Patents

Literature

61 results about "Performance engineering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Performance engineering encompasses the techniques applied during a systems development life cycle to ensure the non-functional requirements for performance (such as throughput, latency, or memory usage) will be met. It may be alternatively referred to as systems performance engineering within systems engineering, and software performance engineering or application performance engineering within software engineering.

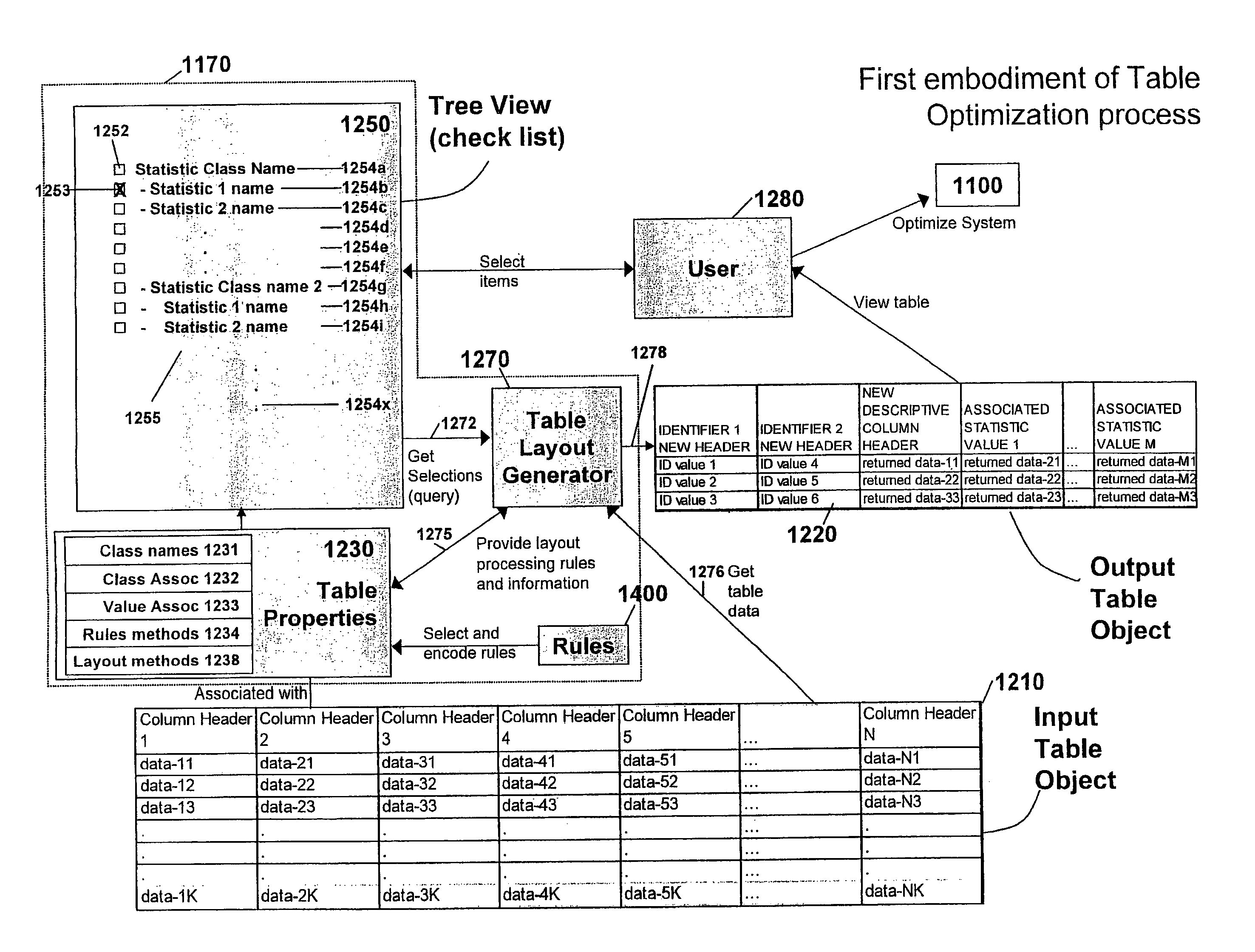

Method and apparatus for organizing, visualizing and using measured or modeled system statistics

InactiveUS20060041539A1Good correlationFast constructionDigital data information retrievalOffice automationPerformance engineeringModel system

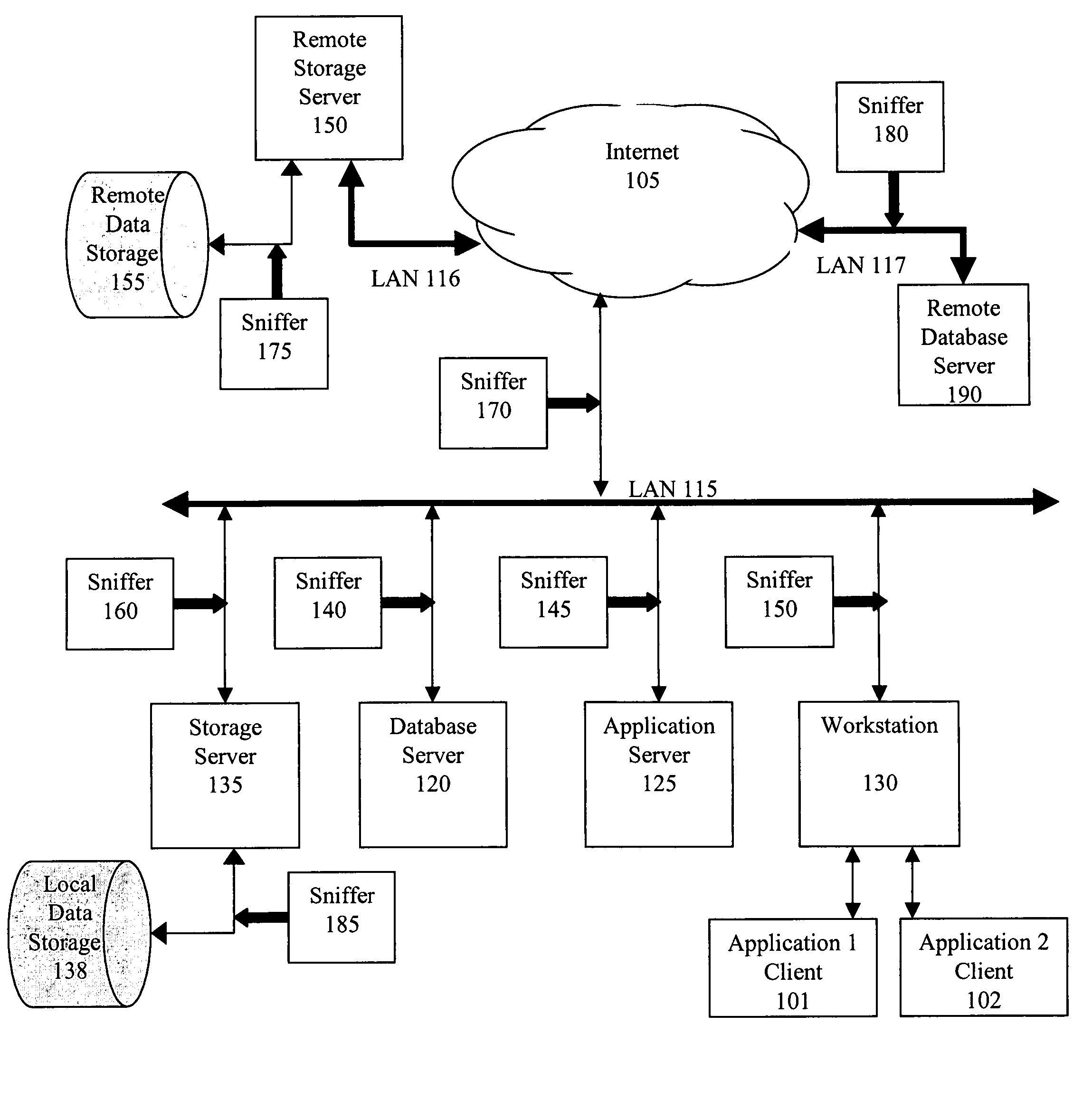

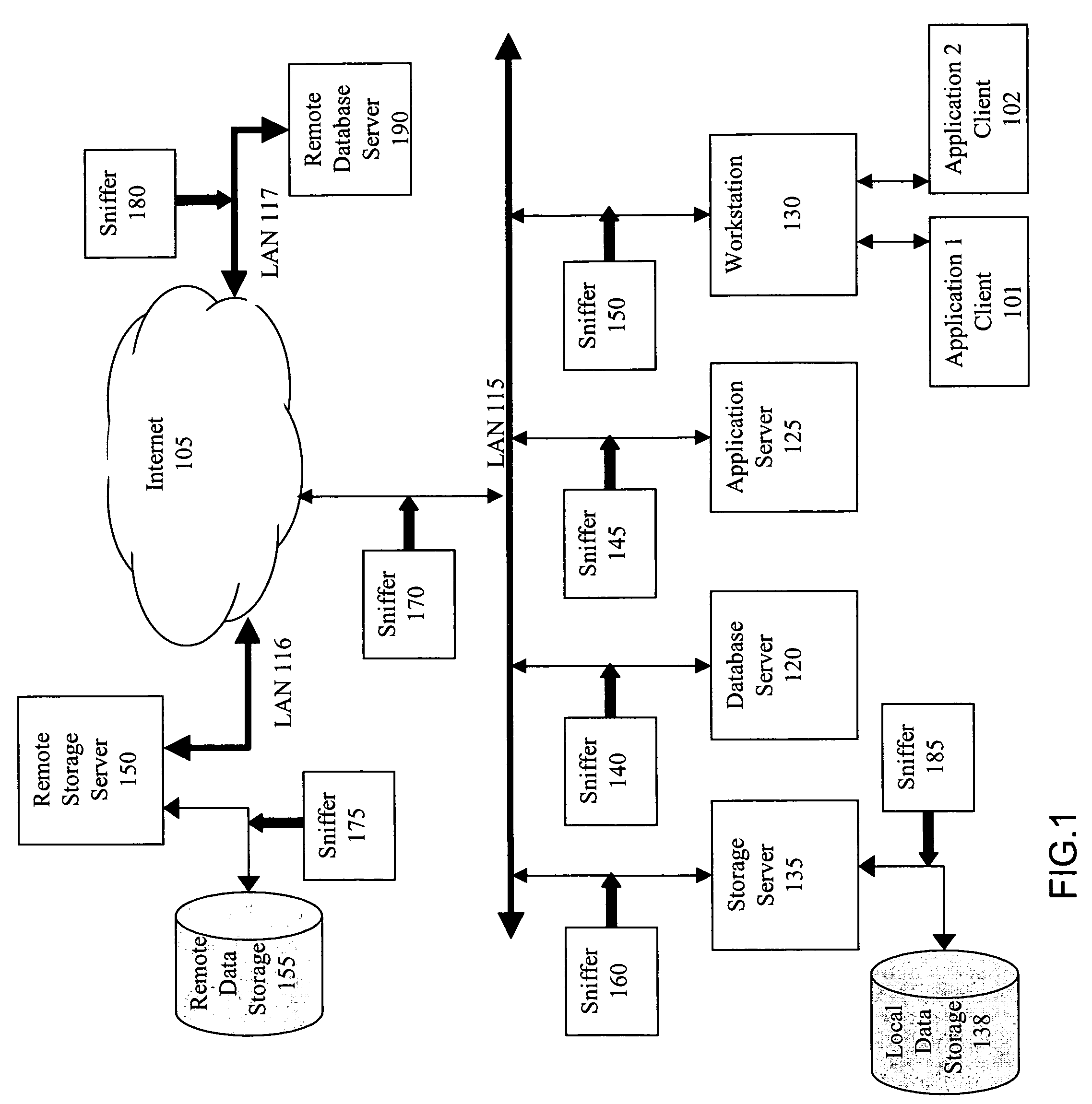

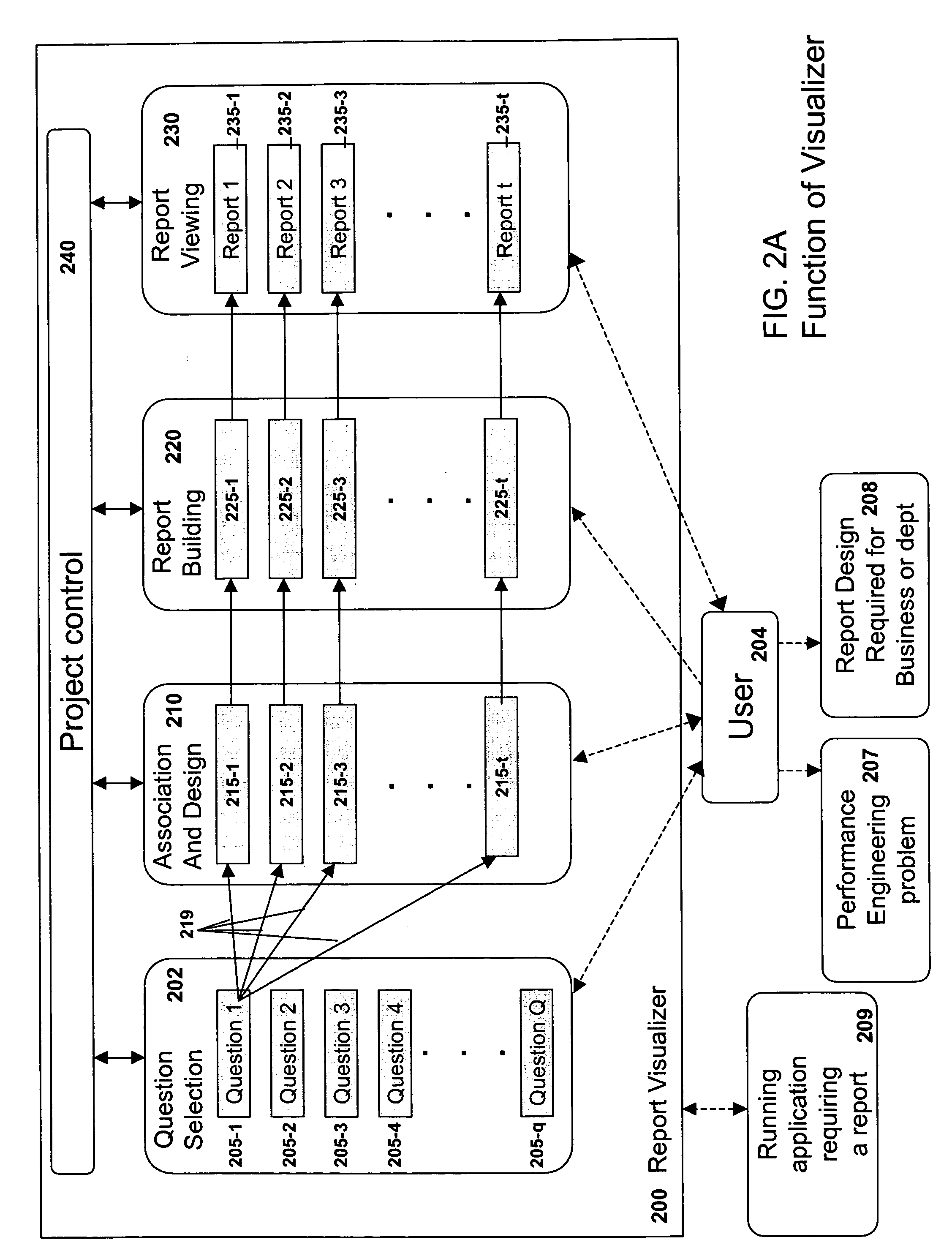

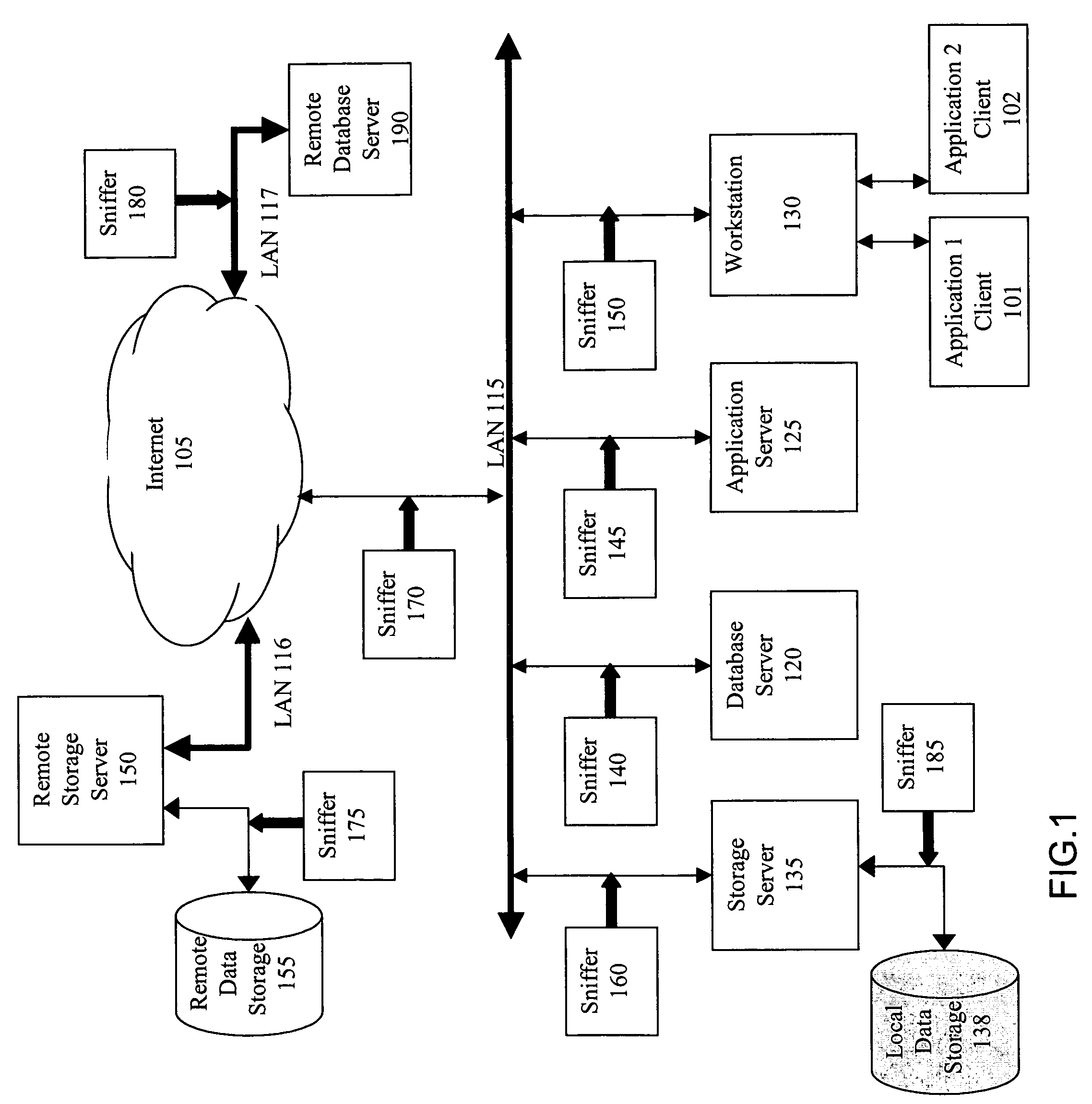

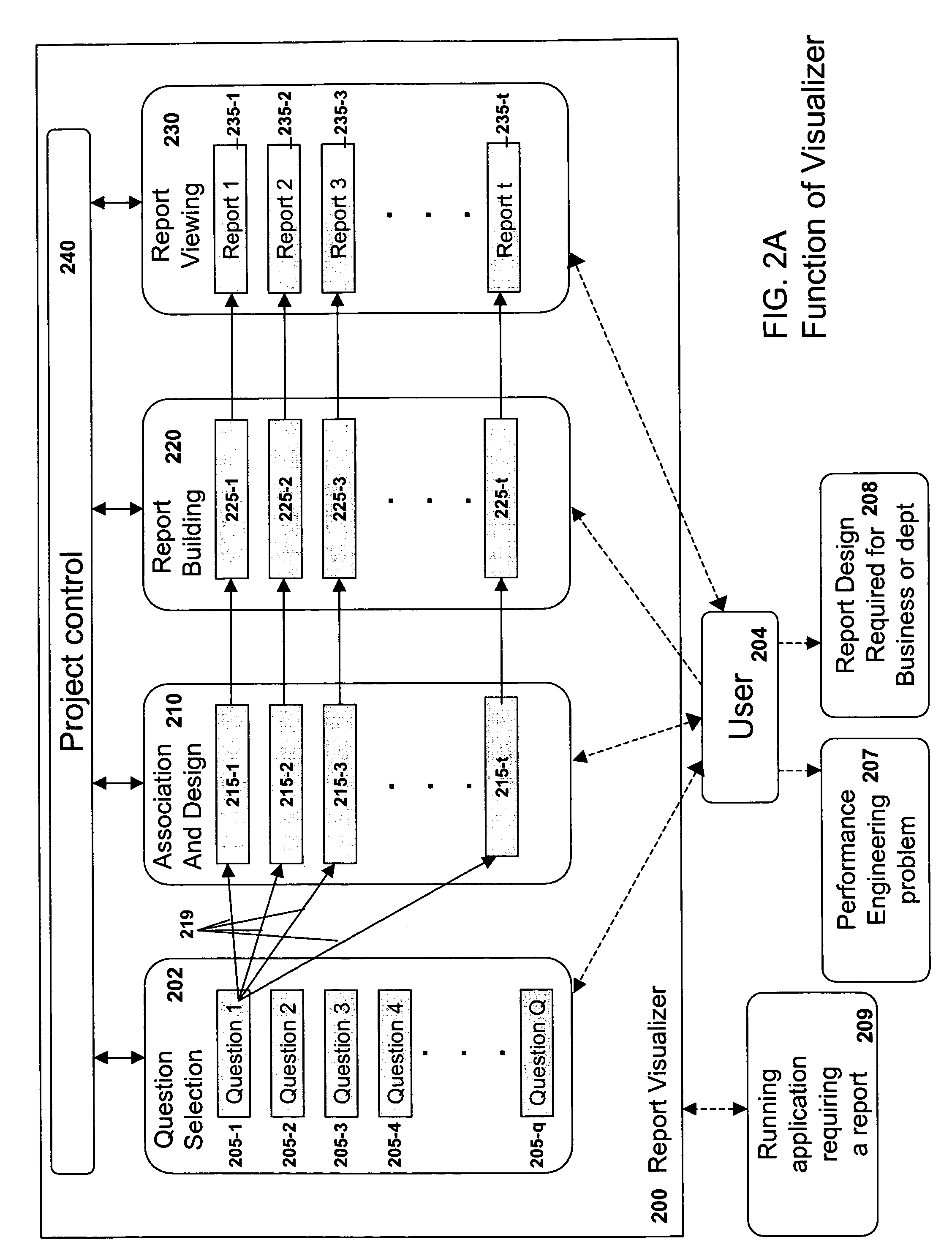

An apparatus and methodology to acquire and organize measured or modeled statistical data into optimal reports with a performance engineering mode of use and a design mode of use. In a performance engineering mode of use, the engineer may select from a set of performance questions, and guided by the apparatus and largely automated, create well-defined answers to the performance questions of interest. A series of template manipulations whereby report objects that are embedded within templates may be defined, reused, modified and improved upon to optimize reports and to aid in a report building process in a design mode of use. Methods are taught for the automatic selection and population of data tables. Column selection and column header information is optimized for relevance to the report design or system question at hand. The automatic joining of data from a variety of data sources is taught that allows for the rapid construction of specific reports from within multiple data tables of different types, structures and formats.

Owner:HYPERFORMIX

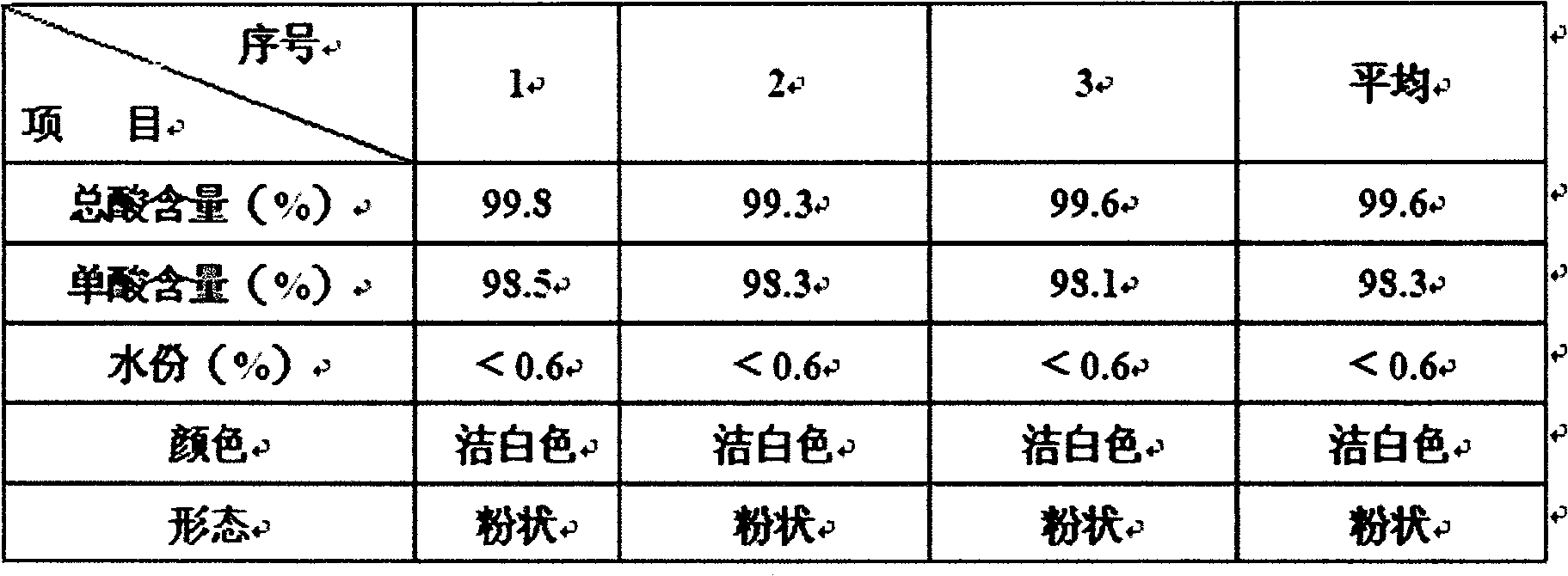

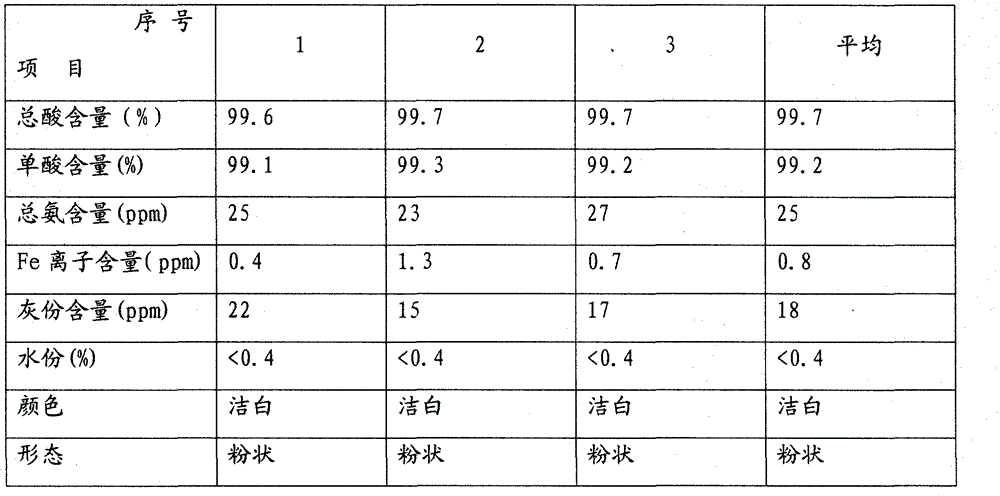

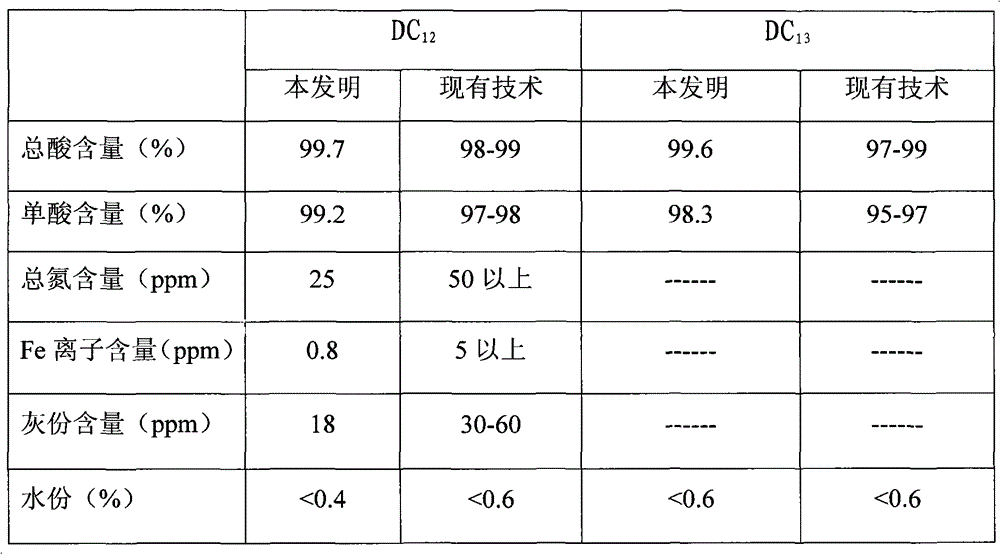

Refining technology for producing long carbon chain dicarboxylic acid by using biological fermentation process

ActiveCN101985416AHigh monoacid contentImprove thermal stabilityCarboxylic compound separation/purificationDielectricCarbon chain

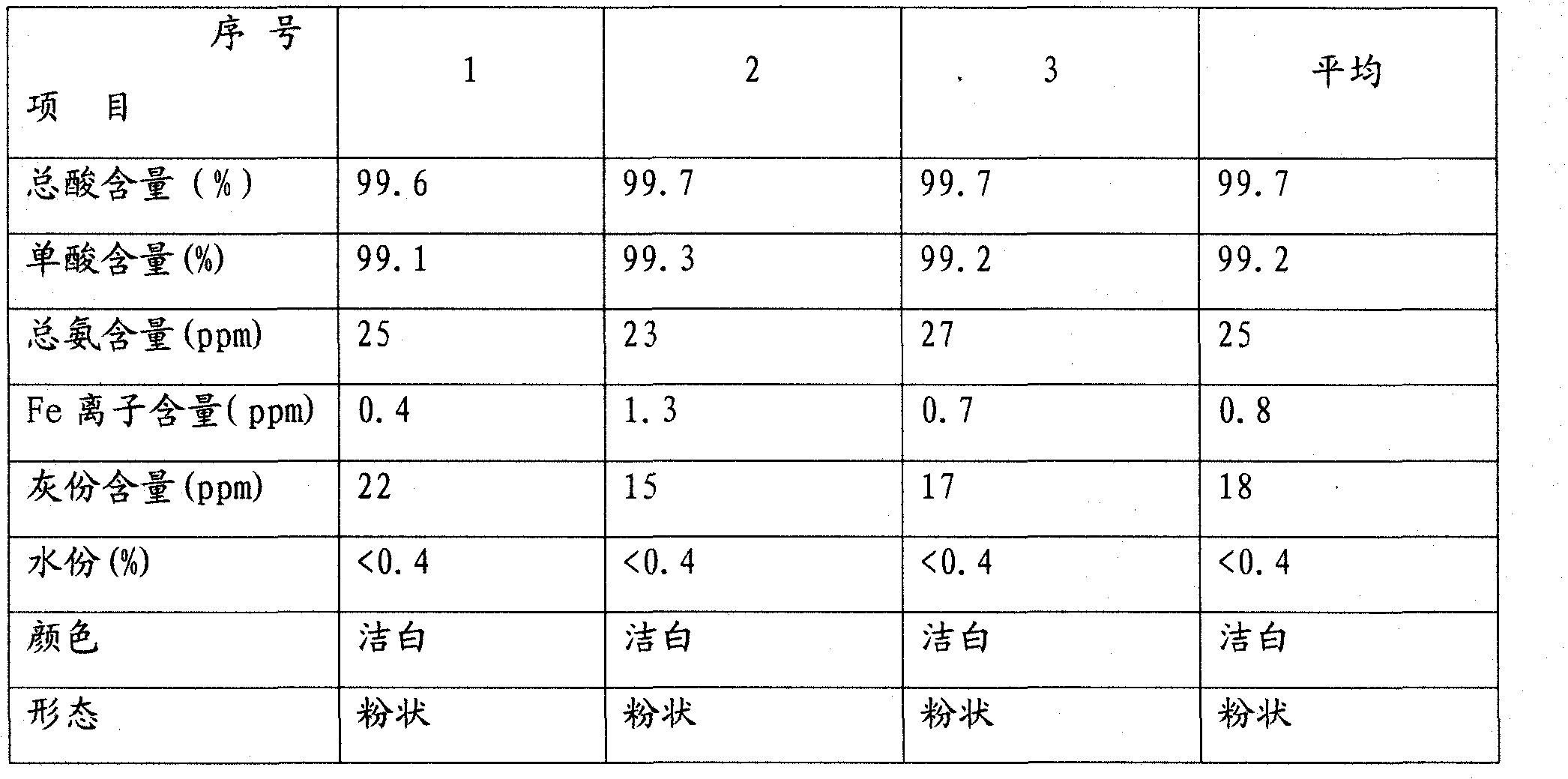

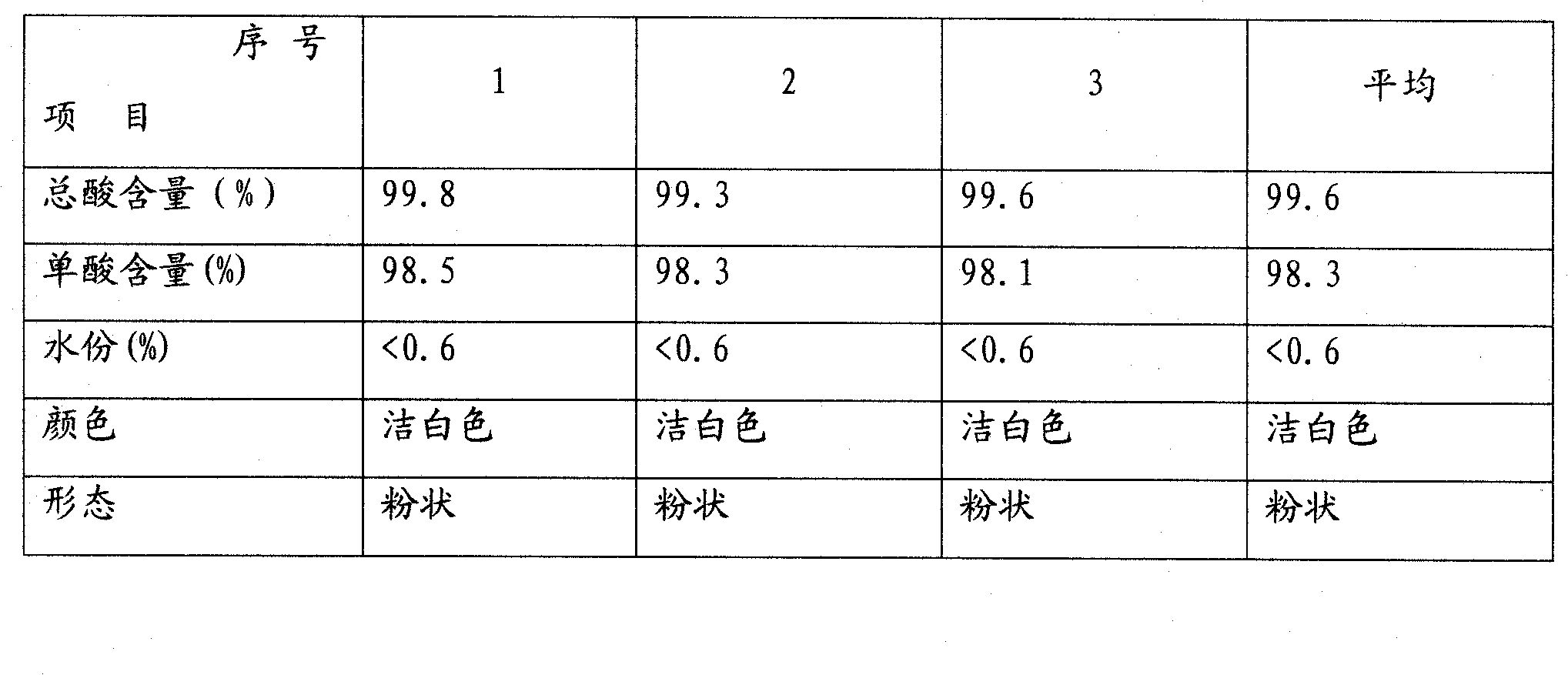

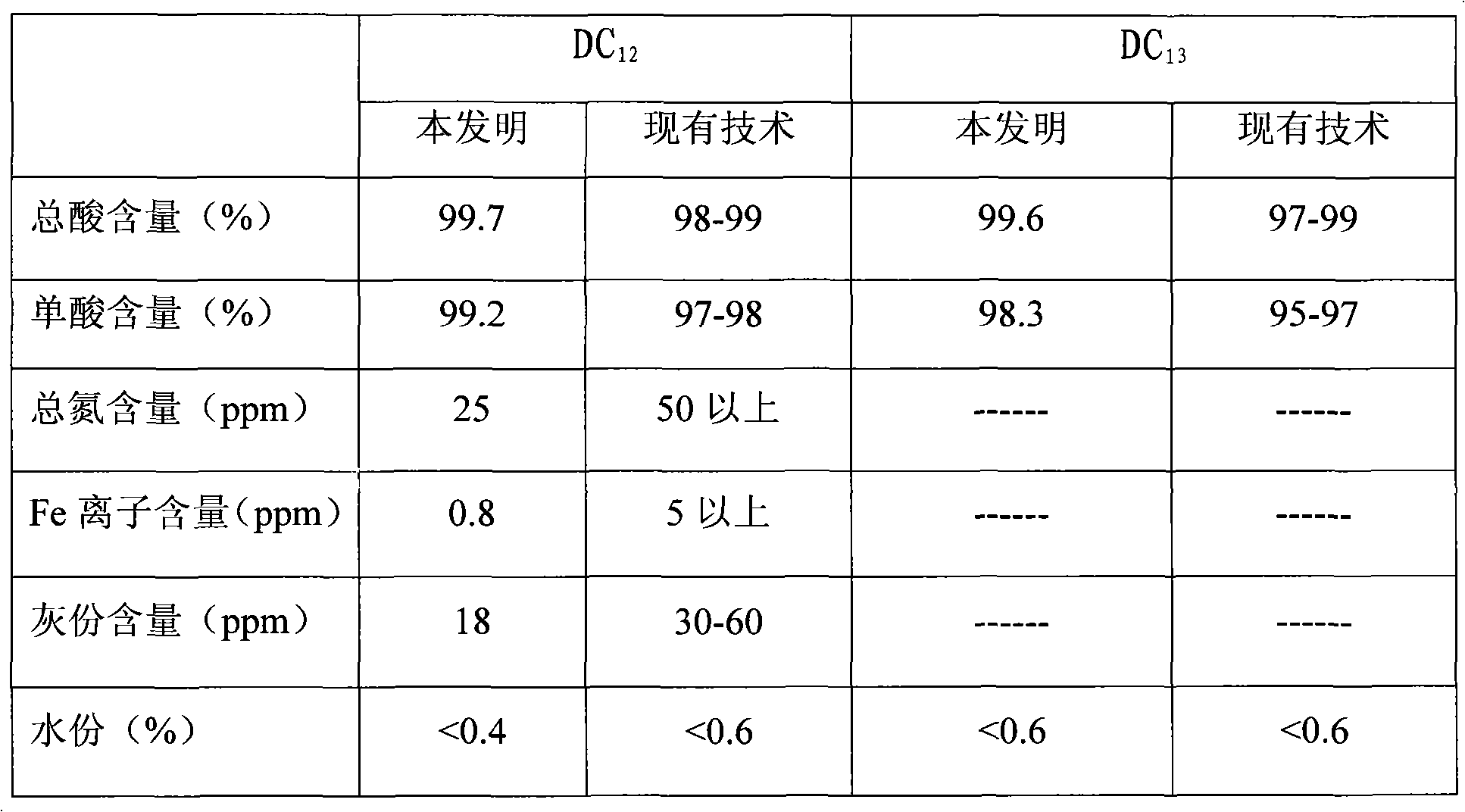

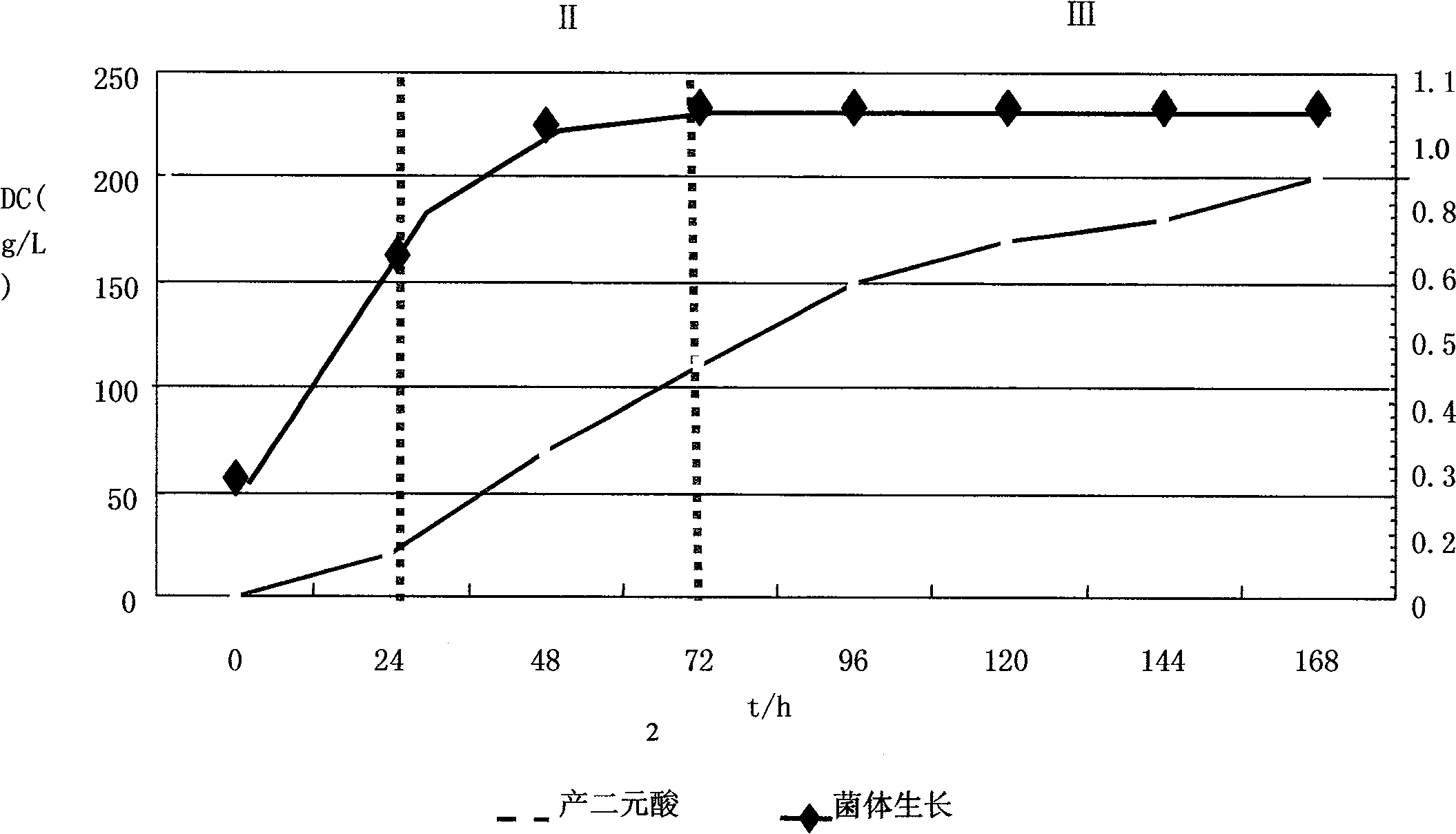

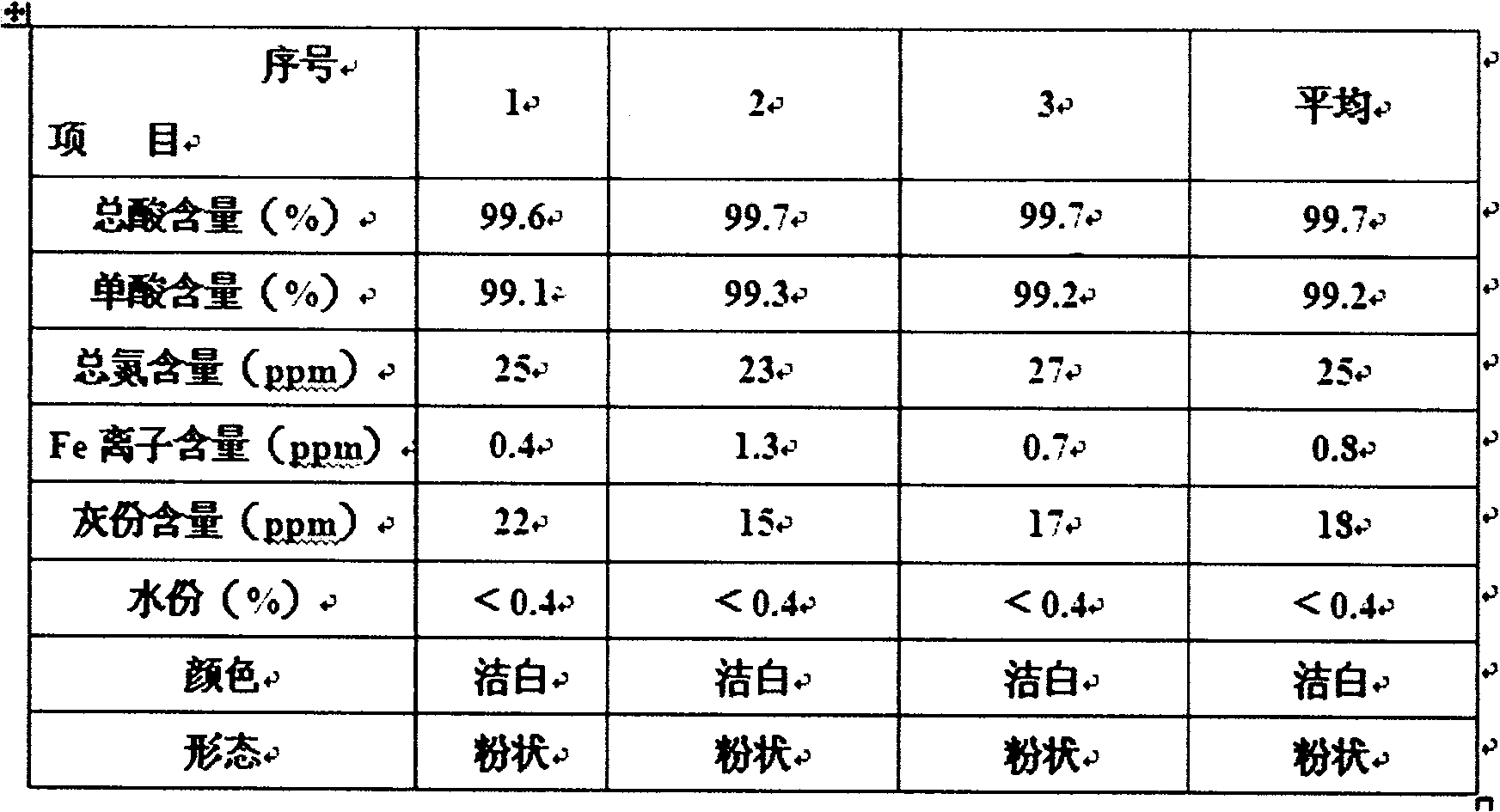

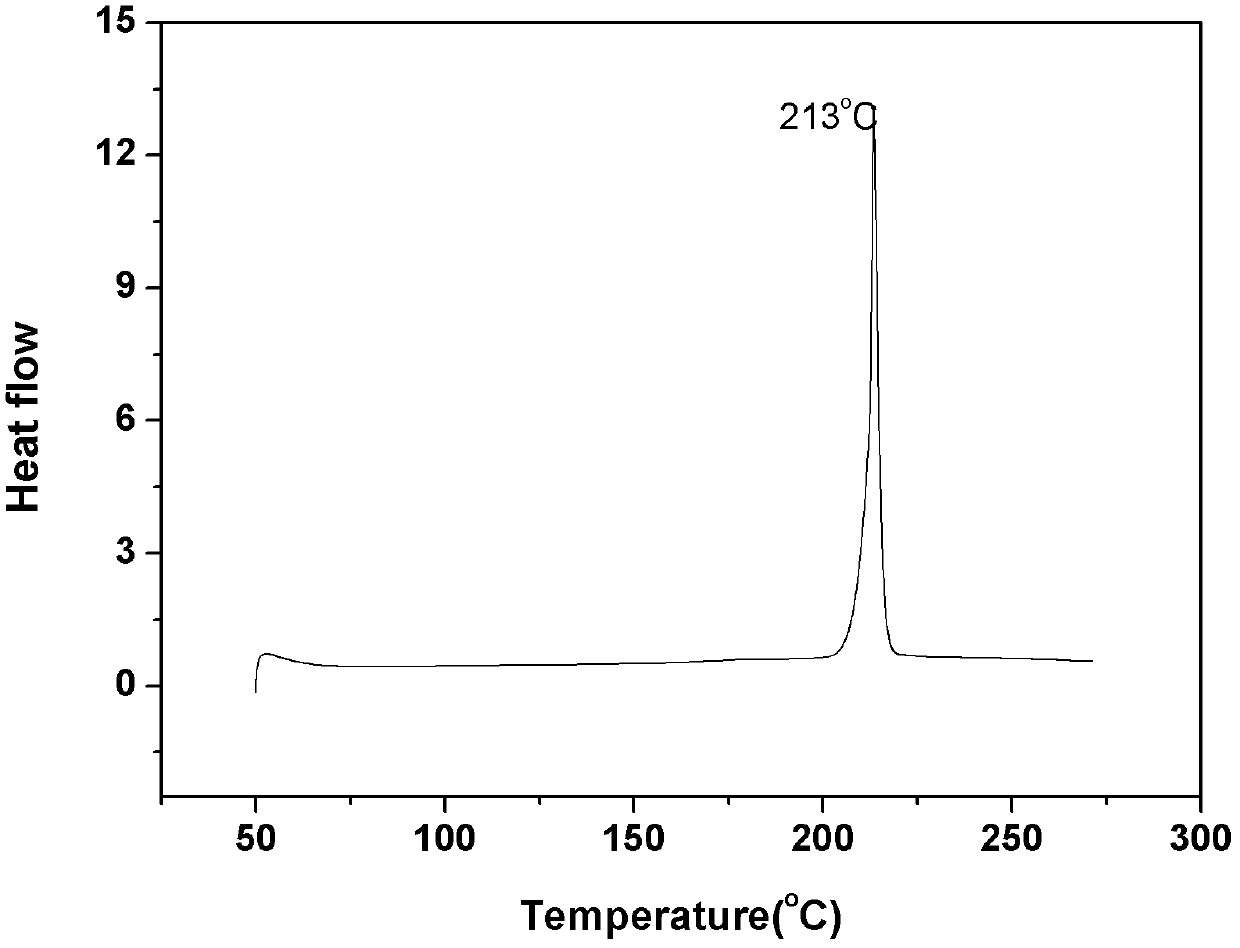

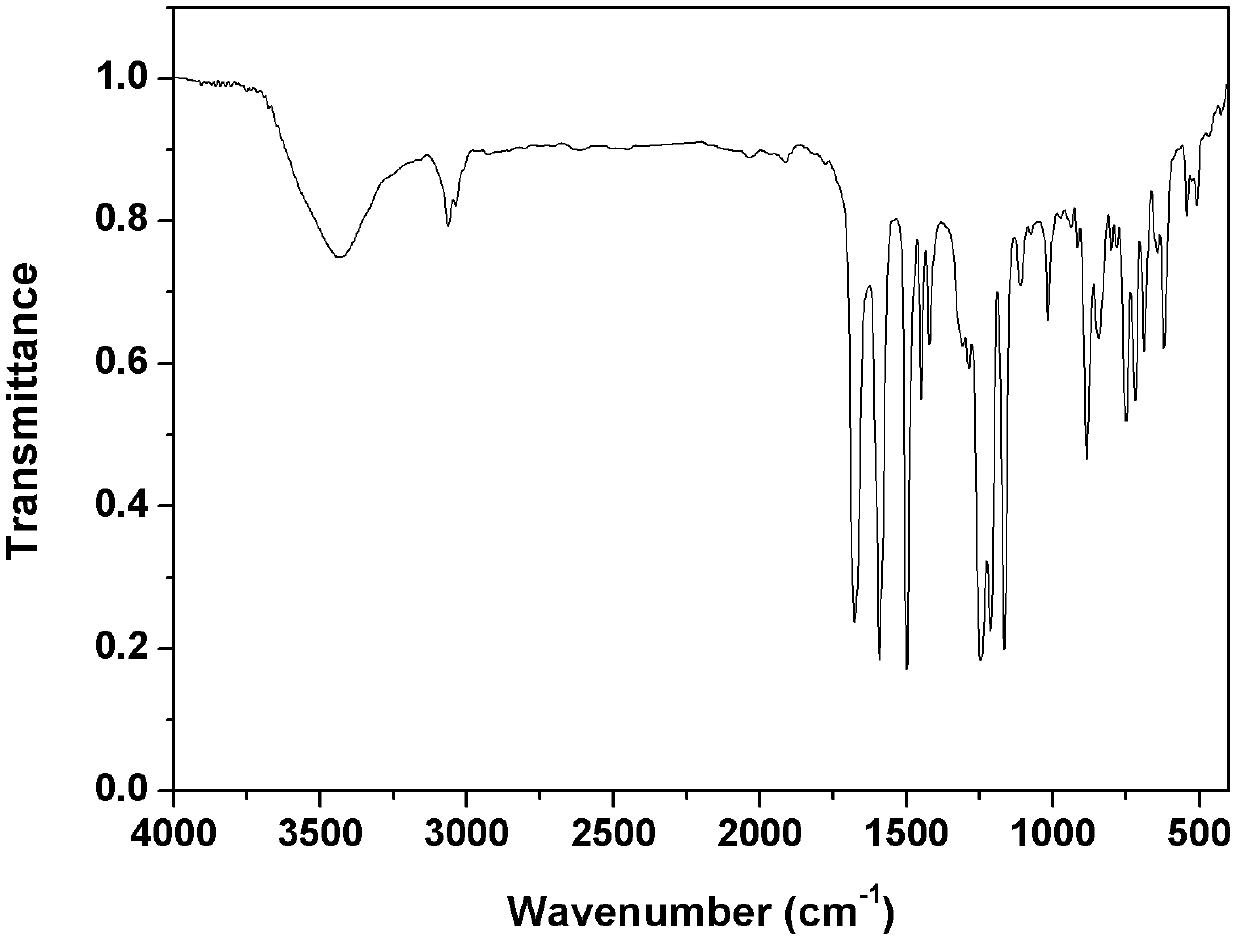

The invention belongs to the technical field of preparing long carbon chain dicarboxylic acid by using a biological fermentation process, in particular relating to a refining technology for producing long carbon chain dicarboxylic acid by using a biological fermentation process. The technical scheme of the invention is the refining technology for producing long carbon chain dicarboxylic acid by using the biological fermentation process, which comprises the following steps: (1) decoloration and filtering; (2) primary crystallization and separation; (3) crystallization and separation of high-temperature water; and (4) drying. The obtained long carbon chain dicarboxylic acid product has the advantages of high single acid content, good photopermeability and high heat stability, can meet demands from different users, can be used for producing advanced spices, high-performance engineering plastics, high-temperature dielectric medium, advanced hot melt adhesive, cold-resistant plasticizer, advanced lubricating oil, advanced paint and coating and the like, and greatly broaden development space on down-stream products of the long carbon chain dicarboxylic acid.

Owner:CATHAY R&D CENT CO LTD

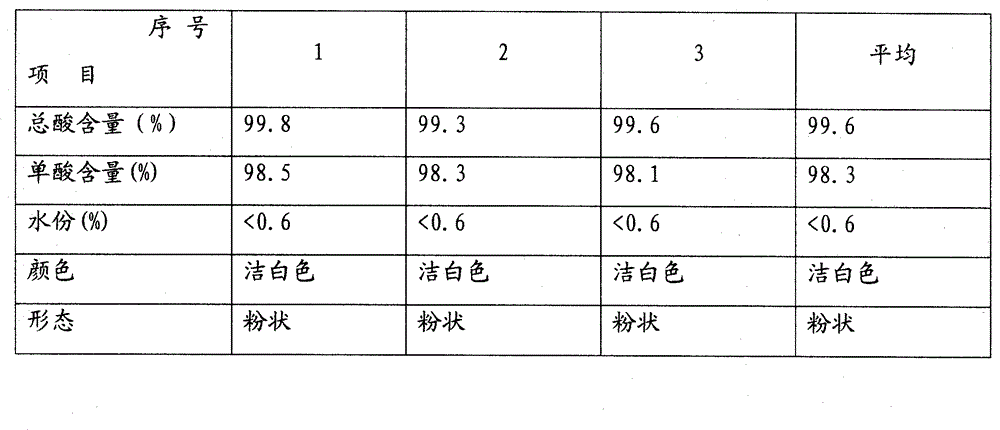

Preparation method of long carbon chain dibasic acid

The invention relates to a preparation method of a long carbon chain dibasic acid. C11 and upper alkane is used as a substrate to produce a corresponding long carbon chain dibasic acid product through the conversion of the substrate into the long carbon chain dibasic acid by using a microbial fermentation method as well as the extraction and the separation of fermentation liquid and the refining processes of a crude product of dibasic acid. Through technological innovation and process innovation, the invention researches a new preparation method of the long carbon chain dibasic acid, greatly decreases the production cost of the long carbon chain dibasic acid, improves the yield and the product quality of the long carbon chain dibasic acid, can produce C11 and upper long carbon chain dibasic acid, finally solve the bottleneck problem restricting the rapid development of the long carbon chain dibasic acid, and form the industrialized scale and the technological predominance. The long carbon chain dibasic acid produced by using the bioanalysis provided by the invention has the advantages of high acid generation level, low production cost, good product quality, complete variety, and the like, the prepared long carbon chain dibasic acid product has high single acid content, good light transmission and high thermal stability, can meet the requirements of different clients, and can be used for producing high-grade spices, high-performance engineering plastics, high-temperature dielectric medium, high-grade hot-melt adhesive, coldness-resistant plasticizer, high-grade lubricating oil, high-grade paint, coating, and the like. The invention greatly widens the development space of the downstream products of the long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD +2

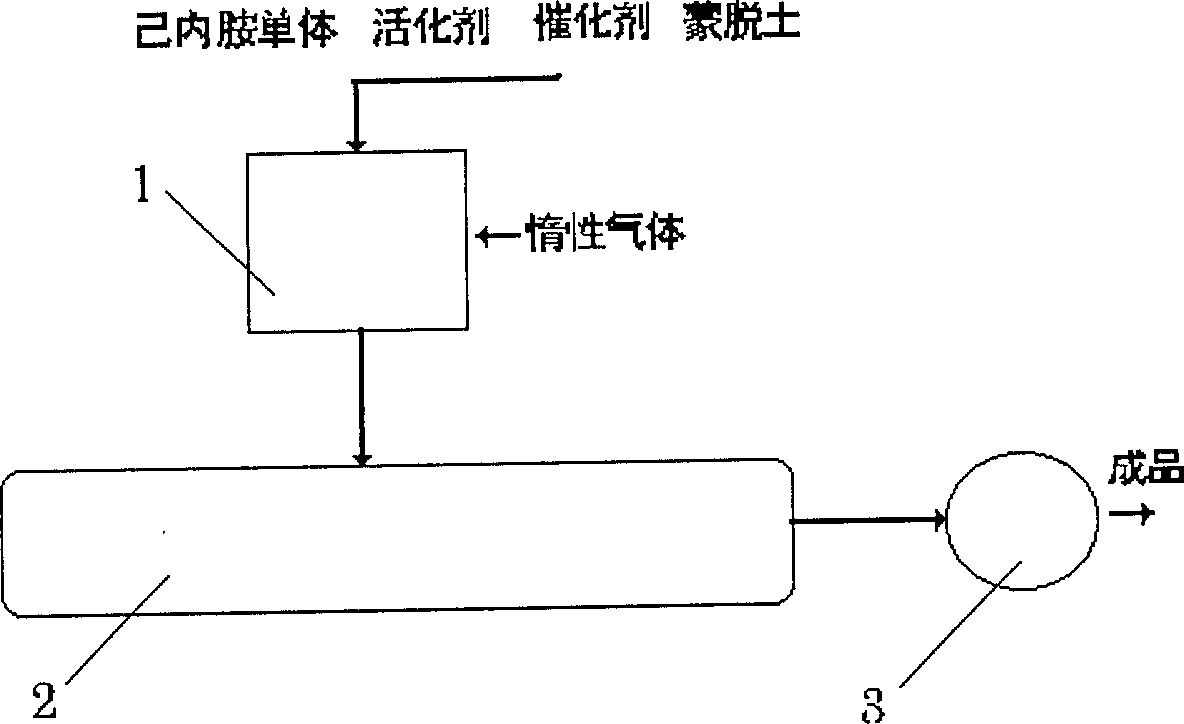

Process for preparing nylon 6/montmorillonite composite

A process for preparing nylon 6 / montmorillonite composite is characterized by use of reaction-extrusion method, that is, the caprolactam and said montmorillonite take part in intercalation polymerization in the reaction extruder to inserting the caprolactam monomers in anionic layers of montmorillonite. Its advantages are high strength, modulus and thermal deformation temp, better isolating performance, simple process, and low cost. It can be used to prepare high-performance engineering plastics and fibres.

Owner:DONGHUA UNIV

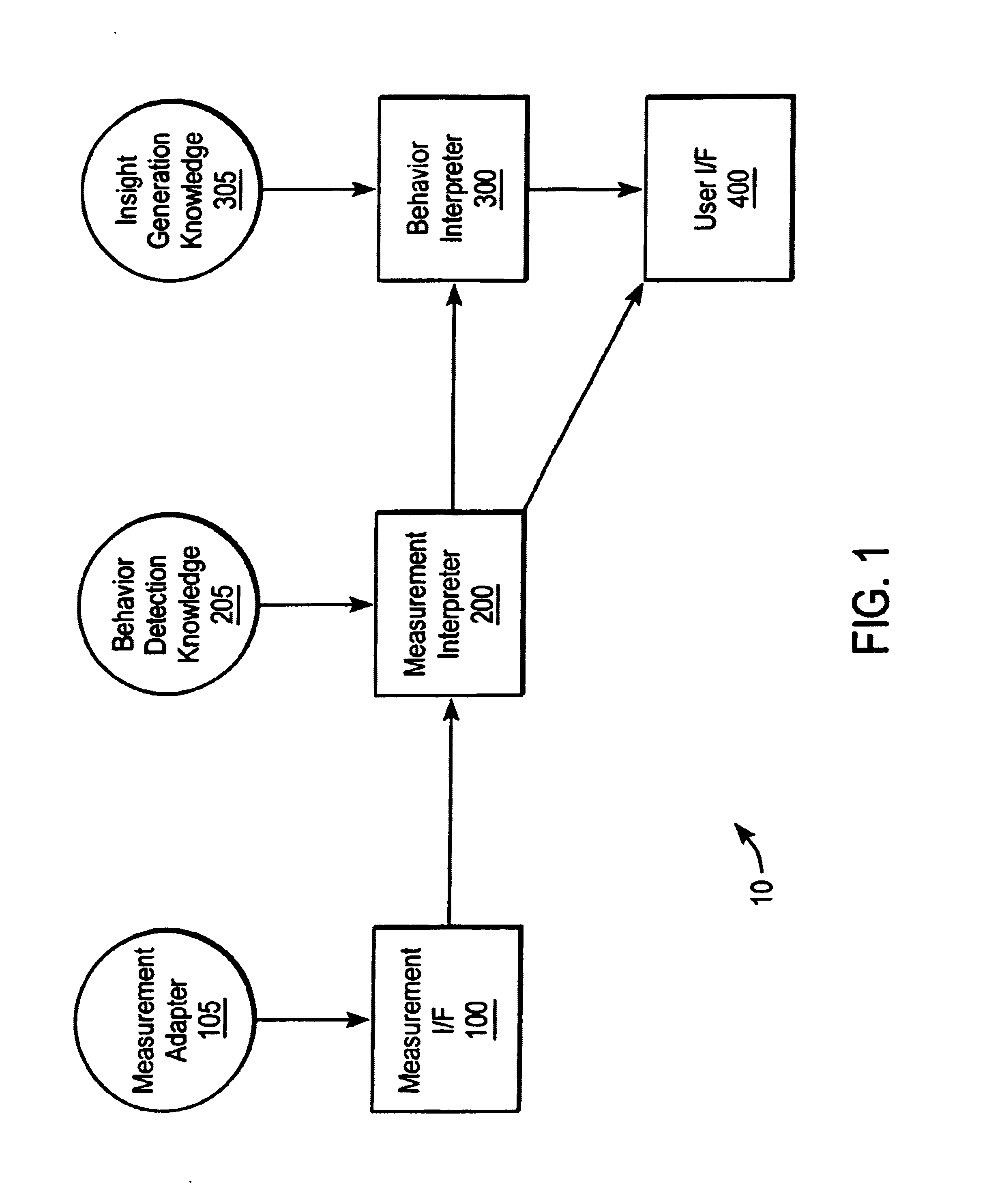

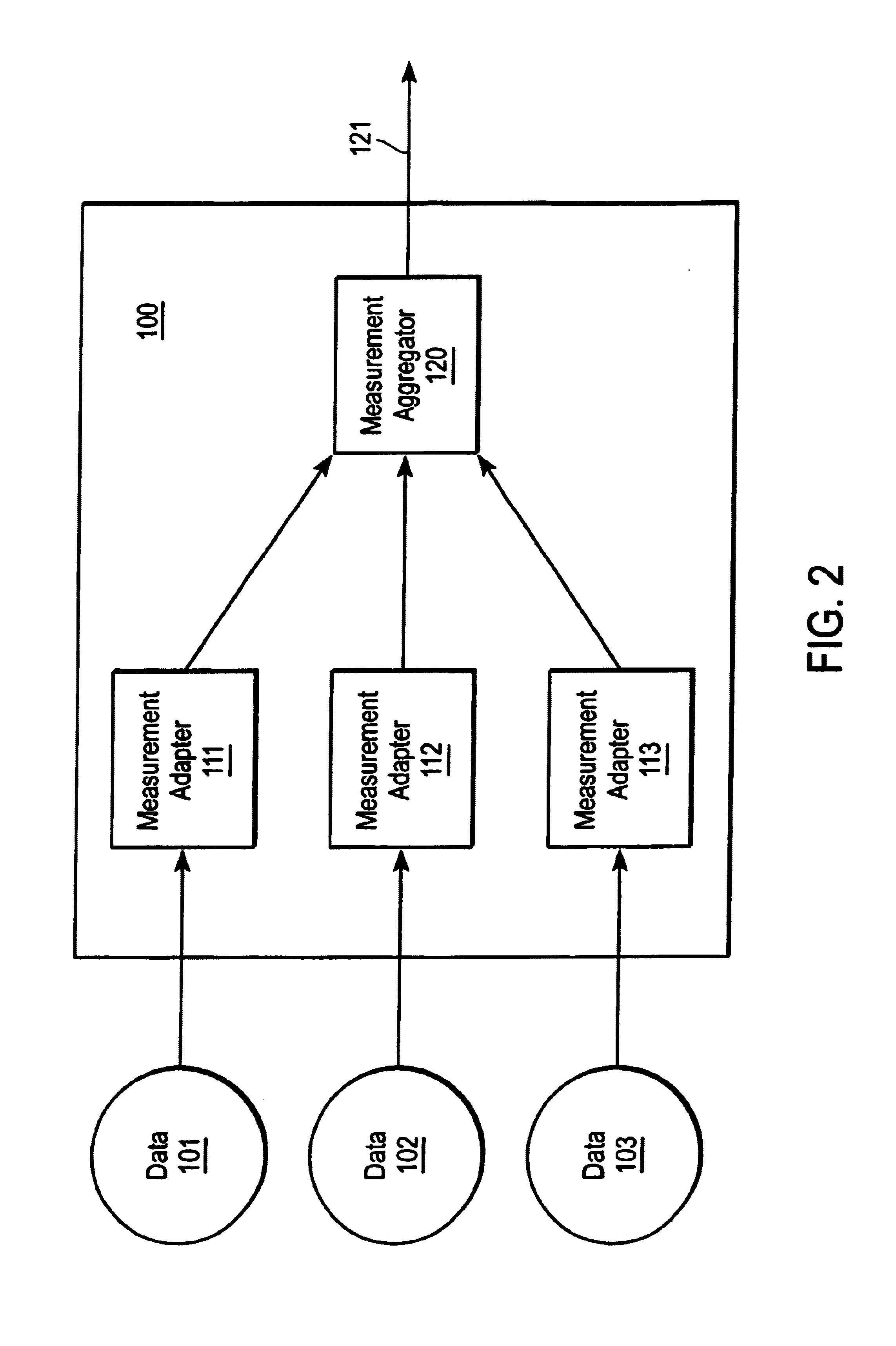

Method and system for automatically interpreting computer system performance measurements

InactiveUS7016809B1Quick understandingDigital computer detailsNuclear monitoringGraphicsPerformance engineering

An improvement in applying and interpreting encoded knowledge about computer system performance engineering and in enabling a user to more readily understand and apply that knowledge to improve computer system performance. Textual and graphical depictions of insights, advice, behaviors, and explanations can be presented, all related to improving computer system performance. Fuzzy logic can be employed to accommodate incomplete measurement data and to present results in a qualitative format, presenting relevant data as being high, low, substantial, etc., rather than simply presenting the values of the associated counters leading to those determinations. Intermediate values used to generate the results can also be processed with qualitative rather than quantitative values.

Owner:INTEL CORP

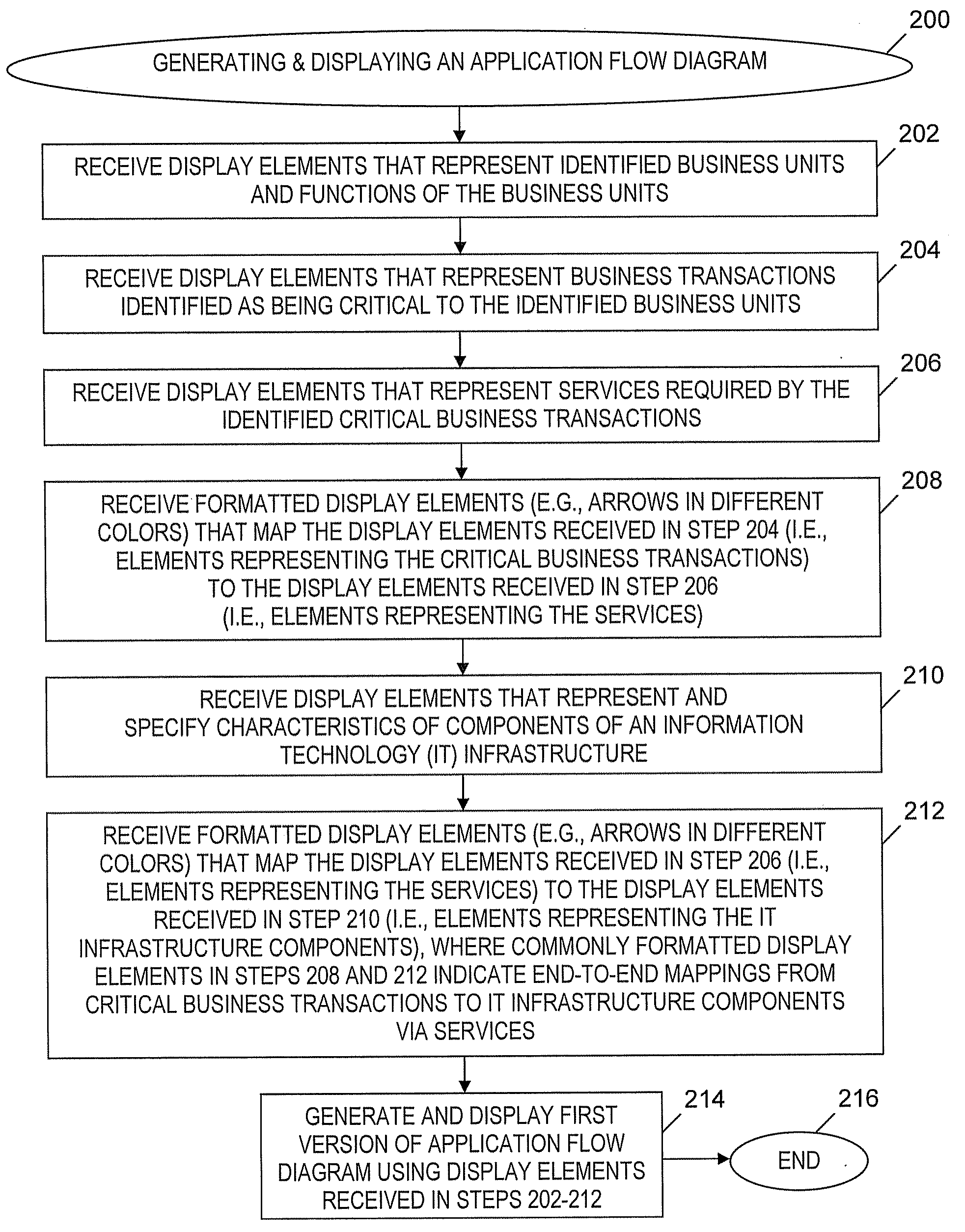

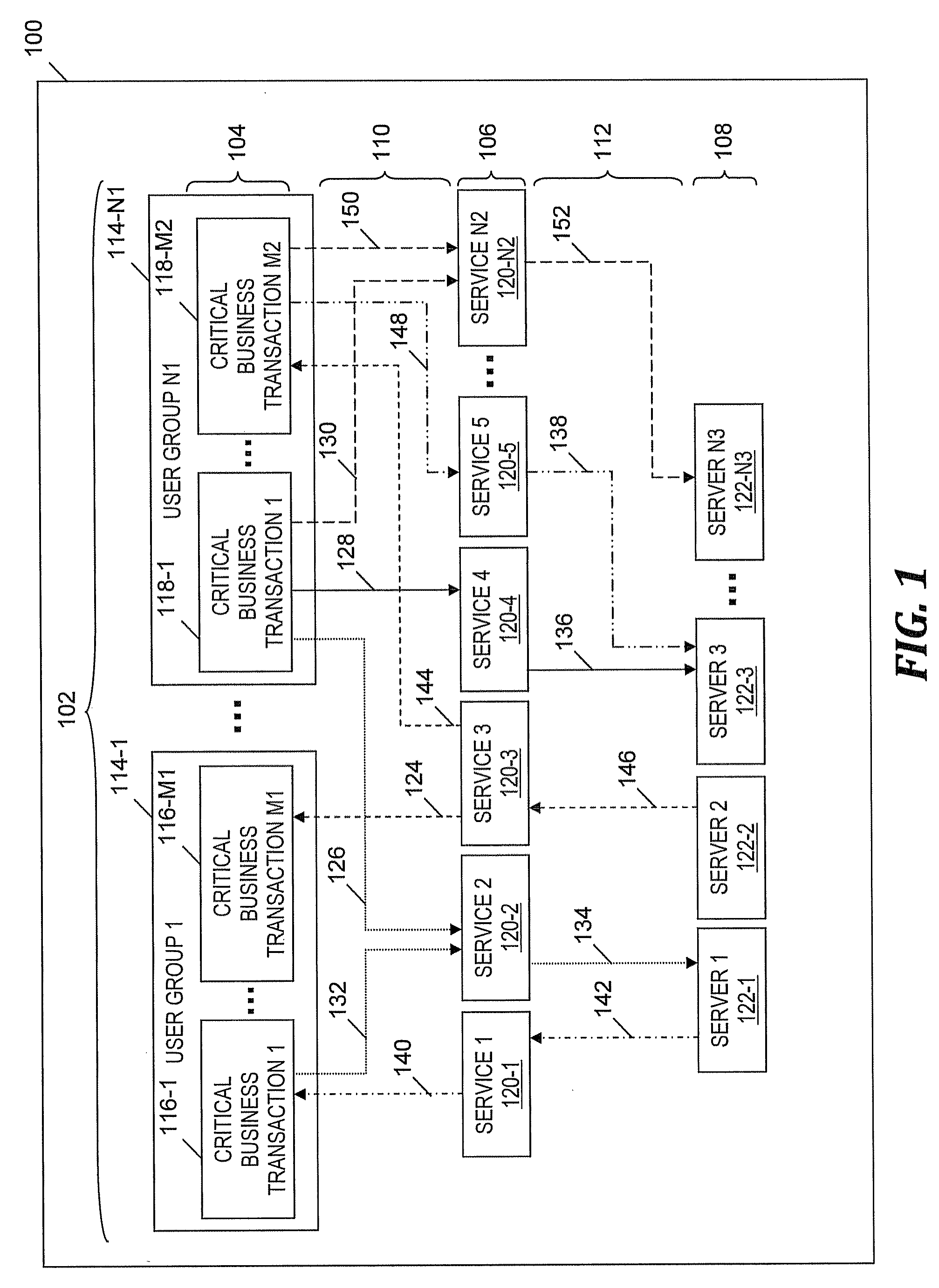

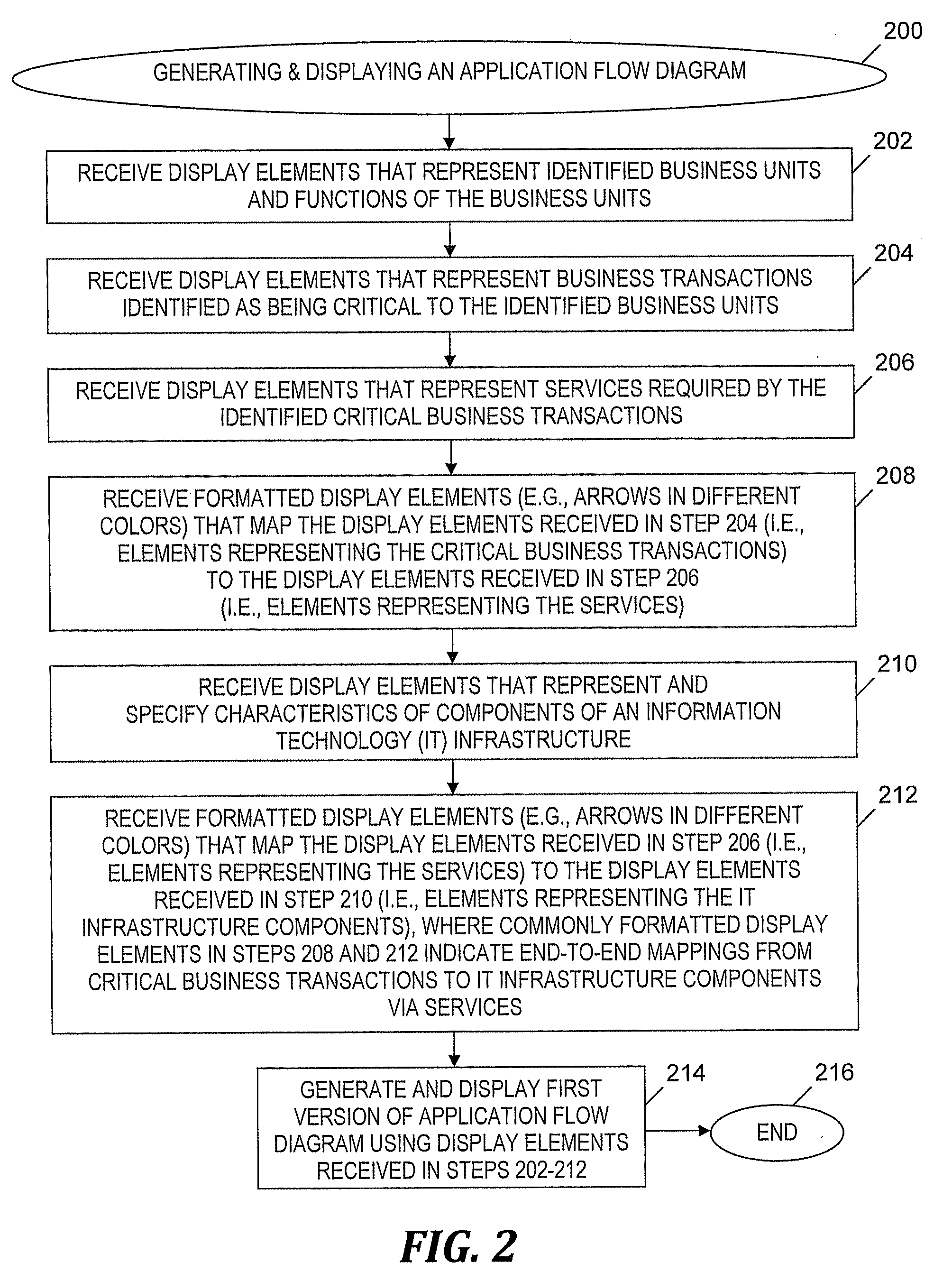

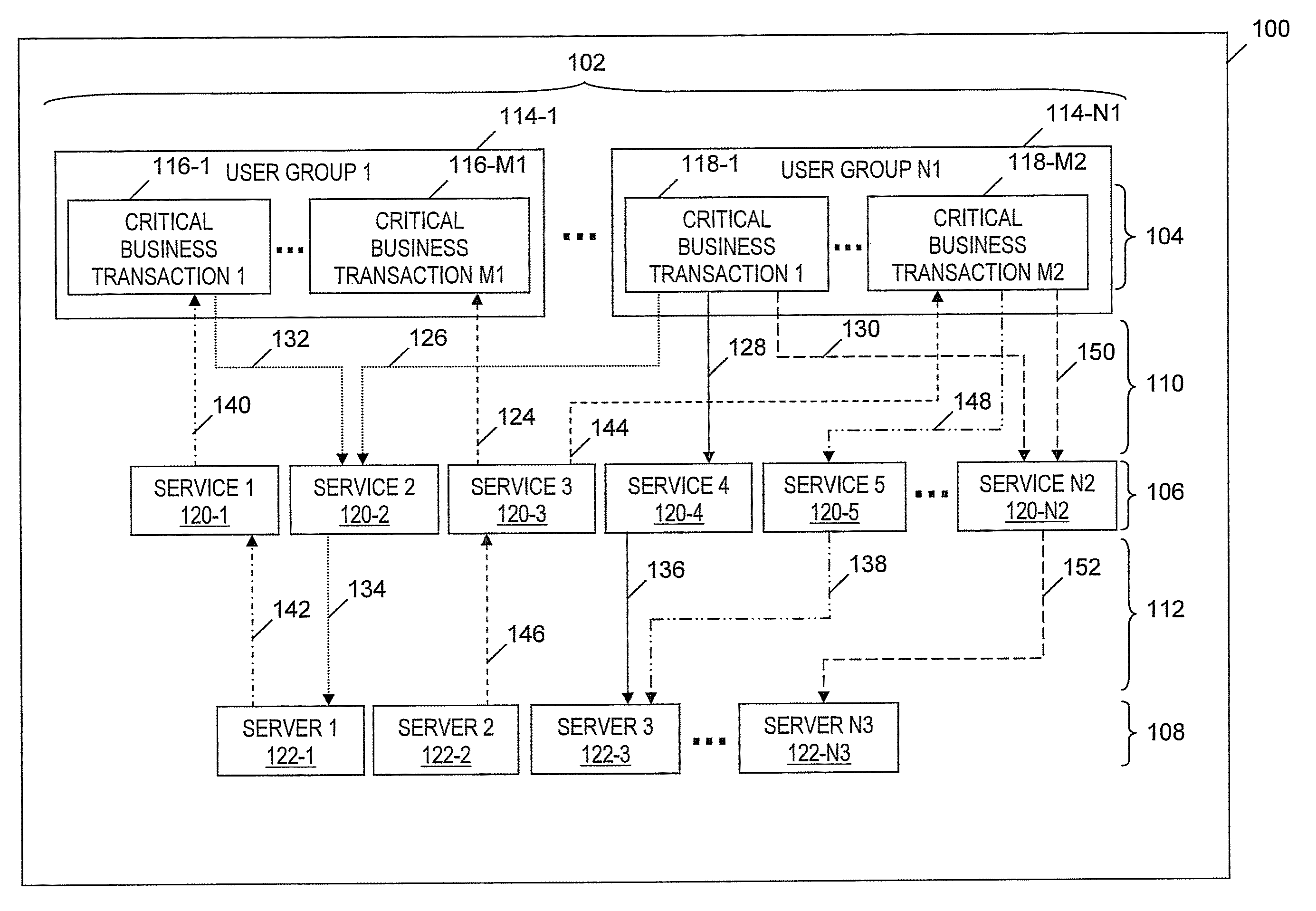

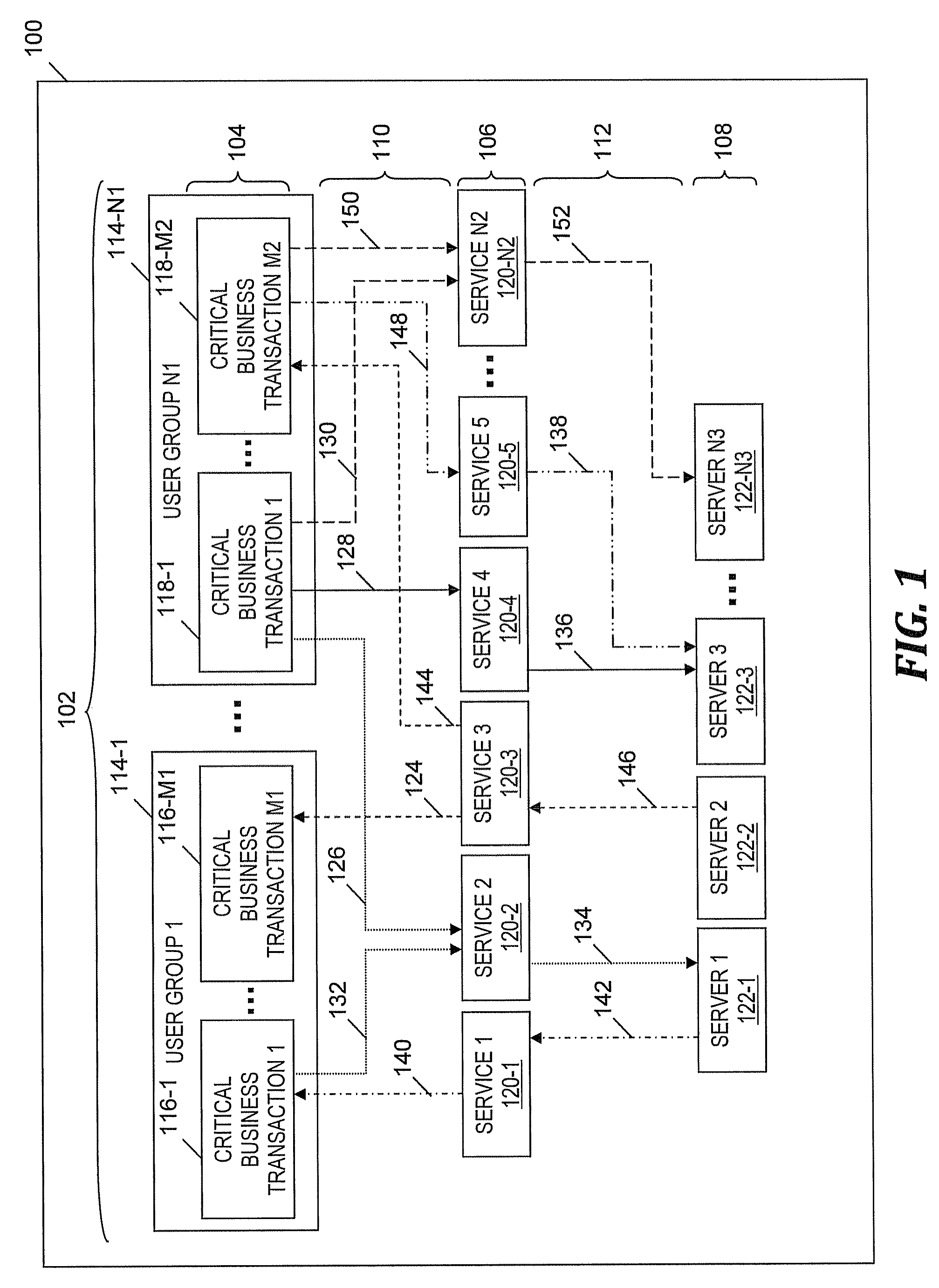

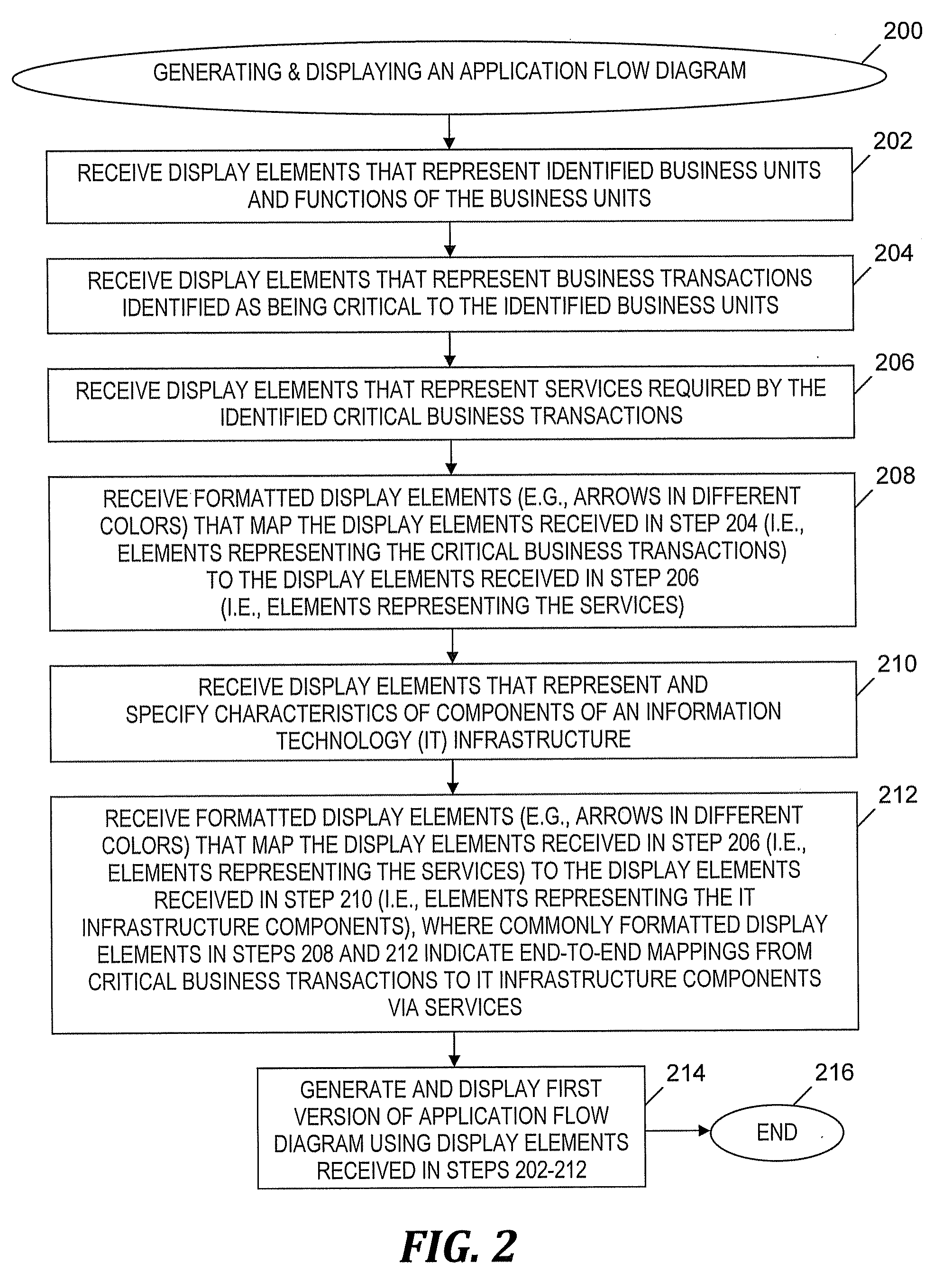

Generating and displaying an application flow diagram that maps business transactions for application performance engineering

InactiveUS20100302248A1Data processing applicationsDrawing from basic elementsPerformance engineeringApplication software

A method and apparatus for generating and displaying an application flow diagram for an application. The application flow diagram includes: a set of business transaction display elements representing critical business transactions that sustain or provide revenue for an organization; a set of service display elements representing services required by the critical business transactions; a set of infrastructure display elements representing information technology (IT) infrastructure components utilized by the services; and formatted display elements (e.g., arrows) that map the business transaction display elements to the service display elements and the service display elements to the infrastructure display elements, thereby indicating an end-to-end flow of data between the critical business transactions and the IT infrastructure components.

Owner:IBM CORP

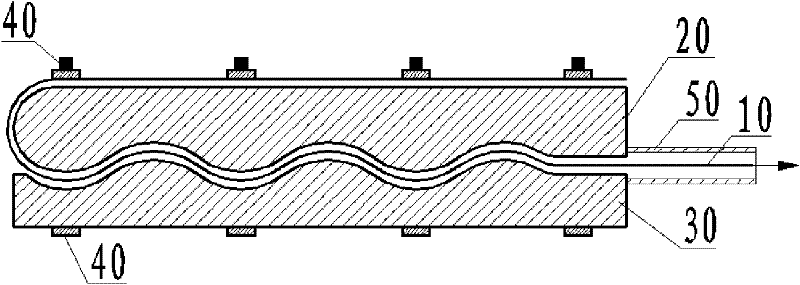

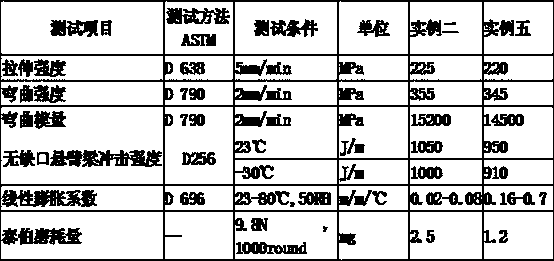

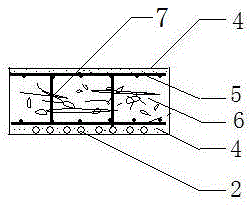

frp sheet anchor and its anchoring method

InactiveCN102261166ADurableReduce weightBuilding reinforcementsBuilding material handlingPerformance engineeringEngineering

The invention discloses an FRP (Fiber Reinforced Polymer, fiber reinforced polymer) sheet anchor and its anchoring method, and relates to an anchor for engineering structures in the field of high-performance polymer structural materials. The present invention comprises a sheet (10), an upper anchor plate (20), a lower anchor plate (30) and a bolt (40); the sheet (10) passes through a bellows (50) and is placed on the upper anchor plate (20) and the lower Between the anchor plates (30), the upper anchor plate (20) and the lower anchor plate (30) clamp the sheet (10) together, and the bolts (40) pass through the upper anchor plate (20) and the lower anchor plate (30) The upper anchor plate (20) and the lower anchor plate (30) are anchored tightly by the plate holes (25). The anchorage is non-corroding, and it is placed in a completely non-metallic engineering structure together with the FRP sheet, which has durability; it is light in weight and is used in bridges and other structures to enhance the spanning ability; it has good electromagnetic insulation.

Owner:湖北金力工程复合材料有限公司

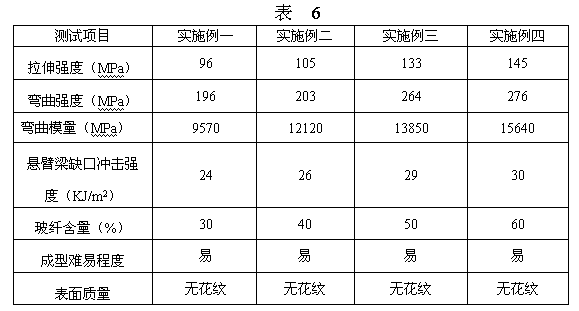

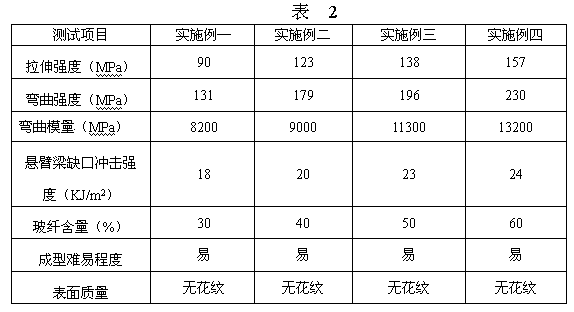

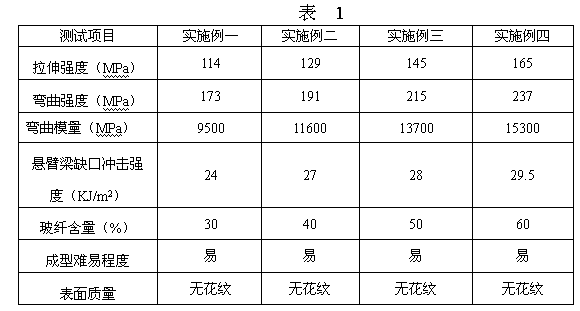

Novel polyamide material for replacing metal material, and preparation method thereof

InactiveCN109294227AEasy to absorb waterImprove impact performanceGlass fiberPerformance engineering

The invention relates to the field of high-performance engineering plastics, and especially relates to a novel polyamide material for replacing a metal material, and a preparation method thereof. Theformula (100 wt%) of the novel polyamide material for replacing the metal material comprises polyamide, glass fibers, glass microbeads, a toughening agent, an anti-wear agent, a weather-resistant additive and other additives. The preparation method comprises the following steps: weighing raw materials in proportion; treating the surfaces of the glass fibers and the glass microbeads with a couplingagent; stirring the treated glass microbeads, the toughening agent, the anti-wear agent and other additives in a high-speed mixer for 1-5 min, and discharging the obtained material; and adding the material into a twin-screw extruder having a rotating rate of 200-800 r / min and a temperature of 250-300 DEG C, and adding a specific proportion of the treated glass fibers to a side feeder of the extruder in order to obtain the finished product. The preparation method has the advantages of simplicity and convenience.

Owner:宁波塑之华塑化有限公司

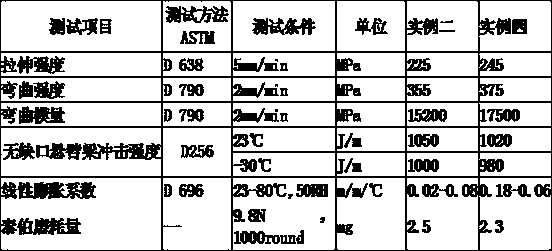

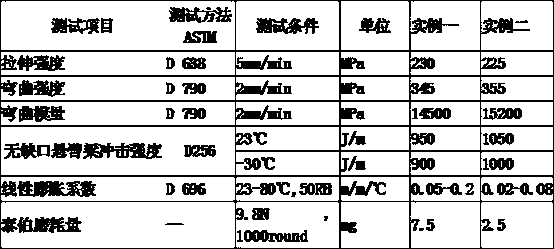

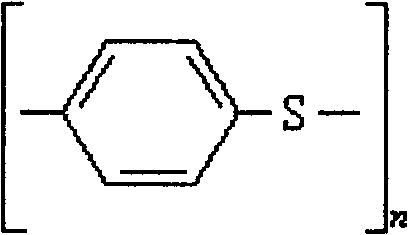

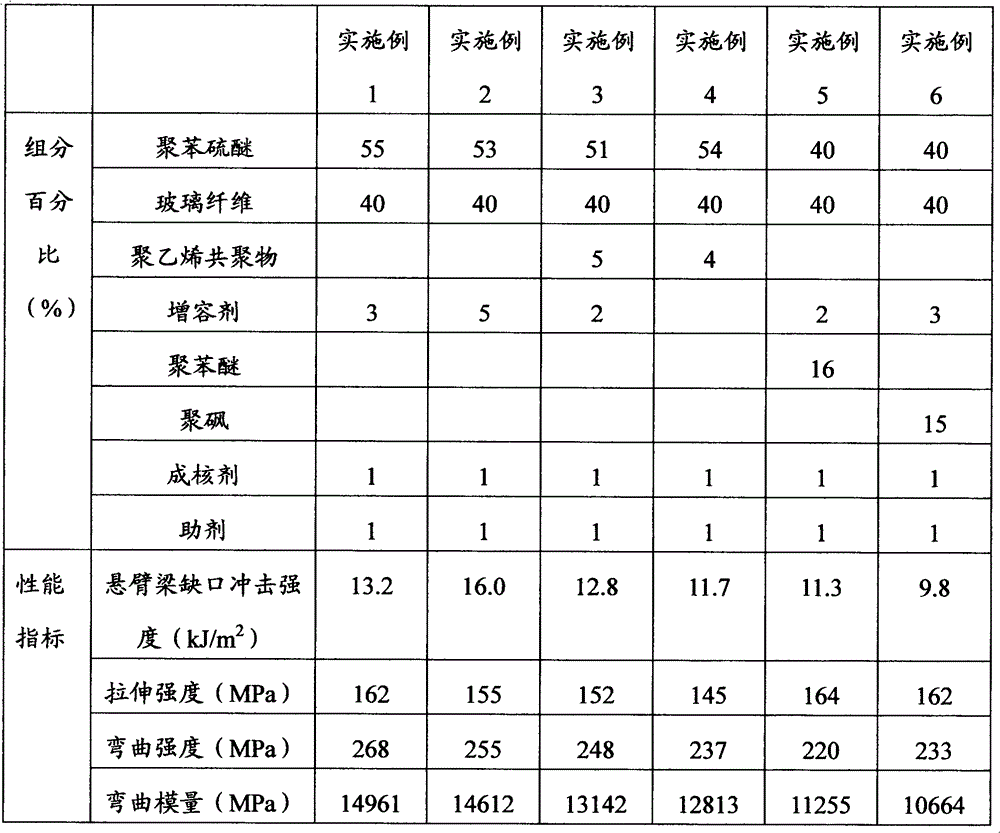

High temperature-resistant high-strength polyphenylene sulfide-based reactively reinforced and toughened composite material

The invention discloses a high temperature-resistant high-strength polyphenylene sulfide-based reactively reinforced and toughened composite material and a preparation method thereof. The high temperature-resistant high-strength polyphenylene sulfide-based reactively reinforced and toughened composite material comprises: by weight, 30 to 55% of polyphenylene sulfide, 30 to 60% of glass fibers, 0 to 10% of one or more compatibilizers, 0 to 10% of one or more polyolefins, 0 to 20% of one or more high-performance engineering plastics, 1 to 2% of one or more nucleating agents and 0.5 to 1% of auxiliary agents. The preparation method is characterized in that through an interface reaction, phase morphology control is realized and through nucleation induction, a crystallization rate is improved so that good interface compatibility and structure reinforcement are realized. The high temperature-resistant high-strength polyphenylene sulfide-based reactively reinforced and toughened composite material has the advantages of low density, high strength, good toughness, high temperature resistance and good formability and is suitable for fields of automobile parts, household appliances and chemical engineering having high temperature resistance, corrosion resistance, torsion and compression resistance, low creep deformation and low cost requirements.

Owner:上海真晨企业发展有限公司

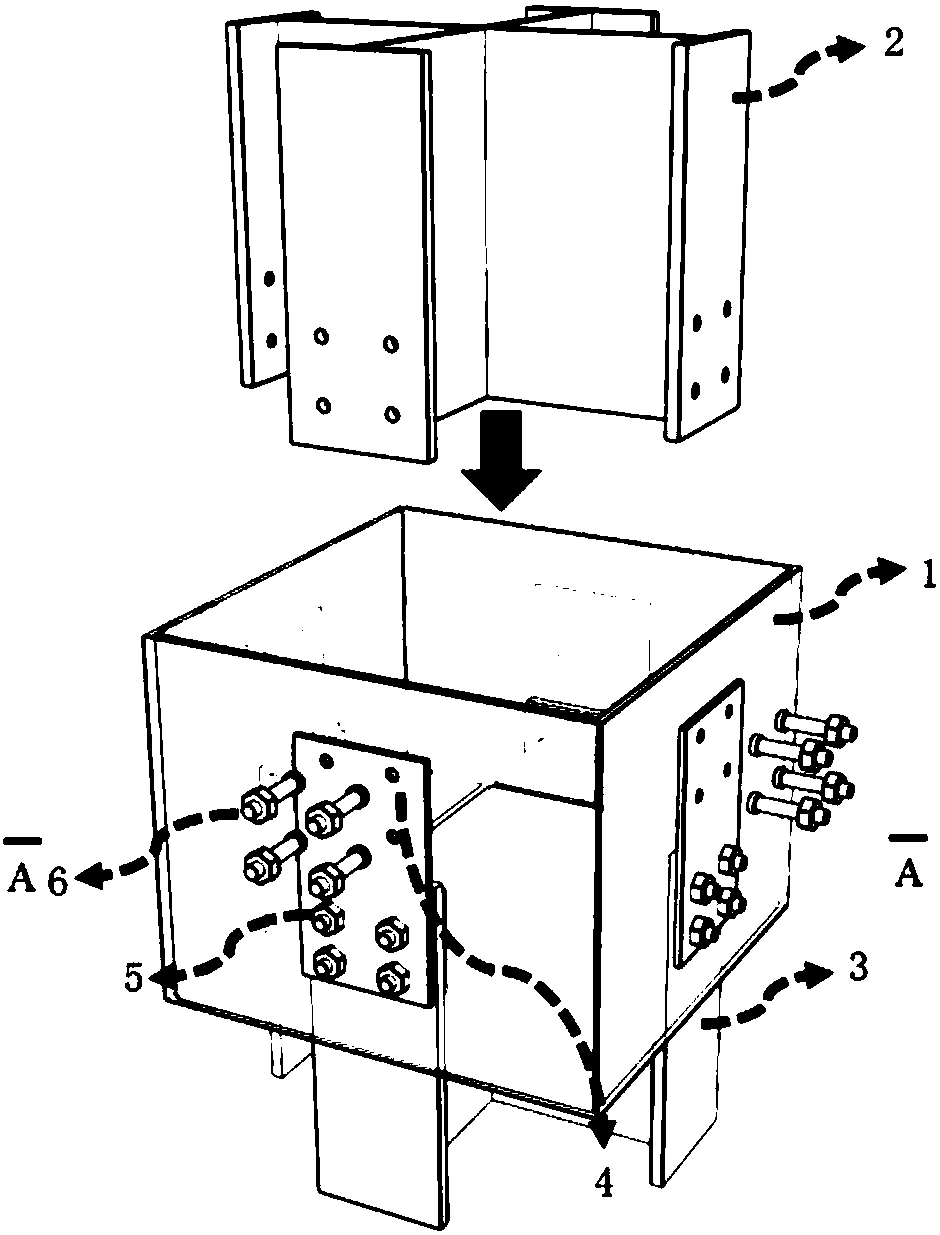

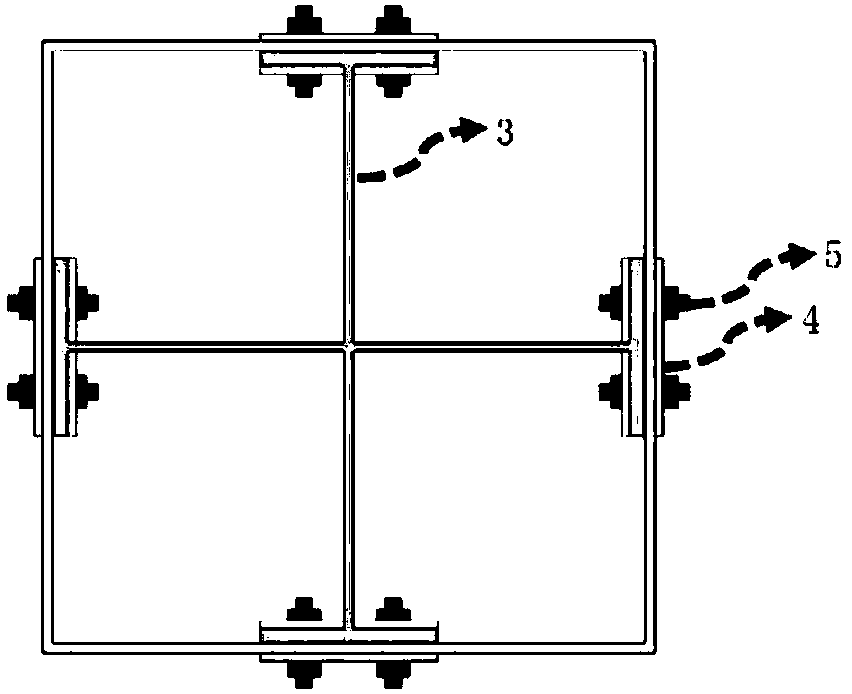

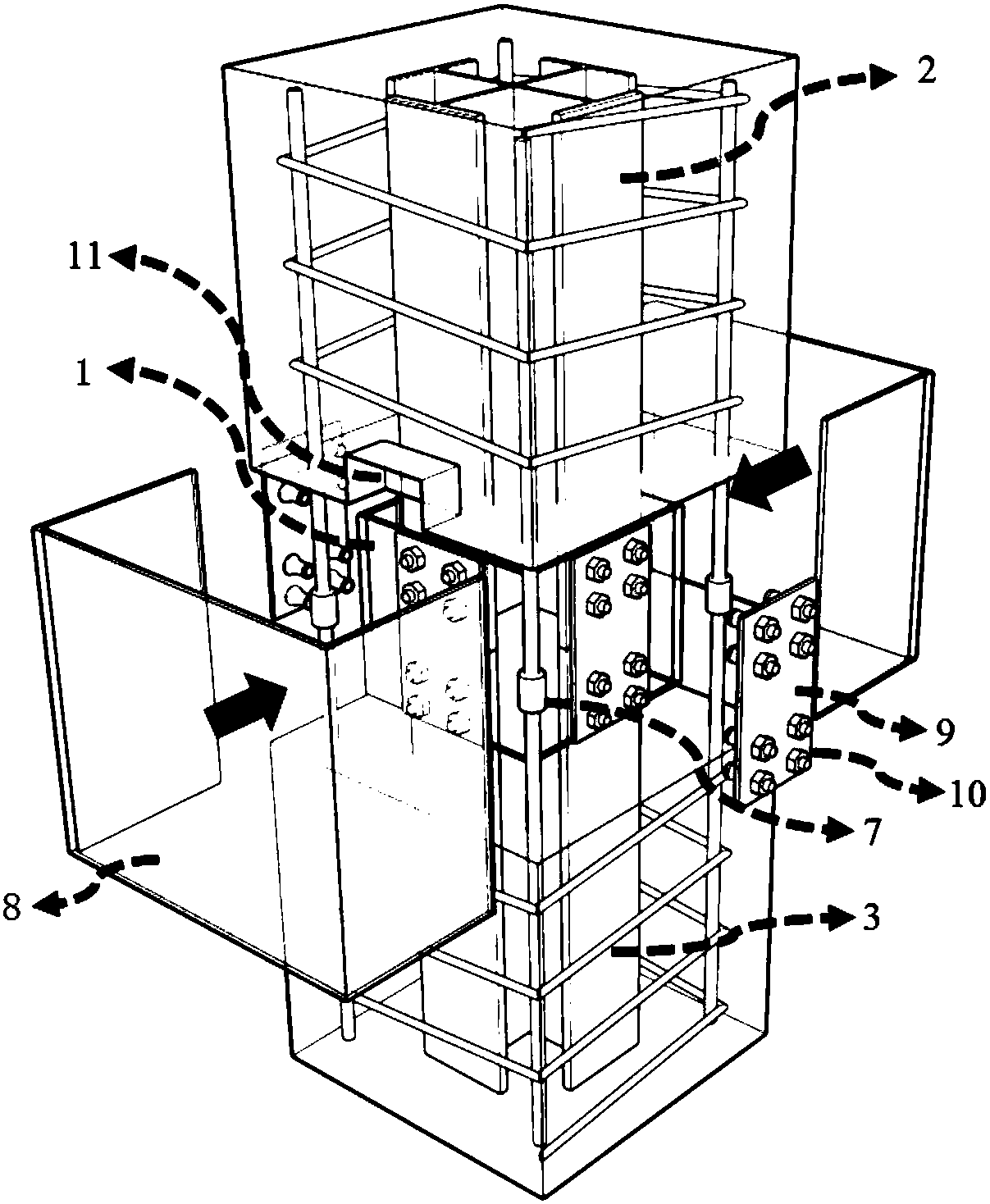

Prefabricated reinforced concrete column connection structure and method

ActiveCN108252424AEasy constructionUse fewer boltsBuilding constructionsReinforced concrete columnPerformance engineering

The invention relates to a prefabricated reinforced concrete column connection structure and method. The idea of equivalent cast-in-place is adopted, based on mechanical optimization analysis, a method connecting to the middle of a column is proposed, shape steel in the column is connected by a shape steel sleeve instead of welding and bolt connection commonly used in engineering, and the construction is simplified; rebars in the column are connected by a mechanical sleeve instead of a grouting sleeve often used in the assembled reinforced concrete structure, and the cost is reduced; the connection part is covered with a steel plate tube and no stirrups are arranged, and the construction is simplified; a hole is reserved in a prefabricated reinforced concrete column at the upper part of the connection part; and after installation of the steel plate tube is completed, high-performance engineering cement-based composite materials (ECC) can be poured to further ensure the integral strength and deformation capacity of the connection part. The prefabricated reinforced concrete column connection structure has high assembly property, the assembly mode is basically a bolt connection with convenient construction, on-site welding and large-area concrete pouring operation are avoided, and the construction is convenient. At the same time, the prefabricated reinforced concrete column connection structure and method is based on the idea of equivalent cast-in-place, and the strength and deformation capability of the connection part can be effectively guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

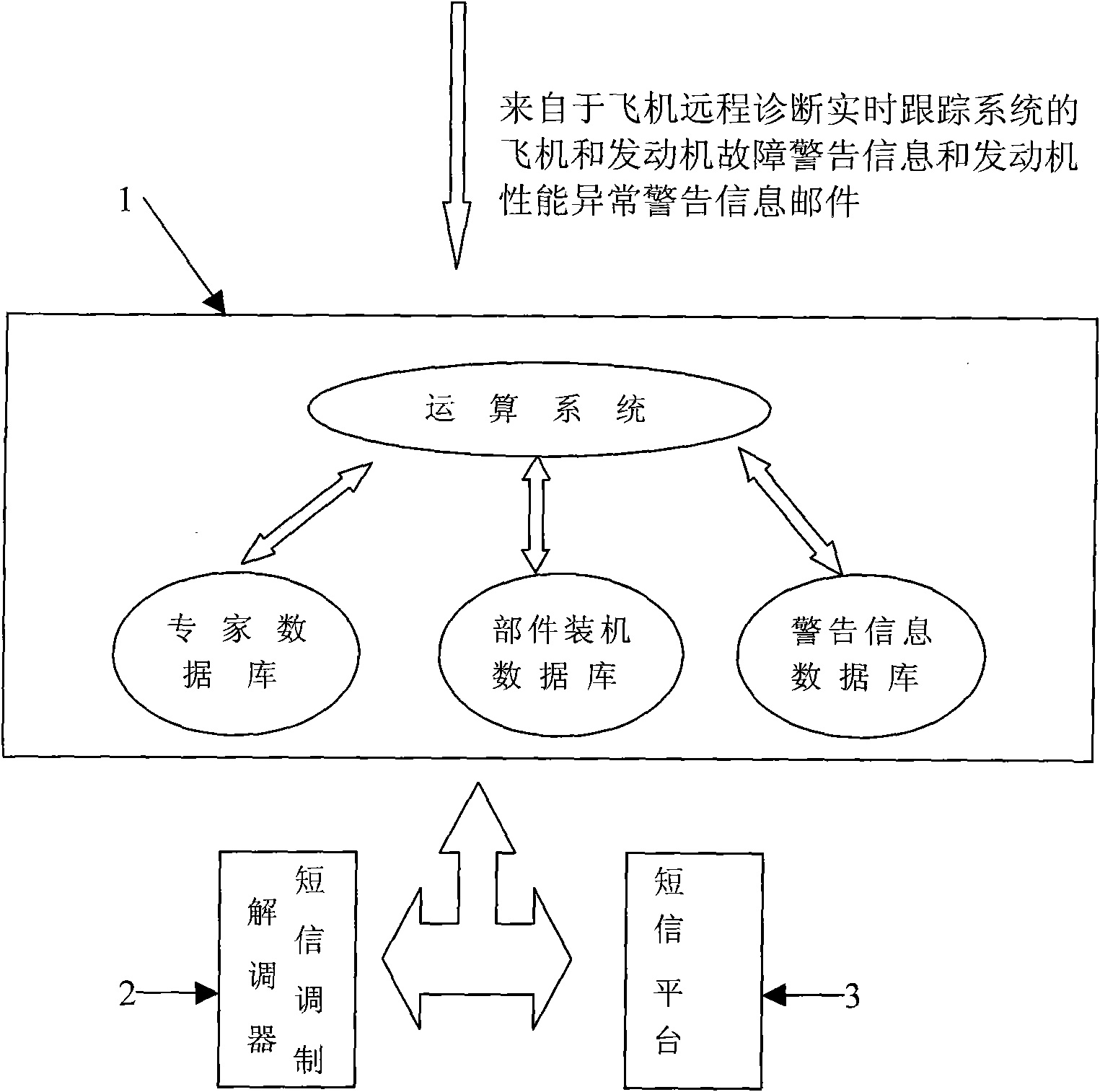

Airplane information real-time message monitoring system and method

InactiveCN101674544ALess likely to be misunderstoodClear up misunderstandingsMessaging/mailboxes/announcementsData switching networksPerformance engineeringMonitoring system

The invention discloses an airplane information real-time message monitoring (ACARS TO SMS) system and a method; the system takes CN02134931.2 airplane remote diagnosis real-time follow-up system as an interface and expands the functions on two ways: (1) an alarm (including airplane and engine failure information and engine performance abnormal information) generated by the airplane remote diagnosis real-time follow-up system is converted into a message and transmits to maintenance personnel and engine performance engineers in a real-time manner, labor and time are saved and transmission is hard to cause misunderstanding, thereby having good functions of improving reaction speed of fault treatment of a flight course and reducing flight delaying rate. (2) An alarming and filtering functionis added, and three databases are led in, one database is component installation database (providing the condition of component installation), another one is an expert database (storing dummy messageitems), the third one is an alarming information database (storing airplane alarming information). An arithmetic system determines weather the alarm is true or false according to the information of three databases and the content of the alarming message, thereby eliminating misunderstanding of the maintenance personnel and reducing unnecessary trouble of the maintenance personnel.

Owner:中国南方航空股份有限公司

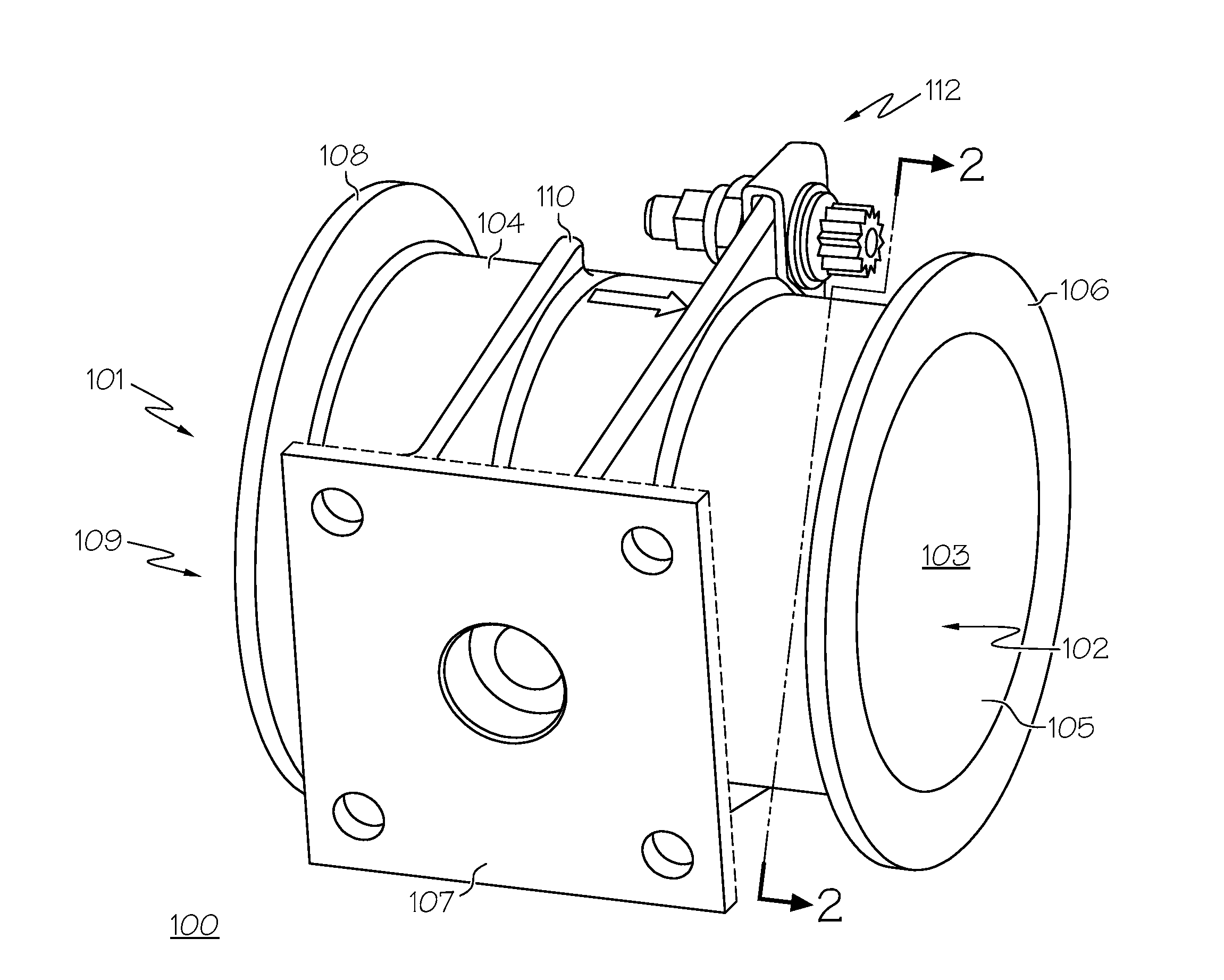

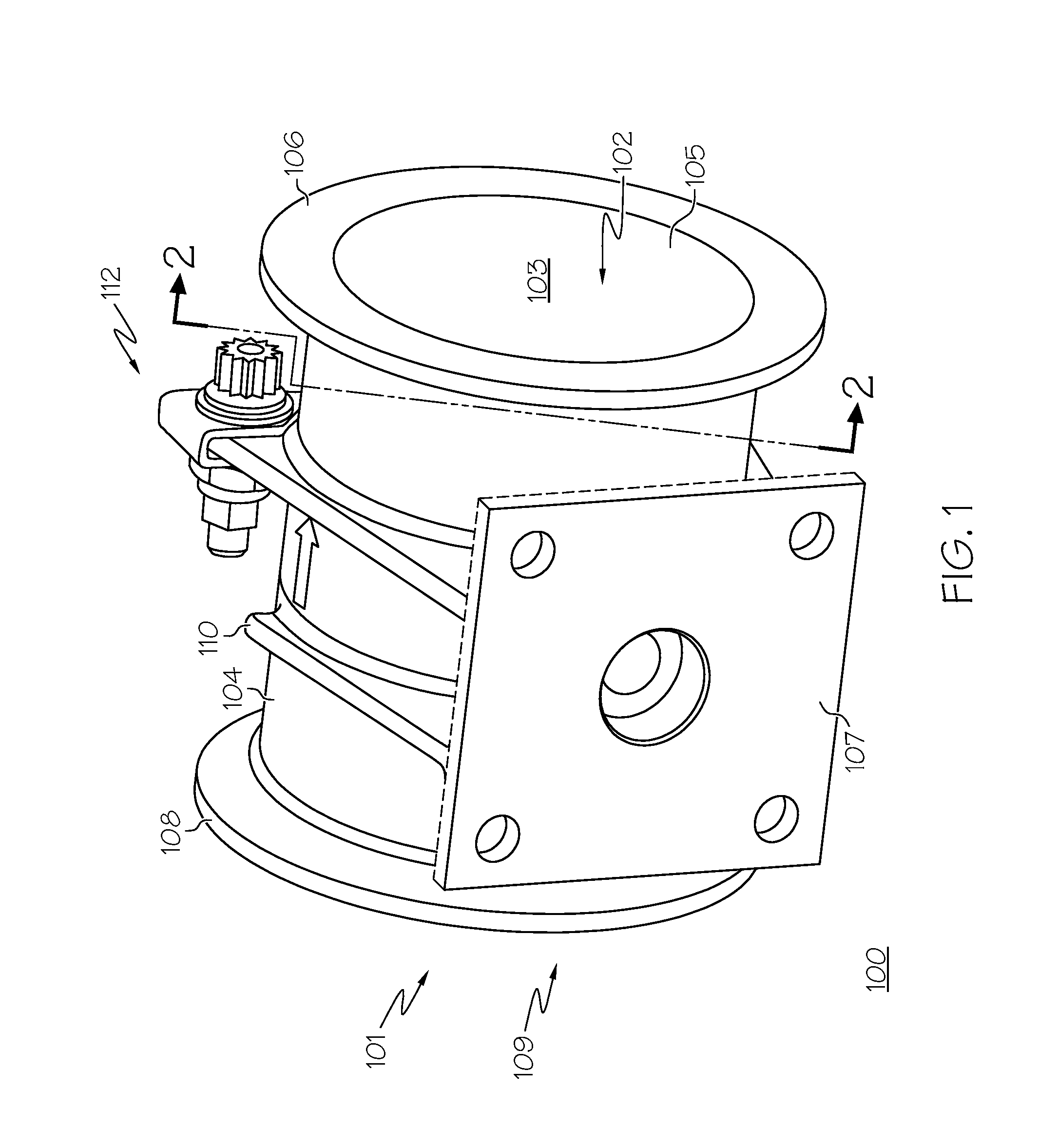

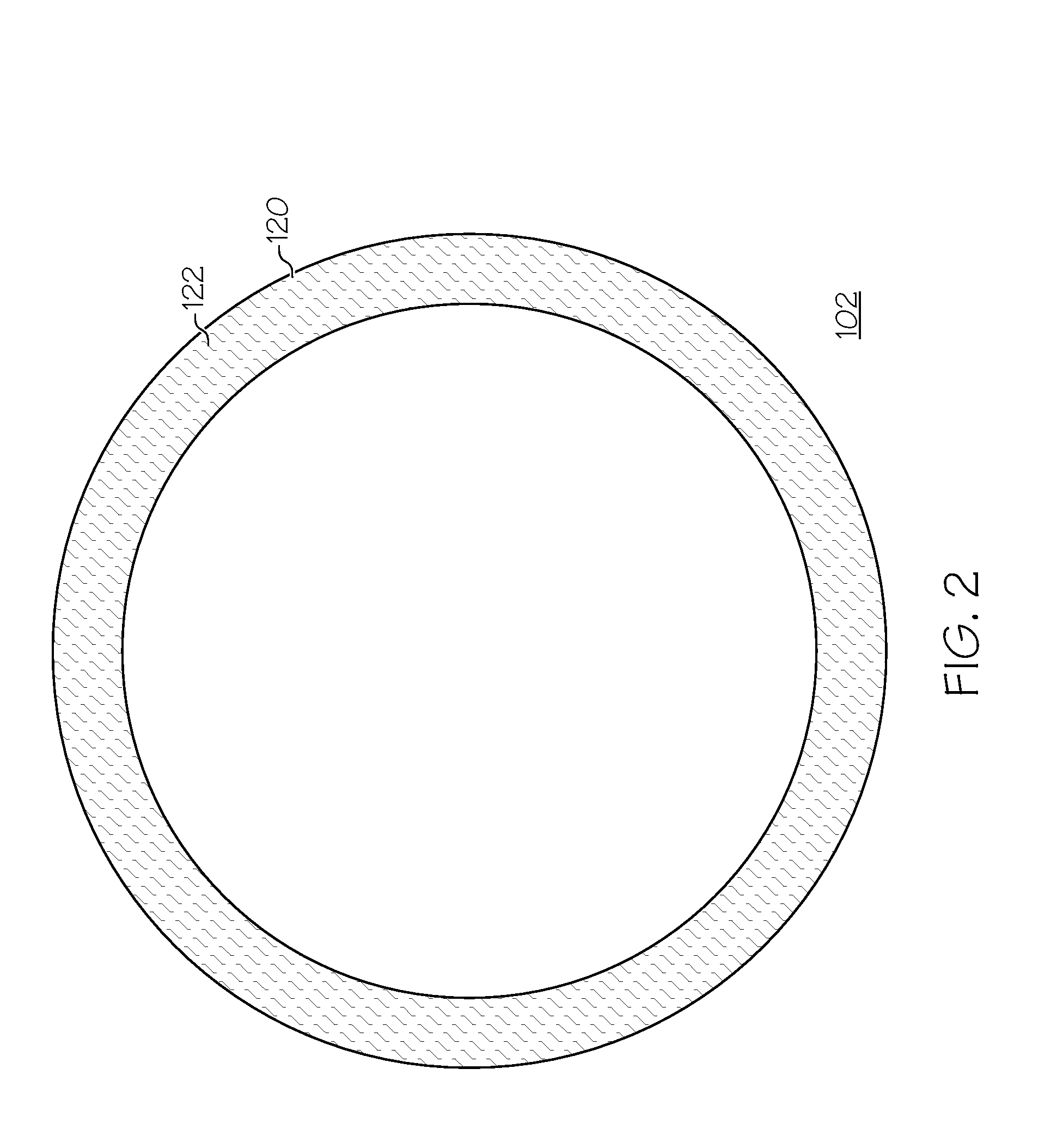

Composite valve assembly for aircraft environmental control systems

A valve assembly is provided including an injection molded flow body having at least one inlet port, at least one outlet port, and a flow passage there between. The injection molded flow body is formed of a high performance engineering thermoplastic resin. A plurality of reinforcement fibers may be homogeneously suspended in the high performance engineering thermoplastic resin and provide increased strength and temperature capability for use in high temperature applications.

Owner:HONEYWELL INT INC

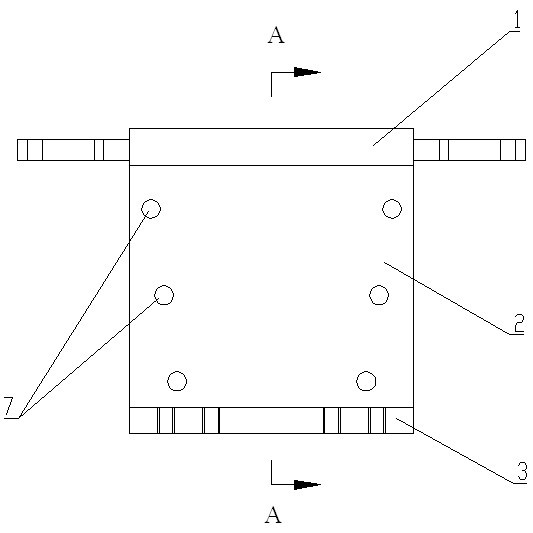

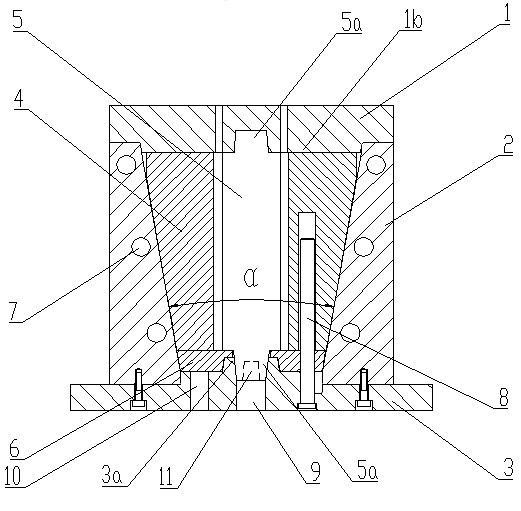

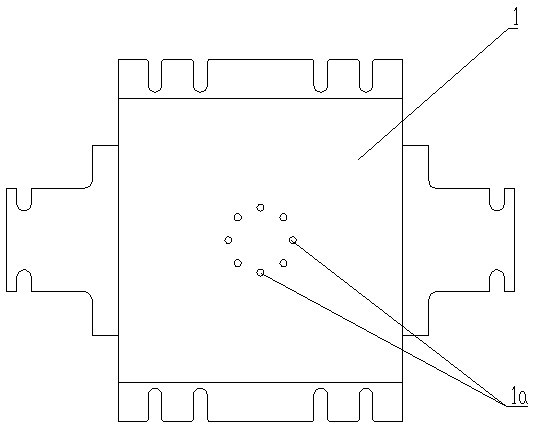

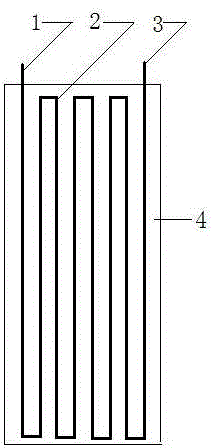

Precision forming mold for engineering composite material transmission pieces

InactiveCN102423911AGuaranteed uniformityReduce hot press vulcanization timeVulcanizationPerformance engineering

The invention discloses a precision forming mold for engineering composite material transmission pieces. The mold comprises an upper mold, a middle mold, a lower mold, a mold body, a mold core, a tray, a heating device and the like, wherein the mold body and the middle mold, the mold core and the lower mold, and the tray and the mold body are positioned in a taper fit mode; a sprue gate communicated with a cavity is formed on the upper mold; the upper mold, the mold body, the mold core and the tray form the cavity; and an intelligent control electric heating device around the mold body is arranged in the middle mold. By the mold, the uniformity of a temperature field of a mold pressing effective vulcanization system can be ensured, the whole physicochemical properties, dimensional accuracy, material compactness and surface quality of the product are improved, mold pressing vulcanization time is shortened, and high efficiency, energy conservation and environment friendliness are achieved; in addition, a workpiece can be respectively separated from the mold core and the mold body through a demolding hole formed on the lower mold, the automation degree is improved, the operating strength of workers is reduced, and the mold can be widely applied to precision forming manufacturing equipment of high-performance engineering composite material transmission pieces such as various bearings, sealing bodies, shock absorbers, elastic couplings and the like.

Owner:CHONGQING UNIV

High-performance engineering plastic/polyester type TPU (thermoplastic polyurethane) alloy material and preparation method thereof

InactiveCN103819829ASolve the defect that it is not easy to wet the glass fiberImprove liquidityFiberAntioxidant

The invention discloses a high-performance engineering plastic / polyester type TPU (thermoplastic polyurethane) alloy material comprising the following components in parts by mass: 15 to 25 parts of polyester type TPU, 30 to 60 parts of long glass fibers, 20 to 45 parts of engineering plastics, 3 to 6 parts of compatilizer, 0.4 to 0.6 part of fluidity aid, 0.8 to 1.2 parts of chain extender and 0.4 to 0.6 part of antioxidant. According to the alloy material disclosed by the invention, the fluidity of the engineering plastics (AS (acrylonitrile styrene), PS (polystyrene), ABS (acrylonitrile butadiene styrene), PC (polycarbonate), PBT (polybutylene terephthalate) or PMMA (polymethyl methacrylate)) is improved, and the problem that resin has low probability of infiltrating glass fibers is solved by adopting the high-fluidity polyester type TPU; the 'floating fiber' phenomenon of the glass fibers can be eliminated and the interfacial strength of the glass fibers and the resin can be improved by adding the fluidity modifier and the compatilizer; the defect of reduction of the molecular weight of the TPU in the processing process is overcome by adding the hydroxy-containing chain extender.

Owner:GUIZHOU MATERIAL IND TECH INSTITUE

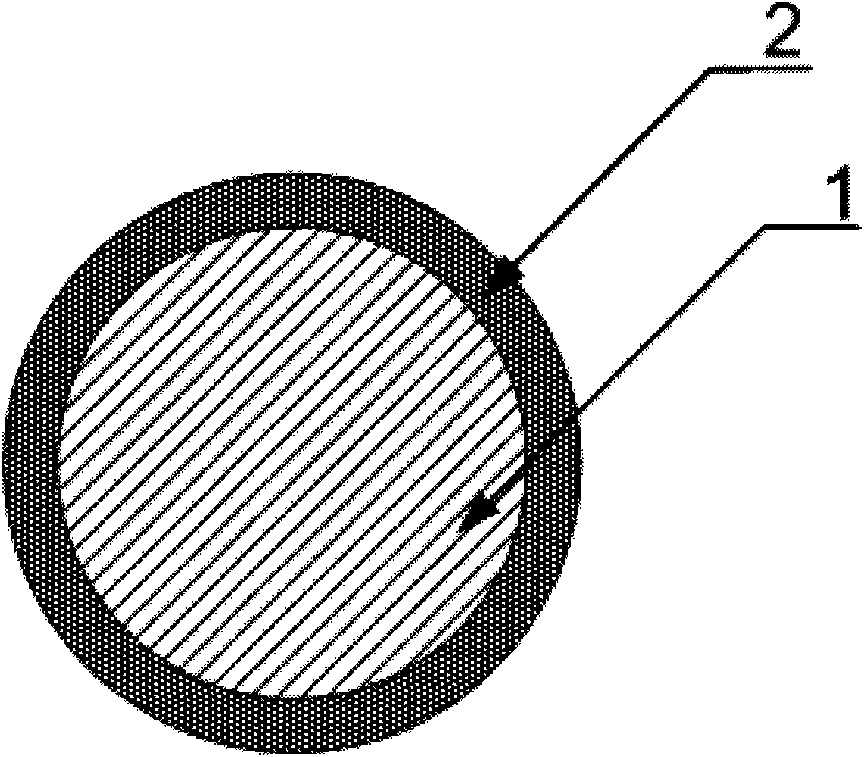

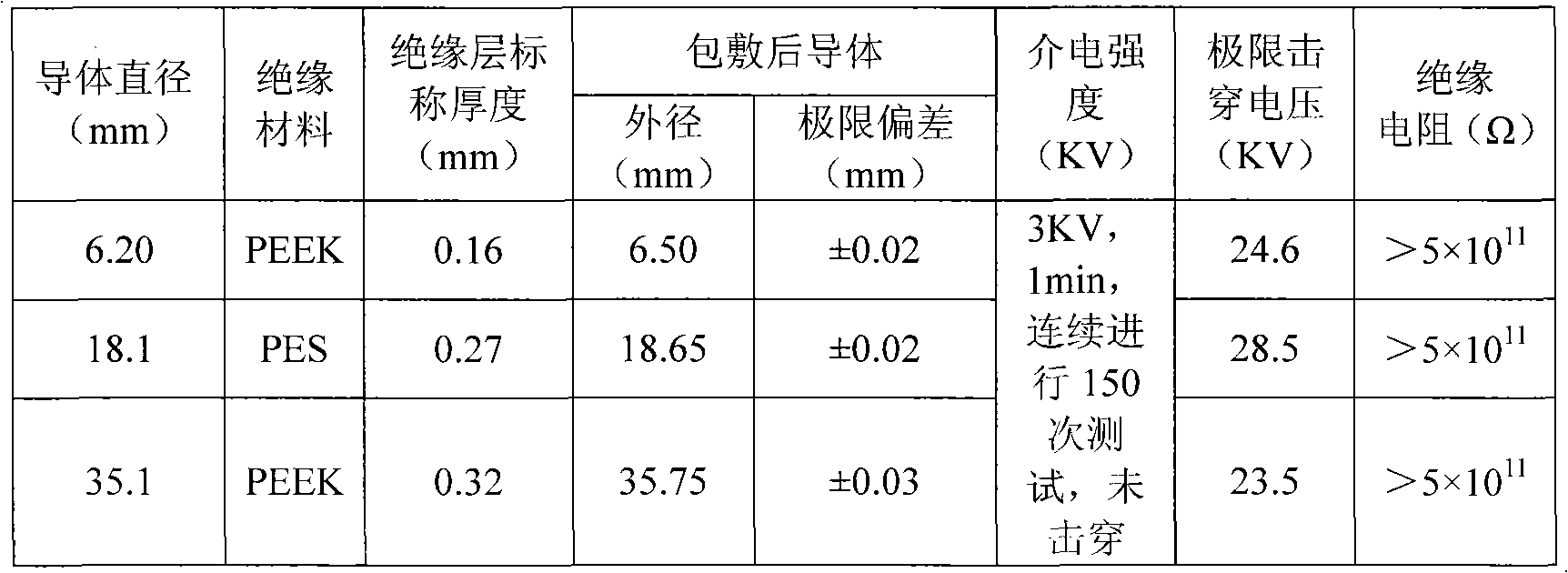

Large wire diameter special insulating conductor and manufacture process thereof

InactiveCN101667469AImprove environmental adaptabilityExtended service lifeInsulated cablesInsulated conductorsElectrical conductorPerformance engineering

The invention belongs to the field of nuclear grade special insulating conductor, in particular to a large wire diameter special insulating conductor and a manufacture process thereof, which aim to solve the problems that the prior extruding technology cannot realize insulation on large wire diameter conductors, and the prior insulating conductor has reduced insulativity after long-term use. The large wire diameter special insulating conductor consists of a large wire diameter inner conductor (1) and an insulating layer, wherein the inner conductor is made of a copper material; the insulatinglayer adopting high performance engineering plastics is attached to the conductor. The process for manufacturing the large wire diameter special insulating conductor mainly comprises five steps, namely aligning the inner conductor, processing the surface of the inner conductor, fusing an insulating material, coating the insulating material on the conductor, and cooling and solidifying. The conductor and the process have the advantages of excellent environment adaptability, long service life, excellent insulating performance, good surface quality, feasible die design, simplicity and convenience, even size of the insulating layer, no uneven internal stress generation, and fatigue life improvement.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

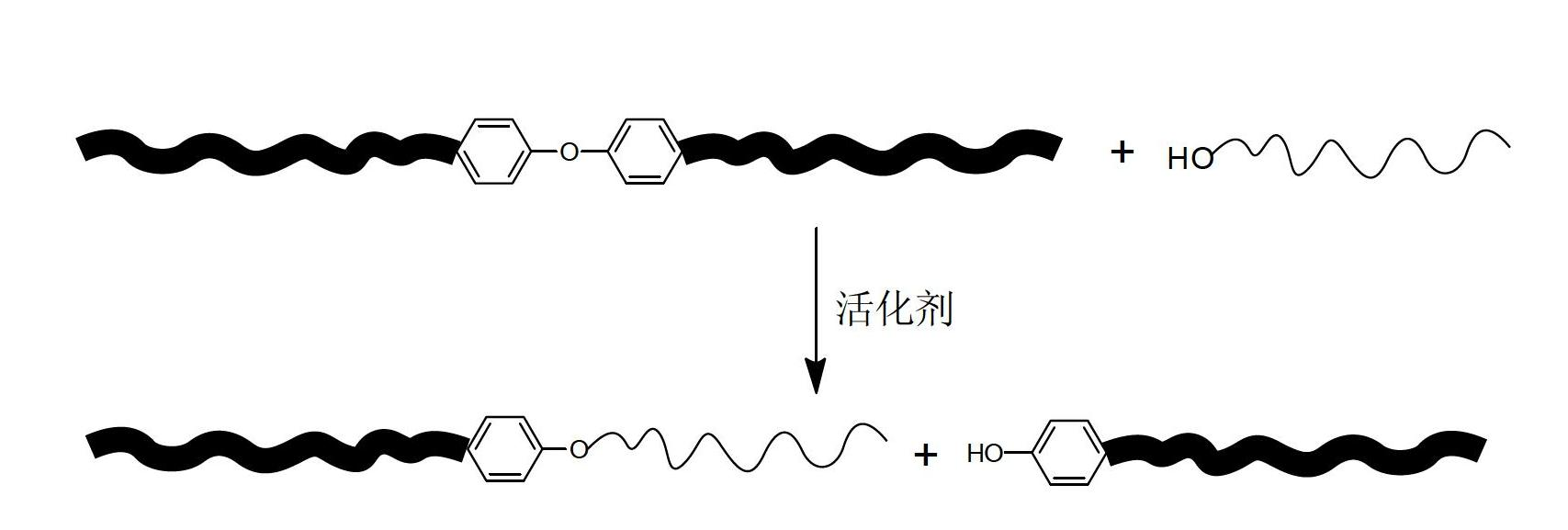

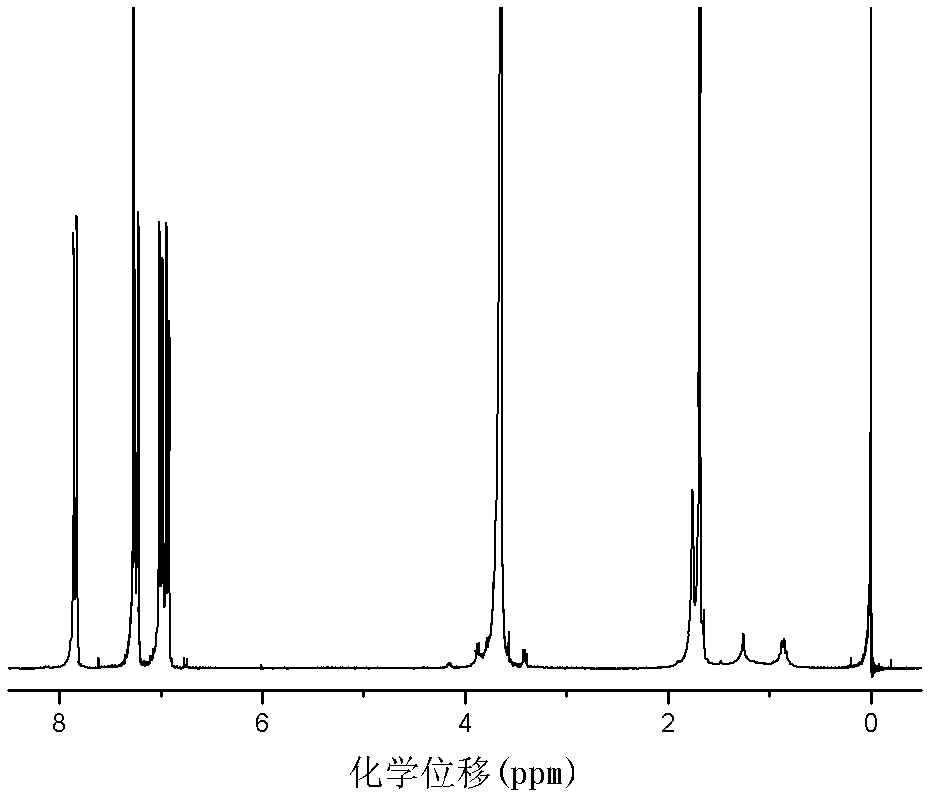

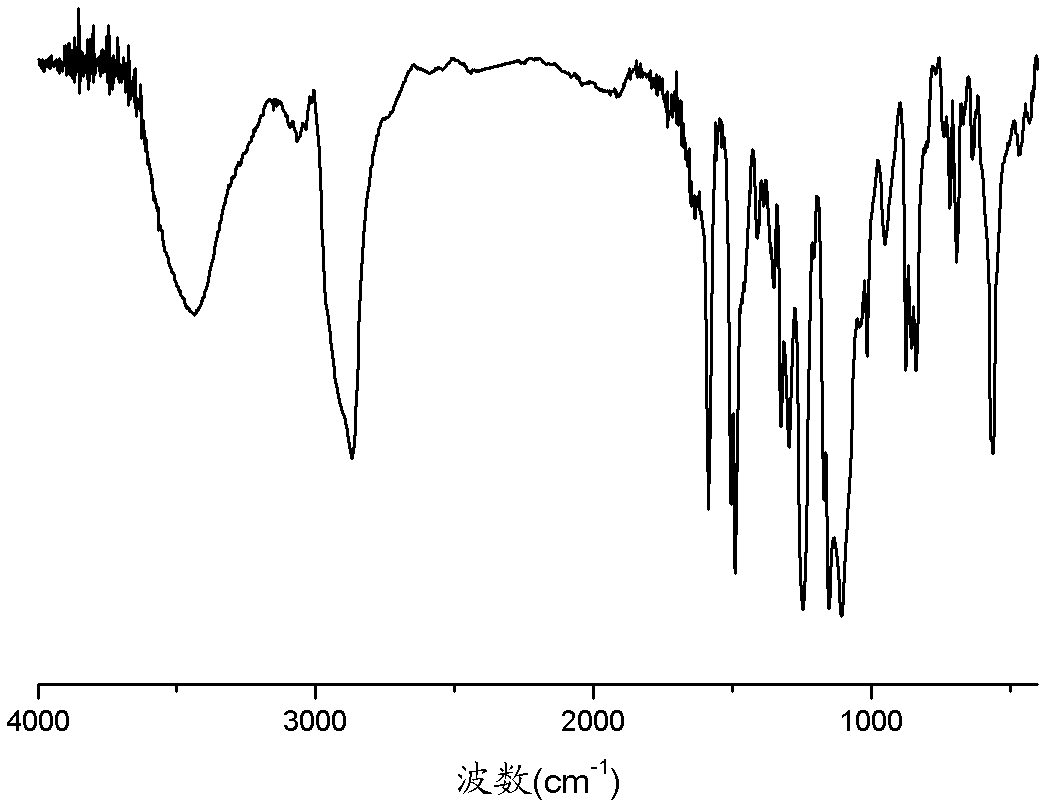

Preparation method for modified polyarylether

The invention discloses a preparation method for modified polyarylether, which includes: dissolving polyarylether and hydroxyl polymer into solvent, adding deprotonation agent, carrying out a stirring action for 1-48 hours at the temperature of 10-220 DEG C, terminating the reaction, pouring reaction liquid into precipitator or directly evaporating to lead a product to be separated out, and filtering, crushing, washing and drying the product, so that the modified polyarylether is obtained. The preparation method leads the polyarylether and the hydroxyl polymer to realize trans-etherification under the action of the deprotonation agent, so that the modified polyarylether with ether bond chaining between the hydroxyl polymer and the polyarylether is obtained. The preparation method is simple in operation, low in reaction temperature, high in efficiency, easy in product separation, easily controllable in molecular weight and hydroxyl polymer chain content, the solvent can be recycled after separation, and a preparation process is low in cost and environmental pollution, less in side reaction, high in yield and easy in large-scale production application. The prepared modified polyarylether has the advantages of high chemical stability, high heat stability, high pH (potential of hydrogen) stability, high disinfectant resistance and the like, and serves as important raw materials for high-performance engineering plastics and functional polymer materials.

Owner:河南迈纳净化技术有限公司

Method and apparatus for organizing, visualizing and using measured or modeled system statistics

InactiveUS7596546B2Good correlationFast constructionDigital data information retrievalDigital data processing detailsPerformance engineeringModel system

An apparatus and methodology to acquire and organize measured or modeled statistical data into optimal reports with a performance engineering mode of use and a design mode of use. In a performance engineering mode of use, the engineer may select from a set of performance questions, and guided by the apparatus and largely automated, create well-defined answers to the performance questions of interest. A series of template manipulations whereby report objects that are embedded within templates may be defined, reused, modified and improved upon to optimize reports and to aid in a report building process in a design mode of use. Methods are taught for the automatic selection and population of data tables. Column selection and column header information is optimized for relevance to the report design or system question at hand. The automatic joining of data from a variety of data sources is taught that allows for the rapid construction of specific reports from within multiple data tables of different types, structures and formats.

Owner:HYPERFORMIX

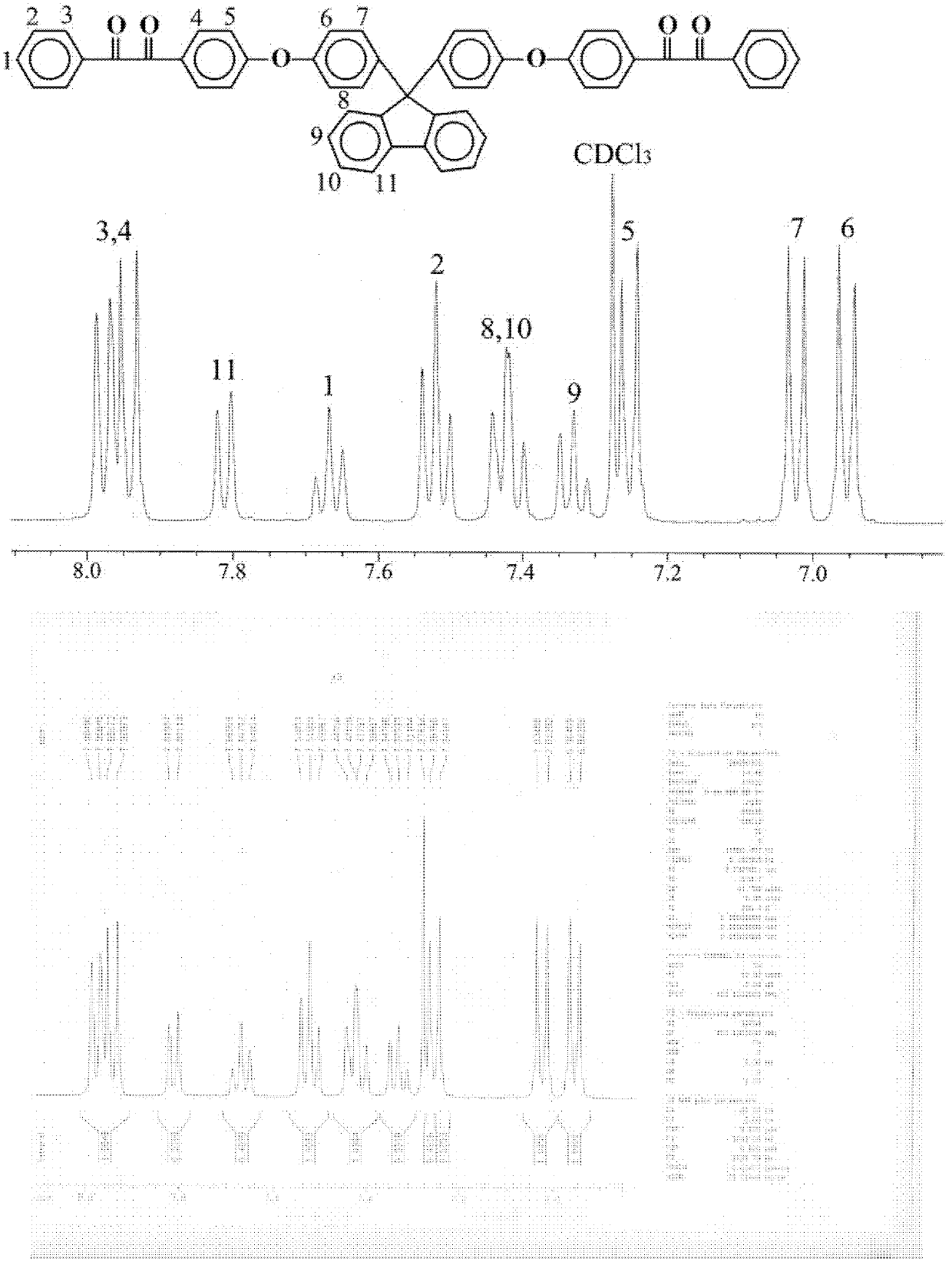

Thermosetting polyphenylquinoxaline resin, its preparation method and application

InactiveCN102443170AReduce melt viscosityImprove high temperature resistanceOrganic chemistryAdhesivesPolymer scienceEnd-group

The invention discloses a polyphenylquinoxaline polymer, its preparation method and application. The polymer has a structure general formula as shown in formula I. With an aromatic tetraone compound, an aromatic tetramine compound and an aromatic end-capping agent as raw materials, the polymer is prepared by a high temperature polycondensation method. By designing an appropriate molecular weight, the polymer material can obtain good fusion performance, and can obtain a good thermal property and a mechanical property through high temperature curing reaction of a reactive terminal group. The material of the invention can be used as high performance engineering plastics, a high temperature resistance adhesive, a fiber reinforced resin matrix composite material and its products, etc., and can be applied in the high technology fields of aerospace, petrochemical engineering, and automobiles, etc.

Owner:INST OF CHEM CHINESE ACAD OF SCI

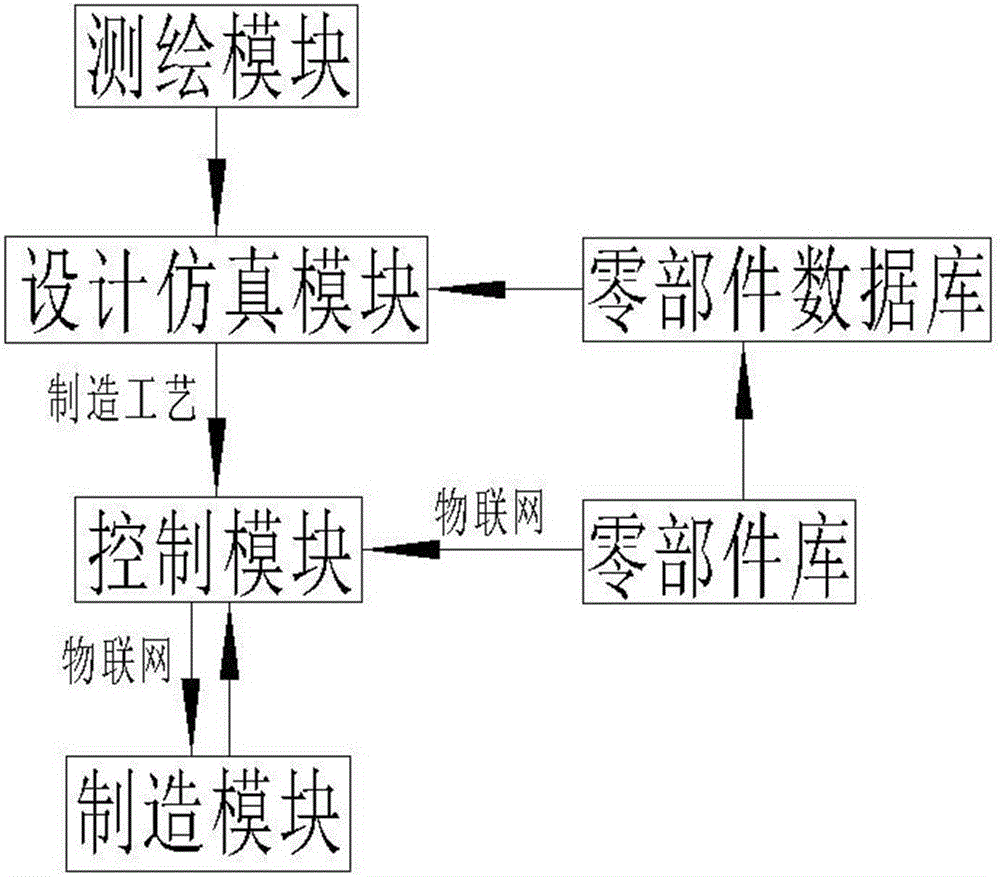

Engineering modularized manufacturing system and engineering modularized manufacturing method

PendingCN106354943AReduce mistakesReduce quality problemsGeometric CADDesign optimisation/simulationPerformance engineeringSpatial structure

The invention discloses an engineering modularized manufacturing system which comprises a control module, a design simulation module, a surveying and mapping module, a part database, an internet of thing and a manufacturing module. The engineering modularized manufacturing method includes surveying and mapping on construction site, carrying out engineering designing, preparing parts, dividing modules, assembling the modules, and carrying out engineering assembling to obtain the reasonable high-performance engineering structure. By the step of dividing the modules for manufacturing, installation time of space structure on the construction site is shortened, construction difficulty of workers is lowered effectively, work load of the workers is reduced, installation error and quality defects caused manually during construction are reduced effectively, performance of engineering is guaranteed effectively, and the whole construction period is shortened greatly while work efficiency is improved. The engineering modularized manufacturing method accords with national constructional engineering industrialization standards well, makes construction more scientific and reasonable, and is much suitable to popularize in the field of manufacturing of space structures.

Owner:赖正伦

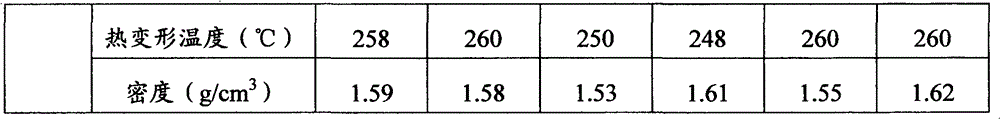

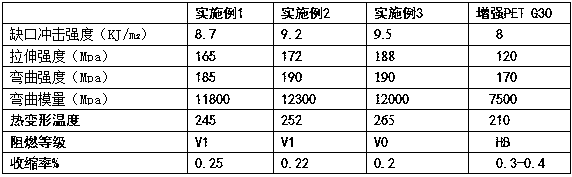

Heat-resistant and high-crystallized enhanced PET/LCP (polyethylene terephthalate/liquid crystal polymer) alloy material and preparation method thereof

InactiveCN110041665AGood compatibilityHigh crystallinityPolyethylene terephthalate glycolAntioxidant

The invention discloses a heat-resistant and high-crystallized enhanced PET / LCP (polyethylene terephthalate / liquid crystal polymer) alloy material and a preparation method thereof. The alloy materialis prepared from components in parts by weight as follows: 40-50 parts of PET, 20-30 parts of LCP, 30-40 parts of glass fibers, 0.1-0.5 parts of an ester exchange inhibitor, 0.2-0.5 parts of a coupling agent, 0.2-2 parts of a nucleating agent, 0.2-0.5 parts of an antioxidant, 0.2-0.6 parts of a lubricating agent and 0.5-3 parts of a compatible toughening agent. The alloy material prepared with themethod has the characteristics of high heat resistance, good crystallization and the like, is applied to heat-resistant and high-performance engineering plastics used by electric appliance forced members, structural members and accessories with requirements for heat resistance and high rigidity and has good electrical performance, the safe and environment-friendly raw materials are adopted, the crystallization rate of PET is increased by LCP, and meanwhile, rigidity and heat resistance of the material are improved.

Owner:SUZHOU WEIRUICHENG NEW MATERIAL

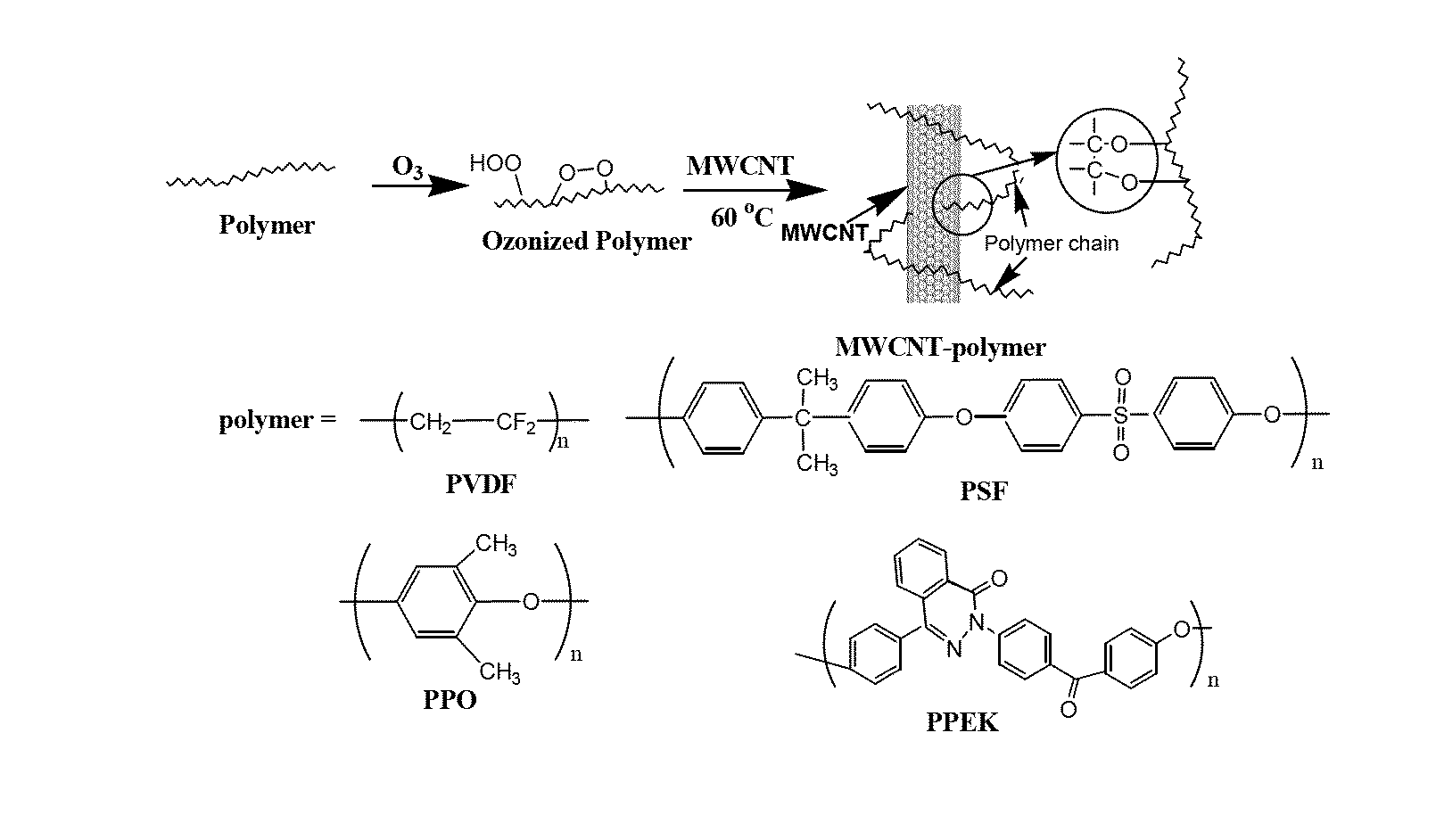

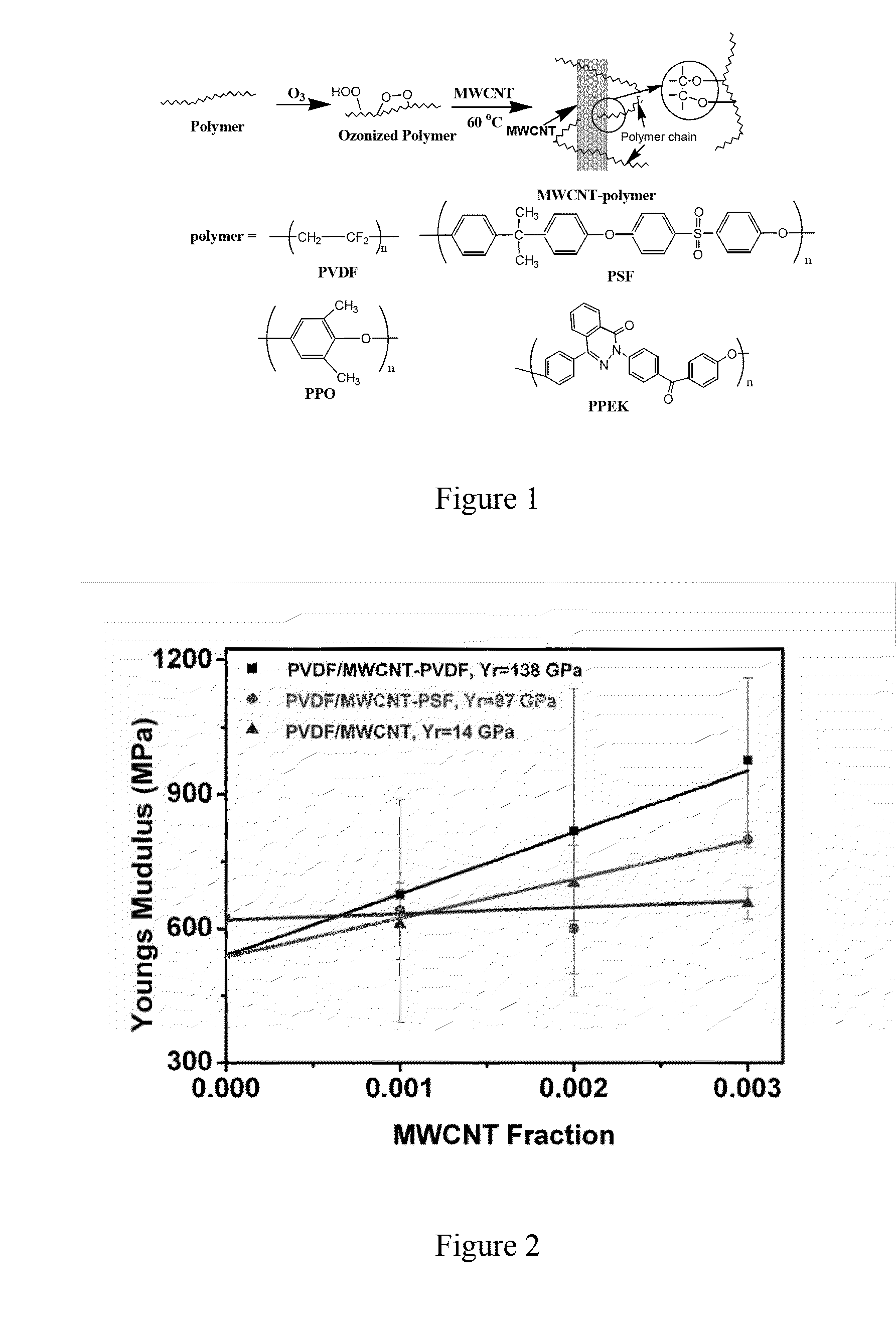

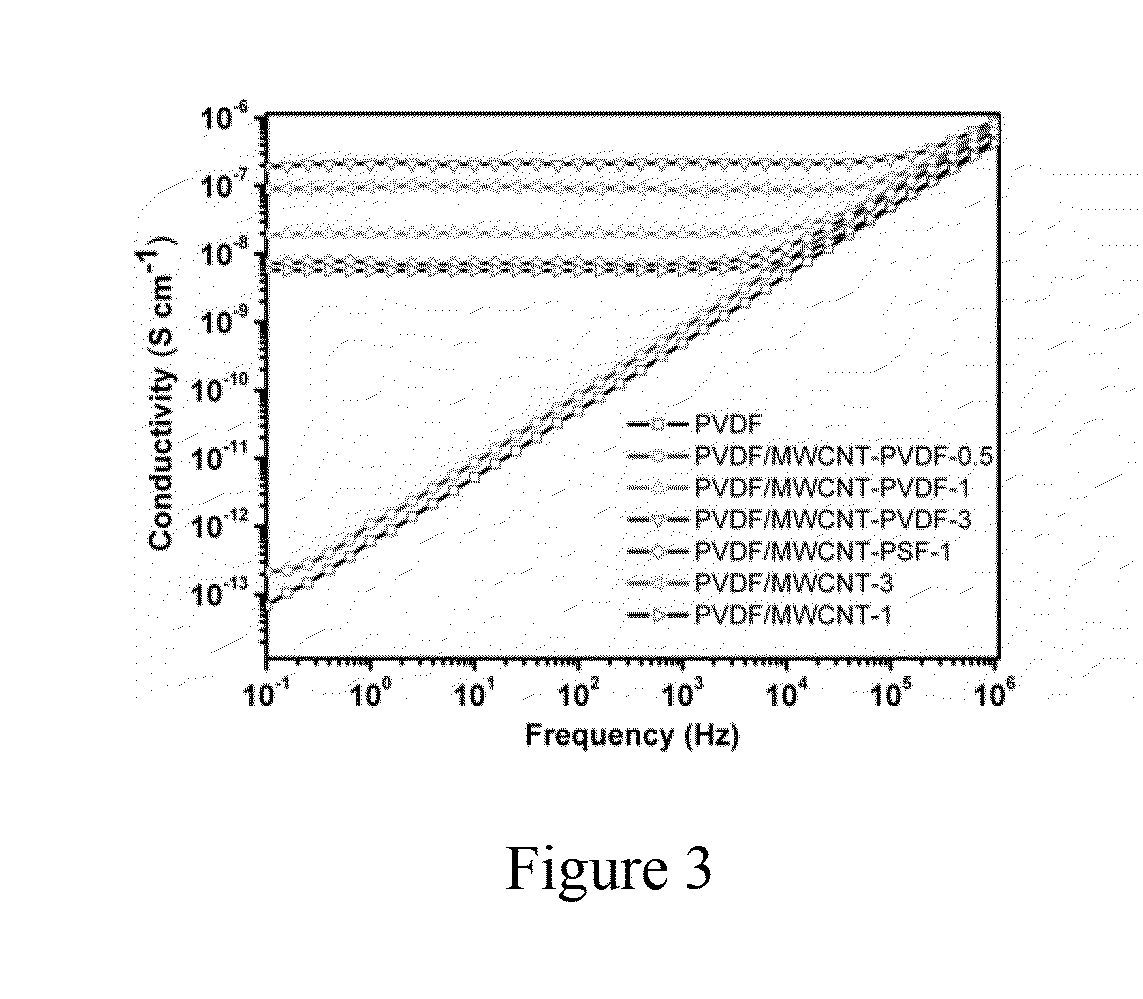

Chemically Bonded Carbon Nanotube-Polymer Hybrid and Nanocomposite Thereof

ActiveUS20110217618A1High mechanical strengthImprove proton conductivityMaterial nanotechnologySolid electrolyte fuel cellsPerformance engineeringCarbon nanotube

The present invention provides a chemically bonded carbon nanotube-polymer hybrid and the nanocomposite thereof, having the following advantages: functionalizing carbon nanotubes and also effectively having the carbon nanotube covalently bonded with a wide variety of polymers, even for stable and non-reactive polymers, such as commercially available polymers and high performance engineering plastics. The nanocomposite material according to the invention, compared to its matrix polymer, has higher mechanical strength, conductivity, proton conductivity, and heat stability.

Owner:CHUNG YUAN CHRISTIAN UNIVERSITY

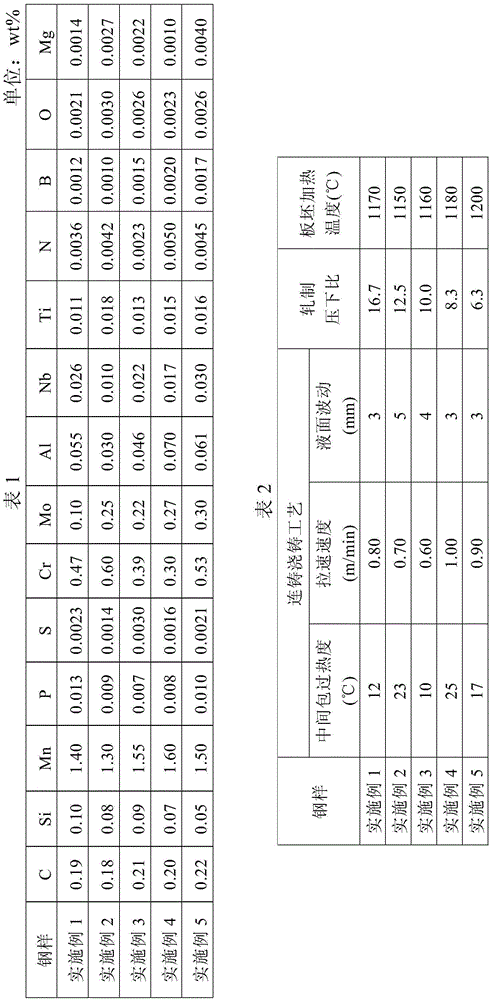

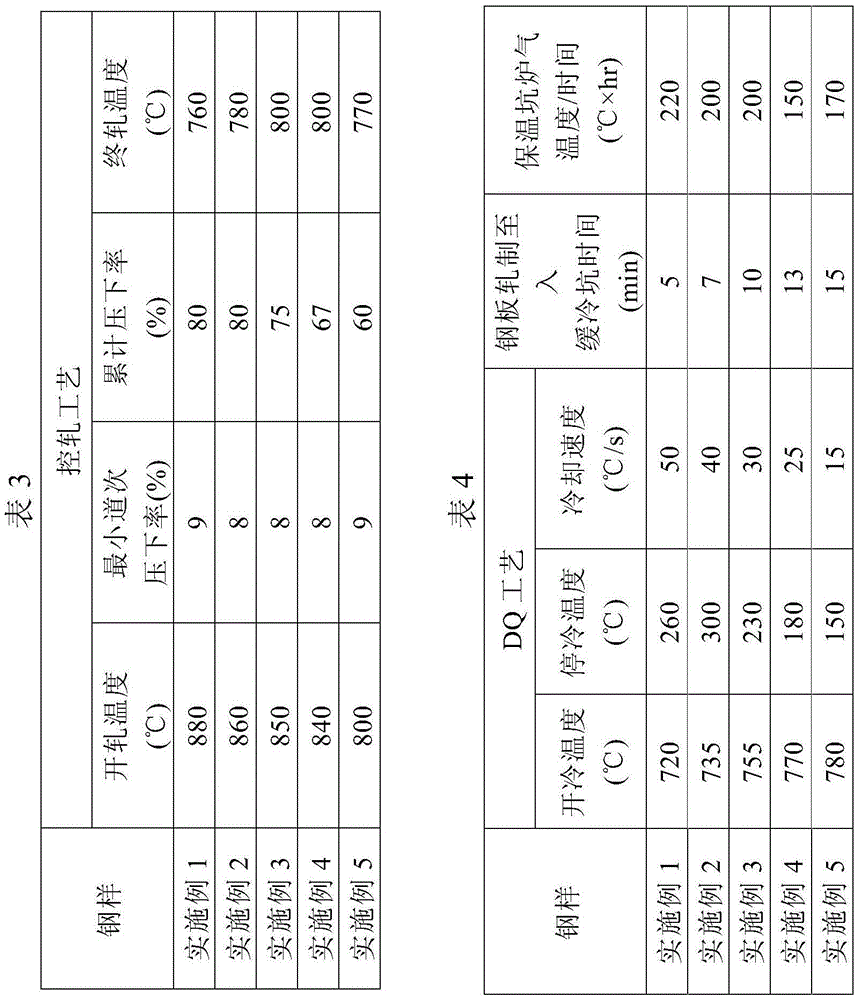

Low-cost, high-performance ultra-high-strength steel for construction machinery and manufacturing method thereof

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

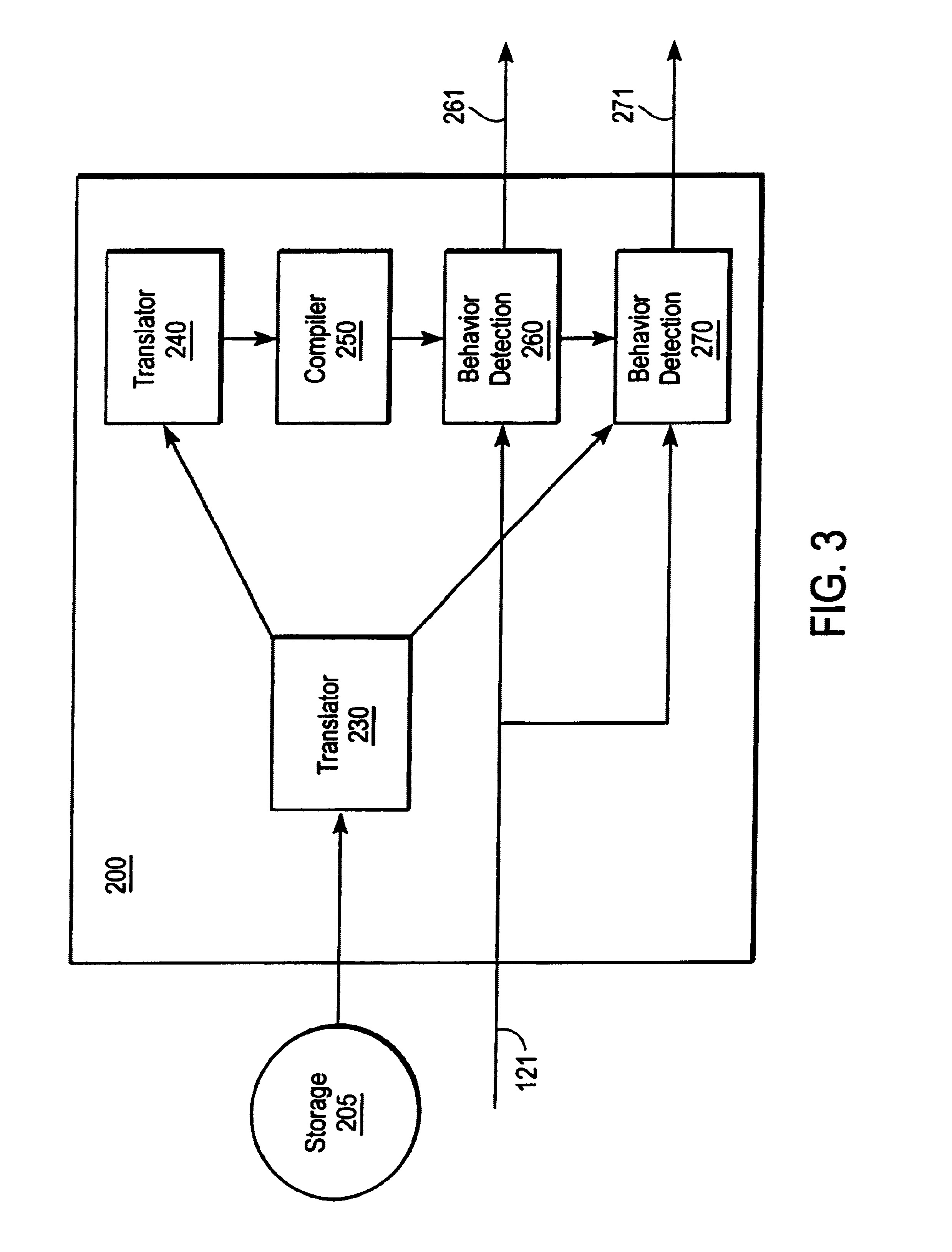

Generating and displaying an application flow diagram that maps business transactions for application performance engineering

InactiveUS8395623B2Drawing from basic elementsCathode-ray tube indicatorsPerformance engineeringStructure of Management Information

A method and apparatus for generating and displaying an application flow diagram for an application. The application flow diagram includes: a set of business transaction display elements representing critical business transactions that sustain or provide revenue for an organization; a set of service display elements representing services required by the critical business transactions; a set of infrastructure display elements representing information technology (IT) infrastructure components utilized by the services; and formatted display elements (e.g., arrows) that map the business transaction display elements to the service display elements and the service display elements to the infrastructure display elements, thereby indicating an end-to-end flow of data between the critical business transactions and the IT infrastructure components.

Owner:INT BUSINESS MASCH CORP

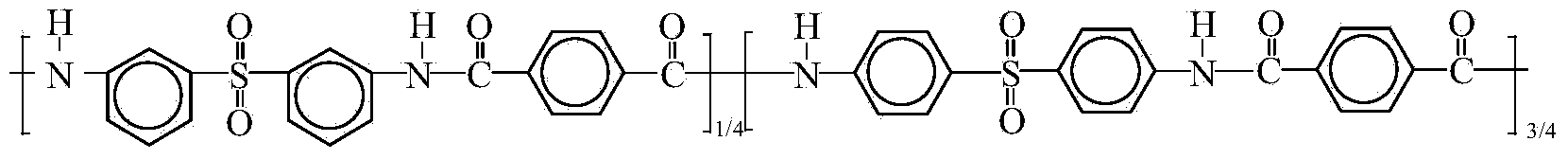

Polysulfonamide-based carbon fiber reinforced composite material and preparation method thereof

The invention discloses a polysulfonamide-based carbon fiber reinforced composite material and a preparation method thereof. The polysulfonamide-based carbon fiber reinforced composite material is prepared from the following raw materials in percentage by weight: 70-90% of polysulfonamide chopped fiber and 10-30% of short carbon fiber. The polysulfonamide-based carbon fiber reinforced composite material is prepared by adopting the following method: (1), carrying out ultrasonic treatment on the polysulfonamide-based carbon fiber and the short carbon fiber in a pretreating agent, washing and drying; and (2), carrying out hot-forming. The polysulfonamide-based carbon fiber reinforced composite material is prepared from the polysulfonamide and the carbon fiber which are used as the raw materials, is used for preparing high-performance engineering plastics by virtue of a hot-pressing technique, has good mechanical performances, heat resistance and electrical insulation property, and can be used for the electrical insulation fields of motors and transformers.

Owner:SHANGHAI TANLON FIBER CO LTD +1

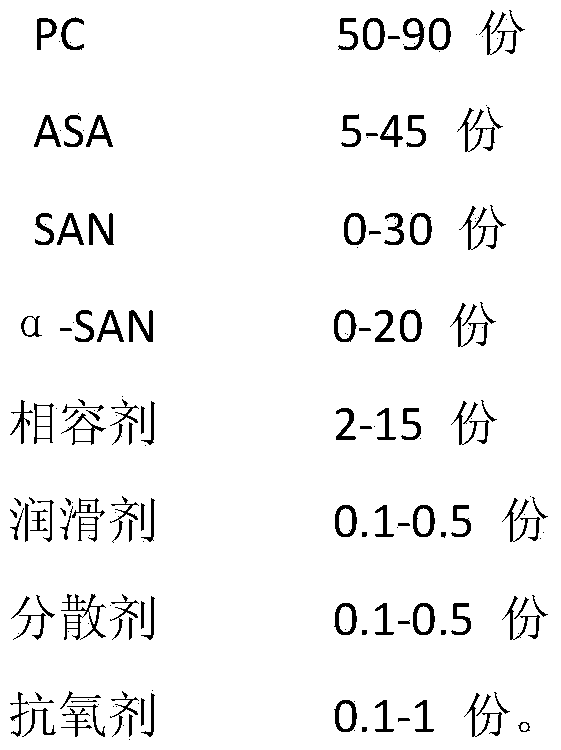

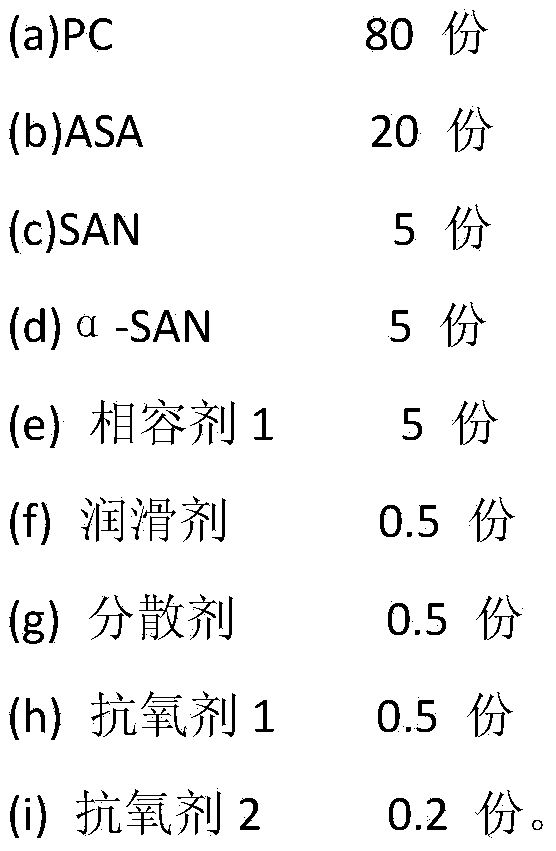

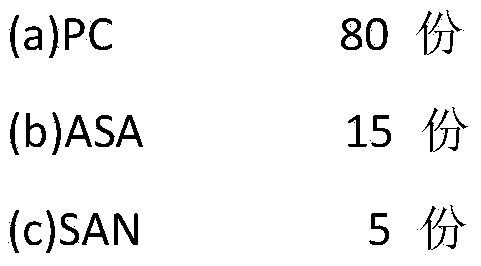

High-heat-resistance polycarbonate (PC)/acrylonitrile styrene acrylate copolymer (ASA) alloy material and preparation method thereof

ActiveCN102443256BImprove outdoor weather resistanceImprove heat resistanceEngineering plasticAcrylonitrile

The invention discloses a high-heat-resistance polycarbonate (PC) / acrylonitrile styrene acrylate copolymer (ASA) alloy material and a preparation method thereof. The stress cracking performance and the processing performance of a PC can be improved through the mixing of the PC and an ASA resin, and the chemical resistance and the weatherability of the PC are improved. Along with the PC content increase, the impact intensity and the heat deformation temperature of the alloy material are obviously improved. In order to improve the heat resistance of the PC / ASA alloy, alpha-vinyltoluene-acrylonitrile copolymers (alpha-SAN) are used for replacing the styrene-acrylonitrile copolymer (SAN) phase in the alloy, the heat deformation temperature can be improved to about 140 DEG C, and the heat resistance, the high intensity and the toughness of the PC as well as the weatherability, the chemical resistance and the processing performance of the ASA are integrated in the PC / ASA. Therefore, the PC / ASA alloy can meet the market variation requirements through being used as novel good-performance engineering plastics and has considerable application prospects, and the PC / ASA alloy can be widely used for the fields of electric appliance engineering materials, automobile engineering materials, building plastic products and the like.

Owner:四川鑫达企业集团有限公司

Preparation process of high-performance engineering plastic resistant to strong acid and alkali

The invention discloses a preparation process of high-performance engineering plastic resistant to strong acid and alkali. The plastic is prepared from, by mass, 60-70 parts of unsaturated polyester resin, 8-10 parts of nano zirconia, 8-10 parts of glass fibers, 12-15 parts of titanium dioxide, 15-18 parts of pulverized fuel ash, 5-6 parts of zinc phosphate, 5-6 parts of mica powder, 2 parts of leveling agent, 1 part of methyl ethyl ketone peroxide, 1.2 parts of LCC compound accelerator and 0.3 part of benzoin. According to the preparation process of the high-performance engineering plastic resistant to strong acid and alkali, the rosin-modified unsaturated polyester resin is used as a main material and has good corrosion resistance, the processing performance of the finished product is good, and the plastic can be widely applied to chemical reagent storage containers. The high-performance engineering plastic resistant to strong acid and alkali prepared by the rosin-modified unsaturated polyester resin is low in curing temperature, and the energy consumption can be greatly reduced during production.

Owner:NANJING OUNAYI ORGANIC PHOTOELECTRICITY CO LTD

High-performance engineering plastic/polyester type TPU alloy material, and preparation method thereof

InactiveCN107446289ASolve the defect that it is not easy to wet the glass fiberImprove liquidityPolyesterPolyvinyl alcohol

The invention discloses a high-performance engineering plastic / polyester type TPU alloy material. The high-performance engineering plastic / polyester type TPU alloy material comprises, by mass, 15 to 25 part of polyester type TPU, 30 to 60 parts of polymethyl acrylate, 20 to 45 parts of engineering plastic, 3 to 6 parts of phytosterol, 0.4 to 0.6 part of phthalic anhydride, 0.8 to 1.2 parts of polyvinyl alcohol, and 0.4 to 0.6 part of stannous octoate. According to a preparation method, polyester type TPU is adopted to solving problems that the fluidity of engineering plastics (AS, PS, ABS, PC, PBT, and PMMA) is poor, and infiltration of glass fiber by resin is not easily caused; a flow modifier and the phytosterol are added so improve glass fiber exposure and the interfacial strength of glass fiber with resin; and polyvinyl alcohol containing hydroxy is added to solve a problem that TPU molecular weight is reduced by processing.

Owner:FOSHAN BEICHAOYUAN TECH SERVICES CO LTD

Straw stalk roof panel with heat dissipation function

InactiveCN104947864AIncreased load-bearing capacityHigh priceRoof covering using slabs/sheetsRoof covering using tiles/slatesPerformance engineeringArchitectural engineering

The invention discloses a straw stalk roof panel with the heat dissipation function. According to the technical scheme, a proper width and length of the roof panel are selected according to the room design of a construction drawing; pipe diameters and the distance between pipes are determined according to the water supply temperature and the flow in unit time; high-performance engineering plastic pipes are bound on a steel wire net of the straw stalk roof panel, pipeline connectors are reserved on the two sides of the roof panel, and different heat dissipation pipes of the roof panel can be connected through the reserved connectors according to the requirements of different circulating paths; fine aggregate concrete is sprayed, the straw stalk roof panel and the heat dissipation pipes are integrally prefabricated, and the thickness of the roof panel is 30 mm. The roof panel and a radiator are integrated, manufacturing is easy, installation is convenient, and manufacturing cost is reduced; meanwhile, the straw stalk roof panel is comfortable and capable of saving energy.

Owner:QIQIHAR UNIVERSITY

The Refining Technology of Long Carbon Chain Dibasic Acids Produced by Biological Fermentation

ActiveCN101985416BHigh monoacid contentImprove thermal stabilityCarboxylic compound separation/purificationFiltrationCarbon chain

The invention belongs to the technical field of preparing long carbon chain dibasic acid by biological fermentation method, and particularly relates to a refining process for producing long carbon chain dibasic acid by biological fermentation method. The technical scheme of the present invention is: a refining process for producing long carbon chain dibasic acid by biological fermentation, and the refining process steps include: (1) decolorization and filtration; (2) primary crystallization and separation; (3) high temperature water crystallization and separation; (4) Drying. The obtained long carbon chain dibasic acid product has high monoacid content, good light transmission and high thermal stability, which can meet the needs of different customers and can be used to produce high-grade spices, high-performance engineering plastics, high-temperature dielectrics, high-grade hot melt adhesives, Cold-resistant plasticizers, advanced lubricants, advanced paints and coatings, etc. It has greatly expanded the development space of downstream products of long carbon chain dibasic acid.

Owner:CATHAY R&D CENT CO LTD

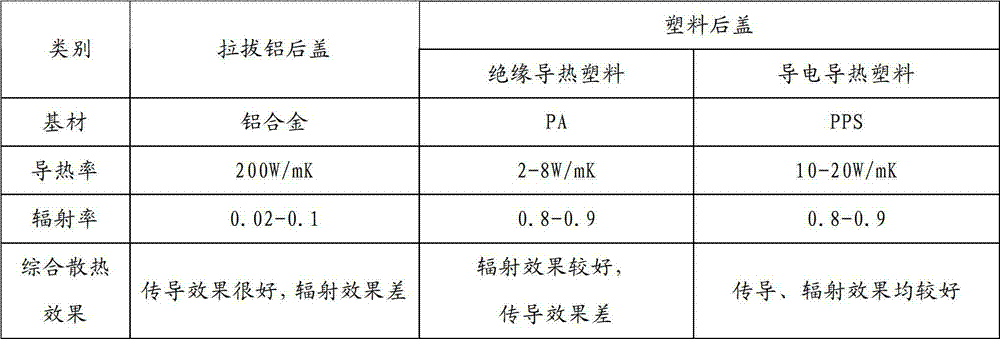

Modified polyphenyl thioether composition and LED (light-emitting diode) display screen back cover prepared therefrom

InactiveCN102964835AExtended service lifeImprove thermal conductivityCasings/cabinets/drawers detailsFiberCarbon fibers

The invention discloses a modified polyphenyl thioether composition and an LED (light-emitting diode) display screen back cover prepared therefrom through an injection molding process. The modified polyphenyl thioether composition comprises polyphenyl thioether, processing assistants and carbon fibers, wherein the weight percent of the carbon fibers is 70-80%. According to the LED display screen back cover prepared from the modified polyphenyl thioether composition disclosed by the technical scheme of the invention, the electric-conducting carbon fibers are added in the high-performance engineering plastic base material polyphenyl thioether, thus preparing the novel composite electric-conducting and heat-conducting engineering plastic material having high electric conduction and heat conduction coefficients and enough mechanical strength. The LED display screen back cover prepared from the electric-conducting and heat-conducting engineering plastic material through the existing traditional injection molding process can meet the requirements of an LED display screen back cover product for heat conduction, electric conduction, EMC (electro magnetic compatibility) prevention and the like, thereby solving the problem that the existing heat-conducting plastic material can not meet the requirements for heat conduction, electric conduction and EMC simultaneously, and achieving a better heat conduction effect. Thus, the temperature of an LED display screen case can be effectively controlled, and the normal service life of a display screen can be prolonged.

Owner:SHENZHEN AOTO ELECTRONICS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com