Method for activating and regenerating waste industrial activated aluminum oxide

An activated alumina, industrial technology, applied in the direction of alumina/aluminum hydroxide, aluminate/alumina/aluminum hydroxide purification, chemical instruments and methods, etc., can solve environmental pollution and other problems, and achieve environmental pollution, Less damage and lower energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

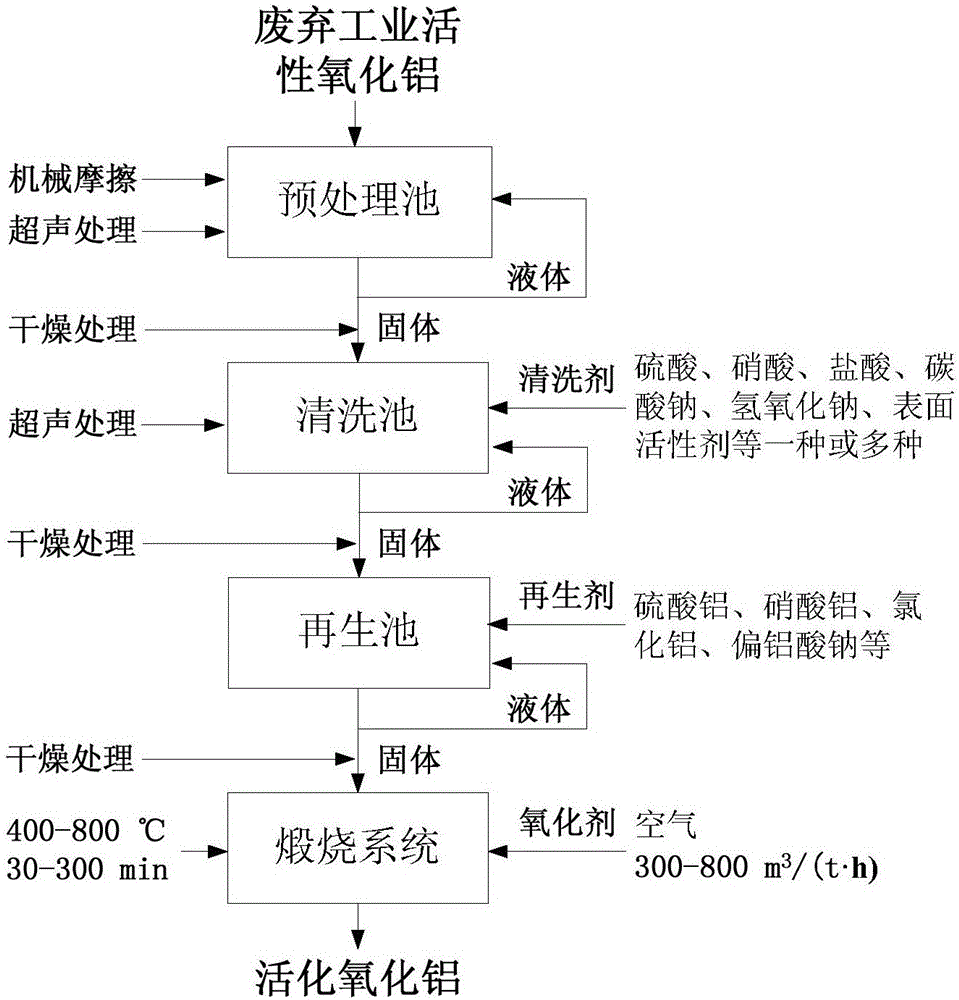

Method used

Image

Examples

Embodiment 1

[0058] Immerse the waste air separation special alumina desiccant and water at a ratio of 1:5, use mechanical stirring to suspend and rub the alumina balls, separate the solid and liquid after 40 minutes, reuse the liquid, and put the solid phase in a blast drying oven at 105°C for drying 3h; immerse the pretreated alumina in a mixed solution of 4.0wt% sodium carbonate+5.0wt% nonylphenol polyoxyethylene ether (TX) in a volume ratio of 1:1 for 1h, and then Use 40kHz ultrasonic treatment for 30min, solid-liquid separation, liquid phase recycling, solid phase into 105 ℃ blast drying oven for 3h; wash the alumina according to the volume ratio of 1:1 to 4.0% (according to Al 2 o 3 total) aluminum sulfate solution for 60 minutes, solid-liquid separation, liquid phase recycling, solid phase was placed in a 150 ° C blast drying oven to dry for 1 h, then placed in a calciner and heated to 500 ° C at a rate of 17 K / min, and kept at 0.5 h, according to 500m during the calcination proces...

Embodiment 2

[0060] Immerse the waste air separation special alumina desiccant and water at a ratio of 1:5, use mechanical stirring to suspend and rub the alumina balls, separate the solid and liquid after 60 minutes, reuse the liquid, and put the solid phase in a blast drying oven at 105°C for drying 3h; Immerse the pretreated alumina in the mixed solution of 4.0wt% sodium carbonate+10.0wt% nonylphenol polyoxyethylene ether (TX) according to the volume ratio of 1:3, keep it for 2h, and then use 40kHz ultrasonic treatment for 60min, solid-liquid separation, liquid phase recycling, phase and solid phase were placed in a blast drying oven at 105°C for 3 hours; the cleaned alumina was immersed in 4.0% (according to Al 2 o 3 total) aluminum sulfate solution for 30 minutes, solid-liquid separation, liquid phase recycling, solid phase was placed in a 105 ° C blast drying oven to dry for 3 h, and then placed in a calciner to raise the temperature to 500 ° C at a rate of 10 K / min, keeping 0.5 h, ...

Embodiment 3

[0062] Immerse the waste air separation special alumina desiccant and water at a ratio of 1:1, use 25kHz ultrasonic cleaning for 20min, separate the solid from the liquid, reuse the liquid, and dry the solid in a blast drying oven at 90°C for 4h; Immerse aluminum in 8.0wt% nitric acid solution at a volume ratio of 1:3, keep it for 1h, then use 50kHz ultrasonic treatment for 10min, separate solid from liquid, reuse the liquid phase, put the phase and solid phase into a blast drying oven at 105°C and dry for 3h ; Immerse the cleaned alumina to 5.0% according to the volume ratio of 1:1 (according to Al 2 o 3 total) aluminum sulfate solution for 30 minutes, solid-liquid separation, liquid phase reuse, solid phase was placed in a 105 ° C blast drying oven to dry for 3 h, and then placed in a calciner to raise the temperature to 500 ° C at a rate of 10 K / min, and maintain 2.0 h, according to 500m during the calcination process 3 / (h·t) rate of air flow, get the specific surface ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com