High rigidity and light space camera lens cylinder and test method for vibration resistance stability thereof

A space camera, high stiffness technology, applied in the field of support between the primary mirror and secondary mirror of space high-resolution cameras, high stiffness and lightweight space camera lens barrels, can solve the problems of poor stability of resin-based composite materials, and reach the market Broad application prospects, improved stability and strong versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to make the solution of the present invention clearer, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

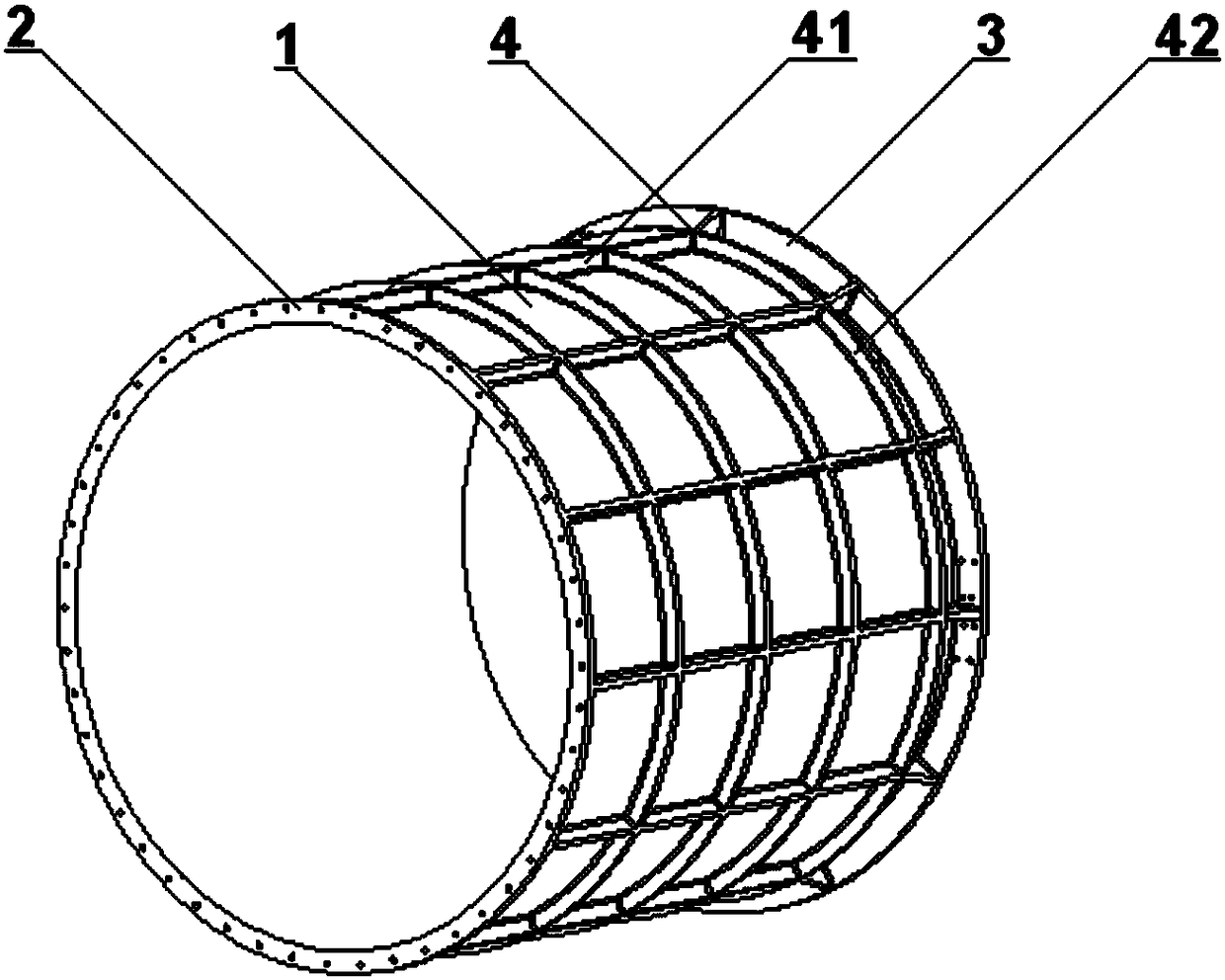

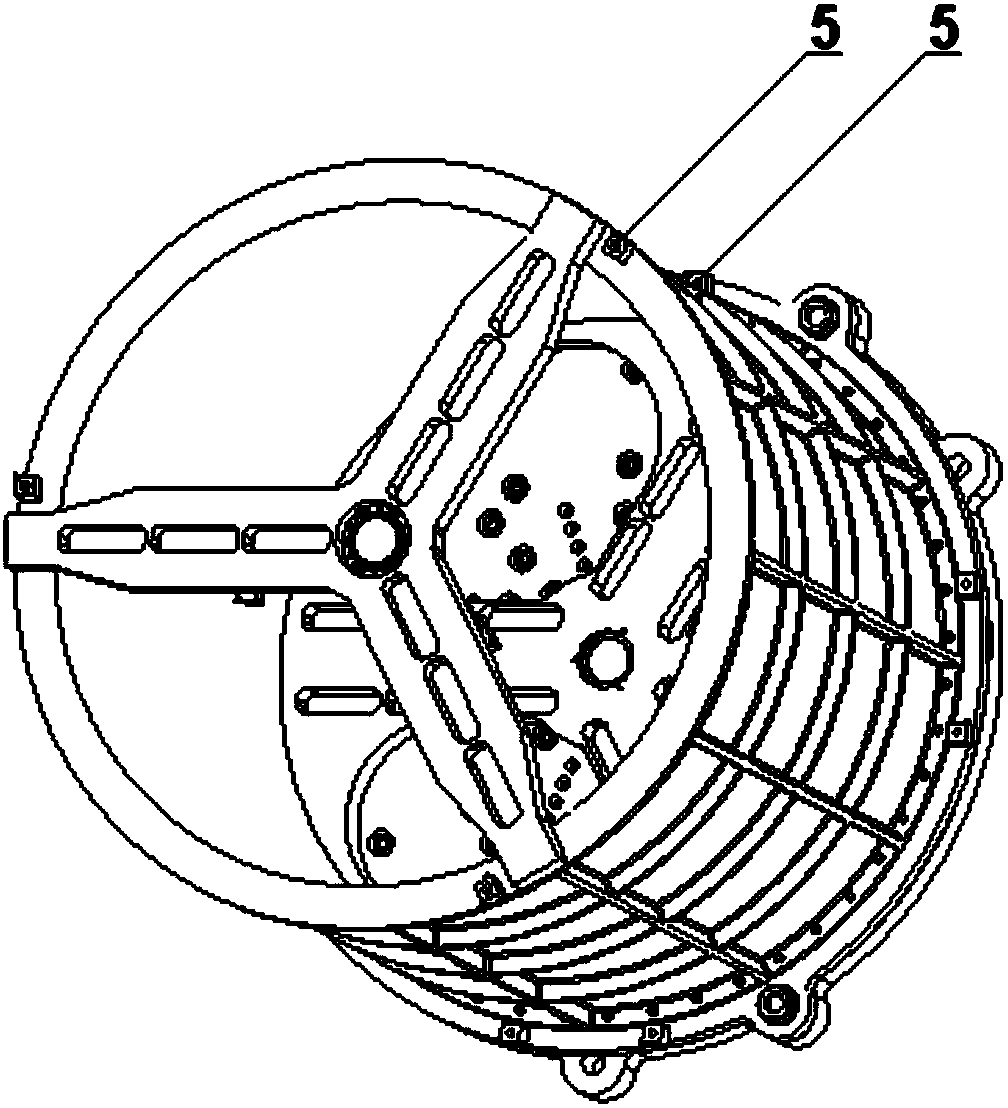

[0030] Such as figure 1 As shown, a high-rigidity light-weight space camera lens barrel includes a barrel body 1, a primary mirror flange 2, a secondary mirror flange 3 and a reinforcing rib 4; the barrel body 1 is a hollow cylinder, and one end of the barrel body 1 is provided with a The main mirror flange 2 of the main mirror of the space camera and the other end of the cylinder body 1 are provided with a secondary mirror flange 3 for connecting the secondary mirror of the space camera, and the outside of the cylinder body 1 is provided with reinforcing ribs 4 for reinforcing the structure. The primary mirror flange 2, the secondary mirror flange 3 and the rib 4 are integrally formed by three-dimensional braiding of silicon carbide.

[0031] Preferably, the ratio of the inner di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com