Novel silicon substrate heterojunction solar cell

A technology of solar cells and silicon substrates, applied in circuits, photovoltaic power generation, electrical components, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

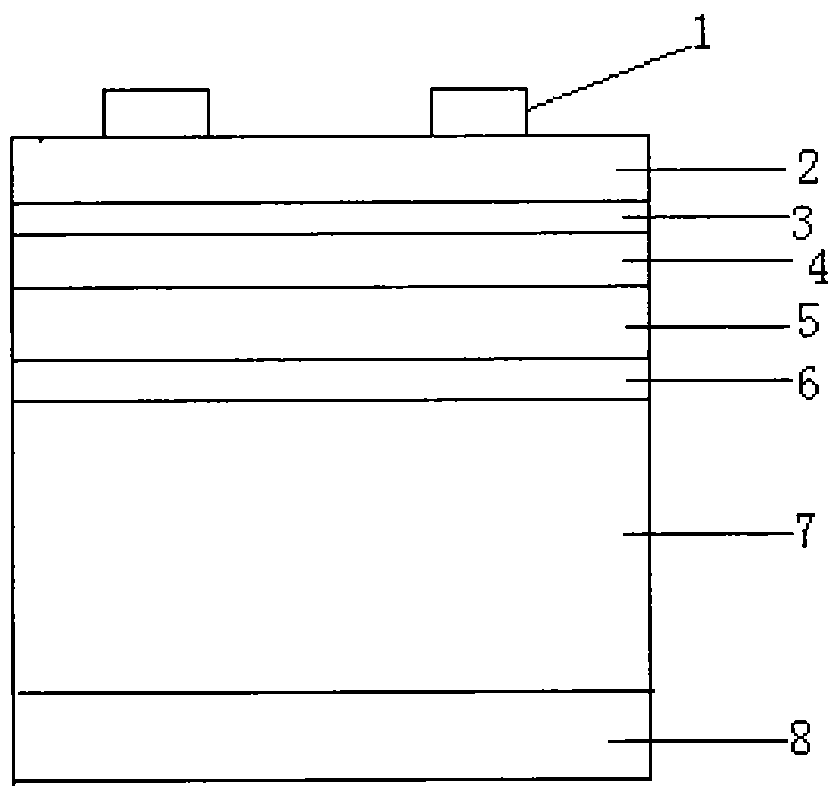

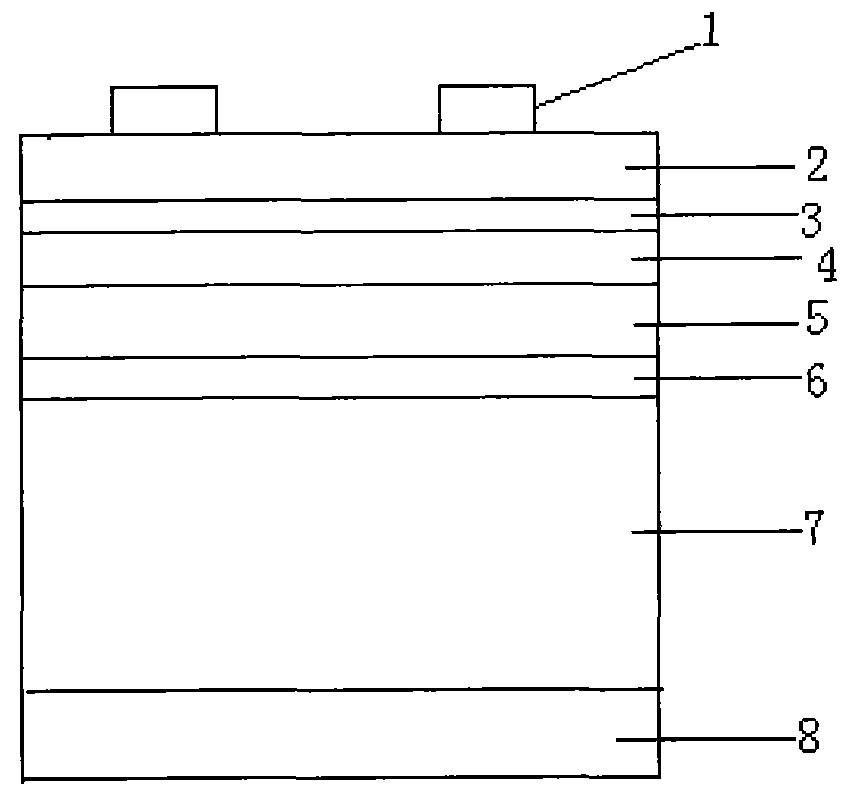

[0027] Such as figure 1 As shown, the silicon substrate 7 is an N-type Czochralski monocrystalline silicon wafer with a crystal orientation of and a resistivity of 2Ω·cm, polished on one side, and a thickness of 260 μm. The thickness of the ITO film 2 grown by magnetron sputtering is 80nm; the thickness of the intrinsic amorphous silicon film 3 deposited by PECVD is 2nm; the thickness of the deposited P-type heavily doped amorphous silicon film 4 is 5nm; the deposited P-type nano-silicon film The thickness of 5 is 12 nm; the thickness of deposited intrinsic amorphous silicon thin film 6 is 3 nm; the thickness of evaporated Ag back electrode 8 is 3 μm.

[0028] After measurement, in the simulated light source AM1.5, 100mW / cm 2 Under the standard light intensity irradiation, the efficiency of the novel silicon-based heterojunction solar cell prepared in this example reaches 17.2%, and the effective area of the cell is 0.28cm 2 , where the open circuit voltage is 602mV and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com