Patents

Literature

168 results about "Amorphous silicon solar cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thin film photovoltaic module manufacturing methods and structures

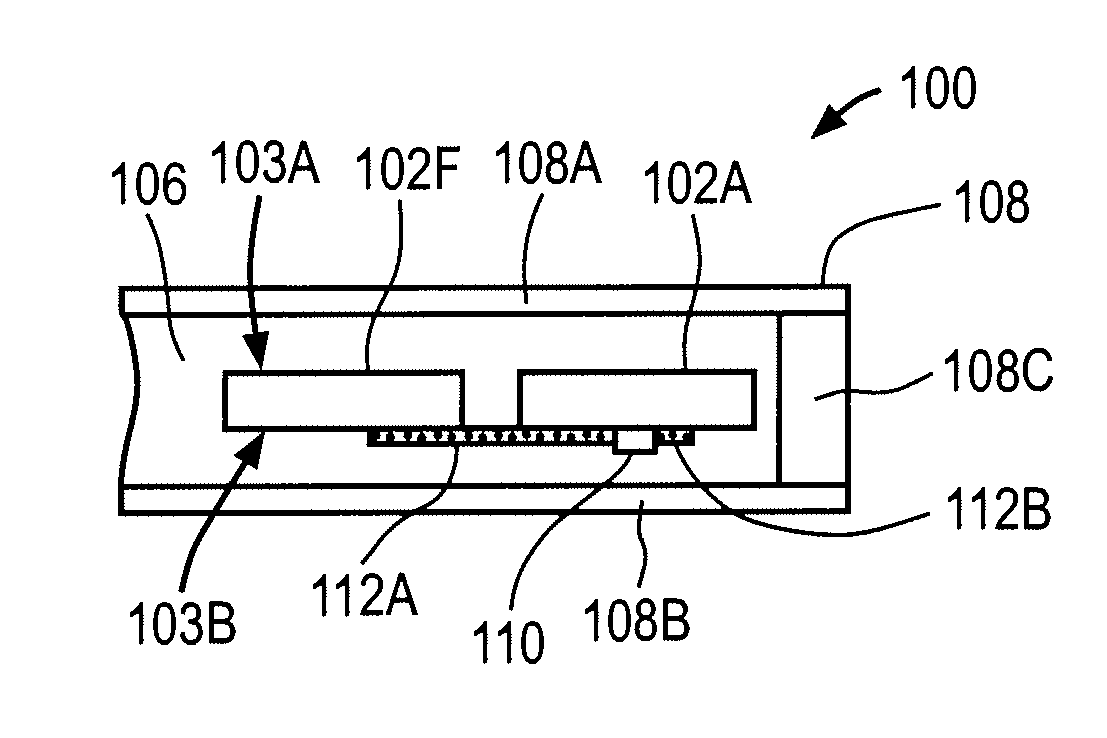

InactiveUS20100147364A1Reduce effective series resistance of devicePV power plantsSemiconductor/solid-state device manufacturingMetallic foilAmorphous silicon solar cell

Owner:SOLOPOWER

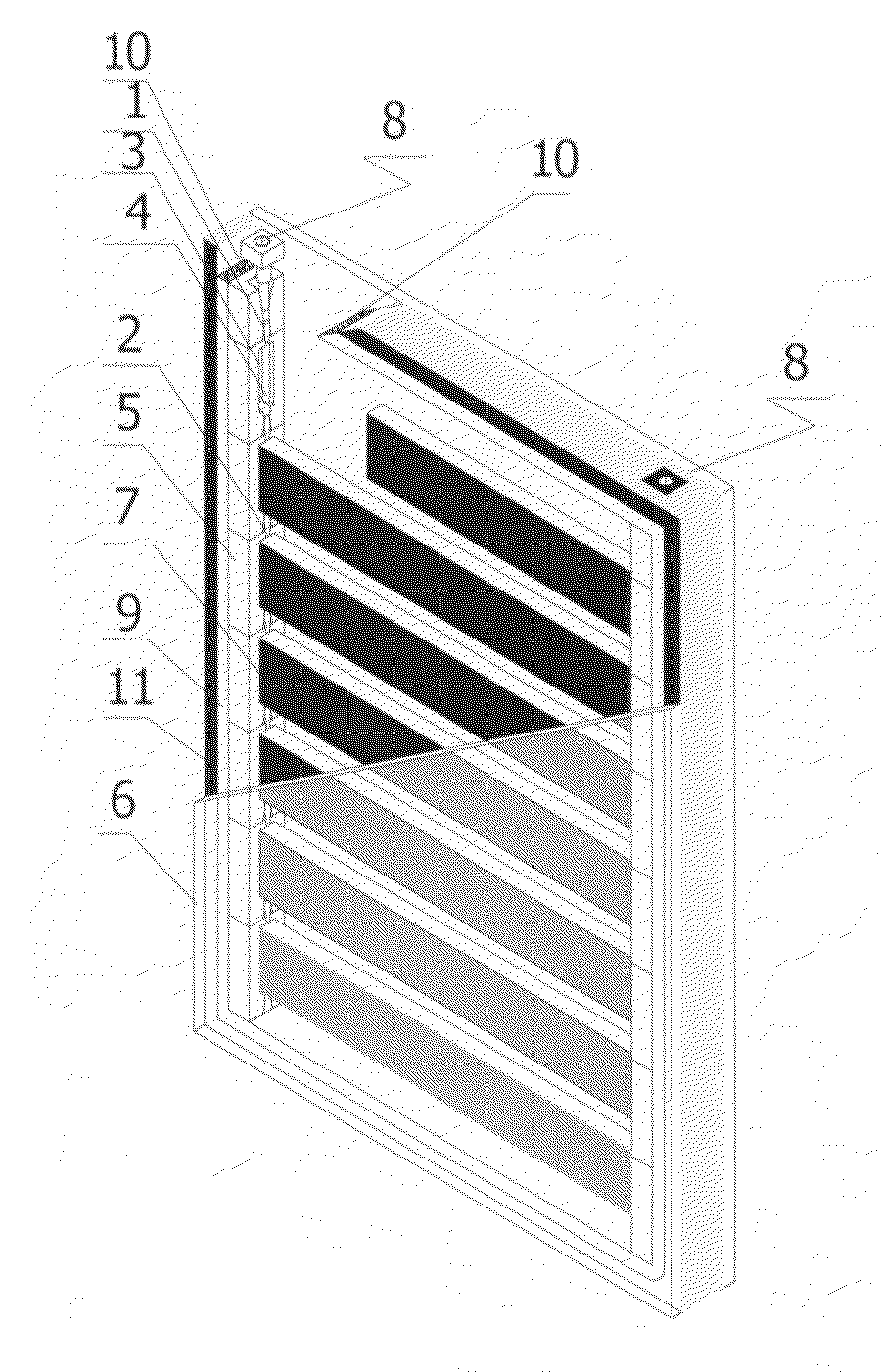

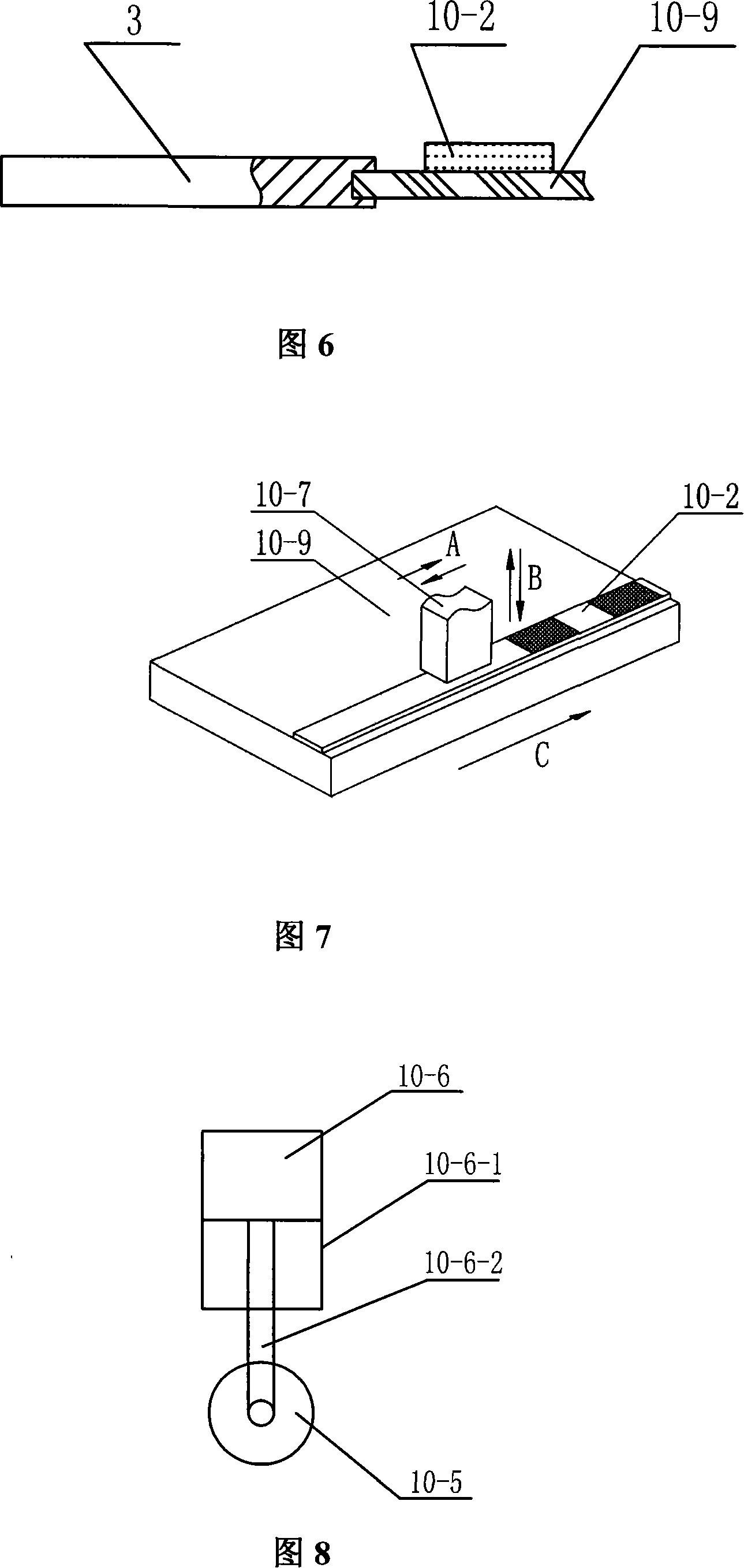

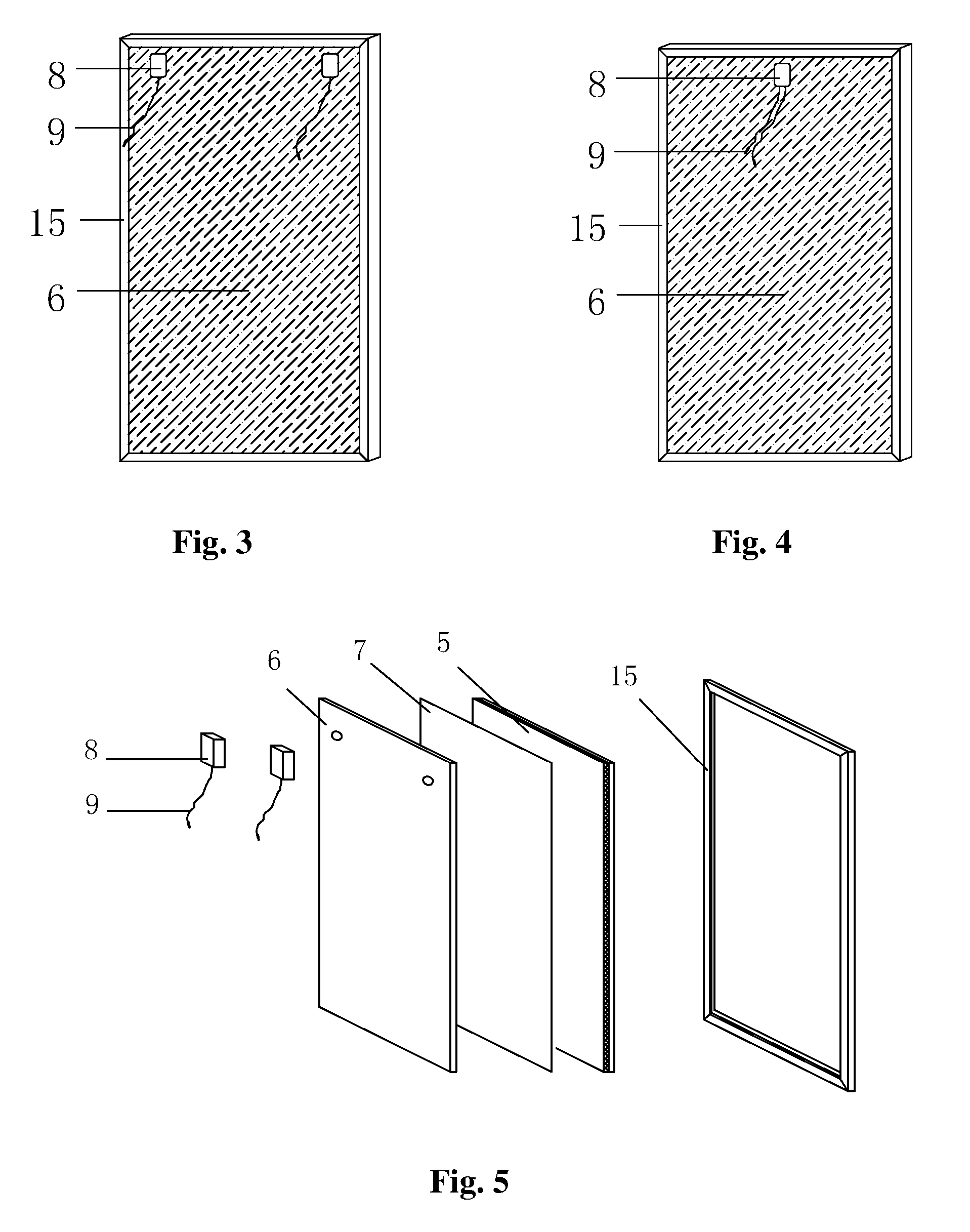

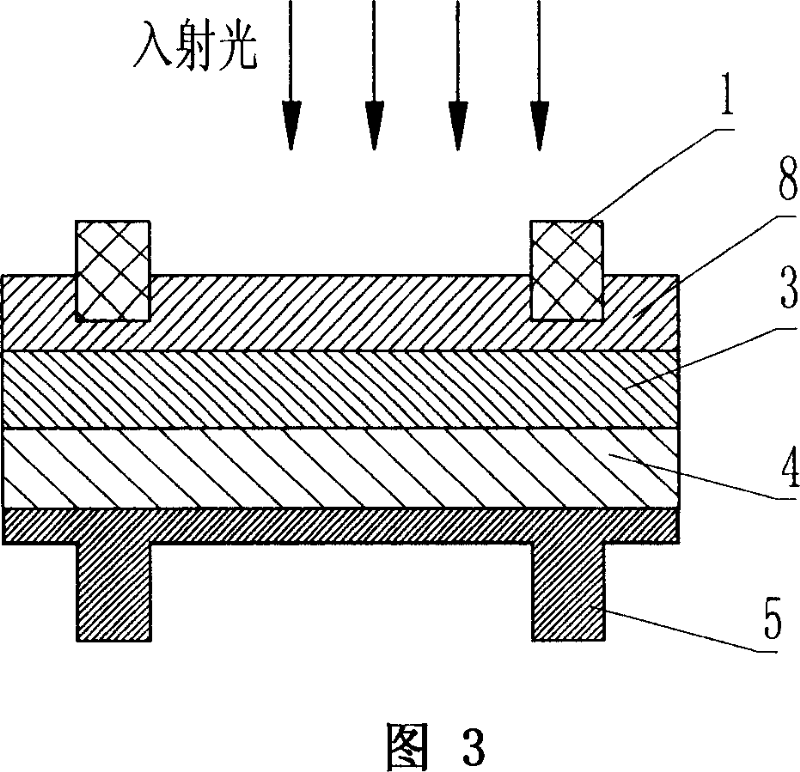

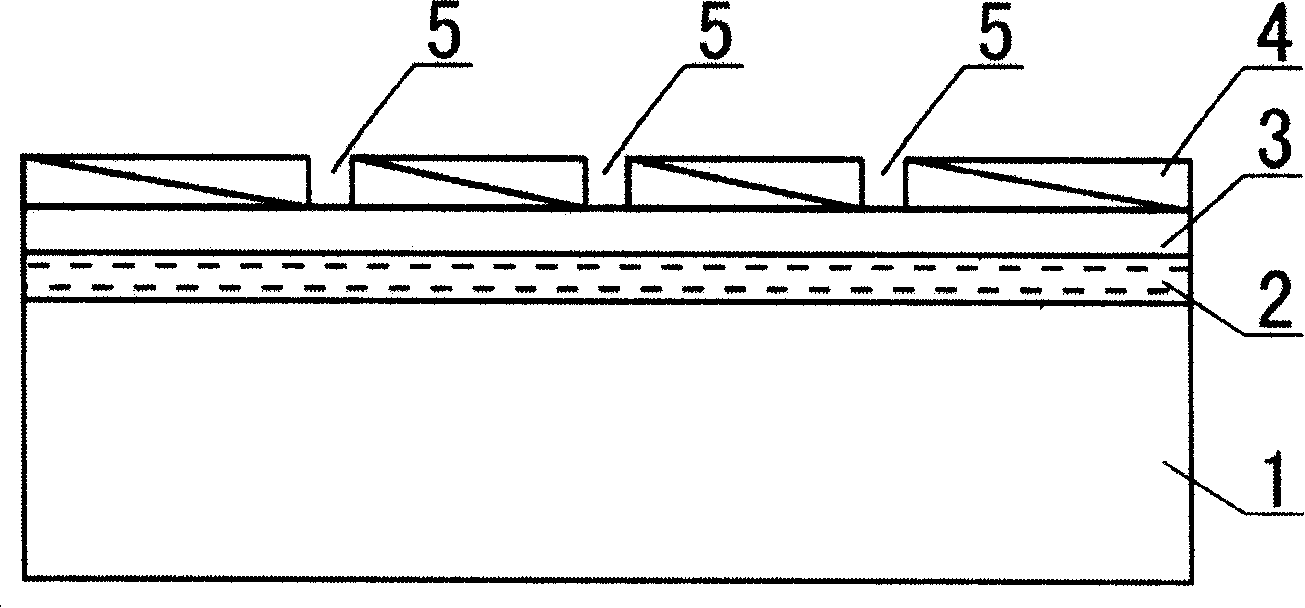

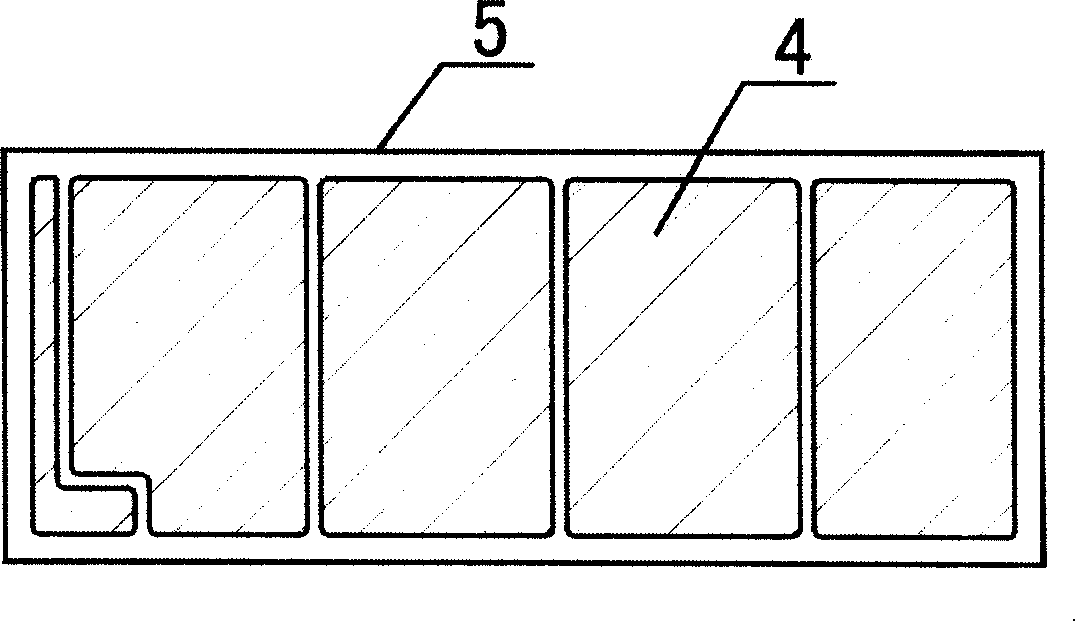

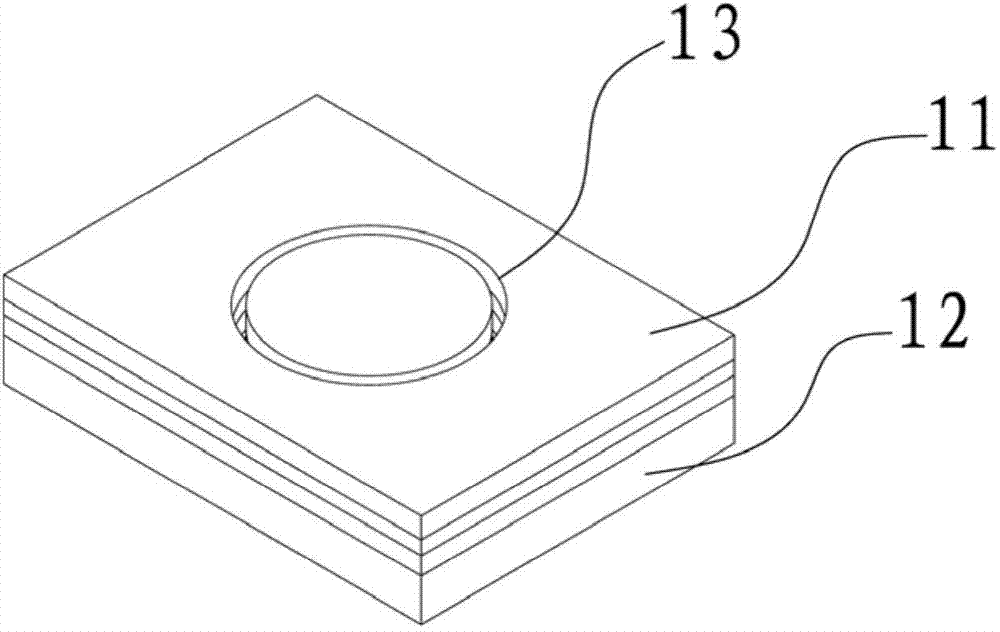

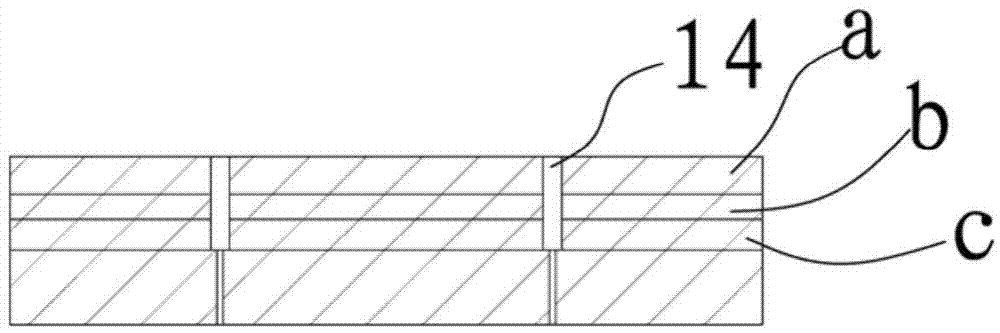

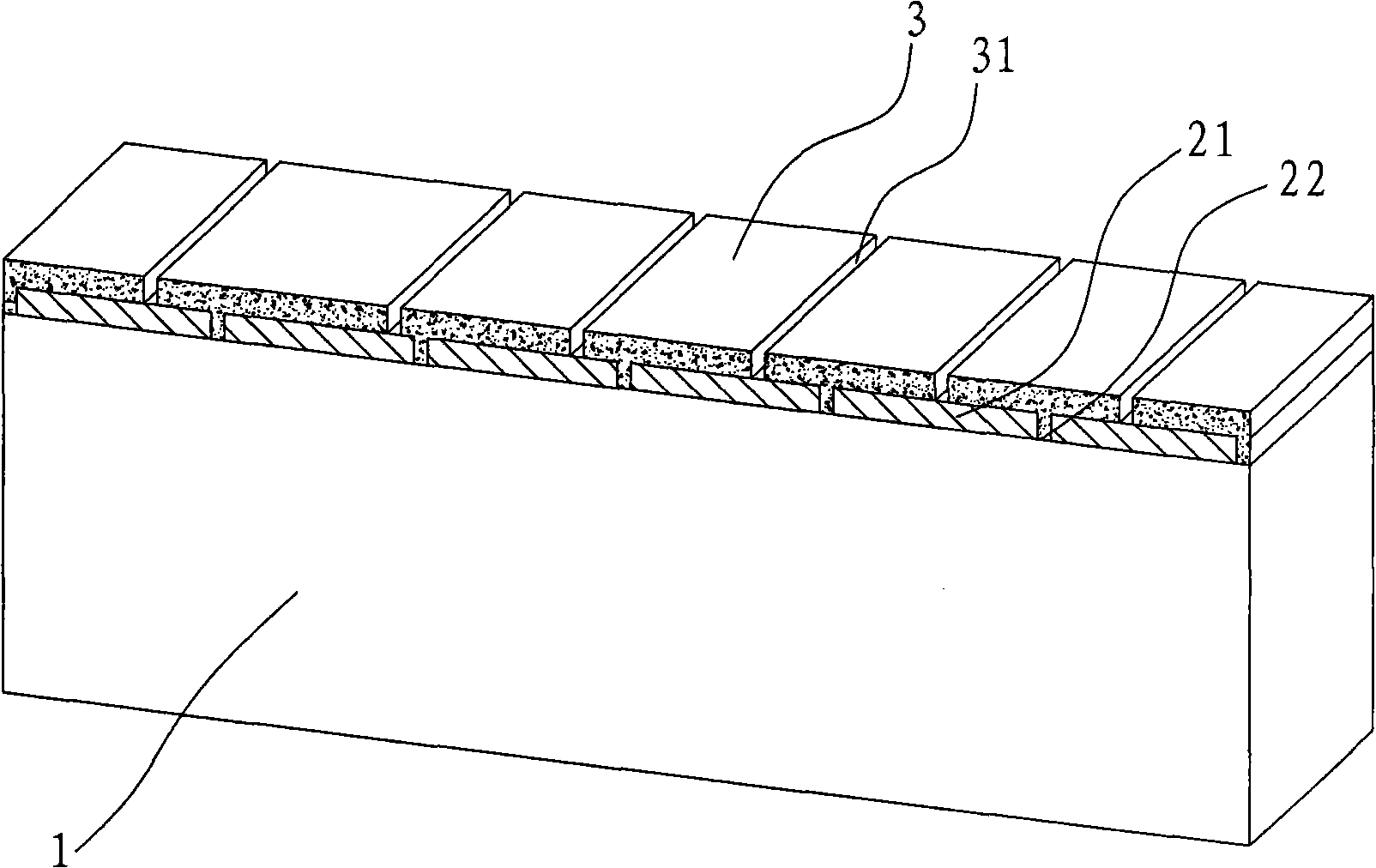

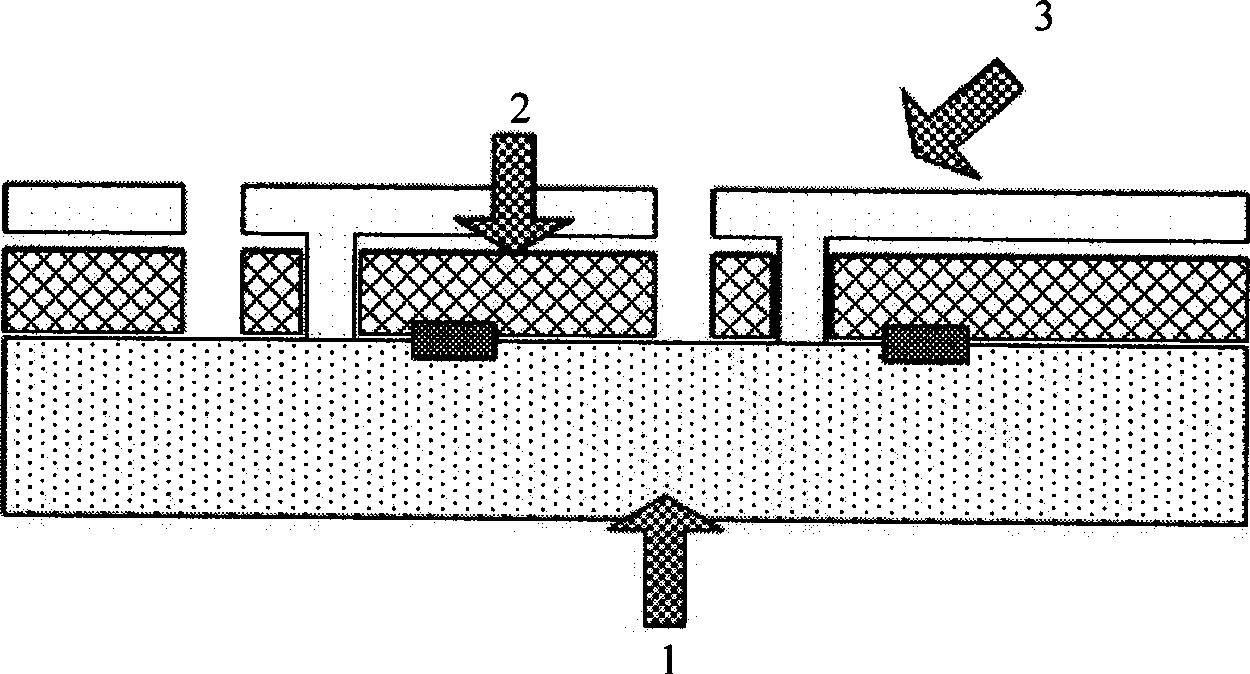

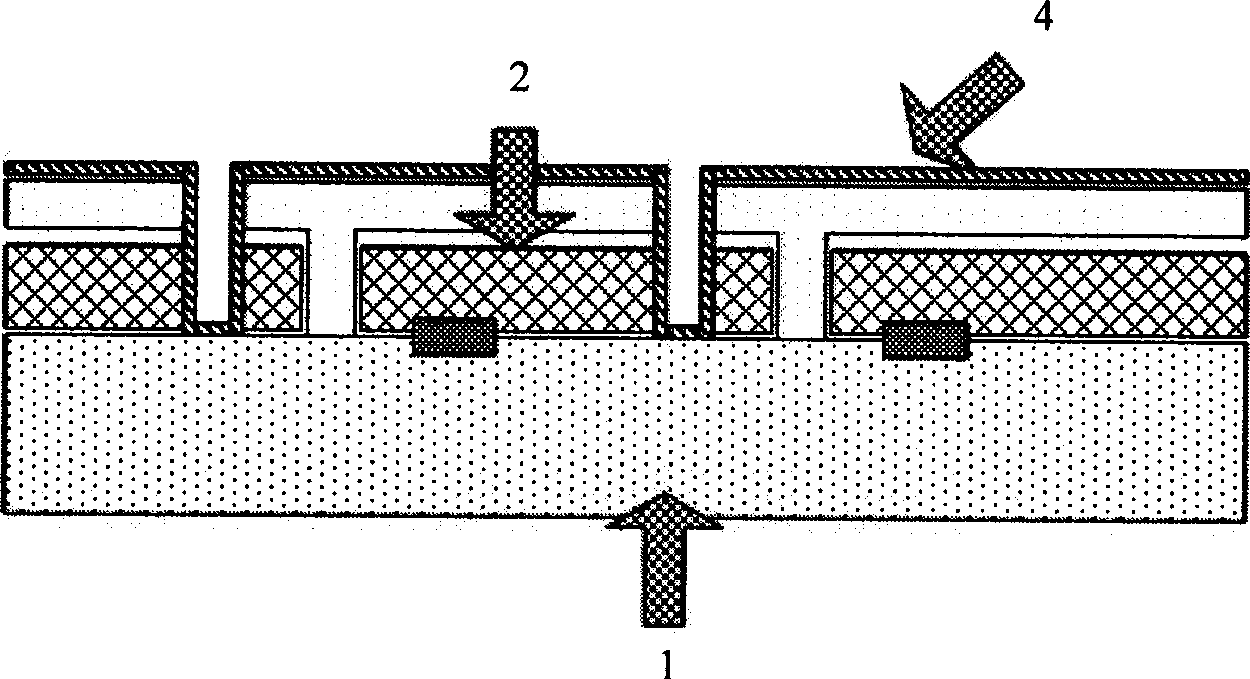

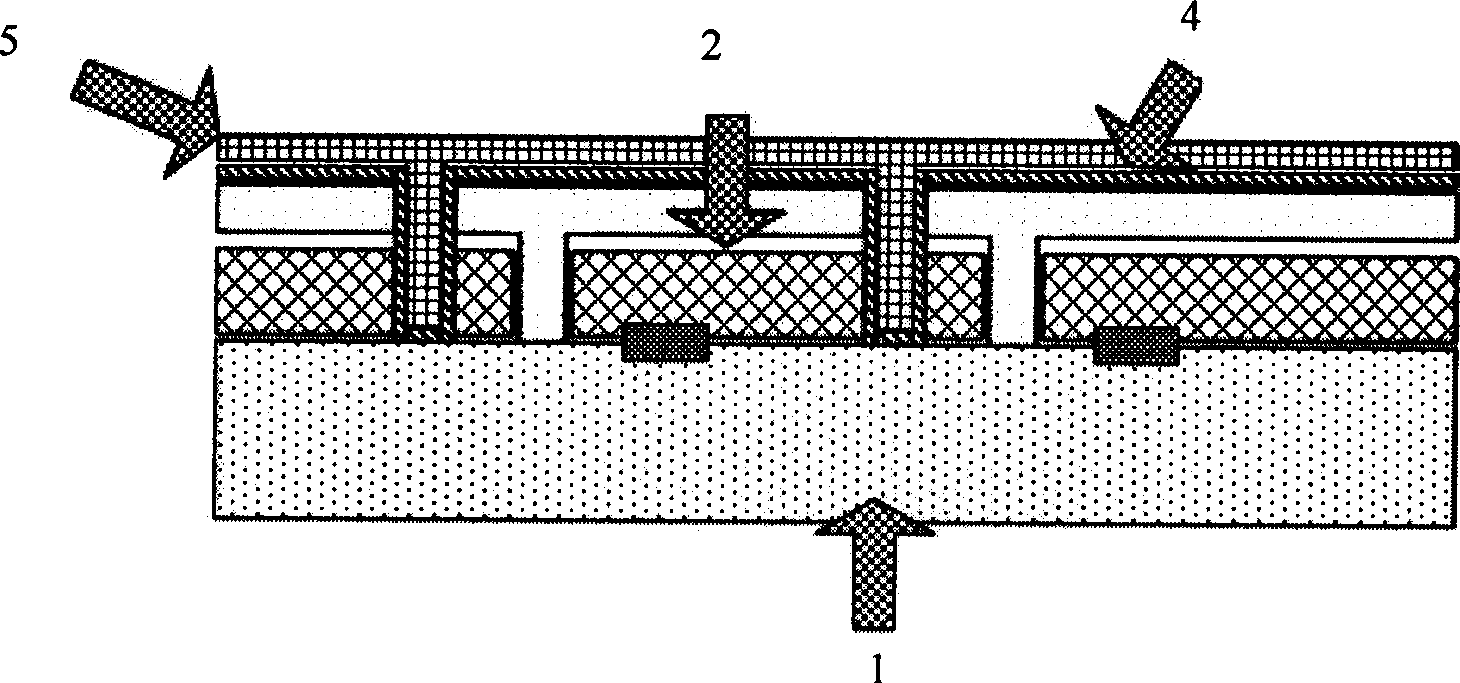

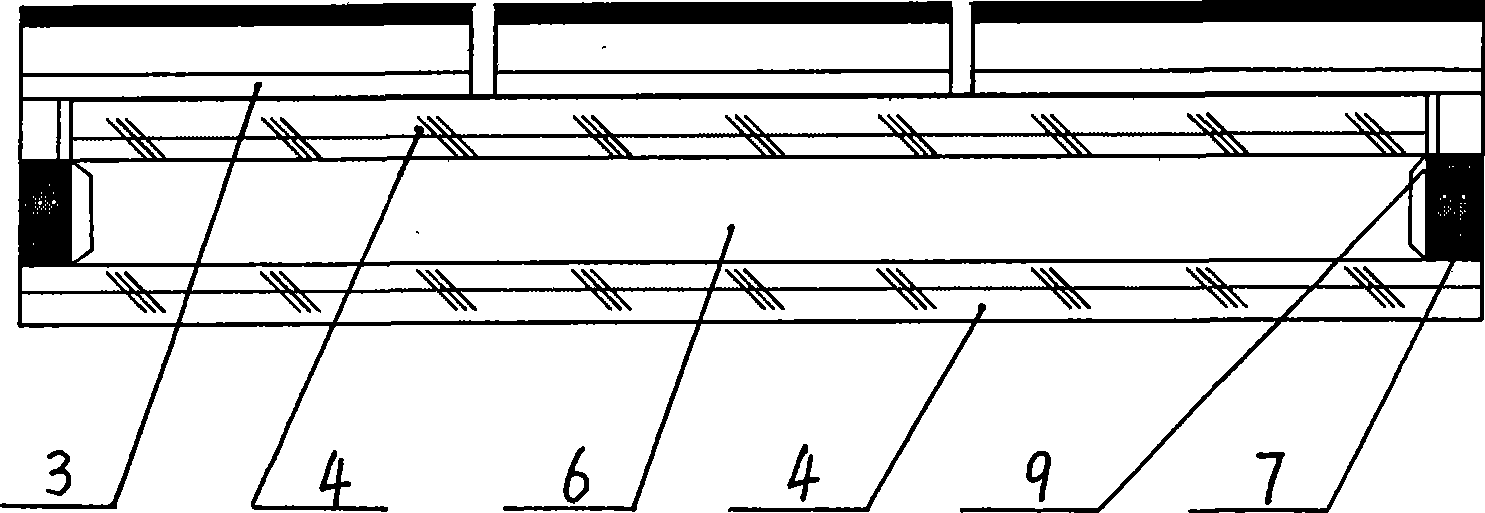

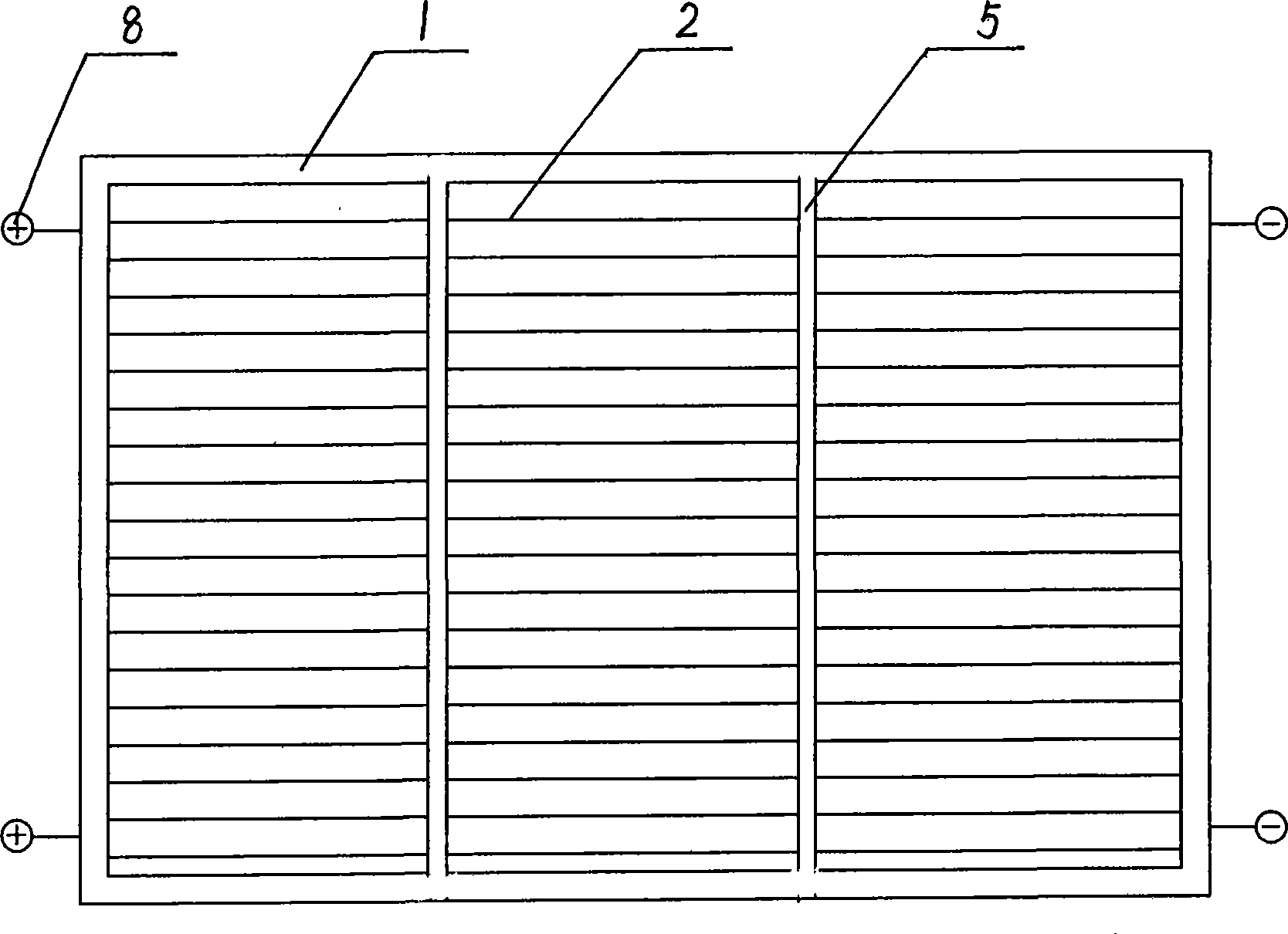

Integrated photovoltaic modular panel for a curtain wall glass

ActiveUS20080163918A1Easy to modifySuitable for mass productionWallsPV power plantsPlastic injection moldingAmorphous silicon solar cell

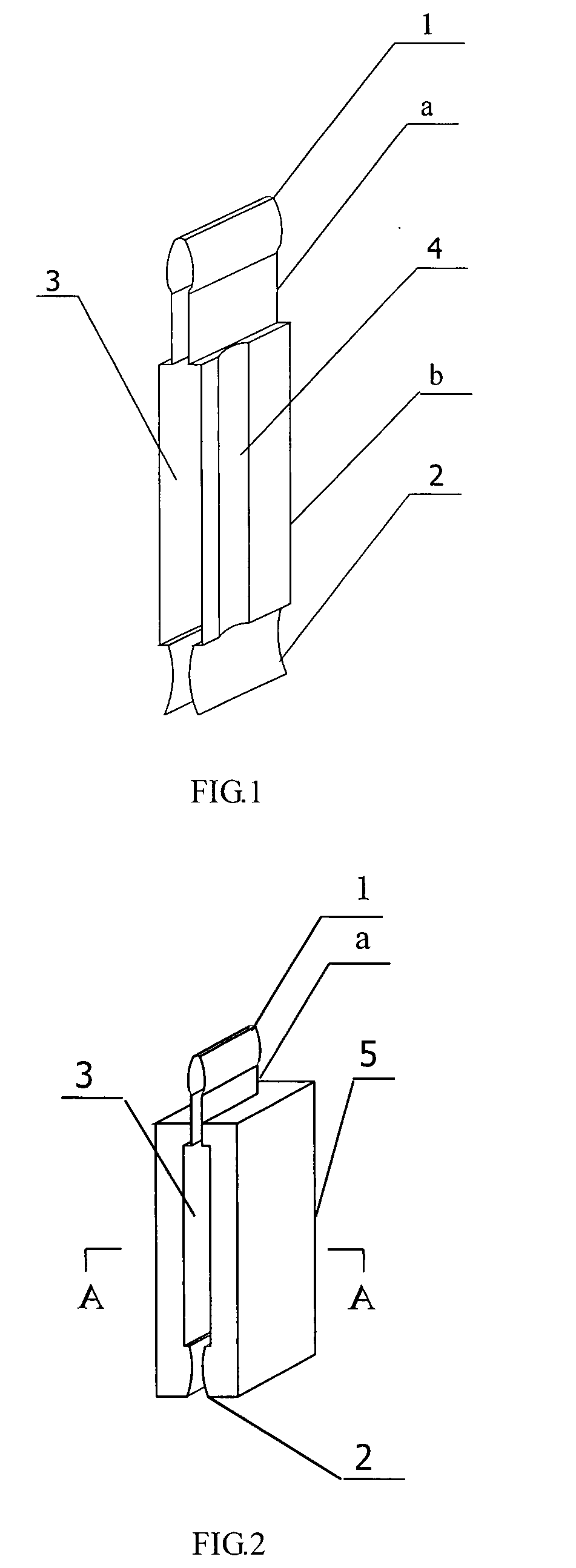

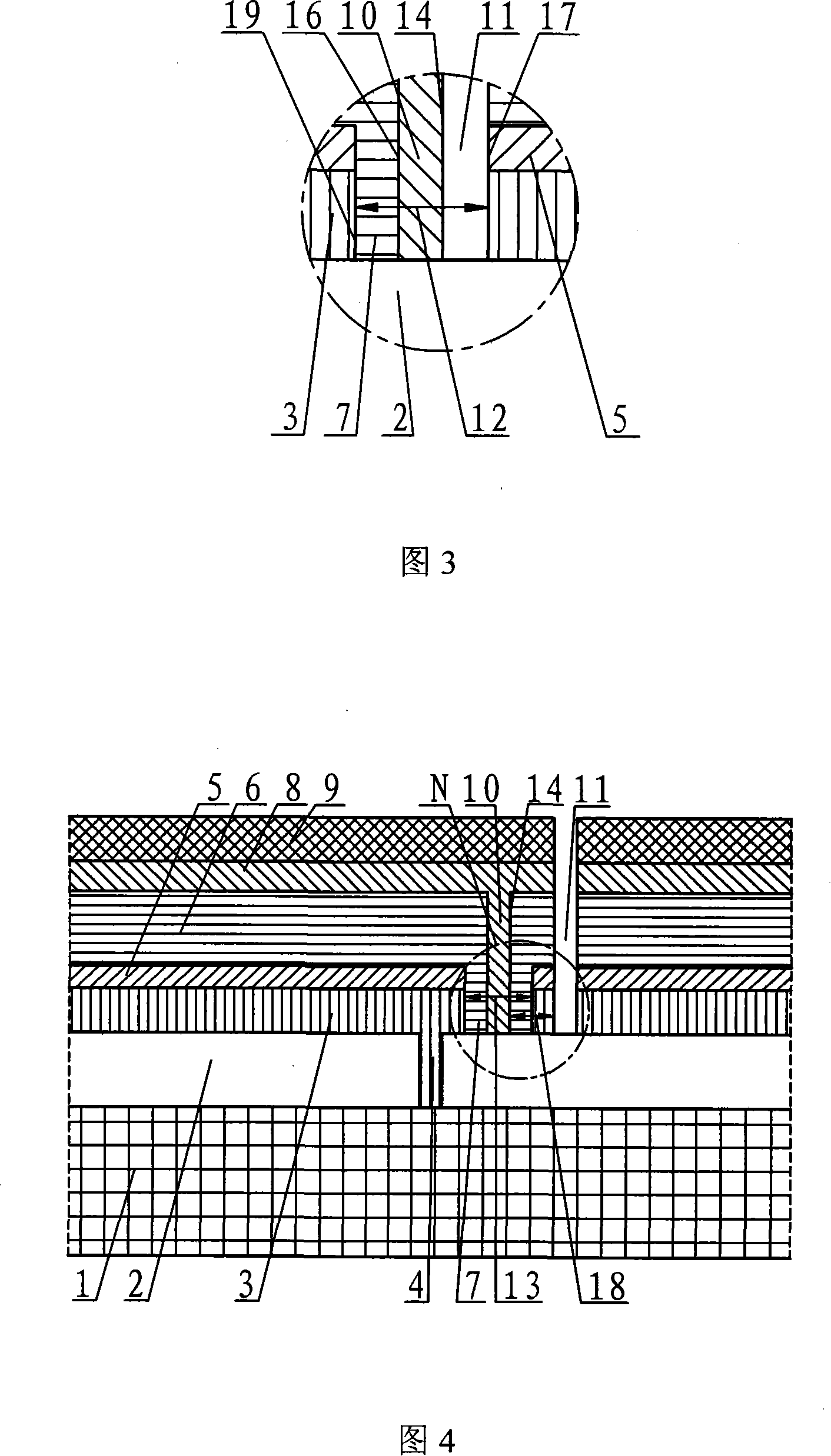

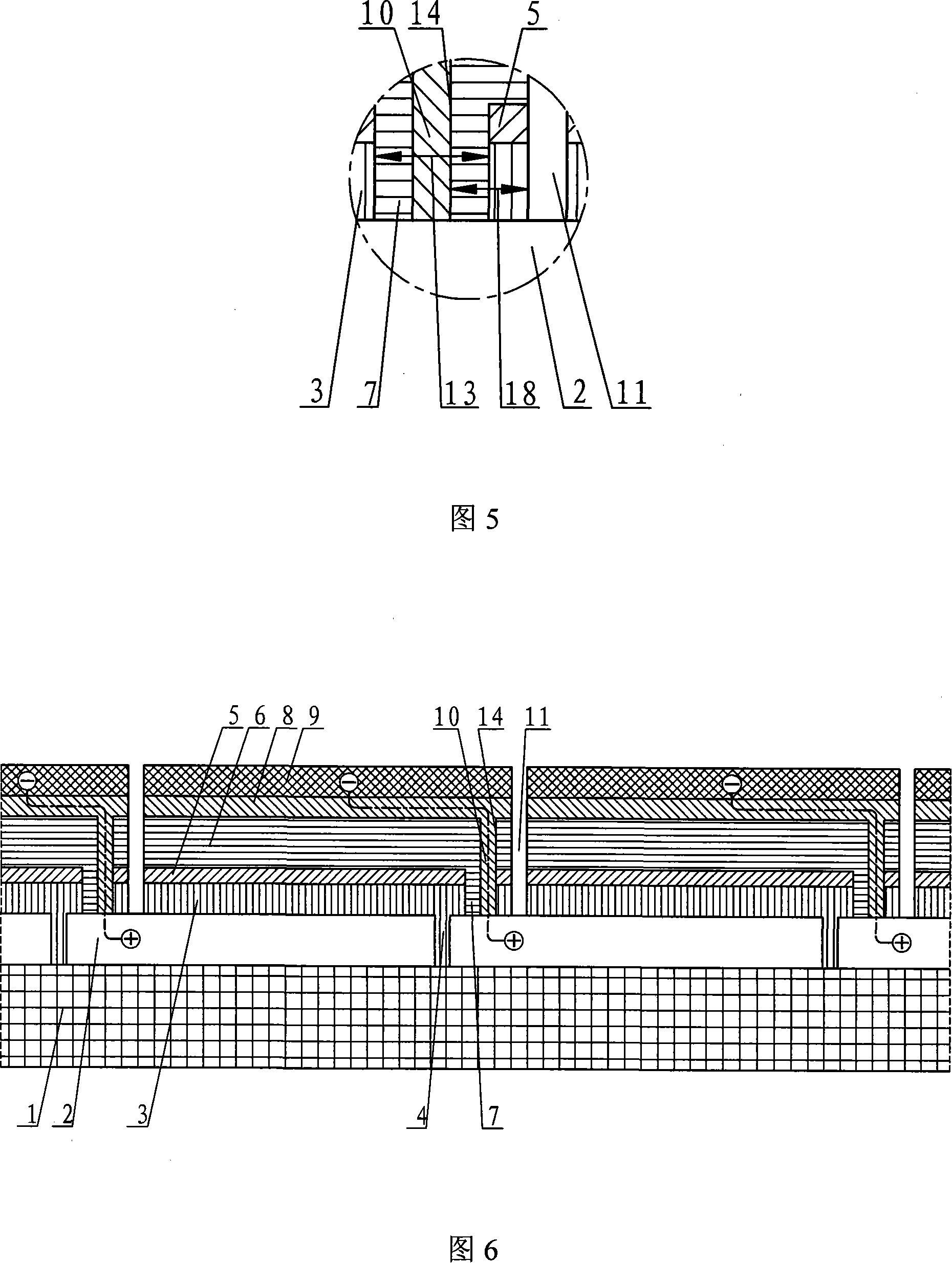

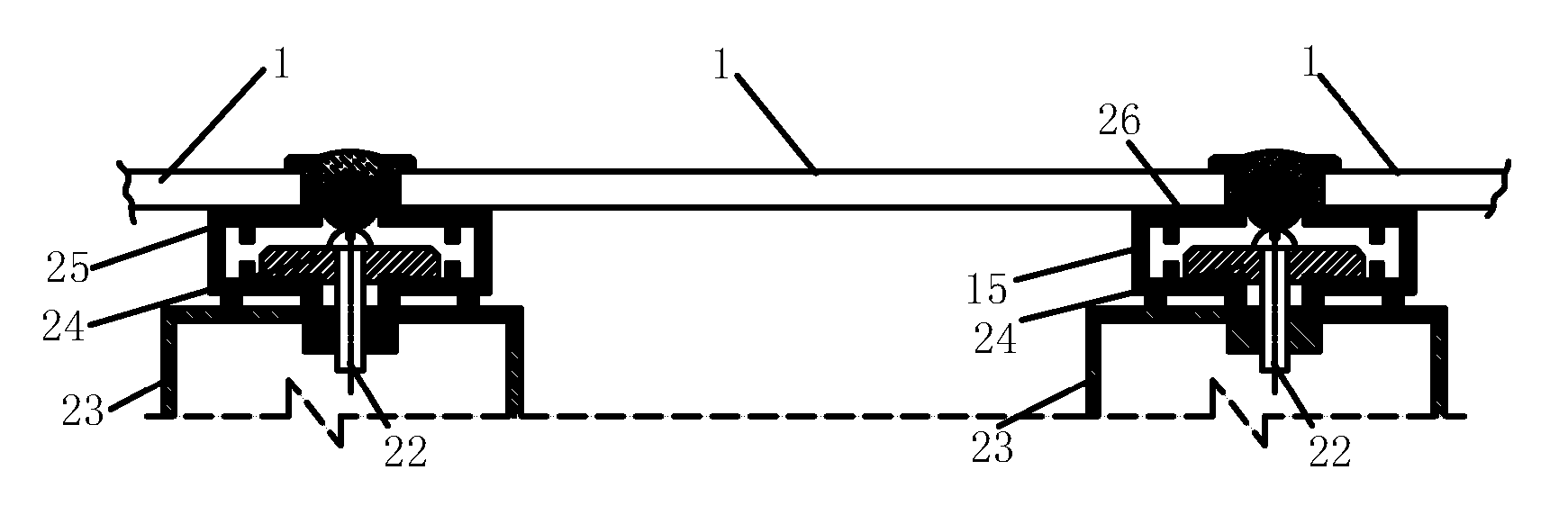

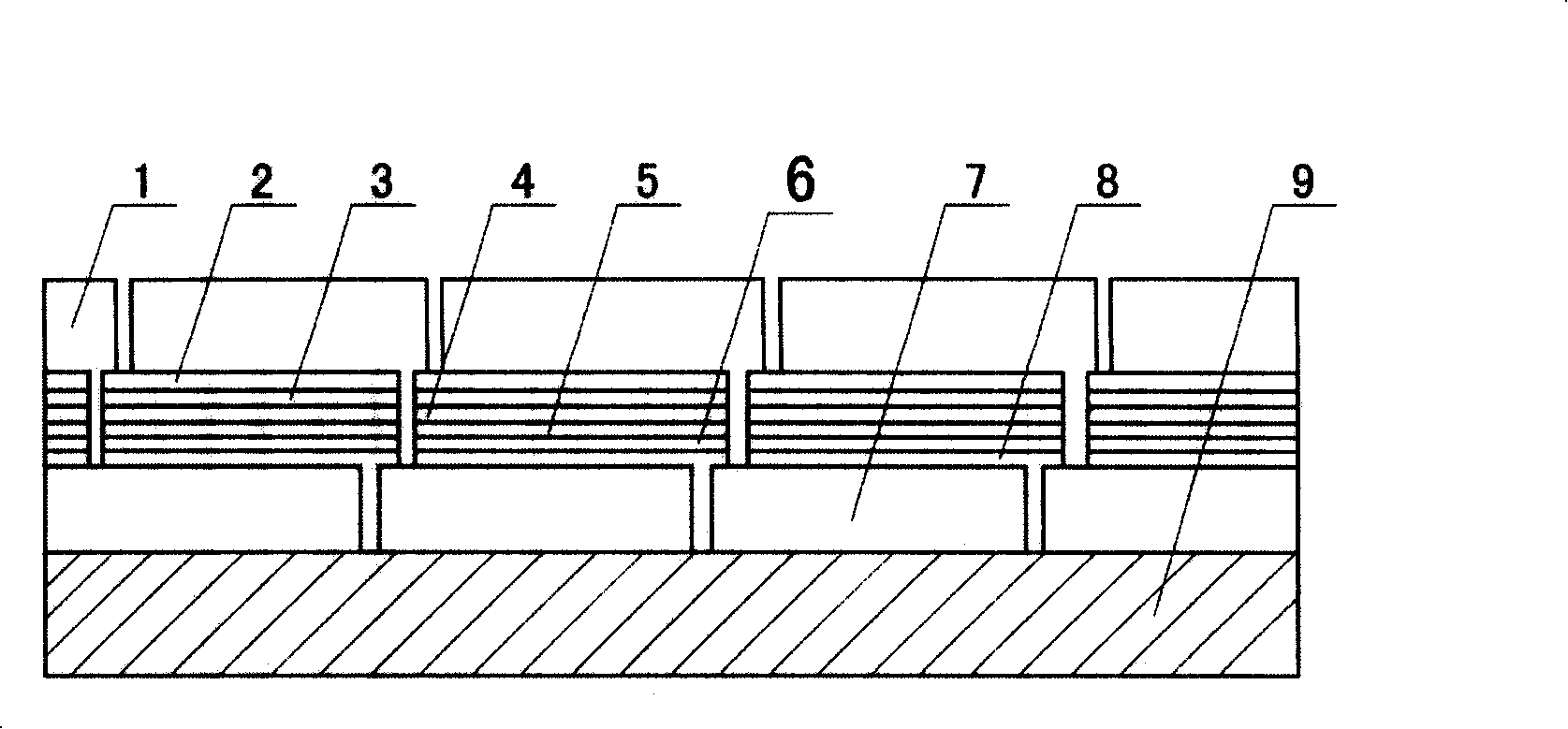

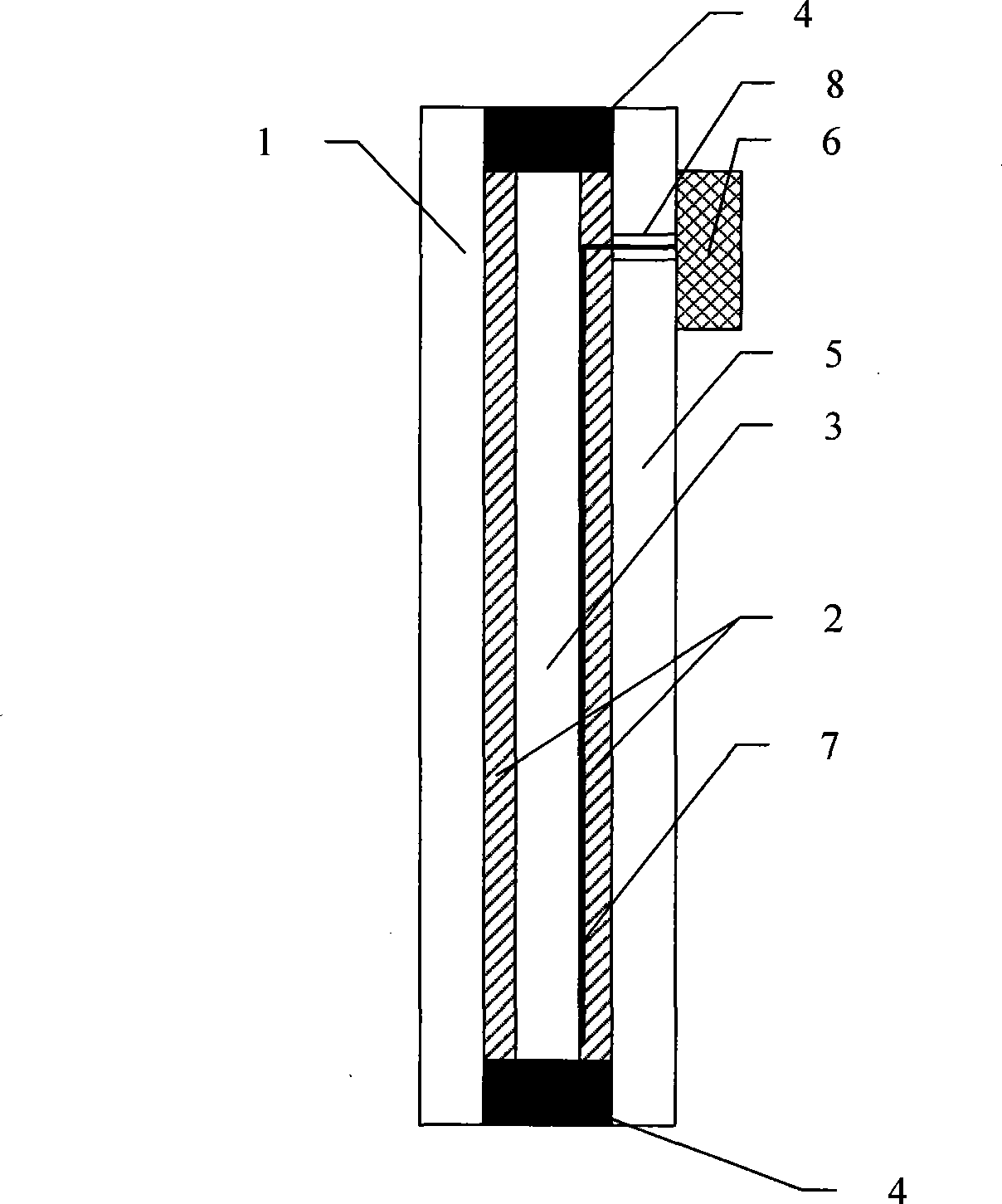

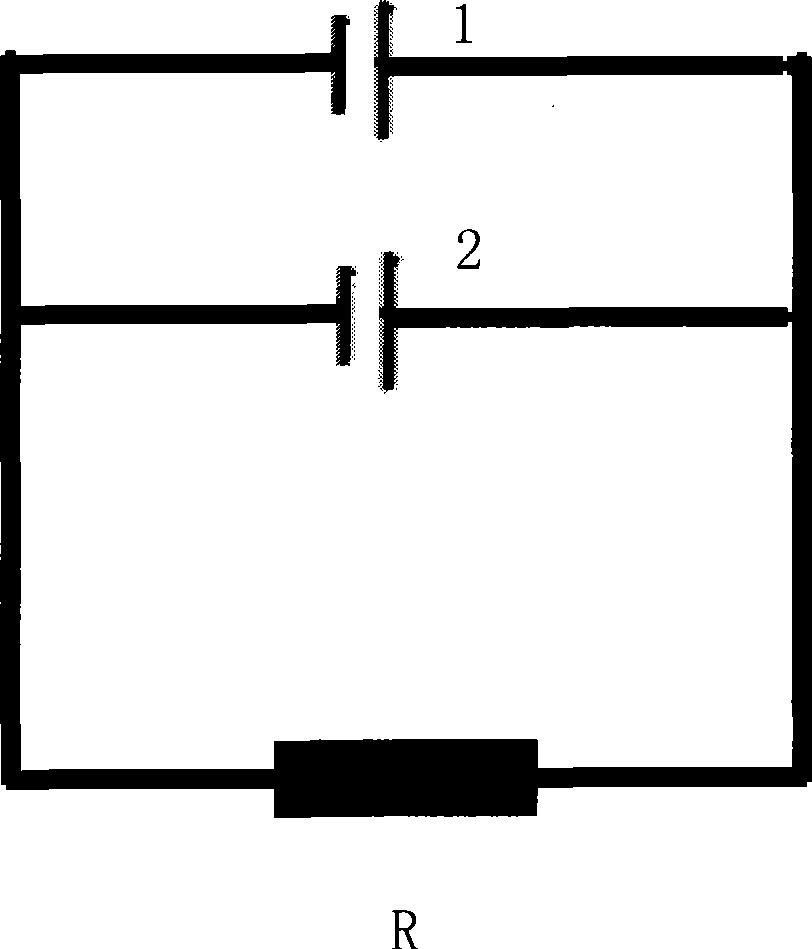

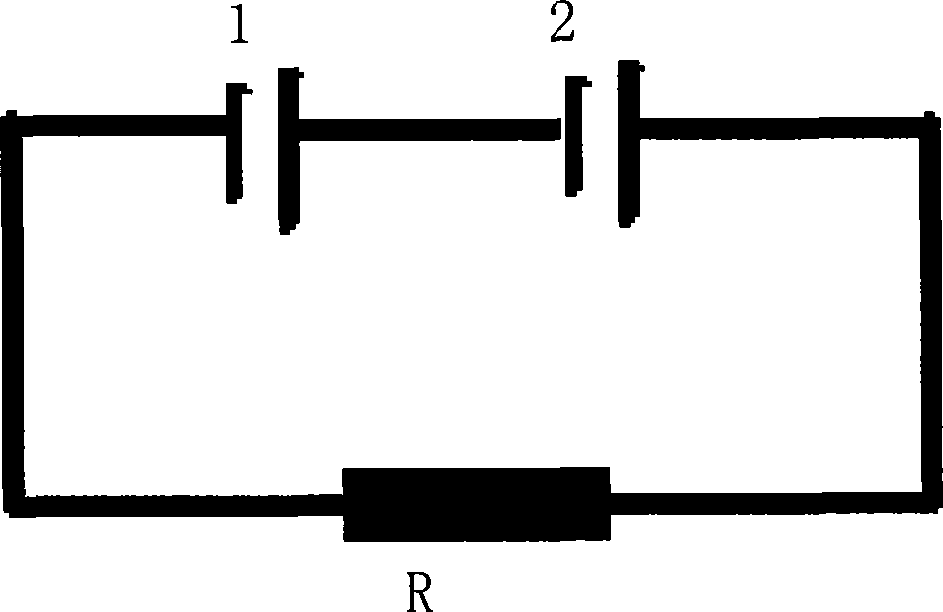

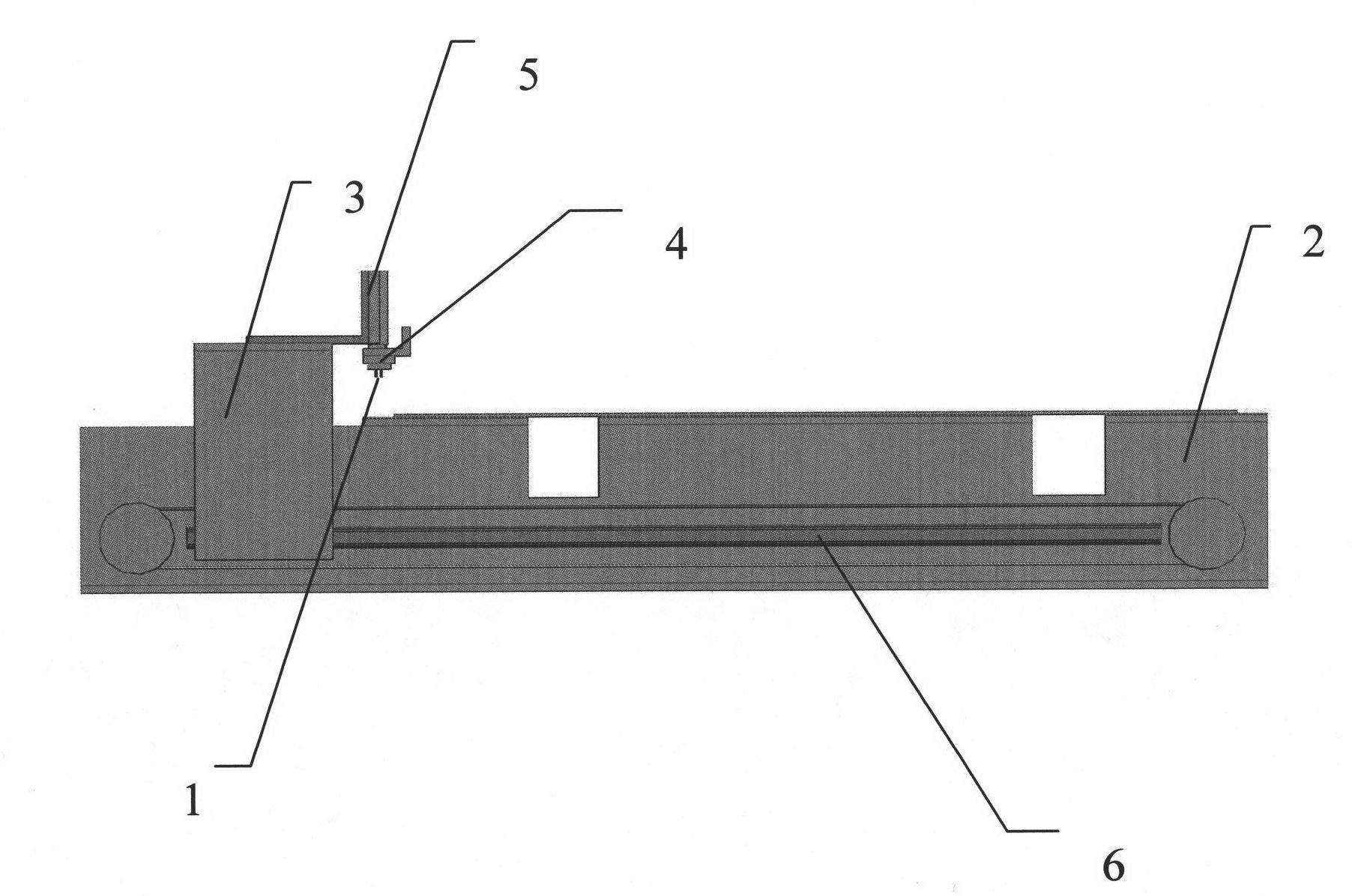

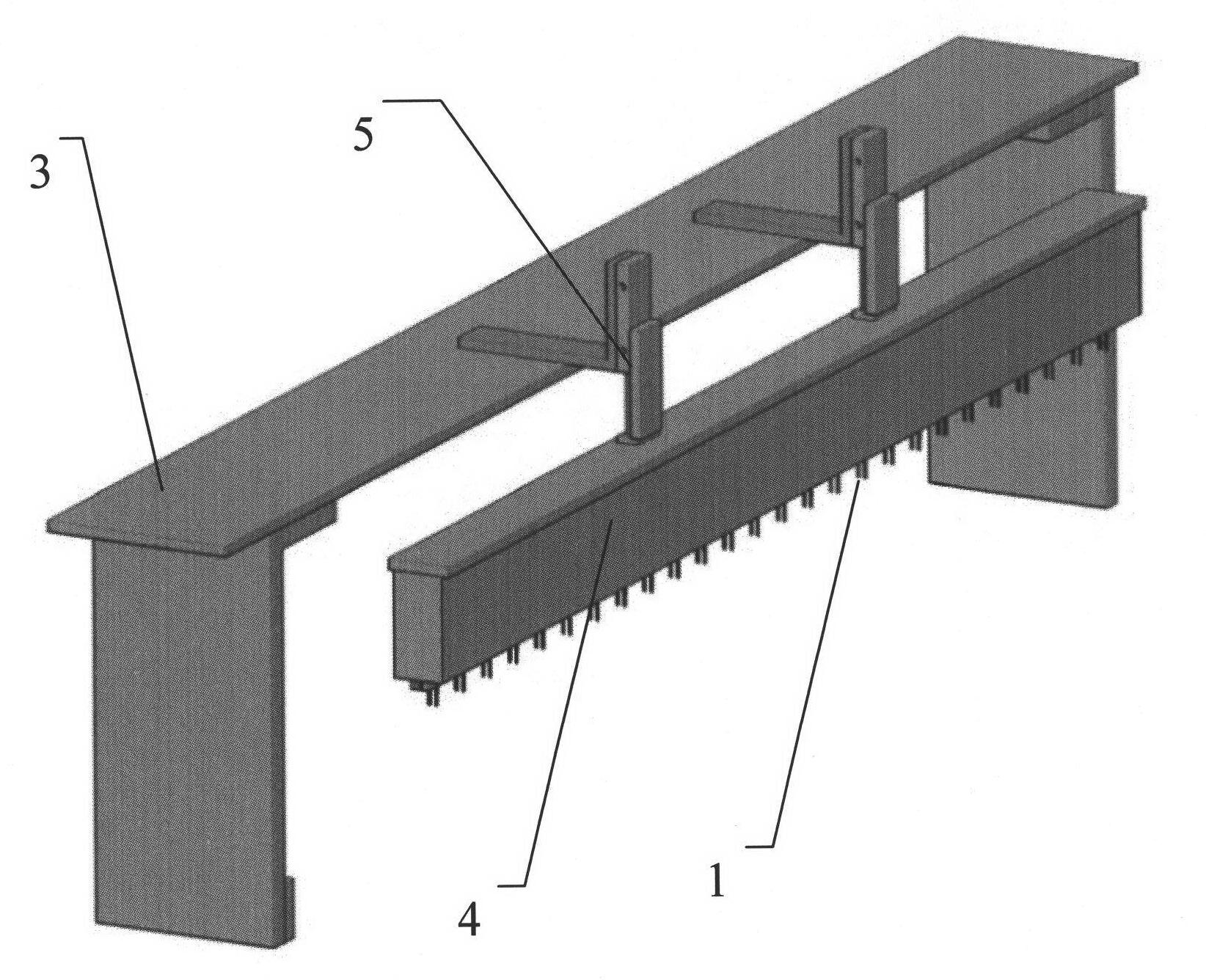

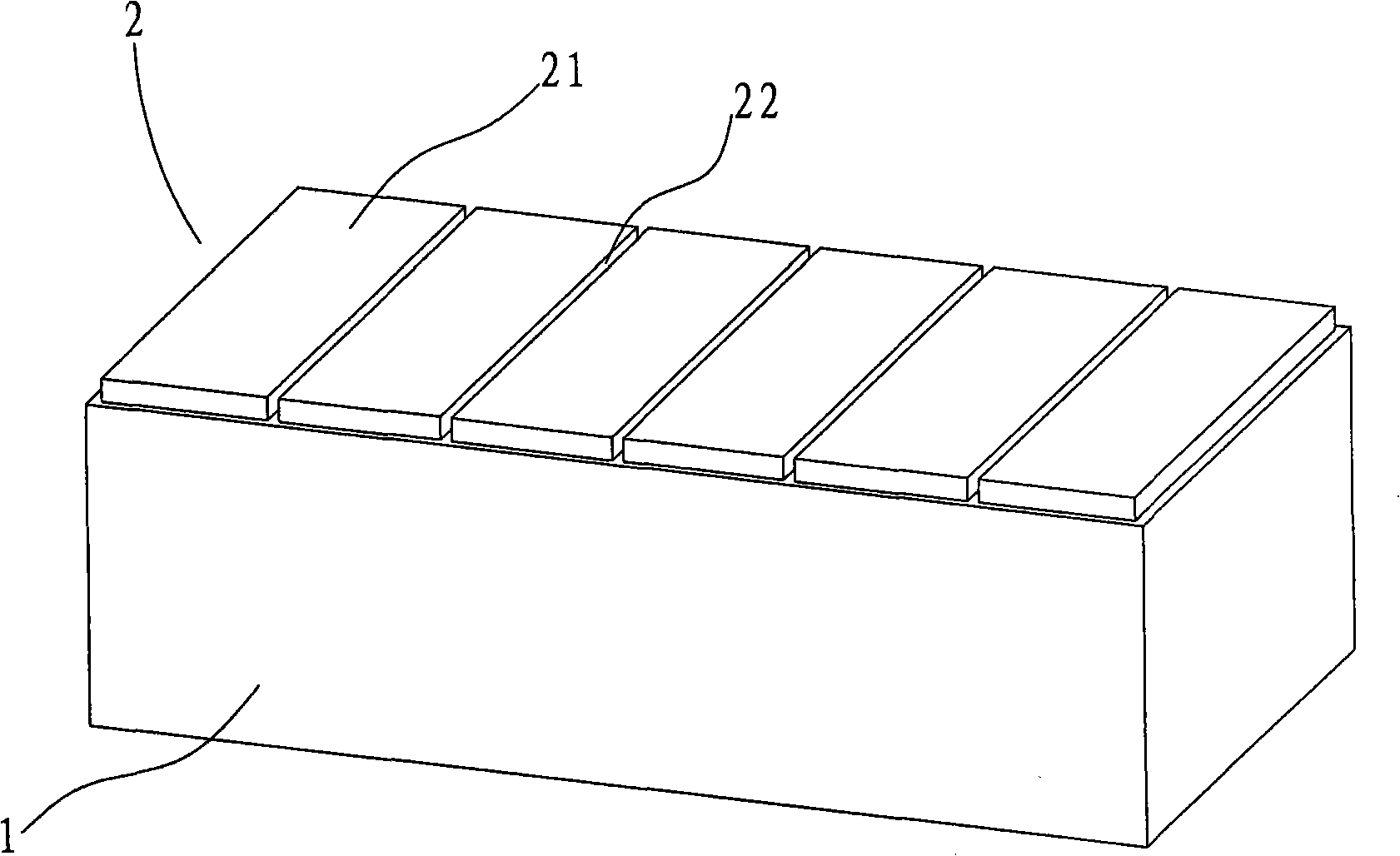

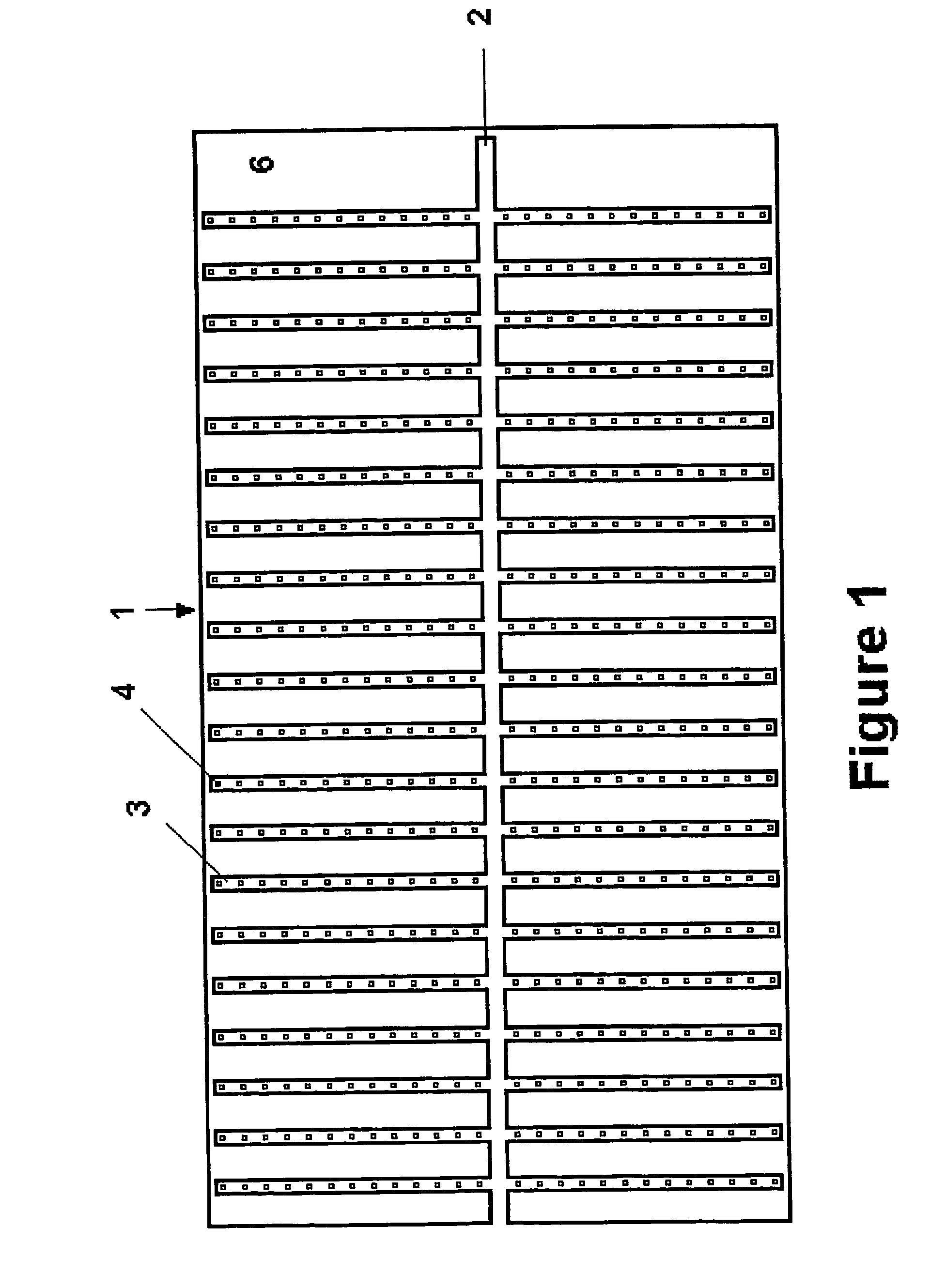

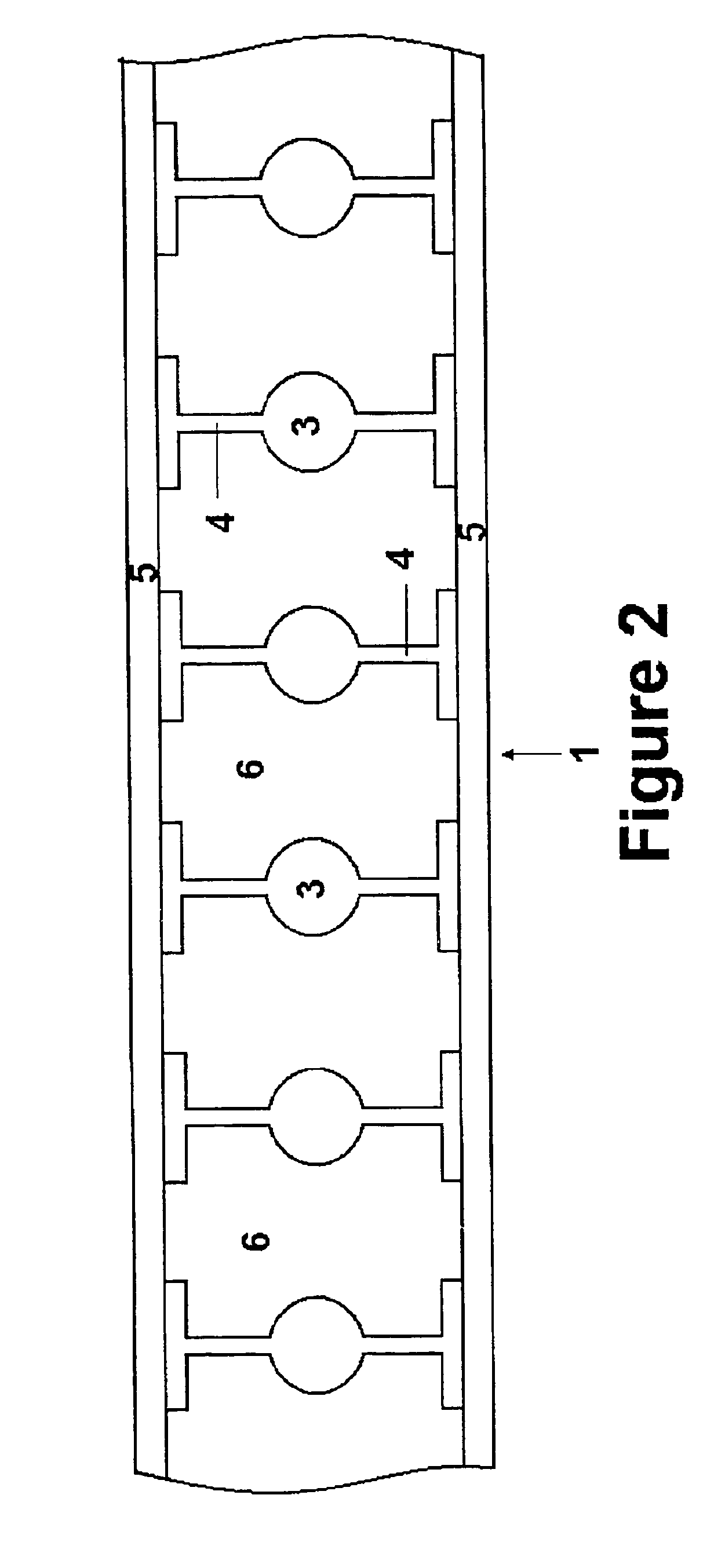

An integrated photovoltaic modular panel for a curtain wall glass is used for the field of building integrated photovoltaic. The invention provides the standardized photovoltaic units, so that the electrodes in a photovoltaic panel main body can be internally parallel connected. The connector may be a metal piece of stamping or casting, which has a plug 1 and a socket 2 on both ends, a waist b in the middle, an inward concave straight strip 4 on both sides of the waist, an electrode plug-in socket 3 in the waist for firmly clamping solar cell, a plastic injection molding crust 5 for fixing and securing the connector, forming a module. It can combine with different kinds of glass, forming different kinds of photovoltaic curtain wall glass. The solar cell here may be an amorphous silicon solar cell.

Owner:LI YI

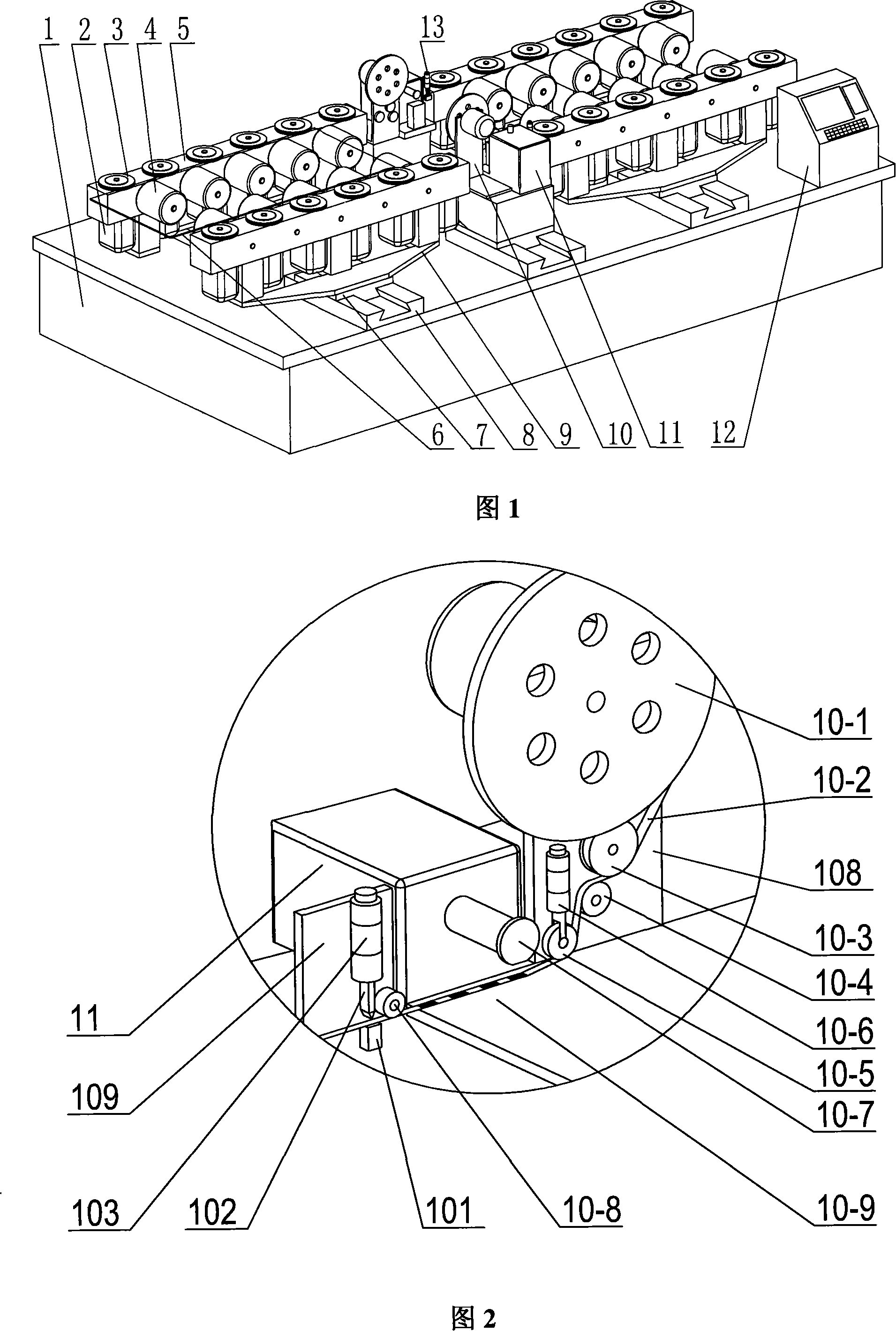

Novel apparatus used for film engraving and dotting of thin-film solar cell

InactiveCN101431126AReach deflectionImprove consistencyFinal product manufactureLaser beam welding apparatusEngravingHigh volume manufacturing

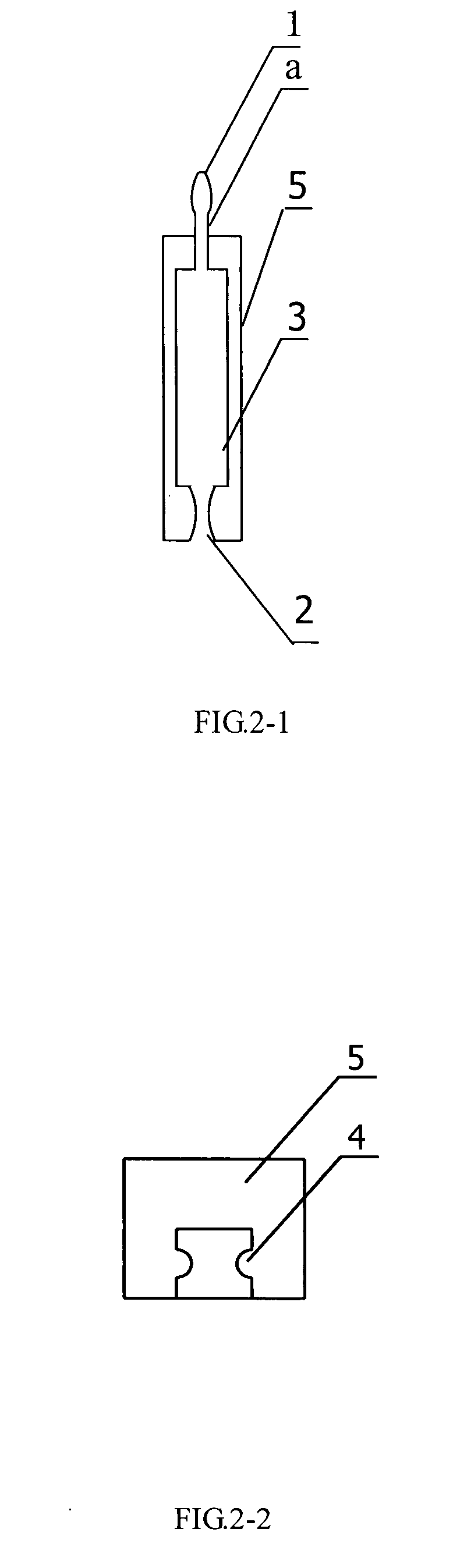

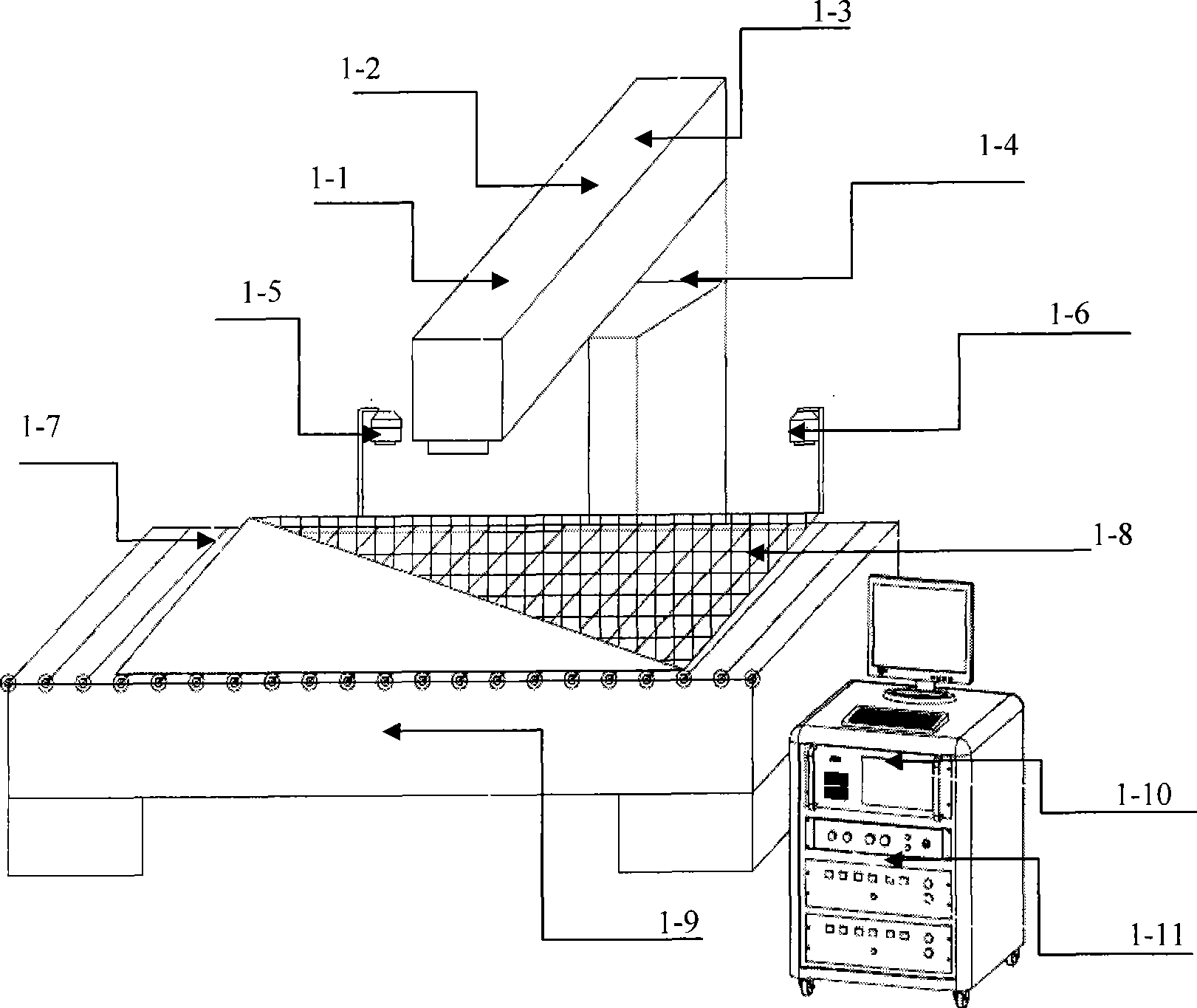

The invention relates to a new device used for scribing and pointing of a thin film solar cell. The device comprises a laser, a support pedestal, an automatic focusing control subsystem, an automatic photographing positioning subsystem, an optical platform, an industrial control computer, a power supply and a dynamic galvanometric scanning subsystem. The device is characterized in that a feeding mechanism is arranged on the optical platform, wherein, the support pedestal, the automatic focusing control subsystem and the automatic photographing positioning subsystem are arranged on one side surface of the optical platform. An X-Y-axis galvanometric scanning unit, a Z-axis front focusing unit and the laser are arranged in a beam of the support pedestal. The industrial control computer is respectively connected with the laser, the X-Y-axis galvanometric scanning unit, the Z-axis front focusing unit and the power supply by cables. The invention has the advantages of simple structure, standard process, low production cost, easy mass production, wide scanning range, small focusing spot, good consistency, automatic and accurate positioning, high working efficiency, and the like, thereby being capable of being widely applied in scribing, pointing and other production fields of amorphous silicon solar cells.

Owner:WUHAN LINGYUN PHOTOELECTRONICS SYST

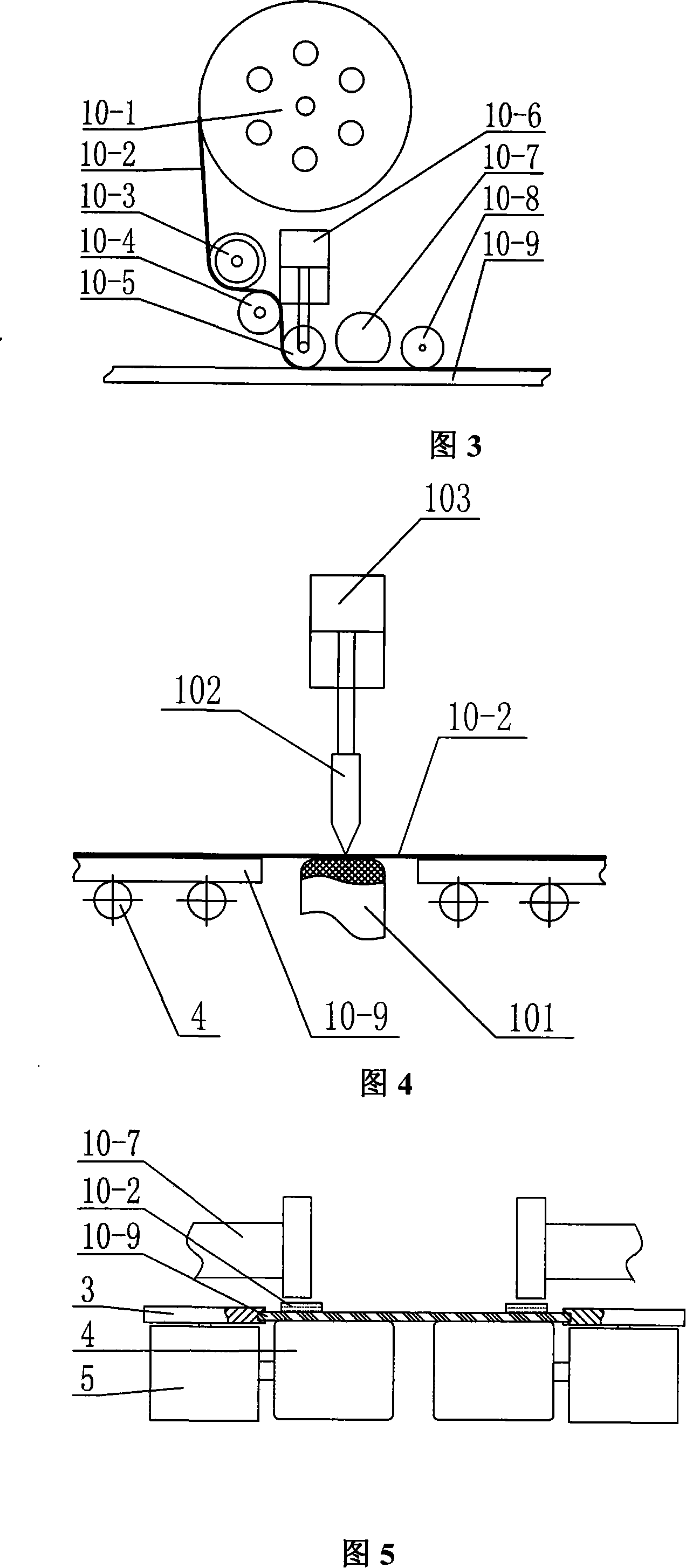

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

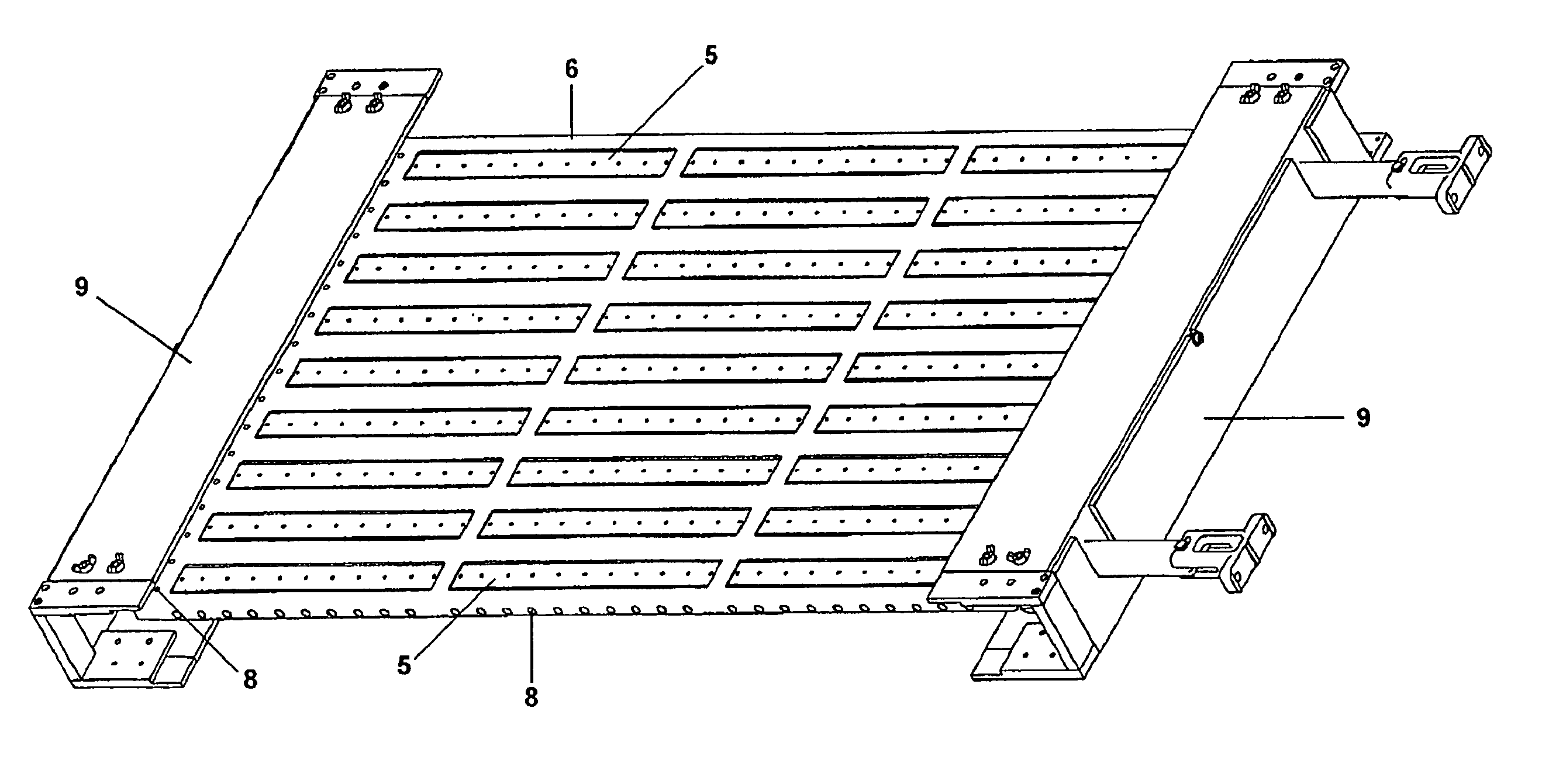

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

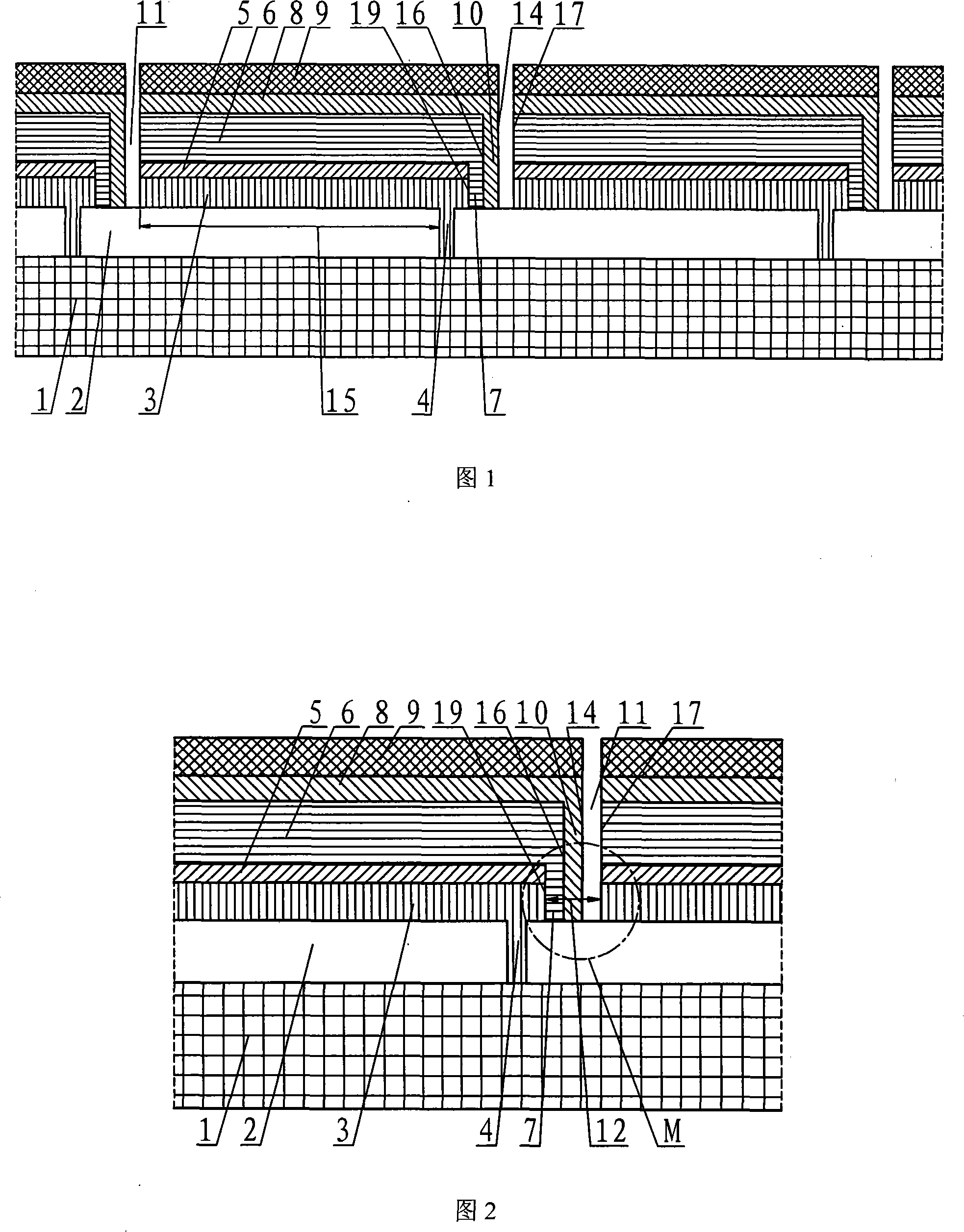

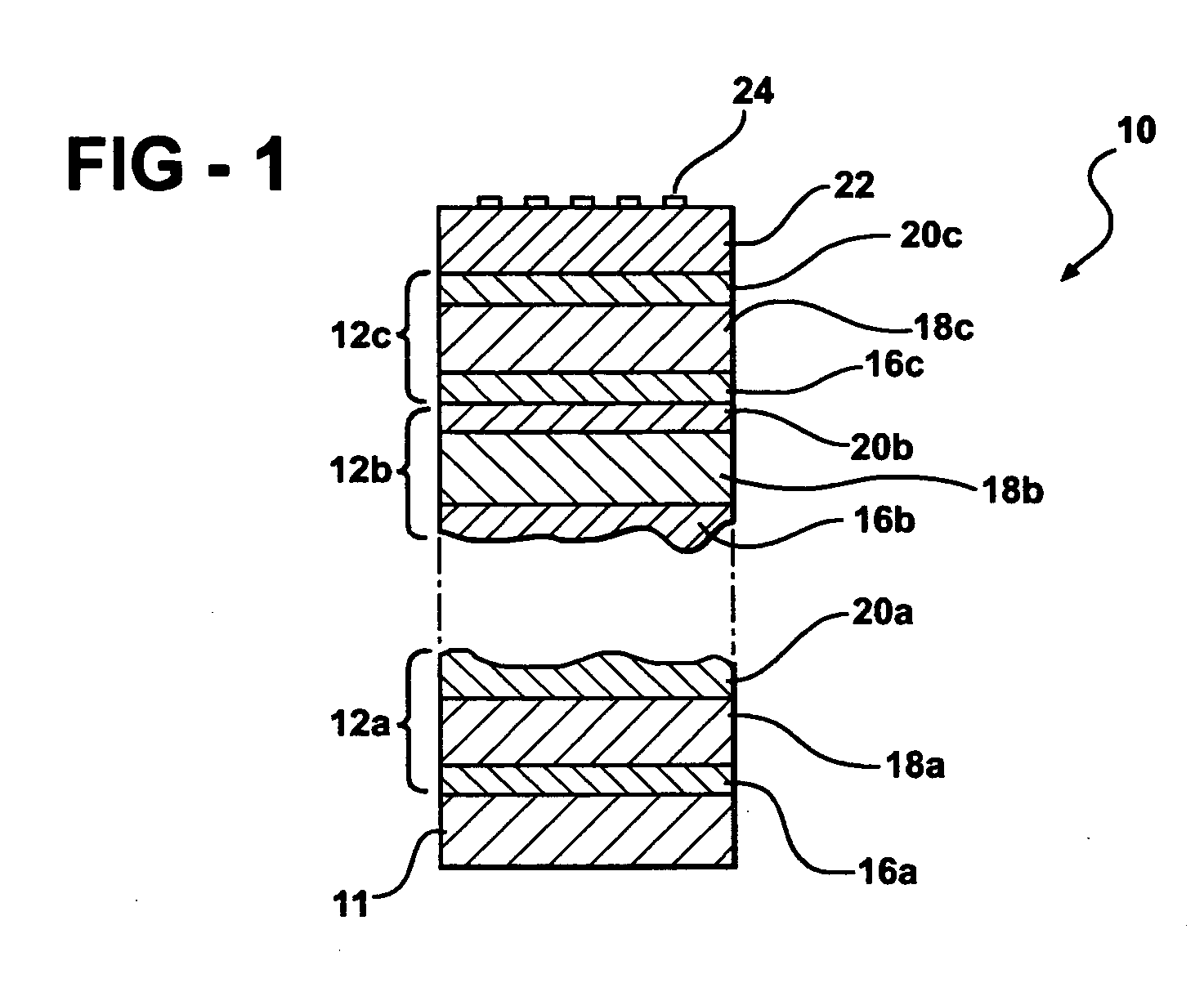

Solar cell and manufacturing method

ActiveCN101118914AReduce process stepsSimple production processFinal product manufactureSemiconductor/solid-state device manufacturingHigh volume manufacturingAmorphous silicon solar cell

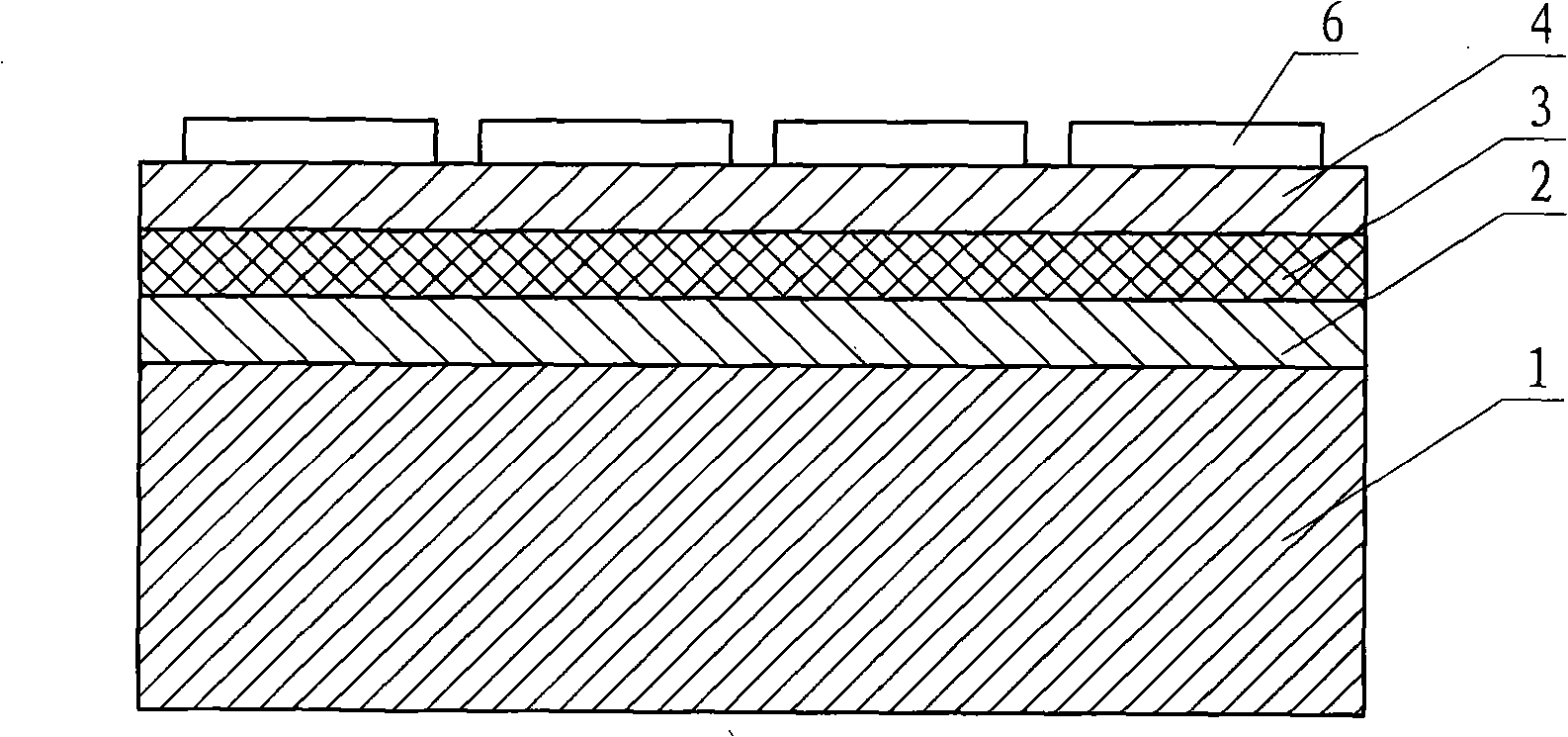

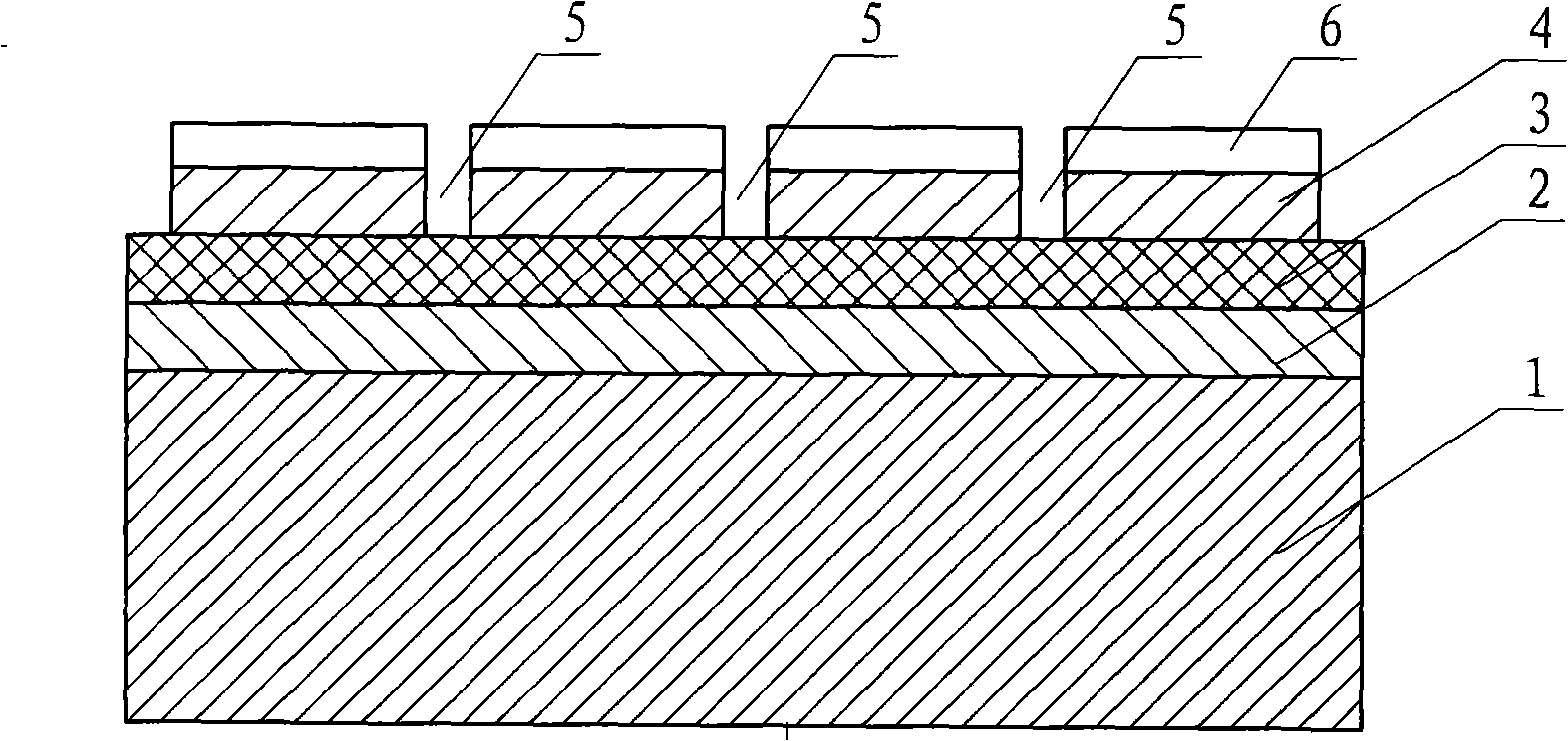

The present invention relates to a multi-stack amorphous silicon solar battery, which adds a transparent reflection film between the stacks and belongs to the thin film solar battery making field. The present inventionhas the technical characteristics that the transparent conductive film between two stacked photoelectric conversion layers is coated on the N face of one amorphous silicon P-I-N photoelectric conversion layer, while the middle transparent conductive film is made of nanometer conductive material. Moreover, a photoelectric unit consists of a stacked amorphous silicon solar battery, and the P film of the amorphous silicon P-I-N photoelectric conversion layer forms a top battery on the back of the front electrode in a roll coating manner. The present inventionis applicable to the mass production, reducing the cost.

Owner:李毅

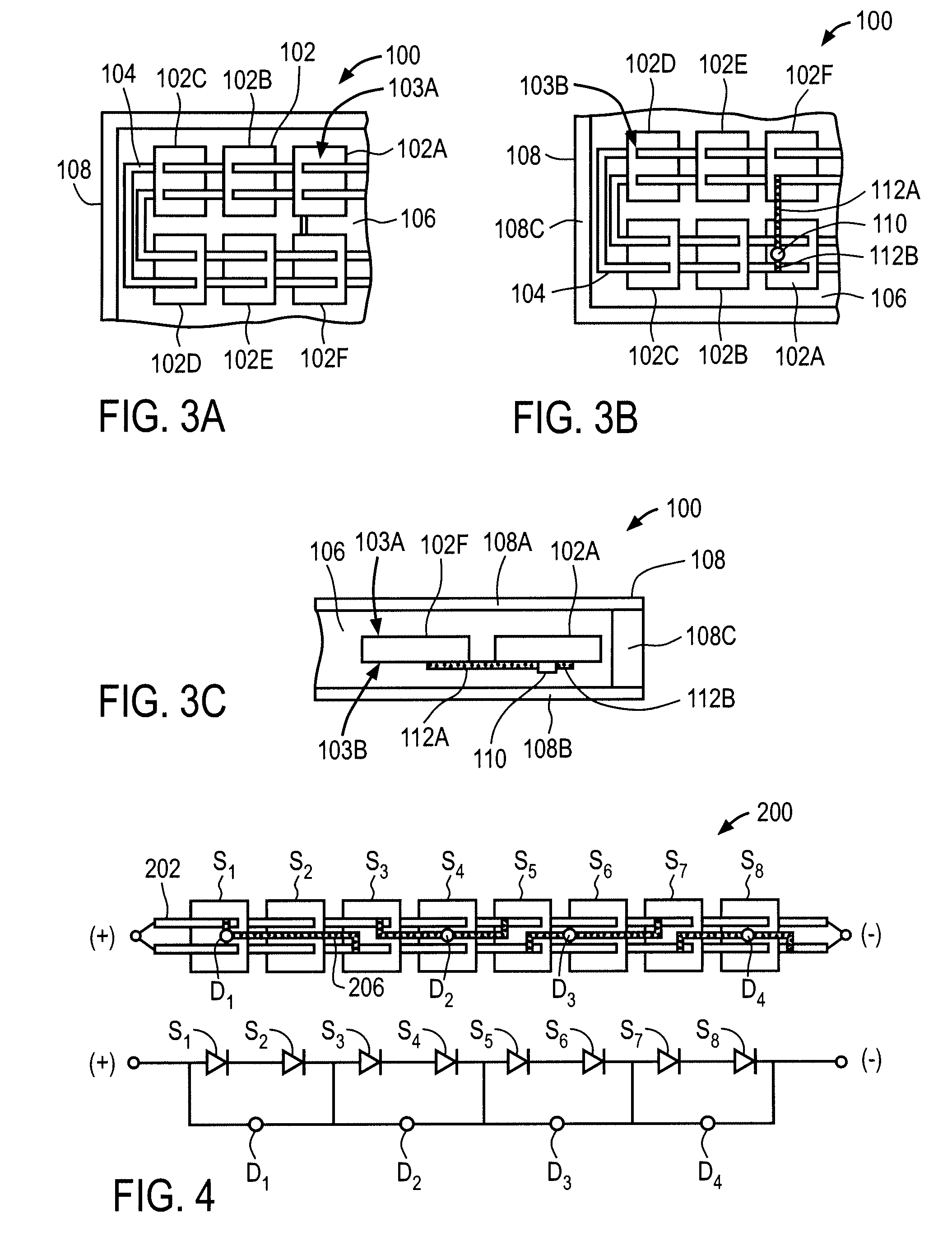

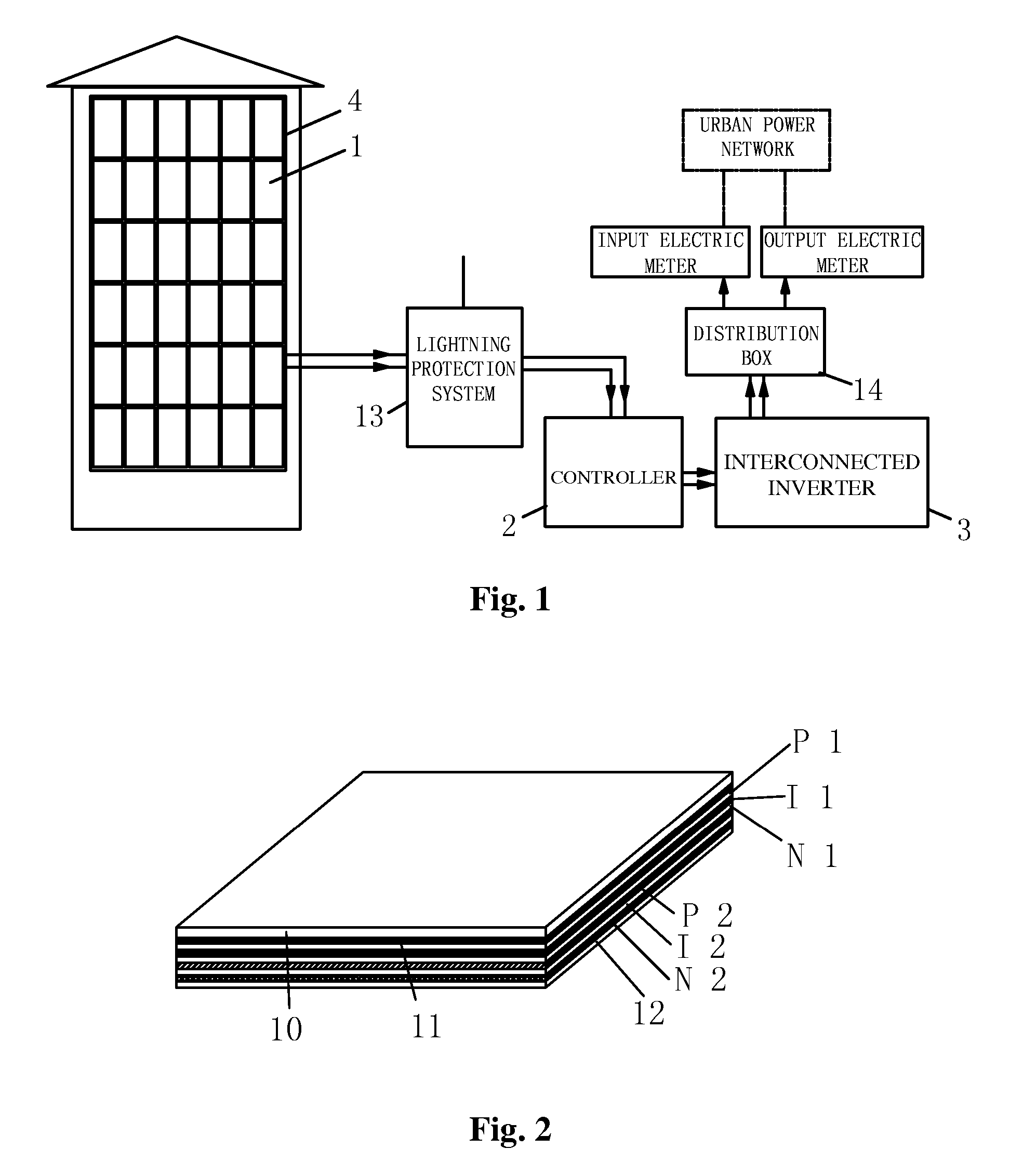

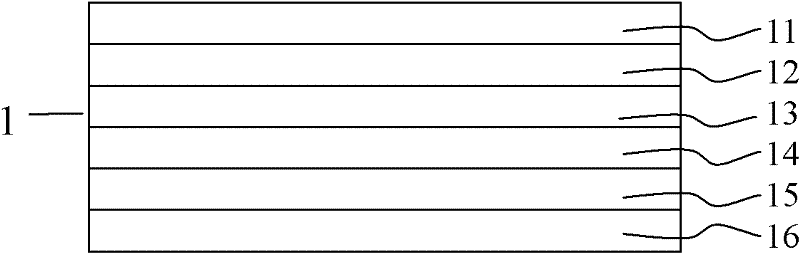

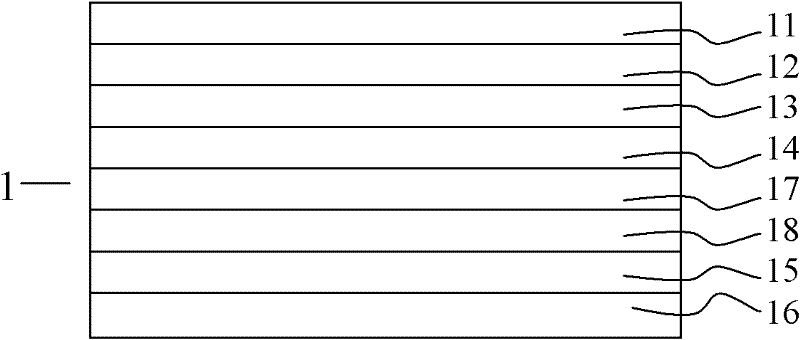

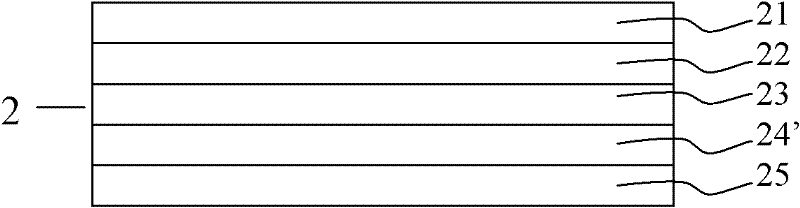

Integrated amorphous silicon double-junction solar cell curtain wall and methods for manufacturing and using the same

InactiveUS20080092952A1Provide energyImprove performanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar power

Provided is an integrated amorphous silicon double-junction solar cell curtain wall, comprising a plurality of photovoltaic curtain wall plates, each of which being encapsulated by a double-junction amorphous silicon solar cell chip with a glass substrate, a glass plate, a glue film, a junction box, a lead and a frame; and an electric control unit having a controller; wherein an output of the photovoltaic curtain wall plate is connected to the controller of the electric control unit. A double-junction double-layer solar cell top cell film layer and a bottom cell film layer are disposed on a glass substrate of the cell chip, each of the top cell film layer and the bottom cell film layer comprising a P-layer, an I-layer, and an N-layer; an I-layer of the top cell film layer is amorphous silicon; and an I-layer of the bottom cell film layer is amorphous silicon or amorphous germanium-silicon. The invention solves problems of solar power generation and application, and features with good energy saving effect, safety, reliability and wide applications. Generated energy of the cell chip per square meter is 30-60 W, photoelectric conversion efficiency is 5-7%, an attenuation rate is 20-30%, output efficiency after conversion is approximately 80%. The invention is usable for solar power generation and wall decoration of buildings.

Owner:CHEN WUKUI +2

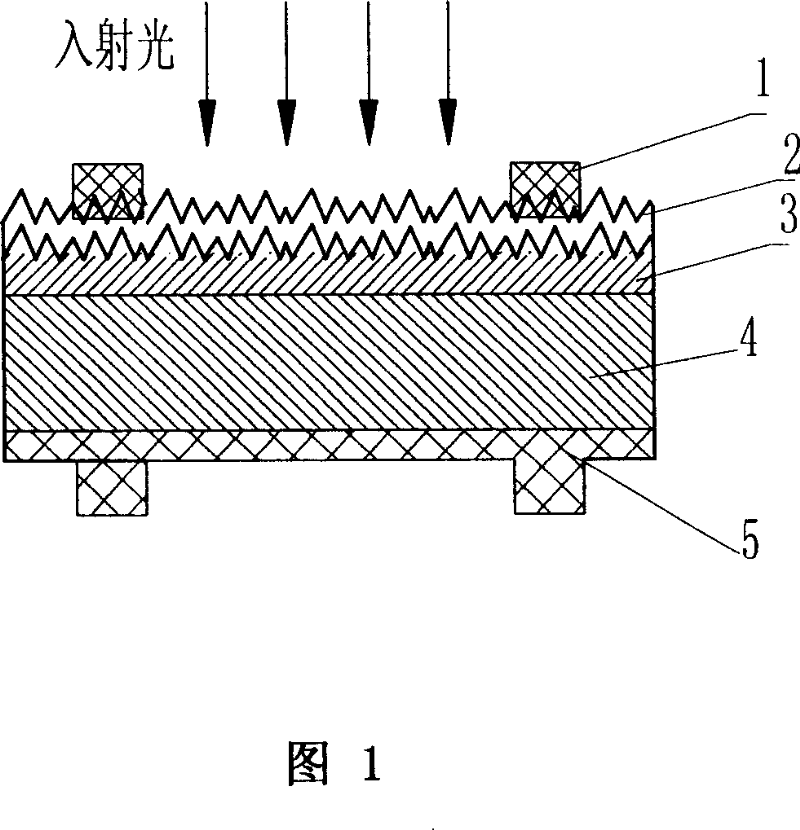

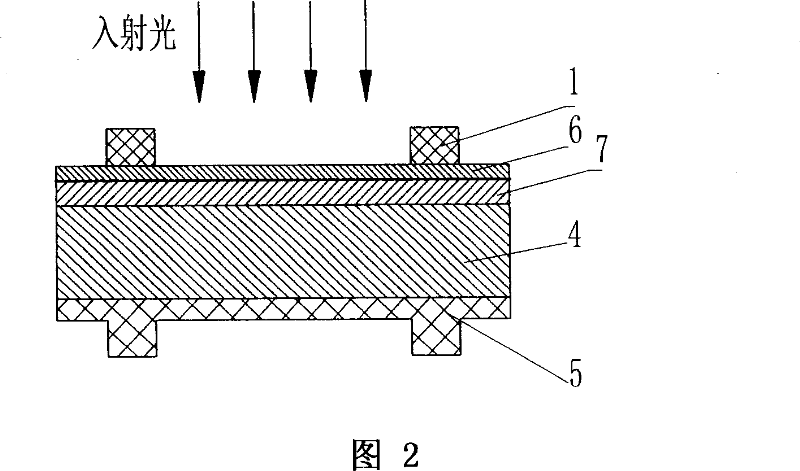

Crystalline silicon solar battery and amorphous silicon solar battery

InactiveCN102456762AIncrease profitImprove conversion efficiencyPhotovoltaic energy generationSemiconductor devicesUltraviolet lightsSolar battery

The invention discloses a crystalline silicon solar battery and an amorphous silicon solar battery. The crystalline silicon solar battery comprises an antireflective film layer, a light-transmitting glass layer, a second sealing layer, a crystalline silicon battery piece, a first sealing layer and a TPT backboard which are sequentially combined, wherein the antireflective film layer, the light-transmitting glass layer, the first sealing layer and / or the second sealing layer respectively contain illuminant. The amorphous silicon solar battery comprises an antireflective film layer, a light-transmitting glass layer, a transparent conductive film, an amorphous silicon pin film layer and a metal back electrode, wherein the antireflective film layer, the light-transmitting glass layer and / or the transparent conductive film respectively contain illuminant. According to the solar batteries disclosed by the invention, sunlight can be subjected to spectrum down-conversion, spectrum up-conversion and / or spectrum transfer; and ultraviolet light and near-infrared light in the sunlight can be converted into visible light, so that the utilization ratio of the sunlight is effectively improved, the conversion efficiency is effectively promoted, and the generated energy is effectively increased.

Owner:XINYI PHOTOVOLTAIC IND (ANHUI) HLDG CO LTD

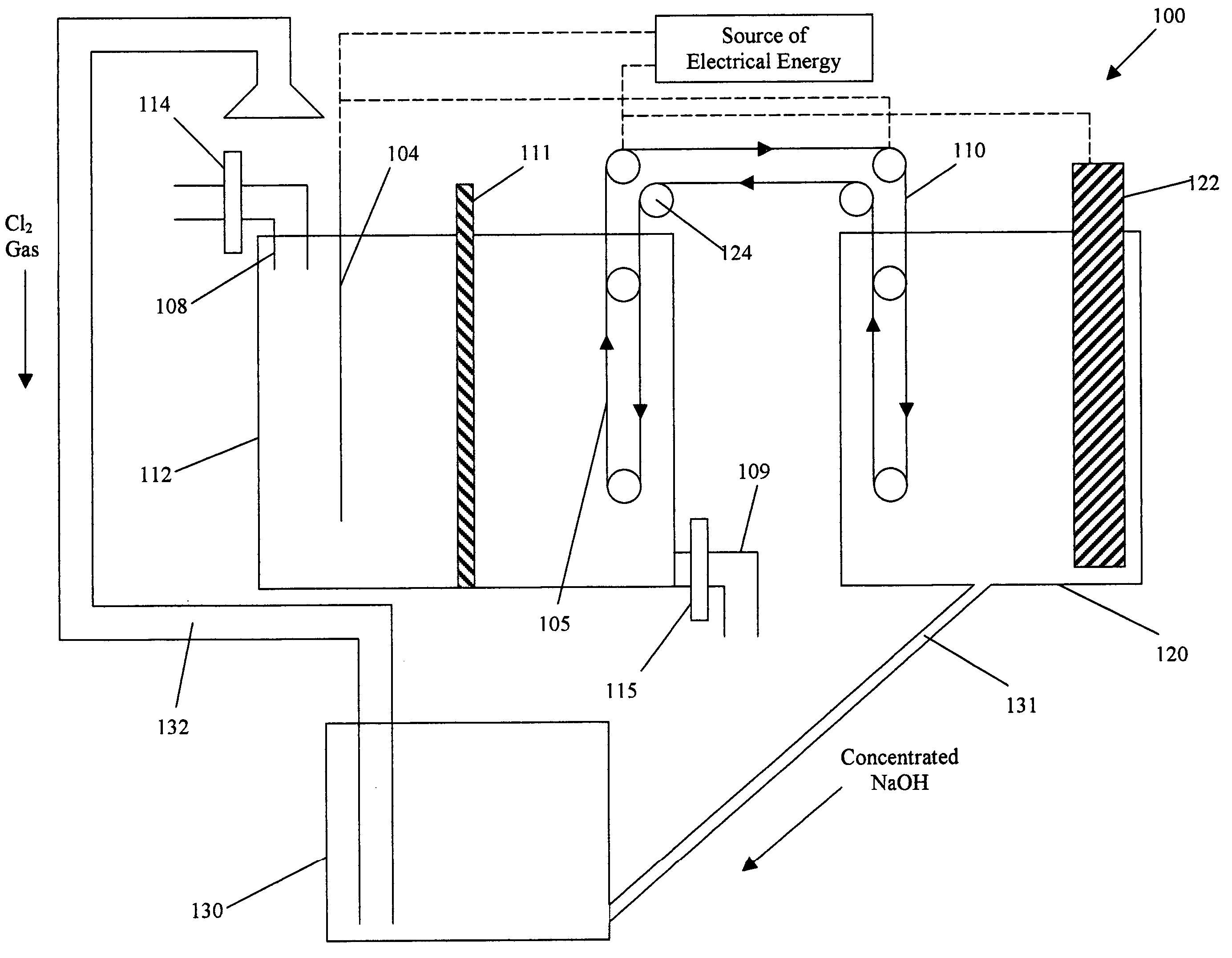

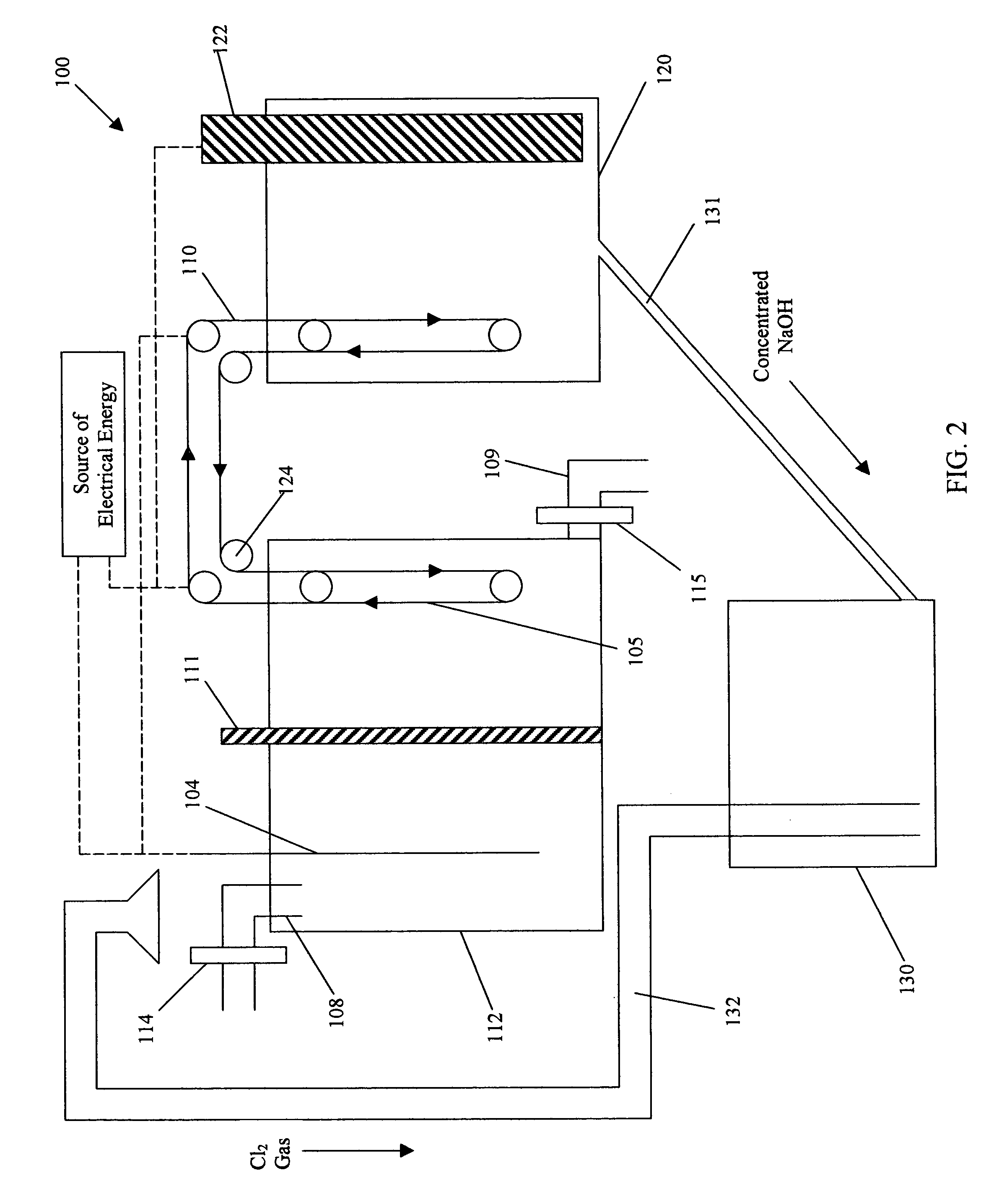

Process and apparatus for removing chloride and sodium ions from an aqueous sodium chloride solution

InactiveUS20050092618A1Reduce salt (NaCl) contentFuel and primary cellsCellsSodium amalgamTriple junction

The present invention discloses a process and apparatus for removing sodium and chloride ions from an aqueous sodium chloride solution, such as seawater or brine. The process includes electrolyzing aqueous sodium chloride to remove chloride and sodium ions in the form of chlorine gas and sodium metal. Preferably, a photovoltaic device, such as a triple junction amorphous silicon solar cell, provides the electrical energy for the electrolysis. The process utilizes electrode material that facilitates the production of chlorine gas and inhibits the evolution of hydrogen from the aqueous sodium chloride solution. The sodium is deposited onto a metal surface having a high hydrogen overpotential to produce sodium amalgam. The processed solution from the electrolysis has a reduced sodium chloride content and may be further processed to produce fresh water for human consumption or agricultural purposes. The sodium amalgam is removed from the aqueous sodium chloride solution and transported to and coupled against an air depolarizing fuel cell in water to produce electrical power with the sodium air fuel cell, power that may be used to operate the apparatus or other machinery. The product of the reaction between the sodium amalgam and the fuel cell is sodium hydroxide that may be reacted with the chlorine gas to produce sodium hypochlorite.

Owner:ENERGY CONVERSION DEVICES INC

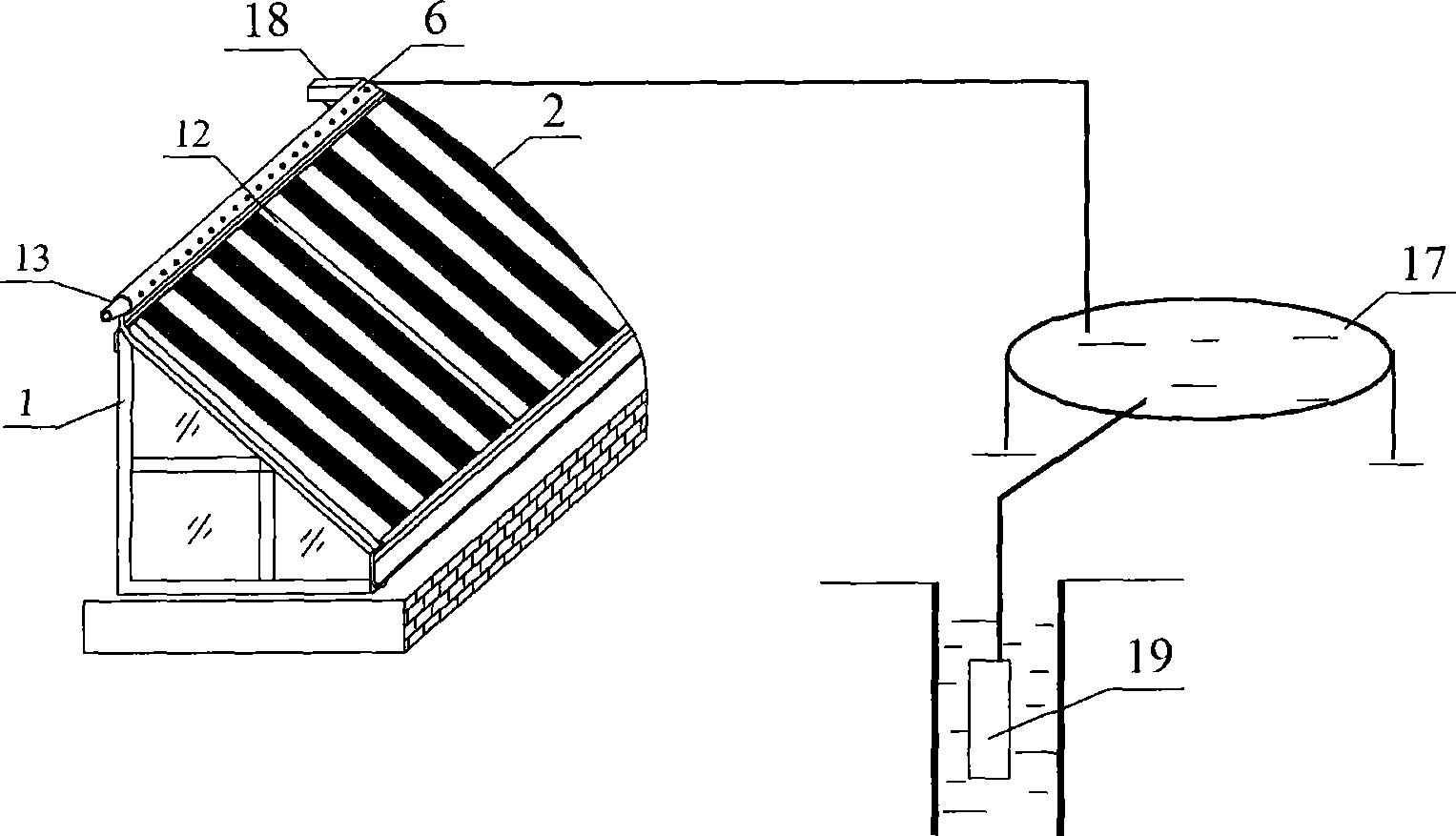

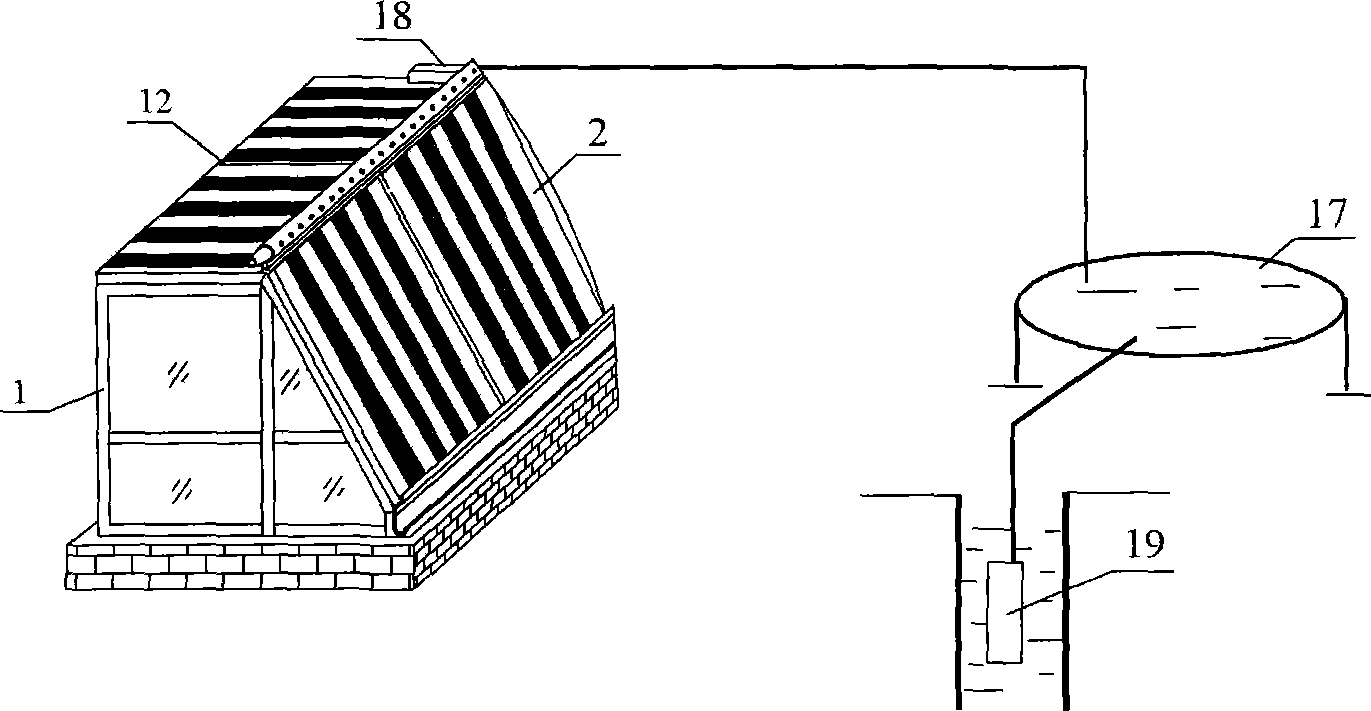

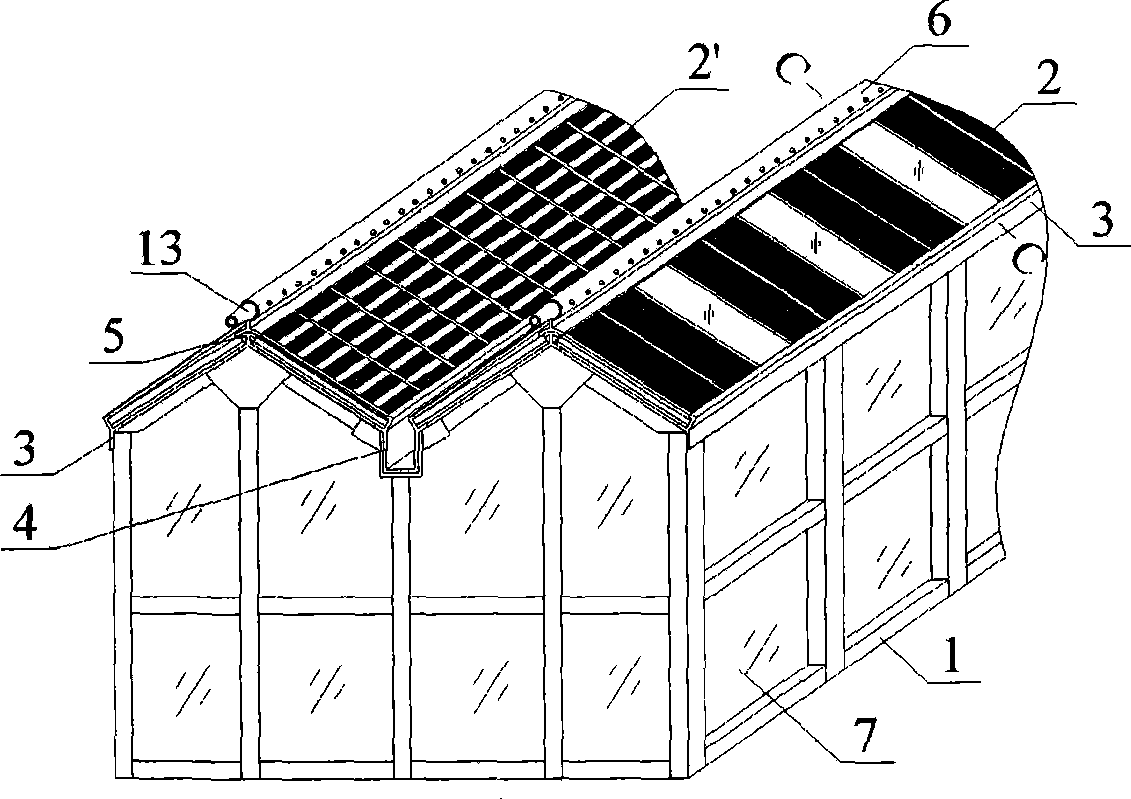

Solar photovoltaic green-house for rearing tomatoes

InactiveCN101455165AGood light transmissionTranslucency fastPhotovoltaic supportsBatteries circuit arrangementsElectricityAmorphous silicon solar cell

The invention relates to a solar energy photovoltaic booth comprising a main body frame, a ventilation unit and an attemperator. The present invention is characterize in that the solar energy photovoltaic booth also comprises a light transmittance adjustable plate-type module formed by solar modules and transparent glasses and installed on a frame, the frame is installed on the surface facing the sun of the main body frame, a booth with a half inclined roof is formed, and a cleaning device with a lift pump is installed on the roof of the booth; furthermore, the solar energy photovoltaic booth comprises photovoltaic arrays of the half inclined roof and an output power supply system. The present invention has positive effects that amorphous silicon solar modules having low cost and transparent materials such as glasses and the like can be combined randomly according to the design requirement, the combination not only can satisfy the transmittance but also can generate electricity and can be used as roof, wall and the like of the booth, and a cleaning device with a lift pump is installed on the roof of the booth, which can keep the battery surface clean and improve the service efficiency of the battery.

Owner:李毅

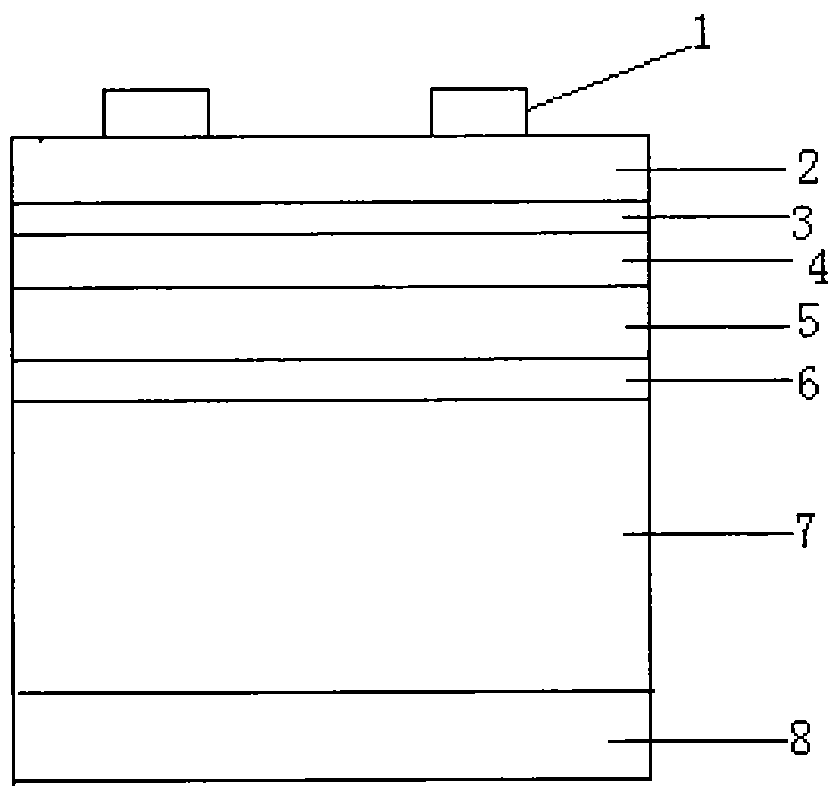

Amorphous silicon-crystal silicon heterojunction solar battery

InactiveCN101043058AIncrease the output voltageHigh electron mobilityPhotovoltaic energy generationSemiconductor devicesSemiconductor materialsAmorphous silicon solar cell

The invention discloses a structure of amorphous silicon- crystal silicon heterogeneity node solar cell, a layer of amorphous silicon film is at the photic surface of the solar cell which is between electrode and N type silicon pervasion layer; the amorphous silicon film layer and the N type silicon pervasion layer form a heterogeneity height node structure. The invention adopts the different light absorption property of different semiconductor material and two dimension electron gas effect introduced by semiconductor heterogeneity node to realize the higher photoelectricity transition efficiency than normal crystal silicon solar cell; batter stability for long time and higher photoelectricity transition efficiency than normal amorphous silicon solar cell; and lower series-wound resistance and higher photoelectricity transition efficiency than pure amorphous silicon-monocrystalline silicon heterogeneity node solar cell.

Owner:SHANGHAI SOLAR ENERGY S&T

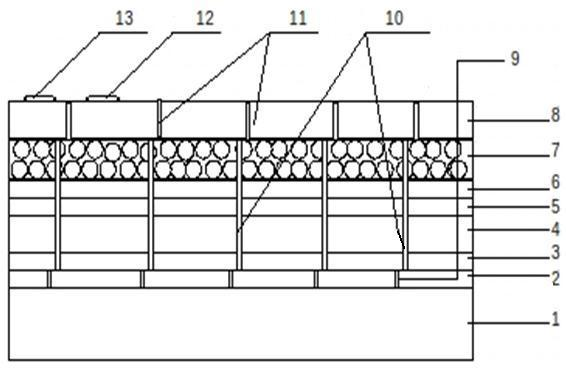

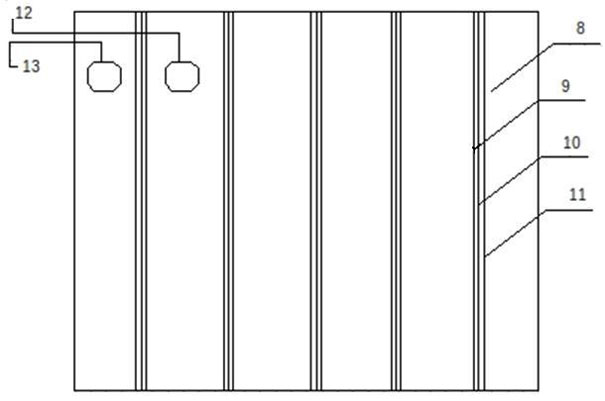

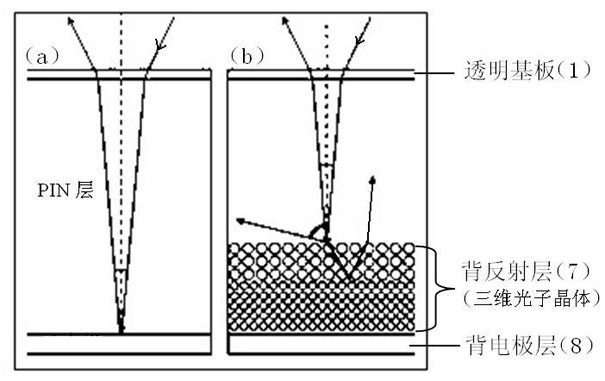

Amorphous silicon solar cell with three-dimensional photonic crystal serving as back reflecting layer and manufacturing method thereof

InactiveCN101807613AImprove utilization efficiencyIncreasing the thicknessFinal product manufacturePhotovoltaic energy generationGas phaseAluminum doped zinc oxide

The invention discloses an amorphous silicon solar cell with a three-dimensional photonic crystal serving as a back reflecting layer and a manufacturing method thereof, relates to the method for manufacturing the amorphous silicon solar cell and solves the problem of low efficiency of the solar cell caused by low reflectivity of the traditional A1 back reflecting layer. The back reflecting layer of the amorphous silicon solar cell is a three-dimensional macroporous sequential aluminum-doped zinc oxide photonic crystal. The manufacturing method comprises the following steps: depositing a front electrode layer by low-pressure chemical vapor deposition, depositing a P-I-N layer by PECVD, preparing an ITO transparent conductive film by magnetron sputtering, preparing a colloidal crystal template by a vertical deposition process or spin-coating process, performing electrodeposition to obtain the back reflecting layer, and performing vacuum evaporation on a back electrode layer to obtain the back reflecting layer. The AZO has high transmissivity for visual light and can realize over 80 percent transmissivity for 600 to 1,000nm visual optical band when combined with the bandgap effect of the three-dimensional photonic crystal. The three-dimensional photonic crystal has big reflecting angle, so transmission optical path of optical waves in an absorbing layer is increased; the utilization rate of photons is improved; and photocurrent density and photoelectric conversion efficiency are increased.

Owner:HARBIN INST OF TECH

Flexible solar battery and manufacturing method thereof

ActiveCN101232055AHigh visible light transmittanceHigh light transmittanceFinal product manufacturePhotovoltaic energy generationManufacturing technologyAmorphous silicon solar cell

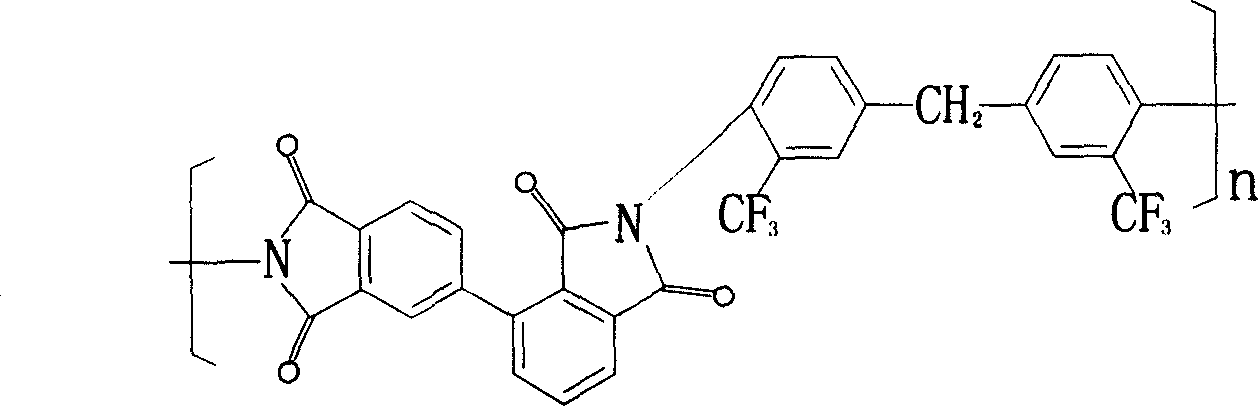

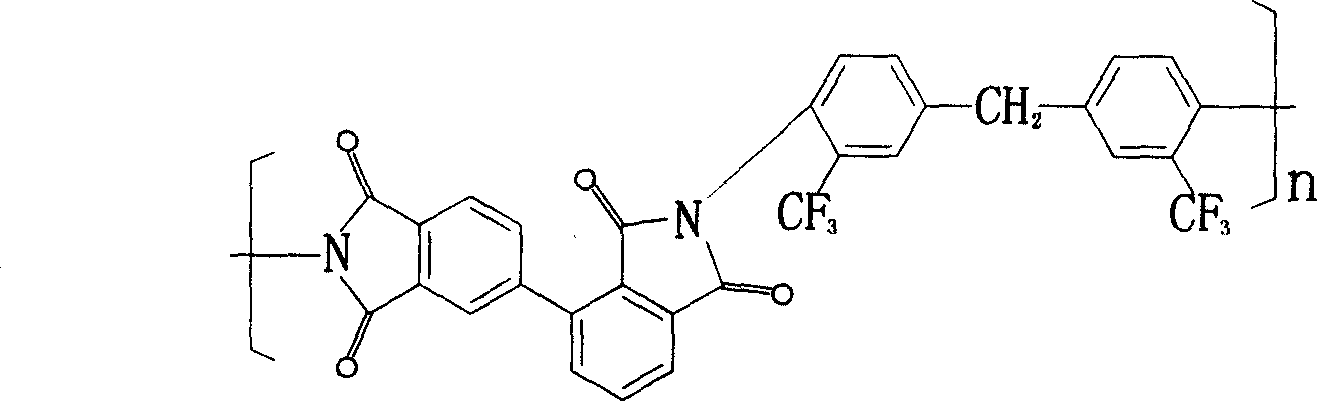

The invention relates to a solar photovoltaic battery manufactured on modified flexible substrate with high light transmittance, which belongs to the field of flexible amorphous silicon film solar cell manufacture technology. The invention aims to improve the photoelectric conversion efficiency and is manufactured by following steps: selecting a modified PI (polyimide) material with light transmittance of 90 to 93% as the substrate, changing the lamination structure of an amorphous silicon PIN film, depositing a transparent conductive oxide (TCO) thin film by sputtering at a temperature above 350 DEG C, and manufacturing single-junction or multi-junction flexible amorphous silicon battery by using the PI substrate with high light transmittance. The invention has the positive effects that the modified substrate in the manufacture and application does not deform in four hours at a temperature between 350 to 400 DEG C, thus significantly improving the photoelectric conversion efficiency and the performance price ratio of the flexible amorphous silicon solar battery.

Owner:李毅

Silicon thin-film photocell electric pole pattern and etching method

InactiveCN101192627AReduce pollutionSimple processFinal product manufactureSemiconductor devicesAdditive ingredientPrinting ink

The invention relates to an etching technology for etching a pattern on a photocell with a silicon film, and an etching agent as well as an etching method for manufacturing amorphous silicon solar cells and a pattern on an aluminum dorsal electrode. The purpose of the invention is to provide a cell with a silicon film with a complicated pattern, a method for etching an aluminum film, and an etching agent. Printing ink etched by a silk-screen is unlikely to destroy amorphous silicon and an ITO conductive film on a lower layer when etching the aluminum film. The raw materials in the printing oil for etching are made up of the following ingredients according to the weight ratio: 3 to 7 portions of deionized water, 1 to 3 portions of bluestone, 1 to 3 portions of ferric trichloride, 0.3 to 0. 8 wt per cent of ammonium persulfate, and 2 to 4 portions of starch. The raw materials are mixed at a temperature of 60 DEG C and w-090 (0.1 to 0.5 per cent) and absolute alcohol (2-5 wt per cent) are added at last.

Owner:李毅

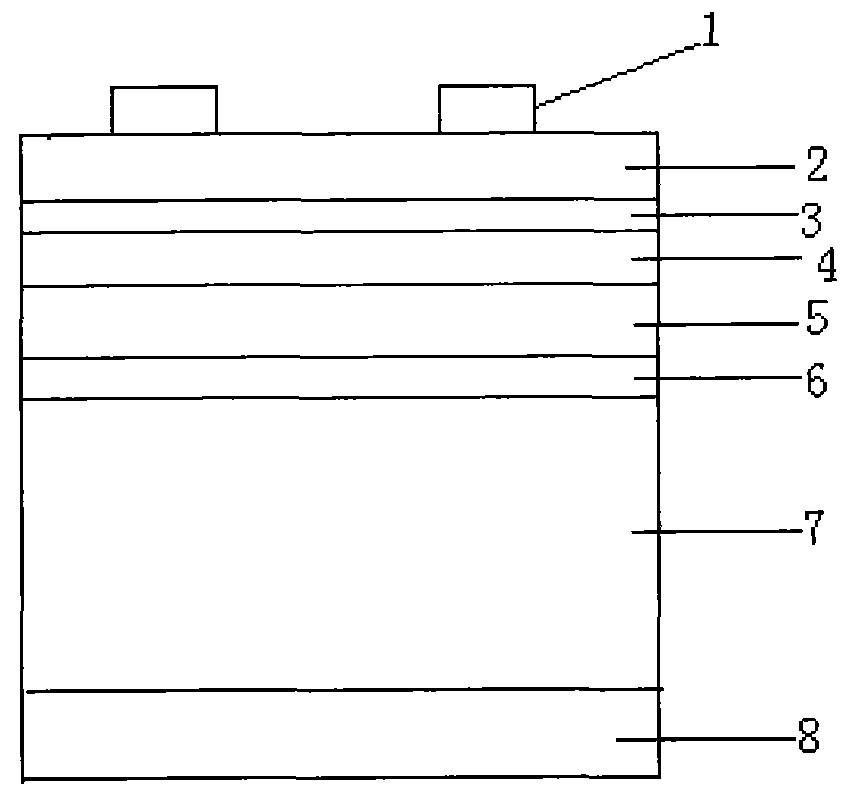

Novel silicon substrate heterojunction solar cell

InactiveCN102148280ALow costImprove photoelectric conversion efficiencyFinal product manufacturePhotovoltaic energy generationHeterojunctionAmorphous silicon solar cell

The invention discloses a novel silicon substrate heterojunction solar cell. An Ag back electrode is formed on the back surface of an N-type monocrystalline silicon or polycrystalline silicon slice through evaporation; intrinsic amorphous silicon (i-a-Si:H), P-type nanosilicon (p-nc-Si:H), P-type heavily doped amorphous silicon (p+-a-Si:H) and ultrathin intrinsic amorphous silicon (i-a-Si:H) are deposited on the front surface (light receiving surface of a cell) of the silicon slice in sequence; finally an ITO (Indium Tin Oxide) transparent conductive thin film is sputtered on the silicon; and an Ag gate line electrode is printed by a screen. The solar cell with the novel structure has lower cost than that of the normal silicon solar cell, so that the light-induced degradation of the normal amorphous silicon solar cell is reduced, and the cell has higher stability in long-term use, high light absorbing capacity and high photoelectric conversion efficiency. The efficiency reaches 17.2 percent at the standard analog light intensity of AM1.5, 100mW / cm<2>.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Laser drilling method for amorphous silicon solar cell glass substrate

ActiveCN104722932AAvoid membrane surface contaminationGuaranteed normal processingLaser beam welding apparatusProduction lineAmorphous silicon solar cell

The invention belongs to the field of amorphous silicon solar cell drilling and provides a laser drilling method for an amorphous silicon solar cell glass substrate. The laser drilling method comprises the steps that firstly, a membrane face of the glass substrate coated with a membrane layer is upward, and a membrane layer within a round ring is removed inwards from the edge of the portion to be drilled; secondly, within the round ring without the membrane layer, layered laser drilling is conducted on the lower surface of the glass substrate. By the adoption of the laser drilling method, the membrane face of the amorphous silicon solar cell glass substrate is placed on a processing production line, the membrane layer within the round ring is removed through laser, and drilling is conducted along the track of the hypocycloid in a layered mode; in this way, the equipment cost is reduced, production line processing of amorphous silicon solar cell glass substrates is guaranteed, and the membrane face of the membrane layer is prevented from being polluted.

Owner:HANS LASER TECH IND GRP CO LTD

Cascade solar cell with amorphous silicon-based solar cell

InactiveCN101197398ALight-sensitive devicesSolid-state devicesAmorphous silicon solar cellSilicon solar cell

A cascade solar cell structure includes an amorphous silicon-based solar cell on a non-silicon solar cell to be configured for an anti-reflective surface and absorbing incident light with short wavelength.

Owner:HIGHER WAY ELECTRONICS +1

Special-shaped solar photovoltaic curtain wall glass and manufacturing method thereof

ActiveCN101487308ASuitable for buildingPerformance electricityWallsFinal product manufactureElectricityElectrical battery

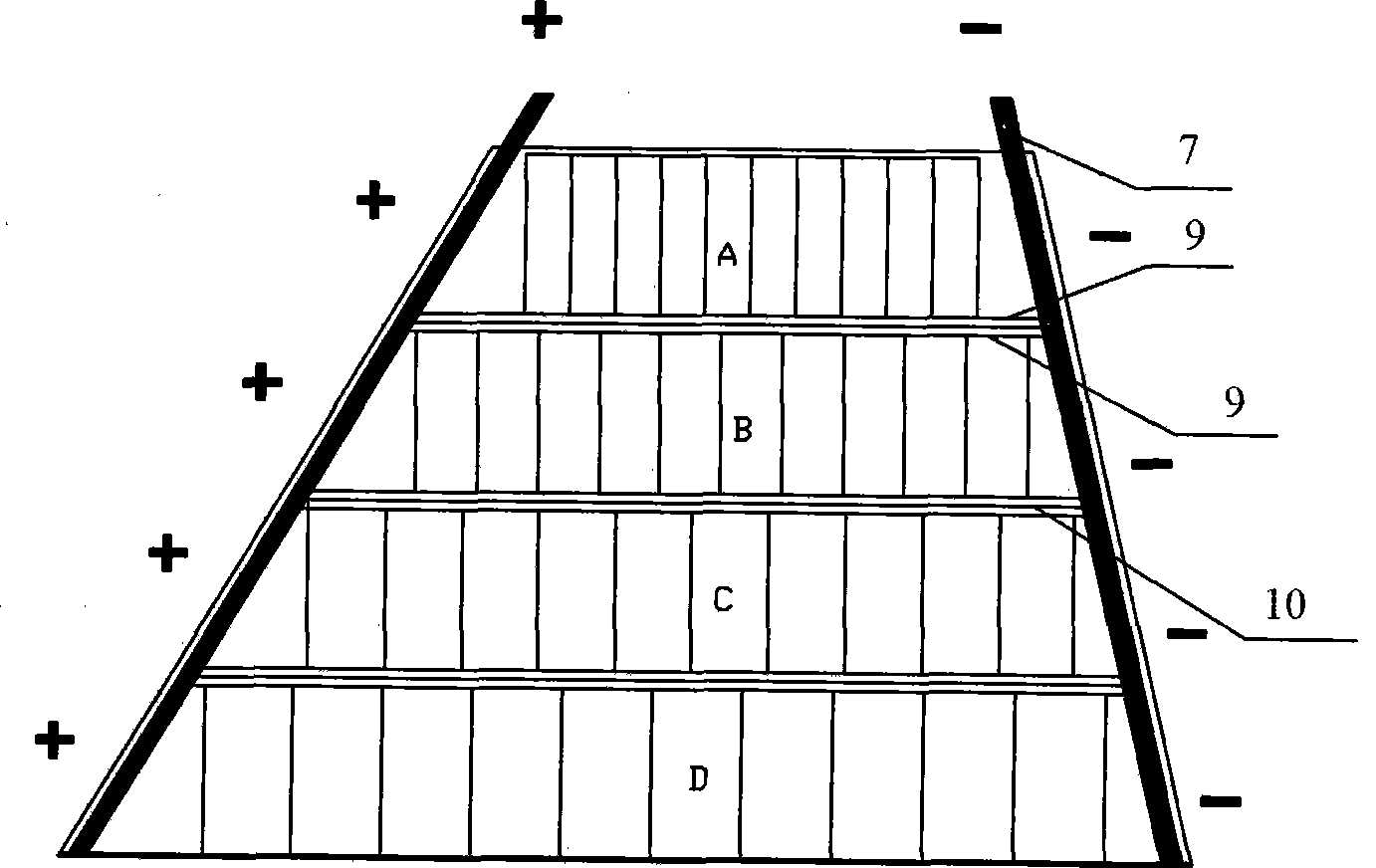

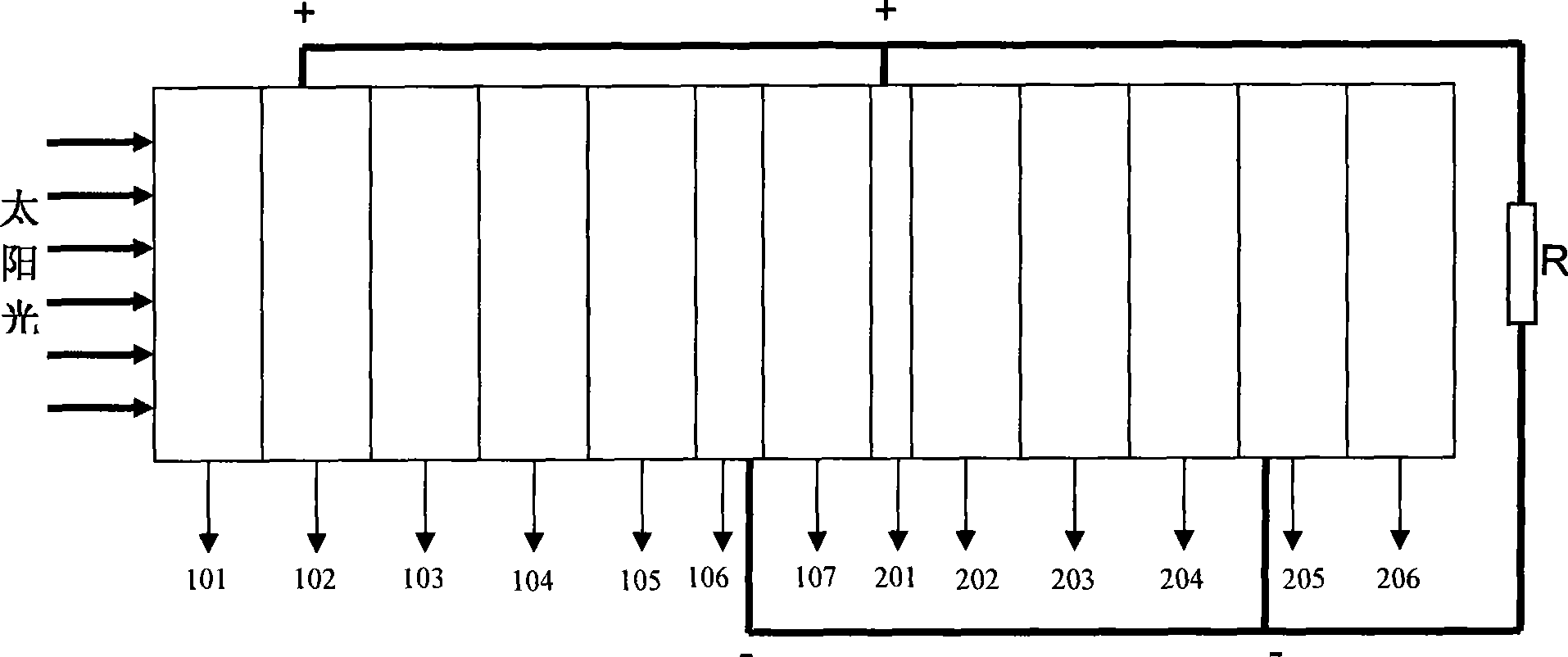

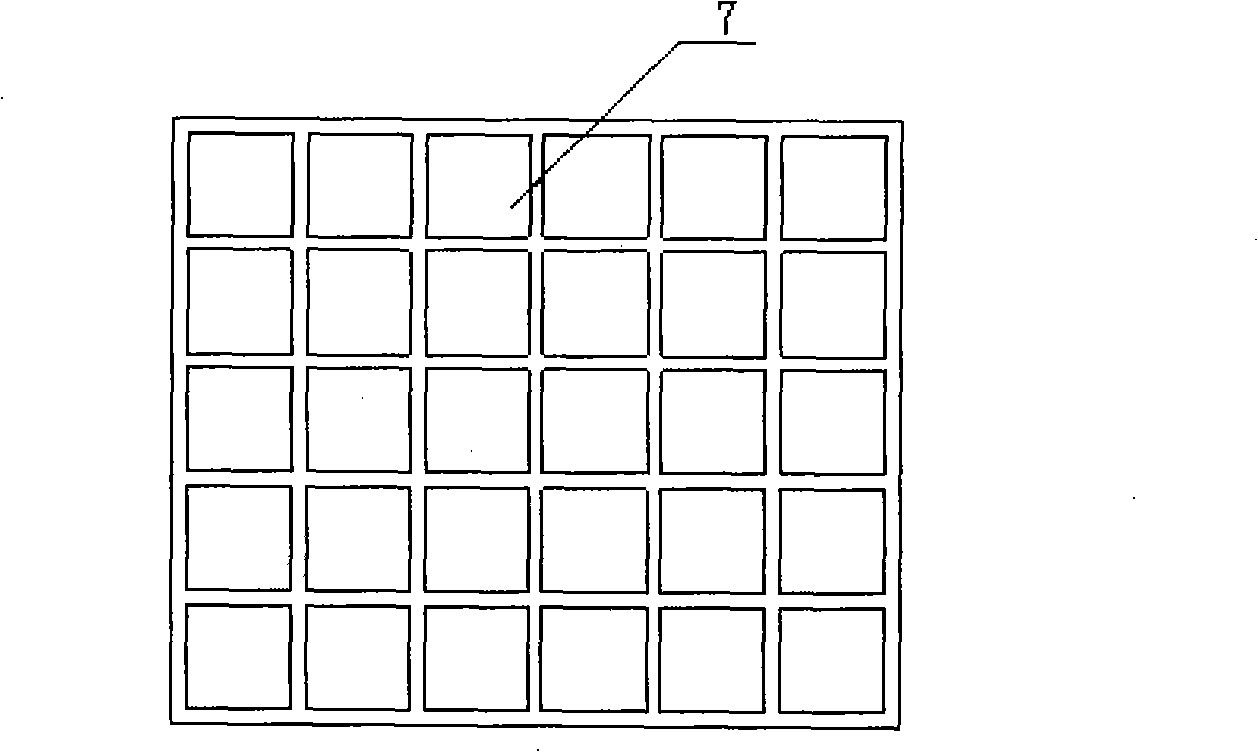

The invention relates to an abnormal solar energy photovoltaic curtain wall glass and a manufacturing method thereof; the abnormal solar energy photovoltaic curtain wall glass comprises an inner layer glass and an outer layer glass, and is characterized by also comprising an abnormal photovoltaic interlayer; the photovoltaic interlayer is a photovoltaic array formed by a solar energy battery component, the solar energy battery component is formed by series connected sub-batteries with same effective area or parallel connected sub-batteries with same amount and voltage on a large-scale integrated solar energy battery core board, an insulated separated wire is arranged between neighboring solar energy battery components, and positive and negative electrodes of the battery component are led out by a conductive strip to output and supply power. The beneficial effect is as follows: the shortcomings in the prior art that a plurality of amorphous silicon solar energy battery components are needed for completing series or parallel connection are solved directly from the structure design and technology of the large-scale integrated solar energy battery core board, the solar cell battery core boards with various shapes are applicable to the building of photovoltaic curtain walls with large area and various shapes, and meet the electrical performance of photovoltaic construction.

Owner:李毅

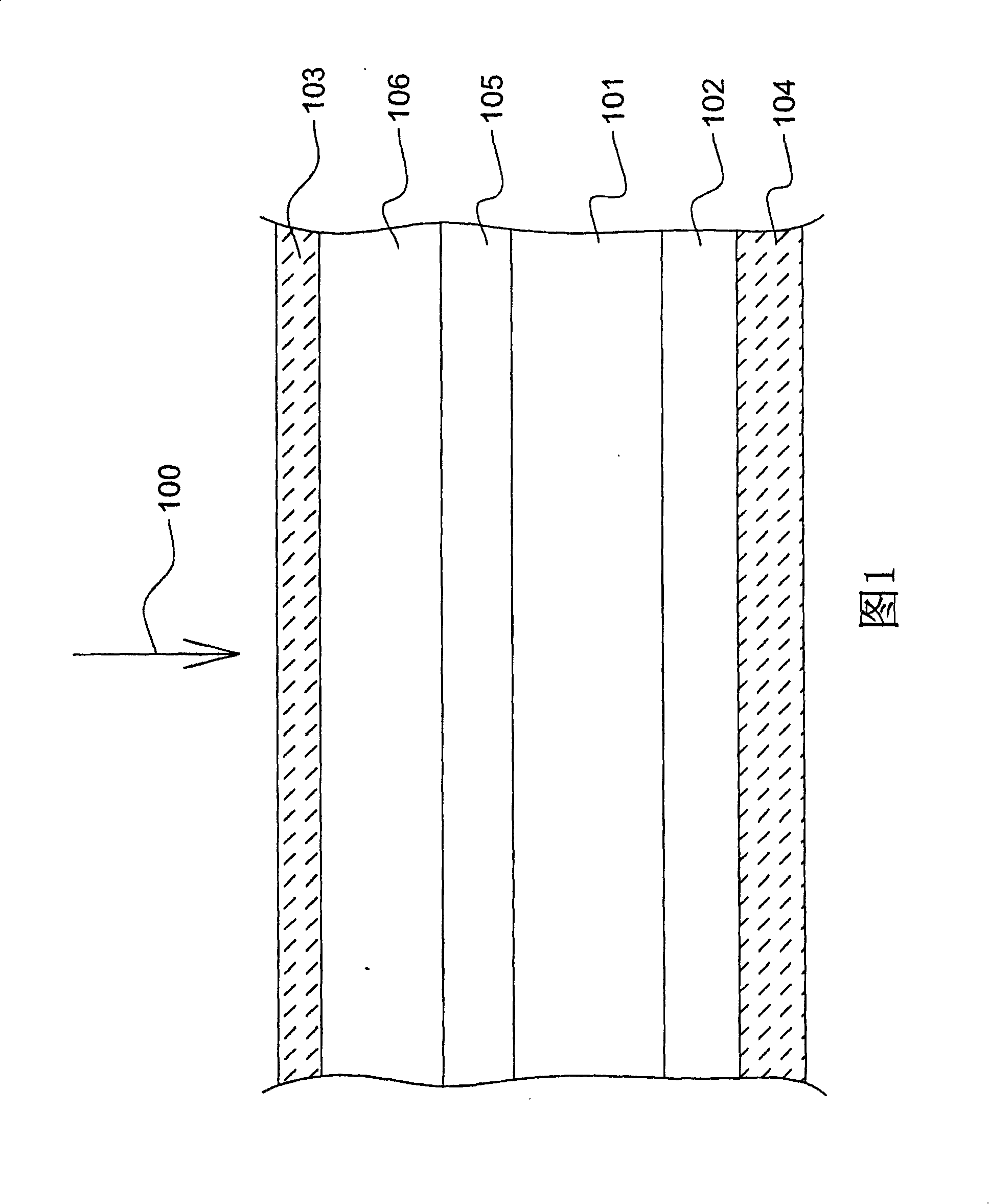

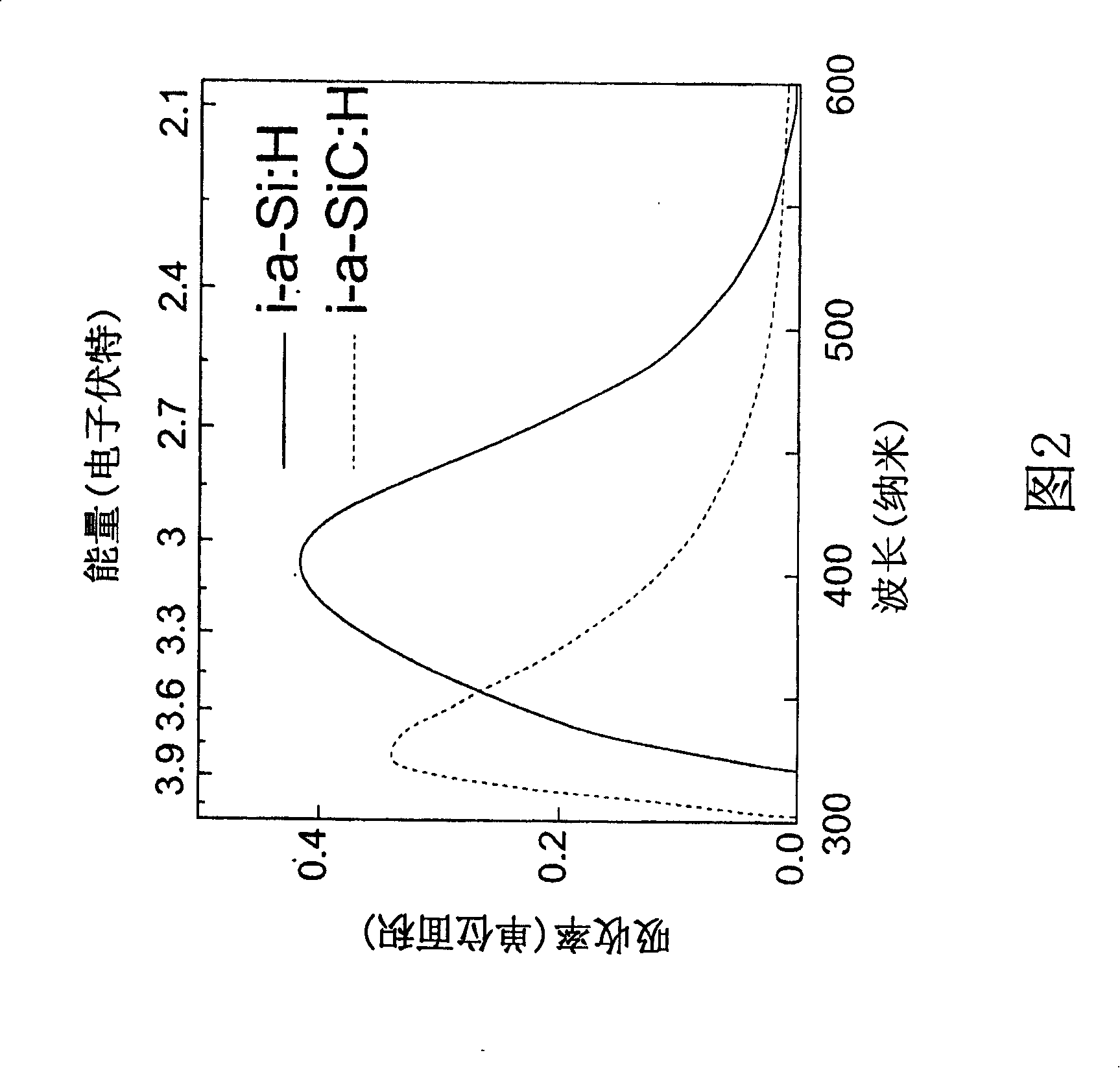

Laminated structure of amorphous silicon solar battery and dye sensitization battery

InactiveCN101510470AAchieve absorptionSimple preparation processLight-sensitive devicesFinal product manufactureSensitized cellLight energy

The invention relates to an amorphous silicon solar cell and dyestuff sensitized cell laminated structure which comprises an amorphous silicon solar cell positioned at the top and used for absorbing high-energy sunlight with biased shortwave, and a dyestuff sensitized cell positioned at the bottom and used for absorbing low-energy sunlight with biased long-wave, wherein, the amorphous silicon solar cell and the dyestuff sensitized cell are connected in series or in parallel; the amorphous silicon solar cell and dyestuff sensitized cell laminated structure can achieve the following effects: the dyestuff sensitized cell can be used for adsorbing close infrared light; the designed laminated cell is characterized by simple manufacturing technique and low price; the problem that the conventional solar cell has low photoelectric transformation efficiency and narrow solar energy absorbing spectrum can be solved; and the structure can increase the utilization rate of sunlight to the greatest extent, improve transformation efficiency and reduce light energy loss.

Owner:上海拓引数码技术有限公司

Manufacturing process of flexible amorphous silicon solar cell

InactiveCN101290955ALow costSimple processFinal product manufactureSemiconductor devicesPolyimide membraneRadio frequency

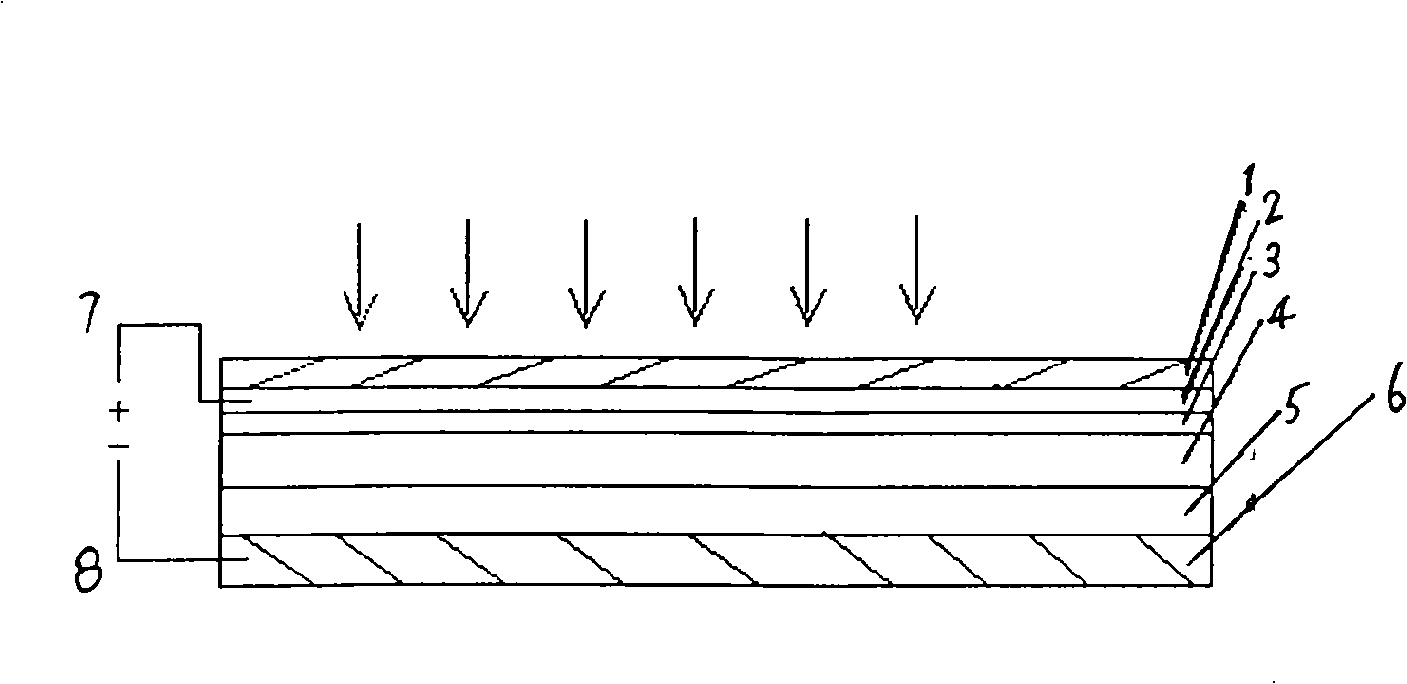

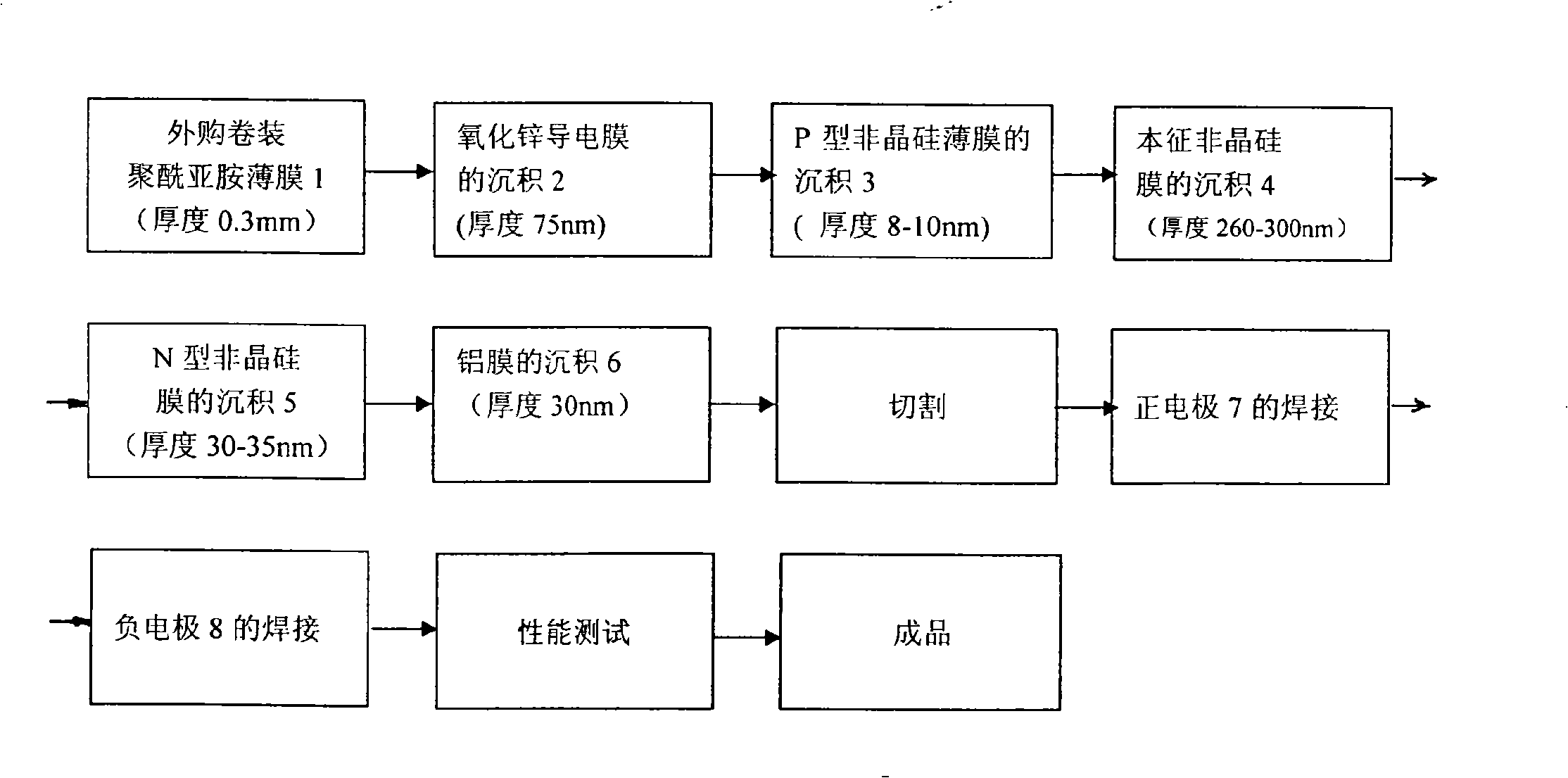

The invention provides a technique for manufacturing a flexible amorphous silicon solar cell, wherein, a bought-in rolled transparent polyimide film with a thickness of 0.3 millimeter is used for coating according to the following technical steps: firstly, a roller which is rolled with the polyimide film is supported on a bearing bracket and a layer of ZnOx conductive film with an electricresistivity less than 10ohm-cm is generated through magnetron sputtering; secondly, the polyimide film roller which is plated with the ZnOx conductive film is taken out and sent into another single-chamber large-scale PECVD device, with an internal deposition temperature 210 DEG C; a p type amorphous silicon film, an i type amorphous silicon film and an n type amorphous silicon film are deposited by adoption of 13.5 MZ radio frequency as power and by utilization of the plasma reinforcement method; thirdly, the roller with is provided with the polyimide film is arranged inside a magnetron sputtering device which is specially used for depositing an aluminum layer; a layer of aluminum is deposited by adoption of the direct-current magnetron sputtering method; n type electrodes are ultrasonically welded by adoption of aluminum and p type electrodes are packaged by adoption of the low-temperature silver-aluminum grouting method. The technique has the advantages of simple technique, low cost and suitability of being mass-produced.

Owner:胡宏勋 +1

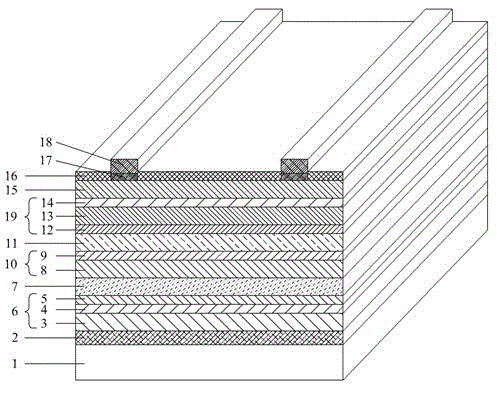

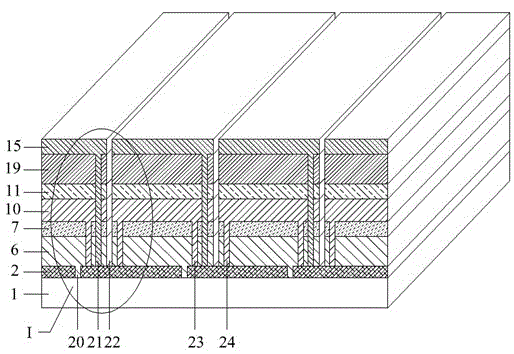

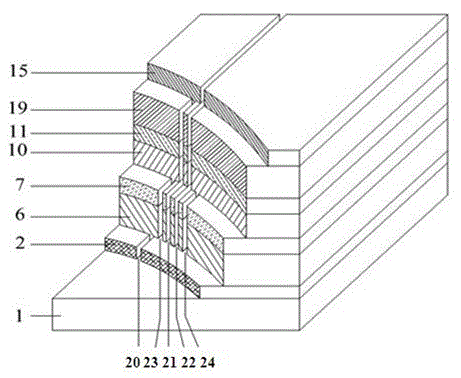

Three-junction laminated thin film solar cell and fabrication method thereof

ActiveCN102983204ADoes not reduce transmittanceDoes not reduce conductivityFinal product manufacturePhotovoltaic energy generationEngineeringGreen-light

The invention discloses a three-junction laminated thin film solar cell, and belongs to the technical field of solar photovoltaics. The thin film solar cell aims at improving photoelectric conversion efficiency of the thin film cell and allowing the photoelectric conversion efficiency of the thin film cell to be approximate to that of a crystal cell. The thin film solar cell is characterized in that a top cell is an amorphous silicon solar cell, has an intrinsic layer energy gap of 1.7-1.8eV, and absorbs blue sunlight; the middle cell is a cadmium telluride cell, has an energy gap of about 1.45eV, and absorbs green light; and the bottom cell is a copper indium gallium selenide cell, has an energy gap of about 1.05eV, and absorbs red light. A middle layer is introduced, an optical path and optical trap structure is added, the light absorption efficiency is improved, the dividing precision can be improved by a step-by-step dividing method, the series connection and short circuit in a cell module are reduced, the product cost is lowered, and the reject rate is reduced.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

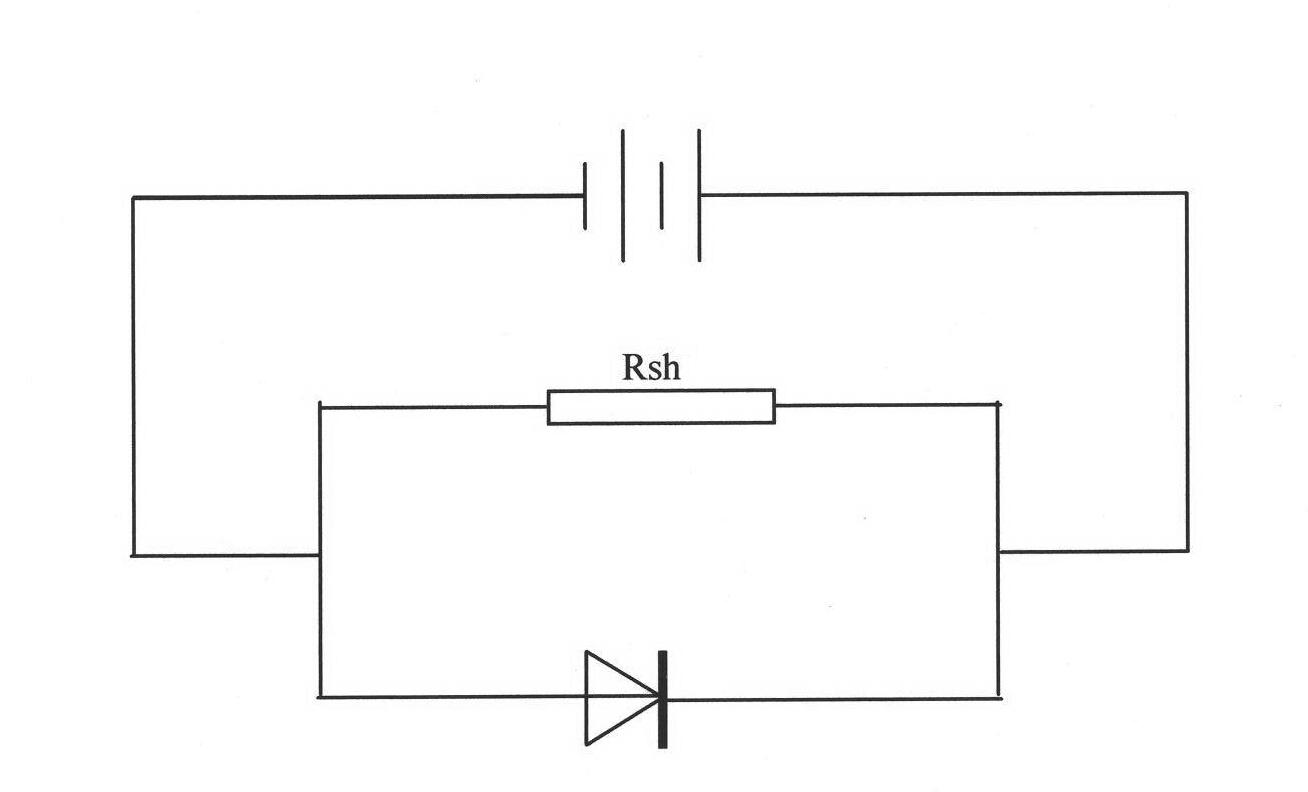

Restoring method of eroded defective products of amorphous silicon cells and special device

InactiveCN101834234AFinal product manufactureSemiconductor devicesAmorphous silicon solar cellEconomic benefits

The invention discloses a restoring method of eroded defective products of amorphous silicon cells. 10-30 V reverse DC voltage is applied to cell units with slight metal residues to form short-circuit current for fusing the slight metal residues, thereby restoring the eroded defective products. The invention also discloses a special device used in the restoring method of eroded defective products of amorphous silicon cells, comprising a DC power supply with adjustable output voltage, a conducting probe, an operation platform, a probe bracket and a probe holder. The restoring method of eroded defective products of amorphous silicon cells and the special device can be used for effectively restoring most of eroded defective products generated in the production of amorphous silicon cells, greatly improve the production yield, and have favorable economic benefit.

Owner:江苏综艺光伏有限公司

Weak-brightness non-crystal silicon solar cell manufacture method using laser etching transparent electrode

InactiveCN101308883AIncrease light receiving areaReduce lossFinal product manufactureSemiconductor devicesLacquerScriber

The invention discloses a method to fabricate a weak light amorphous silicon solar cell, which scribes the transparent electrodes through laser. The method includes the following processes(1), transparent electrode isolation grooves are scribed on the film of an ultra-thin conductive glass through a red laser scriber so as to form insulated transparent electrodes for the amorphous silicon solar cell;(2), a P-I-N amorphous silicon layer is deposited on the surface of the ultra-thin conductive glass through vacuum plating.; (3), isolation grooves penetrating the P-I-P amorphous silicon layer are scribed on the surface of the amorphous silicon film through a green laser scriber so as to expose the transparent electrodes in the isolating grooves; (4) conductive printing ink is printed on the surface of the amorphous silicon layer through a screen printing machine so as to form insulated and isolated back electrodes which respectively penetrate the isolation grooves and are electrically connected with the corresponding transparent electrodes through the amorphous silicon layer; (5), protective lacquer, conductive copper slurry and characters are processed on the back electrodes through screen printing. The invention can not only reduce production cost but also simplify production process and is good for improving the electrical properties of the products.

Owner:PUTIAN WEITE ELECTRONICS

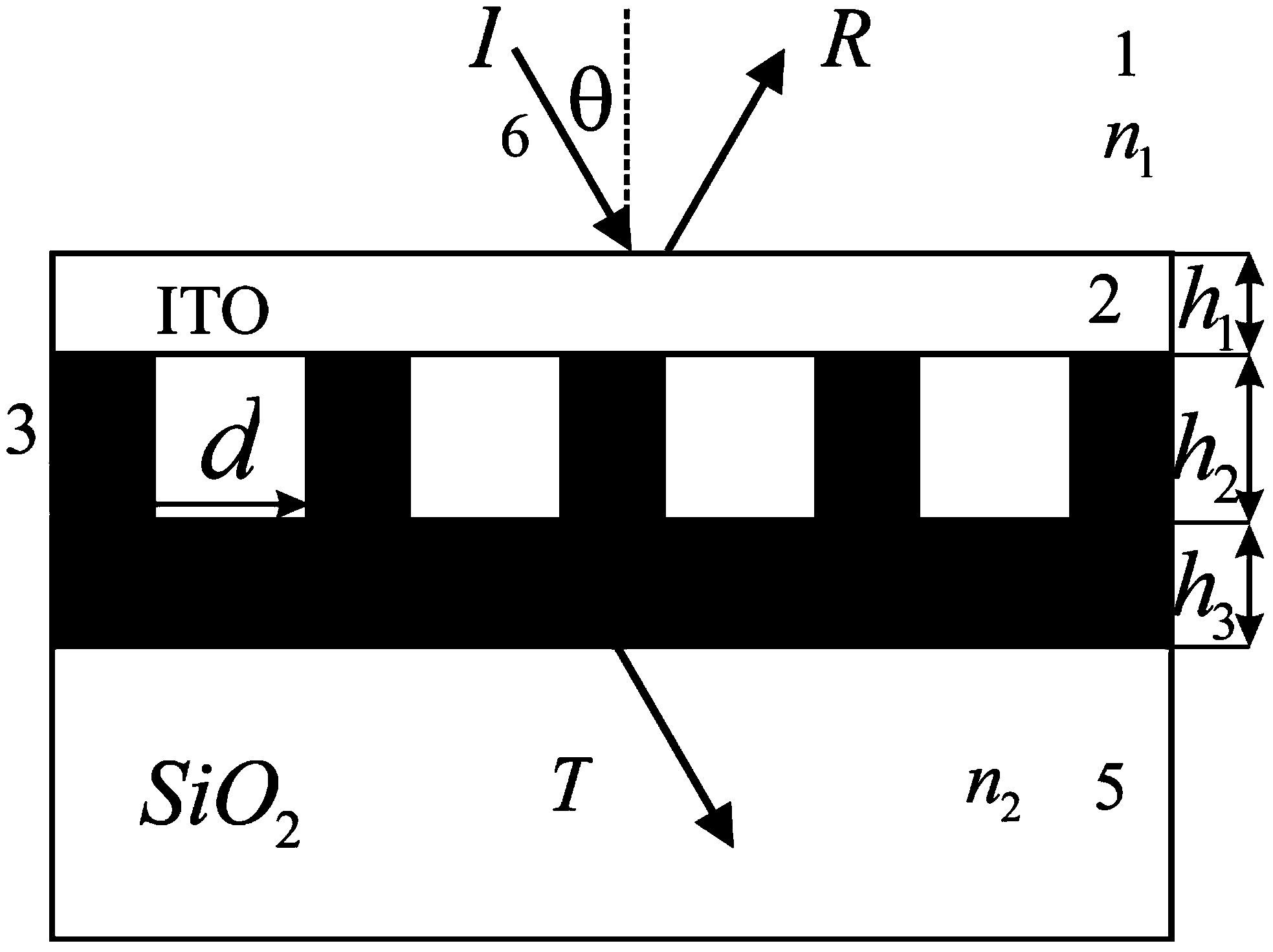

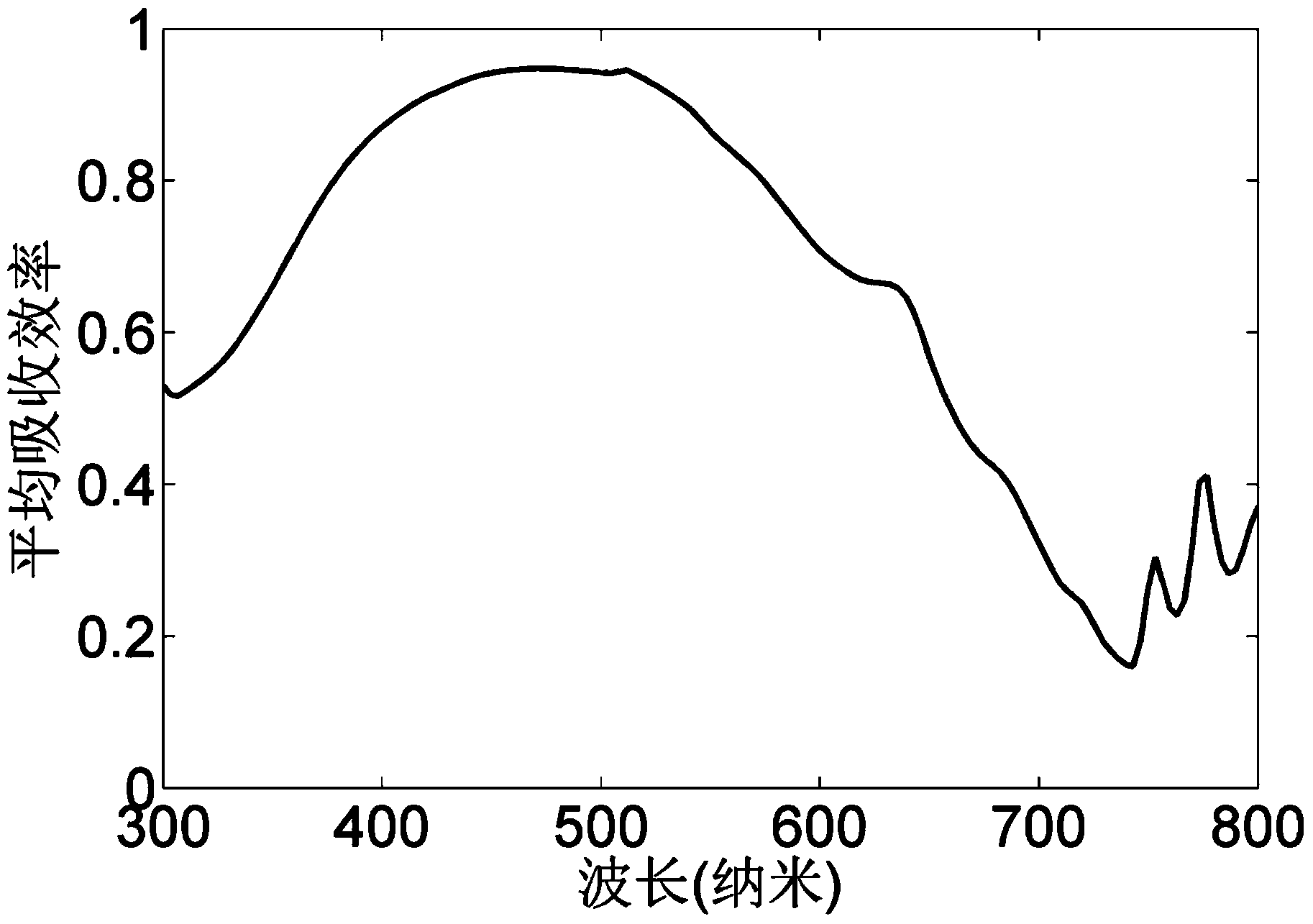

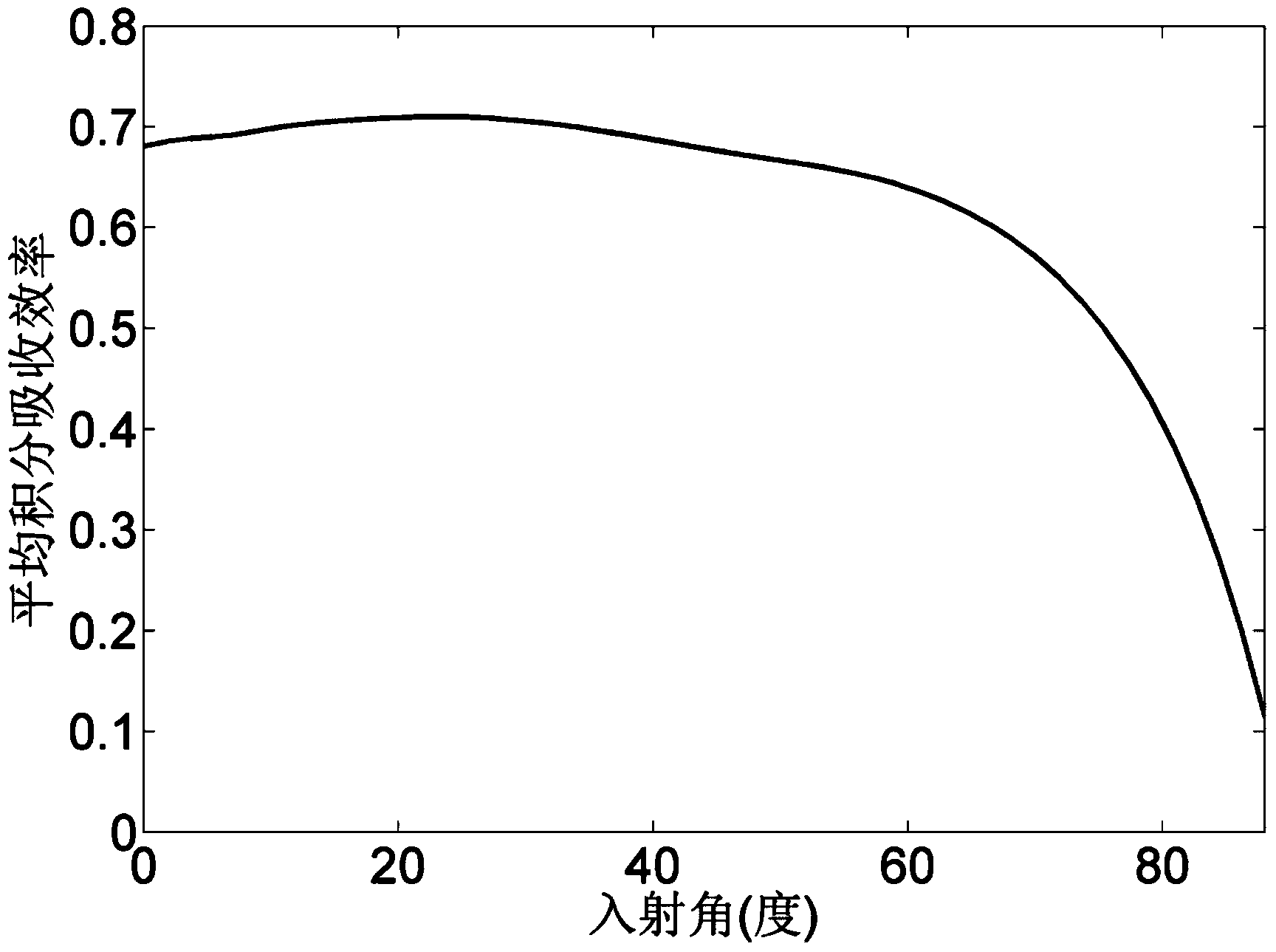

Thin film amorphous silicon solar cell based on antireflective structure and guided-mode resonance

ActiveCN104362184AImprove performanceEasy to use and flexibleDiffraction gratingsPhotovoltaic energy generationEtchingGrating

The invention relates to a thin film amorphous silicon solar cell based on an antireflective structure and guided-mode resonance. The thin film amorphous silicon solar cell used for visible wavelengths ranging from 300 nanometers to 800 nanometers is characterized in that the top antireflective film of the solar cell is 55-60 nanometers in thickness, the period of the middle grating absorption layer is 505-515 nanometers, the middle grating absorption layer is 95-105 nanometers in thickness and 0.7-0.75 in duty ratio, and a waveguide absorption layer is 45-55 nanometers in thickness; when light comes in vertically, the average integral absorption efficiency of the light in the wavelengths of 300-800 nanometers is higher than 66%, the average integral absorption efficiency is large in angle independence, and the average integral absorption efficiency is higher than 60% in the incidence angle of 0-66 degrees. The thin film amorphous silicon solar cell based on the antireflective structure and guided-mode resonance has the advantages that the solar cell is machined by an electronic beam direct writing device combining with micro-electronics deep etching, and the solar cell is convenient in material taking, low in manufacturing cost, capable of achieving large-batch production, and promising in application prospect.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

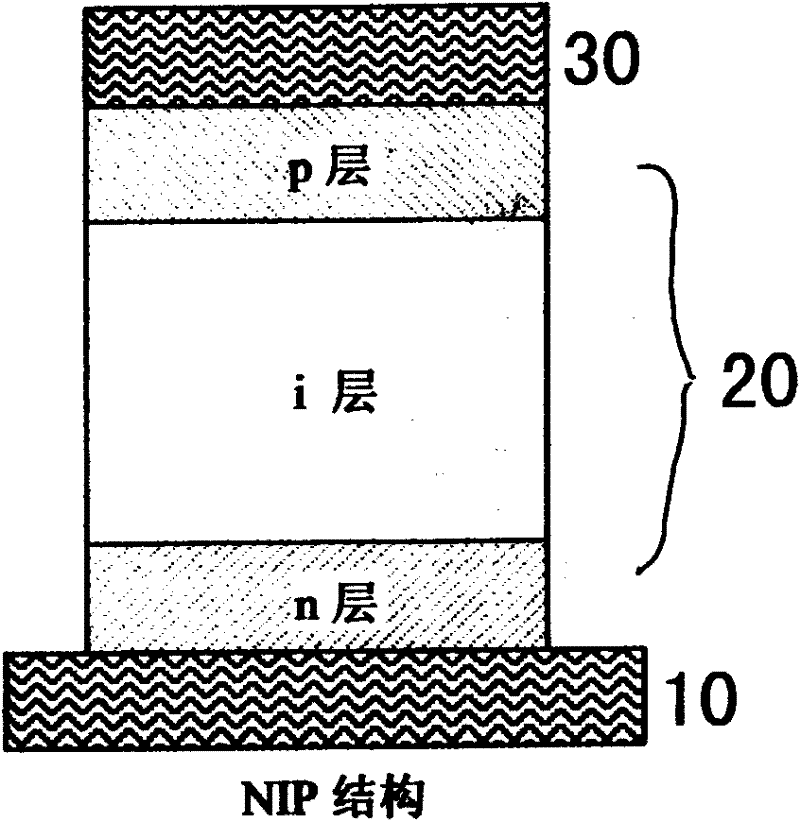

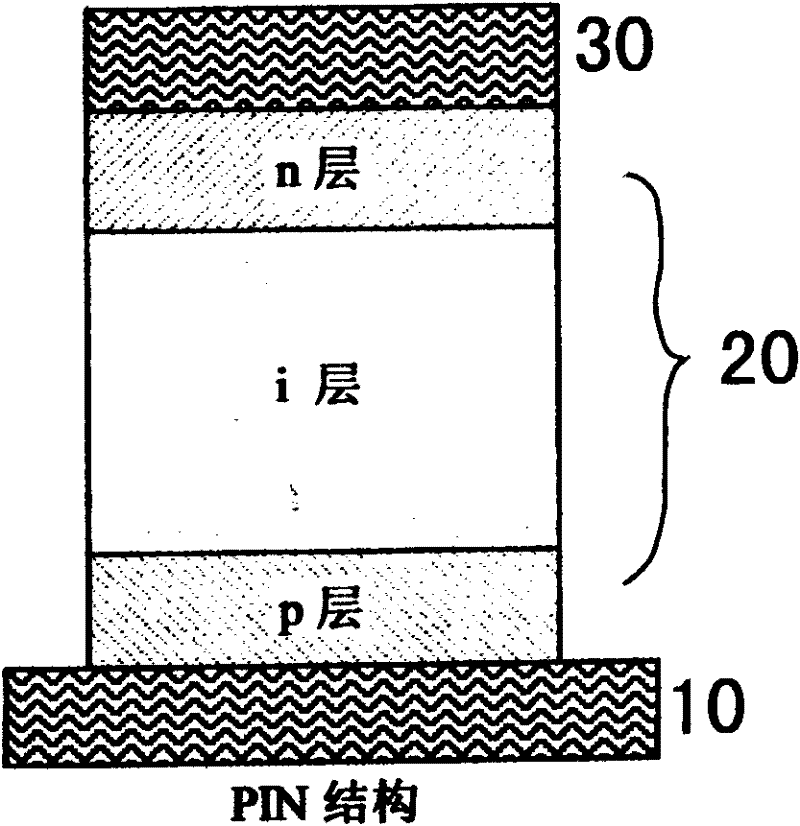

Amorphous silicon solar cell optimized by modulating energy band structure of intrinsic layer via hydrogen and manufacturing method thereof

InactiveCN102176496AImprove performanceReduce lossesFinal product manufactureFrom chemically reactive gasesHydrogenGas phase

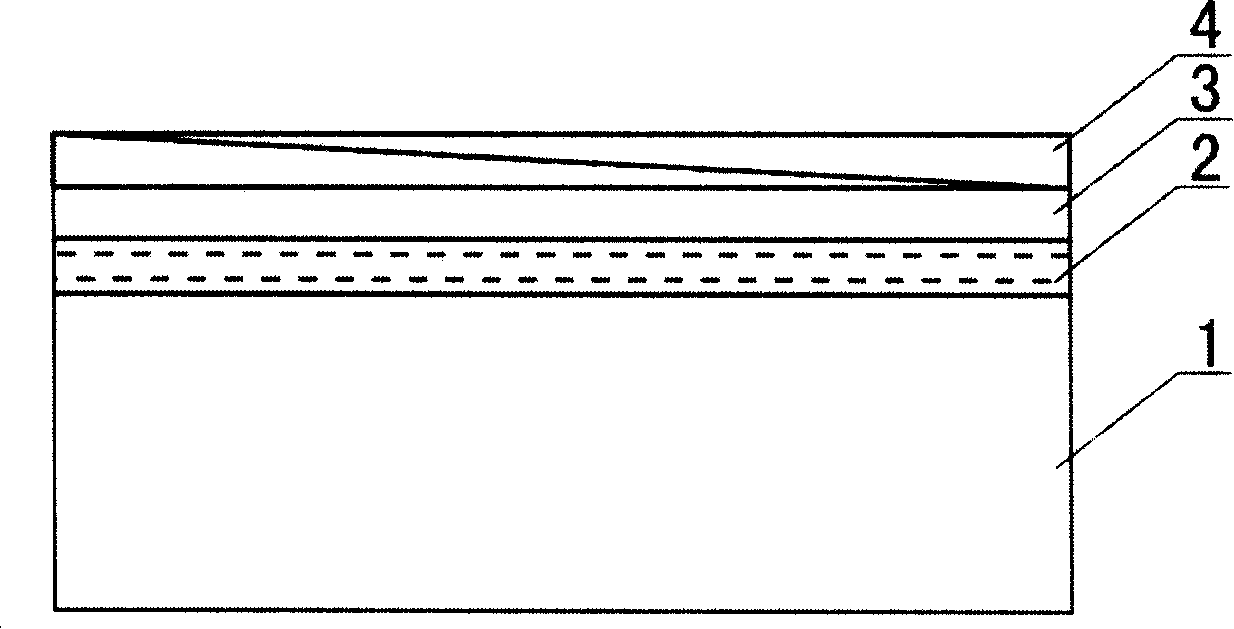

The invention provides a method for manufacturing an amorphous silicon solar cell optimized by modulating an energy band structure of an intrinsic layer via hydrogen, comprising the following steps: step 1, cleaning a substrate, placing the substrate into a plasma enhanced CVD (chemical vapor deposition) system, and baking and pumping high vacuum; step 2, manufacturing an interlayer on the substrate; and step 3, manufacturing an electrode layer on the interlayer. The method is characterized in that the hydrogen is utilized to modulate the energy band structure of the intrinsic layer (I layer) so as to optimize the light absorption performance and the interface performance of the solar cell, thereby improving the efficiency of the solar cell.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

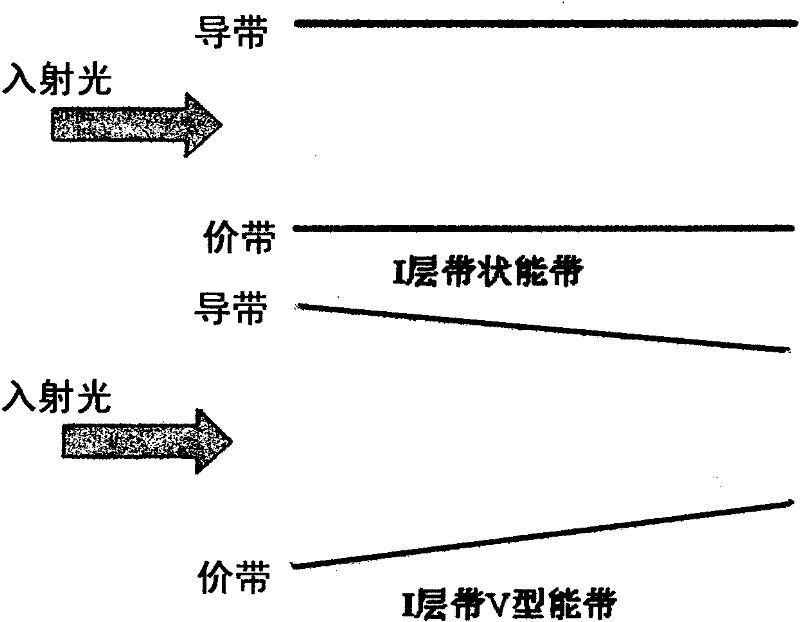

Method for rapidly depositing hydrogenated amorphous silicon solar battery thin film at low temperature

InactiveCN101834233AReduce the temperatureAvoid bombardmentFinal product manufactureVacuum evaporation coatingHydrogenAmorphous silicon solar cell

The invention discloses a method for rapidly depositing a hydrogenated amorphous silicon solar battery thin film at low temperature, which comprises the following steps of: firstly, placing a cleaned substrate on a substrate platform of an opposite target magnetron sputtering device; then vacuumizing a reaction chamber of the opposite target magnetron sputtering device and cleaning the substrate platform of the opposite target magnetron sputtering device and the wall of the reaction chamber by argon plasma; heating the substrate platform; charging a reaction gas into the reaction chamber and adjusting air pressure; starting a sputtering power supply and depositing the amorphous silicon thin film till an amorphous silicon thin film sample is obtained; finally cooling to room temperature under the protection of hydrogen, taking out the sample and finishing the deposition of the hydrogenated amorphous silicon thin film. The invention can rapidly deposit the hydrogenated amorphous silicon thin film at low temperature by utilizing an opposite target magnetron reaction sputtering deposition technology.

Owner:HEBEI UNIVERSITY

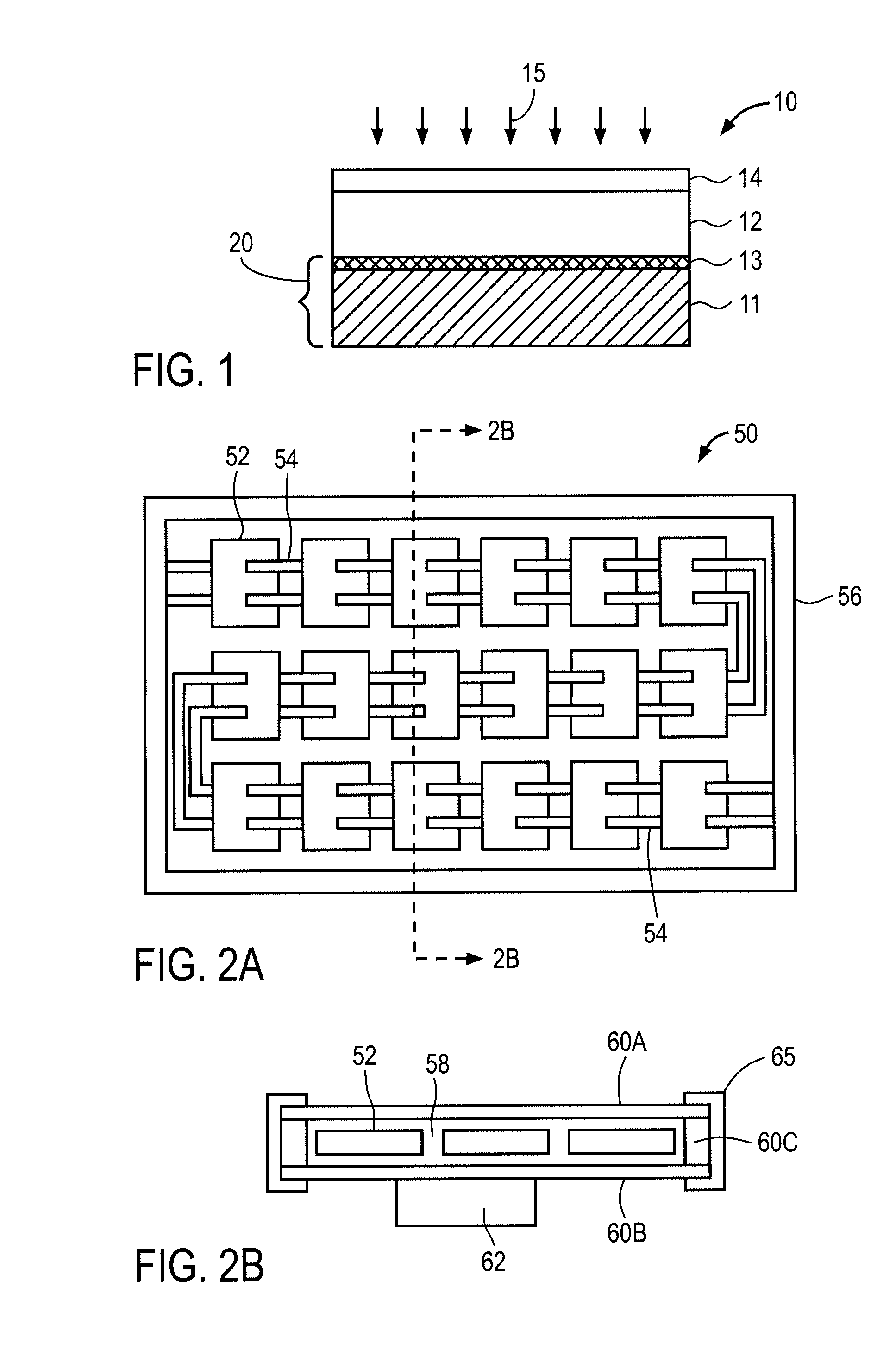

Pore cathode for the mass production of photovoltaic devices having increased conversion efficiency

InactiveUS20060219170A1Enhances continuous deposition of photovoltaicMinimizing effect of non-homogeneityElectric discharge tubesChemical vapor deposition coatingSemiconductor materialsPlasma deposition

A pore cathode for use in a deposition chamber for the plasma enhanced deposition of photovoltaic materials onto one or more webs of substrate material. The cathode is planar and serves the dual functions of (1) an electrode for the plasma deposition process and (2) a distribution conduit for the flow of fresh reaction gas to and for the evacuation of the spent reaction gas from the plasma region to maintain a uniform, constant pressure plasma reaction. The gas outlet pores of the inventive cathode are uniquely sized, shaped and spaced to provide new plasma chemistry and physics to insure optimization of the zoo of chemical species within the plasma regardless of deposition speed. That is, the distribution of ions, electrons, free radicals and neutral species in the plasma are optimized to deposit high quality photovoltaic semiconductor material while also increasing the utilization of the process gases, thus allowing the economical mass production of amorphous silicon solar cells having at least 8% photovoltaic efficiency on large area substrates. The pores can be covered by gas dispersion plates which prevent direct, line-of-sight, flow of the process gases to the adjacent deposition substrate and more uniformly distributes the gases flowing into the plasma region between the cathode and the substrate, thus minimizing the effects of non-homogeneity of the depositing species.

Owner:ENERGY CONVERSION DEVICES INC

Method and ink for etching amorphous silicon solar battery aluminum membrana

InactiveCN101276789AAvoid short circuitEasy to cleanFinal product manufactureSemiconductor/solid-state device manufacturingSlurryOptoelectronics

The invention relates to an etching ink and a method for etching amorphous silicon solar energy battery aluminum film, alkaline etching slurry is used to silk-screen and etch isolation trough for preventing short circuit on the back electrode aluminum film around the amorphous silicon unit battery, the alkaline etching slurry is an ink which is silk-screened on the aluminum film electrode, the proportions of raw materials are that: alkali: 2.7-0.1% (W / W), water, 81-86% (W / W), thickening agent: 5.4-7.3% (W / W), water defoaming agent: 0.3-0.7and (W / W), water flow agent: 1.5-1.8% (W / W). Manufacturing the solar energy battery by adopting the method provided by the invention not only can efficiently prevent circumference of the unit battery from the short circuit, but also has low cost, convenience for cleaning after etching, thus improving production efficiency and being beneficial to large-scale continuous production.

Owner:李毅

Passivation encapsulation method for back electrode of solar cell

InactiveCN101399295ANo pollution in the processGood effectFinal product manufactureSemiconductor devicesAmorphous silicon solar cellSilicon solar cell

The invention discloses a passivation packaging method of a back electrode of a solar cell, and the passivation packaging method comprises: step one, a passivation layer is coated on a back electrode layer and the surface of a channel thereof which are etched by laser; step two, an adhesive layer and a substrate are overlapped on the back surface of the passivation layer and laminated together. The passivation packaging method isolates and protects the amorphous silicon solar cell by a passivation film which is arranged at the back surface of the cell and packages insulating materials. The passivation film is not only a barrier of exogenous impurities, but also causes the surface of the device to have good mechanical performance.

Owner:上海拓引数码技术有限公司

Non-crystal silicon thin-film solar cell component used for building and processing method thereof

InactiveCN101419991AIncrease power generationWon't break easilyWallsFinal product manufactureElectrical batteryAmorphous silicon solar cell

The invention discloses an amorphous silicon thin film solar cell assembly which is made by fixing amorphous silicon thin film solar cells on glass or toughened glass by film and is used in construction as well as a production method thereof. The solar cell assembly is characterized in that an integrated curtain wall assembly is composed of the amorphous silicon solar cells, the film, the toughened glass and connecting terminals, the amorphous silicon thin film solar cells are fixed on the glass or the toughened glass by the film, and the connecting terminals are led out at two sides of the amorphous silicon thin film solar cell assembly. The amorphous silicon thin film solar cell assembly has the advantages of low cost, increasing the competitive edges of products, lowering the mounting angle requirements of the cell assembly, convenient construction and installation, long service life, low processing cost and the like.

Owner:威海中玻光电有限公司

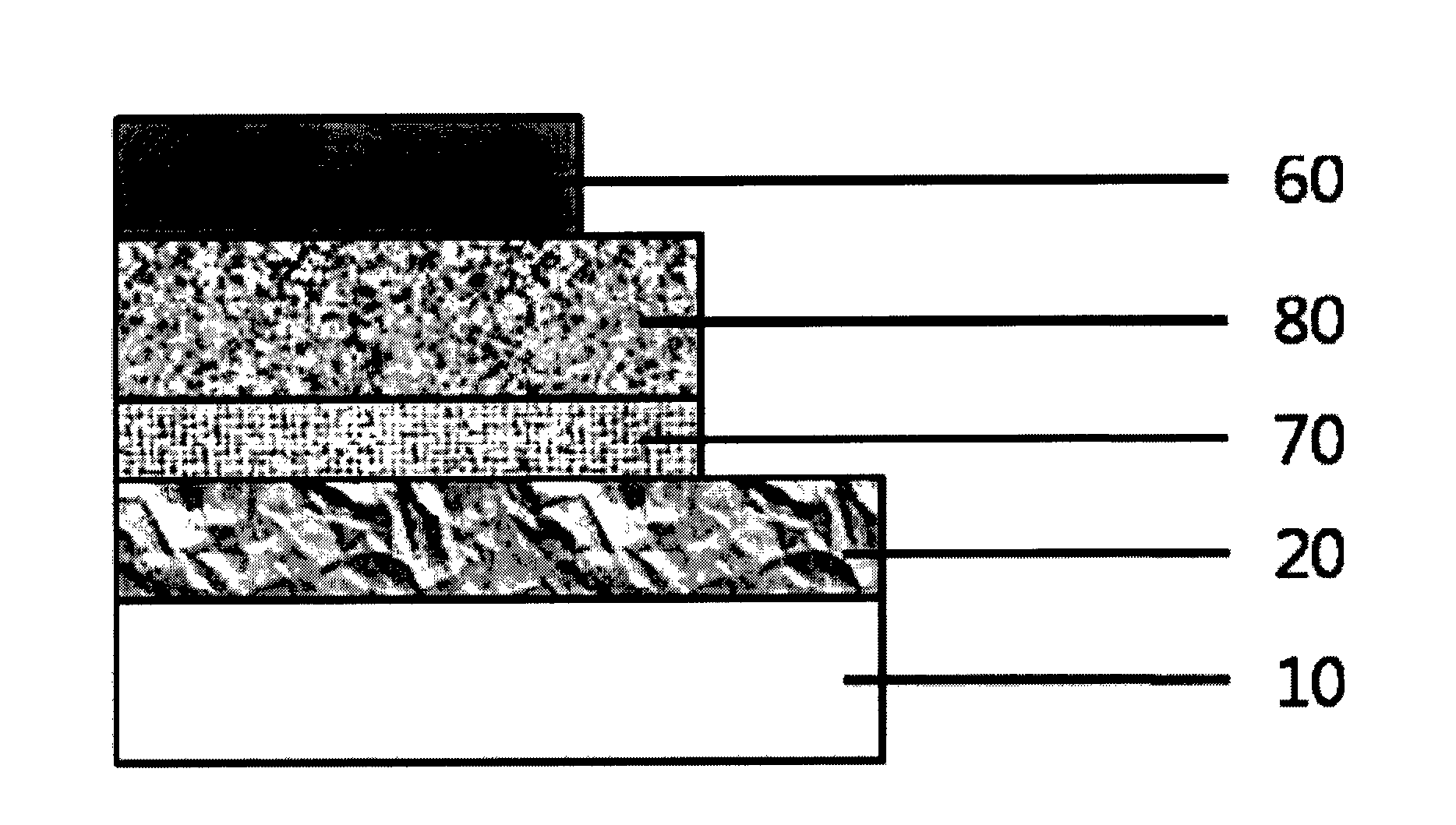

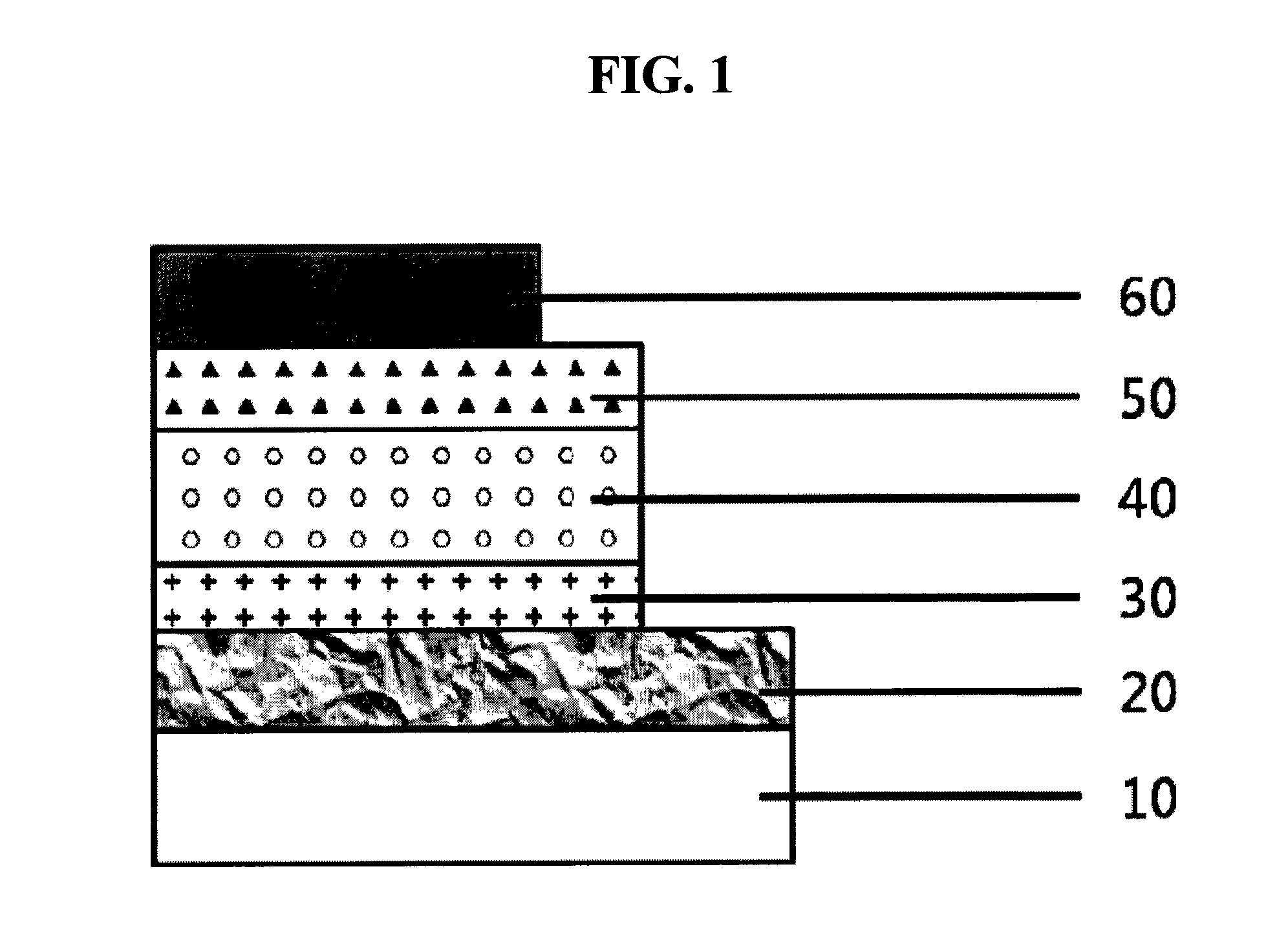

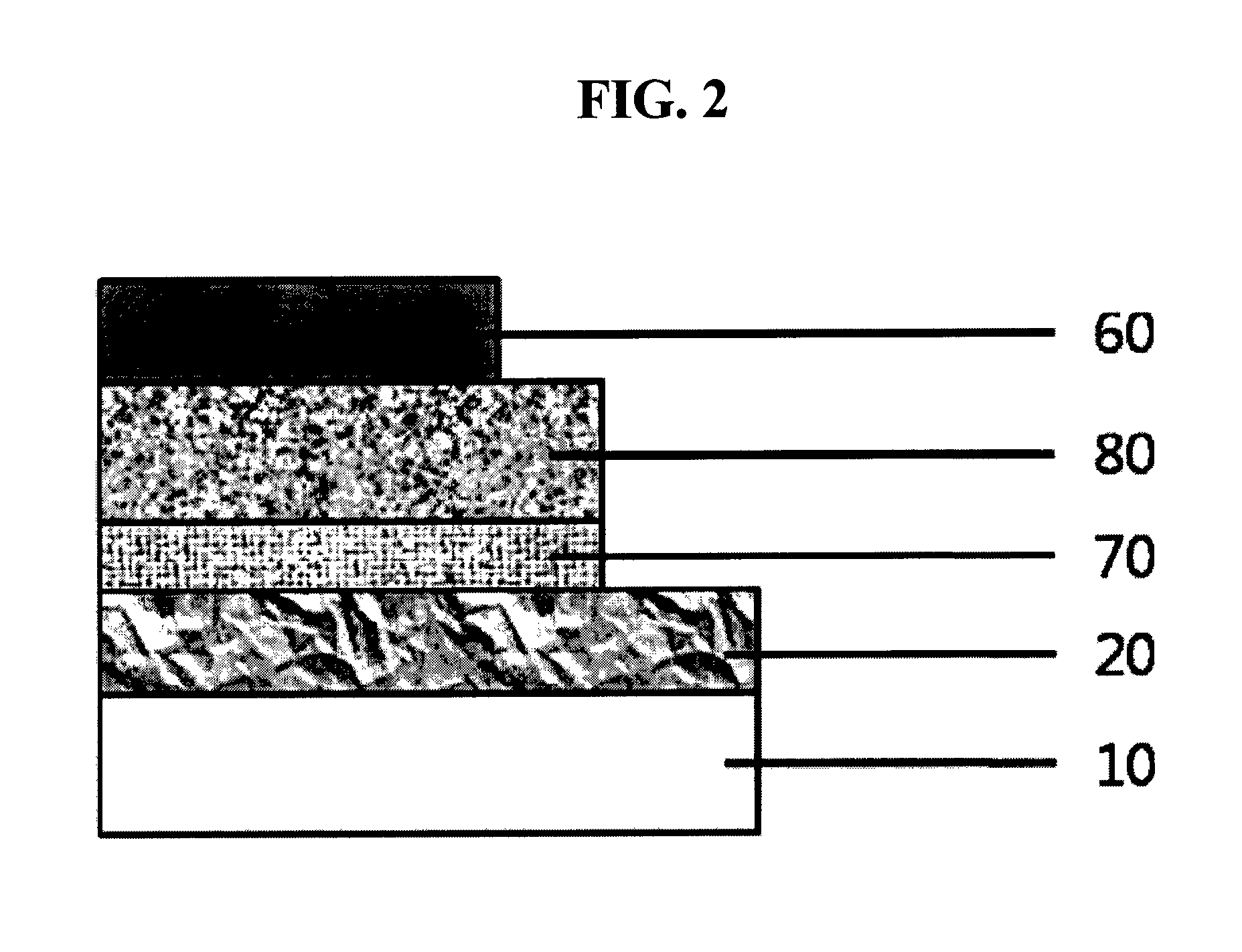

Tandem solar cell using amorphous silicon solar cell and organic solar cell

InactiveUS20130118567A1Wide range of lightingImproved open-circuit voltage (Voc) performanceSolid-state devicesPhotovoltaic energy generationAmorphous silicon solar cellTandem solar cell

A tandem solar cell comprising an amorphous silicon solar cell including a photoactive layer made of amorphous silicon; and an organic solar cell including a photoactive layer made of an organic material, which are stacked and electrically connected in series can absorb a wider wavelength range of light, exhibit improved open-circuit voltage (Voc) performance, and be mass produced in a simple manner at low cost.

Owner:KOREA INST OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com