Patents

Literature

527results about How to "Less investment in infrastructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

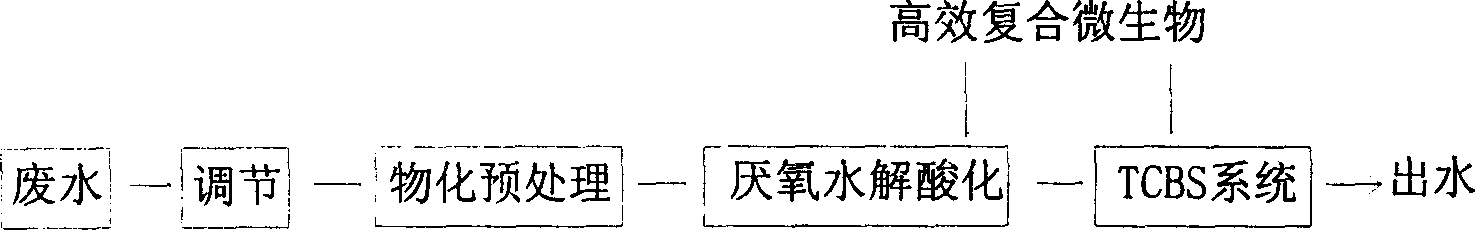

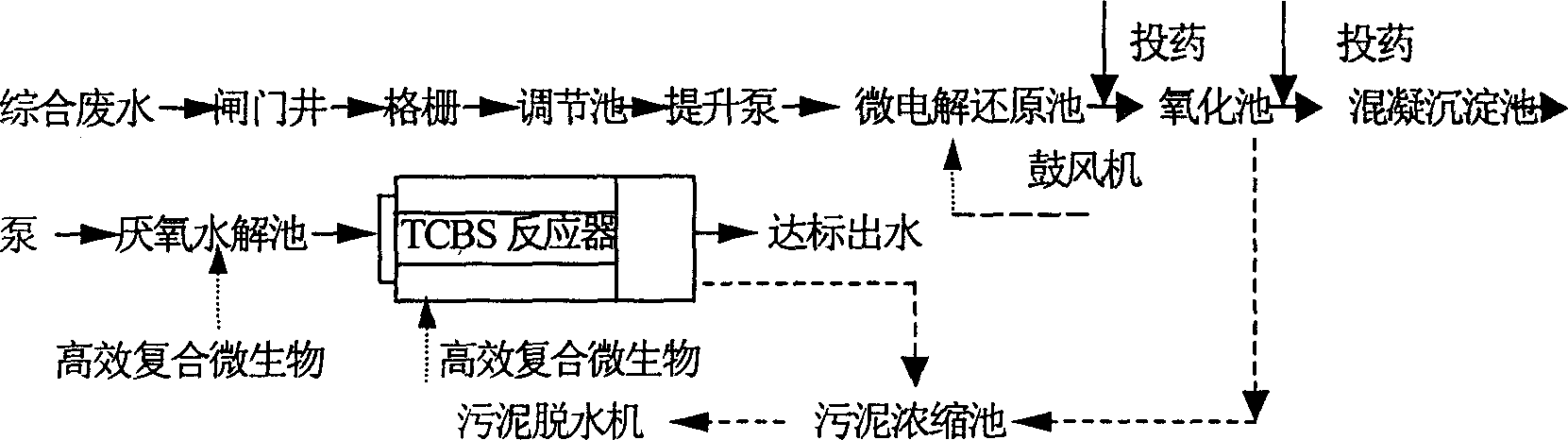

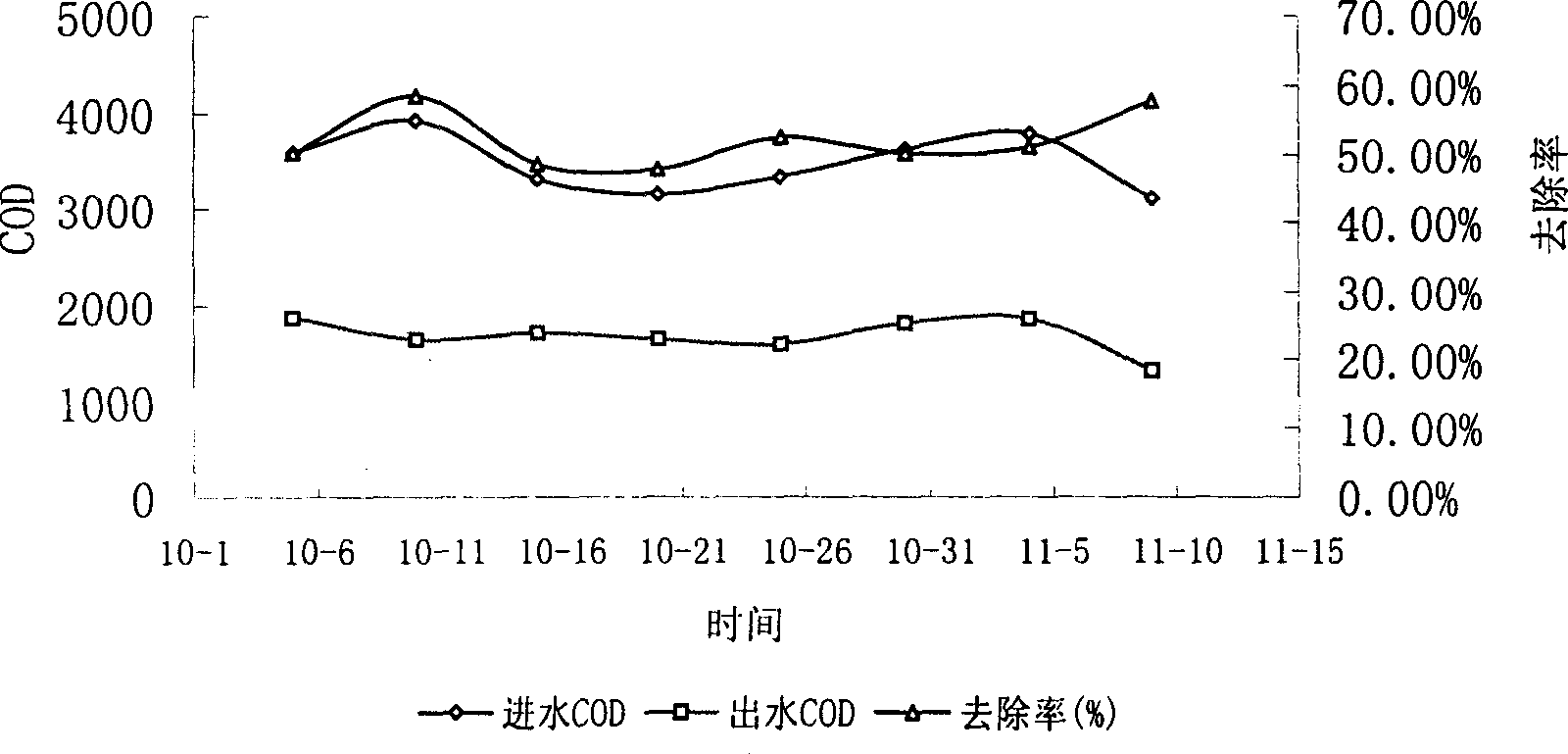

Organic waste water treatment process

InactiveCN1631818AAvoid toxicityHigh removal rateMultistage water/sewage treatmentHigh densityElectrolysis

Disclosed is a technique for processing organic waste water, including the following steps: (a) preprocession: pour the waste water into the micro electrolytic reducing pool where the iron-carbon micro electrolytic reaction occurs under the agtatering effect, add hydrogen peroxide into it to have. Fento oxidation, then the water enters into coagulation pool into which add NaOH and PAM; (b) anaerobe hydrolysis oxidation procession: power the organic waste water preprocessed into high effective anaerobe hydrolysis oxidation pool in which add into the TCBS reactor in which add into high effective compound microbe, making the water mix with the flowing-back mud with high density after denitrification. The invention can increase the biochemical of organic waste water, strengthen its resistance to poison and impact as well as the biological denitrification funcation, and making the waste water reach the national environment protection requirement by reducing the polluting load by steps.

Owner:何义亮 +1

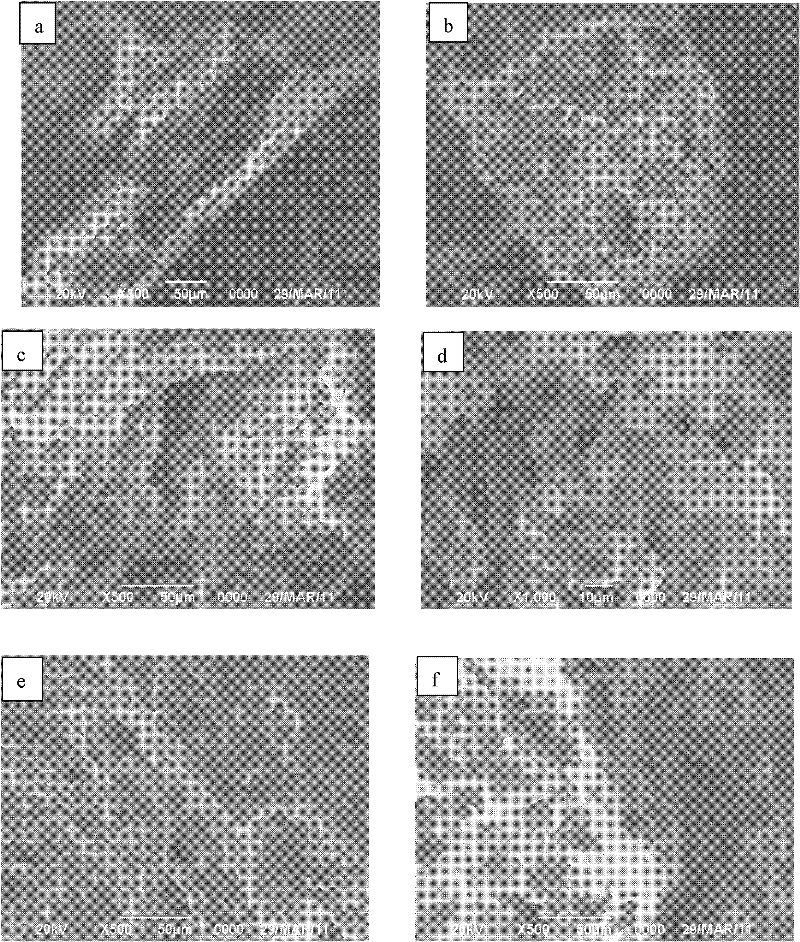

Attapulgite clay porous ceramsite, and preparation method and purpose thereof

ActiveCN102225870AWide variety of sourcesLow priceCatalyst carriersTreatment with aerobic and anaerobic processesWater resistancePorosity

The invention discloses an attapulgite clay porous porous ceramsite, a preparation method of the ceramsite, and a purpose of the ceramsite. The ceramsite is prepared from raw materials of attapulgite clay and biomass, and a binder of industrial soluble glass. The ceramsite is prepared through calcining and oxidizing. The attapulgite clay porous ceramsite prepared by the present invention has advantages of high porosity, large specific surface area, high strength, strong water resistance, high water absorption, high catalytic activity, and the like. The porous ceramsite prepared by the presentinvention can be applied as a carrier for a catalyst, and a filling material for an aerated biological filter.

Owner:HEFEI UNIV OF TECH

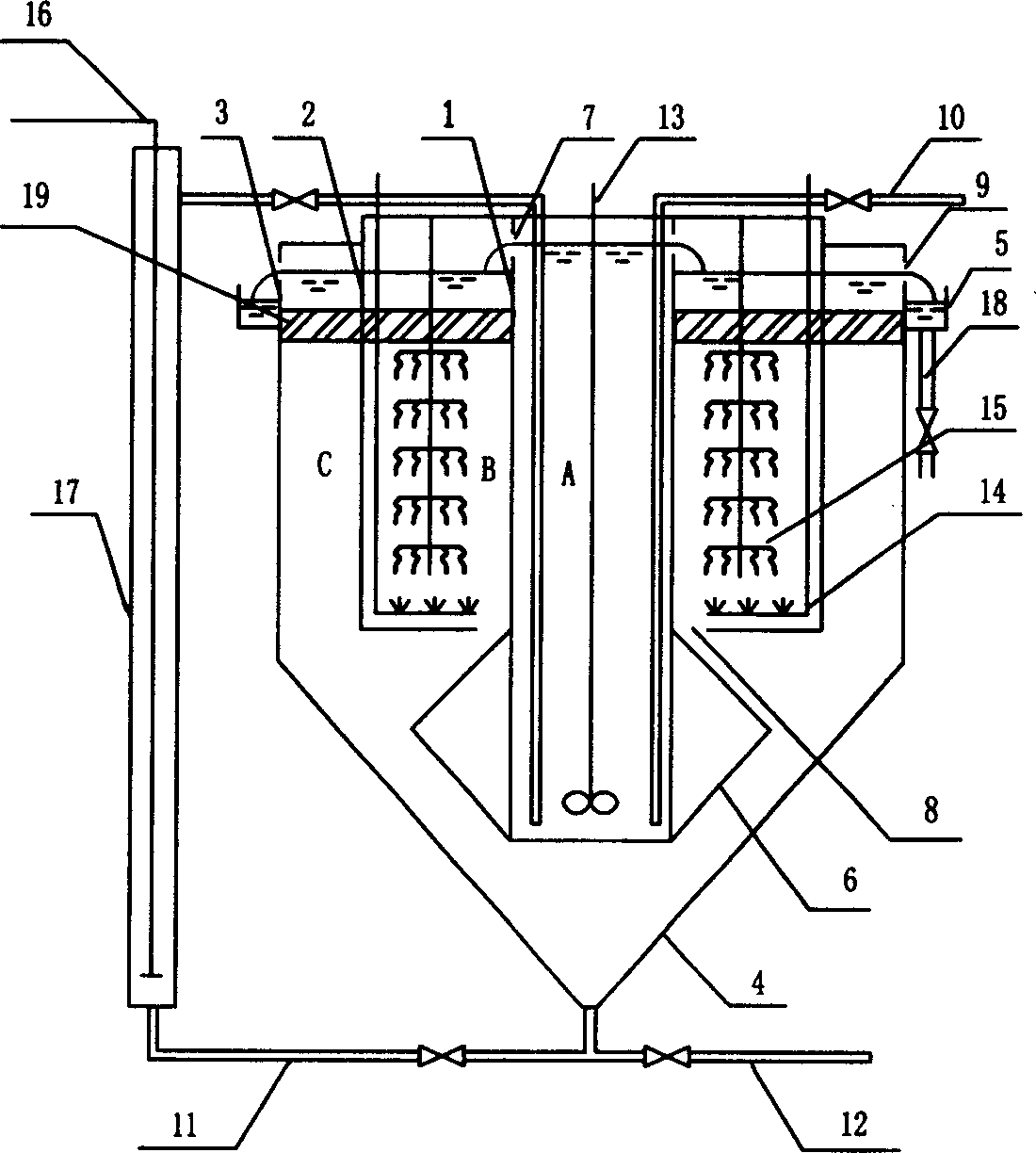

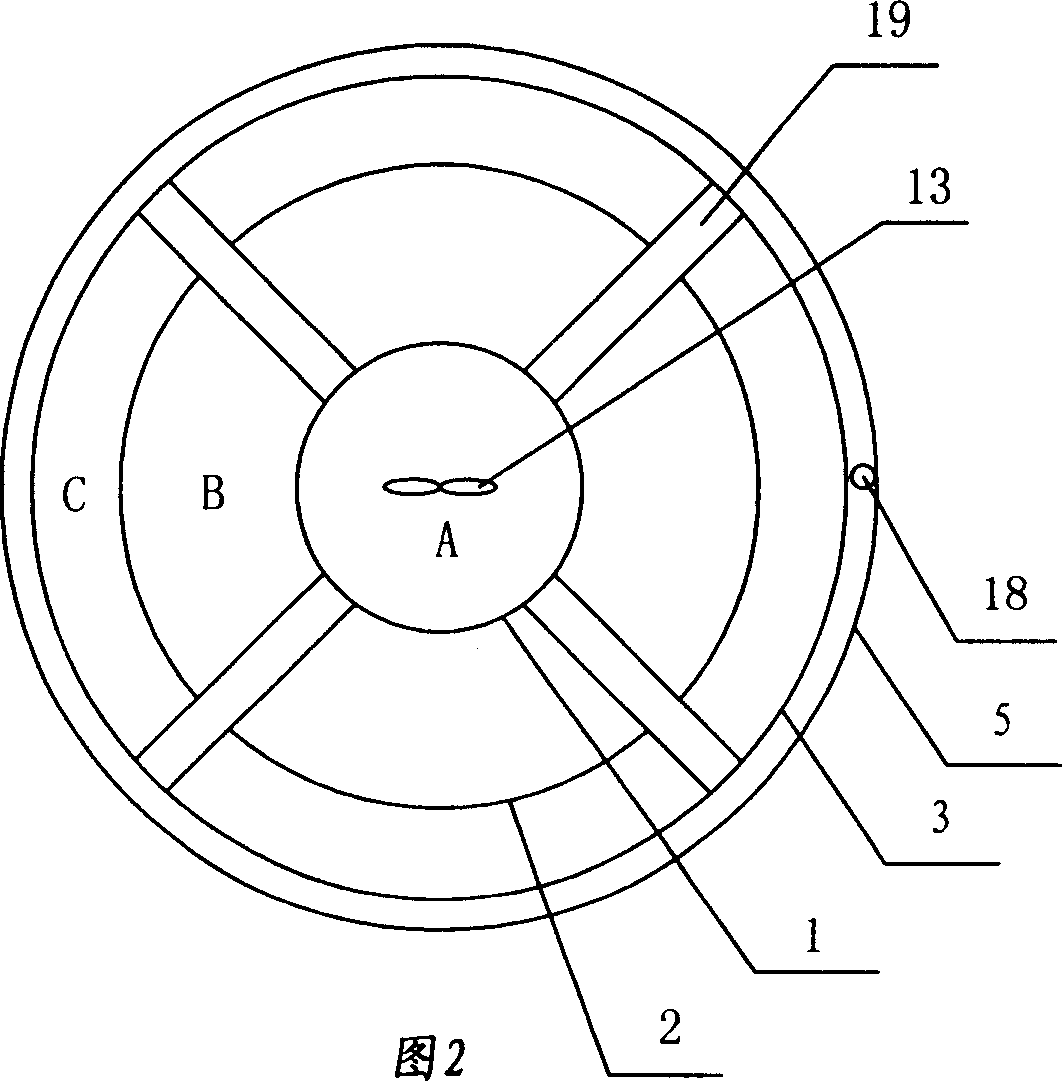

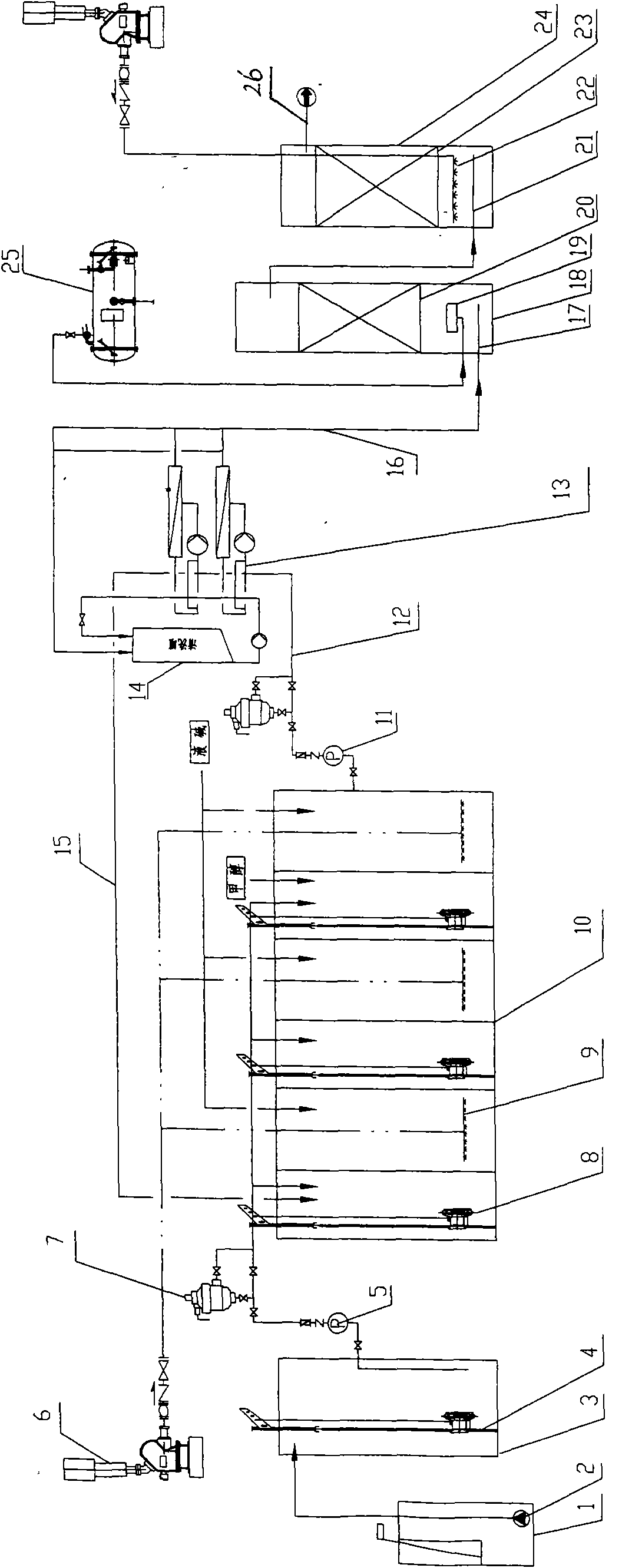

Active sludge-biomembrane compounding integral sewage treating method and apparatus

InactiveCN1887739AIncrease sludge concentrationAvoid churnTreatment with aerobic and anaerobic processesActivated sludgeEngineering

The active sludge-biomembrane compounding integral sewage treating method includes the first leading the sewage to be treated to the anoxic area through stirring for mixing sewage to be treated and active sludge, the subsequent leading the sewage to aerobic area with stuffing for aeration treatment with combined active sludge and biomembrane, and final leading the sewage to the precipitation area for natural deposition to separate sludge and water, leading out purified water, reflowing the mixed sludge liquid to the anoxic area and draining the residual sludge. The present invention also relates to the corresponding sewage treating apparatus. The present invention has the advantages of high treating capacity, resistance to impact load, simple operation, etc. and is especially suitable for use in medium and small towns.

Owner:CHONGQING UNIV

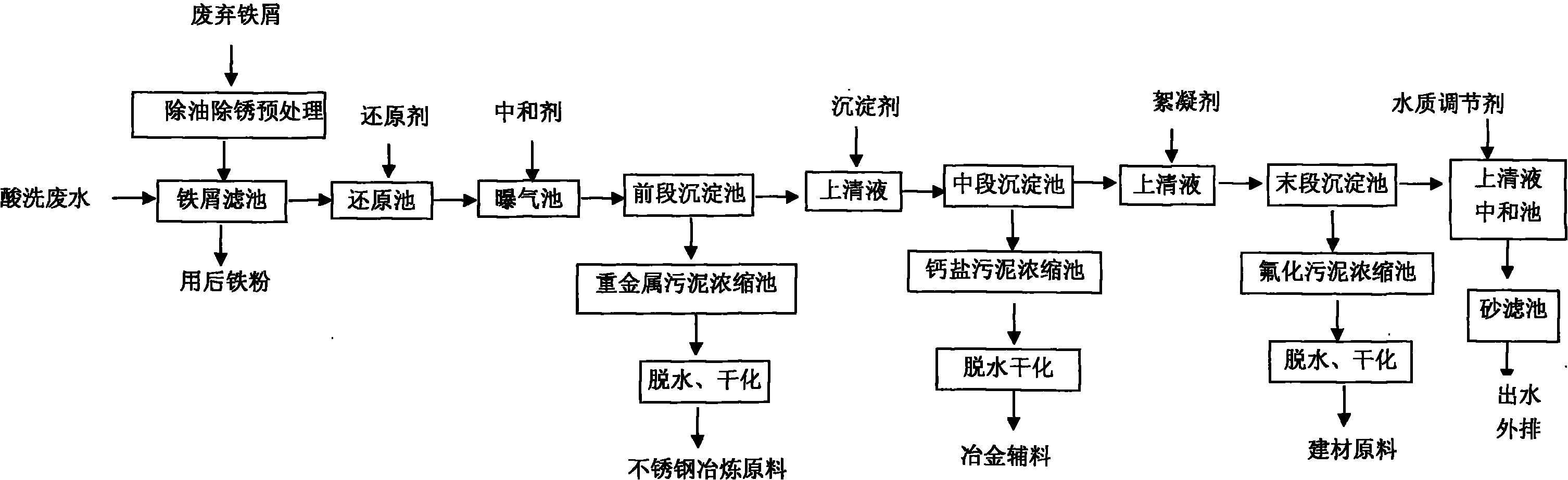

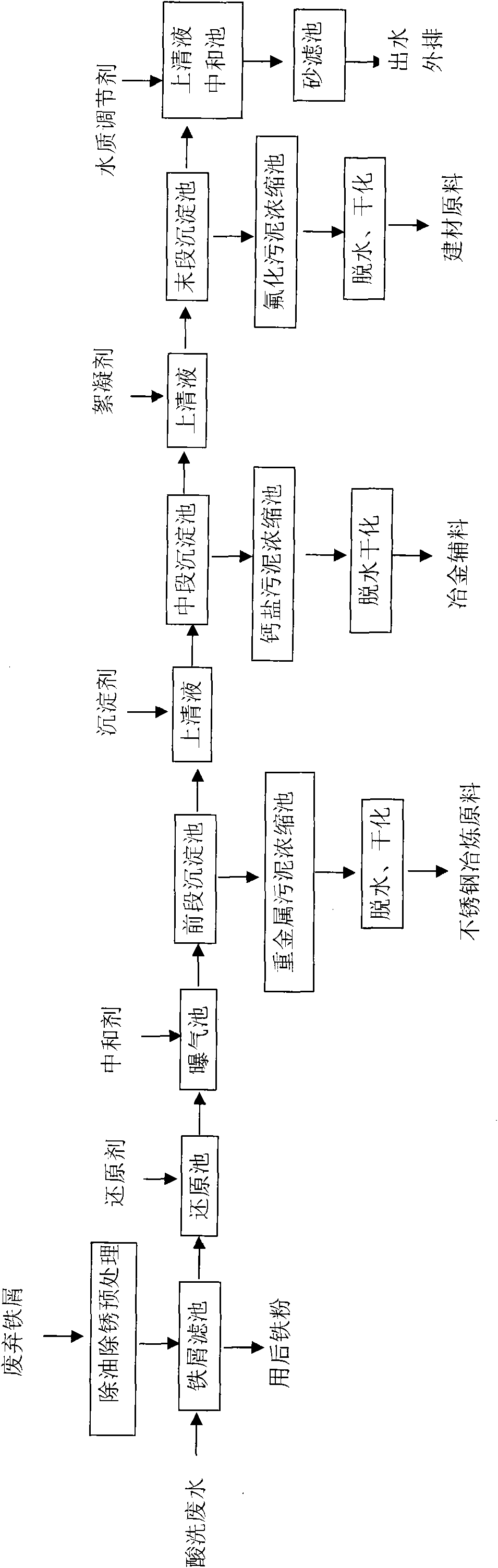

Processing method of stainless steel cold rolling pickling wastewater

ActiveCN101811792AIncrease dosageIncrease productionSludge treatment by de-watering/drying/thickeningWaste water treatment from metallurgical processScrapHexavalent chromium

The invention relates to a processing method of stainless steel cold rolling pickling wastewater. The pickling wastewater enters a hexavalent chrome secondary reduction pool after the actions of micro-electrolysis and hexavalent chrome preliminary reduction of a scrap iron filtering pool; the reduced wastewater enters a front-segment precipitation tank after neutralization and aeration, heavy metal sludge is concentrated and dehydrated, and the heavy metal sludge and scrap iron after the use of the scrap iron filtering pool are recycled and used as stainless steel smelting raw materials; middle-segment precipitation is carried out after a primary supernatant acts with a precipitant, and dehydrated and dried fluoride sludge is recycled and used as a metallurgical adjuvant material; final-segment precipitation is carried out after a secondary supernatant continues to act with a flocculating agent to obtain calcium salt which can be used as a building material raw material; and after the three segments of precipitation of acidic wastewater, the final third level supernatant reaches a standard and is discharged through water quality regulation and sand filtering. The invention has the advantages of less investment, low wastewater processing cost, convenient maintenance and the like, and not only can effectively utilize discarded scrap iron of a stainless steel enterprise, but also can greatly lower the subsequent wastewater processing cost and the operating load.

Owner:BAOSHAN IRON & STEEL CO LTD

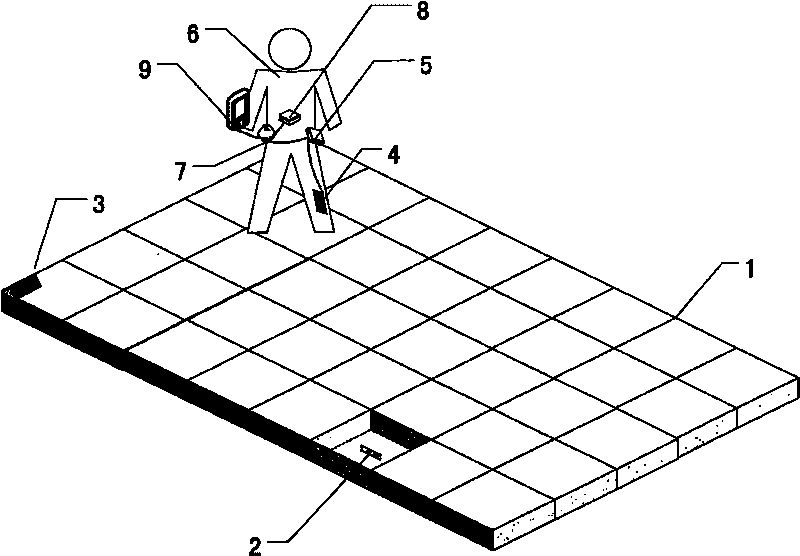

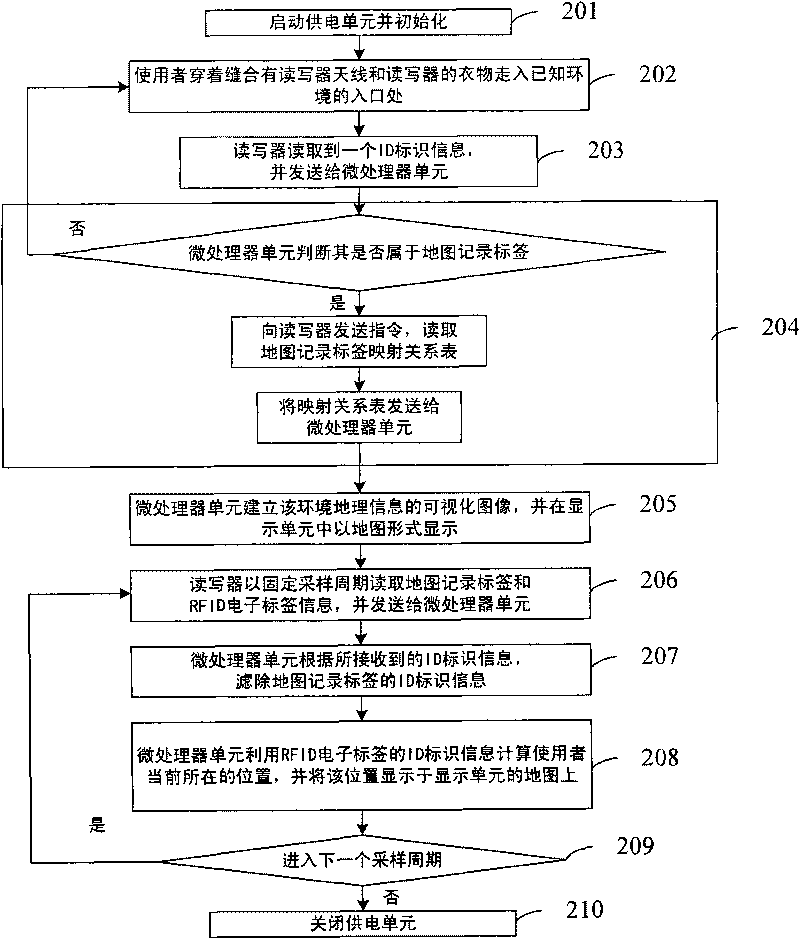

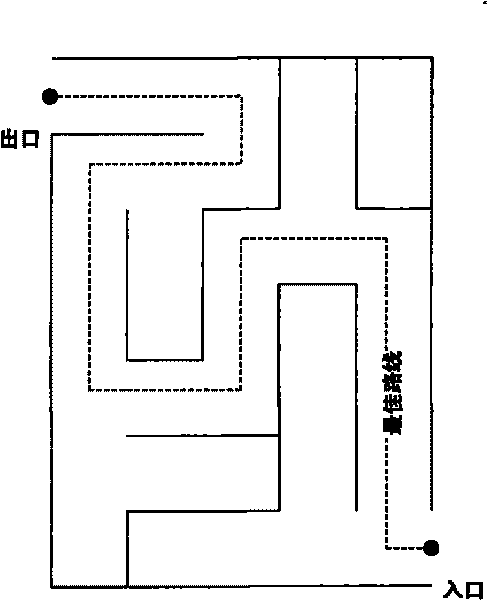

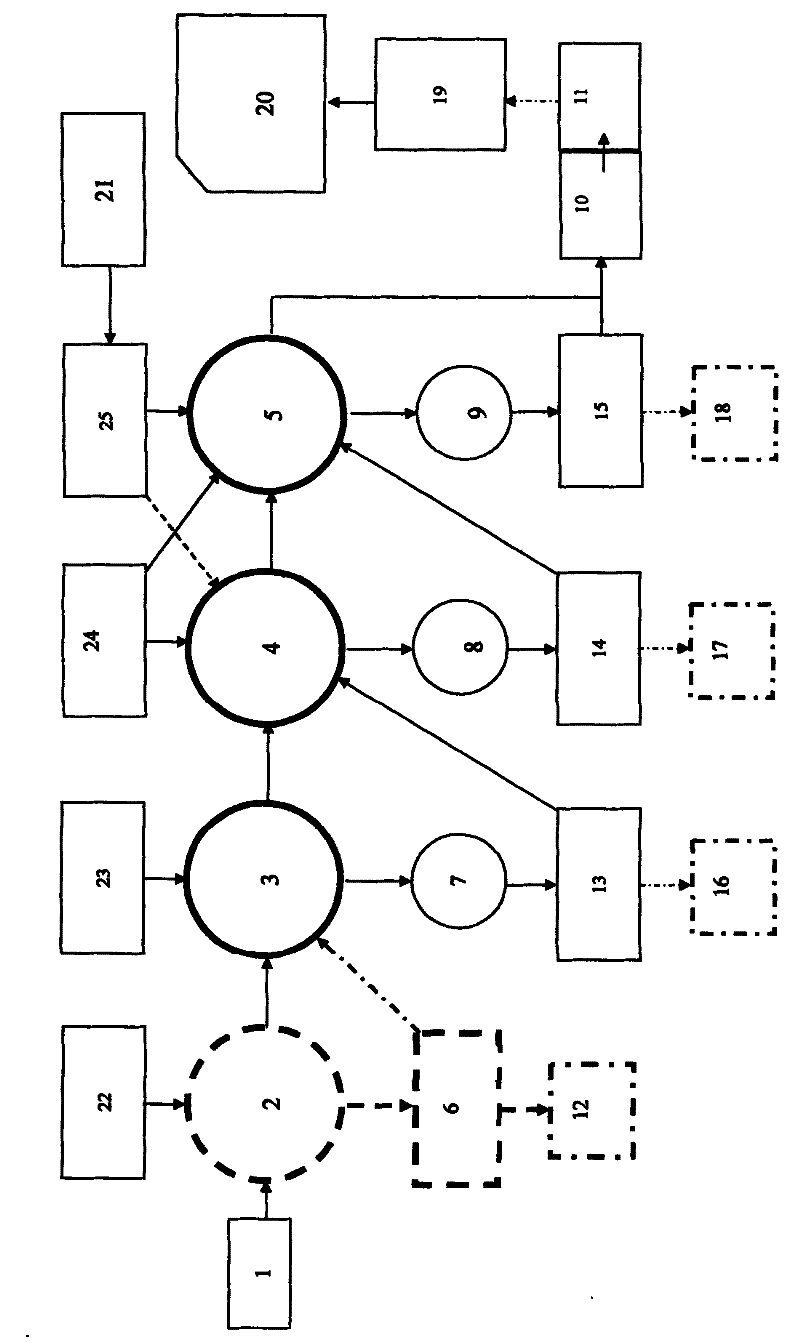

Wearable indoor positioning system based on radio frequency identification technology and method thereof

InactiveCN101750598ALess investment in infrastructureDoes not affect normal movementBeacon systems using radio wavesCo-operative working arrangementsTime responseReader writer

The invention discloses a wearable indoor positioning system based on a radio frequency identification technology and a method thereof, wherein the method comprises: using an RFID electronic tag as a receiving end infrastructure and burying on the ground of a known environment, establishing the one-to-one mapping between the ID mark of each RFID electronic tag and the coordinate information of the position where the RFID electronic tag is; sewing a transmitting end reader-writer and a reader-writer antenna on the clothes of a user; firstly reading a mapping relationship list of the ID mark of the RFID electronic tags in the known environment and geographic information stored in a tag user area recorded on a map after the user enters the known environment, reading the ID mark information of the RFID electronic tag in the known environment in the actuating range of the reader-writer antenna by using a fixed sampling period, calculating the position where the user is at present in real time, and displaying the position on the map of a display unit so as to provide the solution for indoor positioning with real-time response, high precision and low cost for the user.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

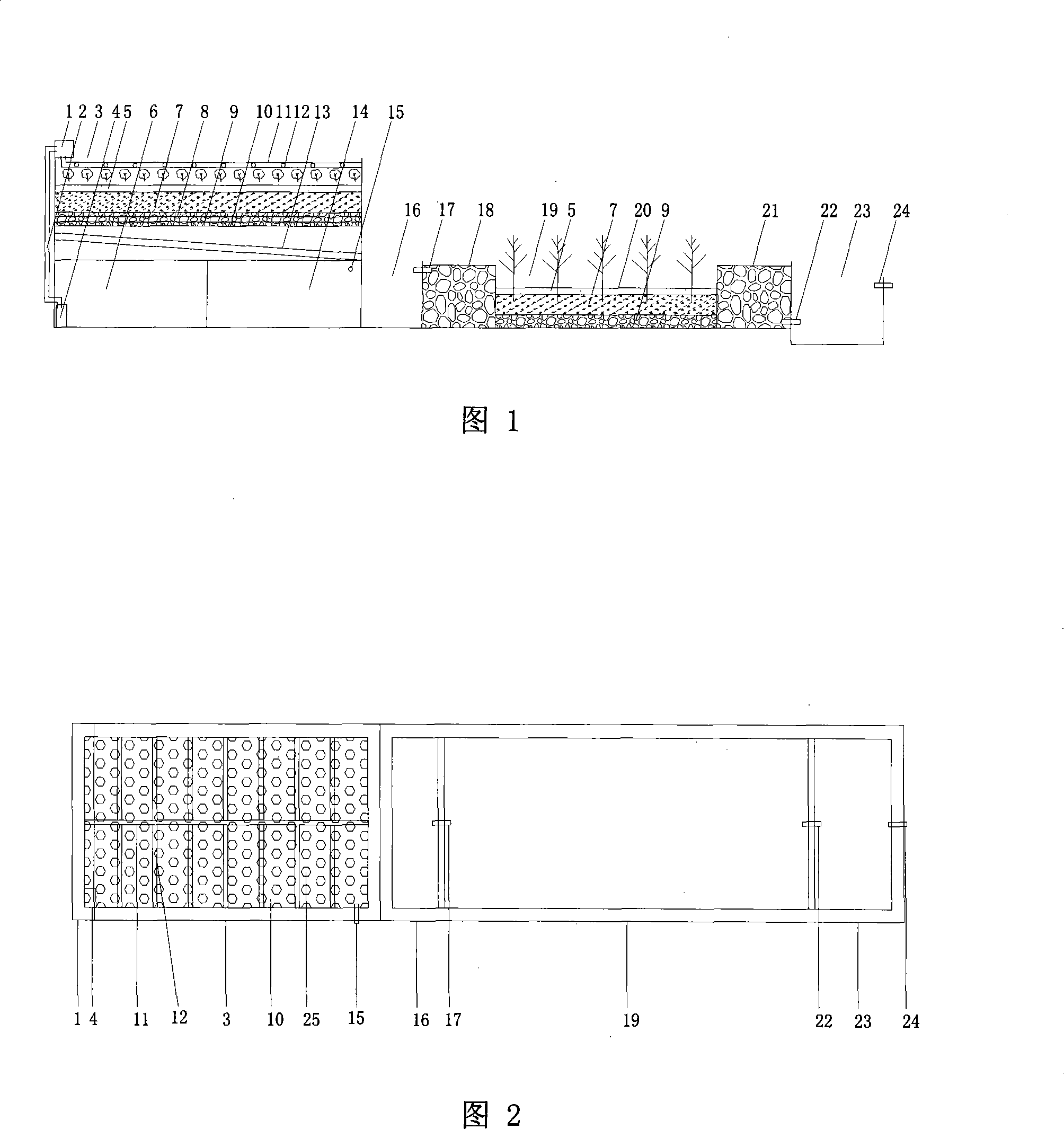

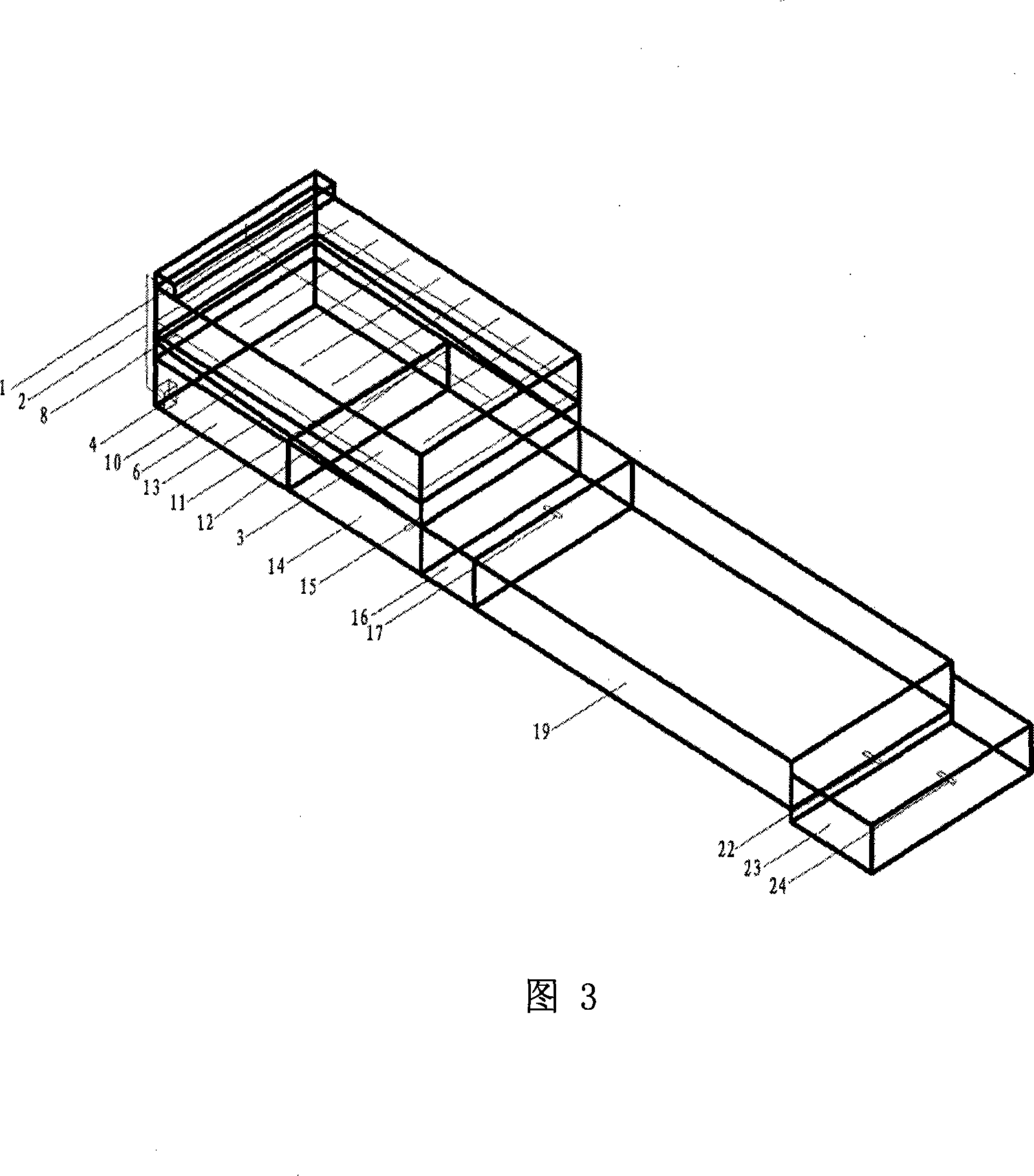

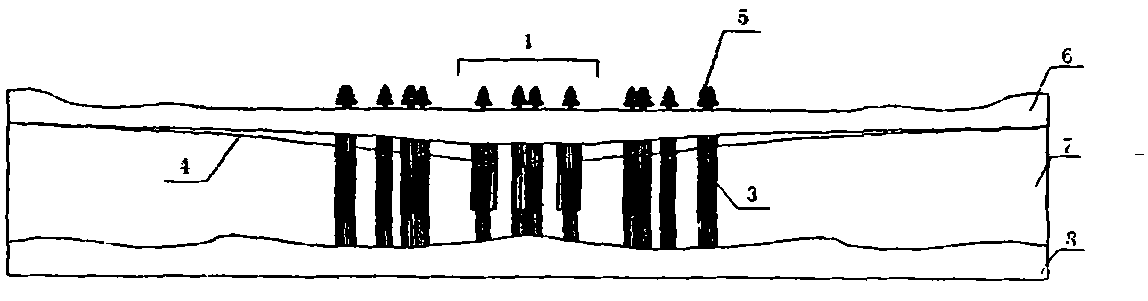

Stereo artificial wetland system for treating sewage

InactiveCN101186382AReduce closureHigh porositySustainable biological treatmentBiological water/sewage treatmentConstructed wetlandIndustrial waste water

The invention relates to the technical field of sewage treatment, in particular to a sewage treatment tridimensional artificial wetland system that is used for the industrial waste water treatment of small-scale isolated pollution sources. The invention aims at providing a tridimensional artificial wetland system that is used for sewage treatment and that has small floor occupancy, high hydraulic load, high pollution load and long service life so as to overcome the defects of the current sewage treatment of big artificial wetland floor occupancy, low hydraulic load, low pollution load and short system service life. The key points of the invention are that: the artificial wetland for sewage treatment adopts a tridimensional assembled structure of vertical current artificial wetland and horizontal subsurface flow artificial wetland, and base materials are filled in various directions to form the tridimensional artificial wetland system for sewage treatment; the tridimensional artificial wetland system for sewage treatment comprises a water collecting header, a porous water-filtering vertical current artificial wetland bed, a first-stage regulating tank, a water drop chute, a grid tank, a second-stage regulating tank, a horizontal subsurface flow artificial wetland bed and a water collecting tank.

Owner:ZHEJIANG NORMAL UNIVERSITY

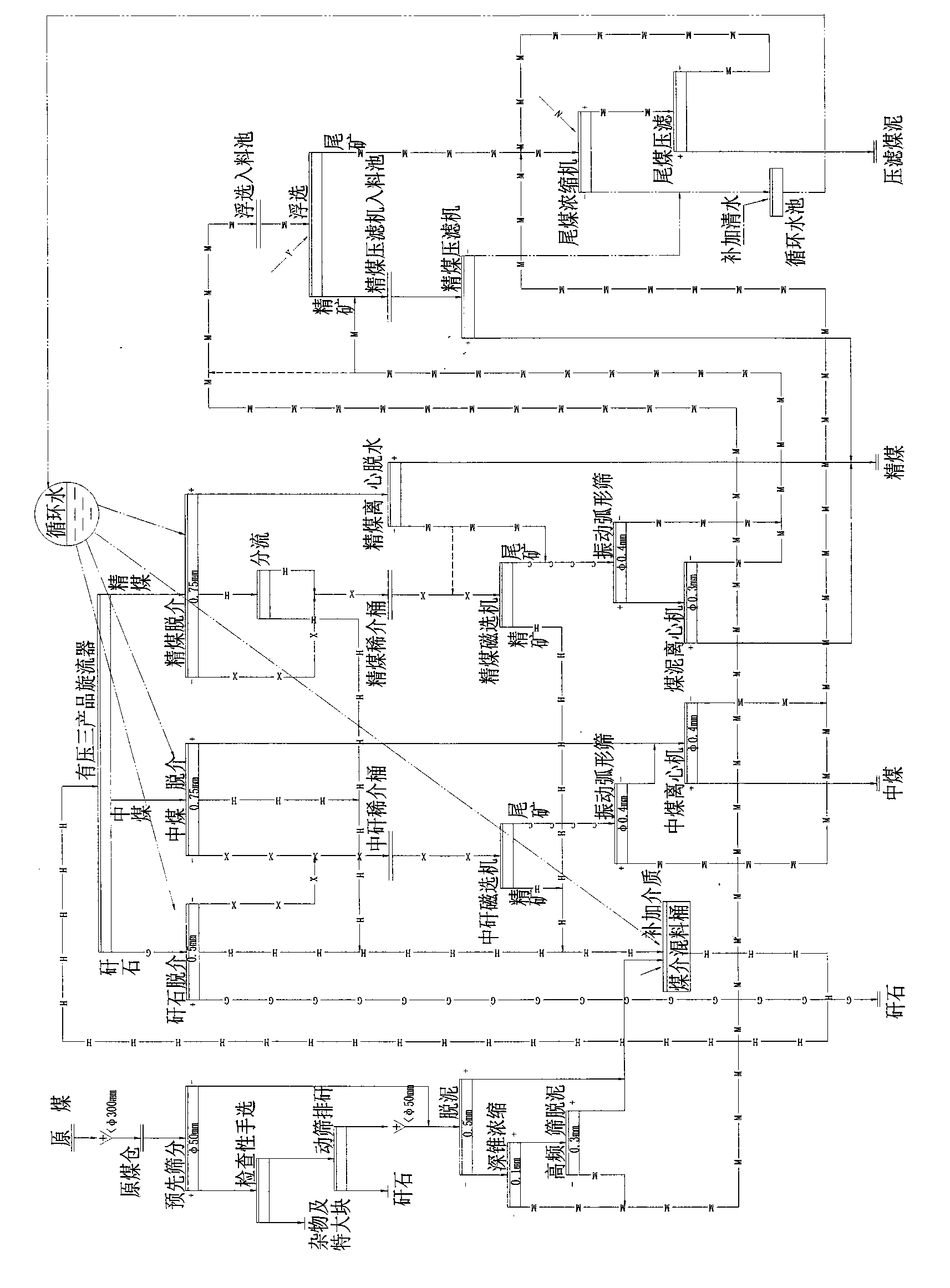

Classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process

InactiveCN103350027AImprove sorting efficiencyFlexible structureWet separationThermodynamicsMagnetic separator

Provided is a classified-desliming pressurized-feeding three-product dense medium cyclone coal preparation process. The process comprises the steps that wet classification and primary desliming are carried out on raw coal after prescreening, gangue predischarging and breaking are carried out on the raw coal, secondary desliming is carried out on the screen underflow of the raw coal after the screen underflow is concentrated, the oversize products of the secondary desliming and the screen underflow of the primary desliming are together fed in a pressurized three-product cyclone, three products are obtained after separation, and clean coal, middle coal and gangue are obtained after medium separation and dehydration are carried out on the three products. Part of qualified suspension liquid and dilute suspension liquid are obtained when the medium separation is carried out on the three products, magnetic concentrate is obtained after the dilute suspension liquid is recovered by a magnetic separator, and the magnetic concentrate and the qualified suspension liquid are directly fed in a medium blending barrel. The magnetic tailings of the dilute suspension liquid and the undersize mixtures of pre-desliming, the overflow of concentration classifying equipment and a secondary desliming screen enter a coal slime recovery processing system together. The process is high in separation efficiency, flexible in product structure, low in producing and operating cost and prone to achieving the large-scale single system, the modularization and the integrating intellectualization of plant layout.

Owner:煤炭科学研究总院唐山研究院

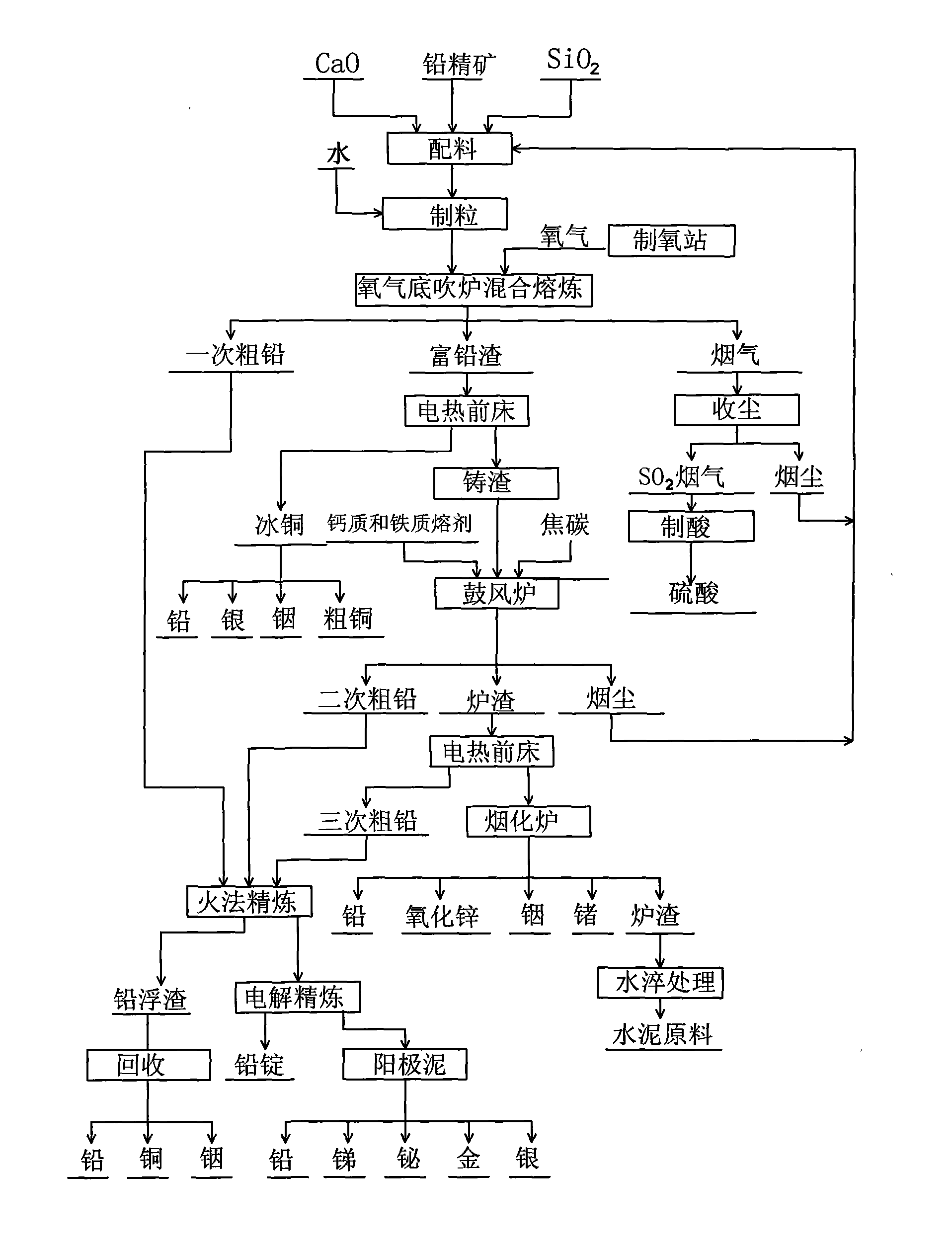

Balancing lead smelting process for comprehensive resource utilization and device thereof

InactiveCN101514399AHigh melting temperaturePromote oxidation reactionPhotography auxillary processesProcess efficiency improvementIndiumElectrolysis

The invention relates to a balancing lead smelting process for comprehensive resource utilization and a device thereof. The process comprises the following steps: granulating a raw material containing lead and a fluxing agent after proportioning, sending to an oxygen bottom-blown smelting furnace for smelting to produce primary crude lead, lead ash and flue gas of SO2; sending the flue gas of SO2 to a sulfuric acid system for acid making after recovering waste heat by a waste heat boiler and duct collection by a dust arrester installation; adjusting form of the lead ash and adding the lead ash to a blast furnace together with coking coal for reducing smelting to produce secondary and third crude lead; electrorefining the crude lead to obtain refined lead and anode slime, treating and recovering the anode slime to obtain lead, stibium, bismuth, gold and silver metals; and separating slag of the blast furnace from the crude lead and sending to a fuming furnace to recover zinc oxide, the lead, indium and germanium. A system for realizing the process comprises the oxygen bottom-blown smelting furnace, an oxygen lance, an electrically-heated settler, a slag casting device, the waste heat boiler with a vertical ascending segment of membrane wall structure, the blast furnace, the fuming furnace and a ventilating device. The process design and system improvement help realize balancing optimized recovery of Pb, Zn, Au, Ag, Bi, Cu, In, Sb and S elements.

Owner:CHENZHOU YUTENG CHEM IND

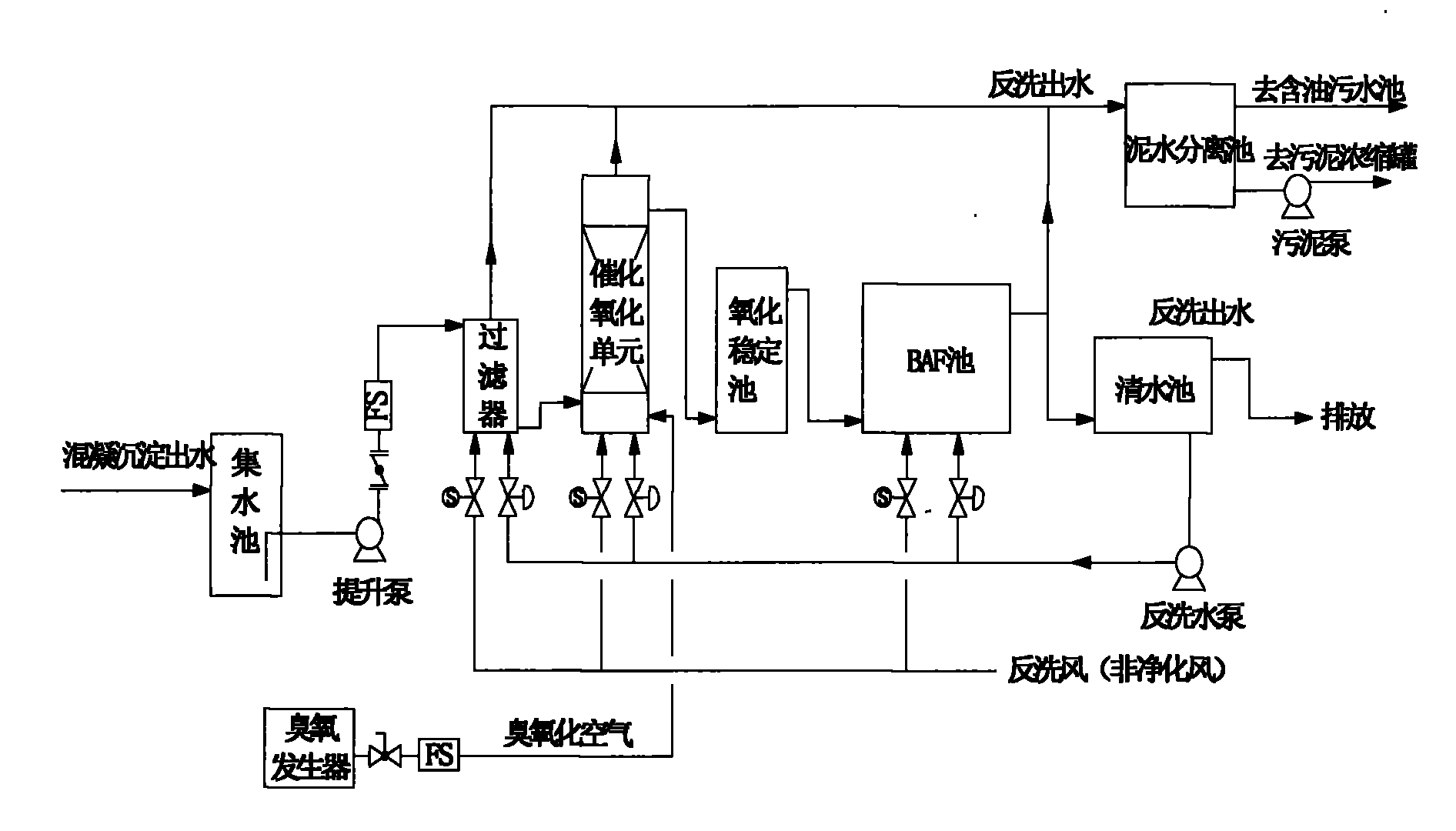

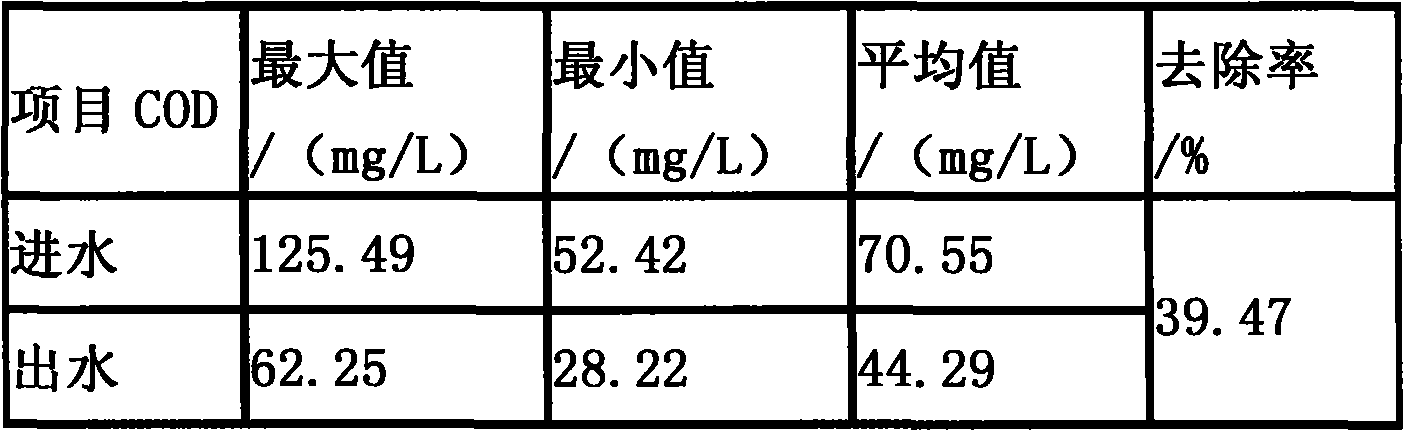

Method for advanced treatment of wastewater by using combination of catalytic ozonation and internal circulation biological filter

ActiveCN101863589ABreak through the biochemical limitImprove biodegradabilityMultistage water/sewage treatmentChemical industryBiological filter

The invention discloses a method for the advanced treatment of wastewater. The method comprises the following steps of: 1) filtering off-standard wastewater, delivering the wastewater into a catalytic ozonation tower, and simultaneously adding ozone for contact oxidization reaction; 2) delivering the effluent of the catalytic ozonation tower into an oxidization buffer stabilization basin for stabilization; 3) and after the stabilization, delivering the effluent into a BAF basin for treatment, and delivering discharged water into a clean water basin. The method reduces the addition amount of the ozone, improves the utilization efficiency of the ozone, converts the ozone into hydroxyl radicals by using a metal catalyst, and reduces the activation energy of hydroxyl radical oxidation reaction to promote hardly biodegradable macromolecule organic substances in the wastewater to be oxidized into easily biodegradable micromolecule substances, so that the biochemical limit to refining the wastewater is broken through and the biodegradability of the wastewater is increased; and the water quality of the effluent can meet the provincial standard of Jiangsu province, namely Chemical Industry Main Water Pollutant Discharge Standard, completely by further treatment in the BAF basin.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite

InactiveCN101525690AImprove leaching rateHigh dissolution rateProcess efficiency improvementSlagLaterite

A method for separating and recovering nickel, cobalt, magnesium, iron and silicon from nickel-bearing laterite is disclosed; nickel, cobalt, magnesium and iron therein are leached out by using high-temperature peracid, leachate is pre-neutralized via serpentine powder, after the pre-neutralization, the leachate is neutralized by magnesite powder for de-ironing, and the scum is delivered for ironmaking after being dewatered by smoke gases in a fluidized bed furnace for making sulfuric acid, the de-ironed clear nickel liquid uses magnesite powder to precipitate nickel carbonate, and the precipitated liquid is concentrated and crystallized to obtain magnesium sulfate heptahydrate. The leached slag mainly contains silicon and can be used for making white carbon black. The invention can sufficiently recover and utilize nickel, cobalt, magnesium, iron and silicon in the nickel-bearing laterite, and the invention is simple in technology, low in energy consumption and pollution-free on environment.

Owner:广西冶金研究院有限公司 +1

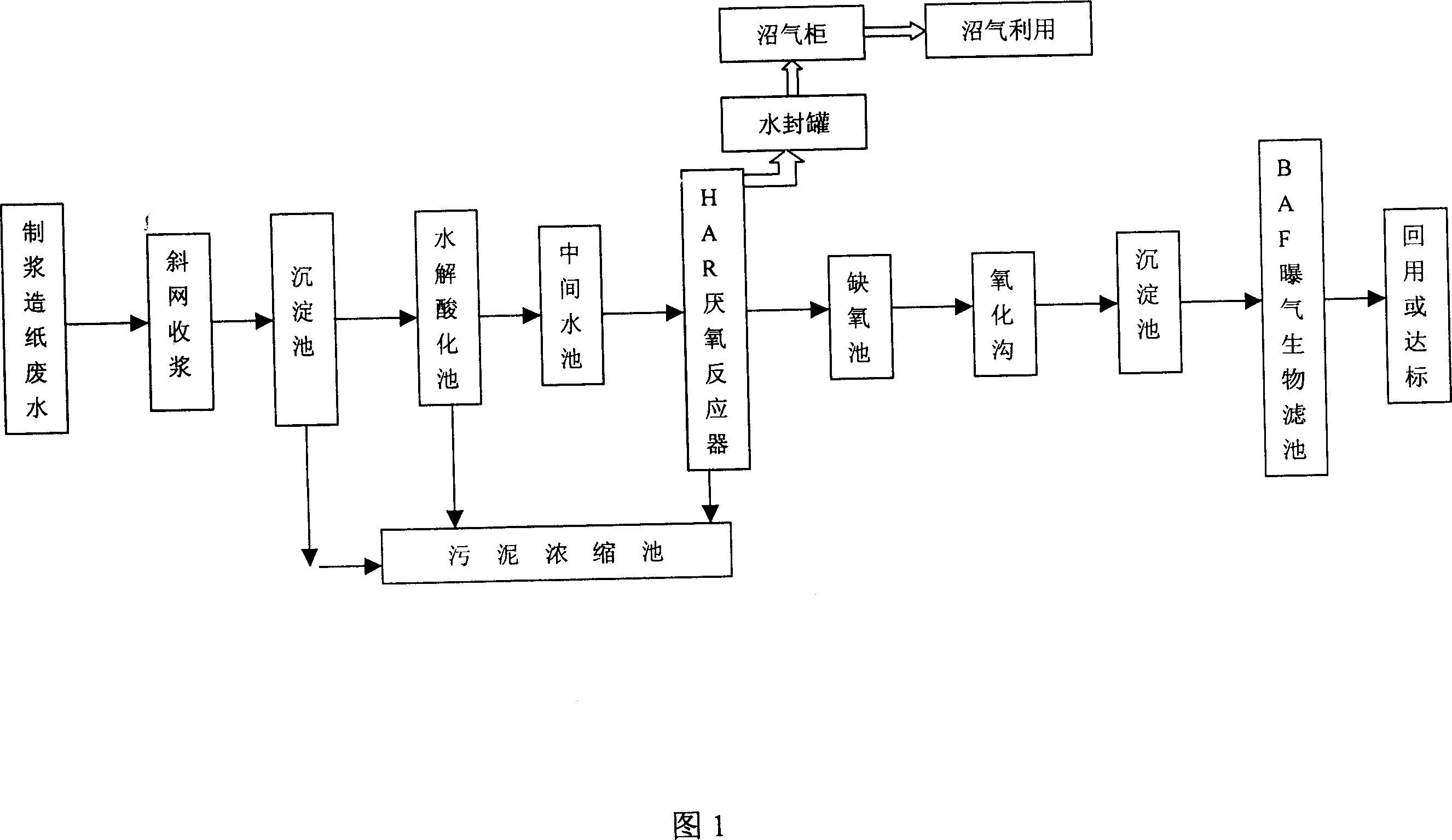

Paper-making effluent purifying treatment process

InactiveCN1931749AAchieve resource utilizationTo achieve the purpose of resource utilizationTreatment using aerobic processesWaste based fuelMedicineWastewater

The present invention is paper-making effluent purifying treatment process including hydrolyzing acidification, anaerobic biological treatment, anoxia treatment, aerobic biological treatment and aerobic biofilter treatment mainly. The present invention has low treating cost, low power consumption, capacity of generating energy source with produced methane, high treating efficiency, high COD and SS eliminating rate, and other advantages.

Owner:山东贵和显星纸业有限公司

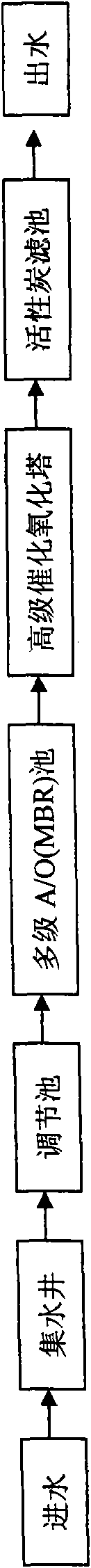

Landfill leachate wastewater treatment system and process thereof

ActiveCN101560039AFlexible operationFlexible Removal EffectsTreatment using aerobic processesBiological treatment apparatusPtru catalystCatalytic oxidation

The invention relates to a landfill leachate wastewater treatment system and a process thereof. The system comprises a collecting well, an adjusting tank, a filter, a multi-stage anoxia / aerobic pool and membrane bioreactor comprehensive treatment system, an advanced catalytic oxidization tower and a biological carbon filter. The treatment process has the following flows that: wastewater enters the adjusting tank to undergo the adjustment of water quality and water quantity in the adjusting tank; then, the wastewater enters the filter, the water out of the filter enters the multi-stage anoxia / aerobic pool and membrane bioreactor comprehensive treatment system to undergo biochemical treatment in the system, organic matters and ammonia nitrogen are removed, and the water out of the system enters the catalytic oxidization tower; in the presence of a catalyst, organic matters in the wastewater are oxidized by ozone, and the biodegradability is improved; and the water after catalytic oxidization enters the carbon filter, residual pollutants are further removed through cooperation of the aerobic oxidative degradation of a biomembrane on a filling material in the filter and the absorption of active carbon, and then the water out of the carbon filter can meet the national first grade emission standard or the emission standards of related industries.

Owner:SHANGHAI TONGJI CONSTR TECH

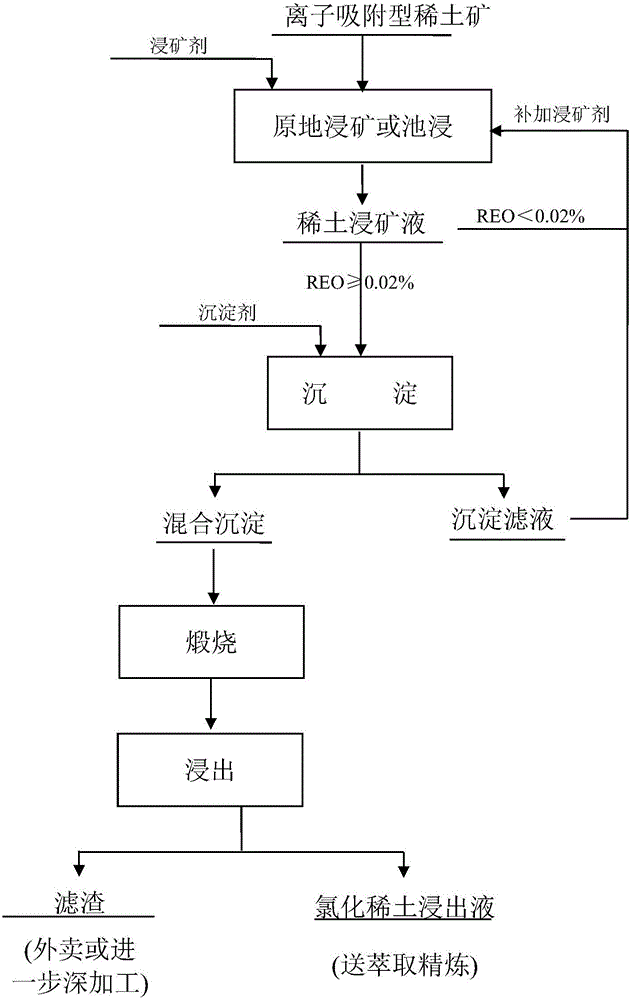

Method for extracting rare earth and aluminum from ion adsorption type rare earth ores

ActiveCN105803226AEfficient separationAchieve purificationProcess efficiency improvementAluminum canRare earth

The invention relates to a method for extracting rare earth and aluminum from ion adsorption type rare earth ores. The method includes the steps that (1), ore leaching is performed, wherein an ore leaching agent is added for in-situ ore leaching or pond leaching, and rare earth ore leaching liquid with the rare earth concentration higher than 0.02% is obtained; (2), precipitation is performed, wherein solid and liquid separation is performed after a precipitation agent is added into the rare earth ore leaching liquid for precipitation, and precipitated filter liquor and mixed precipitate containing rare earth and aluminum are obtained; (3), calcination is performed, wherein the mixed precipitate containing rare earth and aluminum is calcinated, and calcinated products containing rare earth oxide and alpha-aluminum oxide are obtained; and (4), leaching out is performed, wherein solid and liquid separation is performed after a chlorination leaching agent is added into the calcinated products containing rare earth oxide and alpha-aluminum oxide for leaching out, chlorinated rare earth leaching-out liquid and filter residues containing alpha-aluminum oxide are obtained, rare earth oxide is extracted from the chlorinated rare earth leaching-out liquid, and aluminum oxide fine products are extracted from the filter residues containing alpha-aluminum oxide. The method is simple in technology, precipitation is directly performed without impurity removal, and by means of the dissolution property difference of the calcinated products in an acid environment, the rare earth and the aluminum can be separated and recycled.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Fenton and air-float integral water treating method

InactiveCN101041475AImprove removal efficiencySave gasWater/sewage treatment by flocculation/precipitationWater/sewage treatment by flotationStop timePollutant

The invention discloses a Fenton and air-float integral water disposal method, which comprises the following steps: adding Fenton agent into armed waste water; setting mass ratio of hydrogen dioxide solution of Fenton agent against COD of armed water at 0.3-3:1; reacting at 0.5-5 h; using alkality material to adjust Fenton agent armed water pH value at 6-10; proceeding floating treatment; setting air-float air-solid ratio at 0.03-0.06, surface loading at 7-15m3 / m2.h and stopping time at 10-40 min; removing floating contaminant and most of dissolving organic contaminant.

Owner:SOUTH CHINA UNIV OF TECH

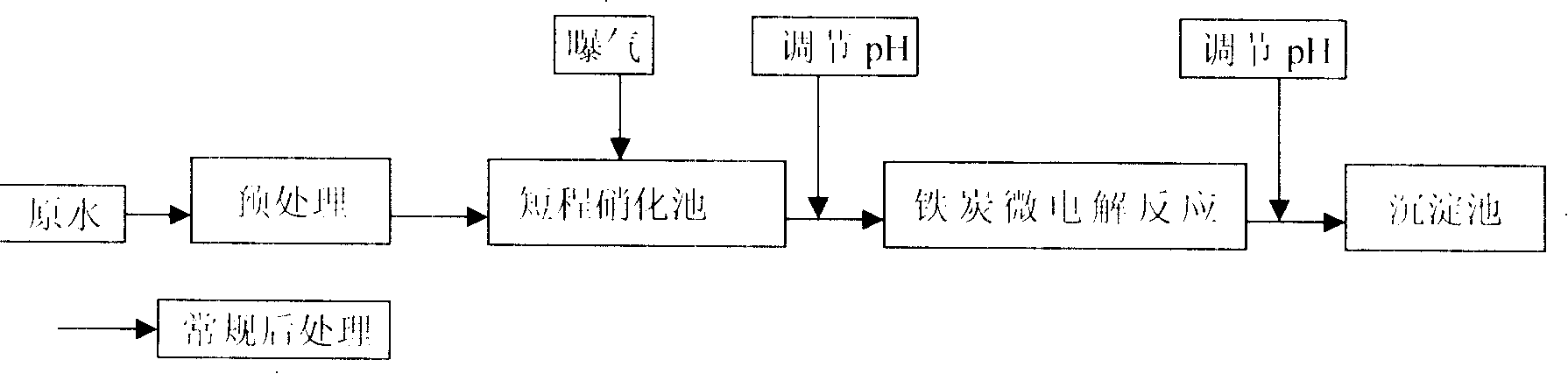

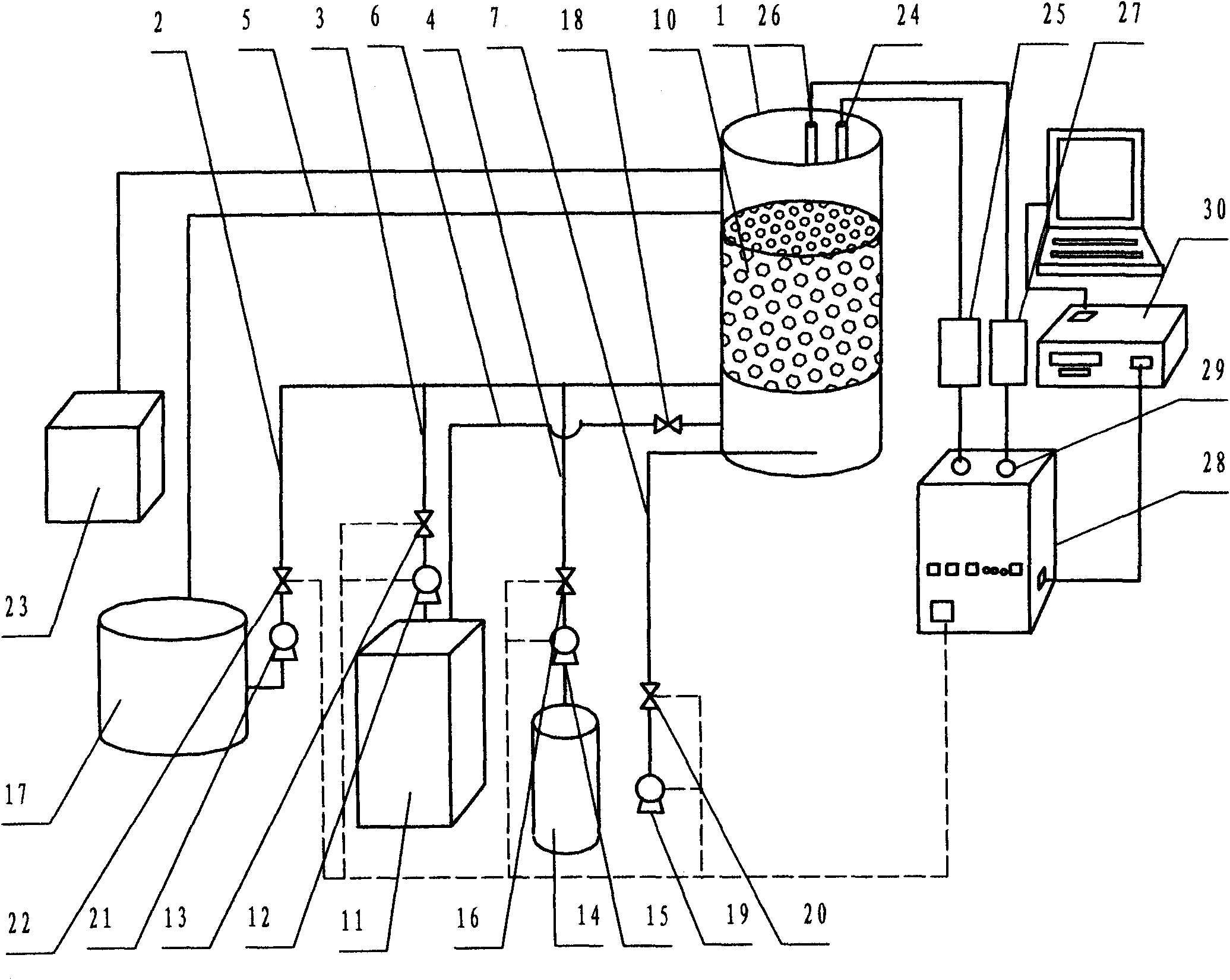

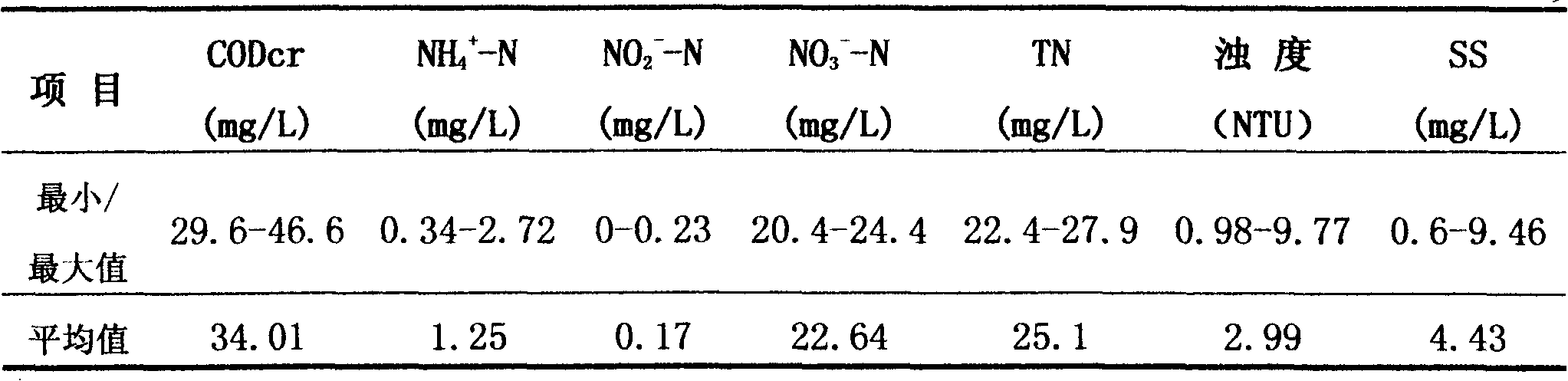

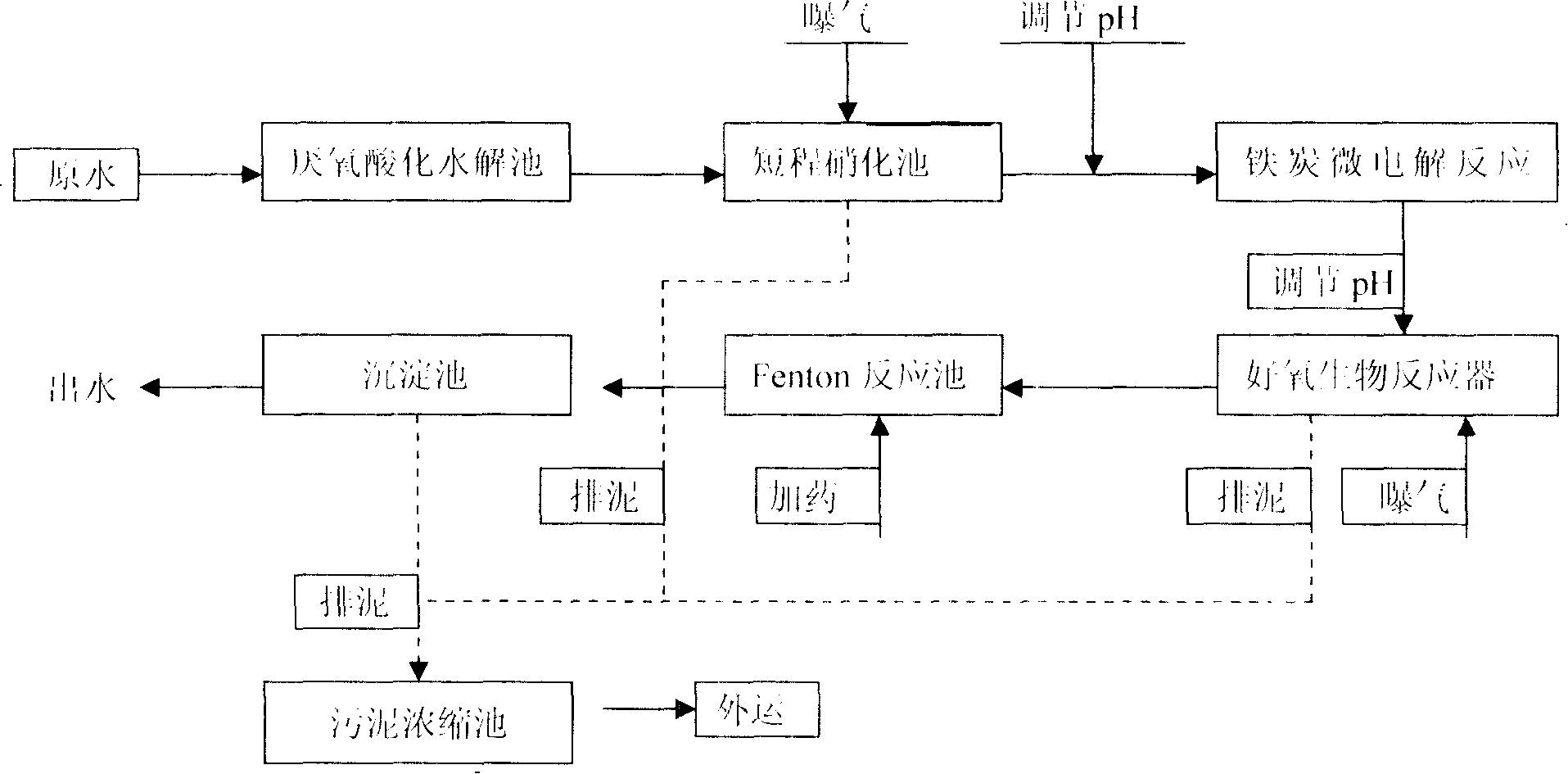

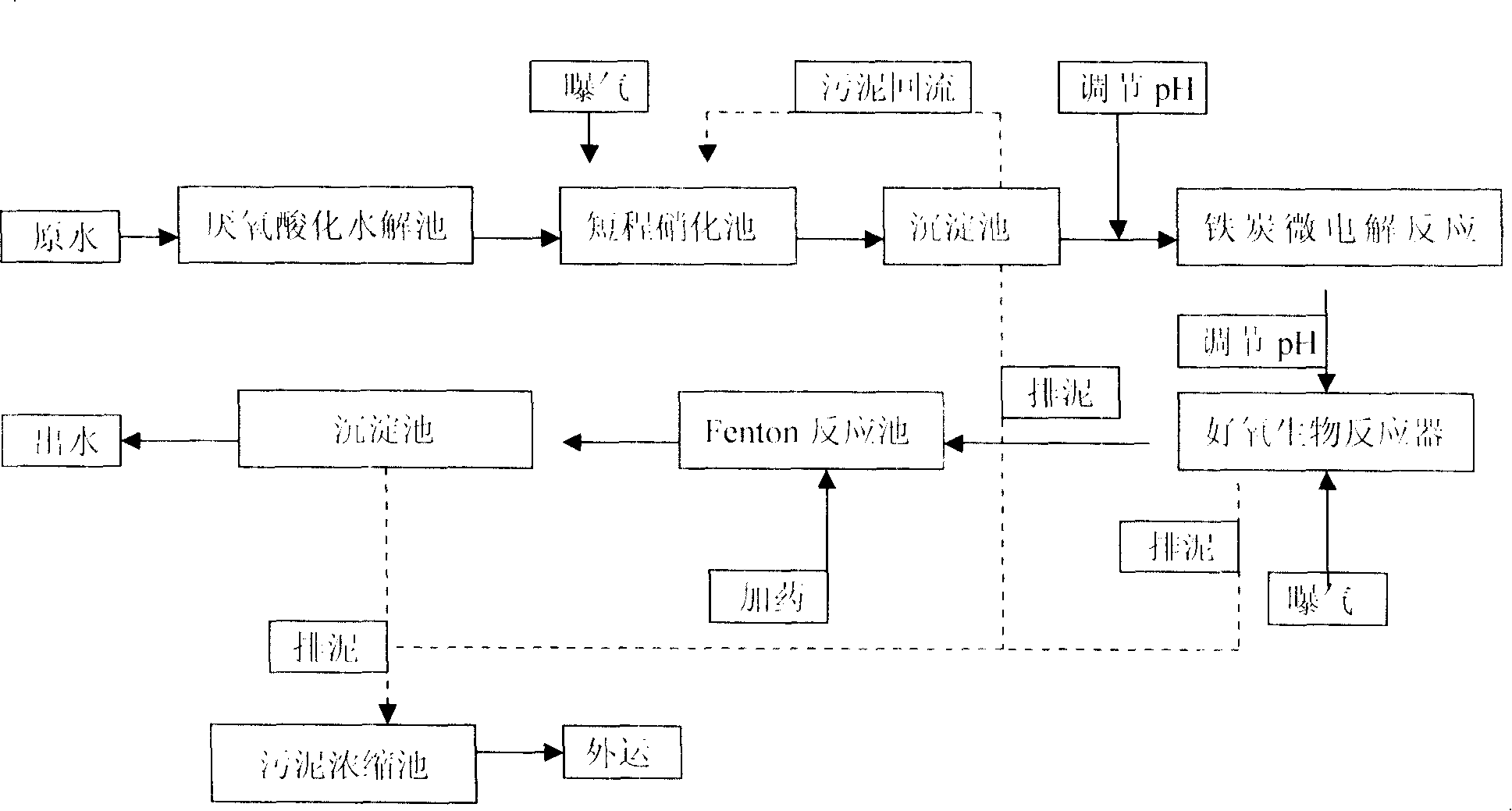

Energy-saving process for treating high ammonia nitrogen waste water

InactiveCN101195513AHigh removal rateReduce consumptionTreatment using aerobic processesMultistage water/sewage treatmentElectrolysisWater quality

In the invention discloses an energy-saving treatment method of high strength ammonia wastewater, which comprises procedures of pre-processing, short-cut nitrification, micro-electrolysis and after-treatment. The method is characterized in that firstly wastewater is preprocessed to transform Kjeldahl nitrogen into amino nitrogen, then the wastewater enters a main body of the process to be processed. In a short-cut nitrification tank, the amino nitrogen in the wastewater is nitrated and controlled to a nitrite nitrogen stage, then a micro-electrolysis reactor is employed to replace anaerobic denitrification or ammonoxidation process to be denitrified, the nitrite nitrogen and organic pollutants in the wastewater are highly effectively degraded and are further subsequently processed by employing biological method and physicochemical oxidation method, and outlet water of the wastewater reaches standards. The method makes full use of water quality of raw water, the additional medicament consumption is saved, the process flow is shortened, and the process operation is simplified. Compared with the conventional denitrification process, the denitrification rate is increased, the total nitrogen removal rate reaches 60%-75%, and the treatment effect of degrading hardly degradable organics is remarkably increased. The treatment cost of wastewater per ton by employing novel method can be reduced by 30-50%.

Owner:UNIV OF SCI & TECH LIAONING

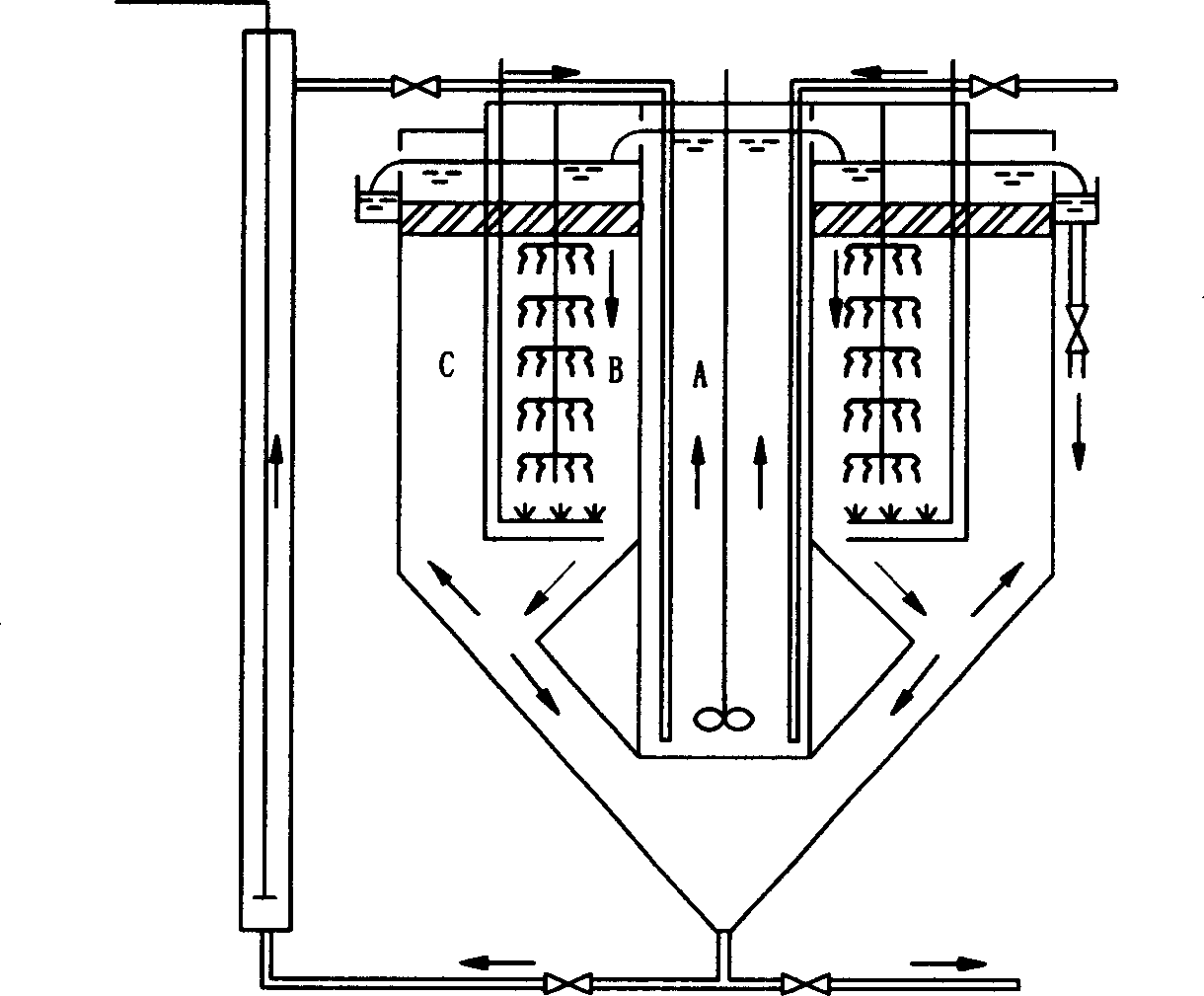

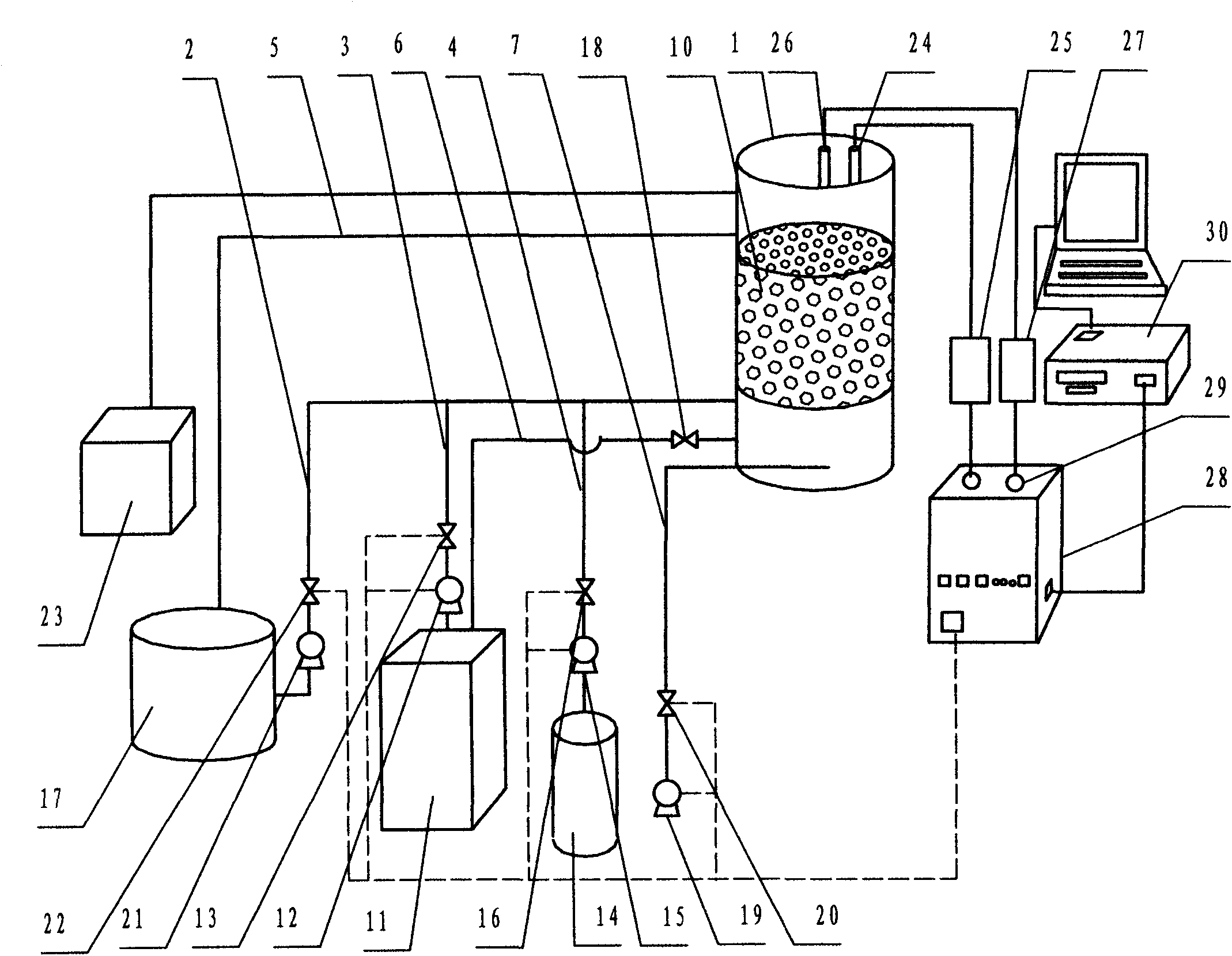

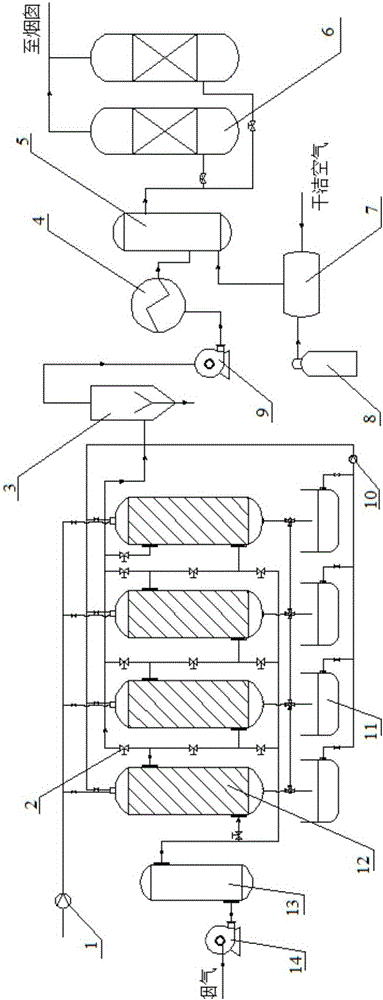

Real-time automatically back-flushing control system of denitrification filter pool and running method

ActiveCN102063115AImprove filtering effectImprove effluent qualityTreatment with anaerobic digestion processesTotal factory controlWater dischargeControl manner

The invention relates to a real-time automatically back-flushing control system of a denitrification filter pool and a running method. The system comprises an online water turbidity sensor, a nitrate sensor, a turbidity tester and a nitrate tester, and further comprises a process controller and an industrial personal computer. The online water turbidity sensor, the nitrate sensor, the turbidity tester and the nitrate tester are arranged in the denitrification filter pool. The process controller is provided with a plurality of relays of a water feeding pump relay, an intake valve relay and the like, and the relays are sequentially and respectively connected with corresponding pumps and valves in a control manner. A clean water tank is further provided with a water discharging pipe and a mud storage tank, the water discharging pipe is communicated with the upper part of a filter material layer of the denitrification filter pool, and the mud storage tank is communicated with the upper part of the denitrification filter pool. The running method of the back-flushing control system comprises the following steps of: 1, control system starting; 2, parameter treatment judgment; 3, drainage process; 4, single gas back-flushing; 5, gas-water combined back-flushing; and 6, single water back-flushing. The invention is suitable for the urban sewage advanced treatment and the nitrogenous industrial wastewater treatment, and has the advantages of perfected structure, convenience of operation, high efficiency and good effect.

Owner:BEIJING DRAINAGE GRP CO LTD

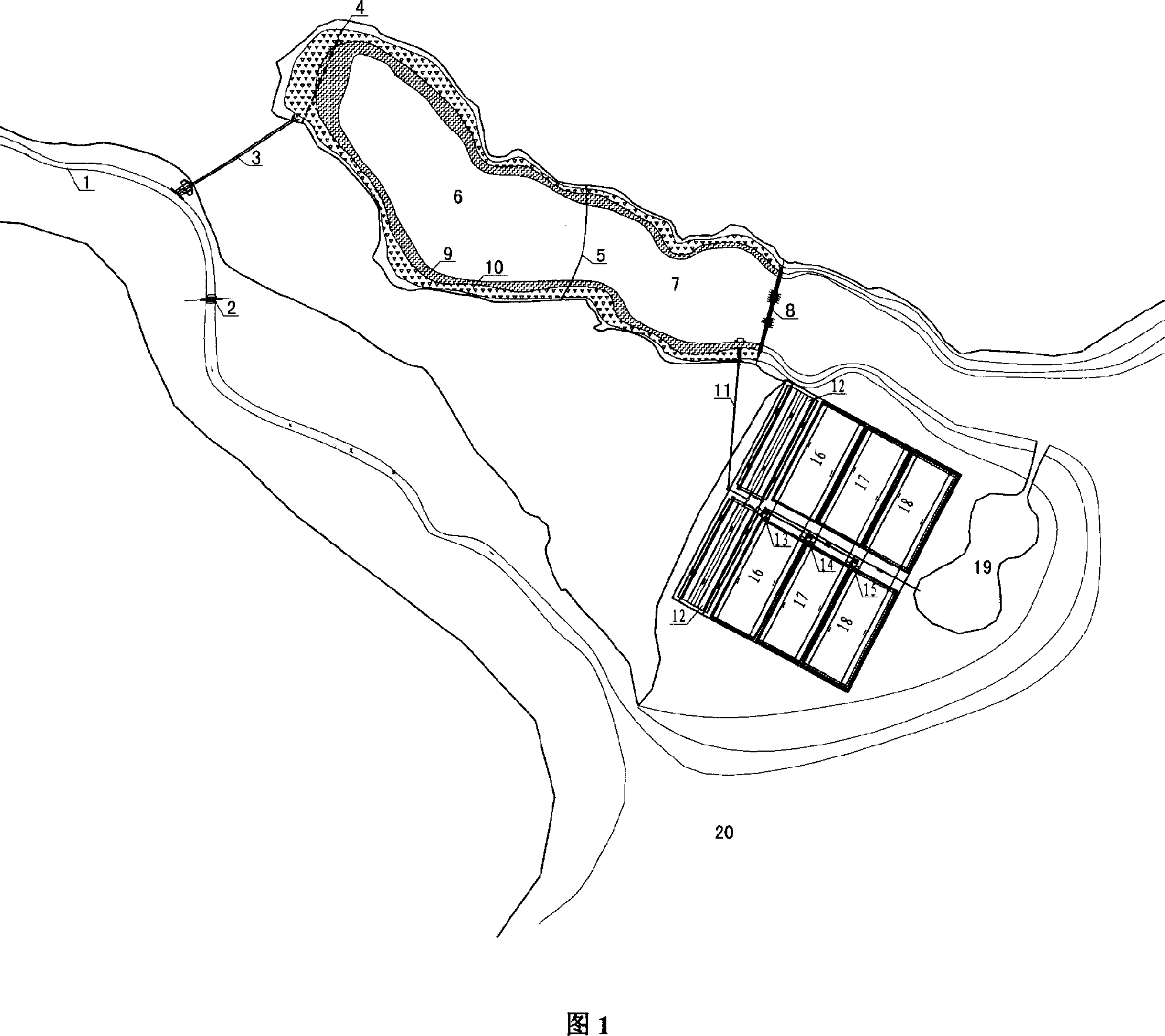

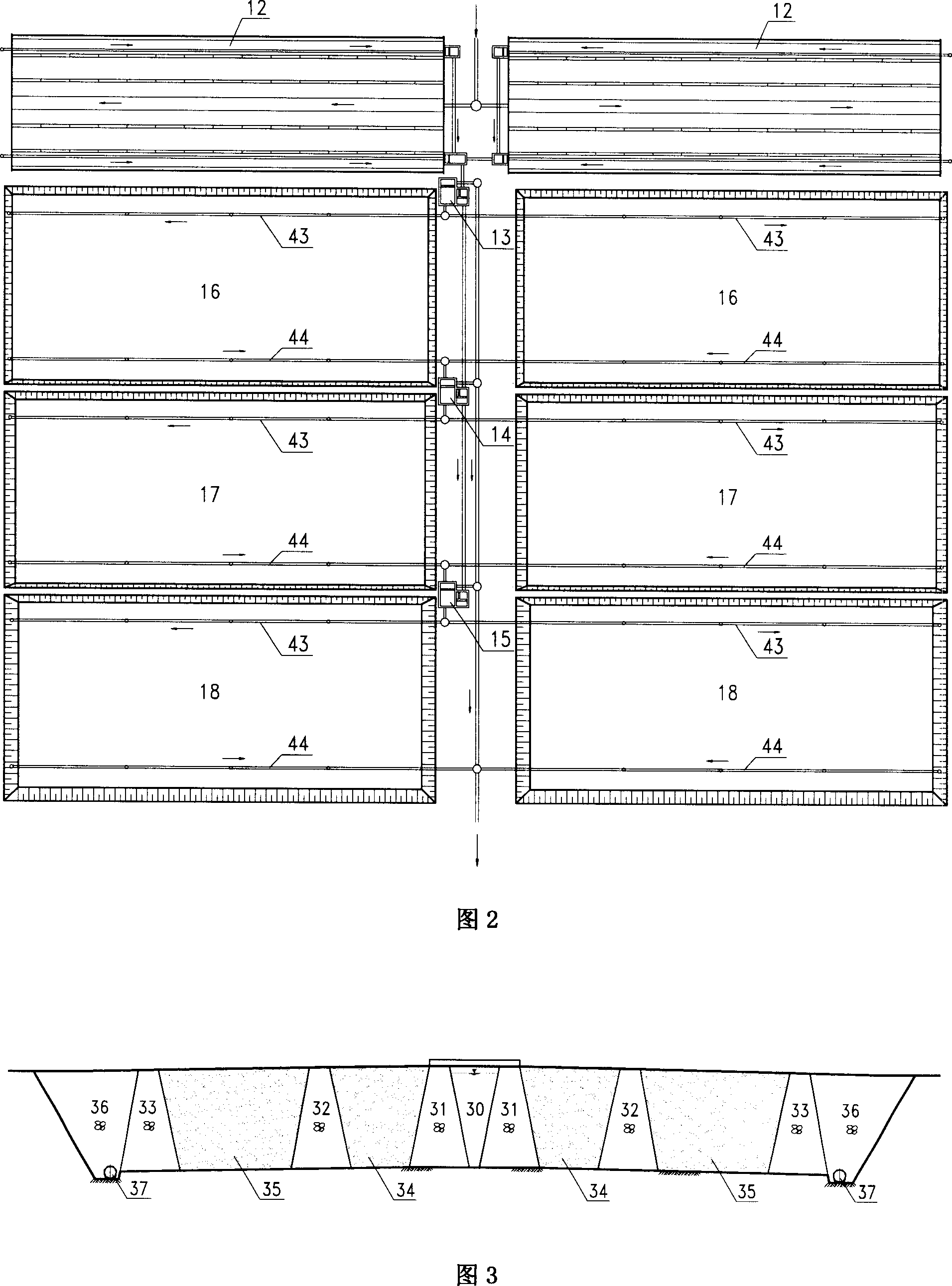

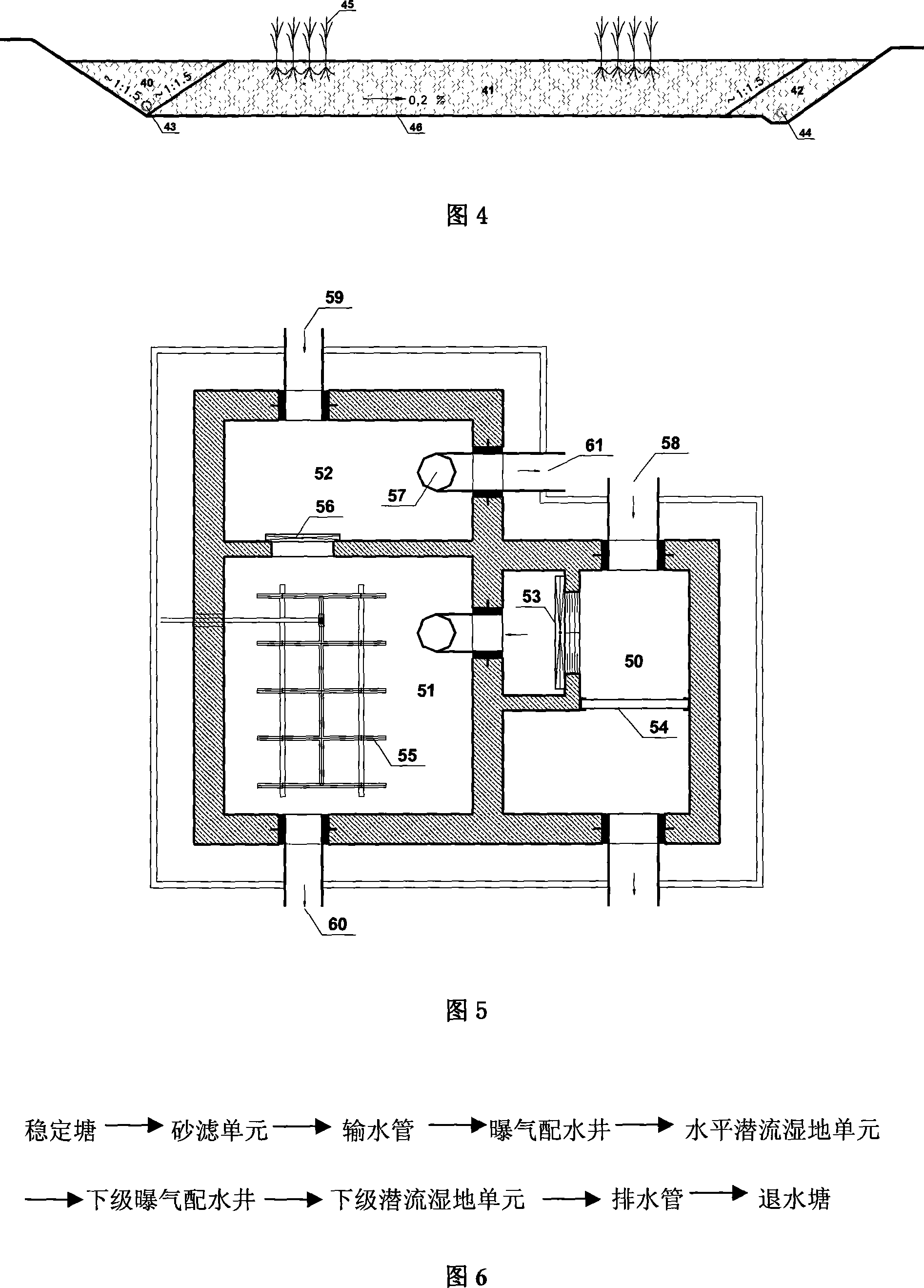

Composite artificial marshland water quality clarification system in north low-temperature area

InactiveCN101081713AImprove the ecological environmentTo achieve the purpose of purifying water qualityTreatment using aerobic processesSustainable biological treatmentConstructed wetlandWater quality

The composite water-purifying wetland system for northern low temperature region consists of three serially connected subsystems, including one stabilizing pond subsystem, one undercurrent wetland subsystem and one water draining pond subsystem. The stabilizing pond subsystem has one flexible partitioning wall to separate the pond into one front reservoir and one purifying area, and planted emergent vegetation zones and submerged plant zones. The undercurrent wetland subsystem consists of sand filtering modules, wetland modules and aerating water-distributing wells. The water draining pond subsystem consists of water draining canals and serially connected biological ponds. The present invention has well combined engineering measures and ecological measures to purifying polluted water for several times, saving in investment, high water purifying effect and high economic and ecological benefits.

Owner:北京市水利科学研究所

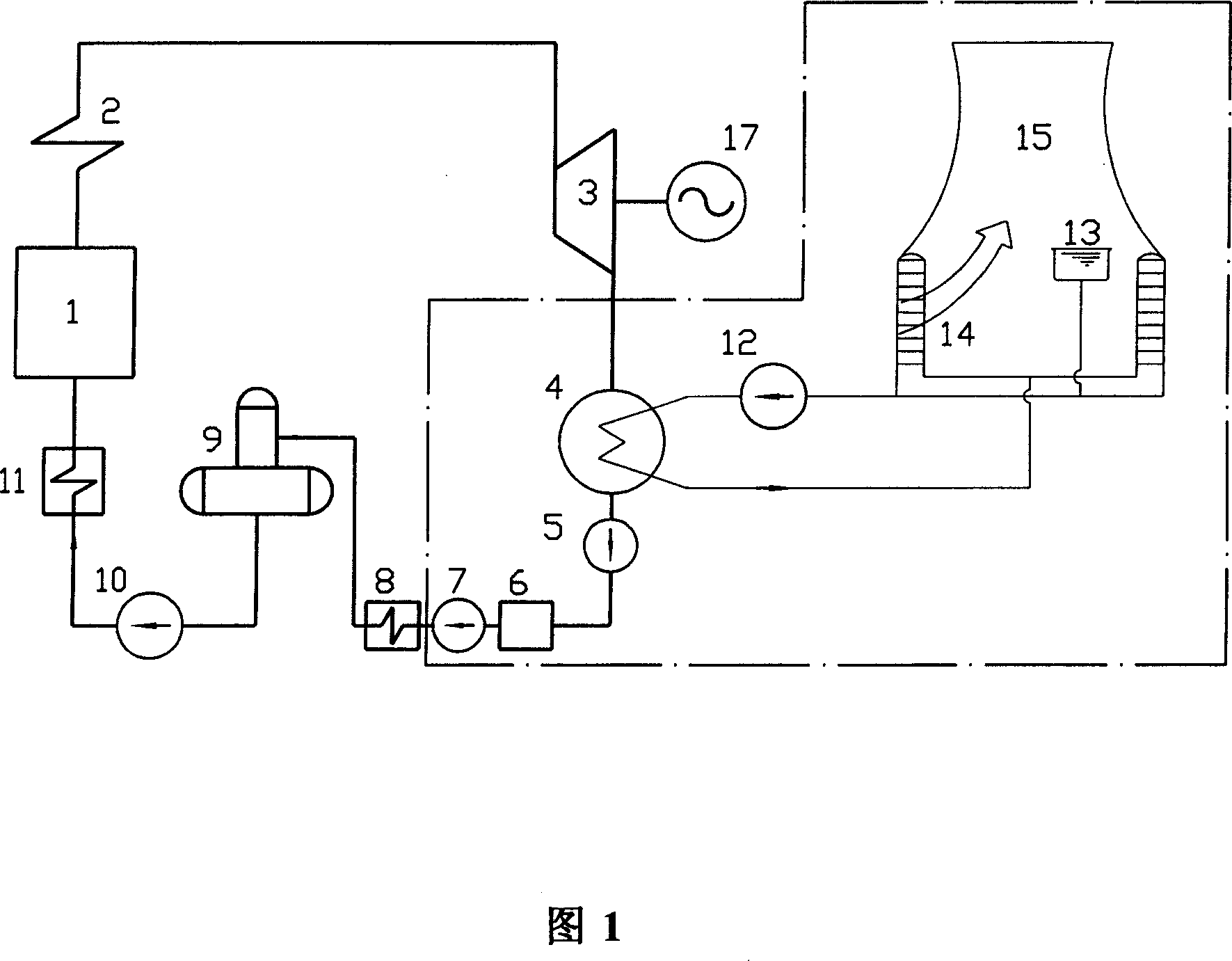

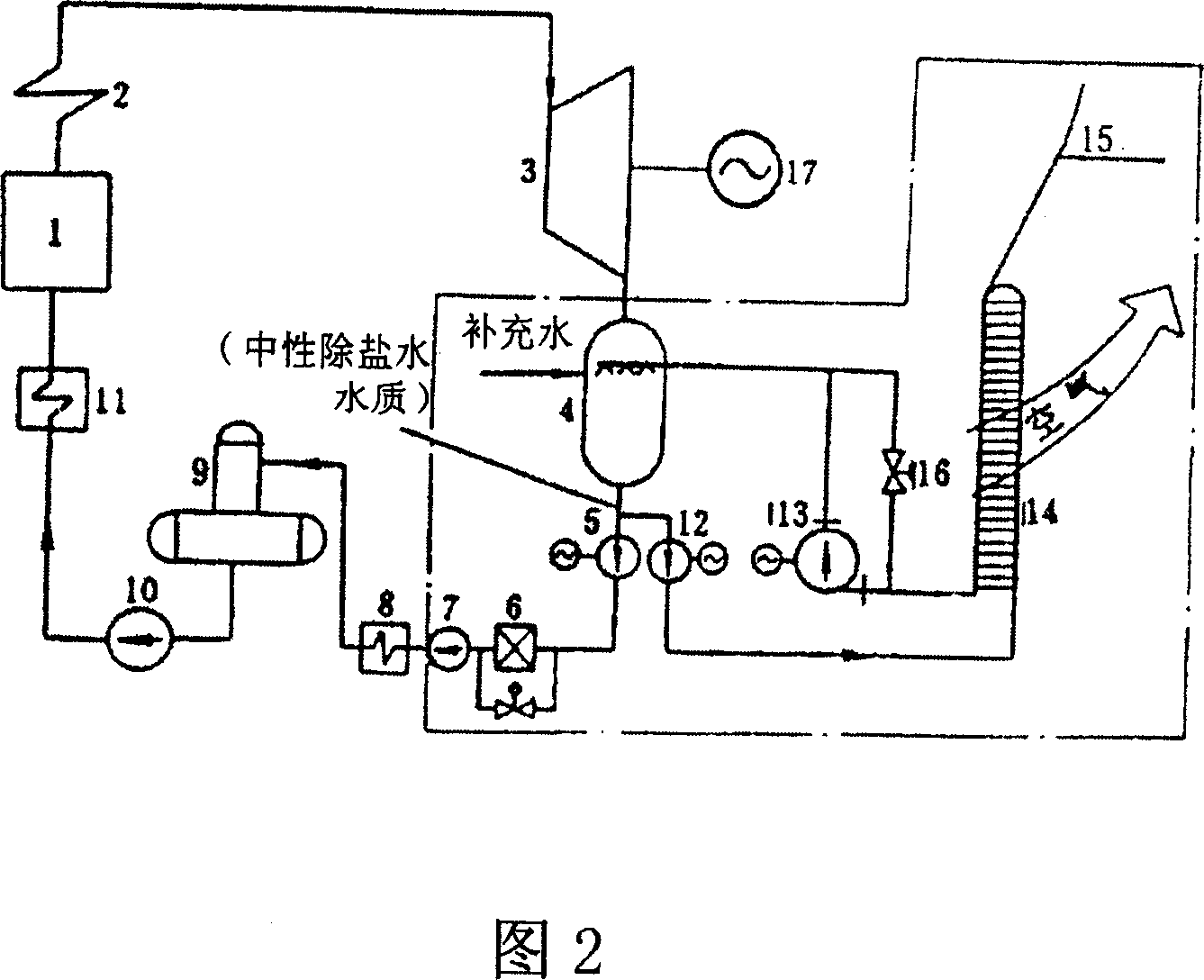

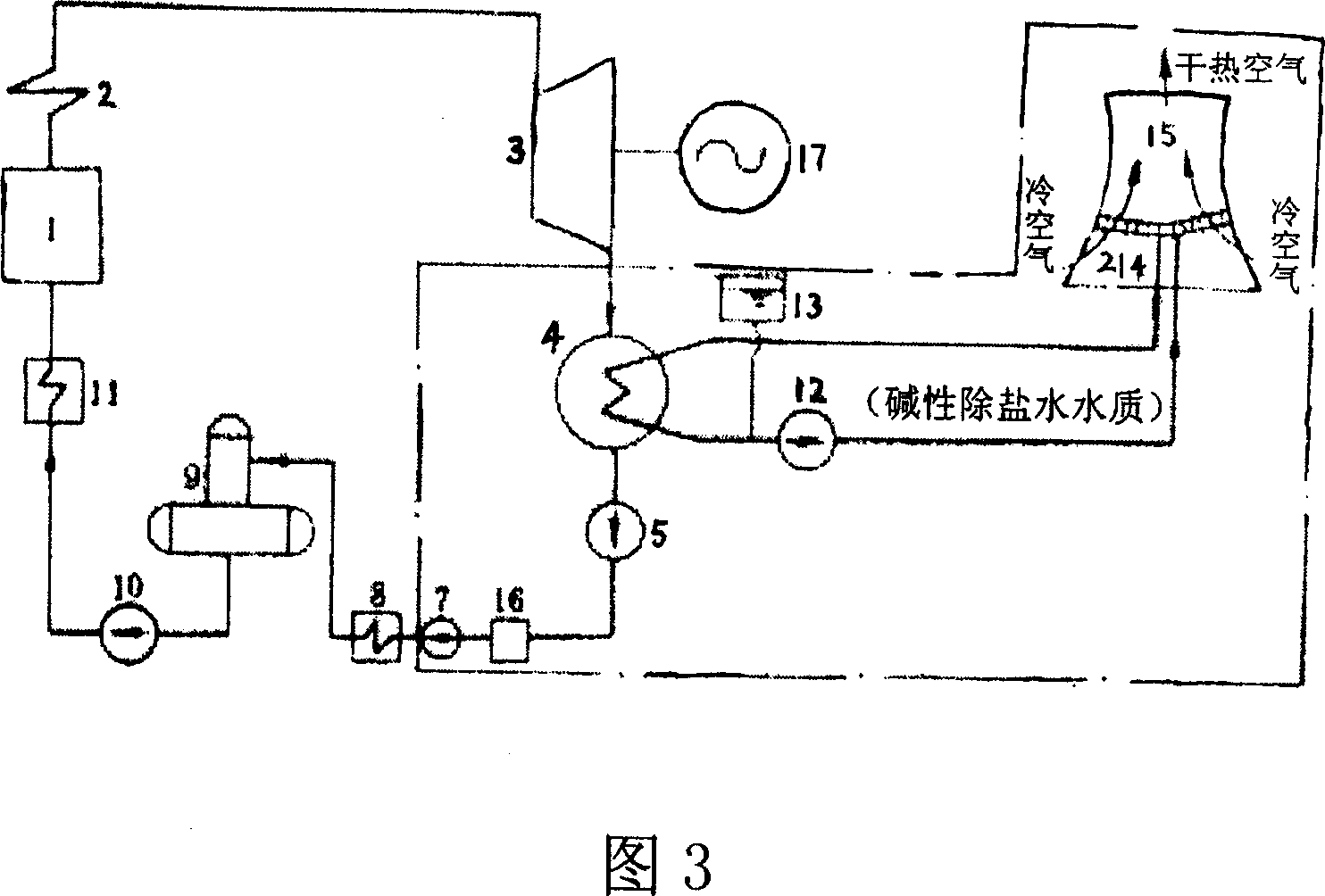

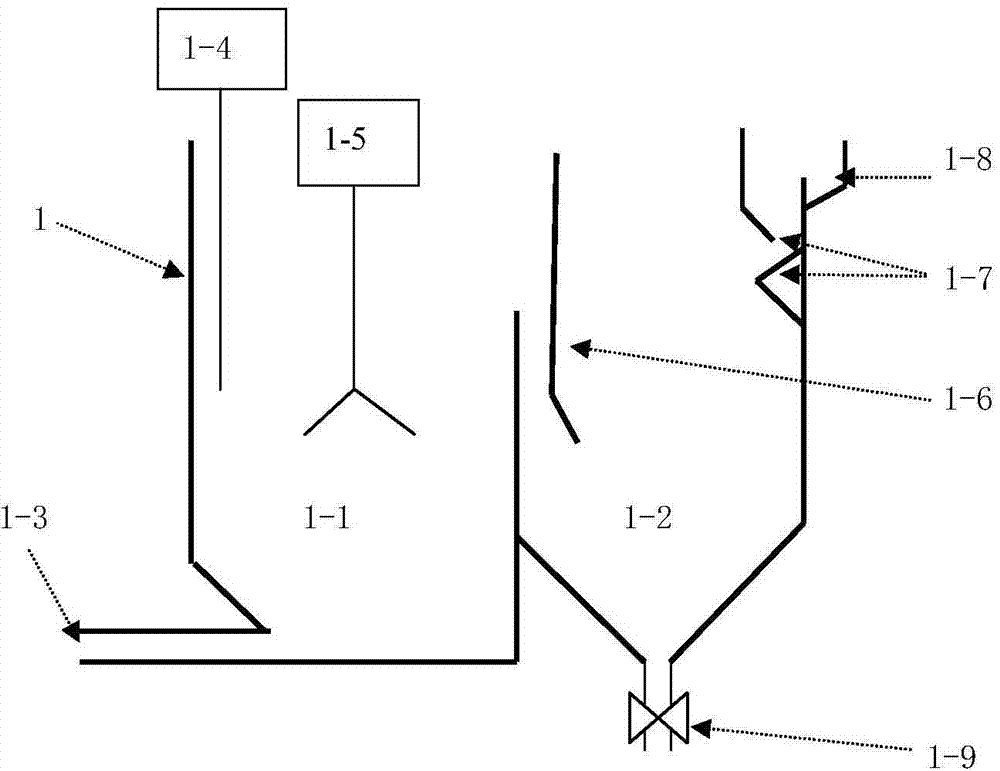

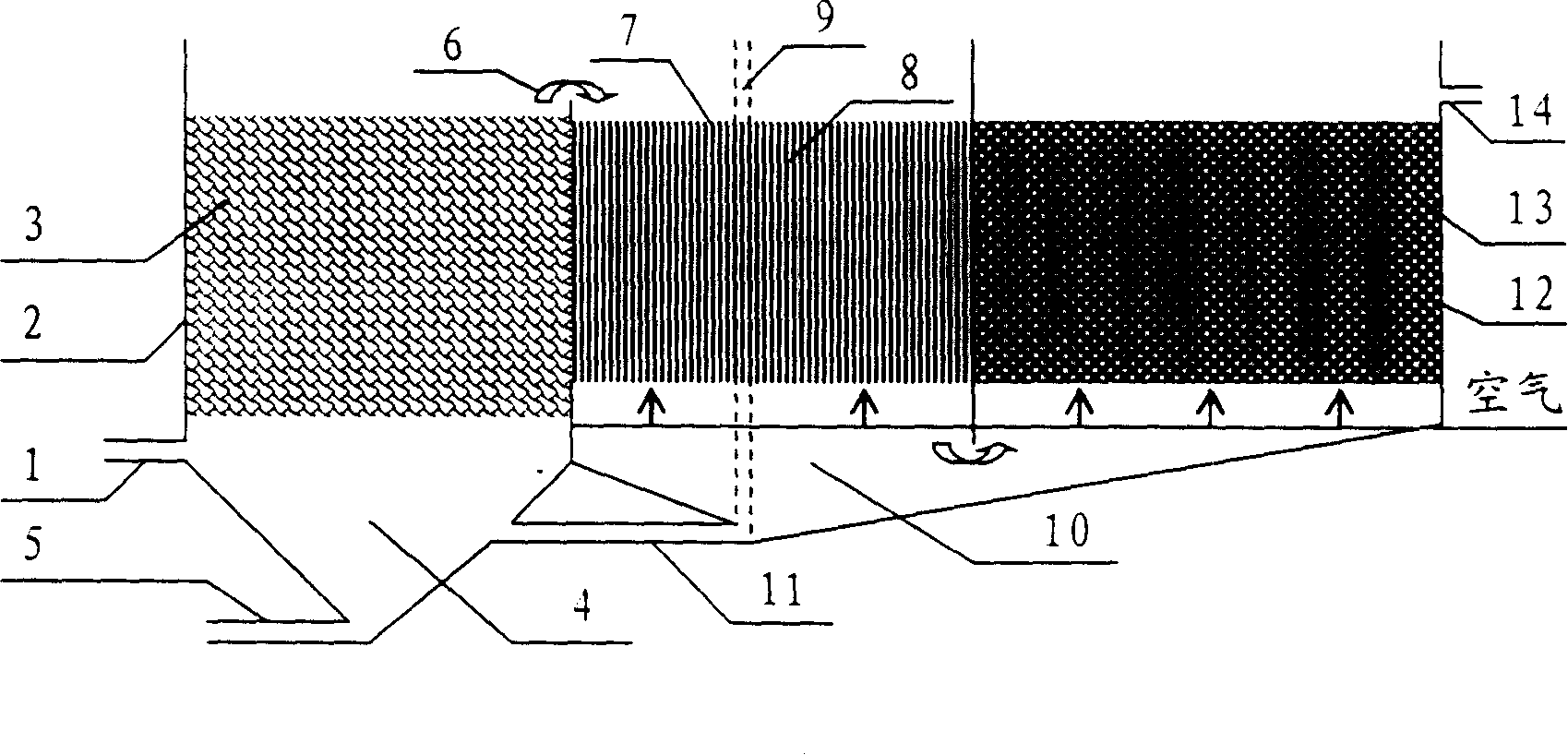

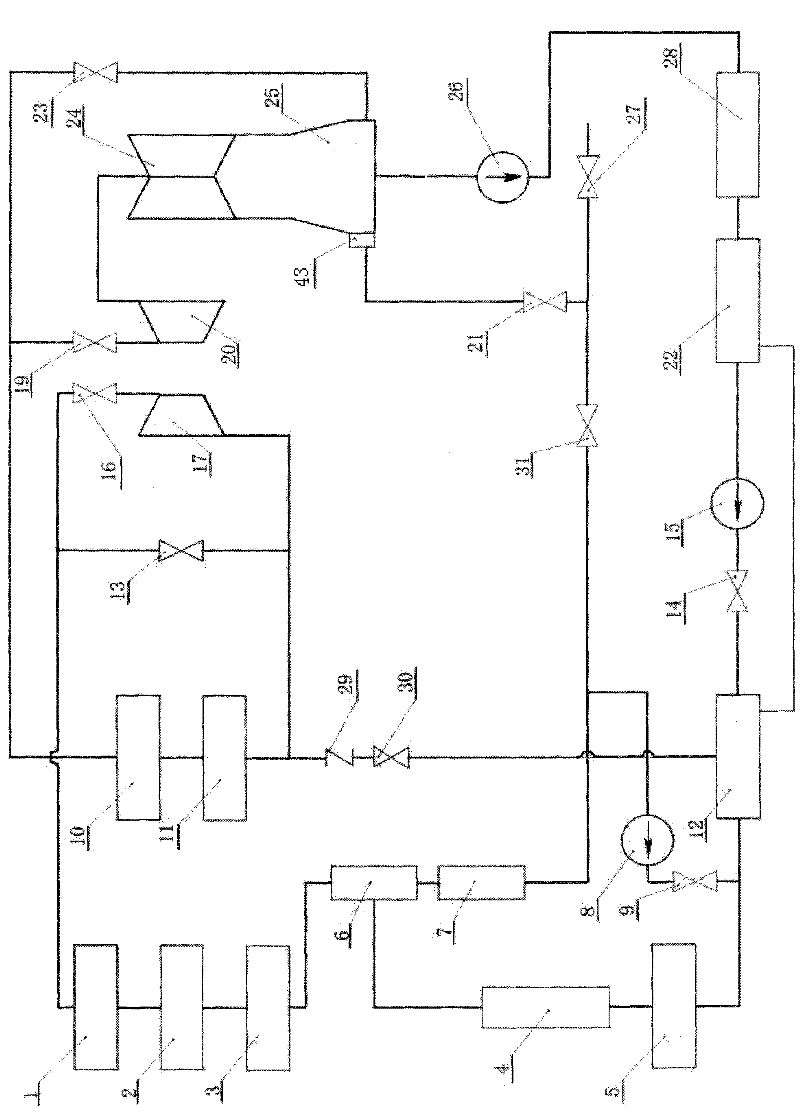

SCAL indirect air cooling system

ActiveCN101063595AReduce sizeSmall footprintSteam/vapor condensersStationary conduit assembliesCooling towerWater quality

The invention relates to a SCAL indirect air-cooling system, mainly comprising a surface condenser, a recycling water system, a fog type aluminum pipe and aluminum flake radiator and an air-cooling tower, wherein in the surface condenser, after the wasted steam discharged from the steam turbine performs the first heat exchange with the cooling water, the wasted steam transmits the heat to the cooling water and condensed to condensed water, then flow back to the air-cooling system heat system, the cooling water flows to the fog type aluminum pipe and aluminum flake radiator via the recycling water pump after it is heated up, and the cooling water secondarily exchange heat with the environmental air, the cooling water transmits the heat to the air and makes the water temperature decrease, and then return to the cooling steam turbine of the surface condenser, the system recycles like this. The invention has the advantages that the Haman type indirect air-cooling system is separated from the steam water system, the water quality controlling and disposing is easy, the Hailer system air-cooling tower has a small body, The invention takes up small area and the capital cost of reactor plant is low.

Owner:NORTH CHINA POWER ENG +1

Pharmaceutical wastewater advanced treatment system

ActiveCN104773919AEasy to handleRealize resourcesMultistage water/sewage treatmentAir blowerPrecipitation

The invention relates to a pharmaceutical wastewater advanced treatment system. The pharmaceutical wastewater advanced treatment system comprises a wastewater regulating tank, a coagulative precipitation tank, an ozone oxidation floatation tank, a packed-type anoxic / anaerobic reaction tank, an aerobiotic contact oxidation tank, a secondary sedimentation tank, an electrolytic tank, a countercurrent type biological aerated filter and a clear water tank, wherein the coagulative precipitation tank comprises a stirring mixing zone and a precipitation zone, the ozone oxidation floatation tank comprises a mixing zone and a separation zone, the packed-type anoxic / anaerobic reaction tank is divided into a facultative anaerobic section, an anoxic section and an anaerobic section by baffle plates, the aerobiotic contact oxidation tank is provided with a water inlet pipe and a water distribution triangle pyramid, an aeration regulation control system is arranged at the lower part of the water distribution triangle pyramid and comprises an aeration tray, an air blower and a dissolved oxygen measurement regulation control device, the electrolytic tank is divided into a left compartment and a right compartment which are respectively a positive electrode compartment and a negative electrode compartment, the bottoms of the positive electrode compartment and the negative electrode compartment are communicated, the middle upper parts of the positive electrode compartment and the negative electrode compartment are separated by baffles, and the positive electrode compartment and the negative electrode compartment are respectively provided with a positive electrode plate and a negative electrode plate, and the countercurrent type biological aerated filter comprises a downstream zone, an upstream zone and a sludge zone.

Owner:如东文园投资开发有限公司

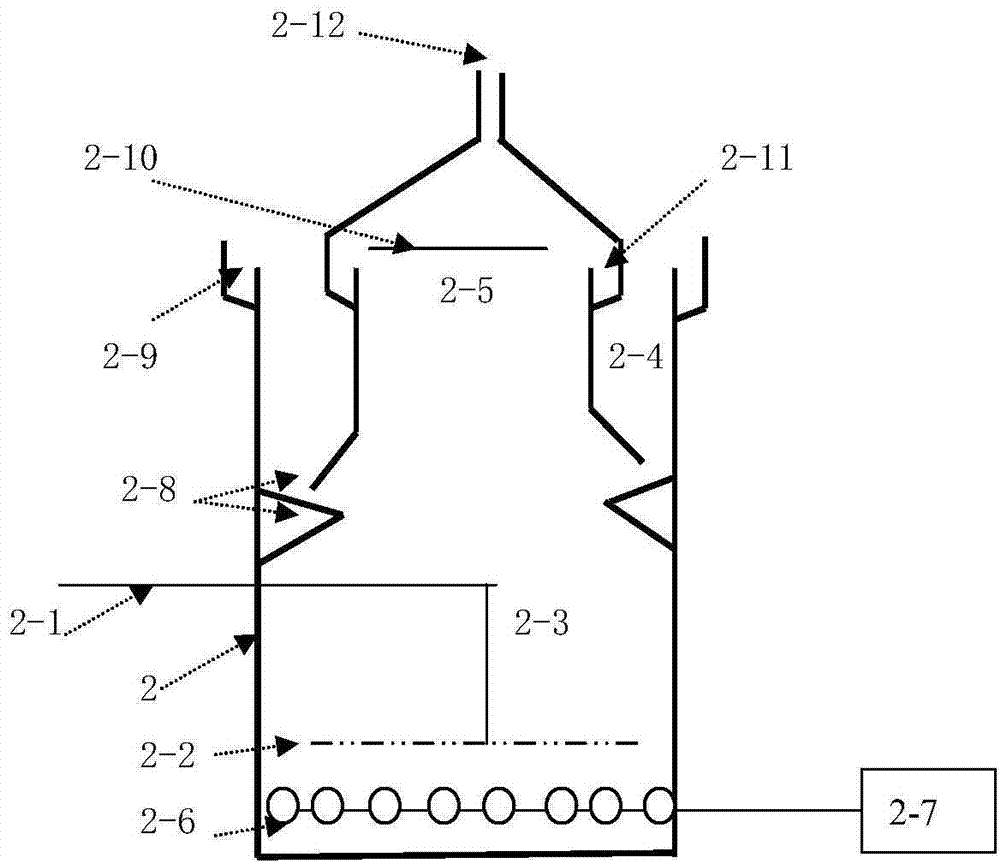

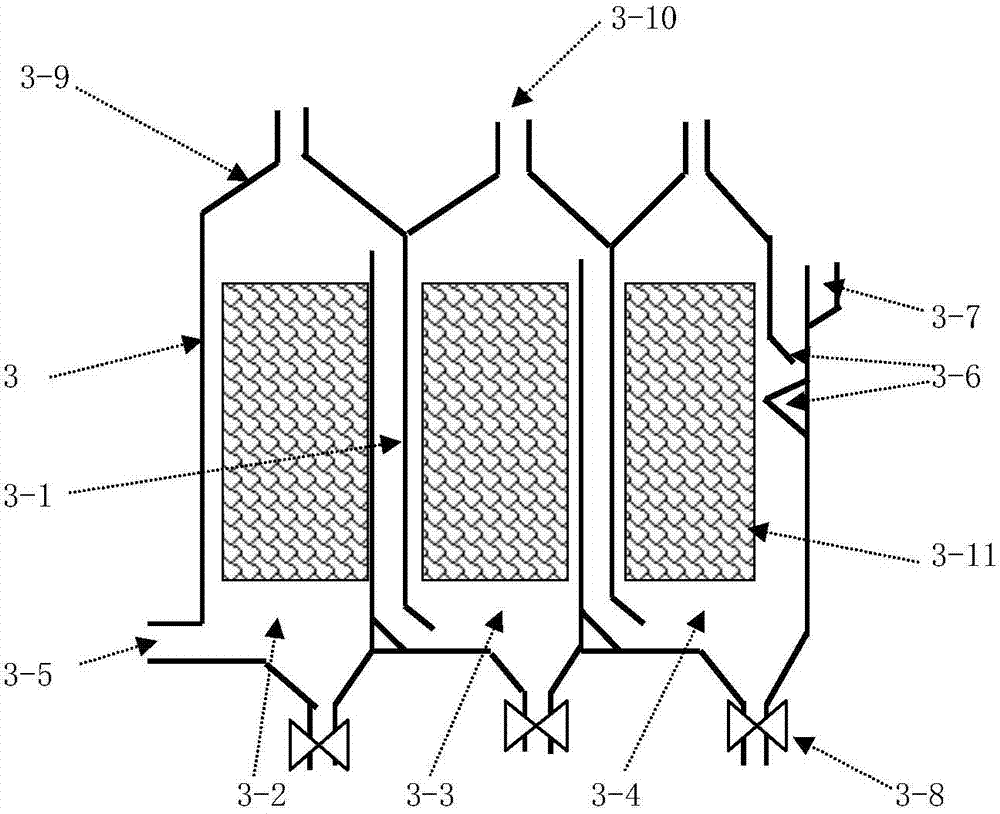

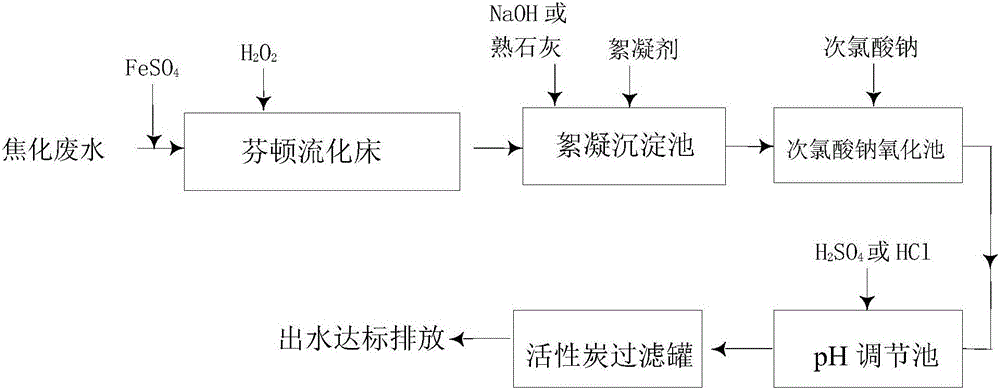

Method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide

ActiveCN106745961AGood effectImprove reaction efficiencyWater treatment compoundsWater contaminantsActivated carbon filtrationWater quality

The invention provides a method and system for deeply treating coking wastewater to decarbonize, decolor and remove cyanide. The method comprises the following steps: 1) introducing the coking wastewater into a Fenton fluidized bed, and adding a mixed solution of ferrous sulfate, sulfuric acid and water into a solution; 2) adding hydrogen peroxide into the solution of the Fenton fluidized bed and sufficiently reacting; 3) leading out a reaction solution in the Fenton fluidized bed, adjusting the pH (Potential of Hydrogen) value of the reaction solution, adding a flocculating agent, and after precipitating, taking supernatant; 4) mixing the supernatant with sodium hypochlorite, and carrying out an oxidization reaction; and 5) adjusting the pH of the reaction solution, and carrying out adsorption treatment by active carbon to obtain a deeply treated water body. According to the method and the system, the Fenton fluidized bed, flocculation and sedimentation, sodium hypochlorite oxidization, and active carbon filtering and adsorption are effectively combined; the Fenton fluidized bed and the flocculation and sedimentation are carried out, residual cyanide in output water mainly exists in a CN<-> form, the oxidization efficiency of the sodium hypochlorite is higher, and the cyanide can be removed; and the adsorption effect of the active carbon is combined, so that the water concentration of the output water is lower.

Owner:CISDI ENG CO LTD

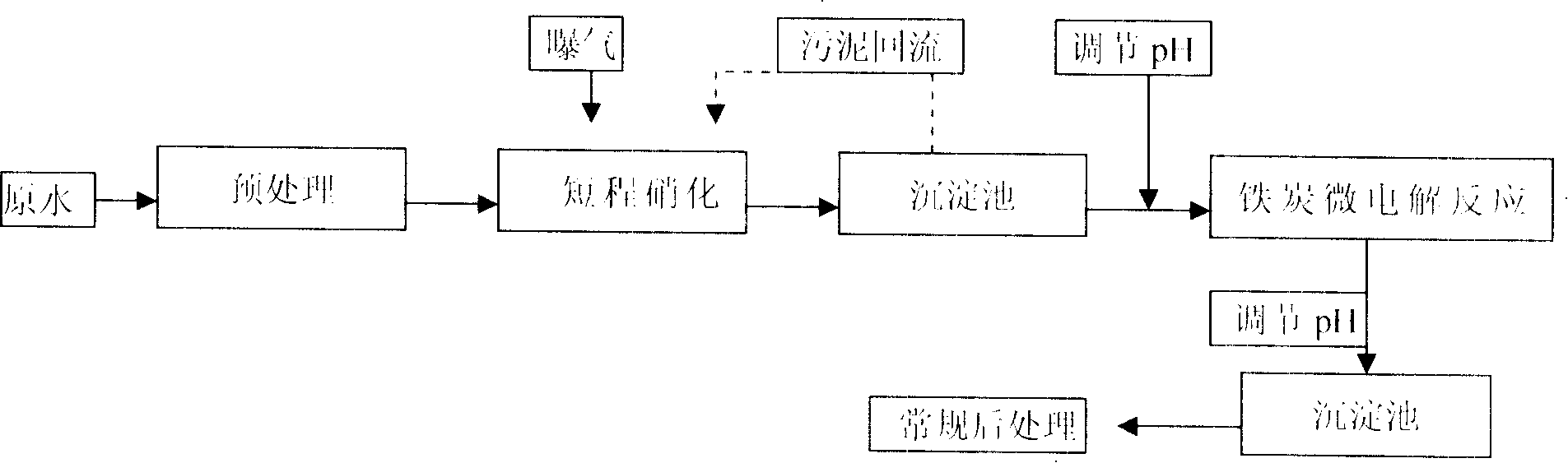

Energy-saving method for processing leachate of middle-aged or old refuse landfill

InactiveCN101195512AReduce consumptionHigh removal rateTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentElectrolysisNitration

The invention discloses an energy-saving treatment method for middle-aged and elderly stage refuse landfill leachate, which comprises a first-stage biochemical treatment, a first-stage physicochemical treatment, a second-stage biochemical treatment and a second-stage physicochemical treatment. The first-stage biochemical treatment stage includes anaerobic hydrolytic-acidification reaction and aerobic short-cut nitrifying reaction, further a micro-electrolysis reactor is employed to replace traditional anaerobic denitrification technique to process the first-stage physicochemical treatment and then two-stage aerobic treatment is processed, nitrite and organic pollutants discharged by the micro-electrolysis reactor are further processed, finally in the stage of the second-stage physicochemical treatment, Fention reagent is employed to subsequently process the discharged water, and the water is enabled to reach standards. The method makes full use of water quality of raw water, carbon source and acid-base neutralization agent need not be added, ammonia nitrogen is enabled to be transformed to nitrosification stage, and the additional medicament consumption is saved. And cheap scrap iron is employed as stuffing of the reactor to largely reduce capital investment and operation cost of wastewater treatment, increasing the denitrification rate.

Owner:UNIV OF SCI & TECH LIAONING

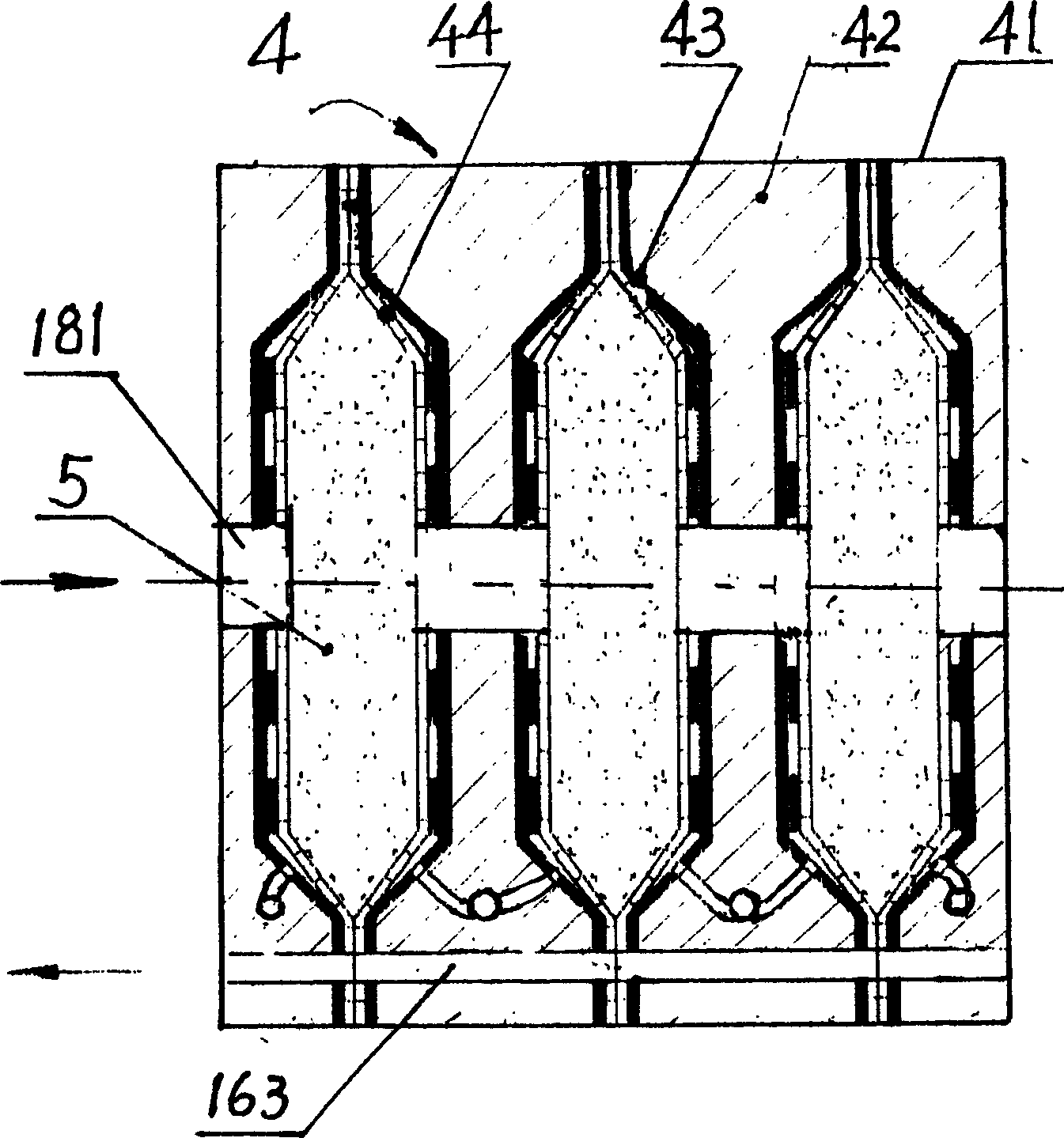

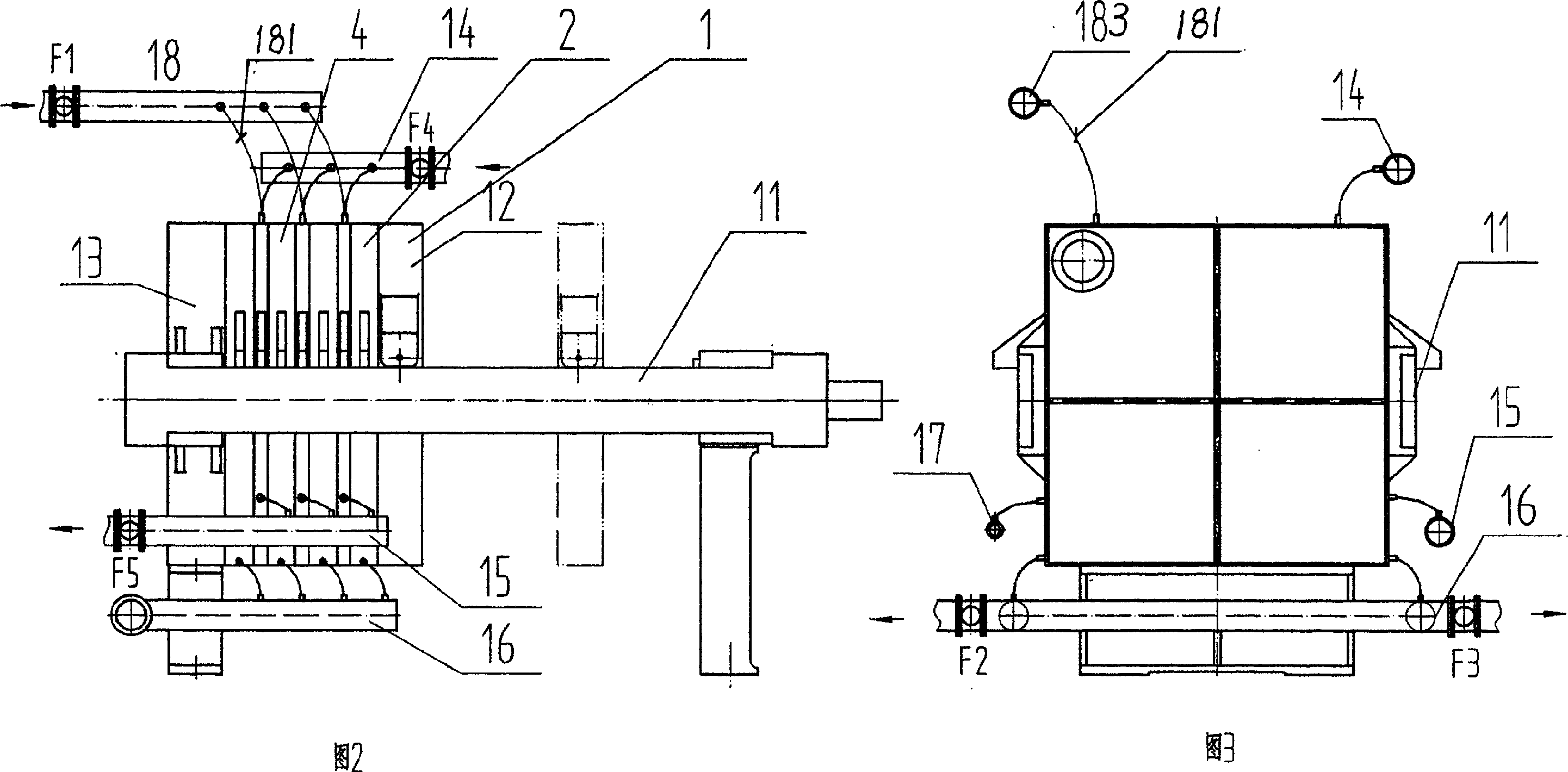

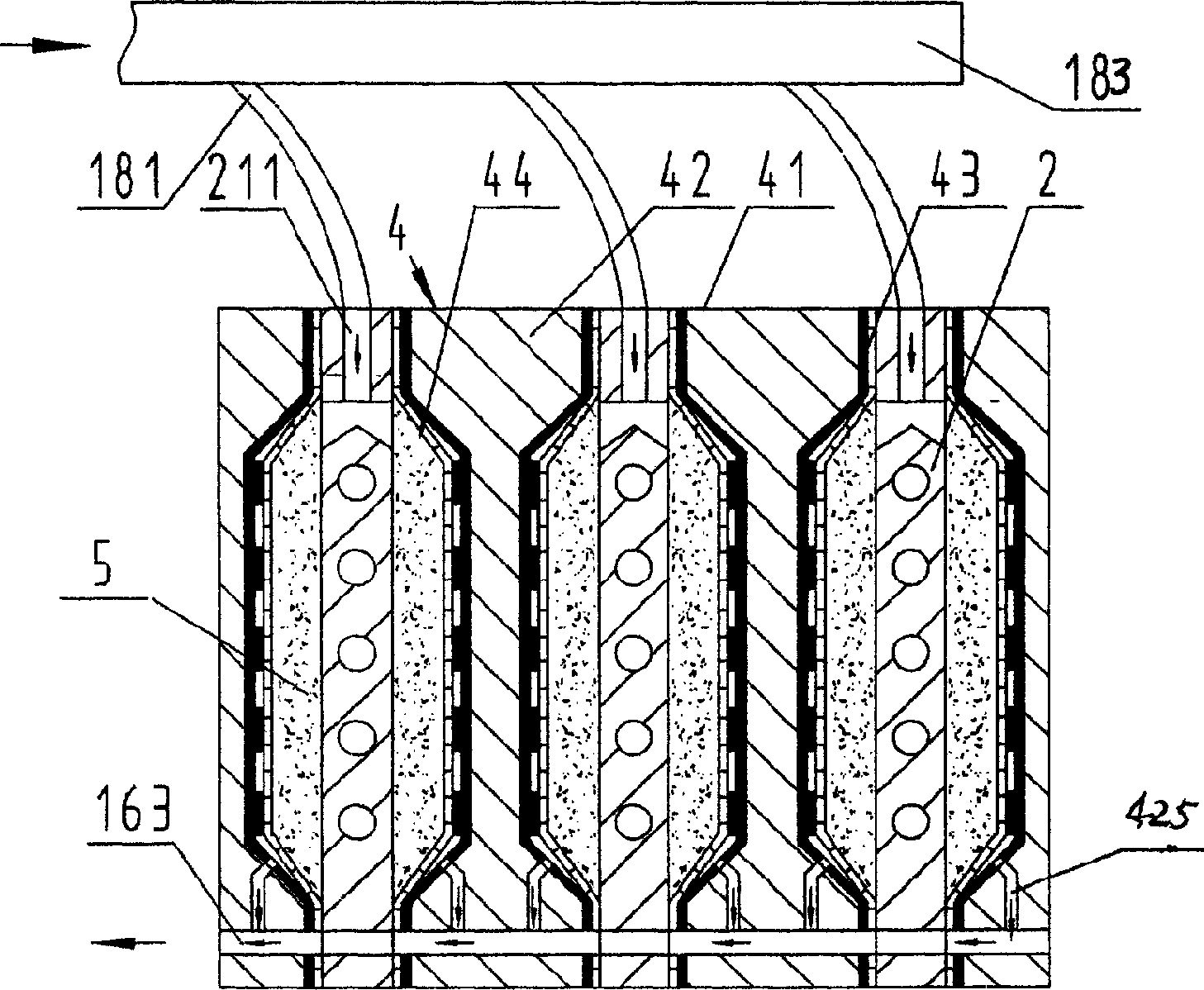

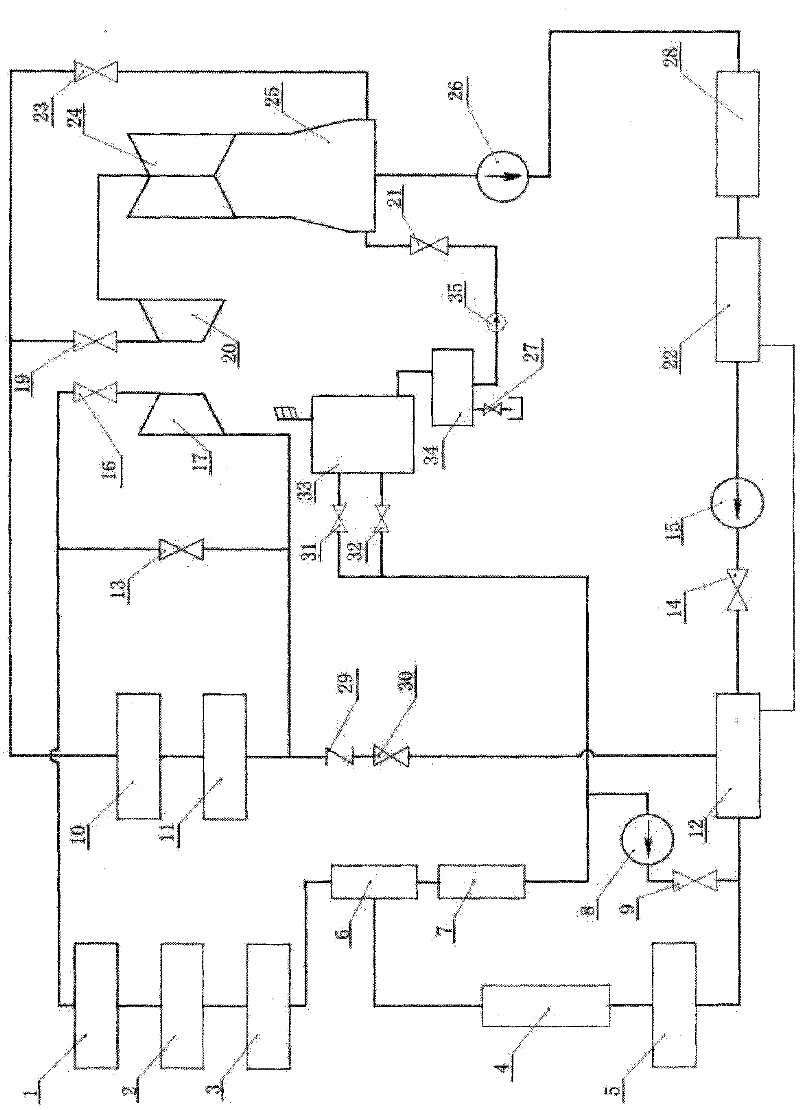

Thermal pressure filtration process for deep dehydration of fine coal suspension liquid and apparatus therefor

InactiveCN1634630ASave industrial landLess investment in infrastructureFiltration separationSeparation technologyCapillary water

The invention relates to a hot pressure filtration process and equipment for deep dehydration of fine-grained coal suspension, and relates to the technical field of solid-liquid separation of suspension. This process and equipment integrate mechanical pressure filtration and thermal drying. Mechanical pressure filtration is first performed on multiple sets of diaphragm filter plates—the drying plate unit, and a large amount of filtrate is discharged. The solid material forms a filter cake in the filter chamber, and then the drying plate Heating, pressurizing the diaphragm in the diaphragm filter plate at the same time, making the filter plate stick to the drying plate for hot pressure filtration, evaporating the capillary water into steam, and using the driving force of the steam itself to dehydrate, and at the same time to clean the drainage channel Vacuumize to speed up the dehydration. After a few minutes, the filter cake has been deeply dehydrated, then stop heating, pressurize, vacuumize, and discharge the solid materials. The membrane filter plate of this equipment - the drying plate unit, the drying plate is placed between the two membrane filter plates, so that the pressure filtration and drying are integrated into one equipment, and the equipment adopts the upper feeding or upper multi-channel feeding structure. The invention has the advantages of saving investment, occupying less land, saving energy, high production efficiency and low cost.

Owner:周明远 +1

Flue gas low-temperature combined desulfurization and denitration technology method

InactiveCN105327612AAchieve recyclingNo entryDispersed particle separationFlue gasConcentration gradient

The invention discloses a flue gas low-temperature combined desulfurization and denitration technology method mainly including the steps: flue gas after dedusting having a purification temperature and humidity meeting desulfurization conditions is sent into a desulfurization tower to flow through a desulfurization catalyst bed, sulfur dioxide in the flue gas is oxidized into sulfur trioxide under the action of a catalyst, and sulfur trioxide acts with water in the flue gas to generate sulfuric acid; the desulfurization catalyst bed is regenerated through progressively-decreased sulfuric acid concentration gradient washing; the flue gas after desulfurization is sent into a denitration conditioning work section, is dehumidified and heated, and is adjusted to meet requirements of a denitration technology; the flue gas after dehumidification and heating is sent into a mixing tower and is mixed with injected ammonia gas, the mixed flue gas mixed with the ammonia gas is sent into a denitration tower to flow through a denitration catalyst bed, and NOx, NH3 and O2 in the mixed flue gas are converted into N2 and water under the action of a denitration catalyst. The problems that a conventional flue gas desulfurization and denitration technology is narrow in flue gas applicable scope, high in heating energy consumption, high in running cost and the like are overcome.

Owner:SICHUAN UNIV +1

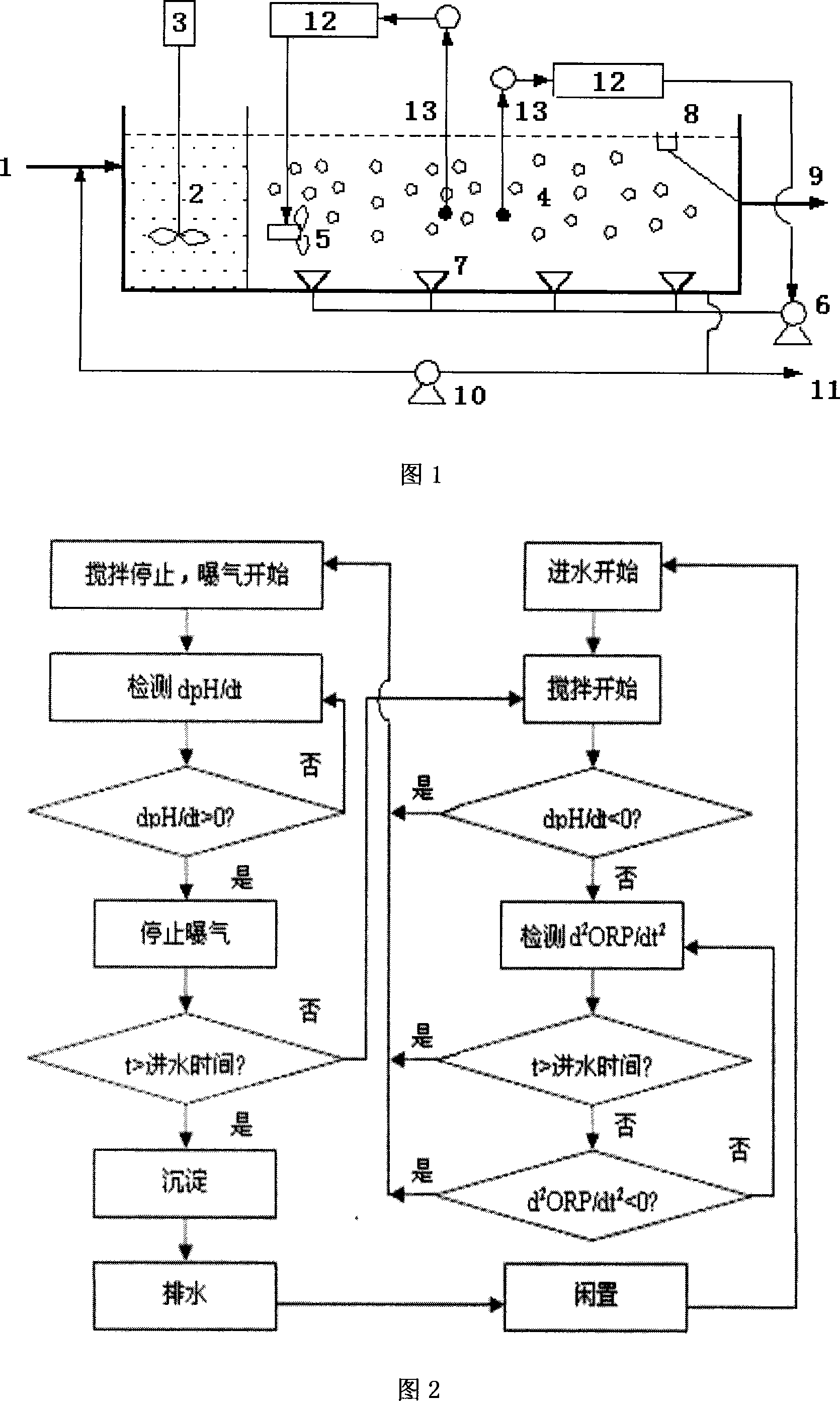

Real-time controlling method for denitrification by reinforced circulating type active sludge process

ActiveCN101182074AAvoid wastingControlled Aerobic AerationTreatment with aerobic and anaerobic processesElectric programme controlReal-time Control SystemSludge bulking

The invention discloses a real-time control method for denitrification by an enhanced circulating activated sludge method, which belongs to the field of biological denitrification of sewage and is suitable for advanced treatment of urban sewage. The effect of circulating activated sludge method on nitrogen and phosphorus removal is not ideal. The steps of the present invention: open the agitator in the main reaction zone at the same time as entering the water, and carry out the denitrification process under the anoxic condition, and stop stirring when a maximum value appears on the pH value curve and an inflection point appears on the ORP curve; Oxygen is supplied to the mixed solution to degrade organic matter and nitrify nitrogenous compounds, and stop aeration when a minimum value appears on the pH curve; repeat the above steps until the end of the water inflow stage, and react with the aerobic aeration stage end of period. The following process is similar to the traditional CAST method. It enters the sedimentation, drainage, and idle stages in turn, repeating all steps in turn and discharging sludge regularly. The whole process is completed by a real-time control system, which is easy to operate, low in cost, strong in impact load resistance, and not prone to sludge bulking.

Owner:CHONGQING KANGDA ENVIRONMENTAL PROTECTION IND GRP

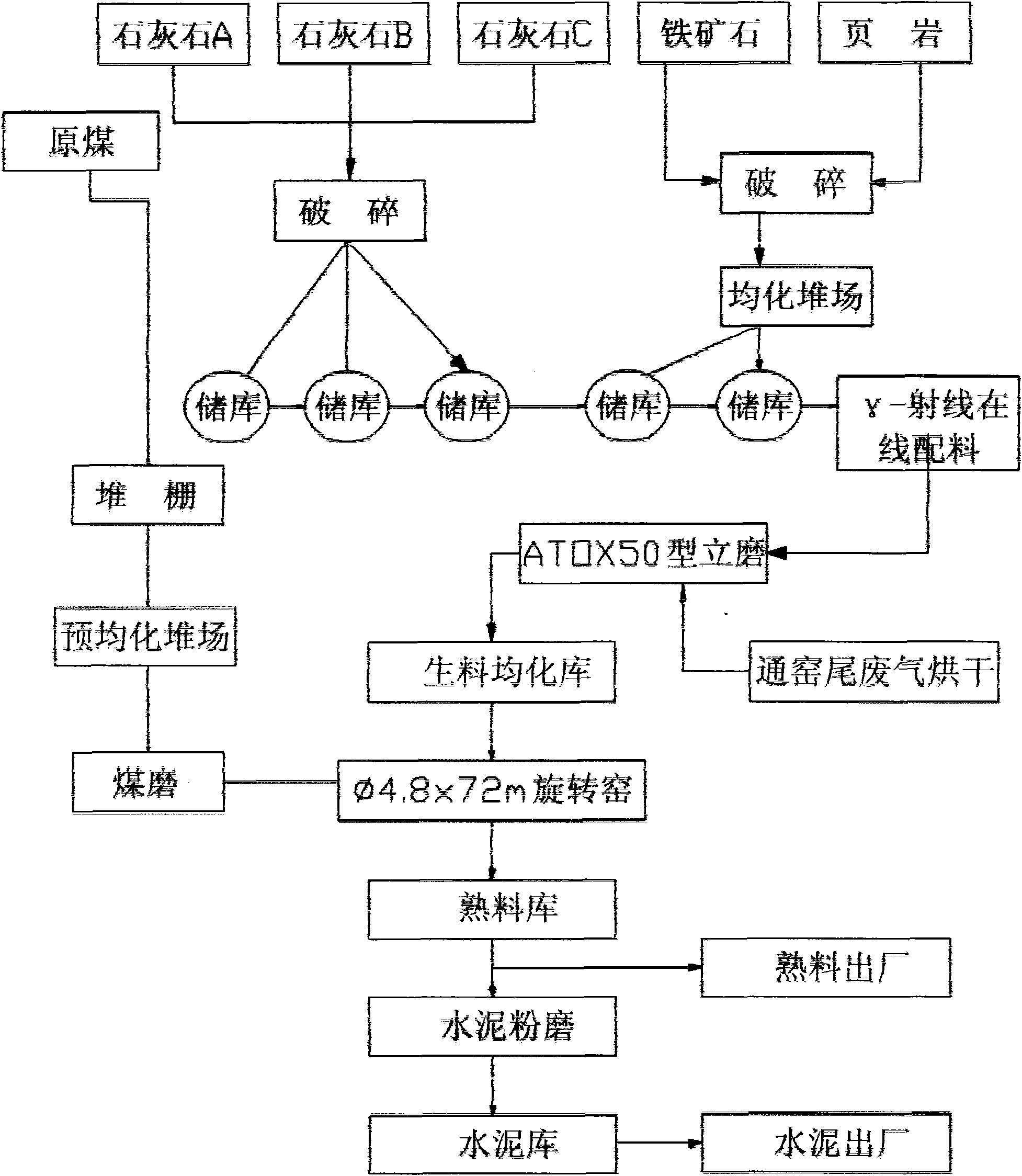

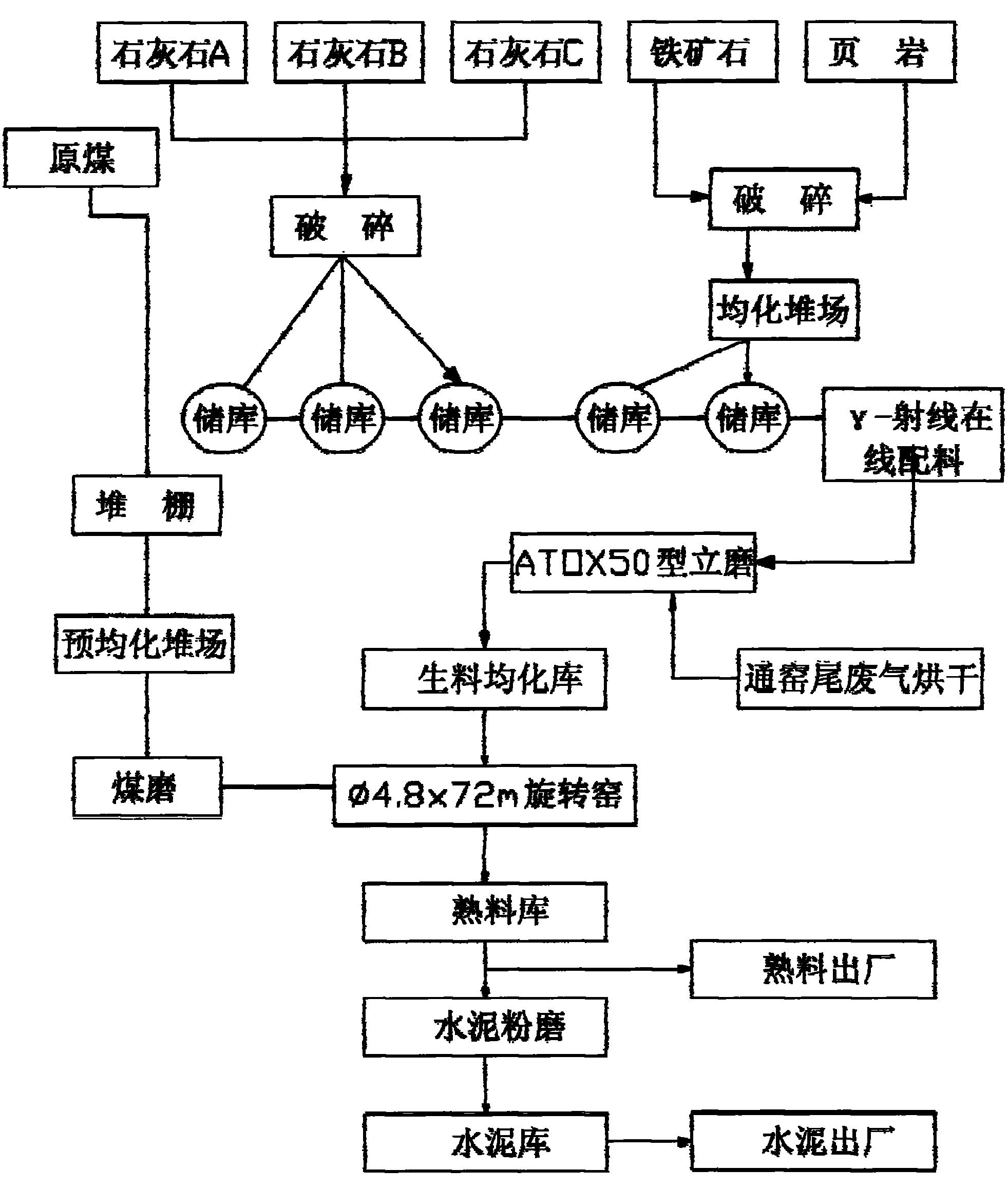

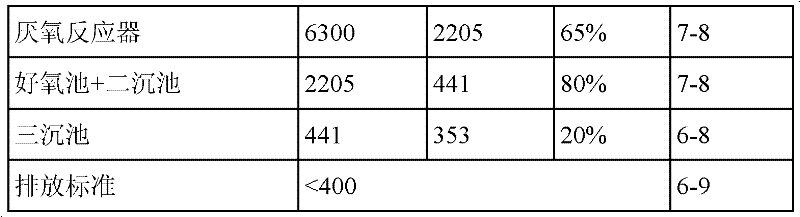

Method for producing cement by utilizing high-silicon low-calcium limestone

InactiveCN101781096AIt has the characteristics of "low calcium and high free silicon"Rich reservesIronstoneMining engineering

The invention relates to a method for producing cement by utilizing high-silicon low-calcium limestone. The cement comprises the following raw materials in percentage by weight: 48 to 50 percent of low-grade high-silicon limestone with CaO content between 42 and 45 percent and f-SiO2 content between 10 and 18 percent, 31 to 33 percent of high-magnesium limestone, 16 to 18 percent of matched limestone, 3 to 6 percent of shale and 2 to 4 percent of ironstone. The method is technology which utilizes low lime saturation ratio and ore of high silicon rate and high alumina rate and has an attribute of low silica modulus; online detection is performed on the mixture ratio of the raw materials by using a gamma ray instrument and a formula is adjusted by using one minute as a cycle; and a plate hammer counterpunch type crusher is used for crushing, a roller-type vertical grinding mill is used for grinding and waste gas at the tail of a kiln is used for drying the raw materials. The method has the advantages of capability of developing and utilizing low-grade limestone resource, accurate material burdening, timely regulation of the mixture ratio, and capability of reducing homogenization facilities and storage yard; and high quartziferous rock ore can be used in vertical milling and has high grindability. The method is suitable for utilizing high-dissociative silicon low-calcium limestone.

Owner:SINOMA TIANSHAN YUNFU CEMENT

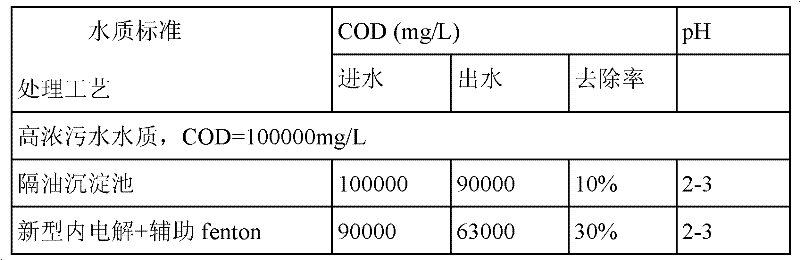

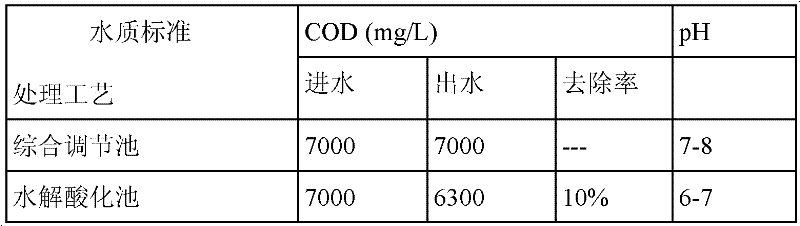

Combination type treatment method for pharmaceutical waste water

InactiveCN102336502AEfficient removalGuaranteed treatment effectMultistage water/sewage treatmentWater/sewage treatment by neutralisationHigh concentrationWater quality

The invention discloses a combination type treatment method for pharmaceutical waste water, which belongs to the technical field of water treatment. The method comprises the following steps of: first, improving the biodegradability of high concentration of waste water by adopting an efficient pretreatment technology, and finally removing a main pollutant COD (Chemical Oxygen Demand) in the waste water until reaching the standards. The invention has the advantages of stable running, flexible operation, convenience for maintenance, and strong impact resistance capability and strain capability for the variation of water inlet quantity and water quality.

Owner:WUXI TONGYUAN ENVIRONMENTAL PROTECTION TECHNG

Water treatment method of circulating-water culture system

InactiveCN101200337AImprove operating conditionsImprove water qualityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentPolyolefinSludge

The invention relates to a treatment method of recirculation aquaculture system, relating to the aquaculture treatment, which solves the problem about high density aquaculture water treatment device integration. The invention adopts filling type bio-flocculation sedimentation, biological film filtering and water quality stabilizing adjusting, the invention is characterized in that: the 2 / 3 of the upper part of the filling type bio-flocculation sedimentation is filled with polyolefin and polyamide composite filling layer for removing the organic substances, suspended substances, nitrogen, and phosphor, the 1 / 3 of the lower part of the filling type bio-flocculation sedimentation is the sludge collection area; the 2 / 3 of the upper part of the biological film is filled with a filtering filling layer made of poly(4-vinylpyridine)-halide for realizing deep purification of aquaculture, the 1 / 3 of the lower part of the biological film is the micro-oxygen aeration / sludge collection area, the sludge enters the sludge collection area of the filling type bio-flocculation sedimentation from the bottom of the biological film filtering unit; the water quality stabilizing adjusting unit filled with a filling layer mixed by clinoptilolite, vermiculite, shale and limestone for realizing caustic balance and ion compensation of aquaculture water quality. The invention is used for aquaculture integrated biological treatment.

Owner:SHANGHAI OCEAN UNIV

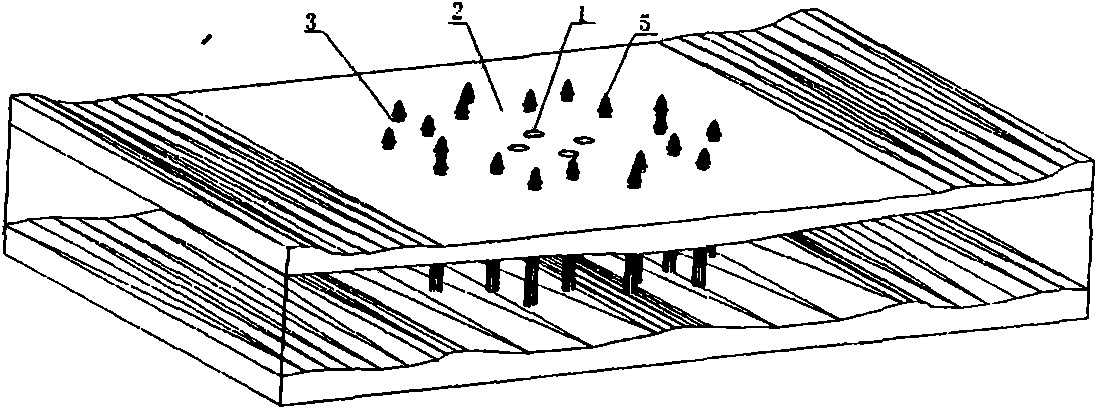

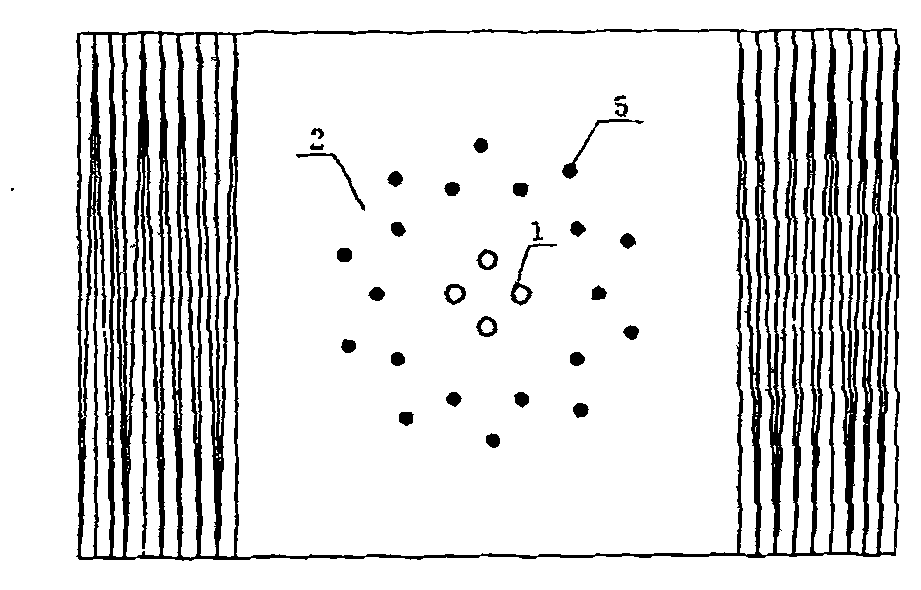

Groundwater pollution remediation technology for multiple-row column form PRBs (Permeable Reactive Barrier) in annular structures

InactiveCN101880087AInnovative designExtended service lifeBiological water/sewage treatmentEnvironmental engineeringReaction zone

The invention provides a groundwater pollution remediation technology for multiple-row column form PRBs (Permeable Reactive Barrier) in annular structures. A system constructed by the technology is made of filled columns which pass through aquifers and are distributed discontinuously, and clear water plants with developed root systems can be grown in soil layers above the filled columns. The system is distributed in an annular space, can be in multi-ring arrangement and is further provided with a spare reaction zone in addition to a main reaction zone. The technology solves the problems that the traditional PRB technology medium is difficultly updated and has potential hazard after becoming invalid, and the like, prolongs service life of the system under the premise of saving construction and maintaining cost, and synchronously and fully utilizes advantages of a phytoremediation technology so as to enhance the operational efficiency of the PRB system. The technology is suitable for eliminating single or compound pollutants in homogeneous aquifers or inhomogeneous aquifers.

Owner:王鹤立

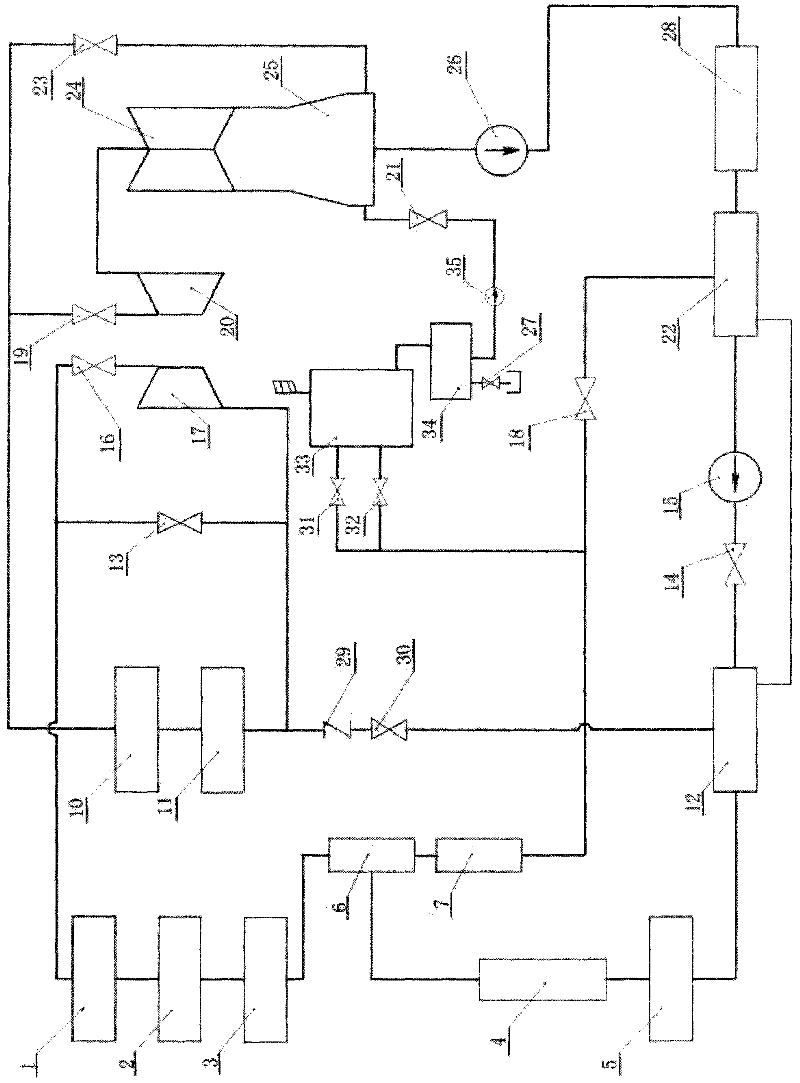

Pump-free direct current furnace starting system capable of recycling working medium and heat comprehensively

The invention relates to a pump-free direct current furnace starting system capable of recycling a working medium and heat comprehensively, and provides a direct current furnace starting system which is used for a supercritical direct current furnace without a starting furnace water circulation pump at a power station and can recycle the working medium and heat comprehensively. According to the invention, during the starting period of the direct current furnace, three high-pressure heaters at the side of a turbine are utilized as a water heat exchanger, heat is emitted in echelon by the starting of the drainage with high enthalpy, pressure is reduced, thus the enthalpy is reduced to be suitable for the safe recovery by a deaerator; double control logic of the high-pressure heater by a machine set DCS (data conversion system) with special design ensures each high-pressure heater to complete the starting whole process of the direct current furnace and a heat regenerative system working pattern safely and economically under two different working patterns; the working medium and heat can be recycled comprehensively by each starting working condition and starting whole process, and therecycled effect is superior to the direct current furnace starting system with a starting furnace water circulation pump; and the maintaining expense of the infrastructural construction investment and operation can be reduced greatly by the starting furnace-free circulation pump and a subsystem thereof.

Owner:章礼道

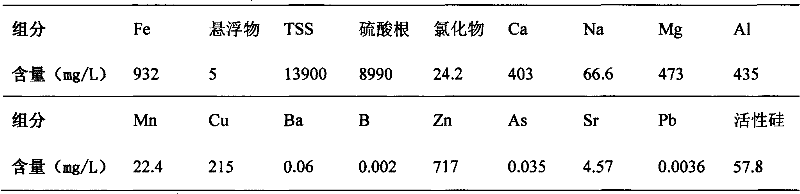

System for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage

ActiveCN102311189AEliminate pollutionEliminate hidden dangers of secondary pollutionWater contaminantsMultistage water/sewage treatmentSolubilityAcid mine drainage

The invention belongs to the field of wastewater treatment and specially, relates to a system for treatment of acid mine drainage and resource recovery of iron, aluminum, copper and zinc in drainage. The system is characterized in that the system is composed of an iron removal system, an aluminum removal system, a copper removal system, a zinc removal system, a sedimentation basin 1 and a sedimentation basin 2 by sequential connection. Based on differences of precipitation performances of a metal ion under pH conditions and differences of solubility products (Ksp) of a reaction between copperand a sulfur-containing organic chelating agent and a reaction between zinc and the sulfur-containing organic chelating agent, through a fractional precipitation method, iron, aluminum, copper, zinc and the like are separated effectively; resource recovery and utilization is realized; hidden troubles of secondary pollution caused by waste residues are eliminated; and treated drainage reaches a reuse standard and can is fed directly into mineral processing pool for reuse. The system has the advantages of simple process, good effect of drainage treatment, stable operation, low costs of treatment, capital construction investment, energy consumption and operation, and wide application prospect.

Owner:马前 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com