Down-slope oblique jacking accelerating core pulling mechanism assembly in injection mold

A core-pulling mechanism and injection mold technology, applied in the field of downslope inclined roof acceleration core-pulling mechanism components, can solve problems such as difficult molding, and achieve the effect of flexible design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

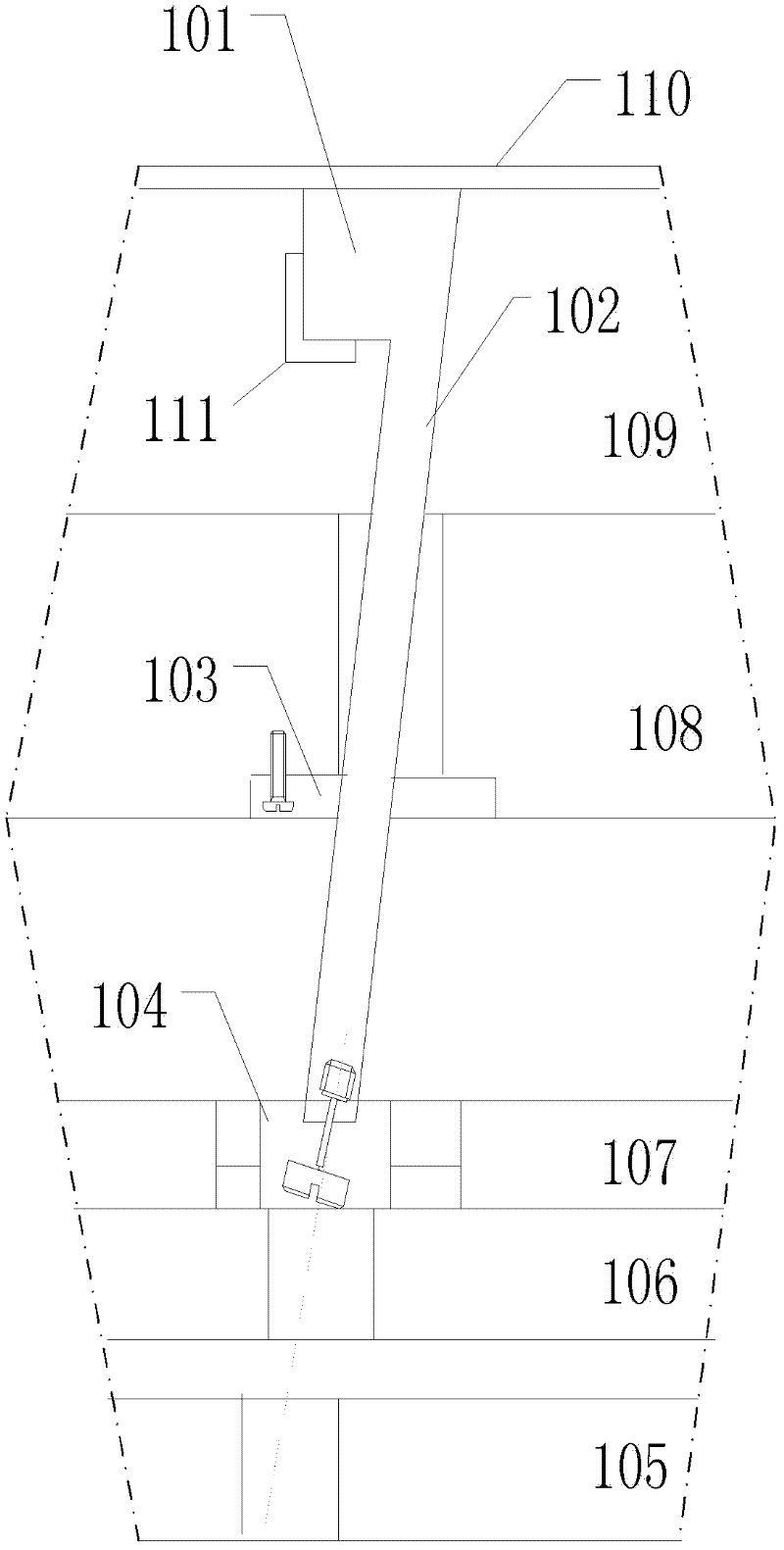

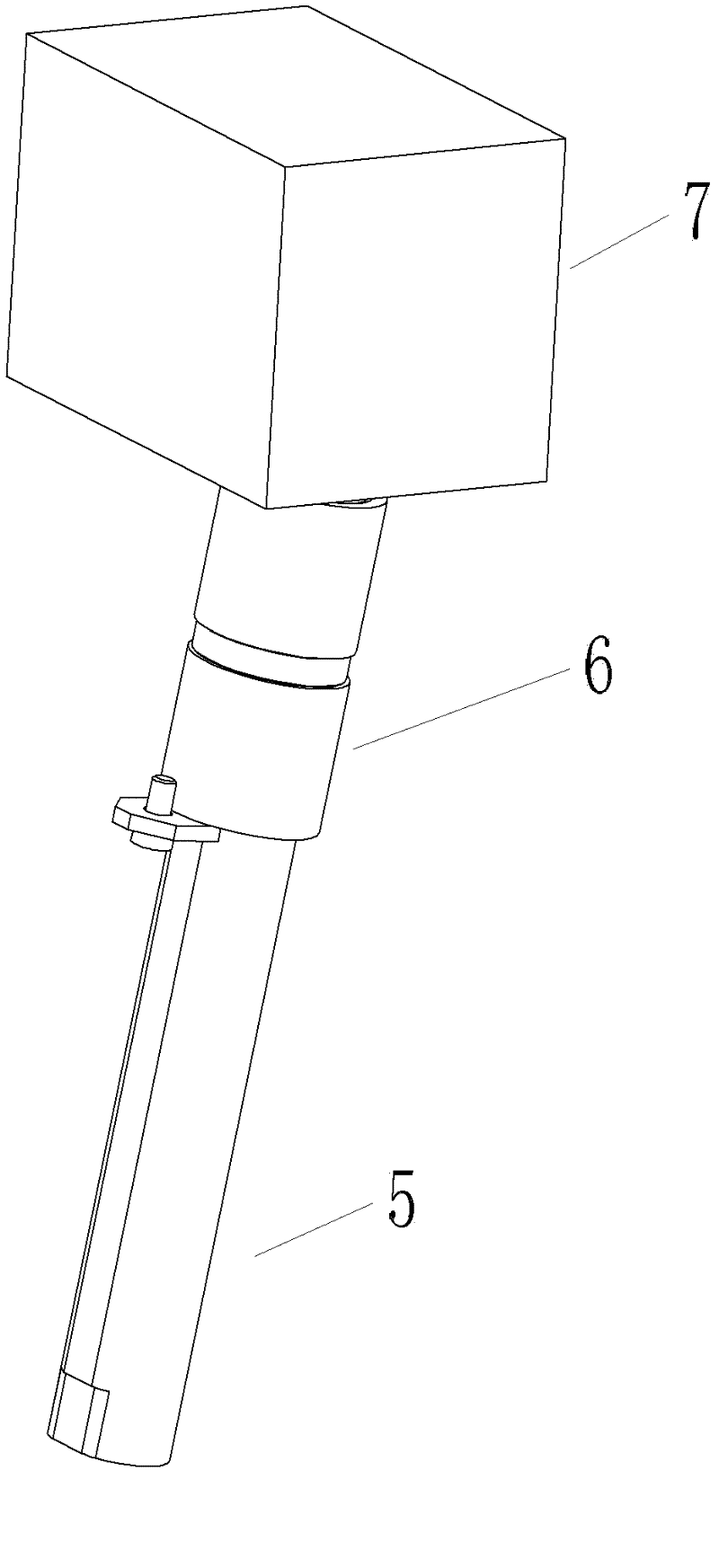

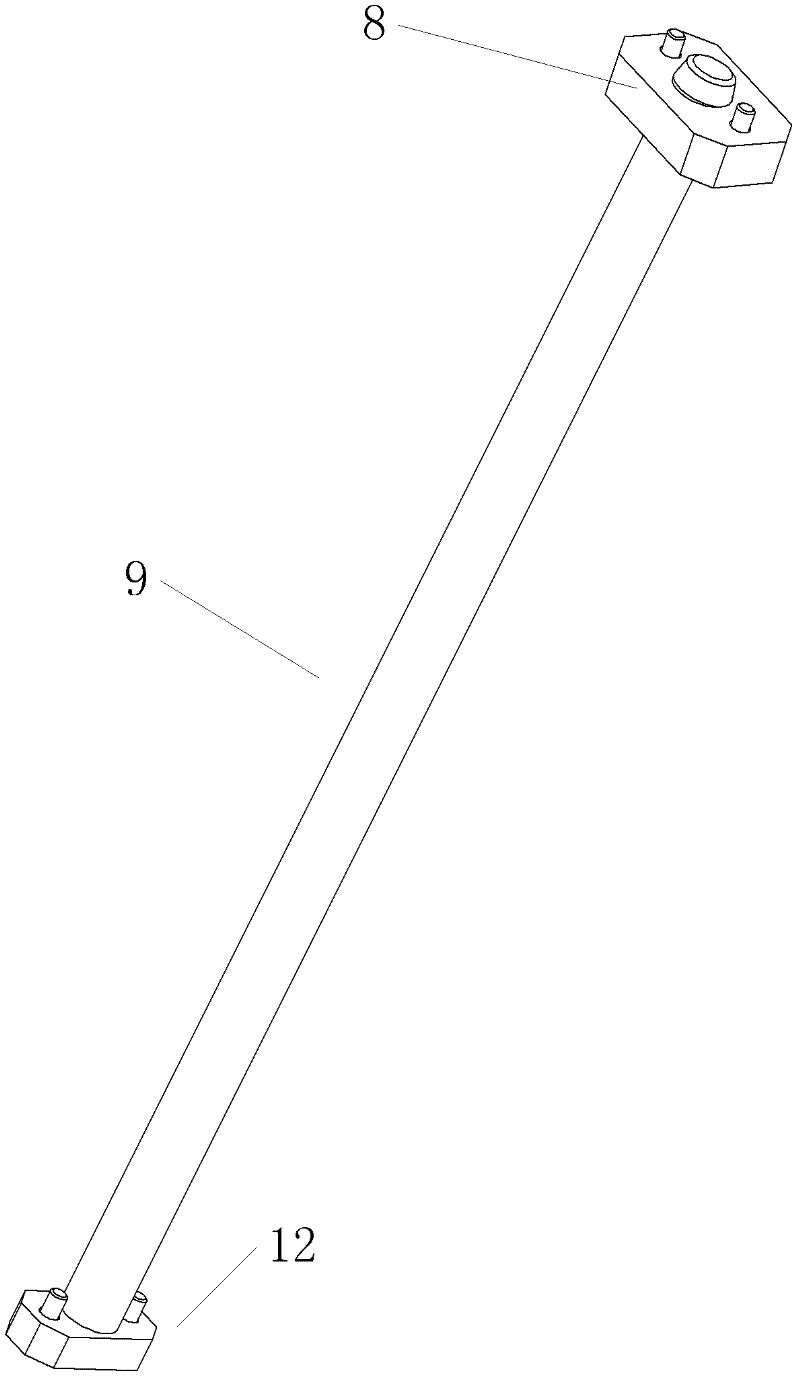

[0049] Such as Figures 2 to 8 As shown, a specific embodiment of the inclined top accelerated core-pulling mechanism assembly capable of realizing a super-large angle downhill is given, and its main components include: inclined top head 7, inclined ejector rod 5, inclined top T-shaped block 4, Guide rod 9, inclined roof seat with slideway 10, accelerated guide rod 2 for accelerating downhill and peripheral auxiliary mechanism, the peripheral auxiliary mechanism includes accelerated guide rod pressing plate 1, accelerated guide rod fixed block 3, inclined ejector rod guide slide Block 6, guide rod pressing plate 8, slideway pressing plate 11, guide rod pressing plate 12.

[0050]Wherein, the first end of the inclined ejector rod 5 and the inclined ejector head 7 are fixedly connected together by a wedge block, the inclined ejector rod 5 is preferably a rod with a circular section, and the shape and structure of the inclined ejector head 7 are designed according to the shape of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com