Preparation method and application of micronized cellulose/MXene composite film

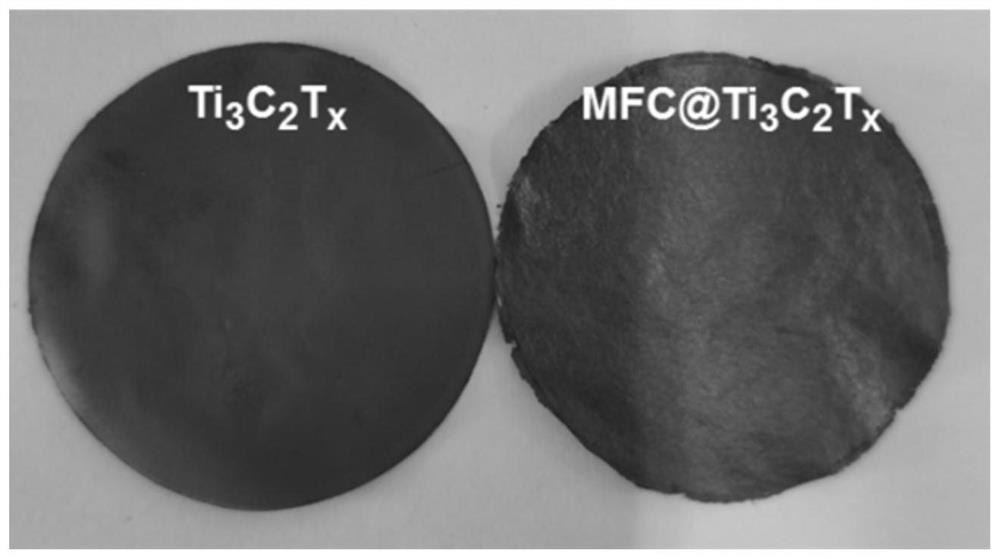

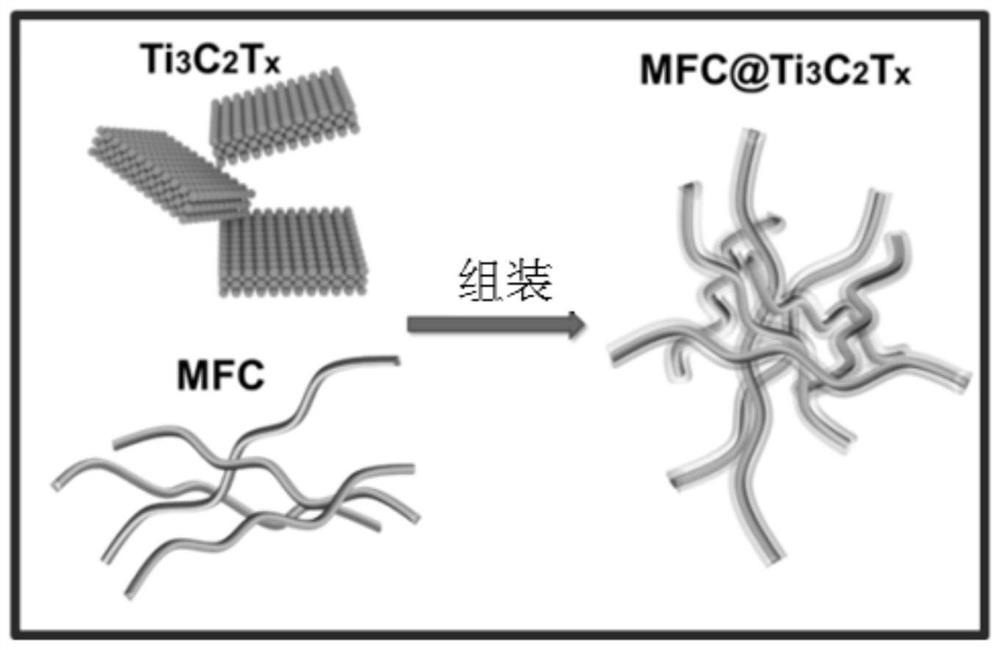

A composite film and cellulose technology, which is applied in the manufacture of hybrid/electric double layer capacitors, hybrid capacitor electrodes, etc., can solve the problems of poor mechanical properties and capacitance of MXene composite films, and achieve enhanced mechanical properties, comprehensive performance, and tensile strength. The effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0028] Embodiment 1: This embodiment is a preparation method of an independently supported micronized cellulose / MXene composite film, which is completed in the following steps:

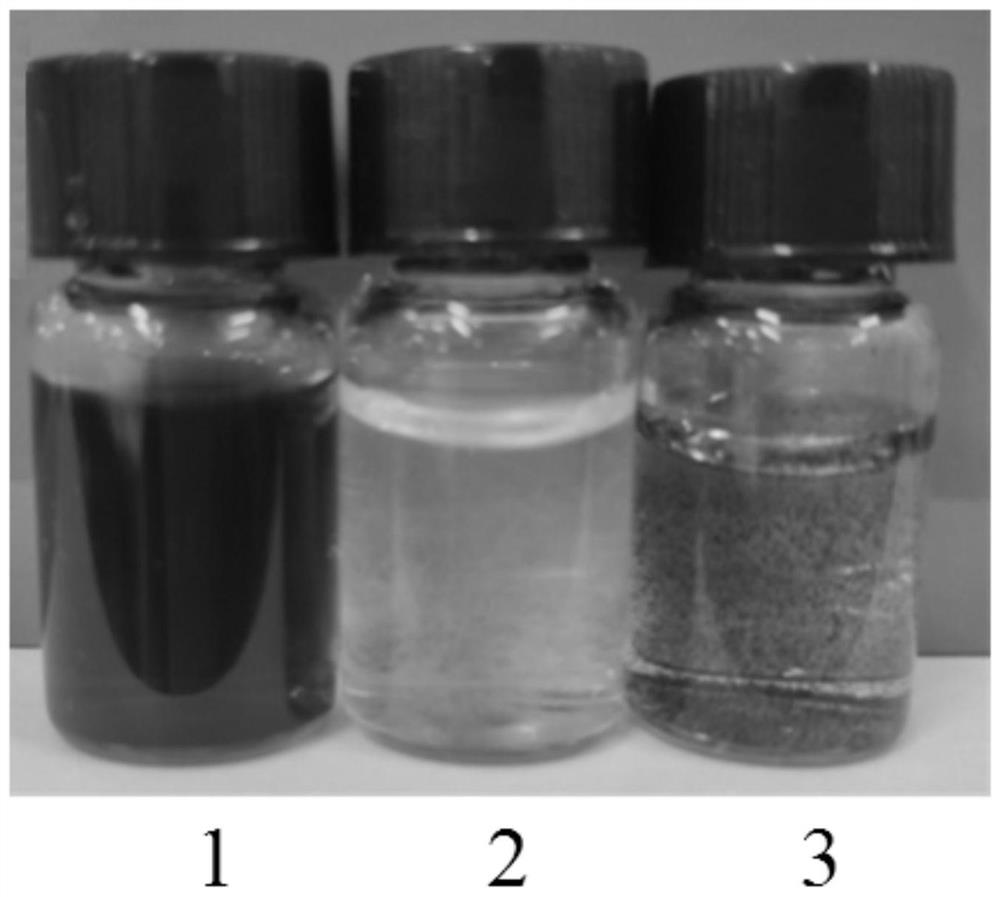

[0029] 1. Preparation of dark green few-layer Ti 3 C 2 T x Colloidal supernatant:

[0030] ①. Add LiF to the HCl solution, stir at room temperature until completely dissolved, and then add Ti in an ice-water bath 3 AlC 2 , and then reacted for 18h to 28h in a nitrogen atmosphere and at a temperature of 30°C to 35°C to obtain a reaction solution;

[0031] ②. First, use deionized water as a cleaning agent, and centrifuge the reaction solution at a centrifugal speed of 3500r / min to 4000r / min to pH>6, pour out the supernatant to obtain a precipitate; add deionized to the precipitate water,

[0032] Then perform ultrasonication, centrifuge at a centrifugal speed of 3500r / min to 4000r / min for 1h to 1.2h, collect the supernatant, and obtain dark green few-layer Ti 3 C 2 T x colloidal supernatant;

...

specific Embodiment approach 2

[0038] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the concentration of the HCl solution in step ① is 8 mol / L-10 mol / L. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0039] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the volume ratio of the mass of LiF described in Step ① to the HCl solution is (1g-2g):20mL. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com