Energy-saving process for treating high ammonia nitrogen waste water

A wastewater treatment, high ammonia nitrogen technology, applied in water/sewage multi-stage treatment, oxidized water/sewage treatment, water/sludge/sewage treatment, etc. Low problems, to achieve the effect of saving pharmaceutical consumption, high processing efficiency, and low operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

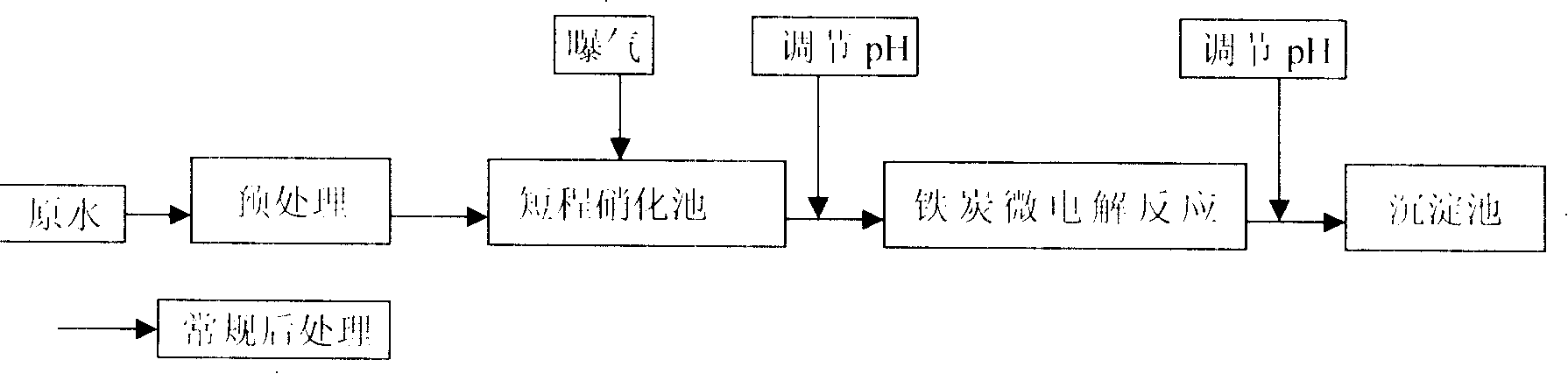

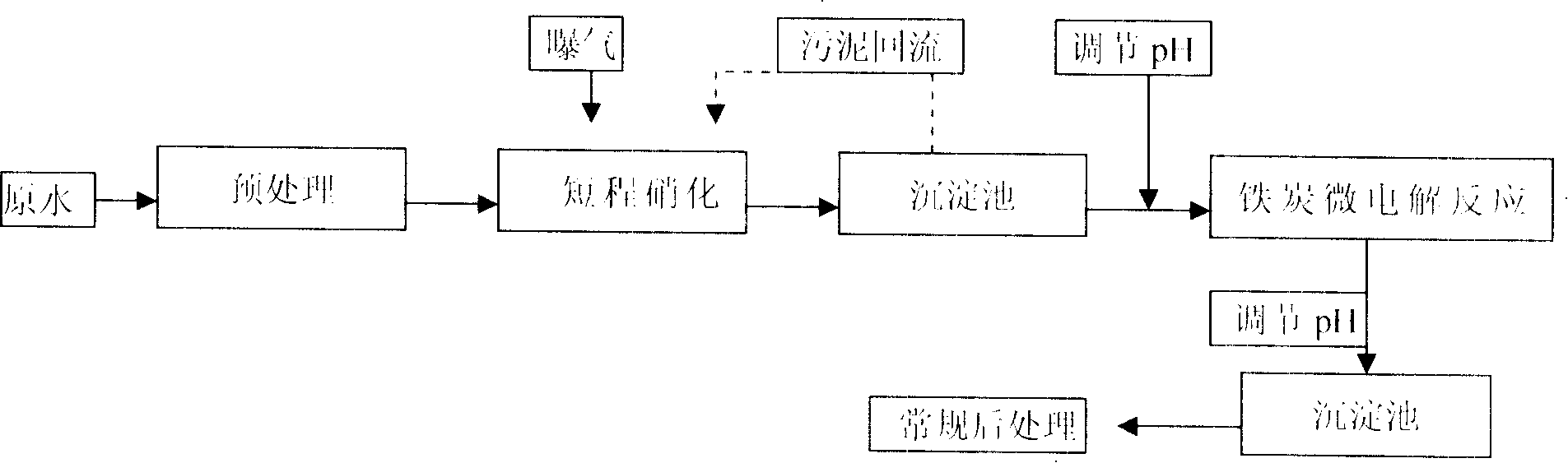

[0007] The new energy-saving high ammonia nitrogen wastewater treatment process includes pretreatment-short-range nitrification-micro-electrolysis-post-treatment.

[0008] In the pretreatment stage, the Kjeldahl nitrogen is converted into ammonia nitrogen as much as possible, and then the ammonia nitrogen in the wastewater is nitrified to the nitrite nitrogen stage in the aerobic short-range nitrification tank. Ammonia nitrogen is converted to nitrite nitrogen through a short-cut nitrification reaction. The temperature in the short-range nitrification biological reaction tank is controlled at 25-40°C, the pH value is 8.0-9, the sludge age is 50-80 days, the DO is controlled at 2-5mg / L, the hydraulic retention time is 20-40 hours, and COD removal is realized at the same time Rate 20%-30%. The short-range nitrification tank can be filled with film (such as figure 1 ) or suspended sludge (such as figure 2 ) in two ways (the operating conditions are as described above).

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com