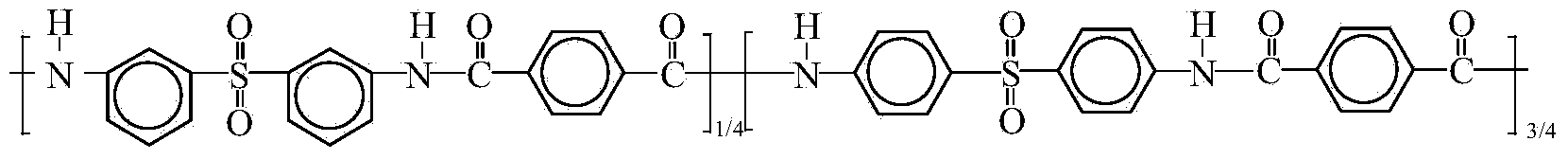

Polysulfonamide-based carbon fiber reinforced composite material and preparation method thereof

A technology of reinforced composite materials and len-based carbon fibers, which is applied in the field of mechanical parts materials, can solve problems such as enlargement, and achieve the effects of increasing interface bonding strength, high mechanical strength and elastic modulus, and improving compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Raw materials: 75wt% of chopped sulfonamide fibers and 25wt% of chopped carbon fibers. The length of the aramid sulfonamide chopped fibers and chopped carbon fibers is 6mm.

[0023] First, mix sulfonamide chopped fibers and chopped carbon fibers, perform ultrasonication in a pretreatment agent for 0.5 hours, wash with deionized water, then dry at 200°C, and add them to a hot pressing mold with a bulk density of 1.43g / cm 3 , raise the temperature to 240°C at a heating rate of 2.0°C / min, hold the temperature for 5min, and exhaust the air at the same time, then continue to raise the temperature to 360°C at a heating rate of 2°C / min, apply an instantaneous pressure of 60MPa, keep the pressure for 10min, and then increase the temperature at 5°C / min If the temperature is lowered to 25° C. at a rate of 1 min, the arylsulfone fiber-based carbon fiber-reinforced composite material of the present invention can be prepared.

[0024] The pretreatment agent is a mixed solution of...

Embodiment 2

[0027] Raw materials: 75wt% of chopped sulfonamide fibers and 25wt% of chopped carbon fibers. The length of the aramid sulfonamide chopped fibers and chopped carbon fibers is 6mm.

[0028] First, mix sulfonamide chopped fibers and chopped carbon fibers, perform ultrasonication in a pretreatment agent for 0.5 hours, wash with deionized water, then dry at 200°C, and add them to a hot pressing mold with a bulk density of 1.43g / cm 3 , raise the temperature to 240°C at a heating rate of 2.0°C / min, hold the temperature for 5min, and exhaust the air at the same time, then continue to raise the temperature to 360°C at a heating rate of 2°C / min, apply an instantaneous pressure of 60MPa, keep the pressure for 10min, and then increase the temperature at 5°C / min If the temperature is lowered to 25° C. at a rate of 1 min, the arylsulfone fiber-based carbon fiber-reinforced composite material of the present invention can be prepared.

[0029] The pretreatment agent is a mixed solution of...

Embodiment 3

[0032] Raw materials: 75wt% of chopped sulfonamide fibers and 25wt% of chopped carbon fibers. The length of the aramid sulfonamide chopped fibers and chopped carbon fibers is 6 mm.

[0033] First, mix sulfonamide chopped fibers and chopped carbon fibers, ultrasonicate for 0.5 hours in a pretreatment agent, wash with deionized water, then dry at 200°C, and add them to a hot pressing mold with a bulk density of 1.43g / cm 3 , raise the temperature to 240°C at a heating rate of 2.0°C / min, hold the temperature for 5 minutes, and exhaust air at the same time, then continue to raise the temperature to 360°C at a heating rate of 2°C / min, apply an instantaneous pressure of 60MPa, keep the pressure for 10 minutes, and then increase the temperature at 5°C / min If the temperature is lowered to 25° C. at a rate of 1 min, the arylsulfone fiber-based carbon fiber-reinforced composite material of the present invention can be prepared.

[0034] The pretreatment agent is a mixed solution of di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com