Patents

Literature

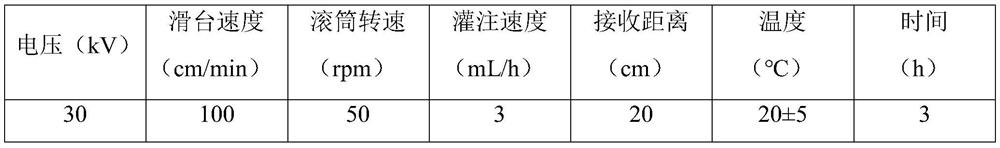

84results about How to "Avoid pores" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

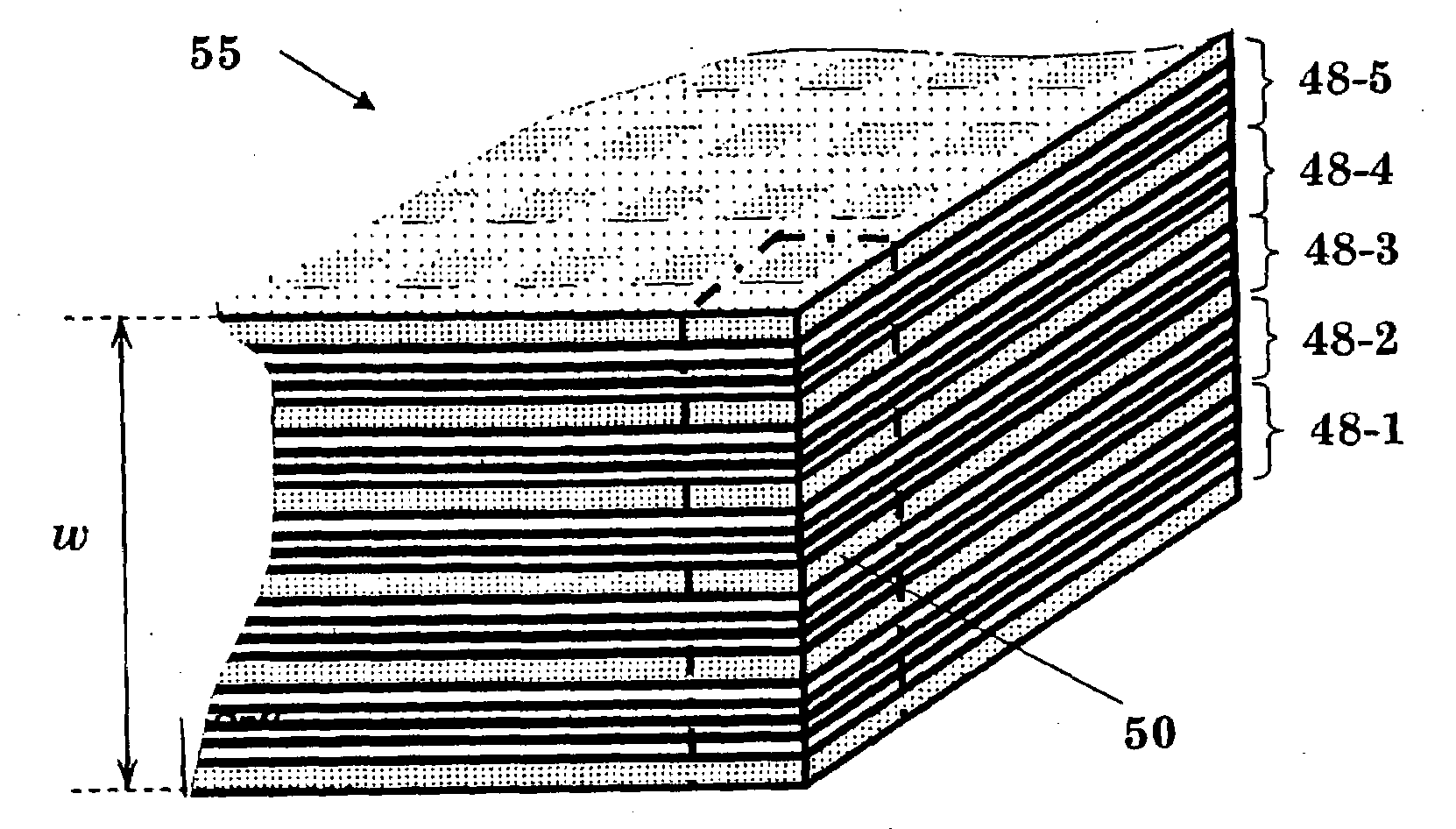

Flame retardant EMI shielding materials and method of manufacture

InactiveUS6248393B1Maintains drapabilityEasy constructionScreening gaskets/sealsPretreated surfacesEngineeringViscosity

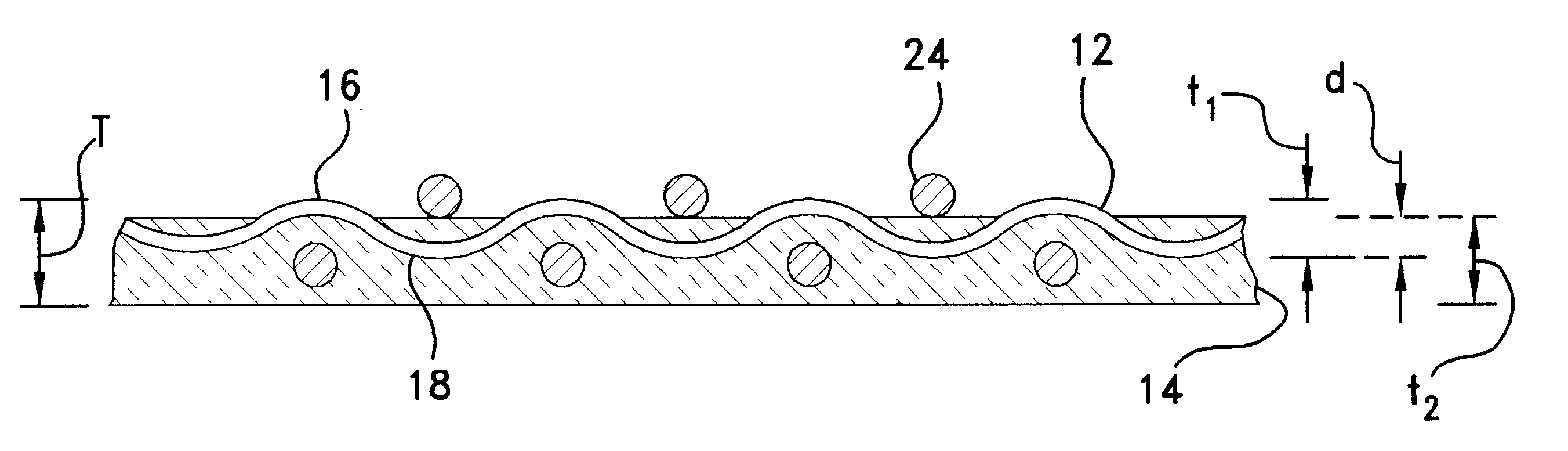

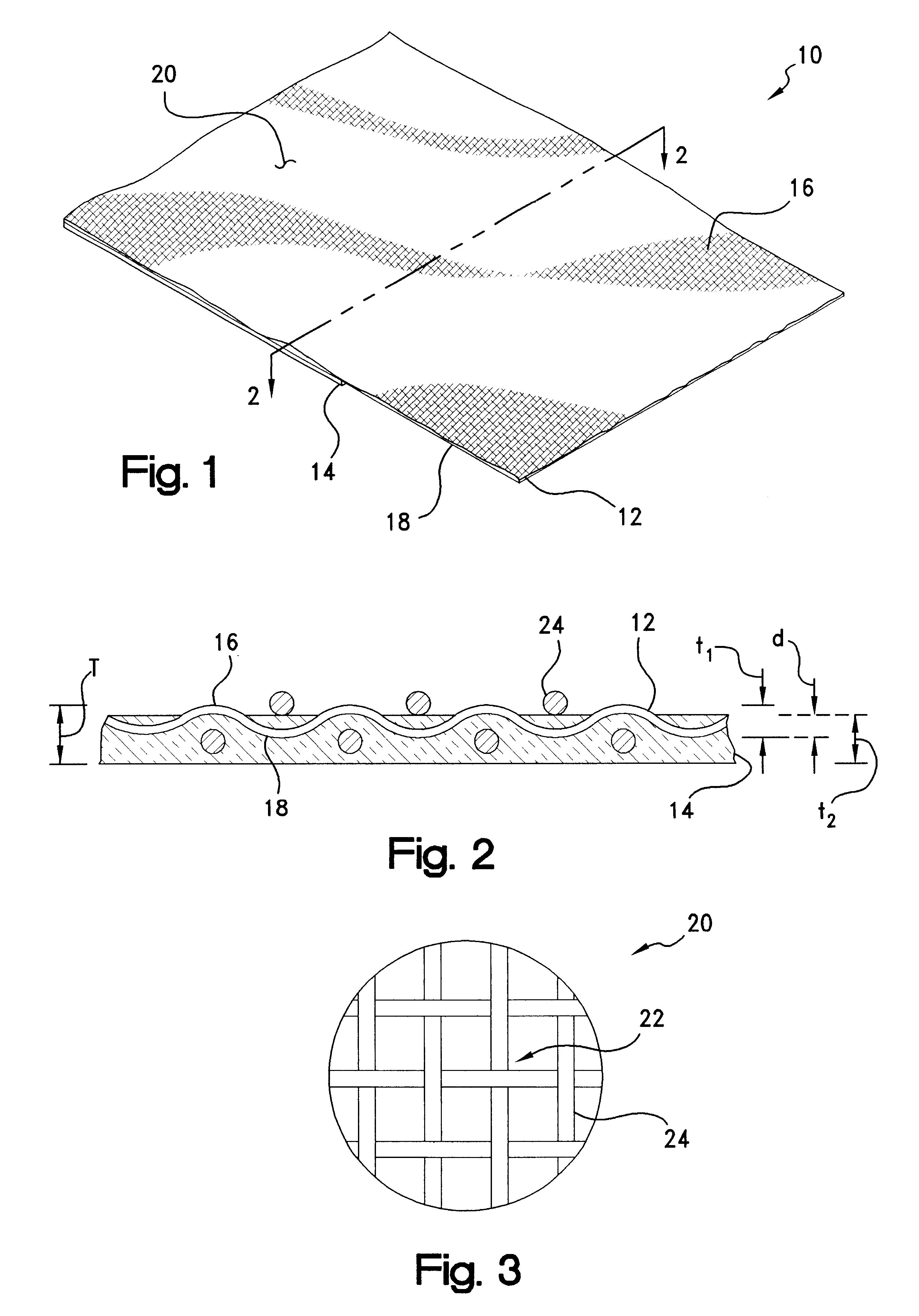

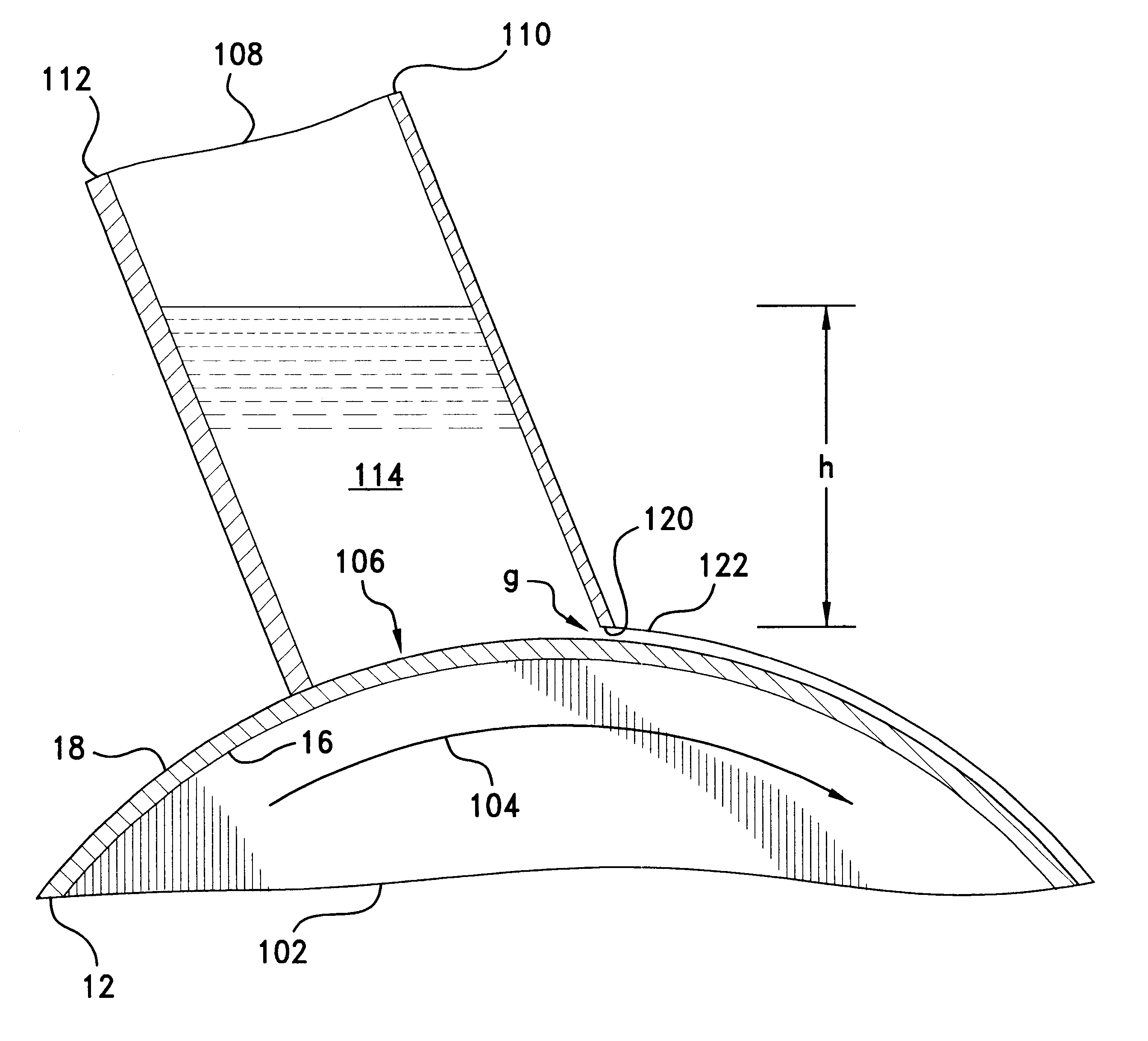

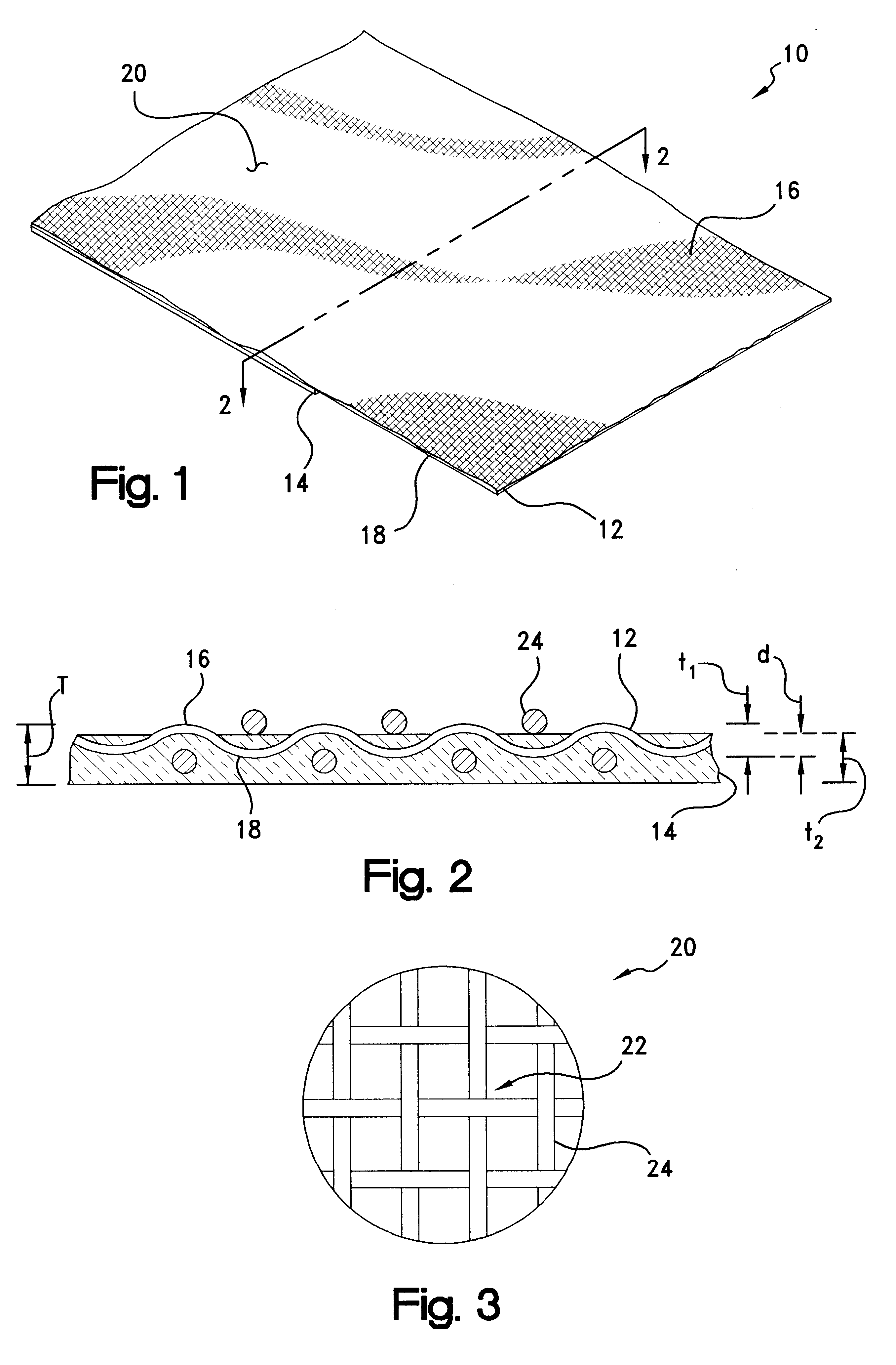

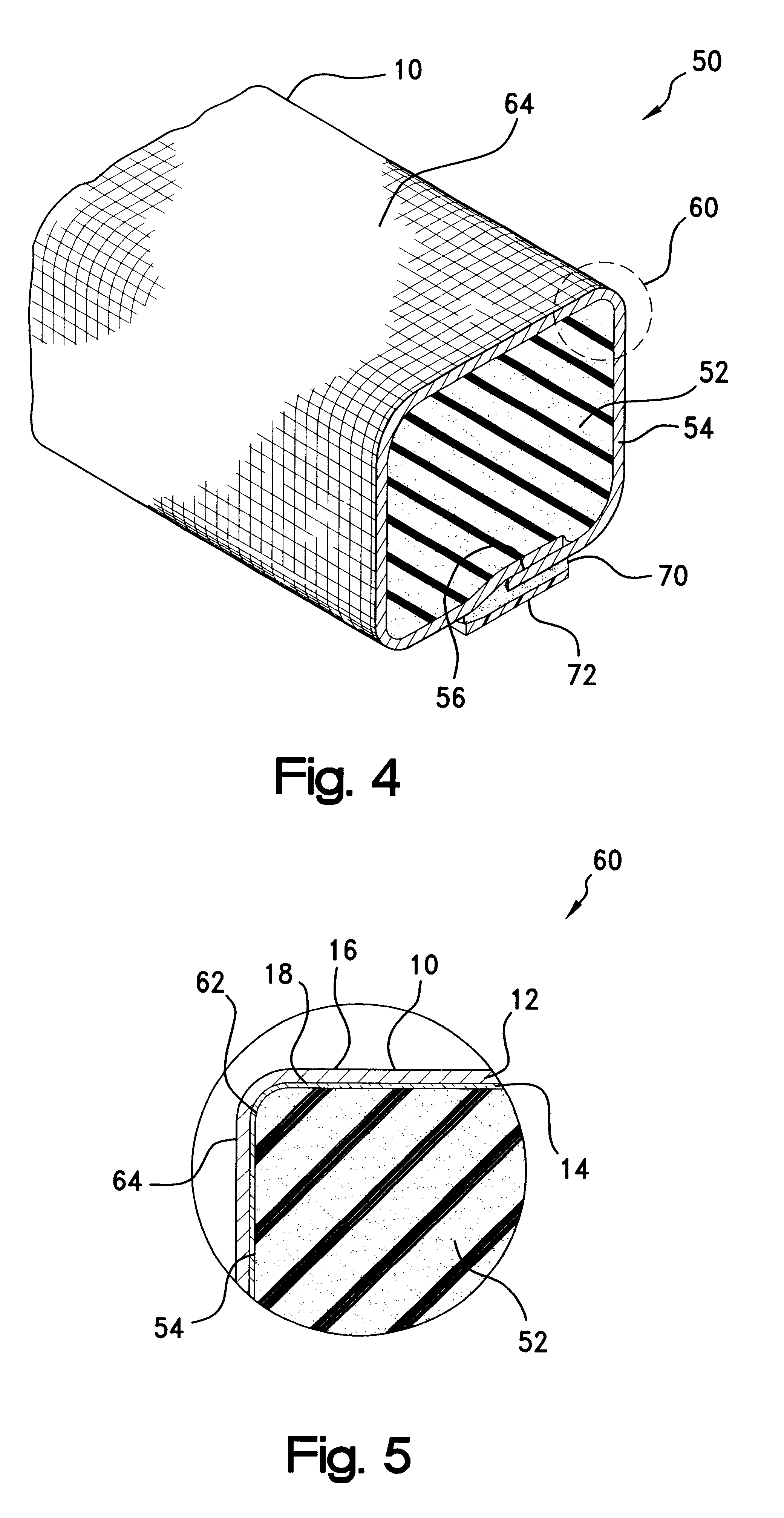

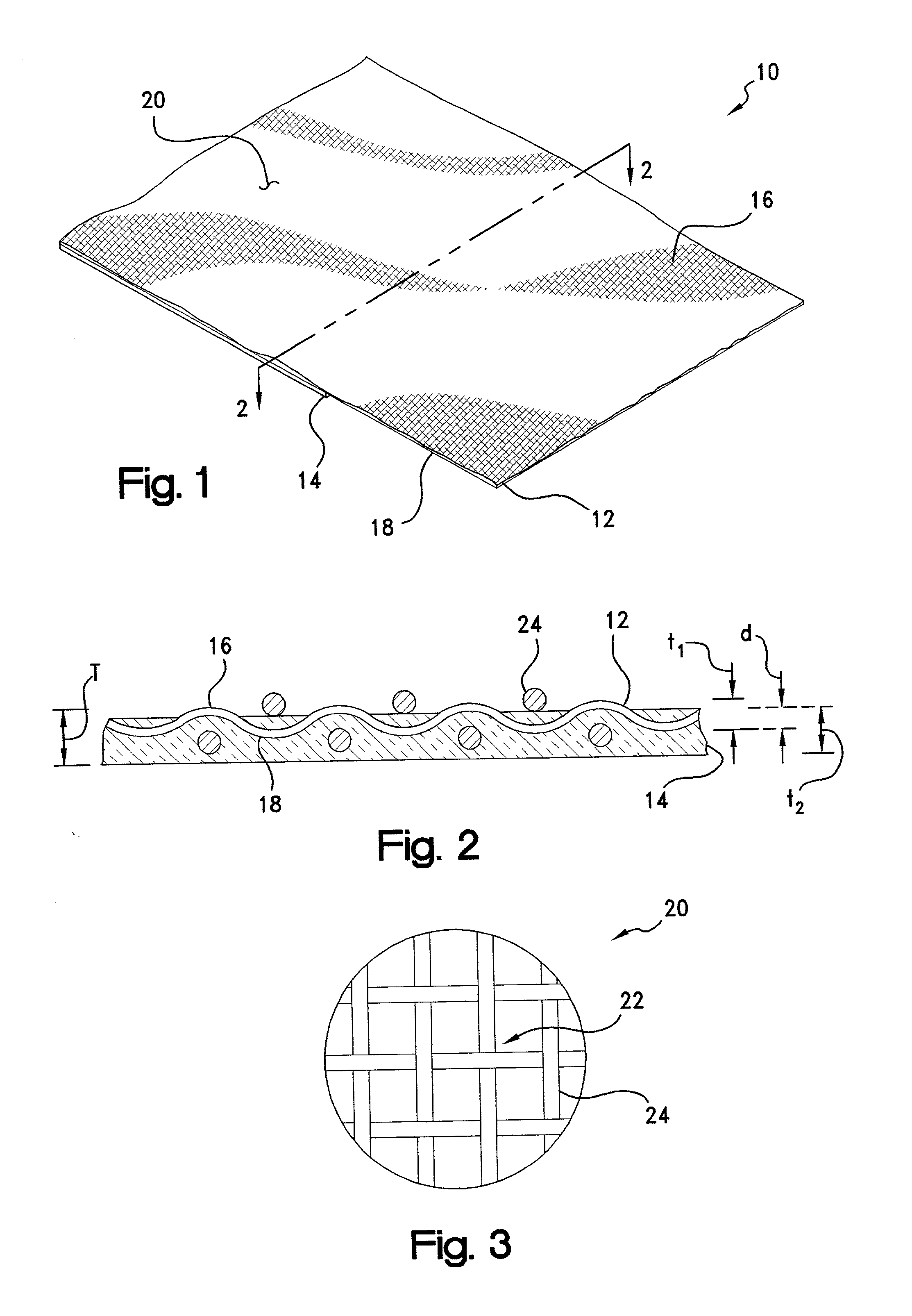

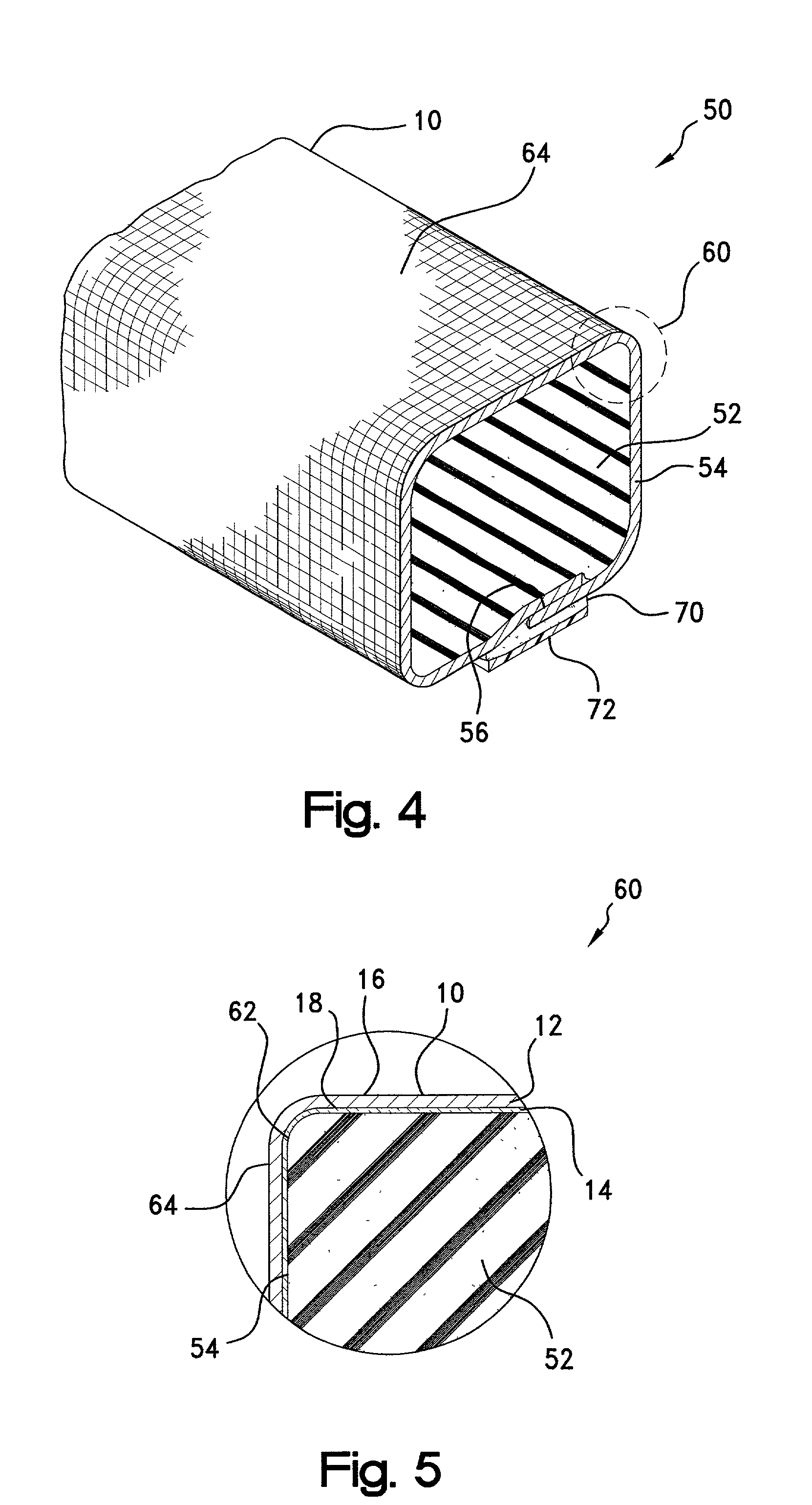

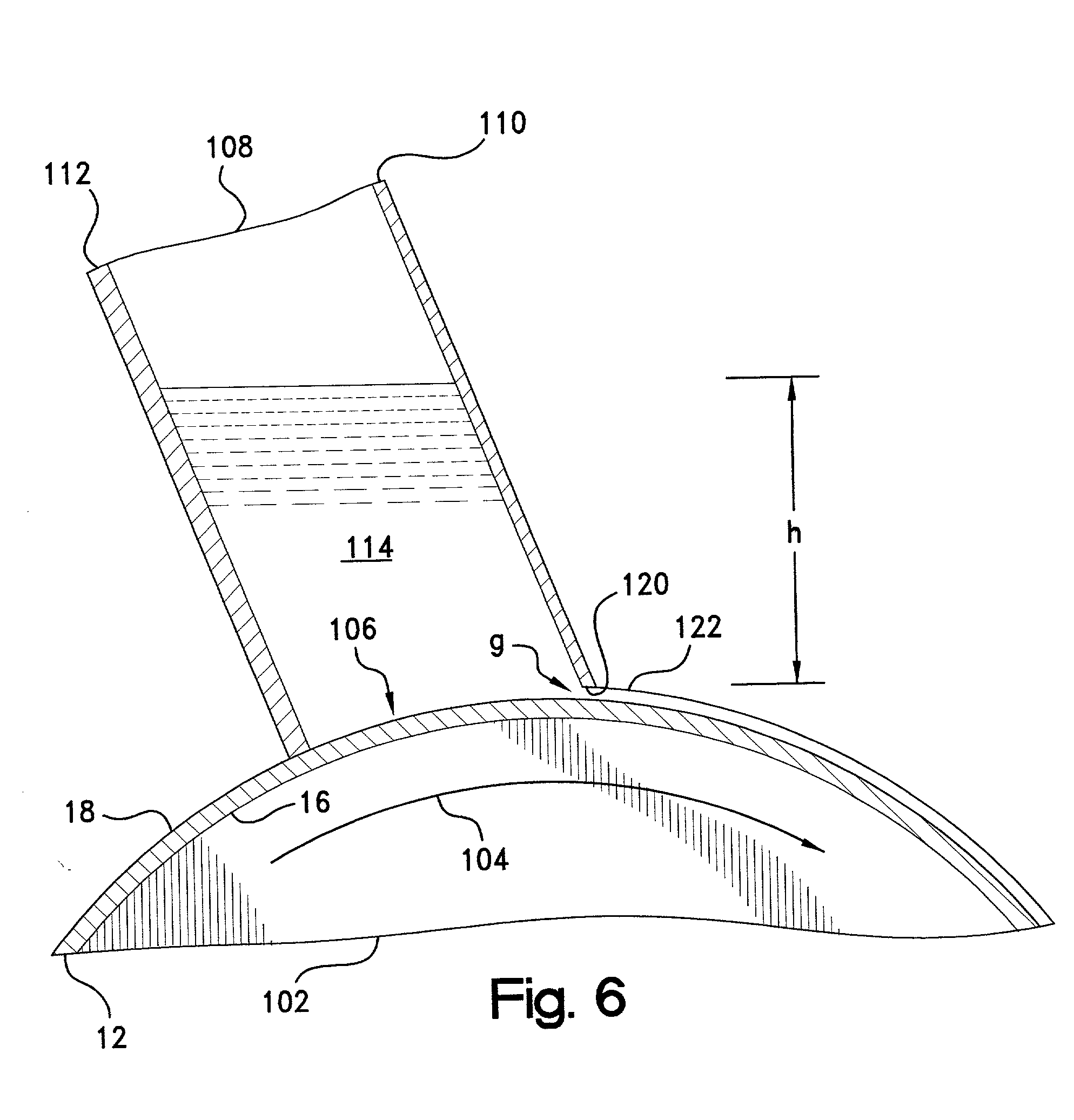

An flame retardant, electrically-conductive EMI shielding material and method, the material being particularly adapted for use in fabric-over-foam EMI shielding gasket constructions. In construction, a generally planar, porous fabric member is provided as having at least an electrically-conductive first side and a second side defining a thickness dimension therebetween. A curable layer of a fluent, flame retardant composition is applied under a predetermined hydrodynamic pressure and viscosity to at least a portion of the second side of the fabric member. The hydrodynamic pressure and viscosity of the composition are controlled to delimit the penetration of the layer into the fabric member to a depth which is less than the thickness dimension of said fabric member. The layer then is cured to form a flame retardant surface coating on the second side of the fabric member such that the first side of said fabric member remains electrically-conductive.

Owner:PARKER INTANGIBLES LLC

Flame retardant EMI shielding gasket

InactiveUS6387523B2Maintains drapabilityEasy constructionScreening gaskets/sealsSynthetic resin layered productsElastomerElectromagnetic interference

Owner:PARKER INTANGIBLES LLC

Flame retardant EMI shielding gasket

InactiveUS20010031589A1Maintains drapabilityEasy constructionScreening gaskets/sealsSynthetic resin layered productsElastomerElectromagnetic interference

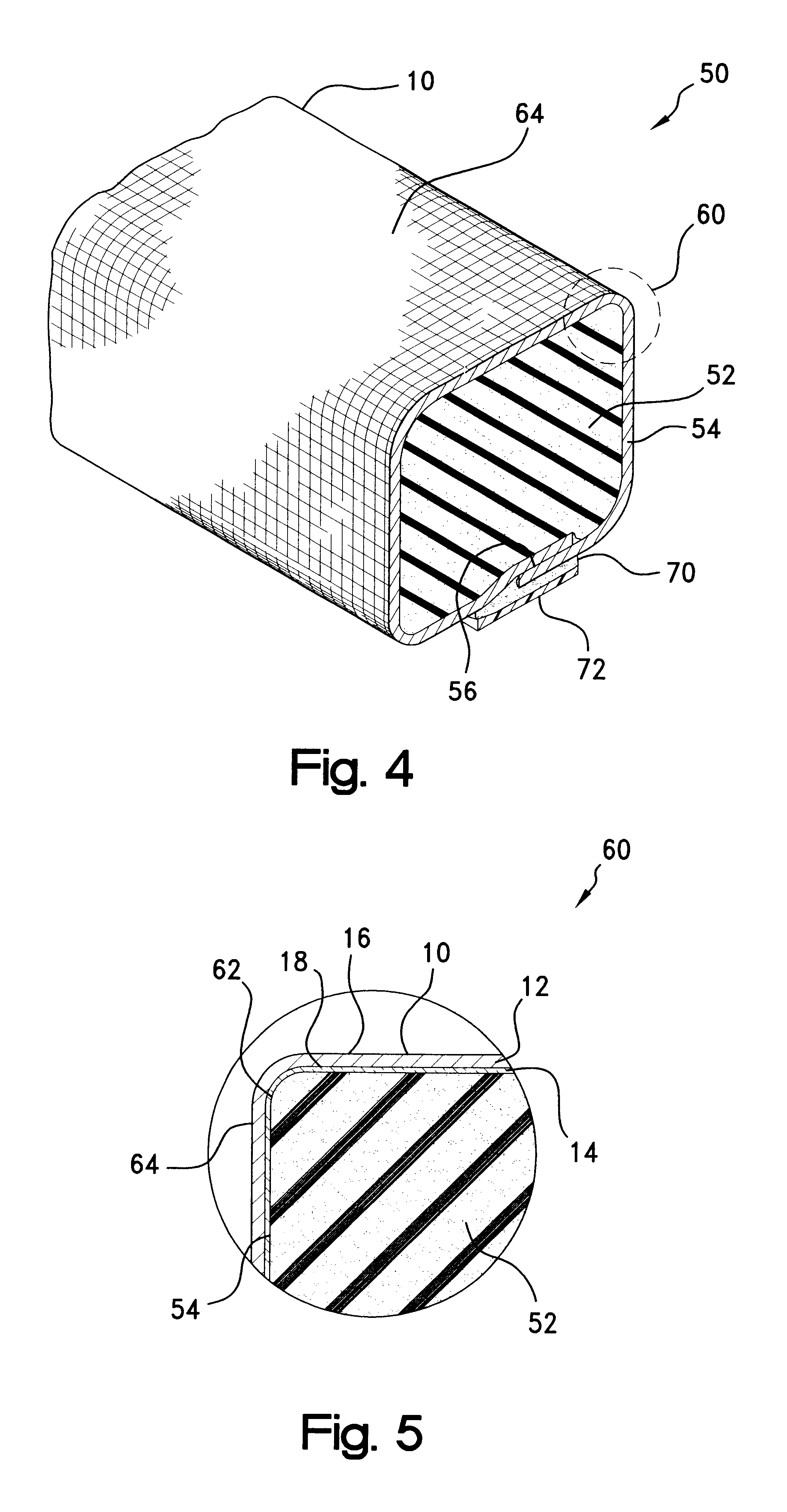

A flame retardant, electromagnetic interference (EMI) shielding gasket construction. The construction includes a resilient core member formed of a foamed elastomeric material, an electrically-conductive fabric member surrounding the outer surface of the core member, and a flame retardant layer coating at least a portion of the interior surface of the fabric member. The flame retardant layer is effective to afford the gasket construction with a flame class rating of V-0 under Underwriter's Laboratories (UL) Standard No. 94.

Owner:PARKER INTANGIBLES LLC

Hard alloy using iron-aluminum intermetallic compound as bonding phase and preparation method thereof

ActiveCN101985718AUniform tissue structureGood mechanical properties at room temperatureIron powderAlloy

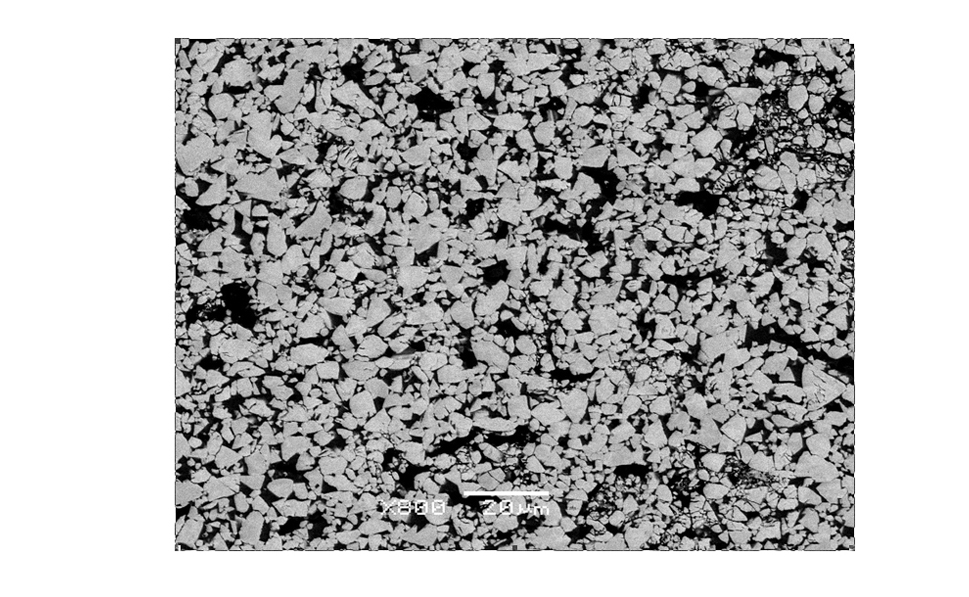

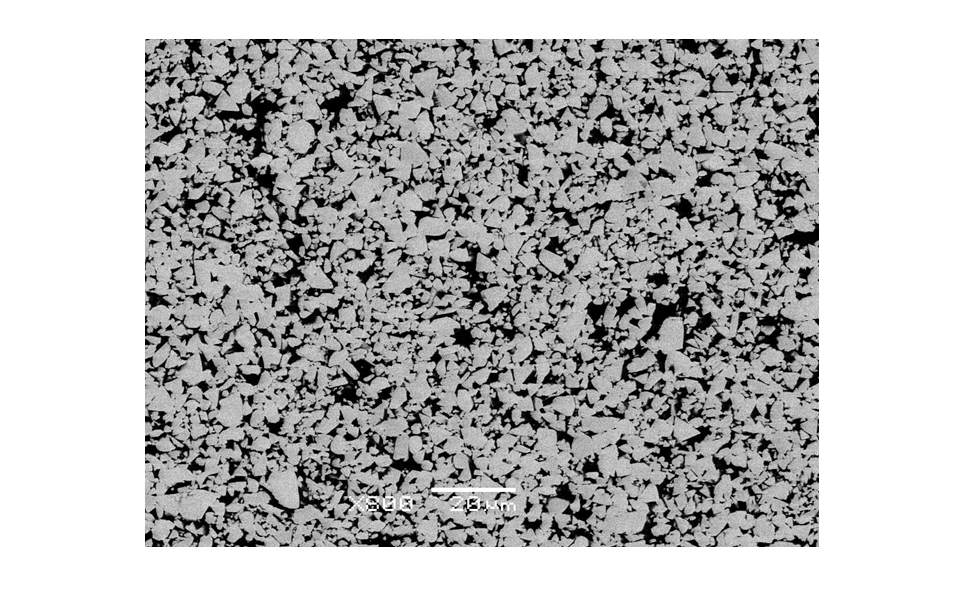

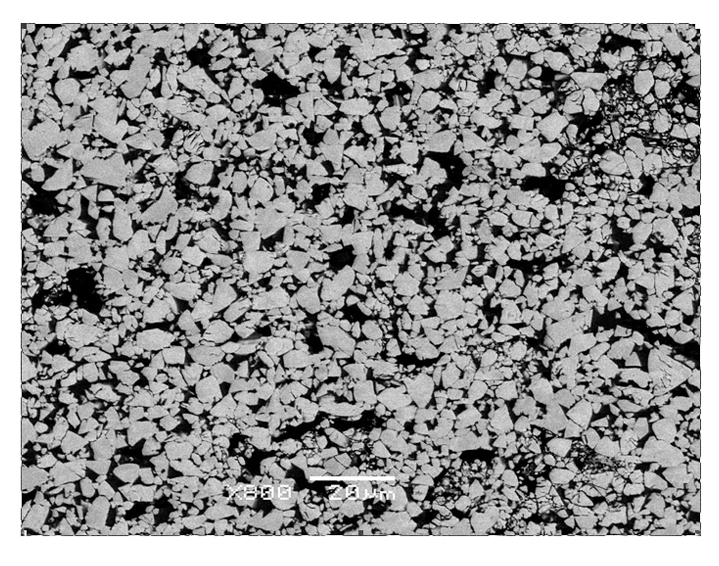

The invention discloses a hard alloy using an iron-aluminum intermetallic compound as a bonding phase and a preparation method thereof. The hard phase is carbide, and the bonding phase is 10 to 40 volume percent of FeAl or Fe3Al. The preparation method comprises the following steps of: ball-milling and mixing 1.69 to 19.09 mass percent or 1.31 to 13.75 mass percent of pre-alloying powder of Fe2Al5, 2.10 to 23.78 mass percent or 3.23 to 33.81 mass percent of iron powder and the balance of carbide powder based on the component of FeAl or Fe3Al for 18 to 36 hours, preparing the obtained ball-milling mixture into uniform mixture powder by spray drying, pressing the mixture powder to form a blank, preserving the heat for 1 to 2 hours at the temperature of 1,200 + / - 20 DEG C under the vacuum condition during sintering the pressed blank, and then performing low-pressure liquid phase sintering at the temperature of between 1,250 and 1,550 DEG C to obtain the hard alloy using the FeAl or the Fe3Al as the bonding phase, wherein the FeAl or the Fe3Al is 10 to 40 volume percent. The preparation method has simple process and is low in manufacturing cost; holes are difficult to form in the liquid phase sintering process or are small; and the obtained hard alloy has high strength, good abrasion resistance and excellent high-temperature oxidation resistance and sulfur corrosion resistance.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

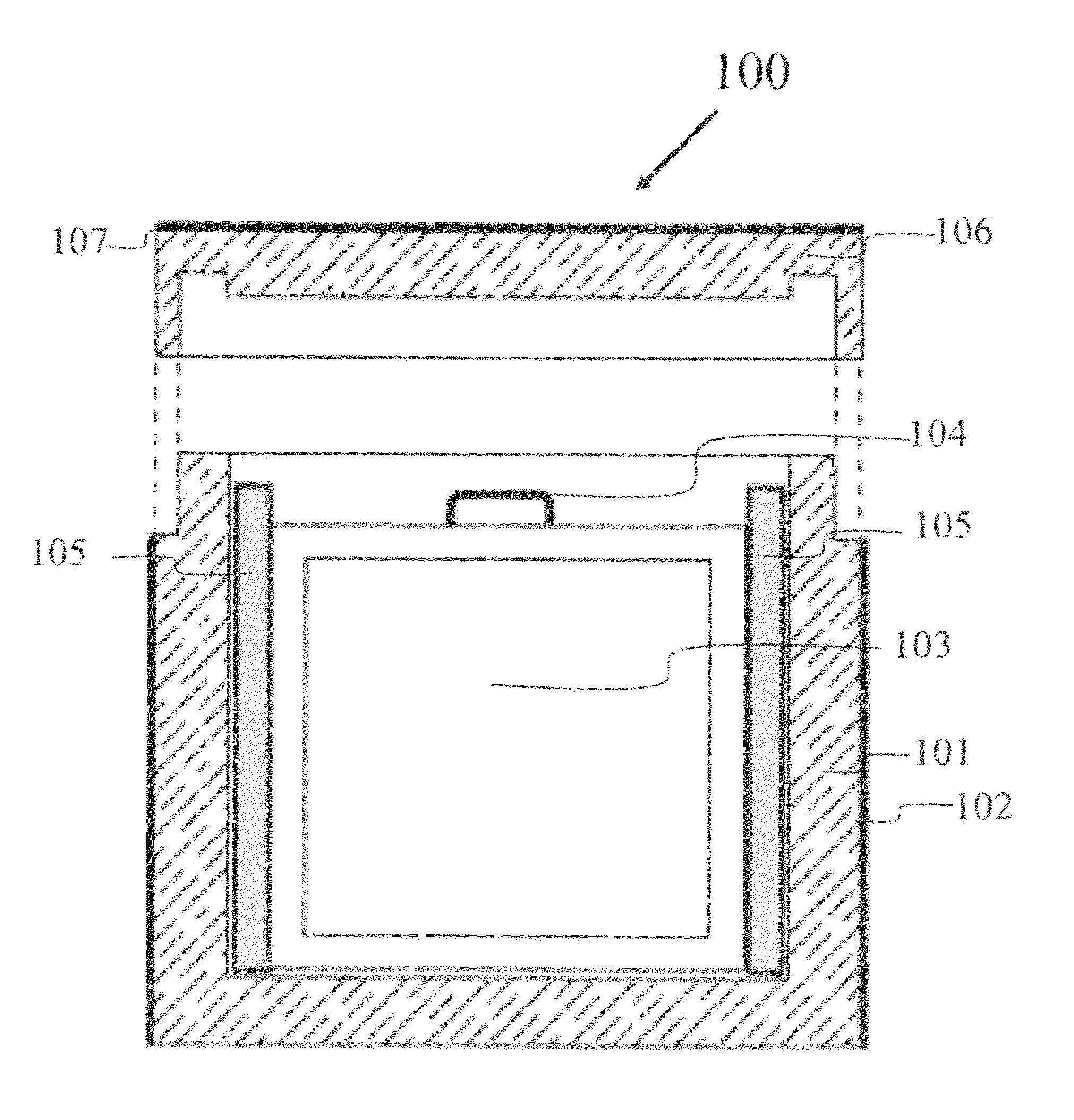

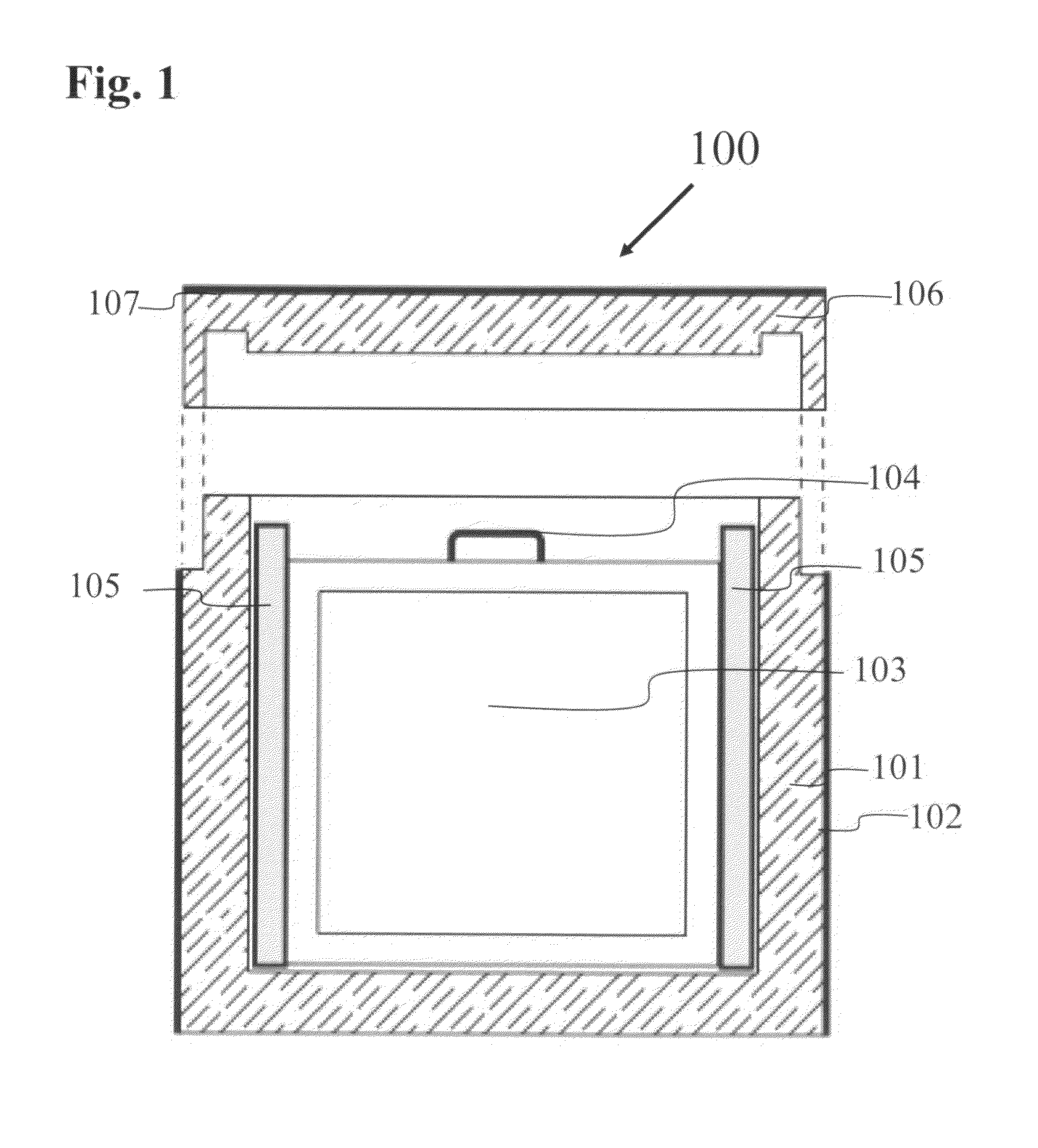

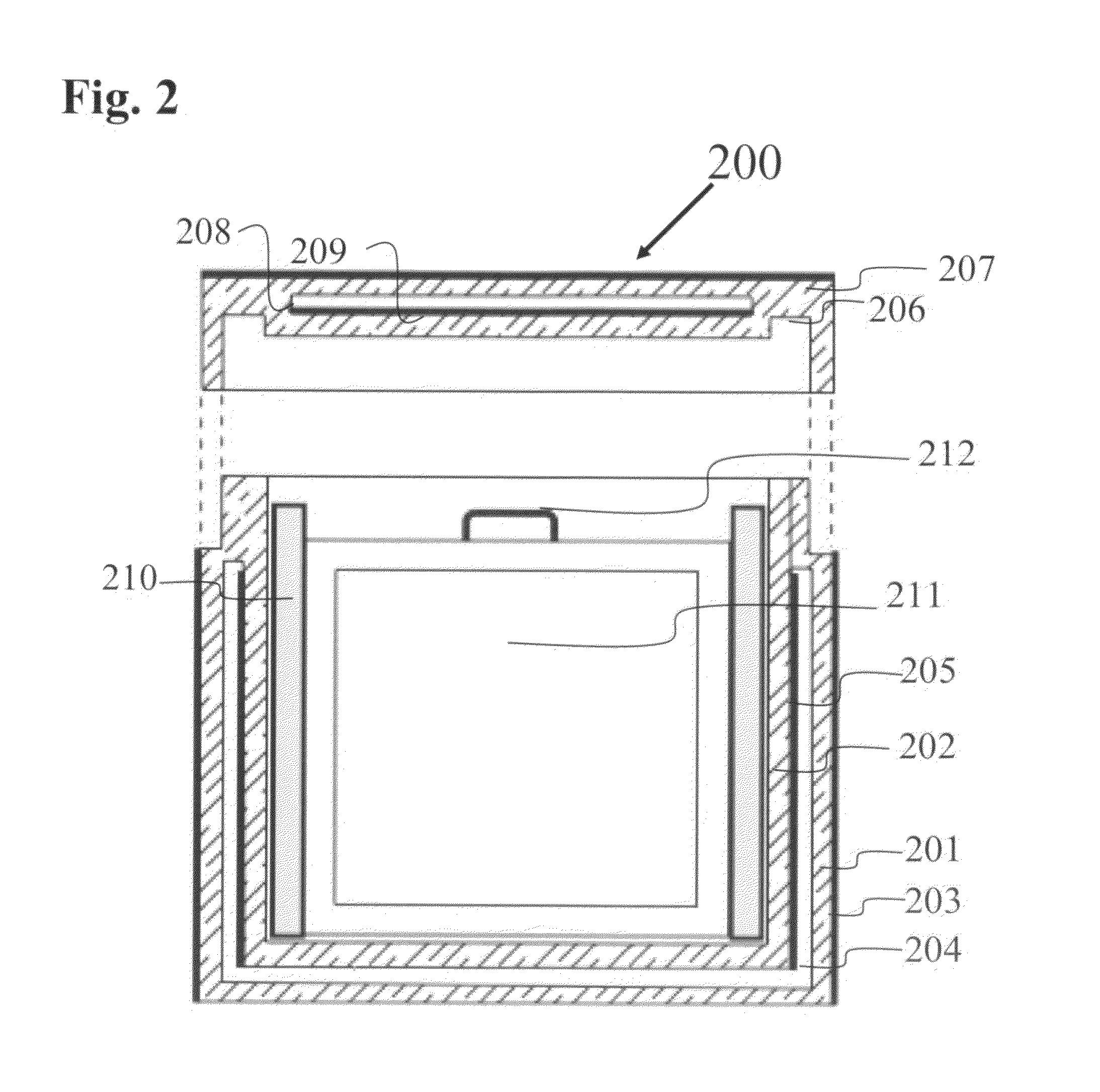

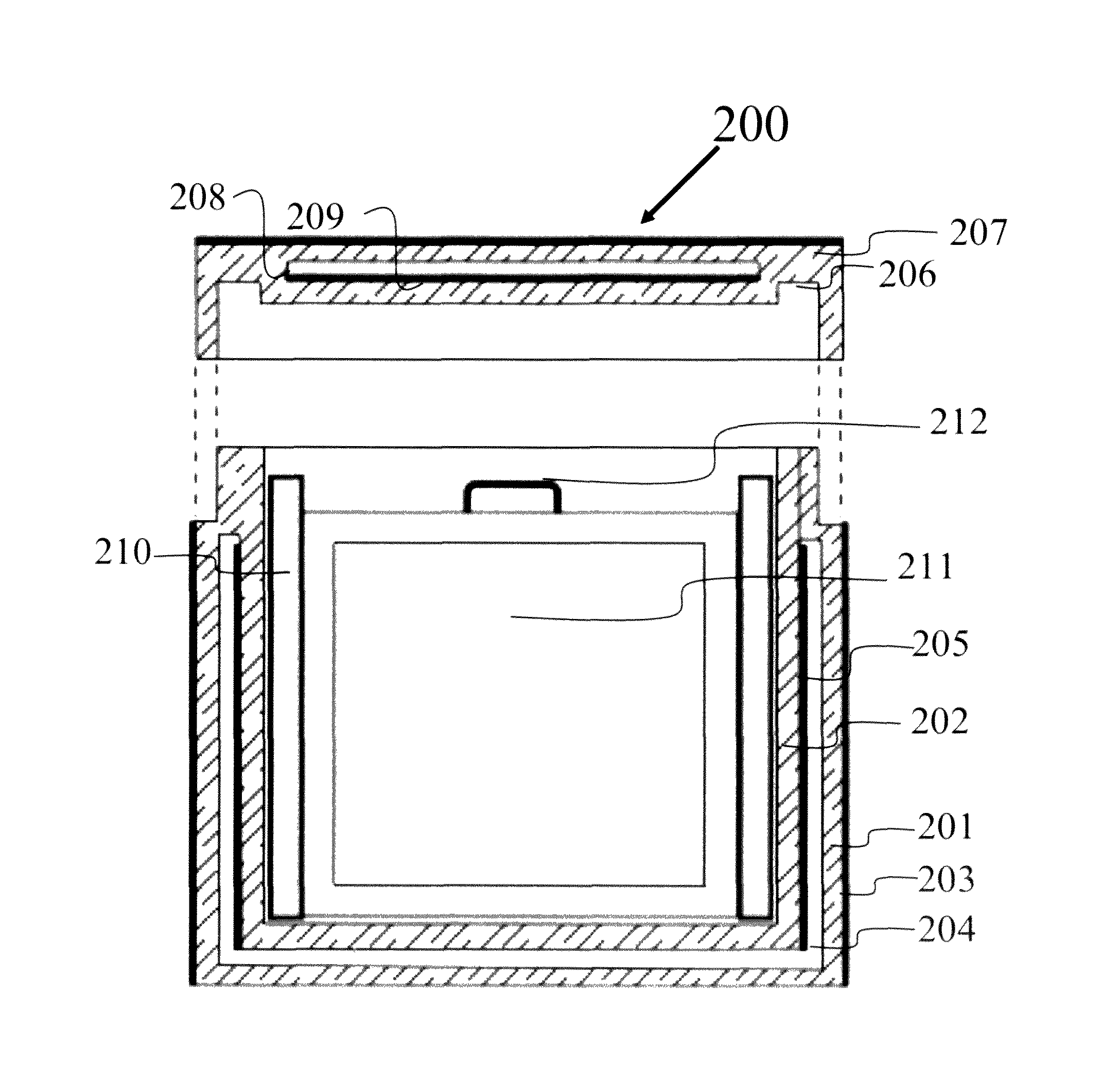

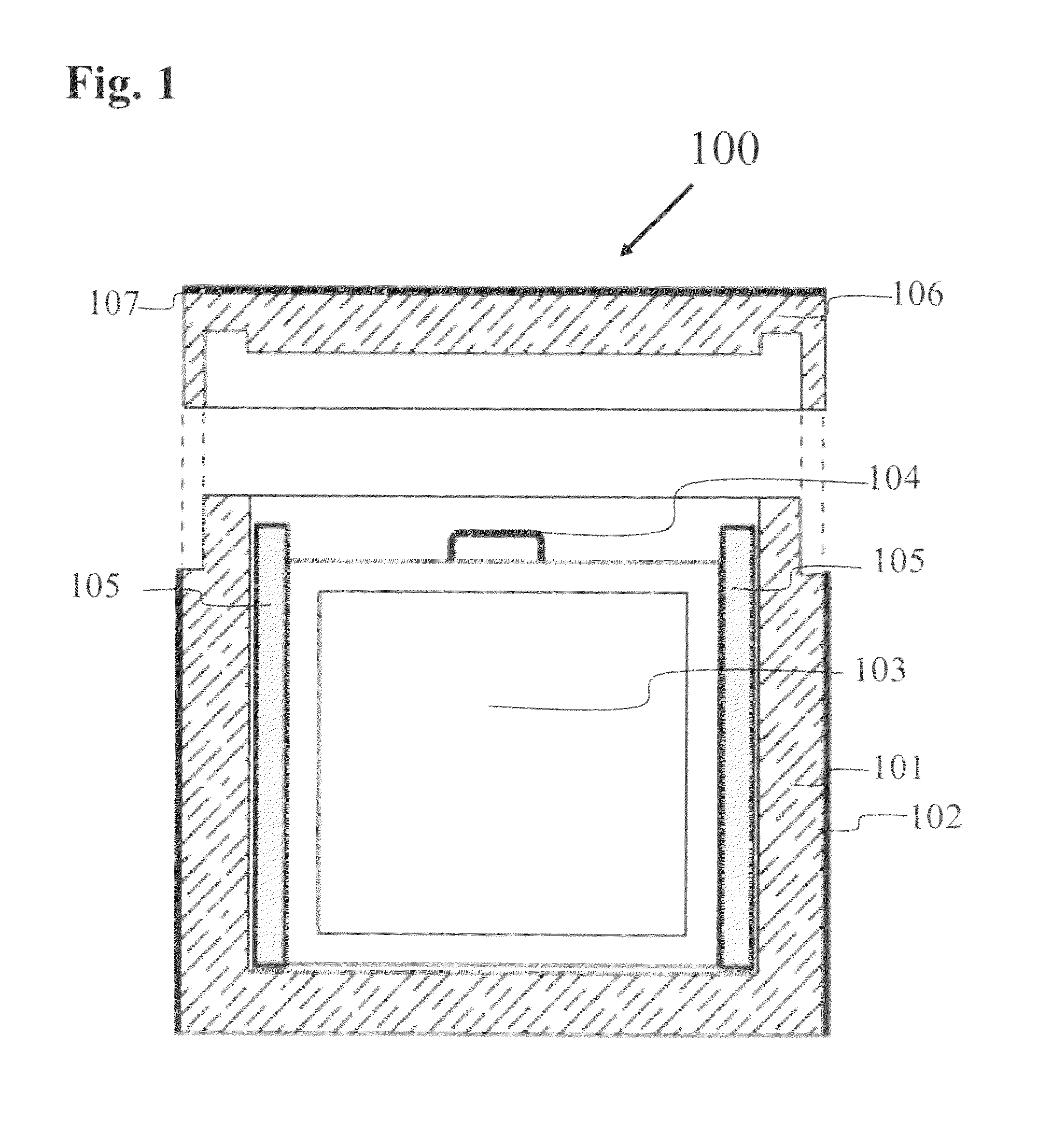

Fire resistant containment system having a light weight portable removable enclosure

A lightweight portable fire resistant containment system comprises an outer shell and a lid. Free surfaces of the outer shell and lid are covered to prevent ingress of hot gas. The outer shell may have an inner shell forming an insulating air gap. Outer shell, inner shell and lid are fabricated from inorganically bonded high temperature resisting ceramic fibers. The outer surface of the inner shell has a metallic infrared reflecting wrap. An encased phase change material containment absorbs heat by melting or decomposition. A wooden or plastic lightweight portable box enclosure with cover is placed within the interior surface of the containment for storage of valuable documents, photographs and magnetic media. A jump drive within the portable box preferably houses the magnetic media. When the fire resistant containment system is exposed to 1550° F. for 30 minutes the interior of lightweight portable box enclosure remains below 125° F.

Owner:DELLORUSSO JR ANTHONY J

Fire resistant containment system having a light weight portable removable enclosure

A lightweight portable fire resistant containment system comprises an outer shell and a lid. Free surfaces of the outer shell and lid are covered to prevent ingress of hot gas. The outer shell may have an inner shell forming an insulating air gap. Outer shell, inner shell and lid are fabricated from inorganically bonded high temperature resisting ceramic fibers. The outer surface of the inner shell has a metallic infrared reflecting wrap. An encased phase change material containment absorbs heat by melting or decomposition. A wooden or plastic lightweight portable box enclosure with cover is placed within the interior surface of the containment for storage of valuable documents, photographs and magnetic media. A jump drive within the portable box preferably houses the magnetic media. When the fire resistant containment system is exposed to 1550° F. for 30 minutes the interior of lightweight portable box enclosure remains below 125° F.

Owner:DELLORUSSO JR ANTHONY J

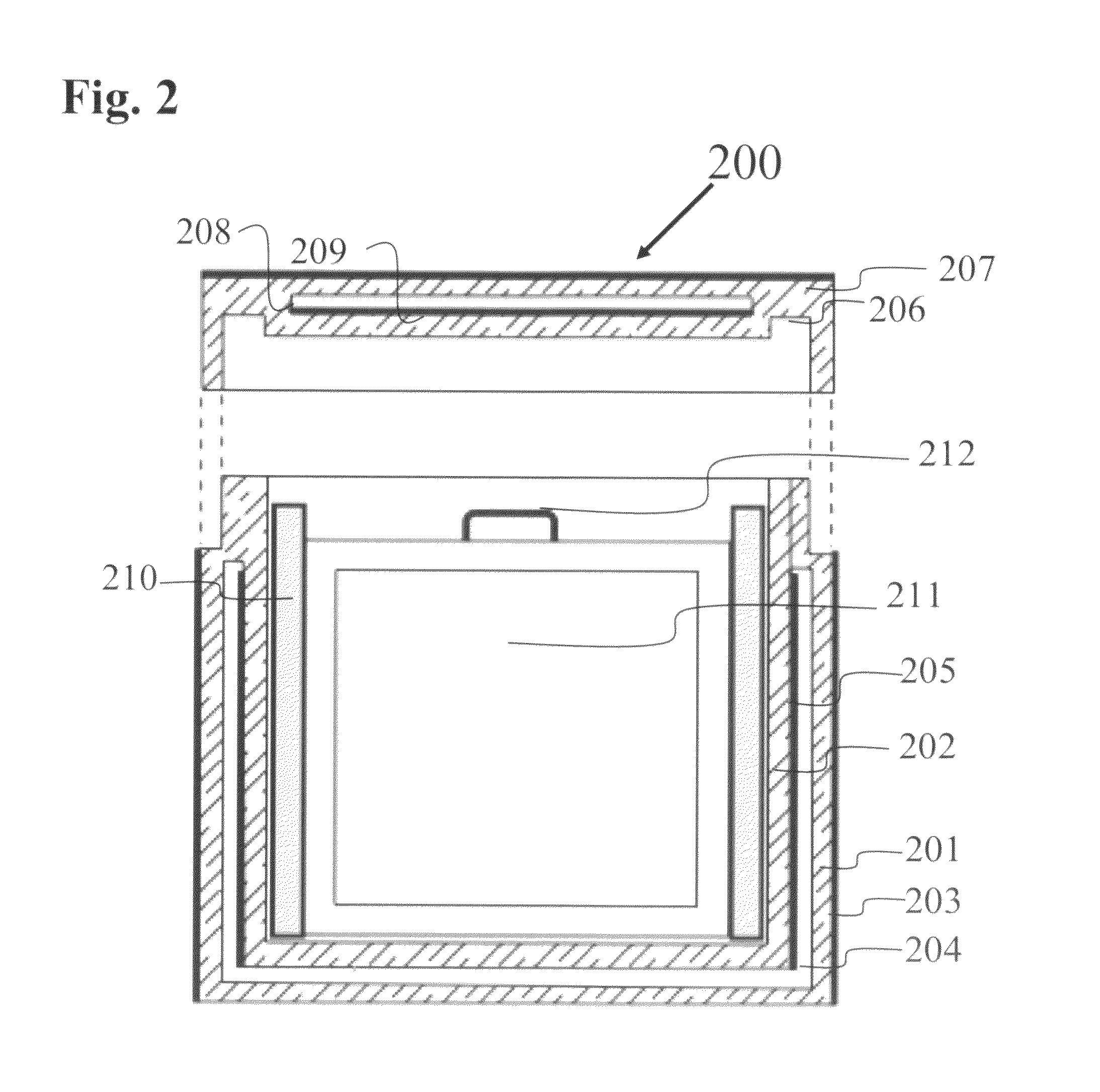

Vacuum concrete mixing process

The invention provides a vacuum concrete mixing process. The vacuum concrete mixing process is characterized in that via simple structural modification, after a mixing drum of a mixer is sealed, the interior of the mixing drum is vacuumized, that is, before mixing, a certain vacuum degree is formed in the mixing drum, so that contact between freshly mixed concrete slurry and air in the mechanical mixing process is greatly reduced, formation of bubbles in concrete is reduced, and accordingly, the porosity is greatly reduced. Furthermore, the minimum pressure in the mixing drum is controlled, so that the ambient temperature is lower than the boiling point of moisture in the mixing drum, accordingly, moisture evaporation is avoided, the phenomenon that pores are formed by moisture evaporation is prevented, and the porosity is further reduced. The vacuum concrete mixing process is simple, is convenient to operate, and can efficiently improve the concrete compactness, strength and durability.

Owner:HUNAN UNIV OF TECH

Anti-corrosion spraying process based on polytetrafluoroethylene material

InactiveCN110394290AHigh hardnessImprove wear resistancePretreated surfacesCoatingsFluorocarbonWear resistance

The invention discloses an anti-corrosion spraying process based on a polytetrafluoroethylene material. The anti-corrosion spraying process based on the polytetrafluoroethylene material comprises thefollowing steps that 1, the surface treatment is carried out on a rolled steel, specifically, the cleaning treatment is carried out on the surface of the rolled steel firstly, sundries and stains on the surface of the rolled steel is washed and cleaned by using pressure water of 290 Kpa, and the time length is 10-15min; then an abrasive paper is used for grinding treatment, projections on the surface of the rolled steel is polished uniformly, and the roughness of the surface of the rolled steel reaches about 20 microns; a fluorocarbon diluting agent is used to wipe the surface of the rolled steel cleanly, and exposing and airing are carried out to obtain the clean and polished rolled steel. According to the anti-corrosion spraying process based on the polytetrafluoroethylene material, through the multiple spraying step process and the anti-corrosion function of the polytetrafluoroethylene material, the adhesiveness of the coating rolled steel is improved, the coating is not prone to fall off in use, and the quality of the rolled steel is improved; and meanwhile, the combination degree among primer, finish paint and the rolled steel is improved, the gap condition is avoided in the coating, the anti-corrosion property and the wear resistance of the rolled steel are greatly improved, and a good application prospect is realized.

Owner:江苏优氟防腐科技有限公司

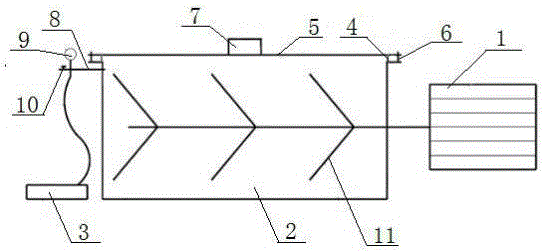

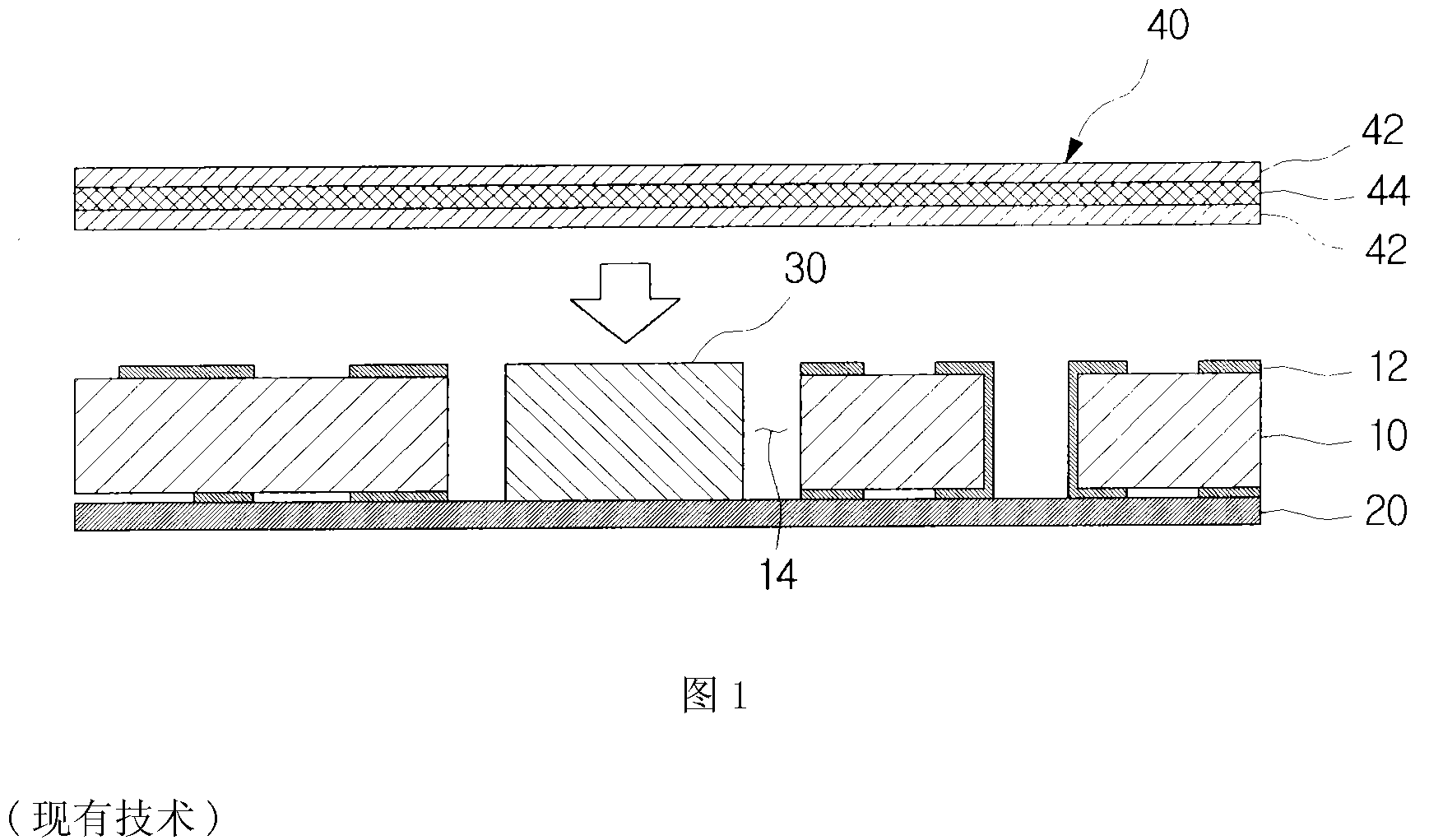

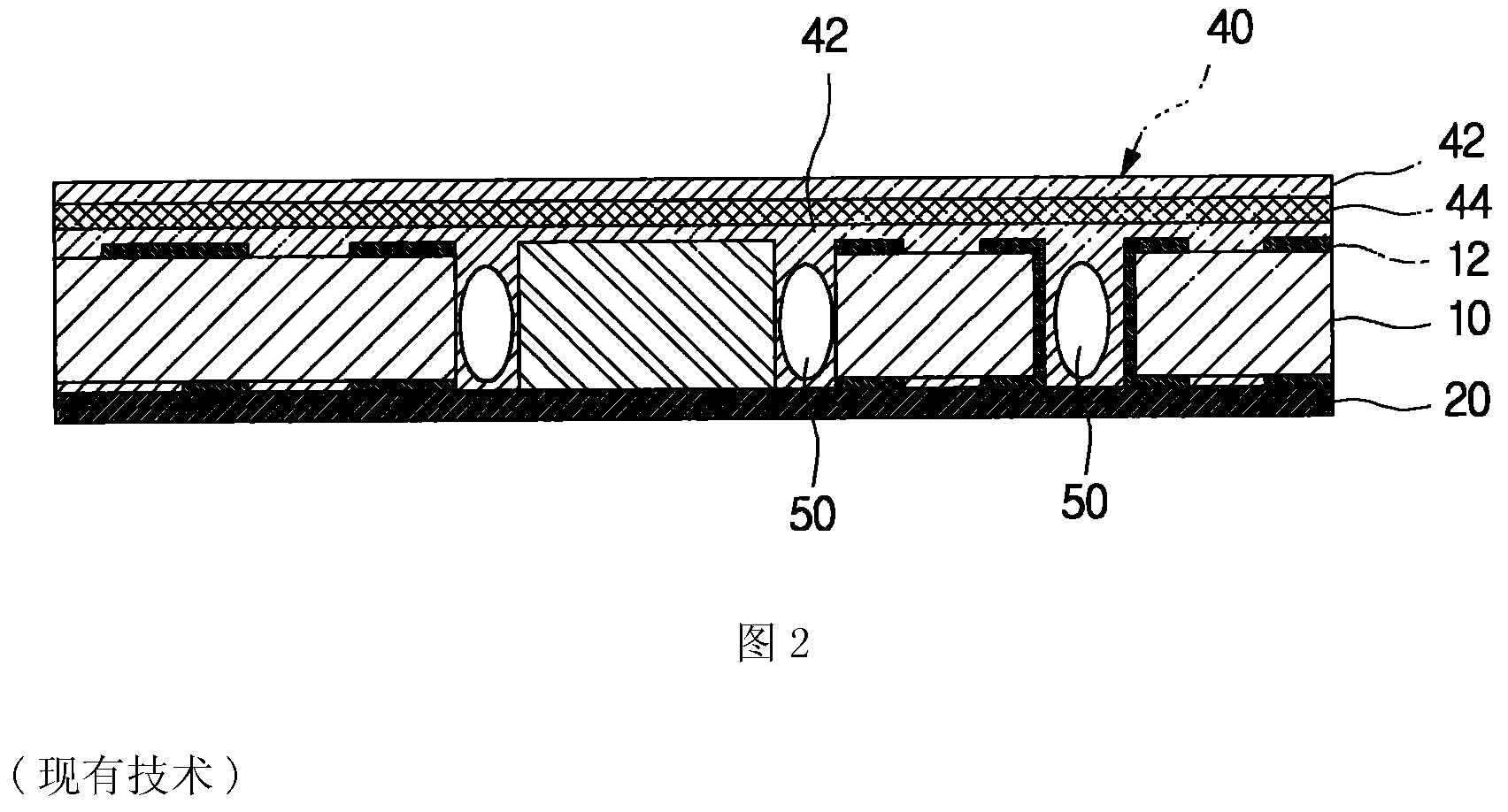

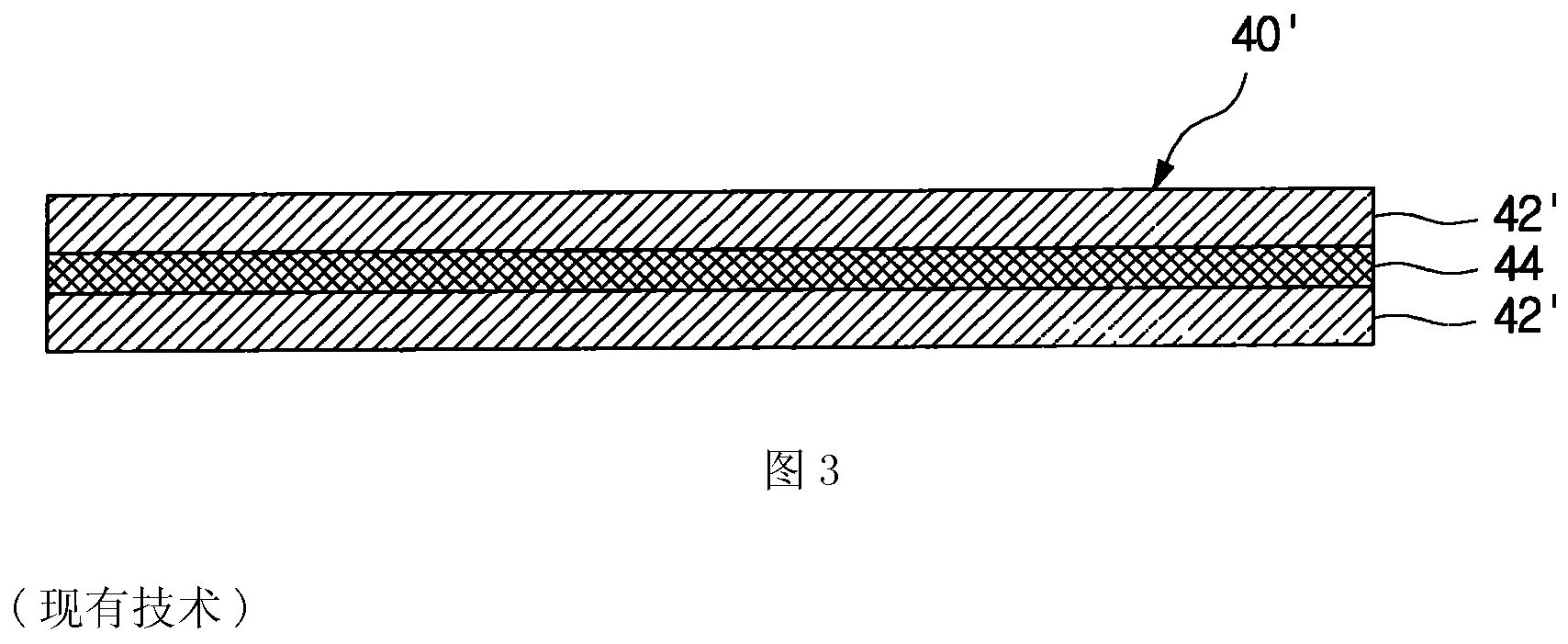

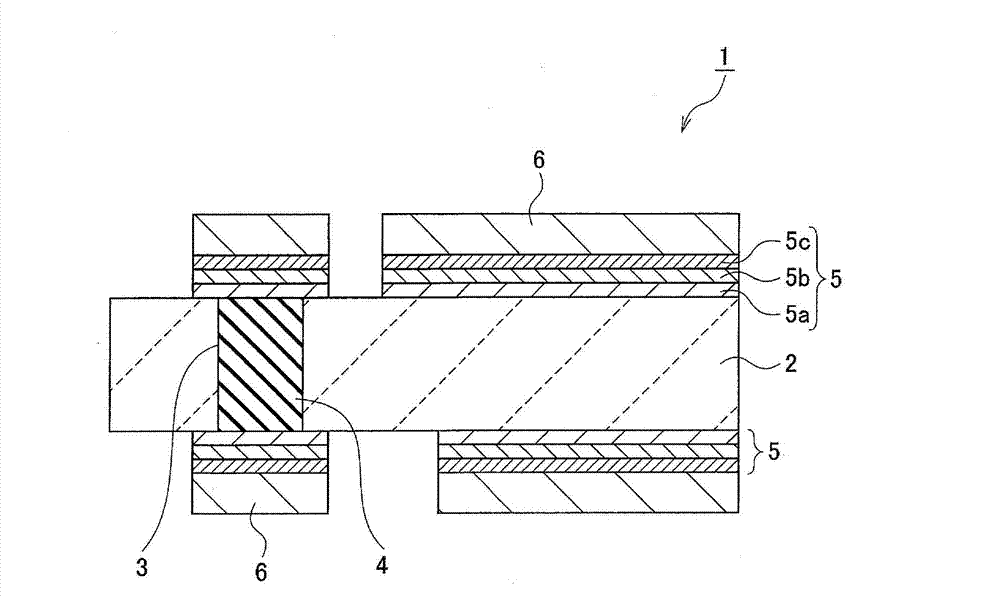

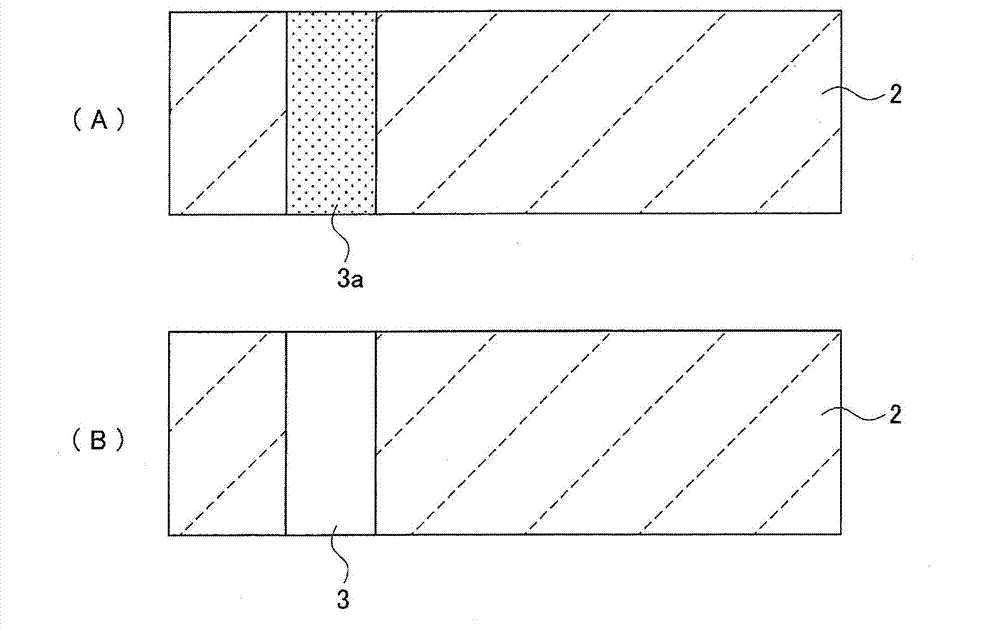

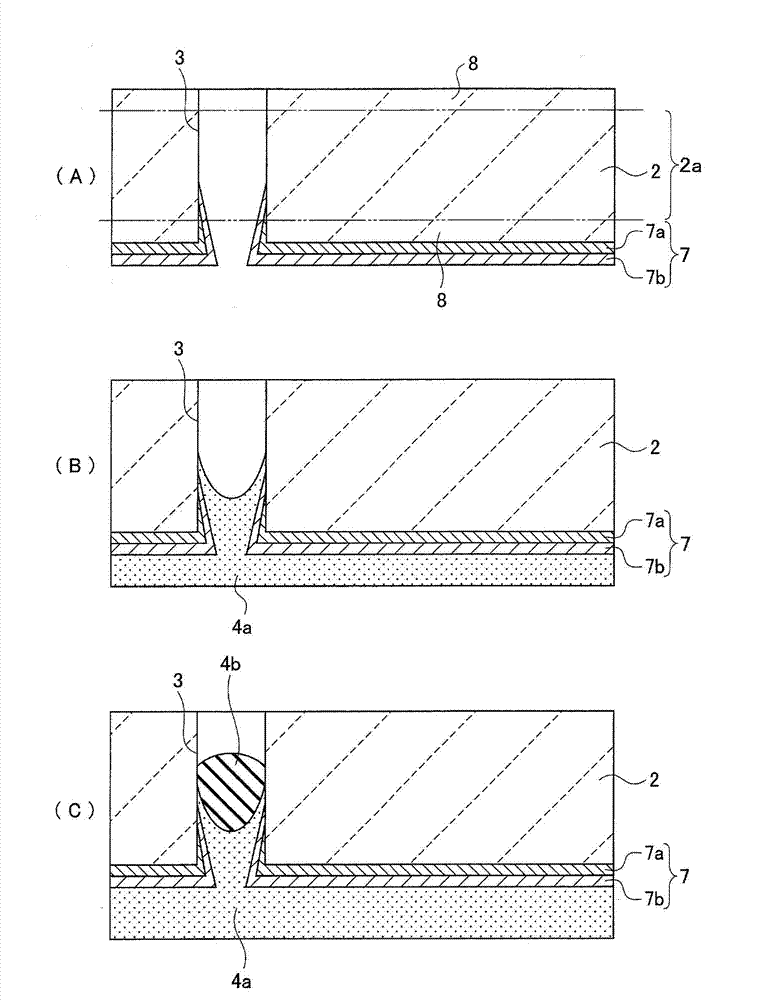

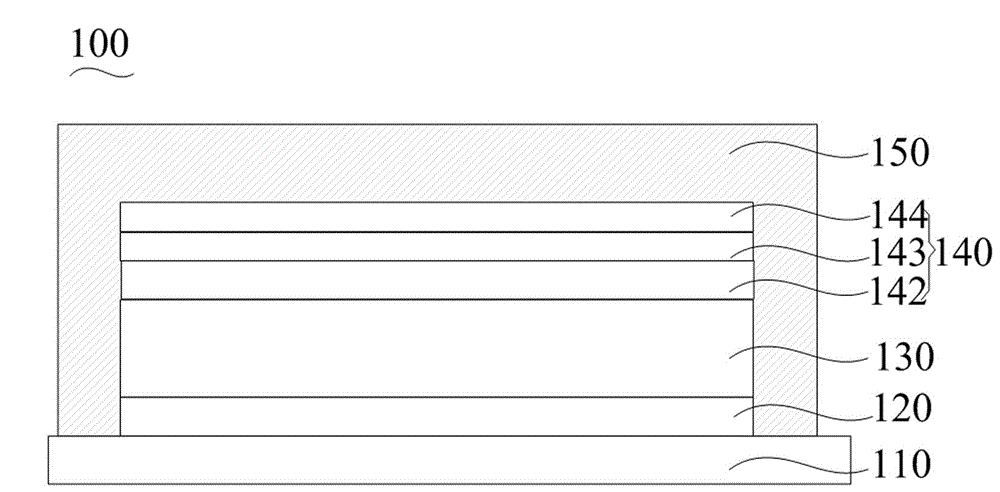

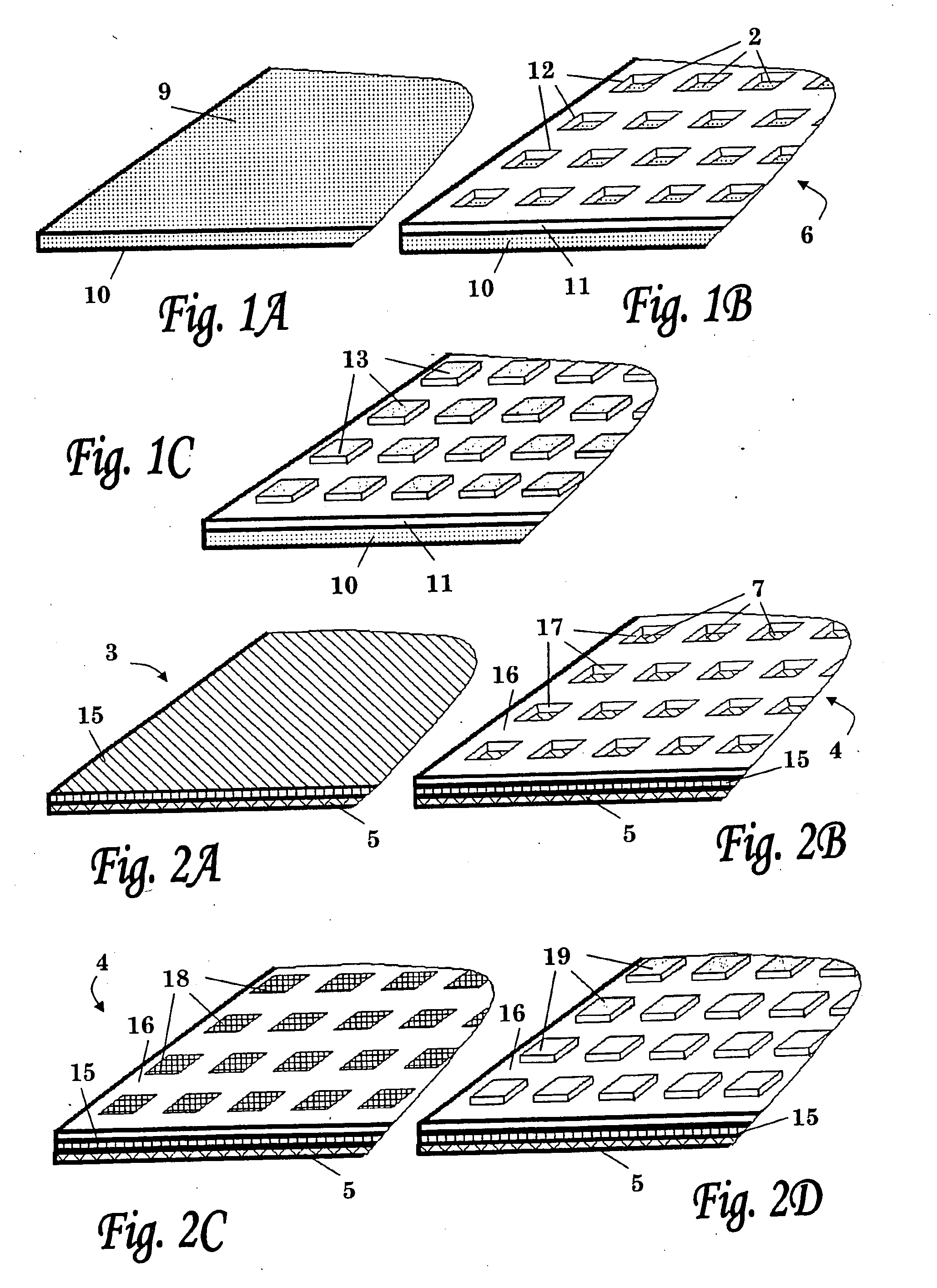

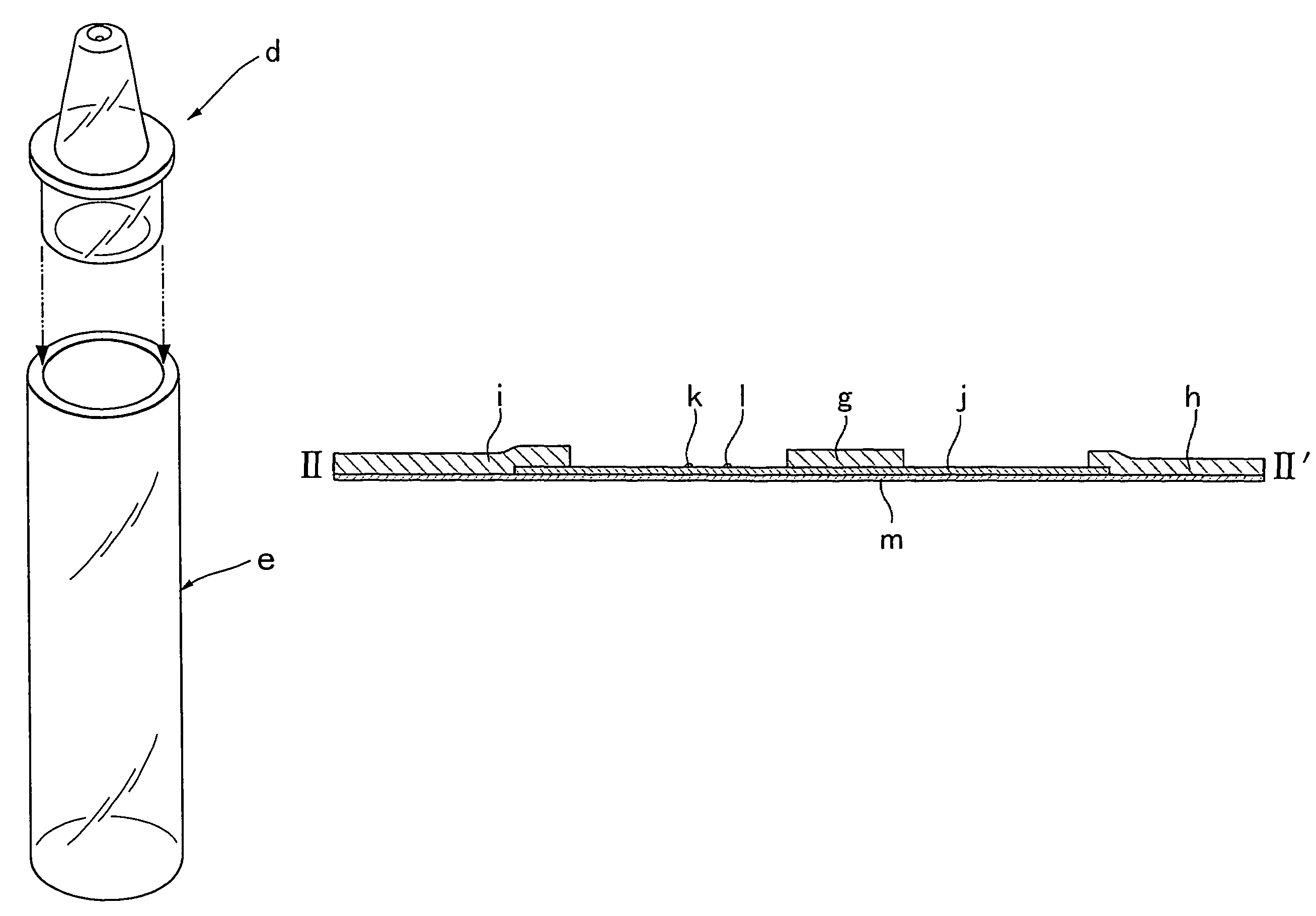

Insulating layer, printed circuit board with electronic component and producing method thereof

InactiveCN101951733ASolve the deformationAvoid poresPrinted circuit assemblingPrinted circuit detailsEngineeringElectronic component

The invention discloses a printed circuit board with electronic component and producing method thereof. The method comprises steps of providing the circuit pattern chip plate which is disposed on the surface and is penetrated by a hollow cavity; bonding an adhesion layer to the lower surface of the chip plate to cover the hollow cavity; disposing an electronic component on the upper surface of the adhesion layer, corresponding to the position of the hollow cavity; stacking a first insulating layer which dose not have supporting materials filled in the hollow cavity on the upper surface of thechip plate to cover the circuit pattern so that the hollow cavity is filled; stacking a second insulating layer which has supporting materials filled in the hollow cavity on the upper side and the lower side of the chip plate.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

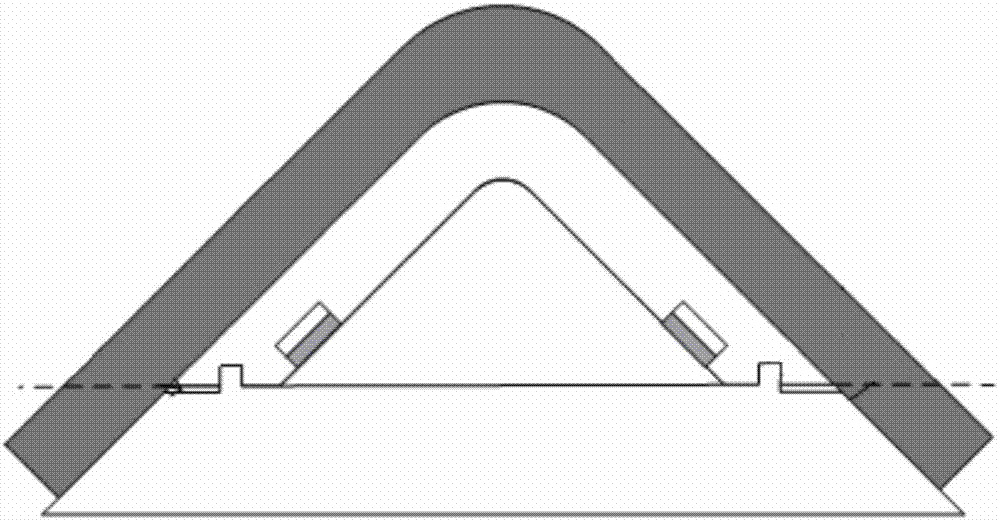

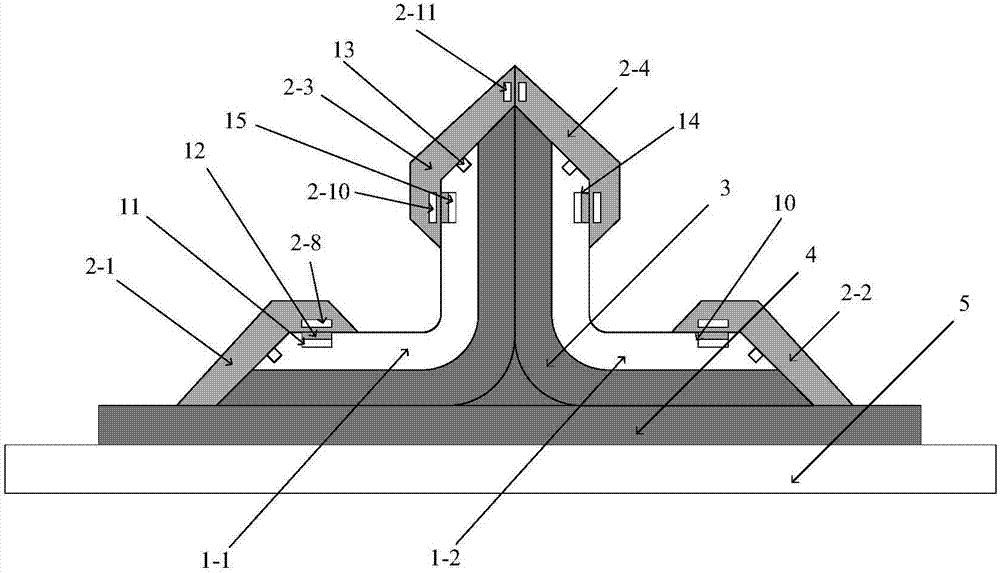

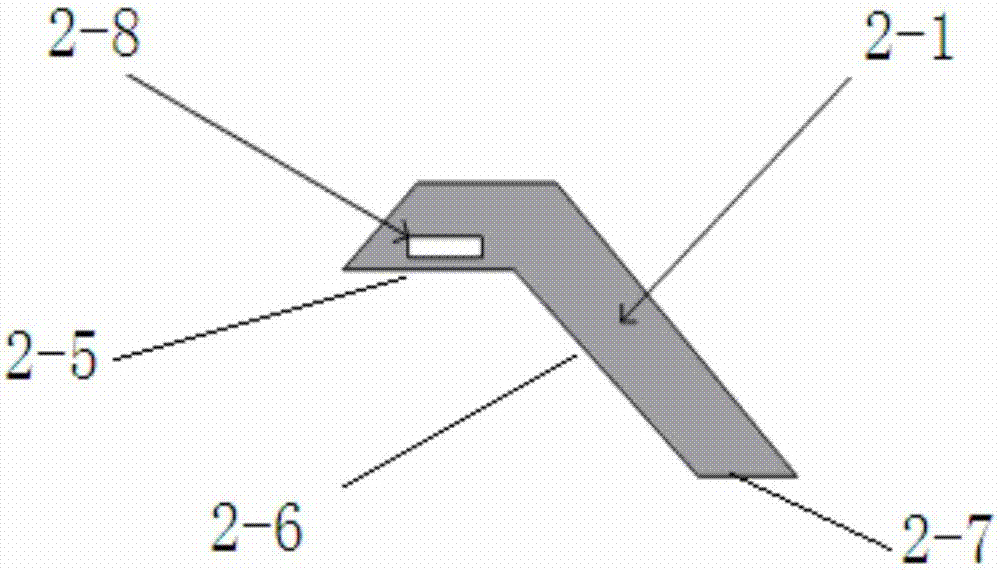

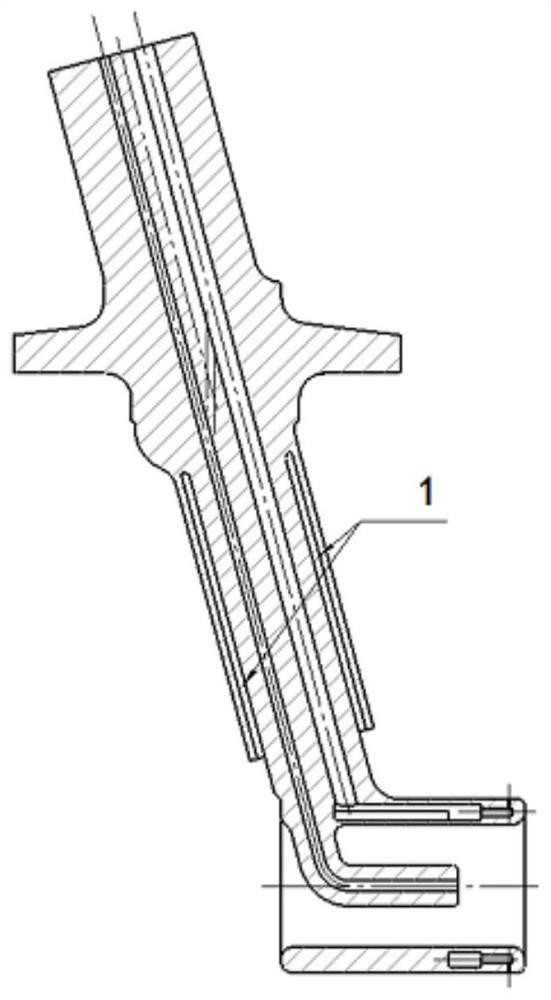

Mold and technology for forming composite T-shaped stringer stiffened wallboard

The invention belongs to the field of technological manufacturing and particularly relates to a mold and technology for forming a composite T-shaped stringer stiffened wallboard. The mold comprises a rigid module and a flexible module arranged at the end of the rigid module, the end of the rigid module and the end of the flexible module are each arranged to be in a wedge shape, and the rigid module and the flexible module are positioned and fixed through pre-buried magnets. By adopting the technological scheme, the rigid module is combined with a base and can be used for preforming of a hot membrane; the rigid module and the flexible module are easy to position and fix by adopting the pre-buried magnets; the rigid module is of an open type structure and is easy to demold; and through the scheme, impressed pressure can be promoted to be transmitted to a corner area and a triangle area of a stringer along a flange and a web through the flexible module, the effect that the forming pressure of fibers in the areas meets the solidification requirement is ensured, fiber compaction is facilitated, and the situation that pores and other defects occur due to the fact that the pressure in the corner area and the triangle area are transmitted in place is effectively avoided.

Owner:BEIJING AERONAUTIC SCI & TECH RES INST OF COMAC +1

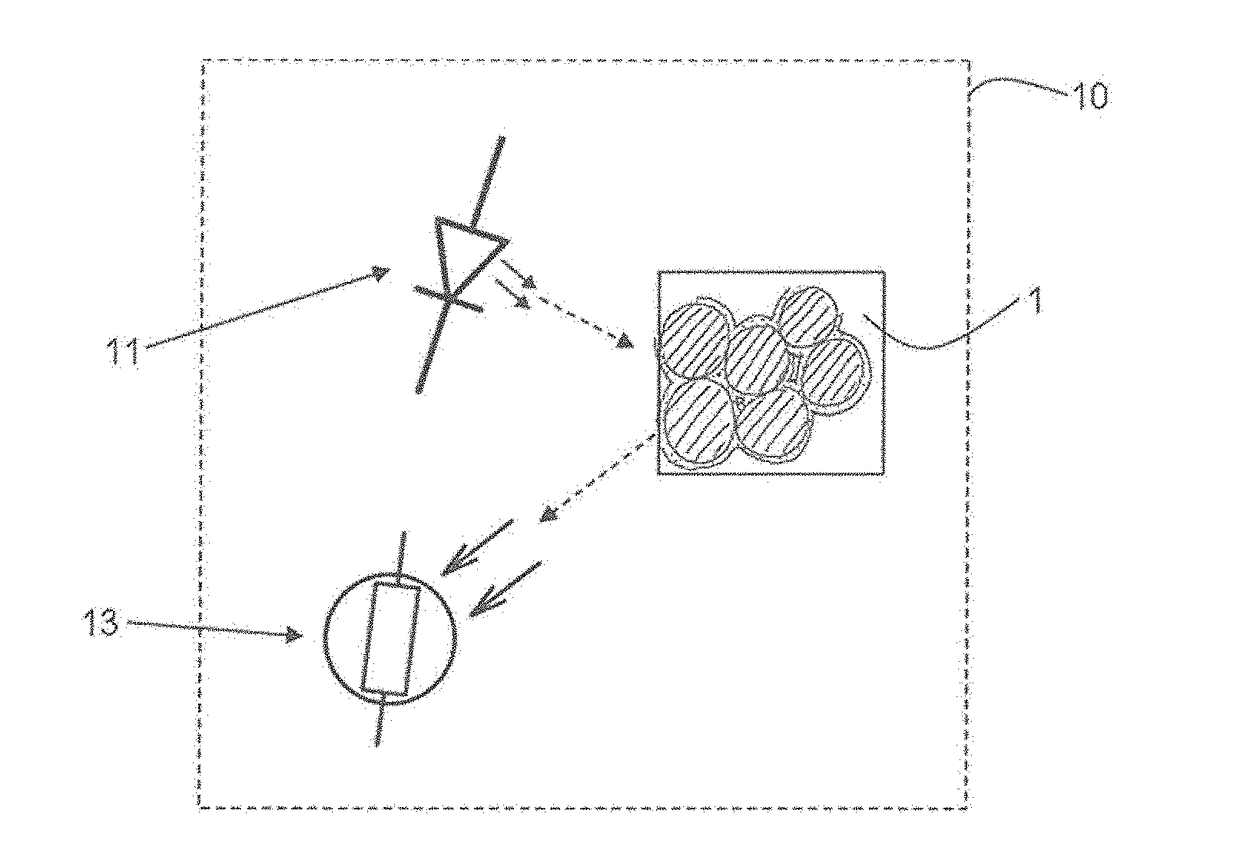

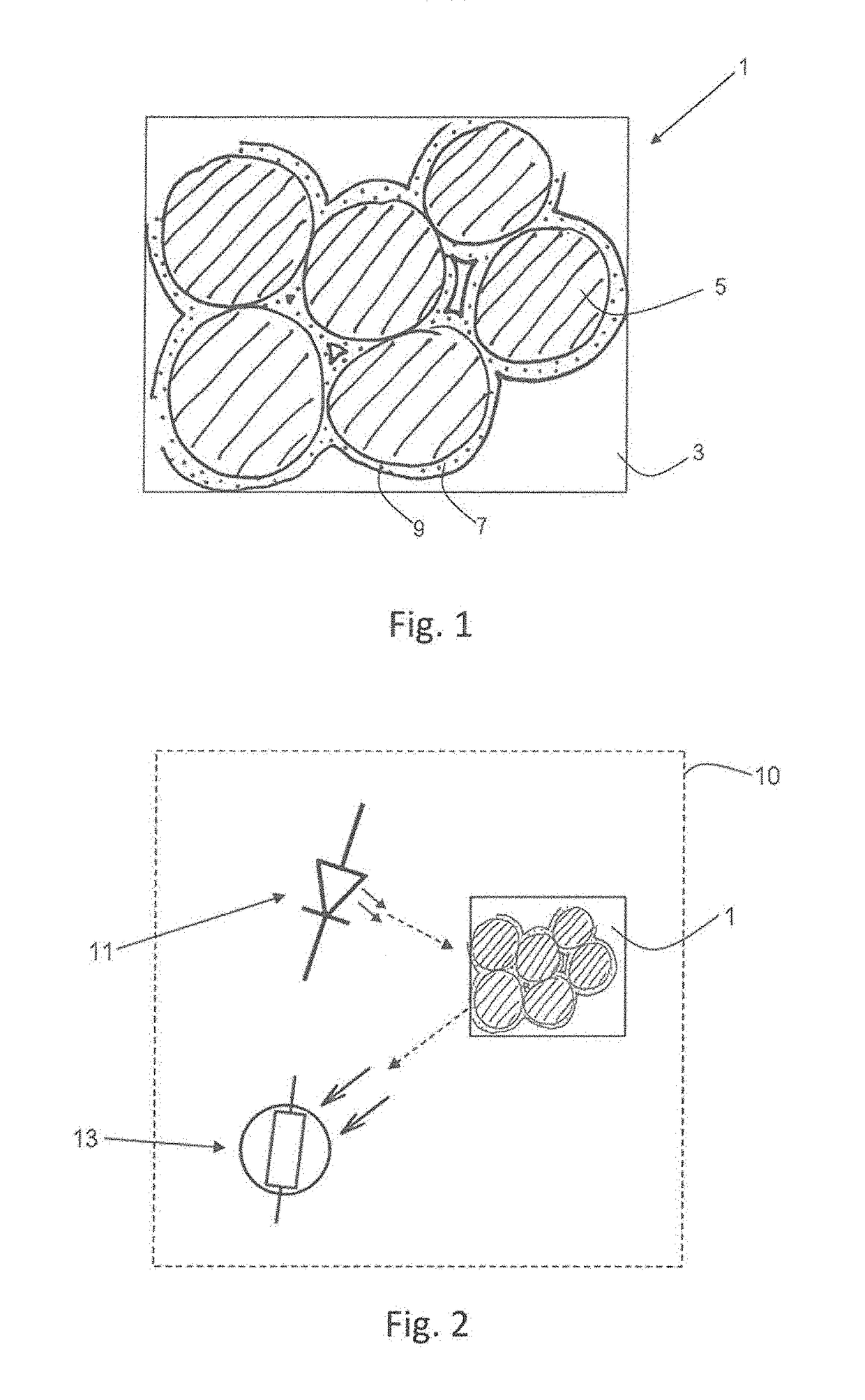

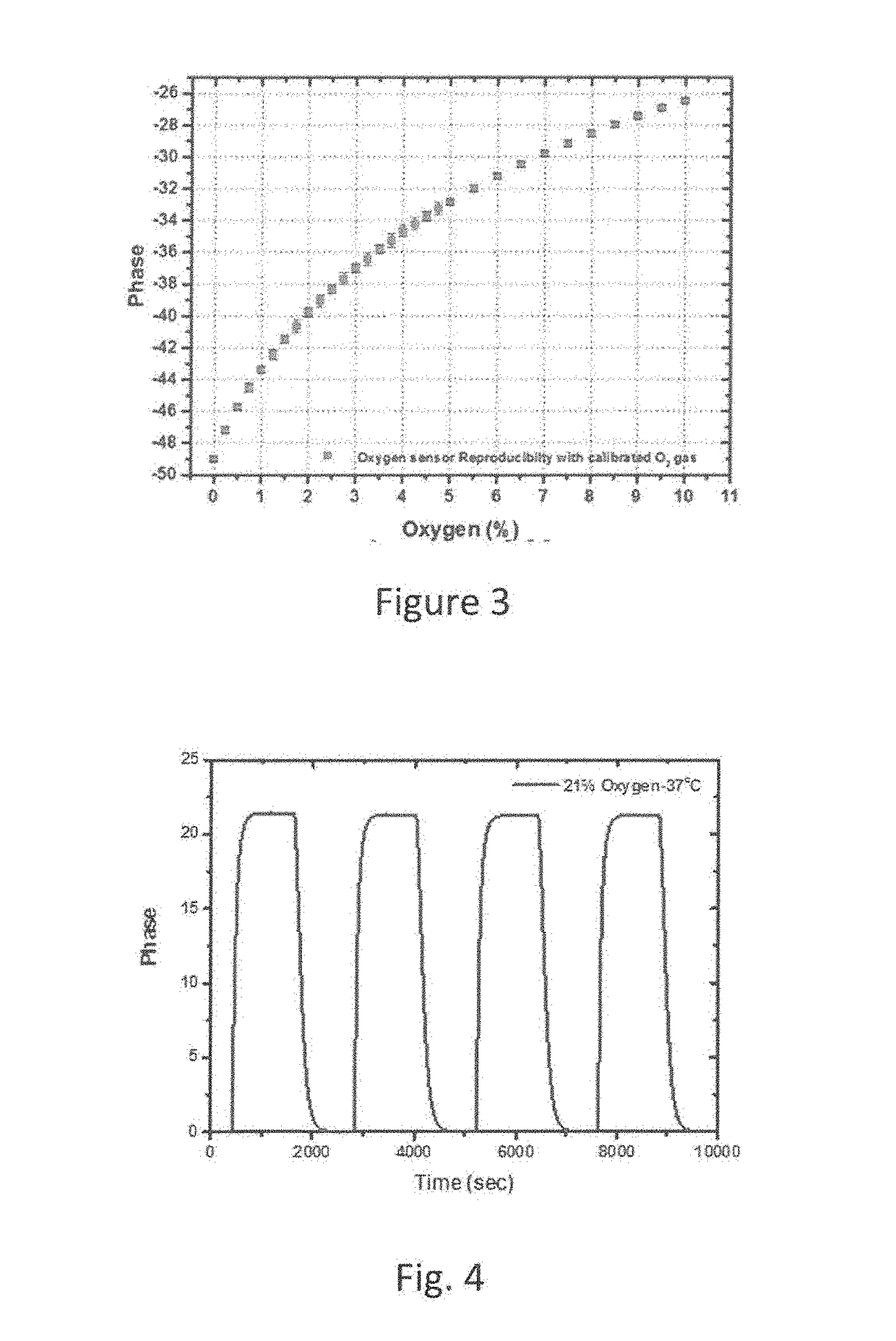

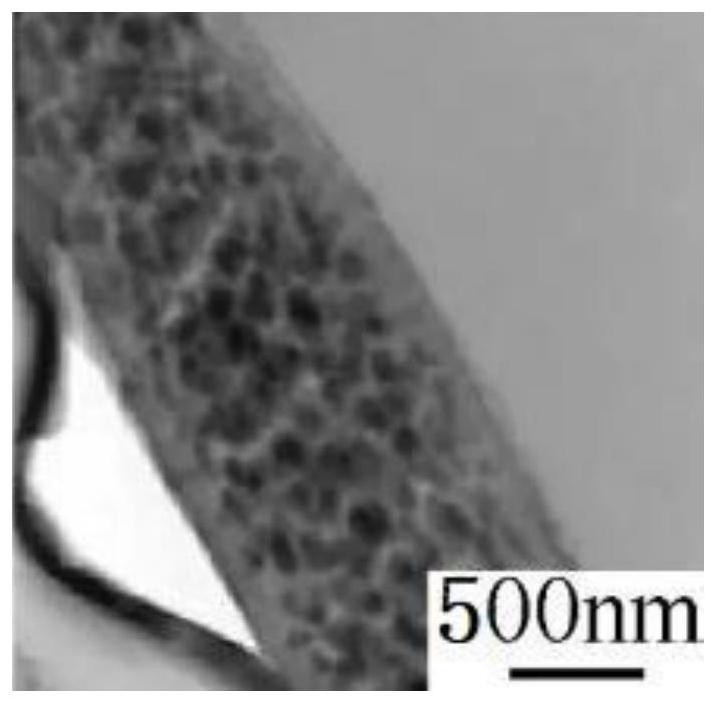

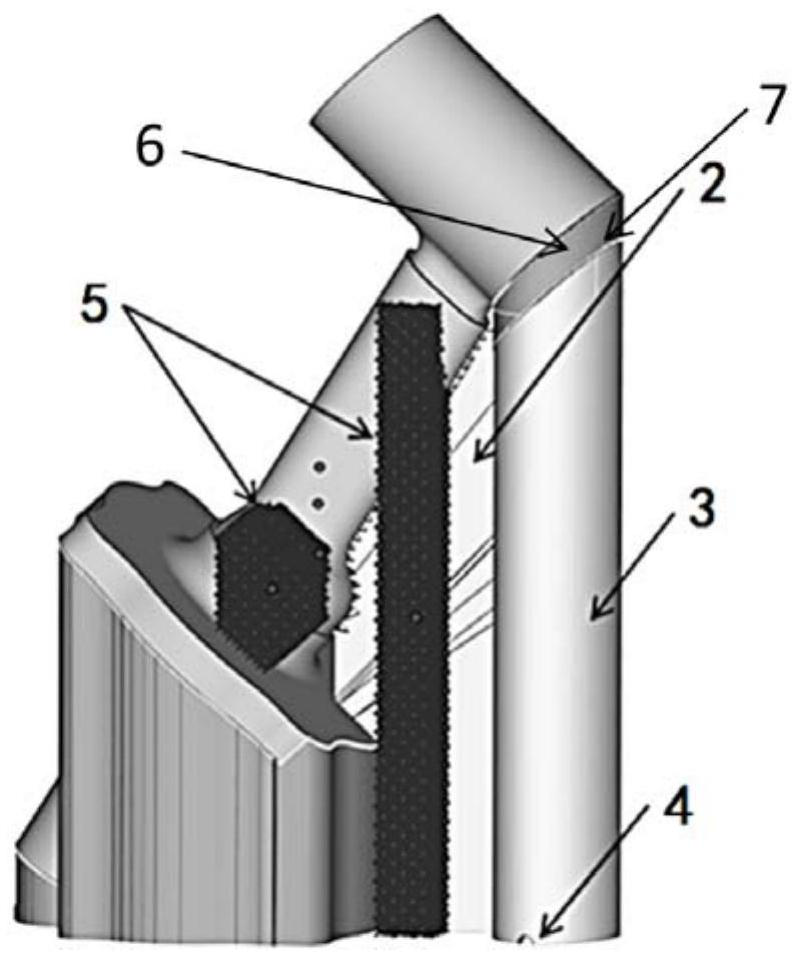

Optical sensor for detecting a chemical species

ActiveUS20170176332A1Short response timeImprove compromiseMaterial nanotechnologyMaterial analysis by observing effect on chemical indicatorChemical speciesOptical property

Disclosed is an optical sensor (1) for detecting a chemical species, including:a substrate (3);a mesoporous matrix (5) disposed on the substrate;a microporous matrix (7) disposed within the mesoporous matrix, the microporous matrix (7) including an indicator dye (9) dispersed therein, the indicator dye (9) exhibiting changes in its optical properties in response to the presence of the chemical species.

Owner:CSEM CENT SUISSE DELECTRONIQUE & DE MICROTECHNIQUE SA RECH & DEV

Preparation method of dense sintering type composite aluminum nitride ceramics

The invention discloses a preparation method of dense sintering type composite aluminum nitride ceramics, and belongs to the technical field of inorganic ceramic materials. The preparation method comprises the following steps: firstly uniformly mixing alcohol aluminum salt, silicate ester, fatty acid, an alcohols solvent-nano-iron powder and sodium fluoride, then adding carbon fiber / graphene oxideaerogel, and carrying out ultrasonic immersing, thus obtaining a mixed immersing solution; after heating and carrying out ultrasonic reaction on the mixed immersing solution, filtering, washing, anddrying, thus obtaining loaded filling aerogel; then reducing the loaded filling aerogel by hydrazine hydrate, thus obtaining reduced loaded filling aerogel; then carrying out temperature rising reaction on the reduced loaded filling aerogel step by step under a nitrogen protection state, thus preparing composite aluminum nitride powder; then mixing the composite aluminum nitride powder with calcium oxide, magnesium oxide, polyvinyl butyral and a solvent, molding through injection molding, then carrying out high-temperature sintering, and cooling, thus obtaining the dense sintering type composite aluminum nitride ceramics. The dense sintering type composite aluminum nitride ceramics obtained by the invention has excellent mechanical performance and excellent heat conduction efficiency.

Owner:常州欧利莱照明有限公司

Manufacturing method of substrate and manufacturing method of wiring substrate

InactiveCN103002675AIncrease production capacityShorten the timePrinted circuit aspectsInsulating layers/substrates workingEngineeringElectroplating

Provided are manufacturing methods of a substrate and a wiring substrate, including a step A of forming a primary plating layer on a lower side of a glass substrate having a through-hole; a step B of sealing a lower opening of the through-hole by forming a first layer on an upper side using electroplating; and a step C of filling the through-hole by depositing a second layer in the through-hole using electroplating from the upper side. In the step A, the primary plating layer is formed on from a lower opening edge to a partial sidewall surface of the through-hole. In the step B, the lower opening is sealed by growing the first layer from a primary plating layer surface inside the through-hole. In the step C, the through-hole is filled with plating metal by growing the second layer from a first layer surface inside the through-hole toward an upper opening.

Owner:HOYA CORP

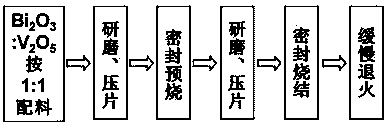

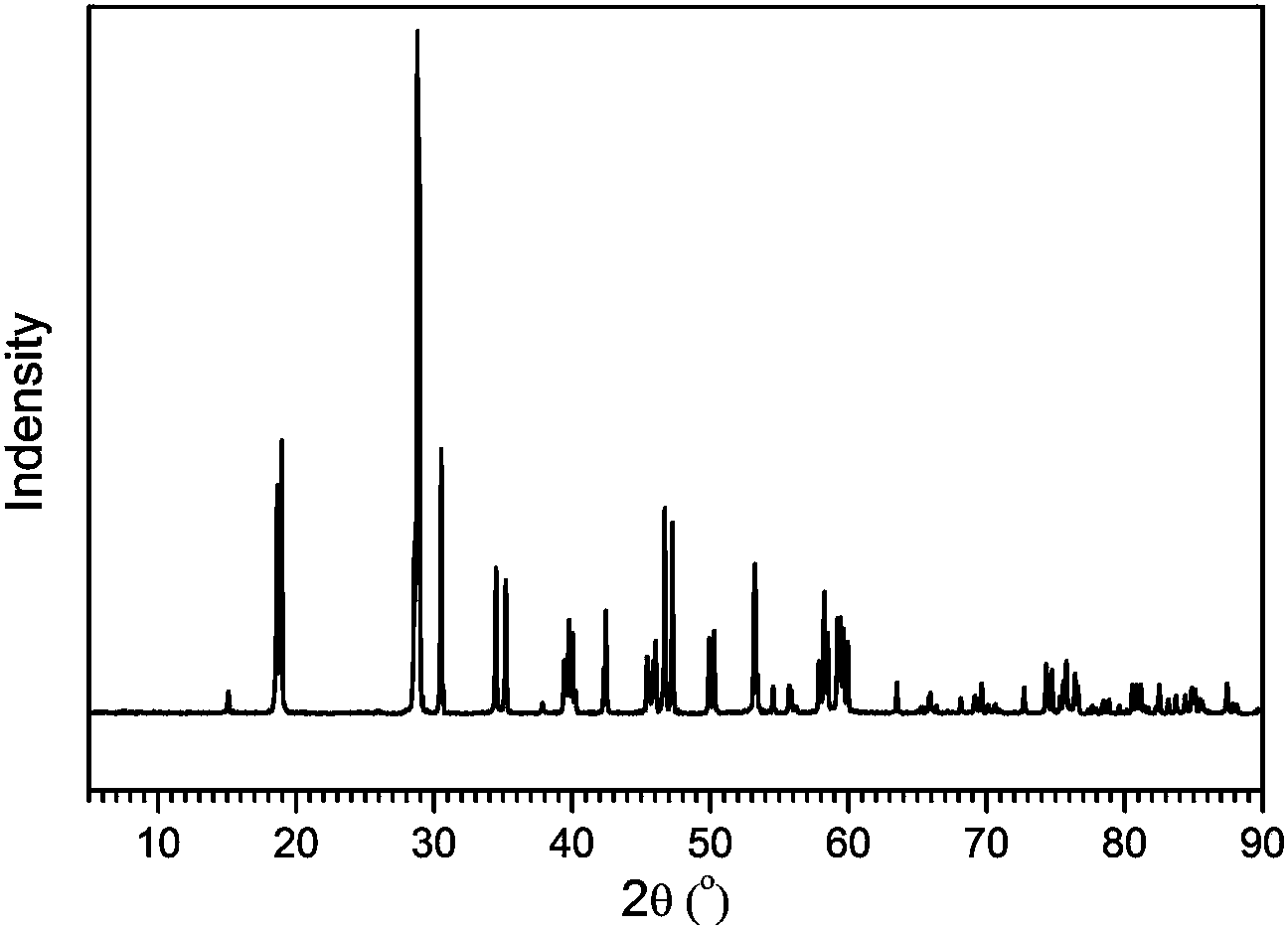

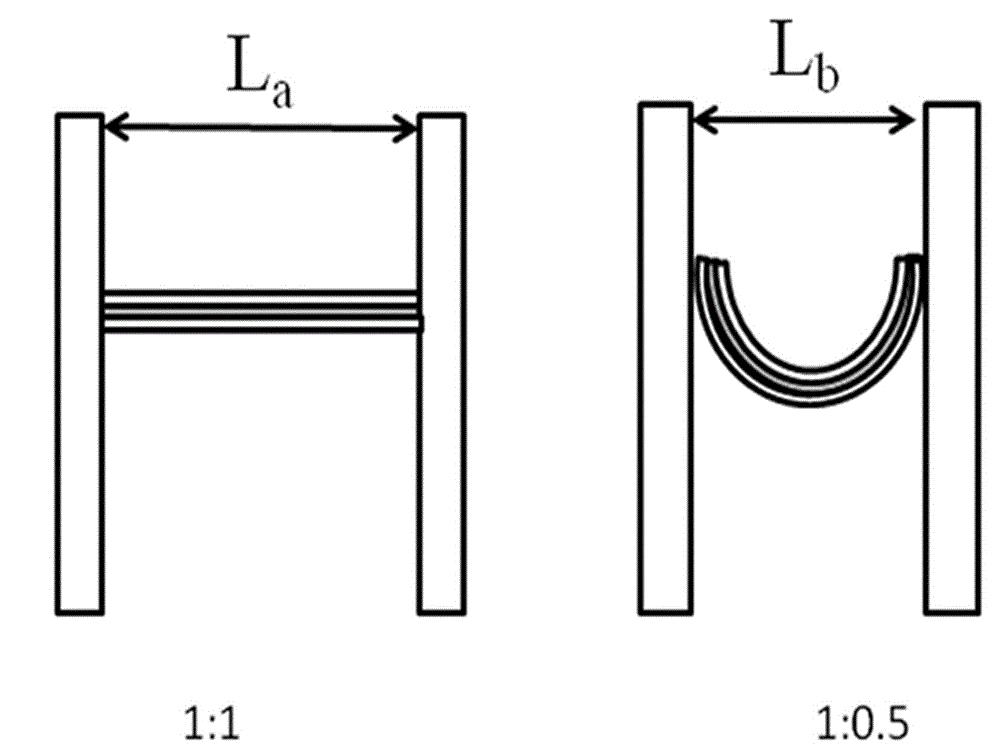

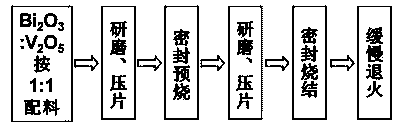

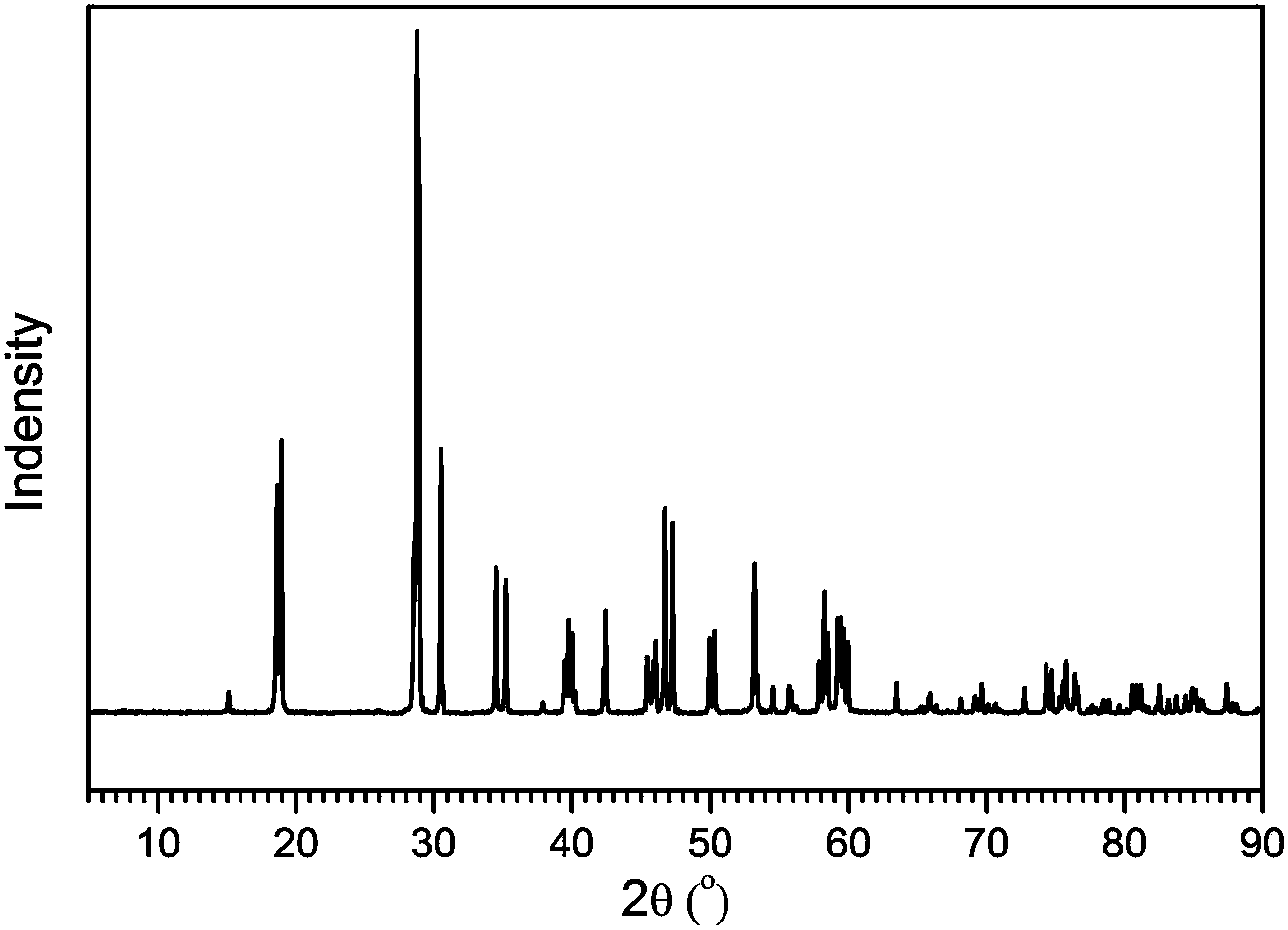

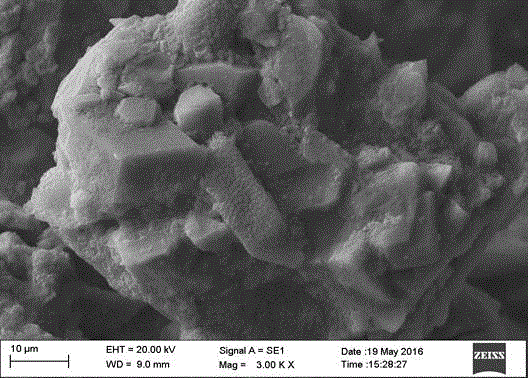

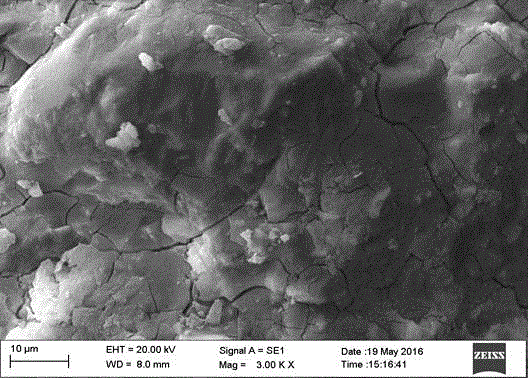

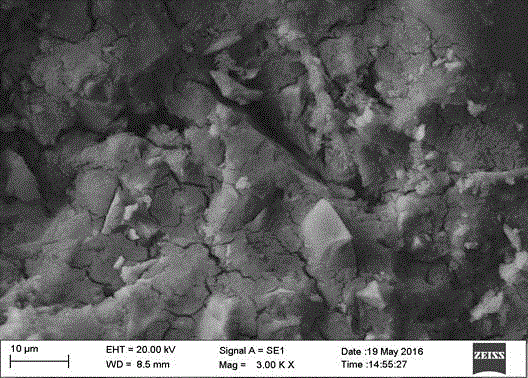

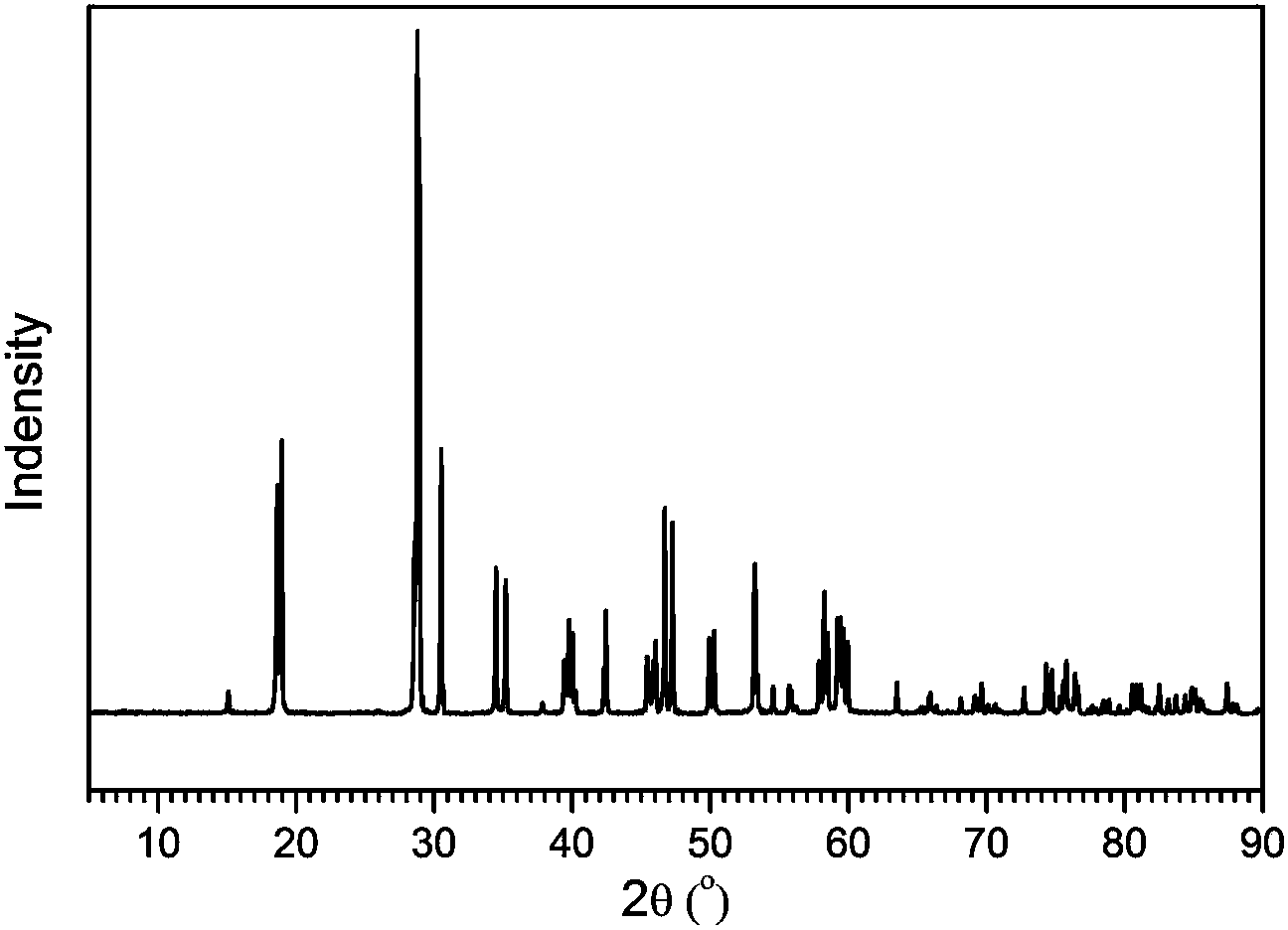

Preparation method of high-density bismuth vanadate ceramic

The invention discloses a preparation method of high-density bismuth vanadate ceramic. The prepared bismuth vanadate ceramic has the density of more than 97%. The preparation method comprises the steps of with Bi2O3 powder and V2O5 powder as raw materials, mixing and tabletting, then, presintering at the temperature of 890 DEG C in a sealed quartz die, and then, grinding into powder; tabletting again, and calcining in the sealed quartz die; after the calcining is ended, cooling from 890 DEG C to 800 DEG C at the speed of 1.5 DEG C / min, cooling to 700 DEG C at the speed of 1.7 DEG C / min, then, cooling to 550 DEG C at the speed of 2.5 DEG C / min, and next, cooling to 350 DEG C at the speed of 3.3 DEG C / min; finally, naturally cooling to room temperature, and then, polishing to obtain the orange yellow bismuth vanadate ceramic.

Owner:CHEM & CHEM ENG GUANGDONG LAB

Processing process of environment-friendly sound insulation pad

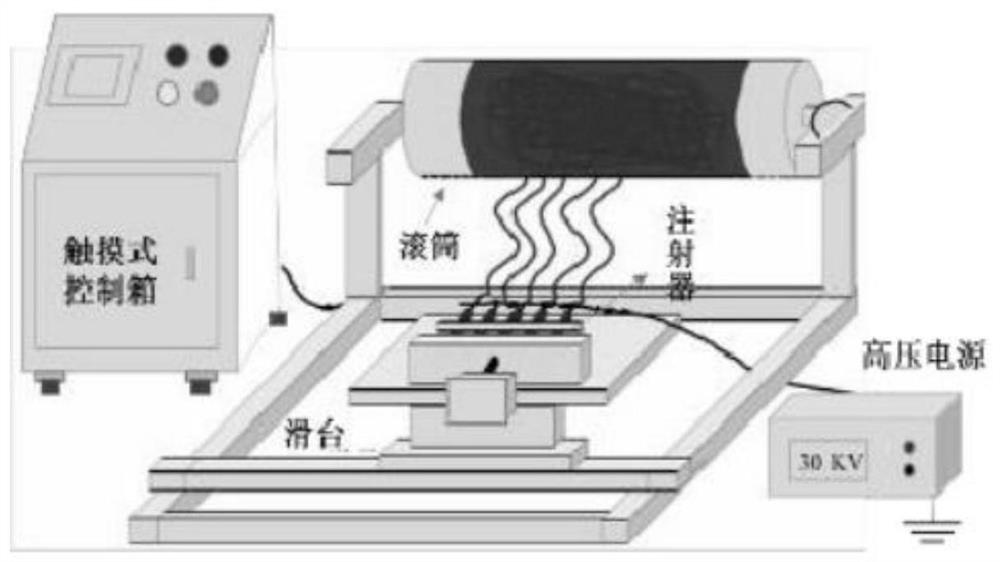

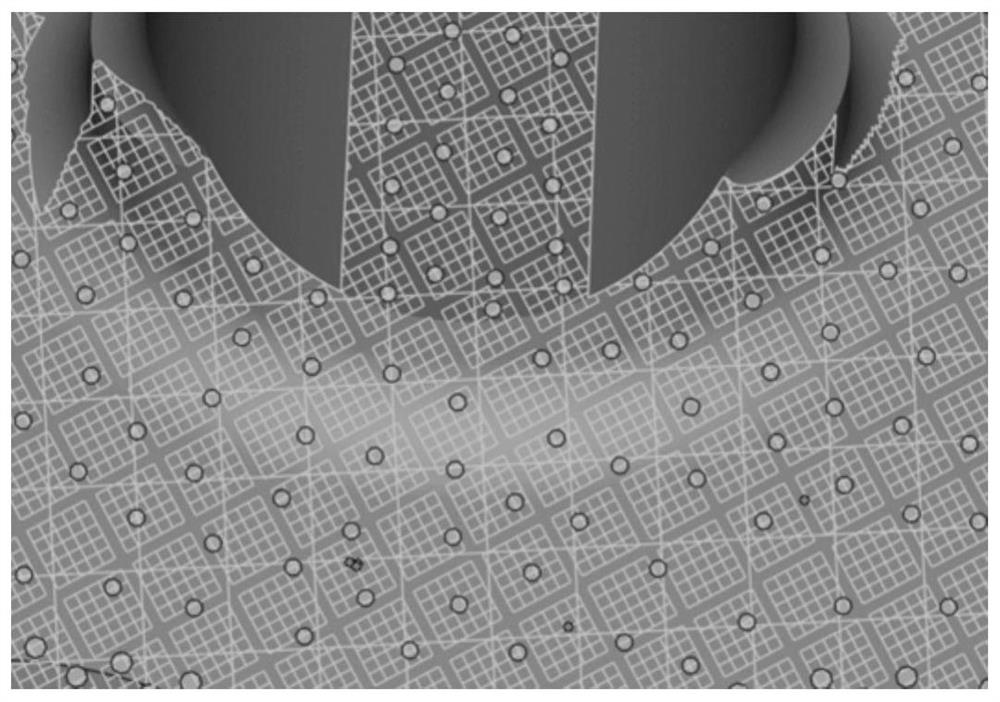

ActiveCN113306238AImprove sound absorptionLow fiber densityNon-macromolecular adhesive additivesSynthetic resin layered productsPorous fiberFiber density

The invention discloses a processing process of an environment-friendly sound insulation pad. The processcomprises the steps of porous PET fiber spinning film forming, mesoporous fiber film spinning film forming and multilayer film compositing. PET fibers are made to present a porous morphology by changing condition parameters during electrostatic spinning, and nanoscale micropores in the PET fibers and micron-sized pores formed by interweaving the fibers form a two-stage pore mechanism, so that under the condition that the thickness of the material is not increased, the sound absorption capacity of the material is effectively improved; SiO2 aerogel is added into the colloid, so that pores in the fiber membrane can be effectively prevented from being densely filled with the colloid, and meanwhile, the pores can assist in silencing; by adding the mesoporous material with a porous structure in a proper proportion, not only can the fiber density be reduced and the silencing effect be improved, but also the mechanical strength of the fiber can be maintained, so that the porous PET fiber is reinforced after compounding, so that the composite film is not easy to break during use; and the sound attenuation performance of the compounded membrane material is higher than that of a single PET fiber membrane or a single mesoporous fiber membrane.

Owner:芜湖尚唯汽车饰件有限公司

Forming method for selective laser melting forming technology

ActiveCN112496343AReduce porosityReduce defects such as cracksAdditive manufacturing apparatusSelective laser meltingEngineering

The invention discloses a forming method for a selective laser melting forming technology, and belongs to the technical field of additive manufacturing. The forming method comprises the steps of according to the actual design size of a target part, carrying out allowance compensation to optimize a three-dimensional model, and constructing a three-dimensional entity model suitable for selective laser melting forming; according to the obtained three-dimensional entity model, designing and slicing a supporting structure suitable for the target part; after the supporting structure is designed, carrying out process arrangement to form a model file, and slicing the obtained model file; and setting process parameters of the selective laser melting forming technology, and carrying out integrated printing forming, wherein the target part is of a cavity thin-wall structure. Through the forming method, the defect that in the integrated forming process of the part with the cavity thin-wall structure, the part is prone to being scratched by a scraper due to thermal stress can be effectively overcome, and the percent of pass is increased.

Owner:AECC AVIATION POWER CO LTD

Organic light emission diode and preparation method thereof

InactiveCN104681726AExtended service lifeImprove flexibilitySolid-state devicesSemiconductor/solid-state device manufacturingOrganic layerHole transport layer

The invention relates to an organic light emission diode, which comprises a substrate, an anode layer, an organic light emission unit and a cathode layer covered with a packaging film, wherein the substrate, the anode layer, the organic light emission unit and the cathode layer are successively laminated; the organic light emission unit comprises a hole transmission layer, a light emission layer and an electron transmission layer, wherein the hole transmission layer, the light emission layer and the electron transmission layer are successively laminated on the surface of the anode layer. Since the cathode layer of the organic light emission diode adopts a lamination structure characterized in that a metal layer is doped with organic layers, the thickness of a metal film of the cathode layer is lowered, and the toughness of the metal film is improved. In addition, a plurality of organic layers are arranged, internal stress generated by the metal film in a flexure process is dispersed, the metal film is prevented from generating cracks or pores, the flexural property of the whole diode is improved, and the service life of the organic light emission diode is prolonged. In addition, the invention also provides a preparation method for the organic light emission diode.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +2

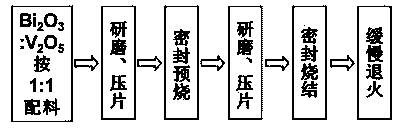

Method for preparing bismuth vanadate functional ceramic and obtained bismuth vanadate functional ceramic

The invention discloses a method for preparing a bismuth vanadate functional ceramic and the obtained bismuth vanadate functional ceramic. The method comprises the following steps: by adopting Bi2O3 and V2O5 as raw materials, mixing the Bi2O3 and the V2O5 powders in the molar ratio of 1 to 1 and grinding for 5 hours by adopting absolute ethyl alcohol as a solvent, volatilizing the solvent out, pressing into pieces, putting the pieces into a quartz mould, sealing the quartz mould to inhibit the volatilization of components, putting the sealed quartz mould into a muffle furnace to carry out primary firing, grinding into powder after the firing is completed, pressing into pieces again, putting the pieces into the sealed quartz mould again to carry out secondary firing, controlling the cooling rate to be not more than 3.3 DEG C / min after the firing is finished, and cooling to room temperature to obtain the bismuth vanadate functional ceramic. The obtained bismuth vanadate functional ceramic has the characteristics that the chemical component is BiVO4; the density is above 97%; the dielectric constant is 60 and the dielectric loss is less than 0.005.

Owner:CHEM & CHEM ENG GUANGDONG LAB

Retarder-free waterproof magnesium ammonium phosphate cement and preparation method thereof

ActiveCN106746811AReduce dissolution rateGood flexibilityIsolation effectMagnesium ammonium phosphate

The invention discloses retarder-free waterproof magnesium ammonium phosphate cement and a preparation method thereof. The cement comprises dead burned magnesia coated with graphene oxide, ammonium dihydrogen phosphate and mineral admixtures, wherein the mass ratio of dead burned magnesia coated with graphene oxide and ammonium dihydrogen phosphate is (62-78):(22-38), and the mineral admixtures are 5-15% of the total mass of dead burned magnesia and ammonium dihydrogen phosphate. According to the cement, dead burned magnesia powder is pretreated by graphene oxide, so that a comparatively obvious isolation effect is formed between magnesia and an external environment, therefore, the dissolution rate of magnesia is greatly decreased, a forming process of a hydration product is delayed, and the heat release of a whole reaction system is reduced; macroscopically, the time of coagulation is greatly prolonged, and any retarders do not need to be added. Moreover, a dissolution process of the hydration product and phosphate is inhibited, a large amount of pores are prevented from being formed in the cement, and the strength of hardened cement paste is ensured.

Owner:UNIV OF JINAN

Regeneration method of waste concrete and modified recycled concrete

ActiveCN113968686AHigh mechanical strengthImprove impermeabilitySolid waste managementFiberAggregate (composite)

The invention relates to the field of concrete, and particularly discloses a regeneration method of waste concrete and modified recycled concrete. The waste concrete regeneration method comprises: S1, crushing waste concrete blocks, soaking in a hydrochloric acid solution, stirring the mixture, taking out the concrete blocks, and washing the mixture to obtain crushed aggregates; s2, soaking and stirring the crushed aggregates in a sodium carbonate solution, then taking out the crushed aggregates, and washing the crushed aggregates with water to obtain loaded aggregates; s3, soaking and stirring the loaded aggregate in a water-based acrylic resin solution, and then taking out the loaded aggregate to prepare a modified aggregate; s4, spray-coating composite fibers on the surface of the modified aggregate, wherein the weight ratio of the modified aggregate to the composite fibers is 1:(0.01-0.025), and performing stirring, drying, grading and drying to obtain the regenerated aggregate. The modified recycled concrete is prepared from recycled aggregate prepared by a waste concrete regeneration method. The recycled concrete has the advantage of good mechanical strength.

Owner:深圳市正强混凝土有限公司

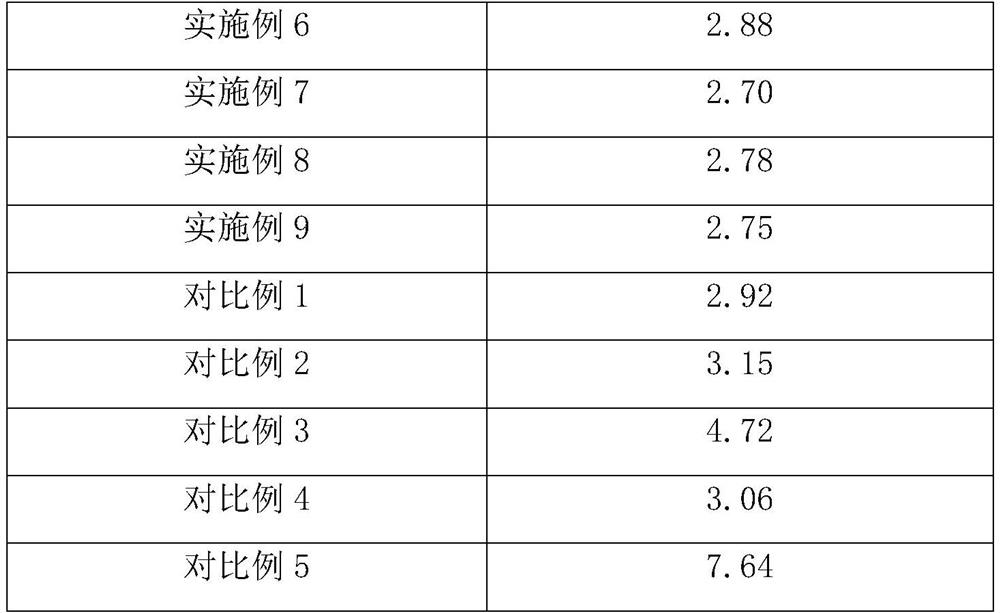

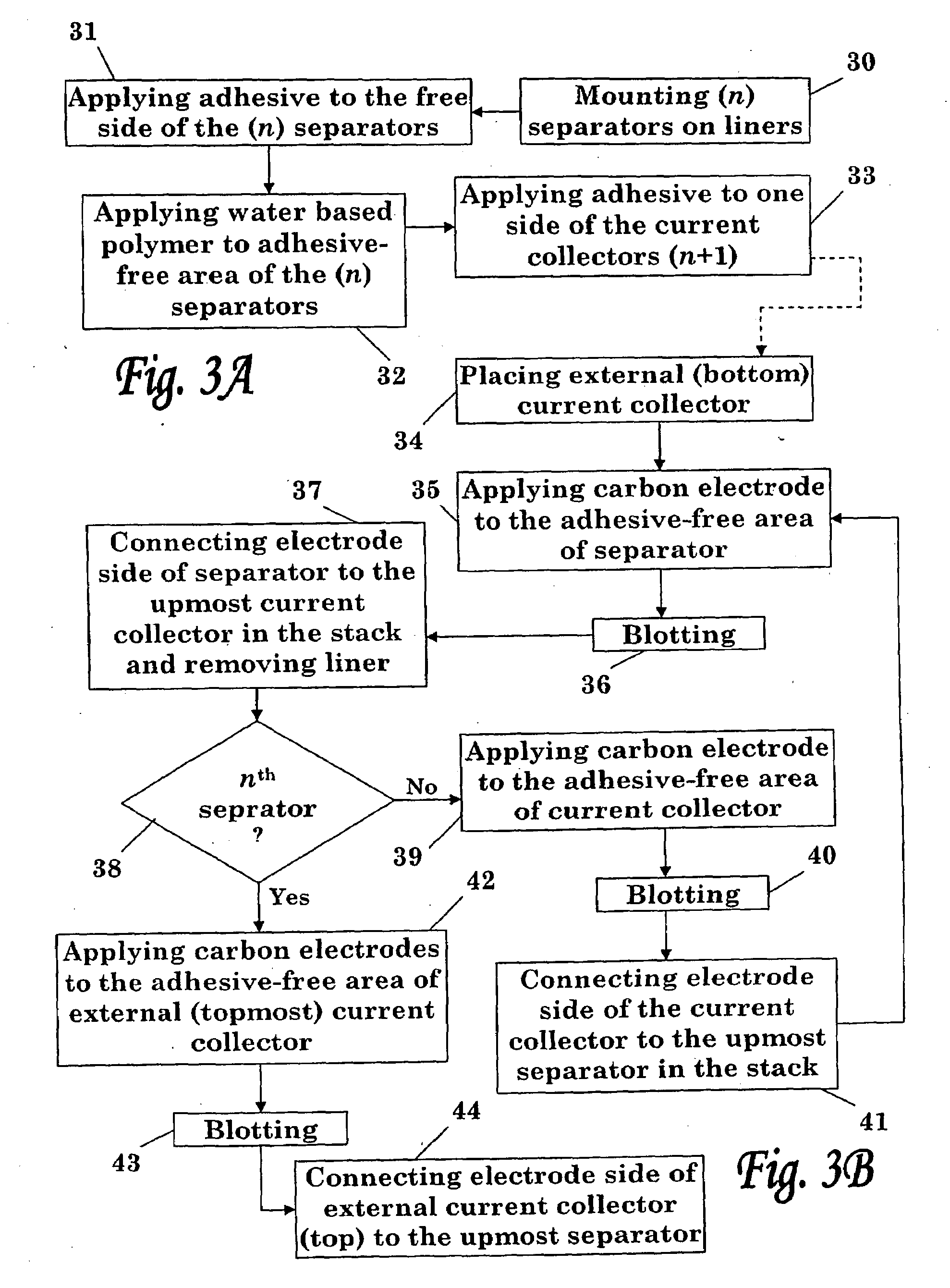

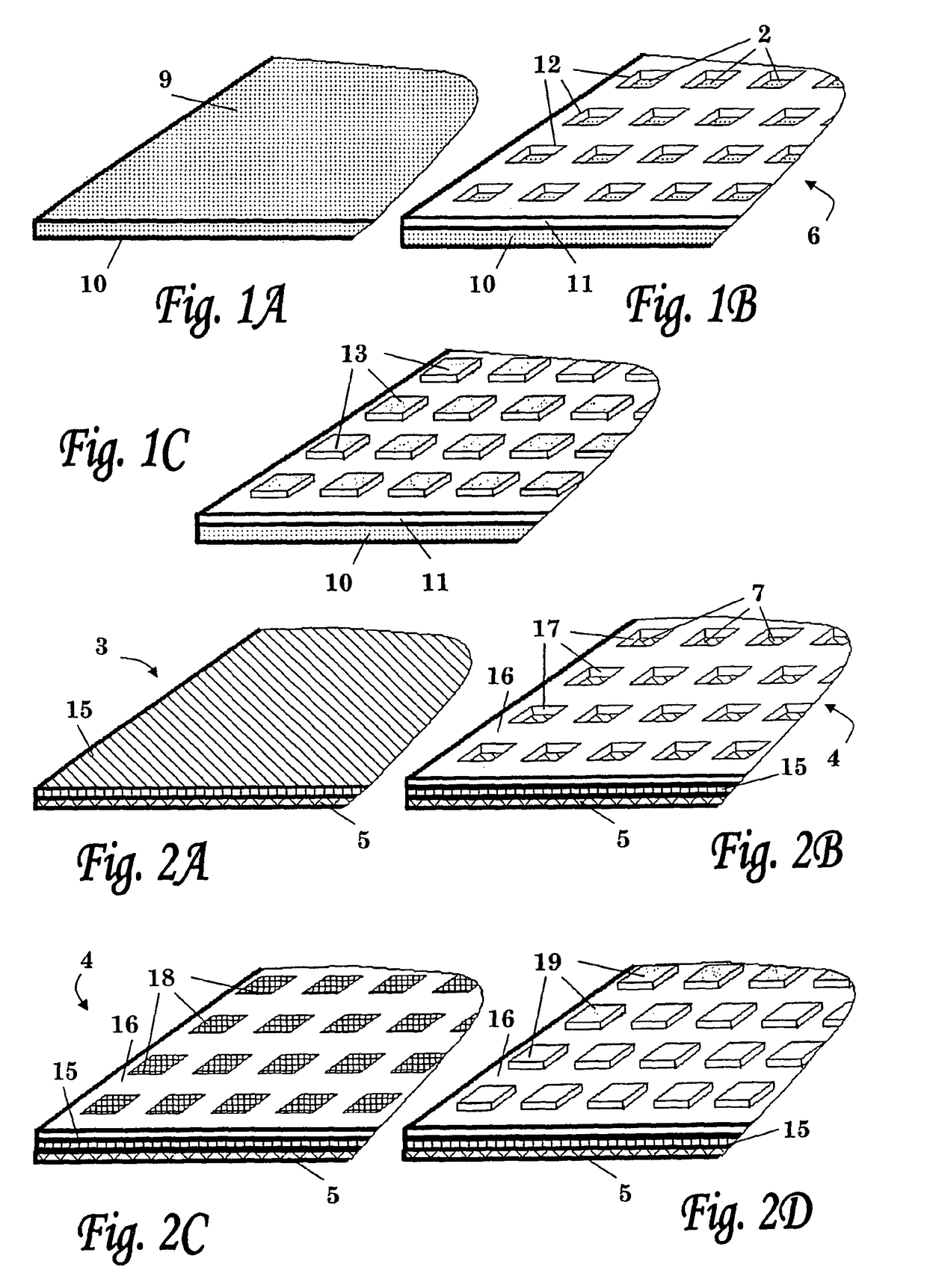

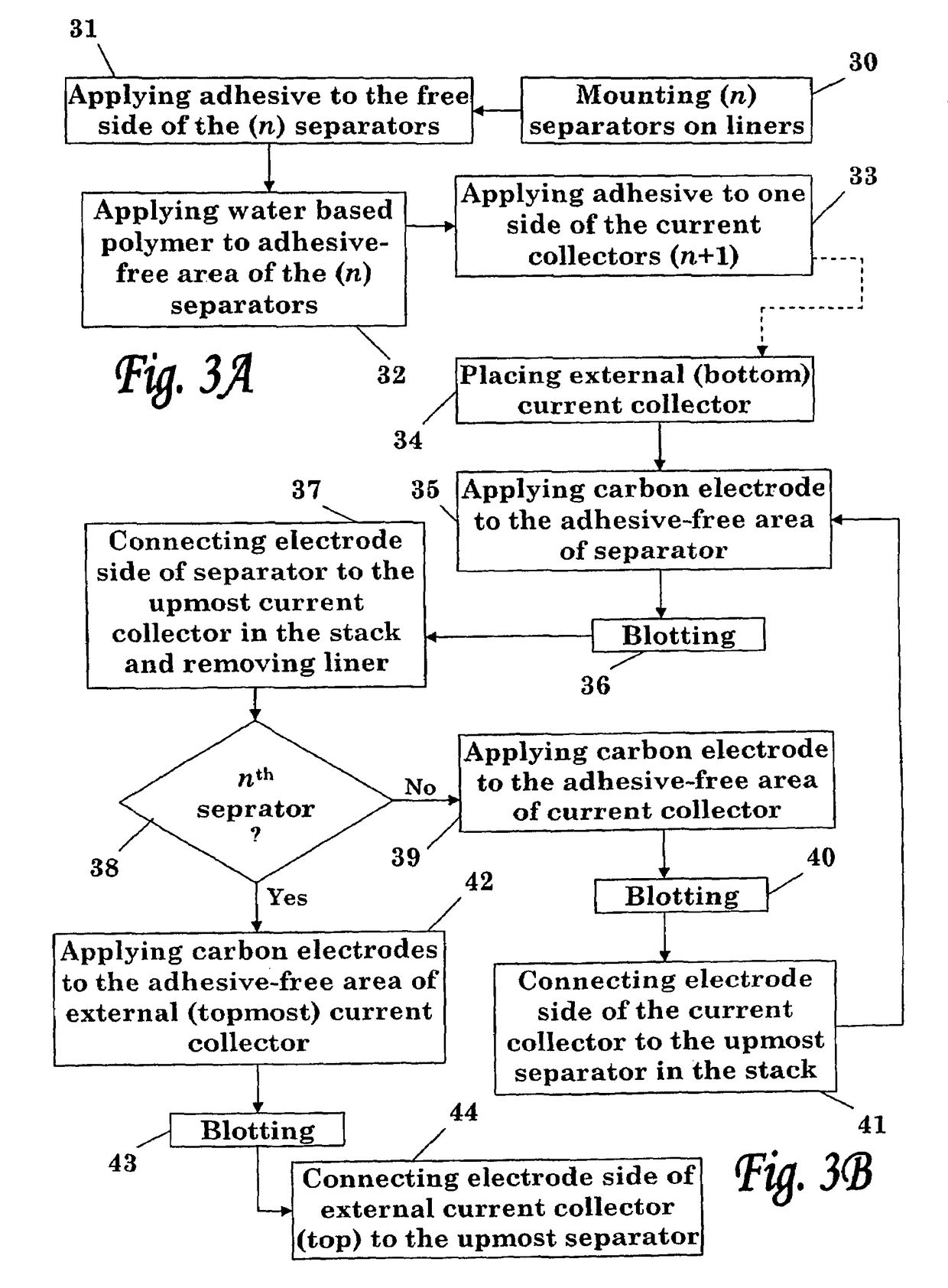

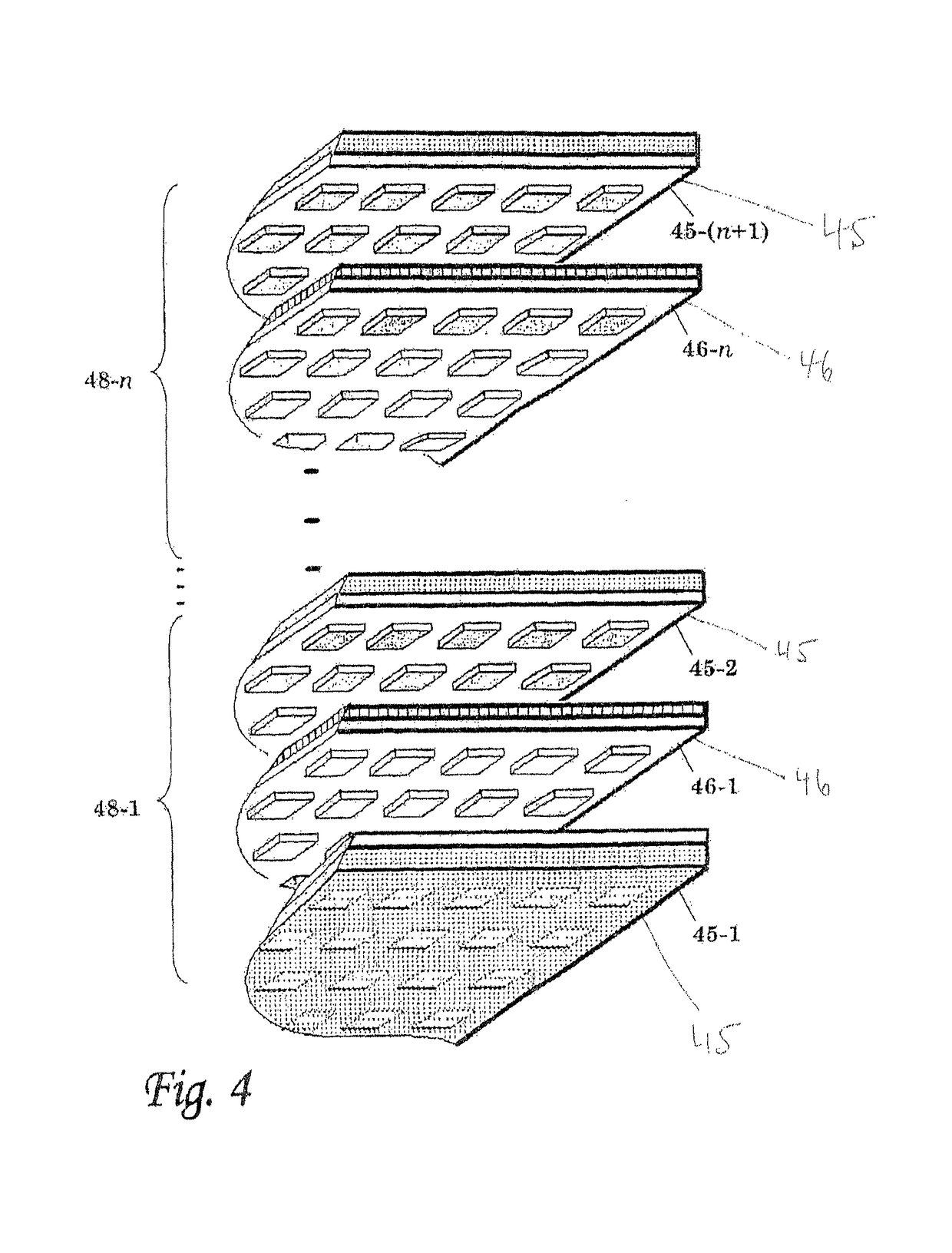

Multilayered Electrochemical Energy Storage Device and Method of Manufacture Thereof

InactiveUS20090201629A1Efficient preparationPrevent leakageHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersElectrical batteryEngineering

An energy storage device comprising one or more cells, wherein each cell is defined by a pair of electrodes and a separator placed therebetween, wherein each cell is bounded by two current collectors, the geometric form and size of said separator being identical to the form and size of said current collectors, and wherein in each cell, one electrode is printed on one of said two current collectors and the other electrode is printed on one face of the separator, the two electrodes being electronically insulated by means of said separator, and wherein the peripheral region of the separator, which surrounds the electrode printed thereon, is sealed.

Owner:CELLERGY

Preparation technique of nanoparticle composite material film for welding

The invention relates to the technical field of preforming welding material, and particularly discloses a preparation technique of a nanoparticle composite material film for welding; the technique includes steps of material mixing-vacuum defoamation- curtain coating and film formation-drying and curing-after-treatment. The preparation technique is featured by simple and feasible practice, strong controllability, high efficiency, and low cost; the technique can effectively guarantee the component of the prepared nanoparticle composite material film, uniform and stable dimension, excellent processing performance and high reliability of low-temperature sintering and welding; the preparation technique can be widely applied to the field of preforming welding material.

Owner:SOLDERWELL MICROELECTRONIC PACKAGING MATERIALS CO LTD

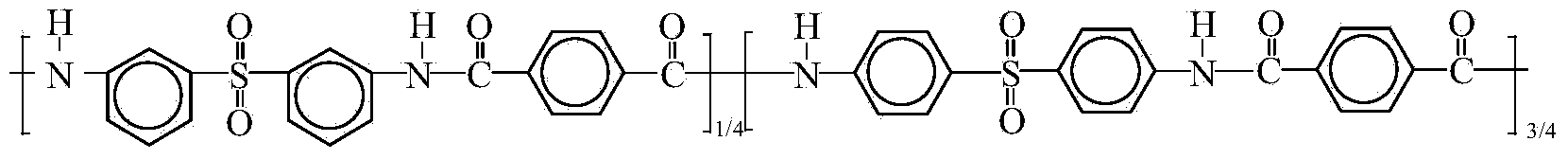

Polysulfonamide-based carbon fiber reinforced composite material and preparation method thereof

The invention discloses a polysulfonamide-based carbon fiber reinforced composite material and a preparation method thereof. The polysulfonamide-based carbon fiber reinforced composite material is prepared from the following raw materials in percentage by weight: 70-90% of polysulfonamide chopped fiber and 10-30% of short carbon fiber. The polysulfonamide-based carbon fiber reinforced composite material is prepared by adopting the following method: (1), carrying out ultrasonic treatment on the polysulfonamide-based carbon fiber and the short carbon fiber in a pretreating agent, washing and drying; and (2), carrying out hot-forming. The polysulfonamide-based carbon fiber reinforced composite material is prepared from the polysulfonamide and the carbon fiber which are used as the raw materials, is used for preparing high-performance engineering plastics by virtue of a hot-pressing technique, has good mechanical performances, heat resistance and electrical insulation property, and can be used for the electrical insulation fields of motors and transformers.

Owner:SHANGHAI TANLON FIBER CO LTD +1

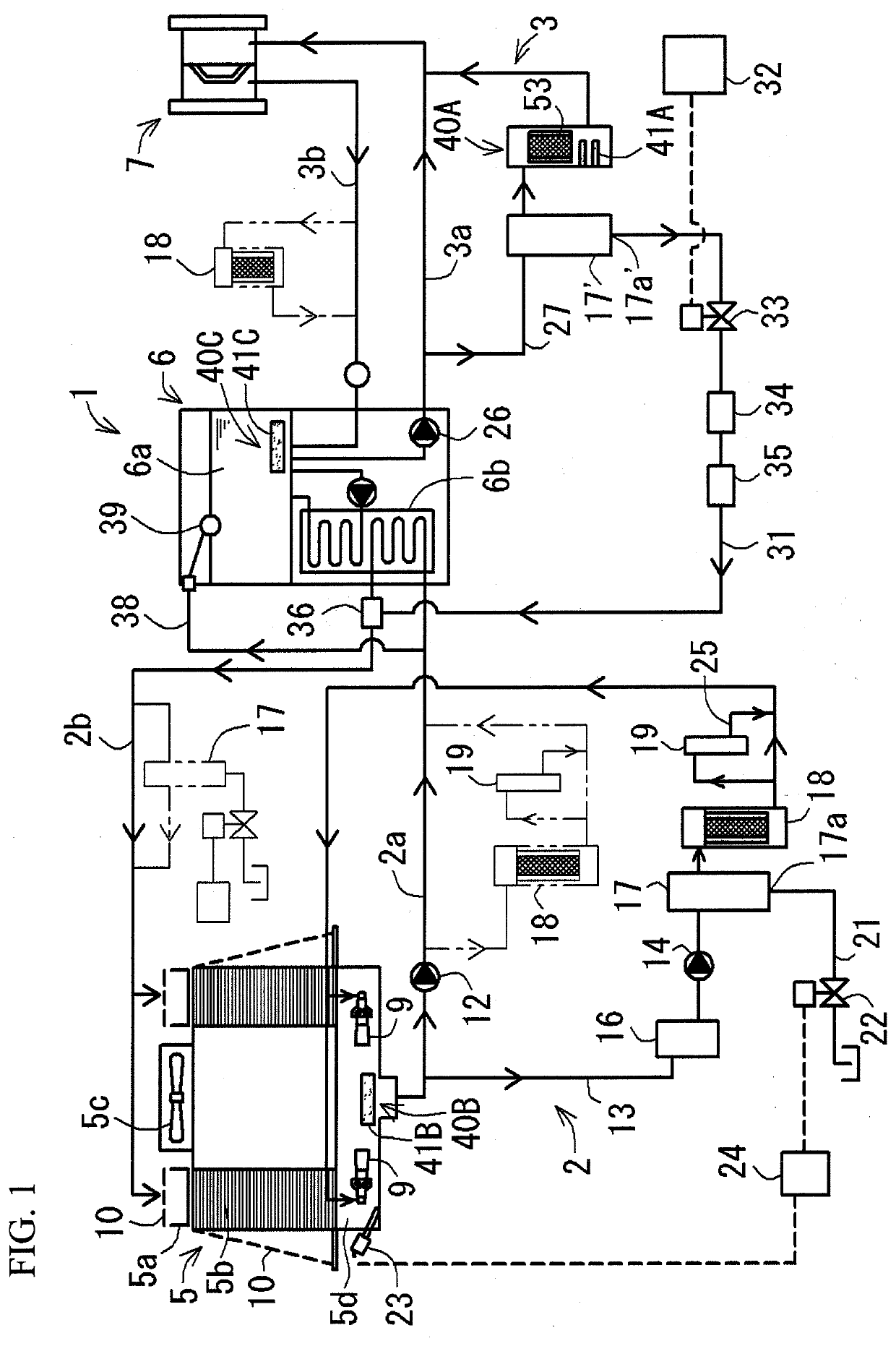

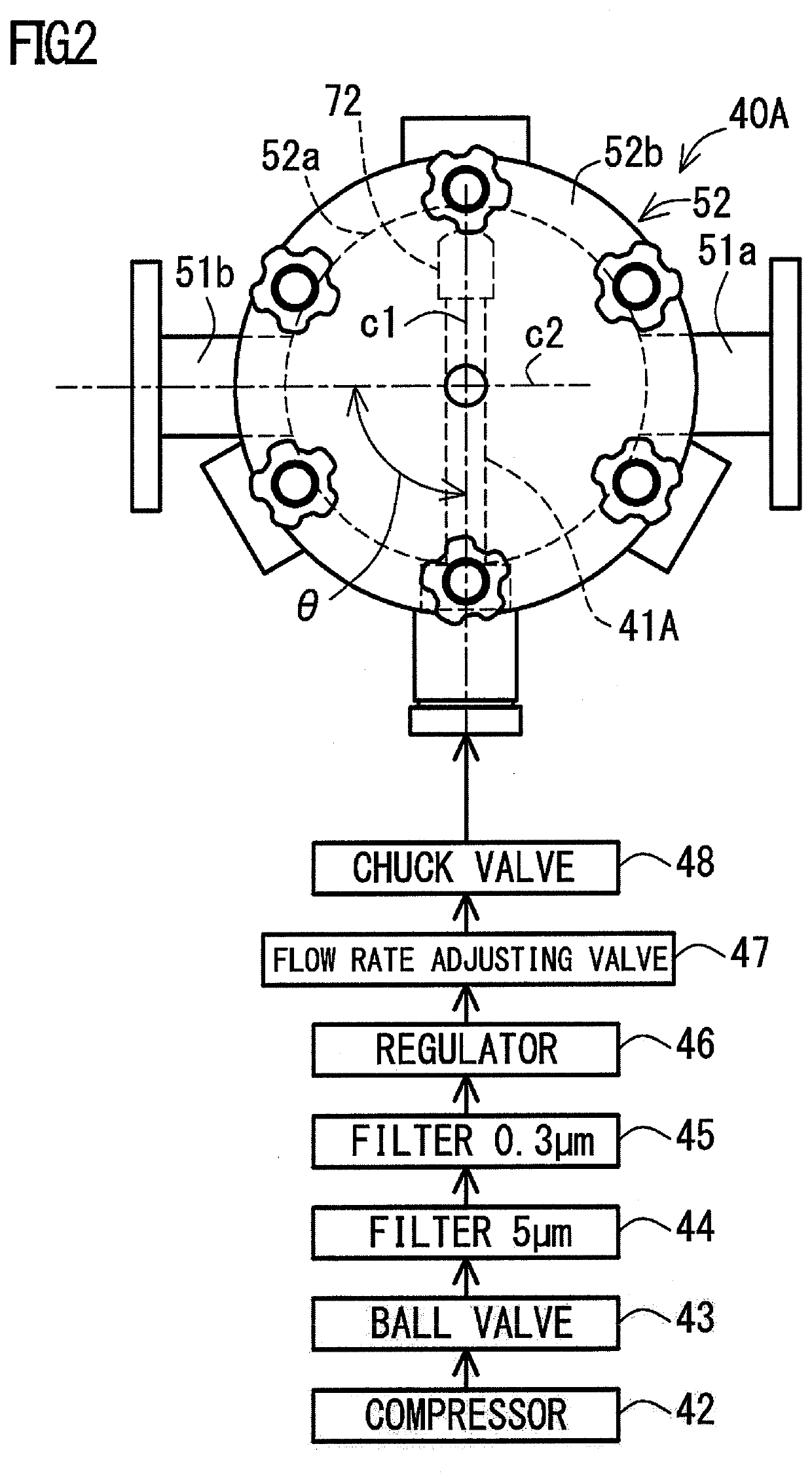

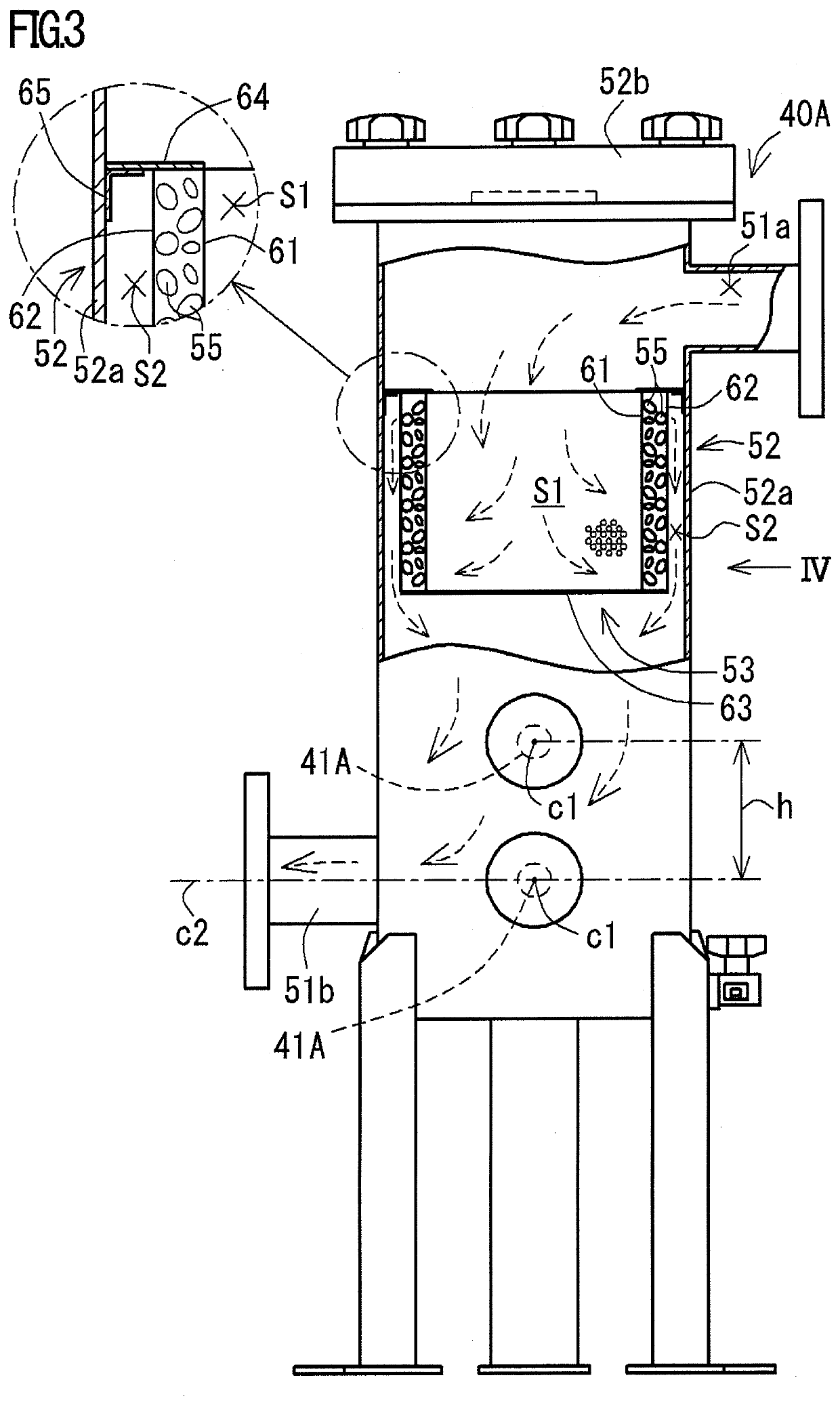

Microbubble generator and cooling water circulation system equipped with same

InactiveUS20200398231A1Simple and inexpensive structurePrevent cloggingTreatment using aerobic processesFlow mixersWater circulationMicrobubbles

The present microbubble generator is a microbubble generator for generating microbubbles in a liquid, including a straight pipe made of porous ceramics, having one end connected to a compressor and the other end blocked, and the straight pipe having an average pore diameter of 1.5 μm or less.

Owner:TOYOTA BOSHOKU KK

Bismuth vanadate functional ceramic and preparation method thereof

The invention relates to a bismuth vanadate functional ceramic and a preparation method thereof. For the bismuth vanadate functional ceramic, the chemical component is BiVO4, the compactness is more than 97%, the dielectric constant is 60 and the dielectric loss is less than 0.005. The preparation method of the bismuth vanadate functional ceramic comprises the following steps: by taking Bi2O3 and V2O5 powder as raw materials, mixing and preforming the raw materials, putting in a closed mold, and carrying out primary sintering; after sintering is completed, grinding into powder and preforming again; then putting into the closed mold again and carrying out secondary sintering; after the sintering is completed, controlling the cooling speed to be less than or equal to 3.3 DEG C / min, and cooling to room temperature so as to obtain the bismuth vanadate functional ceramic.

Owner:CHEM & CHEM ENG GUANGDONG LAB

Multilayered electrochemical energy storage device and method of manufacture thereof

InactiveUS8472162B2Efficient preparationPrevent leakageHybrid capacitor separatorsCell seperators/membranes/diaphragms/spacersEngineeringEnergy storage

Owner:CELLERGY

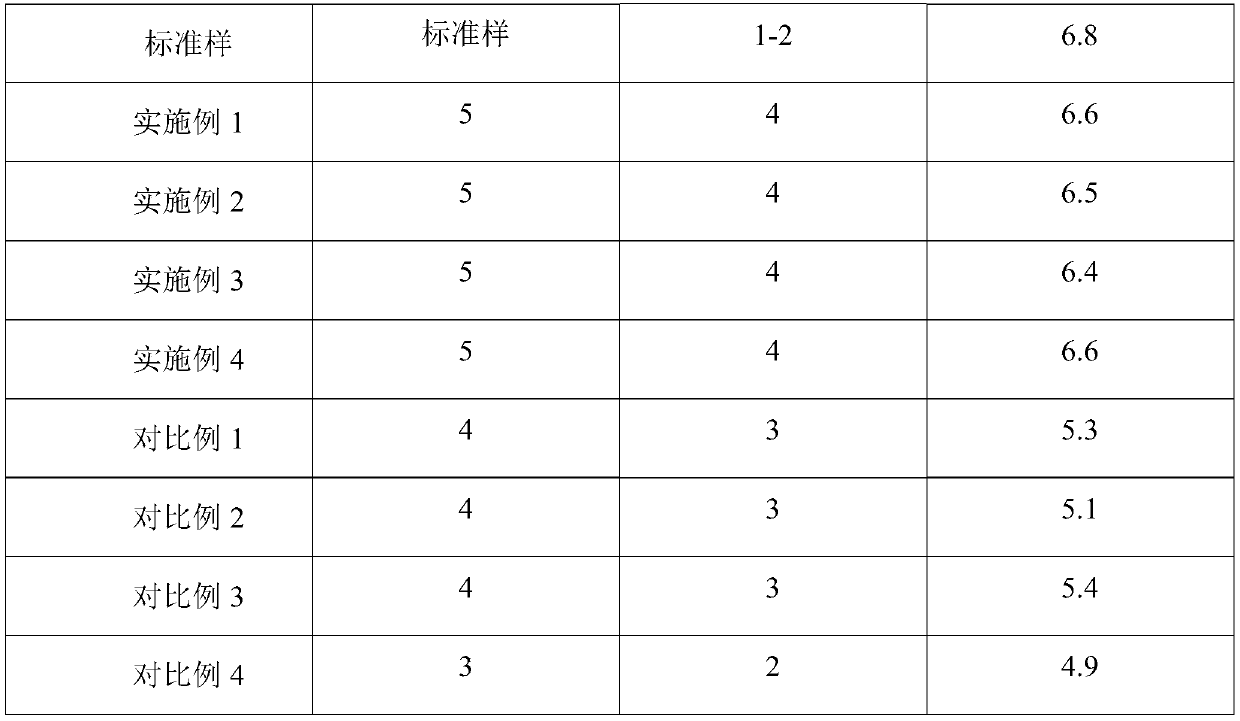

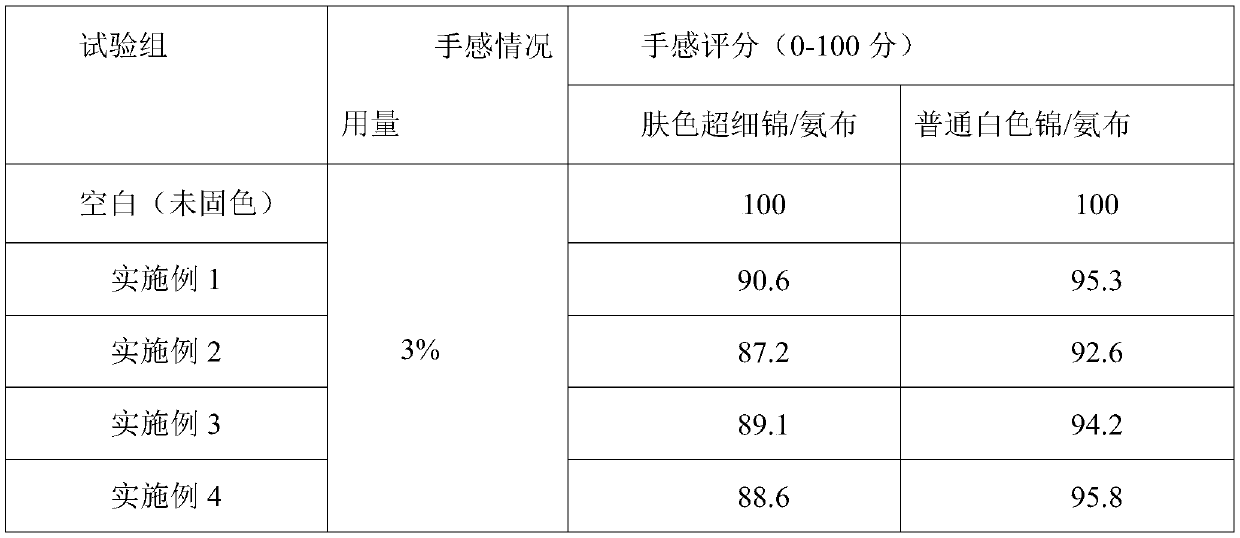

Acidic color-fixing agent and preparation method thereof

ActiveCN110699991AGood working fluid pH control abilityGood color fixing effectDyeing processSodium stearateSodium salicylate

The invention belongs to the field of dye color-fixing agents, and particularly relates to an acidic color-fixing agent and a preparation method thereof. The acidic color-fixing agent comprises polyethyleneimine, modified polyacrylic acid, sodium citrate, sodium salicylate, sodium laureth sulfate, sodium stearate and sodium phenolsulfonate; The preparation method is simple, the color-fixing agenthas a good color-fixing effect, contains no harmful substances such as formaldehyde, and has a good pH-control effect.

Owner:多恩生物科技有限公司

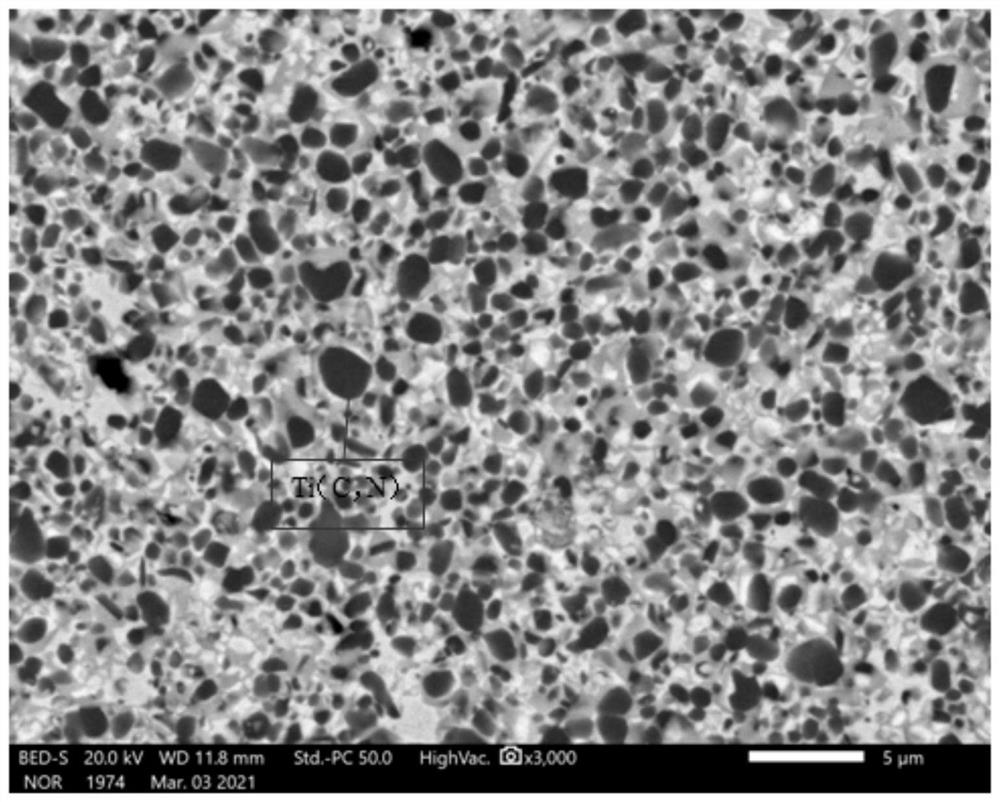

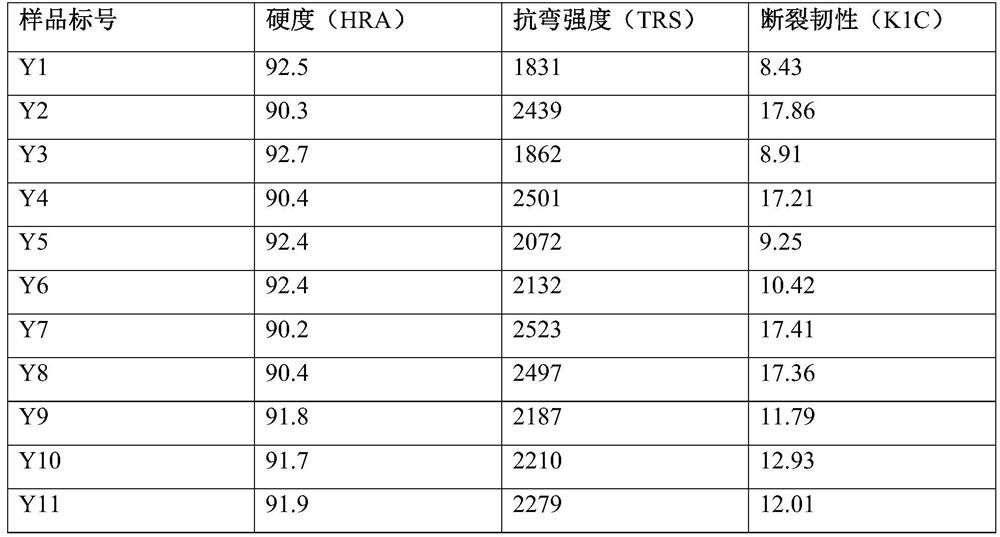

Mixed crystal Ti (C, N)-based metal ceramic material and preparation method thereof

The invention discloses a mixed crystal Ti (C, N)-based metal ceramic material and a preparation method thereof. According to the mixed crystal Ti (C, N)-based metal ceramic material and the preparation method thereof, two kinds of Ti (C, N) with different granularities are combined, Ti (C, N) particles with different granularities serve as a core, TaC, NbC, Mo2C and other carbides form a uniform outer ring structure with the core, finally, a typical core-shell structure is formed, the core-shell structures with different sizes form a mixed crystal structure, and the defect that hardness and toughness of a single and uniform crystal structure cannot be considered at the same time is overcome; and a Ti (C, N) solid solution is an infinite solid solution, when the N / C ratio is larger than 5 to 5, the activity of N is increased, pores are easily formed, and by adopting the combination of Ti (C0.5, N0.5) and Ti (C0.7, N0.3), local pores caused by the fact that the N / C ratio is larger than 5 to 5 are avoided.

Owner:昆山长鹰硬质材料科技股份有限公司

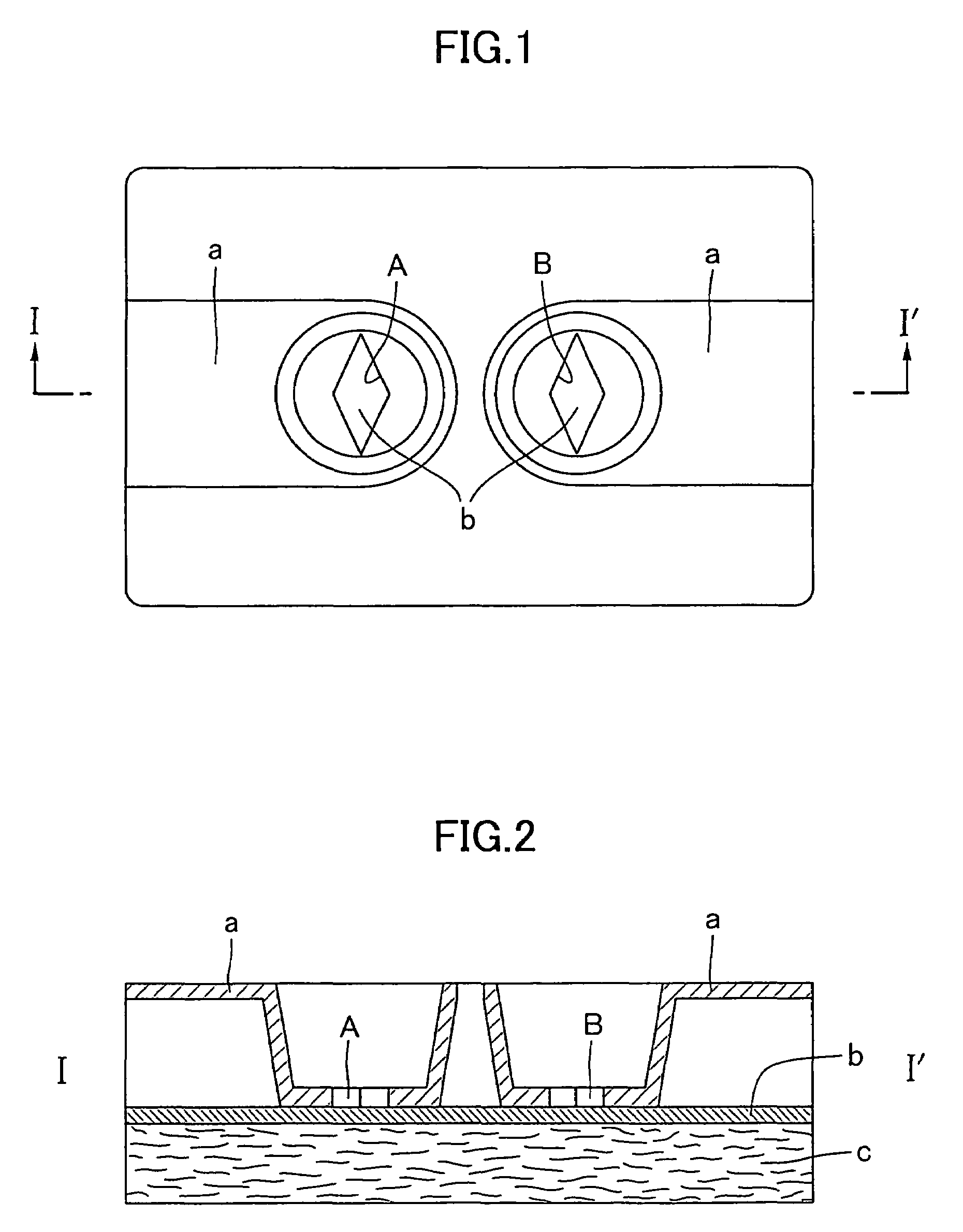

Simple membrane assay method and kit

ActiveUS7579195B2Avoid it happening againImprove accuracyBioreactor/fermenter combinationsBiological substance pretreatmentsAnalyteMembrane bound

The present invention is to provide a simple membrane assay method for detecting or quantitating an analyte in a specimen sample using an assay device equipped with a membrane bound with a capture-substance to capture the analyte, comprising the steps of filtering a specimen sample using a filter, dropping the filtrate onto said membrane and detecting the presence of the analyte in said specimen sample, as well as a simple membrane assay kit for detecting the presence of an analyte in a specimen sample, comprising (1) a filter tube, and (2) an assay device equipped with a membrane bound with a capture-substance to capture the analyte. The method or the kit can decrease the occurrence of false positivity and can provide a highly accurate detection of the analyte such as pathogen and antibody in a specimen collected in a medical scene or by an individual.

Owner:DENKA CO LTD

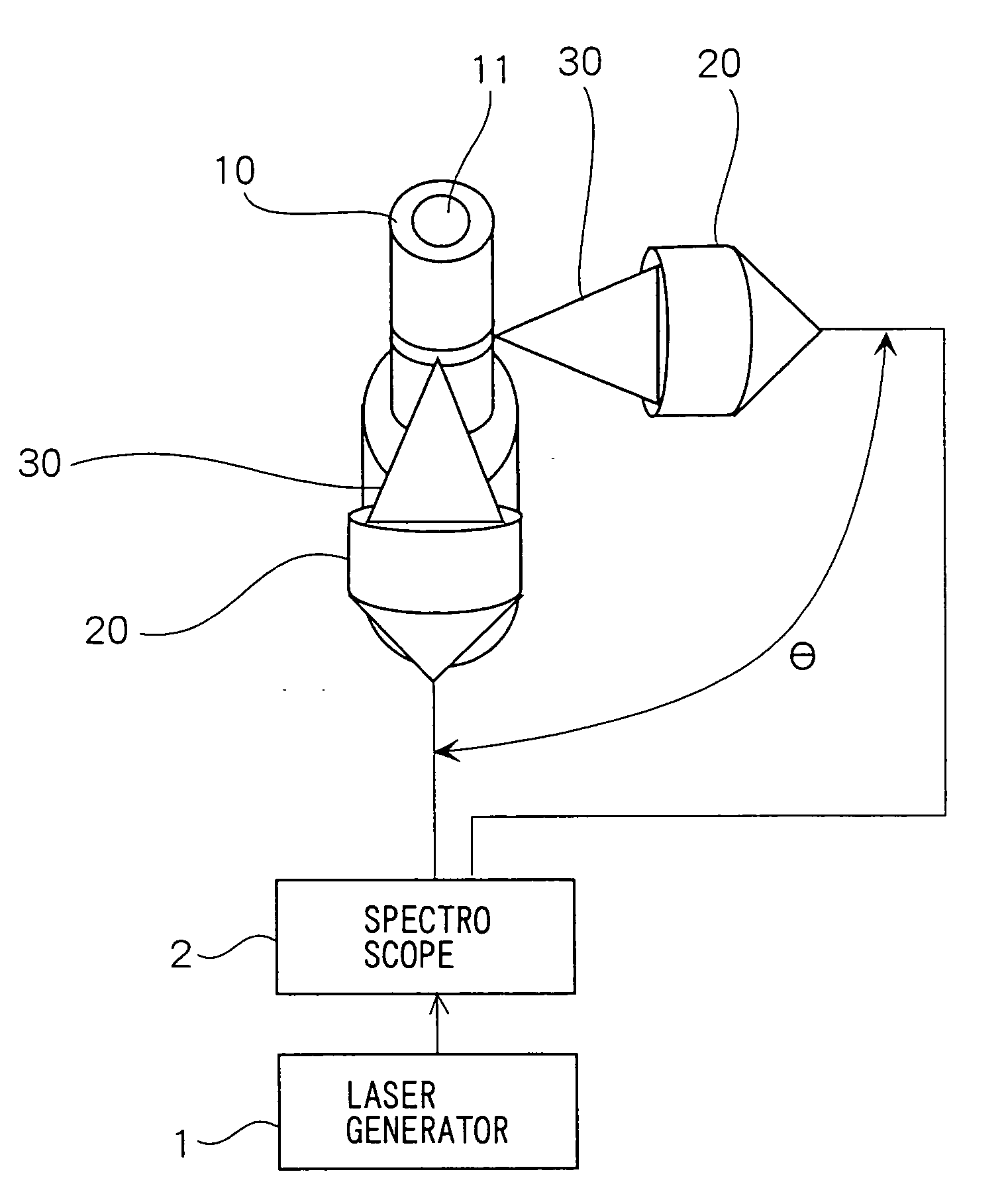

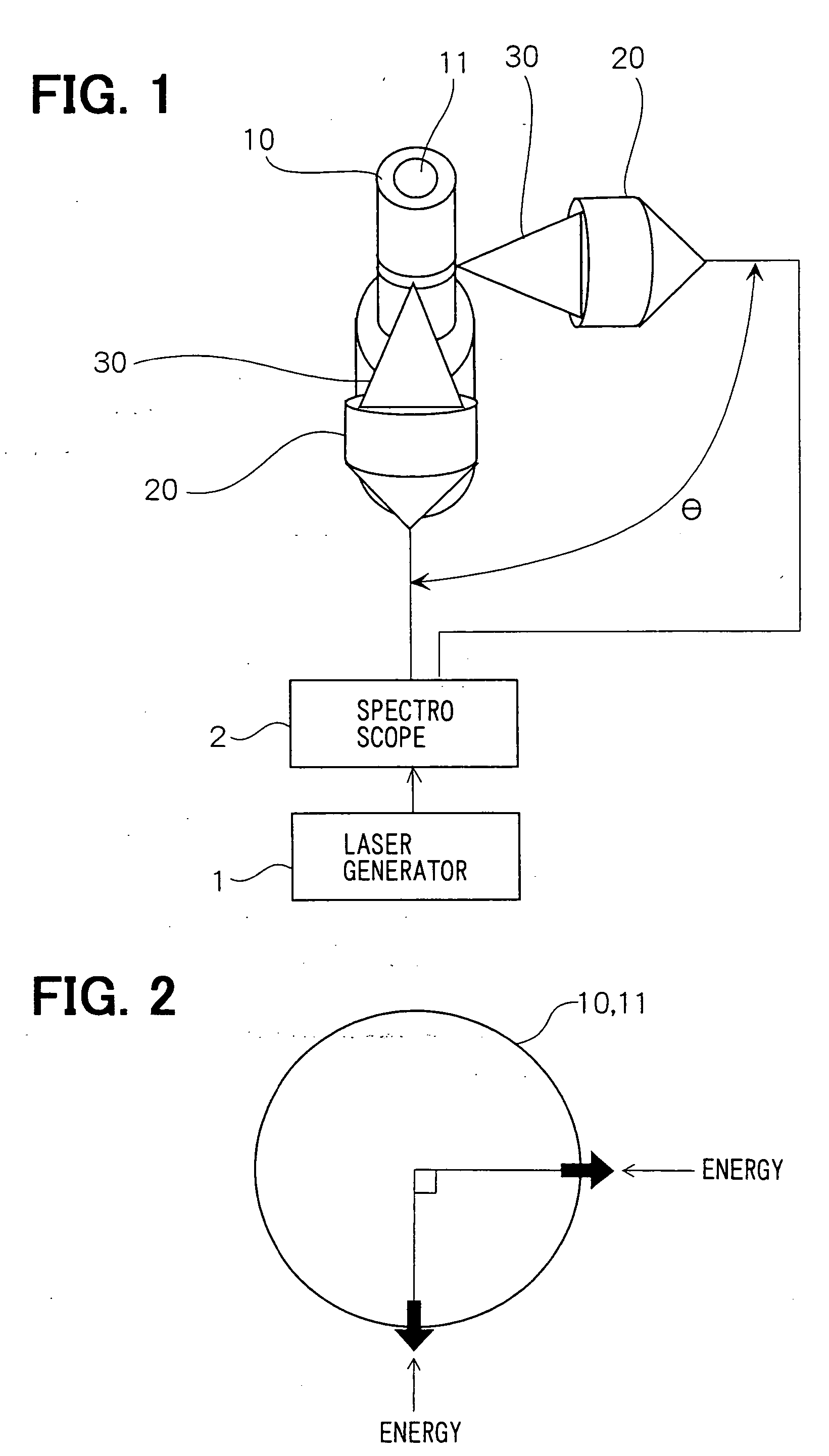

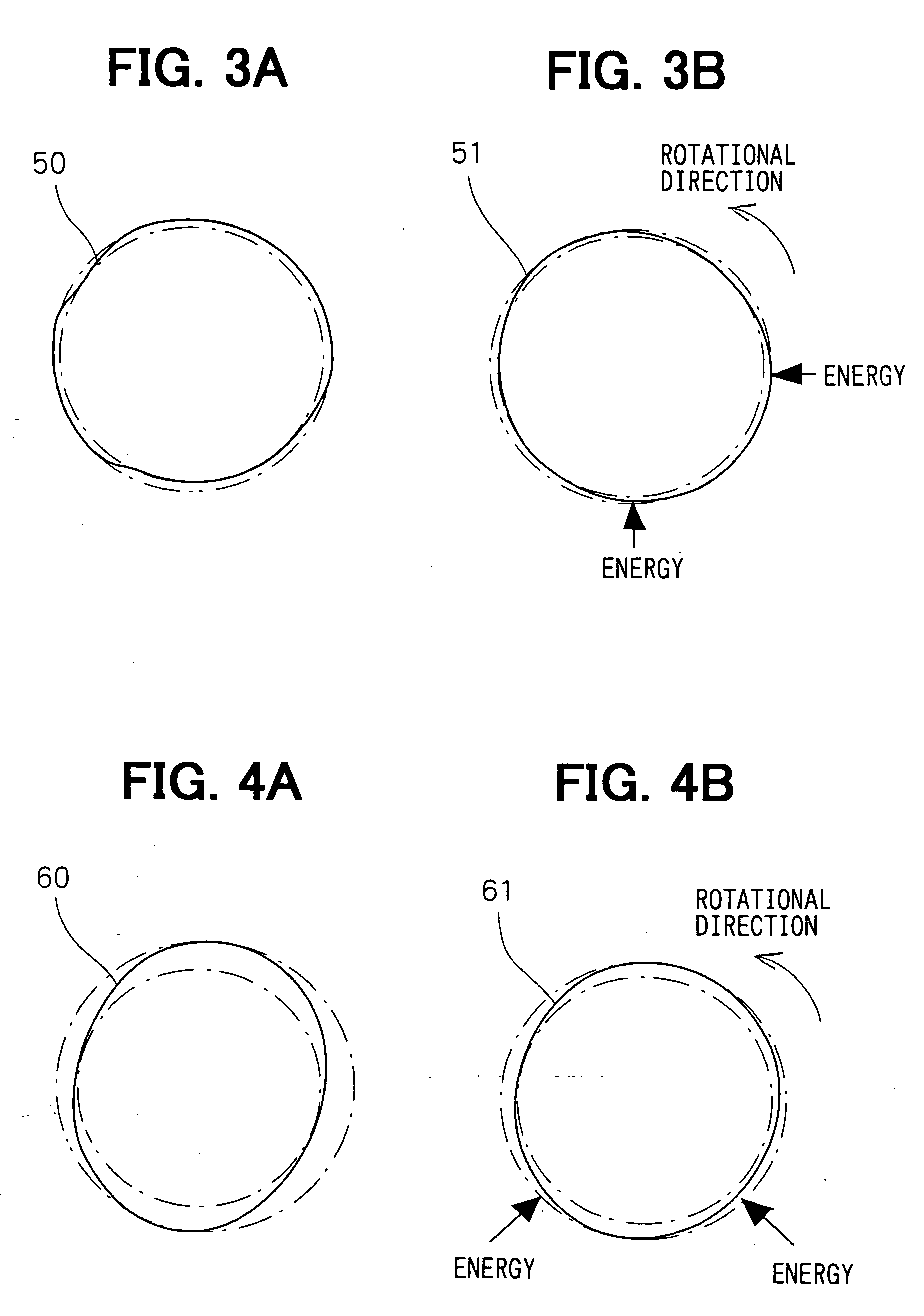

Welding machine and welding method

InactiveUS20050205535A1Reduce fuel leakageAvoid deformationFuel injection apparatusMachines/enginesLaser beamsRadial deformation

Owner:DENSO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com