Patents

Literature

129 results about "Crevasse" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crevasse is a deep crack, or fracture, found in an ice sheet or glacier, as opposed to a crevice that forms in rock. Crevasses form as a result of the movement and resulting stress associated with the shear stress generated when two semi-rigid pieces above a plastic substrate have different rates of movement. The resulting intensity of the shear stress causes a breakage along the faces.

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759AImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

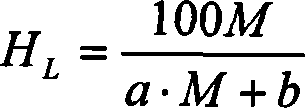

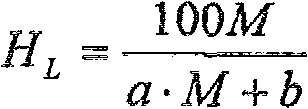

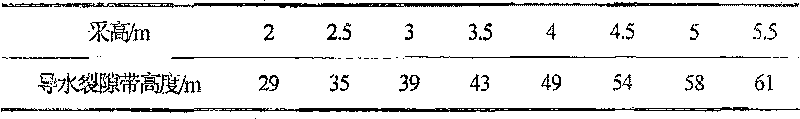

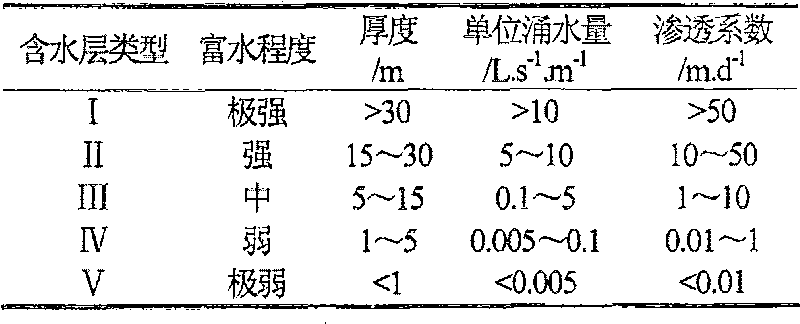

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

Method for non-contact laser cutting of quartz glass product and device thereof

InactiveCN102898014AEnsure consistencyReduce labor intensityGlass severing apparatusLaser beam welding apparatusCrevasseEngineering

The invention discloses a method for non-contact laser cutting of a quartz glass product and a device thereof. The method comprises the following steps: firstly firing the quartz glass product with a laser beam emitted by a laser generator to form a groove, and then cutting off by using a pneumatic unit. The device provided by the invention comprises a laser automatic cutting unit and the pneumatic unit. According to the invention, the product quality can be guaranteed, crevasses can be reduced, the consistency of the kerf and the kerf section can be guaranteed, waste is reduced, thus the operation is safe; and the laser cutting has noncontact with the quartz glass tube or quartz glass rod, thus the speed of drawing is raised, the production cost is reduced, the labor intensity is reduced, and the yield is raised.

Owner:JIANGSU PACIFIC QUARTZ

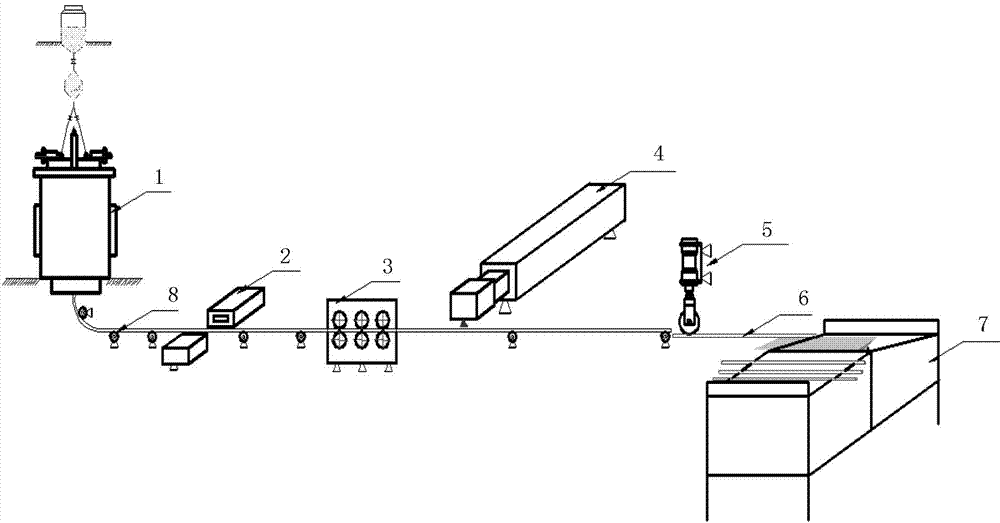

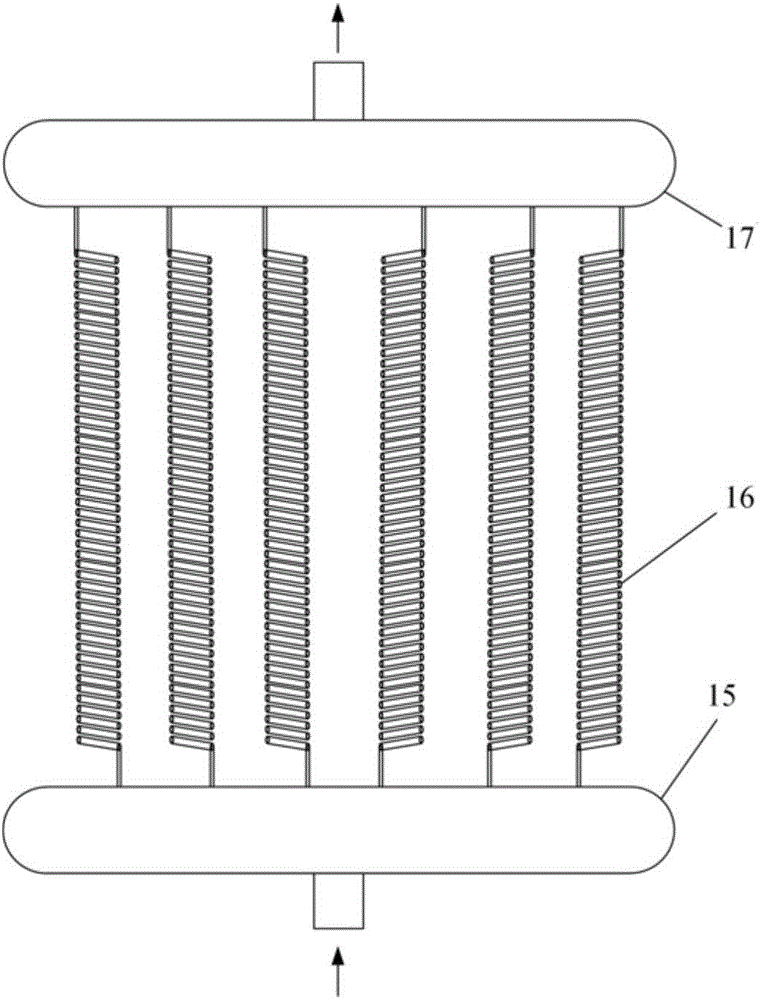

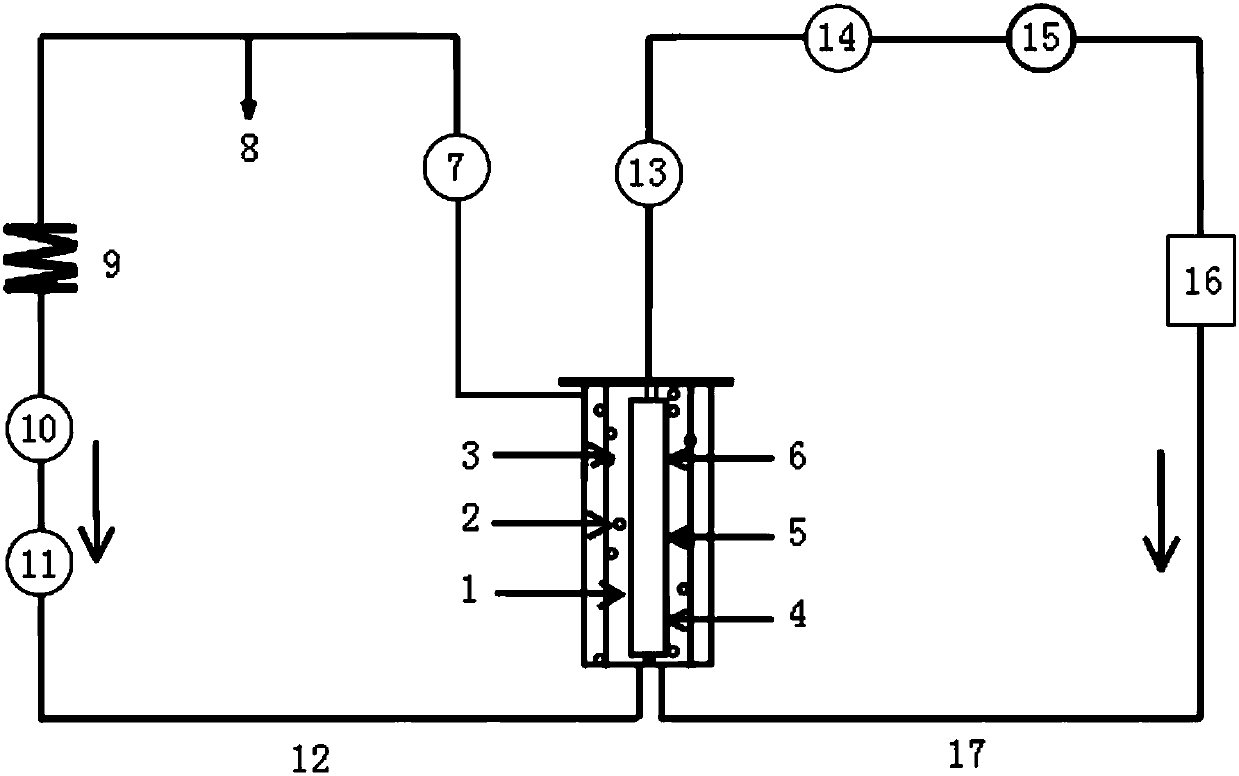

Long-term efficient passive containment cooling system utilizing jetting technique

ActiveCN106782698AImprove cooling efficiencyReduce evaporationNuclear energy generationCooling arrangementDischarge efficiencyWater vapor

The invention aims to provide a long-term efficient passive containment cooling system utilizing a jetting technique. A built-in heat exchanger of a containment and upper and lower pipe sections form a first-stage heat discharging system; an air cooler, a water tank baffle plate and a steam-air jet device in an external water tank form a second-stage heat discharging system of a cooling system; the steam-air jet device is located on the side wall surface of a gas space in the water tank and is used for introducing water steam produced by virtue of the first-stage heat discharging system into an ejector to jet air of the second-stage heat discharging system, so as to decrease the inlet temperature of the first-stage heat discharging system, so that the heat discharging efficiency of the system is improved; and a passive containment heat exchanger adopts an intensified heat exchange pipe and is located in the containment, the heat exchange pipe adopts a small-coil-pipe light pipe, and drainage plates are mounted on the periphery of the heat exchanger. According to the long-term efficient passive containment cooling system, when a crevasse accident occurs at a main cooling agent loop or a main steam pipeline, the internal heat in the containment can be efficiently taken away in a long term, so that the internal temperature and pressure of the containment can be below safety limit values for a long time under accident conditions.

Owner:HARBIN ENG UNIV

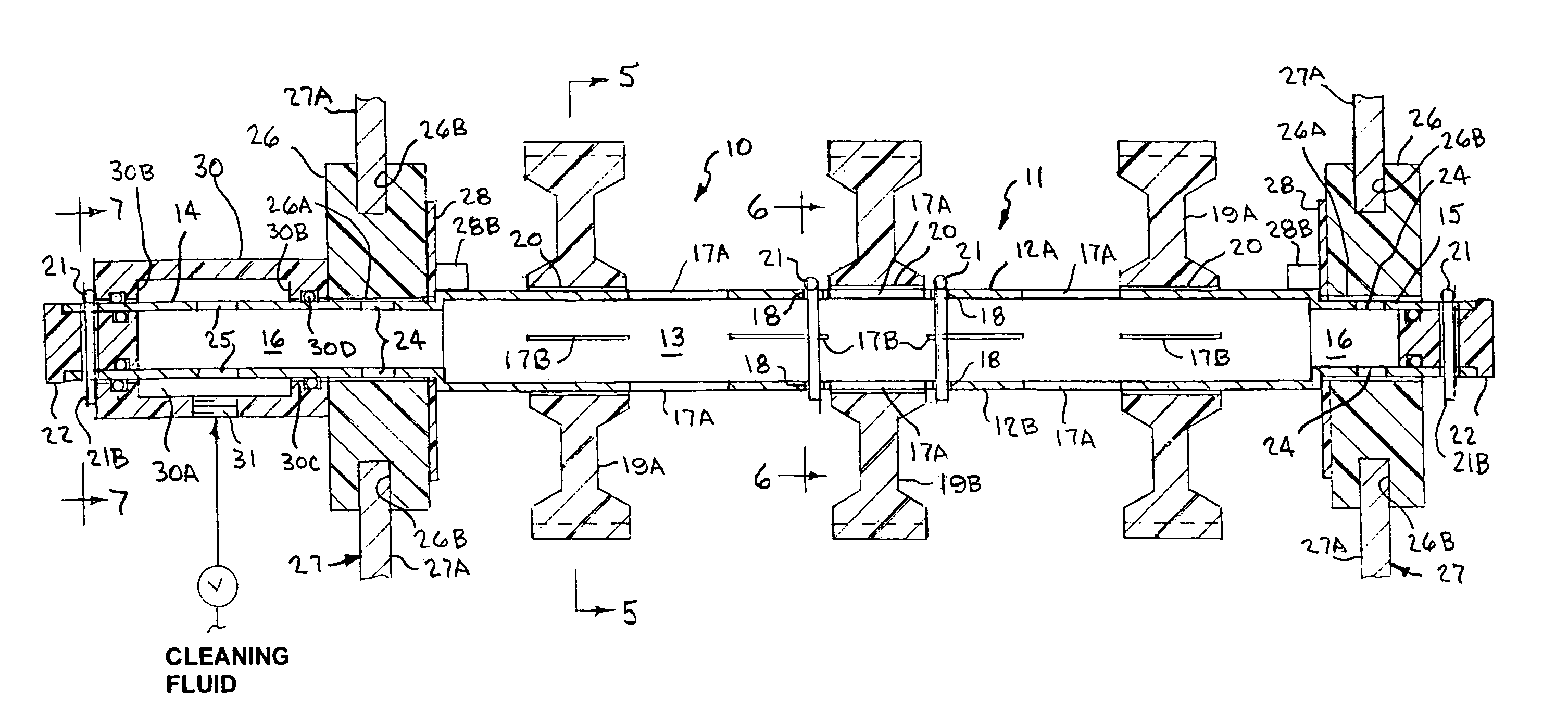

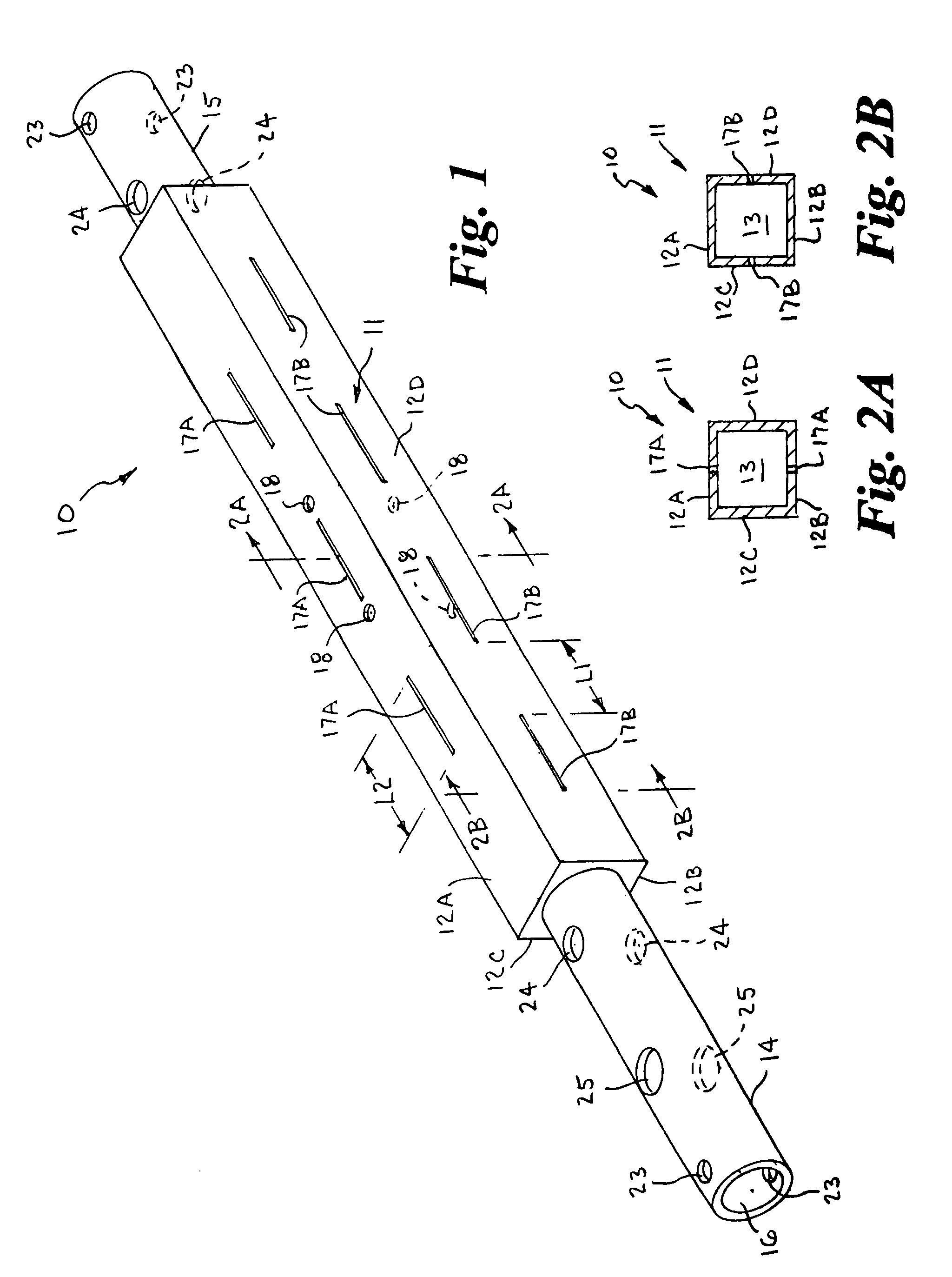

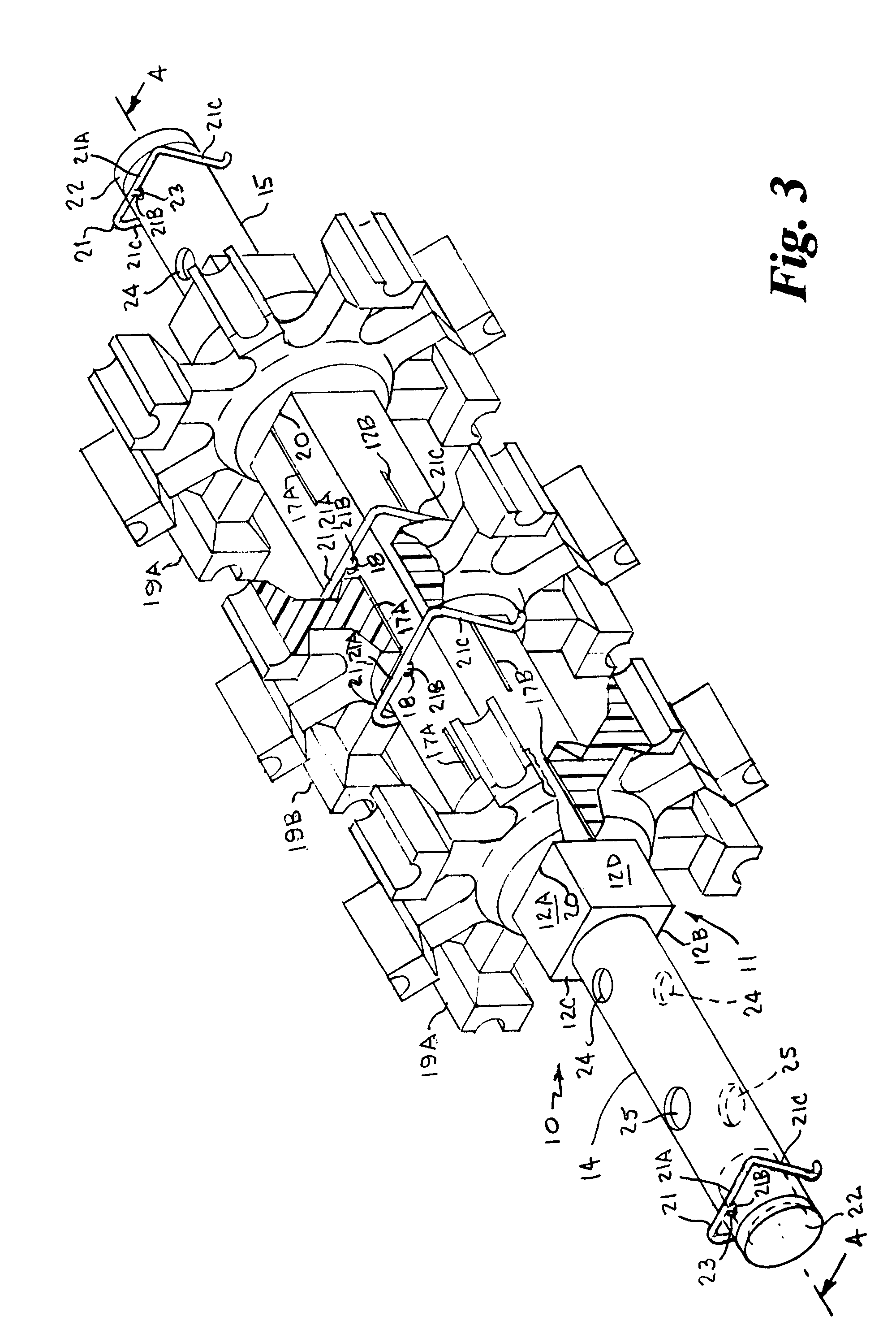

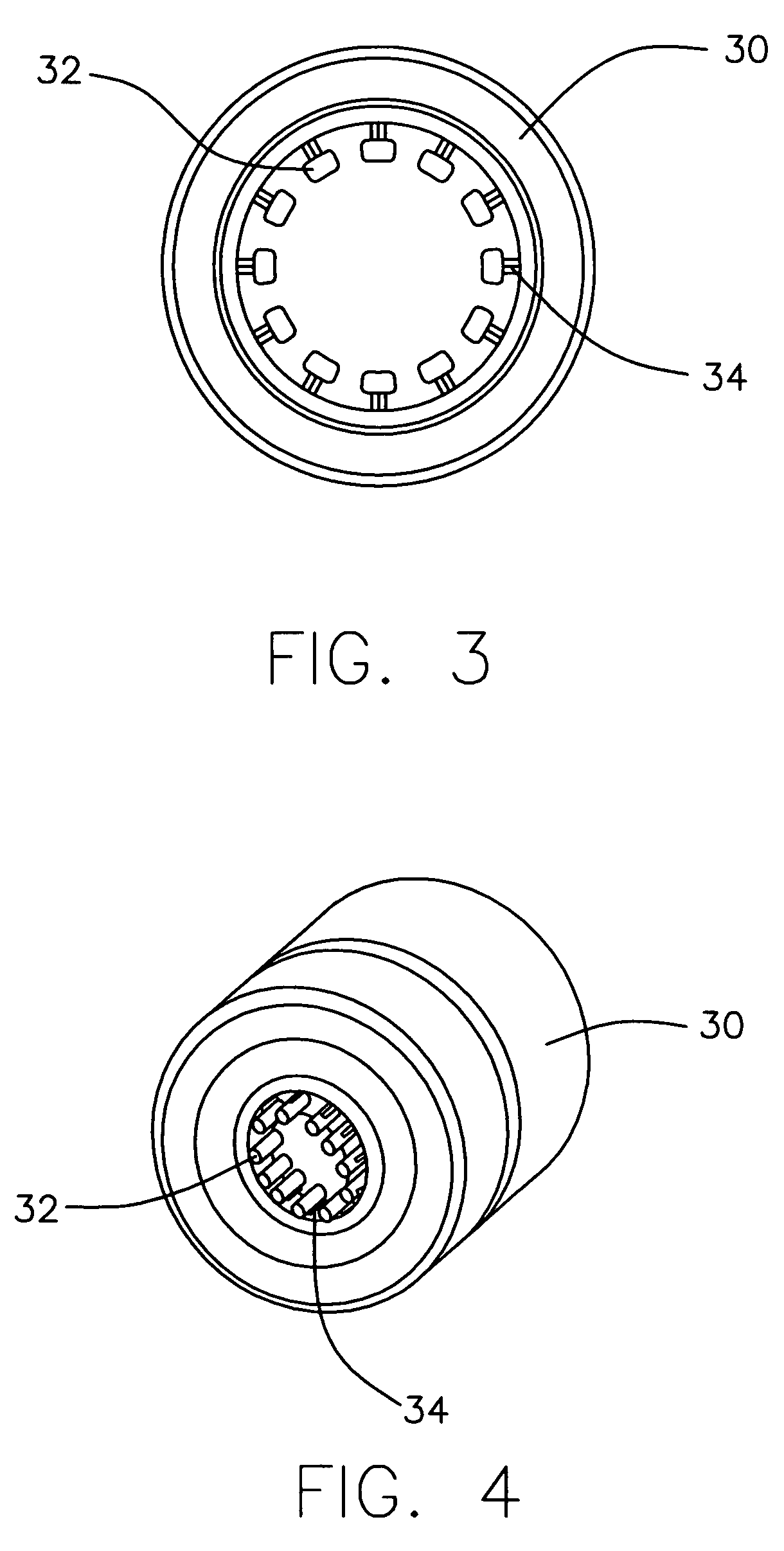

Nozzleless conveyor belt and sprocket cleaning shaft

A nozzleless belt-cleaning sprocket support shaft for cleaning endless conveyor belts has a first end, a second end, a central portion of generally square transverse cross section with a plurality of elongate narrow slits in each of the side walls in longitudinally spaced apart relation along its length, and a plurality of sprockets mounted thereon. Cleaning fluid is simultaneously discharged through the slits in a fan spray pattern onto the inside surface of the conveyor, through crevasses, joints, hinges, interfaces and openings in the belt to effect cleaning of the belt, and between the exterior surfaces of the shaft and interior surfaces of the bores of the sprockets and the bearings that support the shaft to effect cleaning of the overlapping surfaces, during rotation of the belt. The cleaning shaft may be used with various types of conveyor belts and the ends may be mounted in conventional bearings.

Owner:FARRIS MIKE +1

Room temperature crosslinked foam

Foams for filling cavities and crevasses and for forming foamed products are provided. The latex foam may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Room temperature crosslinked foam

InactiveUS20080161432A1Safe disposalSafe installationBuilding reinforcementsFoaming agentRoom temperature

Foams for filling cavities and crevasses and for forming foamed products are provided. The latex foam may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

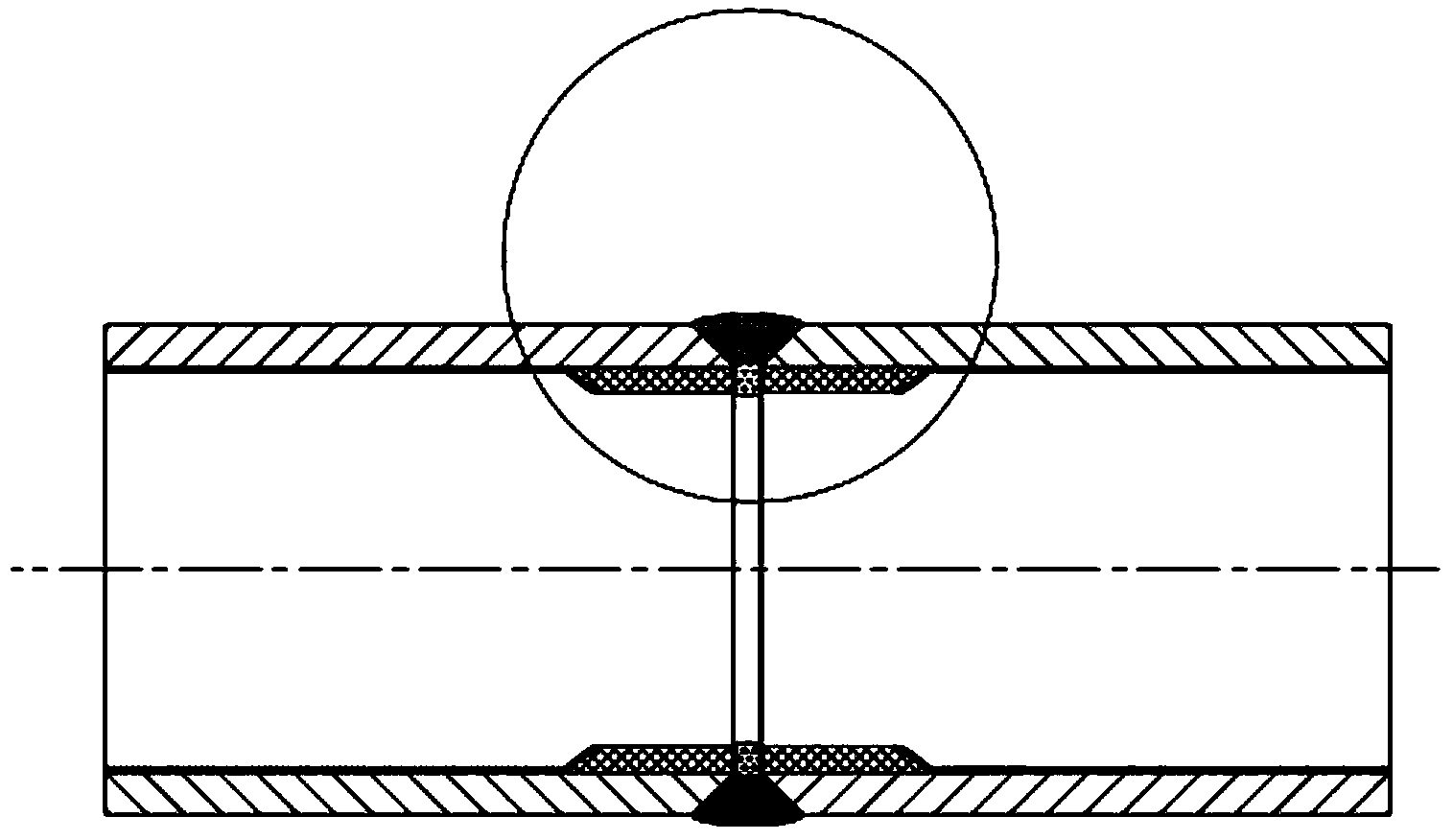

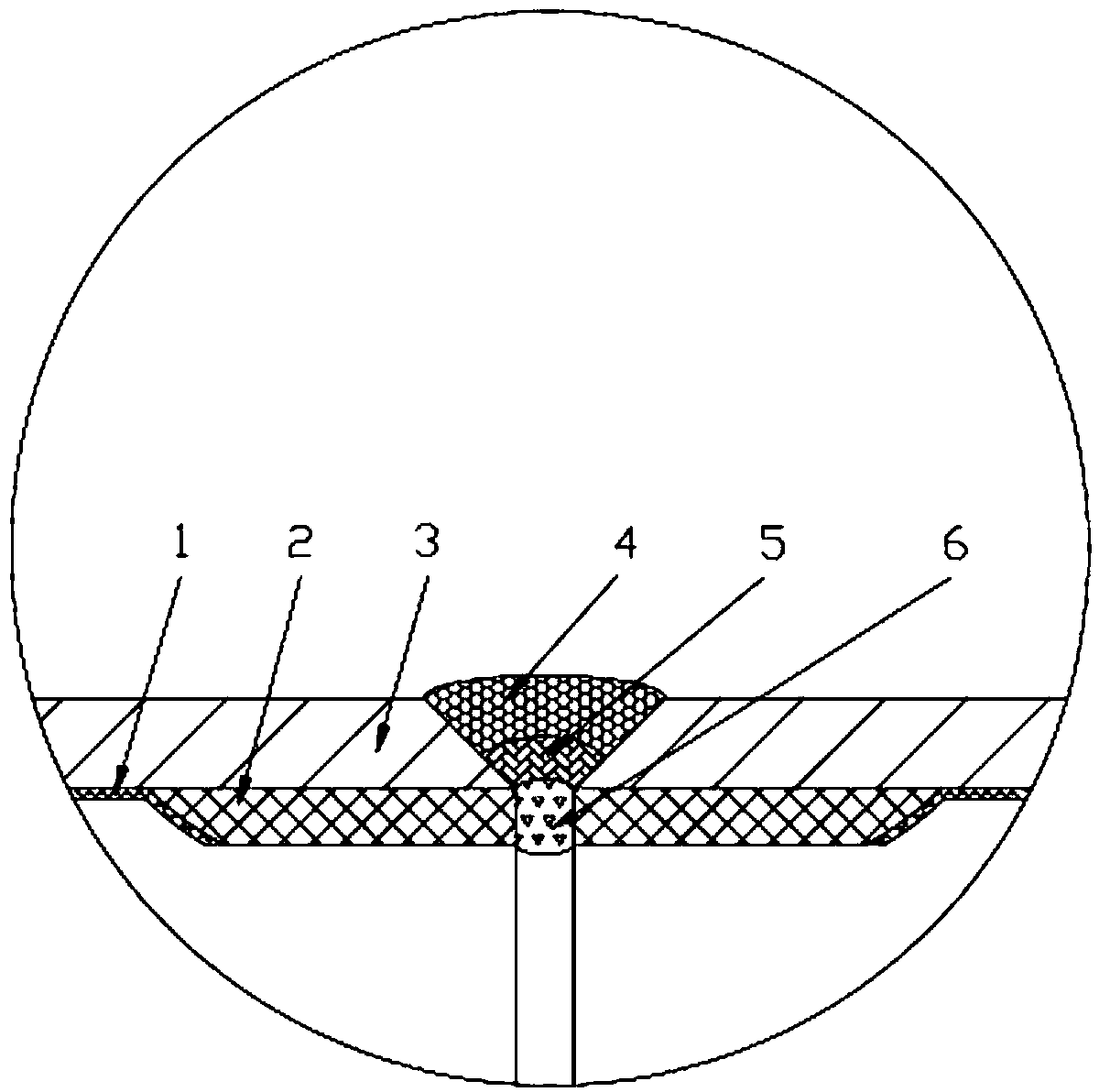

Reinforcing measures for balcony crevasse

The invention relates to a balcony crack reinforcing method, consisting of a chemical pressurized grouting stage and a carbon fiber obturation stage, wherein the chemical pressurized grouting stage consists of the following processes: grouting nozzle embedding, crack obturating, pressure testing, pulp preparation, and grouting; the carbon fiber obturation stage consists of the following processes: substrate processing, adhesive coating, leveling, and carbon fiber attaching. After the above-mentioned processes, the balcony cracks are strengthened well. The balcony crack reinforcing method of the invention is capable of completely mending the cracks of balconies, restoring the rigidity of the balcony wall to almost the original level, thereby ensuring safety effectively.

Owner:华新建工集团有限公司

Room temperature crosslinked foam

Foams for filling cavities and crevasses and for forming foamed products are provided. The latex foam may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

Combination of chlorinated polythylene insulating material

ActiveCN101290818AComprehensive technical performanceGood weather resistancePlastic/resin/waxes insulatorsInsulated cablesLow voltageRare earth

The invention discloses a chlorinated polyethylene insulating material combination. The compositions in portion by weight of the combination are: 60 portions of chlorinated polyethylene, 40 portions of EPDM, 5 to 8 portions of composite rare earth stabilizing agent REC-LS, 3 to 5 portions of thiadiazoles derivate vulcanizing agent and 1.5 to 2 portions of aldehyde-amine condensation compound accelerating agent. The chlorinated polyethylene insulating material combination meets the requirements of a low-voltage rubber-insulated wire for insulation property, and ensures that the wire has performances such as weathering resistance, cold resistance, oil resistance, high temperature (105 DEG C) resistance, acid-alkali resistance, corrosion resistance, ozone resistance, low cost and free color matching; moreover, the combination finds out in principle the reasons of the disqualification problems such as blistering, perforation and crevasse of a cable product, and solves the problems from the formula stage.

Owner:四川川东电缆有限责任公司

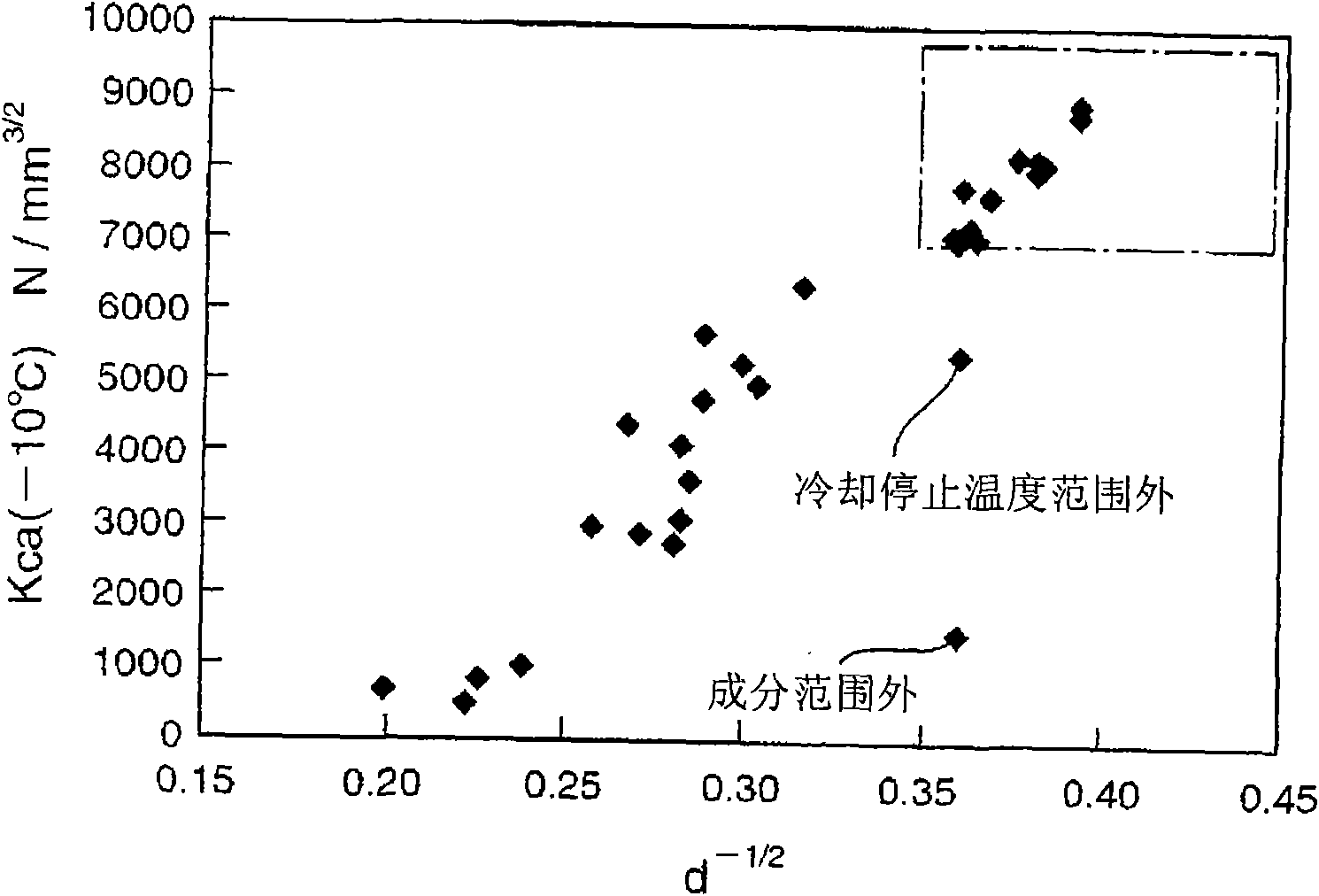

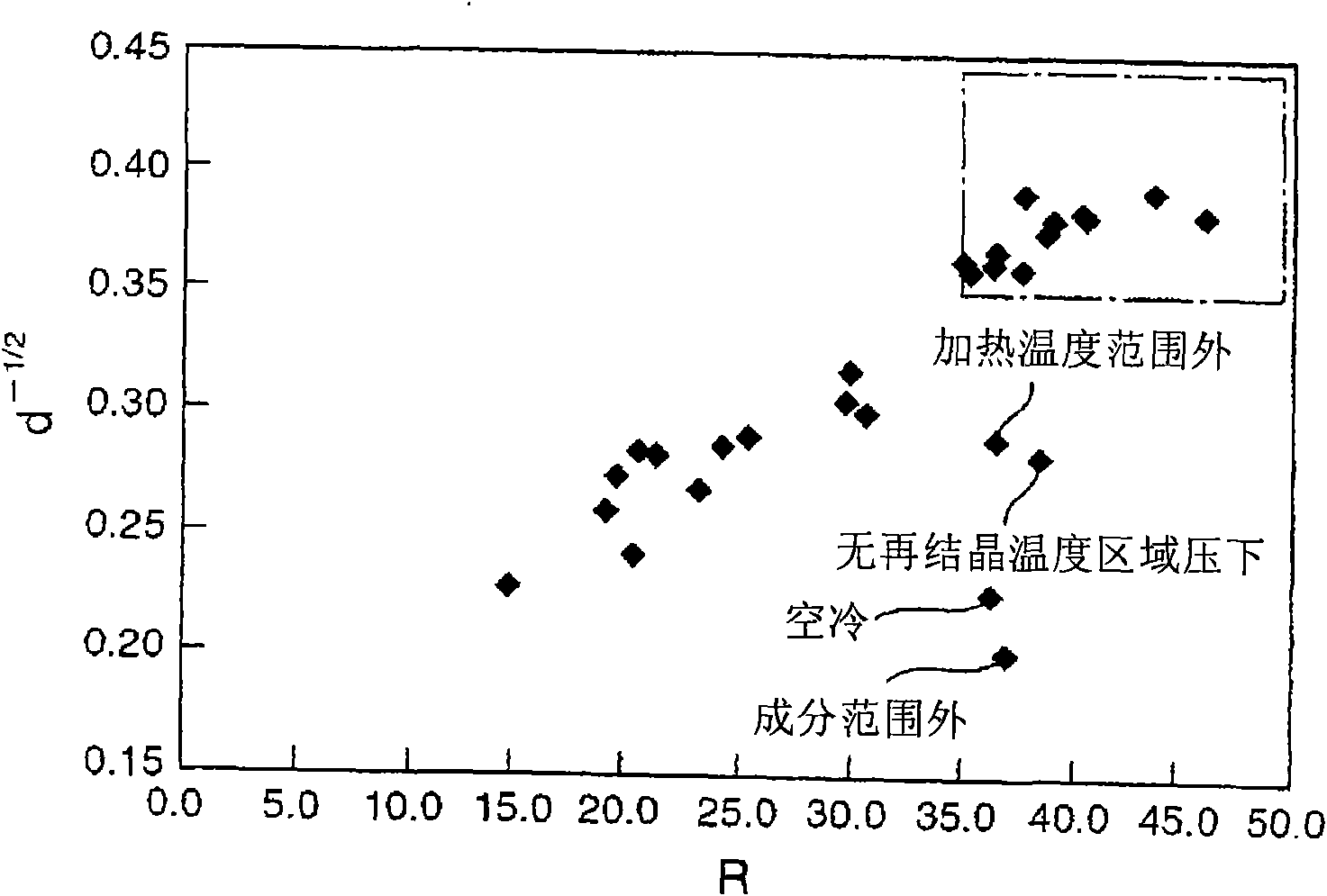

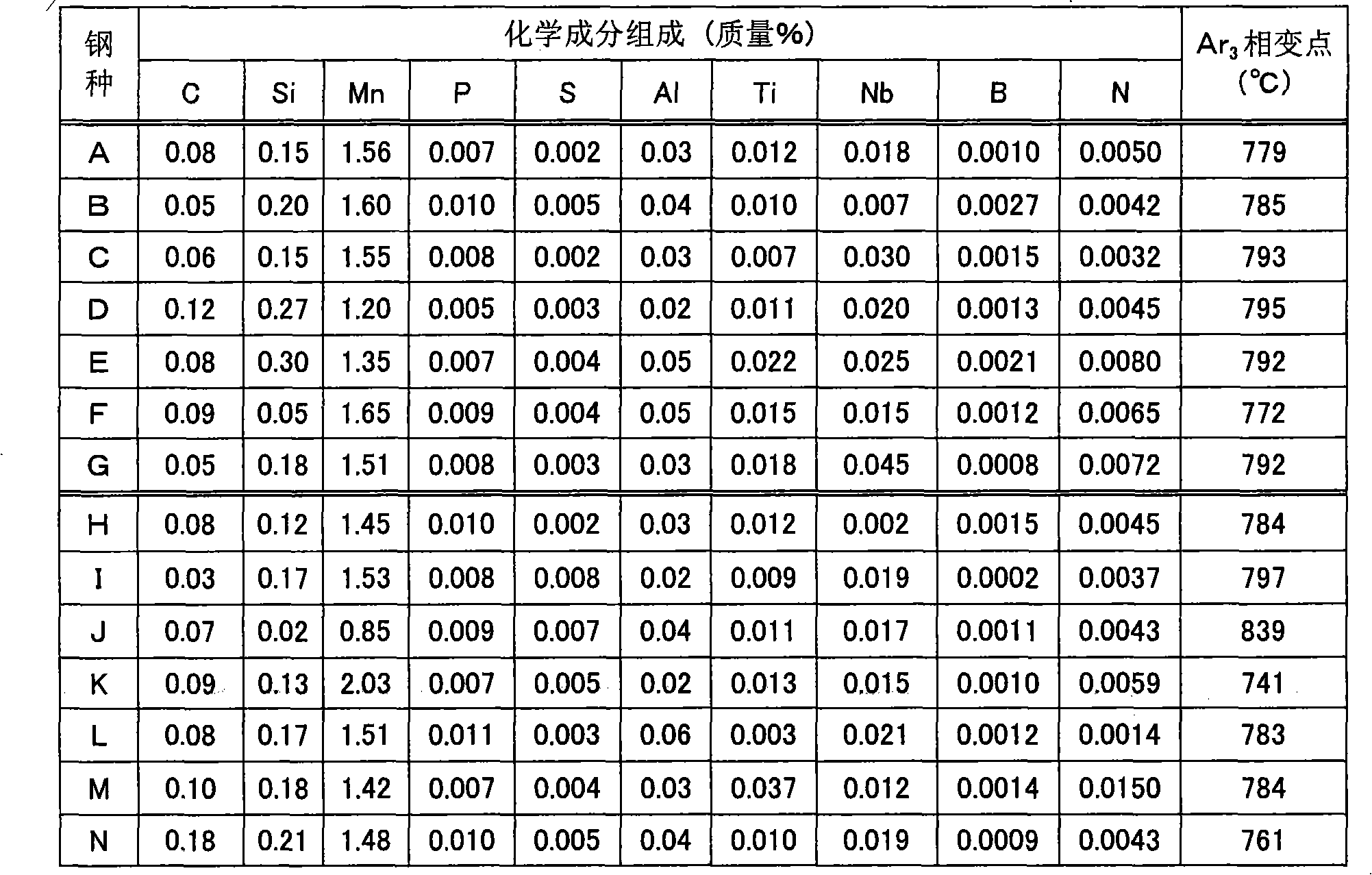

Thick steel plate with excellent brittlement crevasse crack propagation halt characteristic and manufacturing method thereof

The steel plate of the invention contains a C-grade chemical component and the balance of iron and unavoidable foreign substances, is formed by a structure of more than 95% of bainite by area on a prescribed position in the plate thickness direction. On a position from the surface by a depth of t / 8-t / 4 (t represents the plate thickness), an average diameter of granular equivalent circles is less than 8[Mu]m when a region enclosed by a greater horn grain boundary of two neighboring crystals with a more than 15 DEG azimuth error is used as a grain. By means of implementing the minuteness of the grain diameter, it is capable of obtaining the thick steel plate with an excellent brittlement crevasse crack propagation halt characteristic.

Owner:KOBE STEEL LTD

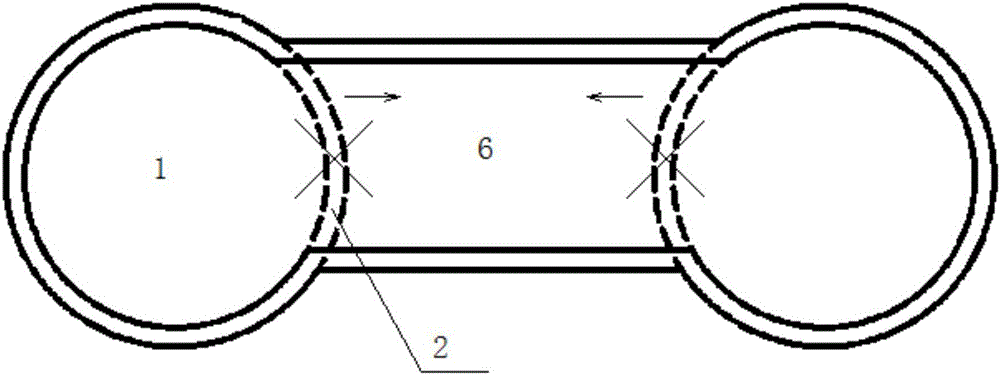

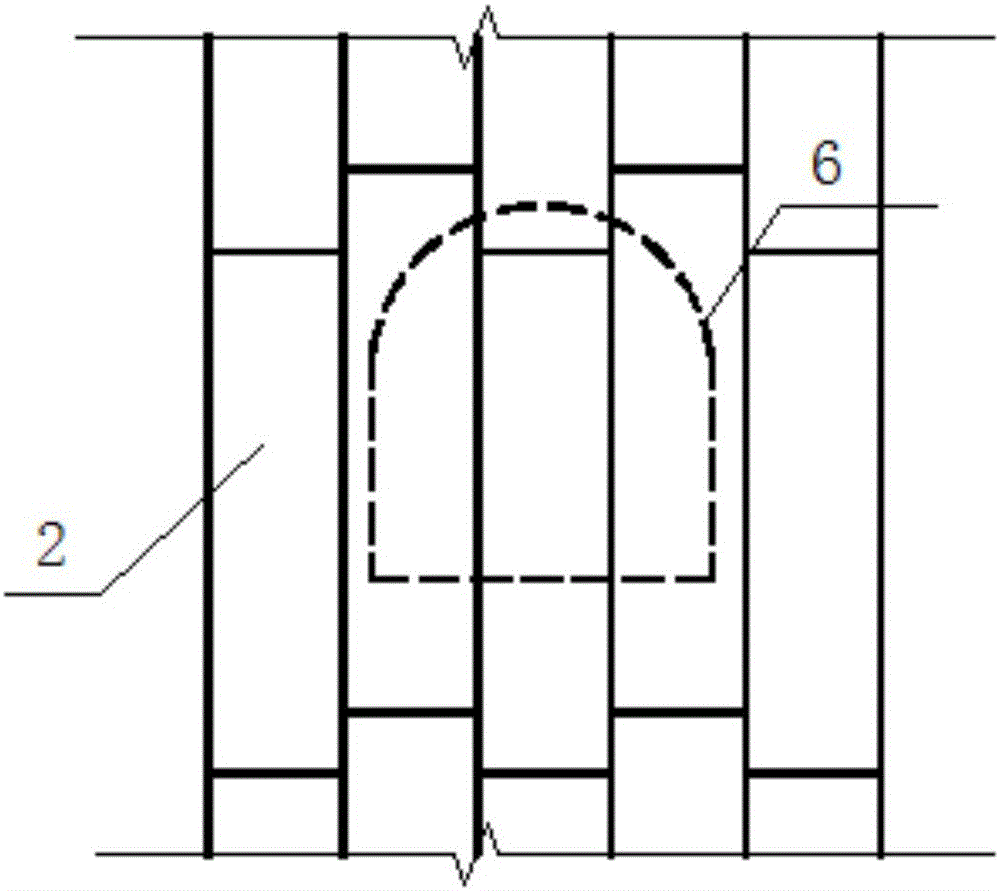

Large-span cross aisle building method applied to segmental lining tunnels

ActiveCN105927233ALittle impact on structural strengthPrevent collapseMining devicesUnderground chambersClosed loopCrevasse

The invention discloses a large-span cross aisle building method applied to segmental lining tunnels. A plurality of rings of tunnel linings are sequentially dismounted at the joint portions of a built large-span cross aisle in the designing direction, expanded excavation is conducted outwards every time the tunnel linings are dismounted, then primary lining structures in a closed loop in the cross section direction at the crevasses are constructed in time after expanded excavation, secondary tunnel linings of a main tunnel and the large-span cross aisle are constructed under protection of primary lining, and building safety of the joints of the large-span cross aisle is ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

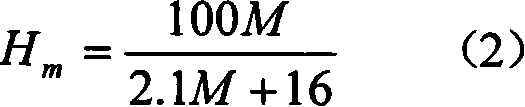

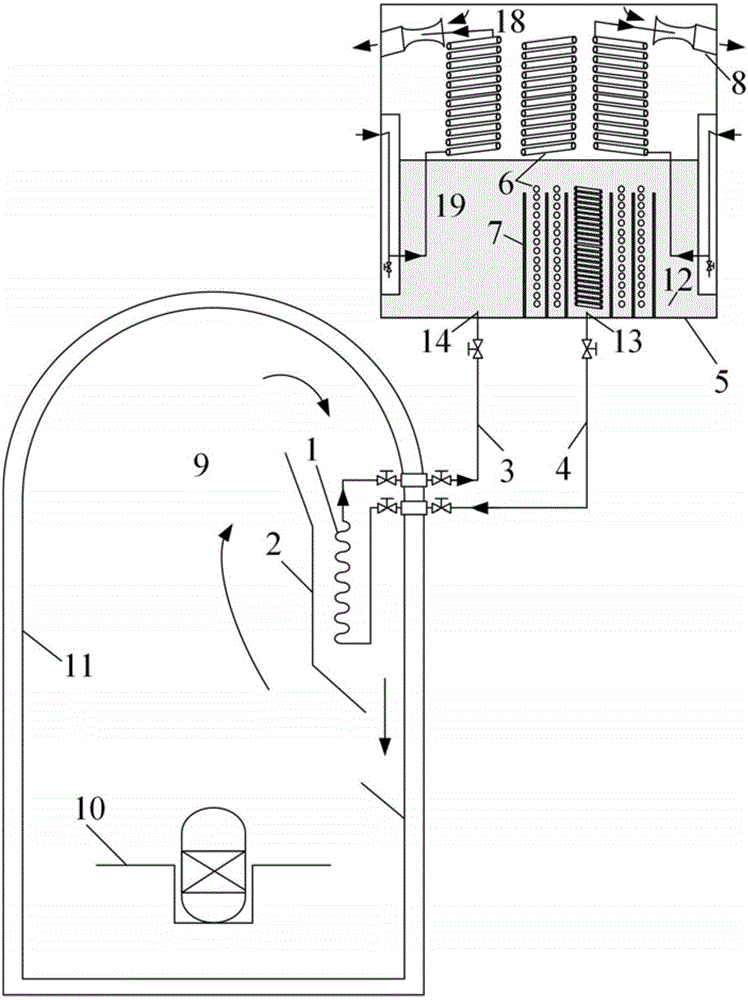

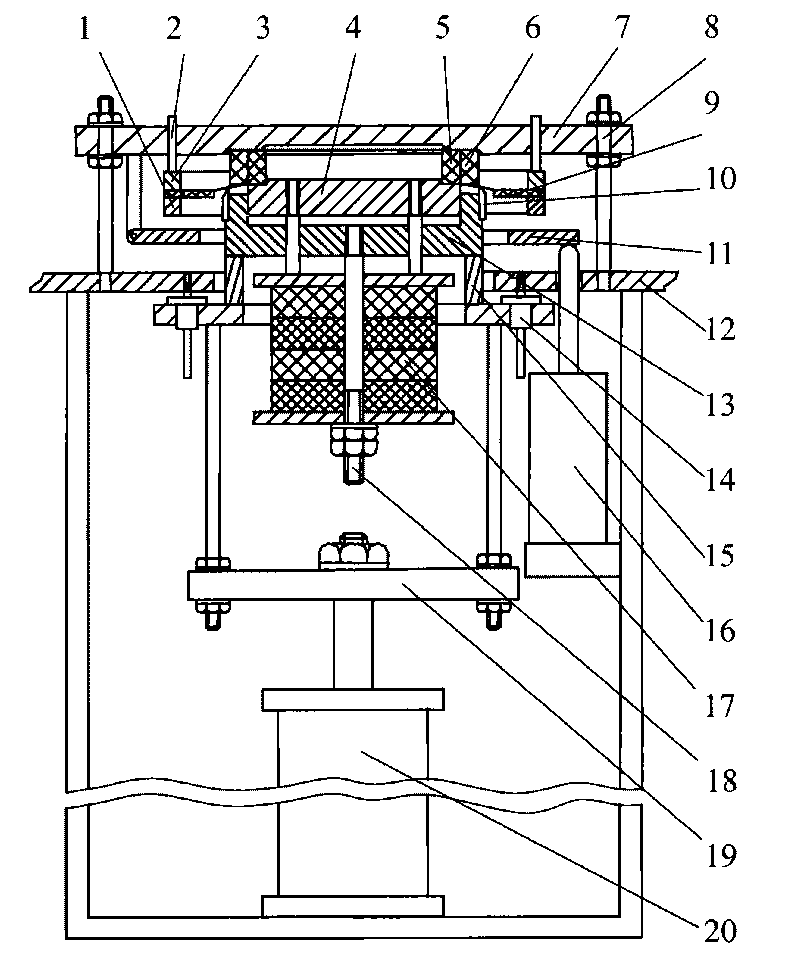

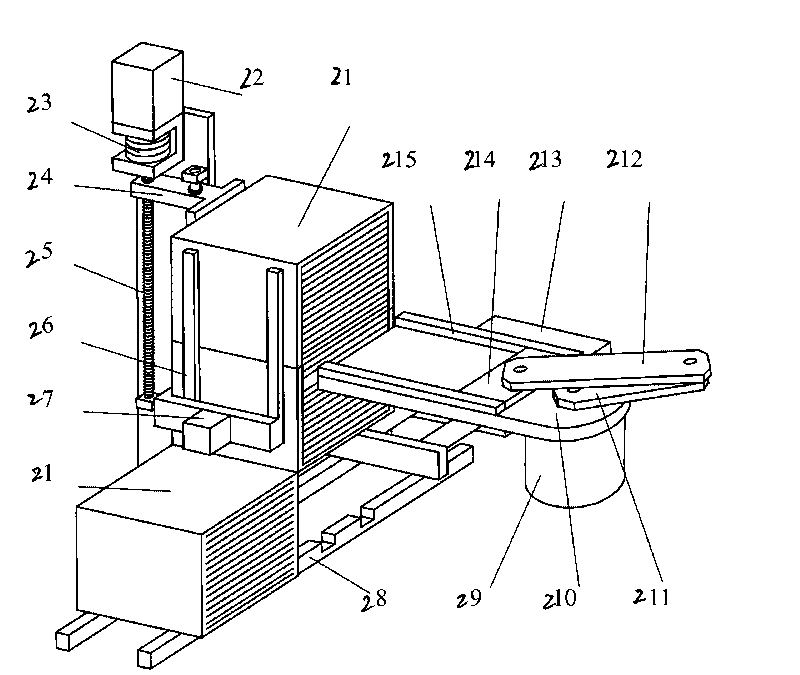

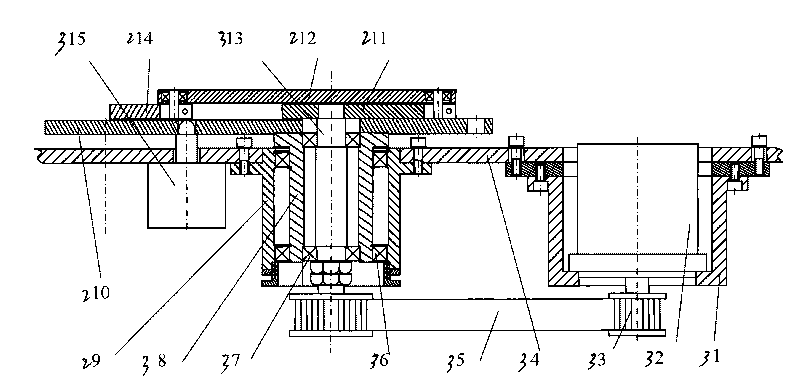

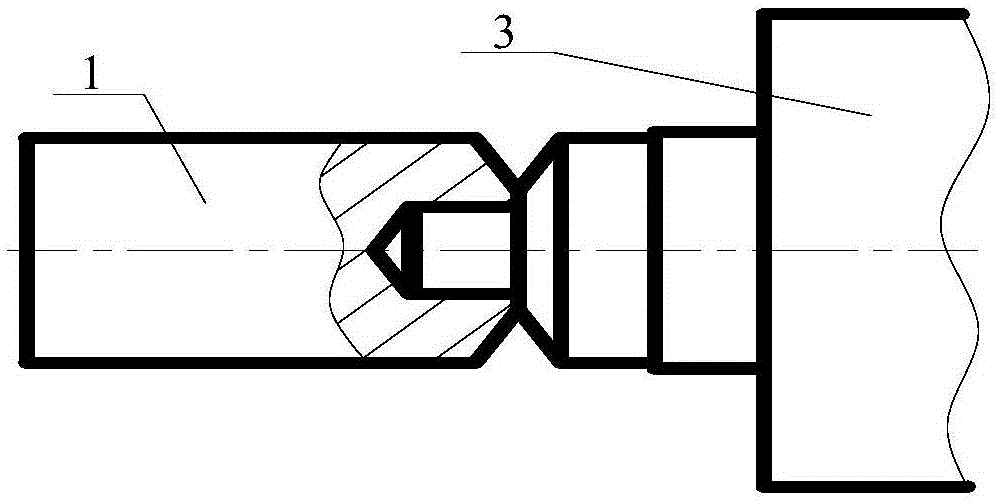

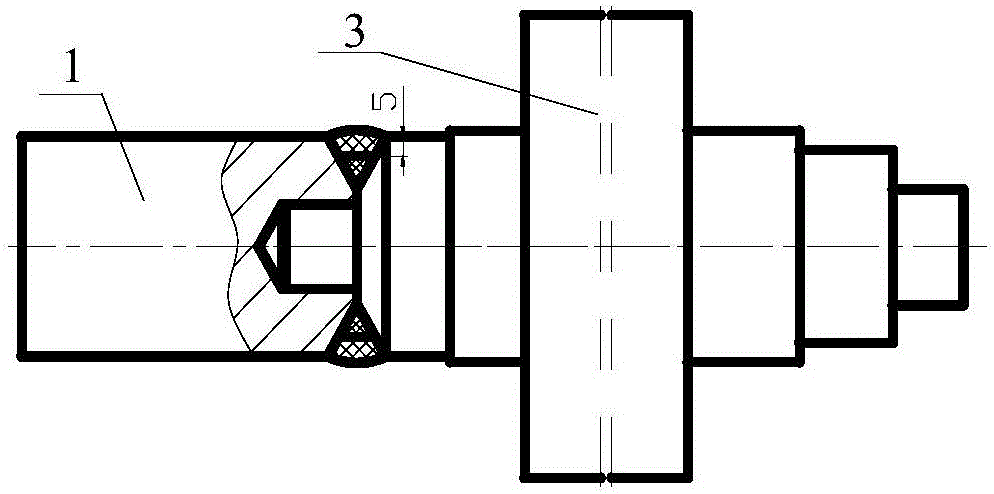

IC (integrated circuit)-packaged wafer expanding device

InactiveCN101740350AIngenious designImprove performanceSemiconductor/solid-state device manufacturingConveyor partsCrevasseWafer dicing

The invention relates to an IC (integrated circuit)-packaged wafer expanding device which comprises a wafer box feeding mechanism, a wafer picking mechanism, a wafer expanding mechanism and the like. In the wafer box feeding mechanism, a screw rod rotates and an undercarriage drives a wafer box to descend grid by grid under the driving of a stepping motor; the wafer box stops for a period of time for each one-grid descent so that the wafer picking mechanism can take a wafer from a wafer disc; and when the feeding of one wafer box is finished, a new wafer box is fed sequentially. The wafer picking mechanism is powered by only one electric motor to finish the whole wafer picking, wafer transferring and wafer delivering processes by being matched with the operation of an electric magnet. In the wafer expanding mechanism, the inner ring of a wafer can be pressed into the outer ring with the middle clamped with a rubber film, so that the silicon wafer can be tightened, thereby finishing the operation of tightening the inner ring and the outer ring. The process is powered by a main air cylinder. When the inner ring is pressed into the outer ring and placed in position, a piston rod of the main air cylinder moves upwards sequentially, a serrated knife contacts the tightened rubber film, a serrated tip punctures the rubber film, and a crevasse is torn towards the direction between two teeth, thereby enabling a liner frame to be separated from the expanded wafer. The invention can realize the mechanization and the automation, has high production efficiency, and can ensure the production quality.

Owner:GUANGDONG UNIV OF TECH

Method for repairing ceramic tableware

The invention relates to a method for repairing ceramic tableware. The method comprises the following steps of: processing crevasses, sliming, polishing, glazing and roasting, wherein in the sliming process, plastic steel mud and a high-temperature ceramic bonding agent are used as repair mud; and in the glazing process, a mixture of environment-friendly water-base nanophase ceramic low-temperature glaze and chemically-resistant liquid are used as a glazing material. The surfaces of the ceramic tableware repaired by the method is ultrawhite, fine and smooth, and the ceramic tableware has the characteristics of corrosion resistance, high temperature resistance, oil stain resistance and the like. Simultaneously, the method is low in repair cost.

Owner:温州瓷爵士科技股份有限公司

Room temperature crosslinked foam

Foams for filling cavities and crevasses and for forming foamed products are provided. The latex foam may include an A-side containing a functionalized latex and a B-side that contains a crosslinking agent and optionally a non-functionalized latex. The A- and / or B-side contain a blowing agent package or components forming the blowing agent package. The blowing agent package may be the combination of two or more chemicals that when mixed together form a gas or a chemical compound that, when activated by heat or light, forms a gas. In an alternate embodiment, the latex foam includes a functionalized latex, an acid, and an encapsulated crosslinking agent and base. Alternatively, the spray latex foam may include a functionalized latex, a crosslinking agent, and an encapsulated dry acid and dry base. The encapsulating agent may be a protective, non-reactive shell that can be broken or melted at the time of application.

Owner:OWENS CORNING INTELLECTUAL CAPITAL LLC

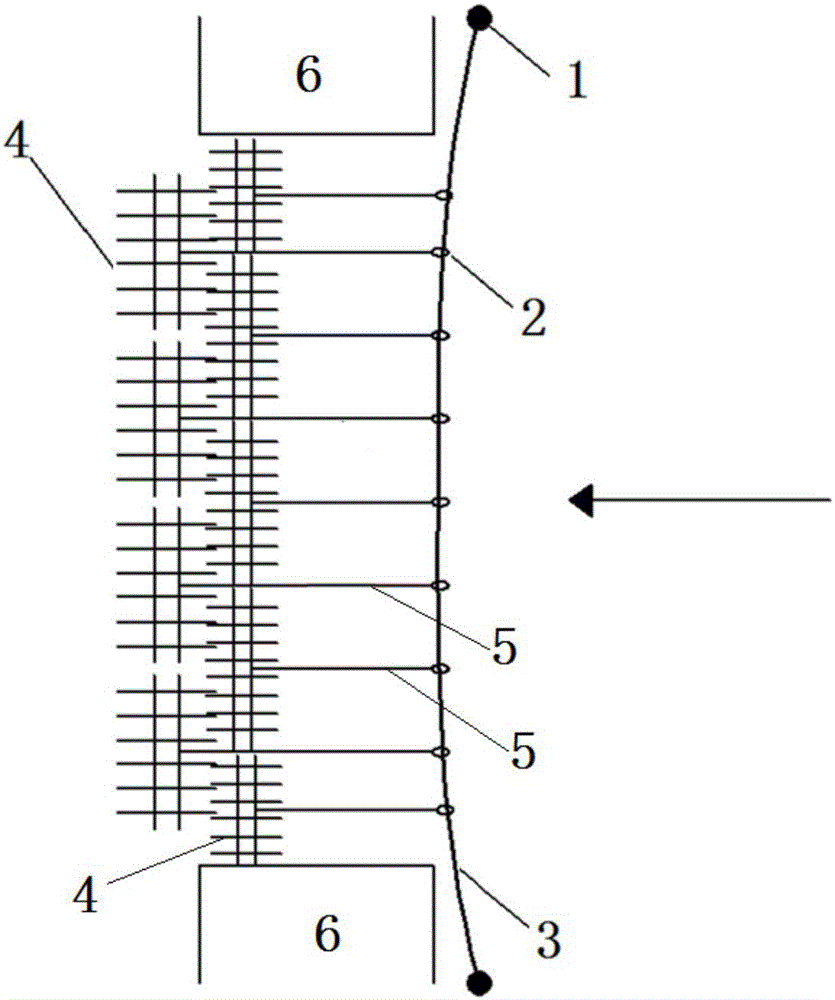

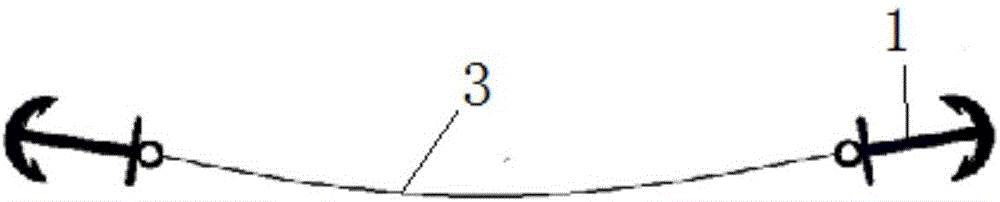

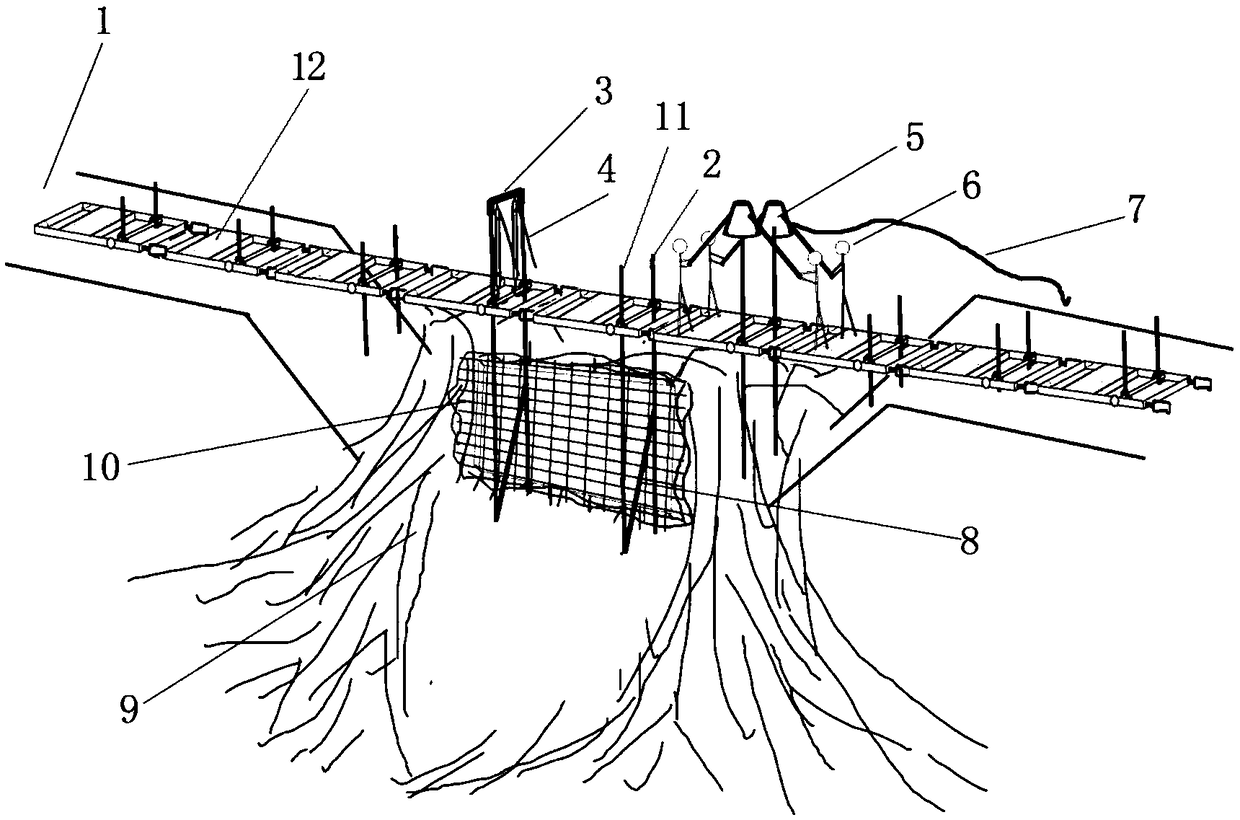

Novel plugging method and device used after dike breaking

ActiveCN106400740AImprove structural stabilityNot easy to runDamsClimate change adaptationCrevasseArchitectural engineering

The invention discloses a novel plugging method and device used after dike breaking. The device comprises iron anchors, a steel wire rope and trusses; each truss is provided with a connecting rope with a hook, and the iron anchors are used for pulling the two ends of the steel wire rope and fixed to dike heads at the two ends of a crevasse; and the trusses are connected to the steel wire rope through the hooks, and thrown into the crevasse to form a basic water blocking framework together with the steel wire rope. The method is characterized in that the device is put into the crevasse to form the water blocking framework, and then building stones are thrown into the crevasse for plugging. By means of the method and device, the preparation work is less, construction is simple, and plugging is rapid.

Owner:WUHAN UNIV

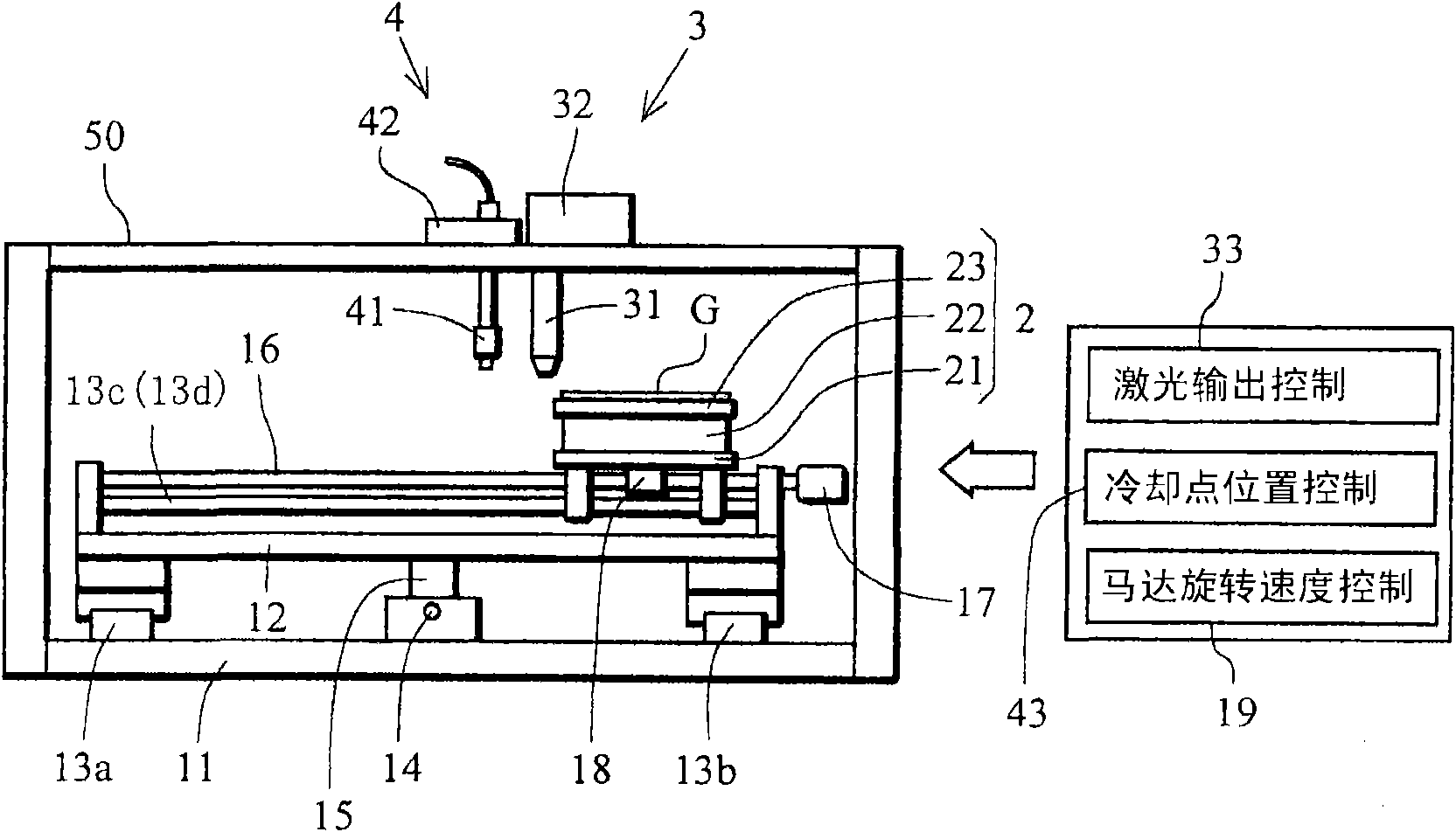

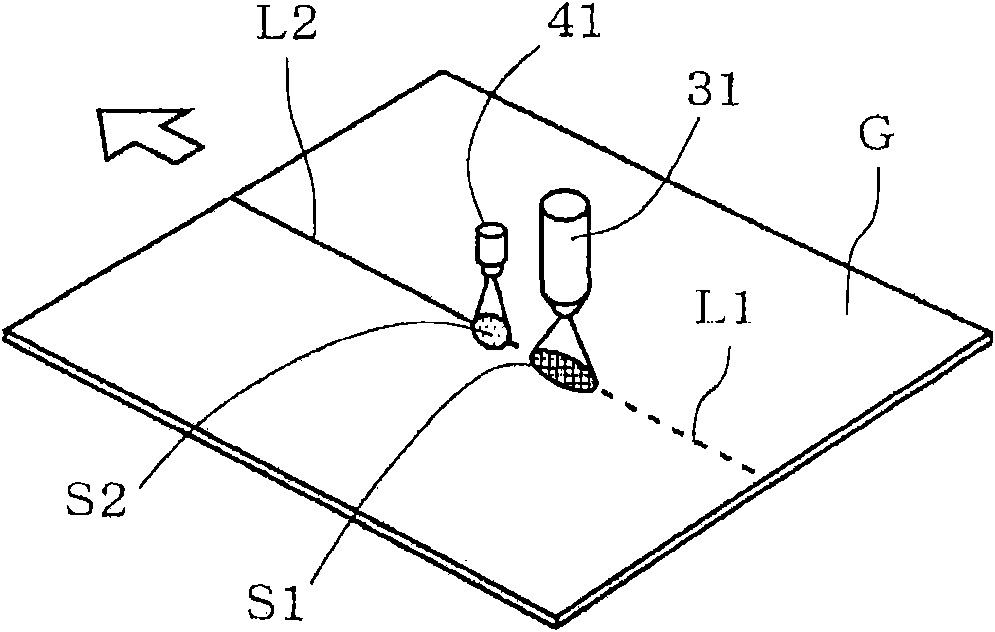

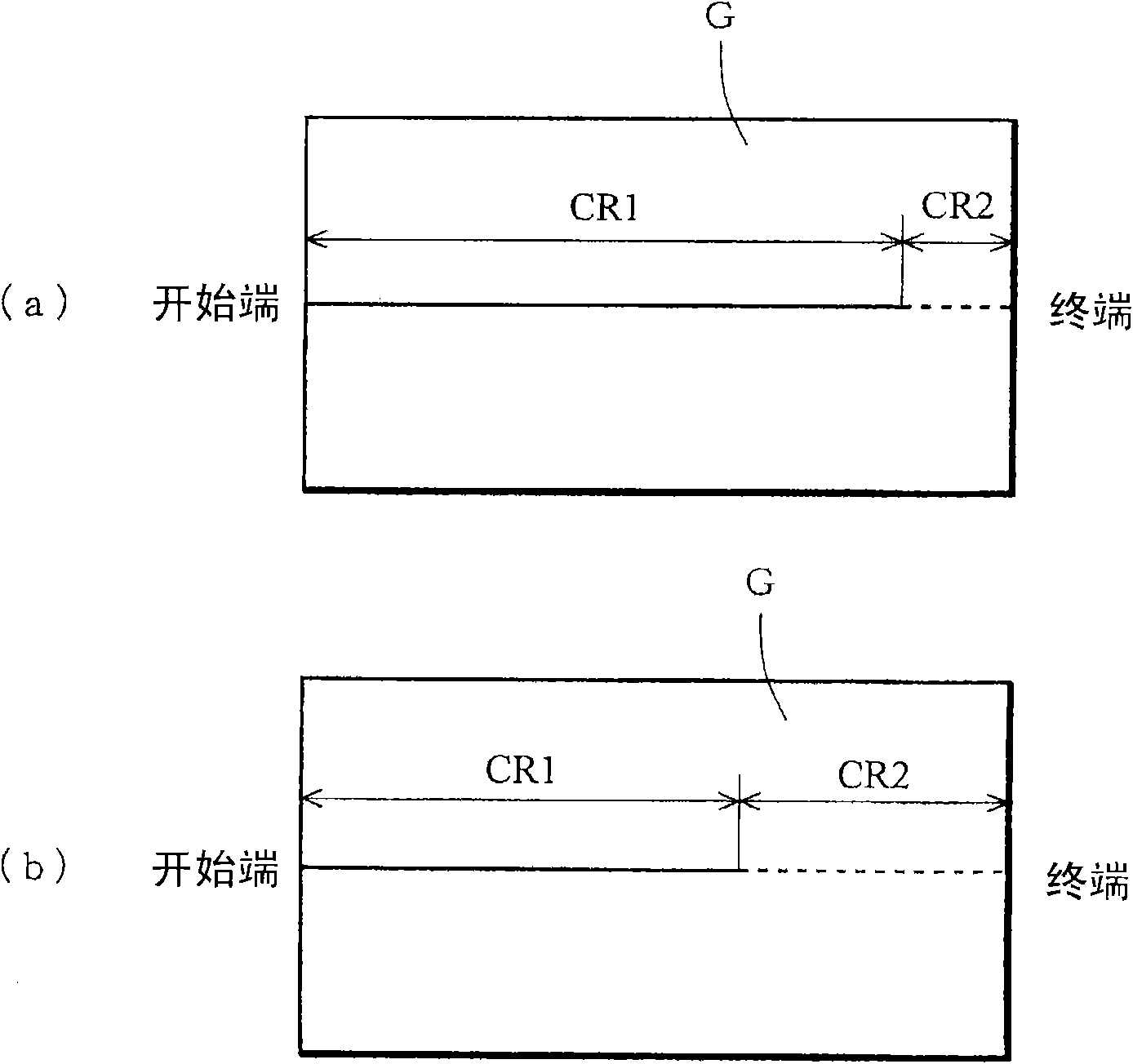

Method for cutting brittle material substrate

InactiveCN101934427AImprove end face qualityEasy to control thermal stressFine working devicesGlass severing apparatusCrevasseEngineering

In a method for cutting a brittle material substrate by laser, a terminal is used to make a vertical crevasse crack to a cutting destined line. The method includes: a step of forming an initial crevasse crack on a cutting beginning end of the cutting destined line on one surface of the brittle material substrate; and steps of moving and irradiating a laser beam from the initial crevasse crack along the cutting destined line, heating the substrate at a temperature less to a fusion temperature, then immediately cooling the substrate by a cooling medium so as to make the substrate to generate a thermal stress to make the initial crevasse crack to evolve along the cutting destined line, so as to form a vertical crevasse crack arriving the back face of the substrate. Furthermore, by means of changing one of the heating condition of the laser beam and the cooling condition of the cooling medium in the step of evolving the initial crevasse crack, the vertical crevasse crack will not arrive the back face of the substrate.

Owner:MITSUBOSHI DIAMOND IND CO LTD

Rotary Kiln Tire and Roller Fracture Repair Technology

The invention discloses a process for repairing the breakage of a rotary kiln tyre / roller, comprising the following steps of: performing fixed connection at the two sides of a crack, cutting out a U-shaped crevasse, grinding, sequentially depositing a binding layer, a transition layer, a work layer and a processing layer at the crevasse, dismounting a fixing plate, and carrying out overall grinding and polishing. The process for repairing the breakage of the rotary kiln tyre / roller provided by the invention is low in repairing price, which is only 100,000-1500,000 Yuan, low in investment, simple in process, convenient to operate, easy to learn and grasp, novel in technology, low in cost, and practical and reliable; therefore, the process not only increases income and reduces expenditure for the country but also makes an enormous contribution to consumption reduction and energy conservation as well as resource conversation and efficiency improvement for an enterprise.

Owner:湖北开明高新科技有限公司

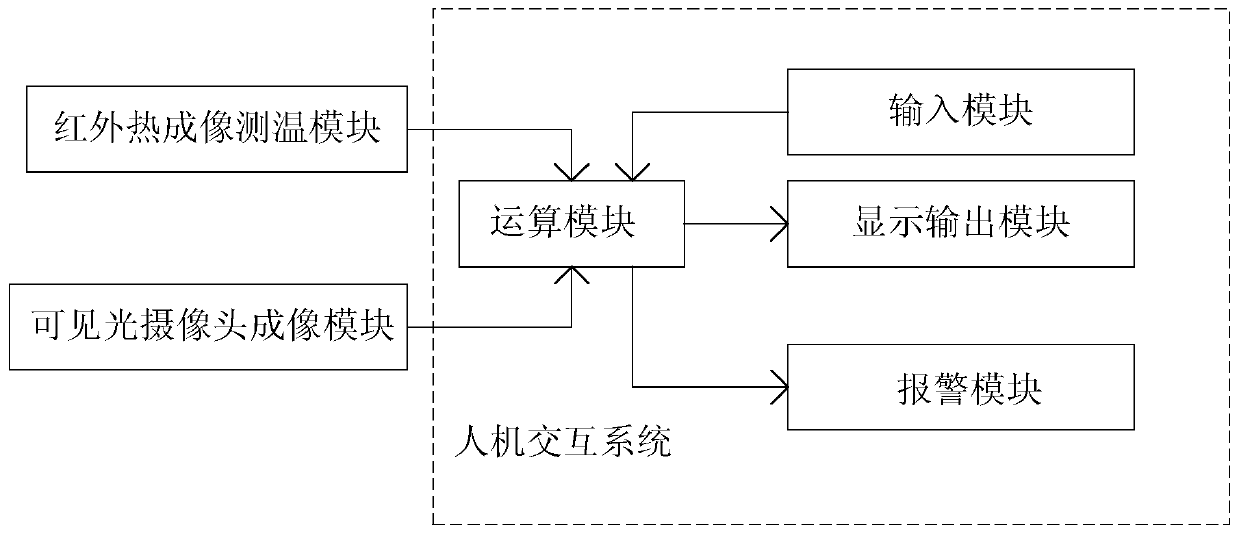

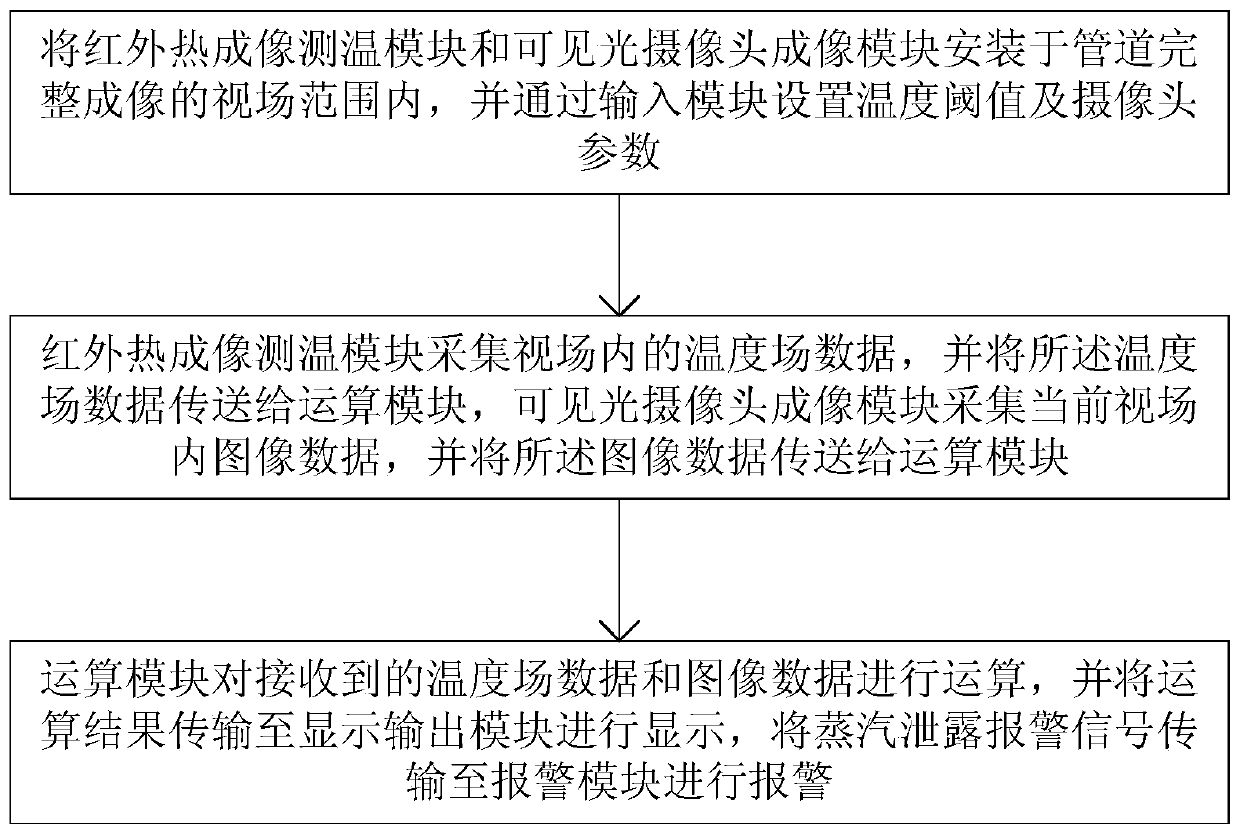

Binocular-vision-based steam leakage positioning system and method

ActiveCN109854964ASolve the problem that the degree of breach cannot be obtained accuratelyPipeline systemsGray levelCrevasse

The invention discloses a binocular-vision-based steam leakage positioning system and method. The positioning method comprises the steps of collecting temperature field data and image data in a view field through an infrared thermal imaging temperature measurement module and a visible light camera imaging module; comparing the two front and back frames of temperature field data of the view field to obtain steam leakage point information, finding and displaying a steam leakage area and give an alarm; and determining the degree of a crevasse of a pipeline according to a gray level channel framedifference image of a current frame and a background frame collected by the visible light camera imaging module and the steam leakage area obtained through the temperature field data. Through the binocular-vision-based steam leakage positioning system and method, the steam leakage position is accurately positioned, and the degree of the crevasse is judged accurately.

Owner:SHENYANG HONGJI ELECTRICAL

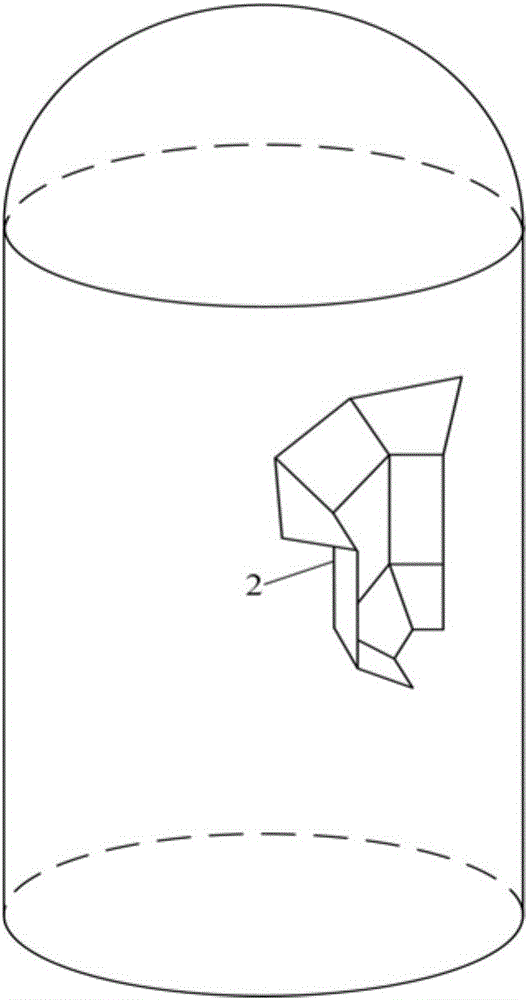

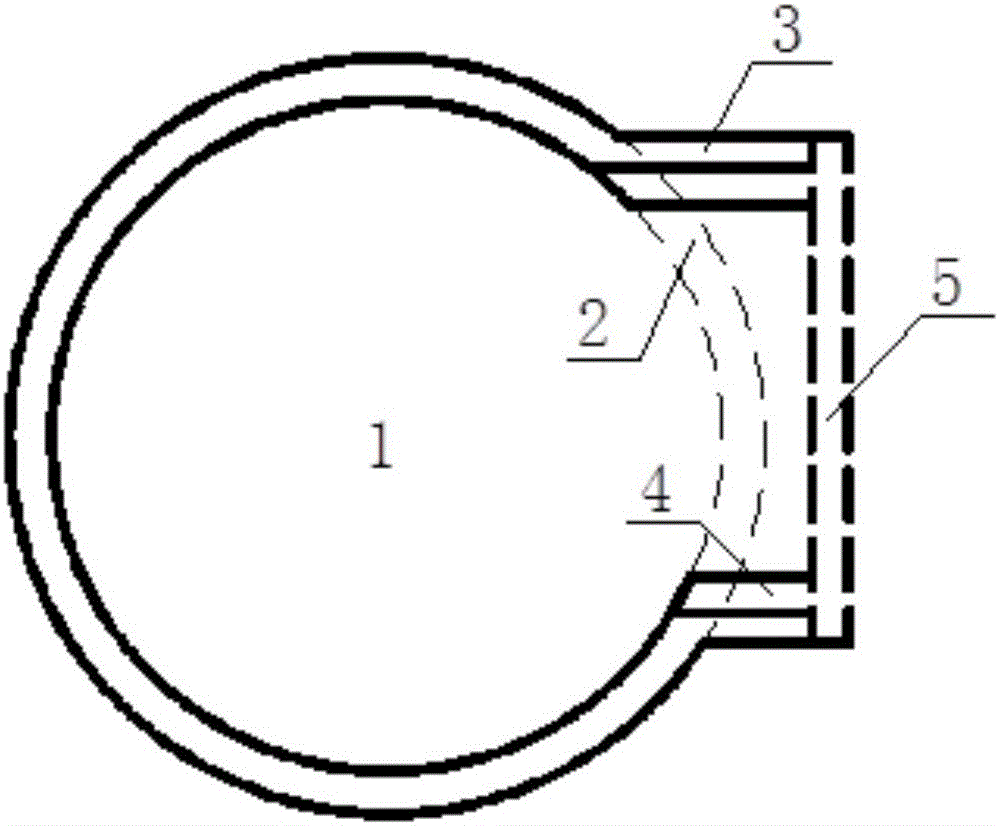

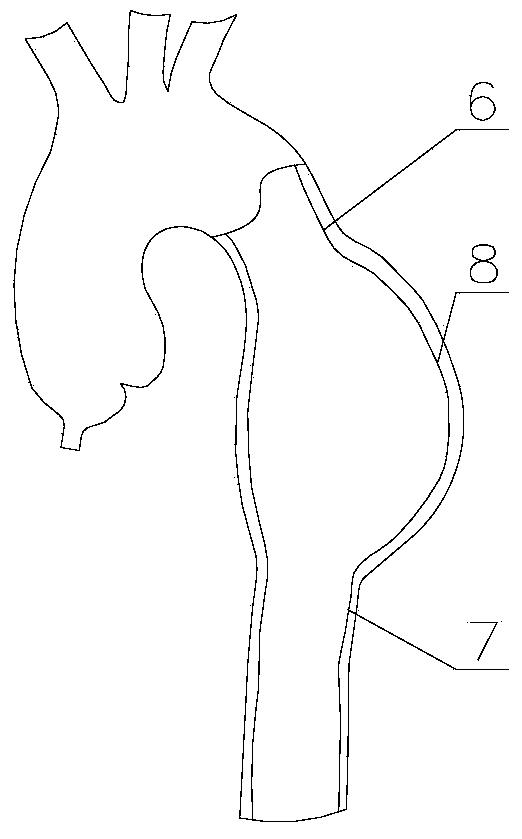

Aortic dissection aneurysm covered stent

The invention provides an aortic dissection aneurysm covered stent which comprises a cylindrical metal supporting portion and a cylindrical covered portion coated on the cylindrical metal supporting portion. A bulging covered portion is coated outside the cylindrical covered portion, and the middle portion of the bulging covered portion bulges outwards. By adopting the above structure, a false lumen crevasse can be sealed and isolated, space of a false lumen can be actively reduced, blood flow speed and blood flow in the false lumen can be changed, and the false lumen is ensured to quickly form thrombus within expected time; the outwards-bulging portion can effectively prevent displacement and sliding caused by blood flow impact after the stent is implanted in a human body, and disease relapse caused by exposure of an original aortic crevasse due to displacement of the stent is avoided.

Owner:黄连军

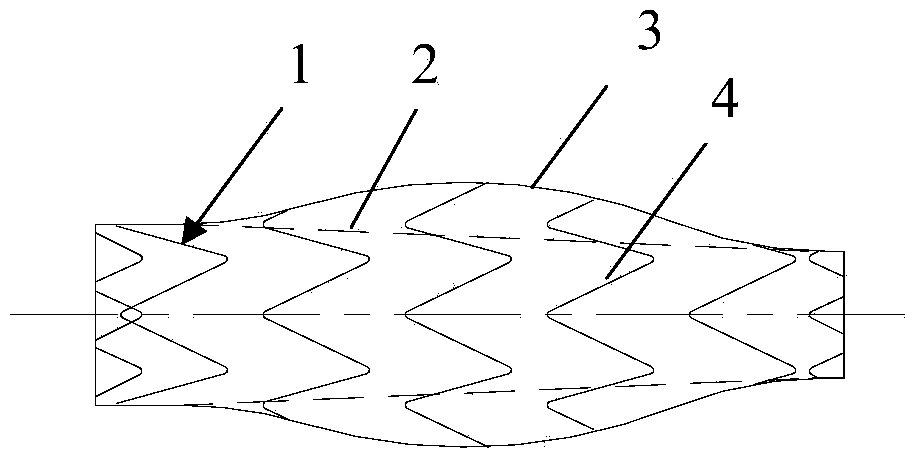

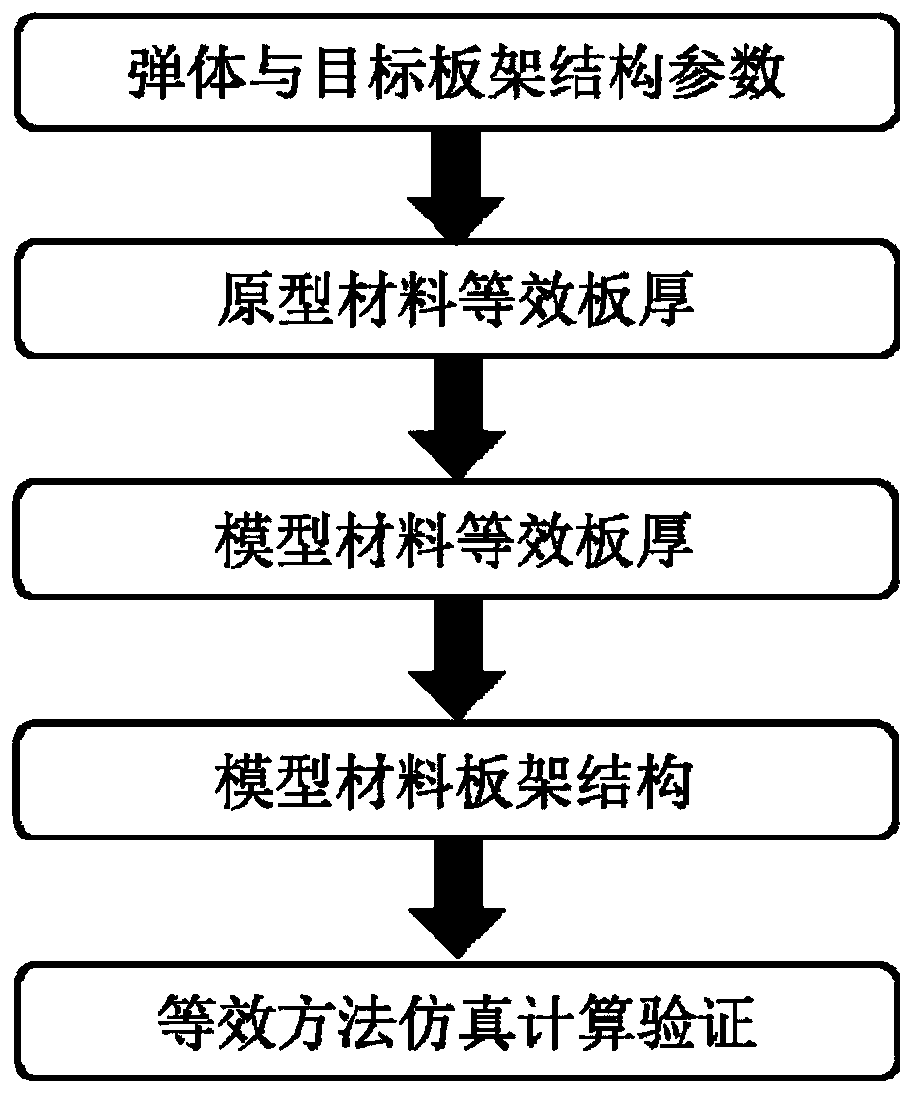

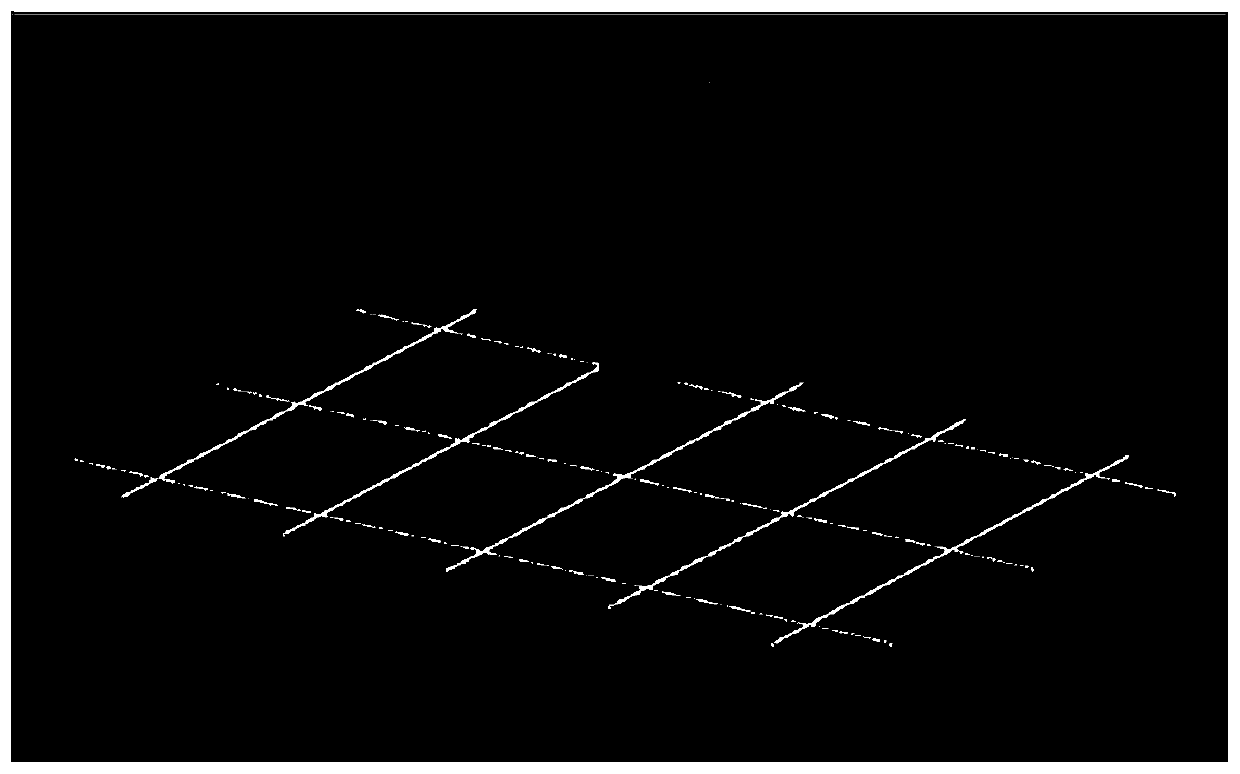

Penetration damage similarity-based metal plate frame structure equivalent design method

ActiveCN110532656AReduce manufacturing costEngineering valueSustainable transportationSpecial data processing applicationsEngineeringStructure based

The invention provides a penetration damage similarity-based metal plate frame structure equivalent design method, which comprises the following steps of: determining the weight and the speed of a warhead and the geometric dimension and the material of a target plate frame structure according to the specific conditions of the warhead and a penetration ship target; enabling the prototype grillage structure reinforcing ribs to be equivalent to the thickness of a flat plate through ultimate bending moment; for the prototype material equivalent thickness flat plate, calculating the equivalent thickness of the model material flat plate through a deformation equivalent method considering the strain rate effect; converting the model material equivalent thickness flat plate into a model material grillage structure based on an extreme bending moment equivalence principle and a ship structure statistical law; based on a finite element method, calculating penetration dynamic responses of the prototype grillage structure and the model material grillage structure, wherein the penetration dynamic responses comprise the residual speed, the crevasse diameter and the plastic zone diameter, and checking effectiveness of material equivalent design. A single-layer target material equivalent design method can be guided, the similarity of the remaining speed, the crevasse and the plastic area is guaranteed, and the manufacturing cost is reduced.

Owner:HARBIN ENG UNIV

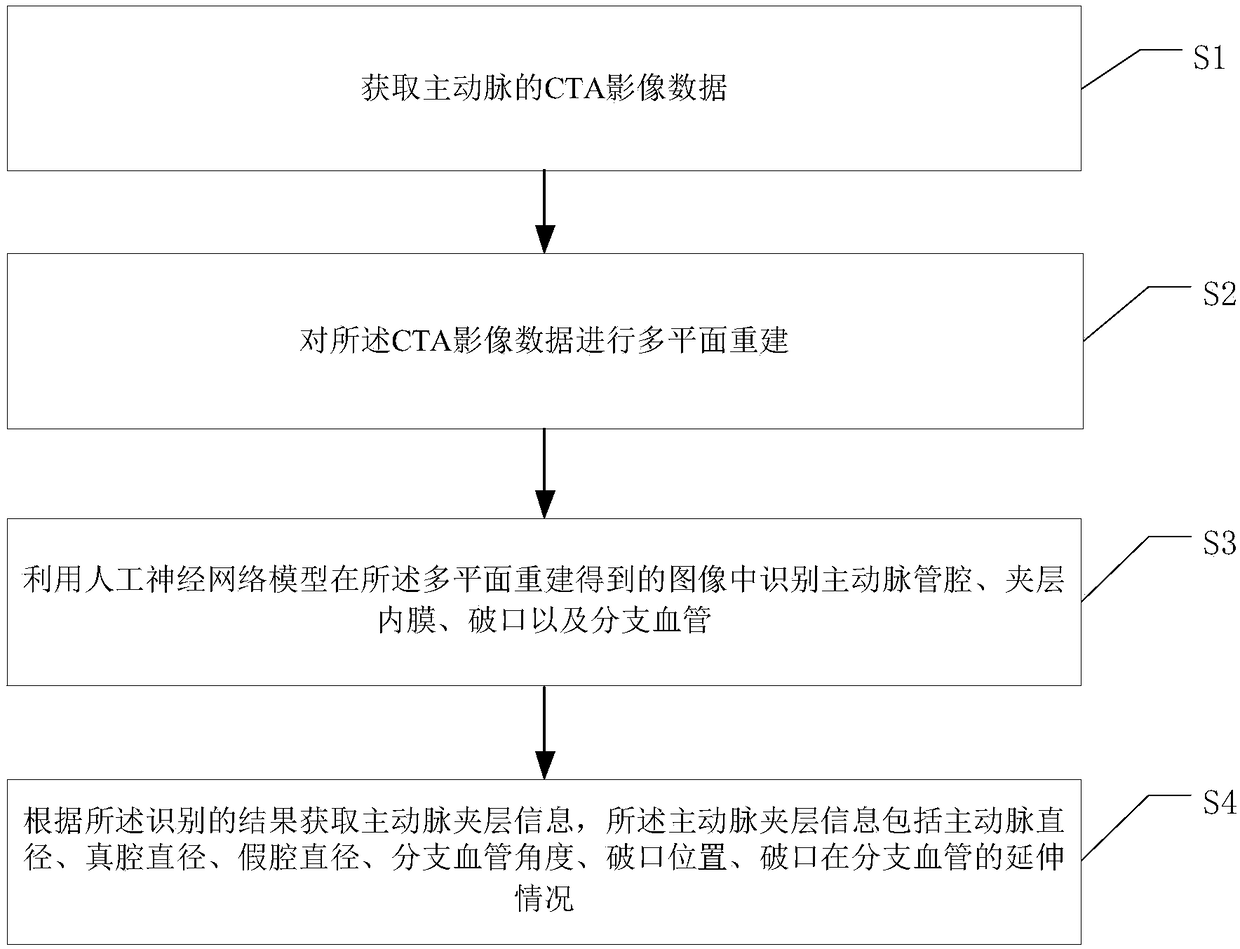

Aortic image analyzing method and system

InactiveCN108764221AFully automatedReduce manual workloadSubcutaneous biometric featuresBlood vessel patternsObservational errorFalse lumen

The present invention discloses an aortic image analyzing method and system. The aortic image analyzing method comprises the following steps: step S1: acquiring CTA image data of the aorta; step S2: performing multiplanar reconstruction on the CTA image data; step S3: utilizing an artificial neural network model to identify the aortic lumen, the intima of the interlayer, the crevasse, and the branch vessel in the image obtained through multiplanar reconstruction; step S4: acquiring aortic dissection information according to the result of identification, wherein the aortic dissection information comprises the aortic diameter, the true lumen diameter, the false lumen diameter, the branch vessel angle, the location of the crevasse, and the extension status of the crevasse in the branch vessel. The aortic image analyzing method provided by the invention facilitates achievement of automation and rapidity of diagnosis and measurement of the aortic dissection, which not only can reduce the manual workload, but also can reduce the measurement error and avoid the influence of subjective factors.

Owner:于存涛 +1

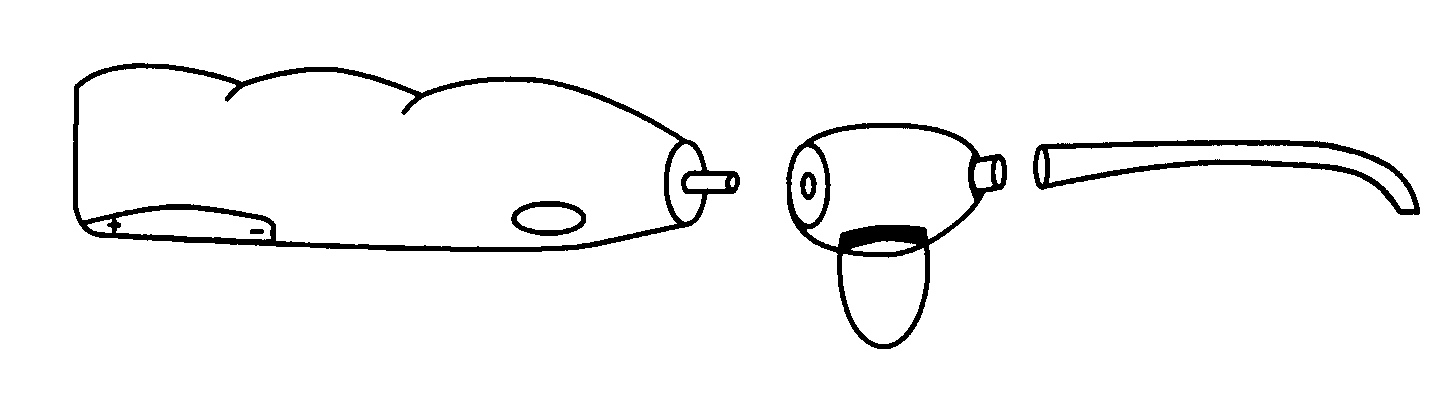

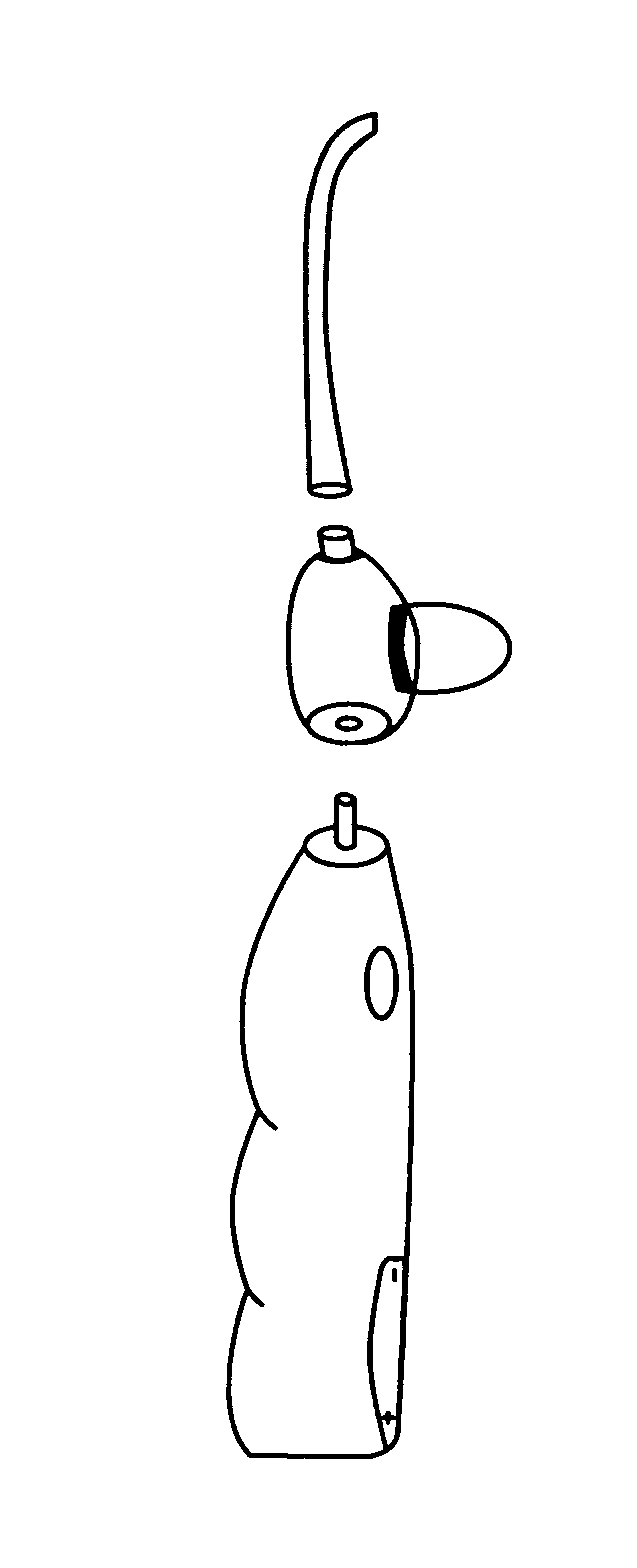

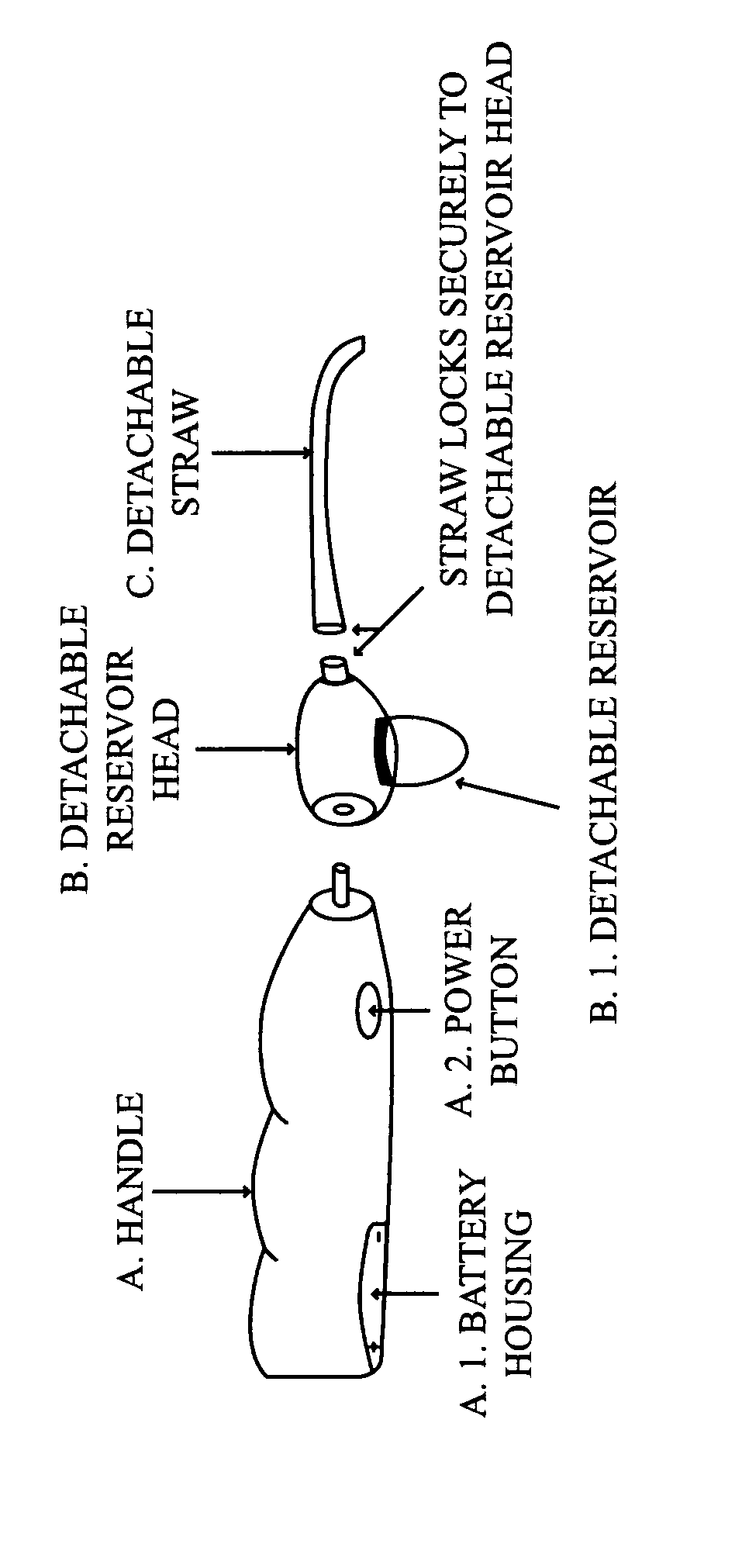

Oragienic Personal Dental Assistant

A hand-held suction device used to remove tonsilloliths, food, and other foreign matter from the mouth. Tonsilloliths form in the tonsil crypts or crevasses of the mouth and are a cause of chronic halitosis. Tonsilloliths generally become lodged in crevasses of the mouth and are unable to be removed without outside manipulation.

Owner:MCCLURE RYAN

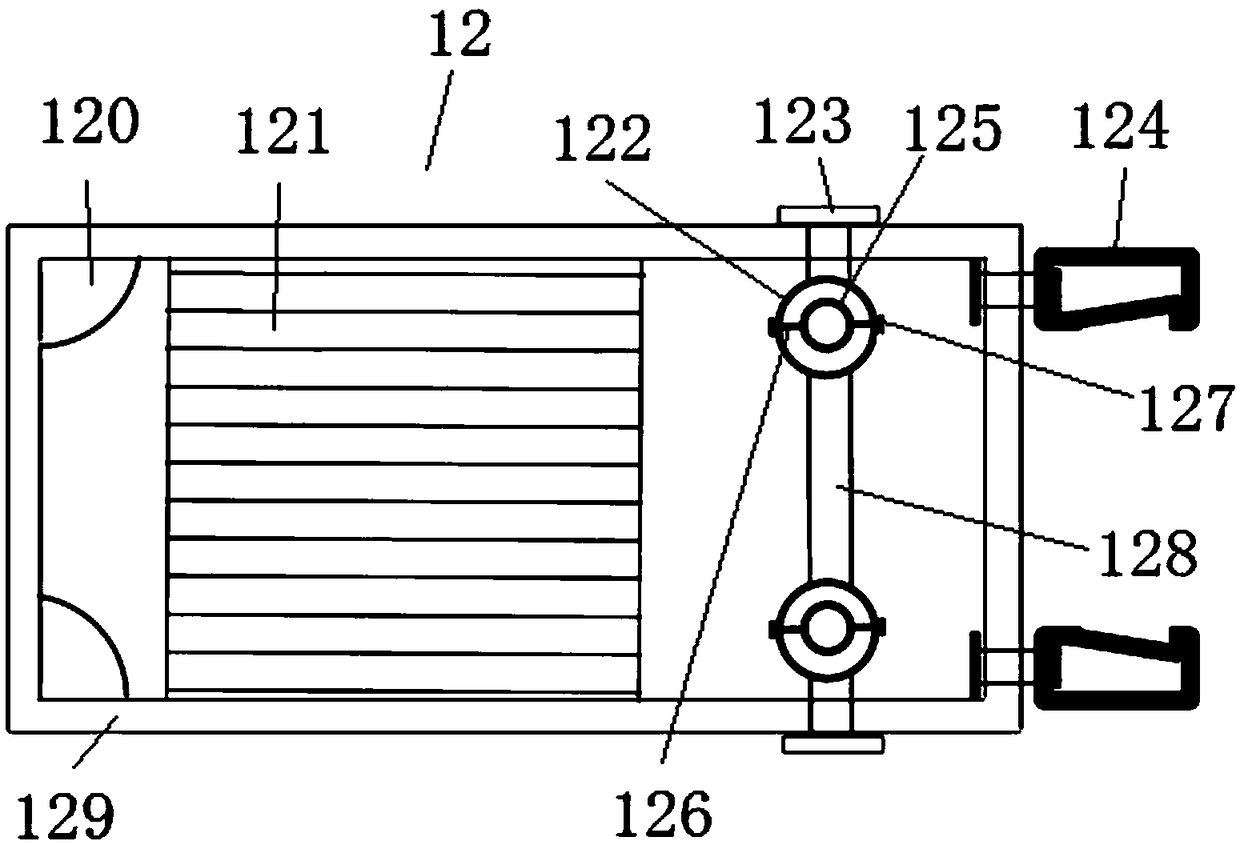

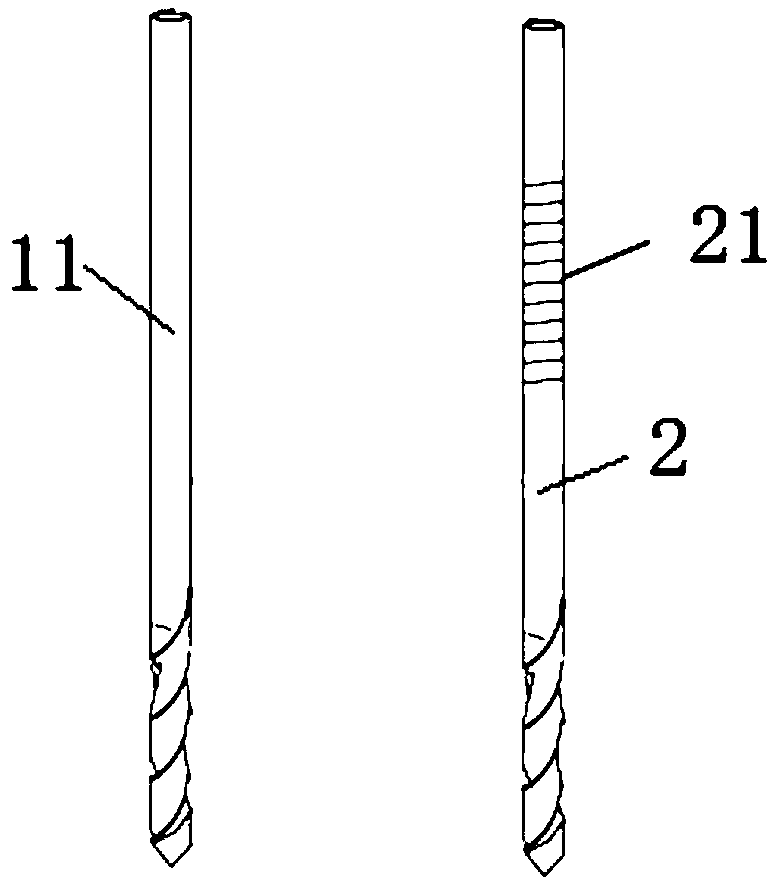

Crevasse plugging system and plugging method

ActiveCN109322285AAvoid homeworkAct as a temporary flood barrierMarine site engineeringCrevasseEngineering

The invention relates to a crevasse plugging system and plugging method. The crevasse plugging system comprises a hanging bridge used for being suspended above a crevasse; the hanging bridge is provided with a plurality of pile holes, and a stopping pile rod is arranged in each pile hole in a penetrating manner; the lower end of each stopping pile rod is used for being inserted into a riverbed ofthe crevasse; and the crevasse plugging system further comprises a water stopping piece abutting against the stopping pile rod in the flood flowing direction to stop flood. Due to the fact that the two ends of the hanging bridge are correspondingly fixed to the two sides of the crevasse, a channel for an operator to pass through is formed, and it is avoided that a person performs operation in theflood; each hanging plate, suspending above the crevasse, of the hanging bridge is provided with the stopping pile rod in a penetrating manner, and the stopping pile rods are used for being inserted into the riverbed; the water stopping piece is placed on the side, close to the inner side of the crevasse, of each stopping pile rod; each water stopping piece is limited due to stopping by the corresponding stopping pile rod, and a role of stopping the flood temporarily can be played; and at the moment, soil and stone, sand bags and other filler are thrown into the side, backing onto the riverbed, of the water stopping pieces, and washing away by the flood is not likely to be caused, the crevasse plugging time is shortened, and the work efficiency is improved.

Owner:吕震伟

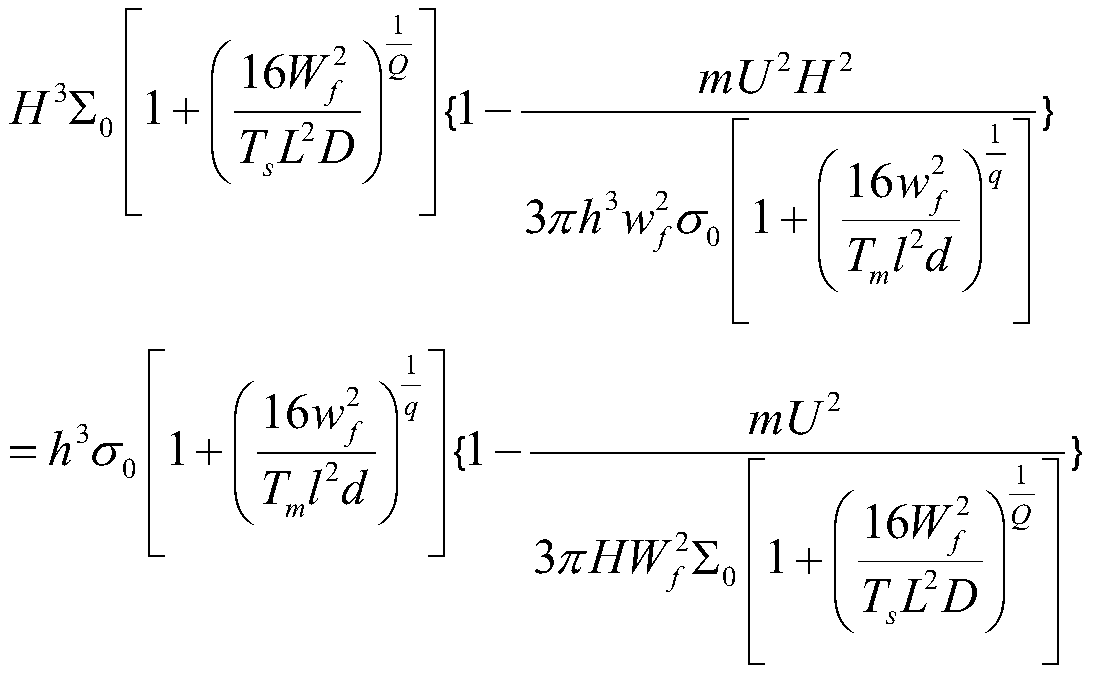

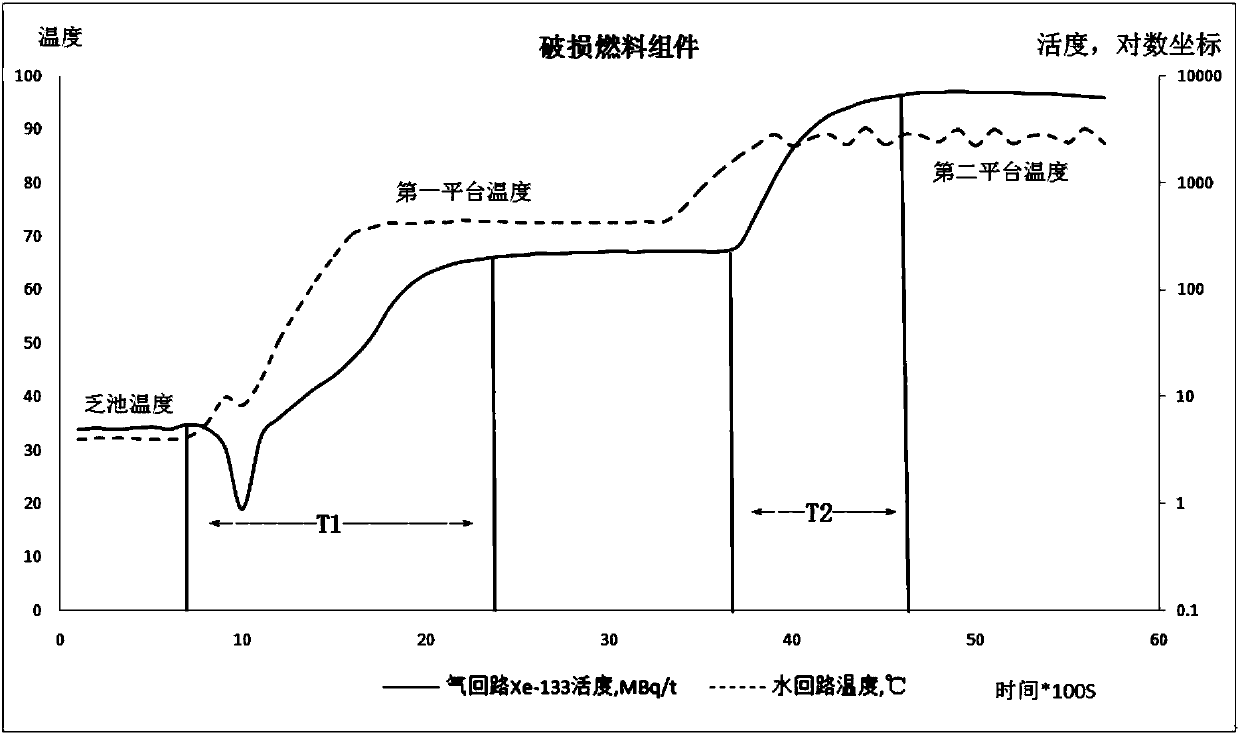

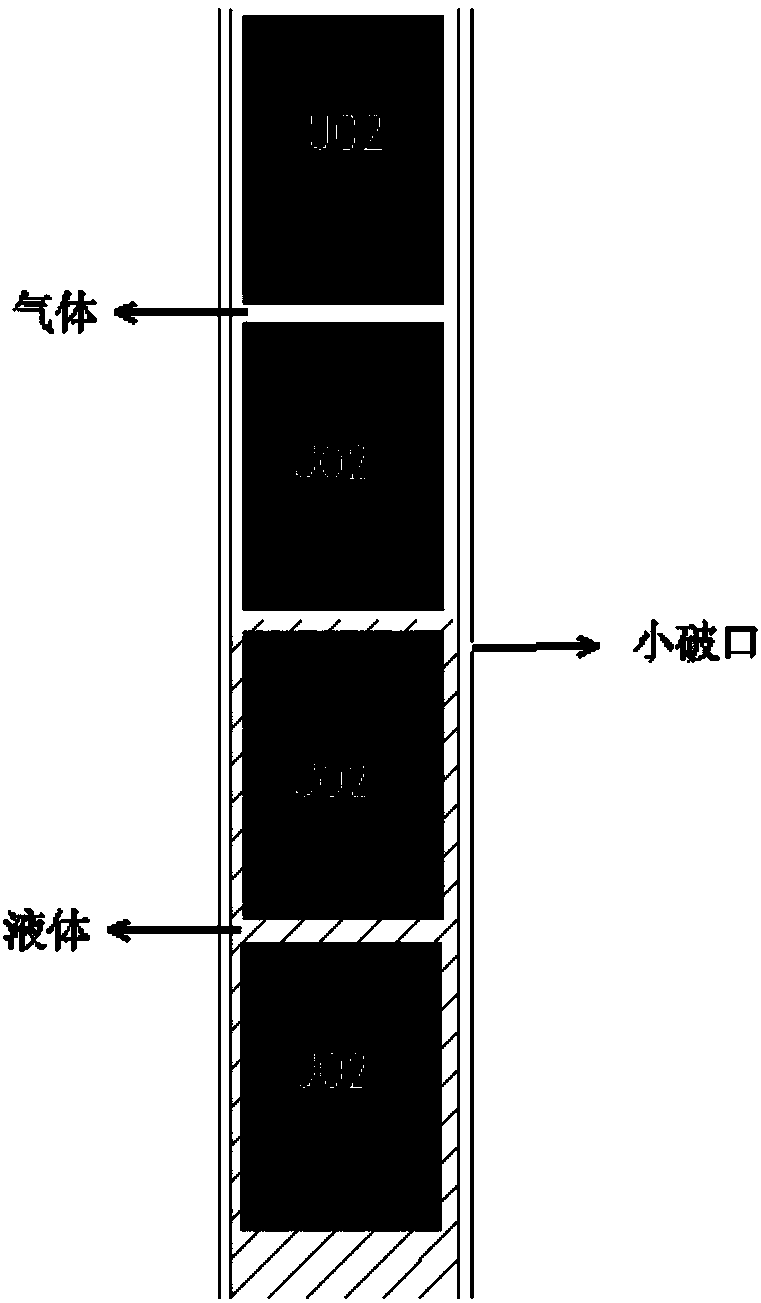

Method for evaluating fuel cladding crevasse equivalent weight of nuclear power station

The invention belongs to the technical field of operation maintenance of nuclear power stations and particularly relates to a method for evaluating the fuel cladding crevasse equivalent weight of a nuclear power station. The method comprises the following steps: firstly, an off-line sipping device is determined, fuel components are placed in a sipping room in the off-line sipping device, the sipping room is positioned on different temperature platforms through temperature rise of a water circuit, a gas fission product is released from a fuel cladding crevasse and enters a gas circuit, and a sodium iodide spectrometer performs continuous monitoring; secondly, test conditions are set; thirdly, the types of media are determined; and fourthly, the crevasse equivalent weight range of failed fuels is given according to first platform temperature, second platform temperature, the temperature rise rate and the types of the released media in combination between the correlation chart of the failed fuel crevasse equivalent weight and the Xe-133 balance time. A Fuqing nuclear power No.1 unit and a Fuqing nuclear power No.2 unit are subjected to fuel cladding failures in the first cycle, and byapplication of the method, the damaged fuel components are searched out, and the crevasse equivalent weights of damaged fuels are given out.

Owner:CNNC FUJIAN FUQING NUCLEAR POWER

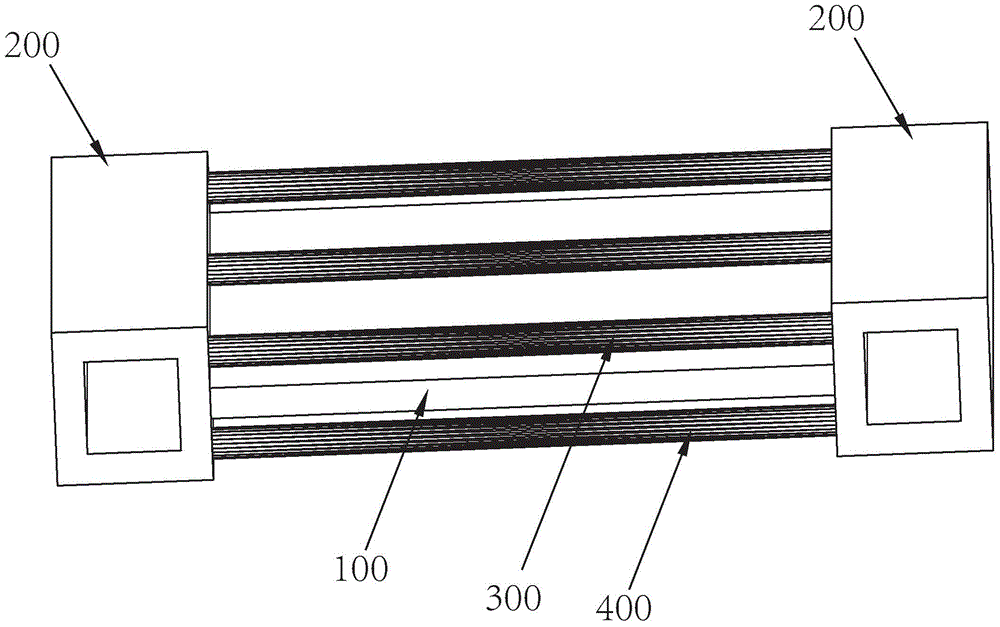

Method for manufacturing steel plate shear wall and temporary supporting structure for steel plate shear wall

ActiveCN104368916AAvoid deformationReduce biasWallsWelding/cutting auxillary devicesSheet steelButt joint

The invention relates to a method for manufacturing a steel plate shear wall and a temporary supporting structure for the steel plate shear wall. The temporary supporting structure for the steel plate shear wall comprises a steel plate, two box-shaped columns, a first supporting column and a second supporting column, wherein the two ends of the steel plate are welded and fixed to the side faces of the two box-shaped columns, the first supporting column and the second supporting column are symmetrically distributed above and below the steel plate, the two ends of the first supporting column are fixed to the two box-shaped columns respectively, and the two ends of the second supporting columns are fixed to the two box-shaped columns respectively. According to the method for manufacturing the steel plate shear wall and the temporary supporting structure for the steel plate shear wall, assembly positioning lines used for assembly of the steel plate are marked on the side faces of the box-shaped columns, the two box-shaped columns can be fixed in advance through the first supporting column and the second supporting column during welding, and thus the steel plate and the two box-shaped columns can be positioned conveniently; in addition, welding crevasses of the steel plate can be firmly in butt joint with welding crevasses of the box-shaped columns, deviation caused by deformation of the thin steel plate is reduced, and both welding precision and assembling precision are improved.

Owner:CHINA CONSTR STEEL STRUCTURE ENG CO LTD

Medical micro-hole composite hemostatic material and preparing method thereof

The invention relates to a biological medical hemostatic material, in particular to a medical micro-hole composite hemostatic material and a preparing method thereof. The medical micro-hole composite hemostatic material is formed by collagen, hyaluronic acid, puffball conidial powder and hemostatic Chinese herb extracts, wherein the collagen can quickly combine with hemoglobin in blood to form hemostatic coagulum, the hyaluronic acid can timely absorb water in the blood to form hydrogel to plug exudation, and the puffball conidial powder contains a lot of porous fiber which can quickly absorb water in the blood and mechanically plug crevasses of a blood vessel and exudation of blood capillaries. The three matters can form physical barriers to isolate a wound and achieve effects of preventing adhesion and stopping bleeding timely. The hemostatic Chinese herb extracts have effects of stopping bleeding, resisting inflammation, resisting bacteria, easing pain, cooling blood, eliminating stasis, subduing swelling, performing convergence, activating a coagulating system and promoting wound healing. The four matters organically combine with each other, are obvious in hemostatic effect, are suitable for hemostasis of all kinds of wound, fresh tissue wound surface exudation, small blood vessel hemorrhage and bleeding areas and can prevent adhesion.

Owner:广西达庆生物科技有限公司 +2

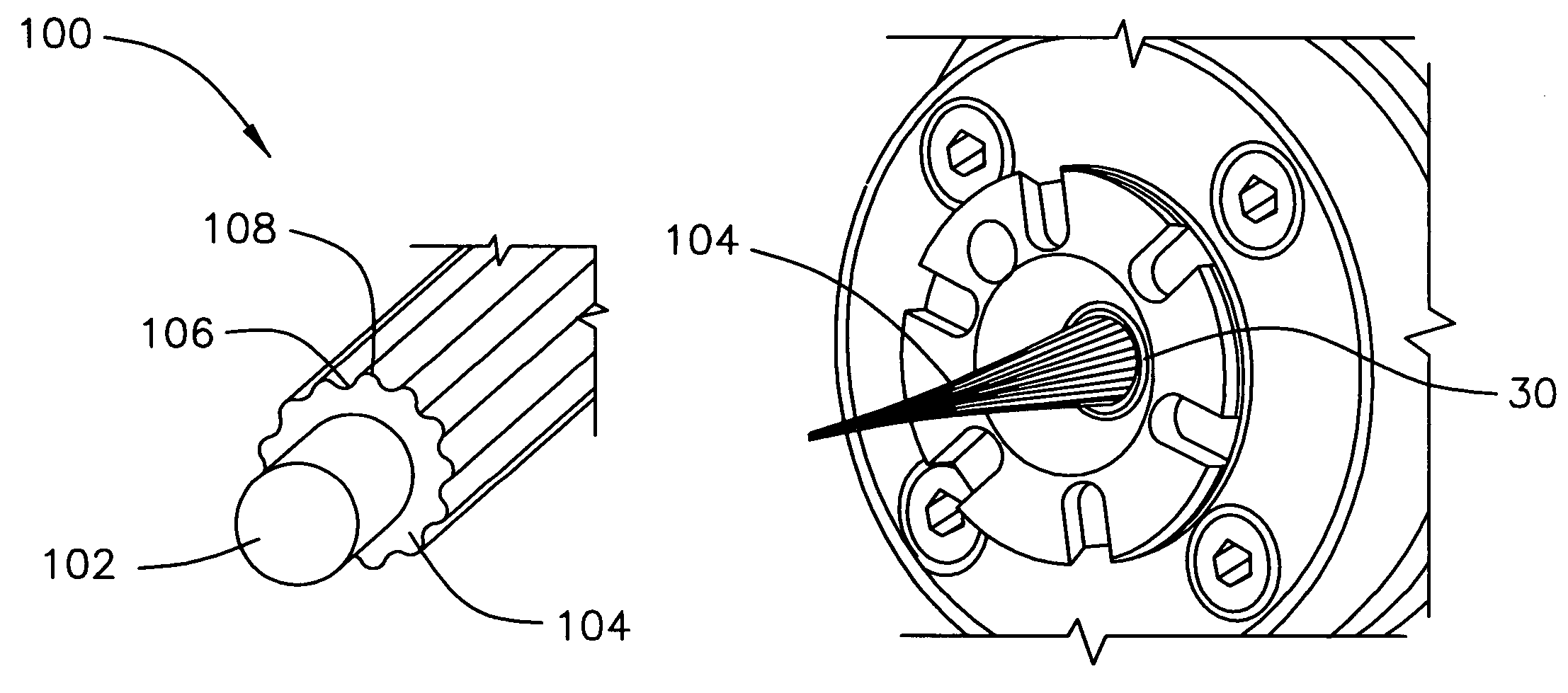

Profiled insulation and method for making the same

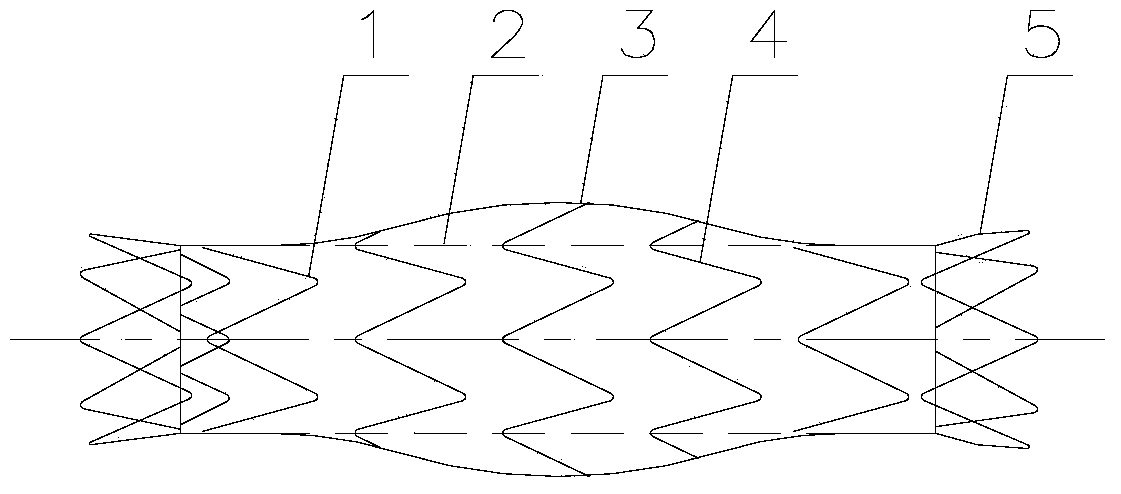

ActiveUS7560646B2Reduce amountPrevent inductive lossPlastic/resin/waxes insulatorsInsulated cablesElectrical conductorCrevasse

A wire has a conductor and an insulation extruded onto the conductor. The insulation has a plurality of alternating crests and crevasses, where the ratio of the distance from the conductor to a top of the crest to the distance from the conductor to a lowest point in the adjacent crevasse is at least 1.1 and where the ratio is sustained within a tolerance variation of not more than 15% along the length of the wire.

Owner:BERK TEK

Tungsten alloy plated pipeline welding port connecting method

InactiveCN104075047AFirmly connectedGuaranteed resistance to corrosive environmentsNon-disconnectible pipe-jointsMetal working apparatusOcean bottomCorrosion resistant alloy

A tungsten alloy plated pipeline welding port connecting method comprises the following welding steps of 1 performing corrosion resistant alloy composite layer surfacing in a port of a carbon steel pipe section base material; 2 integrally plating a tungsten alloy layer in the carbon steel pipe section base material; 3 performing preparation before welding and performing crevasse treatment on tungsten alloy plated pipe sections required to be welded so as to form a crevasse required by welding; 4 welding two tungsten alloy plated pipe sections required to be welded; 5 finishing connection of whole tungsten alloy plated pipe section butt-welded joints. The whole tungsten alloy plated pipe section welding is evolved into alloy composite pipe port welding. The method can enable tungsten alloy plated pipelines to be subjected to direct butt-welded connection, achieves reliable connection of the tungsten alloy plated pipelines under the situation that the overall strength of submarine pipelines is not sacrificed, also solves the problem that a corrosion resistant environment is destructed by high temperature when the tungsten alloy plated pipelines are subjected to butt joint, and ensures the whole corrosion resistant environment of a tungsten alloy plated pipeline system.

Owner:CHINA NAT OFFSHORE OIL CORP +1

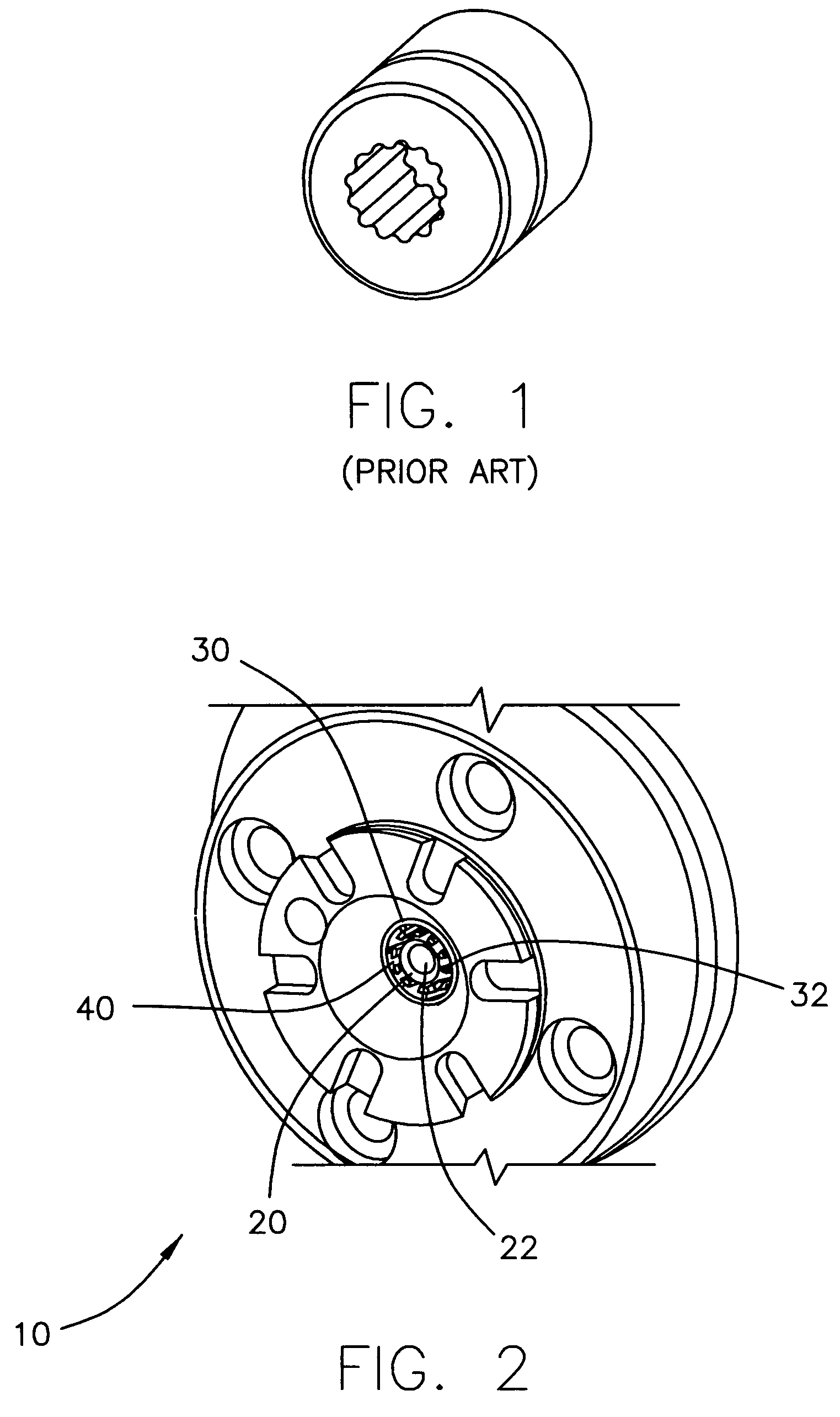

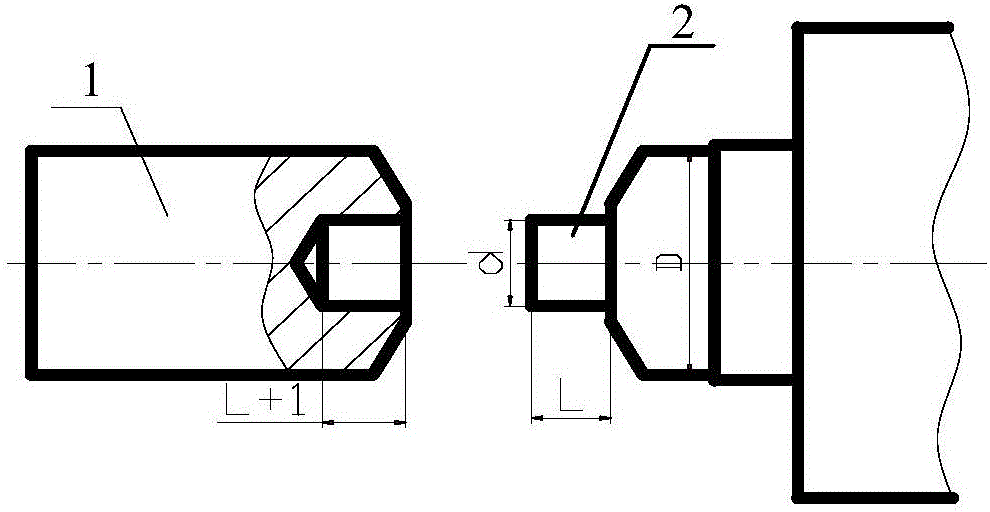

Motor broken shaft reconnection technology

InactiveCN106385141AIncrease profitReduce use costShaftsManufacturing dynamo-electric machinesInterference fitCrevasse

The invention discloses a motor broken shaft reconnection technology. The motor broken shaft reconnection technology comprises steps 1, choosing a reconnection point and choosing a blocking root part of the motor bearing as a reconnection point between a shaft extension portion and an original motor rotor shaft end, 2 adopting a hot charging interference fit on a portion where the shaft extension portion is connected to the shaft end of the original motor rotor shaft end, 3, adopting a heating furnace to continuously heat the shaft extension part to 190 degree to 210 degree for 30-40 minutes and sleeving the shaft extension portion into the original motor rotor shaft end in a hot charging manner, 4, performing surfacing on a crevasse part of a seam after the shaft extension portion to be hot charged is cooled down, and 5, placing the rotor on a lathe after the welding portion of the shaft extension portion is cooled down and processing the portion of the connected shaft into an original shaft size which is originally needed so as to finish motor broken shaft reconnection. The invention discloses the motor broken shaft reconnection technology, and the motor which is repaired by the motor broken shaft reconnection technology can satisfy a stress requirement for the broken portion of a normal shaft extension portion, improves a motor utilization rate and reduces a motor usage cost.

Owner:NINGXIA NORTHWEST HORSE ELECTRIC MFG

Thin-base-rock shallow coal-layer water-retaining production suitable-condition classification method

InactiveCN101070759BImprove resource recoveryHigh recovery rateUnderground miningSurface miningBedrockReturn ratio

The invention discloses applicable classification method for mining under the shallow bedrock of thin seam keeping water conditions. Apply to thin seam overlying shallow bedrock aquifer water loose the protection of water resources. At first according to the feature of structure or Shallow bedrock, the height of leading water crevasse under different mining height is analyzed and calculated. The estimate formula: HL=9.29M+10.6 can be used to determine the height HL of leading crevasse water under the shallow bedrock of thin seam to the different mining height M. The mining waterproofing security coal rock pillar protector thickness of the thin bedrock shallow submersion coal bed long well working surface is 10 m. According to the classification situation of loose water-bearing stratum water body, the bedrock thickness which is needed is determined under the condition of different mining height. According to classification situation and mining height, mining is separated into reinsurance water mining according to the bedrock thickness. This method has good water resources protection effect, is safe in production, and has high coal resource returns-ratio.

Owner:CHINA UNIV OF MINING & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com