Patents

Literature

87results about How to "Does not reduce conductivity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Manufacture method of electroconductive aluminum alloy section

The invention discloses a manufacture method of an electroconductive aluminum alloy section. The manufacture method comprises the following steps: cast ingot component control, fusion casting, extruding, quenching and aging heat treatment; in the step of quenching, the water entry temperature of the section is 520-530 DEG C, the cooling rate is 180-350 DEG C / min; and in the step of aging heat treatment, the heat-insulation temperature of the section is 160-180 DEG C and the heat-insulation time is 10-16 hours. The aluminum alloy section manufactured by the manufacture method disclosed by the invention has tensile strength of more than 245 MPa, electrical conductivity of more than 55%IACS (International Annealed Copper Standard), and hardness of more than 80HB.

Owner:SNTO TECH GRP

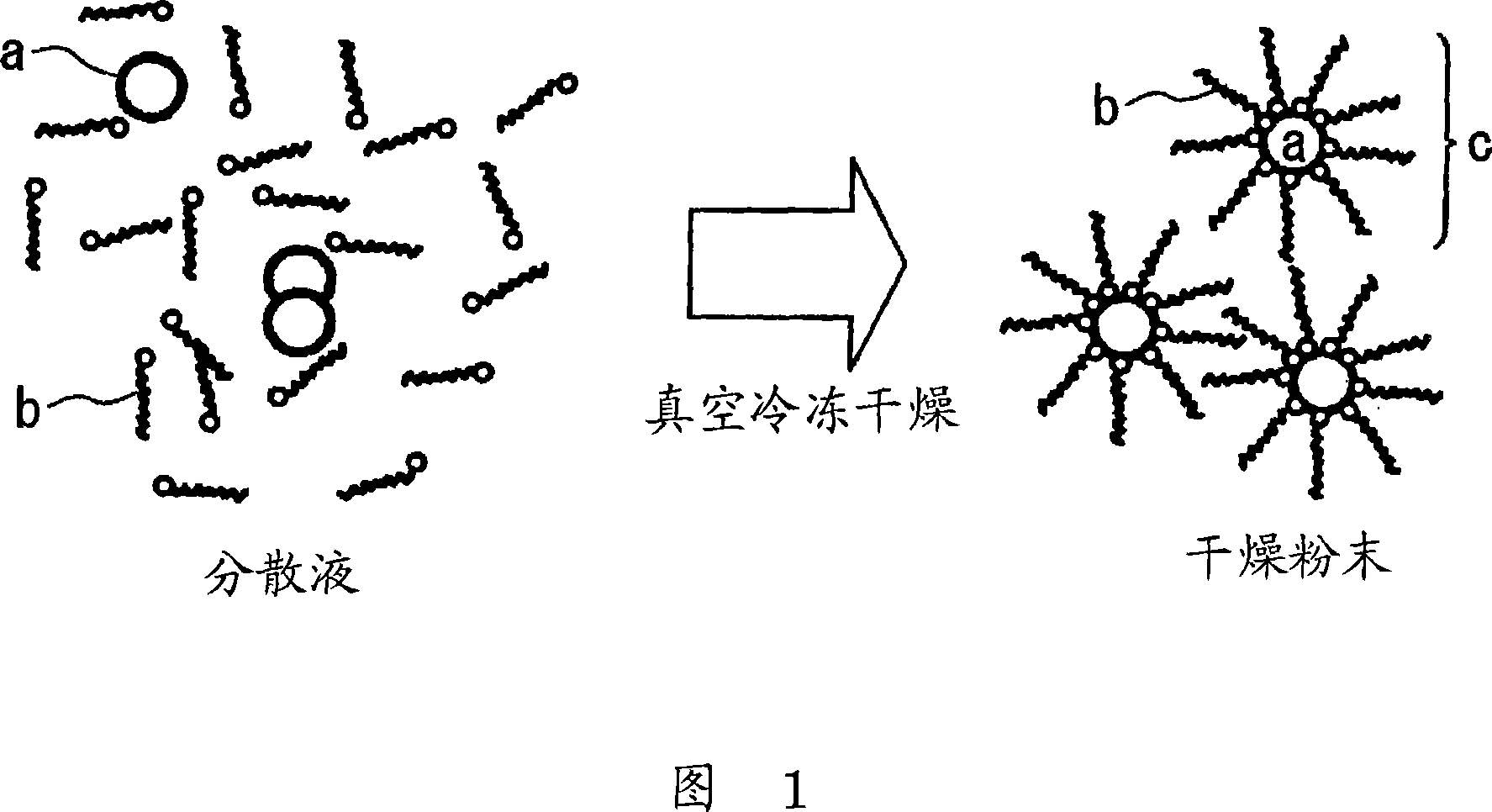

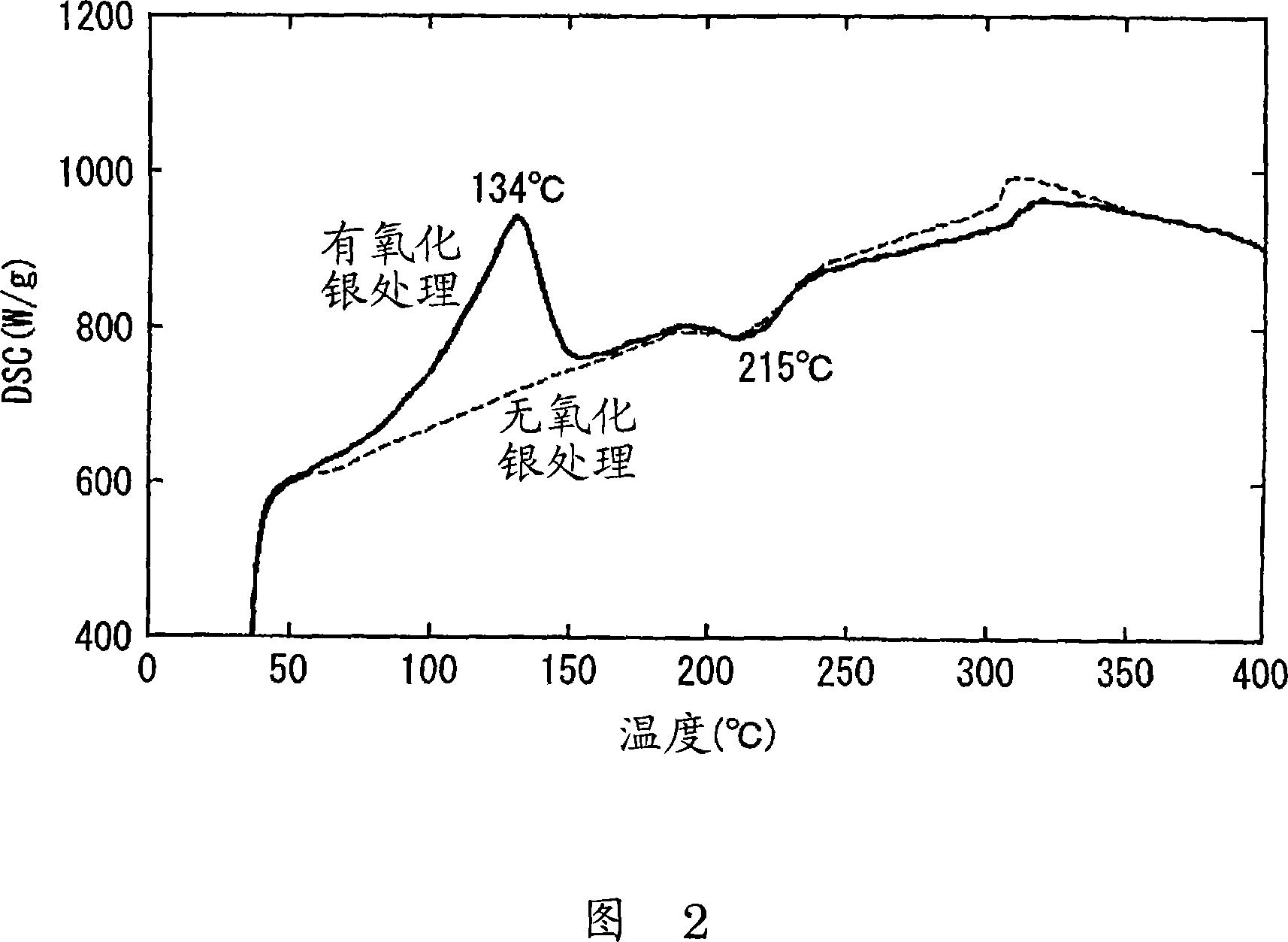

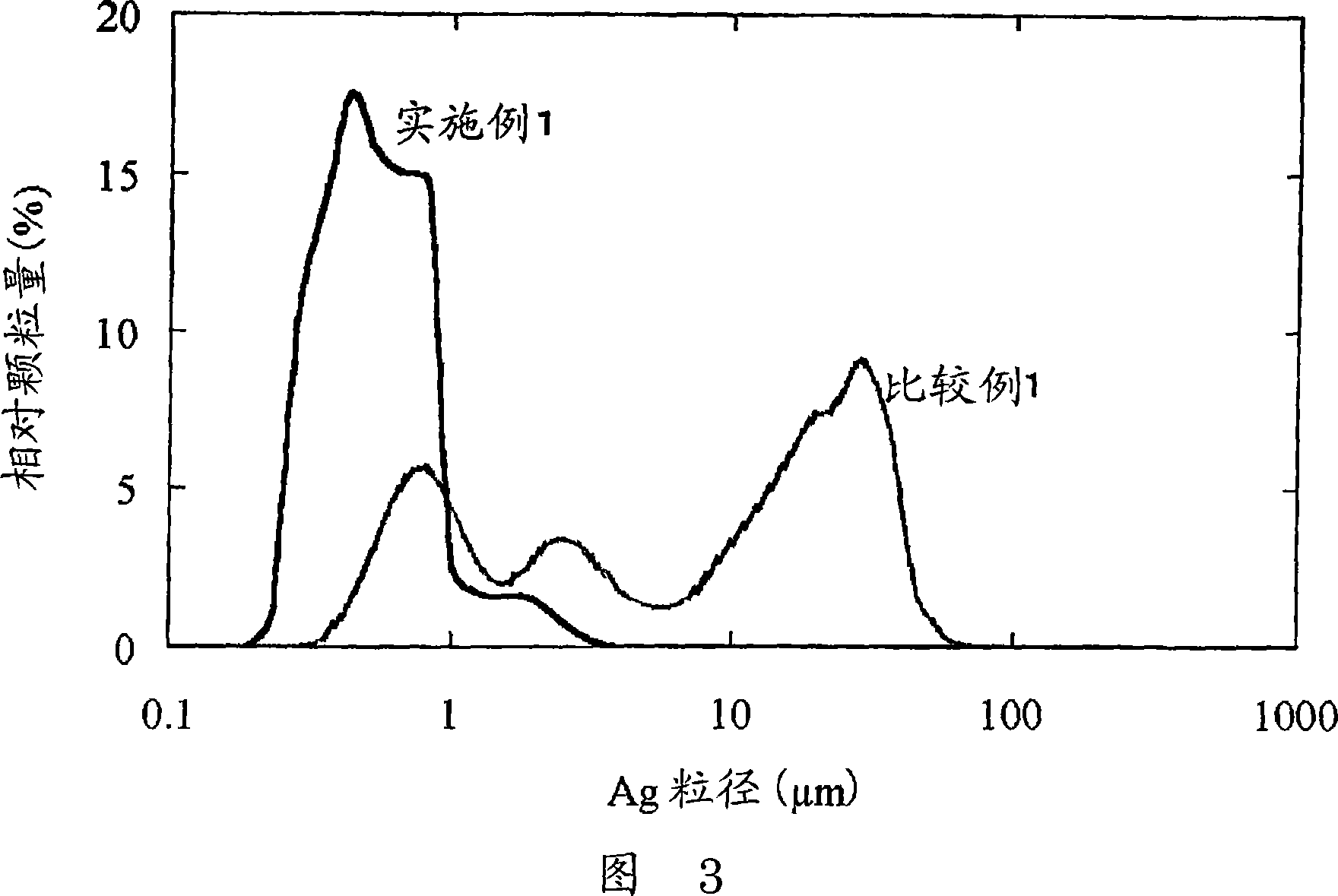

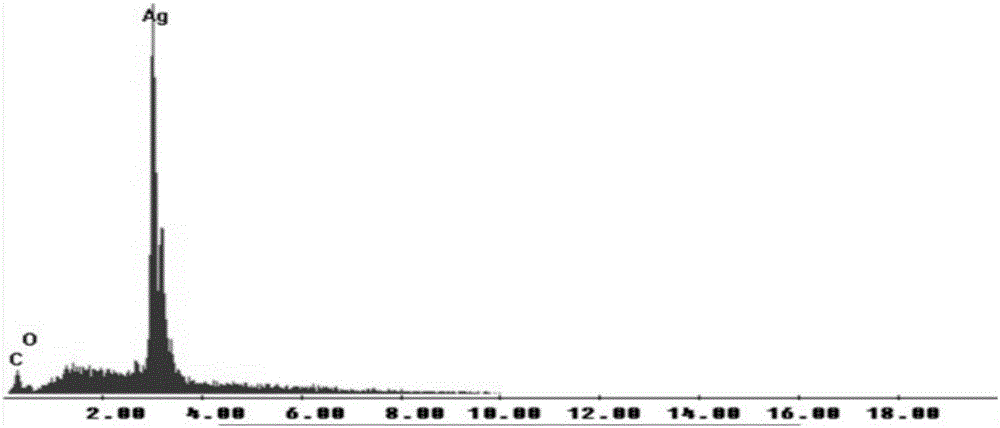

Method for producing surface-treated silver-containing powder and silver paste using surface-treated silver-containing powder

InactiveCN101065203AWrappedImprove adsorption capacityNon-conductive material with dispersed conductive materialSilver pasteFreeze-drying

Disclosed is a method for producing a surface-treated silver-containing powder wherein a dispersion liquid, which is obtained by dispersing silver or silver compound particles (a) in a solvent together with a surfactant (b) of alkylamine type, alkylamine salt type or phosphate type having a phosphorus content of 0.5-10% by mass, is subjected to vacuum freeze drying for having the surfactant (b) adsorbed on the surfaces of the silver or silver compound particles (a), thereby producing a silver-containing powder (c) whose surface is treated with the surfactant (b). Also disclosed is a silver paste produced by dispersing the surface-treated silver-containing powder (c) in a solvent or in a solvent and a resin.

Owner:DAINIPPON INK & CHEM INC

Rolled tungsten-copper alloy material and preparation method thereof

InactiveCN101386948AImprove conductivityImprove thermal conductivityVolumetric Mass DensityElectronic packaging

The invention relates to a rolled tungsten-copper alloy material and a preparation method thereof, and relates to a tungsten-copper alloy material and a preparation method thereof. The invention solves the problems of poor compatibility between phases, less than 99 percent of density, high cost of manufacture equipment, complex technological process, large energy consumption and low production efficiency in the prior tungsten-copper alloy material. The rolled tungsten-copper alloy material is prepared by tungsten powder and copper powder. The preparation method comprises the following steps: firstly, preparation of mixed powder; secondly, preparation of a blank; thirdly, vacuum degassing of the blank; fourthly, preparation of an extruded tungsten-copper alloy material; and fifthly, acquisition of the rolled tungsten-copper alloy material after heating and pressurizing of the extruded tungsten-copper alloy material. The rolled tungsten-copper alloy material has good compatibility between the phases, and increases the density by 0.2 to 0.5 percent. The preparation method is simple, and has low equipment cost required, simple technology, low energy consumption and high production efficiency. The rolled tungsten-copper alloy material and the preparation method are suitable to be used in the fields of preparation, application and so on of electric spark machining electrodes, resistance welding electrodes and electronic packaging and heat sinking materials.

Owner:HARBIN INST OF TECH AT WEIHAI

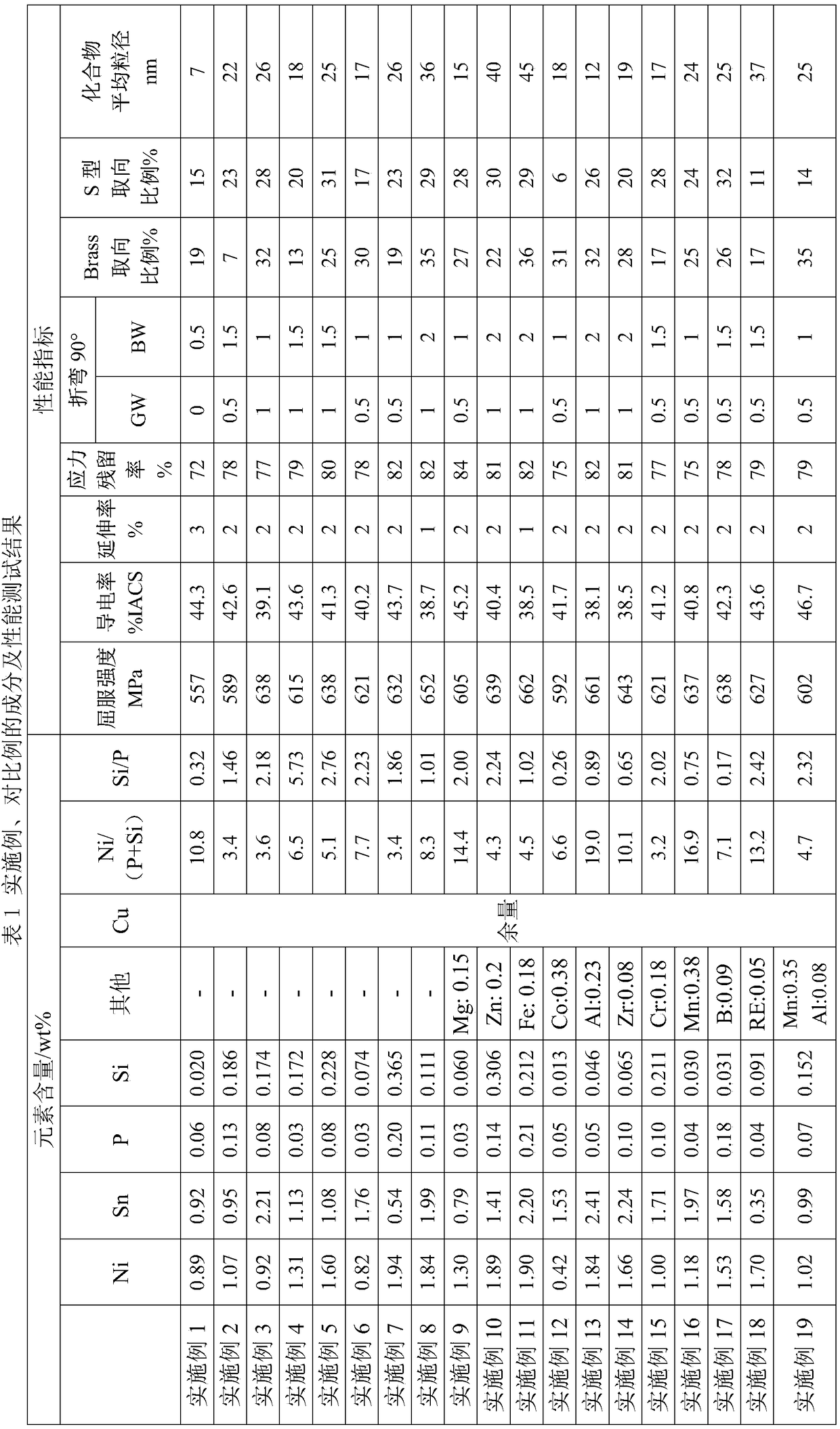

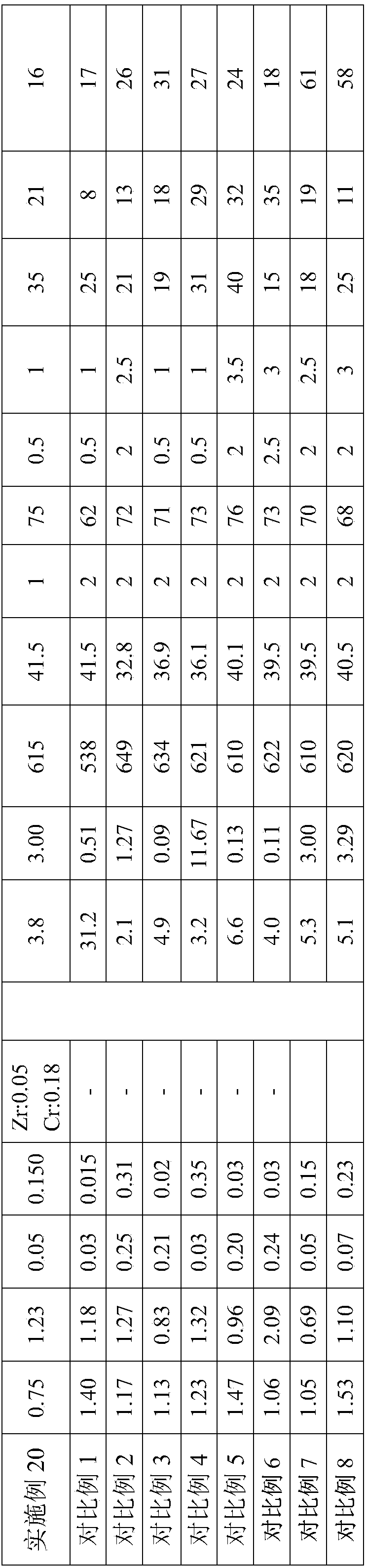

Copper alloy with outstanding comprehensive performance and application thereof

ActiveCN109022900AGuaranteed electrical conductivityHigh strengthConductive materialMetal/alloy conductorsWire rodUltimate tensile strength

Owner:NINGBO POWERWAY ALLOY MATERIAL

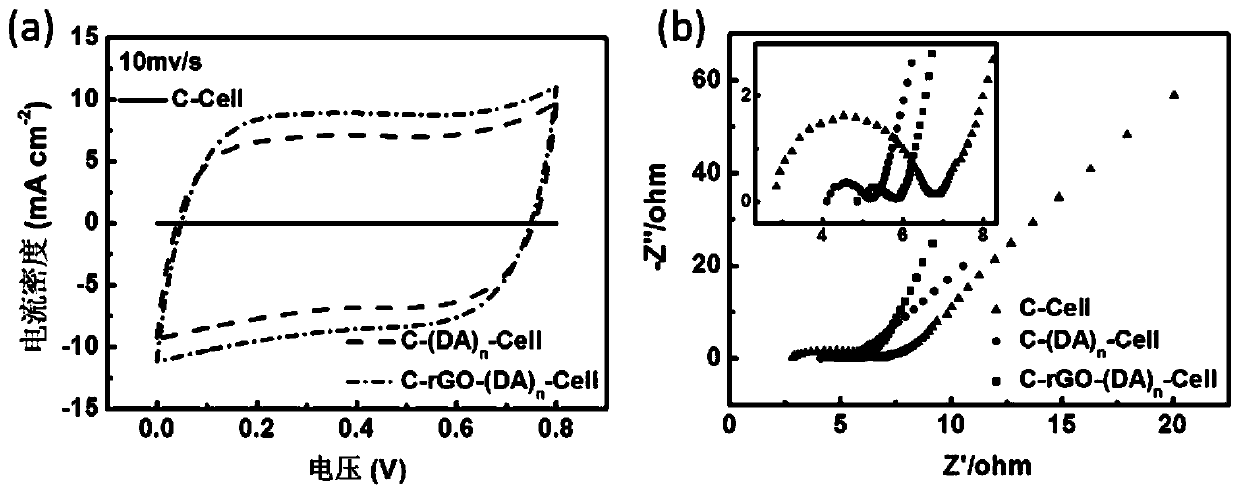

High-temperature-resisting ferro-bronze and preparing method and application of high-temperature-resisting ferro-bronze

ActiveCN106591623AMeet the needs of useExcellent high temperature softening performanceLead frameSolid solution

The invention discloses high-temperature-resisting ferro-bronze. The high-temperature-resisting ferro-bronze comprises, by weight percent, 0.05%-3.0% of Fe, 0.005-0.25% of Sn, 0.01%-0.30% of P and the balance Cu and inevitable impurities. Due to the fact that the ratio and the content of elements such as Fe, Sn and P are rigidly controlled and meanwhile the precipitation amount of iron-phosphorus intermetallic compounds and tin-phosphorus intermetallic compounds in an alloy microstructure is controlled, it can be achieved that the alloy tensile strength is 450 MPa or above, the electric conductivity is 85% of the IACS or above, the hardness is 130 HV or above, meanwhile, after the situation is maintained for 5 min under the temperature of 500 DEG C, the hardness retention rate is larger than or equal to 80% of the original hardness, the good high-temperature-softening resisting performance is achieved, and the high-temperature-resisting ferro-bronze can be used for connectors and lead frame materials under the high temperature. According to the preparing method, it can be ensured that solid solution of Fe and P is achieved in a copper alloy matrix, the iron-phosphorus intermetallic compounds and the tin-phosphorus intermetallic compounds are formed by surplus Fe, P and Sn, dispersion strengthening precipitation is achieved, the alloy strength and hardness are improved, and meanwhile the electric conductivity of the high-temperature-resisting ferro-bronze is not reduced.

Owner:NINGBO POWERWAY ALLOY PLATE & STRIP CO LTD

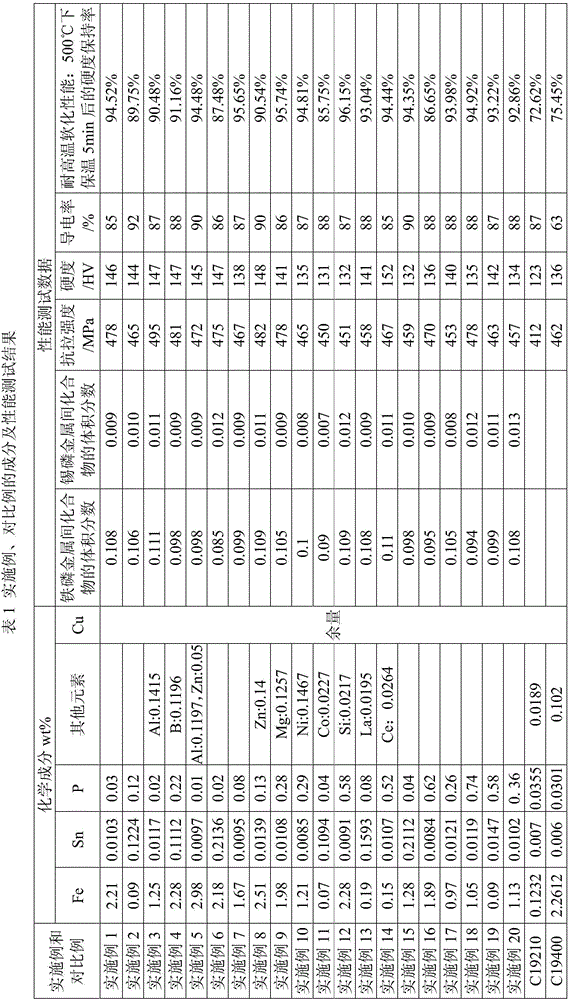

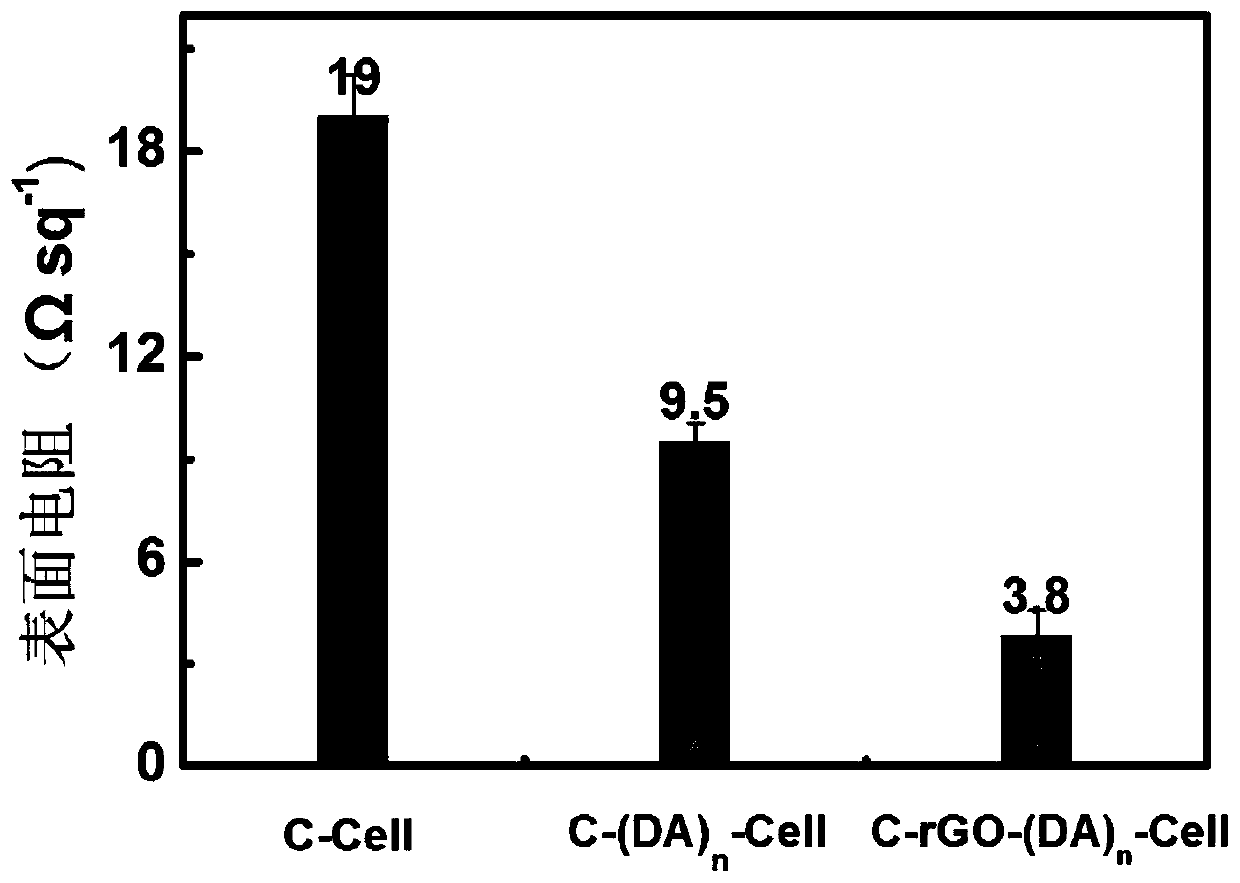

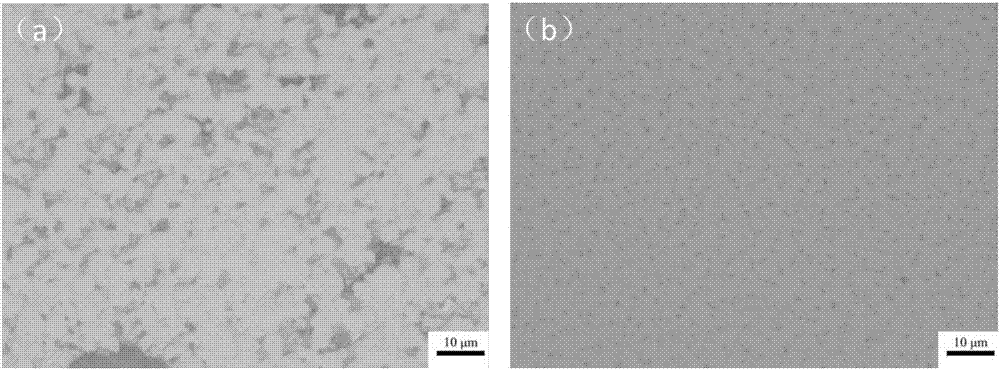

Flexible fabric electrode as well as preparation method and application thereof

ActiveCN110060885AExcellent electrochemical propertiesImprove adhesionCarbon compoundsHybrid capacitor electrodesFiberNanoparticle

The invention belongs to the technical field of supercapacitors, and particularly relates to a flexible fabric electrode as well as a preparation method and application thereof. According to the method, the cleaned fiber fabric is subjected to interface modification by dopamine, and a porous interface layer composed of polydopamine nanoparticles is formed on the fiber fabric; then an electrochemical active material is loaded by utilizing the excellent adhesion of the porous interface layer, so that the adhesion effect of the active material and the fiber fabric substrate is enhanced; and finally the flexible fabric electrode with high loading capacity, large specific surface area and high conductivity is obtained through high-temperature carbonization. The method is simple and efficient, and a universal method for functionalization of the fabric electrode is provided. The surface of the existing fabric is changed by the simple method, the low-cost fabric on the market is converted intothe flexible wearable supercapacitor with excellent electrochemical performance, so that the flexible fabric electrode has wide application in flexible energy storage.

Owner:SOUTH CHINA UNIV OF TECH

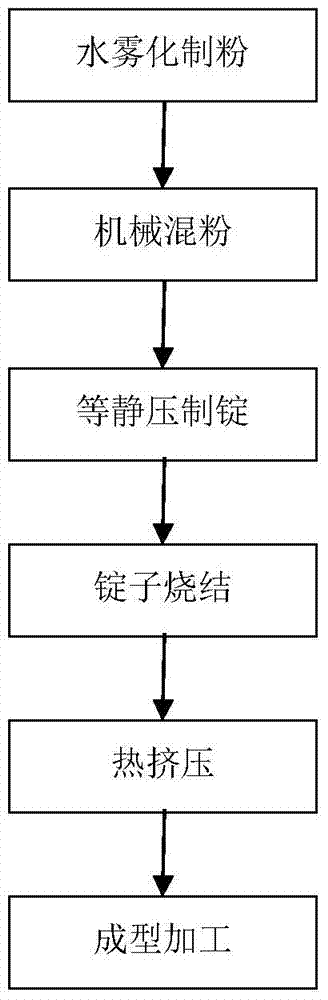

Sliver oxide contact material with base body performance-strengthening additives as well as preparation method and product thereof

The invention discloses a preparation method of a sliver oxide contact material with base body performance-strengthening additives and a product thereof. The preparation method comprises the following steps: preparing an additive alloy with strengthening performance, oxide powder, other additive powder and a sliver ingot which are used as raw materials into powder by water atomization, mixing powder, pressing an ingot, sintering, extruding and finally drawing or rolling to prepare a contact material finished product. The sliver oxide contact material disclosed by the invention has a sliver base body with good electrical performance and mechanical performance, oxide particles and other additive materials are uniformly dispersed in the sliver base body, so that the contact material is ensured to have the characteristics of being uniform and stable in electrical performance, good in processing performance, and the like. Compared with the conventional sliver oxide contact material, the material prepared by the process in the invention has higher burning loss resistance, electro-transfer resistance and fusion welding resistance, can satisfy volume miniaturization and performance optimization needs of a low-voltage electrical appliance. Moreover, the process disclosed by the invention is simple and suitable for mass production. The prepared silver oxide product can be widely applied to a relay, a contact and a circuit breaker.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

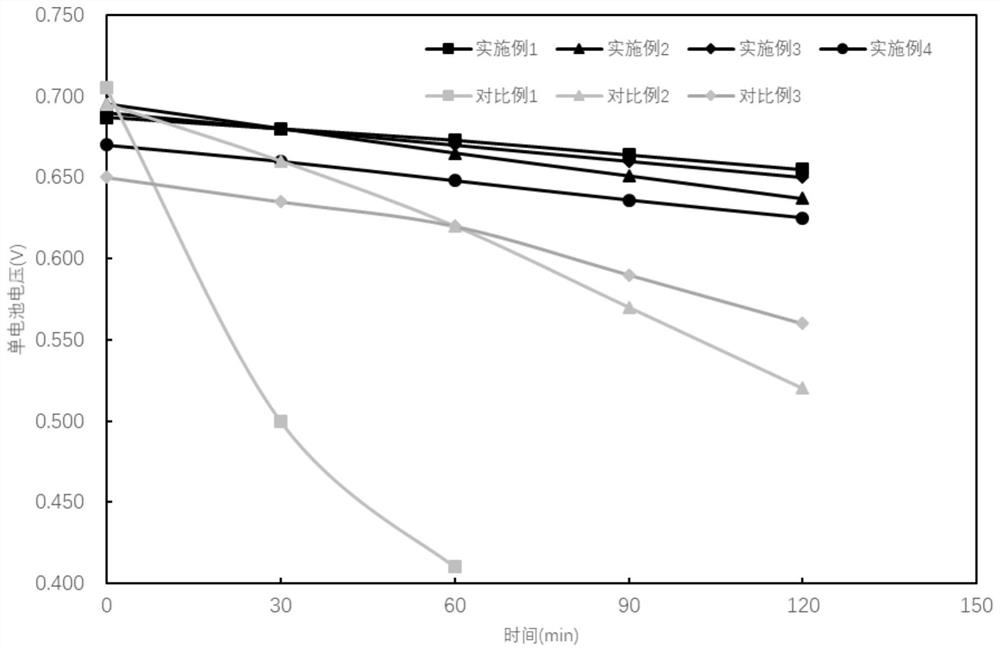

Anode catalyst slurry, anode catalyst layer, membrane electrode and fuel cell

InactiveCN111900420ADoes not reduce conductivityAvoid damageCell electrodesFuel cellsPtru catalystFuel cells

The invention relates to an anode catalyst slurry, an anode catalyst layer, a membrane electrode and a fuel cell and relates to the technical field of fuel cells. According to the main technical scheme, the anode catalyst slurry is used for preparing an anode catalyst layer of a fuel cell and comprises a catalyst slurry body and a water electrolysis catalyst. The catalyst slurry body contains a carbon-supported noble metal catalyst; the carbon-supported noble metal catalyst comprises a carbon carrier and noble metal loaded on the carbon carrier. The water electrolysis catalyst is used for catalyzing water electrolysis reaction; the mass of the electrolyzed water catalyst is 20-100% of the mass of the noble metal. And the anode catalyst layer is obtained by coating the anode catalyst slurryon a proton exchange membrane and drying. The membrane electrode comprises the anode catalyst layer. The anode catalyst slurry is mainly used for improving the anti-reversion performance of the membrane electrode in the fuel cell, and the problem of membrane electrode damage caused by voltage reversion due to insufficient anode fuel supply is solved.

Owner:浙江锋源氢能科技有限公司 +1

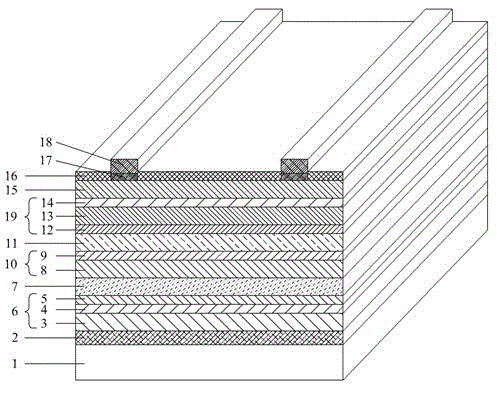

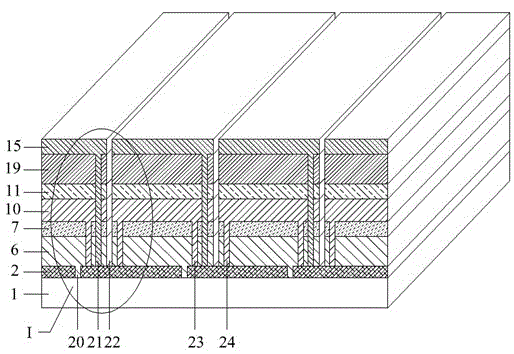

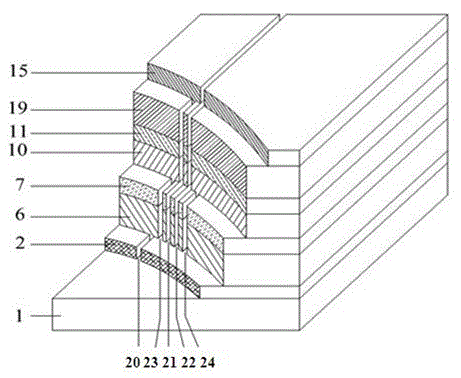

Three-junction laminated thin film solar cell and fabrication method thereof

ActiveCN102983204ADoes not reduce transmittanceDoes not reduce conductivityFinal product manufacturePhotovoltaic energy generationEngineeringGreen-light

The invention discloses a three-junction laminated thin film solar cell, and belongs to the technical field of solar photovoltaics. The thin film solar cell aims at improving photoelectric conversion efficiency of the thin film cell and allowing the photoelectric conversion efficiency of the thin film cell to be approximate to that of a crystal cell. The thin film solar cell is characterized in that a top cell is an amorphous silicon solar cell, has an intrinsic layer energy gap of 1.7-1.8eV, and absorbs blue sunlight; the middle cell is a cadmium telluride cell, has an energy gap of about 1.45eV, and absorbs green light; and the bottom cell is a copper indium gallium selenide cell, has an energy gap of about 1.05eV, and absorbs red light. A middle layer is introduced, an optical path and optical trap structure is added, the light absorption efficiency is improved, the dividing precision can be improved by a step-by-step dividing method, the series connection and short circuit in a cell module are reduced, the product cost is lowered, and the reject rate is reduced.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

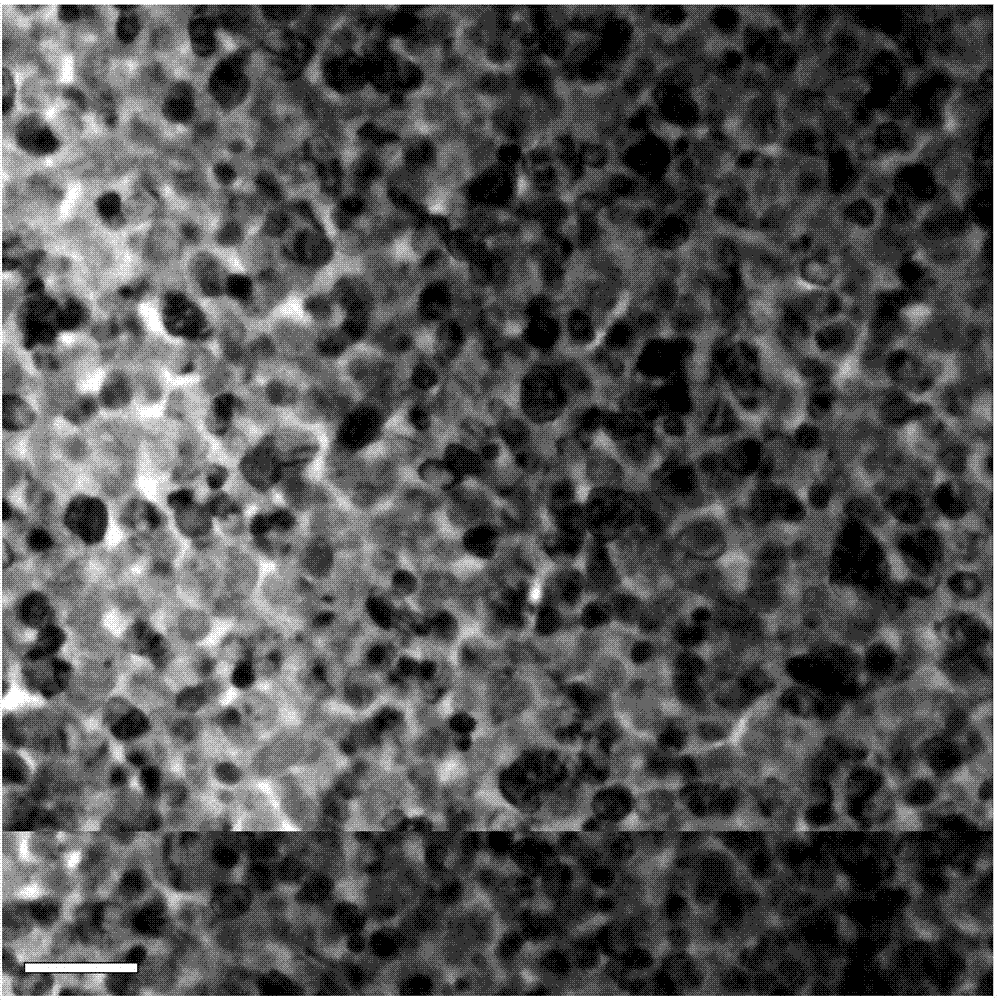

Surface clad layer treatment method of copper tungsten electrical contact material for arc extinguish chamber

ActiveCN106978586AExtended service lifeImprove abnormal breakdown discharge phenomenonVacuum evaporation coatingSputtering coatingDistributed structureArgon atmosphere

The invention discloses a surface clad layer treatment method of a copper tungsten electrical contact material for an arc extinguish chamber. The method includes the steps that the copper tungsten alloy contact material is prepared to serve as a substrate material; mechanical buffing, washing and drying are carried out; the substrate material is placed into a vacuum chamber to deposit a chromium layer, a nickel layer or a titanium layer on a base body through a chromium target, a nickel target or a titanium target under the argon atmosphere; a copper target and a tungsten target are used for codeposition of a copper-tungsten clad layer on the substrate deposited with the chromium target, the nickel target or the titanium target continuously, and a copper tungsten-tungsten clad layer with a certain film thickness is obtained; and annealing is carried out under protection of a mixed atmosphere of inert gas and hydrogen, furnace cooling is carried out, a sample is taken out, and a copper tungsten electrical contact material surface clad layer is obtained. By means of the two-phase nanoscale uniform distributed structure, the ablation uniformity can be greatly improved, the ablation pit depth is reduced, and the service life is prolonged; meanwhile, a provided nanocrystalline tungsten framework can improve the arc ablation resistant capacity. By means of the method, equipment is simple and convenient to operate, the effect is obvious, and the good industrial application prospect is achieved.

Owner:XI AN JIAOTONG UNIV

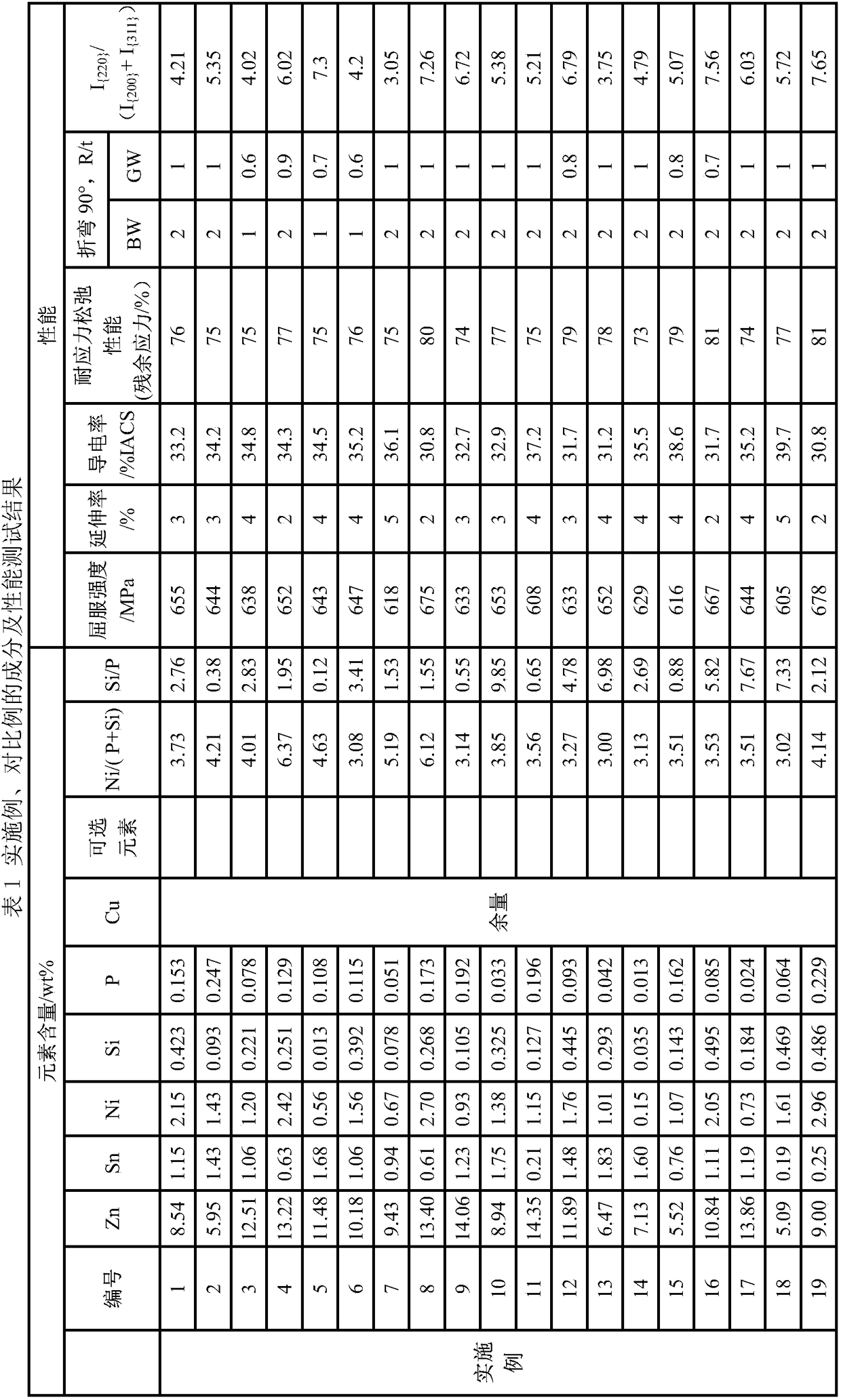

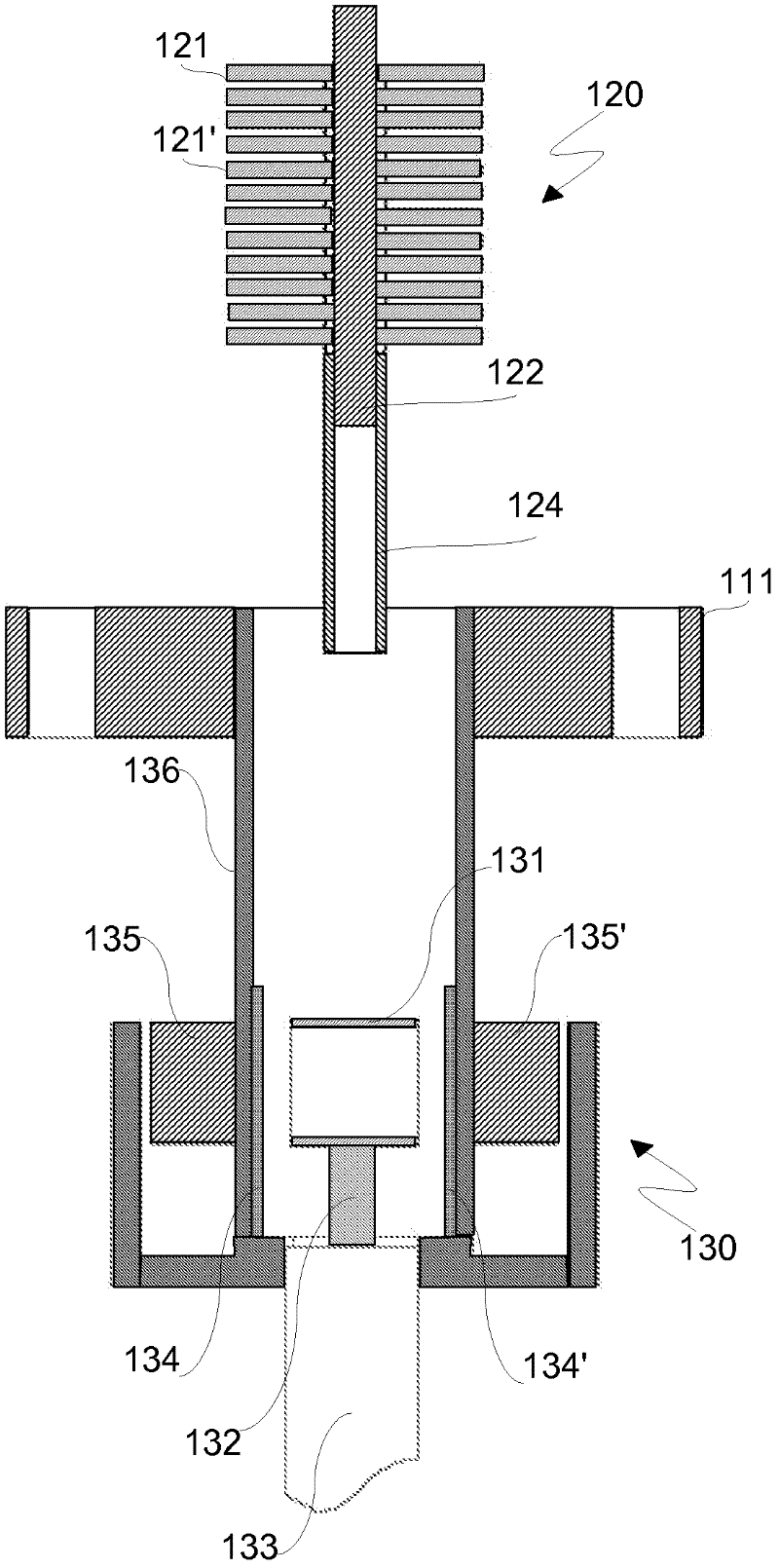

Copper alloy material and application thereof

The invention discloses a copper alloy material. The copper alloy material comprises, by weight percent, 5.01 wt%-15.0 wt% of Zn, 0.1 wt%-3.0 wt% of Ni, 0.1 wt%-2.0 wt% of Sn, 0.01 wt%-0.5 wt% of Si,0.01 wt%-0.25 wt% of P, 0 wt%-0.2 wt% of Mg, 0 wt%-0.3 wt% of Fe, and the balance Cu and inevitable impurities. The copper alloy material is low in cost, and the problem about multi-waste utilizationcan be solved. The yield strength of the copper alloy material is larger than or equal to 600 MPa, the electric conductivity is larger than or equal to 30% IACS, the bending machining performance is excellent (the value R / t in the GW direction is smaller than or equal to 1, and the value R / t in the BW direction is smaller than or equal to 2), the stress relaxation resisting performance is excellent (heat preservation is conducted for 1,000 hours at the temperature of 150 DEG C, and residual stress is larger than or equal to 70%), the copper alloy material can be machined into bar wires, platestrips and other products, and the requirements of connectors, relays, switches, sockets, lead frames and other multiple industries for the copper alloy material are met.

Owner:NINGBO POWERWAY ALLOY MATERIAL

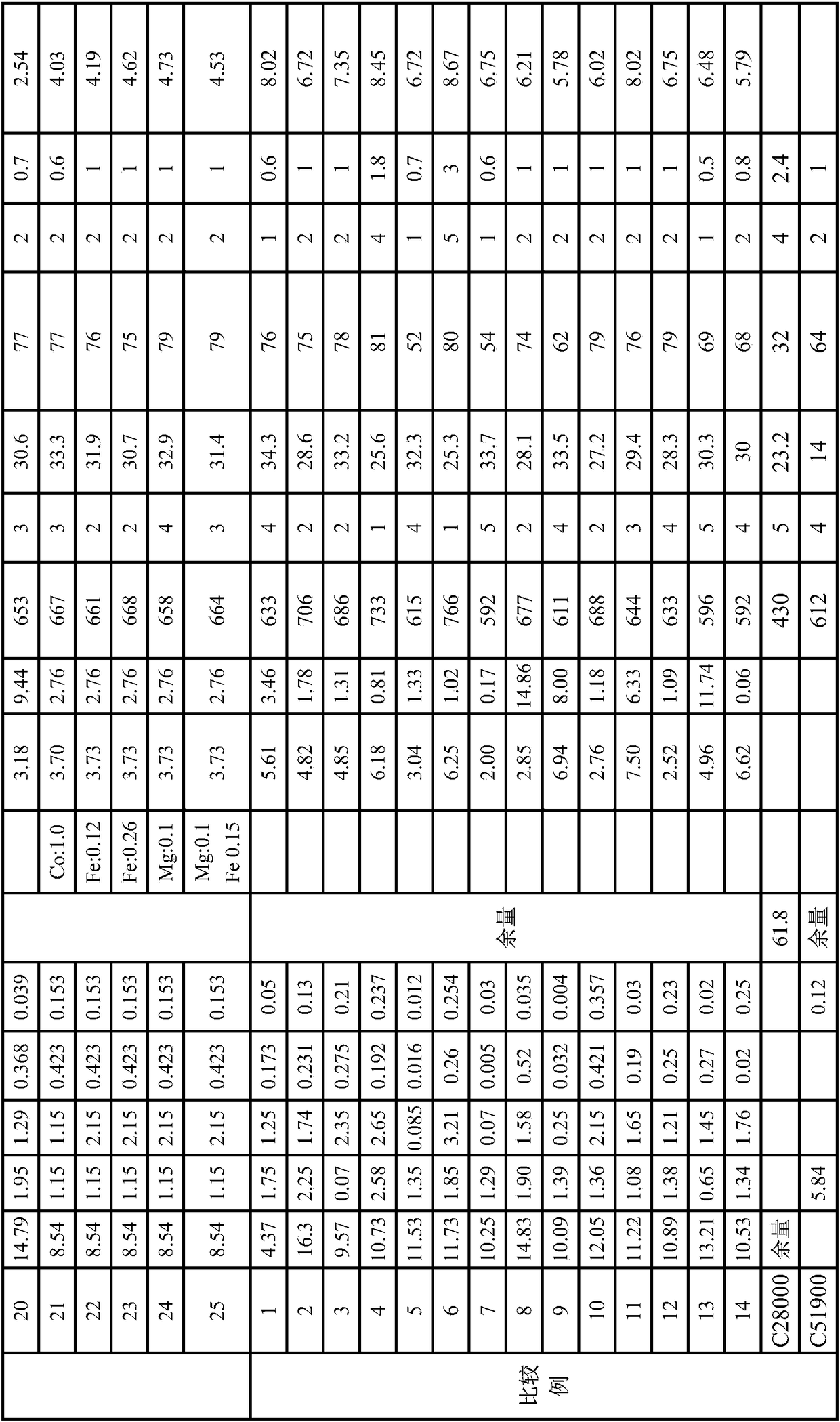

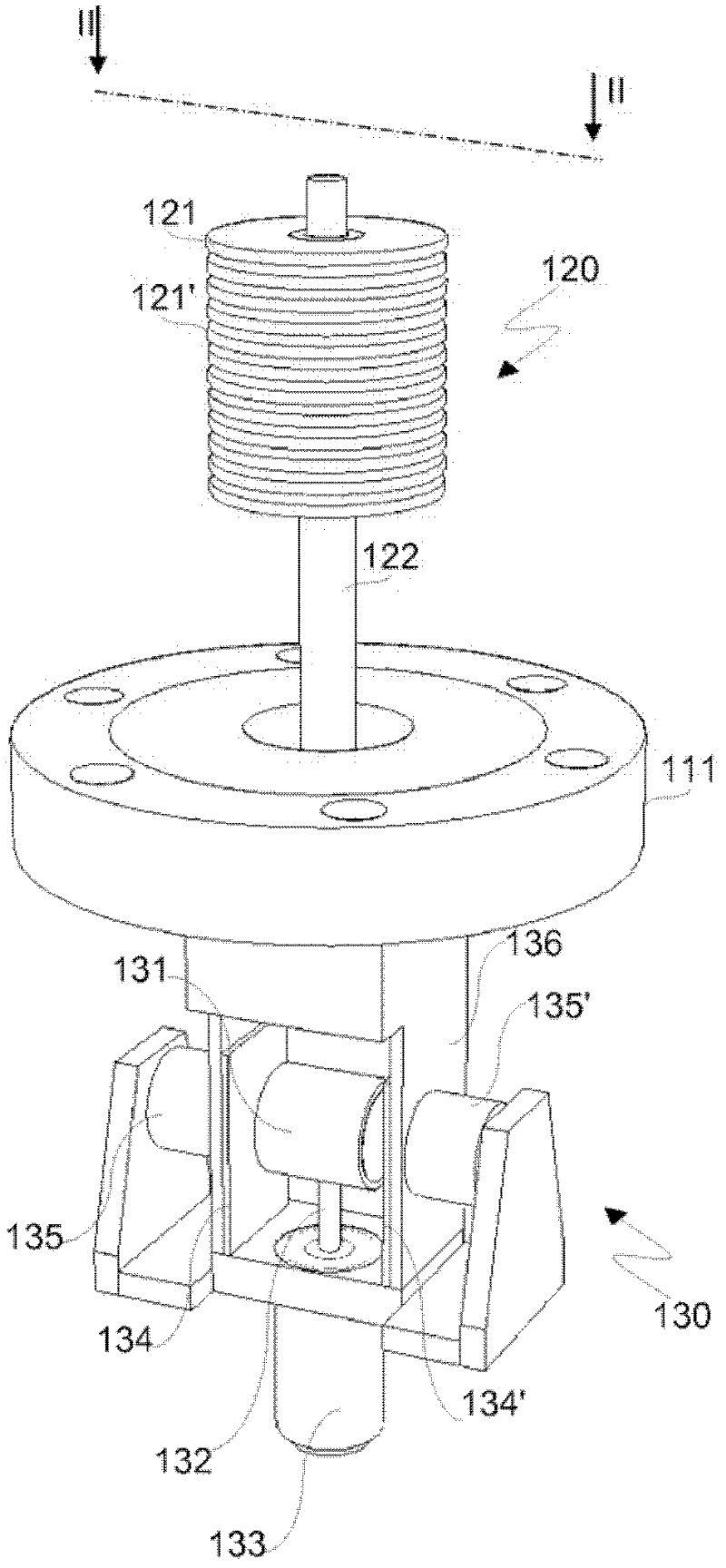

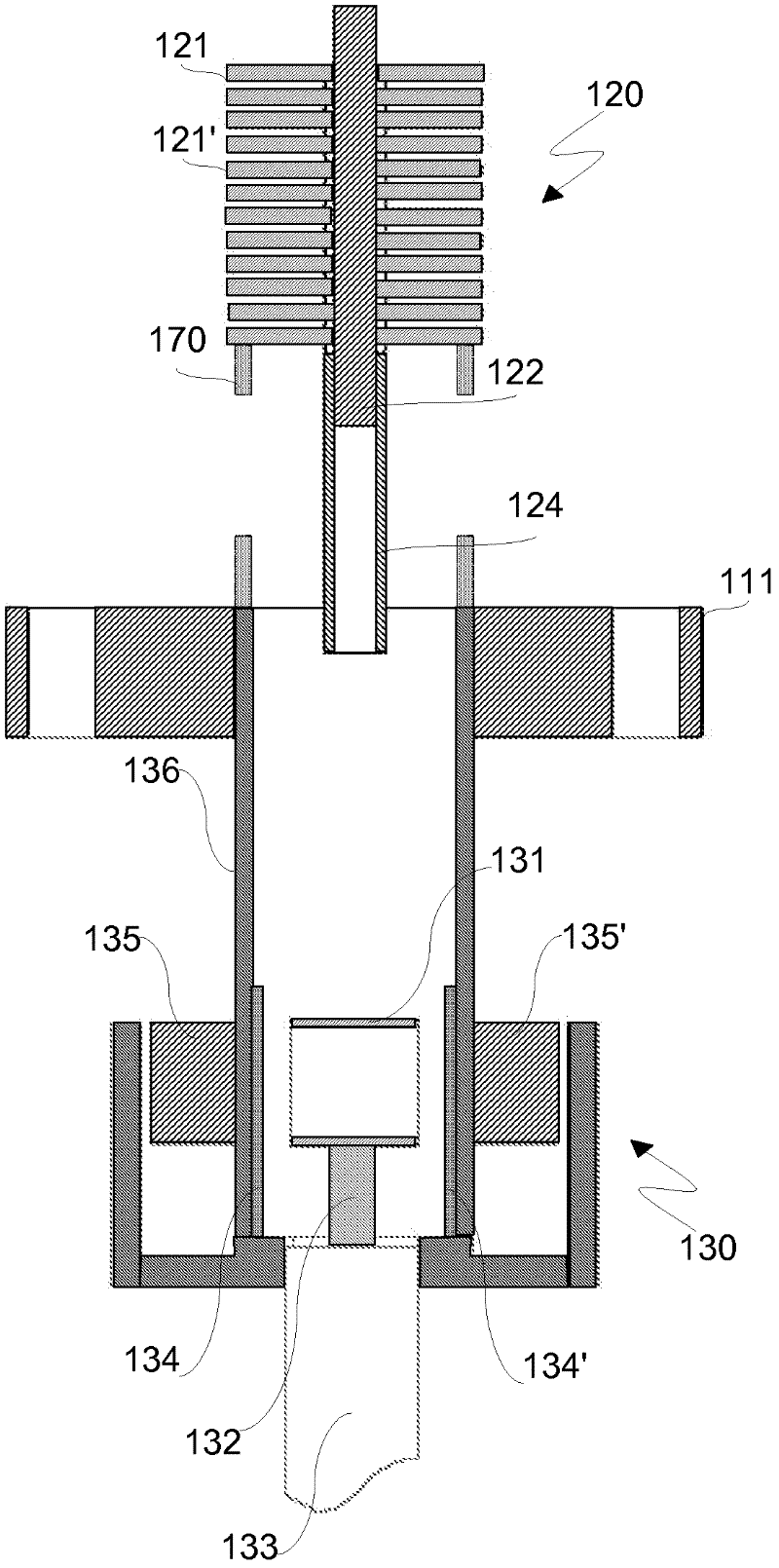

Combined pumping system comprising a getter pump and an ion pump

ActiveCN102356236ADoes not reduce conductivityTube surface sealingVacuum pumps for tubesVacuum levelEngineering

A combined pumping system comprising a getter pump (120; 220) and an ion pump (130; 230) is described. The getter pump and the ion pump (120, 130; 220, 230) are mounted in series on a same flange (111; 211) and respectively arranged on opposite sides thereof so that both getter and ion pumps conductance are maximized towards gas flux sources in a vacuum chamber in order to improve the vacuum level of the system.

Owner:SAES GETTERS SPA

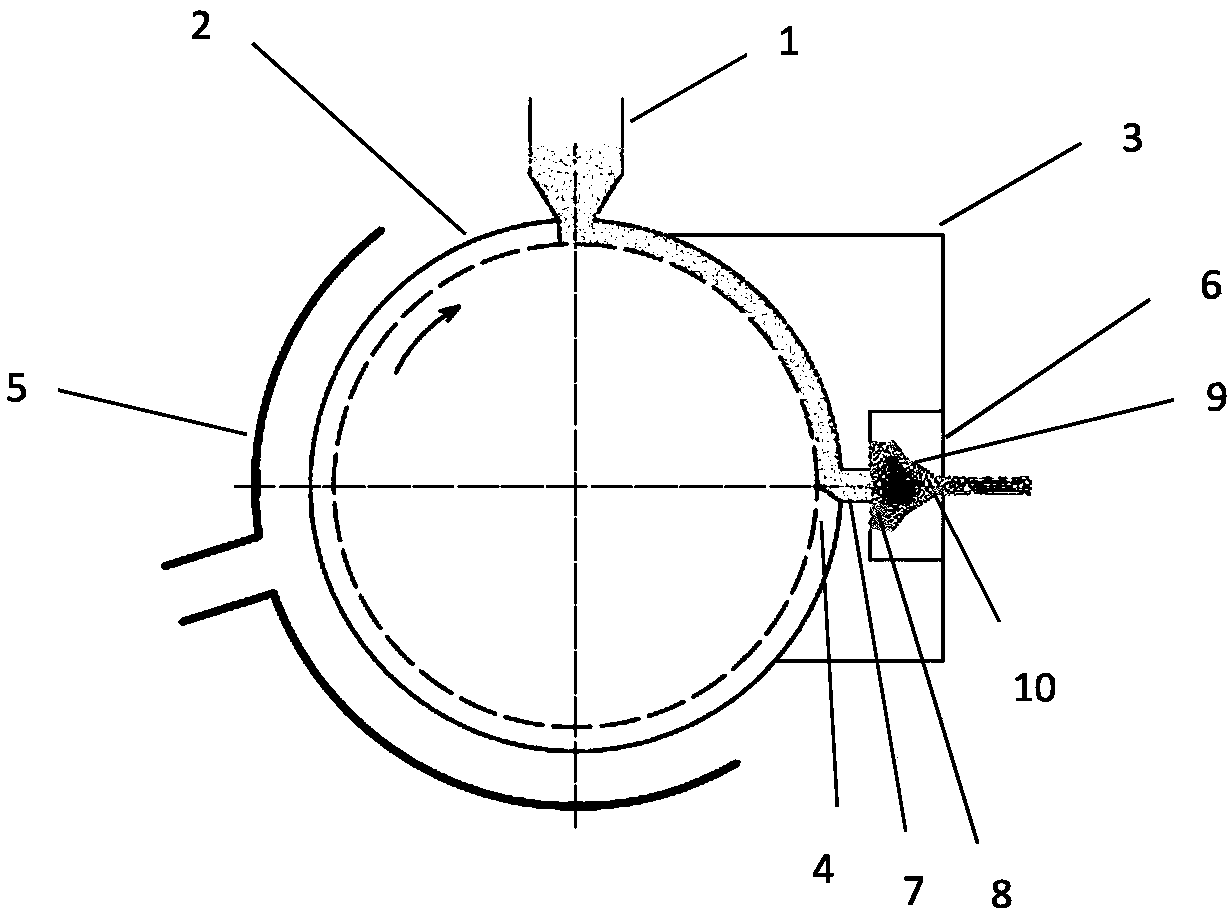

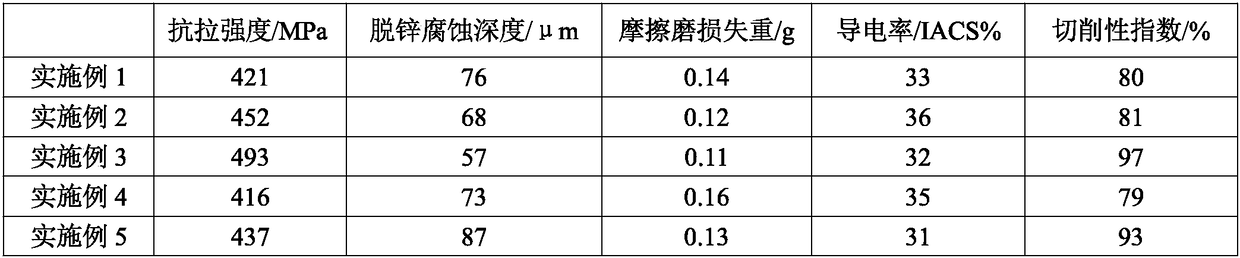

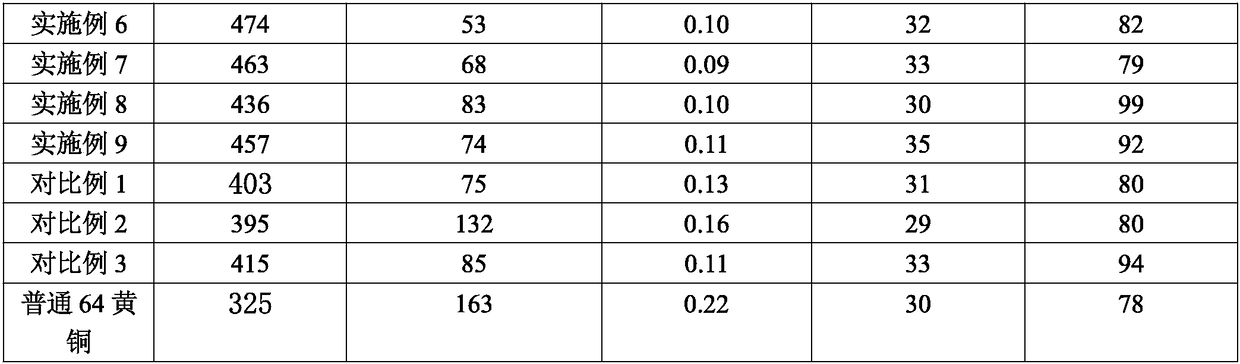

Copper-based composite material with high strength, corrosion resistance and abrasion resistance

The invention discloses a copper-based composite material with high strength, corrosion resistance and abrasion resistance. The composite material is prepared from the following main ingredients in percentage by weight: 55-69 percent of copper, 30-44 percent of zinc, 0.01-5 percent of titanium 0.01-10 percent of graphene and 0.01-5 percent of other optional ingredients, wherein other optional ingredients are one or two of carbon nano-tubes and graphite. The preparation method of the copper-base composite material adopts a powder spinning roller extrusion method, and comprises the following steps: firstly, uniformly mixing copper-zinc alloy powder, copper-titanium alloy powder, graphene powder, carbon nano-tube powder, graphite powder and other powders; filling the space formed by an arc die holder, a spinning roller surface notch and a plug with the uniformly mixed powder from a discharge hopper at a certain speed; extruding the powder into a die, and extruding the powder from a die hole after the powder is compressed in the die cavity so as to mold various pipe materials, plate materials, rod materials, cable materials or sectional materials according to different shapes of the die holes. The copper-based alloy has the advantages of high strength, corrosion resistance, abrasion resistance, conductivity without reduction and the like.

Owner:SHANGHAI DIANJI UNIV

Solid electrolytic capacitor carbon rubber layer and manufacture method thereof

ActiveCN102683038AImprove conductivityStable contentSolid electrolytic capacitorsSilver pasteElectrolysis

The invention relates to a manufacture method of a solid electrolytic capacitor carbon rubber layer, which comprises the steps of: immersing an electrode needing coating a carbon rubber layer into an emulsion containing a conductive nonmetal, a binding agent and an organic solvent, and curing to obtain the carbon rubber layer, wherein the conductive nonmetal is a graphene material. According to the solid electrolytic capacitor carbon rubber layer manufactured by adopting the manufacture method, the binding force of the carbon rubber layer and a silver paste layer is increased, the content of carbon in the solid electrolytic capacitor carbon rubber layer is reduced but the conduction property of the solid electrolytic capacitor carbon rubber layer is not reduced, the contact resistance is reduced, and the heat resistance is increased, therefore, the solid electrolytic capacitor carbon rubber layer is suitable for massive popularization and application.

Owner:THE SIXTH ELEMENT CHANGZHOU MATERIALS TECH

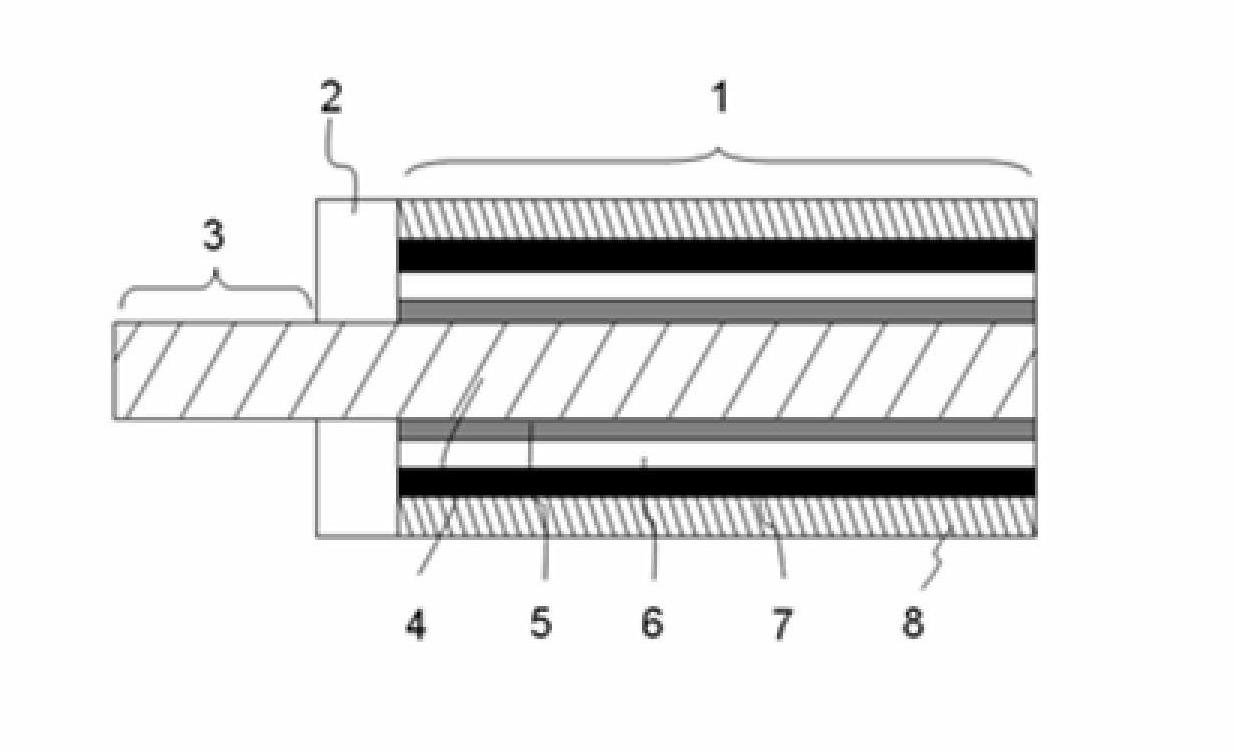

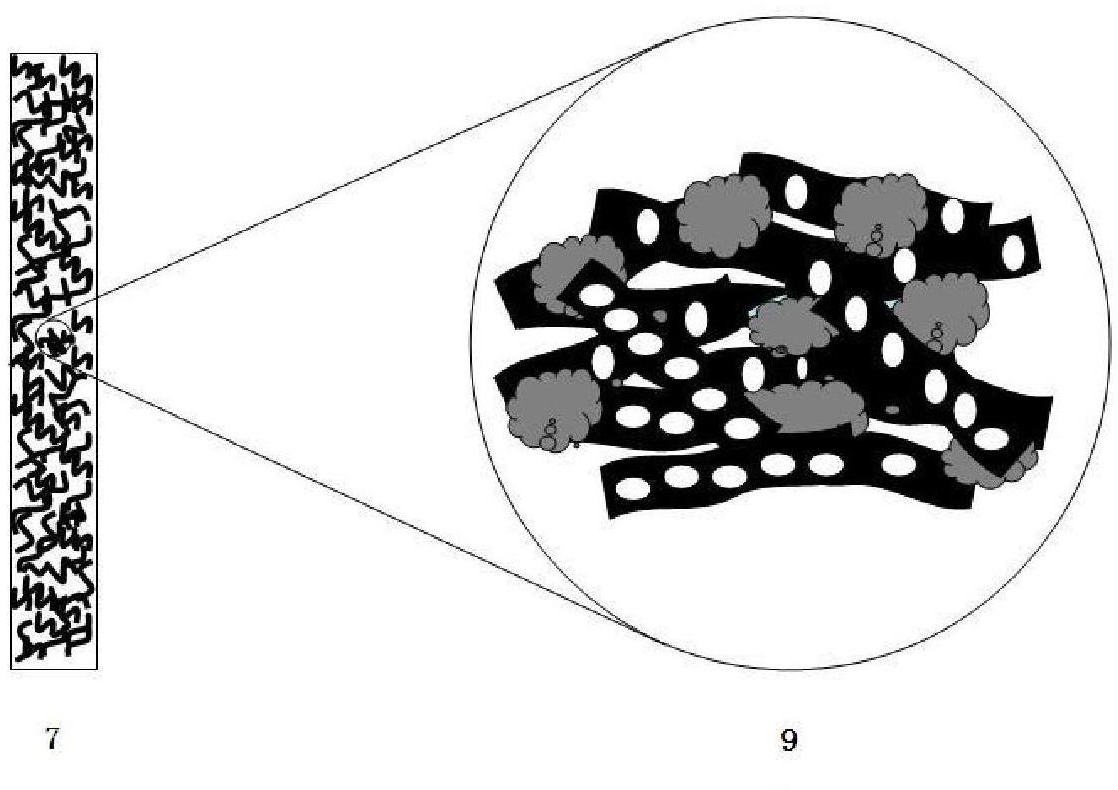

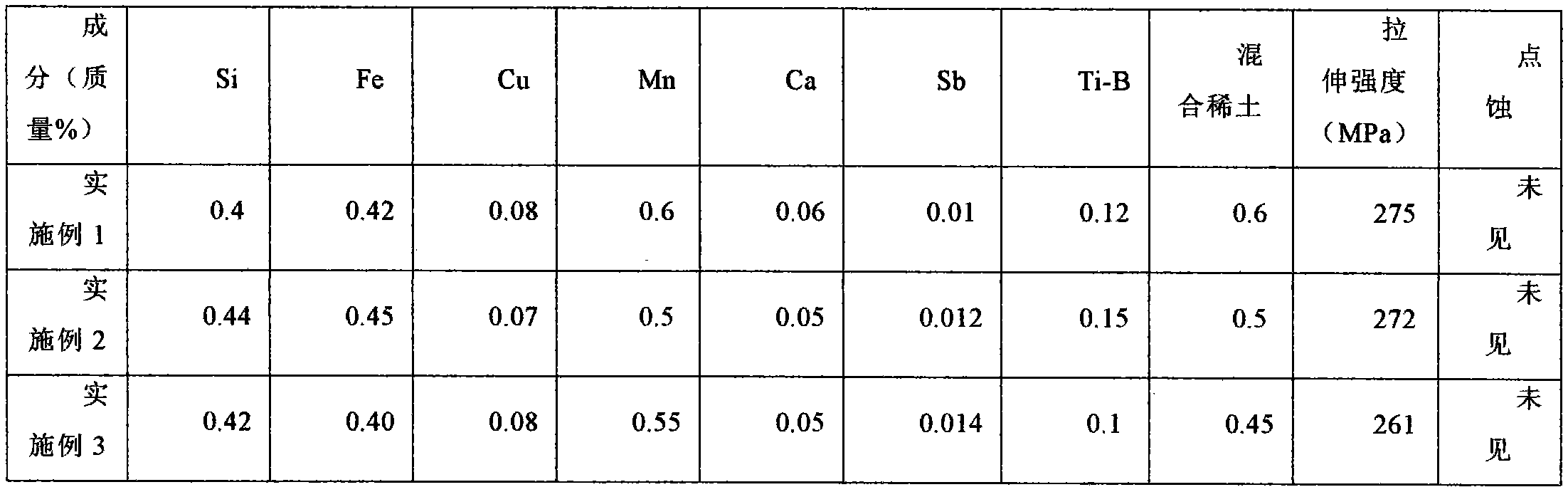

Positive pole current collector of lithium ion battery

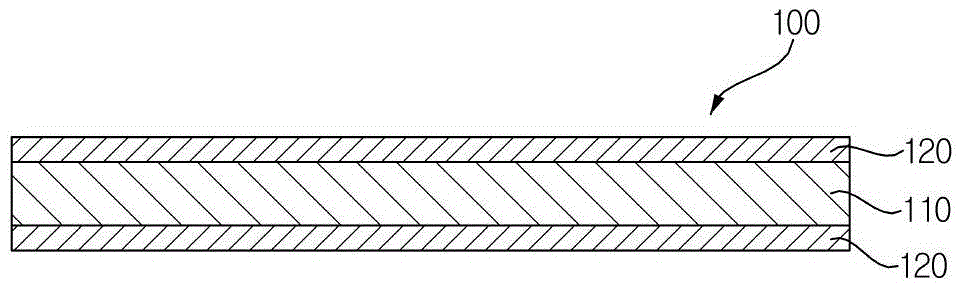

InactiveCN104282917AImprove heat resistanceDoes not reduce conductivityElectrode carriers/collectorsElectrical batteryLithium-ion battery

The invention relates to a positive pole current collector of a lithium ion battery. The current collector is of a three-layer structure, wherein the first layer and the third layer are made of aluminum and have the thickness of 2.5-3 microns; the second layer arranged between the first layer and the third layer is an aluminum alloy layer and has the thickness of 8-10 microns; and the aluminum alloy comprises the following components in percentage by mass: 0.4-0.45 percent of Si, 0.4-0.45 percent of Fe, 0.06-0.08 percent of Cu, 0.5-0.6 percent of Mn, 0.05-0.08 percent of Ca, 0.01-0.015 percent of Sb, 0.1-0.15 percent of Ti-B alloy, 0.45-0.6 percent of RE, 15-20 percent of La, 55-60 percent of Ce, 10-15 percent of Er, 10-15 percent of Sm and the balance of aluminum and inevitable impurities, wherein RE refers to mixture rare earths. The preparation method comprises the following steps: smelting, performing homogenizing treatment, cold rolling and performing two-stage aging. According to the positive pole current collector disclosed by the invention, the tensile strength can be 260-275MPa, a corrosive pitting phenomenon is avoided, and compared with an aluminum foil in the prior art, the positive pole current collector has the advantage that problems of wrinkle and breakage can be effectively solved on the basis that a certain aluminum foil thickness is guaranteed.

Owner:襄阳锦翔光电科技股份有限公司 +1

High-strength, high-conductivity and high-temperature-resistant Cu-Cr-Nb-Zr alloy and preparation method thereof

PendingCN111378865ALow tensile strengthHigh tensile strengthNon-electric welding apparatusCombustion chamberSuperalloy

The invention discloses a high-strength, high-conductivity and high-temperature-resistant Cu-Cr-Nb-Zr alloy and a preparation method thereof, and belongs to the technical field of copper alloys. The preparation process of a copper alloy combustion chamber lining comprises the steps of burdening, atomizing, sheath extruding, plate rolling, plate pressing, friction welding, spinning forming and finished product machining. The Cu-Cr-Nb-Zr alloy has relatively high high-temperature-resistant strength and good ductility, and the low-cycle fatigue performance and the thermal conductivity of the Cu-Cr-Nb-Zr alloy are superior to those of other high-temperature-resistant copper alloys; the tensile strength of the alloy is larger than or equal to 500 MPa, the electric conductivity of the alloy is larger than or equal to 65% IACS, the alloy has the excellent high-temperature resistance that the strength is not obviously reduced after brazing at 935 DEG C, the strength is only reduced by about 30MPa at the temperature condition of 935 DEG C-1000 DEG C, and the softening temperature is larger than 900 DEG C; the alloy is suitable for any heat exchange high-temperature-resistant occasions suchas injection molds, resistance welding electrodes, nozzles, rocket combustion chamber linings and carrier rocket nozzles.

Owner:SHAANXI SIRUI ADVANCED MATERIALS CO LTD

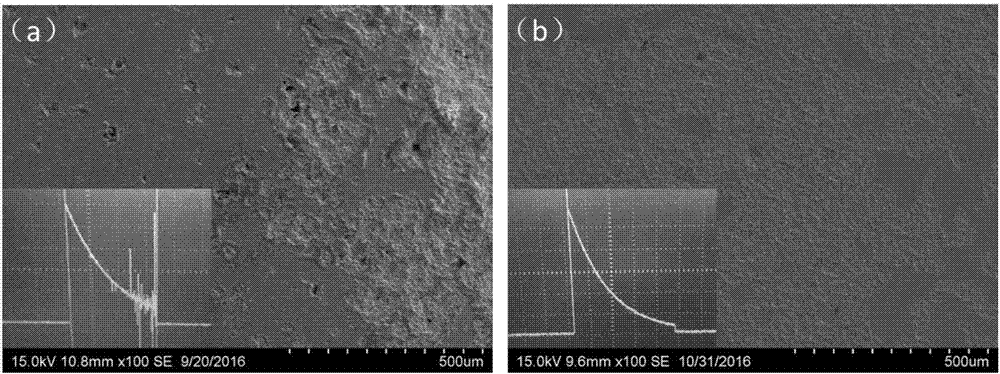

Preparation method of conductive anticorrosive coating on magnesium alloy surface

InactiveCN107955961AImprove anti-corrosion performanceDoes not reduce conductivityAnodisationMicro arc oxidationConductive coating

The invention discloses a preparation method of a conductive anticorrosive coating on a magnesium alloy surface, and relates to the field of conductive coating. The preparation method comprises the following steps of carrying out early treatment on the magnesium alloy materials, and conducting oxidation treatment on the magnesium alloy material in a chromate solution; the non-micro-arc oxidation surface of the magnesium alloy material parts is protected by a polytetrafluoroethylene tool; then micro-arc oxidation treatment and disassembly tool for each magnesium alloy material part in sodium silicate solution. The electric conduction oxidation technology and the micro-arc oxidation technology are combined, and the functions of corrosion prevention and electric conduction on the surface of the magnesium alloy materials are achieved. The method has the beneficial effects that the corrosion resistance of the magnesium alloy material parts is improved while the electrical conductivity between the magnesium alloy materials is not reduced.

Owner:XIAN UNVERSITY OF ARTS & SCI

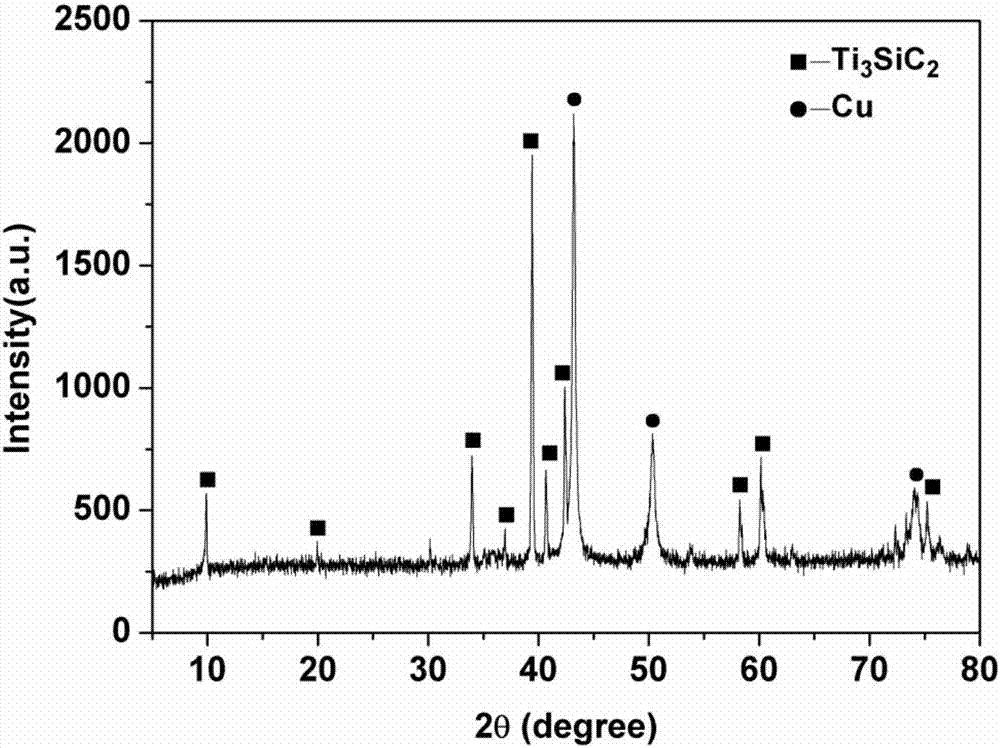

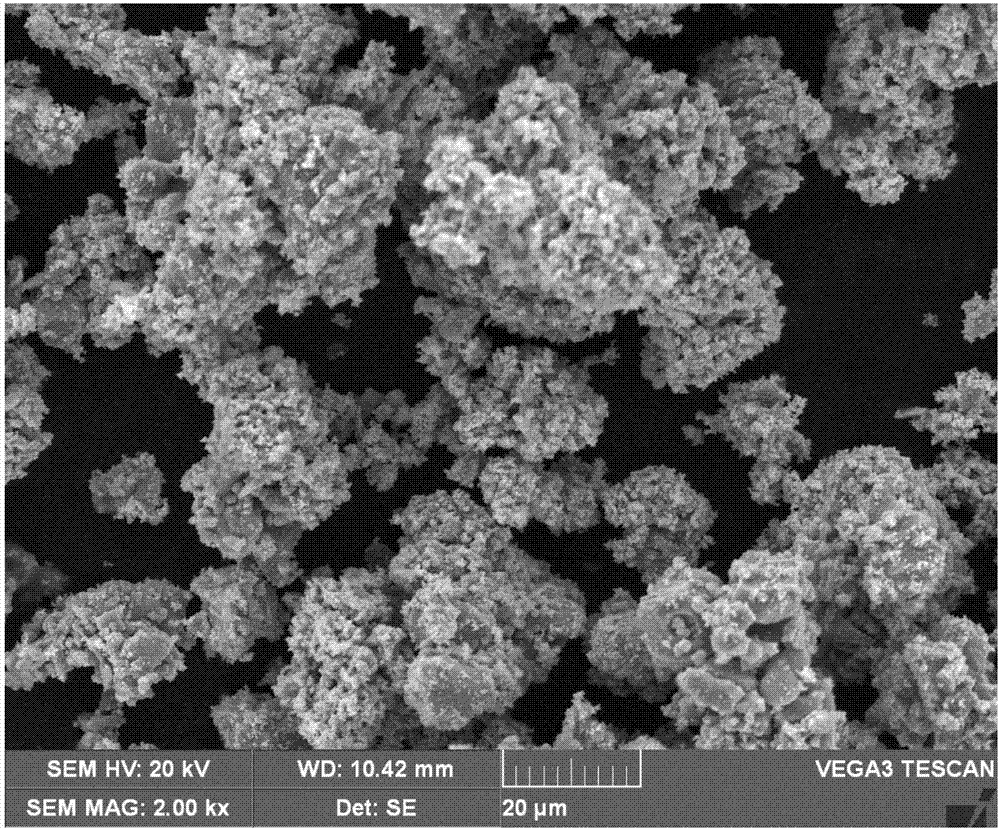

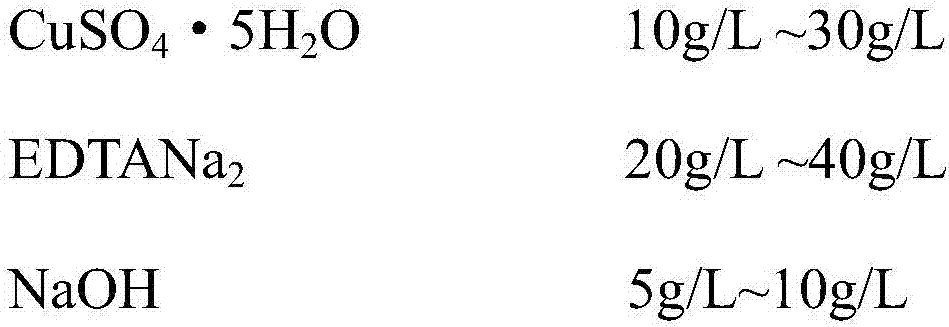

Preparing method for Ti3SiC2/Cu composite conductive powder

ActiveCN107020374AImprove conductivityReduce contentTransportation and packagingMetal-working apparatusCopper platingSensitization

The invention discloses a preparing method for Ti3SiC2 / Cu composite conductive powder. The preparing method comprises the steps that firstly, Ti3SiC2 powder is sequentially subjected to alcohol washing, roughening, sensitization, activating, washing and drying treatment, and pretreated Ti3SiC2 powder is obtained; secondly, a copper plating solution is prepared through CuSO4.5H2O, EDTANa2, NaOH and 2-2'-dipyridyl; thirdly, the copper plating solution prepared in the second step is utilized for conducting plating treatment on the pretreated Ti3SiC2 powder obtained in the first step; and fourthly, after the third step, substances left after plating treatment are filtered, parts left after liquid is filtered out are dried, and the Ti3SiC2 / Cu composite conductive powder is obtained. The Ti3SiC2 / Cu composite conductive powder obtained through the preparing method has low density, good stability and high conductivity.

Owner:上海闻朗新材料科技有限公司

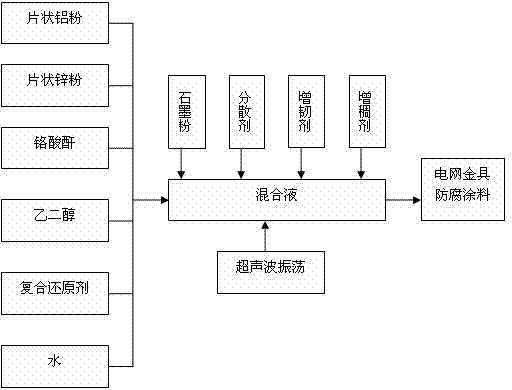

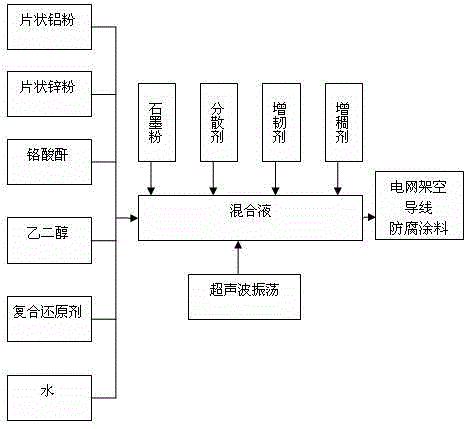

Novel anticorrosive coating for grid fitting

InactiveCN102850831ADoes not reduce conductivityImprove anti-corrosion and anti-rust performanceAnti-corrosive paintsAluminium powderGraphite

A novel anticorrosive coating for grid fitting. A prepared Dacromet solution is added with nanometer fine graphite powder according to a certain proportion, and oscillated by ultrasonic to evenly disperse the nanometer fine graphite powder in the solution; and then coating and curing processing are performed. The formula of the coating comprises, by weight, 10-13% of a graphite powder, 20-55% of a flake zinc powder, 5-10% of an flake aluminum powder, 5-10% of chromic anhydride, 30-45% of ethylene glycol, 6-12% of a dispersant, 0.1-0.2% of a toughening agent, 1-2% of a thickener, and 2-3% of a composite reducing agent and water. According to the present invention, the coating formula is improved by adding the nanometer grade fine graphite powder; and tests prove that the novel coating realizes the goal of no decrease on the conductivity of the coating material, without affecting the anti-corrosion and rust-proof functions. The anticorrosive coating provided by the invention is applicable to antisepsis and rust protection of grid fitting.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

High-strength and corrosion-resistance aluminum-titanium alloy material for electrician and preparation method thereof

The invention belongs to the field of alloy materials, and discloses a high-strength and corrosion-resistance aluminum-titanium alloy material for an electrician and a preparation method thereof. The aluminum-titanium alloy material consists of the following components in percentage by weight: 0.05-0.2 wt% of Ti, 0.01-0.15 wt% of Zr, 0.1-0.4 wt% of B, 0.01-0.3 wt% of Mn, 0.01-0.35 wt% of Cr, 0.015-0.1 wt% of Sr, 0.02-1 wt% of rare earth, and the balance of Al. The preparation method comprises the following steps: all the components are prepared to an alloy in a smelting furnace after the batching; the alloy is cast to an aluminum ingot in a deep well casting mode; and the aluminum ingot is extruded by a hot extrusion process to manufacture a product shape accordant with the requirements. The aluminum-titanium alloy material is excellent in stress corrosion resistance, high in strength and excellent in electrical conductivity.

Owner:安徽华淮新材料有限公司

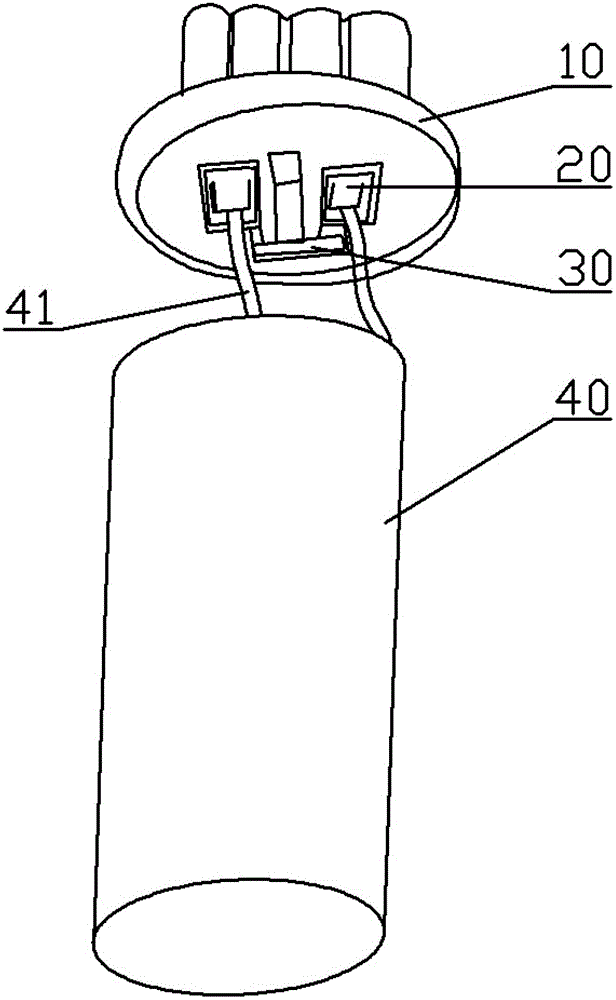

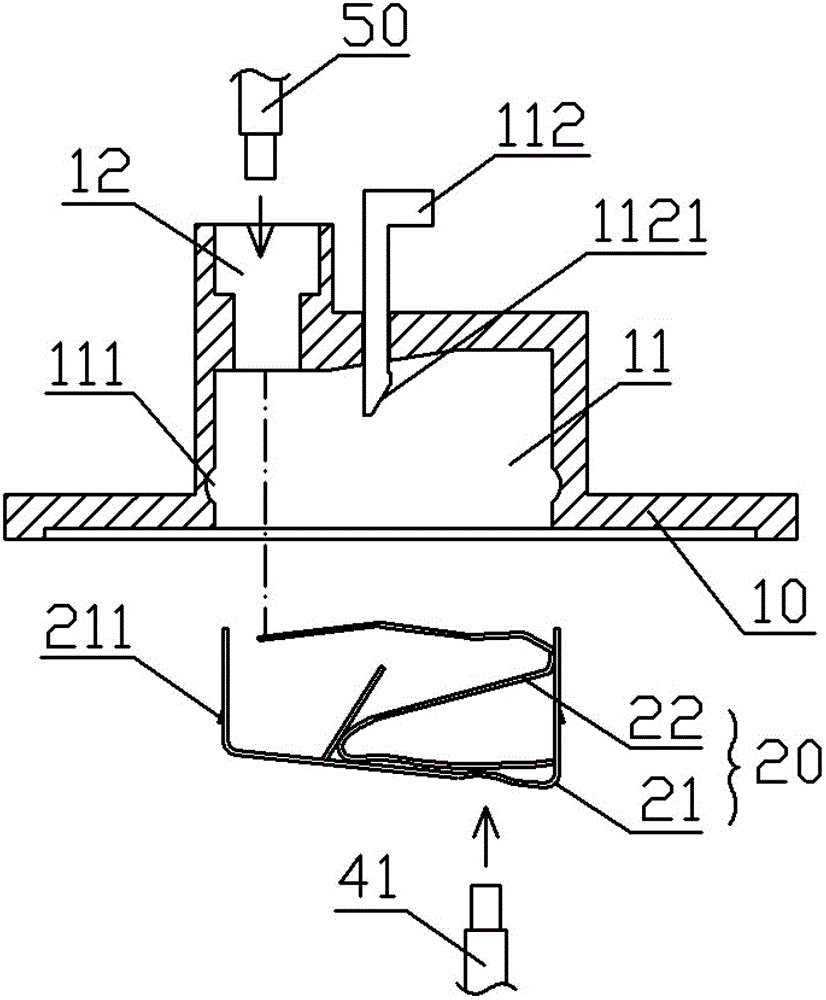

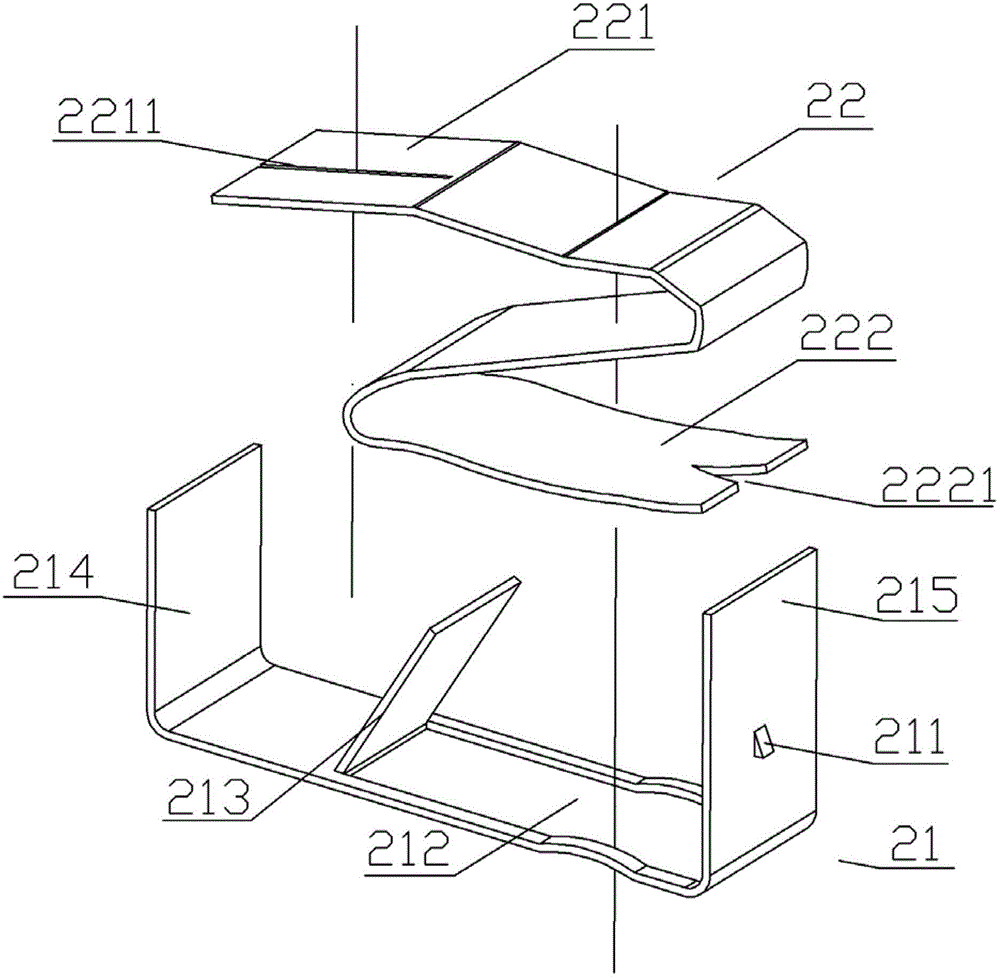

Capacitor pluggable connection device

InactiveCN102723195AGood contactLarge conduction currentFixed capacitor terminalsCoupling contact membersConduction currentCapacitance

The invention discloses a capacitor pluggable connection device. The device is used for realizing fast connection between a capacitor connection wire of a capacitor and an external wire, and comprises a seat body, a terminal and a discharge resistor, wherein a terminal containing nest is arranged on the seat body; an external wire jack is arranged on the terminal containing nest; the terminal is located in the terminal containing nest; the terminal comprises a terminal frame and a spring piece; a left clamp plate and a right clamp plate are arranged on the two sides of the terminal frame respectively, a spring piece clamp piece is arranged at the middle part of the terminal frame, and a capacitor connection wire through hole is arranged at the lower part; the terminal frame is clamped in the terminal containing nest through the left clamp plate and the right clamp plate; the spring piece is S-shaped and is provided with an external wire contact plate and a capacitor connection wire contact plate; the capacitor connection wire contact plate is clamped between the spring piece clamp piece and the right clamp plate; an upper bayonet is arranged on the external wire contact plate; and the external wire contact plate is matched with the left clamp plate. According to the device disclosed by the invention, the contact between the terminal and the external wire is relatively good, and the conduction current is relatively large.

Owner:CIXI RIYI CAPACITOR FACTORY

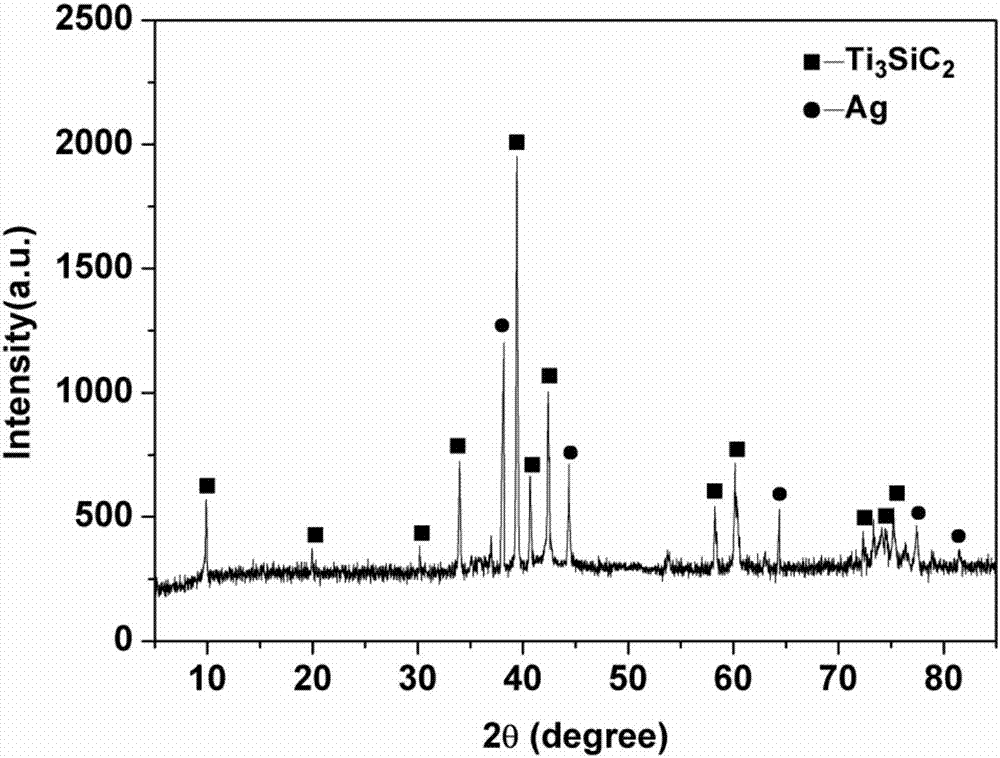

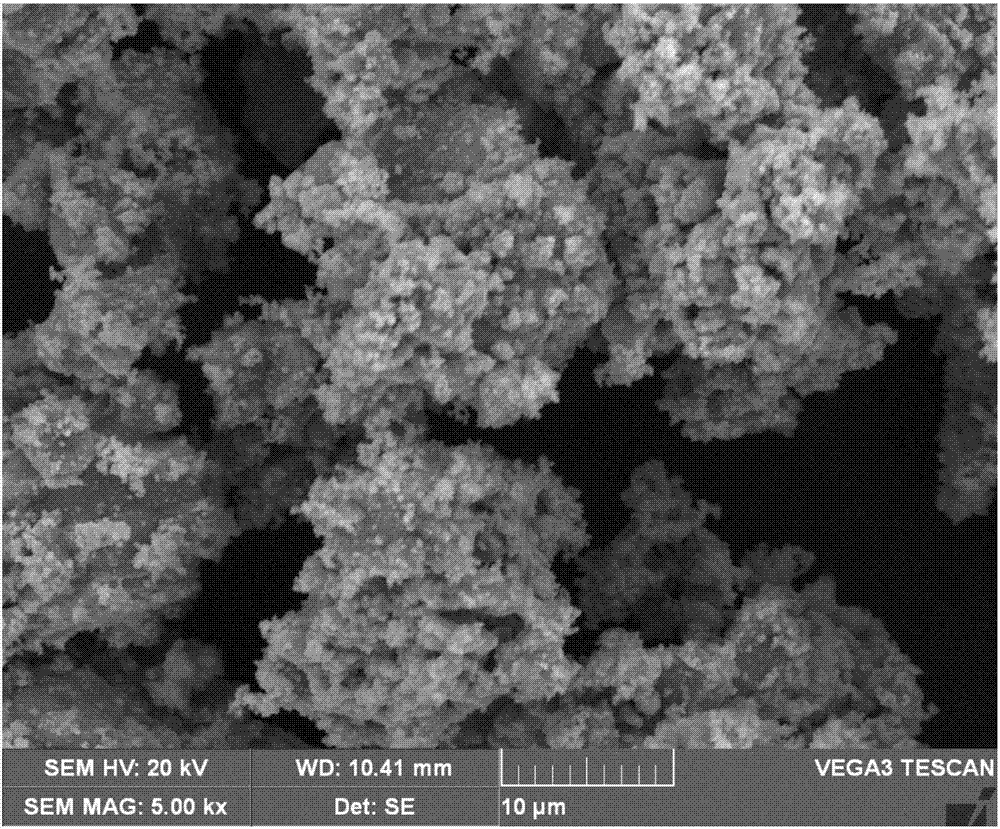

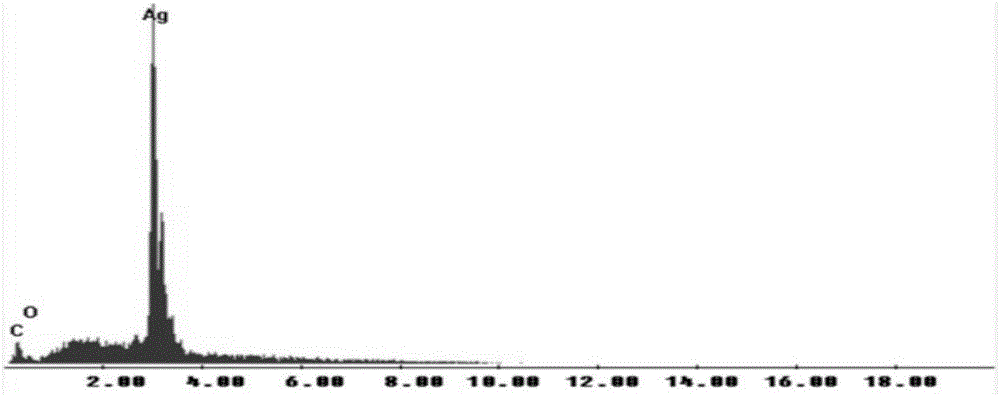

Preparation method of Ti3SiC2/Ag composite conductive powder

ActiveCN107243630AImprove conductivityReduce contentTransportation and packagingMetal-working apparatusAlcoholAmmonium hydroxide

The invention discloses a preparation method of Ti3SiC2 / Ag composite conductive powder. The preparation method comprises the steps of (1) performing alcohol washing, coarsening, sensitization, activation, water washing and drying on Ti3SiC2 powder in sequence, so that pretreated Ti3SiC2 powder is obtained; (2) respectively preparing a silver-ammonia solution and a reduction solution; (3) performing silver and ammonia plating on the pretreated Ti3SiC2 powder obtained in the step (1) by utilizing the silver-ammonia solution and the reduction solution which are obtained in the step (2); and (4) filtering residual substances after the plating in the step (3) is completed, and drying the residual part after liquid is filtered, so that the Ti3SiC2 / Ag composite conductive powder is obtained. By adopting the preparation method, the Ti3SiC2 / Ag composite conductive powder with low density, good stability and high electric conductivity can be prepared.

Owner:XI'AN POLYTECHNIC UNIVERSITY

A kind of all-solid-state lithium-ion battery composite electrode material and its preparation method and all-solid-state lithium-ion battery

ActiveCN103682354BDoes not reduce conductivityConduction does not hinderNon-aqueous electrolyte accumulator electrodesSecondary cells servicing/maintenanceSolid-state batteryAcrylic polymer

Embodiment of the present invention provides a solid-state lithium ion battery electrode composite material comprising an electrode active material and a coating layer provided on the surface of the electrode active material, wherein the material of the coating layer comprising by weight: polymer formed of 0.1-20 parts of polymer monomer and 0.1-50 parts of ethylene glycol derivative, 0.1 to 10 parts of lithium salt, 0.1 to 10 parts of a polymerization initiator, 50 to 99.9 parts of a plasticizer, wherein the polymer monomer is selected from one or several monomers of fluorine-containing polymer monomer, ether polymer monomer, acrylic polymer monomer and acrylonitrile polymer monomer. The coating layer can effectively suppress the formation of space charge layer; reduce interface resistance of the solid-state lithium ion battery, thereby improving solid-state battery cycle stability and durability. Embodiments of the present invention also provide a preparation method of the solid-state lithium ion battery electrode material composite, and solid-state lithium-ion batteries comprising the composite electrode material.

Owner:HUAWEI TECH CO LTD

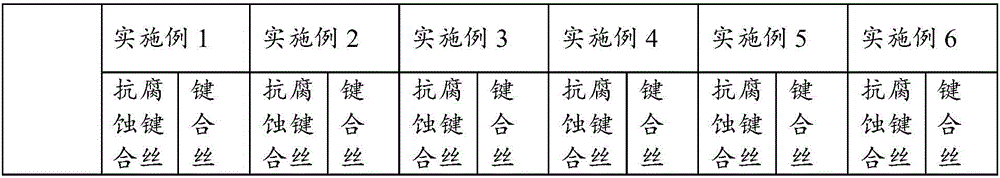

Protective agent composition and corrosion resistant bonding wire and preparation method thereof

ActiveCN106757281AAffect conductivityAffect reflective performanceChromatisationTectorial membraneOXALIC ACID DIHYDRATE

The invention provides a protective agent composition. The protective agent composition comprise Cr3+ salt, conductive salt and solvents. The conductive salt is selected from one kind or certain kinds of sulfate of alkali metal, nitrate of alkali metal and chlorate of alkali metal. The solvents are selected from one kind or certain kinds of formic acid, acetic acid, methanol, glycine, citric acid and oxalic acid. Compared with the prior art, the protective agent composition provided by the invention contains the Cr3+ salt, the non-toxic and environmental-friendly Cr3+ salt serves as a film coating solution to conduct cathode passivation process operation, a transparent protective film with the low content of the Cr3+ salt can be formed on the surface of a bonding wire, the protective agent composition forms the protective film on the surface of the bonding wire, the bonding wire is prevented from color change caused by suffering the corrosion of oxides and sulfides, meanwhile the original reflective rate and electrical conductivity of the bonding wire are not reduced, and the cost is low. The invention further provides the corrosion resistant bonding wire and a preparation method thereof.

Owner:晶逸科技(佛山)有限公司

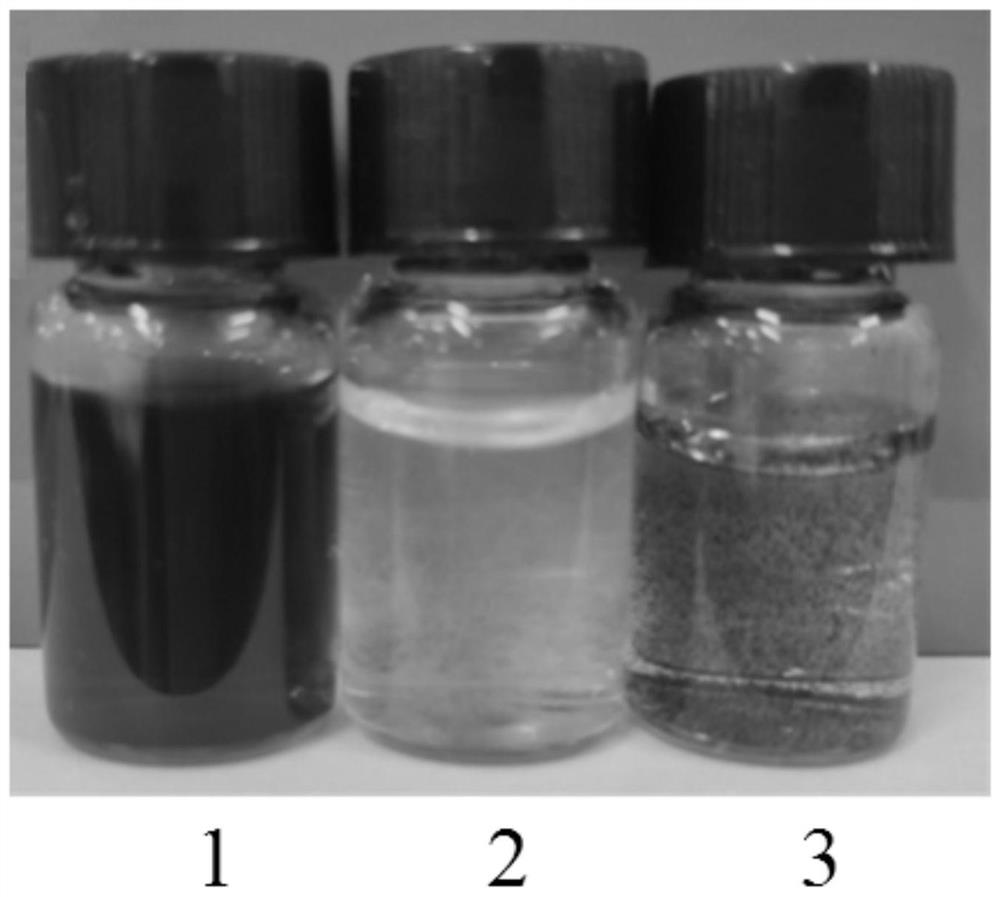

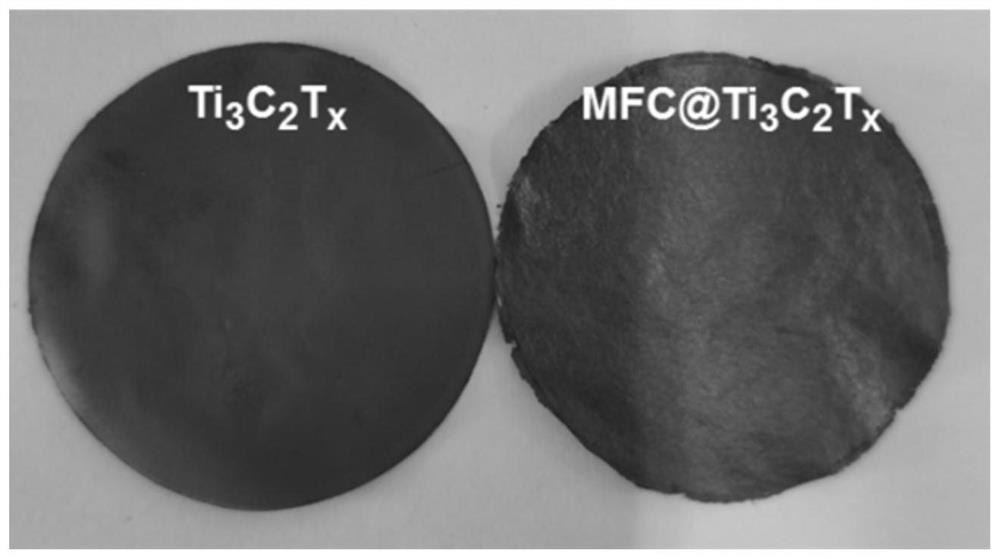

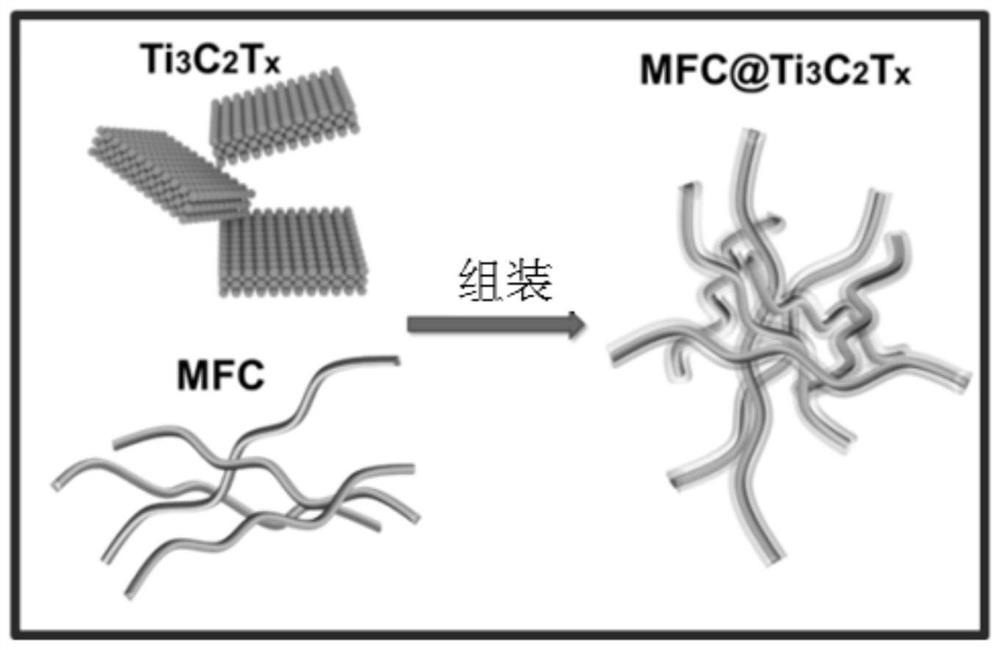

Preparation method and application of micronized cellulose/MXene composite film

ActiveCN112233914AImprove mechanical propertiesDoes not affect electron transportHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceComposite film

The invention discloses a preparation method and an application of a micronized cellulose / MXene composite film, and relates to the preparation method and the application of the MXene composite film. The invention aims at solving problems that a mechanical property and a capacitive property of the existing MXene composite film are poor, and the conductivity of the MXene cellulose composite film hasa linear reduction trend along with the increase of nanocellulose. The method comprises the following steps: 1, preparing a dark green few-layer Ti3C2Tx colloid supernatant; 2, preparing an MFC@Ti3C2Tx microgel; and 3, carrying out vacuum filtration on the MFC@Ti3C2Tx microgel through a mixed cellulose membrane with a pore diameter of 0.22 mum, and drying at a room temperature to obtain the independently supported micronized cellulose / MXene composite film. The independently supported micronized cellulose / MXene composite film is used as a negative electrode material of a capacitor. According to the invention, the micronized cellulose / MXene composite film can be obtained.

Owner:HARBIN INST OF TECH

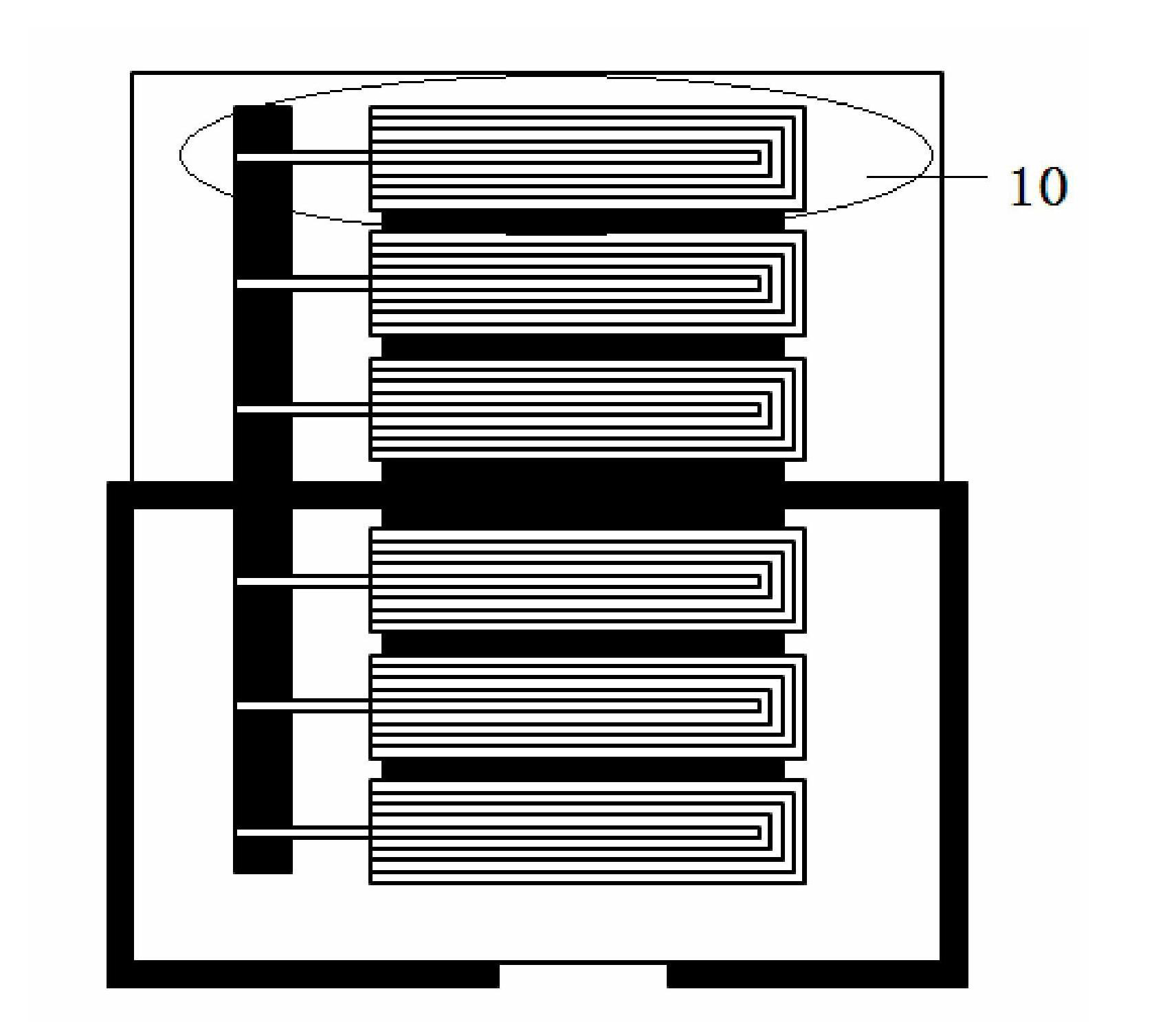

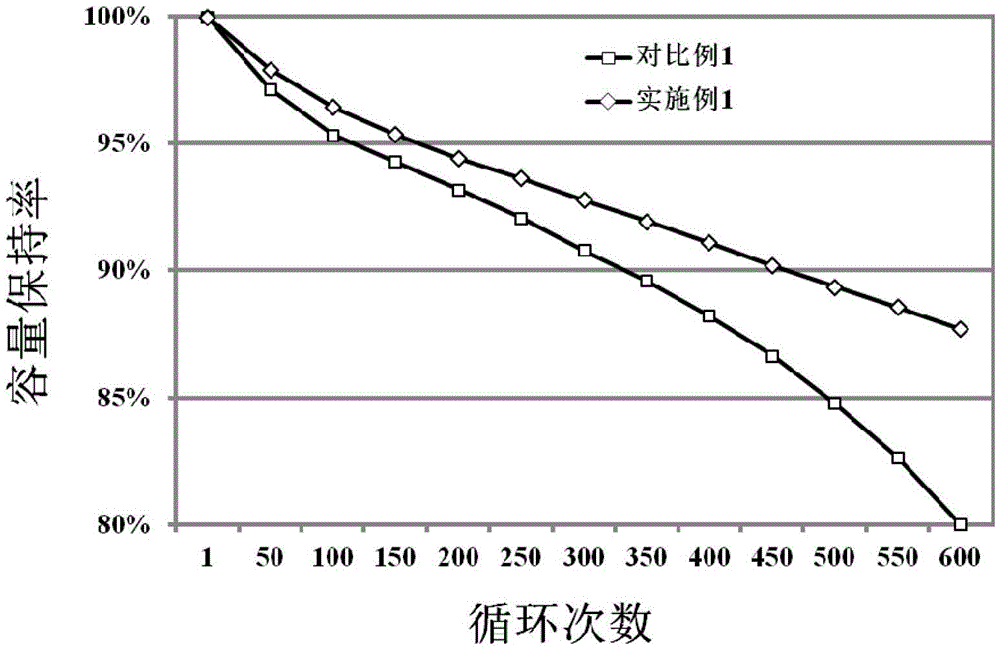

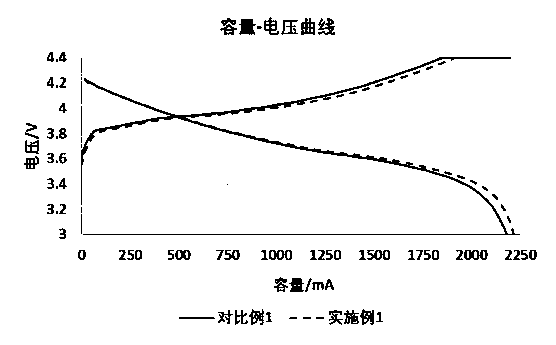

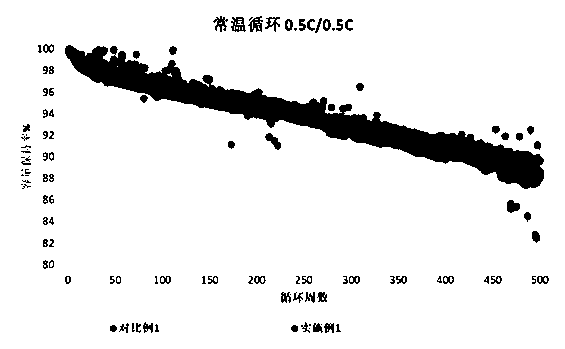

Lithium ion battery with high energy density

PendingCN110137463AIncrease energy densityIncrease the proportionSecondary cellsPositive electrodesHigh energySlurry

The invention provides a lithium ion battery with high energy density, which is composed of a diaphragm, a negative electrode, a positive electrode and an electrolyte system. The negative electrode ismade of artificial graphite or artificial graphite mixed with modified natural graphite. The positive electrode side includes a positive electrode system active substance which is lithium cobalt oxide or a mixture of lithium cobalt oxide and a lithium nickel cobalt manganese oxide ternary material. The conductive agent used in the positive electrode system is single-walled carbon nanotubes or single-walled carbon nanotubes mixed with multi-walled carbon nanotubes. Based on the positive electrode slurry, the amount of conductive agent added in the positive electrode system is 0.04-0.06%. The solvent of the electrolyte system is the mixed solution of EC / DEC / EMC. The lithium salt in the electrolyte system is LiPF6. The lithium ion battery with high energy density has the advantage as follows: because an optimized positive electrode conductive agent and an optimized electrolyte system are adopted, the energy density of the lithium ion battery is increased, the energy density of the electrodes is increased by 1.5-4% compared with the normal system, the lithium ion battery has high specific energy and cycle performance, and the capacity retention rate is as high as 88% after 500 cyclesof 0.5C charging and 0.5C discharging.

Owner:ZHENGZHOU BAK BATTERY CO LTD

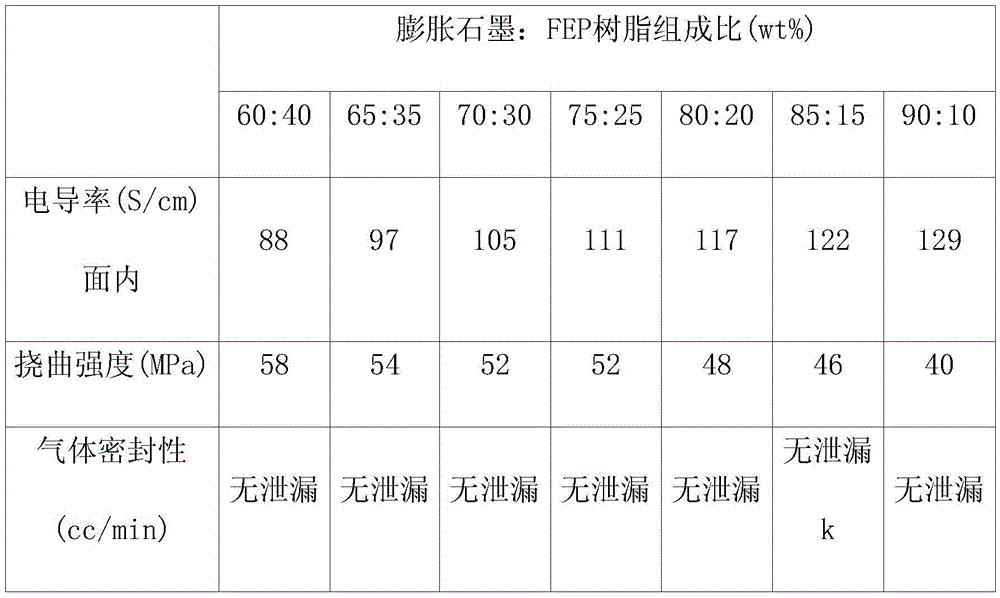

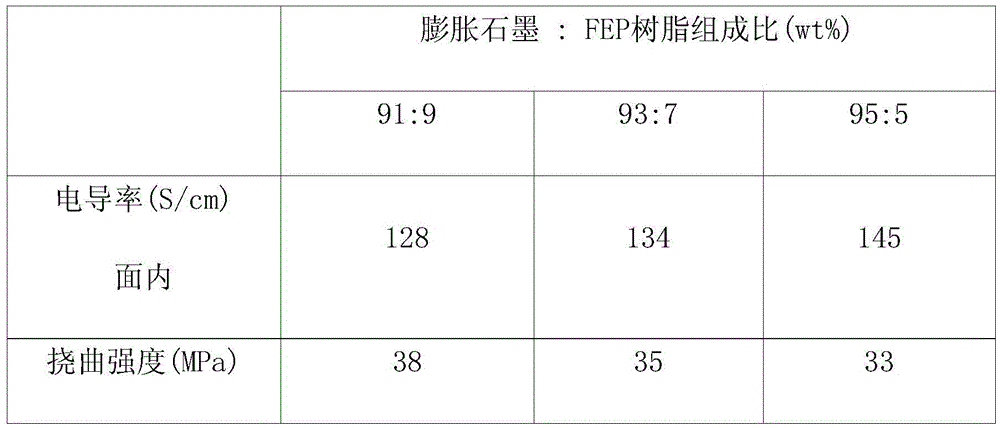

Fuel Cell Separating Plate And Method Of Manufacturing The Same

InactiveCN105762381ADoes not reduce conductivityReduce usageFinal product manufactureFuel cellsFuel cellsGraphite

Disclosed are a fuel cell separating plate having high temperature and acid resistance, and a method of manufacturing the same. The fuel cell separating plate includes a molded product manufactured from a mixture of expanded graphite and thermoplastic resin. The fuel cell separating plate and the method of manufacturing the same according to the present invention do not lower conductivity of the separating plate while decreasing a use amount of a conductive material. In addition, the fuel cell separating plate and the method of manufacturing the same simplify a manufacturing process and shorten manufacturing time.

Owner:HANKOOK TIRE WORLDWIDE

Anti-corrosion coating for power grid overhead conductor

InactiveCN105086558ALow conductivityImprove anti-corrosion and anti-rust performanceAnti-corrosive paintsUltrasonic oscillationMaterials science

The invention provides an anti-corrosion coating for a power grid overhead conductor. The coating is obtained by adding nanometer-scale fine graphite powder to a prepared Dacromet solution according to a certain proportion, conducting ultrasonic oscillation so that the nanometer-scale fine graphite powder can be evenly dispersed in the liquid, and then conducting coating and solidifying. The coating comprises, by weight, 12% of graphite powder, 35% of sheet zinc powder, 8% of sheet aluminum powder, 7% of chromic anhydride, 30% of ethanediol, 5% of dispersing agents, 0.1% of flexibilizer, 0.9% of thickening agents, and 2% of composite reducing agents and water. Through the invention improvement of the coating formula and addition of the nanometer-scale fine graphite powder, tests prove that the novel coating achieves the aim of not reducing the conductivity of coating materials while not influencing the anti-corrosion and anti-rusting effect. The anti-corrosion coating is suitable for corrosion prevention and rust prevention of the power grid overhead conductor.

Owner:ELECTRIC POWER RES INST STATE GRID JIANGXI ELECTRIC POWER CO +1

Heat treatment technology for high-strength high-conduction low-Be Co-free Cu alloy

The invention relates to a heat treatment technology for a high-strength high-conduction low-Be Co-free Cu alloy. The copper alloy comprises the following ingredients in percentage by weight: 0.15-0.5% of Be, 1-2.1% of Ni and the balance of Cu and inevitable trace impurities. The heat treatment technology comprises the following steps of: at 910-930DEG C, carrying out solution hardening; and then carrying out 8-40% of precooling deformation and aging treatment characterized by keeping warm for 2-3 hours at 440-490DEG C. After the low-Be Co-free Cu alloy adopts the heat treatment technology disclosed by the invention, the strength of the alloy is greatly improved, the tensile strength can be 710-830MPa, the yield strength can be 550-735MPa, and the relative conductivity is 45-65%IACS (International Annealed Copper Standard). According to the heat treatment technology system obtained by the invention, the mechanical property is greatly improved while the low-Be Co-free Cu alloy keeps high conductivity. A high-Be Cu alloy and a Co-contained low-Be Cu alloy with high price and serious pollution can be partially replaced.

Owner:CENT SOUTH UNIV

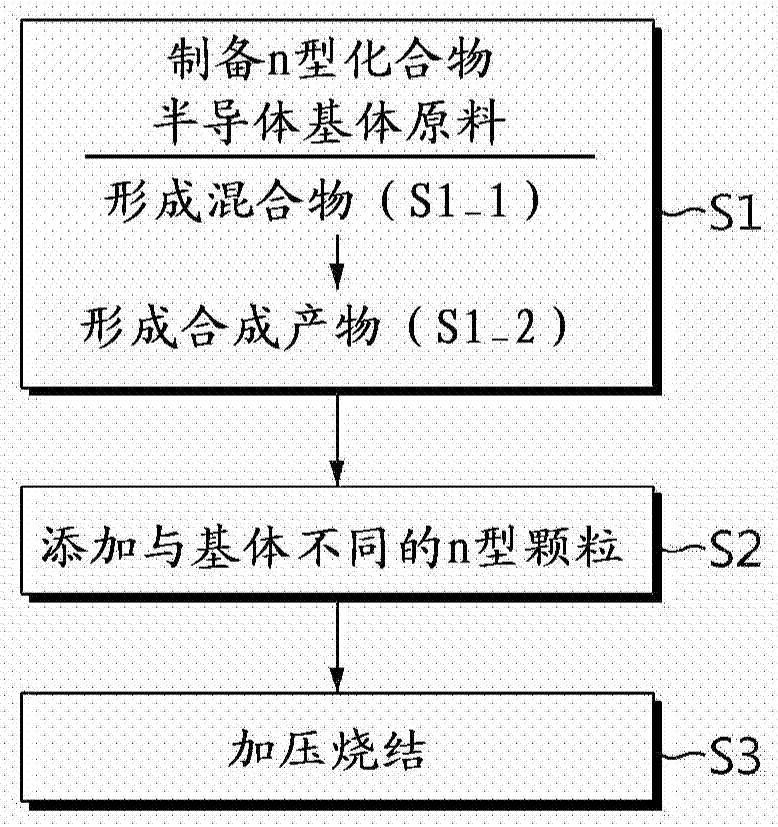

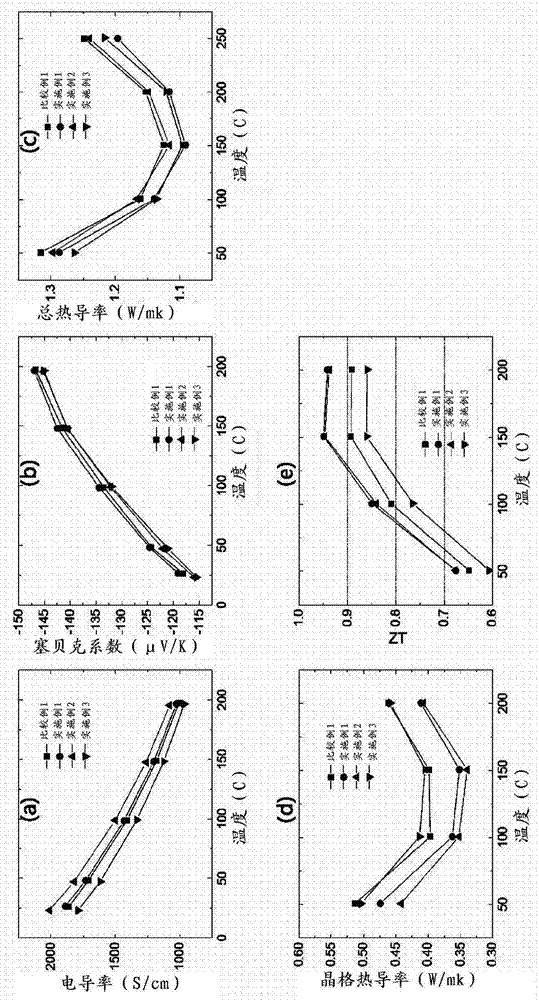

Compound semiconductor thermoelectric material and method for manufacturing same

ActiveCN107408618ALow thermal conductivityDoes not reduce conductivityThermoelectric device manufacture/treatmentThermoelectric device junction materialsThermoelectric materialsThermoelectric cooling

Provided are: a compound semiconductor thermoelectric material, having excellent thermoelectric conversion performance by having an excellent power factor and ZT value, and in particular, having excellent thermoelectric conversion performance at a low temperature; a method for manufacturing the same; and a thermoelectric module, a thermoelectric generator, or a thermoelectric cooling device, etc. using the same. The compound semiconductor thermoelectric material according to the present invention comprises: an n-type compound semiconductor matrix; and n-type particles which are dispersed in the matrix, are compound semiconductors which are different from the matrix, and have an average particle diameter of 1 micrometer to 100 micrometers.

Owner:LG CHEM LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com