Test air duct system for testing heat exchange performance and dehumidifying/icing amount of air heat exchanger

A technology of air heat exchanger and heat exchange performance, which is applied in the testing of machines/structural components, instruments, measuring devices, etc., and can solve problems such as inappropriate testing of air evaporators and condensers, wind speed requirements and control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The technical solutions of the present invention will be described below through specific embodiments in conjunction with the accompanying drawings.

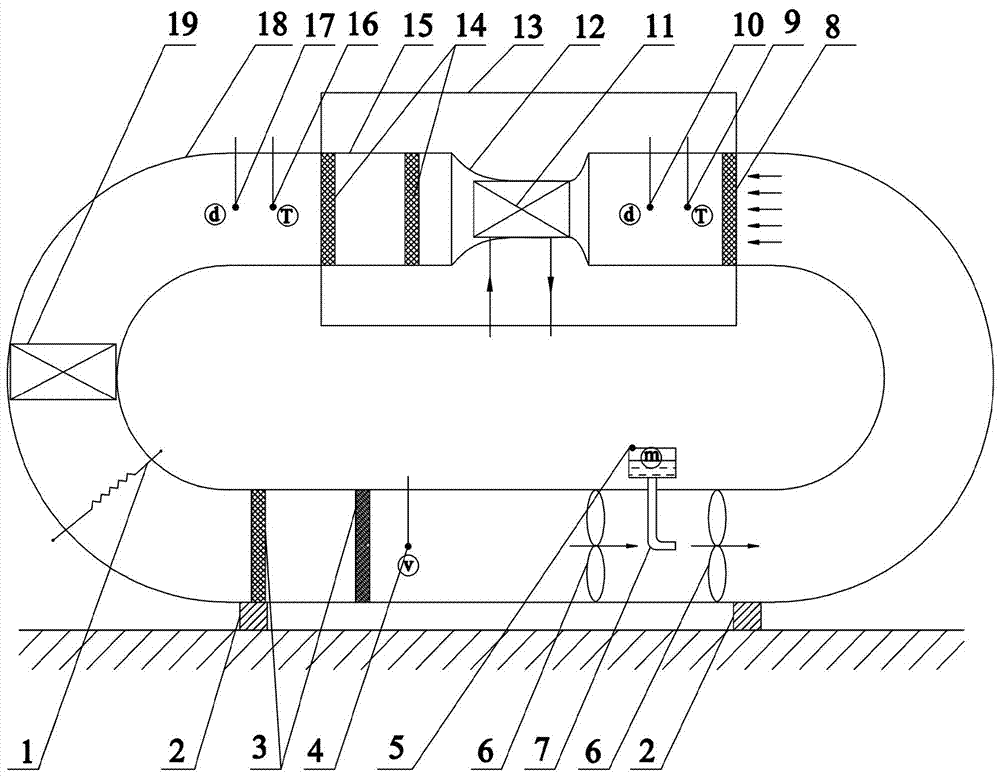

[0049] The embodiment of the present invention provides a test air duct system that provides a constant temperature and humidity environment, please refer to figure 1 , including: circular air duct, electric heater 1, air duct support 2, wind speed sensor front damping rectifier 3, wind speed sensor 4, quality sensor 5, fan 6, ultrasonic humidifier 7, test evaporator / condenser front damping rectifier 8 , Test the temperature sensor before the evaporator / condenser 9, test the humidity sensor before the evaporator / condenser 10, test the evaporator / condenser 11, the soft connection of the circular air duct 12, the insulation box 13, test the back of the evaporator / condenser Damping rectifier 14, special insulation section 15 of annular air duct, temperature sensor 16 after test evaporator / condenser, humidity sensor 17 after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com