Patents

Literature

31results about How to "Break through the size limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

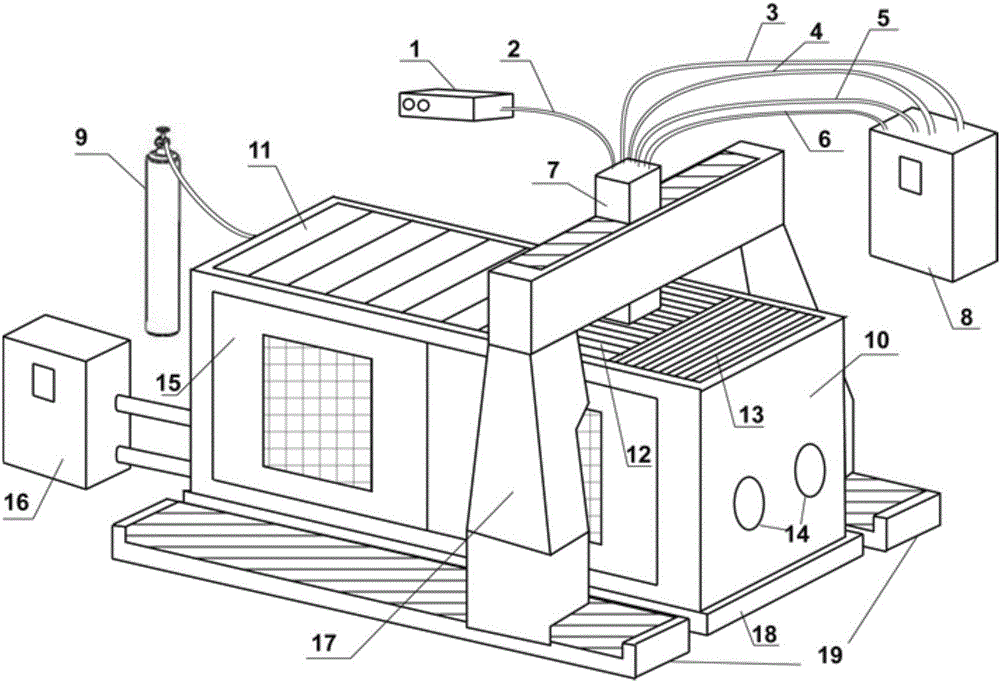

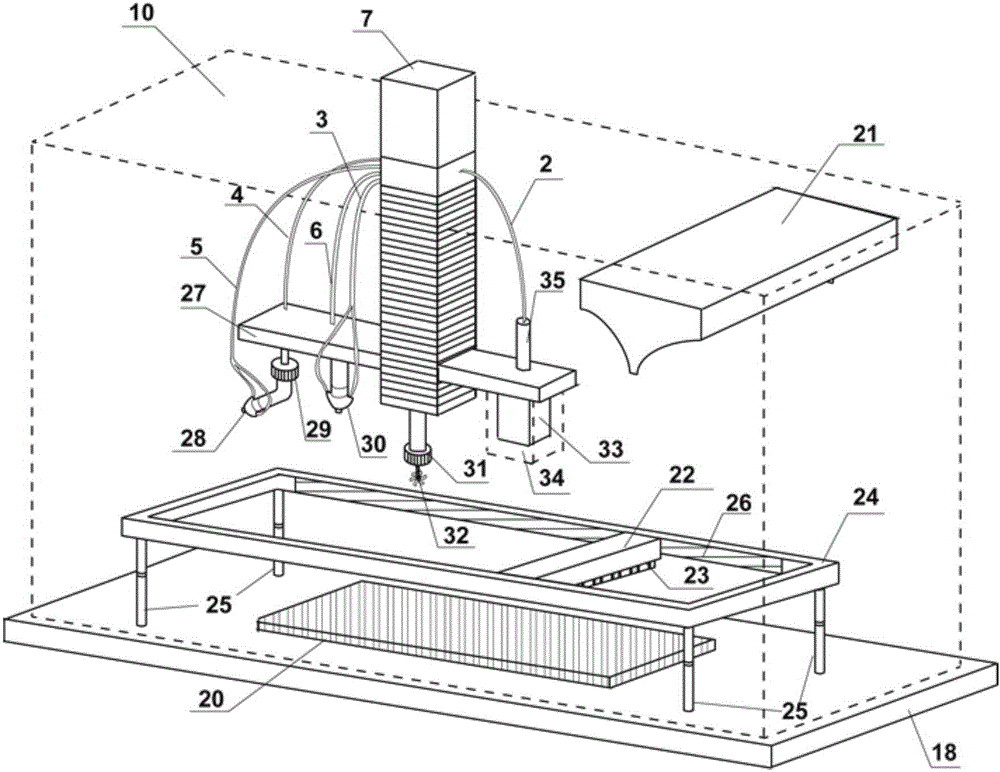

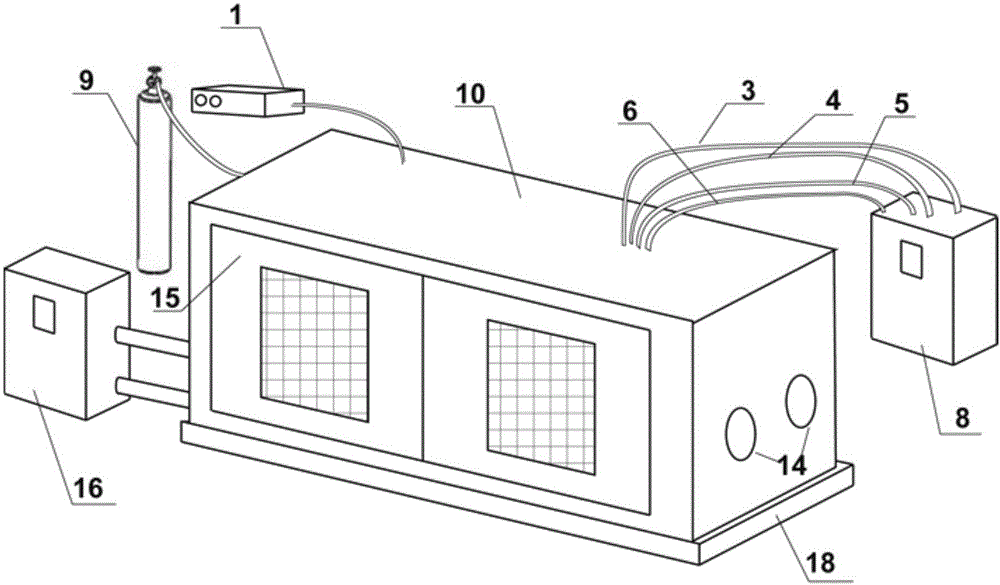

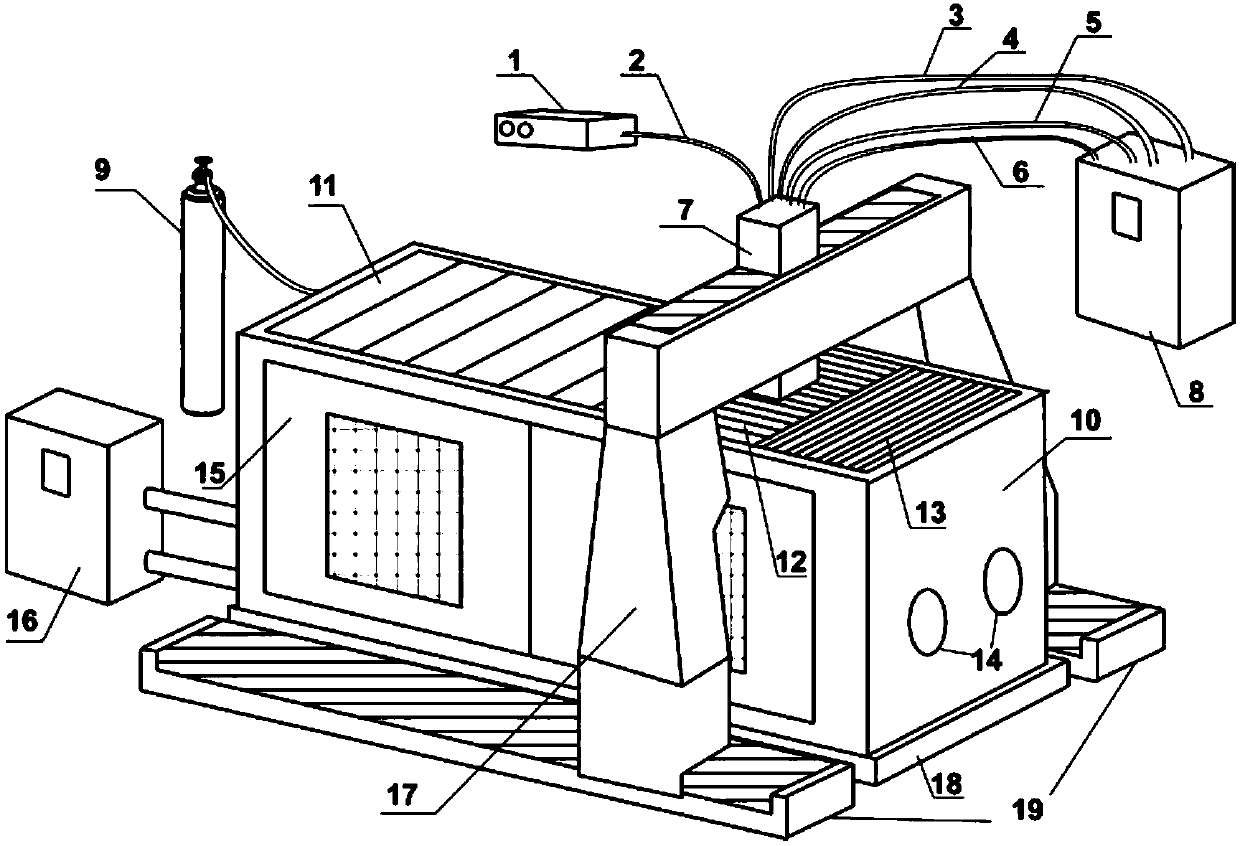

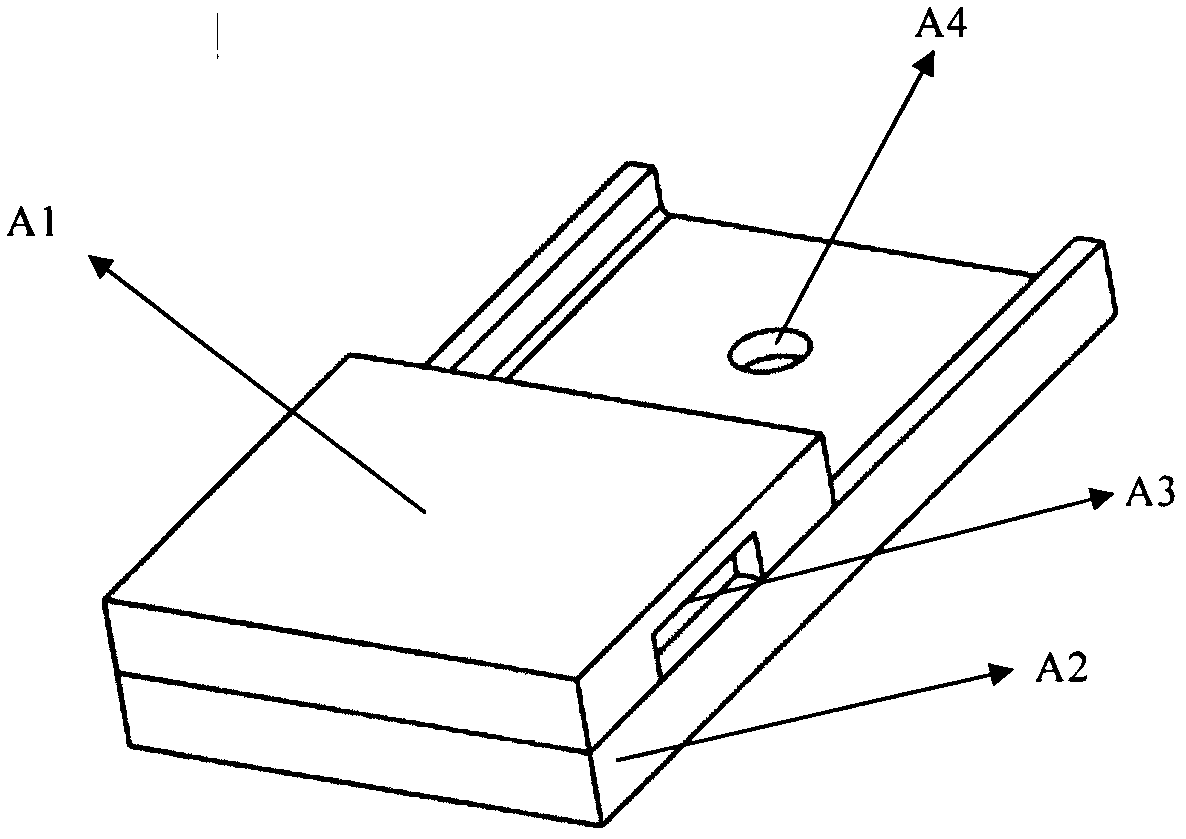

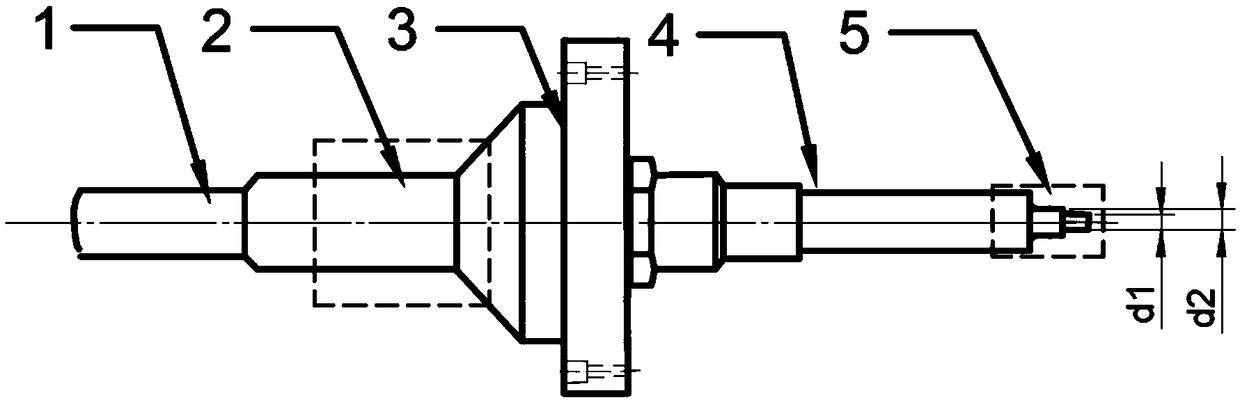

Laser additive manufacturing equipment and method of metal part

ActiveCN106346006ABreak through the size limitBreak outAdditive manufacturing apparatusIncreasing energy efficiencyCylinder setControl system

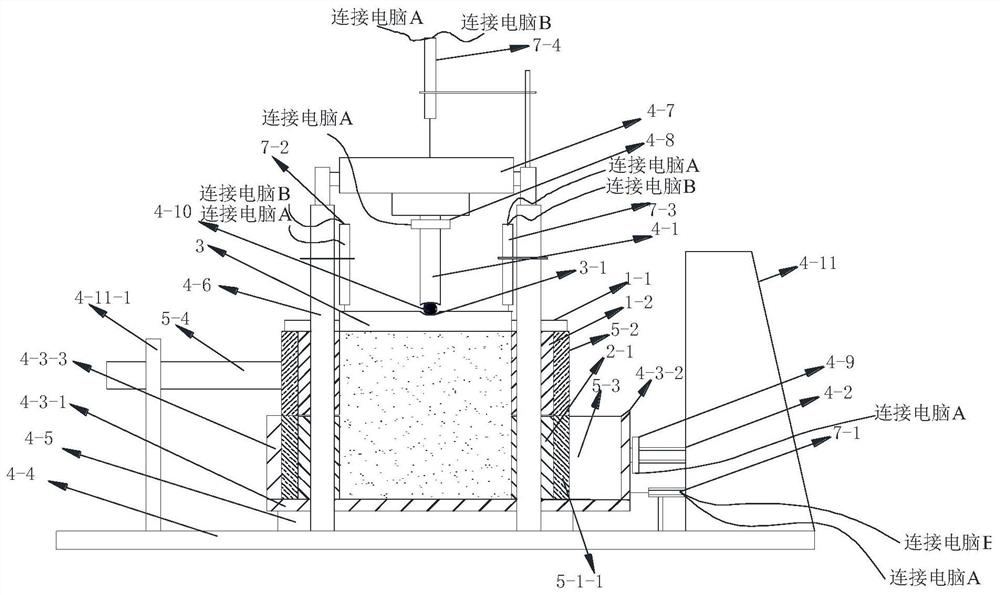

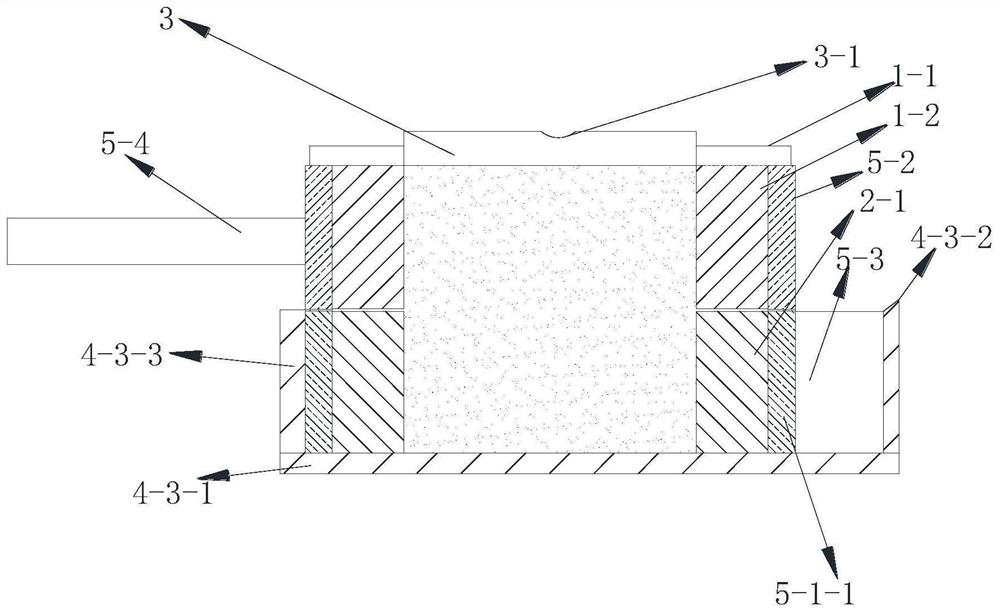

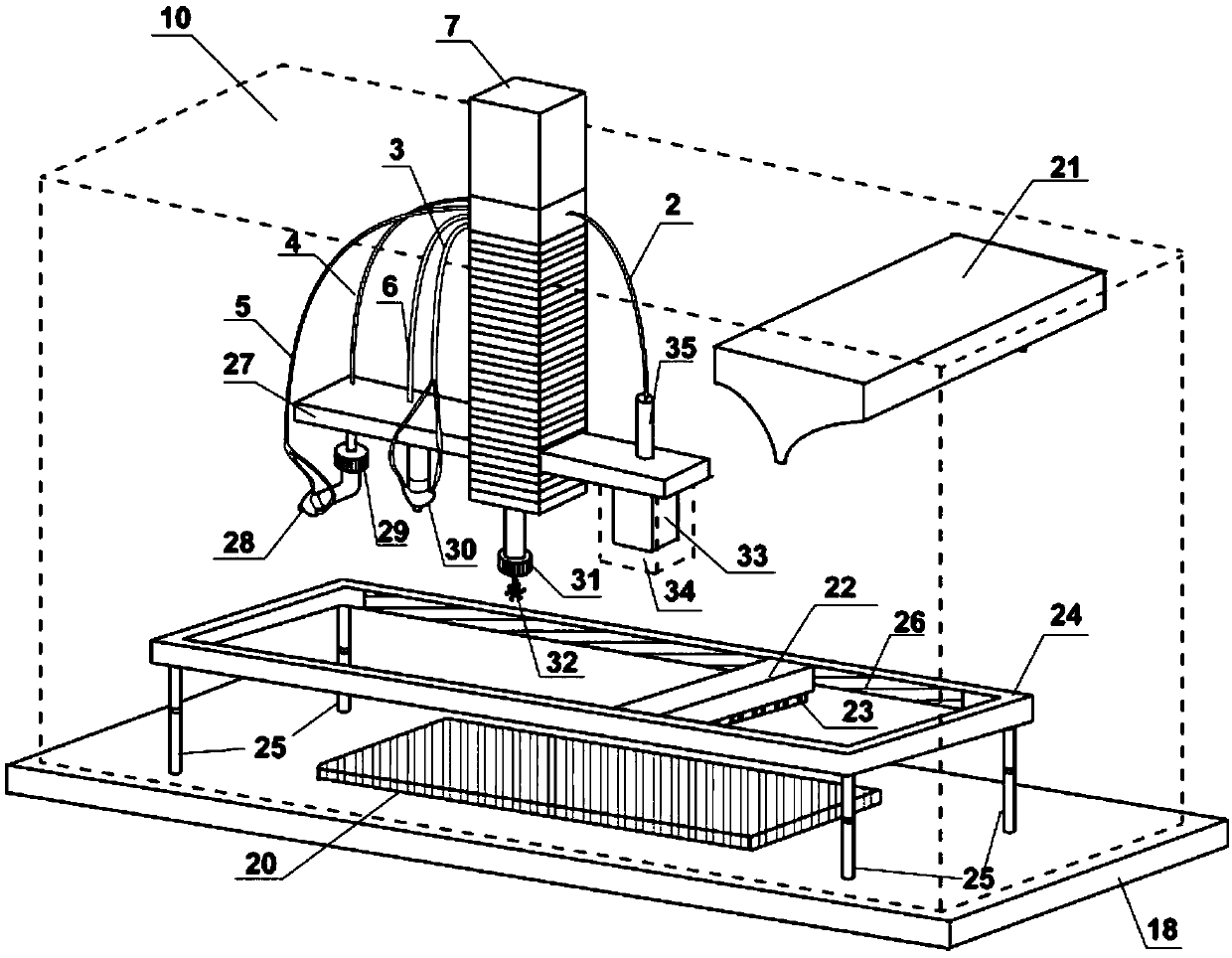

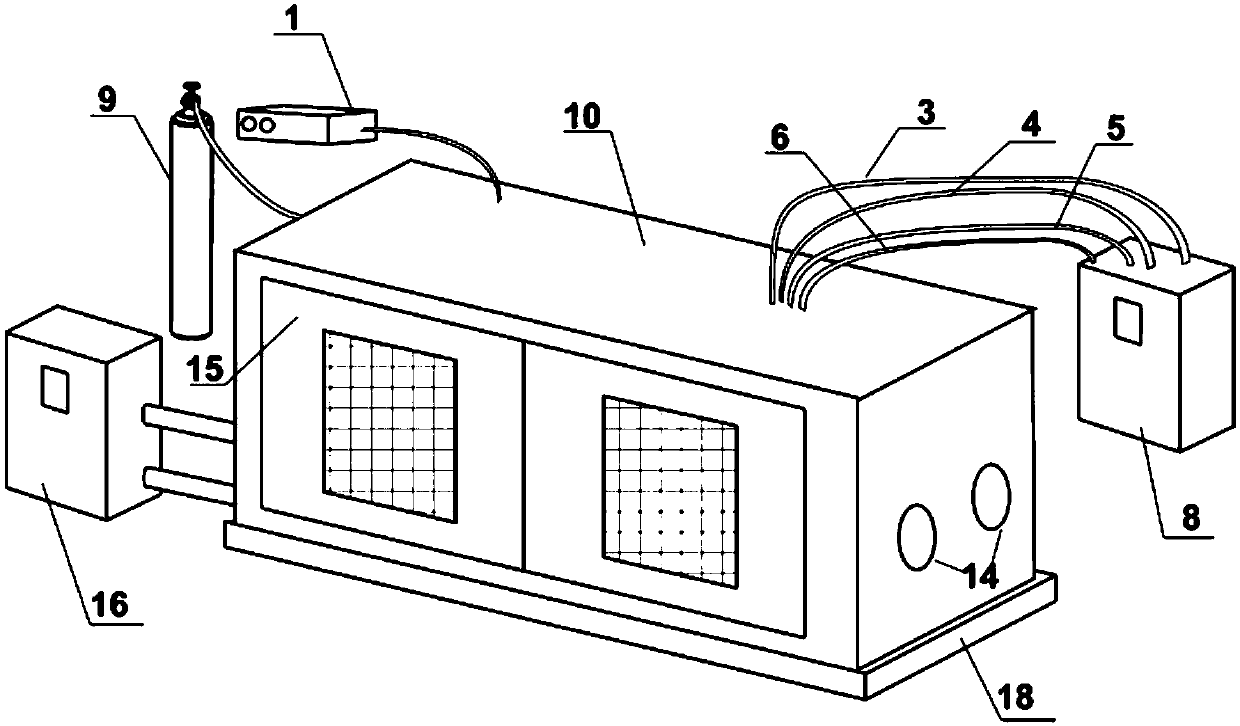

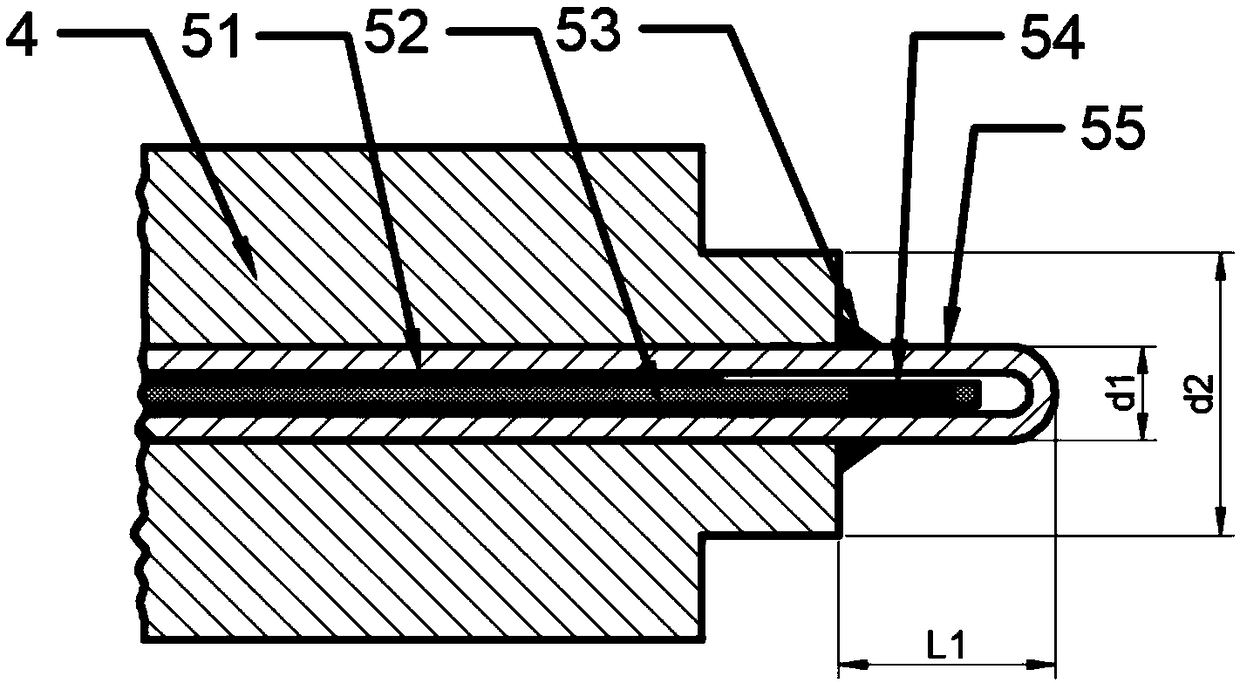

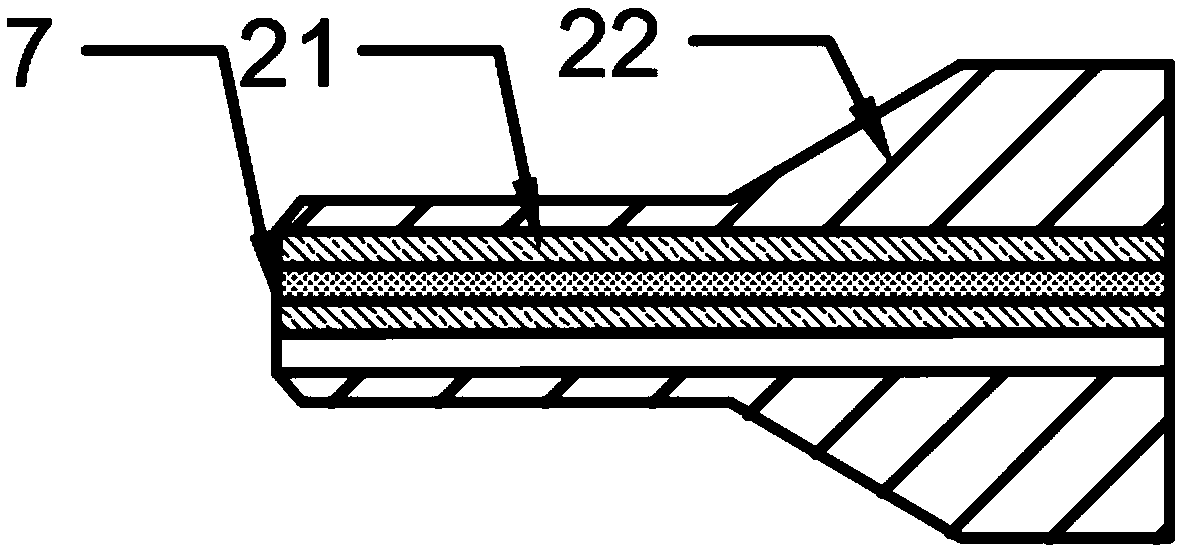

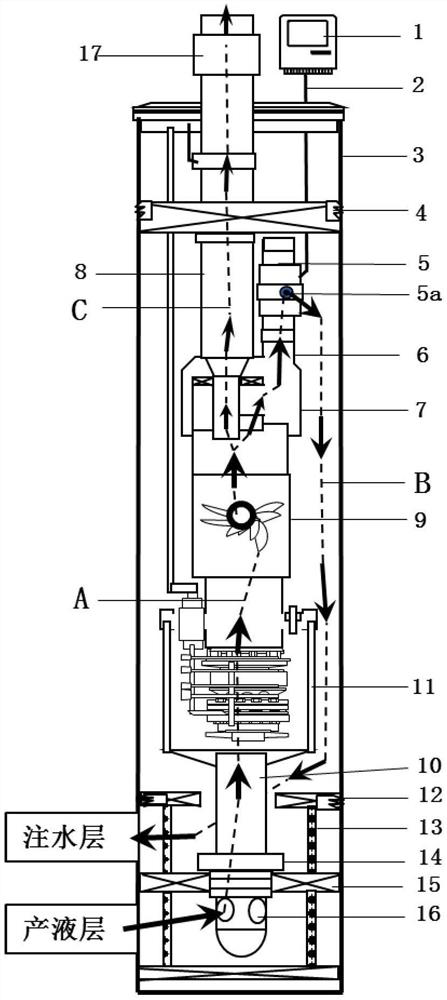

The invention discloses a laser additive manufacturing equipment and a laser additive manufacturing method of a metal part. The equipment comprises a working cabin, a preset powder laying rapid-forming assembly, a shape follow-up cylinder setting and removing assembly, a machining assembly, a moving mechanism and a control system. Firstly a shape follow-up cylinder slicing layer capable of surrounding the slicing contour of the metal part is arranged on the surface of a substrate by using the shape follow-up cylinder setting and removing assembly, a metal powder layer is paved on the interior of the preset powder laying rapid-forming assembly, and laser selective melting is carried out on powder, so that the formation of a first slicing layer of the metal part is completed; according to accuracy requirement, the formed slicing layer of the metal part can be machined by using the machining assembly; the process of shape follow-up cylinder slicing layer setting, powder paving, laser selective meltingand formation of the slicing layer of the metal part and machining (when necessary) is repeated, and high-precision formation of metal parts with various sizes and structures can be realized at one time; and a shape follow-up cylinder can be conveniently removed by using the shape follow-up cylinder setting and removing assembly after formation.

Owner:HUAZHONG UNIV OF SCI & TECH

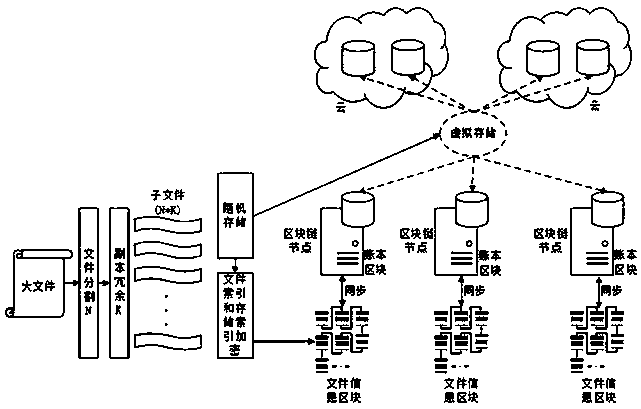

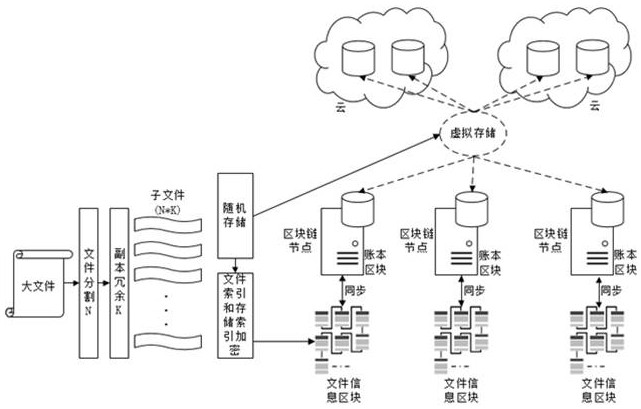

Block chain large file secure storage method and system

The invention relates to a block chain large file secure storage method and system, and the method comprises the steps: 1) registering a large file into a block chain by a block chain node user, splitting the large file by a storage system, and carrying out the redundant storage of a copy of the large file in a block chain storage network; 2) splitting the large file into N blocks, carrying out redundancy on the N blocks into K parts, and randomly storing the K parts into M storage nodes; 3) enabling the storage nodes to be a set of block chain nodes and cloud storage nodes; 4) enabling a userto encrypt the file blocks and the index records of the storage positions into the block chain blocks by using the public key; and 5) after logging in the block chain at any node, enabling the user to decrypt the file block and the storage position index by using the private key to recover the large file. According to the invention, the problems of secure storage and rapid synchronization of thelarge file in the block chain are solved, the system realizes the secure operation of safely recovering the large file by randomly switching the terminal by the user, and the limitation of the size ofthe block chain transaction file is broken through.

Owner:中科天御(苏州)科技有限公司

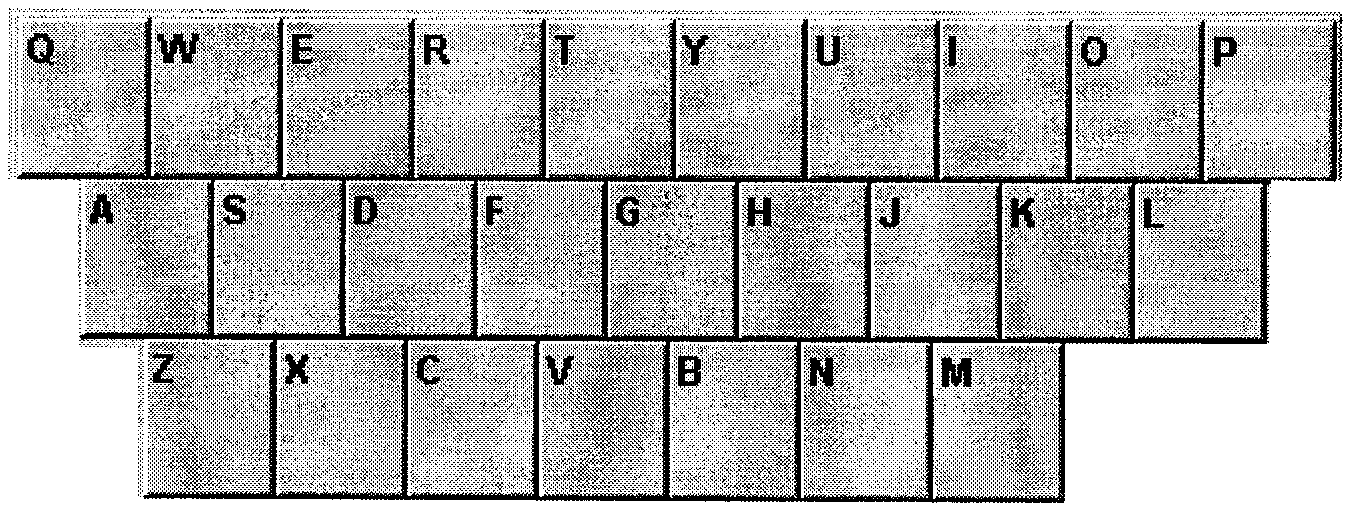

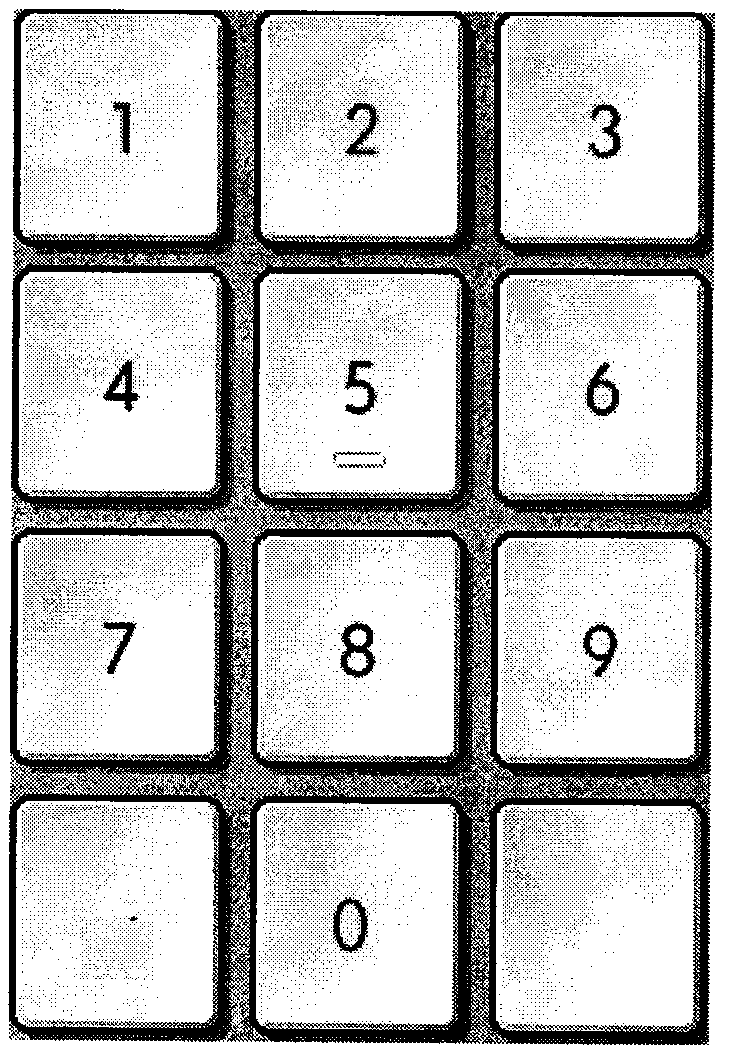

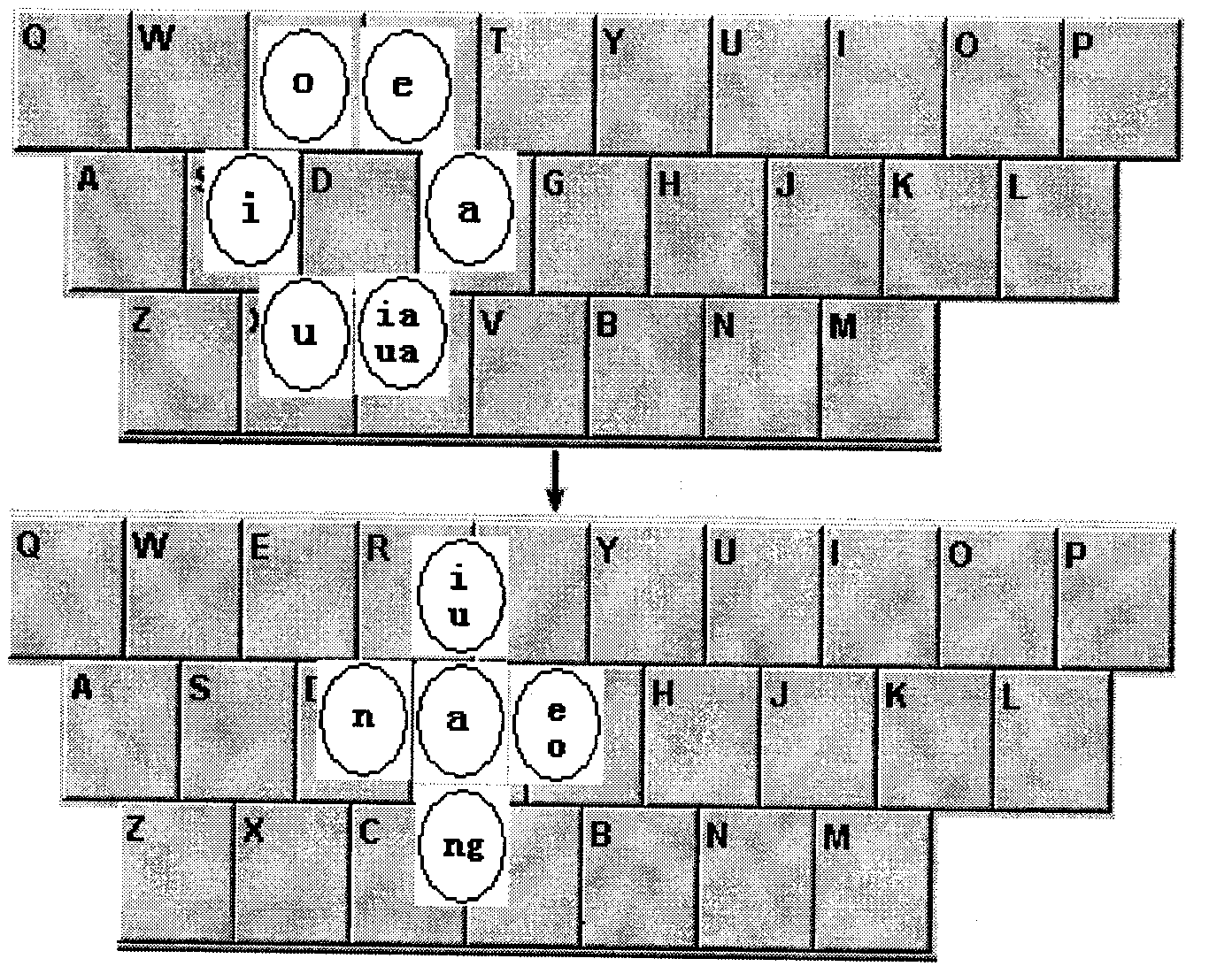

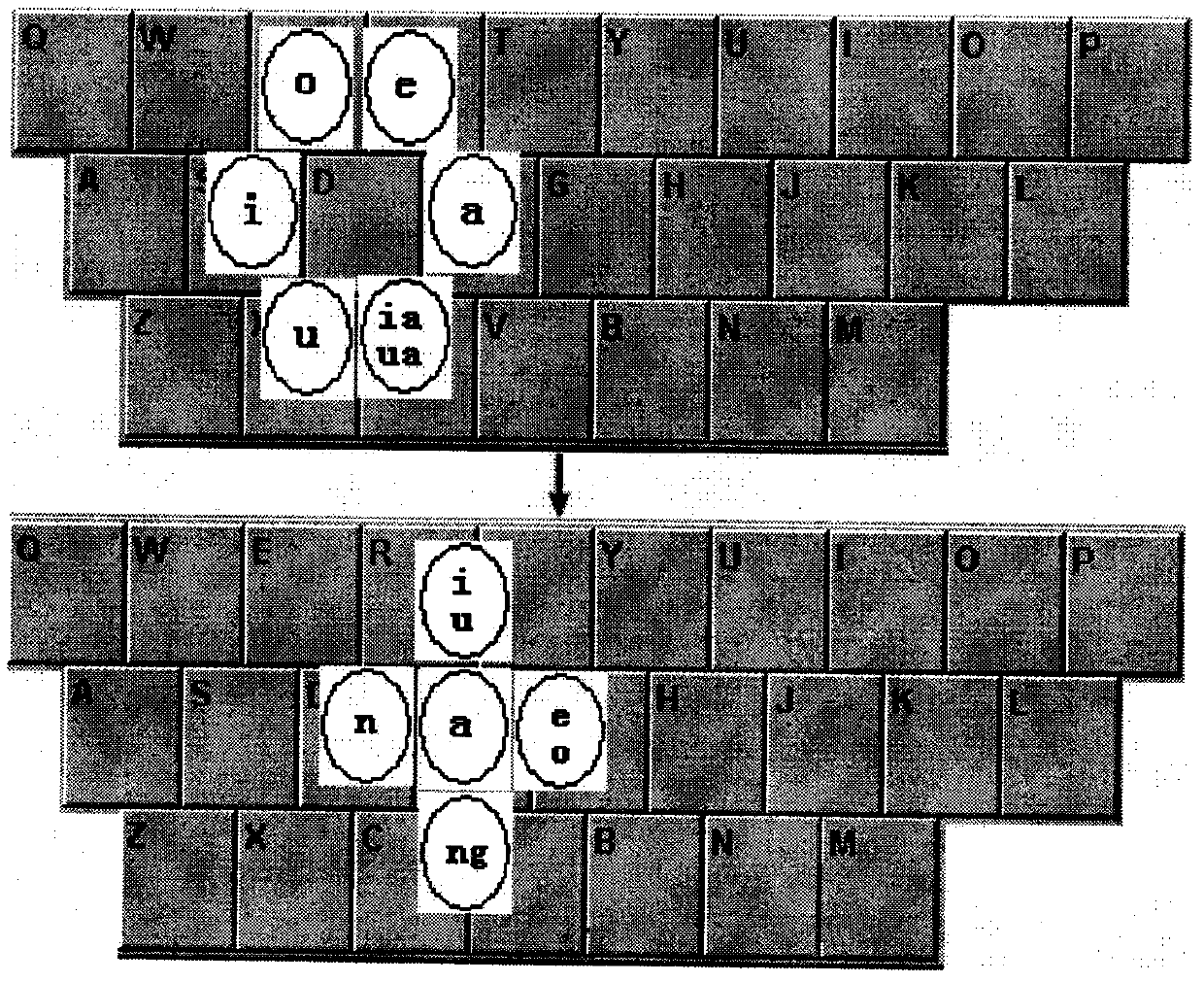

Fast Chinese pinyin input method based on touch sensitive device and achieving system thereof

ActiveCN103235696AIncrease or decrease the number of keysNumber of keys increased or decreasedInput/output processes for data processingKey pressingAssistive technology

The invention discloses a fast Chinese pinyin input method based on a touch sensitive device and an achieving system thereof. The method includes that a marking tool is used for clicking an initial soft keyboard of a touch screen to input an initial consonant of pinyin; a system pops out a vowel suspension soft keyboard covered around an initial consonant key automatically; the marking tool is used for sliding on the vowel suspension soft keyboard for at most two key positions, and vowels of the pinyin are input; and the marking tool is lifted, and the vowel suspension soft keyboard is hidden automatically. Technical systems of six portions are combined and include (1) a suspension soft keyboard system; (2) seven suspension soft keyboards and key position layouts of the seven suspension soft keyboards; (3) a 'one-key one-pinyin' fast pinyin input method; (4) a 'one-character one-key' sentence input mode; (5) a non-switch stroke assisting technology; (6) a fast part input method. By means of the method and the system, only once key clicking is conducted, simplified pinyin and full pinyin are conducted simultaneously, and efficient inputting can be conducted without changing a pinyin scheme or initial soft keyboard setting. Simultaneously, touch screen size limit is broken through, key false identification rate is low, operation fatigue is small, and high-speed typing can be conducted even if a user does not know the pinyin.

Owner:白春荣

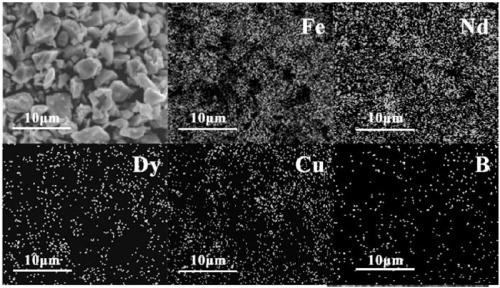

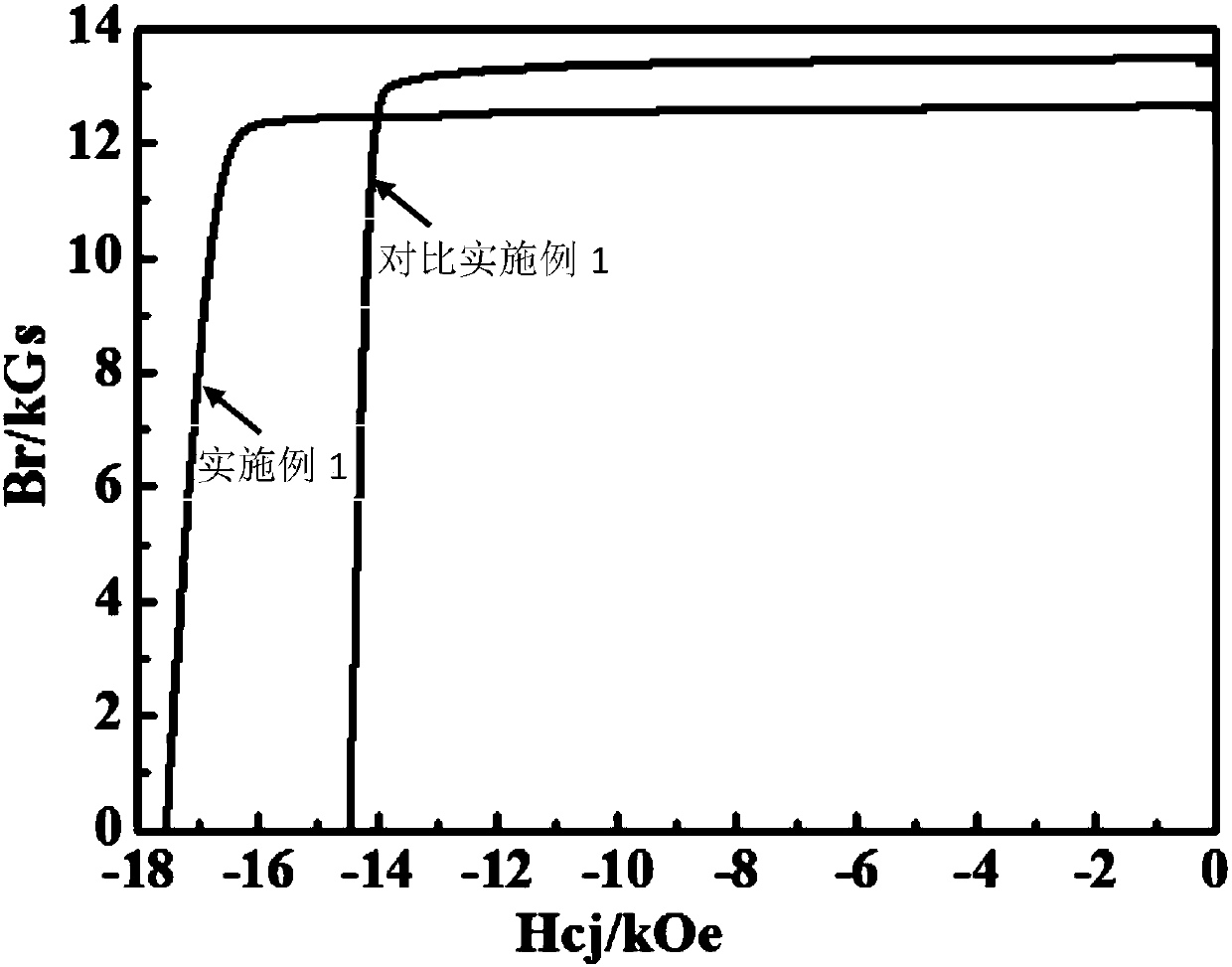

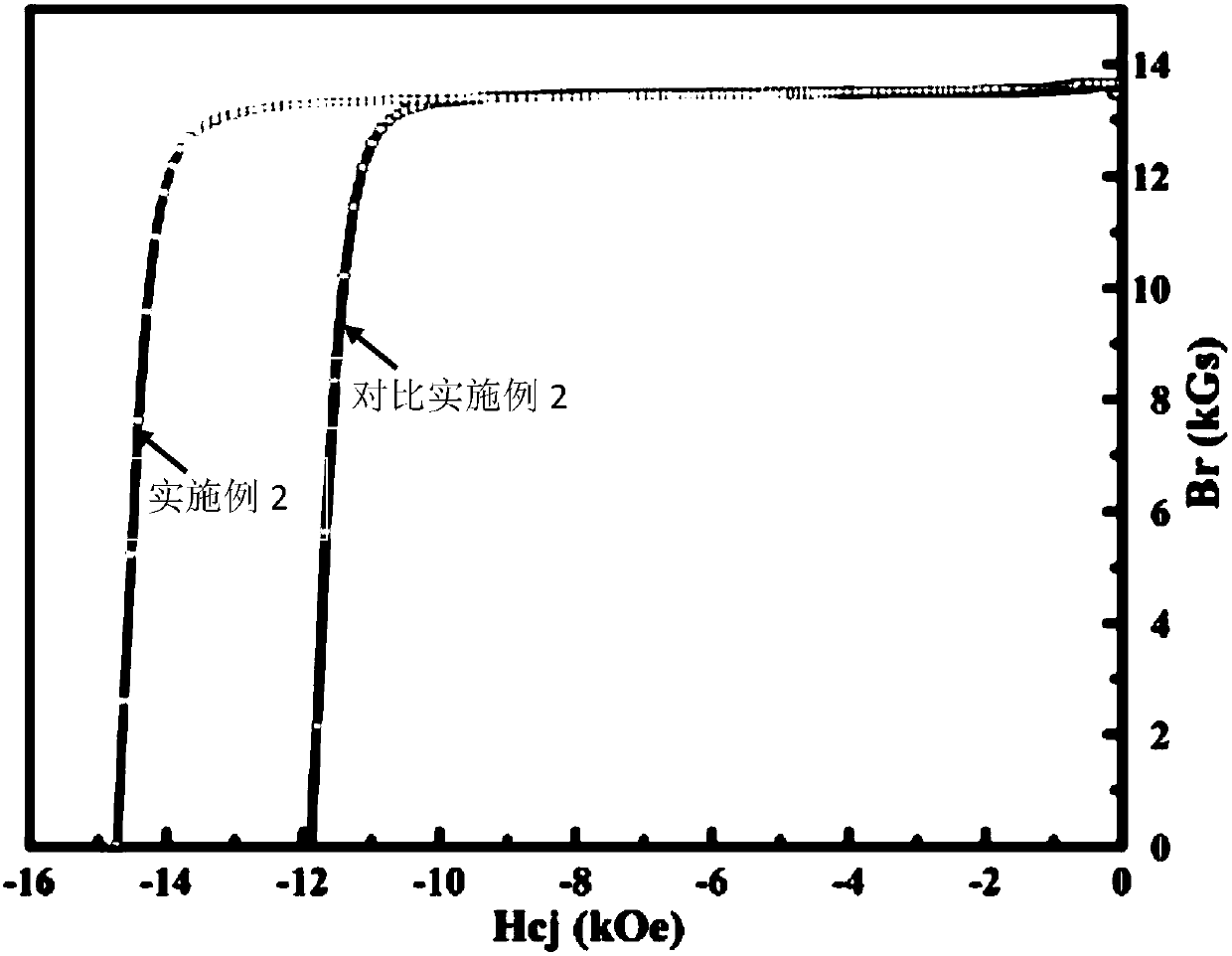

Preparation method of sintered neodymium-iron-boron magnet

InactiveCN110021467AInhibition of agglomerationCoated evenlyInorganic material magnetismInductances/transformers/magnets manufactureRare-earth elementSurface layer

The invention discloses a preparation method of a sintered neodymium-iron-boron magnet. A solution coating method is adopted for mixing alloy magnetic powder with an organic turbid liquid or an organic solution containing heavy rare earth elements, so that the heavy rare earth elements uniformly coat the peripheries of magnetic powder particles; and then molding and sintering tempering treatment is carried out for effectively controlling the heavy rare earth elements on the surface layers and the crystal boundaries of crystal particles, so that the distribution uniformity and the diffusion depth of the heavy rare earth elements in the sintered neodymium-iron-boron magnet can be improved, and the magnetic properties such as the coercive force and the like can be improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

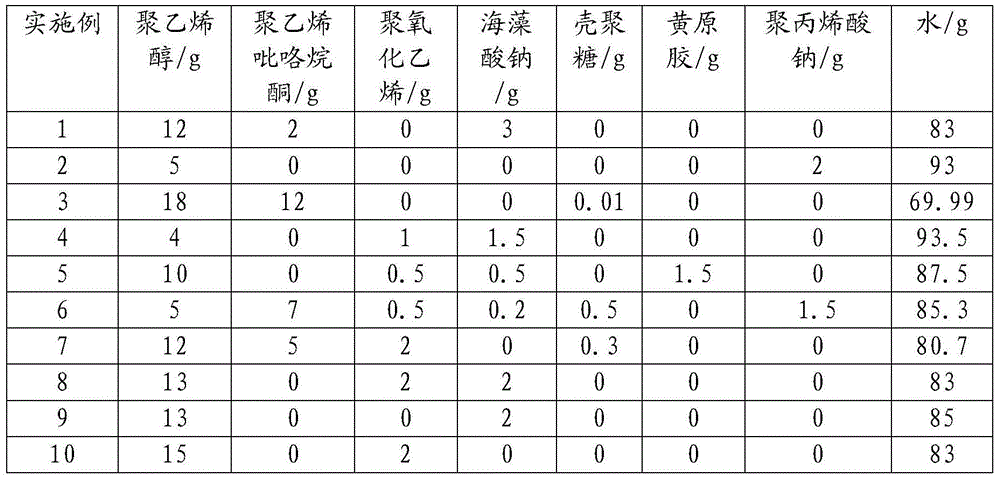

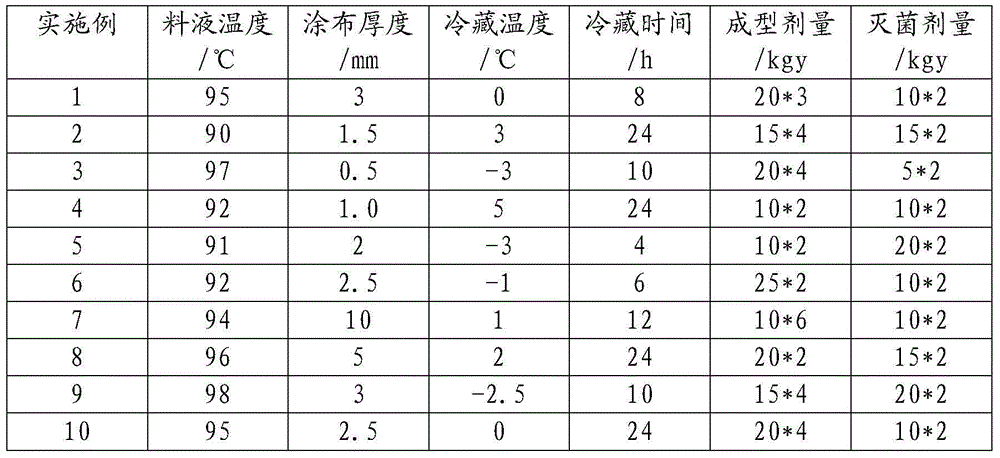

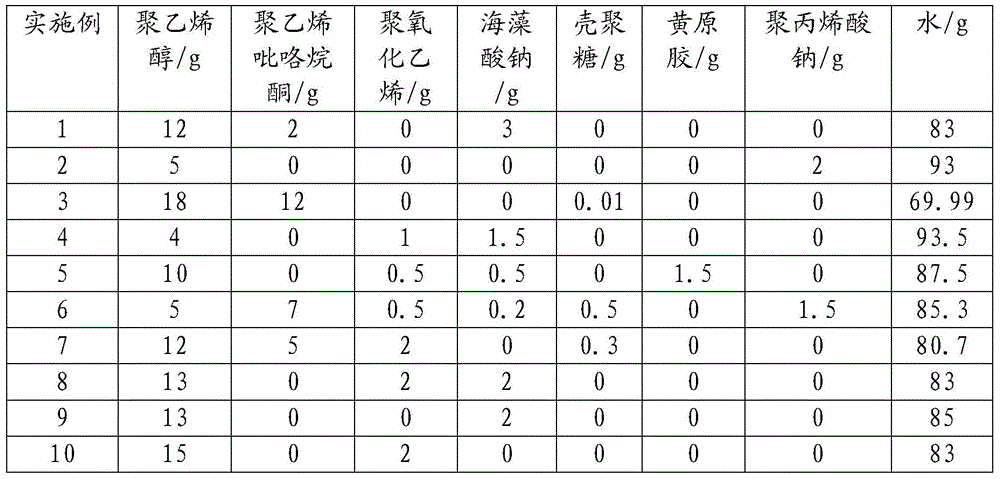

Flake hydrogel material and preparation method thereof

ActiveCN104474583AIncrease moisture contentGood biocompatibilityCosmetic preparationsToilet preparationsBiocompatibility TestingHigh water content

The invention relates to a flake hydrogel material and a preparation method thereof. The flake hydrogel material is prepared from the following raw materials in percentage by total weight: 4-18 percent of polyvinyl alcohol, 0-12 percent of polyvinylpyrrolidone, 0-2 percent of polyoxyethylene, 0-3 percent of sodium alginate, 0-0.5 percent of chitosan, 0-1.5 percent of xanthan gum, 0-1.5 percent of sodium polyacrylate and 69.99-93.5 percent of water. The preparation method of the flake hydrogel material comprises the following steps: heating the raw materials, stirring the mixture to obtain a transparent sticky solution; taking out the solution, cooling, and applying the solution between two release films; refrigerating at low temperature for pre-molding; radiating by virtue of an electron accelerator for molding, cutting and filling in packages; radiating to sterilize to obtain the flake hydrogel material. The flake hydrogel material prepared by the method has high water content, biocompatibility and safety, and the thickness uniformity of the flake hydrogel material is greatly improved compared with the prior art. The preparation method is simple and feasible, has high production efficiency and low production energy consumption, and can be applied to large-scale production of hydrogel flakes.

Owner:长春吉原生物科技有限公司 +1

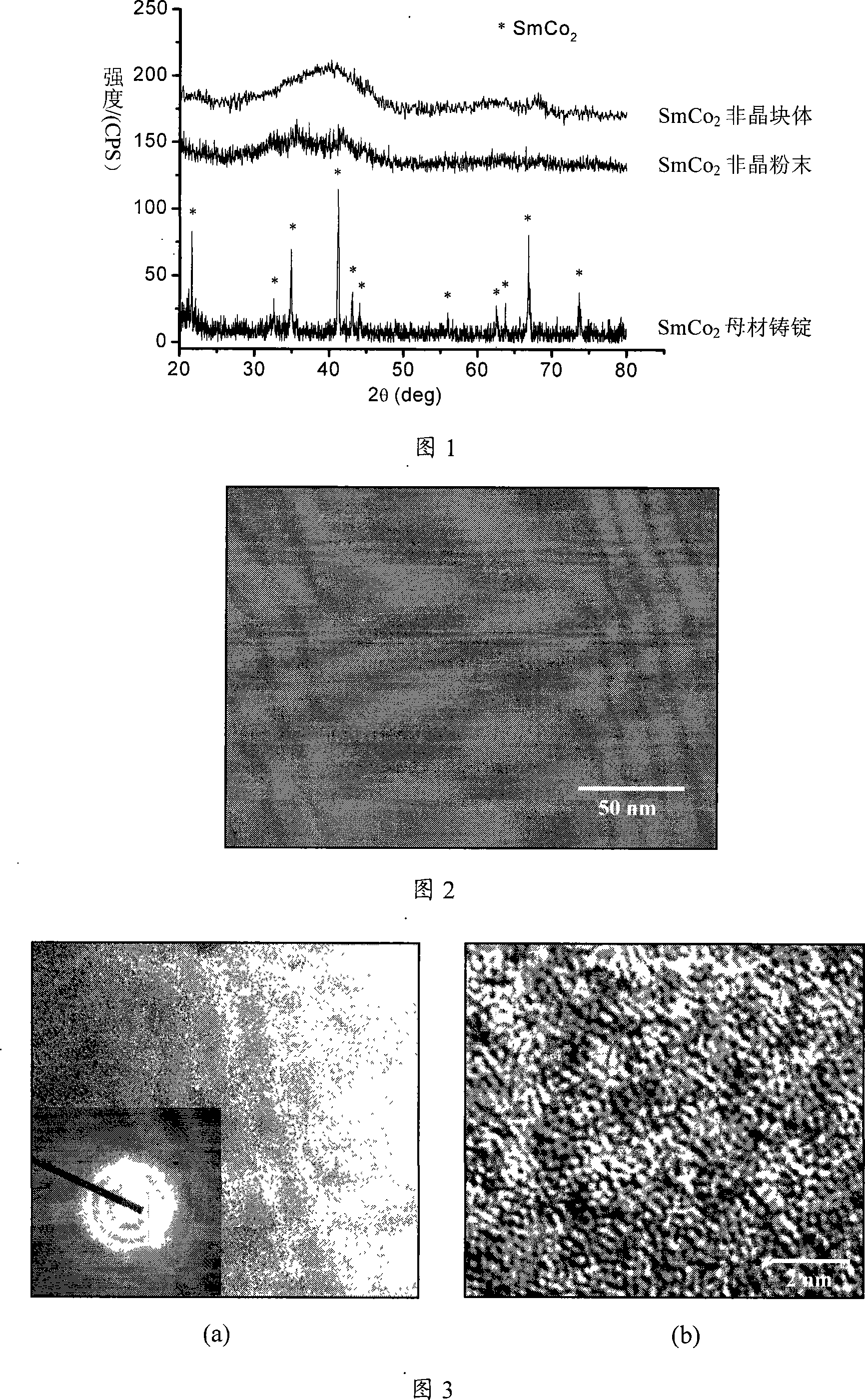

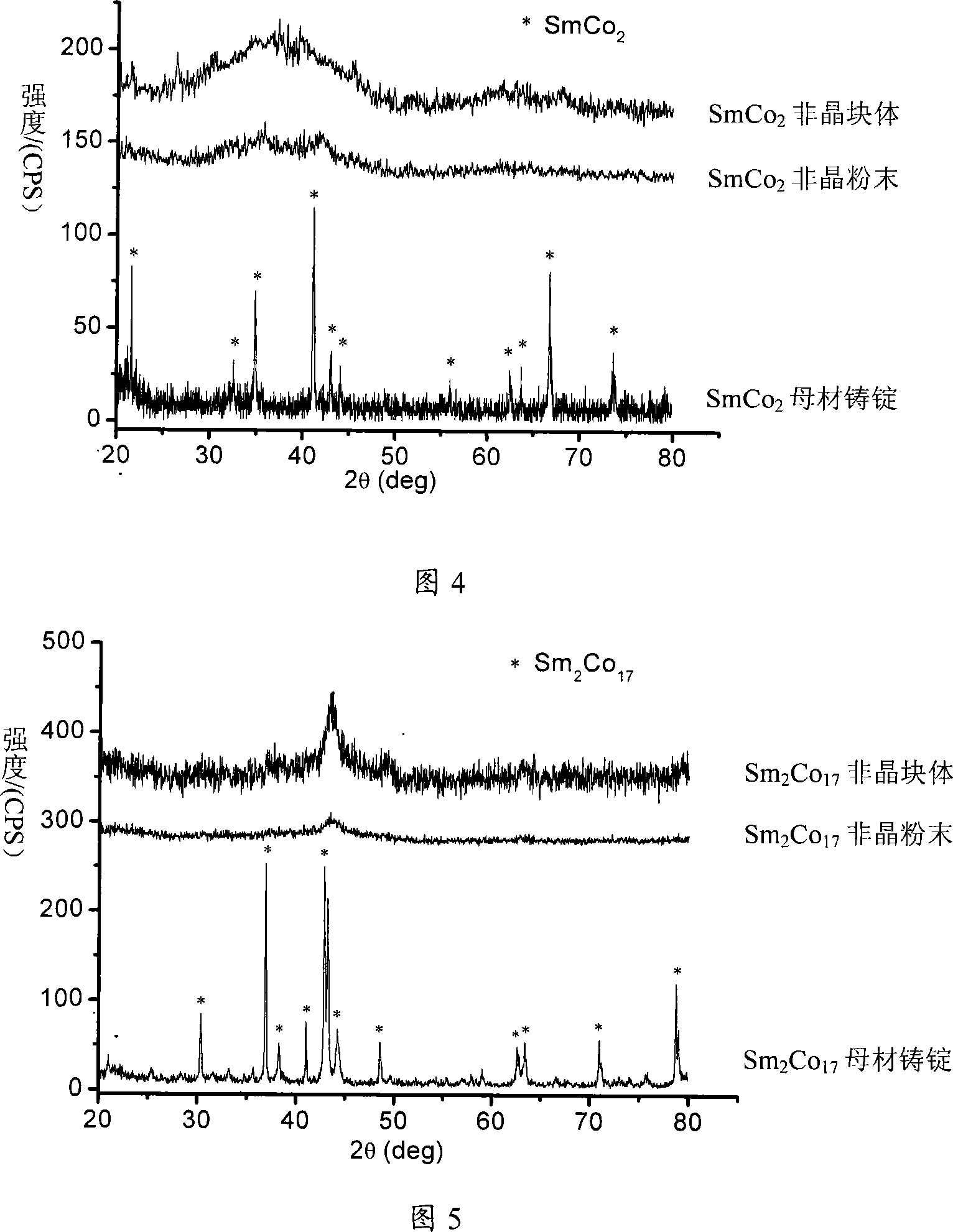

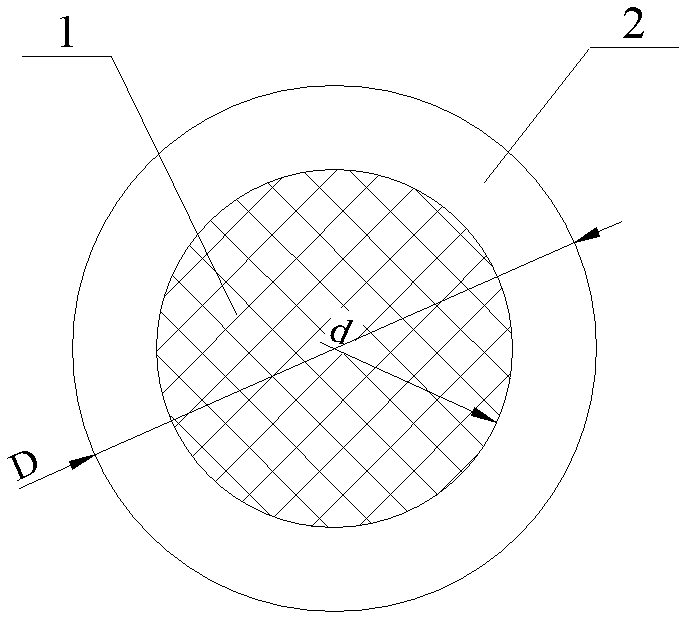

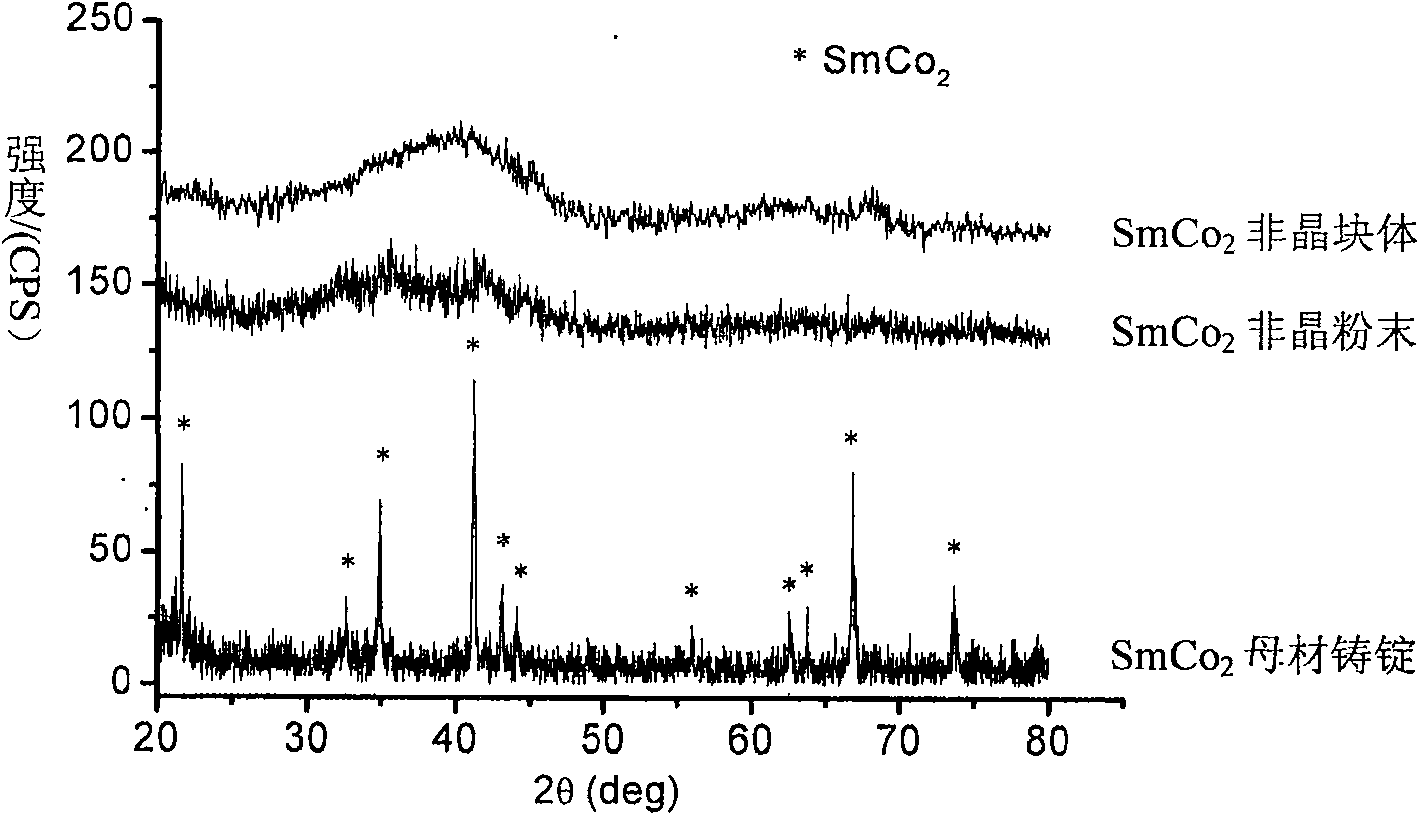

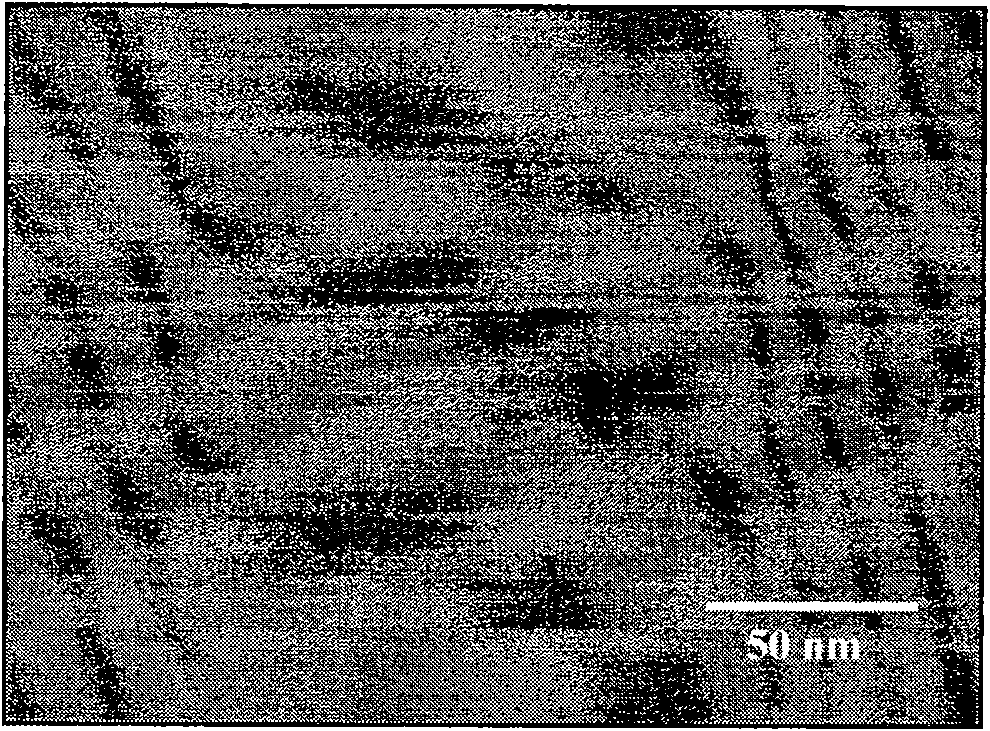

Method for preparing Sm-Co binary alloy amorphous block material

The present invention relates to a preparation method for Sm-Co binary alloy amorphous block body material, and belongs to the powder metallurgy technology field. Because the majority of the binary alloy phase have positive formation enthalpy, the production of amorphous alloy powder with the mechanical alloying method is extremely difficult. The present invention has the steps that pure metals Sm and Co are proportioned and blended according to single phase alloy, and single phase Sm-Co alloy cast ingot is produced by smelting with a vacuum induction furnace; the Sm-Co alloy cast ingot is crushed to be powder grains of below 200 micron, the powder grains are charged into a mill pot with a ball / powder weight ratio of 15:1 to20:1, and after ball milling for eight to twelve hours, the complete amorphous alloy powder can be obtained; under the argon shield, the amorphous alloy powder is charged into a hard alloy die for cold press moulding, is delivered into electric discharge plasma sintering equipment for sintering and densification: the final state sintering temperature is 300-400 DEG C, the temperature rise rate is 80-120 DEG C / min, the sintering pressure is 500 MPa-1 GPa, and heat is not reserved at the final state sintering temperature. The present invention is not limited by the positive formation enthalpy of the binary alloy, and the Sm-Co alloy amorphous block body material has high density and high structural stability.

Owner:BEIJING UNIV OF TECH

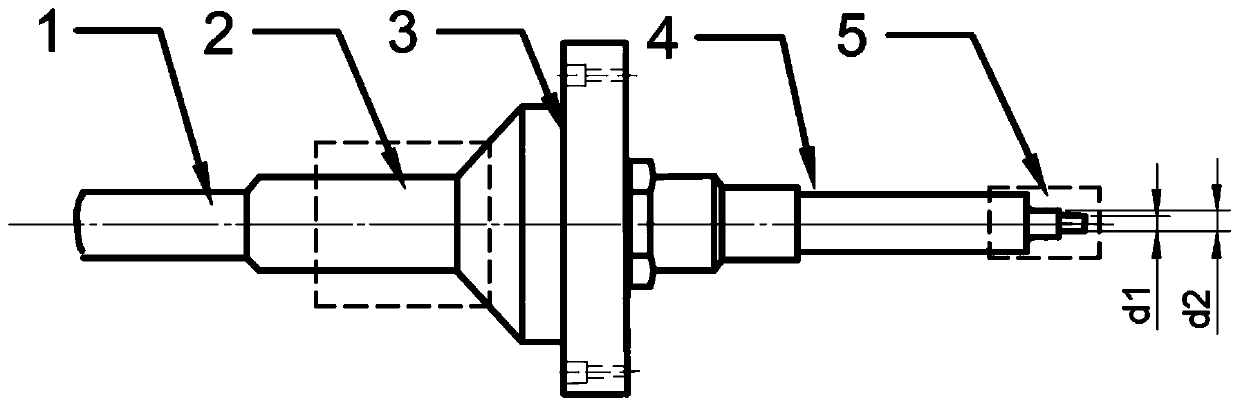

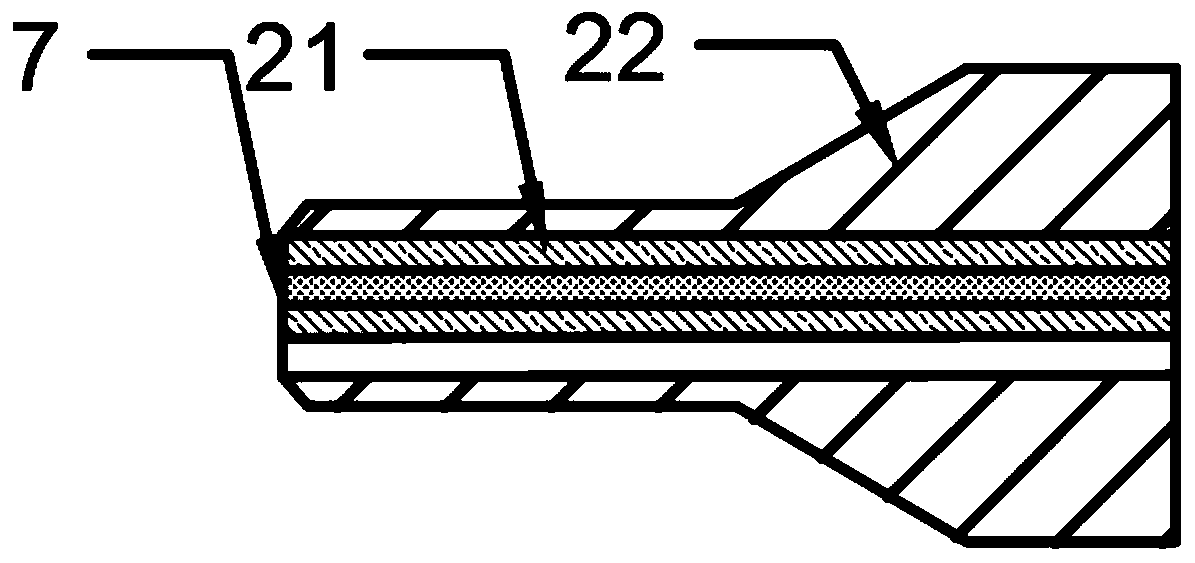

Boron-doped stress bar for manufacturing polarization-preserving fiber and manufacturing method for boron-doped stress bar

ActiveCN102531378AIncrease profitIncrease the doping concentrationGlass making apparatusGlass fibre productsFiberChloride

The invention discloses a boron-doped stress bar for manufacturing a polarization-preserving fiber and a manufacturing method for the boron-doped stress bar. The manufacturing method comprises the following steps of: A10, depositing a boron doping area on the inner wall of a quartz liner tube by using a plasma chemistry vapor deposition (PCVD) process to obtain a prefabricated member, namely introducing mixed gas into one end of the quartz liner tube, and discharging the mixed gas through the other end of the quartz liner tube, wherein the mixed gas comprises silicon tetrachloride vapor with the flow of 700-1,900sccm, high-purity oxygen with the flow of 1,600-5,000sccm and boron chloride with the flow of 70-1,100sccm; and A20, performing high temperature collapsar on the deposited prefabricated member into a solid boron-doped stress bar. BCl3 and SiCl4 are used as raw materials, the boron doping area is deposited at high speed and high efficiency by the PCVD process, and the utilization rate of the raw materials and the doping concentration are improved; and moreover, gradient doping is adopted, so that the problem that the boron stress bar is easily broken and twisted in the processing can be solved, the geometric symmetry of the doping area is improved, the probability of panda eye and cladding breakage in the cutting is reduced, and the welding efficiency of the fiber is improved.

Owner:RUIGUANG TELECOMM TECH CO LTD

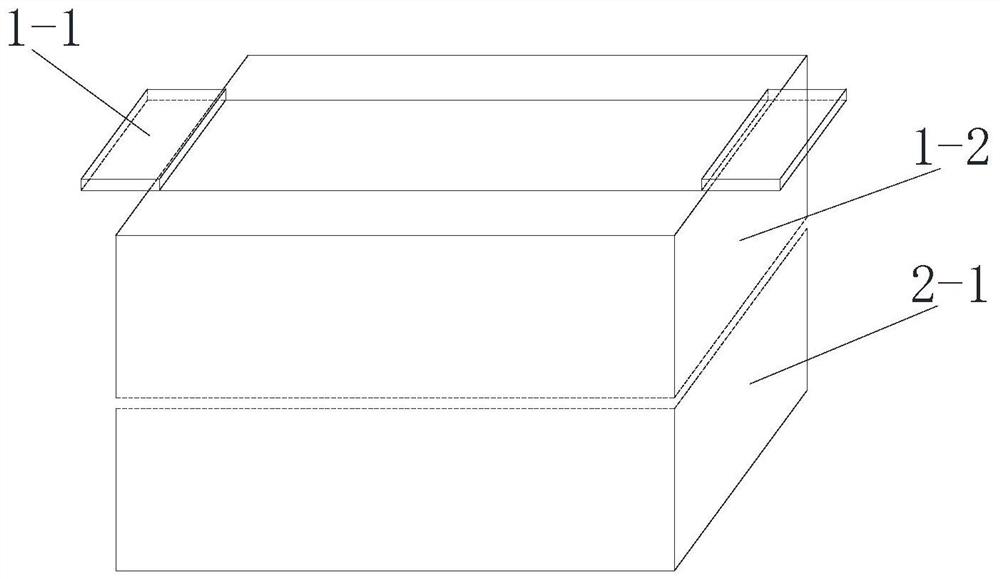

Large-size reinforced soil shear strength testing equipment, and testing method

PendingCN112525728AFulfil requirementsThe evaluation parameters are reasonableMaterial strength using steady shearing forcesTotal factory controlSoil scienceControl system

The invention discloses large-size reinforced soil shear strength testing equipment, and a testing method. The large-size reinforced soil shear strength testing equipment comprises a control unit, a pressure loading unit and a shear box assembly; the control unit comprises an industrial computer A, a normal force motor, a horizontal force motor, a microcomputer control system, a normal force loading driving device, a horizontal force loading driving device, a normal force motor driving device and a horizontal force motor driving device; the pressure loading unit comprises a base, a slide way,a normal force loading shaft rod and a horizontal force loading shaft rod, and an outer blocking piece is arranged on the slide way; and the shearing box assembly is arranged in the outer blocking piece. In addition, the invention also provides a testing method adopting the equipment. The equipment can realize a large-size direct shear test of reinforced soil and obtain a comprehensive evaluationresult of a large-size soil sample shear strength test, has the advantages of reasonable evaluation parameters, high accuracy and high efficiency, and can meet the requirements of a multi-parameter complex test scheme.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Lanthanum titanate-based glass sheet as well as preparation method and application of lanthanum titanate-based glass sheet

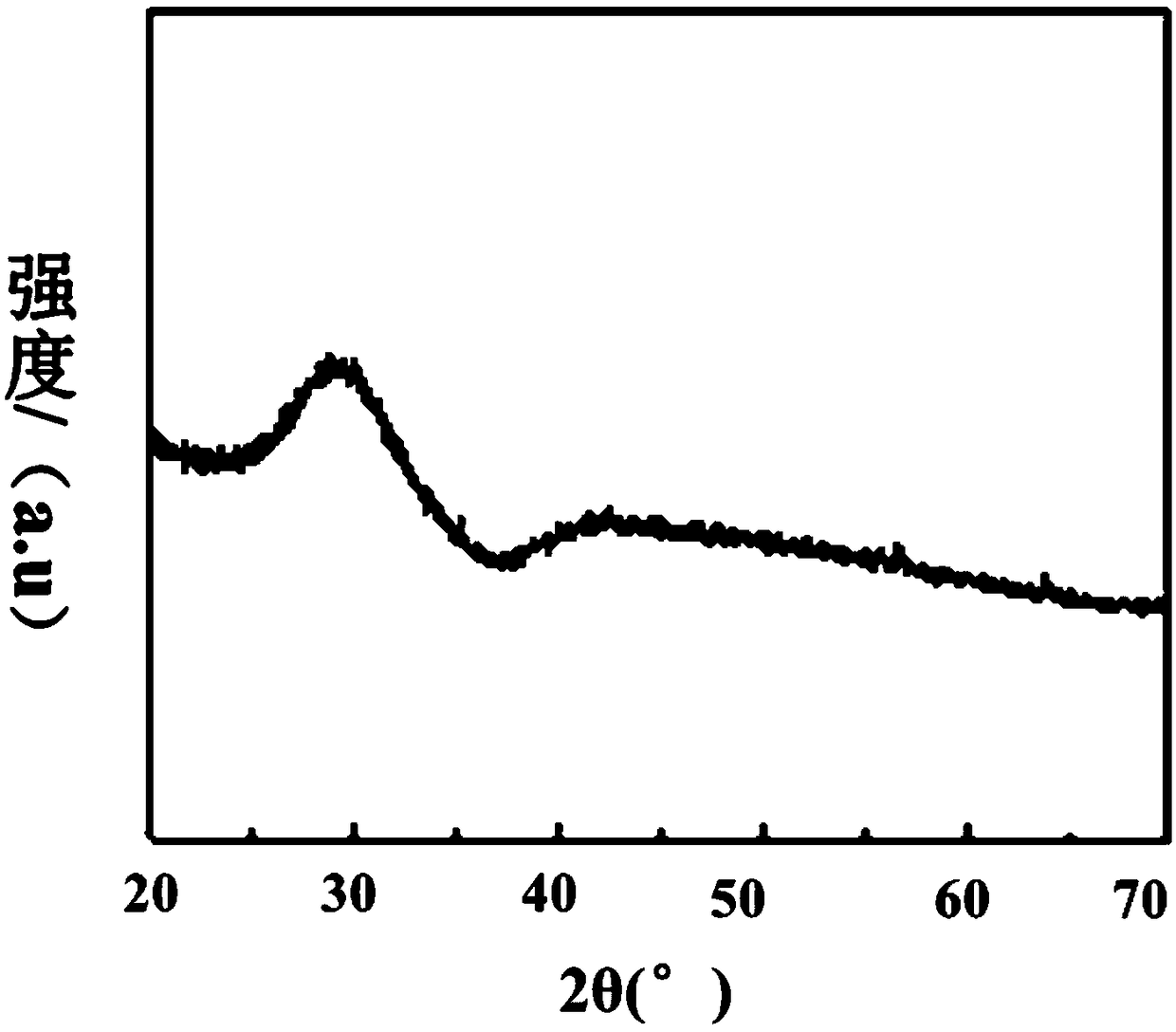

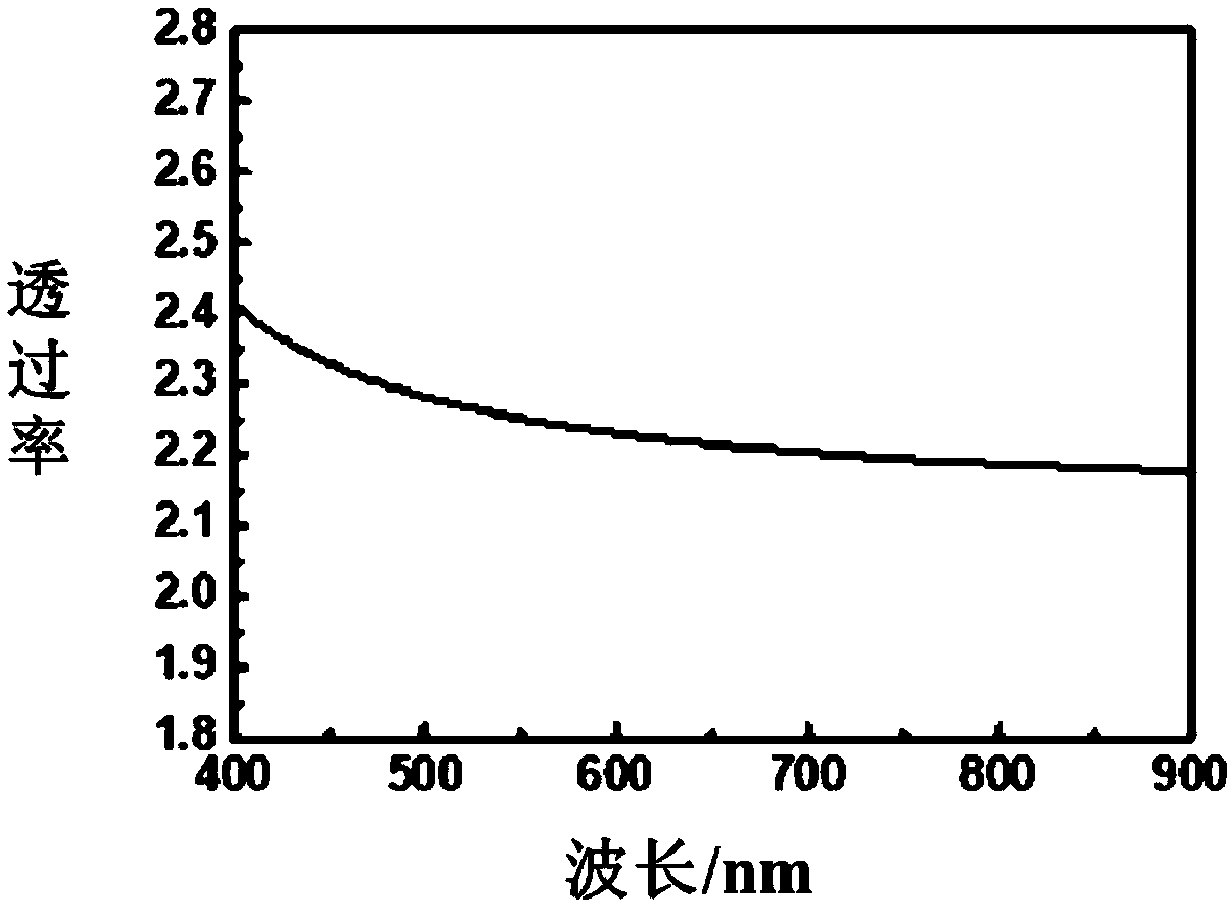

PendingCN108929034AImproved Kinetic WindowImprove the ability to formGlass shaping apparatusOptical partsDevitrificationRefractive index

The invention relates to a lanthanum titanate-based glass sheet as well as a preparation method and application of the lanthanum titanate-based glass sheet. The glass comprises LaO3 / 2, TiO2 and otherthird oxides, the glass phase is La4Ti9O24, and the lanthanum titanate-based glass has the diameter of larger than or equal to 10mm, the refractive index of 2.0-2.5 and the abbe number of 15-25. The preparation method of the lanthanum titanate-based glass comprises the steps: (1) uniformly mixing powders of LaO3 / 2, TiO2 and other third oxides according to the amount specified in a formula to obtain a raw material mixture, and carrying out pretreatment to obtain a raw material for container-free solidification; (2) carrying out container-free solidification treatment on the obtained raw material for container-free solidification to obtain a glass raw material; and (3) smashing glass beads to obtain glass powder, and carrying out pressurized heat treatment on the glass powder according to apreset shape to obtain a glass raw material. By using the method disclosed by the invention, the limit of a traditional melt cooling method is broken, the problem that devitrification is easily causedin a process of preparing a lanthanum titanate-based glass material is solved, and the lanthanum titanate-based glass material is successfully obtained.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

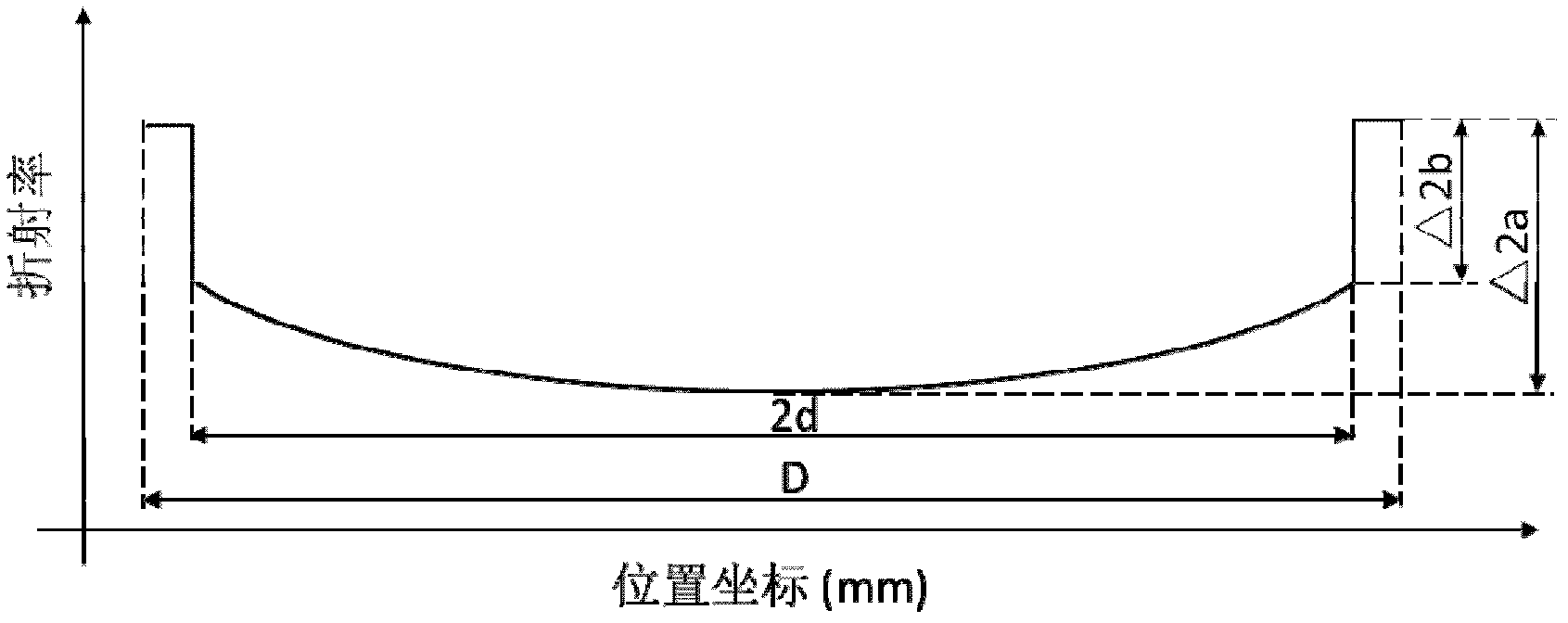

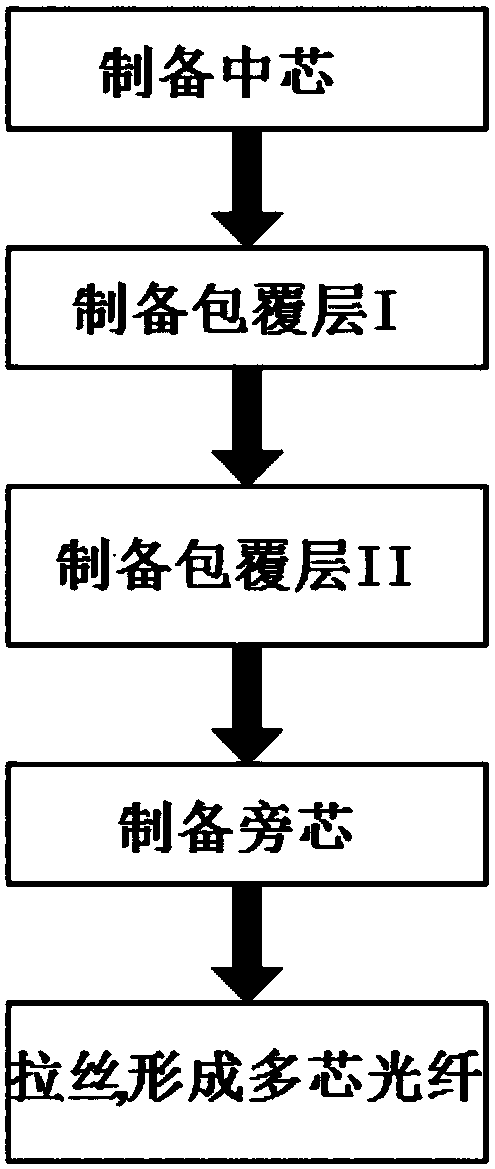

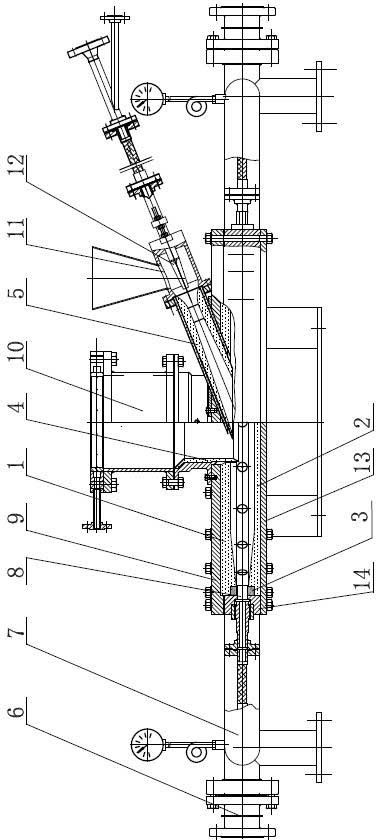

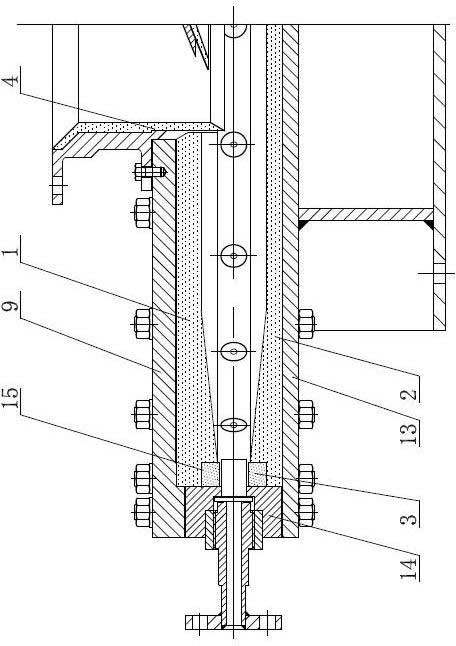

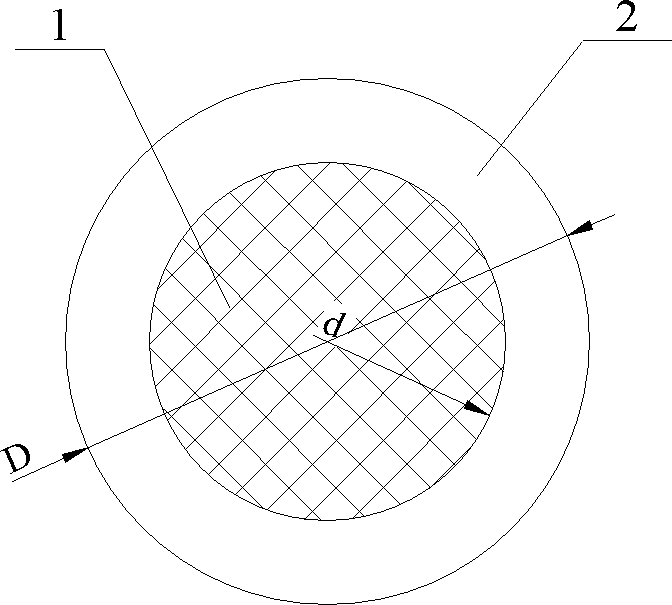

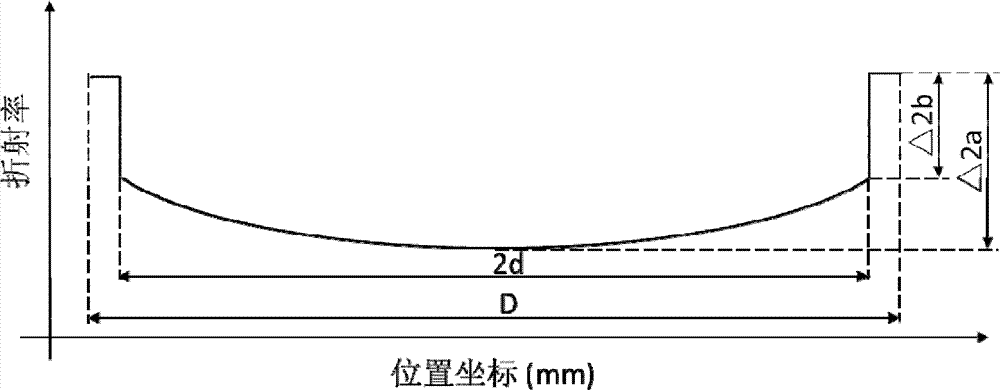

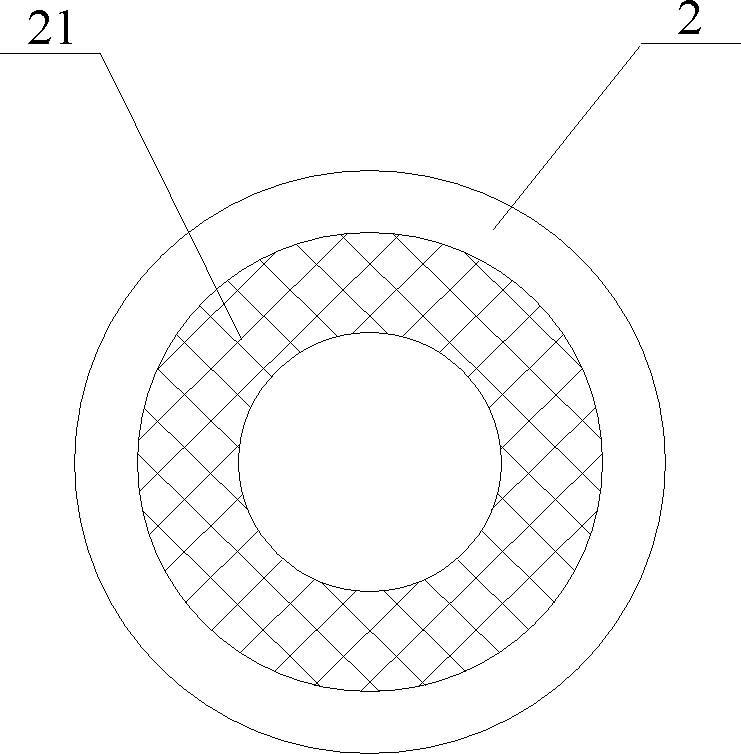

Low-crosstalk large-mode-area multi-core fiber and preparation method thereof

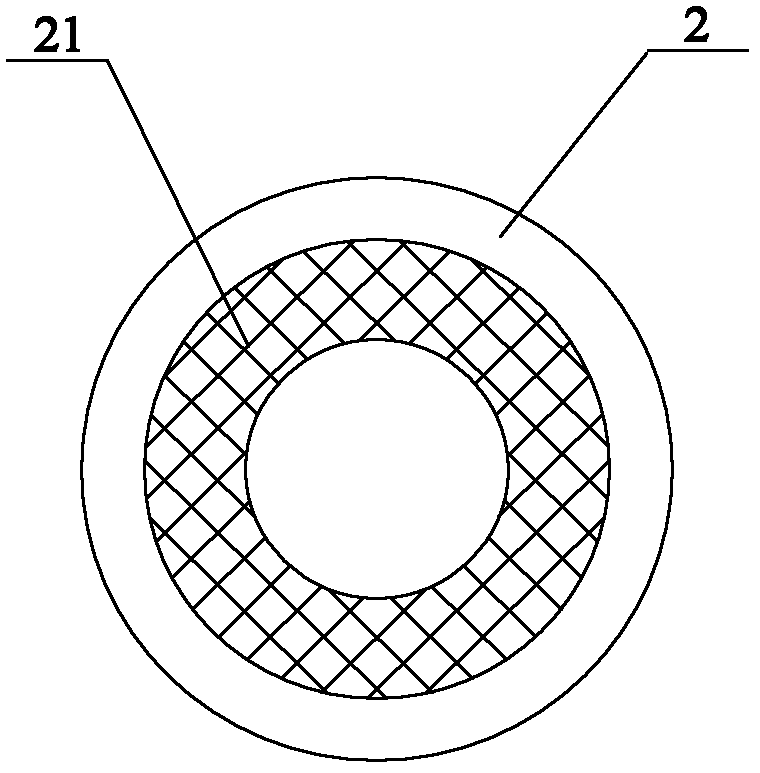

ActiveCN108181683ARestrictedReduce toughnessOptical fibre with multilayer core/claddingMulticore optical fibreRefractive indexLight signal

The invention relates to a low-crosstalk large-mode-area multi-core fiber and a preparation method thereof. The low-crosstalk large-mode-area multi-core fiber is characterized by comprising a centralcore, a coating layer I surrounding the central core, a plurality of bypass cores and a coating layer II, wherein the plurality of bypass cores extend along an optical fiber axis and are arranged in aregular polygon manner; and the coating layer II covers the central core, the coating layer I and the plurality of bypass cores. Different elements are doped into a process for manufacturing the central core, the bypass cores, the coating layer I and the coating layer II, so that refractive indexes of the four parts generate a certain refractive index difference, and the refractive indexes of thefour parts are ranked from the central core to the bypass cores to the coating layer I to the coating layer II from high to low. The purpose of the design is to effectively suppress inter-core crosstalk of the central core and the bypass cores. Meanwhile, by utilizing a principle that the refractive index of the coating layer I is lower than that of the central core or the bypass cores, energy inthe central core is further prevented from leaking out, the coating layer II has the lowest refractive index and located on the outermost side of the multi-core fiber, leakage of energy of the bypasscores is suppressed, the stability of the optical fiber structure is ensured, and the transmission efficiency of light signals is increased.

Owner:JIANGSU STERLITE TONGGUANG FIBER

Large high temperature resistant flat ceramic jet mill

ActiveCN102284335AHigh strengthImprove wear resistanceGrain treatmentsCircular discReaction bonded silicon carbide

The invention discloses a large high-temperature resistance flat type ceramic jet mill. In the jet mill, a metal upper cover, a middle ring and a lower cover are buckled one another to form a flat circular disc, wherein an upper cover liner is arranged inside the upper cover, a lower cover liner is arranged inside the lower cover, and middle ring liners are arranged on outer edges of the upper cover liner and lower cover liner; and the upper cover liner, the lower cover liner and the middle ring liners form a closed crushing cavity. On the flat type jet mill, reaction-bonded silicon carbide is adopted as a liner material, the abrasive resistance is good, and the finished product quality is greatly improved; and according to the block structure of the invention, the manufacture difficulty of the reaction-bonded silicon carbide liner component is greatly reduced, the size limitation to conventional production equipment is broken through, so that a large high-temperature resistance flat type ceramic jet mill with the diameter of over 1m can be manufactured, and the jet mill is in the international leading position to meet the material crushing production requirement of automation, high yield and high quality.

Owner:JIANGSU PROVINCE YIXING NONMETALLIC CHEM MACHINERY FACTORY

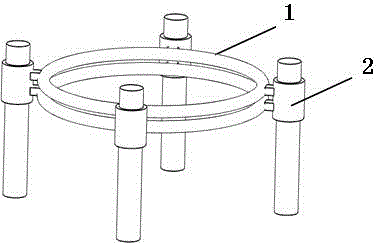

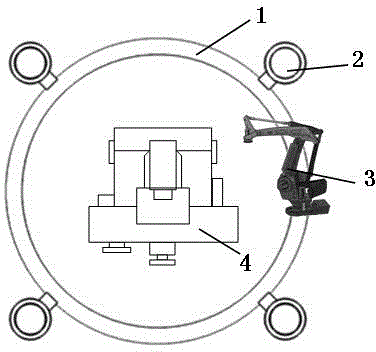

Circular rail shot blasting robot for polishing large-sized workpiece

InactiveCN104589220AAchieve polishingBreak through the size limitAbrasive blasting machinesEngineeringMechanical engineering

A circular rail shot blasting robot for polishing a large-sized workpiece has the technical scheme that for the large-sized workpiece which is difficultly processed by an ordinary shot blasting polishing device, an circular rail which is set to be capable of moving up and down is arranged at the periphery of the workpiece, and the industrial robot walks on the rail and can arrive at different positions. A mechanical arm is provided with a local shot blasting machine, at the same time, a steel shot collecting device and a shot blasting blocking device are additionally added, the robot can perform shot blasting on a small part at each time in a mobile way, and shot blasting polishing processing on the large-sized workpiece is completed. The method provided by the invention breaks restrictions of the traditional shot blasting polishing device on the size of processed workpieces, can achieve polishing processing of the large-sized workpiece with relatively low cost, and is especially suitable for processing the large-sized workpiece having general polishing precision requirements.

Owner:安徽省库仑动力自动化科技有限公司

Method for preparing Sm-Co binary alloy amorphous block material

The present invention relates to a preparation method for Sm-Co binary alloy amorphous block body material, and belongs to the powder metallurgy technology field. Because the majority of the binary alloy phase have positive formation enthalpy, the production of amorphous alloy powder with the mechanical alloying method is extremely difficult. The present invention has the steps that pure metals Sm and Co are proportioned and blended according to single phase alloy, and single phase Sm-Co alloy cast ingot is produced by smelting with a vacuum induction furnace; the Sm-Co alloy cast ingot is crushed to be powder grains of below 200 micron, the powder grains are charged into a mill pot with a ball / powder weight ratio of 15:1 to20:1, and after ball milling for eight to twelve hours, the complete amorphous alloy powder can be obtained; under the argon shield, the amorphous alloy powder is charged into a hard alloy die for cold press moulding, is delivered into electric discharge plasma sintering equipment for sintering and densification: the final state sintering temperature is 300-400 DEG C, the temperature rise rate is 80-120 DEG C / min, the sintering pressure is 500 MPa-1 GPa, and heat is not reserved at the final state sintering temperature. The present invention is not limited by the positive formation enthalpy of the binary alloy, and the Sm-Co alloy amorphous block body material has high density and high structural stability.

Owner:BEIJING UNIV OF TECH

A kind of sheet-like hydrogel material and preparation method thereof

ActiveCN104474583BIncrease moisture contentGood biocompatibilityCosmetic preparationsToilet preparationsBiocompatibility TestingHigh water content

Owner:长春吉原生物科技有限公司 +1

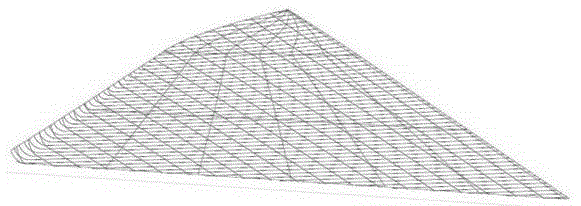

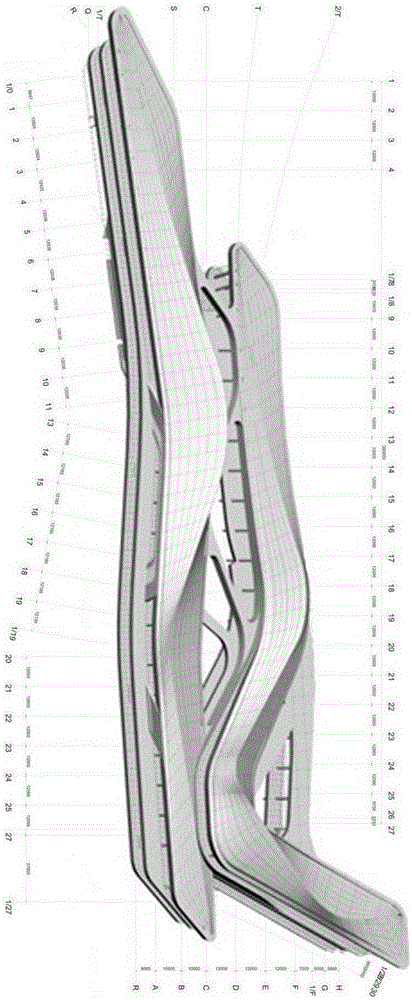

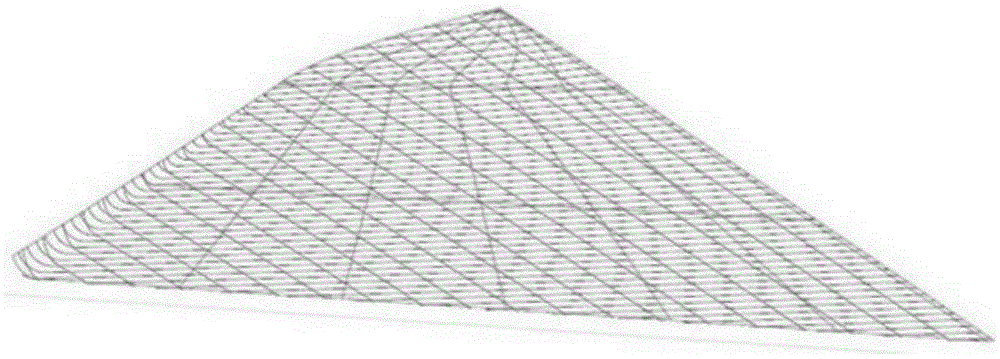

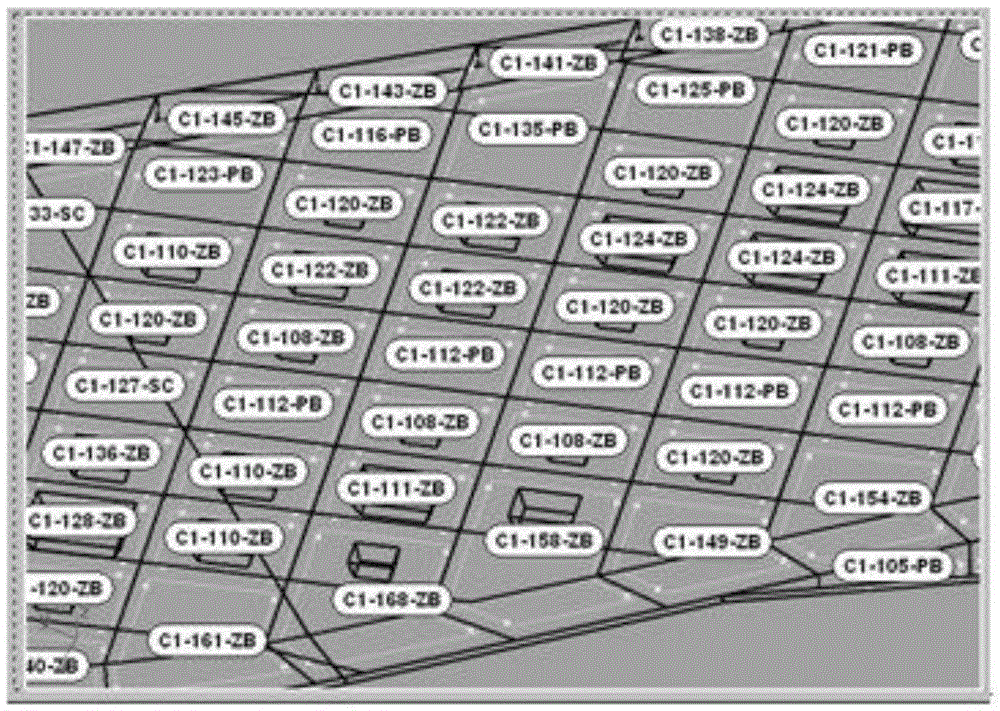

Three-dimensional digital ground mold production method

ActiveCN104029280AReduce molding difficultyBreak through the size limitCeramic shaping apparatusModelSimData source

The invention relates to a three-dimensional digital ground mold production method, comprising steps of: 1, performing whole three-dimensional modeling to a curtain wall by three-dimensional digital software; 2, segmenting the whole model into several single modules; 3, obtaining parameters of the contour line of a delay module, and setting distribution of axes of the whole model; 4, making axis plates and numbering; 5, outputting a projection pattern and forms; 6, completing detail drawing of the projection on site; 7, placing the axis plates according to numbers to form a mold substrate; 8, preparing a mold prototype; 9, drawing up chamber separating lines and border lines on the surface of the mold prototype, thus obtaining a ground mold. According to the three-dimensional digital ground mold production method, the parameters output by the three-dimensional software are used as a unique data source, and parameterization in the whole shaping process of the ground mold is ensured, so that curve effect and performance of the surface of the ground mold can perfectly accord with appearance requirements of buildings; meanwhile, a thinking of virtually modeling and segmenting is adopted, so that size restriction in the manufacture of large-scale double-curved molds is broken through.

Owner:江苏倍立达新材料科技有限公司

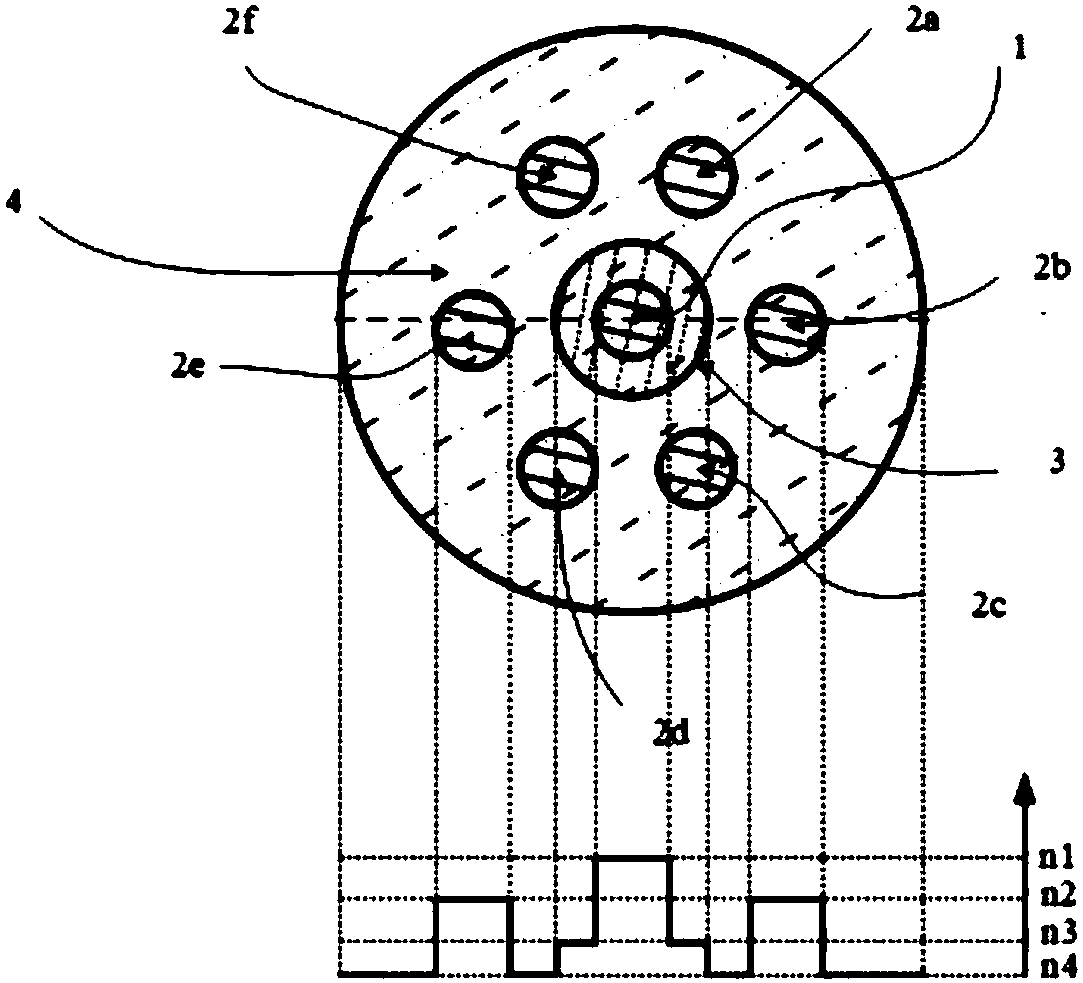

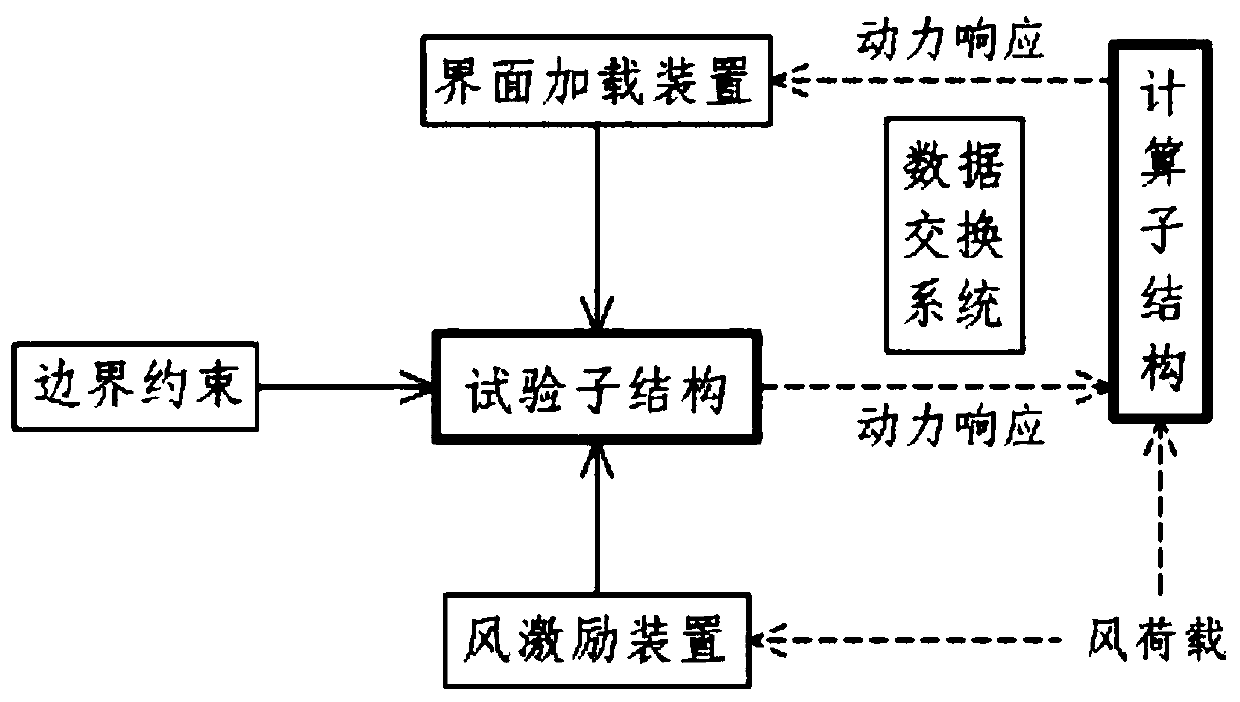

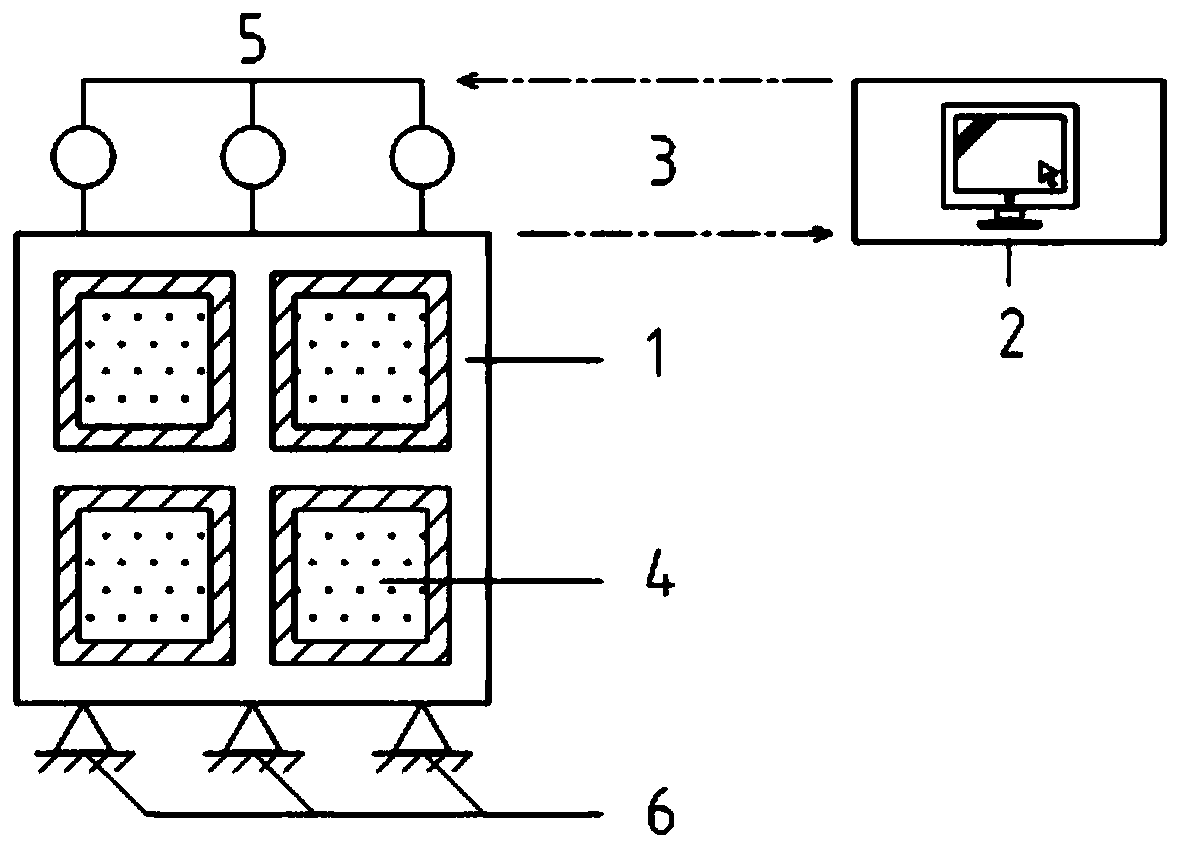

Hybrid simulation test method for researching structural wind excitation response

ActiveCN111027261ARealize simulationThe effect of wind excitation simulation is idealDesign optimisation/simulationCAD numerical modellingStructure analysisEngineering

The invention provides a method for researching dynamic response under a structural wind load by combining numerical simulation with physical test, belongs to the field of structural disaster prevention, and particularly relates to the field of structural wind resistance test research. According to the test method of the invention, an actual engineering structure is divided into a test substructure (1) and a calculation substructure (2), the test substructure (1) is loaded through a novel wind excitation device (4), the calculation substructure (2) performs computer numerical simulation through structure analysis software, and the test substructure (1) and the calculation substructure (2) interact through a data exchange system (3), so that response of the whole structure under external wind excitation is obtained. According to the method, the problem that the response of a complex engineering structure under a wind load is difficult to accurately simulate due to size limitation in a traditional wind tunnel test is solved; and particularly, the defect of high difficulty in a wind loss test and the like are overcome, the size limitation of a structural model is broken through, the test cost is reduced, the extreme wind load simulation effect is more ideal, and the requirements of engineering technologies and researchers can be met.

Owner:SICHUAN UNIV

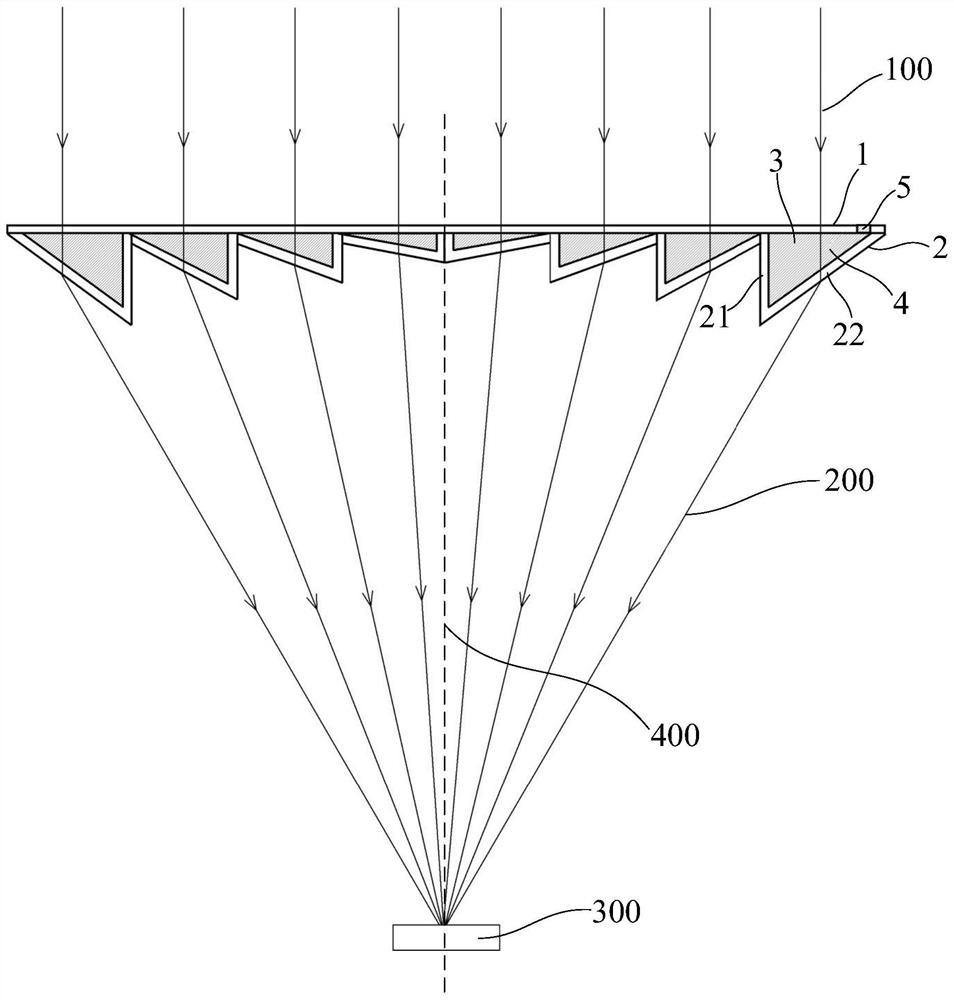

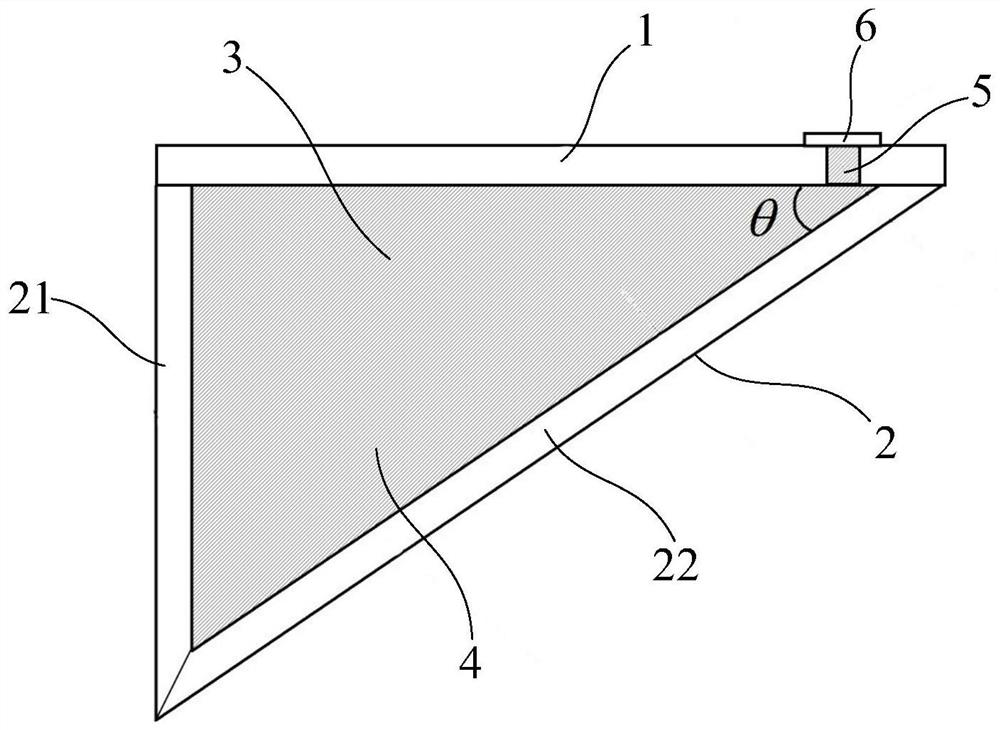

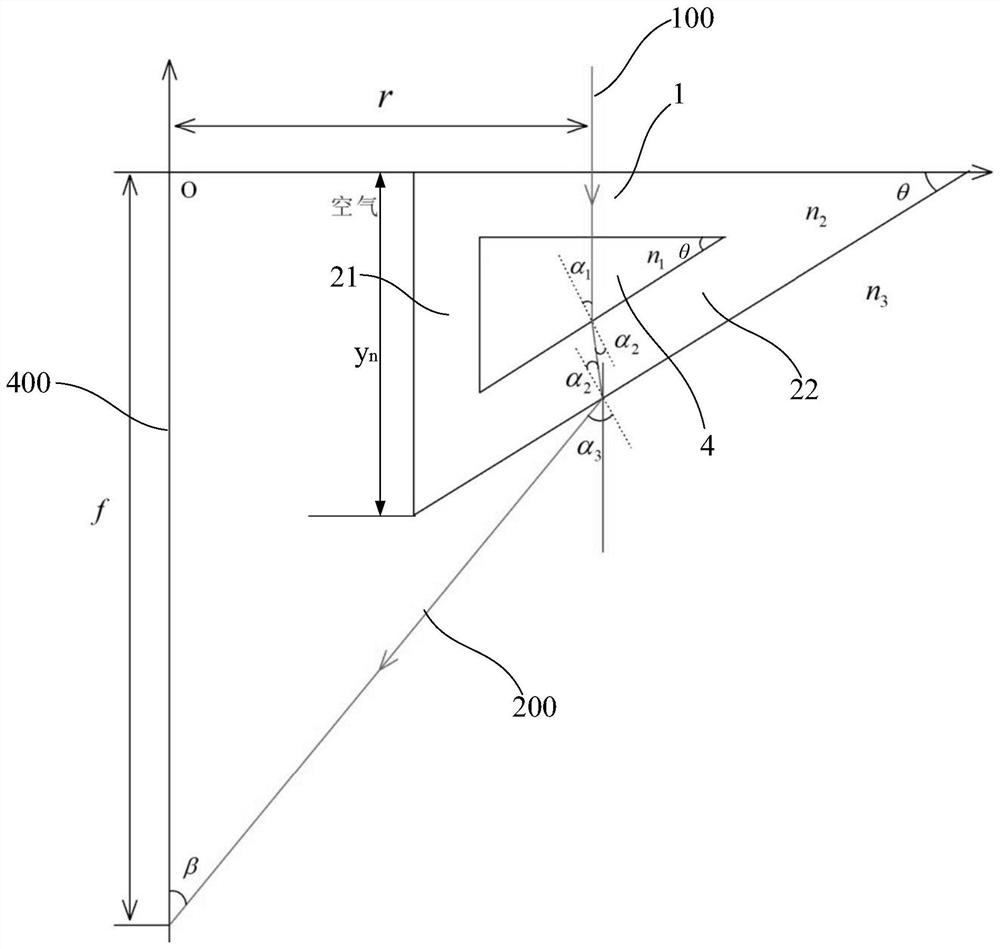

Filling type Fresnel condenser

The invention discloses a filling type Fresnel condenser, which comprises an incident plate and a plurality of lens threads, and is characterized in that the incident plate is made of a transparent material; the lens threads are made of a transparent material, the lens threads are attached to one surface of the incident plate, a containing space is formed between the lens threads and the incidentplate, the containing space is filled with a transparent liquid, and the transmittance of the transparent liquid is larger than 80%. According to the Fresnel condenser, the hollow containing space isformed in the lens thread and is filled with the transparent liquid, and the transparent liquid replaces a transparent material to serve as a light-transmitting medium, so that the production cost ofthe Fresnel condenser can be reduced; particularly, when the size of the Fresnel condenser is large, the manufacturing bottleneck of the large-size Fresnel condenser is solved; when the Fresnel condenser is applied to the field of solar heat utilization, the size limitation of an existing solar condenser can be broken through, and the bottleneck of large-scale application of the Fresnel condenserin the field of solar heat utilization is overcome.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

Laser additive manufacturing equipment and method for metal parts

ActiveCN106346006BBreak through the size limitBreak outAdditive manufacturing apparatusIncreasing energy efficiencyControl systemLaser additive manufacturing

The invention discloses a laser additive manufacturing equipment and method for metal parts. The equipment includes working cabin, pre-set powder spreading rapid prototyping components, conformal cylinder setting and removal components, machining components, moving mechanism and control system. First, use the conformal cylinder setting and removal component to set a conformal cylinder slice layer on the surface of the substrate that can surround the metal part slice contour, and the preset powder spreading rapid prototyping component lays a layer of metal powder inside it, and the powder Carry out laser selective melting to complete the forming of the first slice layer of metal parts; according to the precision requirements, mechanical processing components can be used to machine the formed slice layer of the part; Layer laser selective melting forming-machining (when necessary)" process, which can realize high-precision forming of metal parts of various sizes and structures at one time; shaped cylinder.

Owner:HUAZHONG UNIV OF SCI & TECH

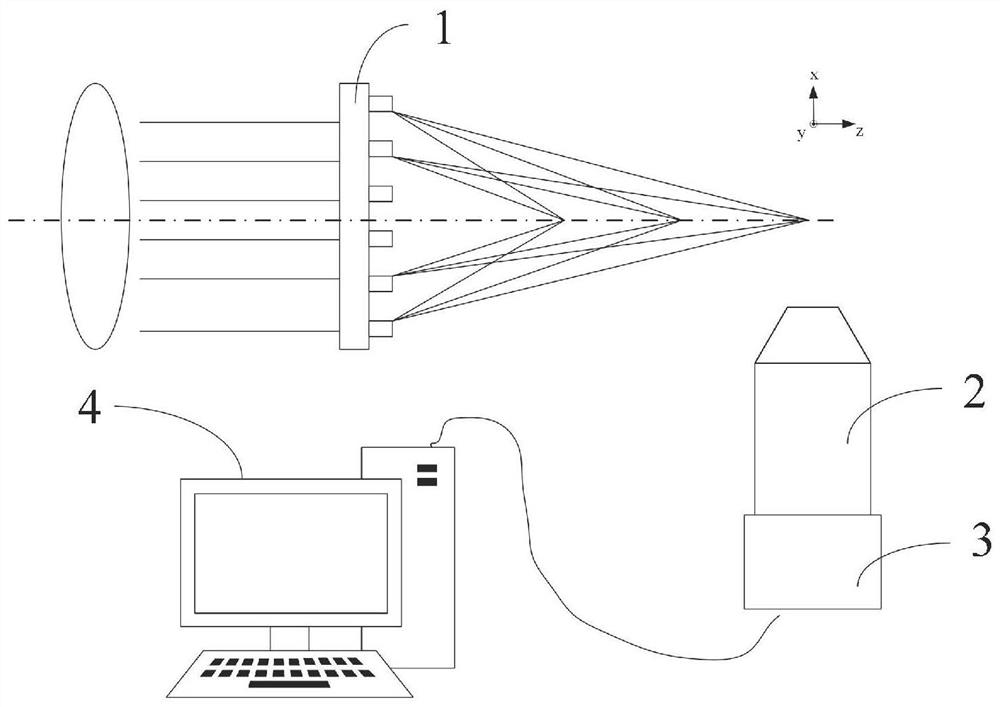

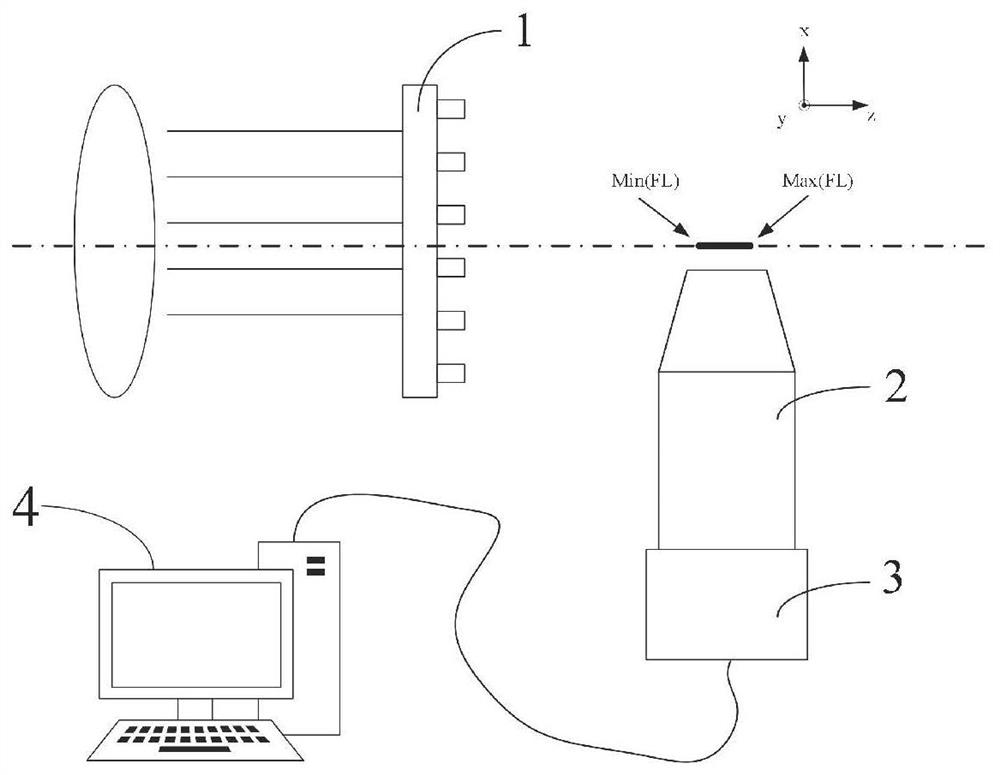

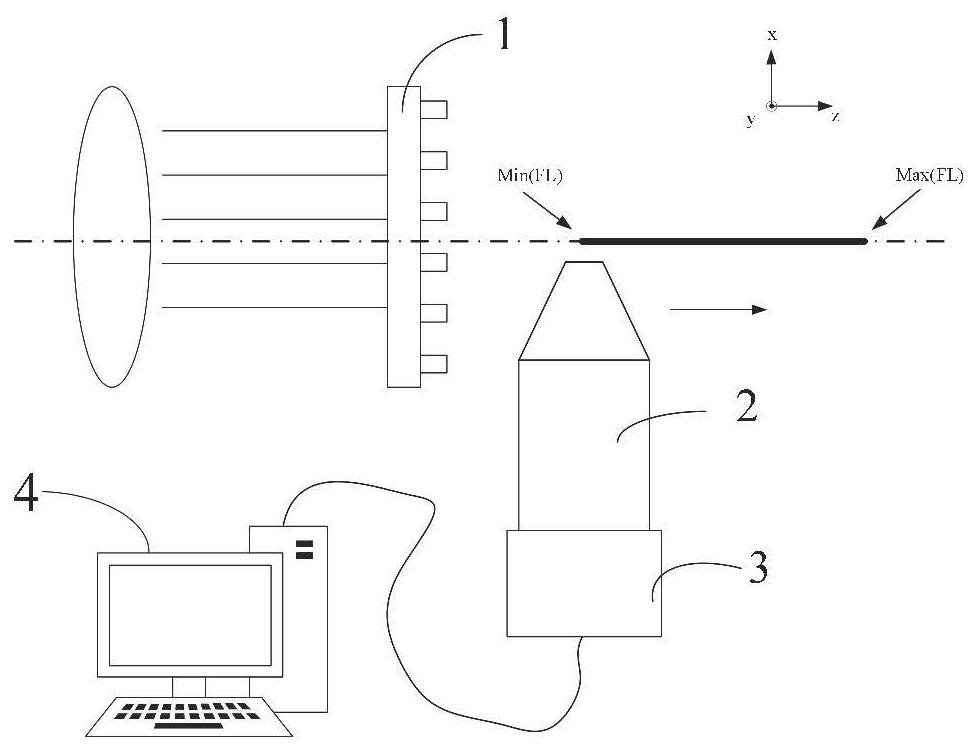

Spectral measurement device and method

PendingCN113834568AHigh precisionSimple structureSpectrum investigationOptical spectrometerOptical axis

The invention provides a spectral measurement device and method, and belongs to the field of spectral measurement. The device comprises a super-lens dispersion system, a microscopic system, a detector and a computer processing system; the optical axis of the super-lens dispersion system is parallel to incident light; the optical axis of the microscopic system is perpendicular to the optical axis of the super-lens dispersion system; the object space focus of the microscopic system is located on the optical axis of the super-lens dispersion system; the microscopic system, the detector and the computer processing system are sequentially connected, and the detector is located on an image space focal plane of the microscopic system. According to the spectral measurement device, the L-shaped super lens dispersion system and the microscopic system are utilized, the limitation of a large-angle dispersion system on the size of a detector is broken through, and the precision of a spectrograph is improved.

Owner:SHENZHEN METALENX TECH CO LTD

A method and system for securely storing large blockchain files

The present invention relates to a method and system for safe storage of large files in the blockchain. The safe storage method is as follows: 1) The user of the blockchain node registers the large file in the blockchain, and the storage system splits the large file and stores it in the blockchain. The copy of the large file is redundantly stored in the storage network; 2) The large file is split into N blocks, and the redundancy is K, and randomly stored in M storage nodes; 3) The storage nodes are blockchain nodes and A collection of cloud storage nodes; 4) The user uses the public key to encrypt the file block and the index of the storage location and records it in the blockchain block; 5) After the user logs in to the blockchain at any node, he can use the private key to decrypt the file block and storage location index to recover large files. The invention improves and solves the problem of safe storage and fast synchronization of large files in the block chain, and the system realizes the safe operation of users switching terminals to safely restore large files, and breaks through the limitation of block chain transaction file size.

Owner:中科天御(苏州)科技有限公司

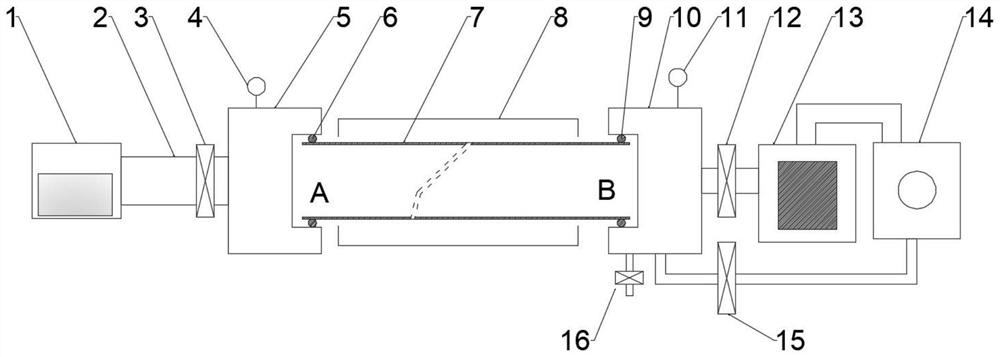

Pipeline inner wall poly-p-xylylene coating equipment and coating method

PendingCN114318240AImprove cooling effectFlexible moving processVacuum evaporation coatingSputtering coatingXylyleneEvaporation (deposition)

The invention relates to equipment and method for coating parylene on the inner wall of a pipeline, and the equipment comprises a to-be-coated pipeline workpiece serving as a deposition chamber, an evaporation furnace, a cracking furnace, a process valve and a first pipeline butt-joint mechanism which are sequentially communicated. The two ends of a coated pipeline workpiece are in sealed connection with the first pipeline butt-joint mechanism and the second pipeline butt-joint mechanism respectively, the second pipeline butt-joint mechanism, the preceding-stage valve, the low-temperature cold trap and the vacuum pump are sequentially communicated, a pipeline cooling cover is arranged outside the coated pipeline workpiece, and the vacuum pump is further communicated with the second pipeline butt-joint mechanism through an auxiliary pumping valve. And a deflation valve is arranged on the second pipeline butt joint mechanism. The pipeline workpiece to be coated is used as a deposition chamber part of the equipment to replace the deposition chamber of the original equipment, so that the production requirement of coating the inner wall of the pipeline is met, the construction problem of large coating equipment is solved, the material utilization rate is increased, and the production cost is reduced. And the process link of cleaning the inner wall of the deposition chamber after conventional coating is completely removed, so that the cost is reduced.

Owner:北京胜泰东方科技有限公司

Boron-doped stress bar for manufacturing polarization-preserving fiber and manufacturing method for boron-doped stress bar

ActiveCN102531378BIncrease profitIncrease the doping concentrationGlass making apparatusGlass fibre productsFiberChloride

Owner:RUIGUANG TELECOMM TECH CO LTD

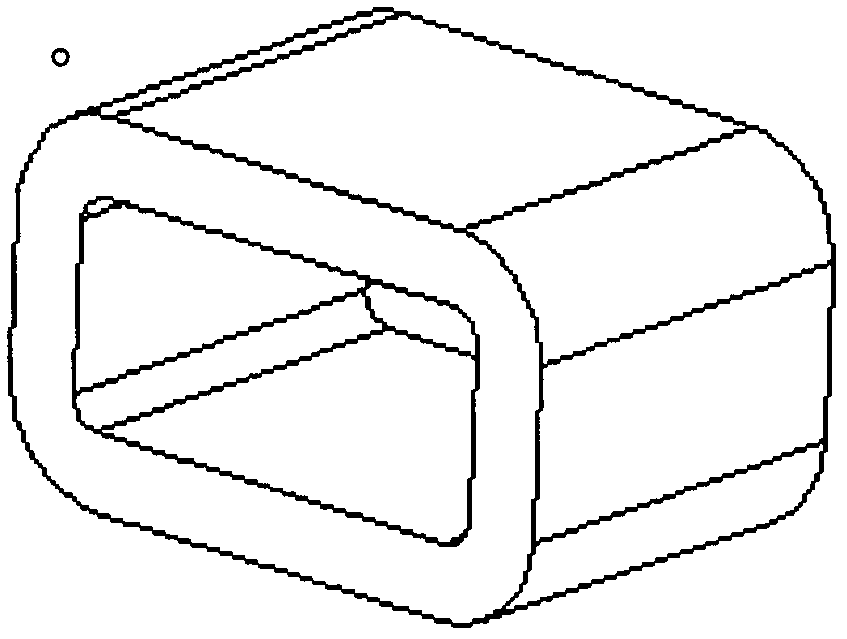

Yoke assembly for moving iron loudspeakers or receivers

ActiveCN103428619BBreak through the size limitSimple structureElectrical transducersMoving iron speakerLoudspeaker

Disclosed is a magnetic yoke apparatus for a moving-iron speaker or telephone receiver, with improved structure and manufacturing techniques. The apparatus comprises an upper and a lower portion, the two portions both being half-box structures enclosed on four sides. One side face of the upper portion of the magnetic yoke apparatus has an open groove, and the bottom face of the lower portion is provided with a through-hole. When the upper and lower portions of the magnetic yoke apparatus are assembled, the portions are aligned along the edges and are fixedly connected, enclosing the front end. The advantages of the present invention at least lie in: while guaranteeing the magnetic circuit of the moving-iron speaker or telephone receiver, the magnetic yoke apparatus enclosed by the upper and lower portions further being able to act as the housing thereof, greatly simplifying the structure of the product and not only reducing the product cost but also overcoming the inherent dimensional restrictions on a moving-iron speaker or telephone receiver, significantly reducing the external dimensions thereof, thus broadening the range of use thereof; and the improved structural design simplifying the construction techniques of the magnetic yoke apparatus, reducing costs, and the techniques involved damaging the magnetic conductivity less than traditional techniques, thus improving the structure of the magnetic circuit and increasing product performance.

Owner:SUZHOU YICHUAN TECH CO LTD

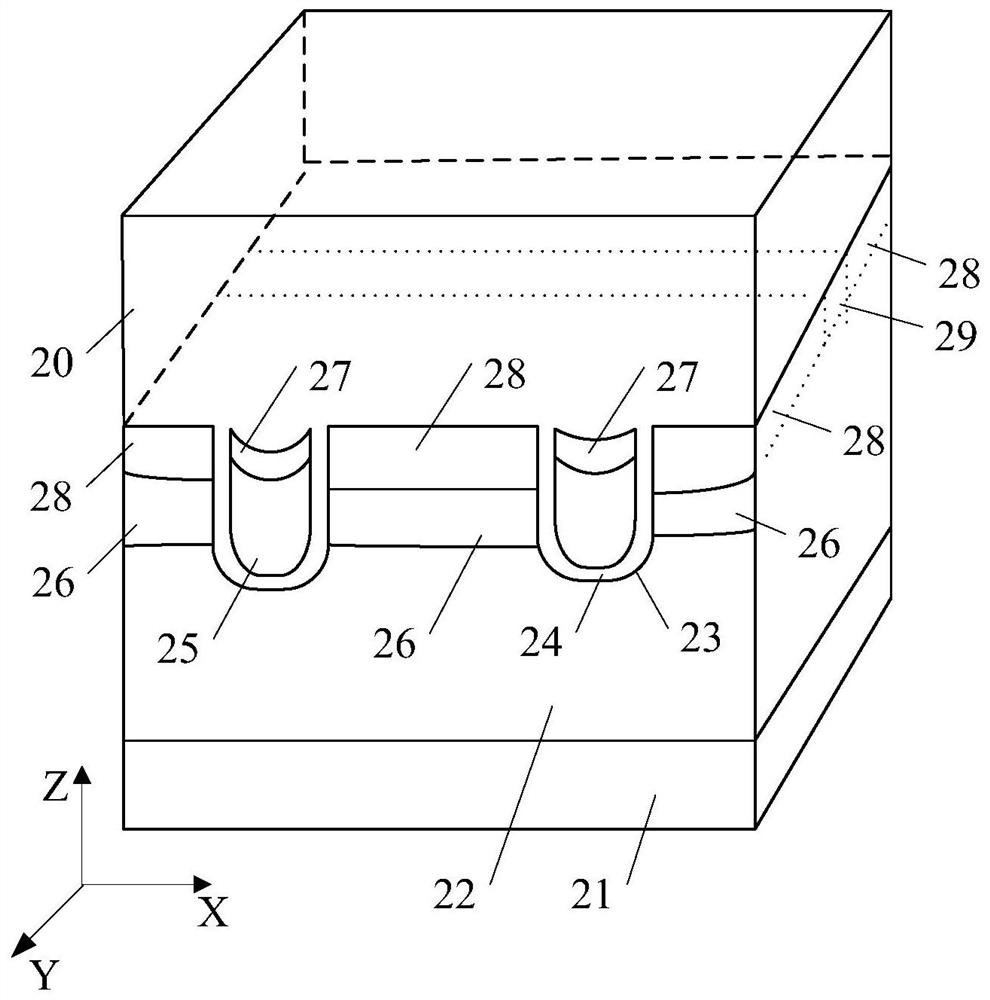

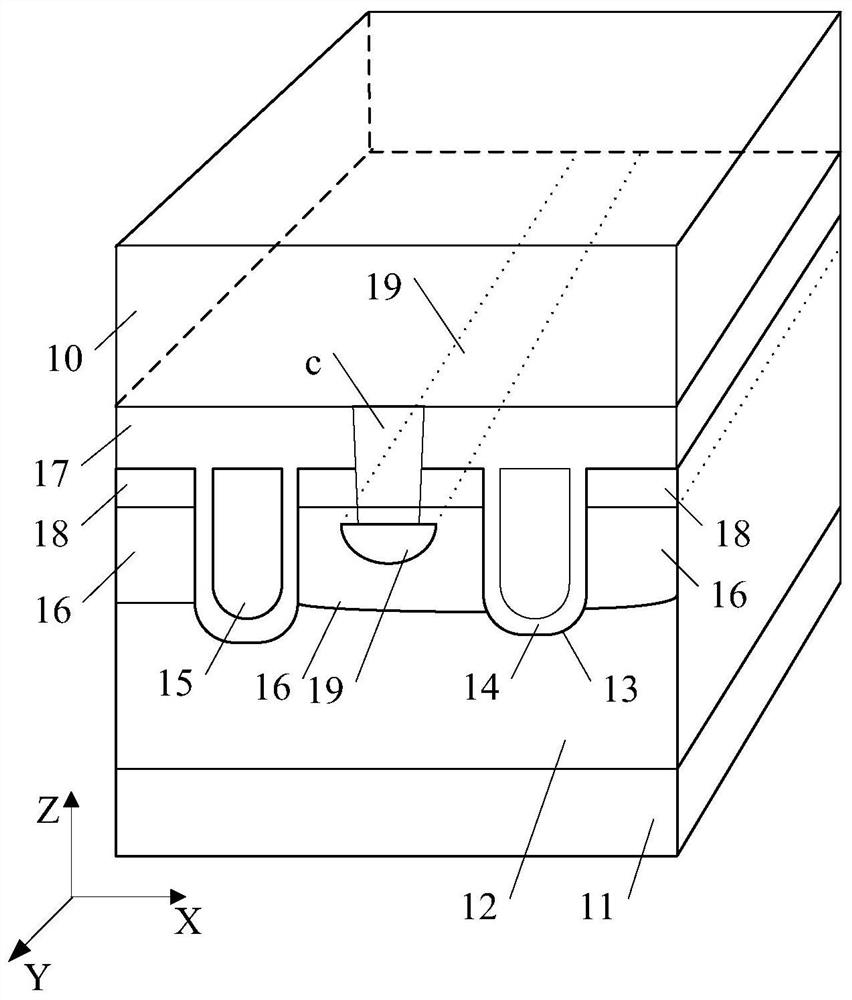

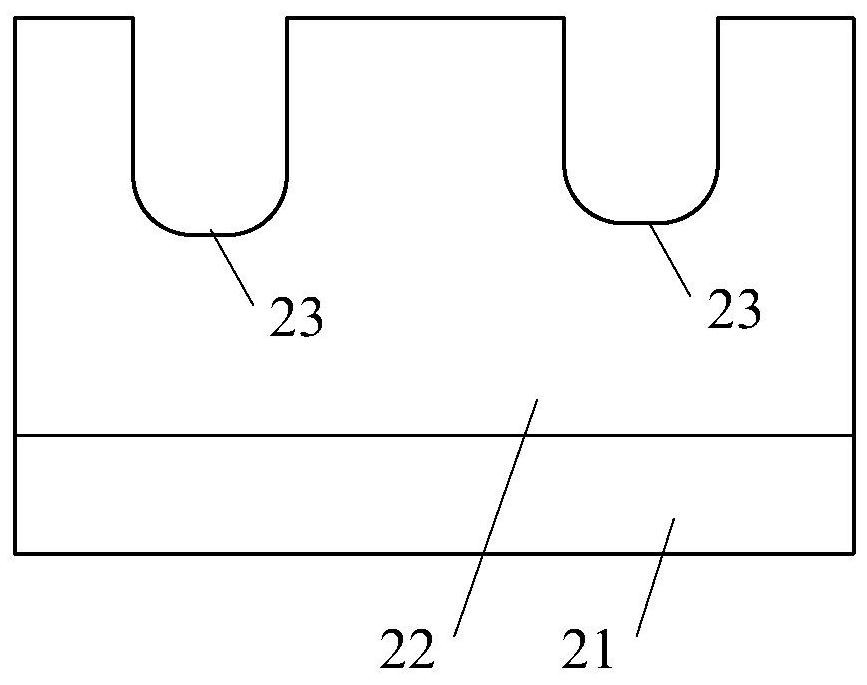

High-density trench device structure and manufacturing method thereof

PendingCN111769157ALower characteristic on-resistanceBreak through the size limitSemiconductor/solid-state device manufacturingSemiconductor devicesTrench mosfetElectrically conductive

The invention discloses a high-density trench device structure and a manufacturing method thereof, and belongs to the field of power semiconductors. According to the high-density trench device structure, an isolation layer sinks into a trench, the whole trench device structure serves as a source region electrode layer, the etching of a source electrode contact hole is not needed, and the whole structure is simplified compared with a traditional trench MOSFET structure; the layout mode that first conductive type source regions and second conductive type source regions are arranged at intervalsin a Y-axis direction is adopted, and the limitation of distribution of the first conductive type source regions and the second conductive type source regions in a transverse direction on the size ofa cellular region is broken through. With the manufacturing method of the high-density groove device structure adopted, the production and manufacturing of an ultra-high-density groove MOSFET with thecell density of 0.5 micrometer or below can be conducted, the cell density is improved by three times or above, and the characteristic on resistance of the device can be reduced by 20% or above on the whole.

Owner:SHANGHAI CHANGYUAN WAYON MICROELECTRONICS

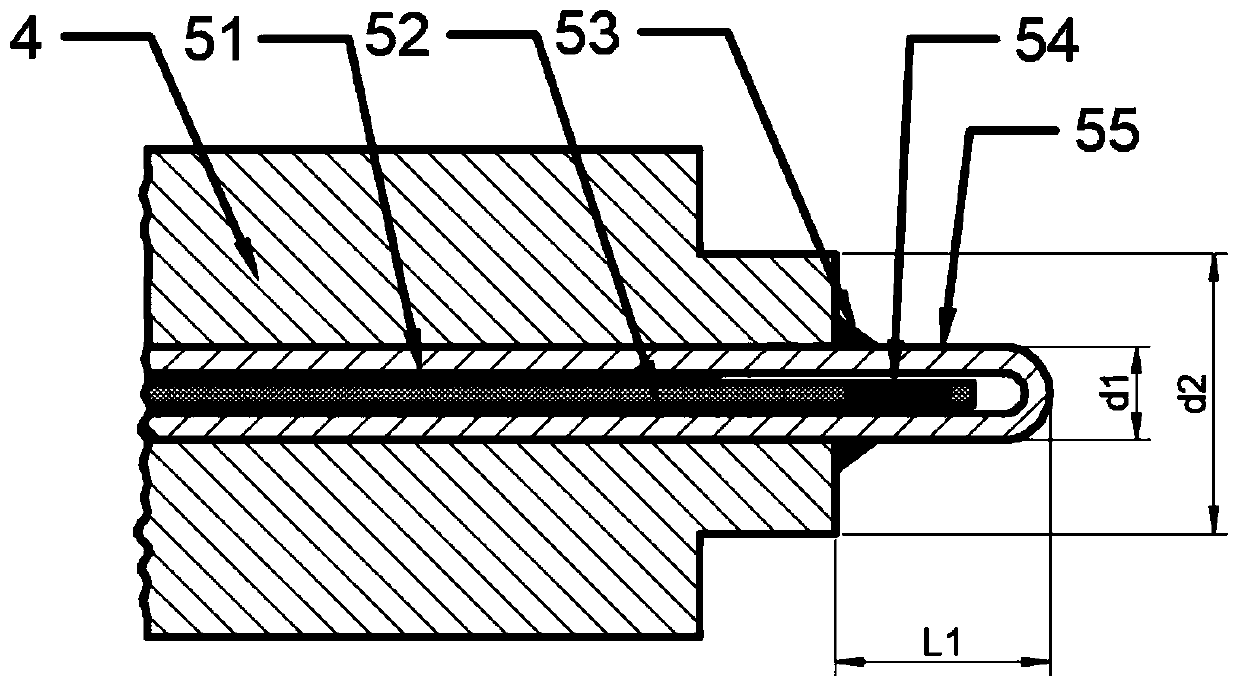

A packaging structure and method of an optical fiber Fab sensor for temperature measurement in nuclear facilities

ActiveCN109307559BBreak through the size limitReduce volumeThermometers using physical/chemical changesLaser beam welding apparatusAdhesiveEngineering

Owner:CHONGQING UNIV

A fast pinyin input system based on a touch-sensitive device

ActiveCN103235696BSolve the stuck word phenomenonRealize touch typing technologyInput/output processes for data processingTypingTouch Senses

The invention discloses a fast Chinese pinyin input method based on a touch sensitive device and an achieving system thereof. The method includes that a marking tool is used for clicking an initial soft keyboard of a touch screen to input an initial consonant of pinyin; a system pops out a vowel suspension soft keyboard covered around an initial consonant key automatically; the marking tool is used for sliding on the vowel suspension soft keyboard for at most two key positions, and vowels of the pinyin are input; and the marking tool is lifted, and the vowel suspension soft keyboard is hidden automatically. Technical systems of six portions are combined and include (1) a suspension soft keyboard system; (2) seven suspension soft keyboards and key position layouts of the seven suspension soft keyboards; (3) a 'one-key one-pinyin' fast pinyin input method; (4) a 'one-character one-key' sentence input mode; (5) a non-switch stroke assisting technology; (6) a fast part input method. By means of the method and the system, only once key clicking is conducted, simplified pinyin and full pinyin are conducted simultaneously, and efficient inputting can be conducted without changing a pinyin scheme or initial soft keyboard setting. Simultaneously, touch screen size limit is broken through, key false identification rate is low, operation fatigue is small, and high-speed typing can be conducted even if a user does not know the pinyin.

Owner:白春荣

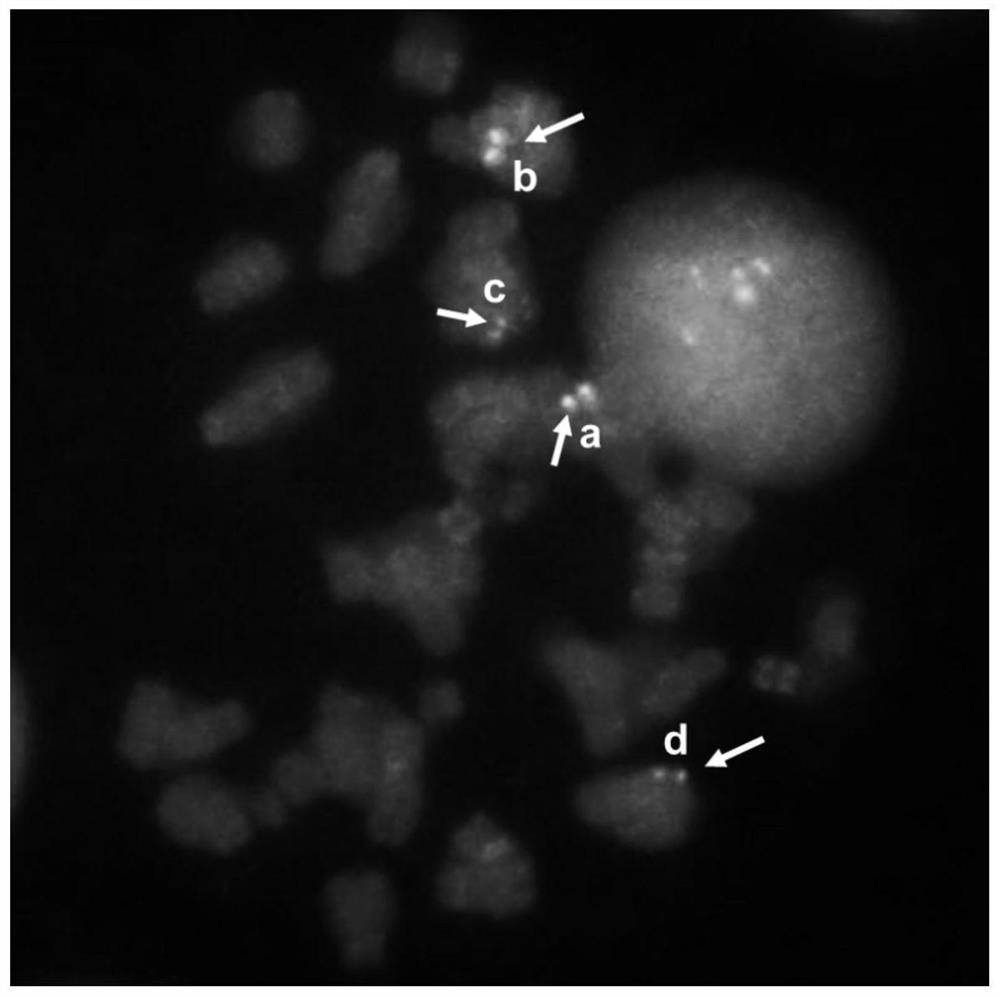

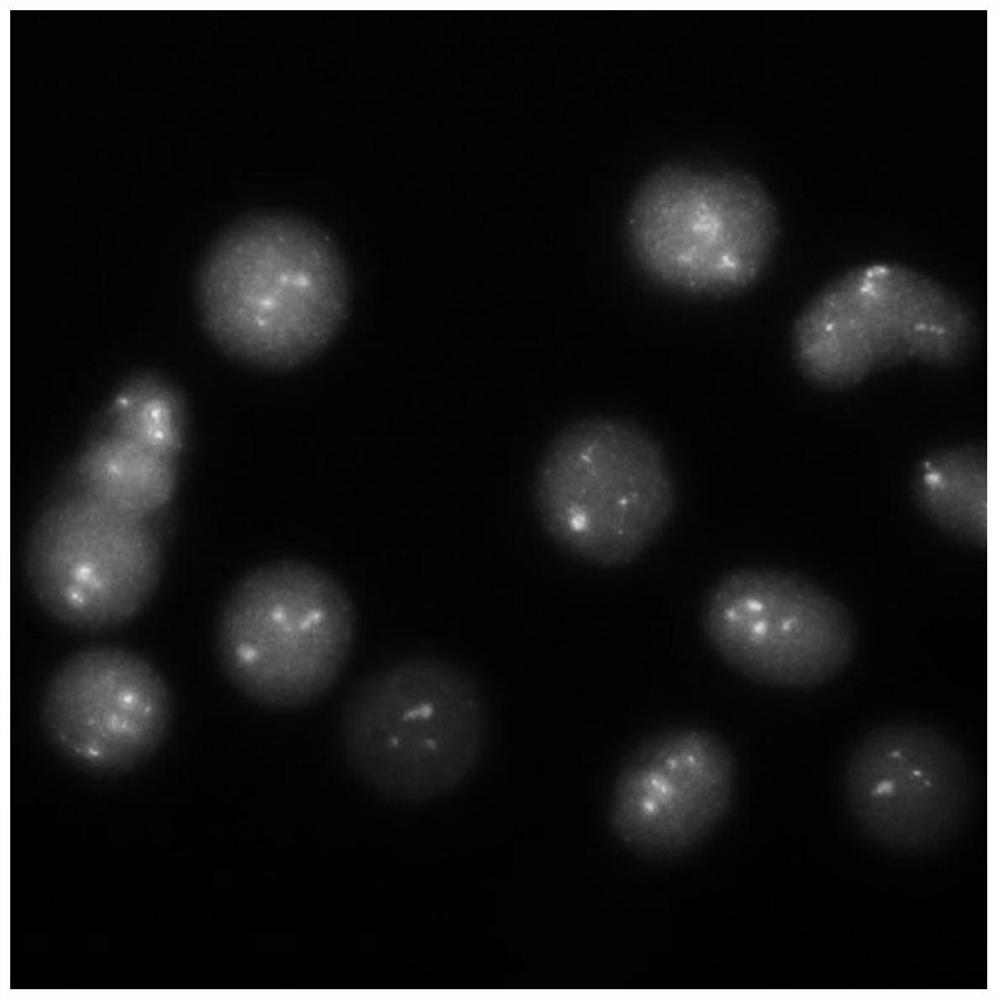

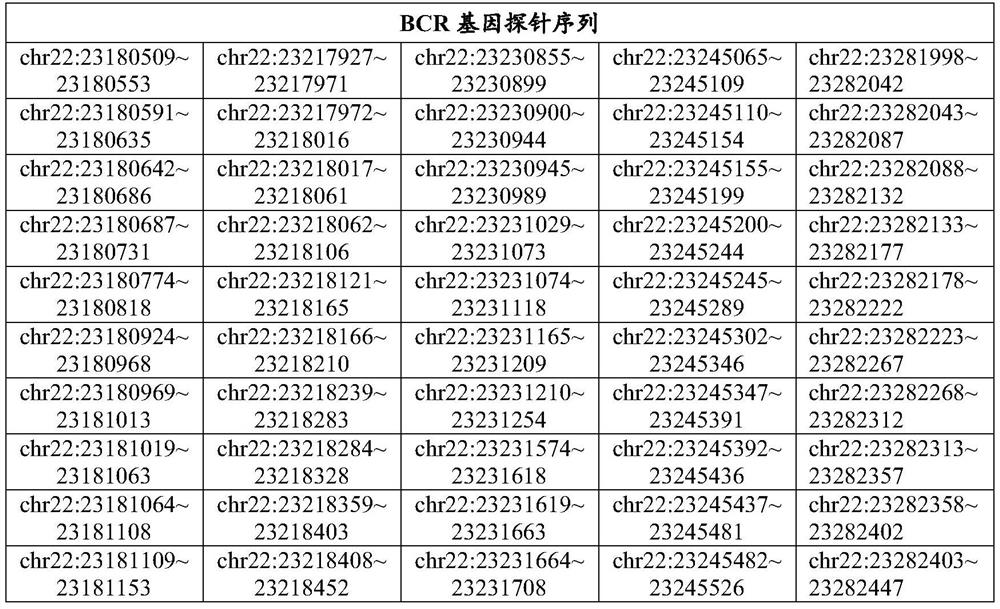

Fluorescence in-situ hybridization probe group for detecting BCR/ABL gene and application of fluorescence in-situ hybridization probe group

PendingCN114196754ABreak through the size limitHigh-resolutionMicrobiological testing/measurementDNA/RNA fragmentationIn situ hybridisationHybridization probe

The invention relates to the technical field of gene detection, in particular to a fluorescence in-situ hybridization probe set for detecting BCR / ABL genes and application of the fluorescence in-situ hybridization probe set. According to the invention, in a non-repetitive region of the BCR / ABL gene, on the basis of using as few probes as possible, the probe resolution is increased, a PCR (Polymerase Chain Reaction) doping method is also adopted in the preparation process to ensure that the product contains more fluorophores, and when the probe group is used for detecting the BCR / ABL gene, the cost is relatively low, and the hybridization of the probes can be completed in about 30 minutes.

Owner:WUHAN YZY MEDICAL SCI & TECH

A three-dimensional digital floor mold production method

ActiveCN104029280BReduce molding difficultyBreak through the size limitCeramic shaping apparatusModelSimData source

The invention relates to a three-dimensional digital floor mold production method, including (1) using three-dimensional digital software to carry out overall three-dimensional modeling of the building curtain wall; (2) dividing the overall model into several individual modules; (3) obtaining the contour line of the delayed module Parameters, set the axis distribution of the overall model; (4) Make axis plates and number them; (5) Output projection drawings and tables; (6) Complete on-site projection large-scale drawing; (7) Place axis plates according to numbers to form mold abutments (8) Prepare the prototype of the mold; (9) Draw the bin line and frame line on the surface of the prototype of the mold, which is the ground mold; the present invention uses the parameters output by the three-dimensional software as the only data source to ensure the parameterization of the whole process of ground mold forming, The surface surface effect and surface performance of the ground mold can perfectly meet the requirements of the building shape, and at the same time, the idea of virtual modeling and segmentation is adopted to break through the size limit of large hyperboloid mold manufacturing.

Owner:江苏倍立达新材料科技有限公司

Packaging structure and method of optical fiber Fabry-Perot sensor for temperature measurement of nuclear facility

ActiveCN109307559ABreak through the size limitReduce volumeThermometers using physical/chemical changesLaser beam welding apparatusTemperature responseAdhesive

The invention relates to a packaging structure and a packaging method of an optical fiber Fabry-Perot sensor for temperature measurement of a nuclear facility, and belongs to the technical field of optical fiber sensing. The structure comprises a single-mode optical fiber, an adiabatic guide column, a flange base, a capillary steel pipe, a stainless steel armored pipe, and an optical fiber Fabry-Perot sensor. The method comprises the following steps of: fabricating the optical fiber Fabry-Perot sensor on the top of the single-mode optical fiber; penetrating the optical fiber into the single-end sealed capillary steel pipe, and bonding and fixing the optical fiber with a high-temperature adhesive; penetrating the capillary steel pipe into the stainless steel armored pipe with an inner diameter of 0.5 mm, and exposing a sensing part to the outside of the stainless steel armored pipe about 2 to 3 mm; separately inserting the adiabatic guide column and the stainless steel armored pipe intothe flange base from two ends; welding and sealing the joint of the capillary steel pipe and the stainless steel armored pipe, and the joint of the stainless steel armored pipe and the base; and carrying out annealing treatment on the entire sensor. According to the packaging structure and the packaging method, the size limitation of a thermocouple sensor on the packaging structure is broken, anda sensing method with a high-speed temperature response is provided for the temperature measurement of the nuclear facility.

Owner:CHONGQING UNIV

An upward hanging type downhole oil-water separation pipe string

The invention discloses an upward suspension type underground oil-water separation pipe column. The pipe column comprises a perforated pipe, an inserted seal, a filling pump system and an oil-water separator which are connected from bottom to top through an oil pipe. The pipe column also comprises a separation joint, wherein the separation joint is connected with the oil-water separator and is ofa three-way structure, the upper end of the separation joint is provided with two ports, the first port is connected with a lifting oil pipe, the second port is connected with an oil return oil pipe,a lower port is connected with an outlet of the oil-water separator, and an upward suspension type structure is formed. Three channels are formed in the pipe column and include the channel for outputliquid of an output liquid layer to enter the oil-water separator, the re-injection channel used after test modification of separated low-oil-content output water and the oil-rich output liquid lifting channel. The pipe column has the advantages that the separated lifting channel is connected with the re-injection channel, so that the problems that a conventional suspension type underwater oil-water separation structure electric pump liquid output channel is connected with the re-injection channel in parallel, the size of a casing pipe is limited and re-injected test modification is difficultare solved; large-displacement underground oil-water separation and re-injected water monitoring are achieved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com