Method for building middle-thickness coal-bed gob-side entry roadside support body supported by gangue

A technology of thick coal seam and support body, which is applied in the directions of earthwork drilling, filling, safety devices, etc., can solve the problems of closed goaf, prevent insufficient air leakage, etc., to reduce the deformation of the roadway, the process is simple, and easy to master Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

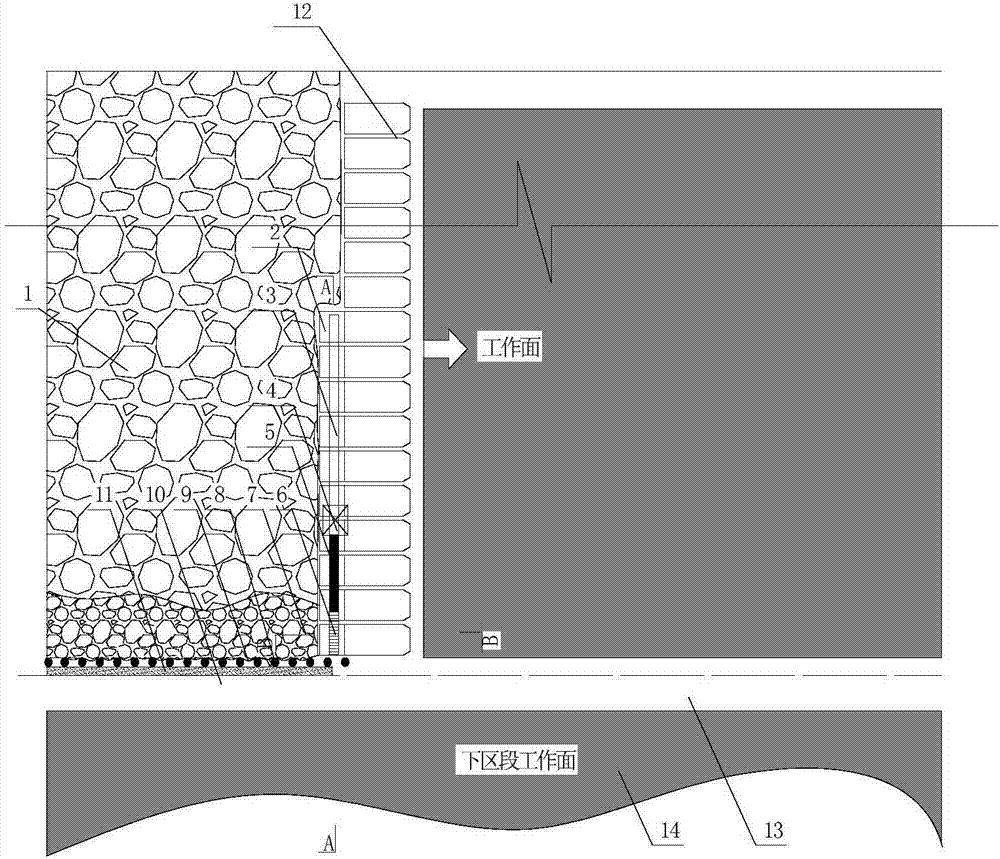

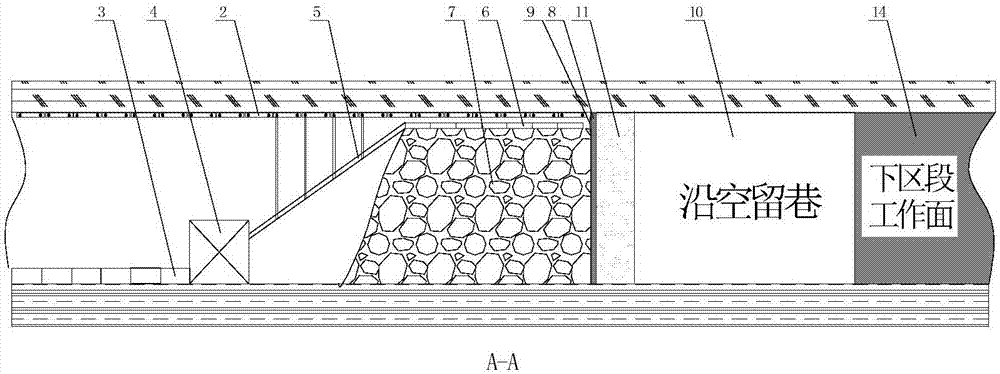

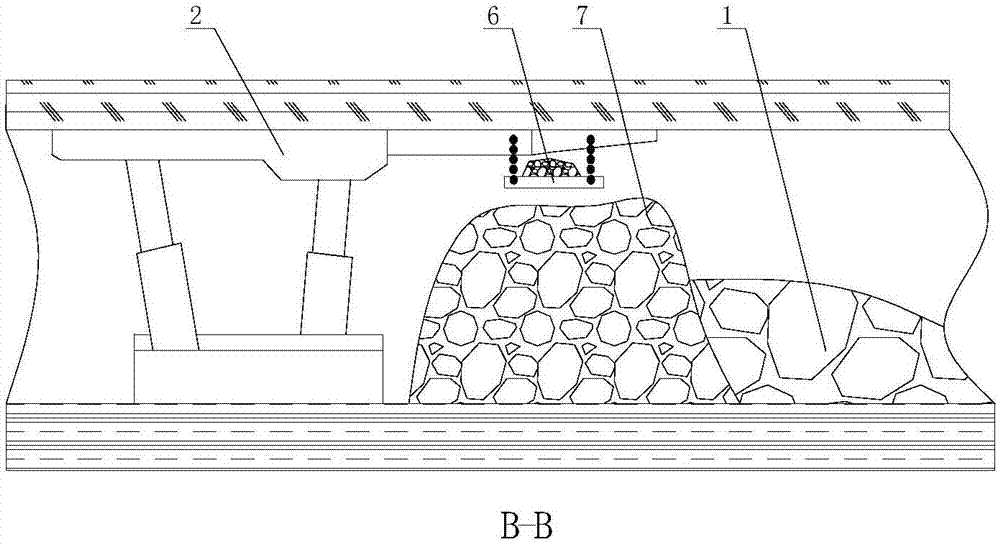

[0022] The present invention will be further described below in conjunction with the embodiment in the accompanying drawings:

[0023] The method for constructing the side support body of the medium-thick coal seam gobside retaining roadway supported by gangue of the present invention, the specific steps are as follows:

[0024] a. When excavating the wide roadway 13 of the first working face, the width of the roadway reused by the adjacent working face 14 is 0.5-1.0m wider, and the anchor net cable is used for support;

[0025] b. Change all or part of the support of the working face to the support of the long tail beam for caving coal, and arrange scraper conveyors, reloading crushers, belt conveyors and lifting conveyors under the support of the long tail beam for caving coal; During mining, the gangue falling from the back of the working face of the caving long tail beam support is transported to the reloading crusher through the scraper conveyor, and after being crushed, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com