Numerically controlled cutting control device and numerically controlled cutting control method

A technology of a control device and a control method, which is applied in the field of numerical control, can solve the problems of insufficient precision, low efficiency, large geometric size of assembly parts, etc., and achieves the effects of accurate marking, reliable marking and fast speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

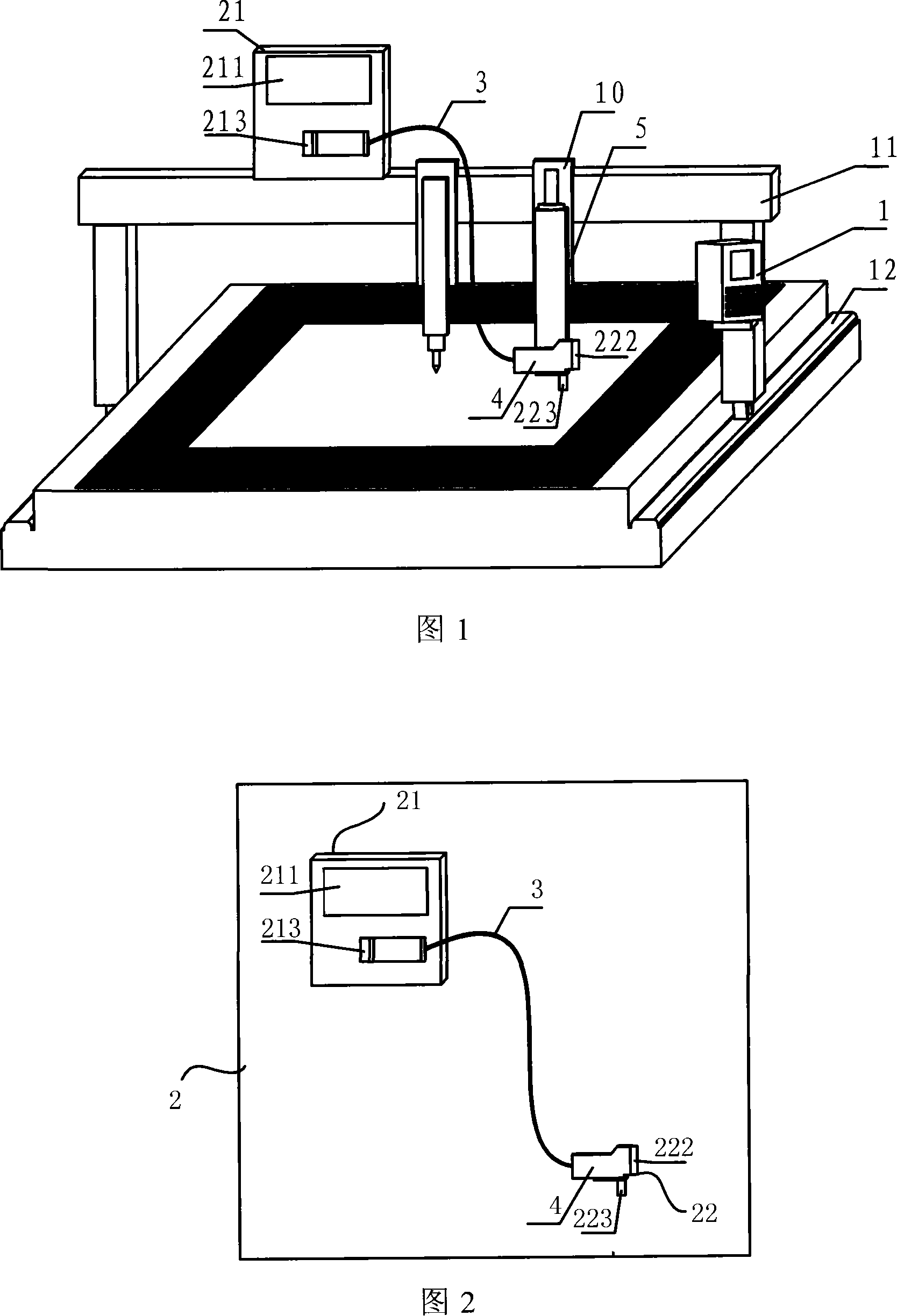

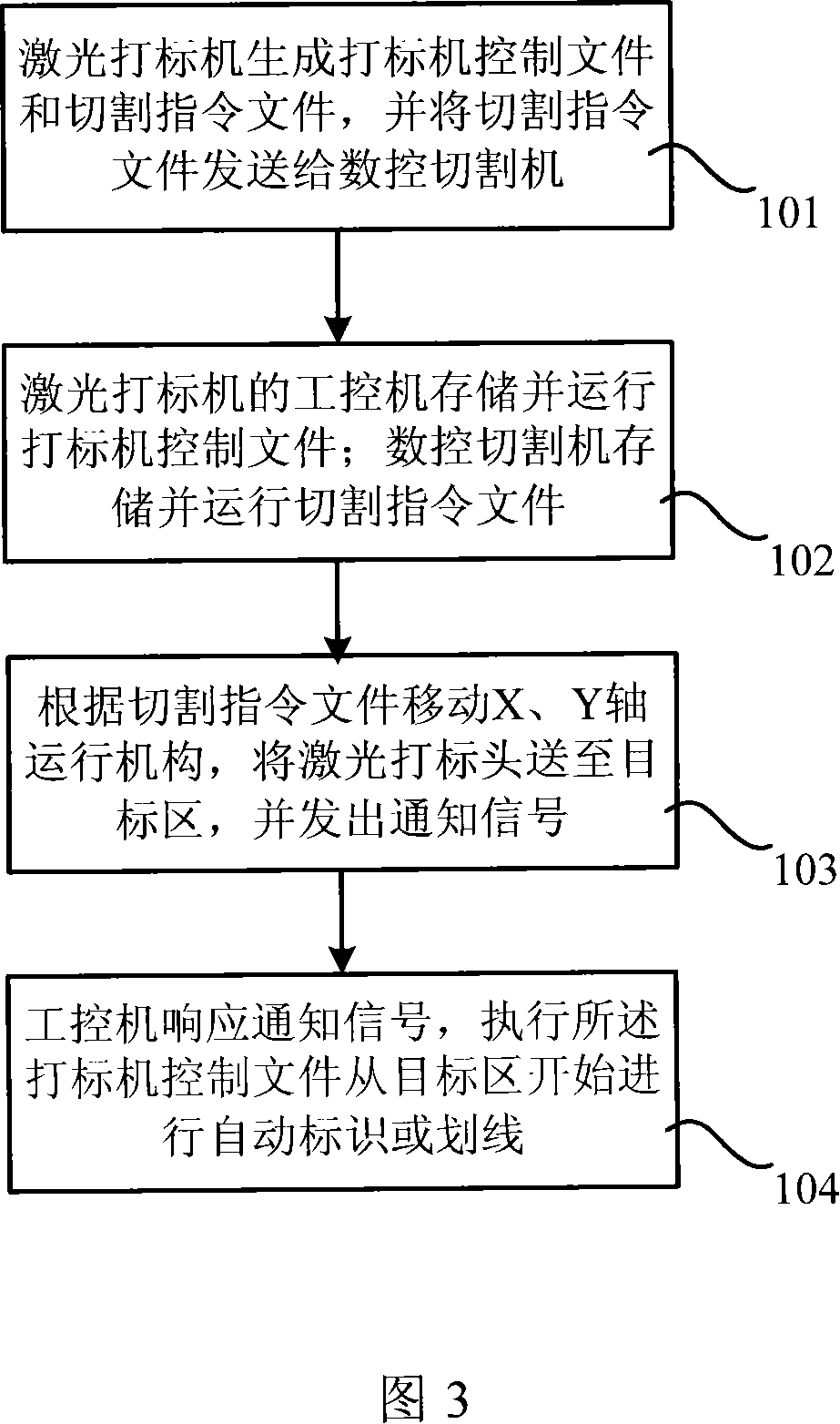

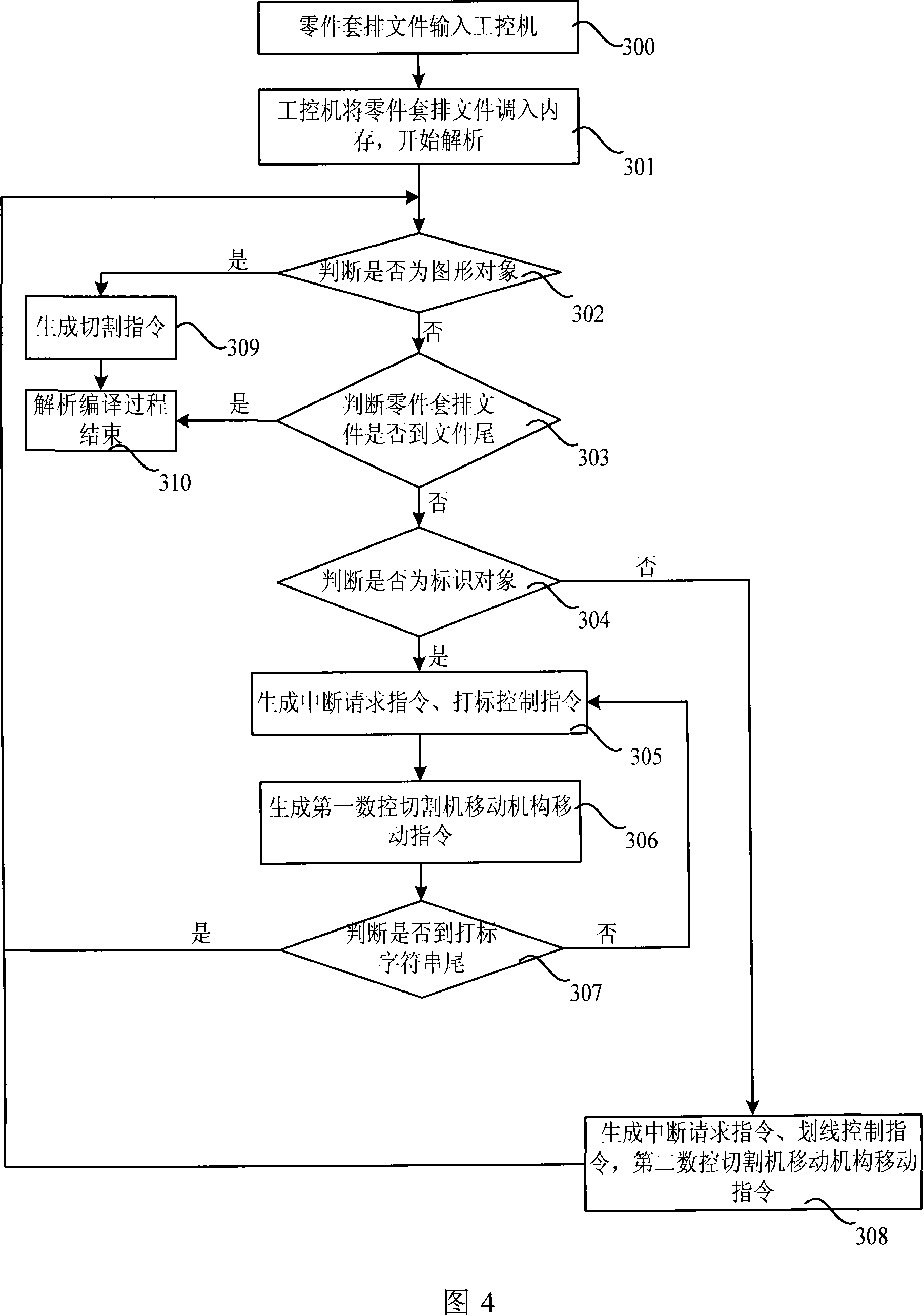

[0039] Fig. 1 is a schematic structural diagram of an embodiment of a numerically controlled cutting control device of the present invention. Fig. 2 is a schematic diagram of the mechanism of the embodiment of the laser marking machine of the present invention. Referring to Fig. 1 and Fig. 2, this numerical control cutting control device comprises: numerical control cutting machine 1, is used for moving its X-axis moving mechanism and Y-axis moving mechanism; Parallel interface connection, used to generate marking machine control files and cutting instruction files, and move the laser marking head to the target area through the X and Y axis moving mechanism of the CNC cutting machine according to the cutting instruction files, and then carry out according to the marking machine control files Automatically identify or underline. The CNC cutting machine used in this embodiment is a 6500*16000 Messer CNC cutting machine. On the basis of keeping the CNC cutting machine 1 unchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com