Tire laser marking device and method based on machine vision identity

A technology of laser marking and machine vision, which is applied in typewriters, electromagnetic radiation induction, printing, etc., to achieve the effects of reducing operating costs, large data volumes, and improving work efficiency and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

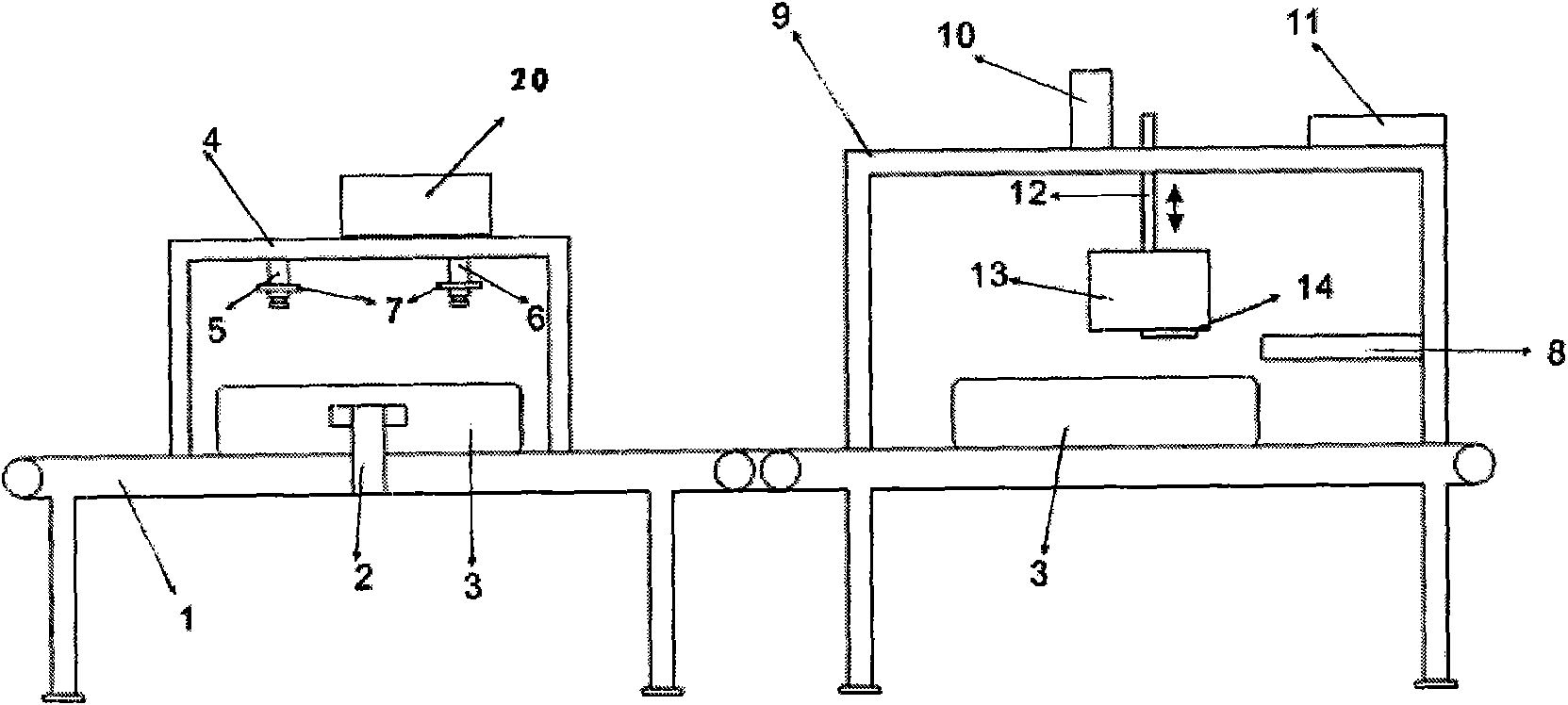

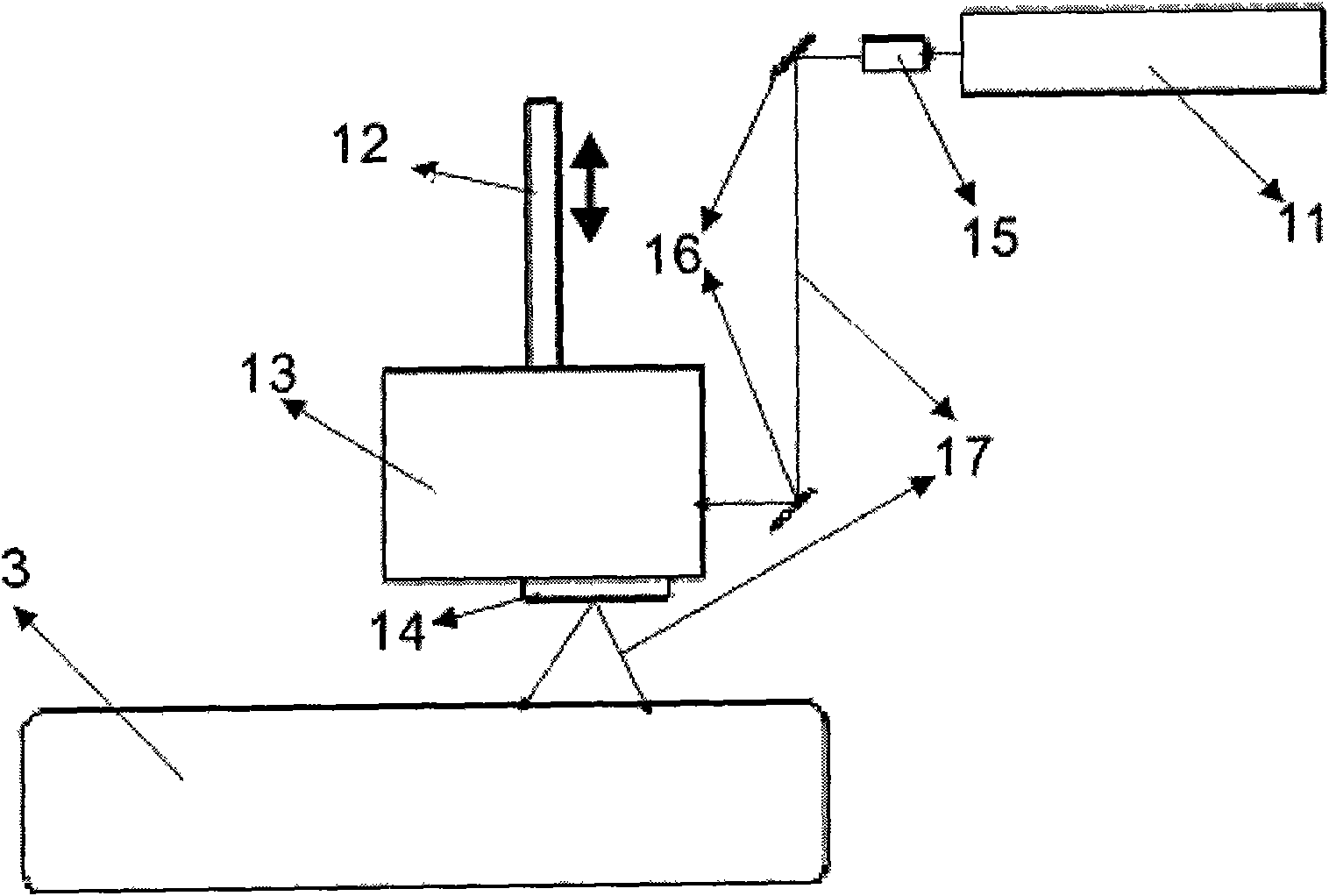

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0016] Such as Figures 1 to 5 As shown, a tire laser marking device includes an assembly line conveyor belt 1, a clamping and rotating device 2, an information collection work area 4, a tire data reader 5, a marking position reader 6, auxiliary lighting equipment 7, smoke Extraction equipment 8, laser marking work area 9, smoke filtration and exhaust equipment 10, radio frequency CO 2 Laser 11, focusing workbench 12, high-speed laser scanner 13, scanning focusing mirror 14, collimating beam expander system 15, reflector 16; install information collection work area 4, Laser marking work area 9, computer system 20 is installed on the top of the information collection work area 4, clamping and rotating device 2 is installed at the bottom of the interior and connected with the assembly line conveyor belt 1, and tire data readers 5 are respectively install...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com