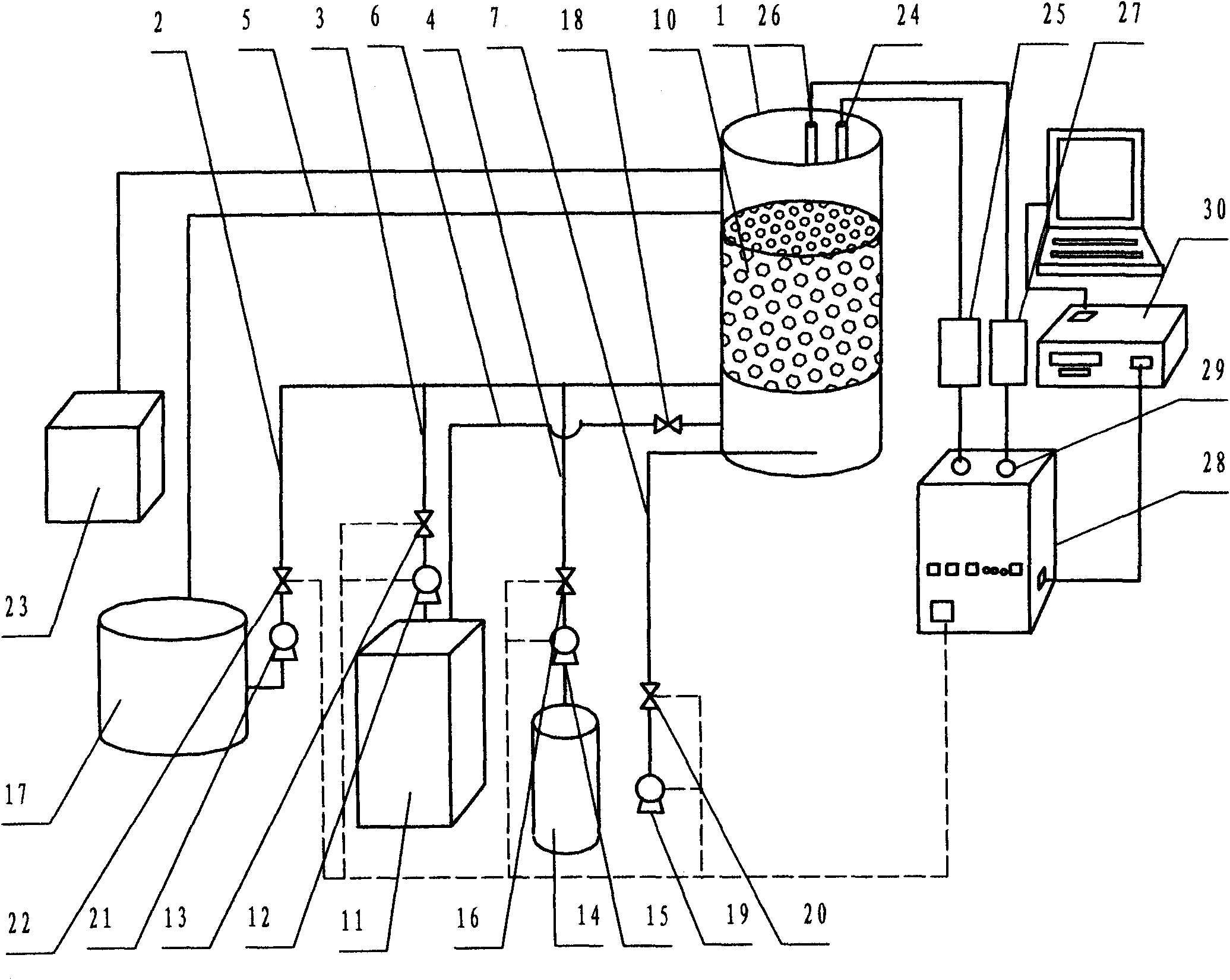

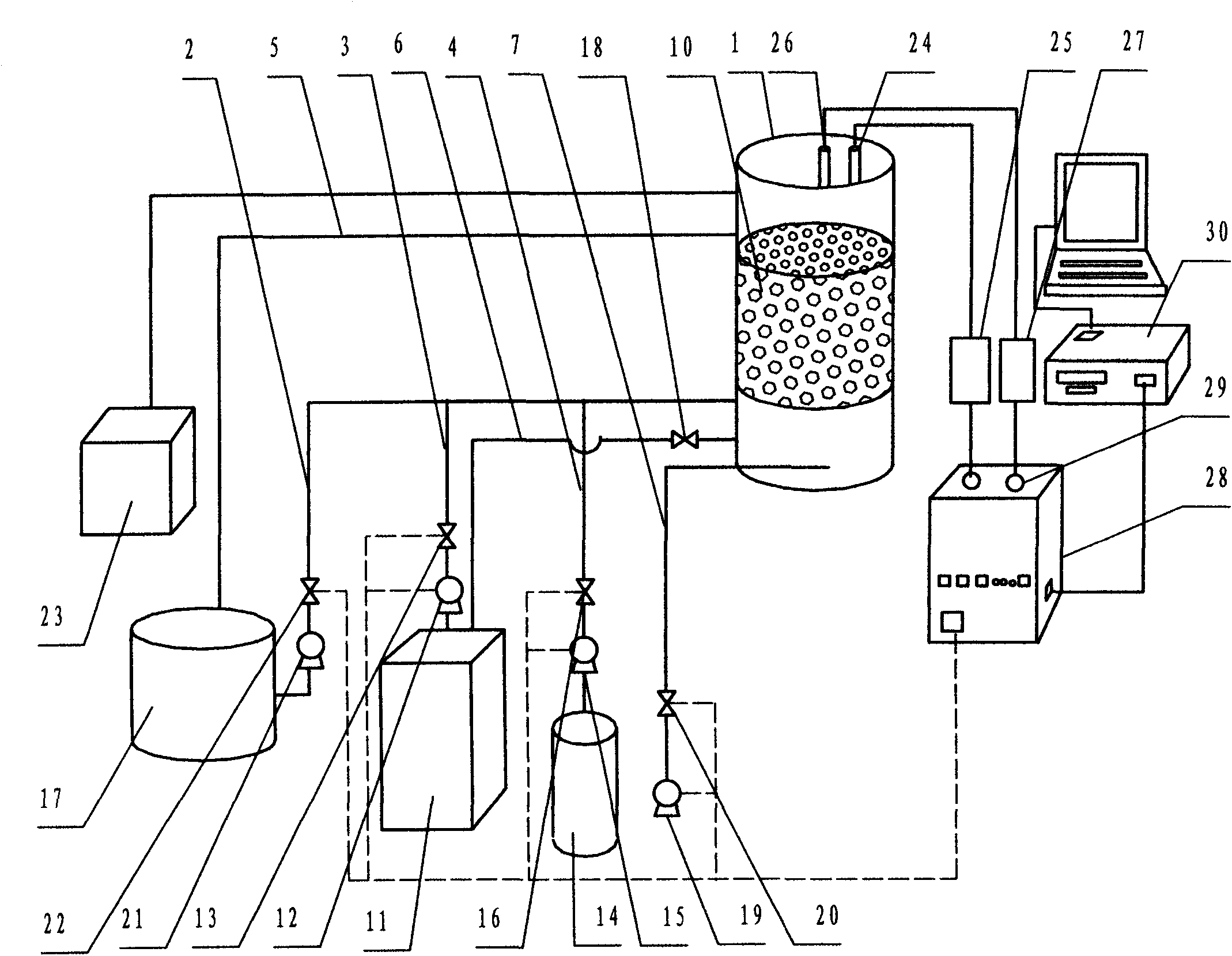

Real-time automatically back-flushing control system of denitrification filter pool and running method

A denitrification filter and control system technology is applied in the field of sewage regeneration and reuse biological treatment. blocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

[0036] Example 2: Operation method of the backwash control system of the denitrification filter process of the present invention:

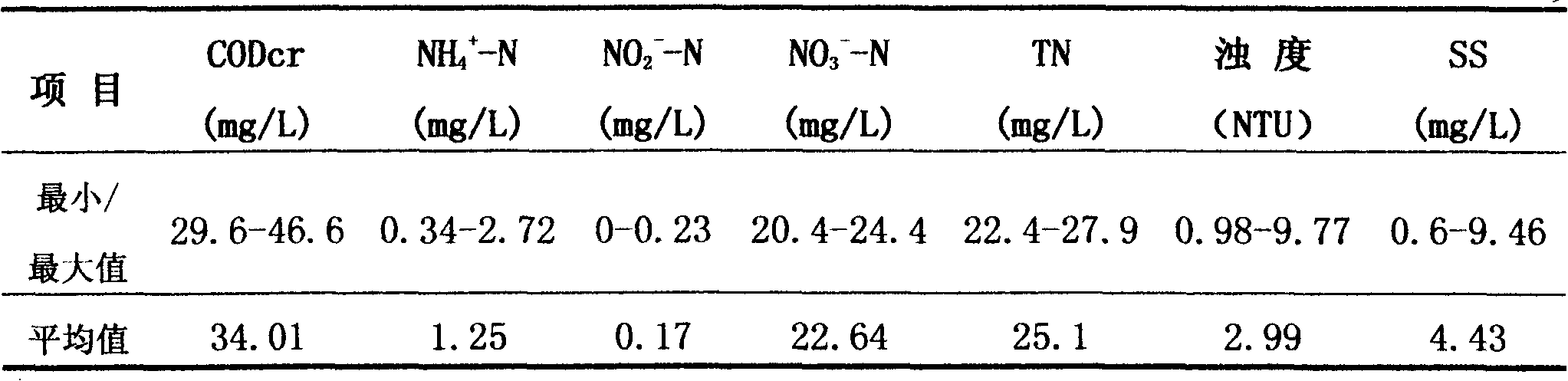

[0037] Taking the actual secondary treatment effluent discharged from a municipal sewage treatment plant as the implementation object, the selected denitrification filter has a processing scale of 360 tons / day, 4-8mm ceramsite is selected as the filter material, and the carbon source is methanol. The data of water quality are:

[0038] Table 1 Water quality of secondary effluent from urban sewage treatment plants

[0039]

[0040] Specific implementation according to the following steps:

[0041] 1) Start-up control system: The control system of the present invention is started at the same time as the sewage treatment process of the denitrification filter. The inlet pump injects the sewage to be treated from the inlet pool into the denitrification filter through the inlet pump and the inlet valve. The source dosing pump and the carbon source dosing valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com