Method of extracting humic acids from rubbish percolation liquid membrane process concentrated liquid

A technology of landfill leachate and concentrate, which is applied in the field of humic acid extraction, can solve the problems of large power consumption and energy waste, and achieve the effects of avoiding energy waste, saving energy, and realizing resource utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

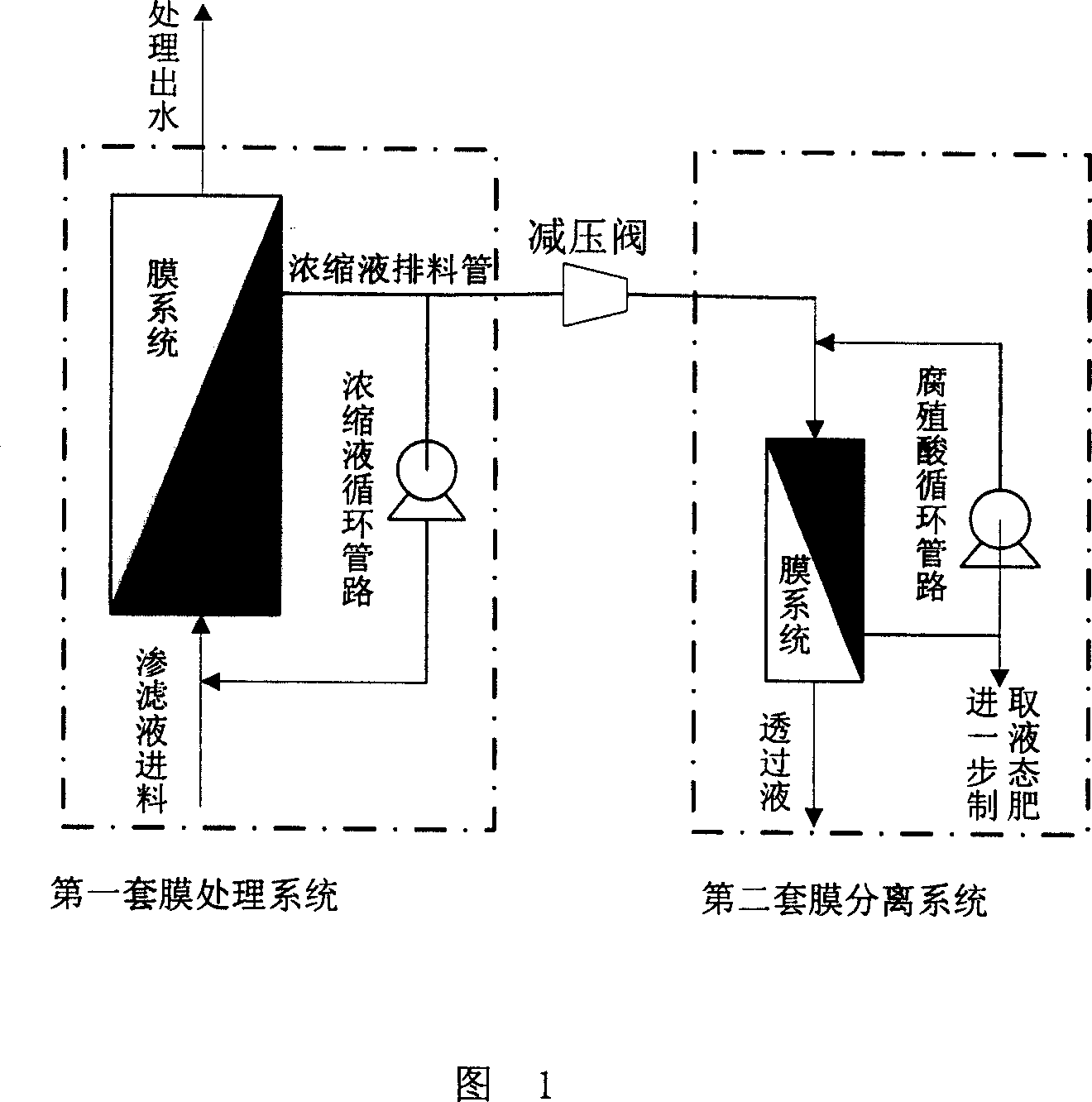

[0019] The method for extracting humic acid from leachate membrane treatment concentrate of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] The present invention combines the characteristics of the high operating pressure of the original leachate membrane treatment system, and connects the humic acid resource recovery membrane separation system based on the membrane module directly through the discharge pipe of the concentrate, and if necessary, through a pressure reducing valve, so as to make full use of the original leachate The operating pressure of the membrane treatment system allows the humic acid in the leachate membrane concentrate to be extracted.

[0021] As shown in Figure 1, the leachate is divided into two parts after being treated by the first set of membrane treatment system (nanofiltration or reverse osmosis): one part is the treated effluent, and the other part is the membrane concentrate, which is r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com