Patents

Literature

4881results about How to "Reduce breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

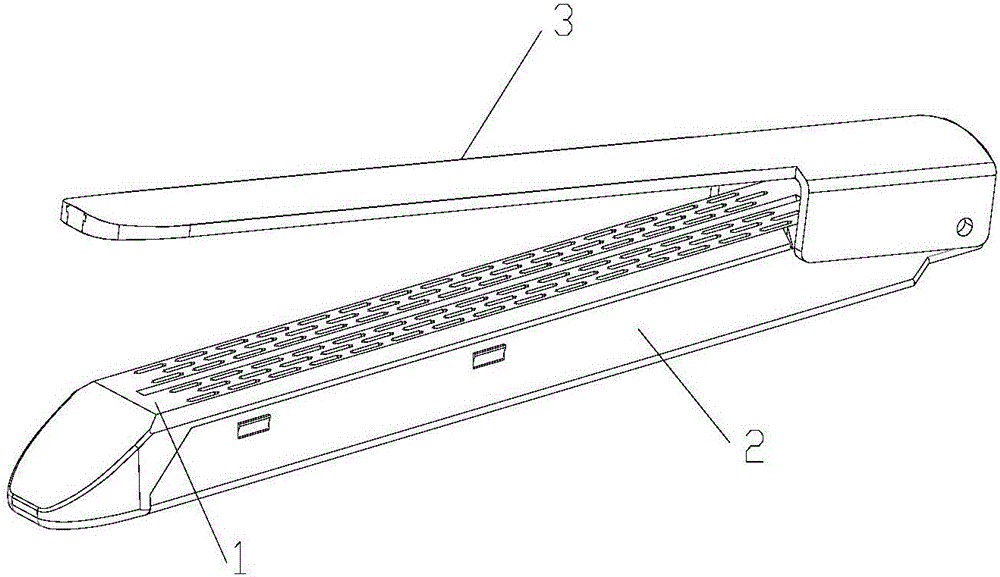

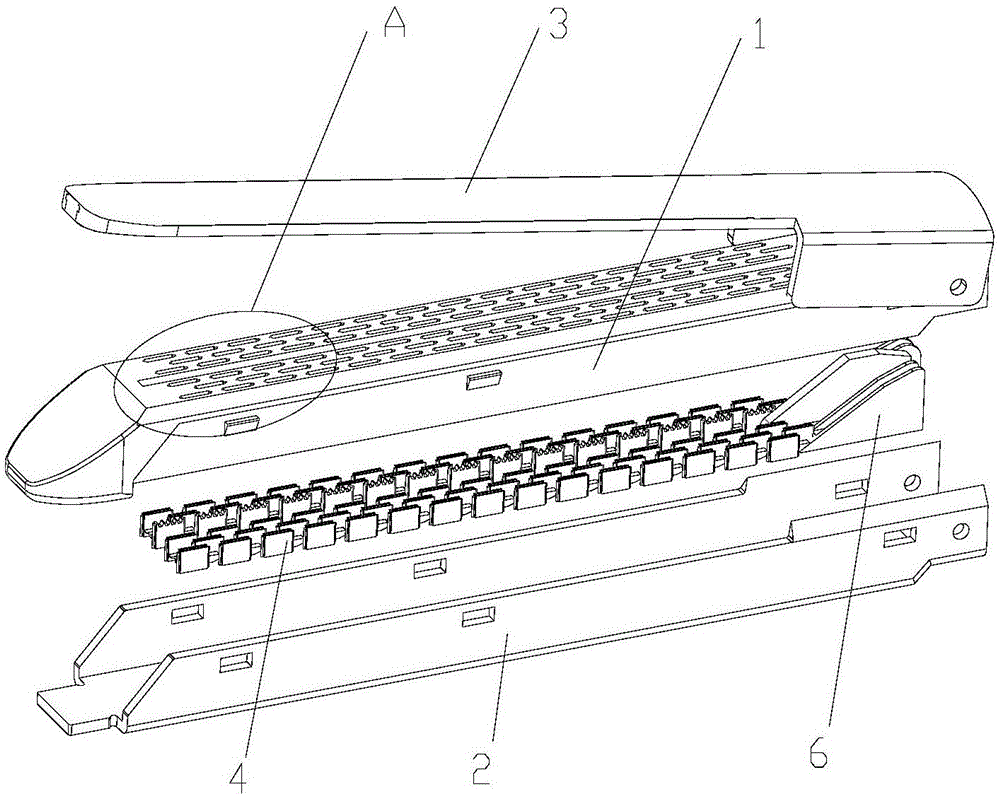

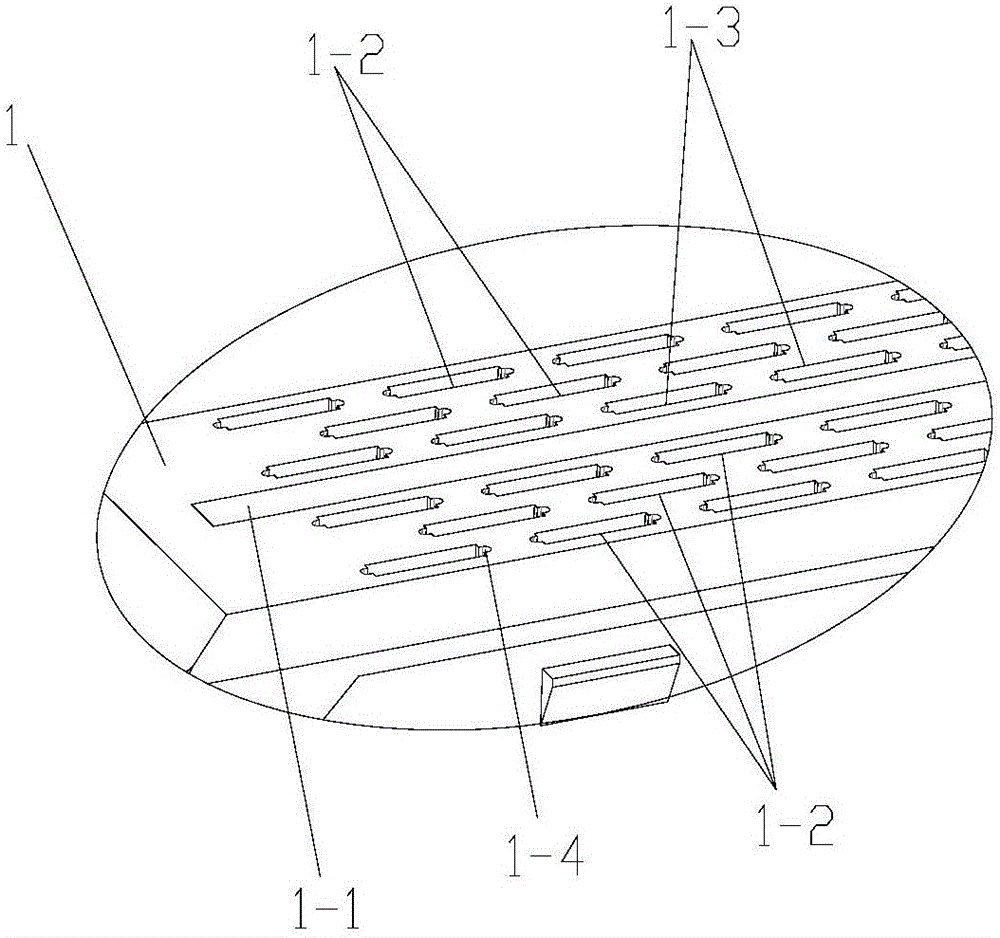

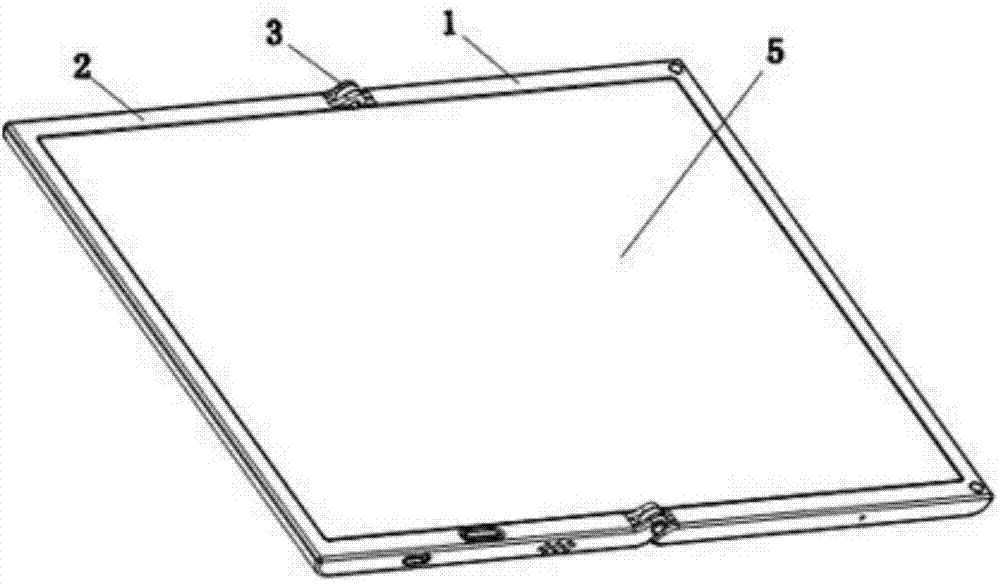

Staple cartridge assembly of disposable intracavity cutting and edge incising anastomat

ActiveCN106344091ARealize compression and fixationEnsure stabilityIncision instrumentsSurgical staplesEngineeringBlood vessel

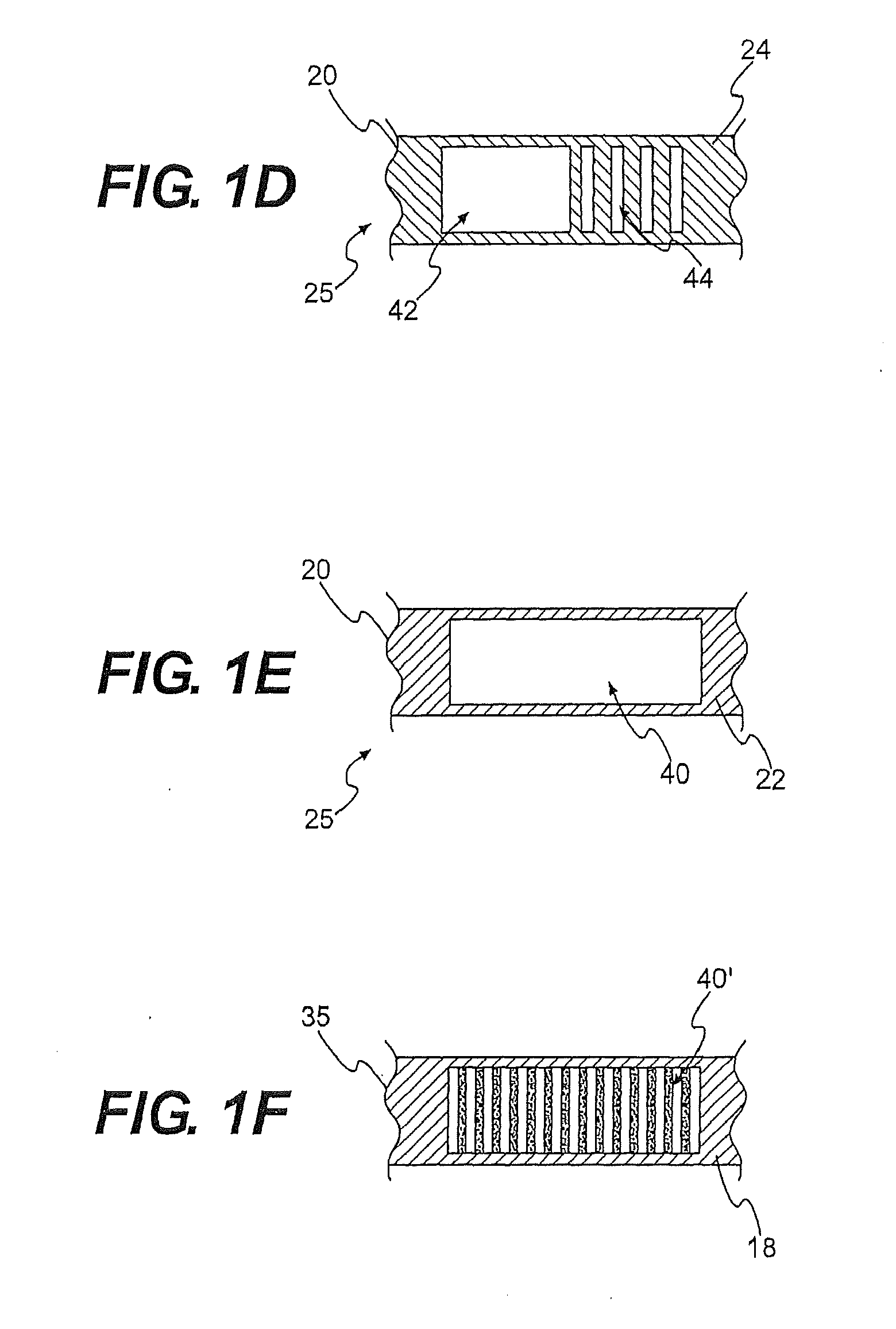

The invention provides a staple cartridge assembly of a disposable intracavity cutting and edge incising anastomat. The staple cartridge assembly comprises a staple cartridge, a staple cartridge base and a staple butting plate, wherein the staple cartridge is arranged in the staple cartridge base, a cutting slot is formed in the middle of the staple cartridge, multiple rows of suturing staple slots are formed in two sides of the cutting slot in the staple cartridge, staple pushing piece groups corresponding to the suturing staple slots are arranged in the staple cartridge seat below the staple cartridge, tissue pressing block slots are further formed in the staple cartridge on one side of the cutting slot and are located on the staple cartridge between one row of suturing staple slots on the innermost layer and the cutting slot, tissue pressing structures are arranged on the staple pushing piece groups and / or staple butting plate corresponding to the tissue pressing block slots, and the tissue pressing structures are tissue pressing blocks at certain heights. With the adoption of the tissue pressing structures, pathological frozen sections after an operation can be made while complete tissue is reserved, the stability of the tissue during the operation can also be guaranteed, blood vessel breakage is reduced, and the operation risk is reduced.

Owner:PRECISION CHANGZHOU MEDICAL INSTR

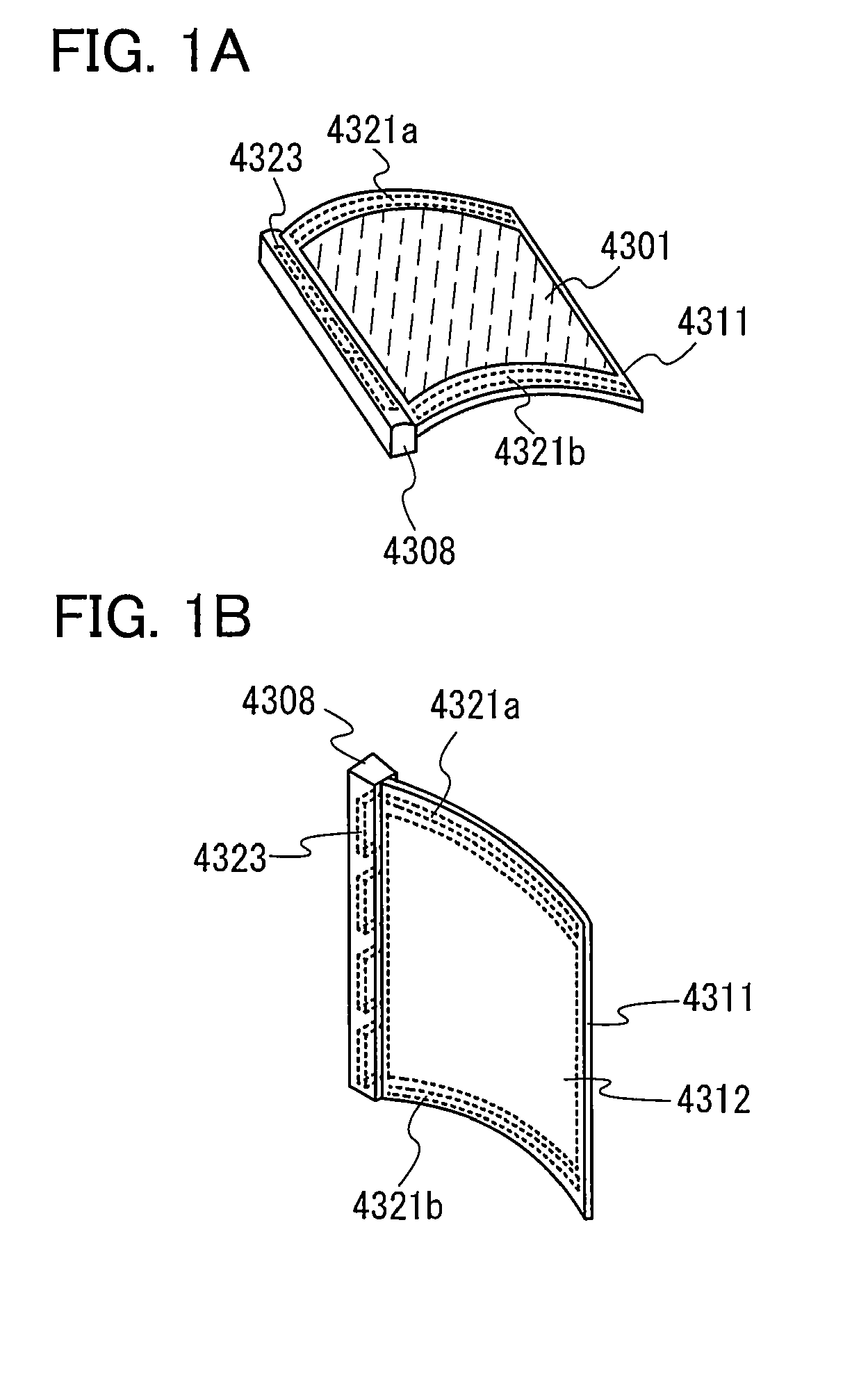

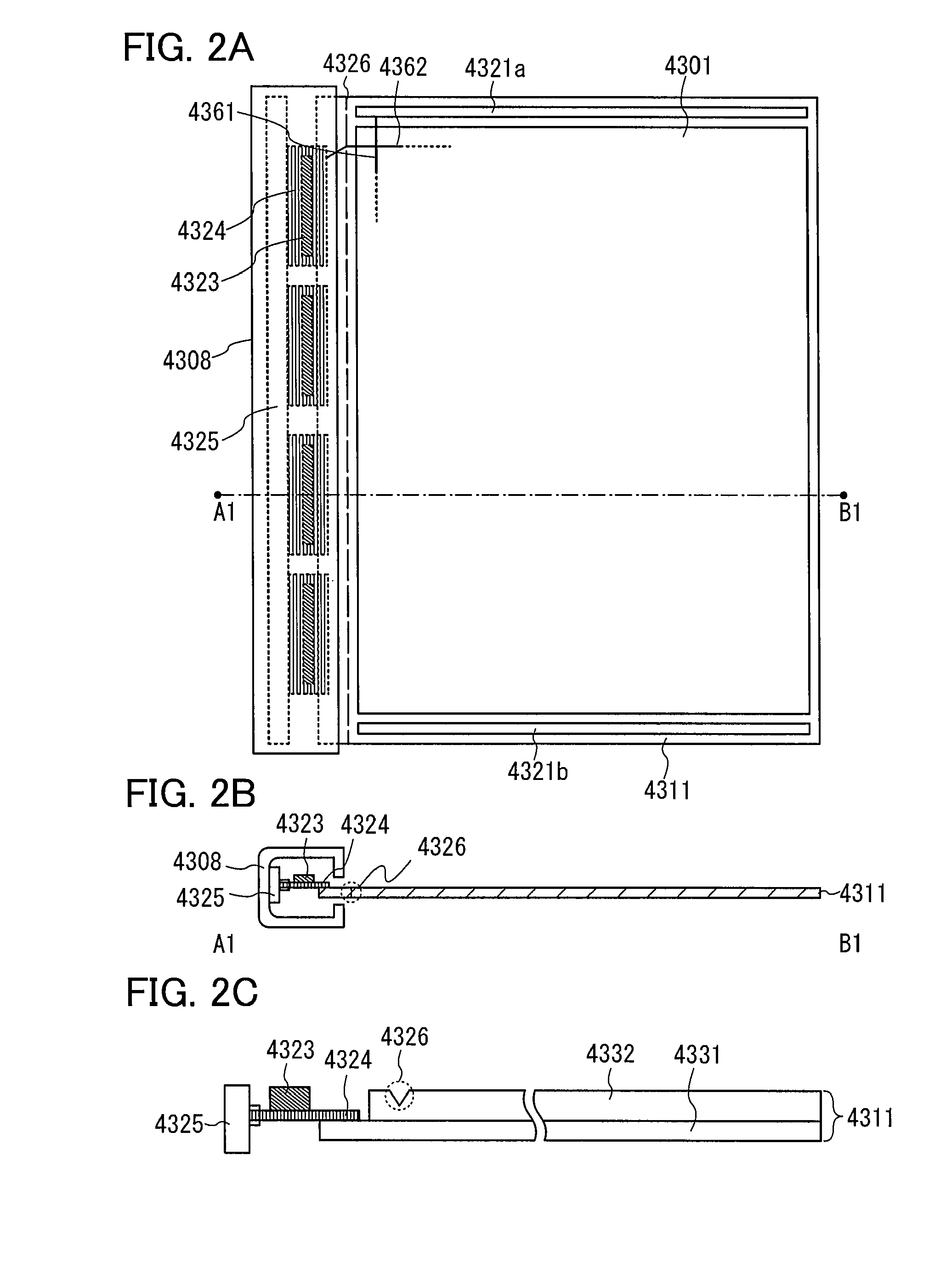

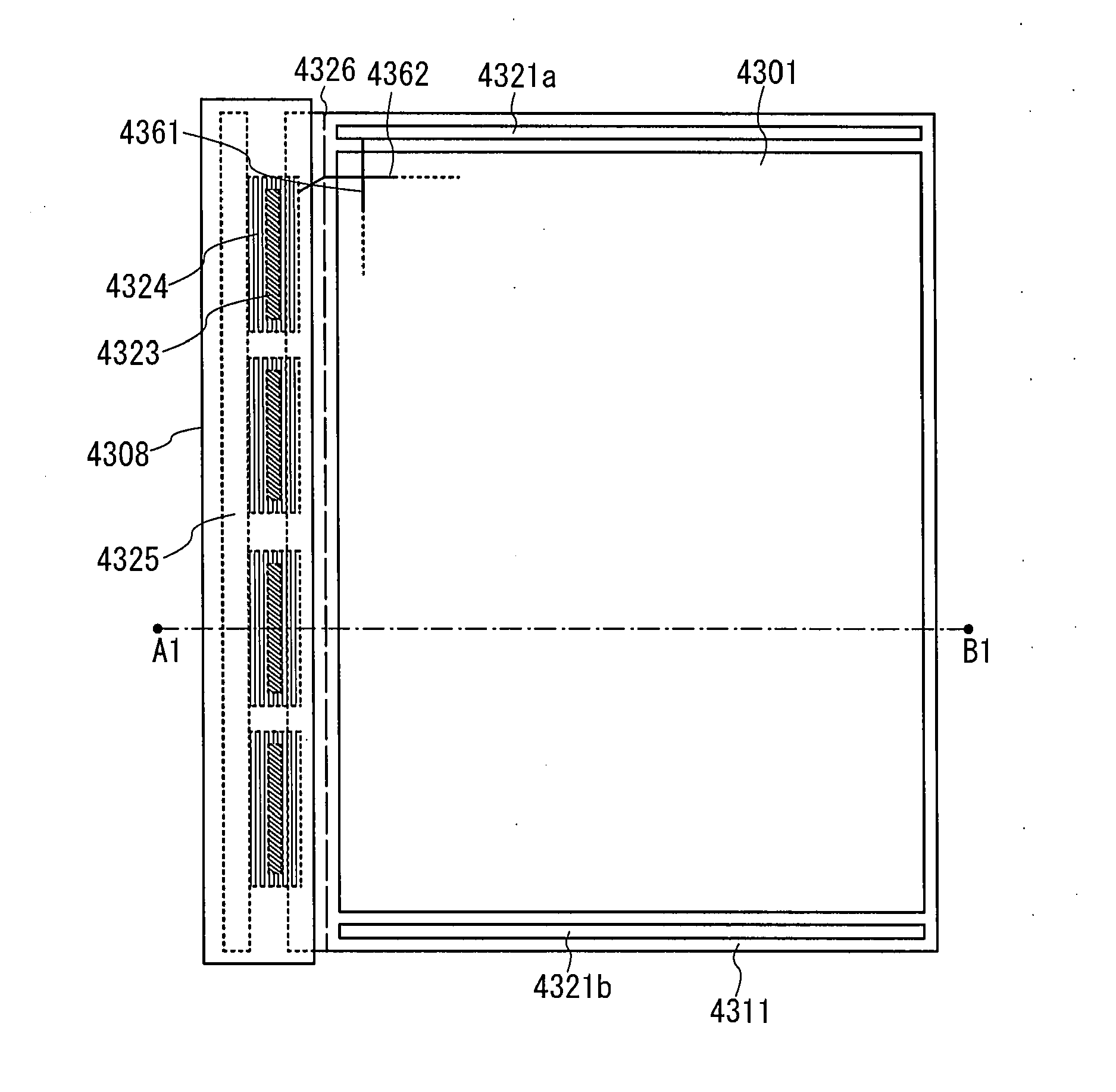

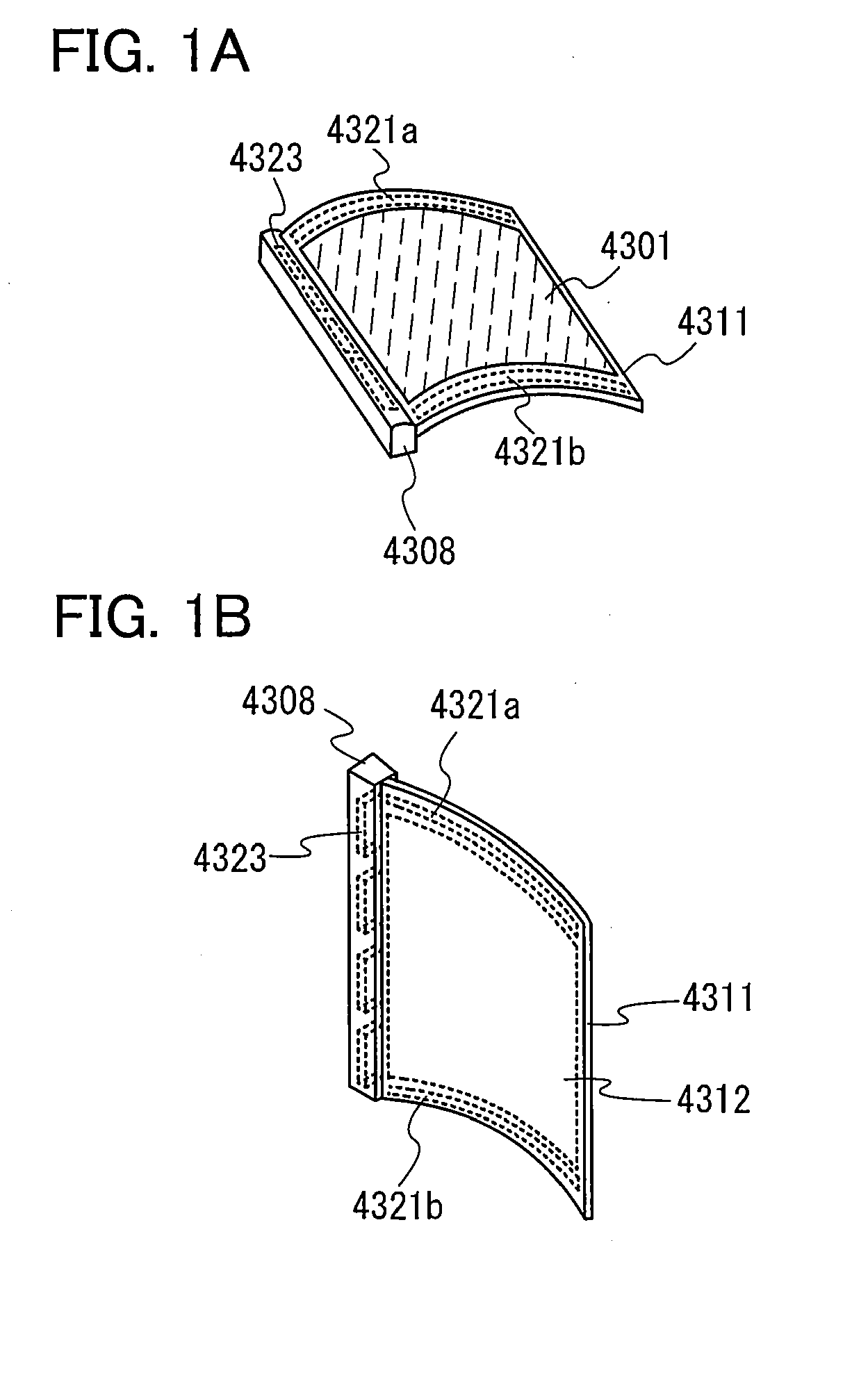

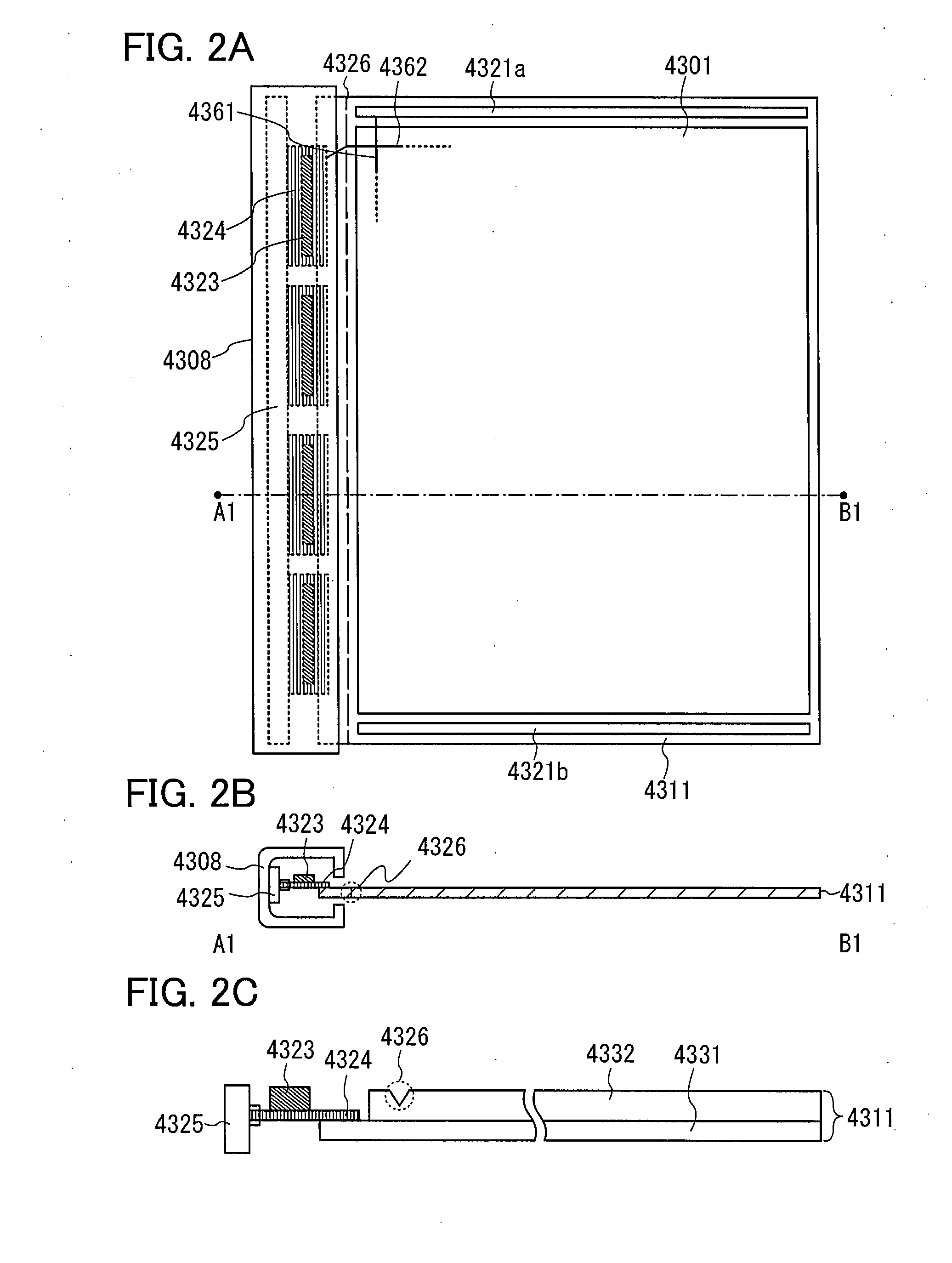

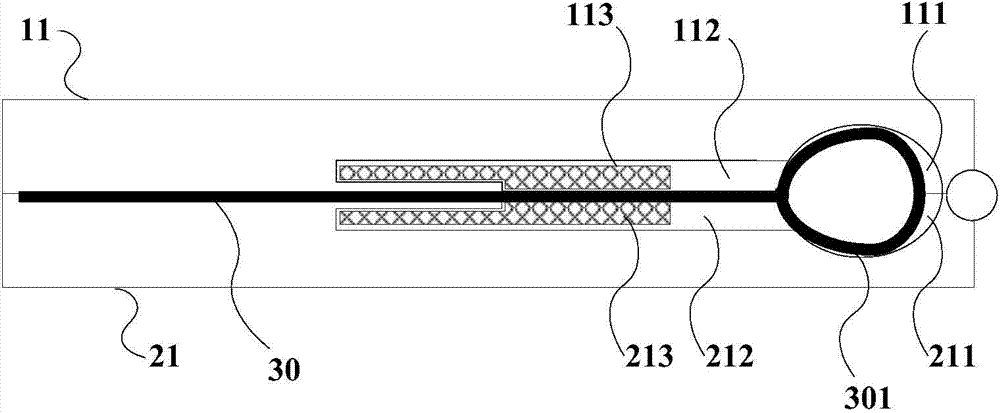

Display device

ActiveUS8319725B2Simple structureReduce breakagePrinted circuit aspectsSolid-state devicesDriver circuitDisplay device

The display device includes: a flexible display panel including a display portion in which scanning lines and signal lines cross each other; a supporting portion for supporting an end portion of the flexible display panel; a signal line driver circuit for outputting a signal to the signal line, which is provided for the supporting portion; and a scanning line driver circuit for outputting a signal to the scanning line, which is provided for a flexible surface of the display panel in a direction which is perpendicular or substantially perpendicular to the supporting portion.

Owner:SEMICON ENERGY LAB CO LTD

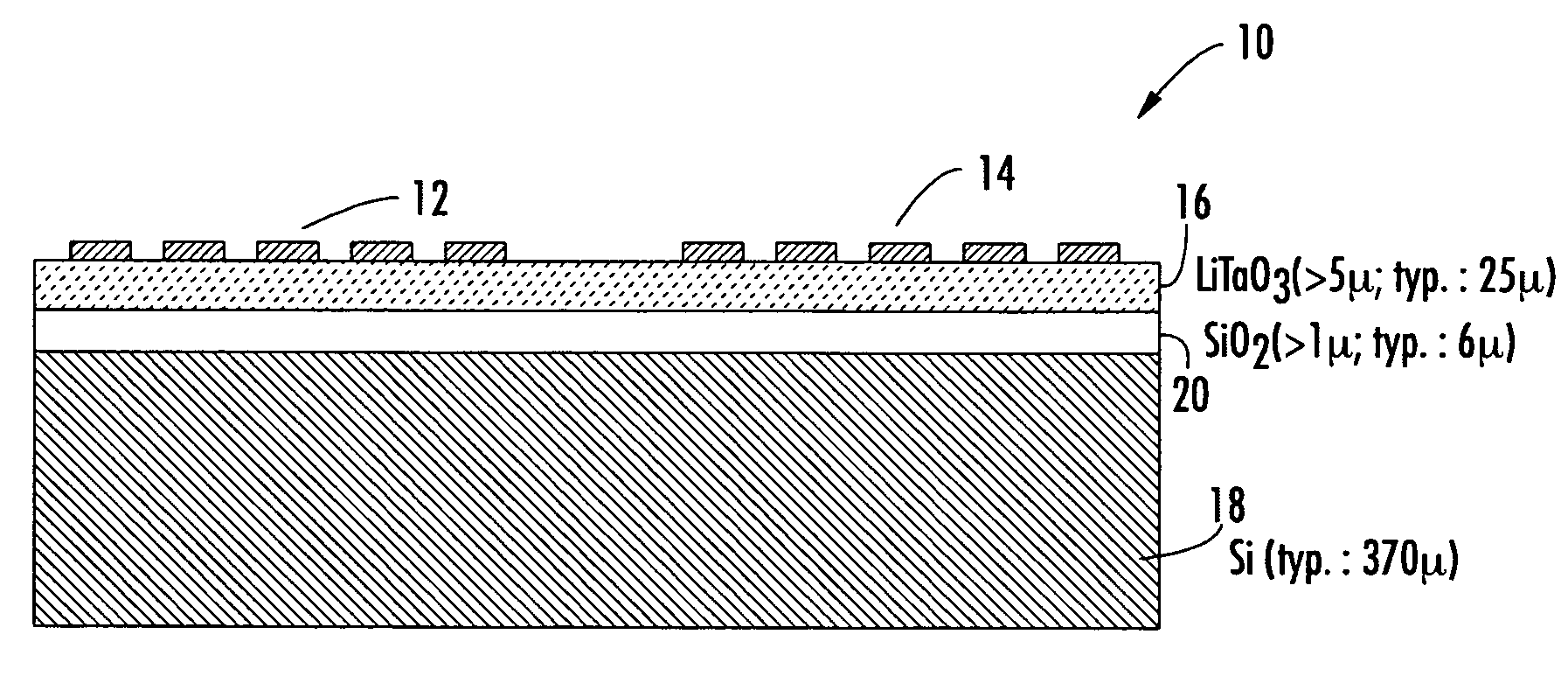

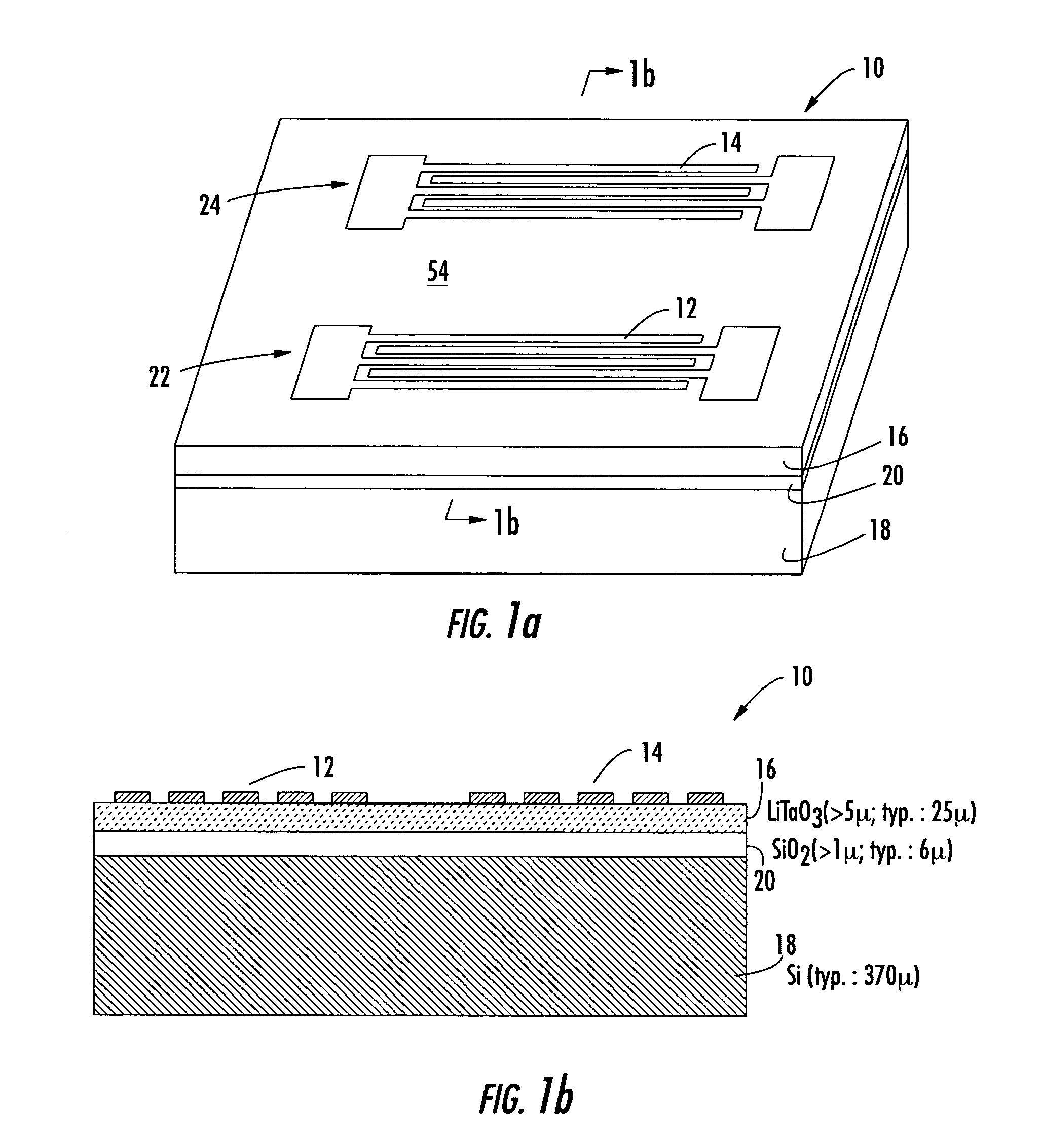

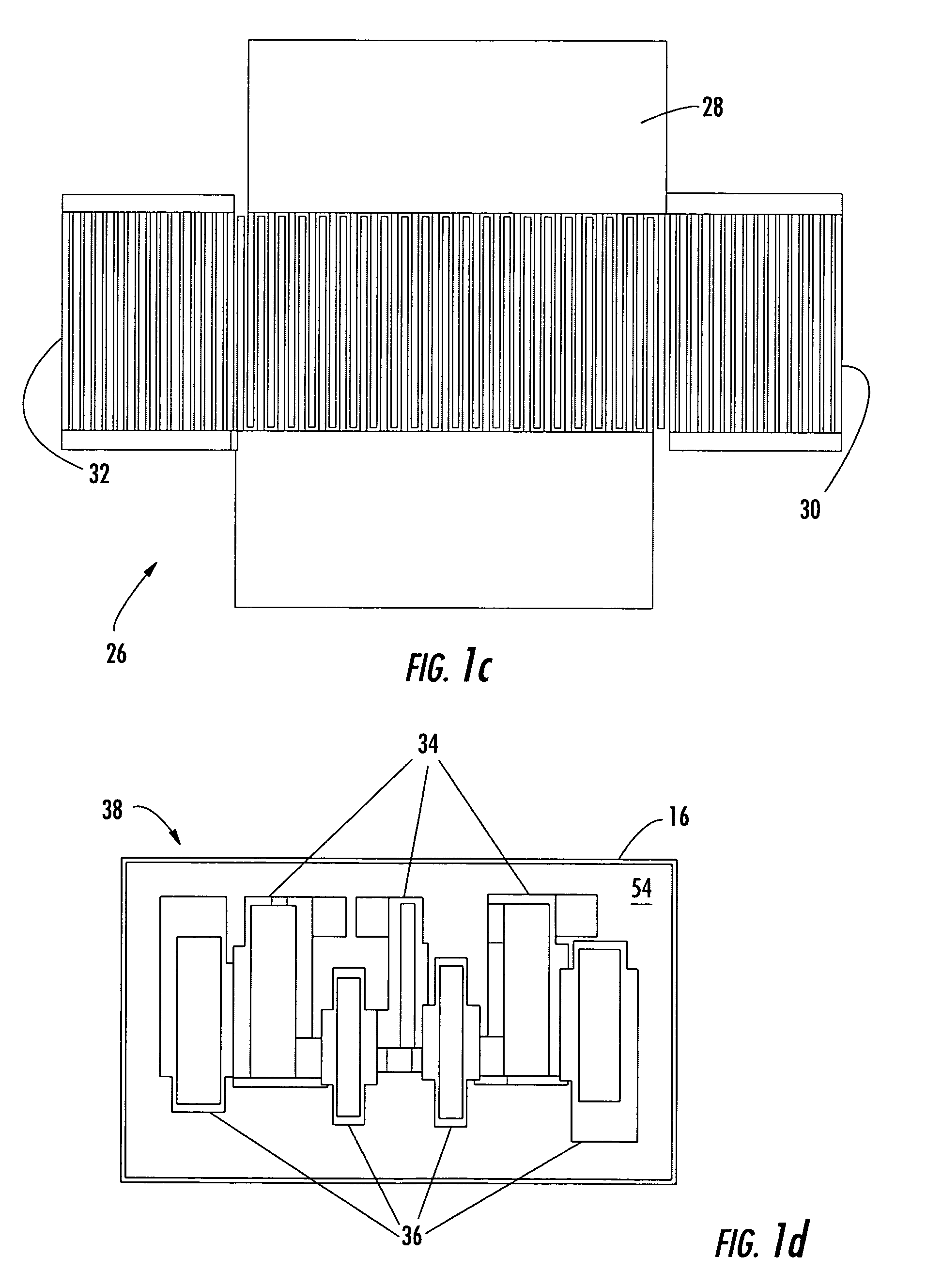

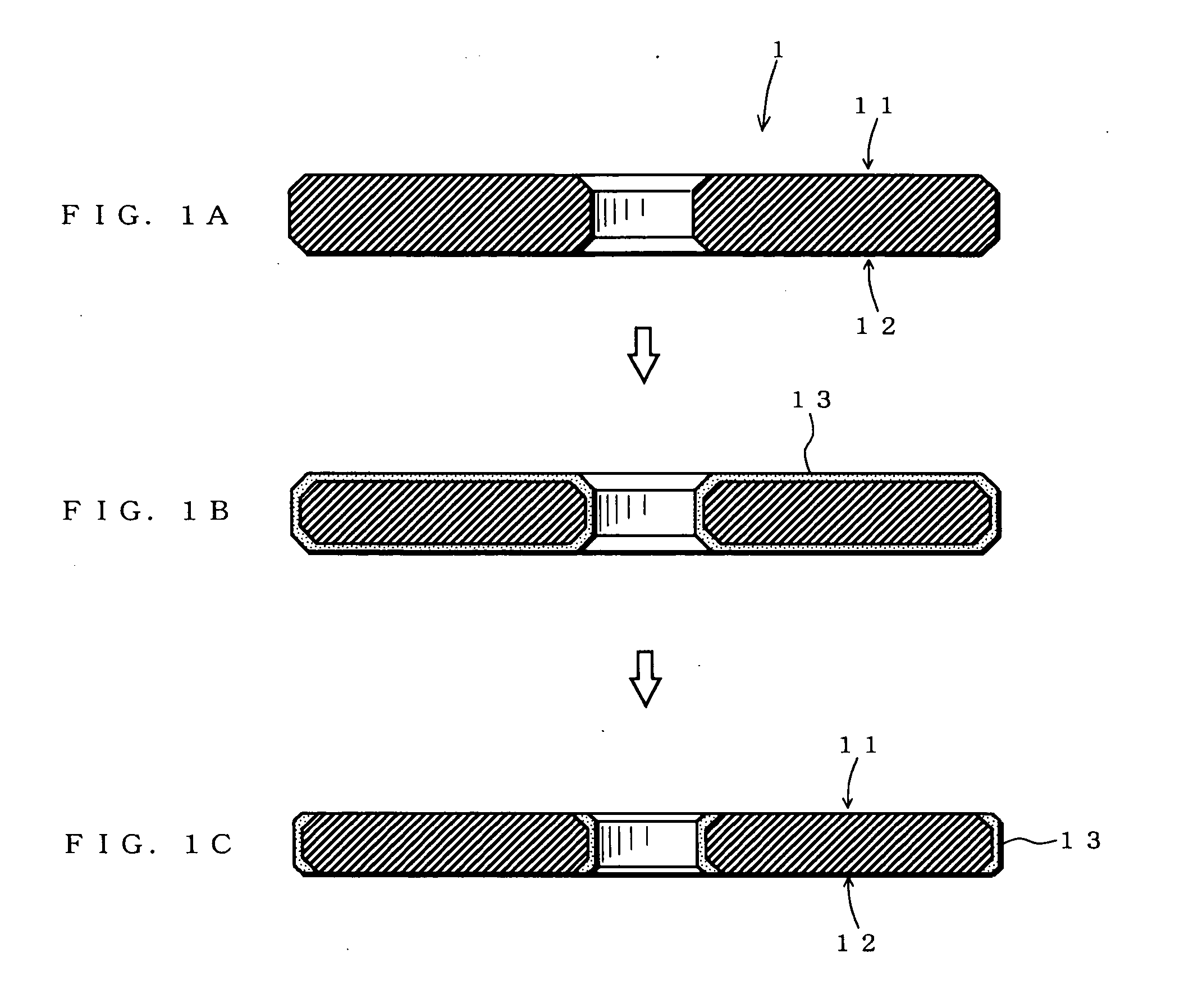

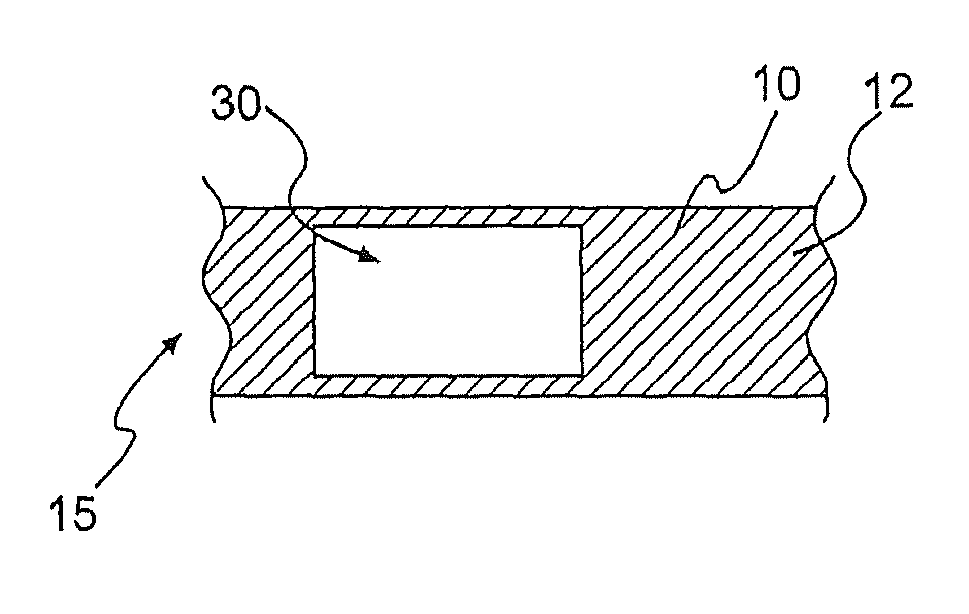

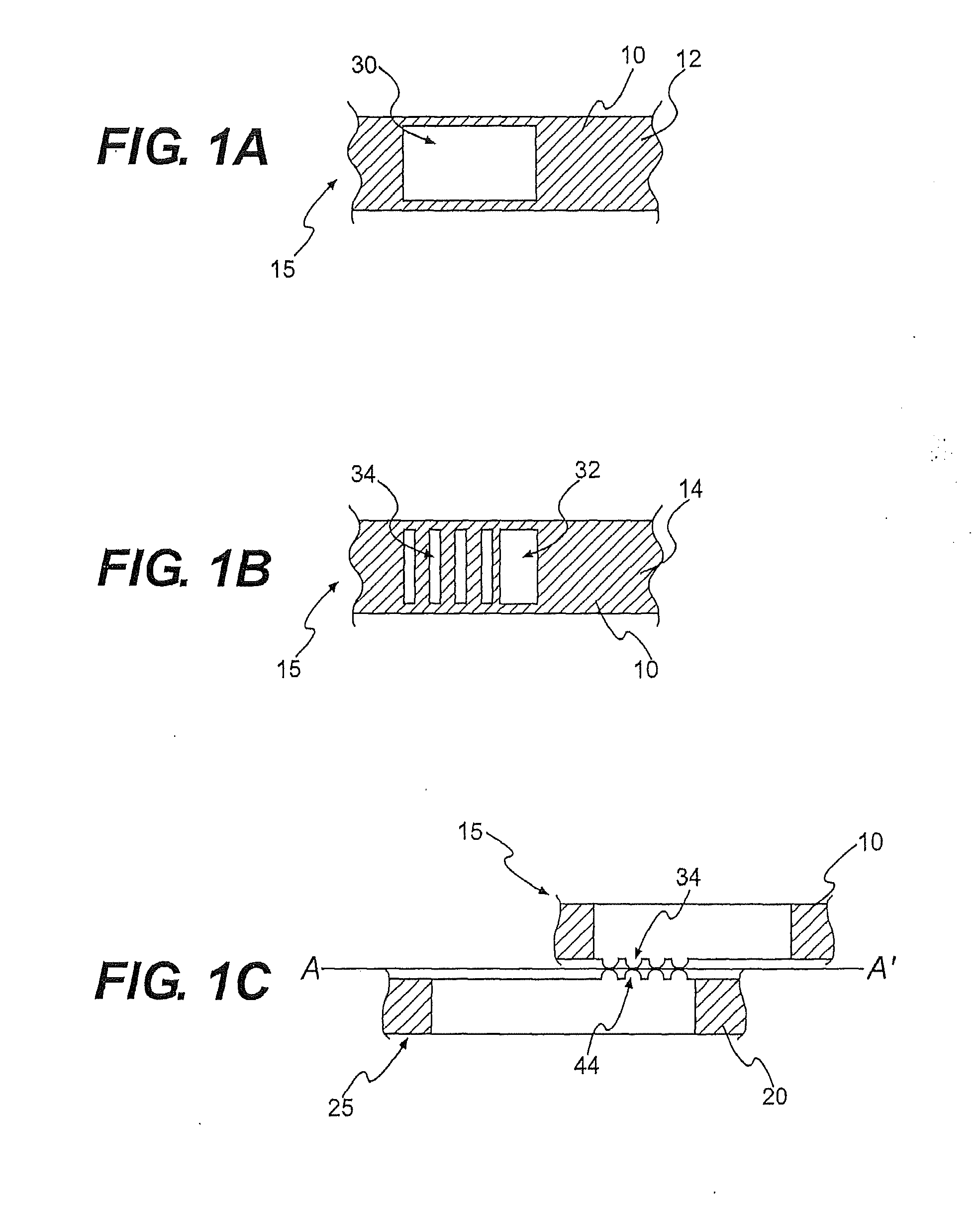

Saw filter device and method employing normal temperature bonding for producing desirable filter production and performance characteristics

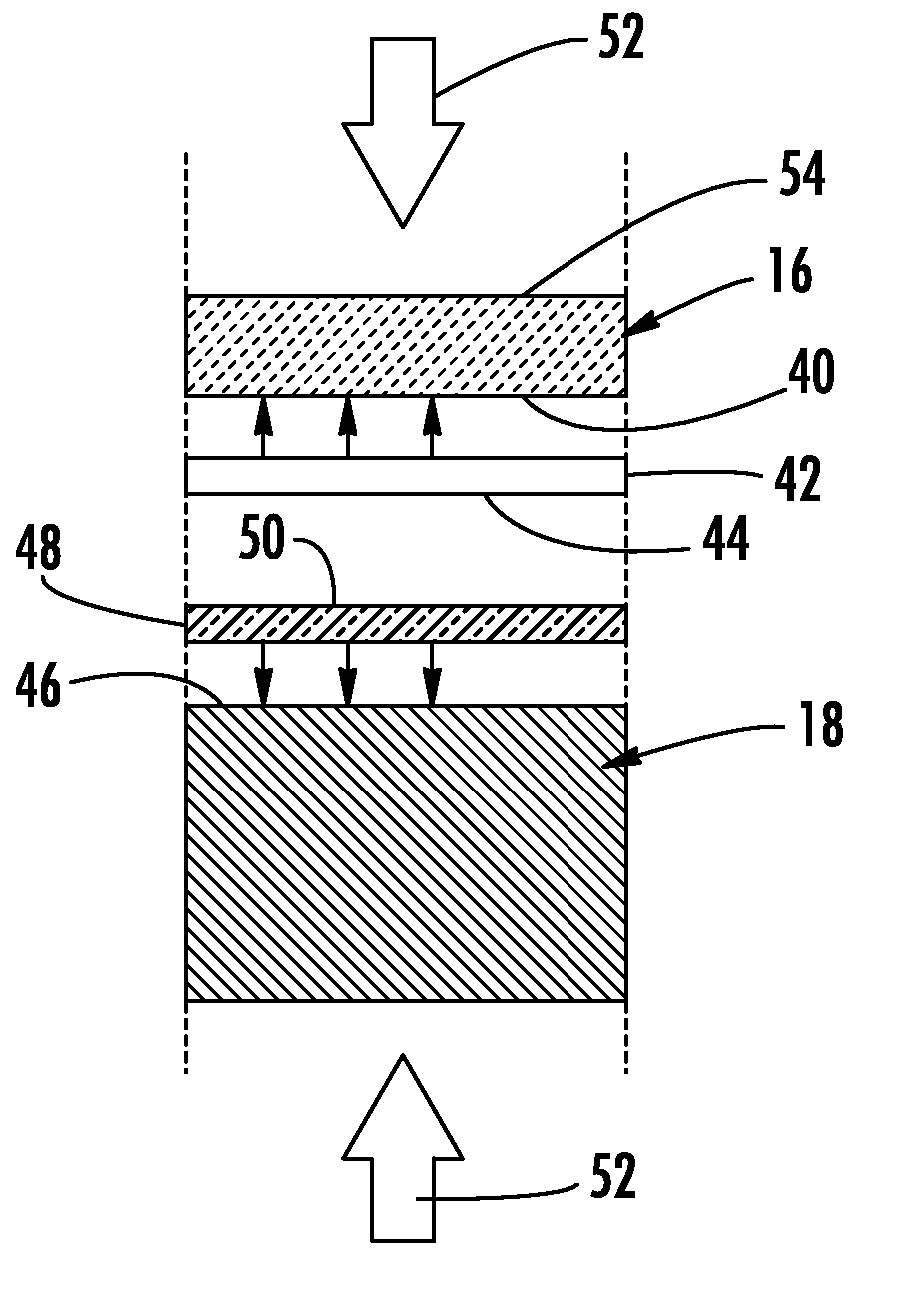

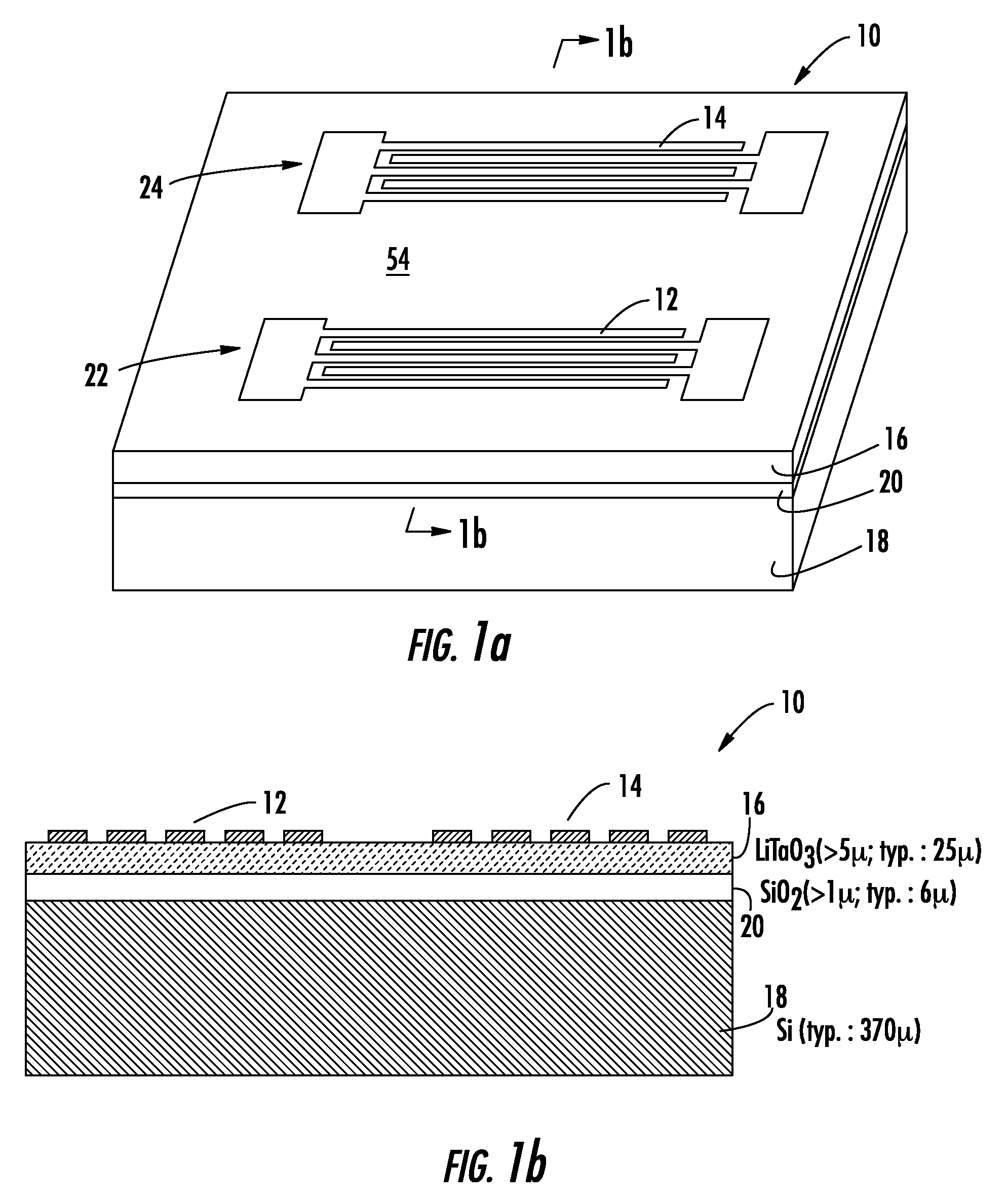

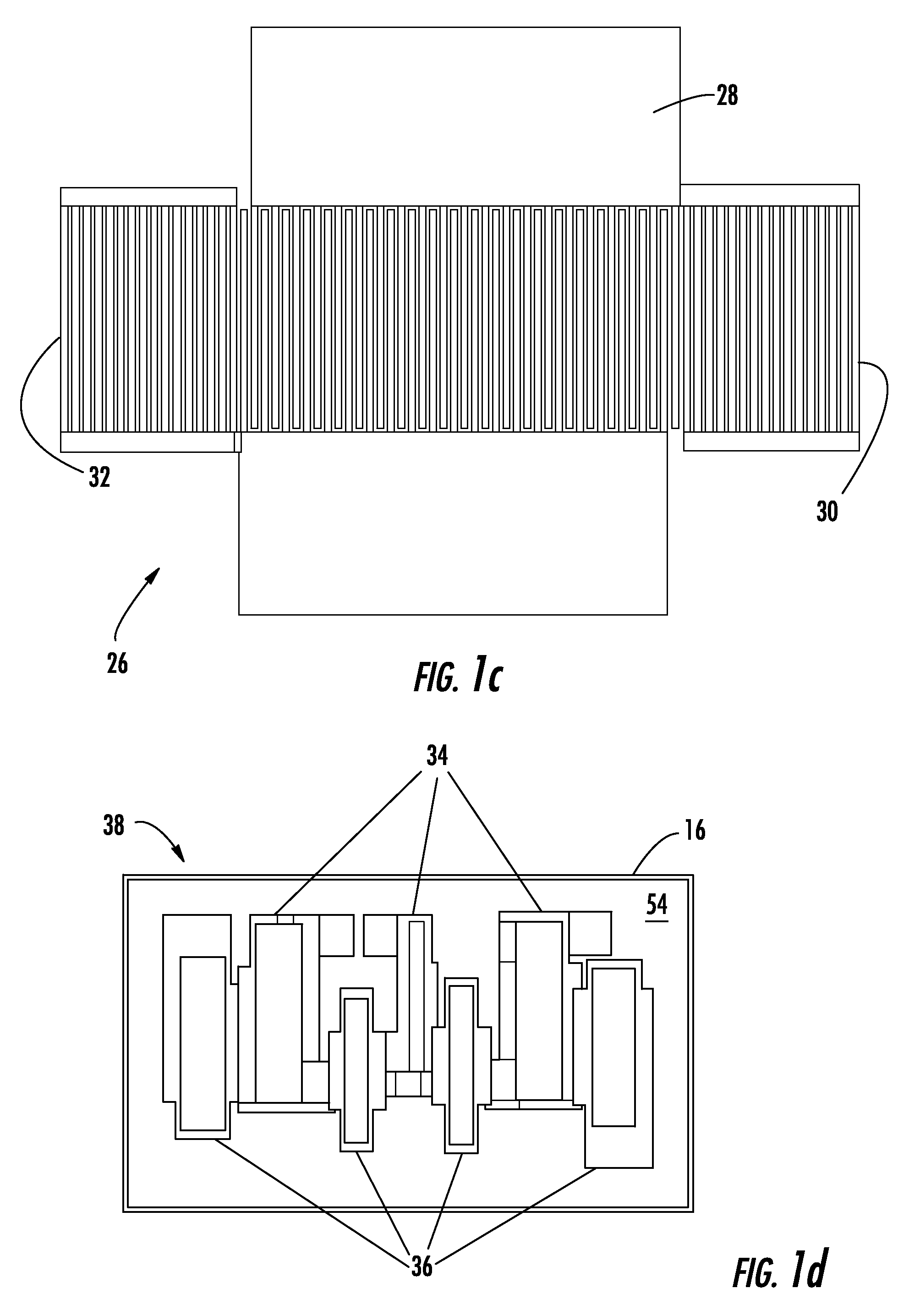

ActiveUS7105980B2Improve reliabilityReduce heat sensitivityImpedence networksPiezoelectric/electrostriction/magnetostriction machinesLength waveSilicon

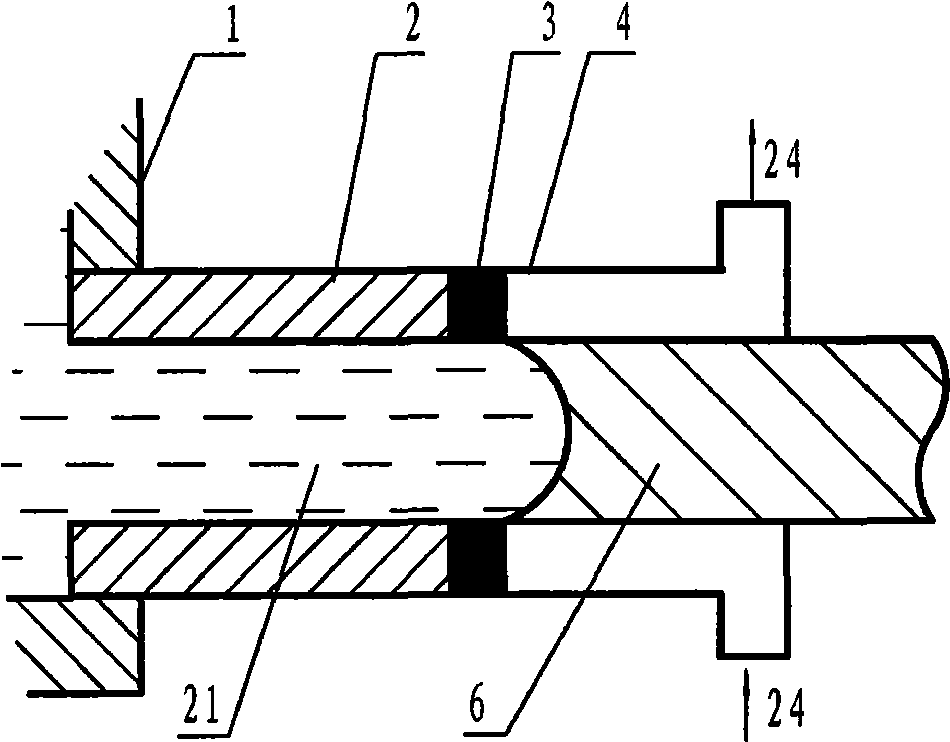

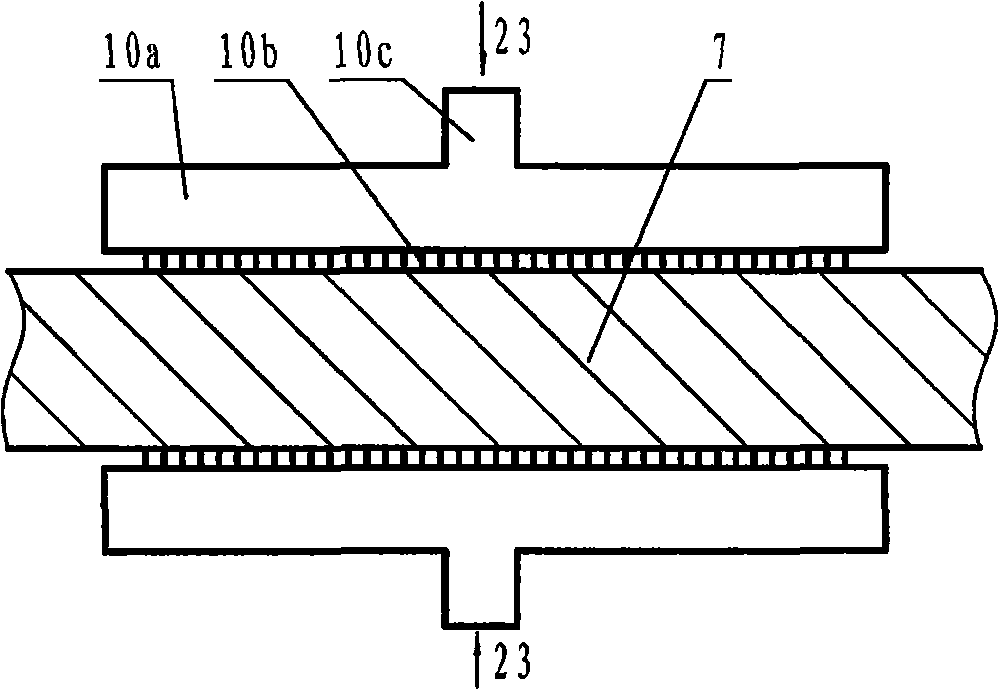

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

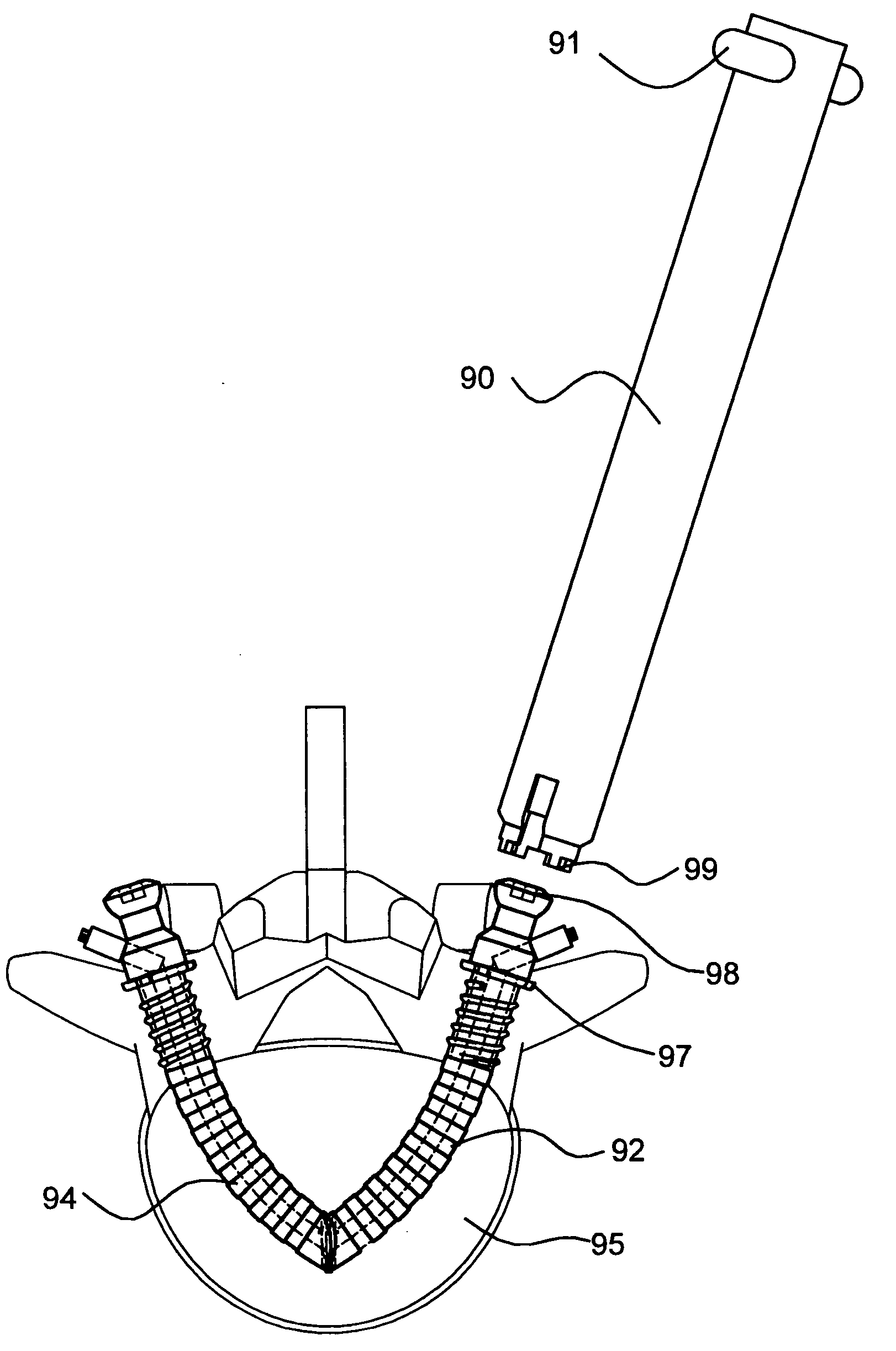

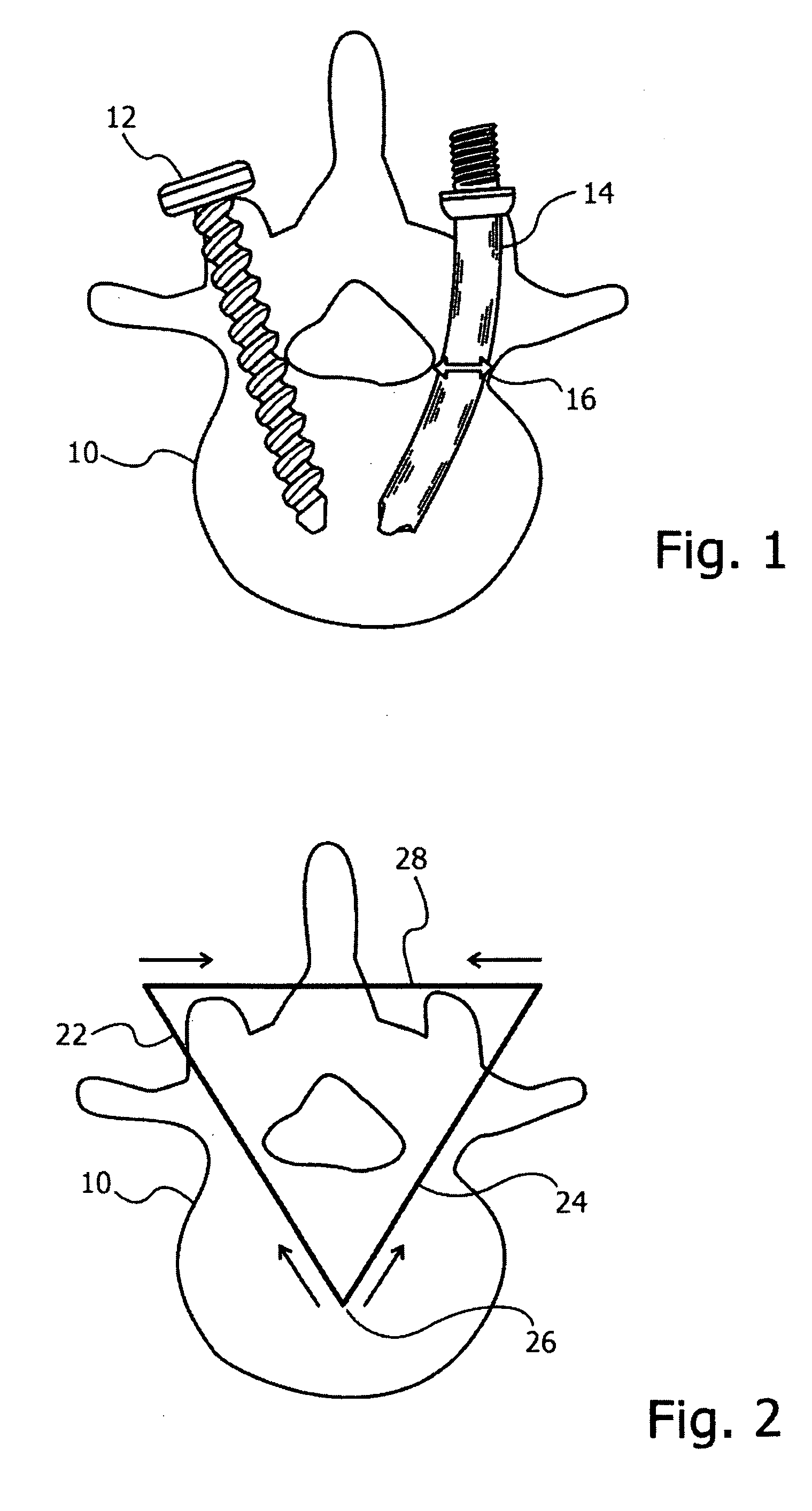

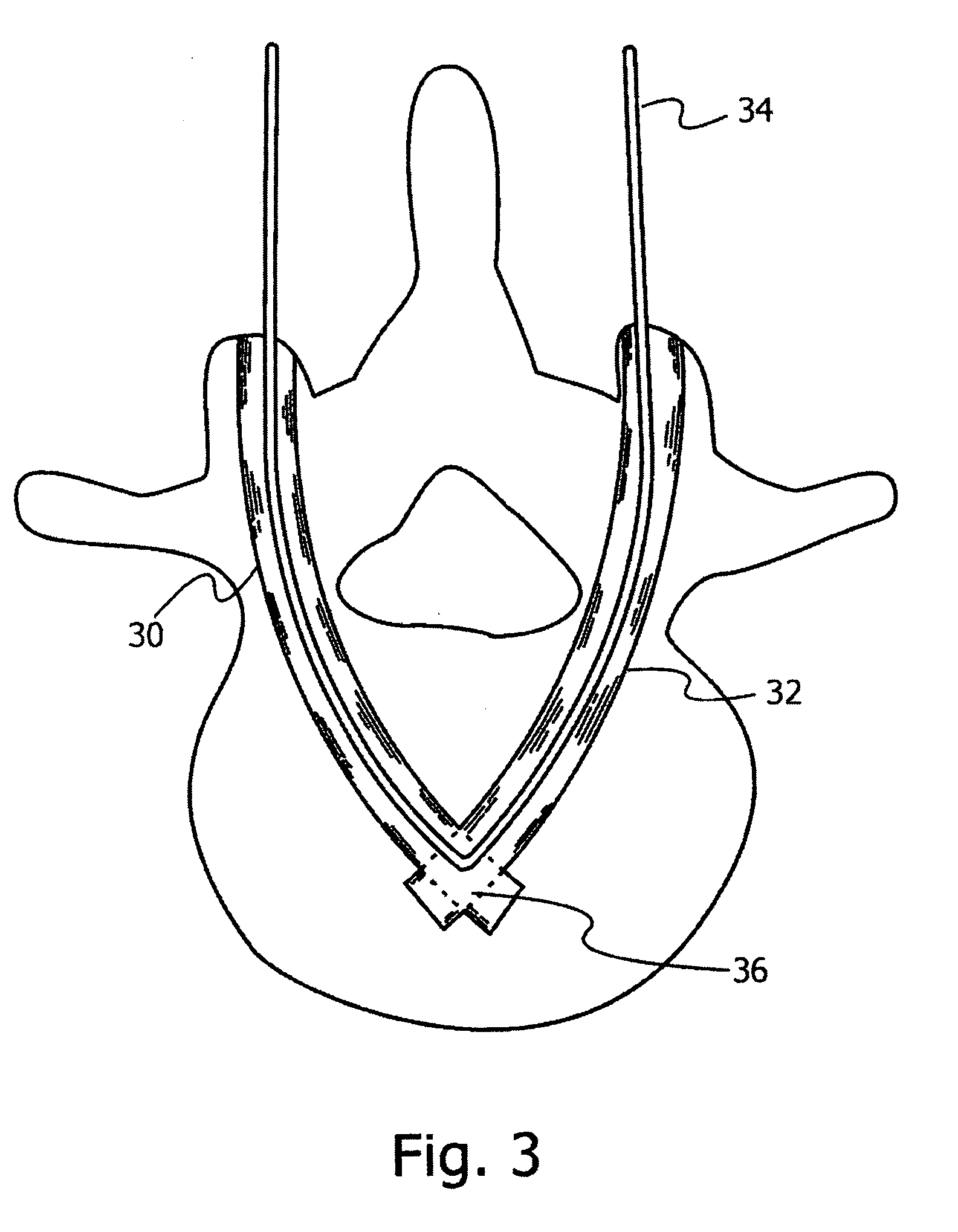

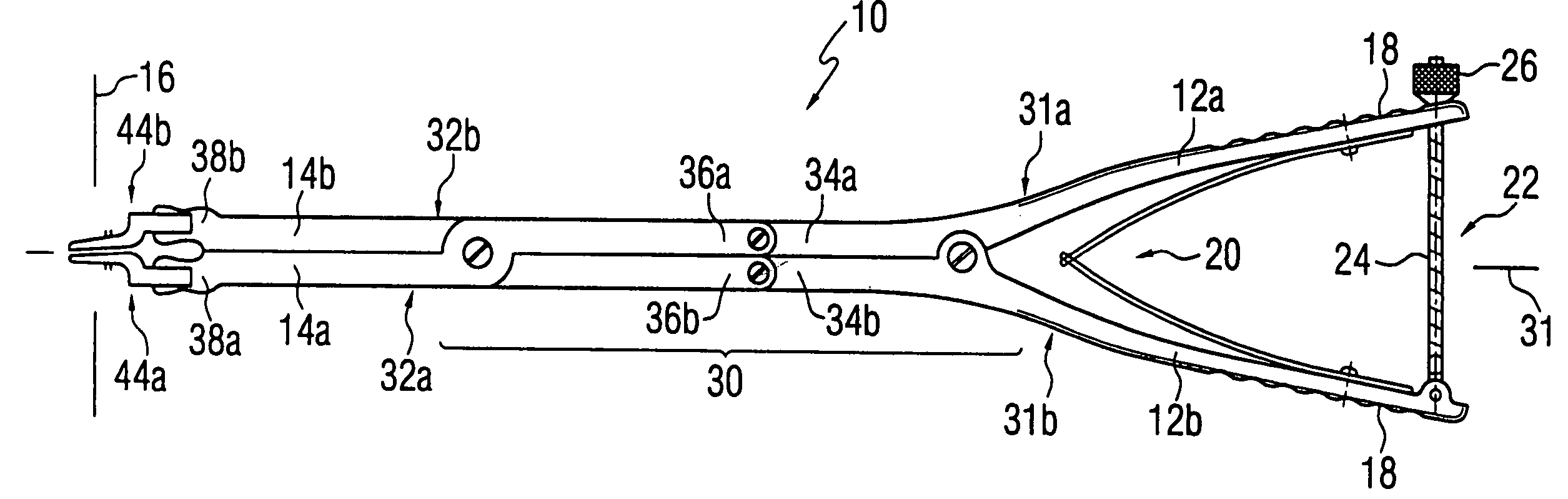

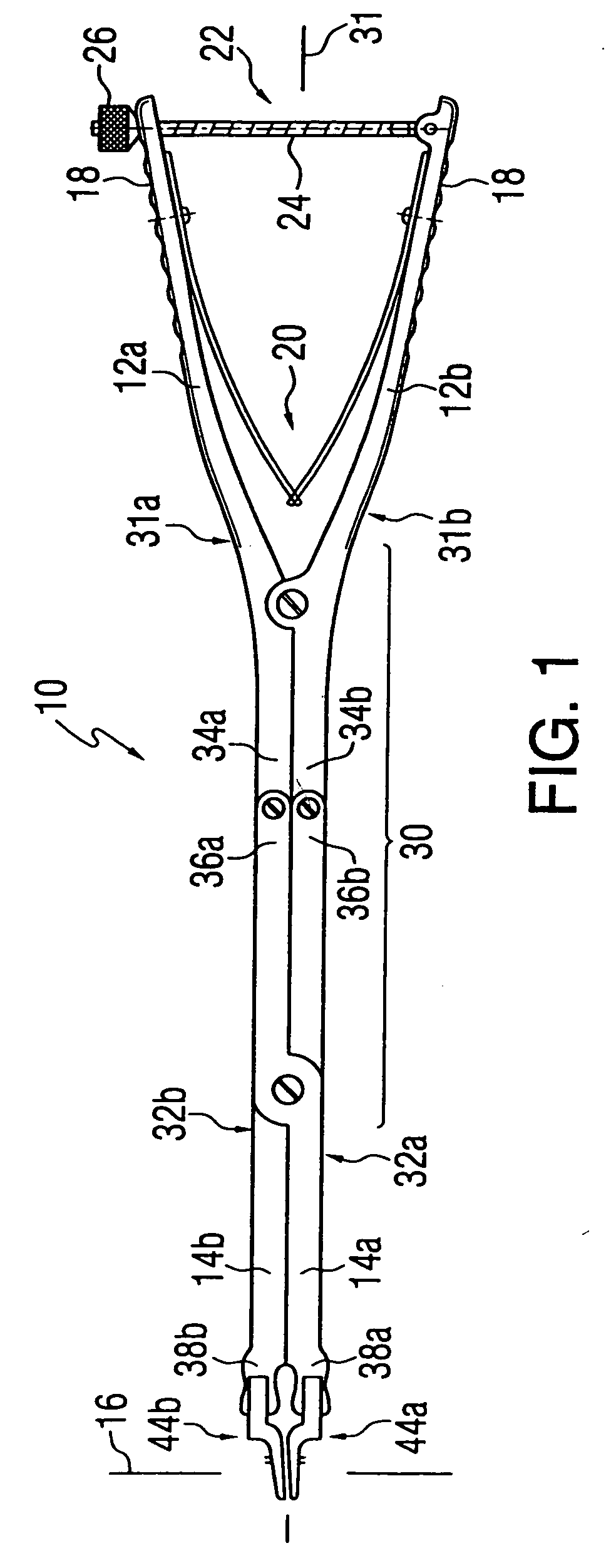

Bone anchoring system

InactiveUS20100305700A1Easy to deployReduces pull-out problemInternal osteosythesisJoint implantsIntervertebral spaceBone anchor

Methods and apparatus for connecting to a bone, which avoid the use of bone screws. A triangular shaped modular implant is used, with two sides of the structure and their respective vertex secured generally within the bone, with the base of the triangle outside the bone. These two arms, whether straight or arcuate, are cannulated, and are held together at their distal ends by a tightened cable that runs through both of the arms. The proximal ends of these arms are connected to a base side that completes the triangular structure. The device may be inserted into a vertebra and the base used for vertebral fusion. Alternatively, the arms themselves may be used to stabilize and fixate adjacent vertebrae, by insertion through adjacent vertebrae trans-segmentally. In the latter case, the vertex may be within the intervertebral space or within the vertebral body close to the intervertebral space.

Owner:SCORPION SURGICAL TECH

Method of forming a surface acoustic wave (SAW) filter device

InactiveUS7213314B2Improve reliabilityReduce heat sensitivityPiezoelectric/electrostrictive device manufacture/assemblyImpedence networksAcoustic waveLength wave

A SAW filter includes a piezoelectric substrate of Lithium Niobate or optionally Lithium Tantalate having a thickness of at least twice an acoustic wavelength. The piezoelectric substrate is bonded to a surrogate substrate of a silicon material. The surrogate substrate is characterized by a resisitivity of at least 100 ohm-cm and an expansion coefficient compatible with the piezoelectric substrate. A catalytic bonding film between the piezoelectric substrate and the surrogate substrate is formed from a first catalytic bonding film deposited onto a surface of the piezoelectric substrate and a second catalytic bonding film deposited onto a surface of the surrogate substrate. The piezoelectric substrate is bonded to the surrogate substrate through a compression force sufficient for providing a bonding at a normal temperature.

Owner:TRIQUINT

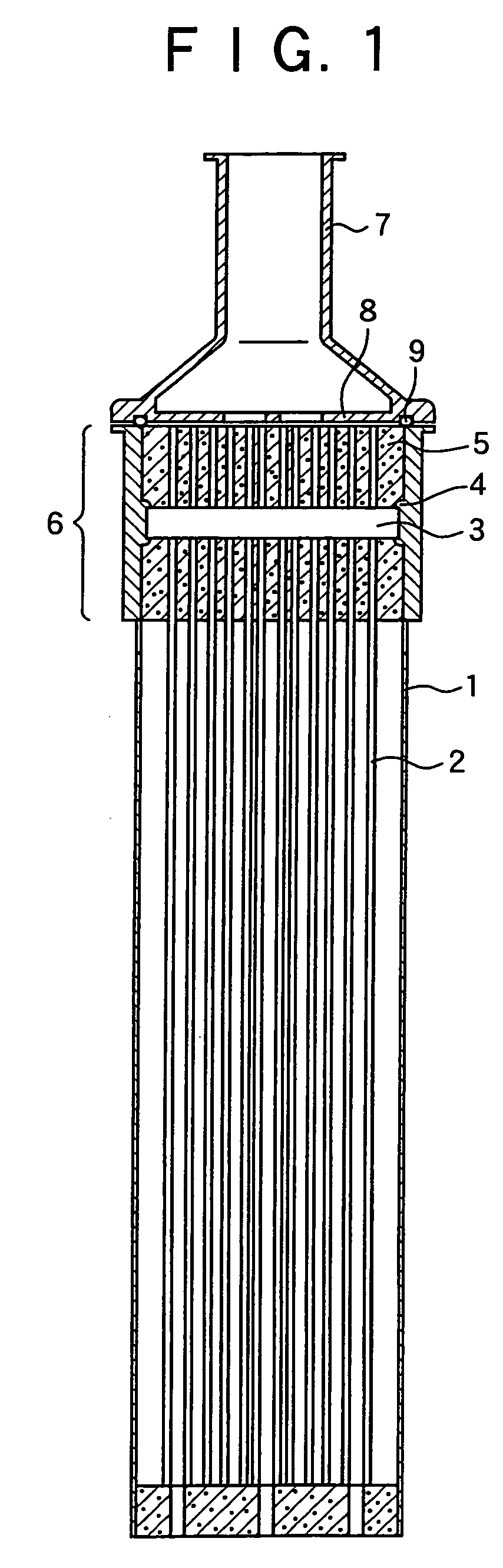

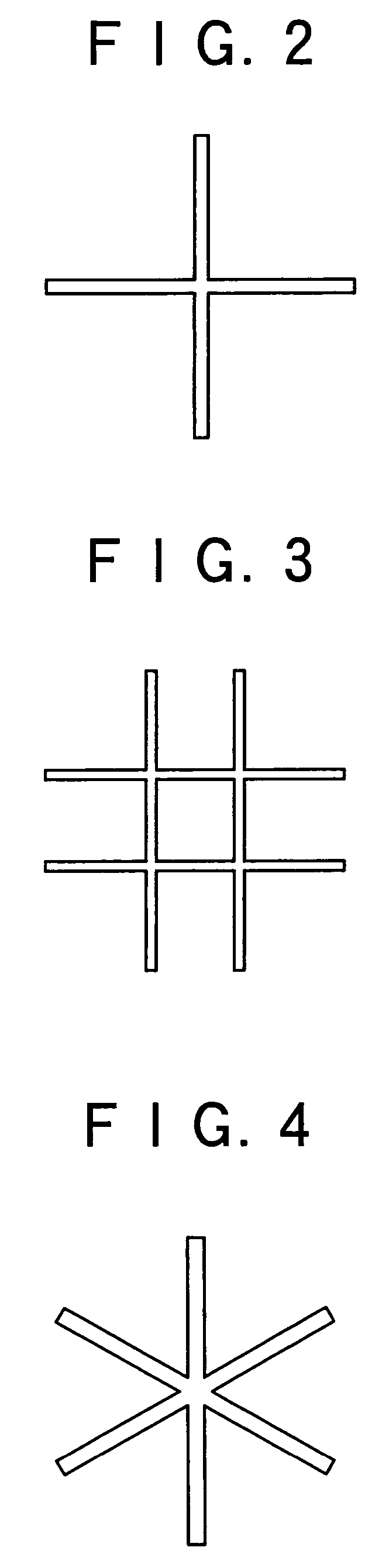

Hollow fiber membrane module

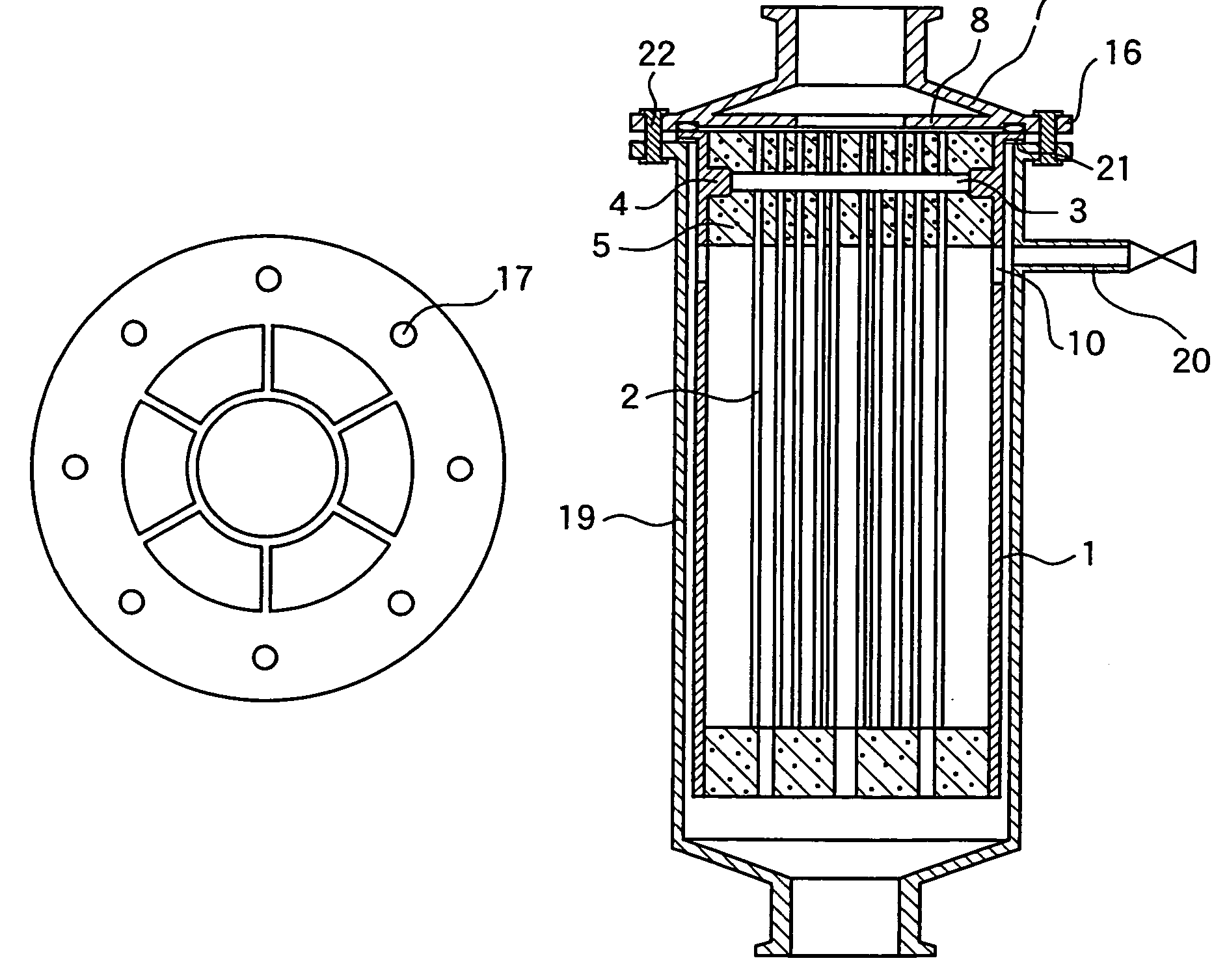

InactiveUS7160455B2Practical pressure resistanceReduce breakageMembranesSemi-permeable membranesFiltrationMechanical engineering

A hollow fiber membrane module comprising a module housing, a hollow fiber membrane bundle comprising a plurality of hollow fiber membranes, at least one end portion of the bundle being fixed on the housing through a flexible potting material, and a rib or ring embedded in the potting portion, the rib or ring being fixed on an inner wall of the housing, and the rib or ring being embedded in the potting portion without directly contacting the hollow fiber membrane, and the filtration method using the same. The hollow fiber membrane module can maintain a practical pressure resistance.

Owner:ASAHI KASEI KK

Spinal disc space distractor

InactiveUS20050177173A1Improve stabilityAccurate placementBone implantJoint implantsBiomedical engineeringDisc space

A distractor for separating adjacent elements, such as vertebrae. The distractor preferably has a scissors-type distracting mechanism, either in a simple scissors or double-acting scissors configuration. A set of blades is provided on each jaw such that an implant may be inserted between the spaced apart blades. The set of blades includes at least two blades.

Owner:DEPUY SYNTHES PROD INC

MBS impact modifiers

A process and composition for MBS modifiers having (A) a rubbery core, (B) an inner graft stage comprised mainly of a hard polymer, (C) an intermediate sealer stage comprised mainly of an alkyl acrylate monomer and / or a polyunsaturated crosslinker, and (D) an outer shell to provide compatibility of the core-shell polymer with the matrix polymer, is disclosed. A process for preparing MBS impact modifiers having suprisingly improved impact performance in matrix polymers is also disclosed. Articles prepared from blends of matrix polymers and the MBS core-shell polymers described herein are also disclosed.

Owner:ROHM & HAAS CO

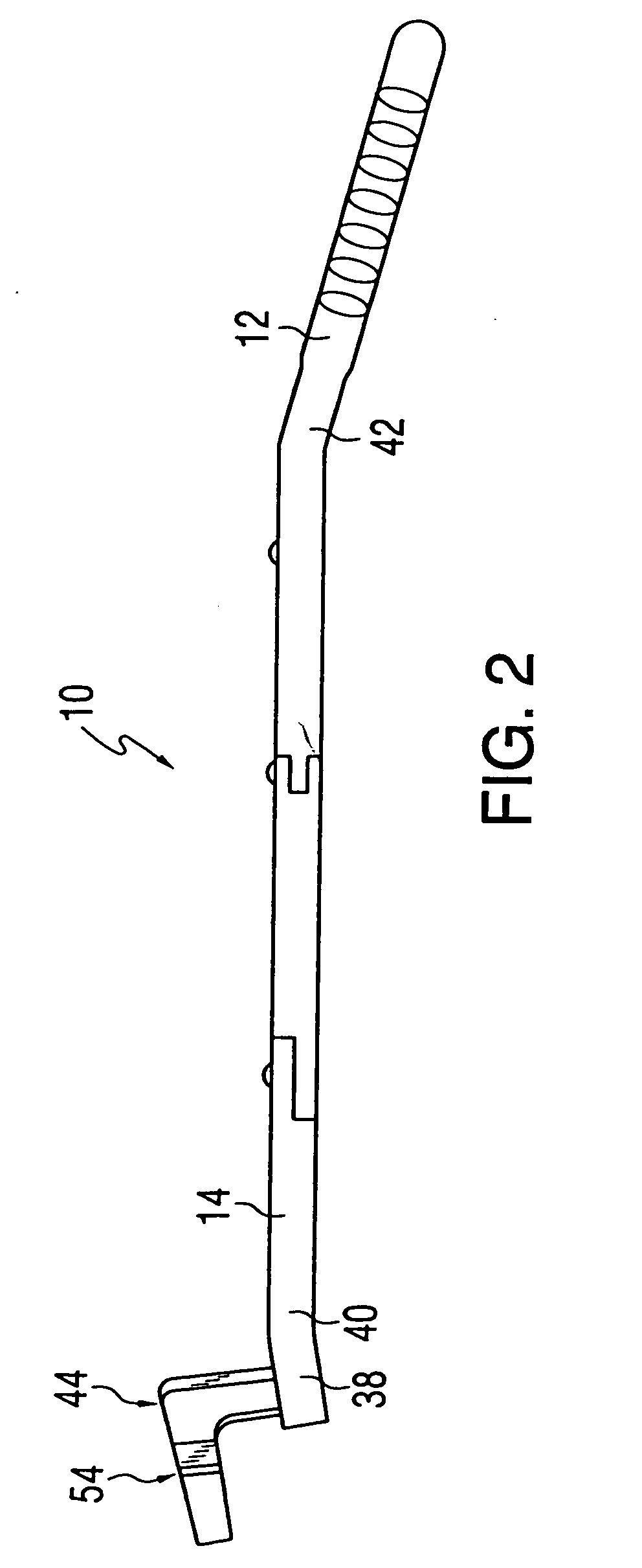

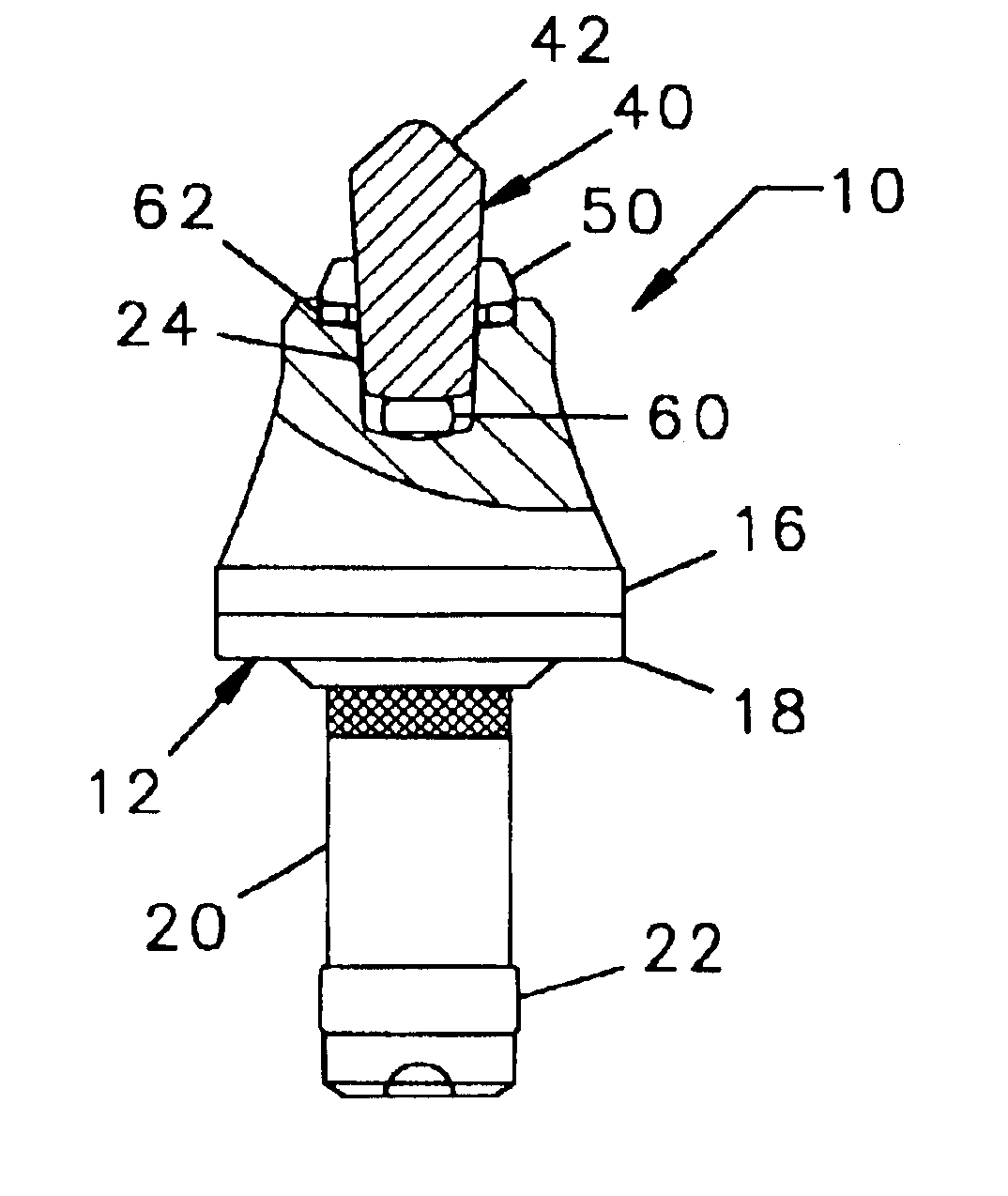

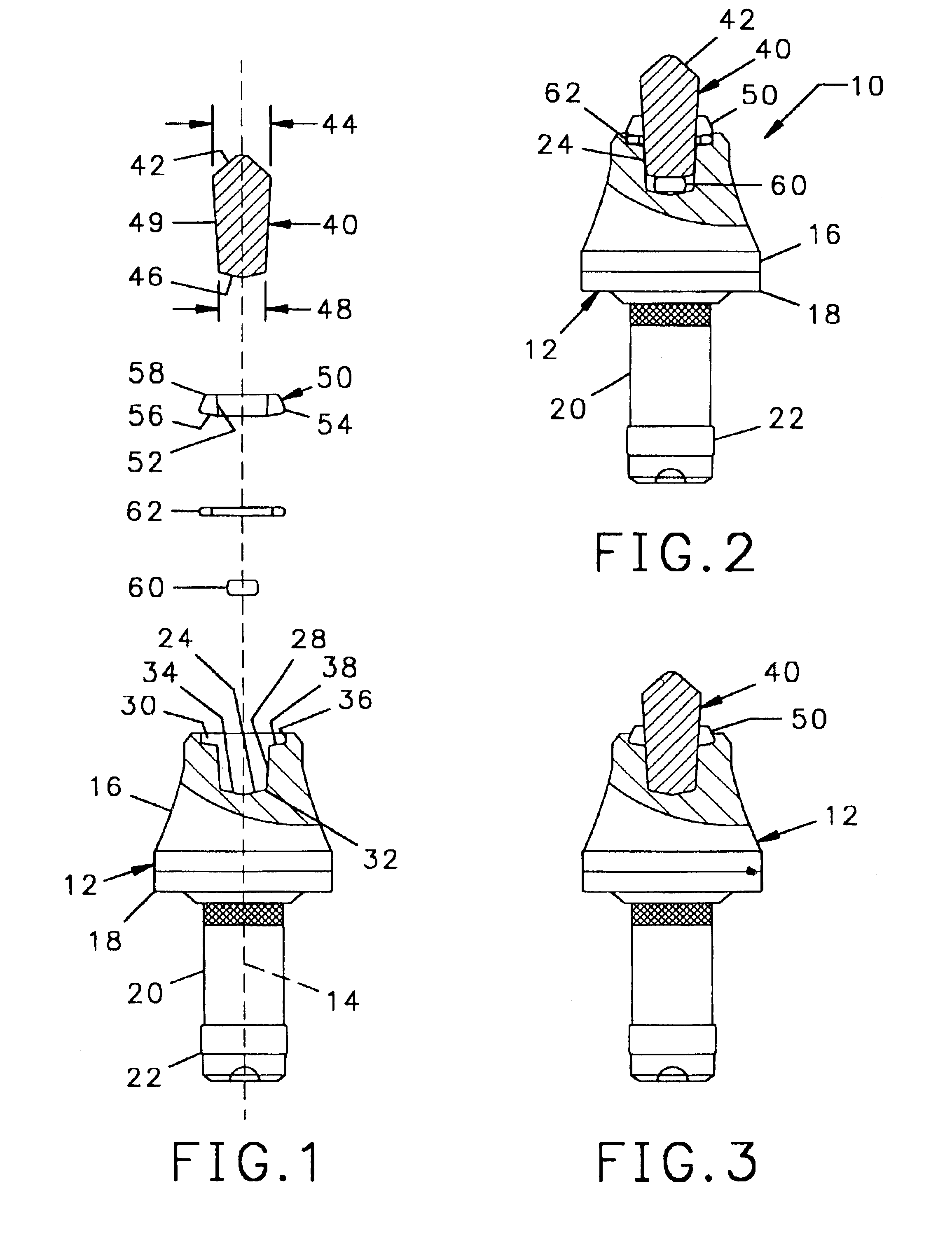

Reverse taper cutting tip with a collar

InactiveUS6846045B2Reduce breakageExtended service lifeSlitting machinesStone-like material working toolsMechanical engineering

A cutting tool has tool body with a seat at a forward end thereof. A hard cutting insert is bonded into the seat. The insert is made of a hard material and Ahas an elongate central portion having a maximum upper diameter and a maximum lower diameter that is less than the maximum upper diameter. A collar, also made of a hard material, surrounds the base of the elongate central portion of the insert.

Owner:THE SOLLAMI COMPANY

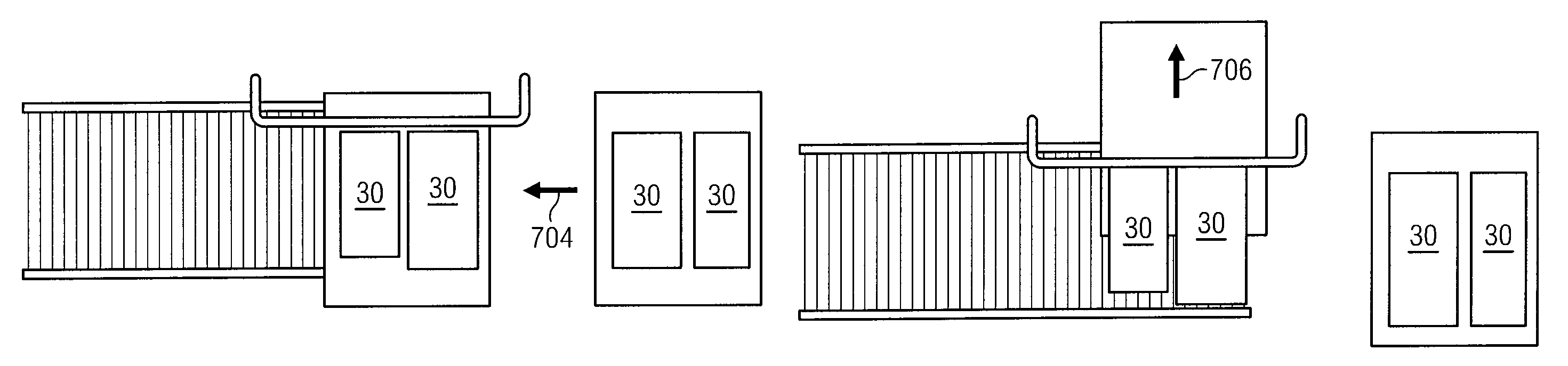

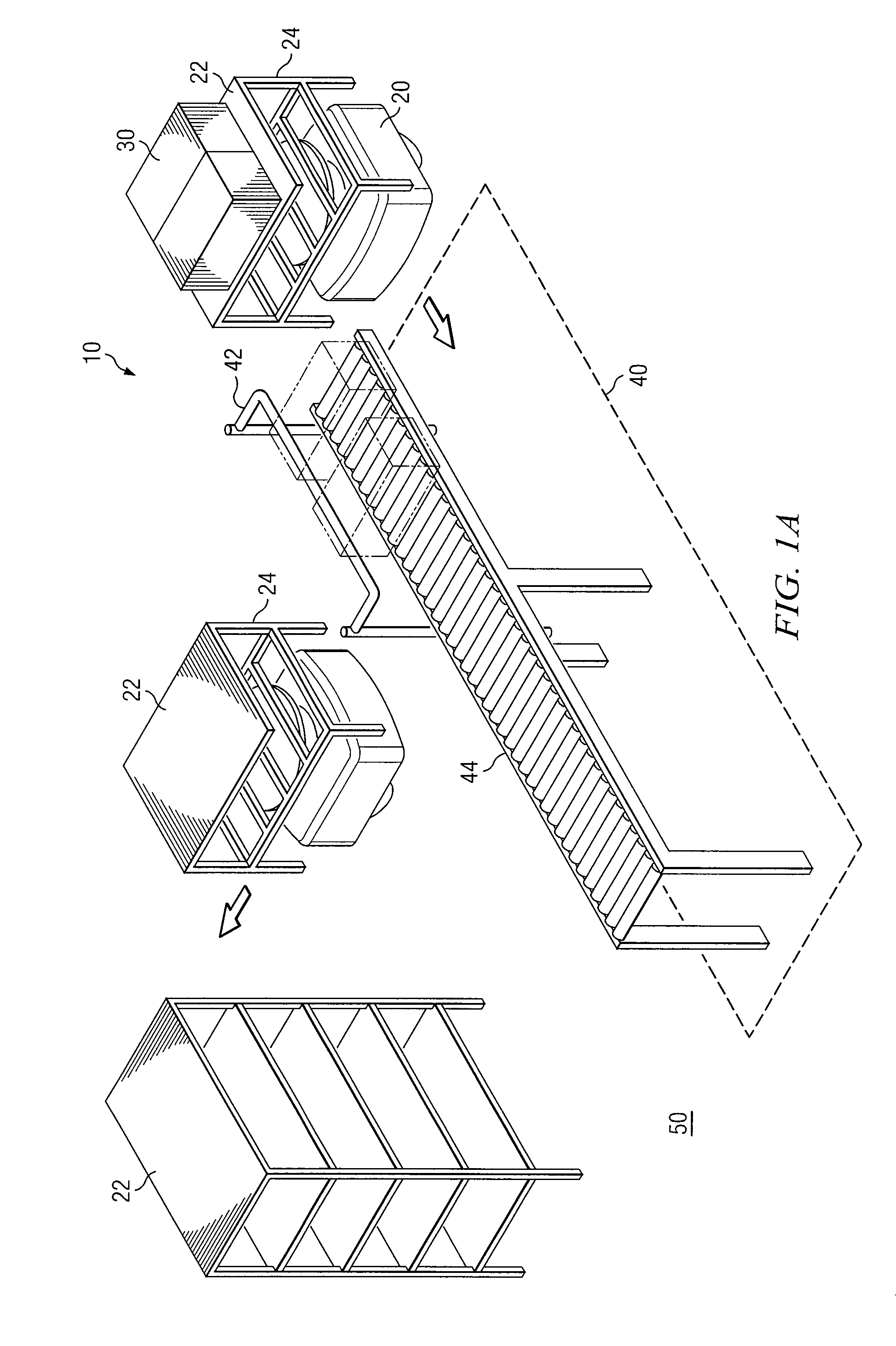

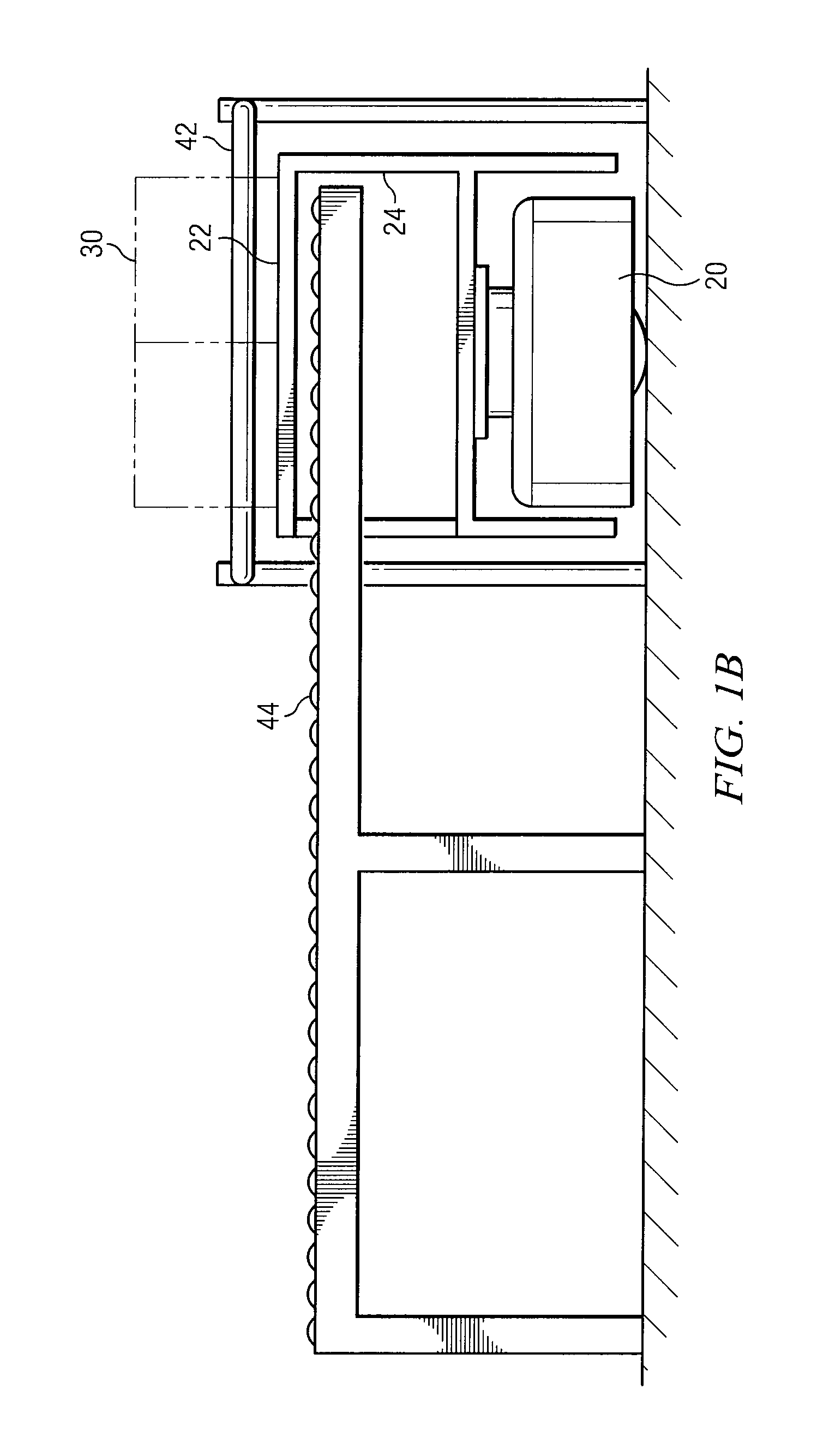

System and method for unloading items

ActiveUS8444369B2Disadvantages and reduced eliminatedInventory reduced eliminatedSemiconductor/solid-state device manufacturingRefuse transferringEngineeringMechanical engineering

A method for unloading inventory items includes storing an inventory item on an inventory holder and moving the inventory holder toward an unloading station with a mobile drive unit. Additionally, the method includes moving the inventory holder past a barrier of the unloading station. The method further includes preventing the inventory item from moving past the barrier as the mobile drive unit moves the inventory holder past the barrier.

Owner:AMAZON TECH INC

Method for injection moulding moulded bodies consisting of (meth) acrylate copolymers

InactiveUS20040104501A1Reduce contentLittle reabsorptionPharmaceutical non-active ingredientsEndocrine system disorderPolymer scienceMeth-

The invention relates to a process for producing mouldings by injection moulding the steps in the process being a) melting and mixing of a (meth)acrylate copolymer composed of from 85 to 98% by weight of C1-C4-alkyl (meth)acrylates capable of free-radical polymerization and from 15 to 2% by weight of (meth)acrylate monomers having a quaternary ammonium group in the alkyl radical, with from 10 to 25% by weight of a plasticizer, and also from 10 to 50% by weight of a dryers [sic] and / or from 0.1 to 3% by weight of a release agent, and, where appropriate, with other conventional pharmaceutical additives or auxiliaries and / or with an active pharmaceutical ingredient, b) devolatilizing the mixture at temperatures of at least 120° C., thus reducing the content of the low-boiling constituents with a vapour pressure of at least 1.9 bar at 120° C. to not more than 0.5% by weight, and c) injecting the devolatilized mixture at a temperature of from 80 to 160° C. into the mould of an injection moulding system and removing the resultant moulding from the mould.

Owner:ROEHM GMBH & CO KG +1

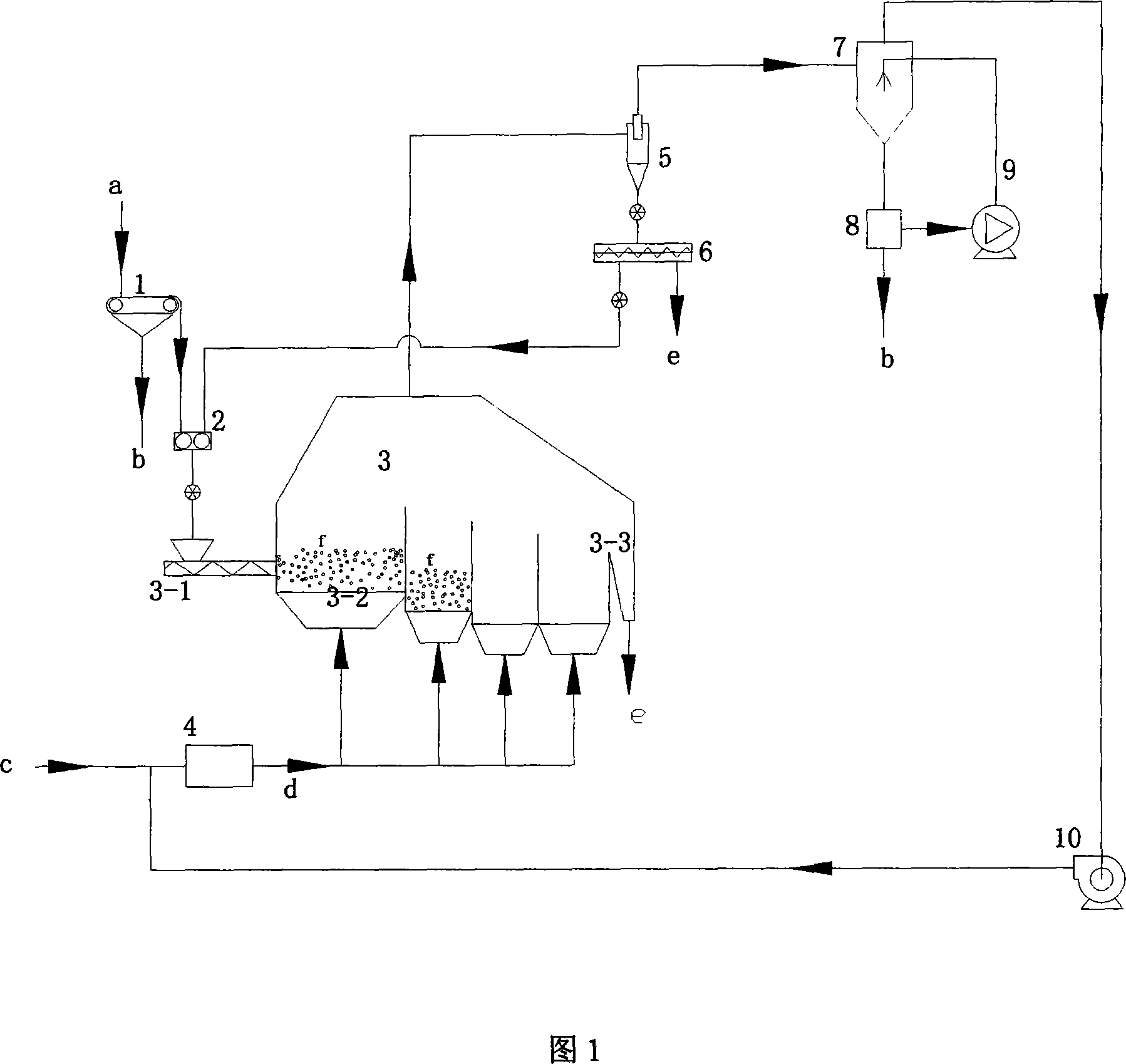

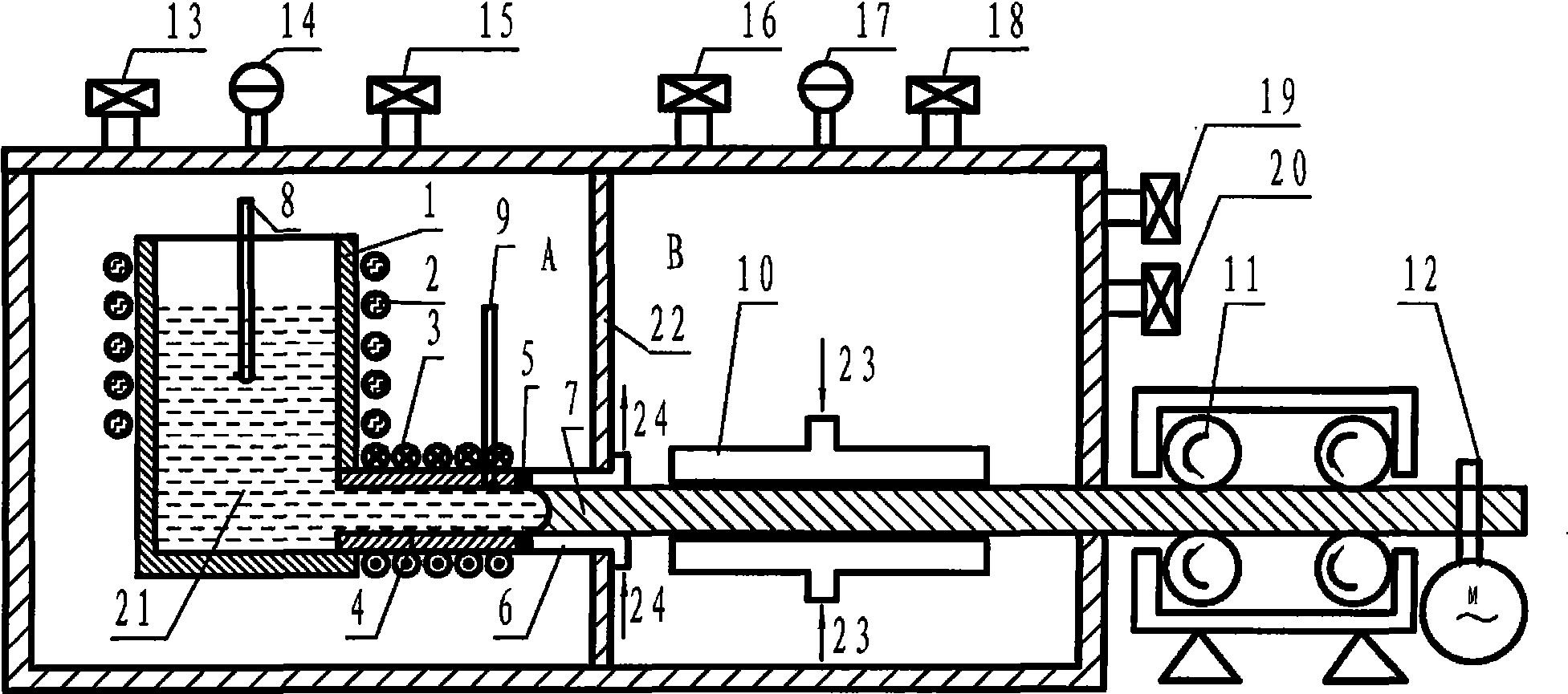

Enclosed multi-chamber fluidized bed drying method for sludge

InactiveCN101186422AUniform humidityReduce breakageSludge treatment by de-watering/drying/thickeningLiquid wasteFluidized bed drying

A closed multi-room fluidized bed sludge drying method is provided, which is a sludge drying method having the advantages of simple equipment structure, convenient operation, strong sludge adaptability, high thermal efficiency, safety, continuity, stability, etc. After the mechanically dewatered sludge is mixed with the back-mixed sludge, the mixture is dried room by room in an inert particles multi-room fluidized bed dryer (3). The first room and the second room of the inert particles multi-room fluidized bed dryer (3) adopt inert particles (f) as heat storage medium. Gas from a cyclone separator (5) goes through a spray tower (7) and returns into an air heating unit (4) through a circulating fan (10). Part of dried sludge (e) at the lower part of the cyclone separator (5) enters the inert particles multi-room fluidized bed dryer (3) through the back-mixing in a mixer (2). Waste liquid from the bottom of the spray tower (7) enters a waste liquid circulating pool (8), with part of waste liquid circulating into the spray tower (7) and part into a sewage treatment system.

Owner:SOUTHEAST UNIV

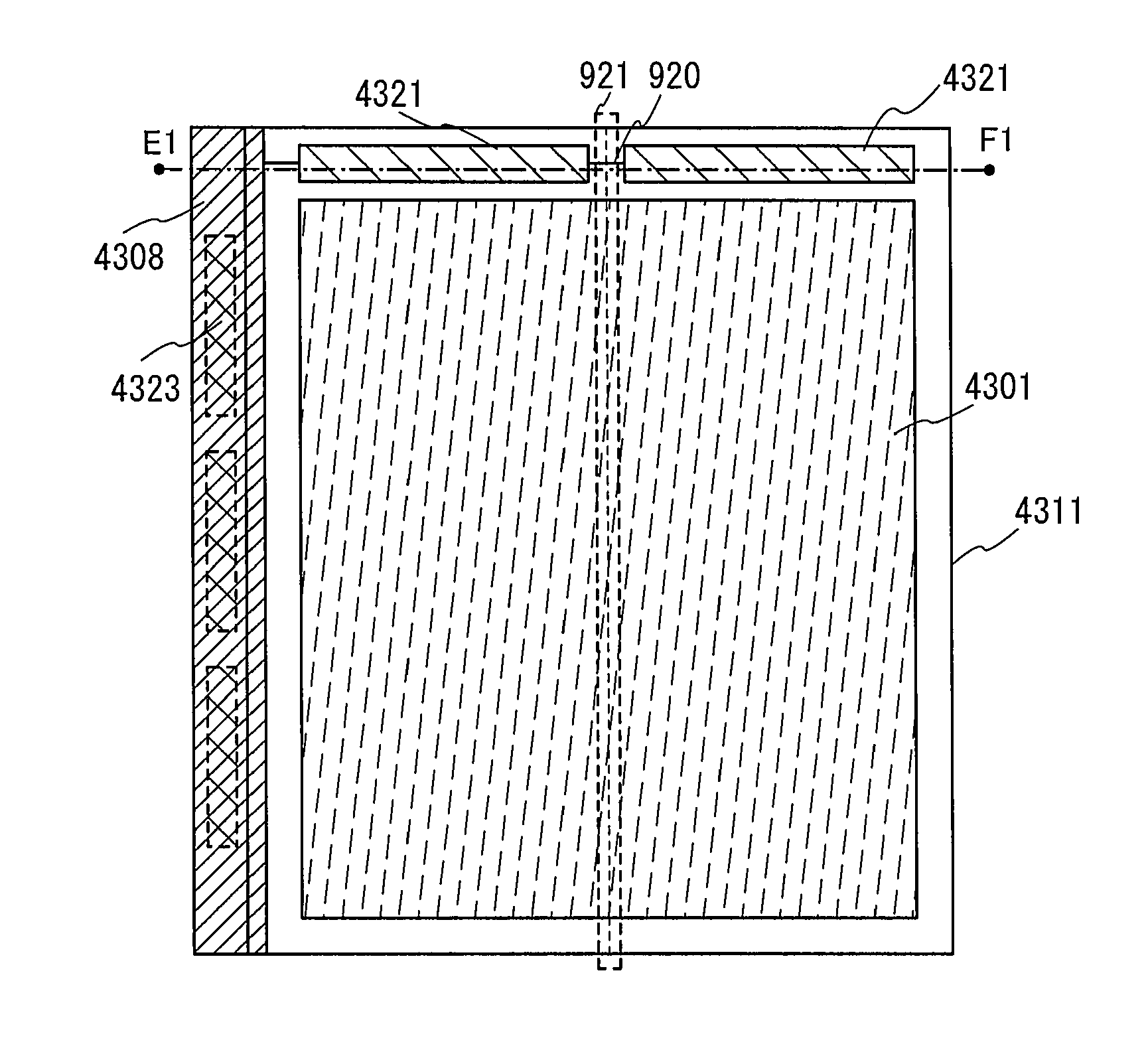

Display Device

ActiveUS20100277448A1Less breakageCost reductionPrinted circuit aspectsSolid-state devicesSignal linesEngineering

The display device includes: a flexible display panel including a display portion in which scanning lines and signal lines cross each other; a supporting portion for supporting an end portion of the flexible display panel; a signal line driver circuit for outputting a signal to the signal line, which is provided for the supporting portion; and a scanning line driver circuit for outputting a signal to the scanning line, which is provided for a flexible surface of the display panel in a direction which is perpendicular or substantially perpendicular to the supporting portion.

Owner:SEMICON ENERGY LAB CO LTD

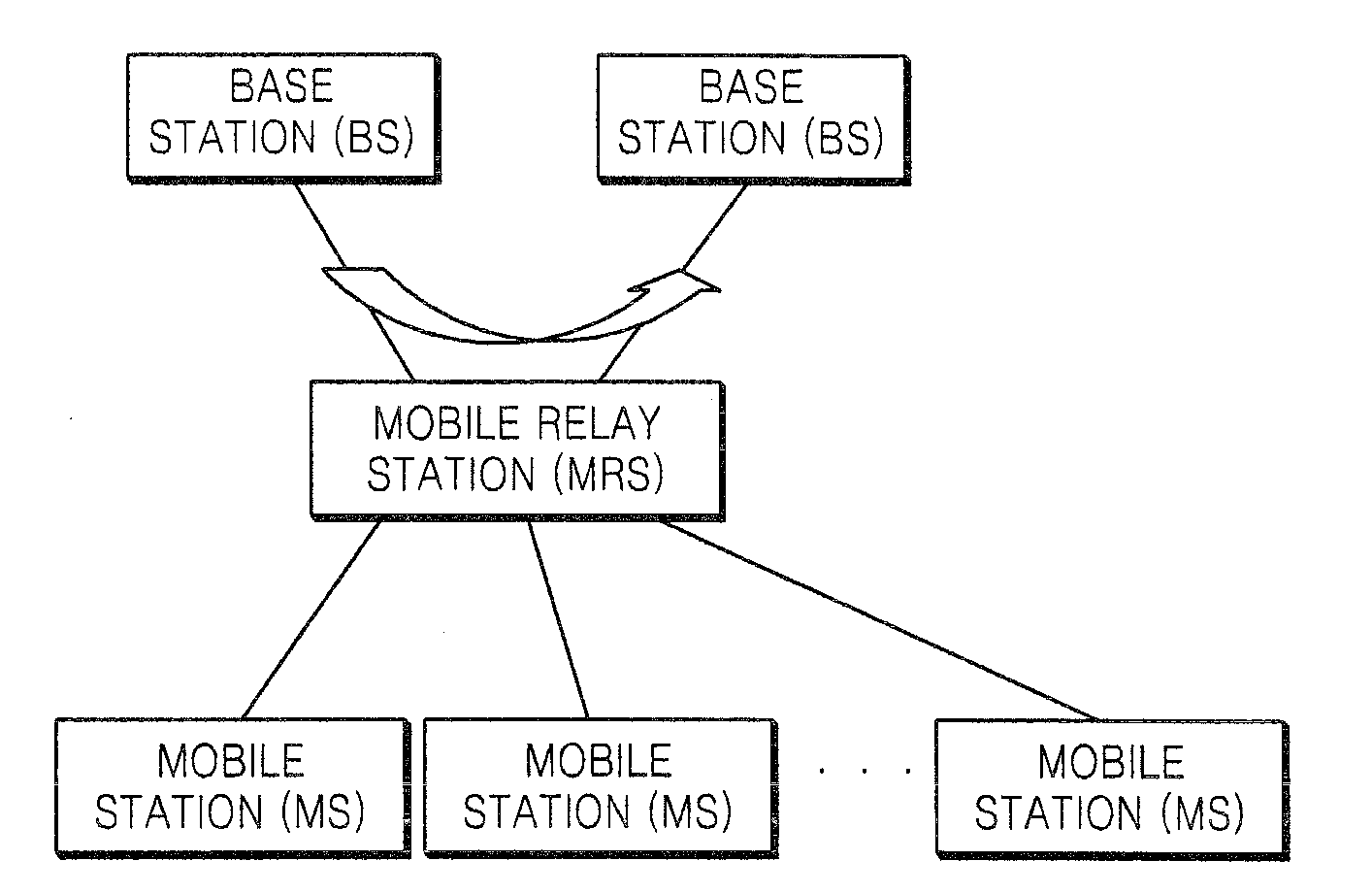

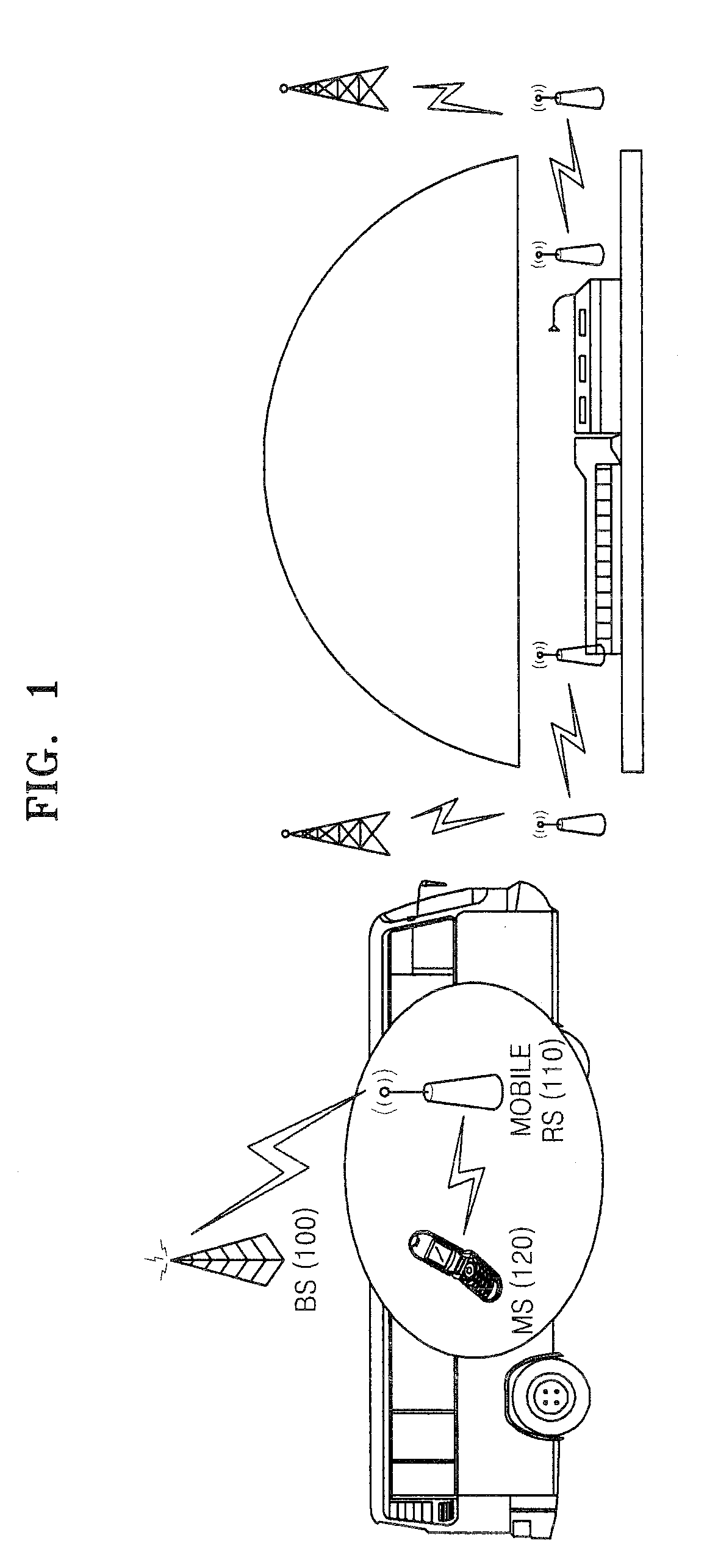

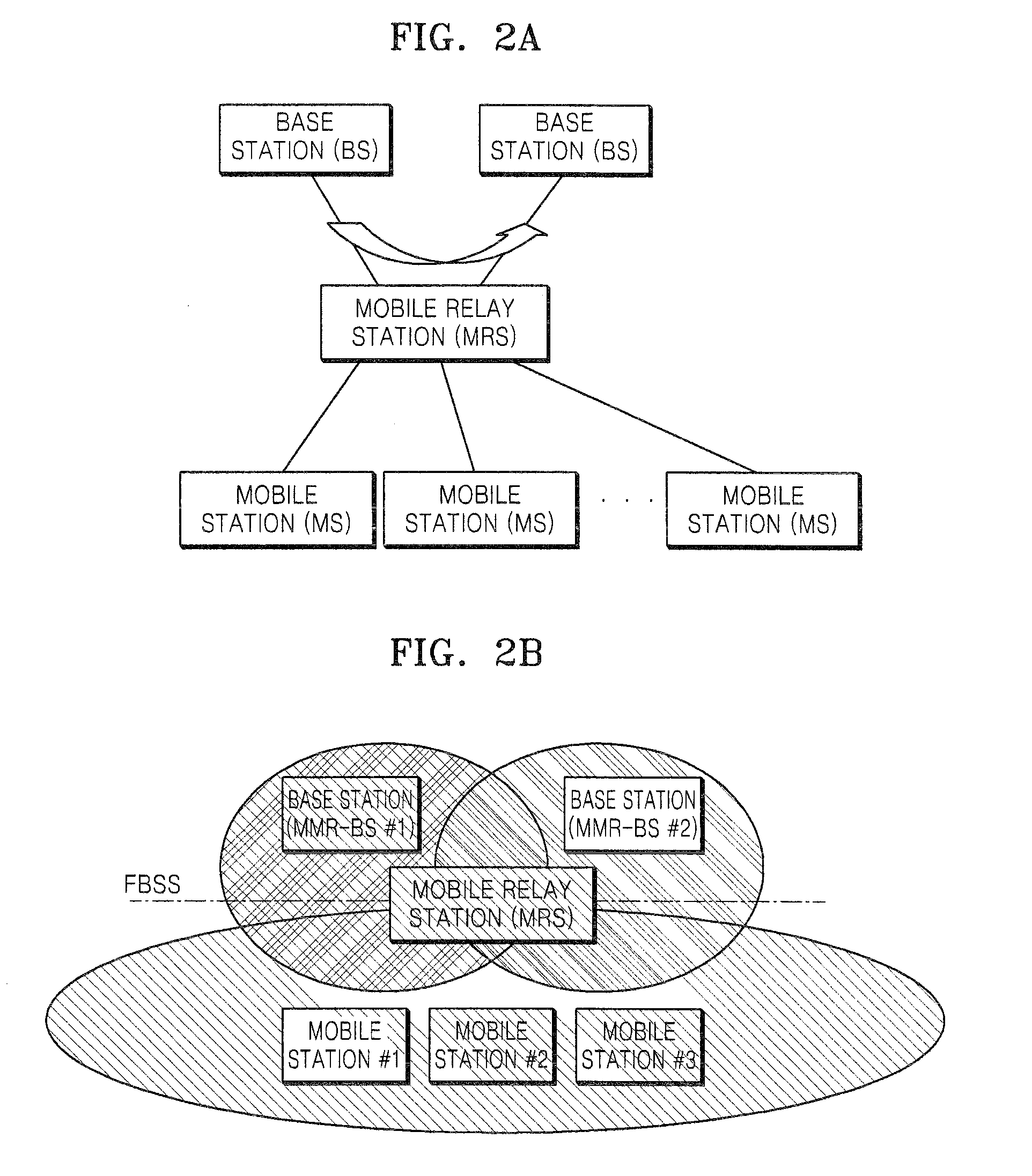

Handover method with mobile relay station

InactiveUS20100061339A1Reduce breakageUse radio resourceNetwork topologiesWireless commuication servicesMobile relayMobile station

There is provided a handover method by a mobile relay station (MRS) or base station (BS) so as to effectively perform a handover of the MRS and mobile stations (MSs) in an environment in which data is communicated through a relay of the MRS. There is also provided a handover method capable of securing backward compatibility of an MS during a handover. There is provided a handover method in which an MRS is considered. It is possible to improve the efficiency of the handover by allowing handovers of the MRS and MSs to which the MRS relays to be initiated by the MRS or BS. It is possible to secure the backward compatibility of the MSs by allowing the MRS to generate and manage a mapping relation between information on communication identifiers (CIDs) of the MSs, which are changed during the handover, and information on previous CIDs of the MSs.

Owner:ELECTRONICS & TELECOMM RES INST

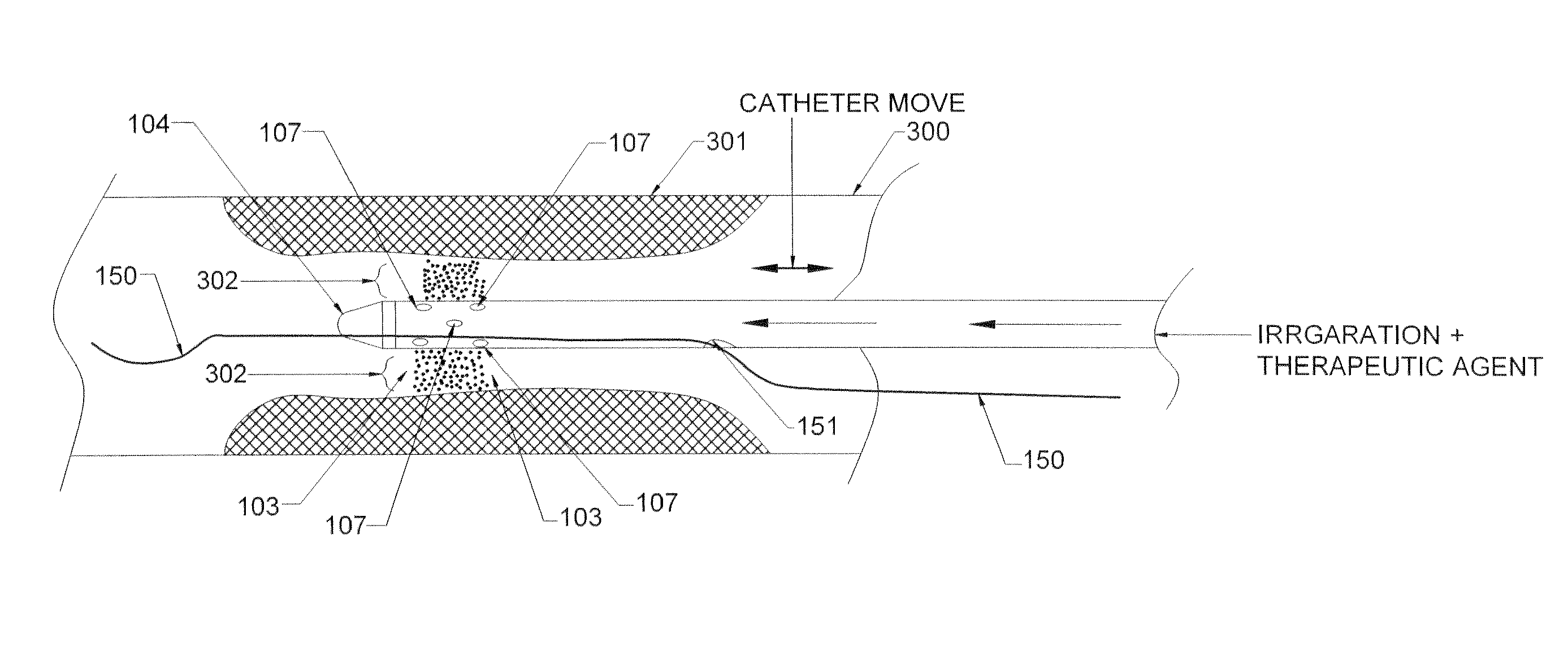

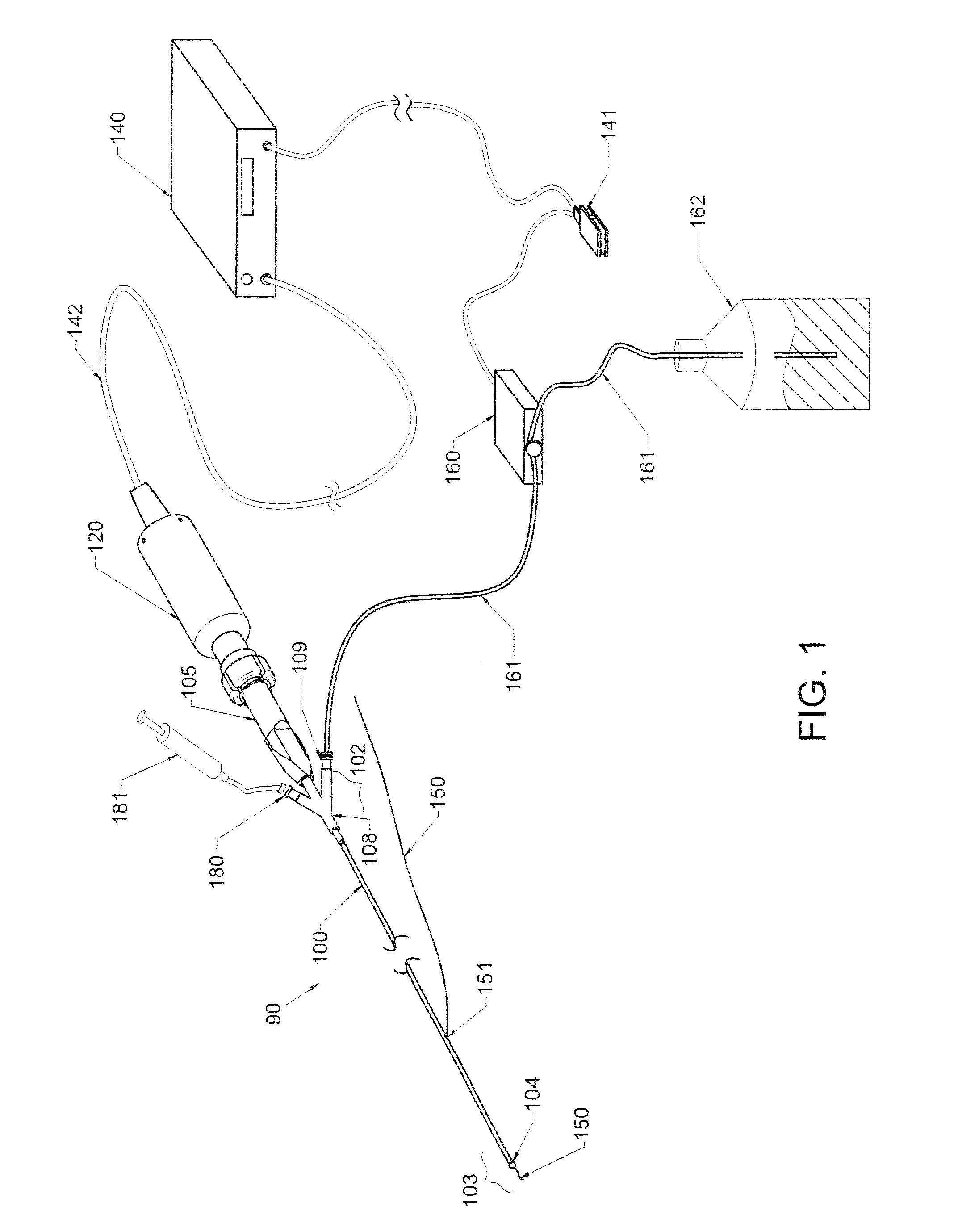

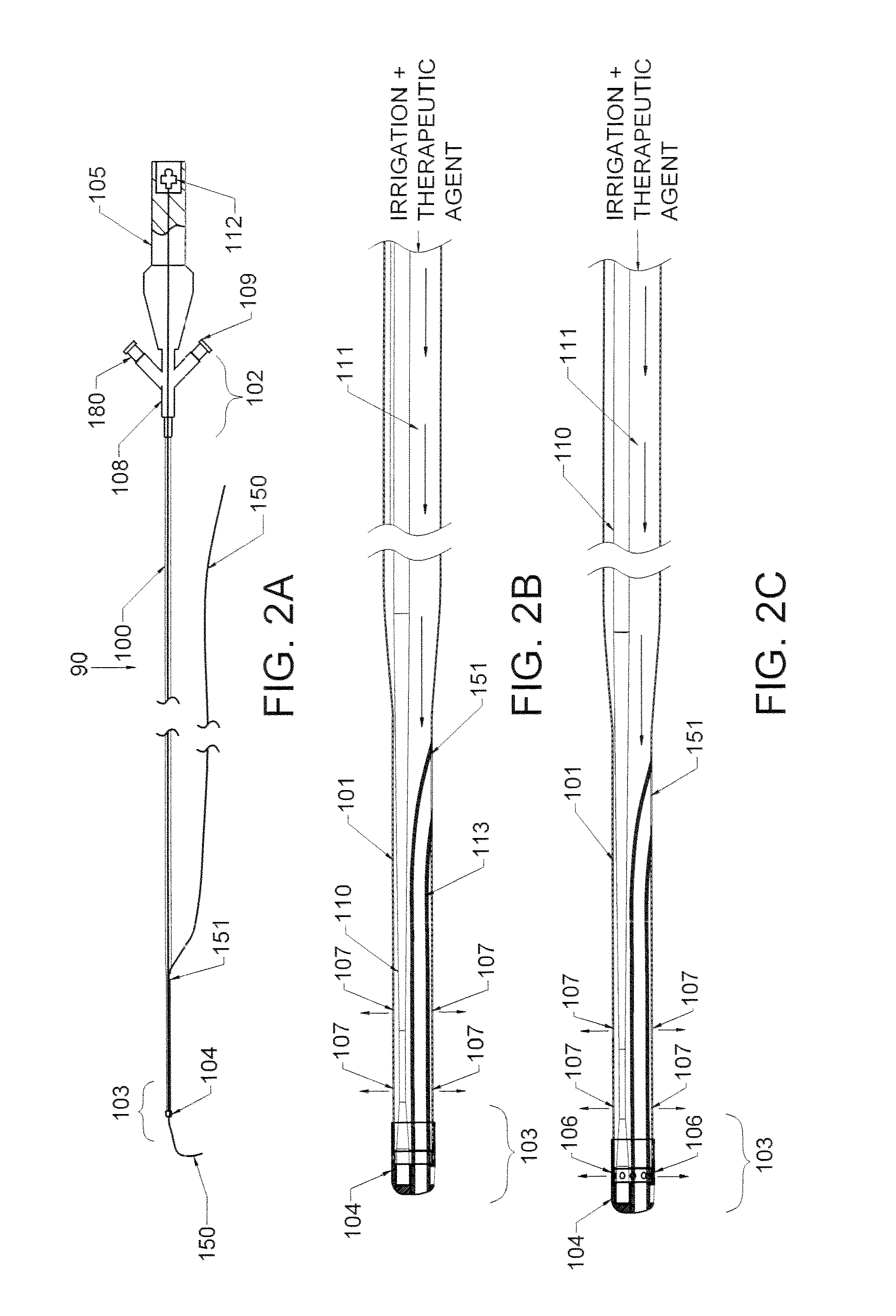

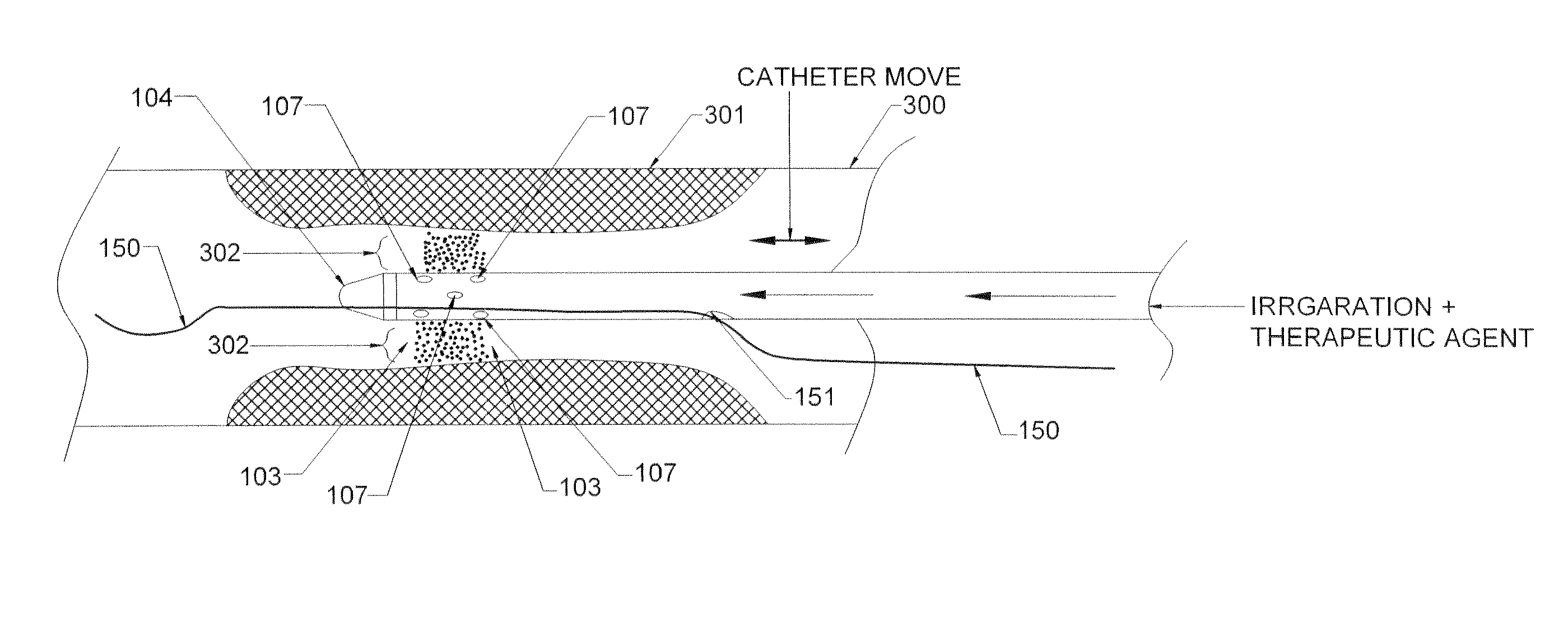

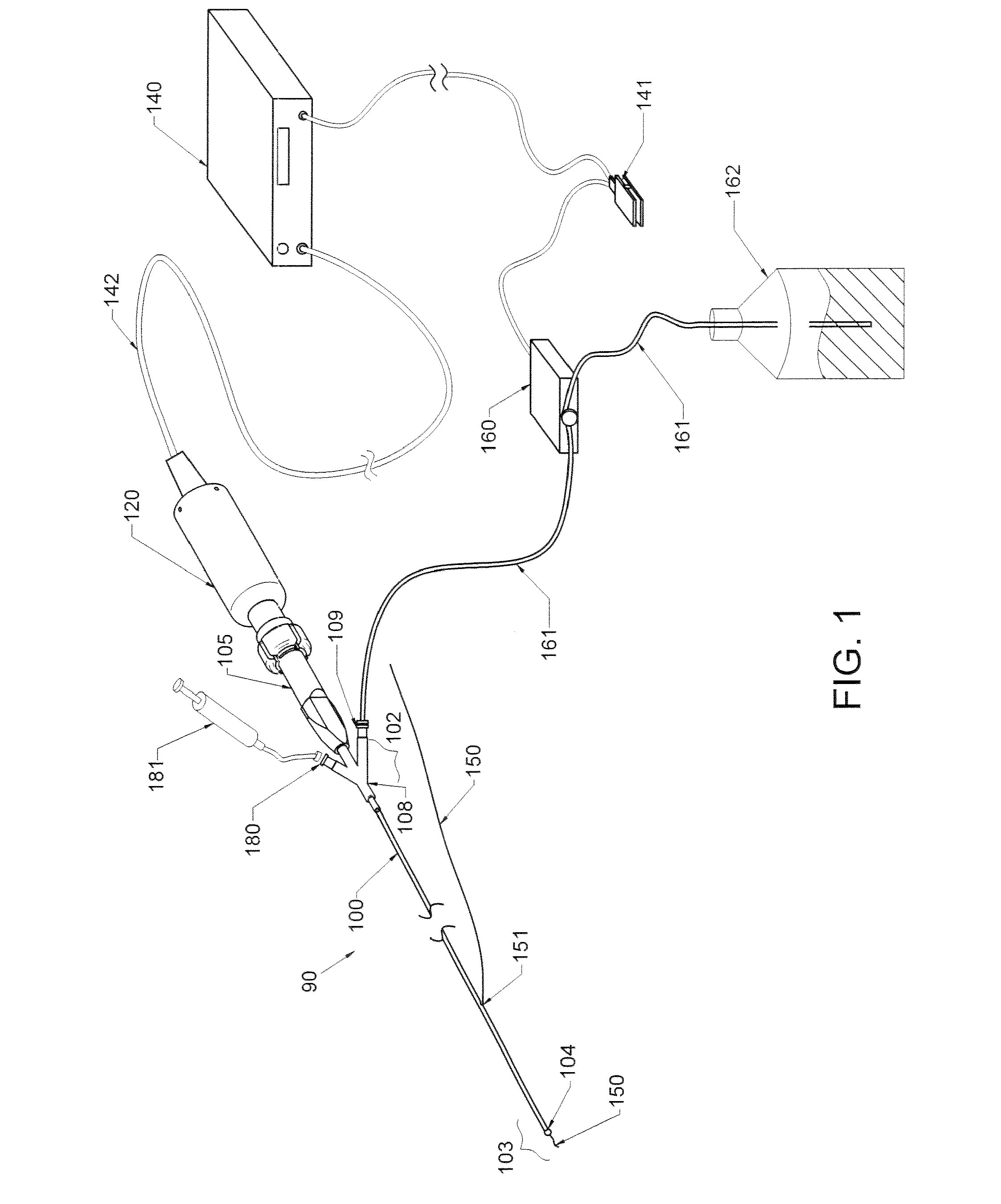

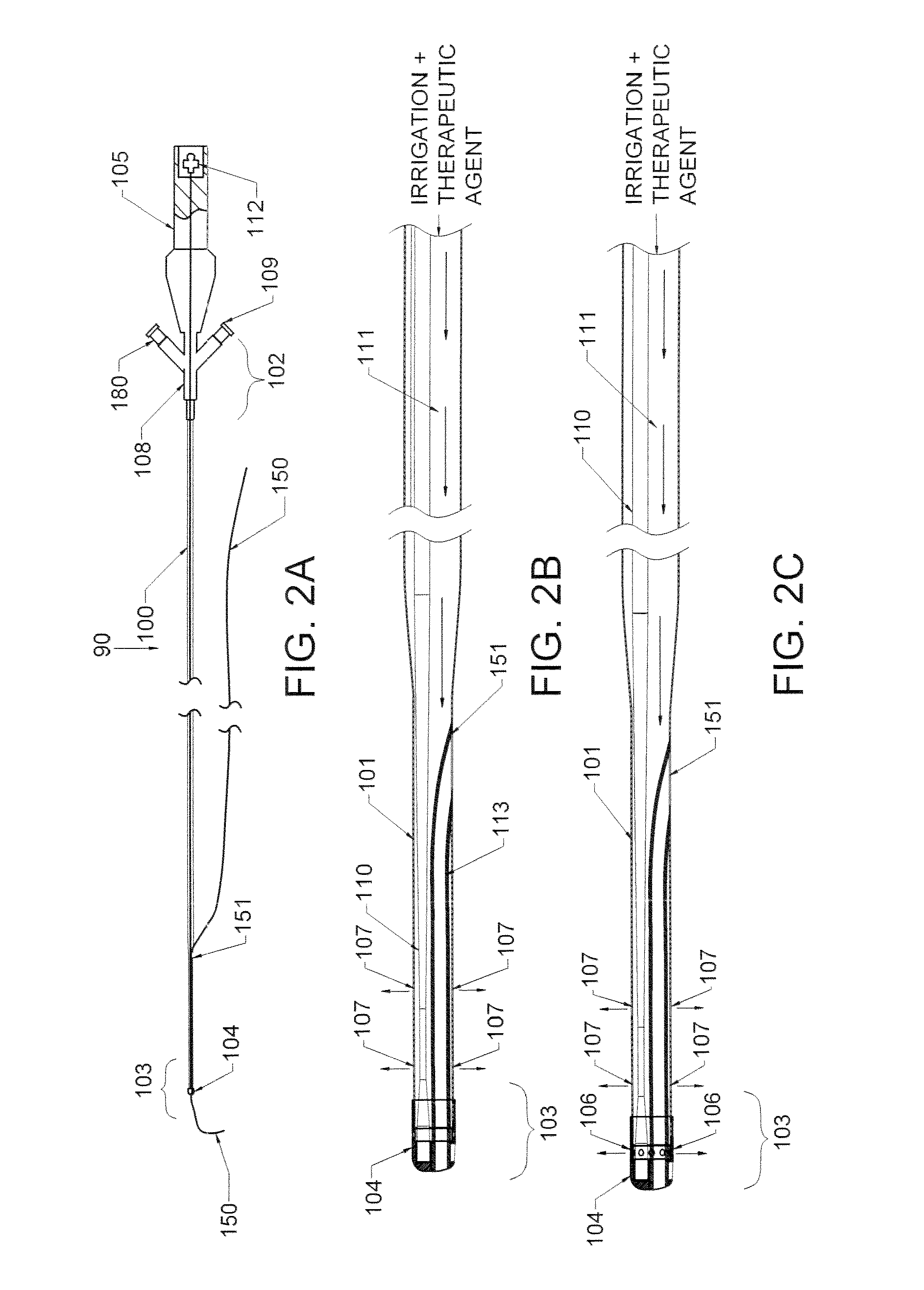

Methods and devices for endovascular therapy

ActiveUS9375223B2Improve drug deliveryReduce breakageMedical devicesCatheterDiseaseEndovascular therapy

The present invention provides methods and devices for treating endovascular disease. Vibrational energy is delivered to change compliance and increase permeability at the treatment area. To improve clinical outcomes, one or more therapeutic drugs may be delivered to the treatment area.

Owner:CARDIOPROLIFIC INC

Methods and devices for endovascular therapy

ActiveUS20160367274A1Improve drug deliveryReduce breakageMedical devicesCatheterDiseaseEndovascular therapy

Owner:CARDIOPROLIFIC INC

Methods and devices for endovascular therapy

ActiveUS20160367275A1Improve drug deliveryReduce breakageMedical devicesSurgical instrument detailsDiseaseEndovascular therapy

The present invention provides methods and devices for treating endovascular disease. Vibrational energy is delivered to change compliance and increase permeability at the treatment area. To improve clinical outcomes, one or more therapeutic drugs may be delivered to the treatment area.

Owner:CARDIOPROLIFIC INC

Liquid soap with vitamin beads and method for making same

InactiveUS6846785B2Reduce breakageAppropriate amount of clarityCosmetic preparationsOrganic detergent compounding agentsCross-linkSuspending Agents

A liquid soap having vitamin-containing microcapsules including a base having an anionic surfactant and a chelating agent, a cross-linked acrylic polymer suspending agent, and multiple vitamin-containing microcapsules uniformly suspended in the liquid soap. The liquid soap is formulated at an elevated temperature which is maintained throughout the formulation process.

Owner:DIAL CORPORATION

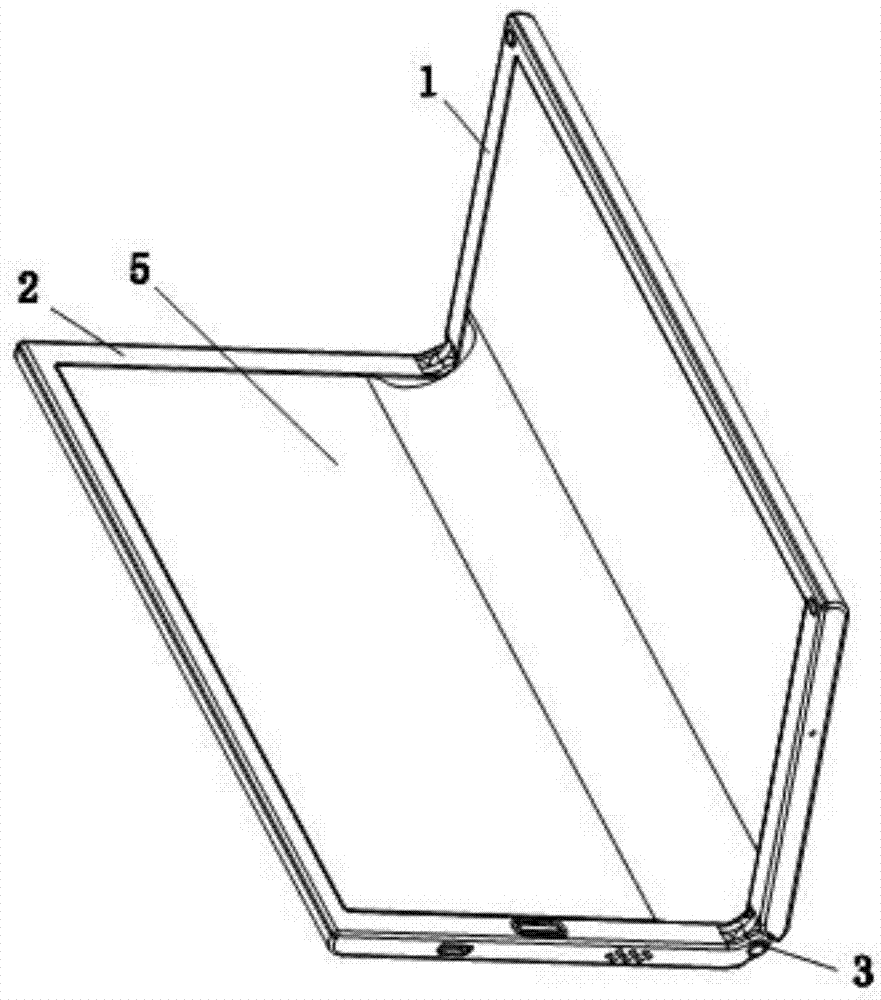

Folding mobile terminal

ActiveCN104506688AExtended service lifeReduce breakageTelephone set constructionsBreakage rateEngineering

The invention discloses a folding mobile terminal. The folding mobile terminal is used to reduce breakage rate of a flexible screen, and then use life of the folding mobile terminal is prolonged. The folding mobile terminal comprises an upper housing and a lower housing which are arranged in hinged mode, and the flexible screen which is arranged on the folding inner side faces of the upper housing and the lower housing, wherein an upper containing cavity is formed in an area on the upper housing, close to the hinged axis, and a lower containing cavity is formed in an area on the lower housing, close to the hinged axis. When the folding mobile terminal is folded, the upper containing cavity is opposite to the lower containing cavity, a bending portion of the flexible screen is contained in the upper containing cavity and the lower containing cavity. Due to the fact that the bending portion of the flexible screen can be contained in the upper containing cavity and the lower containing cavity when the folding mobile terminal is folded, the bending radius can be kept large. By adopting the technical scheme, the rate of breakage of the flexible screen, caused by the large bending angle, can be greatly reduced, and therefore the use life of the folding mobile terminal is greatly prolonged.

Owner:BOE TECH GRP CO LTD

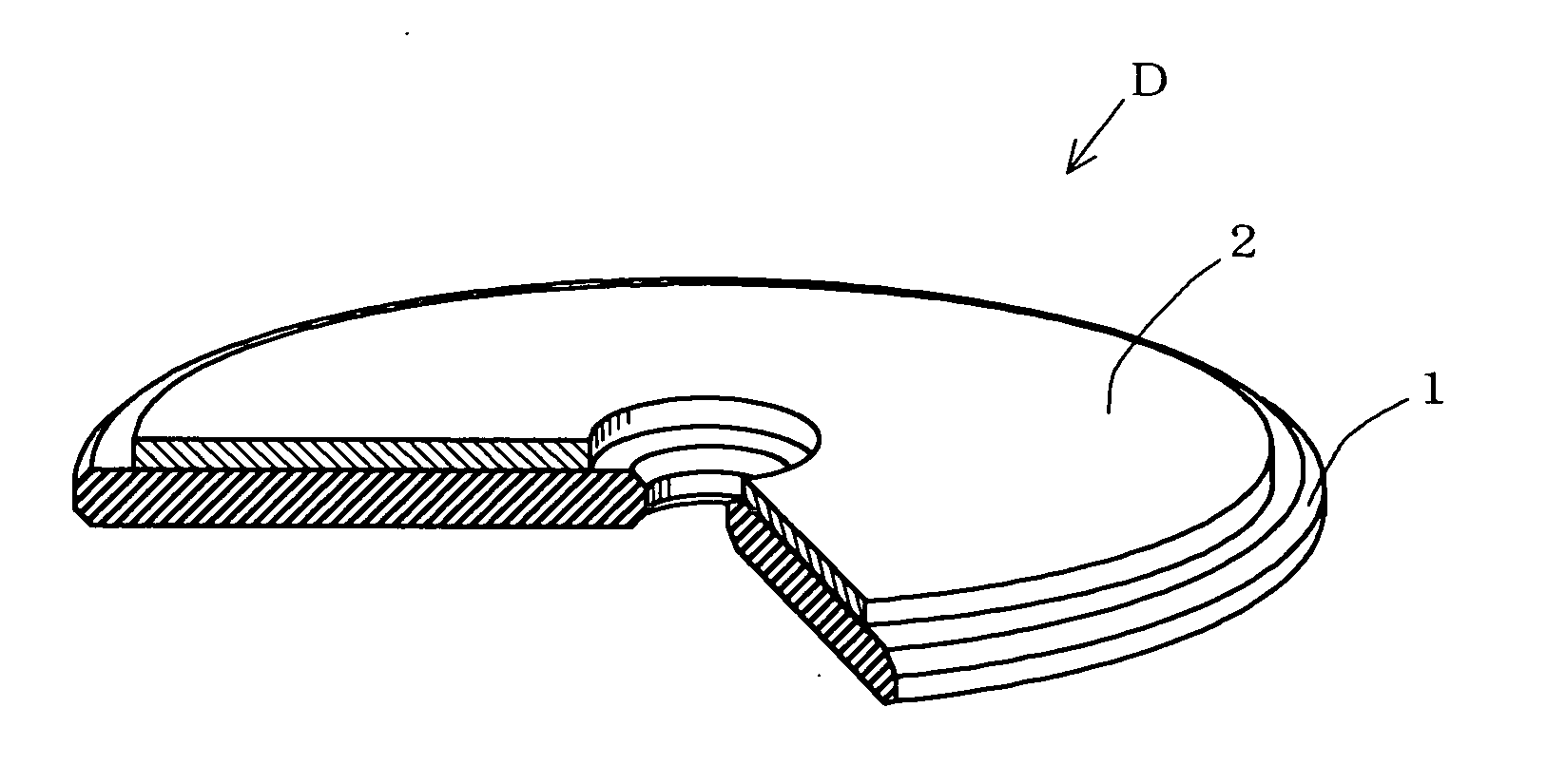

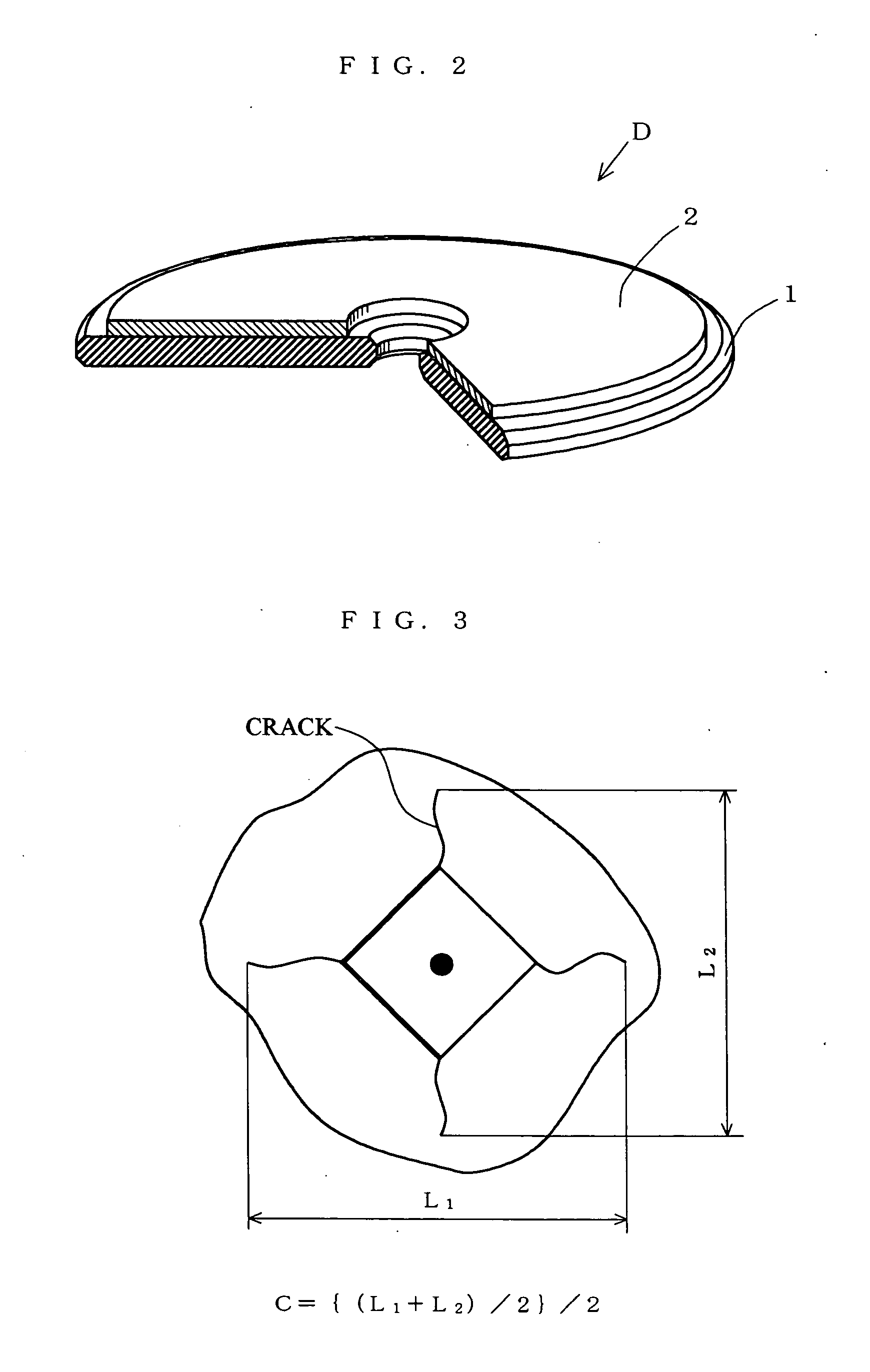

Glass substrate for an information recording medium and information recording medium employing it

InactiveUS20050096210A1Improve yieldIncreased durabilityMagnetic materials for record carriersBase layers for recording layersEdge surfaceRecording layer

A chemically strengthened glass substrate for use as the substrate of an information recording medium such as a magnetic disk, magneto-optical disk, DVD, or MD, wherein a strengthened layer formed by chemical strengthening exists on the outer edge surface and on the inner edge surface but substantially not on a surface on which an information recording layer is formed.

Owner:HOYA CORP

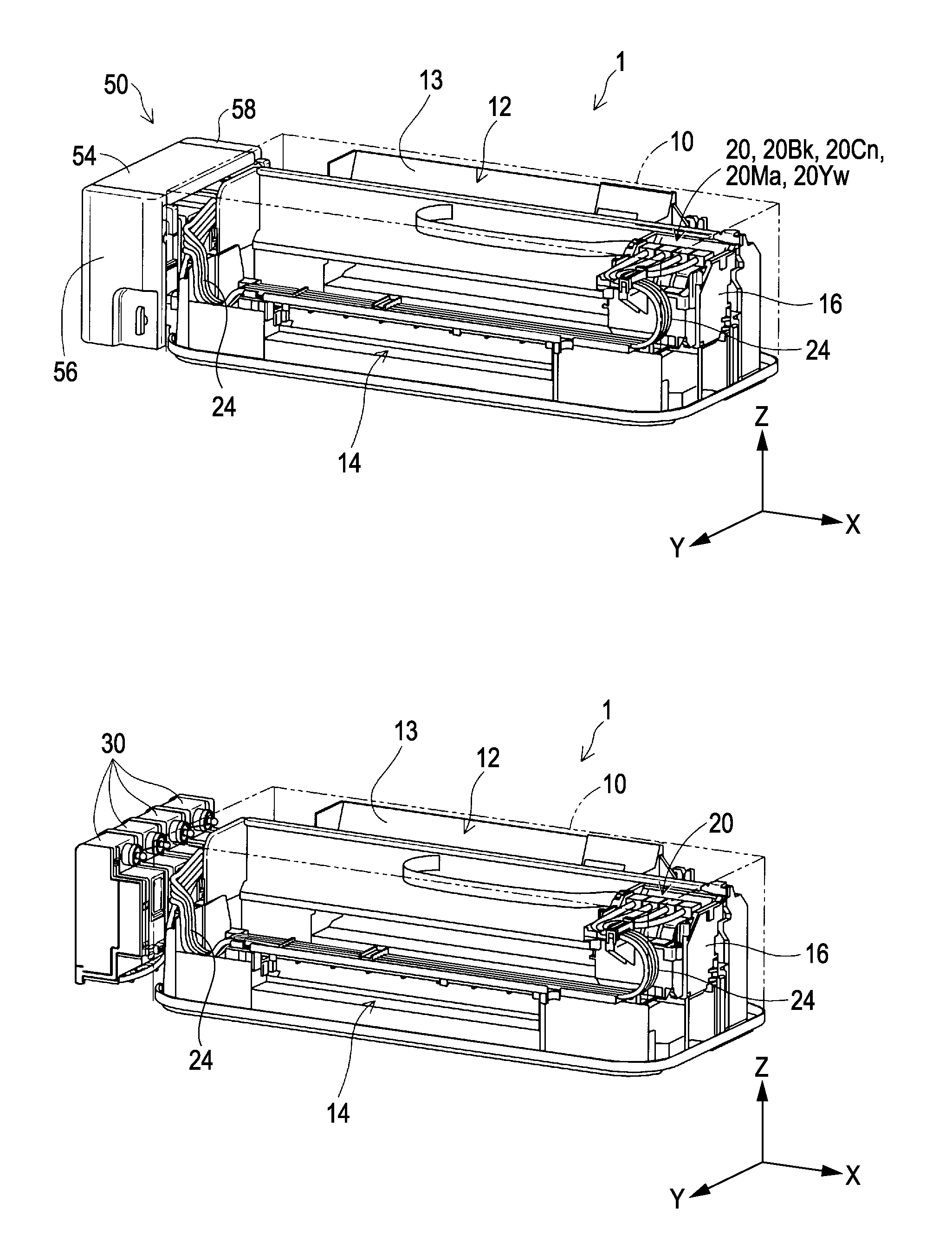

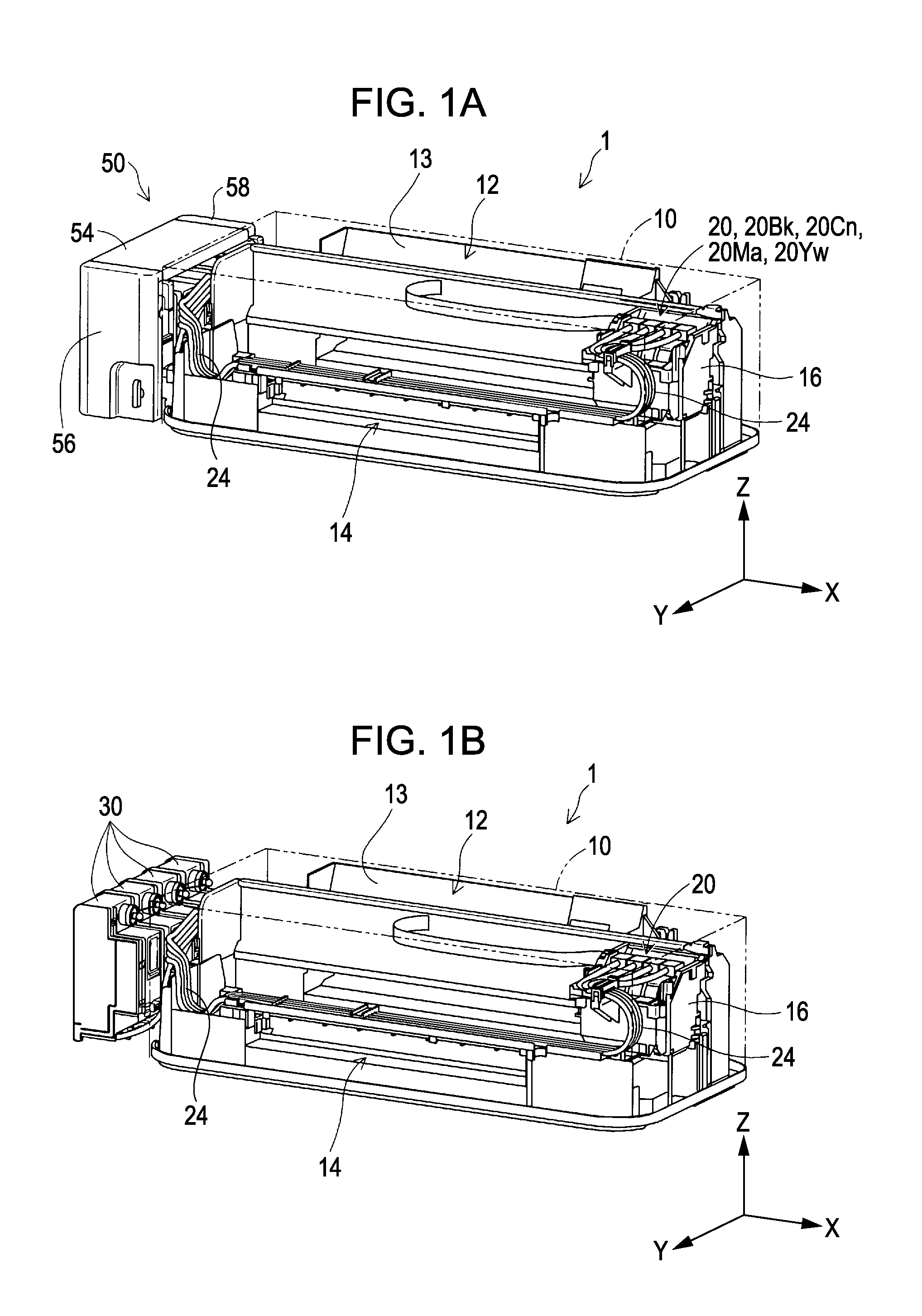

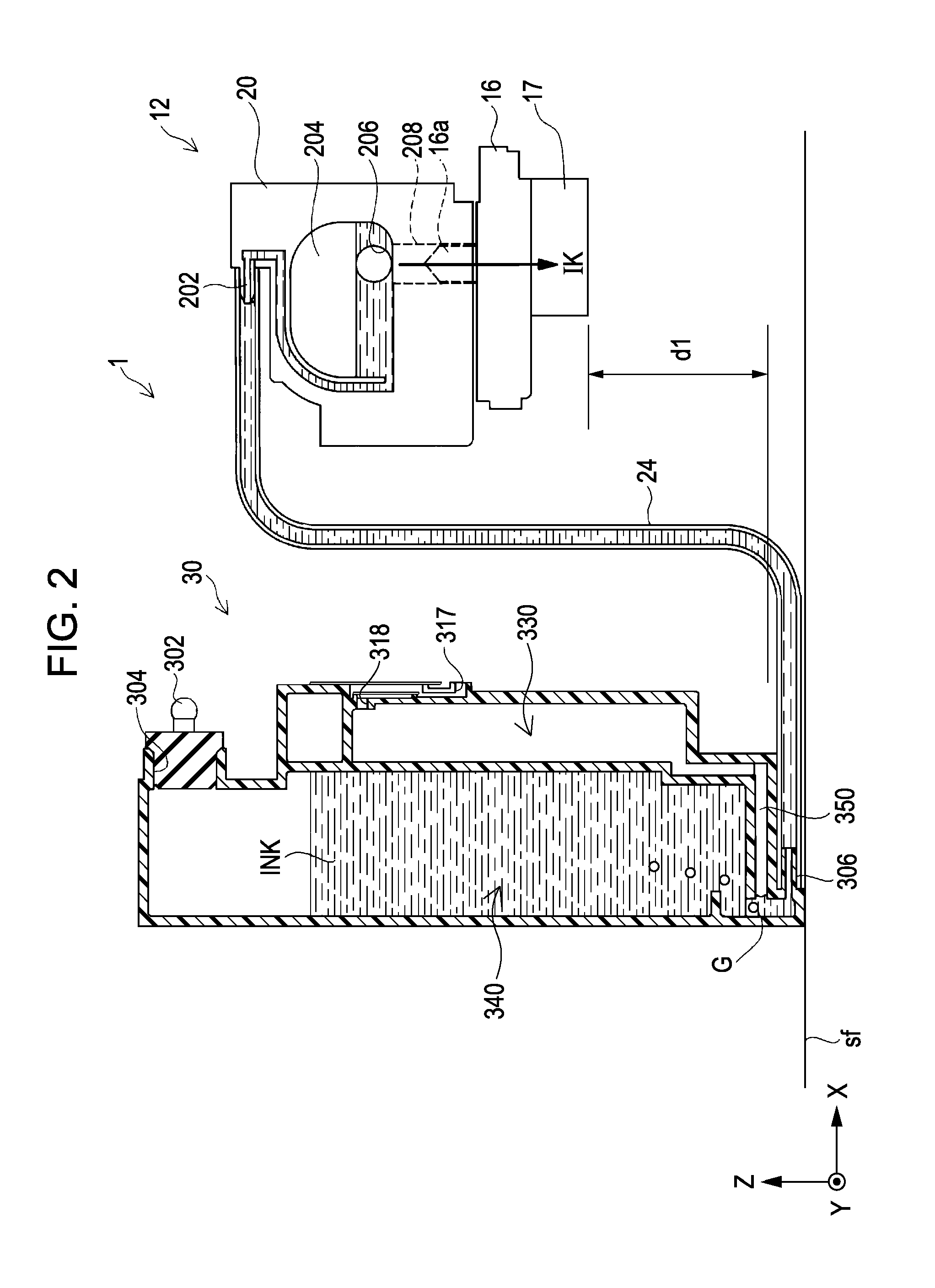

Tank unit and liquid ejecting system having tank unit

ActiveUS20120056938A1Improve fitEasy to integrateWriting implementsMetal-working apparatusEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

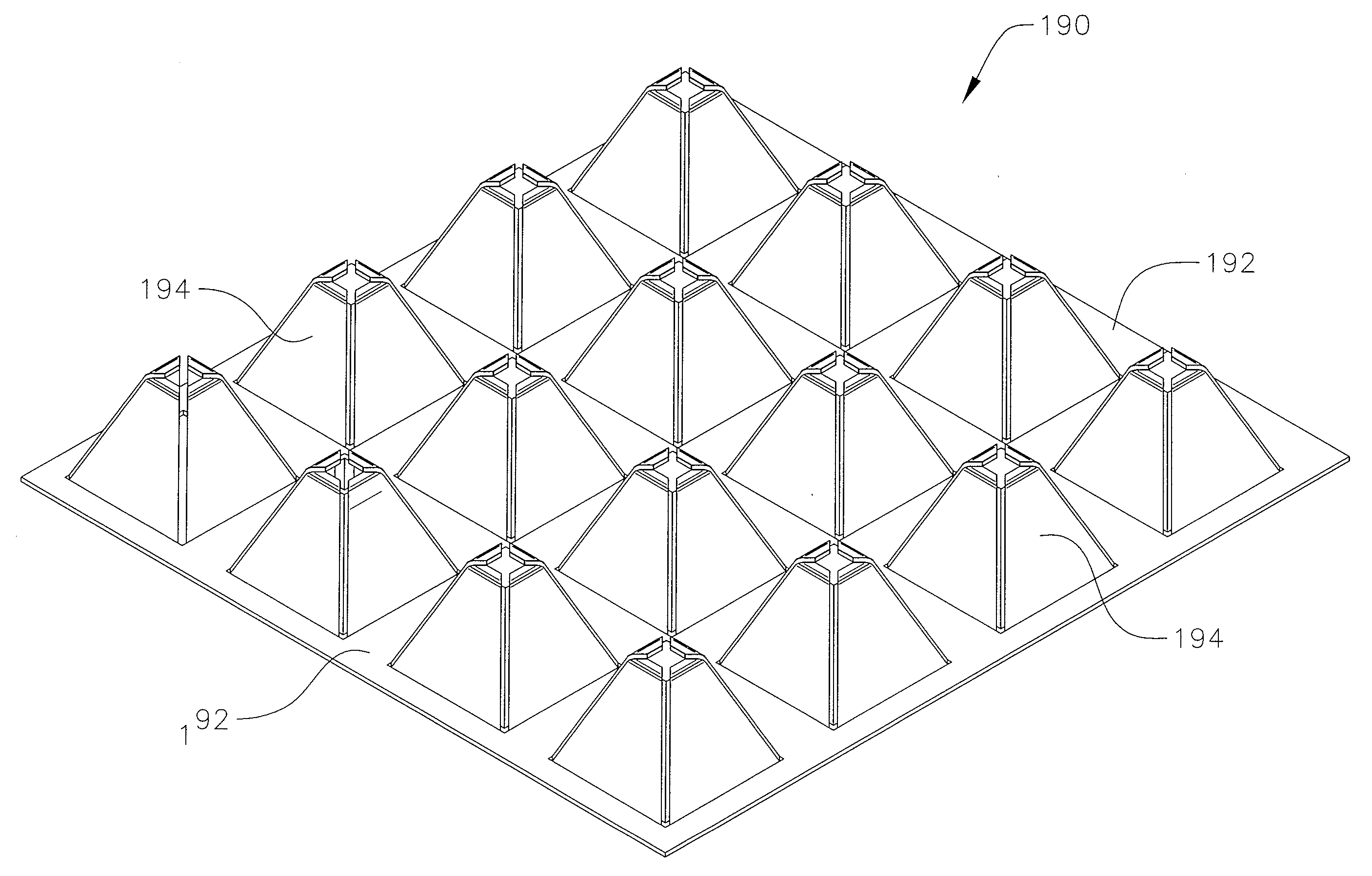

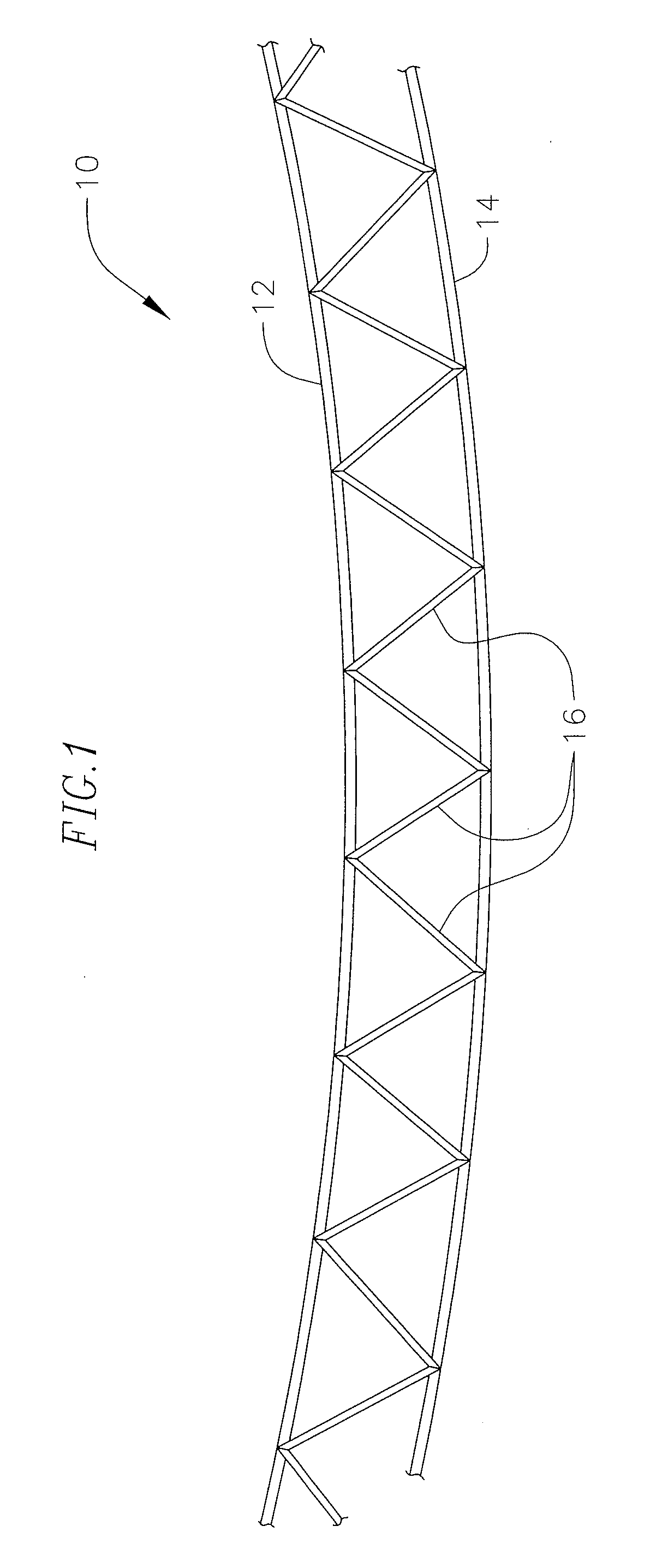

Mini-truss thin-sheet panel assembly

InactiveUS20090101195A1Improve rigidityLight weightSolar heating energySolar heat devicesThin slabThin sheet

A mini-truss thin-sheet panel assembly. In one embodiment, a substantially rigid thin-sheet panel assembly having a non-rigid thin-sheet component includes the thin-sheet component which has selected plan area and shape, a backer having a plan shape and area substantially similar to the thin-sheet component, and plural riser elements of selected height and configuration each extending from the backer to distal ends connected to a reverse surface of the thin-sheet component, the riser elements being configured and disposed in an array which causes the assembly to have substantial rigidity in a selected direction in the thin-sheet component.

Owner:GOSSAMER SPACE FRAMES

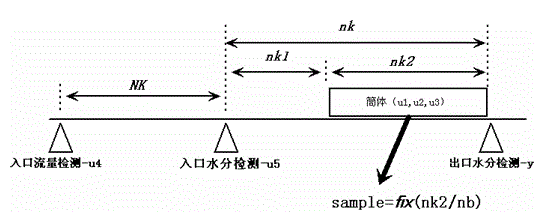

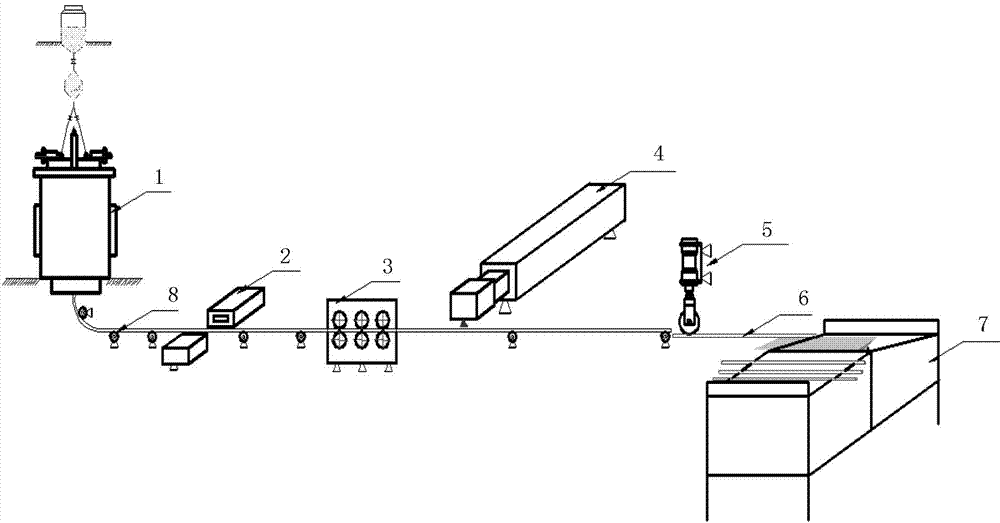

Model prediction based cut tobacco dryer outlet moisture control method

ActiveCN102871214AFully automatedAvoid manual interventionTobacco treatmentControl systemProcess engineering

The invention discloses a model prediction based cut tobacco dryer outlet moisture control method. Aiming at characteristics of complicated state changes of a cut tobacco dryer during working and diversity of production process modes, an intelligent integrated optimizing control system for the cut tobacco dryer based on an intelligent prediction model and an artificial intelligent operating mode is constructed so as to achieve comprehensive optimization and automation during cut tobacco drying. Aiming at different stages and different production process modes in production, a model capable of describing dynamic process characteristics depending on feed quantity and feed moisture is constructed. On the basis of the model, an on-line optimizing control algorithm which is capable of simultaneously or selectively adjusting multiple process variables, adapting to changes of the feed quantity and the feed moisture and overcoming mutual interference among the variables and influences of various uncertainties during cut tobacco drying and has self-adaptive and self-adjustment functions is designed, and strict requirements on outlet cut tobacco moisture in different working conditions can be met.

Owner:QINHUANGDAO TOBACCO MACHINERY

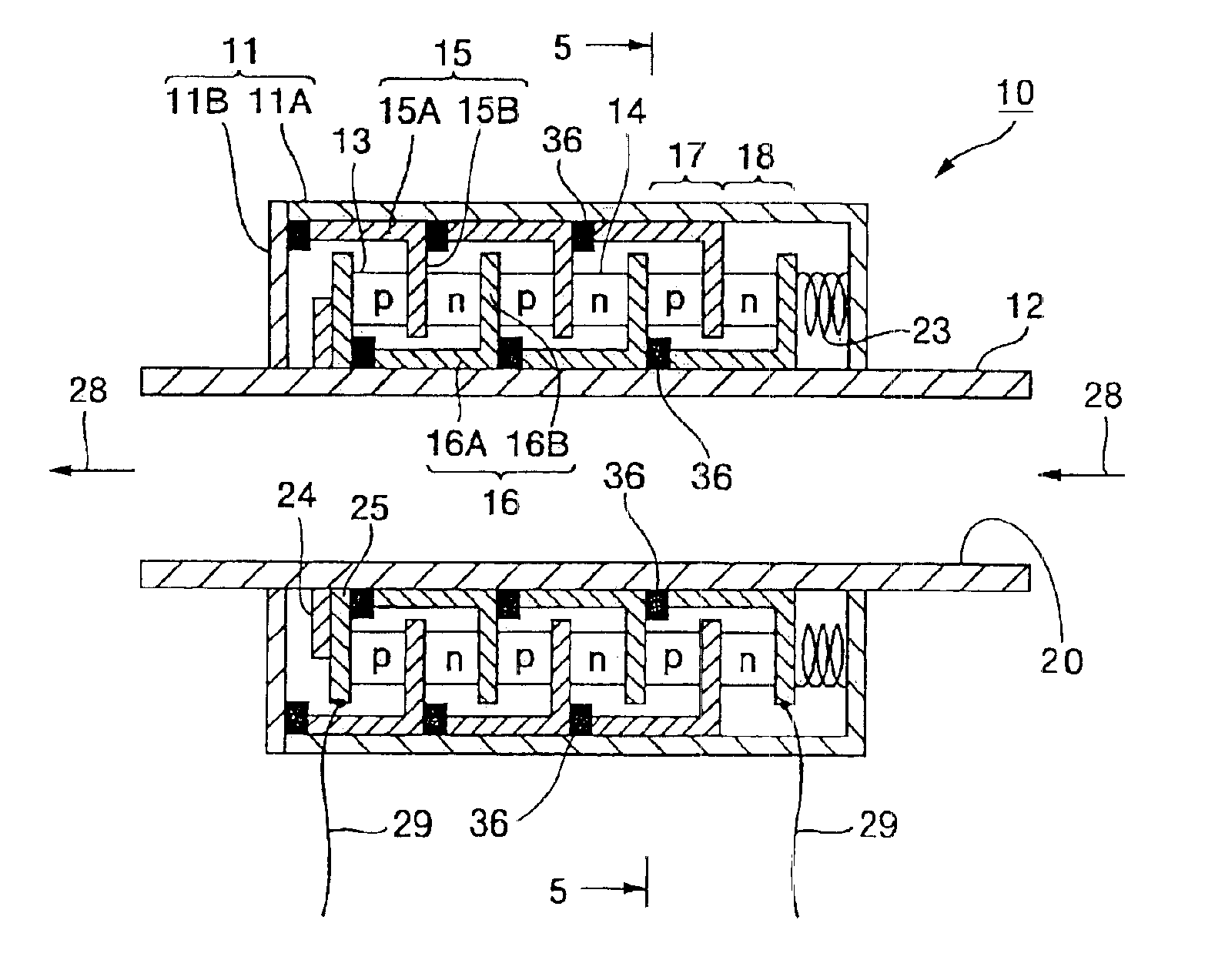

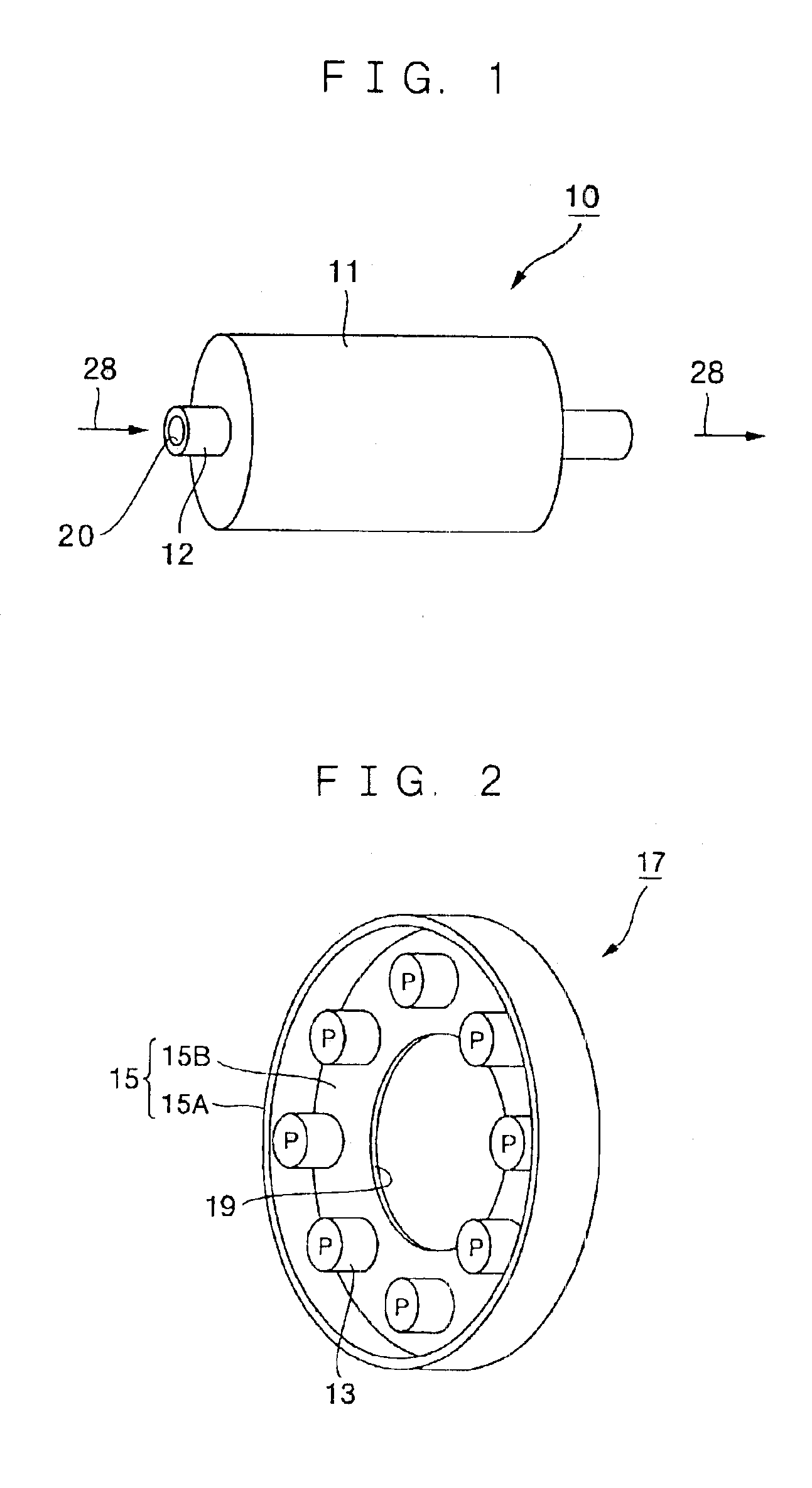

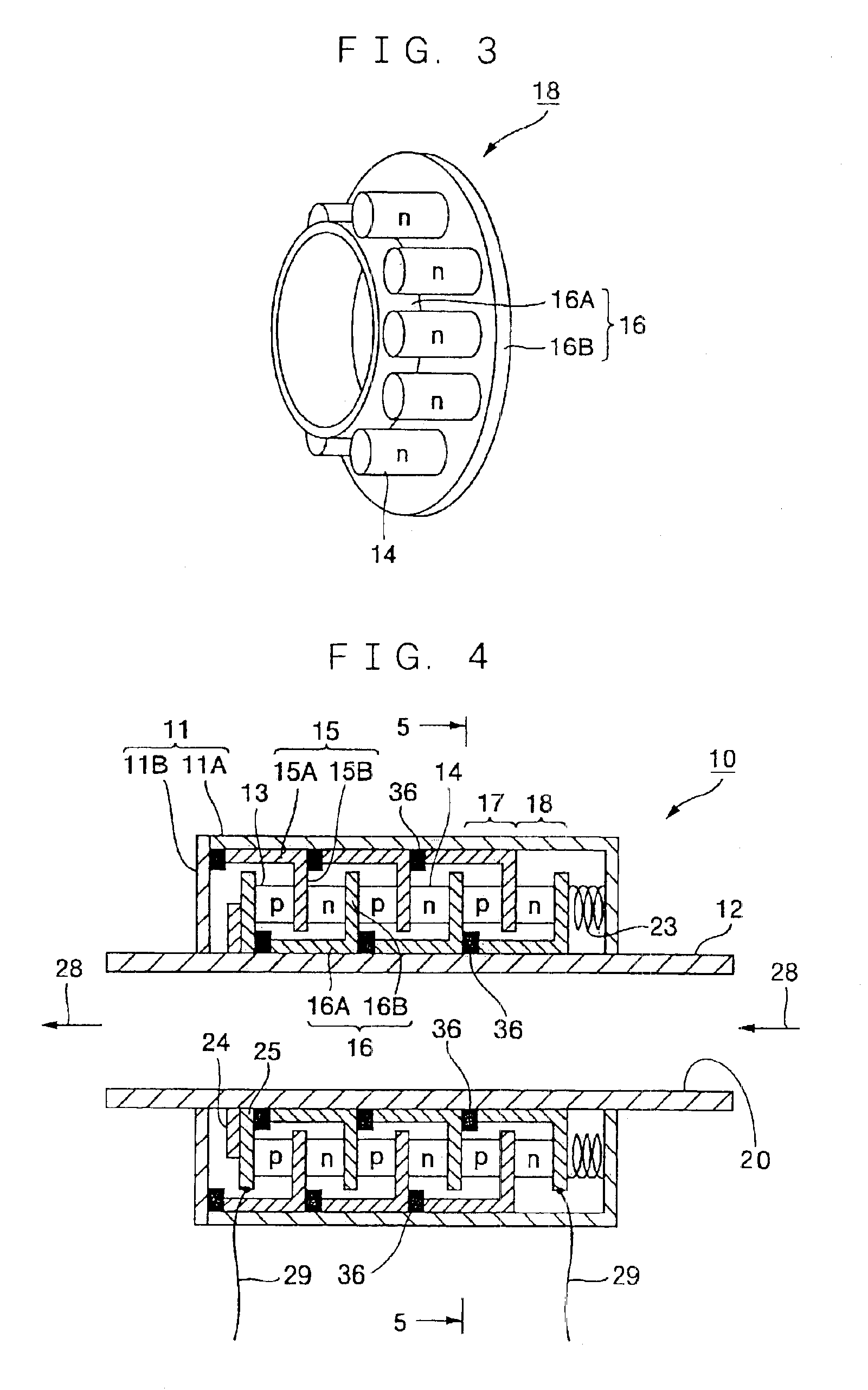

Thermoelectric module

InactiveUS6894215B2Simple structureReduce breakageThermoelectric device with peltier/seeback effectPhotovoltaicsEngineeringThermoelectric element

A thermoelectric module with a simple structure with less breakage by thermal stress is provided. For this purpose, the thermoelectric module includes p-type and n-type thermoelectric elements (13, 14) which are alternately placed, and outer electrodes (15) and inner electrodes (16), which are alternately placed between the thermoelectric elements (13, 14), and at least part of at least either one of the outer electrode (15) or the inner electrode (16) has a shape approximately along an object which exchanges heat with the electrodes (15, 16). The inner electrodes (16) surround an object which exchanges heat with the electrodes (15, 16).

Owner:KOMATSU LTD

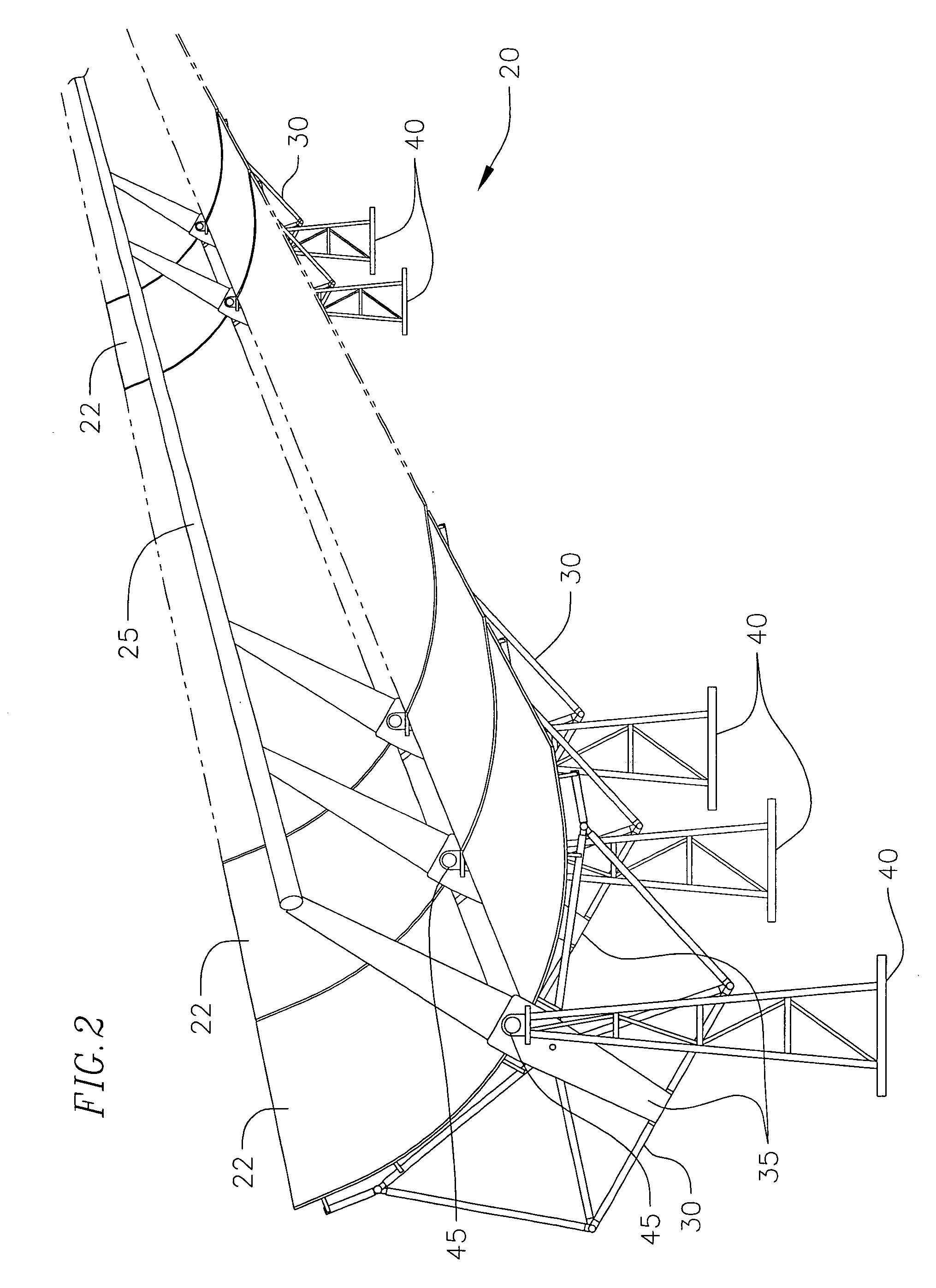

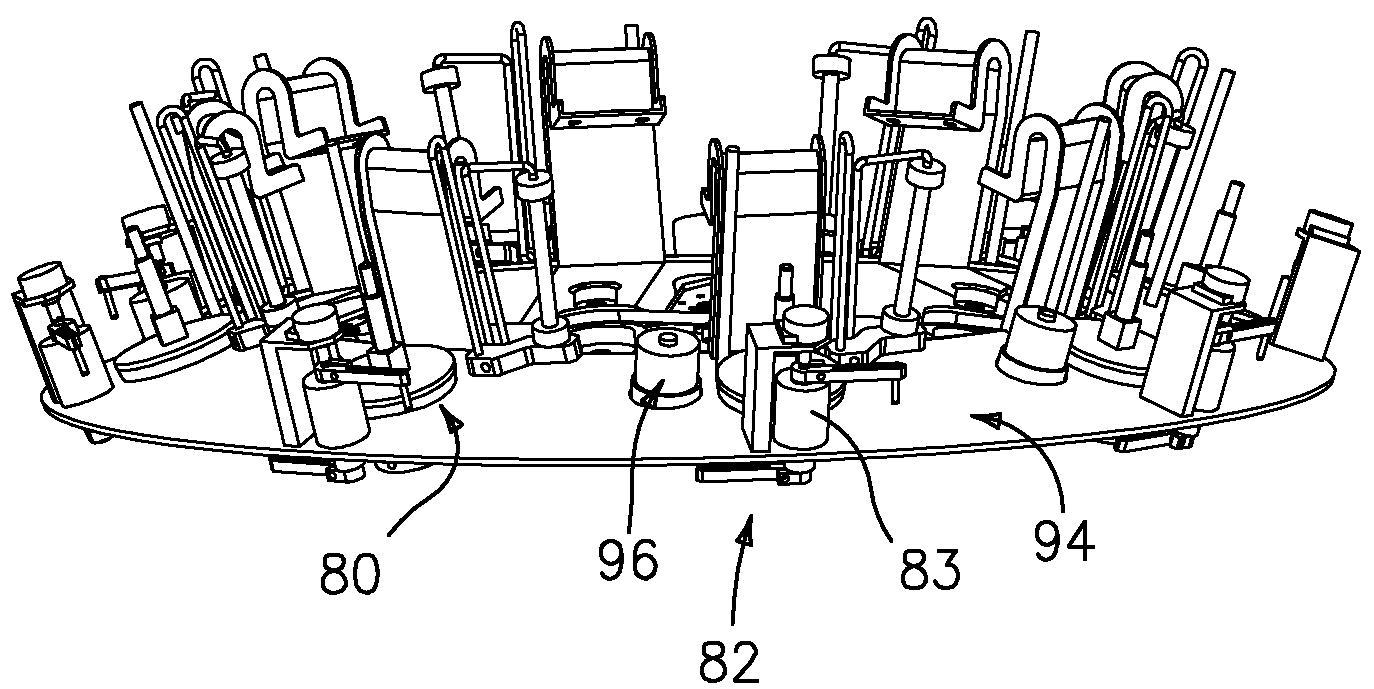

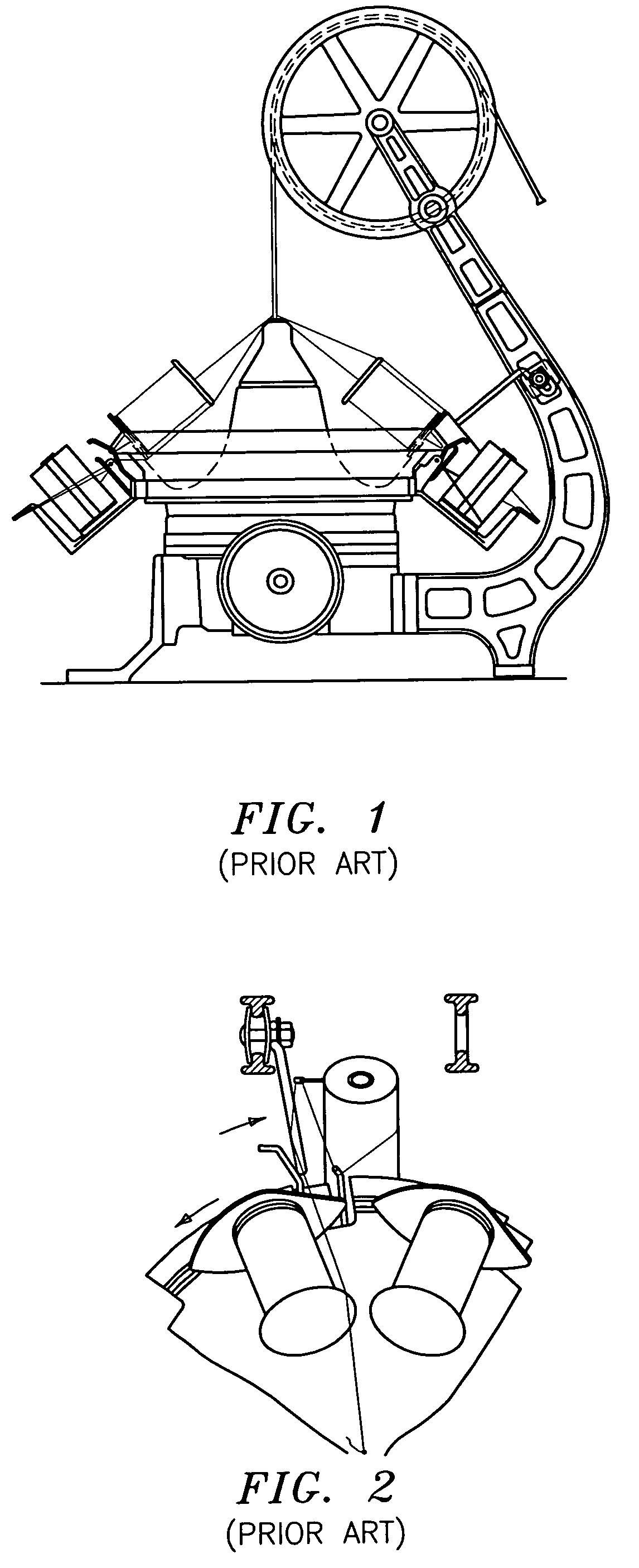

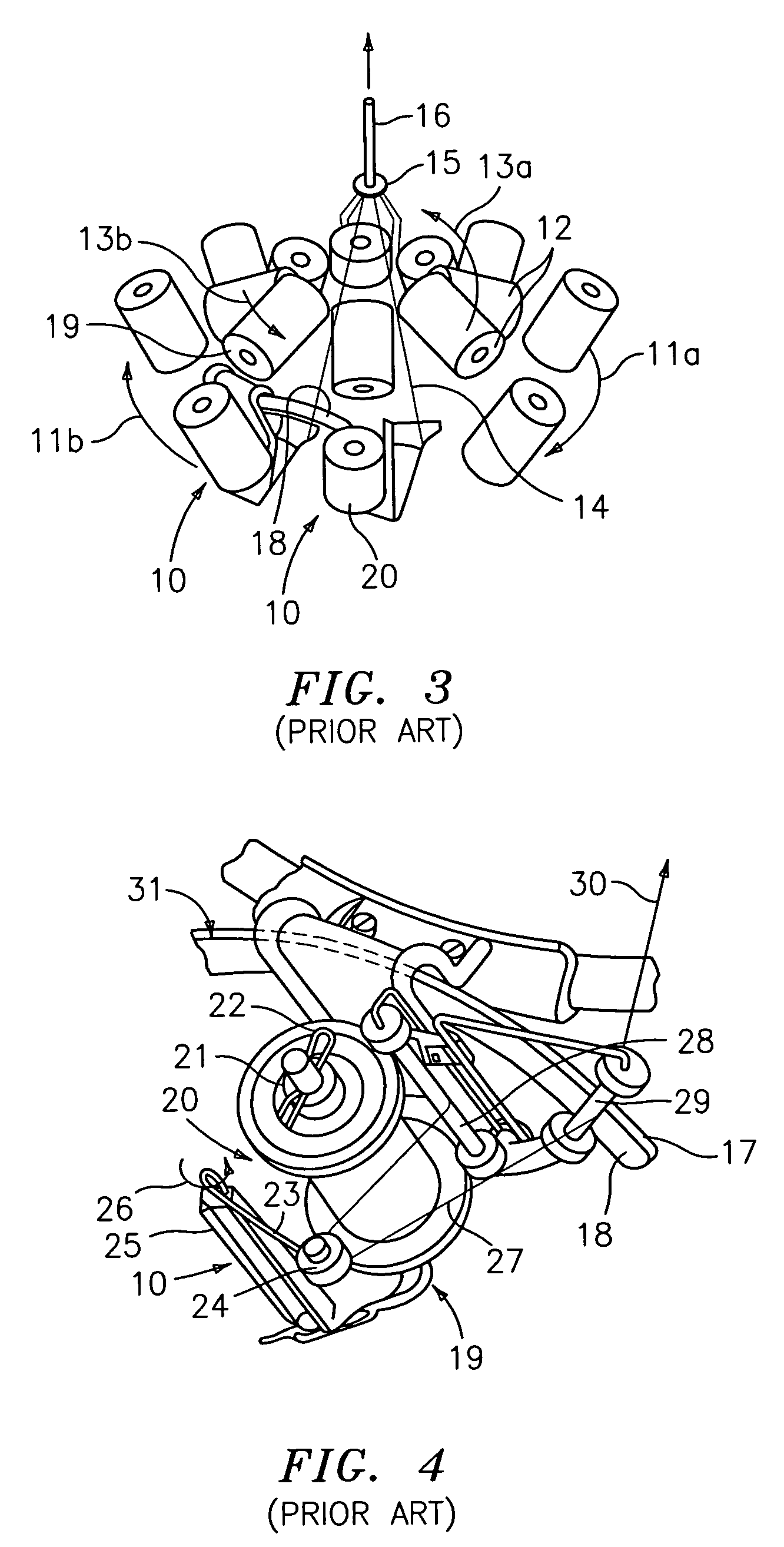

Powered lower bobbin feed system for deflector type rotary braiding machines

A Powered Lower Bobbin Feed (“PLBF”) system is disclosed for improving the operation of deflector type rotary braiding machines, such as the Wardwell Rapid Braider. The PLBF eliminates or reduces the impulsive tension spikes set up by the deflection and feed process in current rotary braiding machines by uniquely controlling the lower bobbin filament feed. These tension spikes result from: the rapid rotational acceleration and deceleration required of the lower bobbin as a result of the feed process; the lever arm tension control and bobbin ratchet mechanism; and the shape of the filament deflector surface. Such failure limits the operating speed of rotary braiding machines, the minimum size of filament that can be braided effectively, or the ability to maintain the quality of the braid produced. By eliminating or reducing these spikes, the PLBF therefore can increase the working speed of circular braiding machines and improve the uniformity of braided filaments generated by such machines at a given speed. In the preferred embodiment, the PLBF comprises: a slip ring designed to provide power to the lower bobbins; a variable speed powered lower bobbin concept; a feedback control system for the bobbins to assure bobbin feed matches braid consumption; and an improved, more contoured, deflector surface to minimize feed tension spikes. The new contour can be created: by retrofitting existing deflectors with a spline; or, by making new deflectors that incorporate the overall contour of a retrofitted deflector.

Owner:STOLBERGER

Method for non-contact laser cutting of quartz glass product and device thereof

InactiveCN102898014AEnsure consistencyReduce labor intensityGlass severing apparatusLaser beam welding apparatusCrevasseEngineering

The invention discloses a method for non-contact laser cutting of a quartz glass product and a device thereof. The method comprises the following steps: firstly firing the quartz glass product with a laser beam emitted by a laser generator to form a groove, and then cutting off by using a pneumatic unit. The device provided by the invention comprises a laser automatic cutting unit and the pneumatic unit. According to the invention, the product quality can be guaranteed, crevasses can be reduced, the consistency of the kerf and the kerf section can be guaranteed, waste is reduced, thus the operation is safe; and the laser cutting has noncontact with the quartz glass tube or quartz glass rod, thus the speed of drawing is raised, the production cost is reduced, the labor intensity is reduced, and the yield is raised.

Owner:JIANGSU PACIFIC QUARTZ

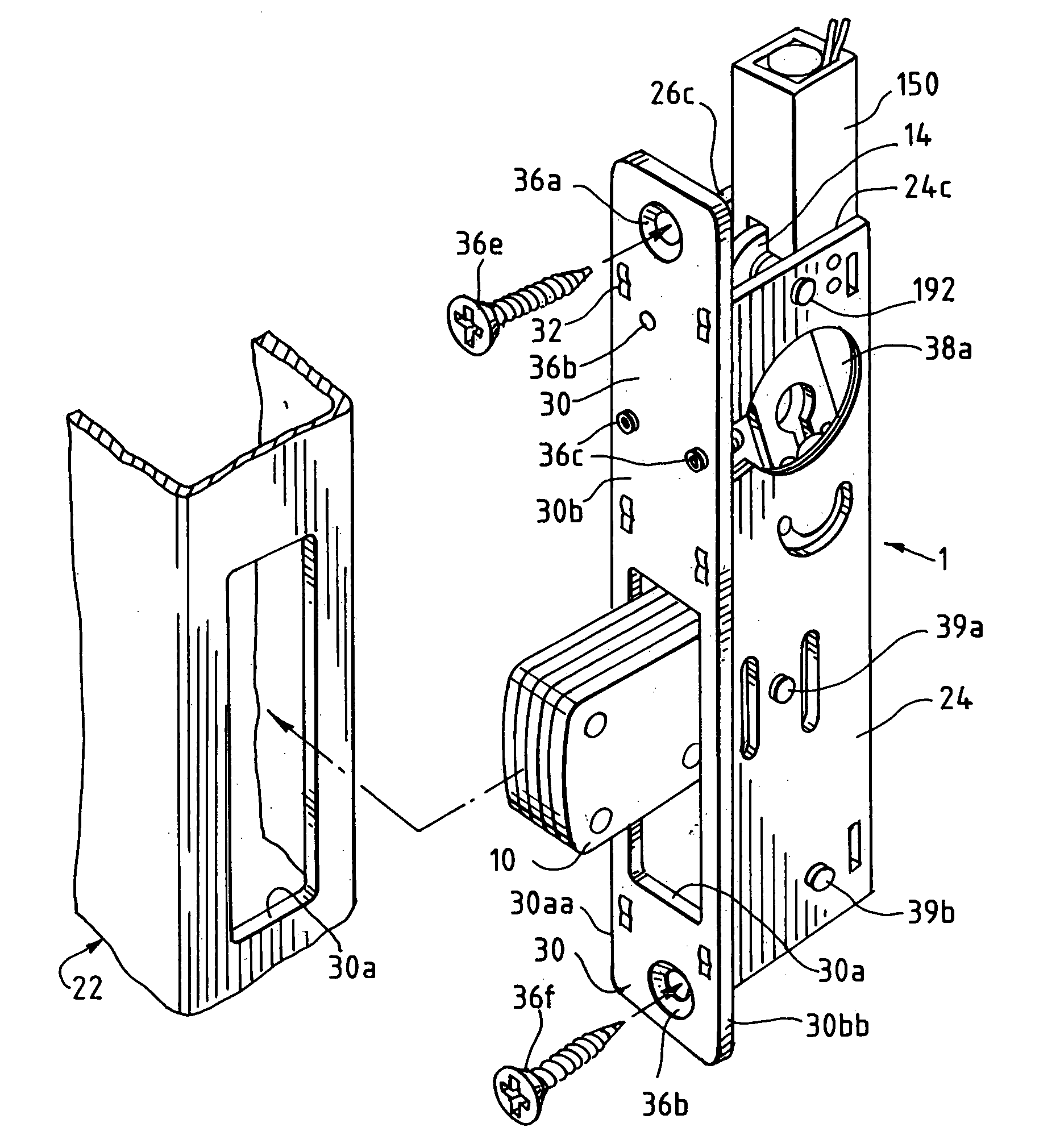

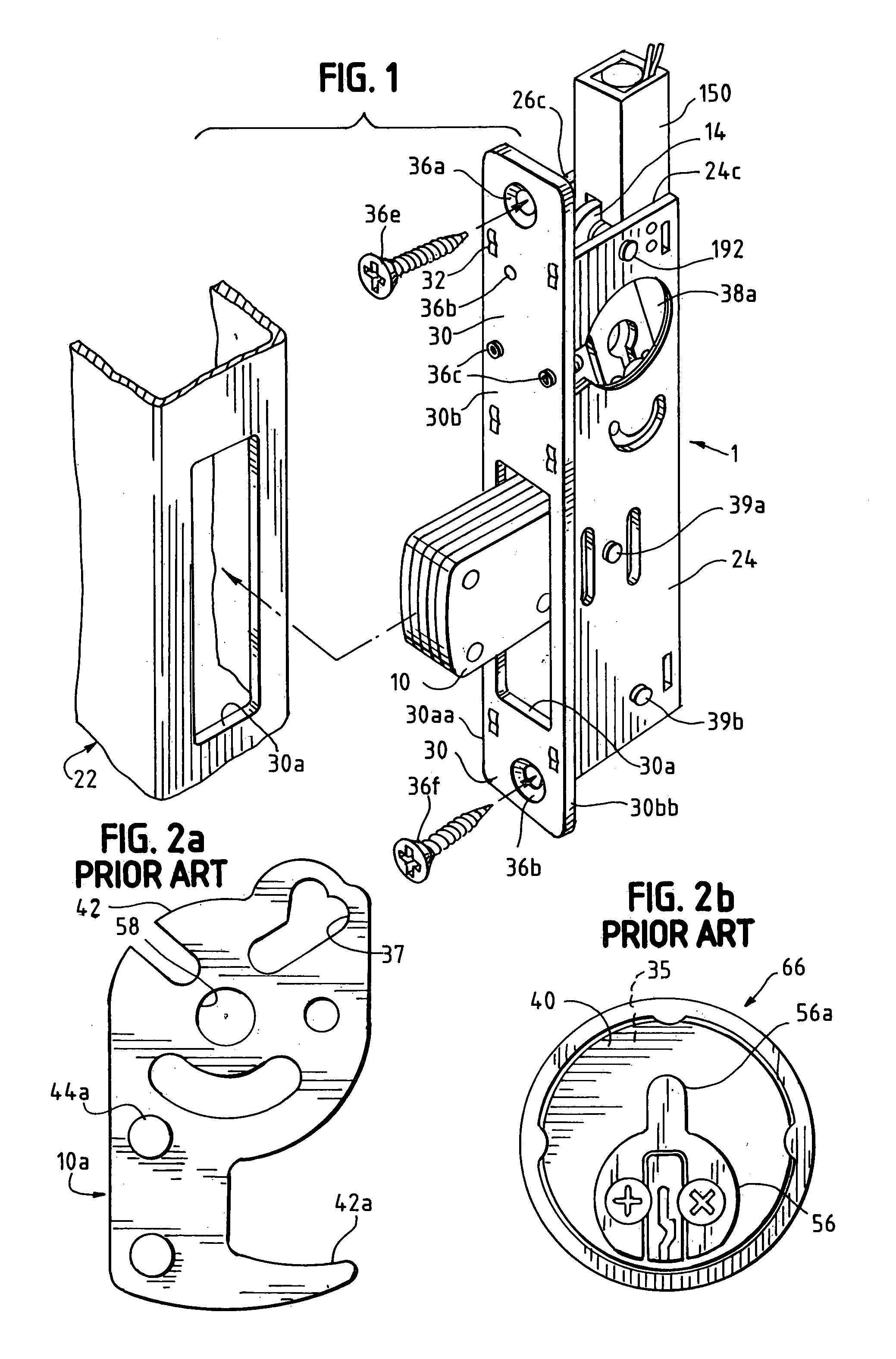

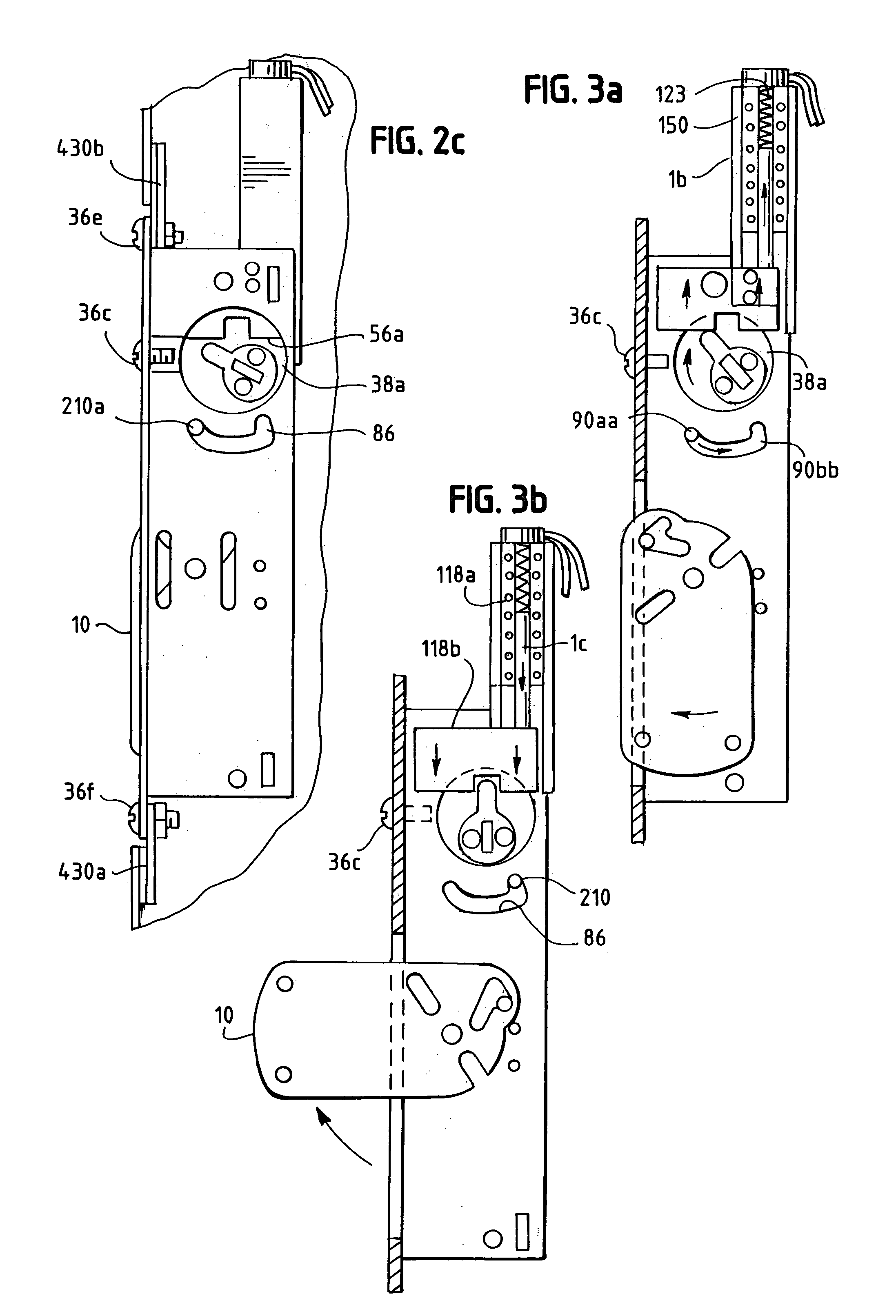

Electromagnetic integrative door locking device

InactiveUS7296448B1Cost per door frameReduce breakageNon-mechanical controlsConstruction fastening devicesElectronic accessMechanical components

Described herein is a locking device which integrates mechanical components in a hollow metal door frame with electronic access components. The preferred embodiment comprises a magnetic field generating device, an appropriately shaped metal solenoid housing and a cam retaining locking bar attached to a hollow stem. The electronic components override the original mechanical components of the lock to create a fail-safe situation in which the original mechanical lock may be disabled. In the preferred embodiment, my upgraded locking device can be re-installed within a hollow door frame, thereby minimizing service costs and doorframe modification costs.

Owner:SHAW BARRY M

Textile-based electrodes incorporating graduated patterns

ActiveUS20110259638A1Lessen needle wear needle needleReduce needle breakageElectrocardiographyWeft knittingBiophysical profileEngineering

Textile-based electrodes incorporating graduated patterns include a fabric portion having non-conductive yarns and an electrically conductive region having electrically conductive yarn filaments. The electrodes can further include float yarns and can be configured in a textured or ribbed construction. When incorporated into a garment, the electrodes can be used to monitor biophysical characteristics, such as the garment wearer's heart rate.

Owner:ADIDAS

Device and method for continuous block metal glass shaping

InactiveCN101543885ASolve the vacuum problemIncrease cooling intensityMetallic materialsPressure difference

The invention relates to a device and method for continuous block metal glass shaping, belonging to the technical field of metal material preparation. A heat insulating ring is arranged between a graphite casting mould and a water cooling copper mould which are arranged in a first vacuum chamber, an air cooler is arranged in a second vacuum chamber, and a traction rod enters the graphite casting mould and horizontally moves by a traction device. The method uses the graphite casting mould and the water cooling copper mould for primary main cooling and the air cooling mode for secondary auxiliary cooling, and the two vacuum chambers have a certain air-pressure difference. The device and the method have a high cooling speed, satisfy the requirements of the amorphous phase change of the block metal glass material. The shaping pressure of a metal melting body can be easily controlled, and the good shaping performance of the metal melting body is ensured by adjusting the pressure in the vacuum chambers. The metal passes through the graphite casting mould in a liquid state and is solidified in the water cooling copper mould, and the casting graphite casting mould has long service. The composite casting mould and the traction device have exchangeability to be convenient for realizing the continuous shaping of rod wires, boards, pipes and abnormal-shaped materials of different section sizes.

Owner:江苏苏州洲盛非晶科技有限公司

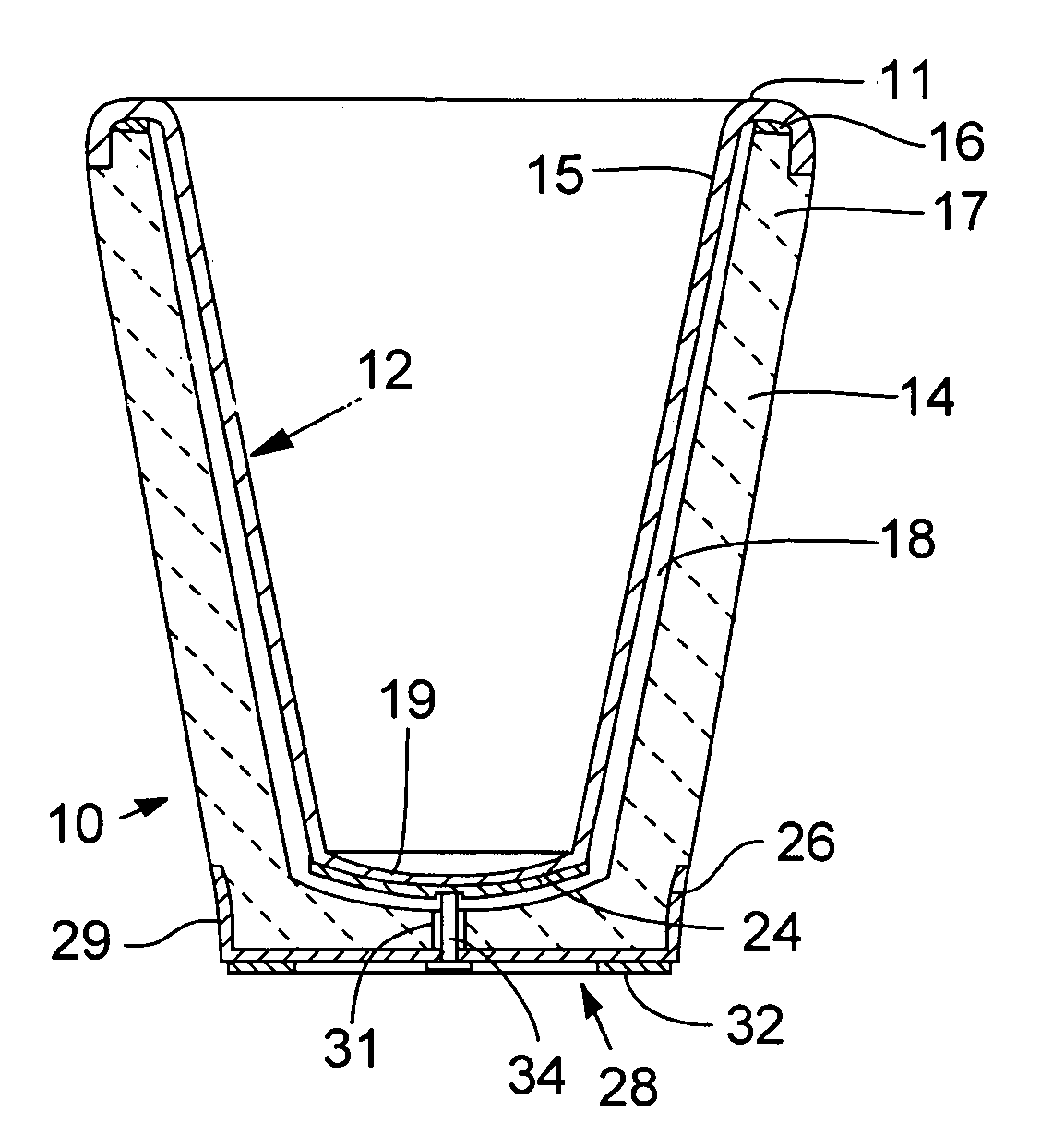

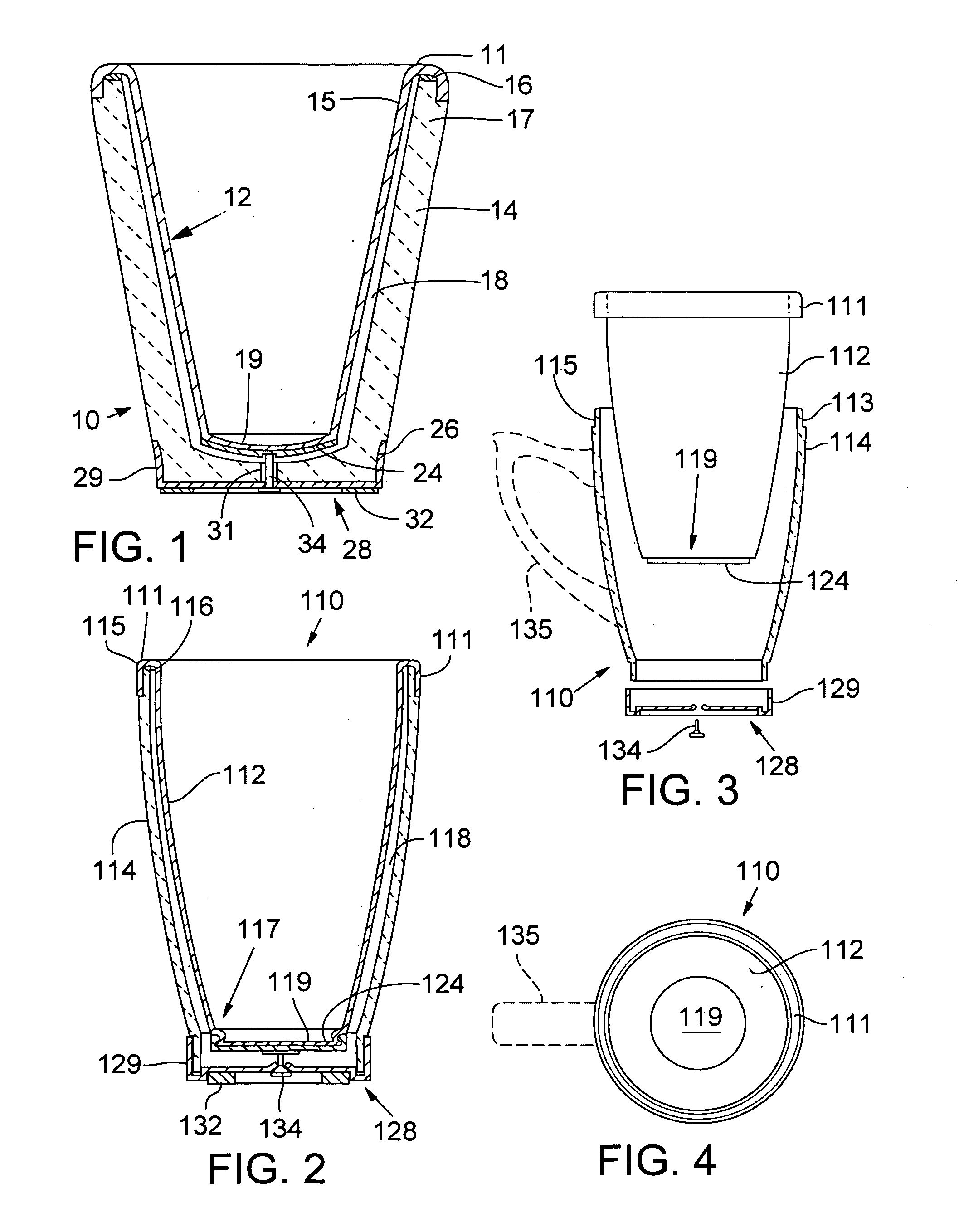

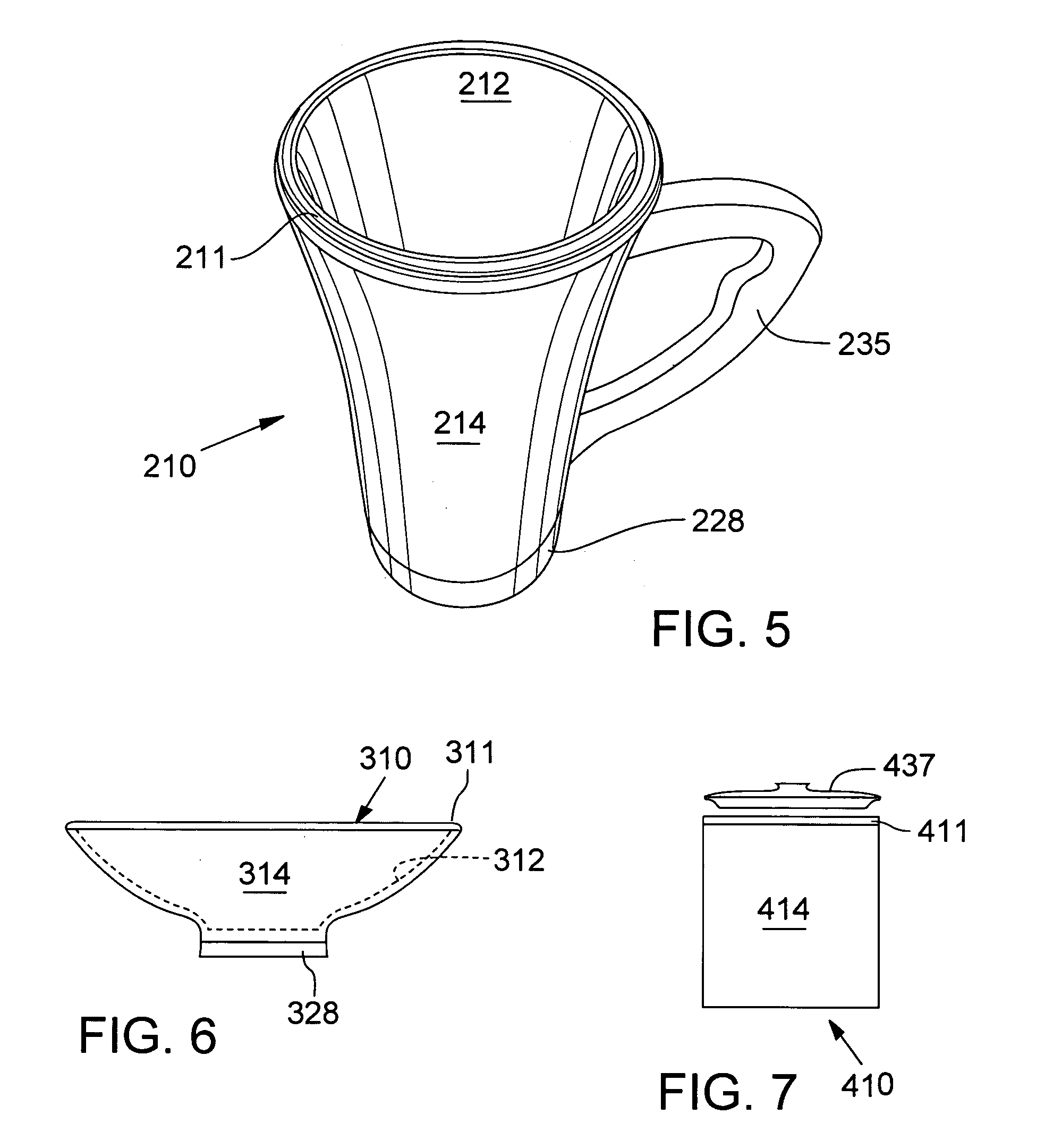

Ceramic metallic liquid holding vessel

InactiveUS7104413B2Reduce breakageReduce chippingDomestic cooling apparatusLighting and heating apparatusMetallic materialsAlloy

A vessel for holding liquid having an outer ceramic shell and an inner metallic lining. The metallic lining may extend over the top of the shell to provide protection from damage. A base member may be provided. The metallic material may be any food safe metal, including stainless steel and aluminum and alloys thereof. The ceramic may be any suitable ceramic including porcelain, earthenware and glass. Handle and non-handles vessels are disclosed as are resealable and non-resealable vessels. The metallic and ceramic materials may be separated by an insulative gap.

Owner:PACIFIC CORNETTA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com