Method for preparing continuous gradient biological coating by utilizing suspension plasma spraying

A bio-coating and suspension technology, applied in the coating, metal material coating process, melt spraying, etc., can solve the problem of low degradation rate, achieve the effect of reducing dissolution rate, reducing internal stress, and improving binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

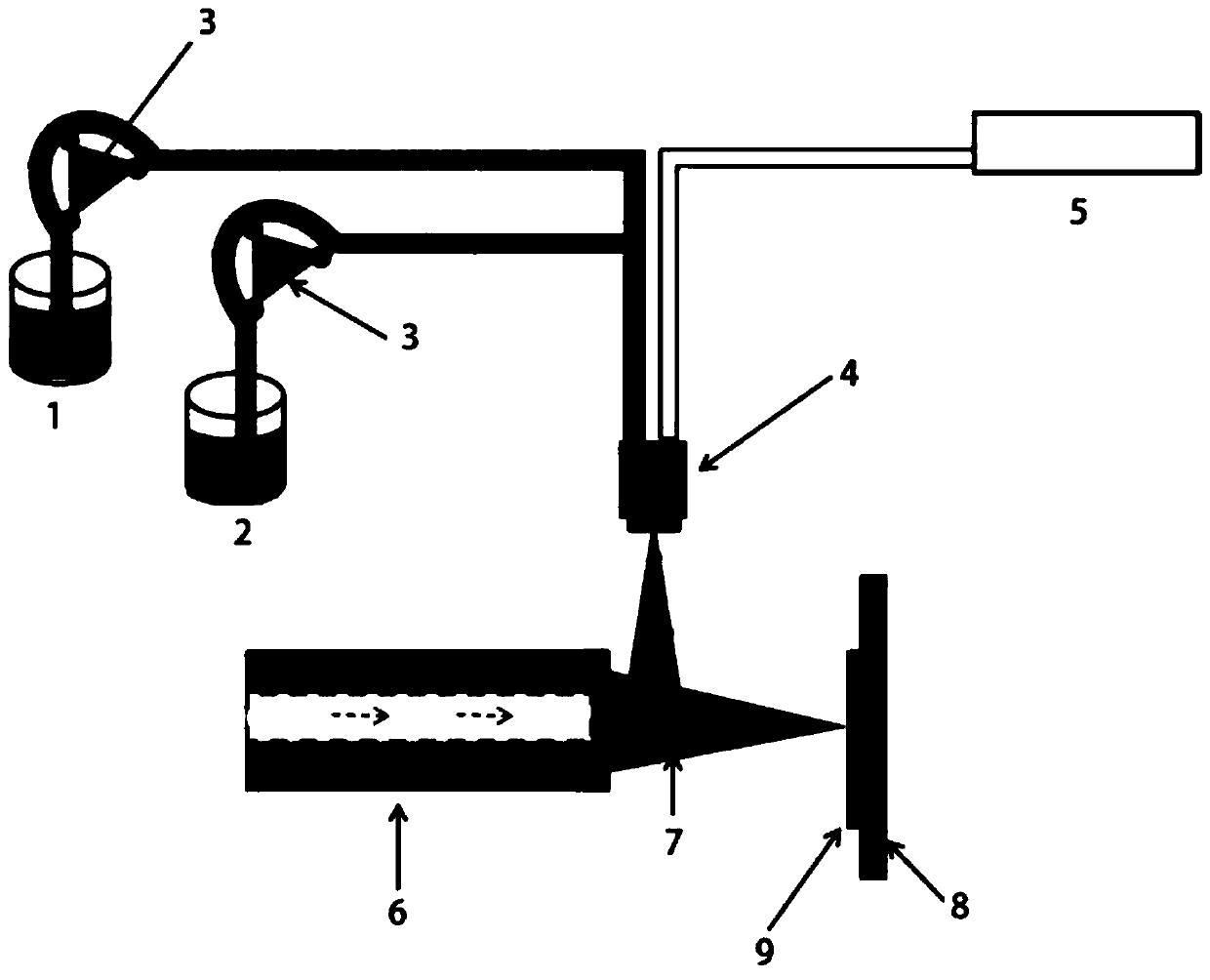

Method used

Image

Examples

Embodiment Construction

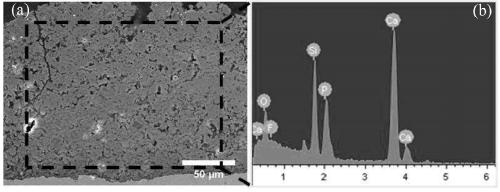

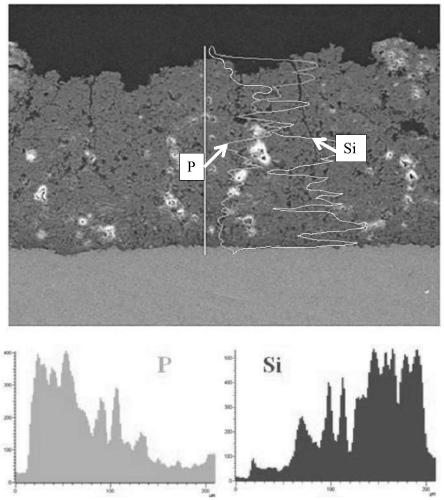

[0047] 1. A continuous gradient biocoating of calcium silicate / fluorohydroxyapatite is prepared on the surface of a titanium or titanium alloy substrate by means of a suspension plasma spraying method.

[0048] 1. Preparation of fluorohydroxyapatite suspension:

[0049] (1-1) Calcium nitrate, diammonium hydrogen phosphate and ammonium fluoride are used as raw materials, and the ratio of the amount of substances is Ca:P:F=16.7:10:1, and the preparation of the reaction raw material aqueous solution is carried out.

[0050] (1-2) Control the reaction temperature at 60°C and keep the pH between 9-10.

[0051] (1-3) After the reaction, the obtained powder is aged and washed with water to obtain fluorohydroxyapatite.

[0052] (1-4) Disperse fluorohydroxyapatite in water to obtain a fluorohydroxyapatite aqueous dispersion; in order to obtain a uniformly dispersed suspension, add ammonium polyacrylate as As a dispersant, the mass fraction of fluorohydroxyapatite in the aqueous dispe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com