Patents

Literature

1212results about How to "Flip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

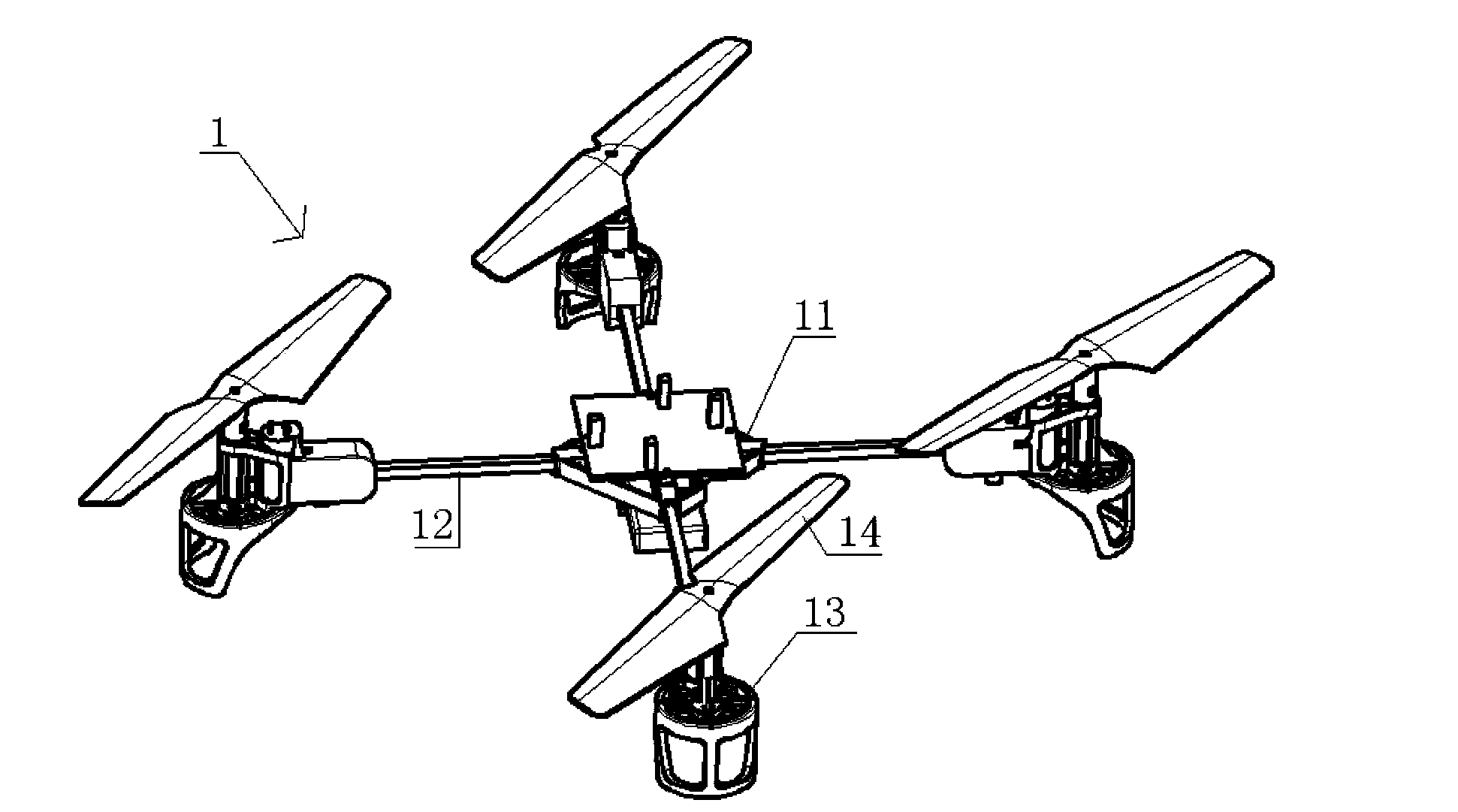

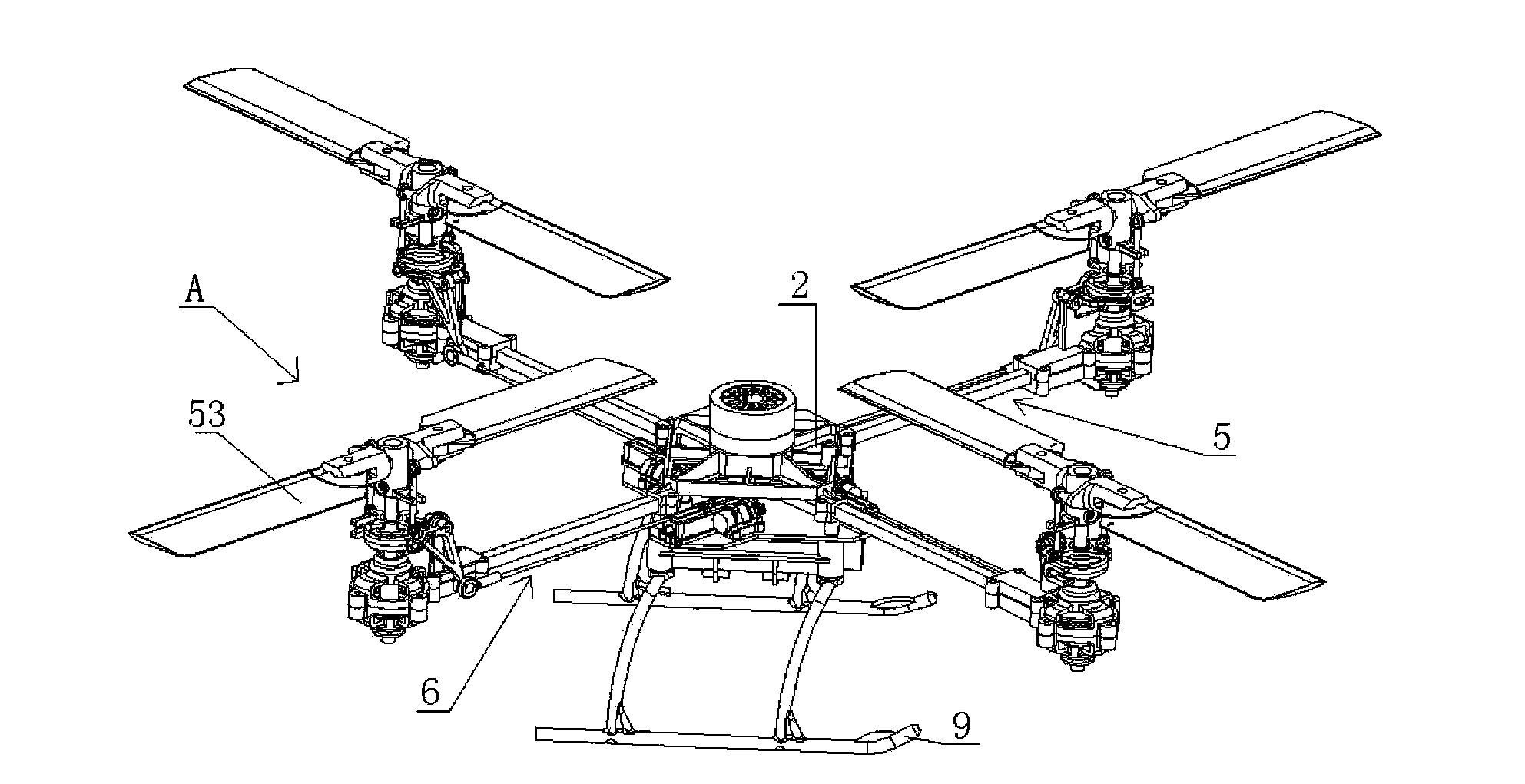

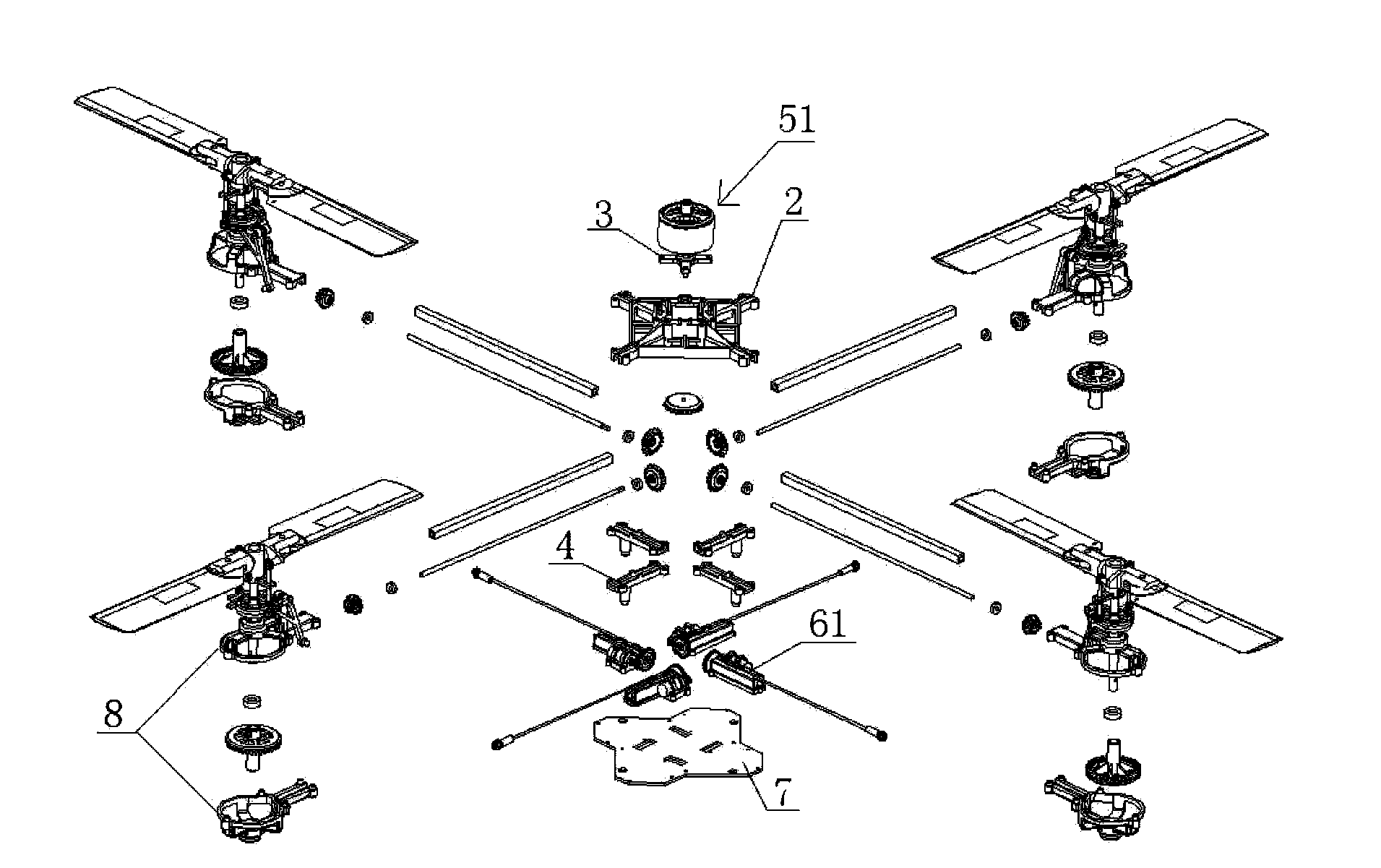

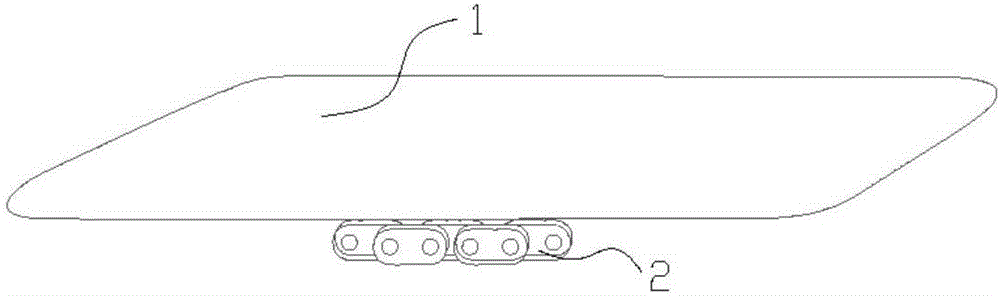

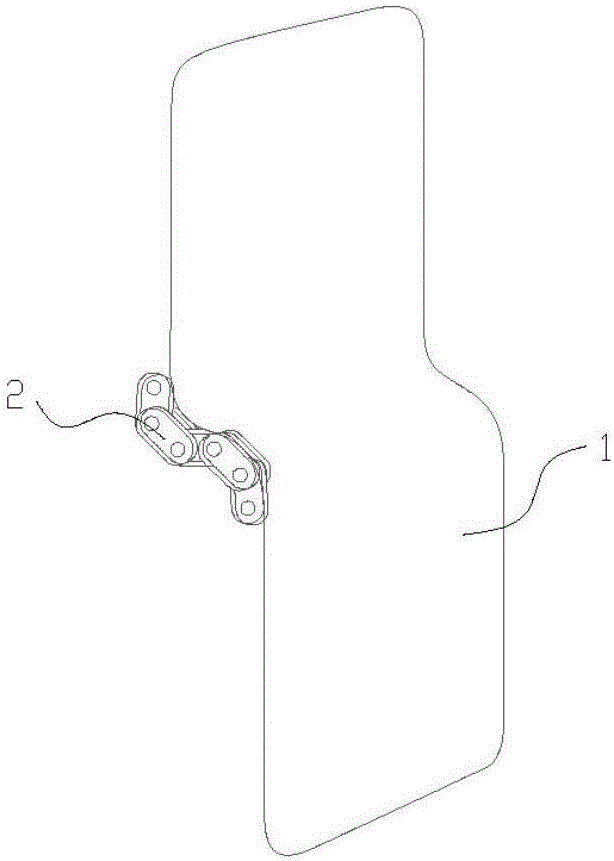

Multi-rotor wing aircraft

The invention discloses a multi-rotor wing aircraft. The multi-rotor wing aircraft comprises a power system and a distance change system. The power system comprises a main rotatable part, multiple driving parts and rotor wings connected respectively to the driving parts. The main rotatable part is provided with a rotatable end. The driving parts are driven by the rotatable end and transmit rotation to the rotor wings so that the rotor wings rotate synchronously. The distance change system comprises multiple distance change units. The distance change units are used respectively for changing incidence angles of the rotor wings. The driving parts are driven by the same rotatable end and the driving parts transmit rotation to the rotor wings so that the rotor wings rotate synchronously. Through distance change of the rotor wings, the multi-rotor wing aircraft can turn over, fly reversely or swing.

Owner:YUNEEC INT (CHINA) CO LTD

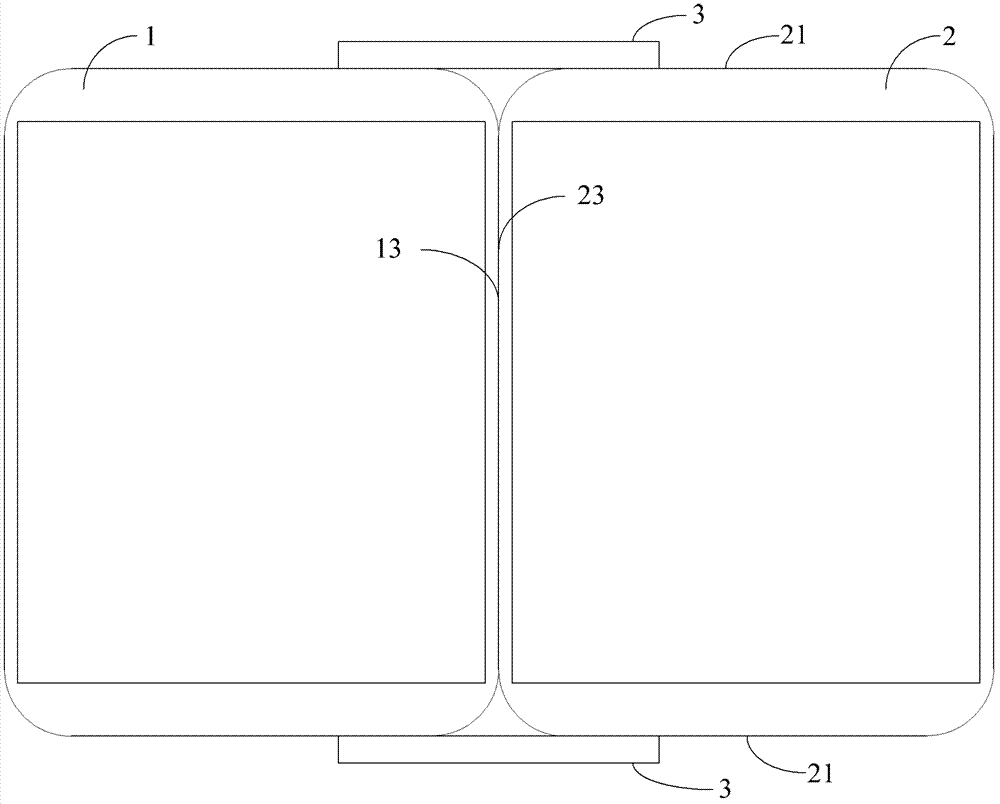

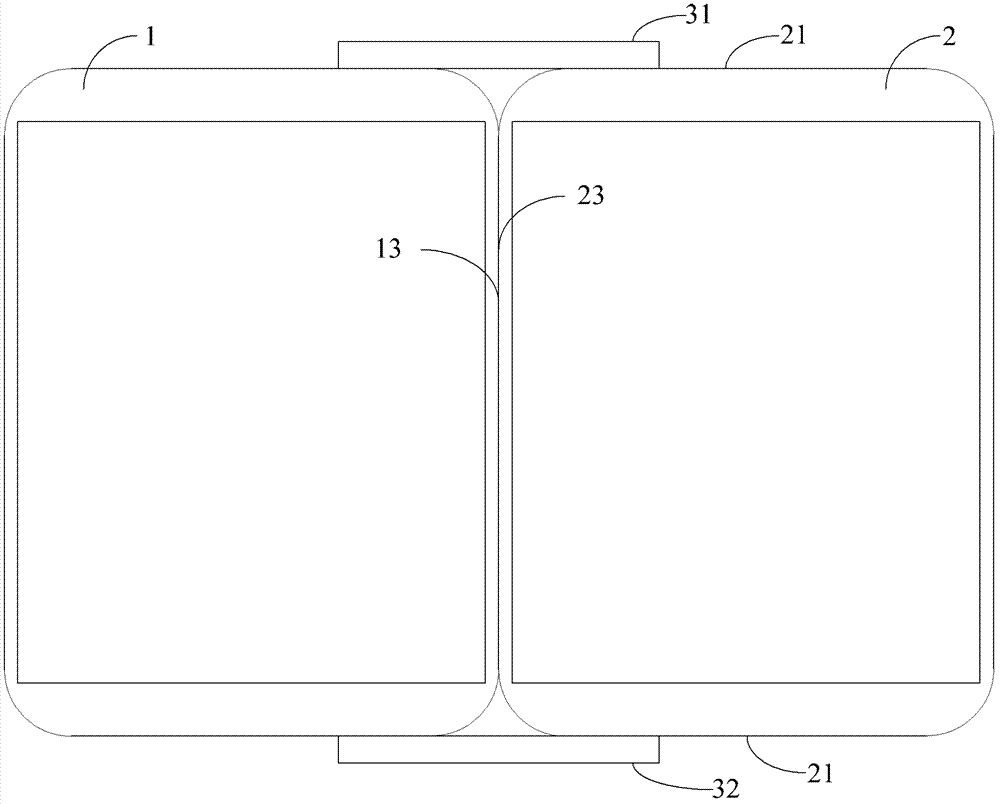

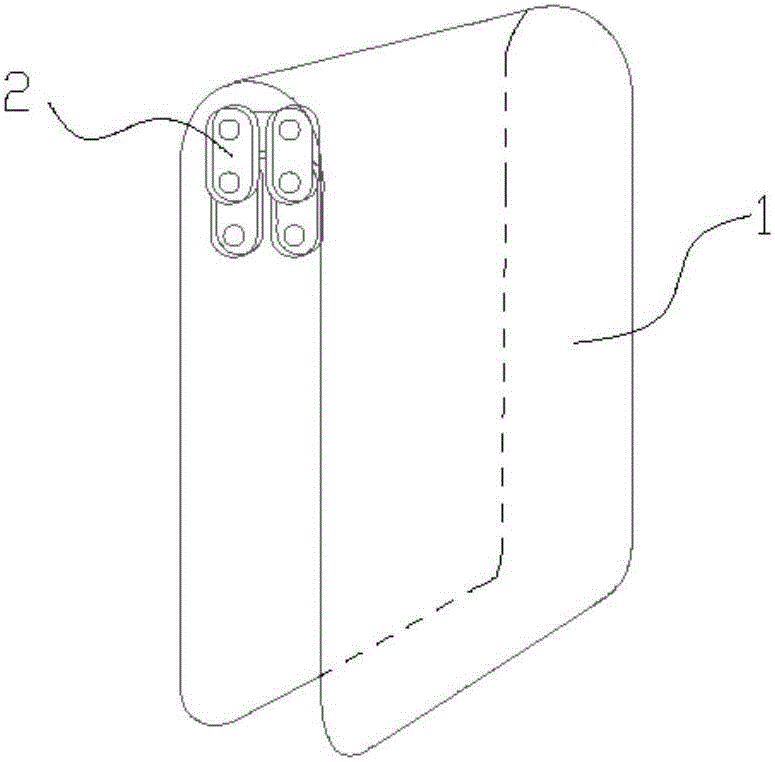

Electronic terminal

Owner:LENOVO (BEIJING) LTD

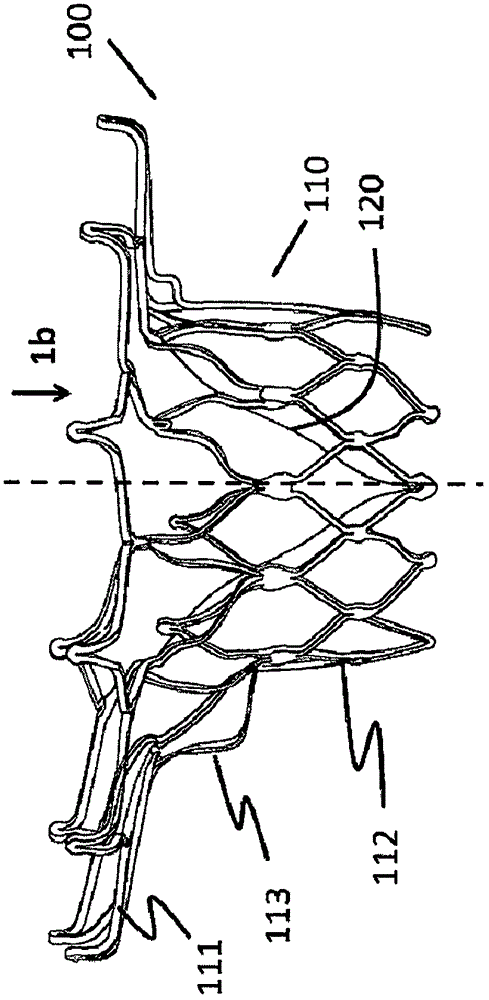

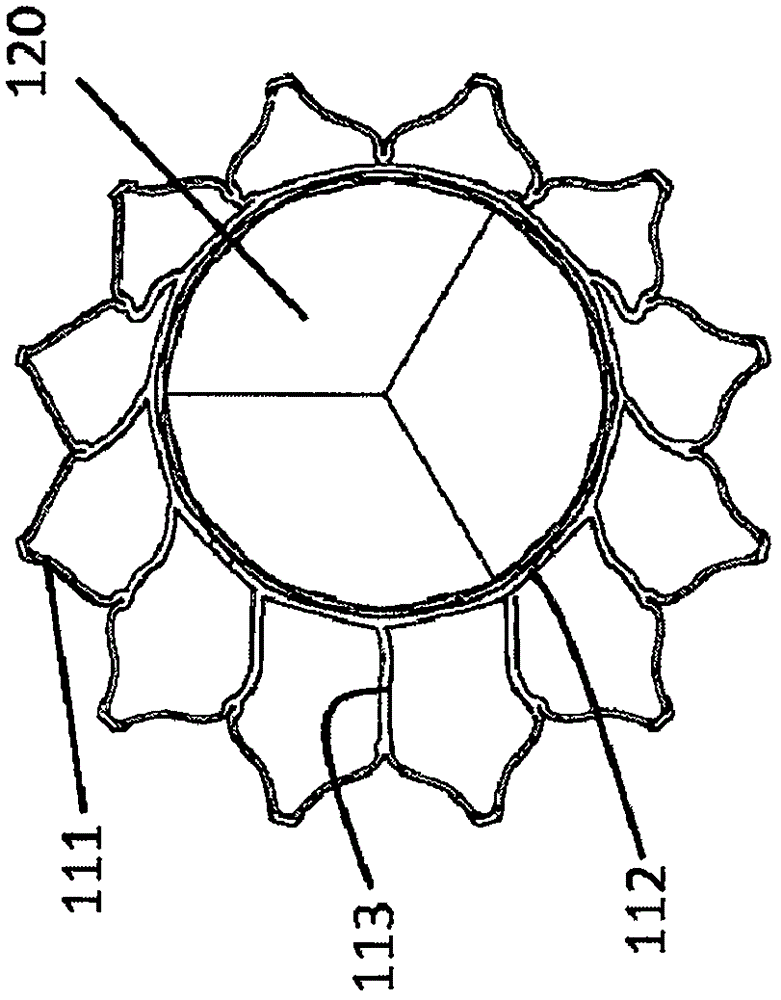

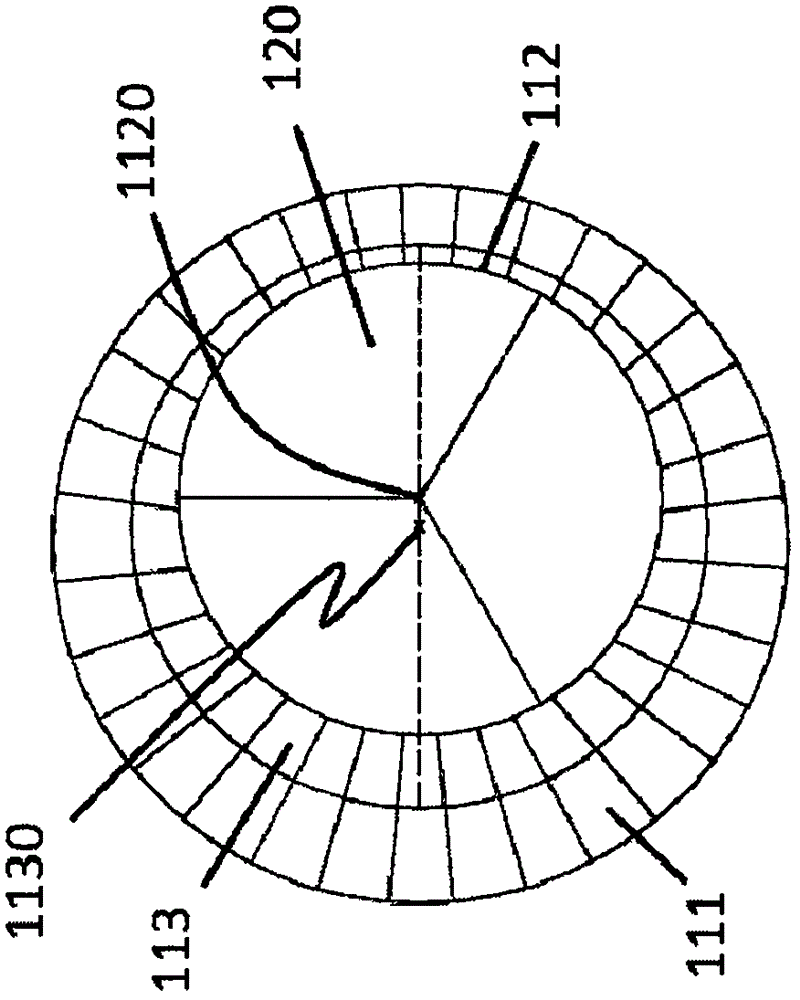

Heart valve prosthesis

ActiveCN106420114AReduced cross-sectional area requirementsImprove performanceAnnuloplasty ringsProsthetic valveFree state

The invention relates to a heart valve prosthesis. The heart valve prosthesis comprises a stent and artificial valves; the stent comprises an atrium section and a valve suturing section, the artificial valves are fixedly connected to the valve suturing section, a skeleton of the far end part of the valve suturing section extends to form a supporting section, and the supporting section and the valve suturing section are of an integrated structure; one end of the atrium section is connected with the far end of the supporting section, the other end of the atrium section is free and is located on the cross section perpendicular to the central axis of the artificial valves, the valve suturing section is located in the supporting section, the center of the valve suturing section does not coincide with that of the supporting section, the cross section area of the supporting section is larger than that of the valve suturing section, the cross section area of the atrium section is larger than that of the supporting section, the cross section area of the valve suturing section is smaller than that of valve rings of autologous valves of a patient, and in a free state, at least part of the supporting section is located among the valve rings of the autologous valves of the patient.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

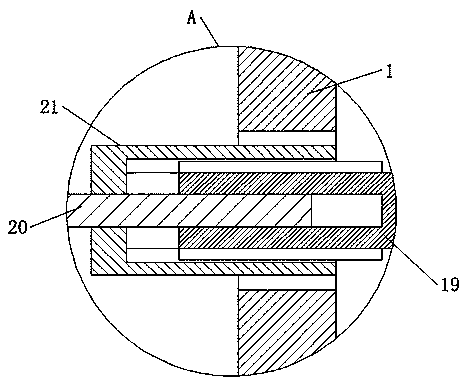

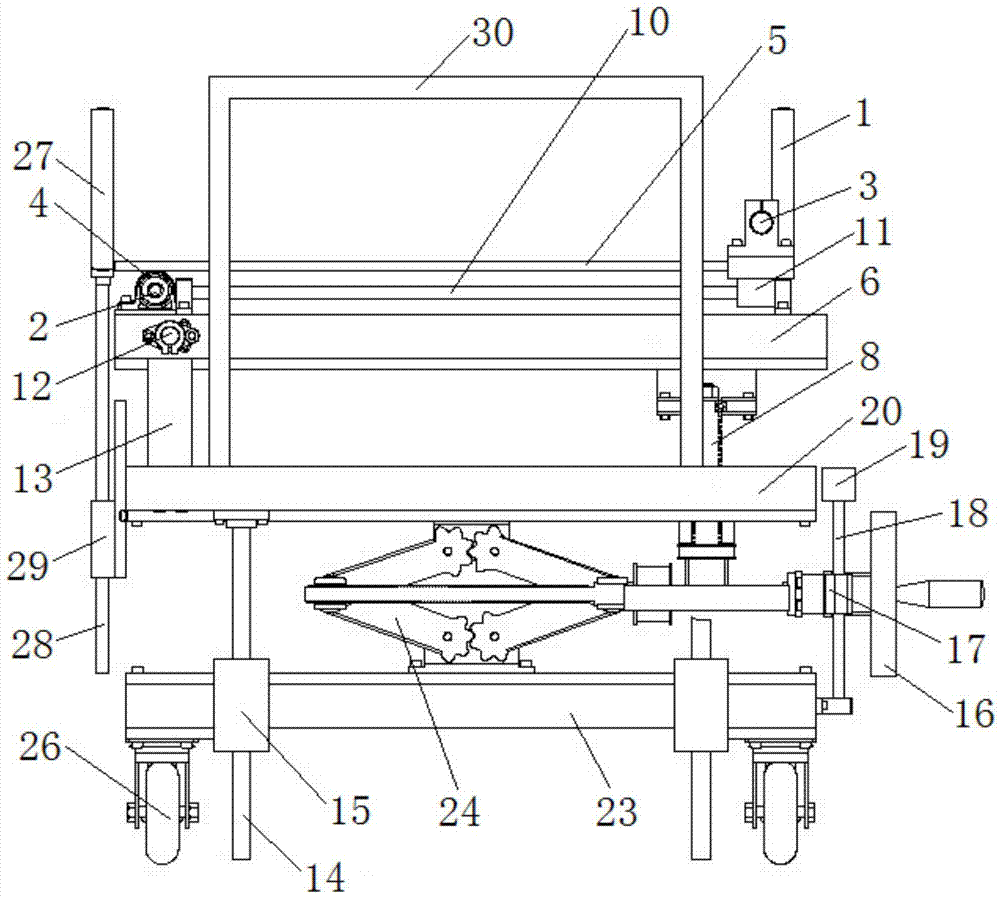

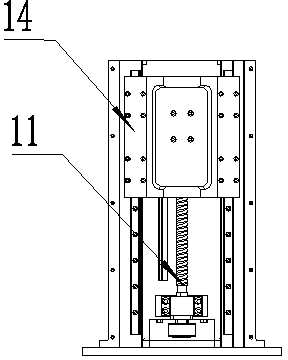

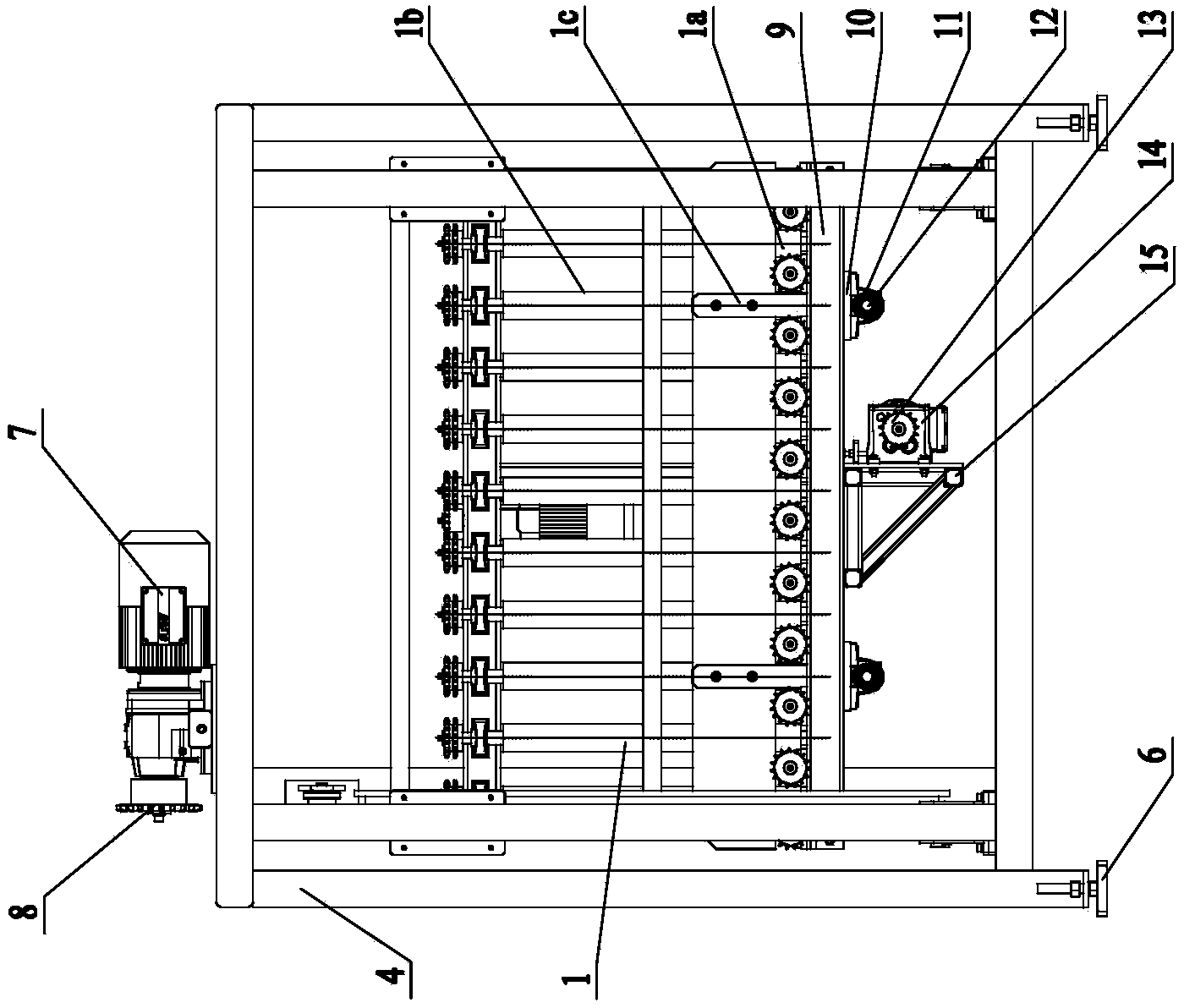

Turnover device for mechanical automatic machining

PendingCN109128921AAvoid severe deformationFlipLarge fixed membersPositioning apparatusEngineeringMachining

The invention discloses a turnover device for mechanical automatic machining. The turnover device comprises a first support plate and a second support plate, wherein the first support plate corresponds to the second support plate, corresponding through holes are respectively formed in the same high position of the first support plate and the second support plate, bearings are fixedly connected tothe inner walls of the two through holes, two symmetrical fixtures are arranged between the first support plate and the second support plate, one fixture is connected with the first support plate by virtue of an adjusting mechanism, a rotating rod is fixedly connected to the center of one side, which is far from the first support plate, of the other fixture, the rotating rod penetrates through thebearing on the second support plate and is rotatably connected with the second support plate, a mounting plate is fixedly connected to one side, which is far from the first support plate, of the second support plate, a motor is fixedly connected to the top of the mounting plate, and the tail end of an output shaft of the motor is fixedly connected with one end, which is far from the fixture, of the rotating rod by virtue of a coupling. According to the turnover device, the purpose of no deformation when a plate is milled is realized by utilizing the lifting support plates.

Owner:QUANZHOU MIAOYI AUTOMATION MACHINERY CO LTD

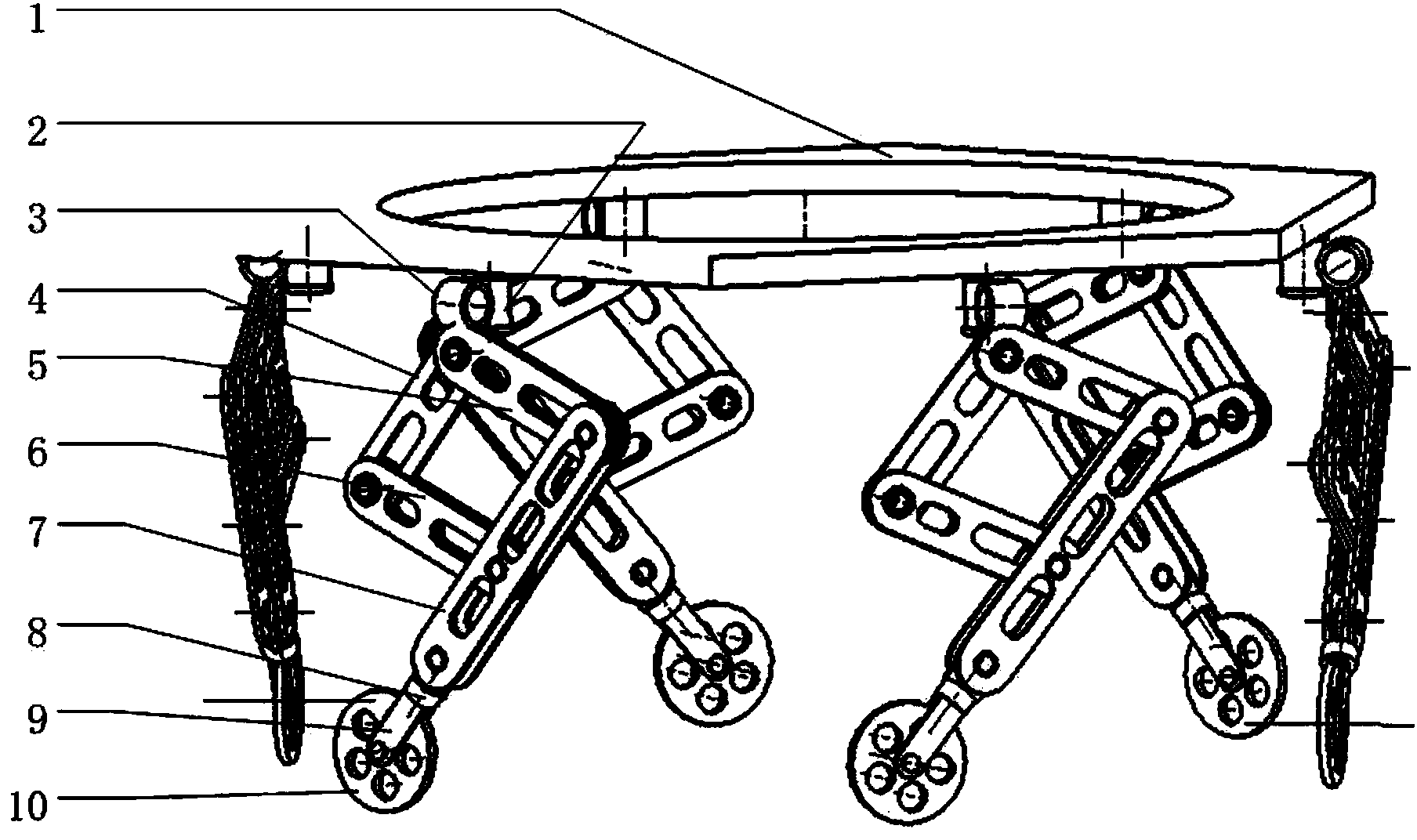

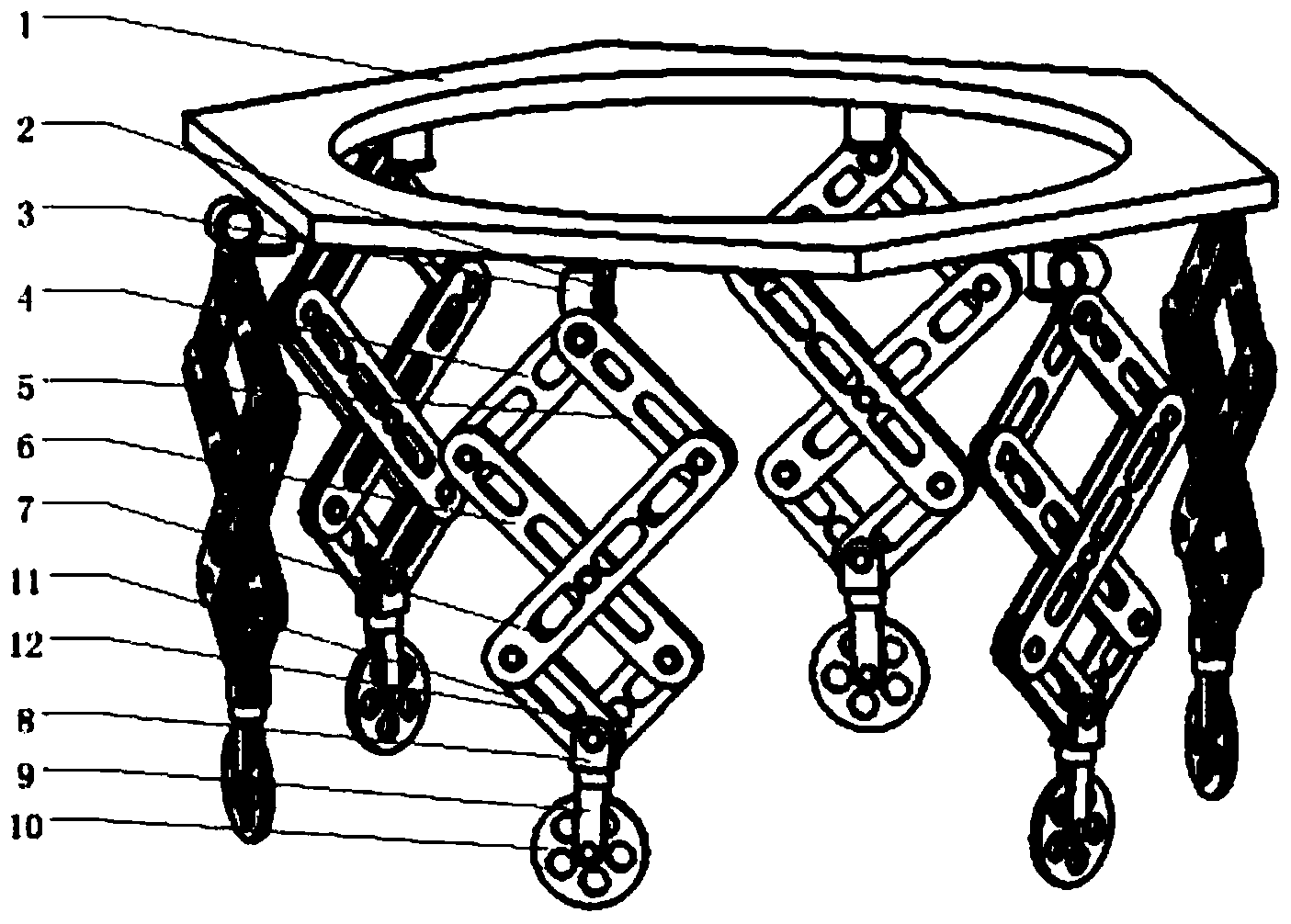

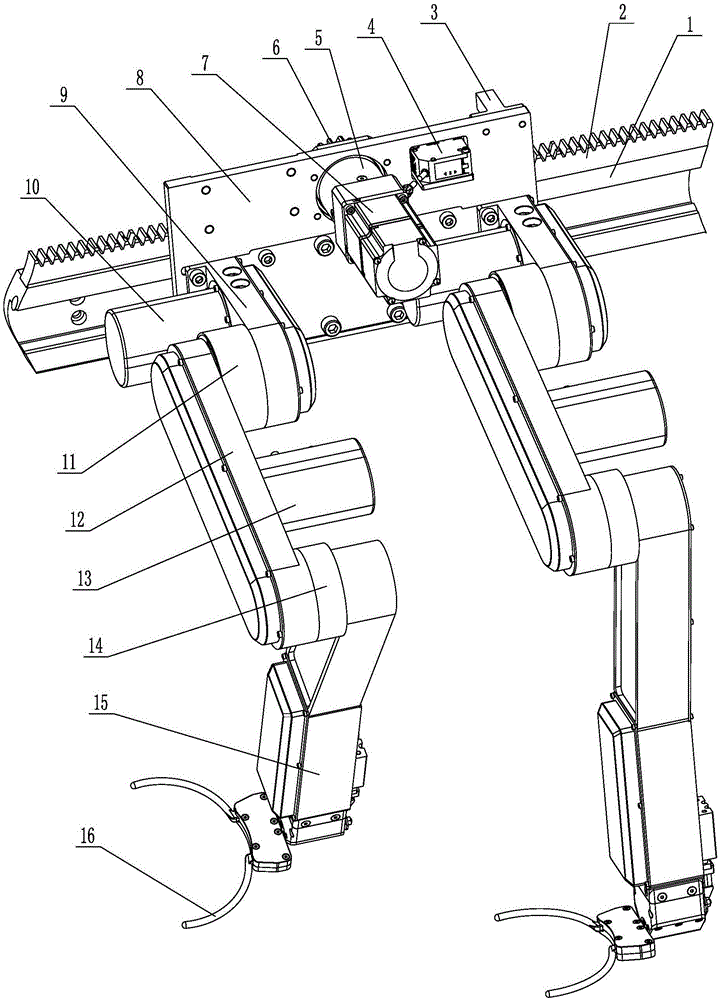

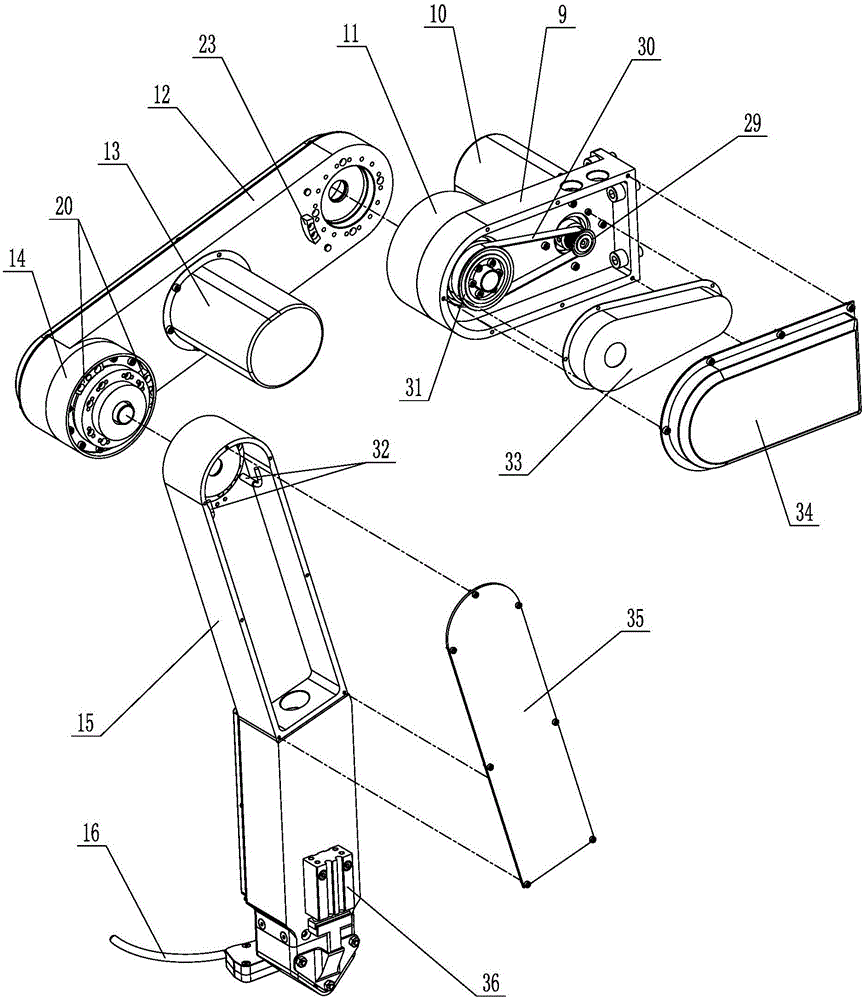

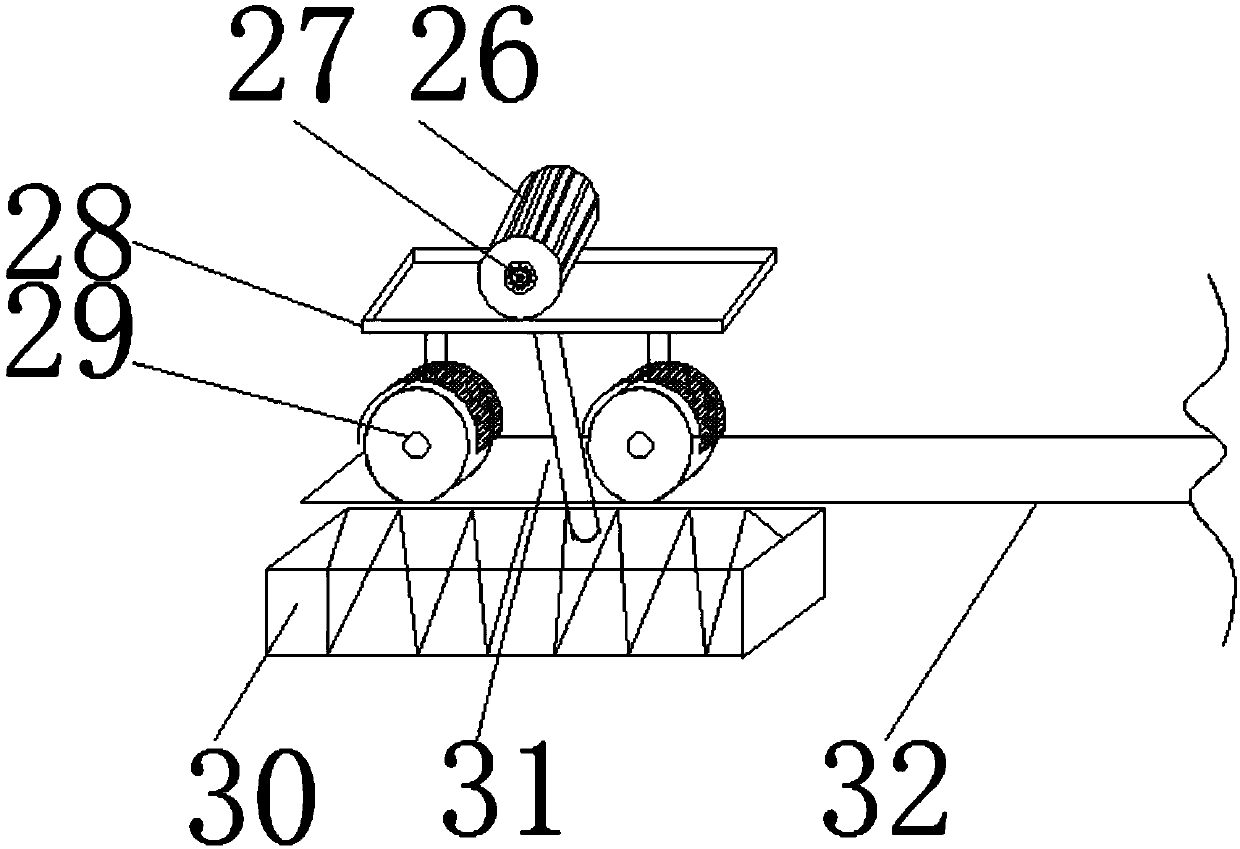

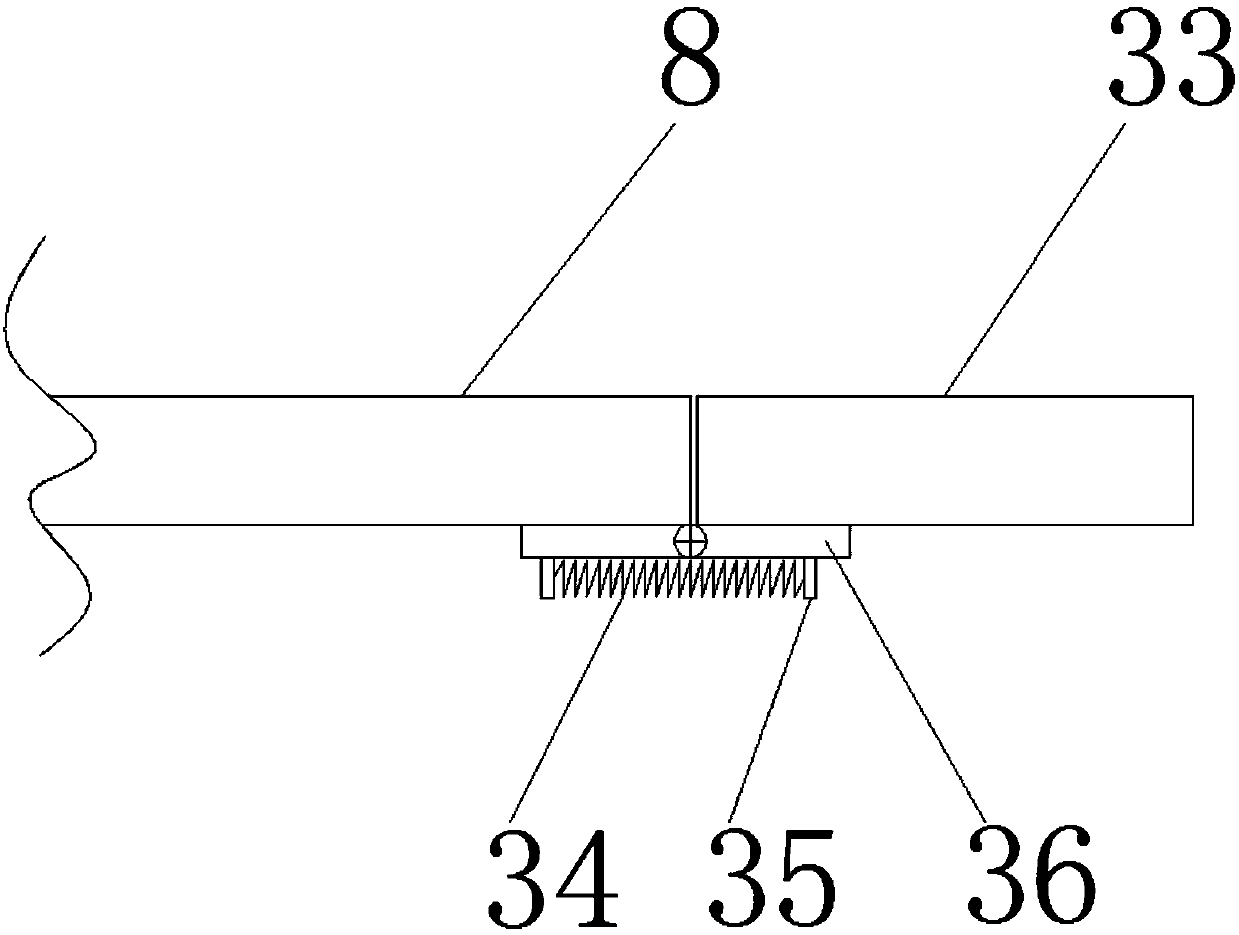

Wheel-legged mobile robot suitable for complicated terrains

A wheel-legged mobile robot suitable for complicated terrains belongs to the technical field of aircrafts, can be used for foreign planet detection, and comprises a platform and six wheel leg systems uniformly arranged on the periphery of the platform, wherein the six wheel leg systems have identical structures, and each wheel leg system comprises a steering mechanism, a turnover mechanism, a swing lifting mechanism, a rotating mechanism and a wheel; each steering mechanism is fixed onto the platform and is connected with the corresponding turnover mechanism; the two ends of each swing lifting mechanism are respectively connected with the corresponding turnover mechanism and the corresponding rotating mechanism; each wheel is connected onto the bottom of the corresponding rotating mechanism. The wheel-legged mobile robot can meet multiple requirements under the complicated environment, can climb a slope, cross an obstacle, span a trough and advance stably on the uneven ground, can be folded for being transported conveniently, and is simple in structure and low in energy consumption.

Owner:SHANGHAI JIAO TONG UNIV

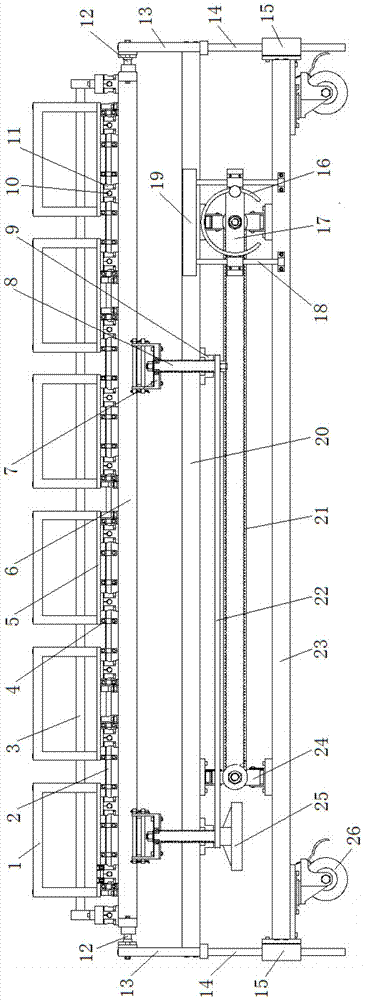

Mechanical patient transferring trolley

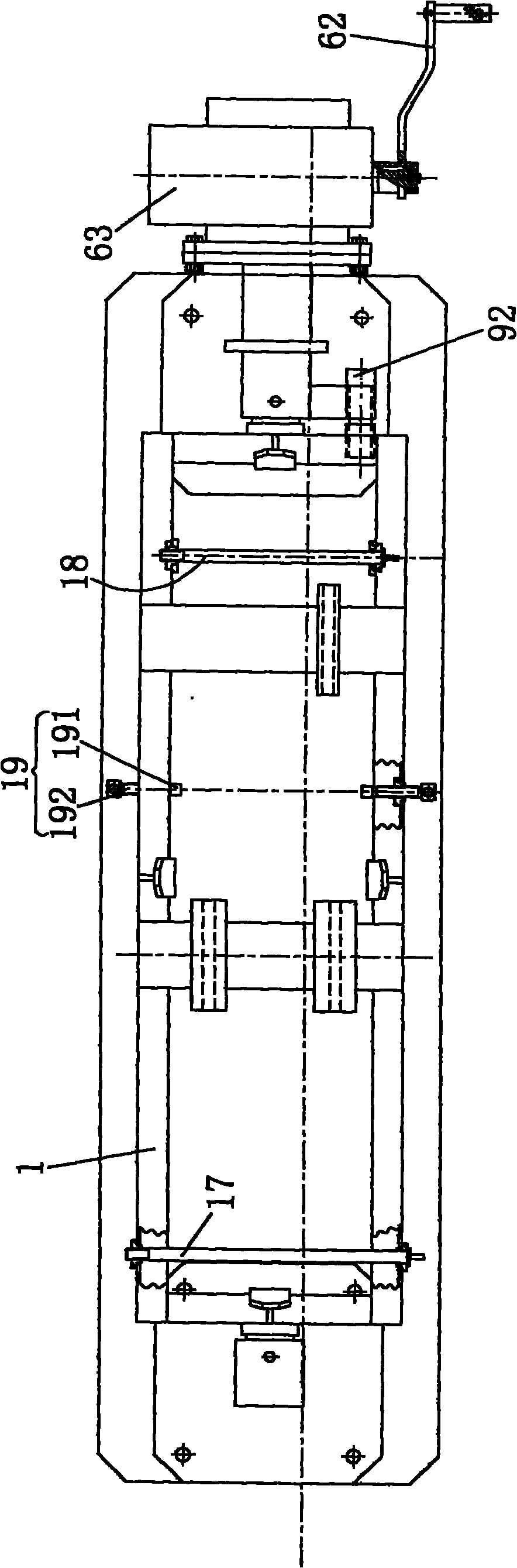

The invention discloses a mechanical patient transferring trolley and belongs to the field of special patient transportation tools. The mechanical patient transferring trolley comprises an upper trolley frame, a middle trolley frame, a lower trolley frame, a lifting device arranged between the lower trolley frame and the middle trolley frame, an overturning device arranged between the middle trolley frame and the upper trolley frame, a horizontal moving device arranged on the upper trolley frame and multiple sliding carrying plates which are mutually isolated. A scissor jack is used for ascending and descending the upper trolley frame and the middle trolley frame. A screw nut pair is used for overturning the upper trolley frame. A horizontal guide rail and a rolling bearing are used for horizontally moving the sliding carrying plates which are used for flexibly transferring a patient. The mechanical patient transferring trolley is flexible and convenient to operate, small in number of nursing personnel, needless of greatly moving the patient and capable of avoiding secondary injury in the patient transferring process and has the advantages of being simple in structure, low in cost, convenient to maintain, stable in operation and low in noise.

Owner:上海稼多医疗器械有限公司

Color steel tile face paint spraying device

A color steel tile face paint spraying device is used for color steel composite plate paint spraying and comprises a base, stand columns and a transverse plate. The stand columns are fixedly arrangedon the two sides of the upper surface of the base, the transverse plate is fixedly arranged between the top ends of the two stand columns, and a drying mechanism is arranged on one side of the top endof the transverse plate. The side, away from the drying mechanism, of the top end of the transverse plate is provided with a paint spraying mechanism. A motor is fixedly arranged above the stand column on one side through a supporting plate. The upper surface of the part, between the two stand columns, of the base is fixedly provided with two fixing columns. Fixing mechanisms are arranged on thetwo fixing columns. A protection cover is arranged outside a paint sprayer and completely wraps the sprayer, so that when the sprayer sprays out paint, the protection cover keeps off the splashed paint, the paint is retained on the protection cover, paint waste is reduced, and the problem that when an existing paint spraying device sprays paint, the paint spraying-out speed is too high, consequently, a coating is scattered and flies, the paint is wasted, and meanwhile the surrounding air environment is polluted are solved.

Owner:ZHONGXIANG DINGMAO TECH

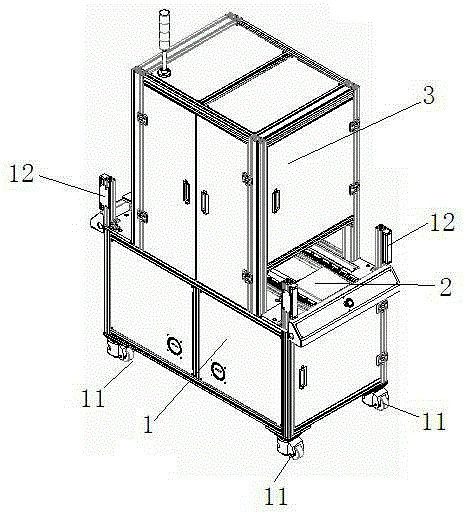

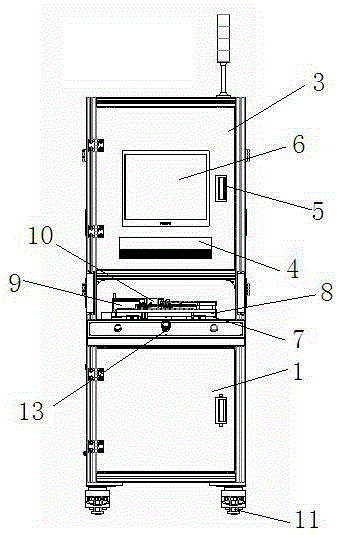

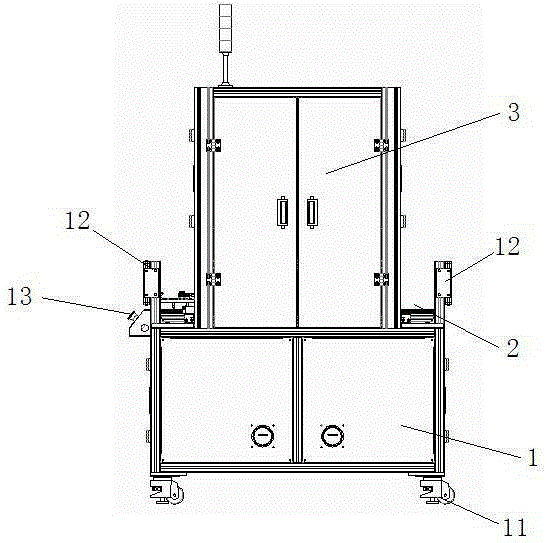

AOI vision detection device with automatic overturning function

InactiveCN105259182AFlipEasy flipOptically investigating flaws/contaminationEngineeringMechanical engineering

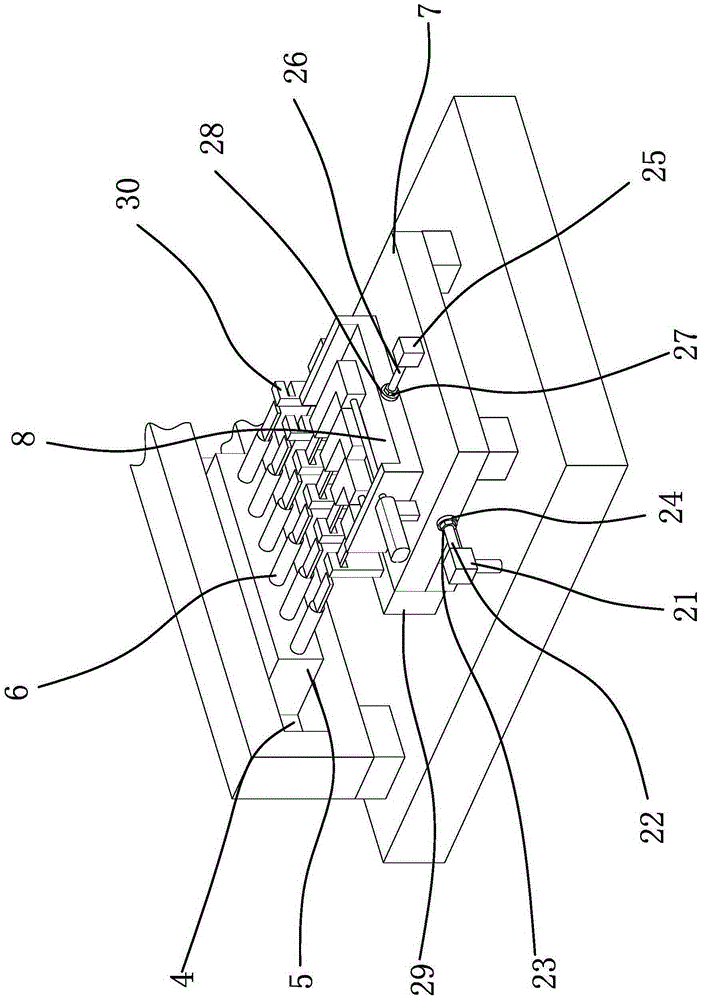

The invention discloses an AOI vision detection device with an automatic overturning function. The AOI vision detection device comprises a bearing machine box, the bearing machine box is provided with a conveying belt for conveying PCBs to be detected, a detection machine box is further arranged above the bearing machine box, and the detection machine box is internally provided with an automatic shooting camera, a processing terminal and a display panel. One side of an inlet of the conveying belt is fixedly provided with a PCB bearing mechanism, and the PCB bearing mechanism comprises a foundation support, a vacuum sucking disc plate, an overturning motor and a grab handle, the foundation support is fixed to the conveying belt, the vacuum sucking disc plate is fixed to the foundation support, the upper surface of the vacuum sucking disc plate is used for absorbing the PCBs to be detected, the overturning motor is arranged on one side of the foundation support, and the output end of the overturning motor is connected with the grab handle to drive the grab handle to grab and turn over the PCBs to be detected at the center of the conveying belt. By means of the AOI vision detection device, two faces can be detected at the same time through one-time conveying, a sucking disc is adopted for adsorption, taking, placing and fixing are facilitated, and detection efficiency is greatly improved.

Owner:KUNSHAN HONGZHIXI AUTOMATION EQUIP

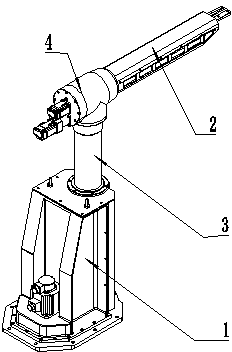

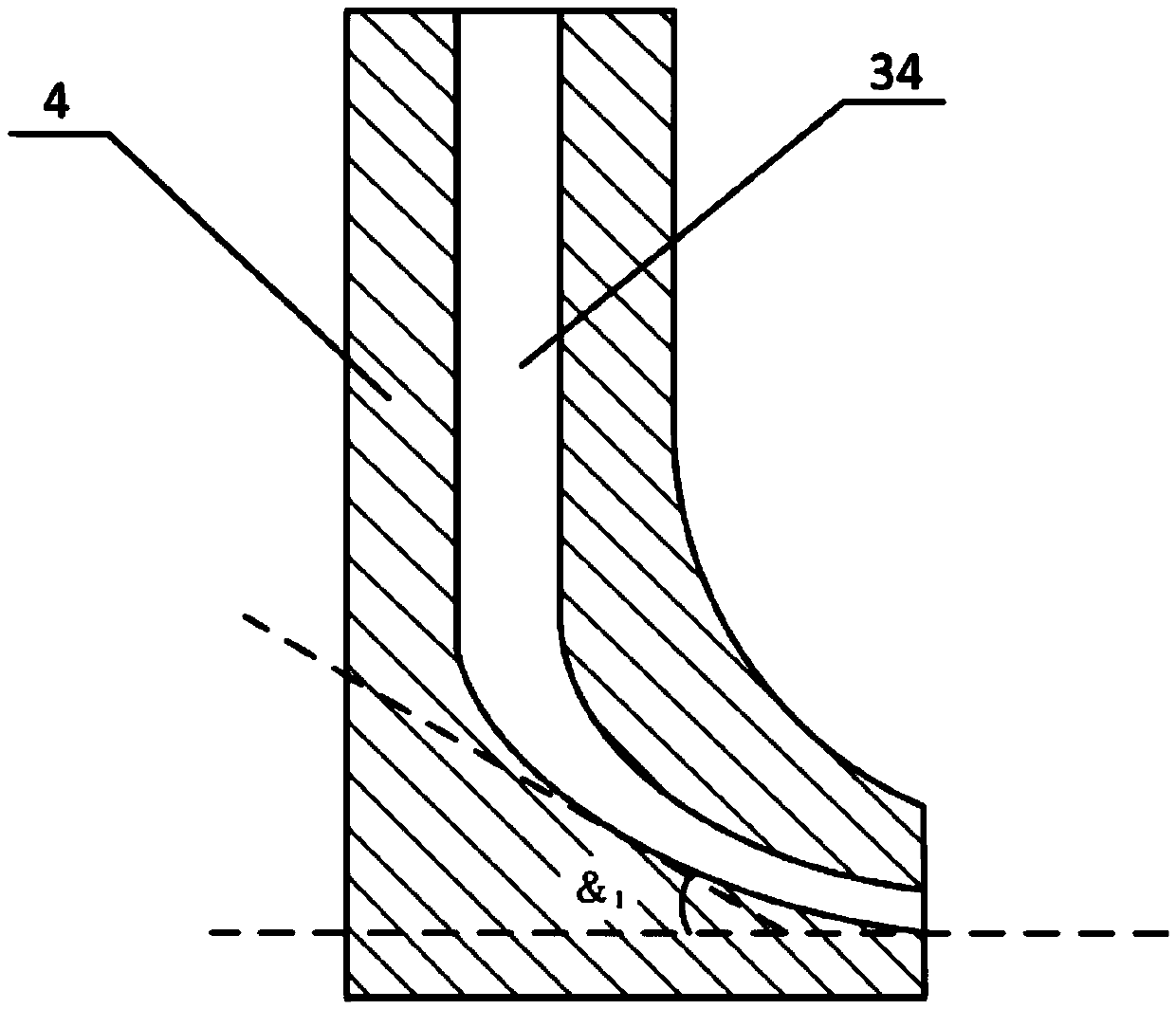

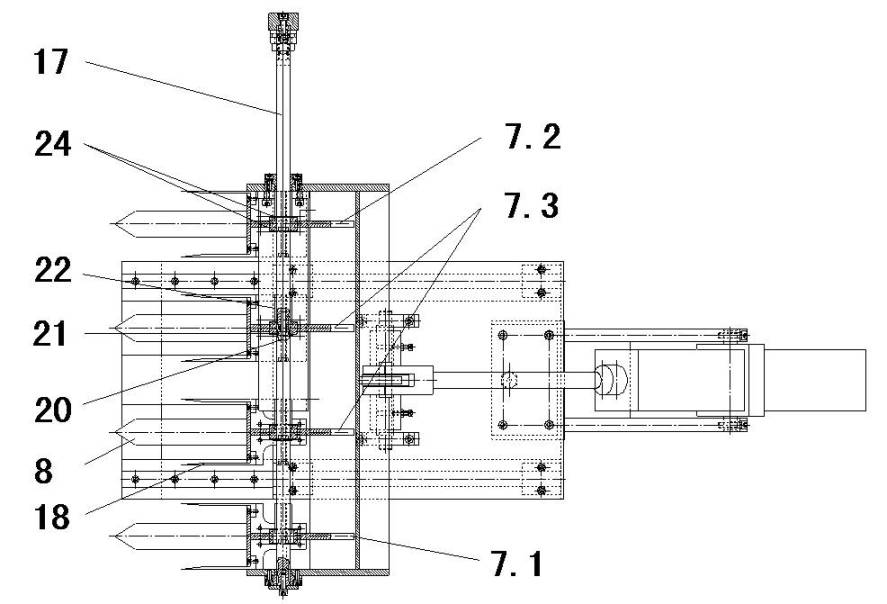

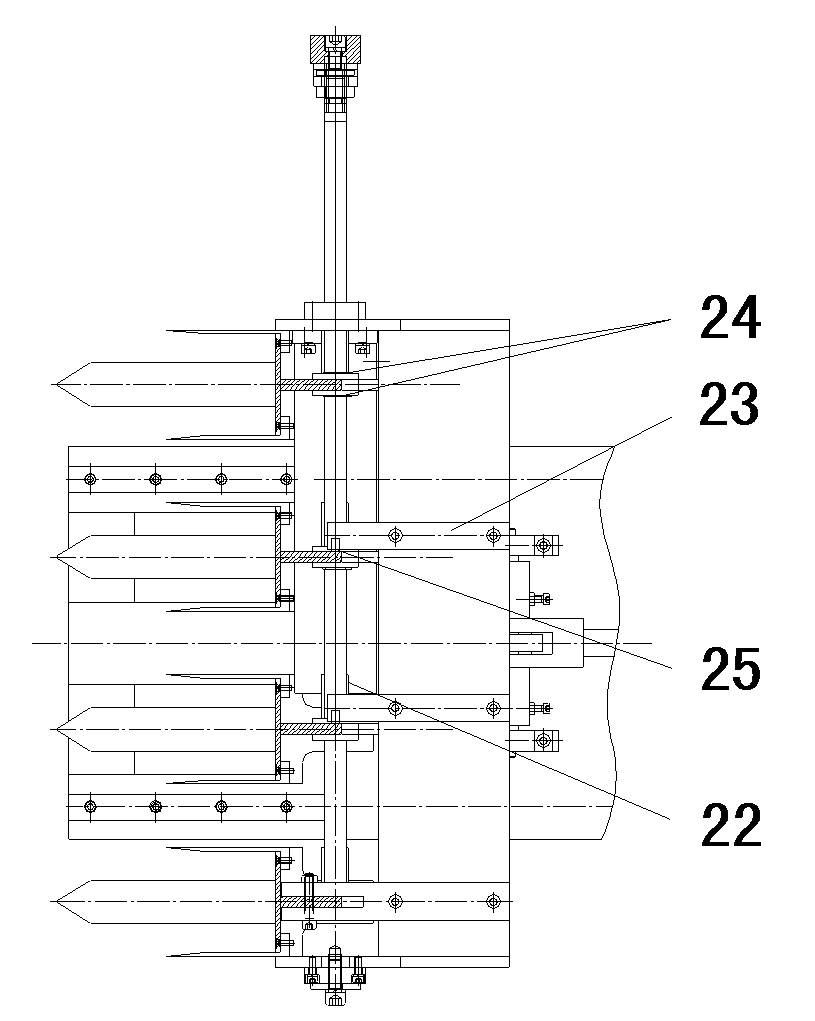

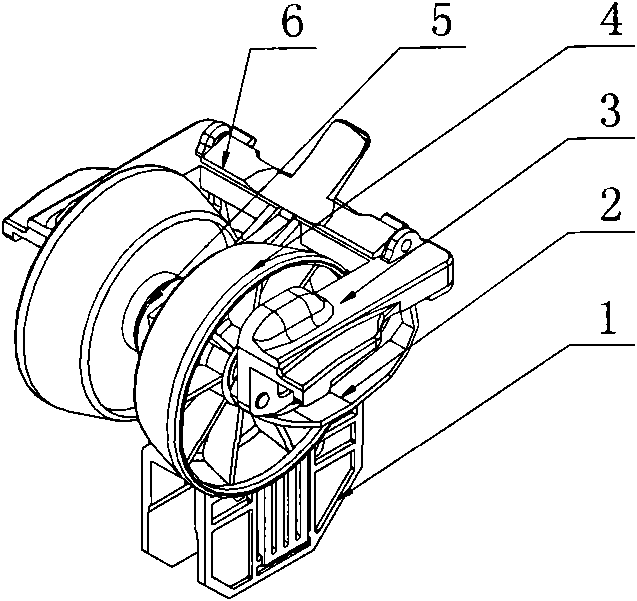

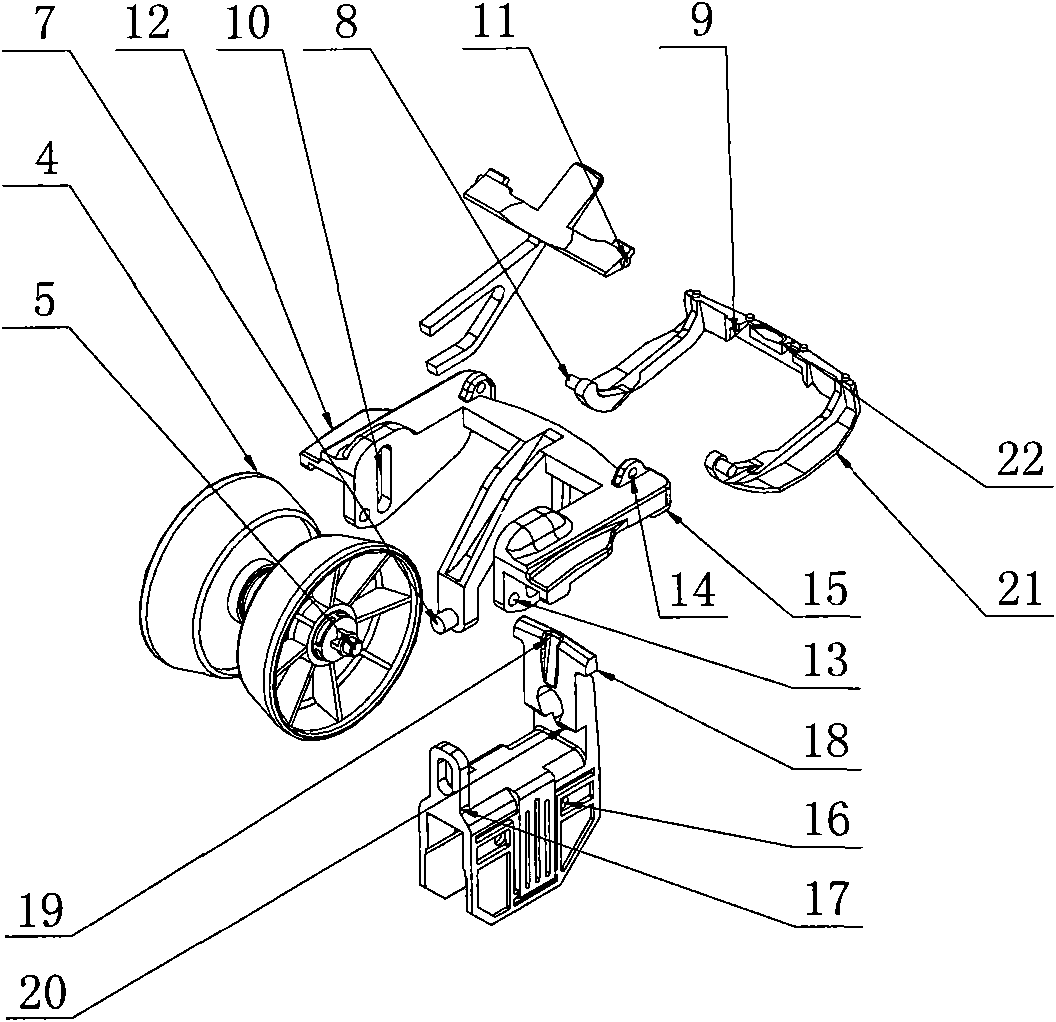

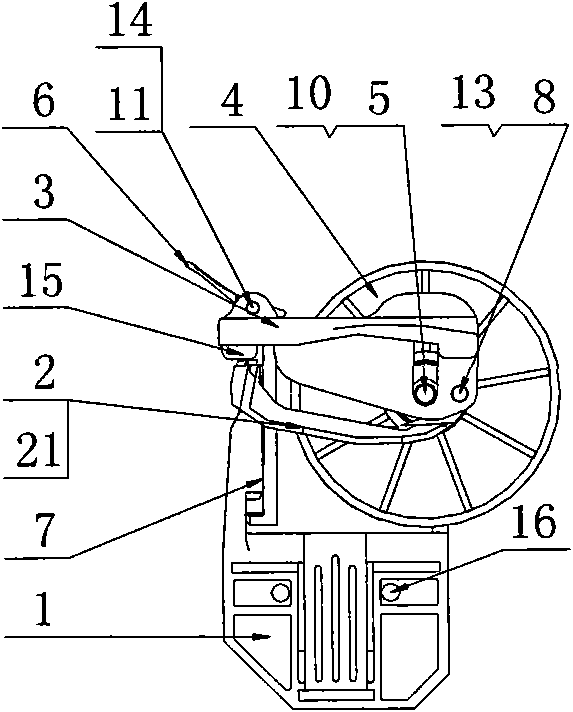

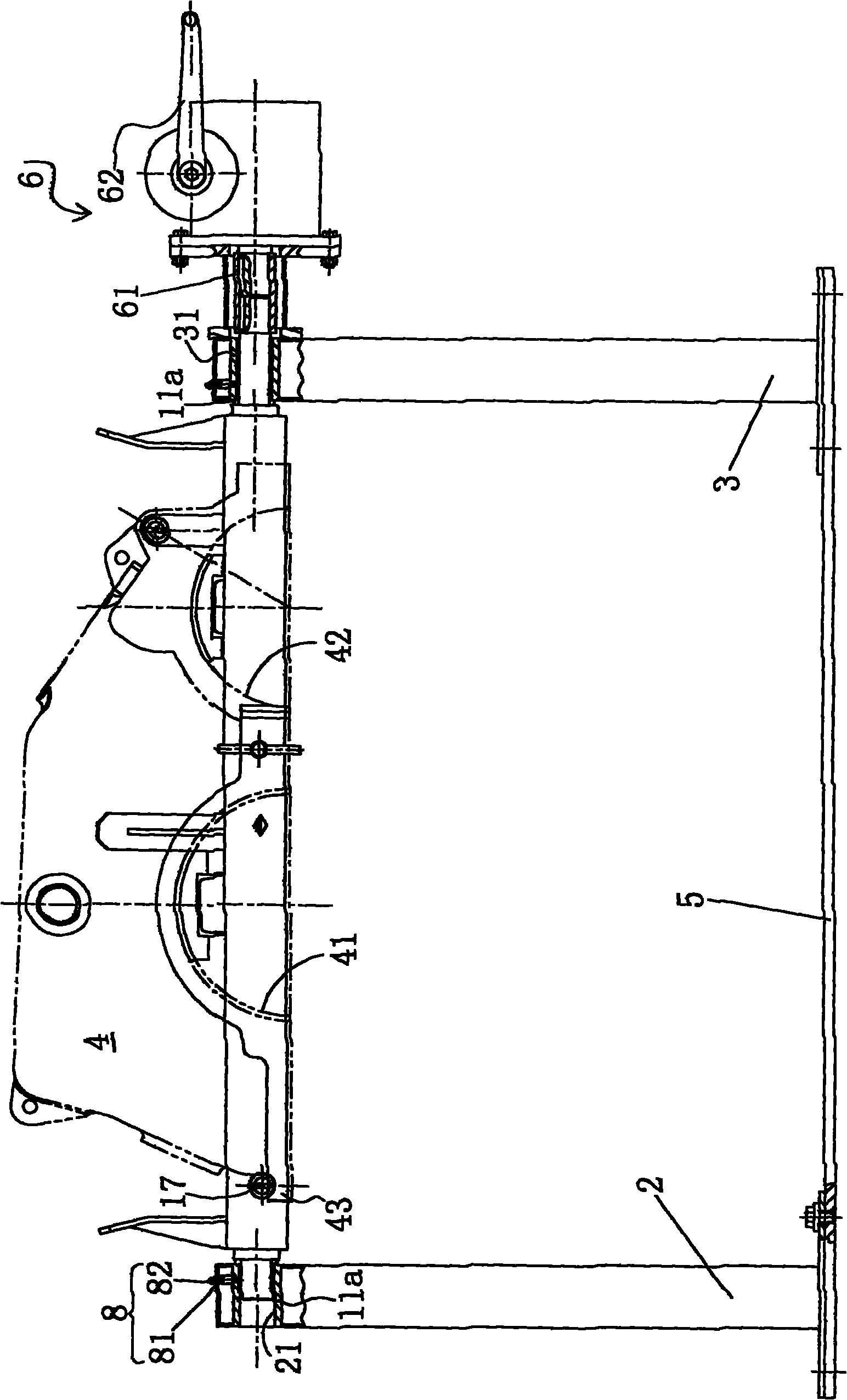

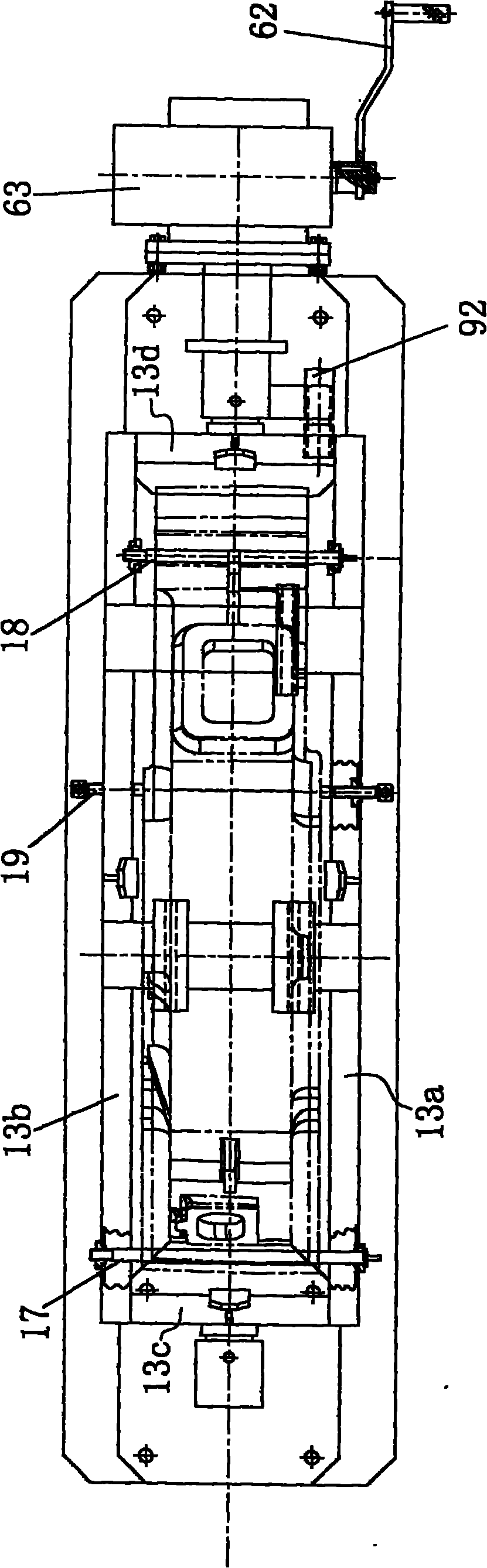

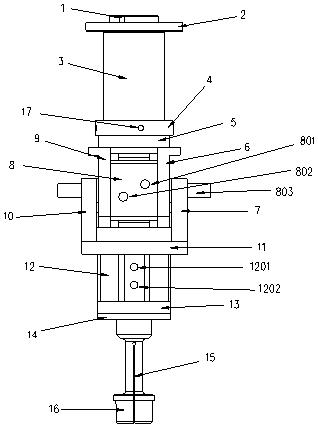

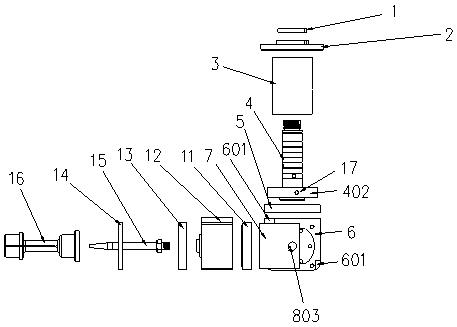

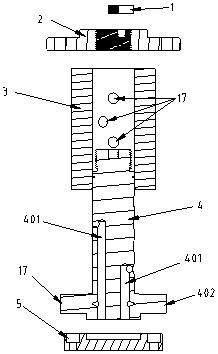

Cylindrical coordinate robot

InactiveCN104440896ASimple structureCompact structureProgramme-controlled manipulatorRotational axisClassical mechanics

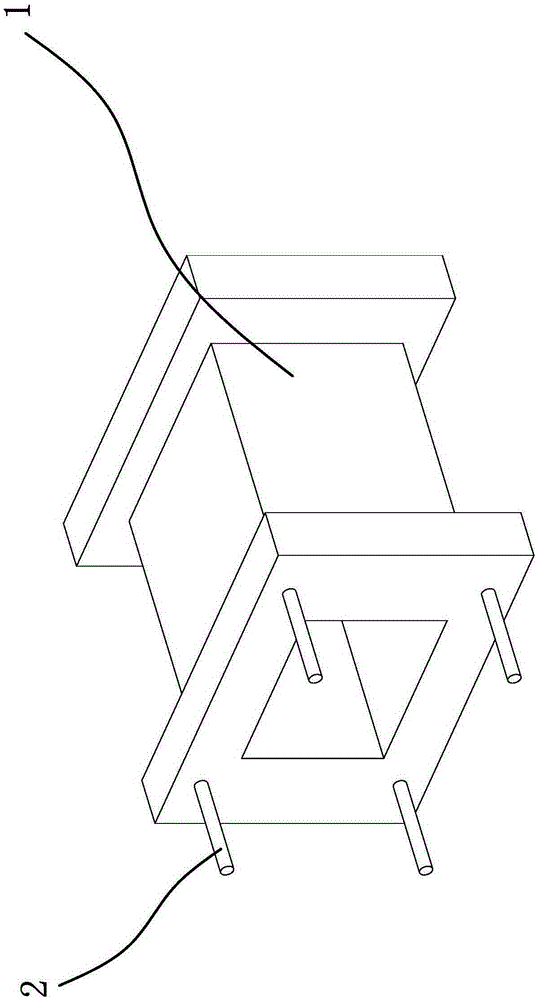

The invention discloses a cylindrical coordinate robot which comprises a Z shaft (1), an X shaft (2), a rotating shaft (3) and a turning shaft (4), wherein the Z shaft (1) can move in the Z direction, and the X shaft (2) can move in the X direction; the rotating shaft (3) can rotate in the Z direction, and the turning shaft (4) can rotate in the X direction; the rotating shaft (3) is arranged on the Z shaft (1), the turning shaft (4) is arranged on the rotating shaft (3), and the X shaft (2) is arranged on the turning shaft (4). The robot can realize turning of materials and also has the advantages of being simple and compact in structure, great in stability and rigidity and small in occupied area.

Owner:CHONGQING LANGZHENG TECH

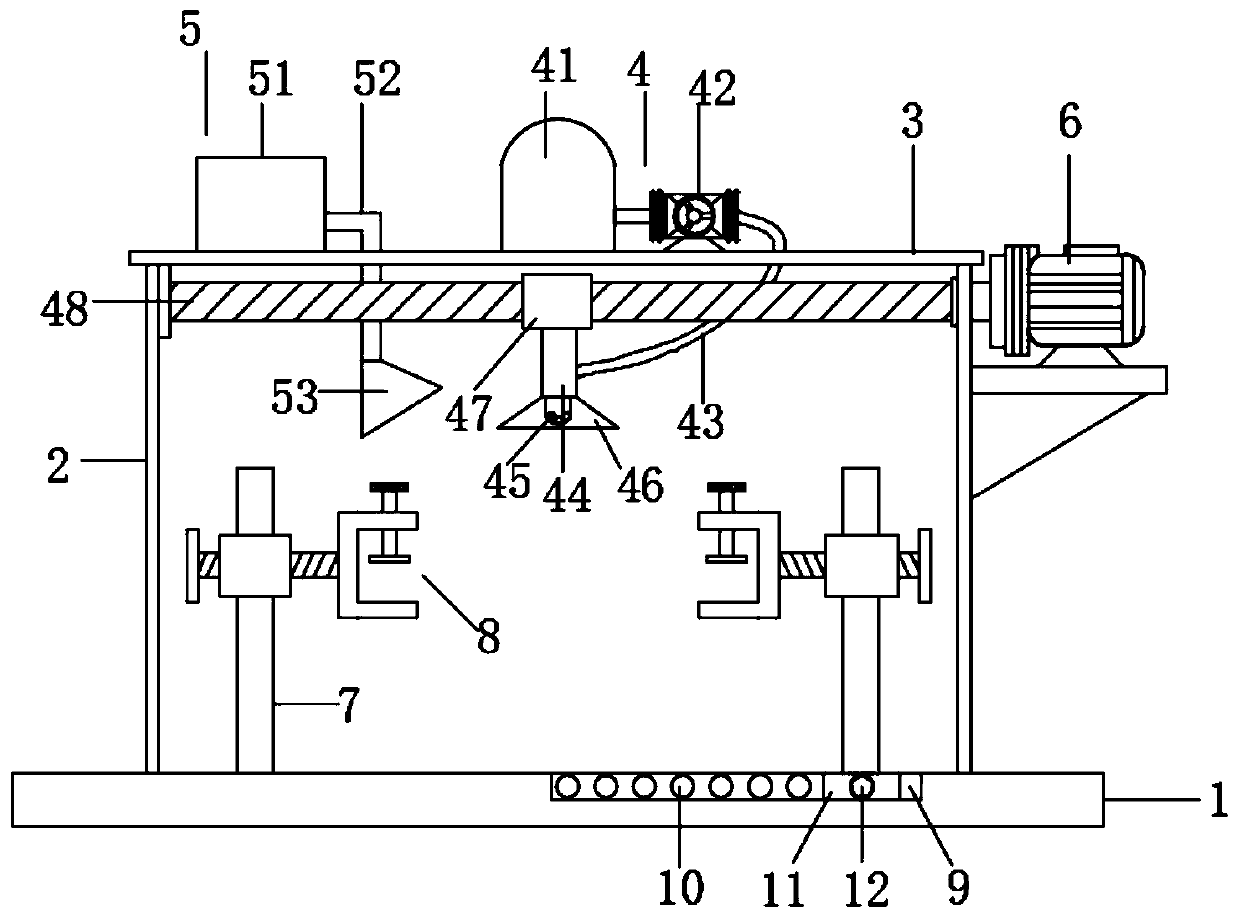

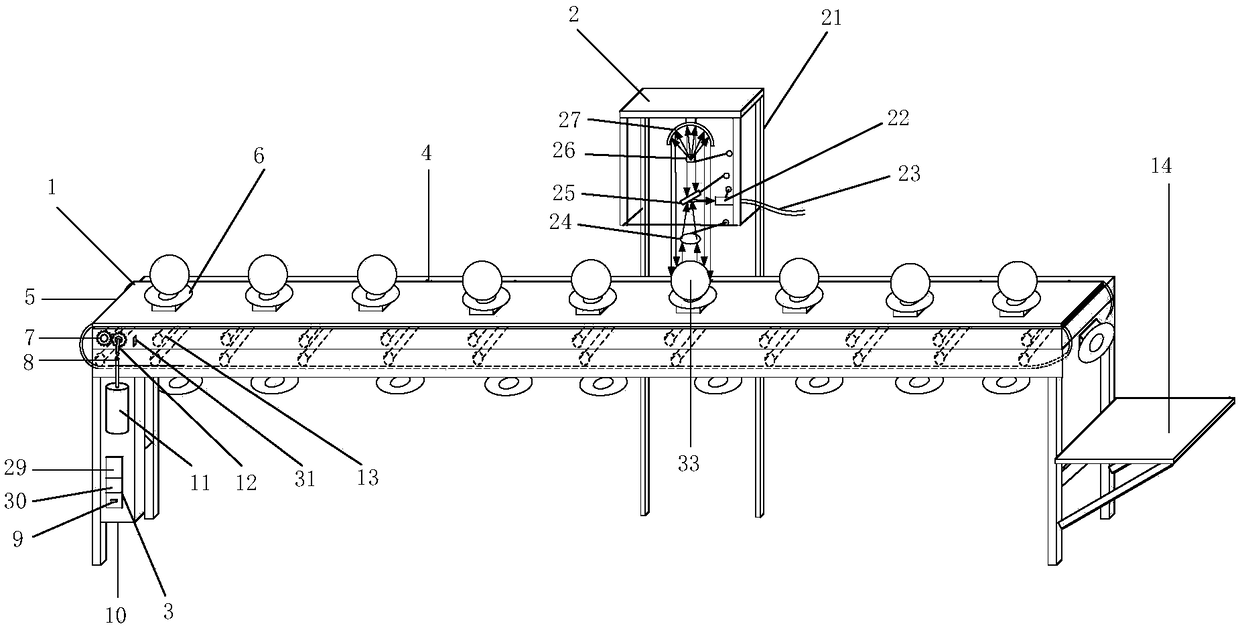

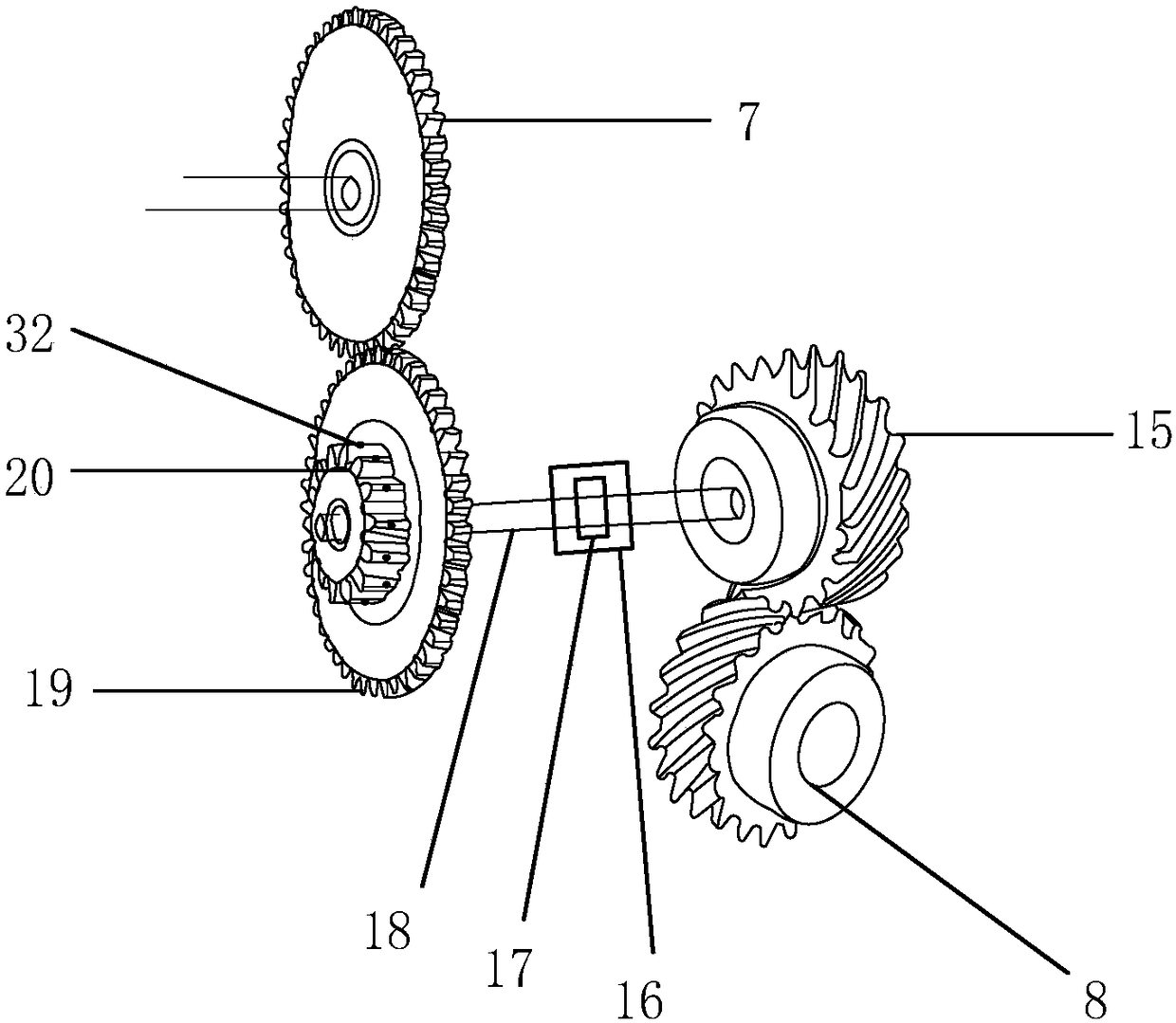

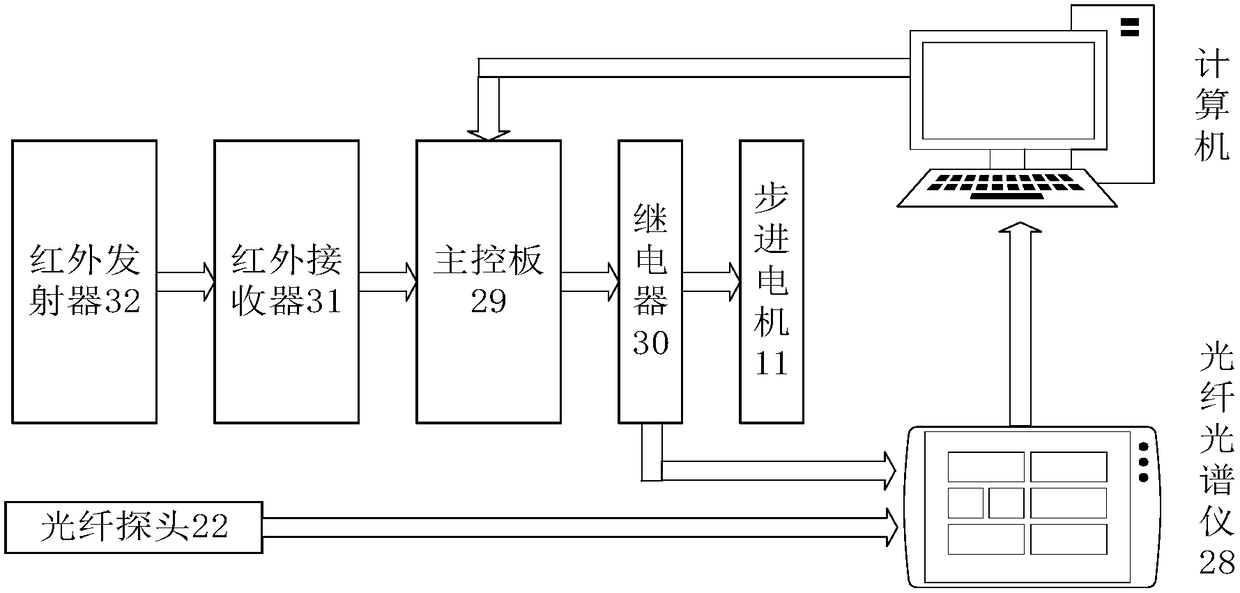

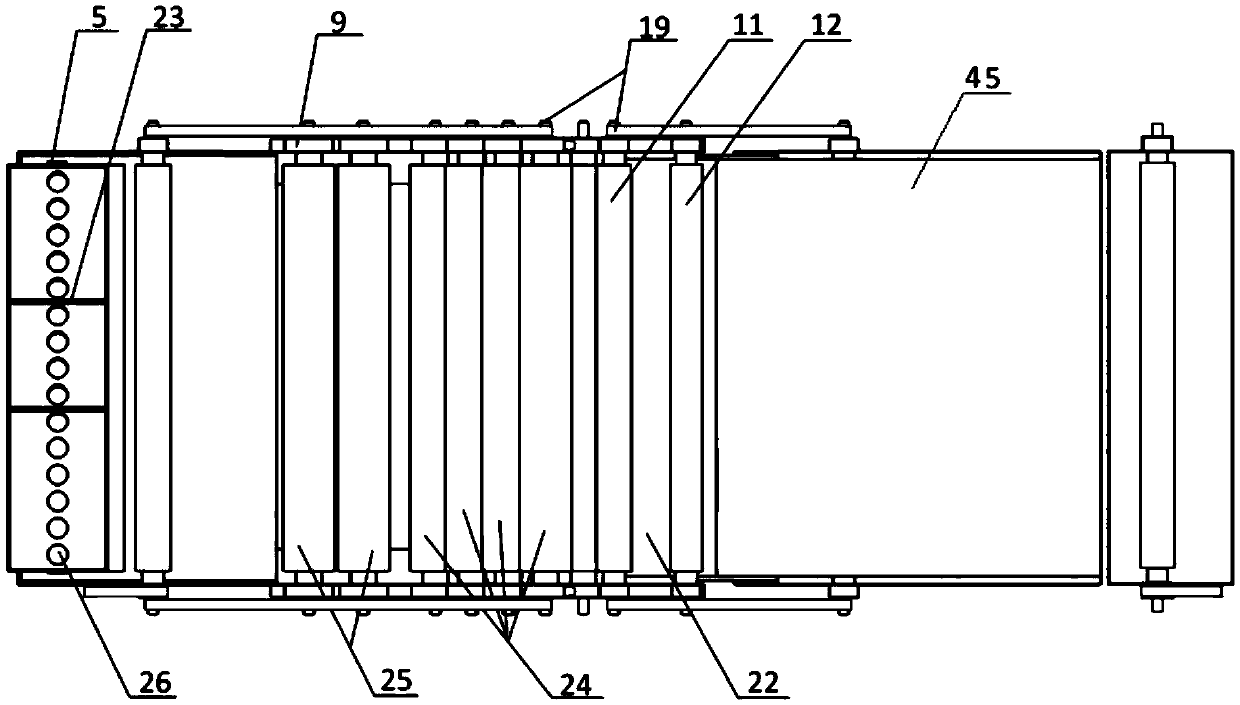

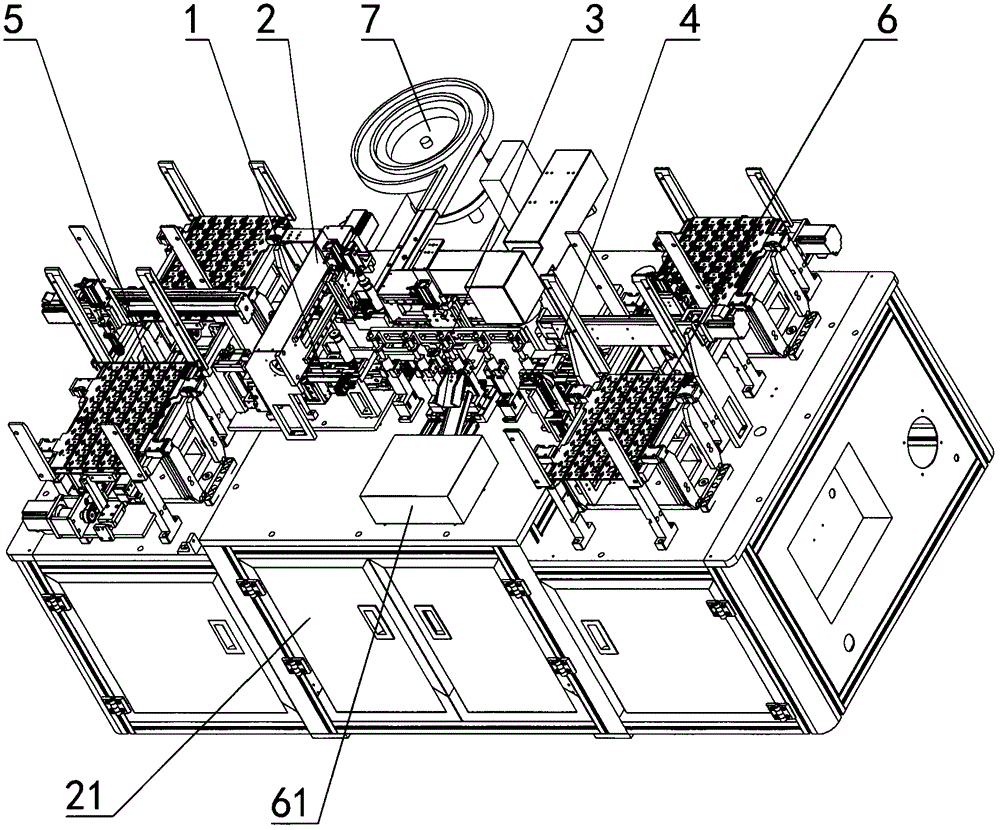

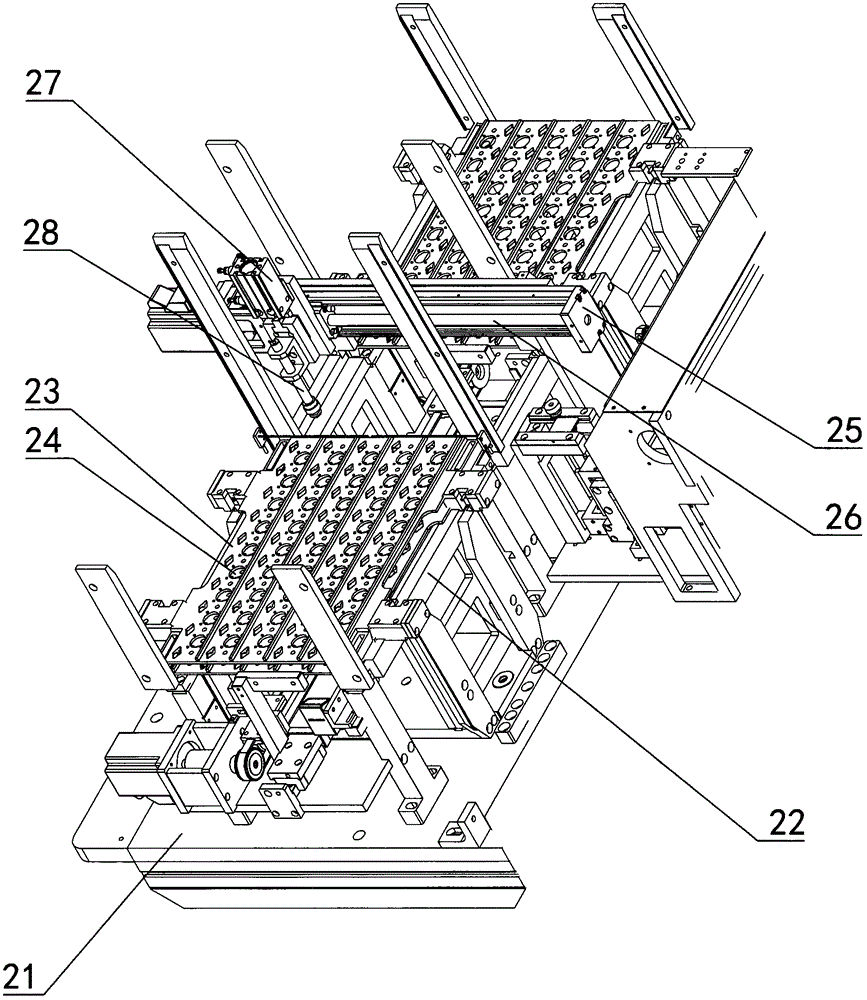

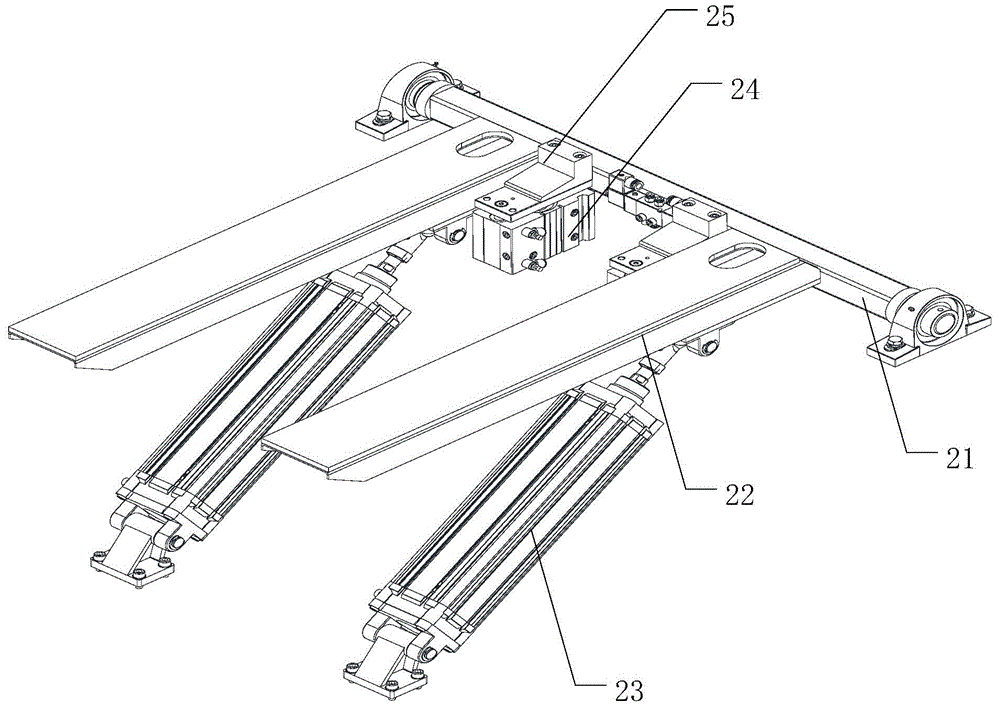

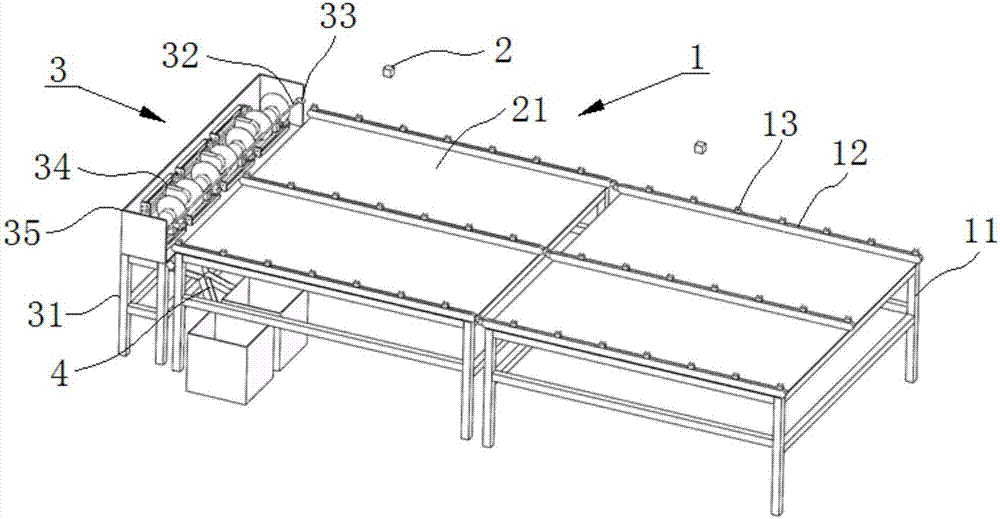

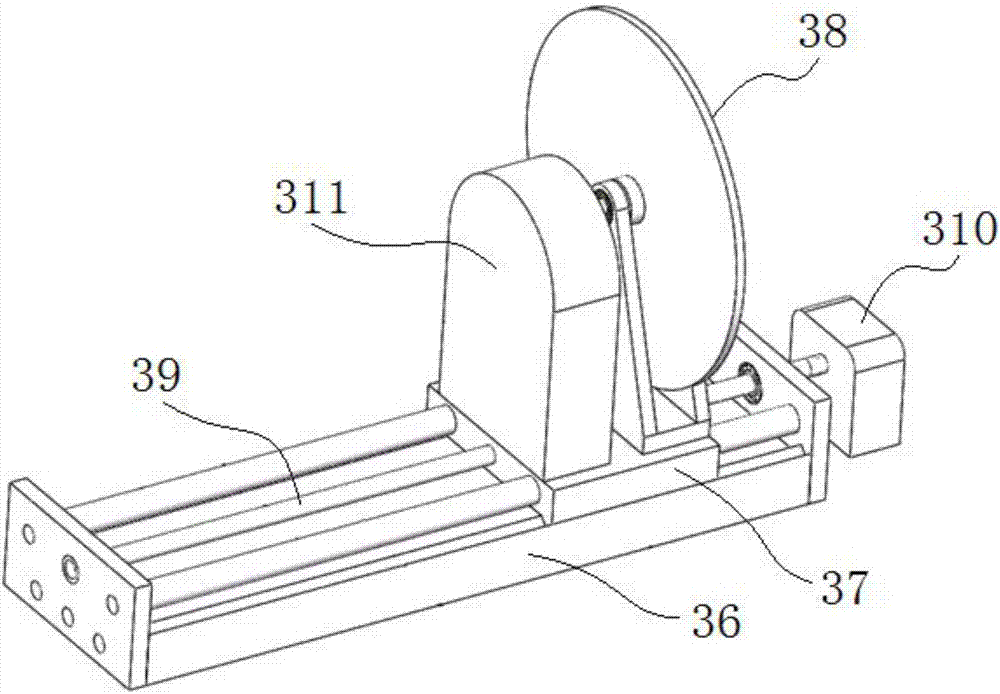

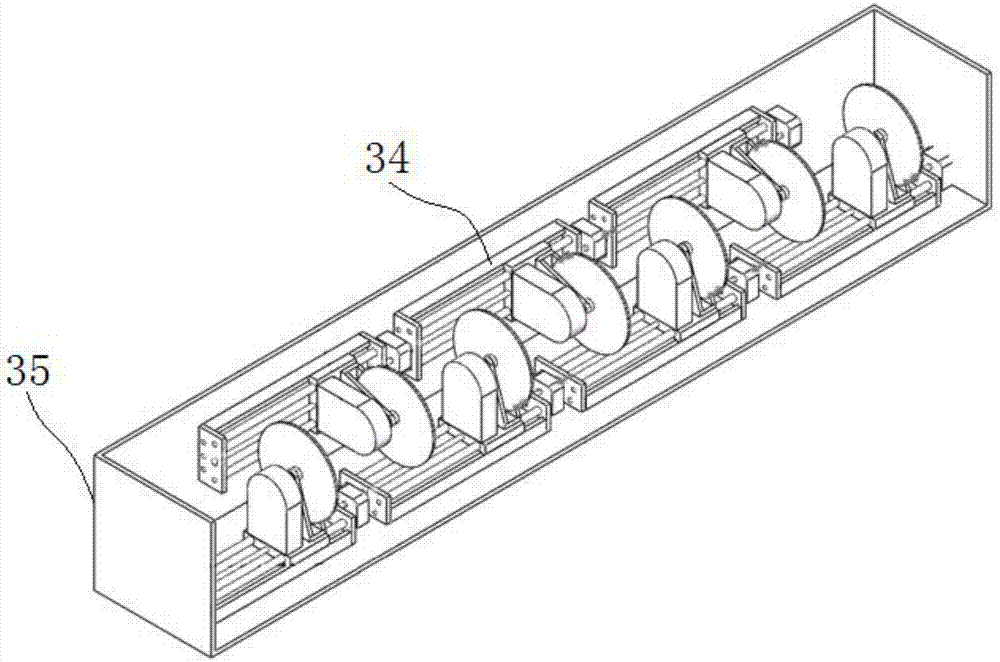

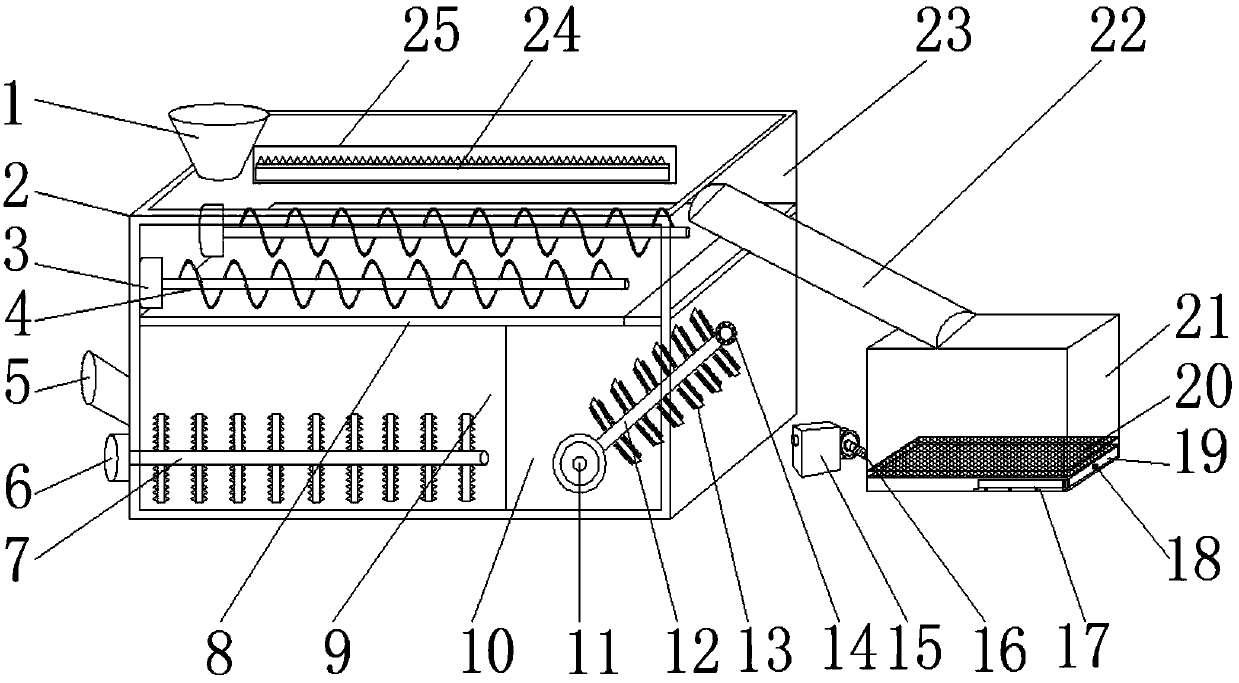

Fruit sugar degree sorting device and method based on weighing and sorting line transformation

InactiveCN108284076AEfficient removalImprove detection accuracySortingReflection spectroscopyAutomatic control

The invention discloses a fruit sugar degree sorting device and method based on weighing and sorting line transformation. The fruit sugar degree sorting device and method based on the weighing and sorting line transformation comprises a mechanical conveying device, a visible near-infrared spectrum detection device and a sorting control device. Fruits are conveyed into the visible near-infrared spectrum detection device by the mechanical conveying device, a vertical light beam is used for irradiating the fruits to be detected. The light beam on the fruits reflects through the diffuse reflectionoptical principle, the visible near-infrared spectrum detection device use a visible near-infrared diffuse reflection spectrum to carry out on-line detection and classification for the sugars and acidity in the fruits, the detected sugars and acidity are transmitted to the sorting control device, and the sorting is achieved by turning over a fruit tray. By collecting the visible near-infrared diffuse reflection spectrum of the fruits in the wave band range of 300nm-1100nm and using a prediction model of predicting the sugars and acidity of the fruits, the content of sugars and acidity in thefruits is calculated, and the on-line detection and automatic sorting of the sugars and acidity are achieved in cooperation with a automatic control system.

Owner:EAST CHINA JIAOTONG UNIVERSITY

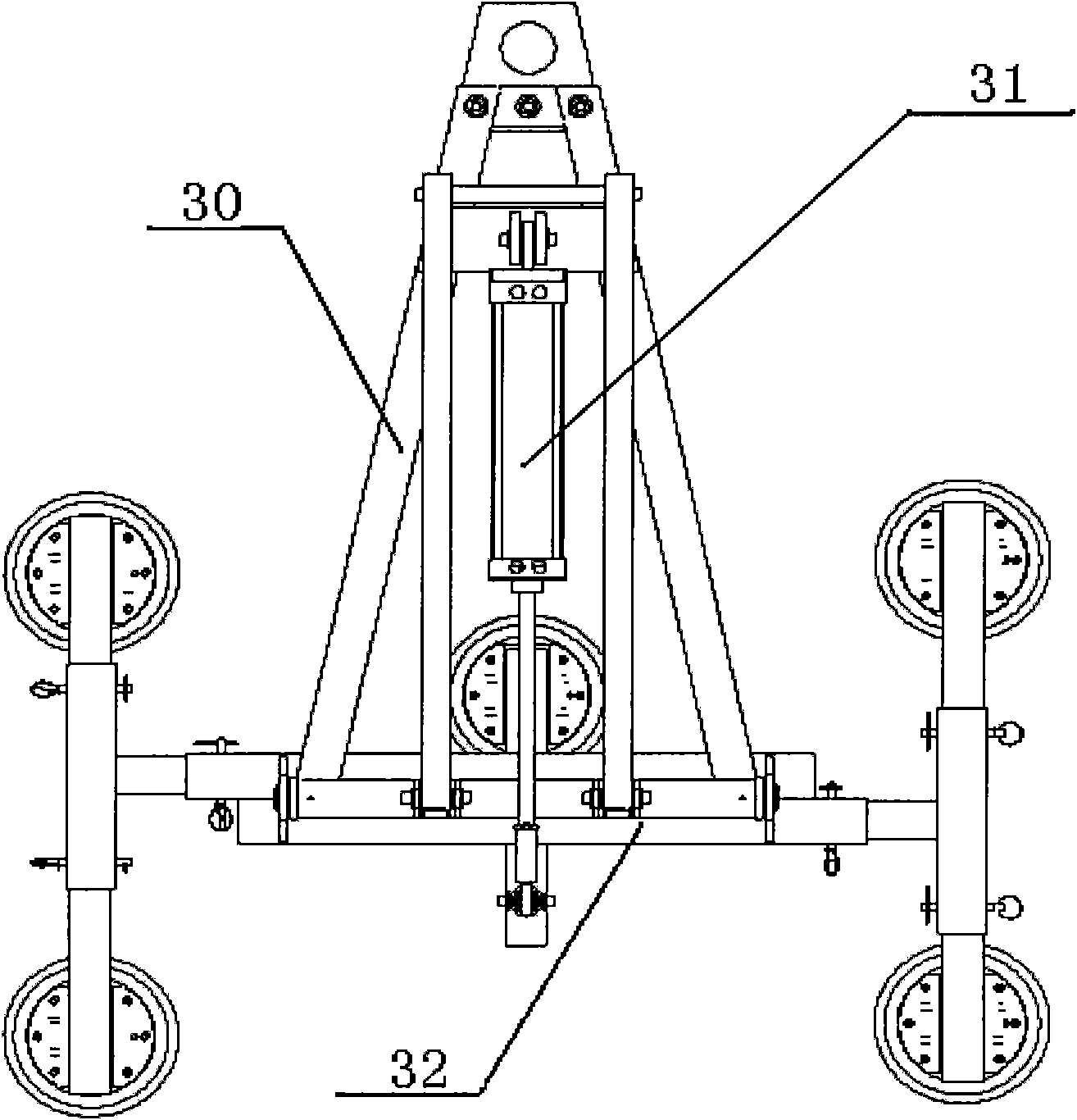

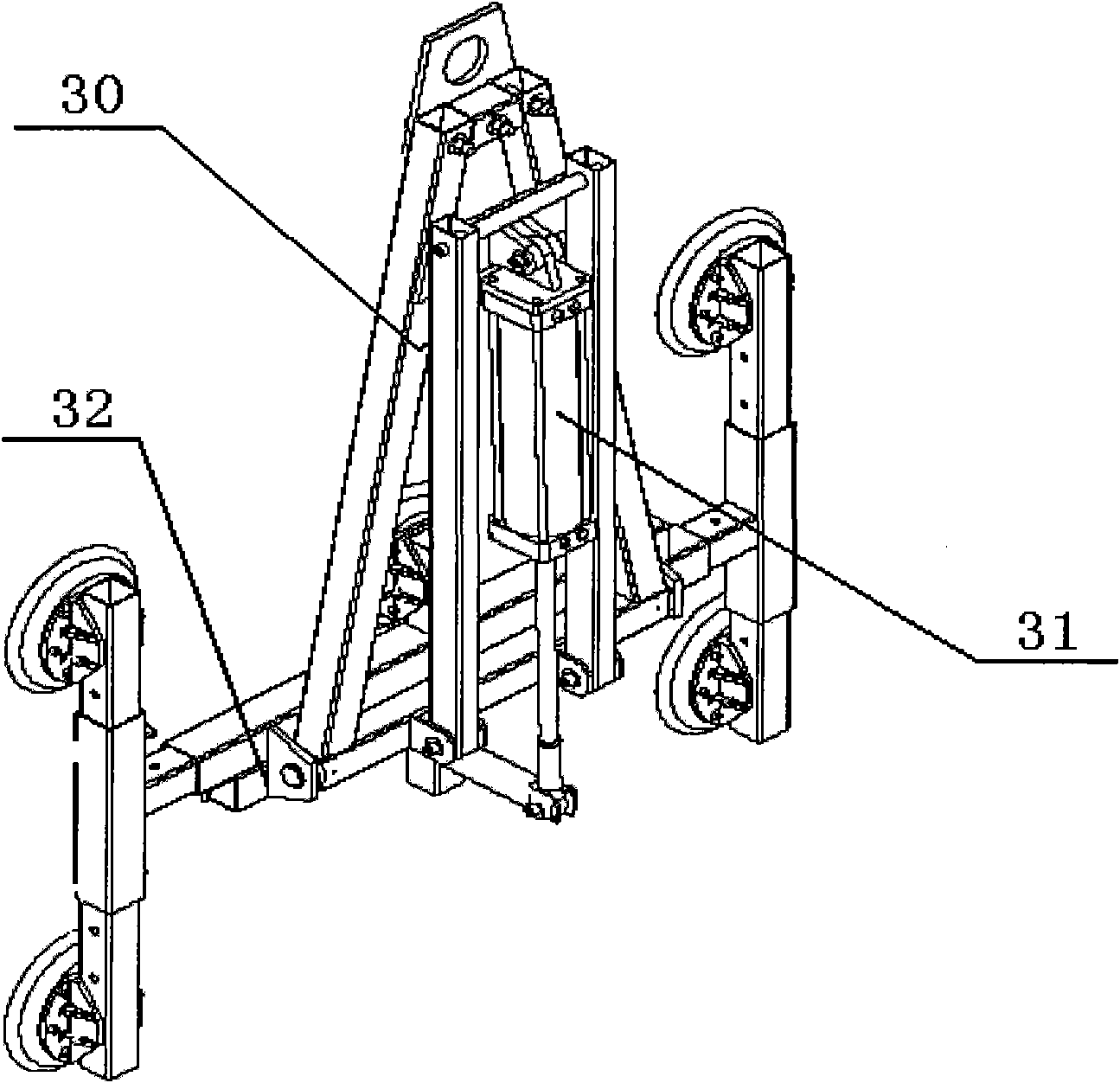

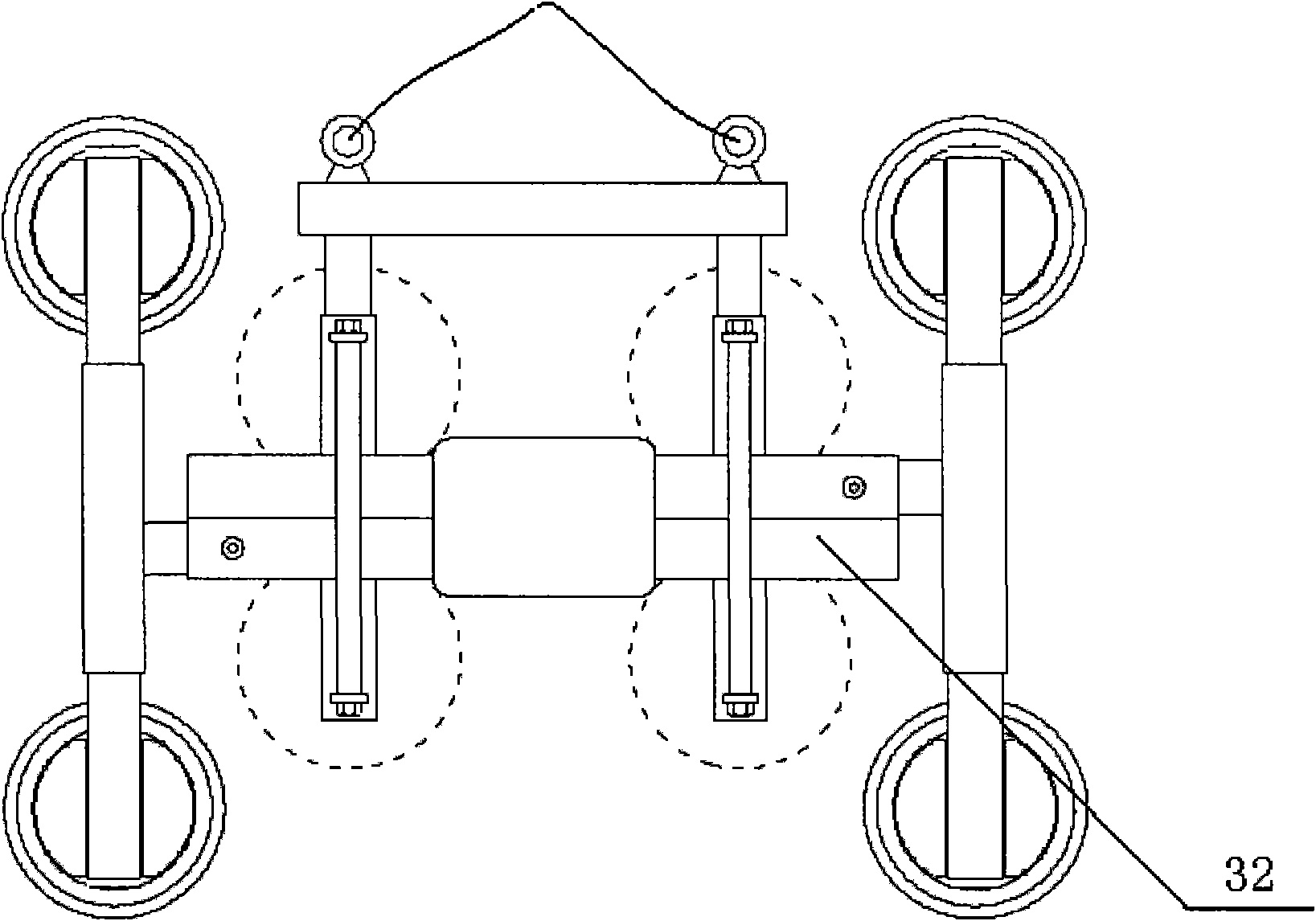

Suction crane

InactiveCN101857162AIncrease production capacityEasy to processLoad-engaging elementsEngineeringWrench

The invention provides a suction crane. The suction crane comprises a suspender, a moveable joint, a main frame and a suction disc body, wherein the suspender is connected with one end of the moveable joint through a suspender lug; the other end of the moveable joint is connected with the main frame which fixes the suction disc body by a suction disc fixing leg; an overturning locking wrench is arranged at the connection position between the bottom of the suspender and the suspender lug; the suspender lug is connected with the moveable joint through an overturning sliding shaft; an overturning locking plate which can fasten the overturning locking wrench is arranged at the connection position between the moveable joint and the suspender lug; a connecting plate is fixed on the main frame; the moveable joint is connected with the connecting plate of the main frame through a rotational sliding shaft; a rotational positioning hole is reserved on the connecting plate of the main frame; the moveable joint is provided with a rotational positioning wrench; and the rotational positioning wrench is spliced with the rotational positioning hole on the connecting plate of the main frame. By using the suction crane, glass and various sheet materials can be sucked and hung in overturning and rotating ways, so that the production, the processing and the installation of the glass, the sheet materials and curtain wall plates are more convenient.

Owner:上海玻乐机械五金制造有限公司

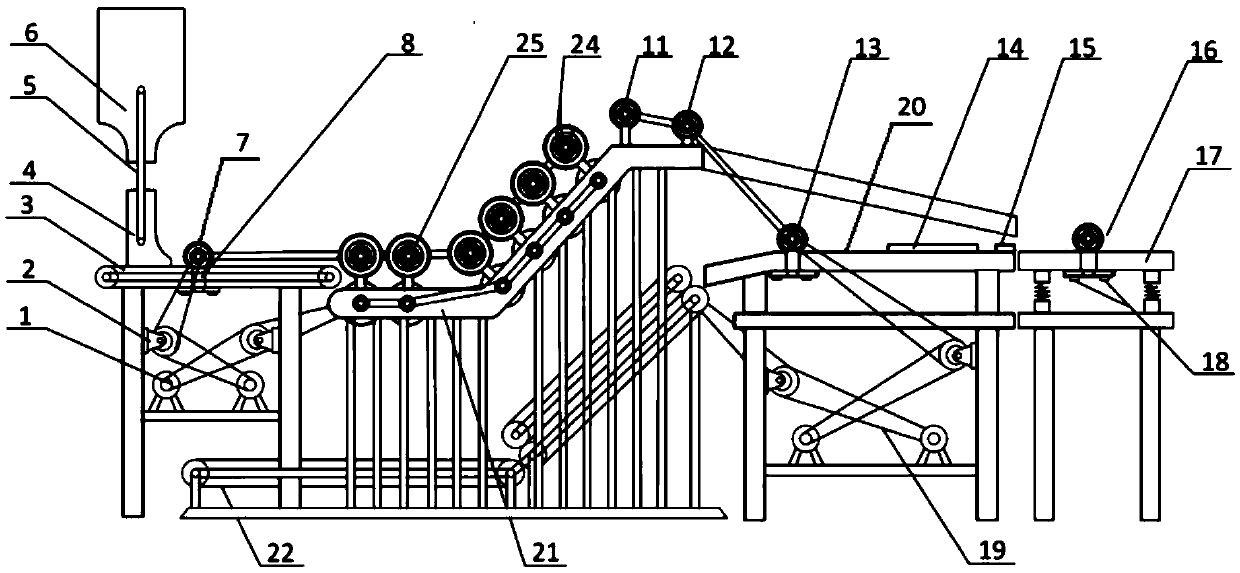

Automatic feeder for bamboo strips

ActiveCN105501900ARealize automatic identificationRealize sortingGrinding feedersSortingEngineeringRaw material

The invention discloses an automatic feeder for bamboo strips. The automatic feeder comprises a feed mechanism and a discharge mechanism, and a recognizing and sorting mechanism and a turning mechanism are arranged between the feed mechanism and the discharge mechanism. The recognizing and sorting mechanism separates the bamboo strips with the yellow surfaces upward and the bamboo strips with the green surfaces upward, a receiving mechanism conveys the bamboo strips with the green surfaces upward to the turning mechanism, and a conveying mechanism conveys the bamboo strips with the yellow surfaces upward to the discharge mechanism. The turning mechanism comprises a turning block, a screw channel is formed in the turning block, and the bamboo strips with the green surfaces upward are turned by 180 degrees after passing through the screw channel and then enter the discharge mechanism. The automatic feeder has the beneficial effects that the bamboo strips with the yellow surfaces upward and the bamboo strips with the green surfaces upward can be effectively distinguished according to the characteristic that the difference between the friction coefficients of the upper surfaces and the lower surfaces of the bamboo strips is great, raw material for bamboo products can be automatically recognized, sorted and turned, the bamboo strips can be conveyed for being processed and waste can be avoided. In addition, the problems that the labor cost is high and the efficiency is low are solved.

Owner:ZHEJIANG UNIV

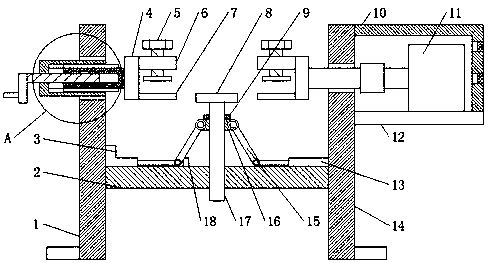

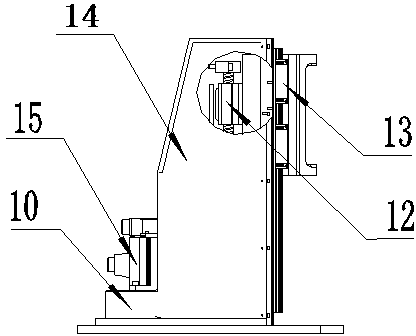

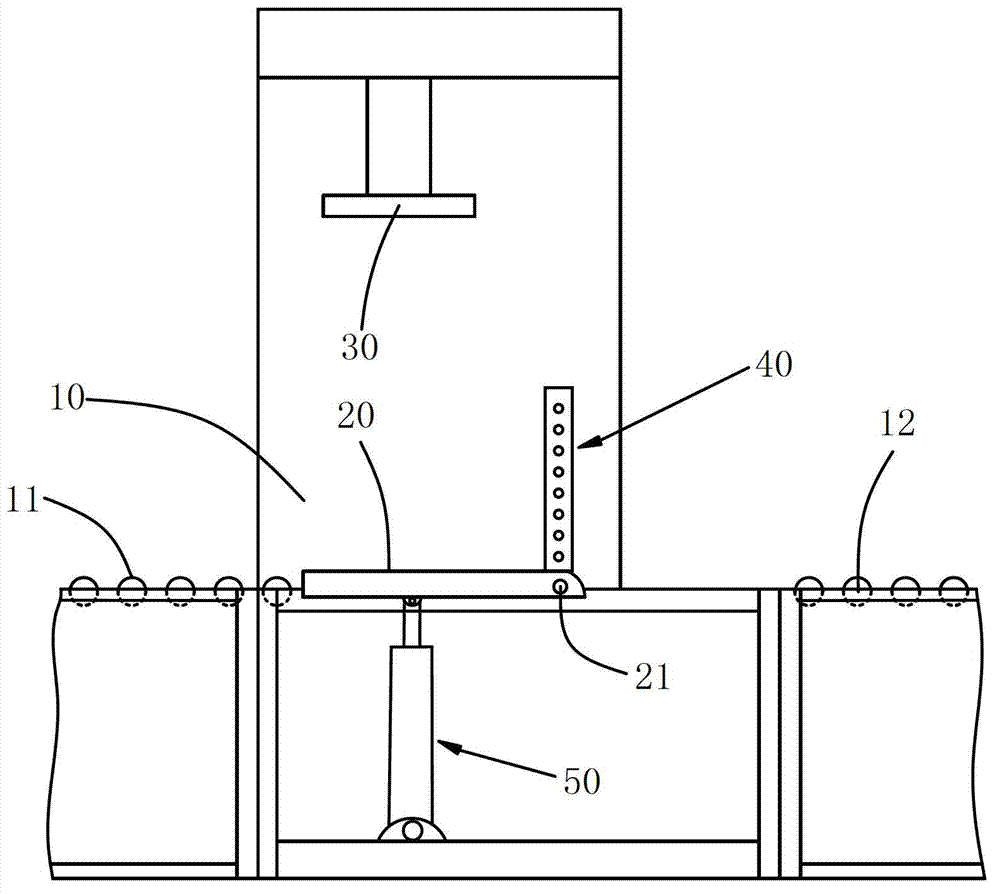

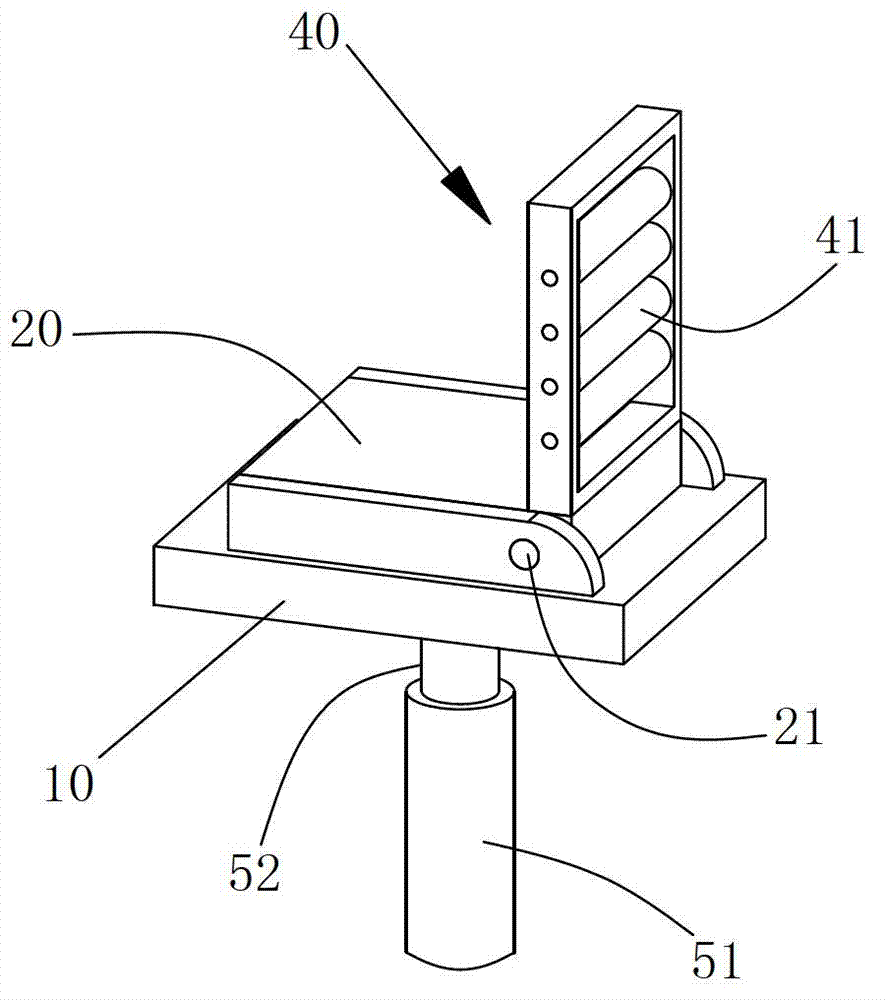

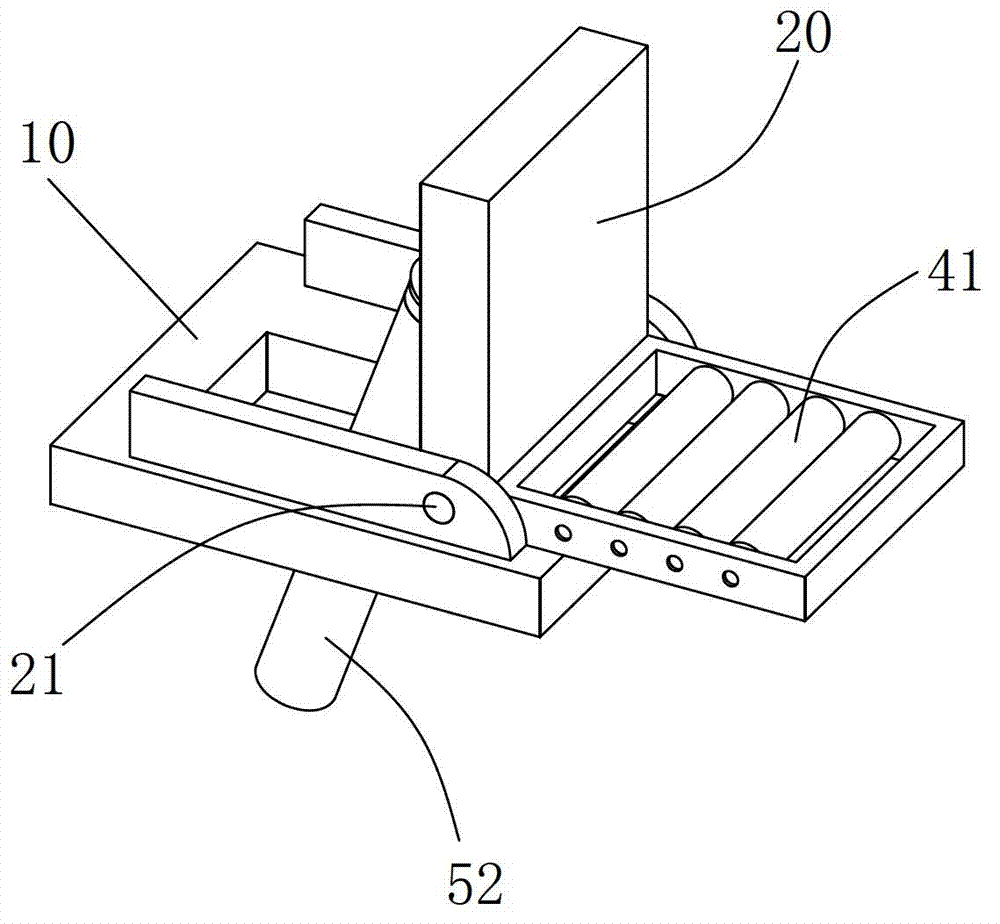

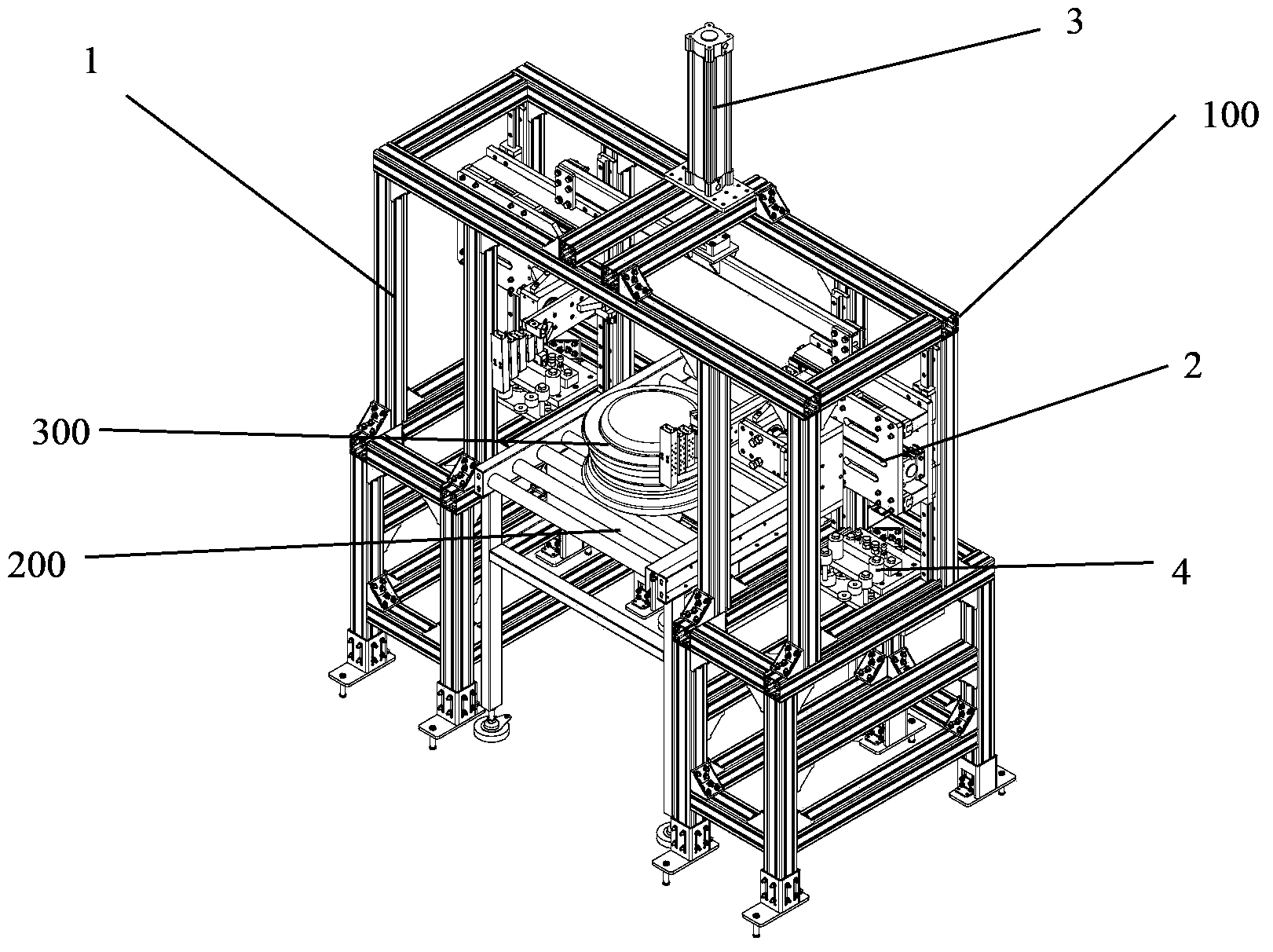

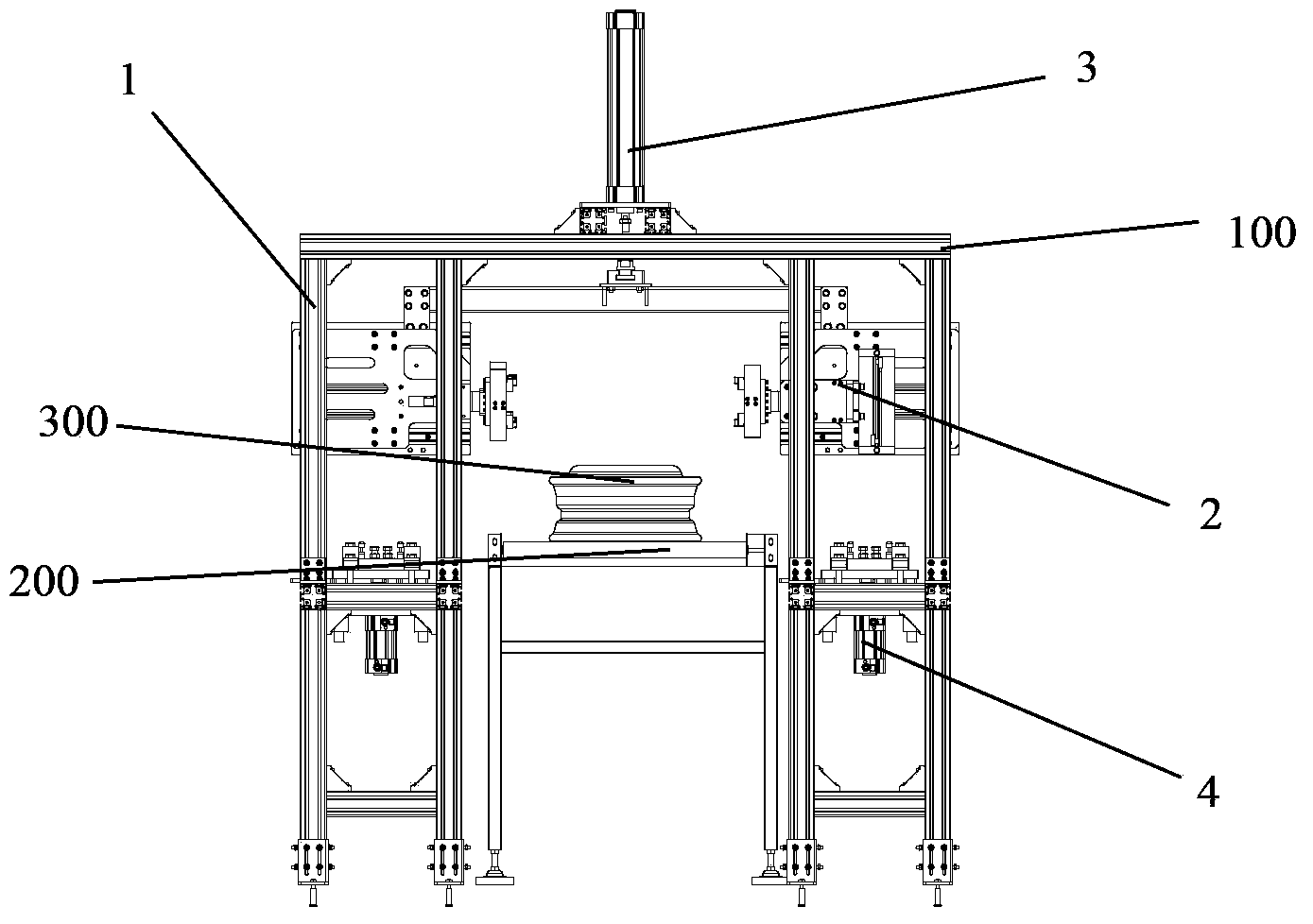

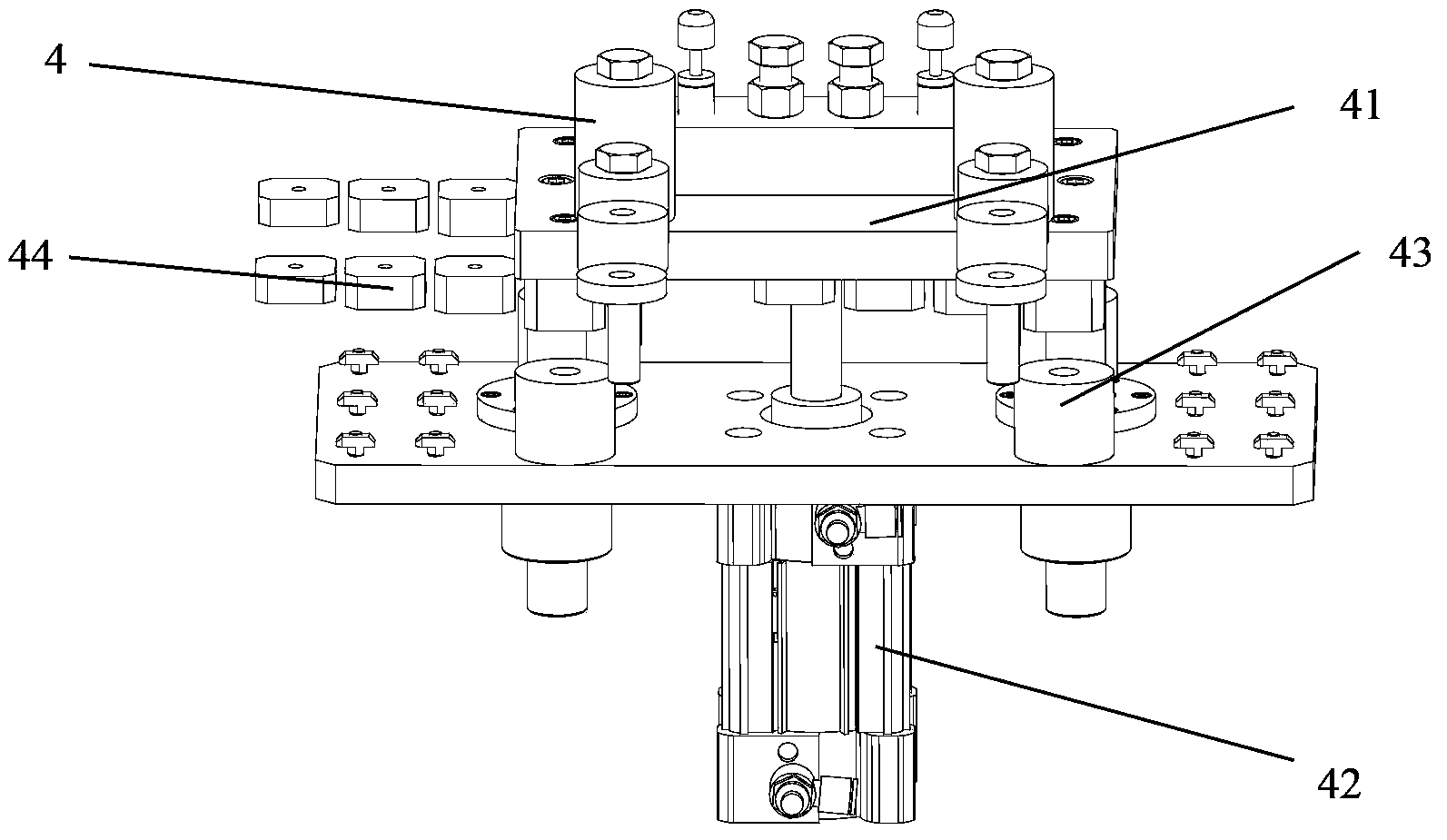

Press and method of utilizing press to press-fit stator and motor shell

InactiveCN103203615AFlipEasy to transportManufacturing dynamo-electric machinesMetal working apparatusEngineeringMechanical engineering

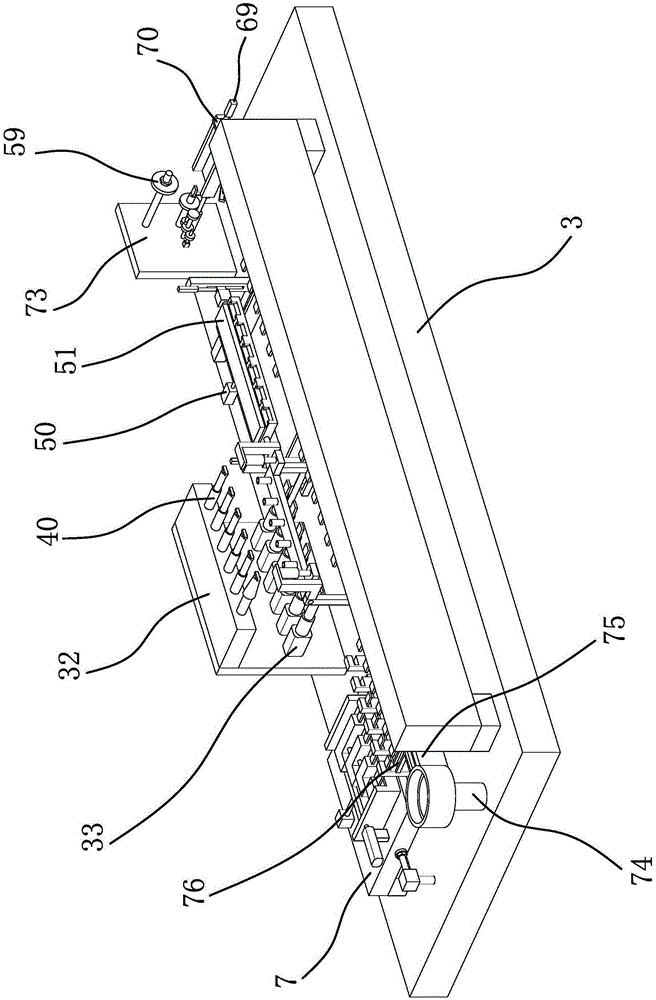

The invention discloses a press. A bracketing component fixedly connected with a bracketing platform and used for bracketing press-fitting members unloaded from the bracketing platform is arranged on the upper side of the bracketing platform of the press, the bracketing component and the bracketing platform are in angle-form arrangement, the bracketing platform / the bracketing component is in hinged connection with a rack, the axis of a first hinging shaft allowing the hinged connection possible is arranged parallelly to a connected line of the bracketing platform and the bracketing component, and a pushing mechanism pushing the bracketing platform and the bracketing component to overturn around the first hinging shaft is further arranged on the rack. By arranging the bracketing component in fixed connection with the bracketing platform on the upper side of the bracketing platform and enabling the bracketing platform / the bracketing component and the rack to be in hinged connection, after members to be press-fitted are press-fitted, the bracketing platform and the bracketing component are pushed to overturn through the pushing mechanism to enable the press-fitted members to be unloaded onto the bracketing component; posture of the press-fitted members is changed correspondingly for the convenience of subsequent transport and processing treatment.

Owner:ANHUI WANXIN MOTOR

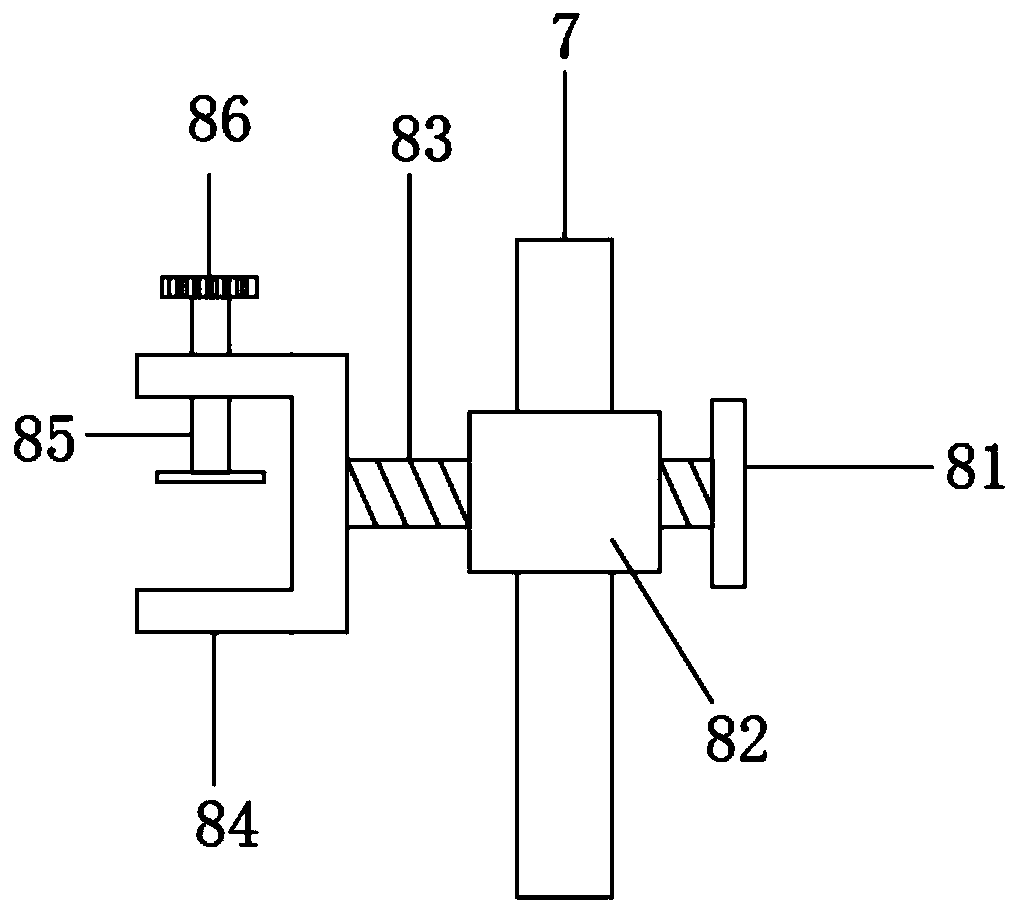

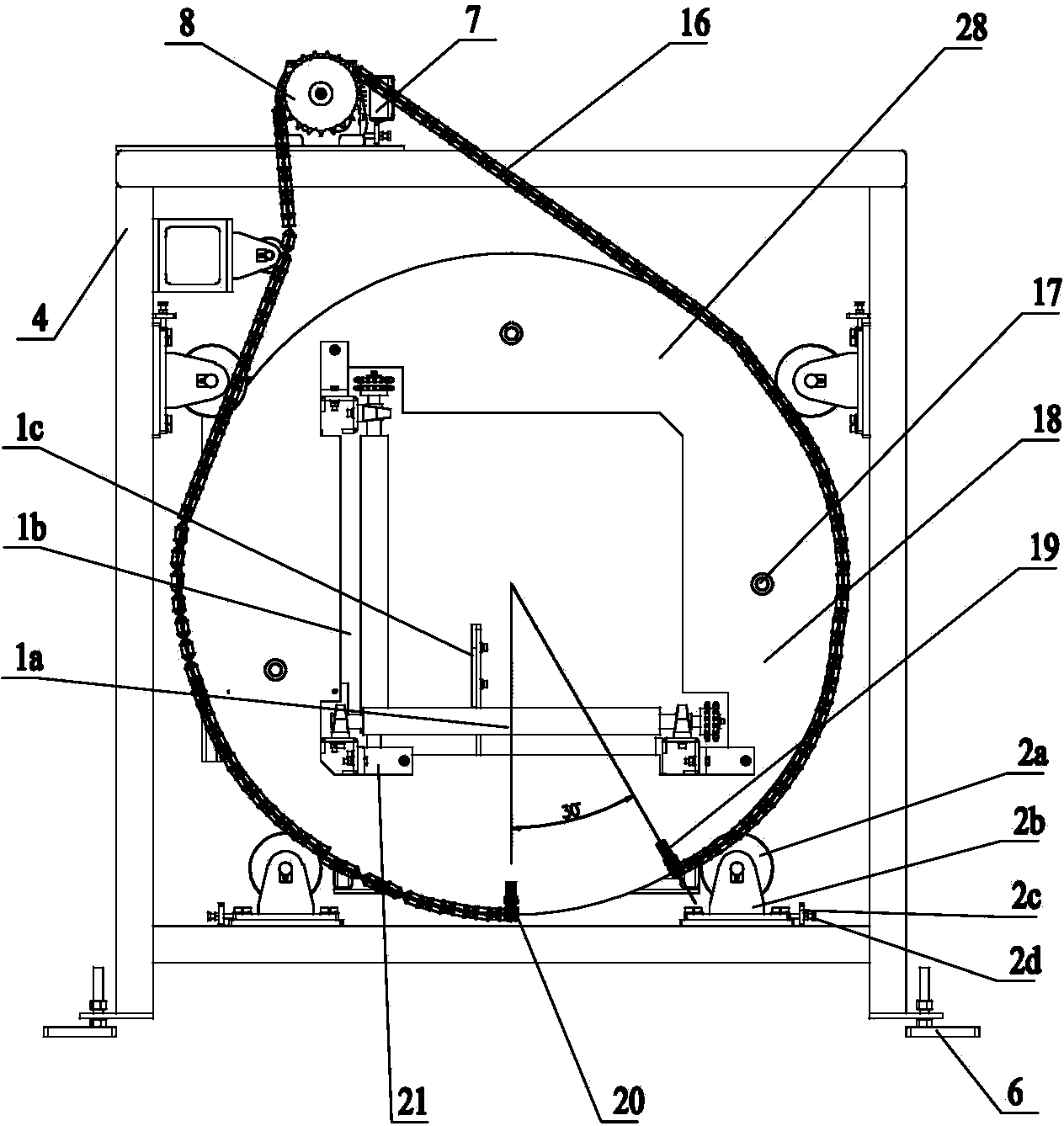

Squirrel-cage turnover device

InactiveCN104108589AIngenious and reasonable structureEasy to operateConveyor partsStructural engineeringMechanical engineering

Owner:WUXI SUNDA INTELLIGENT AUTOMATION & ENG COMPANY

Automatic sealing ring sleeving device

ActiveCN105710626AFlipRealize automatic feeding processVehicle componentsMetal working apparatusEngineeringCopper

The invention discloses an automatic sealing ring sleeving device. The automatic sealing ring sleeving device comprises a power device for providing motion power, a turnover mechanism, a sealing ring assembly mechanism, a detection mechanism, a laser marking mechanism, a feeding mechanism and a discharging mechanism, wherein the feeding mechanism and the discharging mechanism are of the same structure. The feeding mechanism is connected with the head end of the turnover mechanism. A vibration disc for containing a large number of sealing rings is connected to the sealing ring assembly mechanism. The sealing ring assembly mechanism is connected with the tail end of the turnover mechanism. The turnover mechanism is connected with the laser marking mechanism through the detection mechanism. The laser marking mechanism is connected with the discharging mechanism. The automatic sealing ring sleeving device is composed of the power device, the turnover mechanism, the sealing ring assembly mechanism, the detection mechanism, the laser marking mechanism, the feeding mechanism and the discharging mechanism, wherein the feeding mechanism and the discharging mechanism are of the same structure. Mechanization and automation are adopted for replacing manpower to mount the sealing rings on aluminum-copper pole pillars, and the work efficiency is greatly improved.

Owner:NINGBO BLUE WHALE AUTOMATION TECH CO LTD

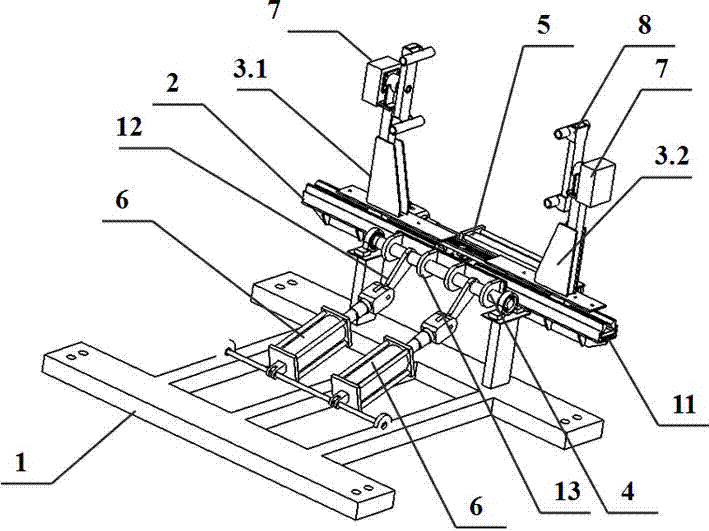

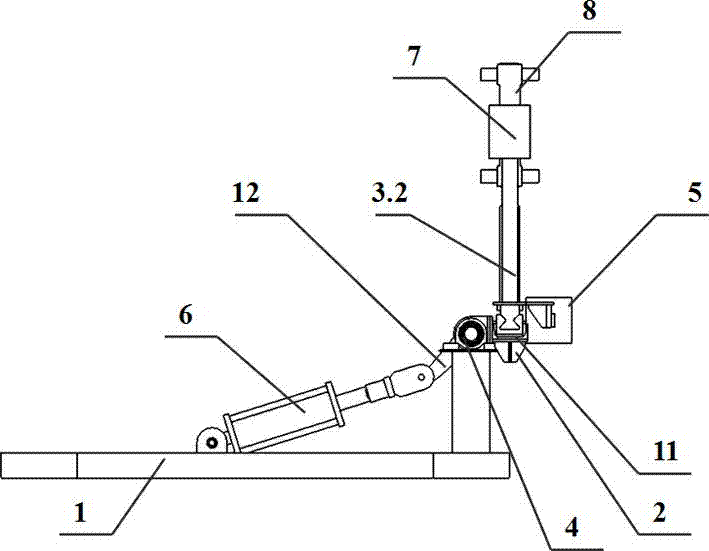

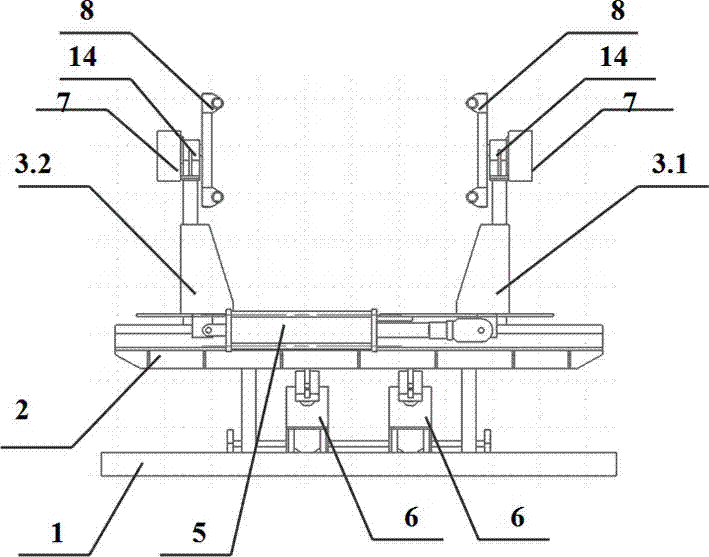

Turning device for assembling tires of heavy duty cars

ActiveCN102381383AMeet the front and back assembly requirementsMeet assembly requirementsVehiclesGeneral assemblyEngineering

The invention relates to a turning device for assembling tires of heavy duty cars, which is necessary non-standard equipment for assembling tires at a tail end station of a tire conveyor line of a general assembly shop and mainly comprises a turning framework, a turning cylinder and a turning clamping arm mechanism. The turning clamping arm mechanism mainly consists of a turning guide rail, a left clamping arm, a right clamping arm, a clamping cylinder, a rotating cylinder and a clamping claw. The turning cylinder drives a rotary shaft to rotate so that the clamping arm mechanism turns between the horizontal direction and the perpendicular direction, the cylinder rotates on the left clamping arm and the right clamping arm, and accordingly requirements on obverse and reverse assembly of tires on rear axles can be met. The clamping cylinder can meet requirements of assembling tires of different sizes, and mixed line production of various types of vehicles is realized. The turning device is reasonable in design, compact in structure, simple and safe in process actions, and applicable to a tire conveying and assembling system with high mechanical degree, labor intensity of workers is reduced, and labor efficiency is improved by 40% at least.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

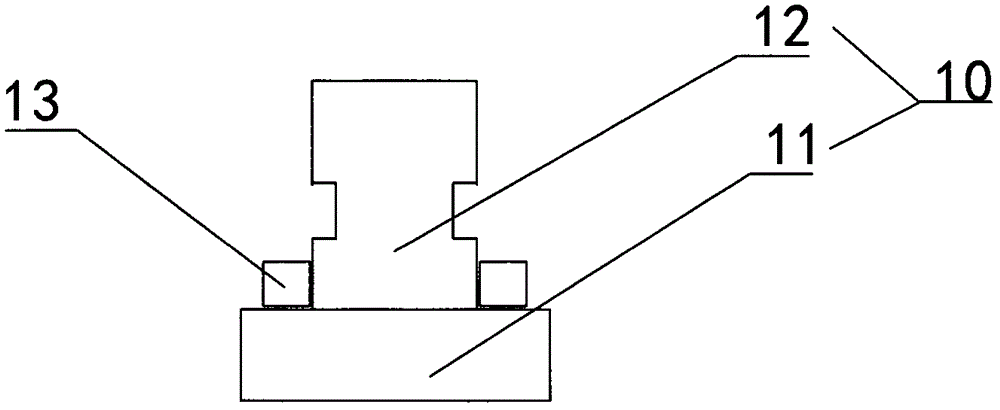

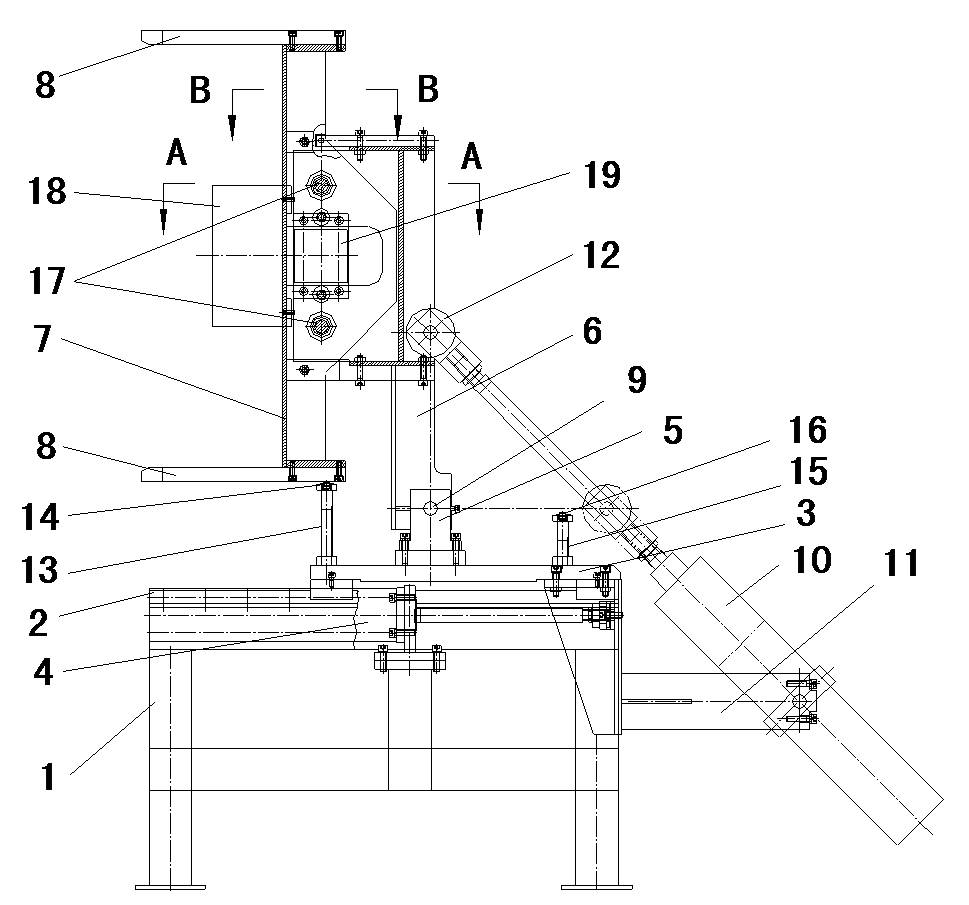

On-line type turnover mechanism for hub

InactiveCN103567805AIncrease productivityWithout breaking the modular designMetal working apparatusConveyor partsModularityModular design

An on-line type turnover mechanism for a hub comprises a supporting frame, a clamping turnover structure and a stroke compensation mechanism; the clamping turnover structure comprises a pair of manipulators, a pair of extensible cylinders which control movement of the manipulators and a pair of rotary cylinders which control rotation of the manipulators; the stroke compensation mechanism comprises a platform, a control cylinder which adjusts the height of the platform, buffer blocks and adjusting blocks which are convenient to replace; stroke differences compensated through the stroke compensation mechanism are gaps between the adjusting blocks and the buffer blocks; the gaps between the adjusting blocks and the buffer blocks are equal to height differences from two end surfaces of the hub to be performed turnover to respective tire installation surfaces. The on-line type turnover mechanism for the hub and an assembly line conveying belt are in no connection and accordingly a modular design of an assembly line is not damaged. The on-line type turnover mechanism for the hub is suitable for hubs in different sizes due to the fact that strokes of the on-line type turnover mechanism for the hub can be compensated and no damage is generated if the hub is dissymmetrical.

Owner:苏州久工自动化科技有限公司

Gypsum wall brick turnover machine

The invention discloses a gypsum wall brick turnover machine, which comprises a base, a slide platform, a turnover device and a turnover power mechanism. The slide platform comprises a guide rail fixedly installed on the base, a sliding panel matched with the guide rail and a sliding cylinder for driving the sliding panel to slide on the guide rail, wherein a plummer block is fixedly installed on the sliding panel, a position-limiting mechanism I and a position-limiting mechanism II are provided on left and right side of the plummer block respectively to limit the rotation range of the turnover device and support the turnover device; the turnover device comprises a support of a turnover frame and the turnover frame parallelly installed on the support of the turnover frame, turnover grabs matched with wall bricks are fixedly installed on the top and the bottom ends of the turnover frame, the bottom of the support of the turnover frame is hinged and installed on the plummer block through a turnover lateral axis; and the power mechanism comprises a turnover cylinder, one end of the turnover cylinder is hinged on the support of the turnover frame and the other end is hinged on the base.

Owner:CHONGQING UNIV

Double-arm feeding and discharging manipulator

PendingCN106625601AImprove efficiencyMovement guidance and repositioning are smoothProgramme-controlled manipulatorGripping headsGrippersManipulator

The invention provides a double-arm feeding and discharging manipulator, and belongs to a manipulator. The double-arm feeding and discharging manipulator comprises a base, wherein two manipulator bodies which are the same are arranged on the base in parallel; each manipulator body comprises a fixed arm, a first rotating arm, a second rotating arm and a manipulator gripper connected to the second rotating arm; each manipulator gripper comprises a support, a hollow rotating shaft, an upper cover plate and a lower cover plate; each support is connected with the corresponding second rotating arm; each hollow rotating shaft is rotatably connected with the corresponding support through a first oil-free lining; each upper cover plate and the corresponding lower cover plate are connected with an end of the corresponding hollow rotating shaft together; two arc-shaped clamping fingers which are clamped on side surfaces of a sheet disc-shaped workpiece are hinged to a position between each upper cover plate and the corresponding lower cover plate; each two arc-shaped clamping fingers are connected with a corresponding first driving mechanism which is used for driving the two arc-shaped clamping fingers to open and close; and each support is provided with a second driving mechanism which drives the corresponding hollow rotating shaft to rotate. In a feeding and discharging process of sheet disc-shaped workpieces, precision of the upper surfaces and the lower surfaces of the sheet disc-shaped workpieces cannot be affected, furthermore, overturning action can be finished, and feeding and discharging can be implemented simultaneously.

Owner:高维智控机器人科技(苏州)有限公司

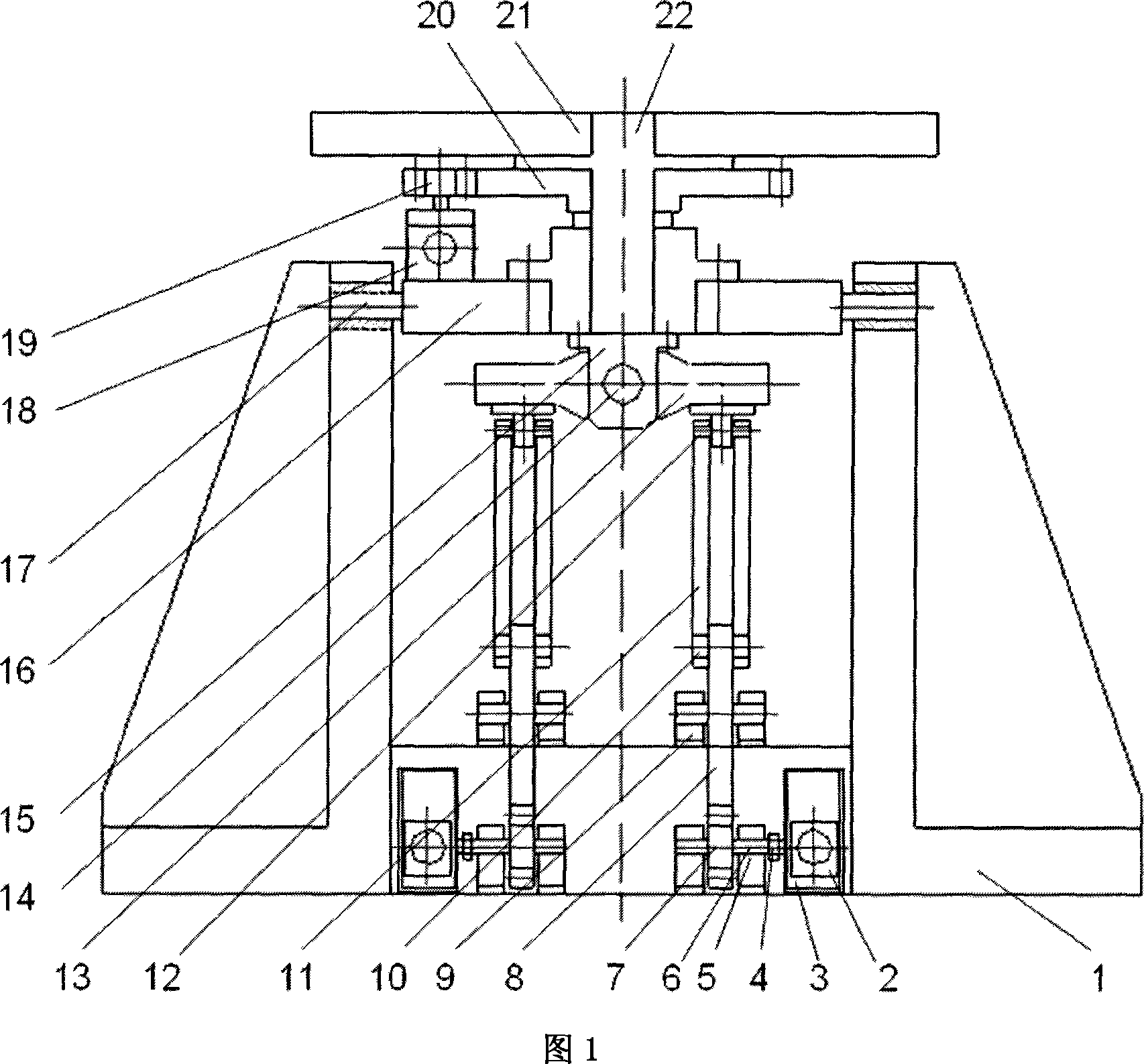

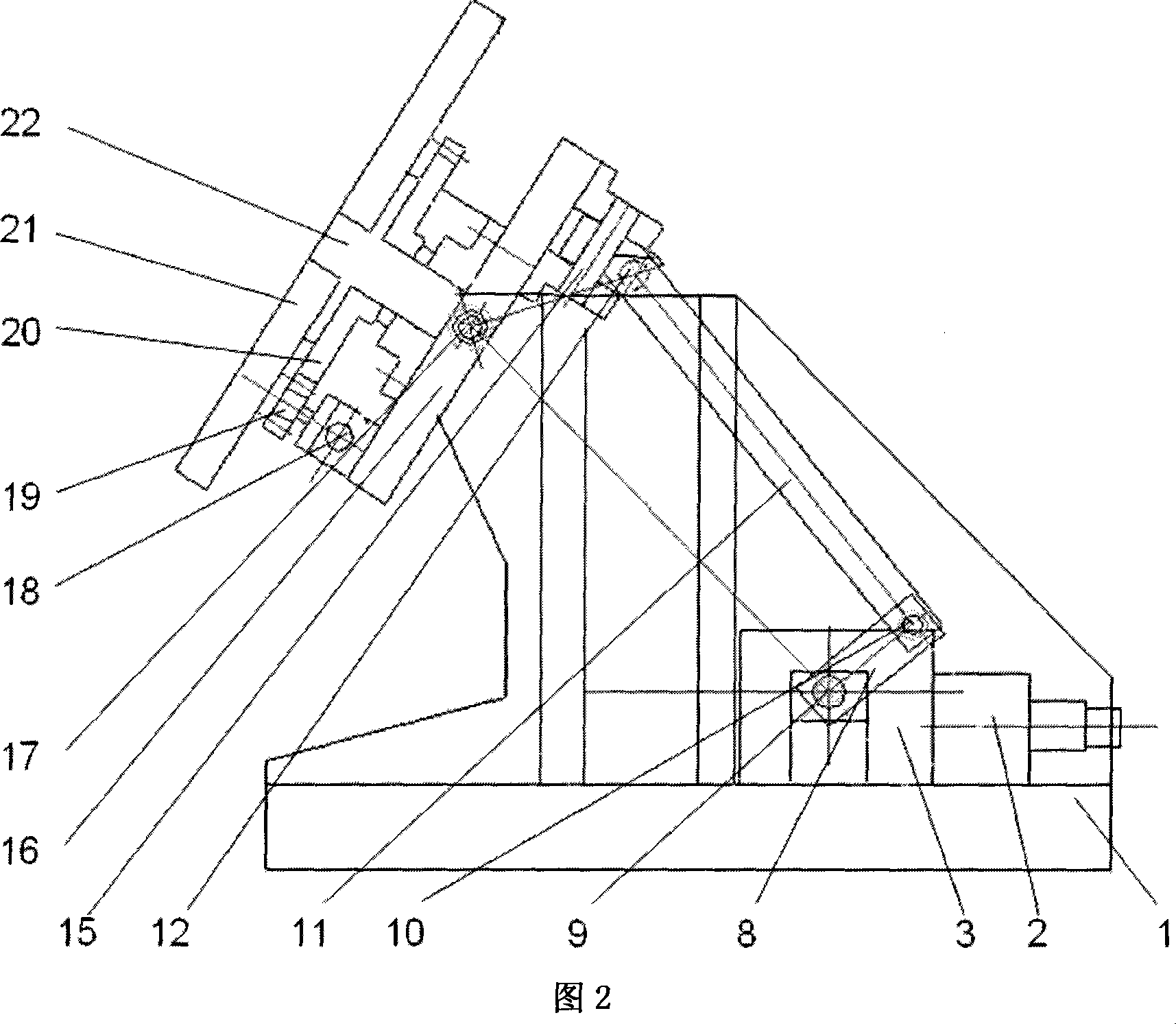

Double connecting rods type reversible table

The present invention relates to a double-link overturning platform, which comprises an overturning platform top and an overturning system driving the overturning platform top, and wherein, the overturning system is composed of a platform top pitching mechanism and a platform top turning mechanism. The platform top pitching mechanism consists of a bench, two main motors, two decelerators, two couplings, two fixed seats, four fixed hinges, two small gears, two big gears, two big gear steady bearings, two lower link hinges, two links, two upper link hinges, a coordinating rod, a coordinating rod hinge, an overturning bench connecting seat, an overturning bench and two upper bench hinges. The platform top turning mechanism consists of a platform top rotating motor, a small platform top rotating gear, a large platform top rotating gear, a rotating platform top and a main shaft. The present invention utilizes the driving of the main motors and the platform top rotating motor to realize the overturning movement of a workpiece on the rotating platform top, the structure is simple, the platform top pitching mechanism has a force-increasing effect, the self-locking protection can be realized at an ultimate overturning position, and the present invention can realize the overturning of large-tonnage workpieces.

Owner:SHANGHAI JIAO TONG UNIV

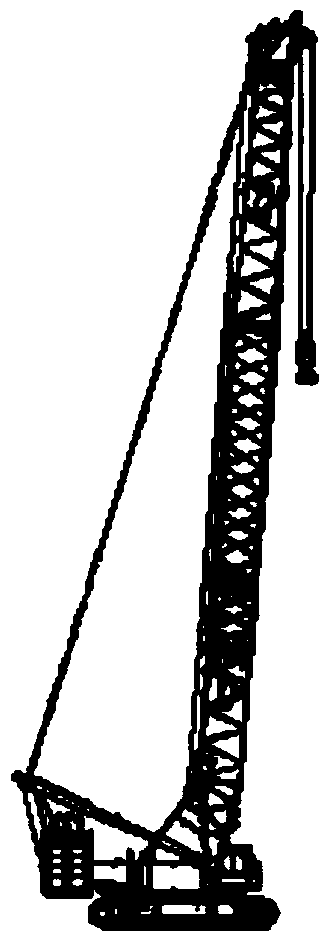

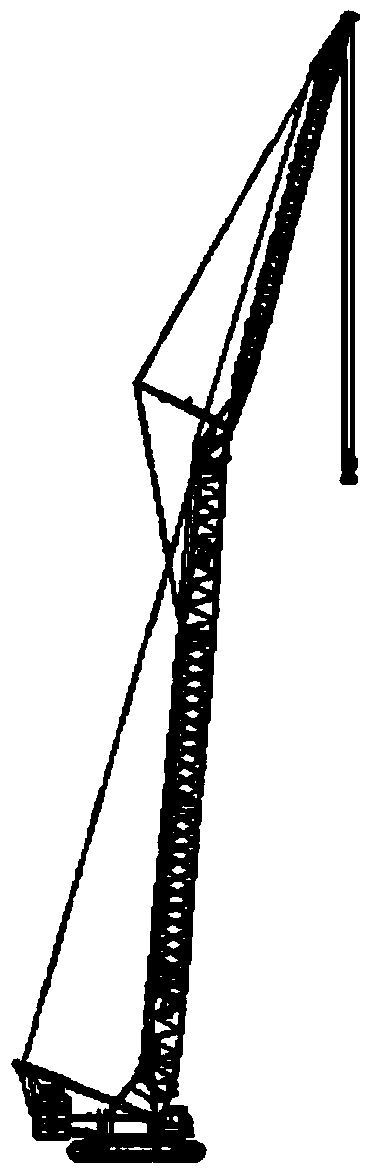

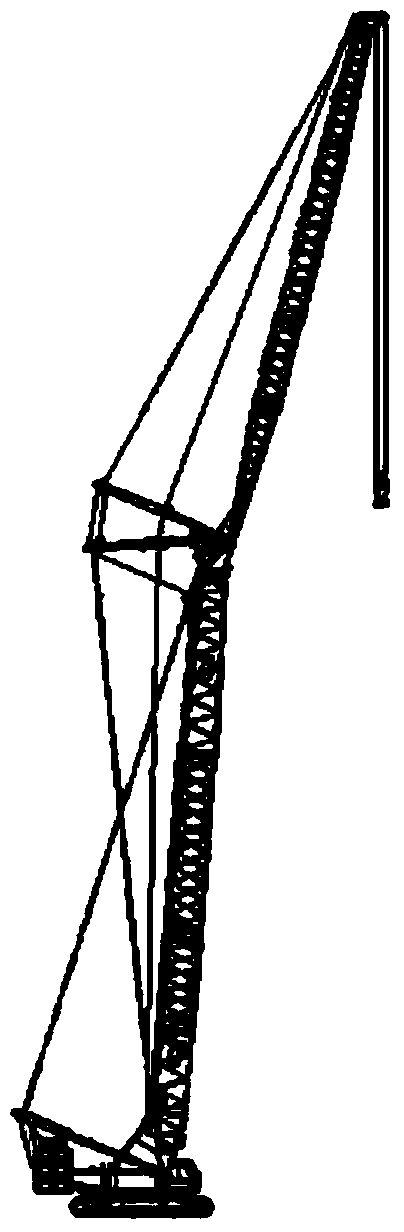

Crawler crane capable of performing double-hook lifting and structure design method thereof

ActiveCN104192732AFlipImprove work efficiencySpecial data processing applicationsCranesMarine engineeringStructural engineering

Owner:XCMG CONSTR MACHINERY

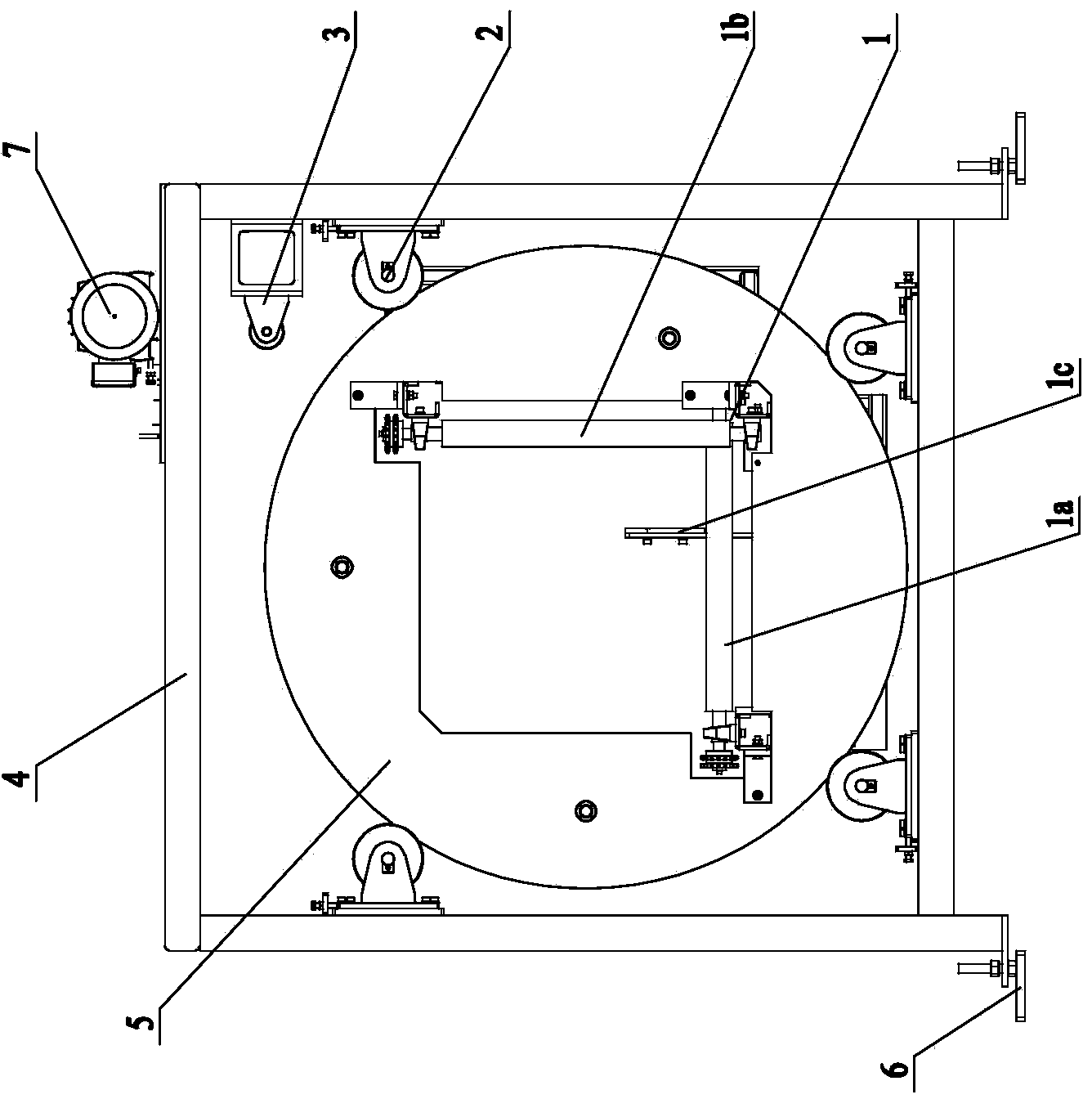

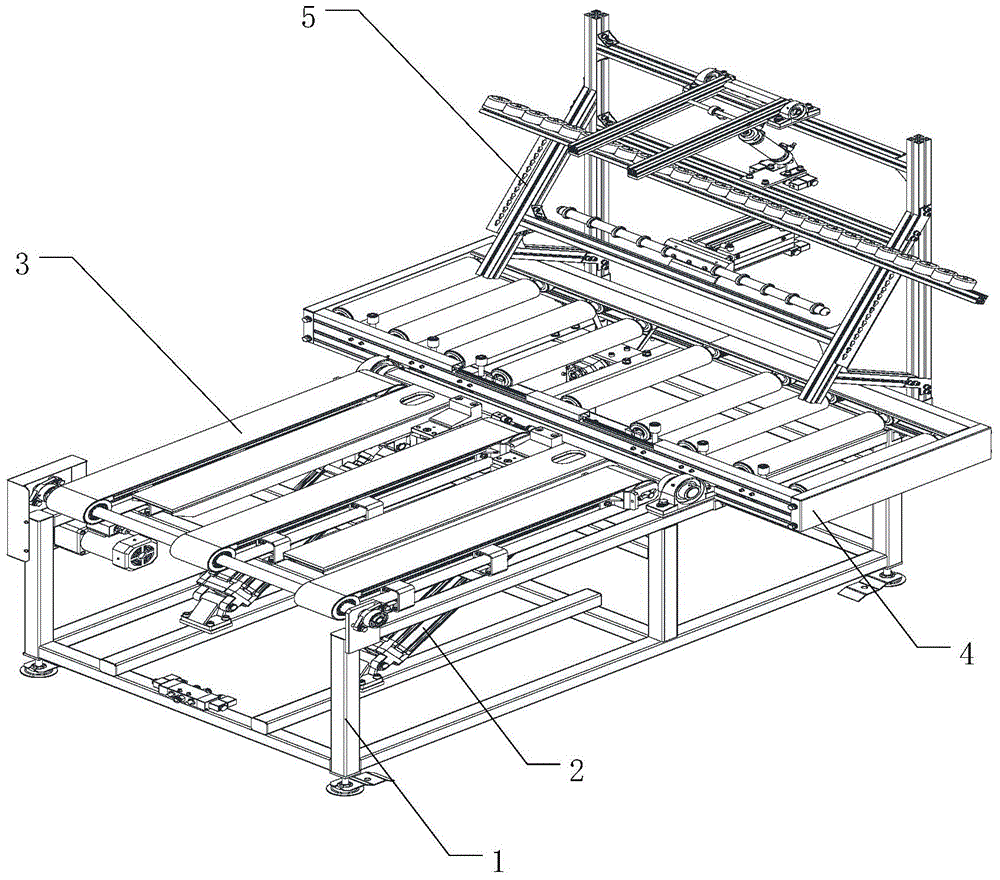

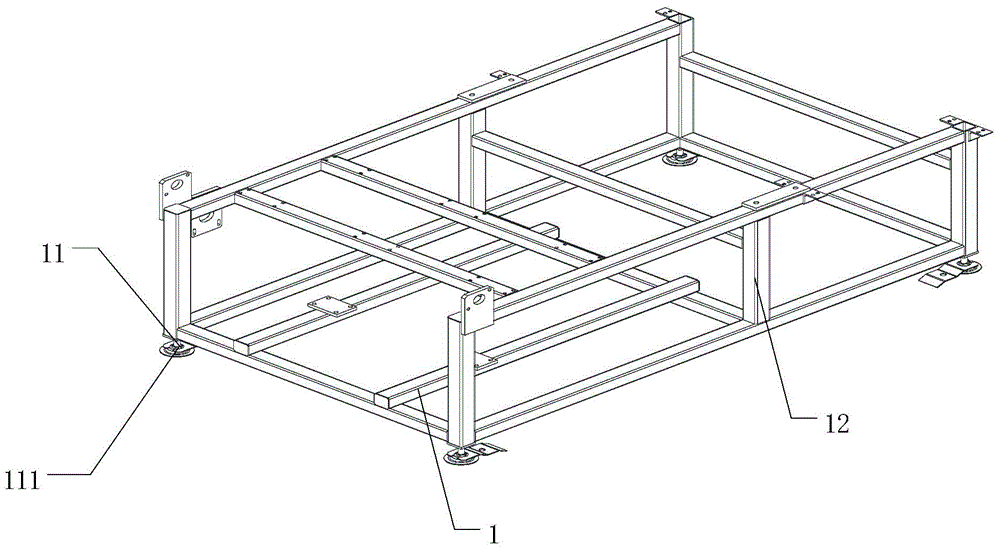

Automatic overturning and leaning device for flat-screen TV

The invention relates to an overturning and leaning device, and discloses an automatic overturning and leaning device for a flat-screen TV. The flat-screen TV can be automatically conveyed in and overturned, leans at a certain angle and is conveyed out. The automatic overturning and leaning device comprises a rack assembly, an overturning assembly, a conveying-in belt assembly, a conveying-out drum assembly and a buffer assembly, wherein the overturning assembly, the conveying-in belt assembly, the conveying-out drum assembly and the buffer assembly are arranged on the rack assembly, and the overturning assembly is arranged below the conveying-in belt assembly; the conveying-out drum assembly is positioned at the back end of the conveying-in belt assembly, and the buffer assembly is arranged at the side of the conveying-out belt assembly. The overturning and leaning device provided by the invention is suitable for producing the flat-screen TV.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Transverse sugarcane pre-chopping machine based on image identification

ActiveCN107186778APrevent fallingFall on the reasonable position of the sugarcane, avoid the incision falling on avoidSeed and root treatmentCharacter and pattern recognitionMechanical engineeringImage identification

The invention discloses a transverse sugarcane pre-chopping machine based on image identification. The transverse sugarcane pre-chopping machine comprises a conveying device, an image-identifying device, a chopping mechanism, a sugarcane-pulling shaft and a plurality of parting tool assemblies, wherein the conveying device comprises a conveying table and a conveying mechanism, the image-identifying device is used for identifying the positions of the cane joints of a sugarcane, and the chopping mechanism comprises a chopping support arranged at the front end of the conveying table; the sugarcane-pulling shaft is arranged on the rear side of the upper end of the chopping support, arc-shaped paddles are arranged at both the left and the right ends of the sugarcane-pulling shaft correspondingly, the multiple parting tool assemblies are arranged on the front side of the upper end of the chopping support, and each parting tool assembly comprises a base, a sliding block and a cutter; and the bases are arranged on the front side of the upper end of the chopping support, the sliding blocks are arranged on the bases and driven to slide through a sliding-block driving mechanism, and the cutters are arranged on the sliding blocks and driven to rotate through a cutter driving mechanism. According to the transverse sugarcane pre-chopping machine based on image identification, the situation that a cut falls near the cane joint or a cane sprout can be avoided, the production efficiency is greatly improved while the cane-planting quality is ensured, and the labor intensity is relieved.

Owner:GUANGXI UNIV +1

Conveying, turning and unloading device used for fruit grading

InactiveCN101658843ARealize the collection of optoelectronicsRealize the weighing functionSortingConveyor partsMechanical engineeringEnergy conservation

Owner:HANGZHOU XINGDI GROUP

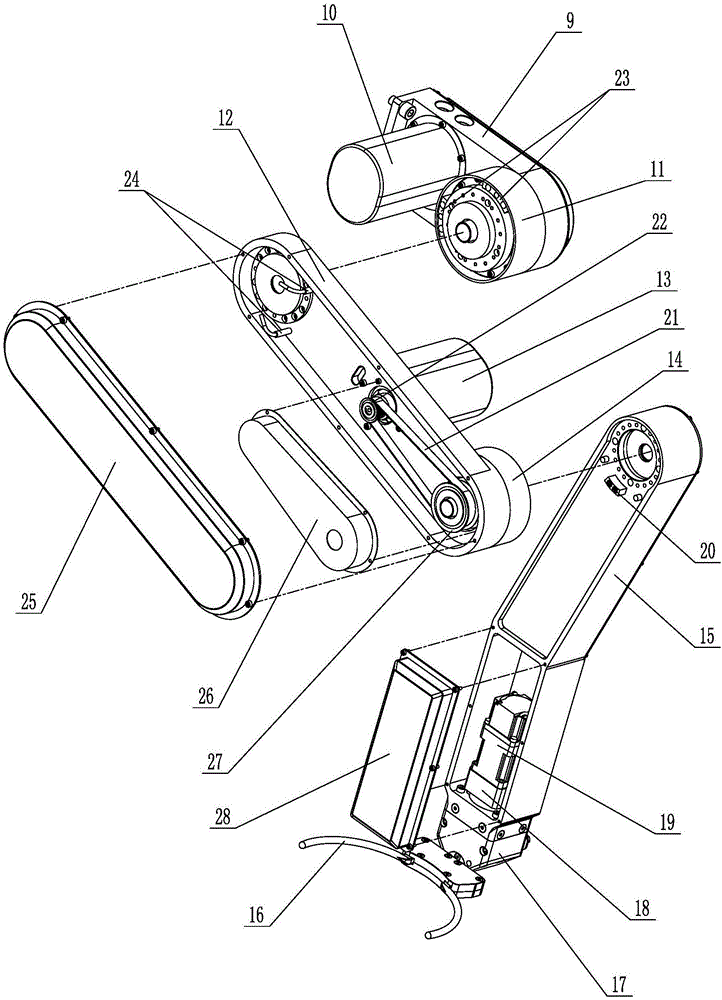

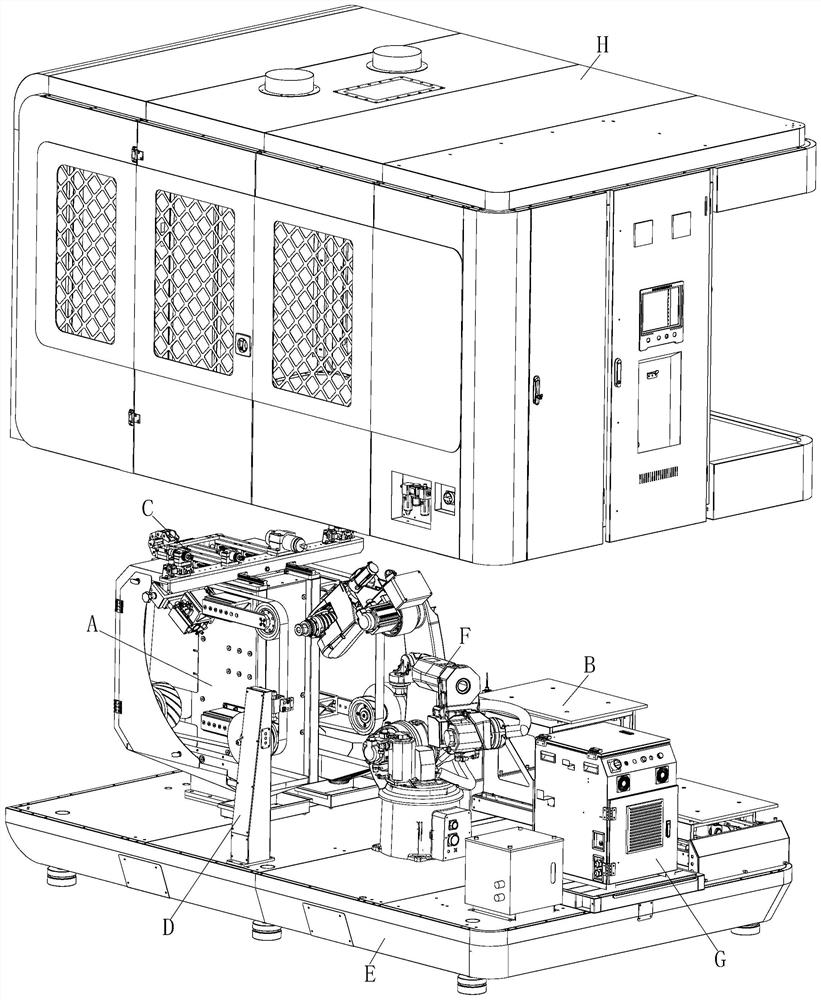

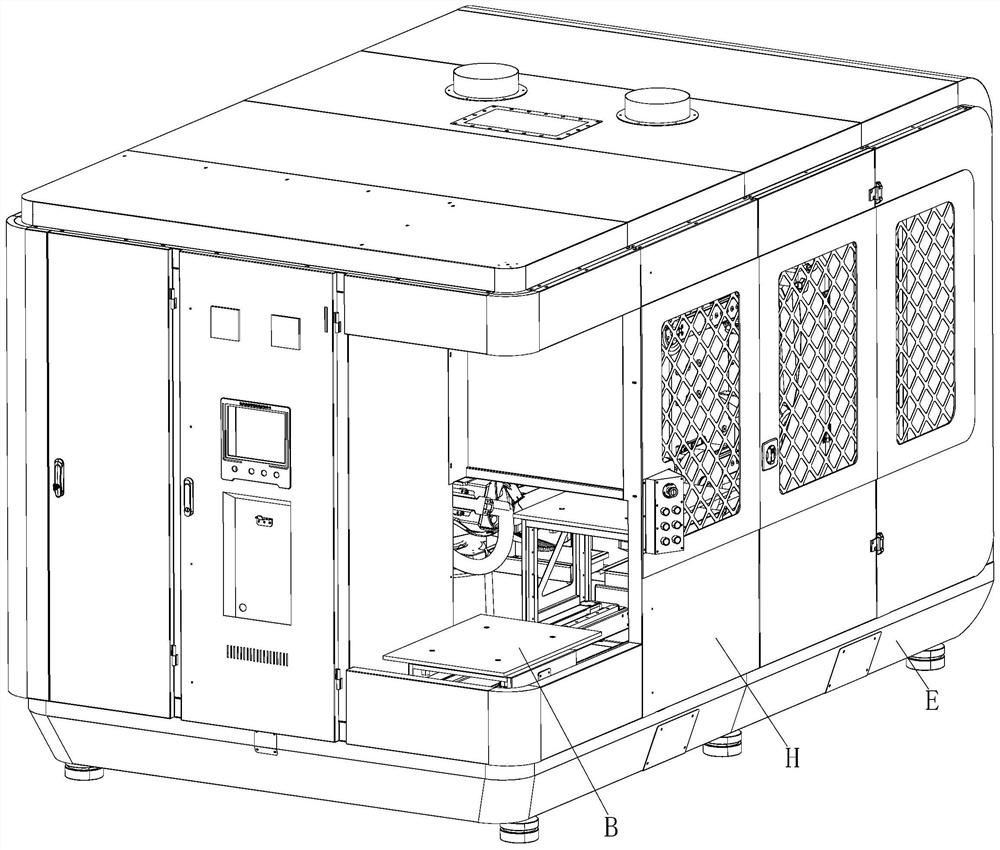

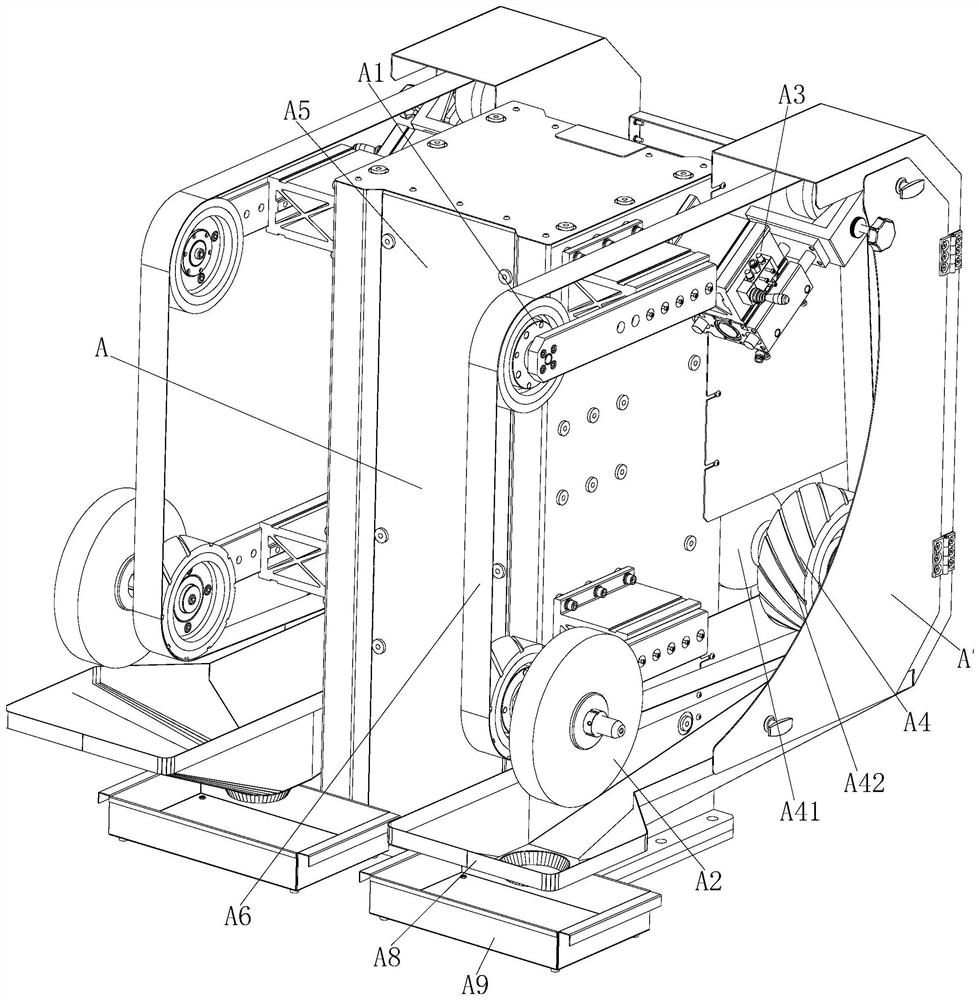

Polishing equipment and working method thereof

The invention relates to polishing equipment and a working method thereof, and belongs to the field of mechanical equipment. The problems that the polishing equipment in the prior art is unreasonablein layout, so that the work efficiency is reduced, the polishing effect is not ideal, most of bases are made of steel, large vibration and noise are generated in the operation process, meanwhile, thestructure of a material table driving device is relatively complex and the production cost is high are solved. The polishing equipment comprises a manipulator, a control cabinet and an equipment outercover, and is structurally characterized in that a belt sander, a double-layer material table and an equipment base are further included, the belt sander, the manipulator and the control cabinet areall located in the equipment outer cover, the belt sander and the double-layer material table are both matched with the manipulator, and the belt sander, the double-layer material table, the manipulator, the control cabinet and the equipment outer cover are all installed on the equipment base. According to the polishing equipment and working method thereof, programs are set through the control cabinet, and workpieces located on the double-layer material table are placed on the belt sander through the manipulator to be polished.

Owner:杭州龙砺智能科技有限公司

Turnover tool for gearbox

The invention discloses a turnover tool for a gearbox, which comprises a support bracket and a rotary body, wherein the support bracket is provided with a left bracket and a right bracket which are arranged correspondingly; a left support hole is formed on the upper part of the left bracket, a right support hole is formed on the right bracket, and center lines of the left and right support holes are arranged coaxially; the rotary body is rotationally arranged on the support bracket, and both ends of the rotary body are respectively connected with the left and right support holes; the gearbox is detachably connected on the rotary body, and can rotate with the rotary body. By the tool, the gearbox can be convenient to turn in an assembly process, and thus, the labor intensity of workers is relieved.

Owner:DATONG ELECTRIC LOCOMOTIVE OF NCR

Automatic coil winding all-in-one machine for transformer

The invention provides an automatic coil winding all-in-one machine for a transformer, and belongs to the field of electronic technique. The automatic coil winding all-in-one machine solves the problem that automatic coil winding for the transformer is inconvenient in the prior art. The transformer comprises a body, a mounting hole and pins. The automatic coil winding all-in-one machine for the transformer comprises a rack, wherein a guide rail is fixed on the rack, a conveying plate is arranged on the guide rail, and a mounting rod is fixed on the conveying plate; a feeding device is arranged at one end of the guide rail, and comprises a feed plate and a transition rail; a conveying device is arranged between a conveying rail and the guide rail, and comprises a working table, a mounting table, a transferring block and a triggering block; a coil winding device is arranged at the middle part of the guide rail, and comprises a wire winding table, a winding motor and a forming tube; a tin soaking device is further arranged at the middle part of the guide rail, and comprises a tin material box and a tin soaking plate; a winding insulated adhesive tape device is arranged at the other end of the guide rail, and comprises a mounting plate, a tape winding plate and a winding shaft. The automatic coil winding all-in-one machine has the advantages that winding for the transformer can be performed effectively and conveniently.

Owner:HAINING QILIANSHAN ELECTRONICS

Polishing and clamping arm adjustment device

ActiveCN102248482ALarge range of motionImprove polishing efficiencyGrinding work supportsMechanical engineeringEngineering

The invention discloses a polishing and clamping arm adjustment device, which belongs to the technical field of polishing and mainly solves the technical problems that polishing dead angles are easy to generate and polishing efficiency is low when polishing and clamping arms are used for clamping and polishing water faucets in bathroom industries in the prior art. The polishing and clamping arm adjustment device comprises a connecting part, a clamping part and a rotation driving mechanism, wherein the rotation driving mechanism is used for driving the clamping part to rotate at the angle of 90 DEG, and a clamped part is also rotated at the angle of 90 DEG, so that the freedom of motion of the part is increased actually, and the polishing dead angles are prevented from being formed. The rotation driving device is relatively close to the part, so that the part has small motion amplitude, and the polishing treatment efficiency of the part is greatly improved.

Owner:黑龙江北鸥卫浴用品有限公司

Garbage classified recycling treatment environmental-protection device

ActiveCN107617626AAchieve the purpose of separationFlipSolid waste disposalDrying gas arrangementsEngineeringMoisture

The invention discloses a garbage classified recycling treatment environmental-protection device. The garbage classified recycling treatment environmental-protection device comprises a second motor, astirring roller, a partition plate, a degradable garbage smashing area, a plastic smashing area, a third motor, a rotating rod, a smashing blade, a bearing, an air heater, an air pipe, sliding rails,a handle, a drawer, a partition net, a metal storage box, a leading-out sliding way, a separation area, a tooth guide rail, a protective shell, a forward and reverse rotating motor, a cylindrical gear, a mounting plate, rotating wheels, an electromagnet, a connecting rod, a rolling groove, a movable plate, a reset spring, a limiting plate and hinges. Through the partition net, the drawer can be mounted at the bottom of the metal storage box; drying agents are placed in the drawer so as to absorb moisture in air; the air heater blows hot air into the metal storage box through the air pipe so that moisture of metal can be conveniently evaporated for achieving dryness, the oxidizing reaction of the metal slows down, accordingly rust of the metal is relived, and the recycling rate of the metal is increased.

Owner:新沂市绅奥环保用品有限公司

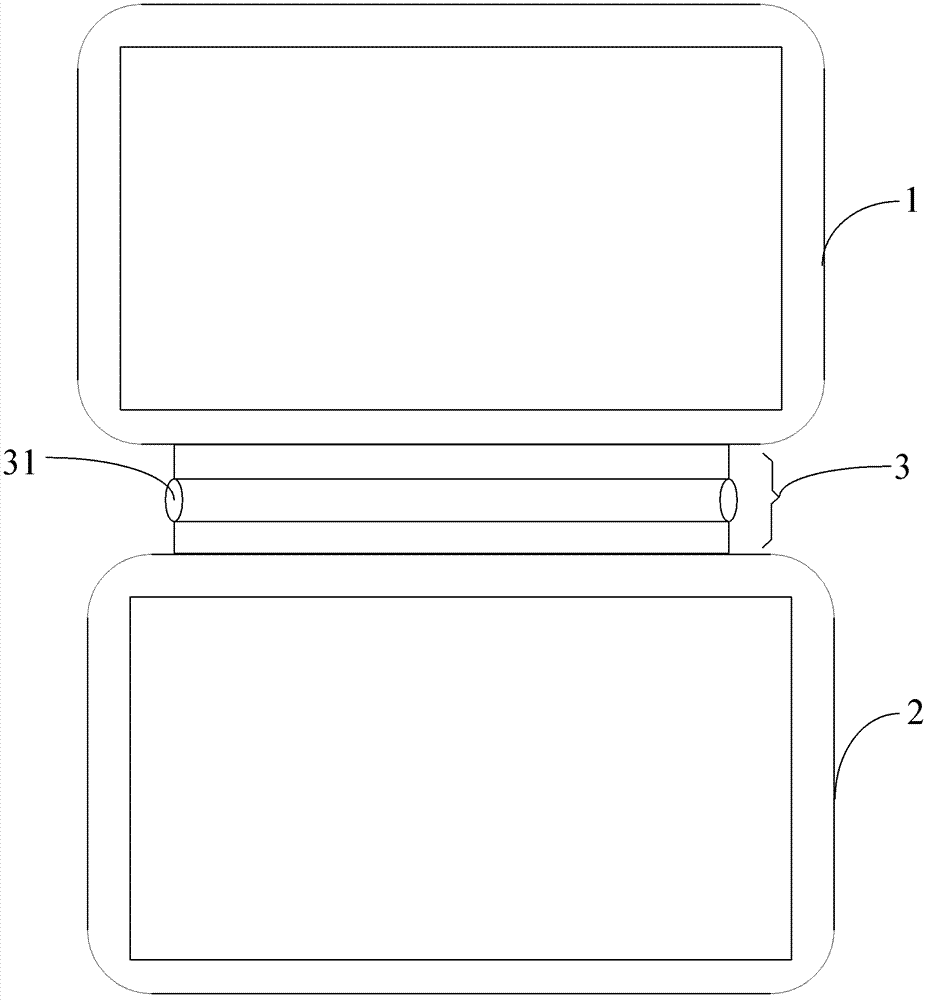

Flexible electronic equipment

InactiveCN106790805AFlipIncrease flexibilityTelephone set constructionsEngineeringFlexible electronics

The invention provides flexible electronic equipment. The flexible electronic equipment comprises a flexible display screen and a rotating component connected to the flexible display screen, wherein a limiting mechanism is arranged on the rotating component; when the rotating component rotates to a target position under the external force, the limiting mechanism limits the rotating component at the target position, and the flexible display screen is in a bending state under the drive of the rotating component. The flexible overturning characteristic of the rotating component and the bendable feature of the flexible display screen are combined to realize forward overturning, reverse overturning and multi-angle overturning of the flexible electronic equipment, so that the flexibility of the flexible electronic equipment is improved, and a carrying way is more convenient.

Owner:BEIJING XIAOMI MOBILE SOFTWARE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com