Patents

Literature

213results about How to "To achieve the purpose of resource utilization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production method of lightweight ceramic bricks

ActiveCN102249694ATo achieve the purpose of resource utilizationLow densitySolid waste disposalCeramic materials productionZero emissionSewage treatment

The invention discloses a method for producing lightweight ceramic bricks by comprehensively utilizing solid wastes from ceramics factories and sludge produced in sewage treatment plants as the raw materials. The method comprises the steps of: subjecting waste residues from polishing, fragmentation treated waste polished tiles, waste blank powder and waste mud powder reclaimed from blank making, recovered dust from dedusters, drainage silt from ceramics factories, fragmented waste abrading blocks for polishing, waste glazes, coal sintering residuals, waste kaolin, waste high temperature sand, sludge, a water reducer and a reinforcing agent to ball milling, deironing through sieving, decaying and homogenization in a wet bowl mill, spray drying the slurry into particle powder, then pressing and sintering the particle powder into bricks. By comprehensively utilizing solid wastes from ceramics factories and sludge produced in sewage treatment plants, the method of the invention reaches the purpose of waste recycling and realizes the effect of zero emission of architectural ceramics and polished tile factories.

Owner:FOSHAN SHI WAN YING BRAND CERAMICS CO LTD +2

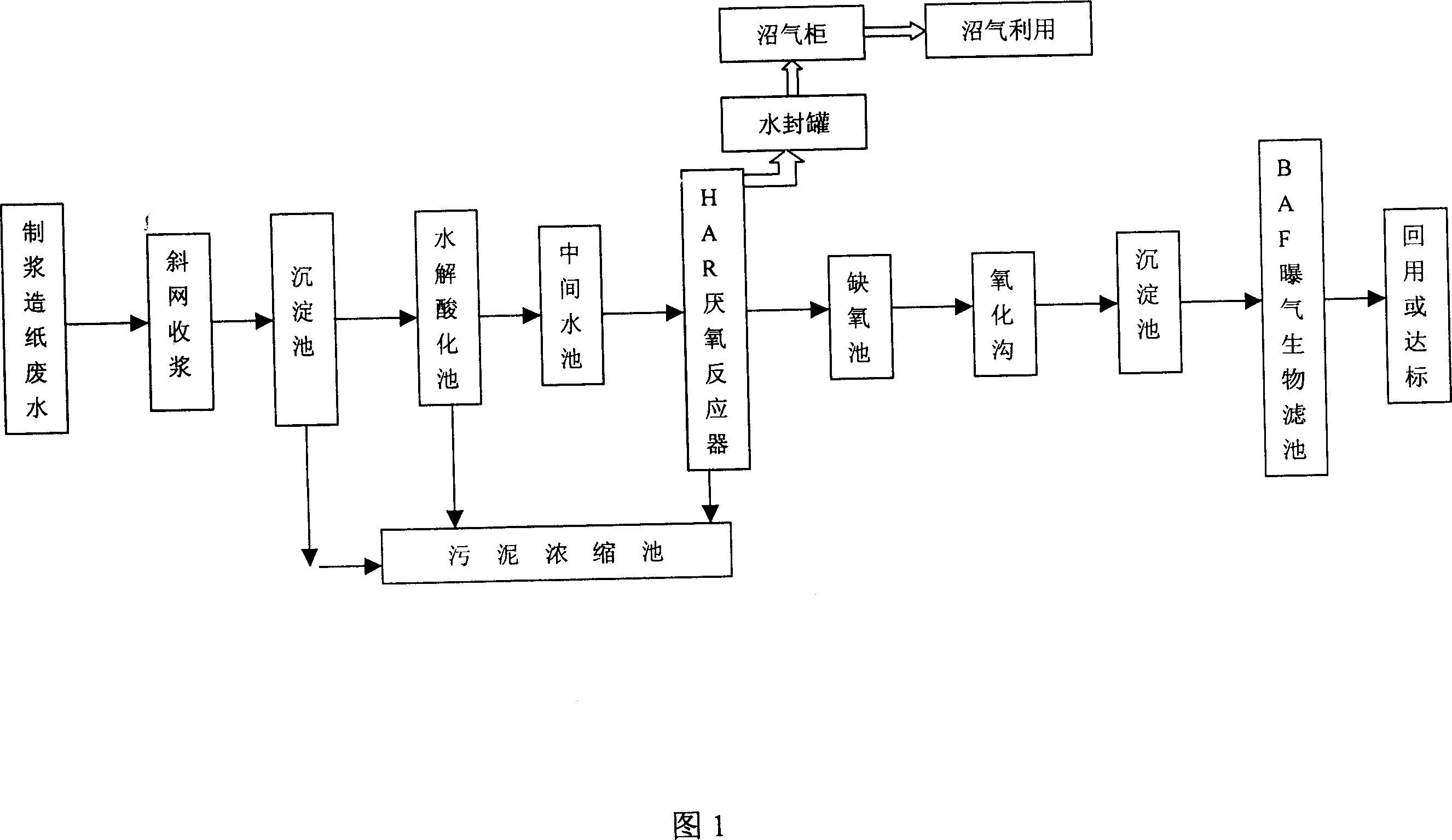

Paper-making effluent purifying treatment process

InactiveCN1931749AAchieve resource utilizationTo achieve the purpose of resource utilizationTreatment using aerobic processesWaste based fuelMedicineWastewater

The present invention is paper-making effluent purifying treatment process including hydrolyzing acidification, anaerobic biological treatment, anoxia treatment, aerobic biological treatment and aerobic biofilter treatment mainly. The present invention has low treating cost, low power consumption, capacity of generating energy source with produced methane, high treating efficiency, high COD and SS eliminating rate, and other advantages.

Owner:山东贵和显星纸业有限公司

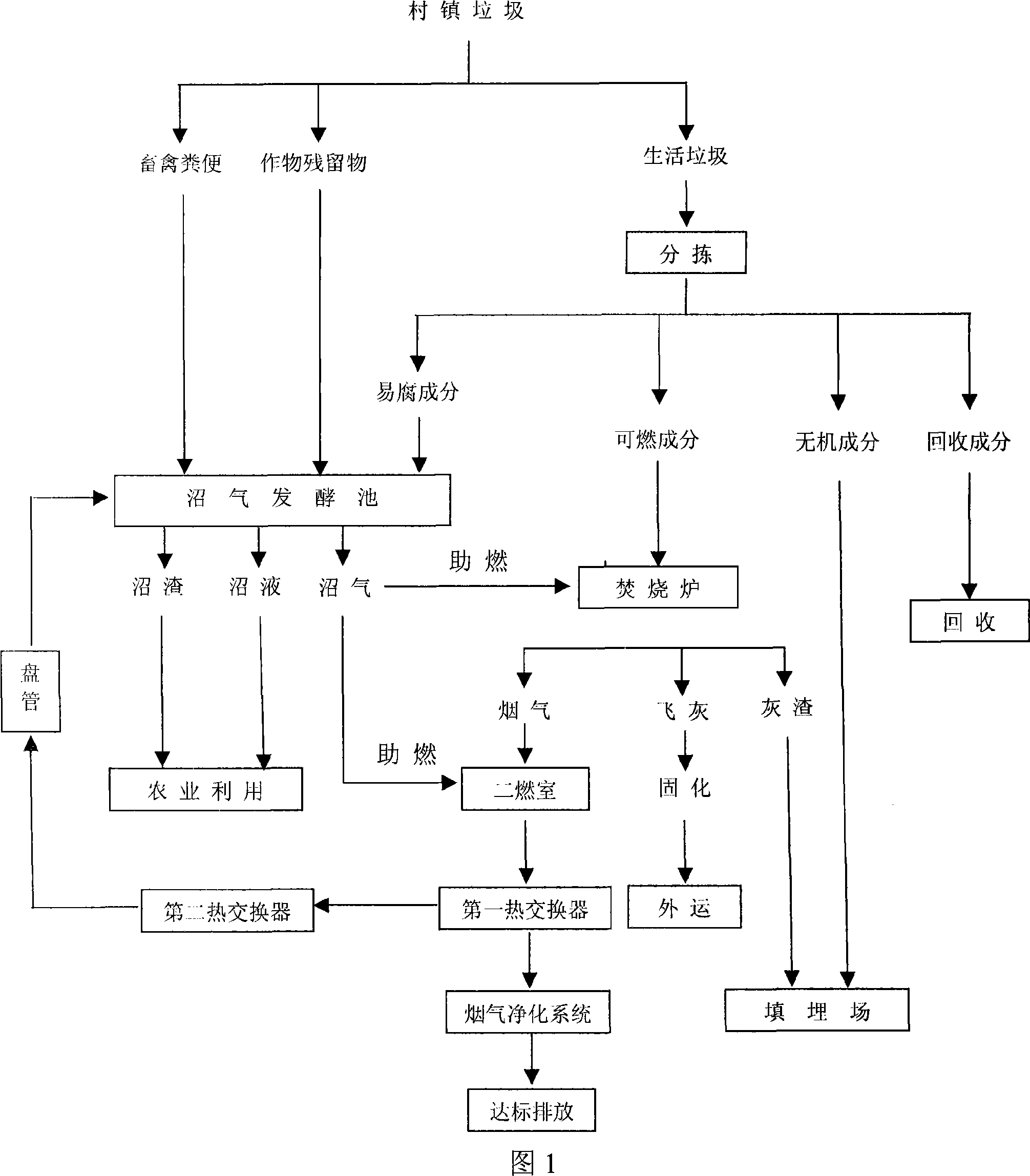

Rubbish comprehensive processing method adapted for village and small town

InactiveCN101062825AIncineration harmlessIncineration reductionBio-organic fraction processingChemical industryThermal energyResource utilization

The invention discloses a garbage comprehensive treatment method for village, which comprises the following steps: sorting life garbage of village to perishable element, combustible constituent, reclaiming element; inorganic element; allocating the perishable element, residues of crop, animal and poultry manure and water with mass ratio at 0. 8-1. 2:0. 8-1. 2:8; proceeding anaerobic fermentation under the insulation action of burning lose heat; generating marsh gas; burning the combustible constituent with combustion-supporting marsh gas completely; getting high temperature smoke gas; recovering thermal energy through the first and second heat exchanger; maintaining the temperature of marsh gas fermenting tank; obtaining resource utilization of marsh liquid or slag, marsh gas and reclaiming component; health-filling the inorganic element and burning ash slag. This invention can prevent twice pollution of the burning smoke gas, which can increase the efficiency and output of mash gas.

Owner:ZHEJIANG UNIV

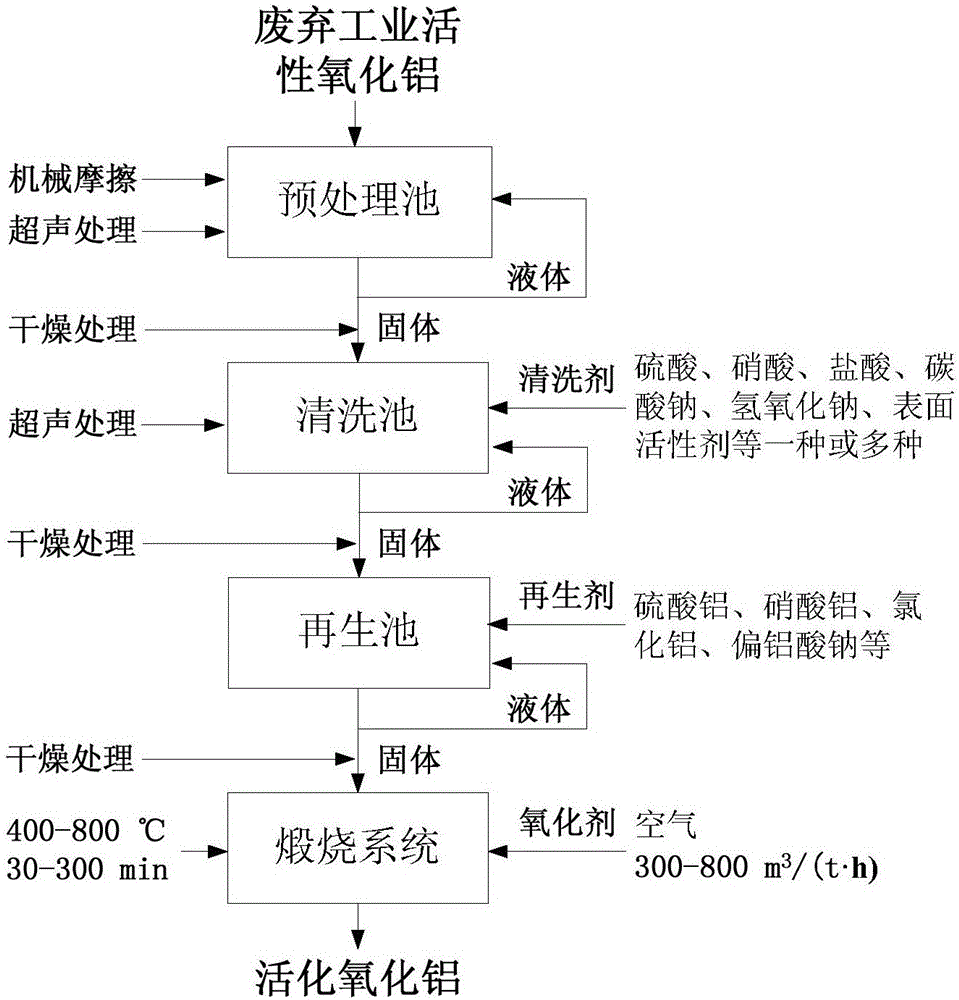

Method for activating and regenerating waste industrial activated aluminum oxide

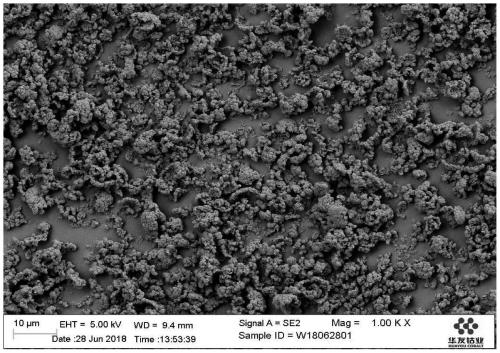

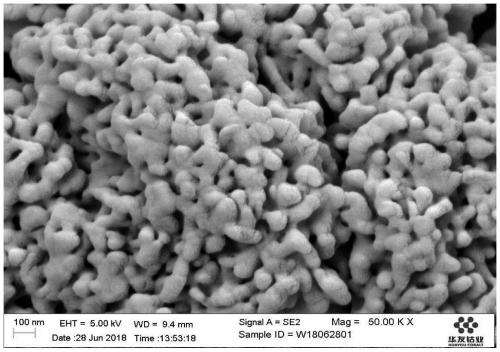

ActiveCN106629796AHigh pore volumeRealize resource utilizationOther chemical processesAluminates/aluminium-oxide/aluminium-hydroxide purificationAir atmosphereActivated Aluminum Oxide

The invention discloses a method for activating and regenerating waste industrial activated aluminum oxide. The method comprises pretreatment, cleaning liquid impregnation treatment and regeneration treatment; adopted cleaning liquid is selected from at least one of acid liquor and alkali liquor and surfactant solution; the regeneration treatment comprises regenerated liquid impregnation and calcination treatment, and adopted regenerated liquid is selected from aluminum-contained solution; the calcination treatment is performed under air atmosphere, and air inlet amount is 300 to 800 m<3> / (h.t). According to the method for activating and regenerating the waste industrial activated aluminum oxide provided by the invention, an original pore structure channel is dredged through a physical and chemical method, and a new pore structure is regenerated on the basis of the existing pore structure to obtain activated aluminum oxide with high specific surface area and high pore volume.

Owner:杭州贝采催化剂有限公司 +1

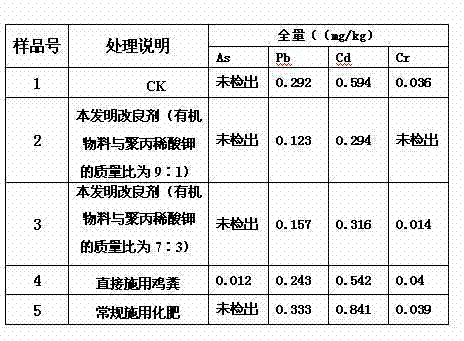

Modifying agent capable of passivating vegetable garden soil heavy metal and preparation method and applying method thereof

InactiveCN102206494AImprove propertiesReduced effectivenessAgriculture tools and machinesContaminated soil reclamationCelluloseMass ratio

The invention discloses a modifying agent capable of passivating vegetable garden soil heavy metal and a preparation method and an applying method thereof. The modifying agent consists of organic material and potassium polyacrylate in a mass ratio of 7:(3-9):1; the organic material comprises the following components in parts by weight: 100-120 parts of gramineous crop straws, 10-12 parts of animal manure, 10-12 parts of potassium sulfate, 20-22 parts of lignite, 0.02-0.03 part of actinomycetes, 0.02-0.03 part of photosynthetic bacteria, 0.04-0.05 part of bacillus, 0.02-0.03 part of aspergillus and 0.06-0.07 part of cellulose decomposition bacteria; the potassium polyacrylate is separately packaged and is mixed with the organic material when applied; during a fermentation period, moisture is controlled at 50-60 percent, and the temperature is controlled at 60 DEG C-70 DEG C; and after the application of the modifying agent, the water-soluble state and full content of Pb, Cd, Cr and the like in soil and vegetables can be reduced greatly.

Owner:INST OF QUALITY STANDARD & DETECTION TECH YUNNAN ACAD OF AGRI SCI

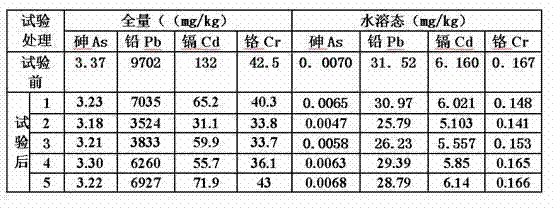

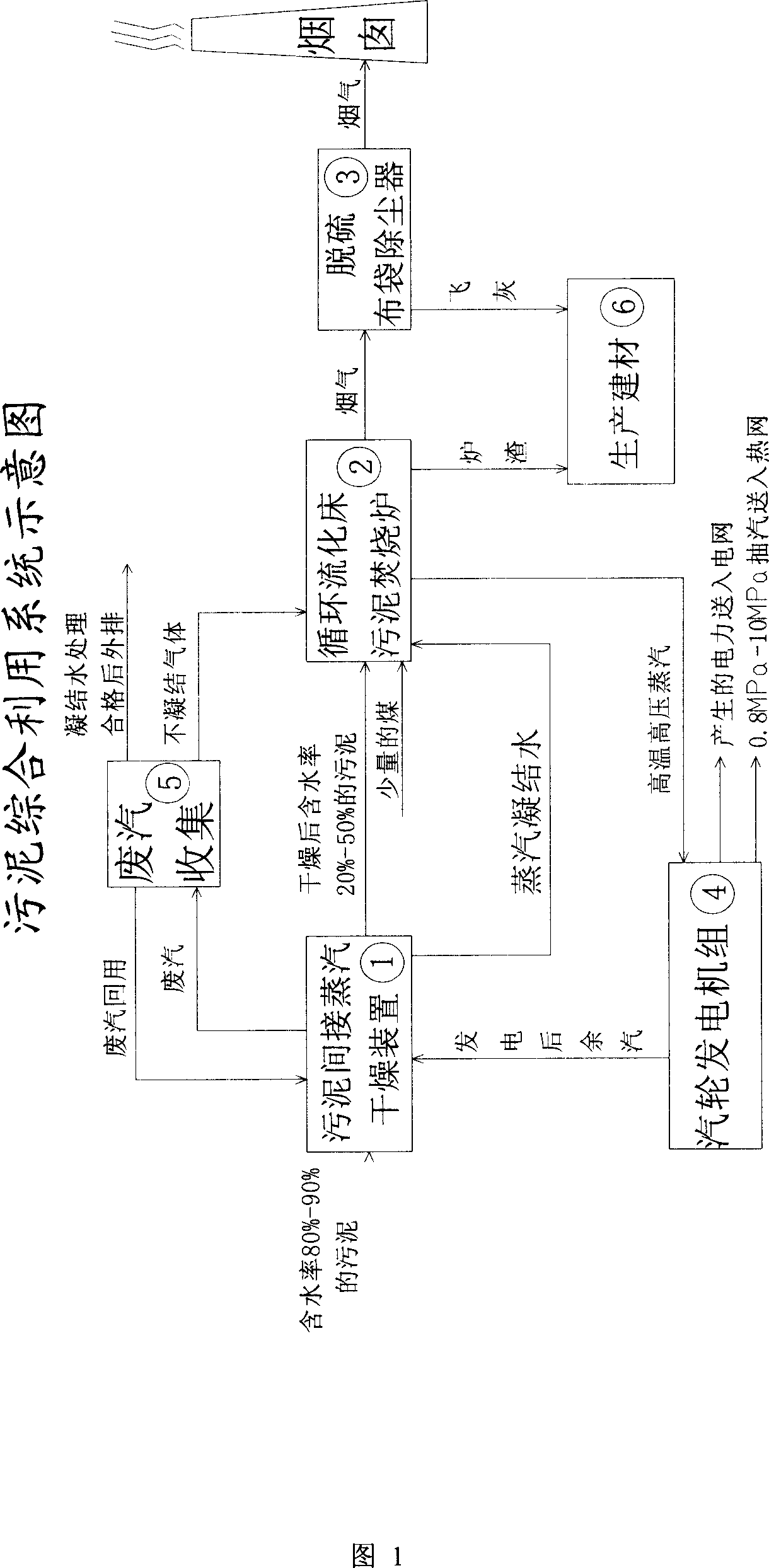

City sludge comprehensive utilization

InactiveCN1978348AAchieve harmlessTo achieve the purpose of resource utilizationSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeTurbine

This invention discloses a method for using city sludge in combination composed of 1, a sludge drying unit, 2, a burning and processing unit, 3, a smoke process unit, 4, a turbine-generator set generation unit, 5, a waste gas collection and process unit, 6, a producing unit for construction materials, which mainly utilizes the steam exhaust generated by the steam turbine set and waste steam generated when drying sludge.

Owner:陈梅铭 +2

Method for improving sludge anaerobic fermentation and acid production

InactiveCN101768609AAchieve reductionImprove efficiencyFermentationSolid phasesVolatile organic compound

The invention discloses a method for improving sludge anaerobic fermentation and acid production, belonging to the environmental protection technical field. The method is taken as follows: the residual sludge of municipal sewage plants are used as the raw material, wall breaking action is applied to the microorganisms in the sludge by control of the operating parameters of ultrasonic in order to ensure most of the organic substances in the cells of the microorganisms to be dissolved, lye is added to the sludge to regulate the pH value of the sludge, and the sludge is transformed furthest from the solid phase to the liquid phase and made to produce volatile organic matter under the action of the lye and the microorganisms. The invention further improves the quantity of the organic acid produced from the sludge on the basis of sludge innoxiousness and resource utilization.

Owner:TONGJI UNIV

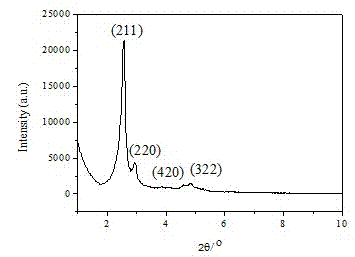

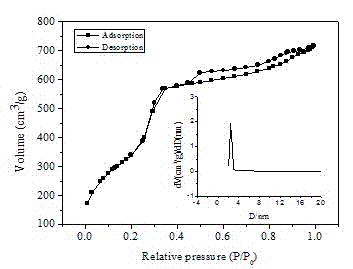

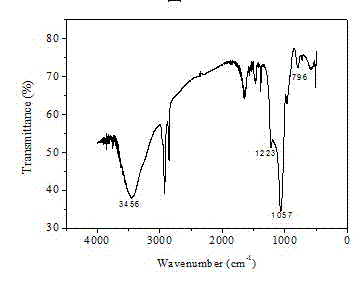

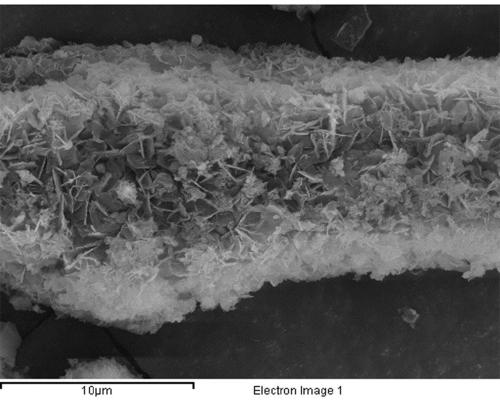

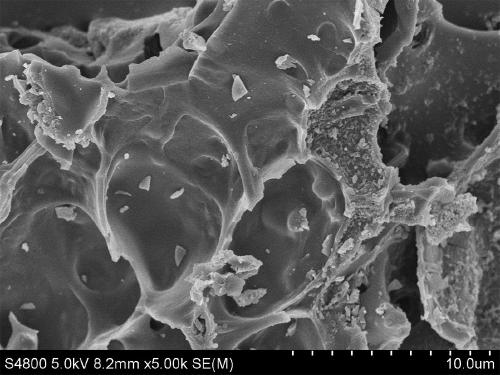

Method for preparing mesoporous molecular sieve

InactiveCN103172080ALower synthesis costAvoid toxicSolid waste disposalCrystalline aluminosilicate zeolitesChemistryMolecular sieve

The invention discloses a method for preparing a mesoporous molecular sieve MCM-48. The method comprises the steps of extracting effective ingredients in coal ash as silicon sources by adopting a single template agent cetyl trimethyl ammonium bromide (CTAB); and synthetizing MCM-48 under alkaline medium by a hydrothermal method. The synthetized mesoporous material is regular in ducts, single in aperture distribution, high in order degree, and large in specific surface area. The method is simple and feasible in actual operation, economic and environment-friendly, and can provide a new path for 'recycling' utilization of the coal ash; and the synthetized sample has practical application value.

Owner:NANJING UNIV OF SCI & TECH

Ferro-manganese humic acid modified biochar, preparation method thereof and application of biochar

InactiveCN110052248ATo achieve the purpose of resource utilizationSimple methodOther chemical processesWater contaminantsIn situ remediationManganese

The invention discloses a ferro-manganese humic acid modified biochar, a preparation method thereof and an application of the biochar. Biomasses soaked by potassium permanganate solution are dried andpyrolyzed and then loaded with ferric oxide and humic acid to prepare the ferro-manganese humic acid modified biochar which can be used for removing cadmium and arsenic in polluted water and achieving in-situ remediation of cadmium and arsenic polluted soil.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI +1

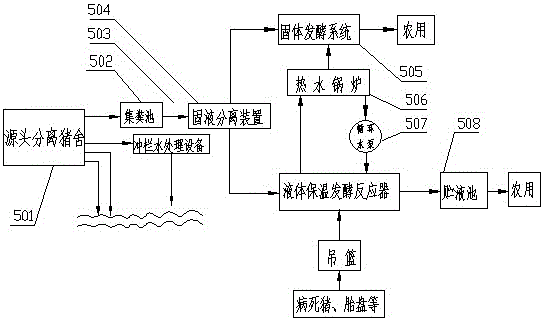

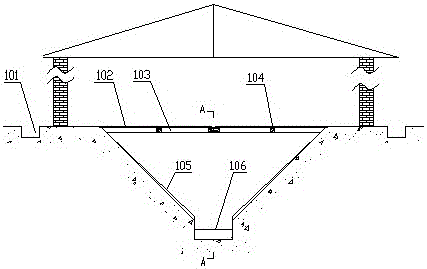

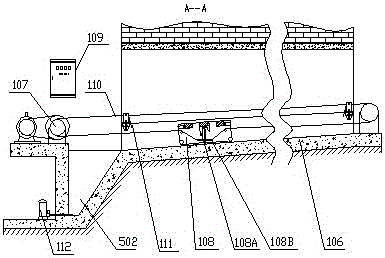

System and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in large-scale farm

ActiveCN106116736AIn line with the cycleReduce the burden onBio-organic fraction processingAnimal corpse fertilisersSludgeThermal insulation

The invention relates to a system and method for controlling excrement and urine of poultries and placentae of disease-caused dead poultries in a large-scale farm. The system comprises a source separated poultry house, a solid-liquid separation system, a liquid high-temperature aerobic fermentation system, a solid fermentation system, a stink-flue gas treatment system, a circulating water system and a detection control system, wherein the source separated poultry house is a poultry house in which rainwater and sewage are separated, drinking water and sewage are separated, and fence flushing water and the excrement and urine of the poultries are separated; the solid-liquid separation system comprises a excrement collecting pool, a sludge pump and a solid-liquid separation device; the liquid high-temperature aerobic fermentation system comprises a liquid thermal-insulation fermentation reactor; the stink-flue gas treatment system comprises a stink heat exchange condenser, a flue gas heat exchange condenser, a biological deodorization filter tower, an aeration fan, an air blower and an induced draft fan; and the detection control system comprises a material temperature sensor, a material level sensor, a pressure sensor, a water temperature sensor and a controller. According to the system, the harmless treatment, the reduction and the recycling are realized, the environment is protected, and the energy is saved.

Owner:HUNAN SAKAL ENVIRONMENTAL SCI & TECH CO LTD +1

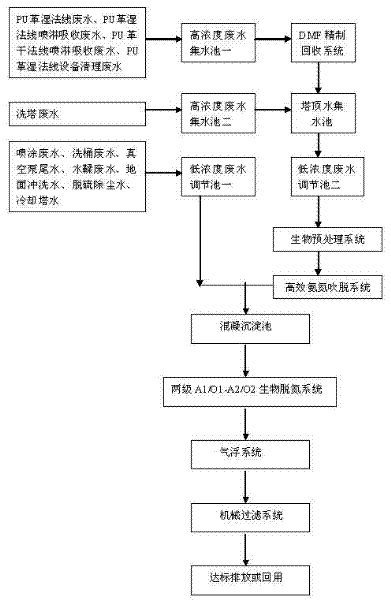

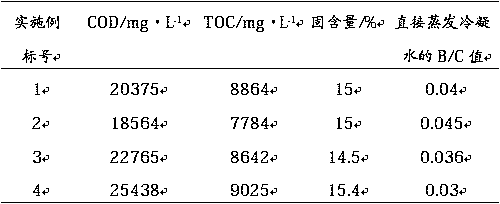

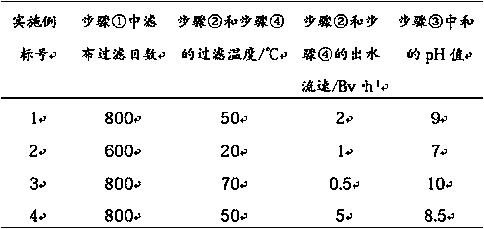

A kind of pu leather wastewater treatment method

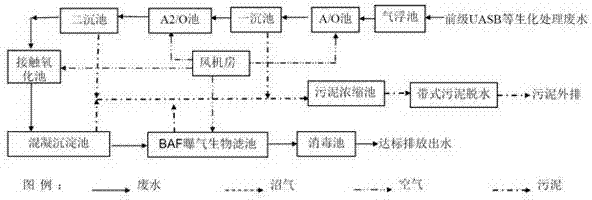

ActiveCN102295391ATo achieve the purpose of resource utilizationLow running costMultistage water/sewage treatmentAmmoniacal nitrogenChemical oxygen demand

The invention discloses a PU (Poly Urethane)-leather wastewater-processing method, which comprises the following steps of: step 1, carrying out classified processing for wastewater in PU-leather production; step 2, carrying out biological preprocessing; step 3, carrying out high-efficiency ammonia-nitrogen blowing processing; step 4, carrying out coagulating-sedimentation processing; step 5, carrying out two-stage A1 / O1-A2 / O2 biological-denitrification processing; step 6, carrying out air-flotation processing; and step 7, carrying out mechanical-filtration processing. Through the PU-leather wastewater-processing method, COD (Chemical Oxygen Demand) and ammonia nitrogen in the wastewater can be removed, the wastewater being processed is ensured to be discharged after reaching standards, the problems of impacts of the high-concentration wastewater to a wastewater-processing system and the influence of biological-denitrifying capability reduction caused by the increase of ammonia-nitrogen concentration after the anaerobic hydrolysis of DMF (Dimethyl Formamide) in the wastewater are solved, the operating expenses are reduced, the wastewater processed can be used for production, and a good economic benefit is generated.

Owner:ZHEJIANG SHUANGLIANG SUNDA ENVIRONMENTAL PROTECTION CO LTD

Casing method of dredging sediment non-sintered ceramsites

The invention relates to a casing method of dredging sediment non-sintered ceramsites, comprising following steps: (1) crushing cement, quicklime, glass fibre powder, and fly ash by using a crusher; (2) mixing the pretreated cement, quicklime, glass fibre powder, and fly ash to make dry mixed casing material, weighing dredging sediment non-sintered ceramsites, wherein the mass ratio is : 10-20 parts of cement, 1-10 parts of quicklime, 1-10 parts of glass fiber powder, 1-10 parts of fly ash, and 50-70 parts of dredging sediment non-sintered ceramsites; (3) adopting a disc shot blasting machine for polishing casing; (4) maintaining for prepared non-sintered casing ceramsites. The casing method can consume a large amount of dredging sediment and meets the requirement for resource utilization of dredging industry, and largely promotes intensity of the dredging sediment non-sintered ceramsites, furthermore the production energy consumption is low, the non-sintered casing ceramsites have a wide application range and meet the requirements of construction markets.

Owner:TIANJIN UNIV OF SCI & TECH

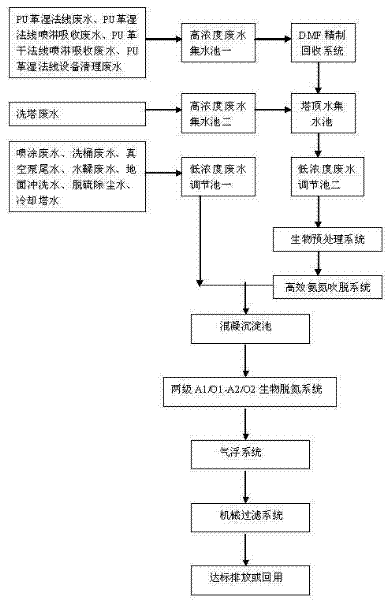

Production of hydrogen for combining mineralize refuse, swill waste and sludge

InactiveCN1896248AIncrease switching capacityAlkalinity improvementBio-organic fraction processingClimate change adaptationHydrogenLitter

Production of hydrogen from mineral refuse with swill waste and sludge is carried out by sieving mineral refuse underground for 1-20years to grain size 1-10mm, washing by water, mixing by proportion of 1:1-10:1 and with 1-10mm sieve sludge, dry-heat sterilizing or wet-heat sterilizing at 100-200degree for 0.5-2hrs, pre-treating for 0.5-2hrs to obtain combined fermented substrate, laying aside in closed thermostatic fermenting container, fermenting to produce hydrogen at 25-55degree, pre-treating and utilizing. It is cheap, simple, has more hydrogen output and no secondary pollution. It can be used as fuel or generation raw materials.

Owner:TONGJI UNIV

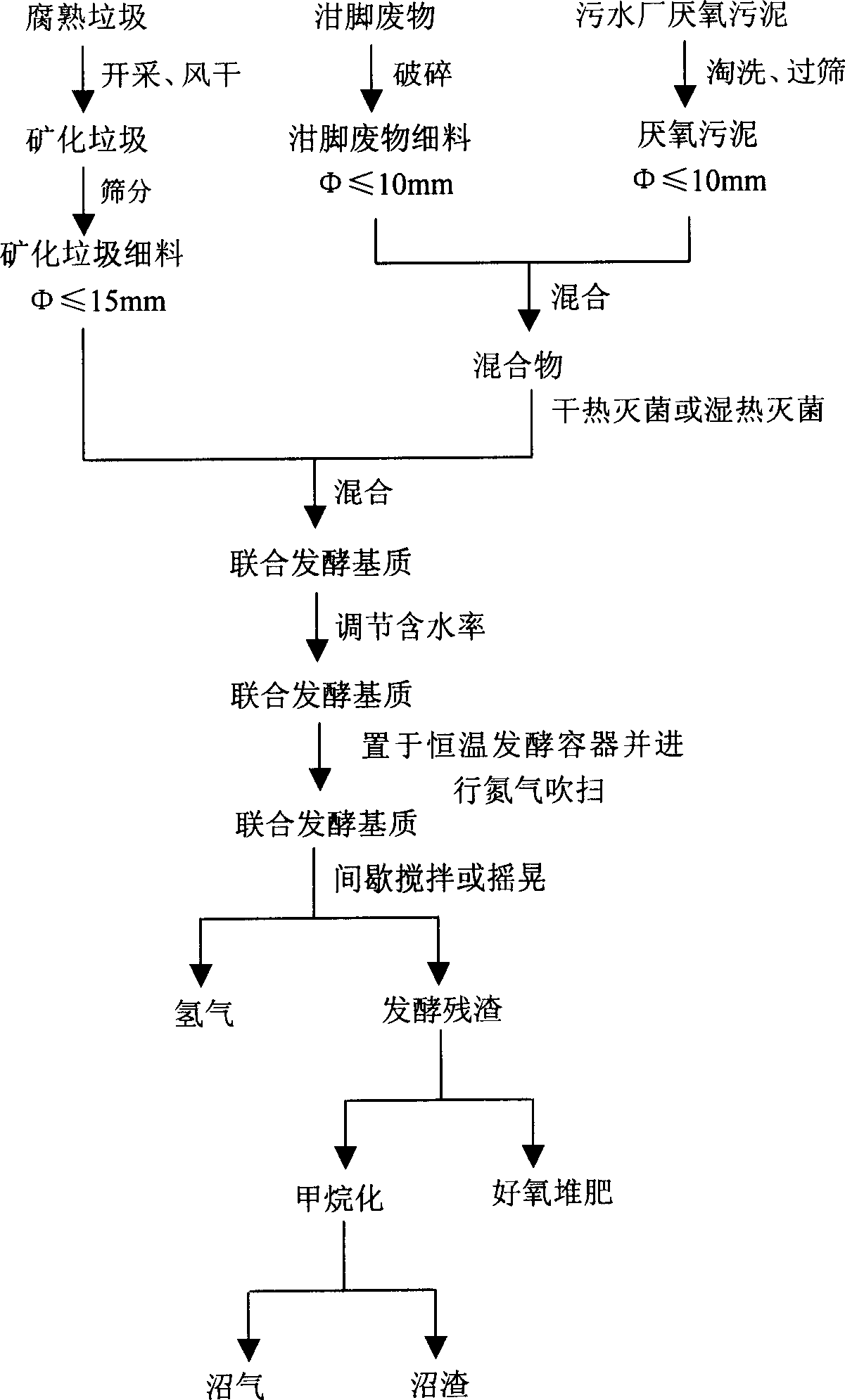

Method for synthesizing ferric phosphate by utilizing waste phosphate generated by precipitation of trace heavy metal

ActiveCN109809382ATo achieve the purpose of resource utilizationReduce manufacturing costPhosphorus compoundsFiltrationPhosphate product

The invention discloses a method for synthesizing ferric phosphate by utilizing waste phosphate generated by precipitation of trace heavy metal. The method is characterized by utilizing the waste phosphate as a phosphorus source, mixing the phosphorus source with an ferric-containing solution or mixing the phosphorus source with a ferrous solution and hydrogen peroxide after dissolving, synthesizing the ferric phosphate under a low-temperature condition, and filtering, thus obtaining filtrate and filter residue; recycling other valuable metal in the filtrate, adding phosphoric acid after washing and pulpifying the filter residue, converting under the condition that the temperature is 90 DE C, carrying out suction filtration after keeping warm, and drying free water in a suction filtrationmaterial, thus obtaining ferric phosphate dihydrate; calcining, thus preparing an anhydrous ferric phosphate product. The method for synthesizing the ferric phosphate by utilizing the waste phosphategenerated by precipitation of the trace heavy metal, disclosed by the invention, is simple in operation, a prepared ferric phosphate product can meet battery-grade standard requirements, the purpose of recycling phosphorus from the waste phosphate is realized, and the synthesis cost of the ferric phosphate can be obviously reduced; meanwhile, waste residue can be recycled, the additional value ofthe waste residue can be increased, and the problem of environment protection caused by the waste phosphate is also solved.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드

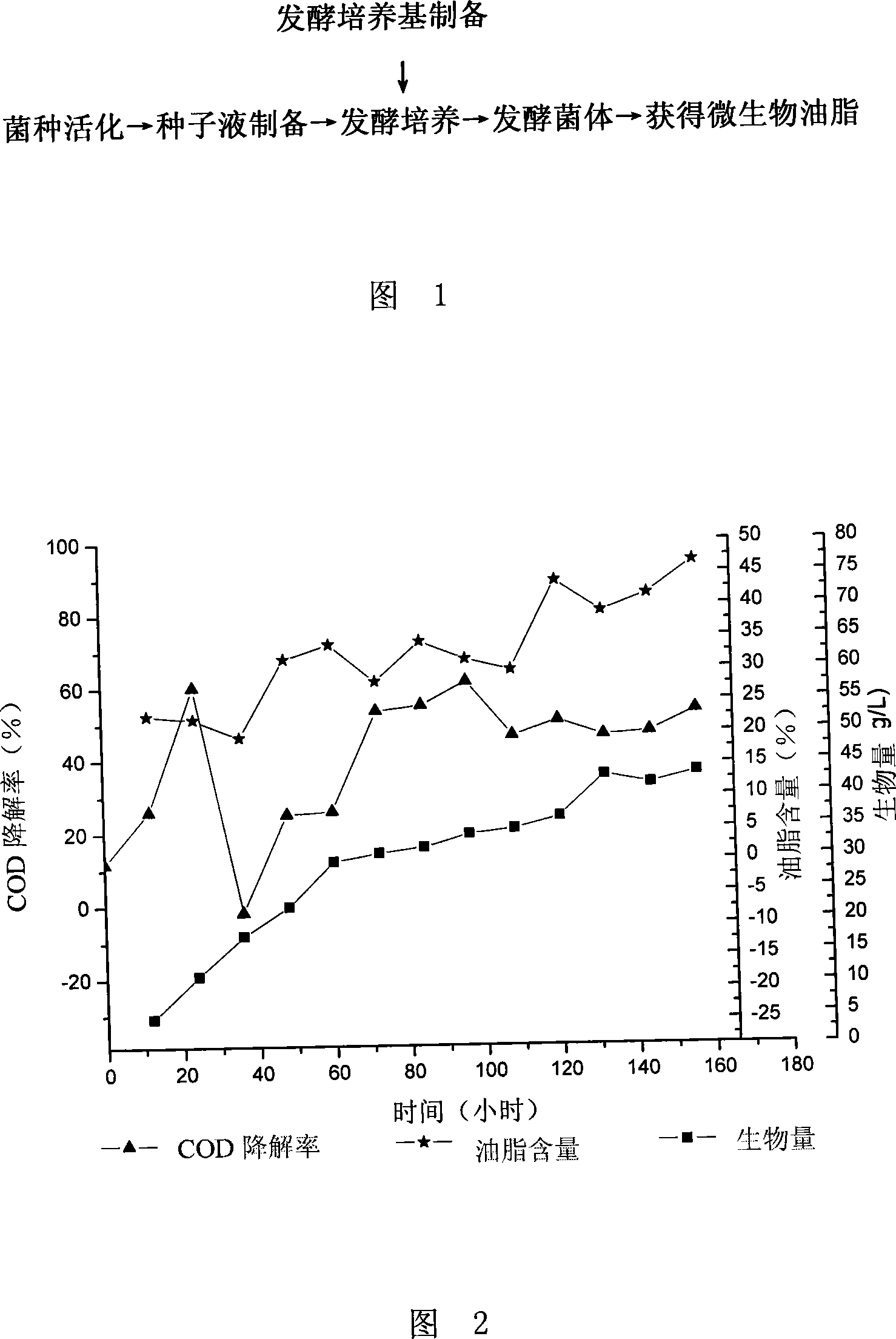

Method for treating industrial waste and fermentation production of microbial oil by microorganism as well as special strain thereof

The invention discloses a method for utilizing industrial wastes to produce microbial grease by means of fermentation and a special strain Rhodotorula glutinis Rh.g CGMCC No.2258. The method of the invention is a method for utilizing the industrial wastes (such as waste water of industrial production like starches, monosodium glutamate, paper making and so on, and / or fermentation industrial residues like soya residues and so on) as culture media to produce the microbial grease through fermentation of the Rhodotorula glutinis; the microbial grease obtained by the method also can be taken as material lipid to prepare biodiesel, and conversion rate can reach 80 to 99 percent. The production method of the microbial grease has the advantages of simple operation, low cost and high use value, and not only pollution of high concentration wastes which are discharged by fermentation industries like starches, monosodium glutamate, paper making, soya residues, etc. on the environment can be reduced but also the wastes can be converted into treasures by using the wastes to produce the grease which is a product in short supply in the current market, thereby the aim of resource utilization of the wastes is reached.

Owner:BEIJING UNIV OF CHEM TECH

Method for kitchen garbage lactic acid fermentation facilitated by mushroom bran

InactiveCN101085999ATo achieve the purpose of resource utilizationIncrease productionMicroorganism based processesFermentationMicroorganismLactobacillus

The invention relates to a method for promoting lactic acid in kitchen rubbish fermentation by using mushroom bran, belonging to industrial bacterial fermentation engineering technique. It comprises following steps: (1) disintegrating kitchen rubbish, adding mushroom bran according to proportion of 10- 20% of that of solid kitchen rubbish; (2) adding water into solid kitchen rubbish according to proportion of 1: 1- 1: 3, moderating water content for fermentation system; (3) disinfecting mixed kitchen rubbish, adding sterile calcium carbonate to keep pH for fermentation system between 5 to 6; (4) inoculating lactic acid bacteria according to proportion of 6- 10%, anaerobic fermenting at 45 Deg. C for 25- 40 hours; (5) separating solid from liquid, purifying fermentation liquor and getting lactic acid. The invention employs mushroom bran as additive, which can not only increase lactic acid production, but aslo makes full use of mushroom bran and releases environment pollution.

Owner:UNIV OF SCI & TECH BEIJING

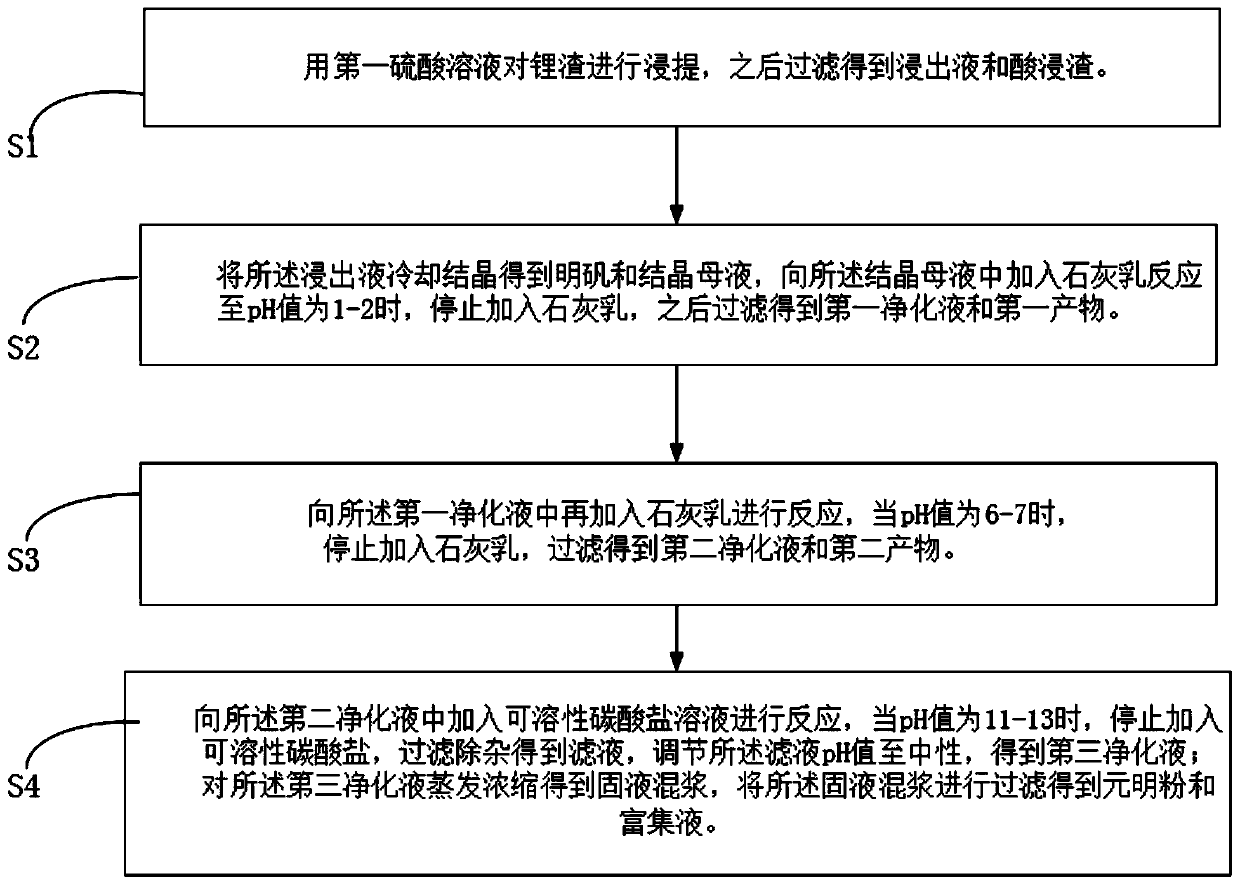

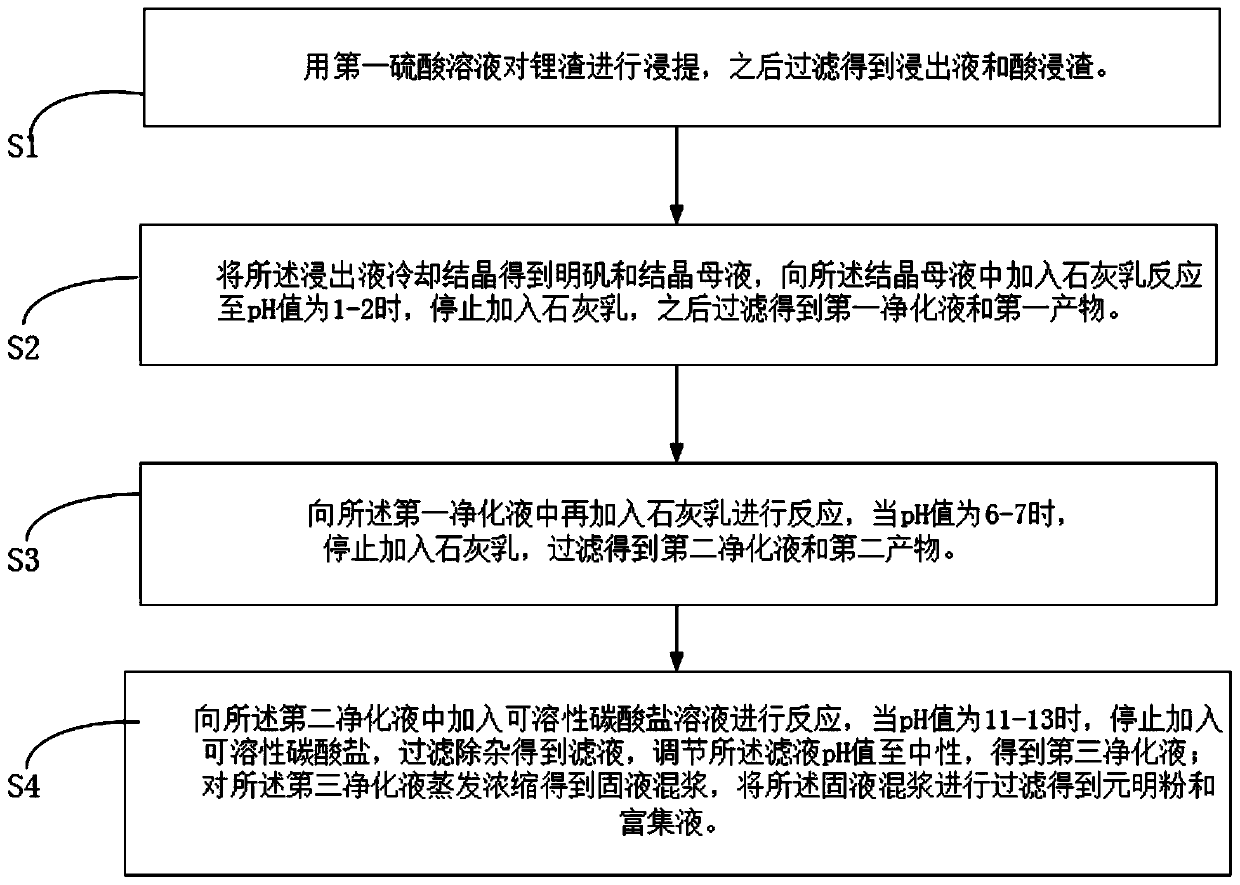

Lithium slag treatment method

ActiveCN110015855ASimple processing methodIncrease profitSolid waste managementCalcium/strontium/barium sulfatesSlagRubidium

The invention relates to a lithium slag treatment method. The method comprises the following steps: leaching a lithium slag with a first sulfuric acid solution, performing filtering to obtain a leaching solution and an acid leaching slag, performing cooling crystallization on the leaching solution to obtain alum and a crystallization mother liquor, adding a lime milk into the crystallization mother liquor and stopping the addition of the lime milk until the pH value is 1-2, and performing filtering to obtain a first purified liquid and a first product. The treatment method of the lithium slagis simple, the lithium slag comprehensive utilization rate is high, and thus the treatment method is suitable for industrial applications. Specifically, by leaching with sulfuric acid, the leaching rates of lithium, rubidium, cesium, potassium, aluminum and sodium are all above 88%, the main components in the obtained acid leaching slag are quartz and gypsum, and the quartz and gypsum can be usedas concrete admixtures for the secondary utilization.

Owner:ZHENGZHOU MINERALS COMPOSITIVE UTILIZATION RES INST CHINESE GEOLOGICAL ACAD

Method of preparing baking-free brick with dredge sediment aggregate

The invention relates to a method of preparing baking-free brick with a dredge sediment aggregate, which includes the steps of (1) sieving the dredge sediment aggregate; (2) smashing cement, quick lime, gypsum and fly ash in a pulverizer; (3) material blending: mixing and stirring the cement, the quick lime, the gypsum and the fly ash to obtain a dry-mixed material, weighing the dredge sediment aggregate, wherein the dry-mixed material comprises, by mass, 5-20 parts of the cement, 3-13 parts of the quick lime, 1-10 parts of the gypsum and 15-30 parts of the fly ash, and the dredge sediment aggregate accounts for 45-70 parts by weight; (4) adding water and stirring the mixture; (5) aging the mixture material; (6) press-moulding the mixture in a brick pressing machine; (7) performing product maintenance to obtain the baking-free brick. The method can consume the dredge sediment in a large quantity, thereby achieving resource recycling. The method can satisfy requirement in dredge industry and is low in production cost due to the baking-free process. The prepared baking-free brick is low in cost, is excellent in performances, can develop a utilization approach of recycling the dredge sediment resource, and satisfies the requirement of building material market.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

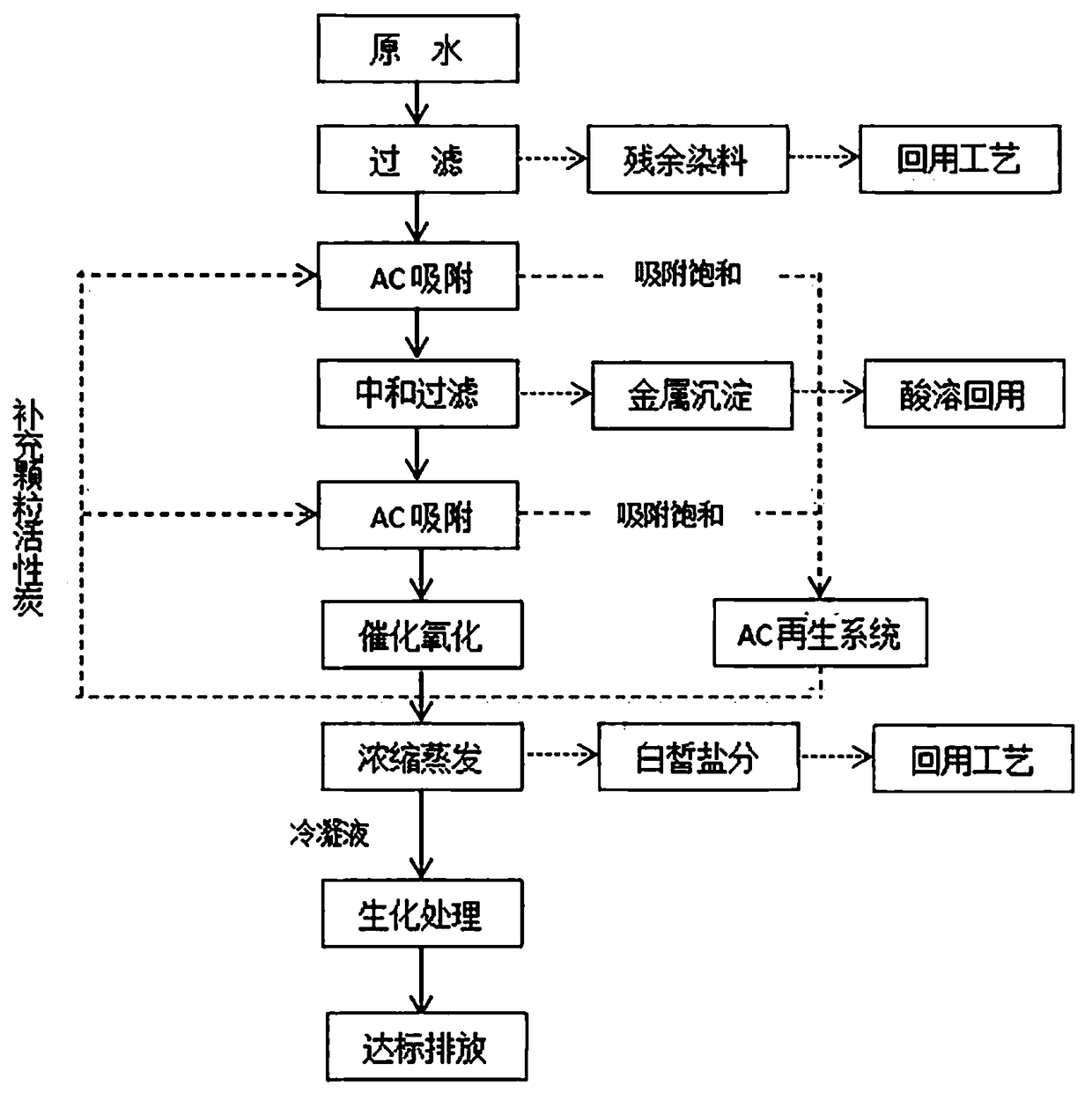

Recycling treatment method of dye wastewater

ActiveCN108328840AHigh degree of automationImprove regeneration efficiencyWater treatment parameter controlSpecific water treatment objectivesTreatment effectEvaporation

The invention discloses a recycling treatment method of dye wastewater and belongs to the technical field of wastewater treatment. The method includes the steps of firstly, filtering; secondly, performing primary adsorption; thirdly, neutralizing; fourthly, performing secondary adsorption; fifthly, performing low-temperature catalytic oxidization; sixthly, performing concentration and evaporation;sixthly, performing biochemical treatment. The recycling treatment method has the advantages that residual dye in the wastewater and catalysts and salt in the wastewater can be recycled, wastewater recycling is achieved, a good wastewater treatment effect is achieved, and stable up-to-standard emission is achieved; meanwhile, the biochemical performance of the wastewater can be increased greatly,the stable operation of a follow-up biochemical system is guaranteed, and solid waste and secondary environment pollution are avoided completely.

Owner:ZHEJIANG QICAI ECO TECH CO LTD

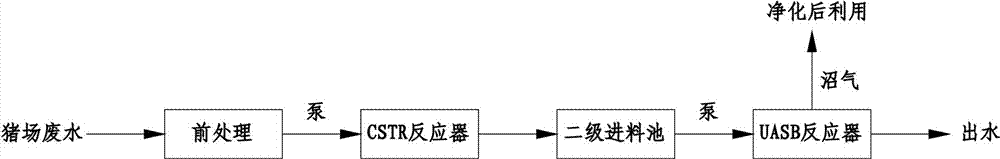

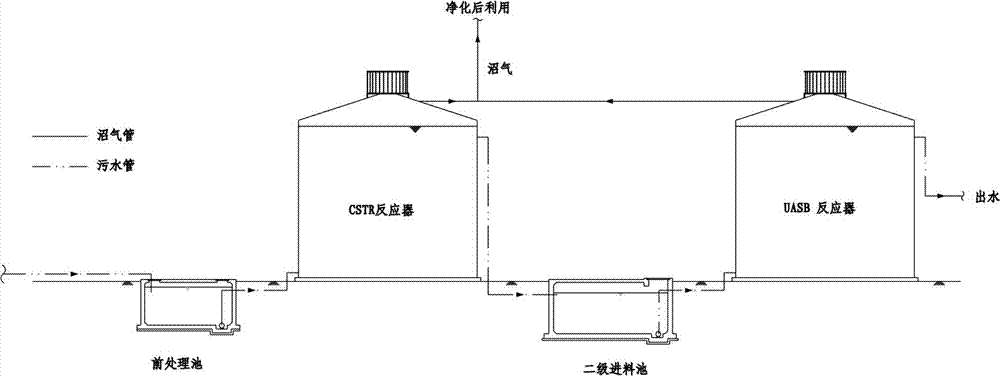

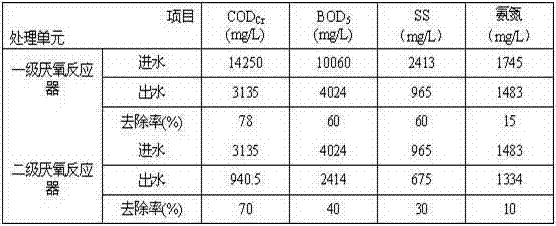

Method and system for producing biogas through two-stage anaerobic processing of high-concentration waste

InactiveCN104291438ALow running costHigh yieldWaste water treatment from animal husbandryGaseous fuelsHigh concentrationThree-phase

The invention discloses a method and system for producing biogas through two-stage anaerobic processing of high-concentration waste, the processing method comprises the following steps: pretreating high-concentration livestock waste water in a pre-treatment pool; introducing the treated livestock waste water into a first stage anaerobic reactor, fermenting in a continuous stirred tank reactor to generate biogas; then introducing effluent into a secondary stage anaerobic reactor through an outlet pipe, completing water distributing, gas production and three-phase separating in an upflow anaerobic sludge blanket, purifying the generated biogas and then introducing biogas into production for usage; and introducing the processed effluent into a sedimentation basin for subsequent processing, and then discharging. The constructed two-stage anaerobic reactor can enforce the high efficiency anaerobic fermentation to high-concentration waste, thereby renewable energy biogas is generated, and effective processing of livestock and poultry waste water is realized simultaneously, and the selected material has the advantages of reliable quality, low cost and obvious energy effect.

Owner:HANGZHOU QINGCHENG ENERGY ENVIRONMENTAL PROTECTION ENG

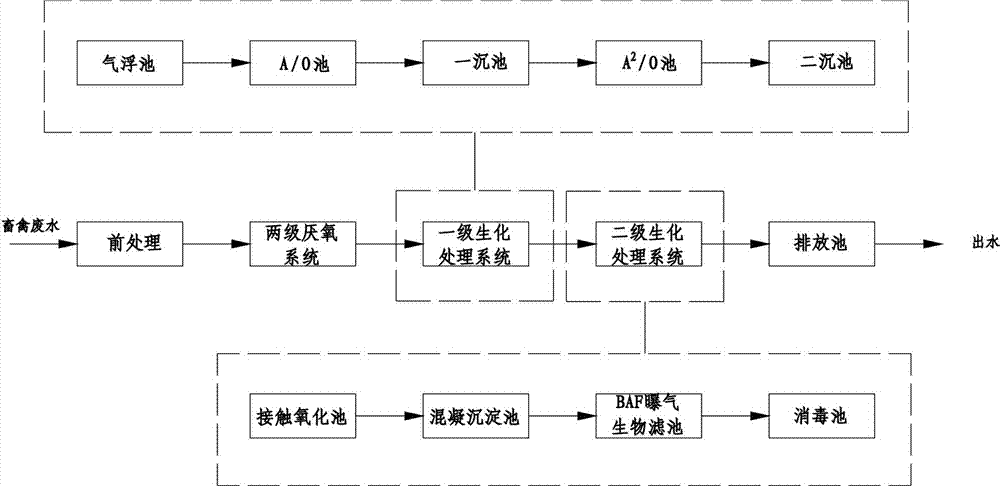

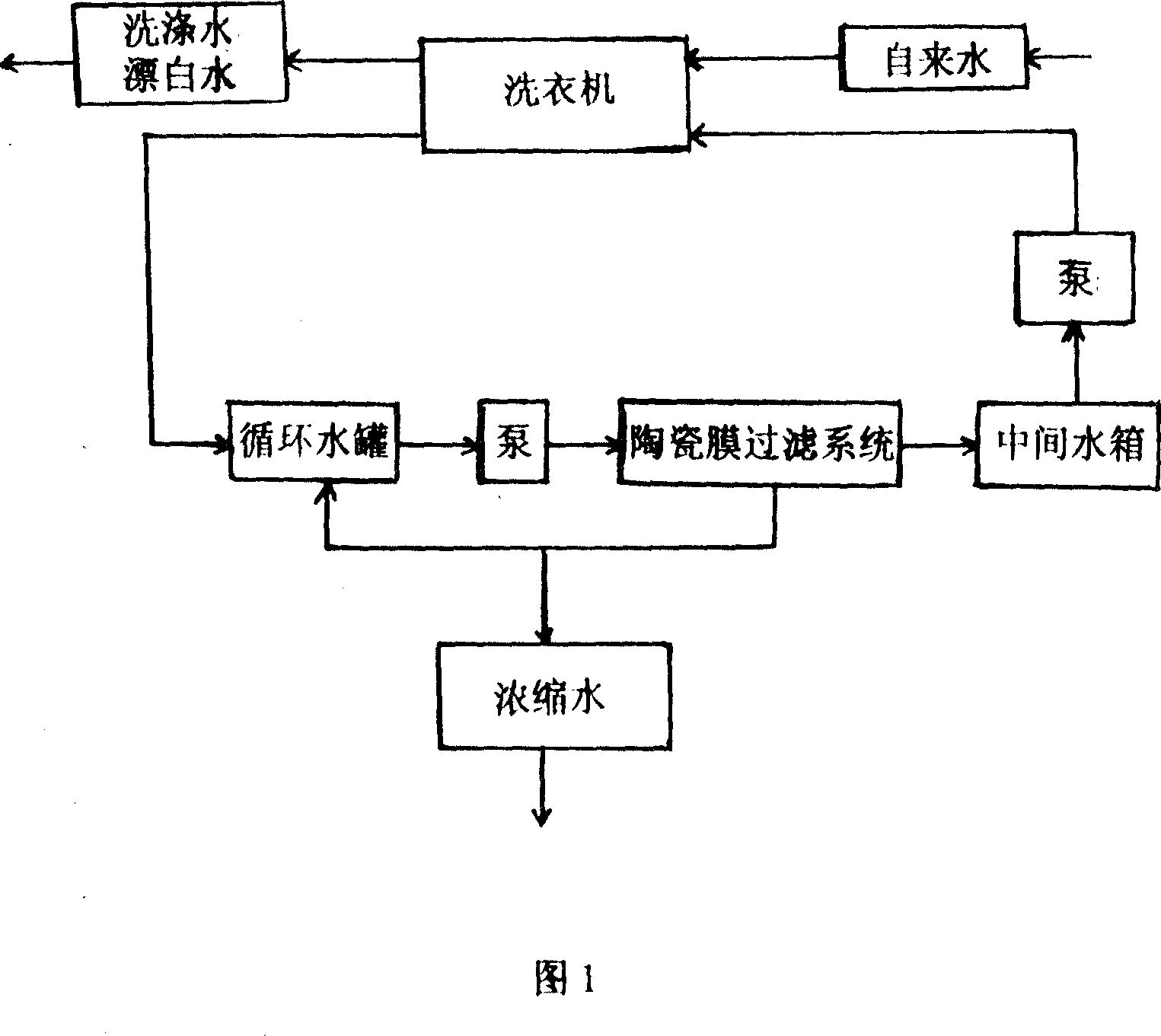

Standard discharge treatment system for livestock and poultry waste water and method thereof

ActiveCN104291517ATo achieve the purpose of resource utilizationLow running costTreatment using aerobic processesWaste water treatment from animal husbandryHigh concentrationOxygen

The invention discloses a standard discharge treatment system for livestock and poultry waste water and a method thereof, the method comprises the following steps: pretreating livestock and poultry waste water with high concentration in a pre-treatment pool; introducing the treated livestock and poultry waste water in a first stage anaerobic reactor, continuously stirring in the reactor, then fermenting to obtain biogas; reacting and introducing in a secondary anaerobic reactor through an outlet pipe, completing water distribution, performing gas production and three-phase separation in an upflow anaerobic sludge blanket; introducing the processed effluent in a first stage biochemical treatment system for processing, performing solid-liquid separation; and then introducing a supernatant in a secondary biochemical treatment system for processing. According to the invention, two stage anaerobic reactors and two stage biochemical treatment systems are combined for performing high efficiency anaerobic fermentation and aerobic operation treatment on the livestock and poultry waste water, so that renewable energy biogas is generated, and treatment for livestock and poultry waste water standard discharge can be simultaneously realized, and the materials have the advantages of reliable quality, low cost, obvious energy effect, energy saving and environmental protection.

Owner:HANGZHOU QINGCHENG ENERGY ENVIRONMENTAL PROTECTION ENG

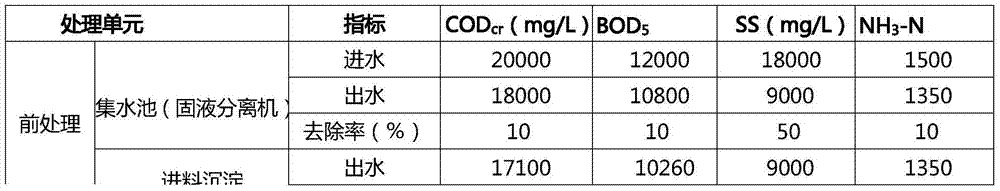

Fine garbage classified recycling processing method

InactiveCN105989567ARealize the requirements of fine recyclingTo achieve the purpose of resource utilizationData processing applicationsComputer terminalShared resource

The invention relates to a fine garbage classified recycling processing method. A garbage produce side, a front-end collection and transportation side, a mid-end collection and transportation side and a terminal processing side respectively hold an intelligent terminal. As for the garbage, unusable garbage weight data are uploaded to a garbage processing system and usable garbage weight data are uploaded to a recyclable garbage trading platform through all the processing links of the garbage produce side, the front-end collection and transportation side, the mid-end collection and transportation side and the terminal processing side in turn. The garbage processing system and the recyclable garbage trading platform are connected with a central server. The central server is also connected with the intelligent terminals of all links. The central server monitors garbage weight information of each link anytime. According to the fine garbage classified recycling processing method, all links of garbage classified recycling processing are enabled to form an organic systematic whole so that the data of all links are monitored in real time, the data are shared and the resources are shared, and thus the efficiency is high and the data are comprehensive and reliable.

Owner:李震

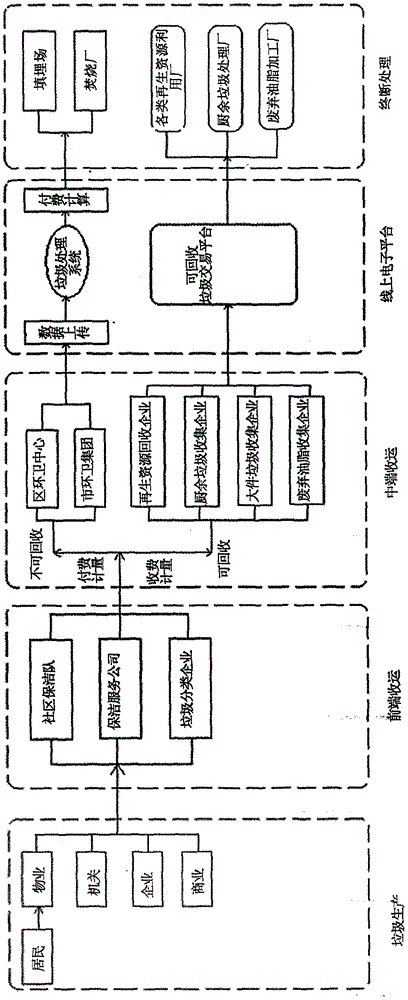

Process for recovery and using sewage of wash house

InactiveCN101089278AReach recoveryReduce doseOther washing machinesWater/sewage treatmentThermal energySewage

The present invention discloses a laundry sewage recovery and reutilization process. It is characterized by that said process adopts inorganic ceramic membrane separation technique and dynamic cross-flowing filtration mode to implement heat energy recovery, sewage recovery and detergent recovery so as to make the laundry sewage be changed into useful resource.

Owner:王歌德

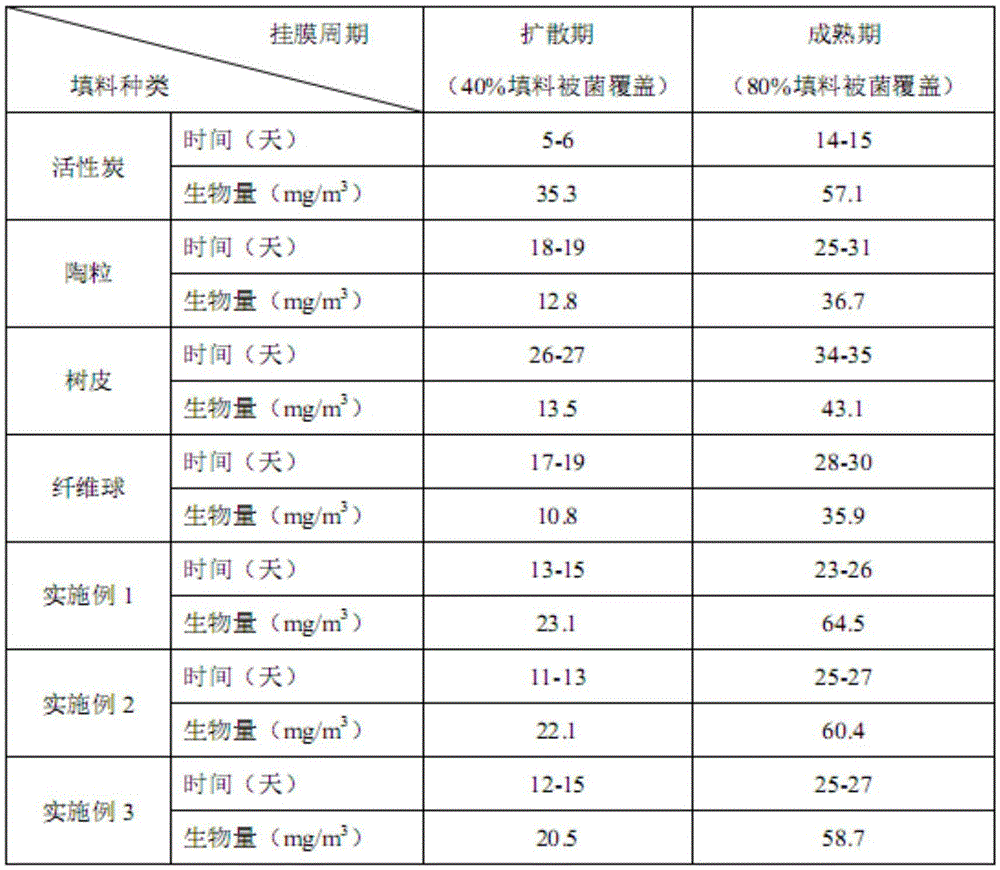

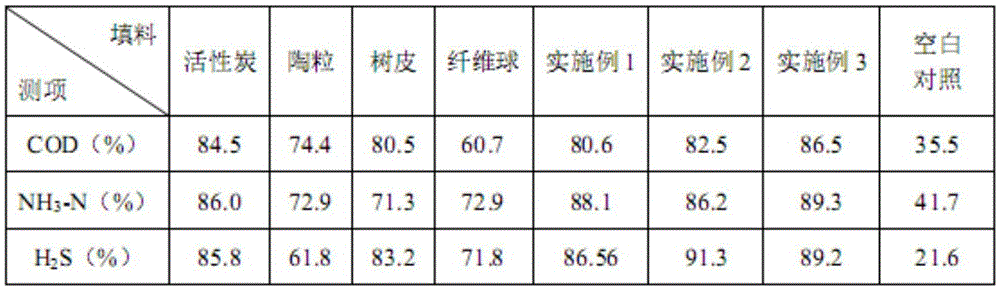

Deodorizing composite biological stuffing special for dyeing and finishing wastewater treatment and preparing method thereof

InactiveCN105536510AWithstand loadImprove breathabilityGas treatmentDispersed particle separationContinuous useSludge

The invention discloses deodorizing composite biological stuffing special for dyeing and finishing wastewater treatment and a preparing method thereof. The stuffing comprises a component A and a component B. The mass ratio of the component A to the component B is 3:(6-8); the component A is prepared from dried sludge, converter slag, coal ash and clay, and the mass ratio of the dried sludge to the converter slag to the coal ash to the clay is (5-8):(5-7):(2-3):(3-5); the component B is prepared from, by mass, 10-20% of bark powder, 5-20% of saw dust, 50-60% of calcium carbonate and 20-30% of adhesive. The component A is prepared at first and then mixed with the component B to obtain the stuffing. The stuffing provides good adhesion space for growth of microorganisms, and provides a stable survival environment for growth of the microorganisms. Compared with inorganic stuffing like volcanic rock and natural or manual organic stuffing such as bark and synthetic resin, the stuffing has the advantages of being low in production cost, better in effect, stable in continuous use time, and beneficial for application to industrialized biological filter tank deodorization.

Owner:XINJIANG ENVIRONMENTAL ENG TECH

Recycling low-cost treatment method for field heavy metal polluted soil

InactiveCN109719115ARelease security stabilityTo achieve the purpose of resource utilizationSolid waste disposalBrickClay minerals

The invention discloses a recycling low-cost treatment method for field heavy metal polluted soil. The method comprises the following steps that firstly, biomass powder and industrial field clay mineral are evenly mixed according to the weight ratio of 1:10-25, the mixture is obtained, 10 g of the mixture is taken and placed in an anhydrous magnesium chloride solution, 150-300 mL of water is added, deposition operation is conducted, sediments are obtained, heating and pressurizing synthesis is conducted in a hydrothermal reaction kettle, the synthesis temperature is 100-200 DEG C, the synthesis pressure is 7-20 Mpa, and drying is conducted under the condition that the temperature is 200-300 DEG C; and the vacuum condition is adopted. According to the recycling low-cost treatment method forfield heavy metal polluted soil, releasing safety of heavy metal in a brick body is more stable, meanwhile, the manufactured brick body material conforms to the brick body industry standard and can serve as a building and garden roadbed brick body material, the purpose of recycling utilization of the heavy metal polluted soil is achieved, the repairing targets that secondary pollution and pollution transferring are avoided, and waste recycling utilization is achieved are achieved, and the recycling low-cost treatment method is more environment-friendly and practical.

Owner:IRONMAN ENVIRONMENTAL TECH CO LTD

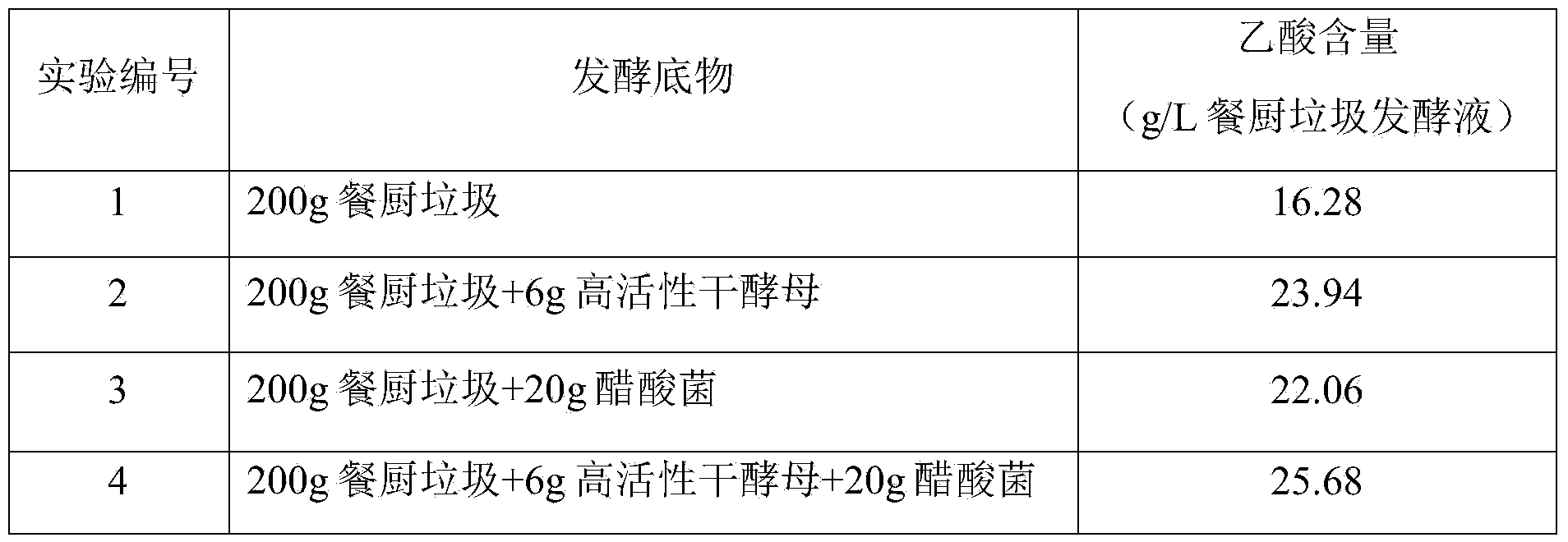

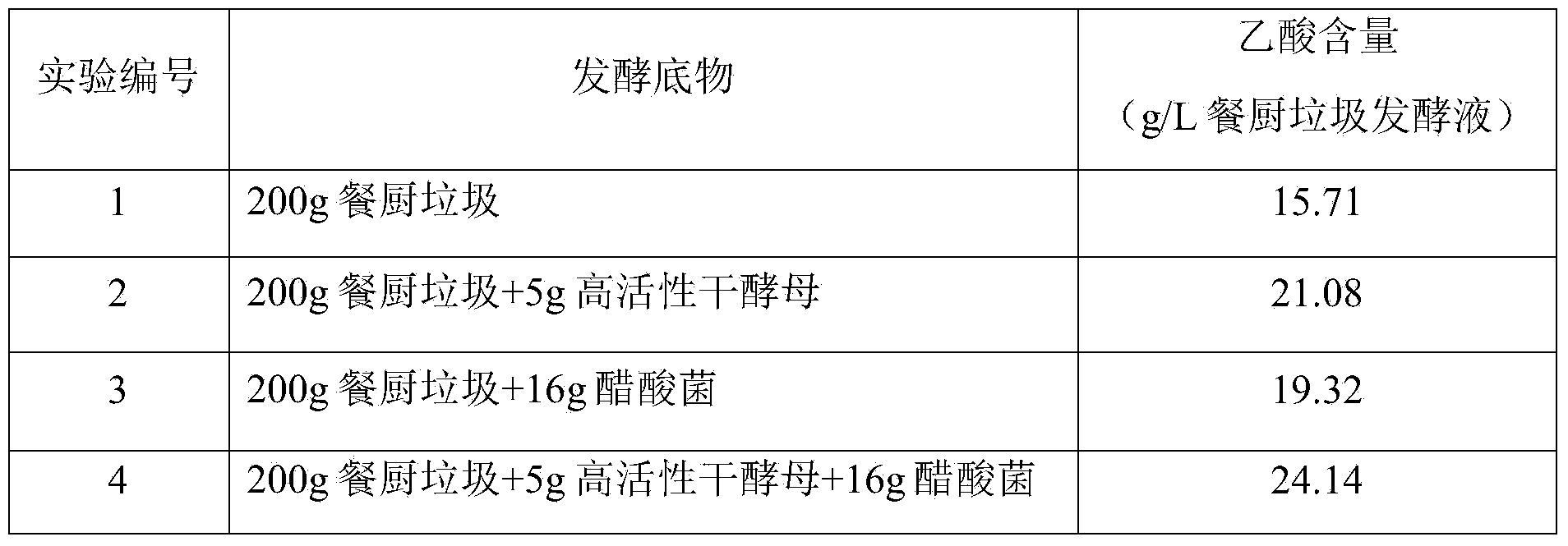

Method for producing acetic acid by fermenting kitchen waste

InactiveCN103865975AIncrease productionReduce pollutionMicroorganism based processesFermentationChemistryOrganic acid

The invention relates to a method for producing acetic acid by fermenting kitchen waste. The method comprises the following steps: firstly adding high-activity dry yeast in crushed kitchen waste, and uniformly mixing, wherein the adding amount of the high-activity dry yeast accounts for 2-5wt% of the weight of the kitchen waste; performing anaerobic fermenting at 20-30 DEG C for 72-96 hours, and then adding calcium carbonate, wherein the adding mount of the calcium carbonate ensures that the pH value is kept at 5.5-6.5 in the fermentation process; then adding acetic bacteria, wherein the adding amount of the acetic bacteria accounts for 8-12wt% of the weight of the kitchen weight; performing aerobic fermenting at 30-37 DEG C for 72-96 hours; then performing the solid-liquor separation to obtain the kitchen waste fermenting liquor and kitchen waste residue, sending kitchen waste residue to refuse landfill, backfilling the kitchen waste residue to refuse landfill and distilling, refluxing and purifying the kitchen waste fermenting liquor so as to obtain the acetic. Each liter of kitchen waste fermenting liquid is capable of producing 24-28g of acetic acid, the acetic acid accounts for 84-93% of the total mass of the organic acid in the fermenting liquor, the heteroacid variety in the fermenting liquor is less, the production cost is low and the aim of re-utilizing the kitchen waste is realized.

Owner:TONGJI UNIV

Method for liquefying surplus solid residue in fermentation of cellulosic ethanol

ActiveCN103740397ALow liquefaction temperatureReduce energy consumptionLiquid carbonaceous fuelsLiquid hydrocarbon mixture productionLiquid productSulfide

The invention discloses a method for liquefying surplus solid residue in the enzymolysis saccharification and ethanol fermentation by adopting lignocellulose as a raw material. The method is characterized in that the solid residue is liquefied in a high-pressure vessel in the presence of a catalyst and an organic solvent, wherein the organic solvent is absolute ethyl alcohol, anhydrous propyl alcohol or absolute butanol, and the catalyst is aluminum chloride, aluminum sulfide and zinc sulfide. The catalyst which is specially selected by an inventor is added in the method, so that the liquefying temperature is effectively lowered, the liquefying rate of the fermented solid residue and the residue degrading degree can be improved, and more liquid products with smaller molecular weight can be generated. The method can be widely used for liquefying the residue produced by fermenting the biomass fuel ethanol and lignocellulose-rich biomass raw material and has the advantages of low liquefying temperature, simplicity in process, high efficiency and the like, and the raw materials are easily obtained.

Owner:SHANDONG UNIV

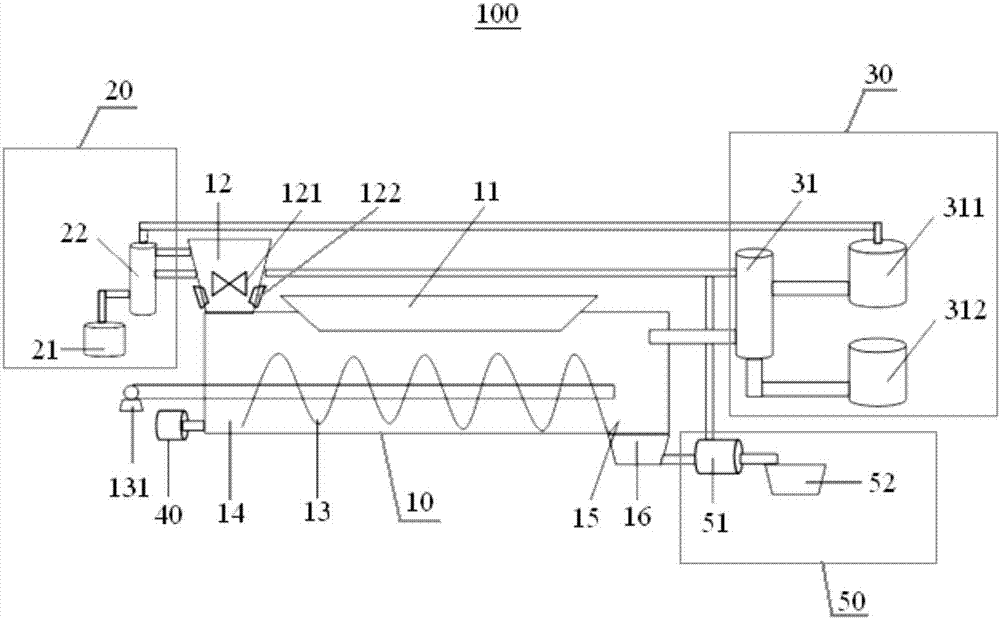

Method and device for microwave pyrolysis of sludge

ActiveCN107200452AFully pyrolyzedFull pyrolysisSpecific water treatment objectivesSludge treatment by pyrolysisCondensation processMicrowave pyrolysis

The invention discloses a method and a device for microwave pyrolysis of sludge. The device for microwave pyrolysis of sludge comprises a microwave reaction device, a vapor recovery device and an oil gas recovery device in communication. The microwave reaction device comprises a microwave reaction cavity, and a first microwave generator arranged in a microwave reaction cavity enables the microwave reaction cavity to have a plurality of temperature areas in sequential temperature rise in the direction from an inlet of the microwave reaction cavity to an outlet. Microwaves serve as a heat source to substitute for a traditional heating method for microwave pyrolysis of sludge, water, pyrolysis gas and pyrolysis residues are obtained sectionally by means of sectional heating and condensation, and heat energy in a condensation process is completely used as a heat source for sludge drying, so that energy saving, environment friendly and sludge recycling are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing hydrophobic silicon dioxide aerogel

ActiveCN106745005ATo achieve the purpose of resource utilizationReduce manufacturing costSilicaNanotechnologyPorosityStrong acids

The invention belongs to the field of comprehensive utilization of solid waste, and discloses a method for preparing hydrophobic silicon dioxide aerogel from fly ash acid process aluminum extraction tailings as raw materials. The method comprises the following steps of performing high-temperature calcination on the fly ash acid process aluminum extraction tailings; performing washing by distilled water; performing strong alkali leaching; then, regulating the pH value of the leaching liquid by inorganic strong acid and performing still standing; performing drying to prepare gel; performing aging, silanization surface modification treatment and washing on the obtained gel; finally, performing normal pressure drying to obtain the hydrophobic silicon dioxide aerogel material with excellent property. The waste is sufficiently utilized; the characteristics of simple process and low cost are realized; the method is applicable to scaled production and application; the prepared aerogel has large specific surface area, high porosity and excellent performance.

Owner:CHINA SHENHUA ENERGY CO LTD +1

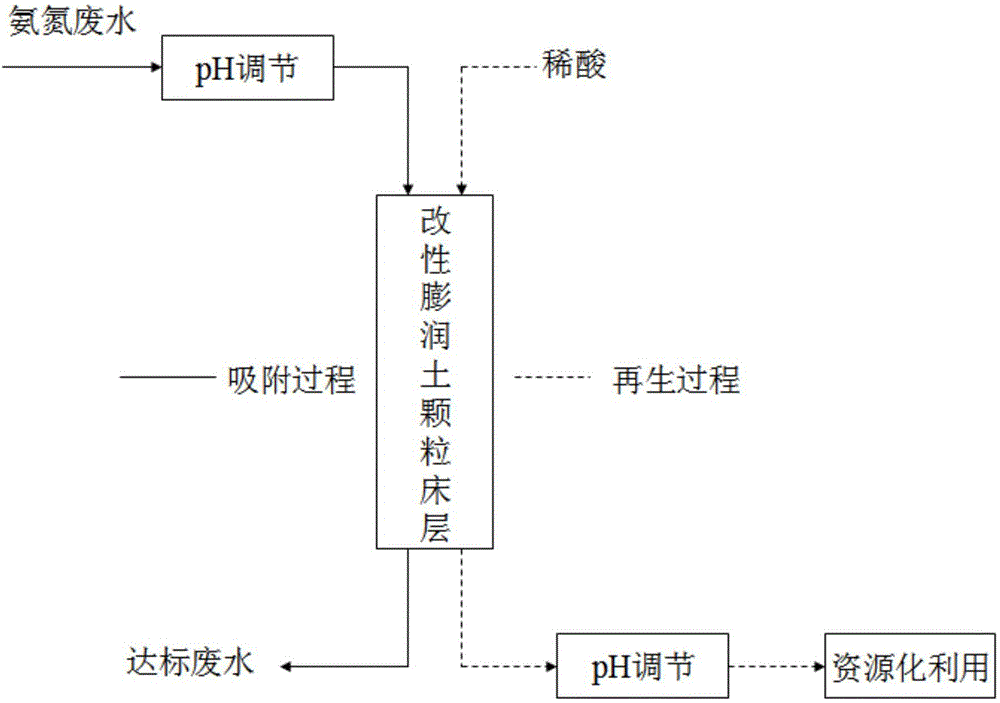

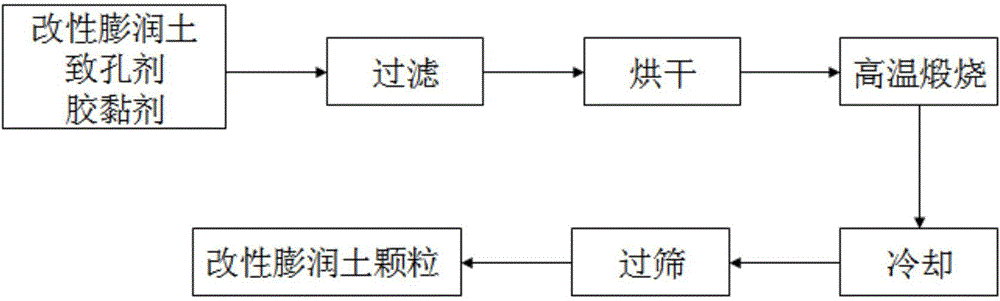

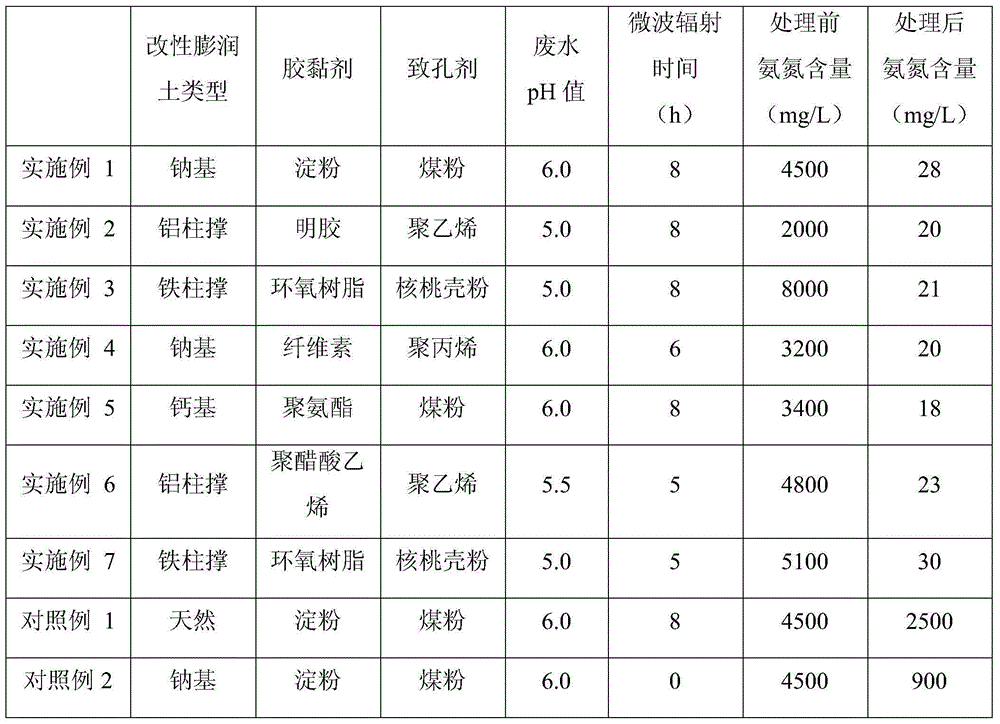

Method for removing ammonia nitrogen in electroplating wastewater

ActiveCN104591331ASimple processAvoid secondary pollutionWater/sewage treatment by irradiationOther chemical processesHigh concentrationSodium Bentonite

The invention belongs to the technical field of industrial waste water treatment, and discloses a method for removing ammonia nitrogen in electroplating wastewater. The method includes the following steps: (1) adjusting the pH value of the raw material of electroplating wastewater containing ammonia nitrogen to 4-6, so that the ammonia nitrogen mainly exist in the form of NH4<+>; (2) passing the pretreated electroplating wastewater through a modified bentonite particles bed under microwave irradiation at constant temperature and constant speed; and (3) regenerating the on the adsorption saturated modified bentonite particles bed layer by dilute acid. The invention employs modified bentonite as an adsorbent, which has larger capacity and better selectivity compared with traditional activated carbon and zeolite adsorbent; microwave radiation can promote the adsorption process, and has no strict requirement on water quality; the regeneration can completely restore the adsorption capacity of the bentonite, and high concentration ammonia nitrogen in the regeneration liquid can be recycled, so as to avoid secondary pollution.

Owner:南京台兴汽车零部件制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com