Thick steel plate with excellent brittlement crevasse crack propagation halt characteristic and manufacturing method thereof

A technology of thick steel plates and steel plates, applied to the field of thick steel plates with special characteristics, and the field of manufacturing such thick steel plates, can solve the problems that it is difficult to apply high-strength thick steel plates, and achieve the effect of excellent brittle crack propagation stop characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

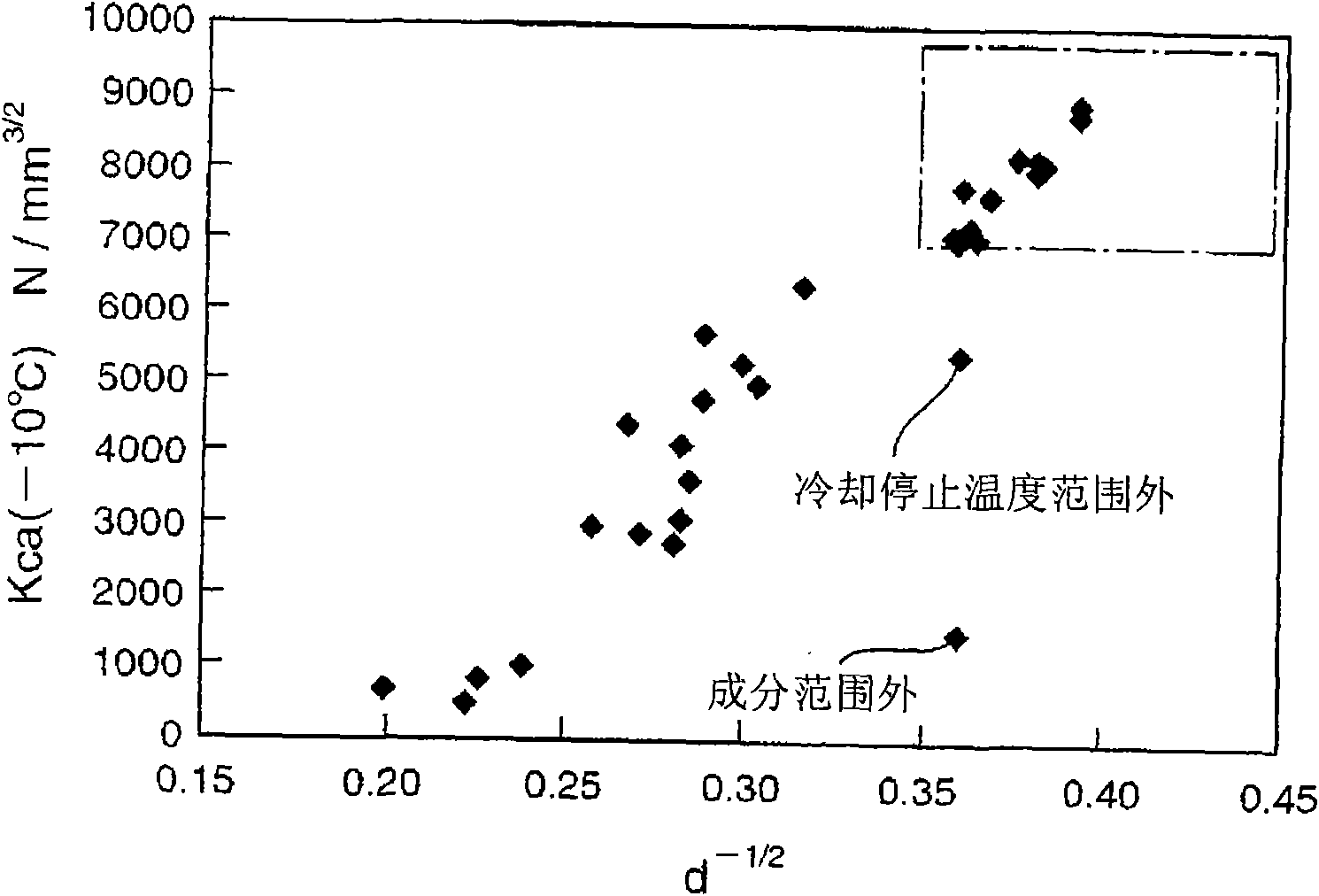

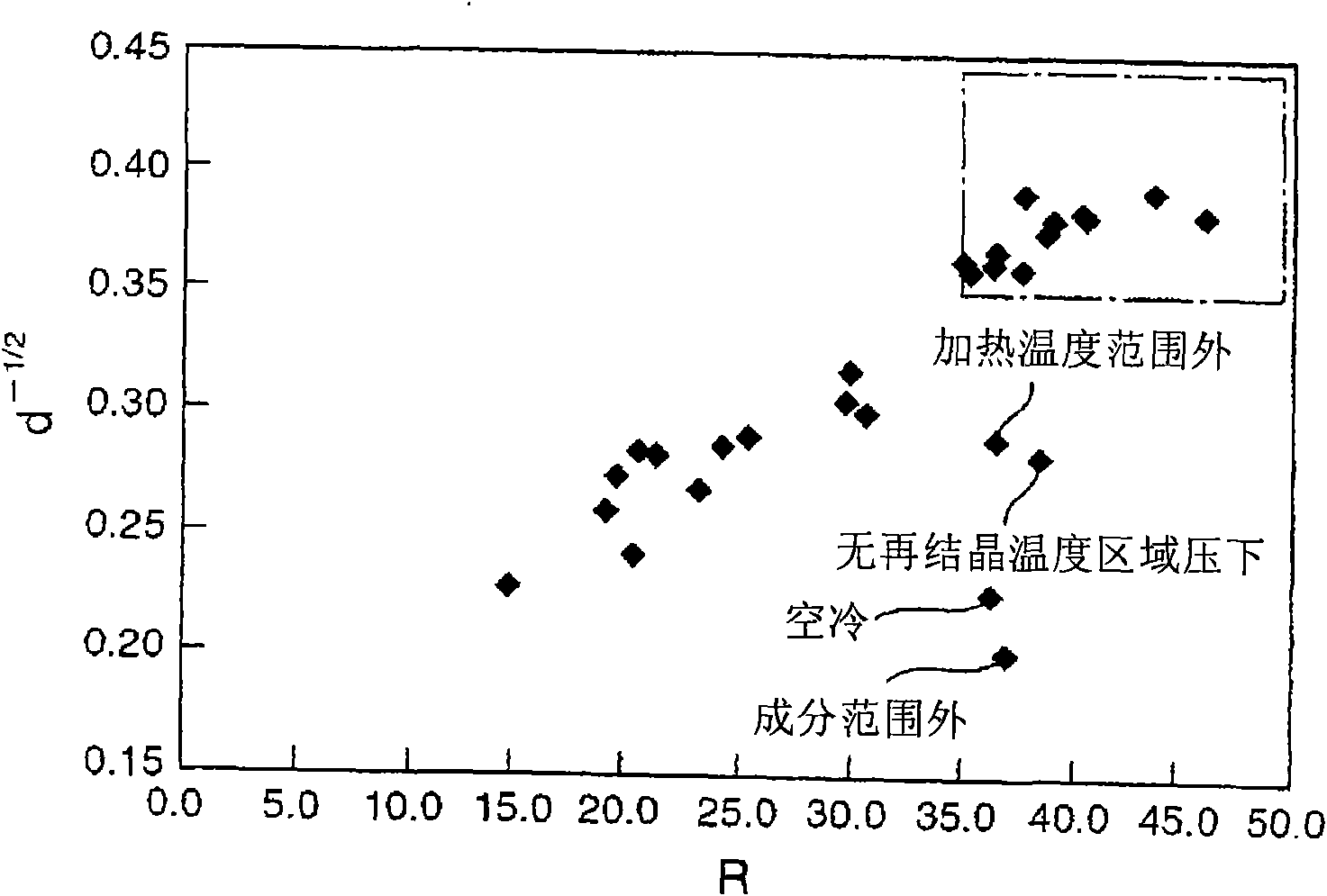

[0014] The inventors of the present invention focused on a thick steel plate with a bainite structure, and studied from various angles a method for making the brittle crack propagation stop property of the steel plate favorable. As a result, it was found that in the bainite structure, the austenite structure is formed regardless of the orientation relationship with respect to the austenite structure, but if the chemical composition of the steel plate, the formation temperature of the structure, and the orientation relationship of each lattice selected based on other conditions, etc. Change, at a predetermined position in the thickness direction of the steel plate, the crystal grains having a characteristic crystal orientation are made finer, and the brittle crack propagation stop characteristic is improved, and the present invention has been completed.

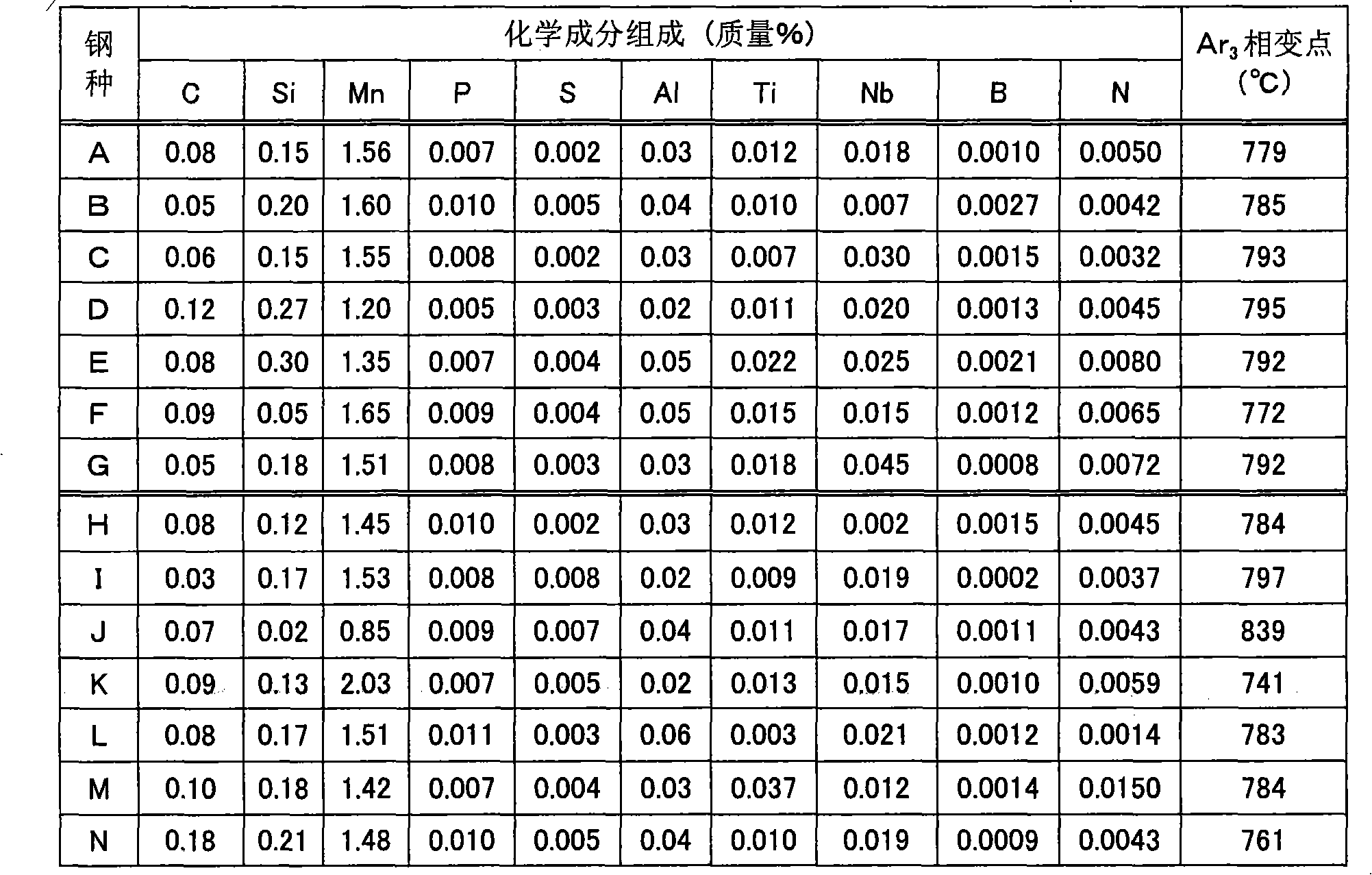

[0015] The steel plate of the present invention is composed of a structure mainly composed of bainite (bainite phase accounts...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com