Patents

Literature

803 results about "Co2 laser" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

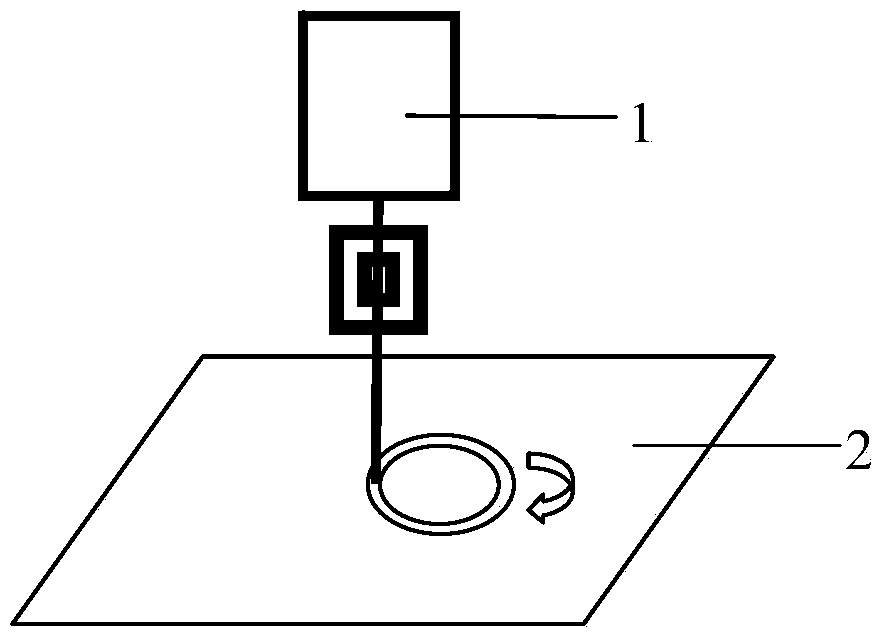

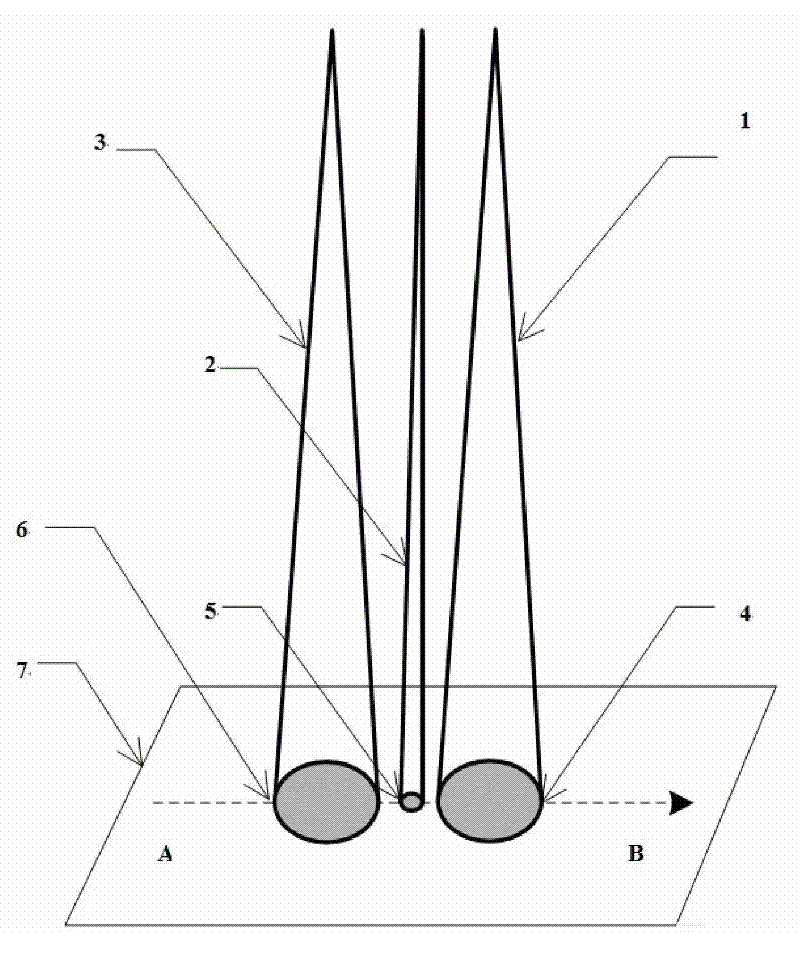

Fast forming method of fusion of metal powder of three beams of laser compound scanning

The invention discloses a fast manufacturing method of three-beam laser compound scanning. The method comprises the following steps of: firstly utilizing long-wavelength laser (CO2 laser) for preheating the metal powder, then utilizing short-wavelength laser (YAG or optical fiber laser) for fusing the metal powder and finally utilizing long-wavelength laser (CO2 laser) to carry out heat treatment to the frozen metal. The fast manufacturing method uses the three beams of laser to carry out compound scanning, namely uses long-wavelength laser to preheat, short-wavelength laser to fuse and then long-wavelength laser to carry out heat treatment, can realize the compound process of preheating, fusion and heat treatment of the metal powder. The three beams of laser compound scanning mode can reduce internal stress of the metal part, avoid warping and cracking, improve organization and improve performance.

Owner:HUAZHONG UNIV OF SCI & TECH

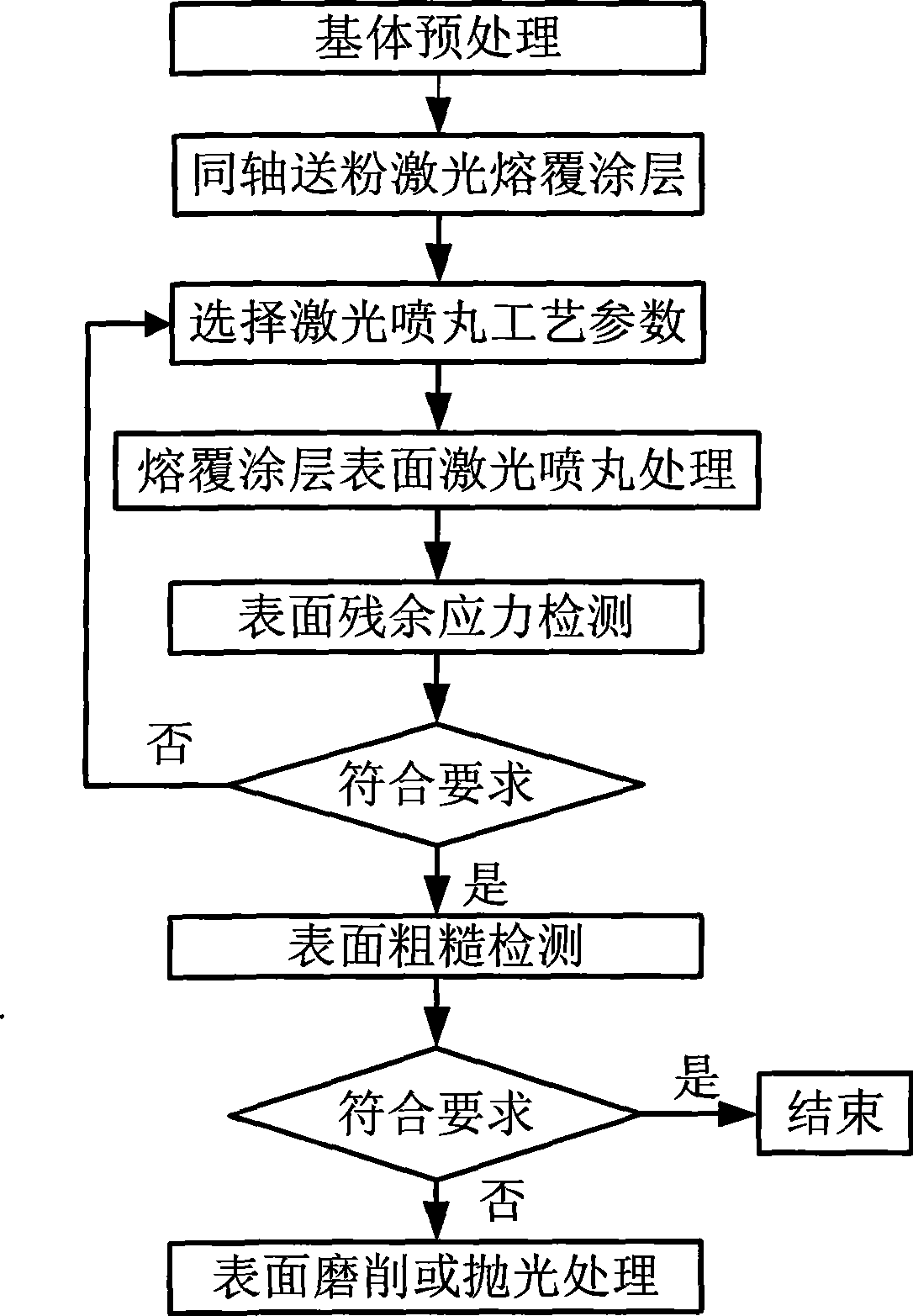

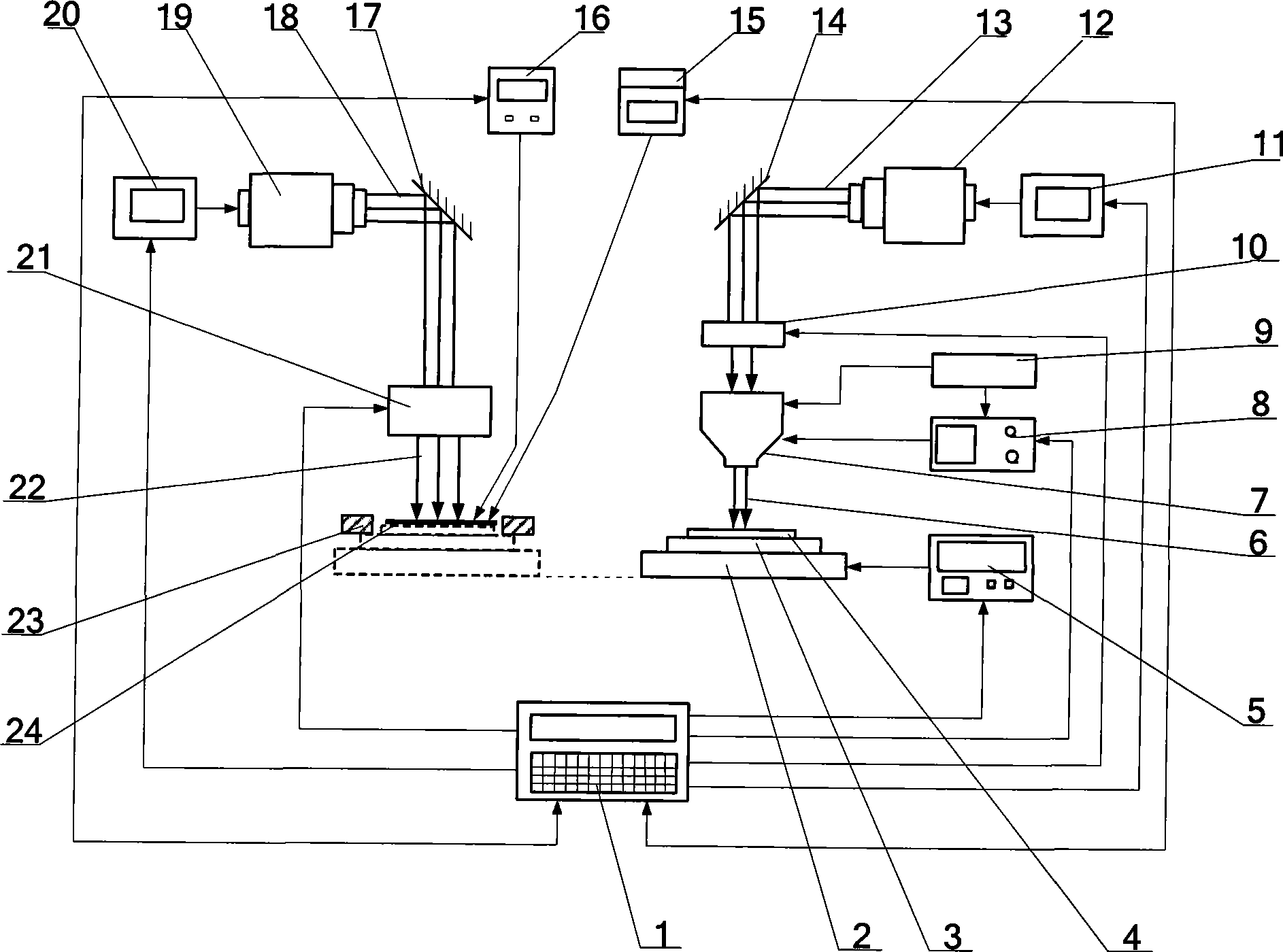

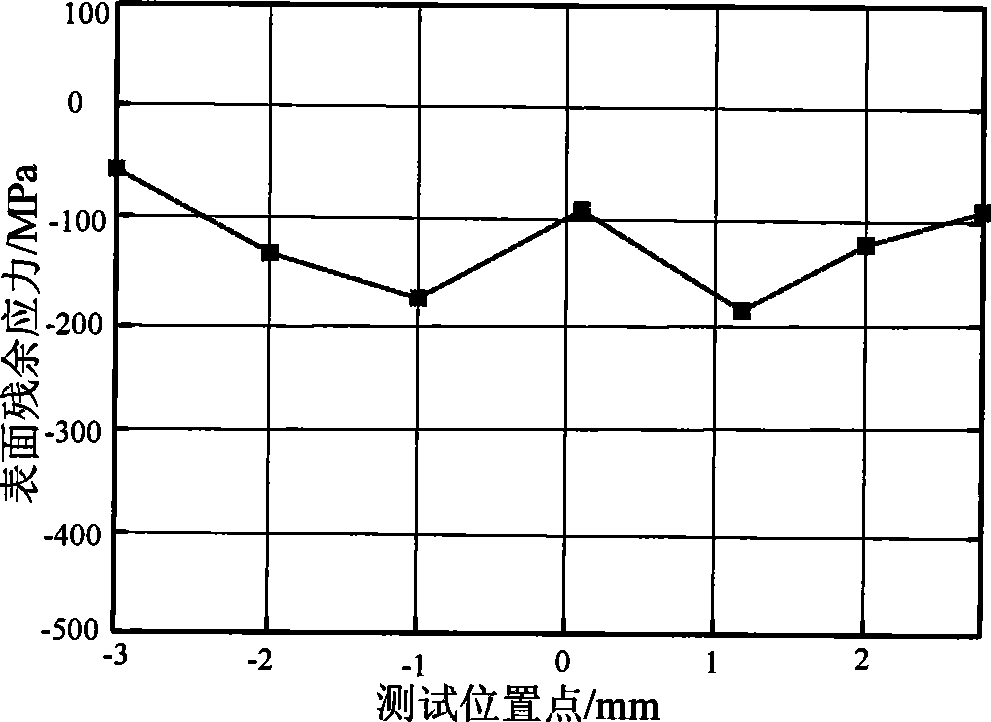

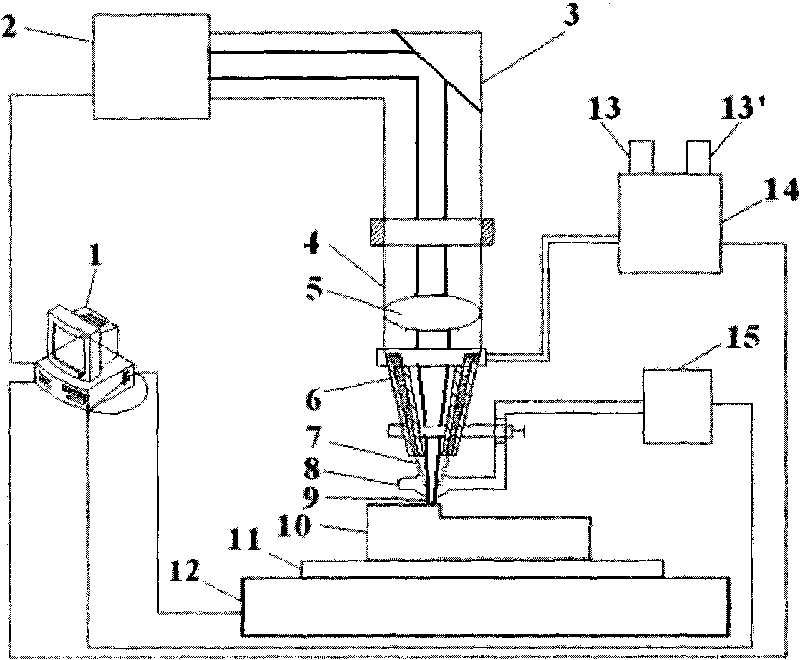

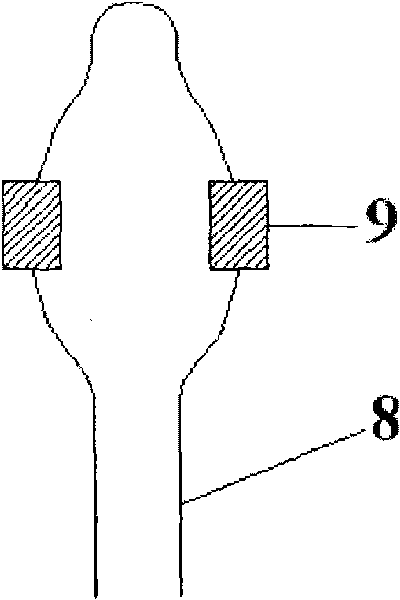

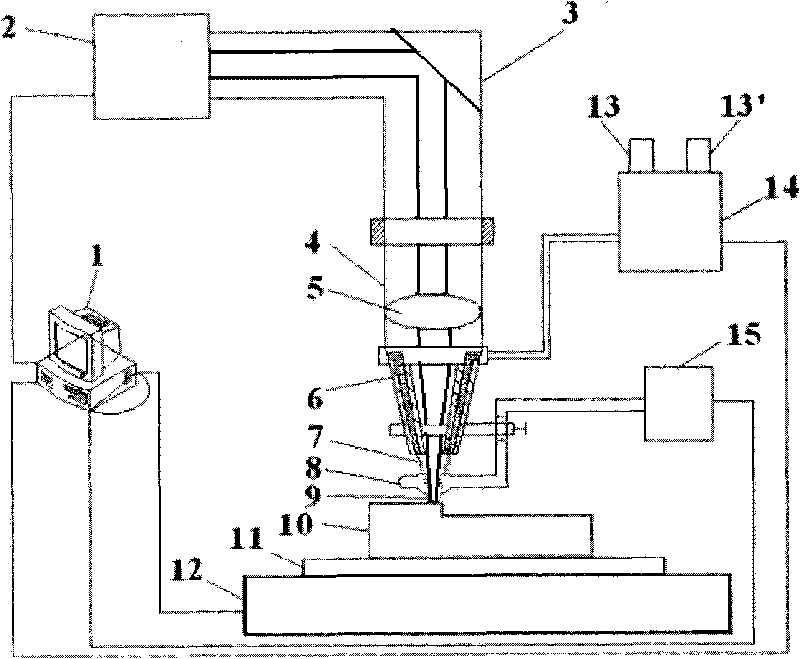

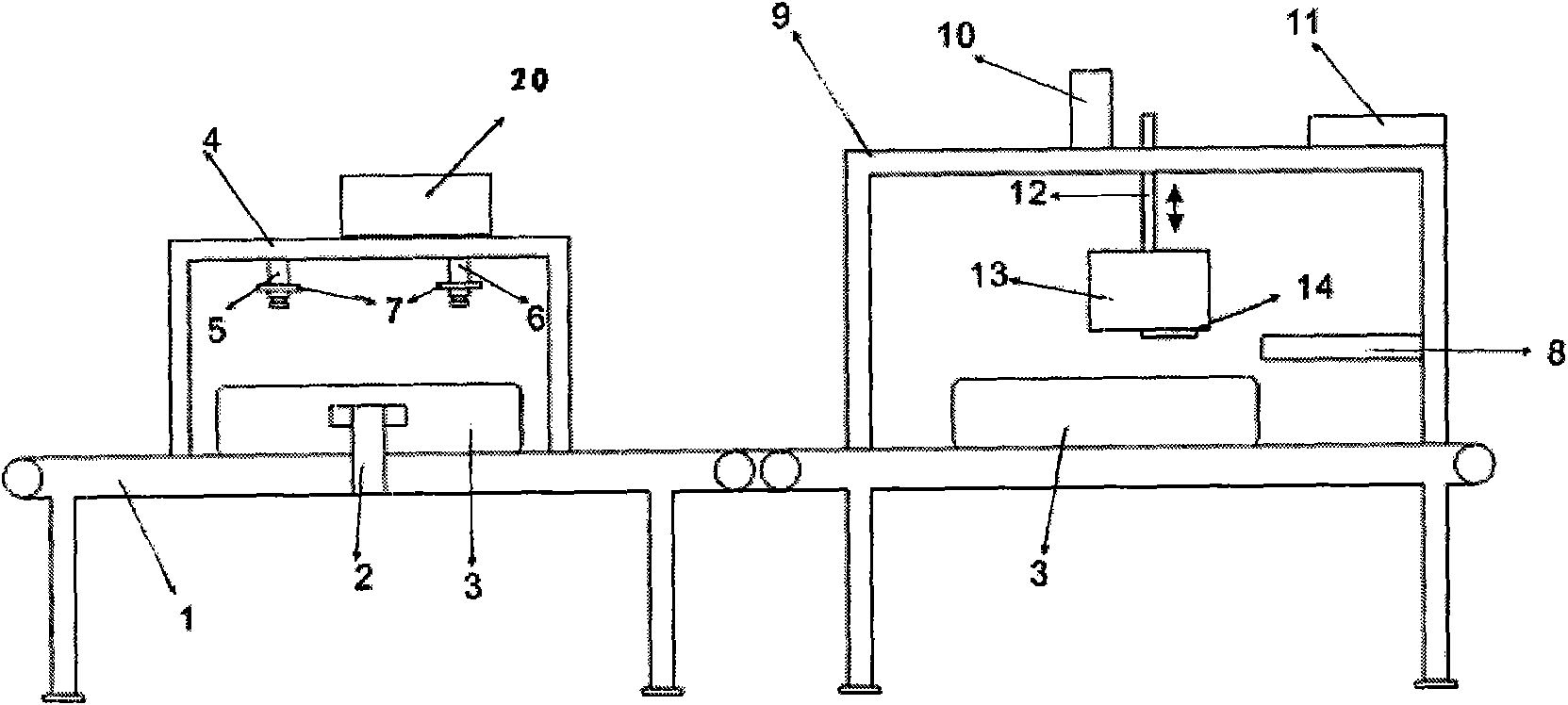

Method and device for strengthening surface modification by combination of laser cladding and laser peening

InactiveCN101392382AQuality improvementResidual stress distribution state changesMetallic material coating processesCoated surfaceSurface roughness

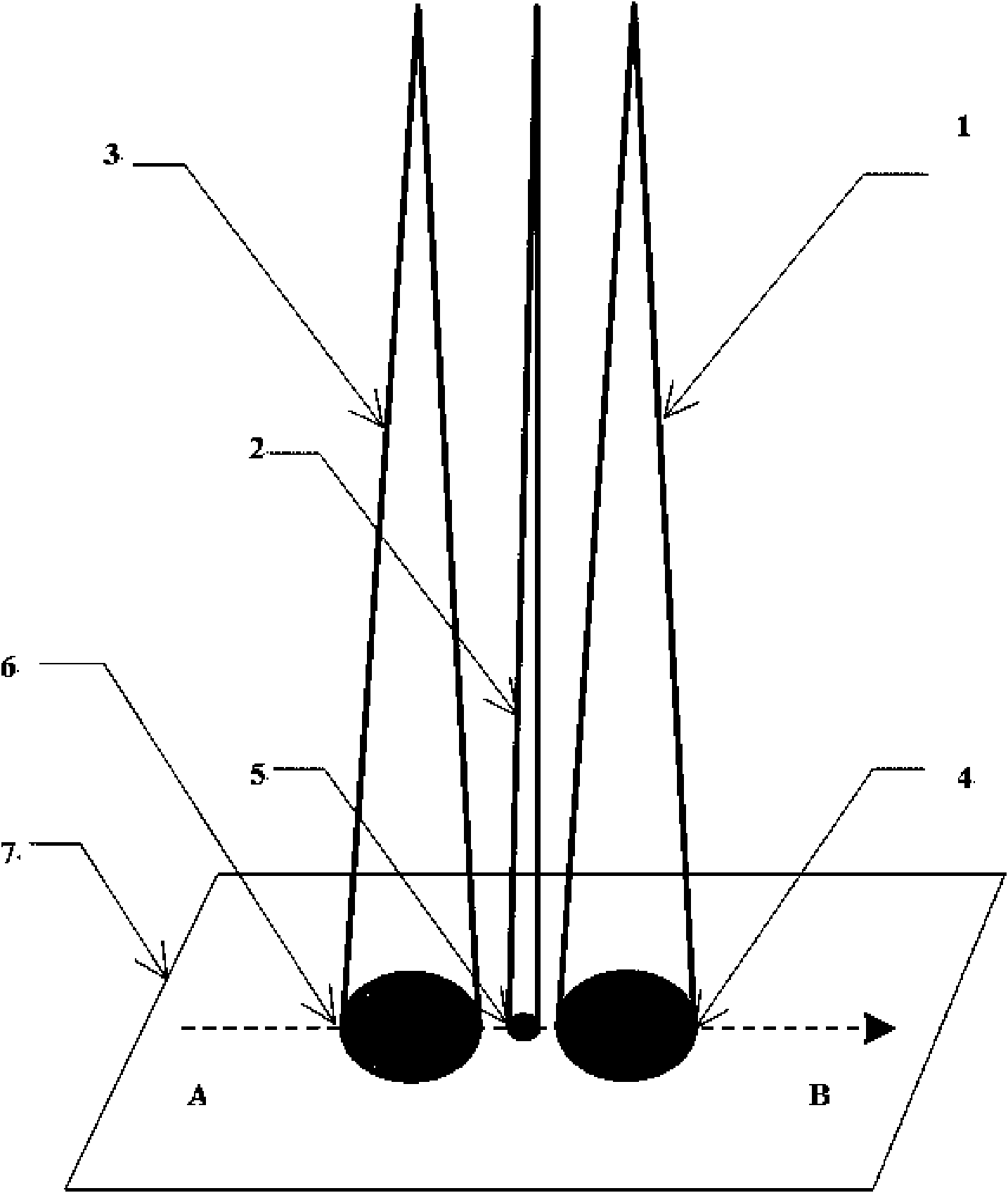

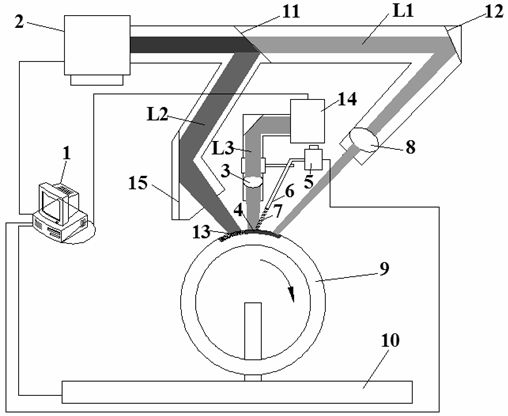

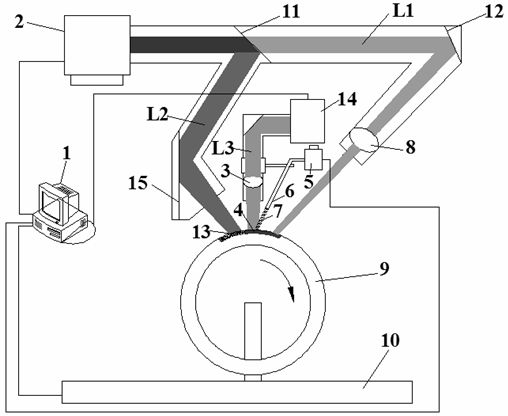

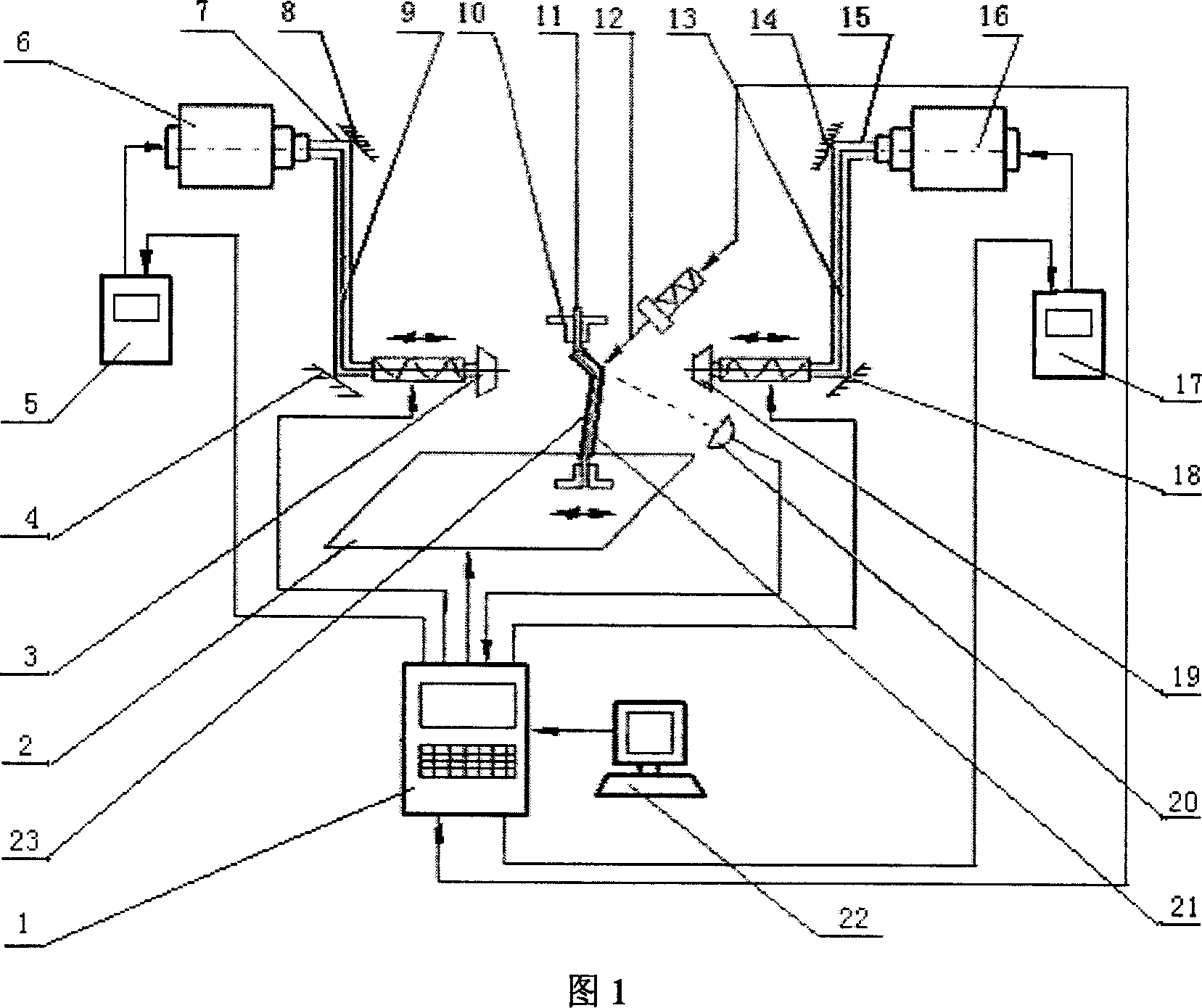

The invention provides a method for modifying a composite surface based on laser cladding and combining laser shock peening, and a device thereof. The method provided by the invention is characterized in that a coaxial and powder feeding type fast axial flow CO2 laser cladding unit clads a layer of coating on the surface of a substrate; then a neophane glass impulse laser shock peening unit is used for the shock peening on the surface of the cladded coating; a measurement feedback system is utilized to detect the surface roughness and the distribution state of residual stress of the cladded coating; the precise control over the surface roughness and the residual stress of the coating is realized by a central control and processing system so as to obtain a high quality surface-cladded coating with good performance. The device comprises the coaxial and powder feeding type laser cladding unit, the laser shock peening unit, a digital control working system, the measurement feedback system and the central control and processing system, and is under integrated control by a computer. The method and the device of the invention can reduce residual tensile stress and improve the quality of the cladded coating and prolong the service life thereof.

Owner:JIANGSU UNIV

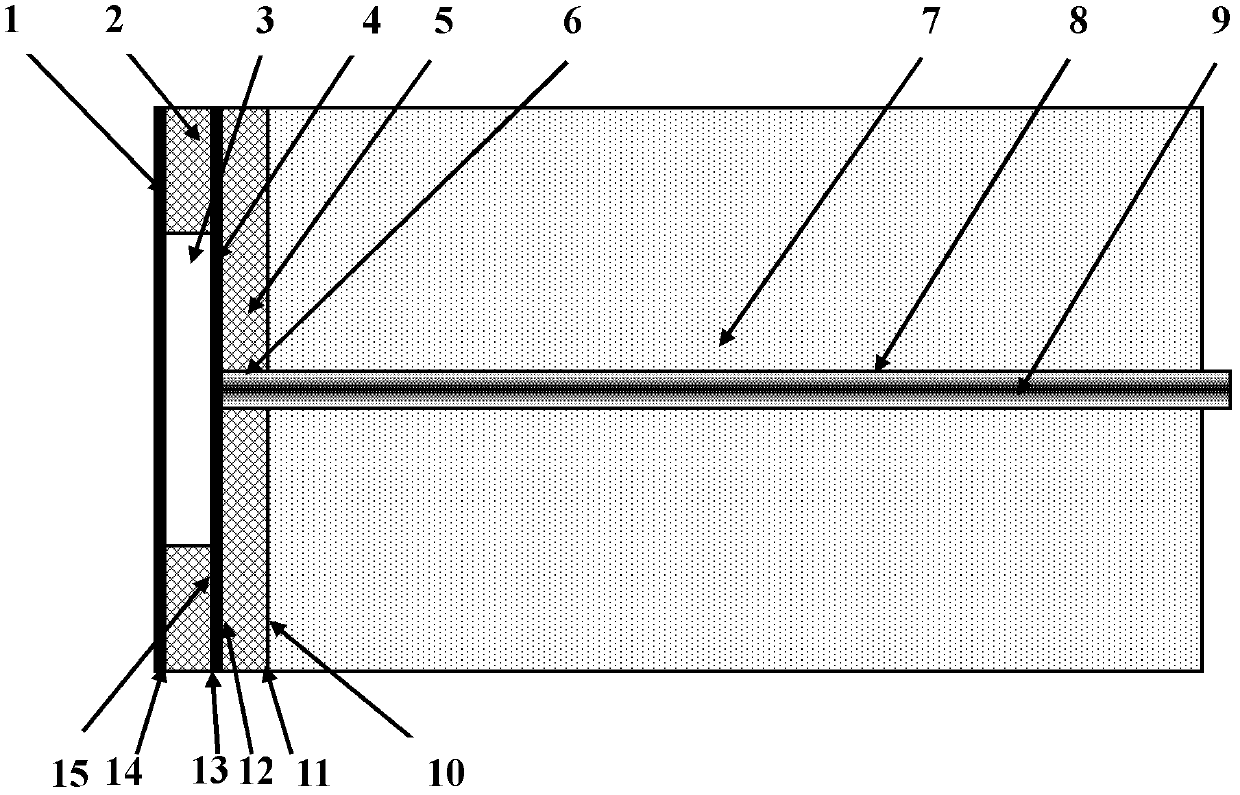

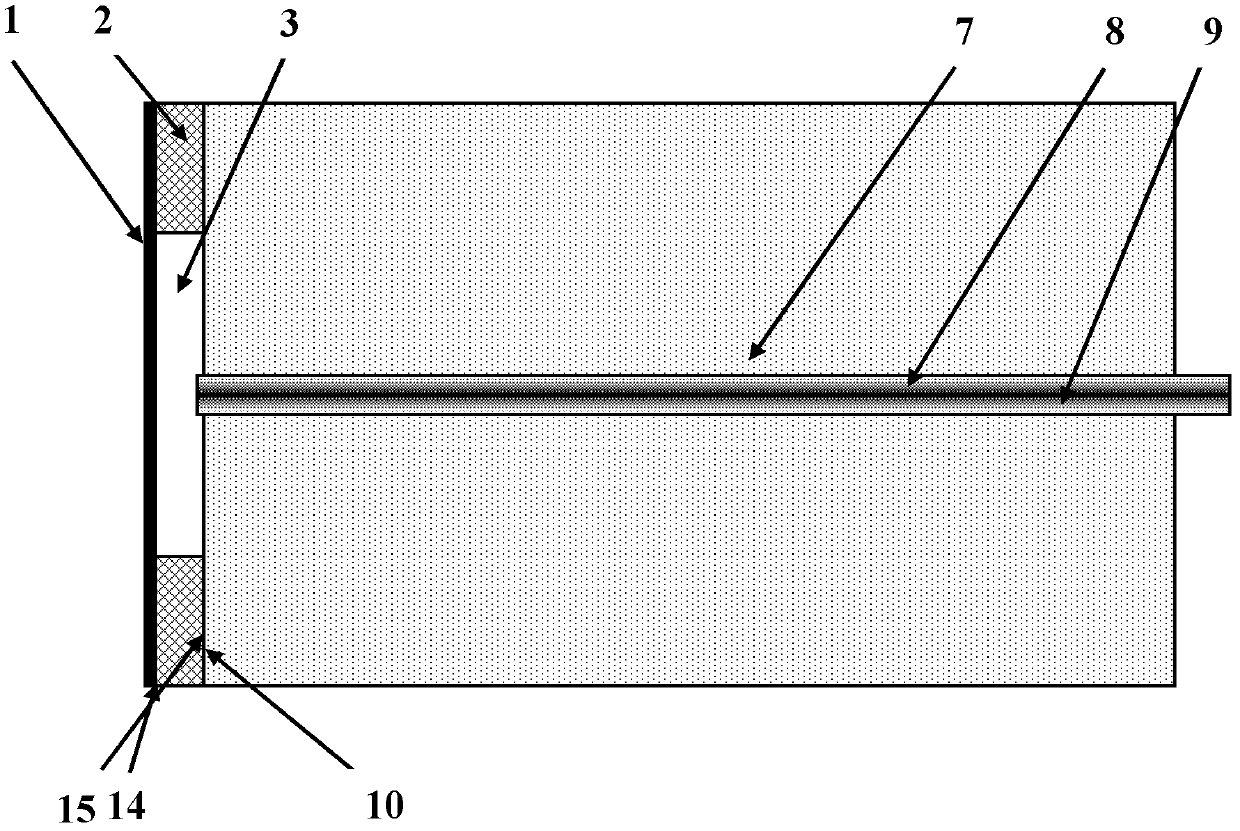

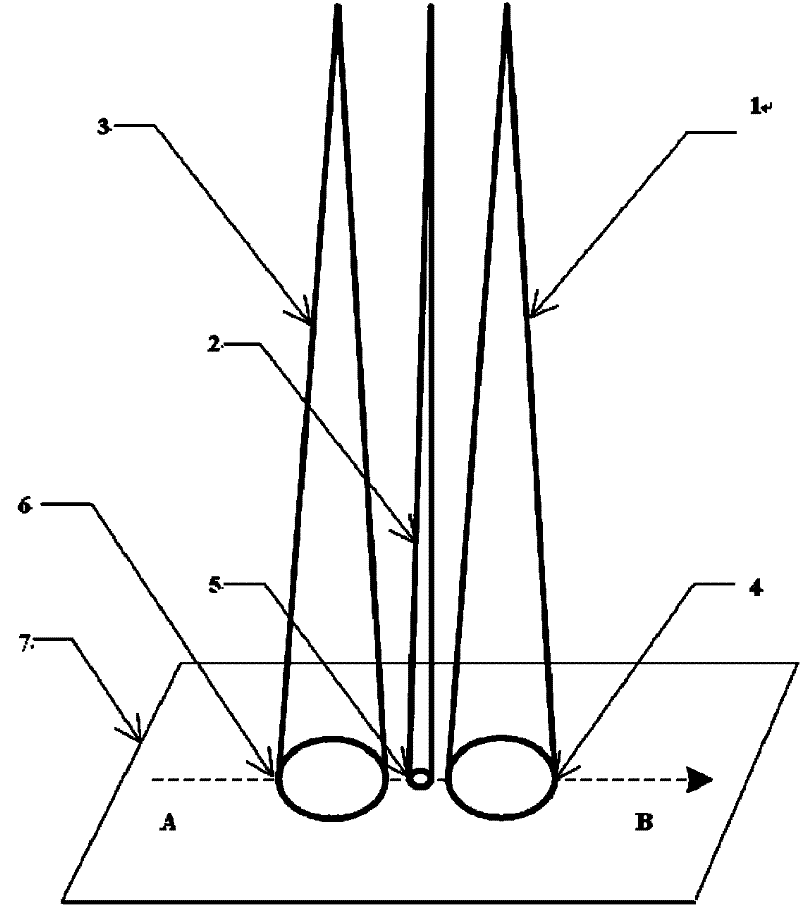

Method with functions of preheating and postheating for forming crack-free coating with high efficiency by three-light-beam laser-cladding technique

InactiveCN102383126ALow and adjustable dilution rateSmall heat affected zoneMetallic material coating processesLaser beam welding apparatusMelting tankHeat-affected zone

The invention discloses a method with functions of preheating and postheating for forming crack-free coating with high efficiency by a three-light-beam laser-cladding technique. The method comprises the following steps of: splitting a laser beam emitted by an Nd: YAG laser into two laser beams by using a laser beam splitter, namely a preheating laser beam for preheating the surface of a base material and a postheating laser beam for postheating the formed coating; then blowing alloy powder into a molten pool which is formed by focusing a laser beam emitted by a CO2 laser and acting the focused laser beam on the surface of the base material by using a powder nozzle, wherein after the CO2 laser beam moves away, a molten layer is cured and crystallized quickly to form the coating; and postheating the formed coating by adopting the postheating laser beam. The method has the advantages that: (1) the dilution rate of the coating is low and adjustable, and the coating is metallurgically combined with the base material, so the base material has a small thermal influence area and is deformation-free and crack-free; (2) residual inner stress in the coating can be eliminated effectively, a tissue can be improved, and the coating has high abrasion resistance, high corrosion resistance, high anti-cracking performance and high thermal shock resistance; and (3) relative to the processing efficiency in the conventional laser cladding technology, the processing efficiency in the method can be improved by 50 times to the maximum extent, so the processing cost is reduced greatly, and a large-scale industrialized application potential is realized.

Owner:NANCHANG HANGKONG UNIVERSITY

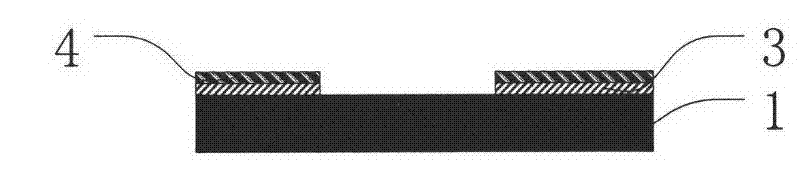

High-stability optical fiber Fabry-Perot pressure sensor packaged without glue and manufacturing method

ActiveCN102384809AEliminate the effects ofEasy to achieve airtightFluid pressure measurement by electric/magnetic elementsOptical light guidesEngineeringCo2 laser

The invention provides a high-stability optical fiber Fabry-Perot pressure sensor packaged without glue and a manufacturing method. The sensor comprises a sensor head, a sensor body with a through-hole in middle, and an optical fiber, wherein a four-layer structure (comprising a first monocrystalline silicon piece, a first Pyrex sheet glass, a second monocrystalline silicon piece and a second Pyrex sheet glass) is adopted by the sensor head; a first reflecting surface of a Fabry-Perot cavity is formed by the back surface of the first monocrystalline silicon piece; the second monocrystalline silicon piece is used for providing a second reflecting surface of the Fabry-Perot cavity; the second Pyrex sheet glass is in butt fusion with the sensor body; and the optical fiber is fixedly arrangedin the sensor body by adopting a CO2 laser, and thereby non-glue packaging is realized. When the first layer of monocrystalline silicon piece is deformed by external pressure changes, the length of the optical fiber Fabry-Perot cavity is changed; and after a broadband light source is accessed to the sensor, the change of the cavity length can be extracted through collecting a reflection spectrum of the sensor or extracting low-coherence interference fringes of the sensor, and thereby pressure information is obtained. By adopting the structure, the influences of environmental changes such as the temperature, the humidity, and the like can be effectively eliminated, and the measurement accuracy can be greatly improved.

Owner:TIANJIN UNIV

Aluminum alloy surface strengthening method using laser melting and coating

InactiveCN101012561APrevent excessive meltingPrevent collapseMetallic material coating processesLaser beam welding apparatusSoluble glassWavelength

The invention discloses a reinforcing method of aluminium alloy surface fused and covered by laser, which comprises the following steps: 1. predisposing aluminium alloy base; 2. allocating laser fusing and covering material with the bulk rate of Al-Si alloy powder and SiC ceramic powder at 1:(4-2); setting the Si content in the Al-Si alloy at 10-15(wt%) with grain size at - 140-+325; setting the grain size of SiC at -200; 2. modulating evenly blended fusing and covering material into paste through soluble glass; coating on the surface of aluminium alloy with thickness at 0.8-1.2mm; drying at 100-150 deg.c for 0.5-2h; 4. adopting crossflow CO2 laser to irradiate the coated layer on the surface of aluminium alloy base; setting the output power of laser at 3-4kW and optical beam scanning velocity at 2-5mm / s and optical spot dimension at 1-4mm; protecting fusing pond through high-purity argon in the laser fusing and covering course with argon flow at 20-30L / min.

Owner:TIANJIN POLYTECHNIC UNIV

Laser ablation cleaning

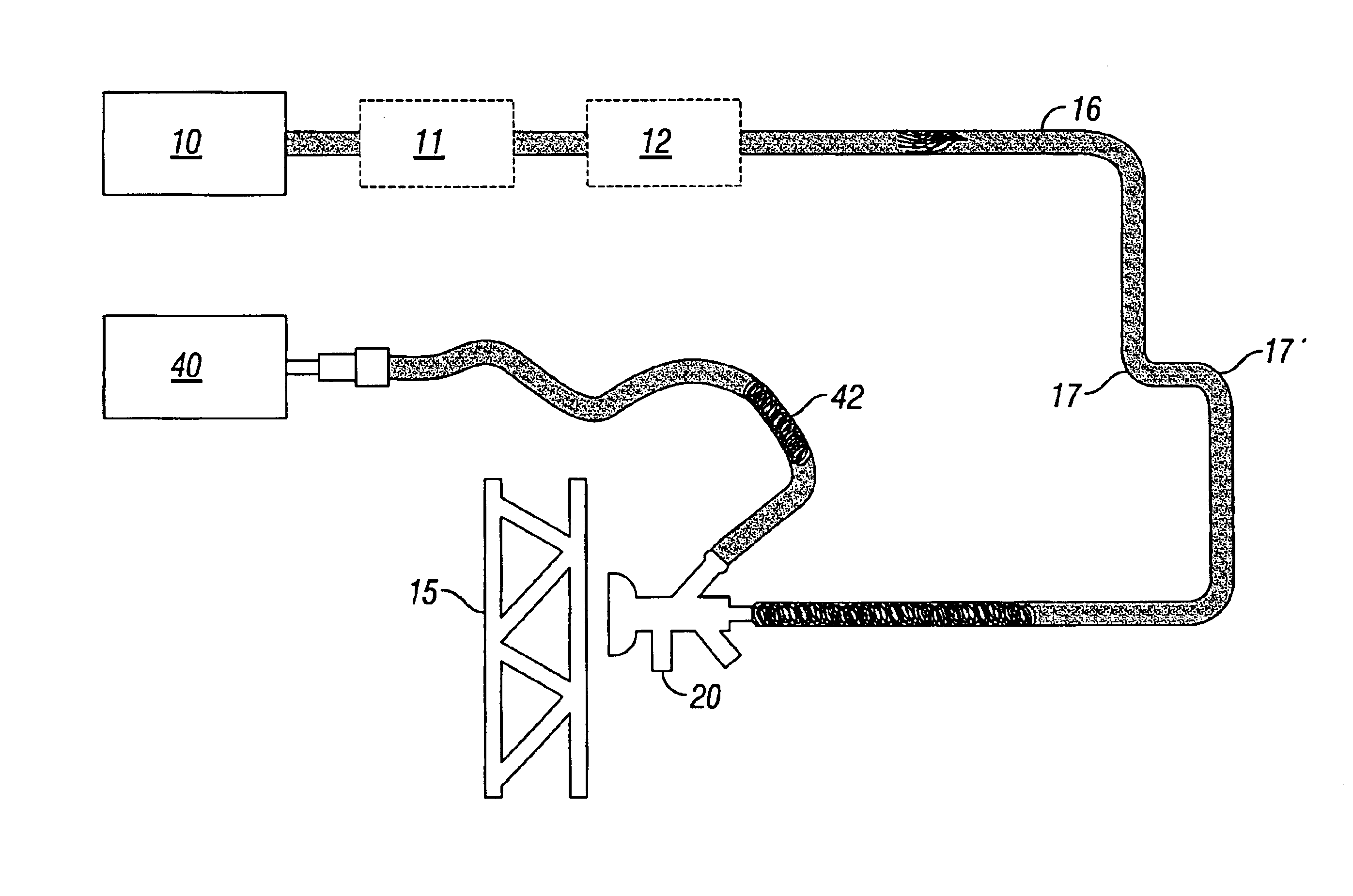

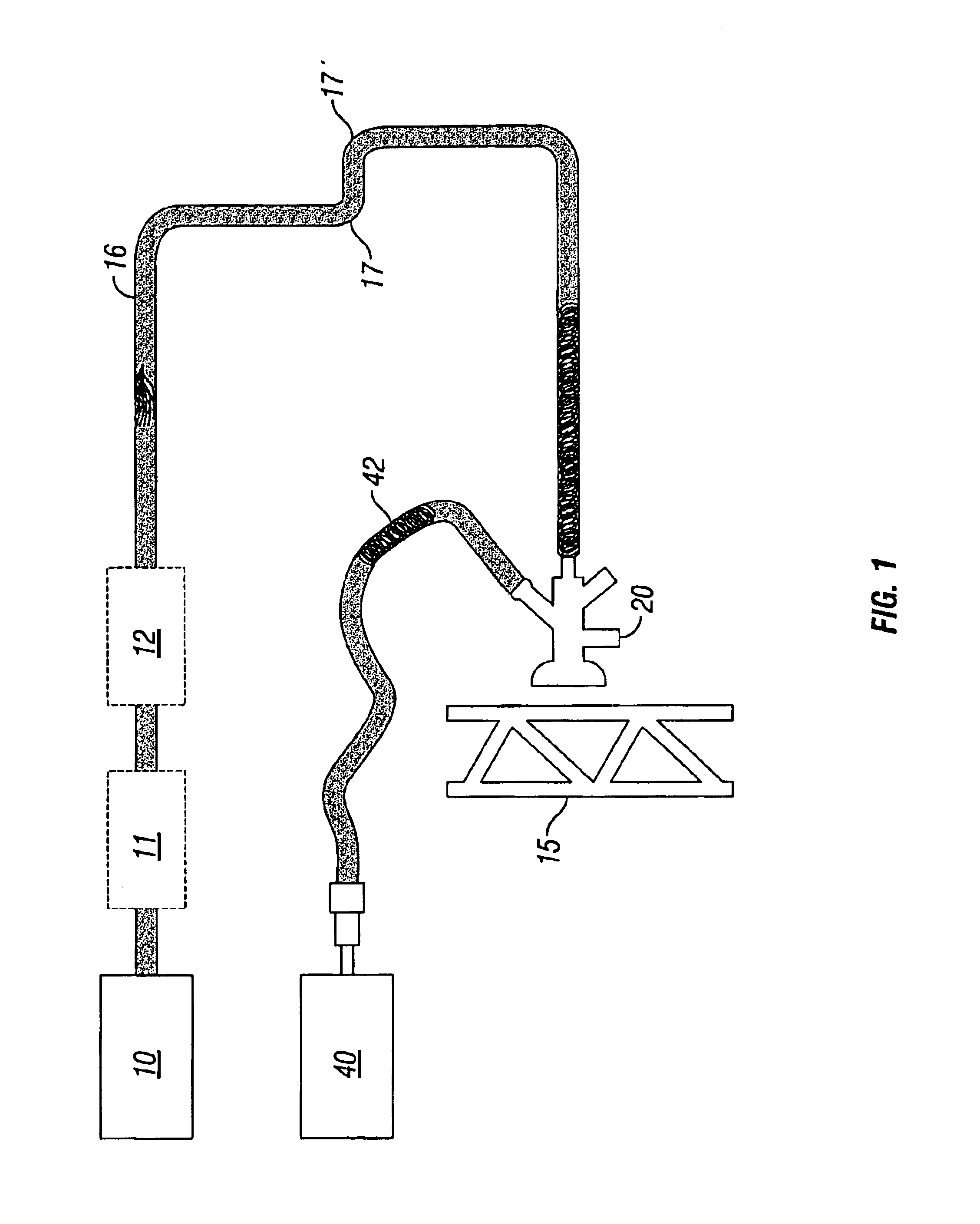

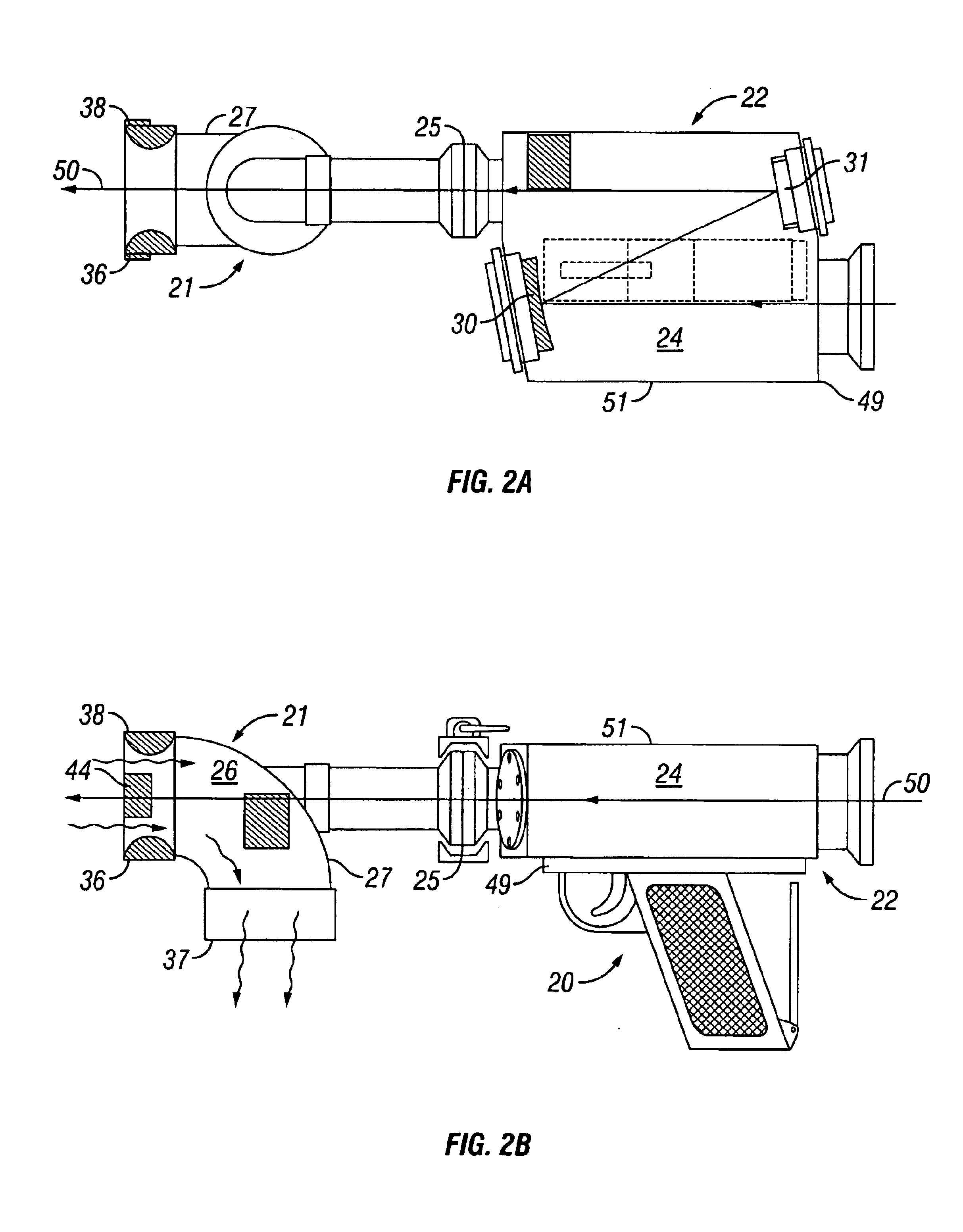

Laser ablation cleaning apparatus. An optical box containing mirrors for specially directing laser light, such as repeated pulsed CO2 laser, is mounted in a hand-held cleaning head or in a custom work head. The hand-held cleaning head can be used to safely direct laser energy to a surface to be cleaned; the laser beam ablates from the surface coatings, corrosion, and the like without harming the substrate. The custom work head is removably mountable upon the iron core stack of a conventional commercial electric generator, and features an optics box carriage that is selectively movable along the axis of the stack to direct a laser beam into the slots of the stack for cleaning.

Owner:RF ENVIROTECH

Laser cladding method for strengthening surface of piercing point

ActiveCN101519778ASolve the problem of easy falling offThickness is easy to controlMetallic material coating processesPiercing pointPre treatment

A laser cladding method for strengthening the surface of a piercing point includes the following steps of: (1) prefabricating WC / Co-base cladding powder; (2) pre-processing the surface of a piercing point workpiece, and cleaning up stain and rust; preheating for 2 to 5 hours at a temperature between 400 DEG C and 600 DEG C; (3) cladding the prefabricated composite powder fed in the way of reverse synchronization or coaxially in multiple steps by a CO2 laser; simultaneously, carrying out synchronous inert gas protection on the laser-cladding area; and (4) subsequent processing. The laser cladding method adopts laser to prepare a WC ceramic particle-strengthened Co-base composite coating on the surface of the piercing point, and the coating is metallically combined with the matrix, so the binding force between the coating and the matrix is enhanced; the maximum thickness of the coating can reach a few millimeters; and as the surfaces of WC particles are coated with Ni, the absorption of laser energy by the WC can be reduced, so that the burnout rate of the WC can be reduced in a laser melting pool. The distribution of the WC particles is uniform in the coating, the rigidity of the coating is high, consequently, the service performance of the piercing point can be improved, and the service life can be prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Method of drilling a hole through Co2 laser directly

InactiveCN1761378AHigh precisionGuaranteed alignmentConductive material chemical/electrolytical removalLaser beam welding apparatusEtchingCopper foil

Drilling method of carbon dioxide laser includes steps: preparing locating point on layer next to the outer layer; before pressfitting added layer, browning oxidizing surface of target bonding pad; after pressfitting added layer, milling location hole / polishing edge, washing surface under high pressure; browning front surface of copper, thinning and coursing the surface before drilling hole by layer; first time to drill hole by laser; positioning film perforation by using plate location hole in original etching method for making window of copper, burning through copper foil and resin above the locating point on layer next to the outer layer so as to expose the locating point; second time to drill hole by laser; using the exposed locating point as position fixing to make micro hole inplate; washing surface under high pressure to remove browning layer after drill hole. The invention saves dry film and etching liquid, and raises process precision.

Owner:WUS PRINTED CIRCUIT (KUNSHAN) CO LTD

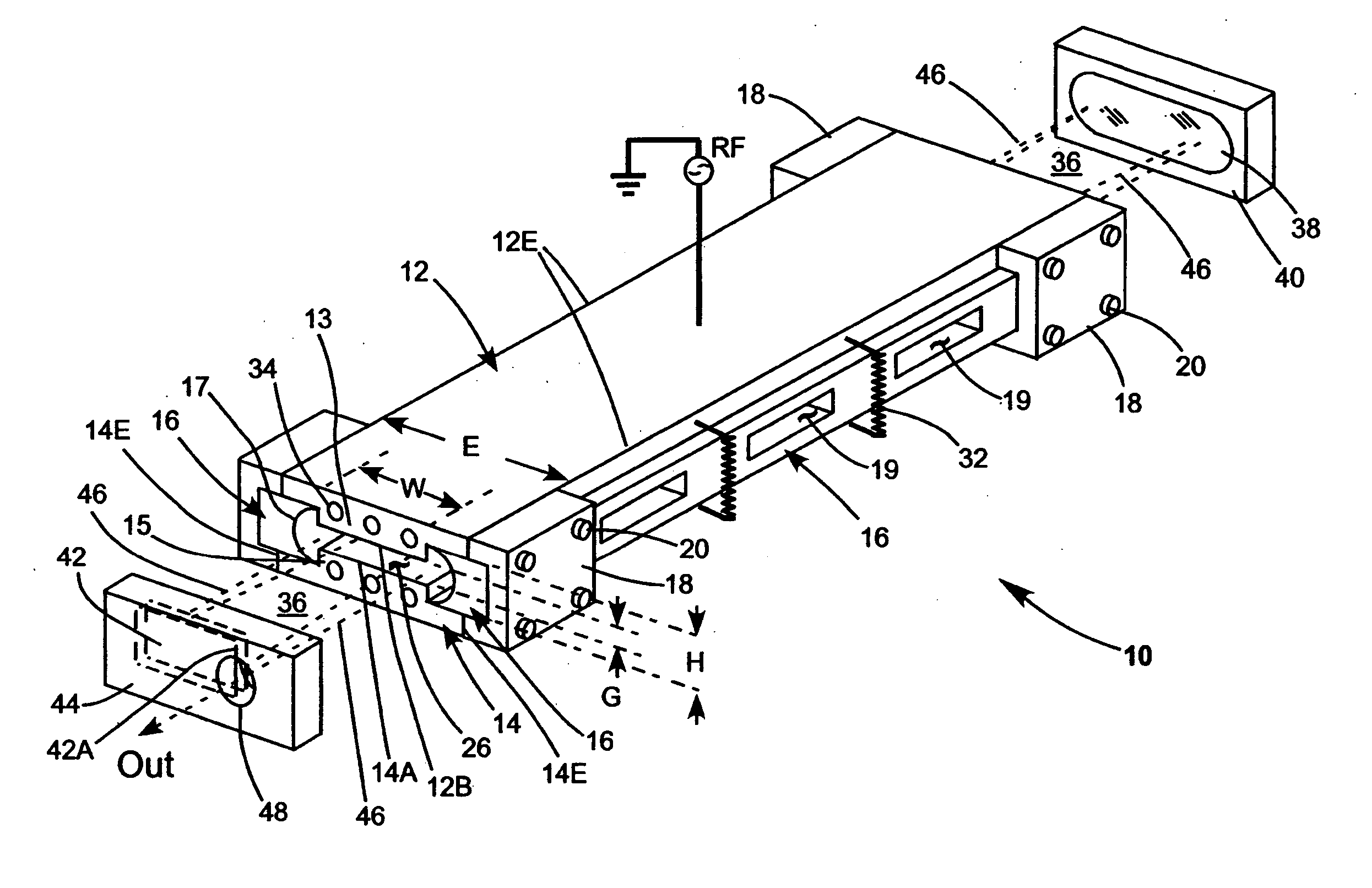

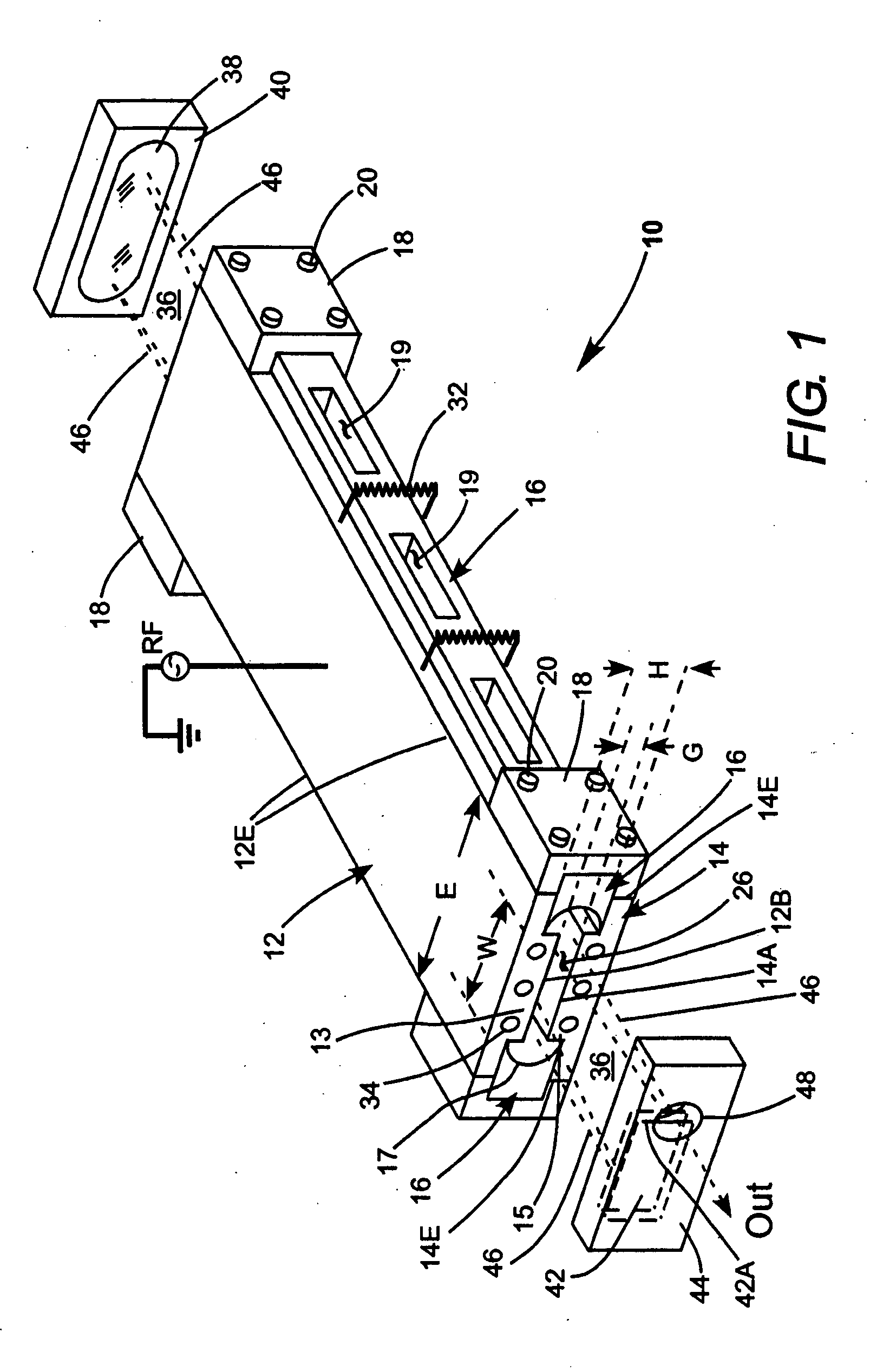

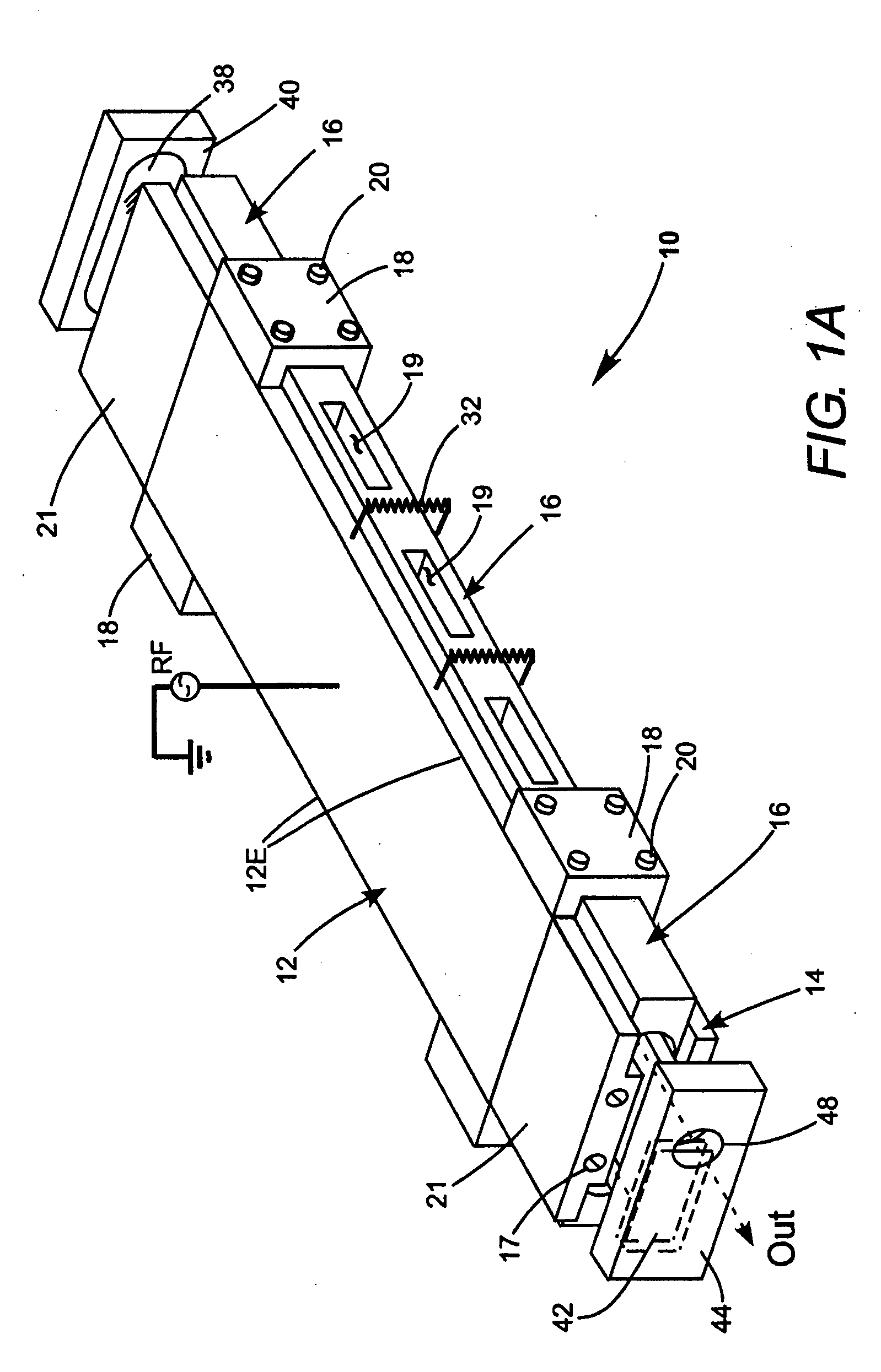

Dielectric coupled CO2 slab laser

InactiveUS20050175054A1Extension of timeDecreases difference in impedanceActive medium materialLaser cooling arrangementsCapacitanceDielectric

An slab CO2 laser includes spaced-apart elongated slab electrodes. A lasing gas fills a discharge gap between the electrodes. An RF power supply is connected across the electrodes and sustains an electrical discharge in the lasing gas in the discharge gap. Either one or two ceramic inserts occupy a portion of width of the electrodes and in contact with the electrodes. A discharge gap is formed between the portions of the width of the electrodes not occupied by the insert or inserts. Provision of the ceramic insert or inserts increases the resistance-capacitance (RC) time constant of the electrode impedance by increasing the capacitive component of the time constant. This hinders the formation of arcs in the discharge, which, in turn enables the inventive laser to operate with higher excitation power or higher lasing-gas pressure than would be possible without the dielectric insert. The ceramic insert also decreases the difference in impedance of the electrodes with and without a discharge. This leads to a better-behaved discharge, and a discharge that is easier to light.

Owner:COHERENT INC

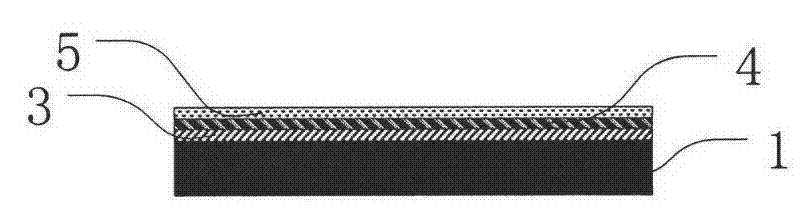

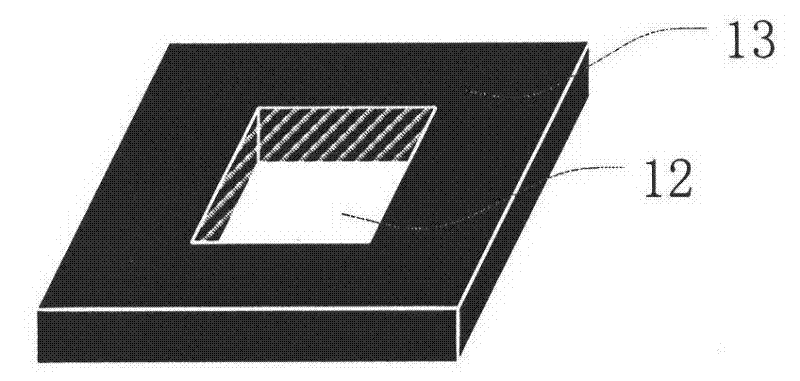

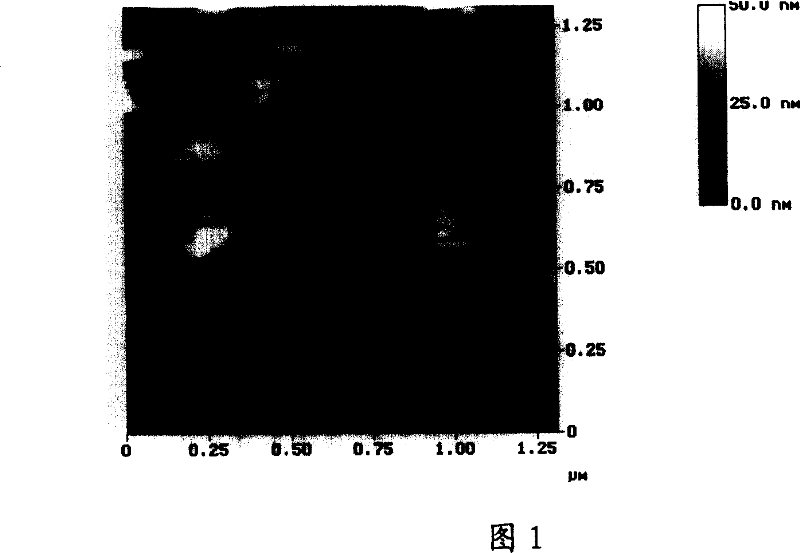

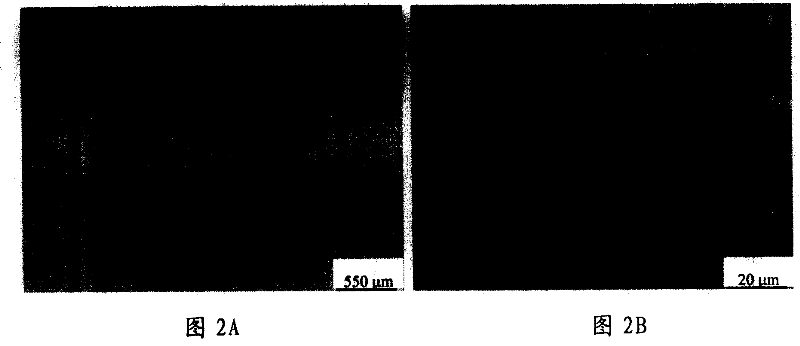

A kind of preparation method of mems atomic vapor chamber and atomic vapor chamber

ActiveCN102259825AEasy to makeIncrease contrastPrecision positioning equipmentDecorative surface effectsWater vaporRubidium

The invention relates to a preparation method for a micro-electro-mechanical system (MEMS) atomic vapor chamber and the atomic vapor chamber. The chamber is prepared by bonding a Pyrex glass sheet, a silicon wafer and a Pyrex glass sheet by an anodic bonding technology; the Pyrex glass sheet is taken as a window of the chamber; a chamber space is formed by etching or corroding the silicon wafer; paraffin packaged alkali metal such as rubidium (Rb) or cesium (Cs) is put into the chamber, and buffer gas with appropriate pressure is introduced simultaneously; paraffin is taken as a packaging material of the alkali metal, so that active alkali metal is isolated from oxidants such as oxygen, water vapor and the like in an environment; the paraffin is also used as a plating material of the chamber, so that collision between Rb or Cs atoms and a chamber wall is slowed down; and a CO2 laser is used for melting the paraffin to release the alkali metal, so that a uniform paraffin plating is formed on the chamber wall. The problem of long-term drift caused by reaction residues generated by a field preparation mode is solved, the collision between the Rb or Cs atoms and the chamber wall is slowed down, and the contrast of atomic resonance line width of the alkali metal is improved.

Owner:江苏智能微系统工业技术股份有限公司

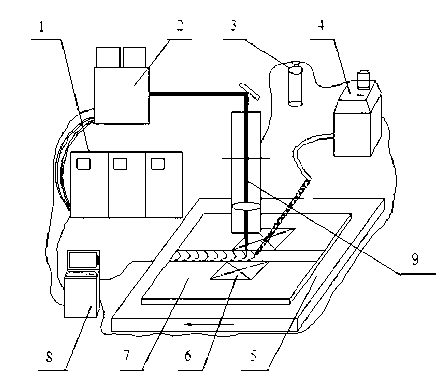

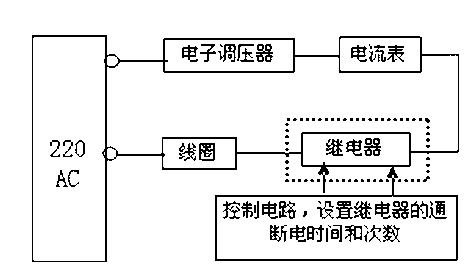

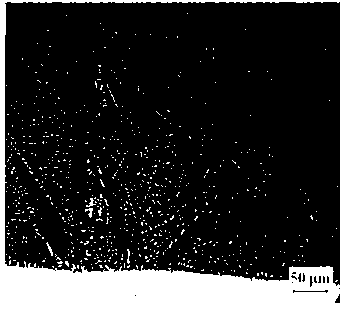

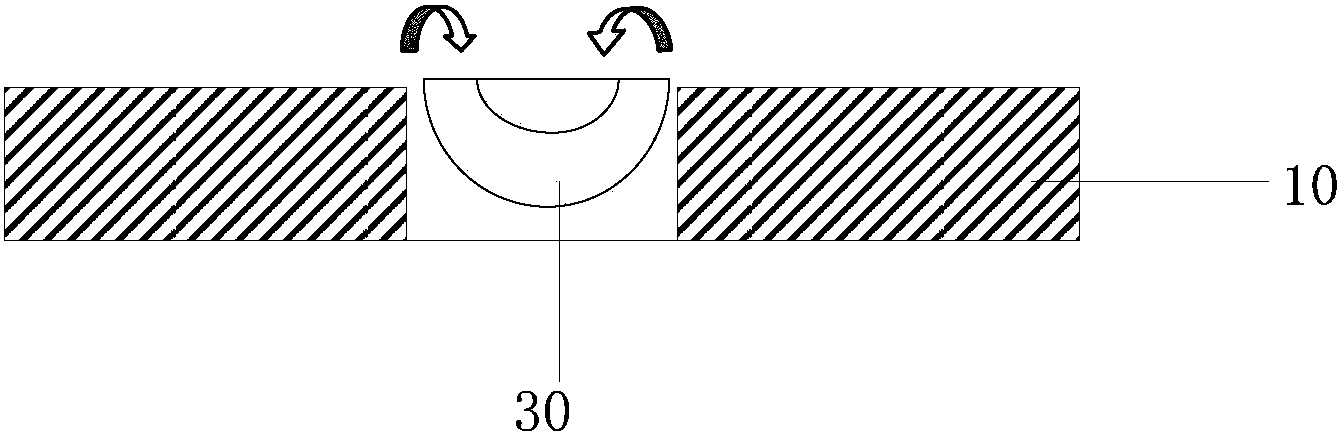

Method for refining solidified structure of laser cladding layer by using alternating magnetic field and device thereof

InactiveCN102703898ARefining solidified tissueChange shapeMetallic material coating processesNumerical controlAlternating current

The invention relates to a method for refining a solidified structure of a laser cladding layer by using an alternating magnetic field and a device thereof, belongs to the technical field of laser processing. A compound coating is prepared on the surface of a substrate in a manner of conventional powder-feed laser cladding; the alternating magnetic field is applied to acting on a laser molten pool during the laser cladding; the powder-feed laser cladding process is carried out under the alternating magnetic field; and the direction of magnetic lines of force generated by the alternating magnetic field is perpendicular to the scanning speed direction of the laser cladding. The device for refining the solidified structure of the laser cladding layer by using the alternating magnetic field comprises a cooler, a CO2 laser, an argon protector, a synchronous powder feeder, a clamping device, an alternating magnetic field, a cladding substrate body and a numerical control operation floor. The method and the device provided by the invention are capable of obviously refining the solidified structure of the cladding layer; when alternating current with certain frequency is introduced into a coil, an alternating magnetic field can be generated between a metal melt and the magnetic field coil; and the intensity of the alternating magnetic field is controlled so as to change a form of the solidified structure of the cladding layer and refine crystalline grains through changing the intensity of an alternating magnetic field. The device provided by the invention is simple, low in investment cost, high in benefit, etc.

Owner:KUNMING UNIV OF SCI & TECH

Method for rapidly preparing gradient metal ceramic composite material by laser induction hybrid cladding

InactiveCN101709468AIncrease profitImprove efficiencyMetallic material coating processesStrength of materialsMechanical property

The invention relates to a method for rapidly preparing a gradient metal ceramic composite material by laser induction hybrid cladding, which is characterized by comprising the following steps of: (1) generating a 3-D CAD solid model of a gradient metal ceramic composite material component by utilizing special CAD software or a reverse technology in a computer; (2) generating a processing program; (3) controlling the distance between the surface of a base material surface and an induction coil within the range of 2-10 mm; (4) locating a focused CO2 laser beam in an induction heating area; and (5) lifting a laser induction hybrid cladding processing head to the distance equal to the thickness of a CAD 2-D sheet. The invention has the advantages that: (1) a bulk metal ceramic composite material part the ceramic phase of which is continuously tunable along the material thickness direction within 0-100percent by weight is obtained; (2) the use ratio of laser energy and laser cladding efficiency are greatly improved; (3) the metal ceramic composite material with compact tissue but without cracks is obtained; (4) special tools and fixtures are not needed in the manufacturing process, and the flexibility is high; and (5) the mechanical property, the abrasive resistance and the corrosion resistance of the gradient metal ceramic composite material are greatly improved.

Owner:NANCHANG HANGKONG UNIVERSITY

Technique of laser hardening ossifying process of vehicle mold

InactiveCN101109032AHigh hardnessImprove wear resistanceFurnace typesHeat treatment process controlSurface finishCleansing Agents

The invention relates to a vehicle mould quenching hardening process, which comprises the following steps: firstly detergent is used to remove oil and dust on the workpiece surface; secondly the Sio2 absorption coating material is sprayed uniformly on the vehicle mould surface in a pre-thickness of 0.02 mm to 0.05 mm with a brush; thirdly the Sio2 coating is naturally dried; fourthly a high power CO2 laser is applied to quickly scan the sprayed mould surface to achieve rapid surface heating and cooling. The laser power P is from 2,000W to 5,000W and the scan speed V is from 200 mm per min to 800 mm per min. The invention controls the surface uniform easily, improves the surface finish and dimensional accuracy of the stamping parts, greatly reduces the grinding time so as to improve the work efficiency and reduce the cost. In addition, the applied NC programming system can quench harden complex shaped moulds. The system is also fit for newly produced moulds without or with surface quenching process.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

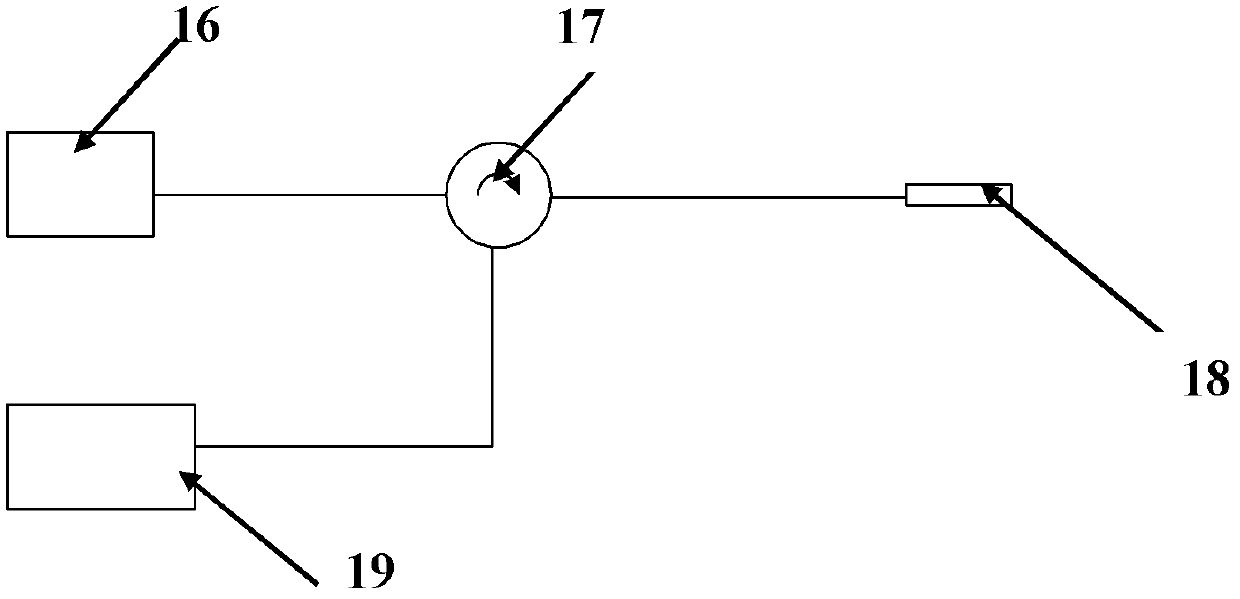

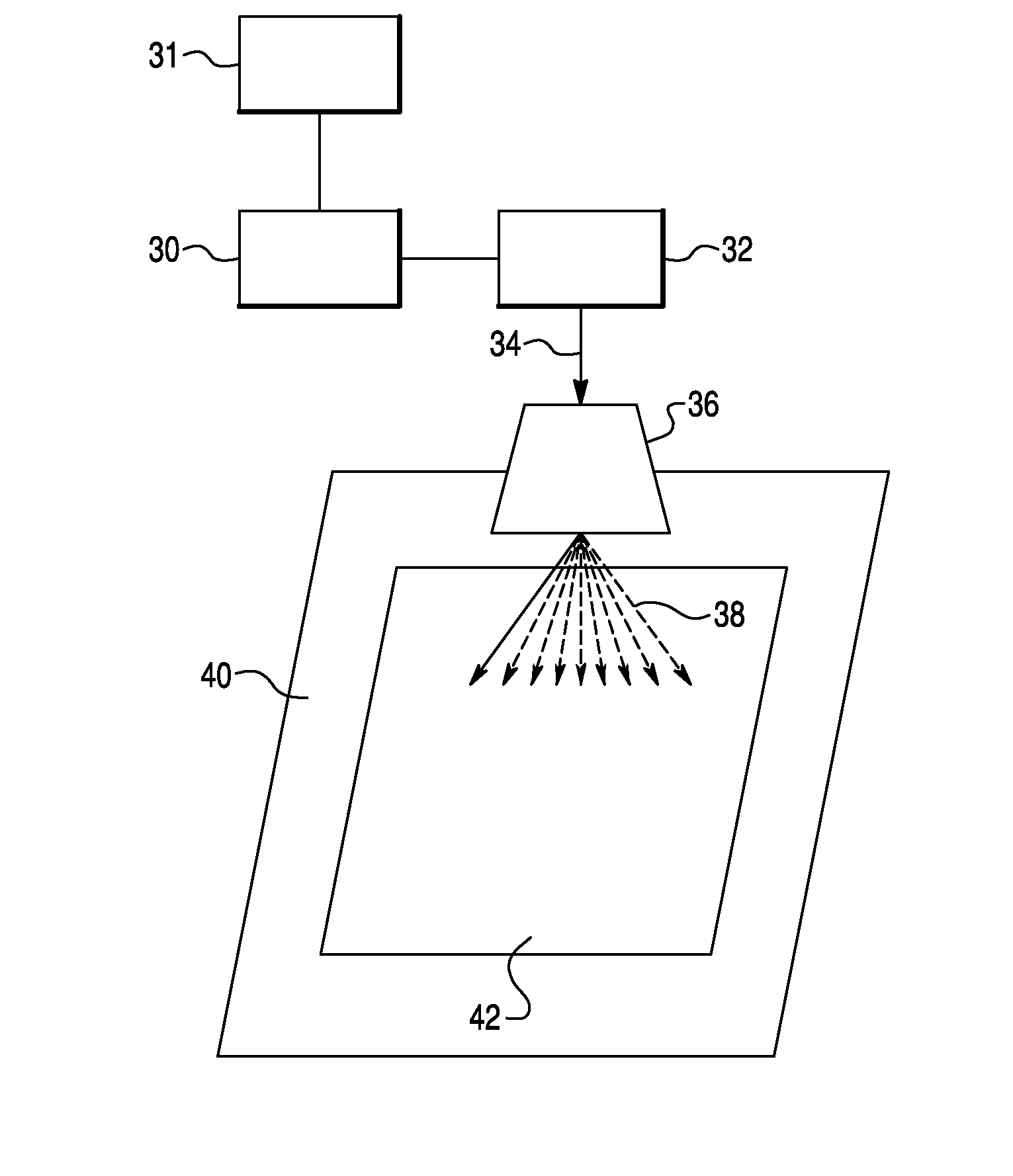

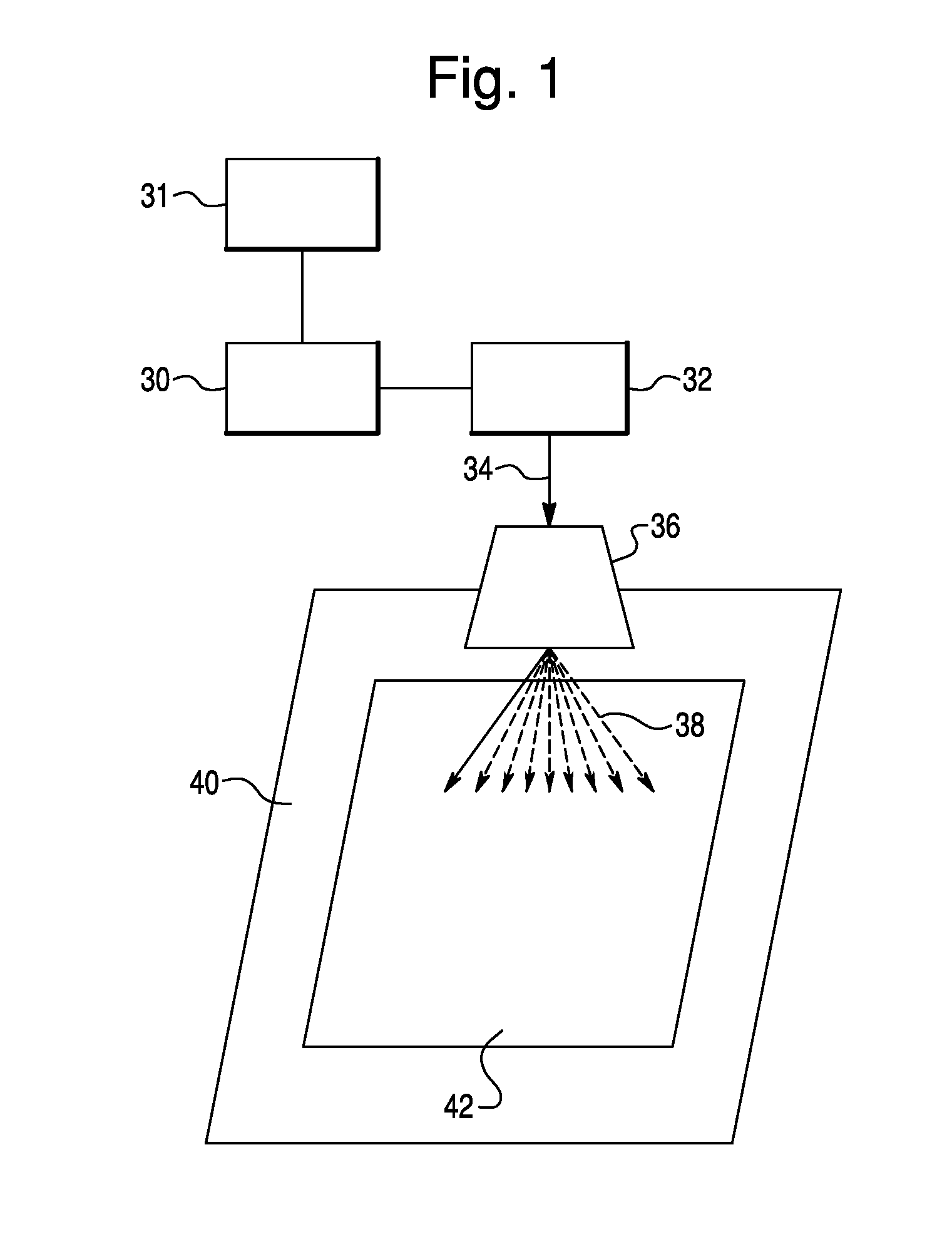

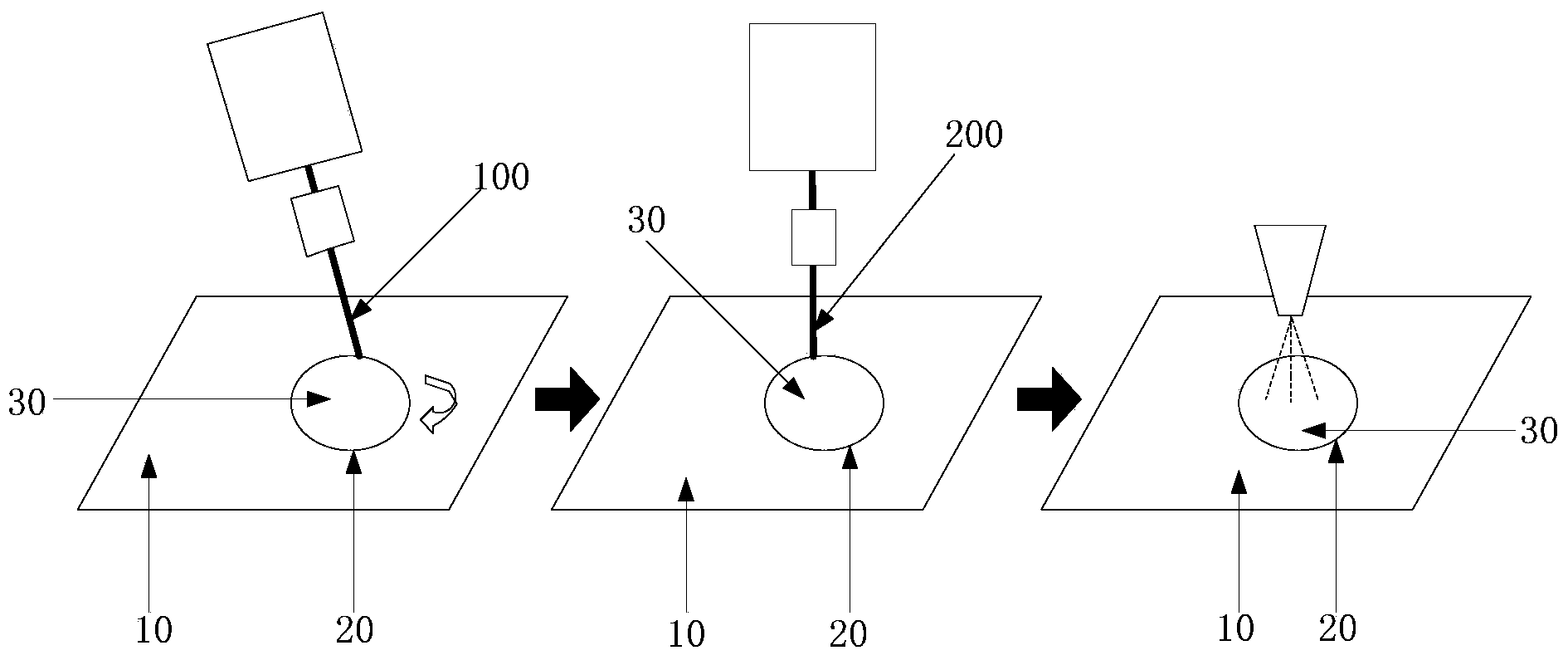

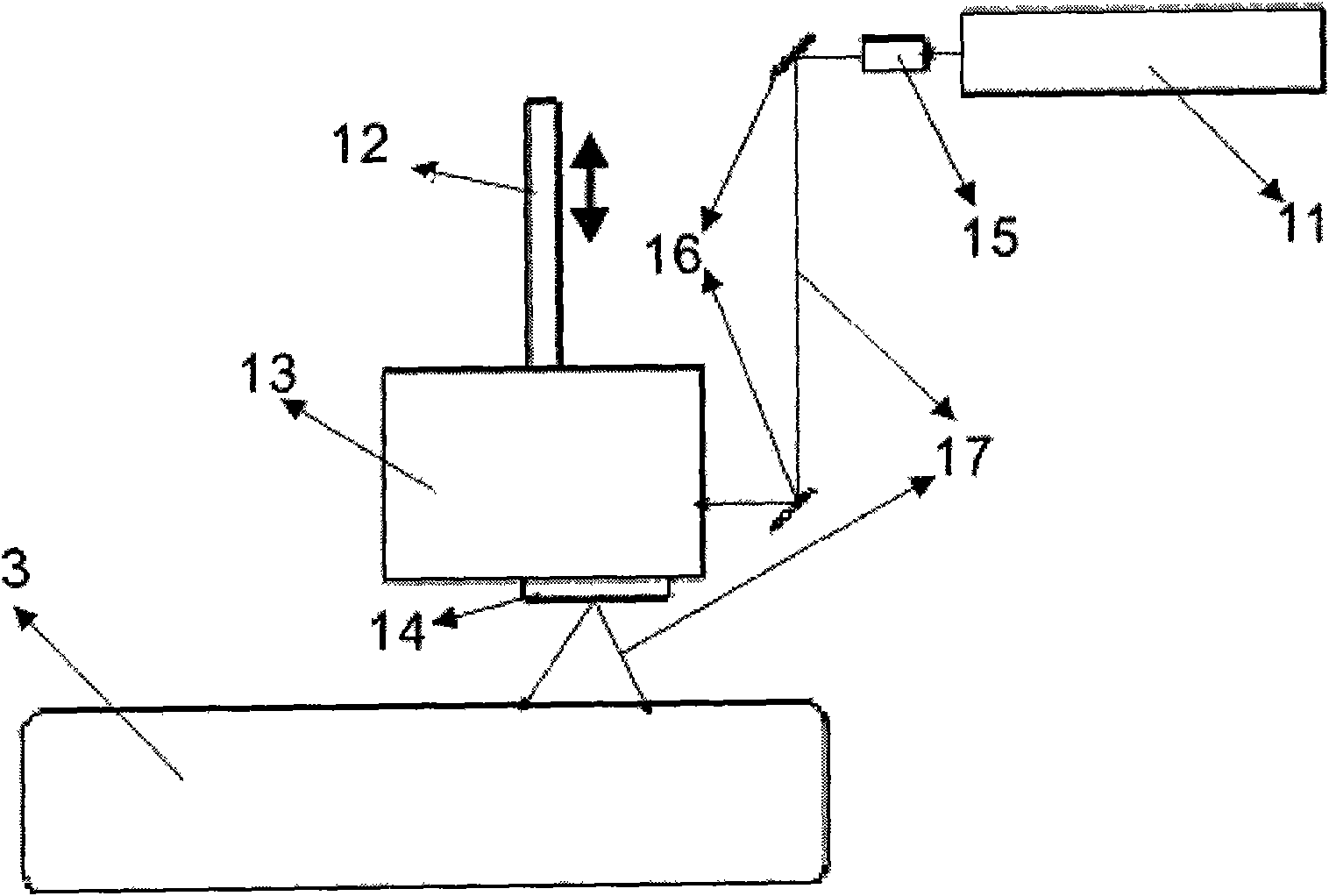

Plate forming process and apparatus

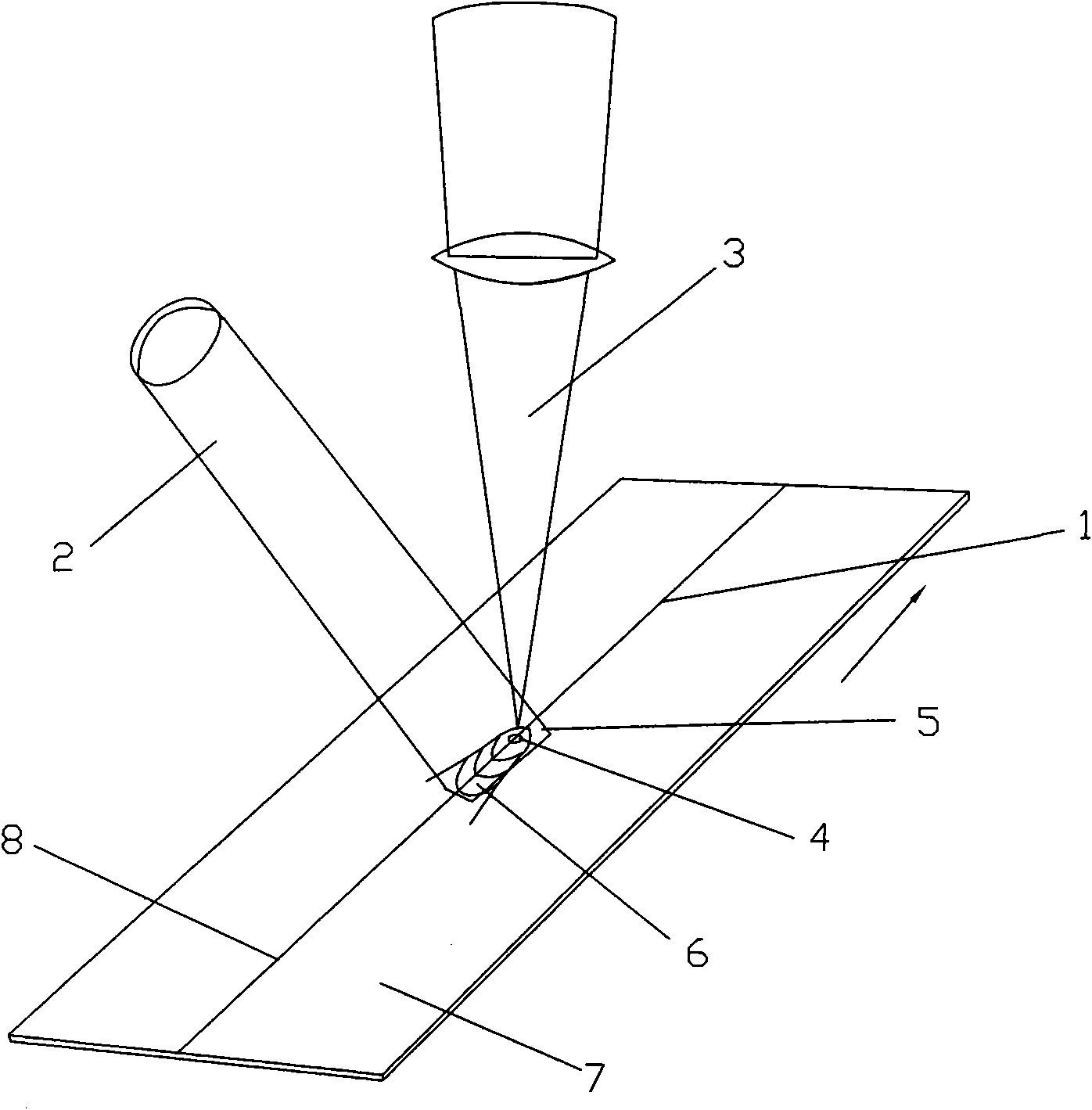

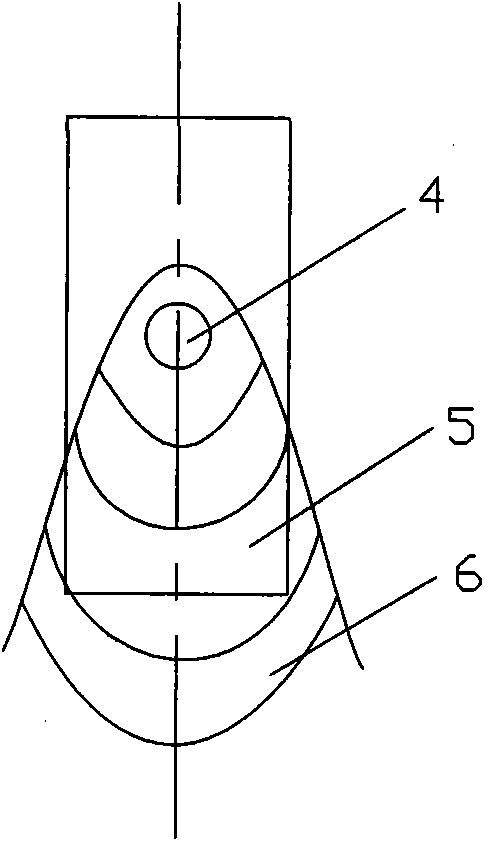

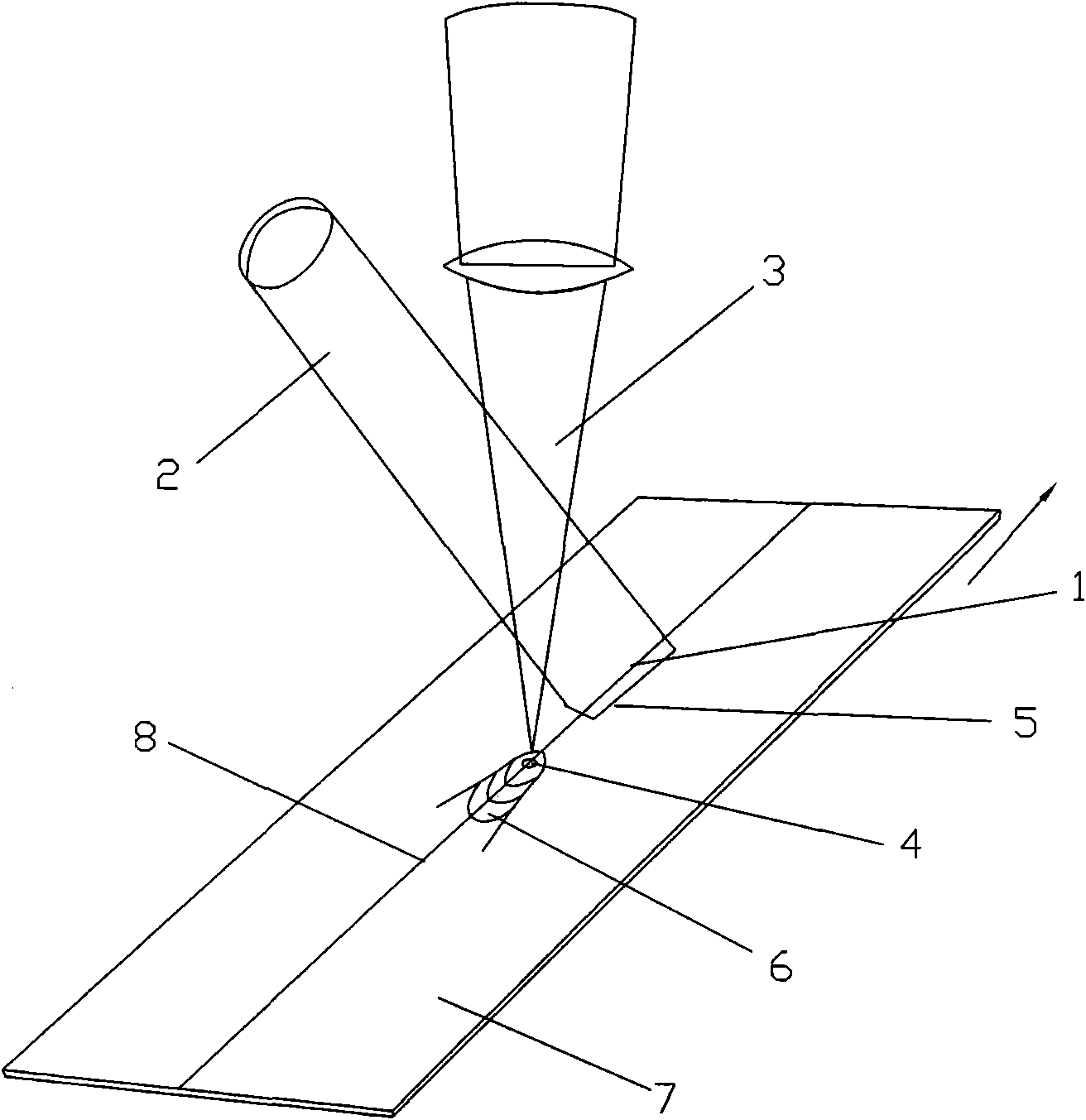

InactiveCN1931467APrecise Local FormingAccurate shapeShaping toolsComputer controlShock waveLaser processing

The plate forming process and apparatus belongs to the field of laser processing technology. The present invention has CO2 laser for pre-heating plate, infrared thermometer for measuring and controlling the plate heating temperature, neodymium glass laser for providing powerful short laser pulse to induce the generation of laser shock wave as the forming force source in processing plate and plate deformation measuring feedback device. The present invention is superior to laser thermal stress forming process, which has inferior formed surface quality, and laser shock forming process, which has small deformation amount, and can form plate directly in relatively great deformation amount, relatively high size precision and relatively high surface quality.

Owner:JIANGSU UNIV

Compound welding method by using semiconductor laser and CO2 laser

InactiveCN101564799AFast preheating and homogenizationReduce temperature gradientLaser beam welding apparatusThermal treatmentCo2 laser

A compound welding method by using semiconductor laser and CO2 laser comprises the steps: using a semiconductor laser and a CO2 laser to be positioned on one side of a welding line of welded metals in a certain angle, adjusting a focusing position of the CO2 laser to cause a light spot of the CO2 laser to be positioned in the light spot of the semiconductor laser so that the welding direction is consistent with the slow axis direction of the semiconductor laser; using the semiconductor laser to pre-heat the welded metals, heating the part to be welded entering into the light spot of the semiconductor laser to 200-400 DEG C, using the CO2 laser to weld, and performing a post-welding thermal treatment to the welded metals by using the semiconductor laser for the welded parts of the welded metals welded by the welding of the CO2 laser. Due to synchronous pre-heating and post-heating treatments to the welding process, the invention can effectively solve the problem of cold cracking in high-strength steel welding and improve the quality of high-strength steel laser welding.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

Laser etching of an acrylic and polyvinylchloride composition, and laser etched article

InactiveUS20110261141A1Reduce visual impactQuality improvementAblative recordingLaser etchingGrating

A laser-markable acrylic and PVC composition (commonly known as Kydex®) is lased using a CO2 laser to differentiate a laser etched graphic or pattern from the base material. A discoloration may be controlled to improve an appearance of the graphic or pattern. An embodiment uses a 500 to 2,500 watt CO2 laser to provide a raster or vector graphic pattern on the Kydex® finished part. Yet another embodiment is to use a 500 to 2,500 watt CO2 laser to provide a seamless raster or vector graphic pattern on a large piece of Kydex® which can then be cut and divided into multiple finished parts. In this case, an embodiment would include providing the necessary software and process controls to insure that the seams between individual parts that make up a larger part are without lines of demarcation.

Owner:REVOLAZE LLC

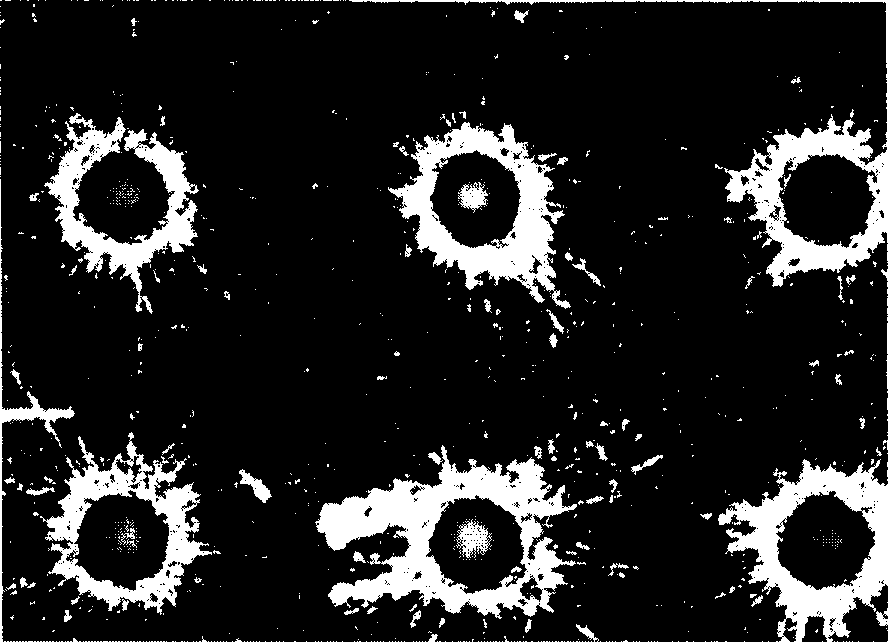

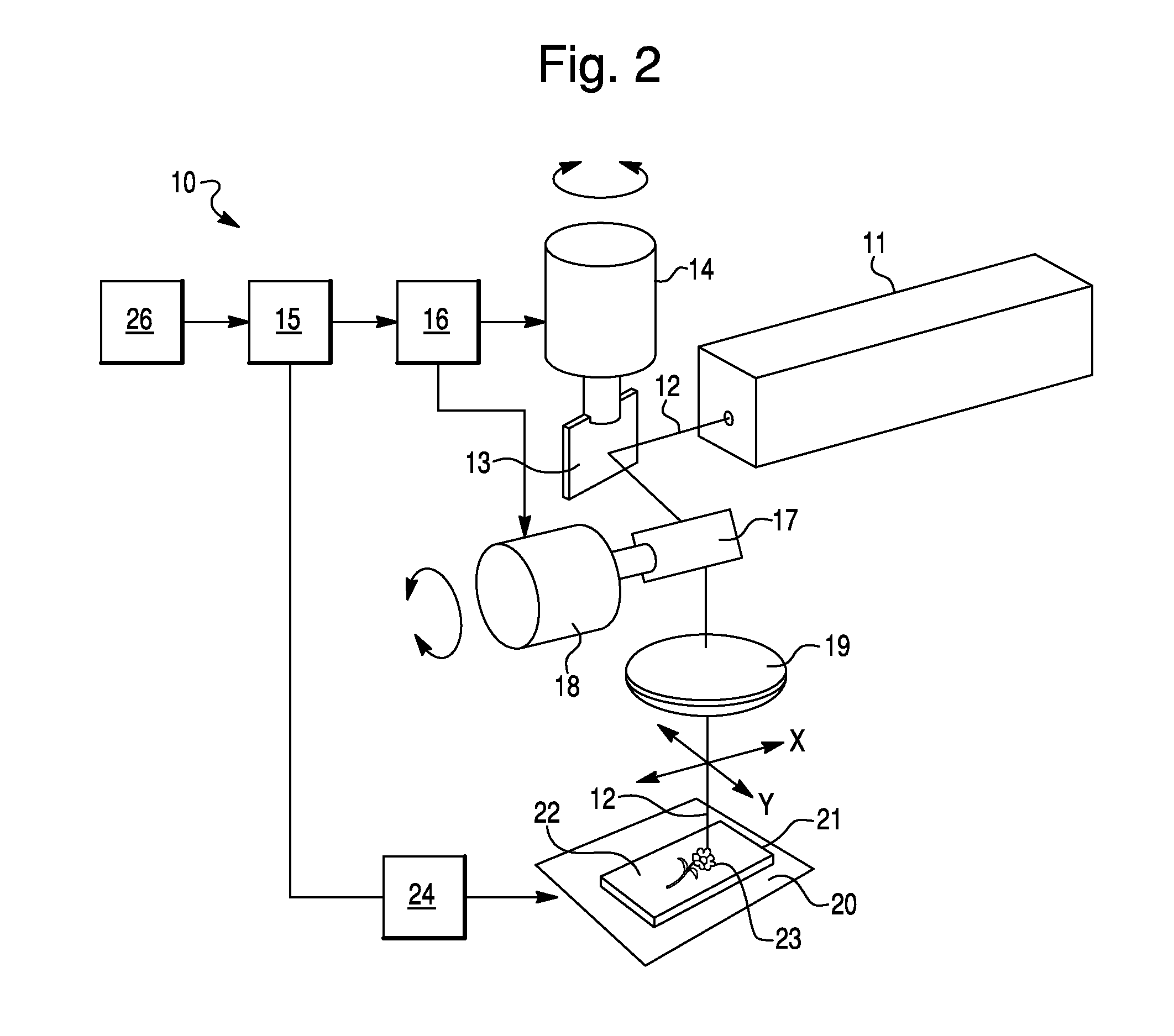

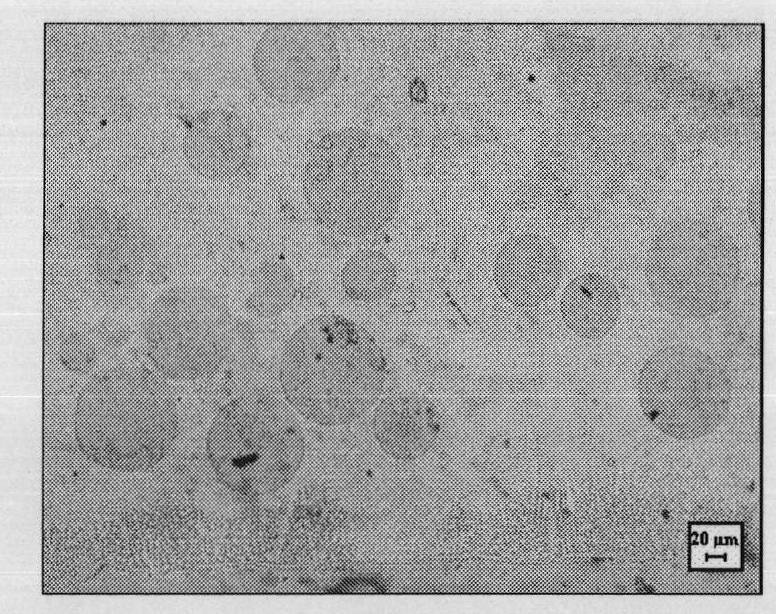

Method and apparatus for producing thermal damage within the skin

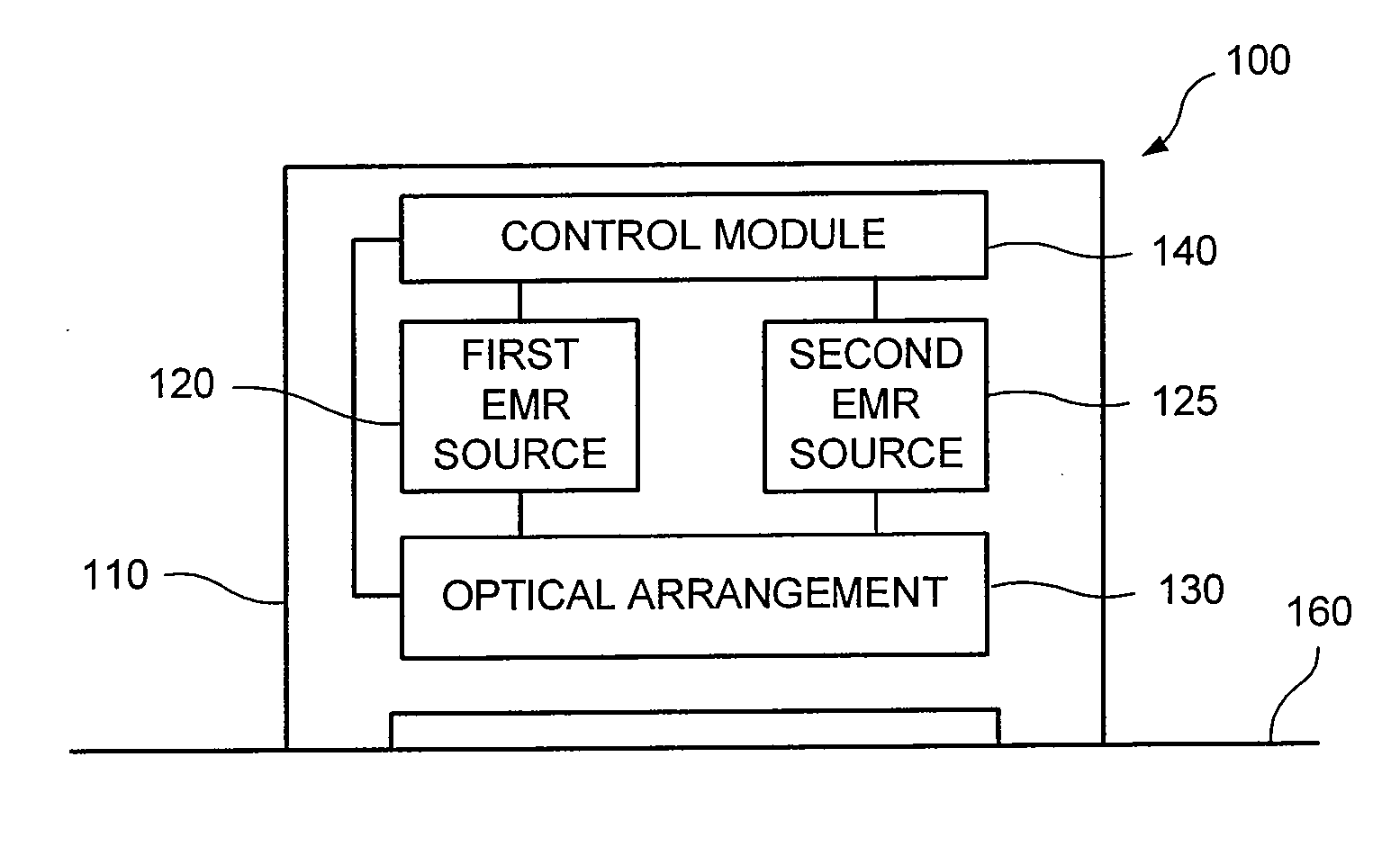

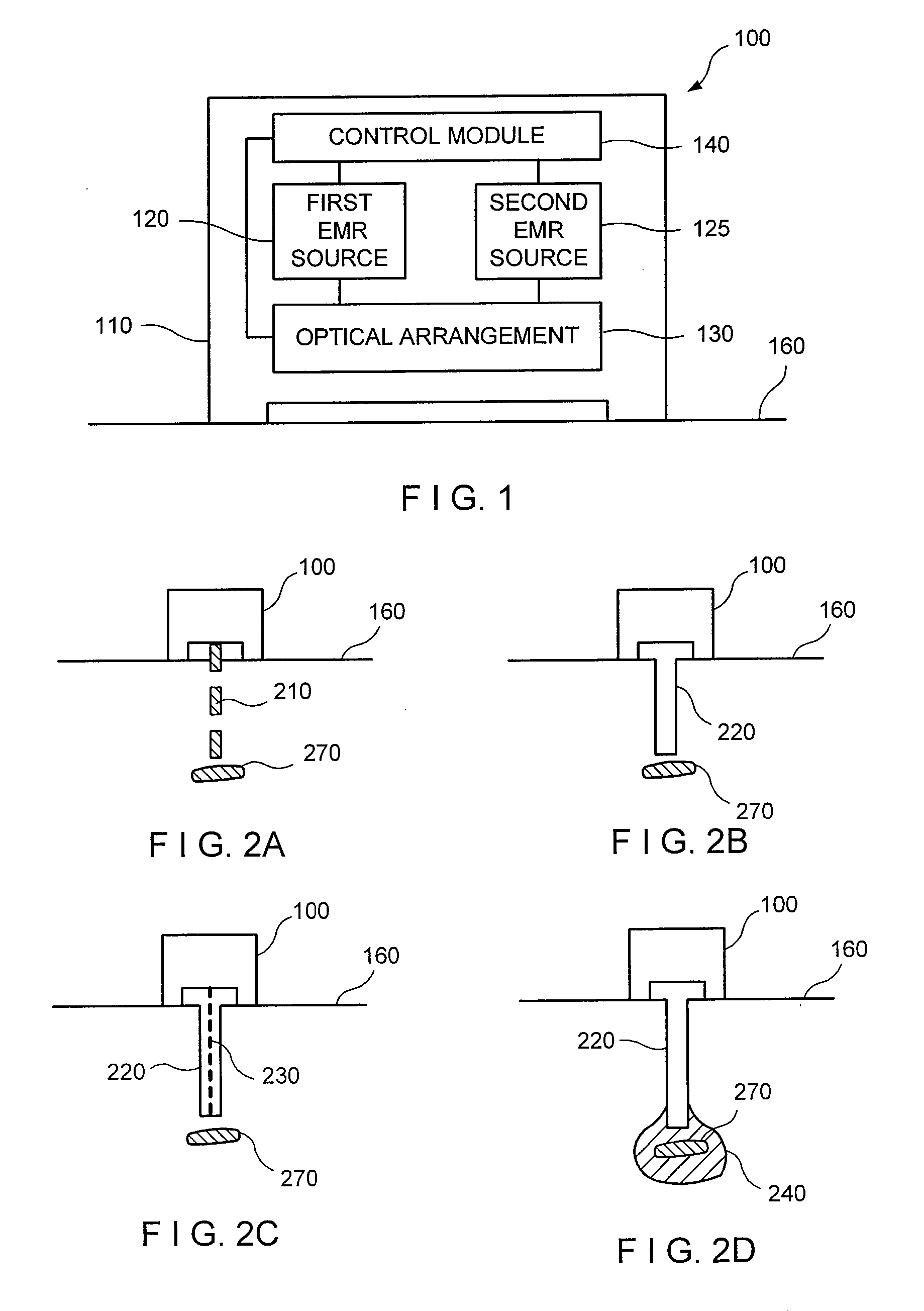

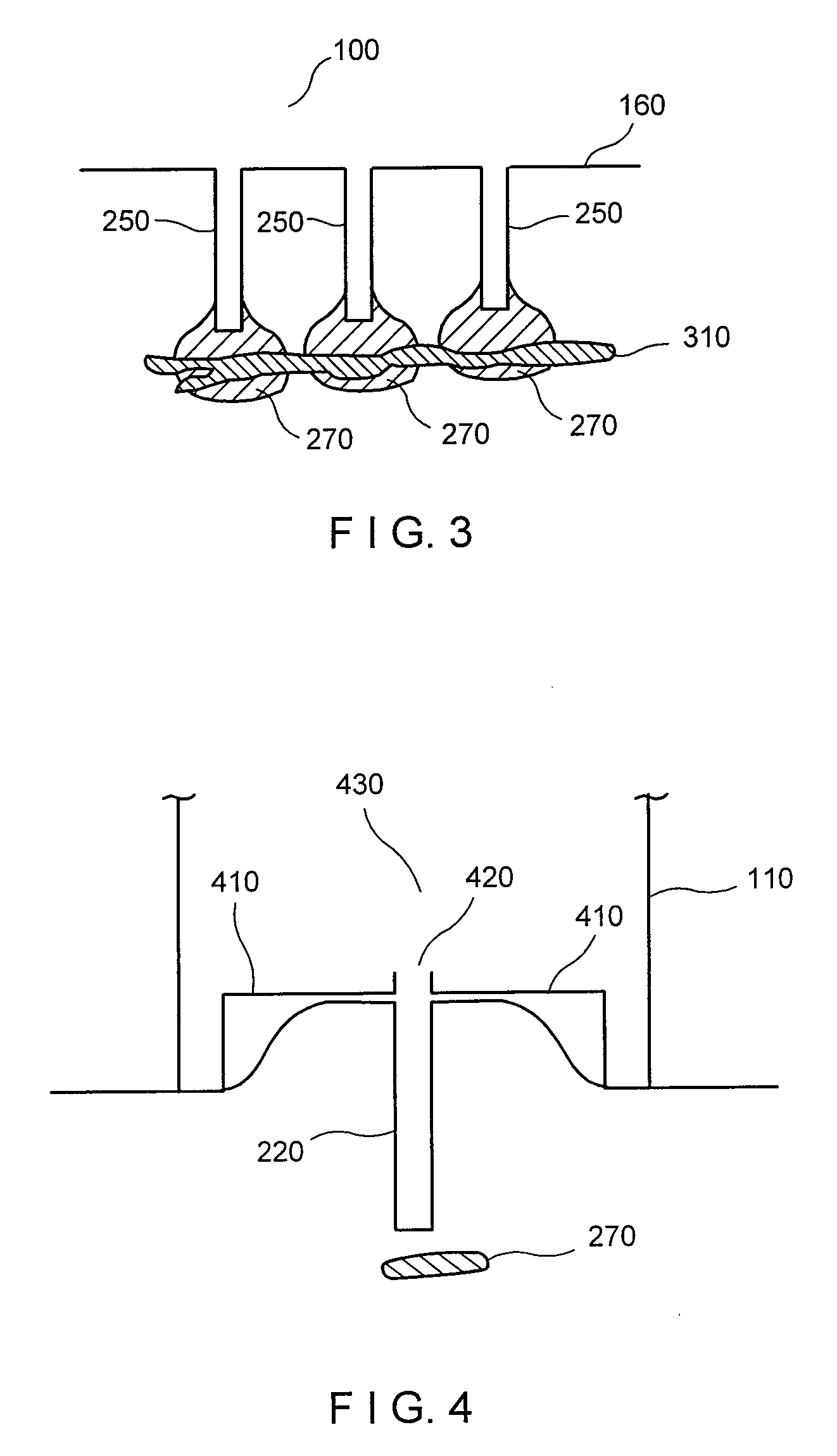

InactiveUS20070239236A1Minor side effectsAccurate locationSurgical instrument detailsLight therapyEr:YAG laserAnalgesics effects

A method and apparatus are provided for treating dermatological conditions, in which a first beam of radiation is used to ablate a hole in skin tissue, and a second beam of radiation is directed into the hole and onto a region of skin tissue adjacent to and / or at the bottom of the hole. The first beam can be provided by an ablative laser such as a CO2 laser or an ER:YAG laser. The second beam can be provided by, e.g., an ablative laser operating at a lower peak power level than the first beam, a non-ablative laser, a flashlamp, a tungsten lamp, a diode or a diode array. A controlled amount of thermal damage can thereby be provided at a desired depth within the skin, using radiation sources that would be absorbed closer to the surface of the skin if an ablated hole were not present. Cooling and / or freezing of the skin prior to ablation can be provided to provide an analgesic effect and / or stabilize the tissue surrounding the ablated hole. The region of skin to be treated can optionally be pulled towards the radiation source using a vacuum to stretch and / or stabilize the skin tissue surrounding the volume to be ablated.

Owner:THE GENERAL HOSPITAL CORP

Laser cladding repair technique for engine crankshaft

InactiveCN101109083AMelting depth is smallSmall machining allowanceMetallic material coating processesNumerical controlOptoelectronics

The invention relates to an engine crankshaft laser cladding repairing technology based on the following steps. A: the crankshaft surface is treated with oil removing stain removal; B: a DL-HL-T10000 type CO2 laser is selected; a working table with numerically-controlled machine tool is applied; an auto-feeding powder apparatus for laser is used to delivered a Fe-based or Ni-base self-fusing alloy powder to a molten pool, and the Fe-based or Ni-base self-fusing alloy powder is repaired and strengthed on the surface of the crankshaft. The technological parameter features that the cladding power P ranges between 1,000w and 10,000w; the spot dismeter D is between 2mm and 20mm; the scanning speed is at 200 mm per min to 2000mm per min; the overlapping rate is from 20 per cent to 40 per cent. The laser cladding technology of the invention features no pollution, high productivity, low energy consumption, small machining allowance and lower comprehensive cost. In addition, the laser cladding is good to the repair of the wear parts, such as strong associativity, small residual stress, no machining deformation, high surface hardness as well as good abrasion resistance, and becomes a process technology with great developing potential in repairing the components.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

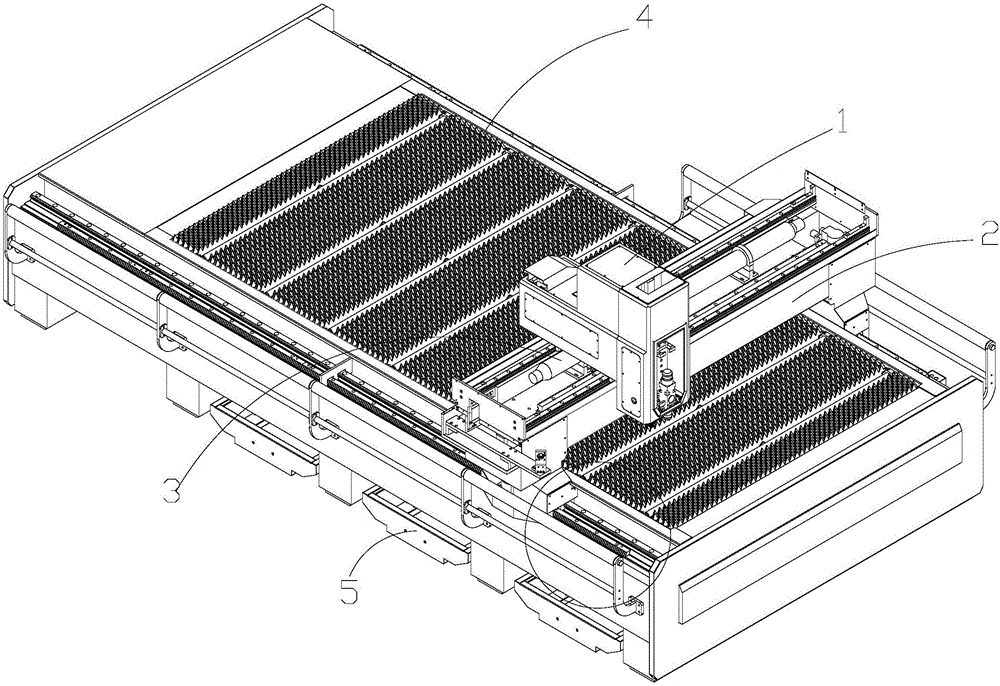

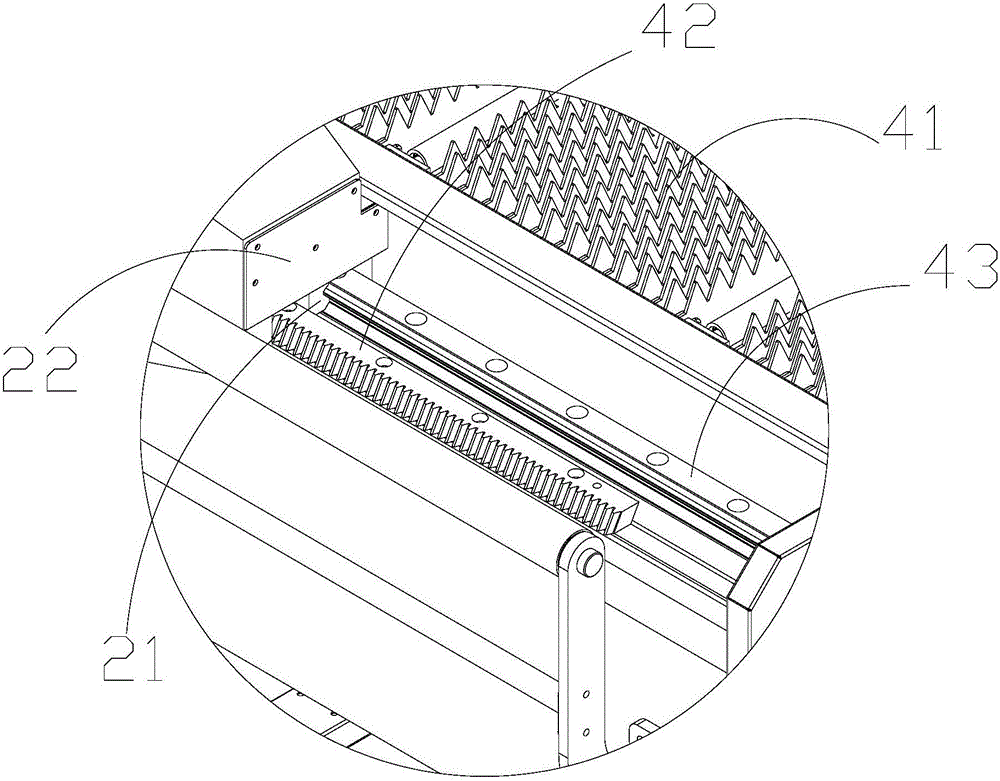

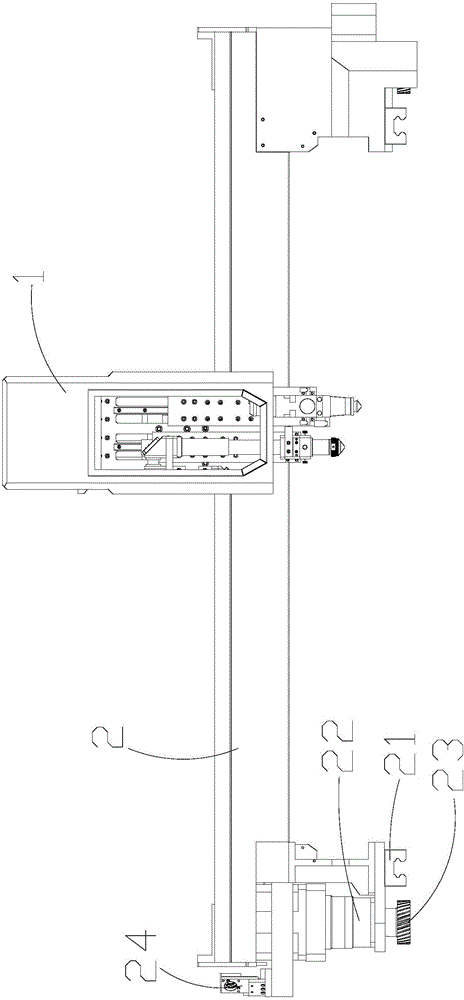

Multi-laser-head laser cutting machine

The invention provides a multi-laser-head laser cutting machine. The multi-laser-head laser cutting machine comprises a workbench, a laser cutting control system, a CO2 laser generator, a CO2 laser power supply, a CO2 laser reflector, at least one non-CO2 laser generator, for example, a fiber laser generator, a multi-laser-head cutting assembly, an X-axis movement assembly, a Y-axis movement assembly, a Z-axis movement assembly, a laser generator cooling system, an object carrying working table, a cutter console, a waste material collecting device and a dust collecting exhaust fan. Two or more than two laser sources are combined on the same laser cutting equipment by the multi-laser-head cutting assembly, so that the cutting processing of composites and the cutting processing of different single materials are realized.

Owner:GUANGZHOU GREAT YEAR LASER TECH CO LTD

Method for preparing TiC-TiB2 nano-micrometre multiple phase ceramic coating

InactiveCN101037771AHigh strengthImprove toughnessSuperimposed coating processCeramic coatingLaser scanning

The invention discloses a method for preparing TiC-TiB2 nanometer-micro complex phase ceramics coating, including the steps of: bonding granule, the gramularity of which is 30 Mum, is produced by ion densification granulating after mixing uniformly the reactive A selected from Ti or TiO2, the reactive B selected from boron, B2O3 or B4C, the reactive C, nanometer TiC and rare-earth oxide powder precursor; hot spraying Ni alloy base coat of 0.1-0.3mm on 45 steel base, then cold spraying a bonding granule of 0.5-1mm; coating liquid absorbing paint comprising nanomete oxide and other addition agent for improving absorptivity for CO2 laser on the surface of pre-assembly coating; TiC-TiB2 nanometer-micro complex phase ceramics coating is produced by laser-scanning the said pre-assembly coating. The invention can solve the defects that today' TiB2 coating has low cost, low efficiency, low toughness and poor binding force with based body.

Owner:SHANGHAI UNIV OF ENG SCI

Low absorption coatings for infrared laser optical elements

InactiveUS6020992AEffective and practical low absorptionReduce absorptionMirrorsOptical filtersOptoelectronicsOptic system

A thorium-free low absorption coating for infrared CO2 laser optics comprises an interior BaF2 layer formed on a substrate and an exterior layer formed over the interior layer to a predetermined thickness sufficient to substantially prevent water adsorption by the interior layer. Generally, the predetermined thickness is greater than about 11000 ANGSTROM , and in one embodiment of a two-layer low absorption coating designed for antireflection at 10.6 microns, the exterior layer has a physical thickness in a range between about 24600 ANGSTROM and 22800 ANGSTROM , and preferably about 24000 ANGSTROM . In the preferred two-layer AR coating embodiment, the exterior layer defines a cover layer and an absentee layer, and the interior layer is relatively thin. The preferred exterior layer and the preferred substrate consist essentially of ZnSe. Multilayer stacked coatings of more than two layer can also be formed to provide low absorption partially reflective or totally reflective coatings as well as AR coatings.

Owner:II VI

Laser drilling method and laser drilling system

ActiveCN103831539AGuaranteed qualityHole punchingGlass severing apparatusWelding/soldering/cutting articlesMachined surfaceLight beam

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

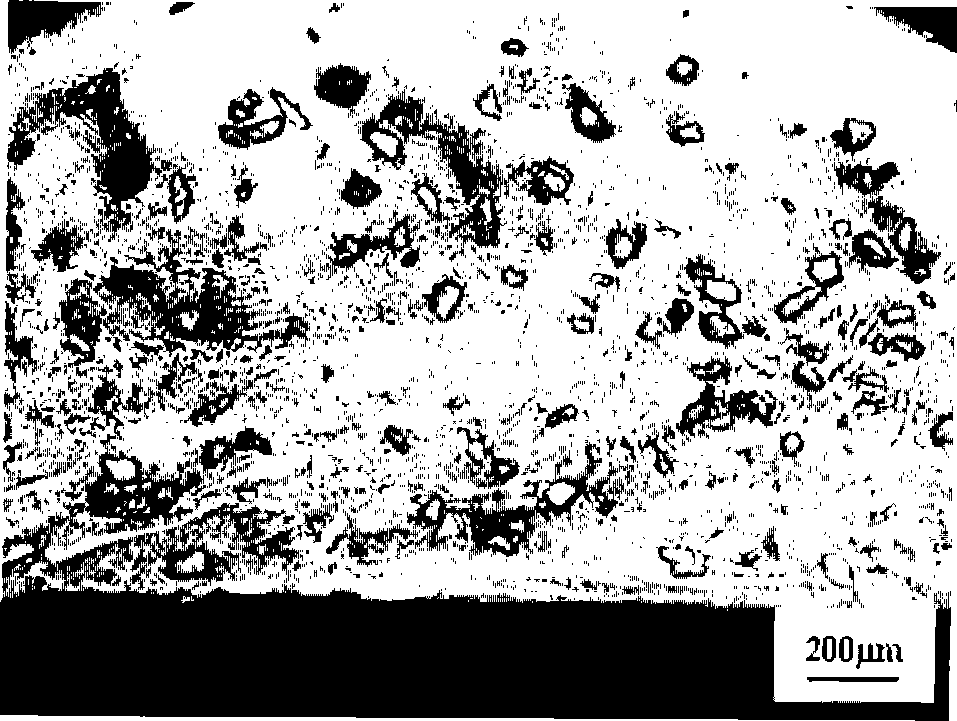

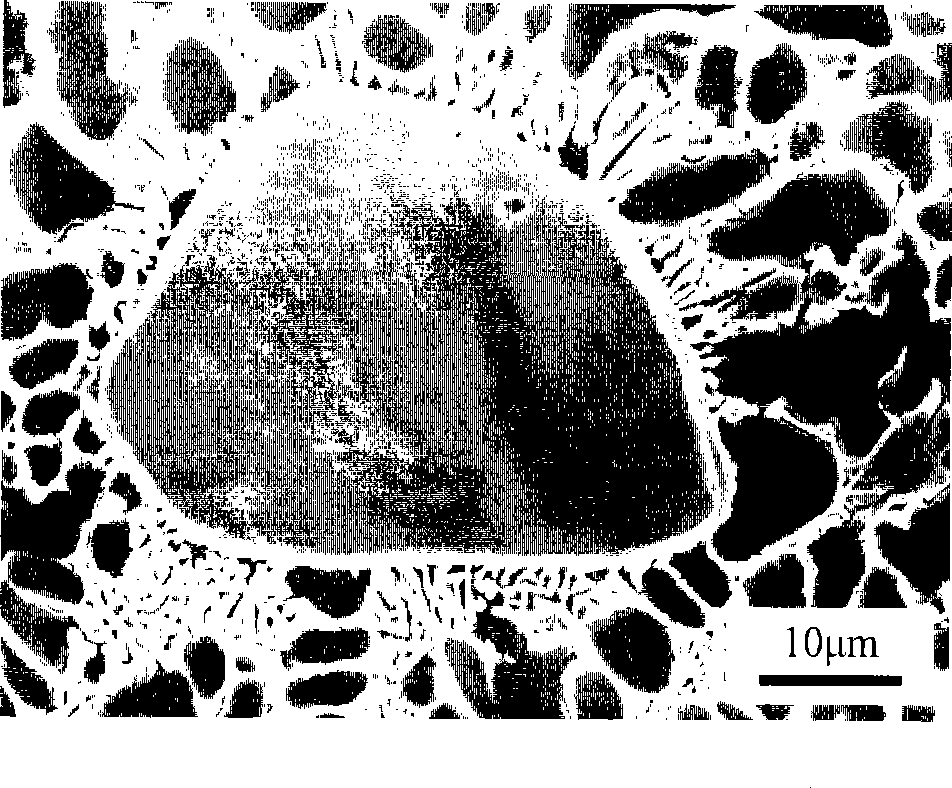

Laser cladding method of composite coating containing spherical tungsten carbide

InactiveCN101818343AStable chemical propertiesImprove liquidityMetallic material coating processesAbrasive blastingAlloy

The invention discloses a laser cladding method of a composite coating containing spherical tungsten carbide, which is characterized by comprising the following steps of: cleaning a metal to be clad by using acetone to remove oil, and blasting sand onto the metal to coarsen the metal; presetting composite powder containing 5 to 50 percent of 0.5 to 2.0 millimeter spherical tungsten carbide and 50 to 95 percent of an iron or nickel based self-fluxing alloy on the surface of the metal; and performing the laser cladding of the metal by using a CO2 laser. In the laser cladding method of the invention, the spherical form of the tungsten carbide composite coating is unchanged, the wear resistance of the cladding is high, defects such as cracks and air holes are avoided, the production working procedures are simple and the working efficiency is high. The method is suitable to be used for metal surface treatment.

Owner:GUANGZHOU RES INST OF NON FERROUS METALS

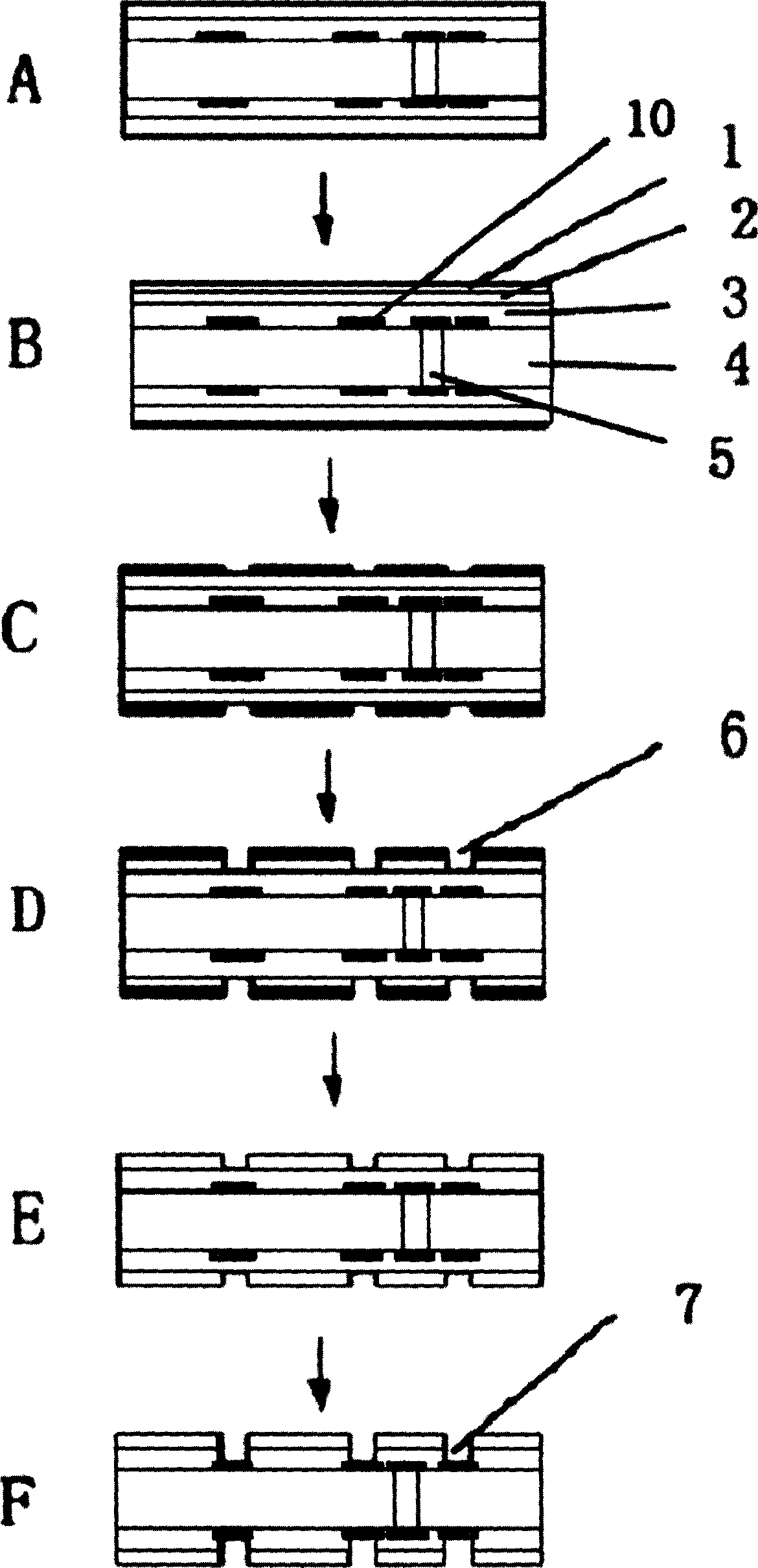

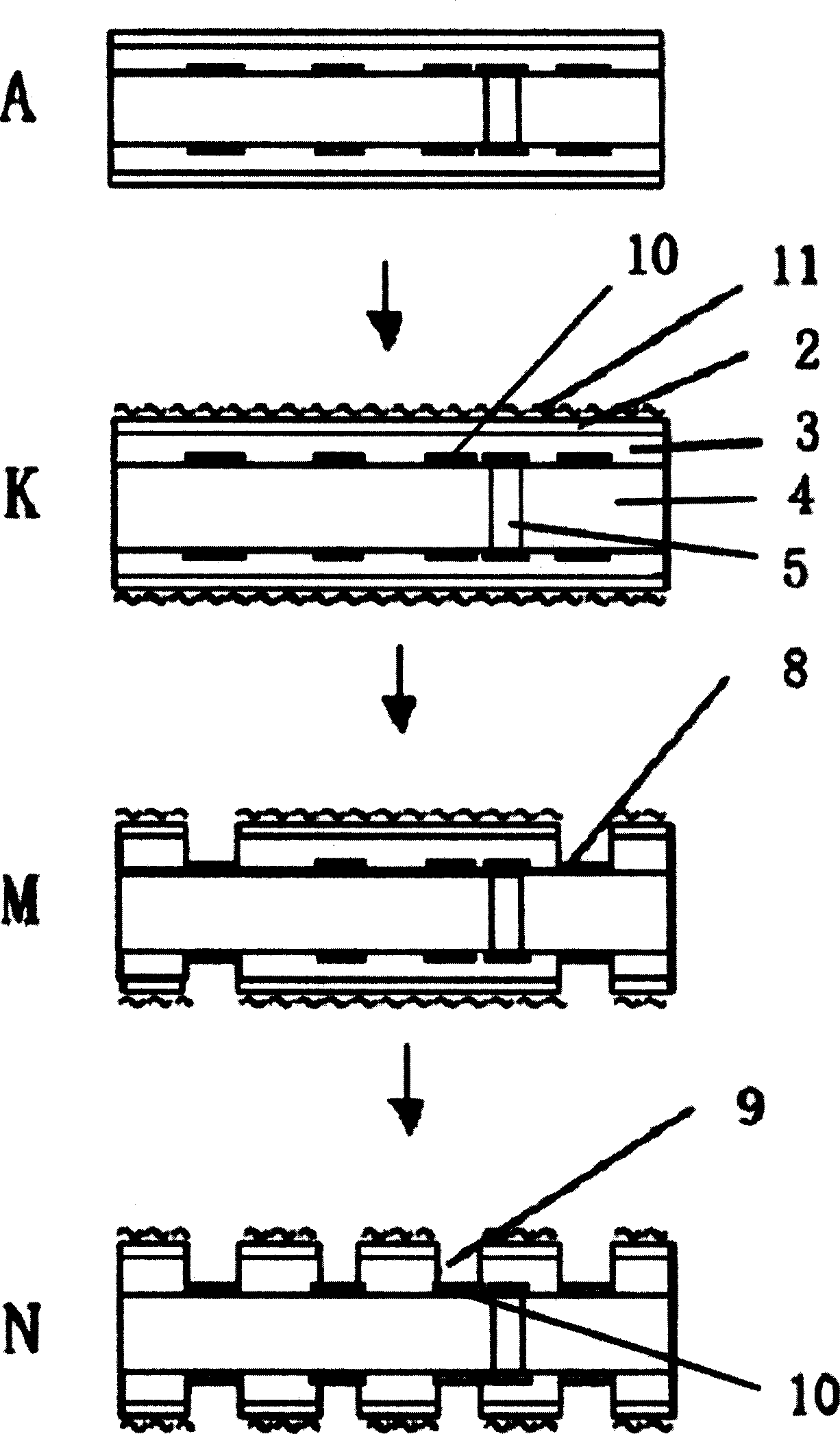

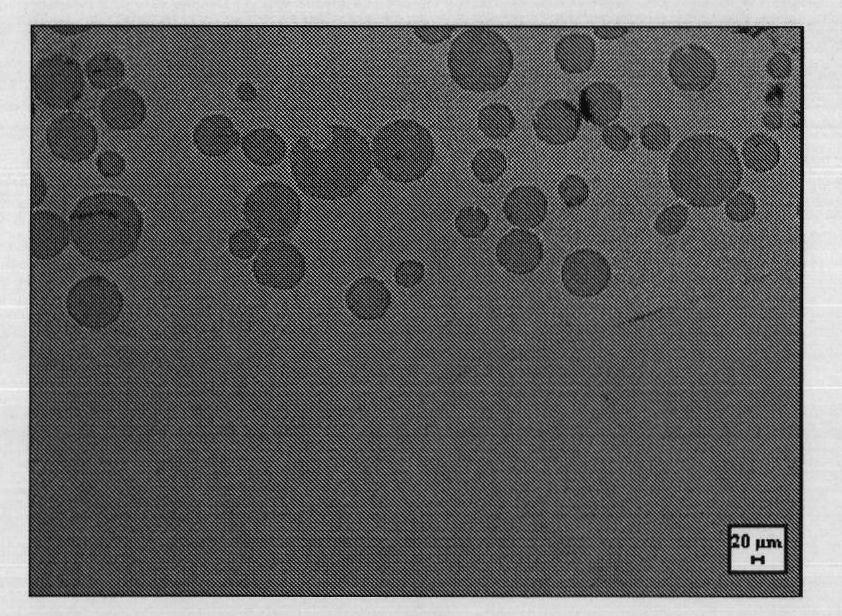

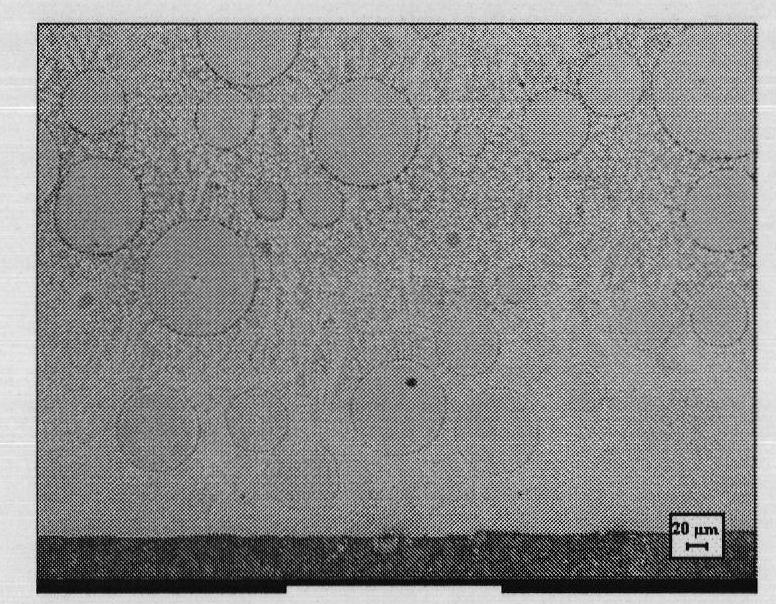

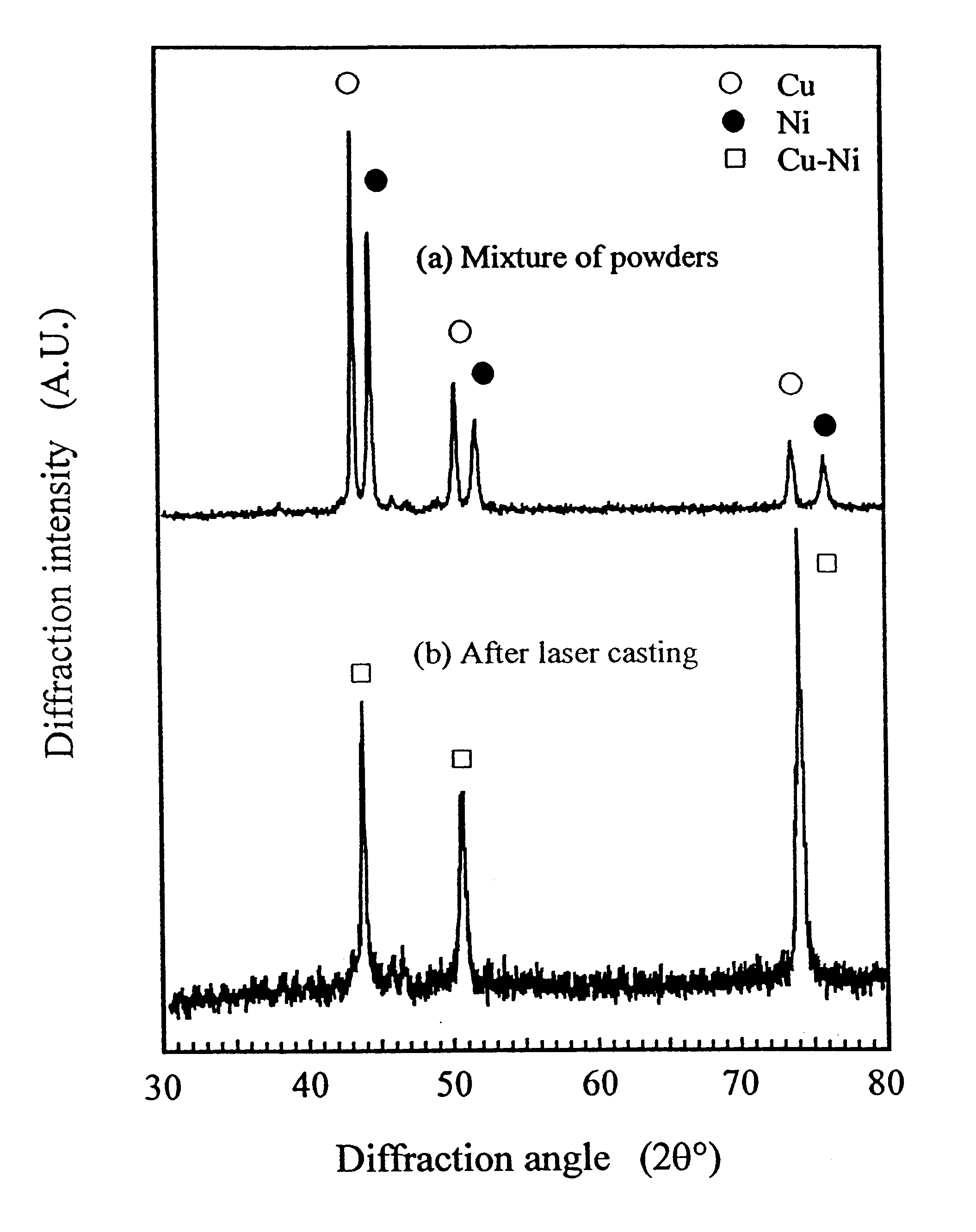

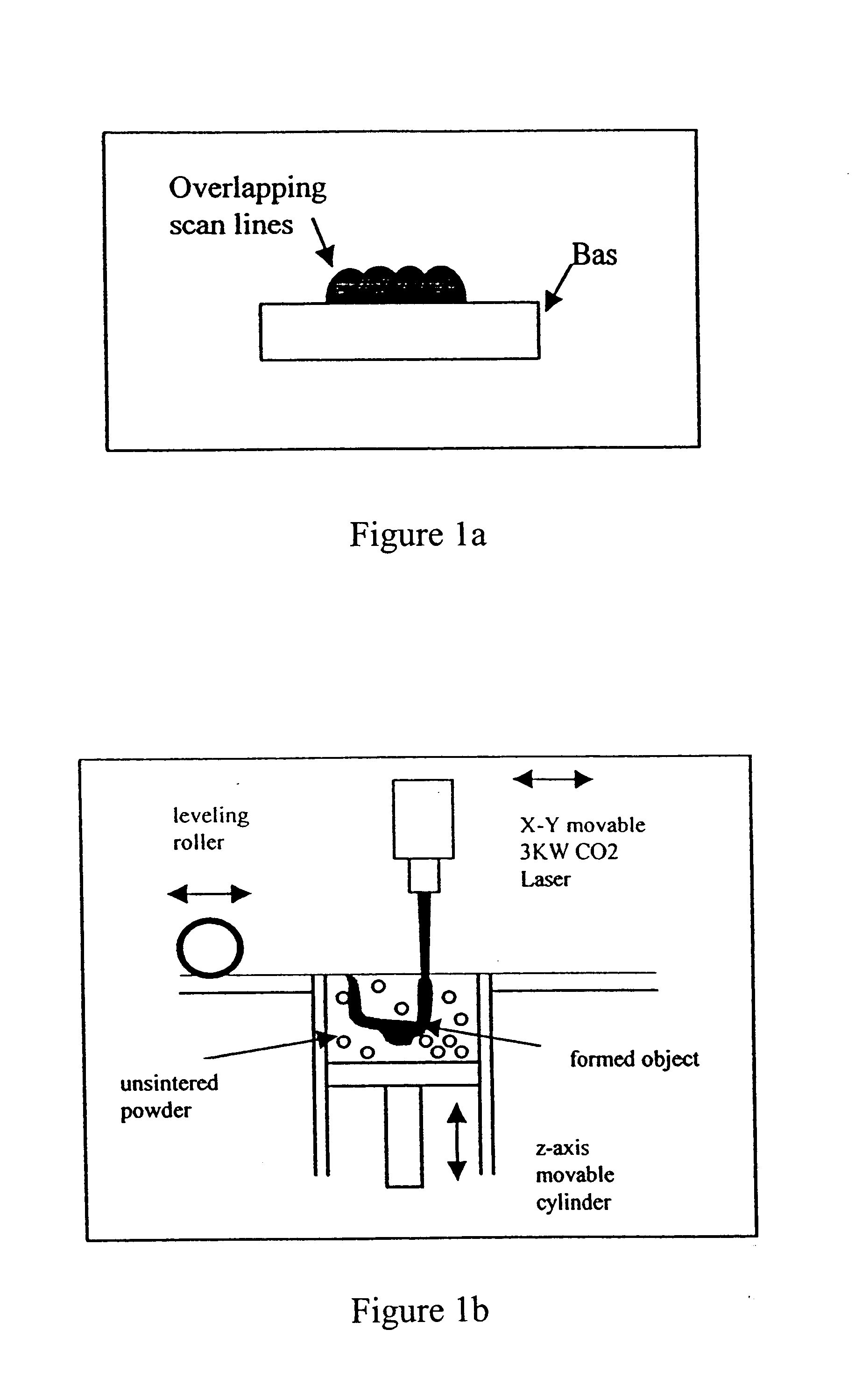

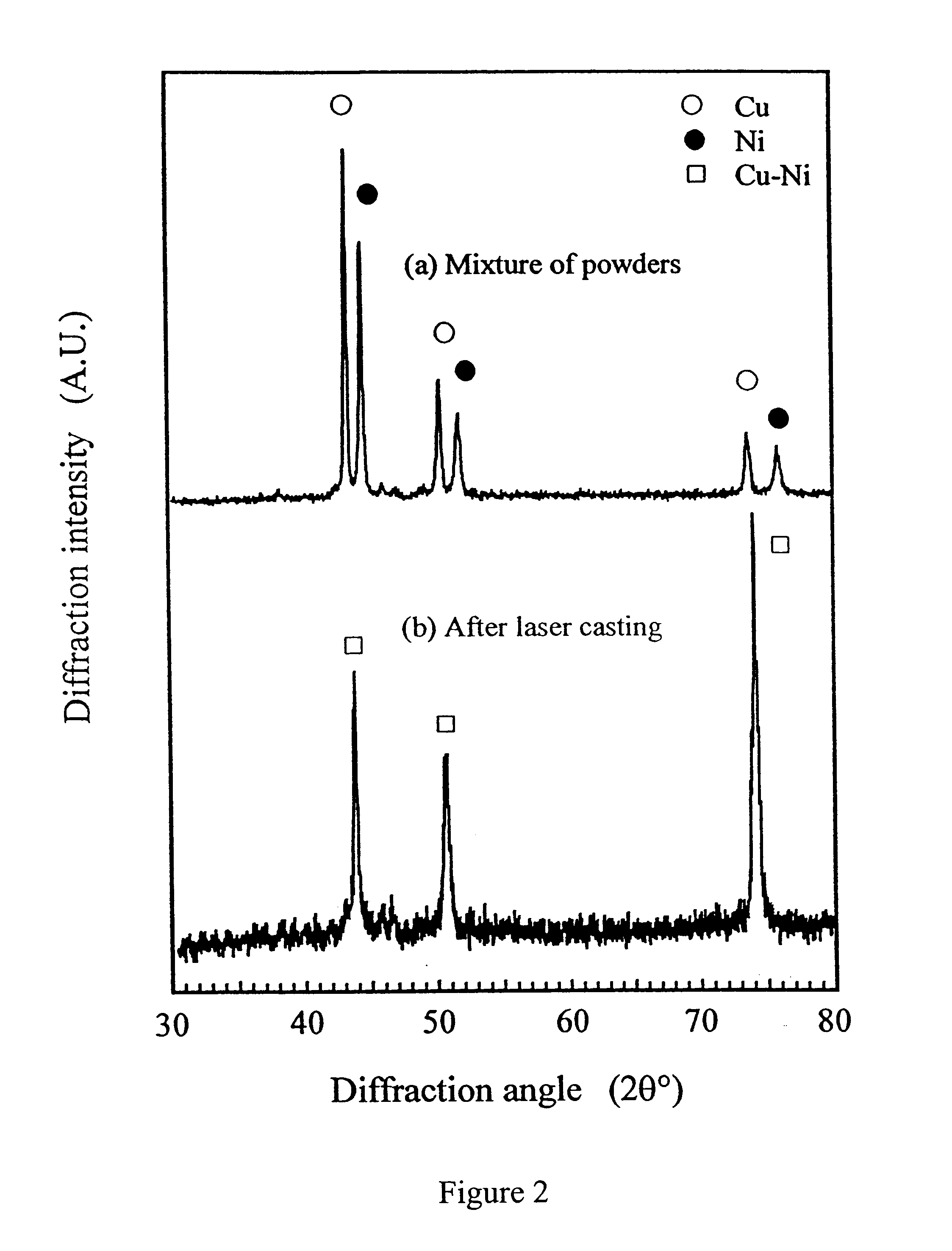

Method of laser casting copper-based composites

InactiveUS6723278B1Additive manufacturing apparatusIncreasing energy efficiencyPowder mixtureMetal powder

This invention presents the process of direct laser casting of copper alloys: Cu-X (where X=Ni, Fe, W;) and their composites Cu-Y and Cu-X-Y (Y=WC, TiC, Ti+C) from powders prepared using mechanical mixing and ball milling processes. Since the metallic powder is combined with a low melting point Cu metal, which has good thermal and electrical conductivity, the combination allows the powder mixture to be melted by CO2 laser and re-solidified into a part with good mechanical properties and conductivity. The laser casting process for the Cu-based in-situ formation and the material systems formed using the said method have been developed. The process can be used to fabricate complex three-dimensional objects by multi-layer overlapping and the material systems can be used to build rapid tooling due to the properties of good thermal conductivity and low wear rate.

Owner:SINGAPORE INST OF MFG TECH THE +1

Fast forming method of fusion of metal powder of three beams of laser compound scanning

ActiveCN101607311BSlow down drastic changesUniform temperature fieldIncreasing energy efficiencyLength waveMetal powder

Owner:HUAZHONG UNIV OF SCI & TECH

Tire laser marking device and method based on machine vision identity

InactiveCN101670715AHigh operating costsBig amount of dataTypewritersSensing by electromagnetic radiationProduction lineMachine vision

The invention discloses a tire laser marking device and a method based on a machine vision identity. The device comprises a production line conveyor belt, a clamping and rotating device, an information collection working region, a tire data reader, a mark position reader, an auxiliary lighting device, a smog extracting facility, a laser marking working region, smog filtering and air discharge equipment, a radio frequency CO2 laser, a focusing work bench, a high speed laser scanner, a scanning focus lens, a collimating and beam expanding system, a reflector and a computer system. The information required to be marked is etched on the surface of the tire through the machine vision identity technology and the laser beam high speed scanning and marking technology by utilizing the radio frequency CO2 laser. The invention has the beneficial effects that: through the machine vision identity technology, the marking position is automatically judged according to the different shapes and the arrayed positions of the tires on the production line and an optical beam scanner is guided to be positioned accurately without a special machinery and a manual marking locating device, then a seamless transition with the production line of the tires is achieved and the work efficiency of equipment is further improved.

Owner:SHANGHAI INST OF LASER TECH

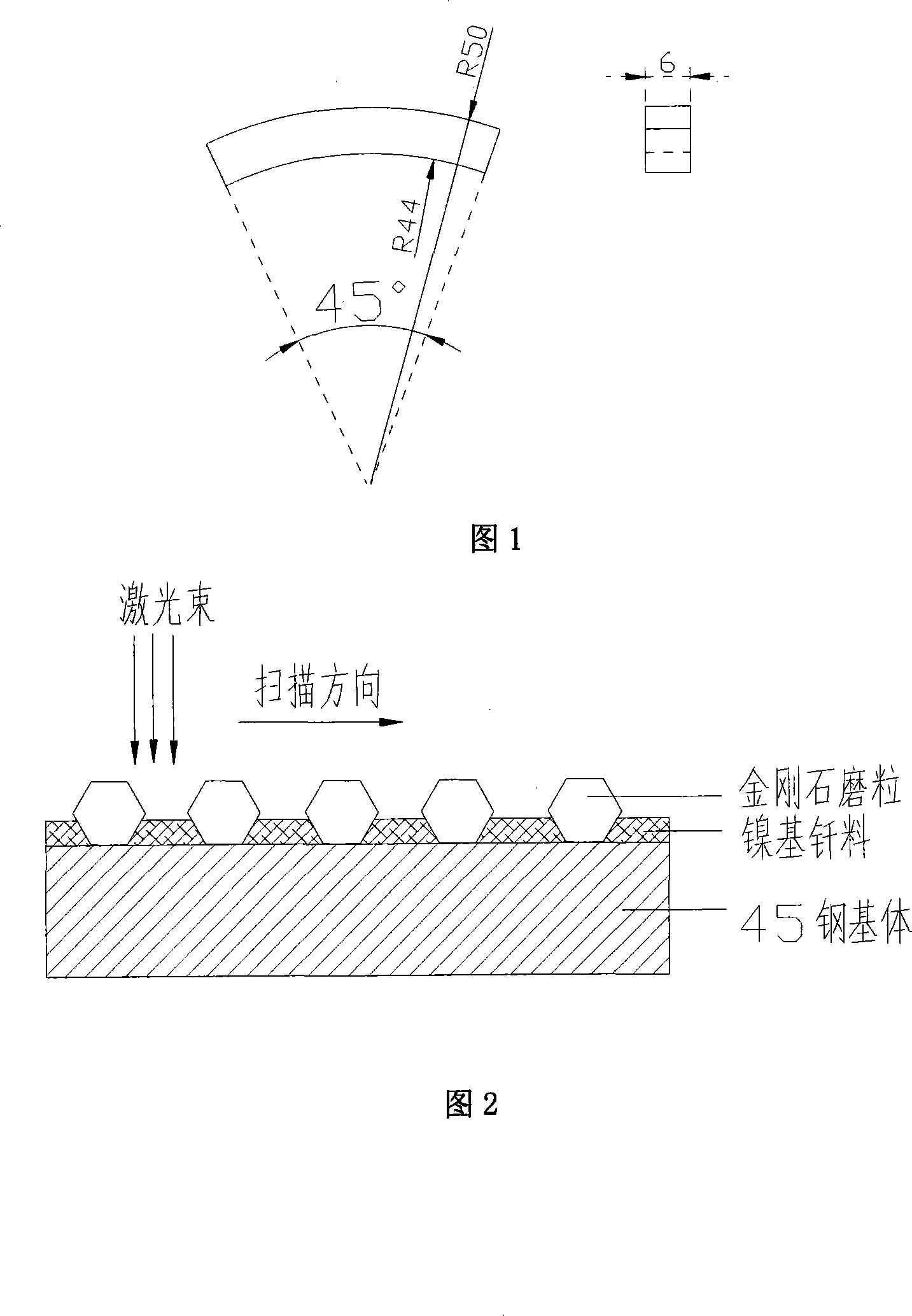

Method for manufacturing nickel base brazing filler metal laser braze welding diamond abrasive grain

ActiveCN101130213ASolve problems such as limited sizeWelding/cutting media/materialsWelding/soldering/cutting articlesFiller metalCo2 laser

The invention discloses a preparing method of nickel-based solder laser brazed diamond abrasive particle in the high temperature brazing technical domain, which comprises the following steps: adopting 45-steel base, nickel base solder and non-coat diamond; placing the manufactured 45-steel base and non-coat diamond in the organic solvent to do ultrasonic wave cleaning; preparing the manufactured sample of three-layered 45-steel base, nickel base solder and non-coat diamond sequently; brazing the sample on the solder equipment with CO2 laser, numeral control machine and gas protective device; heating the nickel-based solder through heating to connect base and diamond strictly. The invention solves some insufficiencies in the high-temperature brazing technique with high manufacturing efficiency, which is easy to control for automation manufacturing.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Manufacturing technology of novel hobbing cutter with laser cladding WC wear-resistant coating

ActiveCN103737273AImprove wear performanceInhibit sheddingMetallic material coating processesNumerical controlHobbing

The invention relates to a manufacturing technology of a novel hobbing cutter with a laser cladding WC wear-resistant coating. The manufacturing technology comprises the following steps: (1) manufacturing the hobbing cutter with a forging method, wherein the hobbing cutter is made of alloy steel; (2) carrying out peel removal cleaning treatment on surfaces to be machined of the intertooth space of an alloy cutter; (3) using a transverse flow CO2 laser, taking a numerical control machine tool as a workbench, and carrying out cladding wear-resistant strengthening treatment on the intertooth space of a cutter ring cutter, wherein the thickness of the WC cladding layer is 1.5-2.5mm; (4) carrying out performance detection on a composite coating. A laser surface cladding technology is adopted, and the tissues of a cladding coating mainly consist of carbides and a supersaturated solid solution superfine casting-state structure, wherein spherical tungsten carbide ceramics are of ultra-high hardness and uniformly distributed on a binding phase with extremely high hardness level, and also achieves an inhibition effect on abrasion, and the grinding resistance between hobbing cutter edges can be effectively improved; the binding phase is good in tenacity and high in strength, the formation of cracks can be effectively reduced, and the wear resistance and corrosive resistance of the hobbing cutter is improved, and the service life of the hobbing cutter is prolonged.

Owner:江苏点金激光科技有限公司

Method for crack resistant treatment of laser cladded nano-ceramic coating

InactiveCN1542166AImprove toughnessGood mechanical propertiesMetallic material coating processesCeramic coatingNanoceramic

The treating process of laser smelting and coating nano anti-cracking ceramic coating onto the surface of metal substrate includes the following steps: bottoming the metal surface to be treated; spraying nano ceramic grain material; painting nano laser absorbing paint; and smelting and coating with high power CO2 laser under protecting Ar atmosphere. The nano anti-cracking ceramic coating formed on the surface of metal substrate has excellent physical and chemical performance.

Owner:SHANGHAI UNIV OF ENG SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com