Patents

Literature

59results about How to "Accurately draw the line" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

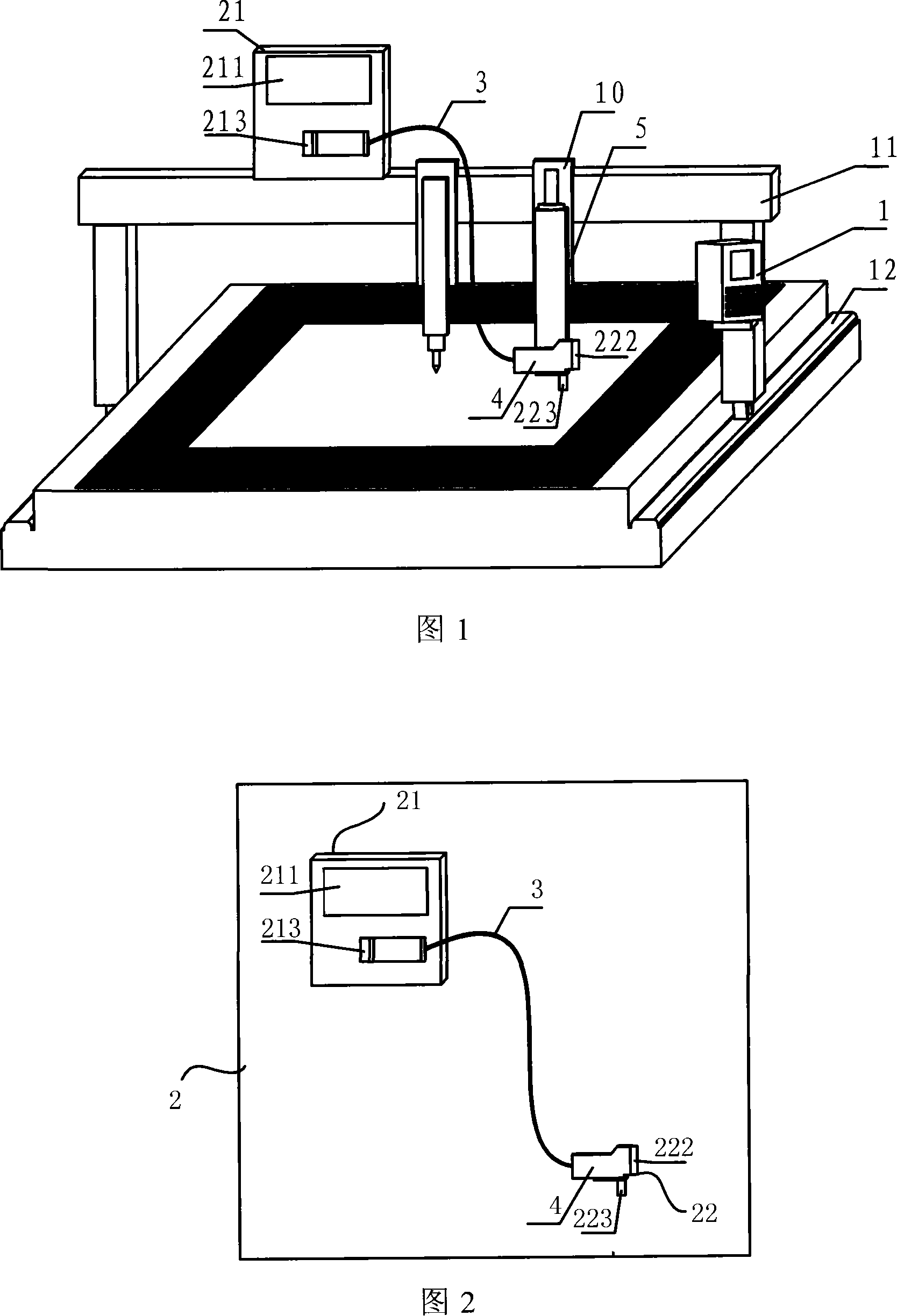

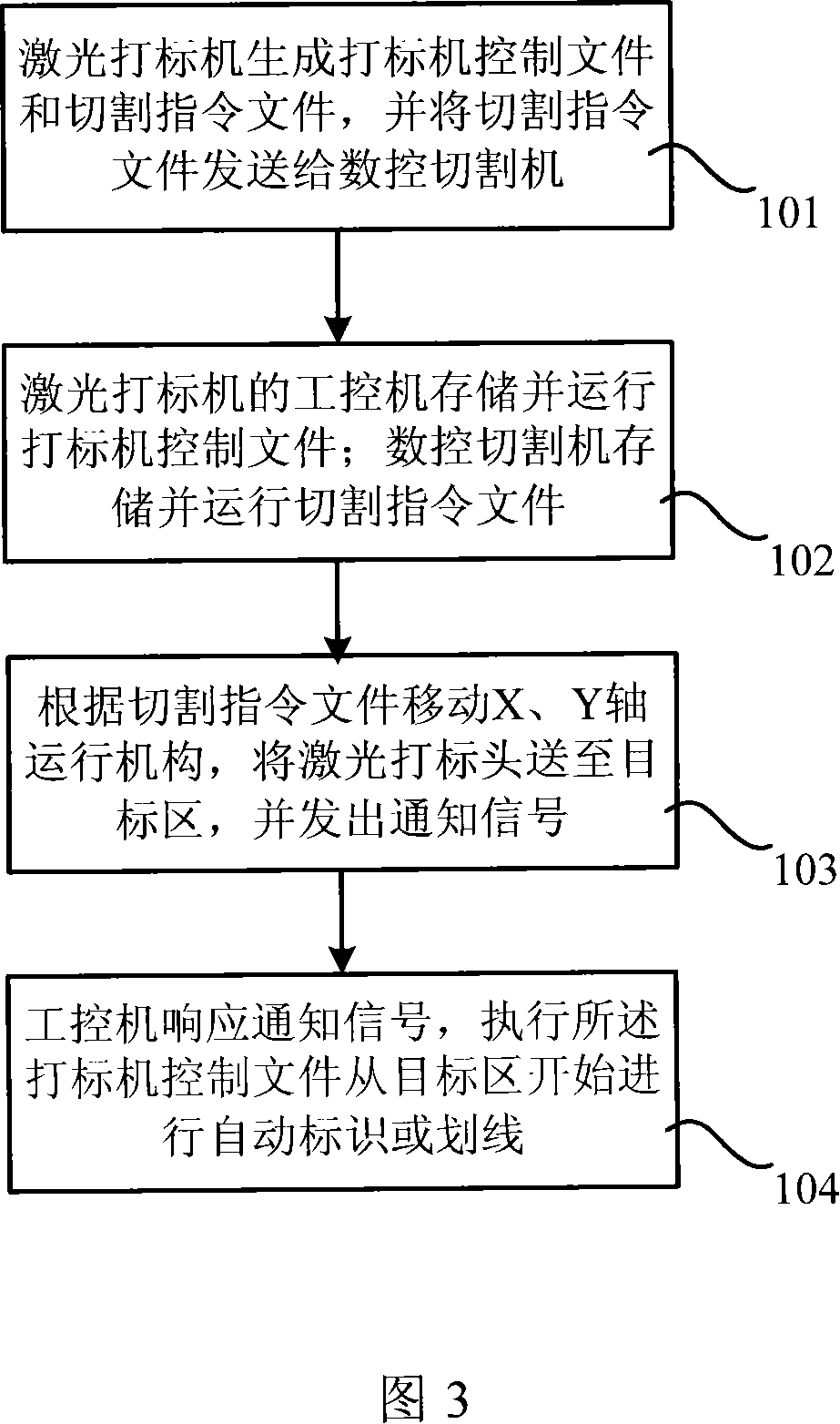

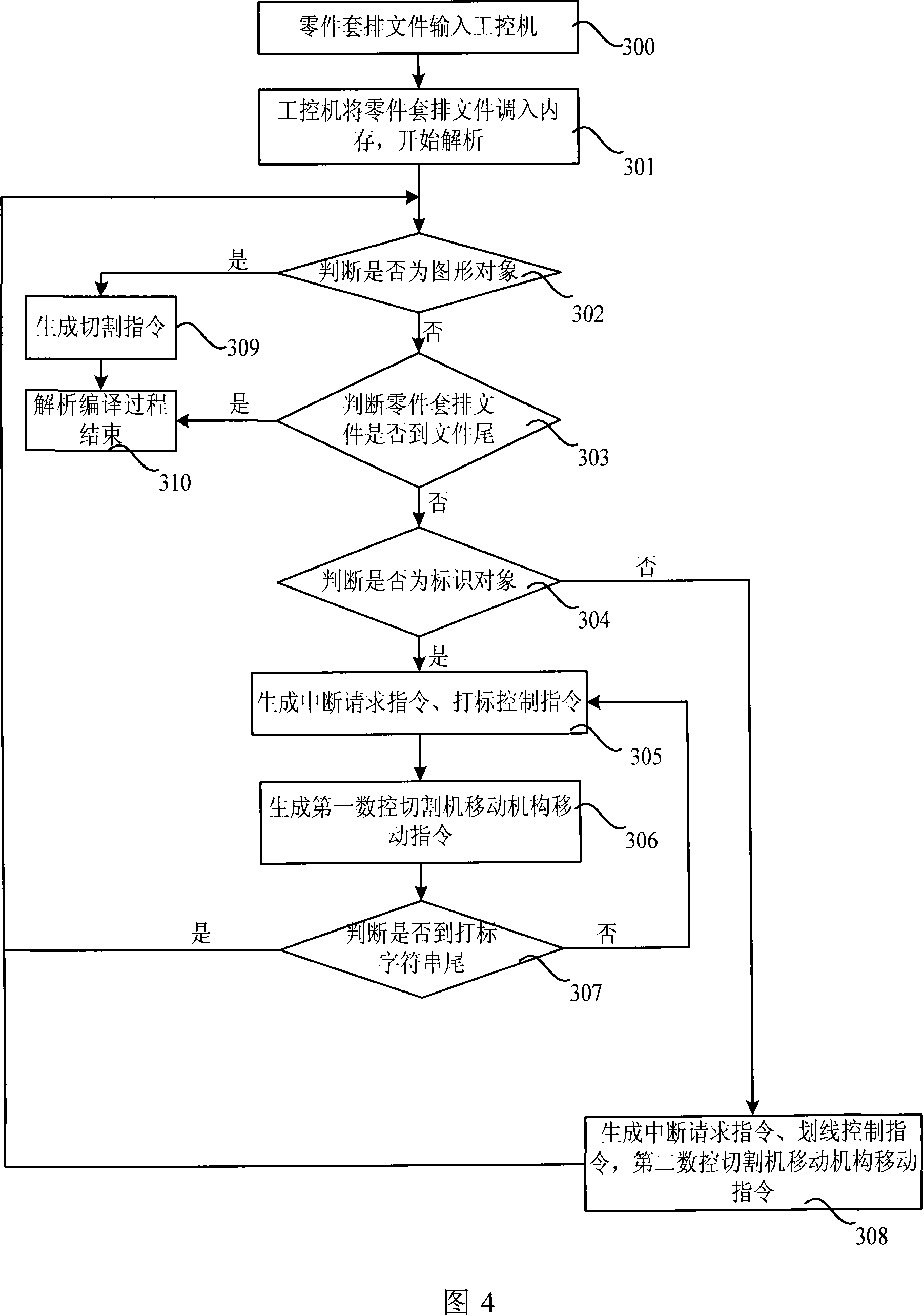

Numerically controlled cutting control device and numerically controlled cutting control method

ActiveCN101104239AIntuitive logoHigh speedTypewritersAblative recordingMachine controlControl engineering

The invention relates to a digital control cutting control device, comprising a digital control cutting machine, which is used to drive moving mechanisms in X and Y axes of the digital control cutting machine; a laser marking machine, which is used to generate marking machine control files and cutting command files, and automatically marks and lines out according to the marking machine control files. The invention also relates to a digital control cutting control method, comprising a laser marking machine storing and operating marking machine controlling files. At the same time, the digital control cutting machine stores and operates the cutting command files. The digital control cutting machine drives the moving mechanisms in X and Y axes according to the cutting command files so as to drive a laser marking head to a target area, and sends out informing signals to the laser marking machine. The laser marking machine responds to the informing signals to automatically mark and line out from the garget area, implementing the marking machine control files. With advantages of reliable, visual and fast marking and accurate lining without damaging steel plates, the invention can automatically line out on parts.

Owner:WUCHANG SHIPBUILDING IND +1

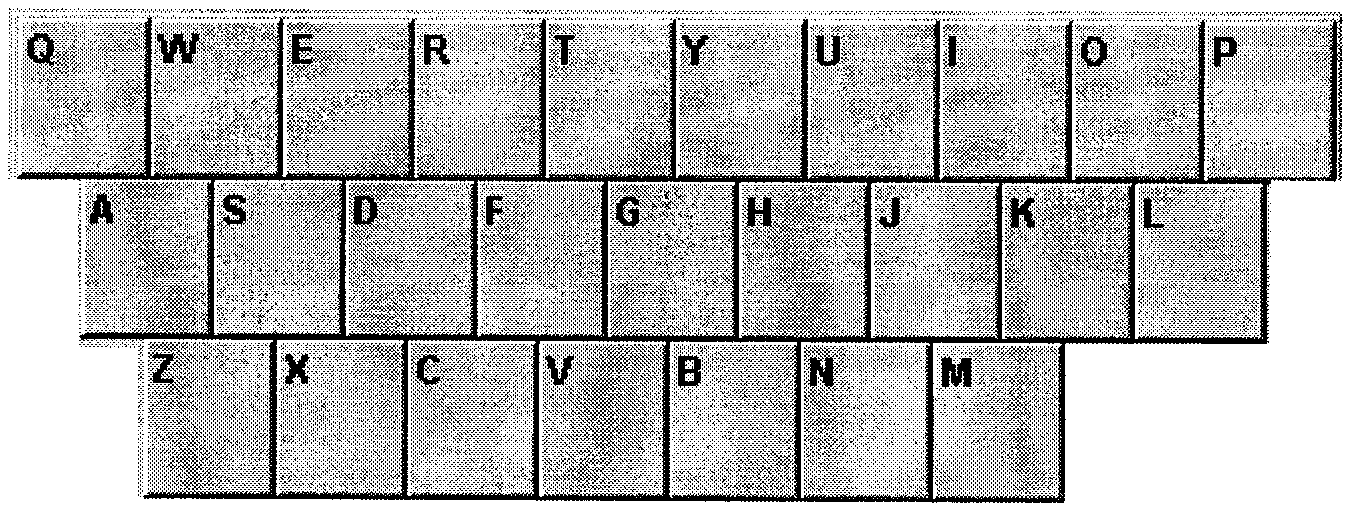

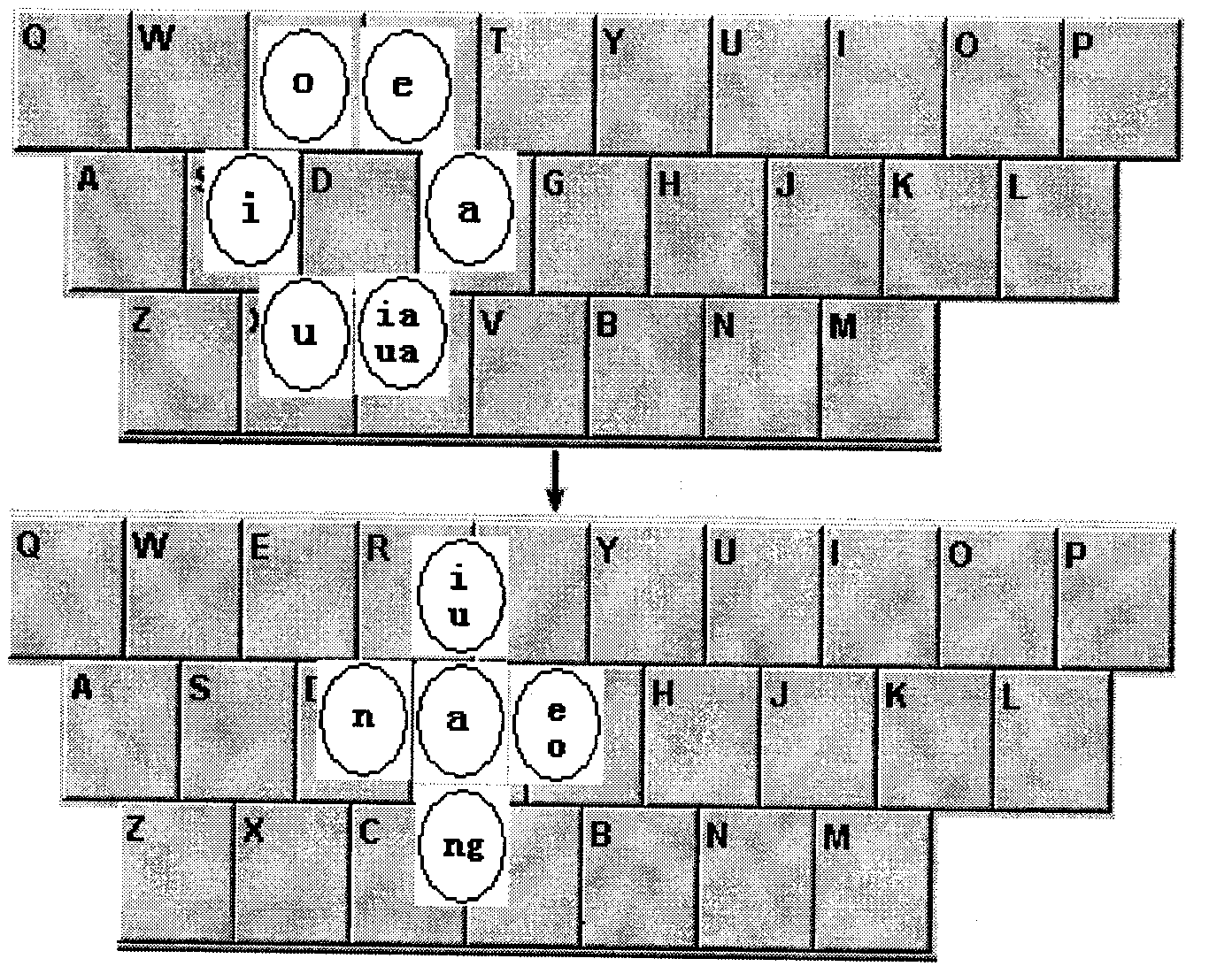

Fast Chinese pinyin input method based on touch sensitive device and achieving system thereof

ActiveCN103235696AIncrease or decrease the number of keysNumber of keys increased or decreasedInput/output processes for data processingKey pressingAssistive technology

The invention discloses a fast Chinese pinyin input method based on a touch sensitive device and an achieving system thereof. The method includes that a marking tool is used for clicking an initial soft keyboard of a touch screen to input an initial consonant of pinyin; a system pops out a vowel suspension soft keyboard covered around an initial consonant key automatically; the marking tool is used for sliding on the vowel suspension soft keyboard for at most two key positions, and vowels of the pinyin are input; and the marking tool is lifted, and the vowel suspension soft keyboard is hidden automatically. Technical systems of six portions are combined and include (1) a suspension soft keyboard system; (2) seven suspension soft keyboards and key position layouts of the seven suspension soft keyboards; (3) a 'one-key one-pinyin' fast pinyin input method; (4) a 'one-character one-key' sentence input mode; (5) a non-switch stroke assisting technology; (6) a fast part input method. By means of the method and the system, only once key clicking is conducted, simplified pinyin and full pinyin are conducted simultaneously, and efficient inputting can be conducted without changing a pinyin scheme or initial soft keyboard setting. Simultaneously, touch screen size limit is broken through, key false identification rate is low, operation fatigue is small, and high-speed typing can be conducted even if a user does not know the pinyin.

Owner:白春荣

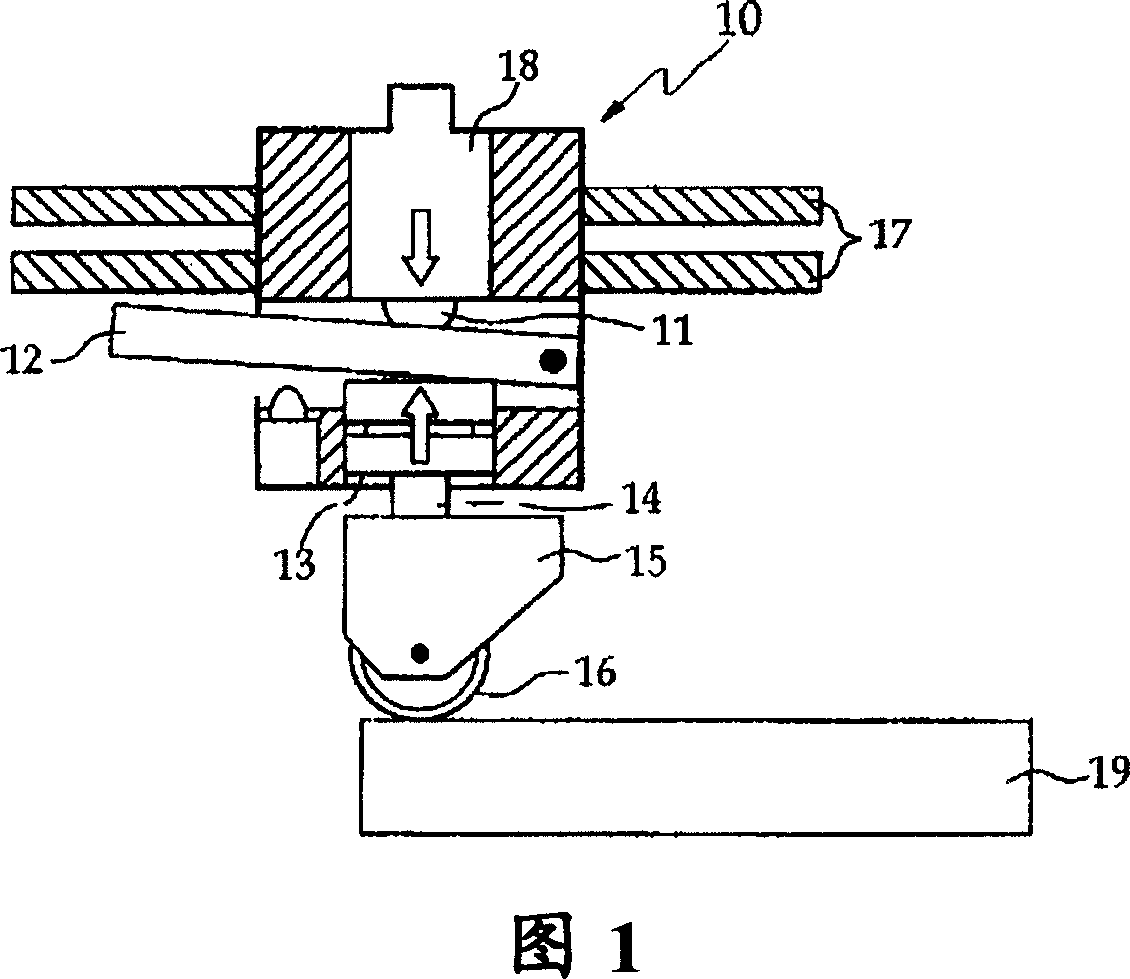

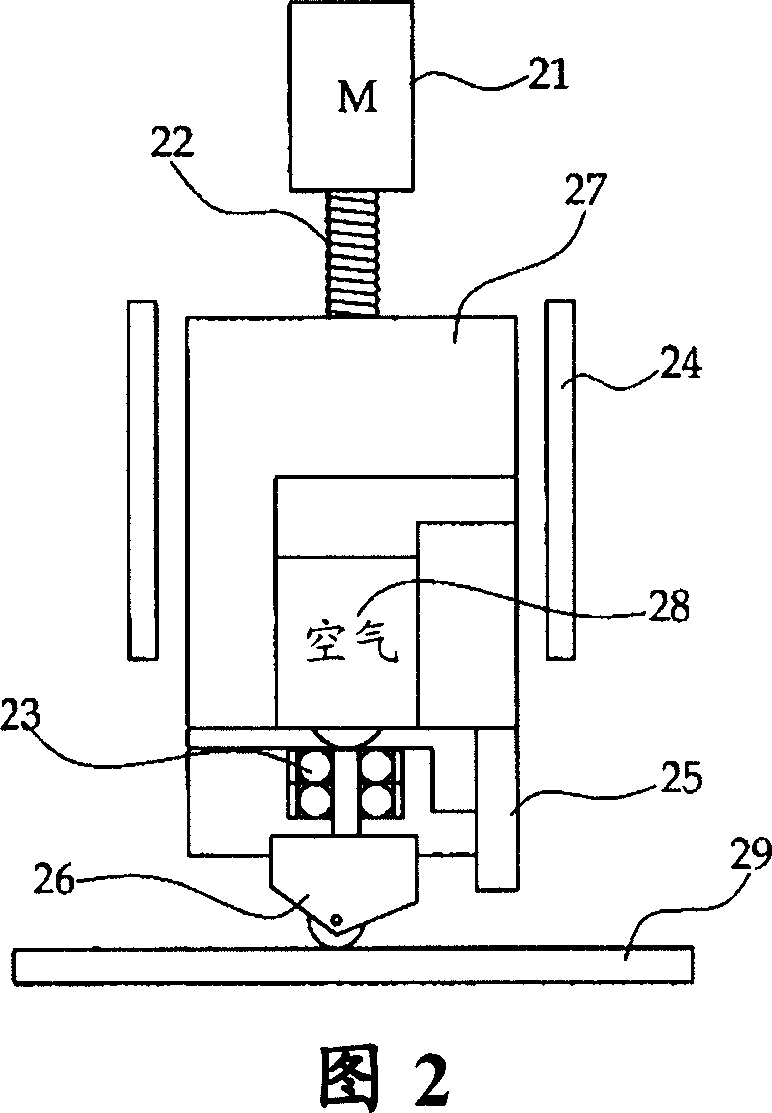

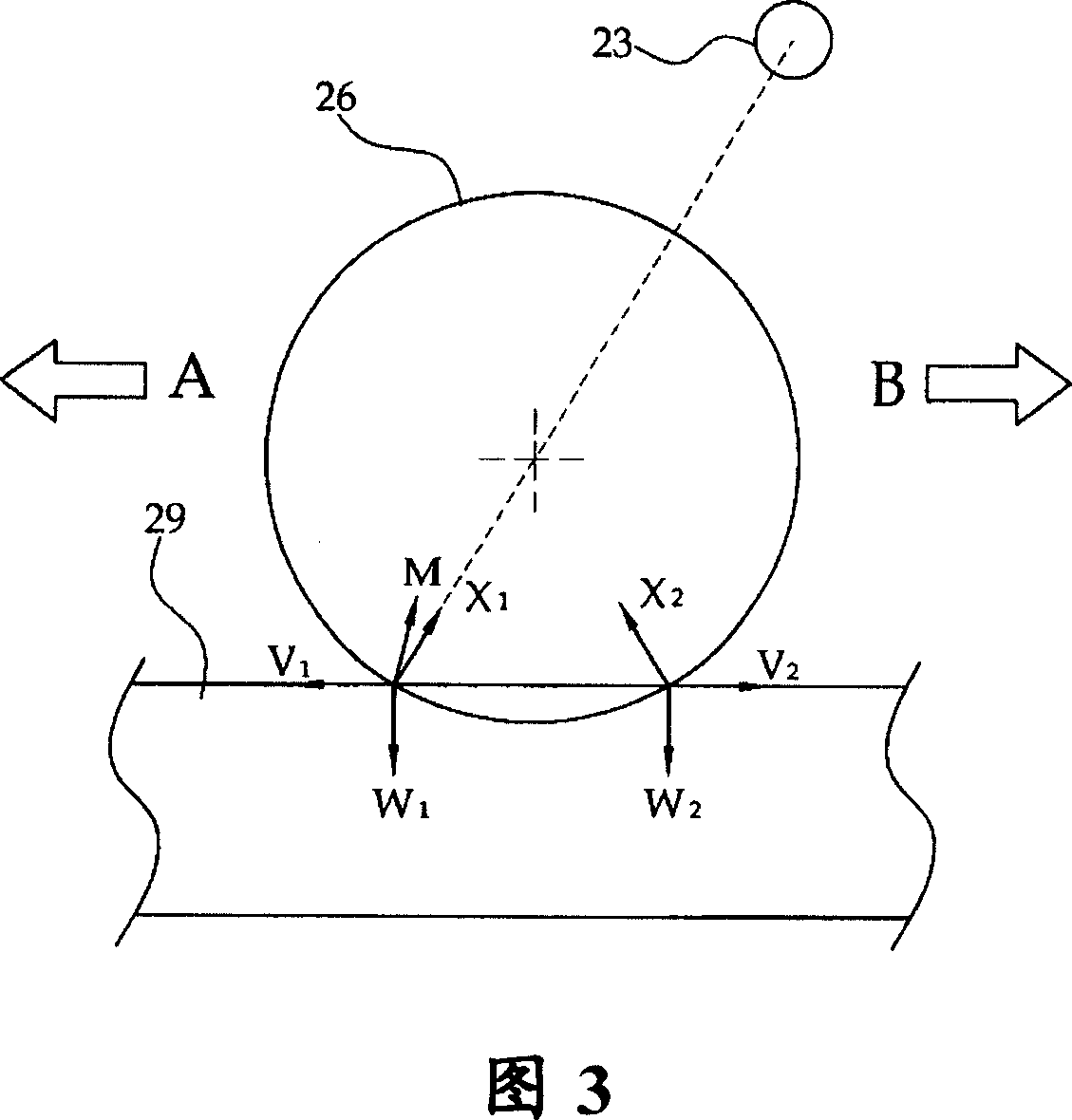

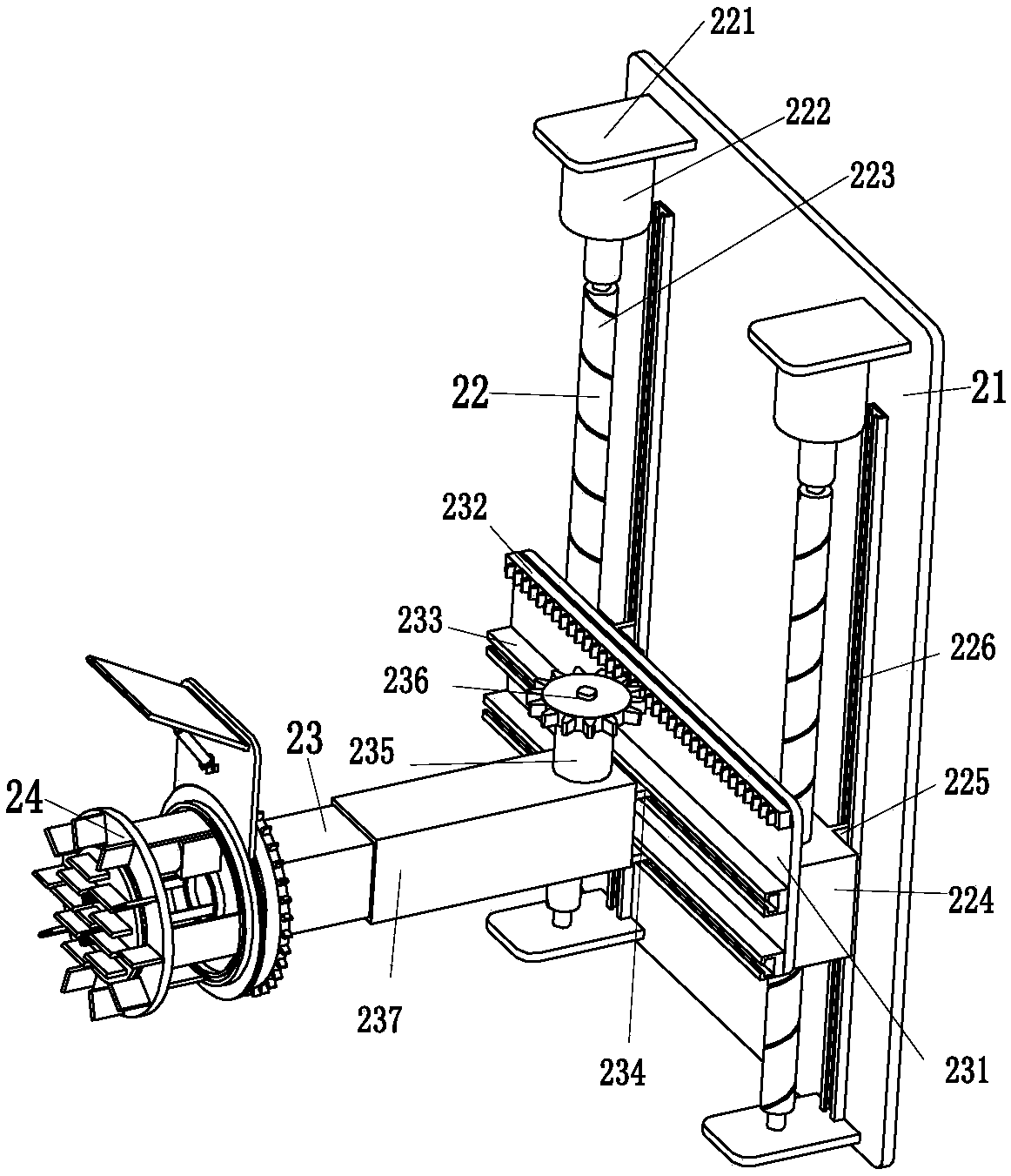

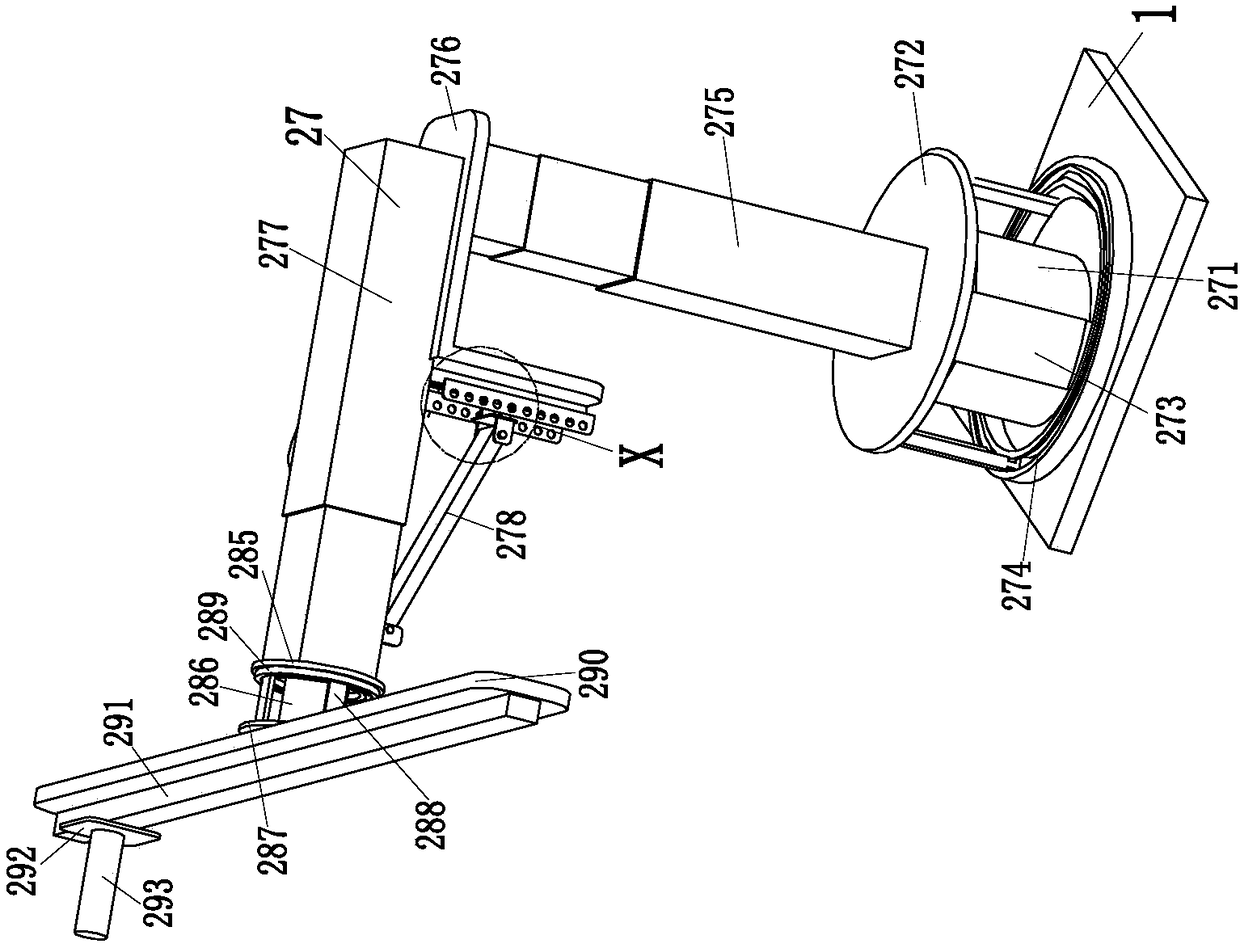

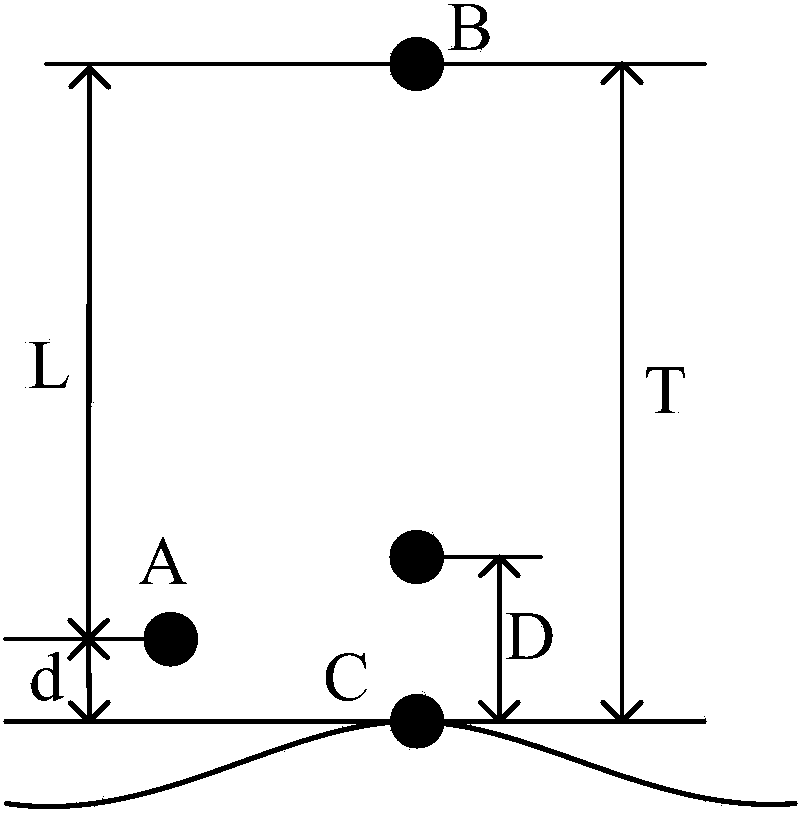

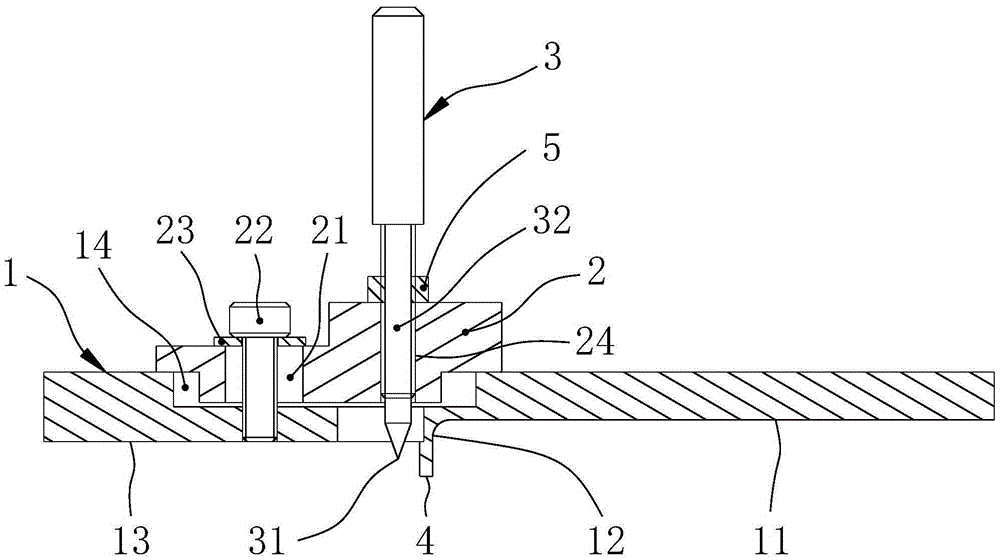

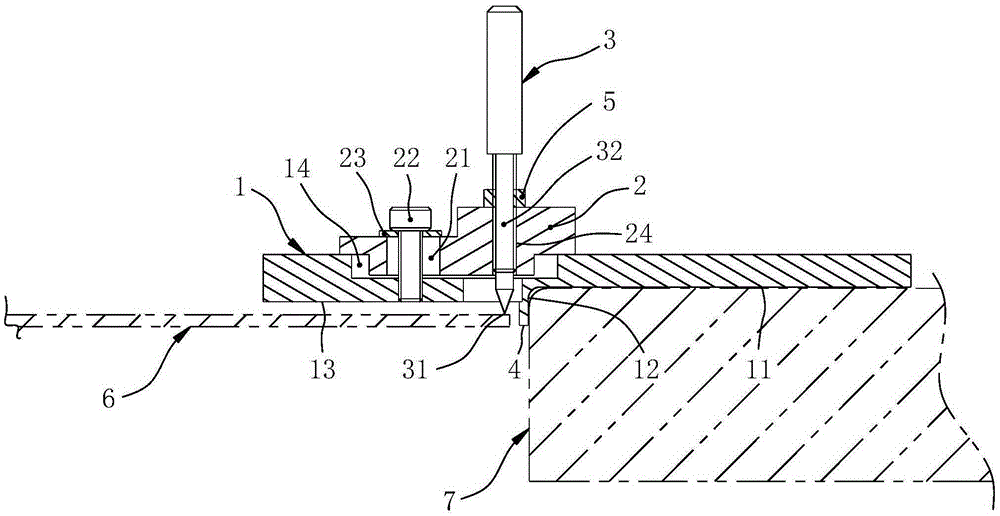

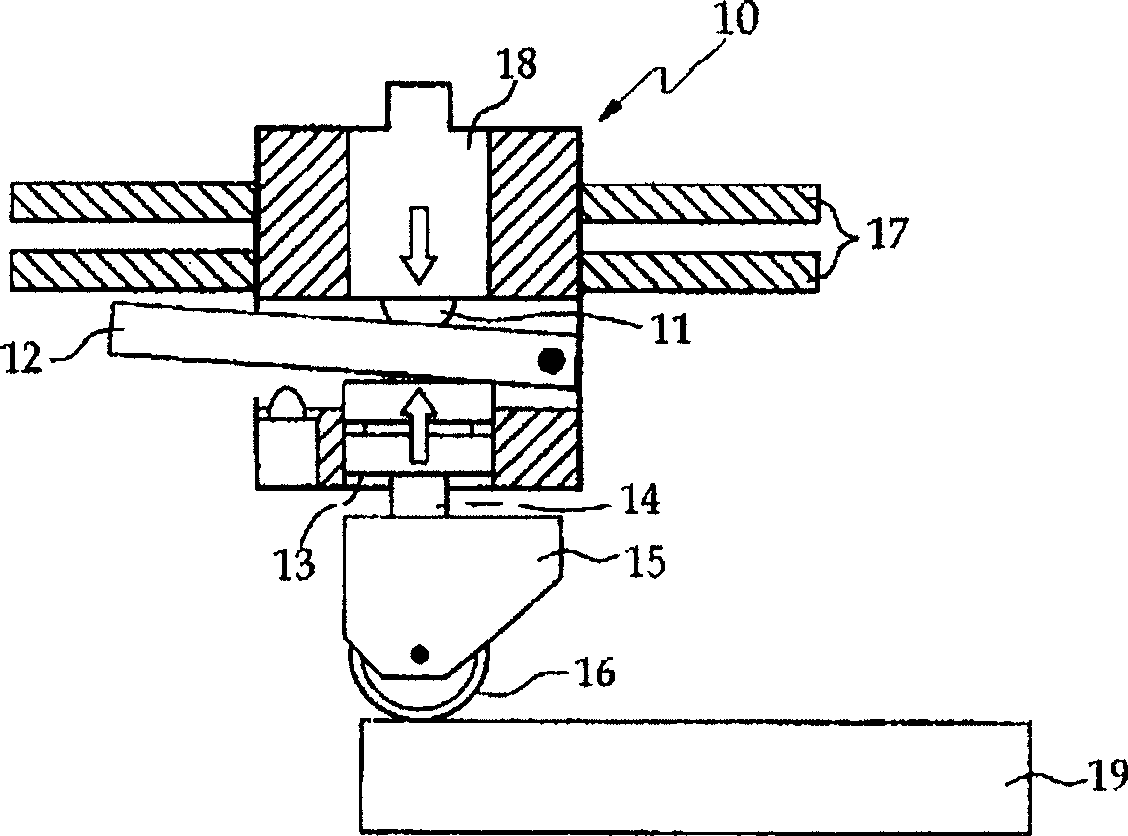

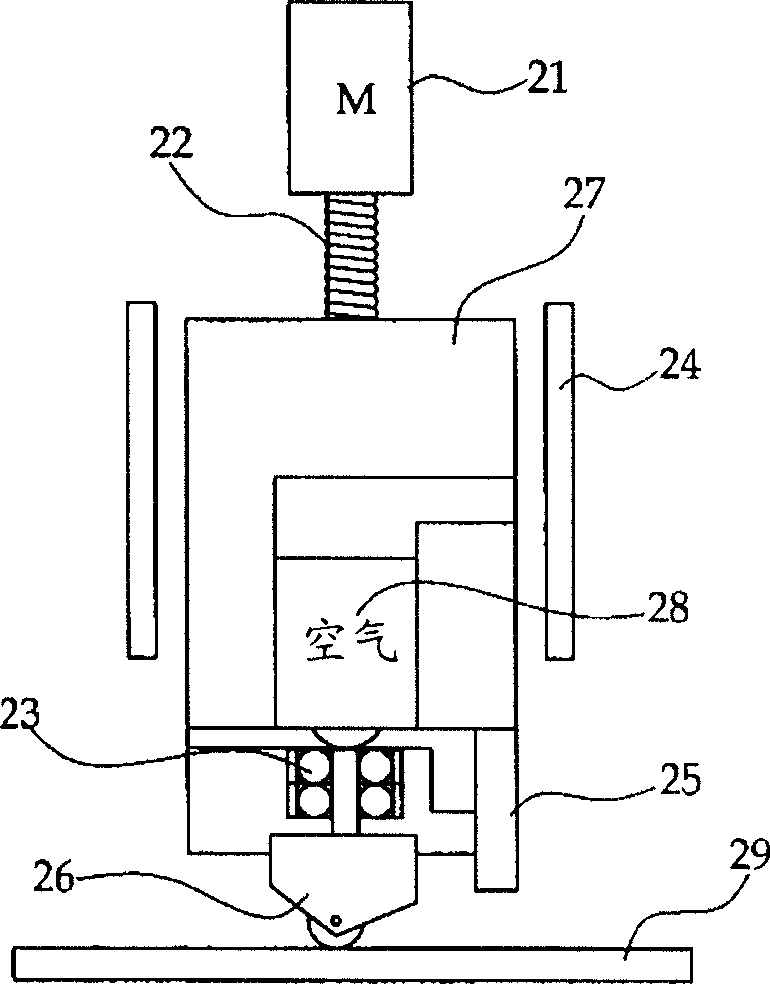

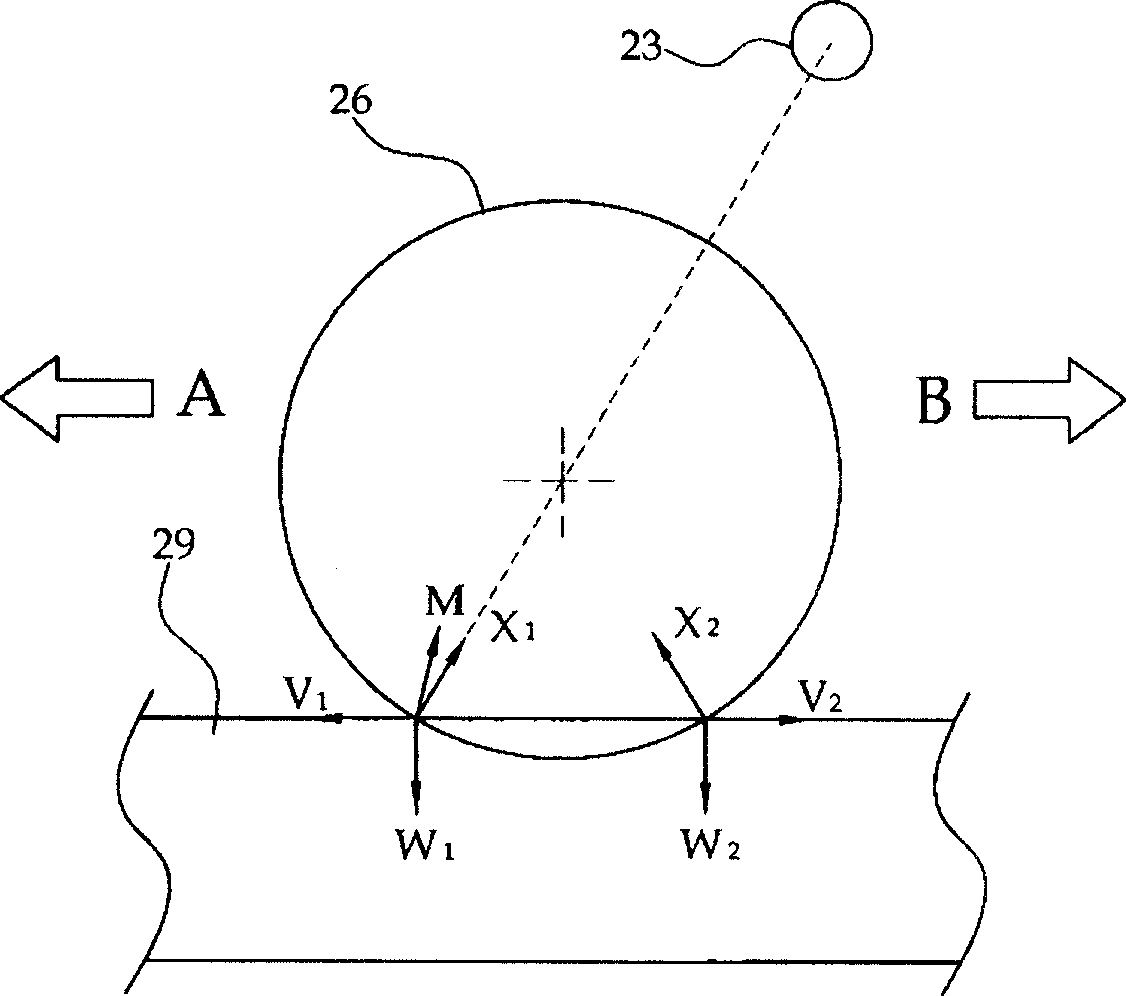

Apparatus for substrate marking

InactiveCN1958488AAccurately draw the lineSemiconductor/solid-state device testing/measurementGlass severing apparatusEngineeringMechanical engineering

An apparatus for substrate scribing which can apply scribing force vertically on a substrate is provided. The apparatus comprises a line-forming part for scribing a line on the substrate, a pressing part for applying pressure on the line-forming part, an elevator for moving the pressing part up and down, an elevating guiding part for leading the elevator, and a pressing guiding part for leading the pressure part. According to the invention, a scribed line can be formed on the substrate precisely by solving the eccentric force which deviates to the X-Y direction.

Owner:TOP ENG CO LTD

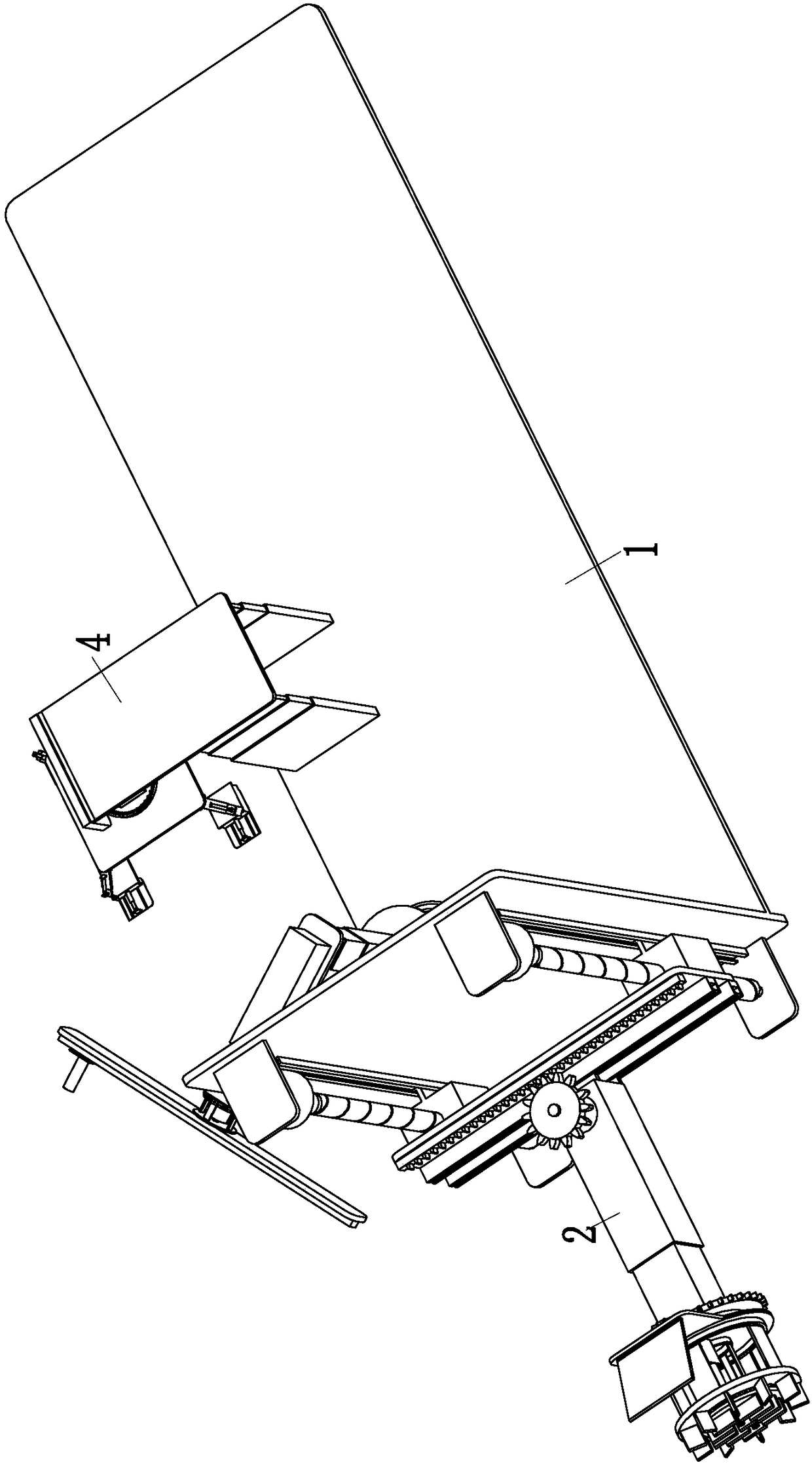

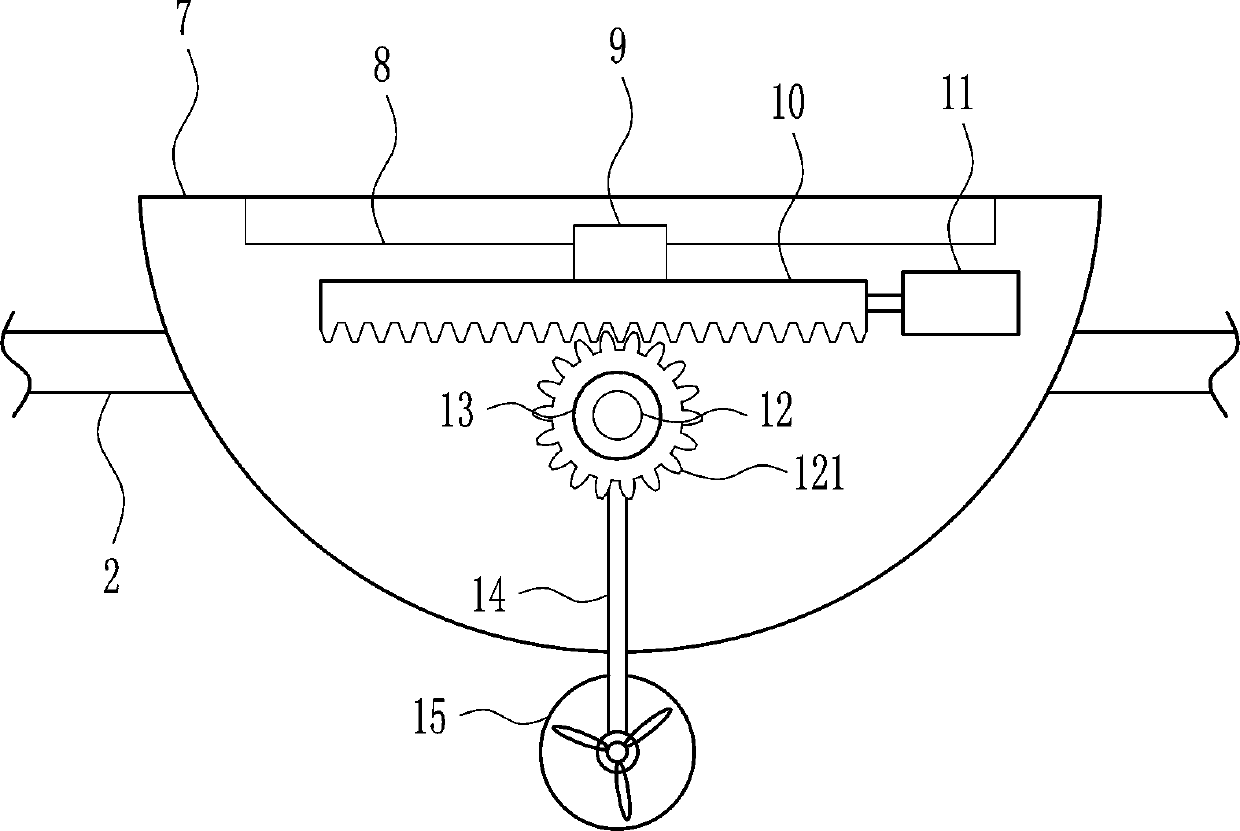

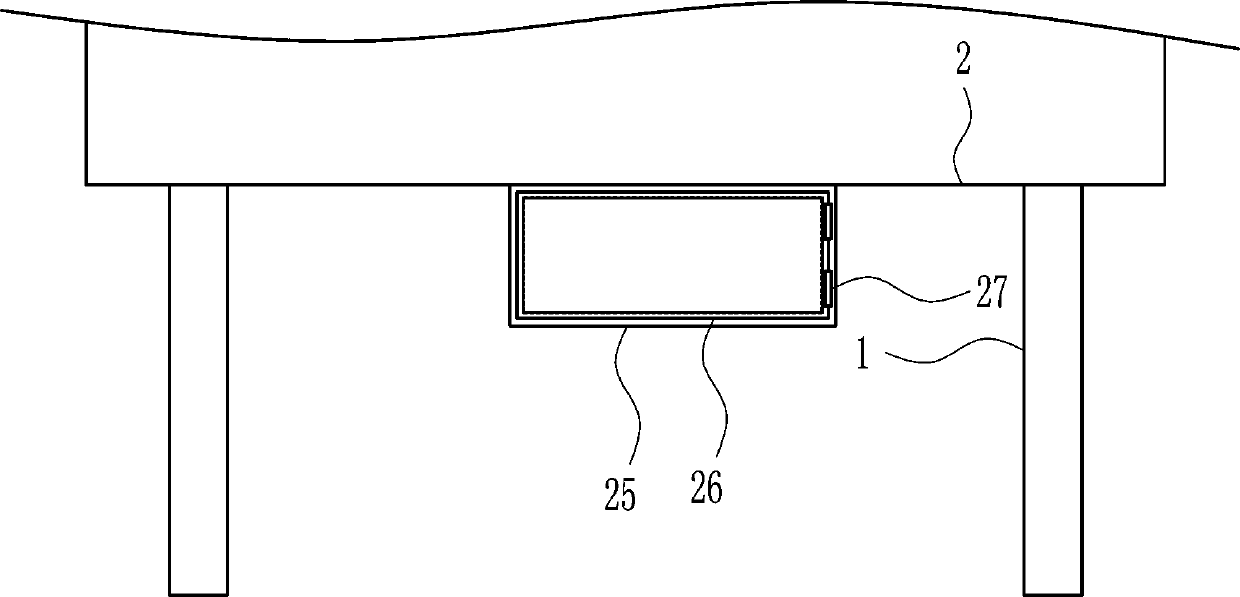

Building floor cement outer wall construction machine with functions of automatic grinding and cement fiber plate mounting

InactiveCN108149933AGuaranteed smoothnessEnsure safetyBuilding material handlingPlane surface grinding machinesFiberCement

The invention relates to a building floor cement outer wall construction machine with functions of automatic grinding and cement fiber plate mounting. The building floor cement outer wall constructionmachine comprises a moving platform, a grinding and scribing device and a face plate mounting device. The grinding and scribing device is mounted at the front end of the moving platform, and the faceplate mounting device is mounted at the left end of the moving platform. The problems that in the existing cement fiber plate mounting process, grinding and scribing of an outer wall and mounting ofa face plate need to be conducted manually; during grinding and scribing of the outer wall, grinding and scribing treatment needs to be conducted by people with the help of a ladder, when the next position is ground, people needs to carry the ladder manually and then climb onto the ladder again for working, and therefore, the process is tedious and complicated; during mounting of the face plate, cooperation division of multiple people is needed, the difficulty of cooperation of multiple people is high, and when multiple people work on the same ladder, the falling-down accident is likely to occur, and consequently potential safety hazards are caused can be solved, and the functions of automatic grinding of the cement outer wall and fixed mounting of the face plate can be achieved.

Owner:黄正秀

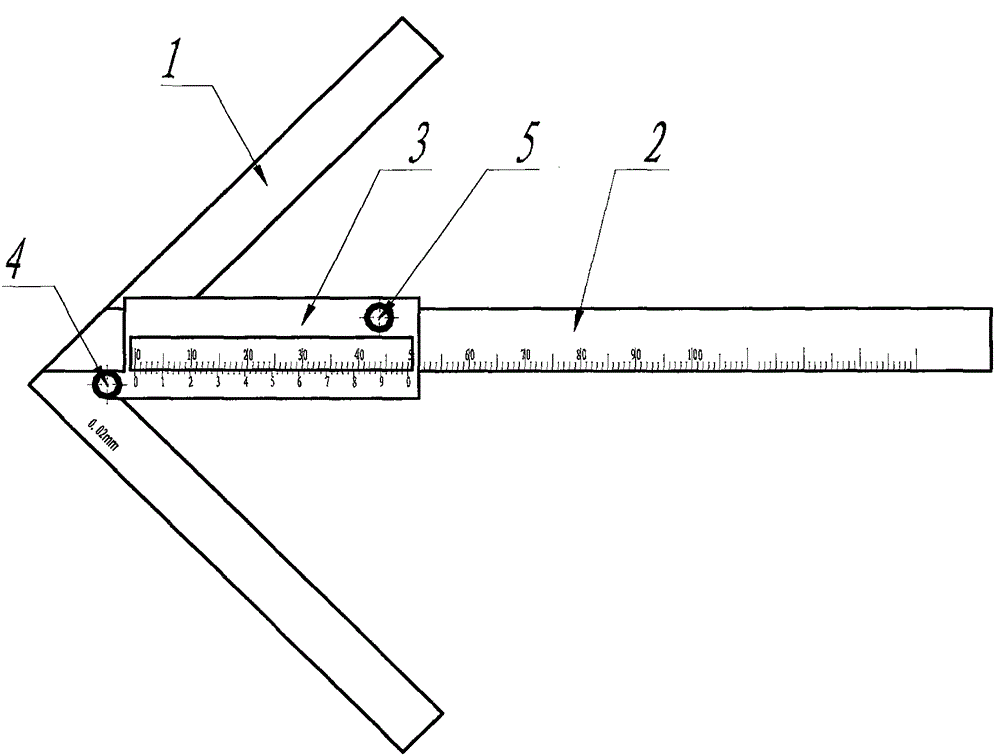

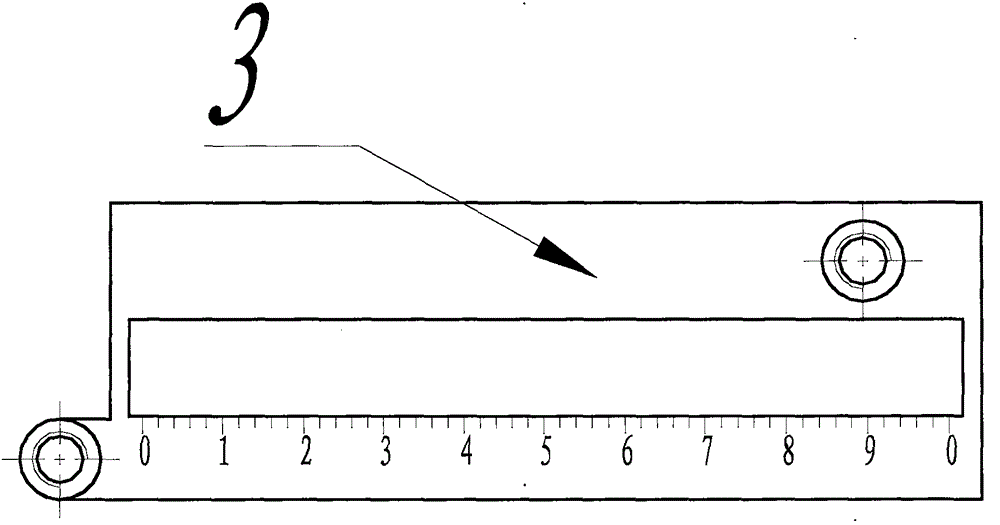

Round pipe end surface lineation machine

The invention discloses a round pipe end surface lineation machine. The round pipe end surface lineation machine consists of a turning plate, a main ruler, a secondary ruler, a lineation needle and a fastening screw; when a center line is drawn, the inner side of the turning plate is tangential to the side surface of a cylinder or a round pipe; the main ruler is tightly bonded on the end surface of the cylinder or the round pipe; and as the axis of the lineation needle mounted on the secondary ruler is intersected with the angle line of the turning plate, the secondary ruler can be pushed to draw the center line on the end surface of the cylinder or the round pipe. When a concentric circle is drawn, the inner side of the turning plate is tangential to the side surface of the cylinder or the round pipe; the main ruler is tightly bonded on the end surface of the cylinder or the round pipe; the diameter of an outer circle is measured by the main ruler and the secondary ruler; the secondary ruler is shifted according to the radius of the drawn circle to enable the lineation needle to locate in the position of the circle to be drawn; the fastening screw is tightened to relatively fix the secondary ruler with the main ruler; the lineation needle rotates to enable the needle tip to contact with the end surface of the cylinder or the round pipe; and the lineation machine and the cylinder or the round pipe relatively rotate to draw the requested circle on the end surface. The round pipe end surface lineation machine can used for conveniently, quickly and precisely drawing the center line and the concentric circle on the end surface of the cylinder or the round pipe.

Owner:CHINA MCC 2 GRP CO LTD

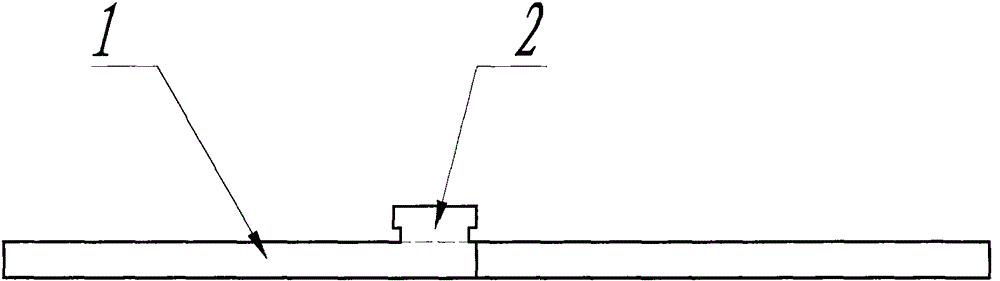

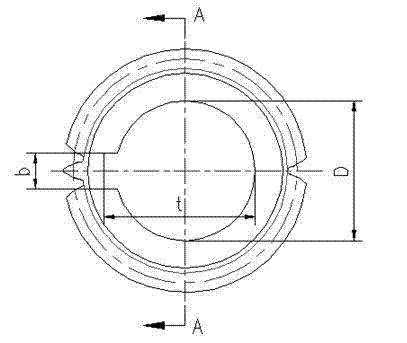

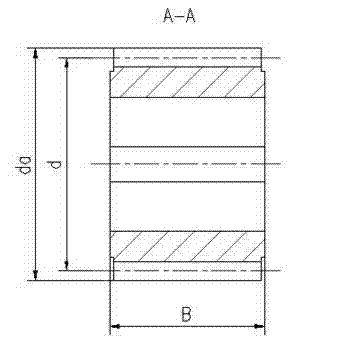

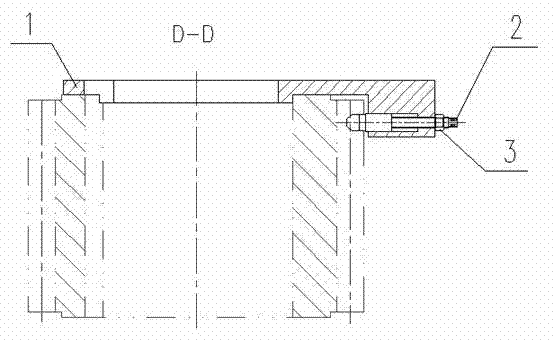

Key groove lineation method for making aligned tooth sample plate and used for helical gear with odd teeth

The invention discloses a key groove lineation method for making an aligned tooth sample plate and used for a helical gear with odd teeth. The aligned tooth sample plate consists of a sample plate body (1), a bulb moving rod (2) and a nut (3). The method comprises the following steps of: screwing a screw of the bulb moving rod into an internal thread hole of a stepped through hole of the sample plate body till the bulb of a sphere exceeds the end face A of a lug boss at the lower end of the right side of the sample plate body; arranging the sample plate body provided with the bulb moving rod into an inner hole of the helical gear with odd teeth; negatively screwing the bulb moving rod, gradually screwing the bulb moving rod into a tooth groove between two adjacent oblique teeth of the helical gear with odd teeth till complete contact with the tooth groove, and then tightening the bulb moving rod at the screw of the bulb moving rod through the nut; marking a key groove width b and a key groove depth t of the helical gear with odd teeth through a key groove formed at the left end face of the inside diameter of the sample plate body and by means of a lineation pen, wherein the key groove width b can correspond to the tooth outline of the end face of a random odd tooth; and then machining the helical gear with odd teeth according to the key groove width b and the key groove depth t.

Owner:CITIC HEAVY INDUSTRIES CO LTD

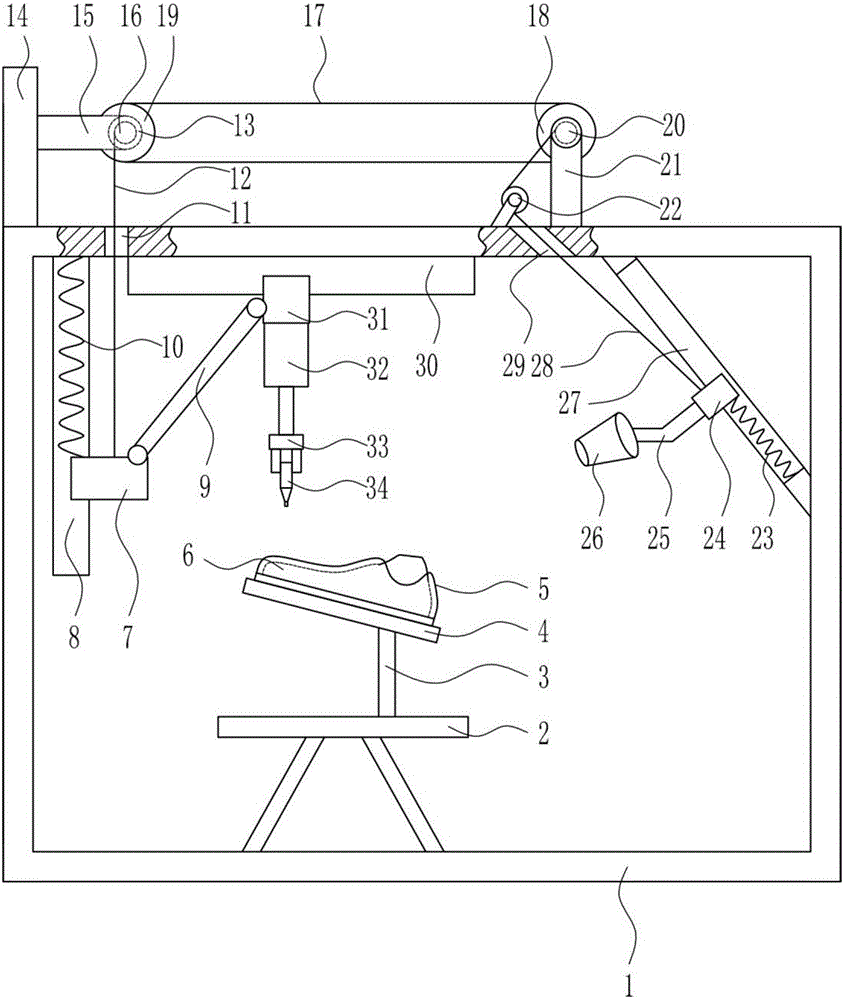

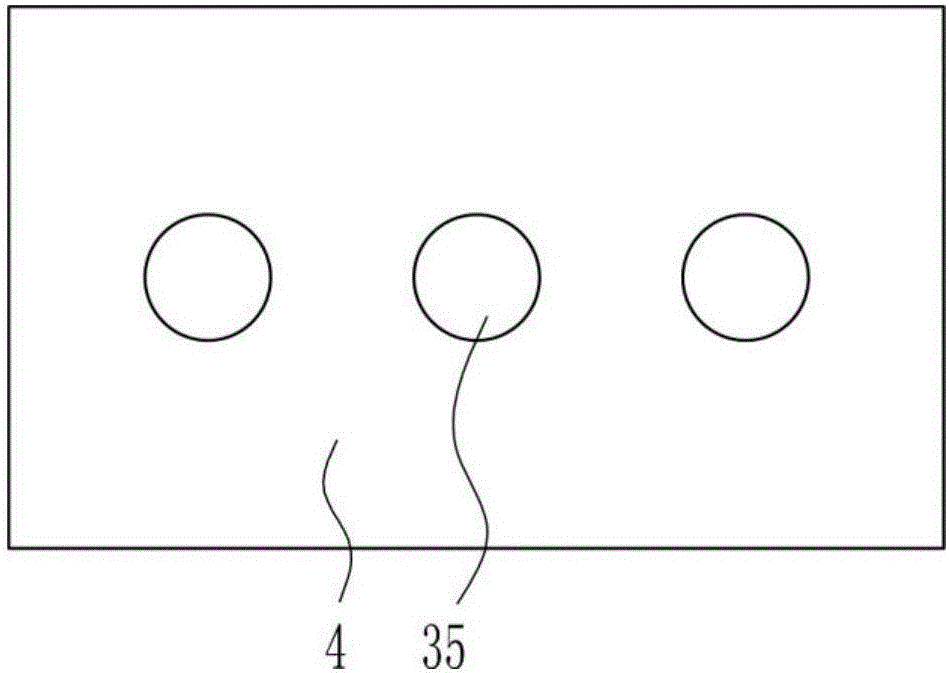

Precision vamp marking device

InactiveCN106263285AAccurately draw the linePlay the role of fixing shoesShoemaking devicesEngineeringMechanical engineering

Owner:刘德平

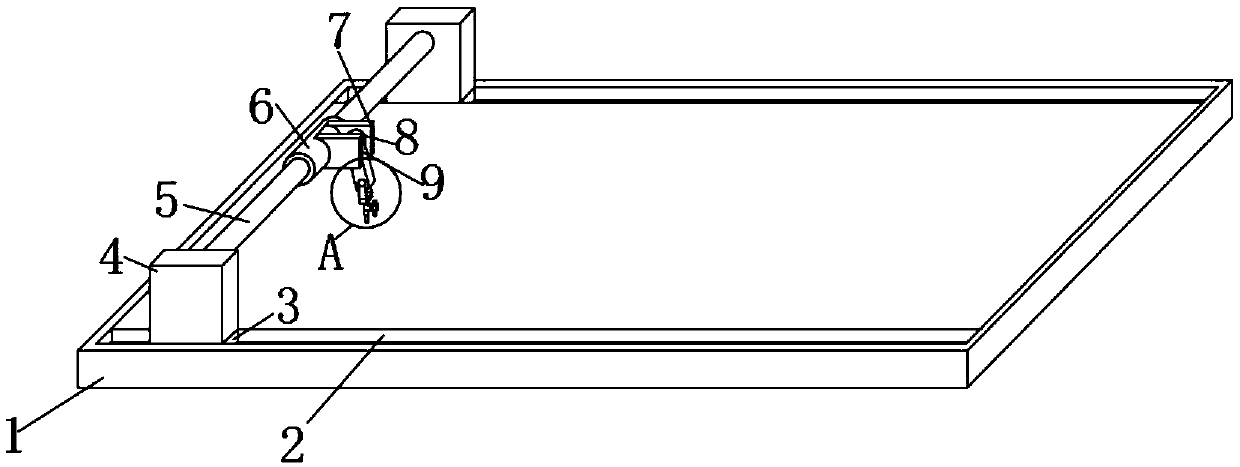

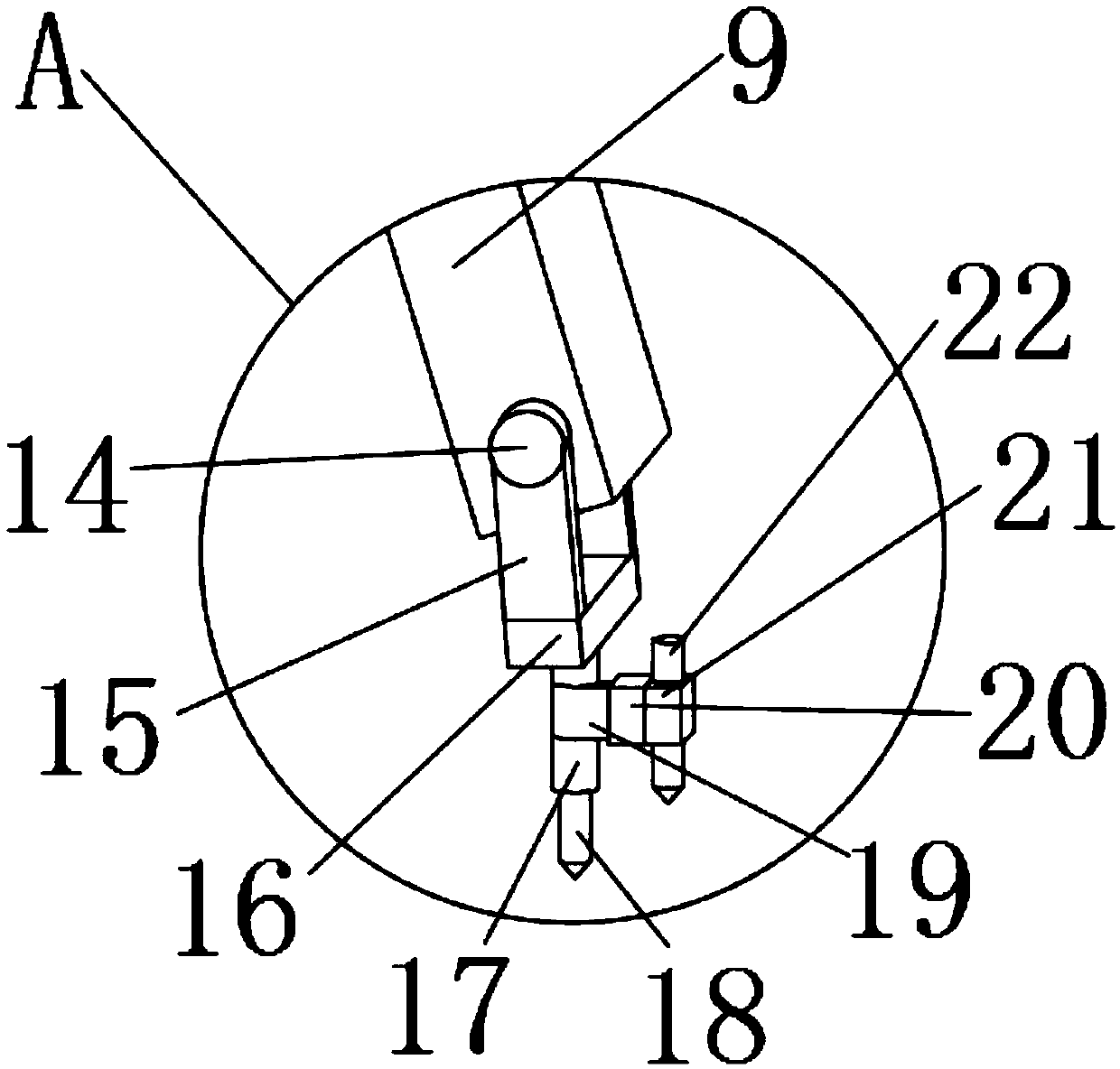

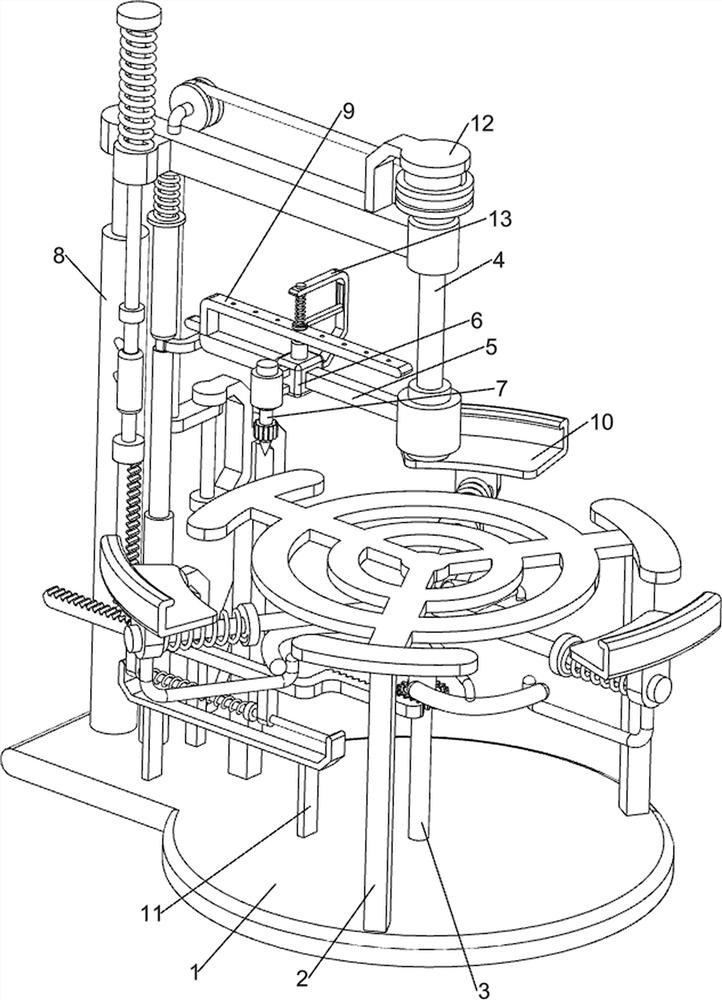

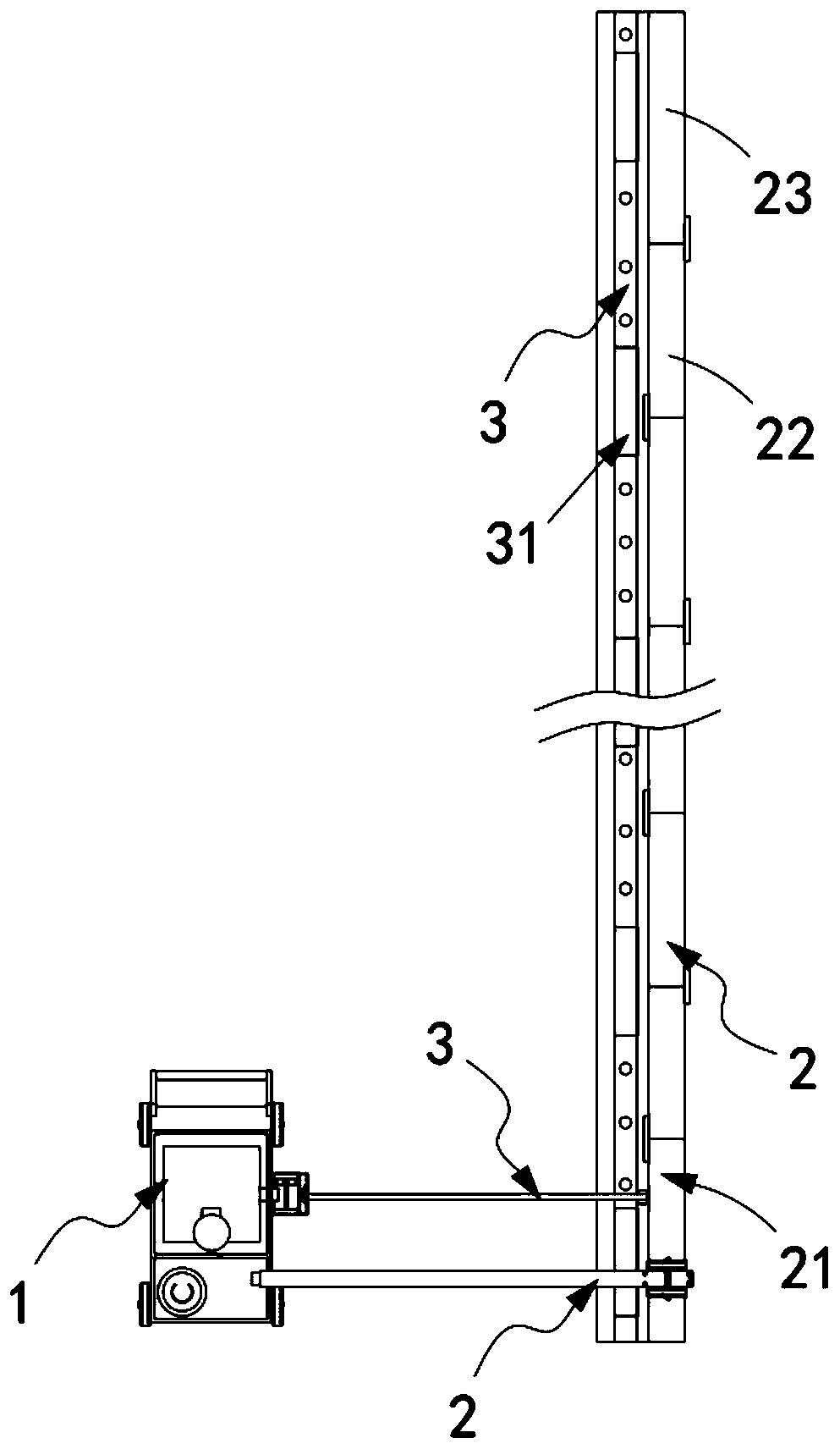

Intelligent tooling fixture for scribing carbon contact strip and operation method of tooling fixture

ActiveCN111055258AImprove free switchingImprove marking efficiencyWork holdersOther workshop equipmentEngineeringSlide plate

The invention discloses an intelligent tooling fixture for scribing a carbon contact strip. The fixture comprises a bottom plate, a vertical plate is arranged on the top surface of a slide plate located on one side, a first mechanism is vertically arranged on the front of the vertical plate, a vertical slide rod facing upwards is arranged on the top surface of a slide plate located on the other side, a rectangular block-shaped slide cylinder sleeves the top of the slide rod, one end surface of a first slide plate in the first mechanism is fixedly connected to one end surface of the slide cylinder through two ends of a horizontal plate, a second mechanism is horizontally arranged on the front of the horizontal plate, and the bottom surface of a second slide plate in the second mechanism isprovided with a scribing component; third mechanisms are arranged on the top surface of the bottom plate and located on the outer sides of the slide rails, and a screw cylinder in each third mechanismis fixedly connected to the outer end surface of one corresponding slide plate. The invention also discloses an operation method of the intelligent tooling fixture for scribing the carbon contact strip. The tooling fixture provided by the invention is simple in structure and convenient to operate, under the assistance of the tooling fixture, the carbon contact strip can be accurately and quicklyscribed, the scribing efficiency and precision can be improved, and the processing costs can be reduced.

Owner:DATONG XINCHENG NEW MATERIAL CO LTD

Device for marking color scale line of tire

ActiveCN102233574AFlexible and convenient marking operationImprove work efficiencyOther workshop equipmentColor ScaleEngineering

The invention discloses a device for marking a color scale line of a tire. The device comprises a clamp plate, a line marking needle, a color paste barrel, vertical columns, bearings and the like. The clamp plate is U-shaped; the vertical columns are arranged on two vertical walls of the clamp plate; the vertical columns are provided with the bearings; the side of the bottom wall of the clamp plate is provided with the color paste barrel; the front end of the color paste barrel is provided with the hollow line marking needle and is communicated with the inner cavity of the color paste barrel;and the end of the color paste barrel is provided with a switch. The color scale line is marked by the device instead of a manual method; the marked line has uniform thickness, and is straight and smooth; and the working efficiency is greatly improved and the manpower and material resources are saved. Moreover, the color scale line marked by the device is very attractive and improves the grade ofa product.

Owner:双钱集团(重庆)轮胎有限公司

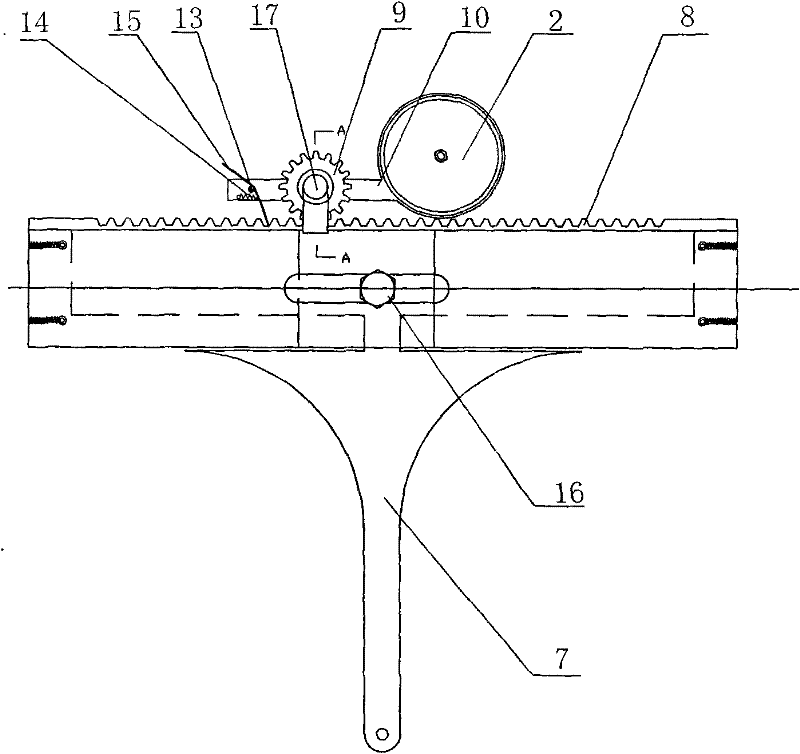

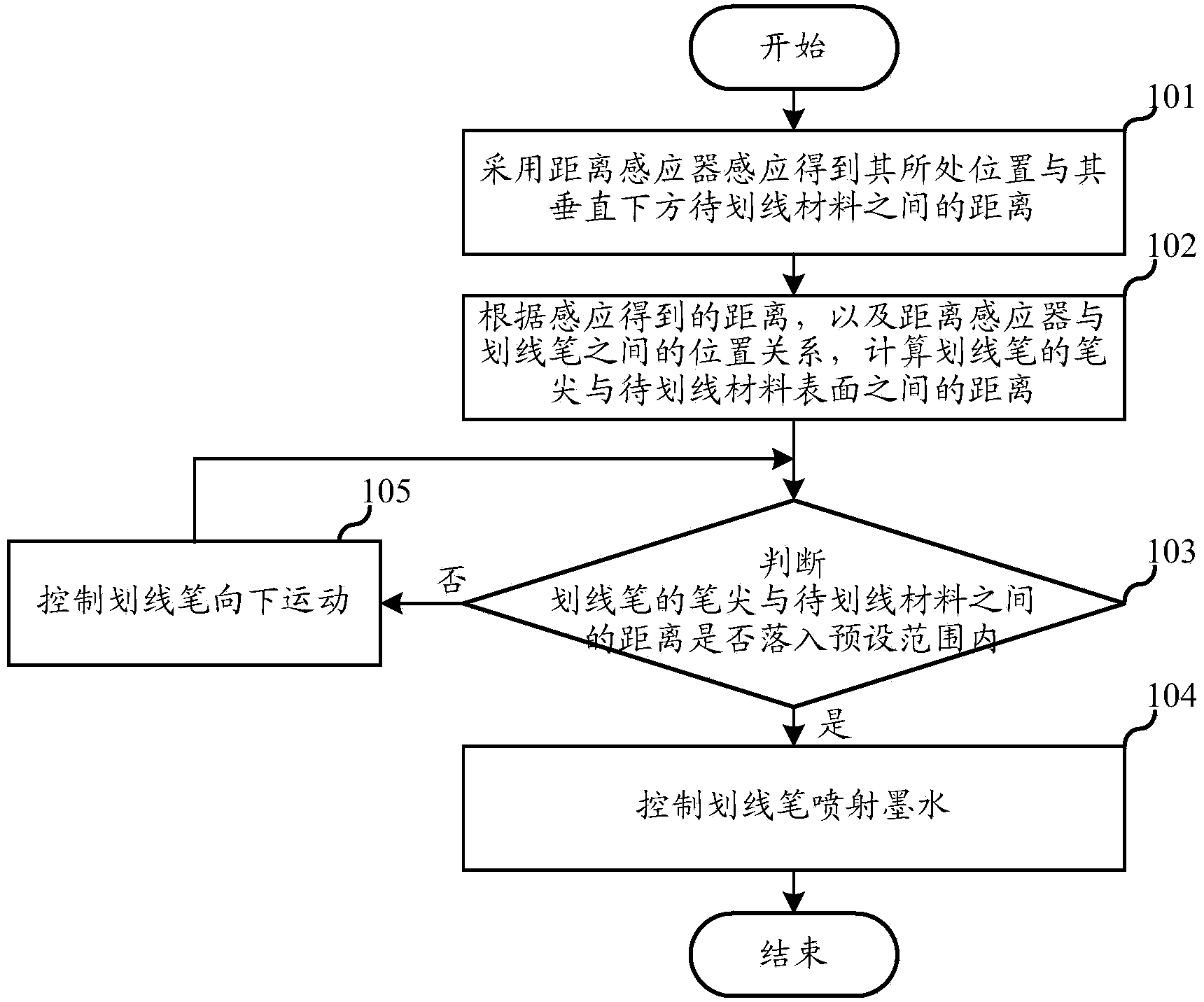

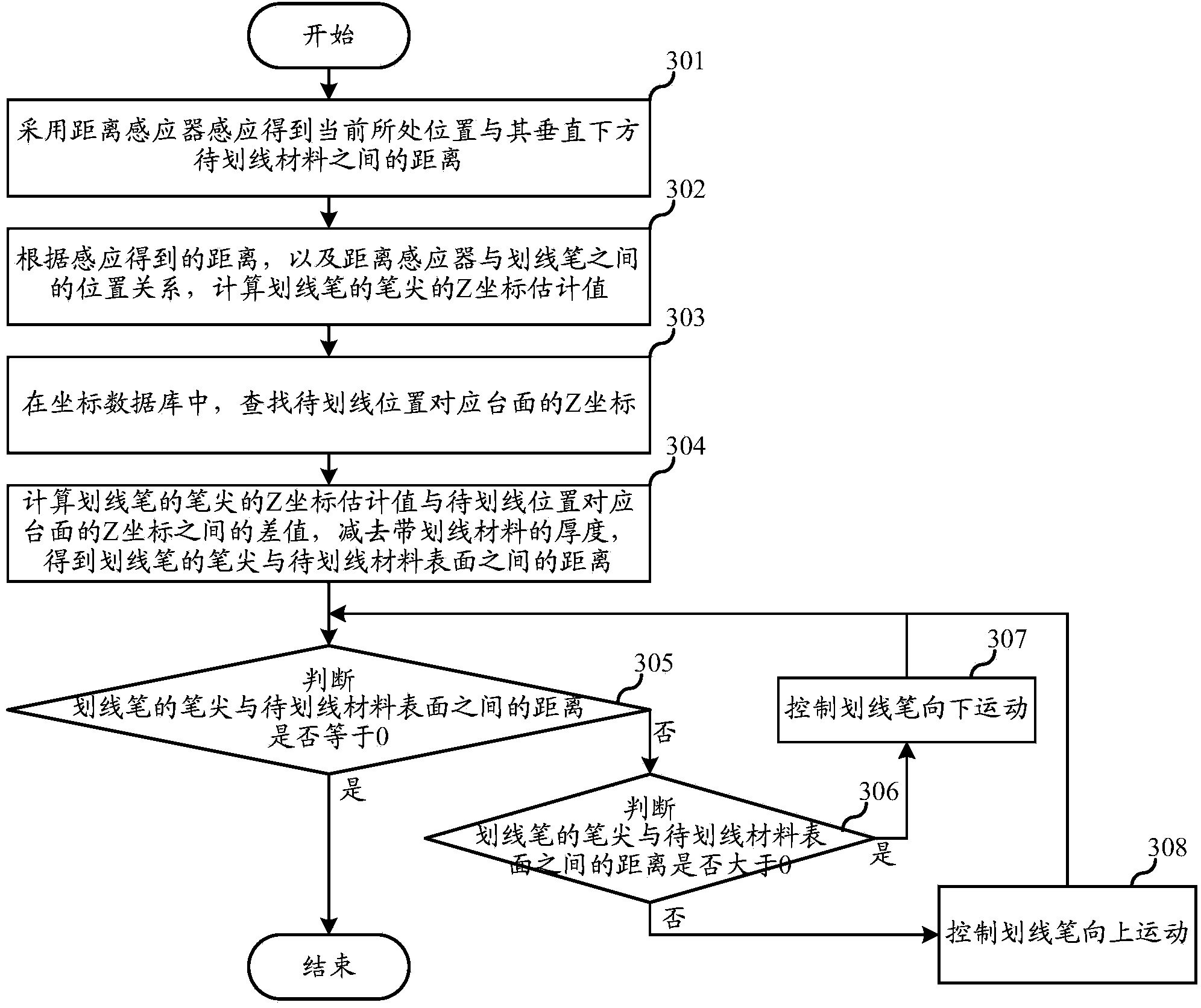

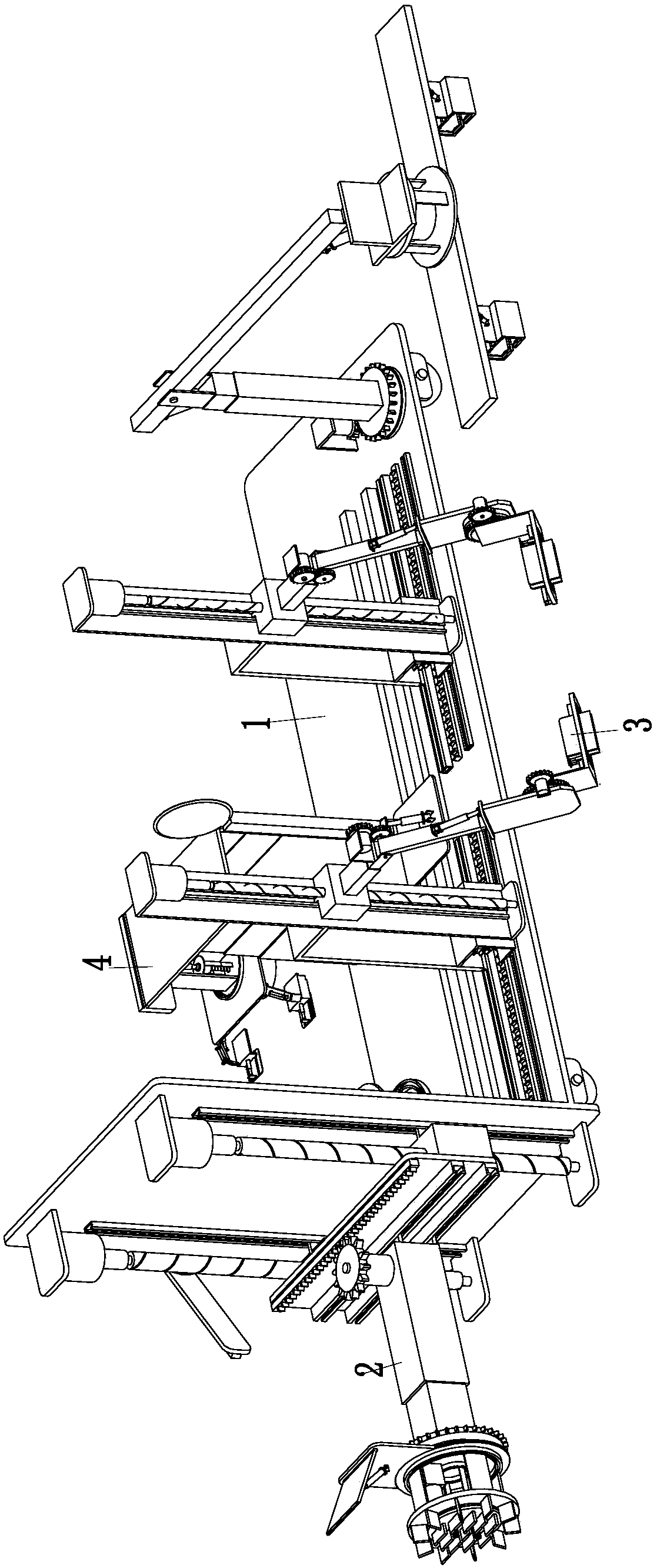

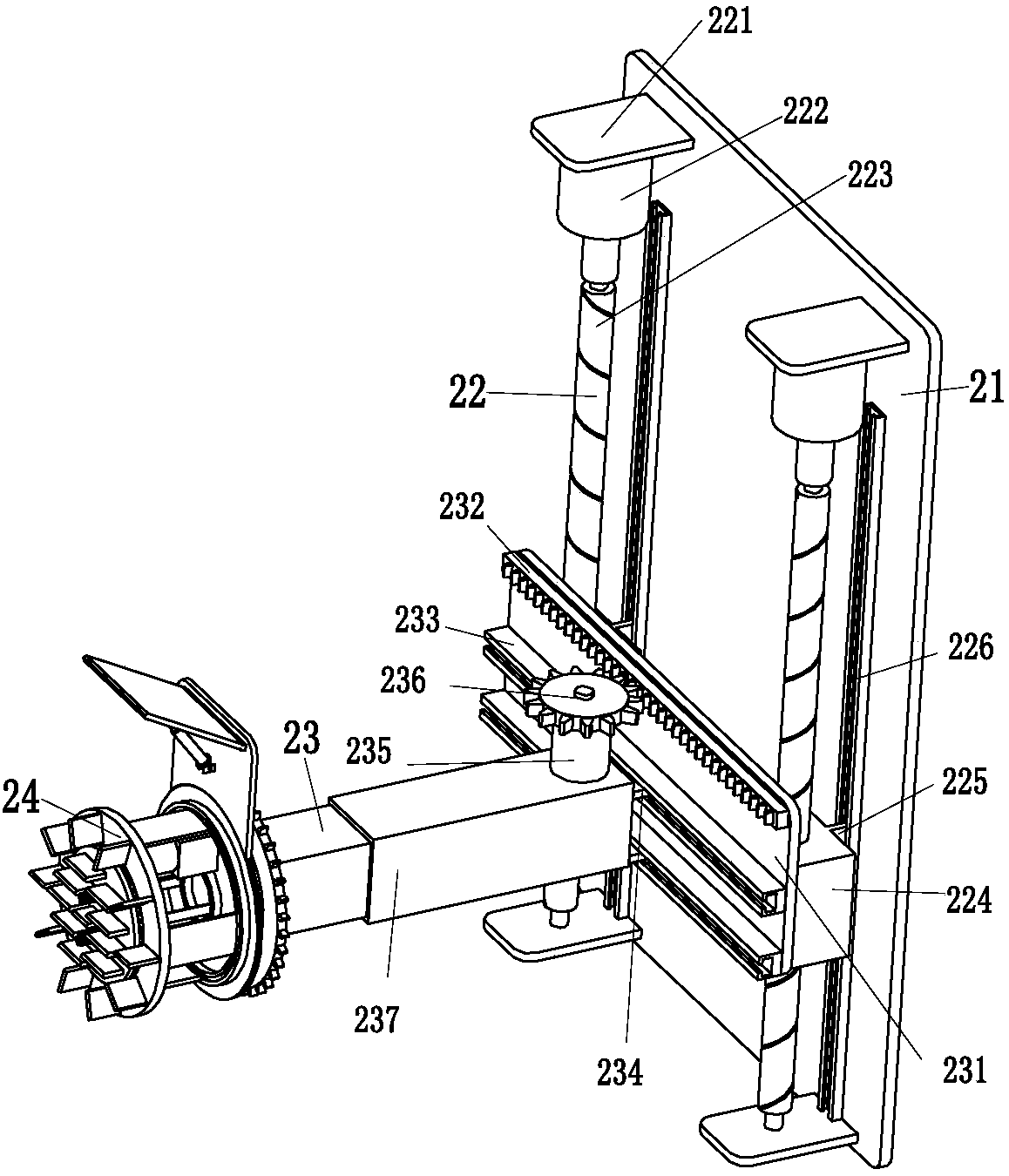

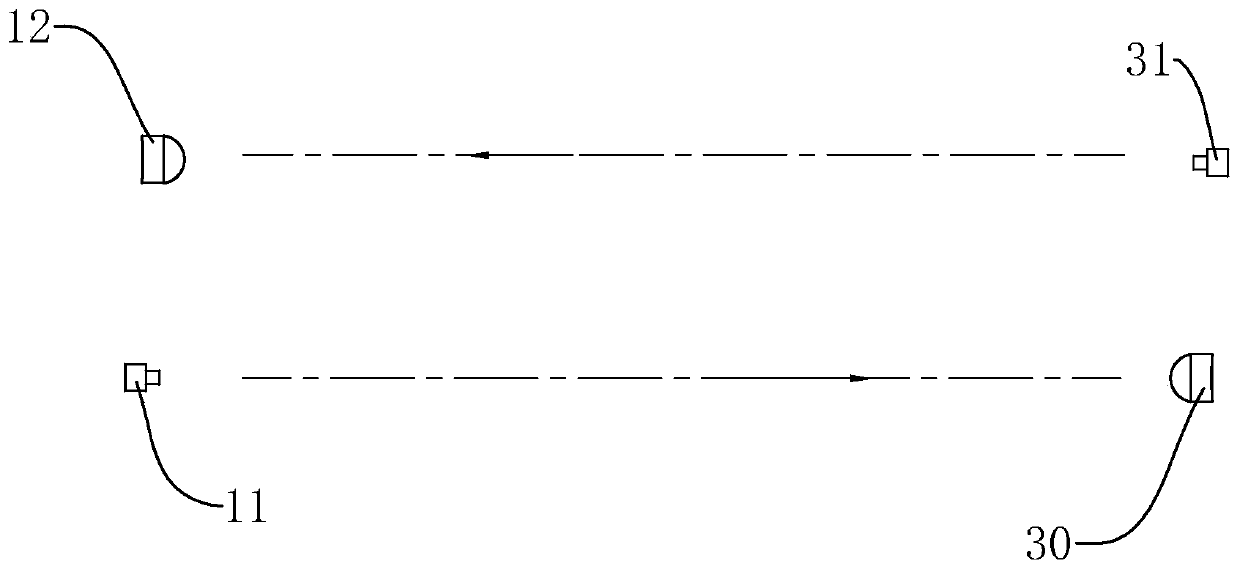

Automatic cutting machine and scribing method thereof

ActiveCN104358095AAccurate and fast markingAvoid damageLeather clicking/perforating/clickingSevering textilesEngineering

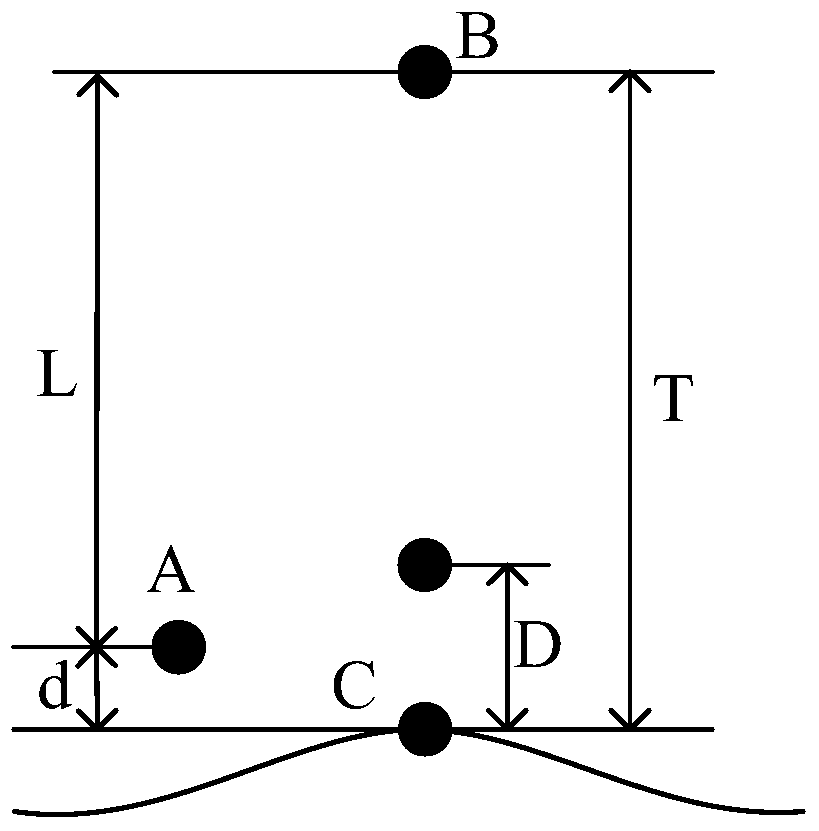

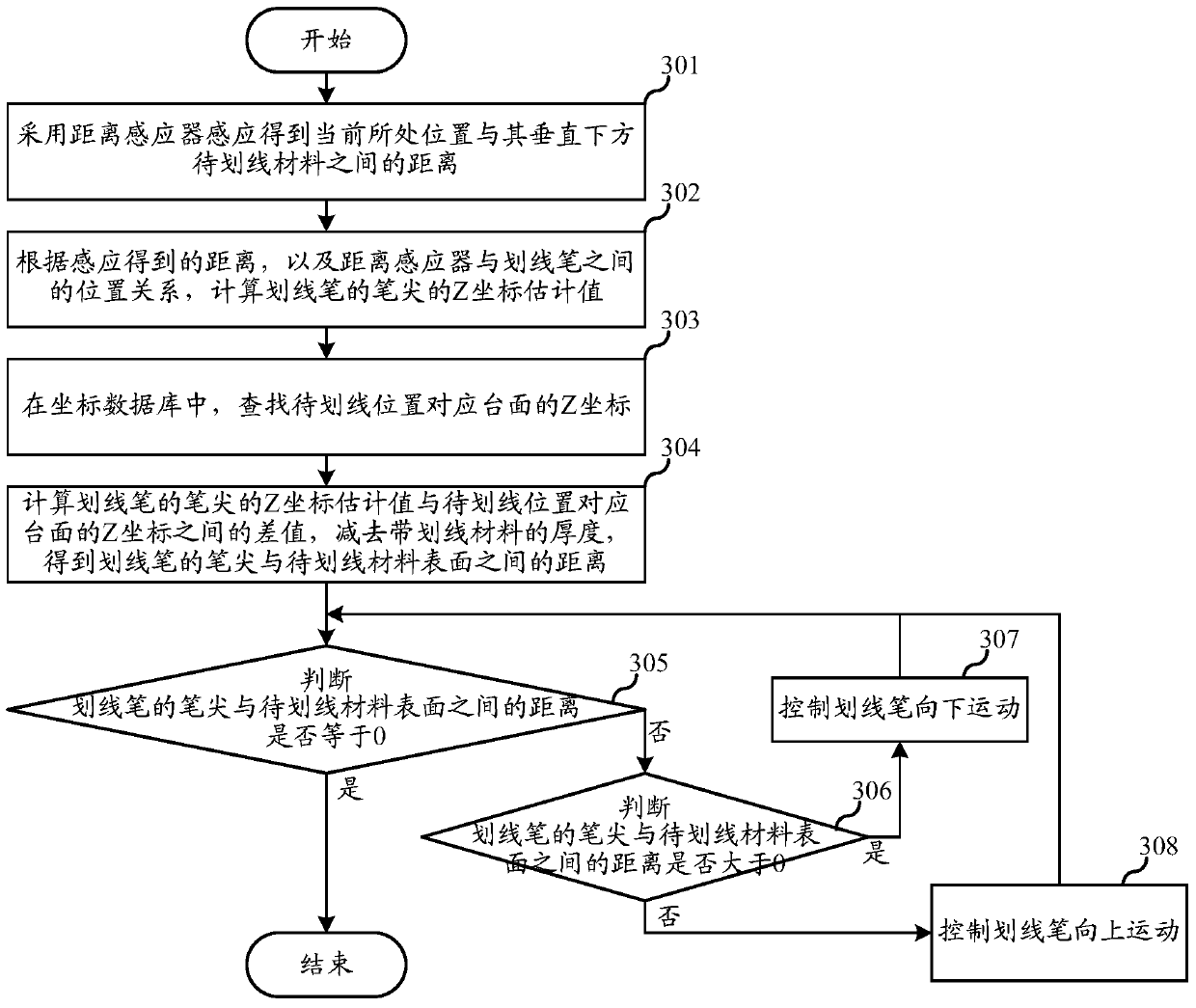

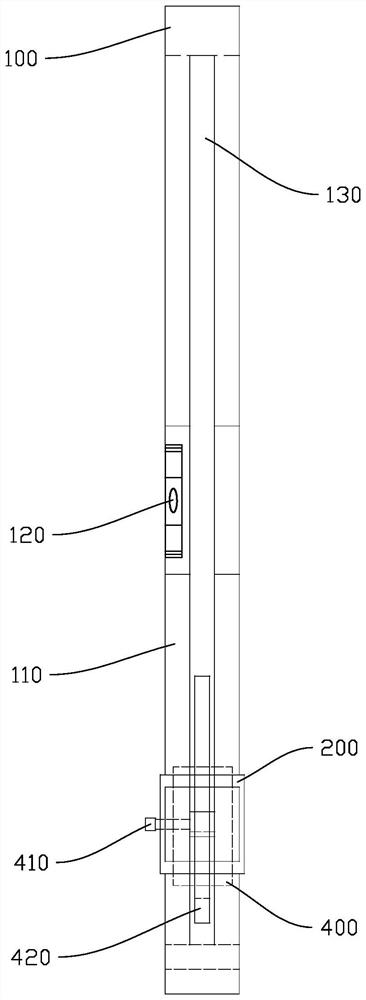

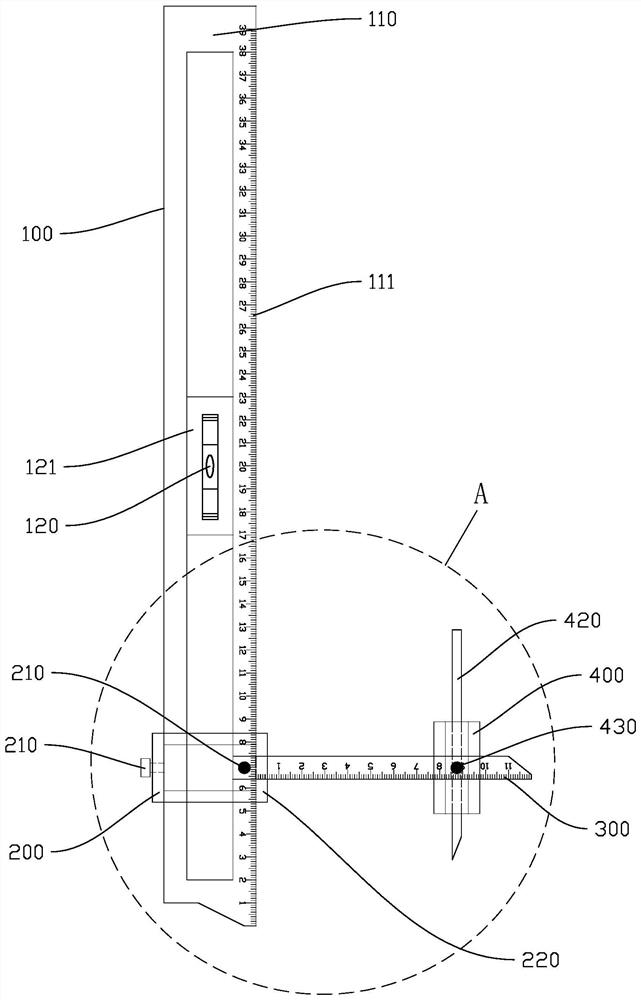

The invention relates to the technical field of automatic cutting, and discloses an automatic cutting machine and a scribing method thereof. The automatic cutting machine acquires the distance between the pen point of a scribing pen and the surface of a to-be-scribed material; if the distance between the pen point of the scribing pen and the surface of the to-be-scribed material is not in a preset range, up and down position of the scribing pen is adjusted until the distance between the pen point of the scribing pen and the surface of the to-be-scribed material is in the preset range. By controlling the distance between the pen point of the scribing pen and the surface of the to-be-scribed material, excessive contact or separation between the pen point and the to-be-scribed material can be avoided, so that scribing is enabled to be accurate and quick.

Owner:长园和鹰科技(河南)有限公司

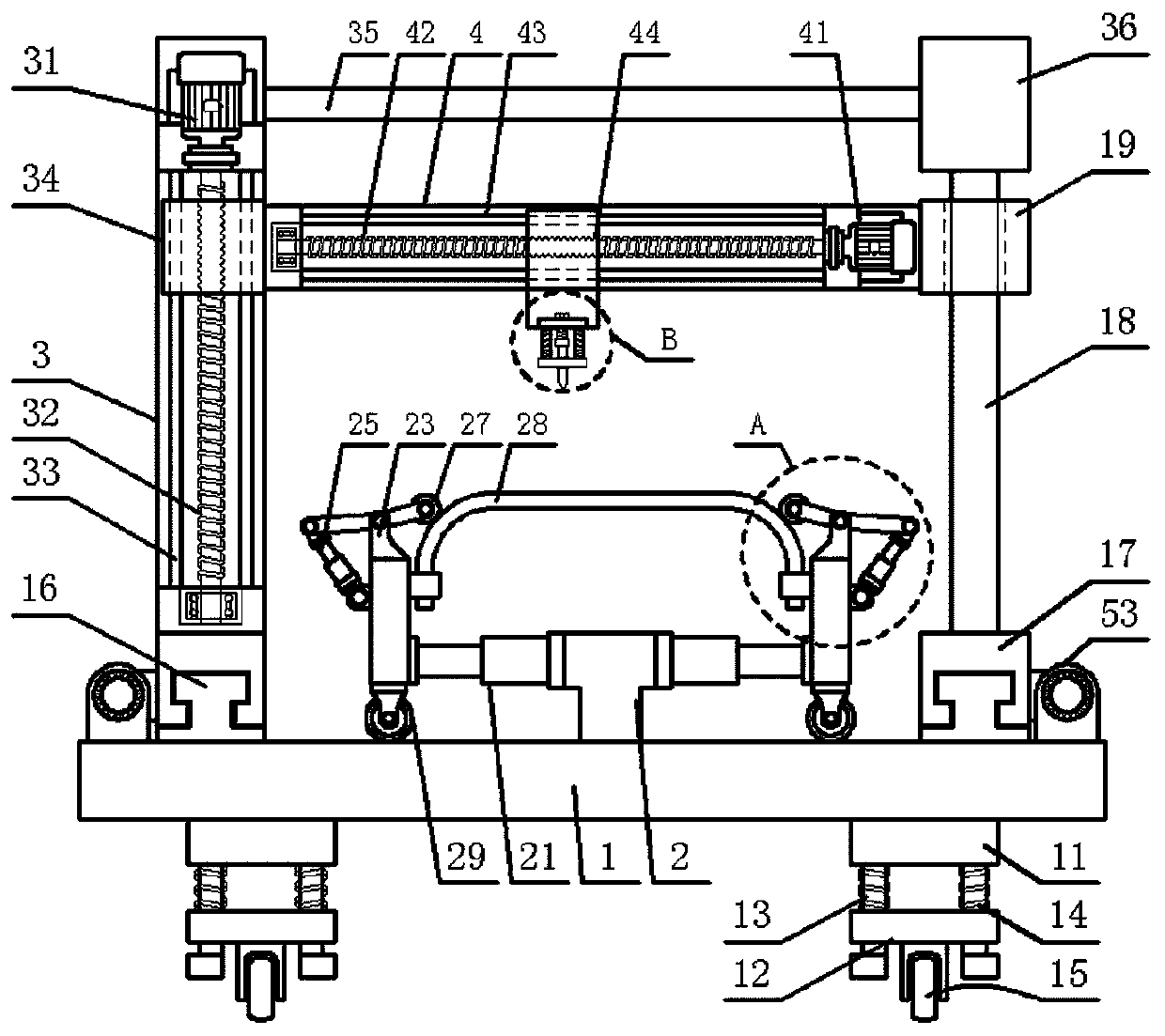

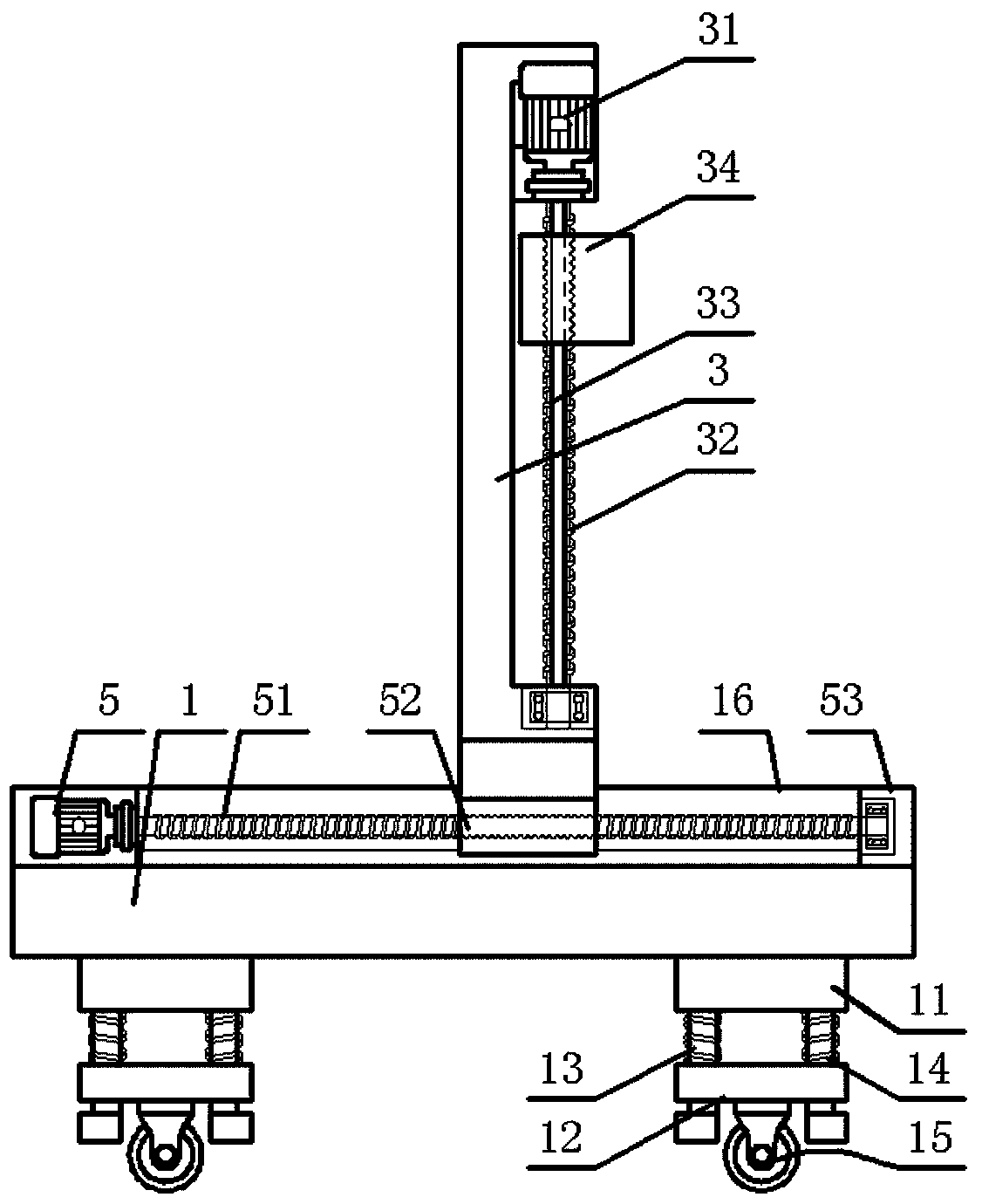

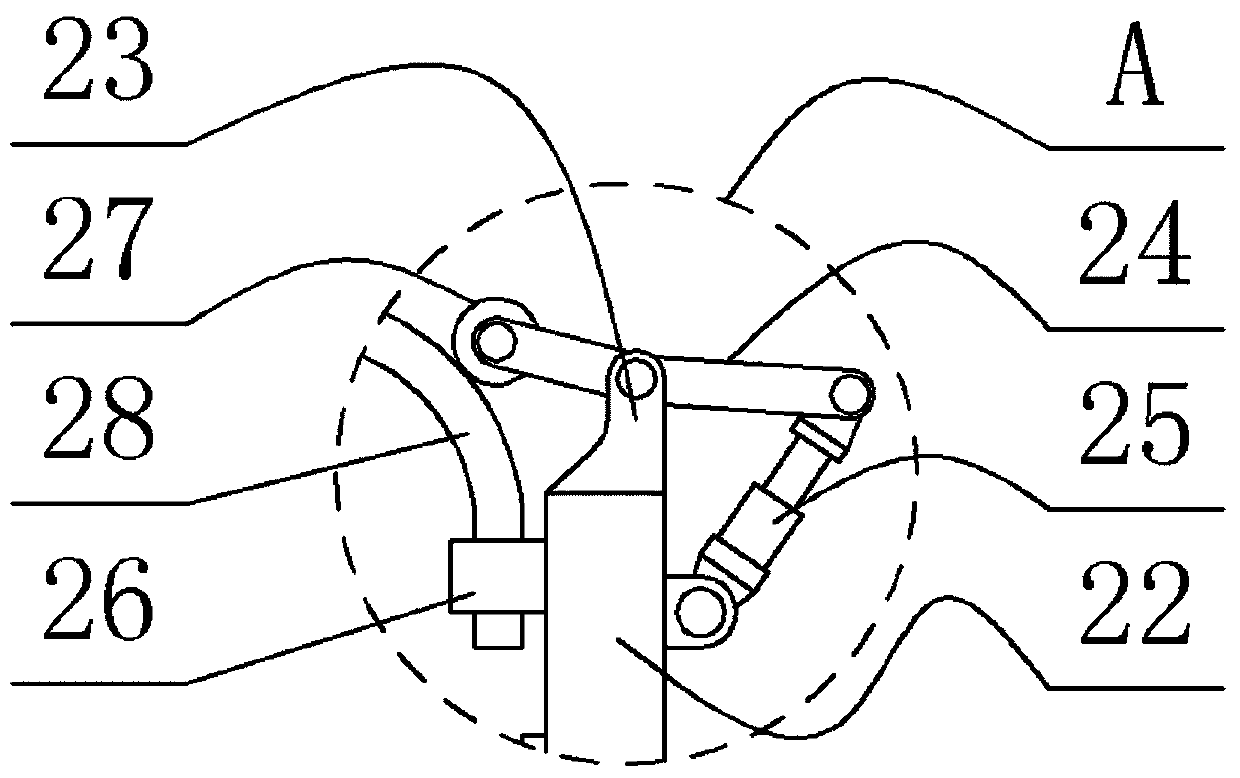

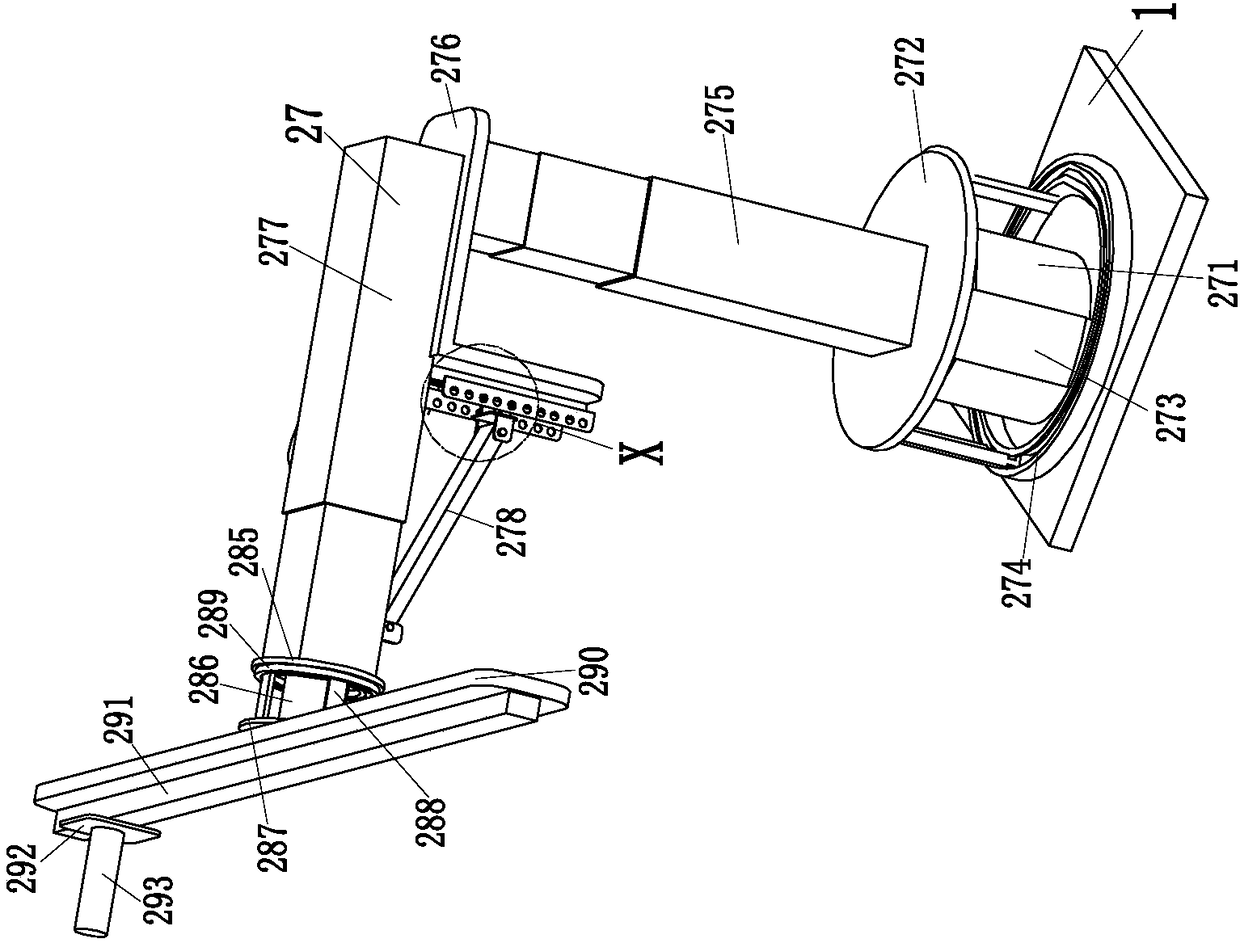

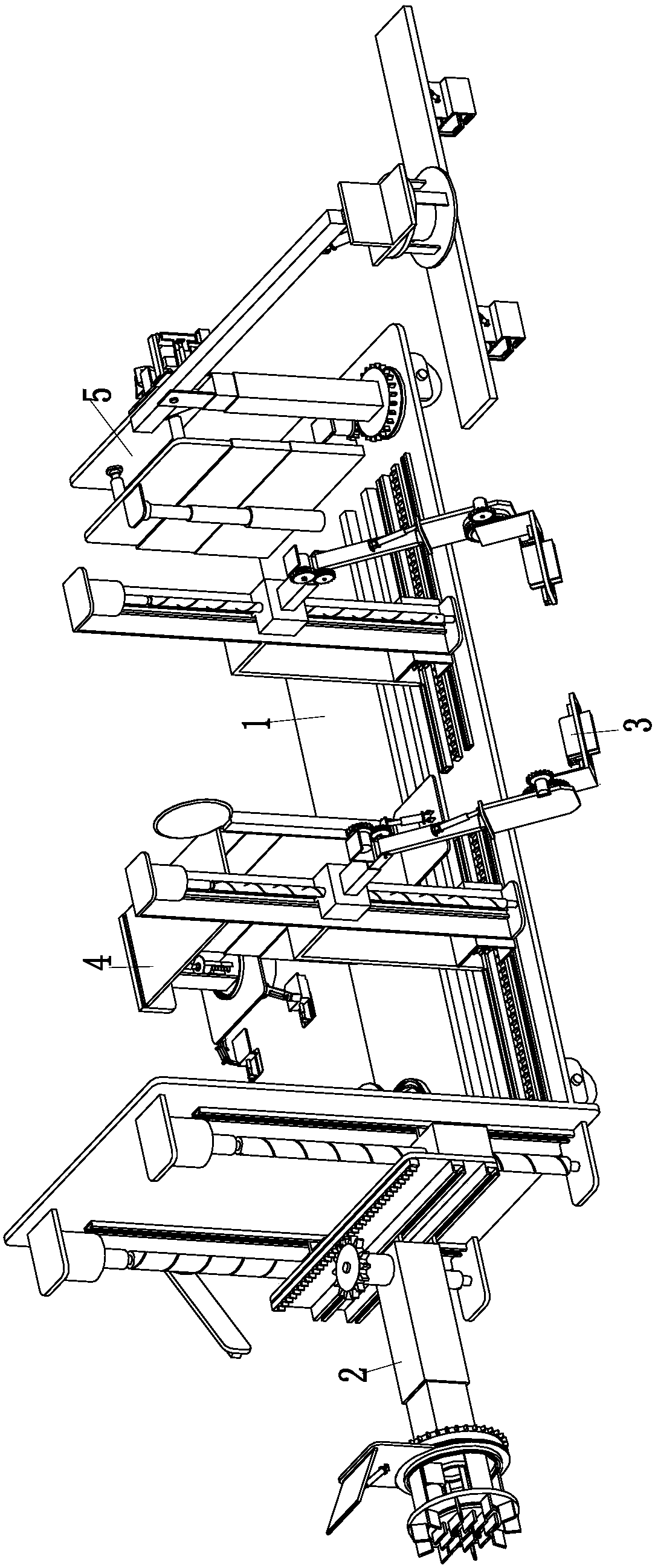

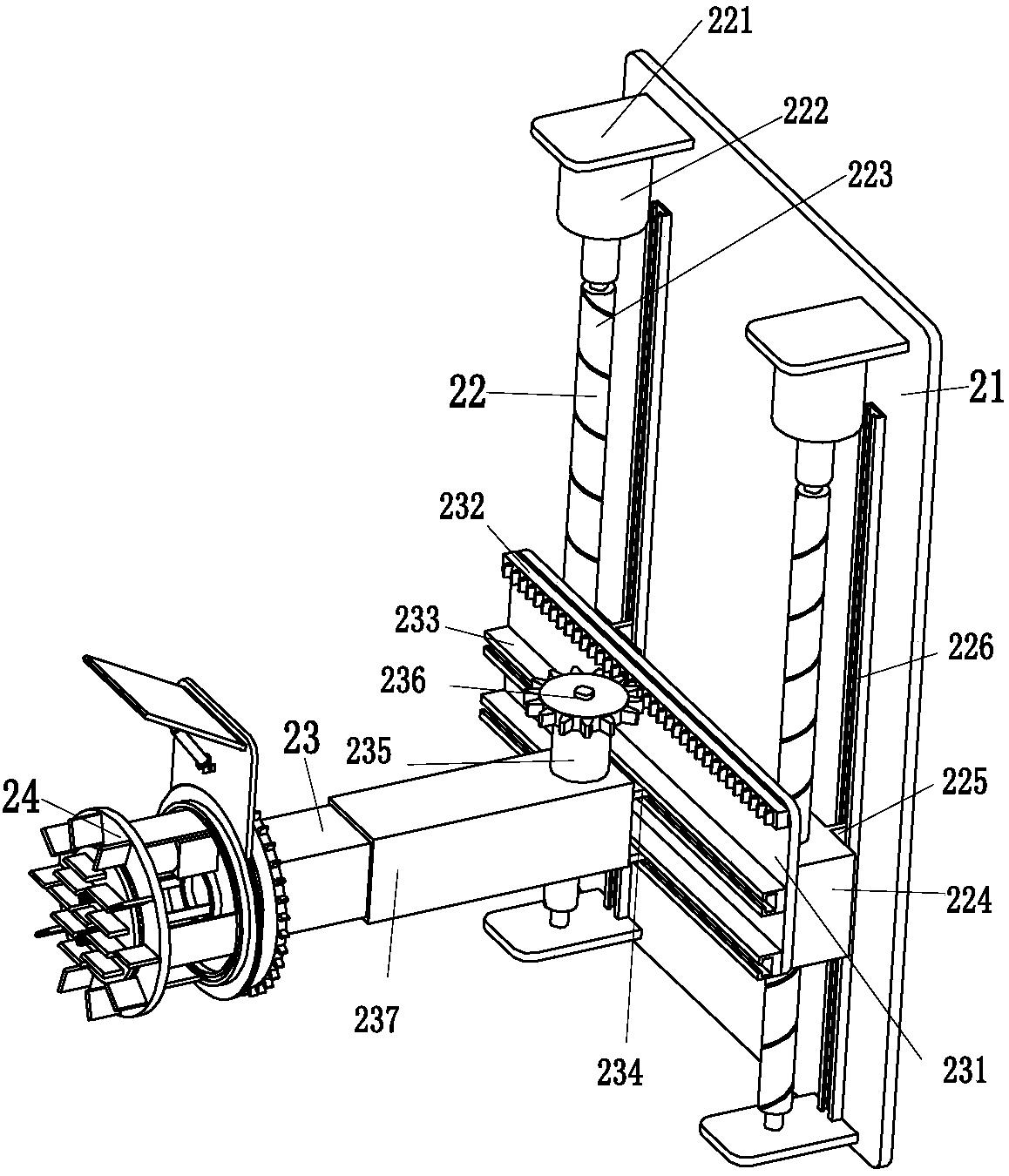

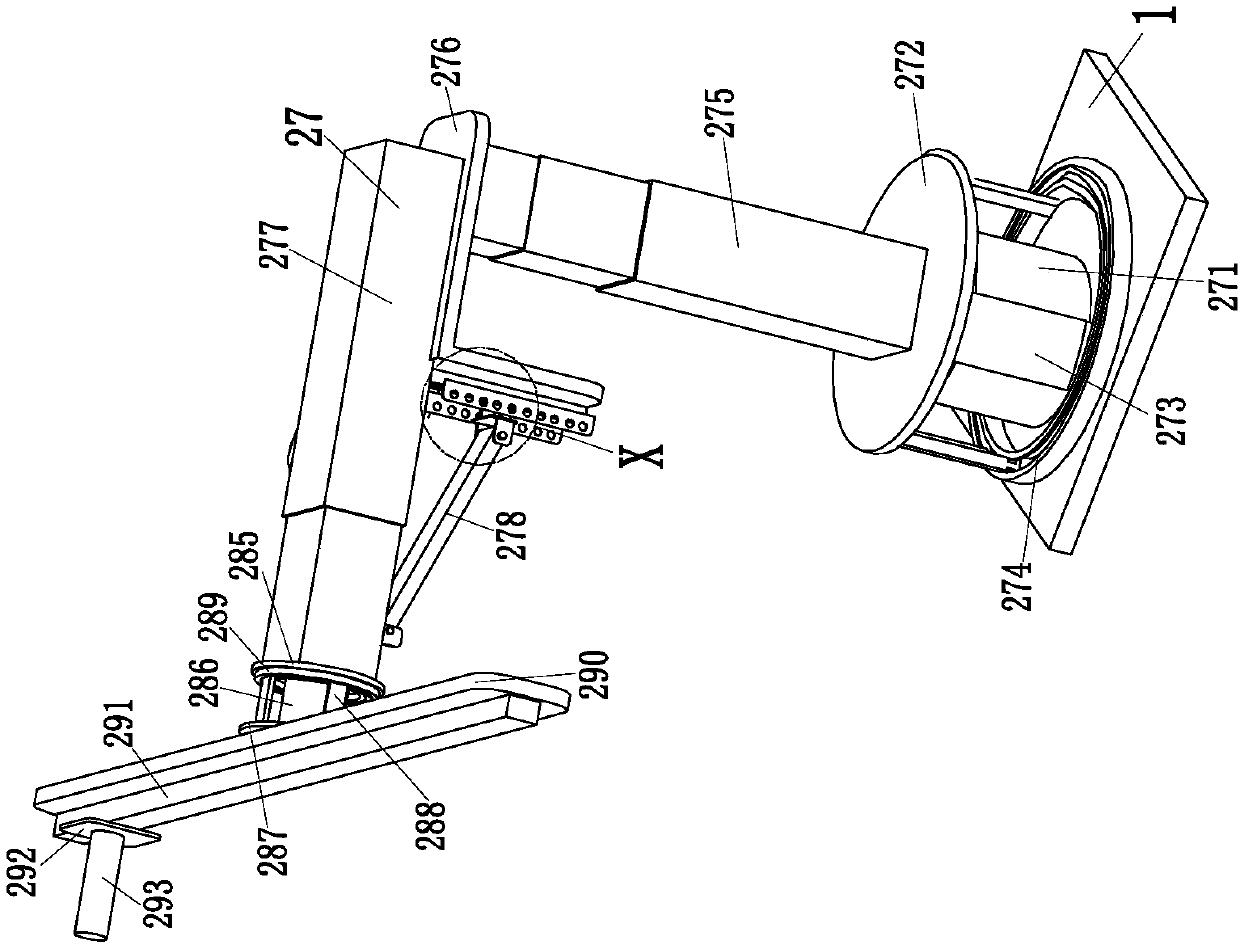

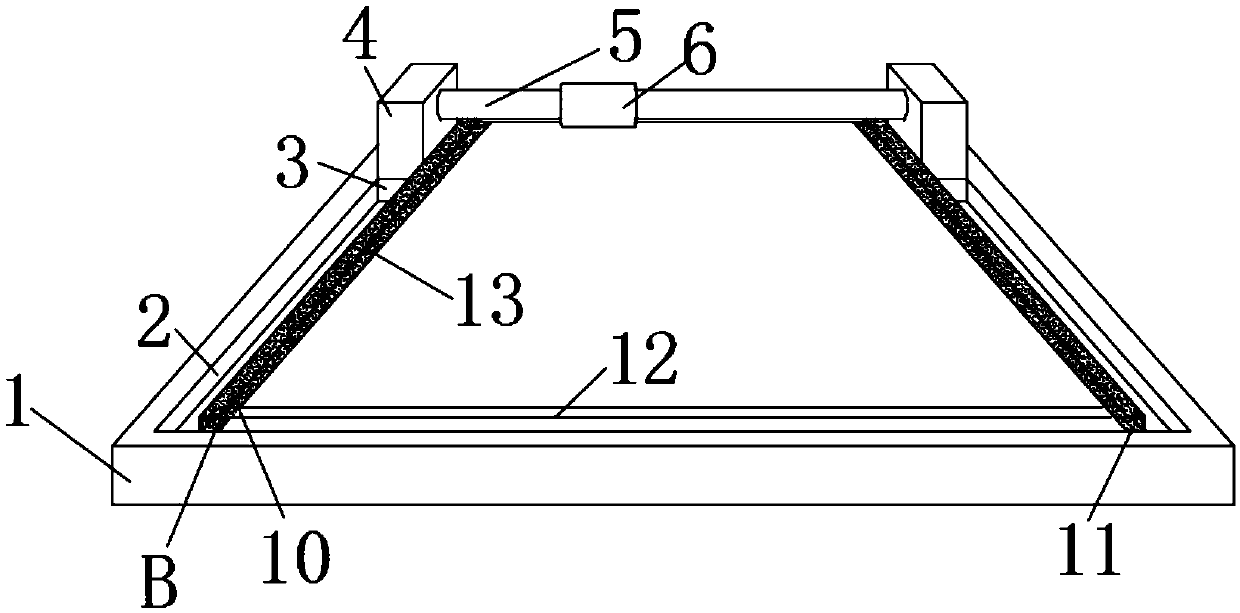

Intelligent construction and installation integrated machine for thermal insulation fiber cement external wall hanging plate

The invention relates to an intelligent construction and installation integrated machine for a thermal insulation fiber cement external wall hanging plate. The machine comprises a movable platform, agrinding and scribing device, a keel installation device and a panel installation device, wherein the movable platform is provided with the grinding and scribing device, the keel installation device is installed on the movable platform, and the panel installation device is installed at the left end of the movable platform. The machine can be used for solving the problems that in an existing cementexternal wall hanging plate installation process, manual grinding and scribing are needed; people need to use a ladder for grinding and scribing when keels and panels are installed and grinding and scribing are conducted on an external wall, and people need to manually move the ladder again to climb for work when a next position needs to be ground; many people cooperate with one another to install the keels; positions are not precise when the keels are manually installed; when the panels are installed, many people need to cooperate with one another; people are likely to tumble and safety hidden hazards are caused when many people work on the same ladder. The function of mechanically installing the cement external wall hanging plate can be achieved.

Owner:倪立秧

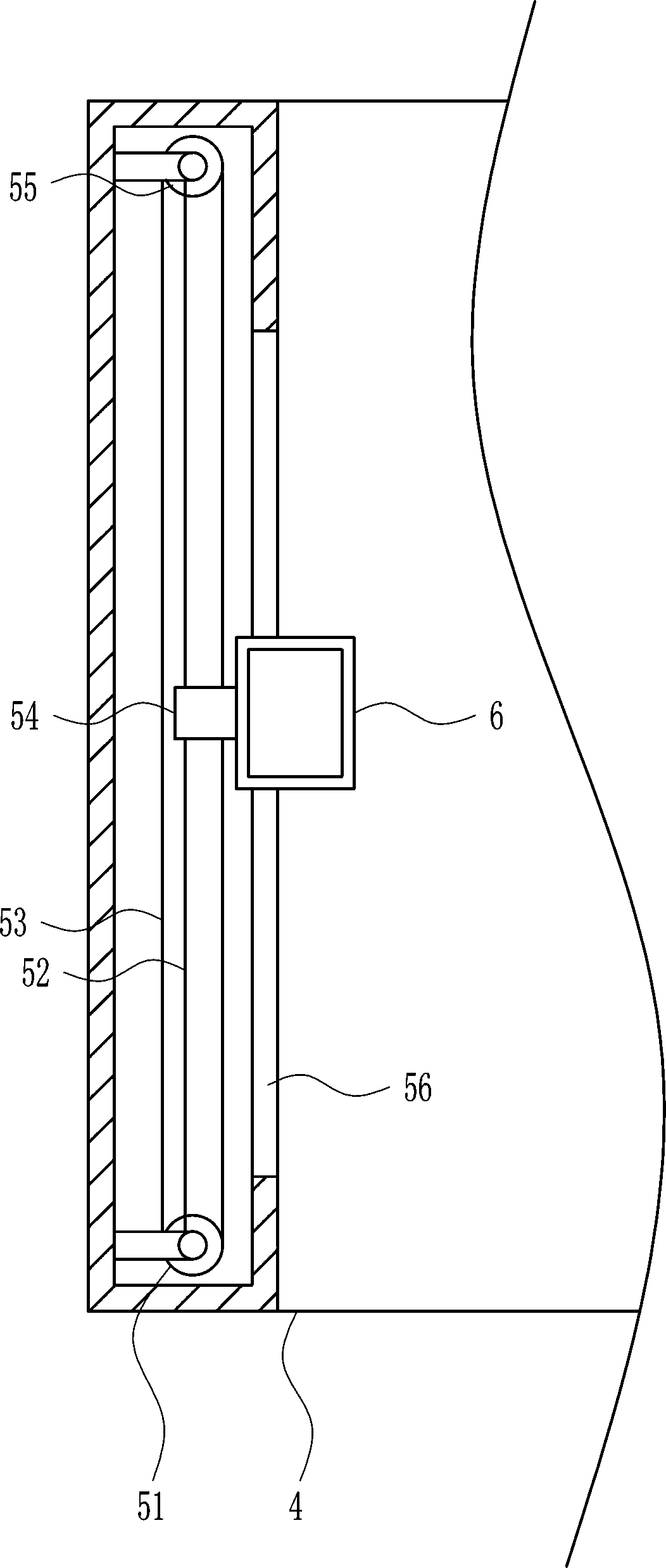

Automatic mounting equipment for fiber cement outer wall hanging board for building wall body

The invention relates to automatic mounting equipment for a fiber cement outer wall hanging board for a building wall body. The automatic mounting equipment comprises a mobile platform, a smoothing and scribing device, a keel mounting device, a face plate mounting device and a jointing device. The smoothing and scribing device is mounted at the front end of the mobile platform, and the keel mounting device is mounted on the mobile platform; and the face plate mounting device is mounted on the mobile platform, and the jointing device is mounted at the rear end of the mobile platform. Accordingto the automatic mounting equipment, the difficult problems that in the existing hanging board mounting process, smoothing and scribing, keel mounting and face plate mounting and jointing need to be manually conducted; during smoothing and scribing, smoothing and scribing treatment needs to be conducted by personnel with the help of a ladder; during keel mounting, multi-person division cooperationis needed, and the position is inaccurate during keel manual mounting; during face plate mounting, multiple persons operate on the same ladder, tumbling is prone to occurring, and thus the potentialsafety hazard is caused; and during jointing, the personnel are needed to conduct joint repairing, roll leveling and joint scraping can be solved. The function of automatic mounting of the fiber cement outer wall hanging board can be achieved.

Owner:倪敏芳

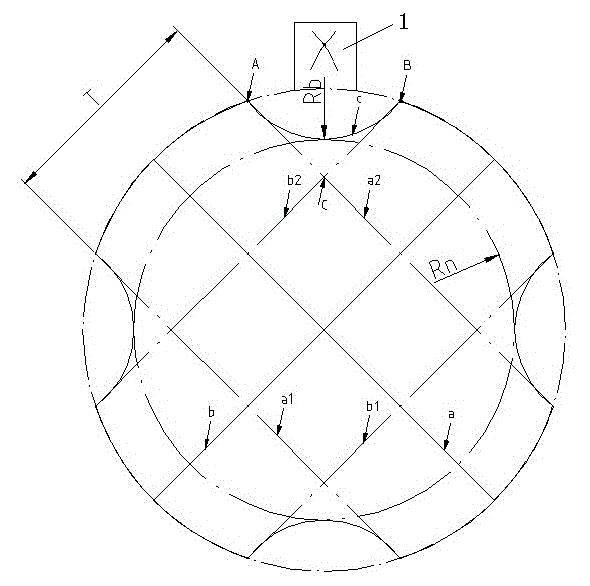

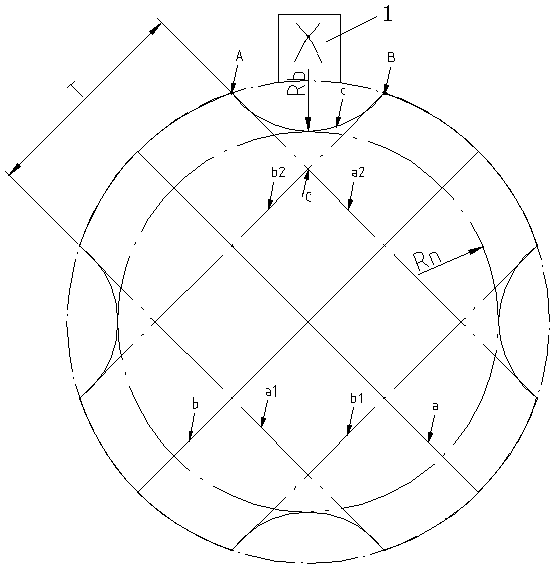

Wobbler crisscross line scribing method

The invention discloses a wobbler crisscross line scribing method. Not only can an Rb processing line be accurately and quickly determined through a linear position limiting method, but also the processing scribing quality and the position degree are improved. According to a relation formula that T is equal to 0.7071Rn-0.5858Rb, the numerical value of T is calculated to scribe an excircle center line. Then, two straight lines are planned by scribing and extend to an excircle of a roller shaft head. Another center line and two corresponding straight lines are scribed on the roller shaft head and extend to the excircle of the roller shaft head. The position of an Rb center point is scribed through two vertical lines of a crisscross line, and then the Rb processing line is scribed. The wobbler crisscross line scribing method has the beneficial effects that the position of a circular arc is firstly positioned by the straight lines through the crisscross line to be conveniently, easily and accurately scribed; the processing correctness and the processing accuracy of the width of a processed residual roller can be directly measured and detected with a caliper, so that the qualified rate of the position degree of a wobbler of the processed roller is high; and moreover, the sample cost is eliminated, and the production cost is reduced.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

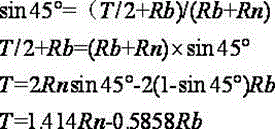

Accurate marking device used for trouser tailoring

The invention relates to a trouser marking device, in particular to an accurate marking device used for trouser tailoring. The invention aims at providing the accurate marking device used for trouser tailoring, which realizes the accurate marking effect. To solve the technical problems, the following technical scheme is adopted: the accurate marking device used for trouser tailoring comprises a box, a second bracing wire, a movable block, a rack, a sliding rail, a reel, a gear, a sliding block, a second electric push rod, a marking pen, a rotation motor, a right bearing block and the like, wherein a second crown block is arranged in the upper left direction in the box, a first crown block, a left bearing block, the right bearing block and the rotation motor are arranged on the top in the box in the sequence from left to right, a lead screw is arranged between the left bearing block and the right bearing block, and the right end of the lead screw is connected with the rotation motor. The accurate marking device has the effects that the marking is accurate, time and labor are saved, resources are saved, and the operation is simple and rapid.

Owner:江苏桓华婴儿用品有限公司

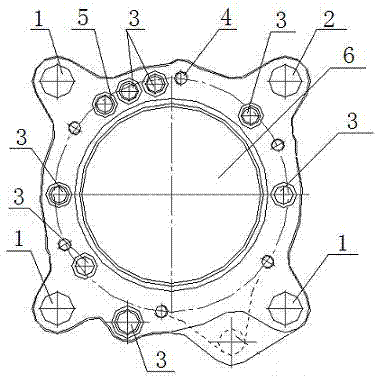

Cylinder liner marking inspection template

InactiveCN103042519AInspection is convenient and intuitiveDash shortcutOther workshop equipmentEngineering

Owner:DALIAN BINCHENG PISTON MFG

Line scribing device for plate machining

The invention discloses a line scribing device for plate machining. The line scribing device for plate machining comprises a line scribing platform; sliding rails are connected to the two sides, whichare far away from each other, of the line scribing platform correspondingly; sliding blocks are connected into the sliding rails; connecting plates are connected to one ends of the sliding blocks; the connecting plates are a pair of connecting plates; a connecting shaft is connected between the two opposite sides of the connecting plates; a movable column is connected to the connecting shaft; a pair of extending plates is connected to one side of the movable column; a rotating shaft is connected between the ends, far away from the movable column, of the extending plates; and a linkage plate is connected to one side of the rotating shaft. By means of clamping blocks on the two opposite sides of the line scribing platform and inserting grooves which are formed in the two opposite sides of the clamping blocks, a plate which needs line scribing can be put on the line scribing platform along the inserting grooves formed in the inner sides of the clamping blocks; through the inserting grooves, the plate can be horizontally attached to the line scribing platform and the function of fixing the plate is achieved; and after plate fixing is finished, a cutting line is scribed on the plate with a line scribing pen.

Owner:南安市瑞创科技有限公司

A teaching board for English teaching

Owner:宝应县文体教玩具协会

Round manhole end socket scribing method

InactiveCN104626087AEasy to operateAccurately draw the lineOther workshop equipmentEngineeringFeeding tube

The invention discloses a round manhole end socket scribing method. The round manhole end socket scribing method includes the operating steps of scribing the altitude line of an end socket, scribing the line of a manhole of the end socket, scribing the lines of a horizontal gauge tube, a balance container tube hole and other small tube holes in the axial or radial direction of the end socket or perpendicular to the axial direction, and scribing the lines of the manhole, a descending tube hole, a water feeding tube hole and other tube holes, wherein certain angles are formed between the centerline of the end socket and the manhole, the descending tube hole, the water feeding tube hole and the other tube holes. Neither platform nor scribing block is needed for scribing the altitude line of the end socket, only simple scribing tools such as chalk lines, steel rulers and compasses are needed, operation is convenient, and scribing is accurate.

Owner:QINGDAO XUSHENG HEAD

Stair surface scribing tool

ActiveCN105345803ASimple and fast operationAccurately draw the lineOther workshop equipmentEngineeringScriber

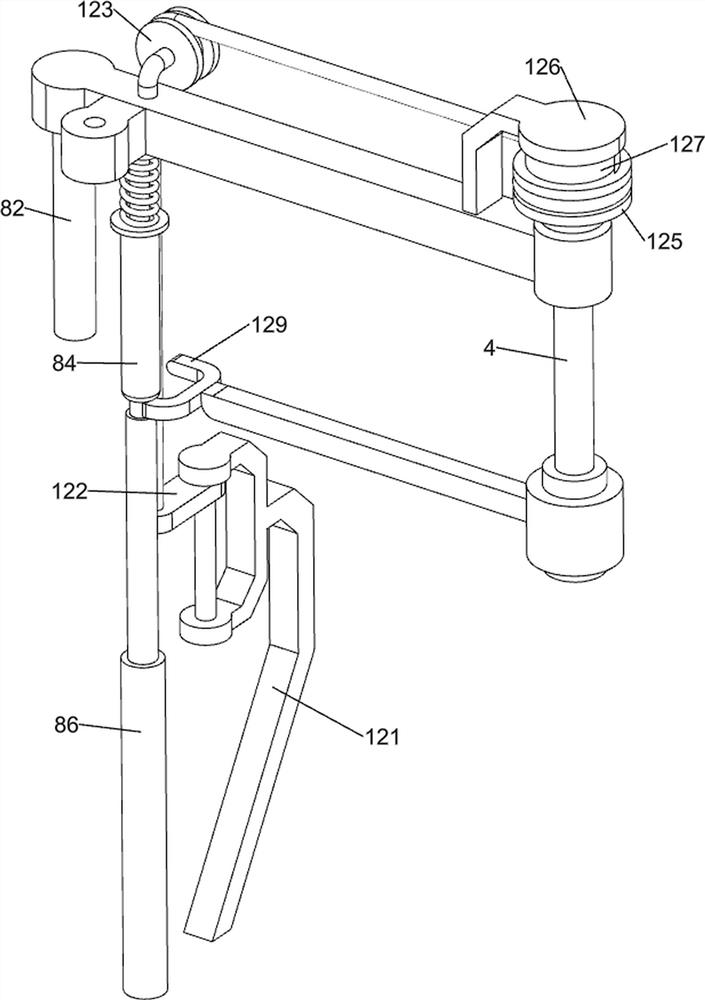

The invention discloses a stair surface scribing tool convenient for scribing lines on step surfaces. The stair surface scribing tool comprises a bottom plate with a positioning structure, a slider arranged on the bottom plate and a scriber, wherein the scriber is arranged on the slider, the scribing end extends out from the lower side surface of the bottom plate, and the scriber can move in the vertical direction so as to regulate the extension quantity of the scribing end. Through regulating the extension quantity of the scribing section of the scriber from the lower side surface of the bottom plate, the step difference between two surfaces on the same plane is adapted, the function of scribing lines on the step surfaces is realized, and the operation is simple and convenient. At the same time, lines are scribed after positioning is carried out through the positioning structure of the bottom plate, so that lines are more accurately scribed.

Owner:AVIC CHENGFEI COMML AIRCRAFT COMPANY

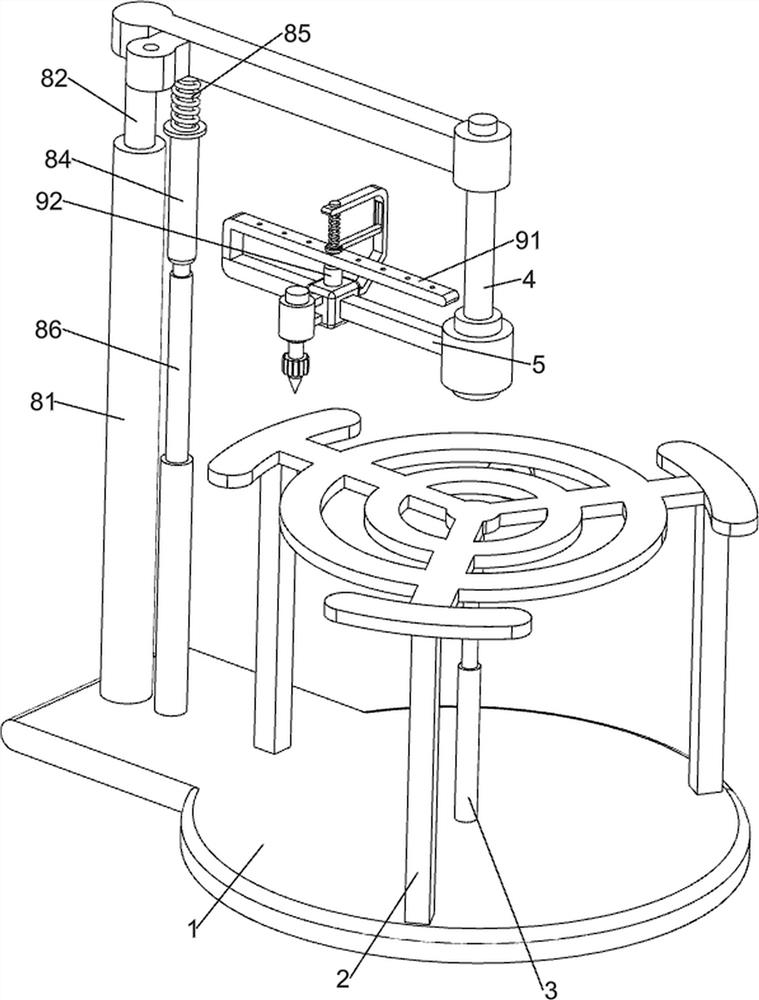

Round wood board marking device for wooden toy production and processing

PendingCN114179050AWide range of applicationsImprove work efficiencyOther workshop equipmentWorkbenchWood plank

The invention relates to a lineation device, in particular to a round wood plate lineation device for wooden toy production and processing. According to the round wood board marking device for wooden toy production and processing, a round wood board can be automatically clamped and marked, and the marking precision is high. The round wood board marking device for wooden toy production and processing comprises a bottom plate and a workbench, and the workbench is arranged on one side of the top of the bottom plate; the connecting column is arranged in the middle of one side of the top of the bottom plate, and the top of the connecting column is connected with the bottom of the workbench; the lifting mechanism is arranged on one side of the top of the bottom plate; the rotating shaft is rotationally arranged on a certain component of the lifting mechanism; and the guide rod is arranged at the lower part of the rotating shaft. Through cooperation of the lifting mechanism and the positioning mechanism, a round wood plate can be automatically and more accurately marked, the marking radius can be adjusted according to the actual situation, and the application range is wide.

Owner:李仟

Pipe preparation positioning device

ActiveCN111906746AAccurately draw the lineReduce labor intensityOther workshop equipmentMechanical measuring arrangementsManufacturing engineeringVertical distance

The invention relates to the technical field of industrial manufacturing, and provides a pipe preparation positioning device. The pipe preparation positioning device comprises a base, rolling portions, a graduated scale and a positioning piece, wherein the base is provided with a containing groove used for containing a pipe; the rolling portions are arranged on the base and located in the containing groove, and the rolling portions are used for supporting the pipe; the graduated scale is arranged on the base and extends in the length direction of the base; the positioning piece is arranged onthe base and is movably arranged in the length direction of the base, and the vertical distance between the positioning piece and the starting point of the graduated scale is the positioning size of the pipe; and reserved gaps allowing the pipe to penetrate therethrough are formed between the positioning piece and the rolling portions. According to the positioning device, the positioning size of the pipe is determined by moving the positioning piece, so that one end of the pipe is aligned to the starting point of the graduated scale, and the scribing portion corresponds to the positioning piece so as to complete quick scribing; and compared with the prior art in which measurement scribing is performed by means of back-and-forth walking by workers, the positioning device has the advantagesthat the labor intensity is relieved, and the production efficiency is improved.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Scribing device for glass cutting

The invention relates to a scribing device, in particular to a scribing device for glass cutting. According to the scribing device for glass cutting, kerosene is automatically added during scribing, and scribing is accurate. The scribing device for glass cutting comprises a supporting frame, a supporting plate, scribing mechanisms and an oiling mechanism, the supporting plate is arranged at the top of the supporting frame, the scribing mechanisms are arranged on the front side and the rear side of the supporting plate, the oiling mechanism is arranged on the front side of the supporting plate,and the lower portion of the oiling mechanism is connected with the supporting frame. The effects that kerosene is automatically added in the scribing process, and scribing is accurate are achieved;the scribing device is provided with the oiling mechanism, kerosene can be automatically added to the scribing device during scribing, time and labor are saved, stress generated by scratches is neutralized with tension of the kerosene in time, component force generated by glass marking is reduced, the component force is reduced, glass is not prone to bursting, and time and labor are saved.

Owner:张玉印

Full-automatic road marked line scribing machine

The invention relates to a full-automatic road marked line scribing machine which comprises a scribing machine body and further comprises a limiting mechanism formed by combining a plurality of sets of guide units; a control mechanism which comprises a protruding assembly which is detachably installed on the limiting mechanism; a first transmission mechanism which is connected with the scribing machine body and slides on the limiting mechanism in a matched mode; and a second transmission mechanism which is connected with the scribing machine body and is matched with the control mechanism to control opening and closing of a discharge valve of the scribing machine body; the technical problems are solved that when dotted line road signs are marked, the interval time of discharging of the scribing machine cannot be accurately controlled, and corresponding regulation and control need to be conducted manually according to actual conditions.

Owner:ZHEJIANG ZHONGXIN NEW MATERIAL CO LTD

Construction method of subway station entrance and exit guard posts

The invention discloses a construction method of subway station entrance and exit guard posts, and relates to a construction method of guard posts, and the key points of the technical scheme are as follows: the construction method comprises the following steps: 1, scribing; 2, manufacturing a guide wall; and thirdly, carrying out drilling and pouring, wherein the construction mode of scribing is that a connecting column is fixed to the end of the preset position, a fine line is wound around the connecting column to form a boundary line, the connecting column comprises a fixing nail inserted into the ground and a line winding column fixed to the end, away from the ground, of the fixing nail, and the fine line is wound around a winding column. According to the invention, the construction efficiency is improved through the convenient installation of the template.

Owner:广州穗岩土木科技股份有限公司

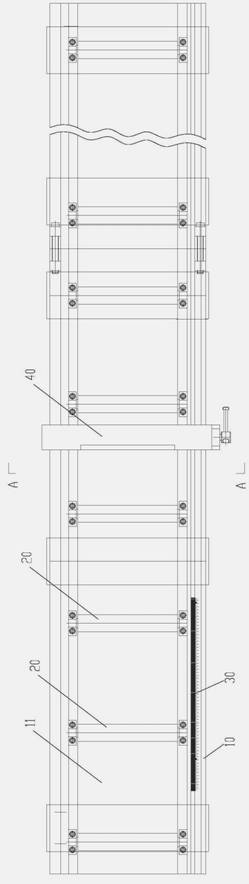

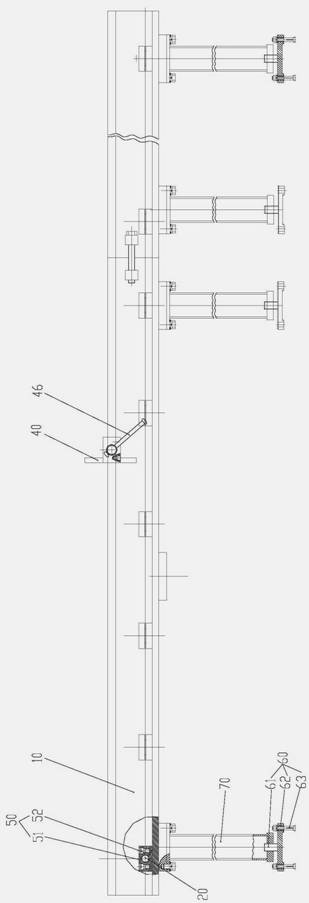

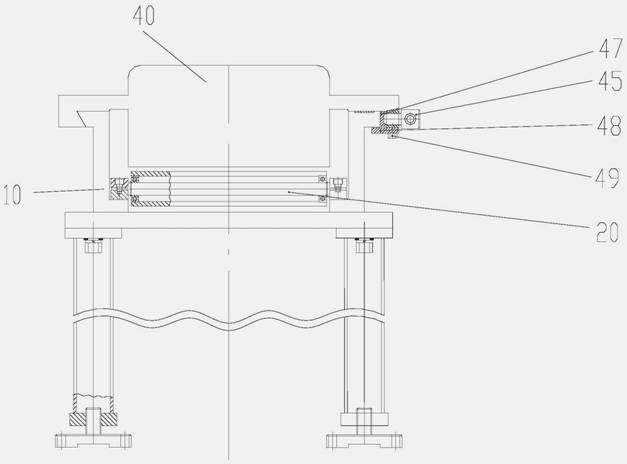

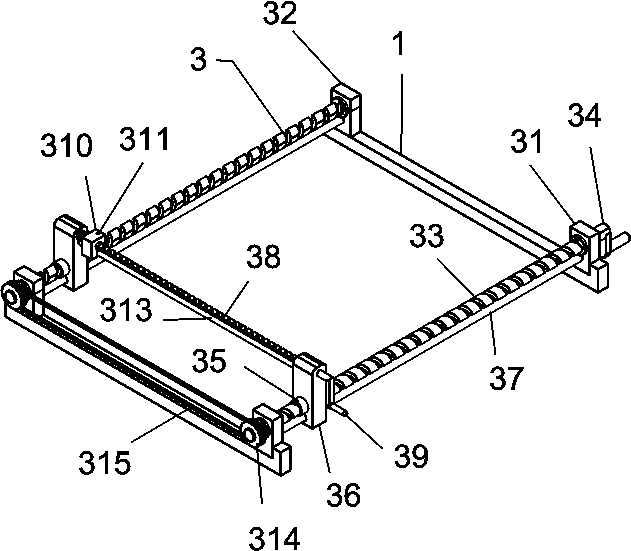

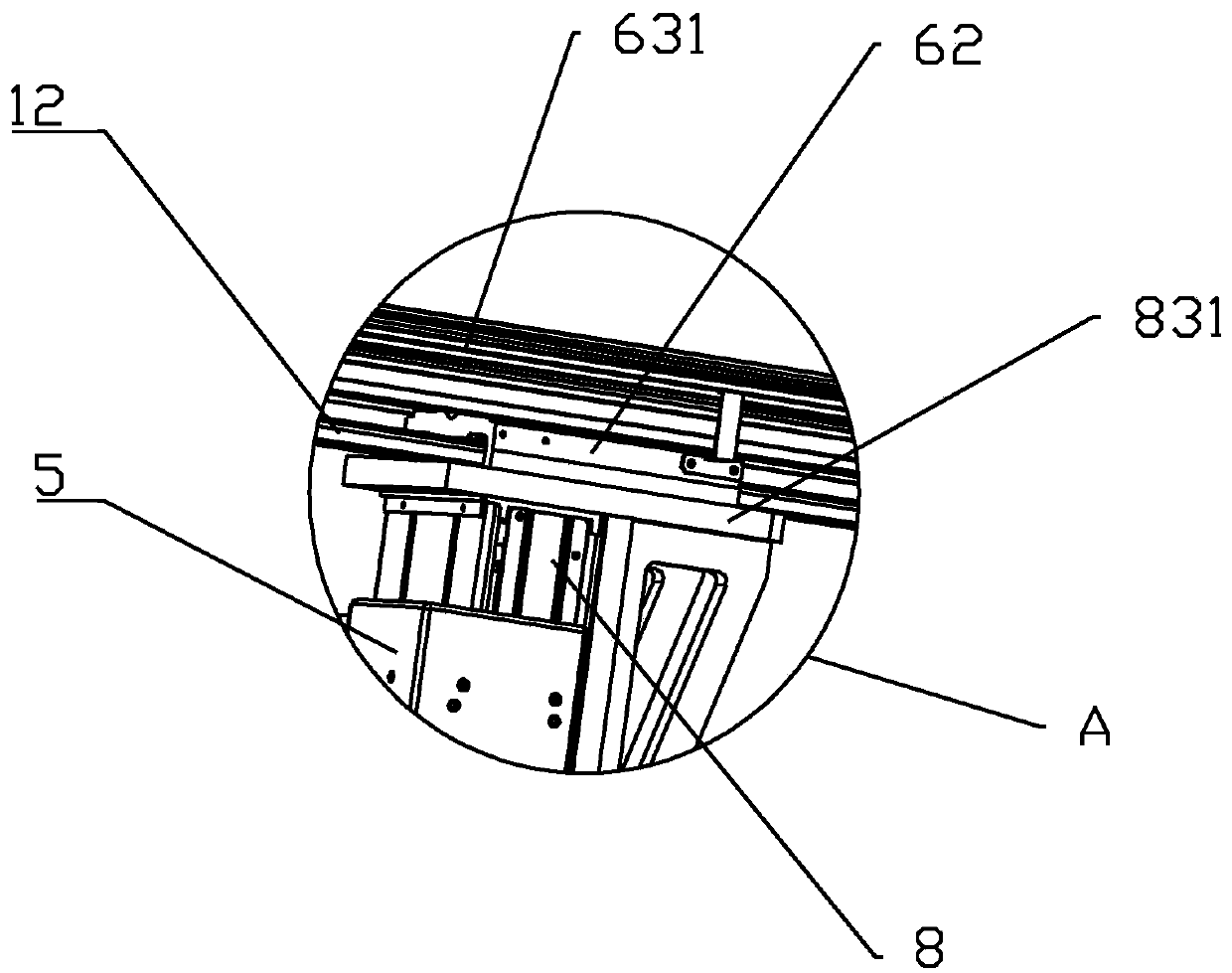

Tight-pressing turnover mechanism and straight pipe section surface scribing equipment

The invention belongs to the technical field of machining of automobile parts and provides a tight-pressing turnover mechanism and straight pipe section surface scribing equipment. The tight-pressingturnover mechanism comprises a working table and further comprises a belt conveying mechanism; the belt conveying mechanism comprises a driving wheel, a driven wheel and a belt; the driving wheel andthe driven wheel are disposed on the working table; the belt is winded on the outer sides of the driving wheel and the driven wheel; the axial directions of both the driving wheel and the driven wheelare parallel to the working table; a gap for placement of a straight pipe section is formed between the belt and the working table; and the tight-pressing turnover mechanism further comprises a driving mechanism which is connected with the driving wheel and used for providing motive power for the belt conveying mechanism. By means of the technical scheme, the problems that in the prior art, during straight pipe section surface scribing, the labor intensity of manual work is high, and the working efficiency is low are solved.

Owner:HEBEI CHINAUST AUTOMOTIVE PLASTICS CORP LTD

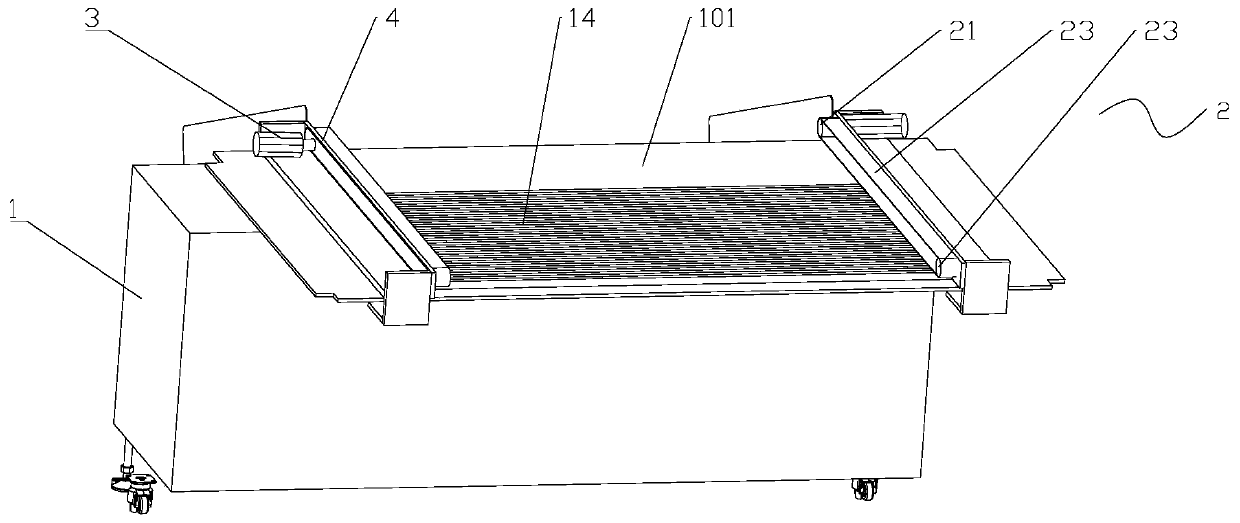

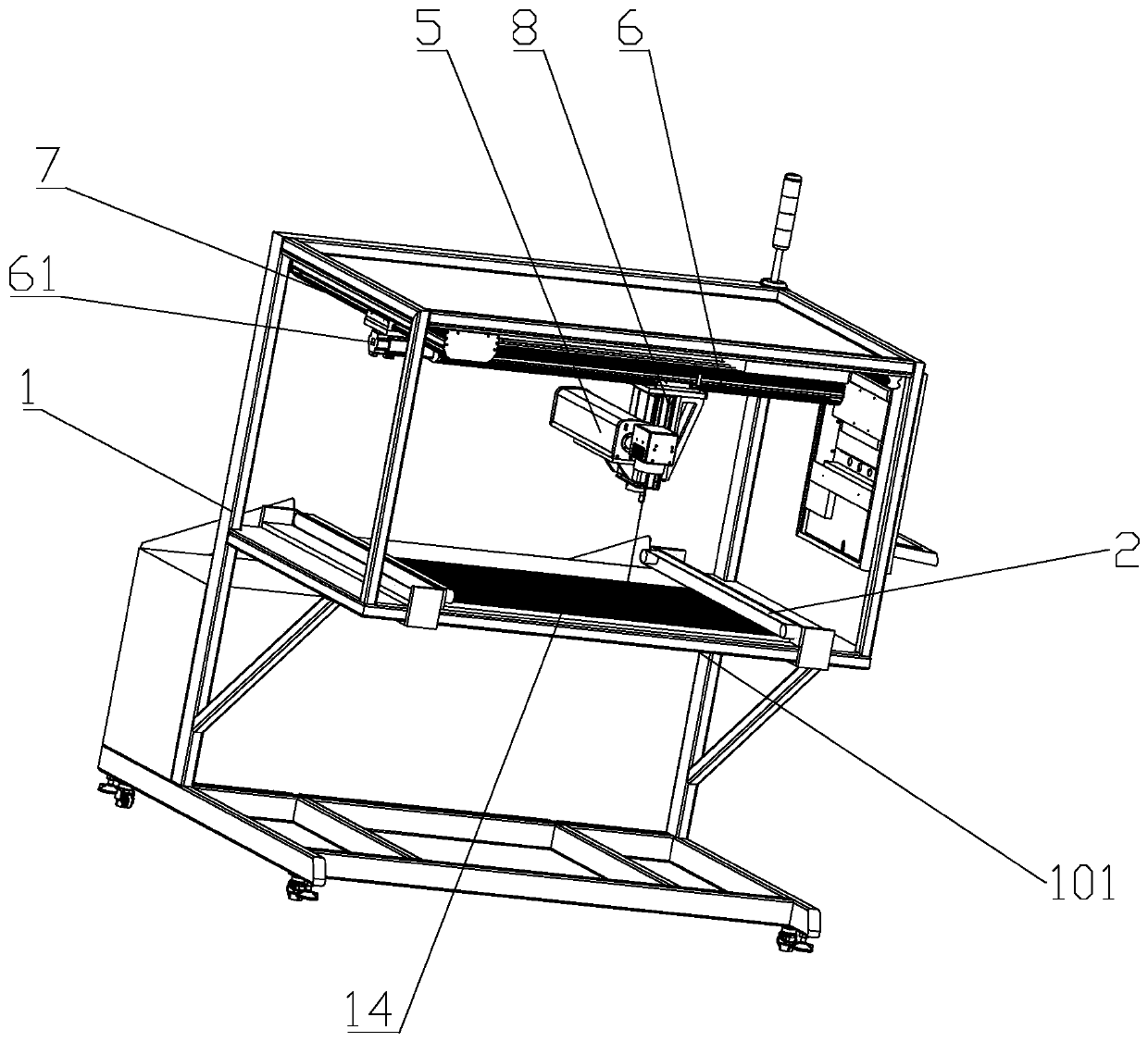

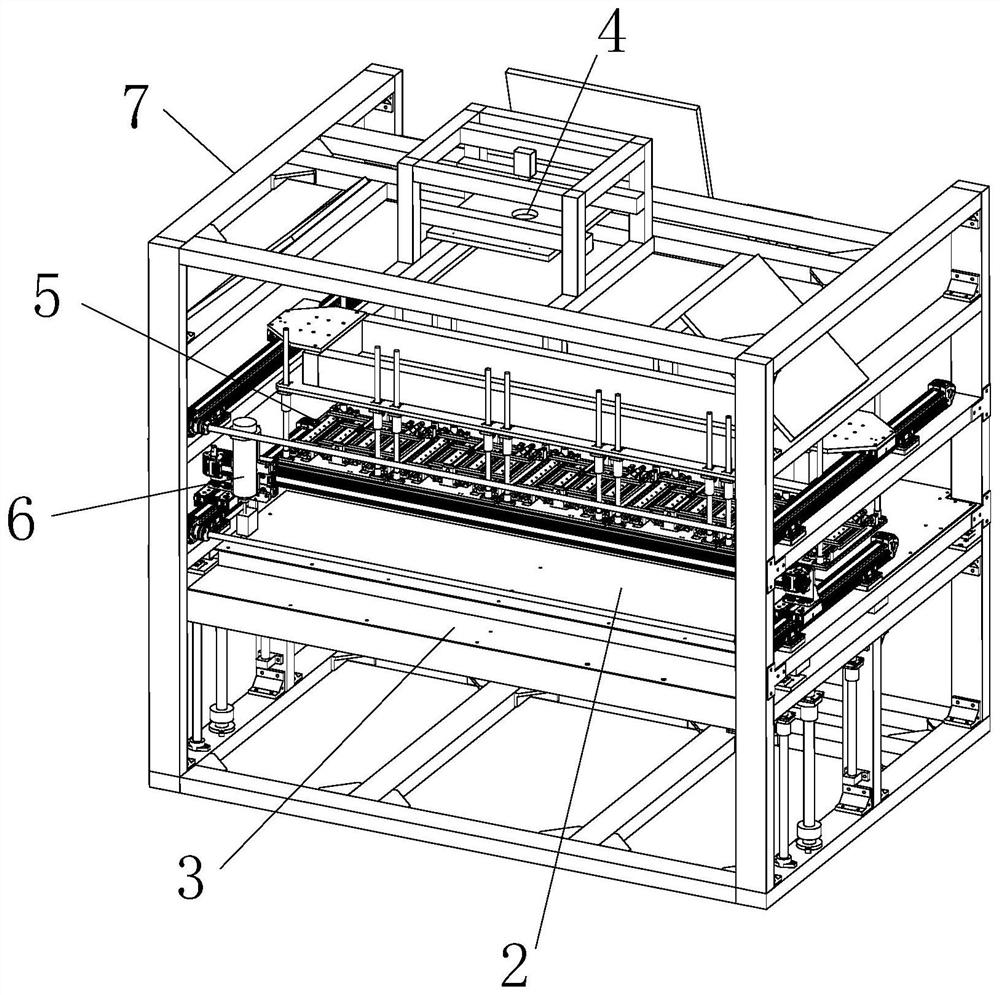

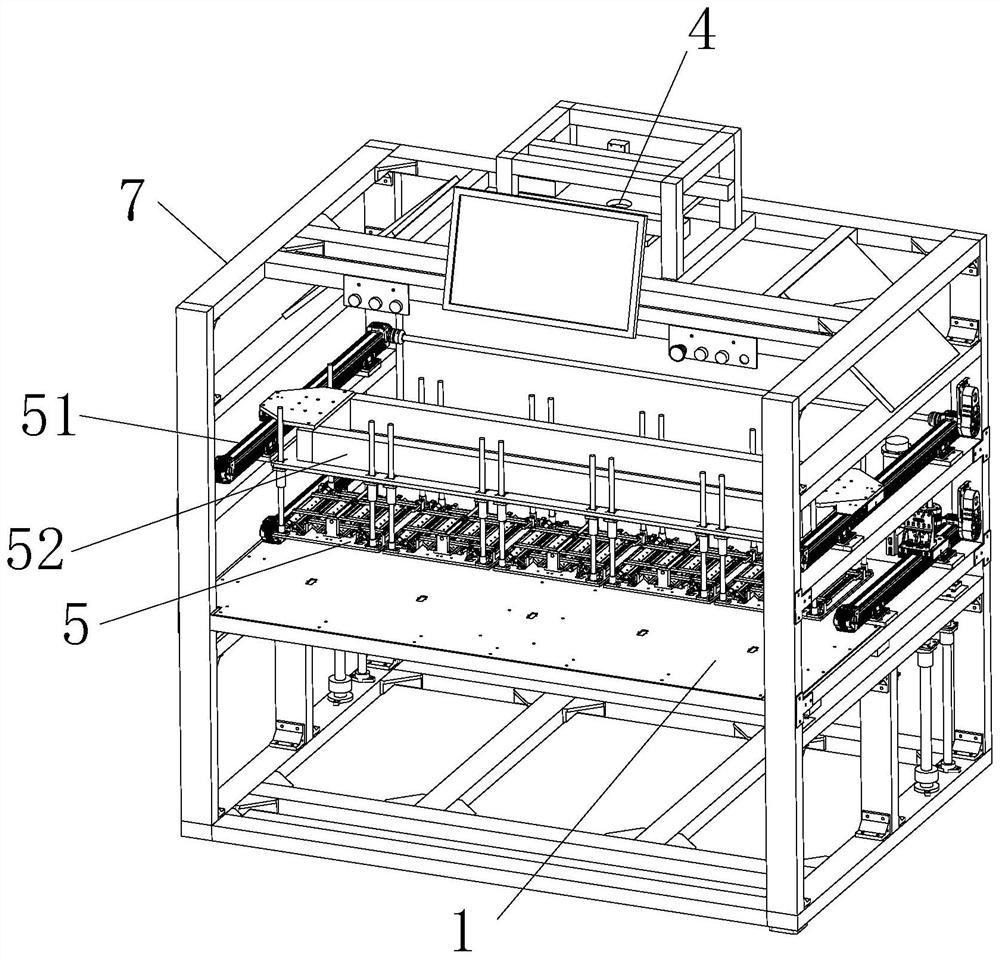

Full-automatic intelligent scribing machine

PendingCN112832005AAccurately draw the lineTake slices evenlyMarking textilesMechanical engineeringIndustrial engineering

The invention discloses a full-automatic intelligent scribing machine. The full-automatic intelligent scribing machine comprises a feeding platform, a scribing platform and a receiving platform which are sequentially and tightly arranged from top to bottom in a stepped mode, wherein the scribing platform is driven to be tightly attached to the bottom face of the discharging platform and the top face of the receiving platform to horizontally move; the feeding platform is used for feeding a cut part; an intelligent camera for photographing the cut part to identify the type of the cut part to form a scribing pattern is erected above the feeding platform; a taking mechanism capable of lifting, inserting and taking the cut part on the feeding platform to press and convey the cut part to the scribing platform is arranged below the intelligent camera; a scribing mechanism is erected above the scribing platform; the scribing mechanism is used for movably spraying the current cut part on the scribing platform according to the scribing pattern transmitted by the intelligent camera; and the receiving platform is arranged below the scribing platform in a lifting manner to bear the scribed cut part to be discharged. According to the full-automatic intelligent scribing machine, accurate scribing can be carried out, the standardized scribing procedures of automatic feeding, scribing and discharging are achieved, cut part taking is uniform, and the operation period is short.

Owner:汉羽科技(广东)有限公司

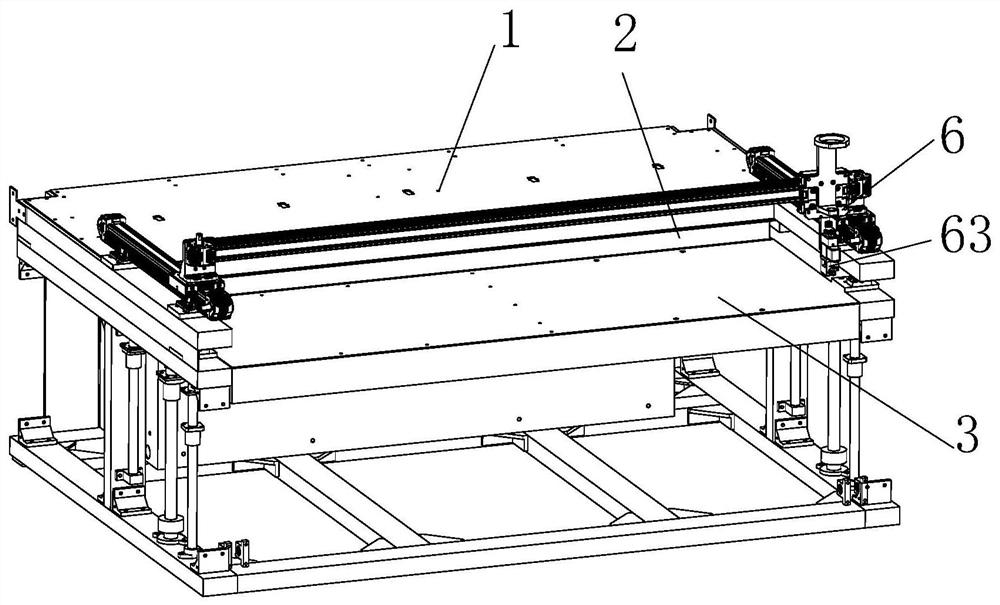

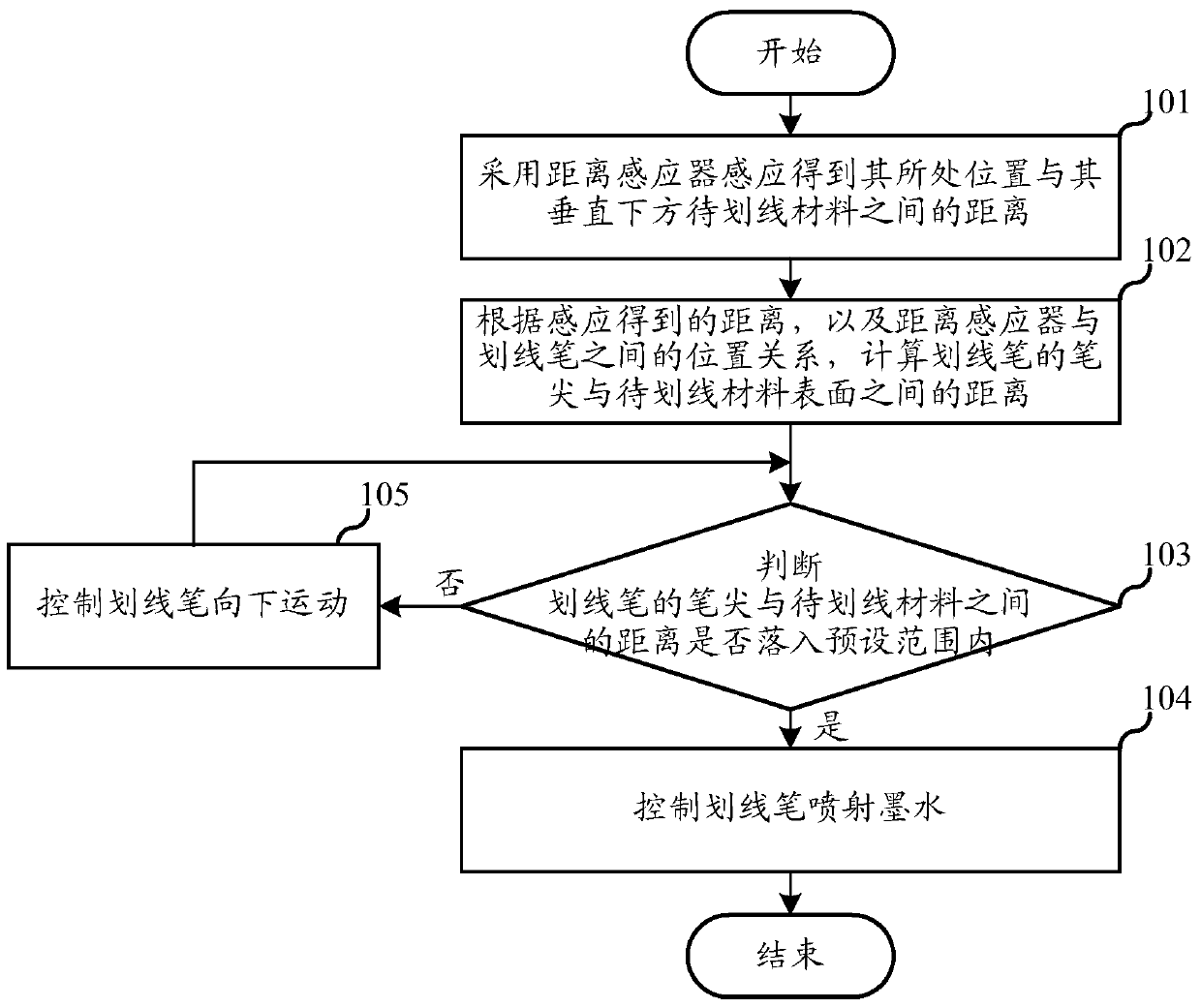

Automatic cutting machine and marking method thereof

ActiveCN104358095BAvoid damageAccurately draw the lineLeather clicking/perforating/clickingSevering textilesEngineering

The invention relates to the technical field of automatic cutting, and discloses an automatic cutting machine and a scribing method thereof. The automatic cutting machine acquires the distance between the pen point of a scribing pen and the surface of a to-be-scribed material; if the distance between the pen point of the scribing pen and the surface of the to-be-scribed material is not in a preset range, up and down position of the scribing pen is adjusted until the distance between the pen point of the scribing pen and the surface of the to-be-scribed material is in the preset range. By controlling the distance between the pen point of the scribing pen and the surface of the to-be-scribed material, excessive contact or separation between the pen point and the to-be-scribed material can be avoided, so that scribing is enabled to be accurate and quick.

Owner:长园装备制造有限公司

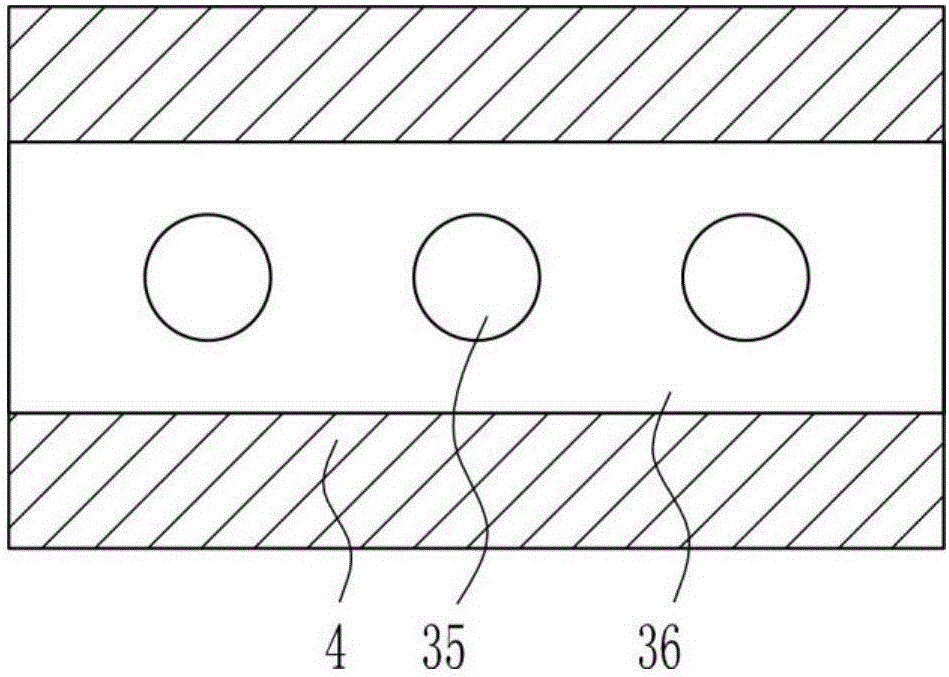

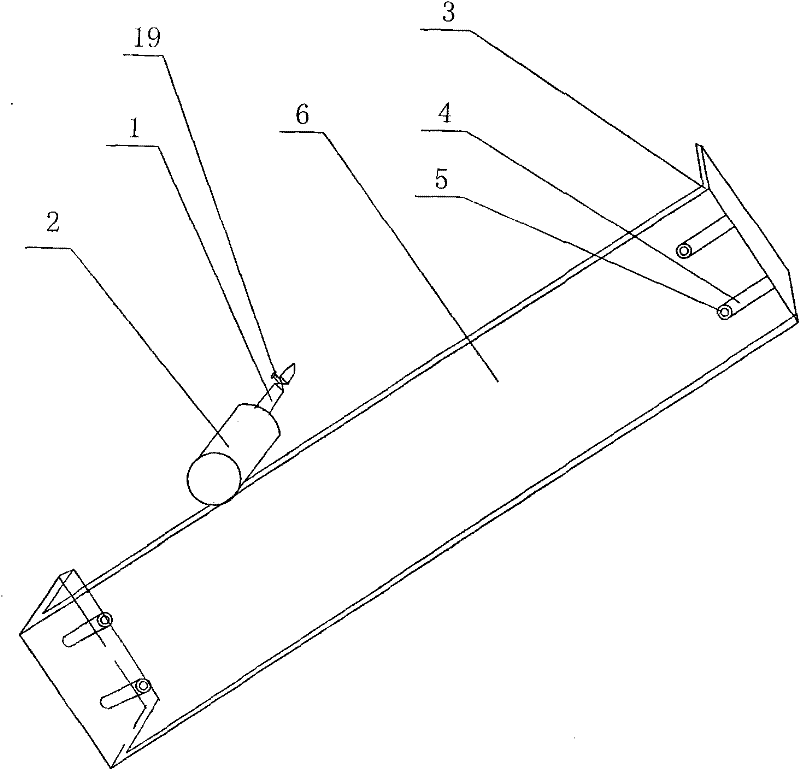

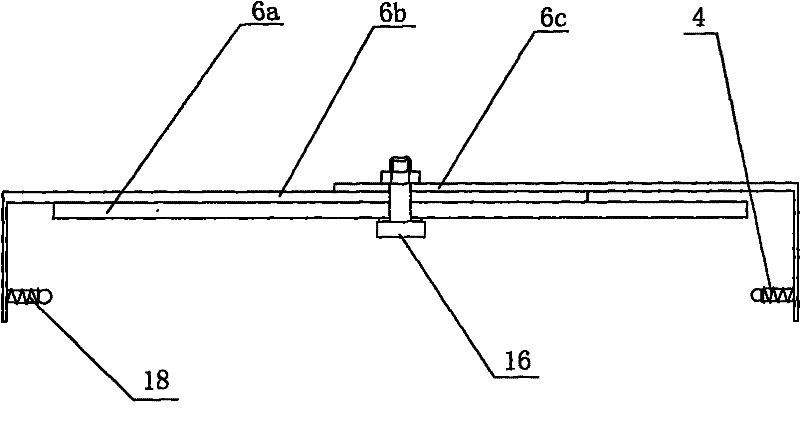

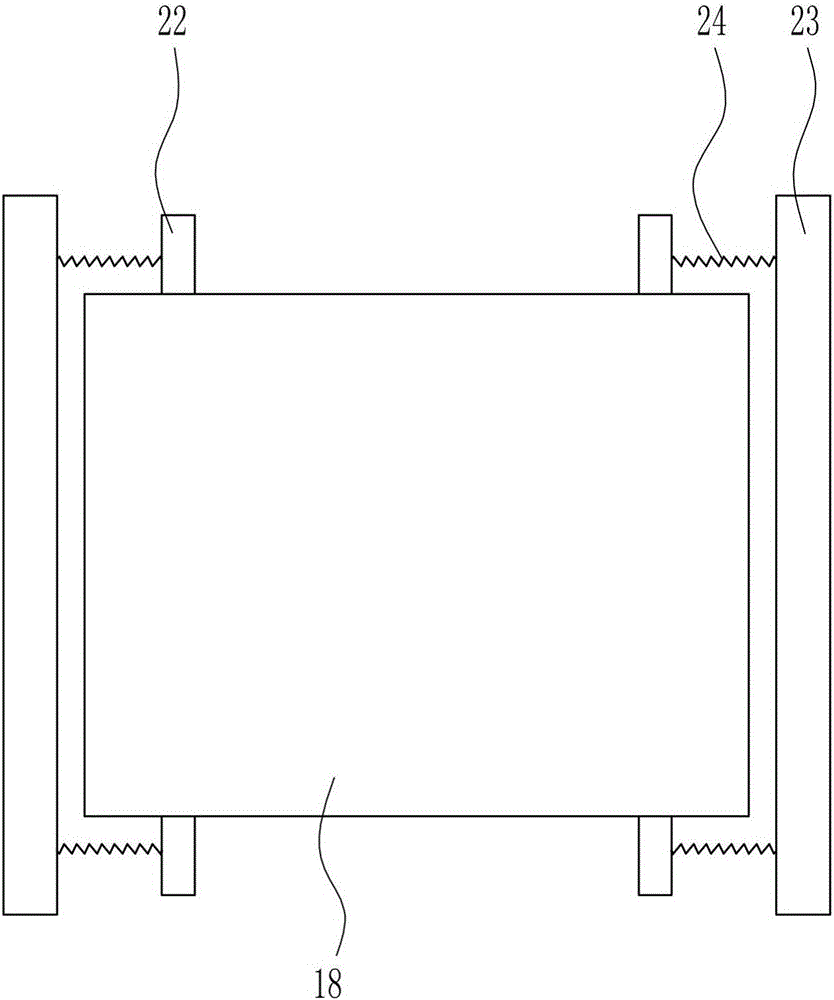

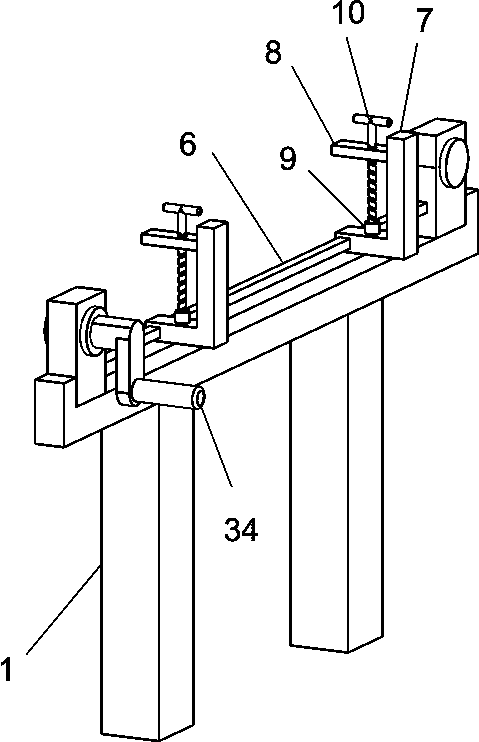

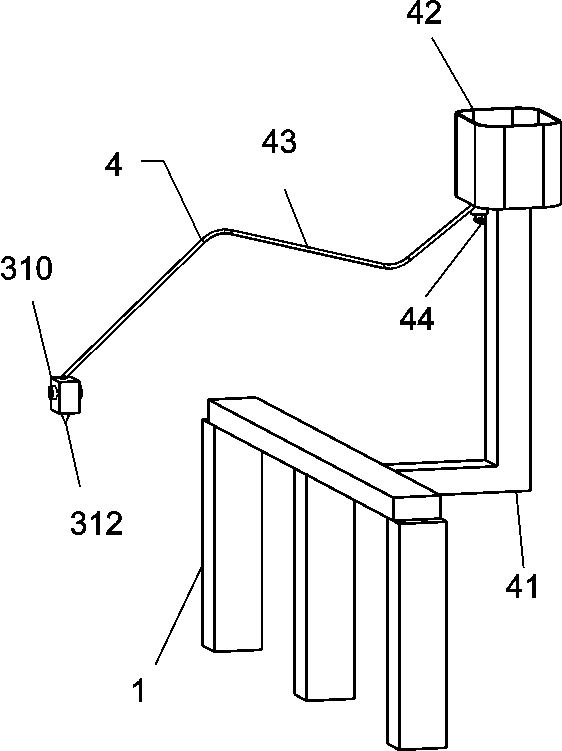

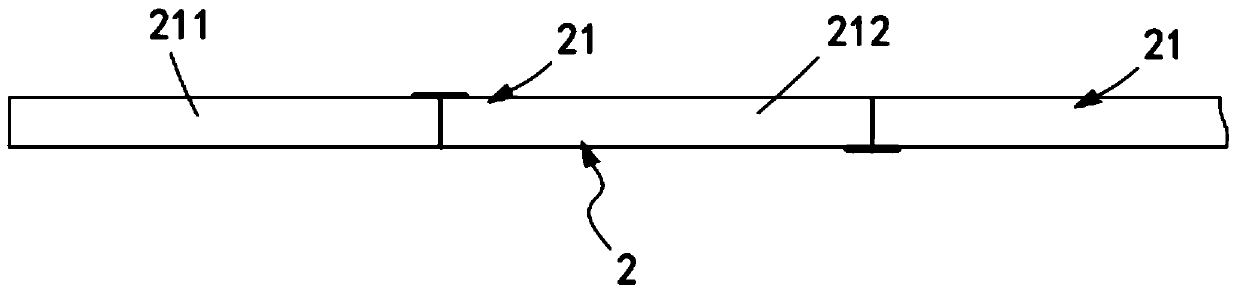

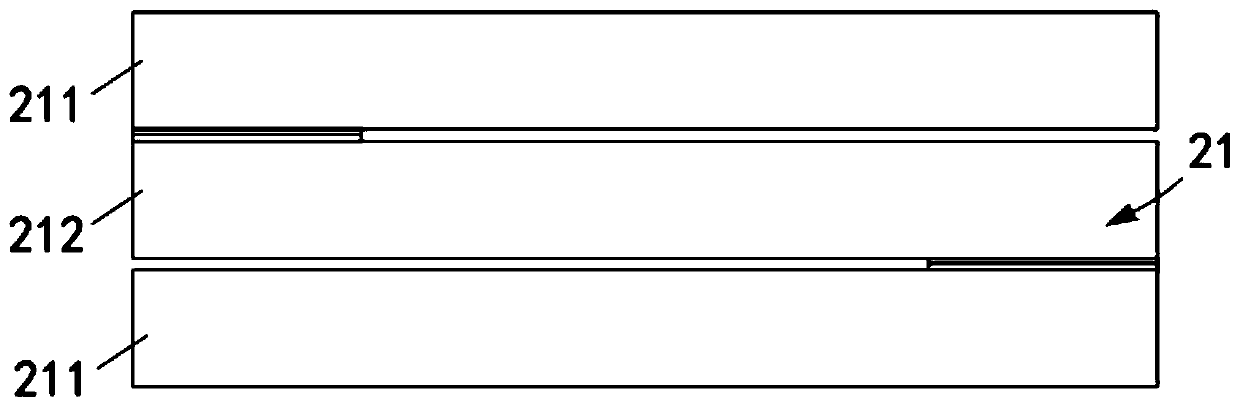

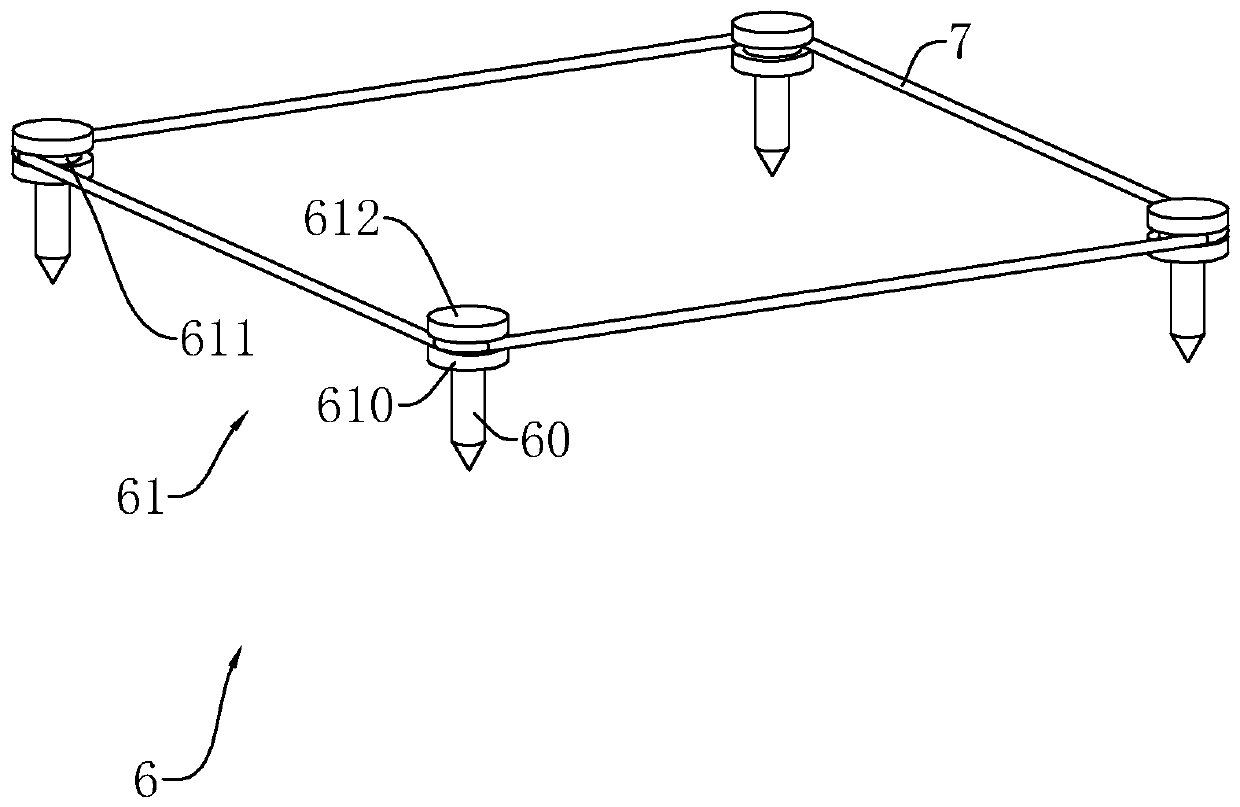

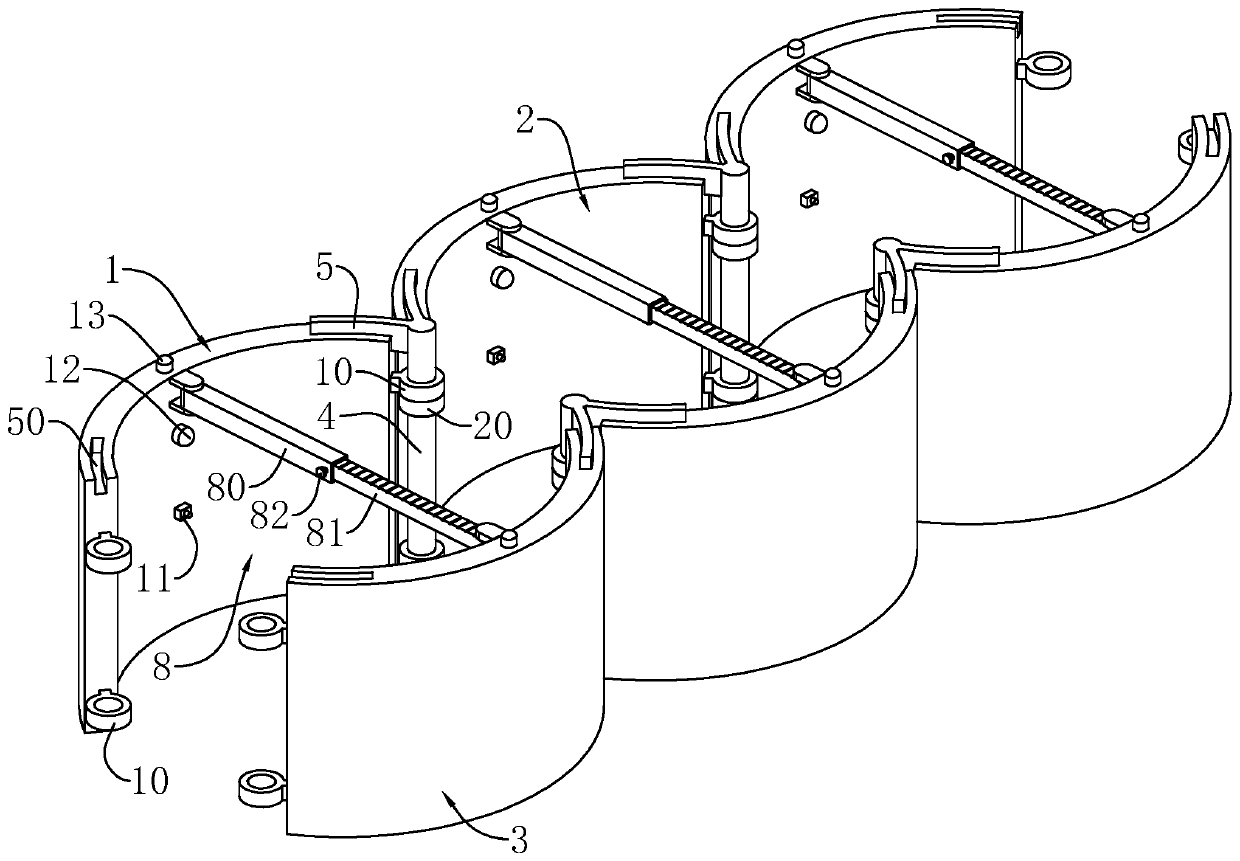

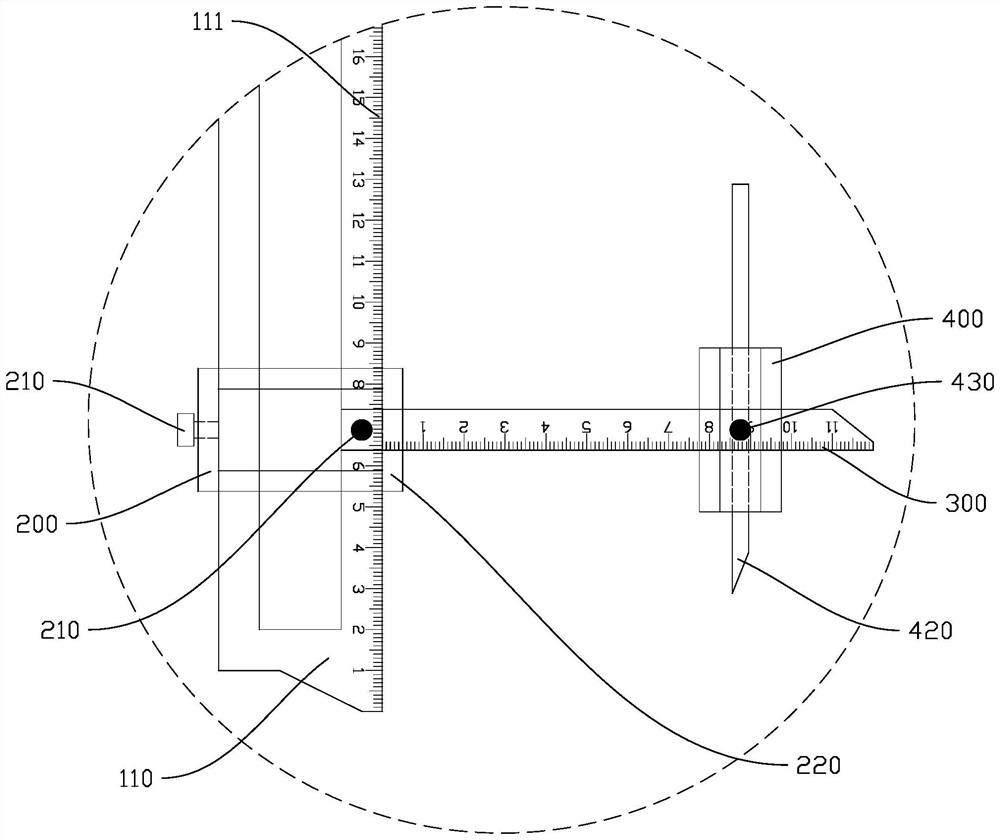

Marine linear segmented lineation device

PendingCN114406974AAccurately draw the lineCompact designOther workshop equipmentBraced frameEngineering

The invention discloses a marine linear segmented lineation device which comprises a support, a supporting frame, an extension scale and a lineation frame, the support is a long-strip-shaped frame, the support is provided with a linear side plate, the side plate is provided with a first graduated scale, the first graduated scale is arranged in the length direction of the side plate, and a long-strip-shaped gradienter is fixed to the support; the supporting frame is connected to the support in a sliding mode, the supporting frame can move along the first graduated scale, and the supporting frame is connected with a first rotary knob to be locked on the first graduated scale; the extension scale is connected to the supporting frame, extends in the direction away from the support and is perpendicular to the first graduated scale. The scribing frame is connected to the extension scale in a sliding mode, the scribing frame is connected with a second rotary knob to be locked on the extension scale, the scribing frame is provided with a through insertion hole, a scribing needle penetrates through the insertion hole, and the scribing frame is connected with a third rotary knob to lock the scribing needle. The scribing device has the advantages of light design, portability, simplicity and convenience in operation, accuracy in scribing and the like, and is suitable for wide application.

Owner:JIANGMEN NANYANG SHIP ENG

Apparatus for substrate marking

InactiveCN1958488BAccurately draw the lineSemiconductor/solid-state device testing/measurementGlass severing apparatusMechanical engineeringPhysics

An apparatus for substrate scribing which can apply scribing force vertically on a substrate is provided. The apparatus comprises a line-forming part for scribing a line on the substrate, a pressing part for applying pressure on the line-forming part, an elevator for moving the pressing part up and down, an elevating guiding part for leading the elevator, and a pressing guiding part for leading the pressure part. According to the invention, a scribed line can be formed on the substrate precisely by solving the eccentric force which deviates to the X-Y direction.

Owner:TOP ENG CO LTD

Plum blossom head tic-tac-toe line marking method

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com