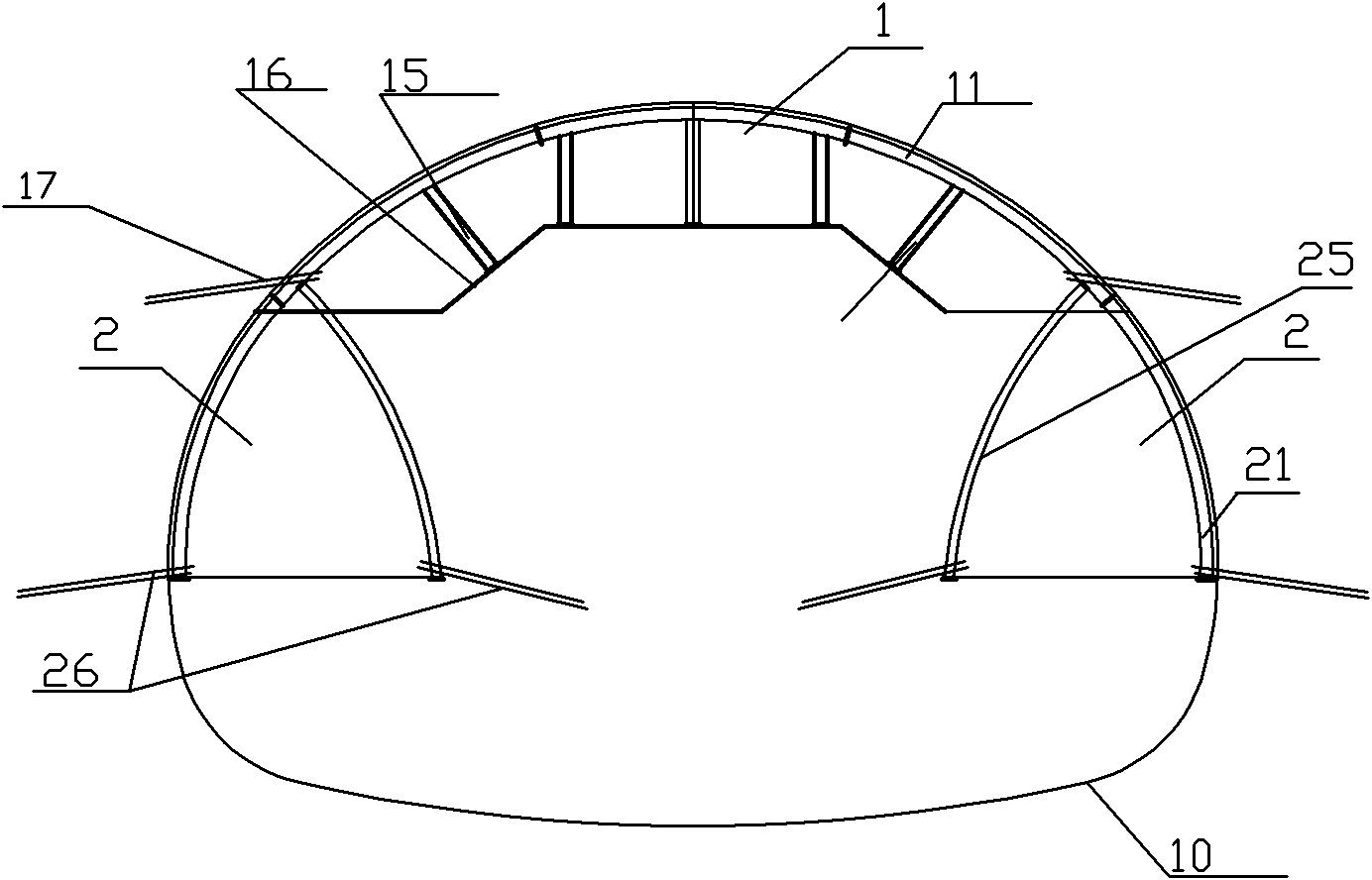

Construction method for weak surrounding rock section of short-step super-large-section tunnel

PendingCN114320317AReduce sinkageShort formation timeUnderground chambersTunnel liningArchitectural engineeringStructure support

The invention discloses a construction method for a weak surrounding rock section of a short-step super-large-section tunnel, and belongs to the technical field of tunnel construction. The construction method comprises the following steps that S1, a top arc-shaped pilot tunnel is excavated; s2, middle steps on the two sides are excavated left and right; s3, excavating lower steps on the left side and the right side; s4, core soil is excavated; and S5, tunnel bottom excavation and inverted arch supporting are carried out. The construction method is high in safety, fast in construction progress, short in construction period, stable in supporting structure, short in forming time of each whole ring, large in construction space, convenient for mechanical deslagging, fast in construction effect and capable of effectively shortening the closed ring forming time.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

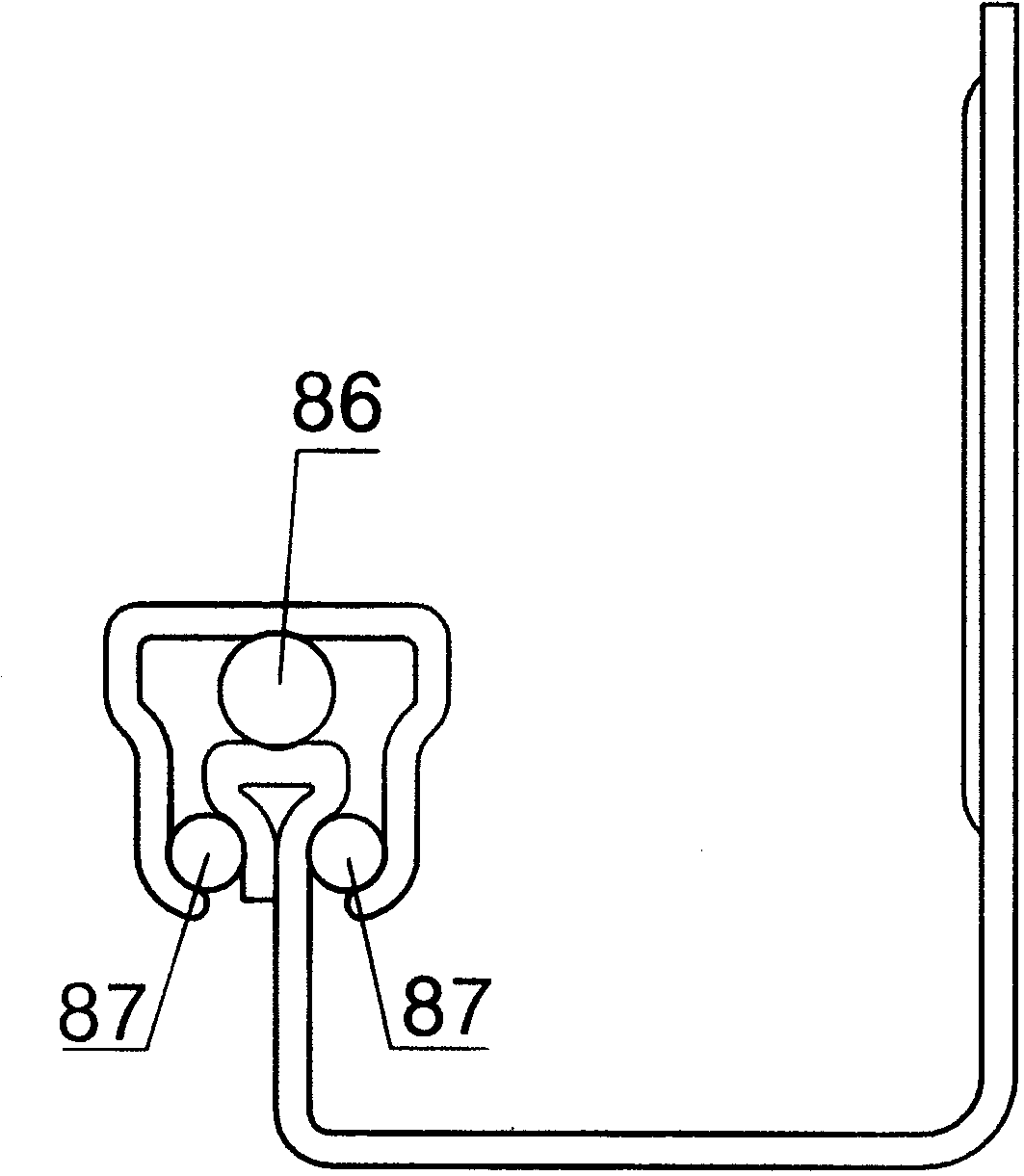

Water-lubricated bearing for pump and water guiding tank molded line optimizing method

InactiveCN106763204ACause severe wear and tearReduce wear lossGeometric CADBearing componentsAlloyPetroleum engineering

The invention discloses a water-lubricated bearing for a pump and a water guiding tank molded line optimizing method. The water-lubricated bearing comprises an outer alloy sleeve and a rubber embedded sleeve with a self-lubricating action. The outer alloy sleeve and the rubber embedded sleeve constitutes the outer wall and the inner wall of the water-lubricated bearing correspondingly. The rubber embedded sleeve is composed of tanks and platforms, and intersecting angles of the water guiding tanks and the platform areas all have fillets. The spiral direction of a water guiding tank molded line is the axis rotating direction. According to the water-lubricated bearing, through the connection of the outer alloy sleeve and the rubber embedded sleeve, damping and protecting actions are achieved. The fillets at the bottoms of the water guiding tanks of the rubber embedded sleeve are designed, so that the residue and abrasion of water dregs are effectively avoided. The fillets at the tops of the water guiding tanks of the rubber embedded sleeve are designed, so that decompressing and abrasion reducing actions are achieved. Due to the water-lubricated materials and water guiding tank molded line characteristics of the water-lubricated bearing, at the time of starting, a certain time of dry friction can be allowed, and deformation fracture does not occur.

Owner:JIANGSU UNIV

Soft foundation building foundation structure and construction method

PendingCN113699984AIncrease frictionReduce sinkageBulkheads/pilesSoil preservationPiston ringArchitectural engineering

The invention relates to the technical field of constructional engineering, in particular to a soft foundation building foundation structure. According to the technical scheme, the structure comprises a plurality of pipe piles, rigid grouting pipes are arranged in the middles of the pipe piles, and the rigid grouting pipes are circumferentially connected with a plurality of sleeves; one end of the sleeve communicates with the interior of the rigid grouting pipe, the other end of the sleeve is fixedly connected with the side wall of the pipe pile, and a soil inserting rod is inserted into the sleeve; a piston ring is fixed outside the inner end of the soil inserting rod, the soil inserting rod and the piston ring can move in the sleeve in the direction away from the grouting pipe, and a plurality of grouting holes are formed in the side wall of the soil inserting rod. A slidable guide rod is arranged in the soil inserting rod in a matched mode, the inner end of the guide rod is fixedly connected with the rigid grouting pipe, and the length of the portion, inserted into the soil inserting rod, of the guide rod is smaller than the movable stroke of the soil inserting rod in the sleeve. The structural strength of the soft foundation and the bearing capacity of the foundation can be improved, the pipe piles and the foundation are connected to form soil piles, and therefore the sinking amount of the foundation piles and a building structure is reduced, and the safety of the building structure is ensured.

Owner:张坤

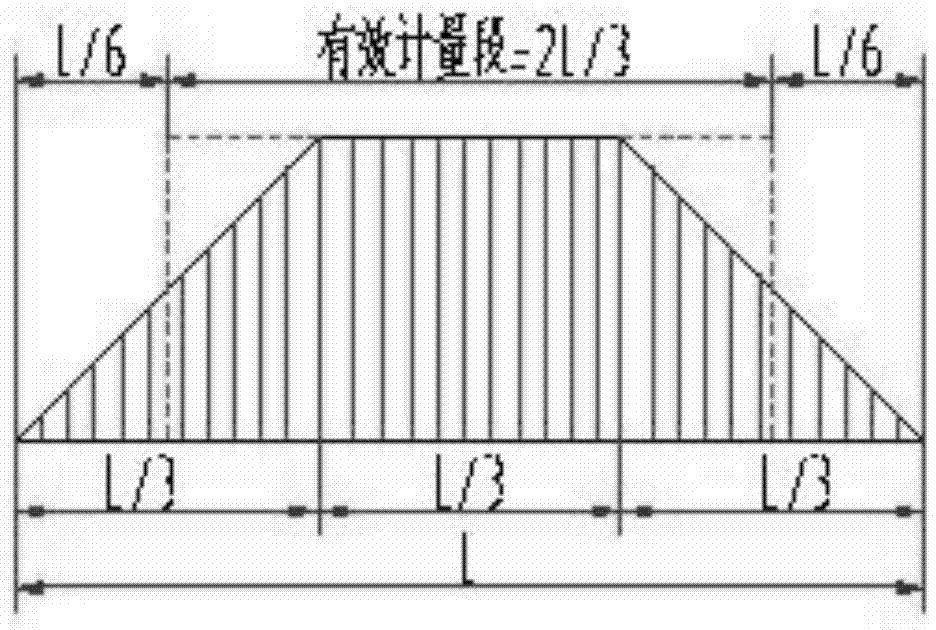

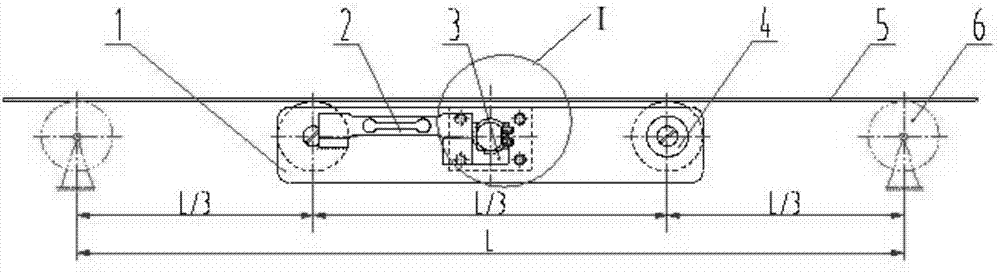

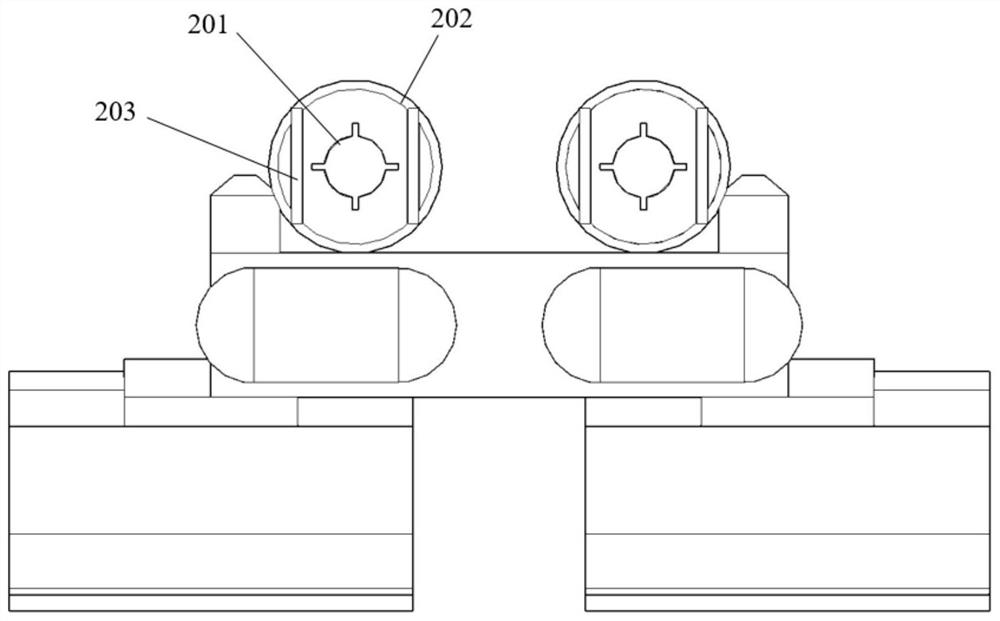

Self-linking type double-carrier roller weighing device

ActiveCN103616061AAvoid bulky structuresSimple structureWeighing apparatus for continuous material flowEngineeringLoad cell

Owner:云南昆船电子设备有限公司

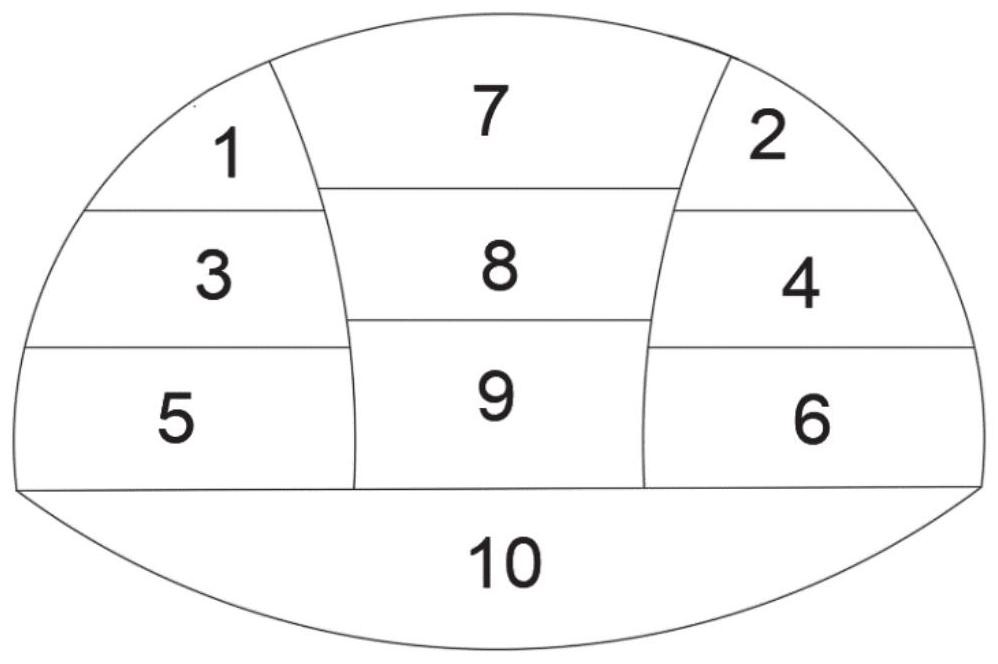

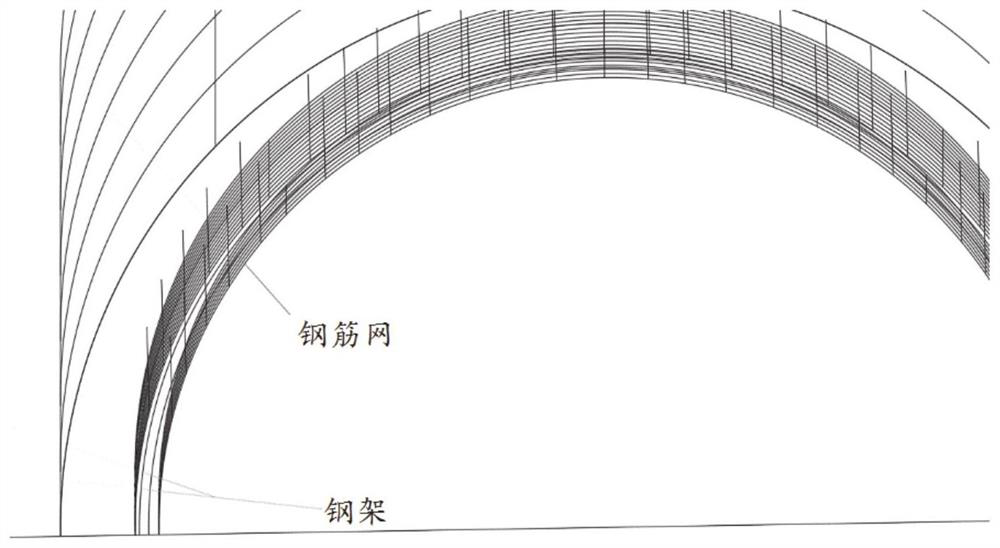

Construction method for soft surrounding rock section of large-span tunnel portal

ActiveCN102071947BReduce sinkageShort formation timeUnderground chambersTunnel liningSteel frameLarge core

The invention discloses a construction method for a soft surrounding rock section of a large-span tunnel portal. The construction method comprises the following steps of: excavating an arc-shaped pilot tunnel on the top of a tunnel section; performing initial support in time after the excavation process is finished and performing temporary support at the same time; excavating upper pilot tunnels on the left side wall and the right side wall at the same time; performing initial support in time after the excavation process is finished and performing temporary support on the core soil side walls at the same time; excavating lower pilot tunnels on the left side wall and the right side wall at the same time, wherein the depth of circulation drilling for each time is 0.5 m; performing initial support in time after the excavation process is finished and performing temporary support on the lower parts of the core soil side walls at the same time; performing large core soil excavation; reserving core soil steps; installing inverted arch steel frames and injecting C25 concrete in time, so that the initial support of the whole tunnel forms a closed ring as soon as possible; and dismantling the temporary support. By the top arc side wall pilot tunnel construction method, vault subsidence can be favorably controlled; and the method is applicable to tunneling excavation construction for strongly differentiating a surrounding rock portal when the tunnel portal is under the protection of a large pipe roof section.

Owner:THE FIRST ENG OF CCCC FOURTH HARBOR ENG

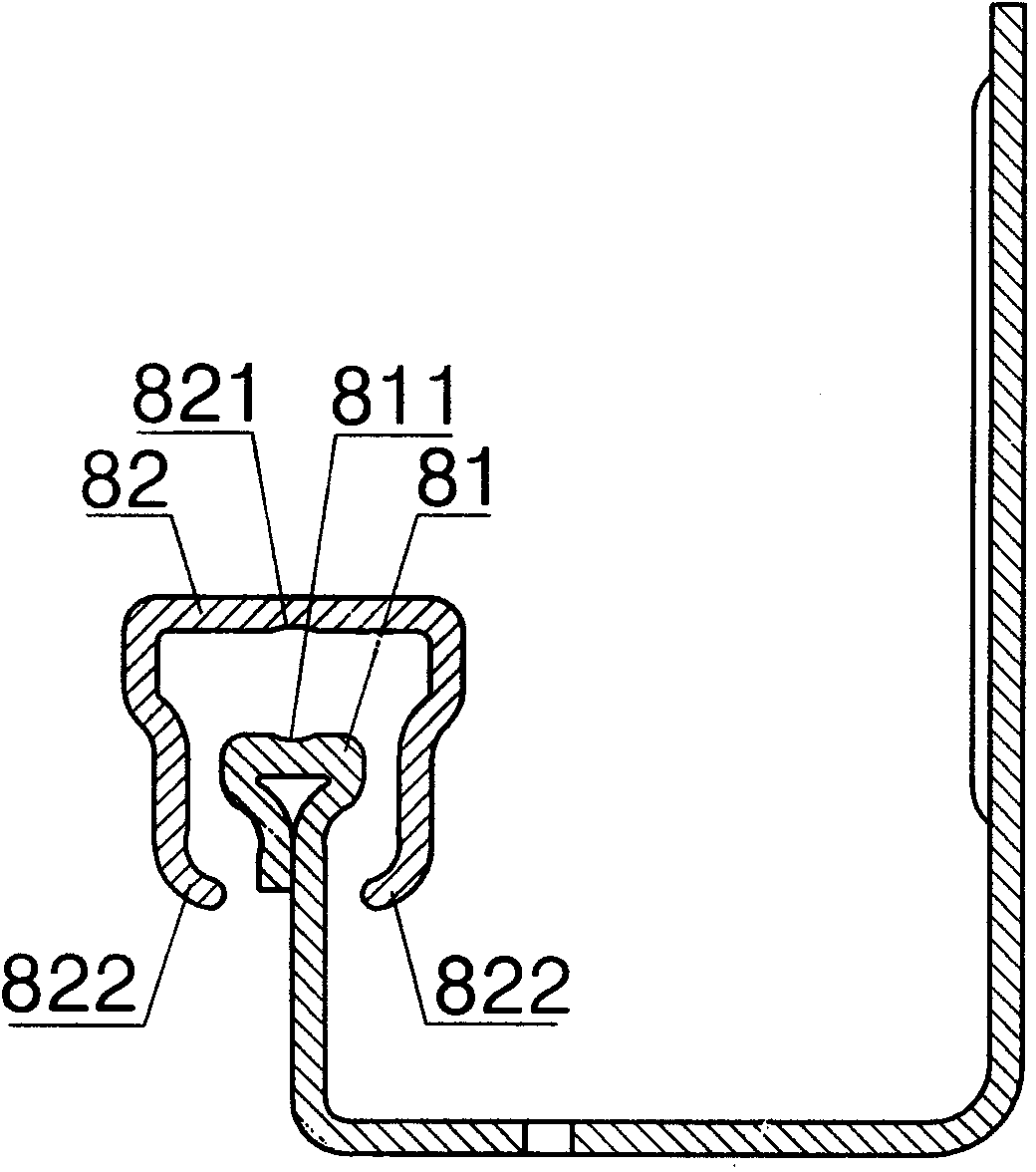

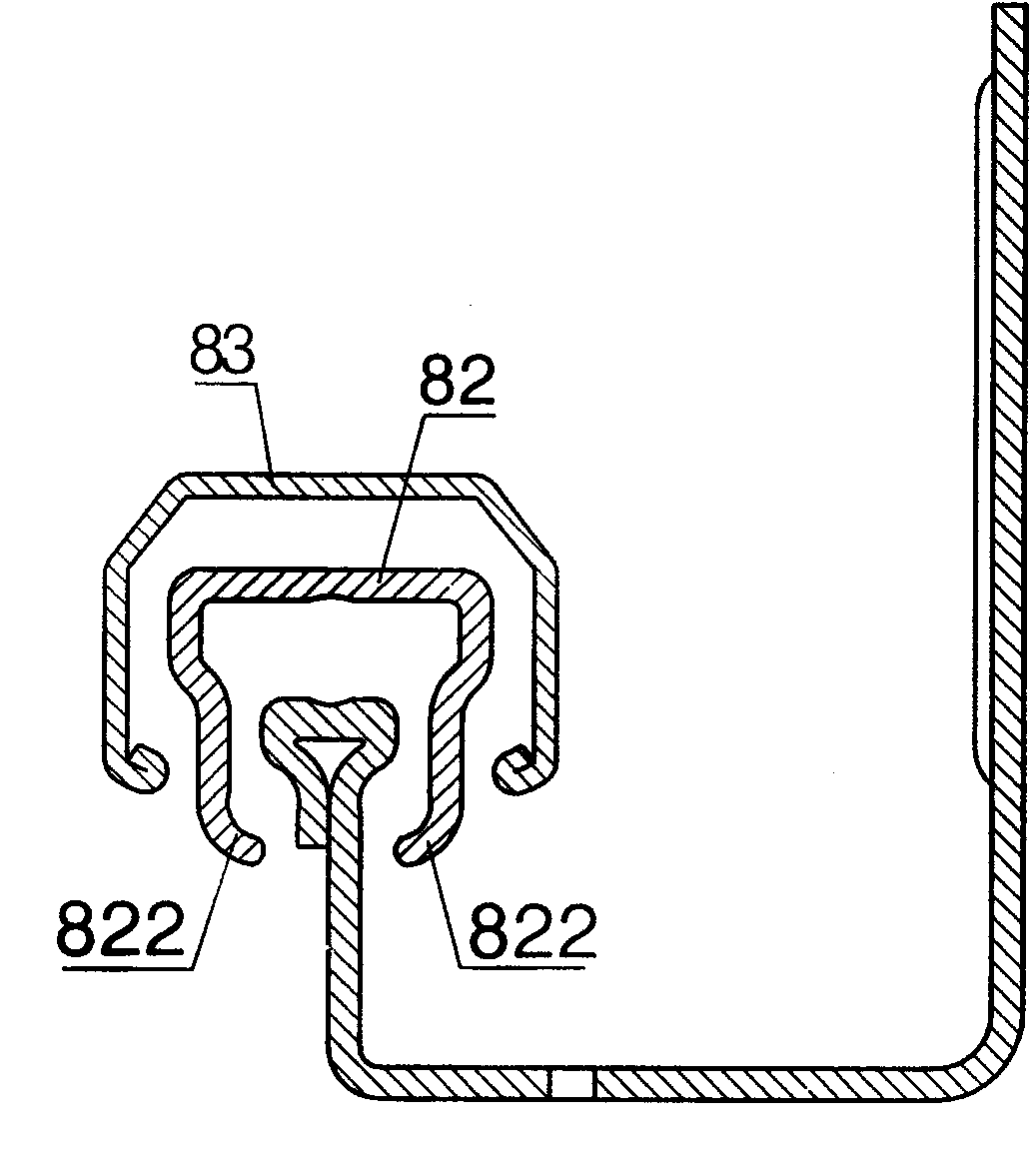

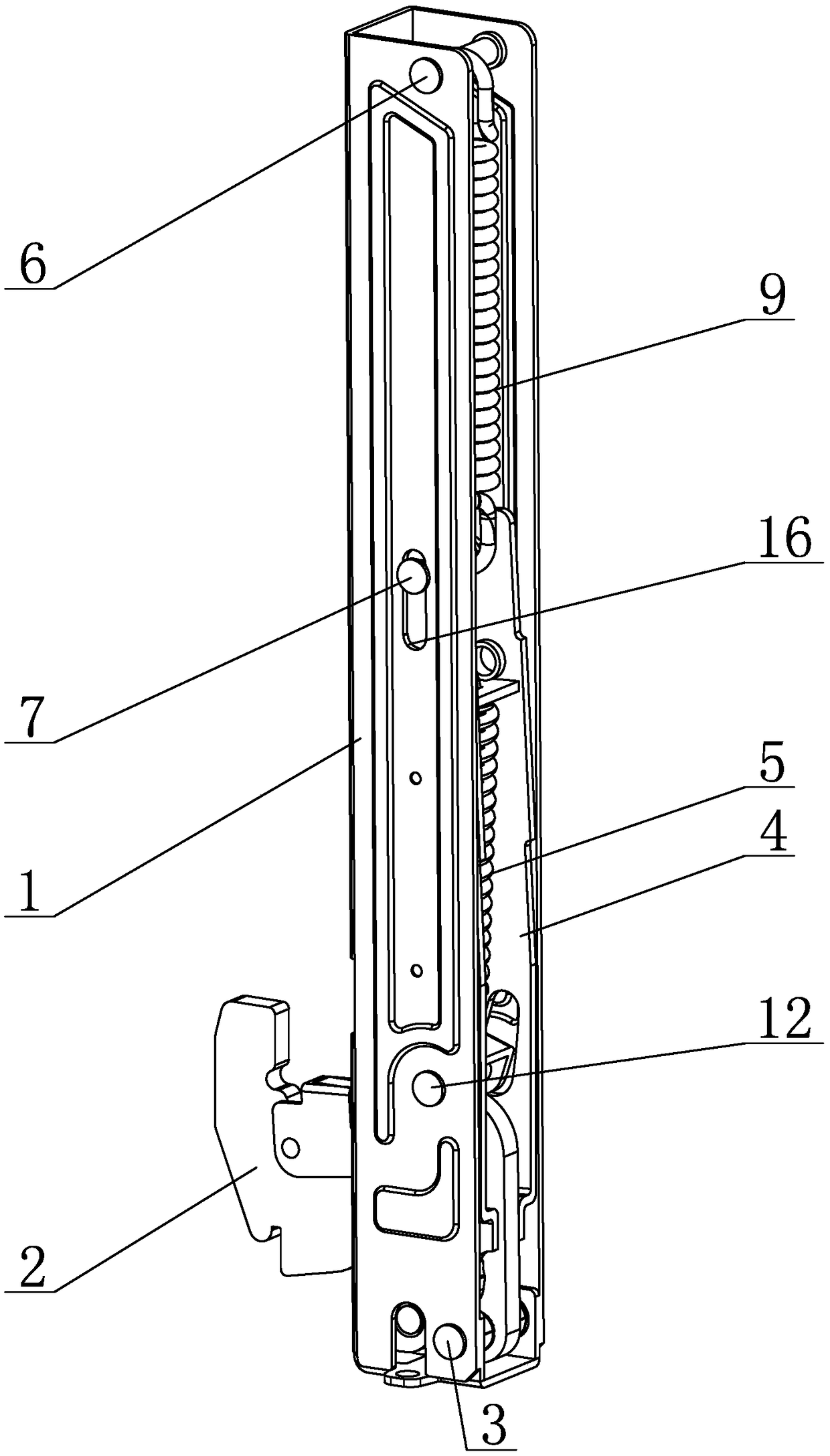

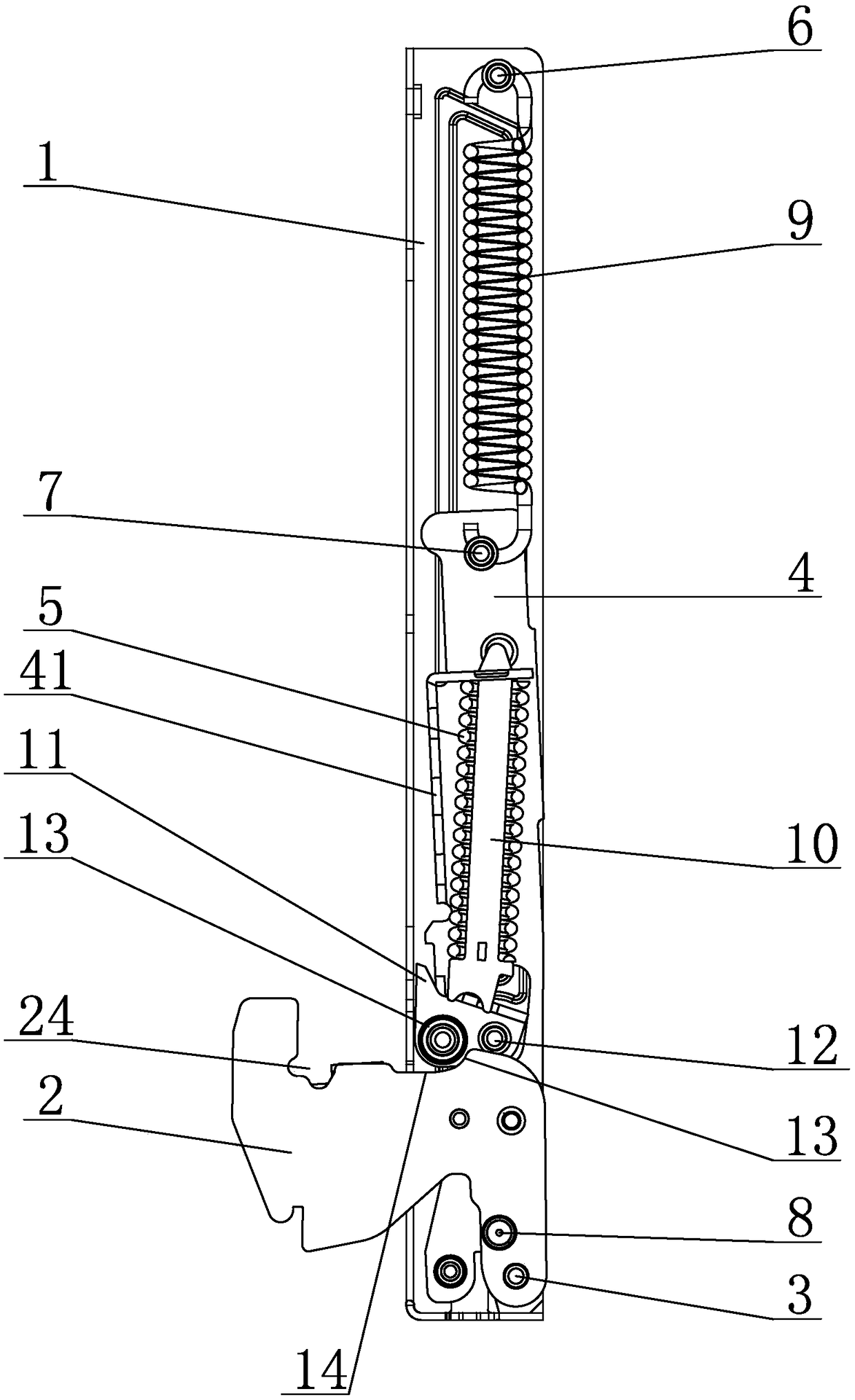

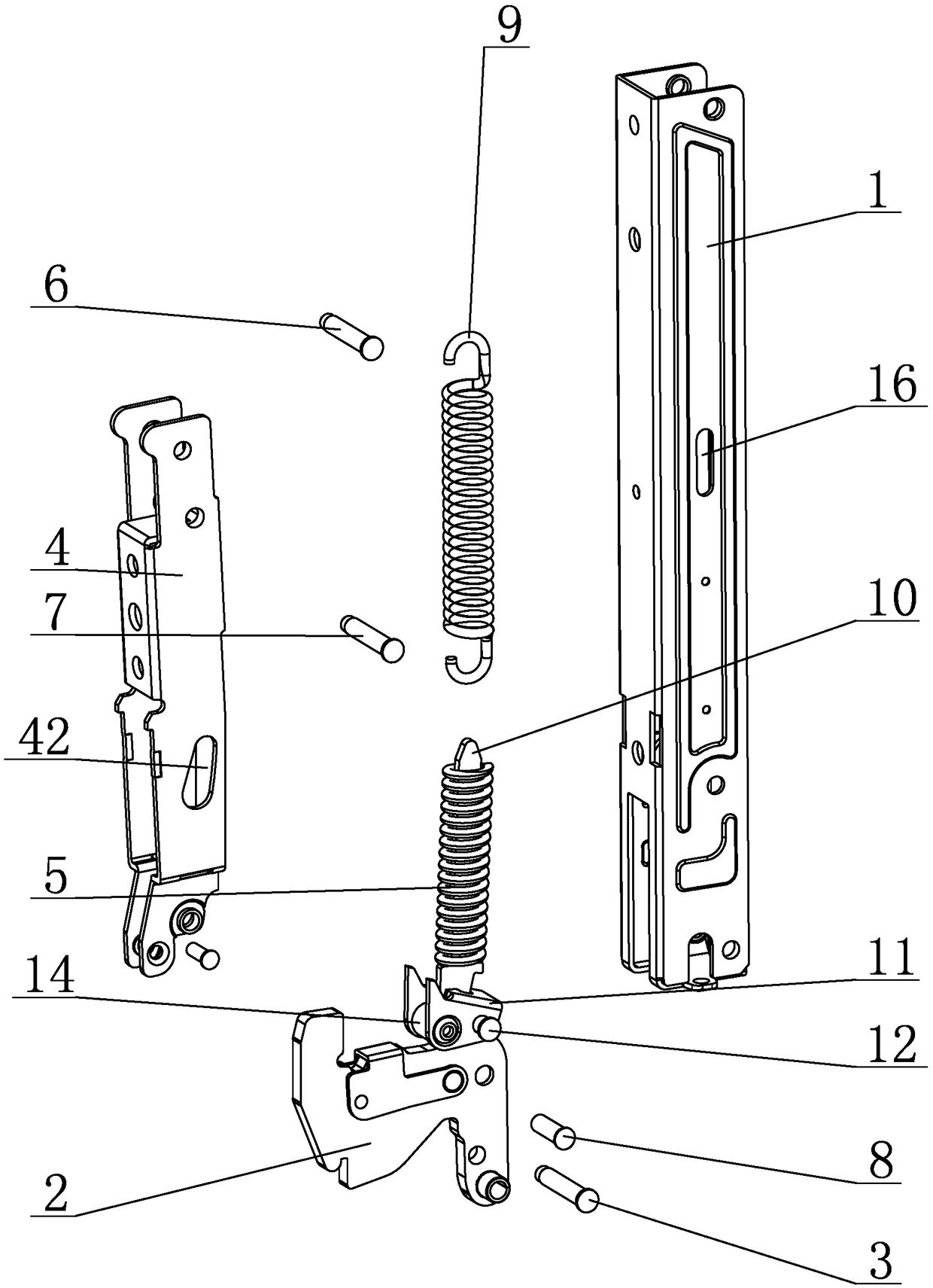

Drawer guide rail structure

InactiveCN103519585AImprove carrying capacityGuaranteed uptimeDrawersMechanical engineeringBearing capacity

The invention belongs to hardware products, and relates to a drawer guide rail structure. The drawer guide rail structure comprises a fixed rail, a middle rail and a movable rail, and a first rolling way is arranged on the horizontal side of the bearing portion of the fixed rail. A second rolling way is arranged on the horizontal side of the middle rail, and a first ball is arranged between the first rolling way and the second rolling way. A rolling column is arranged between the lower surface of the horizontal side of the movable rail and the upper surface of the horizontal side of the middle rail. First bent portions are arranged at the lower ends of the two vertical sides of the movable rail. The two downward sides at the two ends of the horizontal side of the middle rail are respectively provided with a second bent portion, a third bent portion and a fourth bent portion from top to bottom in sequence, and second balls are embedded between the second bent portions and the first bent portions. Third balls are embedded between the third bent portions and the triangular inclined sides of the fixed rail, and the fourth bent portions start to be bent from the tail ends of the third bent portions and extend towards to the outer sides of the downward sides of the middle rail. The drawer guide rail structure increases the bearing capacity of the middle rail, a guide rail is made to operate more smoothly, the overall deflection of a drawing cabinet is reduced, and the drawer guide rail structure is suitable for being arranged on furniture for use.

Owner:李绍汉

Oven hinge with two-section type transmission mechanism

ActiveCN109113477AEasy to useWith automatic door closing functionBuilding braking devicesHingesElectric power transmissionElastic component

The invention provides an oven hinge with a two-section type transmission mechanism. The oven hinge comprises a hinge base and a hinged arm, wherein the hinge base is arranged on an oven door body, the hinged arm is mounted on an oven cabinet body, a hinged shaft hinged to the hinge base is arranged at the lower end of the hinged arm, the hinged shaft is installed at the position close to the inner wall of the bottom end of the hinge base, and the hinge base is provided with a two-section type transmission device; the two-section type transmission device comprises a sliding frame, a transmission elastic component and a power-assisted elastic component, wherein the sliding frame is arranged on the hinge base in a sliding mode, the transmission elastic component has a buffer door weight anddoor hovering function, and the power-assisted elastic component has a door body opening and closing function, so that two-section type power transmission can be provided by the hinge base during opening and closing, the transmission elastic component provides the torque force for balancing the weight of an oven body, the function of turning on and hovering an oven door body at any angle is achieved, a large door closing force is provided by the power-assisted elastic component, and the automatic closing function of the oven door body is realized.

Owner:JIANGSU SACA PRECISION TECH CO LTD

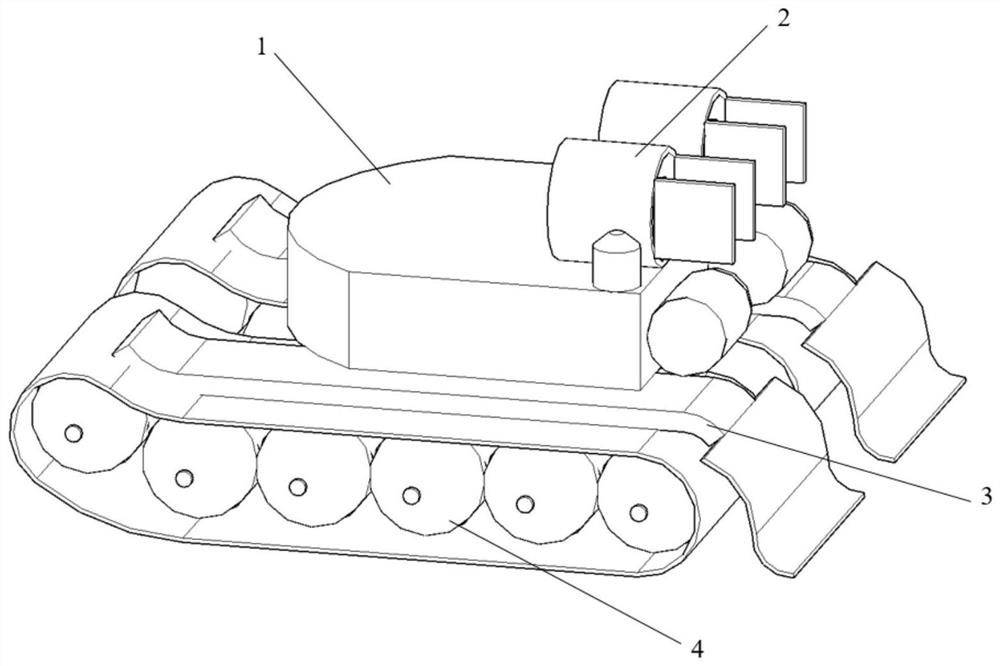

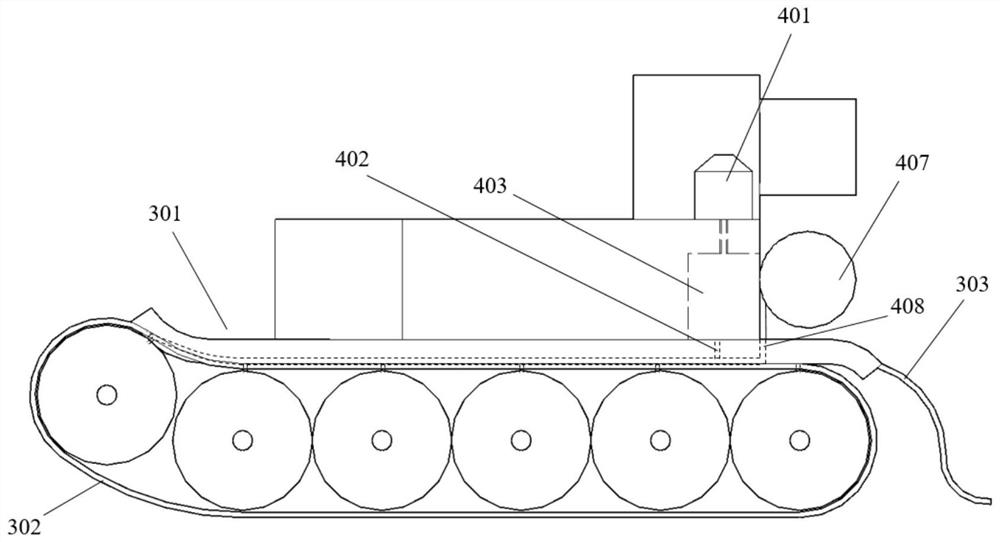

A composite skid-board type submarine mine car traveling device

ActiveCN112960044BIncrease contact areaReduce sinkageWatercraft hull designUnderwater vesselsExhaust valveHigh pressure water

The invention discloses a composite sled type seabed mine car traveling device, which comprises a main body of the mine car, a propulsion steering device, a traveling device and a buoyancy control device. The propulsion steering device includes a propeller propeller, a fairing, and a deflector. Skid board, flexible skid board, rigid skid board is fixedly connected to the lower part of the main body of the mine car, flexible skid board is fixedly connected under the rigid skid board, flexible skid board includes an outer protective layer, water bag, air bag; the outer protective layer is provided with multiple An independent water bag, the upper part of the water bag is closely connected with the skid board, and an air bag is installed inside the water bag; the buoyancy control device includes a high-pressure water pump, a water pipeline, a water distribution tank, a water filling valve, a drain valve, a high-pressure air tank, an air pipeline, an inflation valve, As for the exhaust valve, each water bag is provided with a water filling valve and a drain valve, and the air bag is provided with an inflation valve and an exhaust valve. The invention can make the seabed mine car suitable for different working modes such as placement, walking, self-rescue from trap, recovery and the like.

Owner:OCEAN UNIV OF CHINA

Coal mine mining and filling integrated coal mining method

ActiveCN104675399BImprove securityReduce sinkageUnderground miningSurface miningSocial benefitsEcological environment

The invention discloses a coal mining and filling integrated method for a coal mine. The method comprises the following steps: (1) digging out an air returning and filling pipeline lane, a boundary air lane and a transportation and air intaking lane of a mining region on a working surface of the mining region; (2) mining coal with a narrow strip channel in the working surface of the mining region, in which a ventilating system is formed, after coal mining in each narrow strip channel is finished, communicating the transportation and air intaking lane of the mining region with the air returning and filling pipeline lane of the mining region through narrow strip channels; (3) transporting coal mine cementing filling material slurry into a narrow strip channel excavating region formed after the coal mining in the narrow strip channels is finished for filling; and (4) mining the coal in the narrow strip channels while filling the narrow strip channel excavating region. The mechanical cementing, filling and milling method for the coal mining, disclosed by the invention, is beneficial to sufficiently developing underground coal resources, protecting the ecological environment and ground vegetation, releasing a large number of dull coal and prolonging the service life of a mine, and has remarkable economic benefits and social benefits.

Owner:内蒙古晨德建设工程有限公司

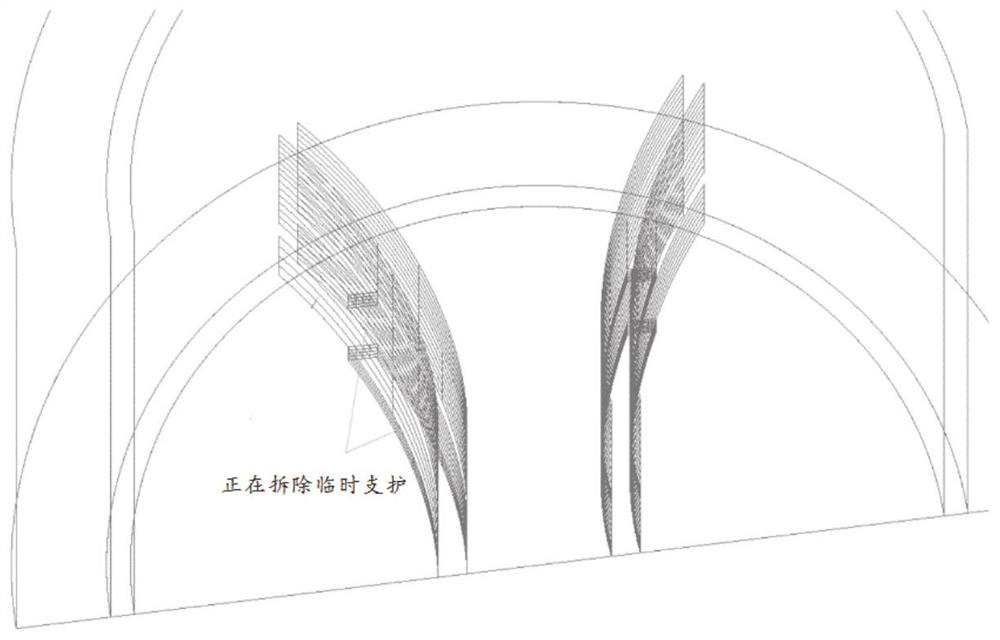

Tunnel construction method

PendingCN113417664AShorten the lengthReasonable forceUnderground chambersTunnel liningArchitectural engineeringTunnel construction

The invention relates to a tunnel construction method. The tunnel construction method comprises the following steps that excavation construction is conducted on the part above an inverted arch of a tunnel through a double-side-wall pilot tunnel construction method; after the part above the inverted arch of the tunnel is excavated to a set safe distance, a temporary support is dismantled; after the temporary support is dismantled by a set distance, the inverted arch part of the tunnel starts to be constructed; and excavation construction of the part above the inverted arch of the tunnel, dismantling of the temporary support and construction of the inverted arch part are synchronously conducted until the construction of the tunnel is completed. According to the construction method, a transverse support does not need to be arranged, so that the operation space is increased; and the temporary support is not prone to breakage, so that the construction safety is guaranteed, and the safety is better than that of a traditional method.

Owner:中铁十四局集团第三工程有限公司 +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com