Modified polypropylene material

A polypropylene material and polypropylene technology, applied in the field of modified polypropylene materials, can solve the problems of not being able to be used as engineering plastics, low mechanical strength, poor creep resistance, etc., achieve good economic and social benefits, and good dimensional stability , good weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

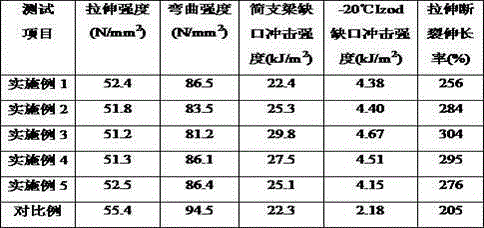

Examples

Embodiment 1

[0017] A modified polypropylene material, which is composed of the following raw materials in weight percentage: 100 parts of polypropylene, 25 parts of ethylene-octene copolymer, 2 parts of modifier, 2 parts of acetyl triethyl citrate, and 7 parts of reinforcing agent 3 parts, 3 parts of diphenylguanidine, 10 parts of filler, 3 parts of zirconium silicate, 10100.2 parts of antioxidant.

[0018] As mentioned, the modifying agent is prepared by the following steps: according to the molar ratio of dimethyl diallyl ammonium chloride: acrylamide: itaconic acid is 1:1:1 In the reaction kettle with 60% distilled water and 1.5% sodium methacrylate in the total mass of the reactants, after 15 minutes of deoxygenation with nitrogen, add 3% of the total mass of the reactants with a mass ratio of 1:1. Block and hydrogen peroxide are used as initiators, react for 6 hours to obtain a copolymer aqueous solution with a molecular weight in the range of 4000-6000, which is the modifier.

[00...

Embodiment 2

[0023] A modified polypropylene material, which is composed of the following raw materials in weight percentage: 100 parts of polypropylene, 30 parts of ethylene-octene copolymer, 1.5 parts of modifier, 1.8 parts of acetyl triethyl citrate, 6 parts of reinforcing agent Parts, 2.5 parts of diphenylguanidine, 9 parts of filler, 4 parts of zirconium silicate, 10100.3 parts of antioxidant.

[0024] The preparation method of modifying agent is the same as embodiment 1.

[0025] As mentioned above, the strengthening agent is obtained by mixing tetrahydroxyethylethylenediamine and aluminum sulfate according to the mass ratio of 1:1.

[0026] As mentioned above, the filler is obtained by mixing diatom powder and zeolite powder in a mass ratio of 1:1.5.

[0027] Add each component to the injection molding machine for injection molding to obtain the product. Among them, the temperature of the front zone of the barrel is 190°C, the temperature of the middle zone of the barrel is 220°C, ...

Embodiment 3

[0029] A modified polypropylene material, which is composed of the following raw materials in weight percentage: 100 parts of polypropylene, 35 parts of ethylene-octene copolymer, 1.2 parts of modifier, 1.5 parts of acetyl triethyl citrate, 5 parts of reinforcing agent 2 parts, 2 parts of diphenylguanidine, 8 parts of filler, 5 parts of zirconium silicate, 10100.3 parts of antioxidant.

[0030] The preparation method of modifying agent is the same as embodiment 1.

[0031] As mentioned above, the strengthening agent is obtained by mixing tetrahydroxyethylethylenediamine and aluminum sulfate according to the mass ratio of 1:2.

[0032] As mentioned above, the filler is obtained by mixing diatom powder and zeolite powder in a mass ratio of 1:1.5.

[0033] Add each component to the injection molding machine for injection molding to obtain the product. Among them, the temperature of the front zone of the barrel is 190°C, the temperature of the middle zone of the barrel is 220°C, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com