Enclosed multi-chamber fluidized bed drying method for sludge

A multi-chamber fluidized bed and sludge drying technology, applied in the direction of dehydration/drying/thickened sludge treatment, can solve the problems of low thermal efficiency and pollutant discharge, and achieve high thermal efficiency, small bed resistance and flexible operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

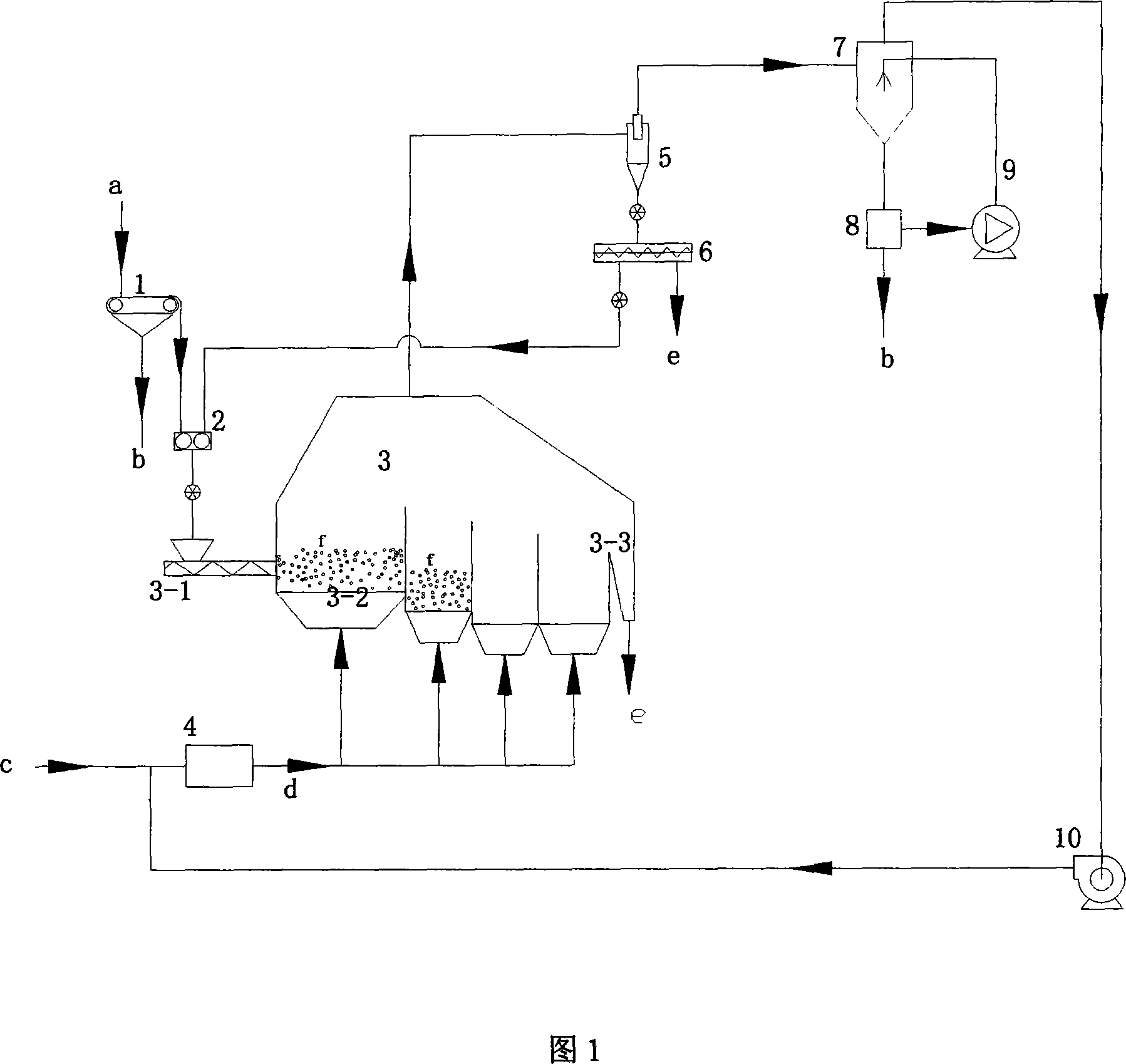

[0026] (1) The present invention aims at the problem that the sludge in the first and second chambers of the current multi-chamber fluidized bed drier is easy to agglomerate, and proposes the following solutions: 1. The temperature of each chamber of the fluidized bed drier in the present invention is 250 ° C to 300 ° C. ℃ to control the sludge cohesive strength. Simultaneously control the residence time of the sludge in the bed to minimize the separation of volatile components in the sludge; 2. in the present invention, a part of the dried sludge is re-mixed to the first chamber of the fluidized bed to make the mixed sludge The moisture content of the mud is about 50%, so that it directly crosses the "adhesive phase" to reduce the adhesion of the sludge in the dryer; ③ the first and second chambers of the fluidized bed dryer in the present invention are fluidized with inert particles The main difference between it and the traditional fluidized bed dryer is that it is filled w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com