Method for producing cement by utilizing high-silicon low-calcium limestone

A high-silicon, low-calcium, and limestone technology is applied in the field of cement production using high-silicon, low-calcium limestone, which can solve problems such as insufficient and insufficient, and achieve the effects of reducing environmental pollution, reducing raw material costs, and avoiding deployment errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

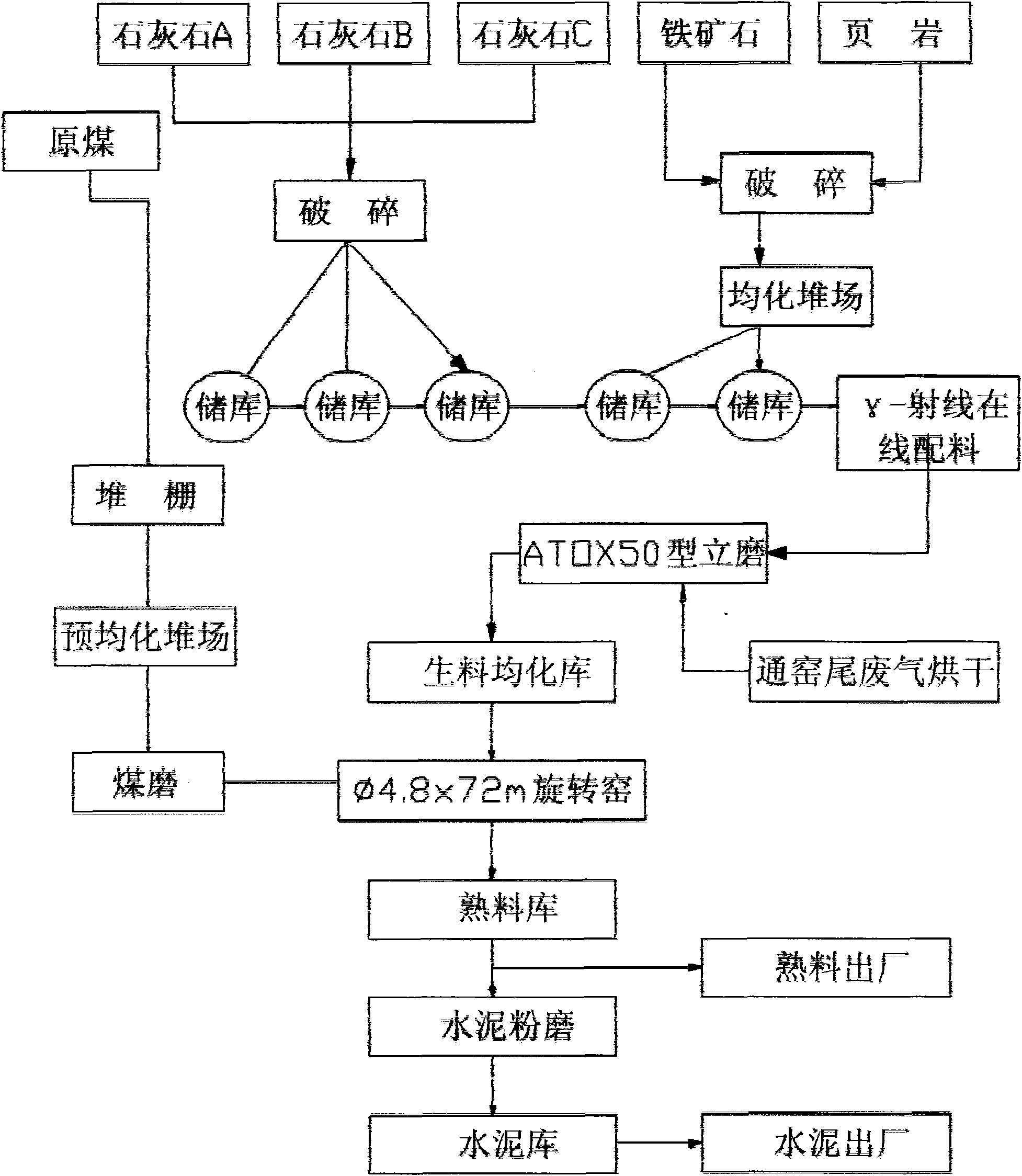

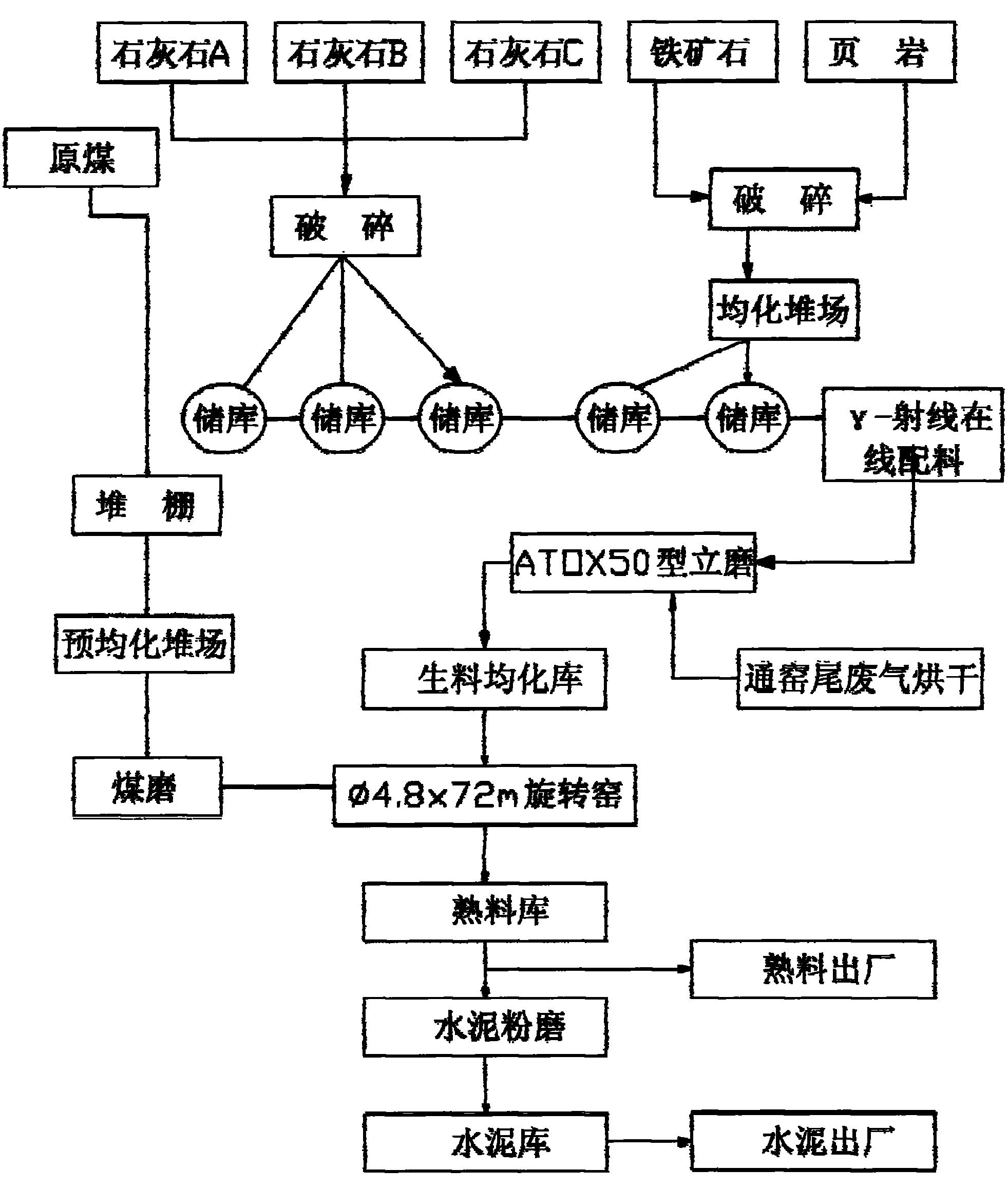

[0048] Such as figure 1 As shown in the schematic flow chart, taking a production line with a daily output of 5000 tons of cement as an example, the method for producing cement of the present invention includes basic processes such as material preparation, crushing, grinding, storage, homogenization, calcination, storage and aging, and the basic equipment includes: Stockyards, storage warehouses, crushers, mills, rotary kilns, clinker warehouses, cement warehouses and gamma-ray instruments, etc. Raw materials include 3 kinds of limestone, shale, iron ore and raw coal, as well as auxiliary materials and active additives. There are 3 types of limestone in the raw material, namely limestone A, limestone B, and limestone C. Among them, limestone A is matched with limestone, which is a conventionally used limestone, that is, limestone that reaches grade II ore, with a CaO content of 46% to 48% by weight, and is generally considered to have low silicic acid rate (SM) and high alumi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com