Full-automatic intelligent scribing machine

A scribing machine, fully automatic technology, applied in the direction of marking textile materials, textiles and papermaking, etc., can solve the problems of high degree of repetition, easy deviation and waste in the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific implementation manners of the present invention in conjunction with the accompanying drawings of the specification below.

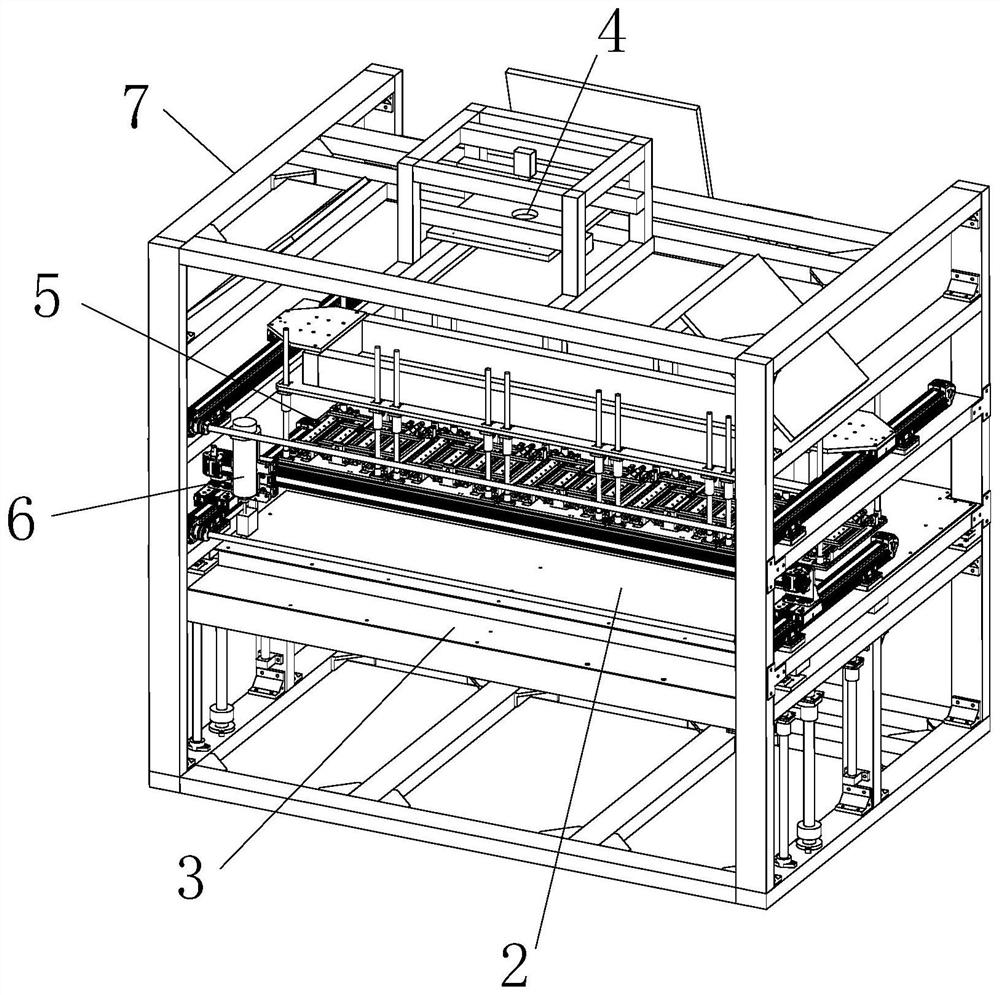

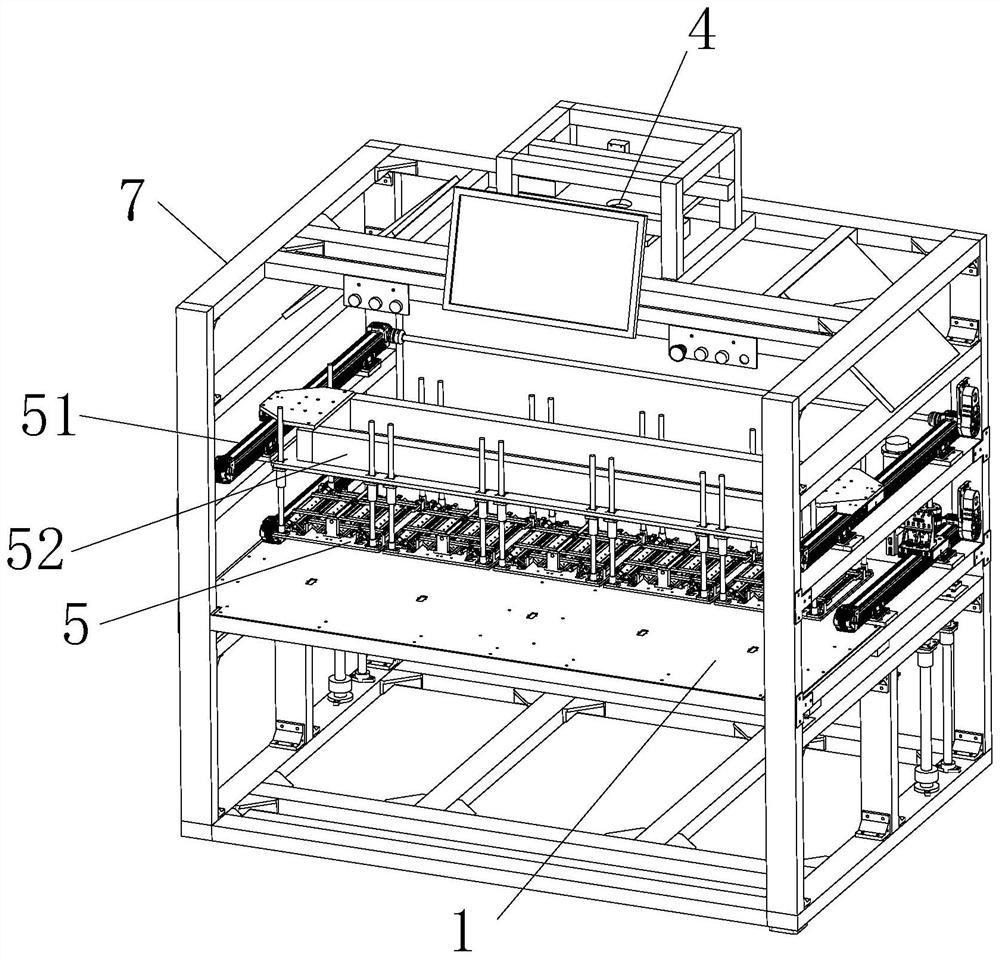

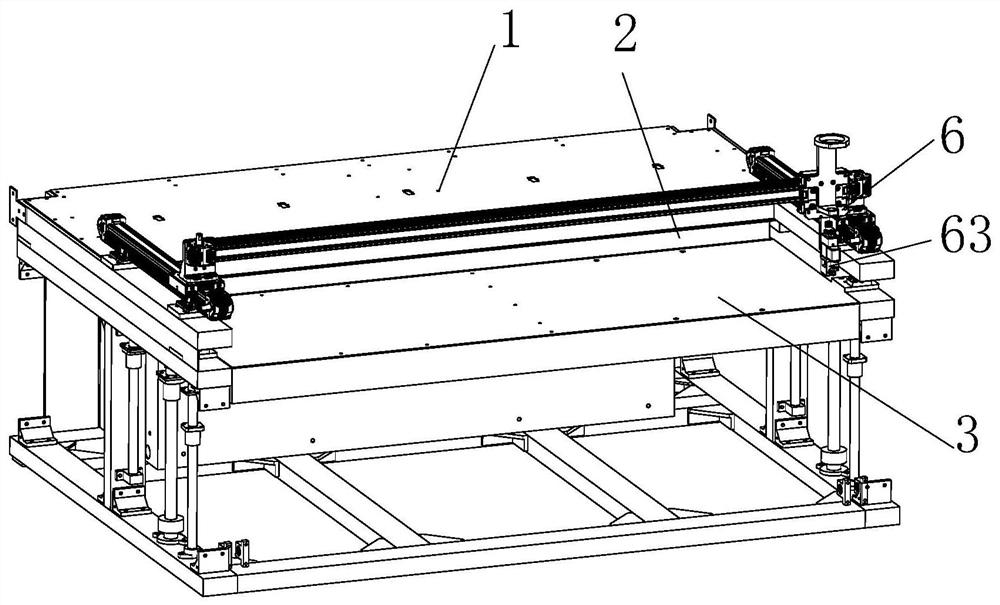

[0031] see Figure 1-10 A fully automatic intelligent scribing machine of the present embodiment shown, the fully automatic intelligent scribing machine includes: a discharge platform 1, a scribing platform 2, a material receiving platform, and a stepwise arrangement from top to bottom Platform 3 and scribing platform 2 are driven to move horizontally against the bottom surface of discharging platform 1 and the top surface of receiving platform 3, and above the scribing platform 2 is set up to take pictures of the cut pieces to identify the type of cut pieces and form a scribing pattern. Smart camera 4, the lower sides of the smart camera 4 are provided with a light source for supplementing light for shooting,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com