Patents

Literature

293results about How to "Avoid risk of breakage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

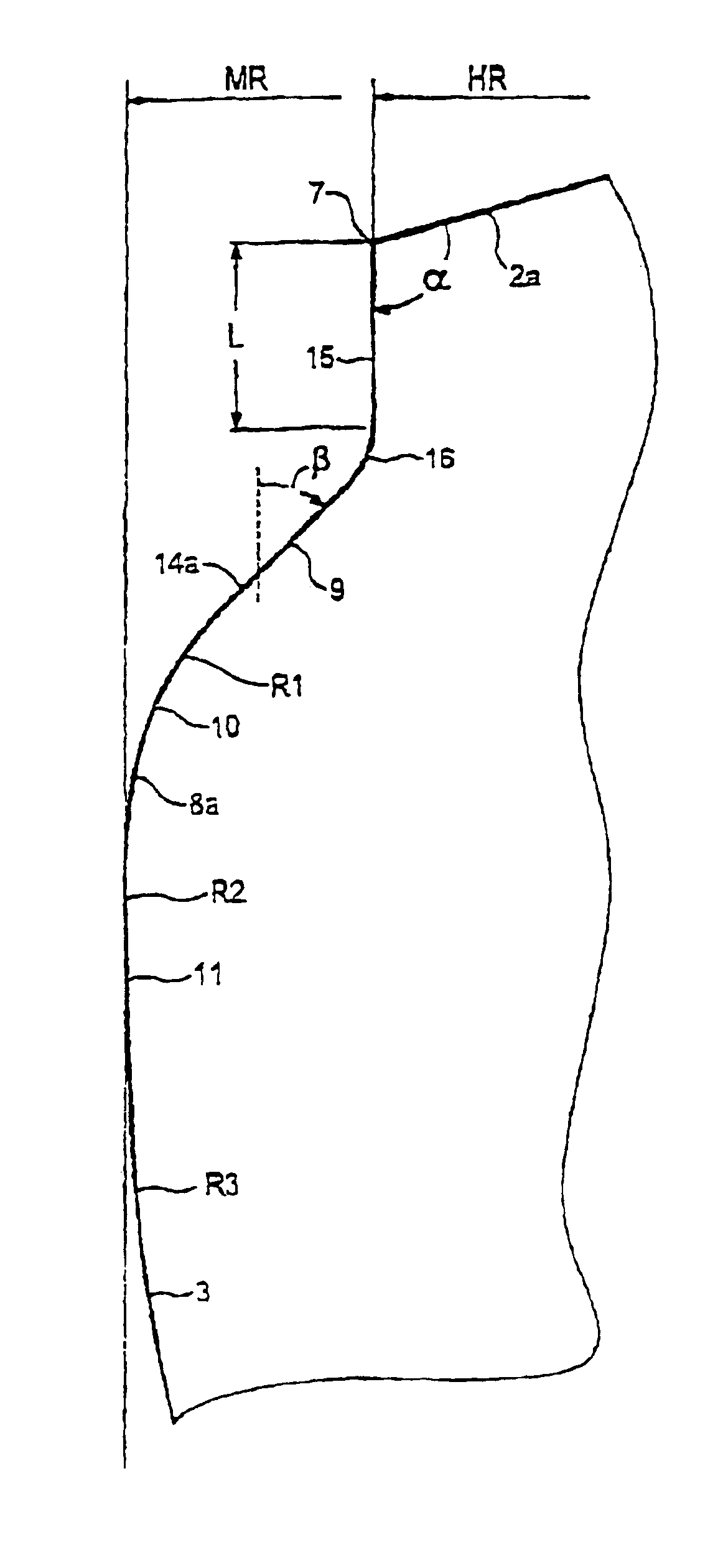

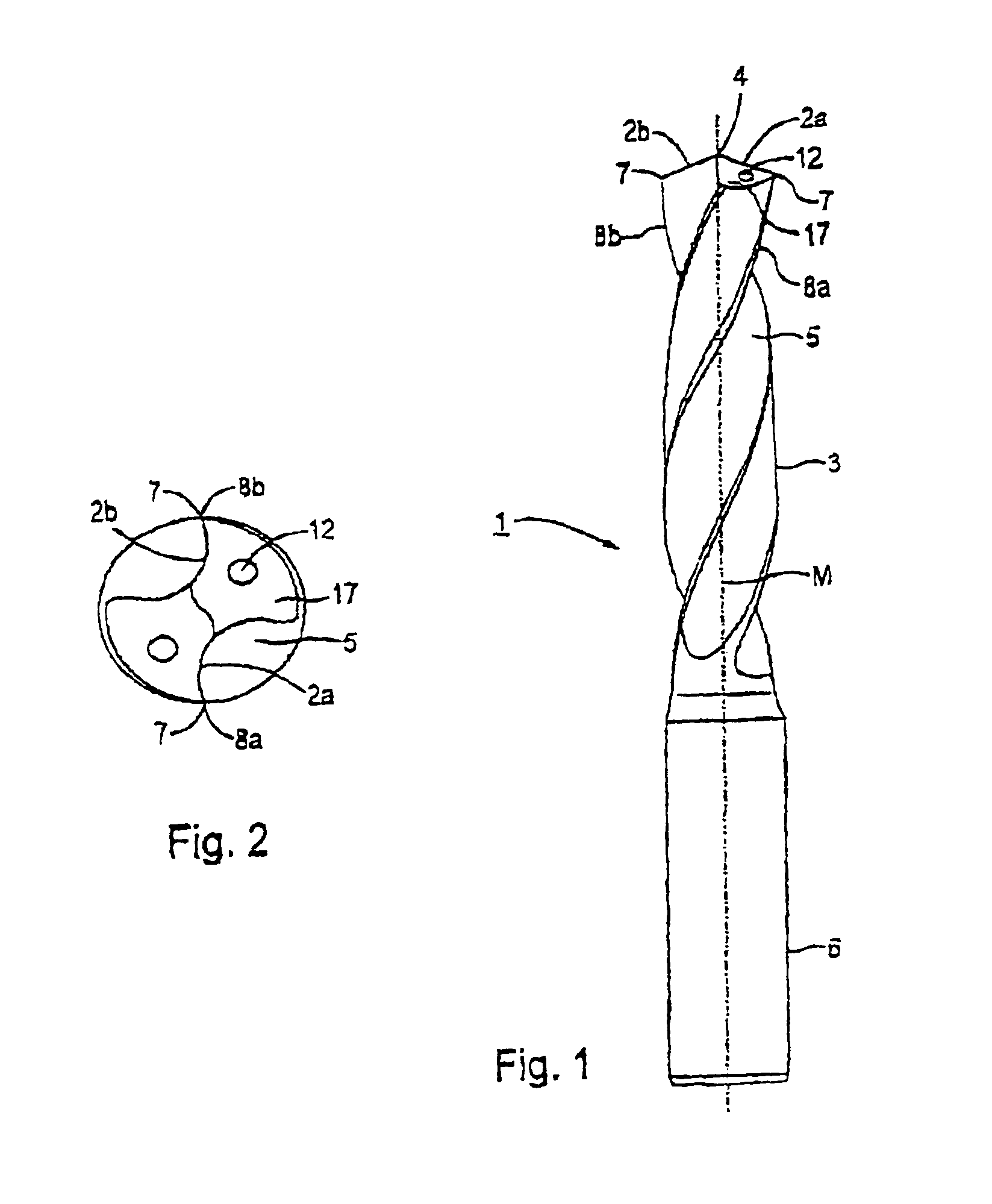

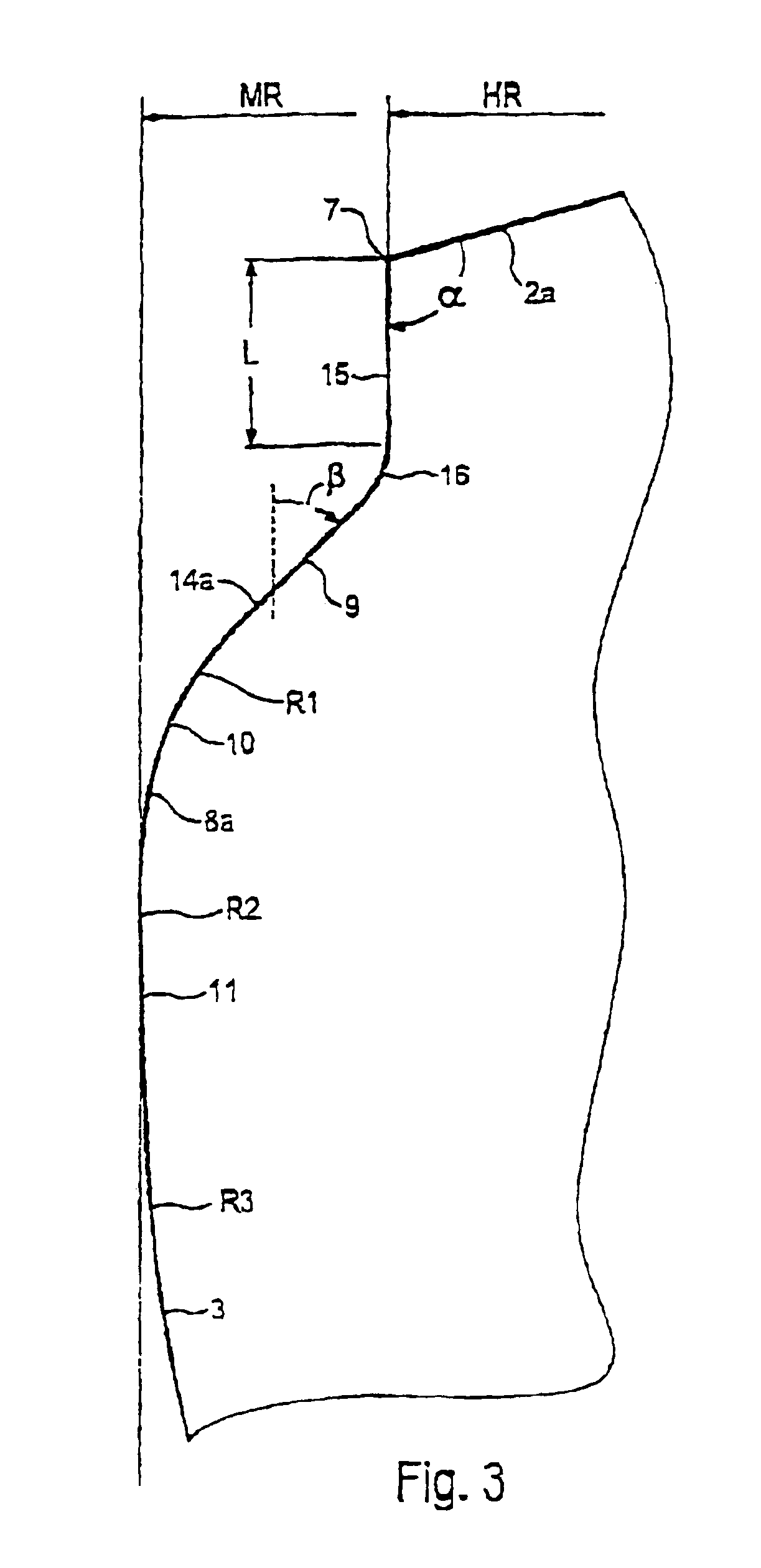

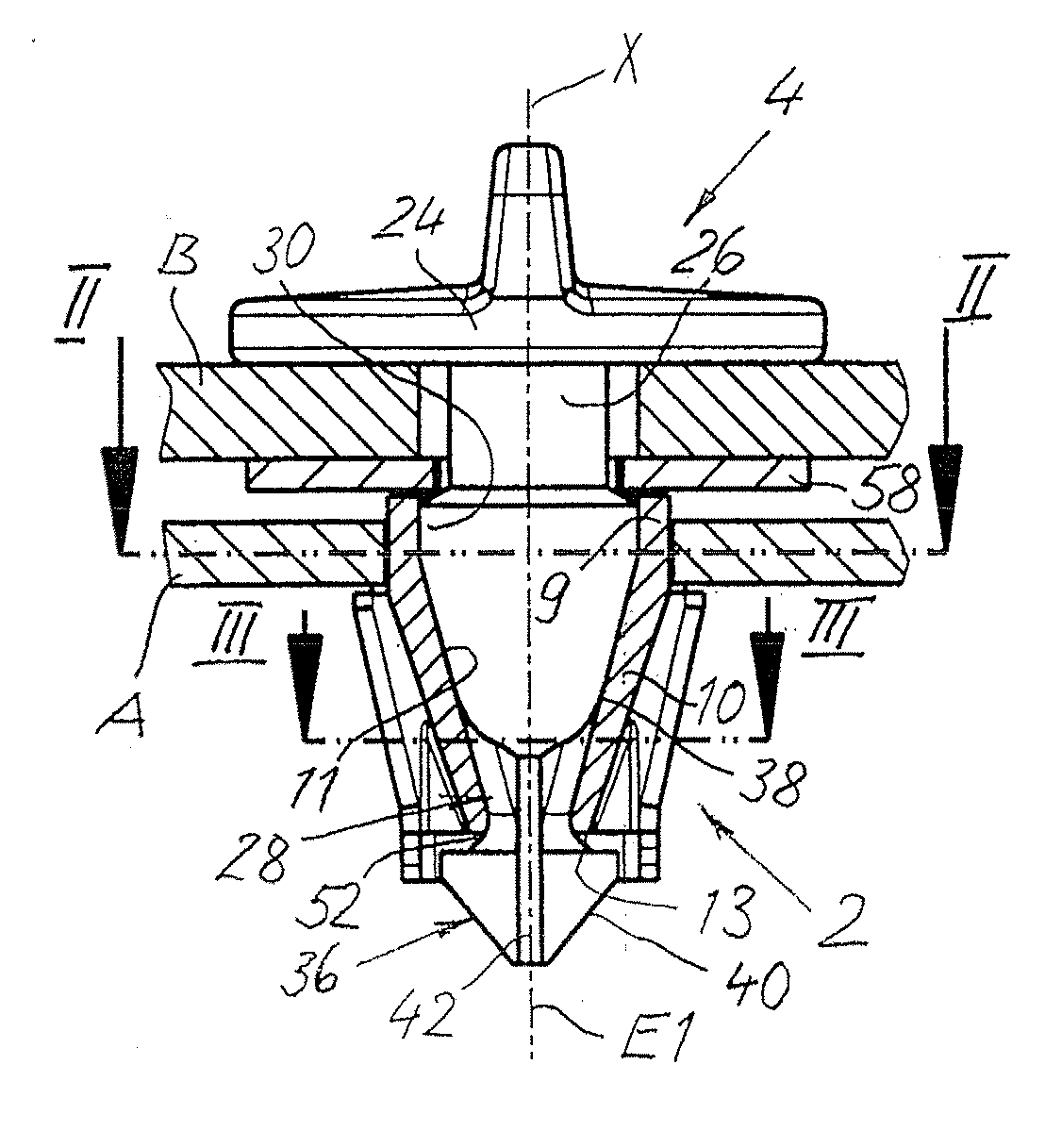

Rotary cutting tool

InactiveUS6929434B2High chip forming productivityImprove surface qualityWood turning toolsTransportation and packagingEngineeringDrill bit

There is now provided a rotary cutting tool, particularly a drill, that has at least two cutting edges that respectively comprise a main cutting edge and that respectively are disposed, particularly symmetrically, with respect to the central axis of a cutter portion, whereby the radius of the main cutting edges is less than the maximal cutting edge radius of the cutter portion. A secondary cutting edge is associated with a main cutting edge, this secondary cutting edge is curvilinear in at least a portion and is configured as smooth finishing cutting edge, this secondary cutting edge comprises a plurality of curve-forming radii, whereby in an outer smooth finishing region within the region of the maximal cutting edge radius, the curve-forming radius of the smooth finishing cutting edge is greater than the maximal cutting edge radius. The cutter portion that is adjacent to the outer smooth finishing region is tapered by a taper that diminishes the size in the direction away from the main cutting edges.

Owner:KENNAMETAL INC

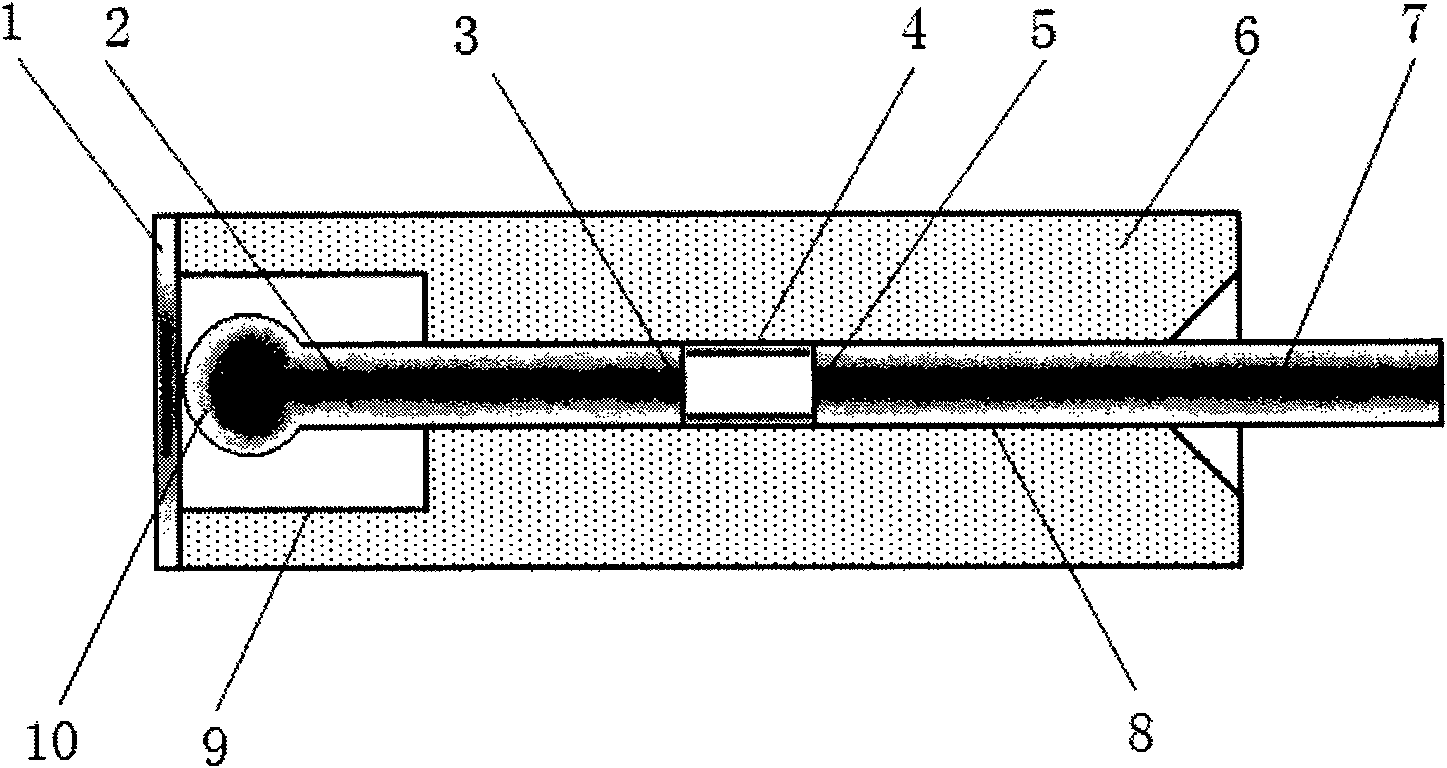

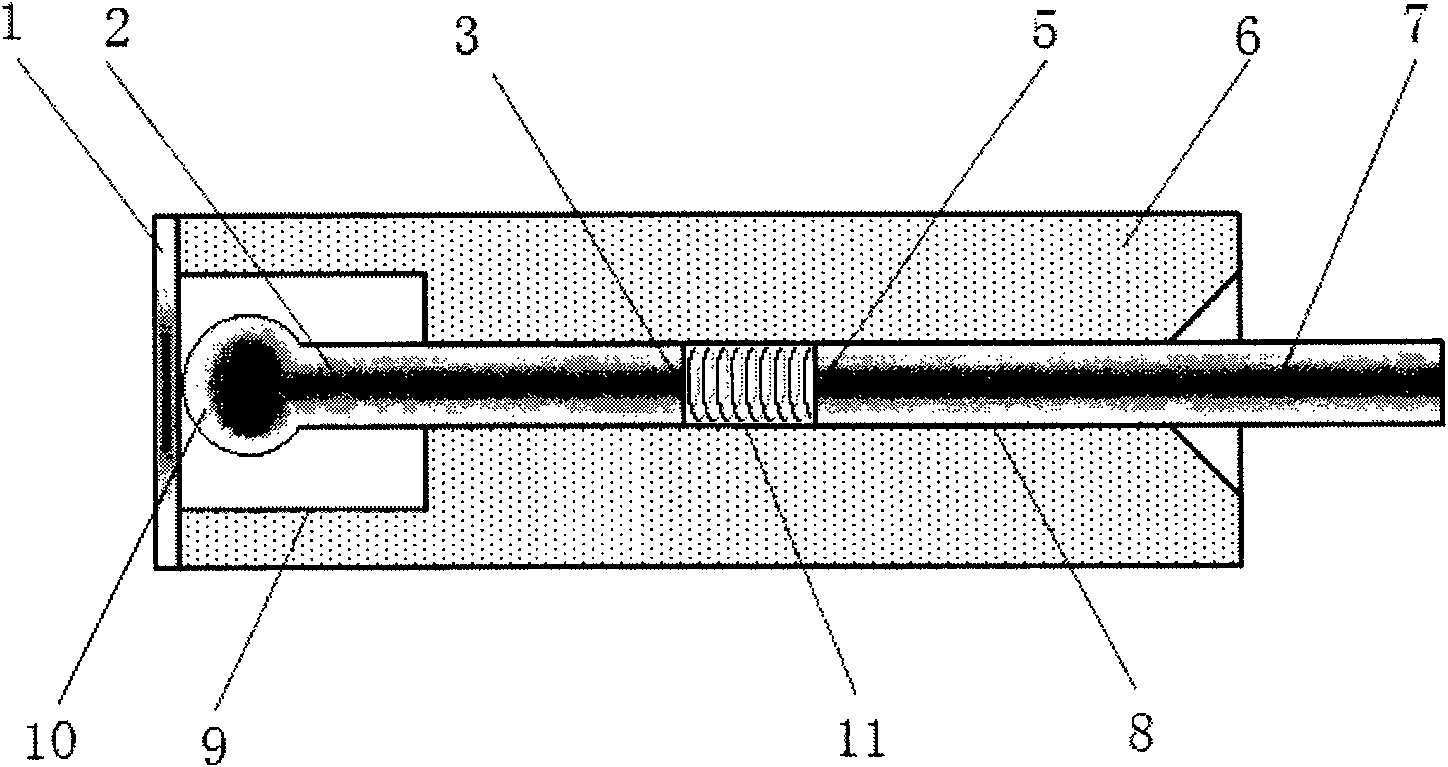

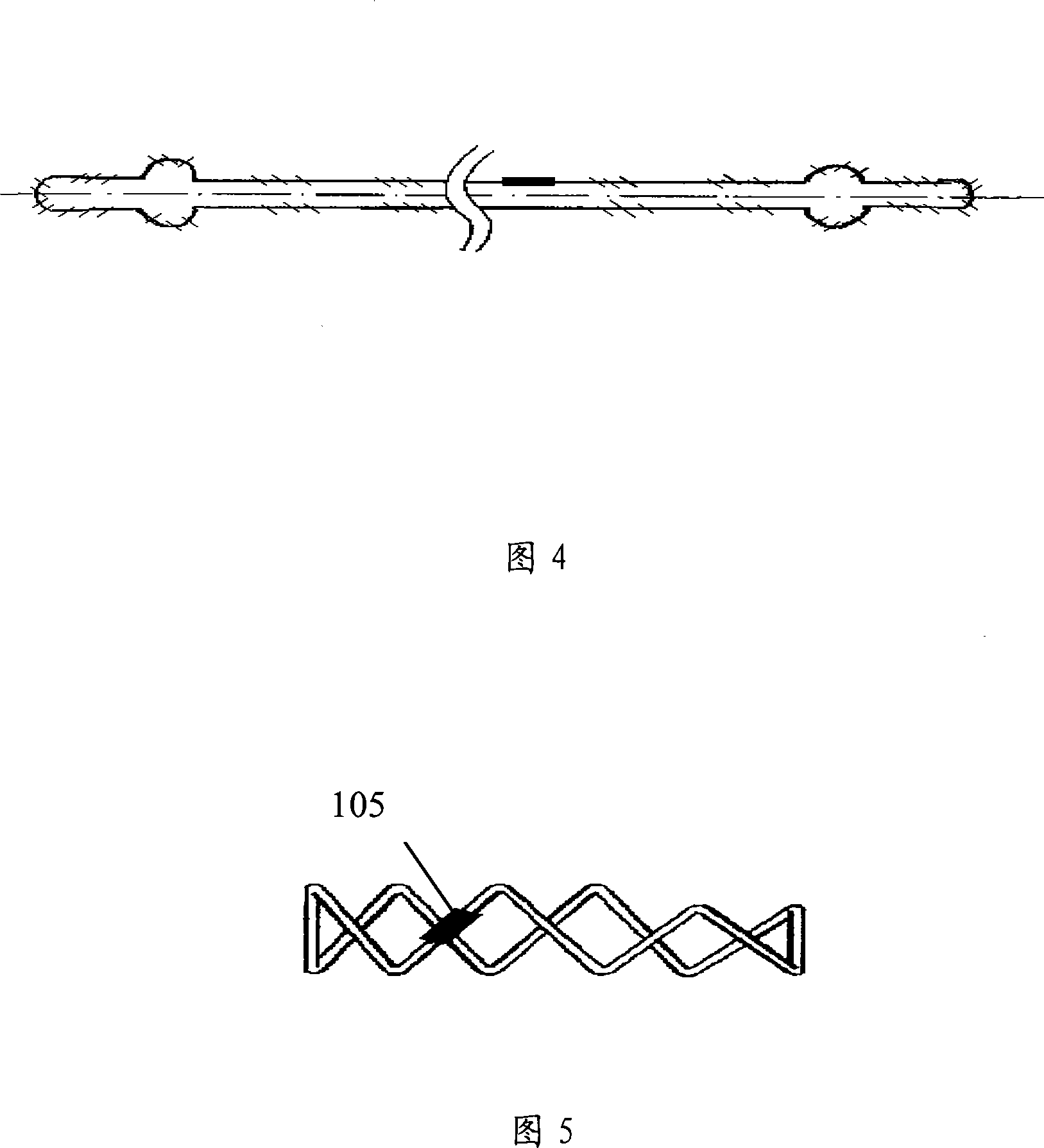

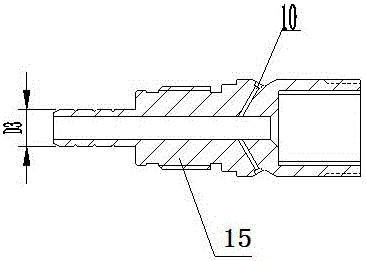

Optical fiber Fabry-Perot pressure sensor and fabrication method thereof

InactiveCN101858809AReduce measurement errorEnsure close contactCoupling light guidesFluid pressure measurement by optical meansEngineeringAlternative methods

The invention relates to a novel optical fiber Fabry-Perot pressure sensor and a fabrication method thereof. The optical fiber Fabry-Perot pressure sensor is used for detecting the relative pressure and absolute pressure of liquid and gas as well as sound wave signals, ultrasonic wave signals and the like. The structure of the optical fiber Fabry-Perot pressure sensor mainly comprises an optical fiber, an elastic diaphragm, a sensor body and a miniature spring. Two methods and an alternative method can be adopted to form a Fabry-Perot cavity and fabricate the sensor. The elastic diaphragm and the sensing optical fiber are tightly contacted in a plane-sphere point contact manner; when the outside pressure is changed to cause the deformation of the elastic diaphragm, the diaphragm can drive the optical fiber to axially move in the sensor body, so that the length of the Fabry-Perot cavity of the optical fiber is changed; after a broadband light source is connected, by scanning the spectrum of the light passing through the optical fiber Fabry-Perot pressure sensor or extracting low-coherence interference fringes, the change of the cavity length can be extracted, and thereby pressure information can be obtained. The structure can avoid the defect that the diaphragm of the conventional optical fiber Fabry-Perot pressure sensor cannot be over-deformed, and can obtain higher measurement precision.

Owner:TIANJIN UNIV

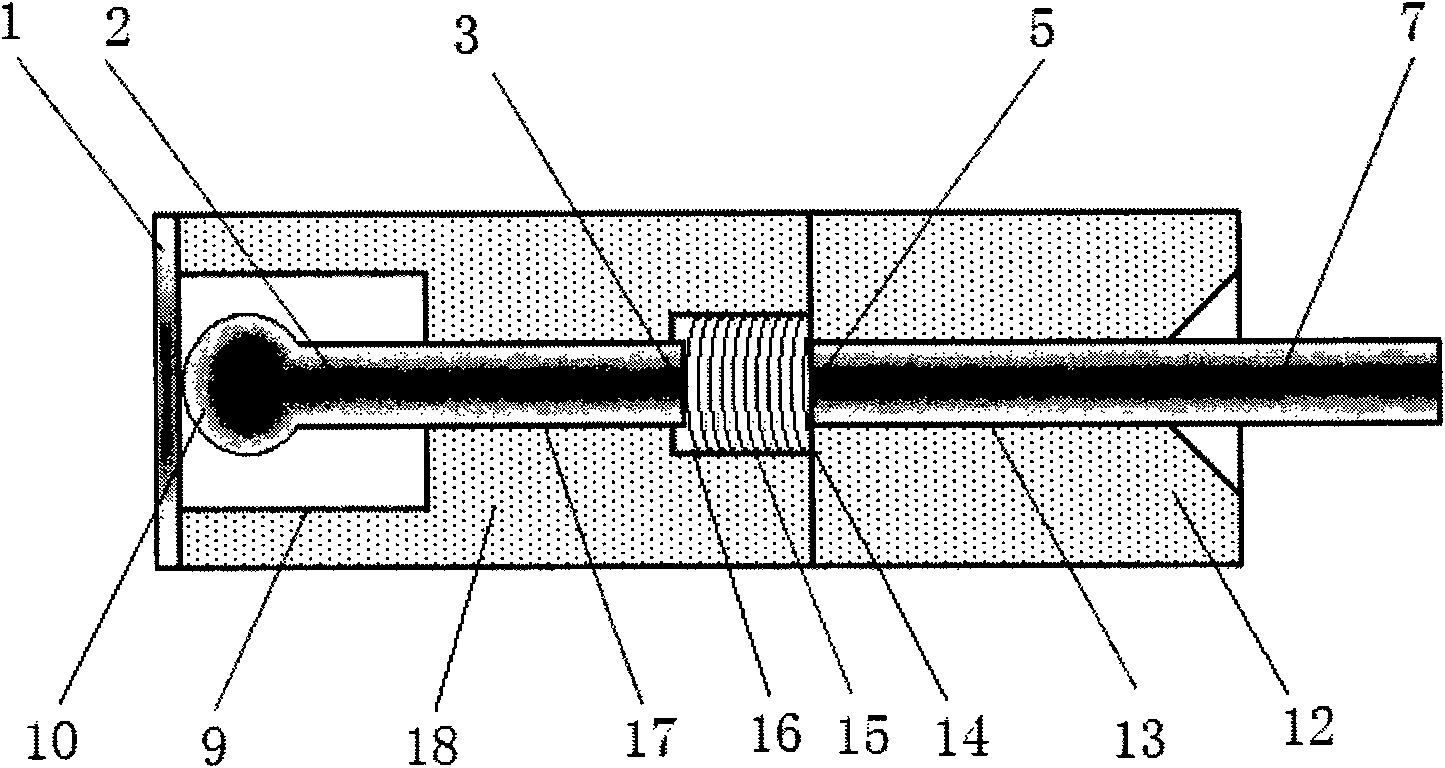

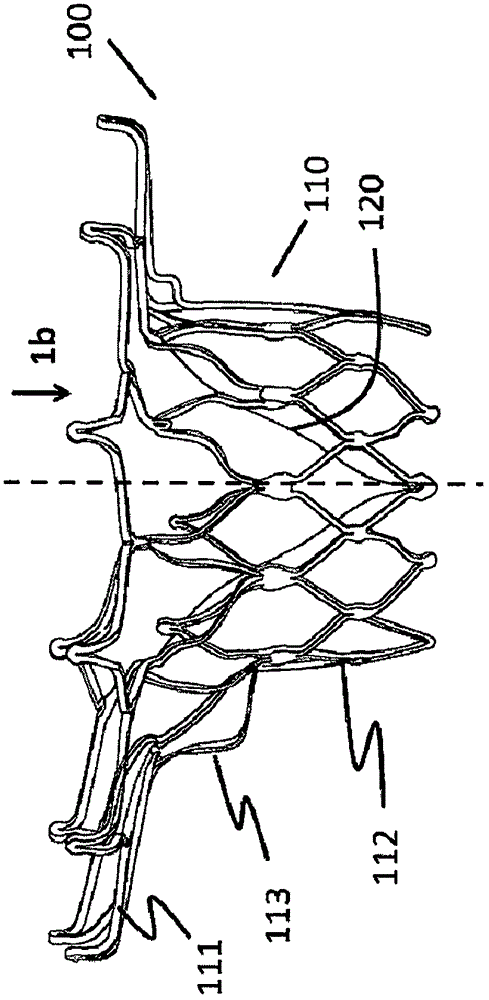

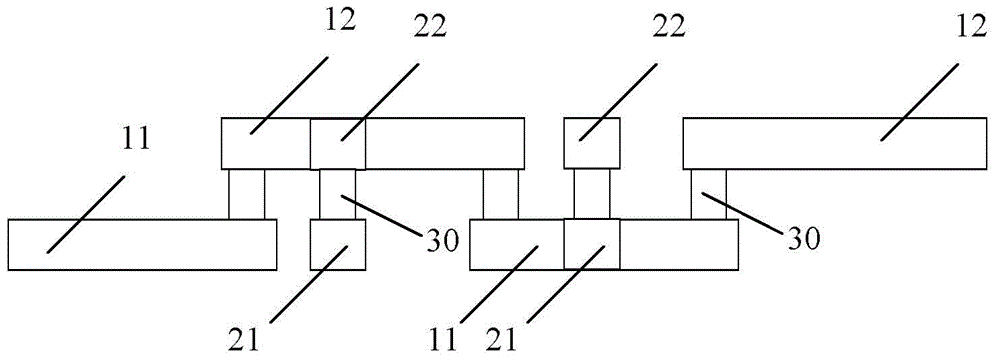

Tectorial bracket

ActiveCN101176686AReduced maximum outer profileEasy to installStentsSurgeryTectorial membraneLead blood

The invention discloses a coated stent, comprising a stent section, a coat and a reinforcement; wherein, two ends of a metal wire are connected to form the reinforcement which is fixed on the coat. The invention is characterized in that: since the coated stent adopts the independent reinforcement, the reinforcement is separated from the stent section, avoiding the risk that in prior art the integral connection of the reinforcement and the front and end stent sections can lead to fracture; furthermore, the hindrance produced in the course of releasing and assembling the whole stent is reduced,which is helpful for the releasing and assembling of the coated stent. The invention also discloses another coated stent comprising a stent section and a coat; wherein, two ends of a metal wire are connected by laser welding to form the stent section. Since two ends of the metal wire in each stent section are not fixedly connected, prior coated stent can lead blood damage; therefore, the risk is avoided.

Owner:SHANGHAI MICROPORT ENDOVASCULAR MEDTECH (GRP) CO LTD

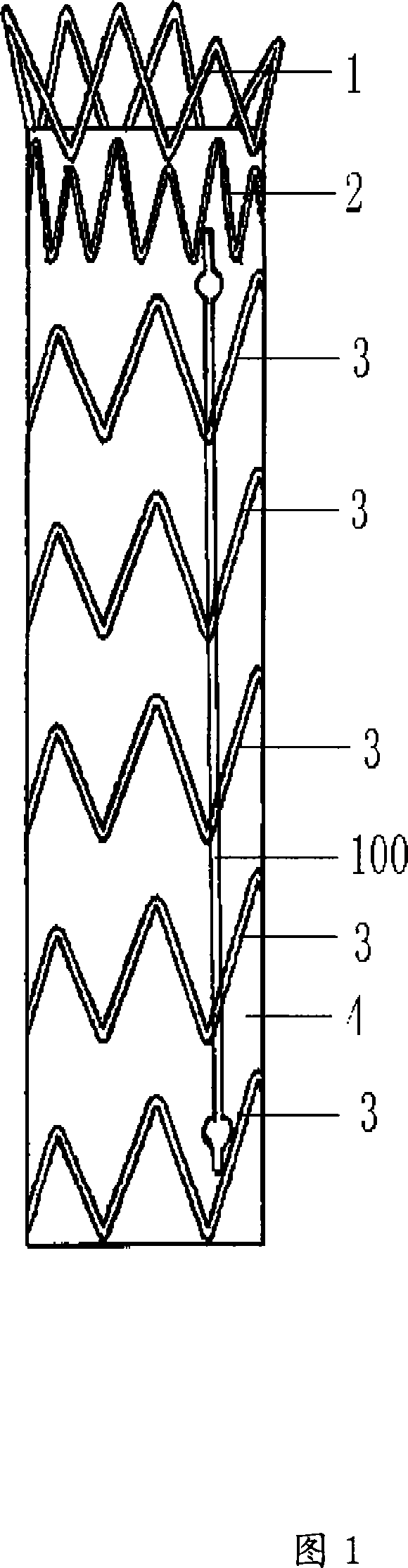

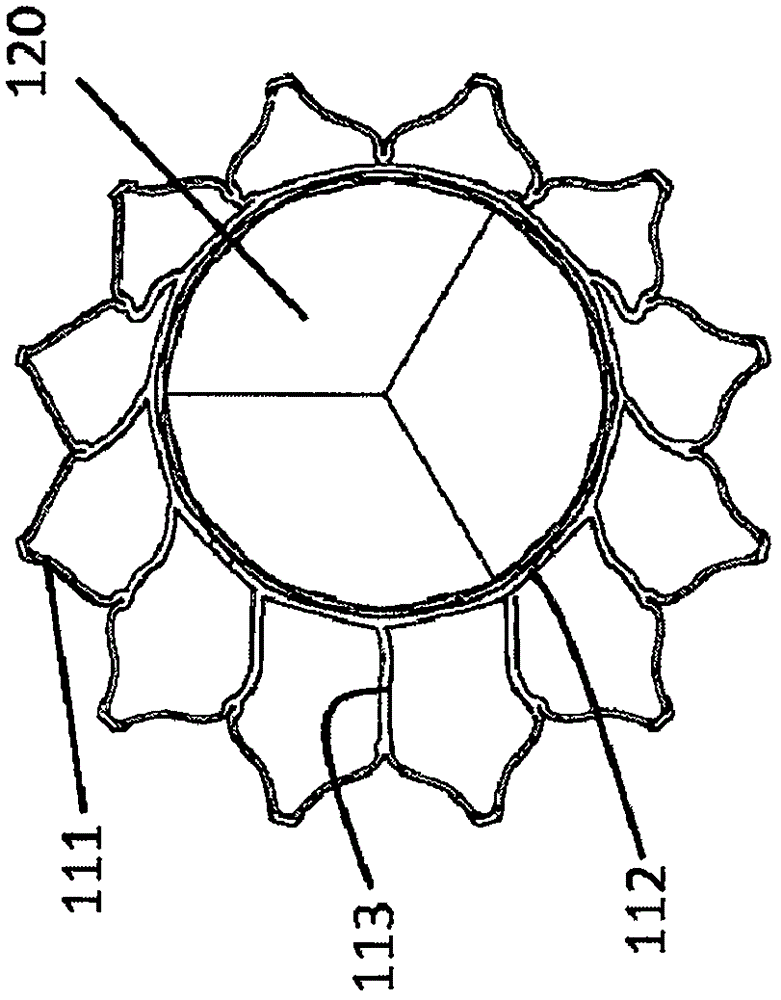

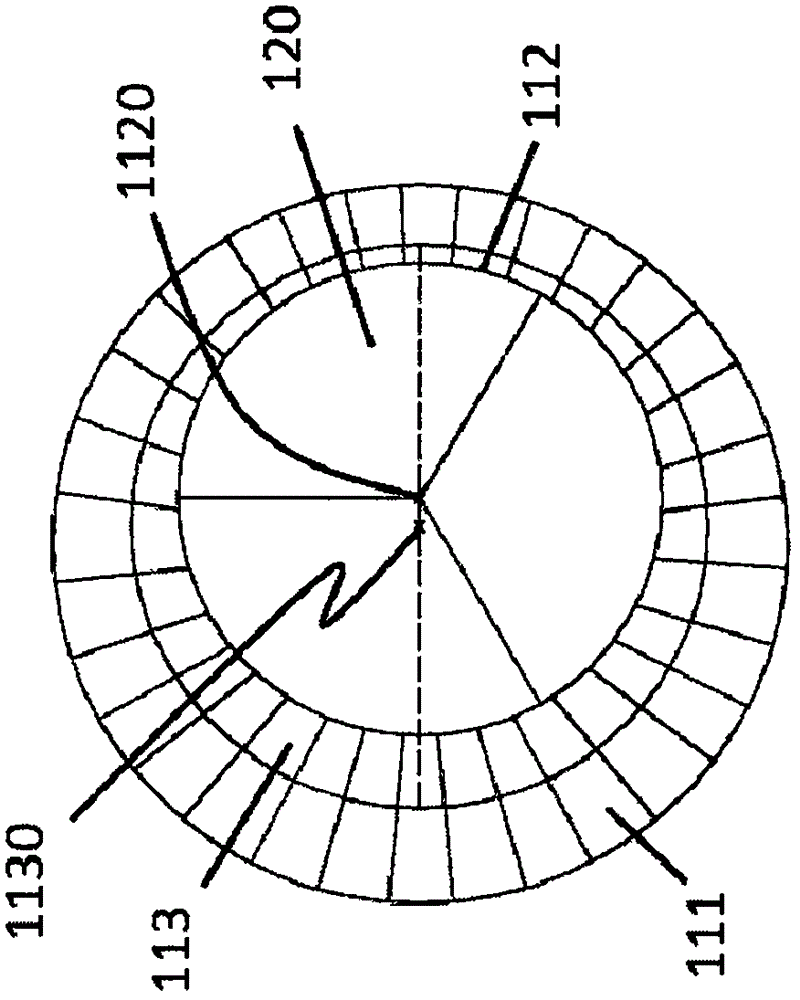

Heart valve prosthesis

ActiveCN106420114AReduced cross-sectional area requirementsImprove performanceAnnuloplasty ringsProsthetic valveFree state

The invention relates to a heart valve prosthesis. The heart valve prosthesis comprises a stent and artificial valves; the stent comprises an atrium section and a valve suturing section, the artificial valves are fixedly connected to the valve suturing section, a skeleton of the far end part of the valve suturing section extends to form a supporting section, and the supporting section and the valve suturing section are of an integrated structure; one end of the atrium section is connected with the far end of the supporting section, the other end of the atrium section is free and is located on the cross section perpendicular to the central axis of the artificial valves, the valve suturing section is located in the supporting section, the center of the valve suturing section does not coincide with that of the supporting section, the cross section area of the supporting section is larger than that of the valve suturing section, the cross section area of the atrium section is larger than that of the supporting section, the cross section area of the valve suturing section is smaller than that of valve rings of autologous valves of a patient, and in a free state, at least part of the supporting section is located among the valve rings of the autologous valves of the patient.

Owner:NINGBO JENSCARE BIOTECHNOLOGY CO LTD

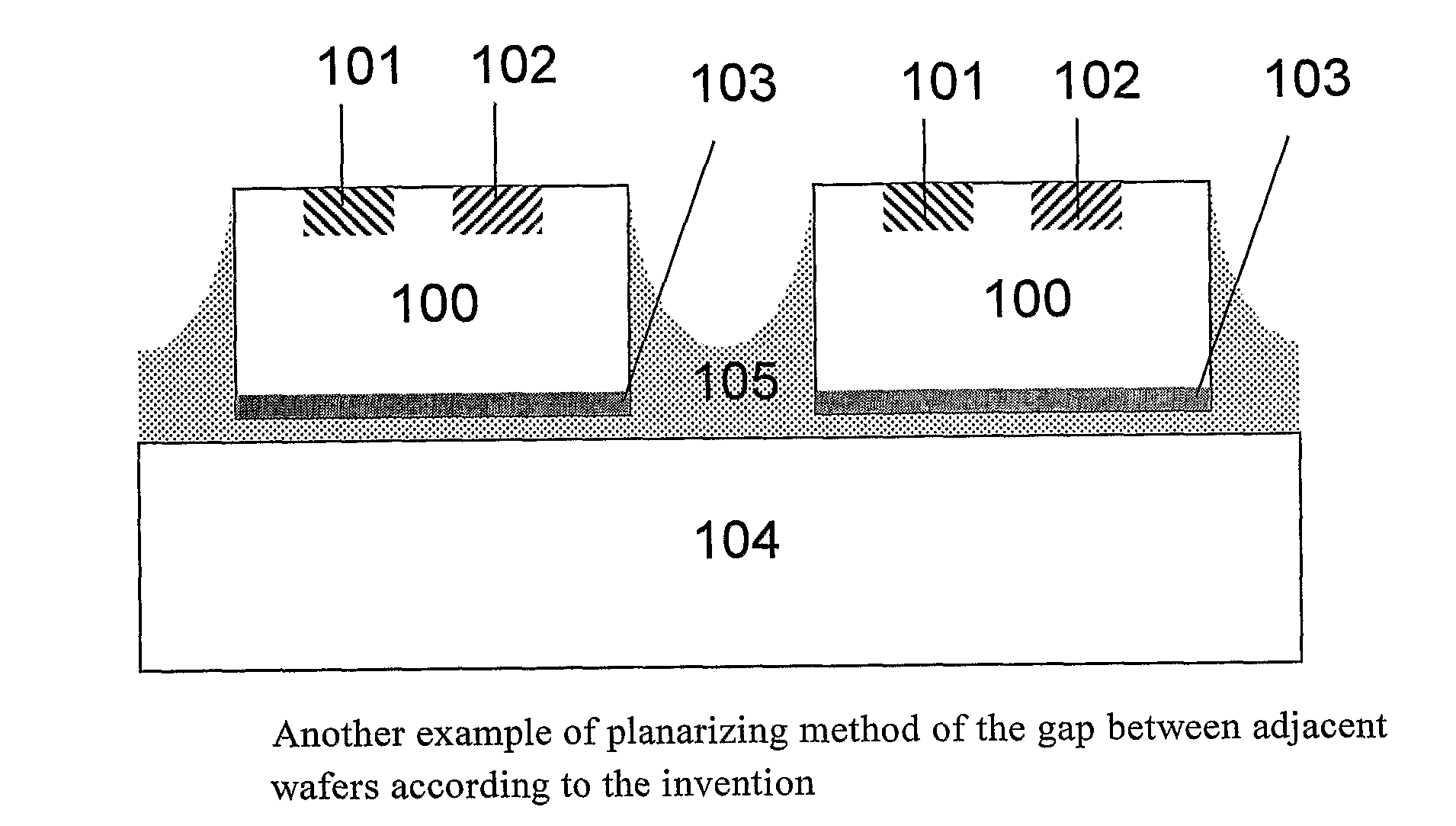

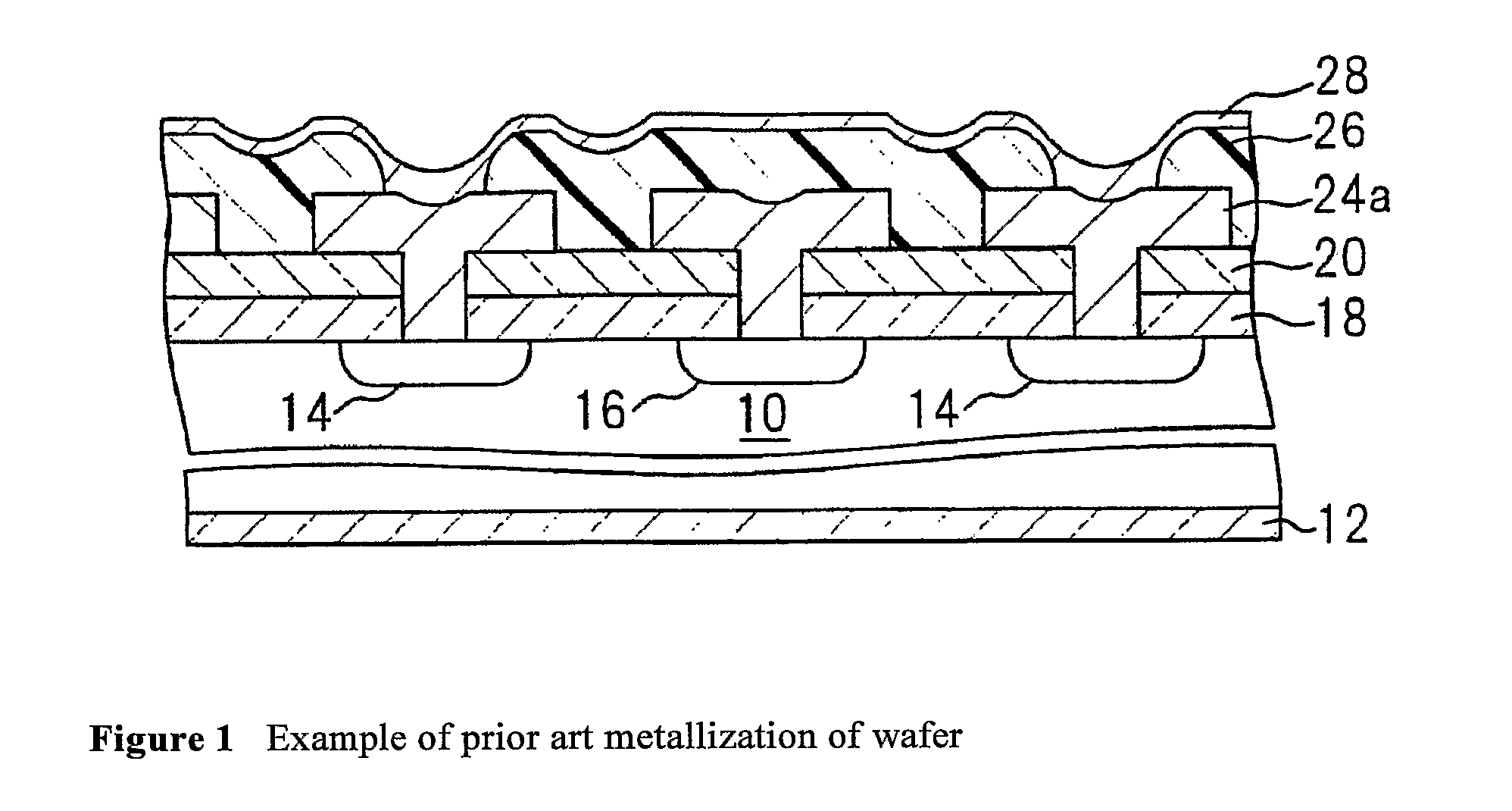

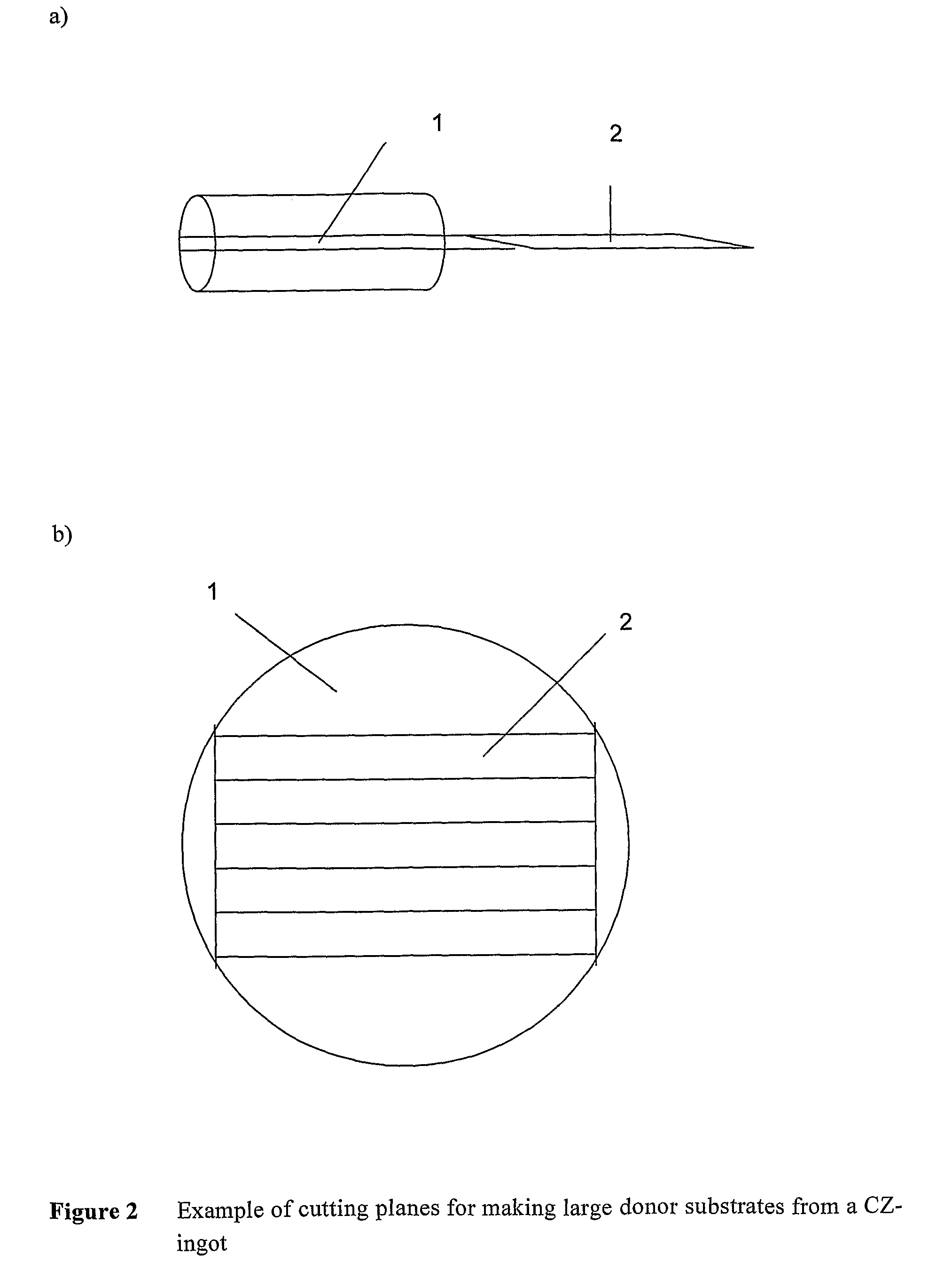

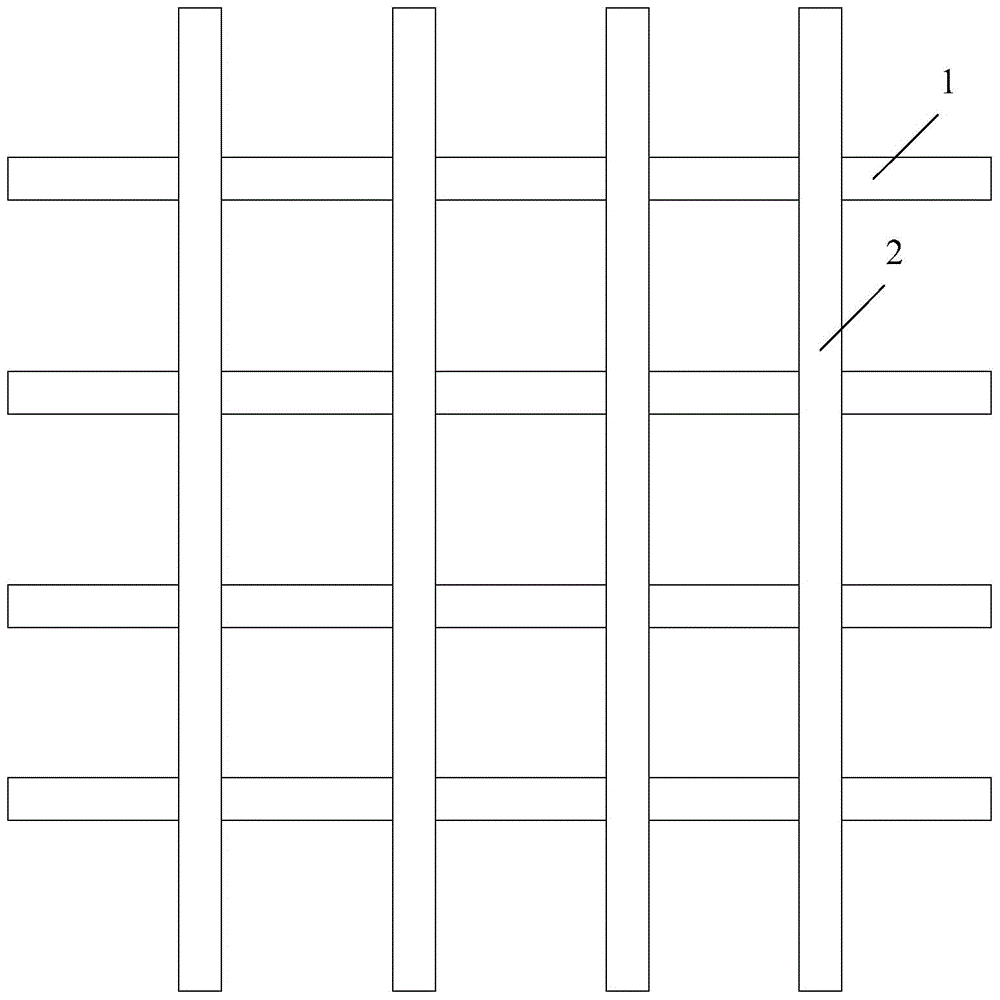

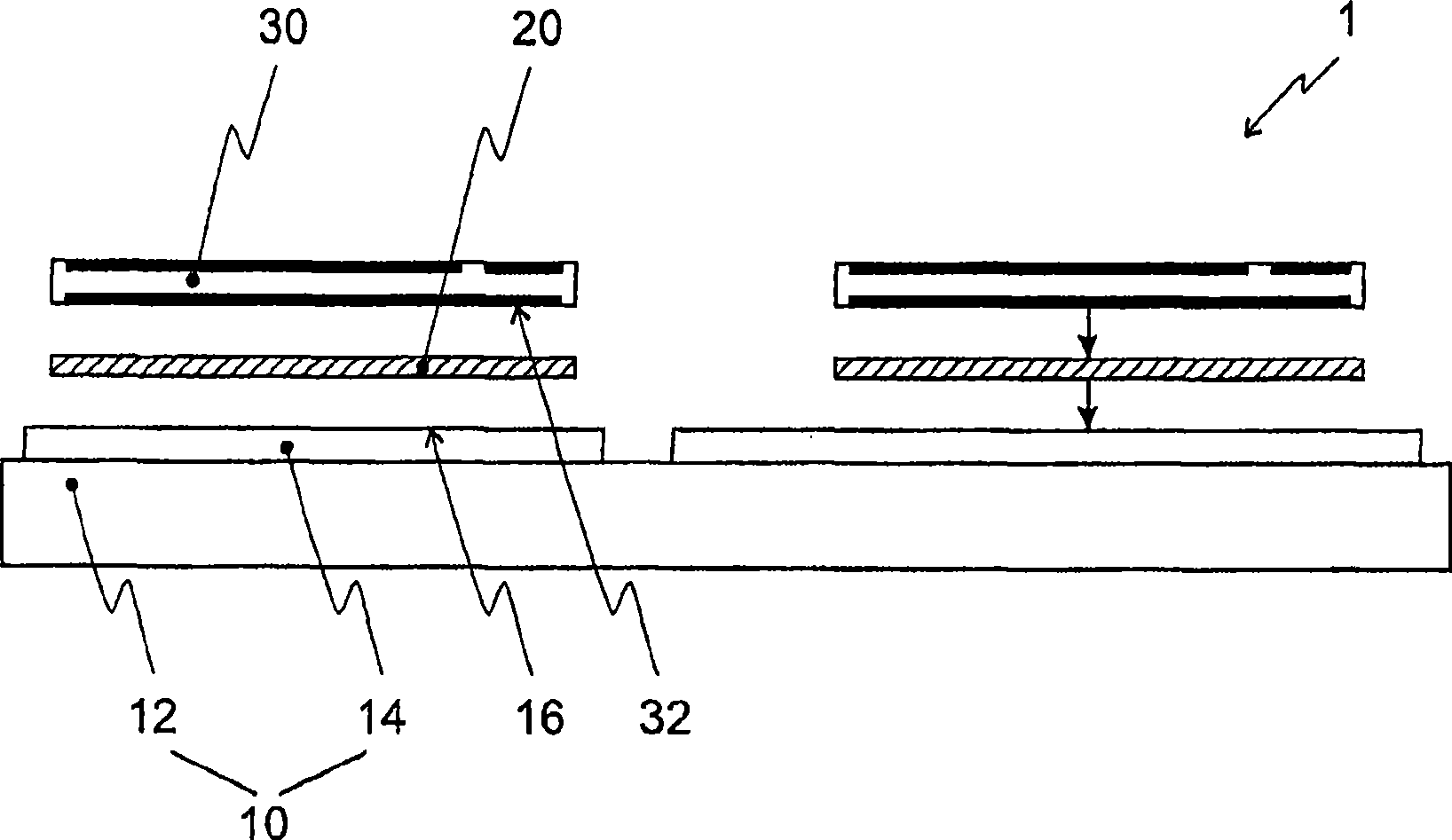

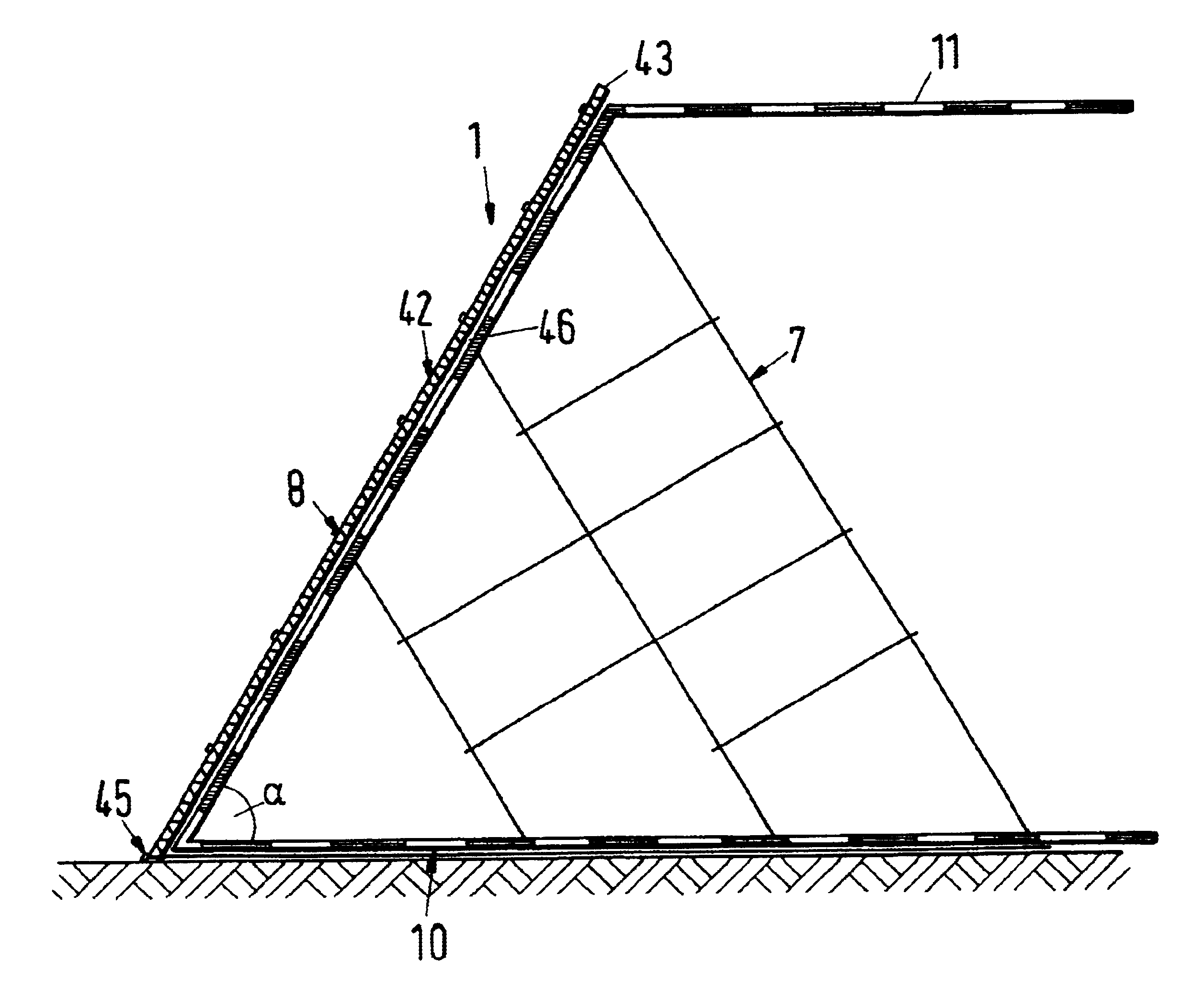

Method for production of wafer based solar panels

ActiveUS20110120531A1Low photovoltaic conversion efficiencyCost effectivePV power plantsFinal product manufactureEngineeringInterconnection

This invention relates to a method for producing solar cells, and photovoltaic panels thereof. The method for producing solar panels comprises employing a number of semiconductor wafers and / or semiconductor sheets of films prefabricated to prepare them for back side metallization, which are placed and attached adjacent to each other and with their front side facing downwards onto the back side of the front glass, before subsequent processing that includes depositing at least one metal layer covering the entire front glass including the back side of the attached wafers / sheets of films. The metallic layer is then patterned / divided into electrically isolated contacts for each solar cell and into interconnections between adjacent solar cells.

Owner:REC SOLAR

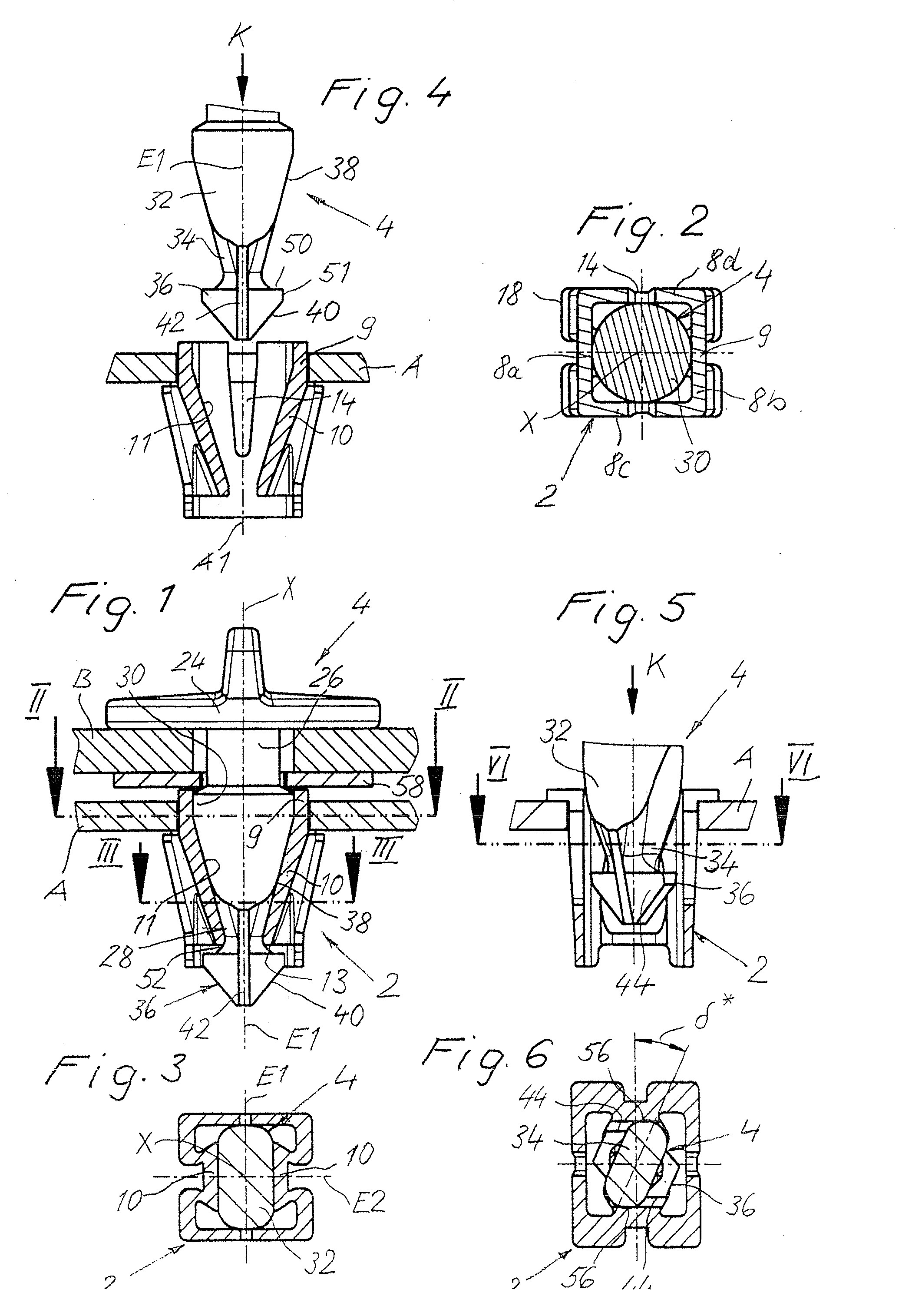

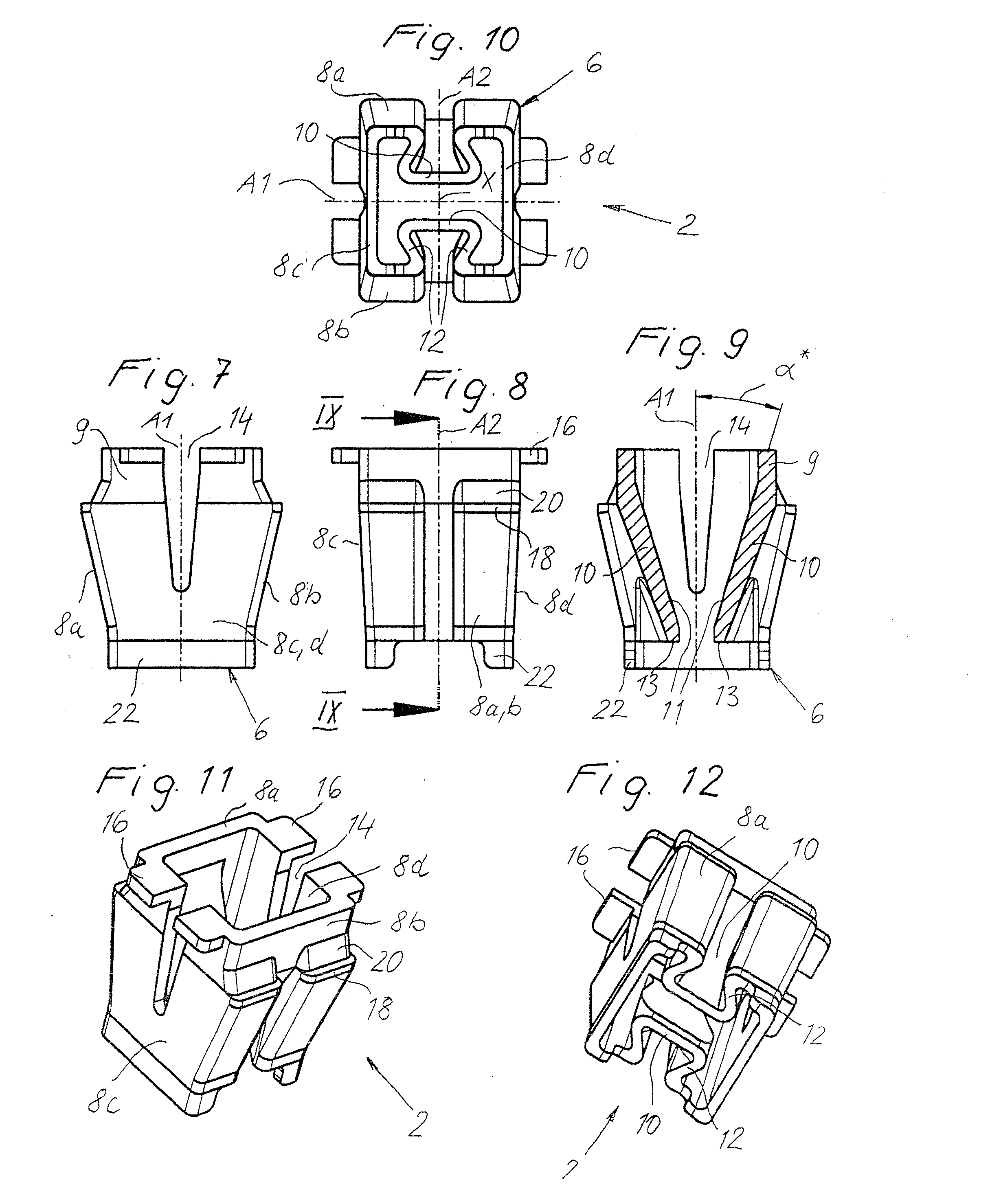

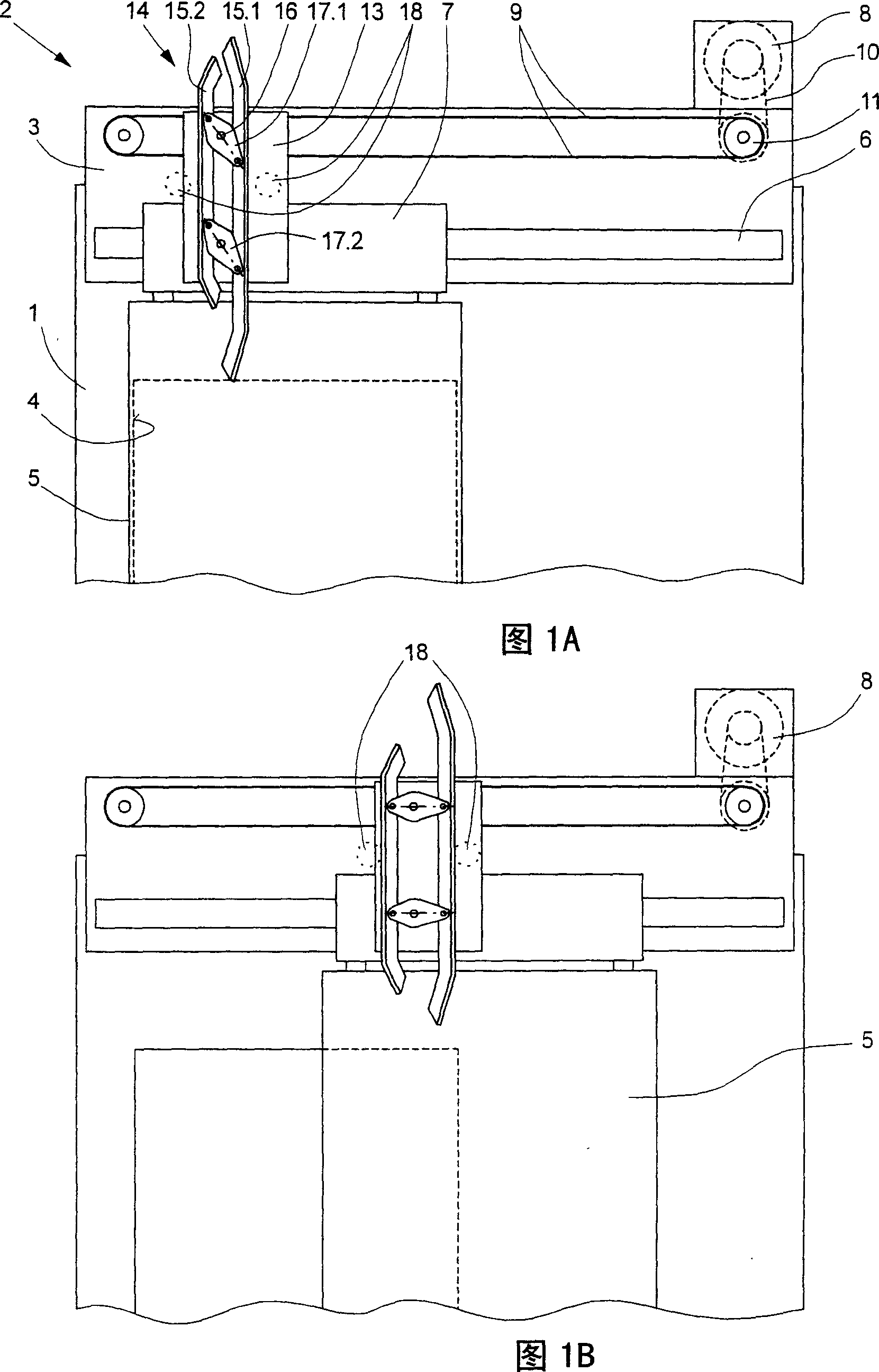

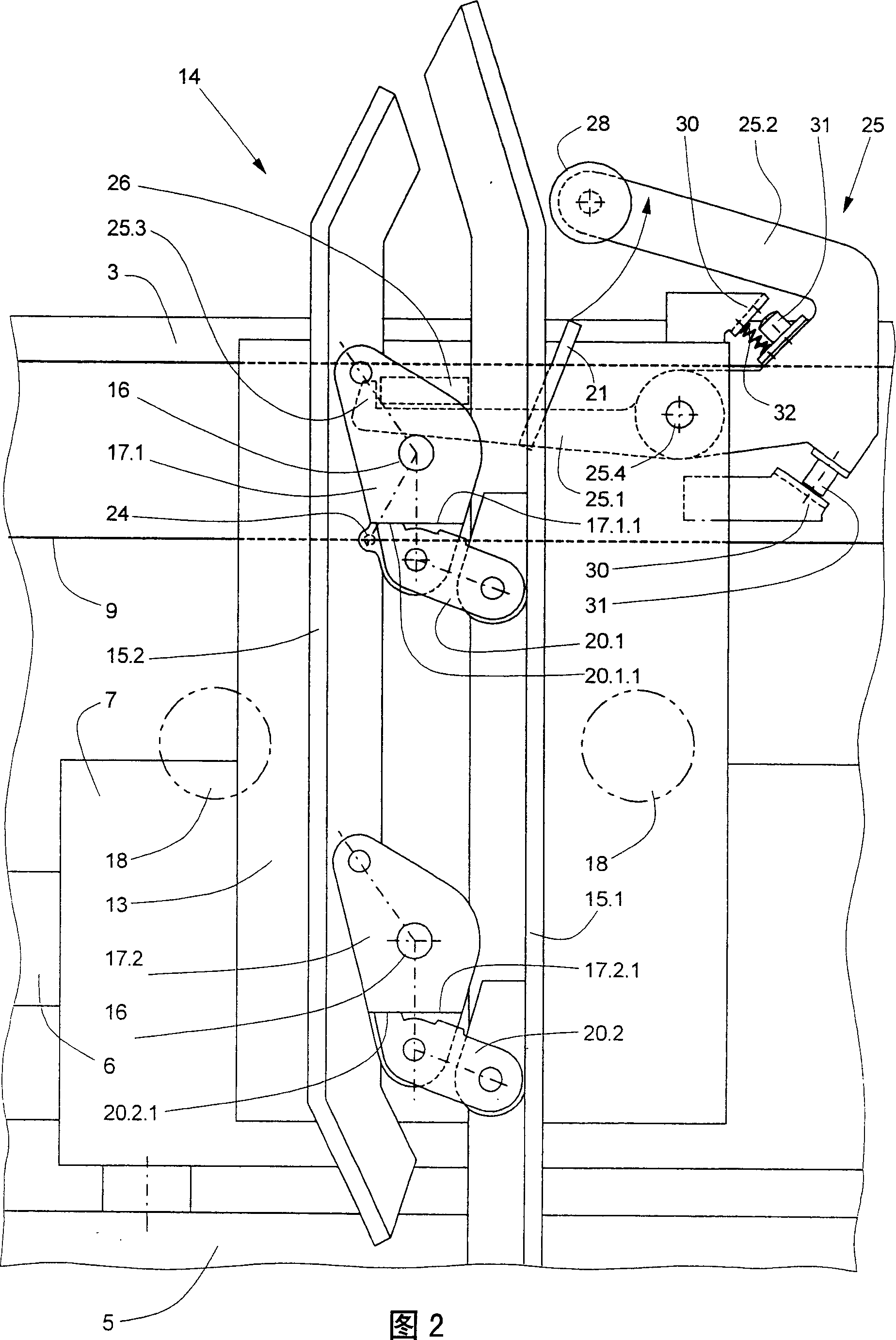

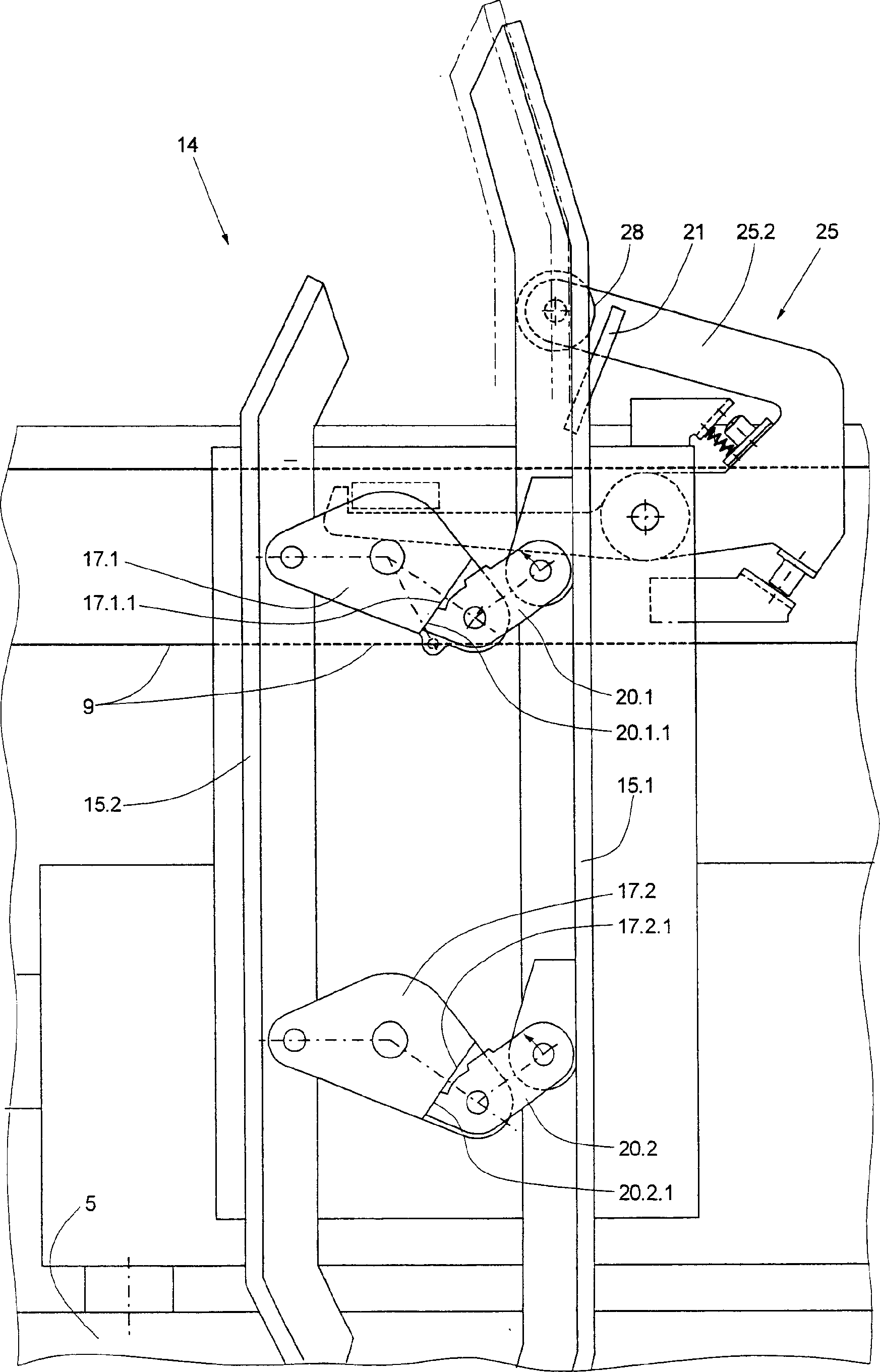

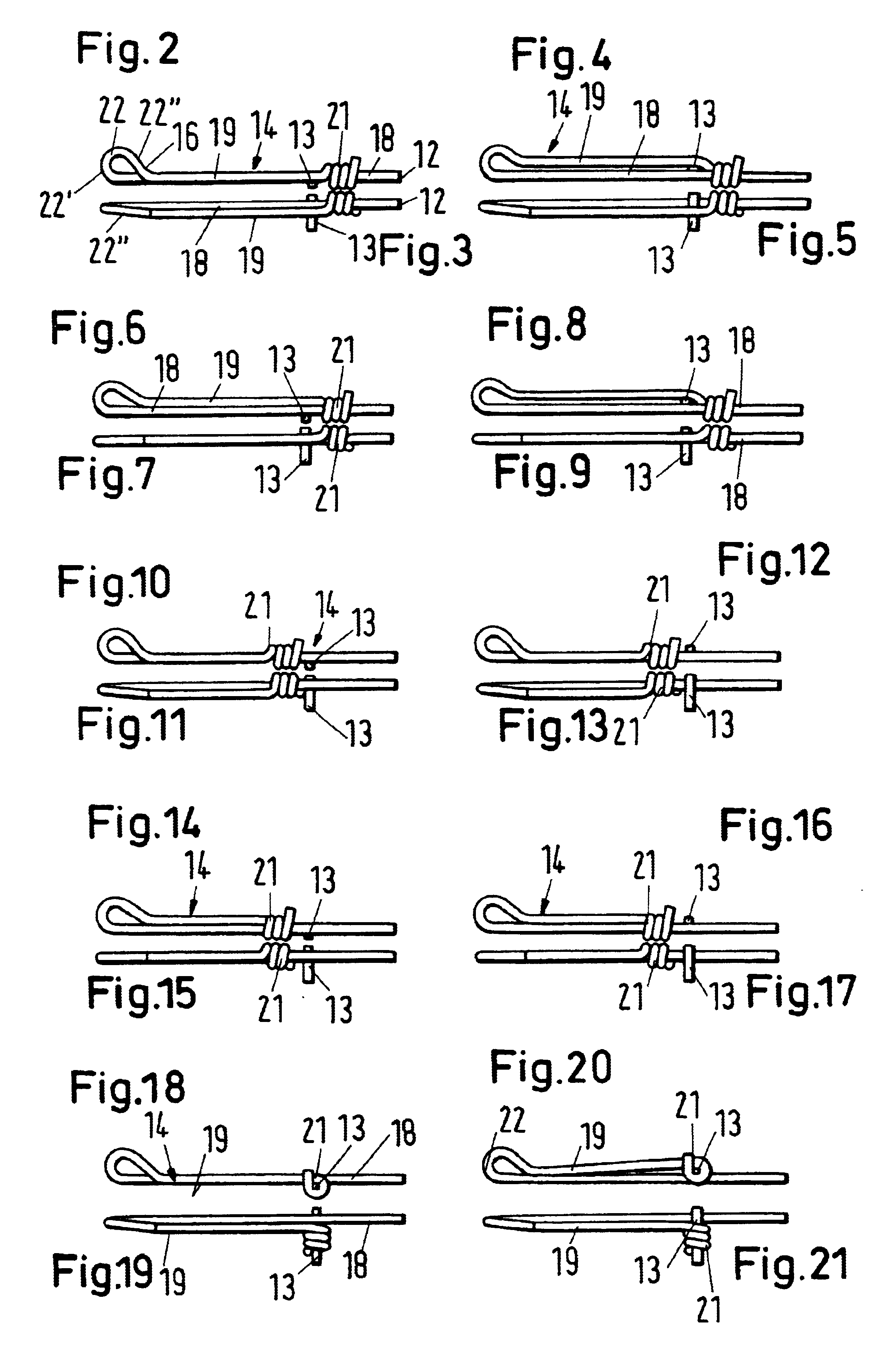

Quick connect closure for connecting two structural members

InactiveUS20080056816A1Operating reliability can be highEasy to manufactureCouplings for rigid shaftsSheet joiningPlastic materialsEngineering

Owner:BOLLHOFF VERBINDUNGSTECHNIK GMBH

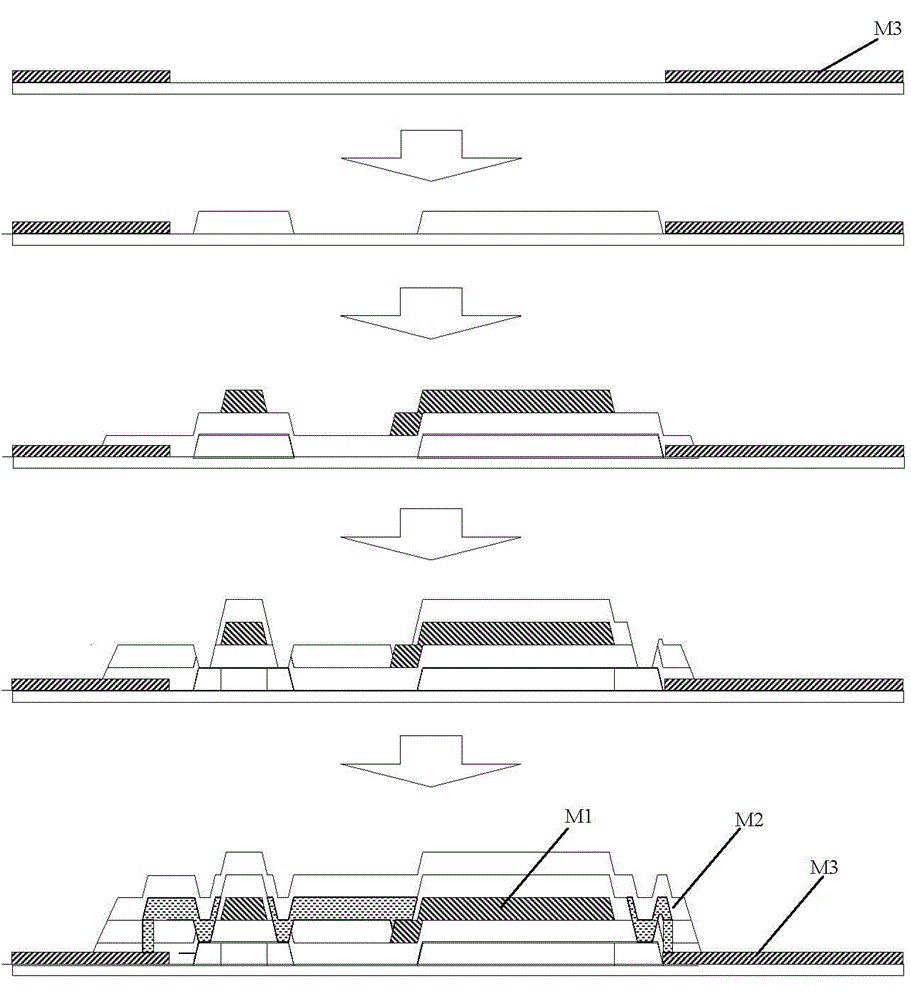

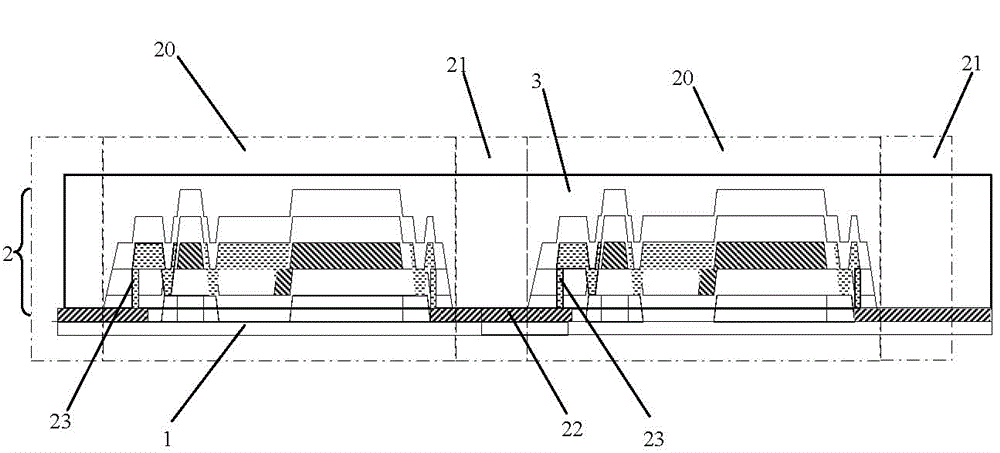

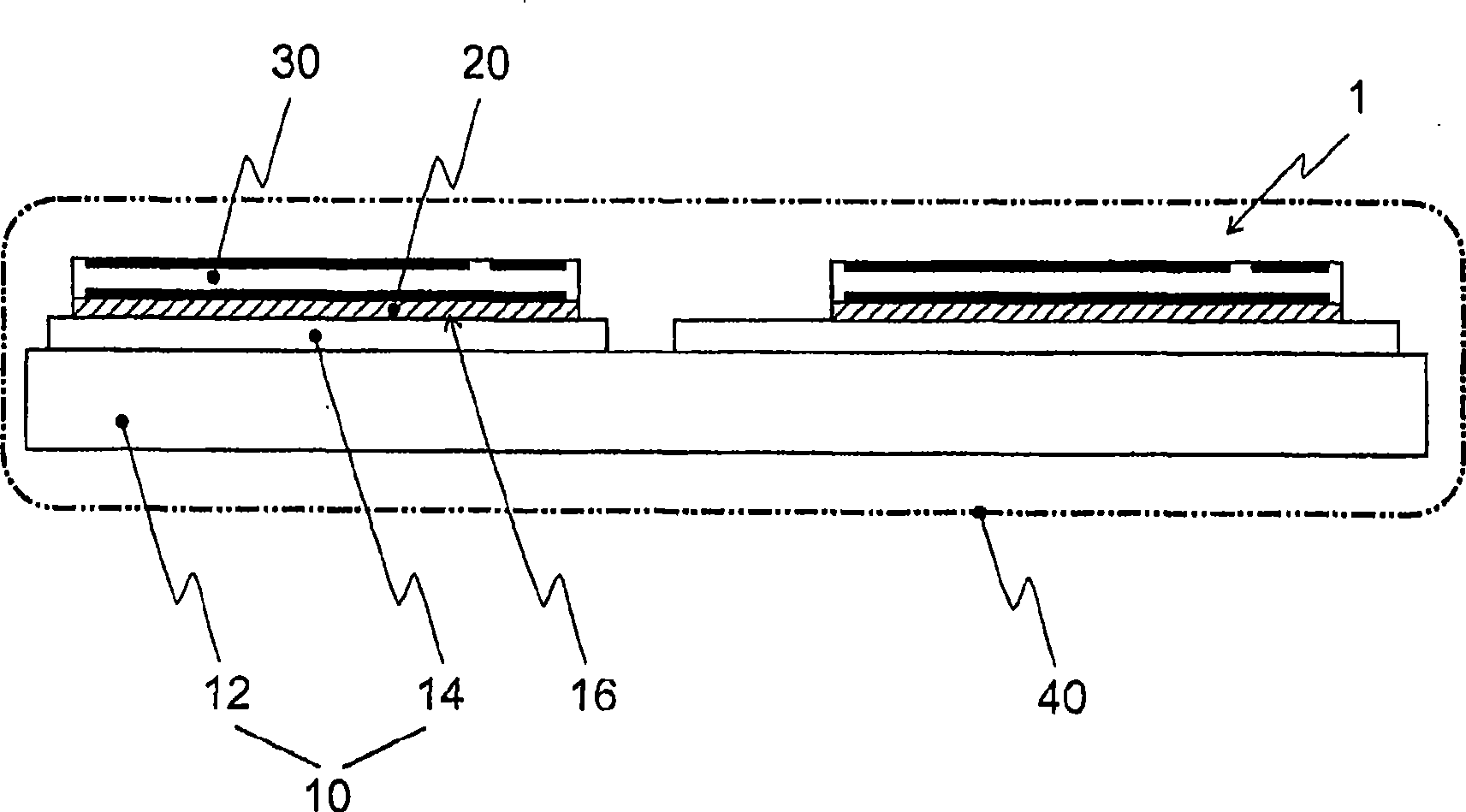

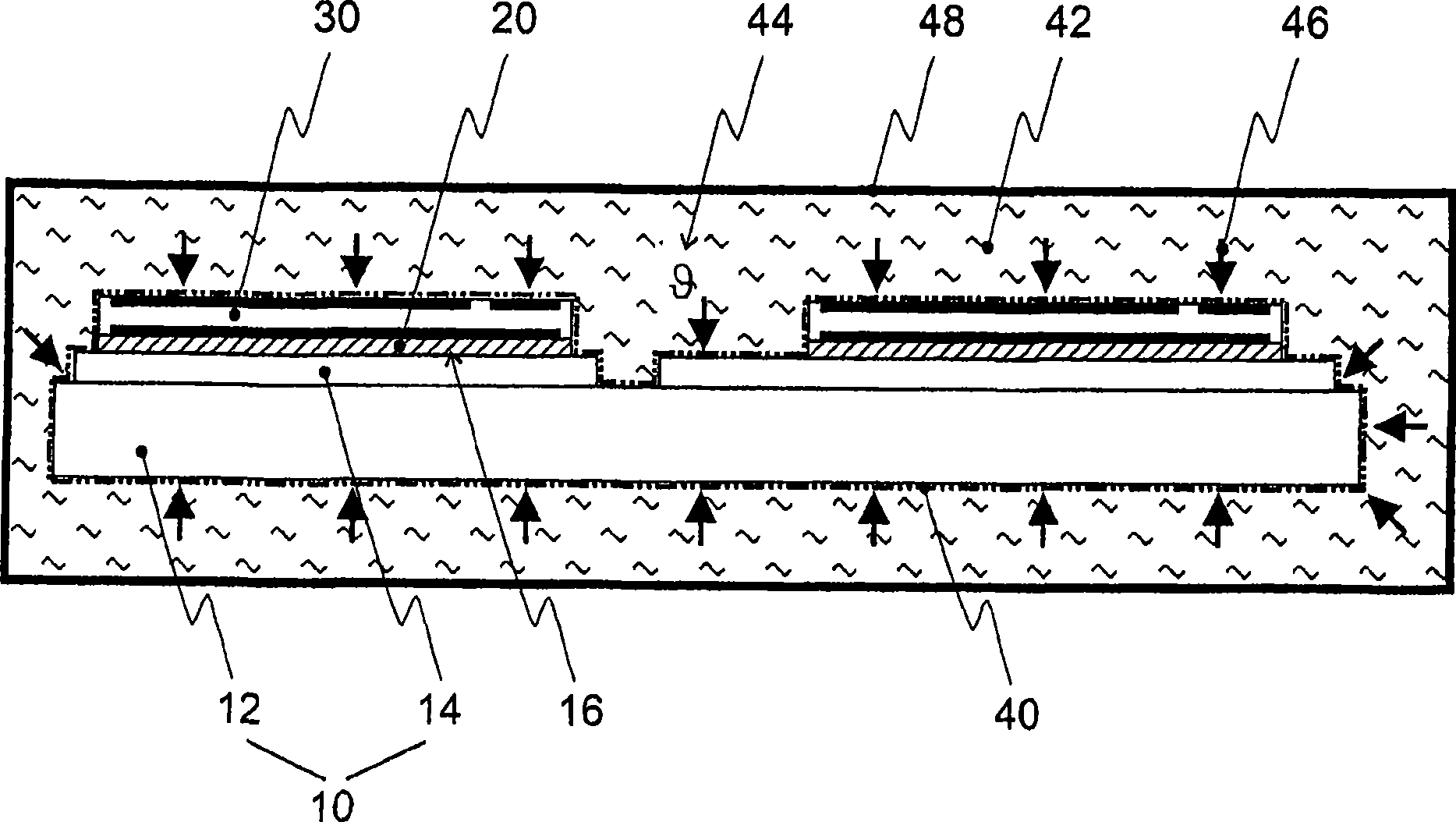

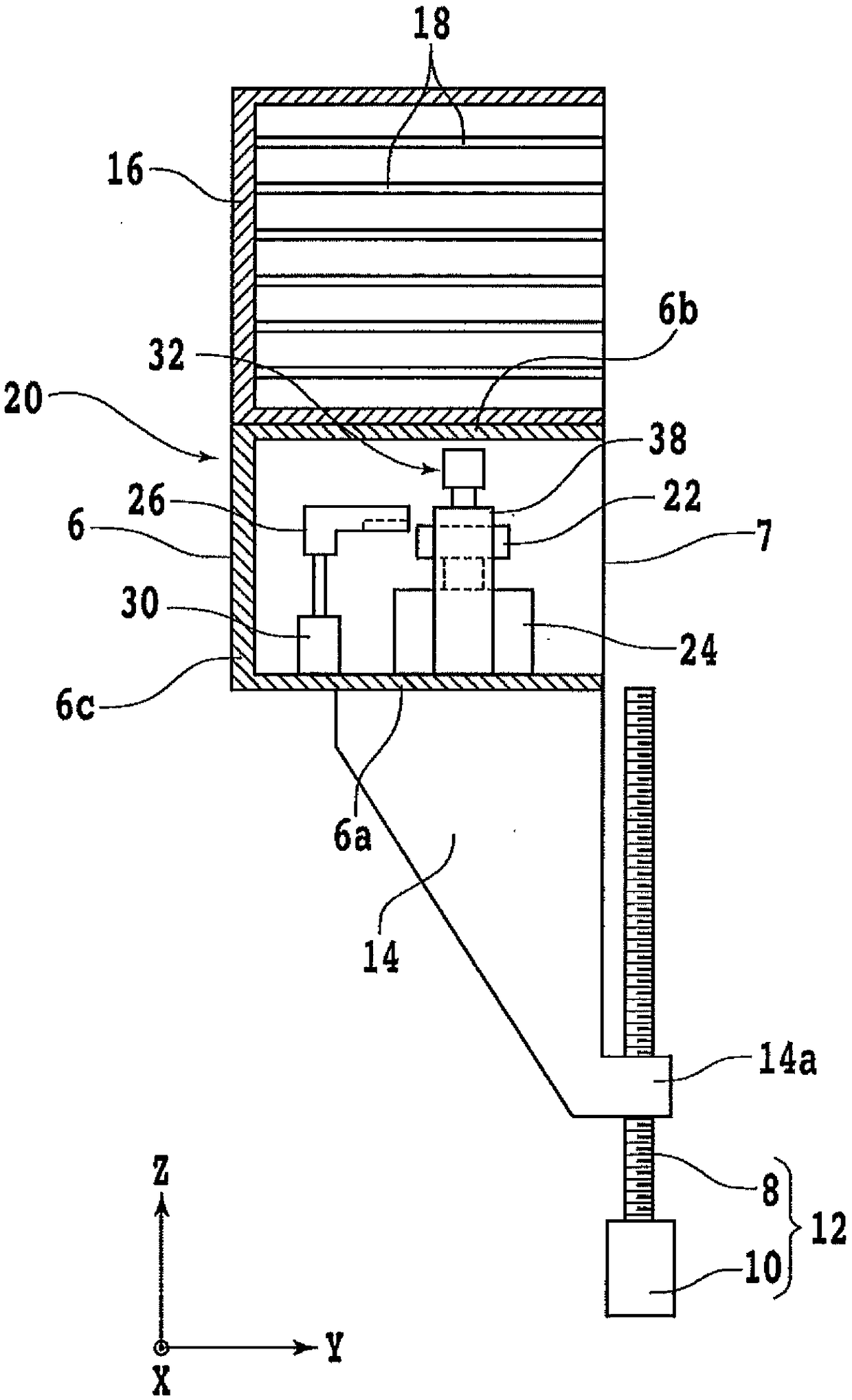

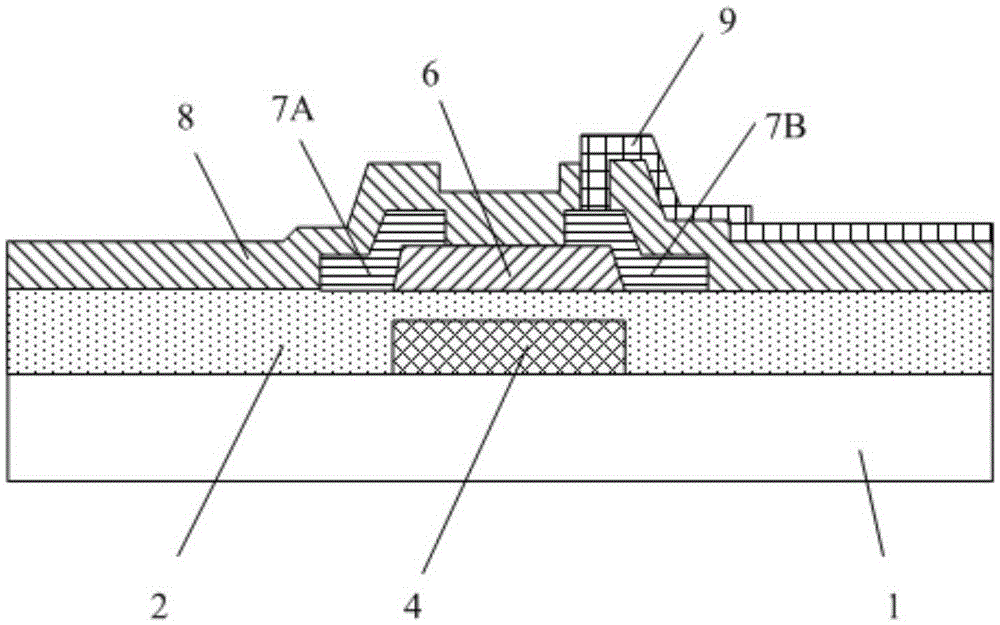

Flexible display device and making method thereof

InactiveCN105845701APrevent featureAvoid risk of breakageSolid-state devicesSemiconductor devicesFlexible displayMechanical engineering

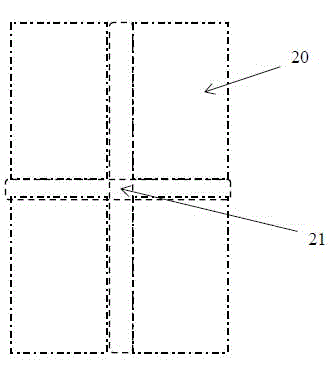

The invention discloses a flexible display device and a making method thereof. The method comprises the following steps: S1, dividing a flexible substrate into pixel regions and a bending region, wherein the bending region spaces the multiple rows of and multiple columns of pixel regions by rows and columns; S2, making a metal connection layer in the bending region of the flexible substrate; S3, making a TFT in the pixel regions of the flexible substrate; S4, after the completion of TFT making, making a flattening layer above the bending region between the pixel regions and above the pixel regions to fill the gaps between the pixel regions with the flattening layer, wherein the metal connection layer is across the flattening layer in the bending region to electrically connect the adjacent pixel regions; and S5, carrying out a subsequent OLED making process. When the flexible display device is bent in the bending region, the stress is concentrated in the bending region, so the risk that the characteristic of the TFT changes or the TFT is broken due to bending of the pixel regions is prevented.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

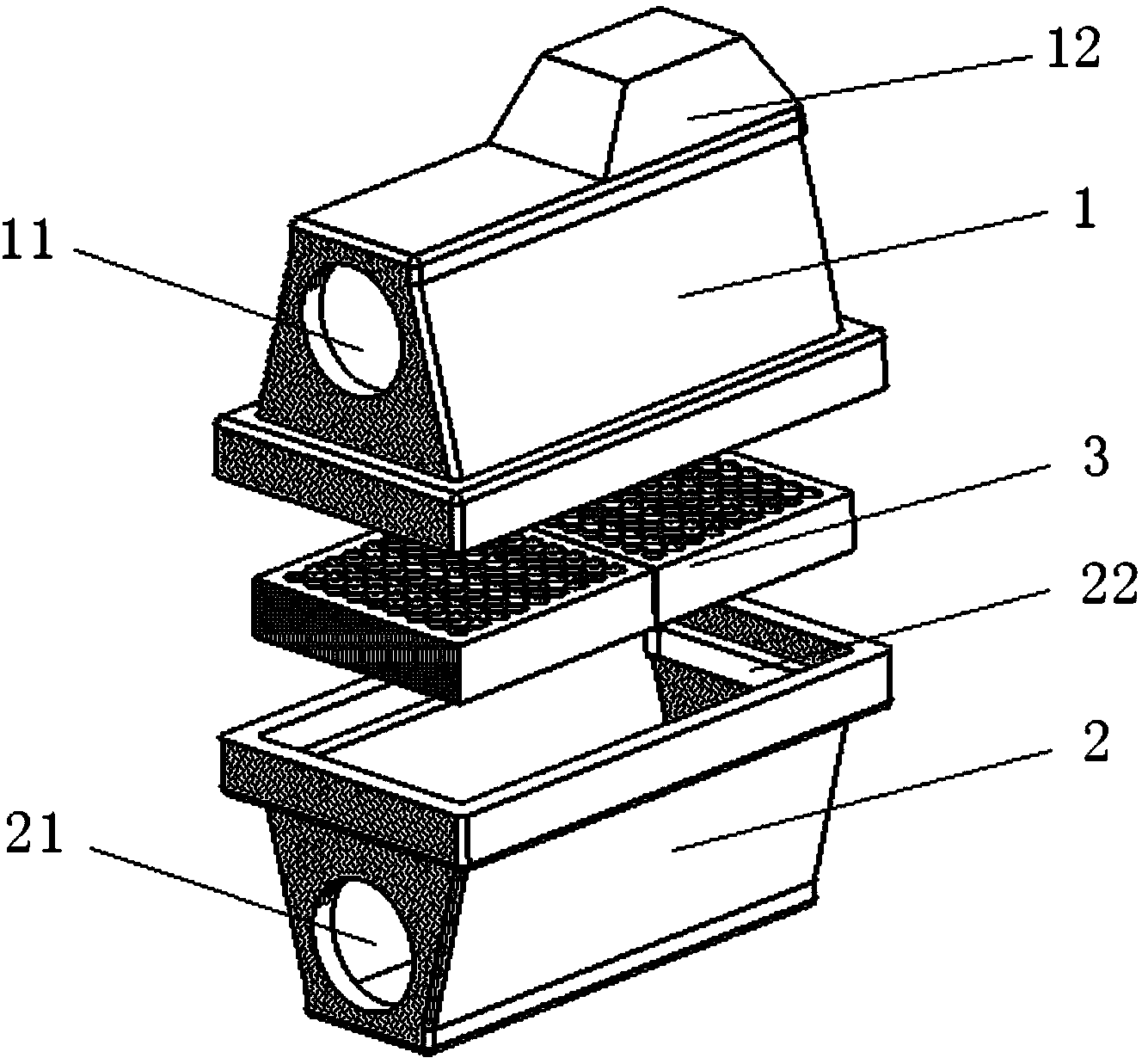

Molten metal filtering device

InactiveCN104128599AImprove filtering effectAvoid risk of breakageCasting cleaning apparatusFiltration separationMolten metal

The invention relates to a molten metal filtering device. The molten metal filtering device comprises a liquid inlet bin, a liquid outlet bin and multiple filters, wherein the liquid inlet bin is located on the upper portion of the filtering device and provided with a liquid inlet, and the liquid inlet is formed in the wall of the liquid inlet bin; the liquid outlet bin is located on the lower portion of the filtering device and provided with a liquid outlet; the multiple filters are arranged between the liquid inlet bin and the liquid outlet bin in parallel. The molten metal filtering device is suitable for casting of heavy castings and easy to manufacture.

Owner:JINAN SHENGQUAN DOUBLE SURPLUS CERAMIC FILTER

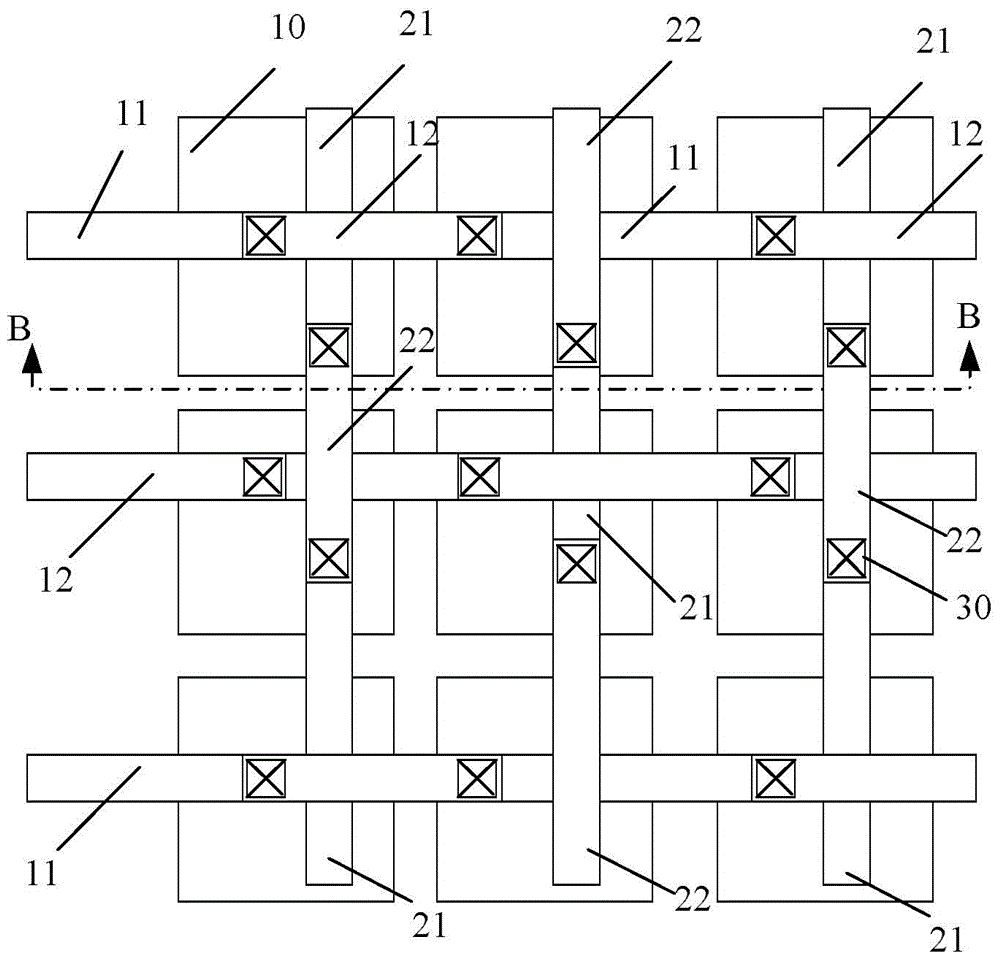

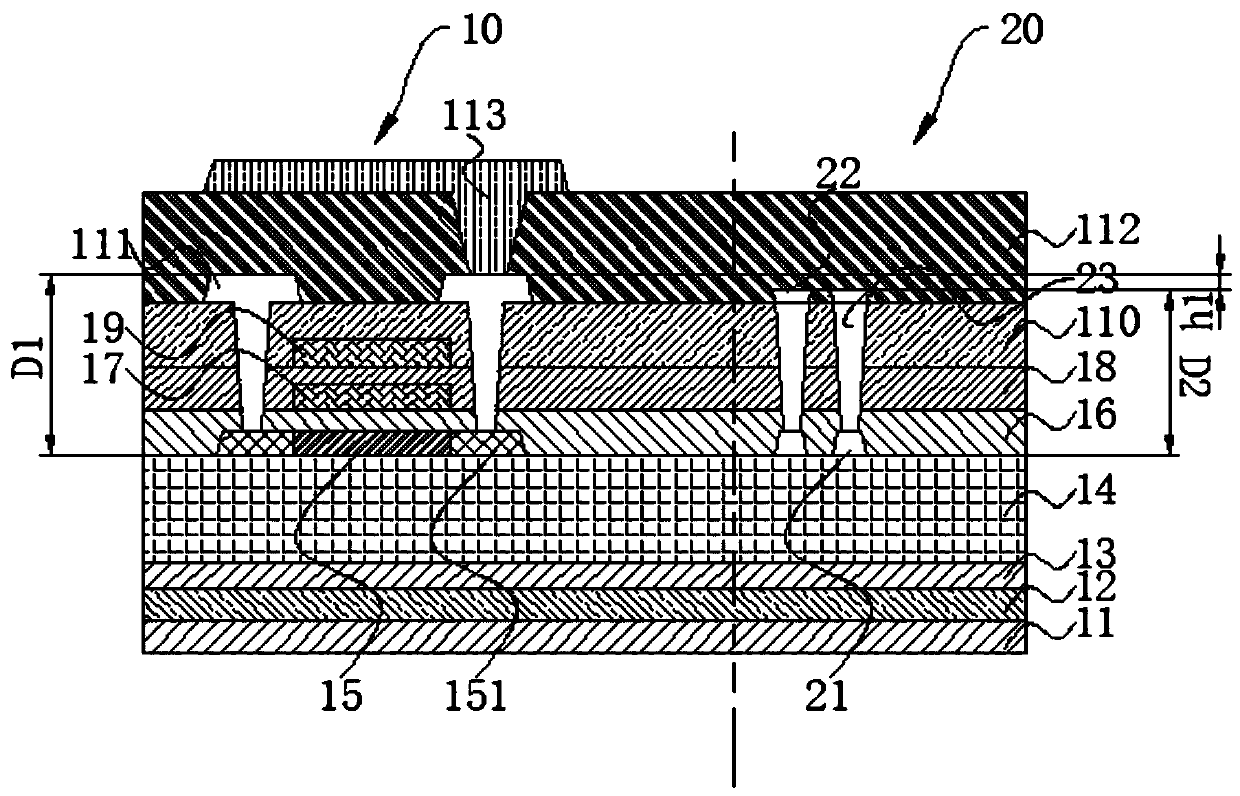

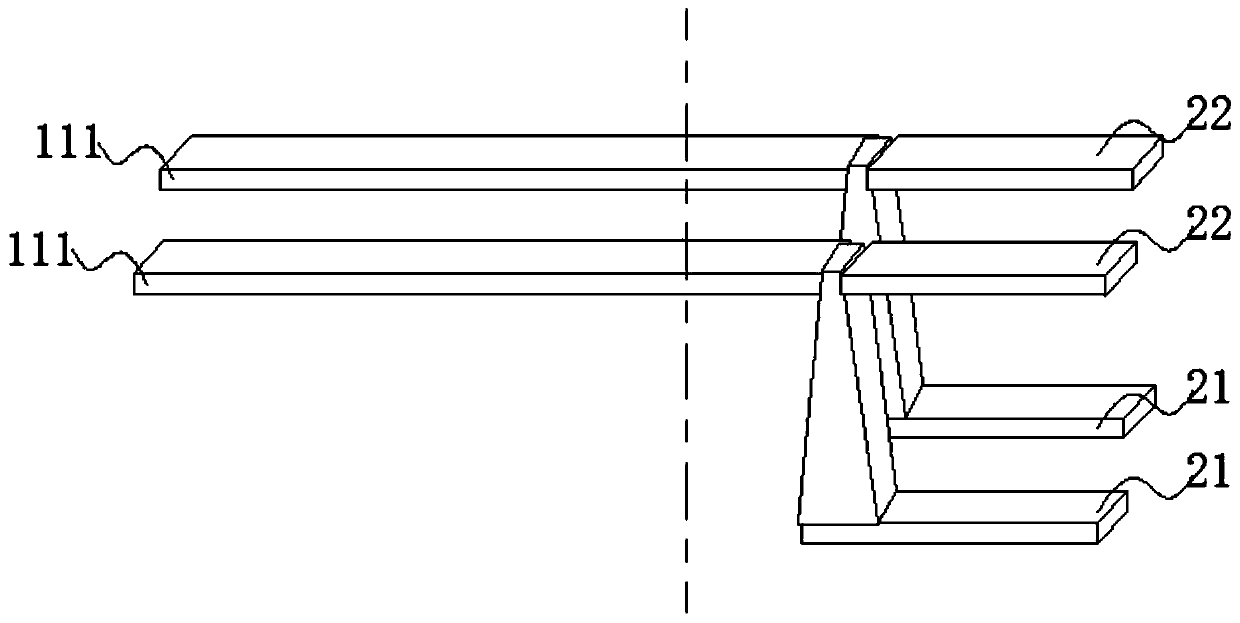

Flexible displaying device and manufacturing method thereof

ActiveCN104538426AReduce stressAvoid risk of breakageSemiconductor/solid-state device detailsSolid-state devicesEngineeringFlexible display

The invention discloses a flexible displaying device which comprises a plurality of gate lines and a plurality of data lines crossed with the gate lines. The gate lines comprise gate line first parts and gate line second parts placed in at least an upper metal layer and a lower metal layer respectively. The gate line first parts and the gate line second parts are electrically connected through plugs. The data lines comprise data line first parts and data line second parts placed in at least an upper metal layer and a lower metal layer respectively. The data line first parts and the data line second parts are electrically connected through plugs. The invention further provides a manufacturing method of the flexible displaying device. According to the flexible displaying device, a line is made into a plurality of small sections, a broken line shape is formed, stress accumulation is effectively removed, and line breaking is avoided.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

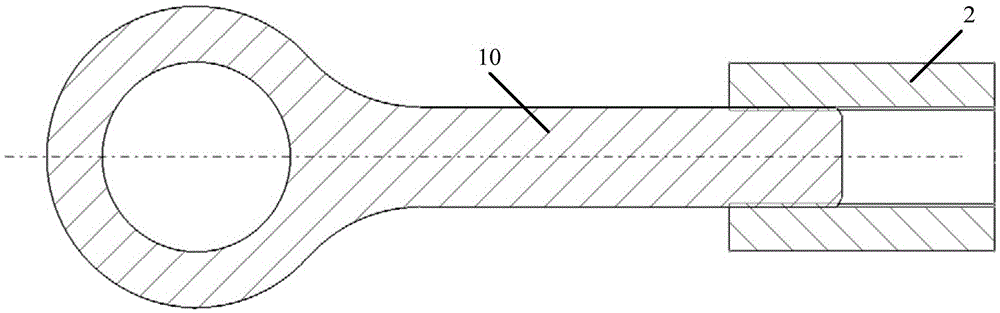

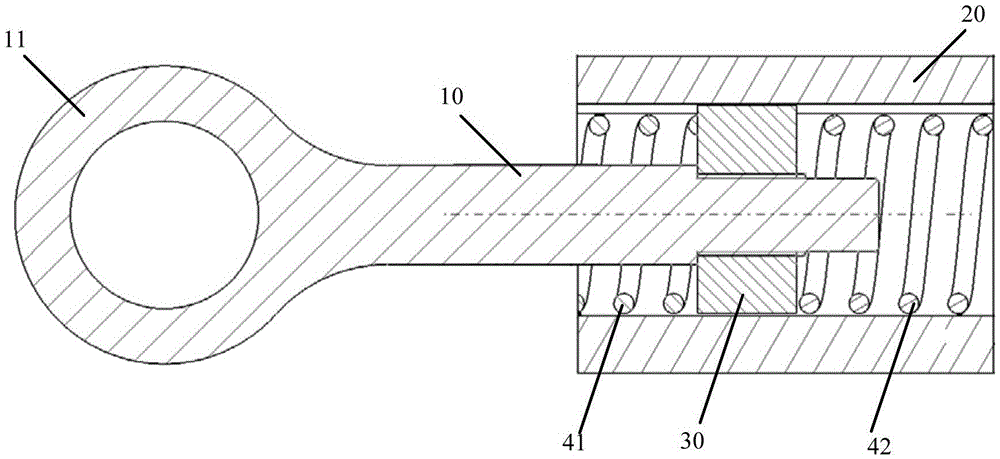

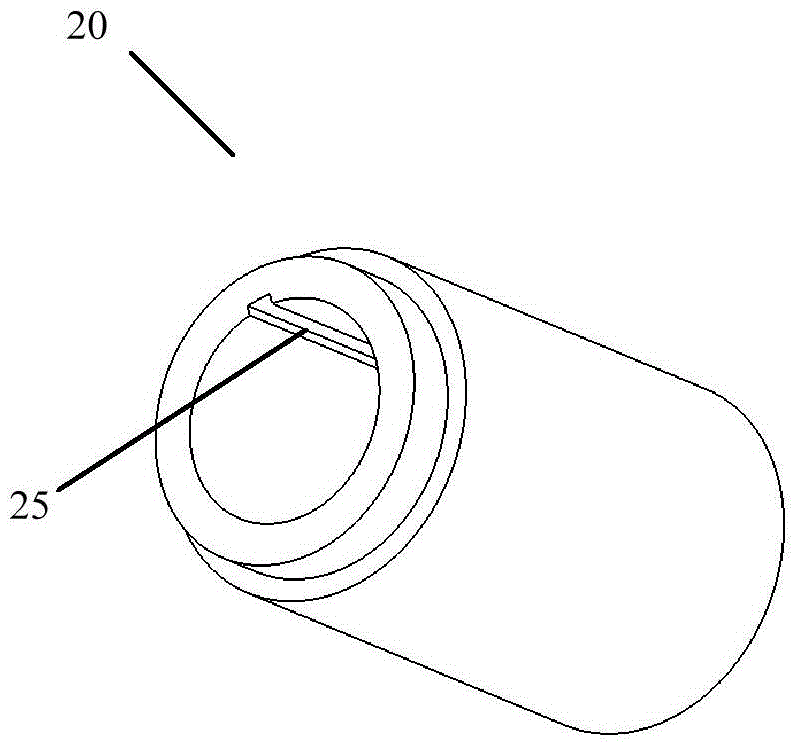

Tow hook structure and automobile

The invention provides a tow hook structure and an automobile. The tow hook structure provided by the invention comprises a tow hook body, a sleeve and a sliding block axially arranged on the inner wall of the sleeve in a sliding manner, wherein one end of the tow hook body is fixedly connected with the sliding block while the other end of the tow hook body is exposed to the sleeve so as to form a limiting ring structure; and a first spring and a second spring are arranged at the two ends of the sliding block respectively, so that the first spring or the second spring is compressed when the sliding block slides. According to the tow hook structure and the automobile, elastic elements are arranged for reducing an impact load, so that the impact and the oblique-pulling breakage can be prevented and the safety of a tow hook can be improved.

Owner:BAIC MOTOR CORP LTD

Equipment at a lift cage for temporarily coupling a cage door leaf with a shaft door leaf and for actuation of a cage door unlocking means

InactiveCN1626427AAvoid risk of breakageGuidance is accurate and reliableBuilding liftsCouplingClassical mechanics

Owner:INVENTIO AG

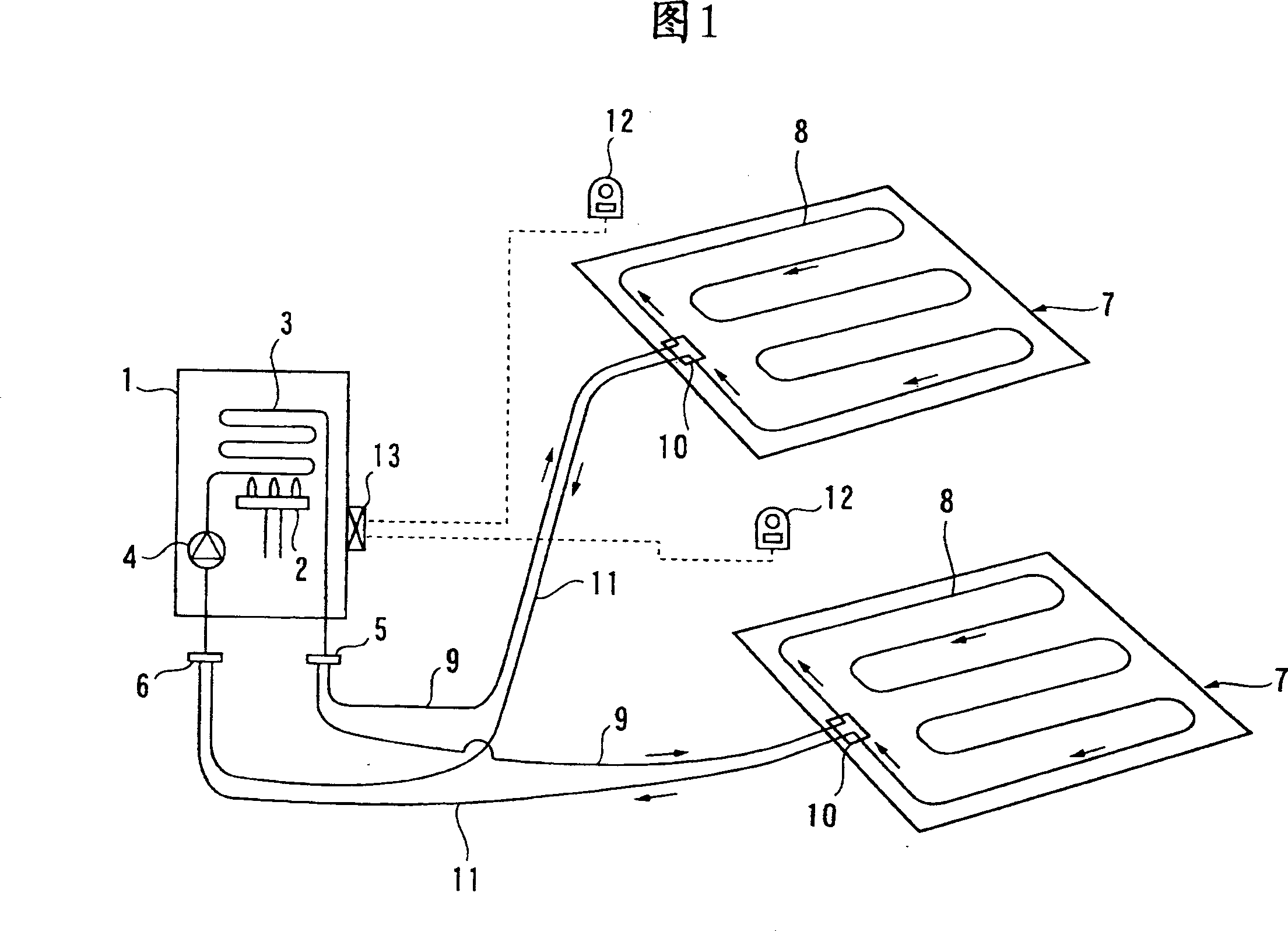

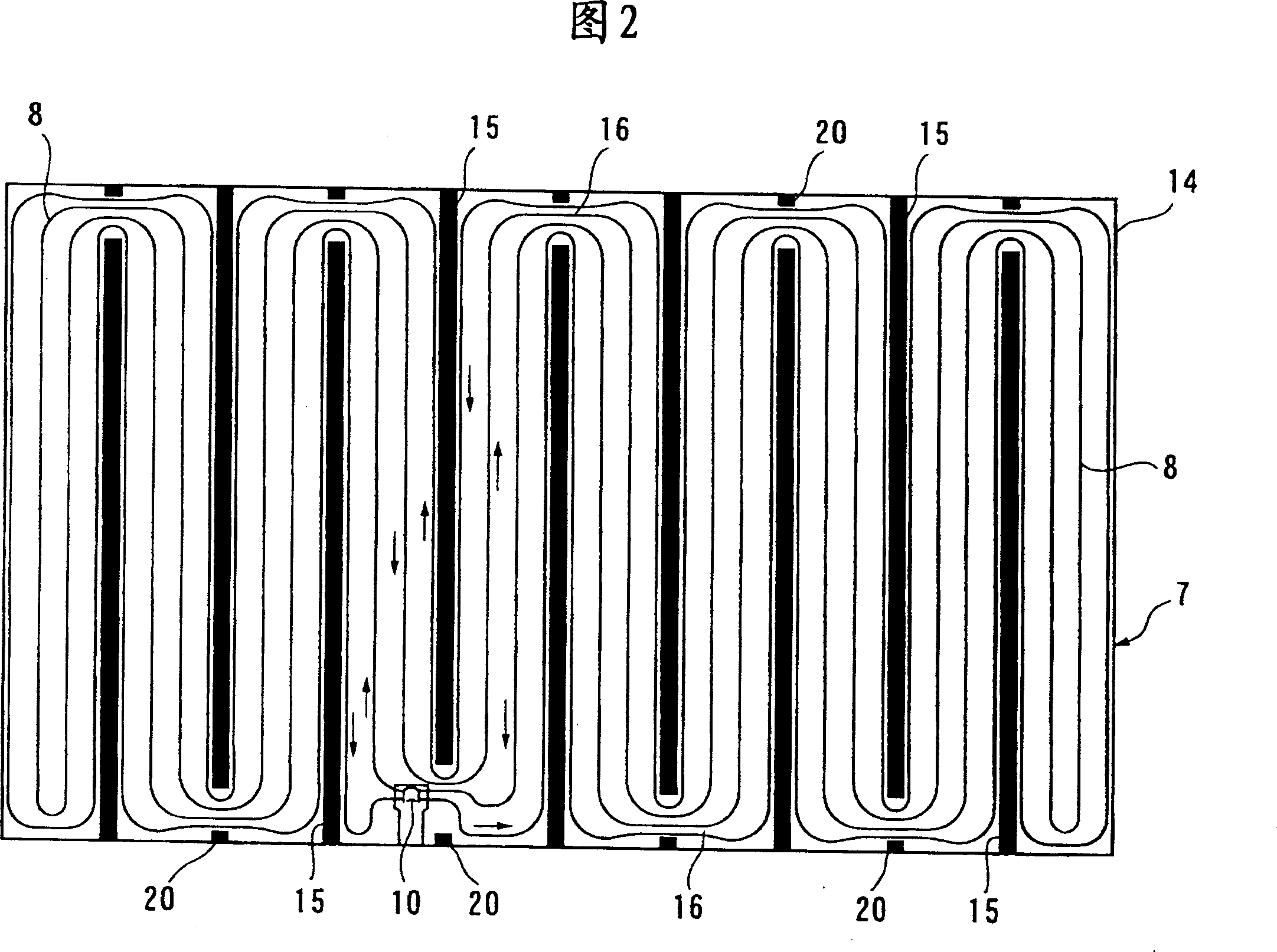

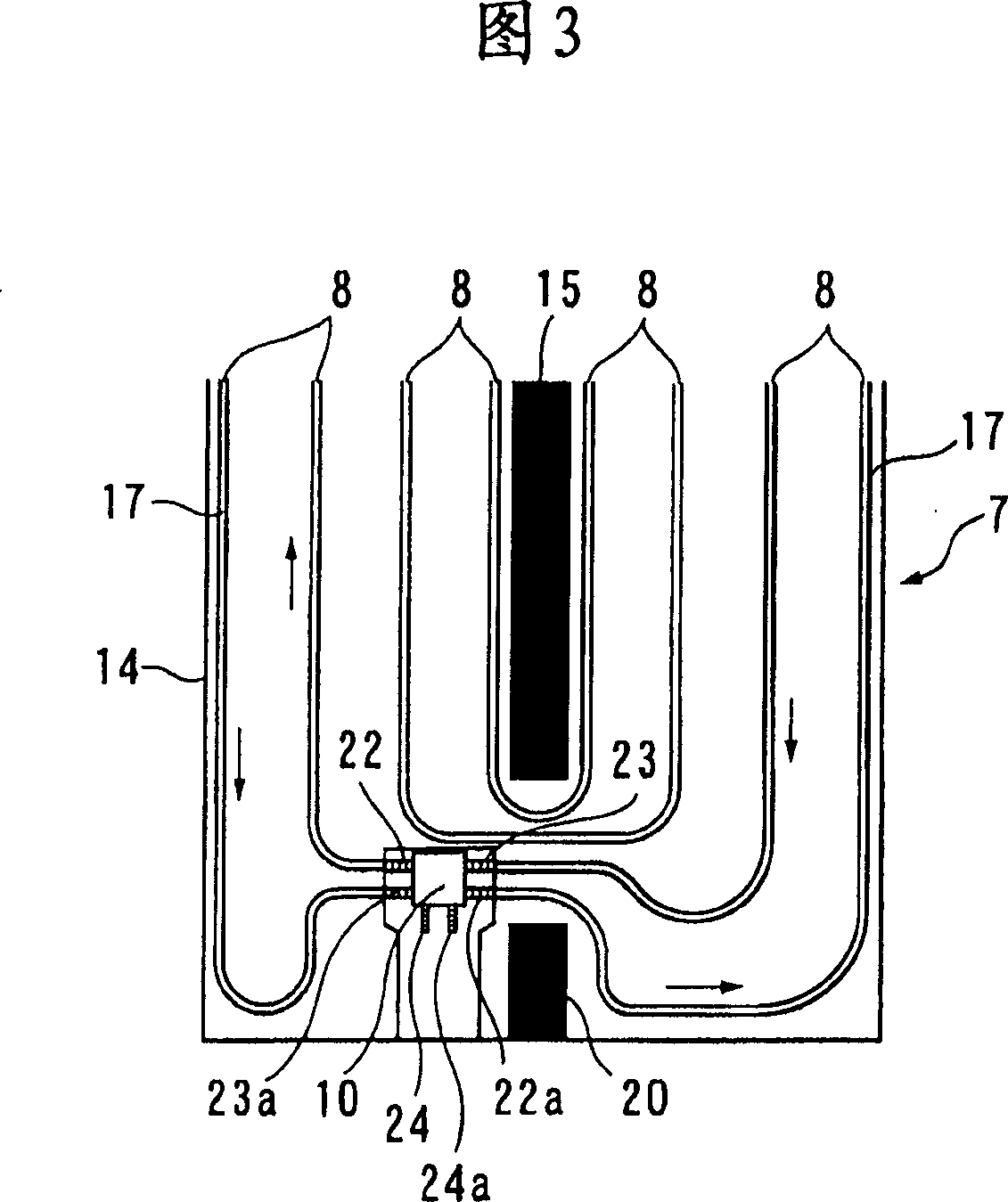

Hot water pad for floor radiator and floor radiation device using the hot water pad

ActiveCN101046309ASimple constructionSave moneyLighting and heating apparatusSpace heating and ventilation detailsHeat sinkCushion

The present invention provides one kind of foldable floor heating cushion and floor heater set with simple construction, easy debugging and no corrosion. The floor heating cushion has small round woods arranged in certain interval, S-shaped hot water pipes arranged alternately with the small round woods, splicing boards with slots for holding hot water pipes, and heat radiating fins.

Owner:前泽生活解决方案株式会社

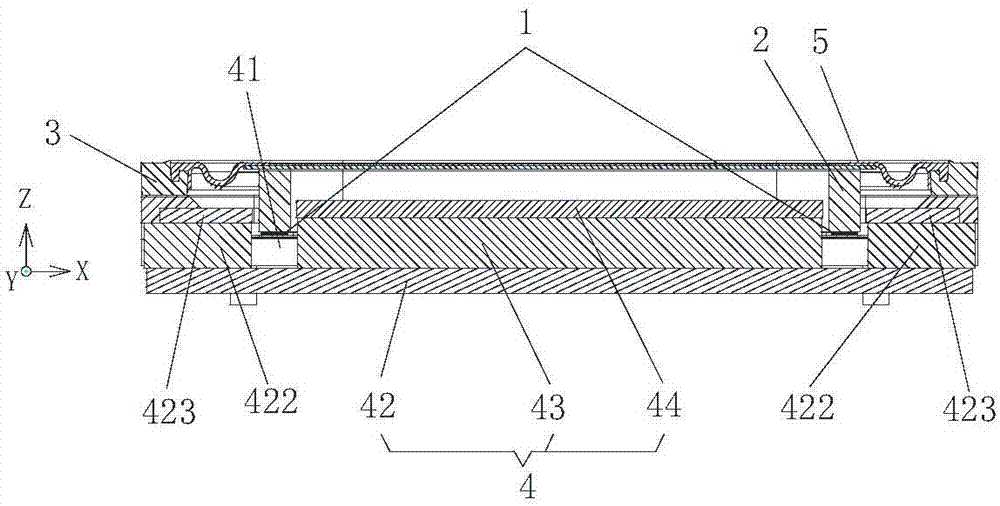

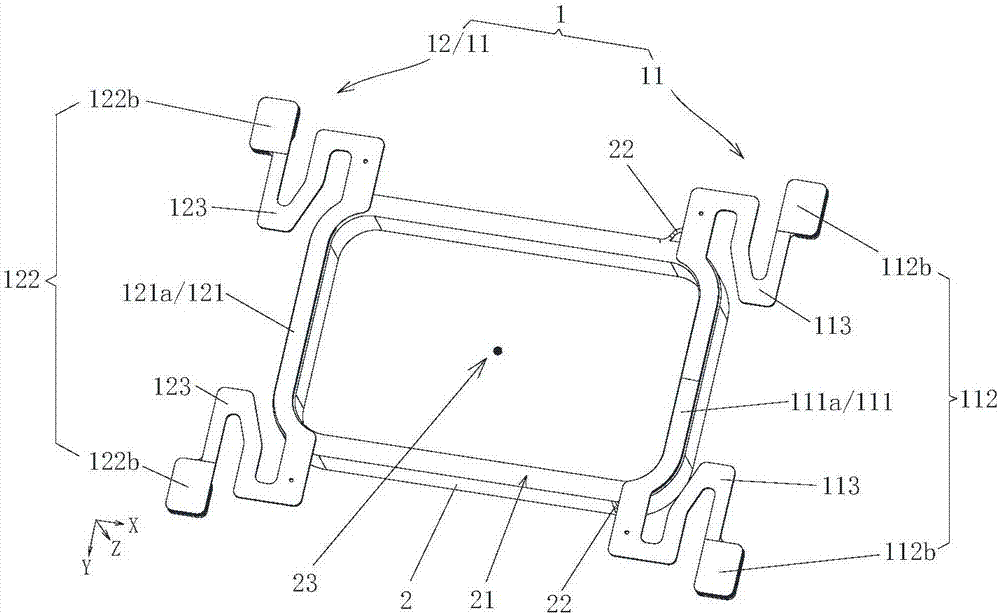

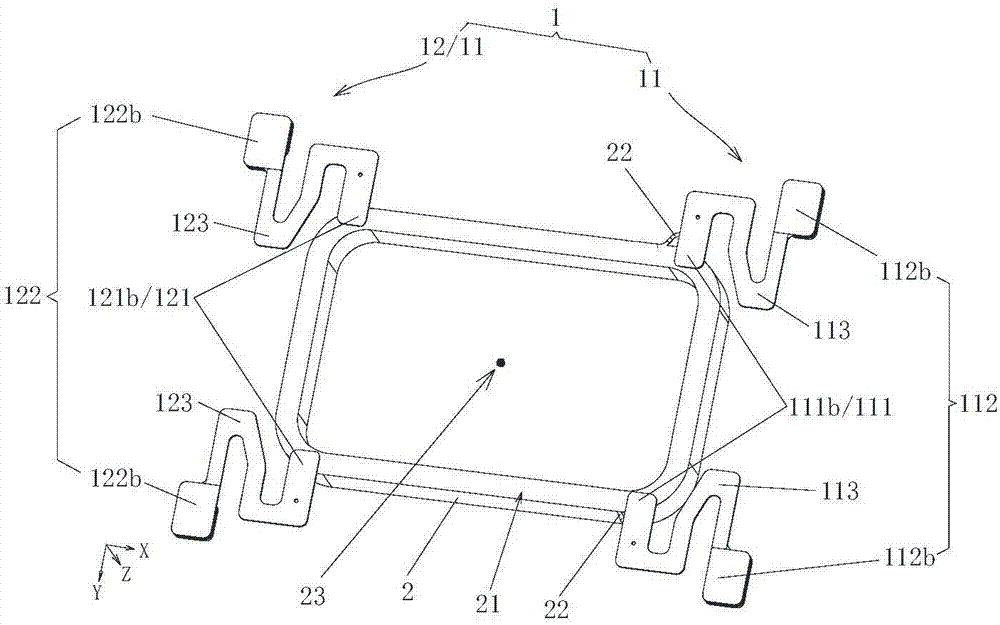

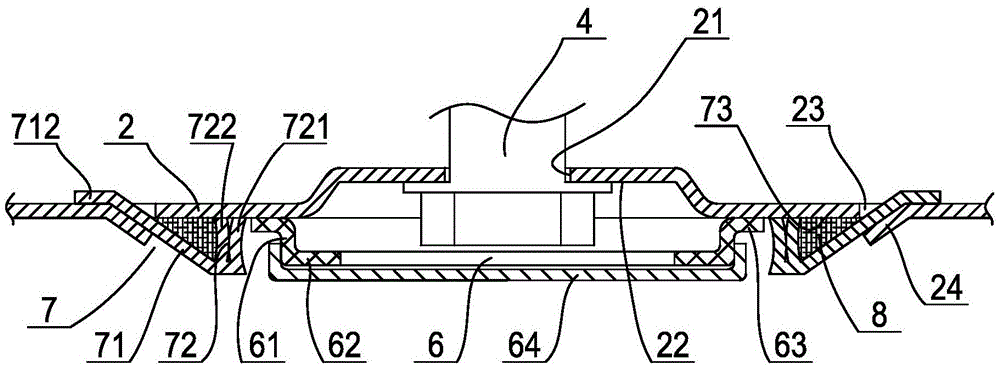

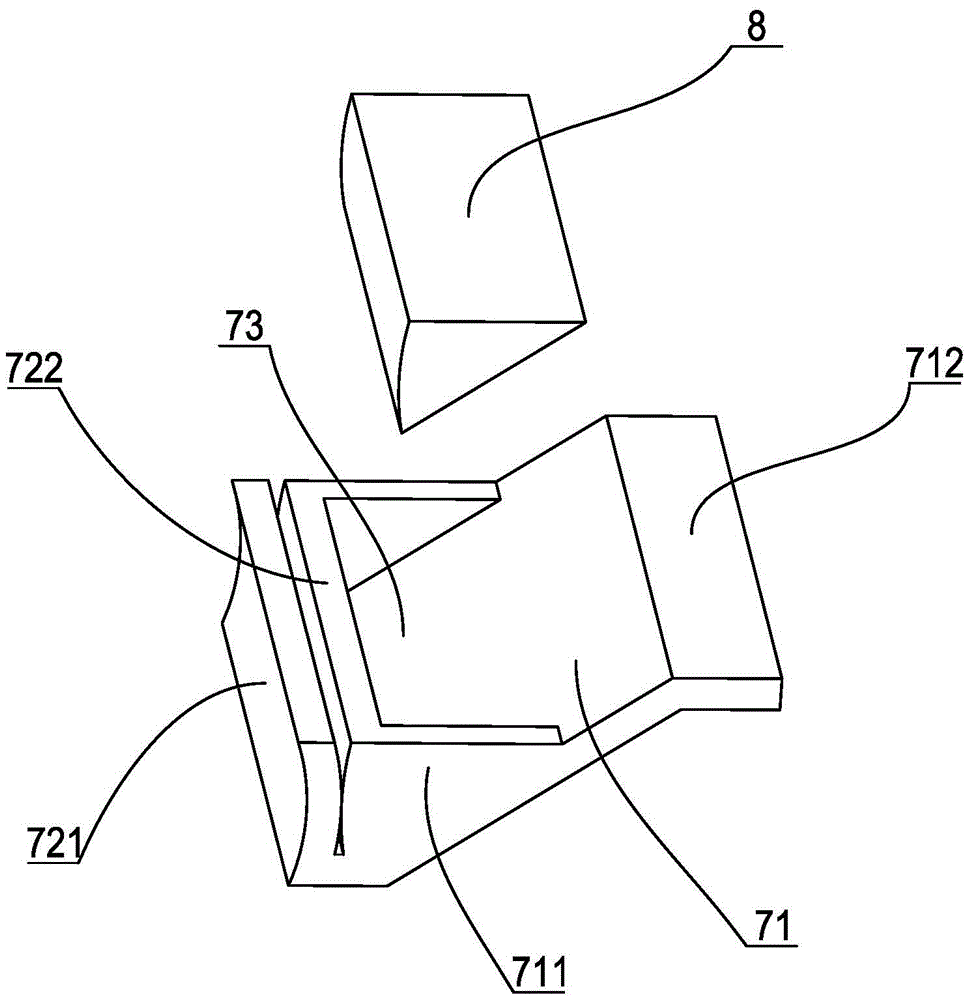

Electrical-acoustic converting device and suspending mechanism thereof

PendingCN107396253ASuppress or even completely solve the problem of rolling vibrationSolve the problem of rolling vibrationElectrical transducersEngineeringVibration Problem

The invention provides an electrical-acoustic converting device and a suspending mechanism thereof. The suspending mechanism of the electrical-acoustic converting device is connected between a voice coil and a basin stand of the electrical-acoustic converting device. The suspending mechanism comprises a first structural part and a second structural part, wherein the first structural part is an elastic conducting part, the elastic conducting part is provided with a conducting internally-connected structure and a conducting externally-connected structure, the conducting internally-connected structure is connected to a free end of the voice coil and is electrically connected with a wire of the voice coil, and the conducting externally-connected structure is connected with the basin stand; the second structural part and the first structural part are in symmetry about the center of the voice coil, and the second structural part is connected between the voice coil and the basin stand. According to the electrical-acoustic converting device and the suspending mechanism thereof, the rolling vibration problem of the electrical-acoustic converting device can be effectively inhibited or even totally solved.

Owner:奥音科技(镇江)有限公司

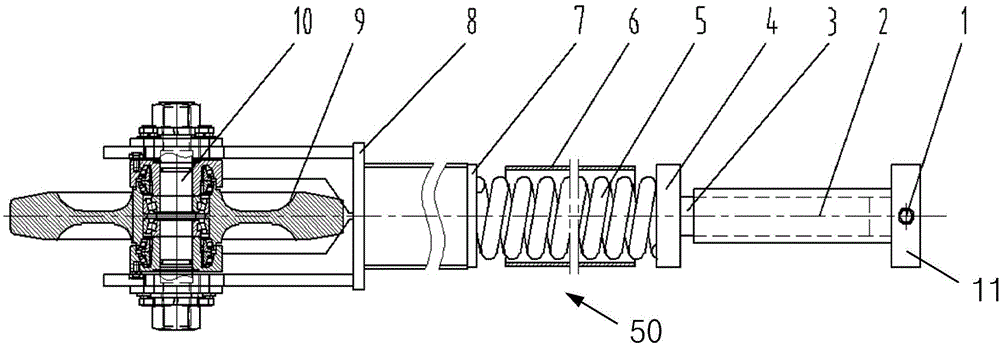

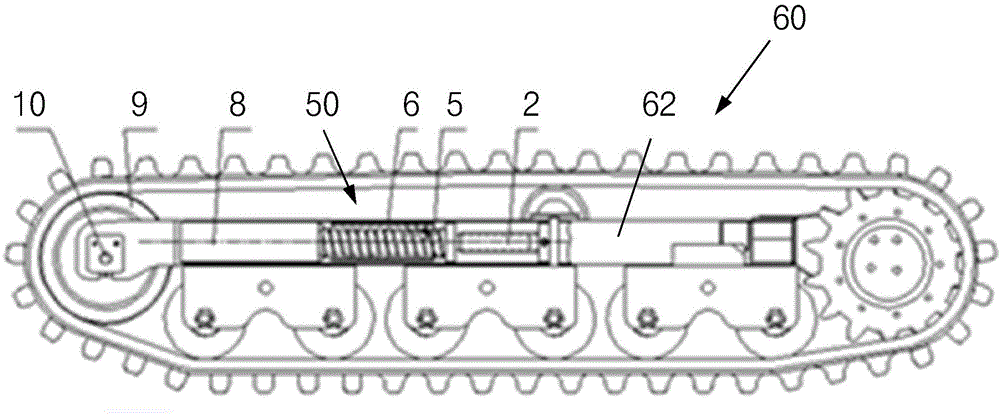

Caterpillar band tensioning device for track vehicle and track vehicle

InactiveCN104527827AGuaranteed tensionAvoid risk of breakageEndless track vehiclesHydraulic cylinderSpring force

The invention provides a caterpillar band tensioning device for a track vehicle. The caterpillar band tensioning device comprises a crawler wheel frame and an elastic bearing mechanism, wherein the crawler wheel frame and a crawler wheel shaft of a crawler wheel are fixedly arranged, and the elastic bearing mechanism is used for providing elastic bearing force for the crawler wheel frame. The elastic bearing mechanism of the caterpillar band tensioning device comprises a spring force bearing mechanism and a hydraulic pressure bearing mechanism which are connected in series. The spring force bearing mechanism comprises a hollow spring and a guiding sleeve surrounding the hollow spring and guiding stretching and retracting of the hollow spring. The caterpillar band tensioning device for the track vehicle can ensure tensioning of a caterpillar band even under the situation that a hydraulic cylinder leaks liquid or breaks down, and the normal running of the track vehicle with the caterpillar band tensioning device is guaranteed. The dismounting and mounting procedures of the caterpillar band tensioning device are simplified through the guiding sleeve on the periphery of the hollow spring. The invention further relates to the track vehicle with the caterpillar band tensioning device.

Owner:ZOOMLION HEAVY MASCH CO LTD

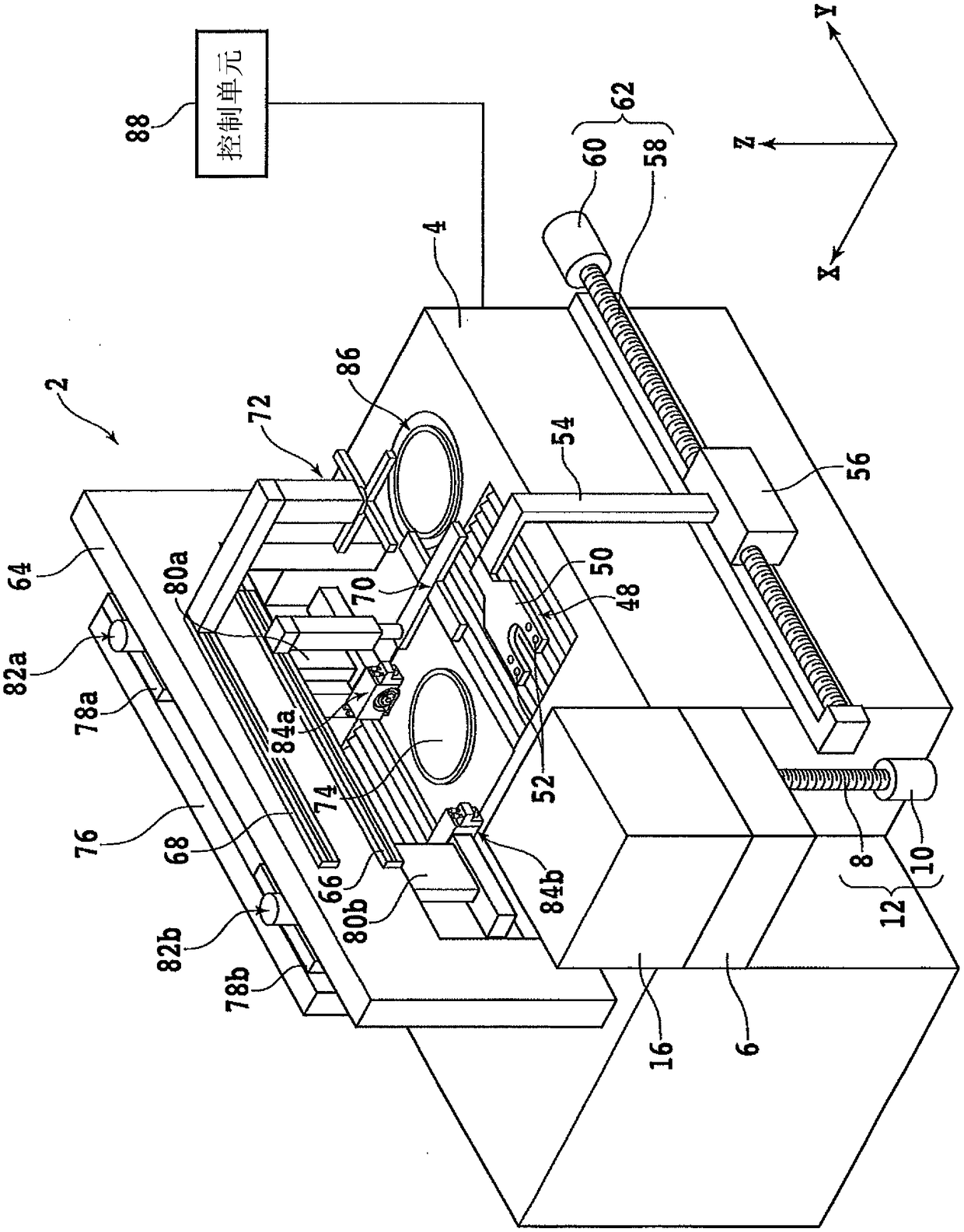

Method for producing a semiconductor component

InactiveCN101436556AAvoid risk of breakageAvoid the disadvantages of the one-piece connection methodSemiconductor/solid-state device detailsSolid-state devicesEngineeringSemiconductor components

The invention relates to a method for manufacturing semiconductor subassemblies and comprises the flowing main procedures: forming a structure which is provided with at least one semiconductor member, at least one connecting device, and at least one variety of conjugation agent arranged between the semiconductor member and the connecting device. The structure is partially or wholly packed, and the at least one semiconductor member and the at least one connecting device are unified into an entity.

Owner:SEMIKRON ELECTRONICS GMBH & CO KG

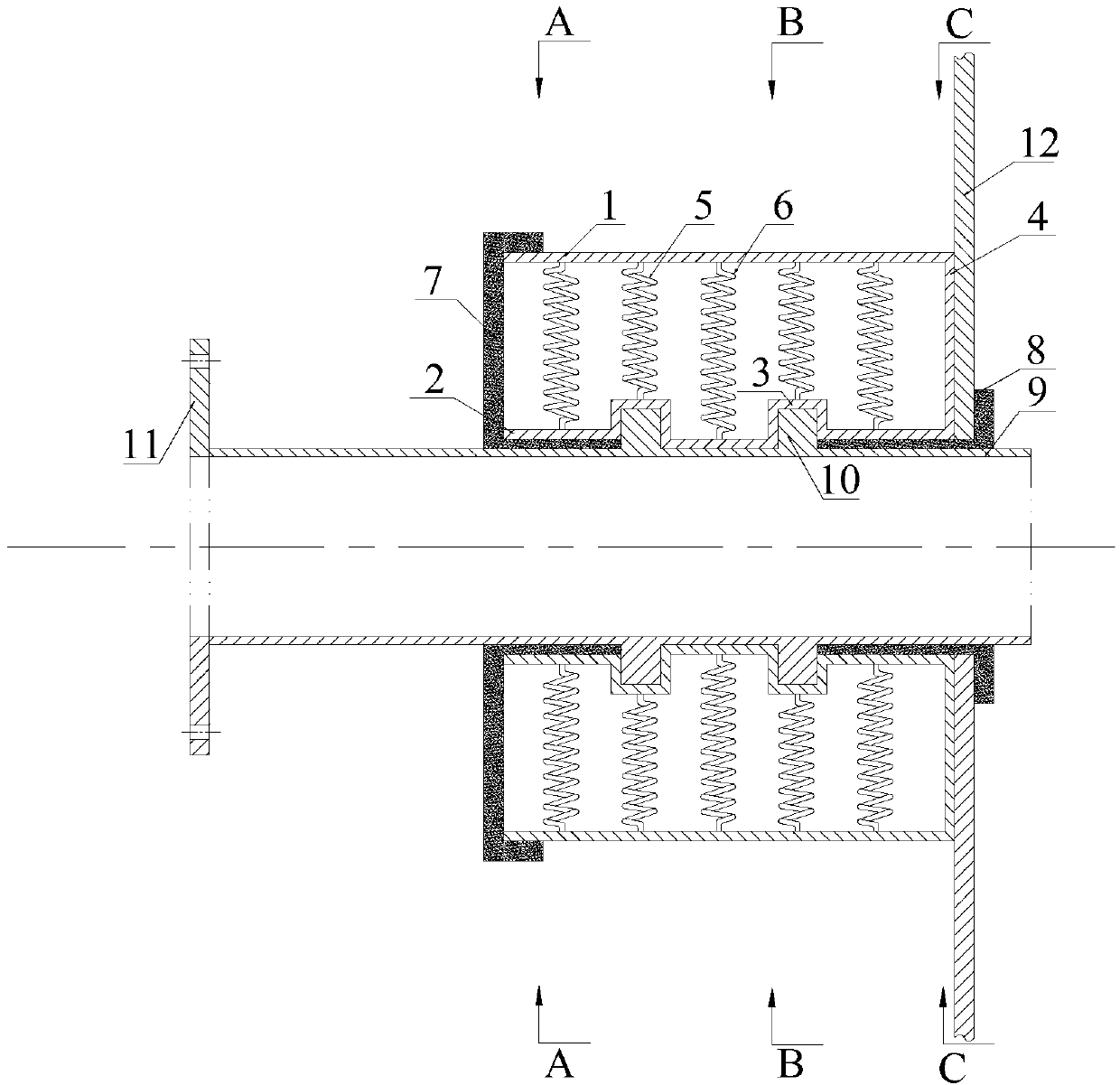

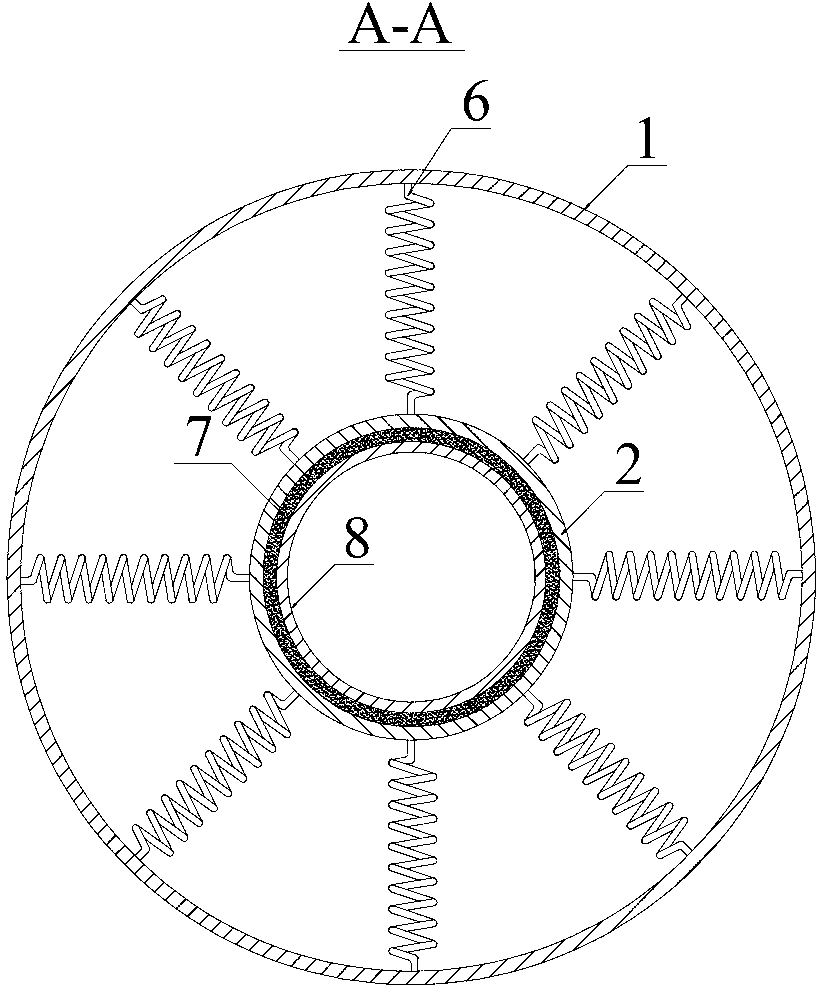

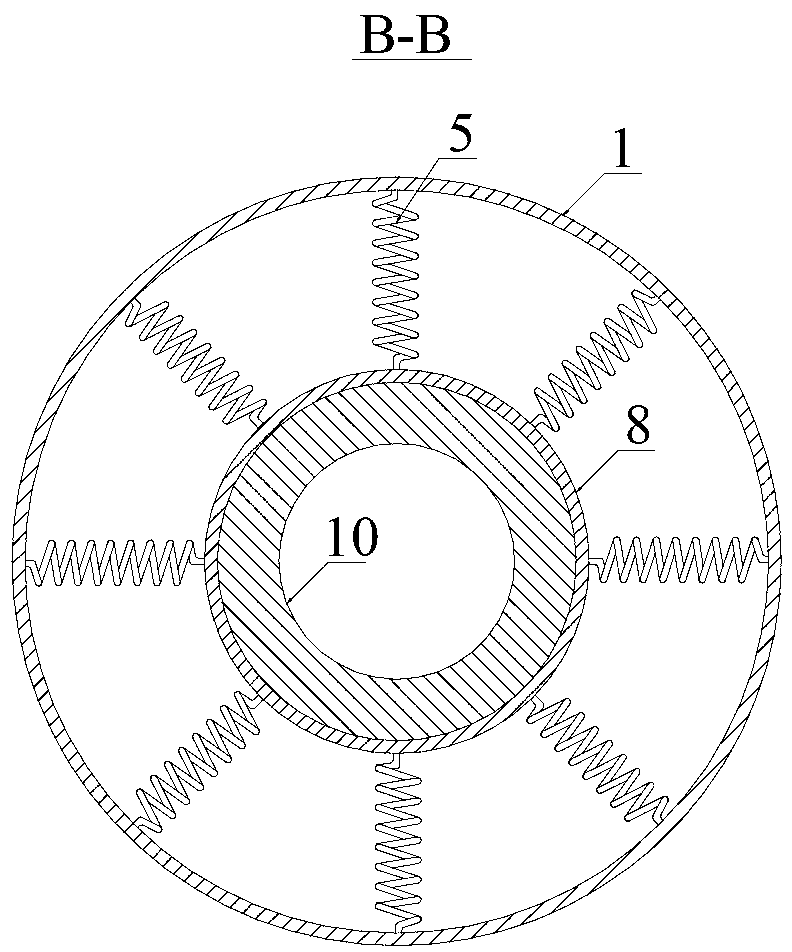

Impact-resistant connecting device of pipeline and equipment

InactiveCN102809007AReduce the risk of large displacementRealize flexible connectionAdjustable jointsPipe protection against damage/wearEngineeringLarge deformation

The invention provides an impact-resistant connecting device of a pipeline and equipment. The impact-resistant connecting device comprises an outer barrel, a cylindrical helical spring, a rubber gasket, a rubber barrel cover, a connecting pipe and a flange, wherein one end of the connecting device is connected with the equipment through the outer barrel which is internally provided with springs, while the other end is connected with the pipeline through the flange and the connecting pipe; at the connecting end with the equipment, the connecting pipe is inserted into the equipment through the rubber gasket to realize the flexible connection of the pipeline and the equipment; the interior of the outer barrel of the connecting device is provided with a plurality of groups of springs which can be used for bearing larger deformation, and the outer barrel and the connecting pipe are fixed through a clamping trough so as to realize a constraint effect in the axial direction and the vertical direction of the pipeline and guarantee the tightness of the connection of the pipeline and the equipment; and meanwhile, the connecting part of the end part of the barrel, the connecting pipe and the equipment is provided with the rubber gasket so as to play the roles of sealing and flexible connection.

Owner:JIANGSU UNIV OF SCI & TECH

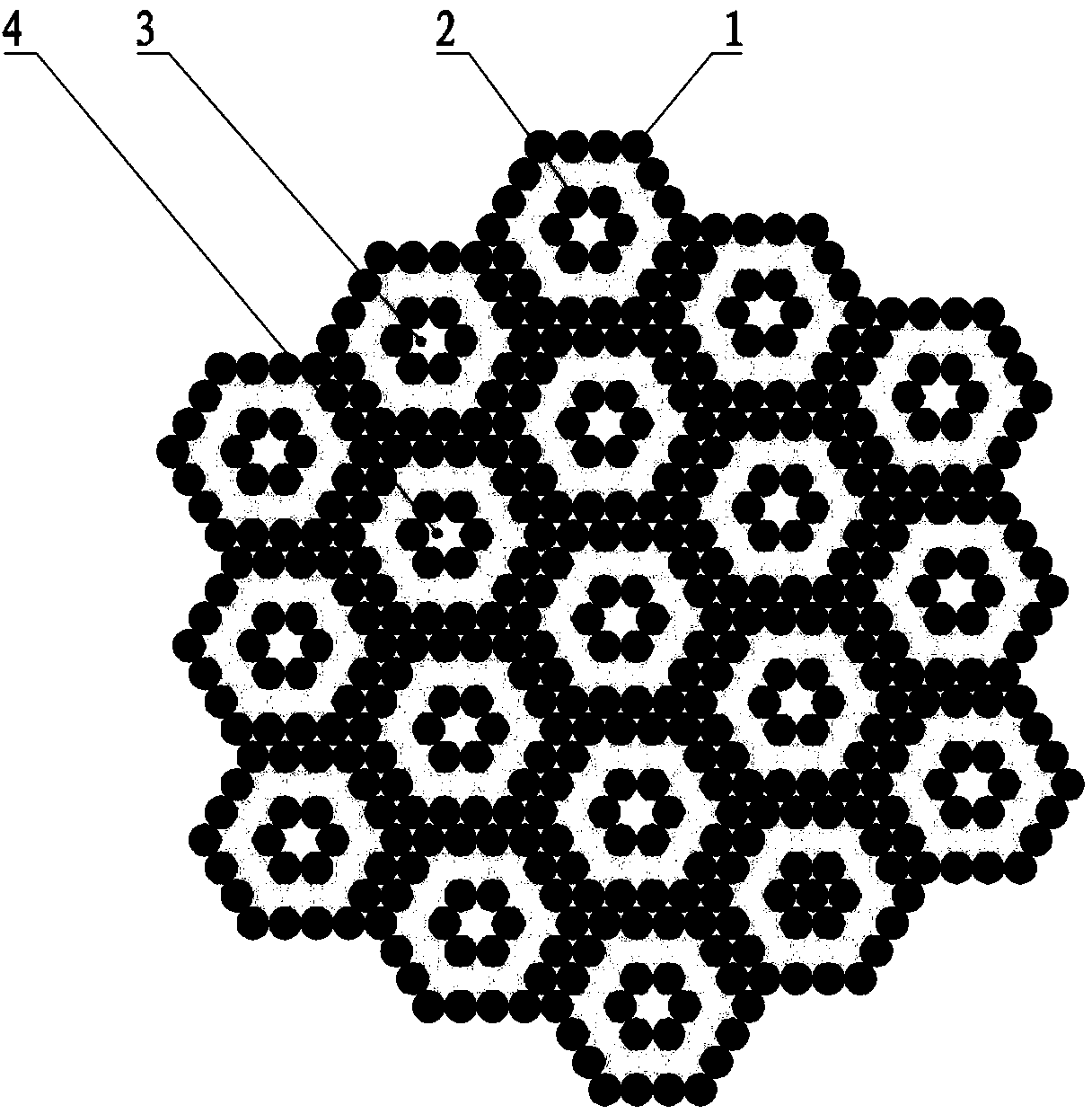

Rope capable of avoiding breakage danger

The invention provides a rope capable of avoiding breakage danger. The rope is of a multi-strand multilayer structure. At least all strands of an outer layer (3) are of leather core structures, and leather layers (1) and core layers (2) are composed of fibers of different colors. According to the rope capable of avoiding breakage danger, the rope is of the multi-strand multilayer structure, at least all strands of the outer layer are in different colors, and accordingly the colors of the fibers of the core layers can be exposed when the fibers of the leather layers of the all strands of the outer layer are abraded. Compared with the prior art, the rope can present color at a certain degree to serve as mark warning information. Thus, the rope can be checked conveniently before being used, and the rope breakage accidents are effectively avoided.

Owner:夏金云 +3

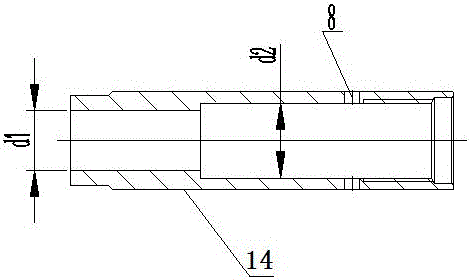

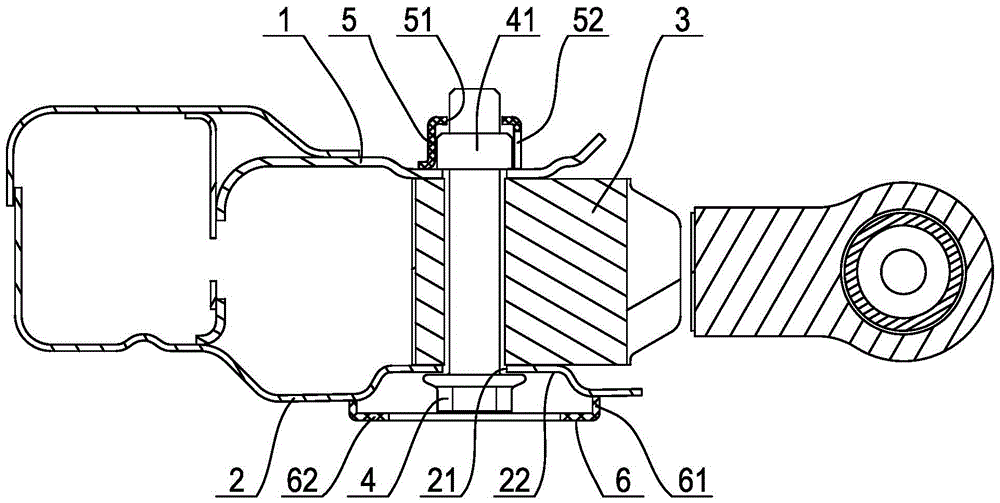

High pressure water rotating nozzle with axial thrust self-balancing function

ActiveCN105797885ASimple structureUnique designMovable spraying apparatusCleaning using liquidsAxial thrustEngineering

The invention discloses a high pressure water rotating nozzle with an axial thrust self-balancing function. The high pressure water rotating nozzle with the axial thrust self-balancing function comprises a cleaning head with eccentric jetting holes in the same, a hollow cylindrical stepped rotation shaft, a stepped sealing outer shell and a water inlet joint, wherein the stepped sealing outer shell is provided with a cylindrical inner hole. The hollow cylindrical stepped rotation shaft penetrates into the stepped sealing outer shell with the cylindrical inner hole; the cleaning head is in threaded connection with the front end of the hollow cylindrical stepped rotation shaft; the water inlet joint with a sealing rod at the front end is screwed into a threaded hole in the rear end of the stepped sealing outer shell with the cylindrical inner hole; and the sealing rod at the front end of the water inlet joint penetrates into the hollow cylindrical stepped rotation shaft. The high pressure water rotating nozzle with the axial thrust self-balancing function is simple in structure and unique in design; the cylindrical stepped gap sealing technology is adopted by the hollow cylindrical stepped rotation shaft and the sealing effect is good; the over-speed rotating condition gets effective control further, the impact force of a water jet is improved, and the cleaning effect is good; and the maintenance and preservation are very convenient, and the using cost is largely lowered.

Owner:天津福禄机电设备有限公司

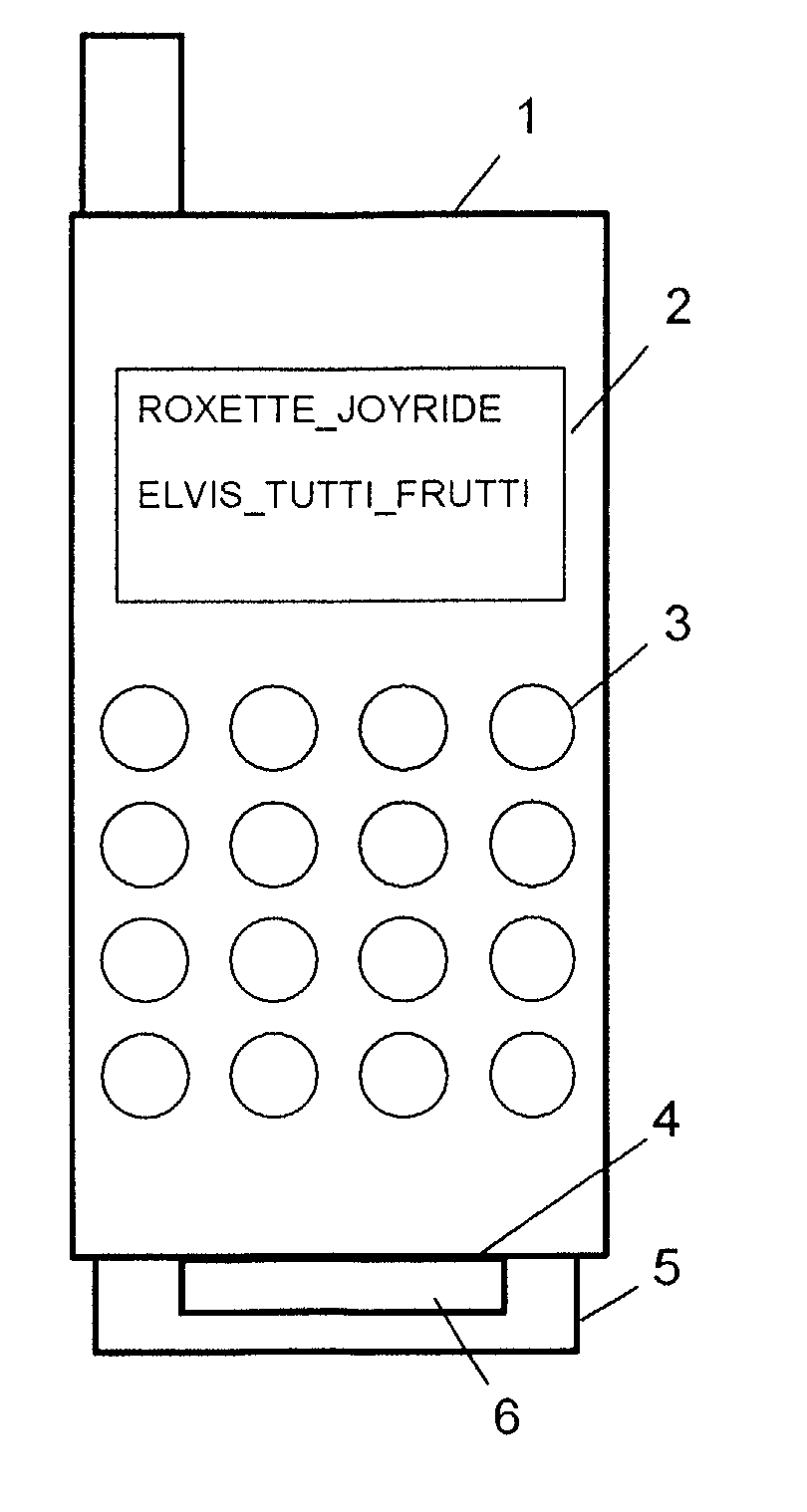

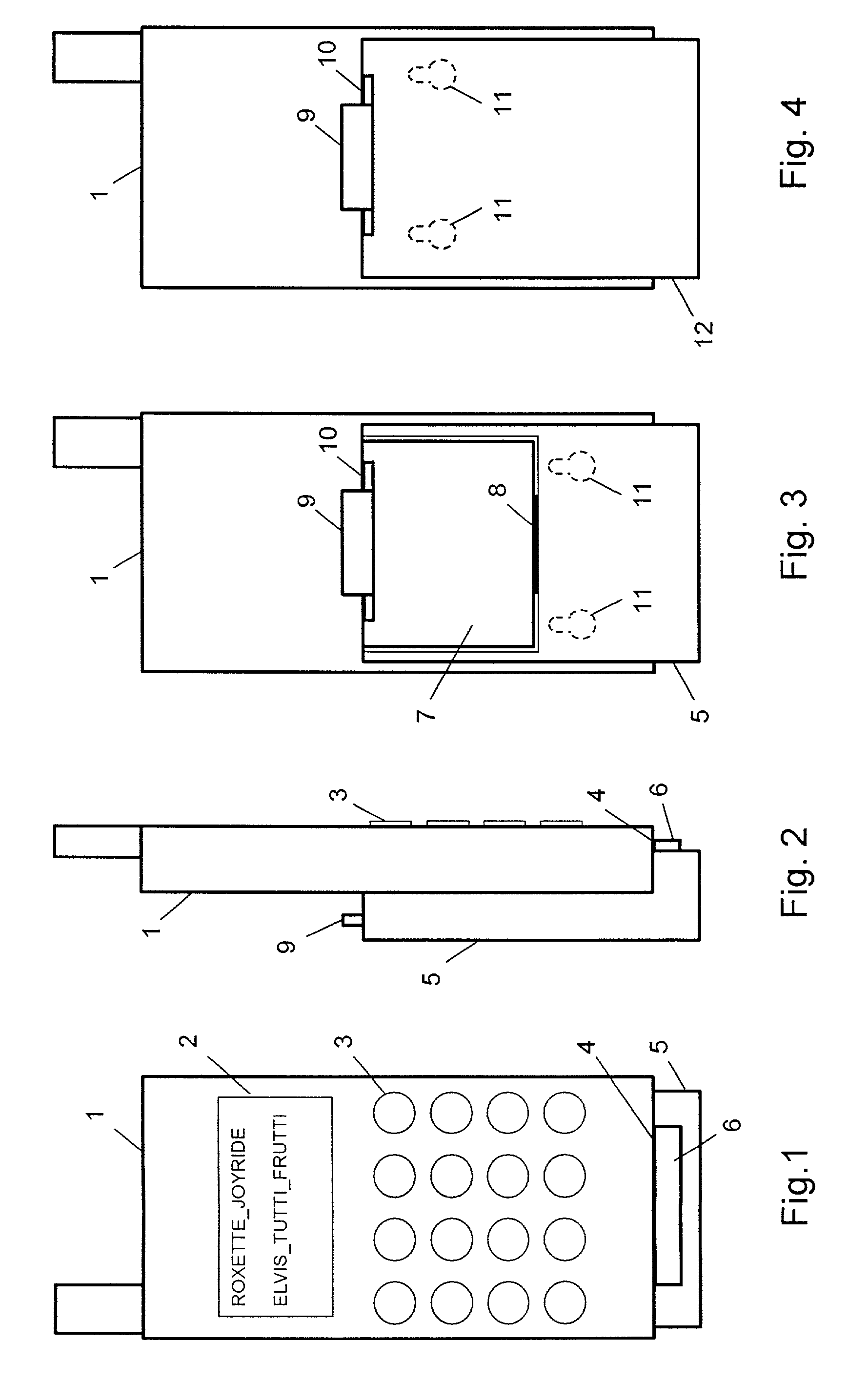

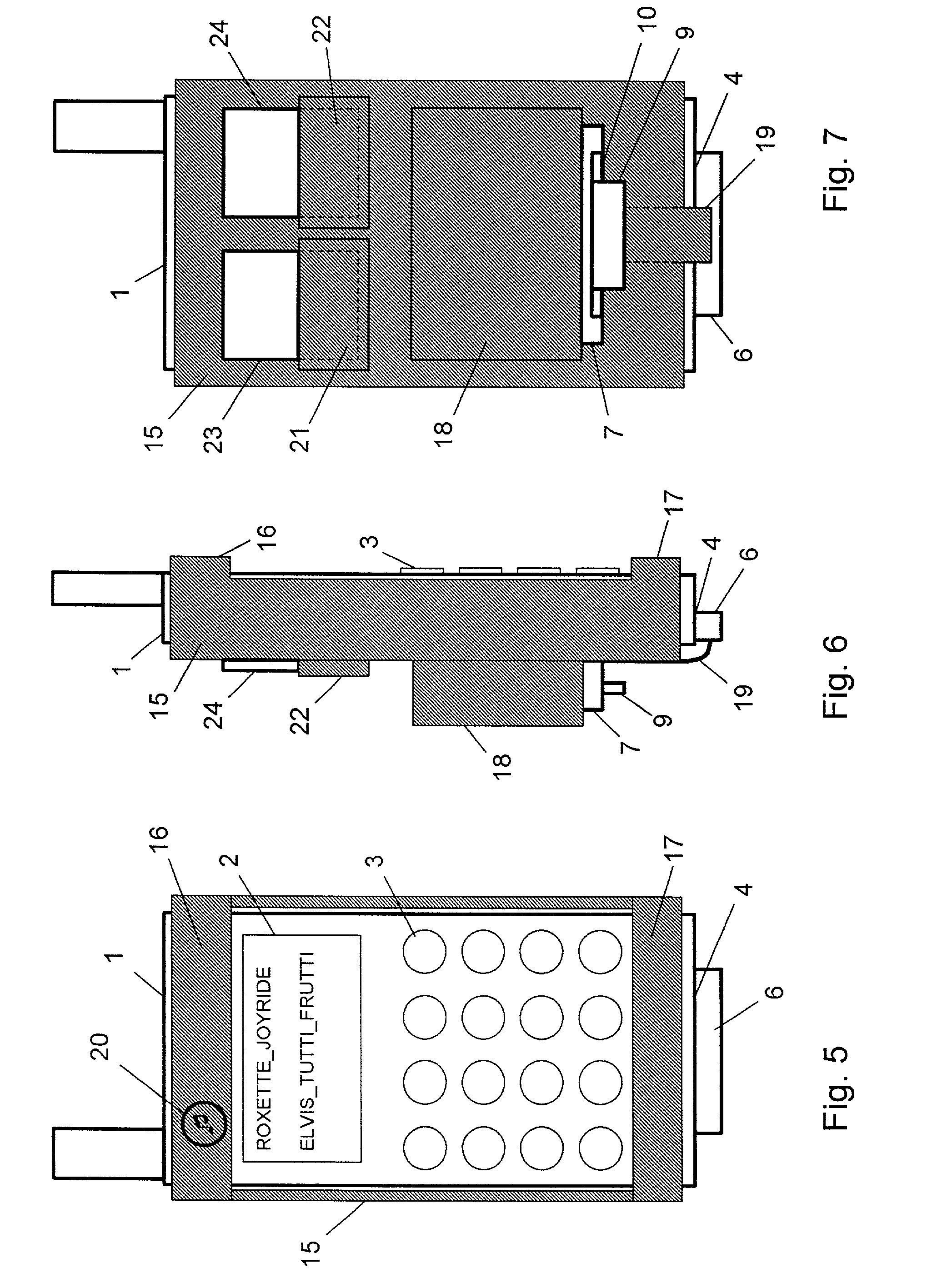

Accessory device for a portable communications device

InactiveUS20020119685A1Convenient positioningExchange of devices can stillDevices with multiple keyboard unitsAlphabetical characters enteringCommunication deviceTelecommunications equipment

A connecting device (5; 15; 31) for connecting an accessory device (7; 32) to a portable communications device (1) is equipped with means (11; 18; 37) for holding the accessory device in a position at a side of the portable communications device (1). When the accessory device is held in a position at a side of the portable communications device, the extension of the communications device in its longitudinal direction, and thus the risk of breakage, is avoided. It is no longer needed to store the accessory device separately. The connecting device may comprise an electrotextile having conductive fibres woven together with traditional non-conducting fibres. The electrotextile provides softness and at the same time the possibility of having electric connections in the material.

Owner:TELEFON AB LM ERICSSON (PUBL)

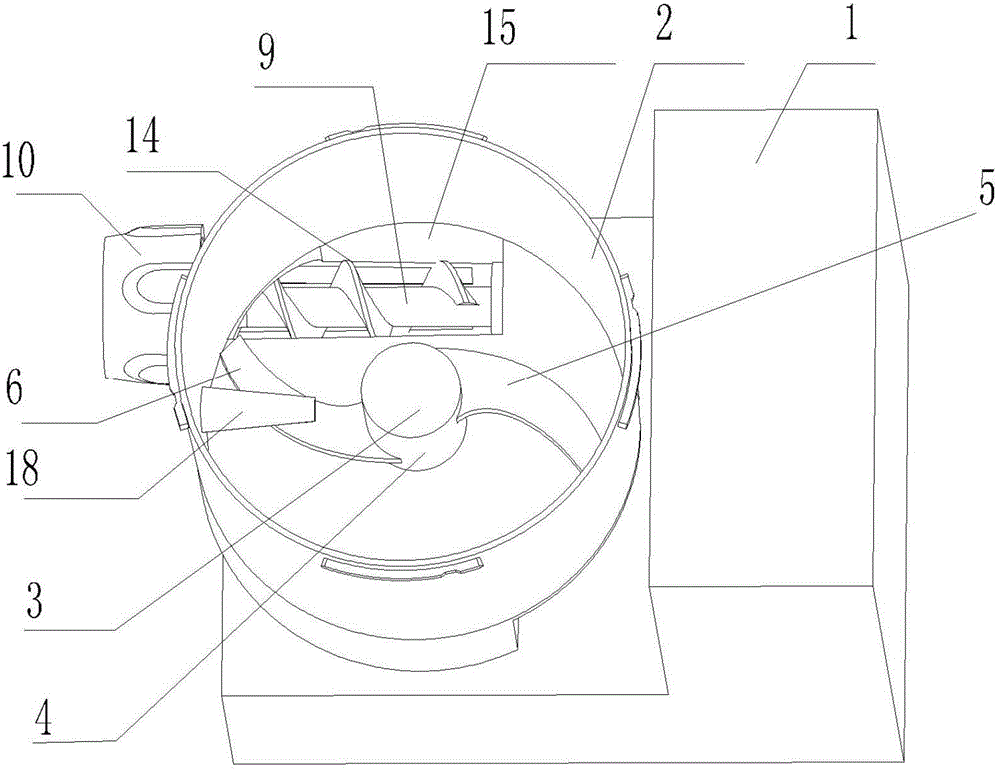

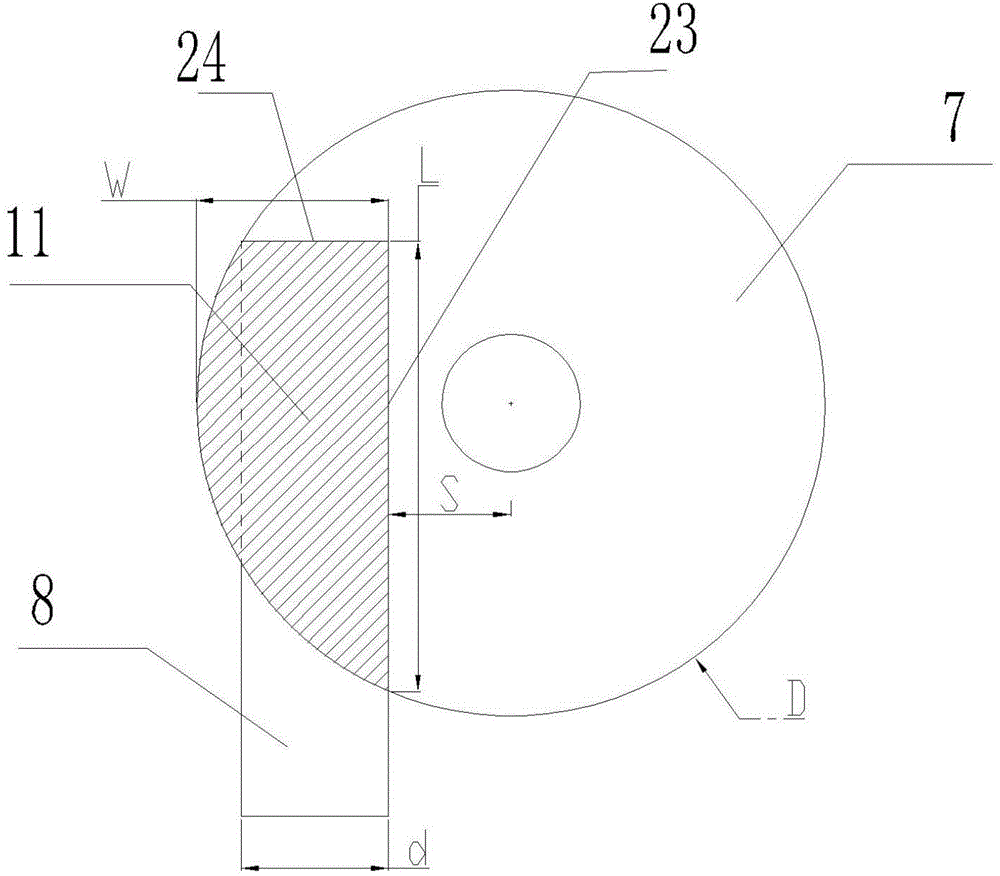

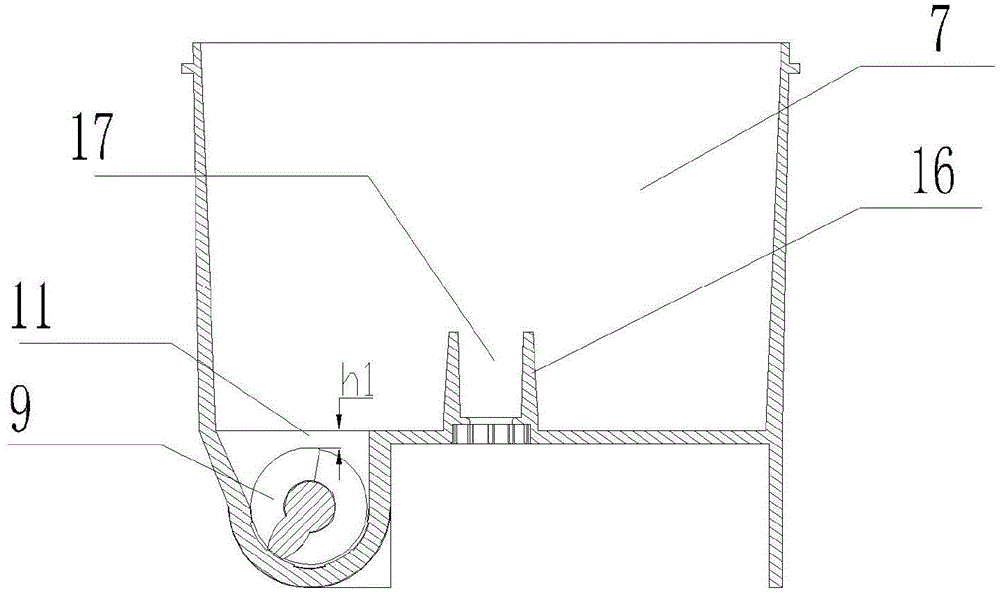

No-residual vertical type household noodle maker

ActiveCN104542787AImprove efficiencySmooth entryMixing/kneading with vertically-mounted toolsDough extruding machinesExtrusionPulp and paper industry

The invention discloses a no-residual vertical type household noodle maker which comprises a motor base, a motor arranged in the motor base, a stirring cup arranged above the motor base, a stirring rod and a dough extruding cylinder arranged in the stirring cup, a screw rod arranged in the dough extruding cylinder and a die head arranged on the end part of the dough extruding cylinder, wherein the dough extruding cylinder is horizontally arranged on one side below the stirring cup and consists of a material advancing cavity and an extrusion cavity, the motor drives the screw rod and the stirring rod to move, wherein a dough inlet communicated with the dough extruding cylinder is formed in the position of the bottom of the stirring cup, far away from the center, the material advancing cavity extends upwards and is intersected with the bottom of the stirring cup to form the dough inlet, and the dough inlet horizontally extends to the direction of the dough extruding cylinder along the bottom of the stirring cup, and extends to the side wall of the stirring cup. By adopting the technical scheme, the area of the dough inlet is largest, so that dough feeding is facilitated, residuals of dough in the stirring cavity can be avoided, and the stirring cavity and the stirring rod are conveniently cleaned.

Owner:JOYOUNG CO LTD

Front auxiliary frame and engine suspension connecting structure

ActiveCN105620552AProtectAvoid risk of breakageUnderstructuresJet propulsion mountingVehicle frameEngineering

The invention discloses a front auxiliary frame and engine suspension connecting structure. The connecting structure comprises an auxiliary frame upper plate, an auxiliary frame lower plate, and an engine suspension arranged between the auxiliary frame upper plate and the auxiliary frame lower plate; the auxiliary frame lower plate is provided with a bolt through hole upwards vertically penetrating through an engine suspension and the auxiliary frame upper plate; a fastening bolt extending out of a bolt through hole in the auxiliary frame upper plate is inserted in the bolt through hole from bottom to top; a protecting ring surrounding a bolt head of the fastening bolt is arranged on the lower side surface of the auxiliary frame lower plate; the protecting ring includes a cylindrical vertical ring connected with the auxiliary frame lower plate; and the lower edge of the vertical ring is inwards bent to extend to form a transverse reinforcing ring, so that the cross section of the protecting ring is L-shaped. The connecting structure is simple in structure, can effectively protect the bolt head for connecting the engine suspension with a front auxiliary frame from being scratched and collided by a ground projected object in advancement or retreating of a vehicle, and facilitates improvement of the vehicle driving safety.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

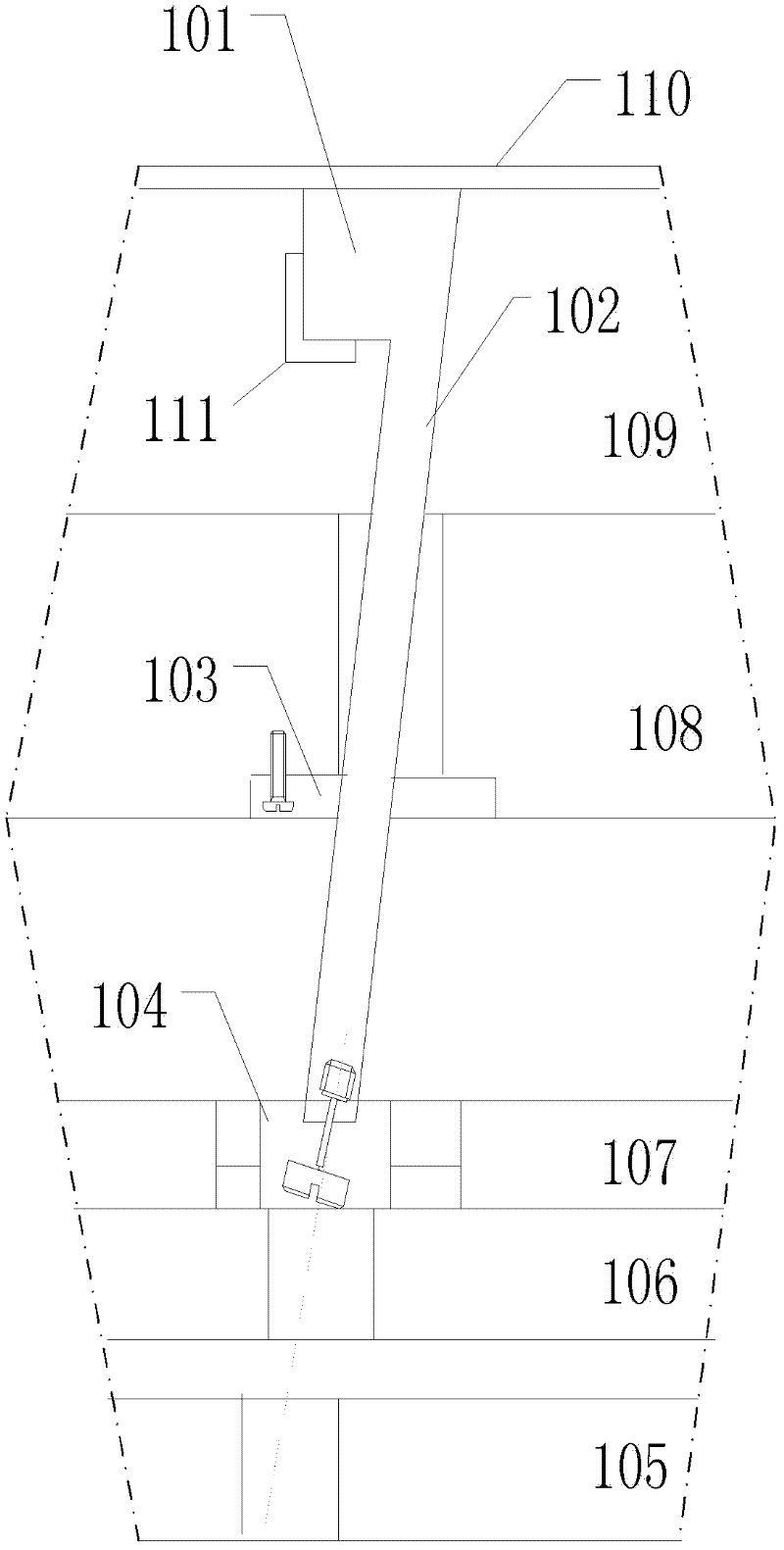

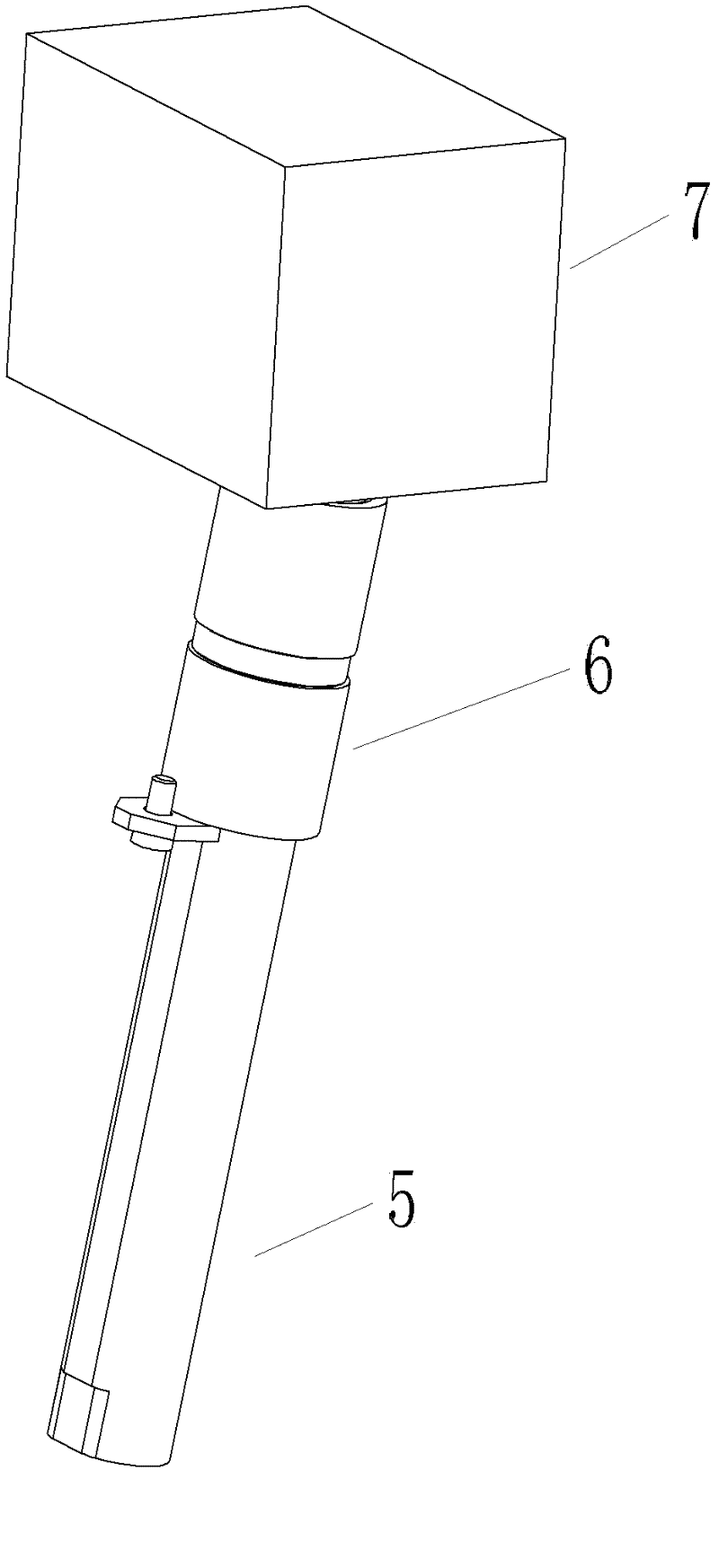

Down-slope oblique jacking accelerating core pulling mechanism assembly in injection mold

InactiveCN102363352AAvoid the risk of scratching the productAvoid risk of breakageEngineeringSlipway

The invention discloses an oblique jacking accelerating core pulling mechanism assembly capable of realizing ultra large-angle down slope. The assembly mainly comprises an oblique jacking head 7, an oblique jacking rod 5, an oblique jacking T-shaped block 4, a guide rod 9, an oblique jacking seat with a slipway 10, an accelerating guide rod 2 for accelerating down slope and a peripheral auxiliary mechanism. Mainly aiming at the defects of a common oblique jacking core pulling mechanism, the core pulling structural form and the core pulling action principle are changed, so that certain potential problems such as insufficient oblique jacking strength, breakage, oblique jacking glue shoveling and the like, the appearance requirement of a product is improved, the performance requirement of the product is met, and the problem of large down-slope inclination angle at the reversely buckled position of the surface of the product in the common oblique jacking core pulling structure is solved.

Owner:QINGDAO HAIER MOLDS +1

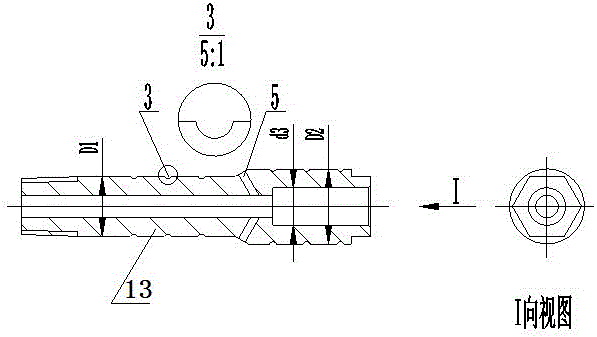

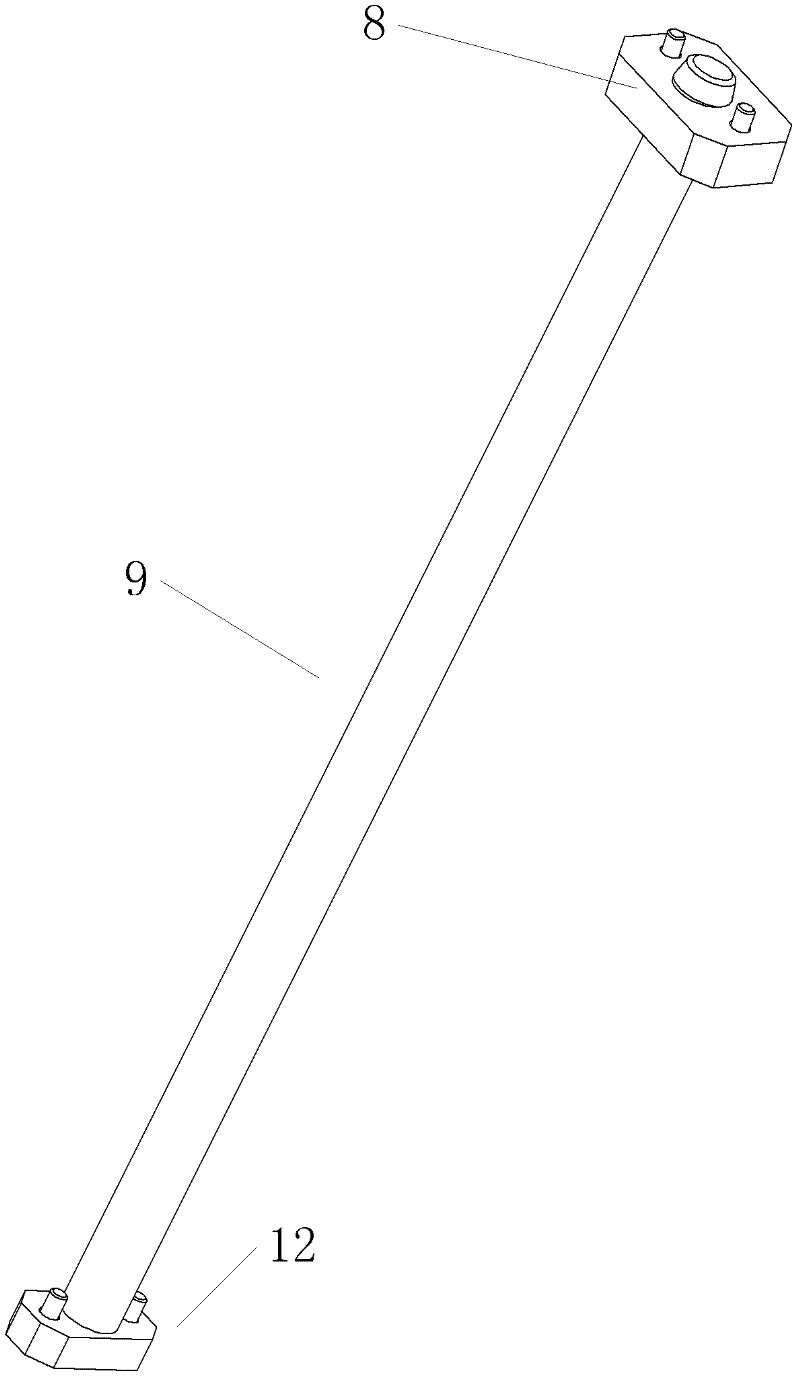

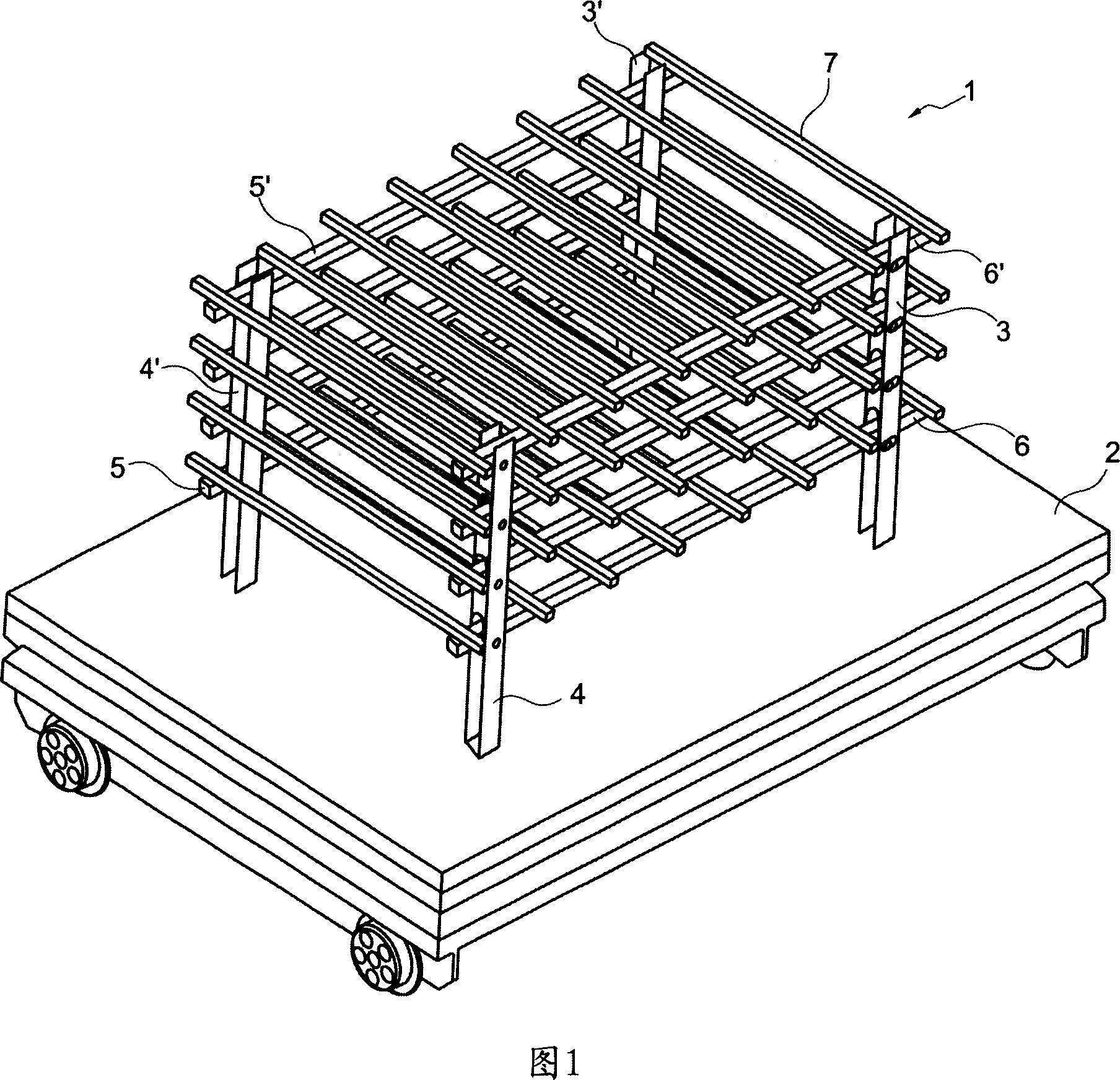

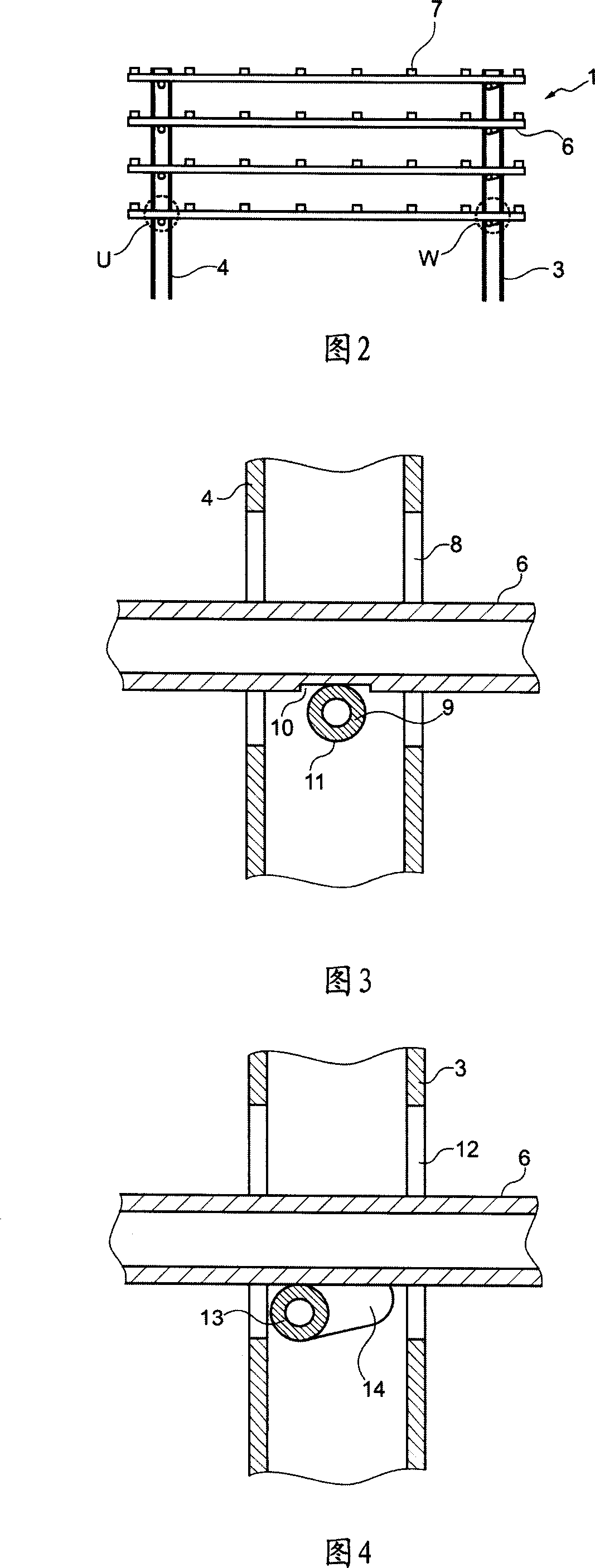

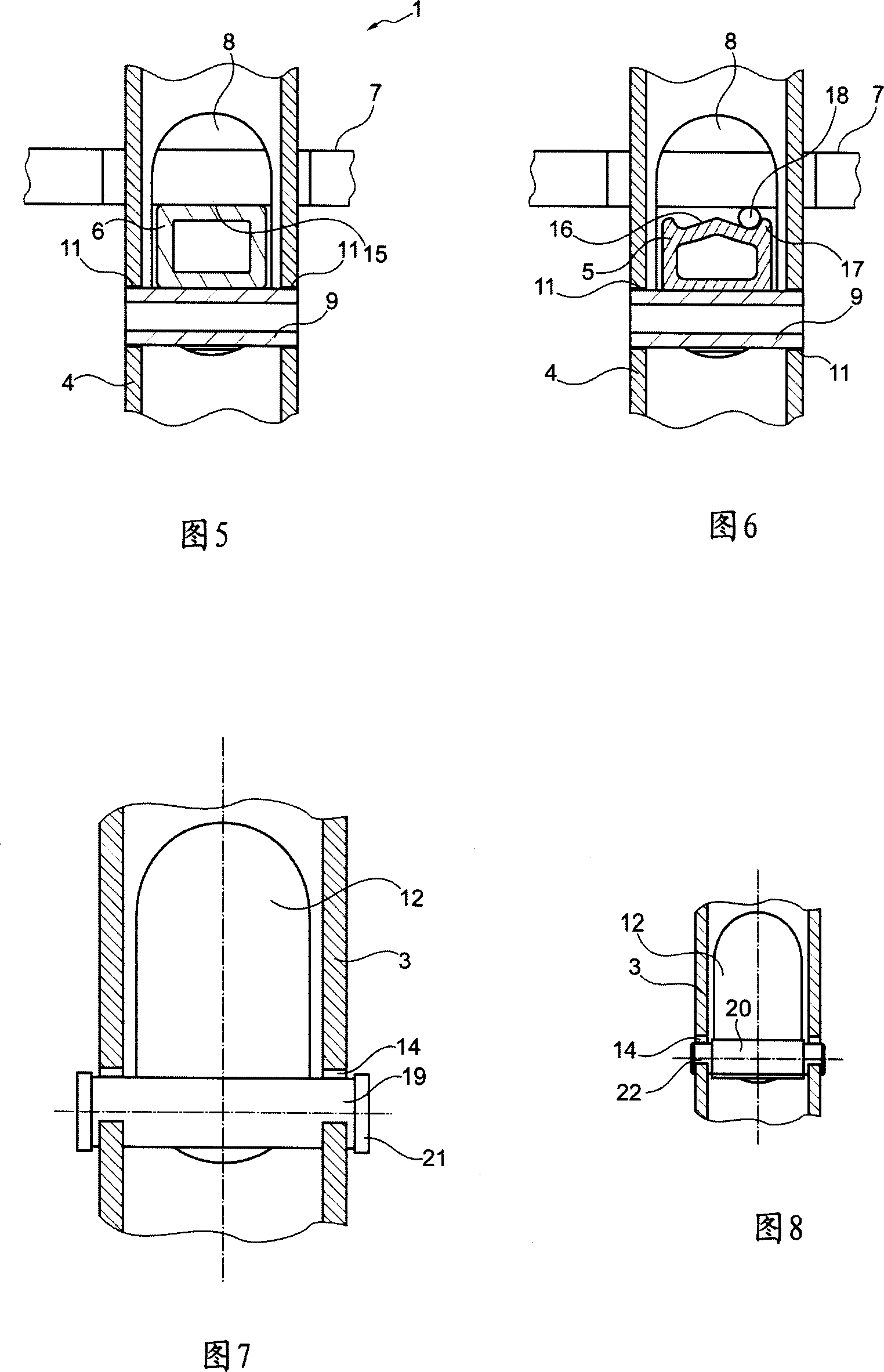

Device for supporting articles to be fired that has a defined compensation of thermal expansions

InactiveCN101142457ALow thermal expansionAvoid thermal expansionCharge supportsFurnace typesThermal expansionMechanical engineering

The invention relates to a device for supporting, stacking and conveying articles to be fired, particularly when firing ceramic products, which comprises an arrangement consisting of supports (3) and of support girders, such as supporting beams (6) and transversal beams on which, in particular, one or more supports are provided for placing the articles to be fired upon them. At least one movable bearing is provided for supporting at least one support girders (6) and has a supporting body (13) that is arranged so that it can be displaced, in essence, in the direction of the support girder (6).

Owner:SAINT GOBAIN IND KERAMIK RODENTAL

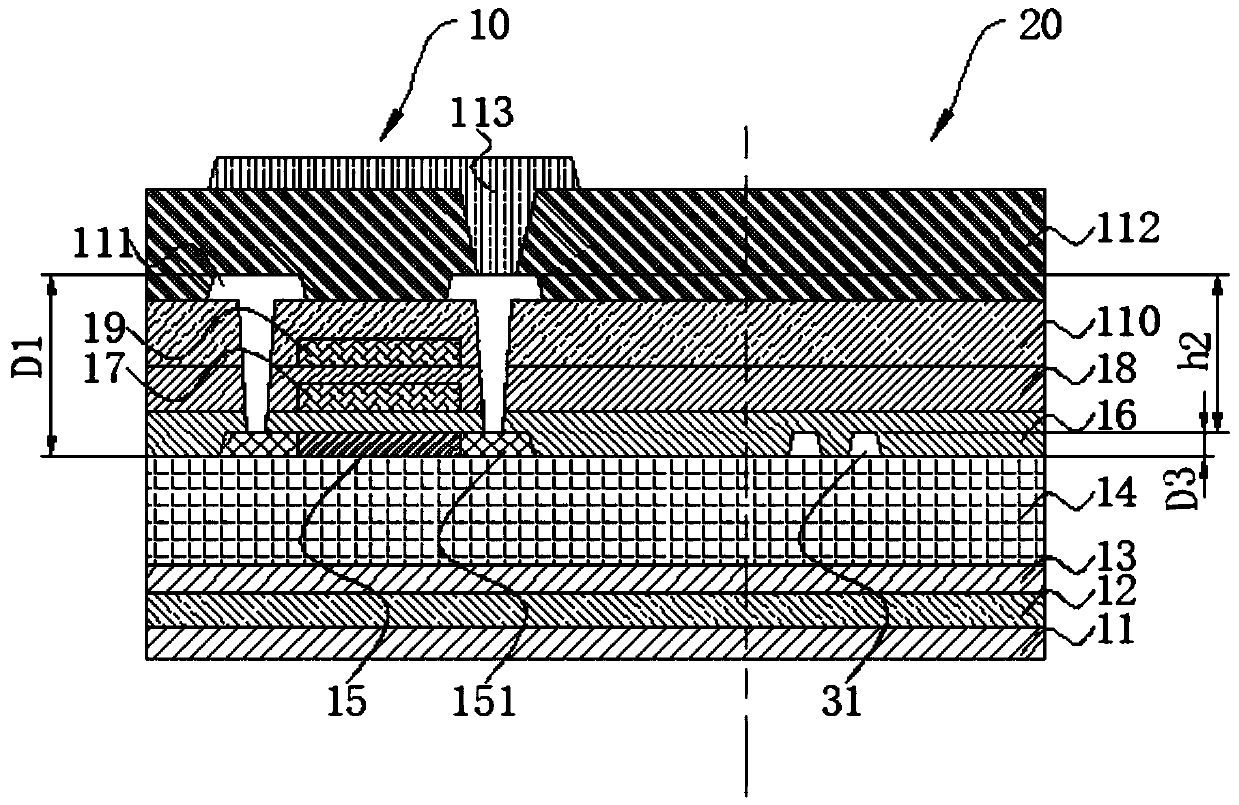

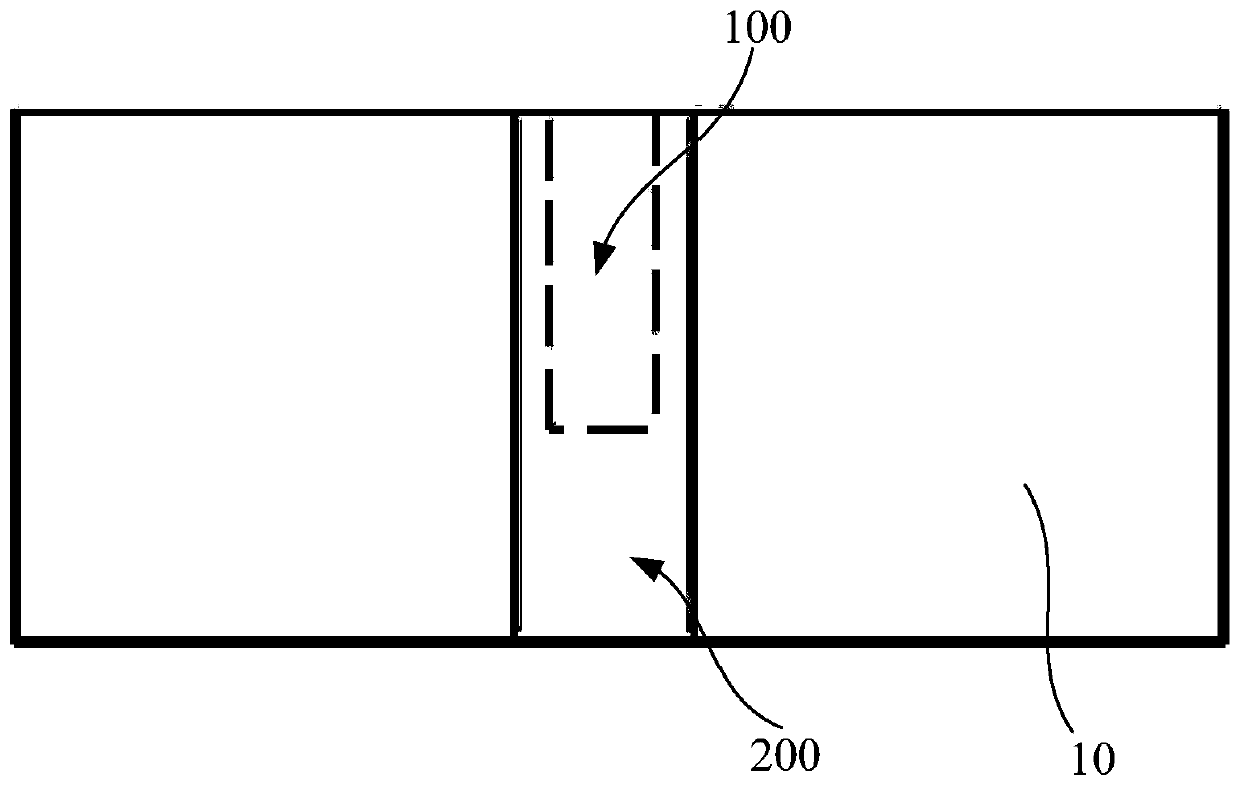

Flexible array substrate and flexible display panel

ActiveCN110391294AImprove reliabilityAvoid risk of breakageSolid-state devicesSemiconductor devicesEngineeringOxygen

A flexible array substrate comprises a display area, a bending area located at one side of the display area, a first flexible substrate, a water and oxygen blocking layer, a second flexible substrate,a buffer layer and an array structure layer, wherein the part of the array structure layer, which is located in the display area, is provided with a first source and drain wire, the part of the arraystructure layer, which is located in the bending area, is provided with a second source and drain wire, and the relative distance between the second source and drain wire and the buffer layer is smaller than the relative distance between the first source and drain wire and the buffer layer.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

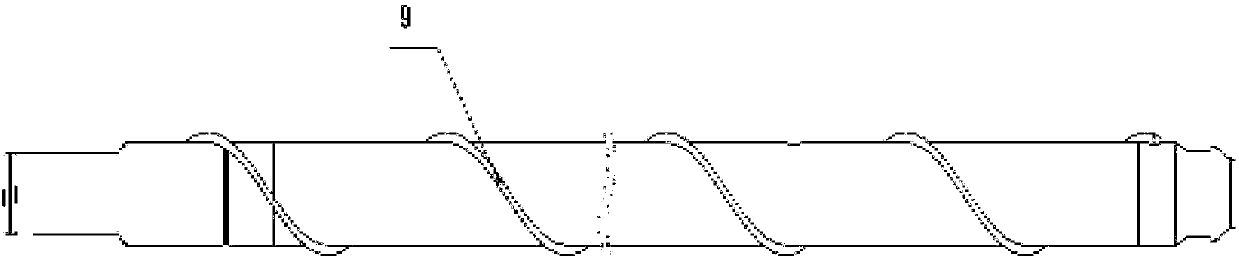

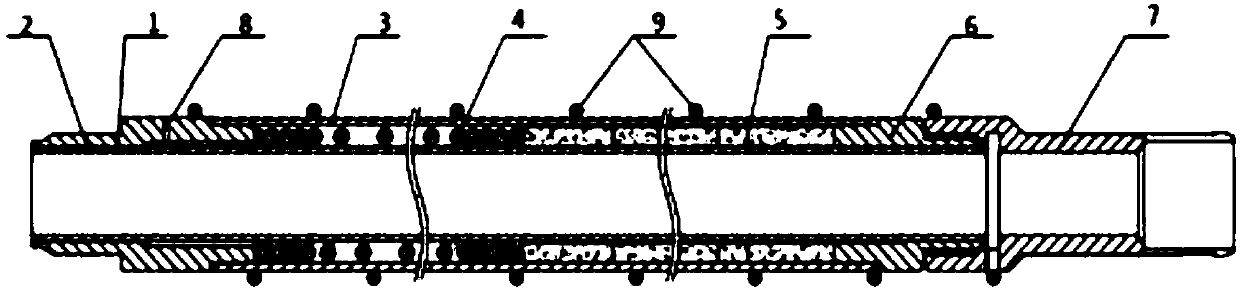

Double-sided cooling annular fuel rod with wrapping wire

PendingCN109935371AIncrease lateral flowImprove heat transfer effectNuclear energy generationReactor fuel elementsEngineeringNucleate boiling

The present invention provides a double-sided cooling annular fuel rod with a wrapping wire. The annular fuel rod comprises an upper end plug, a lower end plug, an inner cladding, an outer cladding and an annular fuel pellet, wherein a cavity formed by nesting the inner cladding and the outer cladding is used is for accommodating the annular fuel pellet, the upper parts of the inner cladding and the outer cladding are connected with the upper end plug, and the lower parts of the inner cladding and the outer cladding are connected with the lower end plug; the outer surface of the outer claddingis wound with one or more wrapping wires, that is the wrapping wire(s) is / are spirally wound around the outer surface of the outer cladding; and the two ends of the wrapping wire(s) are respectivelyfixed to the upper end plug and the lower end plug. The wrapping wire(s) wound around the annular fuel rod can significantly enhance the lateral flow of a coolant and enhance the heat transfer effectof the fuel rod to the coolant, and turbulent flow of the coolant takes away a large amount of channel heat, so the temperature of the fuel rod is reduced, the DNBR (departure from nucleate boiling ratio) is improved, and the safety of the fuel rod is enhanced.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

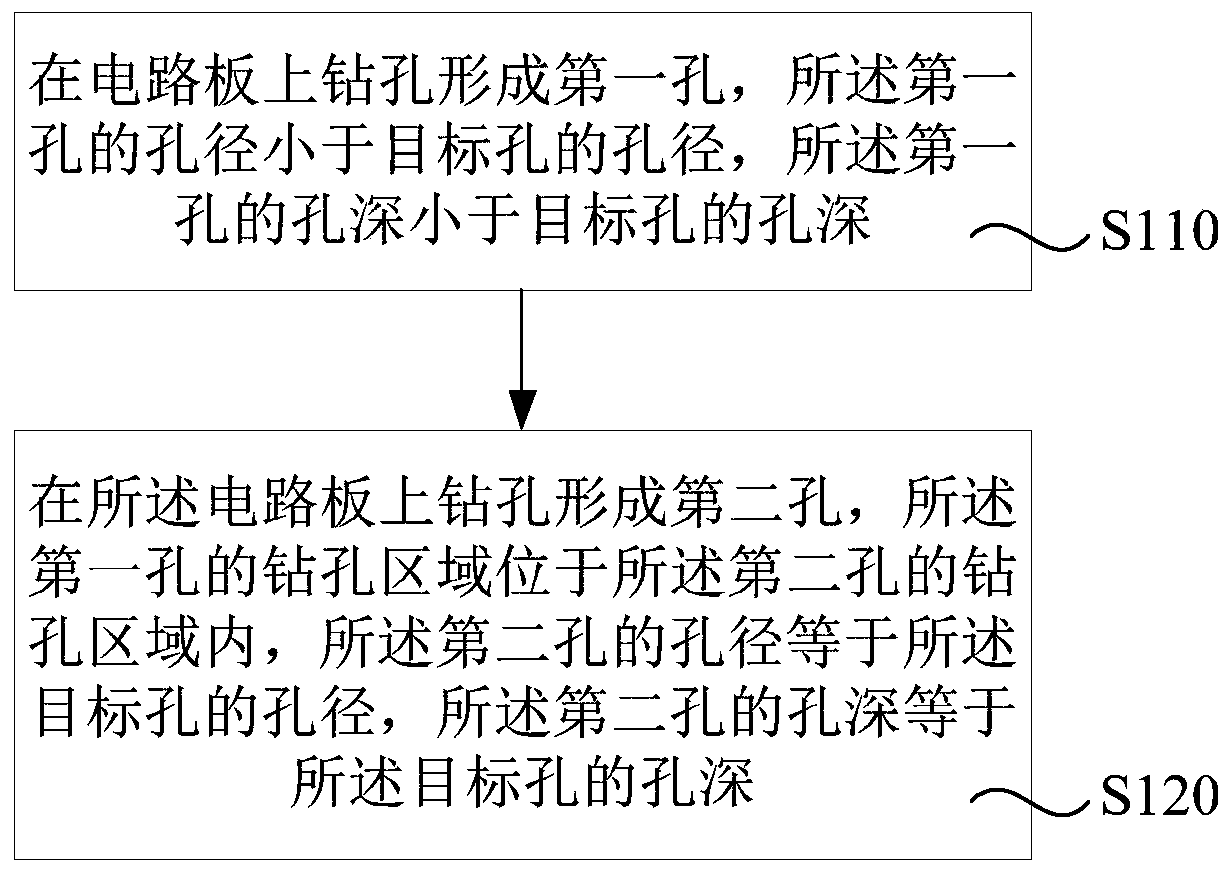

Circuit board and drilling method of circuit board

InactiveCN111356292AIncrease productivityReduce chip removal requirementsPrinted circuit manufactureMachining processMechanical engineering

The invention relates to a circuit board and a drilling method of the circuit board. The circuit board is drilled to form the first hole, the hole diameter of the first hole is smaller than that of the target hole, and when the second hole is drilled, a part of material is cut by drilling the first hole, so that the chip removal requirement for drilling the second hole is reduced; meanwhile, as the drilling area of the first hole is located in the drilling area of the second hole, the hole wall of the first hole can be used for providing supporting and guiding effects for drilling of the second hole, and the breaking risk of the drill bit is reduced. Due to the fact that the hole depth of the first hole is smaller than that of the target hole, the chip removal requirement for drilling thefirst hole and the blade length requirement of the drill bit are lowered, and the problem that in the process of drilling the first hole, the drill bit is broken due to the large drilling depth or chip removal problem of the drill bit is effectively solved. According to the drilling method of the circuit board, especially in the machining process of the circuit board with the high thickness-diameter ratio, the target hole can be formed only through two drilling steps, the drilling steps are simplified, the drilling efficiency is improved, and the production efficiency of the circuit board is improved.

Owner:GUANGZHOU FASTPRINT CIRCUIT TECH +1

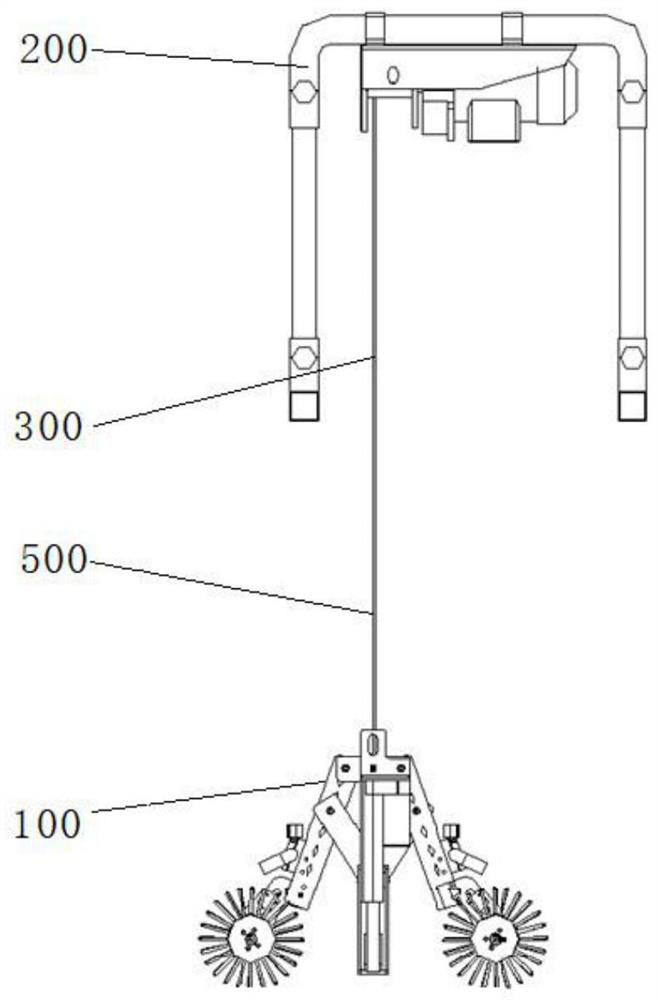

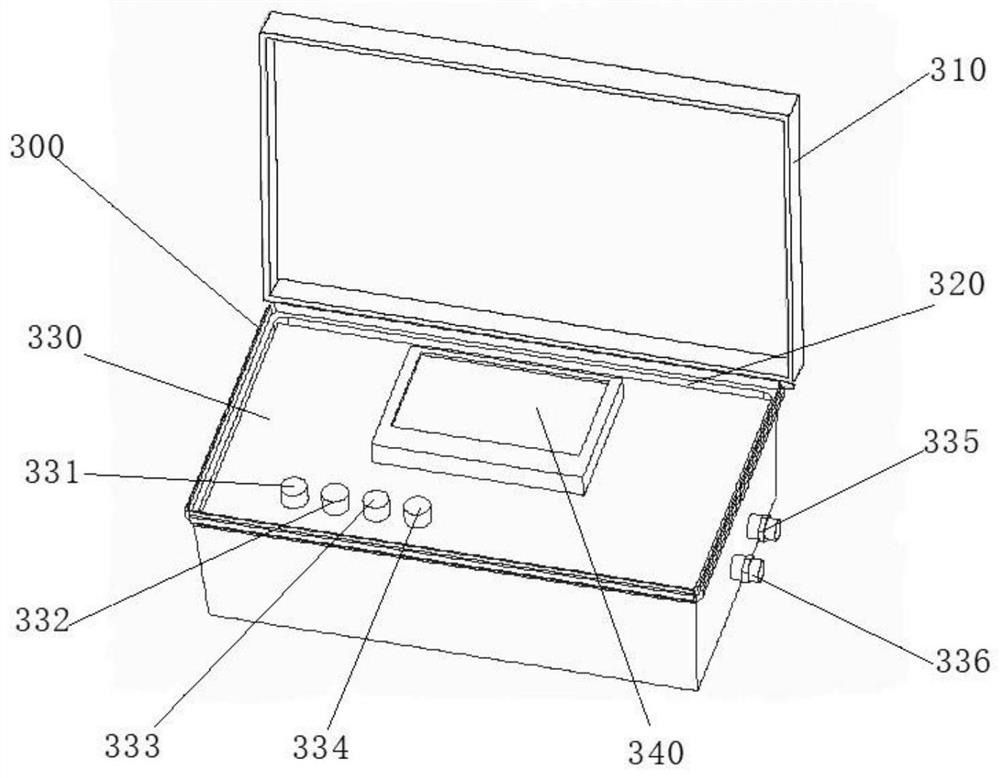

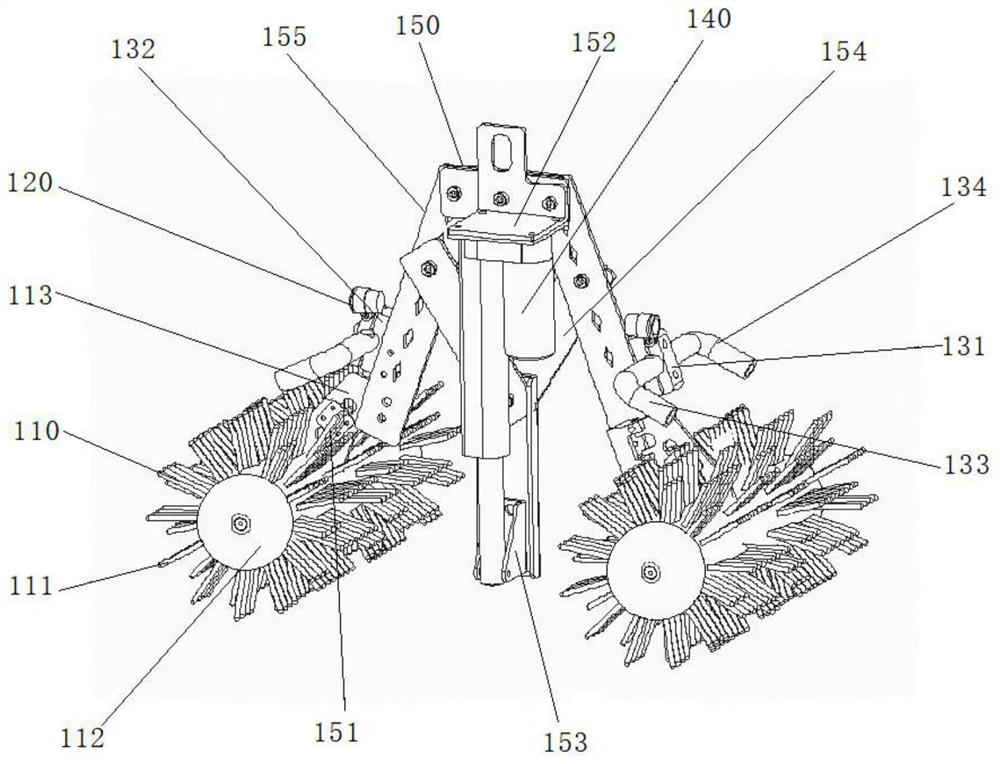

Vertical pipeline cleaning equipment

PendingCN111871980AImprove efficiencyQuality improvementHollow article cleaningElectric machineryCorrosion prevention

The invention discloses vertical pipeline cleaning equipment, and relates to the technical field of vertical pipeline cleaning. In order to solve the problem that the efficiency of manually cleaning the inner wall of a vertical pipeline is low, the vertical pipeline cleaning equipment specifically comprises a telescopic sweeping mechanism, a hanging mechanism, a control box, a transmission cable and an explosion-proof water pipe, the telescopic sweeping mechanism comprises two rolling brush assemblies, a camera, a nozzle assembly, a hydraulic lifting rod and an installation support, and the hanging mechanism comprises a winch and an installation frame assembly; the control box comprises a control box shell, a high-pressure anti-corrosion water pump, a waterproof box, an operation panel, adisplay screen, a waterway connecting assembly and a circuit control part, and the outer walls of the circumferences of the transmission cable and the explosion-proof water pipe are wrapped with one same wire protecting sleeve; and each rolling brush assembly comprises a plurality of bristles, two rolling brush sleeves, a direct-current double-output-shaft motor, two motor clamping sleeves and a rolling brush fixing support. The vertical pipeline cleaning equipment meets the requirement that when pipelines on an existing market are irregular, cleaning operation can be conducted through the vertical pipeline cleaning equipment.

Owner:长沙亚欣电器技术服务股份有限公司

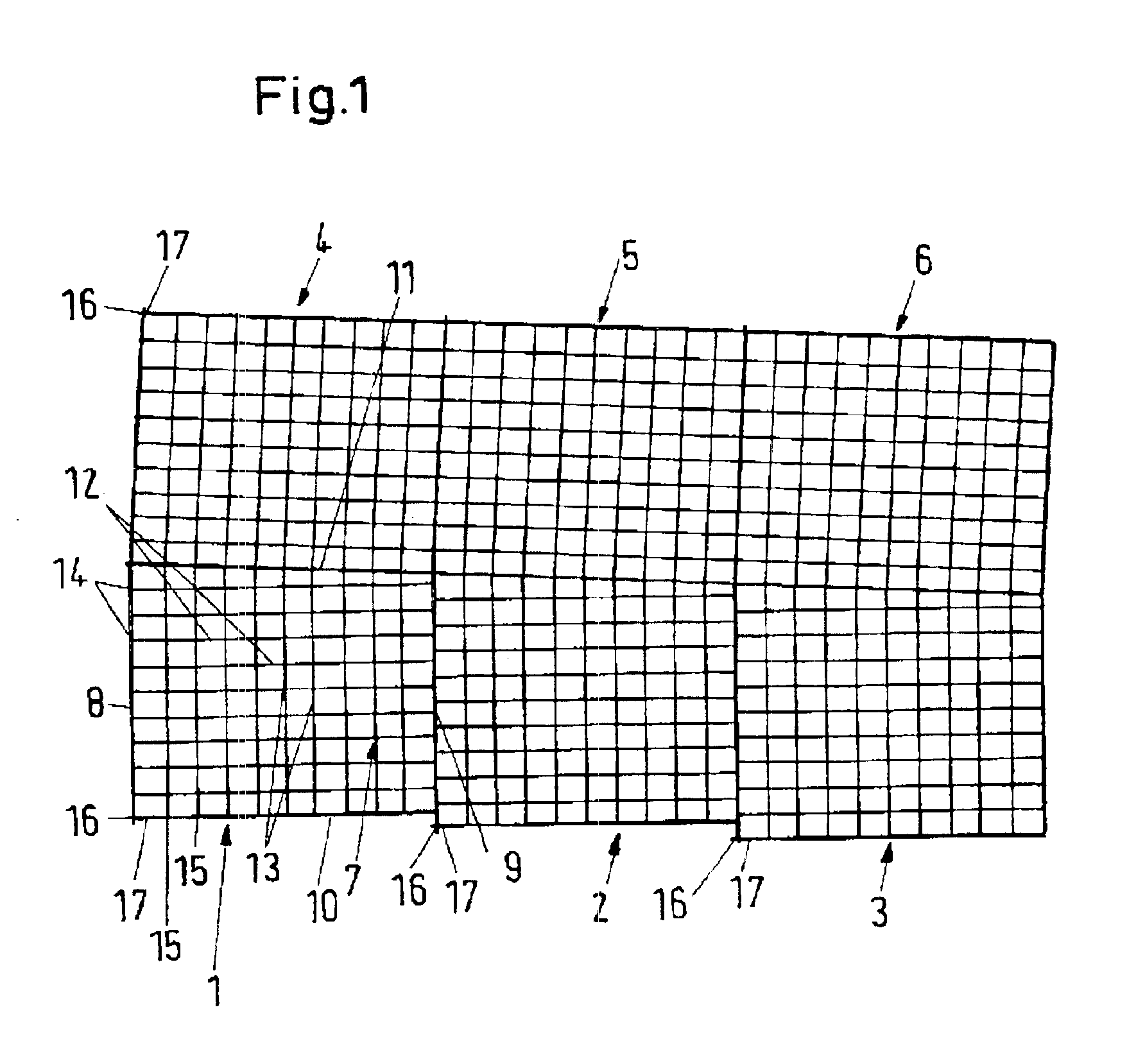

Wire mesh mat, in particular, for Gabion baskets

InactiveUS6857817B2Simple configurationAvoid risk of breakageMetal-working apparatusRigid containersEngineeringGabion

A wire mesh mat for Gabion baskets for securing slopes has longitudinal wires and transverse wires connected to one another and having wire ends, respectively. At least some of the wire ends have an eye, respectively. The wire ends provided with the eye have a compensation section configured to compensate expansions and compressions occurring in a longitudinal direction of the wires. The compensation section has two legs and the eye is positioned between the two legs of the compensation section.

Owner:ROTHFUSS THOMAS

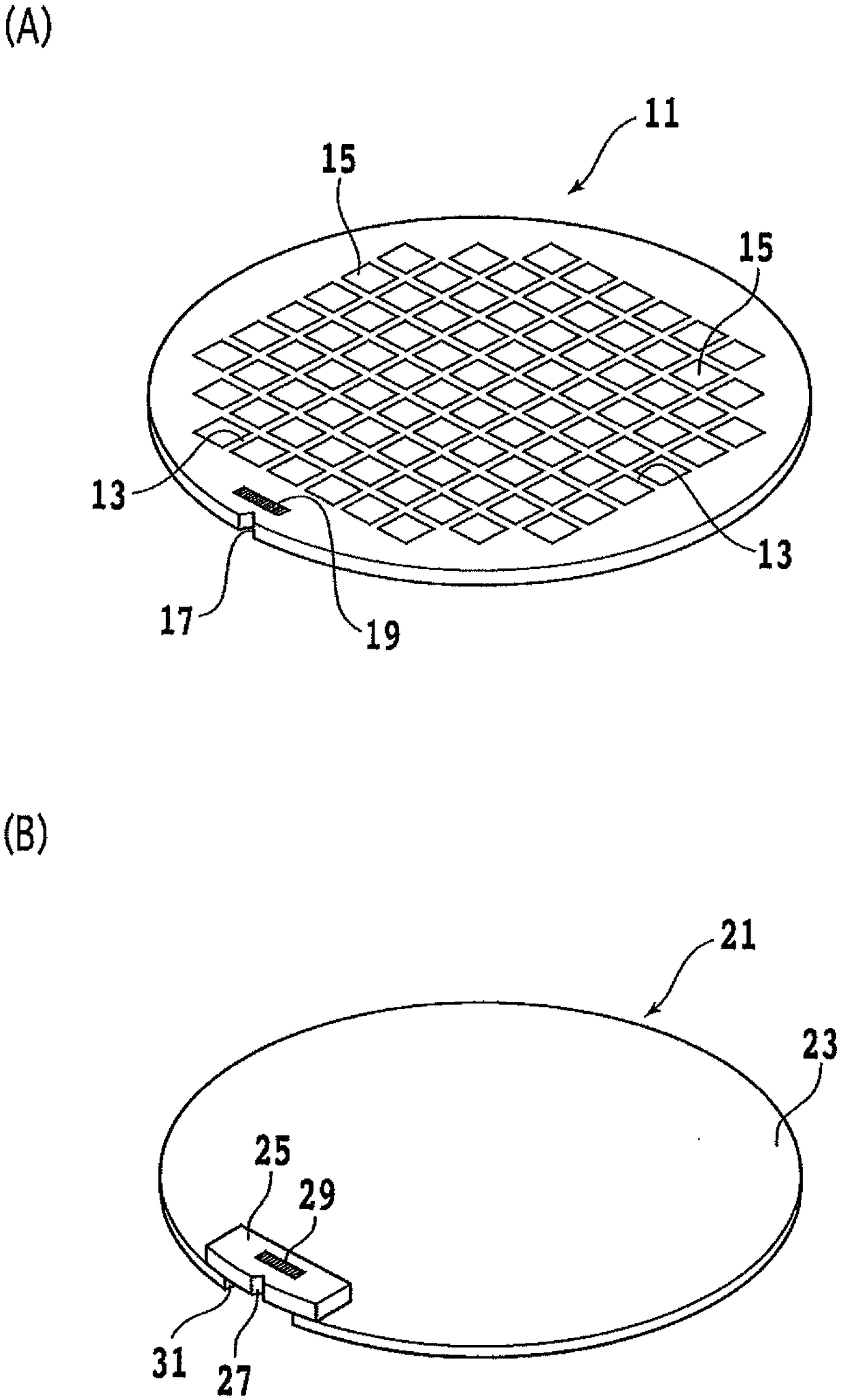

Wafer jig having identification mark

ActiveCN109119359AAvoid risk of breakageImprove efficiencySemiconductor/solid-state device detailsSolid-state devicesWaferingMechanical engineering

The invention provides a wafer jig having an identification mark capable of being used for identifying adjustment of a reading mechanism. Disclosed herein is a wafer jig with an identification mark for use in inspecting the function of an identification mark reading mechanism for reading an identification mark on a device wafer. The wafer jig includes a wafer piece cut from a region of a device wafer where an identification mark is formed, and a circular plate having the same diameter as the device wafer. The wafer piece is fixed to the circular plate such that the identification mark on the wafer piece is positionally aligned with the identification mark on the device wafer.

Owner:DISCO CORP

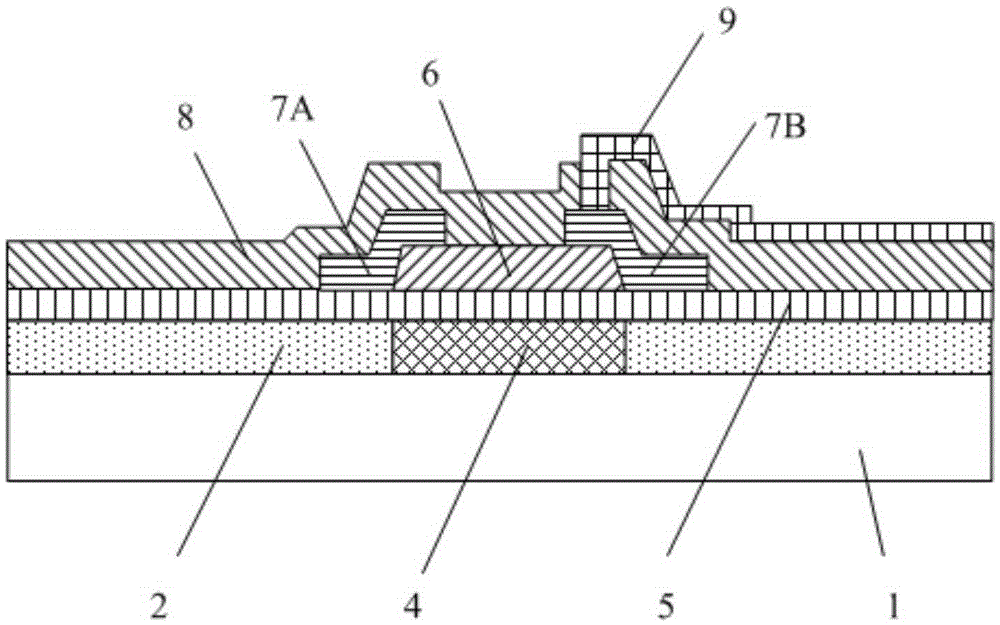

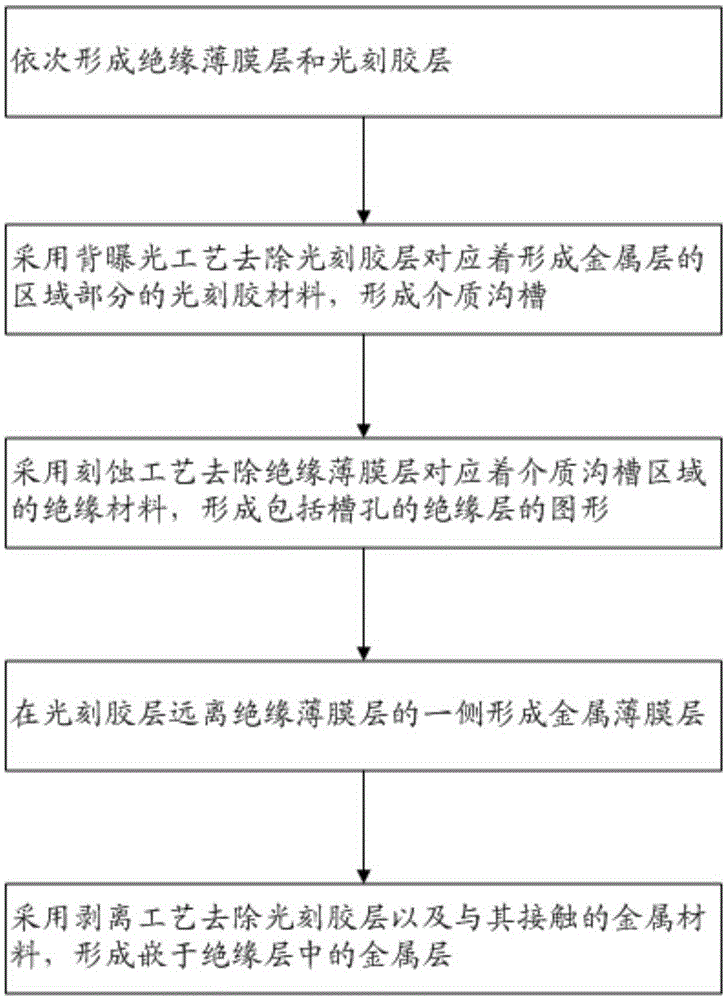

Pixel structure and preparation method thereof, array substrate and display device

ActiveCN105428245AReduce process stepsLow costTransistorSolid-state devicesOptoelectronicsMedia layer

The invention belongs to the technical field of display, and relates to a pixel structure and a preparation method thereof, an array substrate and a display device. The preparation method of the pixel structure comprises the steps of forming an insulation layer and forming a metal layer embedded into the insulation layer and specifically comprises the steps of forming a transparent medium layer, adopting a back exposure process and a stripping process to treat the transparent medium layer, and forming a graph comprising the insulation layer and a graph of the metal layer embedded into the insulation layer; the insulation layer is internally provided with a slotted hole in which the metal layer is embedded, the shape of the slotted hole is adaptive to that of the metal layer, the area of the slotted hole is equal to that of the metal layer, and the depth of the slotted hole is equal to the thickness of the metal layer. According to the preparation method of the pixel structure, the back exposure process and the stripping process are combined, so that the time lag between the two periods of time of forming the insulation layer and forming the metal layer embedded into the insulation layer is effectively avoided, the process is simple and the production efficiency is effectively improved.

Owner:BOE TECH GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com