Tungsten alloy plated pipeline welding port connecting method

A connection method and alloy pipe technology, which is applied to non-detachable pipe connections, welding equipment, pipes/pipe joints/fittings, etc., can solve problems such as crevice corrosion, easy corrosion, and poor reliability of threaded connections, etc., to avoid leakage risks , save the weight of the flange, and break through the size limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

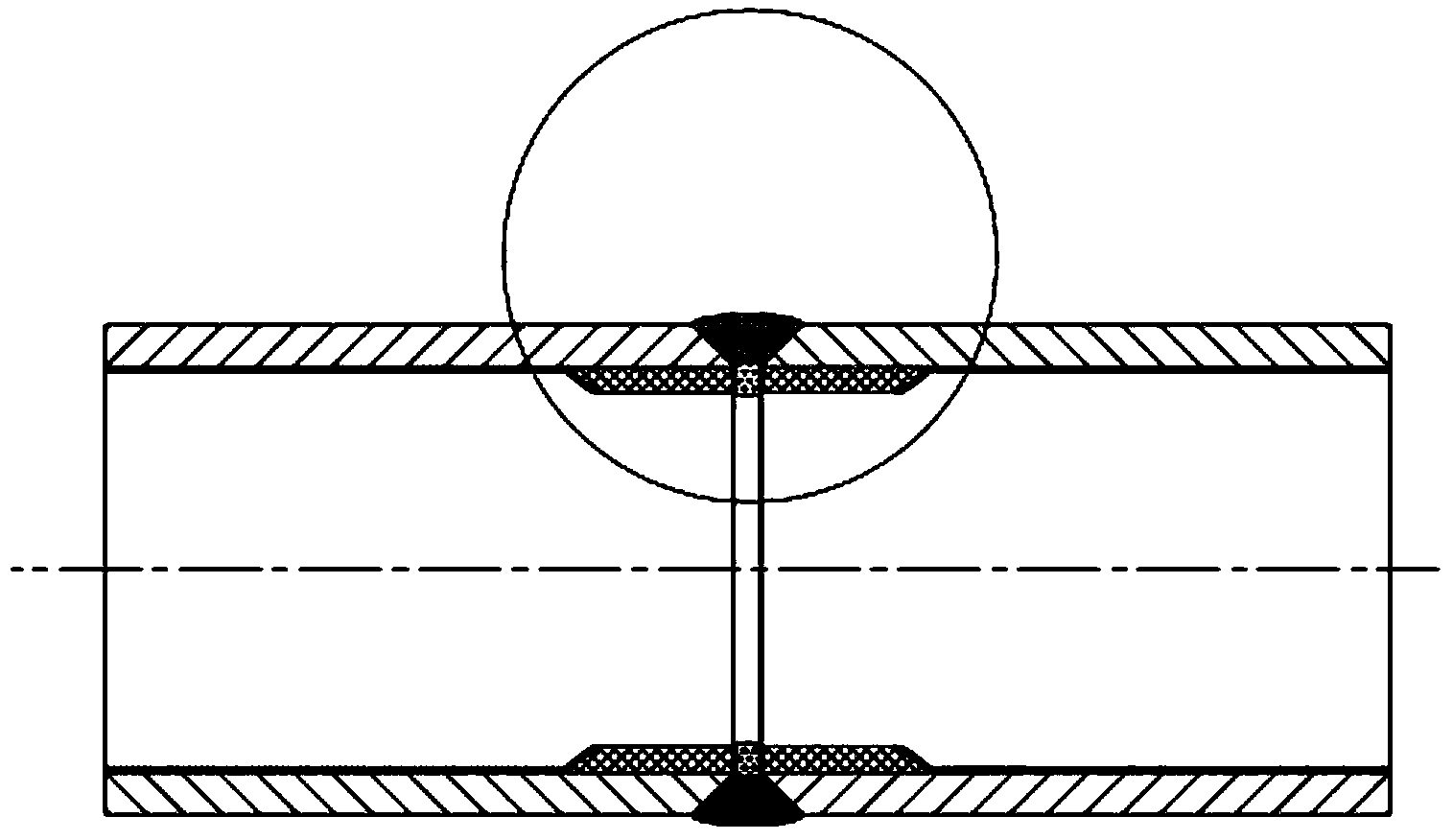

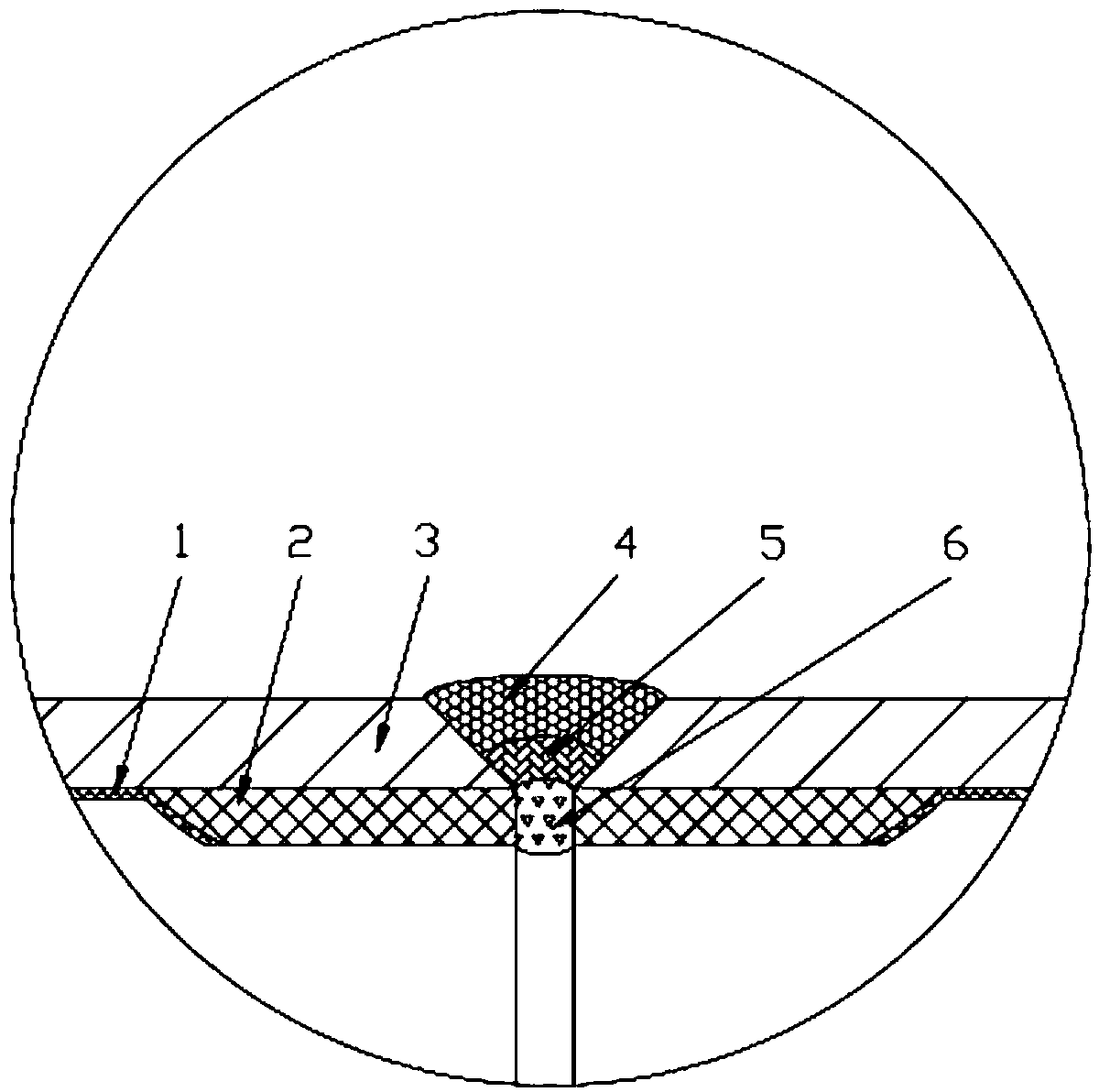

[0027] Such as figure 1 , figure 2 As shown, the present invention adopts the following welding steps:

[0028] Step 1: surfacing a corrosion-resistant alloy composite layer 2 in the port of the base material 3 of the carbon steel pipe section, wherein the thickness of the corrosion-resistant alloy composite layer is 2-3 mm, and the width is 10-20 mm;

[0029] Step 2: Plating tungsten alloy layer 1 as a whole in the base material 3 of the carbon steel pipe section, wherein the tungsten alloy layer 1 does not need to be plated at the corrosion-resistant alloy composite layer 2, only ensuring that there is an overlapping transition between the tungsten alloy layer 1 and the corrosion-resistant alloy layer 2 layer to form a continuous and complete anti-corrosion environment;

[0030] The third step: preparation before welding, the tungsten-plated alloy pipe section to be welded is notched to form the groove required for welding;

[0031] Step 4: Weld two tungsten-plated alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com