IC (integrated circuit)-packaged wafer expanding device

A technology of outer ring and inner ring, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of low production efficiency, inability to effectively realize mechanization and automation, and difficulty in quality assurance, and achieve high production efficiency, The effect of high degree of mechanization and automation and ingenious design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

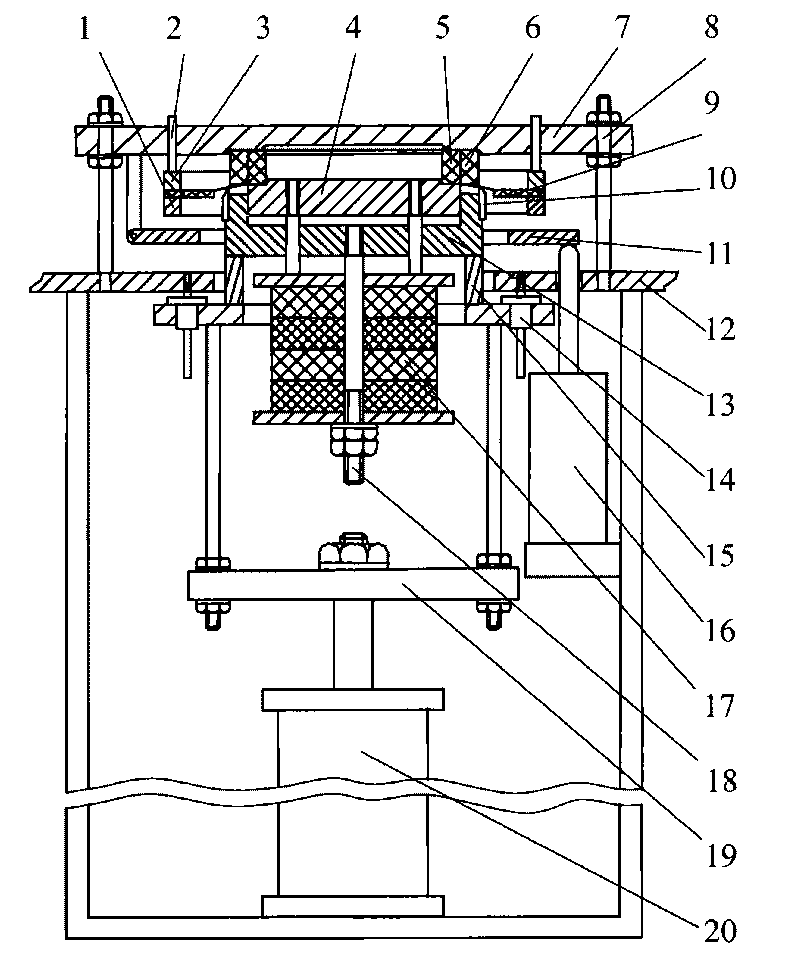

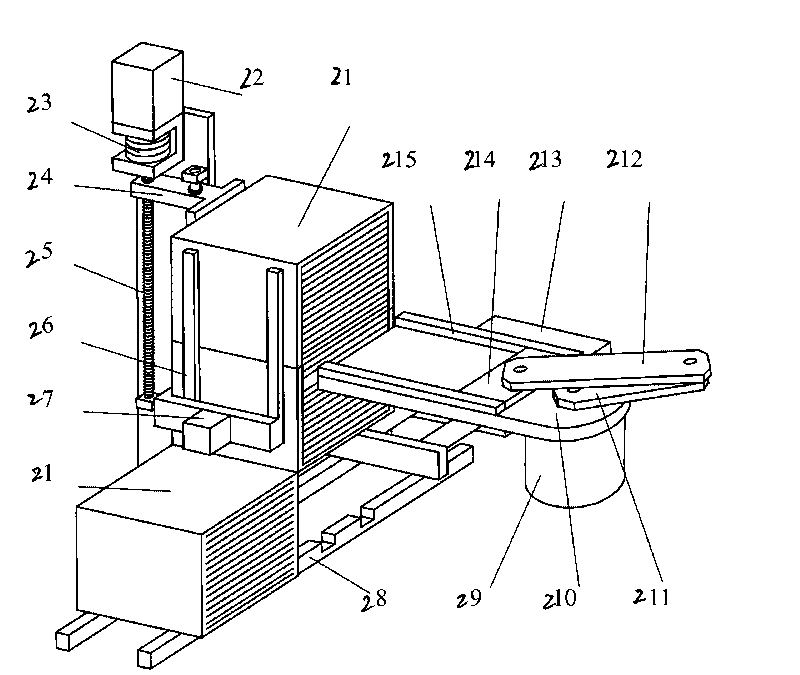

[0026] The schematic diagram of the film box feeding mechanism and the taking-up principle of the present invention is as follows: figure 2 As shown, the silicon wafer is fixed in the liner 9 by the adhesive film, and is stored in the sheet box 21. There are many grids in the chip box 21, and each silicon wafer is inserted in a separate grid and isolated from each other, and the chips are protected during transportation and access. Sheet cassettes 21 are stacked in the sheet cassette station that support 26 and landing gear 24 etc. constitute. Landing gear 24 is restrained by parts such as linear guide rail, nut and screw mandrel 25, and under the drive of stepper motor 22, screw mandrel 25 rotates, and landing gear 24 moves up and down along linear guide rail. Each time, the sheet cassette 21 moves one grid from top to bottom, and then moves down one grid after the sheet taking mechanism takes out a silicon wafer. When a sheet cassette 21 has been supplied, the grid of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com