Patents

Literature

78results about How to "Improve wetting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite combined aluminum oxide-silicon carbide-(carbon) system amorphous refractory material

The invention relates to a complex combination alumina-carborundum-(carbon) series amorphous fire proof material, and the formula comprises: 36 to 32 percent of 8-3mm corundum or bauxite, 18 to 26 percent of 3-1mm corundum or bauxite, 10 to 22 percent of 1-0.0088mm corundum or bauxite, 0 to 15 percent of 1-0.088mm carborundum, 0 to 3 percent of 1-0.0088 spherical asphalt, 0 to 20 percent of d90 less than 0.088mm corundum or bauxite, 0 to 20 percent of d90 less than 0.088 carborundum, 0 to 3 percent of d90 less than 0.088mm high-carbon materials, 0 to 5 percent of alpha alumina micro powder, 1 to 8 percent of alumina hydrate, 1 to 6 percent of silicon ash, 0 to 2 percent of calcium aluminate cement, 0.05 to 0.4 percent of plus super-plasticizer (polycarboxylic acids+sulfonated naphthalene formaldehyde polymer+sulfonated melamine polymer), 1 to 6 percent of plus polypropylene acid series latex and 1 to 6 percent of plus water. Compared with low-cement aluminum carborundum carbon material, the material has good anti-corrosion performance. Therefore, the service life of a kilneye of a cement kiln and a main groove slag line of a blast furnace can be prolonged when a product is combined by the complex combination alumina-carborundum-(carbon) series amorphous fire proof material instead of the cement.

Owner:RUITAI MATERIALS TECHNOLOGY CO LTD

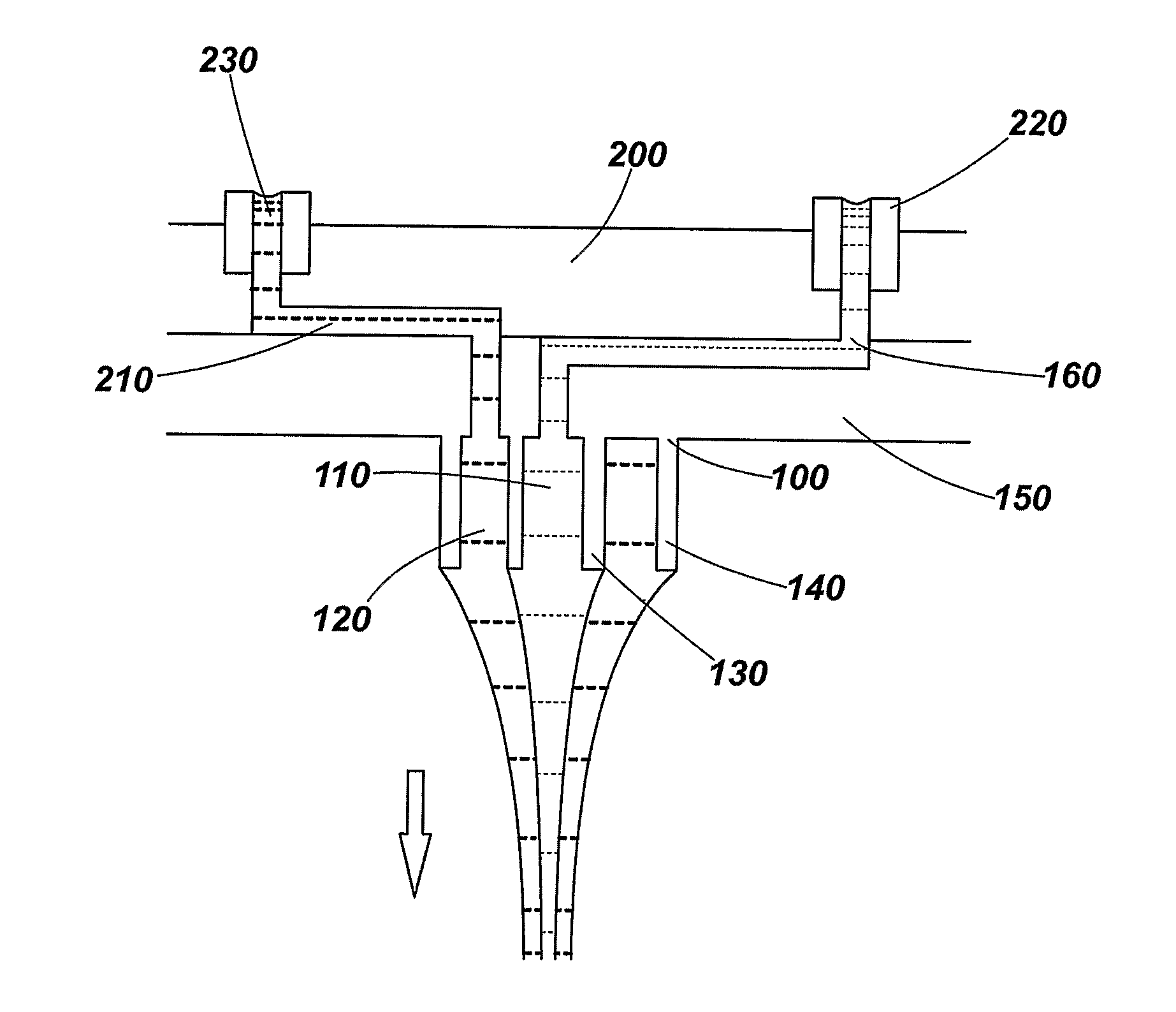

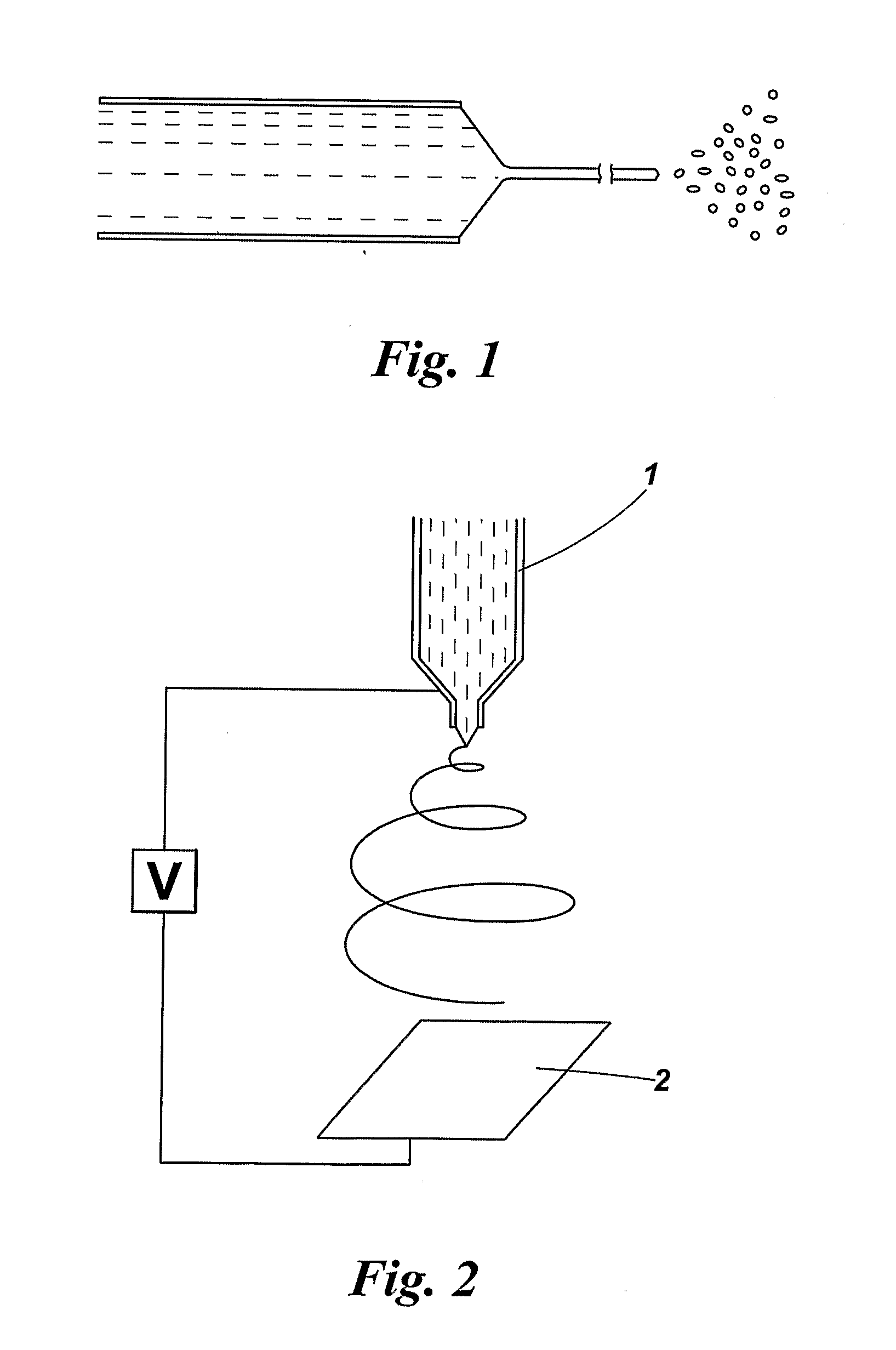

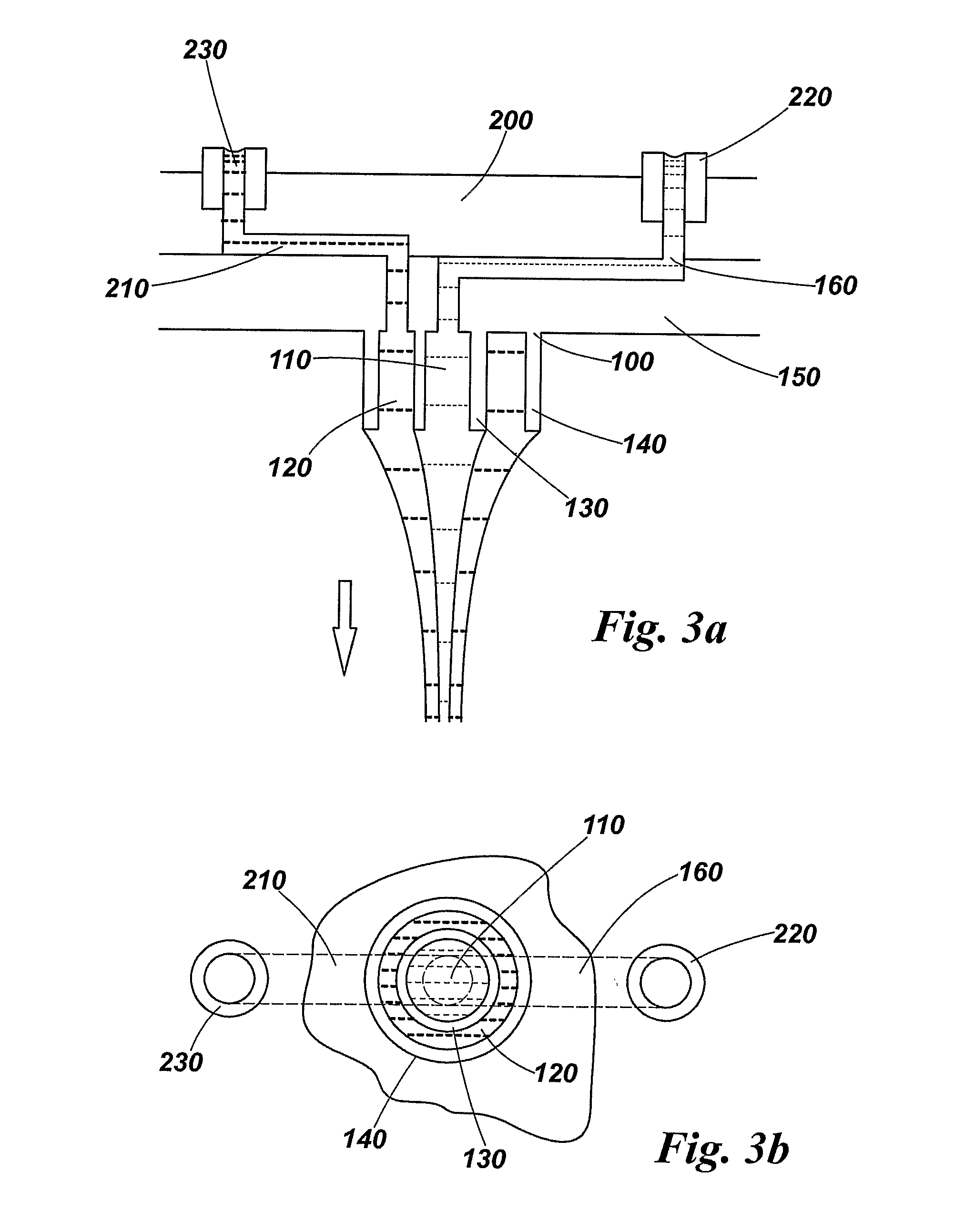

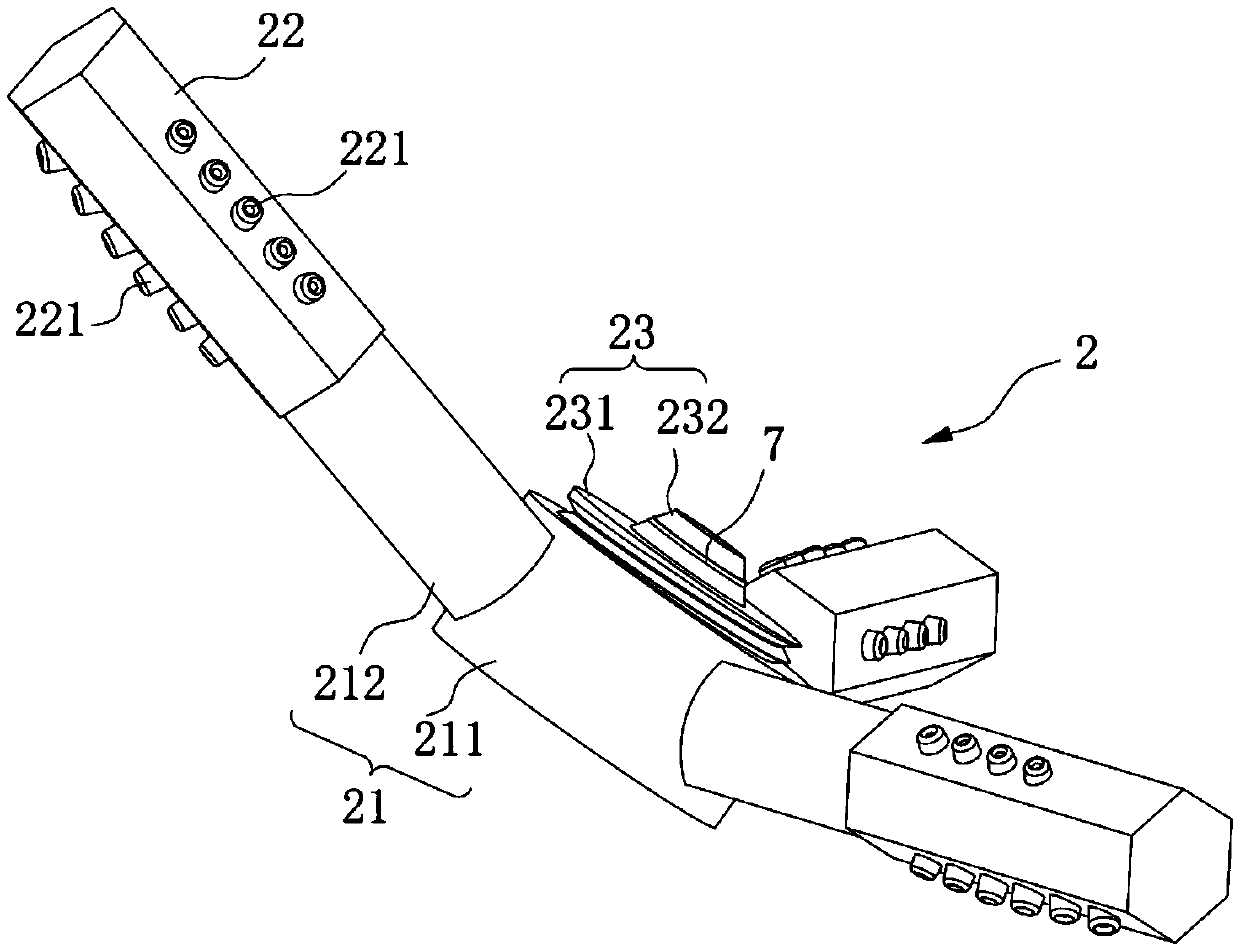

Electrospinning nozzle

InactiveUS20120034461A1Improve wettingPromote wettingElectric discharge heatingFilament/thread formingElectrospinningEngineering

Apparatus and methods for electrospinning, electrojetting and / or electrospraying are disclosed. The apparatus includes a nozzle for the formation of a fluid jet from a fluid cone, the nozzle having a plurality of ducts arranged for supplying a plurality of fluids for use in the formation of the fluid jet. The ducts may issue onto one or more openings, for example, concentric openings for the production of core-shell nanofibres and particles, or core- multishell nanofibres and particles. The apparatus may also include a manifold for supplying the fluids to the nozzle from one or more fluid reservoirs.

Owner:THE SCI & TECH FACILITIES COUNCIL

AlN ceramic bonded copper substrate and preparation method thereof

The invention provides an AlN ceramic bonded copper substrate which comprises an AlN ceramic substrate and copper foil bonded and connected onto the AlN ceramic substrate and is characterized in that a spinel structure compound modification layer is formed between the AlN ceramic substrate and the copper foil and comprises one or two of CuAlO2, CuAl2O4, Cu2O and CuO. The invention further provides a preparation method of the AlN ceramic bonded copper substrate. The method comprises the steps of spraying nano Cu2O on the surface of the AlN substrate, sintering in inert gas with a micro oxygen content and air sequentially, and then removing a surface oxide by a pickling manner. The prepared modification layer is tightly combined with matrix ceramic, and also has good affinity characteristic with the Cu foil. A uniform oxidation layer can be formed on the surface of the Cu foil by putting the Cu foil in a prepared solution at a certain temperature for specified time and more facilitates an AlN-DBC (direct bonded copper) technology.

Owner:NANJING ZHONGJIANG NEW MATERIAL TECH

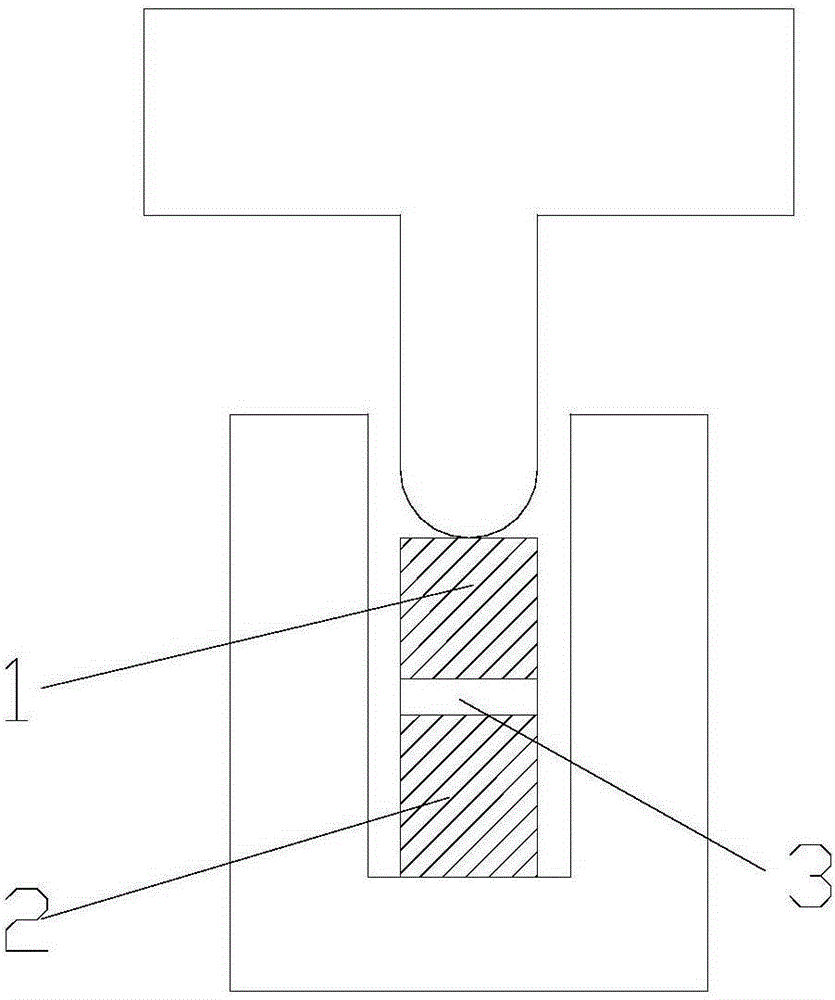

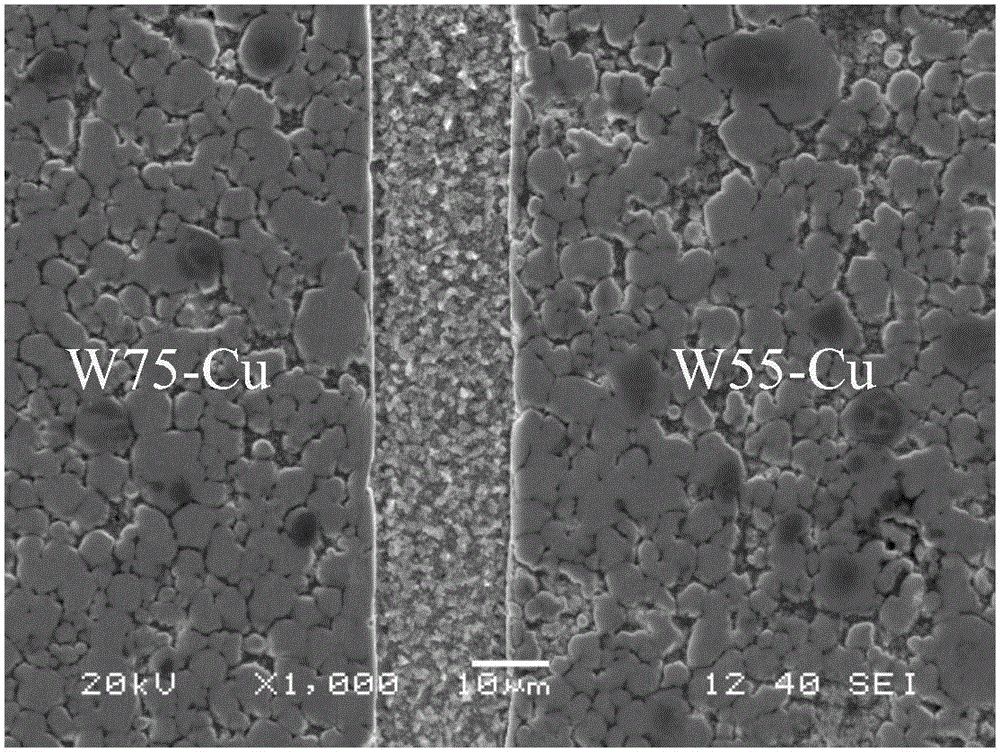

High-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as preparation method and welding method

InactiveCN104858570AEvenly meltedImprove wettingWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalMechanical property

The invention discloses high-temperature Zr-based brazing filler metal for brazing of W-Cu alloy and stainless steel, as well as a preparation method and a welding method. The high-temperature Zr-based brazing filler metal comprises the following elements by weight: 10 to 12 percent of V, 3.0 to 9.0 percent of Nb, 3.0 to 4.0 percent of Si, 8.0 to 16 percent of Cu, 9.0 to 12 percent of Ni, 11 to 14 percent of Cr, 3.0 to 5.0 percent of Sn, and the balance of Zr. The brazing temperature of the brazing filler metal is 1010 to 1090 DEG C and moderate, so that the brazing filler metal is uniformly melted; tinsel made of the brazing filler metal can accelerate atomic diffusion and interface reaction in a high-temperature connection process, so that the wetting and spreading capabilities of the brazing filler metal are improved, the residual stress in a joint is reduced, and the mechanical property of the joint is improved. Through the adoption of the preparation method of the brazing filler metal, the preparation of the brazing filler metal can be reproduced repeatedly, so as to facilitate popularization and application; through the adoption of the brazing technology provided by the invention, sample pieces are connected through vacuum brazing, wherein the sample pieces are in a vacuum atmosphere while being heated, so that problems such as oxidation and pollution are solved, the surface wetting and spreading capabilities are relatively high, convenience is brought for filling of a brazing seam, the strength of the joint is improved, and the obtained welded joint can be stable and reliable.

Owner:江门市新会区华科电器制品有限公司

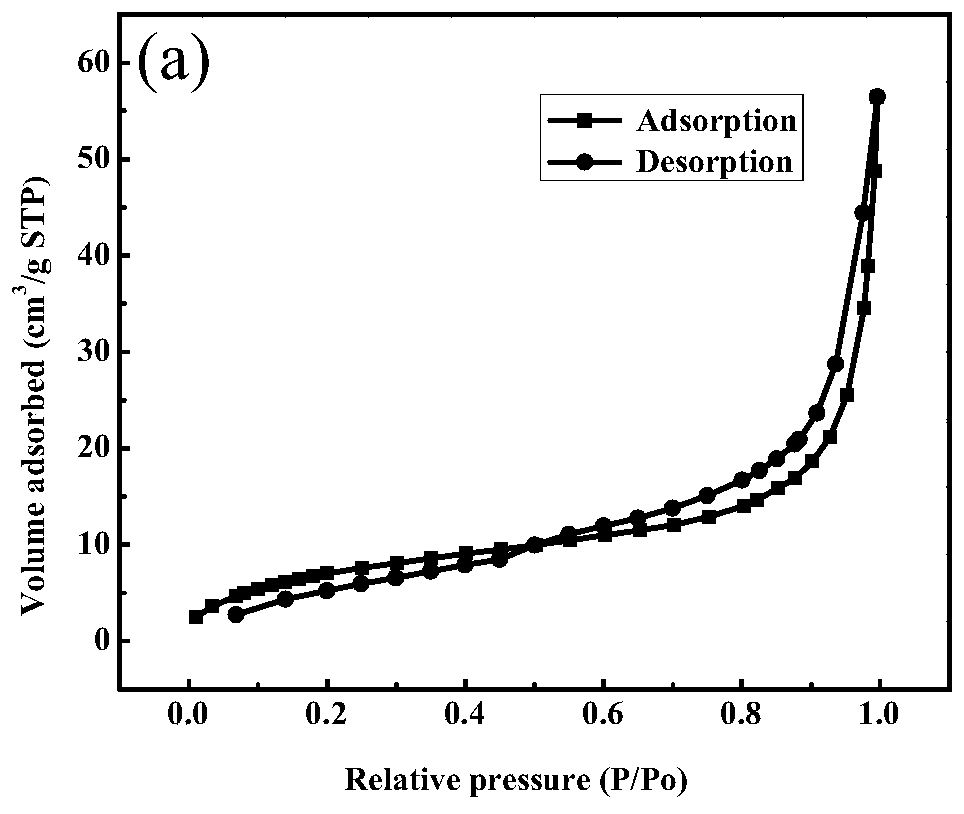

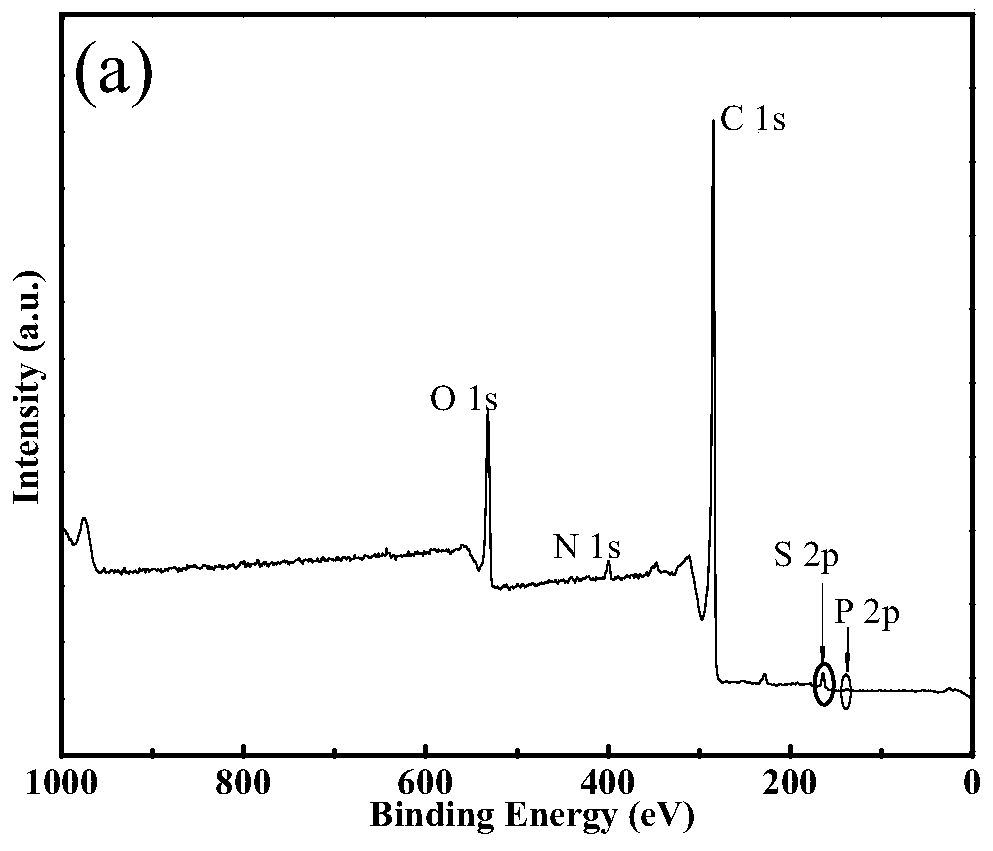

Preparation method of nitrogen-sulfur-phosphorus doped porous graphene oxide material and application of nitrogen-sulfur-phosphorus doped porous graphene oxide material

InactiveCN110391087AImprove performanceHigh densityCarbon compoundsHybrid capacitor electrodesCapacitancePorous graphene

The invention discloses a preparation method of a nitrogen-sulfur-phosphorus doped porous graphene oxide material and application of a nitrogen-sulfur-phosphorus doped porous graphene oxide material.According to the invention, a porous graphene oxide material doped with three elements is prepared by taking graphene oxide as a raw material, adding hydrogen peroxide in a hydrothermal condition forpore-forming and adding a dopant containing three elements of nitrogen,sulfur and phosphorus, and is applied to the electrode material of a supercapacitor. The three-dimensional porous structure is etched on the surface of graphene by using hydrogen peroxide with the strong oxidizing property, so that the specific surface area of a graphene material is further improved, the obtained porous graphene oxide is subjected to ultrasonic dispersion and then is fully mixed with a doping agent containing three elements of nitrogen, phosphorus and sulfur, nitrogen, sulfur and phosphorus heteroatoms areintroduced into the porous graphene oxide to improve the electrochemical performance of the graphene, and the porous graphene oxide is loaded on a conductive current collector to prepare a supercapacitor electrode, so that the capacitor obtains the better capacitance performance and has the good circulation stability.

Owner:HUNAN UNIV OF TECH

Plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing

ActiveCN101597732AGood interface wettabilityGood compatibilityHot-dipping/immersion processesAlcoholEther

The invention discloses a plating assistant agent additive for preventing plating leakage of steel wire hot galvanizing which comprises the following components in percentage by weight: 20-25% of fatty alcohol-polyoxyethylene ether, 20-26% of dodecyl phenyl polyoxyethyleneether, 8-14% of polyoxyethylene octylphenol ether, 3-6% of triethanolamine, 0.8-1.5% of carbamide and 30-36% of methyl alcohol. The method comprises the following steps: weighing the raw materials according to the proportioning of the additive, mixing and stirring the raw materials evenly to form the additive of the invention, adding the stock solution of the plating assistant agent additive of the invention into a slot according to a proportion that the amount of the added stock solution of the plating assistant agent additive accounts for 0.1-0.2% of the plating assistant agent bath solution, stirring evenly, and being able to use at the temperature of 70-75 DEG C. By adding the additive of the invention into the plating assistant agent, the wettability and the infiltrative of the plating assistant agent can be effectively enhanced, the plating effect on the surface of the steel wire is improved, and the plating leakage of the steel wire zinc plating is avoided.

Owner:巩义市恒星金属制品有限公司

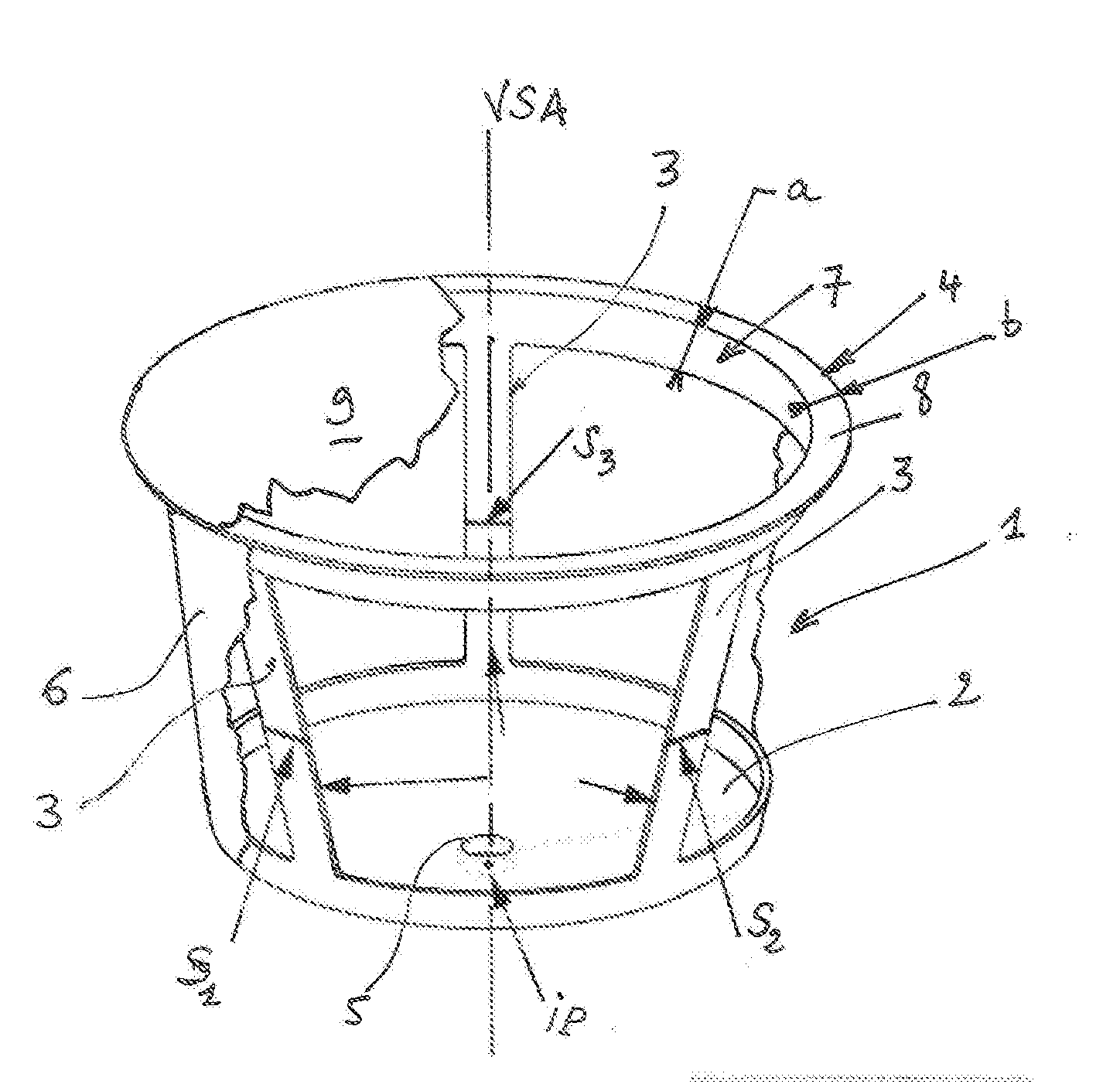

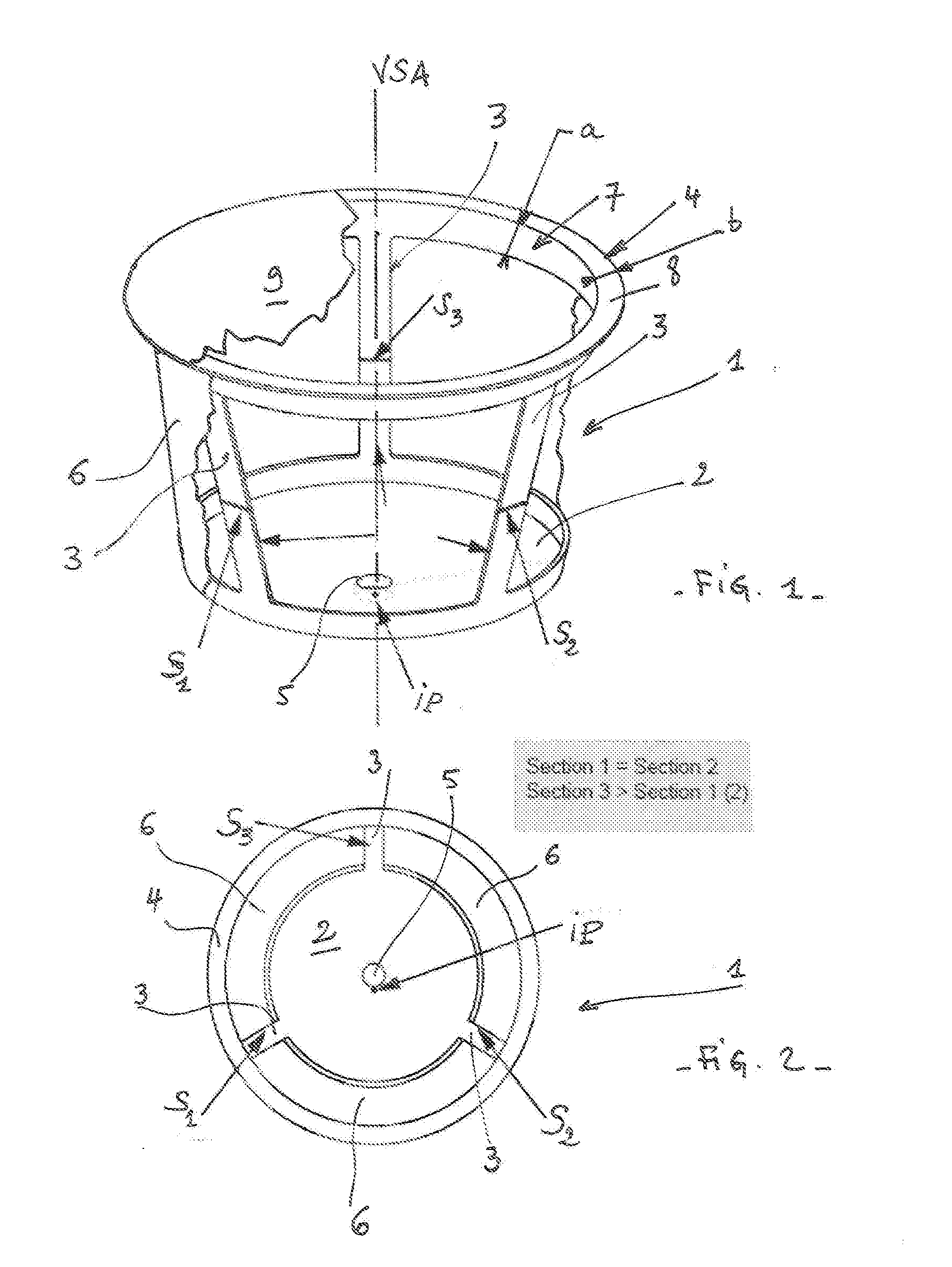

In-mould labelled container

InactiveUS20130146495A1Promote wettingEasy disposalWrappersLaminationBiomedical engineeringFood preparation

The present invention concerns an injection-molded capsule for use in a food preparation machine, said capsule for use in a food preparation machine comprising: (i) a structure (1) with a lower side (2), at least three pillars (3) extending from the lower side and linked to a circular upper frame (4) which defines the surroundings of the capsule top side, the pillars (3) having cross-sections S1, S2 and S3, the lower side (2) being a solid wall that comprises a dispensing opening (5) and is centered across the vertical symmetry axis VSA of said capsule, and (ii) a label (6) attached to the outer surface of the lower side (2), pillars (3) and upper circular frame (4), thus forming an envelope that defines capsule side walls, characterized in that the injection point IP of the capsule is off-centered in the vicinity of said dispensing opening (5), opposed the pillar (3) having a cross-section S3 relatively to the axis VSA, and in that S1=S2 and S3>S1.

Owner:SOC DES PROD NESTLE SA

Solder for soldering different-component W-Cu alloy, preparing method and soldering method thereof

ActiveCN105171270AAccelerated corrosionEasy to processWelding/cutting media/materialsWelding/soldering/cutting articlesSolderingCopper

The invention discloses a solder for soldering a different-component W-Cu alloy, a preparing method and a soldering method thereof. The mass percents of the components of the solder are described as follows: 10.0-16.0% of Mn, 0.5-3.5% of Co, 1.0-5.0% of Ni, 1.0-4.0% of Ti, 0.2-0.6% of Si, 0.1-.03% of B, and the balance of Cu. The soldering temperature of the copper-based solder is 1000-1050 DEG C. Moderate fusing temperature of the solder and high fusion uniformity of the solder are realized. Through adding related beneficial elements, good wetability and high metallurgical miscibility of the solder to the W-Cu alloy are realized. An obtained solder joint has high strength and high corrosion resistance and can be totally applied in a complicated environment. The solder is an economical solder with high comprehensive performance. A prepared copper-based solder foil has functions of facilitating diffusion and interface reaction between alloy elements in a soldering connecting process, improving wetting and spreading capabilities of the solder on the surface of the W-Cu alloy, and facilitating forming of a compact solder joint.

Owner:无锡腾达海川新材料有限公司

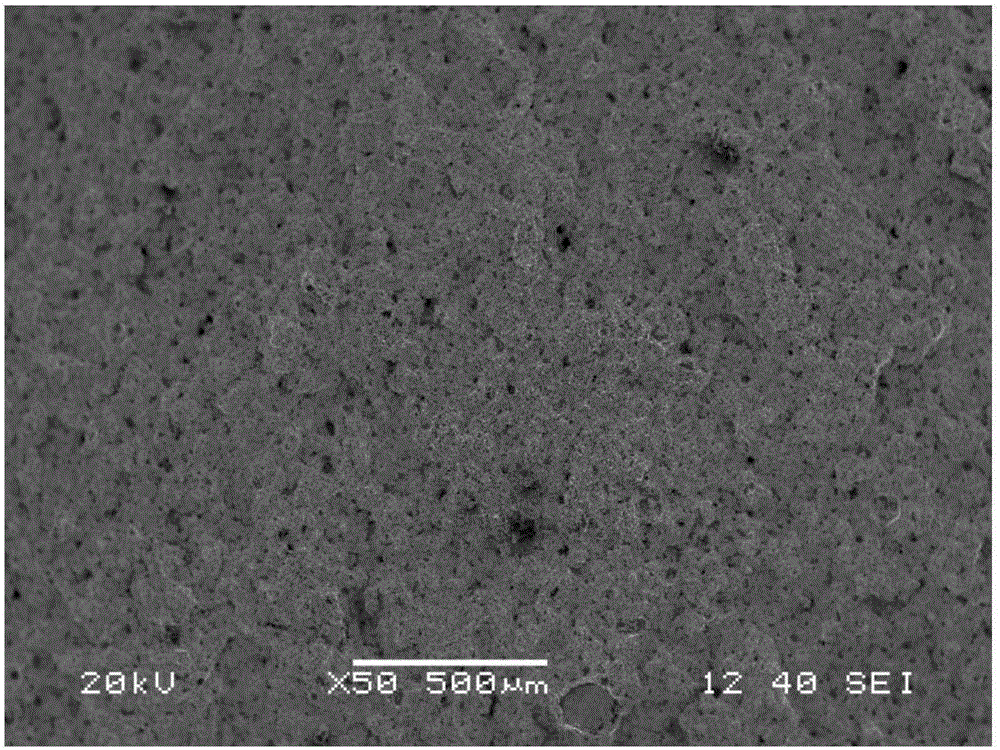

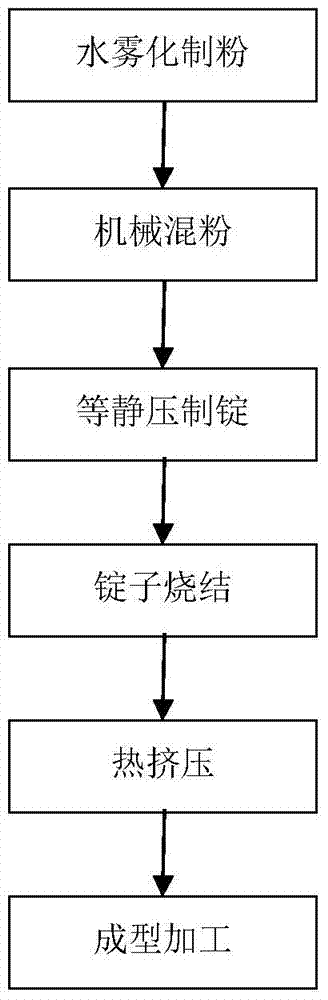

Sliver oxide contact material with base body performance-strengthening additives as well as preparation method and product thereof

The invention discloses a preparation method of a sliver oxide contact material with base body performance-strengthening additives and a product thereof. The preparation method comprises the following steps: preparing an additive alloy with strengthening performance, oxide powder, other additive powder and a sliver ingot which are used as raw materials into powder by water atomization, mixing powder, pressing an ingot, sintering, extruding and finally drawing or rolling to prepare a contact material finished product. The sliver oxide contact material disclosed by the invention has a sliver base body with good electrical performance and mechanical performance, oxide particles and other additive materials are uniformly dispersed in the sliver base body, so that the contact material is ensured to have the characteristics of being uniform and stable in electrical performance, good in processing performance, and the like. Compared with the conventional sliver oxide contact material, the material prepared by the process in the invention has higher burning loss resistance, electro-transfer resistance and fusion welding resistance, can satisfy volume miniaturization and performance optimization needs of a low-voltage electrical appliance. Moreover, the process disclosed by the invention is simple and suitable for mass production. The prepared silver oxide product can be widely applied to a relay, a contact and a circuit breaker.

Owner:ZHEJIANG FUDA ALLOY MATERIALS TECH CO LTD

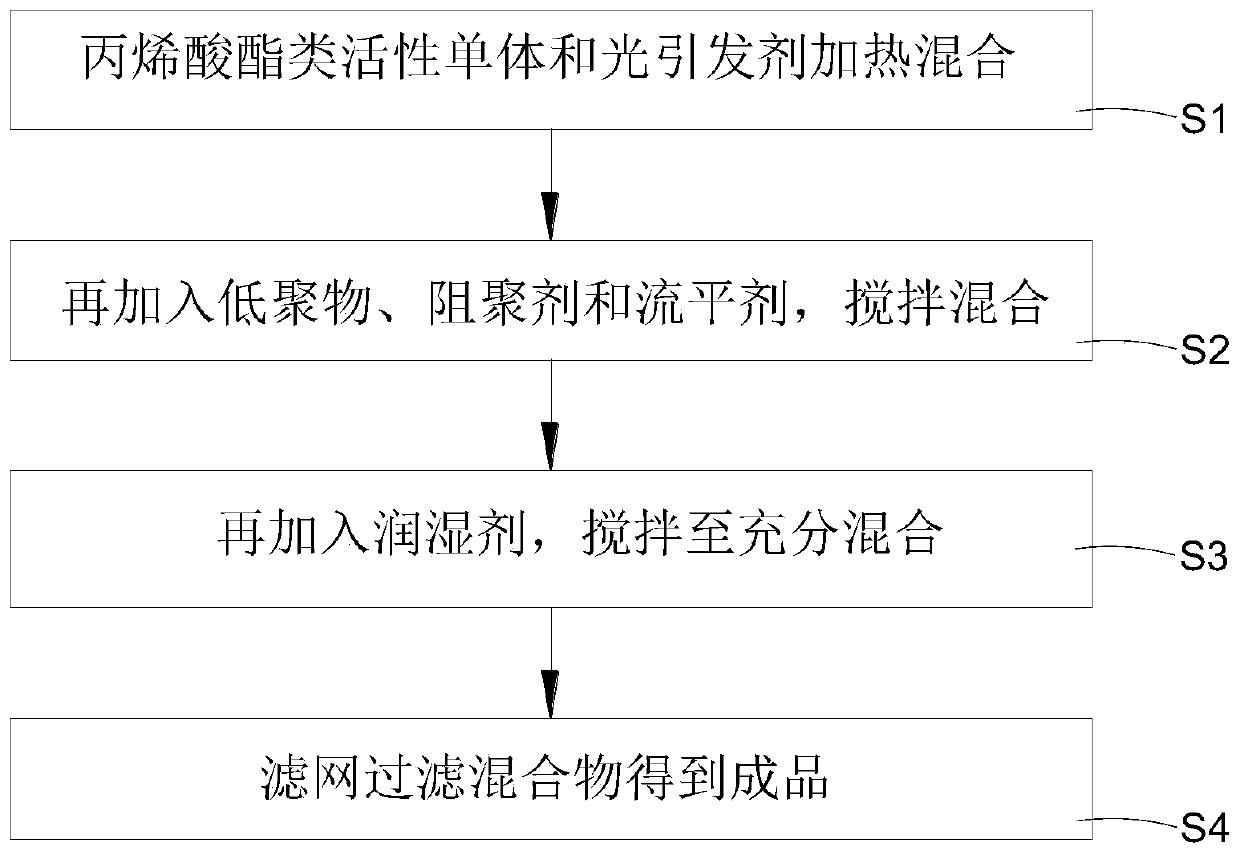

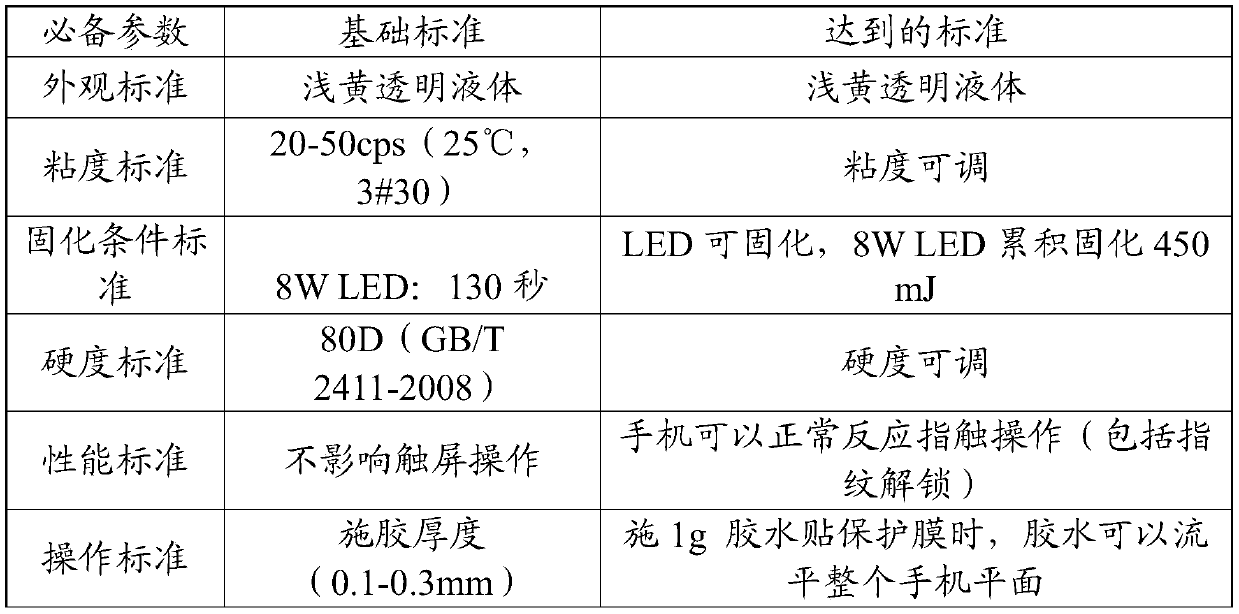

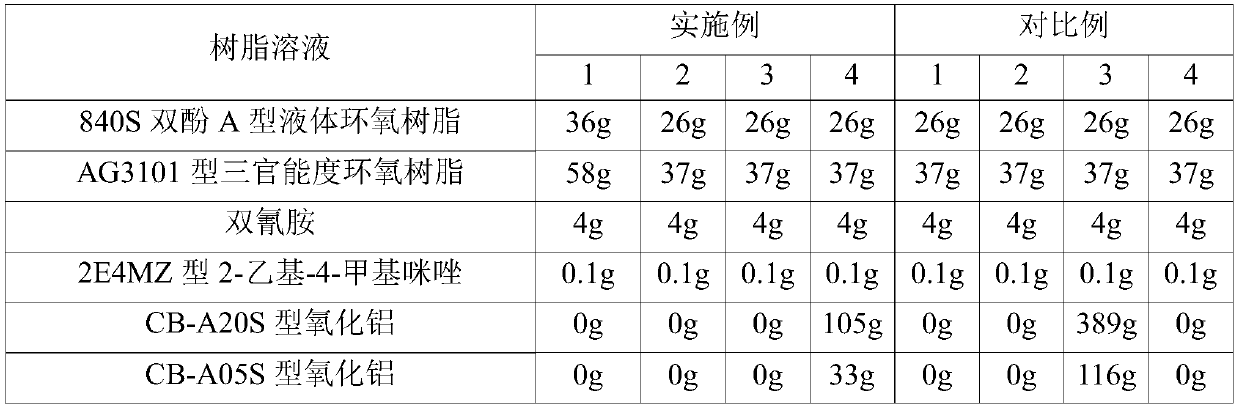

High sensitivity mobile phone protection screen full lamination adhesive and preparation method thereof

InactiveCN110423593AImprove wettingImprove fitFilm/foil adhesivesPolyureas/polyurethane adhesivesOligomerAdhesive

The invention discloses a high sensitivity mobile phone protection screen full lamination adhesive and a preparation method thereof. The high sensitivity mobile phone protection screen full laminationadhesive comprises, by mass fraction, 10-20% of an oligomer, 70-90% of an acrylate active monomer, 2-6% of a photoinitiator and 1-3% of assistants. The high sensitivity mobile phone protection screenfull lamination adhesive provided by the invention not only has the characteristics of high sensitivity, high transparency, low odor, high lamination degree, environmental protection, etc., also is not added with any solvent, has heavy metal, toluene, formaldehyde, methanol meeting the EU ROSH and REACH standards, and has good peeling performance.

Owner:河源然生新材料有限公司

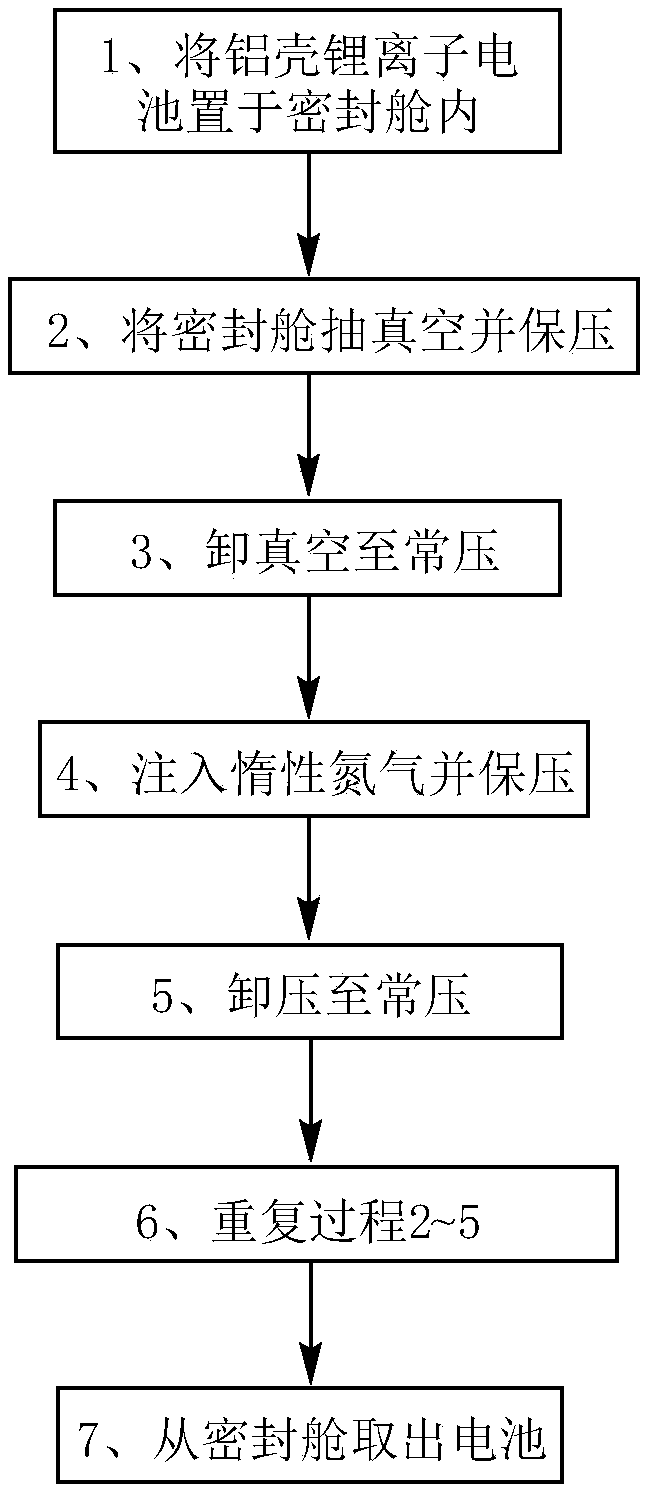

A wetting method of a hard shell lithium ion battery

InactiveCN109244555ASolve the spill problemImprove wettingFinal product manufactureCell component detailsVacuum pumpingPhysical chemistry

The invention relates to a wetting method of a hard shell lithium ion battery, and belongs to the technical field of lithium ion battery preparation. The wetting method of the hard shell lithium ion battery comprises the following steps: 1) vacuumizing the injected hard shell lithium ion battery to a gauge pressure of-70 To -30KPa, keeping pressure, discharging vacuum; 2) carrying out circulatingstatic position according to that following method: vacuuming the hard shell lithium ion battery until the gauge pressure is less than or equal to 30KPa than the gauge pressure of the adjacent previous vacuum pumping, keeping the pressure, relieving the vacuum, injecting an inert gas to keep the pressure, relieving the pressure. The wetting method of the present invention, By controlling the gaugepressure in the hard-shell cell after electrolyte injection, At that initial stage, the electrolyte can be avoid from overflowing when there is much overflow gas in the cell, and the gauge pressure of the vacuum can be reduced with the decrease of the overflowing gas in the circulate static process, the wetting process is accelerated and the electrolyte cannot be overflowed, the wetting efficiency is improved, and the overflowing of the electrolyte is greatly reduced at the same time.

Owner:DO FLUORIDE NEW ENERGY TECHNOLOGY CO LTD

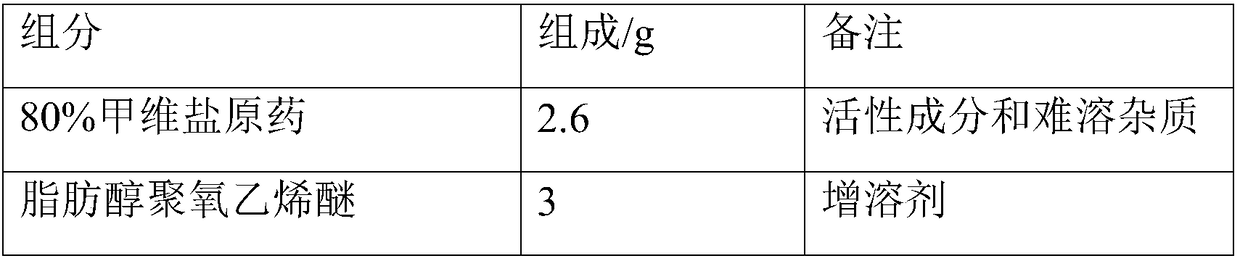

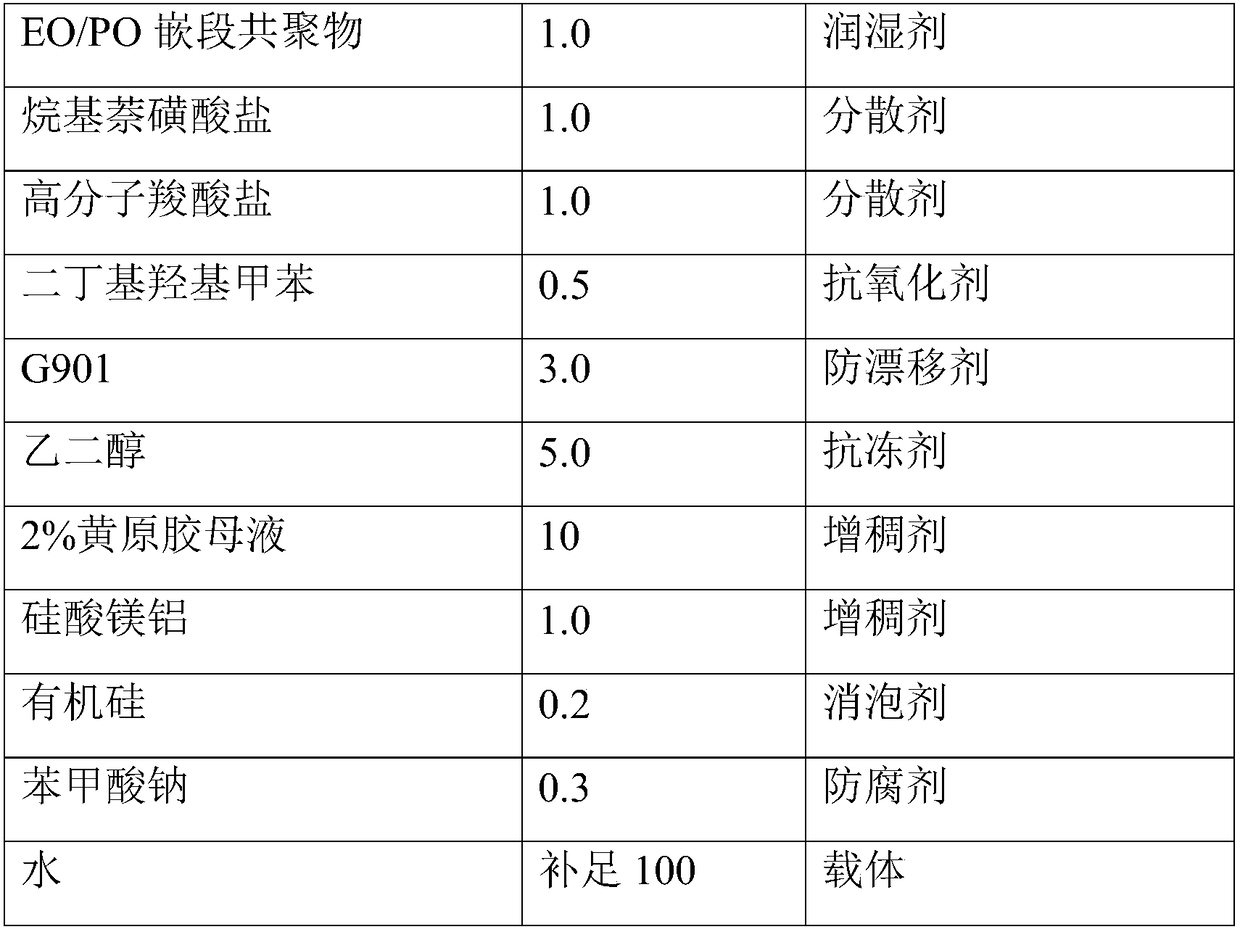

Suspending agent and preparation method thereof

InactiveCN109479876AFacilitate the exertion of medicinal effectStable drug effectBiocideAnimal repellantsOrganic solventPreservative

The invention belongs to the technical field of pesticides and particularly relates to a suspending agent and a preparation method thereof. The suspending agent is composed of, by weight percentage, 0.5-10% of emamectin benzoate, 2-15% of solubilizer, 1-3% of wetting agent, 2-4% of dispersing agent, 0.5-2% of antioxidant agent, 3-10% of drift control agent, 2-5% of antifreezing agent, 0.1-3% of thickener, 0.2-0.4% of defoamer, 0.1-0.5% of preservatives and water as balance. According to the suspending agent, the components synthesize to give stable play to the pesticidal effects of the emamectin benzoate and reduce the application cost; meanwhile, with no organic solvent, the suspending agent is safe during production and application and environmentally friendly.

Owner:SHENZHEN NOPOSION AGROCHEM

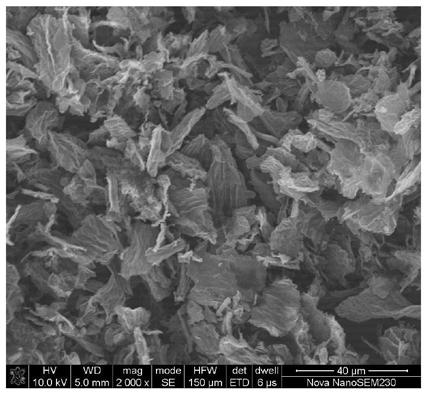

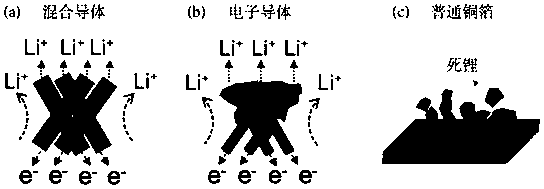

Three-dimensional mixed ion and electron conductor current collector as well as preparation method and application thereof

ActiveCN108808008AIncrease roughnessImprove wettingElectrode carriers/collectorsElectrical conductorLithium metal

The invention belongs to the technical field of a battery, and discloses a three-dimensional mixed ion and electron conductor current collector as well as a preparation method and application thereof.The current collector is of a three-dimensional fiber network structure, and comprises an electron conductor fiber network and ion conductor particles uniformly loaded on the electron conductor fibernetwork, wherein the electron conductor fiber network uses carbon fiber; the ion conductor particle uses LLZO, LLTO or LATP nano ceramic particles; the three-dimensional mixed ion and electron conductor current collector is prepared through the three steps of precursor solution preparation, electrostatic spinning and high-temperature calcination. The prepared three-dimensional mixed ion and electron conductor current collector can stably circulate in a lithium metal battery with the electric current density reaching up to 5 mA cm<-2> or the deposition capacity reaching up to 20 mAh cm<-2>, and can be used in a lithium-lithium iron phosphate battery reaching up to 20 C multiplying power.

Owner:TIANJIN UNIV

Method for preparing bagasse biomass charcoal

InactiveCN107930582APrevent shrinkagePlay a role in fluxingOther chemical processesAlkali metal oxides/hydroxidesNitrogenPhosphoric acid

The invention discloses a method for preparing bagasse biomass charcoal and belongs to the technical field of adsorption materials. The method comprises carrying out steam explosion on bagasse to obtain bagasse subjected by steam explosion, mixing the bagasse subjected by steam explosion and a mixed enzyme liquid so that the bagasse is subjected to enzymolysis, drying the bagasse subjected to enzymolysis until constant weight, mixing the pretreated bagasse and tetraethoxysilane so that the pretreated bagasse is immersed, filtering the pretreated bagasse to obtain filter cake, mixing the filtercake and a saturated borax solution so that the filter cake is immersed, carrying out filtration and drying to obtain modified bagasse, mixing the modified bagasse and a phosphoric acid solution, adding a water-retaining agent into the mixed solution, carrying out immersion and filtration to obtain a blank, pre-carbonizing the blank in a nitrogen protective atmosphere at 300-350 DEG C for 2-3h, carbonizing the blank at 550-700 DEG C for 3-4h, discharging the blank, crushing the blank, and carrying out screening to obtain the bagasse biomass charcoal. The bagasse biomass charcoal has a high specific surface area and good adsorption performances.

Owner:常州琨瑶纺织品有限公司

Protective gas for welding stainless steel

The invention discloses a protective gas for welding stainless steel. The protective gas is characterized by being formed by mixing argon and hydrogen, wherein the weight percentage of argon is 95%, and the weight percentage of hydrogen is 5%. The protective gas can be applied to welding the stainless steel, can improve the thermal input of a weld joint, accelerates the welding speed, increases the depth of fusion, improves the wetting degree of a weld bead and widens the sectional area of the weld joint. After hydrogen is added into the argon, the reducing atmosphere is provided for a welding area, so that oxygen and oxide in the weld joint can be removed.

Owner:SHANGHAI YANJIE MECHANICAL ENG CO LTD

Washing block

InactiveCN1935969ADissolve fastImprove antioxidant capacityInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsSodium bicarbonateWhitening Agents

The invention relates to washing block which includes basis soap and disintegrating agent. The latter includes sodium bicarbonate and sodium chloride. The former includes coconut oil hydroxyl-ethyl sulfonic acid, nonionic surfactant, coconut oil di-ethanol amide, and auxiliary materials which includes whitening agent, preservative agent, essence, stabilizer, soda, filling. The disintegrating agent can fast dissolve washing block, enrich the product foam, and effectively increase decontamination of the liquid soap. The washing block has the feature of convenient using and low residue, make the clothes firmness and puffy after washing at each time.

Owner:常熟市亚德实业有限公司

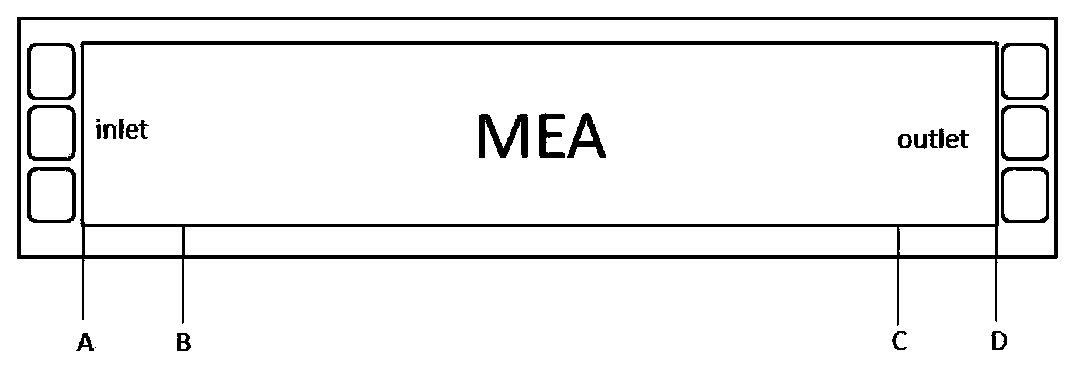

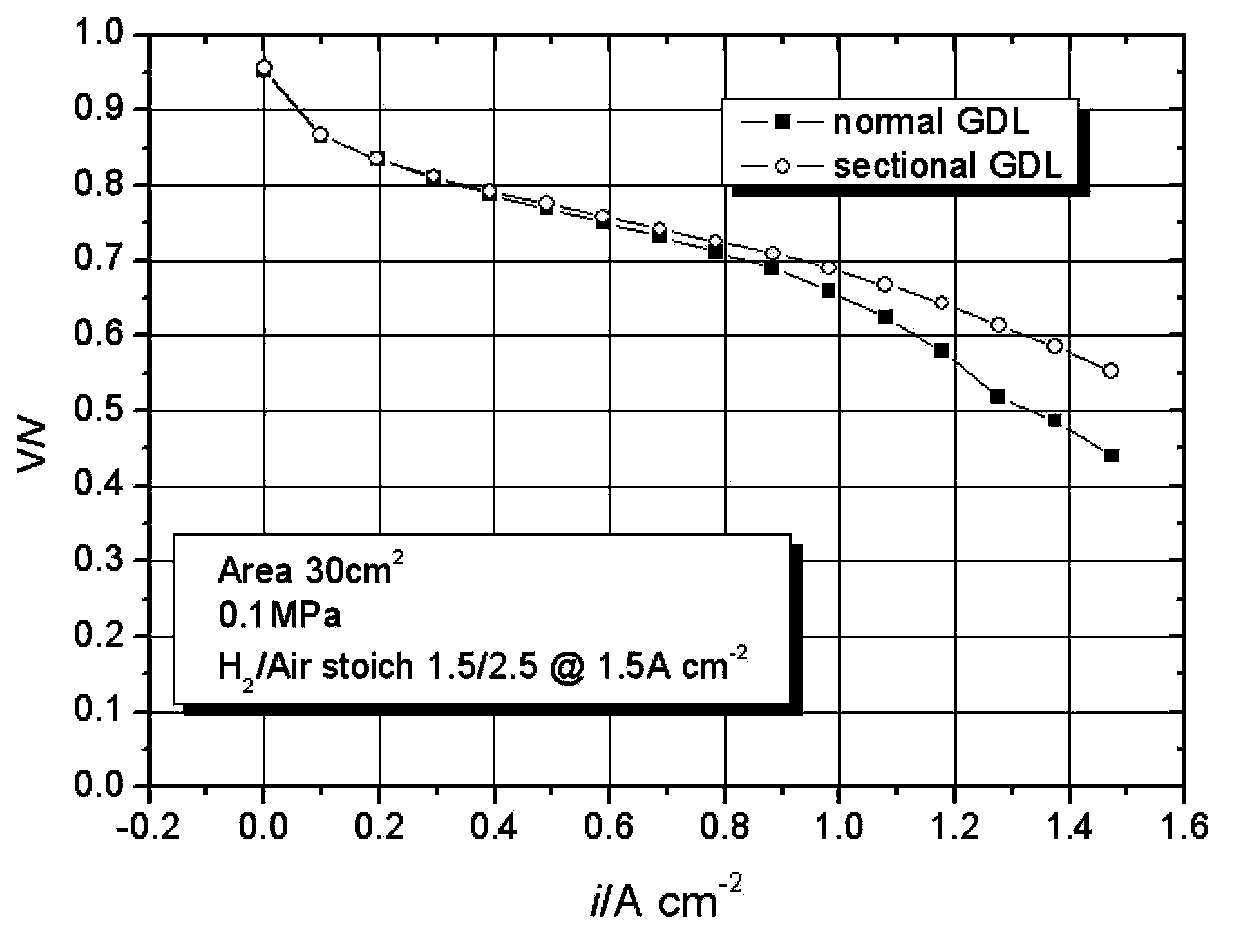

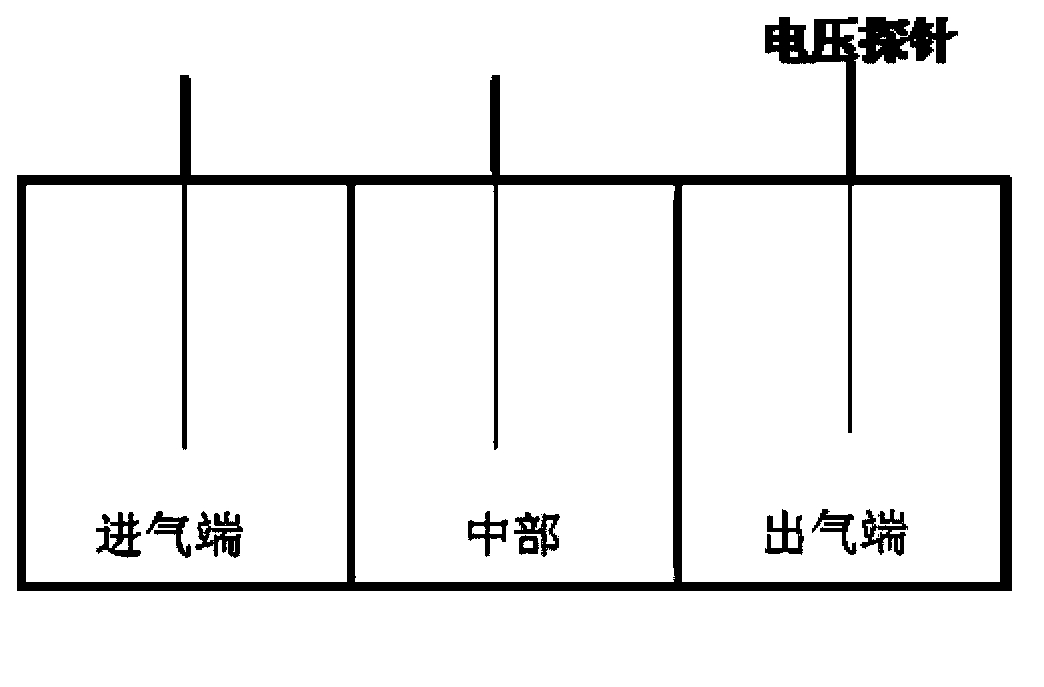

Membrane electrode for improving voltage distribution uniformity

ActiveCN103855407AImprove wettingImprove water repellencyCell electrodesFuel cellsEngineeringDiffusion layer

The invention designs a membrane electrode for improving voltage distribution uniformity. The membrane electrode comprises a diffusion layer with hydrophobicity gradually improved from an air inlet end to an air outlet end, and a catalyst layer with hydrophobicity gradually improved from the air inlet end to the air outlet end. The gradient distribution can be used for overcoming the defects of low voltage caused by insufficient moistening at the air inlet end of an oxygen electrode and voltage reduction caused by water logging of the air outlet end of a battery.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

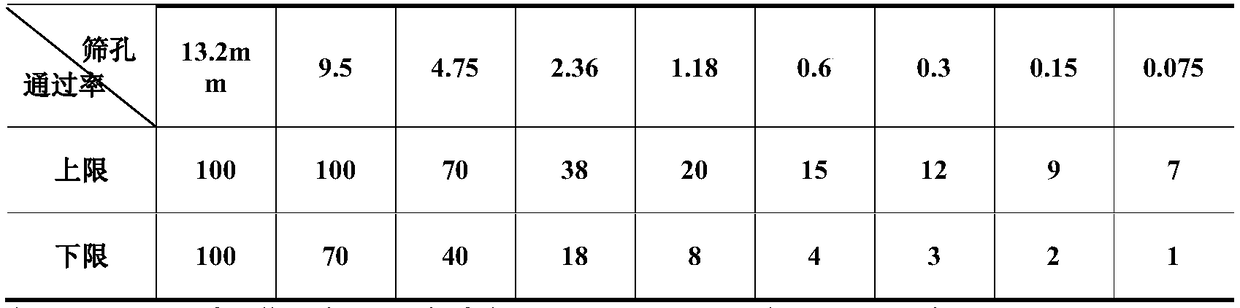

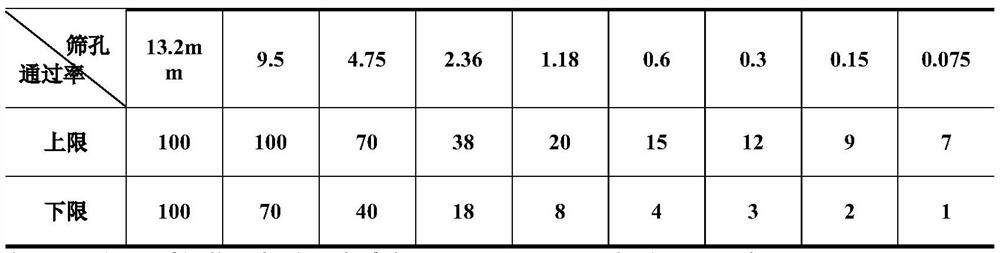

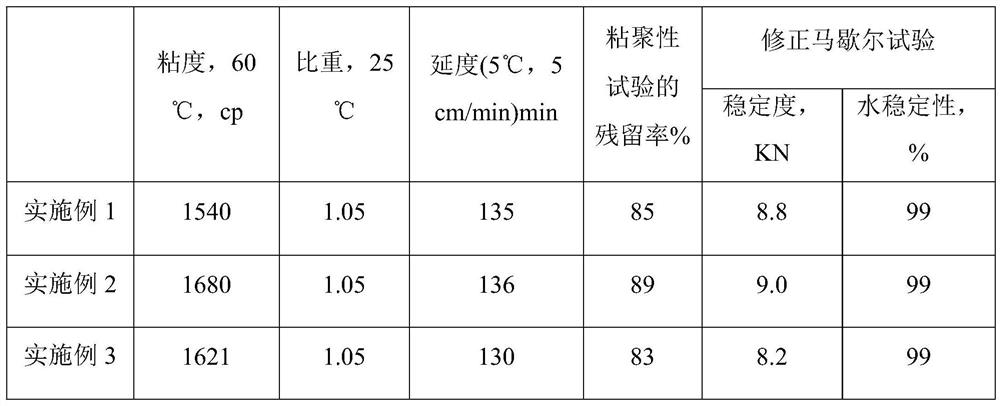

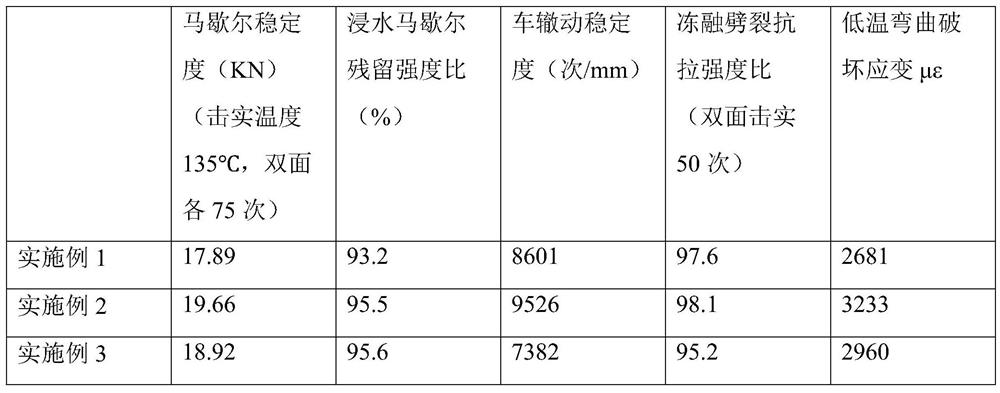

Cold patch material for disease repair of asphalt road pavements and preparation method thereof

InactiveCN108640565AExtended service lifeExtend service life and have broad application prospectsDiseaseCrushed stone

The invention relates to a cold patch material for disease repair of asphalt road pavements. The cold patch material is prepared from aggregate, asphalt and a cold patch agent, wherein the aggregate is prepared from crushed stone, machine-made sand and ore powder; the particle size of the crushed stone is 5mm to 16mm; the ratio of oil to stone is 4 to 6%; the amount of cold patch agent in the coldpatch material is 1.0 to 1.5%. The asphalt cold patch material has the characteristics that the defects of easiness in caking, poor durability and poor peaceability in the traditional cold patch asphalt mixture are overcome; the repair can be performed at any time, the peaceability is good, the temperature stability is good, the forming strength is high, the water stability is excellent, the durability is good, the storage is easy and the like; the service life of the cold patch material is effectively prolonged; the application prospect is broad.

Owner:重庆通力高速公路养护工程有限公司

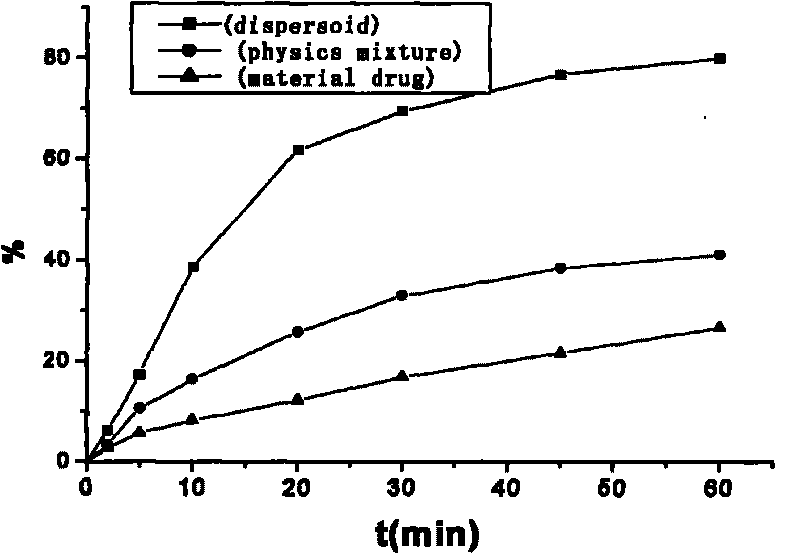

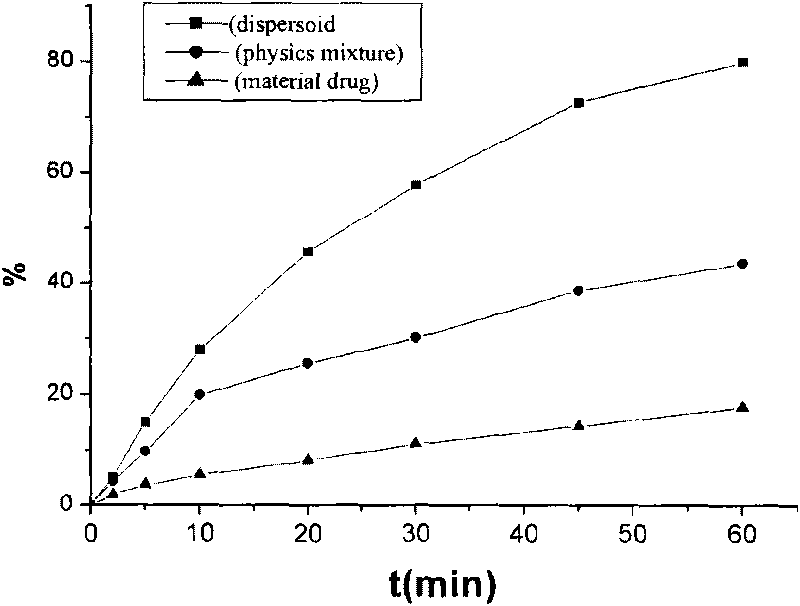

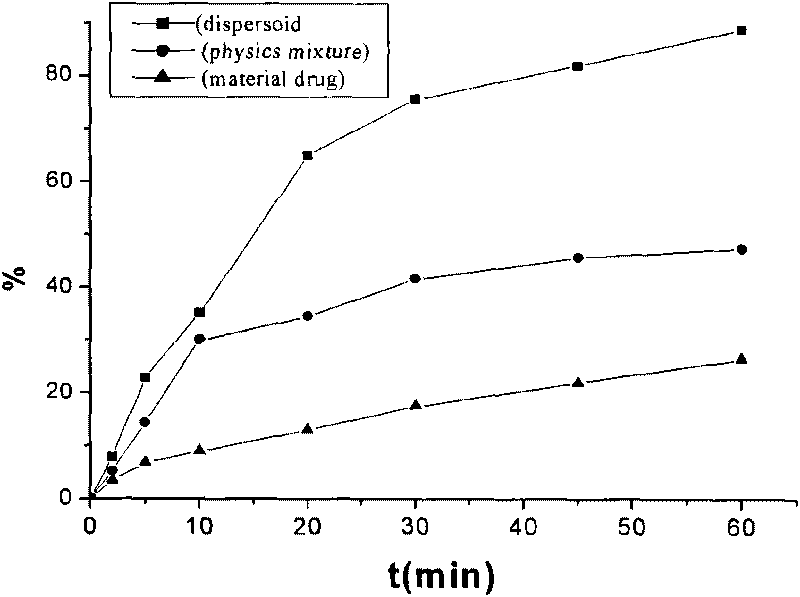

Soy isoflavone solid dispersion suppository and preparation method thereof

InactiveCN101716135AGood dispersionImprove hydrophilicityOrganic active ingredientsSuppositories deliveryDiseaseDispersity

The invention discloses a soy isoflavone vaginal suppository and a preparation method thereof. Raw materials for preparing the suppository comprise soy isoflavone solid dispersion and a water-soluble substrate, wherein the soy isoflavone solid dispersion is prepared from soy isoflavone and a hydrophilic solid dispersion carrier, and the mass ratio of the soy isoflavone and the carrier is 1:1-20. The invention designs and prepares a soy isoflavone solid dispersion suppository for vaginal drug administration on the premise of overcoming the defect of poor absorption effect of the oral administration of the soy isoflavone. The solid dispersion technology improves the dispersity and the hydrophilism of the soy isoflavone and improves the moisture degree on the vagina mucosa, thereby improving the infiltration rate of the prepared suppository by 2-3 times. The suppository greatly improves the curative effect of the soy isoflavone on treating and mitigating a series of diseases of women caused by maladjustment of estrogen level.

Owner:SHANXI MEDICAL UNIV +1

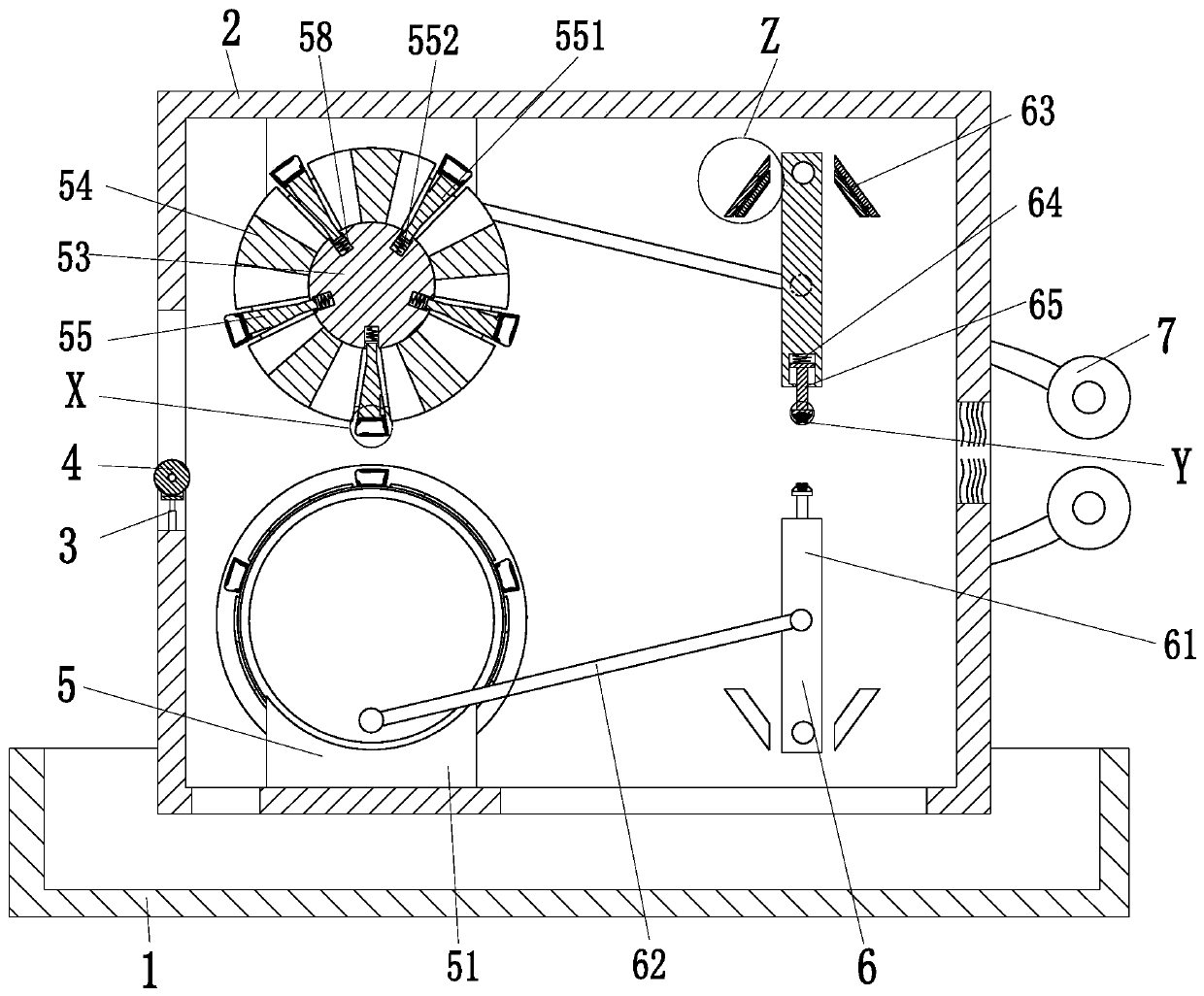

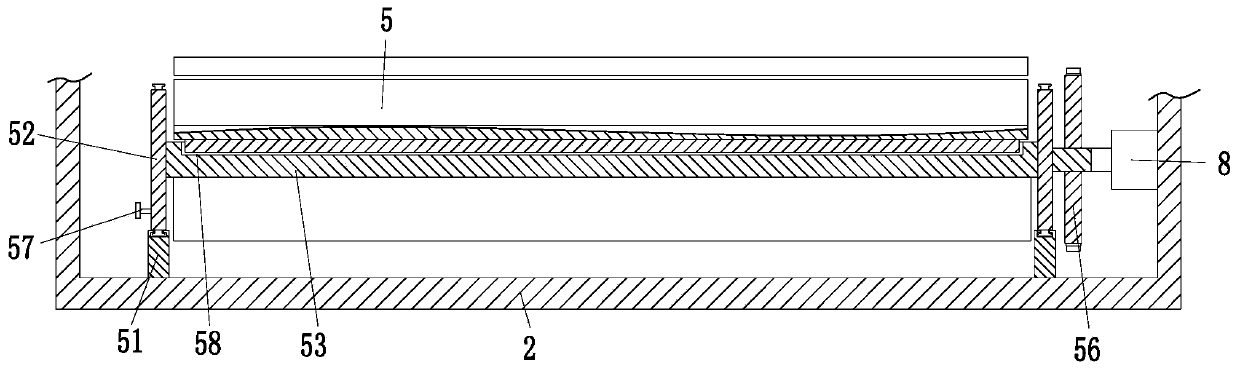

Internal dye extrusion equipment for textile gauze after dip dyeing

ActiveCN110924011AIncrease wettingIncrease the degree of dippingLiquid surface applicatorsLiquid/gas/vapor removal by squeezing rollersElectric machineryDyeing

The invention relates to an internal dye extrusion equipment for textile gauze after dip dyeing. The equipment comprises a waste frame, a work frame, an expansion bracket, a scraping roller, two extrusion devices, two smearing devices, two electric transmission rollers and a motor, wherein the work frame is installed in the waste frame; the expansion bracket is installed at an inlet at the left end of the work frame; the scraping roller is installed at the upper end of the expansion bracket via a pin roll; the two electric transmission rollers are arranged at the right end of the work frame; the two extrusion devices are installed at the left end in the work frame, and the motor is connected to the rear side of the extension device positioned on the lower side; the motor is installed on the inner wall of the work frame; and the two smearing devices are installed at the right end in the work frame. According to the equipment, the problems that the gauze needs time to be completely soaked, and at present, the time of the gauze for being soaked into a dye vat is not long, so that the gauze often has different soaking degrees at different positions, and thus after the gauze is soaked,both the soaking degrees and dye layer thicknesses of the positions are different can be solved.

Owner:湖北延昌纺织股份有限公司

Cement composite dispersant

InactiveCN110015861AImprove surface activityGood amphiphilic surface activityChemical industryHydrolysis

The invention discloses a cement composite dispersant, and belongs to the technical field of chemical industry. The problems that a current commonly used cement dispersant has a poor dispersion effectand influences on the internal mechanical properties are solved. A low critical micelle concentration can be maintained, the lipophilic groups of the dispersant can be adsorbed on the surface of thecement, and the hydrophilic groups can be combined with water, so that the dispersion effect of the cement is improved better. Hydrogen bonds are formed by silicon hydoxyl groups generated through hydrolysis and hydroxyl group contained in a composite dispersing material B, so that the stability of dispersion is enhanced, and the internal bonding force is improved; high-polarity reactive carboxylgroups in acrylic acid are introduced into humic acid molecules of the dispersant, and the influence of steric hindrance is brought through cooperation with acrylic acid grafting, so that the viscosity-reducing effect of the prepared silicon-containing material is improved, the dispersibility inside the obtained blended material is improved, and generation of sedimentation and uneven dispersion isreduced; and furthermore, the cement cohesion strength is improved, and the internal mechanical properties is further improved after blending of the cement is performed.

Owner:刘国荣

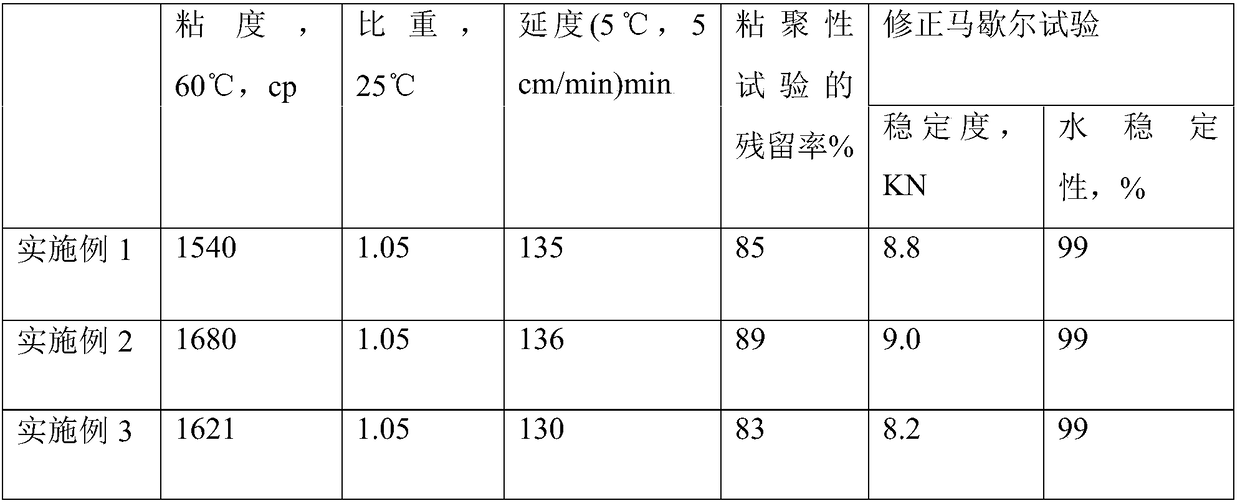

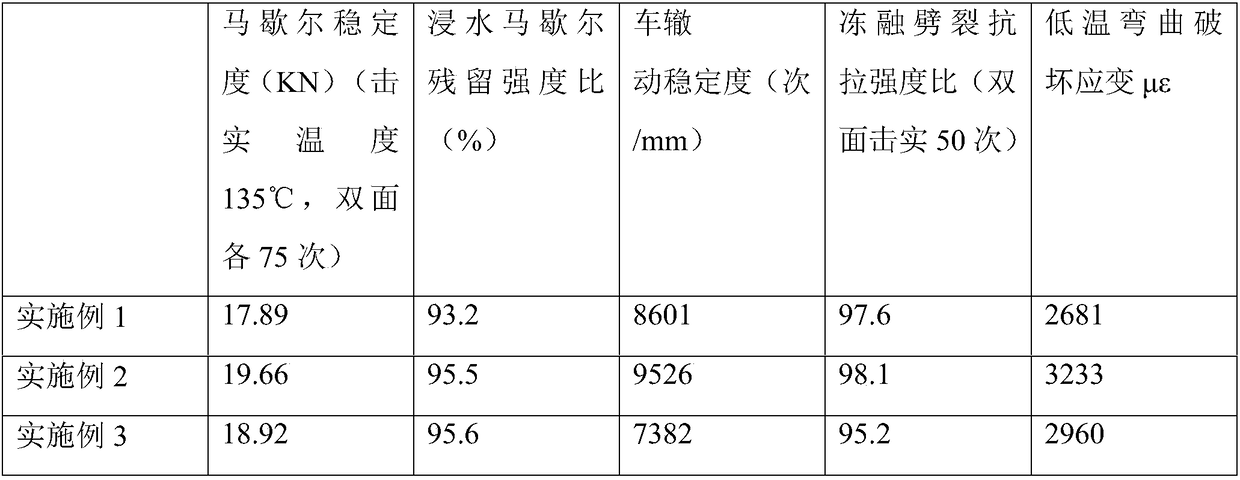

A kind of asphalt cold patching agent and its application

ActiveCN108752826BImprove low temperature fluidityHigh softening pointRepair materialMechanical engineering

The invention relates to an asphalt cold repair agent. The asphalt cold repair agent is yellow oily liquid and comprises 30-34% of a tackifier, 2-4% of a binding agent, 16-18% of heavy oil and 44-52%of a diluent. Low-temperature fluidity of cold repair materials is improved by a reasonable ratio of components, and the asphalt cold repair agent remarkably raises the asphalt softening point, improves rutting resistance and improves resistance to low-temperature bending failure. The cold repair materials prepared from the asphalt cold repair agent have advantages of repairability at any time, high workability, high temperature stability, high molding intensity, high water stability, high durability, easiness in storage and the like, and service lives of the cold repair materials are effectively prolonged.

Owner:重庆通力高速公路养护工程有限公司

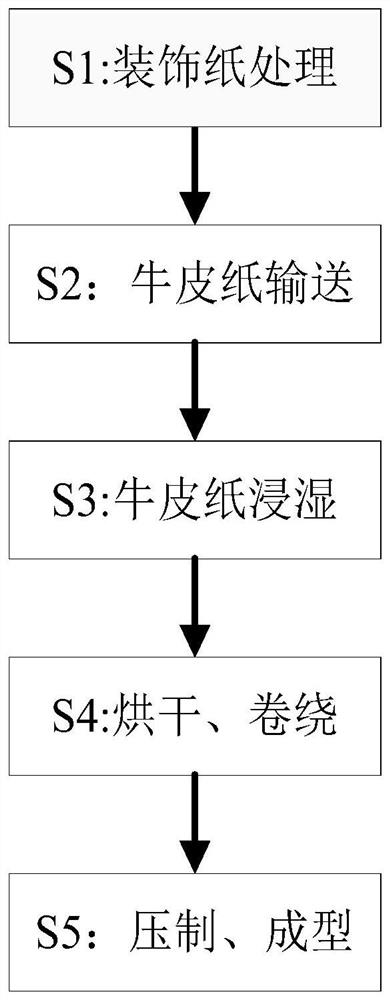

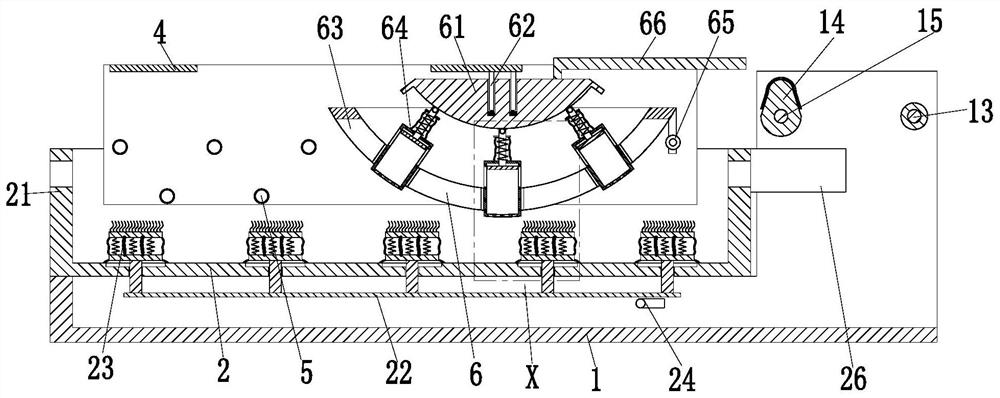

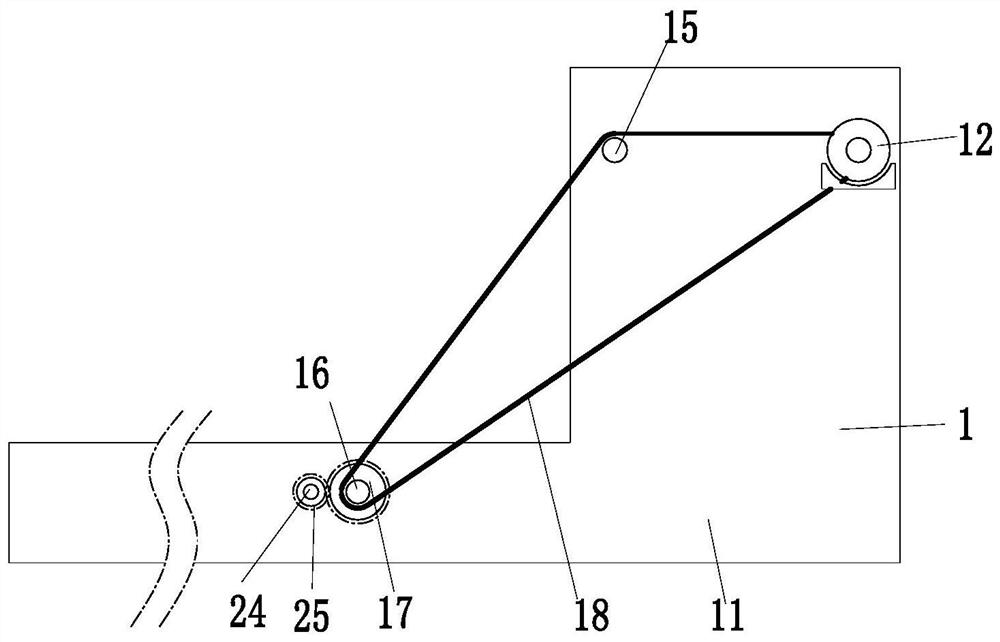

Decorative fireproof plate production and manufacturing process

InactiveCN111636244AAvoid soaking for too longImprove permeabilityNon-fibrous pulp additionMechanical working/deformationProcess engineeringKraft paper

The invention provides a decorative fireproof plate production and manufacturing process. Operation is completed through cooperation of a driving base, a vibration frame set, an air cylinder, a connecting frame, a delay roller and a soaking device. According to the invention, the problems in the traditional soaking process that due to the fact that kraft paper is difficult to soak, the kraft paperis difficult to soak completely through short-term soaking, personnel usually prolong the soaking time of the kraft paper in a solution to soak the kraft paper, and thus the kraft paper is soaked butstill soaked in the solution, and the overall manufacturing efficiency of a fireproof layer is reduced can be solved.

Owner:宛兴怀

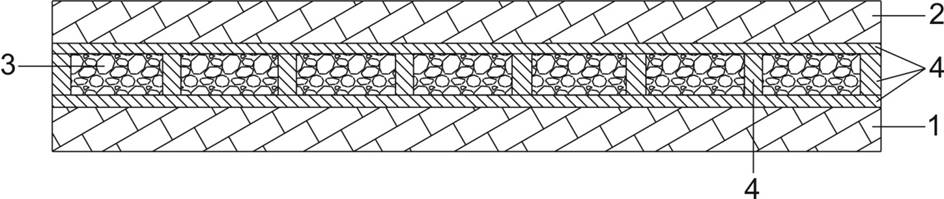

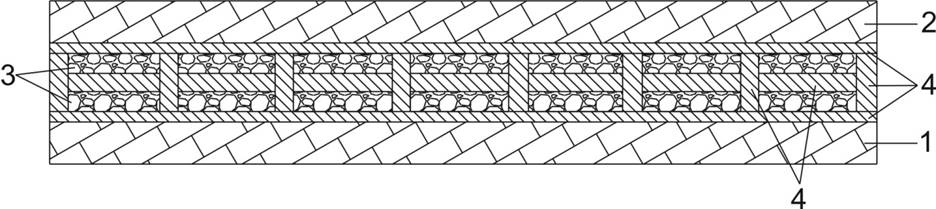

High-strength light-weight carriage plate and preparation method thereof

ActiveCN112757740AHigh implementabilityFlat surfaceLamination ancillary operationsSynthetic resin layered productsMicrosphereResin matrix

The invention belongs to the technical field of preparation of carriage plates, and discloses a high-strength light-weight carriage plate and a preparation method thereof. The carriage plate comprises a first panel layer, a second panel layer, a sandwich layer and a framework supporting layer, wherein the sandwich layer is formed by stacking one foam layer or more than two foam layers, and each foam layer is formed by mutually splicing a plurality of foam blocks; and the skeleton supporting layer is made of a foamed resin matrix composite material. The hollow microspheres added in the skeleton supporting structure endow the skeleton supporting structure with the characteristics of high mechanical strength and light weight, and successful foaming of the expandable microsphere foaming agent promotes the plate to have a flatter and smoother surface, so the prepared plate has excellent impact resistance and compression resistance and good appearance; meanwhile, the composite foam premix is sprayed on the surface of the foam block in advance, so that the wetting degree of the sandwich layer is greatly improved, the bonding strength of the plate is enhanced, and the plate has more stable and excellent mechanical properties.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

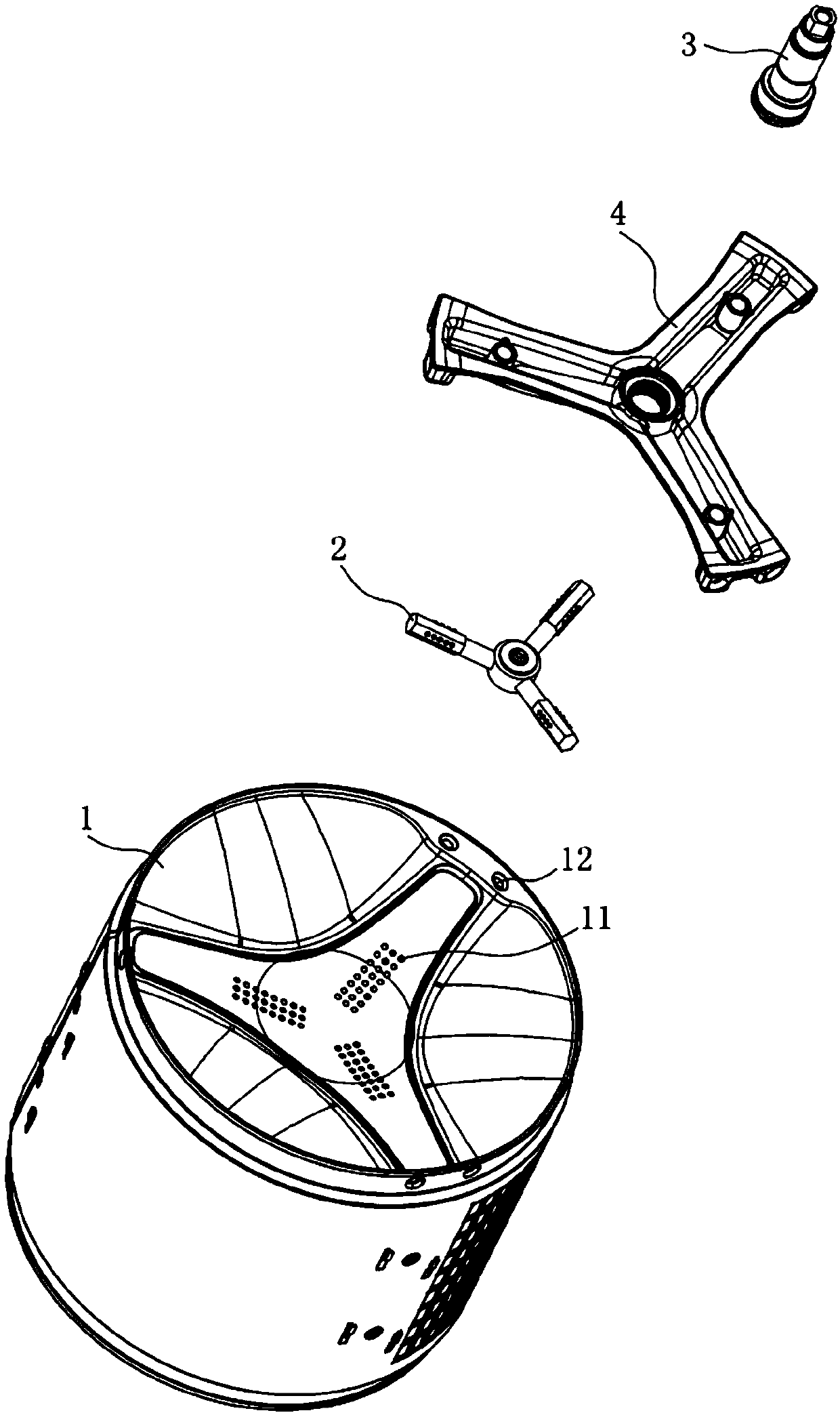

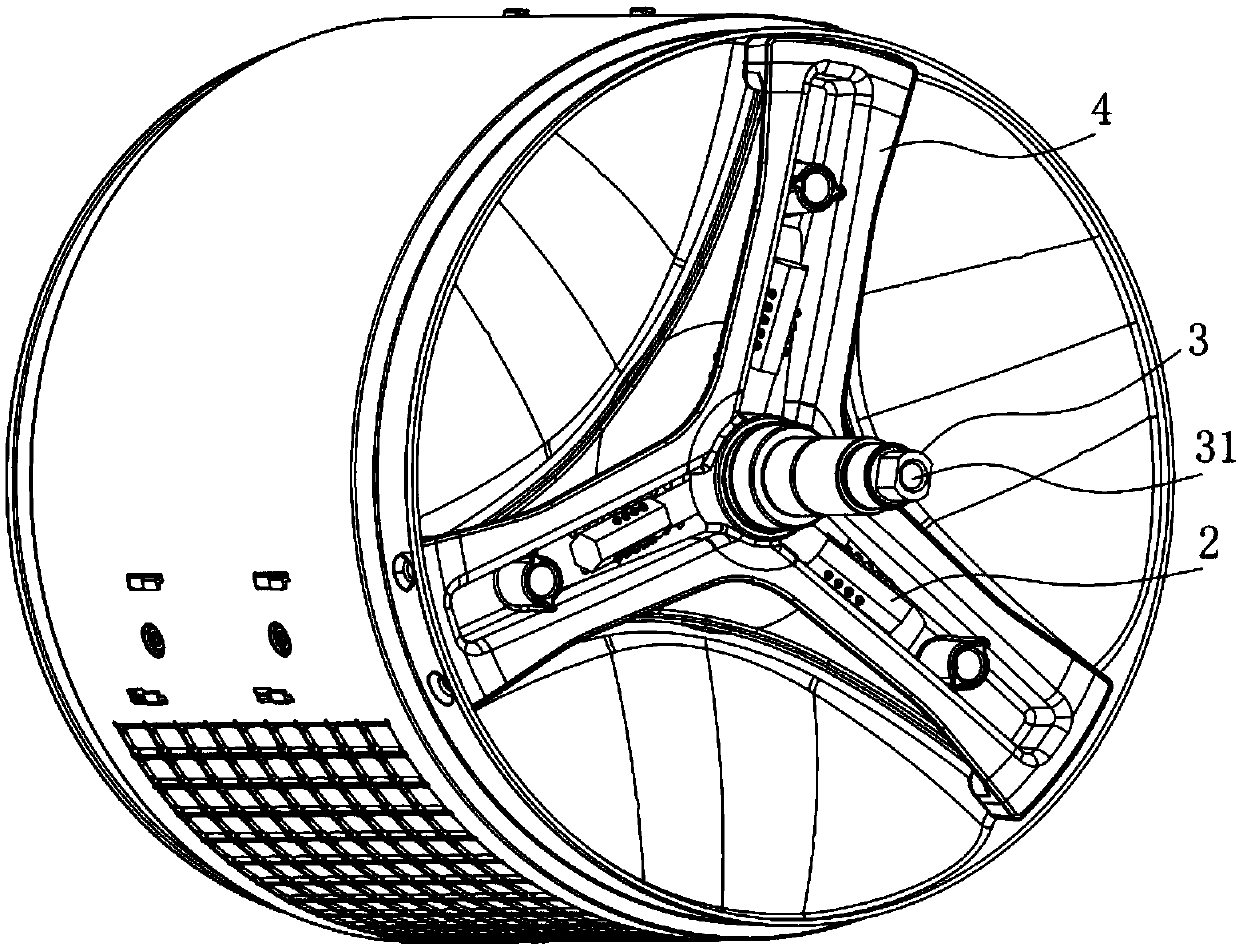

Inner tub for front-loading washing machines and front-loading washing machine

ActiveCN110857509APrevent twistingImprove wettingOther washing machinesTextiles and paperLaundry washing machineSprayer

The invention relates to the technical field of washing machines, in particular to an inner tub for front-loading washing machines and a front-loading washing machine with the same. The inner tub forfront-loading washing machines comprises an inner tub body and a sprayer arranged on the outer side of a rear flange of the inner tub body, the sprayer being communicated with the bottom of the outerbarrel and / or a water inlet pipe; a plurality of water inlets are formed in the inner tub body, a plurality of spraying holes are formed in the sprayer, and each spraying hole is communicated with onewater inlet is communicated in order for spraying water into the inner cylinder body. The inner tub for front-loading drum washing machines has the advantages that the sprayer is arranged on the outer side of the inner drum body, the water inlets capable of allowing water in the sprayer to enter are formed in the inner tub, the sprayer and clothes can be prevented from entangling under the condition that spraying water is sprayed on the rear flange of the inner tub, the sprayer is protected from being damaged by the twisting of clothes, and meanwhile, all-round water discharging from the inner tub can be achieved, the laundry wetting degree is higher, and the foam elimination rate can be increased.

Owner:CHONGQING HAIER ROLLER WASHING MASCH CO LTD +1

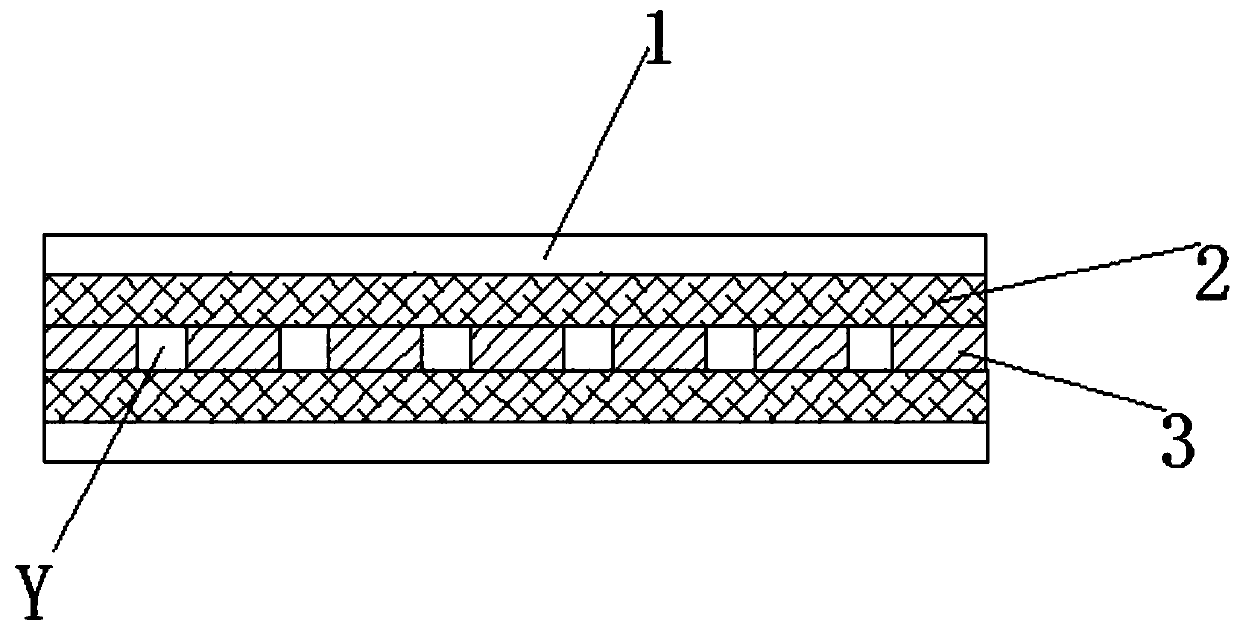

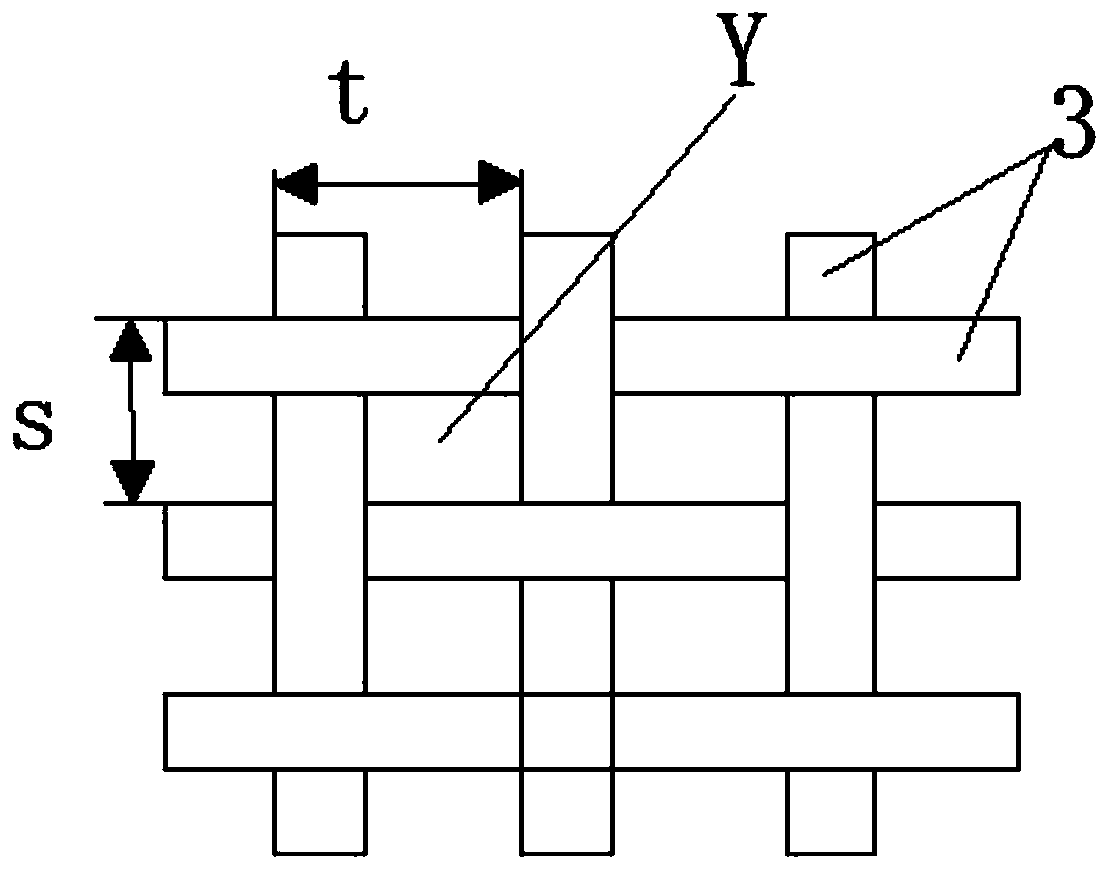

High heat conductivity copper clad laminate

PendingCN110103537AHigh thermal conductivityImprove thermal stabilitySynthetic resin layered productsLaminationCopper foilHigh heat

The invention discloses a high heat conductivity copper clad laminate. The high heat conductivity copper clad laminate comprises high heat conductivity resin film sheets, a porous prepreg, and copperfoils; the high heat conductivity resin film sheets are laminated on the two sides of the porous prepreg; the copper foils are laminated on the two sides of the high heat conductivity resin film sheets; and hot pressing moulding is carried out so as to obtain the high heat conductivity copper clad laminate. The high heat conductivity copper clad laminate is excellent in heat conductivity, thickness uniformity, insulation performance, and comprehensive performance, is used for upside-down mounting large power LED packaging, and the heat conduction coefficient is as high as 3W / m.k. The high heatconductivity copper clad laminate possesses better PCB processing performance; existing equipment can be adopted in production power; integration batch production can be realized; the preparation technology is simple; and performance is excellent.

Owner:广州恒荣电子科技有限公司

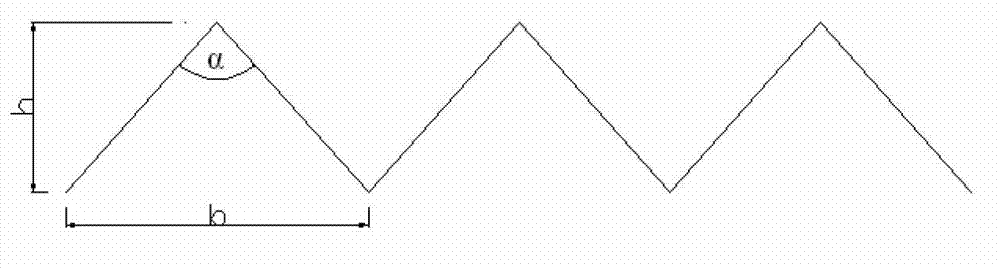

Drained style sawtooth-shaped corrugated filler

The invention relates to a drained style sawtooth-shaped corrugated filler. The corrugated filler is a metal sheet or a plastic sheet which is pressed to be a sawtooth-shaped corrugated sheet; a formed corrugated chine line and a transverse extending direction of the filler form an included angle; the two ends of the corrugated chine line are in circular arc transition and the corrugated chine line is perpendicular to the transverse extending direction of the filler (namely parallel to axial direction). Compared with the prior art, according to the drained style sawtooth-shaped corrugated filler, the flowing direction change of fluid at a filler surface is stable, so that pressure drop loss is less, the shear stress between a gas phase and a liquid phase is reduced, and the flowing speed of the gas phase can be reduced. In addition, because of a sawtooth-shaped channel structure, liquid phase fluid can form a large wetting area at the filler surface. Compared with the existing filler technology, the filler has excellent fluid mechanics characteristics, the pressure drop loss of a filler sheet during a gas and liquid mass transfer process is reduced, energy is saved and consumption is reduced, and meanwhile mass transfer separation efficiency is improved.

Owner:SHANGHAI RES INST OF CHEM IND

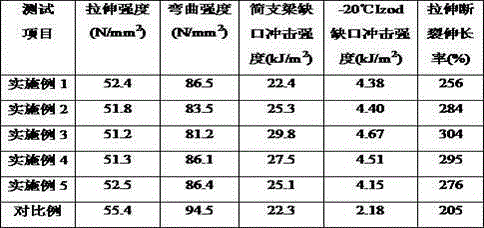

Modified polypropylene material

The invention discloses a modified polypropylene material which is prepared from the following raw materials in percentage by weight: 100 parts of polypropylene, 25 to 45 parts of ethylene-octylene copolymer, 0.5 to 2 parts of modifying agent, 1 to 2 parts of acetyl triethyl citrate, 3 to 7 parts of reinforcing agent, 1 to 3 parts of diphenylguanidine, 5 to 10 parts of filler, 3 to 8 parts of zirconium silicate and 0.2 to 0.4 part of antioxygen 1010. The modified polypropylene material provided by the invention is good in weather resistance, high in mechanical strength and toughness, and stable in quality, and has better economic benefit and social benefit, and is wide in application prospect.

Owner:安徽金利塑业股份有限公司

Makeup remover facial mask and making method thereof

InactiveCN109464303ARemove makeup thoroughlyAvoid damageCosmetic preparationsMake-upAlkaneFlocculation

The invention discloses a makeup remover facial mask and a making method thereof. The making method comprises the following steps: preparing a facial mask solution from 60-80 parts of deionized water,5-10 parts of a dispersant, 0.01-10 parts of a moisturizing agent, 0.1-3 parts of a suspension agent, 1-20 parts of silicon oil, 1-20 parts of alkane, 1-10 parts of an emulsifier and 0.3-0.7 part ofphenoxyethanol; dissolving 0.1-1 part of a polyacrylamide flocculant into 5 parts of the deionized water, soaking facial mask cloth, drying, infiltrating the facial mask cloth with the facial mask solution, and sealing, thereby obtaining a product. According to the product disclosed by the invention, after the product is emulsified and an oil raw material is dissolved, a dispersion and suspensiontechnique and a flocculation adsorption technique are implemented, toner solid granules in makeup can be separated and transferred onto the facial mask cloth from the surface of skin, and a thorough makeup removing effect is achieved.

Owner:DANDONG KANGCHILING CLEANING PROD CO LTD

Hydrophilic elastic waterborne emulsion paint and preparation method thereof

The invention relates to a hydrophilic elastic waterborne emulsion paint. The emulsion paint comprises the following raw materials: water, a thickening agent, a pH value conditioning agent, a wetting agent, a dispersant, titanium dioxide, a filling material, an emulsion, a high-opacity polymer, a hydrophilic aid, a film forming aid, an anti-freezing agent, a bactericide, a mildew inhibitor, an antifoaming agent and an adhesion reinforcing agent. The hydrophilic elastic waterborne emulsion paint provided by the invention overcomes the disadvantage of poor resistance to soiling of current commercially-available elastic waterborne emulsion paints and has the advantage of excellent surface soiling resistance while maintaining good elasticity.

Owner:SKSHU PAINT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com