Patents

Literature

100results about How to "Reduce dissolution rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Matrix Type Sustained-Release Preparation Containing Basic Drug or Salt Thereof, and Method for Manufacturing the Same

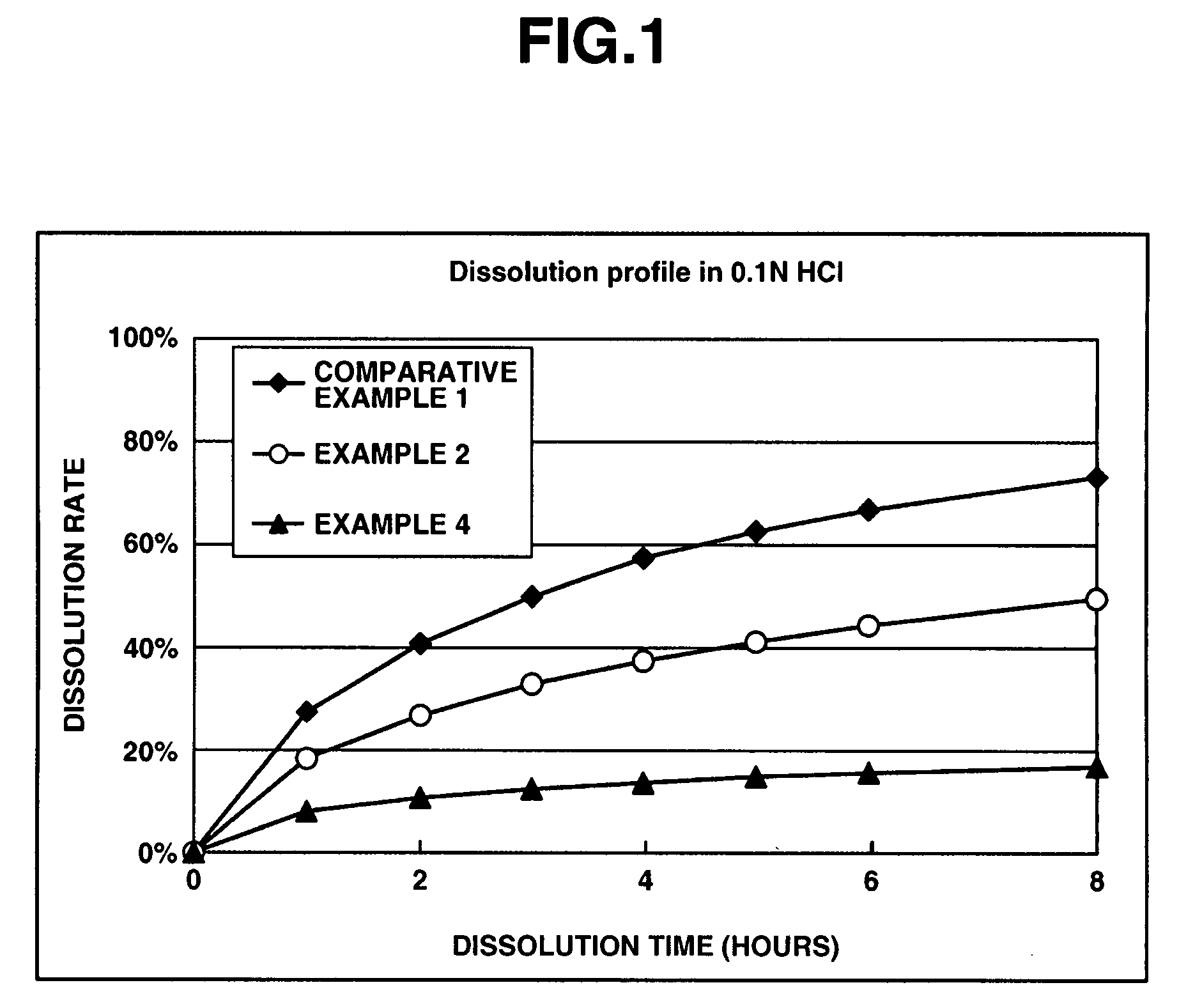

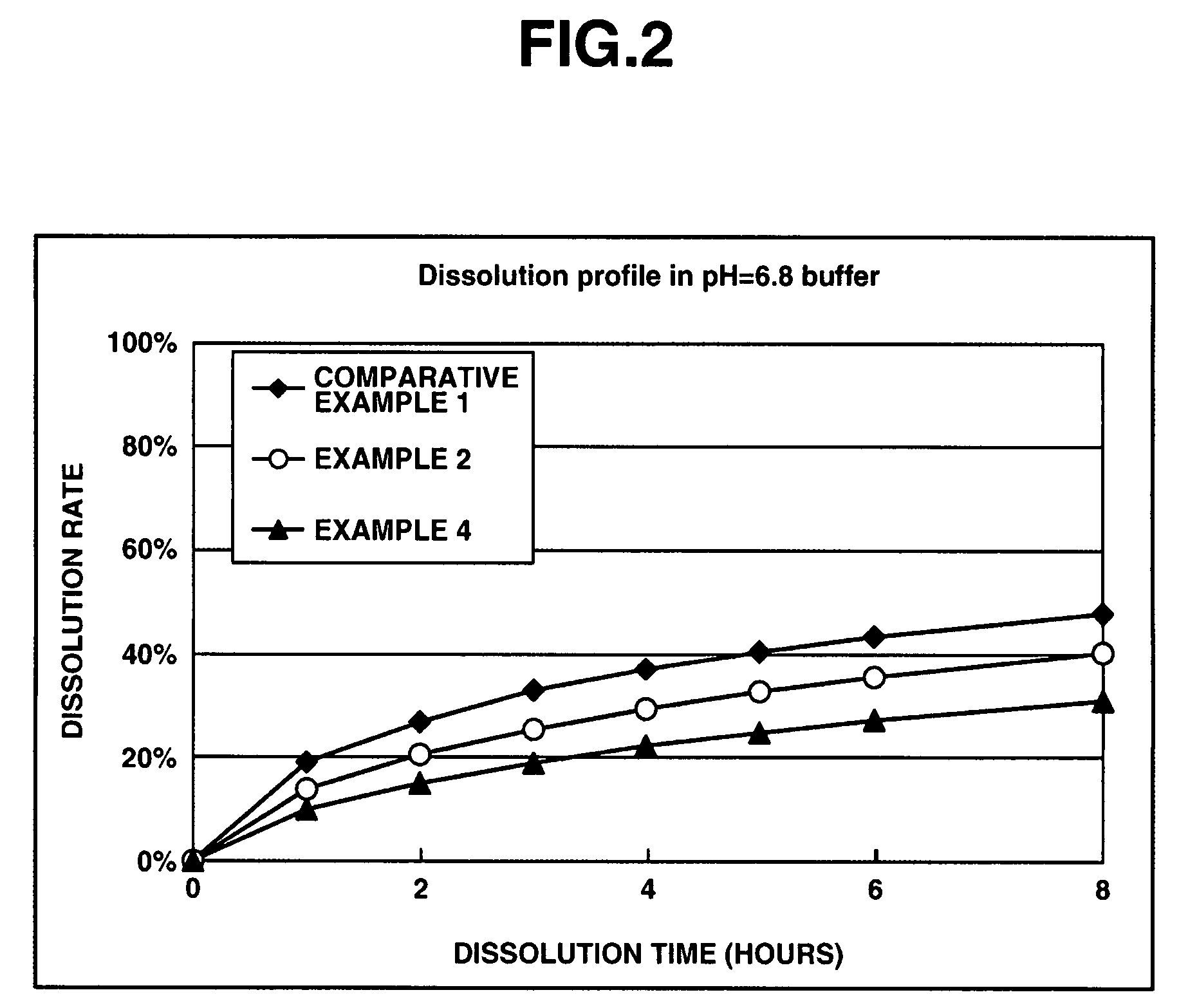

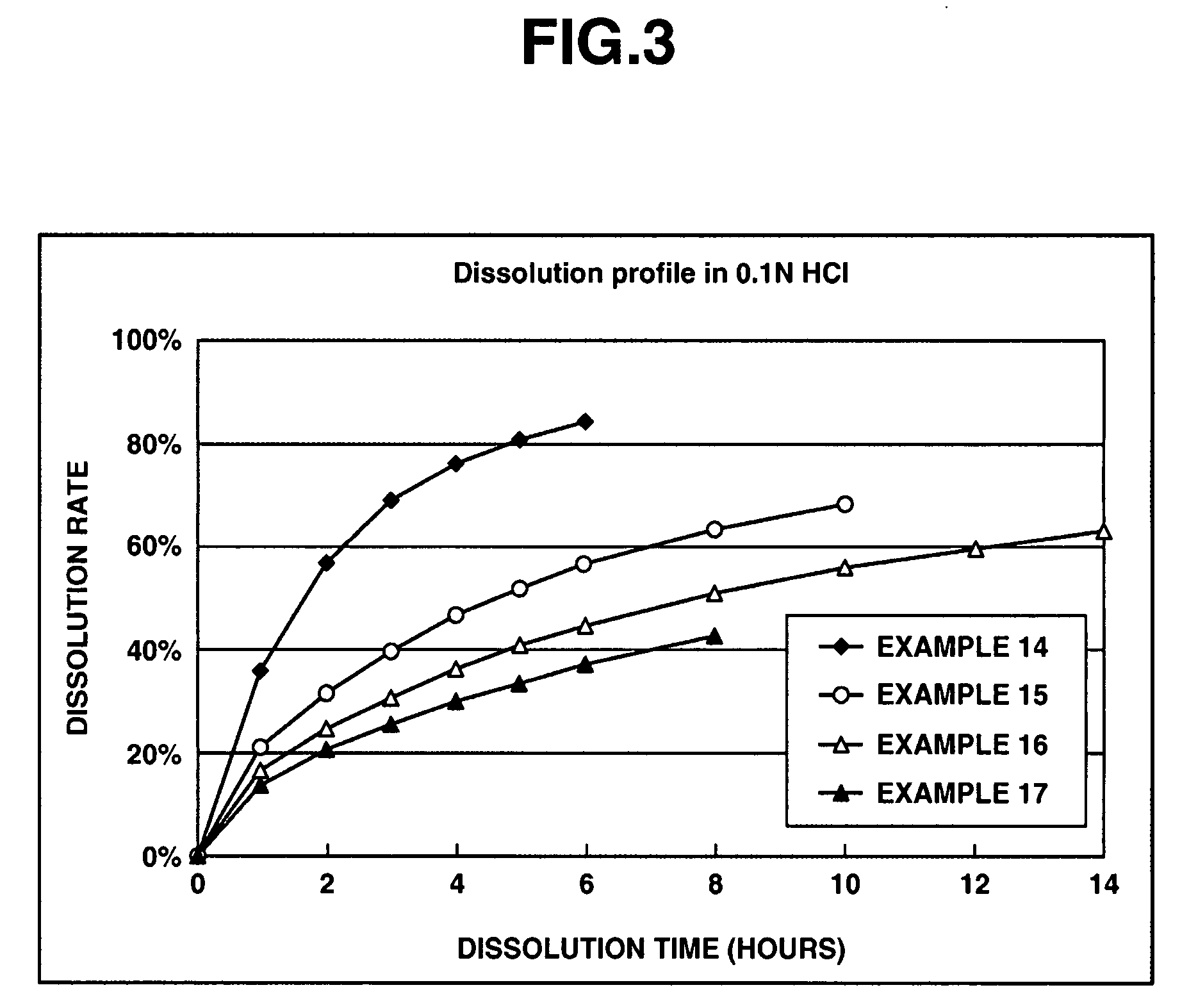

A matrix type sustained-release preparation and a manufacturing method therefor are provided wherein dissolution with low pH dependence of a basic drug or a salt thereof at the early stage of dissolution can be ensured in a dissolution test, and wherein as the dissolution test proceeds, a ratio of a dissolution rate of the basic drug or the salt thereof in an acidic test solution to a dissolution rate of the basic drug or the salt thereof in a neutral test solution (dissolution rate in the acidic test solution / dissolution rate in the neutral test solution) decreases with dissolution time at the late stage of dissolution, as compared to the early stage of dissolution. According to the present invention, the matrix type sustained-release preparation contains a basic drug or a salt thereof and at least one enteric polymer, in which solubility of the basic drug or the salt thereof in a 0.1 N hydrochloric acid solution and a neutral aqueous solution, pH 6.0 is higher than in a basic aqueous solution, pH 8.0.

Owner:EISIA R&D MANAGEMENT CO LTD

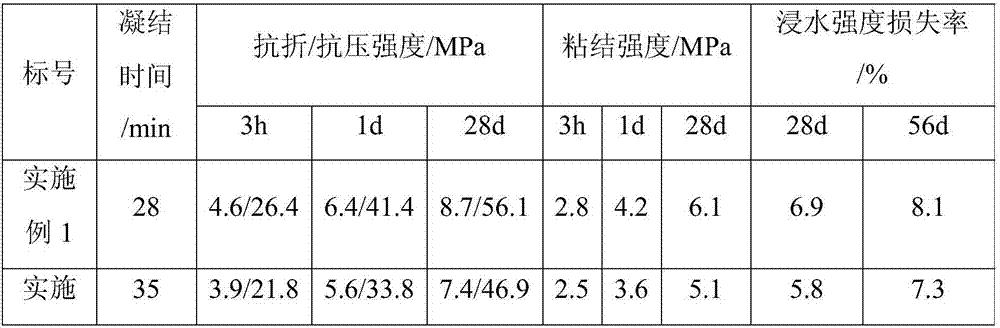

Phosphate cement based patching material and preparation method thereof

The invention relates to a phosphate cement based patching material and a preparation method thereof. The patching material is prepared from the following ingredients in parts by weight: 100 parts of magnesium phosphate cement, 20 to 40 parts of mineral admixtures, 120 to 140 parts of fine aggregates, 0.5 to 1 part of water glass, 0.5 to 1 part of fiber and 20 to 30 parts of water. The preparation method is characterized in that the raw materials are proportionally weighed; magnesium oxide, monopotassium phosphate and composite retarders are firstly stirred and mixed; then, the magnesium phosphate cement is obtained; then, the mineral admixtures and the fine aggregates are added; after uniform stirring, the water glass, the fiber and the water are added; stirring is performed for 3 to 4 minutes by a stirring machine; the phosphate cement based patching material is obtained. The prepared phosphate cement based patching material by the invention has the advantages that the coagulation time is about 30 minutes; the restoration time is short; the construction is not influenced; the restoration effect is obvious; the application requirement of fast patching the damaged road surface is met; the phosphate cement based patching material is applicable to fast restoration projects of cement concrete pavements.

Owner:WUHAN UNIV OF TECH

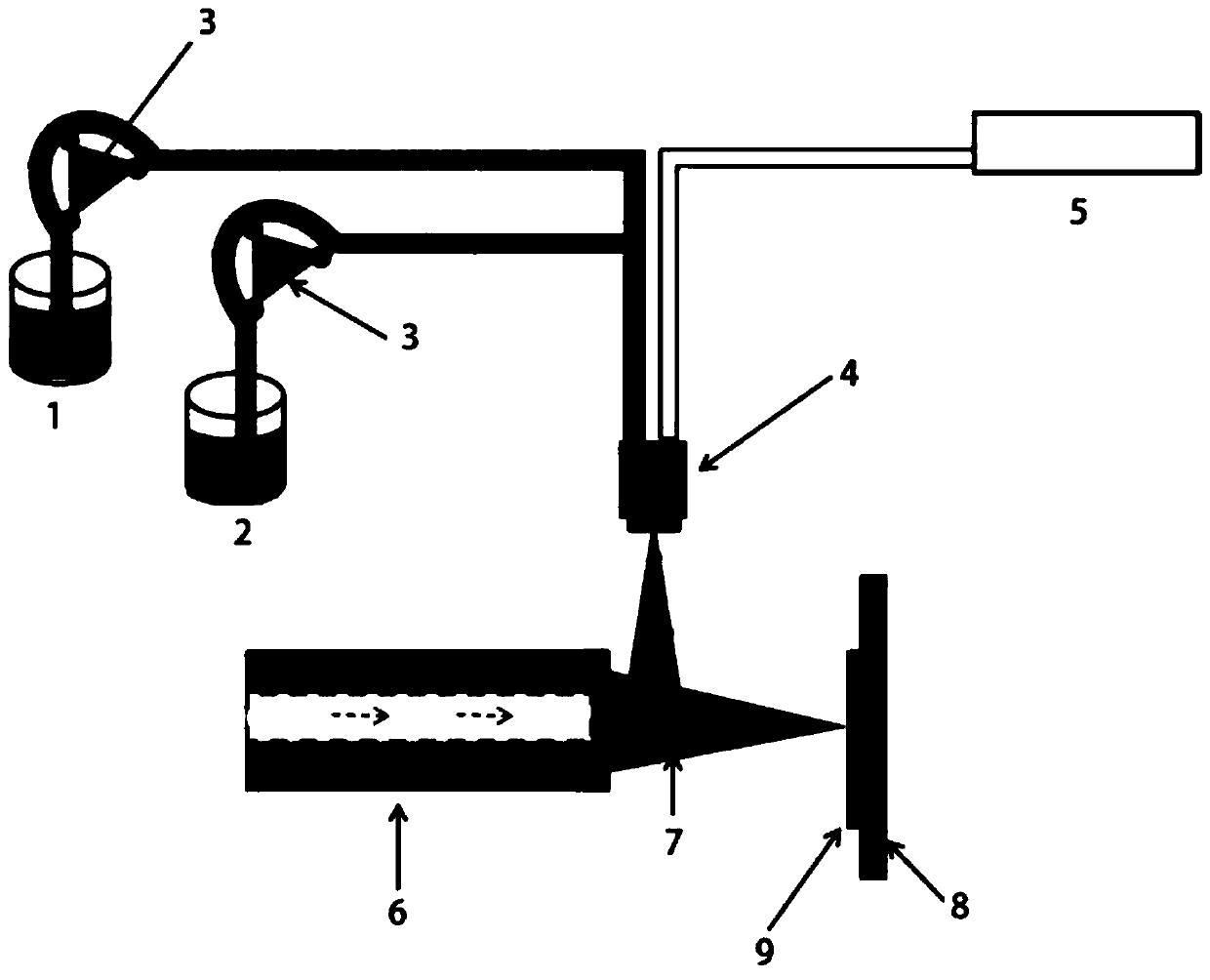

Precursor suspension of lyotropic liquid crystal and preparation method thereof

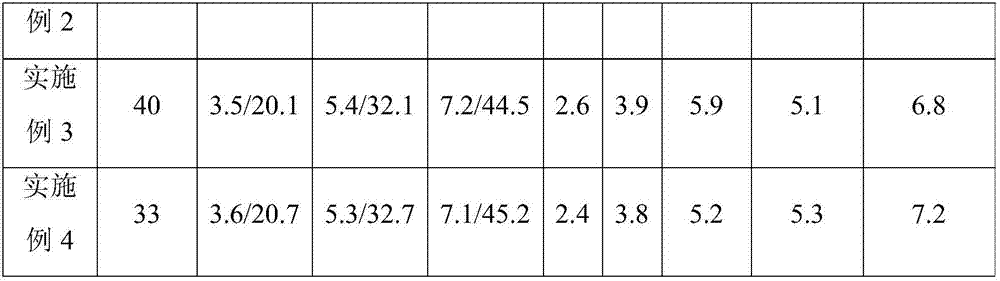

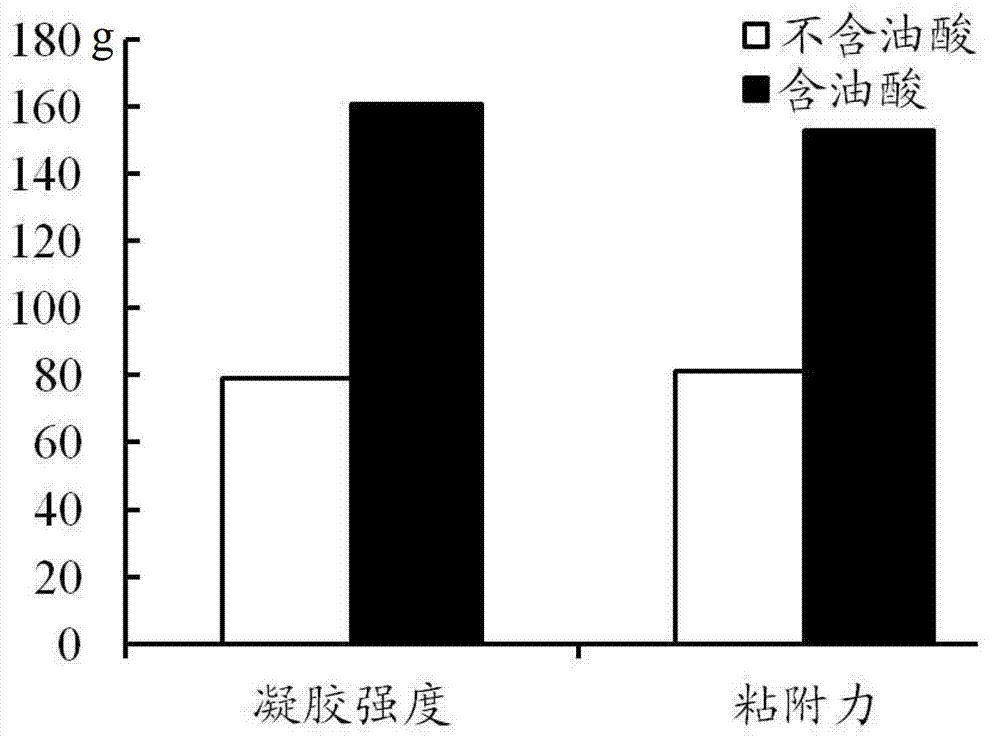

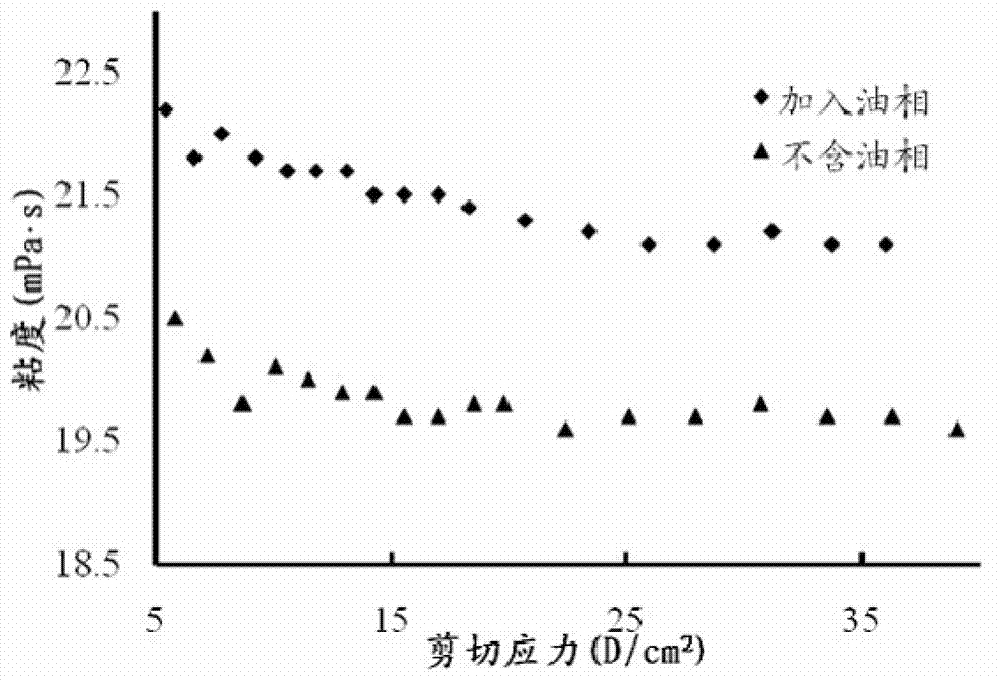

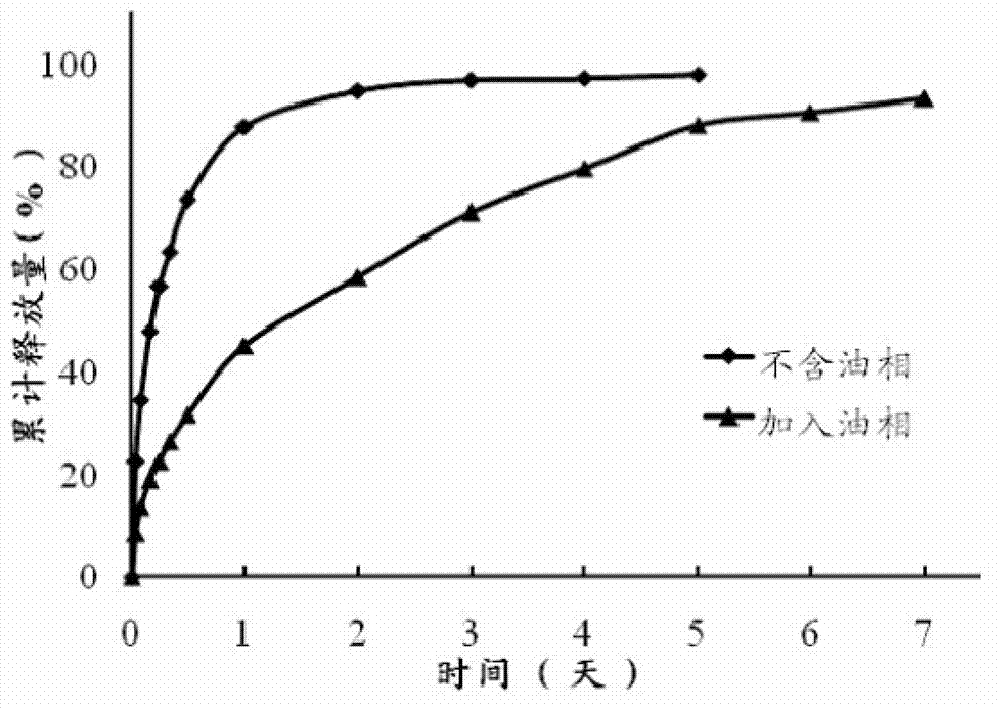

ActiveCN103040741AHigh viscosityHigh strengthSolution deliveryEmulsion deliveryOrganic solventUltimate tensile strength

The invention discloses a precursor suspension of a lyotropic liquid crystal. The precursor suspension comprises lyotropic liquid crystal material, organic solvent, oil phase and a drug, wherein the weight percentage of the oil phase in the precursor suspension is 2-50 percent, the weight percentage of the drug in the precursor suspension is 1-30 percent, and the weight ratio of the lyotropic liquid crystal material and the organic solvent in the precursor suspension is 2-9:1. According to the invention, through the adding of the oil phase into the precursor suspension, the stability of the suspension is improved, the sedimentation rate is reduced, and the strength and the adhesive force of the gel formed are enhanced at the same time; the gel formed in the body is more liable to stay at a lesion location and less liable to be relocated and the shape is less liable to be damaged by the mechanical motion of the body, so that the drug therapy can be located effectively; and the preparation technology is simple and the precursor suspension of the lyotropic liquid crystal is a partial slow-release drug delivering system provided with a favorable perspective.

Owner:GUANGZHOU NEWORLD PHARMA CO LTD

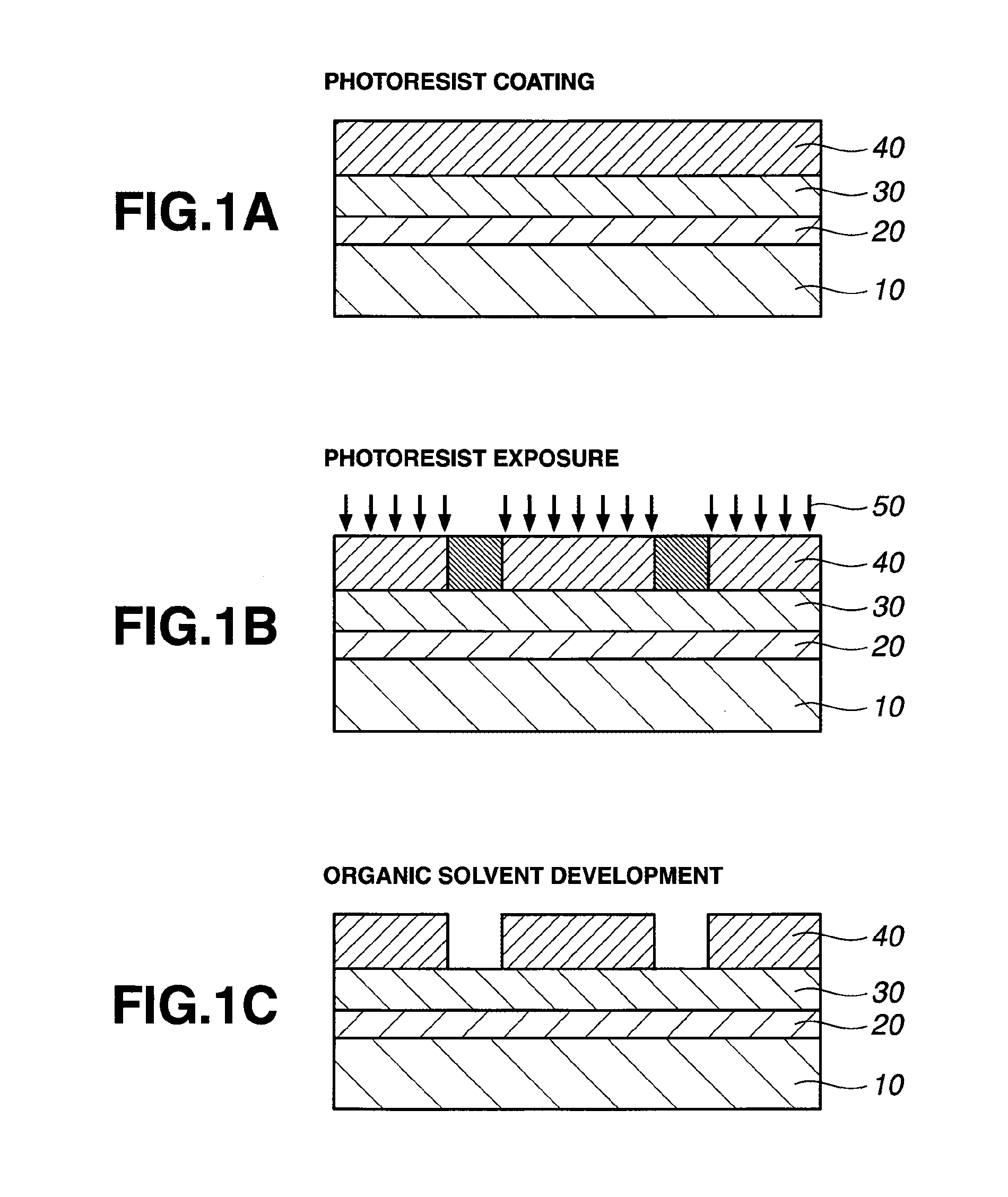

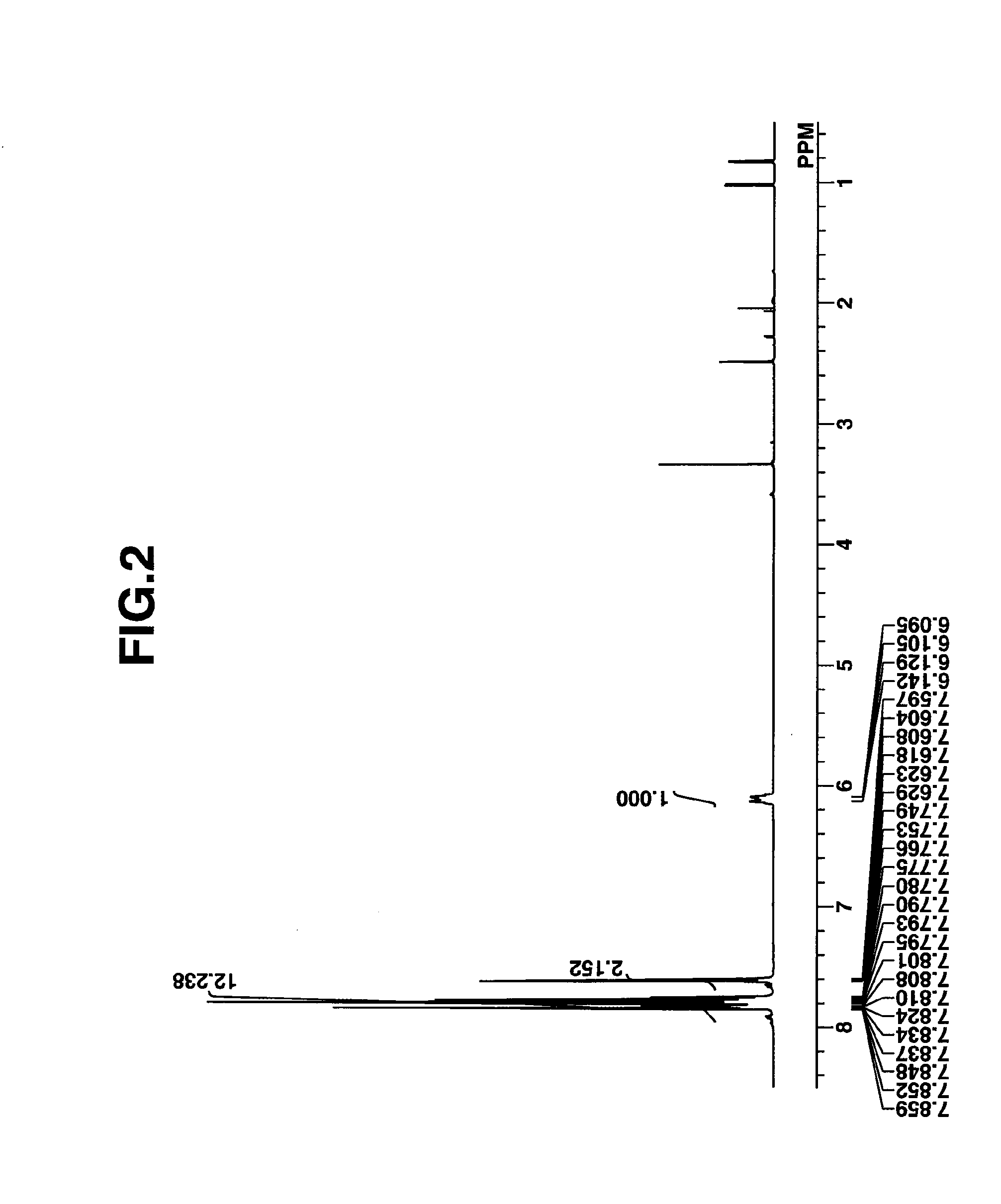

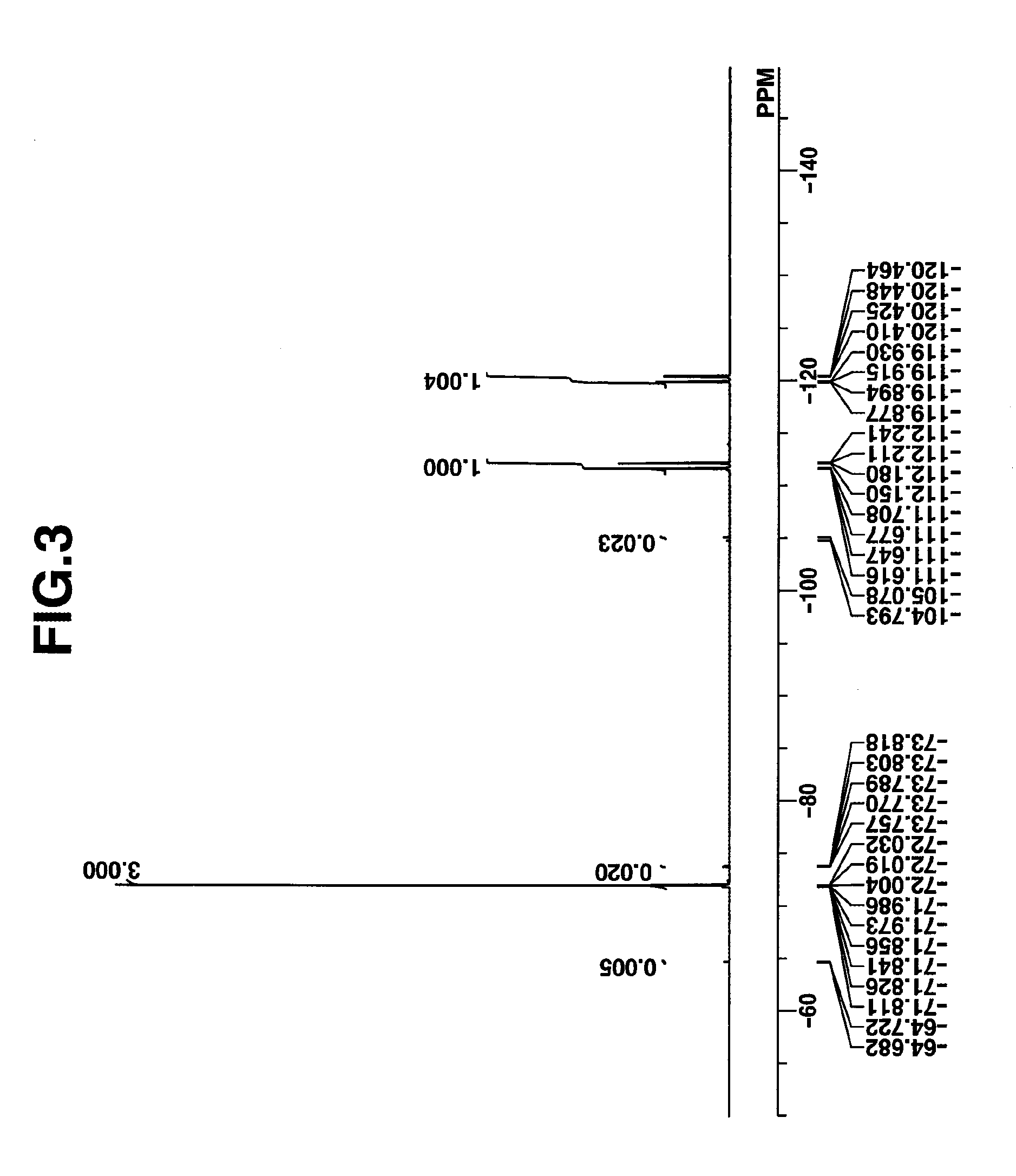

Patterning process and resist composition

ActiveUS20140322650A1High dissolution contrastImprovement in resist performance factorPhotosensitive materialsPhotomechanical exposure apparatusPolymer scienceOrganosolv

A negative pattern is formed by coating a resist composition comprising a polymer comprising recurring units of formulae (1) and (2) and a photoacid generator of formula (3) onto a substrate, baking, exposure, PEB and developing in an organic solvent. In formulae (1) and (2), R1 is H, F, CH3 or CF3, Z is a single bond, phenylene, naphthylene, or (backbone)-C(═O)—O—Z′—, Z′ is alkylene, phenylene or naphthylene, XA is an acid labile group, YL is H or a polar group. In formula (3), R2 and R3 are a monovalent hydrocarbon group, R4 is a divalent hydrocarbon group, or R2 and R3, or R2 and R4 may form a ring with the sulfur, L is a single bond or a divalent hydrocarbon group, Xa and Xb are H, F or CF3, and k is an integer of 1 to 4.

Owner:SHIN ETSU CHEM IND CO LTD

Combating sinus, throat, and blood infections with xylitol delivered in the mouth

InactiveUS20070293587A1Low dissolution rateReduce solubilityBiocideHydroxy compound active ingredientsChewing gumHuman mouth

A method of suppressing bacteria that cause infections of the throat, sinuses, heart and arteries, and joints (arthritis) by delivering xylitol in a human mouth. The method is effective with troches of pure xylitol or with xylitol chewing gum or liquid, provided sufficient quantities of xylitol are delivered. Streptococcus mutans and Staphylococcus aureus in the blood are important contributors to plaque in arteries and on heart valves and bacterial arthritis. For people whose blood is not already infected with significant levels of these bacteria, every day use of xylitol sufficient to suppress these bacteria in the oral cavity will reduce their risk of subsequent cardiovascular disease, arthritis, and sinus infections. Strep throat is a common throat infection caused by Streptococcus pyogenes. Frequent bathing with xylitol, such as from time release in the mouth, will speed recovery from strep throat.

Owner:HALEY JEFFREY T

Method for preparing magnesium alloy with micro-arc oxidation ceramic membrane

ActiveCN103614762AUniform colorFlat surfaceAnodisationMicro arc oxidationPlasma electrolytic oxidation

The invention discloses a method for preparing a magnesium alloy with a micro-arc oxidation ceramic membrane, mainly solving the problem that in the prior art, the membrane is single in variety, and the conventional membrane layers are generally red, black, green and the like in color. According to the method, an alkali electrolyte is prepared by taking sodium metaaluminate, sodium hydroxide, ethylenediamine tetraacetic acid, potassium permanganate and hydrogen peroxide as electrolyte solutes, and using diionized water as a solvent, and the alkali electrolyte is subjected to micro-arc oxidation treatment so as to obtain the magnesium alloy with a yellow micro-arc oxidation ceramic membrane. The method disclosed by the invention is simple in preparation, low in cost, wide in application range and applicable to light metal. The prepared yellow ceramic membrane has the advantages of uniform color, smooth surface, good compactness, high wearing resistance, good corrosion resistance, good stability and the like, and is particularly applicable to danger warning and reminding on yellow labels on traffic signs.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Solid toilet cleanser and preparation method thereof

ActiveCN104762141AGood anti-scaling and toilet cleaning effectReduce dissolution rateInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSodium bicarbonateSodium stearate

The invention discloses a solid toilet cleanser. The solid toilet cleanser is prepared from the following components, by mass, 30-40% of anhydrous sodium sulphate, 3-5% of microcrystalline cellulose, 3-5% of hydroxyethyl cellulose, 15-20% of sodium bicarbonate, 12-15% of sodium dodecyl benzene sulfonate, 5-10% of liquid 6501, 3-7% of sodium stearate, 5-8% of dodecylbenzene sulfonic acid, 3-7% of AES and 3-5% of a surfactant TX-10, and the sum of the mass percentage contents of all the components is 100%. The solid toilet cleanser has the advantages of good scale inhibiting and toilet cleaning effects, small dissolving rate in water, long service time, constant and uniform release speed of effective components in the solid toilet cleanser, and long time maintenance of the toilet cleaning effect. The invention also discloses a preparation method of the solid toilet cleanser. The method comprises the steps of weighing materials, mixing, and molding. The preparation method has the advantages of simple technologic steps and low cost.

Owner:金华市宇瑶生物科技有限公司

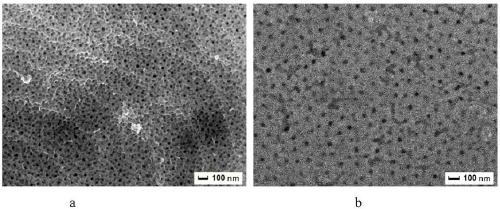

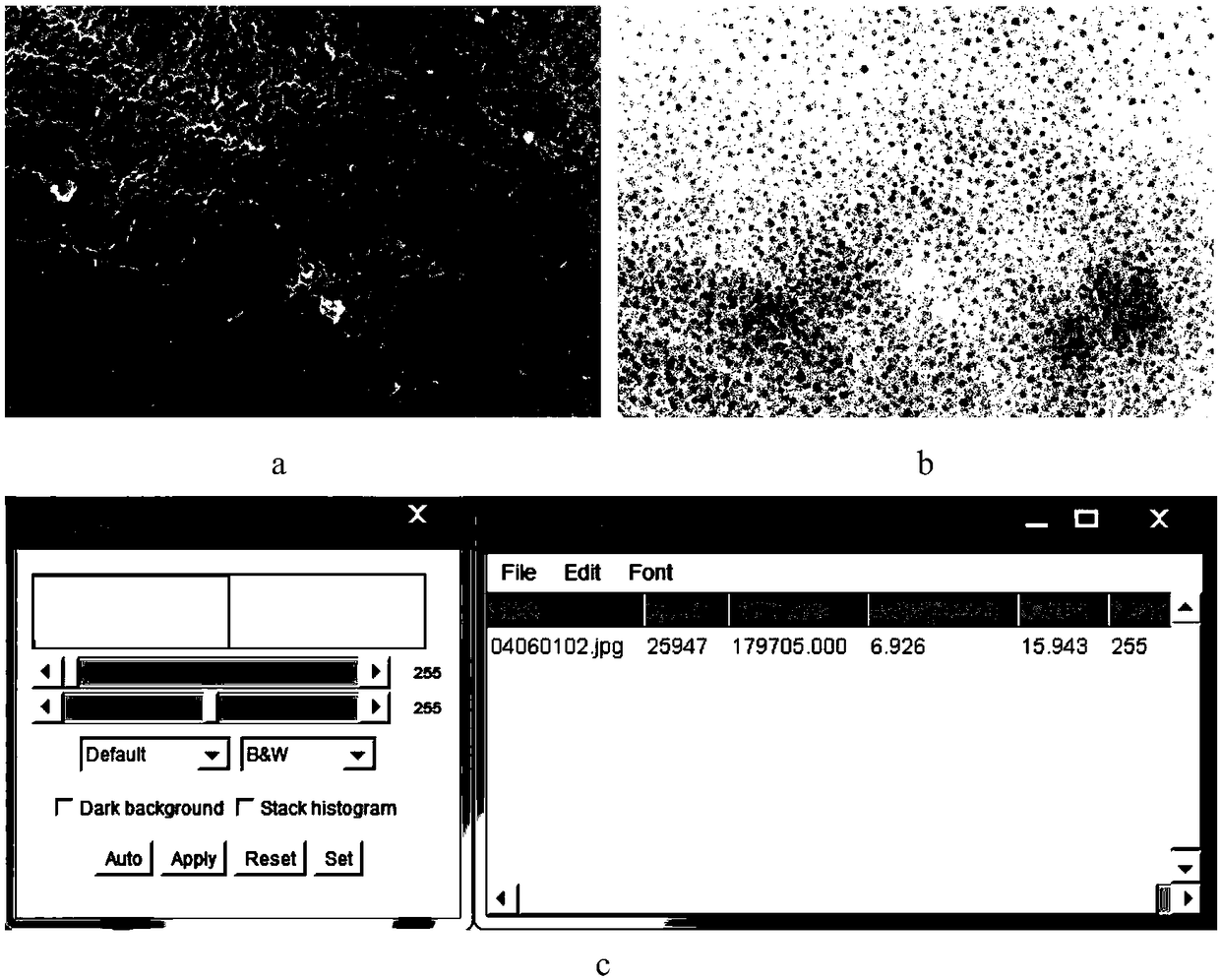

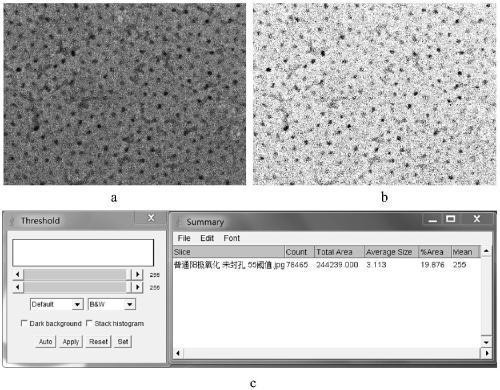

Aluminum alloy electric heater anode oxide film and preparation method thereof

The invention discloses an aluminum alloy electric heater anode oxide film and a preparation method thereof and belongs to the technical field of preparation of film materials. The preparation methoddisclosed by the invention comprises the following steps: adding multiple acids such as sulfosalicylic acid, boric acid, oxalic acid, sulfuric acid, aluminum sulfate octadecahydrate and the like intoelectrolyte, performing mixed acid anodic oxidation treatment at the temperature of 3-10 DEG C for 40 minutes under the mechanical stirring condition, wherein the current density is 1.5-2.5A / dm<2>. The preparation method disclosed by the invention is simple and feasible in process, and the prepared anode oxide film has high corrosion resistance.

Owner:JIANGSU UNIV

Synergist for assisting wet-process desulphurization of thermal power plant, and application method of synergist

InactiveCN103432894AReduce surface tensionIncrease the speed of diffusionDispersed particle separationOrganic acidGas to liquids

The invention discloses a synergist for assisting wet-process desulphurization of a thermal power plant. The synergist comprises the following components in percentage by mass: 55%-60% of organic acid, 15%-20% of organic acid salt, 10%-15% of oxidized catalyst, and 10%-15% of chelating dispersing agent. The acidity of the organic acid is stronger than that of carbonic acid and weaker than that of sulphurous acid, and the organic acid salt is used for providing organic acid groups. The synergist can reduce the surface tension between gas and liquid and improve the dispersion speed of gas to liquid; the concentration of calcium ions in the liquid solution can be increased, the crystallization speed of sulfate ions can be accelerated, and the desulfurization efficiency of the system and the utilization rate of lime stone can be improved; in addition, the characteristics of calcium sulfate crystals can be changed, so that muddy crystals can be produced, the crystals can be prevented from being deposited at parts, such as a spray nozzle.

Owner:杨子江

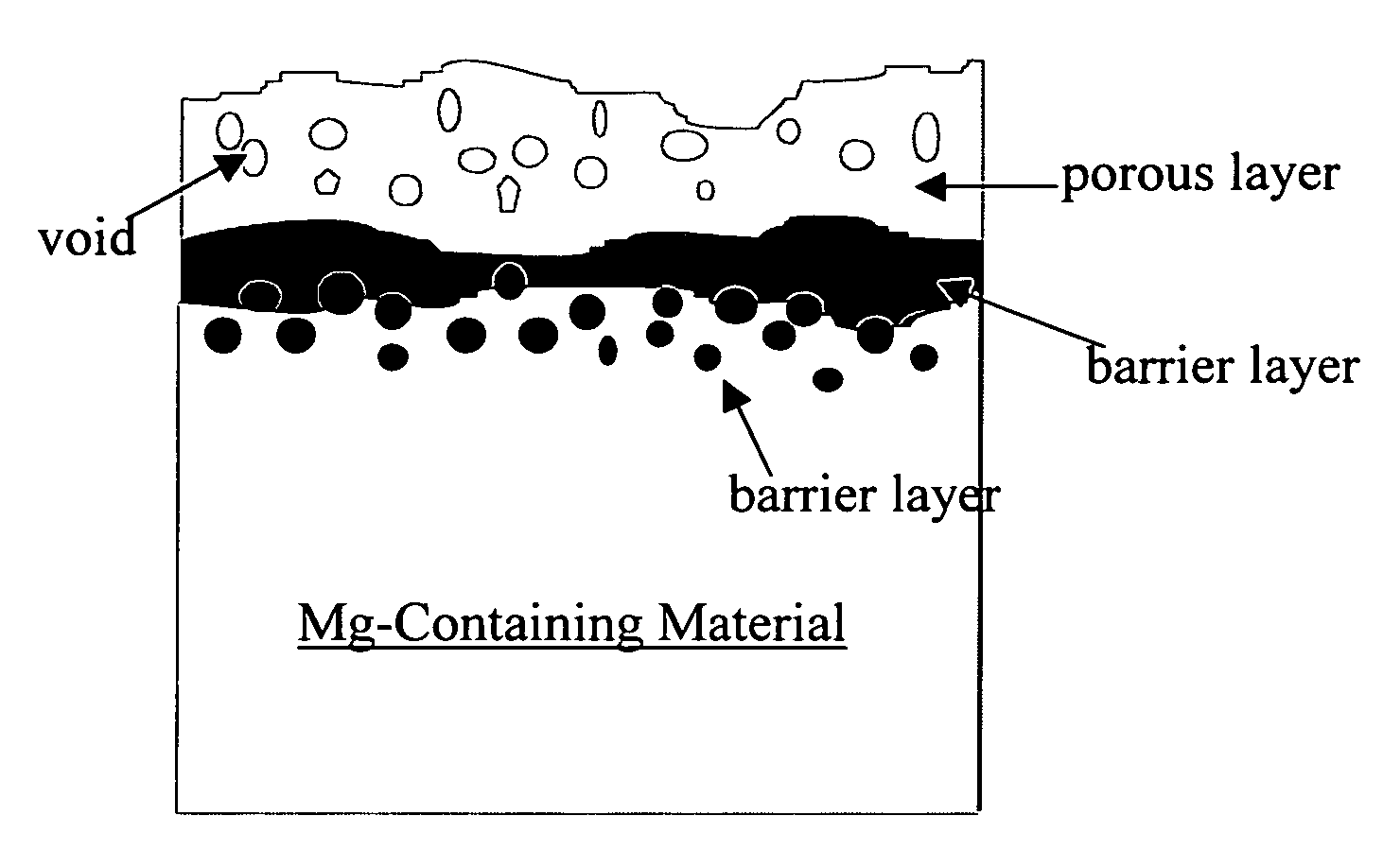

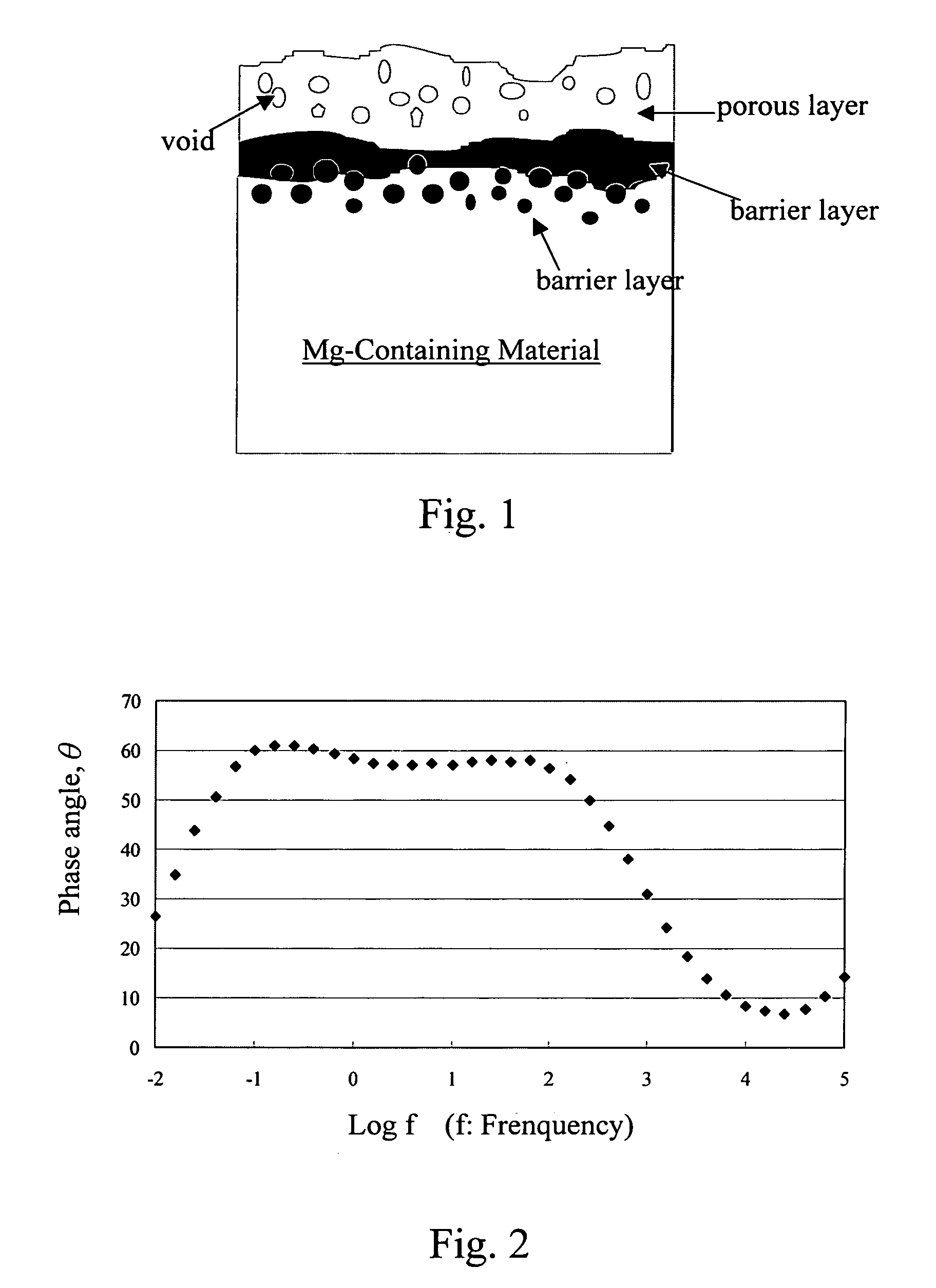

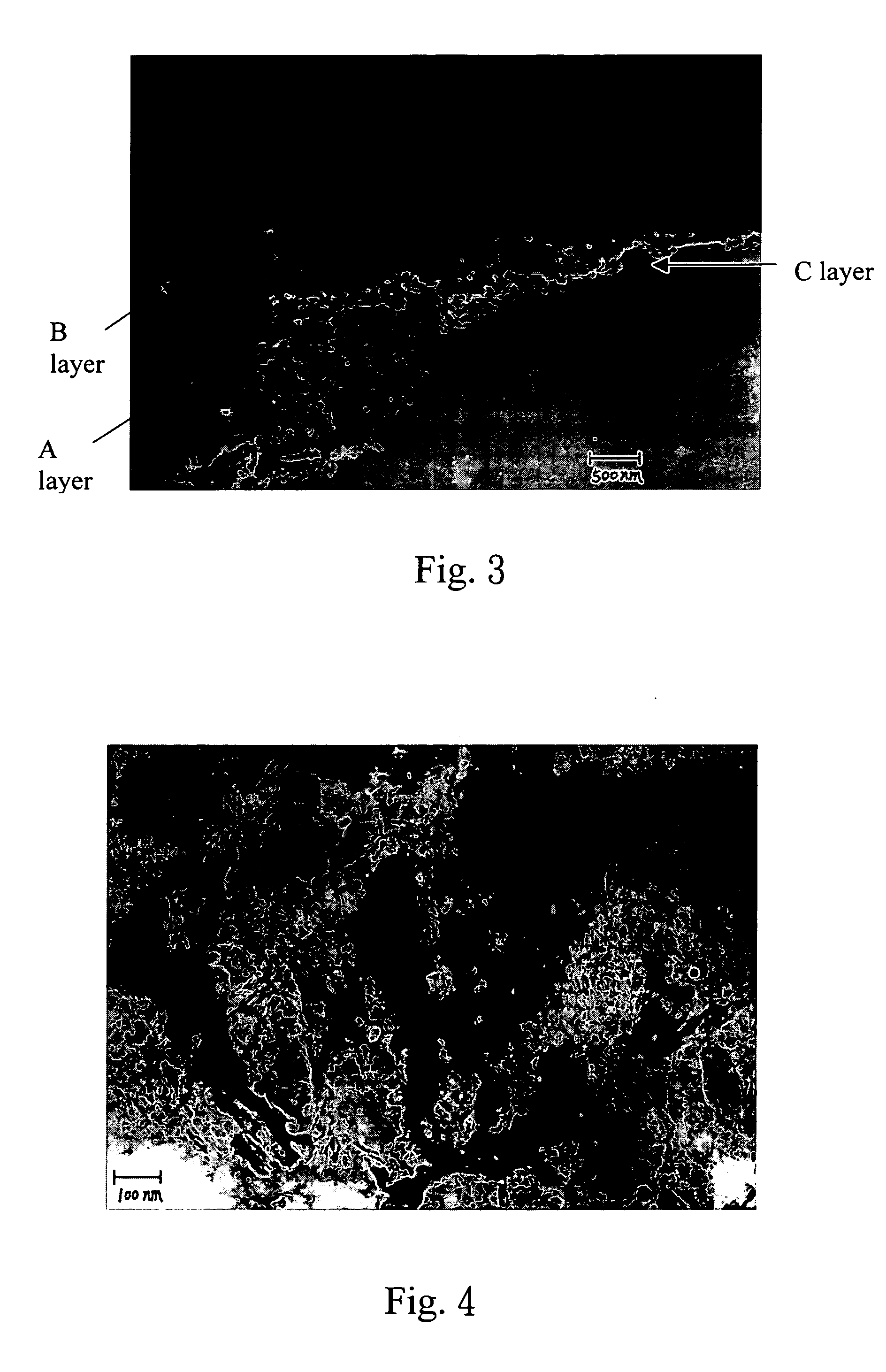

Method for treating surface of magnesium or magnesium alloy

InactiveUS20060237326A1High film forming rateLow dissolution rateAnodisationAnodizingVolumetric Mass Density

A method for surface treatment is disclosed. The method is achieved by forming a MgO film on a metal surface through anode processing of Mg or Mg alloy in an alkaline solution. The alkaline solution includes a hydroxide, a thickening agent, and a film adjusting agent. As the method is performed, the target object is immersed in the alkaline solution, and the target object is connected to an anode with an average electric current density of 1˜5 A / dm, at a temperature of 0˜30° C., and within a time period of 10˜120 minutes to form a film of 5˜25 μm. The forming rate of the film of the method of the present invention is fast, and the formed film is of little stress.

Owner:CHUNG CHENG INST TECH

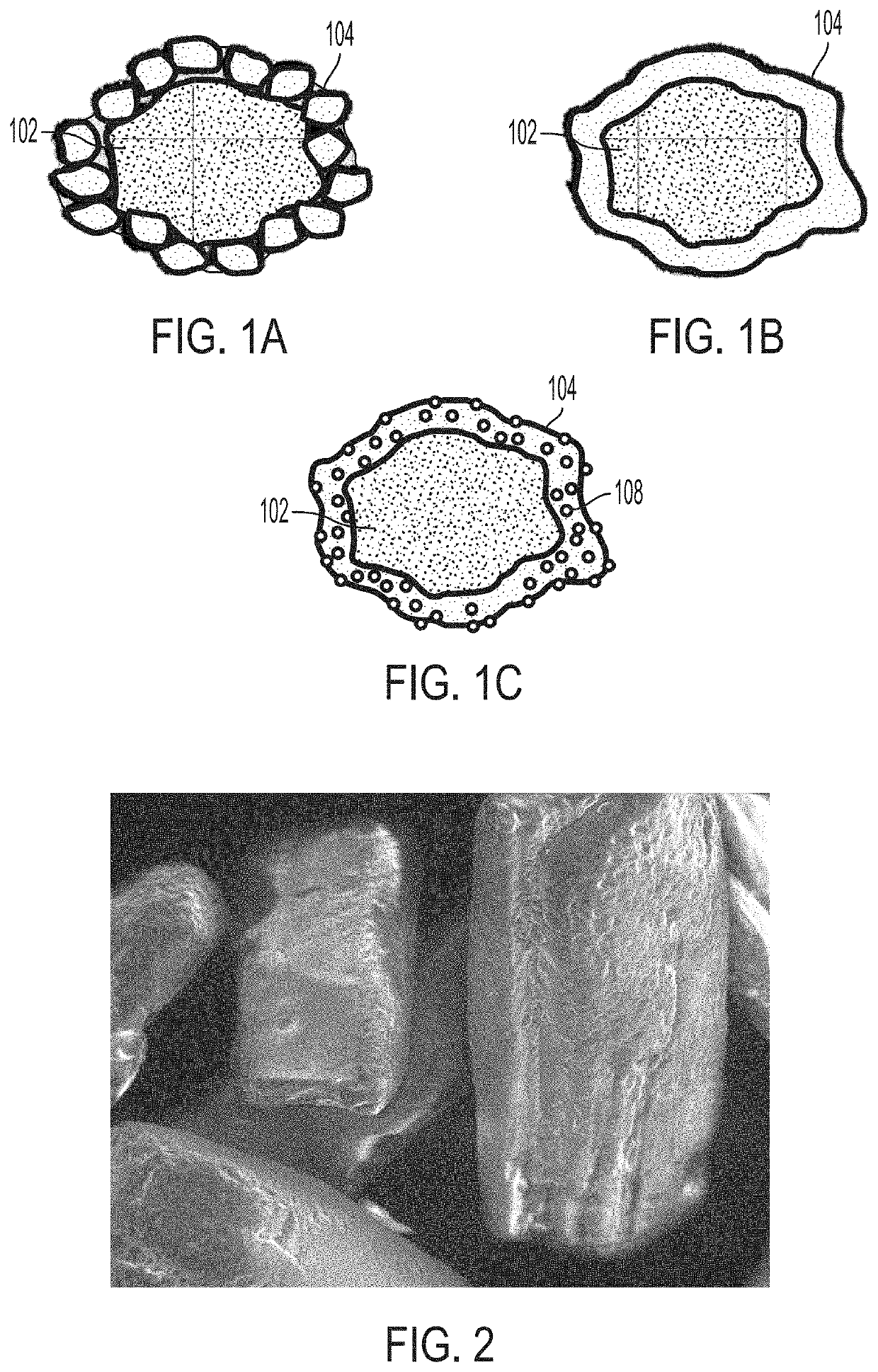

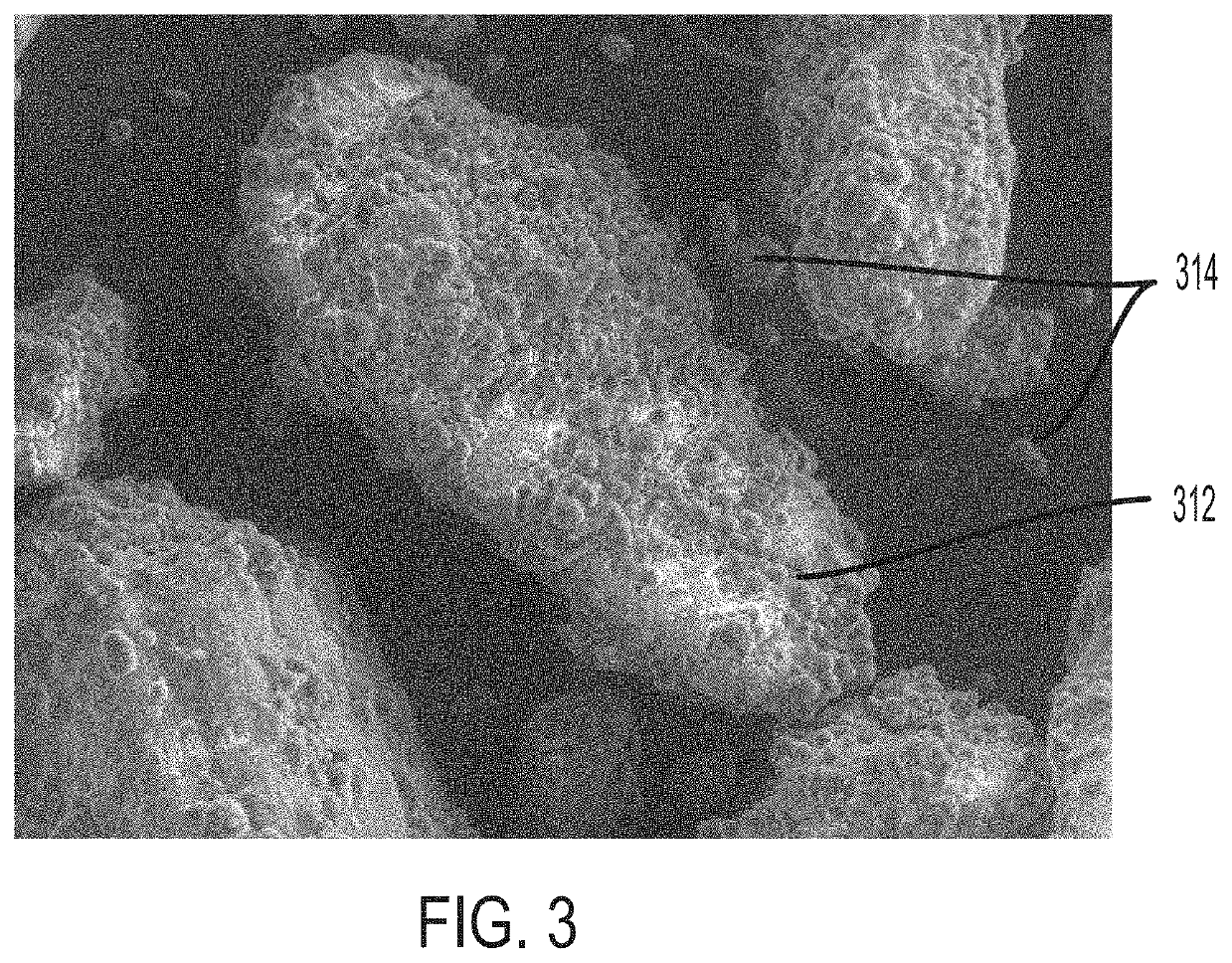

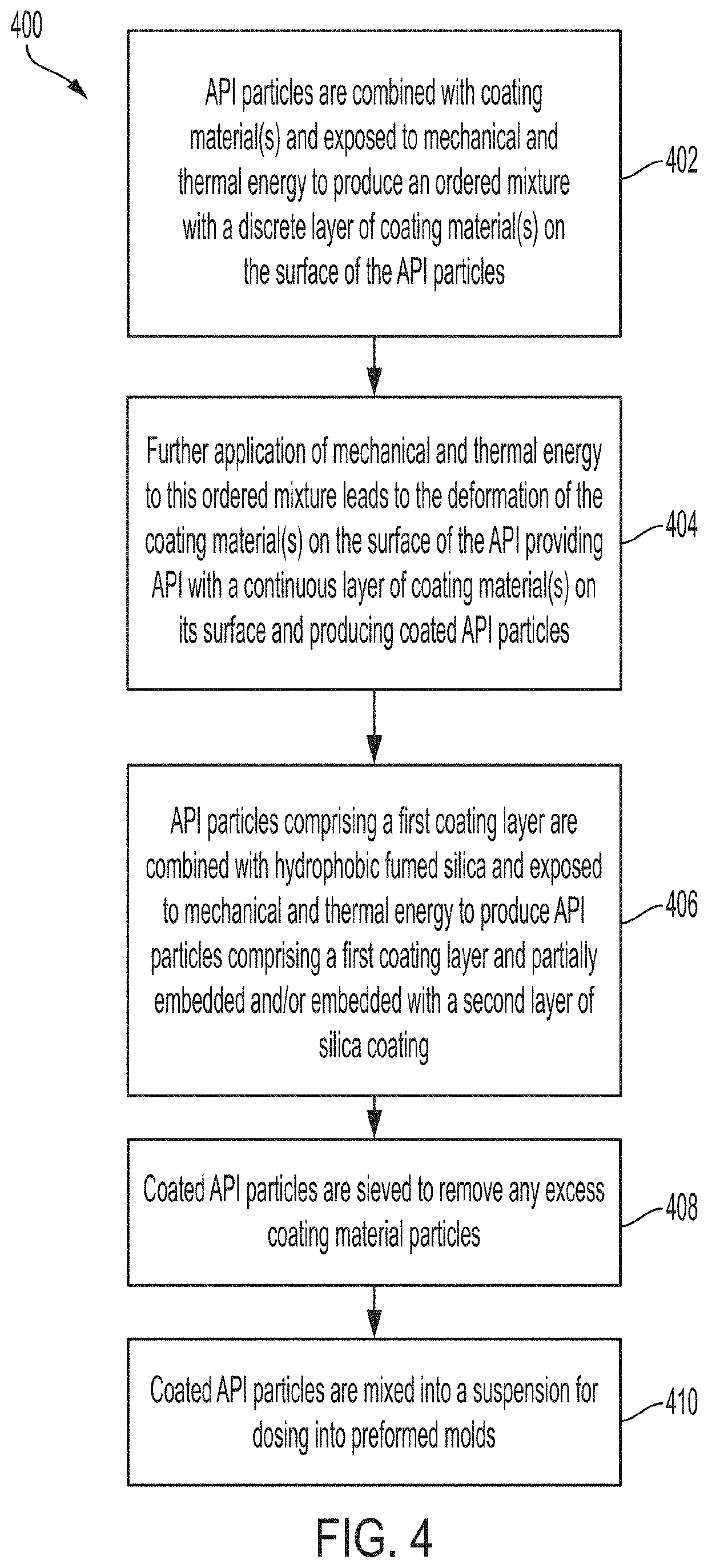

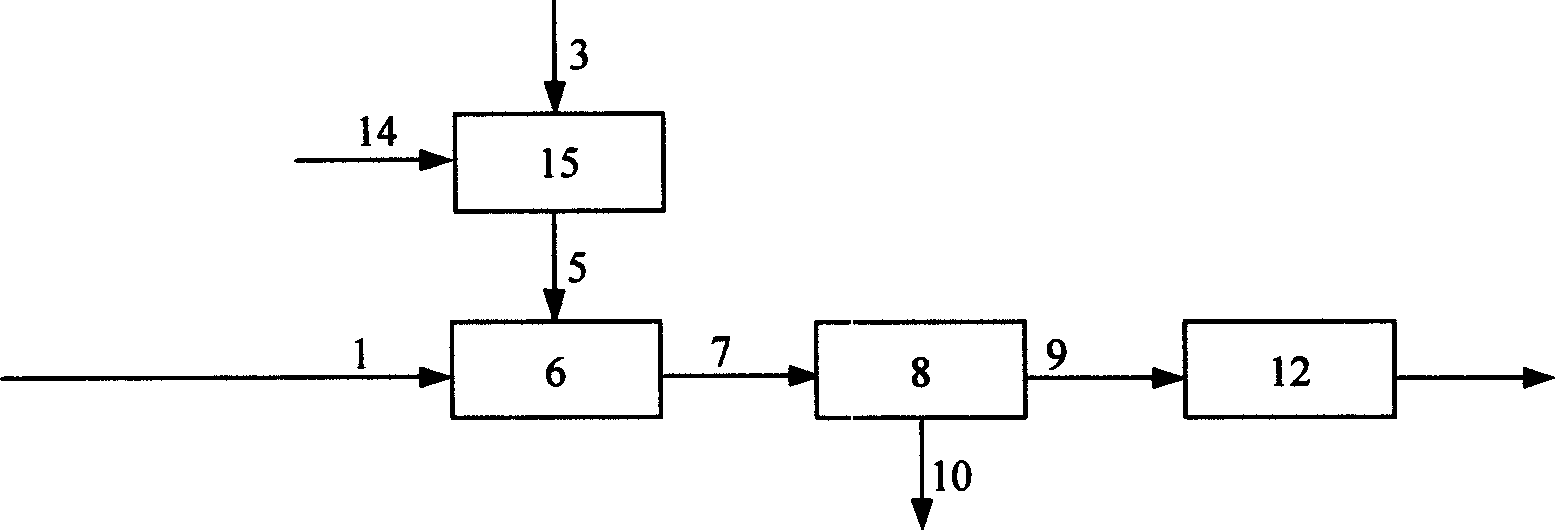

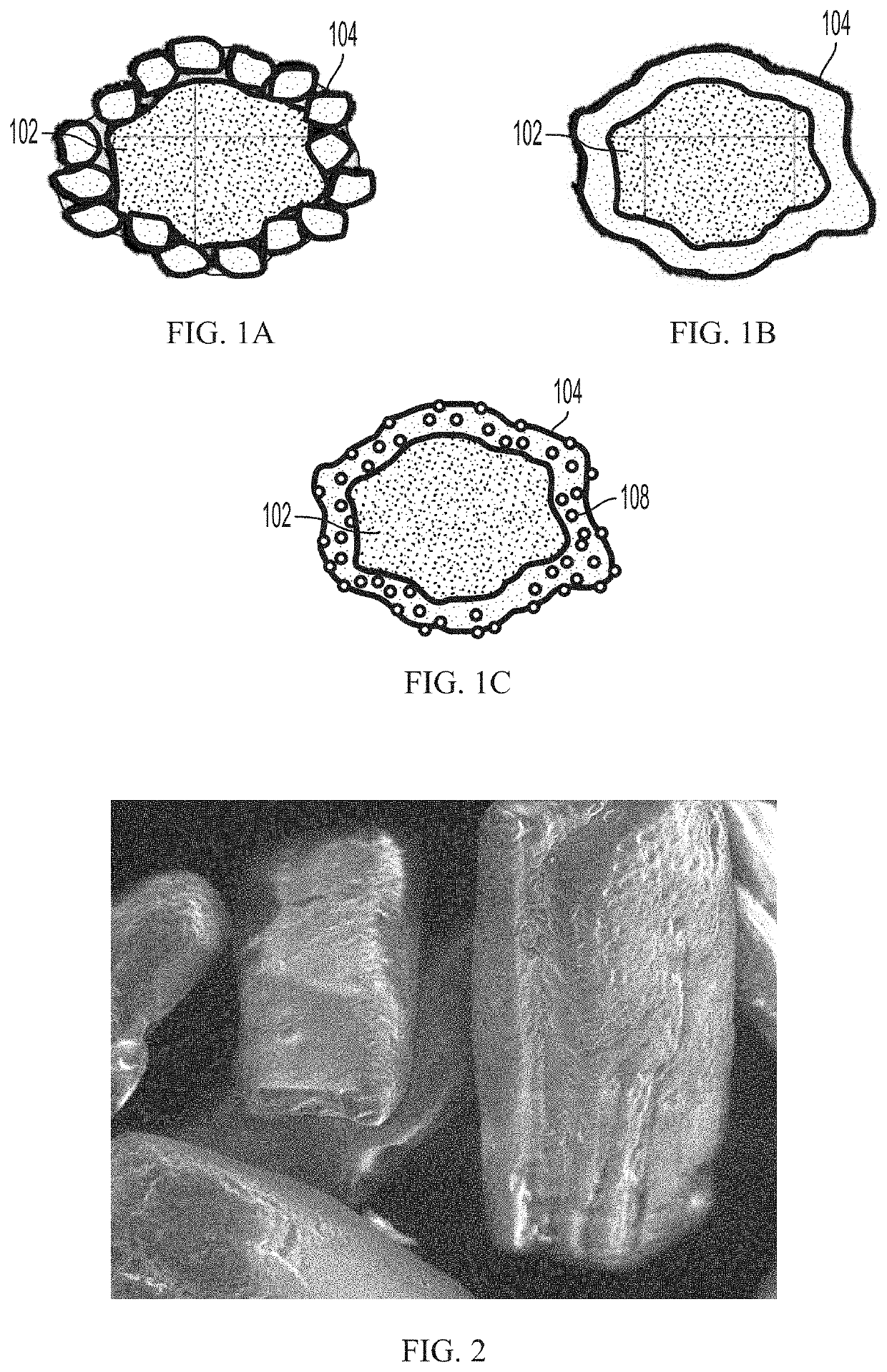

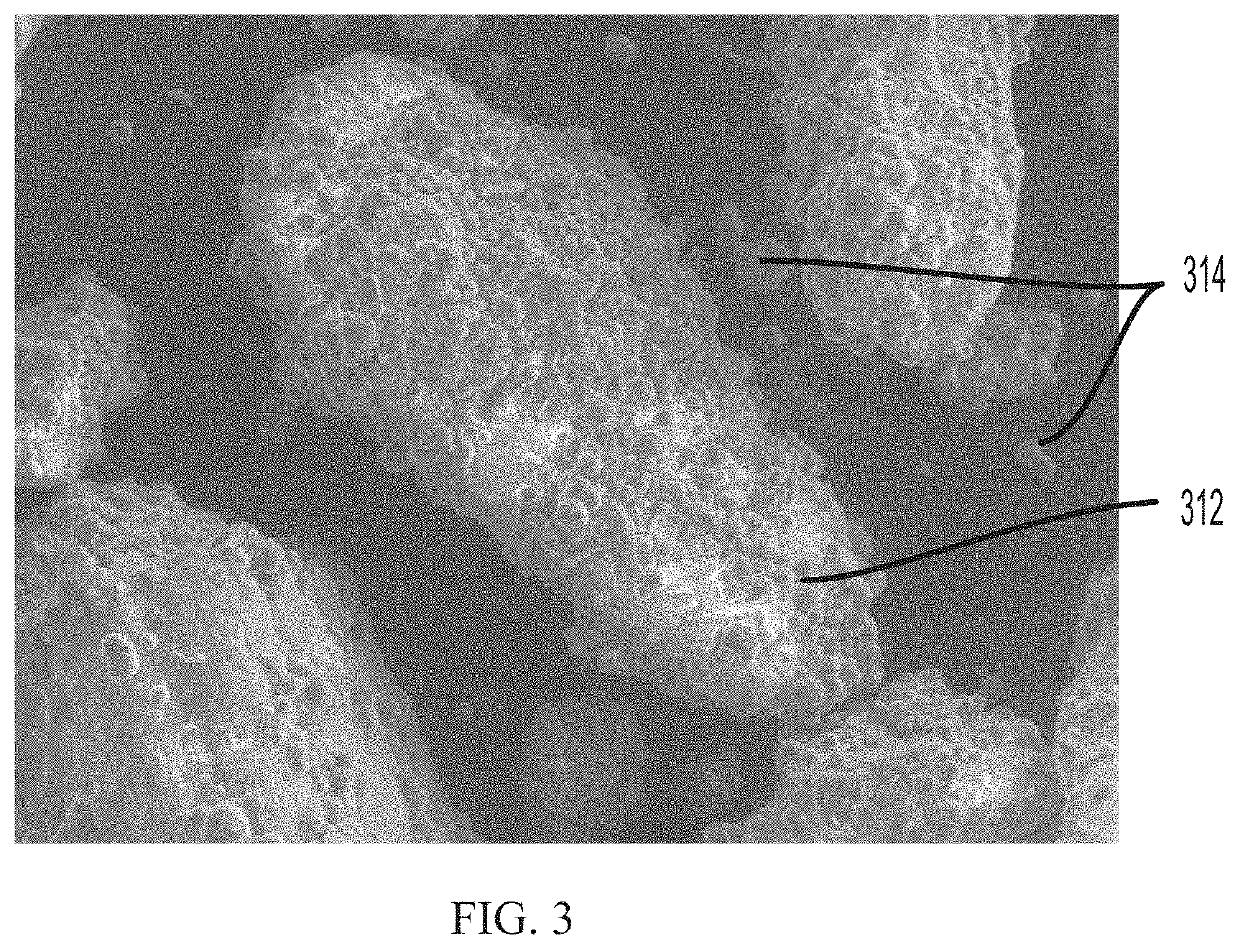

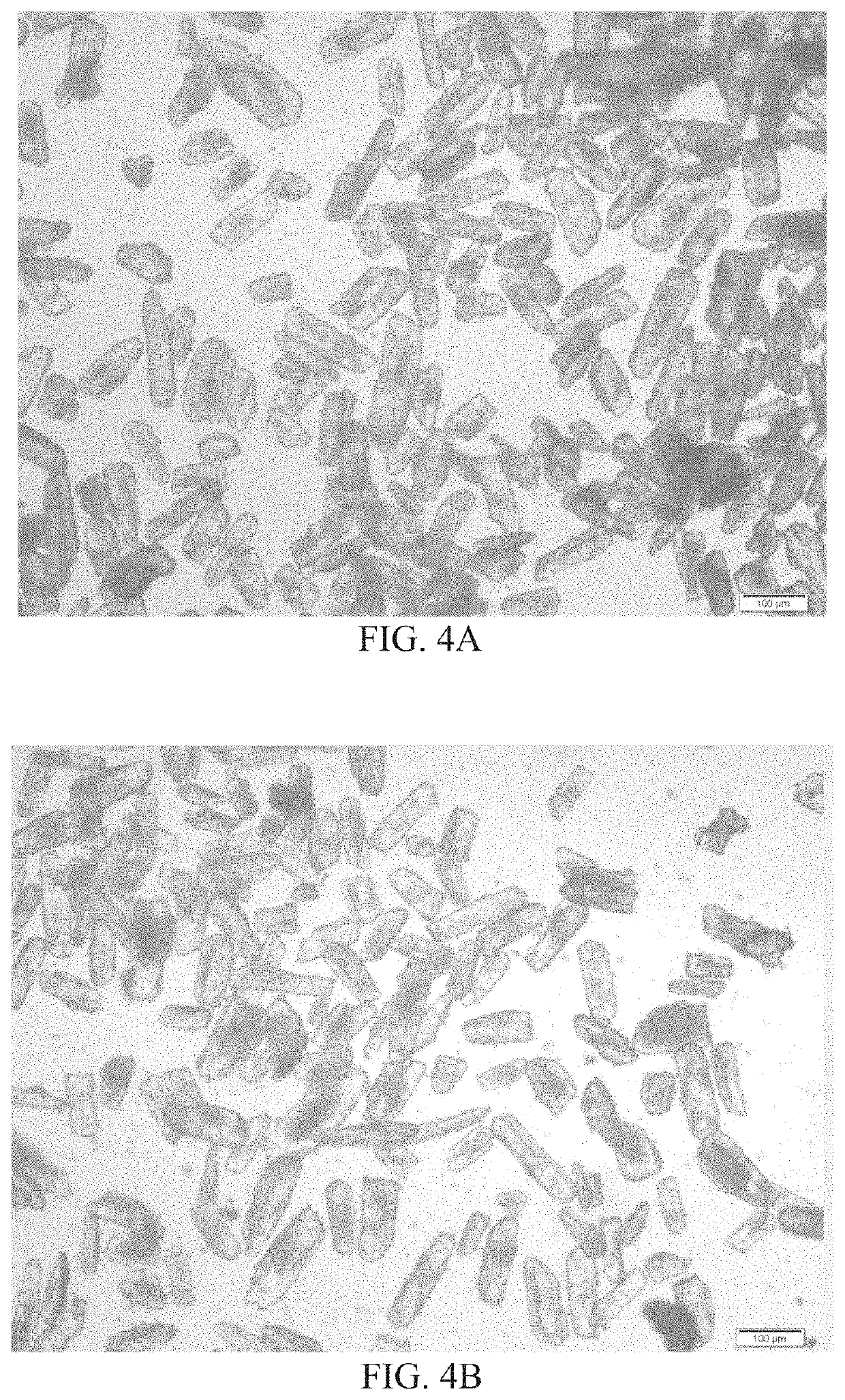

Minimizing agglomeration of drug particle coating material during storage to stabilize disintegration times of pharmaceutical products

ActiveUS20200268667A1Minimize agglomerationReduced stabilityOrganic active ingredientsAntipyreticPhysical chemistrySolvent free

Provided are pharmaceutical compositions and methods for preparing pharmaceutical compositions using solventless mixing methods. Excess coating material that is not bound to a coated API particle may be removed by a sieving process. Coating and dosing ratios can also be optimized to minimize the amount of excess unbound coating material. Specifically, a coating ratio and / or a dosing ratio can be used to minimize the residual amount of excess unbound coating material to minimize agglomeration of coating material during storage. In some embodiments, a pharmaceutical composition is provided, the pharmaceutical composition comprising: 65-85 % w / w API particles; 15-30 % w / w coating material coating the API particles; and 3-15 % w / w matrix surrounding the coated API particles, wherein the pharmaceutical composition comprises a disintegration time rate of less than 10 seconds for at least six months under storage conditions of at least 25° C. and at least 60 % relative humidity.

Owner:CATALENT U K SWINDON ZYDIS LTD

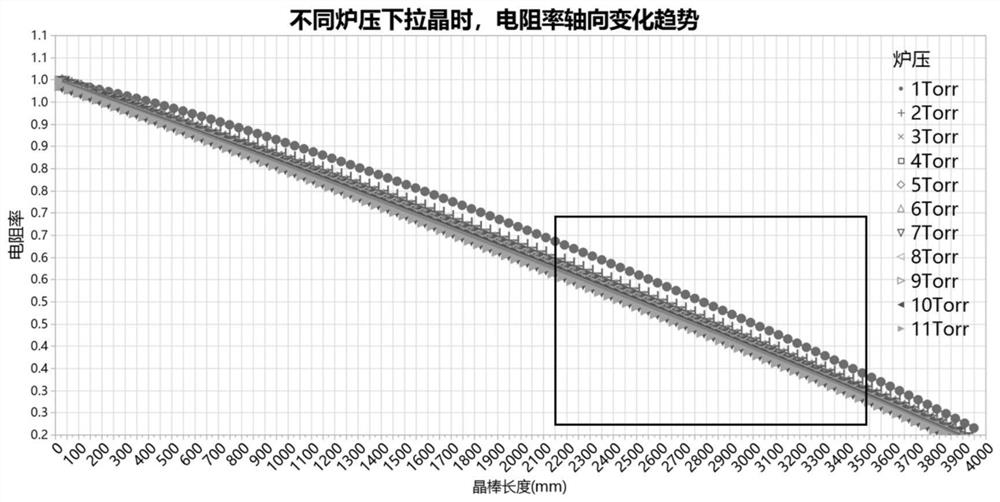

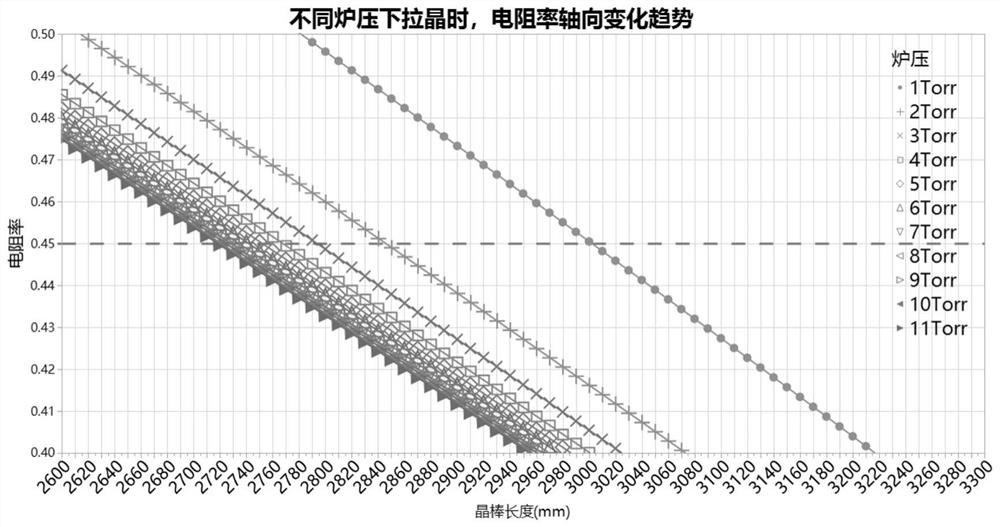

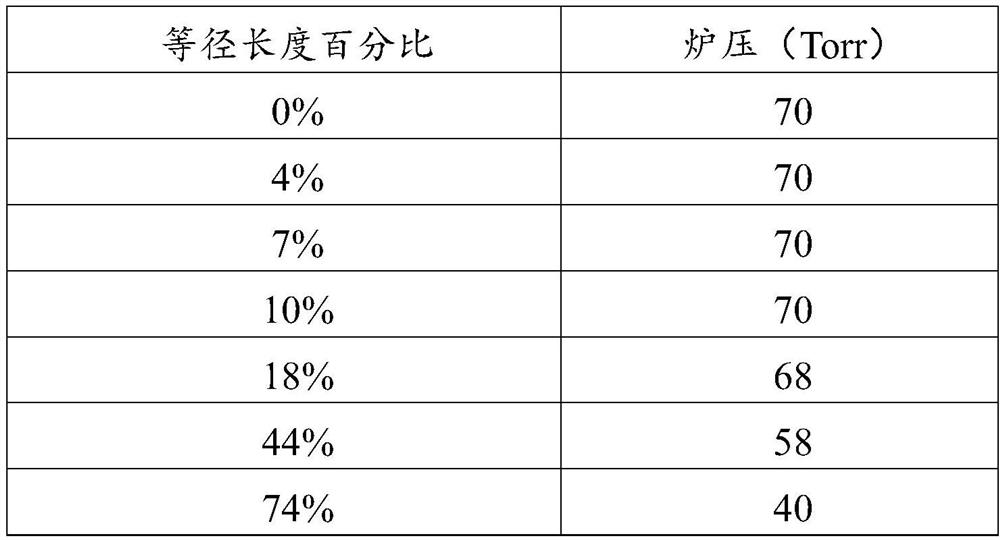

Silicon crystal pulling process method for monocrystalline silicon

ActiveCN113652737ASpeed up evaporationSuppresses resistivity decay ratePolycrystalline material growthFinal product manufactureDopantSingle crystal

The invention provides a crystal pulling process method for monocrystalline silicon doped with a volatile dopant, and the crystal pulling process method comprises the following steps: in an equal-diameter stage of crystal growth, a single crystal furnace adopts low furnace pressure not exceeding 18Torr, and the flow of argon introduced into the single crystal furnace is kept in a constant range. The method realizes equal-diameter crystal pulling under lower furnace pressure. By means of the process method, the axial resistivity attenuation slope of the single crystal doped with the volatile dopant, especially gallium, can be reduced, and the effective length of the resistivity of the single crystal can be increased.

Owner:LONGI GREEN ENERGY TECH CO LTD

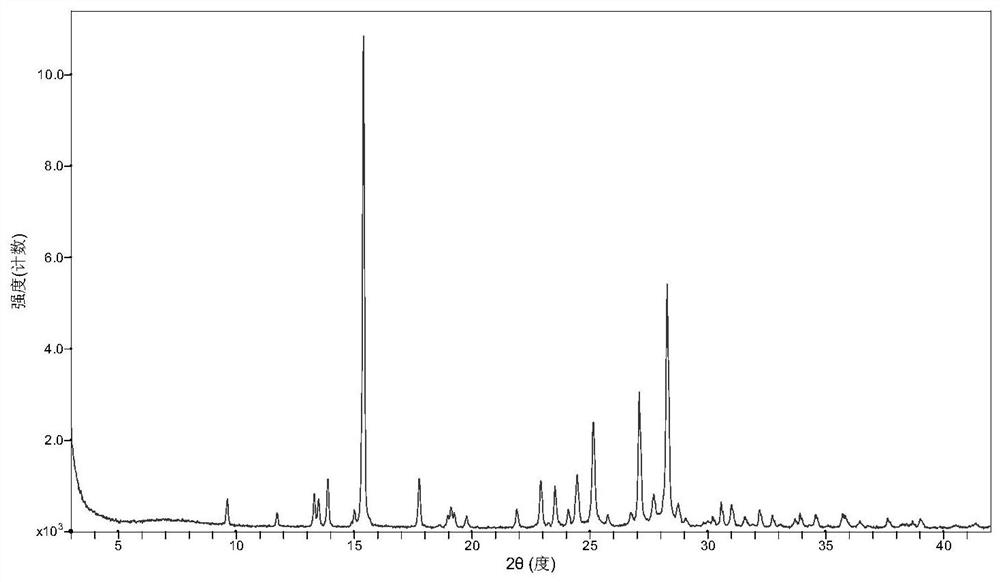

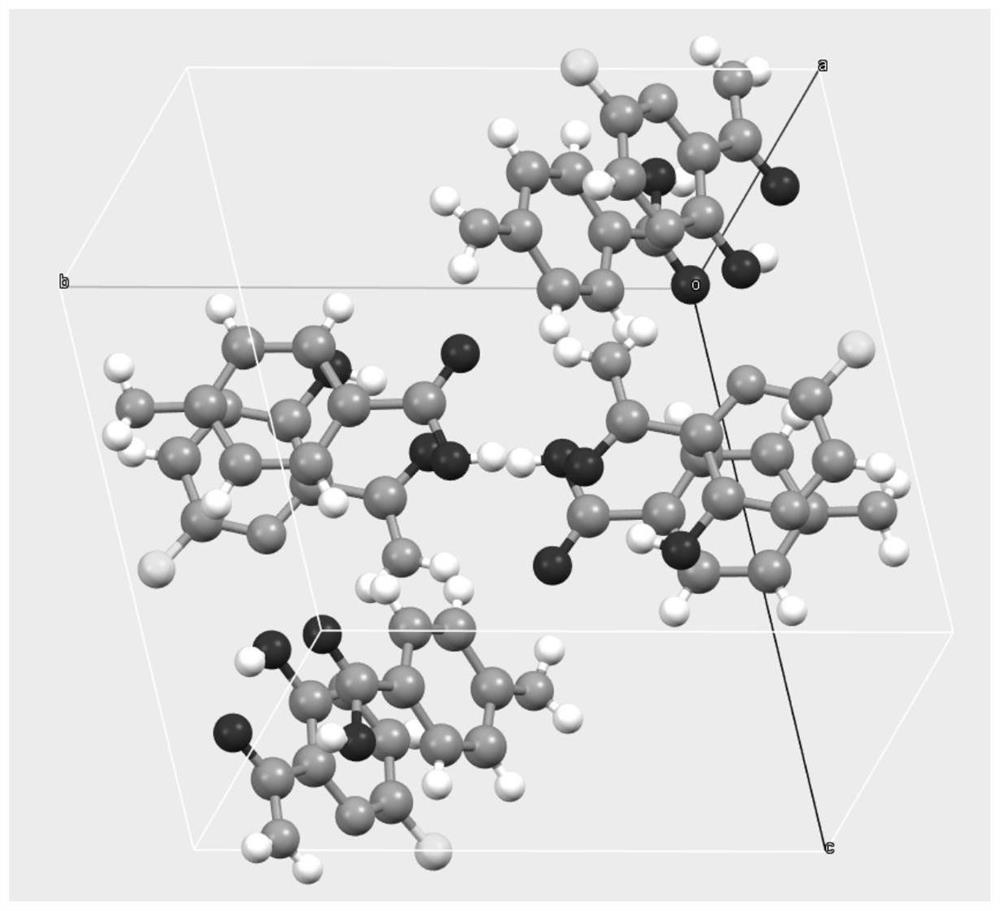

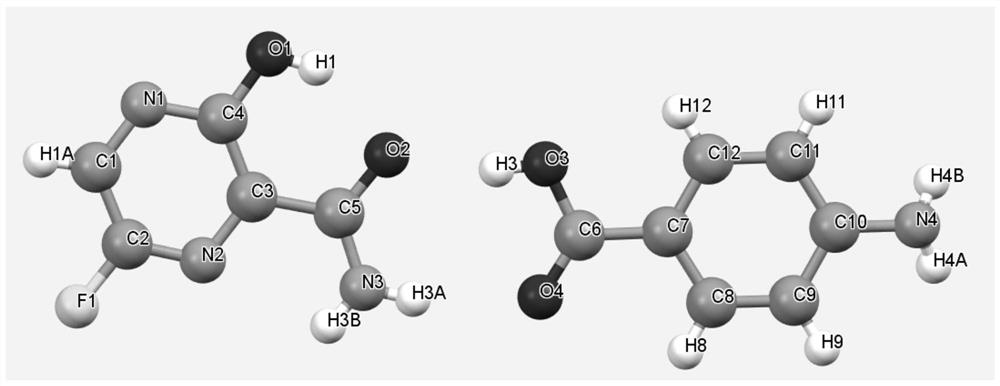

Compound crystal, preparation method and application

ActiveCN112624985AEquivalent Solubility DecreasedReduce dissolution rateOrganic active ingredientsOrganic compound preparationBenzoic acidPhysical chemistry

The invention discloses a compound crystal, and a preparation method and application thereof, belonging to the technical field of chemical medicines. The compound crystal is a eutectic crystal of favipiravir and p-aminobenzoic acid, the unit cell of the eutectic crystal belongs to a monoclinic system and a P21 / c space group, and the unit cell parameters are as follows: alpha = gamma = 90 degrees and beta = 92.578 (3) degrees. The equivalent solubility of the favipiravir in the compound crystal provided by the invention is reduced by about 50%, so that the dissolution rate of the favipiravir is favorably reduced, the onset time of the favipiravir is prolonged, and the toxic and side effects of the favipiravir are reduced.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

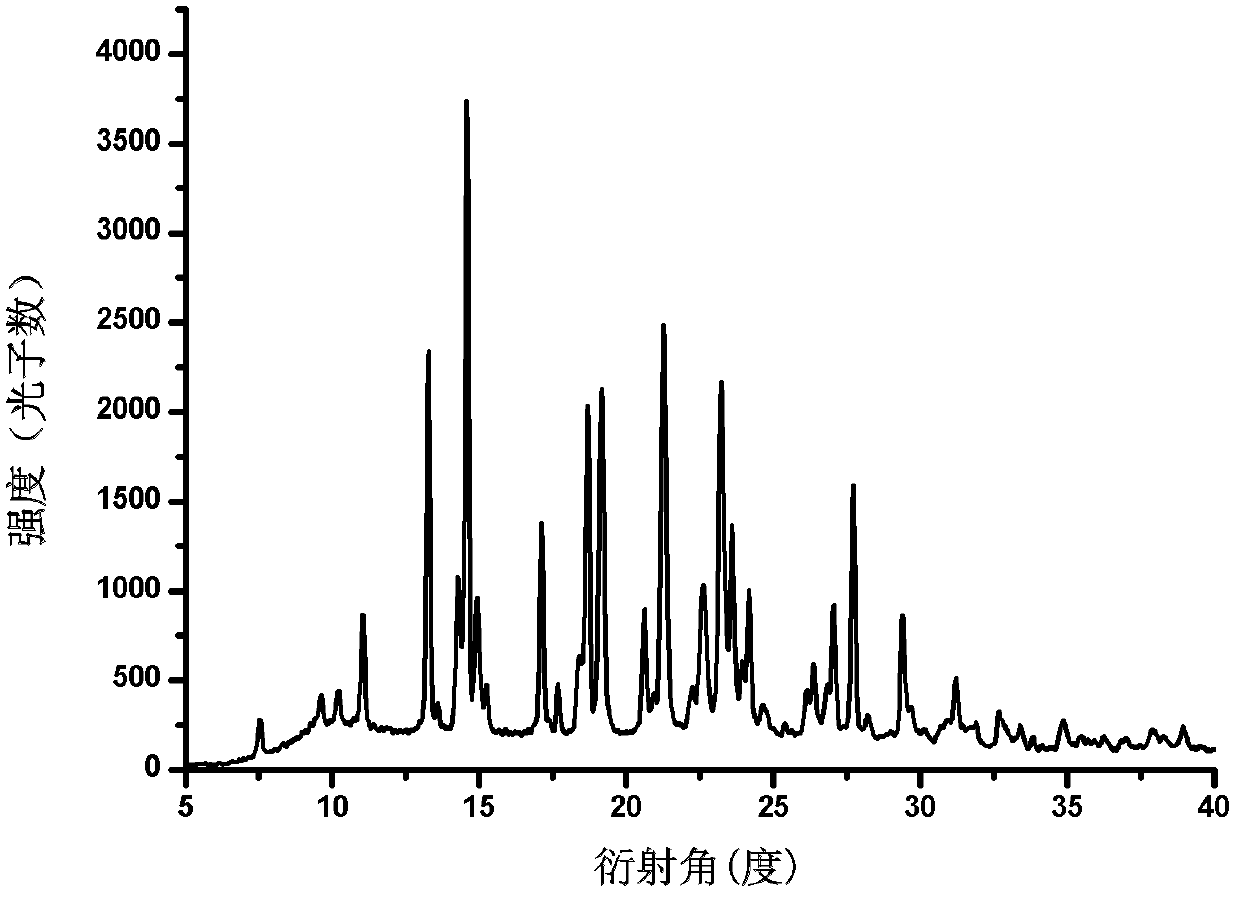

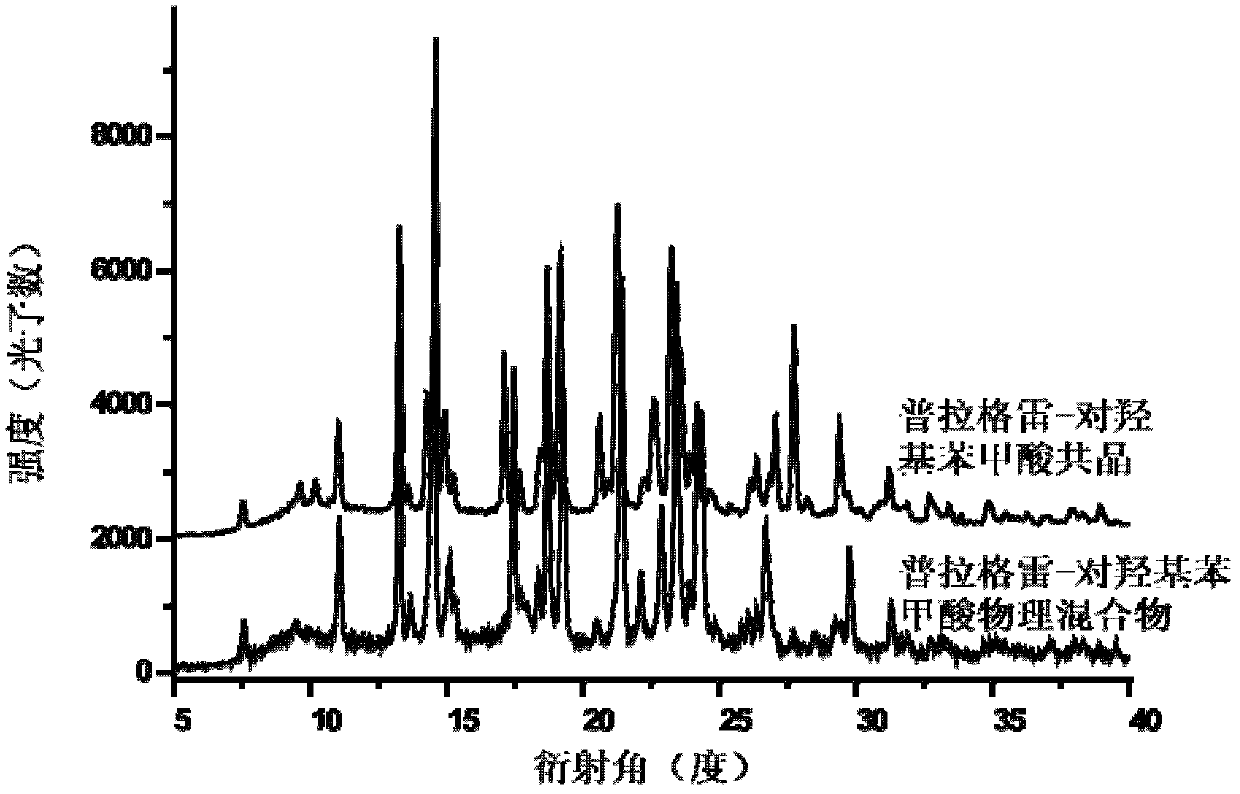

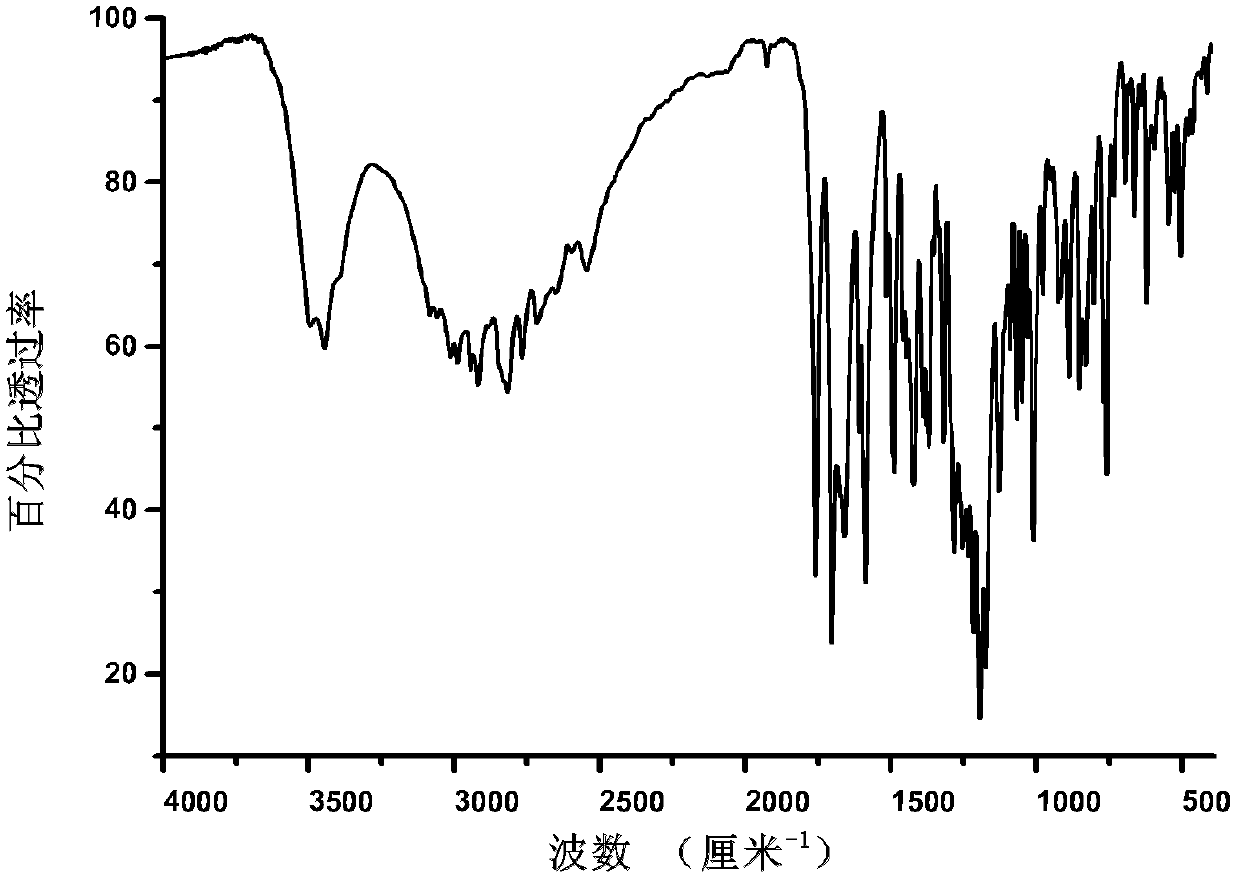

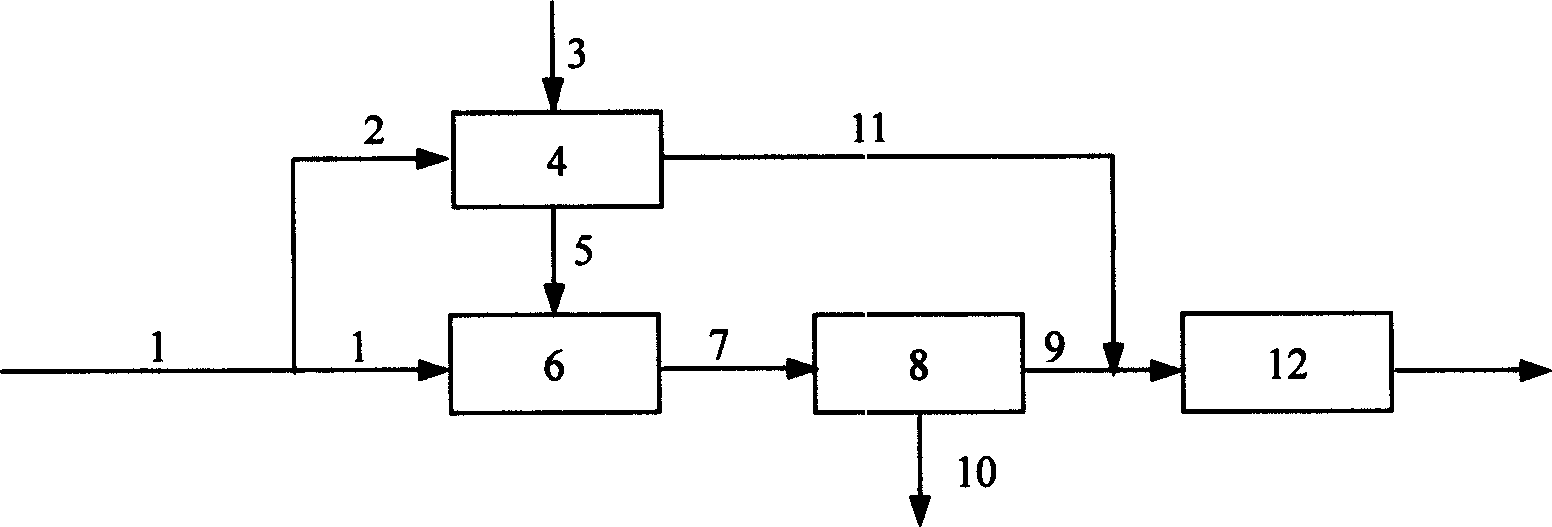

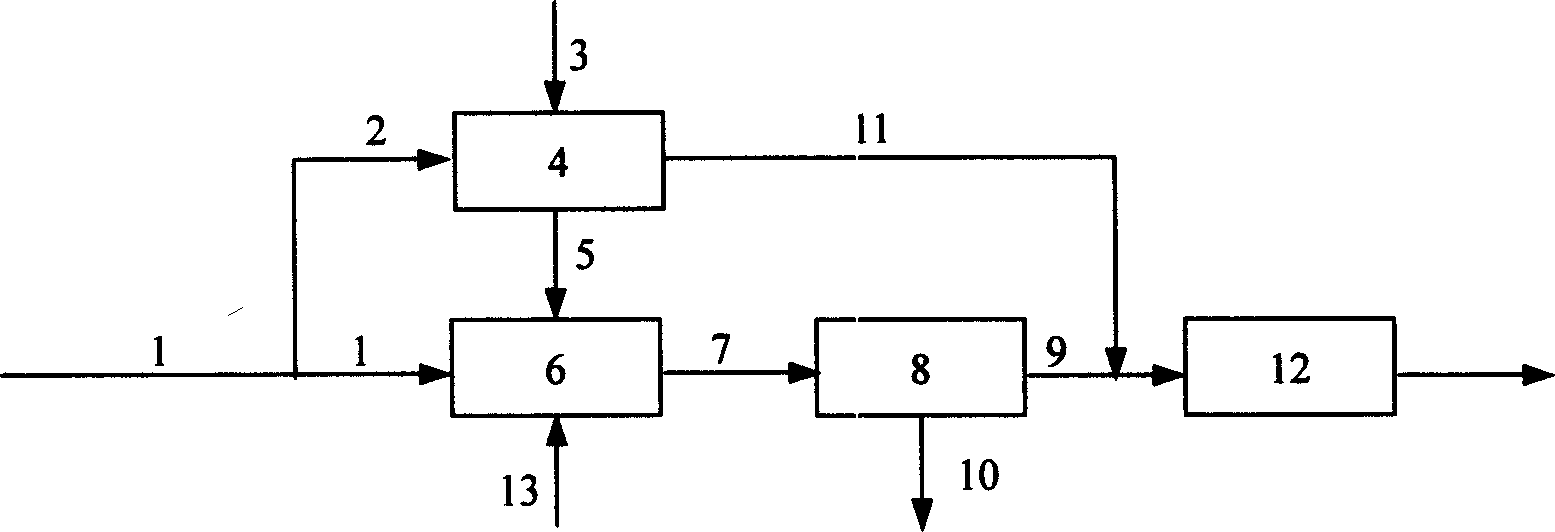

Prasugrel eutectic and preparation method, medicinal composition and application thereof

InactiveCN102617594AReduce humidityReduce dissolution rateOrganic active ingredientsNervous disorderTraditional medicineSolvent

The invention provides a prasugrel eutectic with a structure shown in the specification, and a preparation method, a medicinal composition and application thereof. The prasugrel eutectic does not contain a solvent and is low in hygroscopicity, so that the preparation and storage of Chinese herbal medicines are facilitated. Experiments for testing dissolubility prove that the prasugrel eutectic is relatively low in dissolution speed, so the prasugrel eutectic can be used as a sustained-release agent for prasugrel medicines to overcome the defect of increasing hemorrhagic risks. In addition, the method for preparing the prasugrel eutectic is simple, and easy to operate.

Owner:SHANGHAI INST OF MATERIA MEDICA CHINESE ACAD OF SCI

Oviductus ranae microcapsules and preparation method thereof

InactiveCN105533750ARetain kidney and essenceIt has the function of nourishing kidney and benefiting essenceFood shapingAcetic acidChloride

The invention discloses oviductus ranae microcapsules and a preparation method thereof, and belongs to the technical field of processing of functional oil and fat products. The microcapsules are prepared with sodium alginate and chitosan serving as wall materials and oviductus ranae serving as a core material. The microcapsules are prepared from, by mass, 1-3% of sodium alginate, 1-3% of chitosan, 1.5-8% of oviductus ranae, 2-6% of anhydrous calcium chloride, 0.5-1% of tween-80, 1% of acetic acid and the balance water. The preparation method of the microcapsules includes the main steps that 1, a wall material solution and an immobilization solution are prepared; 2, oviductus ranae and a sodium alginate solution are mixed according a certain proportion; 3, emulsification homogenization treatment is carried out; 4, the microcapsules are prepared through a piercing-solidifying method. According to the microcapsules and the preparation method thereof, bioactive substances of oviductus ranae are maintained, and many defects of oviductus ranae are overcome. The microcapsules are convenient to preserve, and the fishy smell of oviductus ranae is removed. The preparation method is easy to implement and beneficial for industrial production and opens up a new field for deep processing of rana temporaria.

Owner:JILIN UNIV

Acid solution spray dry-process flue gas desulfurization and modulating intensification method

InactiveCN1593731AFull use of desulfurization potentialGive full play to the catalytic oxidation effectDispersed particle separationParticulatesCatalytic oxidation

The invention relates to a kind of acidic-solution spraying dry-way stack-gases desulfurization and tempering intensification method, which is applicable in the field of stack gases desulfurization or desamination and the field of stack gases tempering. Spraying the acidic solution whose PH<=5.5 in the form of vaporific into stack gases, which contains fly ash or granule of the desulfurization agent in the desulfurization reactor or the flue between the tail of coal burning boiler and dust remover. So it can make the fog drip catch fly ash or granule of the desulfurization agent in stack gases efficiently and then form the liquid film on it. With the moisture in fog drip evaporating rapidly, the PH of remaining liquid film tends to step down and the acidity tends to be higher so that it is favorable to digesting the alkaline metal ion and the transition state metal ion having catalysis and oxidization. Then the sweet effective constituent granule contained in granule can be activated and participate in desulfurization reaction. In the result of that described above, then invention can intensify to decline the stack gases tempering of dust to the resistance and the oxidative extent to the sweet by-product; it can decline the proportion of astable sulfite; it can reduce the consumption of Ca matrix desulfurization agent for carbon dioxide; and finally it can improve the use ratio and the sweet efficiency of the drying-way desulfurization agent.

Owner:陶国龙

Minimizing agglomeration, aeration, and preserving the coating of pharmaceutical compositions comprising ibuprofen

ActiveUS20200268676A1Minimize agglomerationReduced stabilityOrganic active ingredientsAntipyreticSolvent freePharmaceutical Substances

Provided are pharmaceutical compositions and methods for preparing pharmaceutical compositions comprising Ibuprofen using solventless mixing methods. Excess coating material that is not bound to coated Ibuprofen may be removed by a sieving process. Coating and dosing ratios can also be optimized to minimize the amount of excess unbound coating material. Additionally, the compositions can be formulated to preserve the functional coating of coated Ibuprofen and to minimize aeration of Ibuprofen when mixed into suspension.

Owner:CATALENT U K SWINDON ZYDIS LTD

Cleaning method of anode net of ionic membrane electrolysis bath

InactiveCN106555205AImprove solubilityEffective dissolutionElectrolysis componentsElectrolysisCleaning methods

The invention discloses a cleaning method of an anode net of an ionic membrane electrolysis bath. Through the method, a compound scale layer on the surface of the anode net can be effectively removed, a surface coating of the anode net can be prevented from being damaged, and a voltage of the electrolysis bath can be lowered. The method includes the steps of carrying out pre-cleaning and leakage testing on a cleaning bath through pure water and placing the electrolysis bath into the cleaning bath after a cathode and an anode of the electrolysis bath are pressed by plastic membranes at an interval; preparing a primary cleaning agent through the pure water, heating the primary cleaning agent to 55-85 DEG C, then cleaning the anode net of the electrolysis bath for 1-4 hours, draining the primary cleaning agent and adding the pure water for flushing, wherein the primary cleaning agent is composed of 2-6% of hydrochloric acid and 0.2-0.3% of lan-826 corrosion inhibitors in concentration percentage; and preparing a secondary cleaning agent through the pure water, heating the secondary cleaning agent to 55-85 DEG C, then cleaning the anode net of the electrolysis bath for 4-6 hours, draining the secondary cleaning agent and adding the pure water for flushing, wherein the secondary cleaning agent is composed of 3-8% of citric acid, 0.2-0.35% of lan-826 corrosion inhibitors and 3-6% of sulfamic acid in concentration percentage.

Owner:PANZHIHUA STEEL ENTERPRISES XINYU CHEM

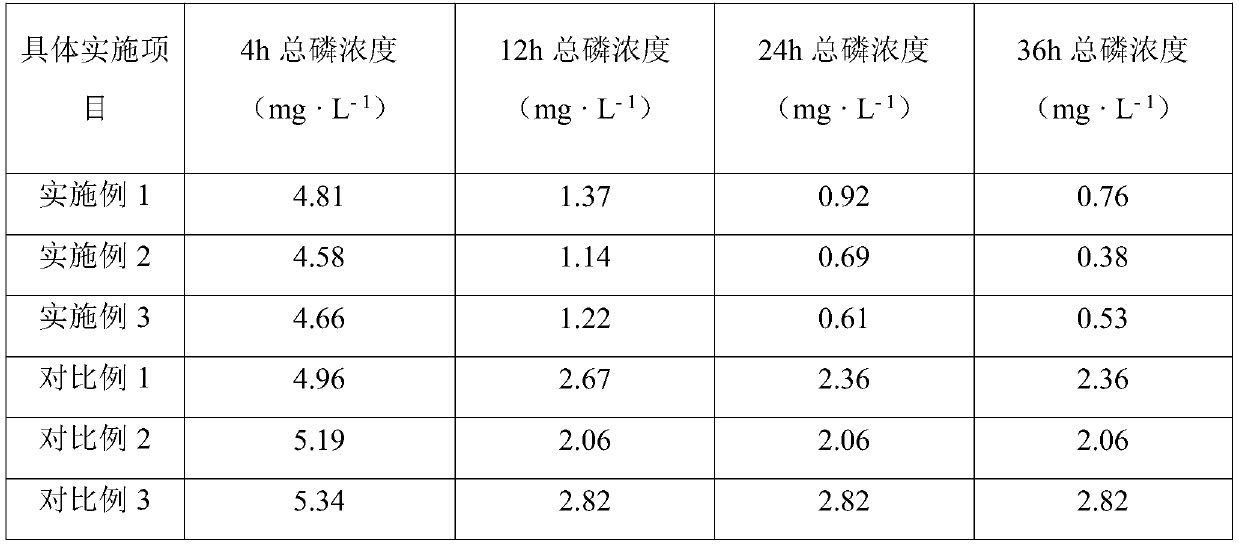

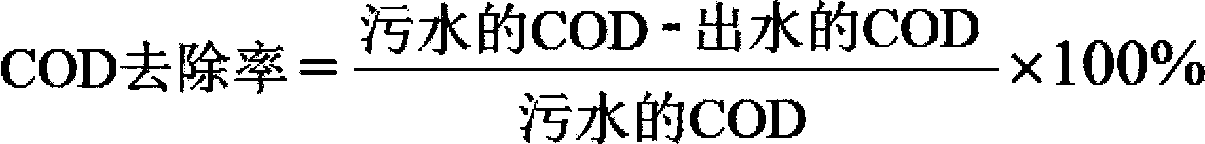

Sewage treatment agent with slow release function and preparation method thereof

ActiveCN110040827ANot subject to disintegrationImproved purificationWater contaminantsWater/sewage treatment by flocculation/precipitationMedicineSewage

The invention provides a sewage treatment agent with a slow release function. The sewage treatment agent comprises the following components in parts by weight: 30-45 parts of dephosphorization flocculant, 15-25 parts of slow release agent and 50-60 parts of solid carrier. The invention aims to provide the sewage treatment agent with the slow release function. The dephosphorization flocculant is effectively and continuously released after the sewage treatment agent reaches the middle and lower layers of sewage, a dephosphorization effect can be achieved while the continuous addition of chemicalagents can be avoided, so that an efficient and stable dephosphorization effect can be achieved.

Owner:襄阳先创环保科技有限公司

Bacillus megaterium strain ZT-P and application thereof

ActiveCN108676744AIncrease vitalityHigh heritabilityBacteriaMicroorganism based processesMicroorganismBacillus megaterium

The invention discloses a Bacillus megaterium strain ZT-P and application thereof. The strain ZT-P is Bacillus megaterium, has the property of dissolving with organophosphorus and inorganic phosphorusbacteria, and was preserved in CGMCC on April, 2018, with a strain preservation number of CGMCC NO.15602. The strain ZT-P provided by the invention has high vitality and adaptability, and can be widely used for fertilizer and pesticide reducing treatment of microbial fertilizer. By tests, the phosphate solubilization capacity of the microbial fertilizer prepared from the strain ZT-P in soil during flask shaking at the 5th day reaches maximum 156.7 [mu]g / mL. Compared with the phosphate solubilization rate before mutagenesis, the phosphate solubilization rate of the strain is improved by 20 percent, and dissolution rates of organophosphorus and inorganic phosphorus in the soil are reduced. Therefore, according to the prepared microbial organic fertilizer, dissolution periods of the organophosphorus and the inorganic phosphorus are shortened, and dissolved quantities of the organophosphorus and the inorganic phosphorus are reduced.

Owner:NANJING AGRICULTURAL UNIVERSITY +1

Biological organic fertilizer and preparation method thereof

InactiveCN108516912APromote thrivingSimple structureBio-organic fraction processingAlkali orthophosphate fertiliserPotassium nitrateTrace element

The invention discloses biological organic fertilizer. Raw materials of the fertilizer includes modified biological carbon, sugarcane leaves, crop straw, corncobs, excrement of livestock and poultry,a fermentation bacterial inoculant, a functional microbial strain, ammonium chloride, potassium nitrate, calcium magnesium phosphate, monopotassium phosphate and compound trace elements. The inventionalso discloses a preparation method of the biological organic fertilizer. Under interaction of each added raw material, nutrients are supplied to meet the growth demands of crops; meanwhile, the utilization rate of fertilizer nutrients can also be increased, the soil structure can be improved, and healthy growth of crops is facilitated.

Owner:ANHUI SIERTE FERTILIZER IND

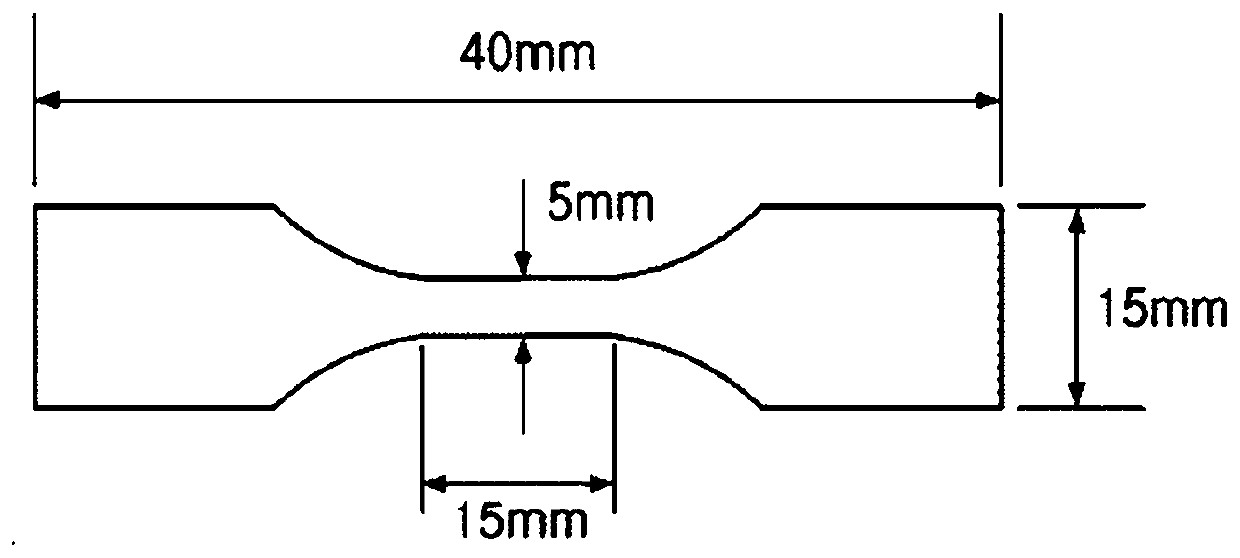

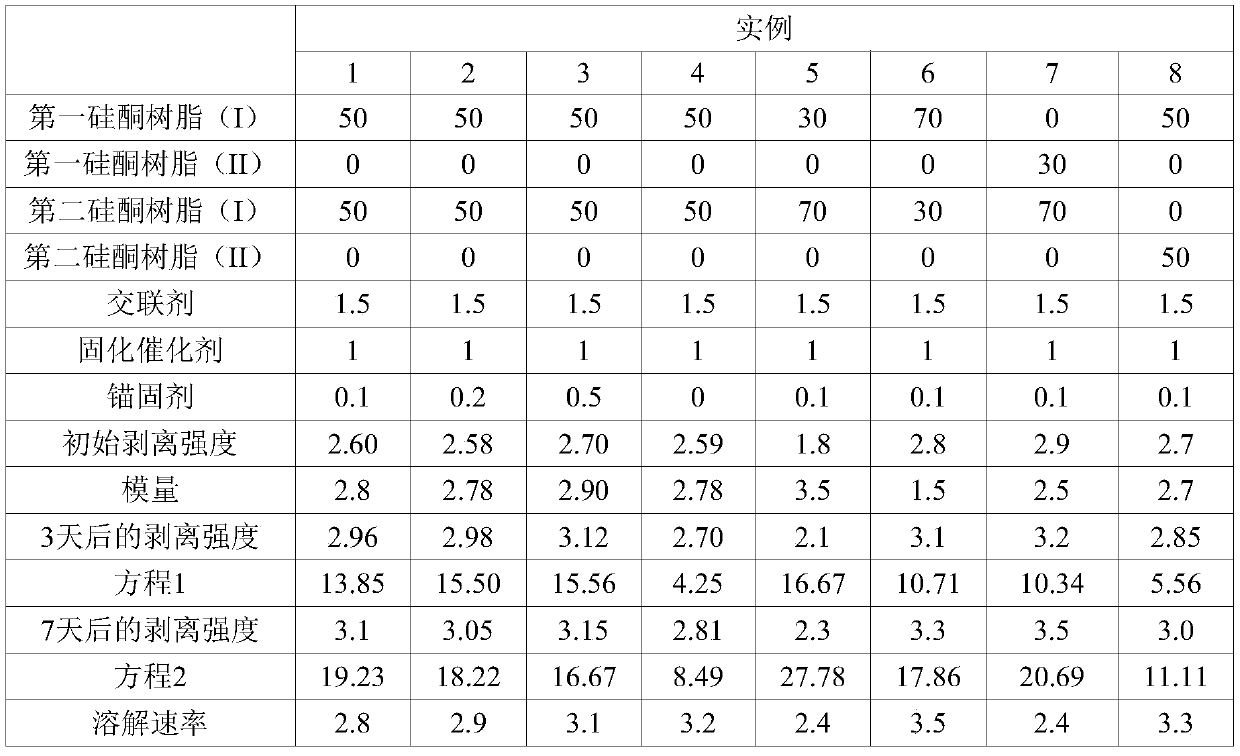

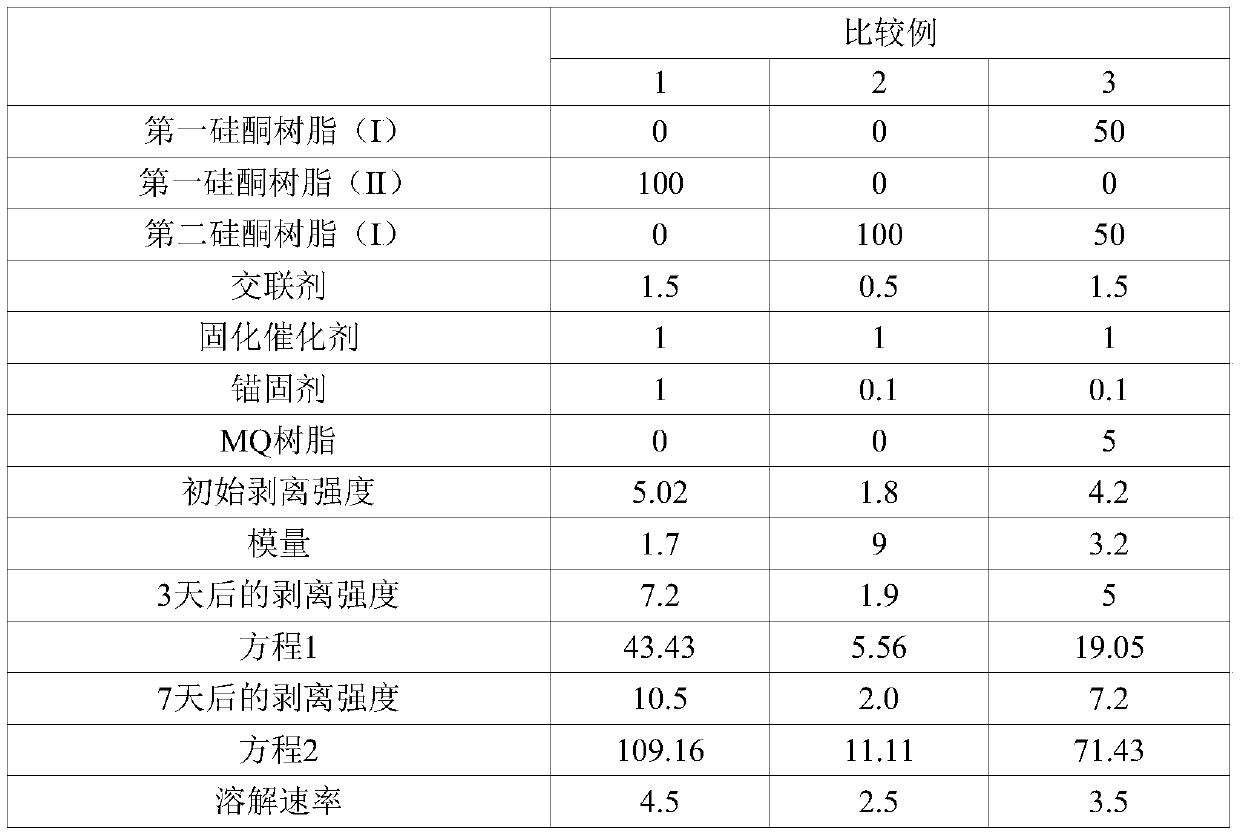

Silicone based adhesive protective film and optical member comprising the same

ActiveCN111378188AReduce dissolution rateNon-macromolecular adhesive additivesPressure sensitive film/foil adhesivesPolymer sciencePtru catalyst

A silicone-based adhesive protective film and an optical member including the same are provided. The silicone-based adhesive protective film is formed of a composition including a silicone resin, a crosslinking agent, and a curing catalyst, and the silicone-based adhesive protective film has a peel strength of about 3 gf / inch or less with respect to a glass plate at 25 DEG C., and a modulus of about 0.5 MPa to about 7 MPa at 25 DEG C. The silicone-based adhesive protective film of the present disclosure has low peel strength, a low peel strength change rate, and good wettability.

Owner:SAMSUNG SDI CO LTD

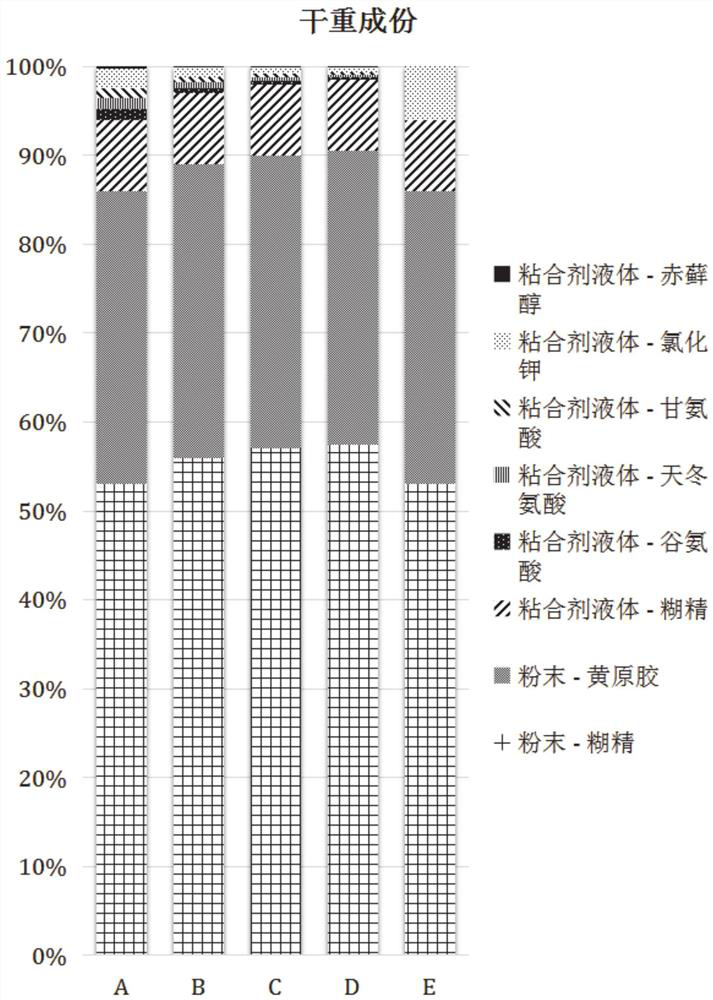

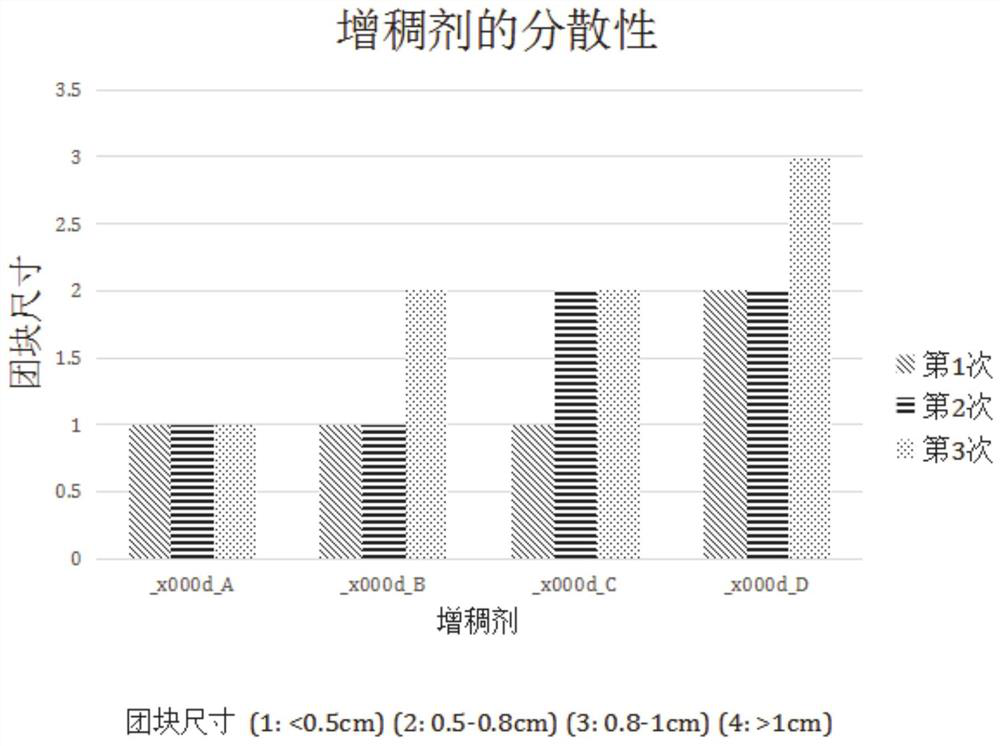

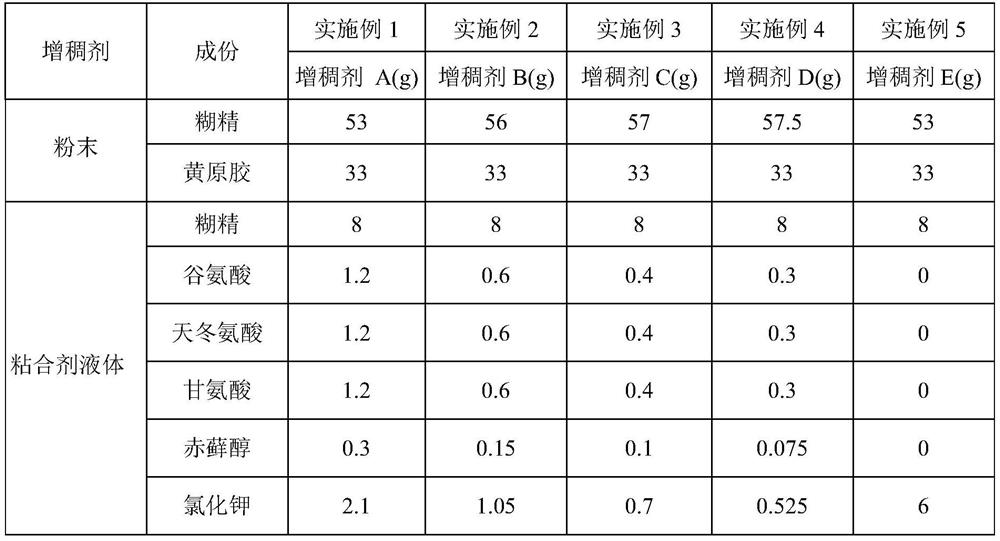

High-dispersity edible instant thickener and preparation method thereof

PendingCN111602805AImprove dispersionSlow down the rate of dissolutionFood ingredient as thickening agentFood ingredient as taste affecting agentChloride potassiumErythritol

The invention discloses a high-dispersity edible instant thickener and a preparation method thereof. The thickener comprises the following raw materials in percentage by mass: 1-10% of a block formation inhibitor, 20-75% of xanthan gum and 20-75% of dextrin, wherein the block formation inhibitor comprises a composition containing one or more of glutamic acid, aspartic acid, glycine, erythritol andpotassium chloride. The composition is prepared from the following components in percentage by mass: 16 to 24% of glutamic acid, 16 to 24% of aspartic acid, 16 to 24% of glycine, 5 to 10% of erythritol and 25 to 40% of potassium chloride. The invention also provides a preparation method of the thickener. The prepared thickener can improve the dispersity of liquid in the thickener and inhibit theblock formation, so that xanthan gum can fully exert a thickening function, and the special taste generated by potassium chloride can also be improved.

Owner:周益俊

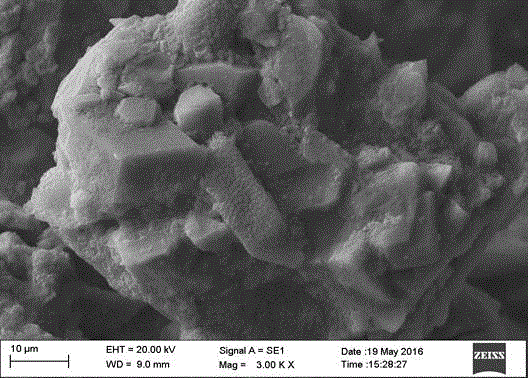

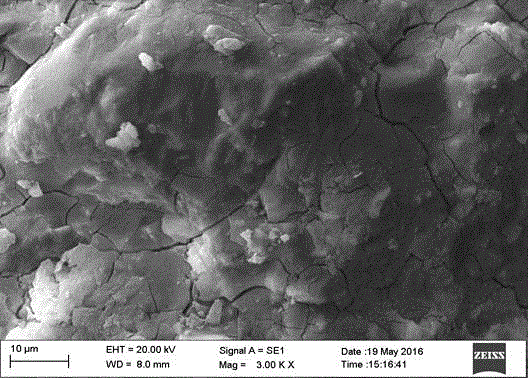

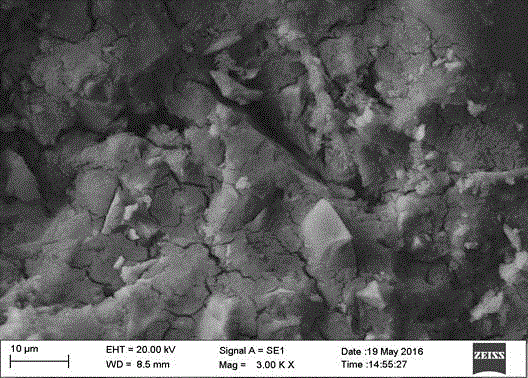

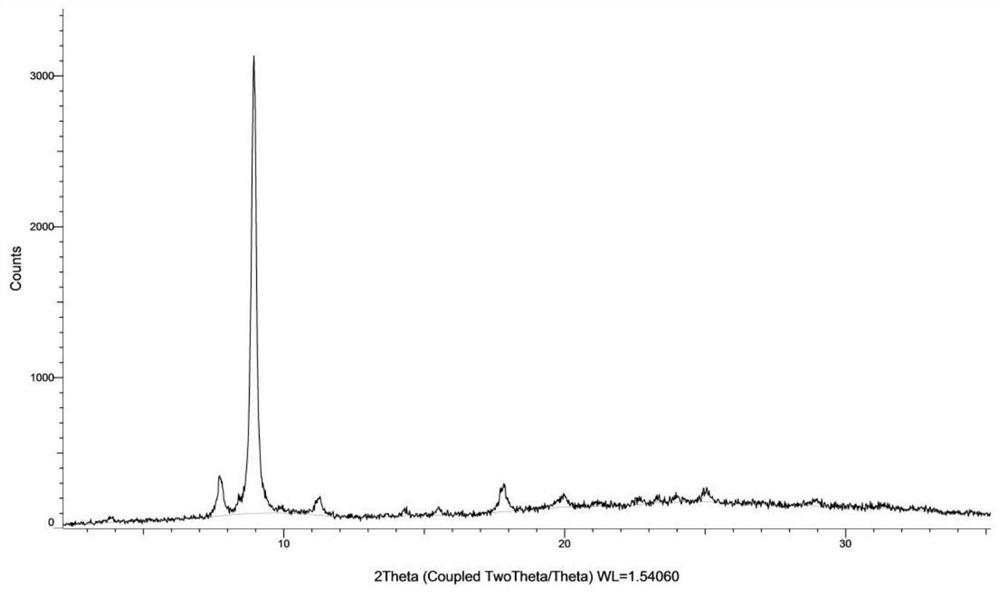

Retarder-free waterproof magnesium ammonium phosphate cement and preparation method thereof

ActiveCN106746811AReduce dissolution rateGood flexibilityIsolation effectMagnesium ammonium phosphate

The invention discloses retarder-free waterproof magnesium ammonium phosphate cement and a preparation method thereof. The cement comprises dead burned magnesia coated with graphene oxide, ammonium dihydrogen phosphate and mineral admixtures, wherein the mass ratio of dead burned magnesia coated with graphene oxide and ammonium dihydrogen phosphate is (62-78):(22-38), and the mineral admixtures are 5-15% of the total mass of dead burned magnesia and ammonium dihydrogen phosphate. According to the cement, dead burned magnesia powder is pretreated by graphene oxide, so that a comparatively obvious isolation effect is formed between magnesia and an external environment, therefore, the dissolution rate of magnesia is greatly decreased, a forming process of a hydration product is delayed, and the heat release of a whole reaction system is reduced; macroscopically, the time of coagulation is greatly prolonged, and any retarders do not need to be added. Moreover, a dissolution process of the hydration product and phosphate is inhibited, a large amount of pores are prevented from being formed in the cement, and the strength of hardened cement paste is ensured.

Owner:UNIV OF JINAN

Repotrectinib crystal form and preparation method thereof

InactiveCN112174982AReduce the risk of crystallizationReduce dissolution rateOrganic active ingredientsOrganic chemistry methodsCombinatorial chemistryPyrazole

The invention provides a new crystal form of (7S, 13R)-11-fluorine- 7, 14-dimethyl-6, 7, 13, 14-tetrahydro-1, 15-ethylene bridge pyrazolo [4, 3-f] [1, 4, 8, 10] -benzoxaza-triazacyclo-tridecyne-4 (5H)-one, and on the other hand, the invention provides a preparation method of the crystal form. Compared with the prior art, the crystal form prepared by the invention is high in stability, low in hygroscopicity, simple and convenient in preparation method, good in solubility and suitable for subsequent preparation research and development and industrial production.

Owner:SHANGHAI ACEBRIGHT PHARMA CO LTD +1

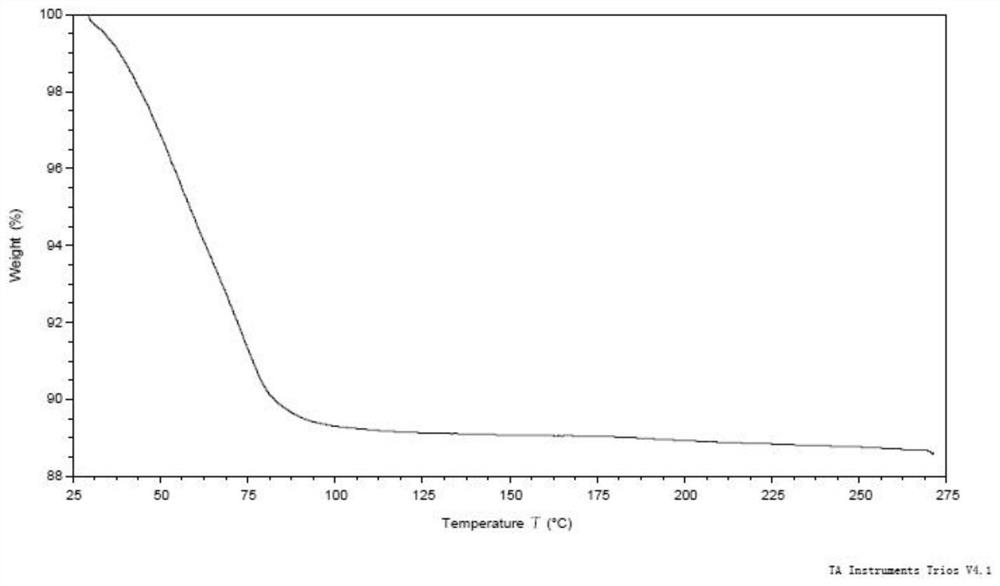

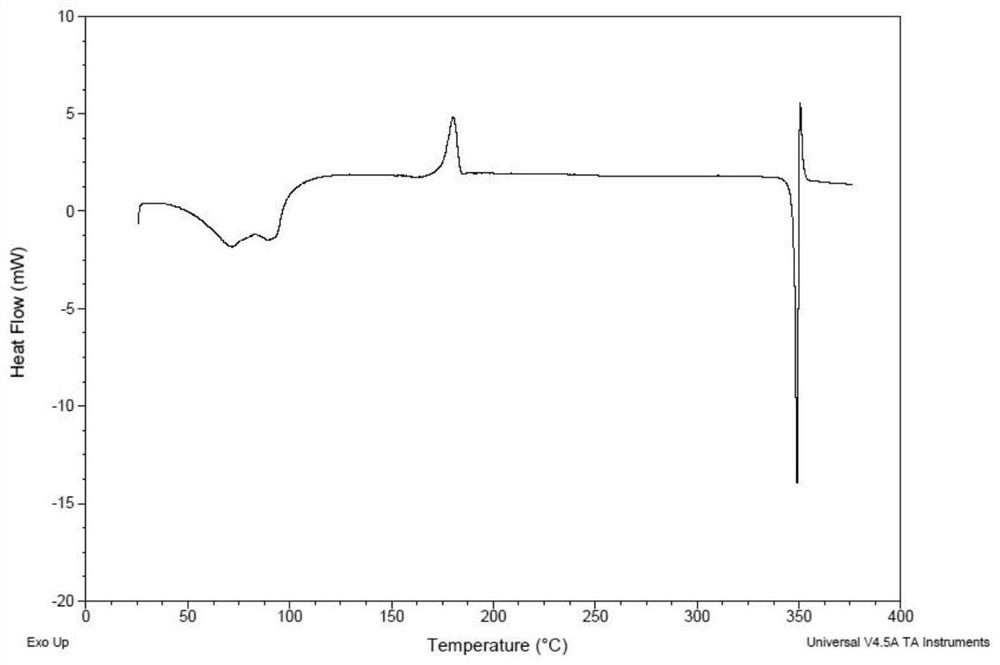

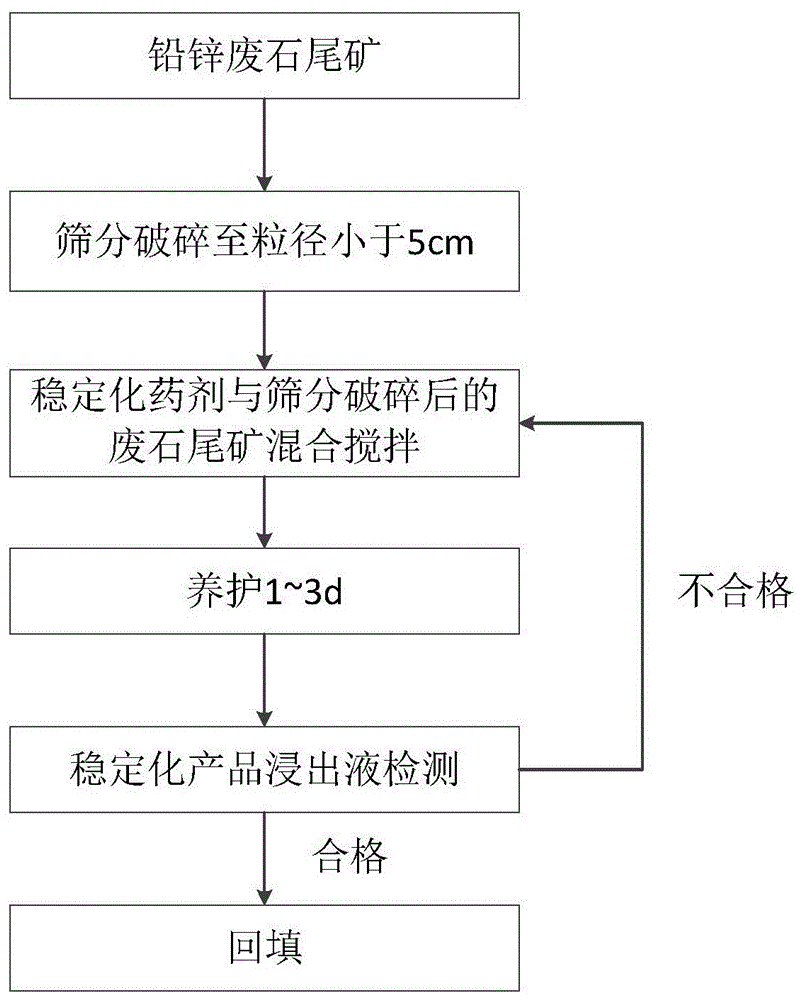

Stabilization medicament of lead-zinc waste rocks and tailings as well as preparation and application of stabilization medicament

ActiveCN106747249AReduce dissolution rateControl the risk of secondary pollutionSolid waste managementContaminated soil reclamationMaceralPollution

The invention discloses a stabilization medicament of lead-zinc waste rocks and tailings as well as preparation and application of the stabilization medicament. The stabilization medicament is prepared from powder and liquid; the powder is prepared from the following components according to the weight percent in the powder: 45 percent to 60 percent of quick lime, 18 percent to 26 percent of a clay ore material, 15 percent to 23 percent of a phosphorus-based compound and 4 percent to 8 percent of sodium trithiosulfate; the liquid is prepared from the following components according to the weight percent in the liquid: 4 percent to 12 percent of a phosphorus-based compound and 88 percent to 96 percent of water. The stabilization medicament disclosed by the invention can be used for treating the problem of dissolving of heavy metal in the lead-zinc waste rocks and tailings and lead-zinc ions can be converted into an ore type compound, so that the dissolving speed of the lead-zinc ions under a leaching state is reduced, and furthermore, risks of secondary pollution caused by the fact that the tailings are discharged are effectively controlled.

Owner:BEIJING GEOENVIRON ENG & TECH

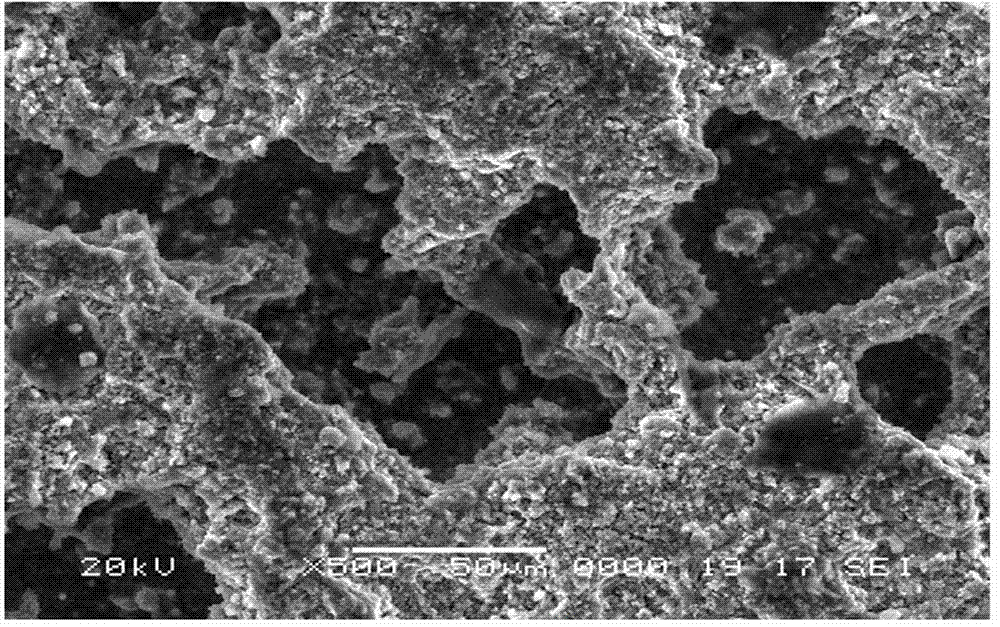

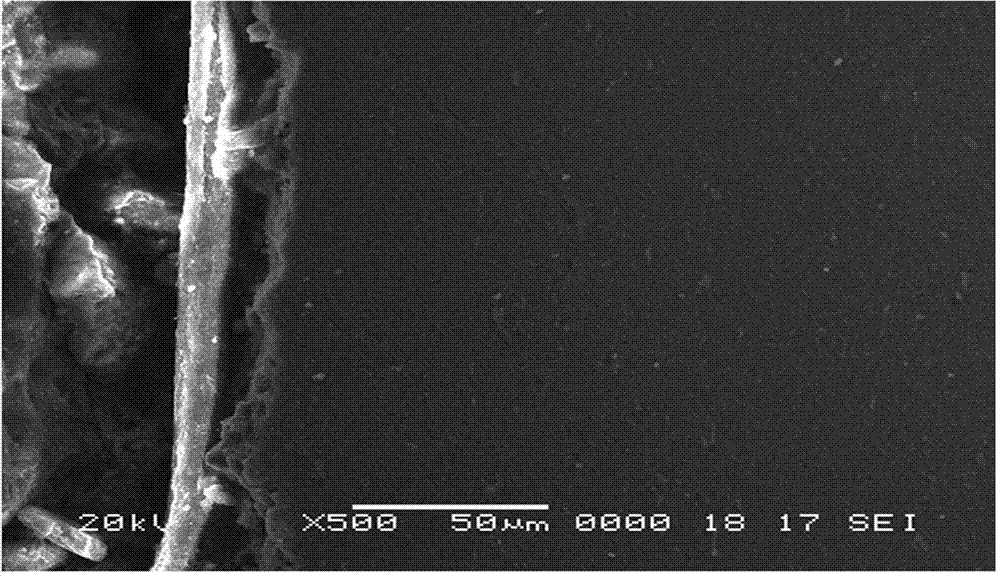

Method for preparing continuous gradient biological coating by utilizing suspension plasma spraying

ActiveCN111286691AReduce internal stressReduce sensitivityMolten spray coatingCalcium silicateFluorohydroxyapatite

The invention discloses a method for preparing a continuous gradient biological coating by utilizing suspension plasma spraying. A calcium silicate / fluorohydroxyapatite continuous gradient biologicalcoating is prepared on the surface of a titanium or titanium alloy matrix by utilizing a suspension plasma spraying method. The high bonding strength between a calcium silicate coating and the titanium matrix and the low solubility of fluorohydroxyapatite are utilized, solid phase components of a mixed solution are gradually changed by adjusting the liquid feeding rates of two suspensions, the continuous gradient coating is prepared on the surface of the titanium or titanium alloy matrix by adopting a suspension plasma spraying technology, namely, the calcium silicate is arranged at the bottomof the coating, the fluorohydroxyapatite is arranged at the top of the coating, gradient component transition is achieved between the top and the bottom, the internal stress of the coating can be greatly reduced through gradient design, and the sensitivity at an interface is reduced. The binding force between the calcium silicate / fluorohydroxyapatite gradient coating and the titanium matrix is obviously improved, the dissolution rate is obviously reduced, and the coating shows good biological activity and antibacterial activity.

Owner:INNER MONGOLIA UNIV OF TECH

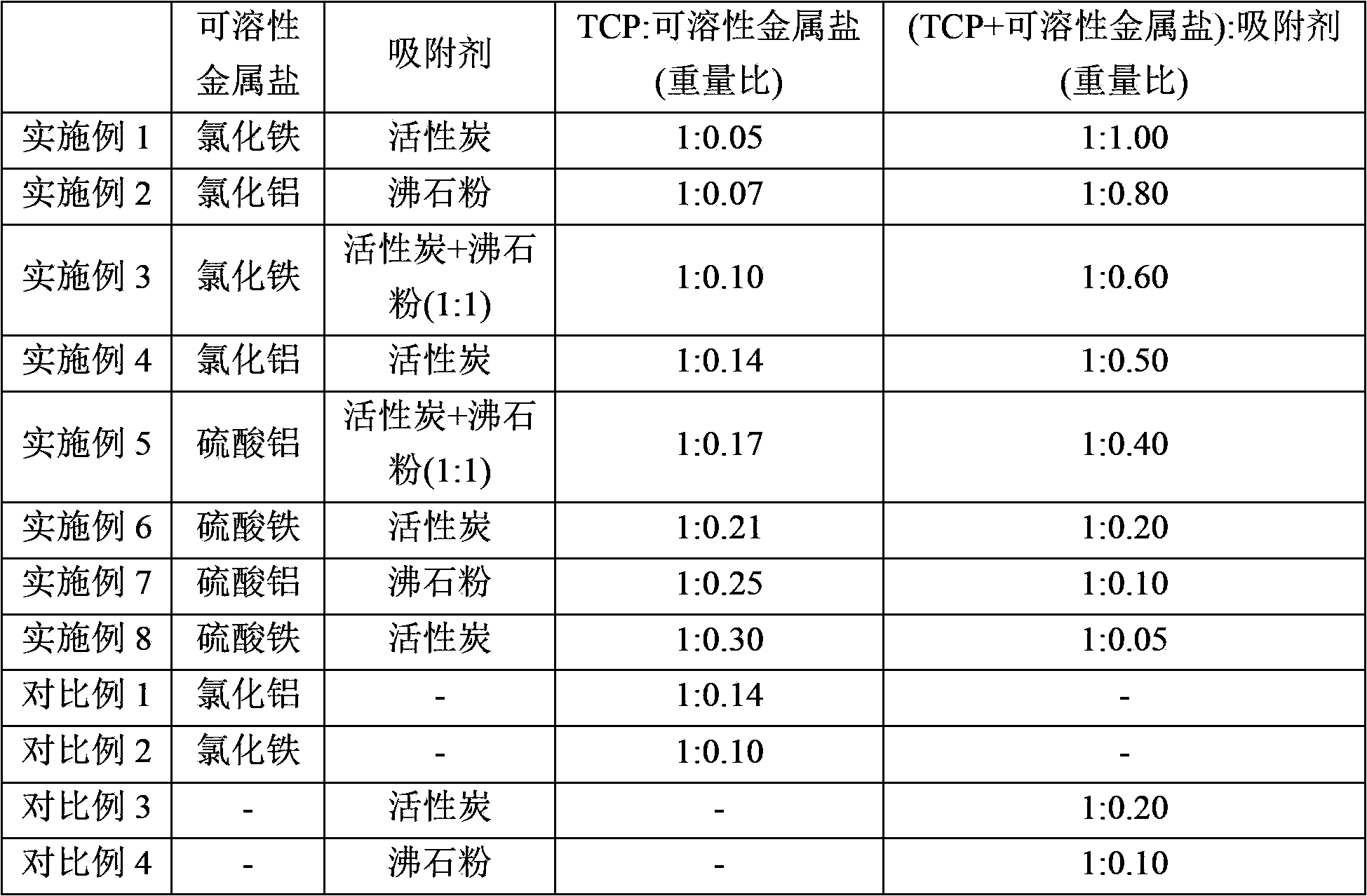

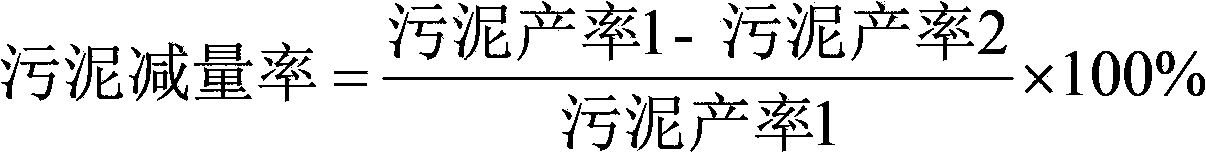

Uncoupling agent and application thereof

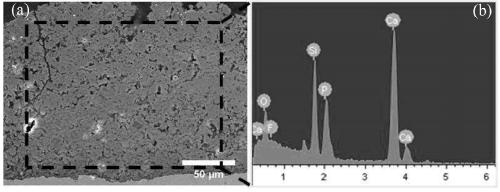

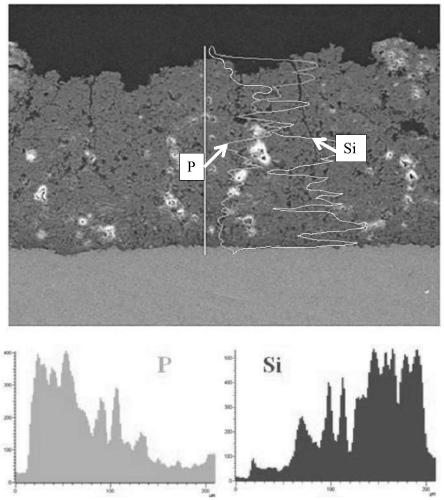

ActiveCN103771579AGood sludge reduction performanceReduce total phosphorus concentrationSustainable biological treatmentBiological water/sewage treatmentReduction rateAluminium

The invention relates to an uncoupling agent containing 2,4,5-trichlorophenol, a soluble metal salt and an adsorbent, wherein the soluble metal salt is soluble ferric salt and / or soluble aluminum salt. The invention also relates to the application of the uncoupling agent to an activated sludge method for the treatment of wastewater. In the process of the activated sludge method for the treatment of wastewater, the uncoupling agent provided by the invention can realize high COD removal rate and sludge reduction rate, and the water outlet has small TP concentration.

Owner:CHINA PETROLEUM & CHEM CORP +1

Transparent anti-fouling membrane preparation method

ActiveCN106318060AHigh mechanical strengthReduce dissolution rateAntifouling/underwater paintsPaints with biocidesPolyvinyl alcoholUltrasonic dispersion

The invention belongs to the technical field of ocean engineering antifouling paint preparation, and particularly relates to a transparent anti-fouling membrane preparation method. The technological process comprises the steps that hydrotalcite nanosheets are dispersed in distilled water to obtain a hydrotalcite aqueous solution through ultrasound, polyvinyl alcohol is added into the hydrotalcite aqueous solution to be heated till polyvinyl alcohol is dissolved to form a mixed solution, standing is conducted on the mixed solution, the mixed solution is naturally cooled and then dispersed through ultrasound, phenolic amide antifoulant is added into the mixed solution, and an anti-fouling mixed solution is obtained through ultrasonic dispersion; the quartz surface is coated with the anti-fouling mixed solution through a spin-coating method or a coating method, and a transparent anti-fouling membrane is obtained after drying; the transparent anti-fouling membrane protects fouling of the parts such as detection shots, light sources and submarine windows of marine optical instruments. The molecular structure and preparation method of the transparent anti-fouling membrane are simple, the technology is scientific and reliable, the raw materials are low in cost and easy to obtain, the light transmittance is high, the antifouling activity is good, the effect is obvious, the application environment is friendly, and an important application prospect in the marine antifouling field is achieved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

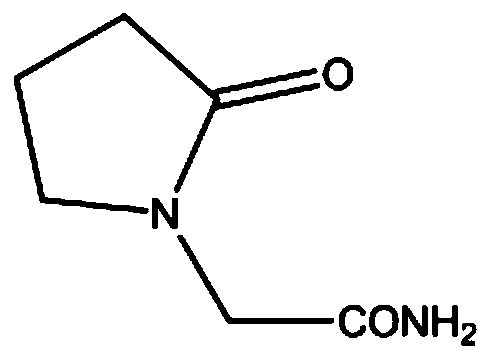

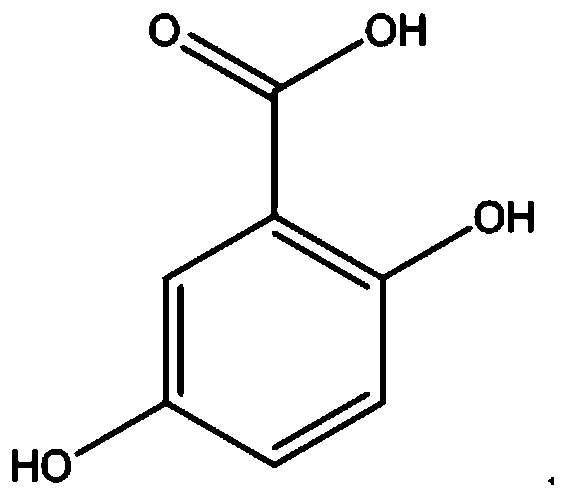

Piracetam eutectic and preparation method thereof

InactiveCN109796393AConducive to production quality controlDelayed dissolution rateCarboxylic compound separation/purificationDouble bondCarboxylic group

The invention relates to the field of pharmaceutical materials, and discloses a piracetam eutectic, which is synthesized by using piracetam and gentilic acid, wherein the molecular formula is C6H10N2O2 C7H6O4, and the molecular weight is 296; the eutectic structure is that O atoms of phenolic hydroxyl groups adjacent to gentilic acid and carboxyl are used as hydrogen bond acceptors, and N atoms onpiracetam amino groups are used as hydrogen bond donors to form intermolecular double bonds; double bond O atoms on the gentilic acid carboxyl are used as hydrogen bond acceptors, and the O atoms onthe adjacent phenolic hydroxyl groups are used as hydrogen bond donors to form an intramolecular hydrogen bond so as to jointly form a basic unit of the eutectic; the crystal is c2 / c and monoclinic, and the cell parameters are shown in the description, wherein alpha=gamma=90 degrees, beta=101.09 degrees, Z=8. Compared with the original piracetam, the dissolution rate and stability of the medicineeutectic are greatly improved.

Owner:YUNNAN OPEN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com