Pixel structure and preparation method thereof, array substrate and display device

A pixel structure and insulating layer technology, which is applied in semiconductor/solid-state device manufacturing, optics, instruments, etc., can solve problems such as process time increase, follow-up process problems, gate insulating layer 2 breakage, etc., to reduce process steps and improve production Efficiency, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] This embodiment provides a pixel structure and its corresponding preparation method. The preparation method is simple, and the prepared pixel structure has high yield and good performance.

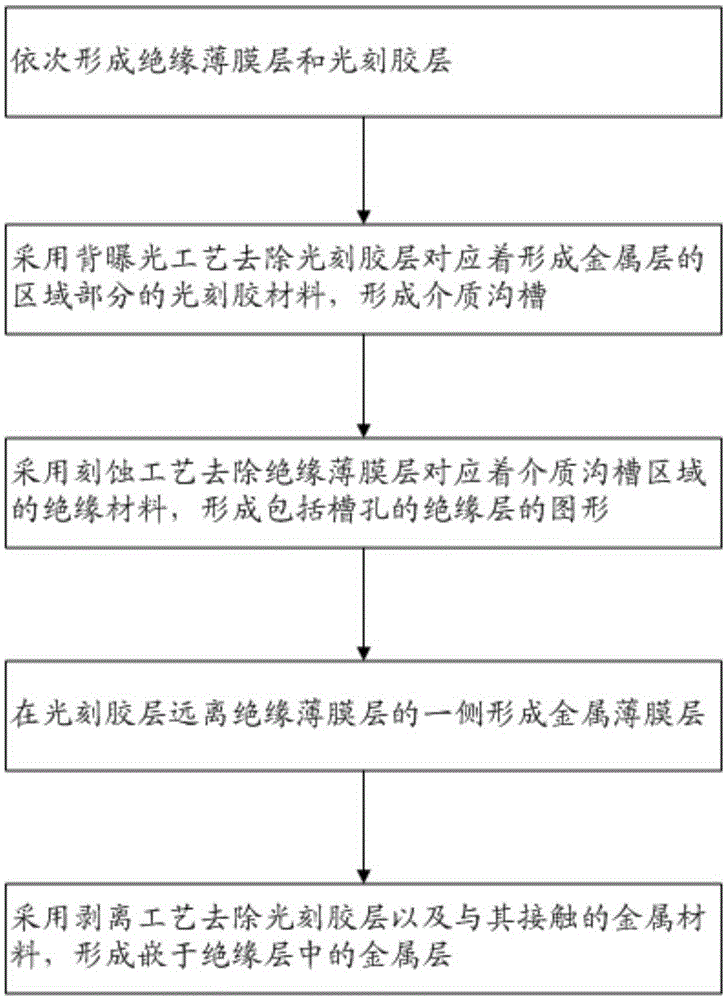

[0055] A method for preparing a pixel structure, comprising the steps of forming an insulating layer and forming a metal layer embedded in the insulating layer, including: forming a transparent medium layer, and using a back exposure process and a lift-off process to process the transparent medium layer, forming a The pattern of the insulating layer and the pattern of the metal layer embedded in the insulating layer; wherein, the insulating layer is provided with a slot for embedding the metal layer, the shape of the slot is suitable for the shape of the metal layer, and the area of the slot is equal to The area of the metal layer and the depth of the slot hole are equal to the thickness of the metal layer.

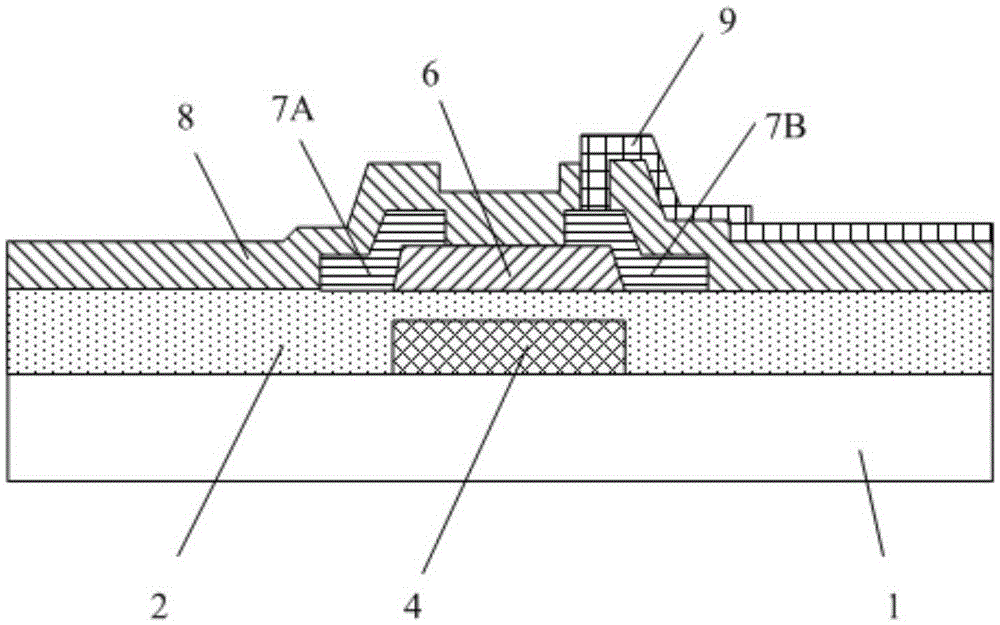

[0056] A pixel structure corresponding to the above preparation method...

Embodiment 2

[0084] This embodiment provides a pixel structure and its corresponding preparation method. The preparation method is simple, and the prepared pixel structure has high yield and good performance.

[0085] This embodiment also takes the formation of the gate insulating layer 2 and the gate 4 embedded in the gate insulating layer 2 in the top-gate thin film transistor as an example to describe the preparation process in detail. Compared with Example 1, the difference in the preparation method of this pixel structure is that when forming the dielectric trench 31 of the photoresist layer 3, in the back exposure process, a semi-permeable film mask is used to form two waists as the outer Convex curved trapezoidal shape.

[0086] Further preferably, the center of the exposure light source corresponds to the center of the dielectric trench 31 to be formed, and the cross-sectional shape of the dielectric trench 31 is an isosceles trapezoid whose two waists are convex arcs.

[0087] In...

Embodiment 3

[0090] This embodiment provides a pixel structure and its corresponding preparation method. The preparation method is simple, and the prepared pixel structure has high yield and good performance.

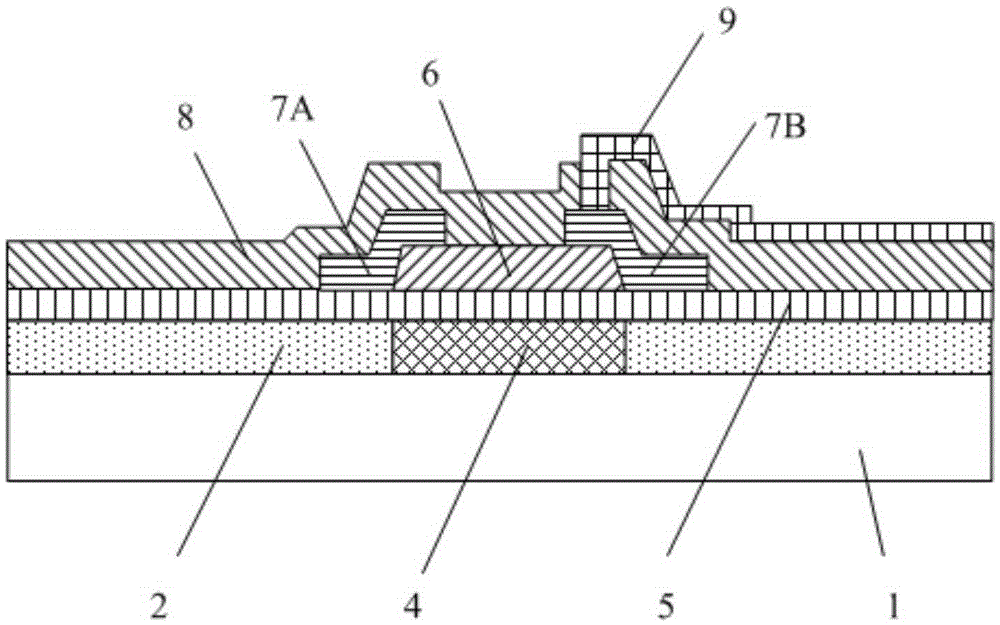

[0091] Compared with Embodiments 1 and 2, the difference in the preparation method of the pixel structure is that this embodiment takes the formation of the passivation layer 8 under the top-gate thin film transistor and the pixel electrode 9 embedded in the passivation layer 8 as an example. Describe the preparation process.

[0092] In the pixel structure of this embodiment, the pixel structure includes a thin film transistor, and a pixel electrode 9 and a passivation layer 8 located below the thin film transistor. Here, the insulating layer is the passivation layer 8 , and the metal layer is the pixel electrode 9 layer. According to the principle of straight-line propagation of light, in order to ensure the effectiveness of the back exposure process, the passivation layer 8 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com