Motor broken shaft reconnection technology

A technology for motor rotor shafts and broken shafts, which is applied in the manufacture of motor generators, shafts, electrical components, etc., can solve problems such as rotor guide bar microcracks, deformation, and motor performance damage, so as to ensure performance, reduce use costs, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The invention provides a motor broken shaft reconnection process comprising the following process steps:

[0024] Step 1, select the reconnection point, select the root of the motor bearing as the reconnection point between the shaft extension and the original motor rotor shaft end;

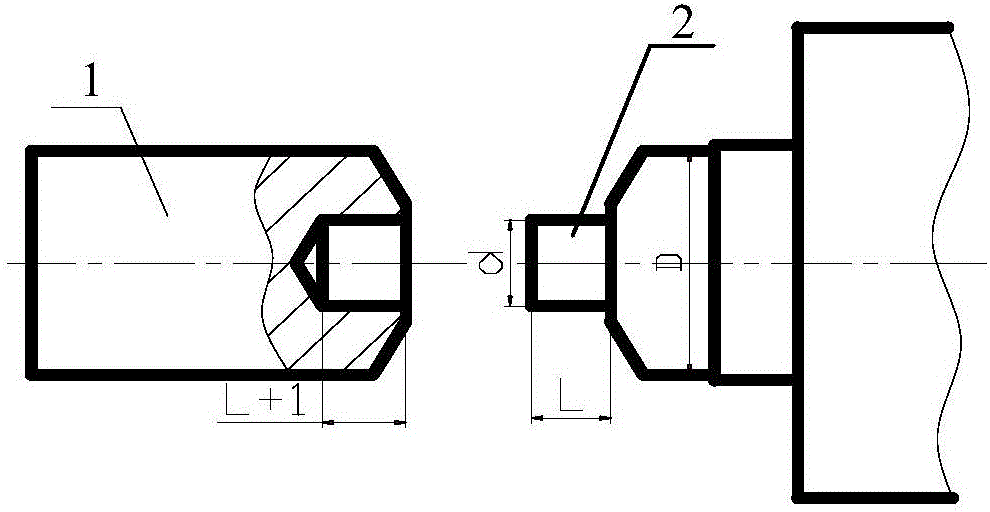

[0025] Step two, see figure 1 , the part where the shaft extension 1 is connected to the shaft end 2 of the original motor rotor adopts shrink fit interference fit; through mechanical analysis, the small diameter interference fit ensures the transmission torque, and it is verified by practice that d=(0.38~0.43)D, L= 0.9d, interference fit 0.08 ~ 0.12, this data formula can best reflect the maximum transmission torque and strength. The shaft extension material selected in the present invention is the same as the original shaft material of the motor.

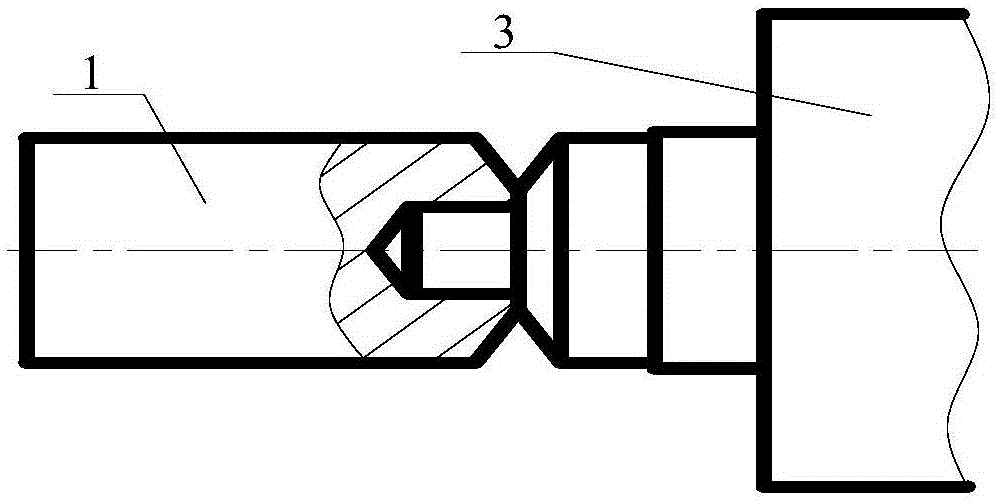

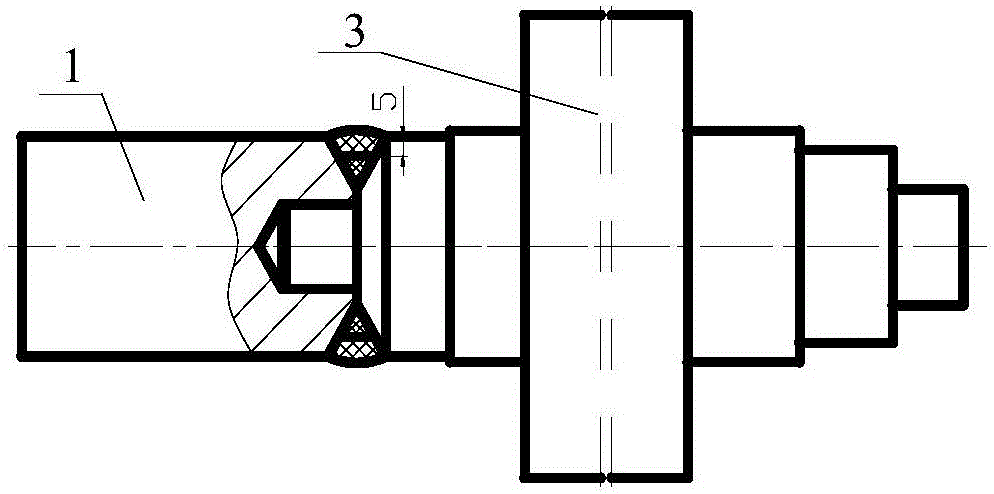

[0026] Step 3, please refer to figure 2 , use a heating furnace to heat the shaft extension 1 to 200 degrees Celsius, continue heating fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com